Patents

Literature

142 results about "Tetramethyl orthosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetramethyl orthosilicate is the chemical compound with the formula Si(OCH₃)₄. This molecule consists of four methoxy groups bonded to a silicon atom. The basic properties are similar to the more popular tetraethyl orthosilicate, which is usually preferred because the product of hydrolysis, ethanol, is less toxic than methanol.

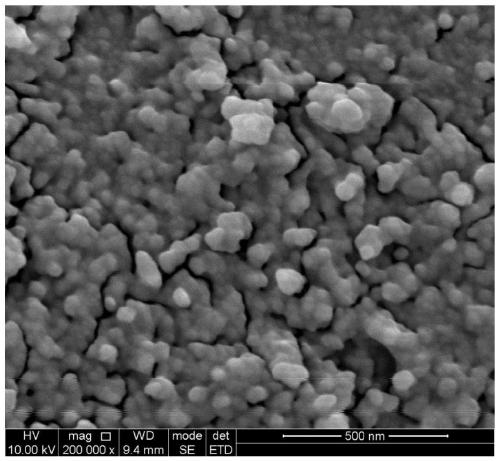

Method for removing thiophene sulfur in fuel oil by using Ag2O/SiO2 composite aerogel as adsorbent

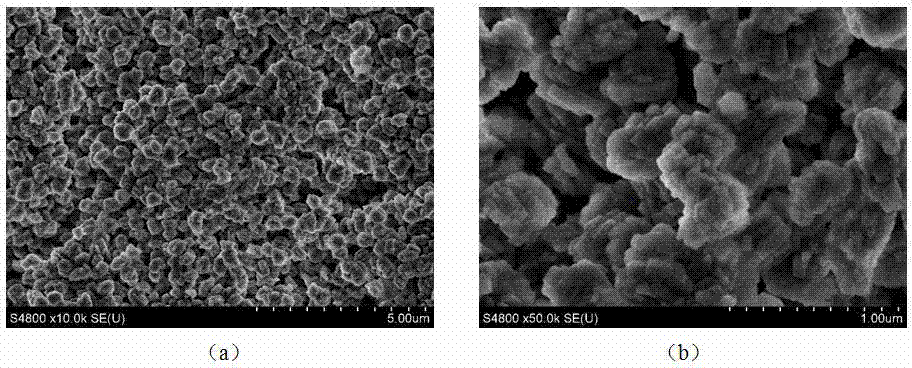

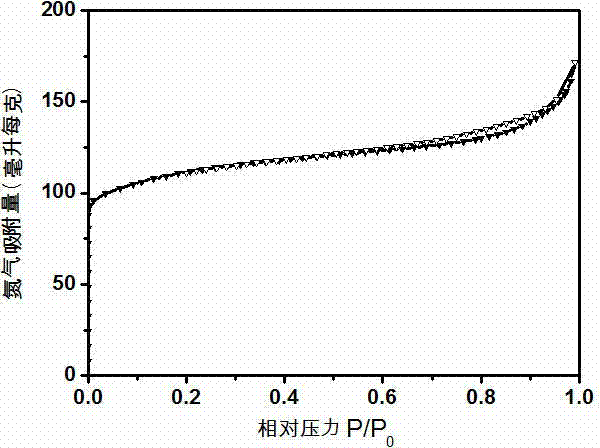

ActiveCN106118717ATypical mesoporous characteristic pore diameterHigh porosityOther chemical processesSolid sorbent liquid separationSorbentFuel oil

The invention discloses a method for removing thiophene sulfur in fuel oil by using Ag2O / SiO2 composite aerogel as an adsorbent, and belongs to the technical field of fuel oil processing. The method comprises the following steps: by taking tetramethyl orthosilicate, tetraethoxysilane, silica sol, sodium silicate and the like as silicon sources, and silver acetate, silver nitrate and the like as silver sources, preparing the Ag2O / SiO2 composite aerogel by adopting a sol gel-normal-pressure preparing drying method; quantitatively filling the aerogel into a fixed bed adsorption device, injecting model gasoline containing thiophene sulfur at certain temperature and air speed, collecting adsorbed model gasoline at the outlet in the lower end of a reaction device, and performing chromatographic analysis. The result shows that the Ag2O / SiO2 composite aerogel has a good adsorption property on thiophene sulfur. The Ag2O / SiO2 composite aerogel is simple in preparation method, low in cost, high in economic benefit, good in environment-friendliness, gentle in adsorption conditions and low in requirement on adsorption equipment, and can be repeatedly used.

Owner:ZHEJIANG UNIV OF TECH

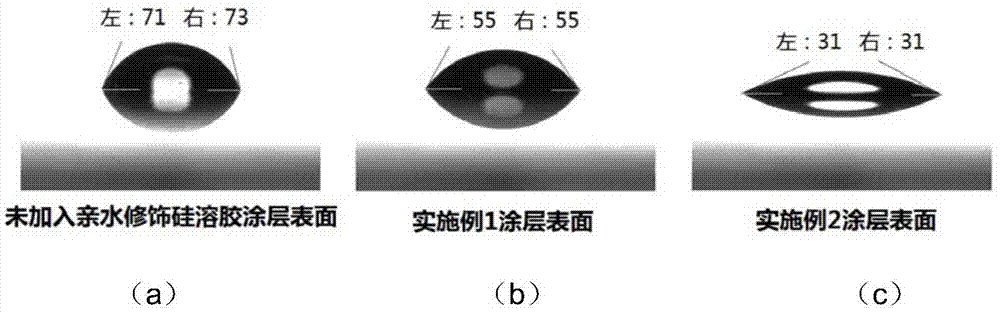

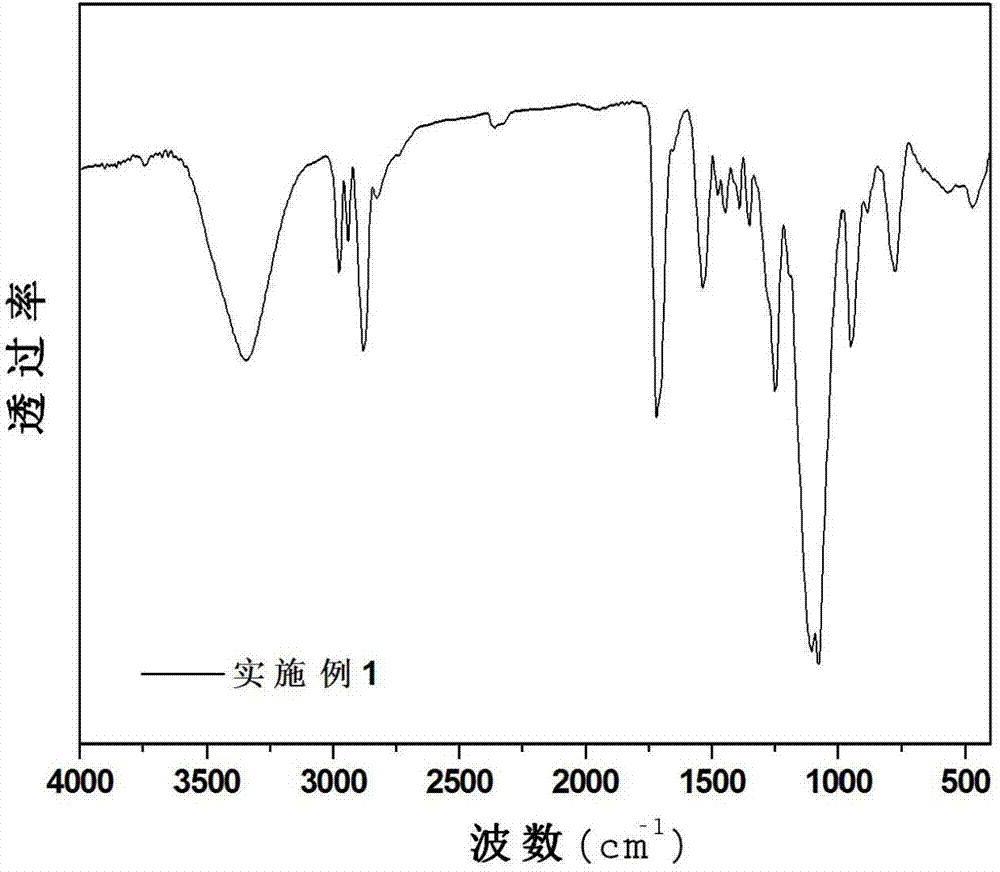

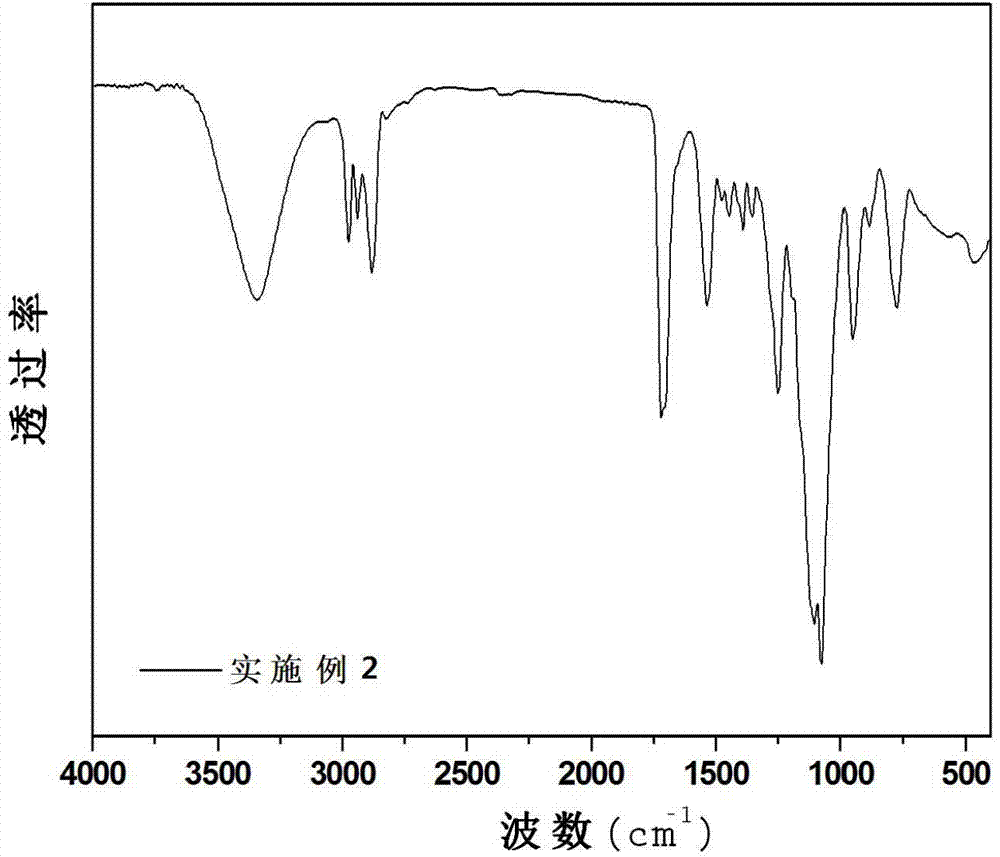

Hydrophilic modified silica sol and application thereof in preparation for hydrophilic anti-fog wear-resistant coating

The invention discloses a hydrophilic modified silica sol and application thereof in preparation for a hydrophilic anti-fog wear-resistant coating, and belongs to the technical field of hydrophilic anti-fog wear-resistant coatings. The hydrophilic modified silica sol is the random hydrolysate of a PEG-modified silane coupling agent and tetraethyl orthosilicate or tetramethyl orthosilicate, and is obtained by adding the PEG-modified silane coupling agent and tetraethyl orthosilicate or tetramethyl orthosilicate in an organic solvent in a mass ratio of (1-10):1 at a room temperature, wherein the solid content of the system is 5-30%; and then adding water occupying 0.1-3% of a total monomer mass and acetic acid occupying 0.1-3% of the total monomer mass, stirring for 10-24 hours, and then ageing for 10-72 hours. The application of the hydrophilic modified silica sol disclosed by the invention in preparation for the hydrophilic anti-fog wear-resistant coating specifically comprises the steps of adding the hydrophilic modified silica sol in an organic anti-fog coating, and stirring to obtain a mixed coating with viscosity of 100-700cps.

Owner:JILIN UNIV

Self-cleaning hydrophilic coating liquid and coating method

The present invention discloses a self-cleaning hydrophilic coating liquid, which is prepared from the following components by weight: 1 to 5% of orthosilicate, 0.1 to 5% of titanate, 0.1 to 5% of polyether siloxane, 0.01 to 0.5% of a catalyst and balance of an organic solvent, the orthosilicate is tetramethyl orthosilicate ortetraethyl orthosilicate, the titanate is tetrabutyl titanate or tetraethyl titanate, the polyether siloxane is polyether trimethoxy silane, when the substrate surface is scoured by water, the water can slide down automatically, the substrate also has superior hydrophilicity without ultraviolet radiation, the substrate surface can be cleaned by nature rain effect or a small amount of water for washing, the self-cleaning hydrophilic coating liquid can be can be cured naturally at room temperature without high temperature and other film forming conditions, energy is saved, and scratch resistance, peel resistance and other mechanical strength the coated film layer are greatly increased. The self-cleaning hydrophilic coating liquid is applicable to engineering glass, photovoltaic glass, stone materials, metal surfaces, automotive exterior mirrors and glasses.

Owner:萍乡亨厚新材科技有限公司

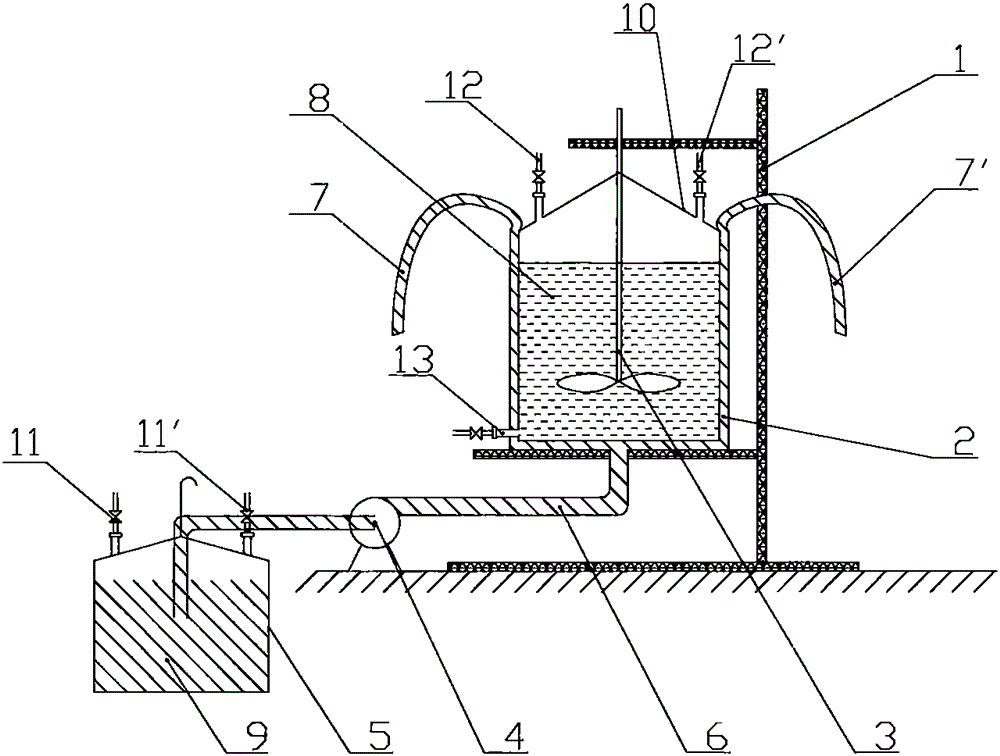

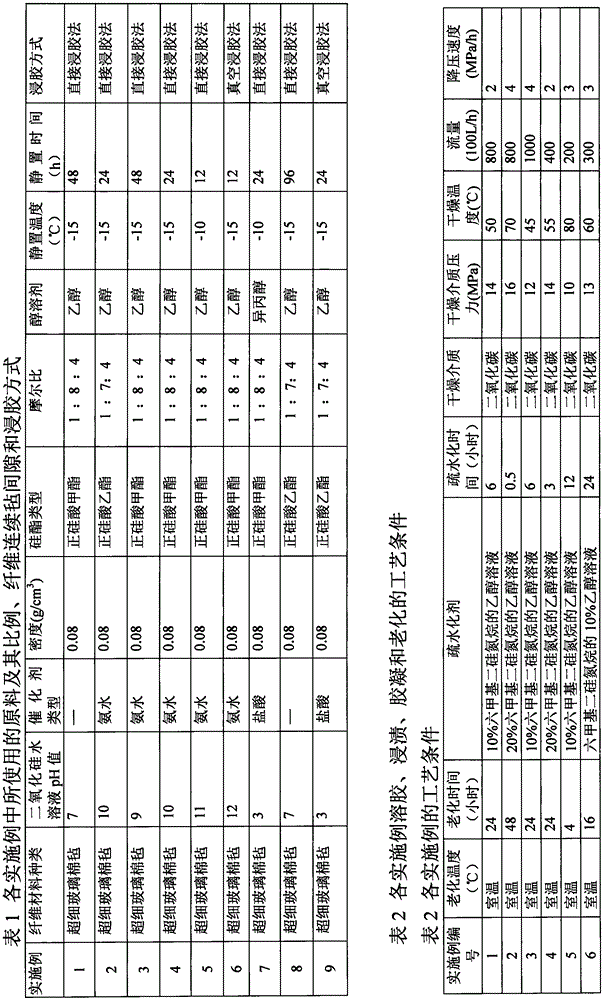

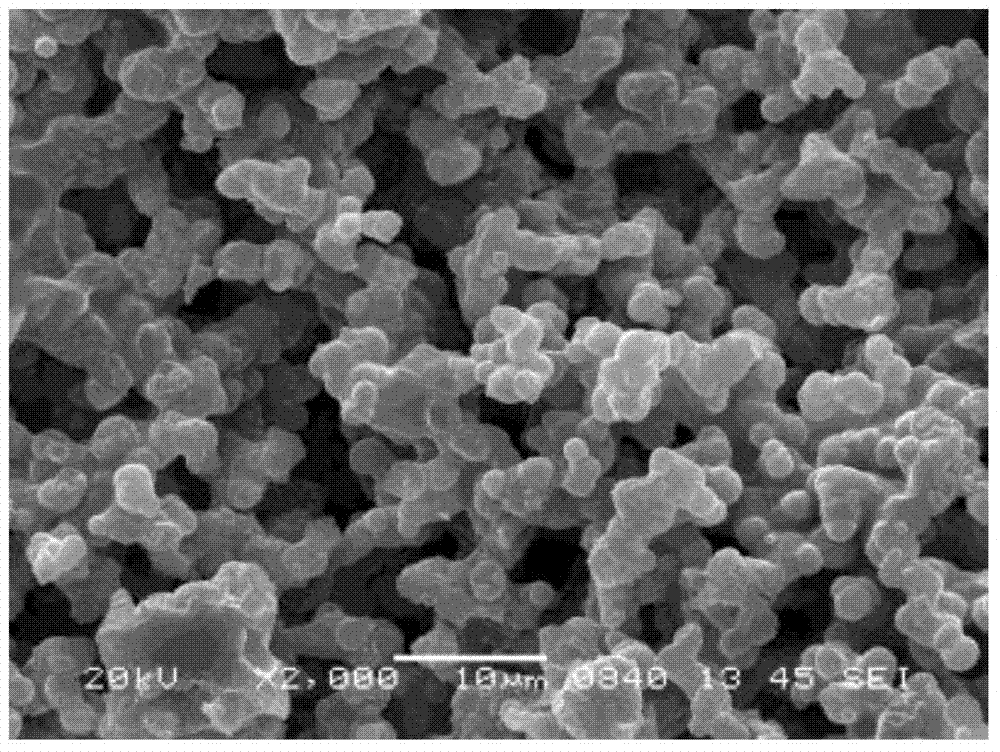

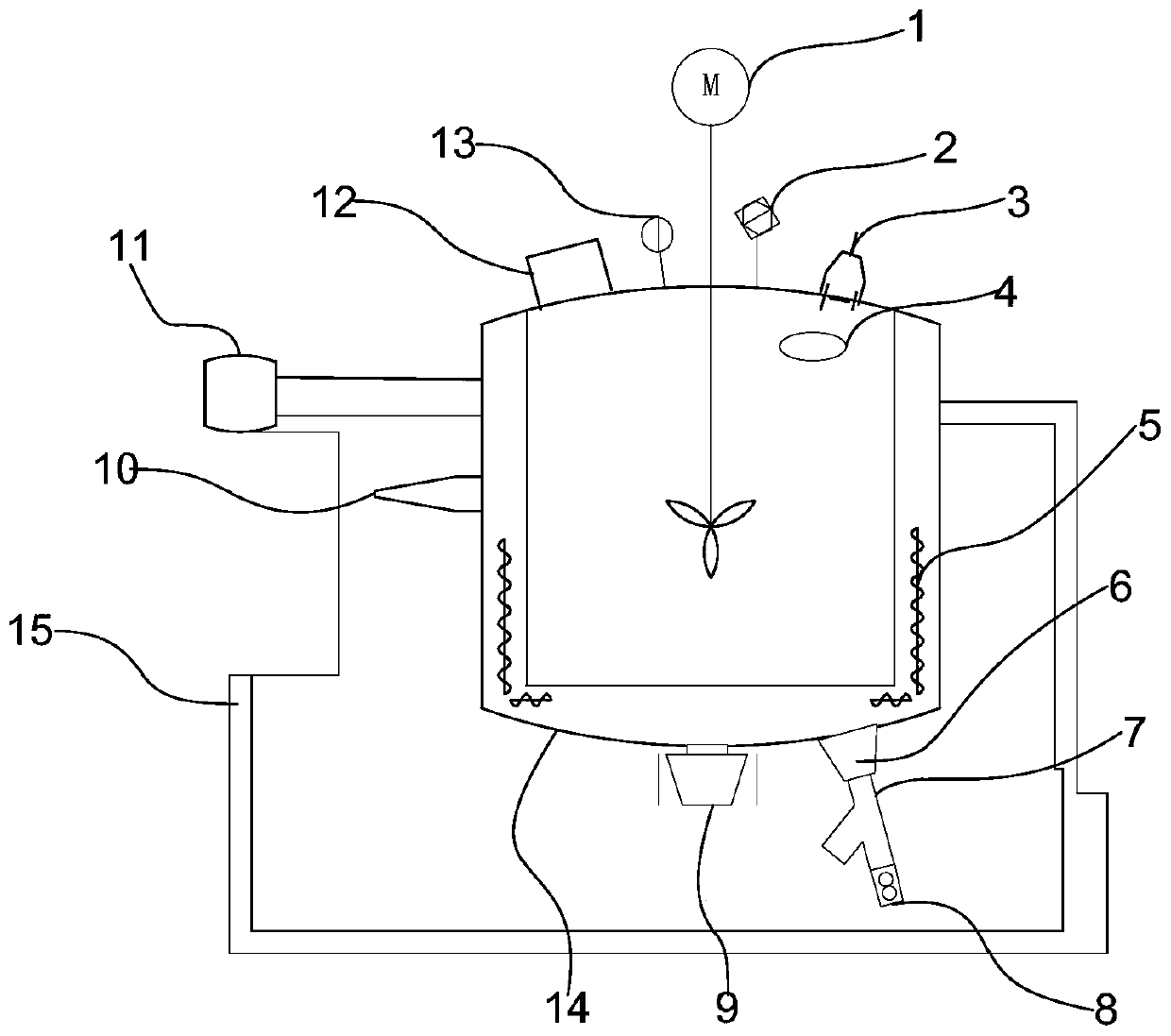

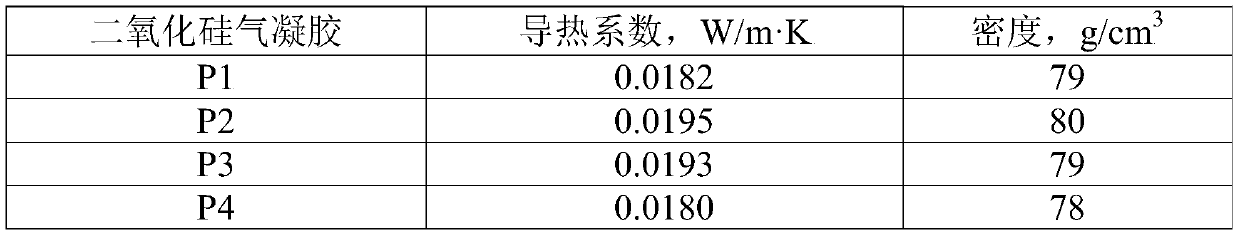

High-performance aerogel composite material, preparation method and equipment thereof

The invention provides a high-performance aerogel composite material, and a preparation method and equipment of the high-performance aerogel composite. The aerogel composite material comprises a silicon dioxide aerogel and a fiber material, wherein the silicon dioxide aerogel uses tetramethyl orthosilicate and water as raw materials and an alcohol solvent as a solvent to prepare a silica sol, and no gel catalyst is added in the silica sol. The equipment comprises a reaction part and a circulated cooling part. The method comprises the steps of preparing the sol, dipping glue, standing, gelatinizing, aging gel, dewatering, drying and the like. With the adoption of the method, materials with planar or abnormal shapes and multiple sizes can be conveniently and selectively prepared, the gelation time is controllable, no catalyst is needed, the kinds of raw materials are few, the operation is simple and convenient, and the environmental pollution is low. The material is excellent in heat-insulating property and has a wide application prospect in the fields of the civil industry, the space flight and aviation industry and the military industry.

Owner:海鹰空天材料研究院(苏州)有限责任公司

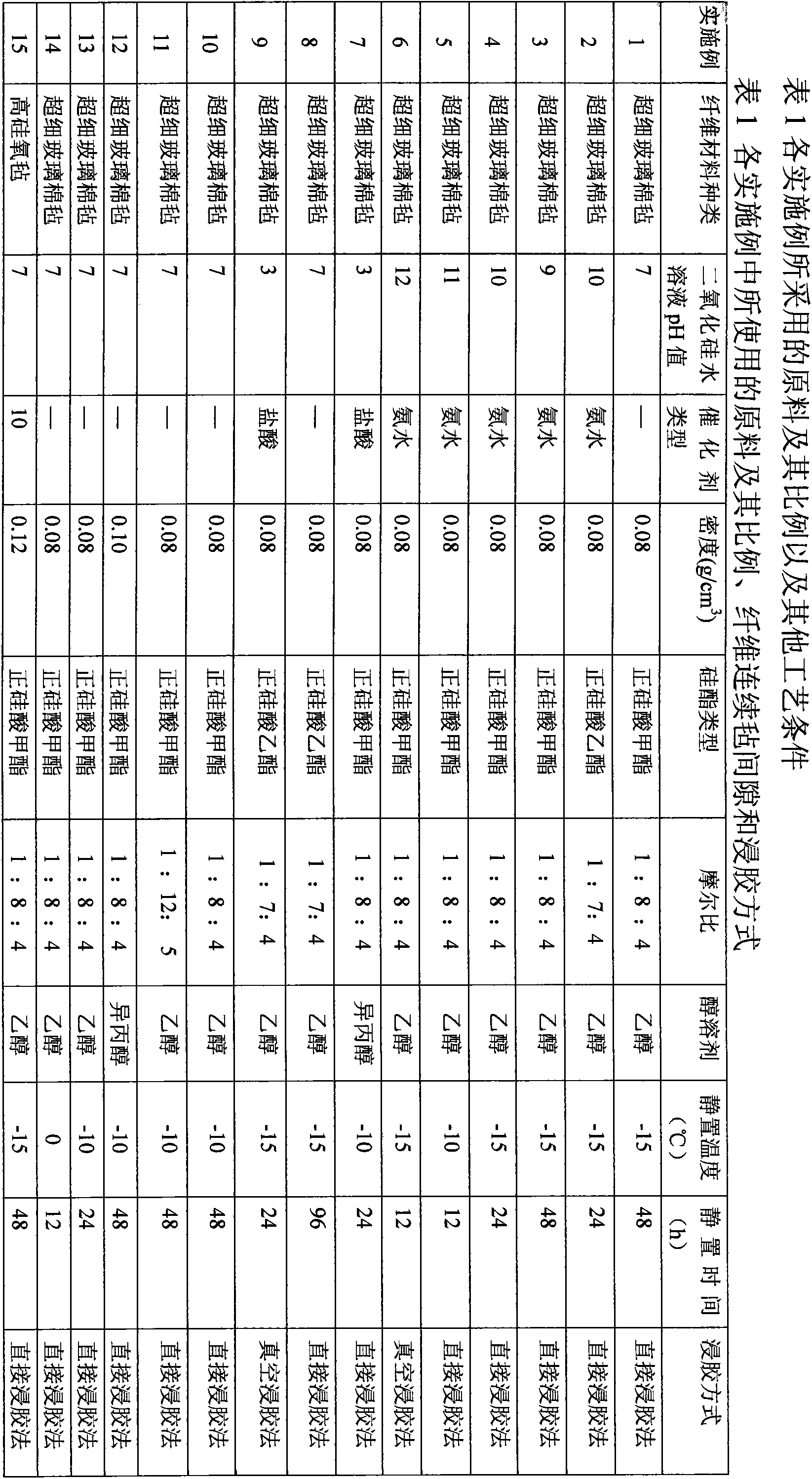

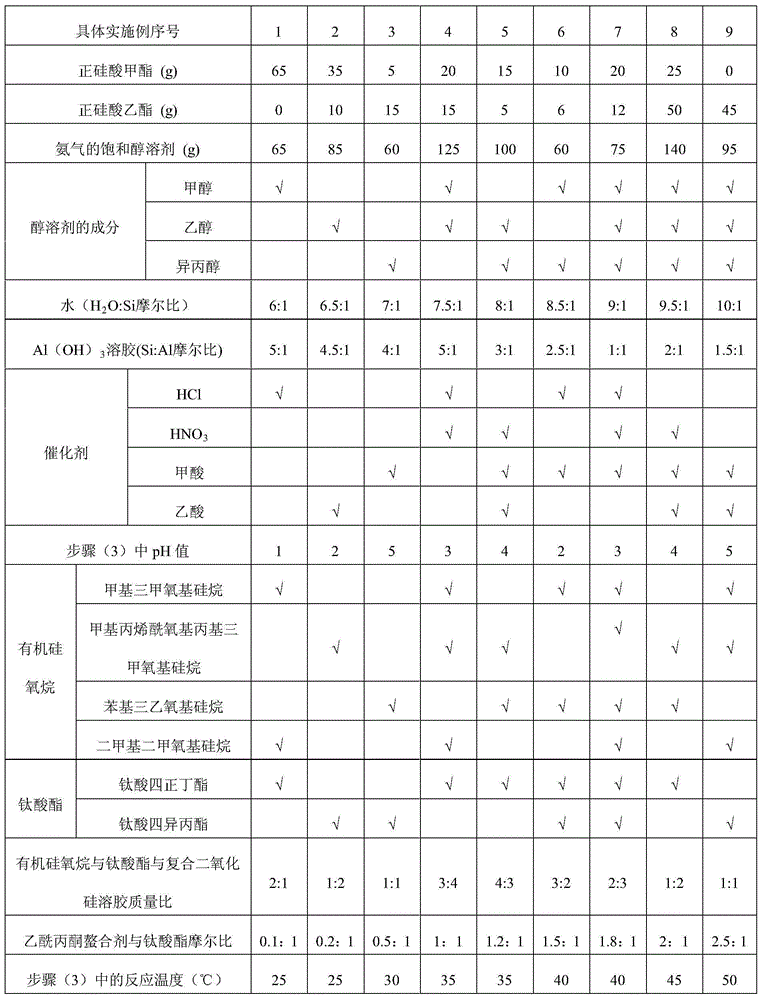

Preparation method of organic-inorganic composite sol for metal aluminum sheet surface corrosion prevention

The invention relates to preparation of a sol, and aims to provide a preparation method of an organic-inorganic composite sol for metal aluminum sheet surface corrosion prevention. The method comprises the following steps: adding tetramethyl orthosilicate or ethyl orthosilicate into a saturated alcohol solvent of ammonia gas, adding water, reacting, heating under reflux to remove ammonia, and carrying out rotary evaporation to obtain a nano silicon dioxide sol; adding the nano silicon dioxide sol into a Al(OH)3 sol, and aging; adding a catalyst while stirring and keeping the pH value at 1-5, adding an acetylacetonate chelator, and continuing stirring; and dropwisely adding an organosiloxane-titanate mixture, and reacting to obtain the sol. The method greatly increases the adhesive force between the coating and metal aluminum sheet by 1-3 levels on the basis of the traditional silicon coating. The high-hardness Al(OH)3 is coated on the nano silicon dioxide particles to further enhance the coating hardness by 2H or so on the basis of the traditional silicon coating, and the corrosion resistance in a neutral salt fog resistance experiment is enhanced by 2-3 times.

Owner:ZIGONG INNOVATION CENT OF ZHEJIANG UNIV

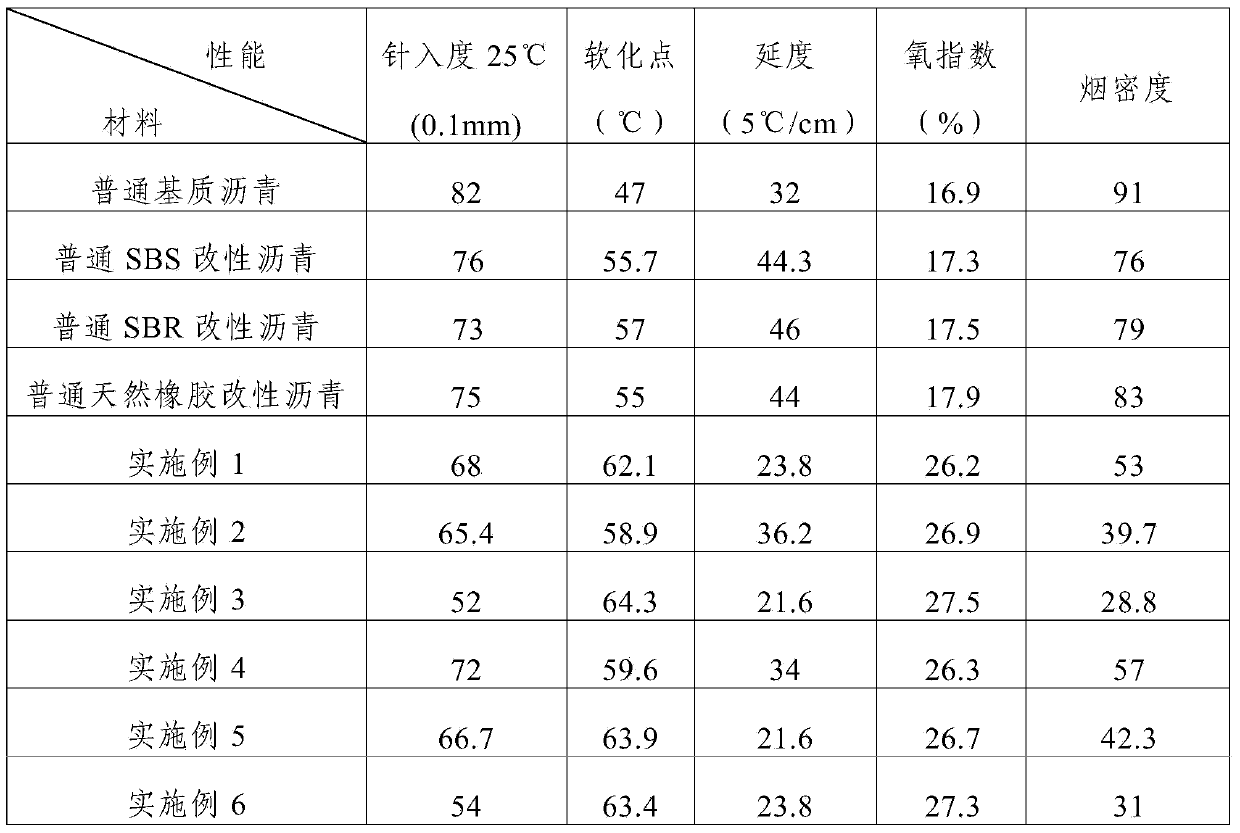

Road modified asphalt

ActiveCN103740121AHigh bonding strengthImprove surface adhesionBuilding insulationsMaterials scienceAcetone

The invention provides road modified asphalt. The road modified asphalt is prepared from the following raw materials by weight: 100 parts of asphalt, 2-9 parts of spodumene powder, 0.45-3.5 parts of camsellite powder, 0.04-0.3 part of nonylphenol, 0.08-0.6 part of diphenylamine and 0.07-0.5 part of crosslinker, wherein one or more of tetramethyl orthosilicate, aluminum isopropoxide and titanium (IV) acetylacetonate is used as the crosslinker. The road modified asphalt has an excellent flame retarding effect and excellent road service performance. Meanwhile, the release quantities of asphalt smote and waste gas in mixing and paving processes can be effectively reduced. The road modified asphalt has great economic benefits and social benefits.

Owner:CHANGAN UNIV

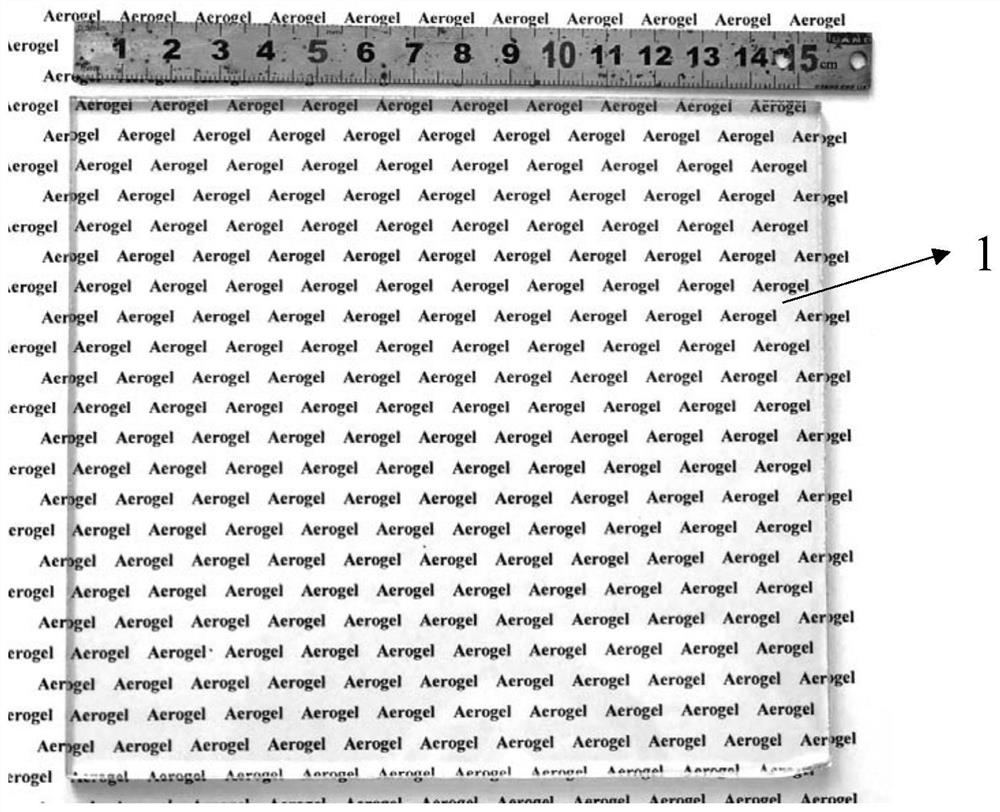

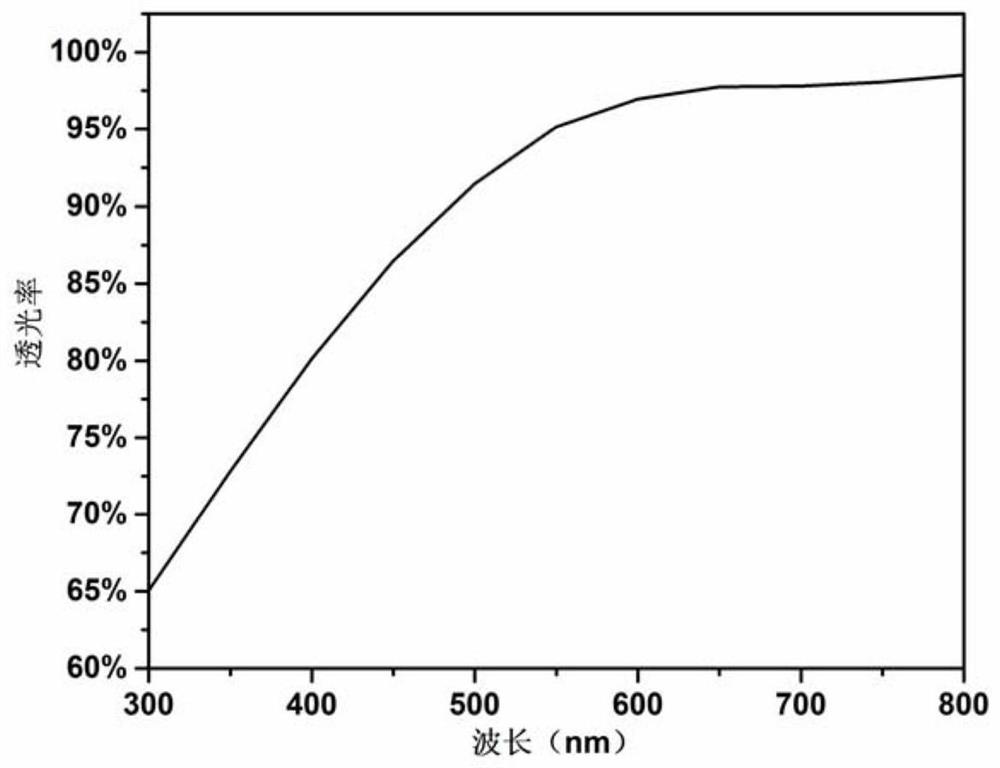

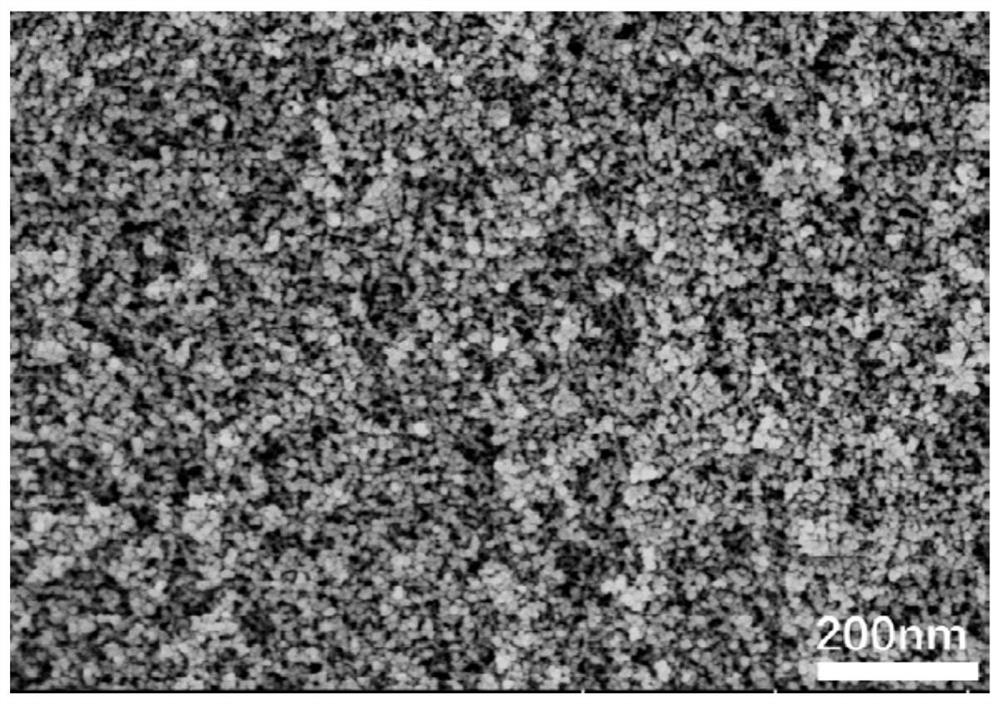

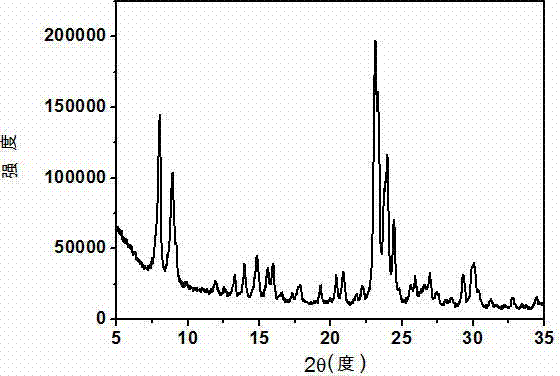

Ultrahigh-transparency large-size block silicon dioxide aerogel and preparation method and application thereof

ActiveCN112174144AControllable adjustment of reactivityImprove uniformitySilicon compoundsPtru catalystSilicic acid

The invention relates to an ultrahigh-transparency large-size block silicon dioxide aerogel and a preparation method and application thereof. The method comprises the following steps: uniformly mixingtetramethyl orthosilicate, long-chain alkyl trimethoxy silane, an alcohol solvent, water and an alkali catalyst, carrying out hydrolysis reaction to obtain sol, and putting the sol into a mold to carry out sol-gel reaction to obtain wet gel; carrying out gradient heating aging on the wet gel to obtain skeleton-reinforced wet gel; and sequentially carrying out solvent replacement and supercriticaldrying on the skeleton-reinforced wet gel to obtain the ultrahigh-transparency large-size block silicon dioxide aerogel. According to the preparation method disclosed by the invention, superfine silicon dioxide sol generated by hydrolyzing long-chain alkyl trimethoxy silane stable tetramethyl orthosilicate is introduced, and the reaction activity of the sol is controllably adjusted so that the accurate regulation and control of a gelling process are realized; the aerogel prepared by the method has the characteristics of ultrahigh transparency, large size, super heat insulation capability, super hydrophobicity and the like, and has great economic value in the field of transparent heat insulation.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Method for one step synthesis of hierarchical porous structured ZSM-5 zeolite with open pores

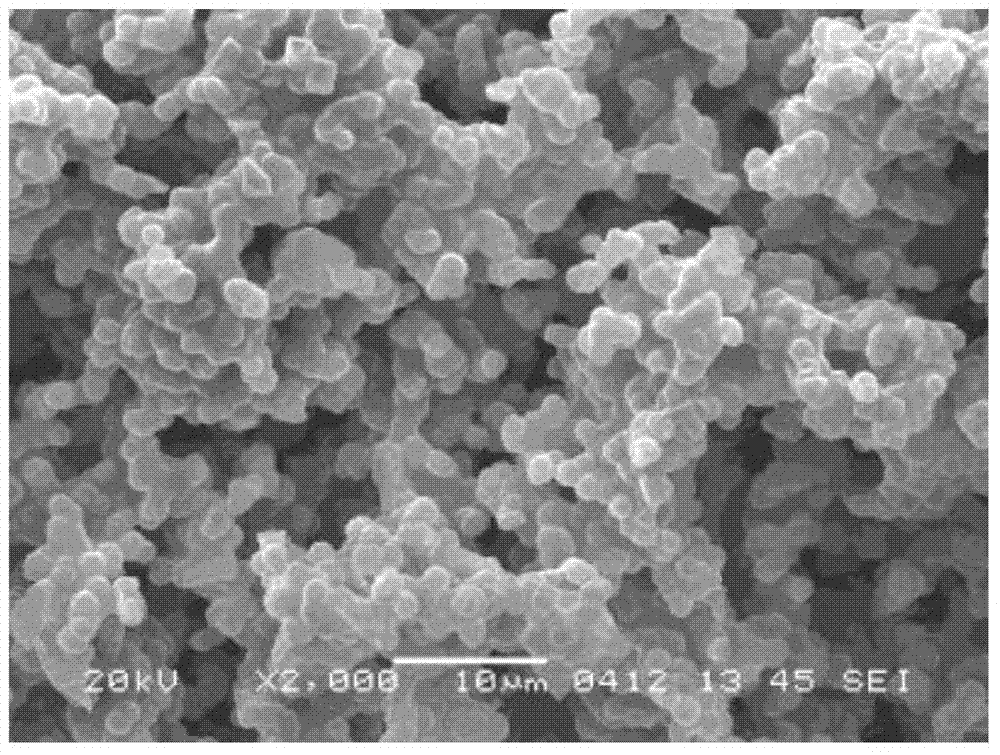

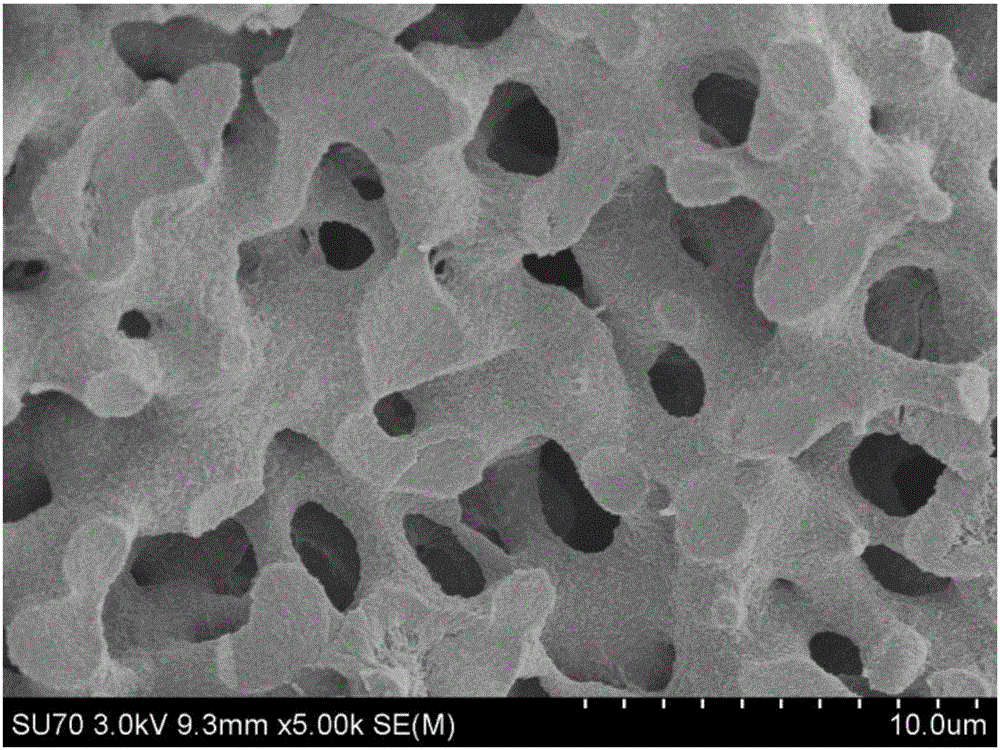

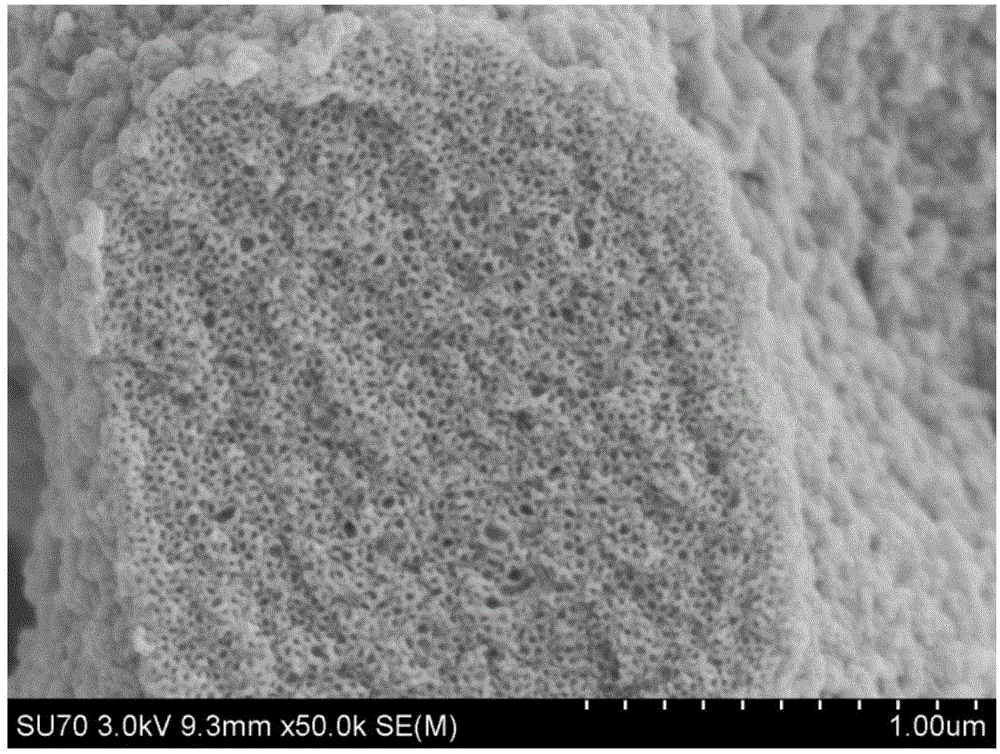

ActiveCN104760974AReduce usageReduce manufacturing costPentasil aluminosilicate zeoliteIon exchangeHierarchical porous

The invention discloses a method for one step synthesis of hierarchical porous structured ZSM-5 zeolite with open pores. The method is characterized in that active colloidal crystal seeds are introduced to a reaction system composed of an inorganic silicon source and an aluminum source in order to realize one step synthesis of the hierarchical porous structured ZSM-5 zeolite with open pores, and the colloidal crystal seeds are prepared through the steps of mixing tetramethyl orthosilicate, tetraethyl orthosilicate or silica sol with a template, hydrolyzing and ageing; and the template is tetrapropylammonium hydroxide or tetrapropylammonium bromide. Compared with zeolite in the prior art, the hierarchical porous structured ZSM-5 zeolite with open pores has accumulated meso-porous properties, has a meso-pore volume approaching 0.3ml / g and an external surface area approaching 100m<2> / g, can realize ion exchange without roasting, well avoids the use of a large amount of a structure directing agent, and has reduced preparation cost; and the method also has the advantages of simplicity, environmental protection, high efficiency, certain industrialization utilization prospect, and substantial economy value.

Owner:江苏黄马化工有限公司

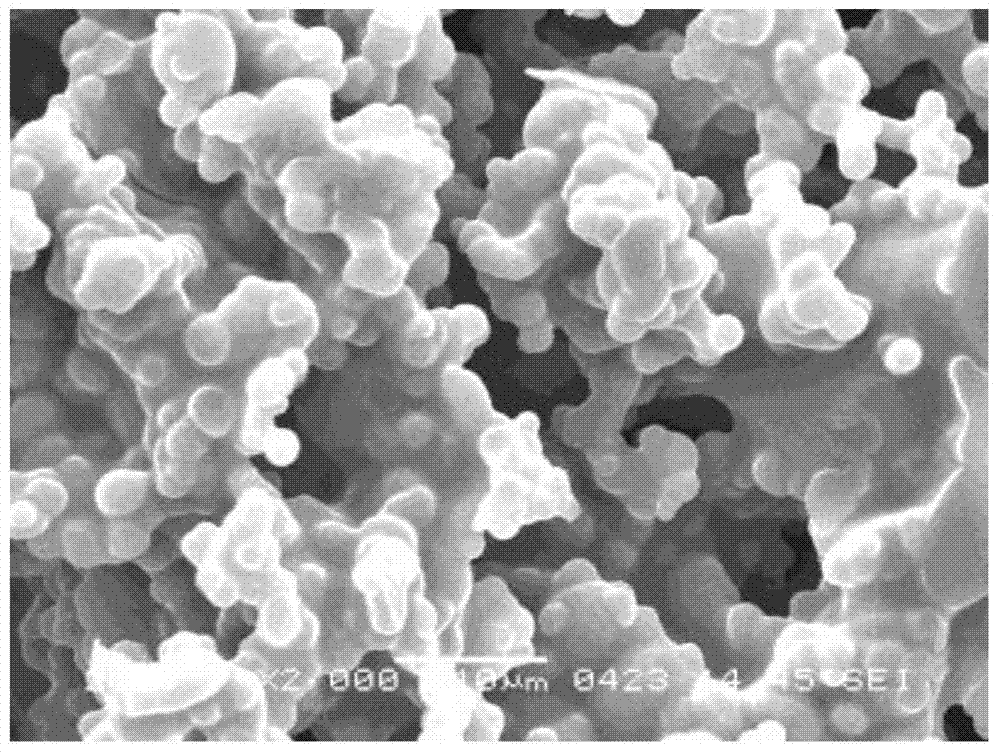

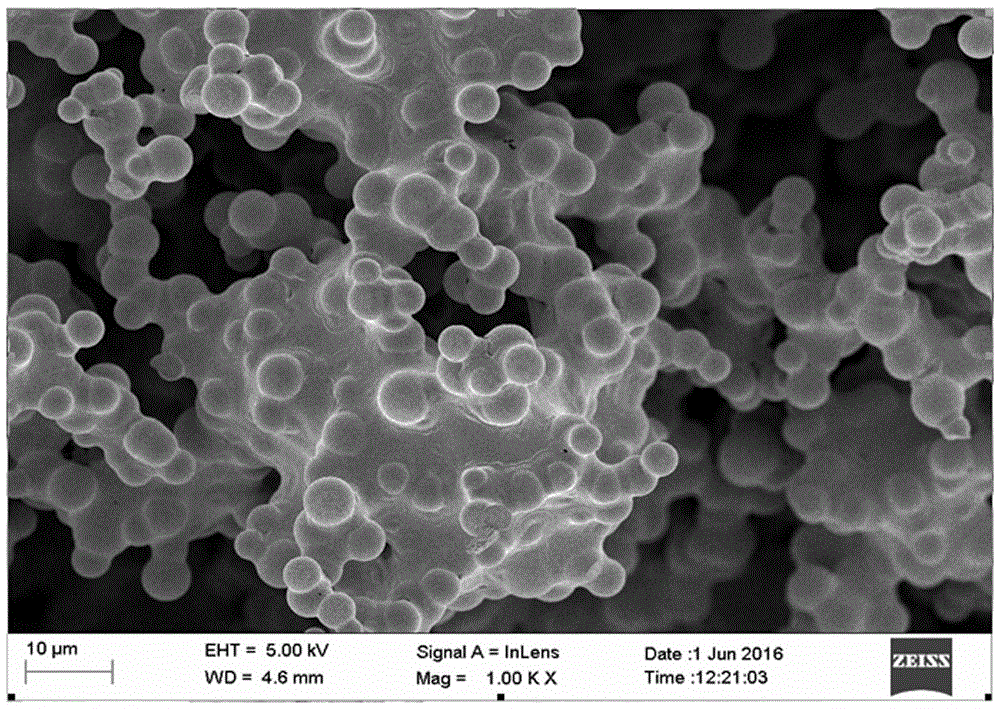

Method for preparing aerogel composite material by using tetramethyl orthosilicate

The invention provides a method for preparing an aerogel composite material by using tetramethyl orthosilicate. The method comprises the following steps: (1) preparing silica sol: preparing the silica sol from tetramethyl orthosilicate and water, which serve as raw materials, in a manner of taking an alcohol solvent as a solvent; and (2) carrying out sol dipping: dipping a fiber material with the silica sol at the temperature of -40 DEG C to 0 DEG C, thereby obtaining a fiber material / sol system. By adopting the method, planar and irregular-profile materials of diverse sizes can be conveniently and selectively prepared, the gelation time is controllable, a catalyst is not required, the variety of the raw materials is small, the operation is simple and convenient, and the environmental pollution is light. The material is excellent in heat-insulating property and has a broad application prospect in the fields of civilian industry, aerospace & aviation industry, military industry, and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

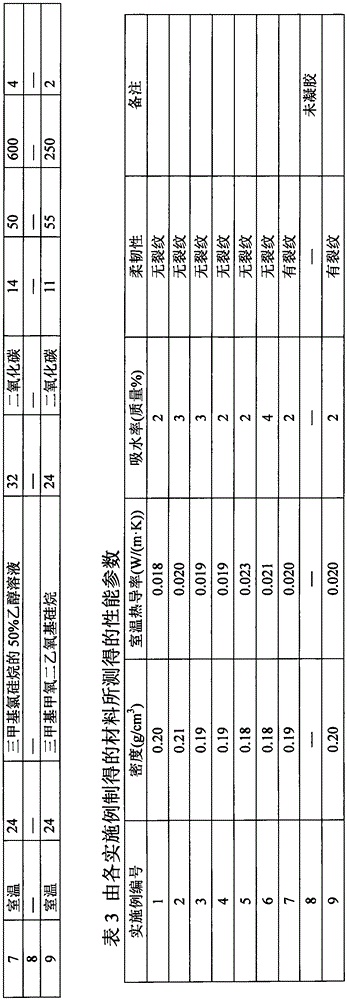

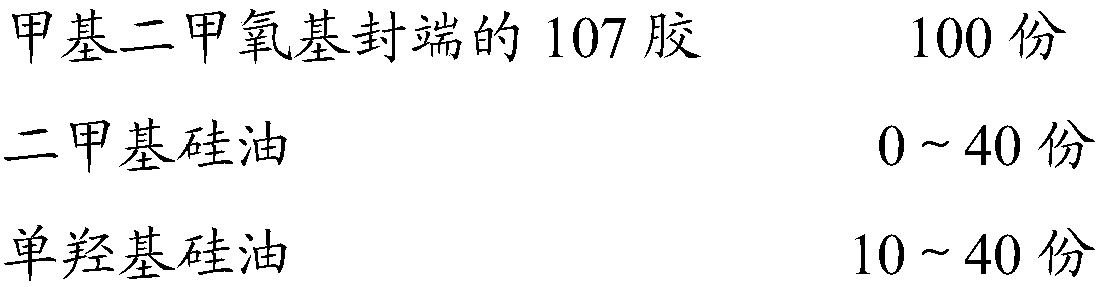

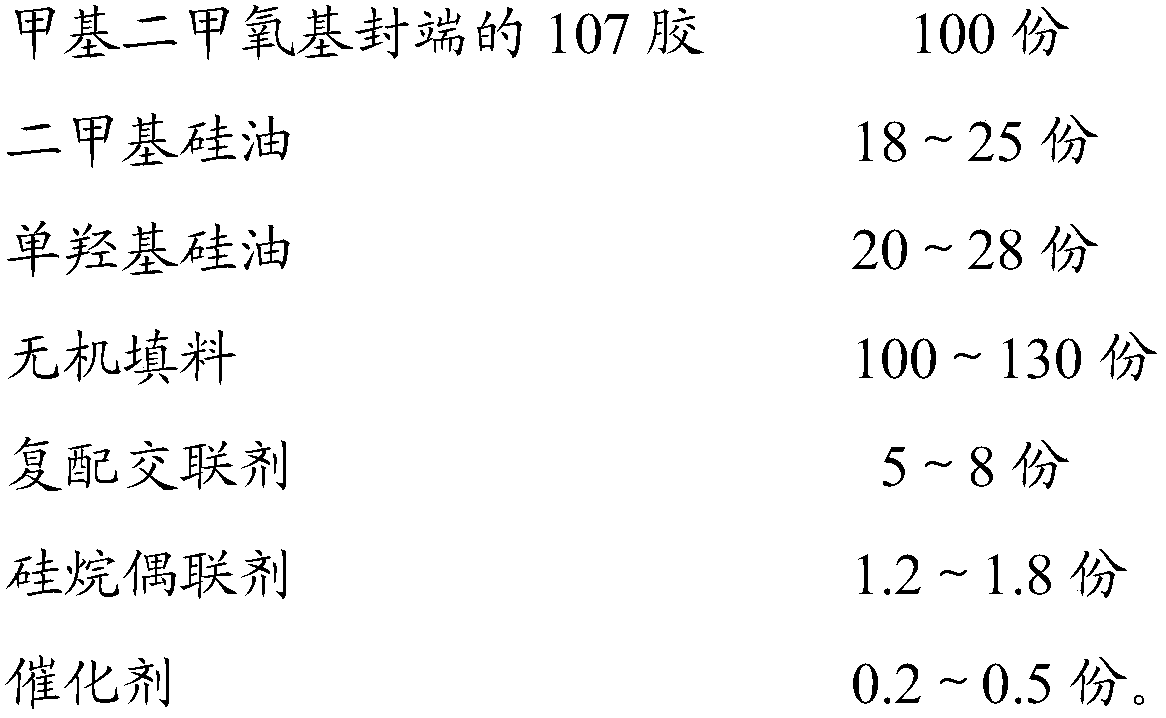

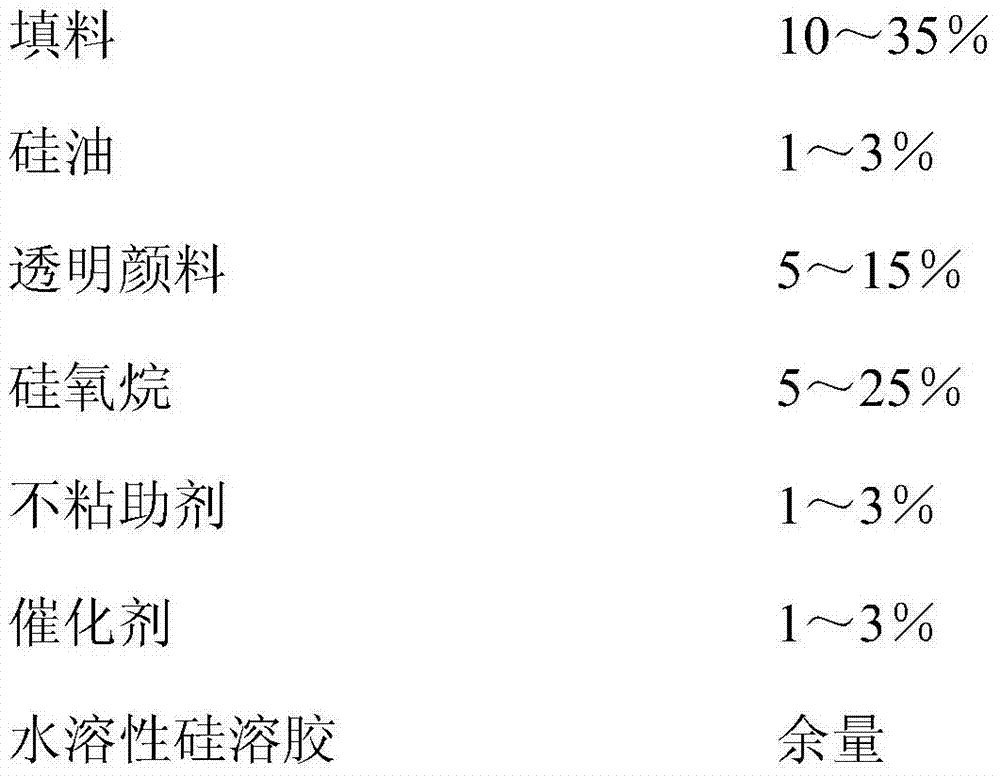

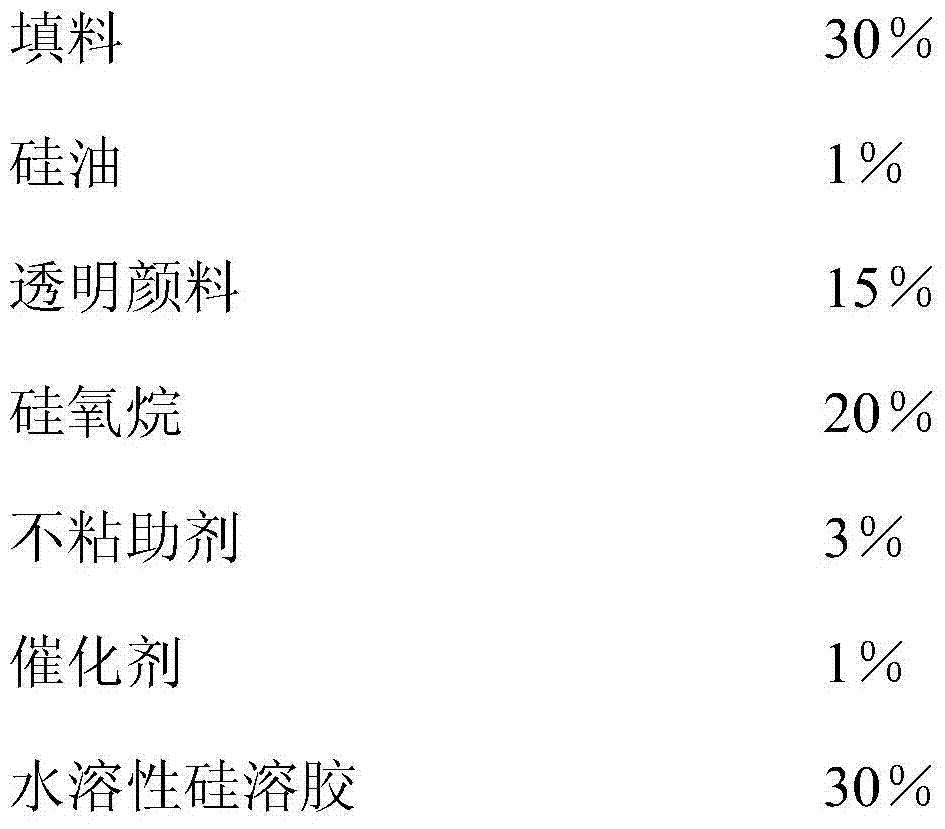

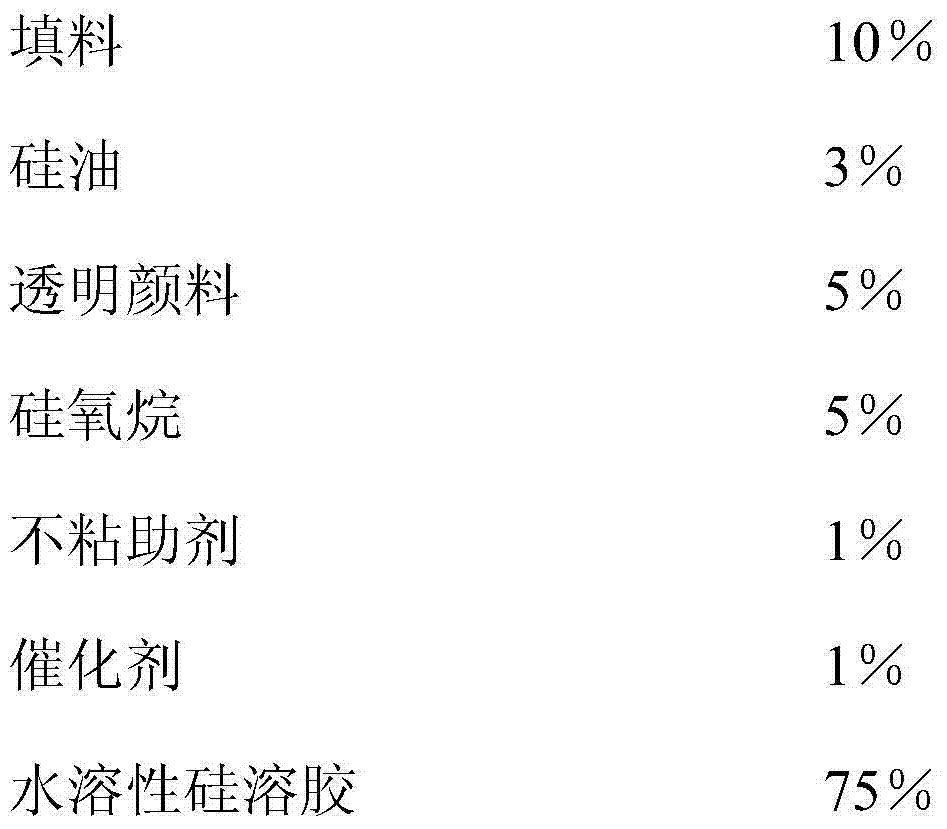

Dealcoholization silicone weather-resistant sealant with low modulus and high displacement capability and preparation method of dealcoholization silicone weather-resistant sealant

ActiveCN108179003ALow modulusReduce stressNon-macromolecular adhesive additivesAdhesiveWater resistant

The invention relates to dealcoholization silicone weather-resistant sealant with low modulus and high displacement capability and a preparation method of dealcoholization silicone weather-resistant sealant. The silicone weather-resistant sealant is prepared from the following raw materials in parts by weight: 100 parts of methyldimethoxy-terminated 107 adhesive, 0 to 40 parts of dimethyl siliconeoil, 10 to 40 parts of monohydroxy silicone oil, 60 to 200 parts of inorganic filler, 2 to 10 parts of a compound cross-linking agent, 0.5 to 3 parts of a silane coupling agent, and 0.05 to 0.5 partof a catalyst; and the compound cross-linking agent is selected from at least two of methyltrimethoxysilane, methyl triethoxysilane, methyltri-n-propoxysilane, tetramethyl orthosilicate, tetraethoxysilane, isopropyl orthosilicate, dimethyl dimethoxy silicane, dimethyldiethoxysilane and dimethyl dipropylsilane. The silicone weather-resistant sealant has low modulus and high displacement capability,has small stress to a curtain wallboard, and has excellent weather resistance, good binding property and good water-resistant binding property.

Owner:GUANGZHOU BAIYUN CHEM IND

Biomimetic immobilization method of multienzyme system

InactiveCN102851273ASimple preparation processMild conditionsOn/in organic carrierPhosphateFreeze-drying

The invention relates to a technique for immobilizing a multienzyme system, which comprises the following steps: 1) preparation of precursor solution, namely, adding TMOS (tetramethyl orthosilicate) into a 1 mmol / L HCl solution at room temperature, adding a phosphate buffer of which the pH value is 5-9 after the TMOS is completely dissolved and the solution becomes clear, and evenly mixing; 2) preparation of immobilized enzyme: evenly mixing the multienzyme solution with a PDADMA (polydimethyldiallyl ammonium chloride) solution to obtain an enzyme-containing solution A; and under the 30 DEG C homothermal condition, adding the pretreated precursor solution into the solution A, immediately shaking, standing at room temperature, carrying out centrifugal separation, washing with the phosphate buffer, and carrying out vacuum freeze drying on the residual solid for 24 hours, thereby obtaining the biomimetic silicified multienzyme. The method provided by the invention has the advantages of simple preparation technique, mild conditions, low loss of enzyme activity, and high enzyme activity recovery rate (up to 85.12%); and the carrier is the TMOS which is cheap and accessible.

Owner:HEBEI UNIV OF TECH

Porous cordierite block preparation method

The present invention discloses a porous cordierite block preparation method, which sequentially comprises: 1) at a room temperature, dissolving magnesium chloride hexahydrate, aluminum chloride hexahydrate and polyacrylamide in a solvent, adding tetramethyl orthosilicate in a dropwise manner, and continuously carrying out a stirring reaction for 50-70 min at a temperature of 50-70 DEG C; 2) naturally cooling the transparent clear solution obtained in the step 1) to a room temperature, adding propylene oxide, and uniformly stirring; 3) placing the homogeneous solution obtained in the step 2) into a container, sealing, and carrying out gelation for 3-5 min at a temperature of 35-45 DEG C; 4) placing the wet gel obtained in the step 3) in an environment with a temperature of 35-45 DEG C, and aging for 60-80 h; and 5) placing the aged gel obtained in the step 4) in an environment with a temperature of 50-70 DEG C, carrying out normal pressure drying for 72-96 h, and carrying out a heat treatment for 4-6 h at a temperature of 900-1300 DEG C. The porous cordierite block prepared by using the preparation method has characteristics of porous structure, high porosity and the like.

Owner:ZHEJIANG UNIV

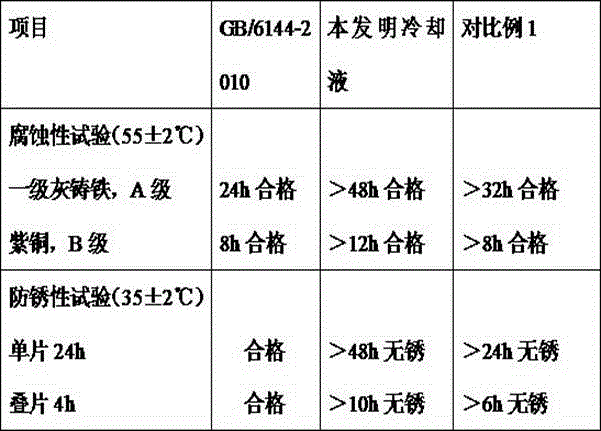

Novel long-acting coolant

InactiveCN104673200AReduce lossEliminate pollutionHeat-exchange elementsOctanoic AcidsPolyvinyl alcohol

The invention discloses a novel long-acting coolant which is prepared from the following raw materials in parts by weight: 25-50 parts of ethylene glycol, 10-15 parts of sorbitol, 5-10 parts of ammonium phosphomolybdate, 3-6 parts of tetramethyl orthosilicate, 2-6 parts of decanedioic acid, 3-7 parts of octanoic acid, 4-8 parts of sodium citrate, 3-5 parts of castor oil triethanolamine, 7-10 parts of sodium nitrate, 1-8 parts of sodium nitrate, 2-7 parts of polyvinyl alcohol, 3-7 parts of tall oil, 4-7 parts of molybdate, 4-8 parts of organosilicate, 1-5 parts of succinic acid, 2-6 parts of undecanoic acid and 3-7 parts of sodium benzoate. The novel long-acting coolant has the advantages of reasonable formula, high corrosion resistance and favorable storage stability.

Owner:QINGDAO KERUN PLASTIC MACHINERY

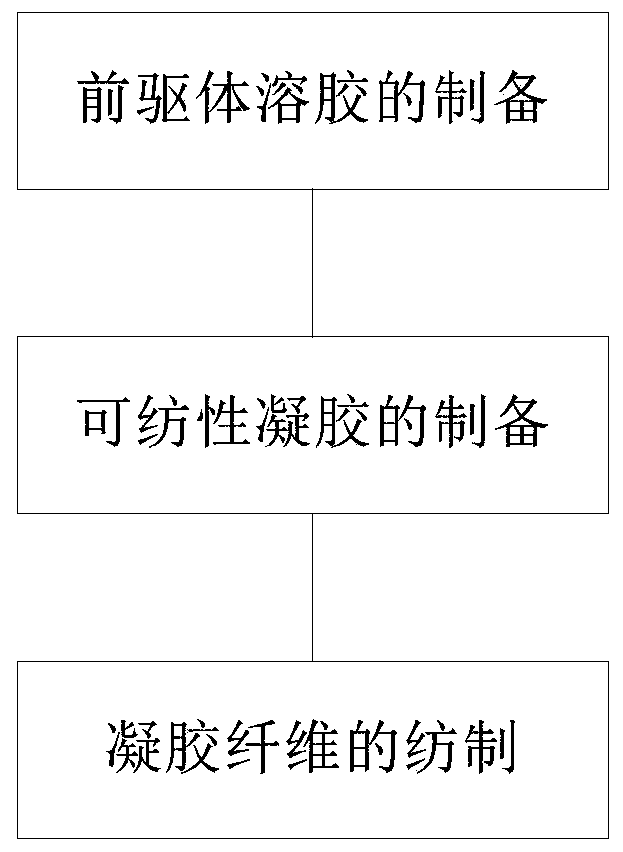

Sol-gel preparing and spinning method of ultrafine continuous alumina fibers

InactiveCN110922170ARaw materials are easy to getLow costInorganic material artificial filamentsFiberSpinning

The invention relates to a sol-gel preparing and spinning method and a reaction kettle of ultrafine continuous alumina fibers. Main raw materials adopted by the preparation method are aluminum powder,alumina and silica. A precursor technology is adopted, a precursor of aluminum is aluminum or aluminum oxide or an inorganic or organic salt solution of aluminum, and a precursor of silicon is tetraethoxysilane, tetramethyl orthosilicate, water-soluble silicone oil, silica sol or silane. The reaction kettle used in the preparation process comprises a liftable stirrer, a circulating medium liquidstorage tank and a kettle body, and meets the complex operation requirements of the special material preparation method.

Owner:莫纶珠海新材料科技有限公司

Preparation method of porous mullite block

InactiveCN103242027AControl Aperture SizeControl pore volumeAluminium silicatesRoom temperatureMullite

The invention discloses a preparation method of a porous mullite block. The preparation method of the porous mullite block comprises the following steps of: (1) dissolving aluminum chloride hexahydrate and polyoxyethylene in a solvent, dropwise adding tetramethyl orthosilicate, and then stirring continuously and reacting for 50-70minutes; (2) under the room temperature, adding epoxypropane in the mixture obtained in the step (1) and stirring uniformly to obtain a homogeneous solution; (3) sealing the homogeneous solution in a container and then gelling at 35-45 DEG C for 8-12minutes to obtain wet gel; (4) aging the wet gel at 35-45 DEG C for 68-76 hours; and (5) drying the aged gel prepared in the step (4) at 70-80 DEG C for 2-3 days, and then carrying out heat treatment at 800-1400 DEG C for 4-6 hours to obtain the porous mullite block. The porous mullite block prepared by the method has the characteristics that the block has a hierarchical porous structure, the size and amount of apertures are controllable, the frameworks are continuous, the specific surface area is large, and the like.

Owner:ZHEJIANG UNIV

Preparation method of lamellar molybdenum disulfide/carbon composite

ActiveCN107256949ALow costGood process repeatabilityCell electrodesSecondary cellsCarbon compositesSilica gel

The invention discloses a preparation method of lamellar molybdenum disulfide / carbon composite; the preparation method comprises the steps of adding tetramethyl orthosilicate to hydrochloric acid solution, deionized water and absolute ethyl alcohol to obtain silica sol; dissolving ammonium molybdate in deionized water, adding glucose, and adding the silica sol in the obtained solution, and standing; drying the obtained wet gel, placing the dried gel in an inert gas protected tubular furnace, and allowing the gel to react with sulfur powder at 600-1000 DEG C for 3-6 h to obtain black powder; dissolving the black powder in NaOH solution, standing at 80-100 DEG C for 18-24 h, and centrifuging to obtain the lamellar molybdenum disulfide / carbon composite.

Owner:ZHEJIANG UNIV

Method for preparing silica aerogel and self-hydrophobic silica aerogel heat preservation felt pad through one-step technology

ActiveCN111039295ASimple production processRealize energy saving and consumption reductionSilicon compoundsPtru catalystSilicic acid

The invention relates to the technical field of materials, and discloses a method for preparing silica aerogel by a one-step technology. The method comprises the following steps: (1) mixing and stirring a silicon source precursor A, a silicon source precursor B, a solvent and water to obtain a premixed solution; (2) mixing a gel catalyst with the premixed solution, and carrying out a gel reactionto obtain silica wet gel; (3) aging and drying the silica wet gel to obtain the silica aerogel, wherein the silicon source precursor A is selected from tetramethyl orthosilicate and / or tetraethoxysilane; the silicon source precursor B has a general formula structure represented by the following formula I: (R1)n-Si-(R2)m; and in the formula I, and R1 is a methyl group, R2 is a methoxy group and / oran ethoxy group, n is an integer from 1 to 3, and m + n = 4. The silica aerogel has a good pore structure, a large specific surface area and low thermal conductivity. The self-hydrophobic silica aerogel heat preservation felt pad not only has low thermal conductivity, but also has high hydrophobicity.

Owner:IBIH ADVANCED MATERIALS CO LTD

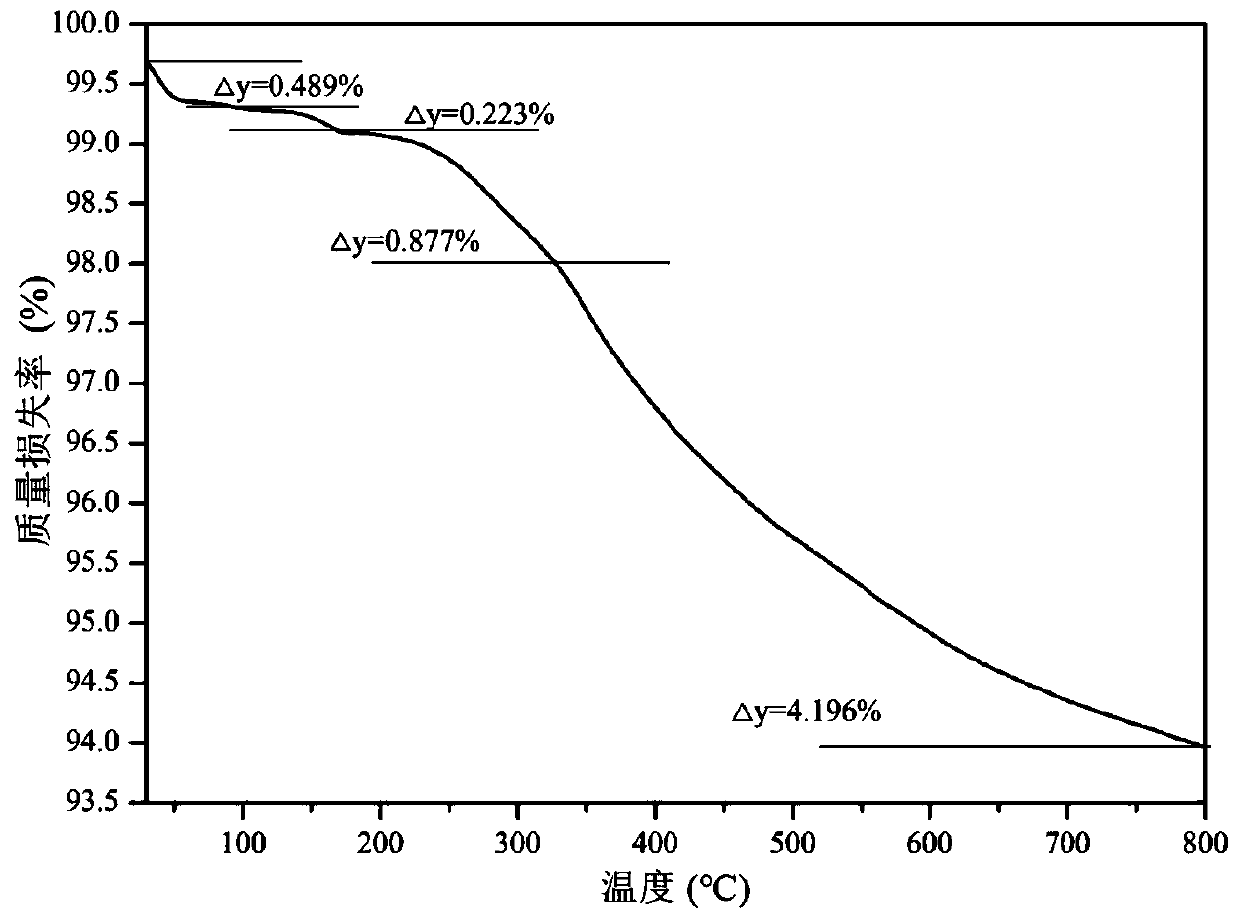

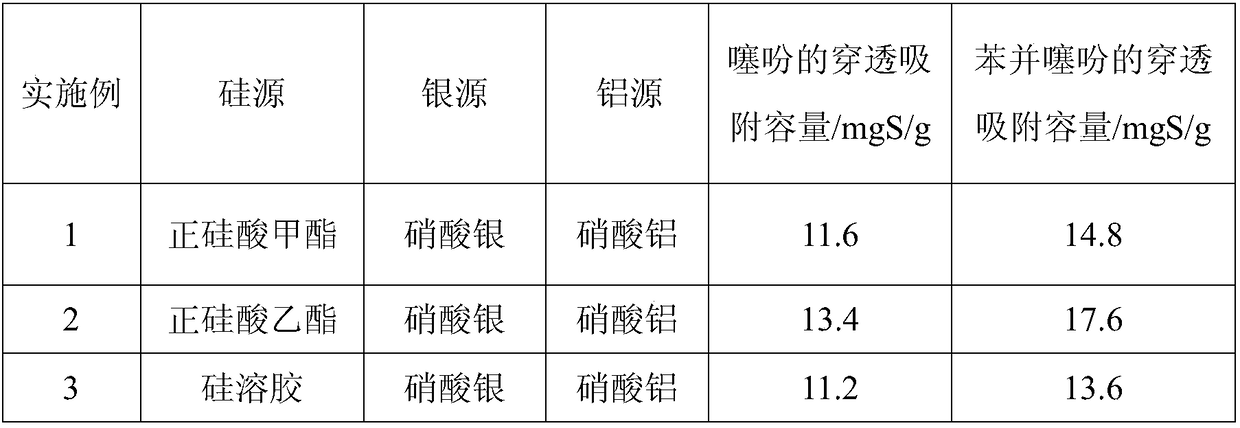

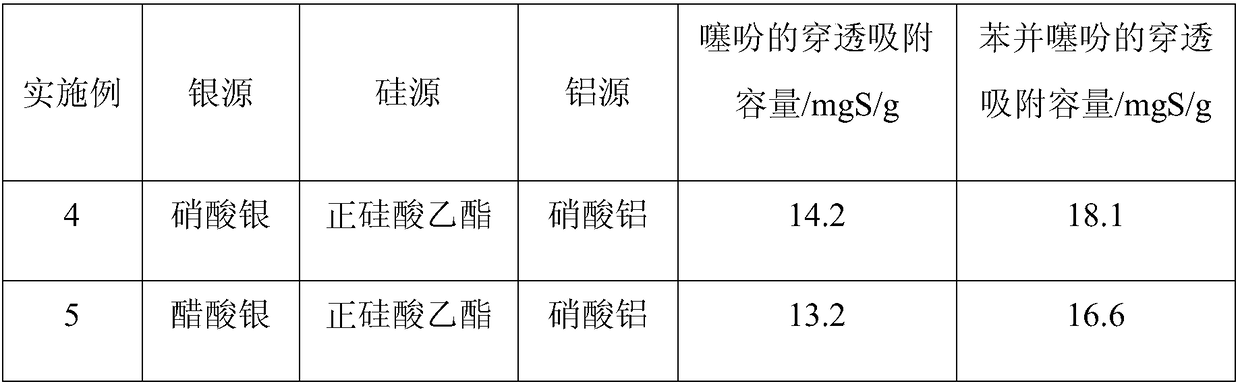

Method for removing thiophene sulfur in fuel oil

InactiveCN108192656AHigh porosityLarge specific surface areaHydrocarbon oils refiningHydrocarbon oils treatment productsSorbentFixed bed

The invention discloses a method for removing thiophene sulfur in fuel oil and belongs to the technical field of fuel oil processing. The method comprises the following steps: using tetramethyl orthosilicate, tetraethyl orthosilicate, silica sol, water glass or the like as a silicon source; using silver acetate, silver nitrate or the like as a silver source; using aluminum nitrate, aluminum acetate or aluminum oxalate as an aluminum source; preparing an Ag2O / SiO2-Al2O3 composite aerogel with a sol-gel-atmospheric pressure drying method; quantitatively filling in a fixed bed adsorption device;injecting a simulated gasoline containing thiophene sulfur at a certain temperature and space velocity; and collecting the adsorbed simulated gasoline at a lower outlet of a reaction device for chromatographic analysis. Results show that the Ag2O / SiO2-Al2O3 composite aerogel has good adsorption performance for thiophene sulfur; an Ag2O / SiO2-Al2O3 composite aerogel adsorbent in the invention is simple in preparation method, low in cost, capable of being repeatedly used, high in economic efficiency, environmentally friendly, mild in adsorption condition and low in requirement on adsorption equipment.

Owner:ZHEJIANG UNIV OF TECH

Cooling liquid for cutting

The invention discloses cooling liquid for cutting. The cooling liquid is prepared from the following ingredients in parts by weight: 80 parts of ethylene glycol, 7 parts of castor oil, 8 parts of simethicone, 5 parts of tetramethyl orthosilicate, 0.5 part of sodium borate, 10 parts of dodecanedioic acid, 3 parts of nanometer diatomaceous earth, 8 parts of lauric acid, 2 parts of methenamine, 0.3 part of lithospermum purpurocaeruleum oil, 0.1 part of a corrosion inhibitor, 0.6 part of a defoaming agent, 1 part of an adjuvant and 78 parts of water. The cooling liquid disclosed by the invention is scientific and reasonable in formula, simple in production technology, high in cooling properties, good in stability, good in corrosion prevention effects, safe and reliable to use, and nonhazardous; the effective circulation of the cooling liquid is guaranteed, the working efficiency can be improved, and the working environment is purified; the product of the cooling liquid has good lubricating properties, cooling properties, anti-rust properties and antifoam properties, is suitable for cutting and processing of various metal such as cast iron, steel, aluminum alloy and copper alloy, is clean, environmentally-friendly, free from smelliness, free from toxins, and tasteless, and does not have any adverse effect on skin.

Owner:BENGBU HAIMING DIE CASTING MACHINE CO LTD

Fuel composition in fuel cartridges for DMFCs

InactiveUS20050081433A1Improve securityImprove ability to signal presenceLiquid carbonaceous fuelsFixed capacity gas holdersActivated carbonFuel cells

Fuel mixtures for direct methanol fuel cells are disclosed. The fuels include methanol and additives that react with water to produce methanol and other easily electro-oxidizable compounds including dimethyloxymethane, methylorthoformate, tetramethylorthocarbonate, trimethylborate, and tetramethylorthosilicate. Other additives to improve safety and efficiency of the fuel cell include sulfonated activated carbon particles and metal hydrides, such as LiAlH4, NaBH4, LiBH4, (CH3)2 NHBH3, NaAlH4, B2H6, NaCNBH3, CaH2, LiH, NaH, KH or sodium bis (2-methoxyethoxy) dihydridaluminate.

Owner:DURACELL U S OPERATIONS

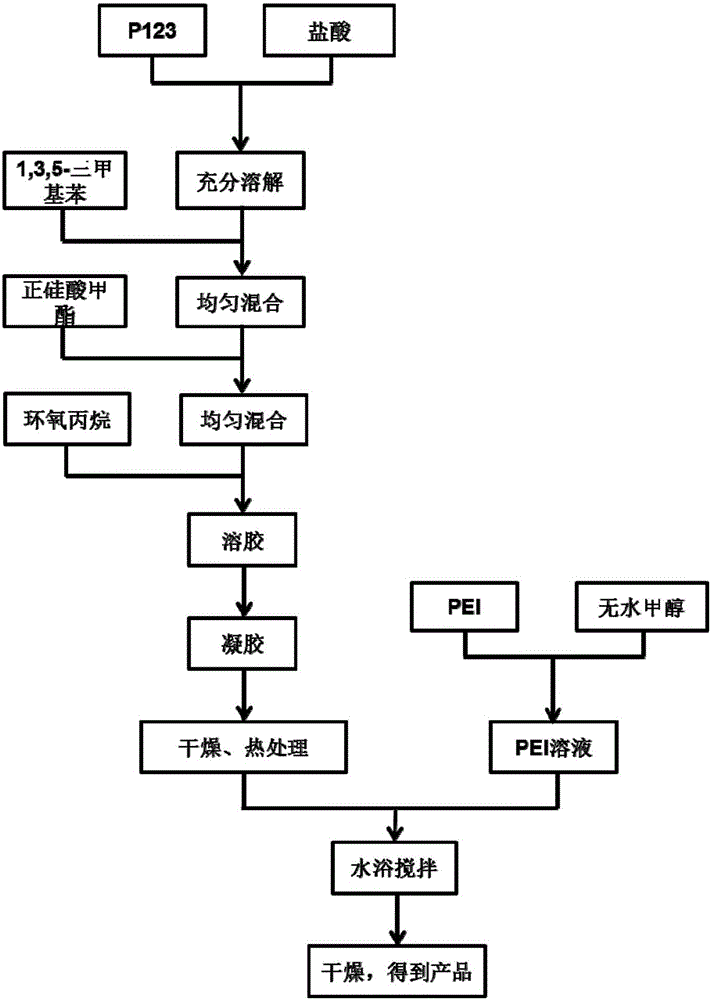

Carbon dioxide adsorbent based on hierarchical porous silicon dioxide block body and preparation method of carbon dioxide adsorbent

InactiveCN106552609AImprove adsorption capacityStrong recycling abilityGas treatmentOther chemical processesSorbentSilicon dioxide

The invention discloses a preparation method of a carbon dioxide adsorbent based on a hierarchical porous silicon dioxide block body. The preparation method comprises the following steps: dissolving a triblock copolymer P123 into a hydrochloric acid solution, and then adding 1,3,5-trimethylbenzene, tetramethyl orthosilicate and epoxypropane in sequence; gelating and drying obtained sol, heating to 400 to 800 DEG C, and preserving the heat for 5 + / - 0.5 hours to obtain the hierarchical porous silicon dioxide block body; putting the hierarchical porous silicon dioxide block body into an organic amine methanol solution to enable organic amine to be uniformly loaded in the hierarchical porous block body; and placing an obtained substance into an oven for drying to obtain the carbon dioxide adsorbent based on the hierarchical porous silicon dioxide block body. The invention further discloses the carbon dioxide adsorbent, which is prepared through the method, based on the hierarchical porous silicon dioxide block body.

Owner:ZHEJIANG UNIV

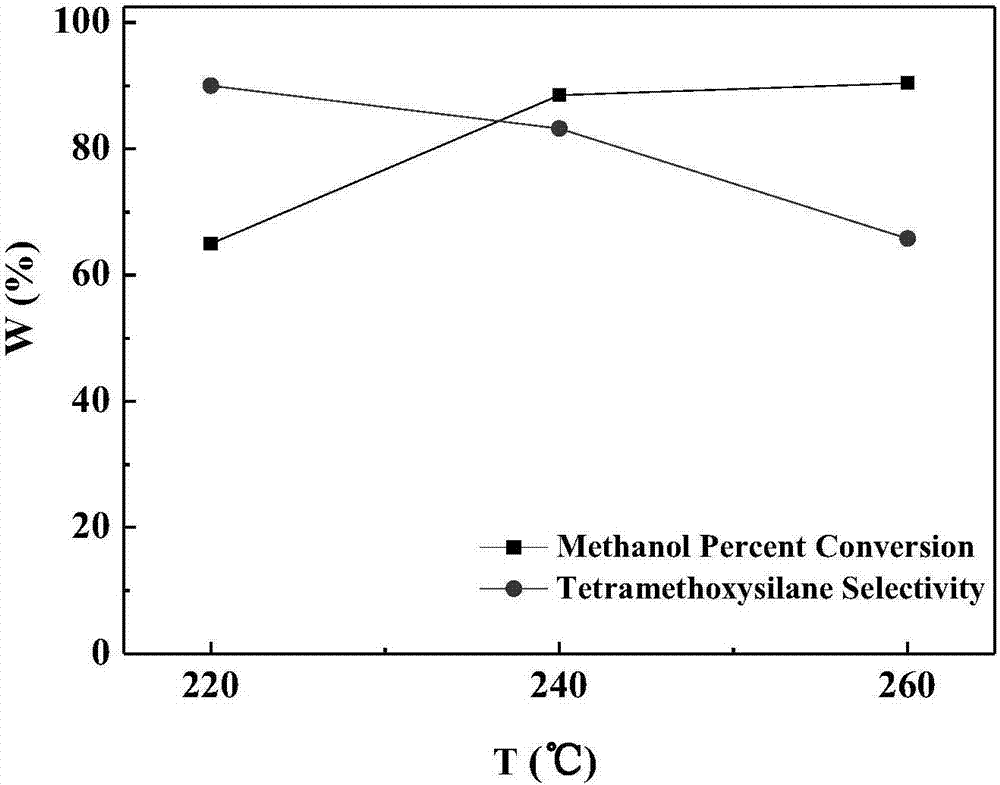

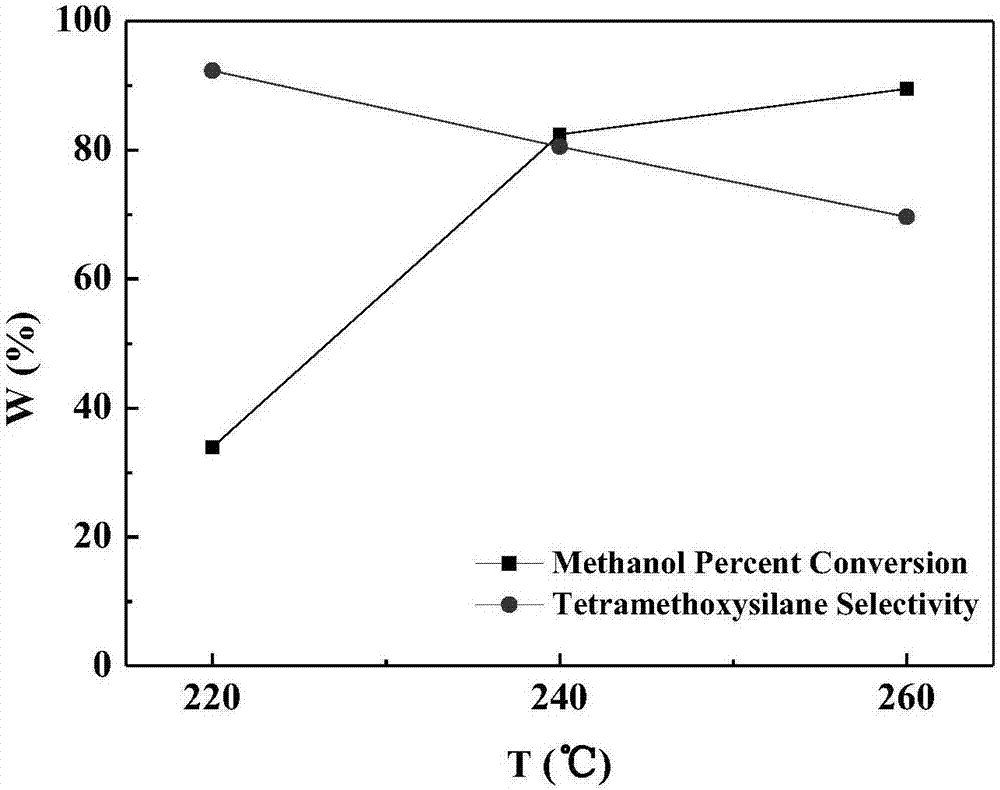

Method for preparing tetramethyl orthosilicate in direct method

The invention provides a method for preparing tetramethyl orthosilicate in a direct method. The method comprises the following steps: (1) measuring silicon powder and catalyst, mixing and uniformly stirring, and then crushing in a crushing machine; (2) pouring the crushed silicon and catalyst mixture into a fixed-bed reactor, assembling an apparatus, and placing the reactor apparatus into a tubular heating furnace; (3) introducing nitrogen into the fixed-bed reactor, heating the tubular furnace by virtue of a program, heating to 240 DEG C, and processing for 2h at 240 DEG C; and (4) lowering the temperature in the fixed-bed reactor to 220 DEG C, beginning the introduction of methanol, performing the reaction timing in 0.5h, performing the reaction, wherein a reaction product is the tetramethyl orthosilicate. The raw materials adopted in the method are silicon powder and methanol and are synthesized to form the tetramethyl orthosilicate in one step. Compared with the traditional method, the method is more environment-friendly and green. No harmful gas hydrogen chloride is produced in the product.

Owner:JIANGSU UNIV

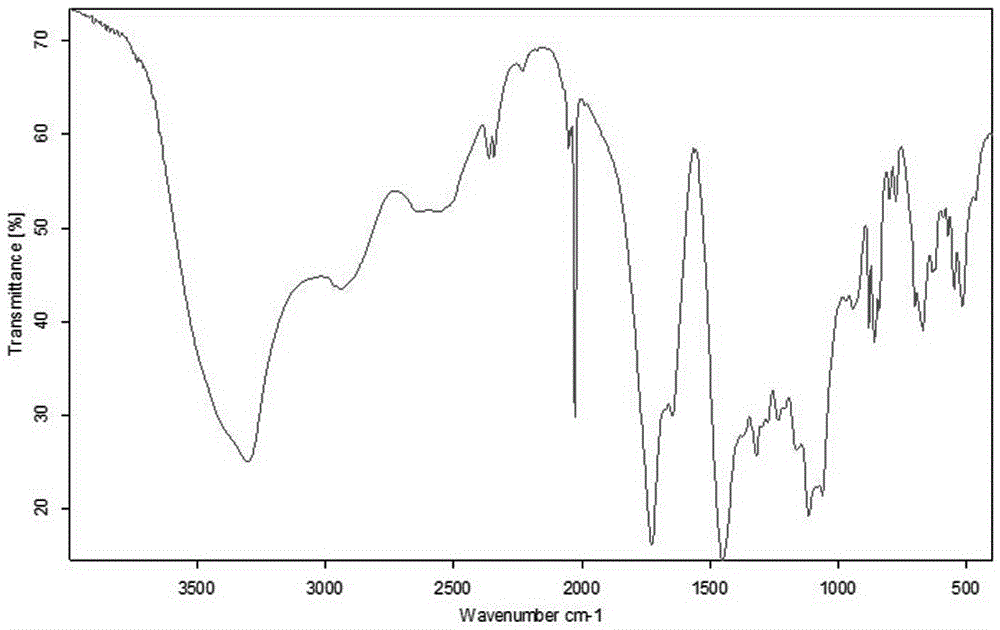

Preparation method of silica and polyacrylate composite emulsion

The invention relates to the industrial field of polyurethane, and particularly relates to a preparation method of silica and polyacrylate composite emulsion. The preparation method comprises the following steps: preparation of silica sol: adding 100 mL of tetramethyl orthosilicate into a three-mouth flask, stirring at room temperature and mixing ammonium hydroxide solution (1:1) with water, slowly dropwise adding into the flask within 3h, continuously stirring for 3h to obtain methanol silica sol with solid content of 30%, and exchanging out methanol through distilled water to obtain silica sol with solid content of 25-30wt%; preparation of silica and polyacrylate composite emulsion through using a semicontinuous in-situ emulsion polymerization method: respectively adding sodium dodecyl benzene sulfonate, alkylphenol polydecoxyethylene ether, silica sol, 200mL of deionized water, 8g of methyl methacrylate and 8g of N-butyl acrylate into a mechanical agitator. The preparation method is simple to operate, and convenient to process, and while the tensile strength and breakage elongation of a composite emulsion membrane are increased, the water absorption is reduced, and the thermal stability performance of the composite emulsion membrane can be enhanced.

Owner:SHAANXI HI-TECH IND CO LTD

Power cable sheathing compound with good thermal stability

InactiveCN106433169AImprove thermal stabilityImprove mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneChlorinated paraffins

The invention discloses a power cable sheathing compound with good thermal stability. The raw materials of the power cable sheathing compound comprises, by weight, 15-35 parts of Ethylene Propylene Diene Monomer, 5-20 parts of low density polyethylene , 20-60 parts of hydrogenated butadiene-acrylonitrie rubber, 0.2-0.8 part of 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane, 1-2 parts of dicumyl peroxide, 1-2 parts of maleic anhydride, 1-2 parts of phenyl trichlorosilane, 20-30 parts of modified composite emulsion, 0.5-1.2 parts of Epoxidized linseed oil, 1-3 parts of chlorinated paraffin, 0.1-0.6 part of black factice, 0.5-1.1 part of tetramethyl orthosilicate, 15-25 parts of silk fiber, 20-40 parts of lignin, 5-15 parts of nanosilicon dioxide, 20-40 parts of white carbon black and 1-8 parts of antimonous oxide. The power cable sheathing compound has good tenacity, excellent thermal stability and good mechanical property, and can effectively avoid phenomenon of brittle failure.

Owner:ANHUI LAND GRP

Preparation method and application of agarose bonded silica gel hybridized monolithic column

InactiveCN106334343AHigh mechanical strengthSkeleton structure is stableComponent separationOther chemical processesHigh concentrationPolyethylene glycol

The invention discloses a preparation method of an agarosebonded silica gelhybridized monolithic column. The preparation method comprises the steps that tetramethyl orthosilicate, agarose, polyethylene glycol and urea are mixed under an ice-bath condition to prepare a prepolymerization system by adopting a sol-gel method, then the prepolymerization system is put in a quartz capillary tube to prepare an affinity monolithic column, and finally the affinity monolithic column is subjected to three-step modification to obtain the agarosebonded silica gelhybridized monolithic column containing amide groups on the surface. The preparation method of the agarosebonded silica gelhybridized monolithic column has the advantages of being simple in operation and making the surface of the prepared monolithic column convenient to modify, the problem that an immunoaffinity column using agarose gel as a carrier is not easily stored and easily produces swelling is solved, and the prepared monolithic column has the advantages of being good in mechanical strength, stable in framework structure, good in permeability, uniform in texture, good in hydrophily and reproducibility and the like and has high selectivity and high concentration rate to biomolecule.

Owner:LUOYANG INST OF SCI & TECH

High-tenacity power cable sheathing compound

InactiveCN106366384AImprove thermal stabilityImprove mechanical propertiesRubber insulatorsHeat stabilityAcrylonitrile

The invention discloses a high-tenacity power cable sheathing compound. The high-tenacity power cable sheathing compound is prepared from the following raw materials in parts by weight: 10 to 25 parts of natural rubber, 20 to 40 parts of isoprene rubber, 25 to 65 parts of hydrogenated butadiene-acrylonitrile rubber, 1 to 2 parts of talcum powder, 0.4 to 1 part of colleseed oil, 2 to 5 parts of epoxidized soybean oil, 25 to 35 parts of modified composite emulsion, 1.5 to 2.5 parts of tetraethylenepentamine, 0.8 to 1.2 parts of dicumyl peroxide, 1.5 to 2.5 parts of phenyl trichlorosilane, 2 to 4 parts of maleic anhydride, 1 to 2 parts of tetramethyl orthosilicate, 25 to 45 parts of titanium dioxide, 20 to 30 parts of clay, 25 to 45 parts of sepiolite powder, 10 to 20 parts of attapulgite and 3 to 9 parts of asbestos. The power cable sheathing compound is high in tenacity, excellent in heat stability performance and good in mechanical property, and the brittle failure phenomenon of a product can be effectively avoided.

Owner:ANHUI LAND GRP

Rubber modified asphalt

InactiveCN105504838AImprove stabilityGood weather resistanceBuilding insulationsFiberSodium stearate

The invention discloses a rubber modified asphalt. The rubber modified asphalt is prepared from the following raw materials in parts by weight: 80 to 85 parts of asphalt, 20 to 25 parts of butadiene styrene rubber, 15 to 20 parts of chloroprene rubber, 6 to 8 parts of polyethylene, 1 to 3 parts of polysiloxane, 0.5 to 1 part of stearamide, 6 to 10 parts of glass fiber, 4 to 8 parts of stearic acid, 4 to 8 parts of sodium stearate, 2 to 6 parts of spodumene powder, 1 to 3 parts of magnesium borate ore powder, 4 to 6 parts of castor oil, 0.5 to 2 parts of coal tar, 2 to 4 parts of tetramethyl orthosilicate, 1 to 3 parts of an activator and 1 to 3 parts of an antioxidant. The rubber modified asphalt is high in stability, resistant to tracks at a high temperature, resistant to cracking at a low temperature, high in weather resistance and resistant to aging.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

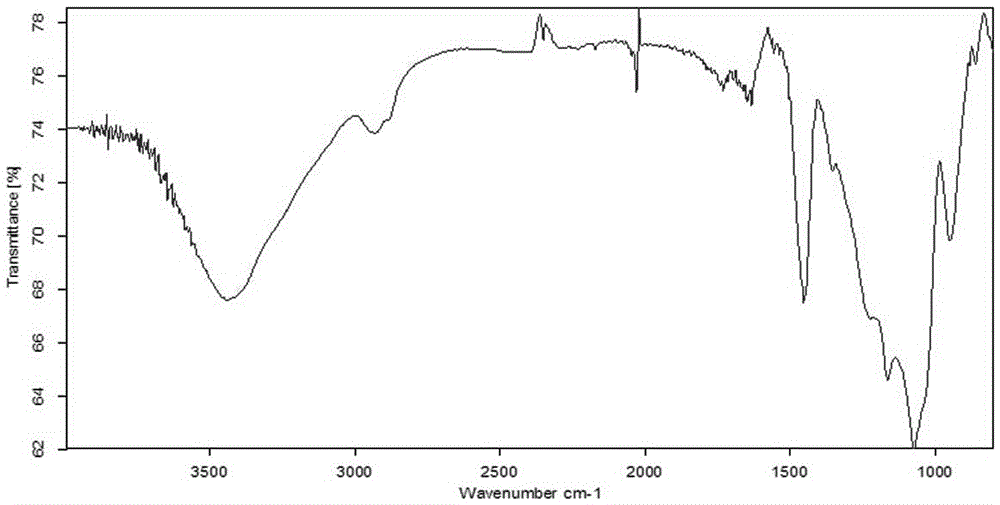

Colored pot cover with water draining function

InactiveCN103494520ABoth decorative effectEasy to cleanCooking-vessel lids/coversCoatingsWater vaporSilanes

The invention relates to a colored pot cover with a water draining function. The colored pot cover with the water draining function comprises a pot cover body, and a layer of colored coating is arranged on the inner surface or the outer surface of the pot cover body. The pot cover body is made of glass materials. The thickness of a decorating layer is 3-20 micrometers, and the decorating layer is a colored layer. According to the colored pot cover with the water draining function, the colored coating can prevent water vapor from being congealed on the pot cover in the cooking process, so that the conditions that sight is bad and dishes inside a pot can not be seen clearly are avoided, and a decorating effect is also achieved. Methyl has low surface tension and non viscosity, siloxane uses one or more of methyltrimethoxysilane, methyl triethoxysilane, dimethyl dimethoxy silicane, ethyl orthosilicate, tetramethyl orthosilicate and the like, hydrolysis can occur to alkoxy under an acidic condition so that silanol can be formed, the alkoxy can be reacted with silica solutions, hydrolyzed silane and -OH on the surface of a base material, so that the methyl is connected into the coating, the non viscosity of the coating is well reflected, and durability is achieved.

Owner:SHANGHAI EXCILON NEW MATERIALS

Bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme

The invention provides a bionic process for preparing silicon oxide nano-microcapsule immobilized enzyme. According to the method, enzyme is coated in liposome nano-microcapsules; with the liposome nano-microcapsules as a template, under the effect of an inducing agent poly dimethyl diallyl ammonium, tetramethyl orthosilicate hydrolysate is dehydrated on the surface of liposome, such that a silicon oxide shell layer is formed. Direct contact of enzyme and a silicon precursor is completely avoided, such that a purpose for maintaining relatively high activity of the immobilized enzyme is realized. Also, with the liposome nano-microcapsules as the template, preparation of the silicon oxide nano-microcapsules with controllable morphology can be realized. Finally, the liposome template is removed by using a low-concentration surfactant octyl polyethylene glycol phenyl ether. With the immobilized enzyme preparation method provided by the invention, an embedding rate can reach approximately 50%, such that problems of free enzyme severe wasting and immobilization cost increasing of a sol-gel method are avoided. The reaction mainly involves water phase, such that the reaction is safe and non-polluting. The preparation process is simple, and conditions are mild. An enzyme activity recovery rate is up to 71.8%.

Owner:HEBEI UNIV OF TECH

Fuel composition in fuel cartridges for DMFCs

InactiveUS7314493B2Improve ability to signal presenceLiquid carbonaceous fuelsFixed capacity gas holdersActivated carbonFuel cells

Fuel mixtures for direct methanol fuel cells are disclosed. The fuels include methanol and additives that react with water to produce methanol and other easily electro-oxidizable compounds including dimethyloxymethane, methylorthoformate, tetramethylorthocarbonate, trimethylborate, and tetramethylorthosilicate. Other additives to improve safety and efficiency of the fuel cell include sulfonated activated carbon particles and metal hydrides, such as LiAlH4, NaBH4, LiBH4, (CH3)2 NHBH3, NaAlH4, B2H6, NaCNBH3, CaH2, LiH, NaH, KH or sodium bis (2-methoxyethoxy) dihydridaluminate.

Owner:DURACELL U S OPERATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com