Patents

Literature

73results about How to "Strong recycling ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

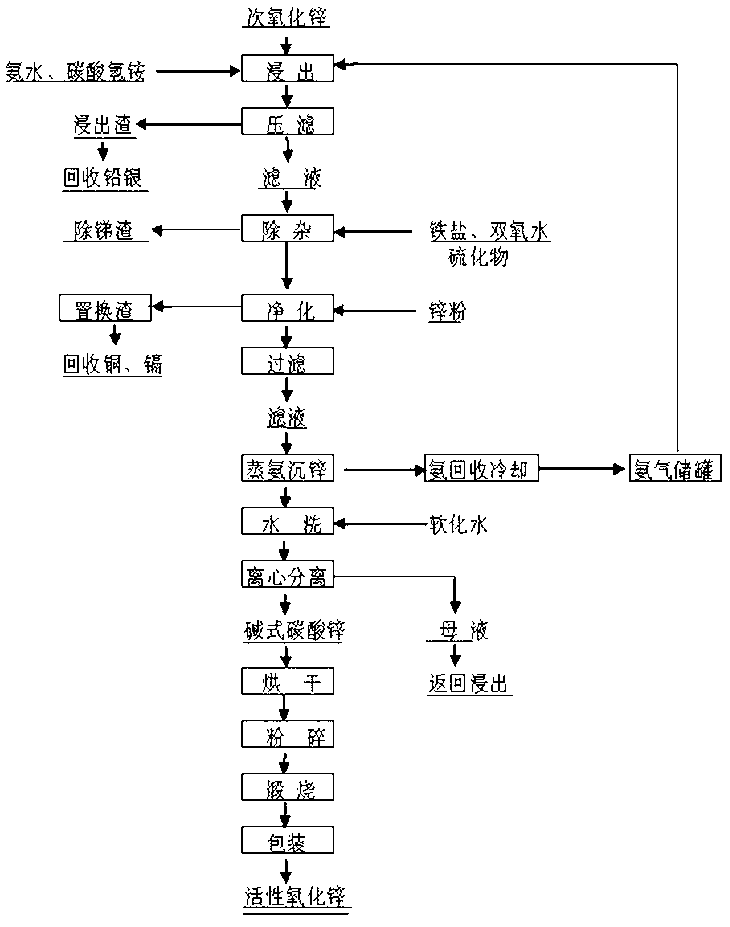

Method for preparing activated zinc oxide by utilizing high-arsenic secondary zinc oxide resource ammonia-ammonium process

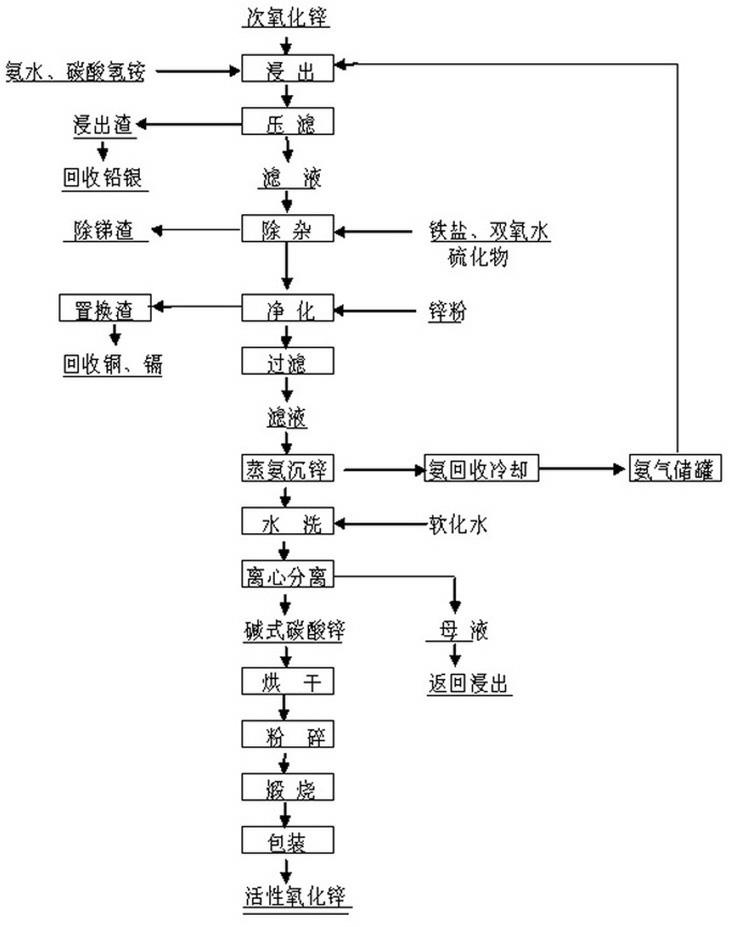

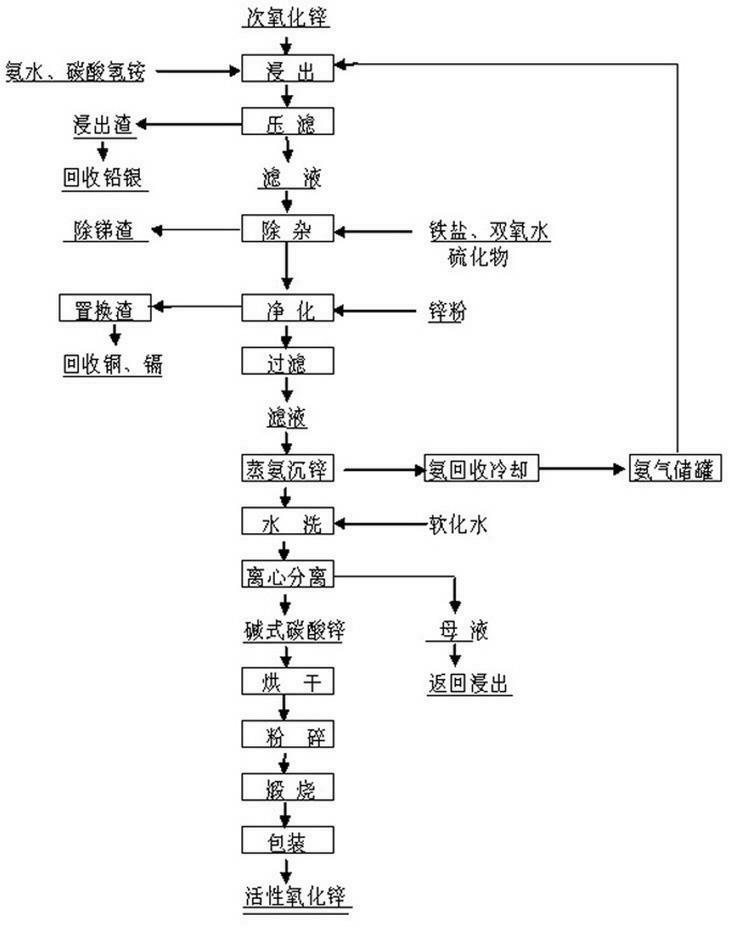

The invention relates to a method for preparing activated zinc oxide by utilizing a high-arsenic secondary zinc oxide resource ammonia-ammonium process, which belongs to the field of inorganic chemical industry and secondary resource recovery. The method comprises the following technical processes in sequence as follows: leaching, purifying, ammonia distillation, washing, dry crushing, calcining and the like. According to the method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process, by taking high-arsenic-antimony secondary zinc oxide generated in a lead and zinc smelting process as a raw material, selective leaching is performed by adding ammonia water and ammonium bicarbonate; then, two-stage purification and deeppurification are performed by ferrous salt, hydrogen peroxide, sulfide and zinc powder; and the ammonia water is recycled and valued metal waste residues are comprehensively recovered. The method forpreparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has strong adaptability on zinc-contained materials and is capable of treating various complicated zinc-contained resources. The method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has the advantages of short flow, production process closed cycle, convenience in operation, low energy consumption, excellent product quality, high economic benefits, low pollution, high comprehensive recovery capacityand the like, and is suitable for industrial production and popularization.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

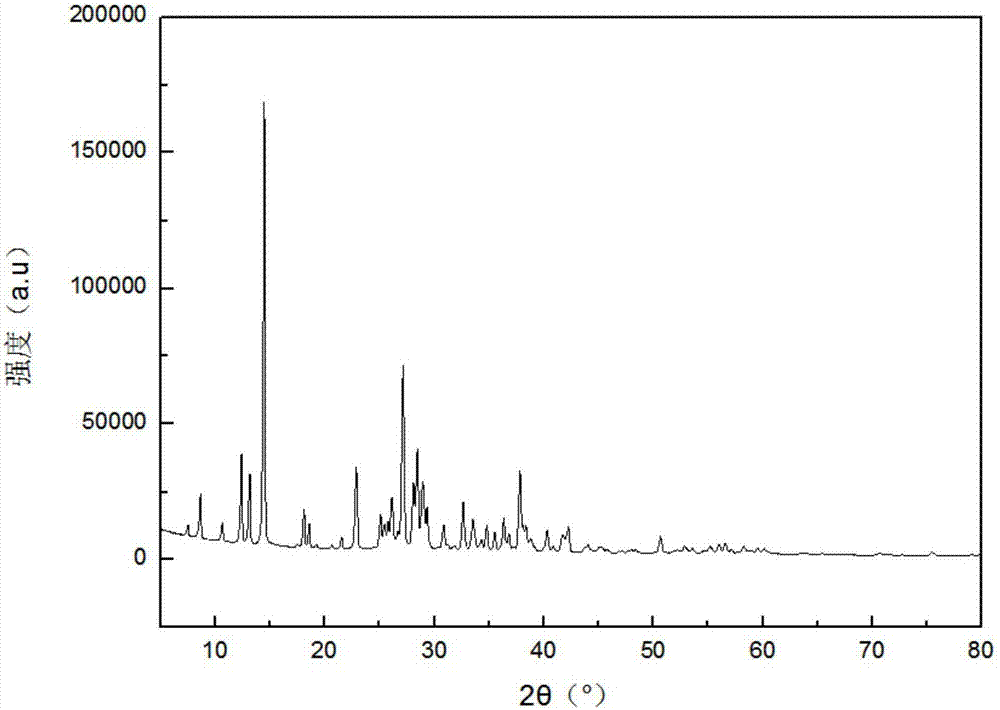

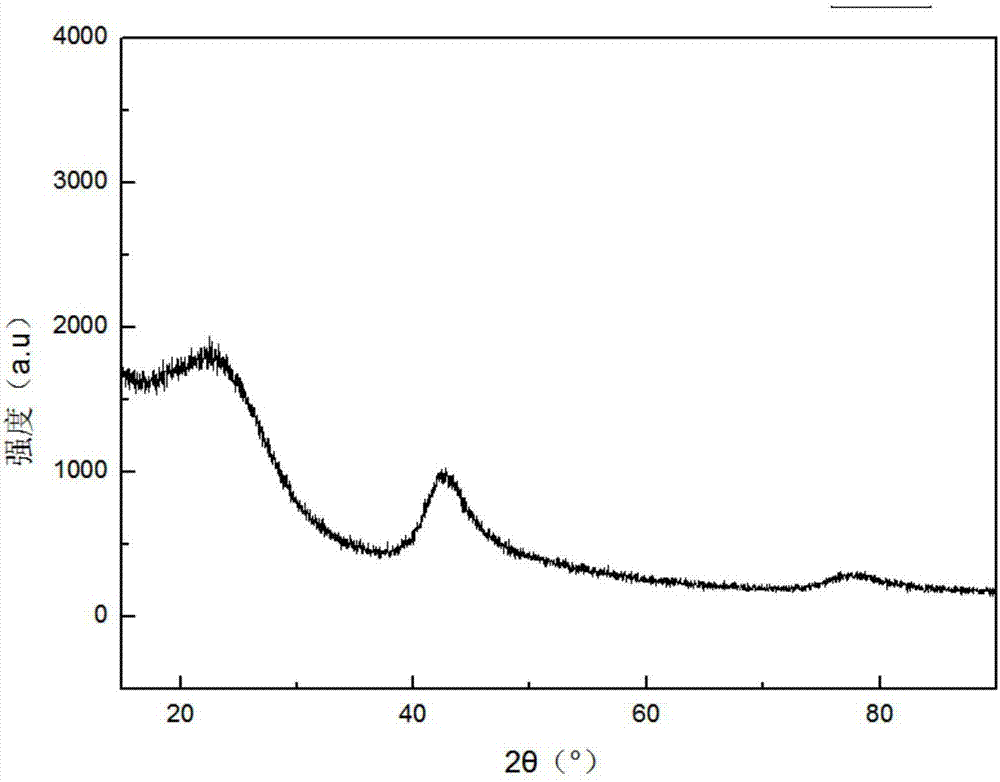

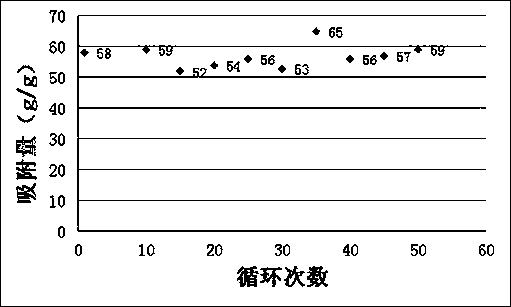

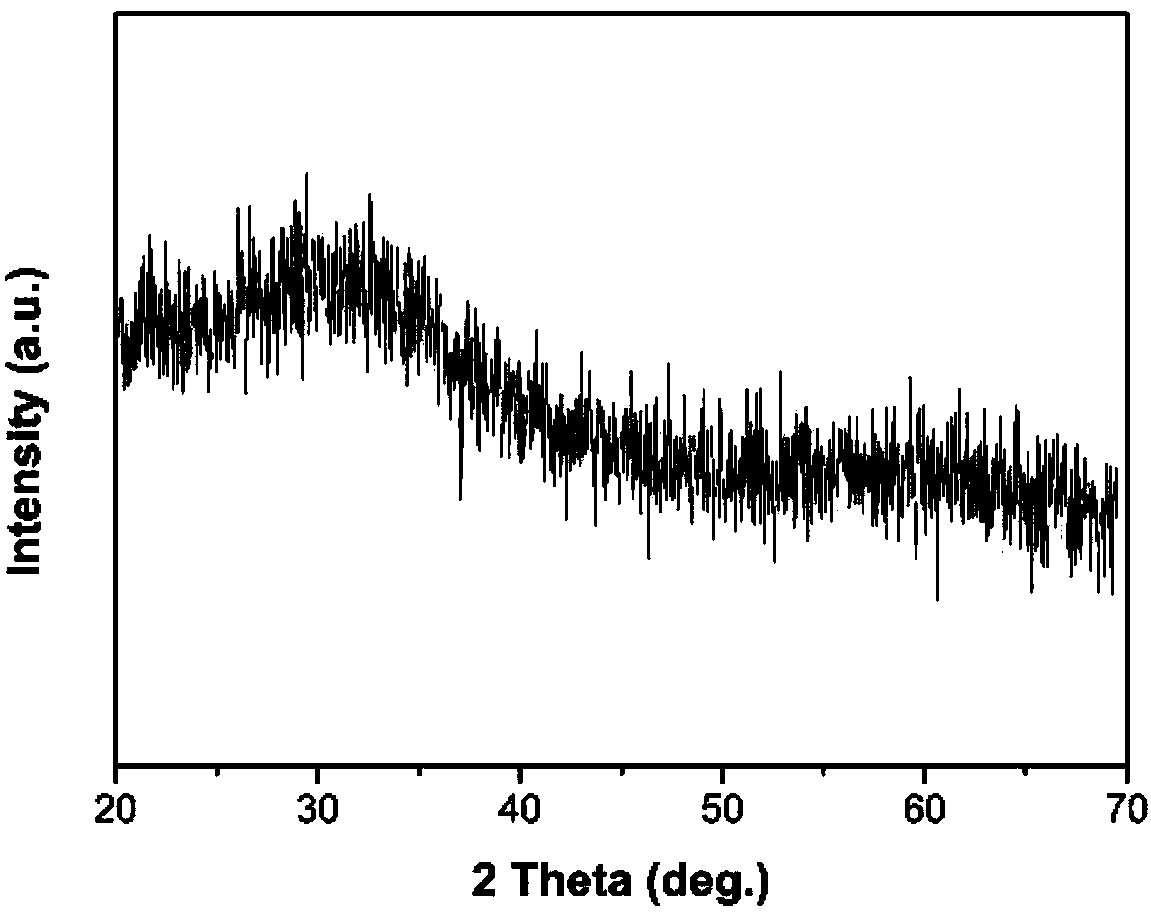

Hexagonal boron-nitride material, preparation method and application of hexagonal boron-nitride material

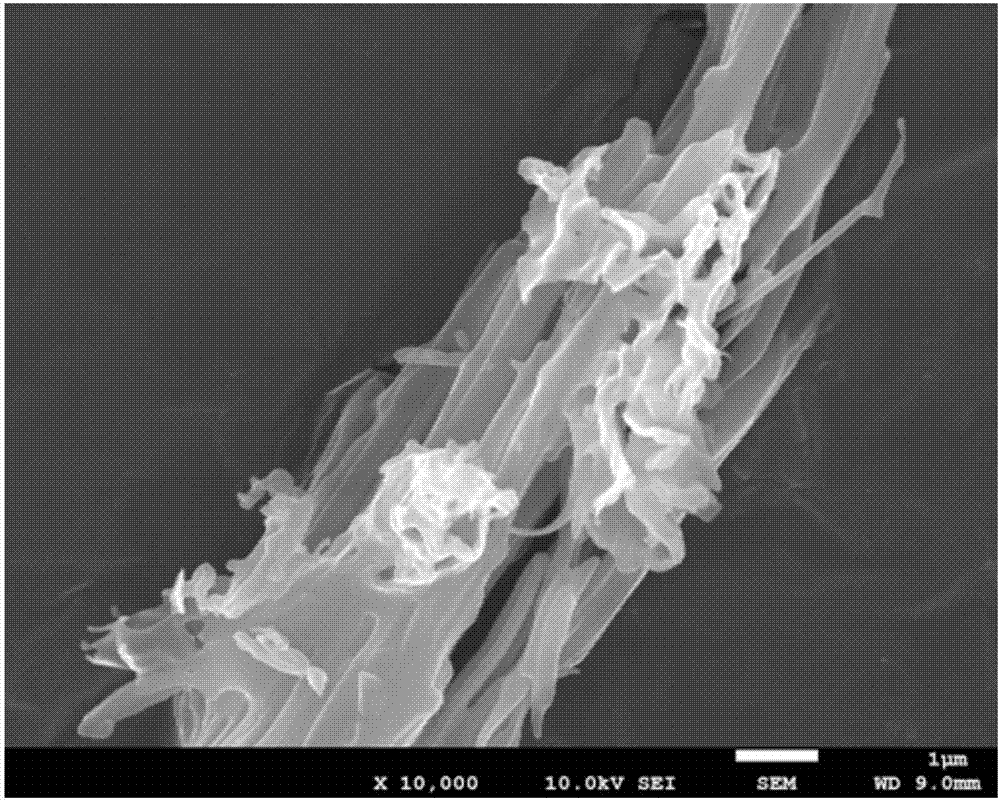

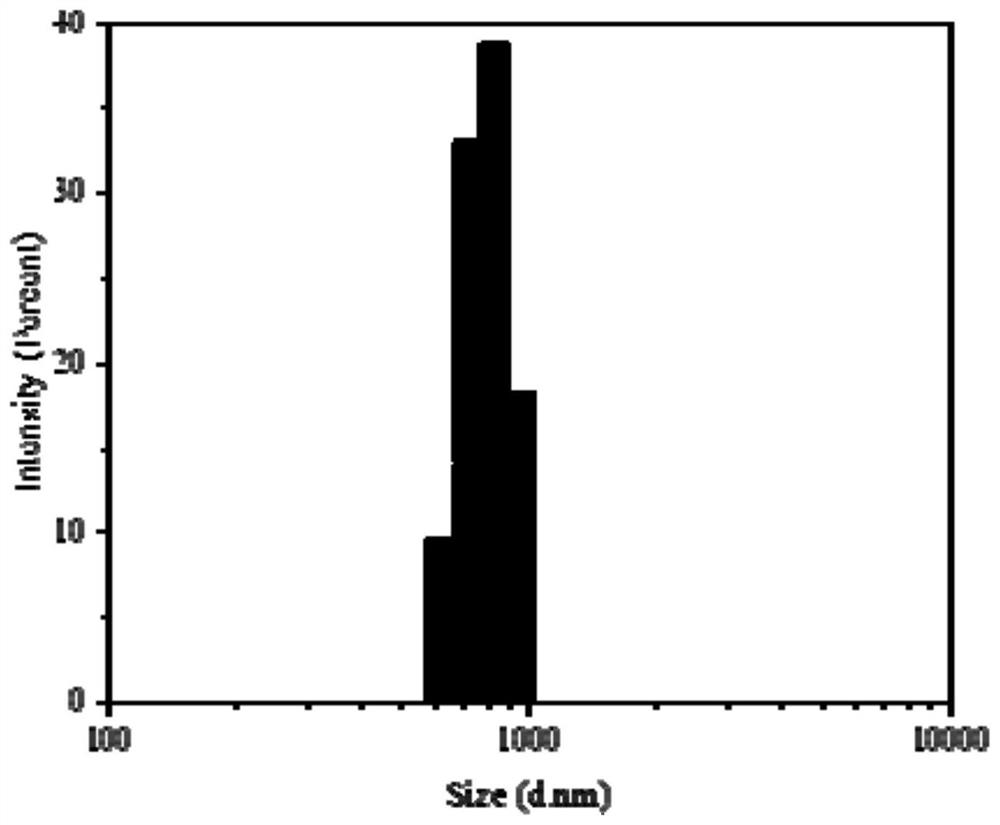

ActiveCN107376825ALarge specific surface areaDiffraction peak intensity is lowOther chemical processesWater contaminantsHexagonal boron nitrideSorbent

The invention provides a hexagonal boron-nitride material, a preparation method and application of hexagonal boron-nitride material. The hexagonal boron-nitride material is of an assembling structure consisting of porous boron-nitride whiskers and porous boron-nitride piece layers, or a porous boron-nitride whisker structure distributed with mesopores and macropores and with the specific surface area reaching 420m<2> / g. The preparation method comprises the following steps: (1) adding boric acid, melamine and optional surface active agent into water, mixing, heating, adjusting pH value of solution to be 3-11, crystallizing, and separating solid and liquid to obtain precursor; and (2) carrying out two-section type calcining reduction on the precursor in the step (1) under the atmosphere of ammonia gas or the mixed atmosphere containing the ammonia gas to obtain the hexagonal boron-nitride material. The hexagonal boron-nitride material can be used as an absorbing agent for absorbing metal ions and / or organic matters. The invention also provides a cyclic regeneration method of the hexagonal boron-nitride material. The hexagonal boron-nitride material is an excellent absorbing agent, is excellent in absorbing performance and cyclic regeneration performance, and has good application prospect in the field of water treatment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

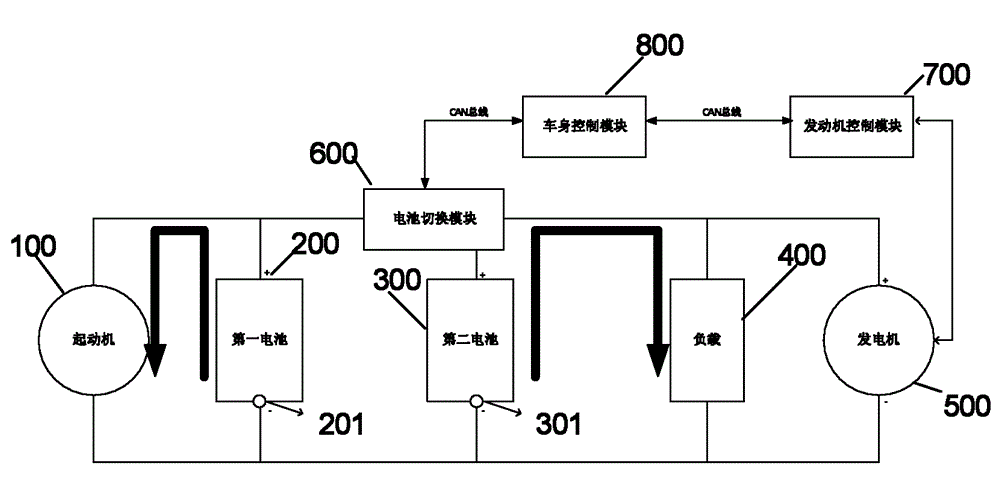

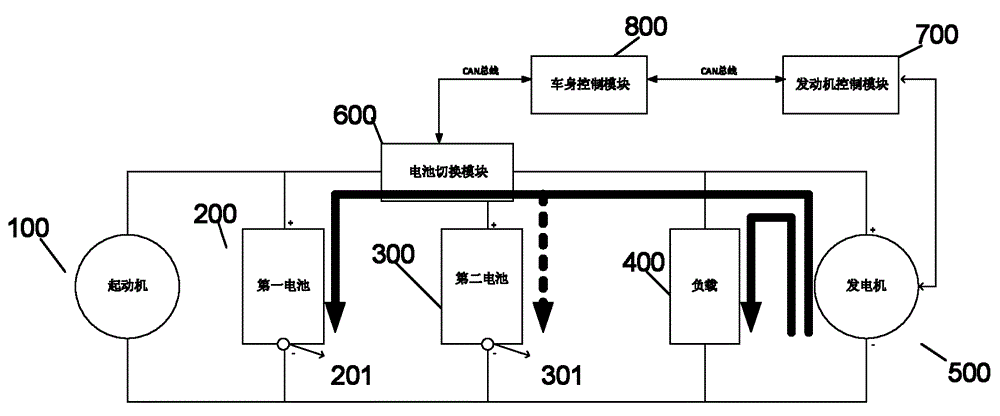

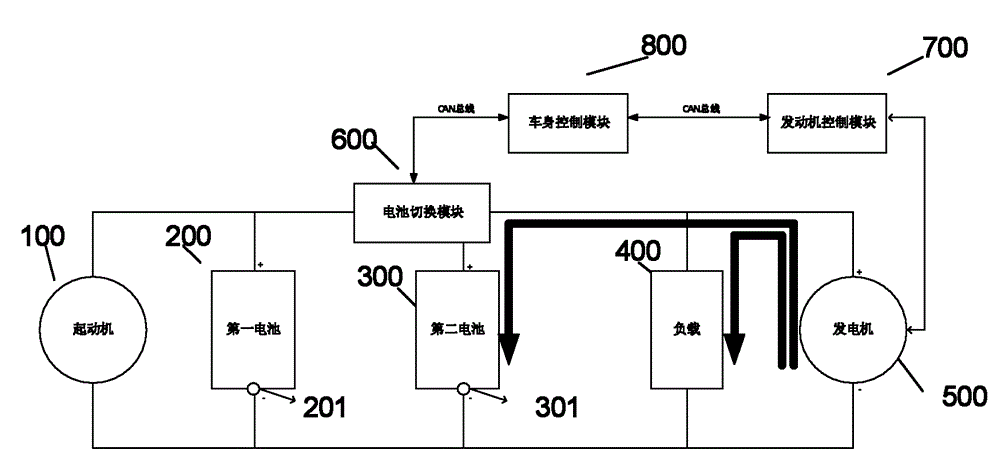

Double battery management system of engine automatic start and stop vehicle

ActiveCN104999920AReduce control complexityContribution to lower fuel consumptionVehicular energy storageElectric propulsionElectrical batteryComputer module

The present invention relates to a double battery management system of an engine automatic start and stop vehicle. The double battery management system is provided with a starter; a first battery only used for power supply of the starter; a second battery used for power supply of loads of the whole vehicle; a generator used for power supply of the first battery and / or the second battery and the whole vehicle; a first battery sensor used for acquiring electric quantity information and charging / discharging information of the first battery; a second battery sensor used for acquiring electric quantity information and charging / discharging information of the second battery; a battery switching module used for switching connection / disconnection of the first battery, the second battery and a whole vehicle network; an engine control module used for controlling an engine; and a vehicle body control module used for controlling the battery switching module and performing information interaction with the engine control module, the first battery sensor and the second battery sensor.

Owner:SAIC GENERAL MOTORS +1

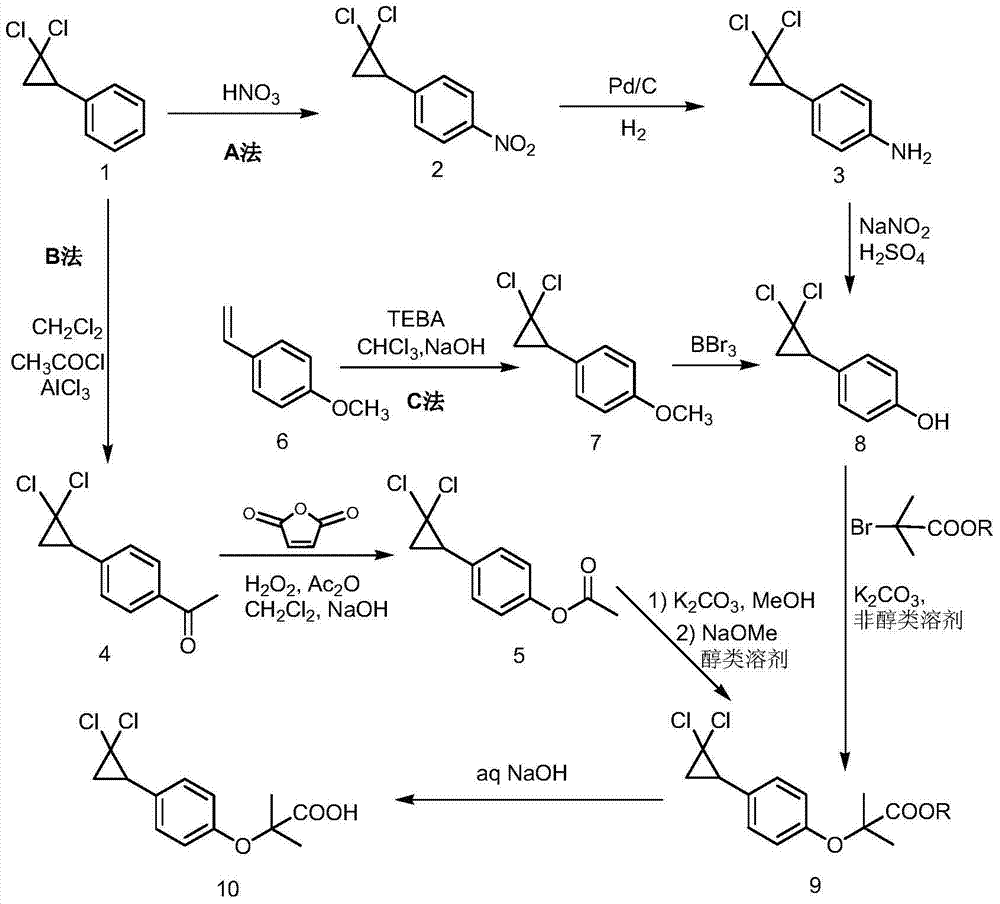

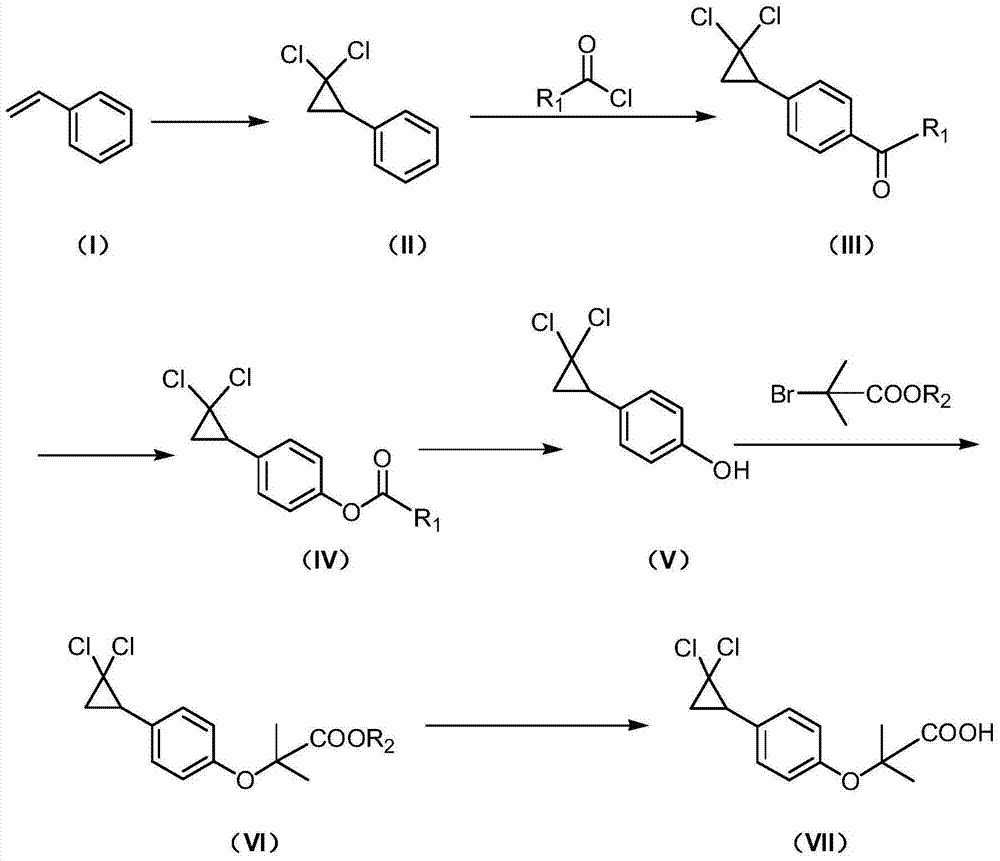

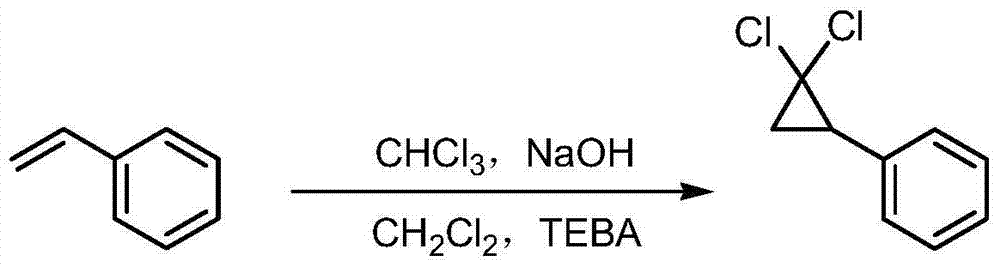

Synthetic method of ciprofibrate

ActiveCN103613498AAvoid generatingHigh yieldOxygen-containing compound preparationOrganic compound preparationAcetic anhydrideOrtho position

The invention discloses a synthetic method of ciprofibrate. The method comprises the following steps: taking styrene as a starting material; obtaining the ciprofibrate by the processes of cyclization, acylation, Baeyer-Villiger oxidation, alcoholysis, alkylation and hydrolysis, wherein an acylation reagent adopted in the acylation process is R1COCl; the R1 is C4-C12 alkyl. Fatty acyl chloride of which a hydrocarbyl structure is a long chain is adopted in acylation reaction, so that the steric hindrance is increased, the reaction activity of acyl chloride is reduced, the content of the produced ortho-position isomer is smaller than 0.2% and superior to that of acetyl chloride reaction (the content of the ortho-position isomer is 0.5-1%), the yield and the purity of the product are improved, and meanwhile, a room-temperature reaction condition is adopted, so that the energy consumption of production is reduced. Urea peroxide instead of hydrogen peroxide is used as an oxidant in the Baeyer-Villiger oxidation, and acetic acid is used instead of acetic anhydride, so that the reaction condition is milder, and the operation is more controllable.

Owner:ZHEJIANG SANMEN HYGECON PHARMA CO LTD

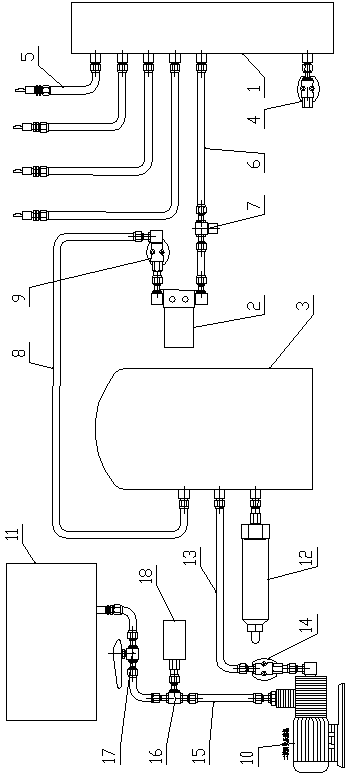

Tail gas recovery device based on pressure balance control method

ActiveCN103463925ASolve driftStrong recycling abilityDispersed particle separationSulfur and halogen compoundsSulfur hexafluorideDifferential pressure

The invention provides a tail gas recovery device based on a pressure balance control method. The device comprises a surge flask, a primary recover flask and a primary recovery compressor, wherein a micro differential pressure transducer is arranged on the surge flask; at least a gas inlet pipe is connected at a gas inlet of the surge flask; a gas outlet of the surge flask is connected with a gas inlet of the primary recovery compressor by a first high pressure pipe; an electromagnetic proportional valve is arranged on the first high pressure pipe; a gas outlet of the primary recovery compressor is connected with a gas inlet of the primary recover flask by a second high pressure pipe; a first electromagnetic valve is arranged on the second high pressure pipe. The device has a simple structure, is easy to operate and control, has small volume and light weight, completely eradicates the adverse effects of sulfur hexafluoride emitted in test processes and decomposition products of sulfur hexafluoride on environments and human bodies, achieves zero emission and recycling of sulfur hexafluoride, has economic, environmental and safety triple benefits and can be broadly applied to collection of toxic tail gases or environment polluting tail gases generated in a laboratory environment or after detection by industrial field instruments.

Owner:HENAN RELATIONS

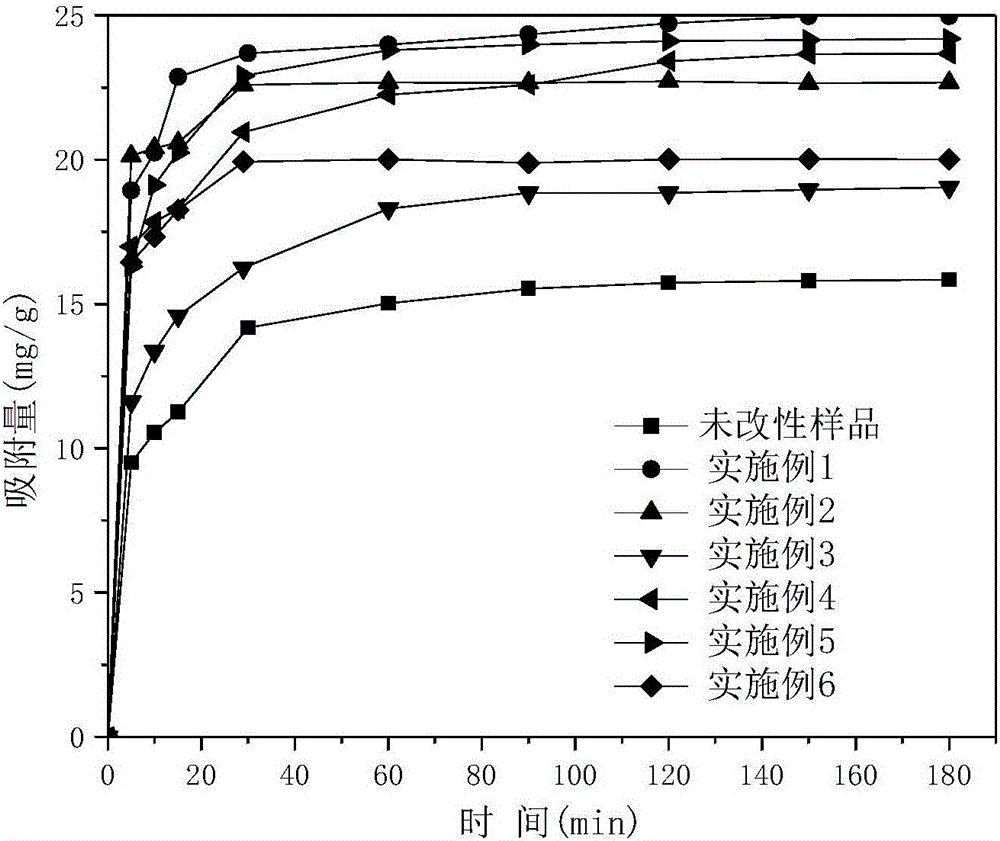

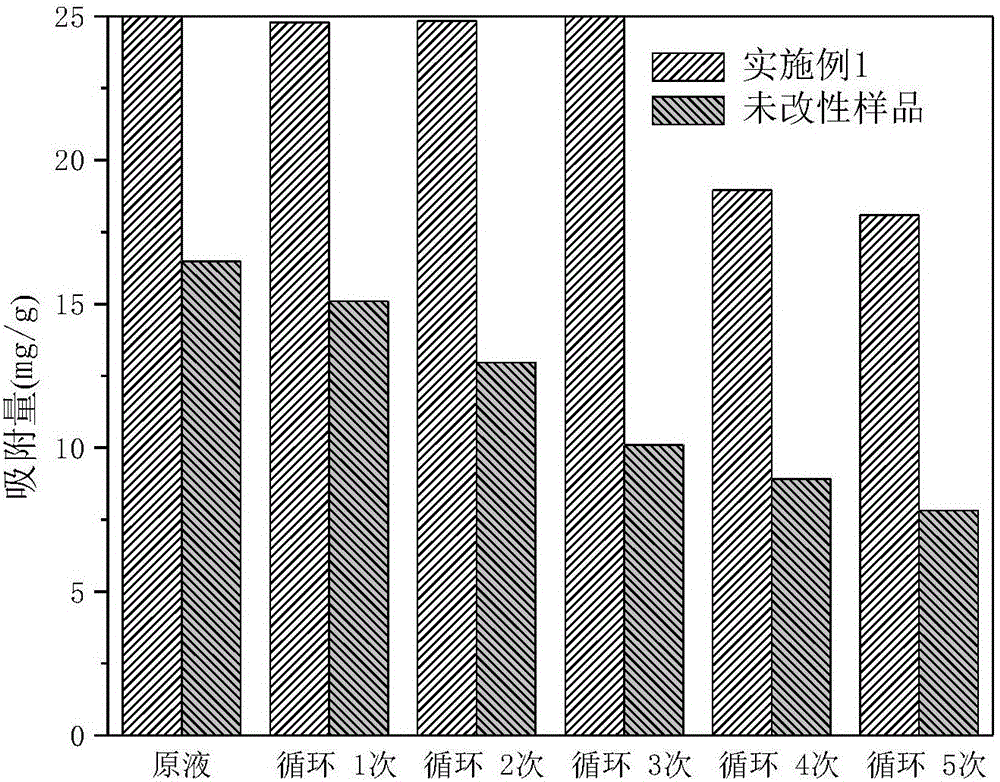

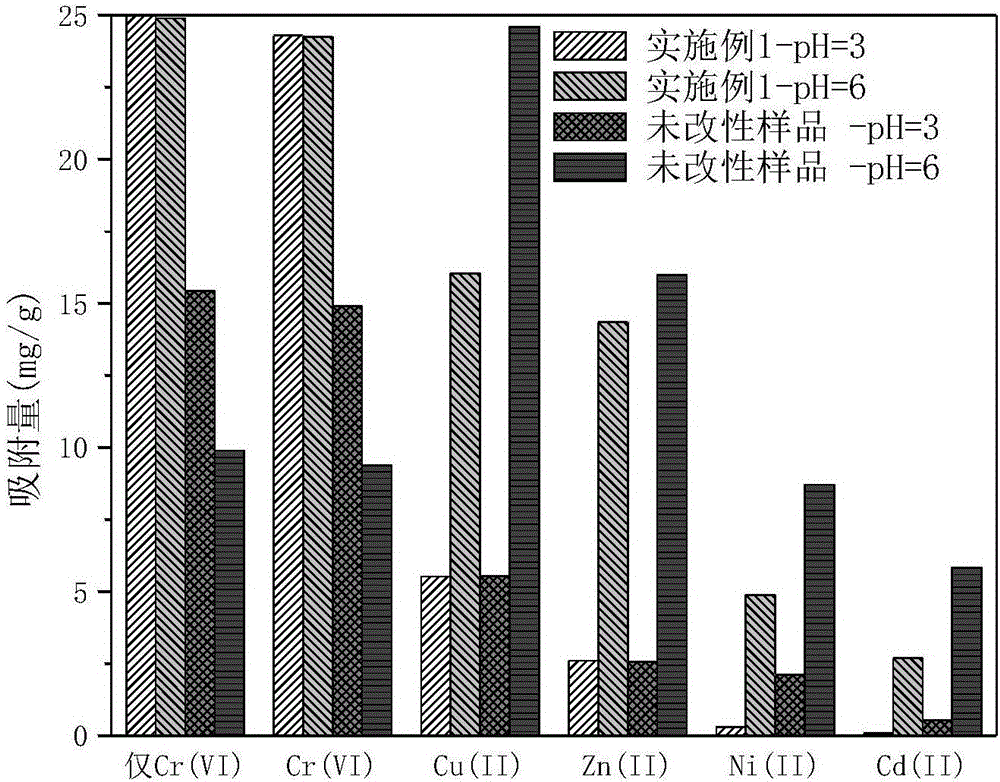

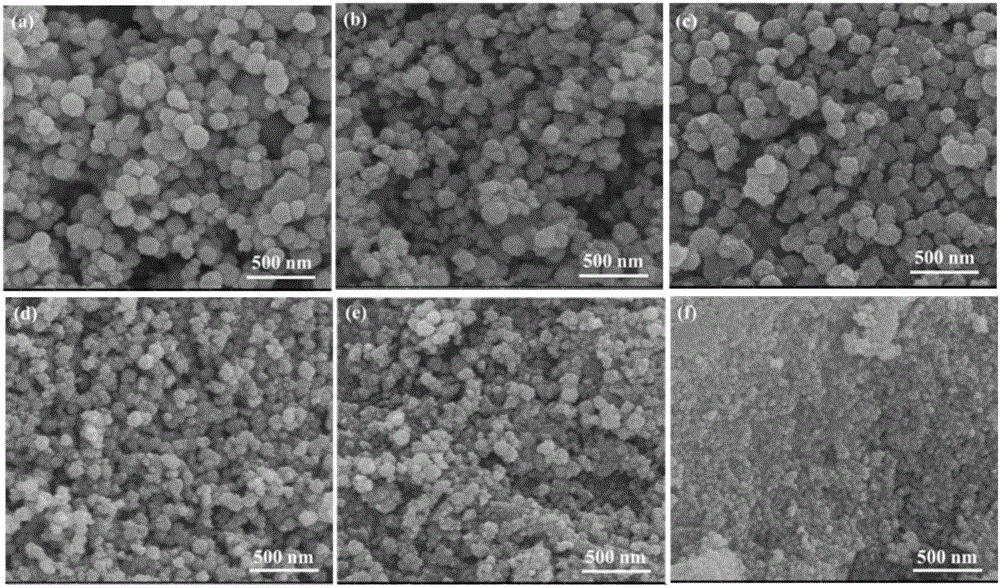

Preparation method of high-selectivity amino-functionalized mesoporous gamma-aluminum oxide-based composite adsorbent

InactiveCN106512949AShort timeImprove adsorption capacityOther chemical processesWater contaminantsSorbentEngineering

The invention relates to a preparation method of a high-selectivity amino-functionalized mesoporous gamma-aluminum oxide-based composite adsorbent. The preparation method comprises the following steps: sequentially adding concentrated nitric acid and aluminum isopropoxide into a P123 ethanol solution under a room-temperature stirring condition, so as to form a solution; carrying out solvent induced evaporation on the solution to obtain gel, and roasting the gel to obtain mesoporous gamma-Al2O3 raw powder; and dropwise adding a certain amount of amino silane into the raw powder which is subjected to ethanol dispersion at room temperature, stirring for a certain period of time to obtain a product, and sequentially carrying out separation, ethanol washing and drying on the product, so as to obtain the gamma-Al2O3-based composite adsorbent. The preparation method has the beneficial effects that the preparation process is simple, and conditions are mild; the prepared composite adsorbent has an adsorption capacity of 67.0mg / g to highly toxic Cr(VI) and still has a removal rate above 99.9% after being circulated for three times; the adsorbent has very good selective adsorption performance to a Cr(VI), Cu(II), Zn(II), Ni(II) and Cd(II) mixed solution at different pH values; and the adsorbent has excellent adsorption performance to Cr(VI) in the respective presence of anions such as SO4<2>, HPO4<2>, NO3 and Cl.

Owner:WUHAN UNIV OF TECH

Copper-cerium co-doped magnetic composite material and preparation and application method thereof

ActiveCN106824046AStrong magnetismImprove performanceOther chemical processesWater contaminantsSodium acetateArsenic pollution

The invention belongs to the technical field of water treatment and particularly relates to a copper-cerium co-doped magnetic composite material, a preparation method thereof and application of the material in water body arsenic removal. Iron salt, copper salt and cerium salt serve as the raw materials, sodium acetate serves as an alkaline source, ethylene glycol serves as a solvent, and the copper-cerium co-doped magnetic composite material is synthesized through the solvothermal method. Dual-metal doped magnetic composite materials with different sizes and specific surface areas are obtained by regulating the molar ratio of doped copper metal to cerium metal salt. The preparation method has the advantages of being low in cost, simple in process, excellent in arsenic adsorption, capable of achieving magnetic separation easily and the like, and plays an important role in solving arsenic pollution in water bodies.

Owner:CENT SOUTH UNIV

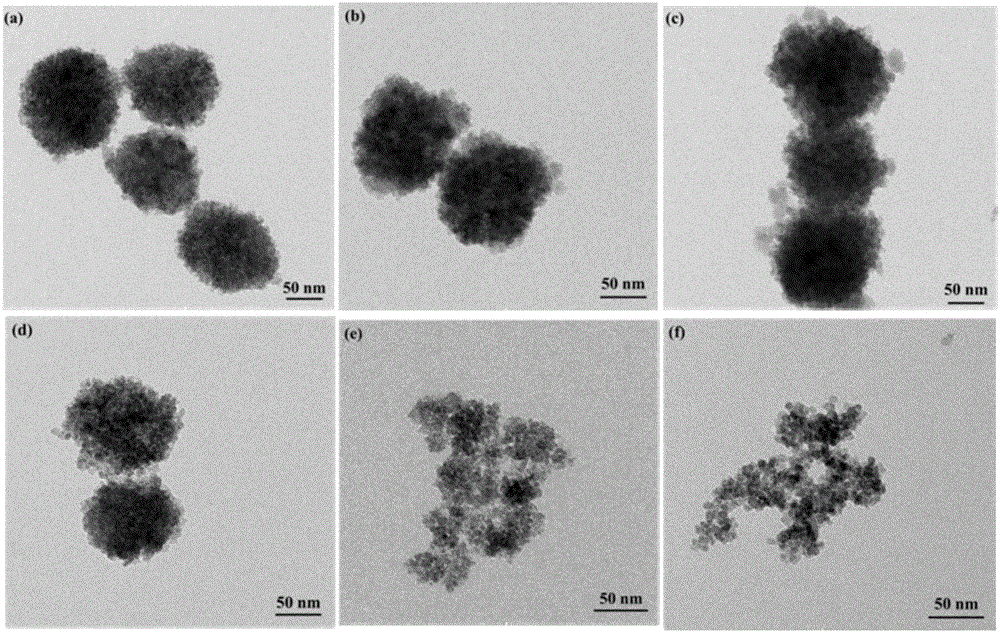

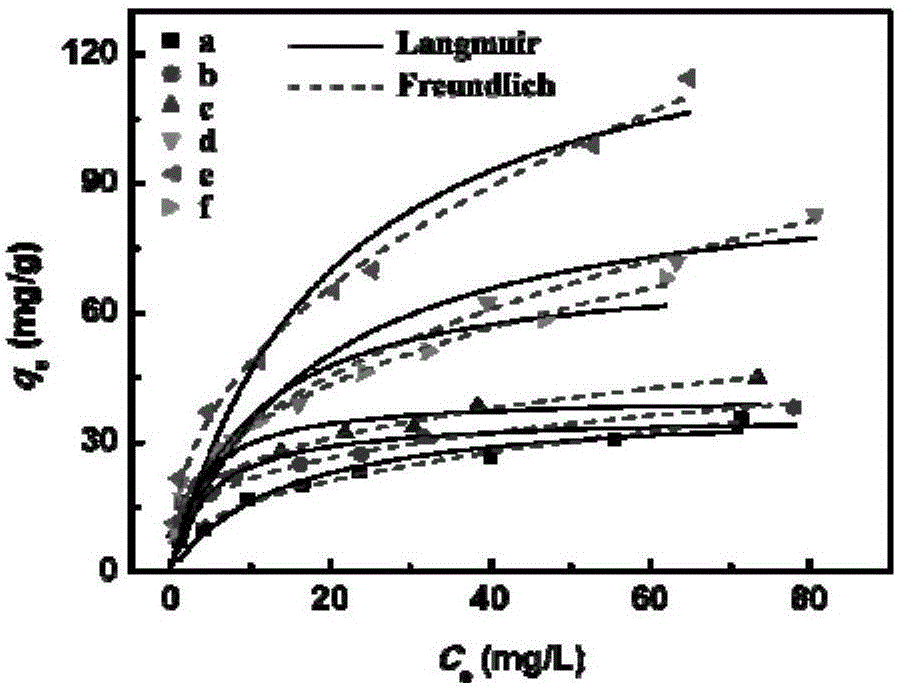

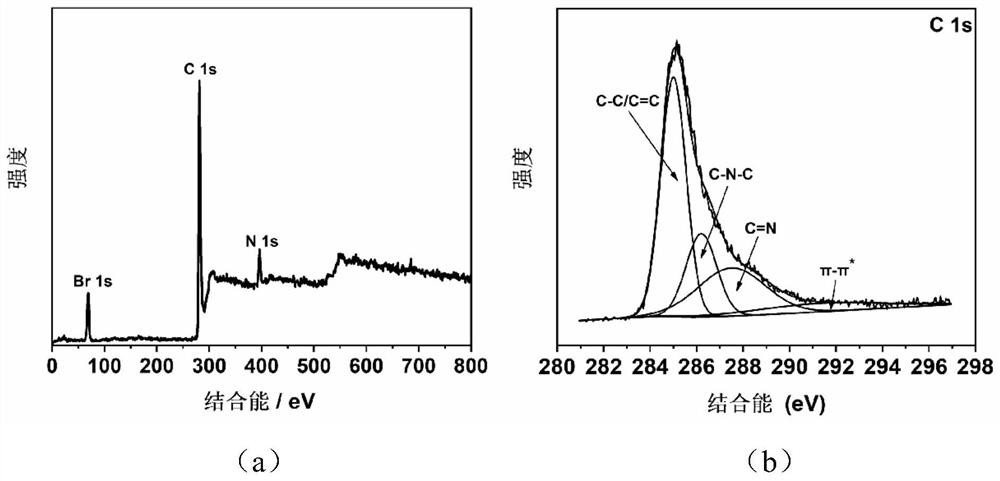

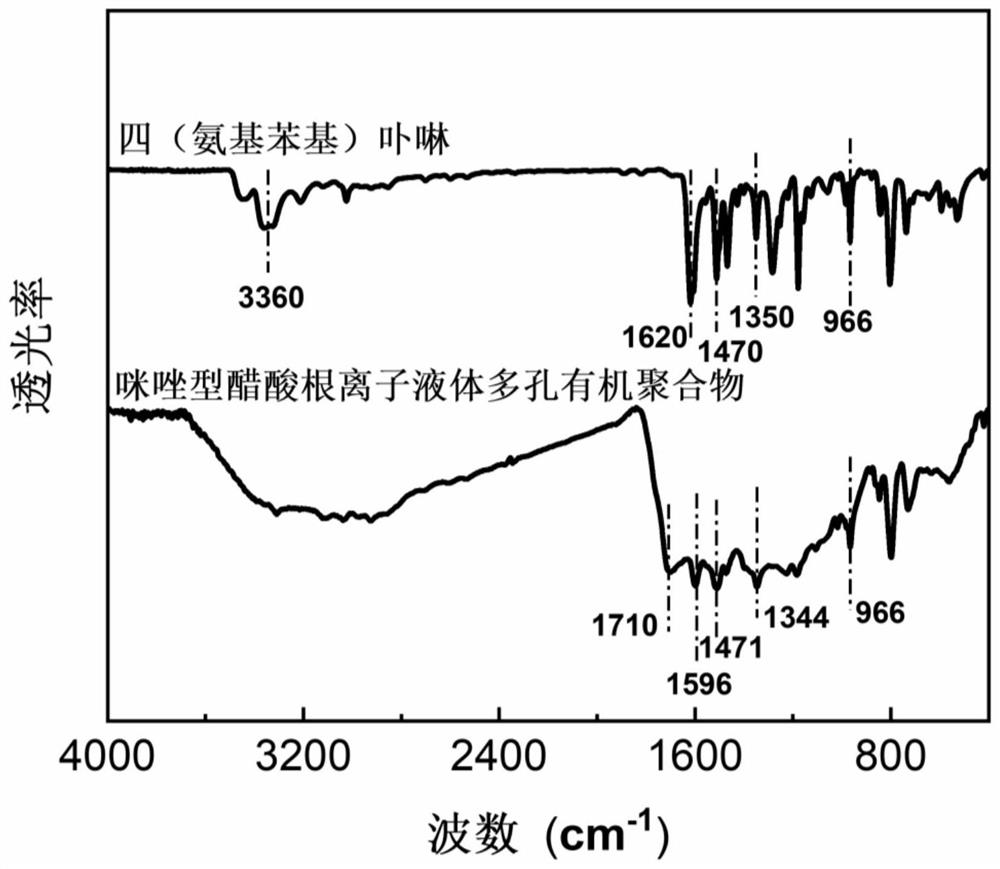

Preparation method of imidazole type ionic liquid porous organic polymer

InactiveCN112321824ASolve pollutionSolve the costOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceAcetic anhydride

The invention belongs to the technical field of polymer synthesis, and discloses a preparation method of an imidazole type ionic liquid porous organic polymer. The method comprises the following steps: synthesizing tetra(nitrophenyl)porphyrin by using p-nitrobenzaldehyde and pyrrole as monomers and propionic acid and acetic anhydride as solvents through a propionic acid-anhydride method; reducingthe tetra(nitrophenyl)porphyrin by using a reducing agent to obtain tetra(aminophenyl)porphyrin; and enabling amino groups to form imidazole ring cations with a 1,2-dicarbonyl compound and an alkylaldehyde compound under an acidic condition, and allowing porphyrin monomers to connected with one another through imidazole rings, thereby forming the heterogeneous porous organic polymer. According tothe preparation method, polymerization can be realized by virtue of Debuus-Radziszewski imidazole synthesis reaction of substituted anilino functional groups on four mutually symmetrical methylenes oftetra(aminophenyl)porphyrin, so the ionic liquid porous organic polymer containing imidazole type cation / anion groups is obtained, and the preparation of a non-metal heterogeneous photocatalyst can be greatly simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for selectively electro-adsorbing halogen ions in composite salt wastewater

ActiveCN110357227AImprove halogen selectivityIncrease the adsorption capacityWater contaminantsDispersed particle separationIonHalogen

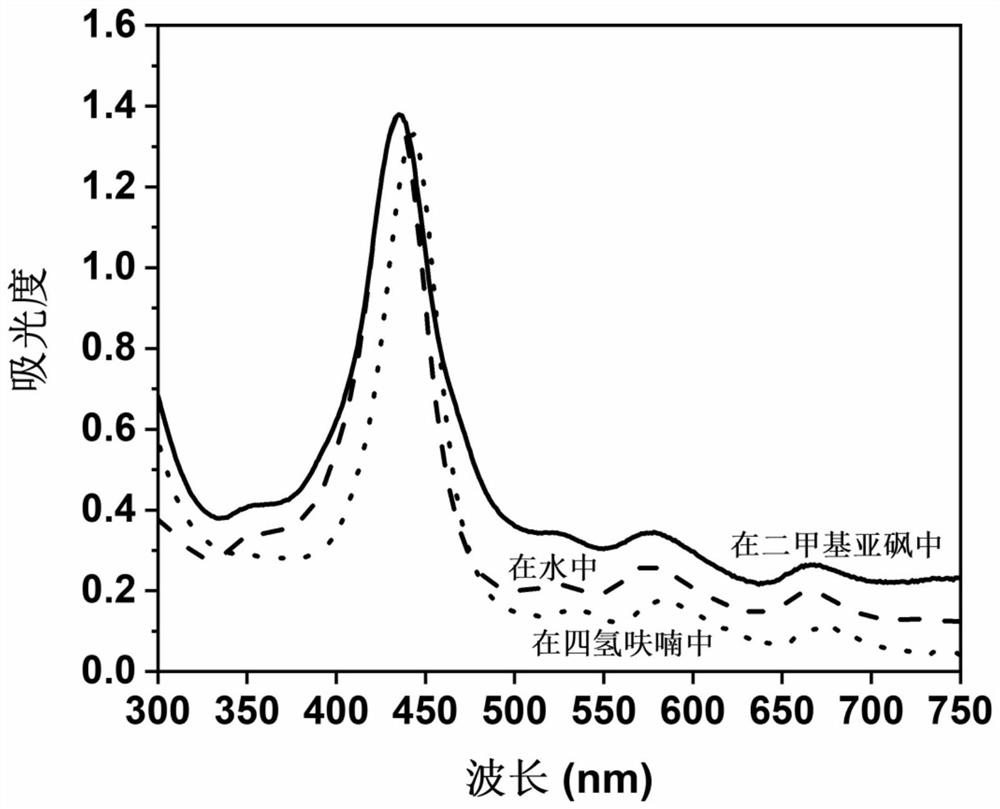

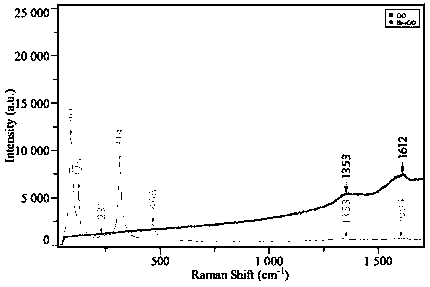

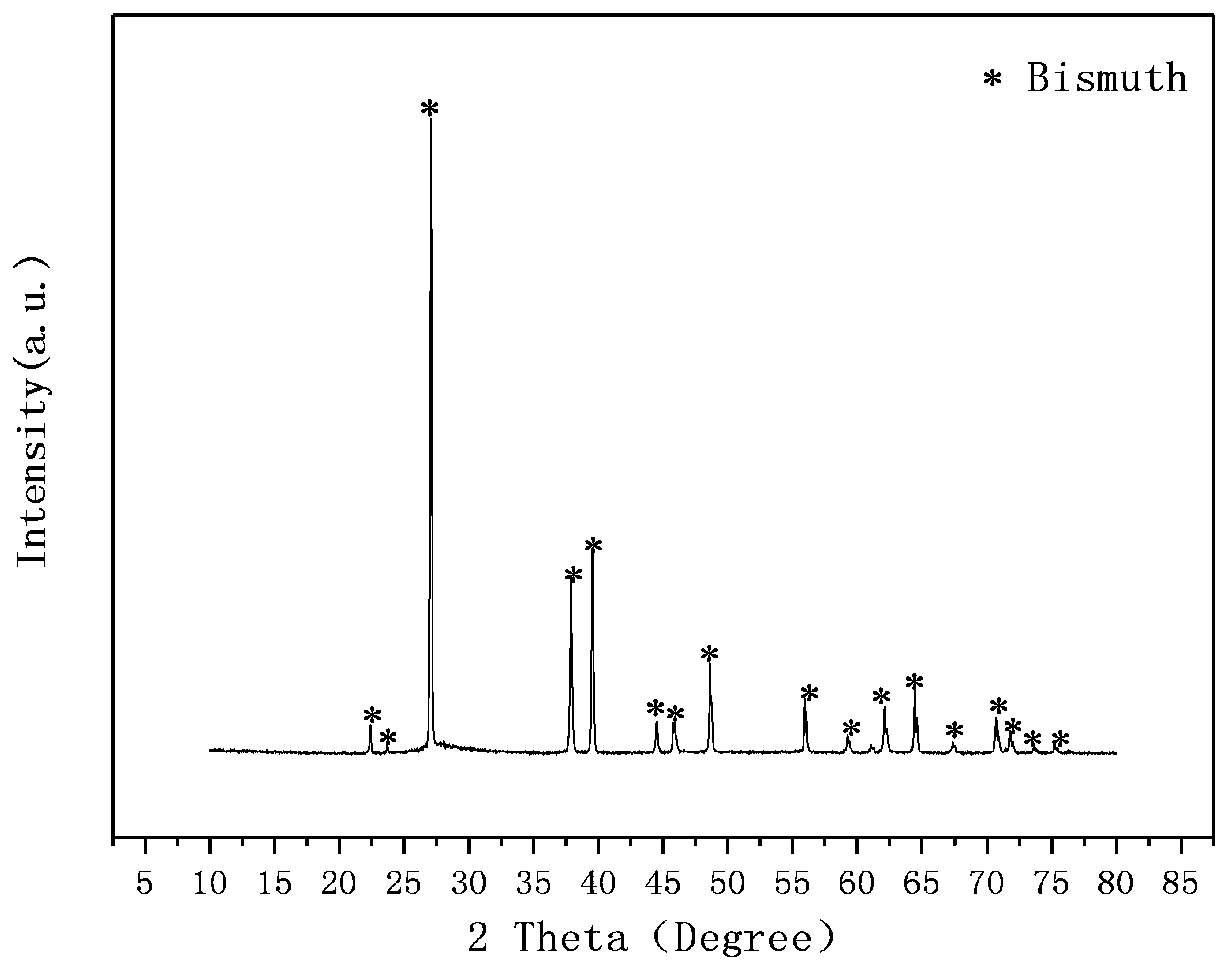

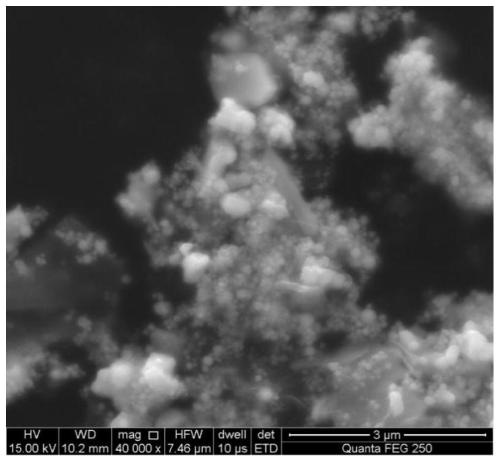

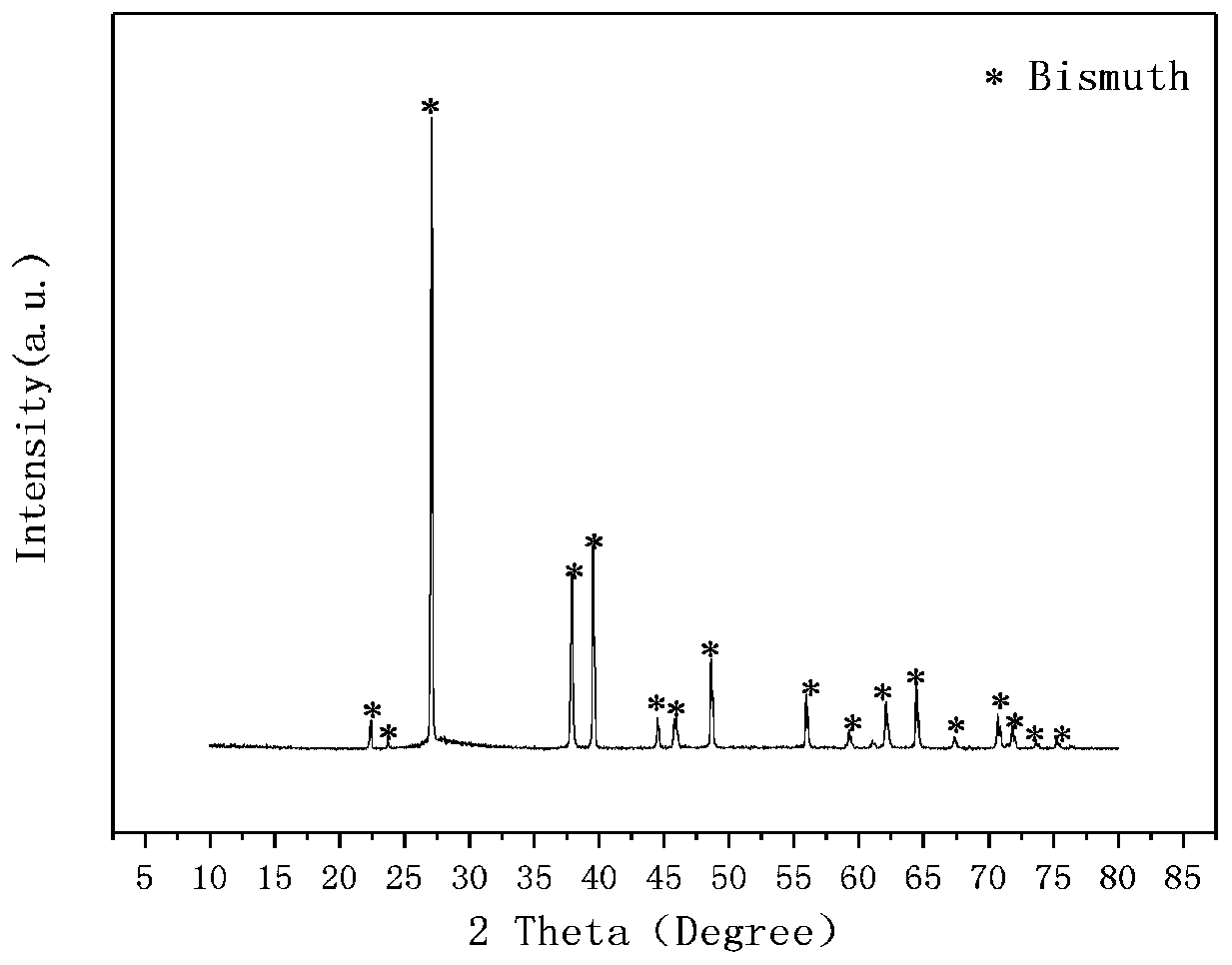

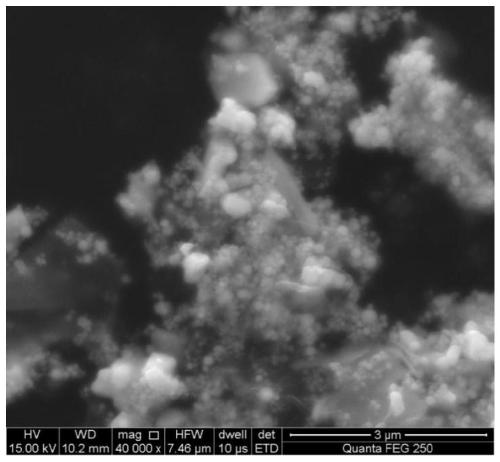

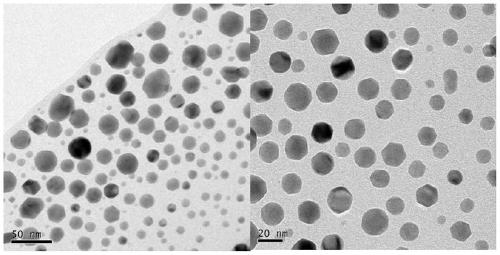

The invention belongs to the field of wastewater treatment, and specifically discloses a method for selectively electro-adsorbing halogen ions in composite salt wastewater. According to the present invention, a composite bismuth electrode compounded with a C@Bi / rGO composite active material is used as an anode, a carbon material is used as a cathode, the anode and the cathode are placed in composite salt wastewater, and electro-adsorption is carried out by electrifying so as to selectively adsorb the halogen ions in the wastewater, wherein the C@Bi / rGO composite active material comprises reduced graphene oxide and carbon coated bismuth elemental particles compounded on the surface of the reduced graphene oxide in situ; and the electrode preparation method is simple, the electrode reversible cycle performance is good, and the asymmetric desalination system formed by combining with the carbon material has good selective electro-adsorption capability to fluorine and chlorine ions in composite salt wastewater.

Owner:CENT SOUTH UNIV

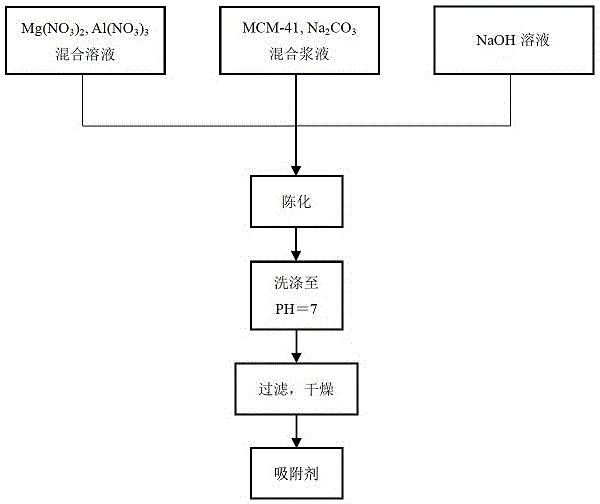

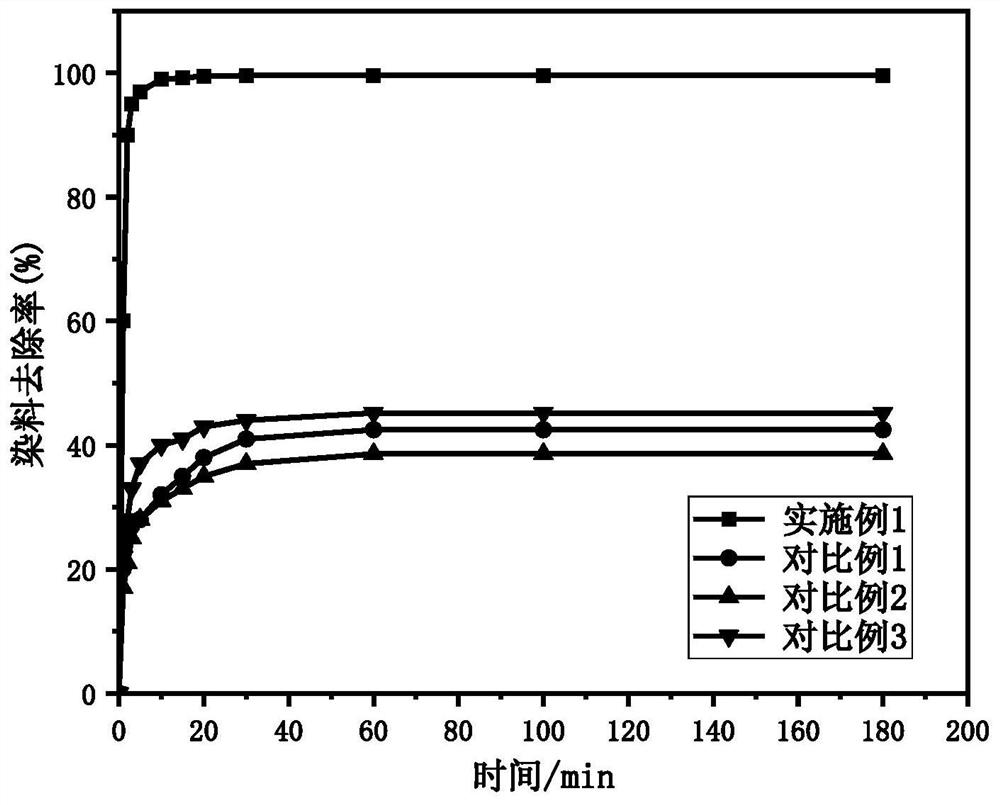

Compound type intermediate-temperature carbon dioxide adsorbent and preparation method thereof

InactiveCN105797678AImprove adsorption capacityGood application effectGas treatmentOther chemical processesSorbentMesoporous silica

The invention belongs to the technical field of environmental protection and discloses a novel compound type intermediate-temperature carbon dioxide adsorbent and a preparation method thereof. The compound type intermediate-temperature carbon dioxide adsorbent is used for adsorbing and separating CO2 in industrial smoke. The carbon dioxide adsorbent prepared with the method is characterized in that the absorbent is a magnesia-alumina type hydrotalcite composite prepared with a coprecipitation method on ordered mesoporous silica MCM-41 serving as a support material, and the problem of low adsorption efficiency of existing intermediate-temperature carbon dioxide adsorbents is solved. The method adopts a simple process and is simple to operate. The adsorbent prepared with the method has higher selective adsorption capability for carbon dioxide in gas containing certain moisture at the temperature of 150-300 DGE C, and smoke is not required to be cooled in advance. Besides, the adsorbent has the characteristics of low preparation cost, good recycling performance and no secondary pollution in the adsorption separation process.

Owner:NORTHEASTERN UNIV

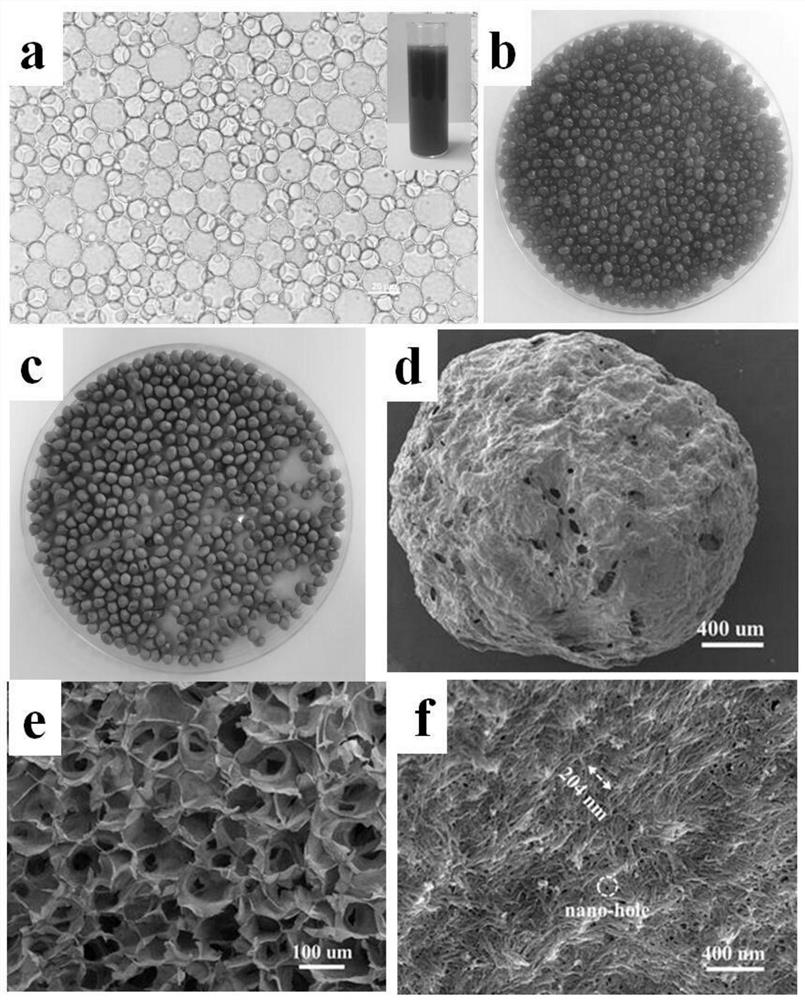

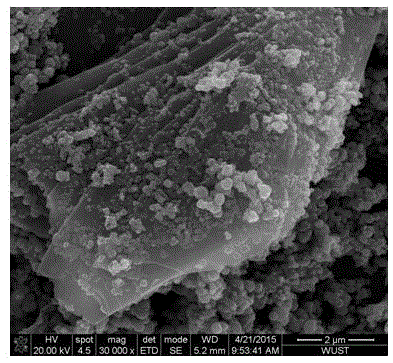

Biomass nanocellulose porous material loaded with nano transition metal oxide on surface, and preparation method thereof

ActiveCN113368838ASolve easy aggregationFully contactedOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic degradationCovalent Interaction

The invention relates to a biomass nanocellulose / nano transition metal oxide porous material, and a preparation method and application thereof. Nano transition metal oxide is loaded on the surface of biomass nanocellulose through non-covalent interaction. The biomass nano cellulose / nano transition metal oxide porous material has both adsorption and catalysis functions, and can be used as a recyclable adsorption and degradation material; when being used as an adsorption catalytic degradation material, the porous material has the advantages of high adsorption catalytic degradation efficiency, environment friendliness, excellent regeneration capacity, easiness in separation, recyclability and no repeated pollution, and has a considerable application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

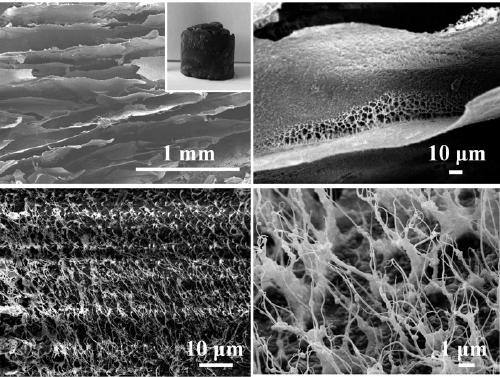

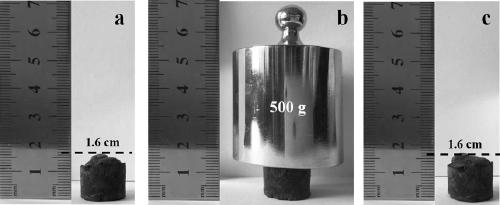

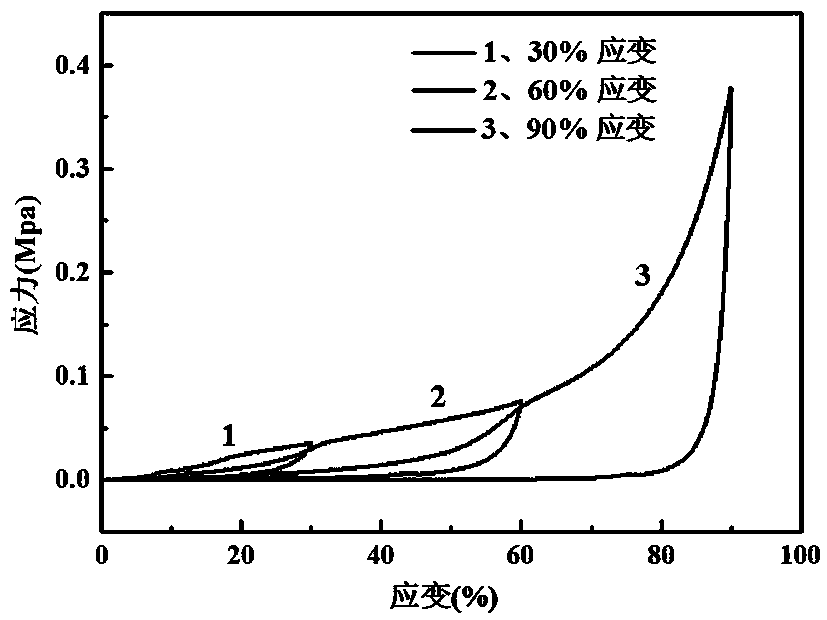

Preparation method of carbon aerogel

ActiveCN110040713AImprove mechanical propertiesGood compression elasticityOther chemical processesCarbon preparation/purificationOrganic solventPolyvinyl alcohol

The invention discloses a preparation method of carbon aerogel. The carbon aerogel is prepared through a one-step method by taking carbon nanospheres as raw materials, and performing a heating reaction in a water solution system and performing freeze drying in the presence of polyvinyl alcohol serving as a crosslinking agent and borax serving as a structure-directing agent. The carbon aerogel prepared by the invention has good mechanical performance, strong adsorption capacity for oil products and organic solvent, high adsorption rate, good recycling and reproduction performance, and high practicability, and can be applied in the fields of oil-water separation, oil stain collection and the like.

Owner:TAIYUAN UNIV OF TECH

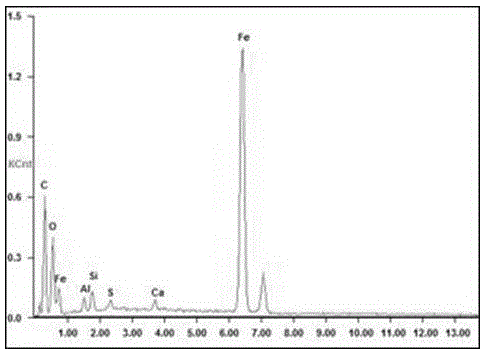

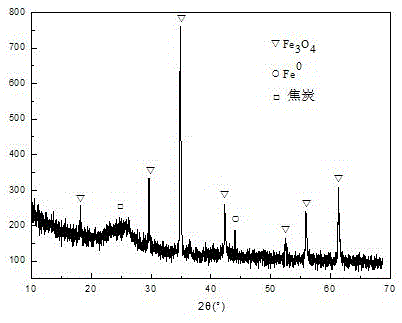

Fe3O4/Fe<0>/coke biomimetic catalyst capable of degrading POPs (persistent organic pollutants) and preparation method of catalyst

InactiveCN105148915ALow costGood dispersionWater contaminantsWater/sewage treatmentPtru catalystPersistent organic pollutant

The invention relates to a Fe3O4 / Fe<0> / coke biomimetic catalyst capable of degrading POPs (persistent organic pollutants) and a preparation method of the catalyst. According to the scheme, FeSO4*7H2O, coke and deoxygenization deionized water are mixed at the mass ratio of 1 to (0.2-0.6) and (40-100) and are stirred, to obtain a suspension; a NaBH4 solution is added to the suspension in the mass ratio of the NaBH4 solution to the suspension being 1:(40-100), and Fe<0> / coke is obtained through separation; blending is performed in the mass ratio of the Fe<0> / coke to the deoxygenization deionized water being 1:(50-100), and a suspension containing the Fe<0> / coke is obtained through stirring; blending is performed in the mass ratio of a FeSO4*7H2O solution to the suspension containing the Fe<0> / coke being (3-7):(50-100), the materials are mixed uniformly and heated, and a catalyst precursor suspension is obtained; finally, NaOH, NaNO3 and the catalyst precursor suspension are mixed uniformly in the mass ratio of 1 to (1-1.5) to (50-100), and the Fe3O4 / Fe<0> / coke biomimetic catalyst is obtained through separation. The Fe3O4 / Fe<0> / coke biomimetic catalyst capable of degrading the POPs (persistent organic pollutants) and the preparation method of the catalyst have the characteristics of available raw materials, low cost, high efficiency and environment-friendliness.

Owner:WUHAN UNIV OF SCI & TECH

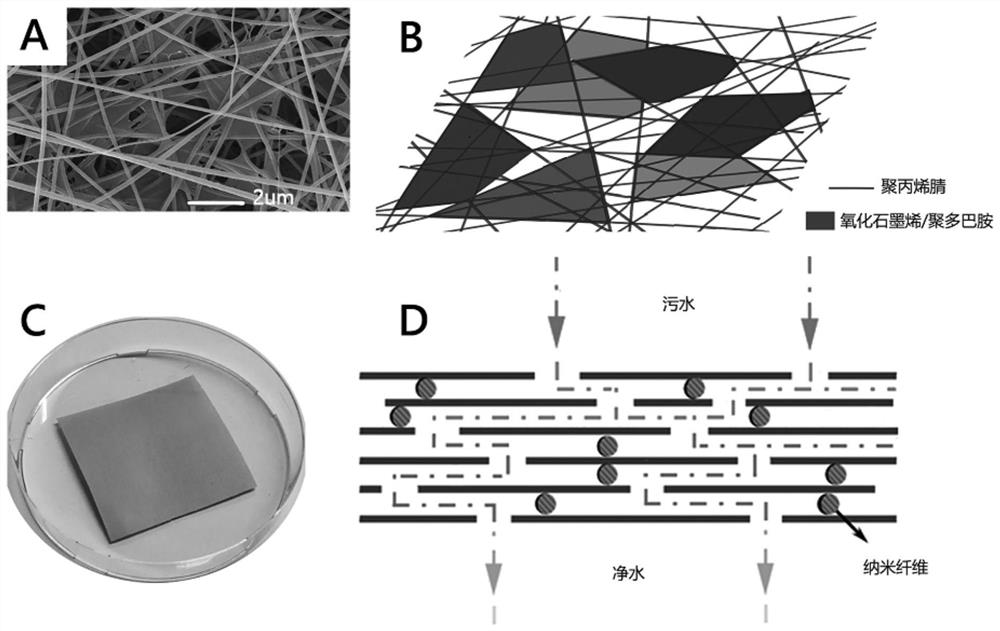

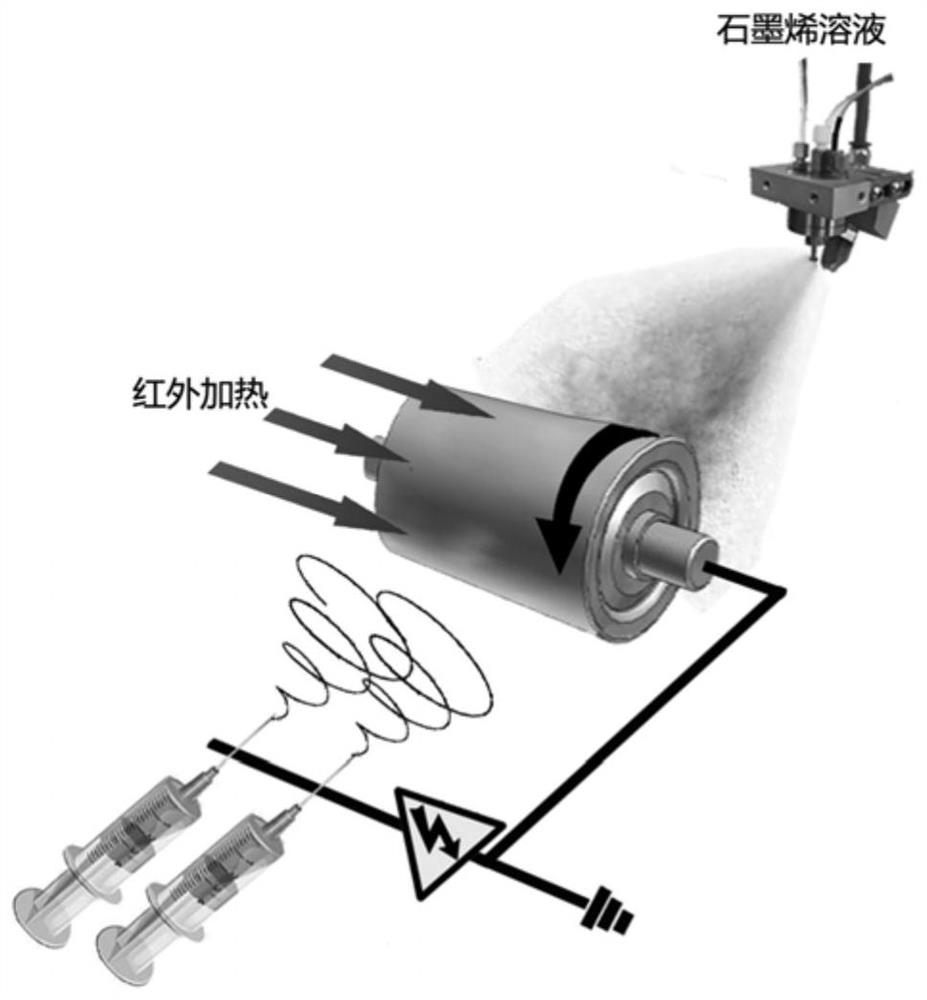

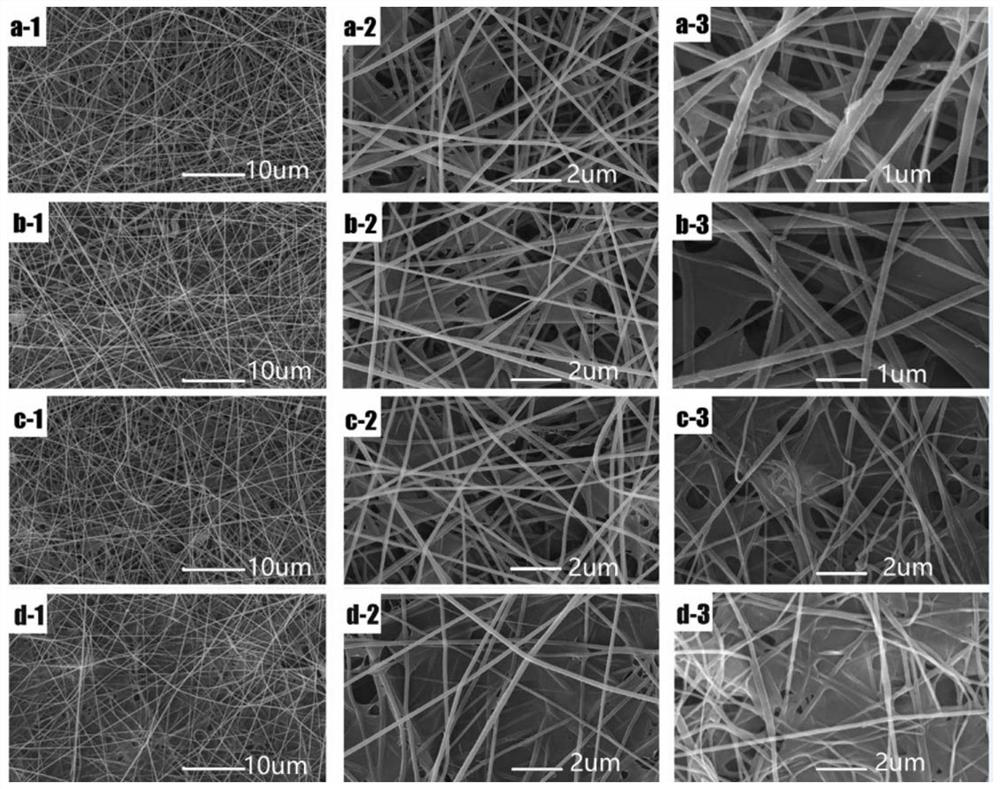

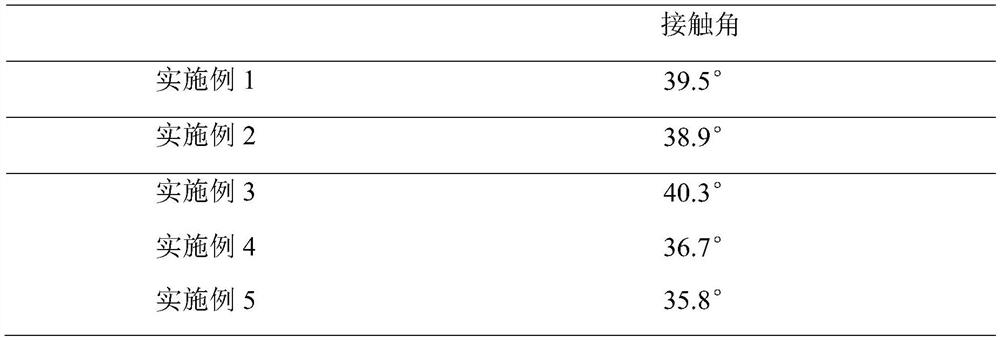

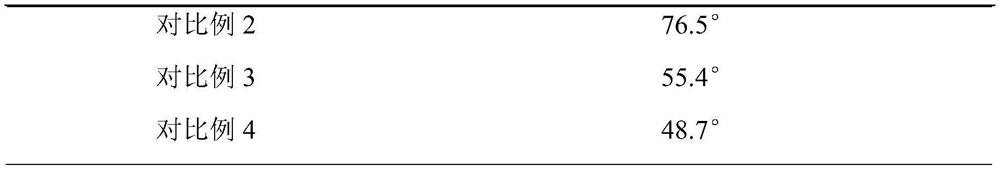

Nano composite fiber membrane capable of efficiently removing ionic dyes and heavy metal ions in water as well as preparation method and application of nano composite fiber membrane

PendingCN112619622AHigh specific surface areaImprove adsorption efficiencySemi-permeable membranesOther chemical processesPolymer scienceIndustrial waste water

The invention discloses a nano-composite fiber membrane capable of efficiently removing ionic dyes and heavy metal ions in water as well as a preparation method and application of the nano-composite fiber membrane. The method comprises the following steps: (1) preparing a polyacrylonitrile electrostatic spinning nanofiber and graphene oxide composite membrane, namely preparing an electrostatic spinning part of a PAN solution and an ethanol solution part of ultrasonic spraying GO at the same time on two sides of a receiving device; and (2) polydopamine modification of the polyacrylonitrile electrostatic spinning nanofiber and graphene oxide composite membrane: preparing a dopamine aqueous solution, then immersing the polyacrylonitrile electrostatic spinning nanofiber and graphene oxide composite membrane into the dopamine aqueous solution, stirring for reaction, and then washing and freeze-drying the membrane to obtain the nano composite fiber membrane. The nano composite fiber membrane synthesized by the method has a good filtering effect on ionic dyes and heavy metal ions, is complete and stable in structure and good in mechanical property, and has a good application prospect in industrial wastewater treatment.

Owner:GUANGZHOU UNIVERSITY

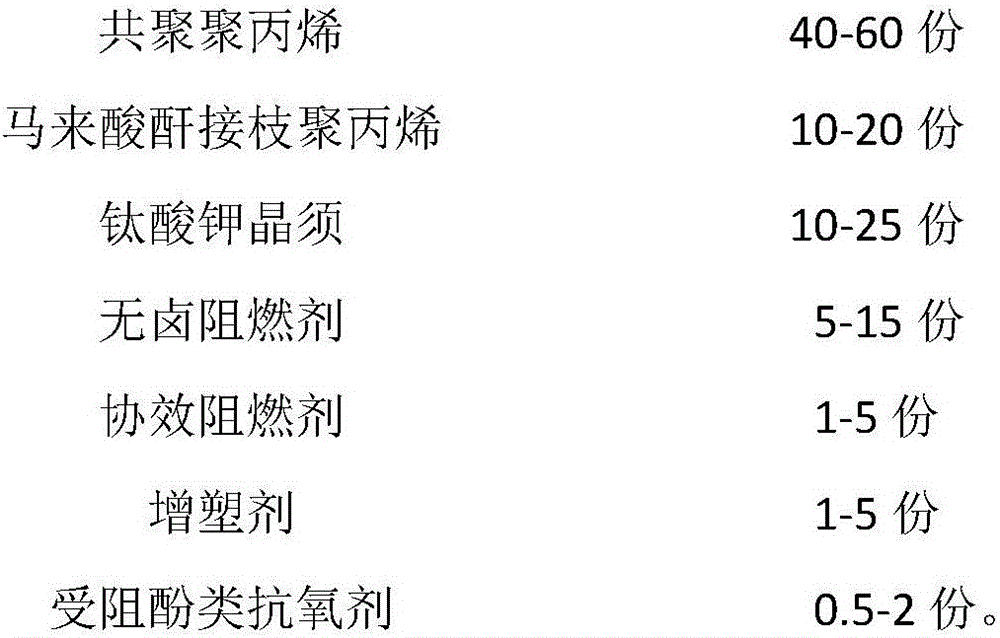

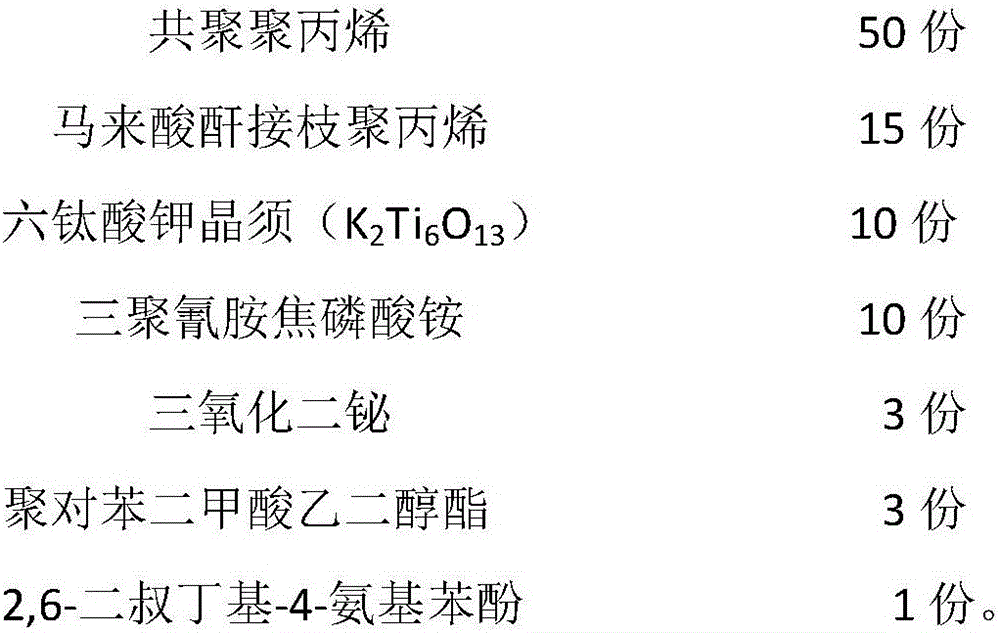

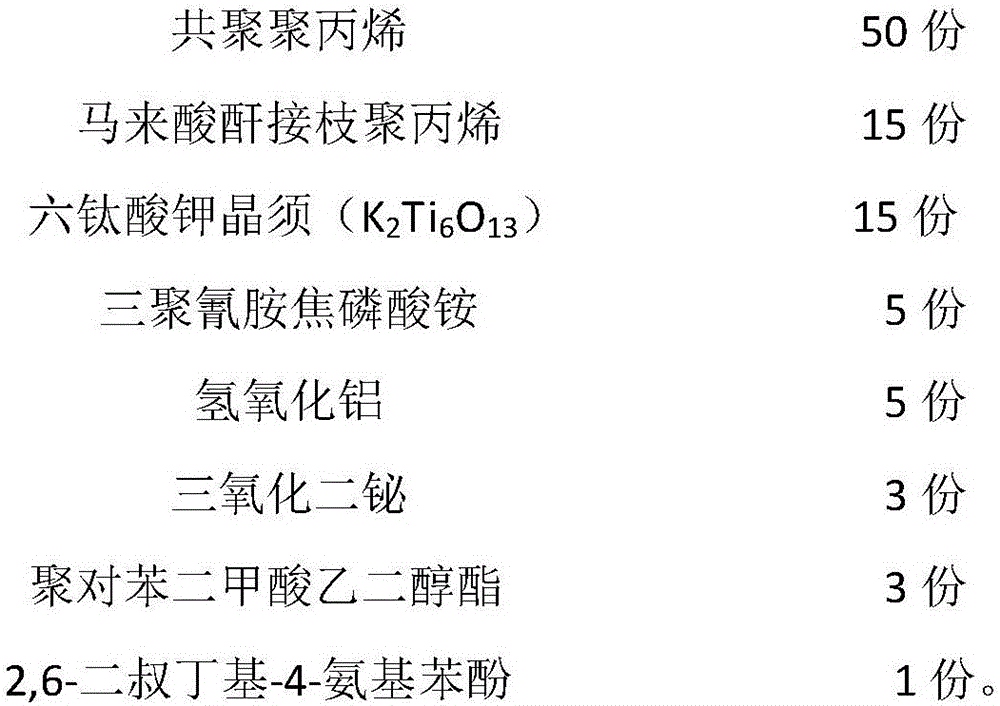

Potassium titanate whisker reinforced and modified PP flame-retardant master batch and preparation method thereof

The invention discloses a potassium titanate whisker reinforced and modified PP flame-retardant master batch and a preparation method thereof. The potassium titanate whisker reinforced and modified PP flame-retardant master batch is prepared from certain proportion of co-polypropylene, maleic anhydride grafted polypropylene, potassium titanate whiskers, a halogen-free flame retardant, a synergistic flame retardant, a plasticizer and a hindered phenol antioxidant. The preparation method comprises the steps that co-polypropylene, maleic anhydride grafted polypropylene, the potassium titanate whiskers, the halogen-free flame retardant, the synergistic flame retardant, the plasticizer the and hindered phenol antioxidant are added into a twin-screw extruder for extrusion pelletization, and the potassium titanate whisker reinforced and modified PP flame-retardant master batch is obtained. The PP flame-retardant master batch has the advantages of being high in strength, good in toughness, high in rigidity, good in bending resistance performance, good in flame retardance and the like. The preparation method is simple in technology, convenient to operate and low in cost.

Owner:WUHAN KINGBULL ECONOMIC DEV

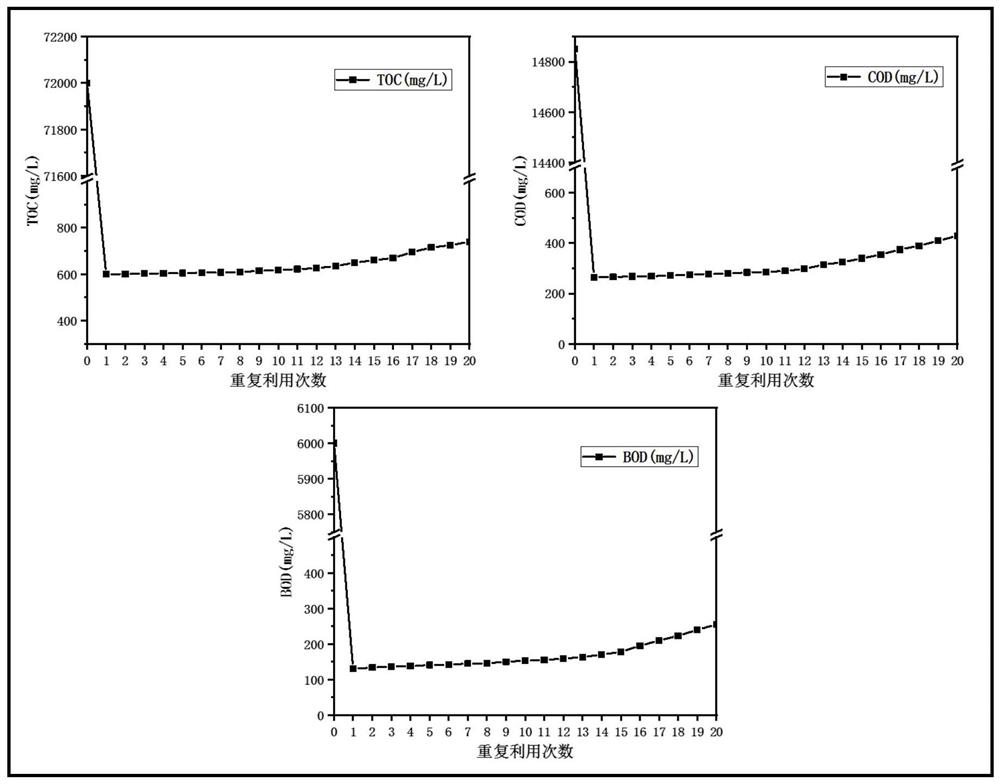

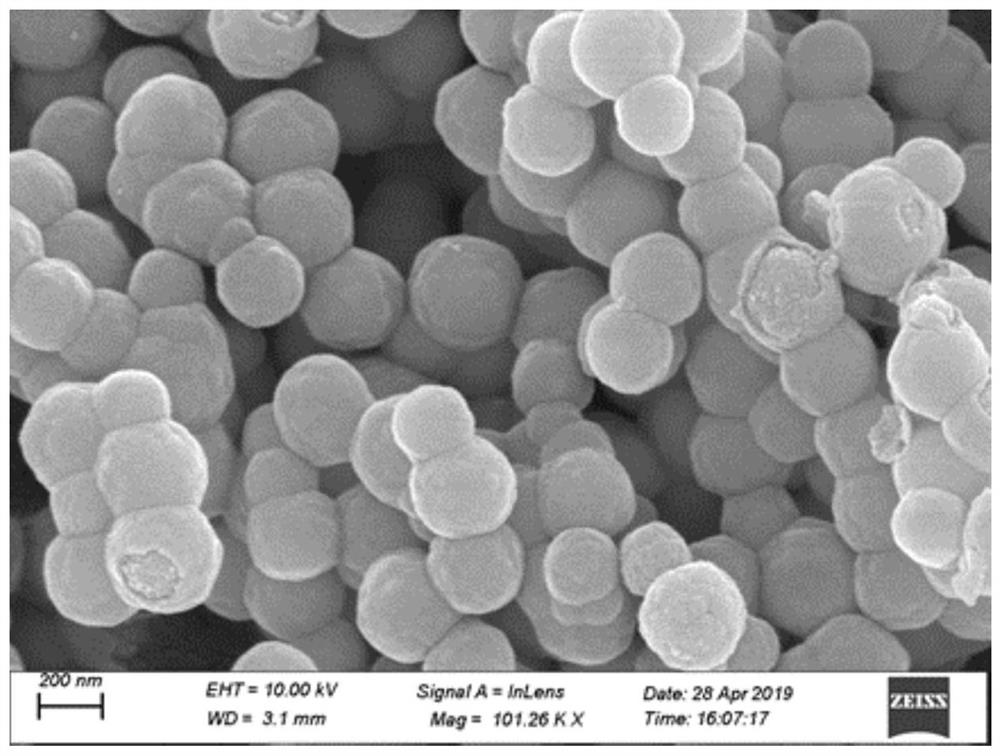

Recycled water treatment adsorption material and preparation method thereof

ActiveCN112973651AExcellent recyclabilityStrong industrial applicabilityOther chemical processesWater contaminantsActivated carbonReclaimed water

The invention relates to the technical field of wastewater purification, in particular to a recycled water treatment adsorption material and a preparation method thereof. The adsorption material is prepared by: compounding activated carbon, a methyl methacrylate monomer, an initiator, a cross-linking agent and the like to form activated carbon composite polymethyl methacrylate microspheres, then carrying out silicon dioxide sputtering on the activated carbon composite polymethyl methacrylate microspheres, then carrying out surface amination treatment, and finally, carrying out magnetization modification on the surface aminated microspheres. The cyclic regeneration water treatment adsorption material prepared by the invention can still keep stable adsorption capacity after multiple times of adsorption-desorption, and has excellent cyclic regeneration performance and strong industrial practicability.

Owner:武汉绿知行环保科技有限公司

Preparation method and application of cyclodextrin improved biomass coffee grounds

ActiveCN110523391AEasy to handleStrong recycling abilityOther chemical processesSpecific water treatment objectivesUltraviolet lightsShielding gas

The invention relates to the technical field of water body antibiotic pollution treatment. The invention provides a preparation method and application of cyclodextrin improved biomass coffee grounds.The preparation method comprises the following steps: step 1, pretreating coffee grounds, wherein firstly cleaning and filtering coffee grounds, then placing the coffee grounds under a vacuum condition, irradiating the coffee grounds for 10-20 minutes with ultraviolet light at the wavelength of 0.2-0.5 mm, and then placing the coffee grounds in an activating solution for activating treatment; step2, preparation of coffee grounds activated carbon: drying the pretreated coffee grounds in a drying box for 5-9 h at a drying temperature of 55-65 DEG C, then putting the coffee grounds into a tubular furnace, introducing protective gas, carrying out carbonization, sintering at the temperature of 400-800 DEG C. According to the preparation method, the low-cost coffee grounds are combined with cyclodextrin with a cavity structure to prepare an improved activated carbon; it is shown by experiment results that the beta-cyclodextrin improved coffee grounds activated carbon is high in efficiency in treatment of antibiotics and possesses excellent regeneration capacity, and can be applied to practical antibiotic wastewater treatment.

Owner:CHENGDU TECHCAL UNIV

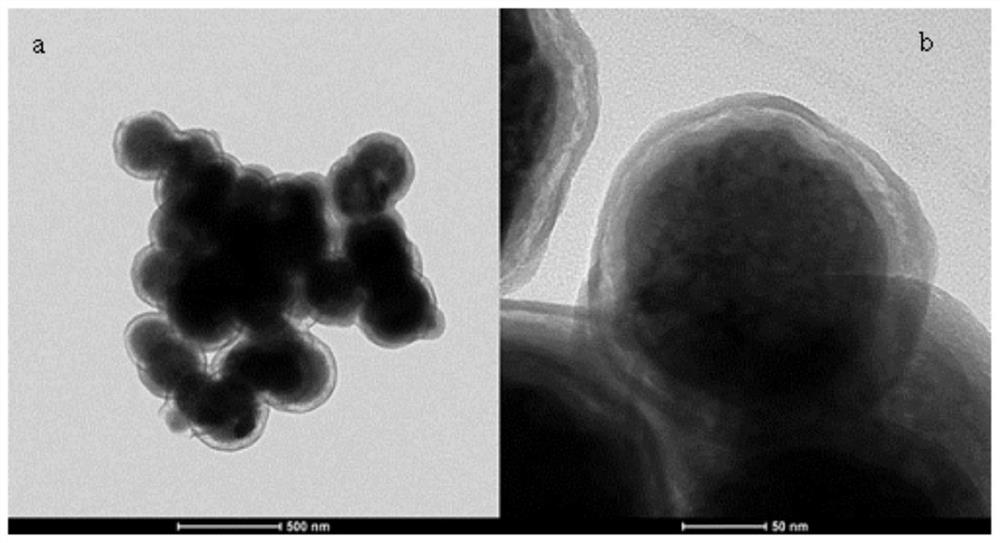

C@Bi/rGO electro-adsorption composite active material, preparation and applications thereof

ActiveCN110357221AImprove adsorption capacityGood choiceDispersed particle separationWater/sewage treatment apparatusHalogenWastewater

The invention belongs to the field of wastewater treatment, and specifically discloses a C@Bi / rGO electro-adsorption composite active material, which comprises reduced graphene oxide and carbon-coatedbismuth elemental particles compounded on the surface of the reduced graphene oxide in situ. The invention further discloses preparation and applications of the composite active material. The invention further relates to an electrode compounded with the C@Bi / rGO, and preparation thereof, and applications in brine. According to the present invention, the composite active material can effectively solve the problems of poor stability, poor reversibility and the like of the material, and can effectively improve the high-adsorption capacity to halogens, excellent circulation stability and excellent regeneration stability in electro-adsorption of halogens.

Owner:CENT SOUTH UNIV

Method for preparing activated zinc oxide by utilizing high-arsenic secondary zinc oxide resource ammonia-ammonium process

The invention relates to a method for preparing activated zinc oxide by utilizing a high-arsenic secondary zinc oxide resource ammonia-ammonium process, which belongs to the field of inorganic chemical industry and secondary resource recovery. The method comprises the following technical processes in sequence as follows: leaching, purifying, ammonia distillation, washing, dry crushing, calcining and the like. According to the method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process, by taking high-arsenic-antimony secondary zinc oxide generated in a lead and zinc smelting process as a raw material, selective leaching is performed by adding ammonia water and ammonium bicarbonate; then, two-stage purification and deeppurification are performed by ferrous salt, hydrogen peroxide, sulfide and zinc powder; and the ammonia water is recycled and valued metal waste residues are comprehensively recovered. The method forpreparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has strong adaptability on zinc-contained materials and is capable of treating various complicated zinc-contained resources. The method for preparing the activated zinc oxide by utilizing the high-arsenic secondary zinc oxide resource ammonia-ammonium process has the advantages of short flow, production process closed cycle, convenience in operation, low energy consumption, excellent product quality, high economic benefits, low pollution, high comprehensive recovery capacityand the like, and is suitable for industrial production and popularization.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Production method of polylactic acid carpet

InactiveCN109943994AEasy to makeGood biodegradability and recyclabilityDyeing processMonocomponent polyesters artificial filamentChemistrySizing

The invention discloses a production method of a polylactic acid carpet. The method comprises the following steps of S1, preparation of a polylactic acid fiber, wherein after corn-husk crops are ground, starch is extracted from the crops and then prepared into non-refined glucose, the glucose is fermented into lactic acid, the lactic acid is concentrated into lactide, a lactide monomer is subjected to vacuum purification and then subjected to loop opening operation, so that the monomer is polymerized into polylactic acid, by adopting the polylactic acid with molecular weight of 330,000, firstly, vacuum drying is conducted, then melting spinning is conducted, and a polylactic acid fiber can be obtained; S2, preparation of a carpet base fabric, wherein spun yarn formed by the polylactic acidfiber is put into a stranding machine for stranding and sizing, the polylactic acid spun yarn after stranding and sizing is put on a tufting weaving machine for weaving, and finally the polylactic acid carpet base fabric is formed; S3, printing; S4, color fixation and drying; S5, washing with water and reduction; S6, winding of a finished product. The production method is simple, the material isdegradable, and a rebound effect is good.

Owner:LONGFU RECYCLING ENERGY SCIENTECH

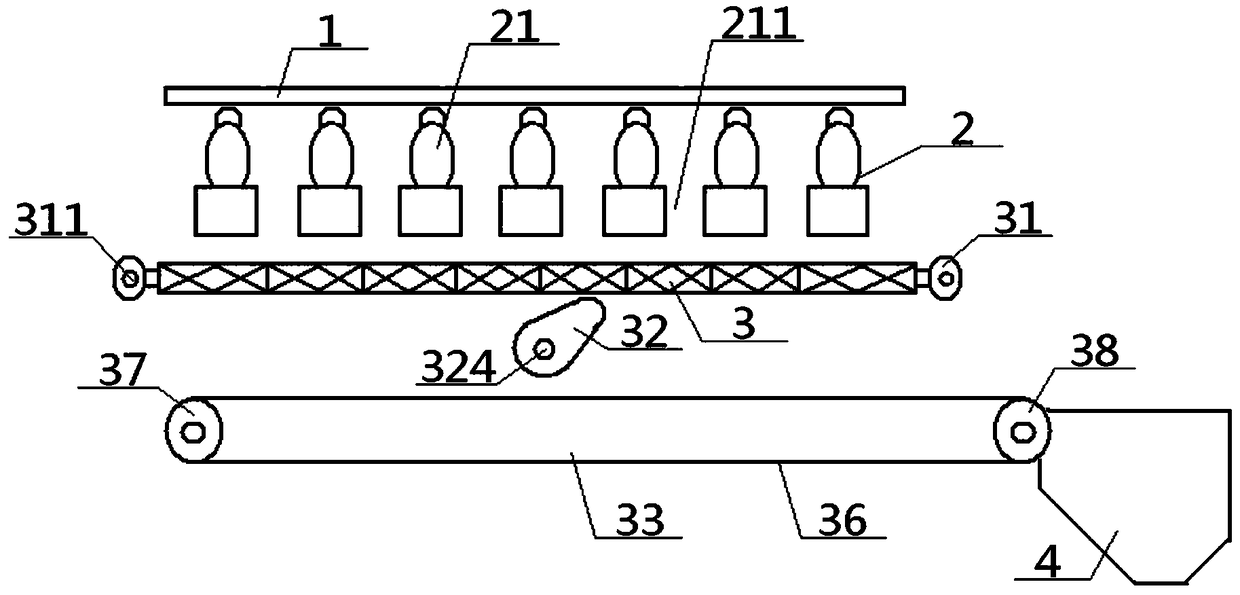

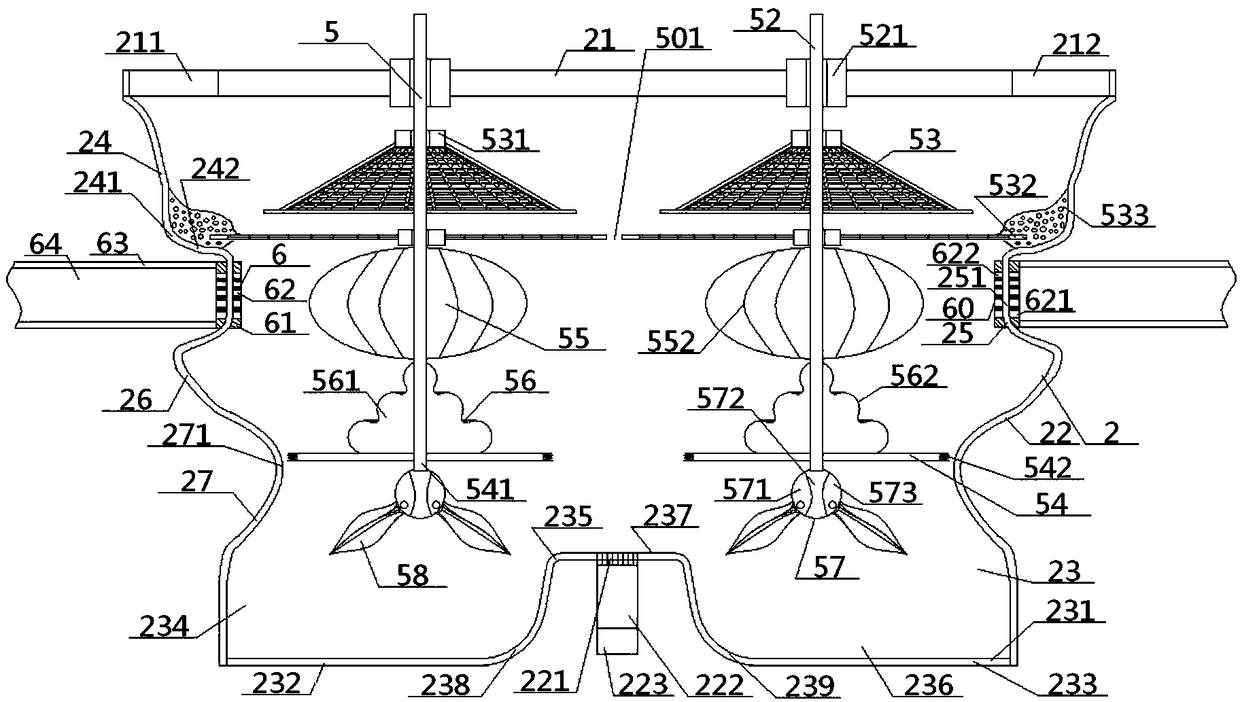

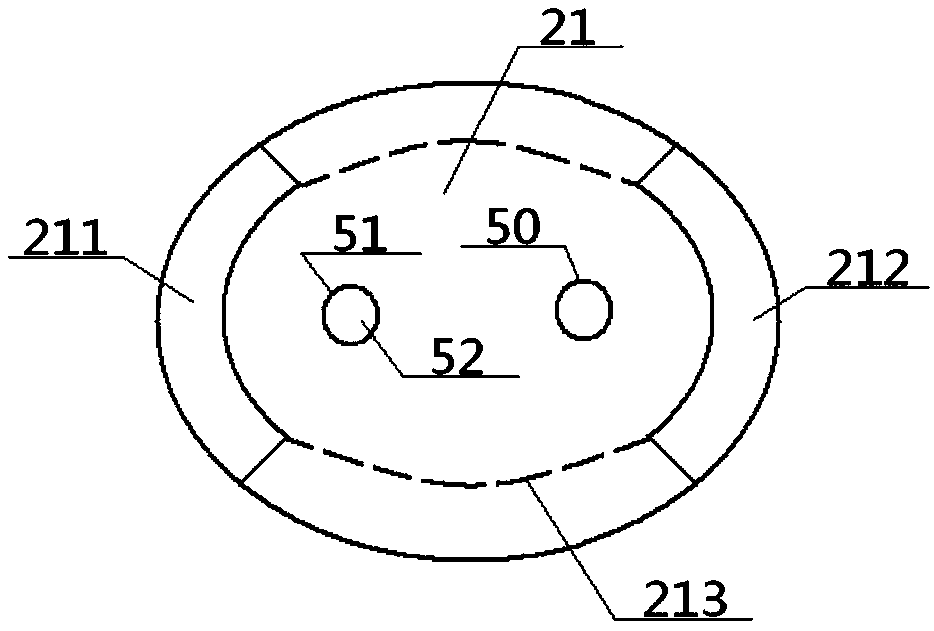

Frequency modulation type self-oscillation jetting device and use method thereof

ActiveCN105536339AReduce energy consumptionOvercome filter deformation and erosion damageMembrane filtersMoving filtering element filtersEngineeringImpact pressure

The invention relates to a frequency modulation type self-oscillation jetting device and a use method thereof. The frequency modulation type self-oscillation jetting device comprises a shell with a tubular opening structure, a base plate, a vertical jetting inlet, a rectification cavity, a mixed flow cavity, a jetting outlet and tangent jetting inlets, wherein an opening in the bottom of the shell is fixedly connected with the base plate; the vertical jetting inlet is vertically arranged at the top of the shell; the inlet end of the vertical jetting inlet is connected with a backwashing pipeline; the outlet end of the vertical jetting inlet is communicated with the rectification cavity positioned at the upper part in the shell; a channel and the mixed flow cavity are arranged below the rectification cavity in sequence in the shell; the lower side of the rectification cavity is communicated with the inlet of the channel; the outlet of the channel is positioned above the inlet of the mixed flow cavity; the outlet of the mixed flow cavity penetrates through the base plate and is communicated with the jetting outlet; a jetting fusion region is formed between the channel outlet and the inlet of the mixed flow cavity; a plurality of tangent jetting inlets communicated with the upper part of the channel are formed in the outer side wall of the upper part of the shell at intervals. The frequency modulation type self-oscillation jetting device is energy-saving, so that the problems of local deformation, washout damage and the like to a filter screen due to extreme-high impact pressure are solved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Manufacturing method of metal plate for power generating boiler supporting beam

ActiveCN109277873AEasy to collectImprove charging effectMaintainance and safety accessoriesReciprocating motionRelative motion

The invention discloses a manufacturing method of a metal plate for a power generating boiler supporting beam. When in applying, firstly, the metal plate to be machined is placed on a cutting unit, the bottom face of the metal plate is in contact with the top end of a strip-shaped supporting base in the cutting unit, then cutting operation is carried out on the metal plate, and the reciprocating sliding sleeve slides along a reciprocating sliding rod to do relative motion, so that an impurity falling net is drove to move forwards and backwards while the cutting is carried out at the same time;a roller rotating rod drives an upper ejecting convex block roller to rotate and do reciprocating motion along the horizontal direction; the rotating upper ejecting convex block roller upwards ejected and downwards fallen at intervals the impurity falling net positioned above the rotating upper ejecting convex block roller, so that the impurity falling net can move up and down; and the impurity falling net which moves front and back as well as up and down is used for continuously vibrating metal chippings which fall on the impurity falling net in the cutting operation, the metal chippings areenable to fall onto an impurity conveying device after passing through the impurity falling net, and then the metal chippings are conveyed to a recycling unit to be recycled through the impurity conveying device. According to the method, the metal chippings collecting effect is good, and the recycling rate is relatively high as well.

Owner:武汉华电工程装备有限公司

Preparation method and application of iminodiacetic acid functionalized magnetic adsorption material

InactiveCN112516966AAchieve separationLarge specific surface areaOther chemical processesSpecific water treatment objectivesSodium acetateSodium chloroacetate

The invention provides a preparation method of an iminodiacetic acid functionalized magnetic adsorption material, which comprises the following steps: weighing ferric chloride, dissolving the ferric chloride in ethylene glycol, after complete dissolving, adding sodium acetate, carrying out ultrasonic treatment, carrying out heating reaction to obtain a solid product, and conducting washing and drying to obtain magnetic Fe3O4 powder; adding absolute ethyl alcohol and deionized water into the magnetic Fe3O4 powder, conducting ultrasonical dispersing, adding concentrated ammonia water, then adding tetraethyl orthosilicate, repeatedly adding tetraethyl orthosilicate for multiple times, and conducting reacting at room temperature to obtain a Fe3O4-coated SiO2 material; dispersing the Fe3O4-coated SiO2 material into absolute ethyl alcohol, adding concentrated ammonia water and 3-aminopropyl triethoxysilane, and conducting reacting at room temperature to obtain aminated magnetic beads; and weighing sodium chloroacetate, dissolving the sodium chloroacetate in deionized water and absolute ethyl alcohol to obtain an ethanol solution of sodium chloroacetate, adding aminated magnetic beads into the ethanol solution of sodium chloroacetate, adding an acid-binding agent, and carrying out a heating reaction to obtain the iminodiacetic acid functionalized magnetic adsorption material. The adsorption material provided by the invention is good in adsorbing effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation of ionic solvent phase change absorption system for carbon dioxide capture

InactiveCN113082945ALarge absorption capacityStrong recycling abilityDispersed particle separationAir quality improvementGlycineAlcohol

According to the invention, a [TETA] [Gly] ionic liquid is synthesized through a one-step method, and is compounded with the DEEA solution to form an ionic solvent phase change absorption system, wherein the phase change absorption system has high absorption capacity and cyclic utilization performance at the same time. The method is simple and efficient, and triethylene tetramine and glycine are mixed in an equal molar ratio, stirred at a constant temperature, subjected to rotary evaporation and vacuum drying and then mixed with DDEA according to a certain molar ratio to form an absorption system. The absorption system has excellent absorption performance at a high temperature, regeneration energy consumption is greatly reduced, the absorption system can replace a traditional alcohol amine solution to a certain extent to capture carbon dioxide, so that the absorption system has a wide industrial application prospect.

Owner:BEIJING UNIV OF CHEM TECH

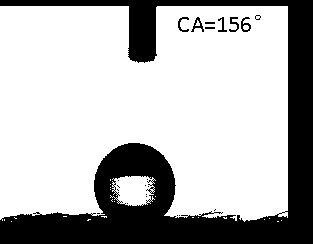

Preparation method of super-hydrophobic natural sponge

PendingCN111171372ASimple manufacturing processImprove hydrophobicityFatty/oily/floating substances removal devicesLiquid separationEnvironmental engineeringLipophilicity

The invention discloses a method for preparing super-hydrophobic natural sponge for treating underground water non-aqueous phase liquid, which comprises the following steps: (1) ultrasonically cleaning natural sponge with ultrapure water and 75% ethanol respectively, removing stains and residues on the surface of the sponge, and drying the sponge for later use; (2) soaking the cleaned sponge intoethanol, adding a certain amount of weighed Zn(NO3)2.6H2O particles into the mixed solution, and then stirring in a constant-temperature water bath; and (3) separating the sponge filled with Zn<2+> from the mixed solution, and washing the sponge with ethanol; and (4) weighing a certain amount of 2-methylimidazole, putting the 2-methylimidazole into 50mL of an ethanol solution, dispersing the sponge filled with Zn<2+> into the 2-methylimidazole ethanol solution, and then stirring in a constant-temperature water bath; and reacting to obtain the super-hydrophobic natural sponge, washing the sponge with ethanol, and drying the sponge for later use. The preparation method is simple, effective, green and environment-friendly. The super-hydrophobic natural sponge prepared by the invention has thecharacteristics of biodegradability and strong hydrophobicity and lipophilicity, the contact angle can reach 156 degrees, and the super-hydrophobic natural sponge can be used for treating undergroundwater non-aqueous phase liquid pollutants and can be recycled.

Owner:中新瑞美(天津)环保科技有限公司 +3

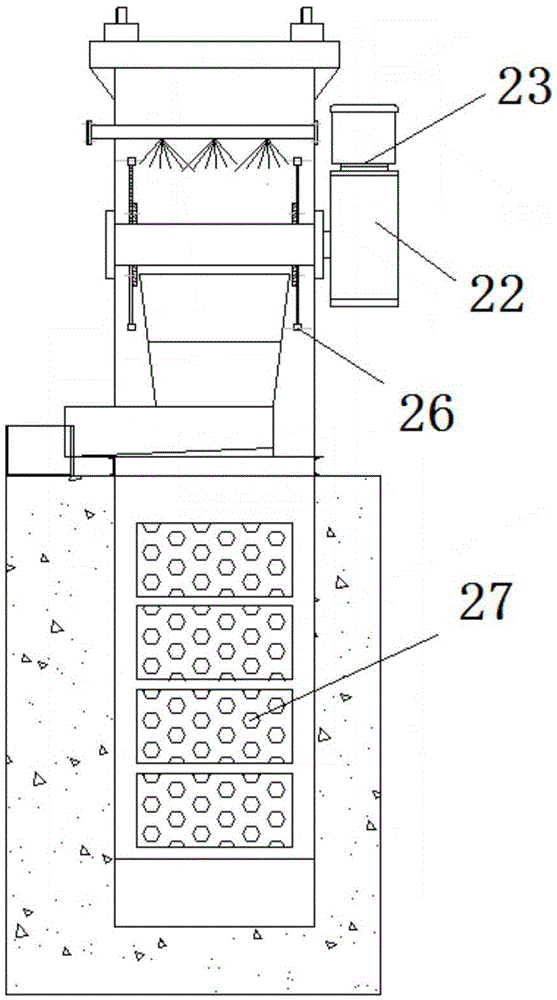

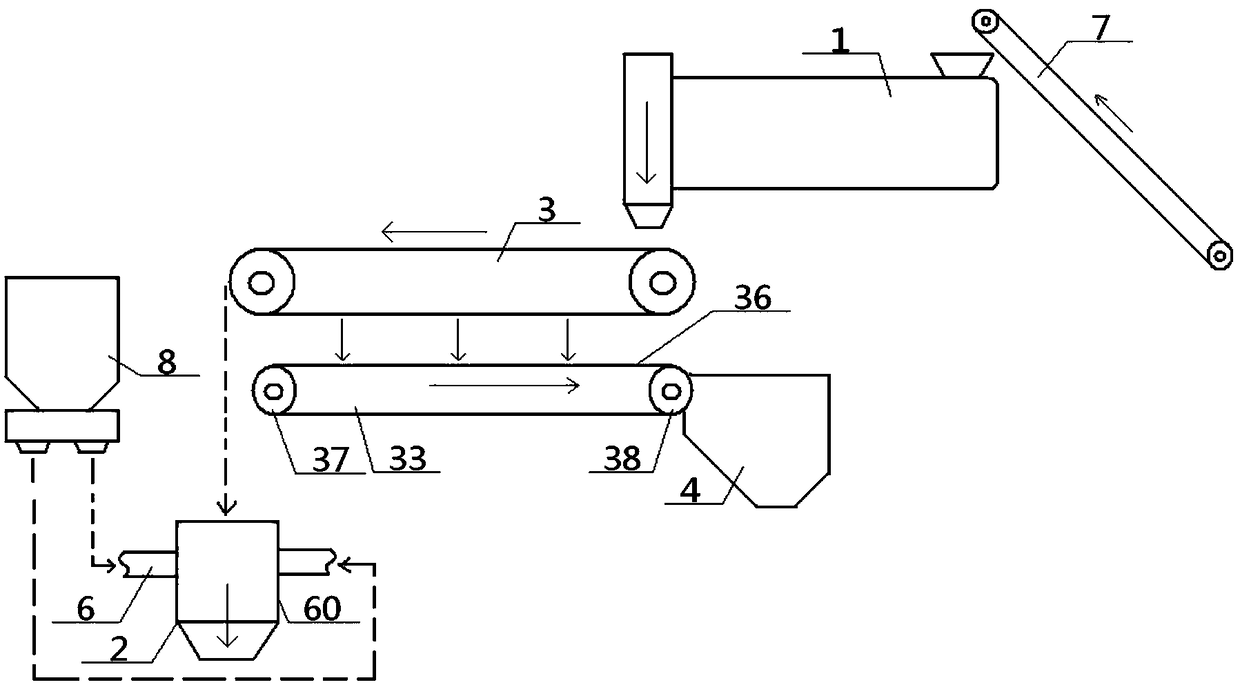

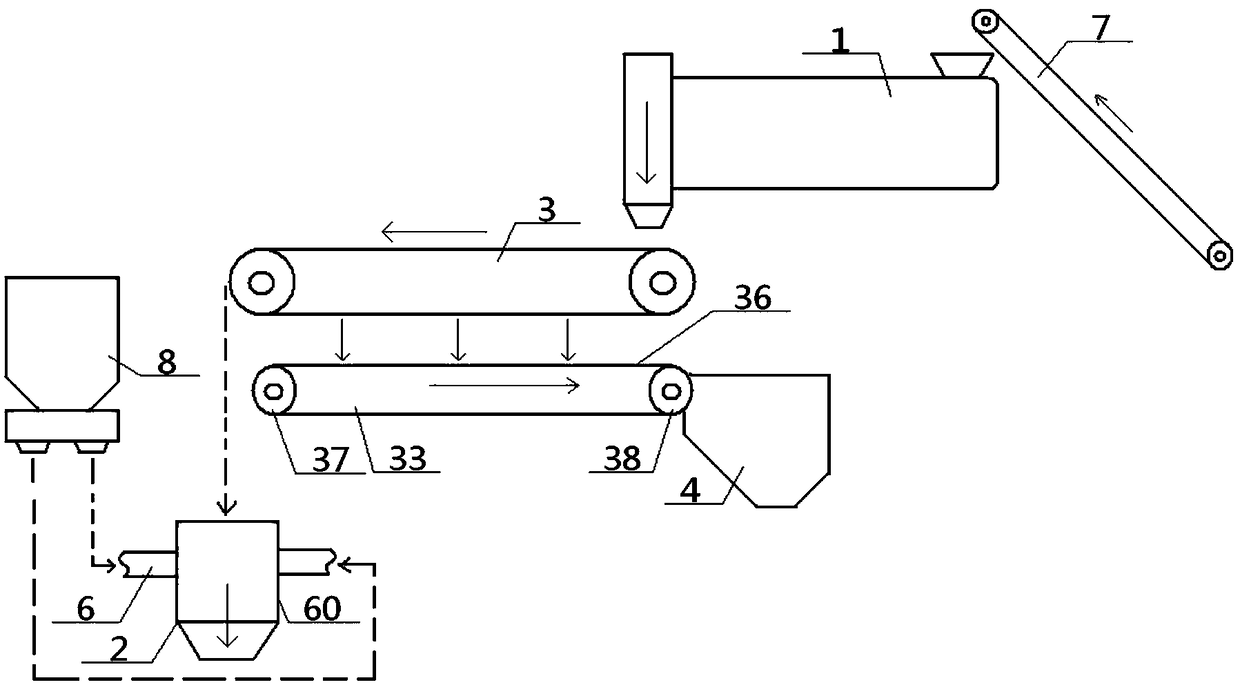

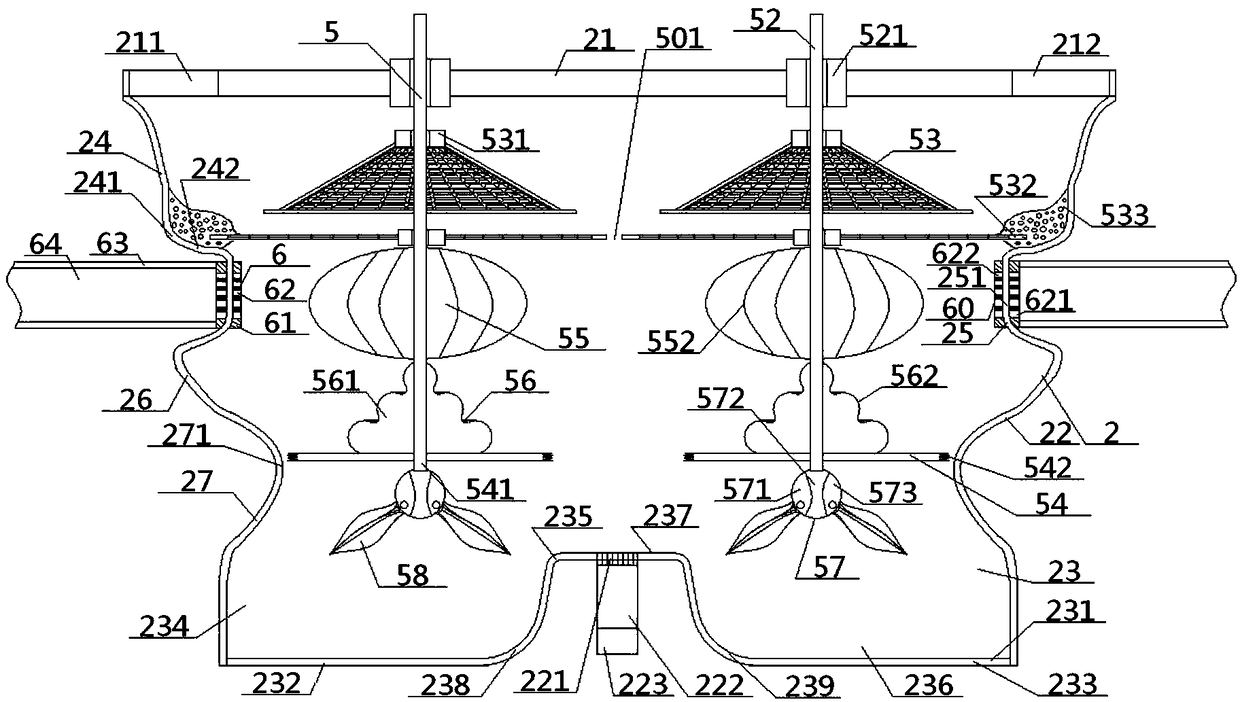

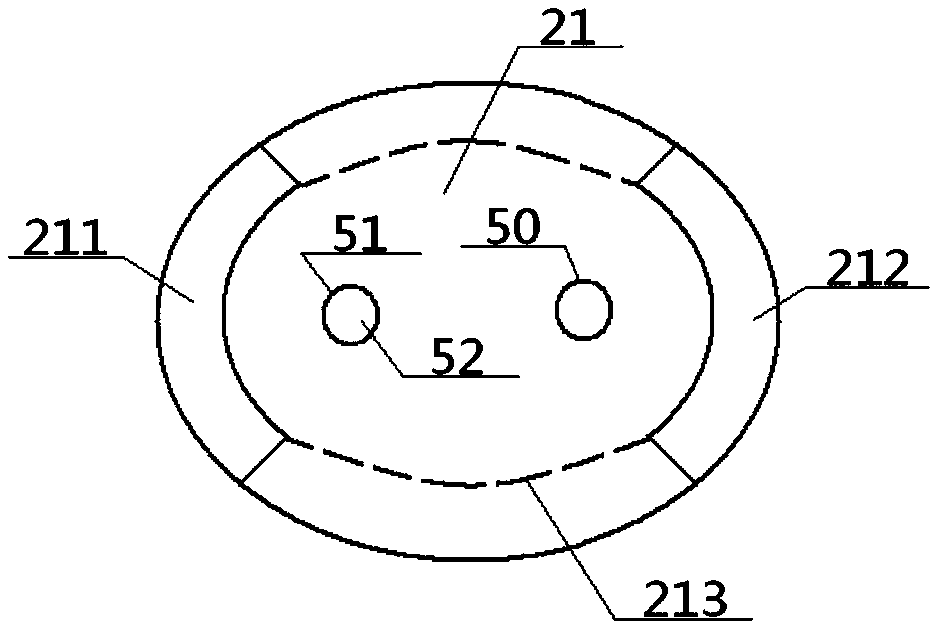

Low-dust production system of common dry-mixed mortar

InactiveCN109435069AImprove refinementRefining to avoidMixing operation control apparatusPretreatment controlPulp and paper industryImpurity

The invention provides a low-dust production system of common dry-mixed mortar. The low-dust production system comprises a sand conveyor belt, a drying roller and a dried material conveyor belt whichcommunicate with one another in sequence; an impurity conveying device is arranged under the dried material conveyor belt, and a discharging outlet of the impurity conveying device communicates with arecovery unit; the dried material conveyor belt and a discharging outlet of an ingredient feeder communicate with the interior of a stirring device which comprises an outer stirring tube and an innerstirrer; a feeding inlet and a discharging outlet are formed in the tube top / bottom of the outer stirring tube correspondingly; a tube side part comprises an upper concave arc way, a middle convex arc way, a middle concave arc way and a lower convex arc way which are connected in sequence; the protrusion part on the middle convex arc way is of a vertical structure, and left and right ingredient spray heads which are symmetrical in the left-right direction are embedded into the protrusion part; and a stirring unit in the inner stirrer comprises a stirring shaft, a stirring disc net and a bottom stirring disc. According to the low-dust production system, the dispersive capacity is high, the mixing uniformity is high, the recovery capacity is high, and the quality of products is high.

Owner:HUBEI HENGFU ENERGY SAVING TECH CO LTD

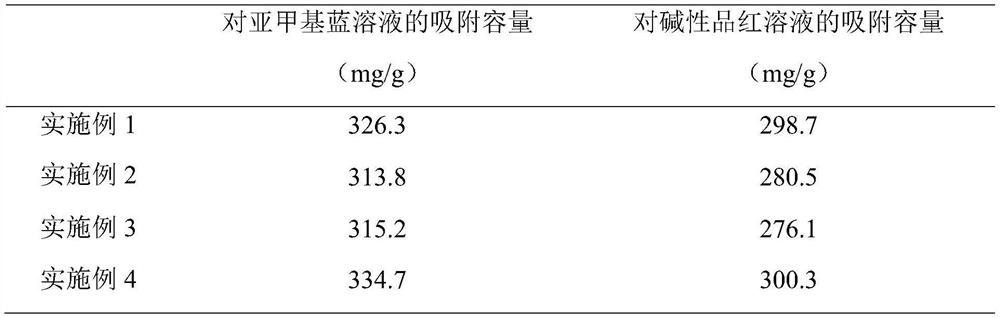

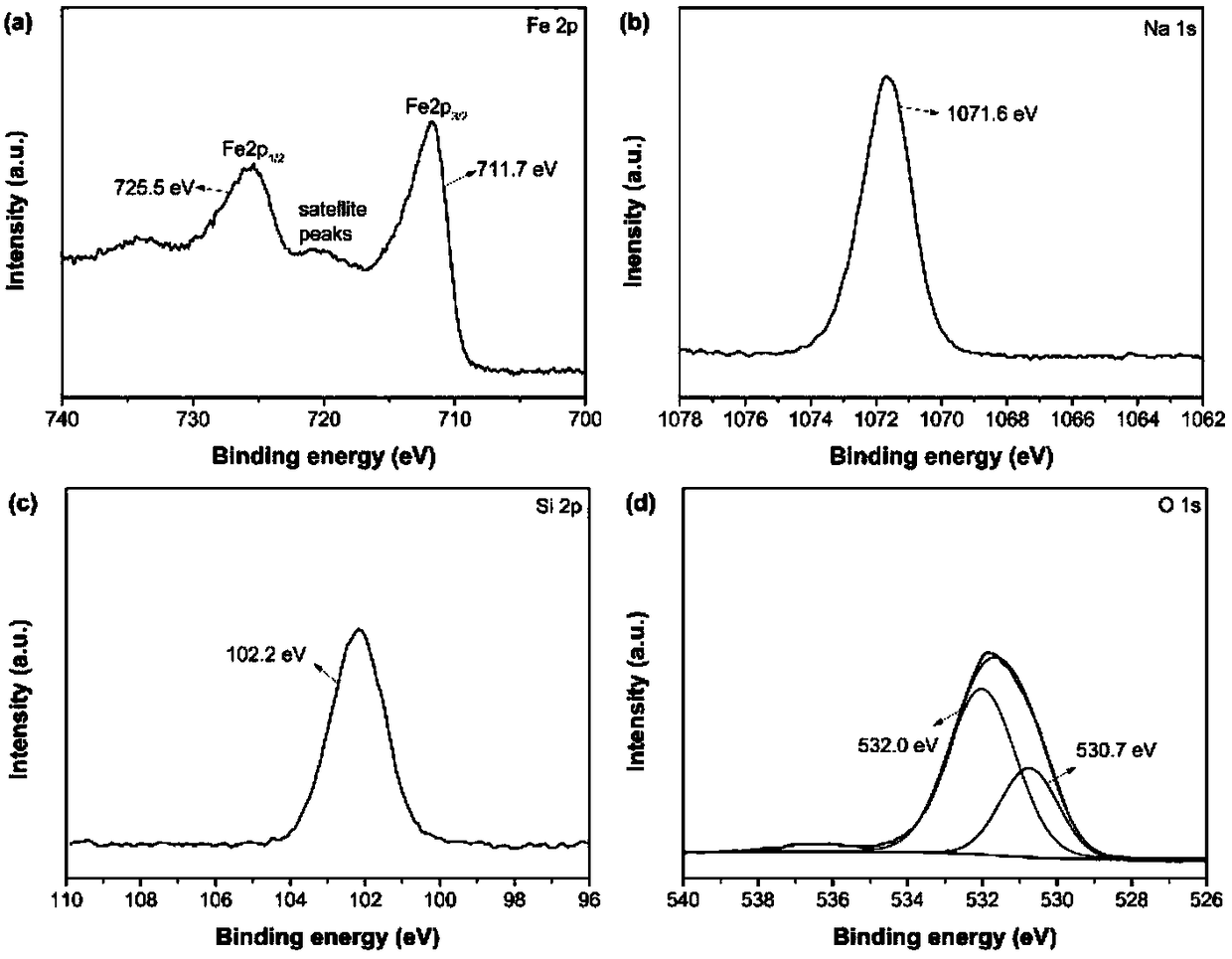

Preparation method of amorphous ferrisodium silicate nano-sheet with selective adsorption performance

ActiveCN108584968AHas selective adsorption propertiesStrong recycling abilityOther chemical processesSpecific water treatment objectivesRoom temperatureWastewater

The invention discloses a preparation method of an amorphous ferrisodium silicate nano-sheet with a selective adsorption performance. The preparation method includes the steps: dissolving Na2SiO3*9H2Oin mixed solvents and magnetically stirring the Na2SiO3*9H2O to be completely dissolved to obtain solution A; dissolving Fe (NO3)3*9H2O in 30mL of mixed solvents and magnetically stirring the Fe (NO3)3*9H2O to be completely dissolved to obtain solution B; controlling dropping speed, slowly adding the solution B into the solution A and constantly stirring the solution by a magnetic stirrer in a dropping process to obtain suspension liquid; transferring the suspension liquid into a stainless steel autoclave with a polytetrafluoroethylene liner, performing sealed reaction, naturally cooling thesuspension liquid to room temperature and then washing and drying a product to obtain a sample. The preparation method has the advantage that the amorphous ferrisodium silicate nano-sheet can selectively adsorb cationic dyes from waste water.

Owner:QUFU NORMAL UNIV

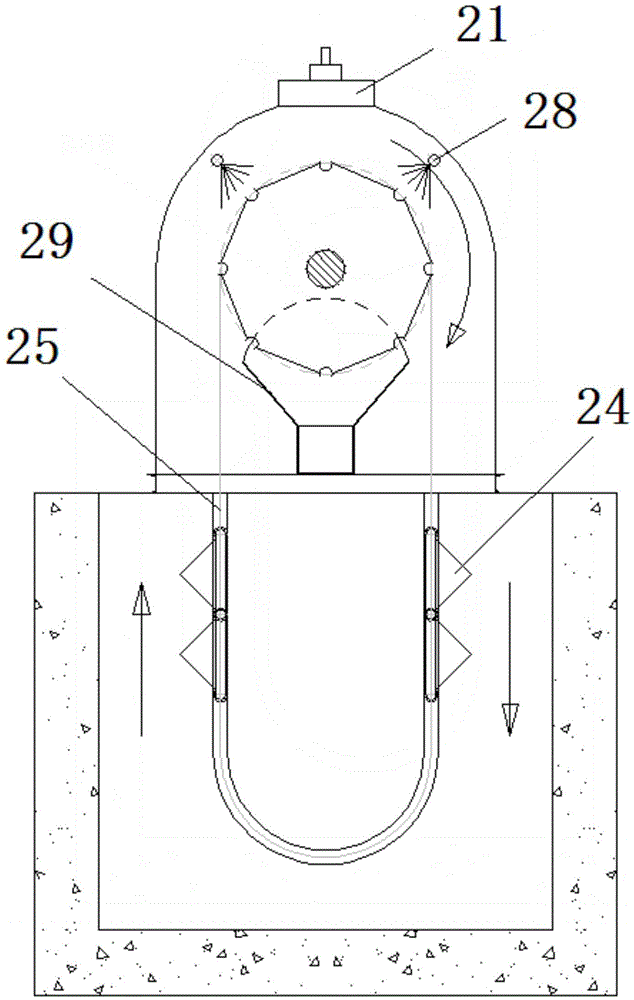

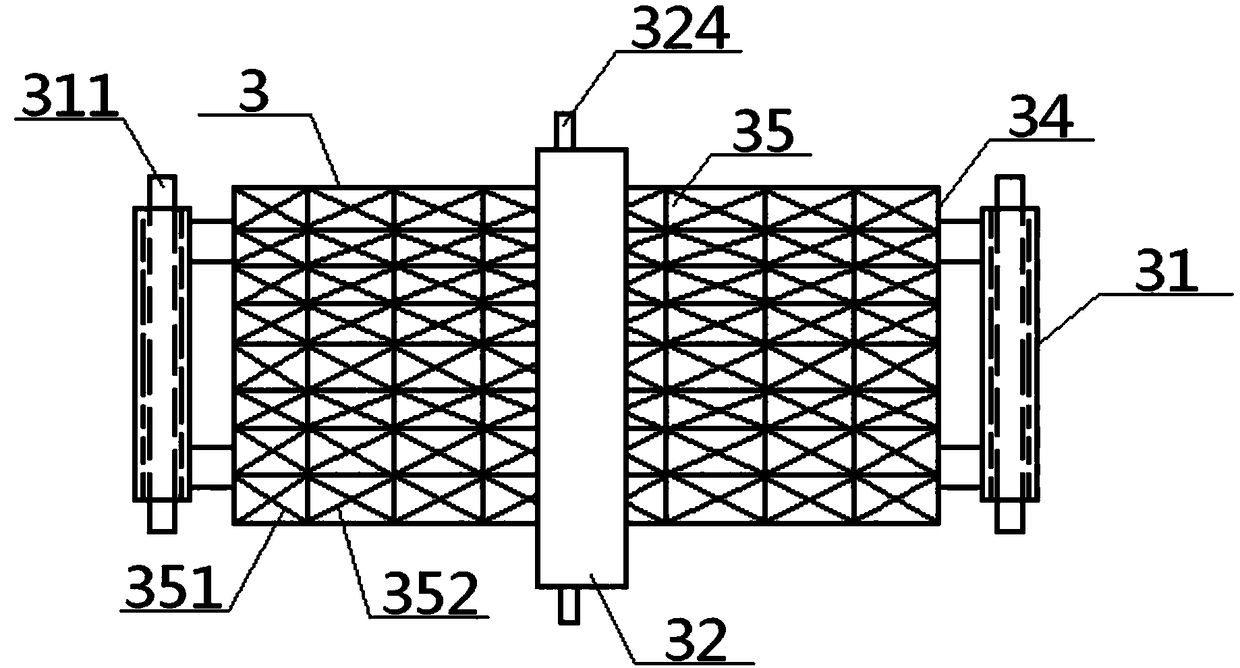

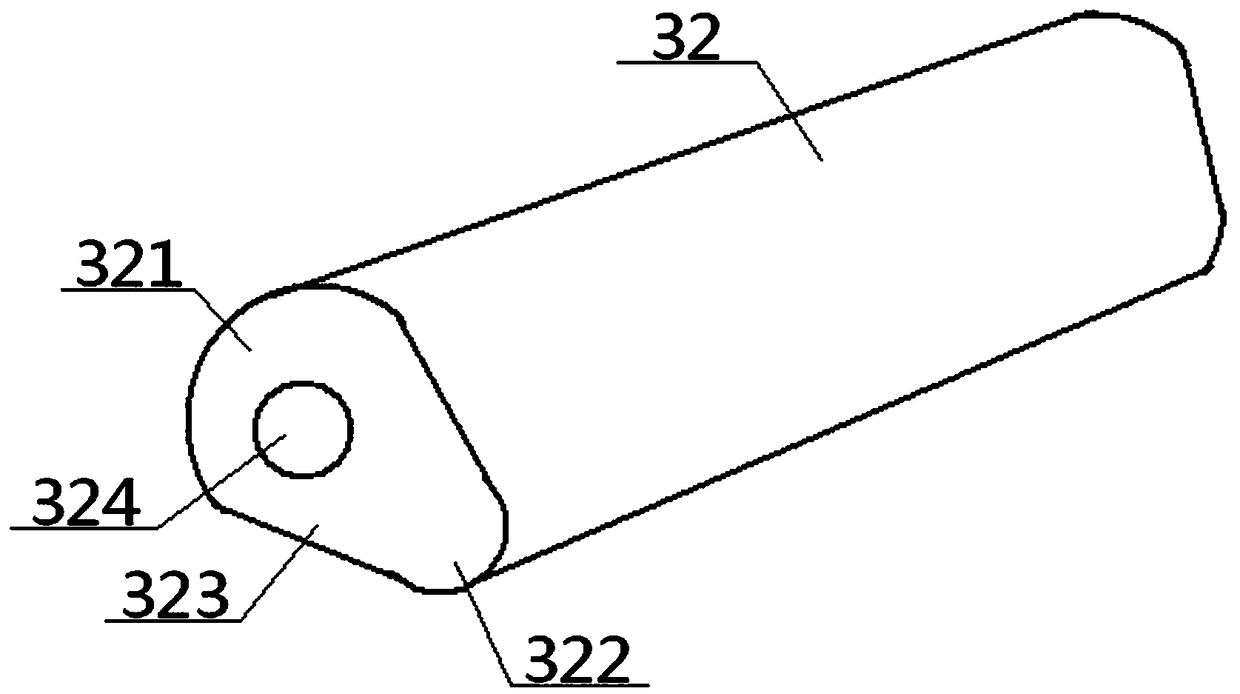

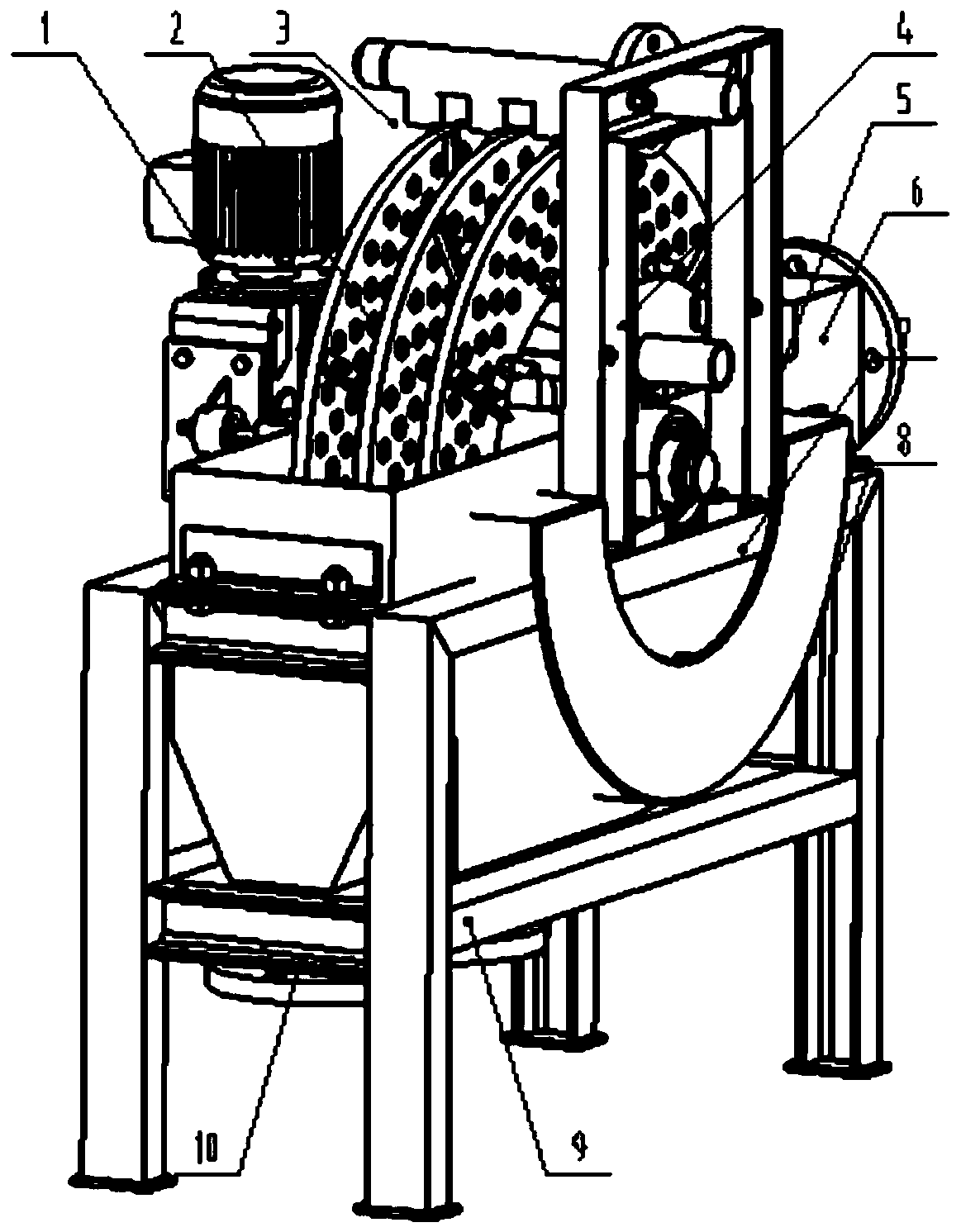

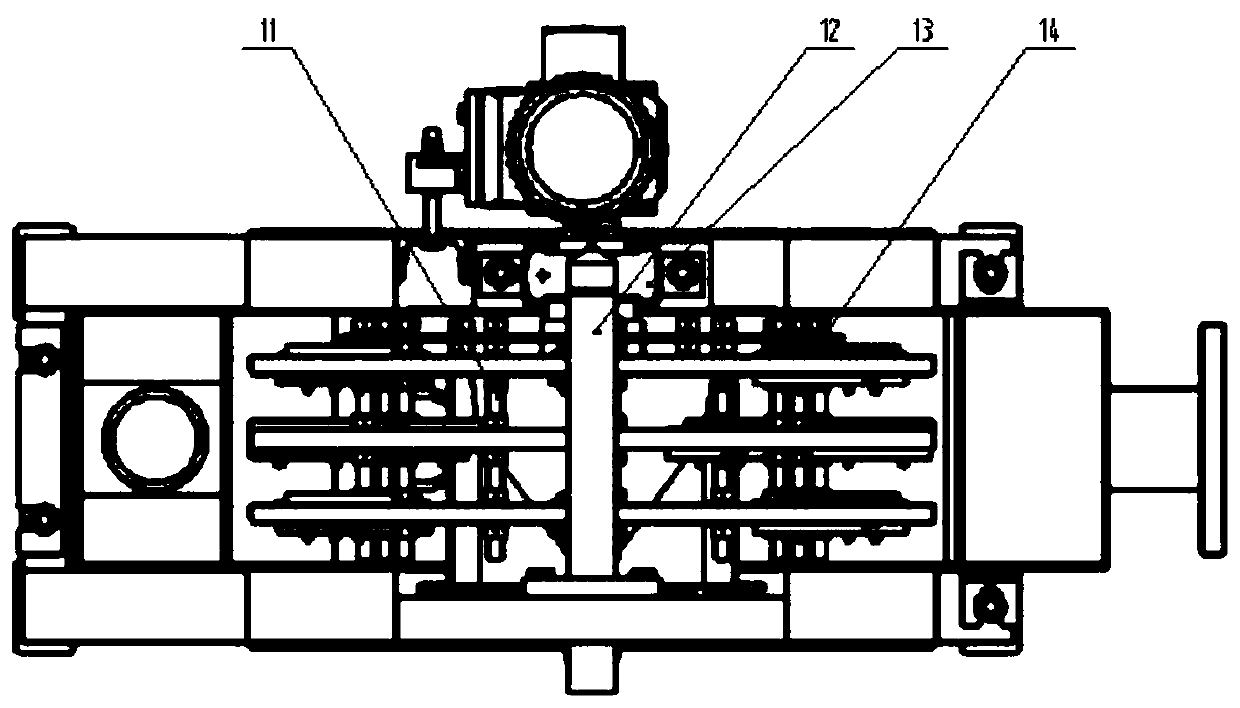

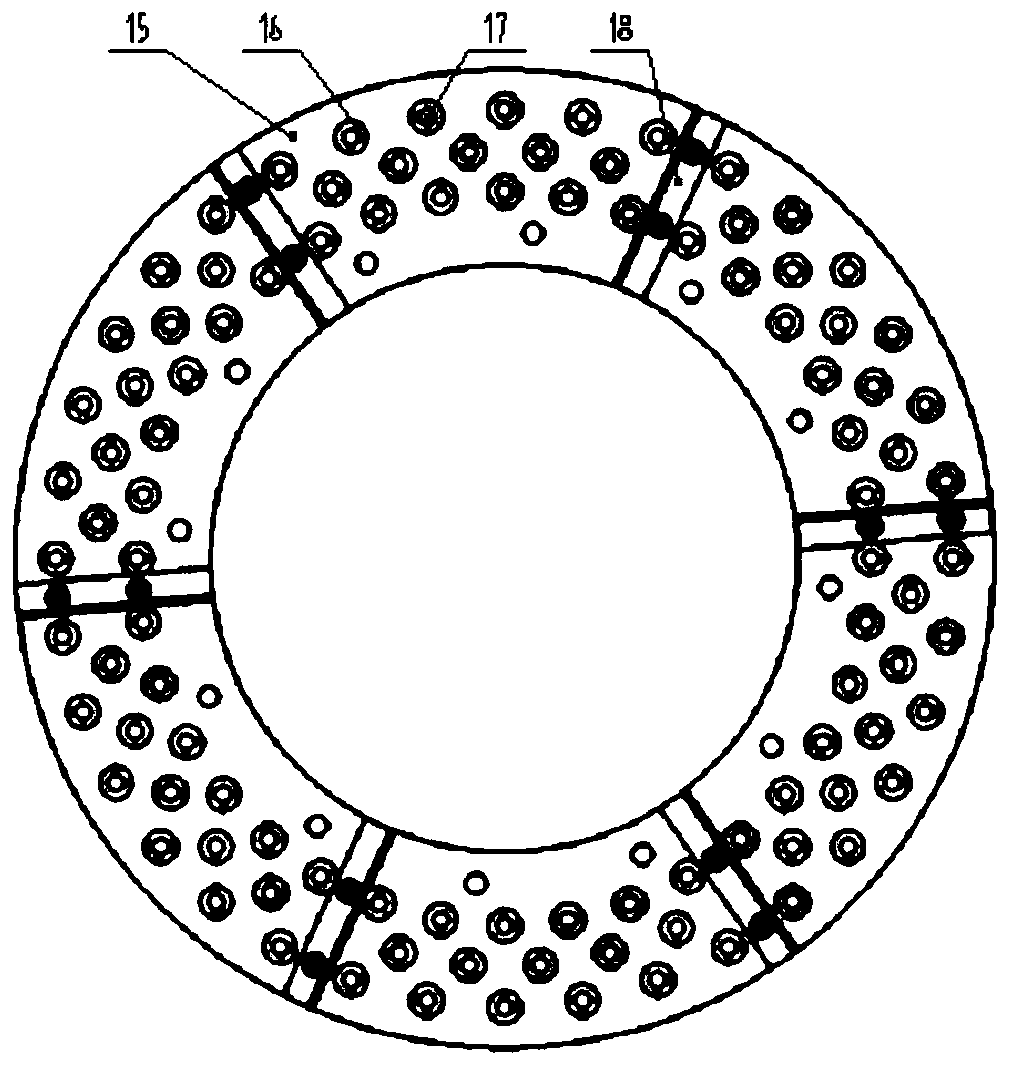

A Permanent Magnet Induction High Gradient Disk Drive

ActiveCN108452943BReduce lossesHigh recovery rateHigh gradient magnetic separatorsHoneycombHoneycomb Pattern

Owner:CHINA UNIV OF MINING & TECH +2

Environment-friendly preparation method of common dry-mixed mortar

InactiveCN109397540AImprove refinementRefining to avoidMixing operation control apparatusPretreatment controlEngineeringMechanical engineering

Owner:HUBEI HENGFU ENERGY SAVING TECH CO LTD

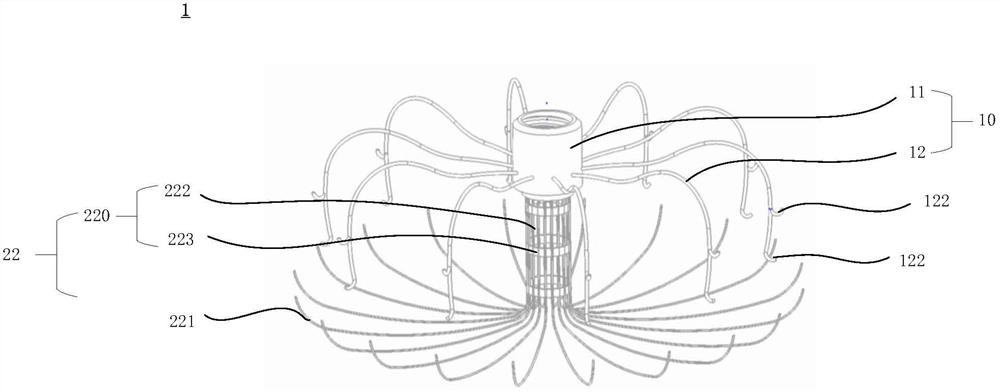

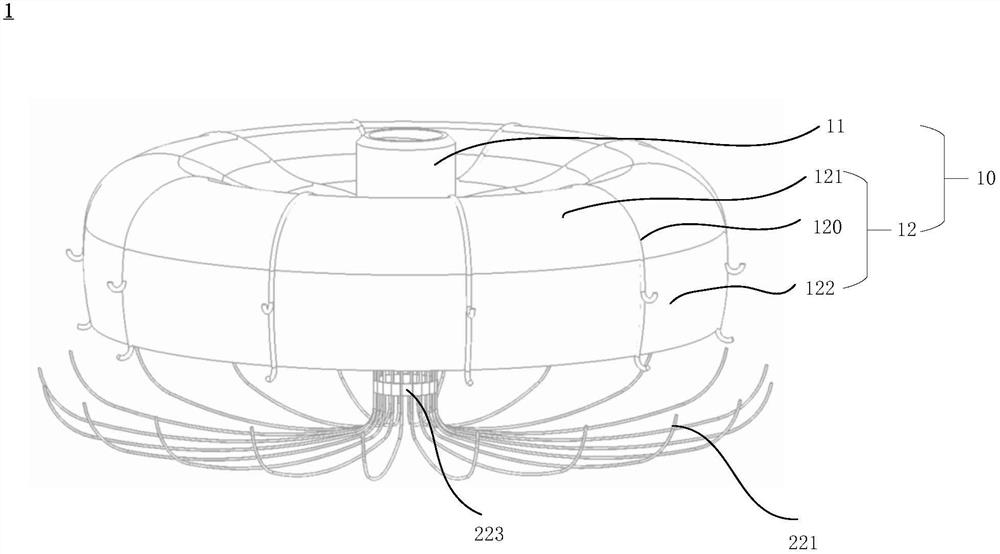

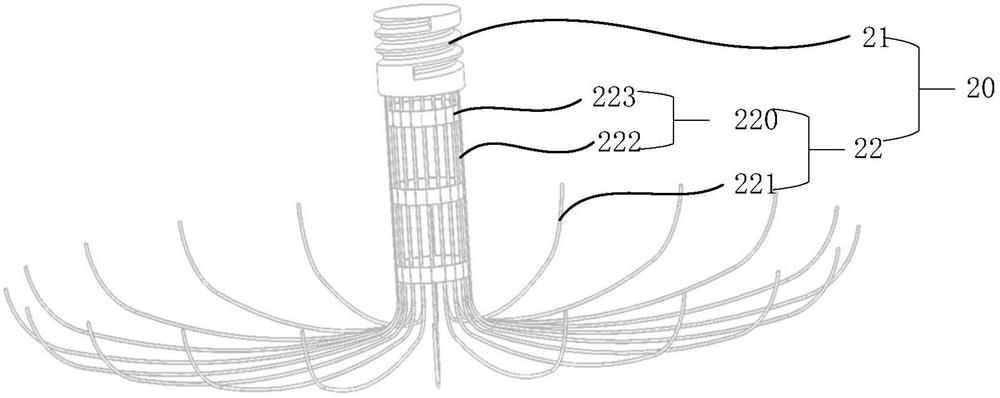

left atrial appendage occluder

The present invention provides a left atrial appendage occluder, wherein the occluder structure includes a first connector and an occluder fixed on the first connector, and the fixing structure includes a second connector and a occluder fixed on the first connector. The fixing parts on the two connecting parts, the first connecting part and the second connecting part are separated or fixed, so that when facing the left atrial appendage with different shapes and different depths, the first connecting part and the second connecting part can be connected through the first connecting part and the second connecting part. After the parts are separated and a suitable fixing structure is selected, the left atrial appendage is blocked after being fixed by the first connecting piece and the second connecting piece accordingly, that is, adaptive selection can be made according to different left atrial appendages, so that the The left atrial appendage occluder is well adapted to left atrial appendages of different shapes and depths.

Owner:SHANGHAI ZUOXIN MEDICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com