High-hardness single-component water-based paint and preparation method thereof

A water-based paint, one-component technology, applied in the direction of coating, can solve the problems of low hardness, poor salt spray resistance of paint film, environmental pollution, etc., achieve high hardness, good salt spray resistance, and ensure film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

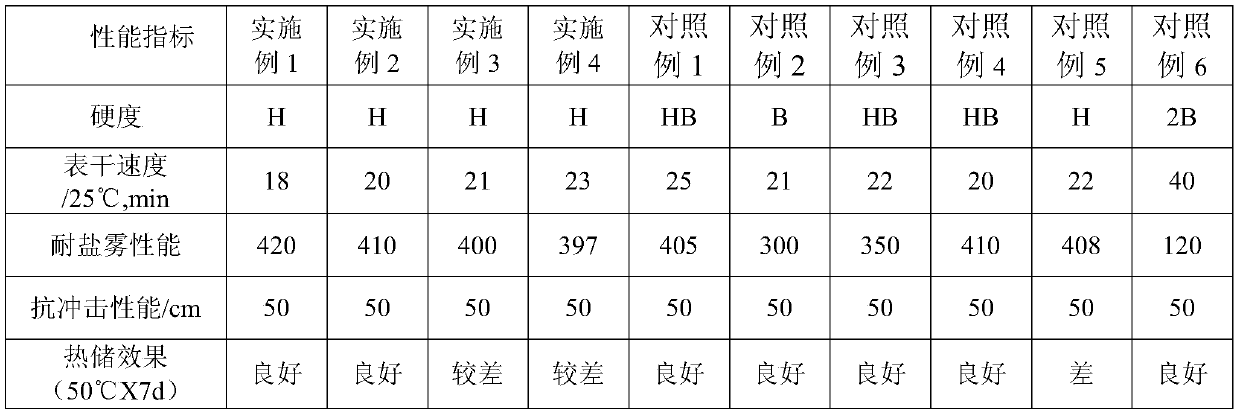

Examples

Embodiment 1

[0039] A method for preparing a high-hardness one-component water-based coating, the specific steps are as follows, counted in parts by mass: the high-hardness one-component water-based coating includes 20 parts of water-based modified acrylic resin, 10 parts of water-based acrylic emulsion, drier 0.3 parts, 1.8 parts of conventional additives (conventional additives include 1 part of dispersant, 0.2 parts of water-based silicone defoamer, 0.3 parts of leveling agent, 0.3 parts of substrate wetting agent), N,N-dimethylethanolamine 0.3 parts, 5 parts of carbon black pigment, 30 parts of filler, 25 parts of deionized water, 0.2 parts of polyurethane associative rheology additive, 2 parts of solvent;

[0040] The solvent is a mixture of ethylene glycol monobutyl ether and alcohol ester-12, and the ratio of ethylene glycol monobutyl ether: alcohol ester-12 is 1:1 in parts by mass;

[0041] The filler is a mixed compound of barium sulfate and iron phosphorus powder, and the compoun...

Embodiment 2

[0049] A method for preparing a high-hardness one-component water-based paint, the specific steps are as follows, counted in parts by mass: the high-hardness one-component water-based paint includes 22 parts of water-based modified acrylic resin, 11 parts of water-based acrylic emulsion, drier 0.3 parts, 1.4 parts of conventional additives (0.8 parts of dispersant, 0.3 parts of water-based silicone defoamer, 0.3 parts of substrate wetting agent), 0.1 part of N,N-dimethylethanolamine, 6 parts of titanium dioxide, filler 25 parts, 30 parts of deionized water, 0.2 parts of alkali thickening aid, 3 parts of solvent;

[0050] The solvent is a mixture of ethylene glycol monobutyl ether and alcohol ester-12, and the ratio of ethylene glycol monobutyl ether: alcohol ester-12 is 1:1 in parts by mass;

[0051] The filler is a mixed compound of barium sulfate and iron phosphorus powder, and the compounding ratio is 1:1 in parts by mass of barium sulfate: iron phosphorus powder;

[0052]...

Embodiment 3

[0059] A method for preparing a high-hardness one-component water-based coating, the specific steps are as follows, counted in parts by mass: the high-hardness one-component water-based coating includes 24 parts of water-based modified acrylic resin, 12 parts of water-based acrylic emulsion, drier 0.3 parts, 2.3 parts of conventional additives (1.3 parts of dispersant, 0.4 parts of water-based silicone defoamer, 0.2 parts of leveling agent, 0.4 parts of substrate wetting agent), 0.2 parts of N,N-dimethylethanolamine, carbon 8 parts of black pigment, 25 parts of filler, 31 parts of deionized water, 4 parts of solvent;

[0060] The solvent is a mixture of ethylene glycol monobutyl ether and alcohol ester-12, and the ratio of ethylene glycol monobutyl ether: alcohol ester-12 is 1:1 in parts by mass;

[0061] The filler is a mixed compound of barium sulfate and iron phosphorus powder, and the compounding ratio is 1:2 in parts by mass of barium sulfate: iron phosphorus powder;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com