curable composition

A technology of curable composition and polysulfide, which is applied in the field of epoxy resin curable composition, can solve the problem of poor flexibility, water resistance, chemical resistance, weather resistance and adhesive performance, and high production cost High-load wastewater, low polymer molecular weight and other problems, to achieve the effect of good adhesion, fast curing and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

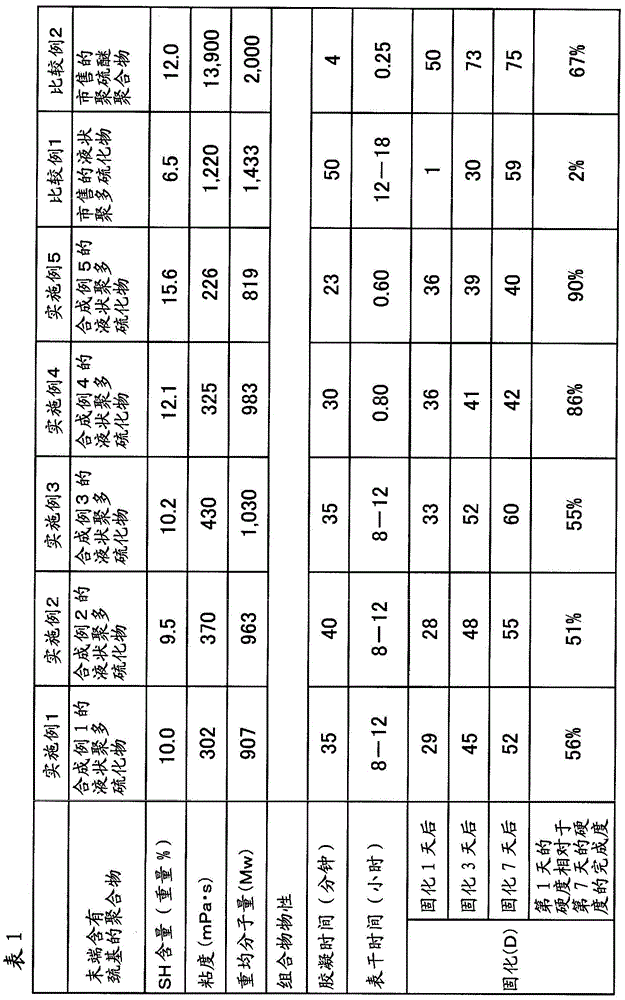

[0057] The present invention will be explained more specifically by the following examples.

[0058] Determination of viscosity

[0059] Toki Sangyo U-EII viscometer was used to measure the viscosity of the sample at 25°C.

[0060] GPC analysis, determination of weight average molecular weight (Mw)

[0061] The column used TSKgelG3000HXL, TSKgelG2000HXL, and TSKgelG1000HXL in series, and the detectors used were MODEL504RRIDetector manufactured by GL Sens Co., Ltd. and L-4000UVDetector manufactured by Hitachi Co., Ltd. The sample was dissolved in THF to make a 1% THF solution, with THF at a flow rate of 1.0 ml / min as the mobile phase, and the column temperature was 40°C for measurement. The molecular weight was calculated using PEG as a standard sample and calculated using the GPC data processing software SIC480II database manufactured by Shoko Chemical Co., Ltd.

[0062] Determination of SH content

[0063] The sample is dissolved in a mixed solution of toluene and pyridine, potassium ...

Synthetic example 1

[0073] Using a 1L separable flask, make 622.0g of sodium polysulfide aqueous solution (2.17mol / L), 2.6g of tetrabutylammonium bromide 50% by weight aqueous solution, 142.4g of 42% sodium hydrosulfide aqueous solution, 154.6g Of water, 271.3g of bis(2-chloroethyl)formal, 4.7g of 1,2,3-trichloropropane in the presence of 365.6g of sodium sulfite 16.3% by weight aqueous solution at 80°C for 10 hours, thereby Without solid polysulfide, a light yellow transparent liquid polysulfide is obtained. The obtained polymer had a repeating unit n of 4.4, a viscosity of 302 mPa·s, a Mw measured by GPC of 907, an SH content of 10.0% by weight, and a Hellige color number of 1.

Synthetic example 2

[0075] Using a 1L separable flask, make 310.3g of sodium polysulfide aqueous solution (2.17mol / L), 6.5g of tetrabutylammonium bromide 50% by weight aqueous solution, 77.4g of 42% sodium hydrosulfide aqueous solution, 48.8g Of water, 131.5g of bis(2-chloroethyl)formal, 5.9g of 1,2,3-trichloropropane in the presence of 182.4g of sodium sulfite 16.3% by weight aqueous solution at 80°C for 10 hours, thereby Without solid polysulfide, a light yellow transparent liquid polysulfide is obtained. The viscosity of the obtained polymer was 370 mPa·s, the Mw measured by GPC was 963, the SH content was 9.5% by weight, and the Hellige color number was 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com