Heat dissipation type solar cell back film

A solar cell and heat dissipation technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing the insulation of the backplane, affecting the safety and service life of solar cells, and achieving film-forming performance and good thermal conductivity. , Solve the effect of poor processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

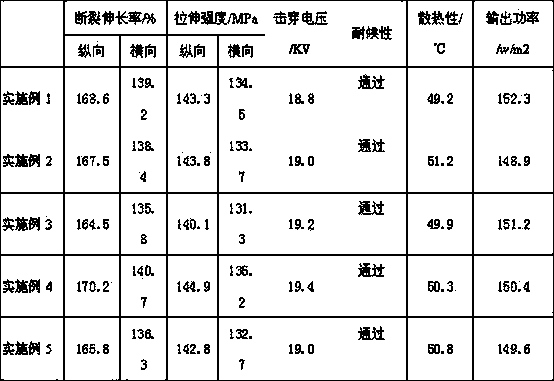

Examples

Embodiment 1

[0036] Take 100kg PET resin, 10kg titanium dioxide (Ti-pure R902), 1kg ultraviolet absorber UV-P, 0.5kg antioxidant 1010, 0.5kg antihydrolysis agent carbodiimide, mix them evenly and add them to the twin-screw extruder to melt Extruded to obtain polyester layer chips.

[0037] Get 100kg of PET resin, 10kg of aluminum nitride particles processed through hyperbranched polyester grafting, and 5kg of graphite processed through hyperbranched polyester grafting, mix them uniformly and add them to a twin-screw extruder for melting and extrusion to obtain the first A thermally conductive polyester layer slice.

[0038] Take 100kg of PET resin and 20kg of aluminum nitride particles that have been grafted with hyperbranched polyester, mix them evenly, and put them into a twin-screw extruder to melt and extrude to obtain slices of the second heat-conducting polyester layer.

[0039] The polyester layer slices obtained above, the first heat-conducting polyester layer slices and the secon...

Embodiment 2

[0042] Take 100kg PET resin, 10kg titanium dioxide (Ti-pure R902), 1kg ultraviolet absorber UV-P, 0.5kg antioxidant 1010, 0.5kg antihydrolysis agent carbodiimide, mix them evenly and add them to the twin-screw extruder to melt Extruded to obtain polyester layer chips.

[0043] Get 100kg of PET resin, 16kg of alumina particles processed through hyperbranched polyether grafting, and 4kg of aluminum powder processed through hyperbranched polyether grafting, mix them uniformly and add them to a twin-screw extruder for melting and extrusion to obtain the first A thermally conductive polyester layer slice.

[0044] Take 100kg of PET resin and 5kg of silicon carbide particles grafted with hyperbranched polyether, mix them evenly, and put them into a twin-screw extruder to melt and extrude to obtain slices of the second heat-conducting polyester layer.

[0045] The polyester layer slices obtained above, the first heat-conducting polyester layer slices and the second heat-conducting p...

Embodiment 3

[0048] Take 100kg PET resin, 10kg titanium dioxide (Ti-pure R902), 1kg ultraviolet absorber UV-P, 0.5kg antioxidant 1010, 0.5kg antihydrolysis agent carbodiimide, mix them evenly and add them to the twin-screw extruder to melt Extruded to obtain polyester layer chips.

[0049] Get 100kg of PET resin, 2.5kg of aluminum nitride particles processed by hyperbranched polysiloxane grafting, and 2.5kg of graphite processed by hyperbranched polysiloxane grafts, mix them evenly and add them to the twin-screw extruder Melt extrusion to obtain slices of the first heat-conducting polyester layer.

[0050] Take 100kg of PET resin and 30kg of aluminum nitride particles grafted with hyperbranched polysiloxane, mix them evenly, and put them into a twin-screw extruder to melt and extrude to obtain slices of the second heat-conducting polyester layer.

[0051] The polyester layer slices obtained above, the first heat-conducting polyester layer slices and the second heat-conducting polyester la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com