Patents

Literature

106results about How to "Strong industrial applicability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

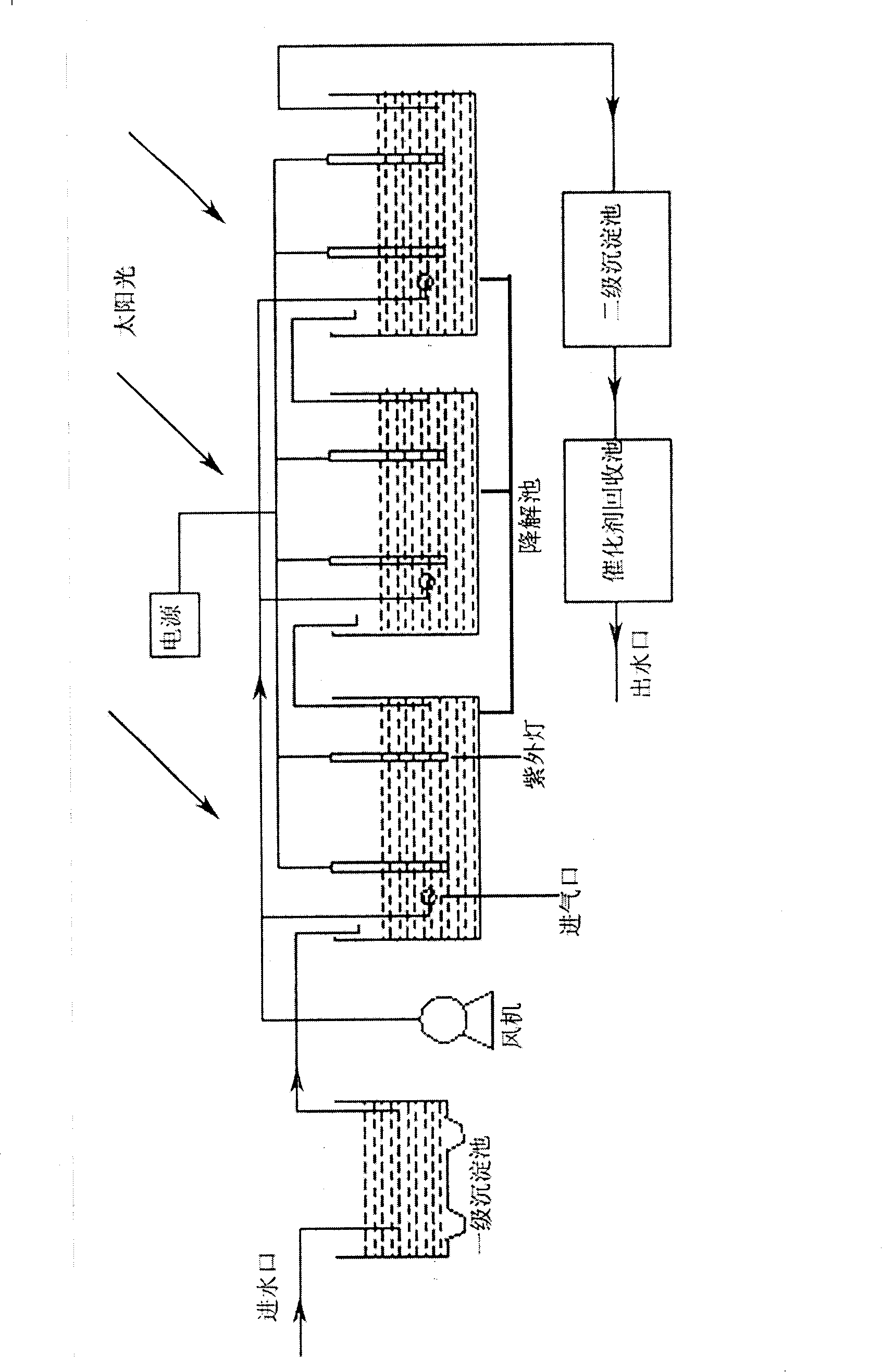

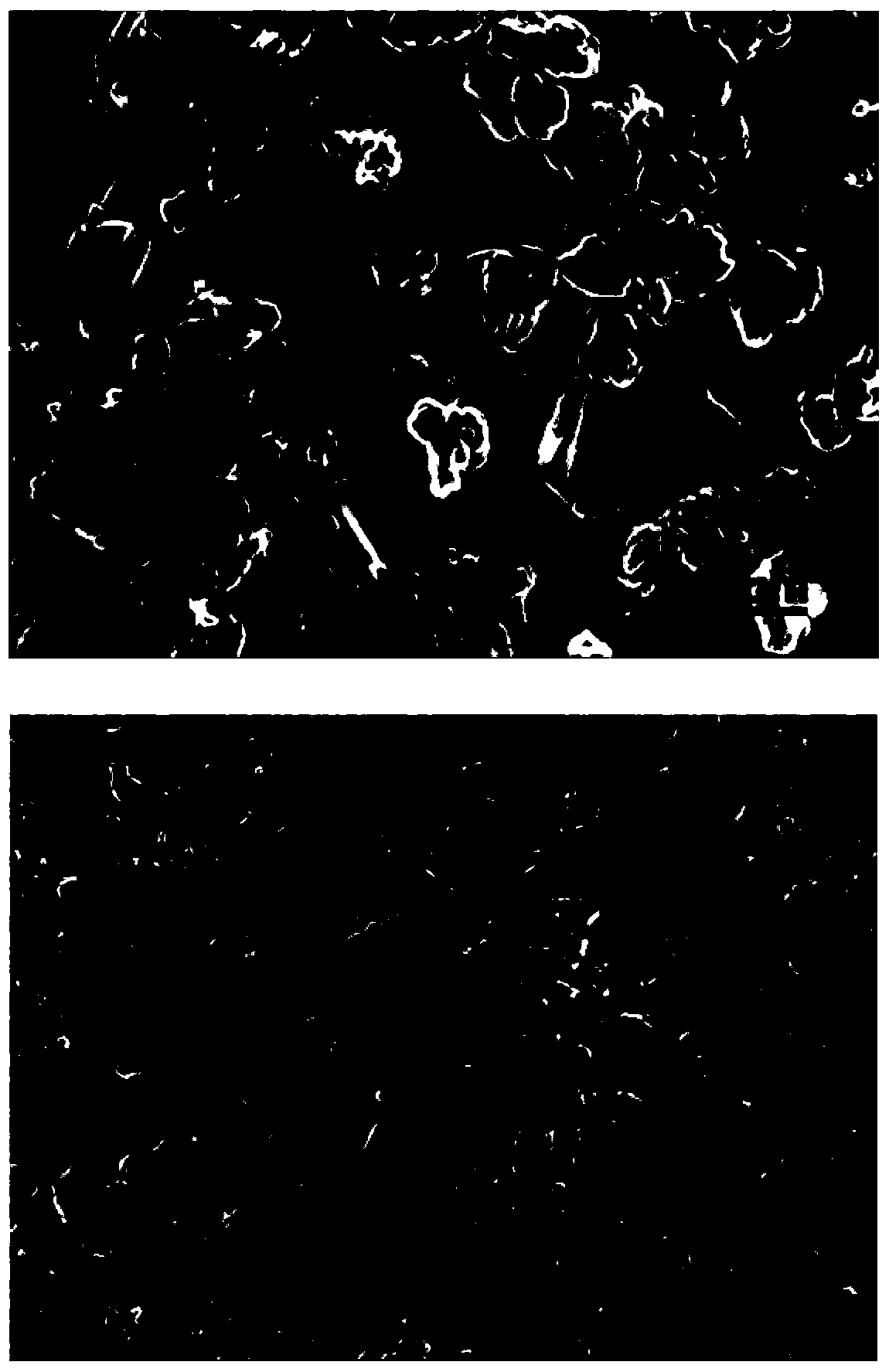

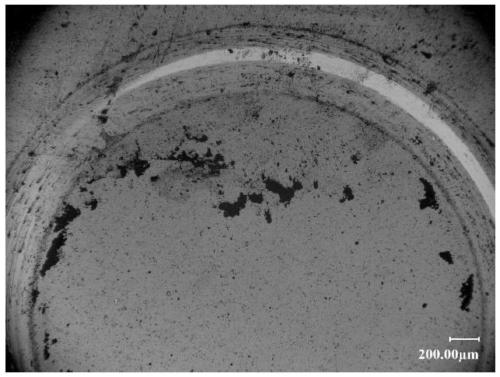

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing carbon-coated MnO coaxial nanowire cathode material for lithium ion batteries

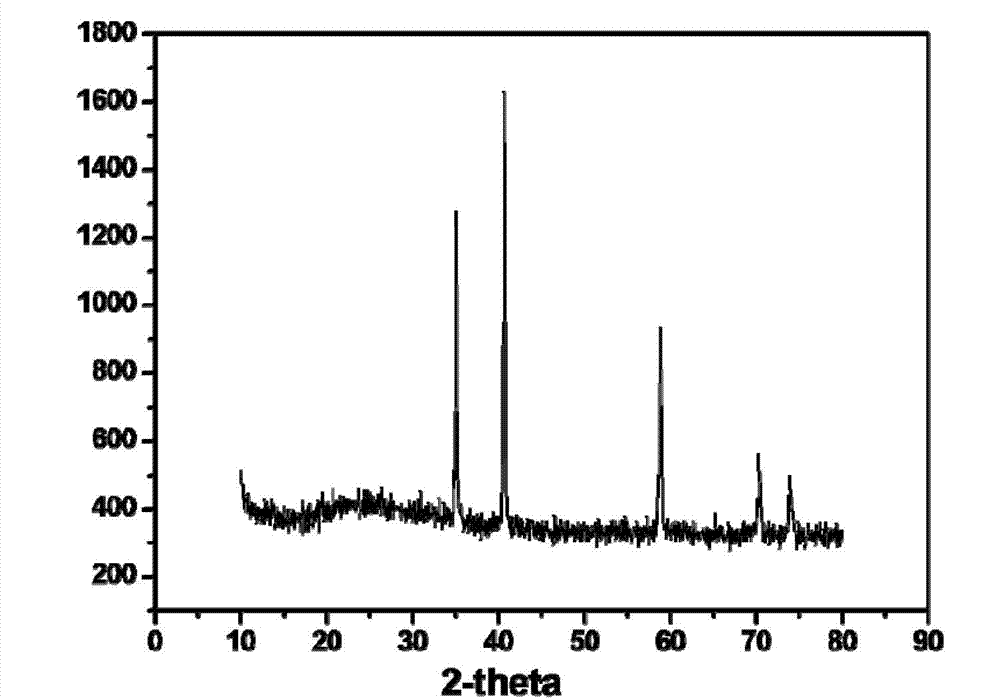

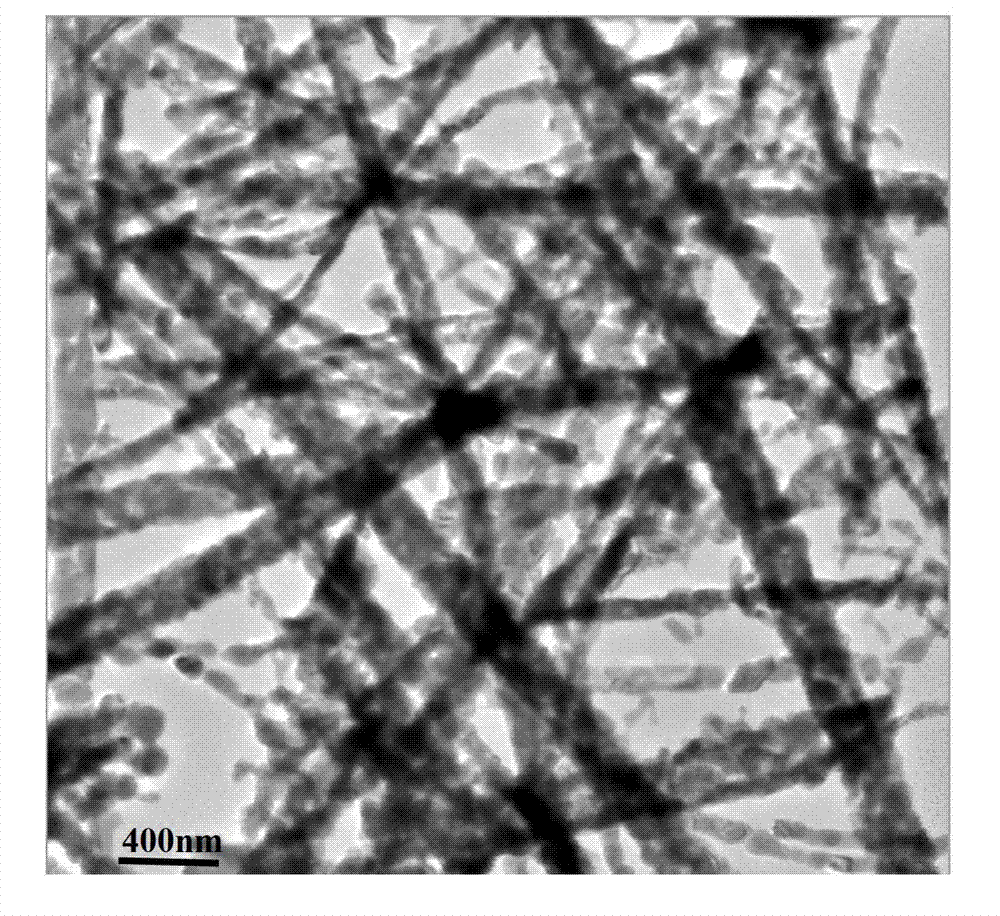

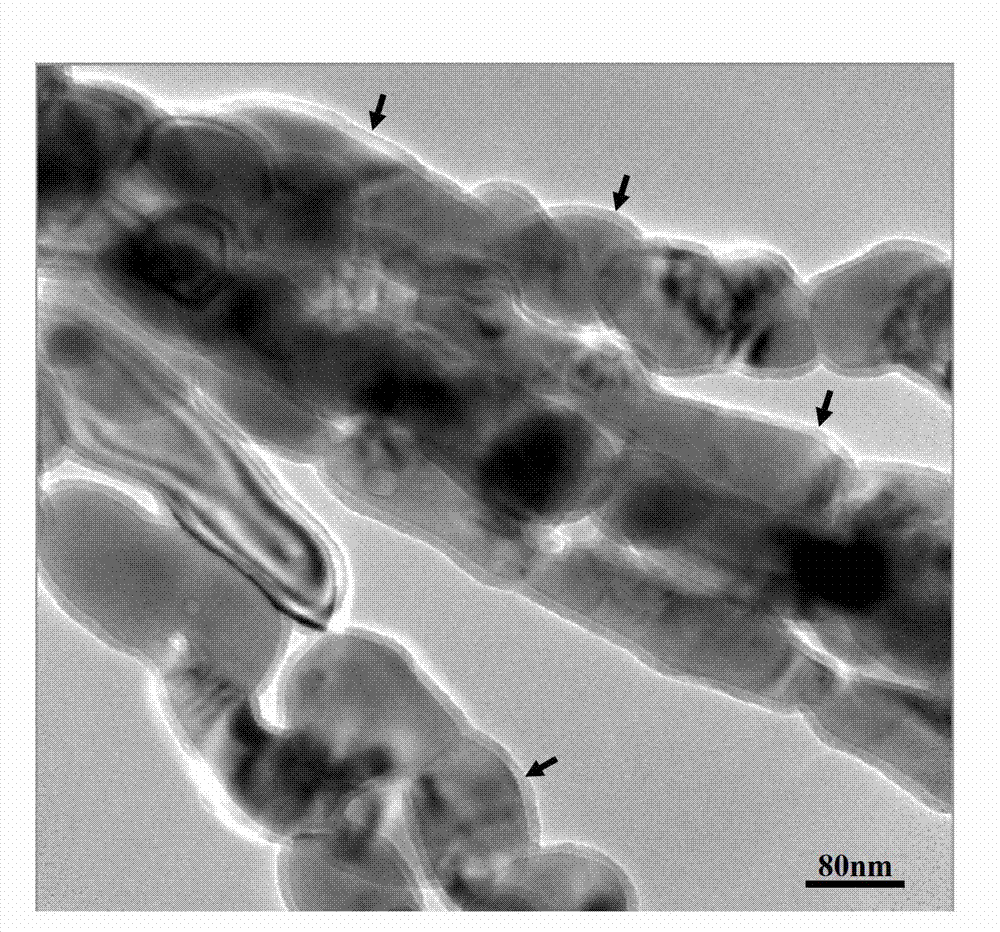

The invention discloses a method for preparing a carbon-coated MnO coaxial nanowire cathode material for lithium ion batteries. The method includes: using polyethylene glycol and potassium permanganate to prepare hydroxyl manganese oxide nanowires, heating the hydroxyl manganese oxide nanowires at 550-650 DEG C for 3-10h, naturally cooling to the room temperature to obtain porous manganese sesquioxide nanowires, feeding mixed gas of acetylene and argon or nitrogen to the porous manganese sesquioxide nanowires at 500-600 DEG C, and cooling to obtain the carbon-coated MnO coaxial nanowire cathode material for lithium ion batteries. The carbon-coated MnO coaxial nanowire cathode material for lithium ion batteries is uniform in carbon layer thickness, stable in structure, simple in preparation method and high in industrial applicability, cycling stability, specific capacity and magnification performance of the cathode material for the lithium ion batteries can be improved, and accordingly energy density and power density are improved.

Owner:SHANDONG UNIV

Phosphate microcapsule flame retardant and preparation method and application thereof

InactiveCN105585737AParticle size controllableImprove interface compatibilityPolymer sciencePolyphosphazene

The invention discloses a phosphate microcapsule flame retardant and a preparation method and application thereof. A phosphate flame retardant is adopted as a core material of the phosphate microcapsule flame retardant. A capsule material is a polyphosphazene dendritic polymer obtained through reaction of one or more of phosphonitrile and a coupling agent. The mass ratio of the capsule material to the core material is 0.1:1-1:1. According to the preparation method, a dispersing agent is utilized for uniformly dispersing the phosphate flame retardant into solvent; then one or more of phosphonitrile and the coupling agent are added under a mechanical stirring state and under an ultrasonic state, an acid-binding agent is added, the mechanical stirring reaction is carried out for 2-10 h, and a product is cooled to room temperature, filtered in a vacuum mode, and dried in a vacuum mode to obtain the phosphate microcapsule flame retardant. The phosphate microcapsule flame retardant is provided with a non-polar surface, and interfacial compatibility of the flame retardant in a non-polar polymer matrix can be improved; meanwhile, a certain toughening effect is achieved; the particle size of microcapsules is controllable, flame retardant performance and a mechanical property of a composite material can be improved, the whole technology process is convenient and controllable, and industrial applicability is high.

Owner:GUANGDONG UNIV OF TECH

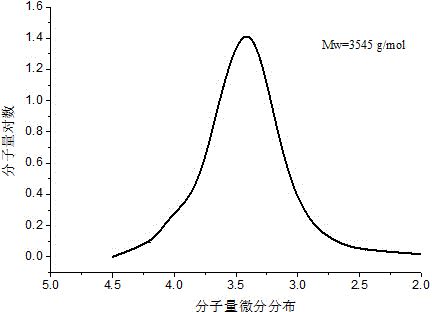

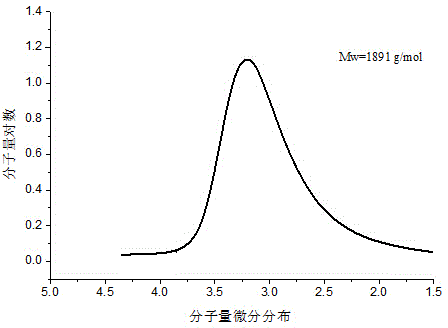

Method of extracting lignins different in molecular weight from bamboo pulping black liquor

The invention discloses a method of extracting lignins different in molecular weight from bamboo pulping black liquor. The method includes: filtering the bamboo pulping black liquor, adjusting pH to 1.5 to 2.0, and acquiring lignin by settling; drying the lignin, dissolving the lignin with 90% acetic acid to obtain lignin acetic acid solution of low viscosity, and subjecting the lignin acetic acid solution to ultrafiltration and grading with ultrafiltration membranes having different cut-off molecular weights; and subjecting ultrafiltrate and cut-off liquid to precipitating with distillate according to the ratio being 1:10 and purifying with dichloroethane / water, diethyl ether and petroleum ether solvents to obtain lignins different in molecular weight distribution range. The pH value of the bamboo pulping black liquor of high viscosity is adjusted with hydrochloric acid to precipitate the lignin therein, the lignin is dissolved with the 90% acetic acid, and the lignin acetic acid solution is of low viscosity and is directly graded with the ultrafiltration membranes to separate the lignins; the method has the advantages that stock liquor needs no dilution, membrane flux is great, attenuating speed is low, a membrane component is simple to maintain, and the industrial applicability is high.

Owner:NANJING FORESTRY UNIV

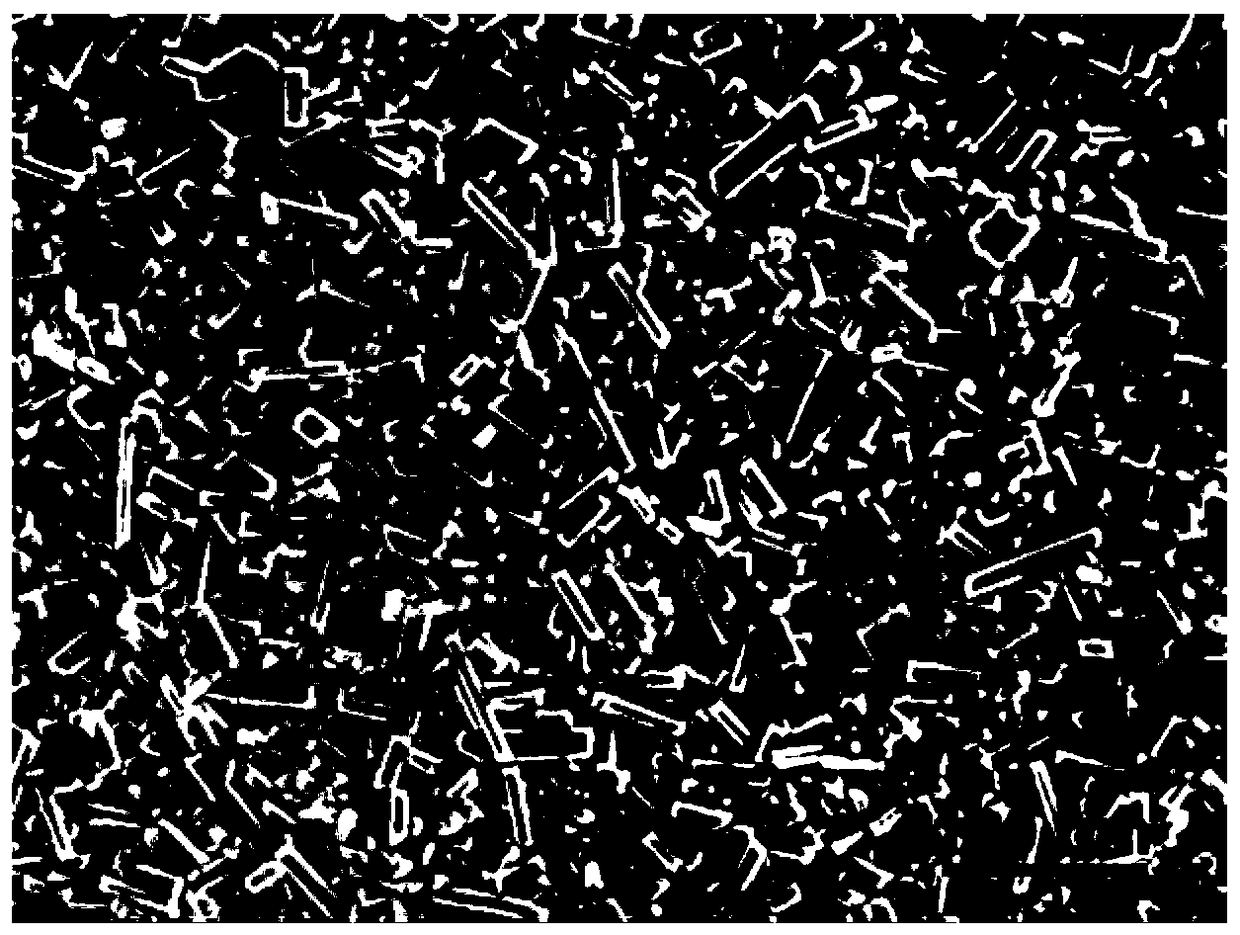

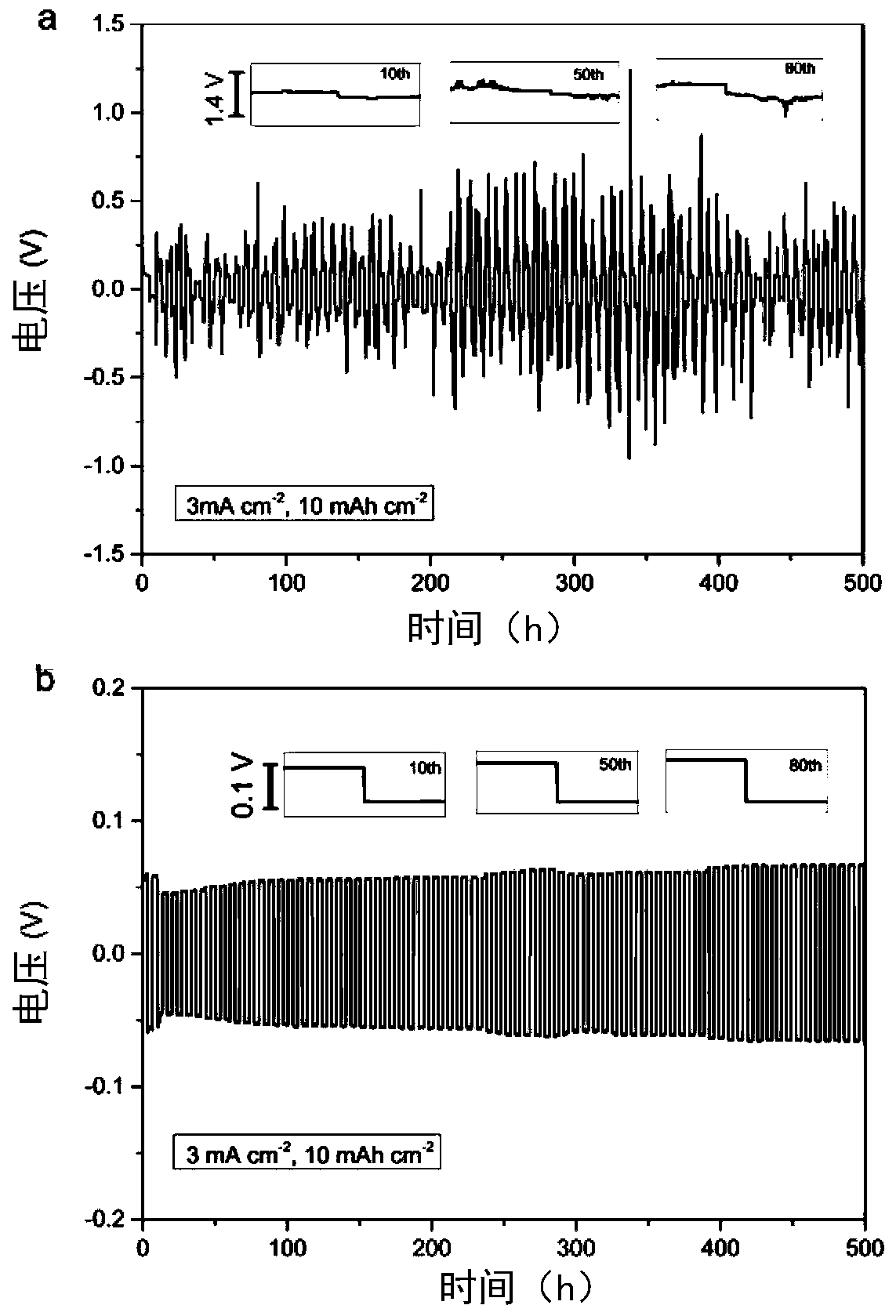

A metal lithium anode with a high specific surface protection layer and a preparation method thereof

InactiveCN109273704AImprove protectionLow costElectrode carriers/collectorsSecondary cellsLithiumCarbon nanofiber

The invention relates to a metal lithium negative electrode with a high specific surface protective layer and a preparation method thereof. The metal lithium negative electrode comprises a substrate and a protective layer formed of a nano-conductive carbon material, which is carbon nanofibers or / and carbon nanotubes, and is coated on the surface of the substrate. The metal lithium with high specific surface area protection layer provided by the invention has obvious protection effect, low cost, simple preparation, easy industrialization and strong industrial application.

Owner:浙江浙能中科储能科技有限公司

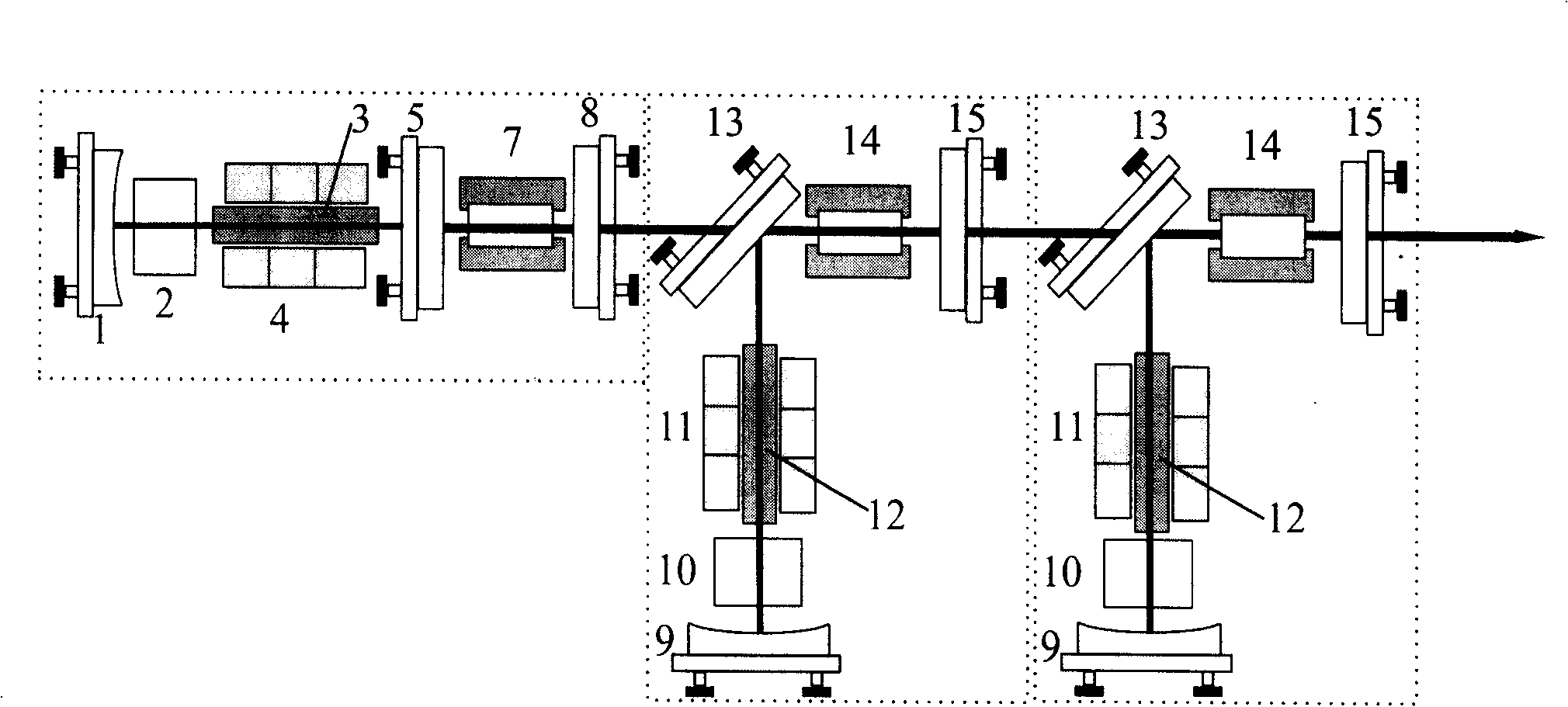

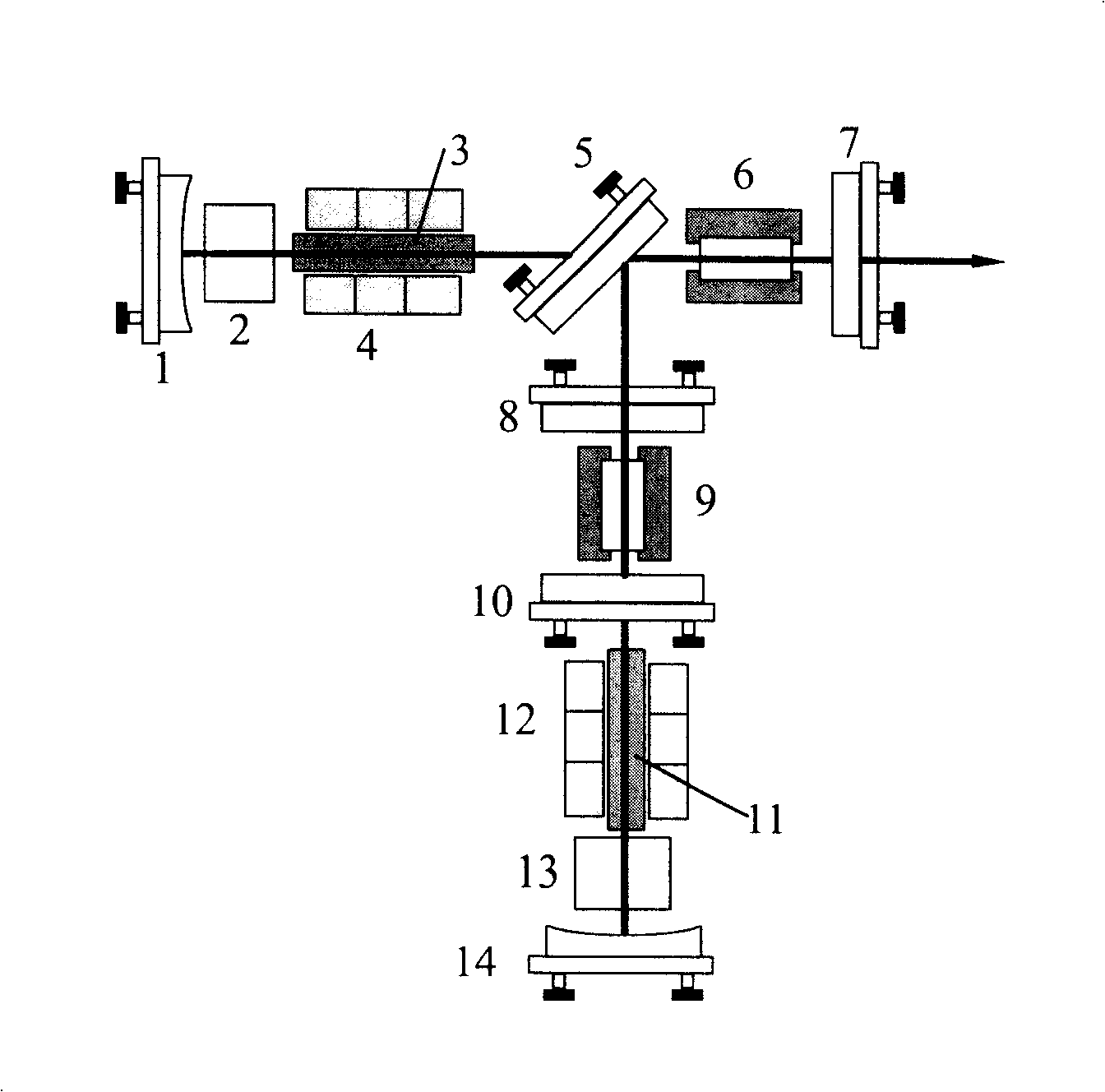

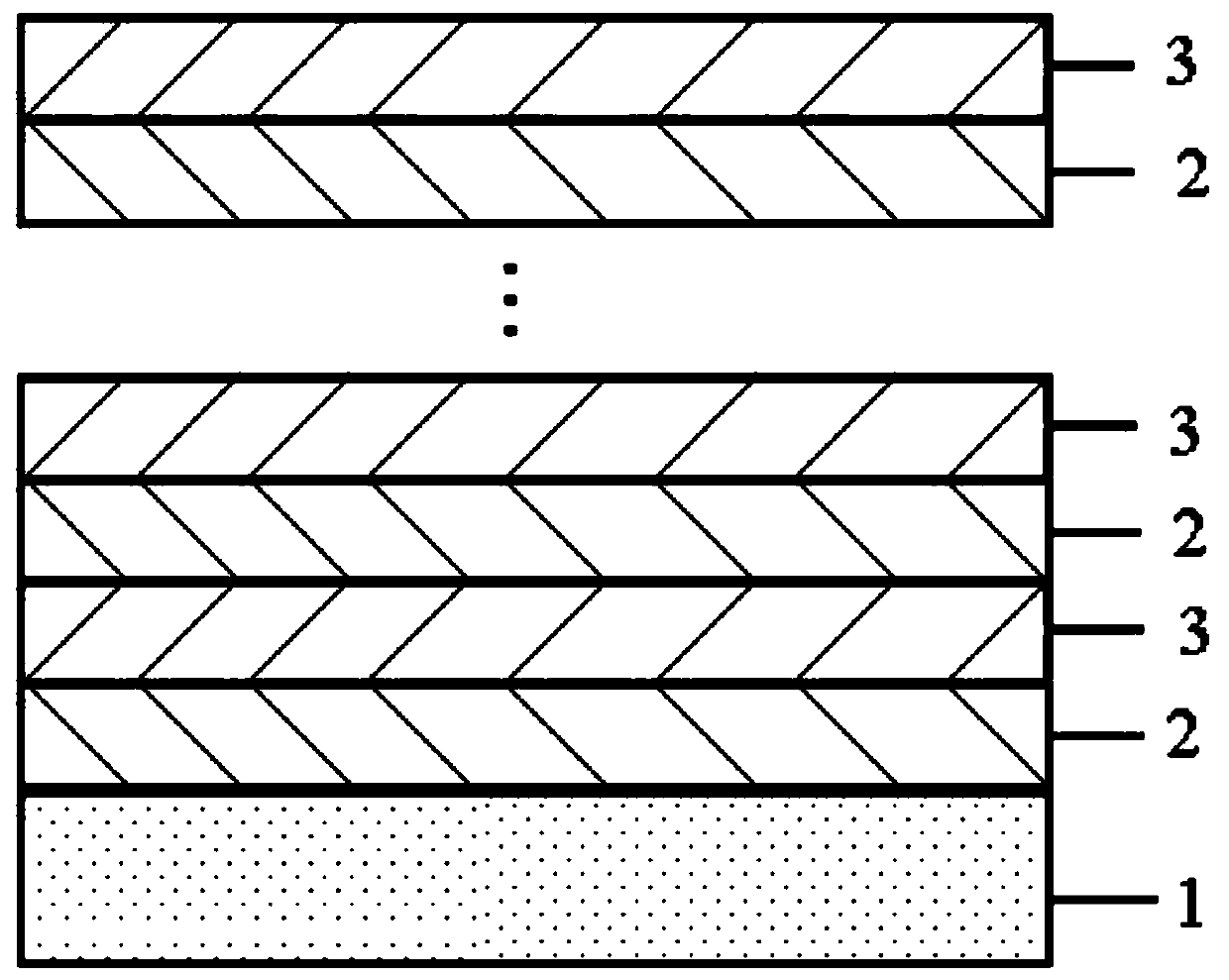

Multiple frequency one-way overlapped output standard continuous green light laser inside full solid multi-cavity combination cavity

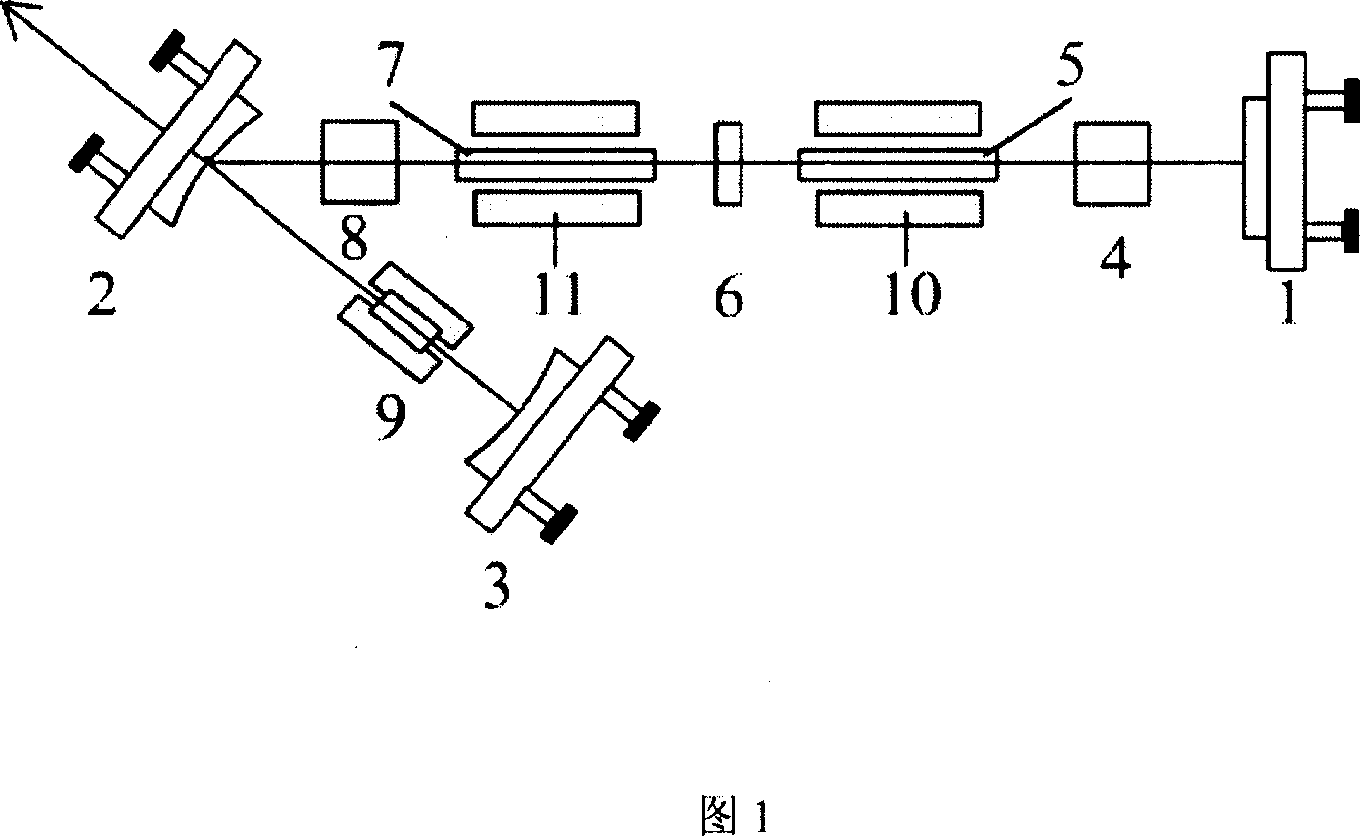

InactiveCN101267083AReduce the risk of injuryIncrease output powerOptical resonator shape and constructionActive medium materialFundamental frequencyAcousto-optics

The present invention provides a laser, especially a frequency doubling single direction overlapping output quasi-cw green laser in a full-solid multi-cavity combined cavity, composed of three or more F-P, each F-P adopts flat-concave cavity structure, F-P adopts side pumped Nd:YAG crystal of the semiconductor laser pumped component having same model, each F-P is optimized design by computer simulation, a stably rotatable 1064nm fundamental frequency laser is formed in the F-P, each F-P obtains 532nm quasi-cw green laser by the audio-optical Q switching and frequency doubling technology, overlapping in the several frequency doubling crystals, reflecting by the harmonic reflector, obtaining secondary frequency doubling and output together. The laser does not need any thermal lens and thermal double refraction compensation element, having high output power, better beam quality, high doubling efficiency, better stability, widely used for fields of laser material process, optical storage, laser full color display, laser medicine, scientific research, communication, defense and amusement.

Owner:NORTHWEST UNIV

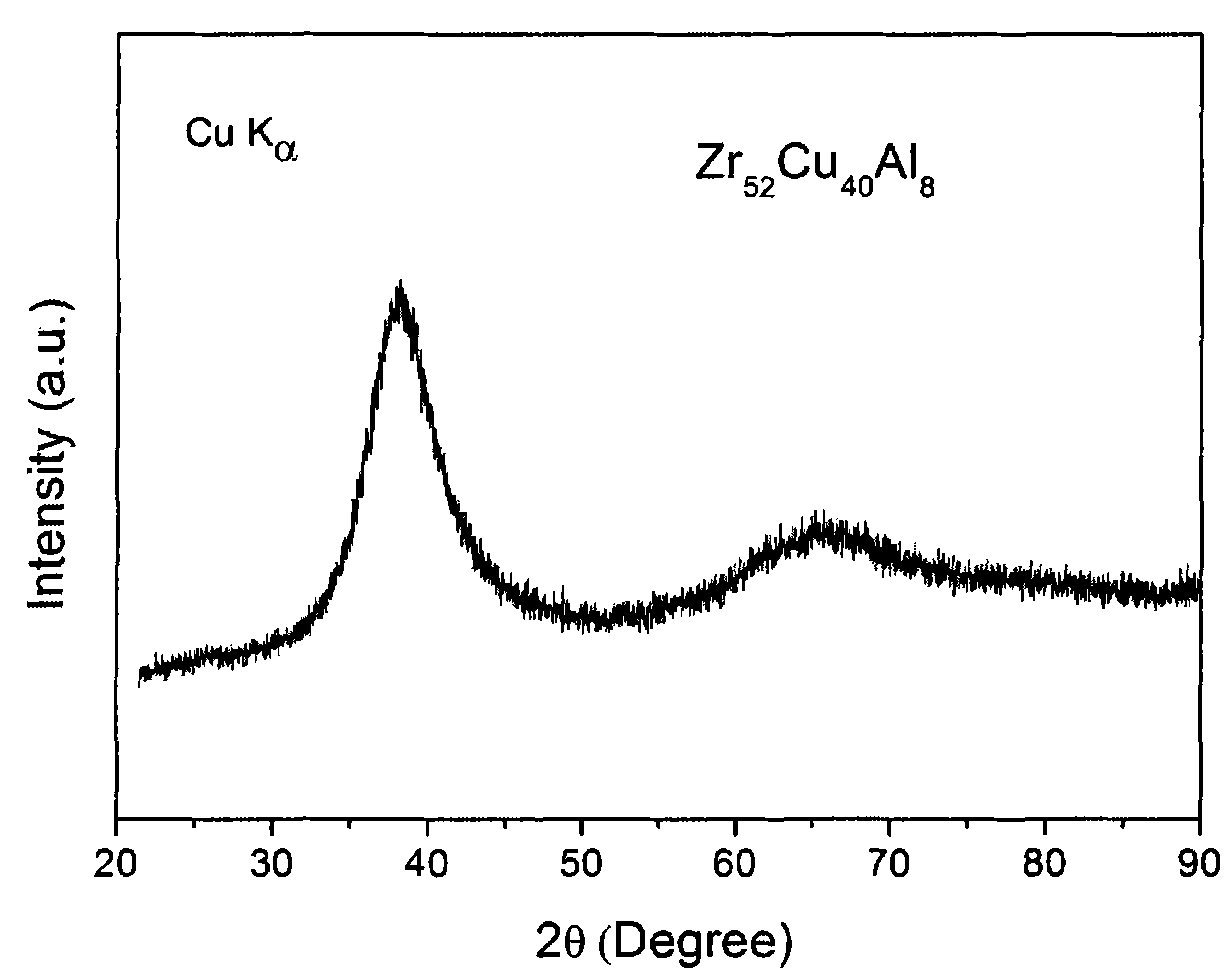

Bulk amorphous alloys of Zr-Cu-Al-Be series and preparation method thereof

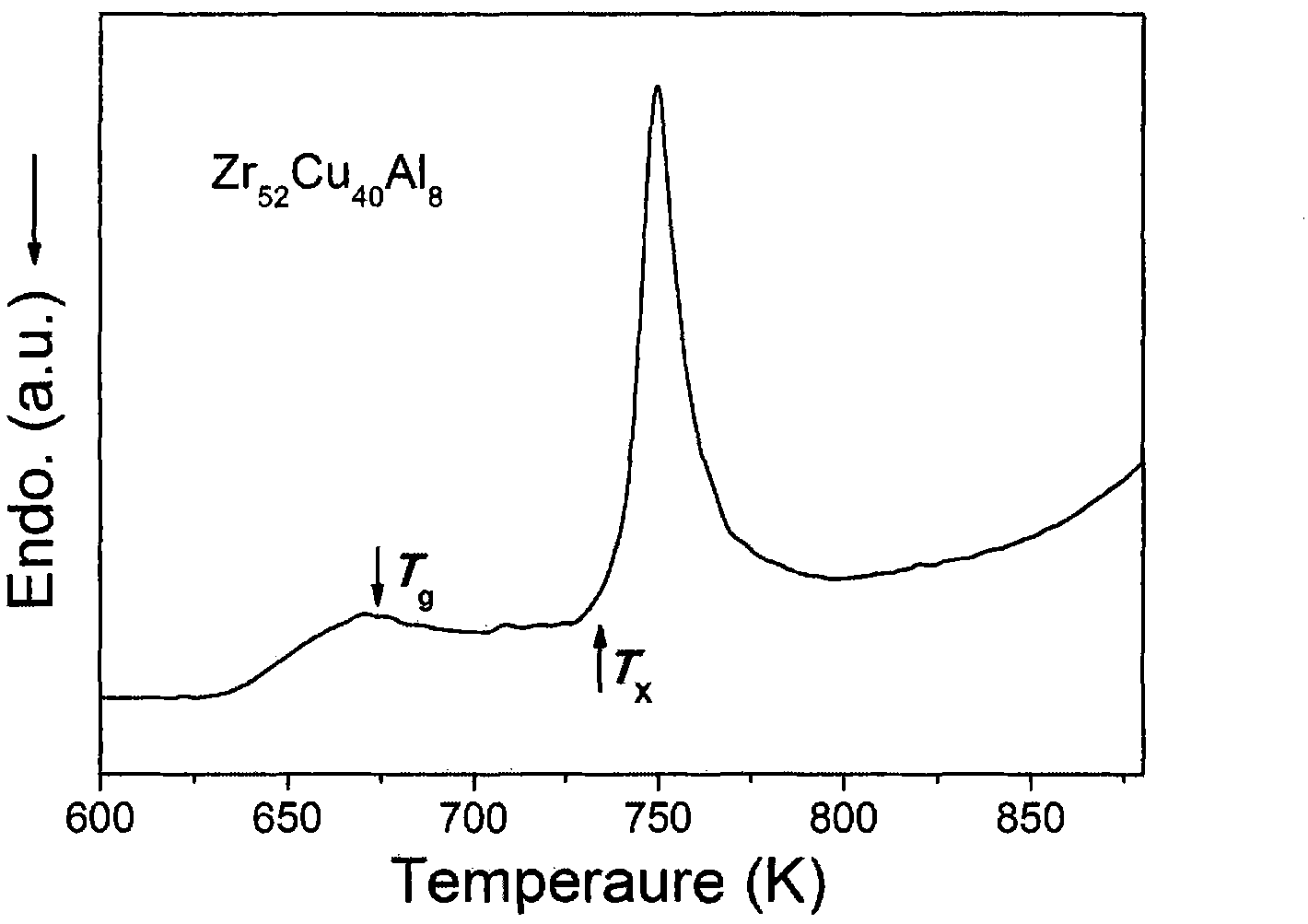

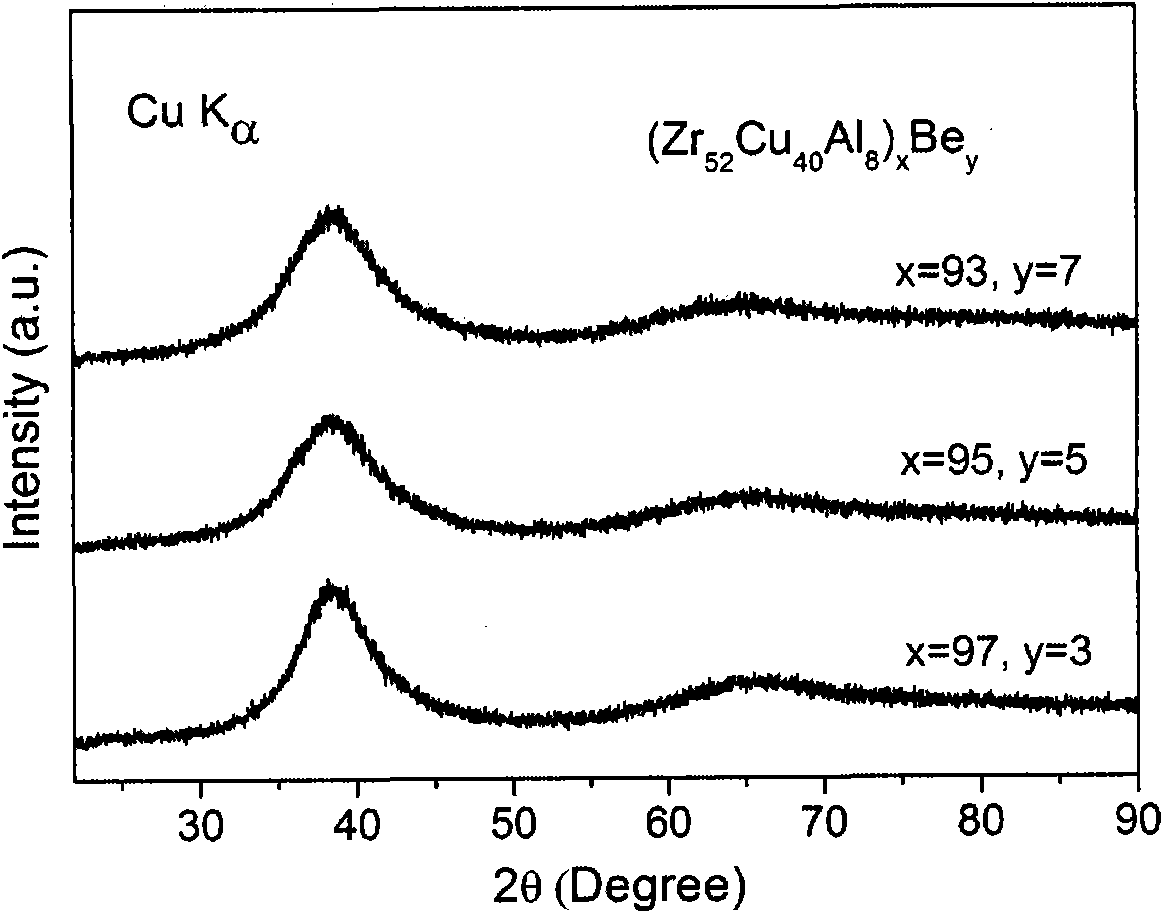

ActiveCN101886234AStrong industrial applicabilityLarge supercooled liquid regionAlloy elementAtomic radius

The invention relates to bulk amorphous alloys of Zr-Cu-Al-Be series with an extra-wide supercooling liquid phase region. The series of alloys take Zr52Cu40Al8 as basic ingredients, and take the metallic element Be with the minimum atomic radius as the alloying element. The composition of the series of alloy is determined through the following formula: (Zr52Cu40Al8)xBey, wherein x is the molar content of Zr52Cu40Al8, y is the molar content of Be, 80<=x<=100, 0<=y<=20, and x+y=100. The series of alloys can generate bulk amorphous alloys with the critical dimension not less than 3mm, the maximum supercooling liquid phase region reaching 123K and with excellent thermal stability. The series of alloys integrate better glass-forming ability and extra-wide supercooling liquid phase region, and can be widely used in the fields of precise parts, microelectronic components and the like.

Owner:UNIV OF SCI & TECH BEIJING

Fluoromethane production process and product

ActiveCN101023051AEfficient separationHigh purityPreparation by halogen replacementBulk chemical productionHydrogen fluorideDistillation

Methyl chloride and hydrogen fluoride are reacted in a gas phase in the presence of a fluorination catalyst and the resulting mixture, containing fluoromethane and hydrogen chloride, is fed to a distillation column for separation and purification of the fluoromethane and hydrogen chloride as the overhead fraction. It is thus possible to efficiently produce high purity HFC-41 which is suitable for use as a semiconductor etching gas.

Owner:株式会社力森诺科

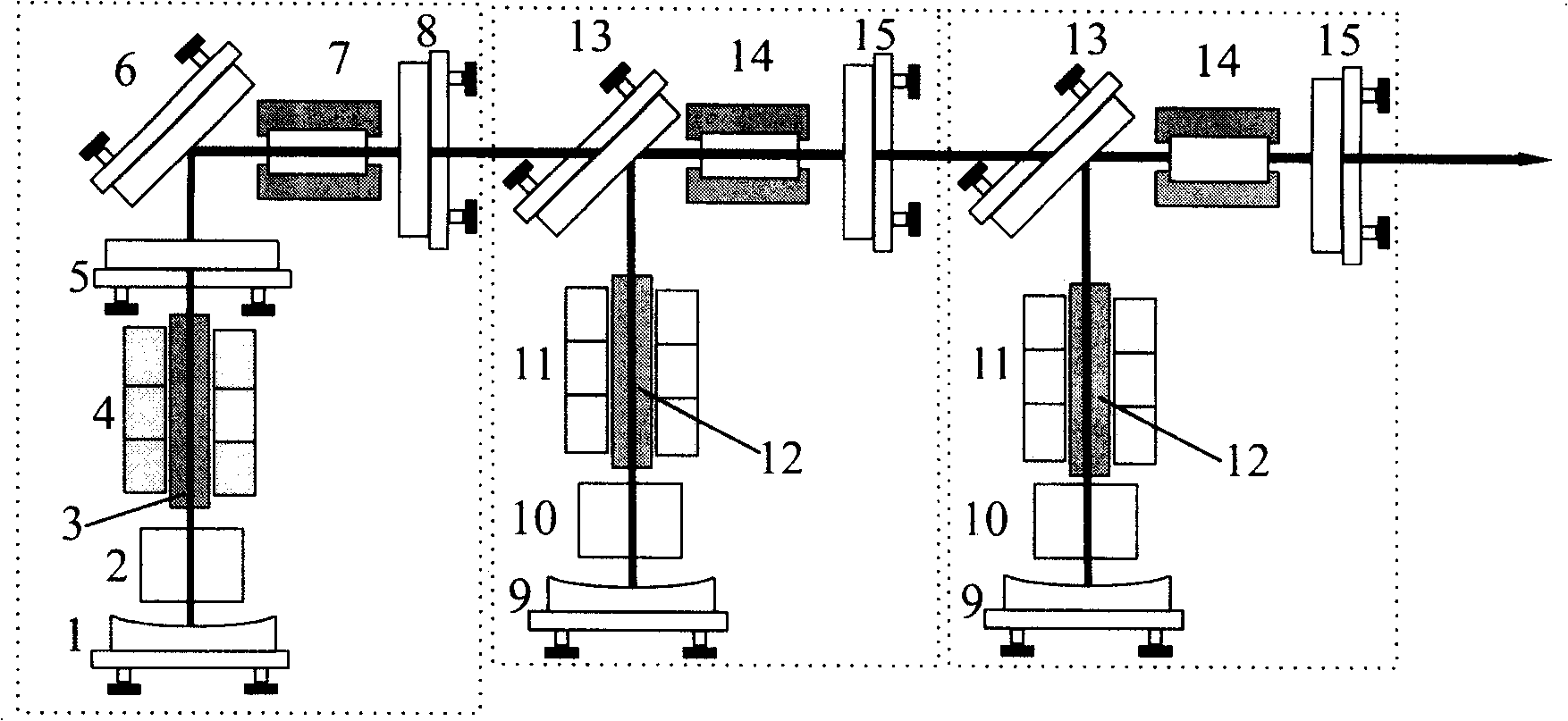

Quasi-continuous two-bar series inner cavity frequency multiflier high power green laser of 200 vatts grade

InactiveCN101000999AIncrease output powerQuality is not affectedOptical resonator shape and constructionActive medium materialLight beamAcousto-optics

The invention relates to a 200 kilowatt-classed quasi-continuous frequency-doubled high-power green laser with two rods series connected with intracavity. It adopts the side-pumped Nd: YAG crystals of the same type of diode laser pumped component controlled by the same driver. It forms a stable 1064-based depolarized fundamental radiation in the folded resonator designed through the optimization of computer's simulation. It eventually achieves a 203.5W output of 532nm green laser with a conversion efficiency of 72.7% through the double-frequency by HGTR - KTP crystals, and dual acousto-optic Q technology and thermally-induced birefringence compensation technology.

Owner:SHAANXI XIDA KELIAO PHOTOELECTRIC TECH

Soybean protein isolate powder as well as preparation method and use thereof

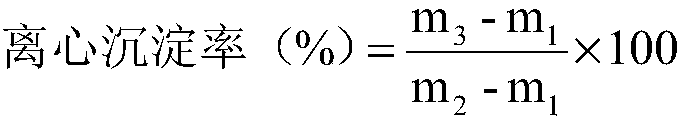

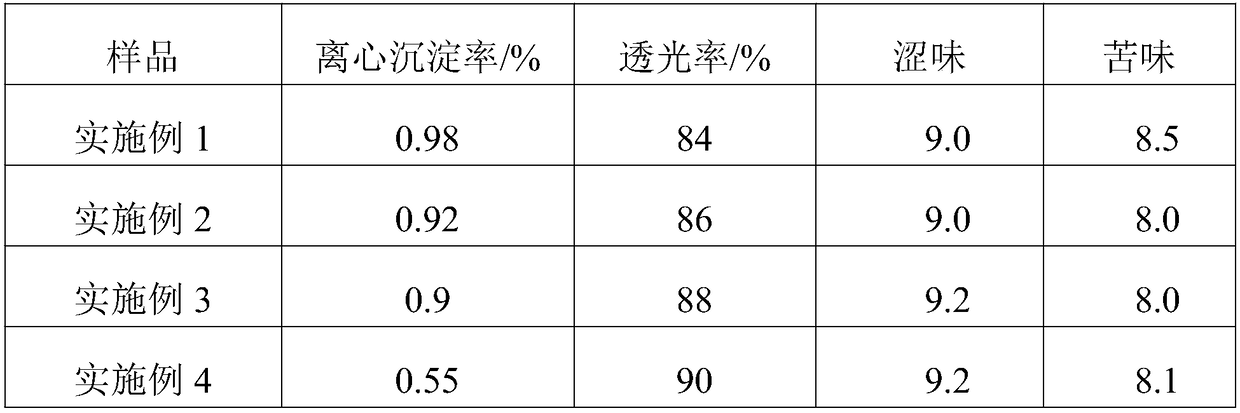

InactiveCN108118078AHigh transparencyReduce sedimentation ratePeptide preparation methodsFermentationSolid phasesEmulsion

The invention relates to soybean protein isolate powder as well as a preparation method and use thereof. The preparation method comprises the following steps: mixing low-temperature degreased bean pulp with water, carrying out shearing, adding phytase and polyphenol oxidase for reaction, carrying out solid-liquid separation, shearing obtained bean dregs, adding water for extraction, carrying out solid-liquid separation, and combining an obtained water extracted bean emulsion with soybean milk extracting liquid, so as to obtain mixed soybean milk; regulating the pH value of the mixed soybean milk to settle soybean protein, and carrying out solid-liquid separation, so as to obtain a fixed phase, namely the soybean acid settled milk protein; preparing protein liquid from the soybean acid settled milk protein, regulating the pH value to 2.5-3.5, adding acid proteinase for enzymolysis, and carrying out solid-liquid separation, so as to obtain protein liquid; and concentrating the protein liquid, and carrying out spray drying on the obtained soybean acid protein fluid, so as to obtain the soybean protein isolate powder. A solution obtained by adding the soybean protein isolate powder into an acidic beverage has relatively good appearance transparency and extremely good storage stability.

Owner:SHANDONG YUWANG ECOLOGY FOOD IND

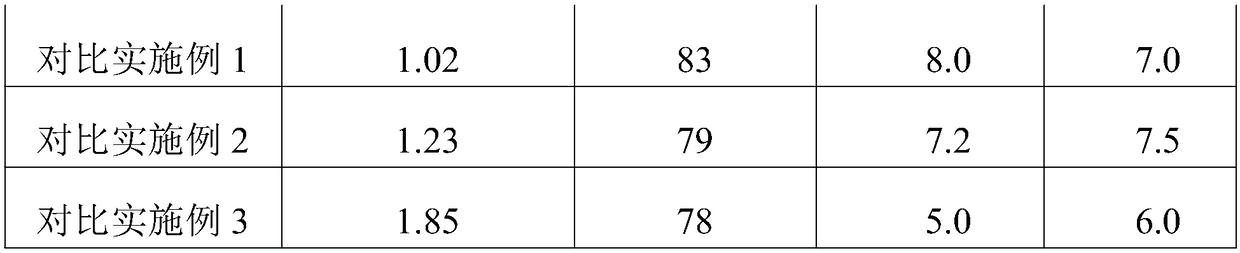

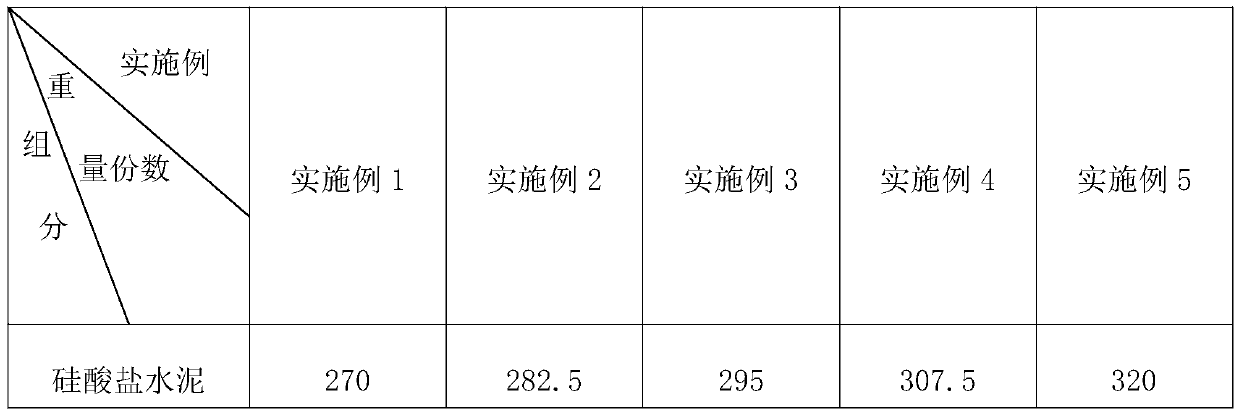

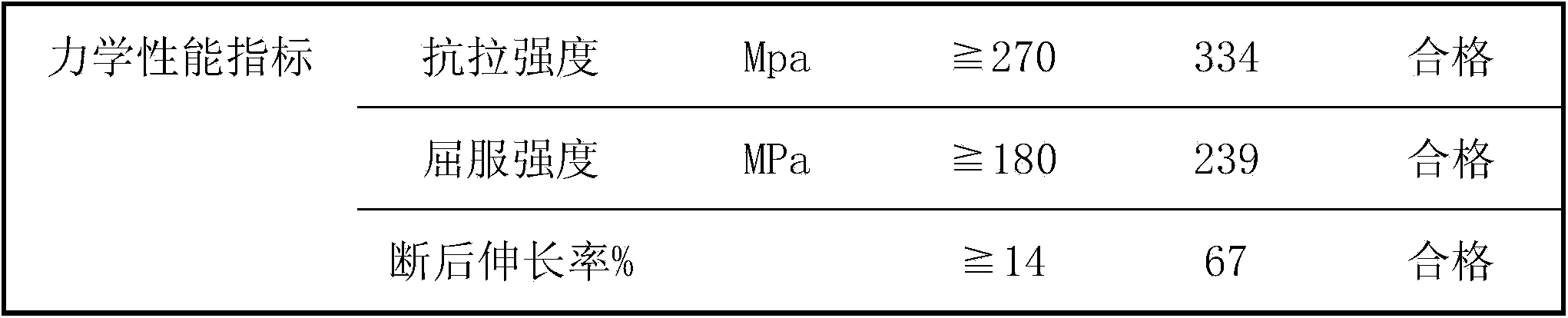

Production process of pipe pile

ActiveCN110053141AShorten the production cycleIncrease productivityMouldsShaping reinforcementsSample waterProcess engineering

The invention discloses a production process of a pipe pile, and relates to the technical field of concrete component processing. The production process solves the problems that in the production process of the pipe pile, waste of energy is easily caused due to unreasonable process design, thereby the poor overall industrial applicability is caused. The pipe pile with high compactness, good strength, good stability and excellent performance is prepared by preparing concrete, making a pipe pile skeleton, conducting splicing and mold entering, conducting pouring mold forming, conducting centrifugal forming, conducting steam curing and conducting high pressure steaming. Meanwhile, in the preparation process, steam curing and high pressure steaming are adopted, the production cycle is greatlyshortened, the production efficiency is better improved, water in centrifugal molding and steam curing is collected, first sample water and second sample water are obtained, then the first sample water and the second sample water are used for cooling a sample of the pipe pile in high pressure steaming, at this time, third sample water at higher temperature is collected, the water can be recycled in a steam cabinet and a high temperature steam furnace, energy and resources are better saved, and the good applicability is achieved.

Owner:江苏泰林建设有限公司

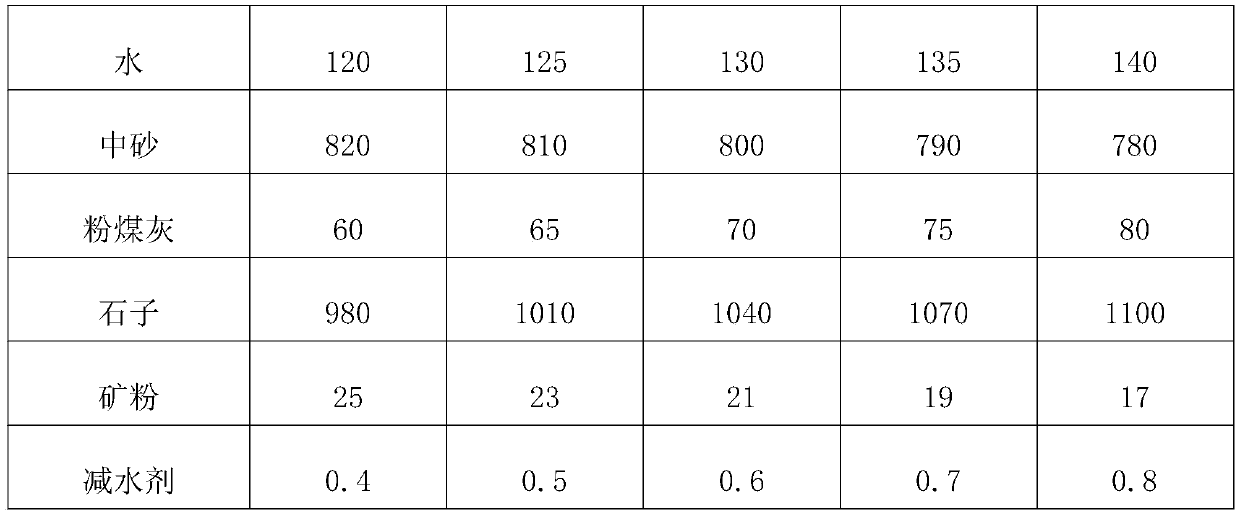

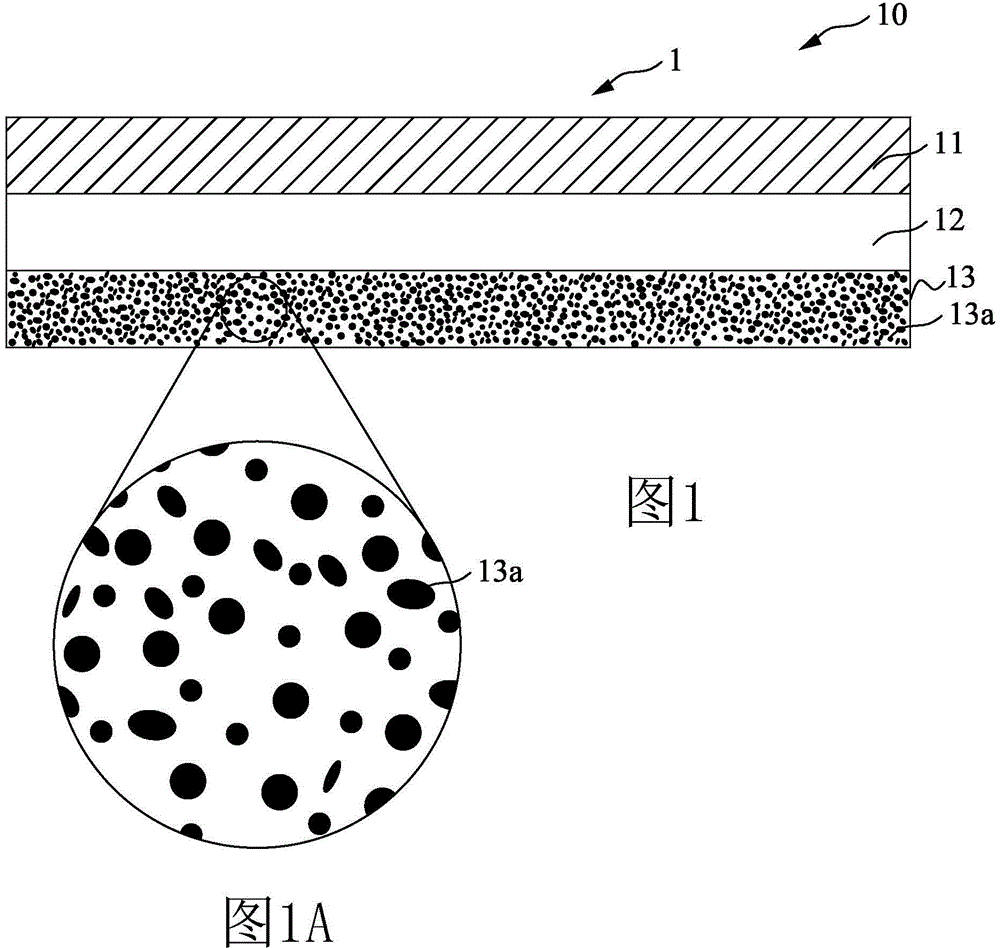

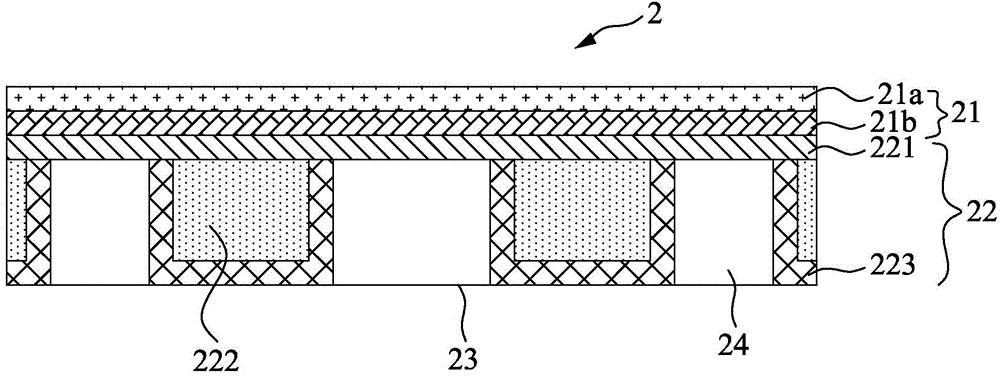

Screened film and preparation method thereof

ActiveCN105324019AImprove conduction propertiesImprove electromagnetic shielding performanceMagnetic/electric field screeningDistribution patternElectromagnetic shielding

The invention relates to a screened film and a preparation method thereof. The screened film structurally comprises an insulating layer, a conductive shielding layer and an adhesive layer. The preparation method of the screened film comprises that (A) a base material and the conductive shielding layer are connected and the form recesses; (B) the insulating layer is formed at the surface of the conductive shielding layer and filled into the recesses; (C) a carrier film is formed at the surface of the insulating layer; (D) the base material is removed; and (E) the surface of the conductive shielding layer is provided with the adhesive layer, and a metal grounding electrode is exposed to form a distribution pattern. According to the structure and preparation method of the screened film, the screened film is good in grounding effect and high in adhesion intensity, the electromagnetic shielding effect is indirectly improved, and the preparation method is characterized by reducing the cost and simplifying the process.

Owner:APLUS SEMICON TECH CO LTD

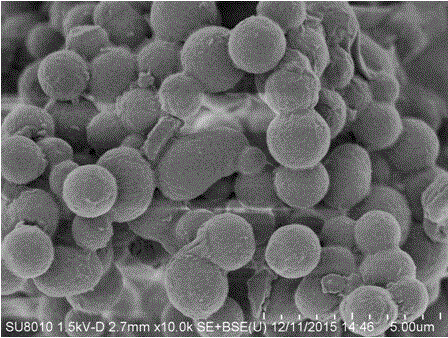

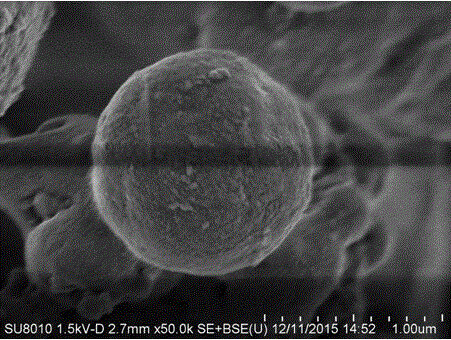

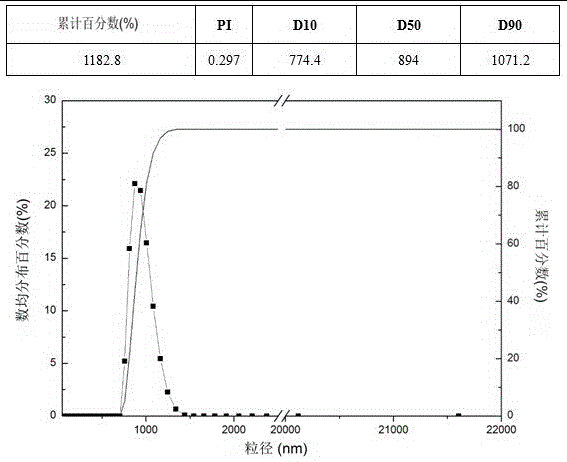

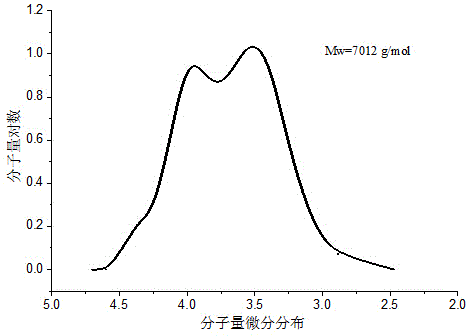

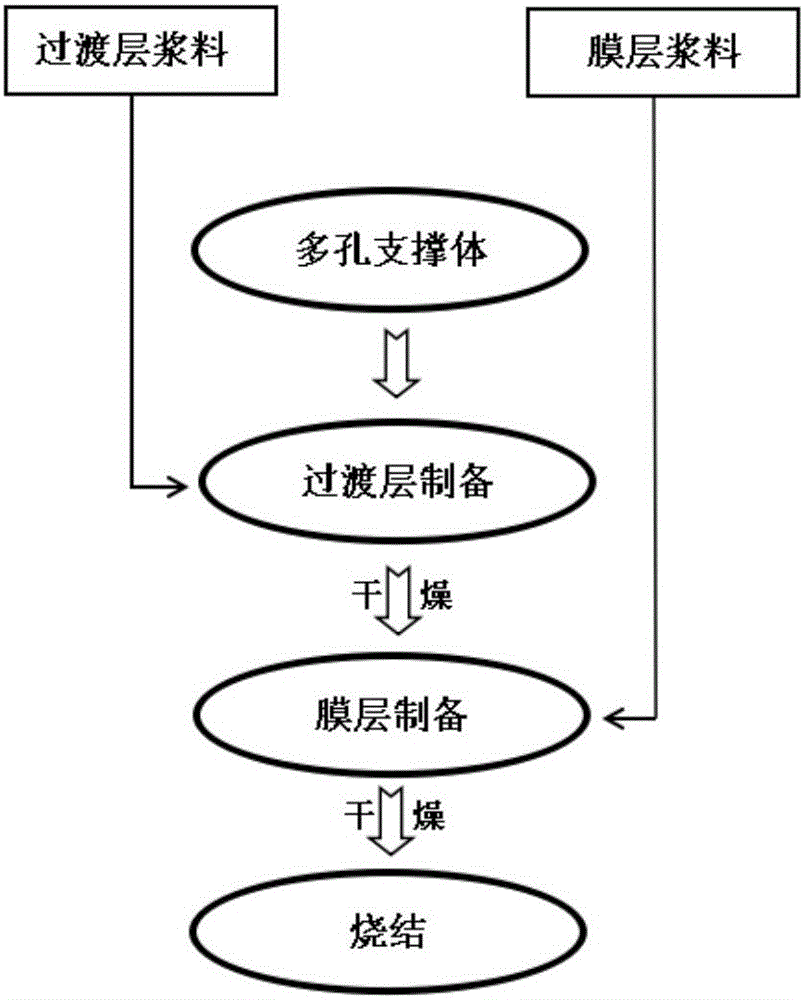

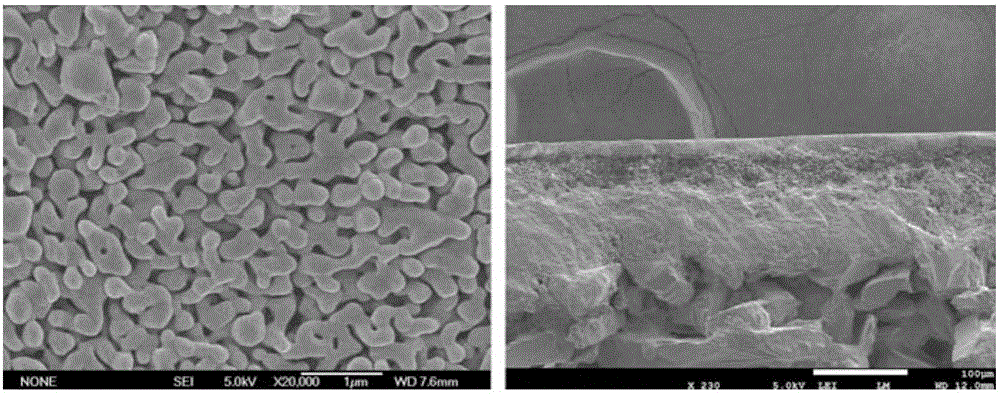

Porous ceramic film and preparation method thereof

ActiveCN106747346AUniform poresAperture adjustableSemi-permeable membranesCeramicwarePolyvinyl alcoholSlurry

The invention discloses a porous ceramic film and a preparation method thereof and belongs to the technical field of porous ceramic films. The porous ceramic film is of a multistage structure and comprises a film layer, a transition layer and a porous supporting body; the film layer is prepared by sintering low-activity nanometer particles with dense sphere and a middle transition phase; the transition layer is prepared by sintering conventional irregular micro-powder; and the film layer and the transition layer are sintered by one time under the same condition. The preparation method comprises the following steps: enabling the transition layer particles and the film layer particles to disperse in a polyvinyl alcohol (PVA) aqueous solution to obtain transition layer slurry and film layer slurry; depositing the transition layer on the surface of the porous supporting body by using a dipping-pulling method, and drying; preparing the film layer on the surface of the transition layer by using the dipping-pulling method, and drying to obtain a ceramic film green body; and finally, obtaining the porous ceramic film through one-step sintering. The porous ceramic film has very good effect on treating suspended matters and can be used in the fields of printing and dyeing material recovery, beverage clarification, powder preparation, oil-water separation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

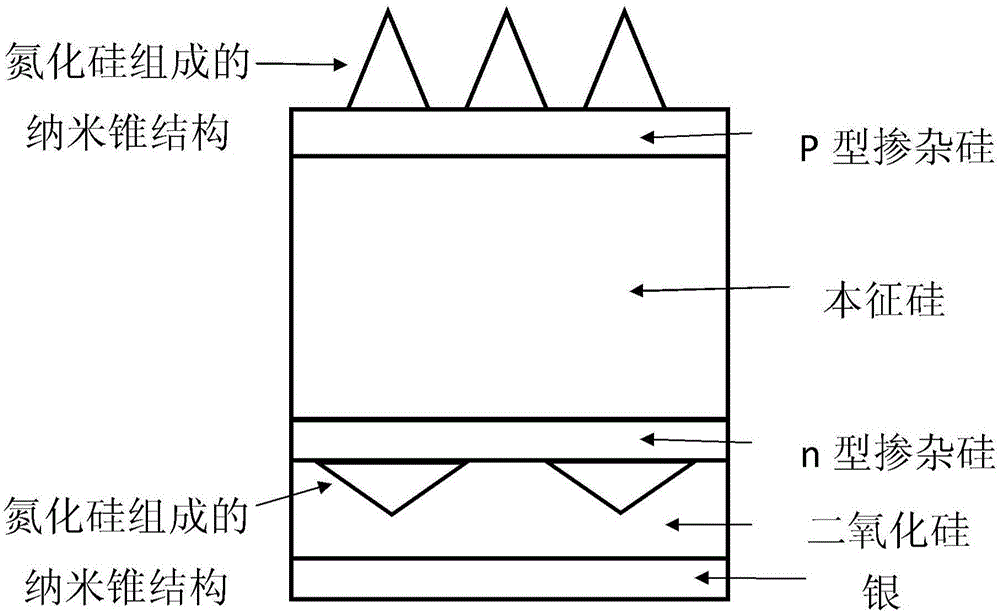

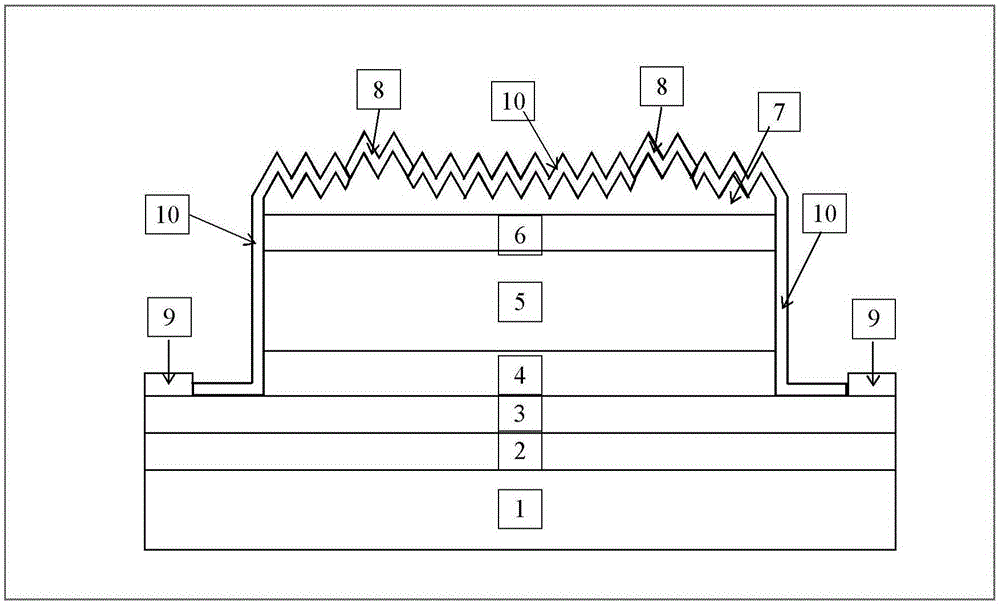

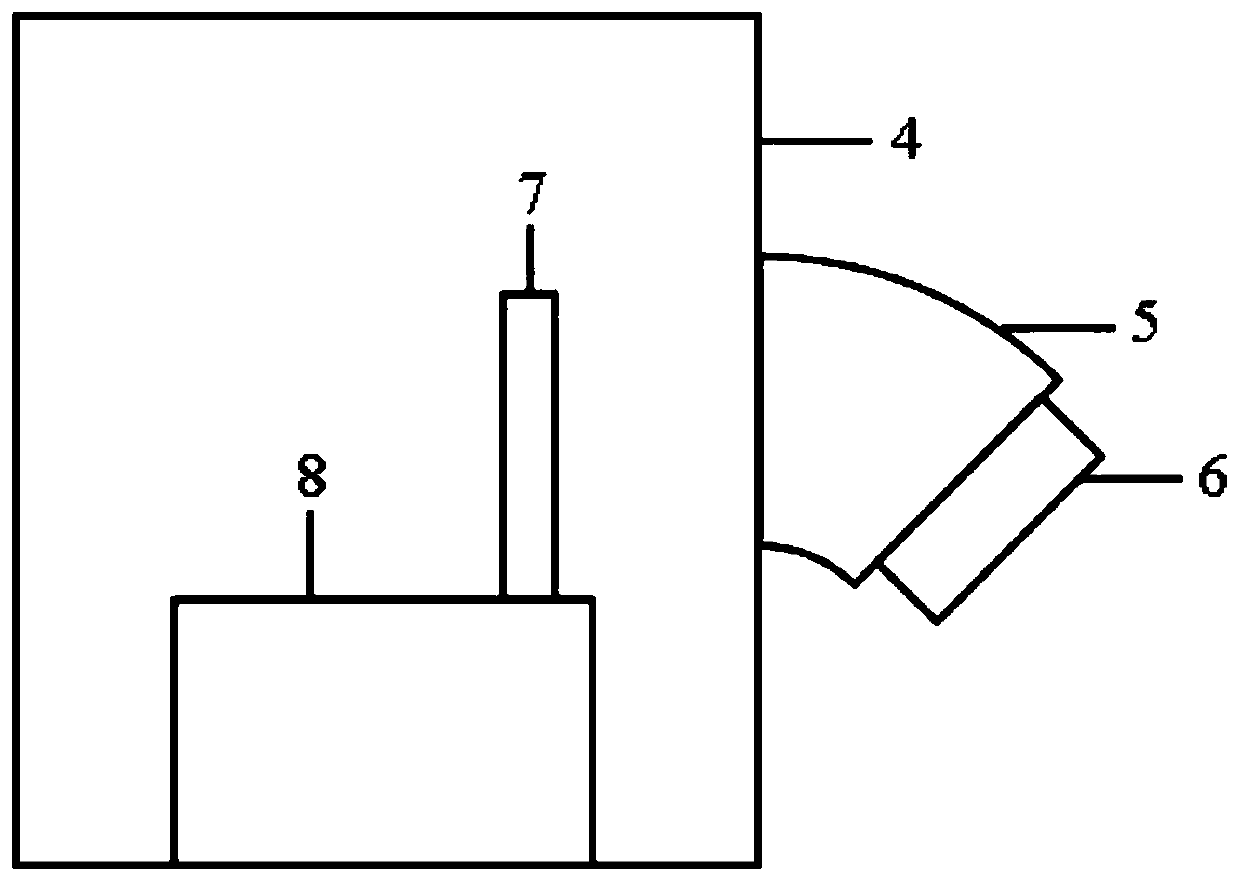

Avalanche photodiode with periodic nanostructure

ActiveCN106057957AGood single photon detection efficiency and time resolutionSimple preparation processPhotovoltaic energy generationSemiconductor devicesPeriodic nanostructuresQuantum information

The invention provides a silicon-based avalanche photodiode applied to single photon detection in quantum information. The silicon-based avalanche photodiode comprises an SOI substrate and a PIN structure formed on the SOI substrate. A periodic Pyramid or inverted Pyramid shaped nanostructure is formed at the outermost layer of the PIN structure as an entrance window, wherein monocrystalline silicon is employed by the nanostructure as the main body material of a Pyramid basic unit. By using the avalanche photodiode structure of the invention, the preparation of the avalanche photodiode can be carried out by using an existing silicon-based preparation process, the layer structure of the diode is simplified, while the improved time resolution ability can be provided, good detection efficiency is provided, and the avalanche photodiode is suitable for industrialized production with a large scale and a high rate of finished products.

Owner:UNIV OF SCI & TECH OF CHINA

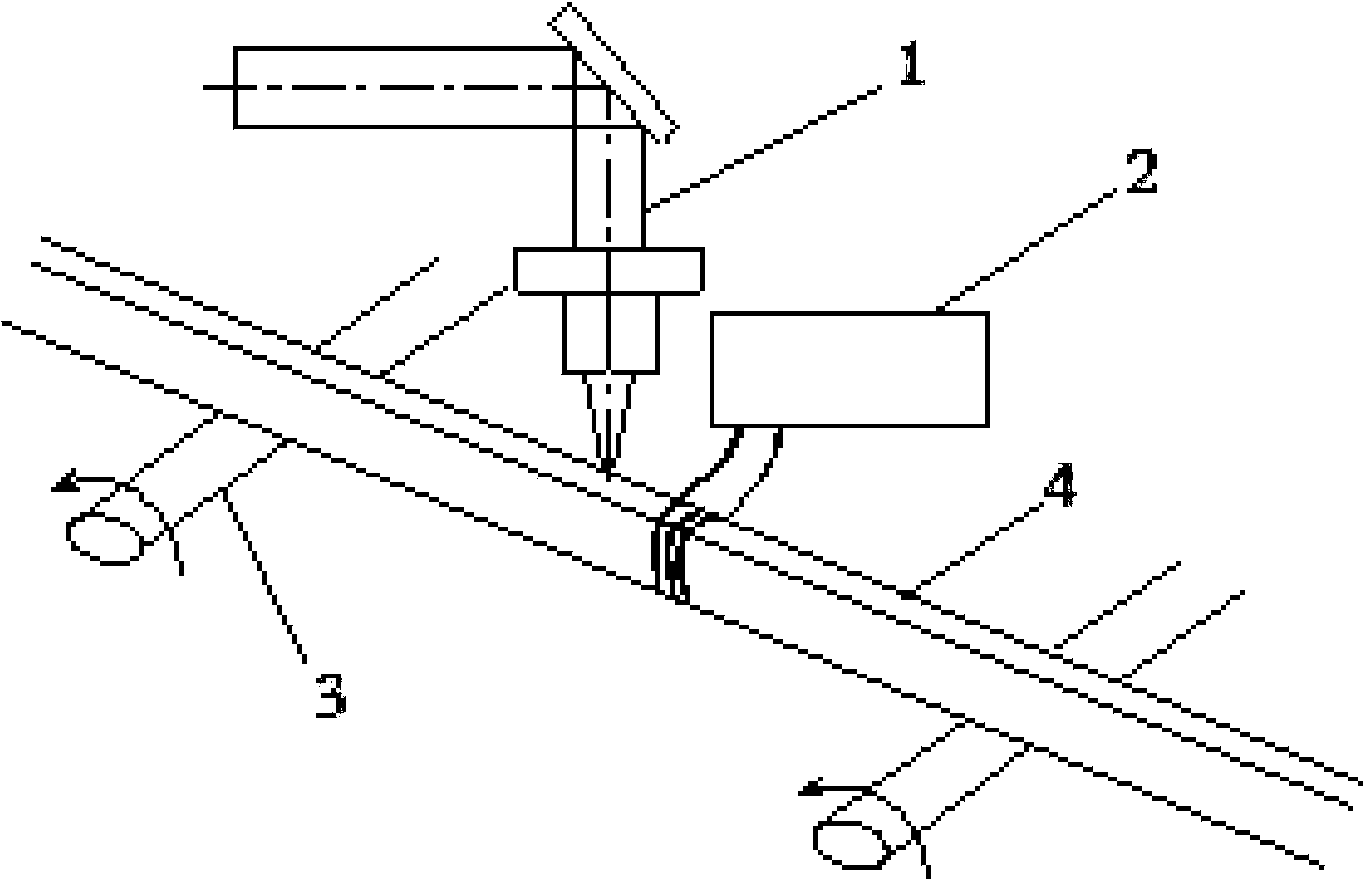

Laser high-frequency composite welding device and welding method of laser high-frequency composite welding device

InactiveCN103447701ALittle impact on performanceHeating fastWelding apparatusInduction heaterEngineering

The invention discloses a laser composite welding device, which comprises a conveying device, a control device, a clamping device, a high-frequency induction heater and a laser, wherein the conveying device carries workpieces and drives the workpieces to move, the control device is connected with the conveying device and controls the speed of the conveying device, the clamping device fixes the workpieces, the high-frequency induction heater heats the workpieces, the laser provides laser beams required by the laser welding, and the positions of the workpieces heated by the high-frequency induction heater are subjected to laser welding. The invention also discloses a welding method. The laser composite welding device solves the problem that in the prior art, the simple laser welding cannot reach the welding temperature, meanwhile, through the addition of a transmission device, the welding effect can be artificially controlled and regulated, the intelligent manufacturing is realized, and the work intensity of workers is reduced.

Owner:ZHANGJIAGANG HENGYUN NEW MATERIAL SCI & TECH

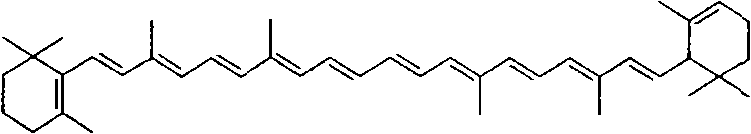

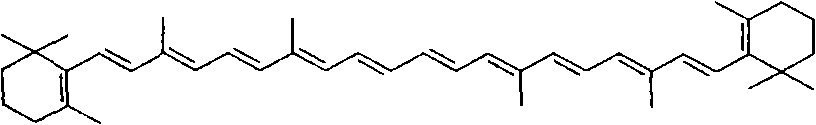

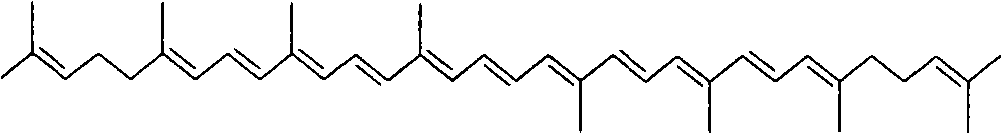

Method for synthesizing crocin glucoside

InactiveCN101514216AHigh yieldHigh purityEsterified saccharide compoundsSugar derivativesCrocinHydrolysis

The invention provides a method for synthesizing crocin glucoside, which comprises the following steps: a, synthesizing a C10 compound, namely 2,7-dimethyl-2,4,6-octatriene-1,8-dial (compound II); b, synthesizing a C5 compound, namely E-2-methyl-4-bromo-2- methyl crotonate; c, synthesizing crocetin dimethyl ester by taking the two compounds as raw materials; d, performing hydrolysis reaction on the crocetin dimethyl ester to obtain crocetin; and e, reacting the crocetin and 1,1'-carbonylbis-1h-imidazo to synthesize crocetin imidazole and further synthesize the crocin glucoside. The synthesizing process has the advantages in aspects of operation simplification and yield, and has high synthetic impurity, high yield, cost saving and strong industrial applicability.

Owner:SICHUAN UNIV

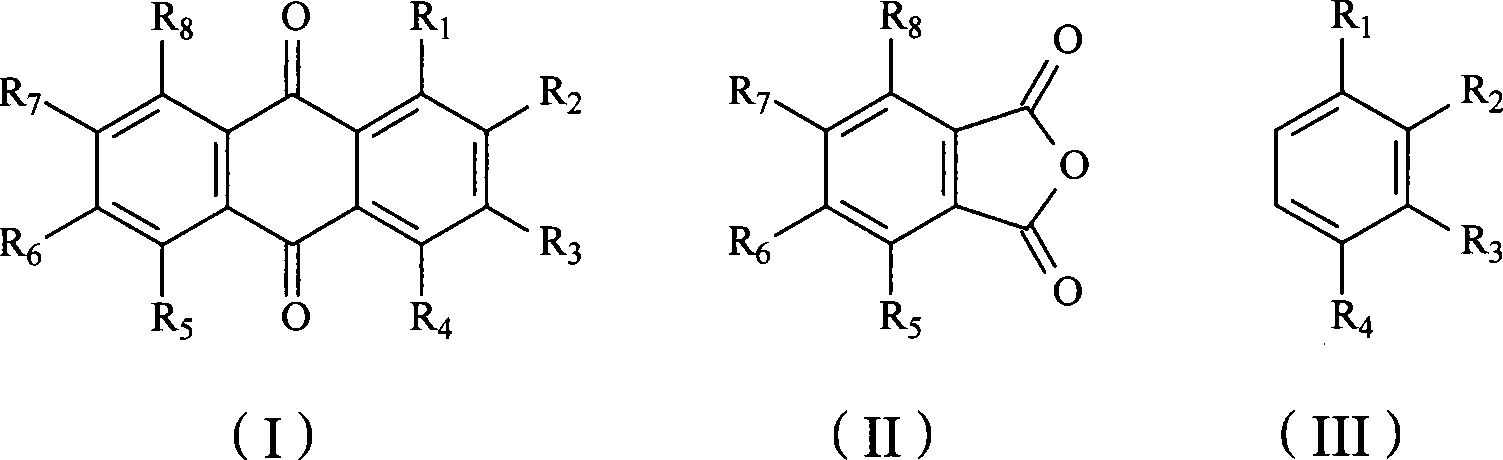

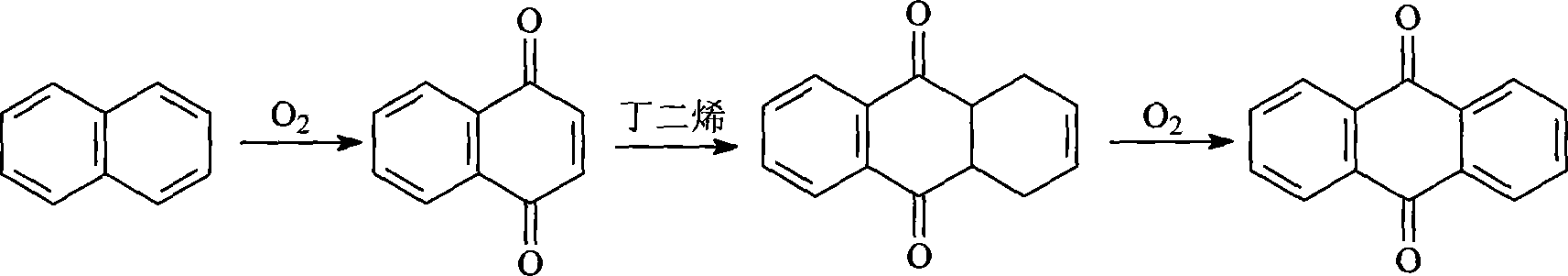

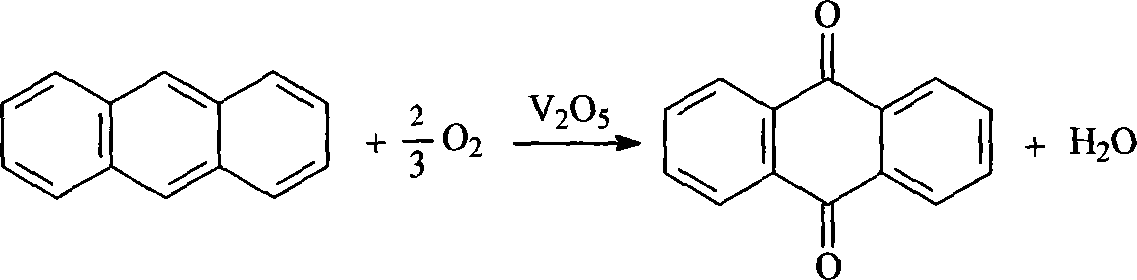

Anthraquinone and preparation method for derivative thereof

InactiveCN101125808AEasy to operatePromote safe productionOrganic compound preparationQuinone preparationBenzeneChemical synthesis

The invention relates to a synthetic method of anthraquinone and ramification thereof, in particular to a chemosynthesis method of the preparation of anthraquinone and ramification thereof in microwave irradiation and the presence of catalyst by only one step. Phthalic anhydride or substituted phthalic anhydride in formula (II) and benzene or substituted benzene in formula (III) are rubbed and mixed in the presence of catalyst under the condition of organic solvent or solvent free condition. Furthermore, the mixture is put in microwave irradiation with power of 50-1000W and reacts for 1 to 120 minutes at the temperature of 130 to 450 DEG C, and finally anthraquinone and the ramification thereof are produced after being separated. The invention has the advantages of simple operation, less reacting steps, being environment-friendly, low production cost, high reacting yield and excellent industrial applicability.

Owner:ZHEJIANG UNIV OF TECH

Intelligent tracer agent, preparation method and application thereof and oil field tracing analysis method

The invention provides an intelligent tracer agent, a preparation method and application thereof and an oil field tracing analysis method and belongs to the technical field of oil reservoir inter-welltracing. The tracer agent comprises a thermo-sensitive polymer and salt. The salt comprises metallic compounds of bivalency and above, third, fourth and fifth main group elements, salt of a lanthanide series metal element, vitamin B2, sodium benzoate or halogenation sodium benzoate. The tracer agent can be applied to oil well tracing measuring analysis to obtain a fluid and reservoir stratum information between a water injection well and an oil producing well (inter-well) and all parameters of crude oil. The preparation method of the intelligent tracer agent is simple. By utilizing the intelligent tracer agent to conduct tracing analysis on the oil well, all parameters of the underground oil well can be conveniently and accurately known, and accurate information is provided for oil well mining.

Owner:盘锦鸿鼎油气技术服务有限公司

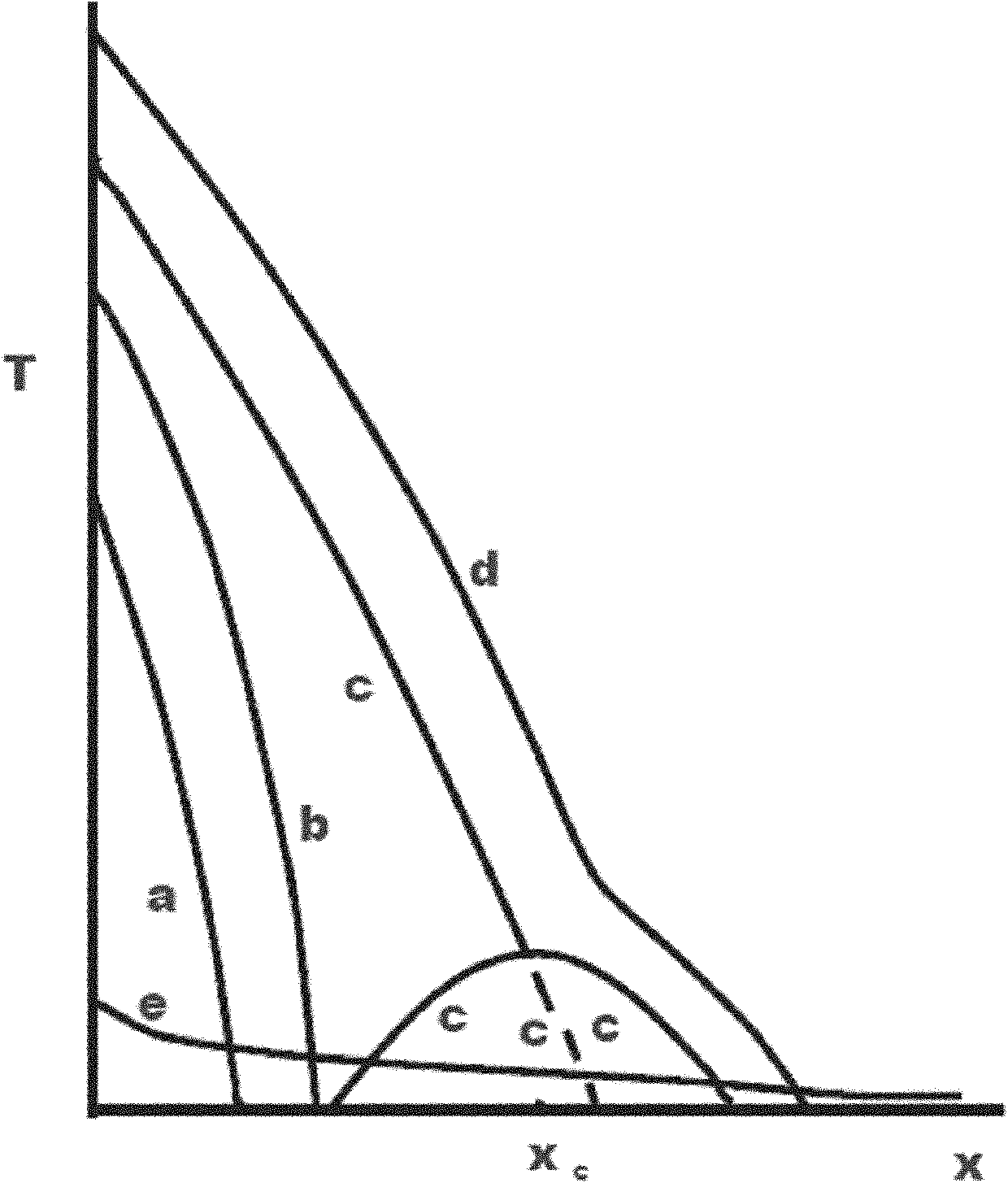

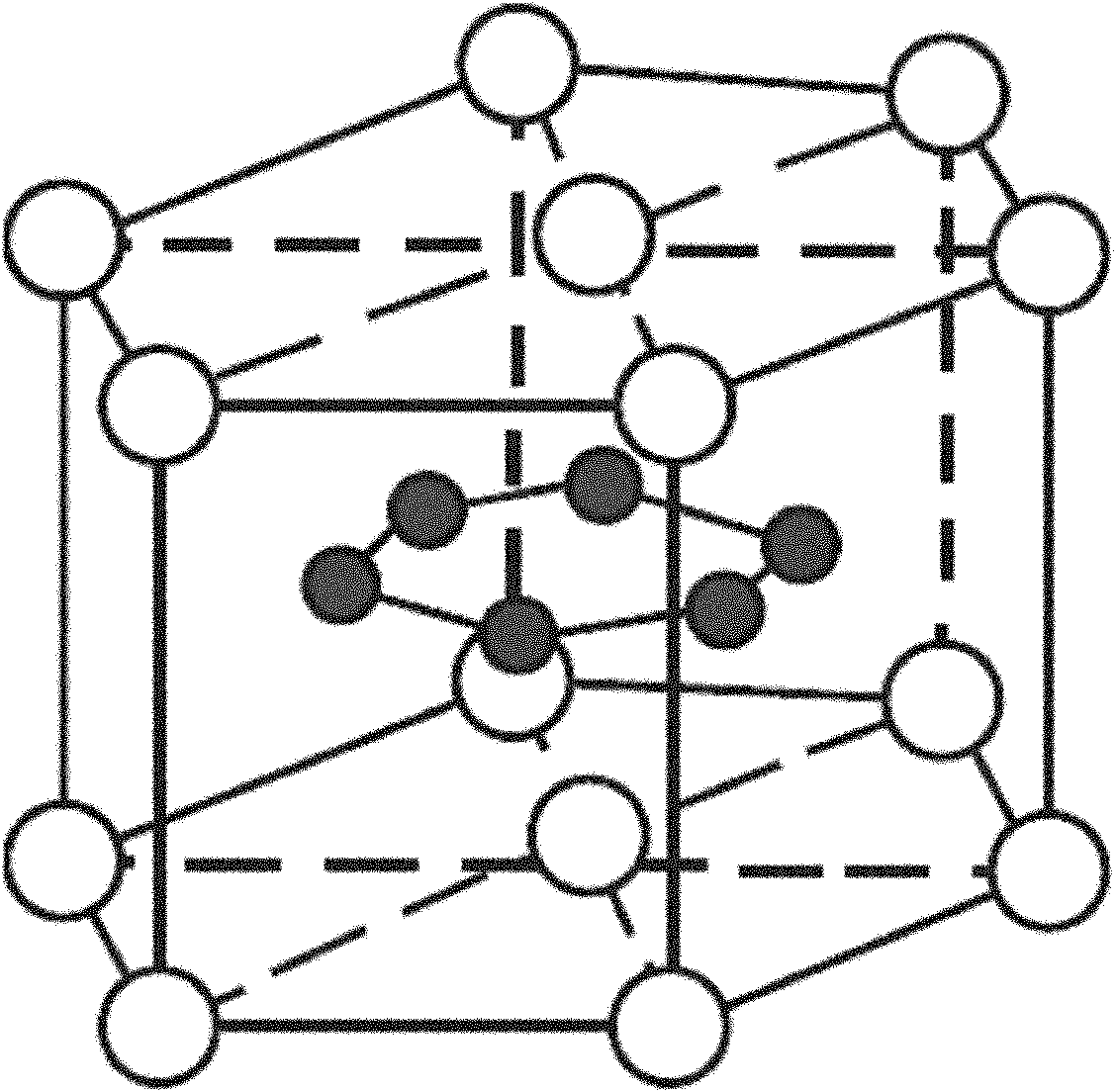

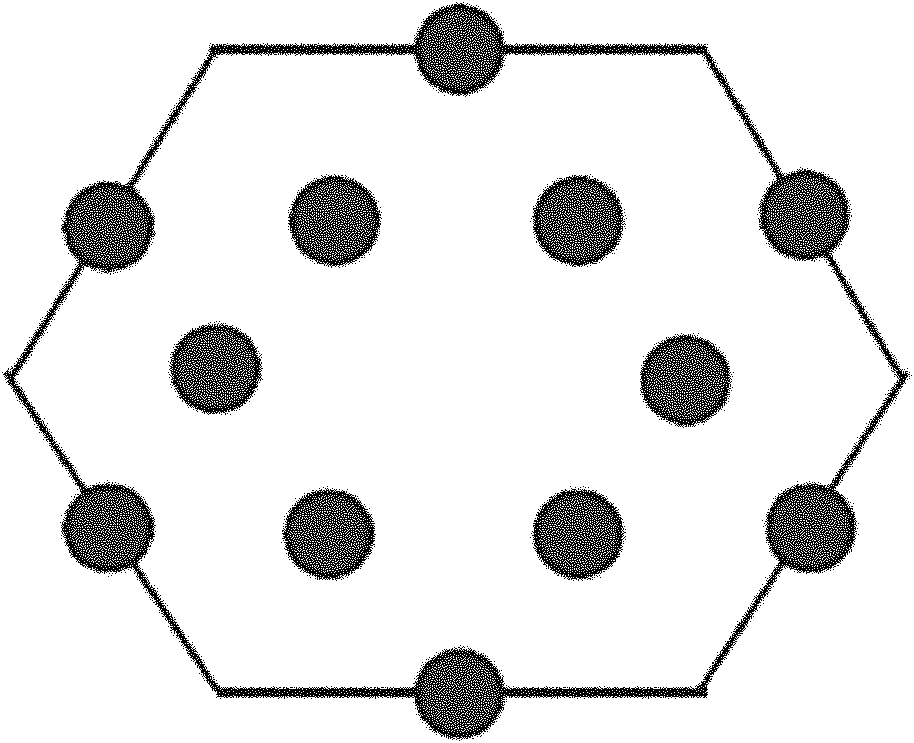

High-temperature superconductor and production method thereof

InactiveCN102568694AStrong industrial applicabilityHas high temperature superconducting propertiesSuperconductors/hyperconductorsAlleged superconductivity devicesHigh-temperature superconductivityElectrical conductor

The invention relates to a high-temperature superconductor. The high-temperature superconductor is an intermetallic compound with the general formula: R1-x'E(1-x'')x'Ax''x'[(Dm(1-x' '')Gmx' '')1-yMy]1+z, wherein m equals to 2 or 5, x' is not smaller than 0 and not greater than 1, x'' is not smaller than 0.01 and not greater than 0.9, x' '' is not smaller than 0 and not greater than 1, y is not smaller than 0 and not greater than 0.02, z is not smaller than 0 and not greater than 0.01, channels of 3d-layer electrons, 3s-layer electrons, 3p-layer electrons, 4s-layer electrons or 4p-layer electrons of the composition D or composition G are in an open state. According to the invention, as the intermetallic compound is of a three-layer hexagonal crystal structure, and the channels of the electrons of the composition D or the composition G are in the open state, the intermetallic compound is the high-temperature superconductor which has a higher critical current density and a critical temperature (Tc) of higher than 300K. The high-temperature superconductor is formed by synthesizing metallics, has a certain flexibility and malleability, and is convenient for production of products of various shapes and structures, thereby greatly increasing industrial application performances.

Owner:吴仕驹

Maleimide copolymer and synthetic method thereof

ActiveCN101538347AImprove production environmentStrong industrial applicabilityMaleopimaric acidAcrylonitrile

The invention provides a maleimide copolymer which comprises the following components: 30% to 55% (w / w) of maleimide, 40% to 69.9% (w / w) of aromatic olefins and 0.1% to 5% (w / w) of maleic acid or maleic anhydride. The maleimide copolymer is prepared by the suspension polymerization method, wherein, the Tg temperature (glass transition temperature) thereof can reach over 200 DEG C; the color thereof can be significantly improved; the residual content of monomers is lower than 3,000ppm; and neither acrylonitrile nor acrylate is involved in the synthesis process as monomers, thereby effectively improving the production environment and improving the industrial applicability.

Owner:SHANGHAI HUAYI GRP CO

Multiple frequency one-way overlapped output standard continuous green light laser inside full solid T double-cavity combination cavity

InactiveCN101267084AReduce the risk of injuryIncrease output powerOptical resonator shape and constructionActive medium materialFundamental frequencyAcousto-optics

The present invention provides a laser, especially a frequency doubling single direction overlapping output quasi-cw green laser in a full-solid T type double-cavity combined cavity, composed of two F-P, each F-P adopts flat-concave cavity structure, F-P adopts side pumped Nd:YAG crystal of the semiconductor laser pumped component having same model, each F-P is optimized design by computer simulation, a stably rotatable 1064nm fundamental frequency laser is formed in the F-P, each F-P obtains 532nm quasi-cw green laser by the audio-optical Q switching and frequency doubling technology, overlapping in the several frequency doubling crystals, reflecting by the harmonic reflector, obtaining secondary frequency doubling and output together. The whole system finally obtains 532nm green laser which power achieves 202W. The laser does not need any thermal len and thermal double refraction compensation element, having high output power, better beam quality, high doubling efficiency, better stability, widely applied in medical, industry.

Owner:NORTHWEST UNIV(CN)

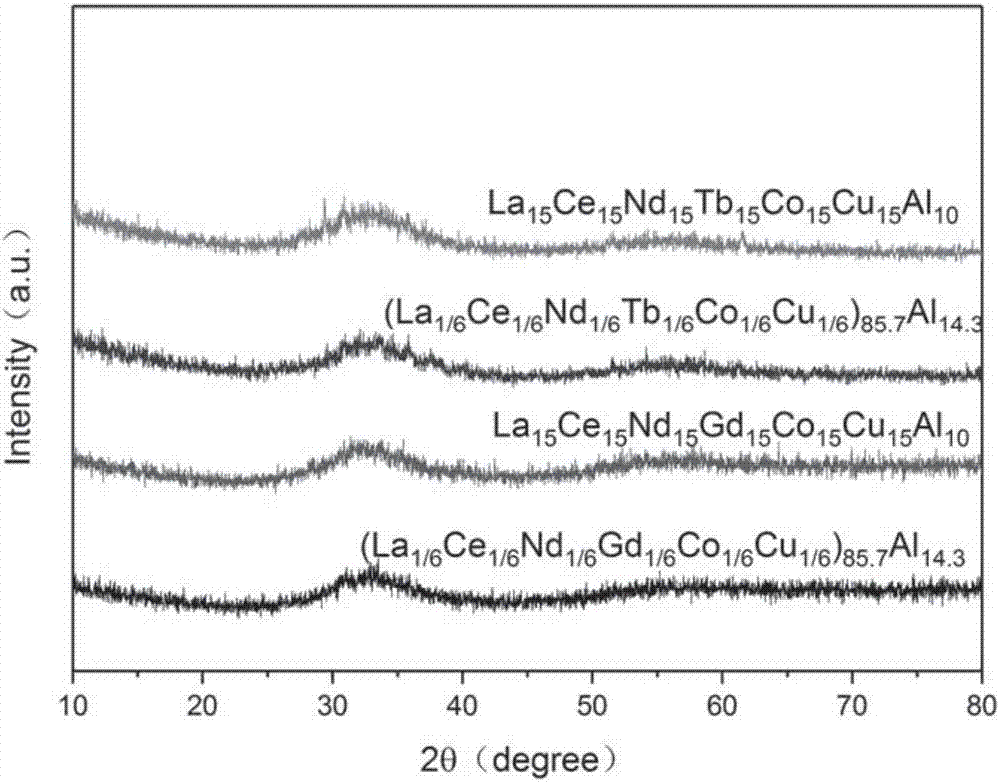

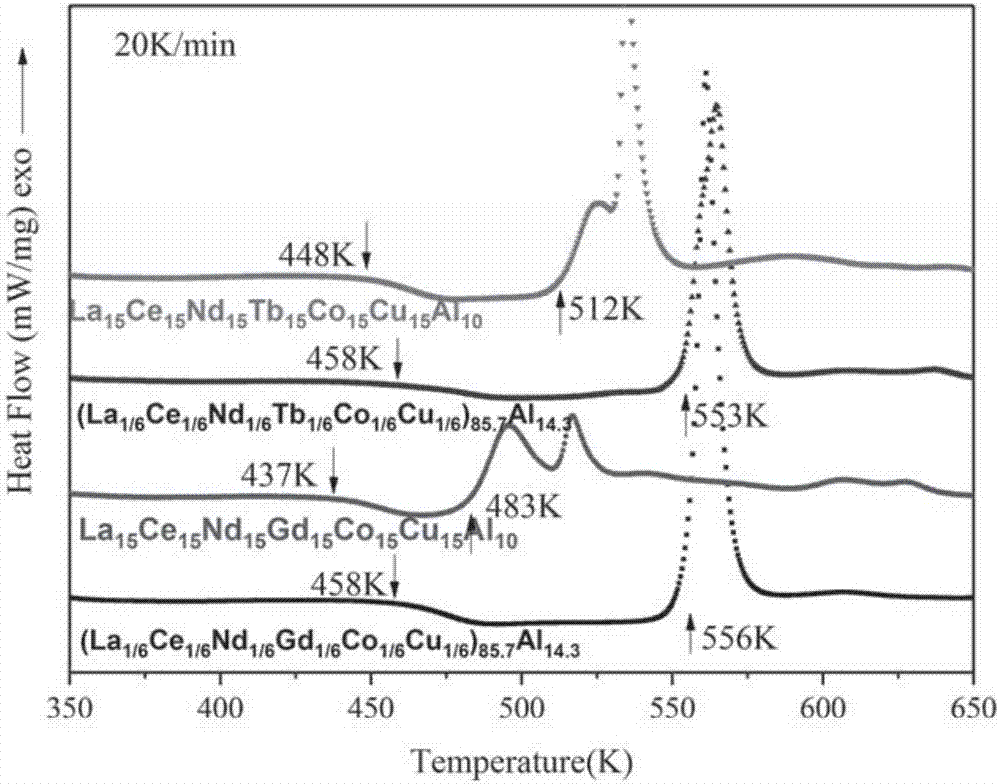

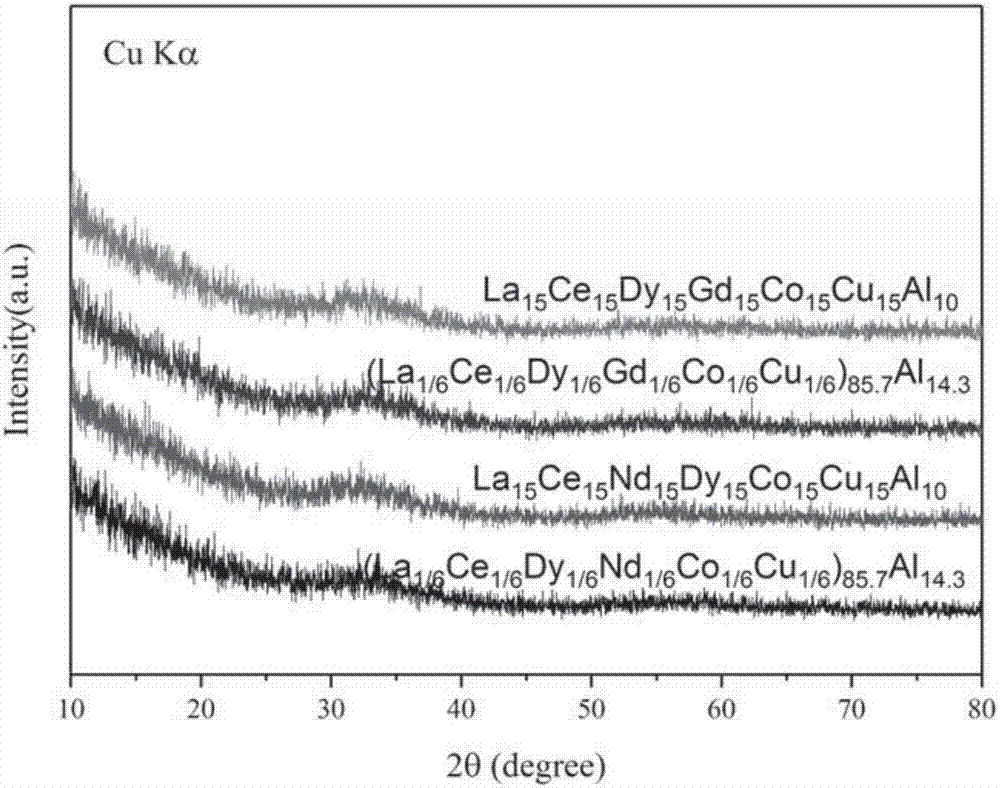

Rare earth high-entropy bulk amorphous alloy with magnetothermal effect and preparation process thereof

ActiveCN107058911AGood Amorphous Formation AbilityMeet size requirementsMagnetic materialsHeat-exchange elementsMain group elementAmorphous phase

The invention relates to a rare earth high-entropy bulk amorphous alloy with a magnetothermal effect and a preparation process thereof. The rare earth high-entropy bulk amorphous alloy comprises an amorphous phase with the volume fraction not lower than 95%. The ratio of various elements is an equal atomic ratio or a near equal atomic ratio. The components of the alloy mainly comprise La, Ce, Nd, Tb, Gd and Dy, transitional elements of Cu and Co, and the III main group element Al. The components of the alloy can be illustrated in formulas as shown in the specification. By adoption of the technical scheme, the rare earth bulk high-entropy amorphous alloy has good heat stability, excellent magnetothermal performance and application prospects in the field of magnetic refrigerating functional materials and structural materials compared with other component-based high-entropy amorphous alloys.

Owner:UNIV OF SCI & TECH BEIJING

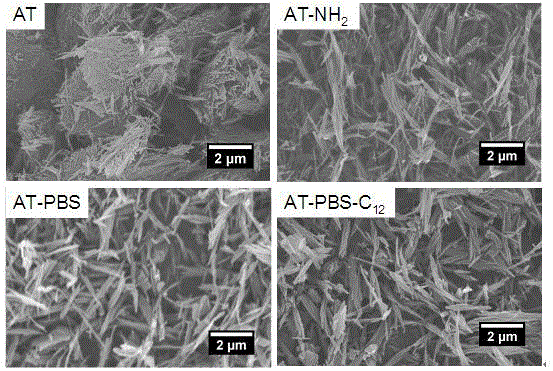

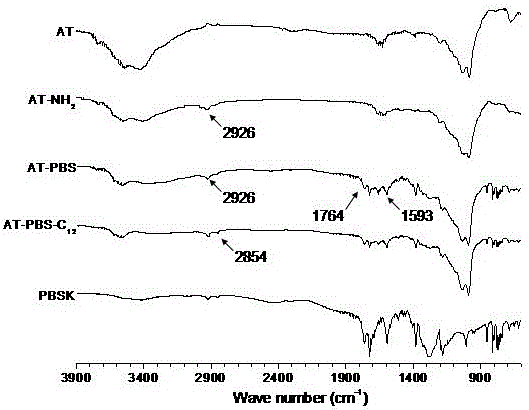

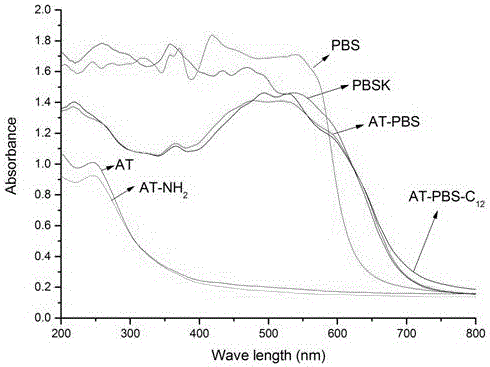

Attapulgite-clay-based composite fluorescent material, and preparation method and application thereof

ActiveCN106244138AExcellent fluorescence propertiesImprove machinabilityFluorescence/phosphorescenceAnthracene dyesPeryleneOrganic group

The invention discloses an attapulgite-clay-based composite fluorescent material, and a preparation method and an application thereof. The attapulgite-clay-based composite fluorescent material is prepared by the following steps: adopting amino-modified attapulgite clay as a substrate material, loading perylene-diimide type organic fluorescent dye on the surface, utilizing large specific surface area, high heat stability and excellent organic-group aging-resistant protective capability of attapulgite clay, adopting the amino-modified attapulgite clay as a substrate, and enabling amino groups to react with perylenetetracarboxydianhydride derivatives. The attapulgite-clay-based composite fluorescent material disclosed by the invention has the advantages that the phenomenon of easy auto-agglutination of perylene-diimide type compounds is improved to a certain extent, the fluorescence intensity is obviously enhanced, multiple organic pollutants can be detected and fast detection of low-concentration organic pollutants is realized.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

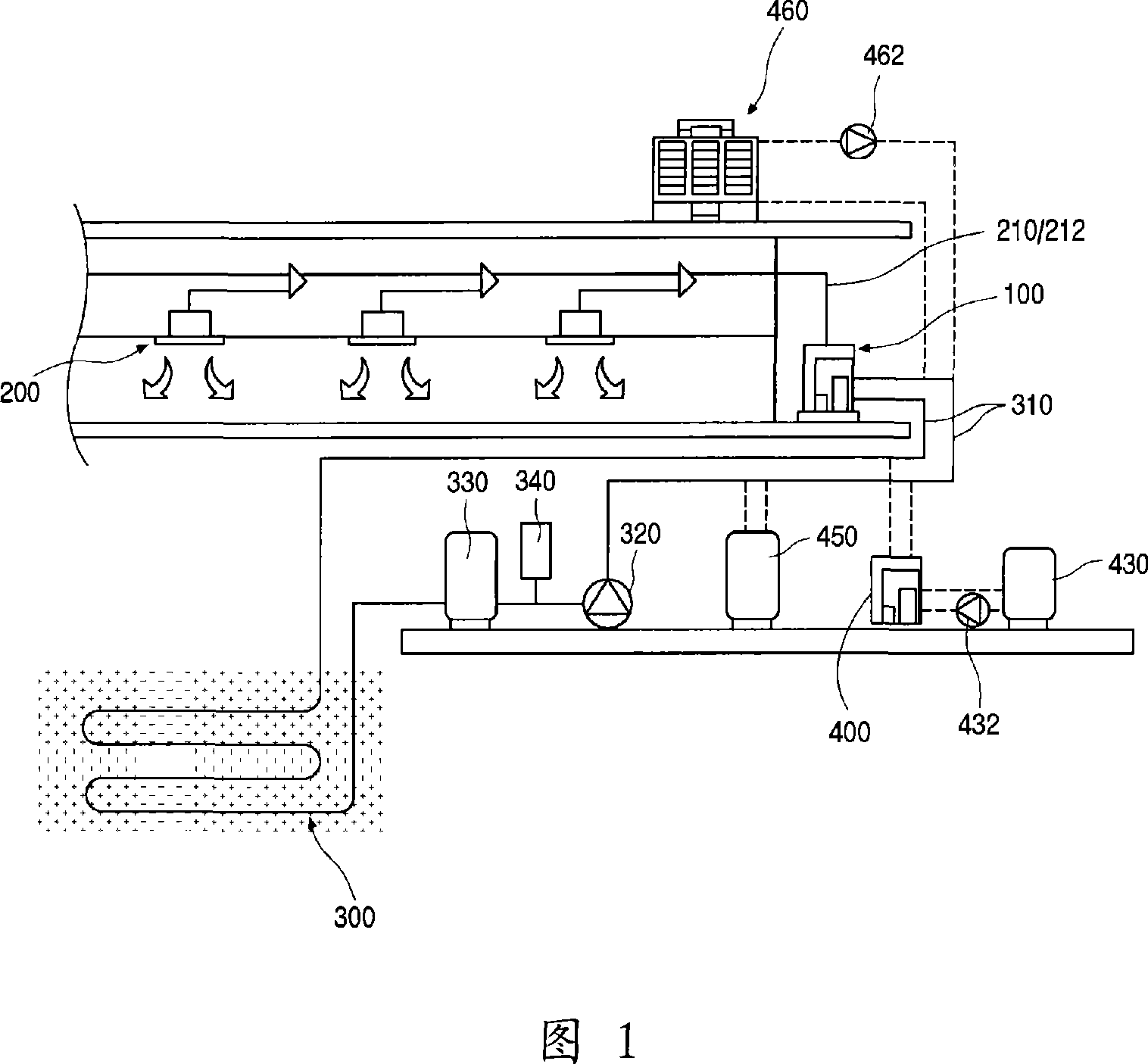

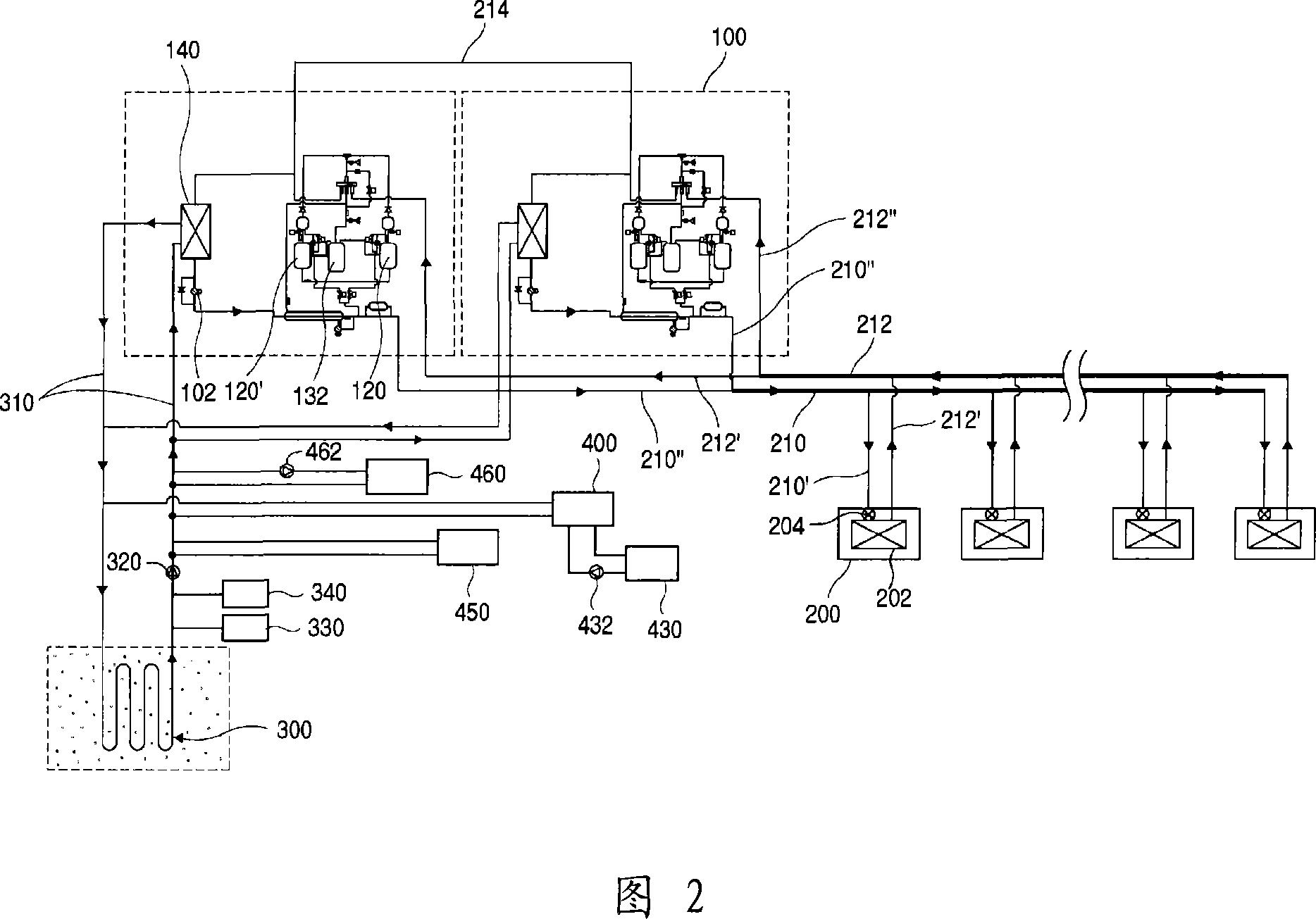

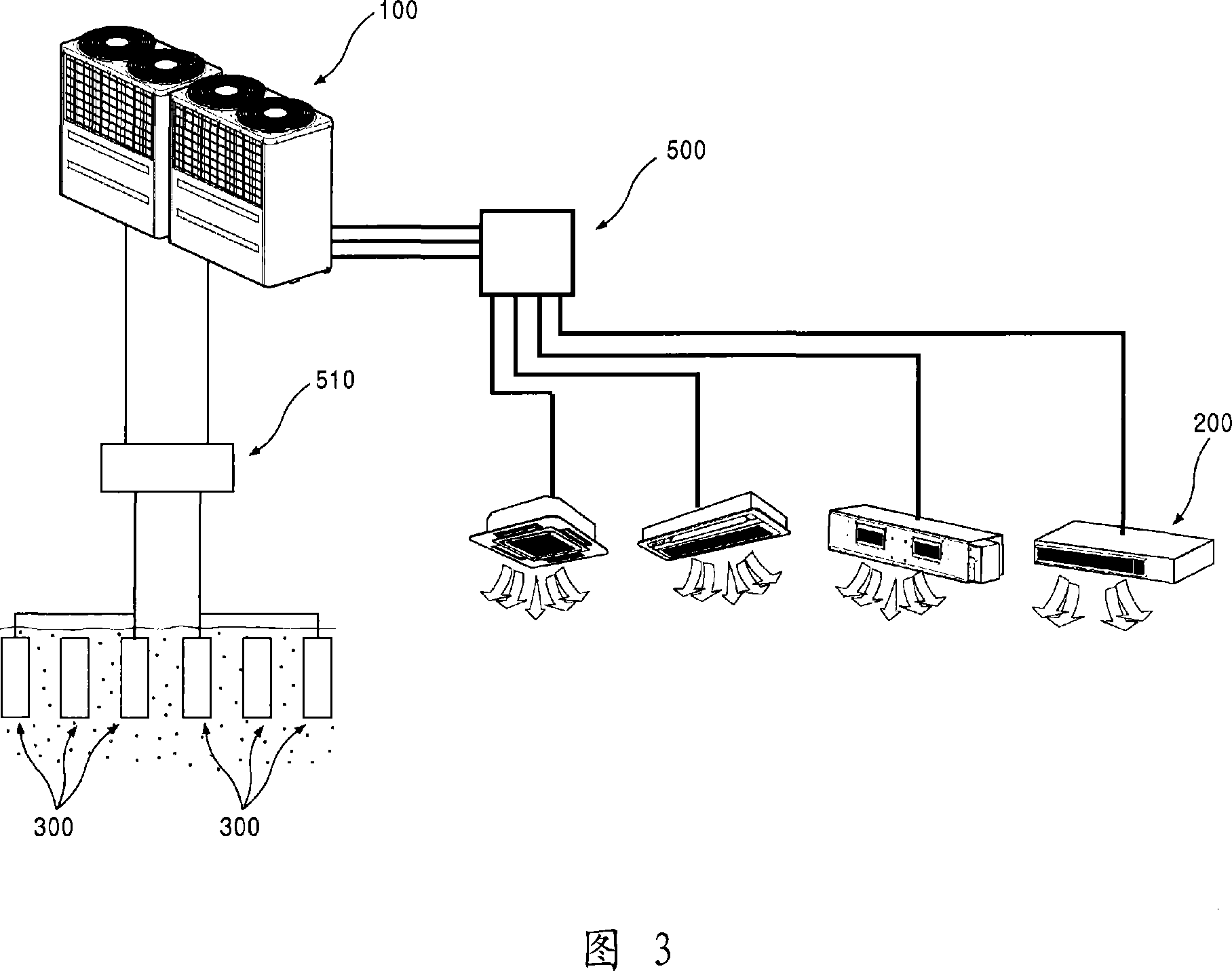

Air conditioning system using ground heat

InactiveCN101074794ASteady cooling/heating cycleImproved cooling/heating efficiencyHeat pumpsCollector components/accessoriesGround-coupled heat exchangerEngineering

Provided is an air conditioning system using ground heat. The system includes one or more indoor units, at least one outdoor unit, a ground heat exchanger, and a plurality of auxiliary heat sources. The one or more indoor units condition indoor air. The at least one outdoor unit communicates with the indoor units via a plurality of pipes, and includes an outdoor heat exchanger where heat exchange occurs. The ground heat exchanger is connected with the outdoor heat exchanger of the outdoor unit, and laid under the ground to allow heat to be exchanged between ground heat and a circulating medium circulating through the ground heat exchanger. The plurality of auxiliary heat sources are installed on one side of the outdoor unit to assist heat exchange of the outdoor heat exchanger. Two or more auxiliary heat sources are simultaneously used, or one of them is selectively used.

Owner:LG ELECTRONICS INC

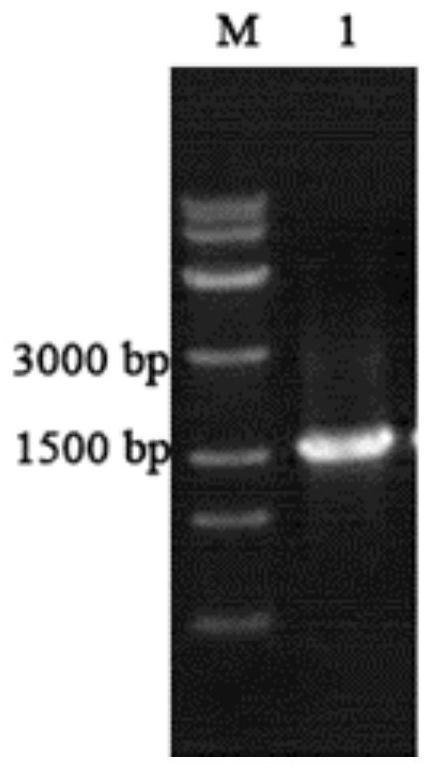

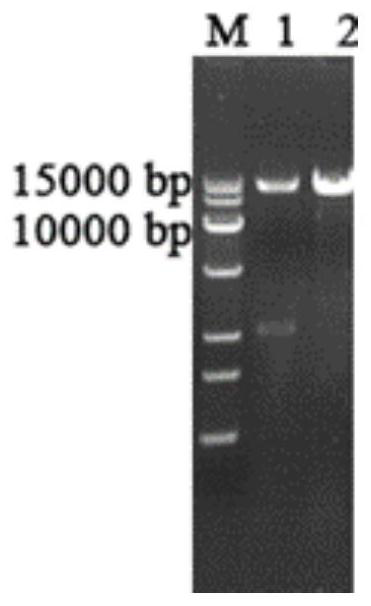

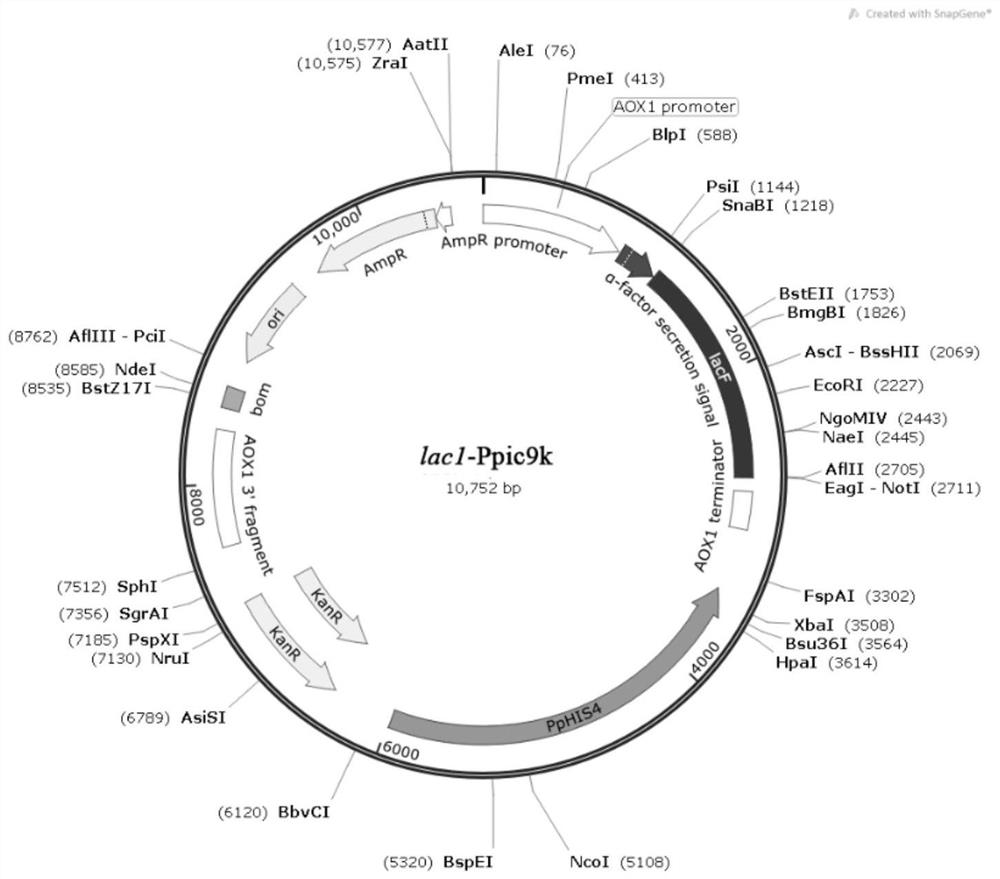

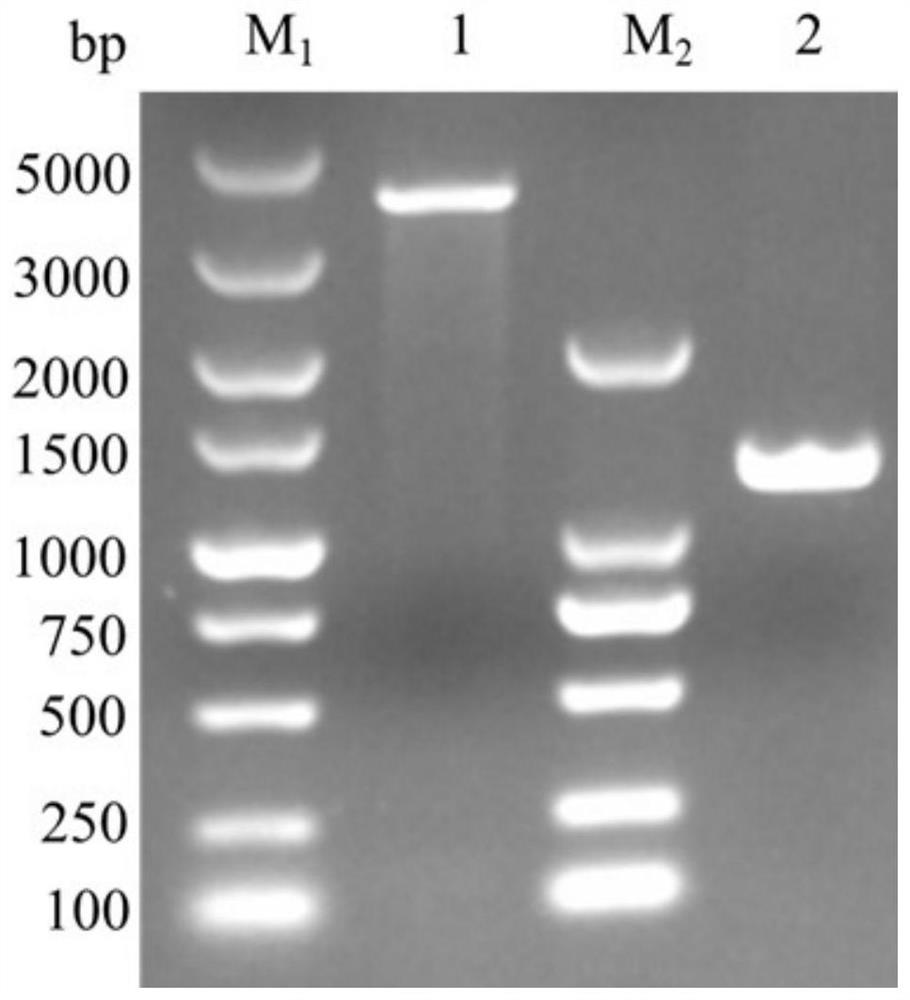

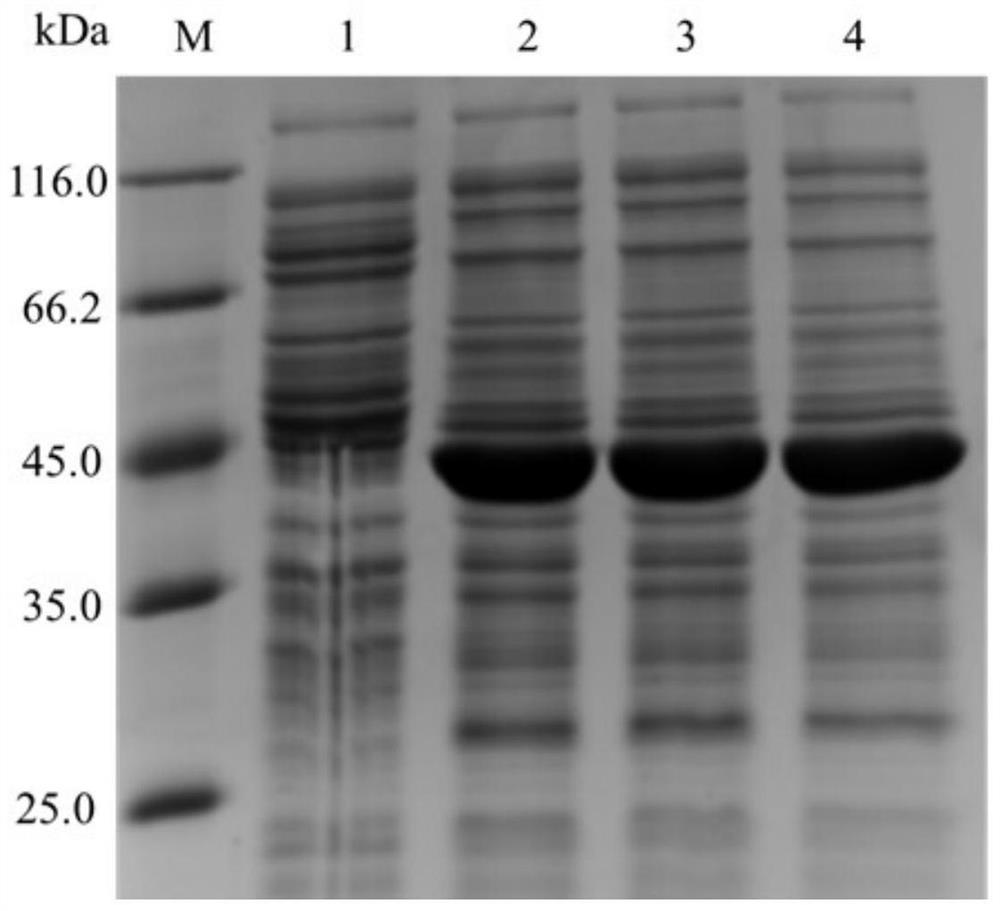

Fungus-derived laccase, recombinant pichia pastoris engineering bacteria thereof and application of fungus-derived laccase

ActiveCN113215179AIncreased specific enzyme activityImprove heat resistanceFungiWater contaminantsPichia pastorisHeterologous

The invention discloses a fungus-derived laccase gene, and relates to the technical field of biology. The laccase gene is lac1, and the cDNA sequence of the lac1 is as shown in SEQ ID NO.2, or the lac1 has a base sequence for encoding an amino acid sequence as shown in SEQ ID NO.3. The invention also provides a recombinant pichia pastoris engineering strain carrying a laccase gene expression vector and an application of the recombinant pichia pastoris engineering strain. The fungus-derived laccase and the recombinant pichia pastoris engineering bacteria thereof have the beneficial effect that the laccase Lac1 newly identified in Trametes sp. Is expressed in a heterologous manner. The obtained recombinant laccase has good thermal stability and good tolerance to metal ions, organic solvents and inhibitors, can catalyze decoloration of indigo blue and other dyes, and has a good application prospect in industry.

Owner:ANHUI UNIVERSITY

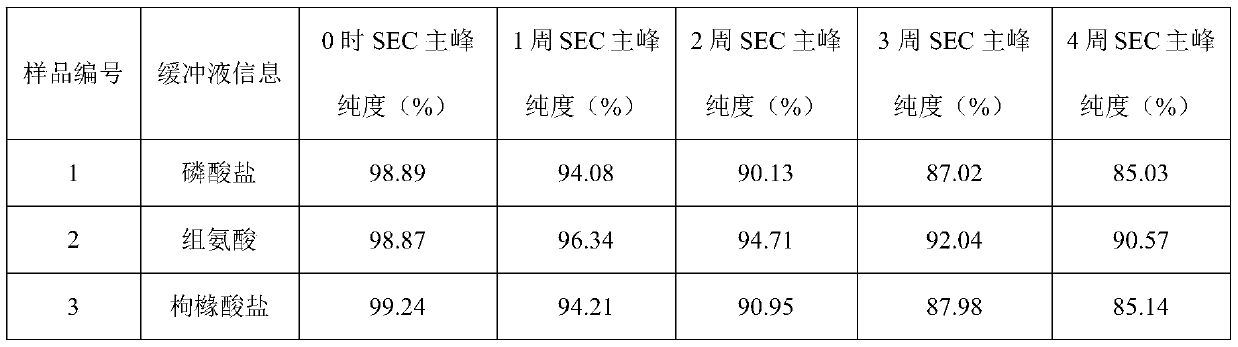

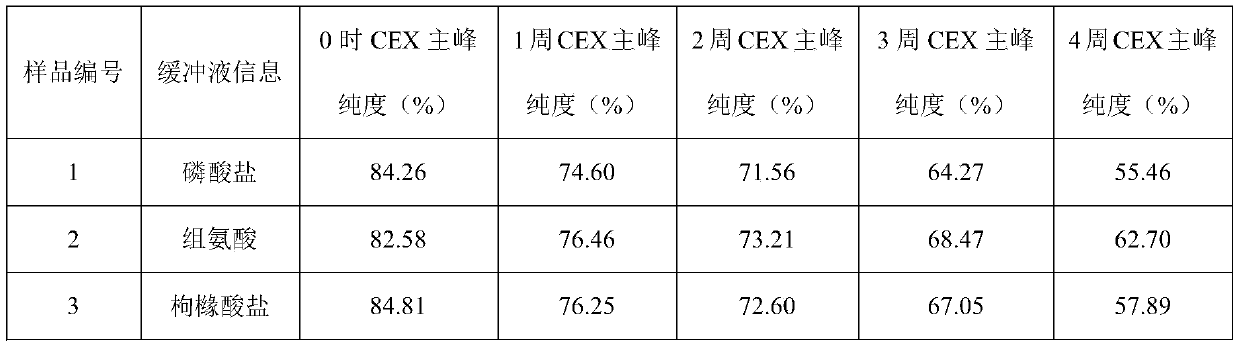

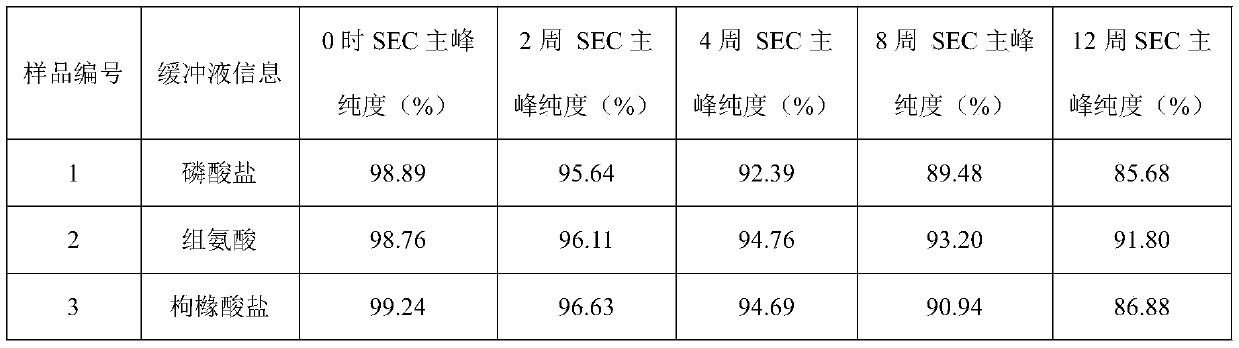

Stable secukinumab injection and preparation method thereof

InactiveCN110179746AImprove stabilityStrong industrial applicabilityPharmaceutical delivery mechanismAntibody ingredientsSugar alcoholAlcohol sugars

The invention provides a stable secukinumab injection. The secukinumab injection comprises the following components: 50 mg / ml-250 mg / ml of secukinumab, 5-50 mmol / L of histidine and histidine hydrochloride, 5-40 mmol / L of methionine, 150 mmol / L-370 mmol / L of lower sugar alcohol, 0.01%-0.02% of polysorbate 80 and the balance of water for injection, wherein the pH of the secukinumab injection rangesfrom 5.0 to 7.0. Stability tests prove that the stable secukinumab injection is stable in quality, the stability is superior to that of commercial varieties on the market, and all indexes conform to relevant regulations of Chinese pharmacopoeia, so that the stable secukinumab injection has good application prospects.

Owner:TONGHUA DONGBAO PHARMA

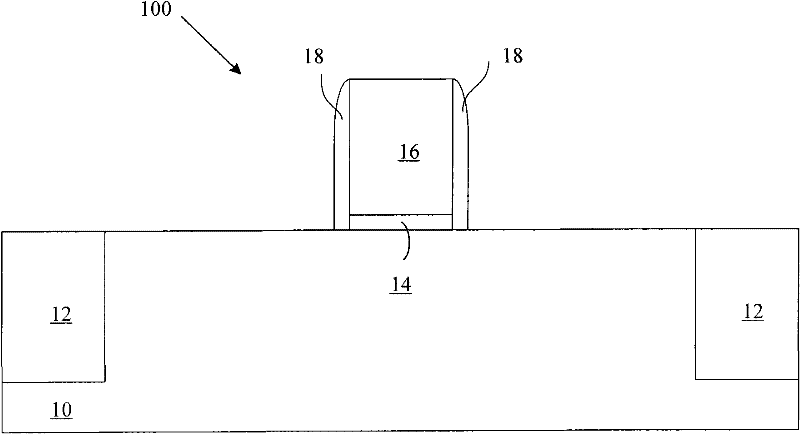

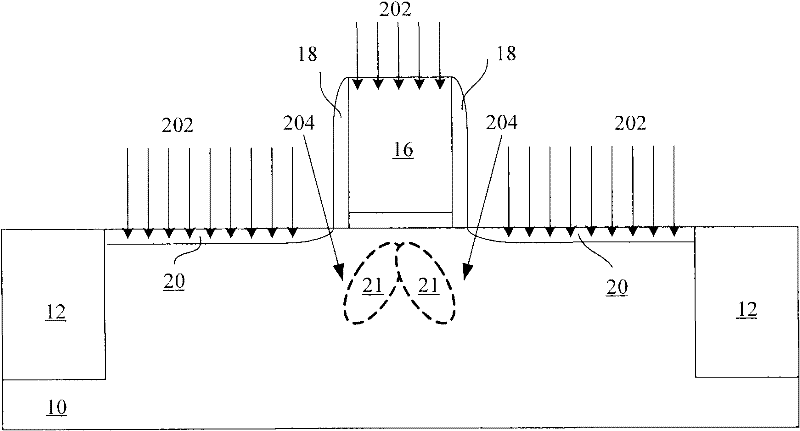

Method for manufacturing semiconductor structure

ActiveCN102446761AEasy to operateStrong industrial applicabilitySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureField-effect transistor

The invention discloses a method for manufacturing a semiconductor structure. The method comprises the following steps of: providing a p-type field effect transistor, wherein the transistor comprises a grid on a substrate; forming a tensile stress layer on the transistor; patterning the tensile stress layer, so that a pressure stress is generated in the channel of the transistor; and annealing to memorize the pressure stress in the channel of the transistor and fulfill the purpose of enhancing the performance of the transistor. According to the method, the pressure stress in the channel of the transistor is memorized by using a stress memory technology, so that the mobility of holes is improved and the integral performance of the semiconductor structure is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

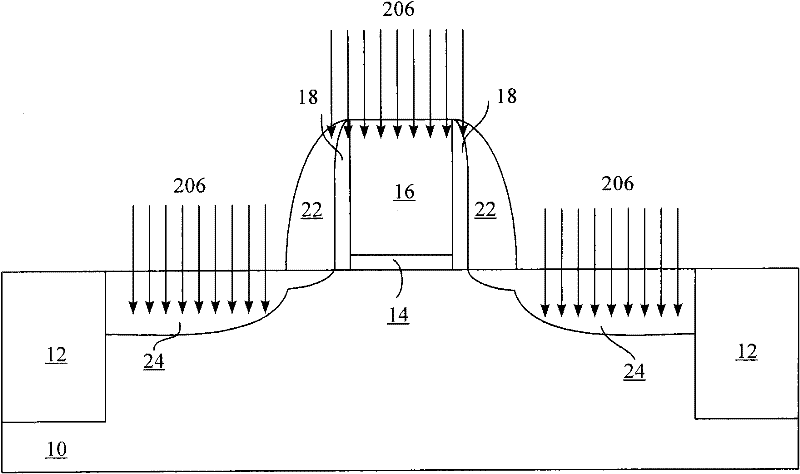

Preparation method of TiAlSi/TiAlSiN multilayer alternating coating with high abrasion resistance

ActiveCN109930106AStrong industrial applicabilityReduce gas contentVacuum evaporation coatingSputtering coatingAlloyHardness

The invention discloses a preparation method of a TiAlSi / TiAlSiN multilayer alternating coating with high abrasion resistance, and relates to a preparation method of a TiAlSiN coating. The technical problem of poor abrasion resistance of existing TiAlSiN coating is solved. The preparation method of the TiAlSi / TiAlSiN multilayer alternating coating adopts a TiAlSi alloy cathode target, coating compositions are changed by changing introduced nitrogen gas, thus, the multilayer alternating coating is prepared, and the coating industry applicability is improved. Due to the low hardness of TiAlSi alloy and the high hardness of a TiAlSiN coating, the soft and hard alternating coating prepared through the method can relieve the coating stress, the plastic toughness of the coating is improved, theabrasion resistance of the coating is improved, and the method has great significance for prolonging the service life of the tool coating.

Owner:HARBIN INST OF TECH

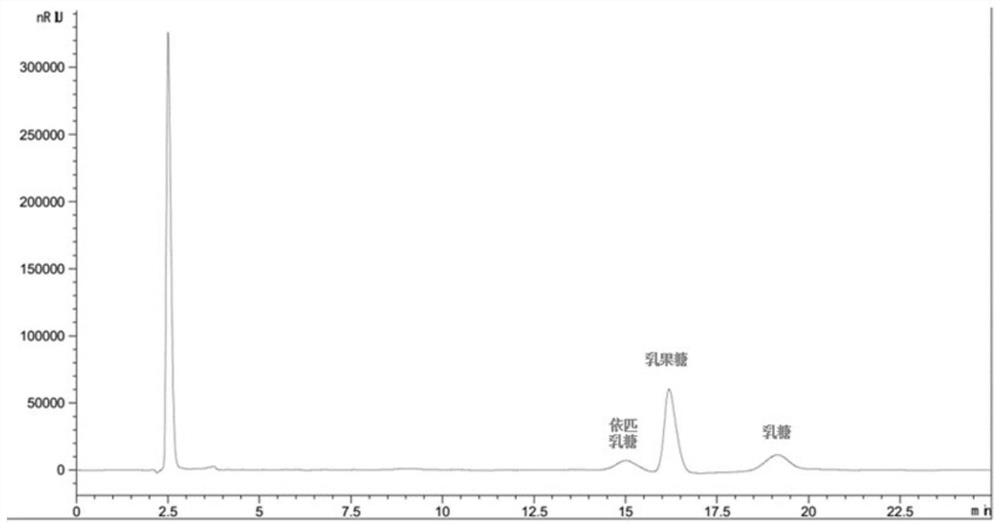

Mutant of CE (cellobiose 2-epimerase) and application of mutant

ActiveCN112695025AImprove conversion rateStrong industrial applicabilityBacteriaMicroorganism based processesIsomeraseMicrobiology

The invention discloses a mutant of CE (cellobiose 2-epimerase) and an application of the mutant, and belongs to the technical field of enzyme engineering. The CE derived from thermophilic anaerobic bacteria Dictyoglomusthermophilum is subjected to directed evolution, the obtained mutant can still have the performance of converting lactose into lactulose, the enzyme activity and the substrate conversion rate are remarkably increased, and under the condition of the same enzyme adding amount, the lactulose conversion rate can reach 58.2% at most and is increased by 35.35% compared with that of a wild type lactulose mutant. Good industrial application performance is realized.

Owner:JIANGNAN UNIV

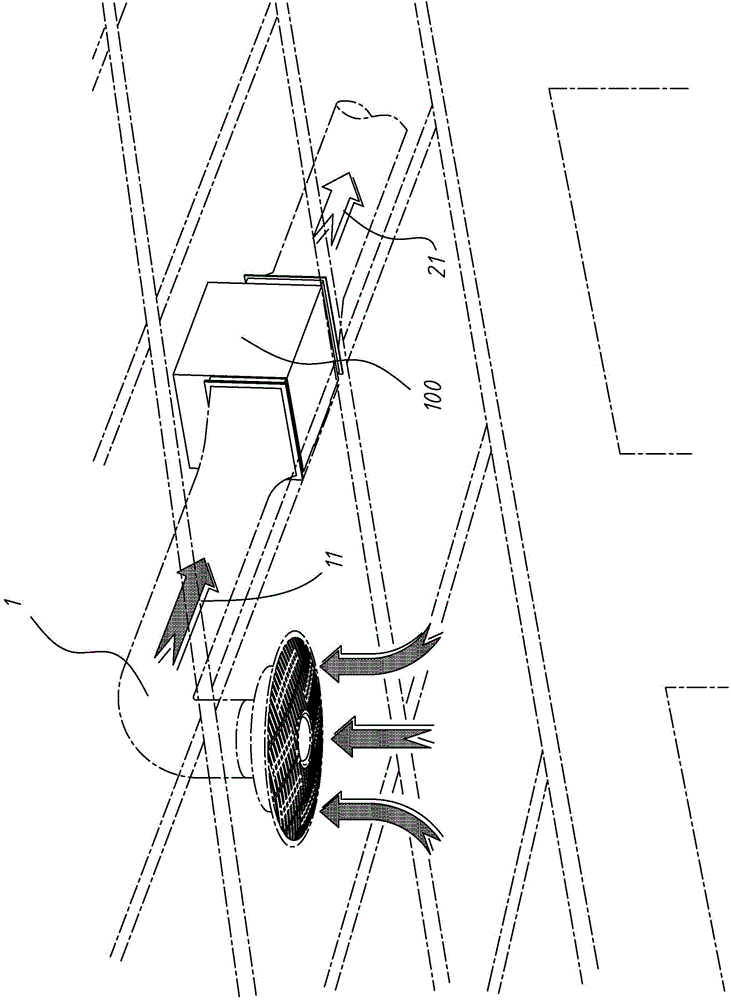

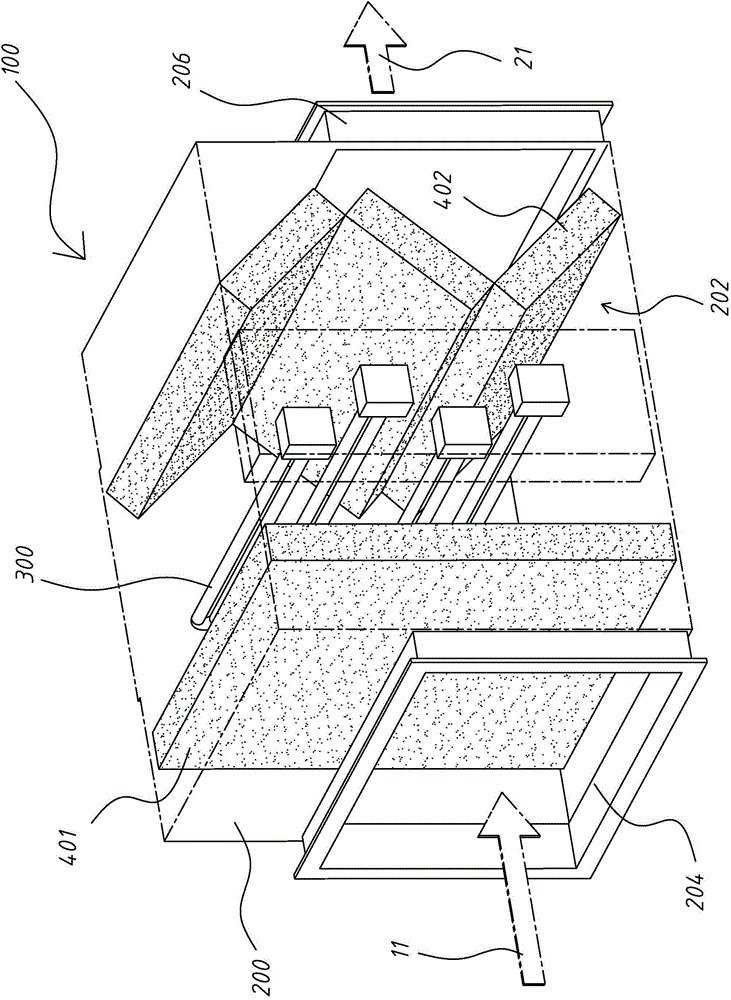

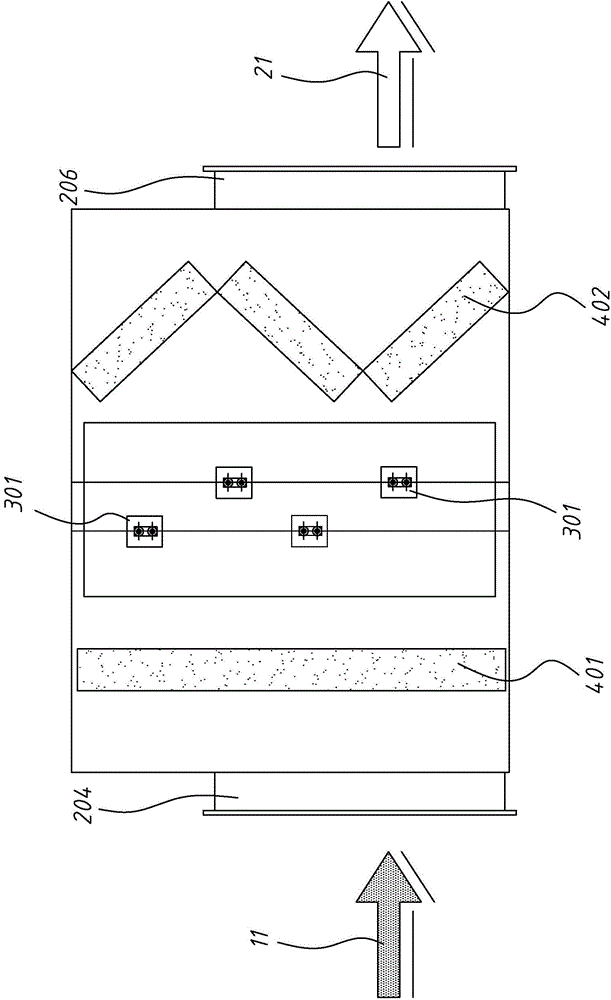

Kitchen fume-cleaning apparatus for degreasing and deodorization

InactiveCN106152209AImprove the removal of oily smoke and odorTo achieve the best effect of oil removalDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

A kitchen fume-cleaning apparatus is provided. The kitchen fume-cleaning apparatus includes a main body having a receiving space therein, in which the main body includes an air inlet mounted on one end thereof and an air outlet mounted on the other end thereof. The air inlet, the receiving space, and the air outlet are configured to communicate with each other. The air inlet is set to allow an exhaust fume to enter the receiving space therethrough. A filter device and a sterilization device are mounted in the receiving space for degreasing, deodorizing, and purifying the fume. Thus, the gas expelled through the air outlet is a clean and non-polluting gas.

Owner:SUNAIR HVAC ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com