Patents

Literature

77results about How to "Guaranteed film formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylate finishing coat core-shell emulsion with boiling water resistance and preparation method therefor

InactiveCN108164638AImprove stain resistanceImprove water resistanceAntifouling/underwater paintsPaints with biocidesEmulsionWeather resistance

The invention discloses an acrylate finishing coat core-shell emulsion with boiling water resistance and a preparation method therefor. The emulsion is prepared from the following ingredients in partsby weight: 0.5-5 parts of emulsifier, 0.05-2 parts of initiator, 20-35 parts of (meth)acrylate hard monomer, 5-20 parts of (meth)acrylate soft monomer, 0.3-1 part of -COOH-containing vinyl monomer, 0.3-1 part of -COOH-free vinyl monomer, 0.5-5 parts of cross-linking monomer, 0.3-1 part of organosilicon monomer, 0.01-0.05 part of pH regulator and 50-65 parts of deionized water. According to the acrylate finishing coat core-shell emulsion with boiling water resistance and the preparation method therefor, an obtained paint film is free of water resistance abnormity, has excellent yellowing resistance and weather resistance and is very applicable to finishing coats of colorful stone-like paint; and according to the preparation method disclosed by the invention, used raw materials are simple and readily available, and thus, the method has a relatively obvious advantage in building coatings.

Owner:上海巴德富实业有限公司

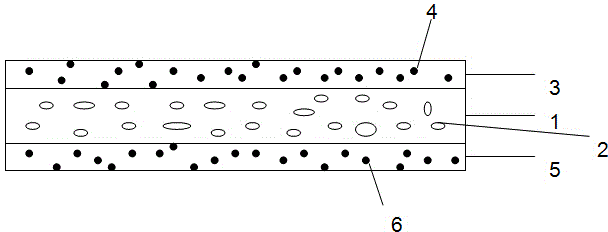

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

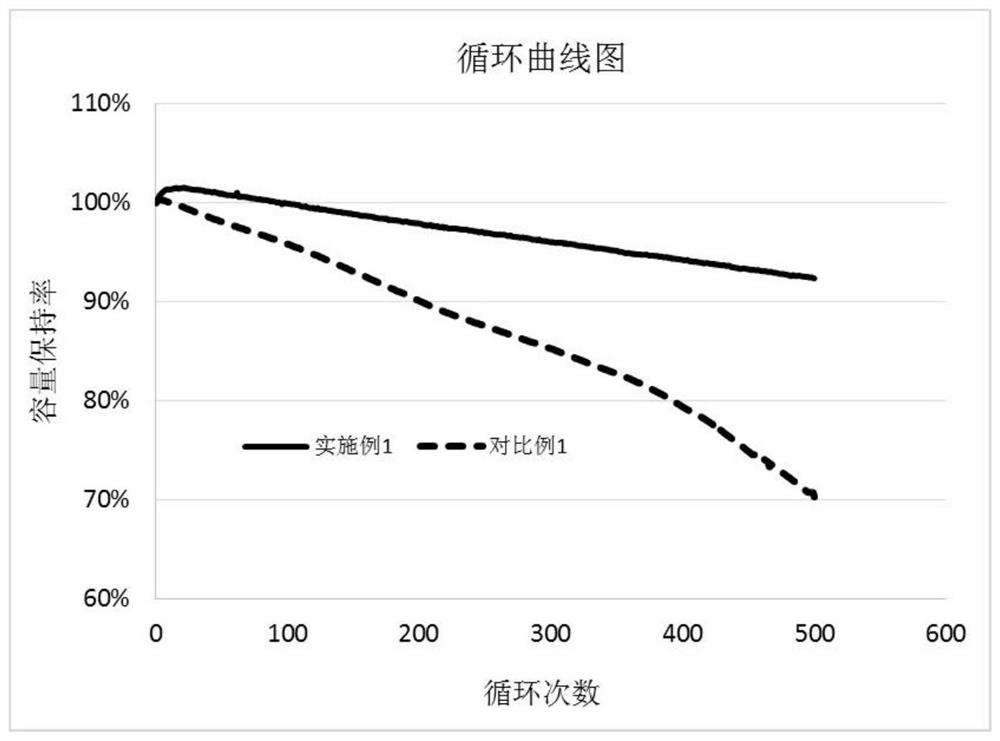

Electrolyte, preparation method thereof, high-energy-density lithium ion battery containing electrolyte and preparation method thereof

InactiveCN111769327AImprove solubilityIncrease the ionic conductivity of the electrolyteFinal product manufactureSecondary cellsVinylene carbonateOrganosolv

The invention discloses an electrolyte, a preparation method thereof, a high-energy-density lithium ion battery containing the electrolyte and a preparation method thereof. The electrolyte comprises alithium salt, a non-aqueous organic solvent, a negative electrode film-forming organic additive and a modified additive. The negative electrode film-forming organic additive is any one or at least two of fluoroethylene carbonate, 1, 2-difluoroethylene carbonate, chloroethylene carbonate and vinylene carbonate, and the modified additive is any one or at least two of potassium carbonate, sodium carbonate and lithium carbonate. The electrolyte provided by the invention can quickly form a layer of compact, stable and thin SEI film with good mechanical properties on the surfaces of negative electrode material particles. The high-energy-density lithium ion battery containing the electrolyte can relieve the problems of lithium battery capacity attenuation, particle pulverization and the like caused by volume expansion of a silicon-based negative electrode in the recycling process, and has good cycling stability and rate capability.

Owner:GUANG DONG GREENWAY TECH CO LTD

Long-acting flame retarding coating fabric with safety protection performance, and preparation process thereof

ActiveCN102615901AHigh strengthImprove uniformityFibre treatmentSynthetic resin layered productsSlurryMoisture permeation

The present invention discloses a long-acting flame retarding coating fabric with safety protection performance, and a preparation process thereof. According to the fabric, a first prime coat and a second prime coat are provided; a surface coating comprises a polyurethane resin, bromoethane, antimony oxide, and zinc borate; and a lining woven from a flame retarding polyacrylonitrile fiber silk is adhered to the other side of a coating layer, wherein the flame retarding polyacrylonitrile fiber silk comprises polyacrylonitrile fiber, cotton and aramid fiber, and a ratio of the polyacrylonitrile fiber to the cotton to the aramid fiber is 4:3.5-4.5:0.9-1.1. The preparation method comprises: respectively soaking and dissolving bromoethane, antimony oxide and zinc borate powder in toluene for at least 24 hours; uniformly mixing the bromoethane, the antimony oxide, the zinc borate powder and a hydrophilic polyurethane moisture permeation primer according to a mass ratio of 40:22-18:4-6:95-105 to form a prime coat slurry; mixing polyacrylonitrile fiber, cotton and aramid fiber according to a mass ratio of 4:3.5-4.5:0.9-1.1, silking to form the flame retarding polyacrylonitrile fiber silk, and adopting a flame retarding lining woven from the flame retarding polyacrylonitrile fiber silk, and adhering on the other side of the surface coating; and uniformly mixing a white slurry and a surface coating slurry to form a blended surface coating slurry. With the fabric of the present invention, the flame retarding time is long, the amount of the smoke generation is small, the droplet is not easily generated, the flame retarding effect is resistant to washing, and the hydrolysis of the flame retarding substances is avoided.

Owner:KUNSHAN HUAYANG NEW MATERIAL

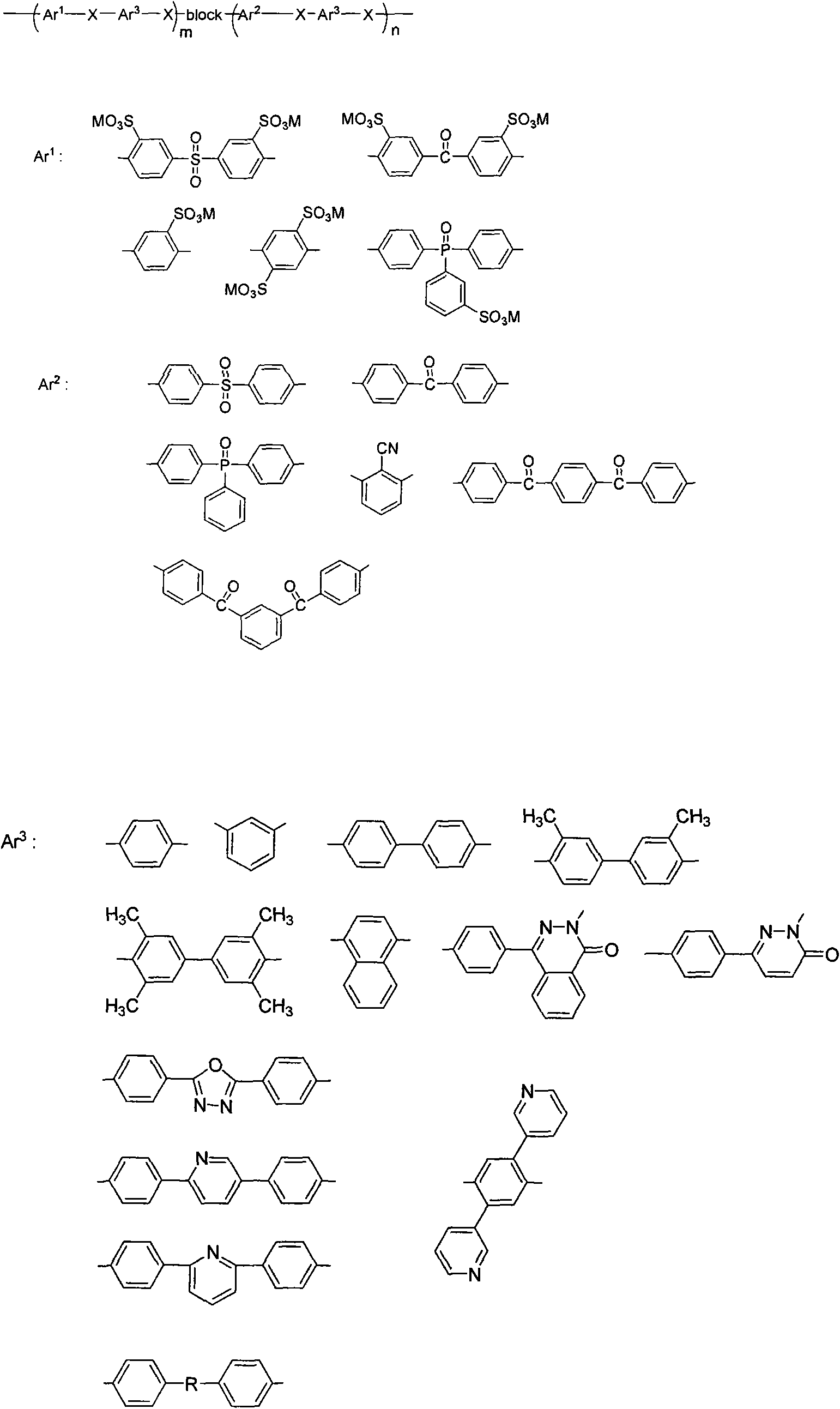

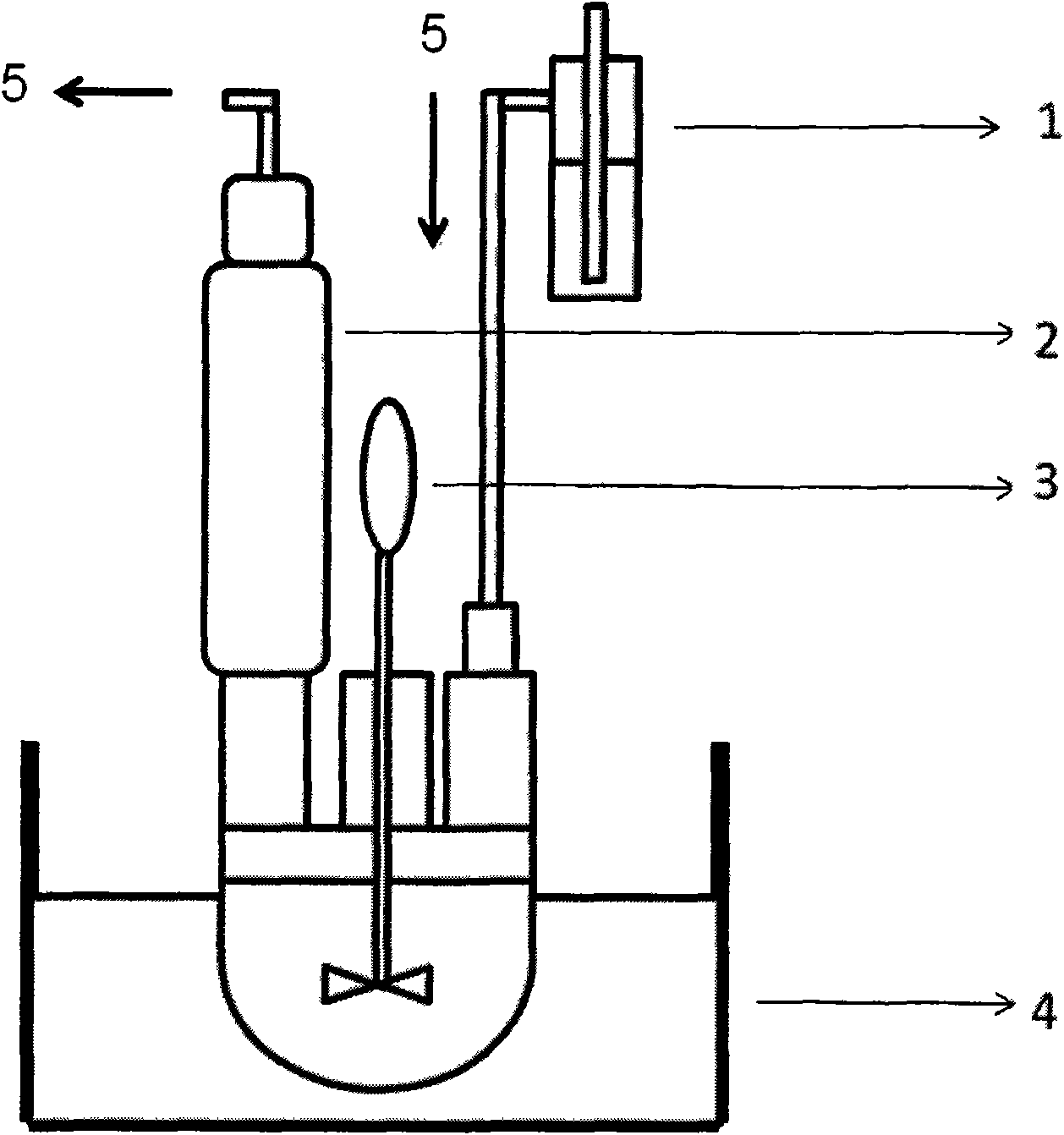

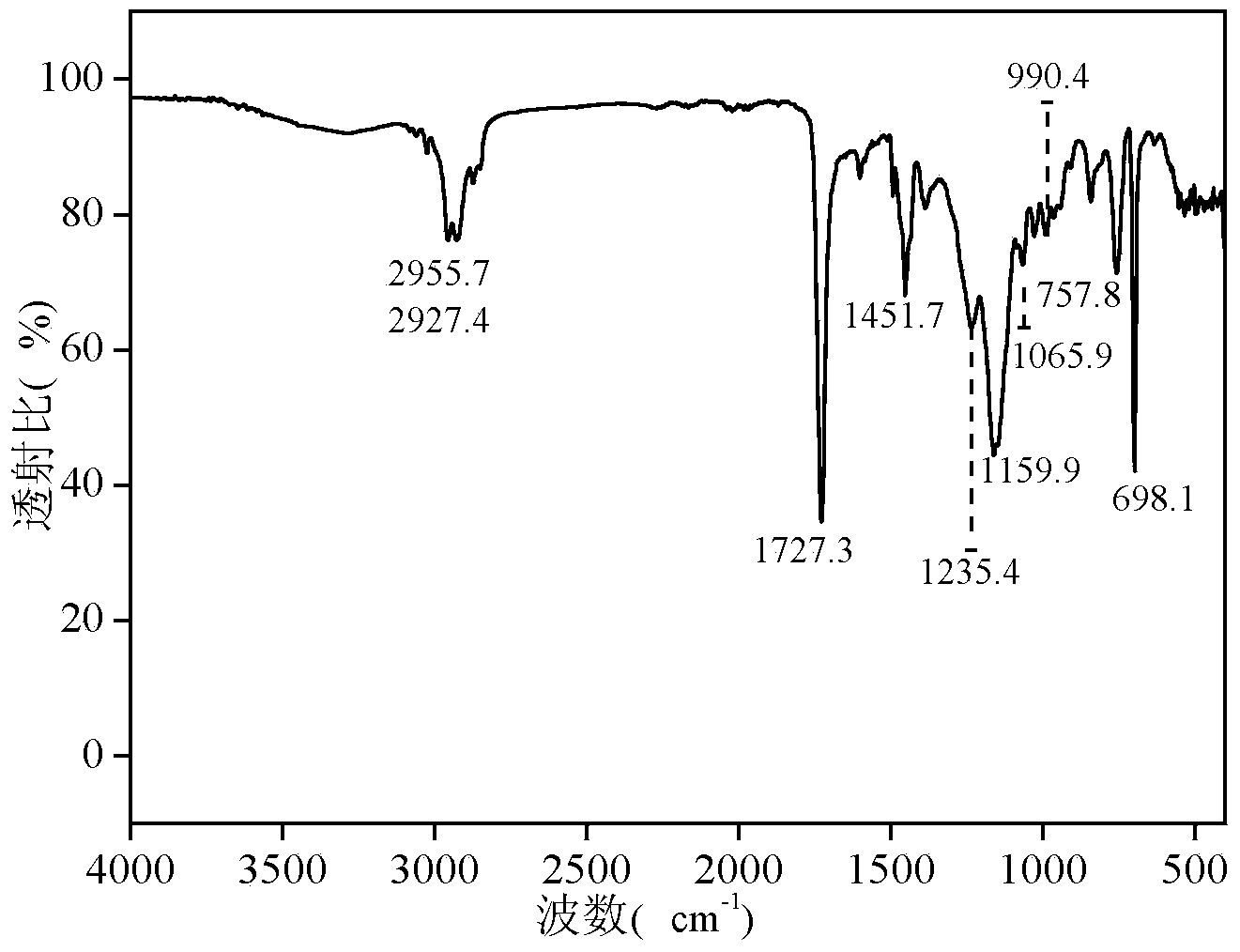

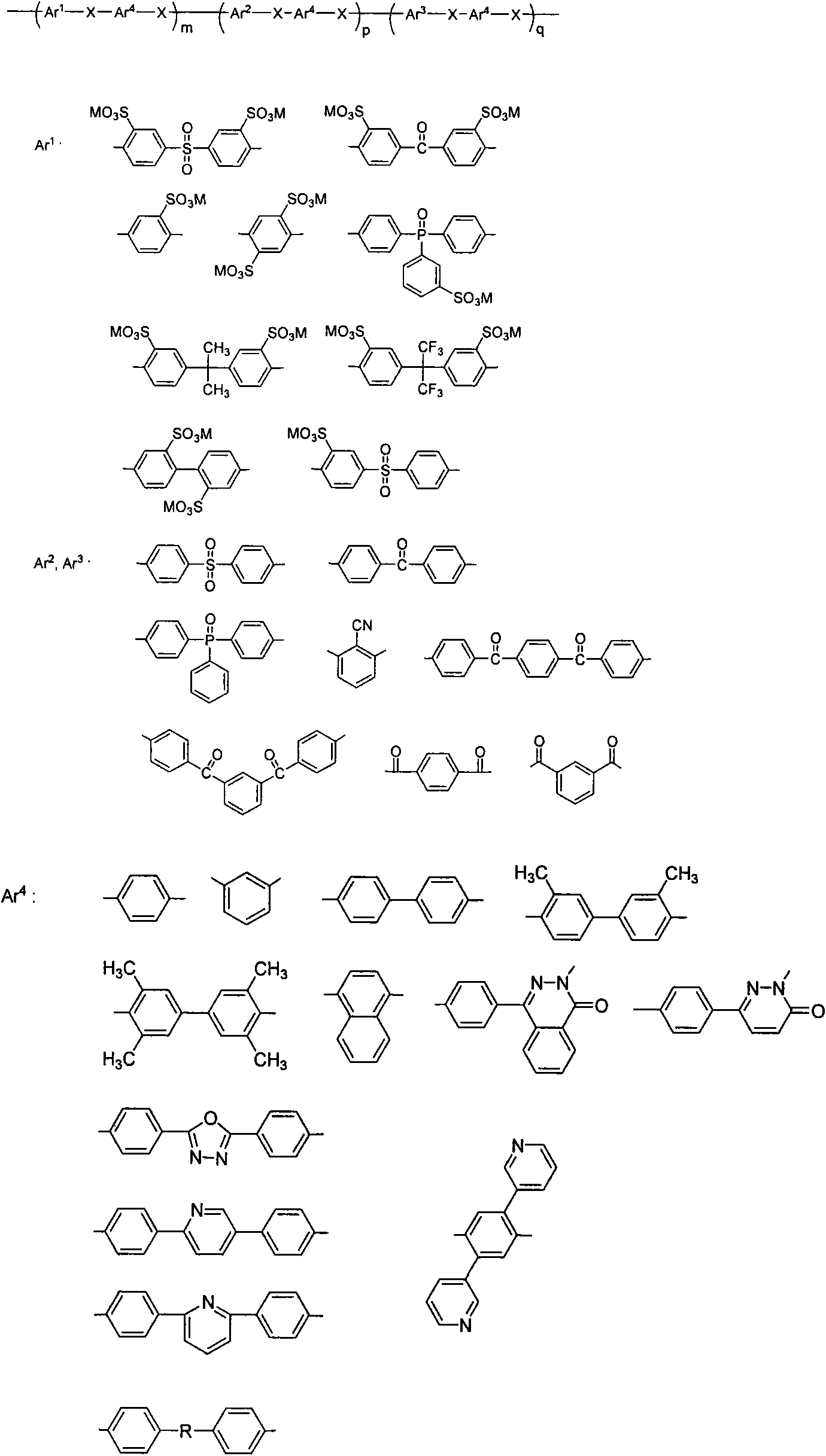

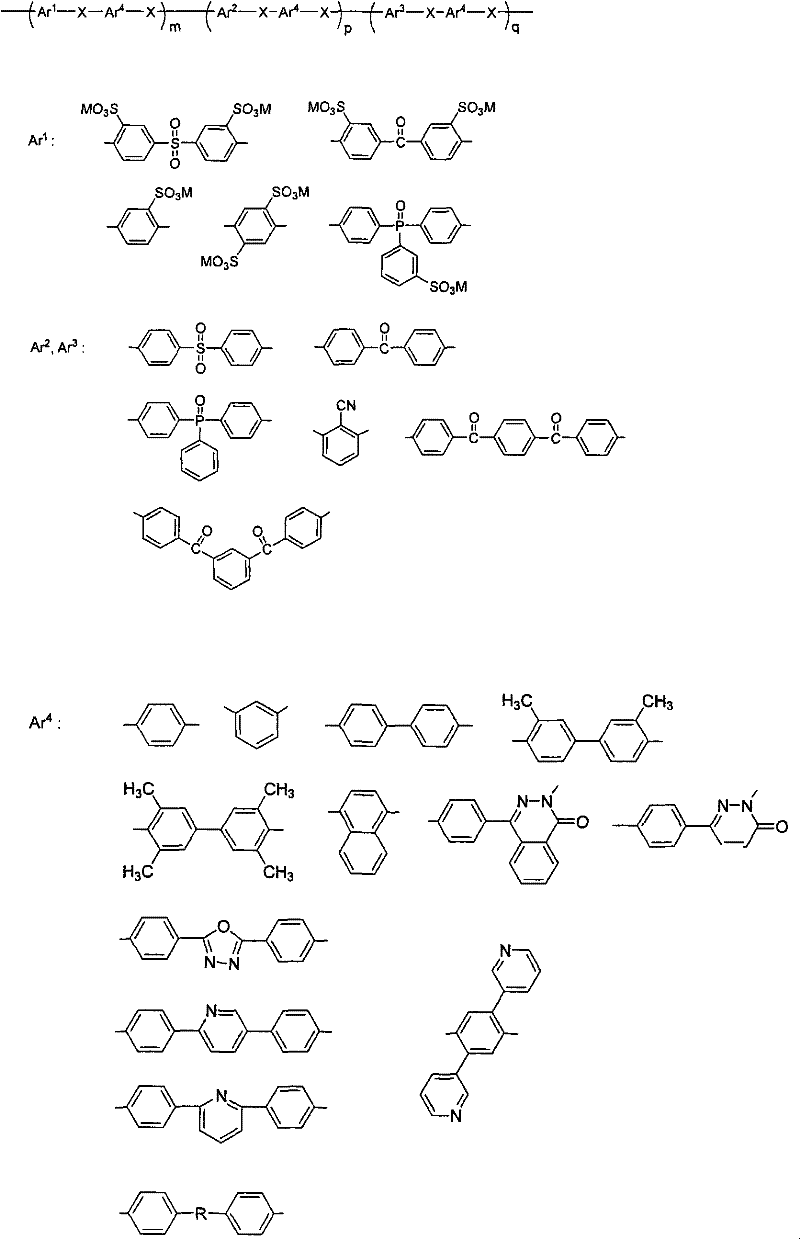

Efficient preparation method of block sulfonated aromatic poly (thio) ether

The invention relates to a preparation method of block sulfonated aromatic poly (thio) ether. In the invention, a sulfonated monomer, a non-sulfonated monomer and a bis (thio) phenol monomer are adopted as starting raw materials and react for 10 to 24 hours under the carbonate alkaline condition of an aprotic solvent with high boiling point with the temperature being controlled between 150 DEG C and 200 DEG C so as to effectively prepare a block sulfonated aromatic poly (thio) ether macromolecular compound. In the preparation method, a toluene organic solvent is omitted, the step of azeotropic water division is omitted, the technology is simplified, the use of a large number of organic, flammable, volatile and toxic solvents and subsequent complicated waste liquid recycling processes are avoided, the volume of reaction liquid is reduced, the reaction time is shortened, energy consumption is reduced, the cost of the production technology is reduced, and the work efficiency is increased.

Owner:安徽摩纳珀里科技有限公司

Preparation method of polystyrene-acrylate core-shell composite emulsion

The invention discloses a preparation method of a polystyrene-acrylate core-shell composite emulsion, belongs to the emulsion preparation field, and solves the problems of adhesion resistance, poor heat resistance and the like of a thermoplastic polystyrene-acrylate random copolymer in the prior art. The preparation method is as follows: 1, weighing raw materials; 2, adding distilled water into a reactor, heating up, adding a compound emulsifier, a pH buffer and then part of a mixed vinyl monomer for emulsifying, adding part of an initiator, heating up to react until no reflux exists to obtain a seed emulsion; 3, continuing heating up, dripping off the rest of the mixed vinyl monomer, synchronously adding part of the initiator, after the dripping of the part of the initiator, keeping warm to obtain a core structure emulsion; 4, dripping a mixed acrylate monomer to the core structure emulsion, in the mixed monomer dripping process, adding part of the initiator, after dripping of the part of the initiator, adding the rest of the initiator, keeping warm, then cooling, adding ammonia water, stirring, further cooling, and filtering. The preparation method is applied in the fields of wood veneering, interior decoration, textiles and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

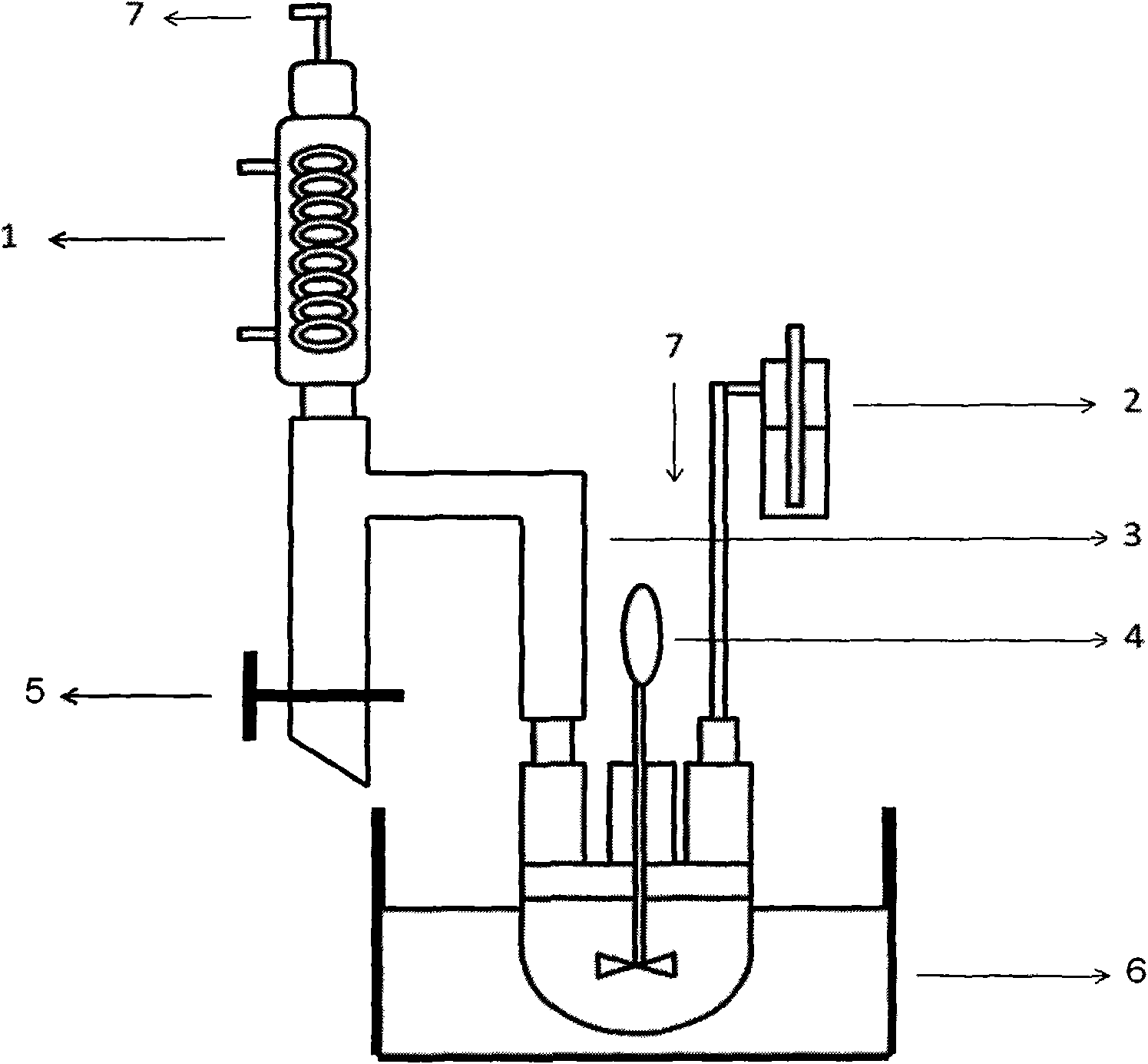

Method for preparing aromatic nucleophilic substitution polymer under anhydrous condition

The invention relates to a method for preparing a polymer by an aromatic nucleophilic substitution reaction under an anhydrous condition. The method comprises the following steps: in an aprotic polar solvent with high boiling point, an aromatic halide and an acyl halide react with phenol, thiophenol or amine respectively by heating according to the feed ratio of the mole number of 1:1 under the existence of anhydrous potassium phosphate to obtain a corresponding macromolecular compound; and a reaction mixture is poured into deionized water after cooled to room temperature to obtain a white fibrous polymer, immersion is carried out for 5 to 10 hours under the condition of 60 DEG C to 80 DEG C and is repeated for 3 to 5 times, and then the processes of filtration, baking and vacuum drying are carried out to obtain the aromatic nucleophilic substitution polymer. The invention omits a toluene organic solvent and takes the anhydrous potassium phosphate as alkali, the alkalescence of the anhydrous potassium phosphate is equivalent to that of potassium carbonate, a sufficient alkaline condition required by the reaction is ensured, monopotassium phosphate generated by the reaction can not decompose to generate water under the reaction temperature of the invention, so the polymerization method of the invention is a novel preparation method under an absolutely anhydrous condition under the precondition of using inorganic moderately strong alkali.

Owner:安徽摩纳珀里科技有限公司

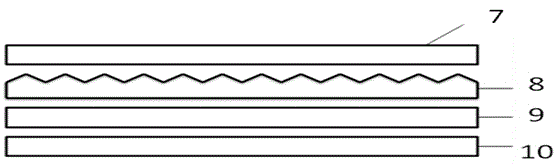

Heat dissipation type solar cell back film

ActiveCN104201225AGood cooling performanceGood thermal conductivitySynthetic resin layered productsPhotovoltaic energy generationOperating temperaturePolyester

The invention relates to a heat dissipation type solar cell back film. The film comprises a weather-proof layer, a base material and an adhesive layer, wherein the base material is made from a heat dissipation type polyester film, and the heat dissipation type polyester film is formed by successively placing a polyester layer, a first heat conducting polyester layer and a second heat conducting polyester layer from top to bottom. The first heat conducting polyester layer contains first heat conducting particles occupying 5%-20% polyester weights of the first heat conducting polyester layer, the second heat conducting polyester layer contains second heat conducting particles occupying 5%-30% polyester weights of the second heat conducting polyester layer, and surface grafting treatment is performed on the first heat conducting particles and the second heat conducting particles by a hyperbranched polymer. The heat dissipation type solar cell back film has the advantages that the heat dissipation property, the heat conducting property and the film forming property are good; the heat quantity generated by a solar cell module is discharged in time; the operating temperature of a solar cell is reduced; the transfer efficiency of the solar cell is improved; and the service life of the solar cell is prolonged.

Owner:乐凯胶片股份有限公司

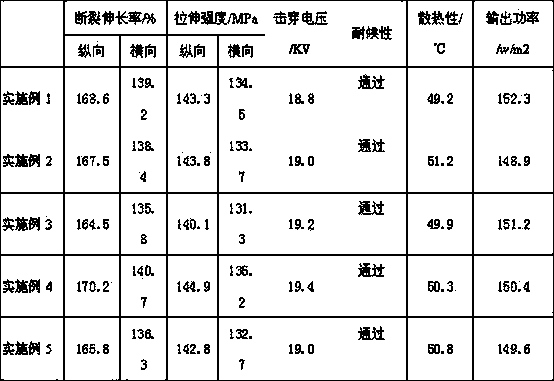

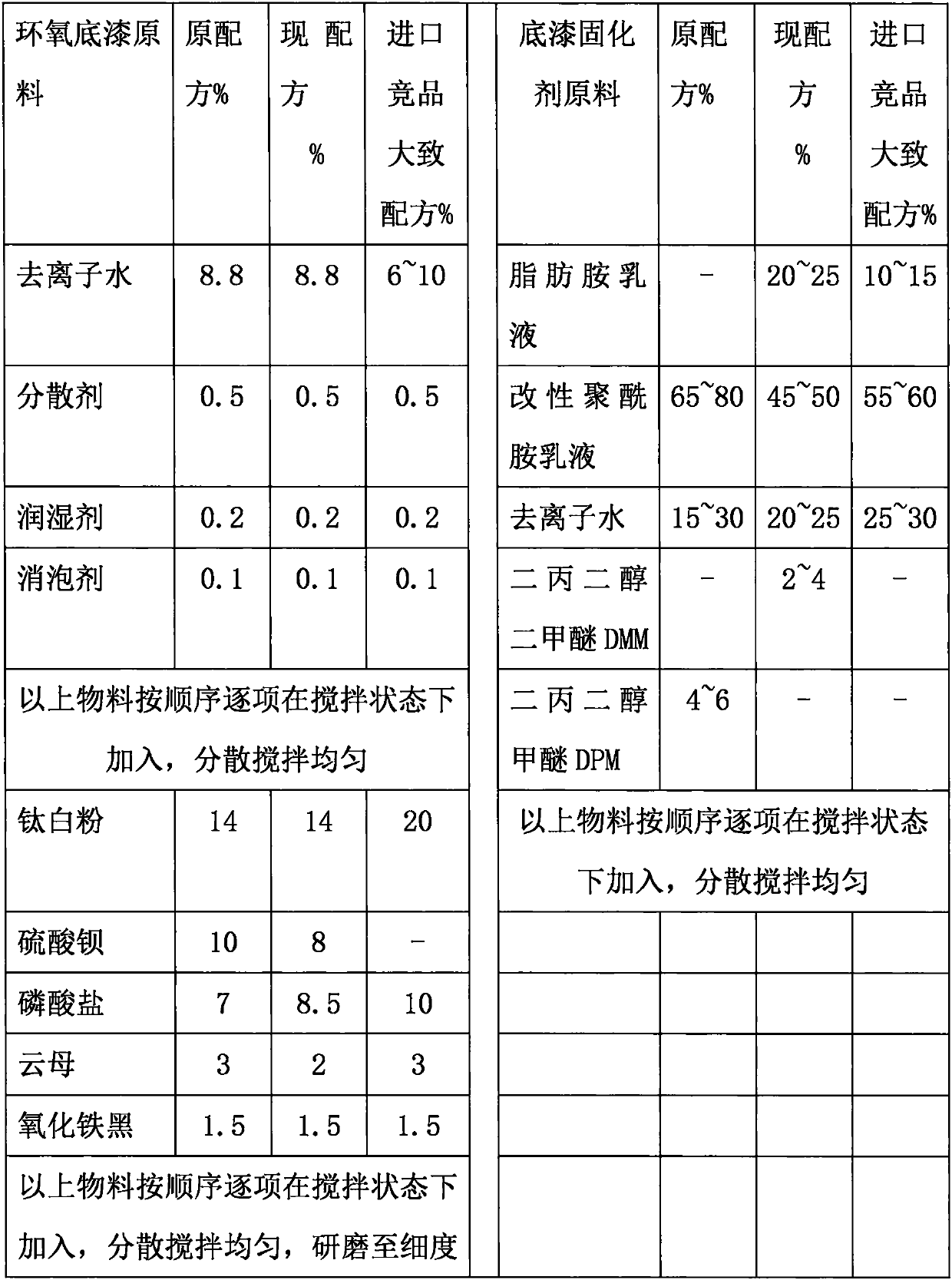

Special two-component water-based paint for buses and coating process of two-component water-based paint

InactiveCN110551437ALow VOCImprove film formationPretreated surfacesAnti-corrosive paintsWater basedEpoxy

The invention provides special two-component water-based paint for buses. The special two-component water-based paint comprises a two-component water-based epoxy primer, two-component water-based intermediate paint and two-component water-based finishing paint. While maintaining the original physical and chemical properties without reducing, compared with traditional solvent-based bus paint, the use of organic solvents can be significantly decreased, and VOC is lowered; compared with existing water-based bus paint on the market, the flash drying time can be shortened, the production pace is speeded up, and the more efficient coating efficiency can be obtained.

Owner:上海时佳涂料有限公司

Permeable crosslinked concrete protective paint and preparation method thereof

InactiveCN105110815AGood adhesionGood permeability and film-forming propertiesCoatingsDefoaming AgentsCarbonization

Owner:WUHAN UNIV OF TECH

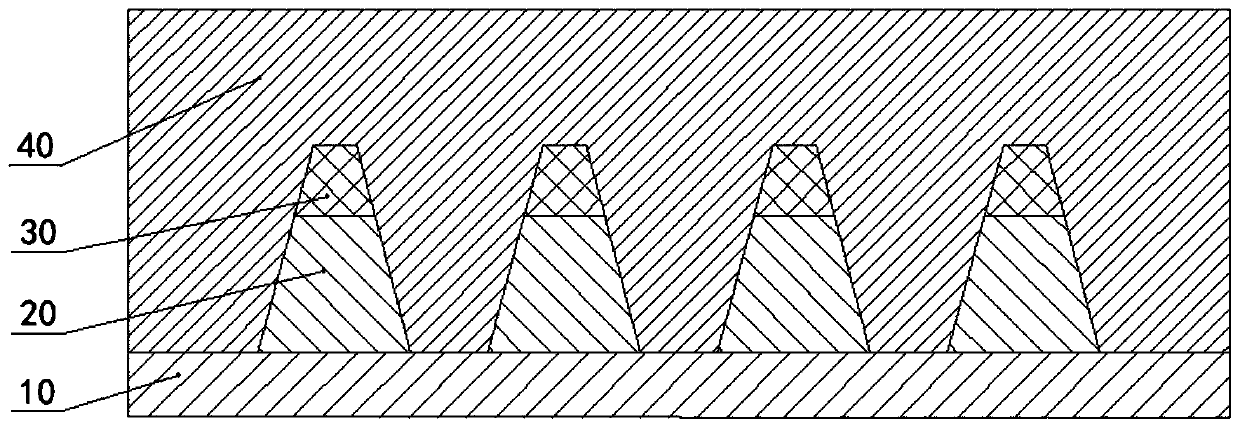

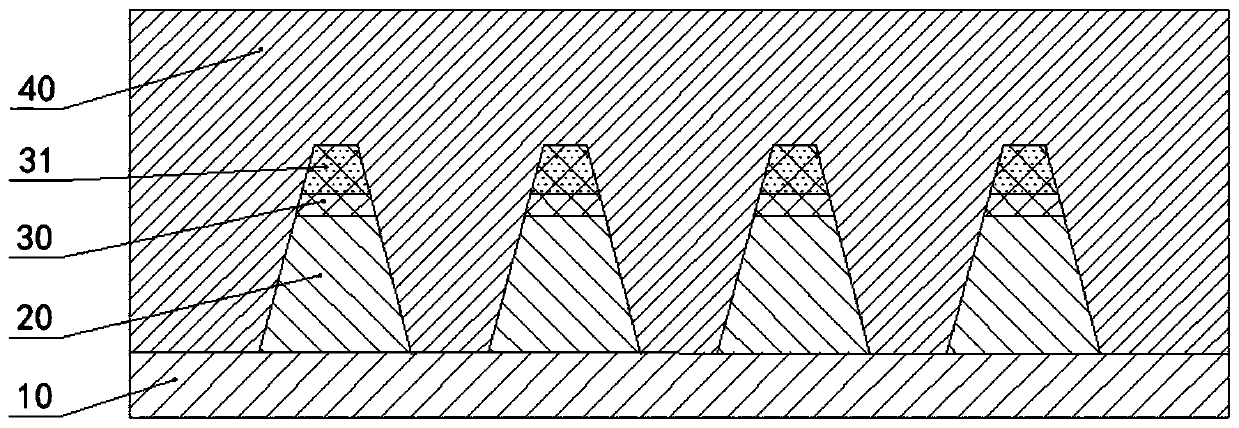

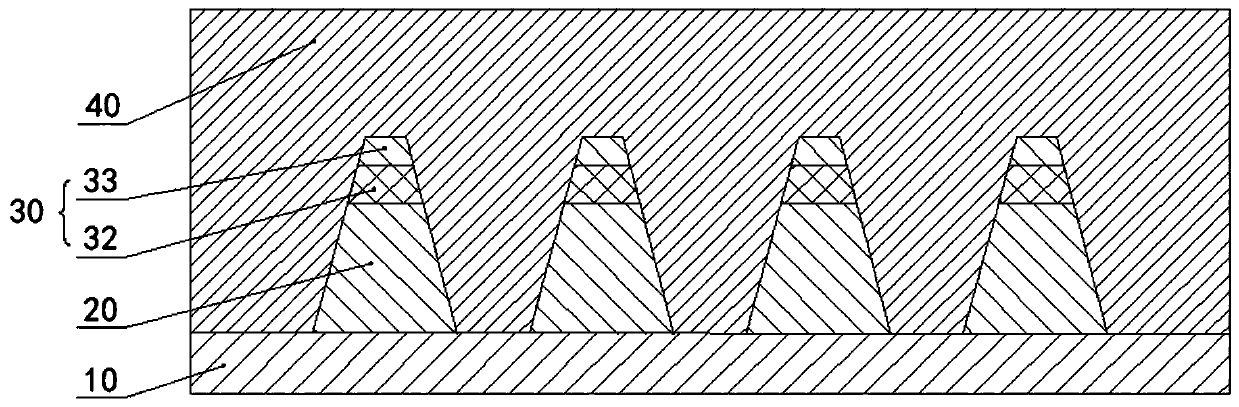

Organic light-emitting display panel, preparation method and display device

PendingCN111244143AImprove wear resistanceAvoid scratchesSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides an organic light-emitting display panel, a preparation method thereof and a display device, and the display panel comprises: a pixel limiting layer which comprises a hollow region for limiting a preparation region of an organic light-emitting layer; and a supporting columns arranged on the surface of the pixel limiting layer, wherein the surface, deviating from the pixel limiting layer, of the supporting column comprises a wear-resistant material. The supporting column comprises the wear-resistant material, so that the wear resistance of the supporting column is improved, the supporting column is effectively prevented from being scratched by the mask plate, the film forming effect of the flexible packaging film layer is ensured, the packaging reliability of a productis improved, and the service life of the product is prolonged.

Owner:HEFEI VISIONOX TECH CO LTD

UV-curable coating and preparation method thereof, super-hydrophilic transparent anti-fog coating and preparation method thereof

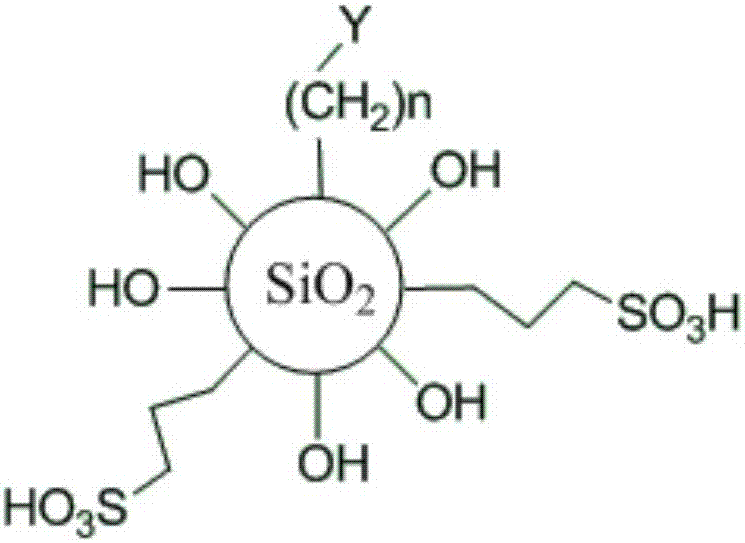

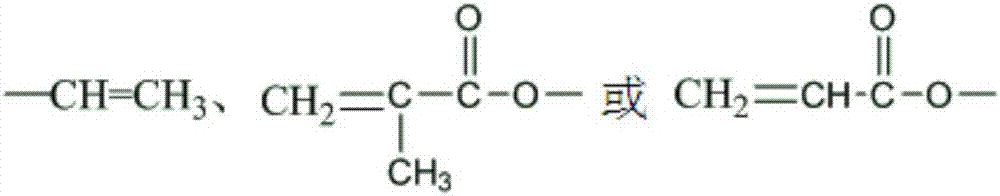

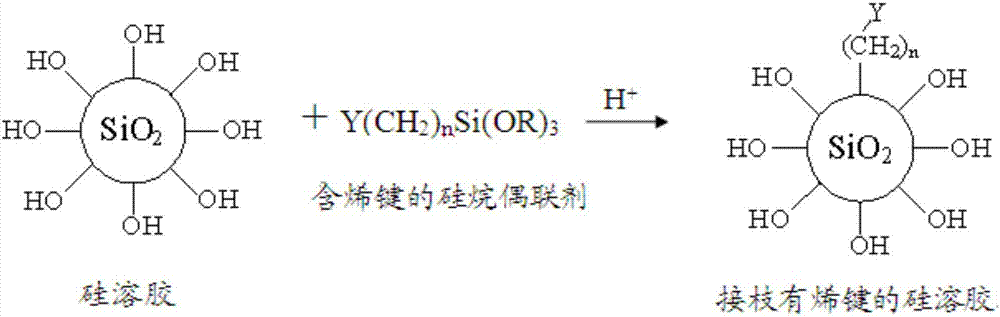

ActiveCN105176371BGuaranteed Super Hydrophilic PropertiesGood anti-fog performanceAntifouling/underwater paintsPretreated surfacesPolymer scienceOligomer

The invention provides a UV-curable coating and its preparation method, and a super-hydrophilic transparent anti-fog coating and its preparation method; the raw materials of the UV-curable coating include 10-50 parts by weight of modified silica sol, 5-30 parts by weight of UV resin oligomer in parts, active diluent in 5-30 parts by weight, surfactant in 0.2-5 parts by weight, photoinitiator in 2-6 parts by weight and solvent in 0-50 parts by weight. The coating prepared by the ultraviolet curing coating of the present invention has long-lasting super-hydrophilic performance and excellent anti-fog performance, and has good water resistance and good weather resistance, and at the same time, its wear resistance, scratch resistance and stain resistance are also very good.

Owner:福建富兰光学股份有限公司

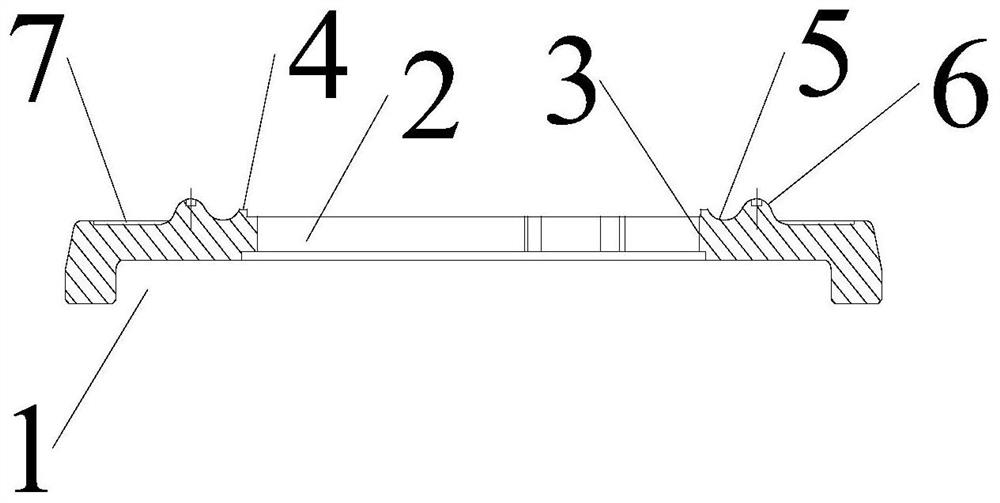

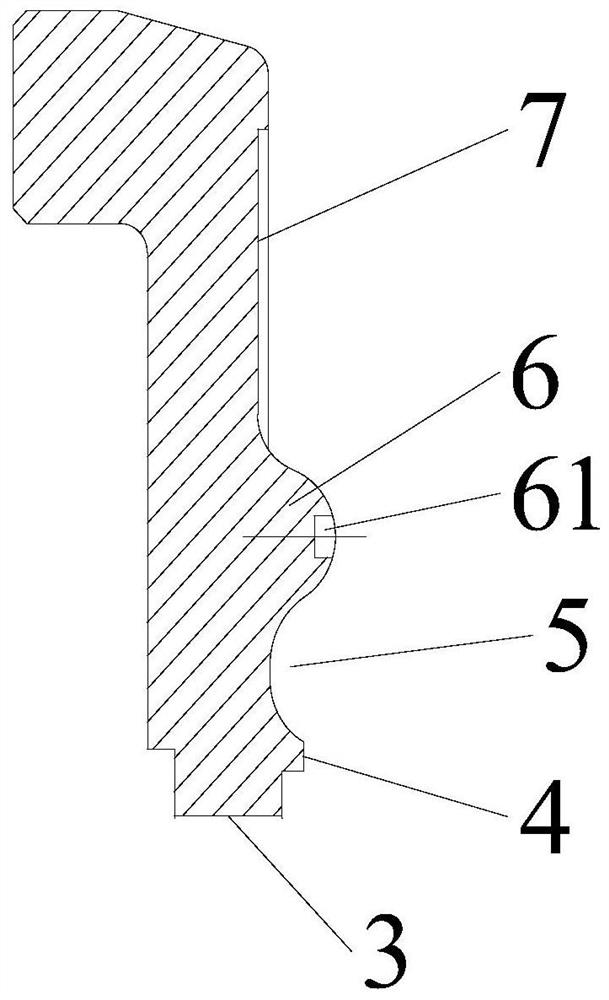

Wafer fixing ring as well as preparation method and application thereof

ActiveCN112501577AAct as shedding particlesAvoid adverse effects of film formationVacuum evaporation coatingSputtering coatingSand blastingWafer

The invention provides a wafer fixing ring as well as a preparation method and application thereof. The wafer fixing ring comprises a bottom face groove and a through hole penetrating through the bottom face groove; at least two protruding parts are symmetrically arranged on the side wall of the through hole; the top face of the wafer fixing ring comprises a sand blasting area and a meltallizing area which are arranged in sequence; the sand blasting area is an equal-width area extending from the side wall of the through hole to the side wall of the wafer fixing ring; and the meltallizing areacomprises a concave meltallizing area, a convex meltallizing area and a plane meltallizing area which are sequentially arranged, and the concave meltallizing area is connected with the sand blasting area. According to the wafer fixing ring as well as the preparation method and application thereof, through specific arrangement of the wafer fixing ring structure, a wafer can be stably fixed by the wafer fixing ring, the service life is long, and particles falling in the magnetron sputtering process can be effectively adsorbed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for preparing novel nutrient recovery type skin-care facial mask

InactiveCN103006518ADelay wrinkle agingInhibition formationCosmetic preparationsToilet preparationsBULK ACTIVE INGREDIENTBiological materials

The invention relates to a method for preparing a novel nutrient recovery type skin-care facial mask. A method for making an efficient cheap facial mask product which contains natural biological materials as the main moisturizing, nutrient and film forming components is designed. The method comprises the step of extracting sericin in natural colorful cocoons by a special method instead of the traditional animal collagen, substituting the compound components of konjaku flour and xanthan gum for hyaluronic acid as the main film forming materials, and simultaneously blending the materials with curacao aloe powder, thereby obtaining the novel facial mask product. The novel facial mask product has the effects of keeping the skin fine and smooth, removing free radicals, supplementing moisture and collagen and the like. The product obtained by the method provided by the invention has multiple bioactivities, is advantageous for the skin to absorbing various active ingredients, and also has obvious effects on softening the skin, preventing and treating acnes, age pigments, freckles and pachulosis, diminishing inflammation and relieving itching, keeping the skin fine and white and the like.

Owner:李卫旗

Method for improving performance of silane film on surface of aluminum alloy

InactiveCN106929863AGuaranteed film formationIncrease production costLiquid/solution decomposition chemical coatingSilanesPhosphate

The invention discloses a method for improving the performance of a silane film on the surface of an aluminum alloy, which comprises the following steps: putting the polished aluminum alloy raw material into a cleaning solution to clean it; After mixing the ionic water and sodium methacrylate sulfonate, stir for 6-10 minutes, the preparation of the film-forming solution is completed, and then the mixed solution is placed in a non-ventilated place for hydrolysis, and the hydrolysis time is 3-5 hours; put the aluminum alloy material into In the prepared film-forming solution, after 2-5 minutes, add diisooctyl phosphate of 0.03-0.05 times the weight of the film-forming solution to the film-forming solution, continue to soak, take out the aluminum alloy material, and place it in a ventilated place for static Set to make a finished product. In the present invention, the silane film prepared on the surface of the aluminum alloy has strong adhesion, good wear resistance, and good corrosion resistance, and the uniformity and density of the film are good, which can effectively prevent aluminum alloy products from being The membrane at the middle surface is mechanically damaged.

Owner:王鑫

Coating for casting automobile flywheel shell

InactiveCN106345968AGuaranteed adhesionGuaranteed film formationFoundry mouldsFoundry coresPolyethylene glycolMullite

The invention discloses a coating for casting an automobile flywheel shell and belongs to the technical field of the casting. The coating is prepared from the following materials: modified swelling vermiculite powder, modified white corundum powder, electric smelting mullite, corn starch, copal resin, terpene resin, butyl acrylate, isopropyl alcohol, micro wax, polyethylene glycol, polyoxyethylene propyl alcohol amine ether, barium stearate and sodium citrate. The coating prepared according to the invention has the advantages of excellent film-forming property, caking property, high temperature impact resistance and damp-proof air permeability, stable property and high quality; in actual use processes, the normal casting process can be guaranteed by only applying the coating in the dosage being 1 / 4-1 / 2 of the dosage of the traditional coating; and the coating has great popularization and application values.

Owner:黄林

Heat conducting reflection film and backlight module set

InactiveCN104965245AEvenly heatedEasy to processMirrorsNon-linear opticsLiquid-crystal displayHeat conducting

The invention relates to a heat conducting reflection film. The heat conducting reflection film includes a reflection layer and a diffusion layer; one surface of the reflection layer is provided with a heat conducting layer; the heat conducting reflection film is formed through multi-layer co-extrusion; the heat conducting layer contains heat conducting particles; and the weight percentage of the heat conducting particles in the heat conducting layer ranges from 1% to 50%. An A / B / C-layer co-extrusion method is adopted; a thick sheet is extruded out from a mould head; the thick sheet is subjected to casting, biaxial stretching, heat setting and coiling; and the heat conducting reflection film can be obtained. The heat conducting reflection film of the invention has excellent heat conductivity, so that deformation phenomena of the reflection film such as bending and wrinkling due to uneven heating can be avoided; the heat conducting reflection film also has a diffusion property; and therefore, production and use cost can be reduced. The heat conducting reflection film is suitable for the liquid crystal display industry.

Owner:HEFEI LUCKY SCI & TECH IND +1

Friction material for automobile brake

InactiveCN102807842AExcellent mechanical and physical propertiesExcellent performance indexOther chemical processesFiberGlass fiber

The invention discloses a friction material for automobile brake, and the friction material consists of following ingredients in parts by weight: 20 to 24 parts of phenolic resin, 6 to 8 parts of hexamethylenetetramine, 1 to 3 parts of steel fiber, 4 to 6 glass fiber, 5 to 7 parts of alumina fiber, 4 to 6 parts of diatomite, 3 to 4 parts of 60-mesh to 80-mesh silicon carbide, 5 to 8 parts of 80-mesh to 150-mesh aluminum oxide, 2 to 3 parts of 200-mesh to 320-mesh mullite, 5 to 7 parts of cashew nut shell powder, 12 to 15 parts of crystalline flake graphite, 3 to 4 parts of sericite and 2 to 4 parts of colloid molybdenum disulfide.

Owner:NINGBO RUITONG NEW MATERIAL TECH +1

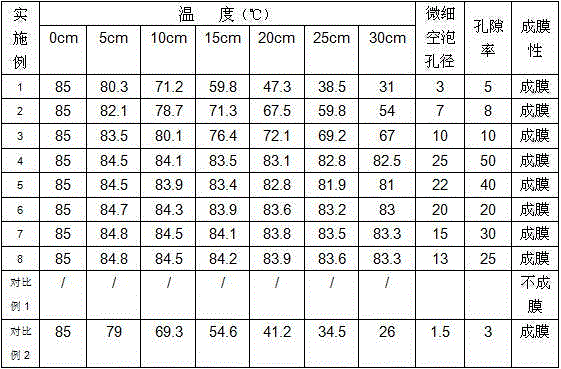

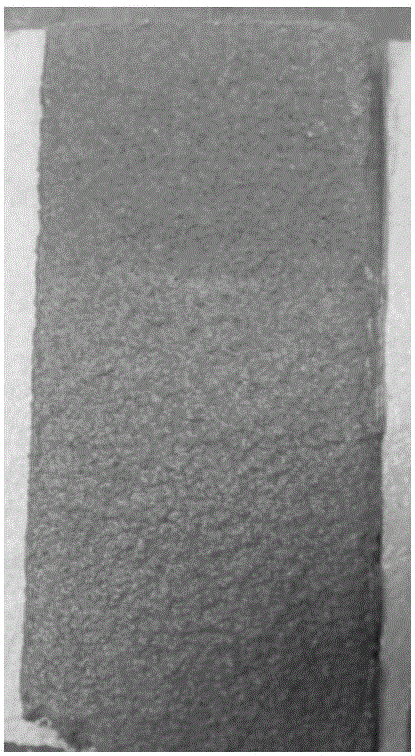

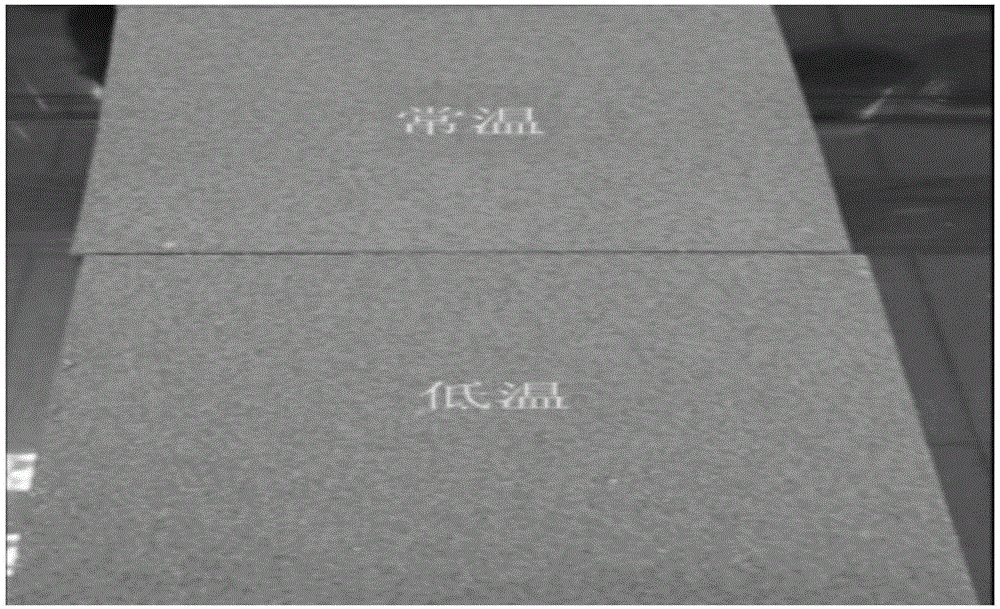

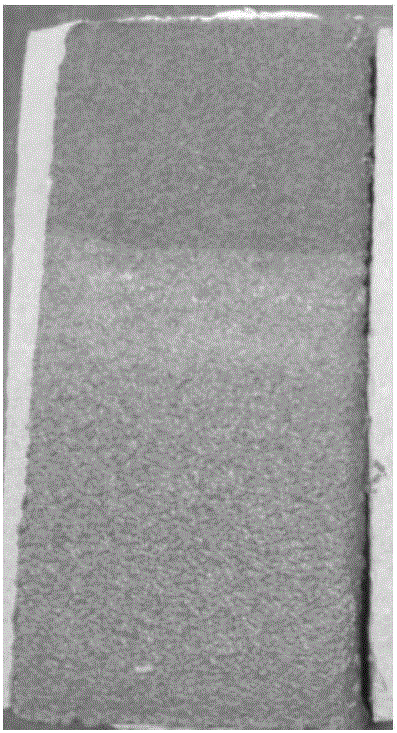

External wall natural stone paint suitable for construction in low-temperature high-humidity environment

ActiveCN106007634AWater resistance and improved adhesion and bond strengthGood water whitening resistanceEthyleneglycol monobutyl etherEmulsion

The invention relates to an external wall natural stone paint suitable for construction in a low-temperature high-humidity environment. The invention is characterized in that the paint is mainly composed of the following components in percentage by mass: 70-80% of colored sand, 12-15% of silicon-modified styrene-acrylic emulsion 8666, 0.6-0.8% of film forming aid, 2.0-3.0% of silica sol, 0.1-0.15% of thickener and the balance of conventional aid, totaling 100%. The film forming aid is mainly compounded from Texanol ester alcohol, ethylene glycol monobutyl ether and benzyl alcohol. The thickener is compounded from a polyurethane thickener and an alkali thickener. The natural stone paint can achieve the constructability of the normal temperature environment in the low-temperature high-humidity environment.

Owner:湖南德泰建筑工程有限公司

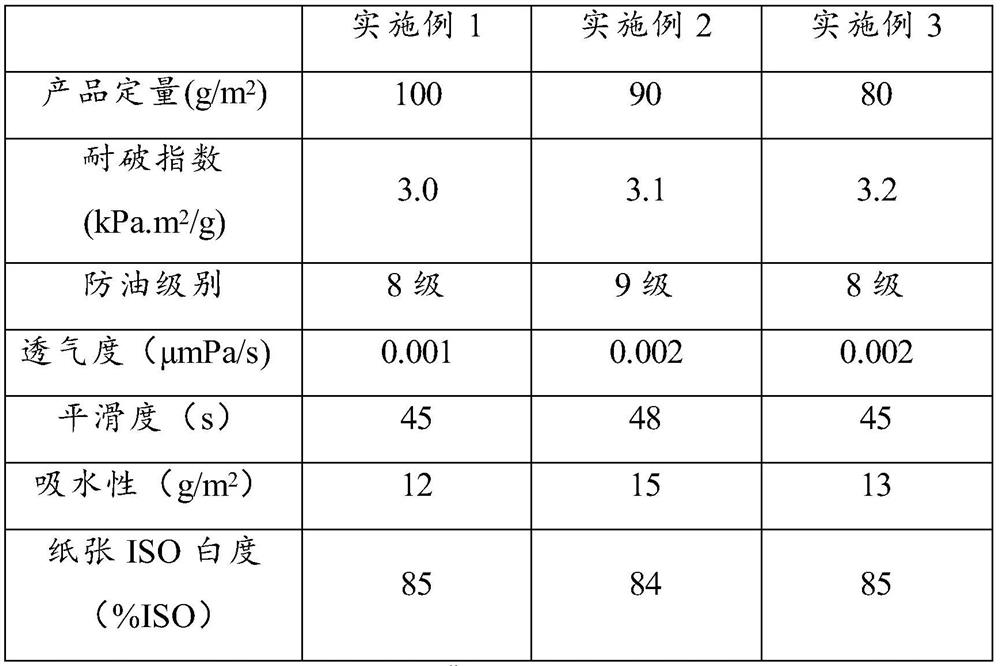

Plastic-removed food paper and preparation method thereof

The invention provides a preparation method of plastic-removed food paper, the preparation method comprises the following steps: mixing bleached sulfate needlebush chemical pulp and bleached sulfate broadleaf wood chemical pulp, carrying out thick pulp screening, blending, slushing, desanding and degassing, sizing, mixing with ASA, and carrying out fine screening to obtain pre-treated pulp; the pre-treated slurry is subjected to headbox treatment, net part dehydration forming, squeezing, first drying, first surface sizing, second drying, second surface sizing, third drying, press polishing and reeling, and the paper is prepared, wherein the first step of surface sizing comprises the step of carrying out surface sizing by adopting an acrylic emulsion; and in the second surface sizing step, polydimethylsiloxane is adopted for surface sizing. ASA sizing and surface sizing are adopted, migration of sizing liquid in the surface sizing section to paper can be reduced, and the film forming effect of the subsequent barrier material is ensured; the blocking layer is formed on the paper surface, so that the paper is ensured to obtain primary waterproof, moisture-proof and oil-proof blocking effects.

Owner:YUEYANG FOREST & PAPER CO LTD

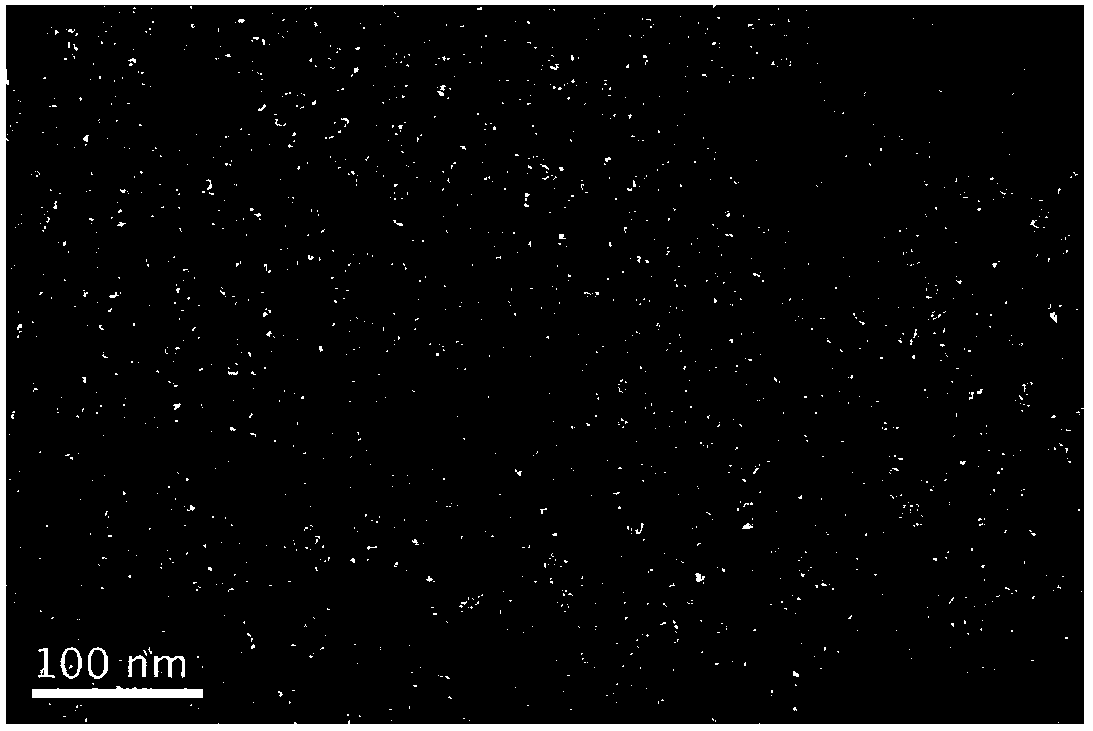

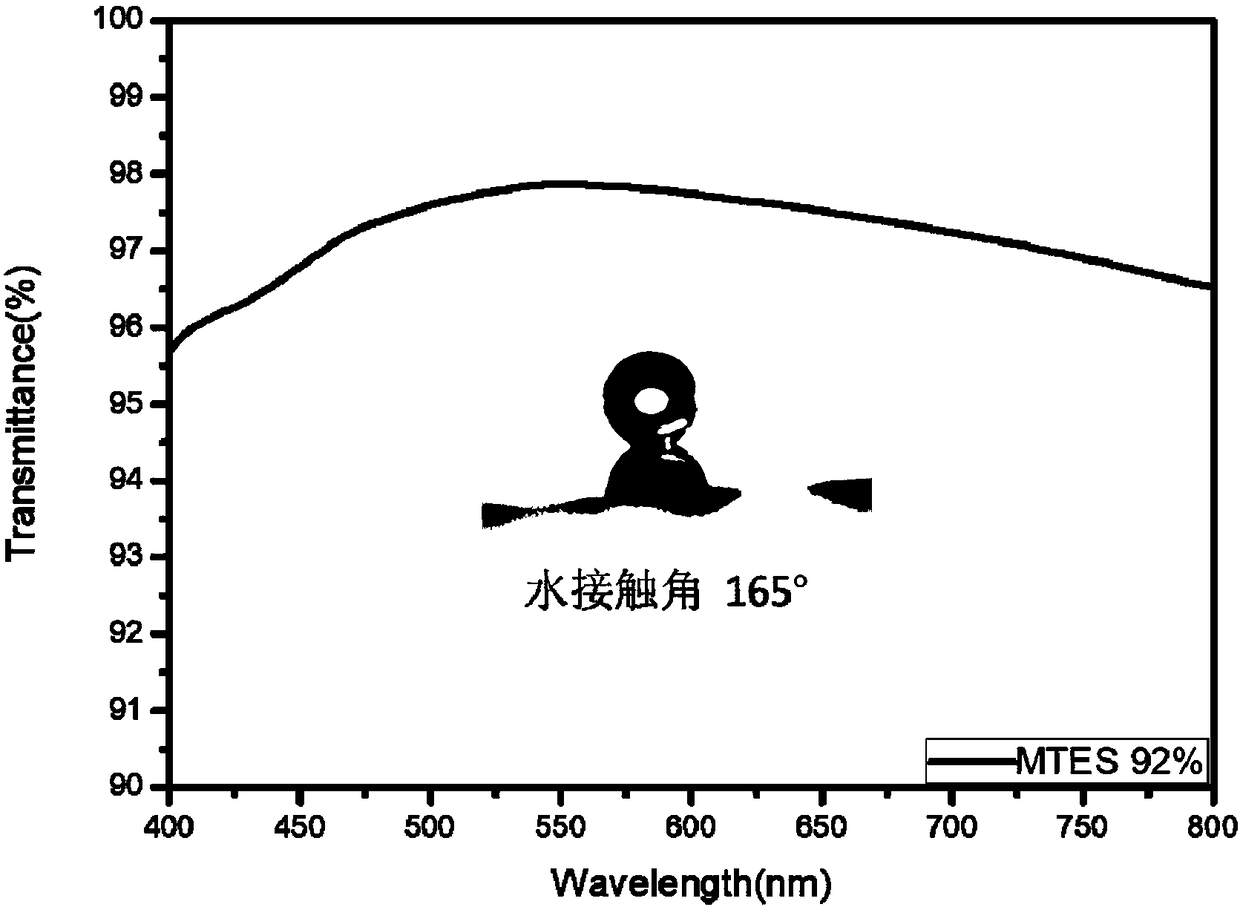

Netlike SiO2 coated sol, and preparation method and application thereof

ActiveCN108545753ALong stable periodGuaranteed light transmissionCoatingsSilicon compoundsUltraviolet lightsTransmittance

The invention discloses a netlike SiO2 coated sol, and a preparation method and an application thereof. The netlike SiO2 coated sol capable of stabilizing for 120 days or more is prepared through copolycondensation of three organosilicons comprising tetramethyl orthosilicate, methyltriethoxysilane and trimethylmethoxysilane, and the netlike SiO2 coated sol is used to prepare an ultraviolet-durablesuper-hydrophobic self-cleaning anti-reflection coating. The surface of glass is coated with a double-sided anti-reflection film by using the coated sol through a pulling-impregnating technology, thedouble-sided anti-reflection film is calcined at 450 DEG C to obtain an anti-reflection film, the average light transmittance of the anti-reflection film in visible light (400-800 nm) is 97% or more,the contact angle is 165 DEG, and after the anti-reflection film is irradiated with 150 W ultraviolet lights for 1000 h, the decrease of the average light transmittance is not more than 0.5%, and thehydrophobic angle still maintains a superhydrophobic state of 150 DEG or more.

Owner:CHANGZHOU UNIV

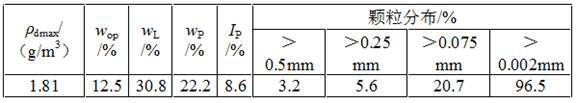

Soil stabilizer prepared from bauxite dressing tailings

PendingCN113136213AIncrease profitConform to energy savingBuilding constructionsOrganic fertilisersSoil sciencePolyvinyl alcohol

The invention discloses a soil stabilizer prepared from bauxite dressing tailings, which comprises a powder component and a liquid component, the powder component is prepared from 20-60% of bauxite dressing tailings, 20-70% of a calcium activator and 0-40% of an auxiliary enhancer, the percentage is the effective dry mass percentage of the raw materials, and the sum of the percentage is 100%; and the liquid component is prepared from polyvinyl alcohol-polyethylene glycol and water according to a ratio of 1: 100. According to the invention, industrial solid wastes such as bauxite tailings and the like are greatly utilized, the utilization rate of the industrial solid wastes is increased, the industrial policies of energy conservation, emission reduction and green development in China are met, and the method has wide and profound significance on resource utilization of the industrial solid wastes. The prepared bauxite dressing tailing-based soil stabilizer can replace cement and lime to be applied to improvement and treatment of a road roadbed, has the advantages of no calcination, energy conservation, environmental protection and the like, has an obvious price advantage compared with cement and lime, and plays a positive role in promoting resource utilization of bauxite dressing tailings and other industrial solid wastes.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Waterborne environment-friendly refractory coating as well as preparation method and application thereof

InactiveCN108410308AReduce contentComply with environmental standardsFireproof paintsPolyester coatingsMontmorilloniteSURFACTANT BLEND

The invention provides a waterborne environment-friendly refractory coating as well as a preparation method and application thereof. The preparation method comprises the steps that a film-forming basematerial and a quaternary ammonium salt type trimeric surfactant are mixed and ground so as to prepare a first material; then organic montmorillonite, ammonium polyphosphate, aluminum dihydrogen tripolyphosphate and sodium hexametaphosphate are mixed and ground so as to prepare a second material; and finally, a defoaming agent and a dispersing agent are added into the first material, grinding iscarried out, then the second material is continuously added, and full grinding is carried out so as to obtain the coating. The coating is a waterborne system, the content of volatile organic compounds(VOC) is low, the environmental protection standards are met, the film forming performance on the surface of a liner of an industry kiln is excellent, and the refractoriness is good.

Owner:张文霞

A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments

ActiveCN106007634BImprove water whitening resistanceGood water whitening resistanceLacquerBENZYL ALCOHOL/WATER

The invention relates to an external wall natural stone paint suitable for construction in a low-temperature high-humidity environment. The invention is characterized in that the paint is mainly composed of the following components in percentage by mass: 70-80% of colored sand, 12-15% of silicon-modified styrene-acrylic emulsion 8666, 0.6-0.8% of film forming aid, 2.0-3.0% of silica sol, 0.1-0.15% of thickener and the balance of conventional aid, totaling 100%. The film forming aid is mainly compounded from Texanol ester alcohol, ethylene glycol monobutyl ether and benzyl alcohol. The thickener is compounded from a polyurethane thickener and an alkali thickener. The natural stone paint can achieve the constructability of the normal temperature environment in the low-temperature high-humidity environment.

Owner:湖南德泰建筑工程有限公司

Method for preparing irregular sulfonated poly aromatic (sulfur) ether with high efficiency

Owner:安徽摩纳珀里科技有限公司

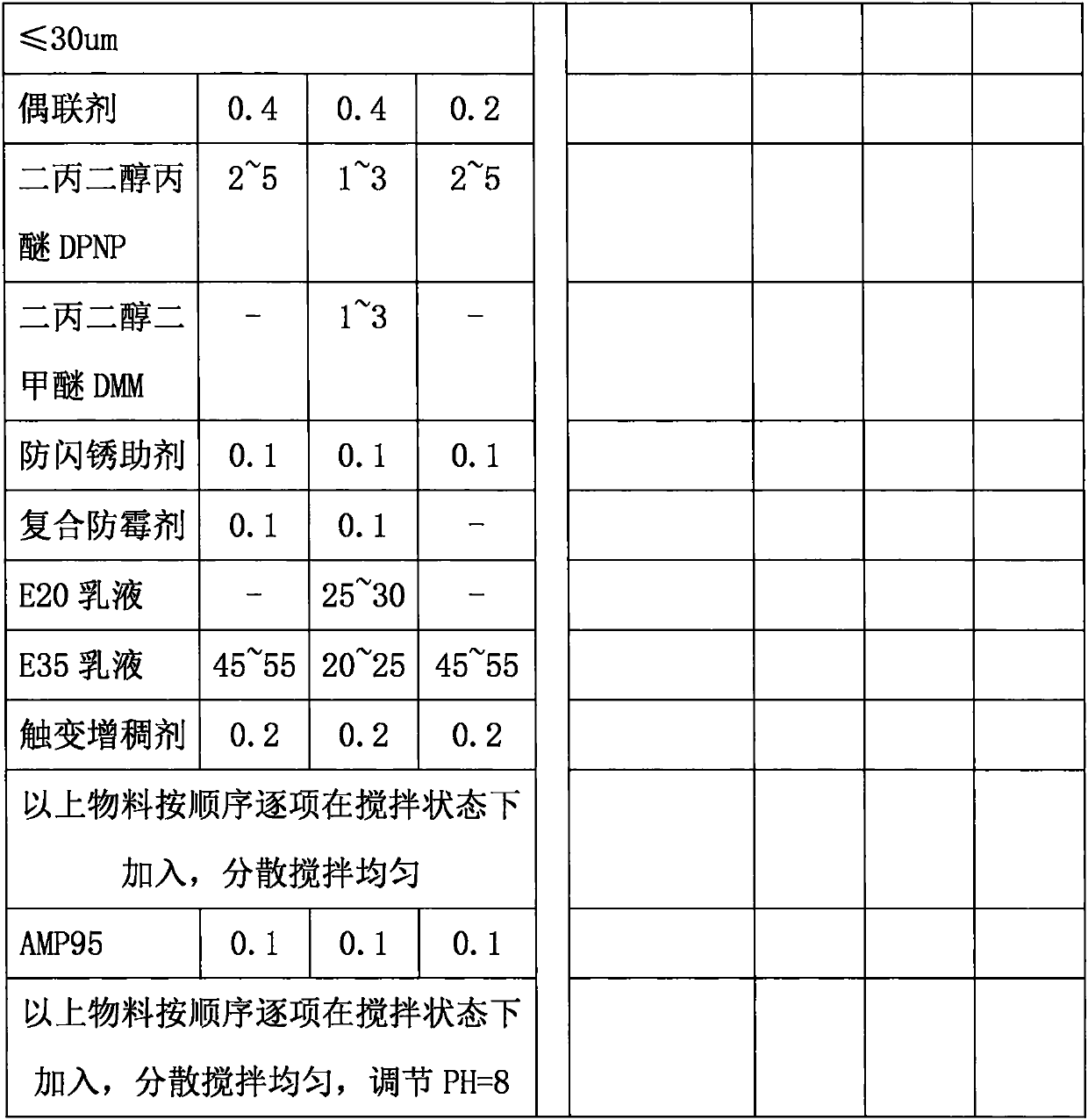

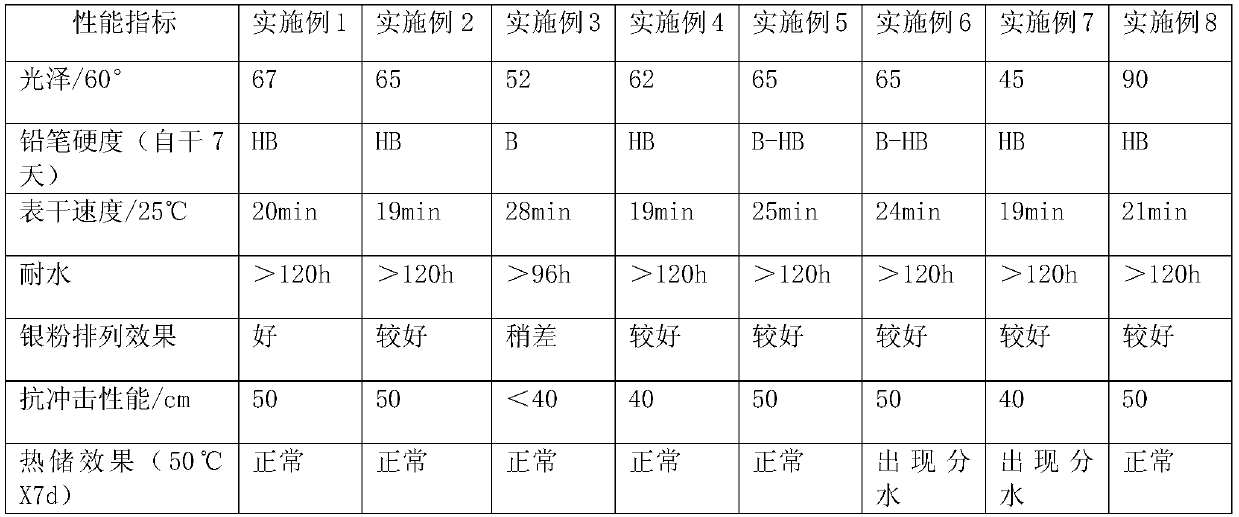

Water-based acrylic silver powder paint suitable for mechanical equipment and preparation method thereof

InactiveCN111286243AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsPaints with free metalsSilver pasteEmulsion

The invention relates to water-based industrial coating, and particularly relates to water-based acrylic silver powder paint suitable for mechanical equipment and a preparation method thereof. The water-based acrylic silver powder paint comprises a water-based self-crosslinking acrylic emulsion, a water-based polyurethane emulsion, a cosolvent, a conventional auxiliary agent, a coalescing agent, an anti-settling agent, aluminum paste, an anti-flash-rust agent, a thickening agent and deionized water. The silver powder paint disclosed by the invention is prepared by matching the water-based self-crosslinking acrylic emulsion with better wrapping property with the proper water-based polyurethane emulsion, and the prepared finished product paint is good in storage stability, high in surface drying speed, high in hardness improvement speed, good in impact resistance and good in silver powder arrangement property. The preparation process is simple, easy to operate and low in production cost,and the working efficiency is improved.

Owner:山东七维新材料有限公司

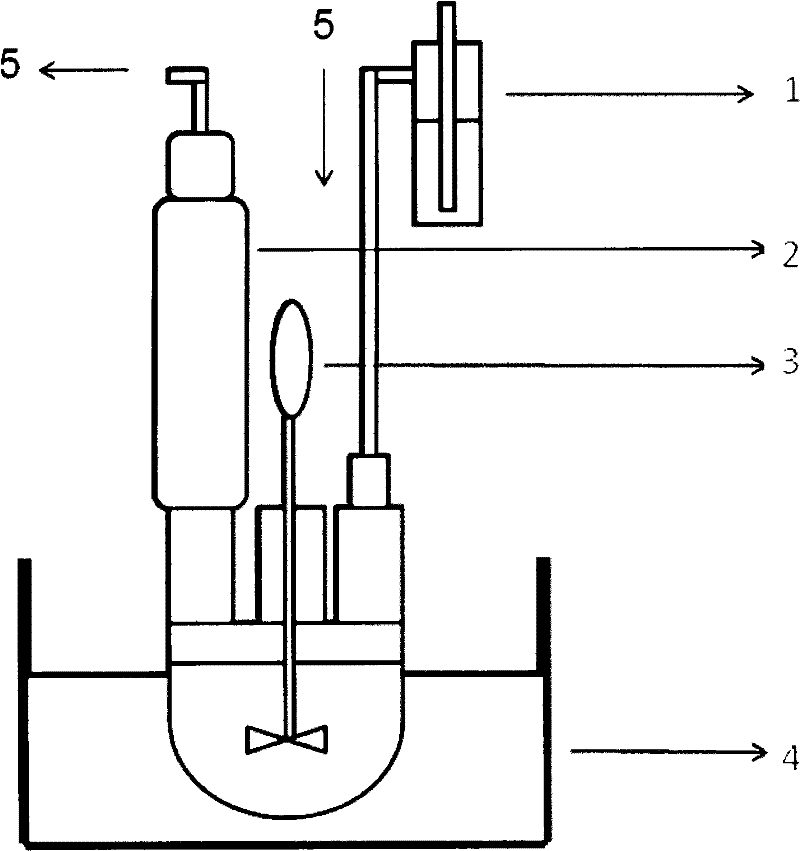

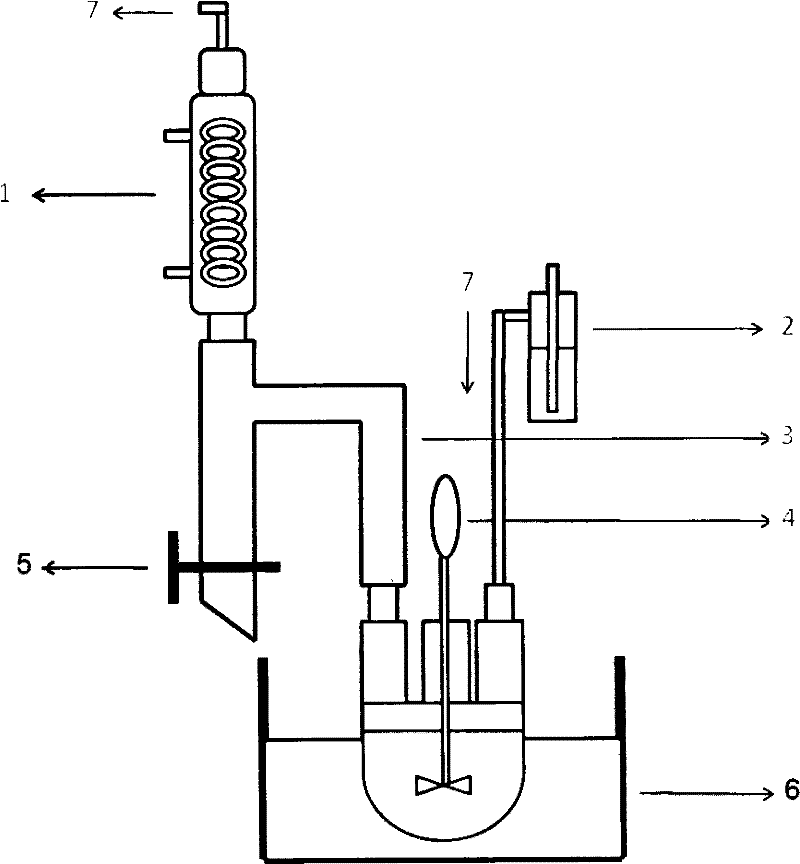

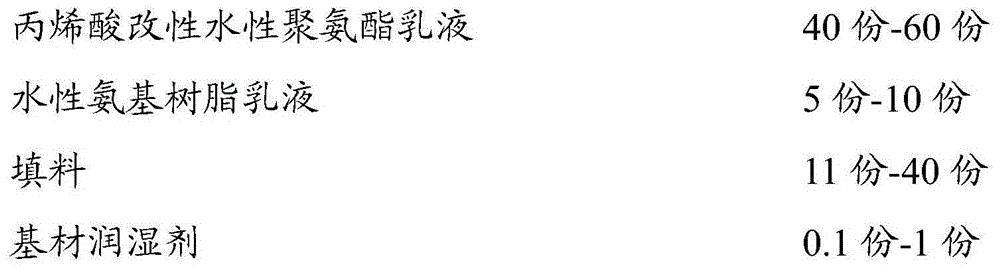

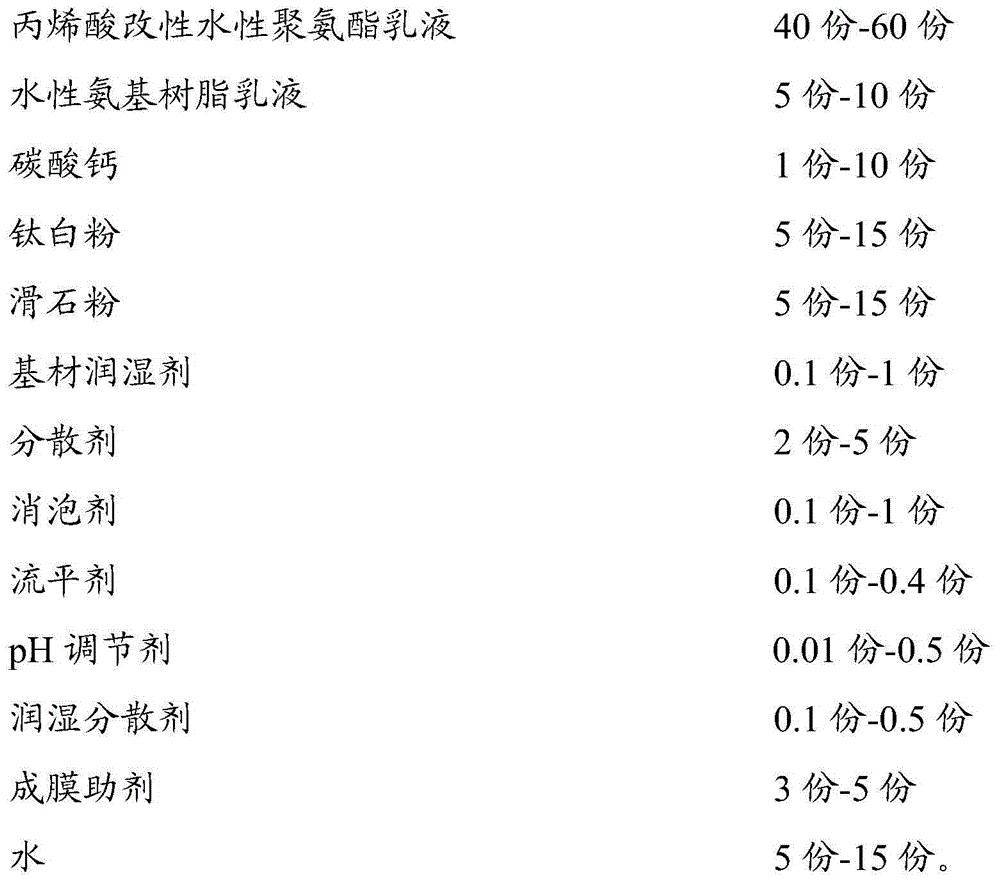

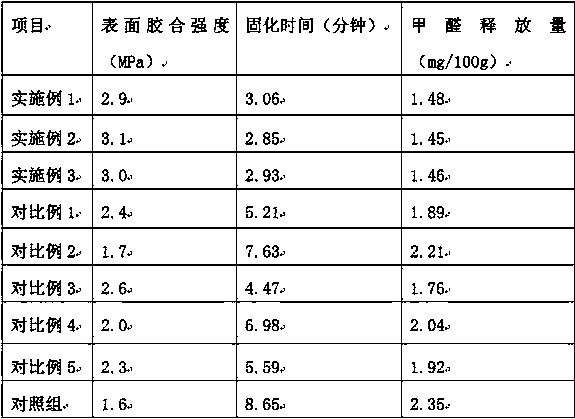

Single-component water-based coating with high film forming performance and preparation method thereof

The invention relates to a single-component water-based coating with high film forming performance and a preparation method thereof. The water-based coating comprises the following components in parts by weight: 40-60 parts of acrylic acid modified waterborne polyurethane emulsion, 5-10 parts of water-based amino resin emulsion, 11-40 parts of filler, 0.1-1 part of a substrate wetting agent, 2-5 parts of a dispersing agent, 0.1-1 part of a defoaming agent, 0.1-0.5 part of wetting dispersant, 3-5 parts of a coalescing agent and 1-25 parts of water. The coating disclosed by the invention can form a film in a short time and is capable of achieving an ideal forming performance quickly.

Owner:惠州市亚美涂料有限公司

Method of increasing curing speed of phenolic resin adhesive

InactiveCN109369868AFast curingIncreased ortho reactivityAldehyde/ketone condensation polymer adhesivesHigh water contentTemperature resistance

The invention relates to the technical field of novel functional materials and discloses a method of increasing curing speed of phenolic resin adhesive. In the phenolic resin preparation process, phenolic aldehyde and formaldehyde are mixed in the molar ratio of 1:(1.9-2.0) for reaction; first, all phenolic resin is added to a three-neck flask, formaldehyde 17-20% in mass percentage is added, andmixing is performed to prepare a modifying catalyst; second, the residual formaldehyde is added to the reaction system; catalytic modification helps reduce steric hinderance effect, improve ortho-reaction activity of phenols, and inhibit the generation of aldehyde gas; curing performance and thermal stability of the phenolic resin adhesive are successfully improved; the problem is overcome that existing phenolic resin adhesive has high water content and hindered water molecular diffusion and therefore, is low in curing speed and poor in stability; the phenolic resin adhesive has high durability and adhesive strength, better temperature resistance and evidently extended service life.

Owner:合肥绿普包装材料有限公司

Eye sticker with gel type eye mask added with plant petals and preparation method of eye sticker

InactiveCN110269826ASimple processParameters are easy to getCosmetic preparationsToilet preparationsSodium hyaluronateNutrient

The invention discloses an eye sticker with a gel type eye mask added with plant petals. The eye sticker comprises, by weight, 5-8% of propylene glycol, 1-3% of glycerol, 1-2% of chondrus crispus powder, 1-2% of xanthan gum, 0.5-1% of the plant petals, 0.4-0.5% of glycerol caprylate, 0.1-0.3% of allantoin, 0.2-0.4% of p-hydroxy acetophenone, 0.2-0.4% of cellulose gum, 0.1-0.15% of chlorphenesin, 0.1-0.2% of methyl hydroxybenzoate, 0.1-0.2% of an oat bran extract, 0.03-0.05% of sodium hyaluronate, 0.03-0.05% of CI 77019 and the balanced deionized water. The invention further discloses a preparation technology of the eye sticker. By means of the technical scheme, locked moisture is released when the eye sticker is in contact with air, so that the moisture is easily absorbed by eye skin; meanwhile, the eye skin can absorb nutrients from the plant petals, so that the eye skin is made to be bright.

Owner:朱思文

Electrostatic spraying antirust oil and preparation method thereof

PendingCN109321338AGood dispersionImprove resistance to acidic atmosphereLubricant compositionSulfonateWax

The invention belongs to the field of metal surface protection and provides electrostatic spraying antirust oil and a preparation method thereof. The antirust oil is prepared from the following ingredients in parts by weight: 5 to 15 parts of oxidized petroleum wax salt, 0 to 5 parts of synthesized ammonium sulfonate and 35 to 90 parts of hydrorefined mineral oil, wherein the oxidized petroleum wax salt is at least one of calcium salt of oxidized petroleum wax, sodium salt of the oxidized petroleum wax or ammonium salt of the oxidized petroleum wax, and the base number of the oxidized petroleum wax salt is 100 to 500 mgKOH / g; the hydrorefined mineral oil is at least one of refined mineral oil with the viscosity of 5 mm<2> / s under 40 DEG C, refined mineral oil with the viscosity of 32 mm<2> / s under 40 DEG C or refined mineral oil with the viscosity of 68 mm<2> / s under 40 DEG C. The antirust oil disclosed by the invention has good environmental protection property and in the meantime, has a reasonable resistance value; the resistance value is only 0.1 to 20 M omega under the temperature of 20 to 60 DEG C; the antirust oil is suitable for electrostatic atomization spraying of metal, can form an even oil film on the plate surface, which cannot be broken down to generate electric spark to be combusted, and has high use safety; furthermore, the antirust performance is excellent, lowtemperature resistance of the product is good, and good fluidity can be achieved under the -20 DEG C environment.

Owner:SHANGHAI PARKER CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com