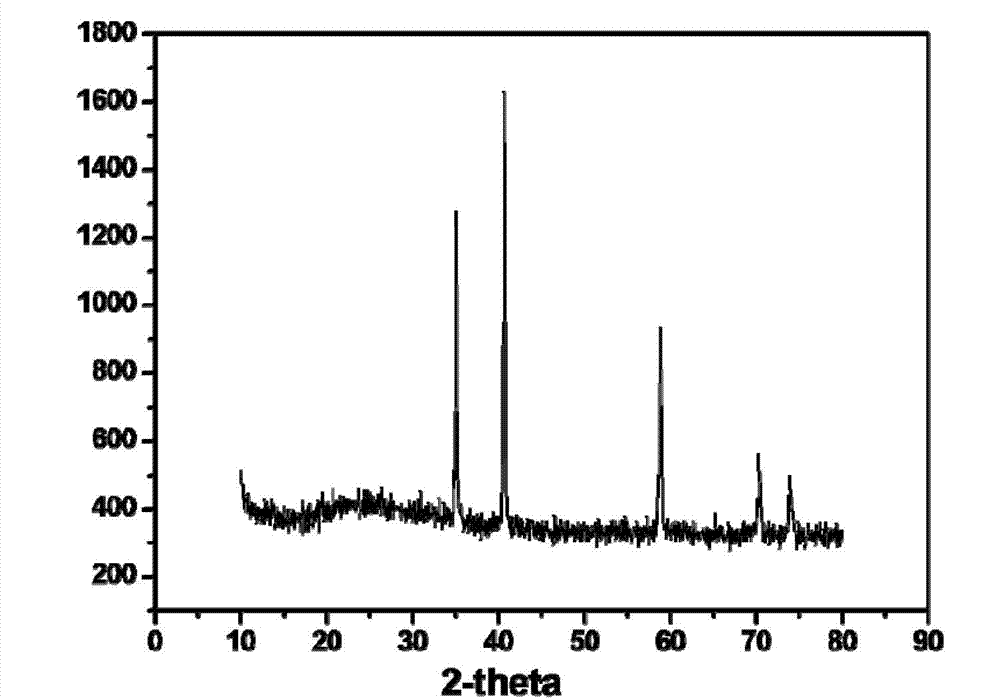

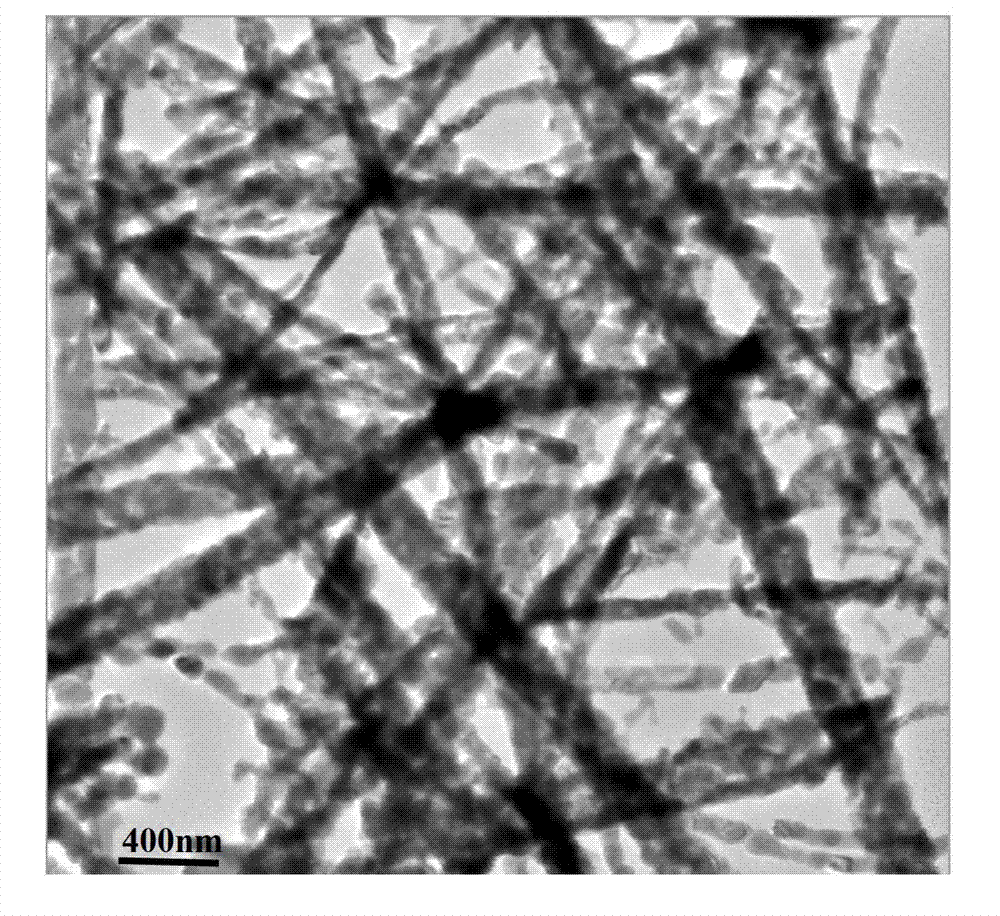

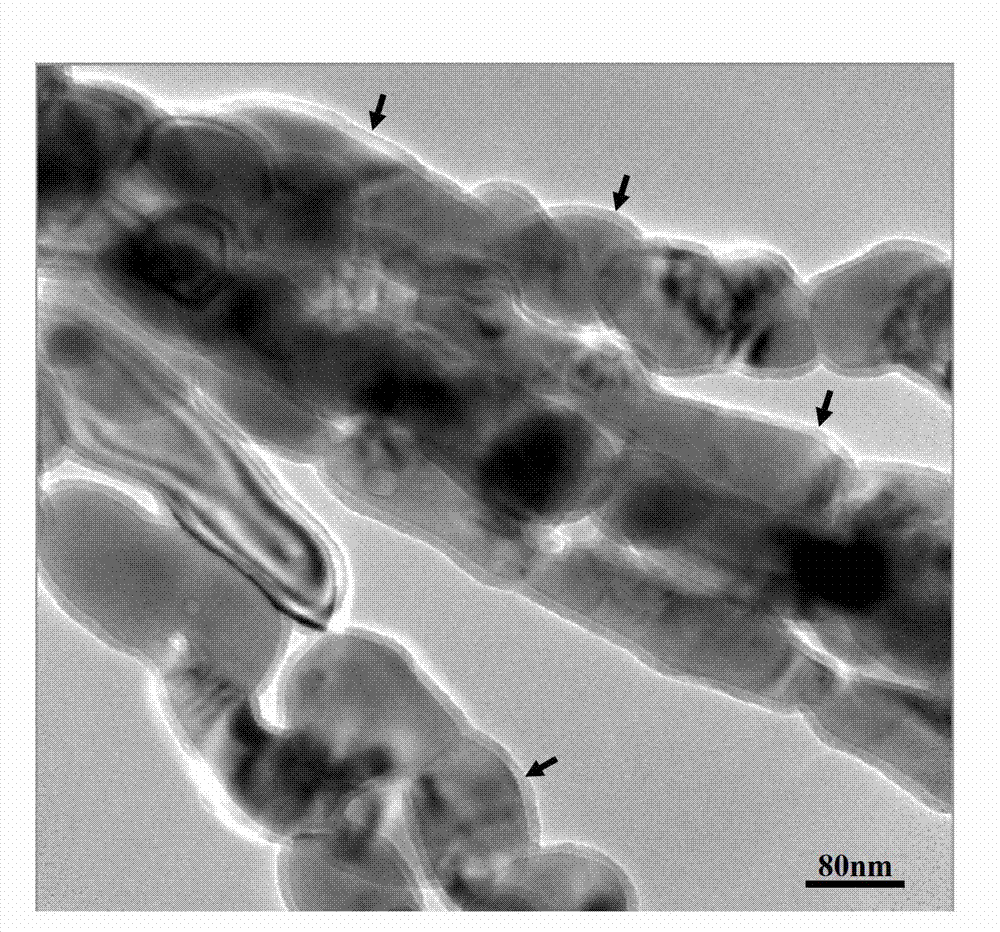

Method for preparing carbon-coated MnO coaxial nanowire cathode material for lithium ion batteries

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problems of unsatisfactory cycle performance and rate performance, difficulty in obtaining carbon coating layer, unsuitable for industrial production, etc., achieve excellent cycle stability and improve cycle performance. The effect of stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of preparation method of carbon coated MnO coaxial nanowire negative electrode material for lithium ion battery, the steps are as follows:

[0034] (1) Preparation of manganese oxyhydroxide nanowires:

[0035] Add 2mL of polyethylene glycol 400 and 0.1g of potassium permanganate to 40mL of purified water, put it into a 60mL reaction kettle, put the reaction kettle into an oven, heat at 170°C for 6 hours, and then naturally cool to room temperature , dried at 80°C after centrifugation to obtain manganese oxyhydroxide nanowires;

[0036] (2) Preparation of porous manganese trioxide nanowires:

[0037] Put the manganese oxyhydroxide nanowires obtained in step (1) into a tube furnace, raise the temperature up to 600°C at a rate of 5°C per minute in an air atmosphere, keep it for 5 hours, and then cool it down to room temperature naturally to obtain porous trioxide Dimanganese nanowires;

[0038] (3) Preparation of carbon-coated MnO coaxial nanowire a...

Embodiment 2

[0042]Example 2: Electrochemical performance test of carbon-coated MnO nanowires

[0043] The carbon-coated MnO nanowire prepared in Example 1 is the negative electrode material, and the electrode is made according to the existing technology, and its electrochemical performance is characterized, and the specific steps are as follows:

[0044] (1) Preparation of electrodes:

[0045] Mix the conductive agent: binder: active material (carbon-coated MnO nanowire material) in a mass ratio of 20:10:70, the conductive agent is acetylene black, and the binder is polyvinylidene fluoride (pvdf) , the binder is dissolved in N-methylpyrrolidone to form a solution with a mass concentration of 10% before mixing; it is evenly coated on the copper foil current collector with a film applicator, and vacuum baked at 80°C for 12 hours, Then cut into electrode sheets with a diameter of 12mm;

[0046] (2) Single electrode test:

[0047] A single-electrode test was formed in the glove box, the li...

Embodiment 3

[0050] Embodiment 3: A kind of preparation method of carbon coated MnO coaxial nanowire negative electrode material for lithium ion battery, the steps are as follows:

[0051] (1) Preparation of manganese oxyhydroxide nanowires:

[0052] Add 1mL of polyethylene glycol 200 and 0.1g of potassium permanganate to 30mL of purified water, put it into a 60mL reaction kettle, put the reaction kettle into an oven, heat at 160°C for 5 hours, and then cool down to room temperature naturally , dried at 60°C after centrifugation to obtain manganese oxyhydroxide nanowires;

[0053] (2) Preparation of porous manganese trioxide nanowires:

[0054] Put the manganese oxyhydroxide nanowires obtained in step (1) into a tube furnace, raise the temperature to 550°C at a rate of 5°C per minute in an air atmosphere, keep it for 3 hours, and then cool it down to room temperature naturally to obtain porous trioxide Dimanganese nanowires;

[0055] (3) Preparation of carbon-coated MnO coaxial nanowire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com