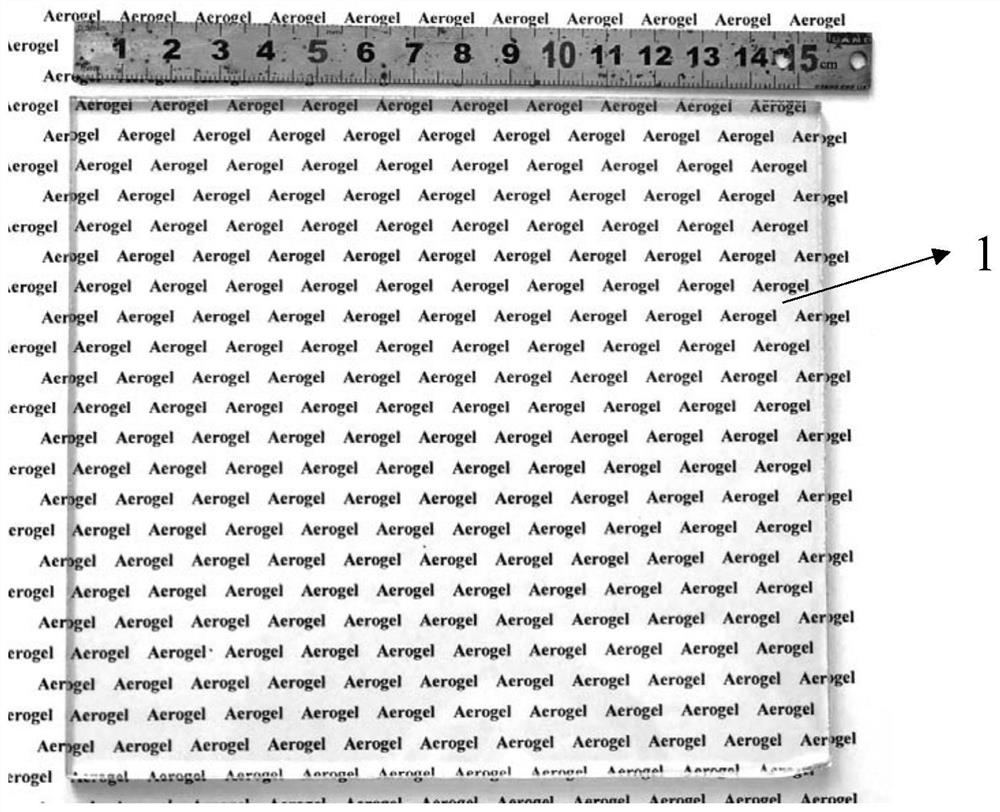

Ultrahigh-transparency large-size block silicon dioxide aerogel and preparation method and application thereof

A technology of silica and transparency, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., to achieve good uniformity, reduce energy consumption and heat loss, and achieve ultra-high heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a first aspect, the present invention provides a method for preparing an ultrahigh-transparency large-size bulk silica aerogel, the method comprising the following steps:

[0035] (1) Silicon source methyl orthosilicate (TMOS silicon source), additive long-chain alkyl trimethoxysilane (C n TMOS), an alcohol solvent, water and an alkali catalyst are mixed uniformly and then hydrolyzed to obtain a sol, and then the sol is placed in a mold to perform a sol-gel reaction to obtain a wet gel;

[0036] (2) subjecting the wet gel to a gradient temperature aging step to obtain a skeleton-reinforced wet gel;

[0037] (3) Perform the steps of solvent replacement (such as solvent replacement in ethanol) and supercritical drying (such as supercritical carbon dioxide drying) of the skeleton-reinforced wet gel in sequence to obtain ultra-high transparency and large-size block silica gas gel.

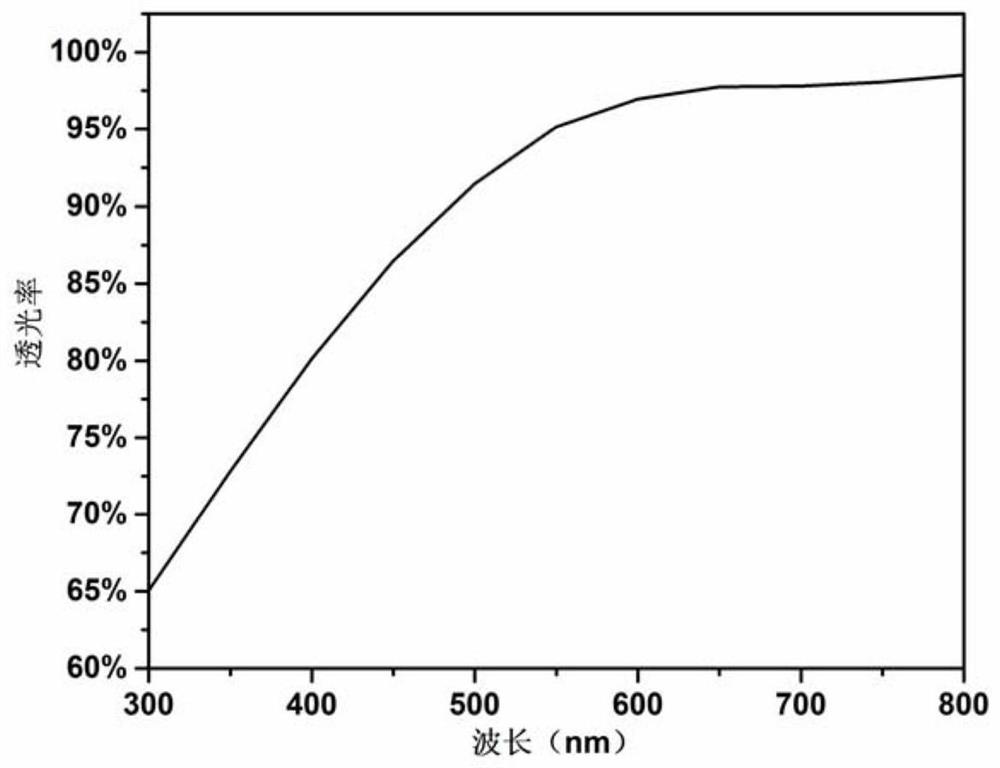

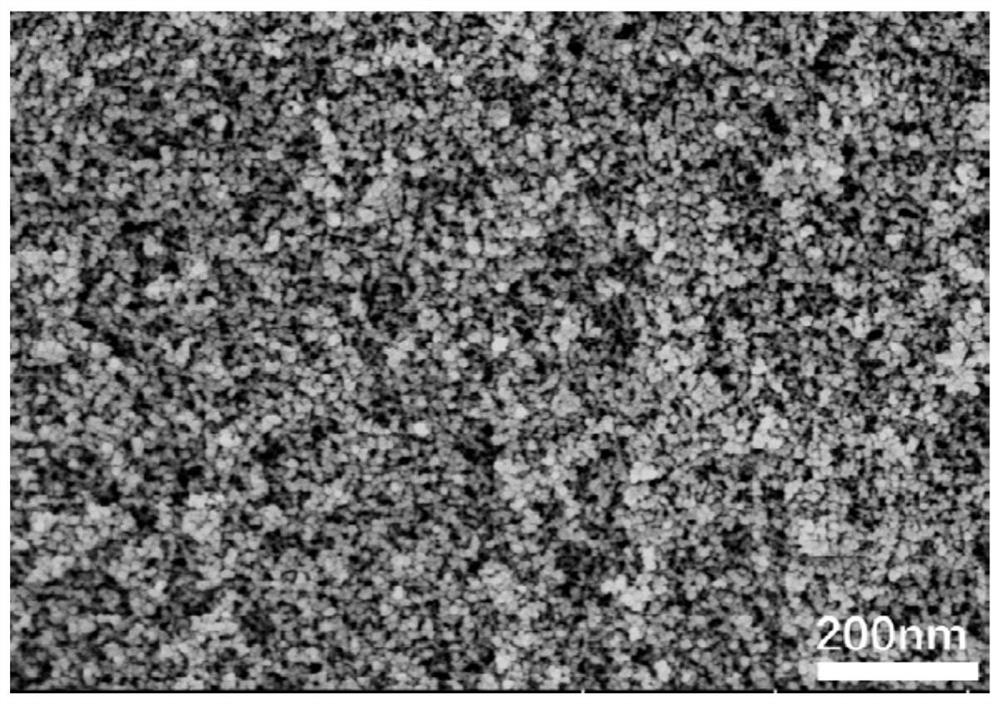

[0038] The invention provides a method for preparing super-high transparency and large-...

Embodiment 1

[0061] ①Add 152g of methyl orthosilicate, 11.2g of octadecyltrimethoxysilane (additive) and 224g of methanol into a beaker, and stir mechanically at -20°C for 30min to obtain mixed solution A. Add 72g of deionized water and 710 μL of ammonia-methanol solution (concentration is 7mol / L) into the beaker, utilize mechanical stirring at room temperature for 3min, obtain mixed solution B (in this example, each component in the raw material is calculated by molar ratio of methyl orthosilicate Esters: Octadecyltrimethoxysilane: Methanol: Water: Ammonia (1:0.03:7:4:0.005). Add the mixed solution B to the mixed solution A drop by drop, and continue to maintain the hydrolysis reaction at -20°C for 90 minutes to obtain a sol; inject the above-mentioned cold sol close to the gel state into a detachable tetrafluoroethylene plate with an area of 16cm×16cm The sol-gel reaction was carried out in the mold at -20°C for 90 min to form a wet gel.

[0062] ②Put the above-mentioned flat mold wit...

Embodiment 2

[0067] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0068] In step ①, 152g of methyl orthosilicate, 3.73g of octadecyltrimethoxysilane and 64g of methanol were respectively added into the beaker, and stirred mechanically at -20°C for 30min to obtain a mixed solution A. Add 36g of deionized water and 426μL ammonia-methanol solution (concentration is 7mol / L) in the beaker, utilize mechanical stirring at room temperature for 3min, obtain mixed solution B (in this example, each component in the raw material is calculated by molar ratio of methyl orthosilicate Esters: Octadecyltrimethoxysilane: Methanol: Water: Ammonia (1:0.01:2:2:0.003). Add the mixed solution B to the mixed solution A drop by drop, and continue to maintain the hydrolysis reaction at -20°C for 90 minutes to obtain a sol. The above-mentioned cold sol close to the gel state is injected into a removable tetrafluoroethylene flat mold at -20°C The sol-gel reaction was carried out for 90 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com