Laser high-frequency composite welding device and welding method of laser high-frequency composite welding device

A laser welding and hybrid welding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as not reaching the welding temperature, reduce performance impact, realize intelligent manufacturing, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

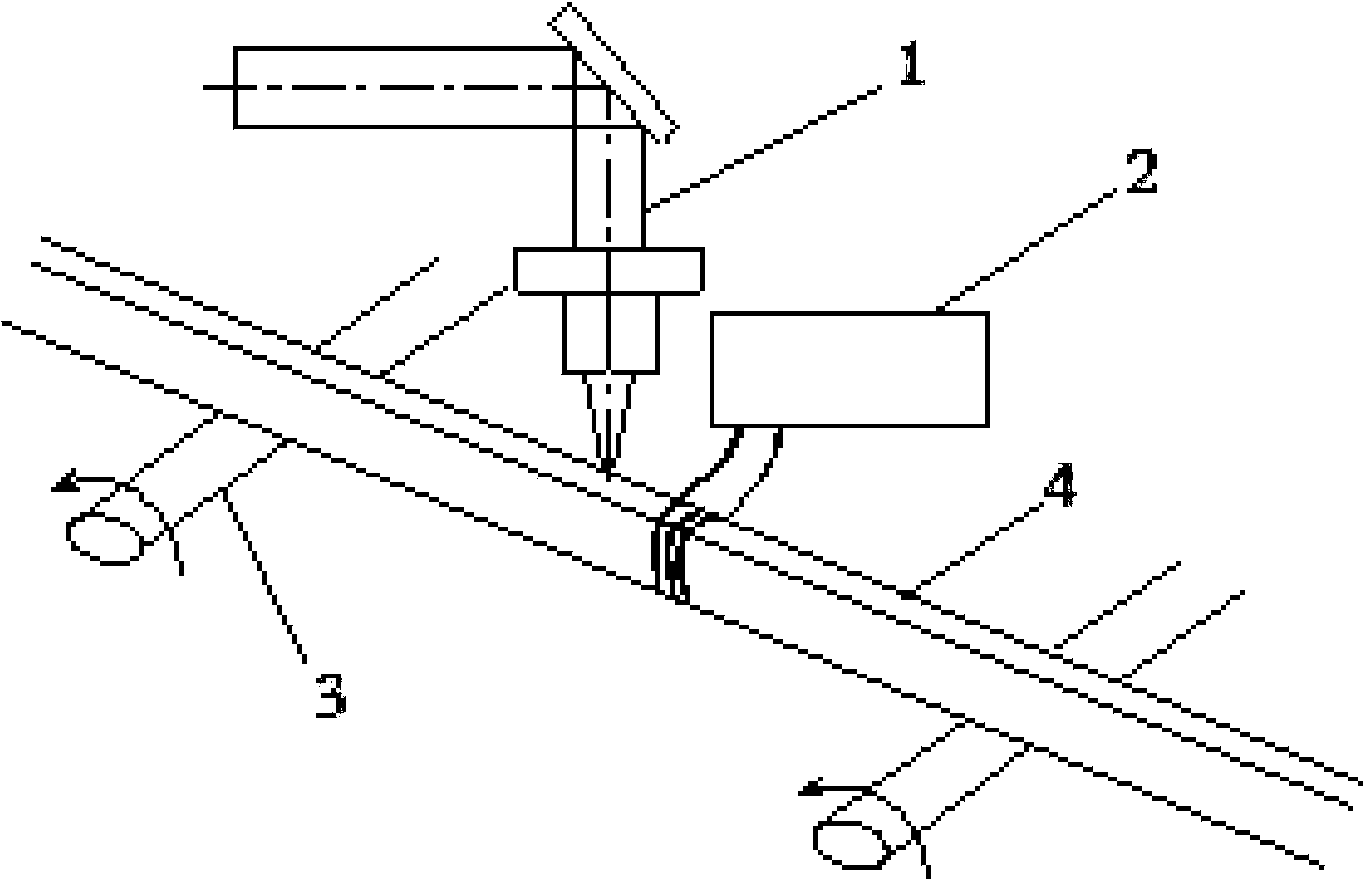

[0033] The power of the existing laser is not large enough to meet the welding temperature requirements, so it is necessary to pre-heat the welding materials. The present invention uses a high-frequency induction heater. Its principle is to use the thermal effect of eddy current, which is non-contact heating. , high heating efficiency, can increase the temperature of the welding material to the required temperature, and the selected high-frequency induction heater has the function of temperature control.

[0034] The workpiece is preheated by high-frequency induction heat source, and the workpiece is welded by laser after the workpiece reaches a certain temperature. Compared with pure laser welding, laser high-frequency hybrid welding can improve the structure and performance of joints, reduce the tendency of cracks and pores, and further improve welding efficiency. In addition, the high-frequency induction heat source and laser have the characteristics of non-contact and envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com