Patents

Literature

101results about How to "Realize intelligent manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual anti-collision control method for industrial robot arm

ActiveCN108247637AImprove the monitoring operating environmentRealize intelligent manufacturingProgramme-controlled manipulatorSupport vector machineObject based

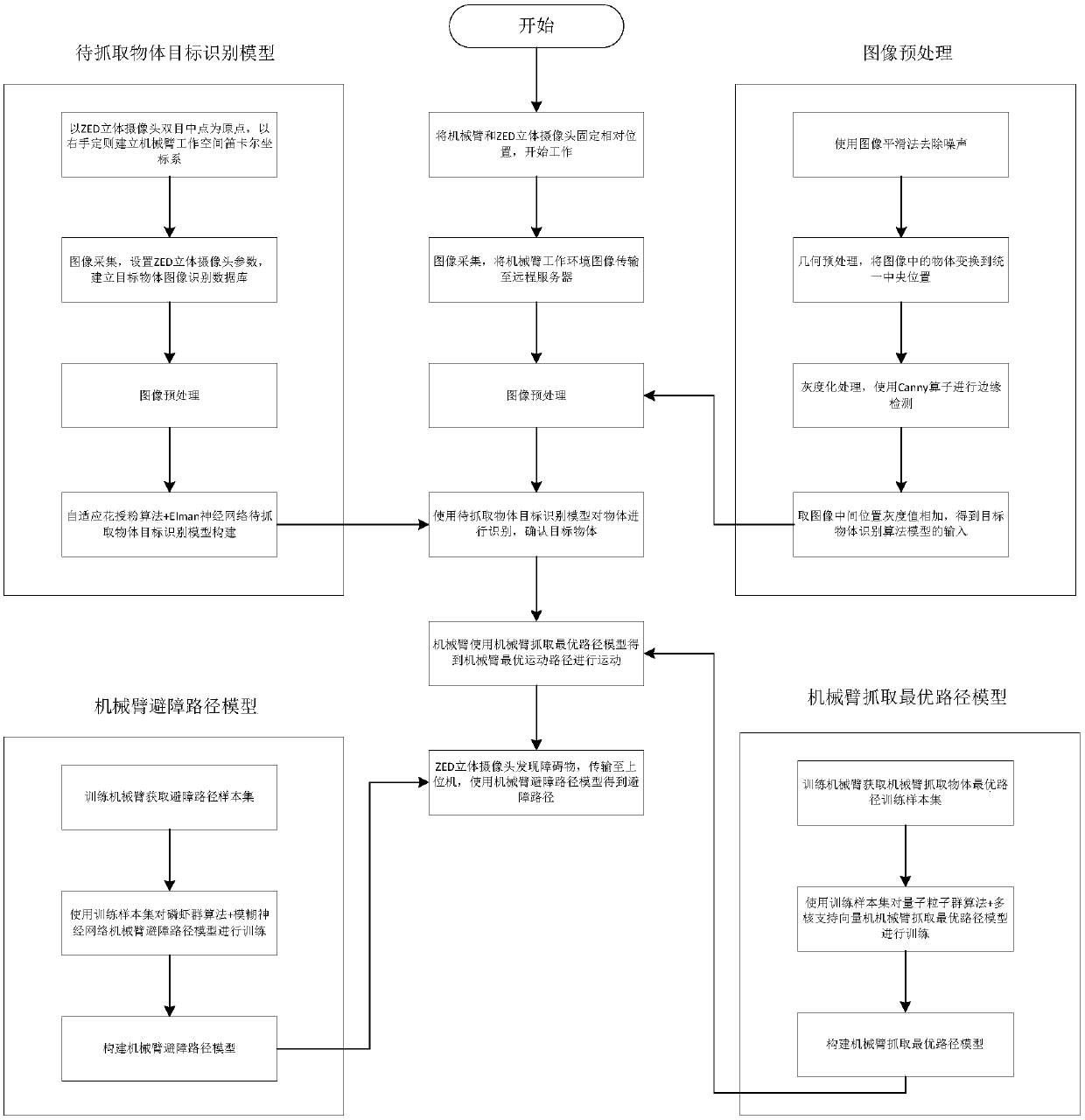

The invention discloses a visual anti-collision control method for an industrial robot arm. The visual anti-collision control method for the industrial robot arm comprises the following steps of 1, establishing a three-dimensional system of coordinates of the working space where the mechanical arm is located; 2, establishing an Elman network based recognition model of a to-be-grabbed object target; 3, establishing an optimal mechanical arm grabbing path model based on a multinuclear support vector machine; 4, collecting the target image of the to-be-grabbed object in real time and identifyingobject category; and 5, determining the gravity center of the object based on the object category, obtaining the grabbing terminal coordinates, obtaining the optimal mechanical arm grabbing path, anddriving the mechanical arm to grab the object. By means of the method, an ideal trace that no collision is caused, the dynamic characteristic meets the margin requirement, and the trace length and movement time are short is figured out in a calculating mode for the mechanical arm to grab the target object, the production efficiency is greatly improved, meanwhile, the personnel cost is reduced, andbenefits are brought to factories.

Owner:CENT SOUTH UNIV

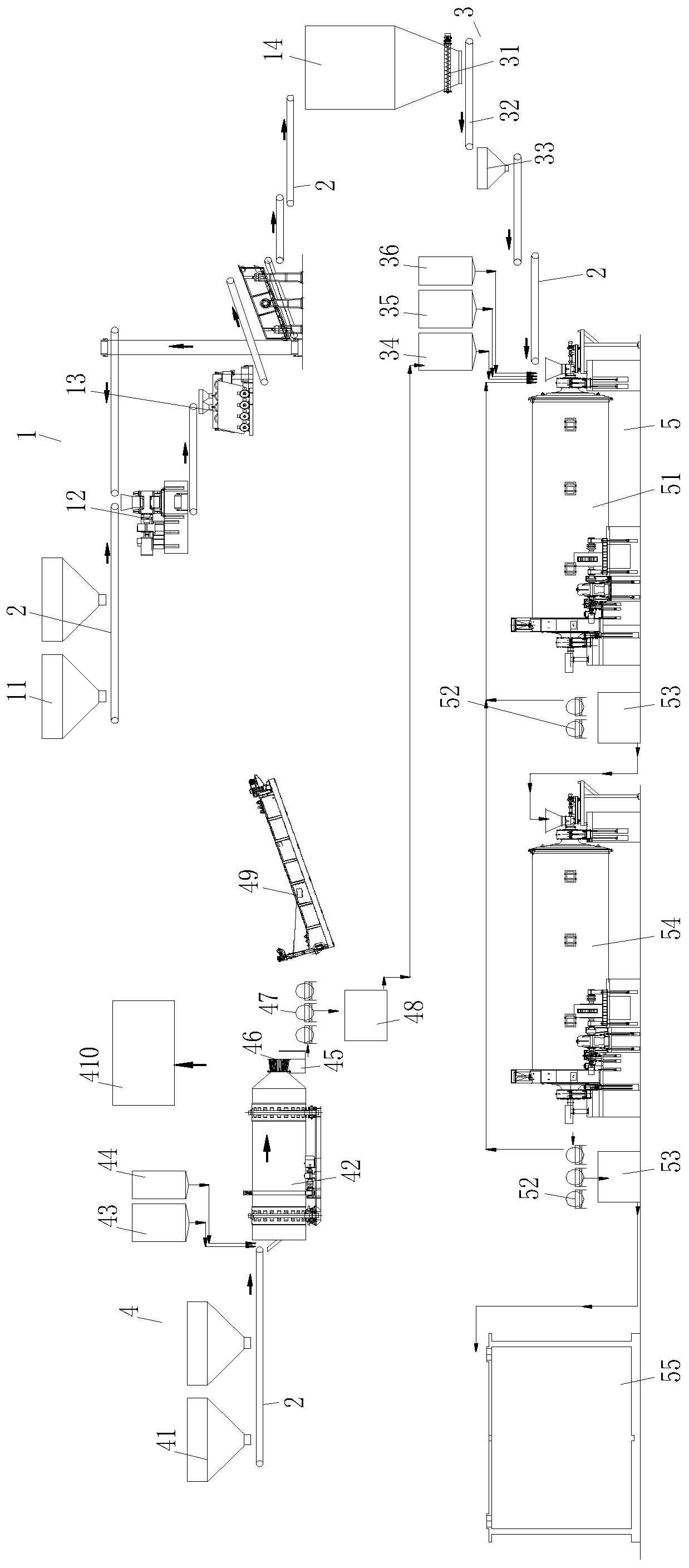

Intelligent wet powdering production technology for ceramic raw materials

InactiveCN110404657ARealize full automationIncrease production capacityGrain treatmentsNumerical controlProduction line

The invention relates to the technical field of ceramic raw material powdering and particularly relates to an intelligent wet powdering production line for ceramic raw materials. The intelligent wet powdering production line for ceramic raw materials comprises a raw material pre-crushing system, a belt conveying line, an automatic metering and batching system, a pug slurrying system and a continuous ball miller system. Transferring and conveying at the discharge end of the raw material pre-crushing system are carried out through a belt conveying line, the automatic metering and batching systemis located on the raw material pre-crushing system, the discharge end of the automatic metering and batching system is communicated with the feeding end of the pug slurrying system, and the other discharging end of the automatic metering and batching system is communicated with the continuous ball miller system. By means of the intelligent wet powdering production line for ceramic raw materials,the purposes of whole process automation, numerical control production and intelligent manufacturing of ceramic wet powdering technology are achieved, and thus the superior product rate and the production efficiency of ceramic products are improved; and besides, good mobility can be still ensured under the condition that the water content of slurry is low, and product defects are reduced.

Owner:广东鼎汇能科技股份有限公司

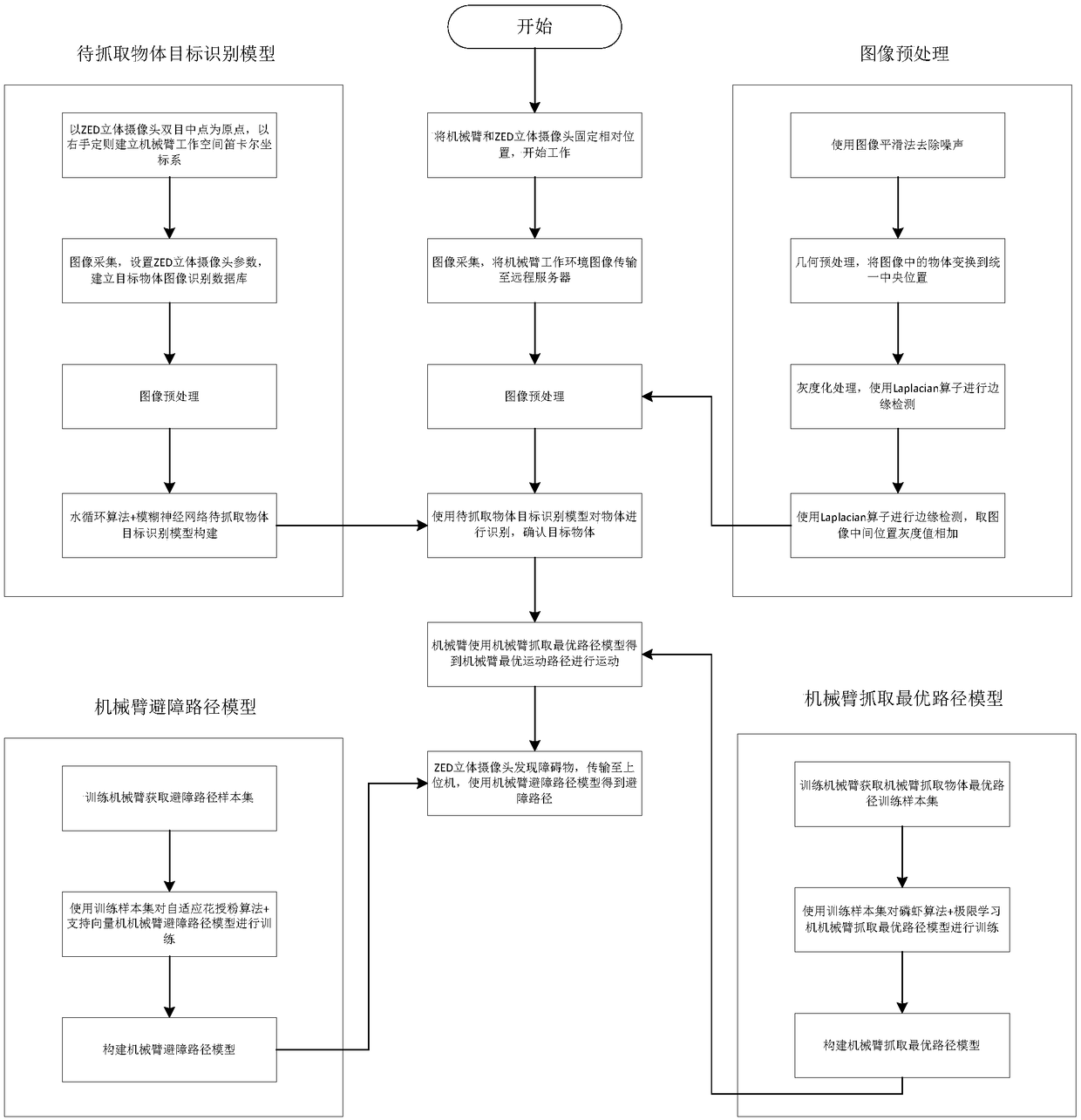

Intelligent calculation method for mechanical arm movement planning group

ActiveCN108196453AImprove the monitoring operating environmentRealize intelligent manufacturingAdaptive controlObject basedComputer science

The invention discloses an intelligent calculating method for a mechanical arm movement planning group, which comprises the following steps: step 1, constructing a three-dimensional coordinate systemof the working space of the mechanical arm; step 2, constructing a target recognition model of an object to be captured based on the fuzzy neural network; step 3, constructing a mechanical arm based on the limit learning machine to grab an optimal path model; step 4, acquiring object image recognition object categories to be captured in real time; step 5; determining the center of gravity of the object based on the object category, obtaining the coordinate of the grabbing end point, acquiring the optimal path of the mechanical arm, and driving the mechanical arm to grab the object; The methodadopts an intelligent algorithm to calculate an ideal track with free collision, dynamic characteristic meeting allowance requirements and short track length and time for a mechanical arm grabbing target object, it greatly improves the production efficiency, saves the personnel cost and brings benefits to the factory.

Owner:CENT SOUTH UNIV

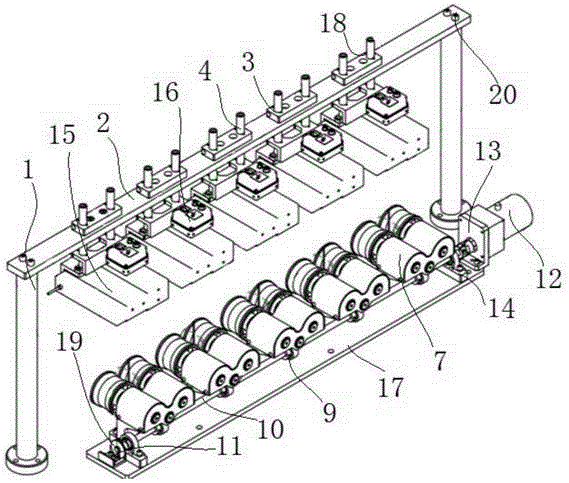

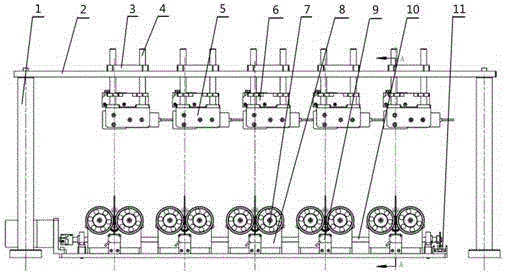

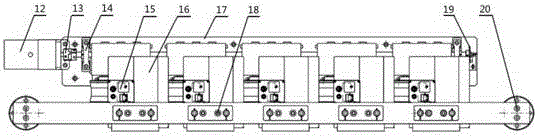

Detection device for piston pin outer circle defects

InactiveCN106290397ARealize quality managementSolve the detection speed is slowMaterial analysis by optical meansVisual recognitionEngineering

The invention provides a detection device for piston pin outer circle defects. The detection device is structurally characterized in that supporting columns and an installing beam are fixed through bolts, fixing plates are arranged on the installing beam, adjusting columns are fixed to the installing beam through the fixing plates, a camera fixing plate and a light source fixing plate are fixed to the corresponding adjusting column, a light source is installed on each light source fixing plate through bolts, a line scanning camera is installed on each camera fixing plate through bolts, and the light sources and the line scanning cameras are located over rolling wheel V-type bases; the rolling wheel V-type bases are installed on a bottom plate, in-place sensors are located below the rolling wheel V-type bases and installed on the bottom plate, and the rolling wheel V-type bases are connected through rolling wheel driving shafts; rolling wheels are arranged on the rolling wheel V-type bases, a rolling rotation driving device is arranged at one side of each rolling wheel, and a shading piece is arranged at the other side of each rolling wheel. The detection device can detect the piston pin outer circle defects, visual recognition is adopted, non-contact dynamic detection is achieved, and the working efficiency is greatly improved while measurement accuracy is ensured.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD

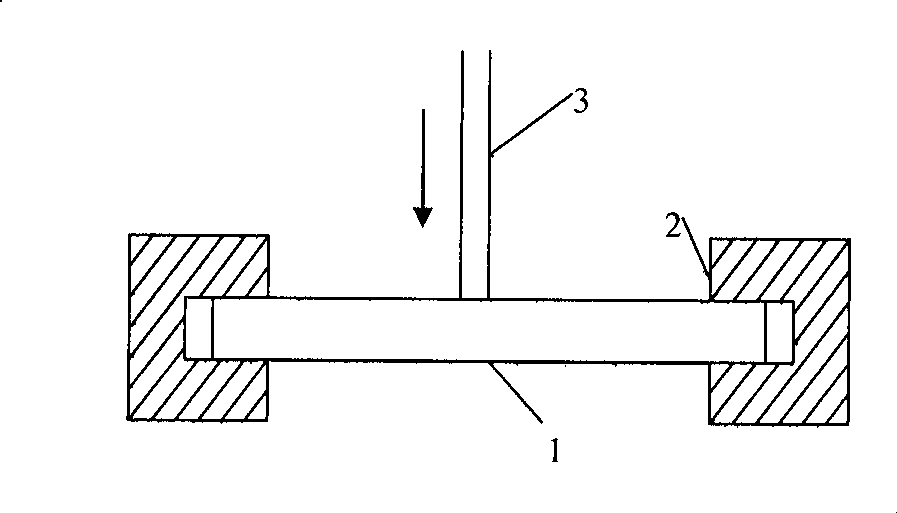

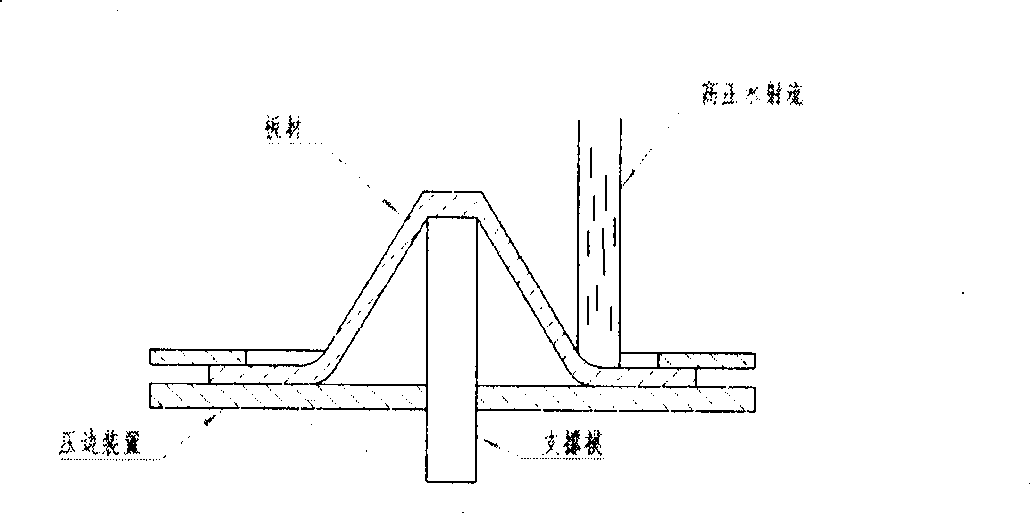

Water-jet asymptotic shaping method of sheet

The invention relates to a water-jet asymptotic forming method of plates, which is the method for processing and forming the plates by utilizing high-pressure water jet and belongs to the mechanical engineering field. The invention can solve the forming problem of plates with small batch and multiple varieties and is characterized in that the high-pressure water jet with large flow is adopted and the high-pressure water jet, the pressure and the flow rate as well as the flow of which can be controlled is jetted to the surfaces of the plates through a nozzle of an injection device to form the plates; the plates are fixed on a working table and move along a preset deformation path under the control of a digital control device; the injection device moves up and down along the vertical direction so as to adjust the working range of the high-pressure water jet. Plates of arbitrary shapes can be formed by adopting the method.

Owner:程晓民

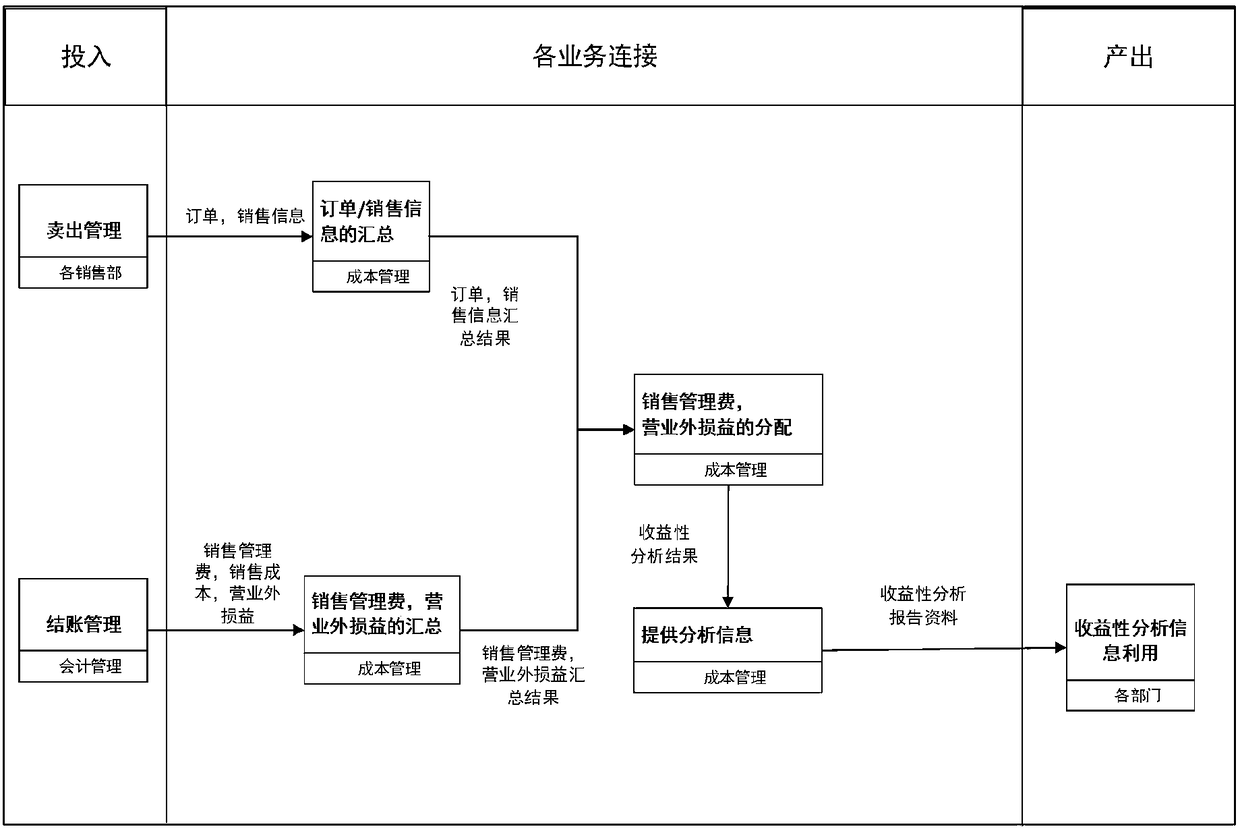

An iron and steel enterprise refined cost accounting control method based on a whole process flow

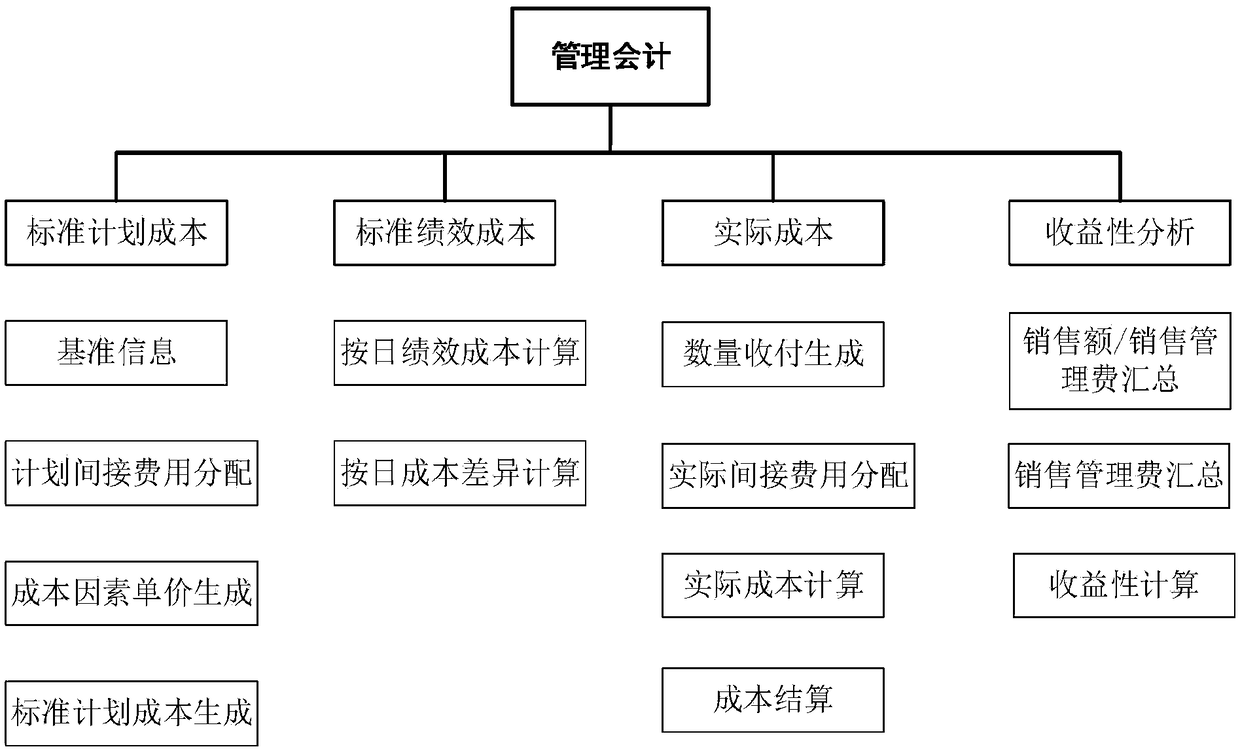

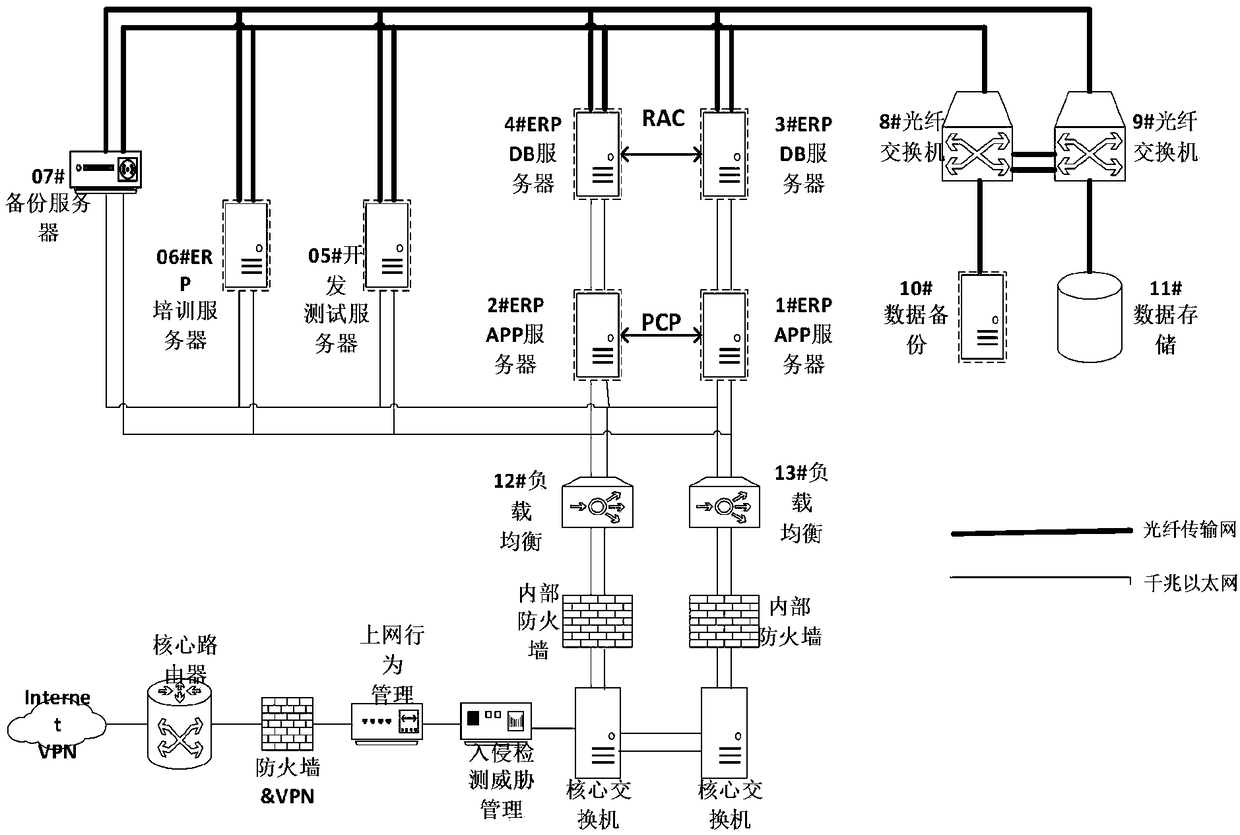

InactiveCN109472474ARealize intelligent manufacturingImprove cost control abilityResourcesManufacturing computing systemsProfit analysisAnalysis data

The invention relates to an iron and steel enterprise refinement cost accounting control method based on a whole process flow, and the method comprises the steps: D1, system function construction: themain functions of a system are management accounting and system hardware architecture, and the hardware architecture of the system is constructed by adopting a PC server and a small hybrid cluster mode; And the system software architecture comprises standard plan cost analysis and calculation, standard performance cost analysis and calculation, actual cost analysis and calculation and profit analysis and calculation. Deepened big data applications, the production cost data of cost accounting are refined; multi-level and multi-dimension effects are realized; Multi-cost factor display, all semi-finished products can be provided in any period; Accurate, refined and comprehensive analysis data are provided for cost control through the actual cost information of any process cost center, effective monitoring and data analysis of the cost of the whole production process of an iron and steel enterprise are achieved, the cost management and control capacity of the enterprise is improved, and therefore cost control is conducted in a targeted mode.

Owner:SD STEEL RIZHAO CO LTD

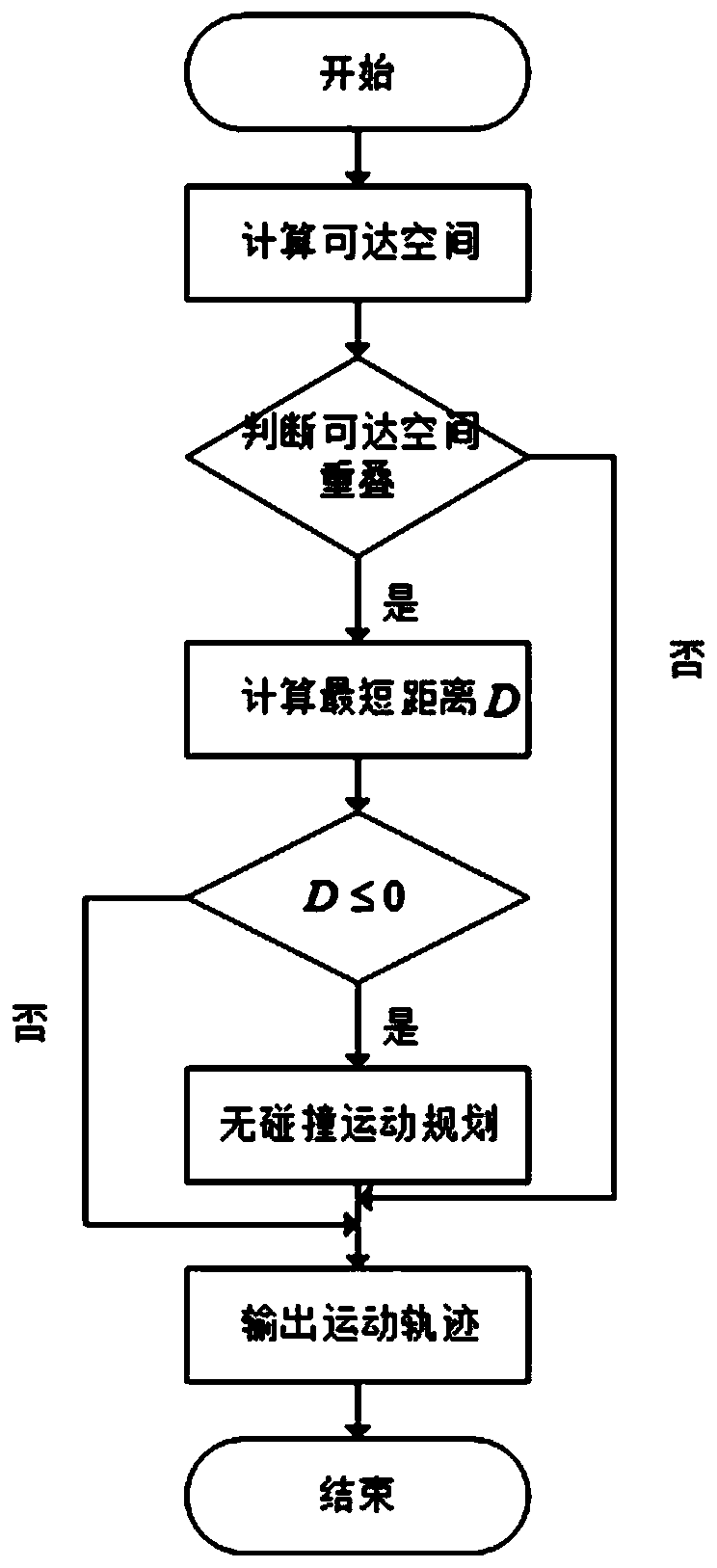

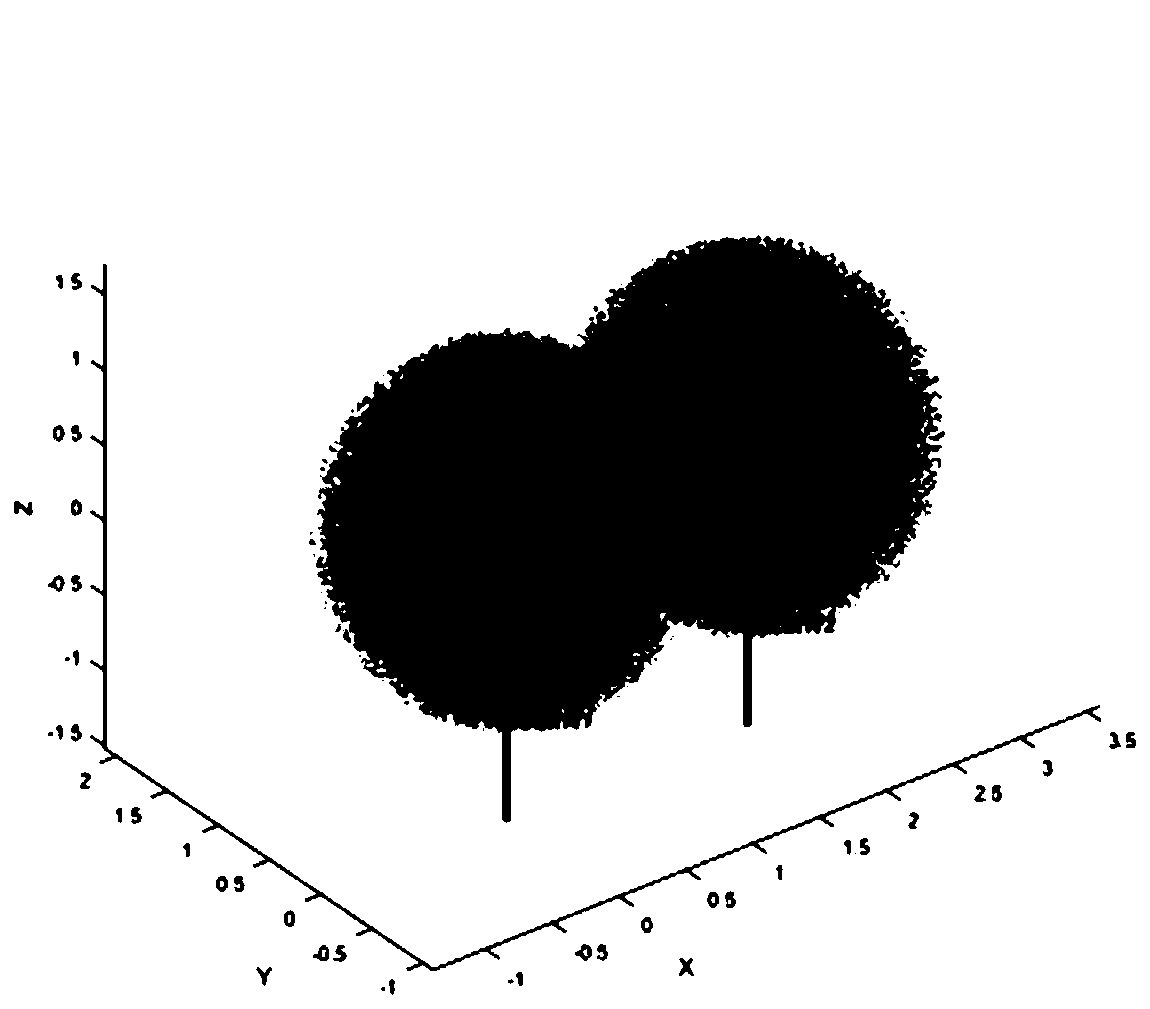

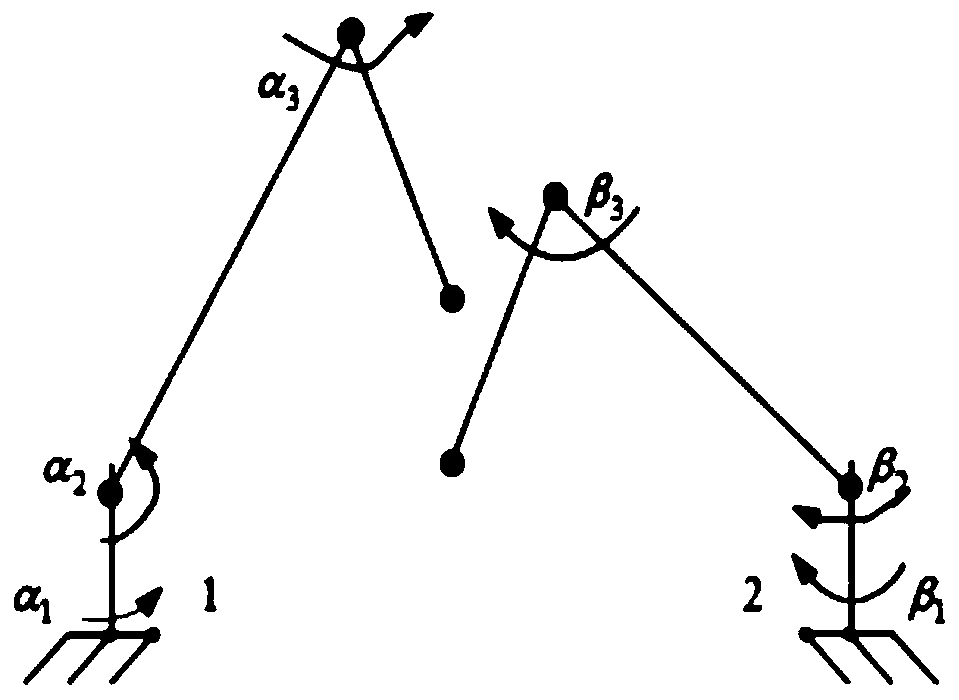

Collisionless motion planning method for curve forming of outer board of ship body based on double mechanical arms

InactiveCN111469129ACollision detection simplifiedSimplify complexityProgramme-controlled manipulatorCollision detectionClassical mechanics

The invention provides a collisionless motion planning method for curve forming of an outer board of a ship body based on double mechanical arms to solve the problem of kinematic collision between themechanical arms caused by a precision error of the double mechanical arms and a working reachable space overlapping factor between the double mechanical arms. By solving and analyzing the reachable space of the double mechanical arms, the overlapped part of the moving space of the double mechanical arms is obtained, and the probability of collision of the double mechanical arms in the space is obtained. A mode of the double mechanical arms is simplified, so that the complex degree of collision detection is simplified. A repulsive force field in a conventional artificial potential field is improved and is introduced, as a potential field, into collision prevention adjustment to calculate a planed adjusting amount, and tracks of the double mechanical arms are adjusted by an interpolation method. Finally, a moving model is established by means of a DH parameter of the double mechanical arms, and a moving track capable of colliding is set to the double mechanical arms, so that the mechanical arms executing a processing task does not collide, and therefore, the collisionless motion planning method is of significant meaning to achieve intelligent manufacturing of ships.

Owner:苏州新传品智能科技有限公司

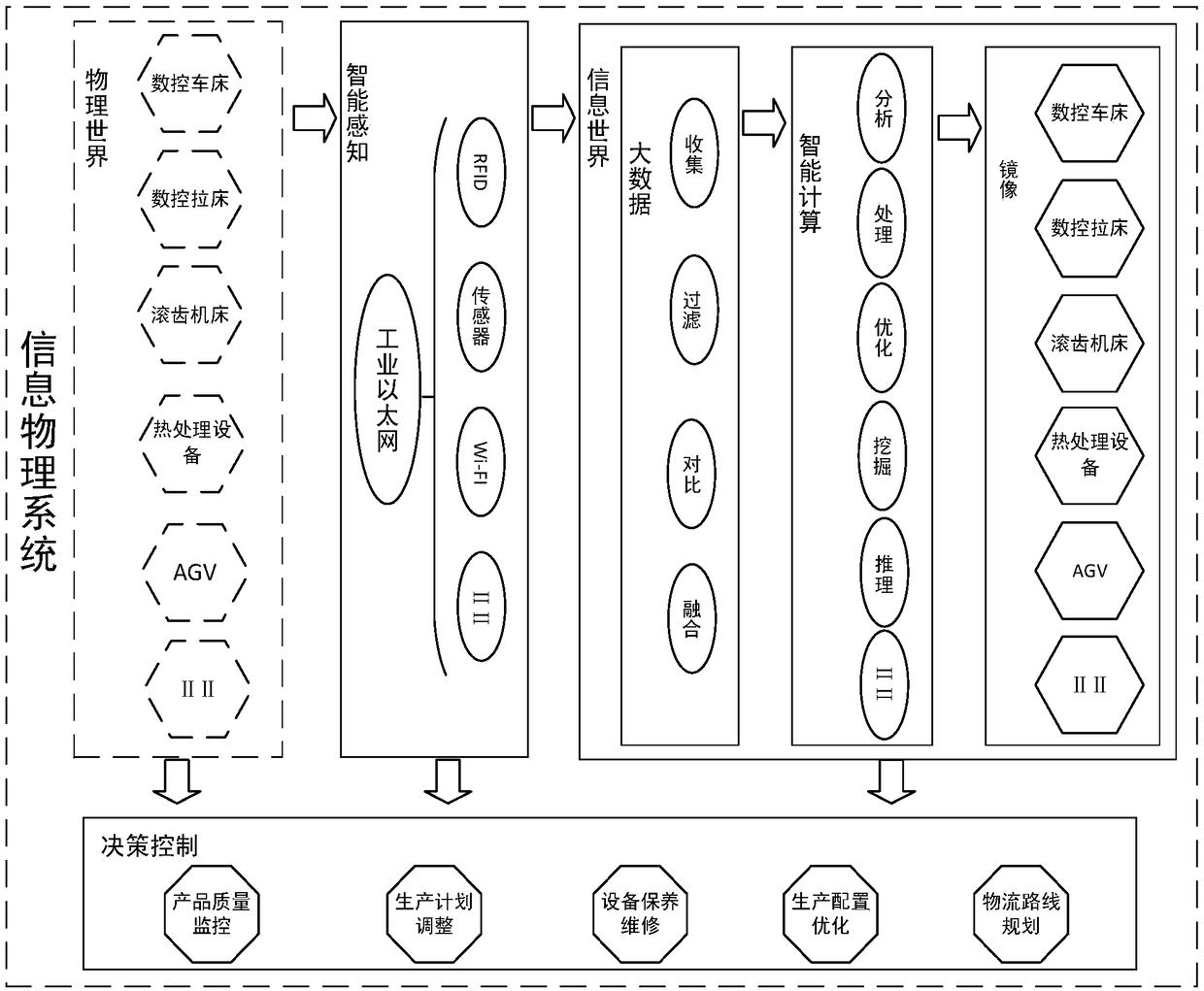

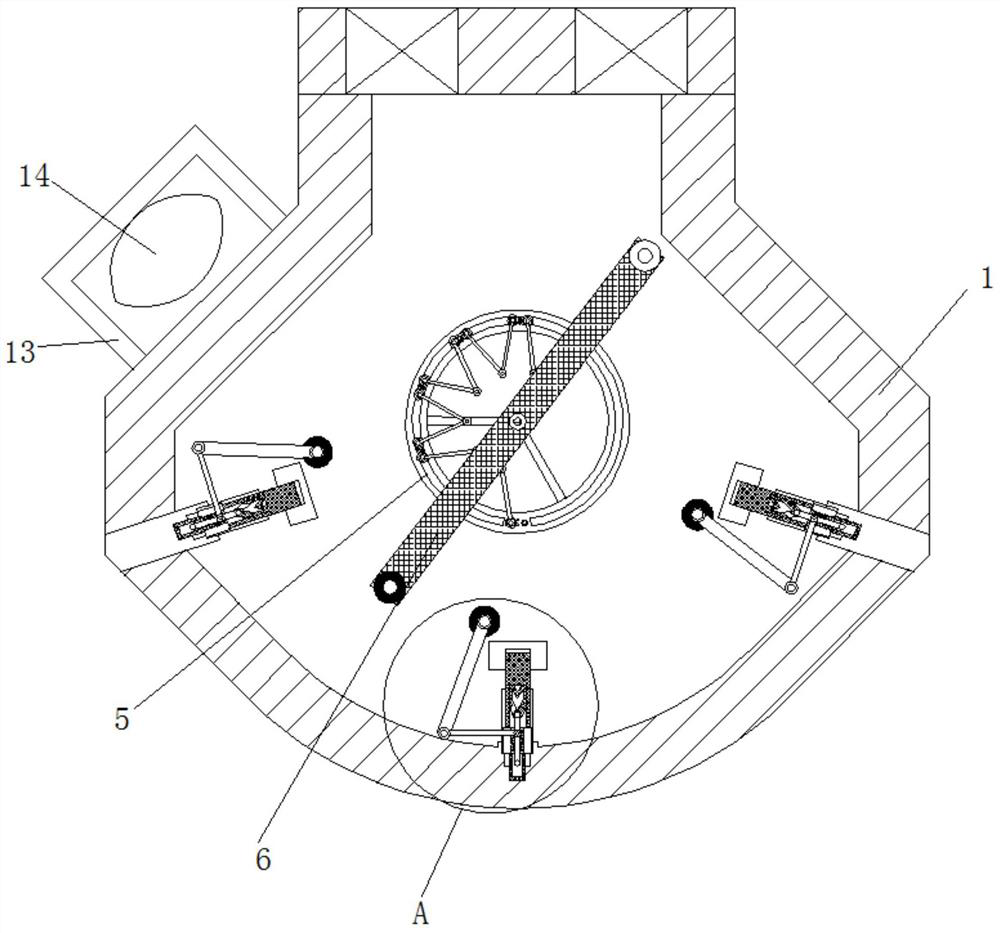

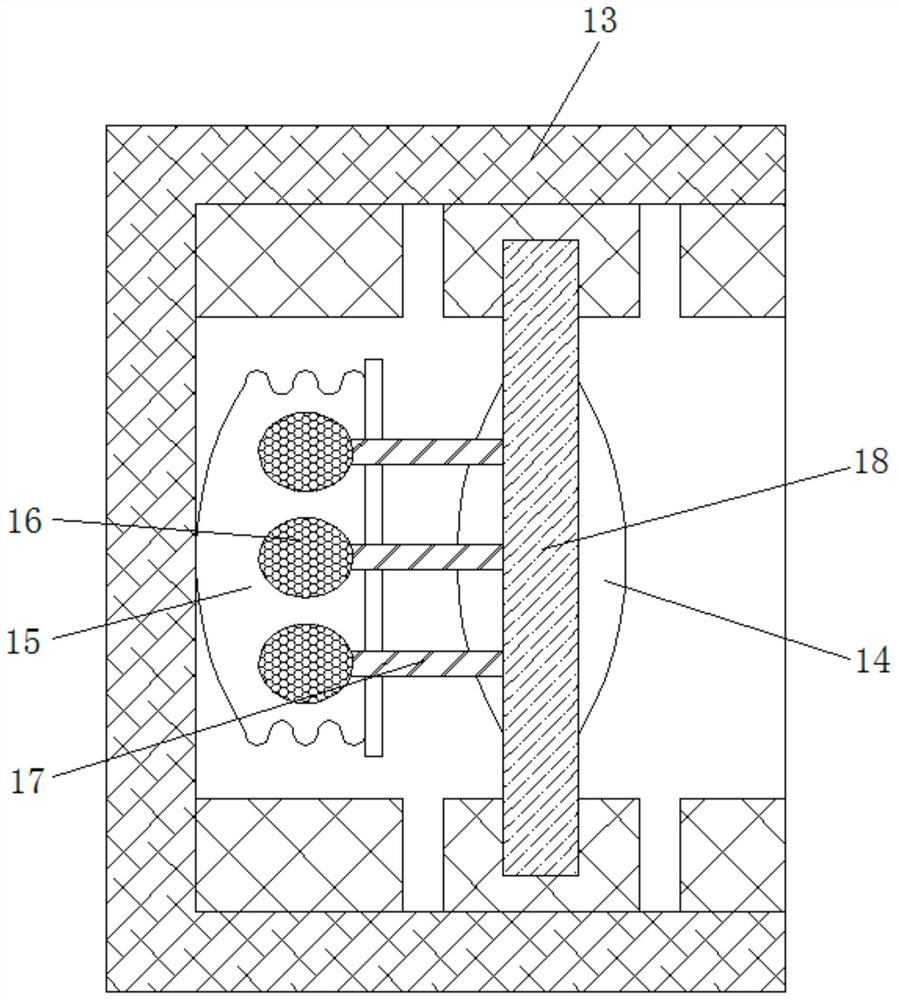

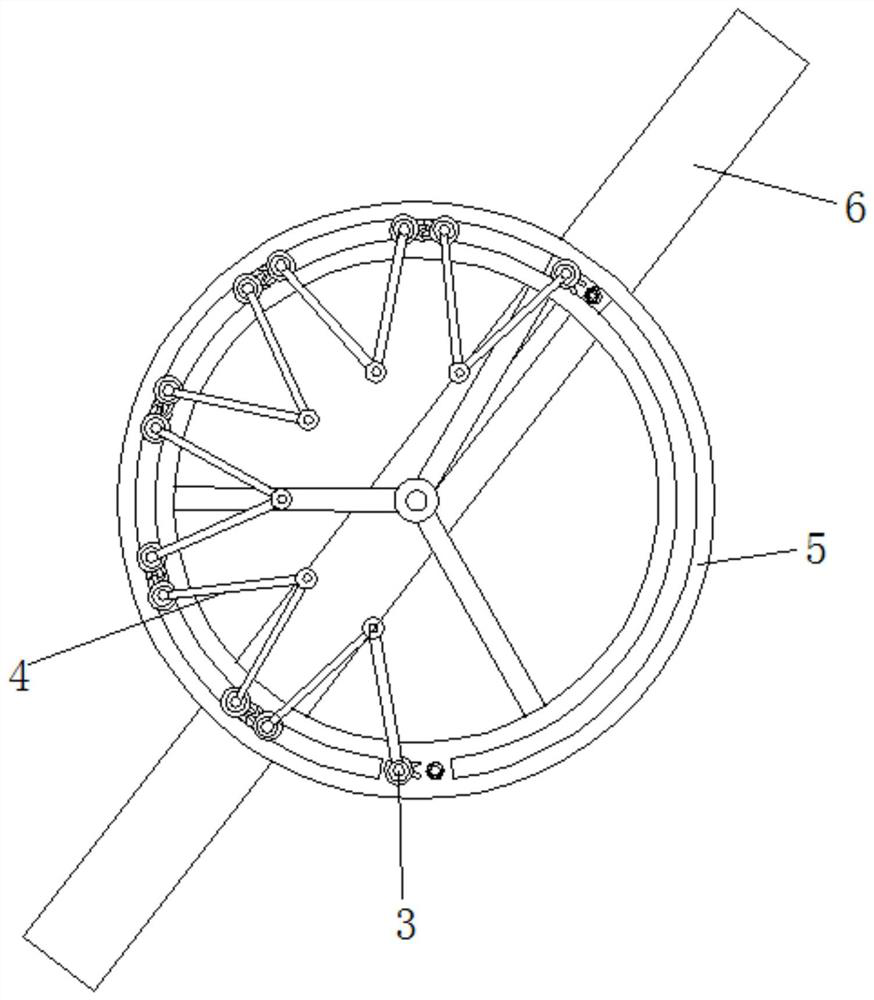

Intelligent manufacturing system for precise speed reducer planetary gears

InactiveCN109249186ARealize intelligent manufacturingImprove product qualityReduction drivePhysical system

The invention relates to an intelligent manufacturing system for precise speed reducer planetary gears, and belongs to the field of machining. The system comprises planetary gear machining equipment,an information physical system and a material system. The planetary gear machining equipment is used for completing a machining process of the planetary gears from blanks to production of finished workpieces; the information physical system is used for optimizing, analyzing and intelligently controlling the planetary gears in the machining process; and the material system is used for completing automatic supply, loading and unloading of workpieces and tool clamps in a planetary gear production process. The production process of the planetary gears is optimized and analyzed, waste of resourcesis relieved, the amount of labor of operators is reduced, the production quality and efficiency of the planetary gears are improved, and thus, intelligent manufacturing of the precise speed reducer planetary gears is realized.

Owner:CHONGQING UNIV

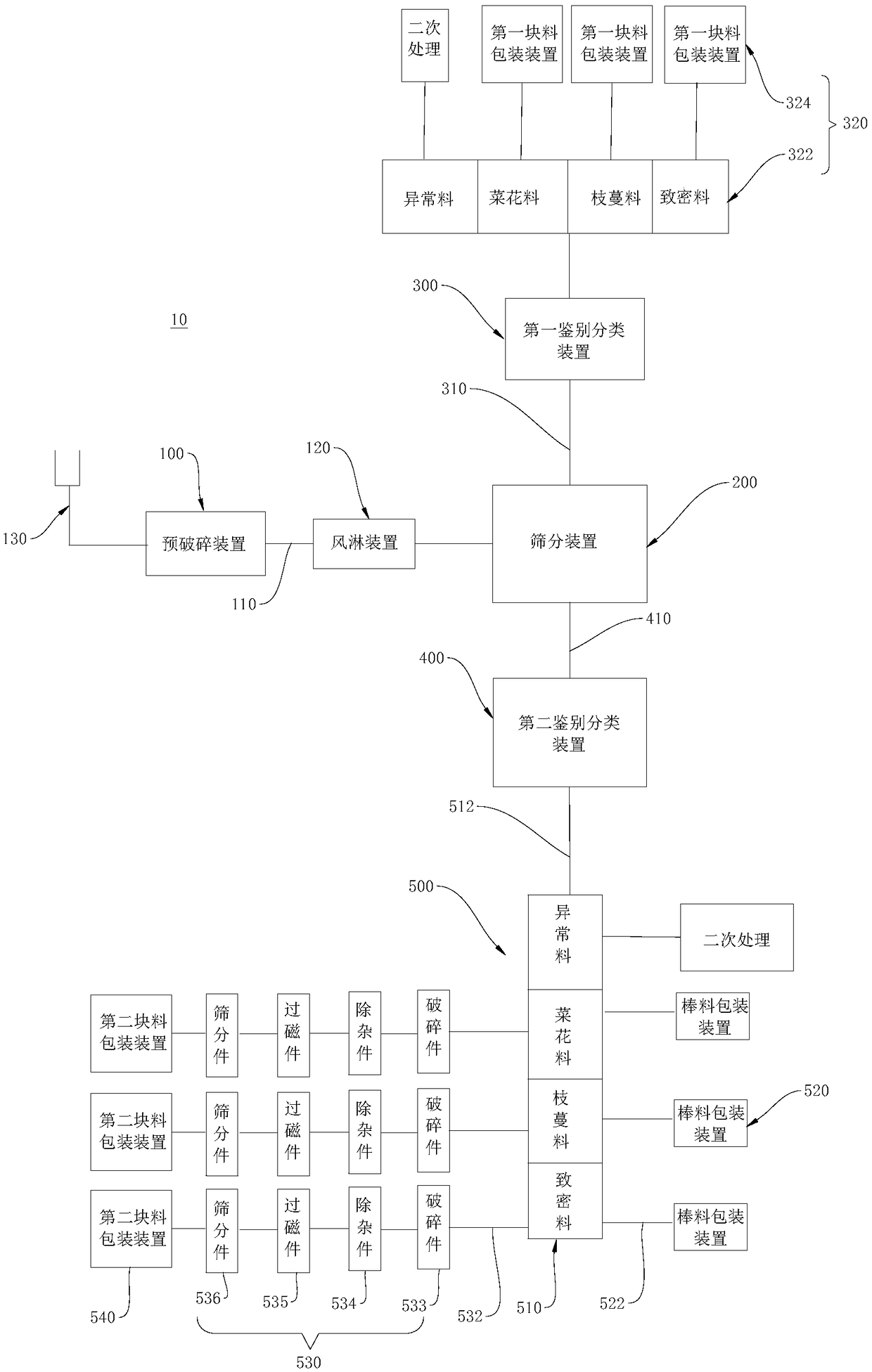

Polycrystalline silicon bar crushing system and method

The invention relates to the field of polycrystalline silicon production, in particular to a polycrystalline silicon bar crushing system and method. According to the provided polycrystalline silicon bar crushing system, polycrystalline silicon bars are subjected to pretreatment, a screening device is used for separating the bars from blocks, the blocks enter a first identifying and classifying device and are distinguished according to different kinds of the blocks; the bars enter a second identifying and classifying device, are distinguished according to different kinds of the bars and enter different bar collection devices of a bar treatment device, and when a user needs the bars, the bars are led into a bar packaging device to be packaged; and when the user needs the blocks, the blocks are led into a crushing device to be crushed. According to the provided polycrystalline silicon bar crushing system, the operation time of operators is saved, pollution caused by manmade operation is avoided, efficiency is improved, and cost is saved. According to the provided polycrystalline silicon bar crushing method, the above polycrystalline silicon bar crushing system is included, and therefore the above beneficial effects are achieved.

Owner:ASIA SILICON QINGHAI

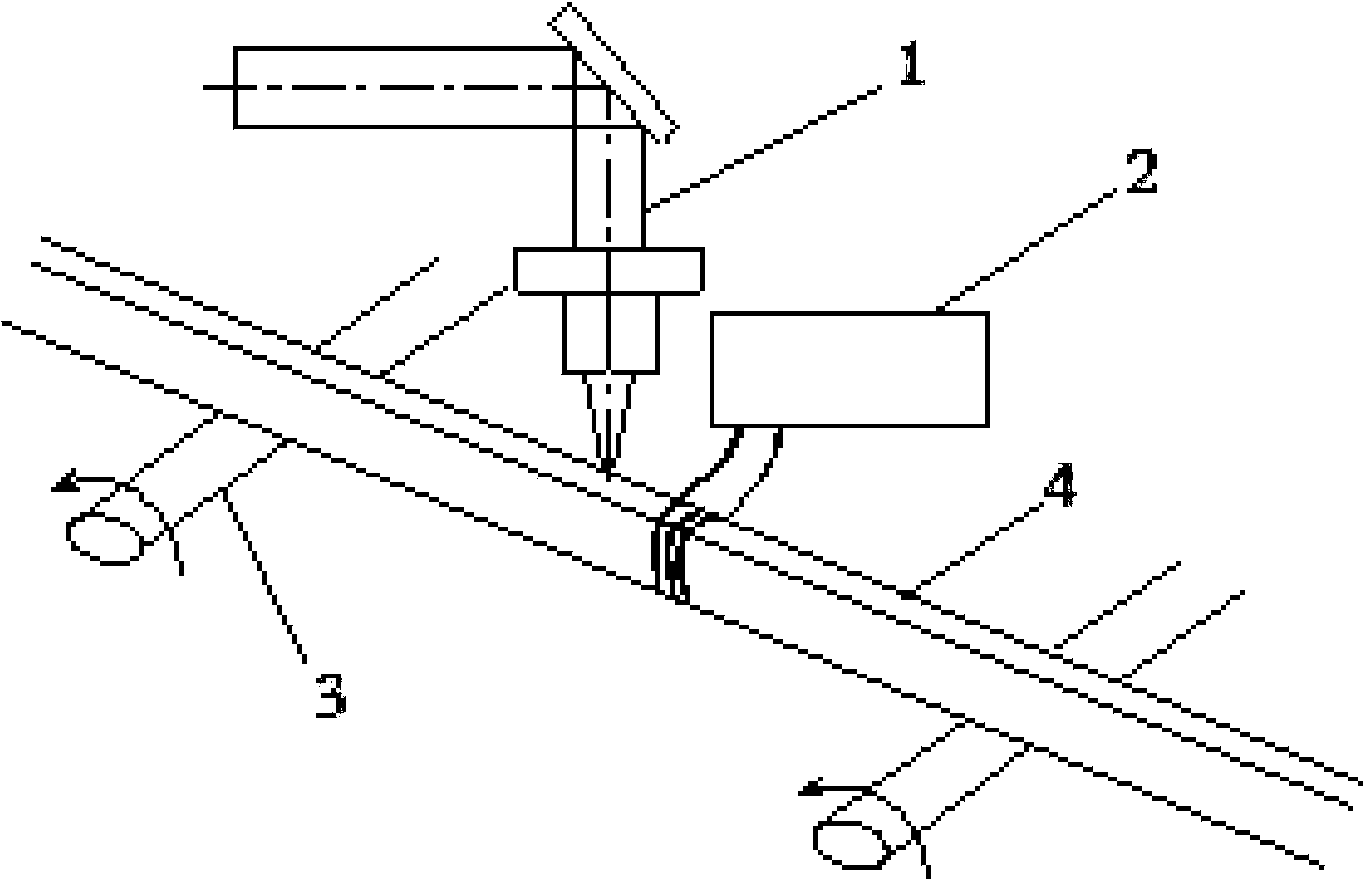

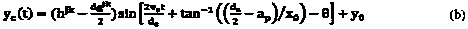

Laser high-frequency composite welding device and welding method of laser high-frequency composite welding device

InactiveCN103447701ALittle impact on performanceHeating fastWelding apparatusInduction heaterEngineering

The invention discloses a laser composite welding device, which comprises a conveying device, a control device, a clamping device, a high-frequency induction heater and a laser, wherein the conveying device carries workpieces and drives the workpieces to move, the control device is connected with the conveying device and controls the speed of the conveying device, the clamping device fixes the workpieces, the high-frequency induction heater heats the workpieces, the laser provides laser beams required by the laser welding, and the positions of the workpieces heated by the high-frequency induction heater are subjected to laser welding. The invention also discloses a welding method. The laser composite welding device solves the problem that in the prior art, the simple laser welding cannot reach the welding temperature, meanwhile, through the addition of a transmission device, the welding effect can be artificially controlled and regulated, the intelligent manufacturing is realized, and the work intensity of workers is reduced.

Owner:ZHANGJIAGANG HENGYUN NEW MATERIAL SCI & TECH

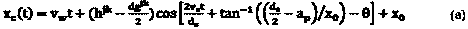

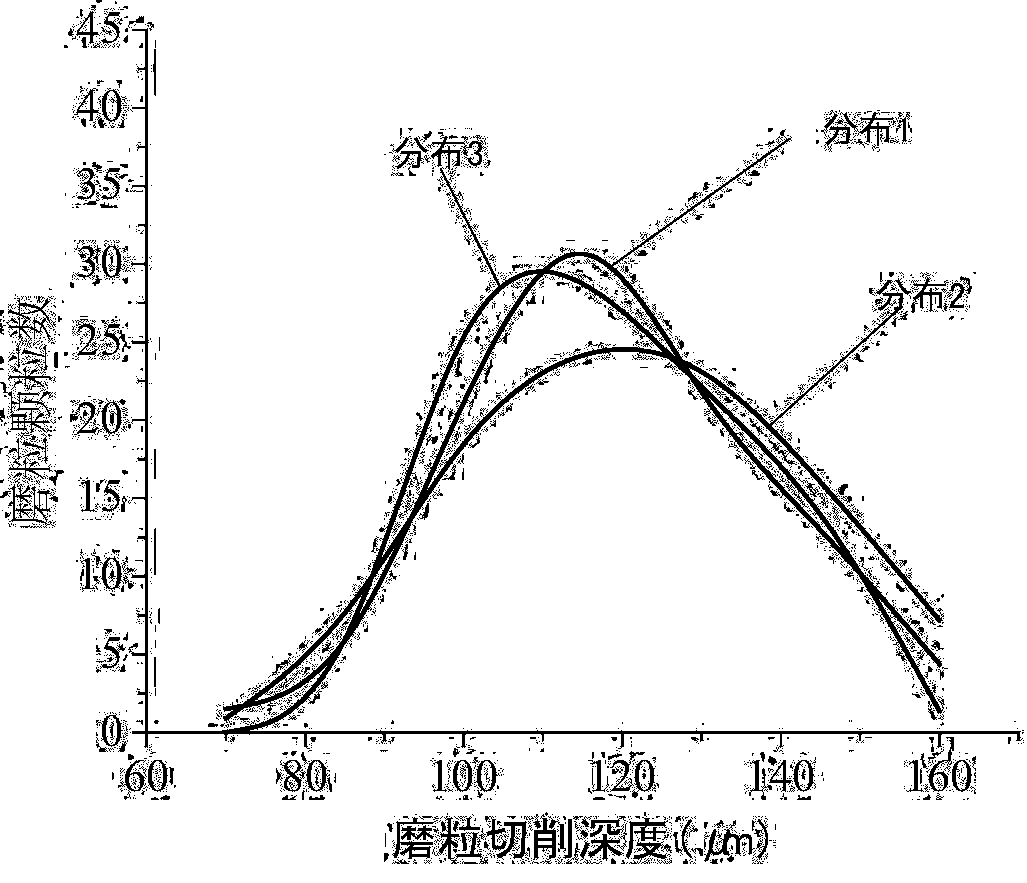

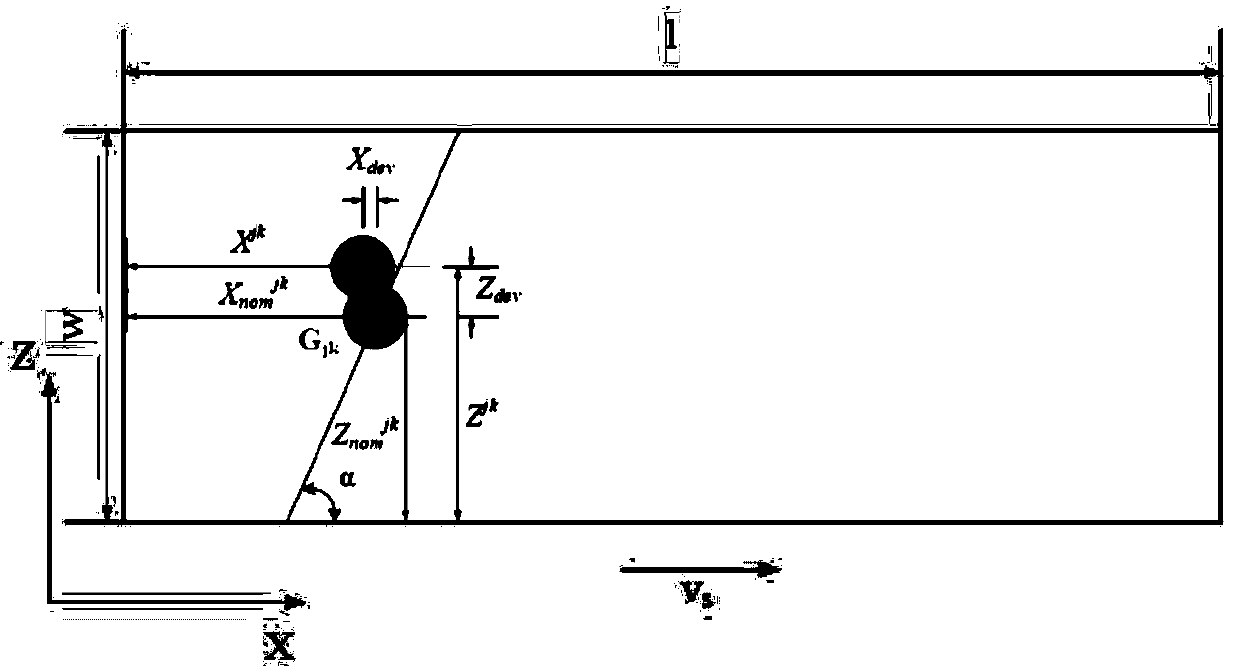

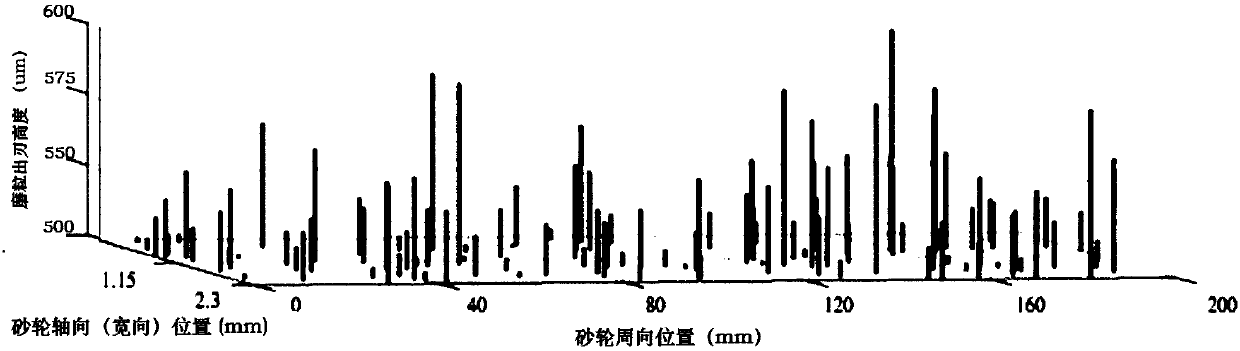

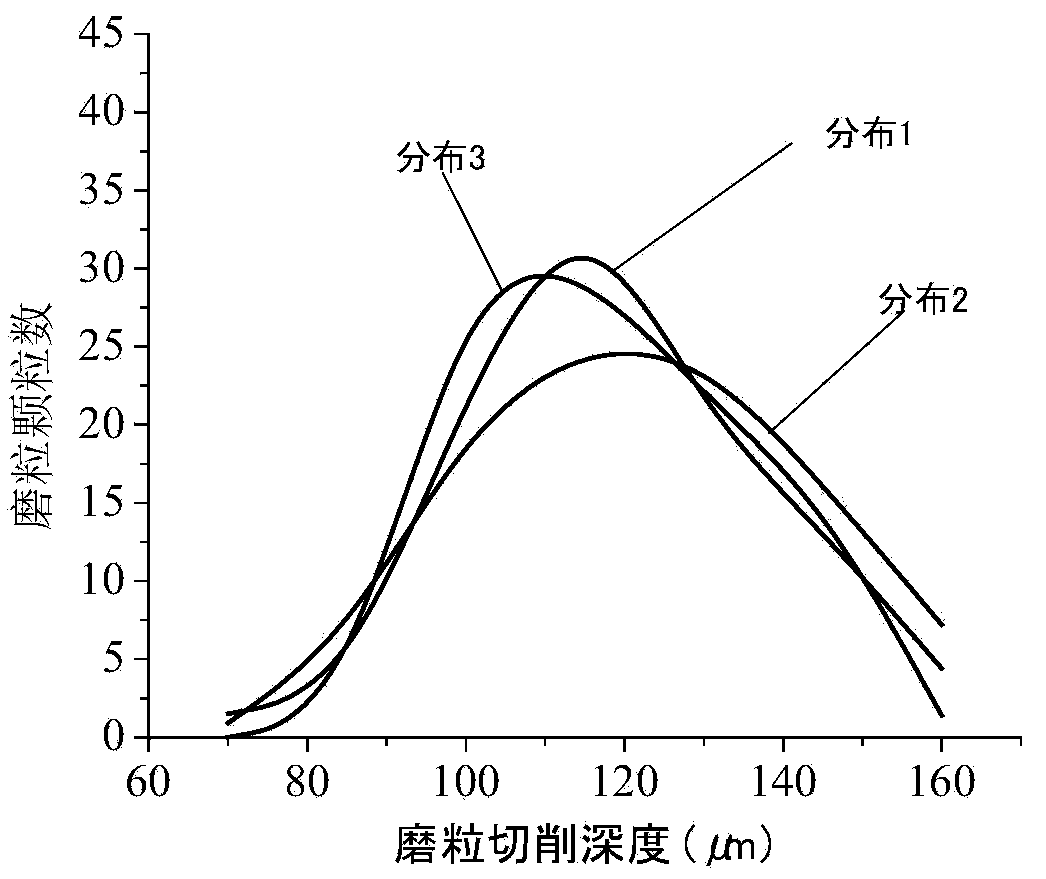

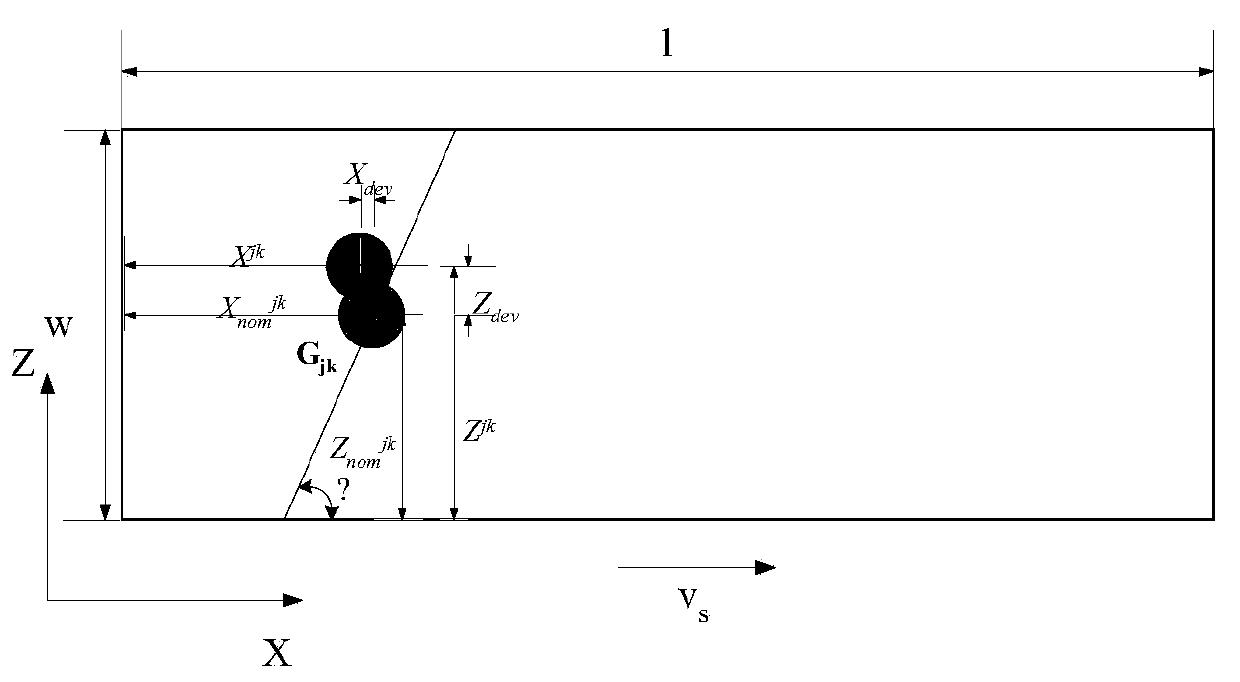

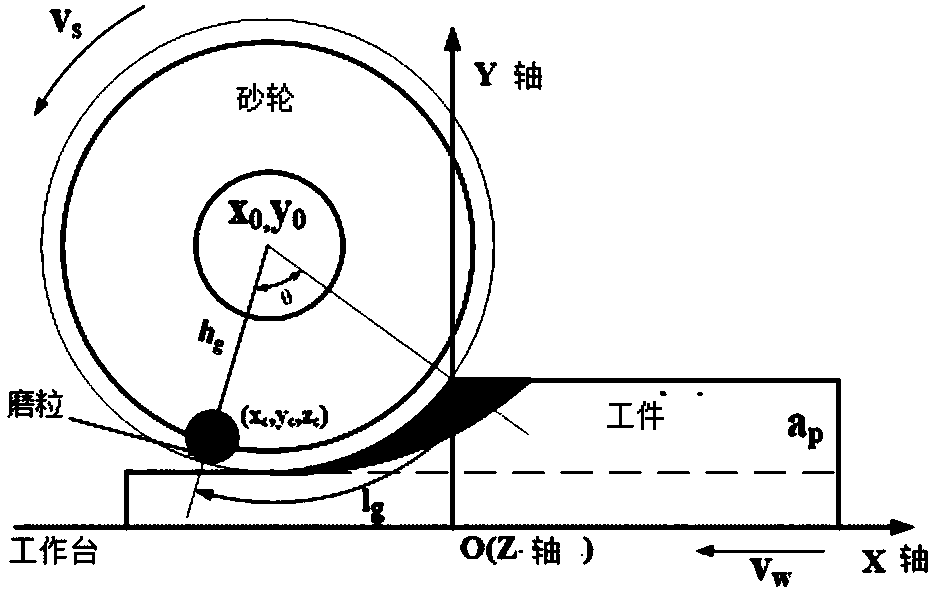

Abrasive particle cutting thickness distribution solution method and application method of abrasive particle cutting thickness distribution solution in grinding process design

The invention discloses an application method of abrasive particle cutting thickness distribution solution in grinding process design. A solution method comprises the steps that A, a digitized grinding wheel is established; B, an abrasive particle track outline is calculated; C, a workpiece is dispersed; and D, abrasive particle cutting thickness distribution is calculated. The application methodof the method applied to the grinding process design specially comprises the steps that the target abrasive particle cutting thickness distribution is set according to a machining result; next, optimal grinding wheel abrasive particle parameters are obtained according to the target cutting thickness distribution constraint; then, by means of the optimal grinding wheel abrasive particle parameters,an actual grinding wheel is prepared and measured, and abrasive particle parameters of the actual grinding wheel are obtained; and finally, the actual grinding wheel abrasive particle parameters areinput and combined with a machining result, and grinding amount optimization is carried out. Grinding machining is carried out by matching the actual grinding wheel manufactured through the optimal parameters and the optimal grinding amount, and an expected machining result can be efficiently achieved with high quality and low cost.

Owner:HUAQIAO UNIVERSITY

Grinding wheel dressing amount optimization design method based on abrasive particle cutting thickness distribution control

ActiveCN108214307AEfficiently obtain processing resultsAchieve expected processing resultsDesign optimisation/simulationAbrasive surface conditioning devicesDistribution controlGrinding wheel

The invention discloses a grinding wheel dressing amount optimization design method based on abrasive particle cutting thickness distribution control. The grinding wheel dressing amount optimization design method based on abrasive particle cutting thickness distribution control comprises the following steps that (1) a set grinding wheel surface abrasive particle parameter is given, the grinding parameter is given, and a target abrasive particle cut thickness distribution is set according to a machining result; (2) after virtual dressing, abrasive particle cutting thickness distribution calculation is conducted on the grinding wheel surface abrasive particle parameter and the grinding parameter, and the abrasive particle cutting thickness distribution is worked out; (3) the abrasive particle cutting thickness distribution worked out in the step (2) is compared with the target abrasive particle cutting thickness distribution set in the step (1), if the difference is excessively large, the virtual dressing amount is adjusted, then the step (2) and the step (3) are executed circularly, and calculation is not stopped until the difference between the abrasive particle cutting thickness distribution worked out in the step (3) and the abrasive particle cutting thickness distribution set in the step (1) meets a set standard. The optimized dressing amount is used for dressing the grinding wheel, the dressed grinding wheel conducts working in combination with the set grinding parameter, and the expected machining purpose can be effectively achieved.

Owner:HUAQIAO UNIVERSITY

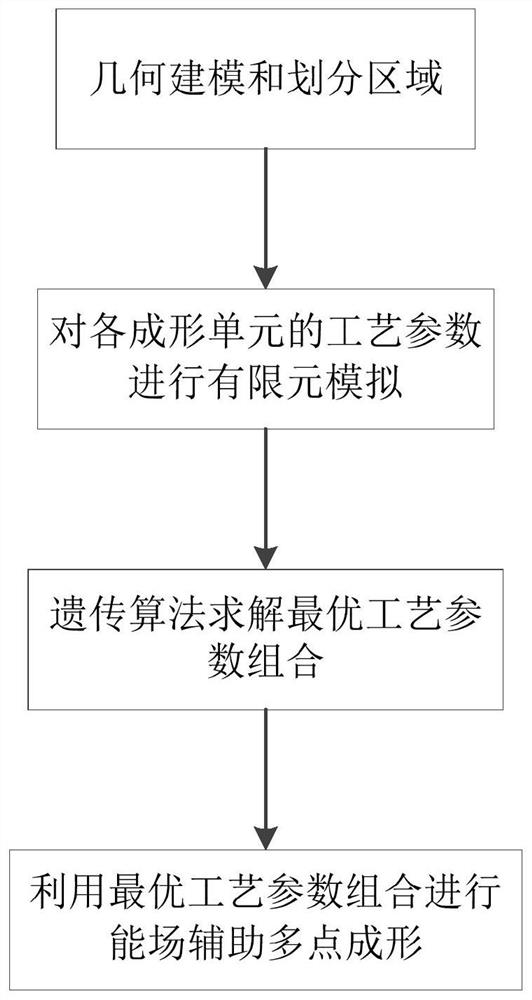

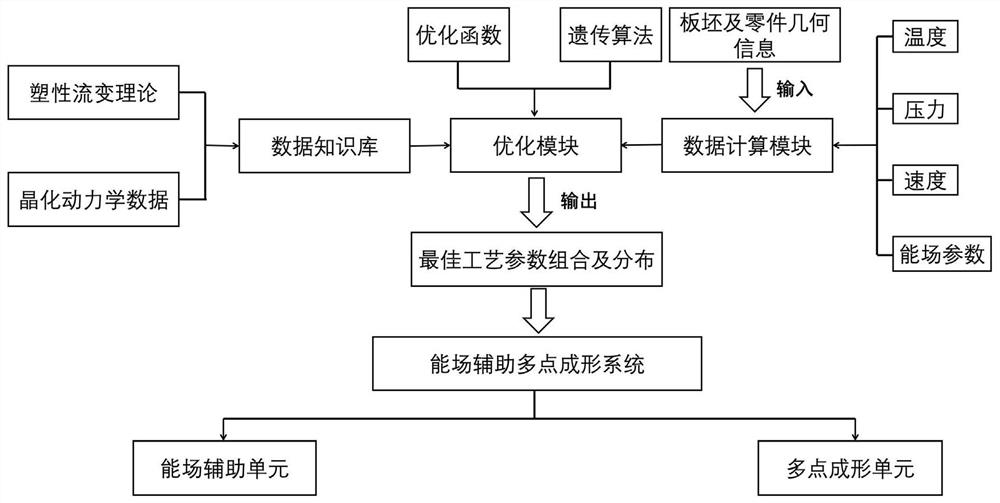

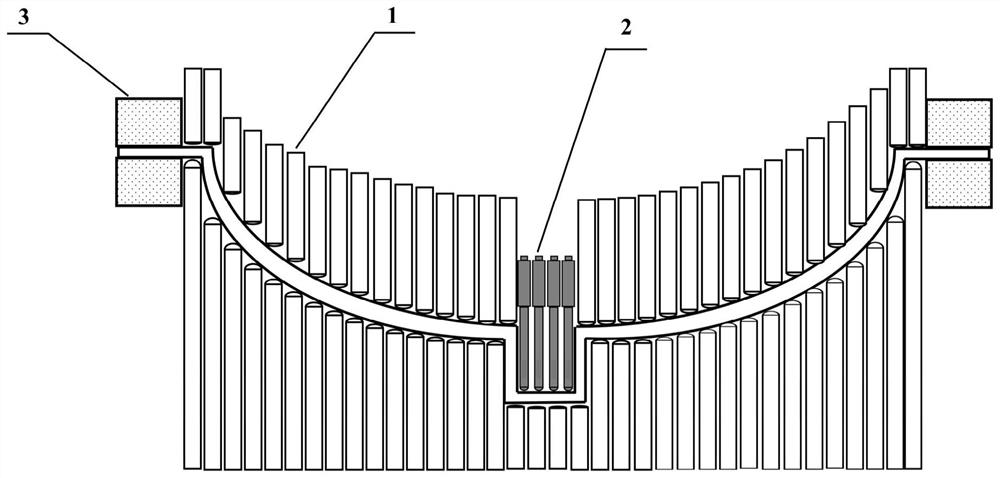

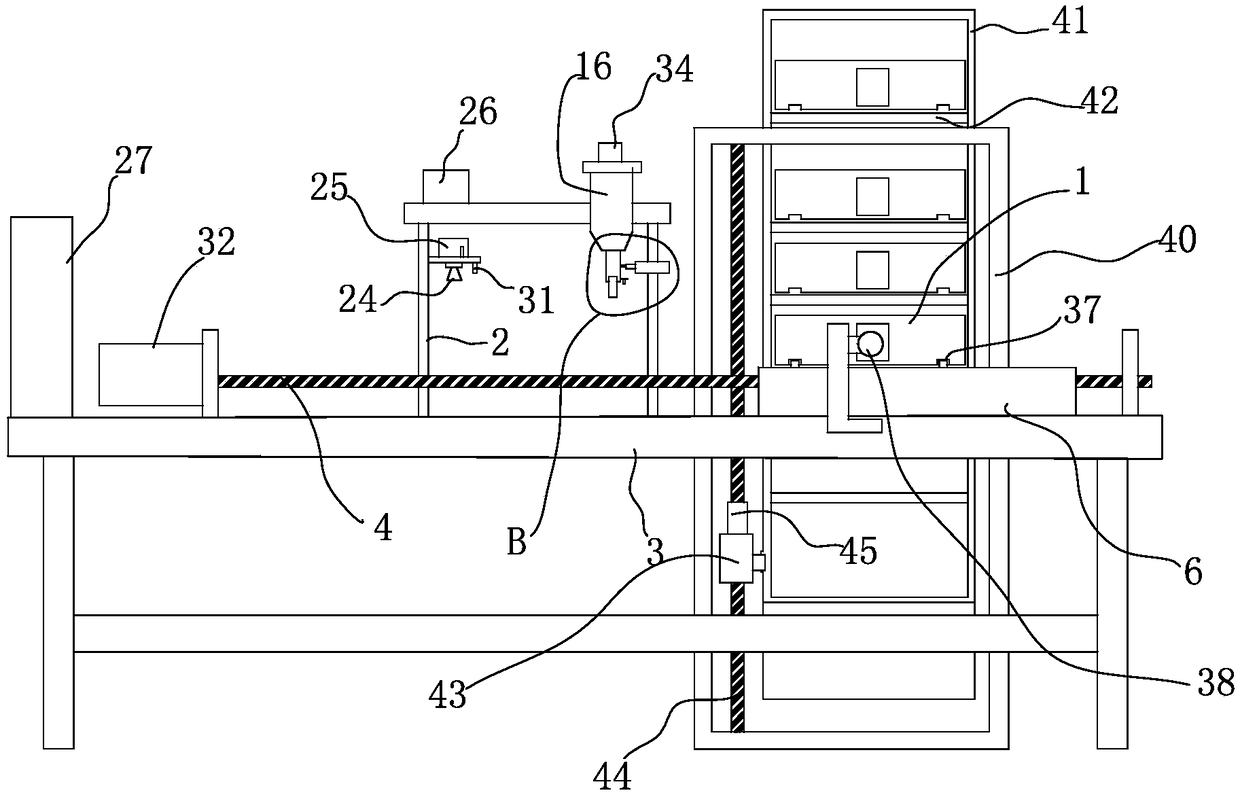

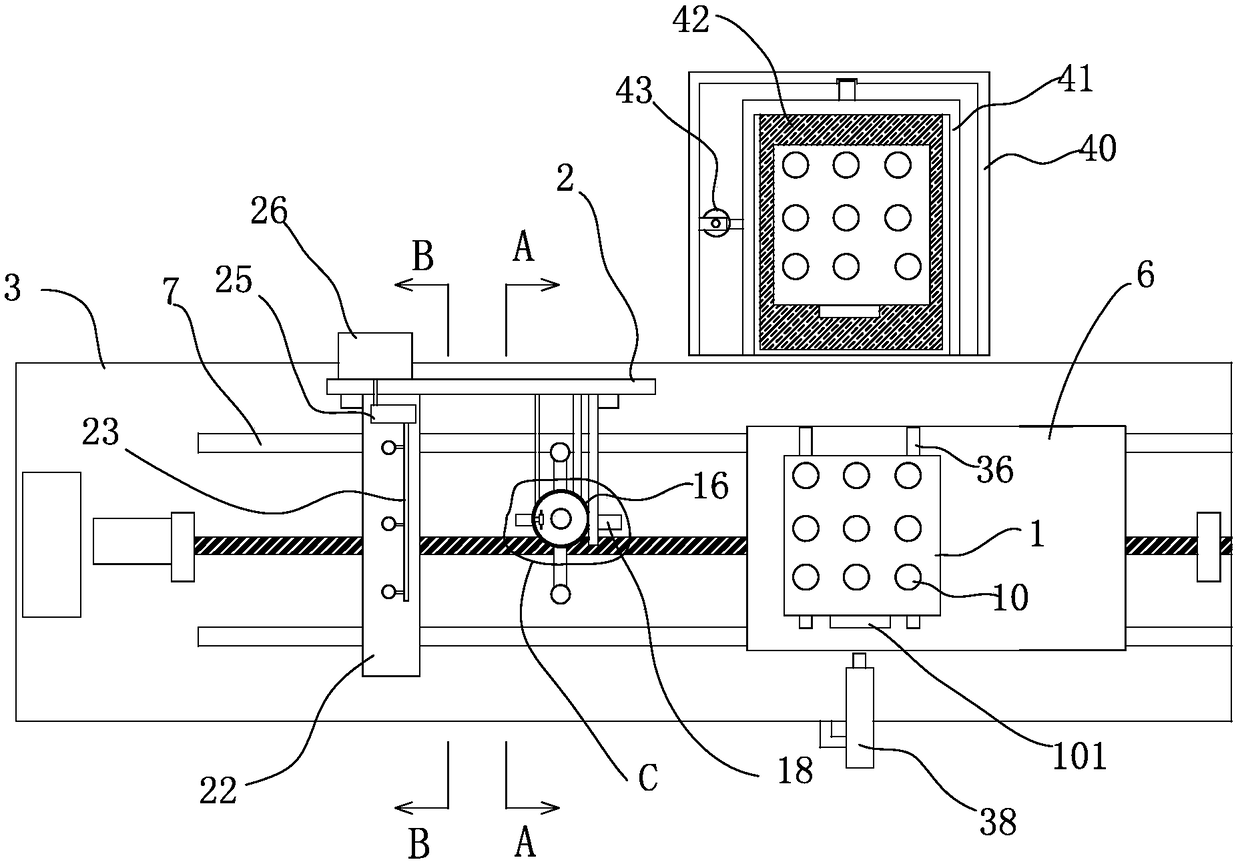

Energy field assisted intelligent multi-point forming method and system for amorphous alloy parts

ActiveCN111753452AShaping coordinationCoordinate shape controlArtificial lifeDesign optimisation/simulationAlloyControl algorithm

The invention belongs to the field of amorphous alloy flexible forming, and particularly relates to an energy field auxiliary intelligent multi-point forming method and system for amorphous alloy parts. The method comprises the steps of firstly, dividing a plate blank into a plurality of forming areas according to geometric profile information of a target amorphous alloy part and the size information of the plate blank; giving forming process parameters including an energy field to each forming area, forming field distribution in the part, performing finite element simulation of the forming process on the amorphous alloy part, then conducting optimization on a data sample through a genetic control algorithm, and obtaining a process parameter combination, namely optimal field distribution,with the optimal effect for different forming areas; and forming the target amorphous alloy part by adopting a multi-point forming process under the obtained optimal field distribution. The field distribution is formed in the part, the integral forming of the part is coordinated, the shape cooperation intelligent manufacturing of a amorphous alloy complex part can be achieved, the production costis reduced, and the product quality is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Intelligent egg tart baking device

ActiveCN109105413ARealize intelligent manufacturingAchieve bakingDough dividingBaking plantsEngineering

The invention aims at providing an intelligent egg tart baking device used for solving the technical problem of egg tart mechanized production. The intelligent egg tart baking device comprises a baking tray, a sequential material adding moving mechanism, a material adding support frame, an egg tart liquid adding mechanism, a tray transfer driving mechanism and a multi-layer baking system. The device has advantages that the intelligent making and baking of egg tarts can be realized, and work efficiency is increased.

Owner:泉州市桥东商贸有限公司

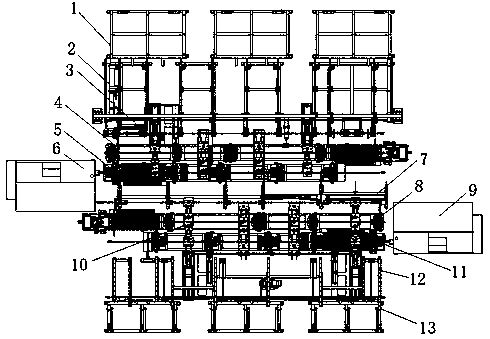

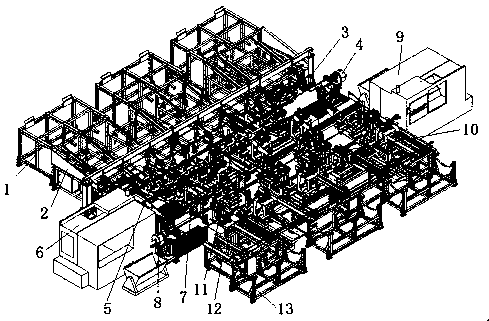

Intelligent manufacturing system and method of motor punching and shearing workshop

PendingCN107537912ARealize unmannedAvoid the Risk of Work InjuryMetal-working feeding devicesManufacturing stator/rotor bodiesPunchingWorkload

The invention relates to an intelligent manufacturing system and method of a motor punching and shearing workshop. The intelligent manufacturing system comprises a servo deflection feeding machine, wherein a discharging hole of the servo deflection feeding machine is connected with a feeding hole of a punching machine tool 1; a material positioned at the discharging hole of the punching machine tool 1 is grabbed to a conveying line 1 or a punching machine tool 2 by a mechanical hand 1; a material positioned at a discharging hole of the punching machine tool 2 is grabbed to a conveying line 2 by a mechanical hand 2; a mechanical hand 3 is arranged near the conveying line 1; the material positioned on the conveying line 1 is grabbed to a punching machine tool 3 by the mechanical hand 3; a mechanical hand 4 is arranged near a discharging hole of the punching machine tool 3; and the material positioned at the discharging hole of the punching machine tool 3 is grabbed to a conveying line 3by the mechanical hand 4. According to the intelligent manufacturing system and method of the motor punching and shearing workshop disclosed by the invention, an unmanned punching operation of an ironcore of a motor can be realized, and the workload is reduced while the risk is reduced at the same time; and meanwhile, through interaction of a PCS (Process Control System) and an upper-layer system, intelligent distribution of operations, automatic issuing of procedures, and real-time acquisition and interaction of data are realized, and intelligent manufacturing of the motor punching and shearing workshop is realized.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

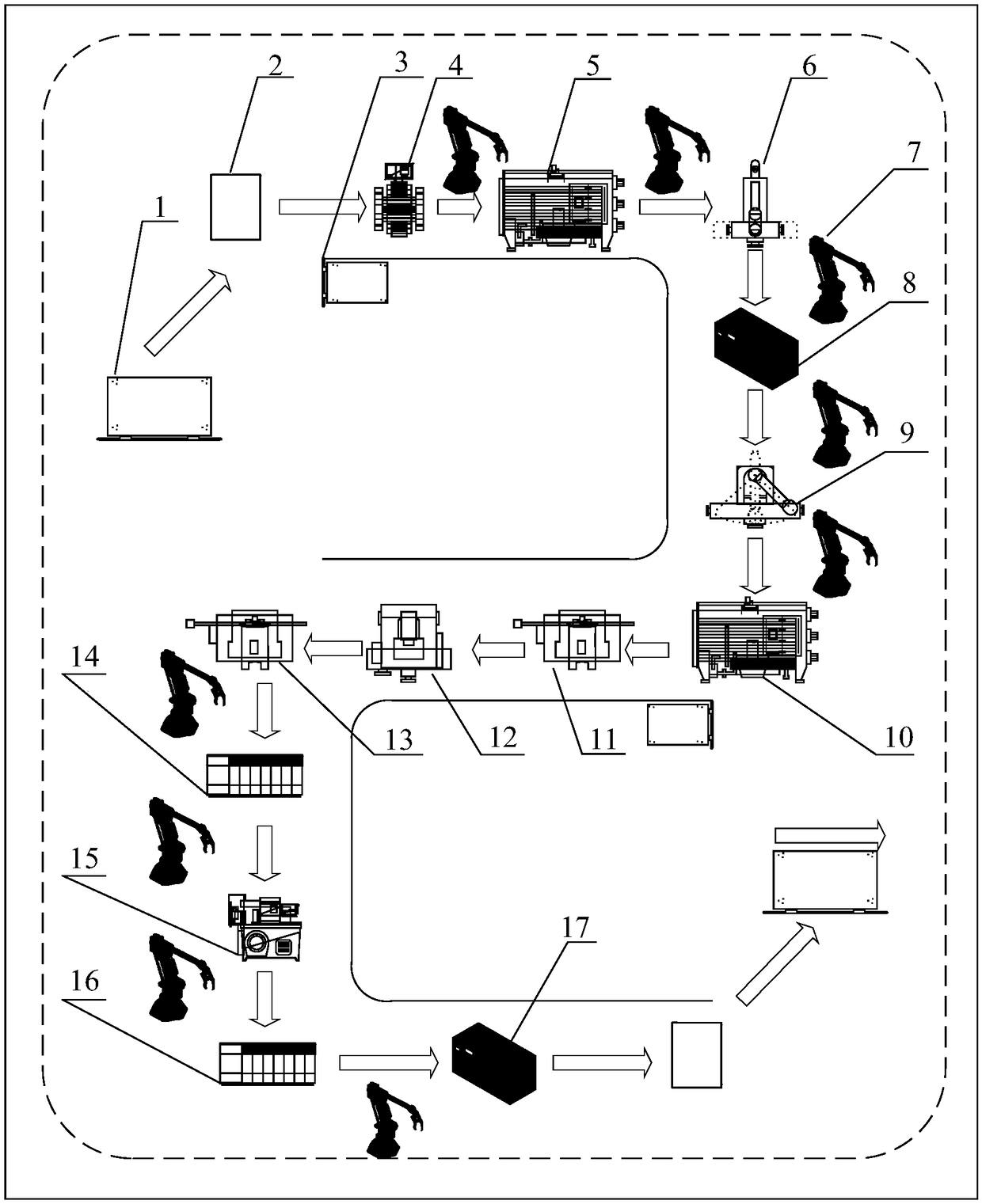

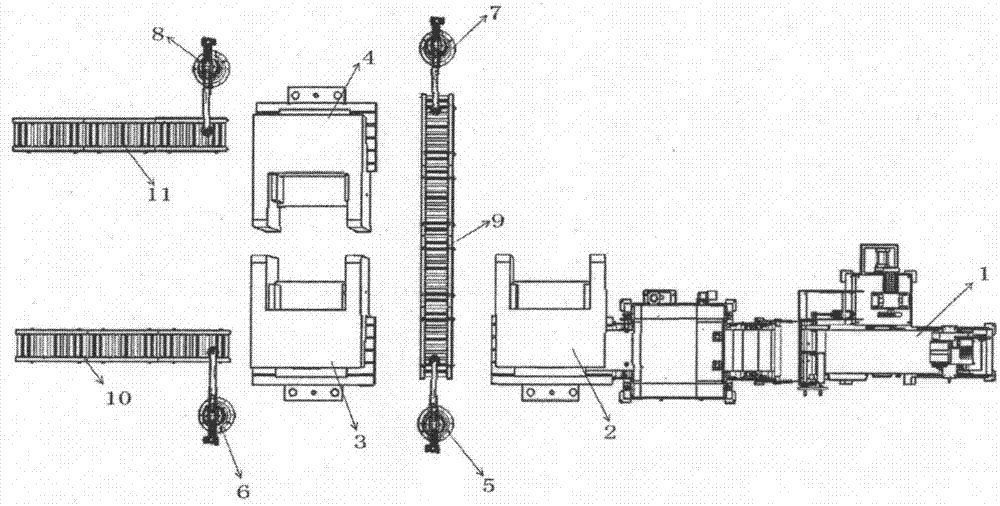

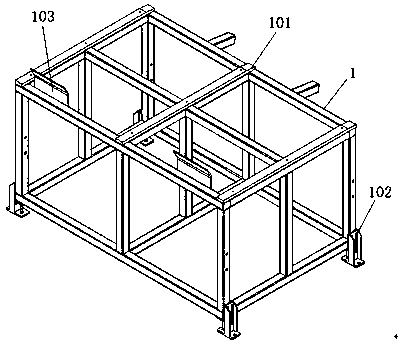

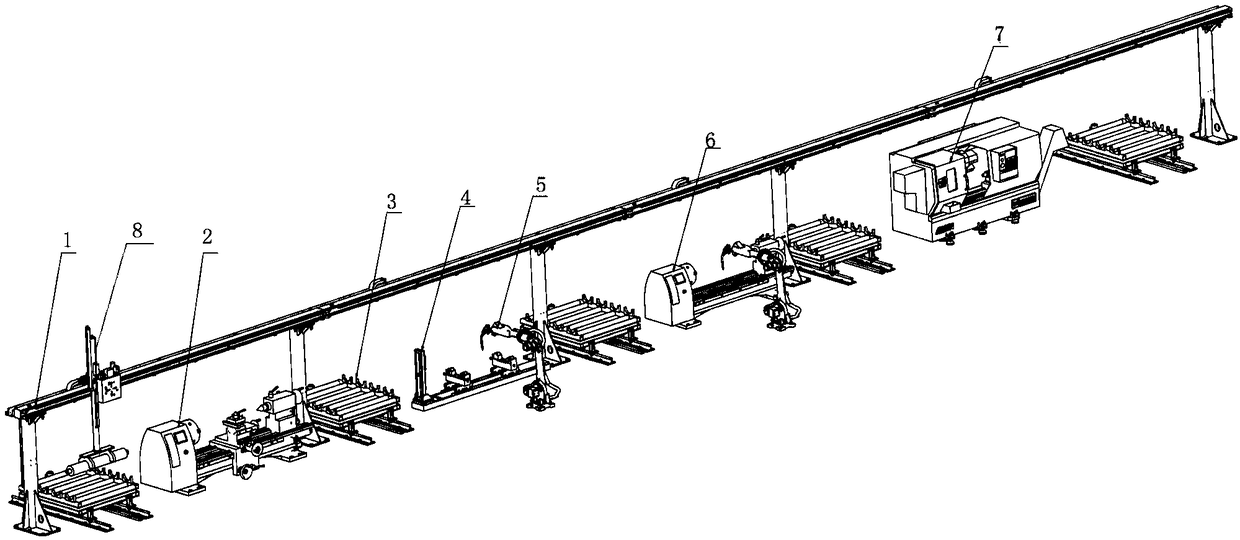

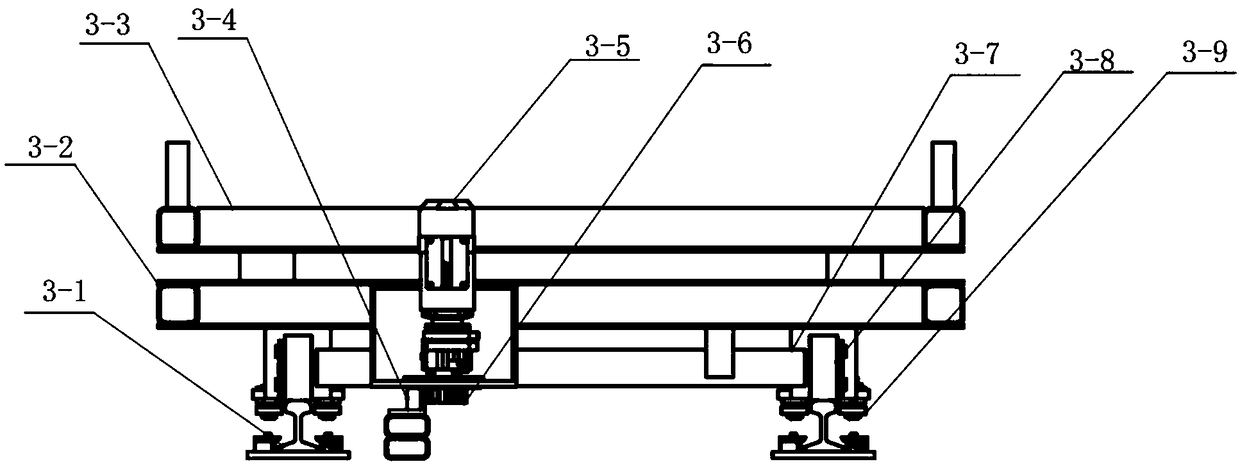

Oil sucker rod intelligent manufacturing production line

ActiveCN111390087AThe transfer process is stableRealize intelligent automatic productionForging/hammering/pressing machinesForging press detailsMachineMachining process

An oil sucker rod intelligent manufacturing production line comprises a feeding bin, a first stepping push device, a first angular positioning device, a first transferring device, an axial operation device, a second angular positioning device, a second stepping push device, a second transferring device and a discharging bin arranged in sequence in the workpiece operating direction; the outer sideof the first transferring device and the outer side of the second transferring device are both provided with machine tools; the first stepping push device pushes workpieces on the feeding bin, the first angular positioning device and the first transferring device forwards in sequence; and the second stepping push device pushes the workpieces on the axial operation device, the second angular positioning device, the second transferring device and the discharging bin forwards. According to the production line, the problems that conveying, clamping and positioning are difficult in the machining process of long and thin oil sucker rods are solved, intelligent automatic production of external threads of two ends of an oil sucker rod is achieved, the workpiece transferring stability is ensured, the paces are intense, the production efficiency is high, and the production cost is reduced.

Owner:山东弘名智能科技有限公司

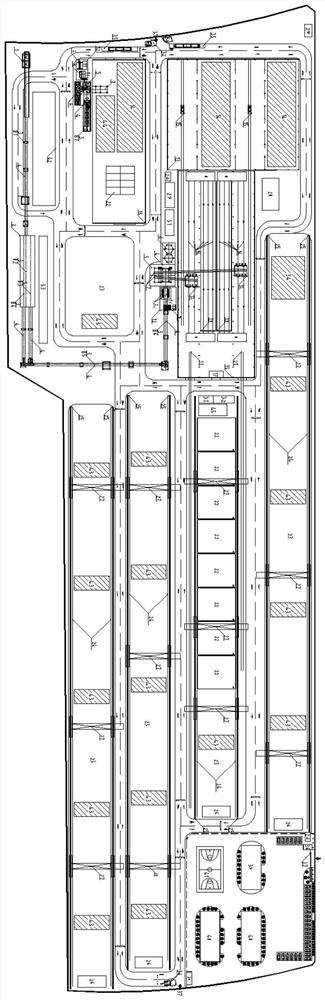

Precast concrete component environment-friendly intelligent production system design method

InactiveCN111941626AQuality assuranceEnsure safetyCeramic shaping plantsAuxillary shaping apparatusInformatizationSystems design

The invention discloses a design method of a precast concrete component environment-friendly intelligent production system. The precast concrete component environment-friendly intelligent production system comprises a totally-enclosed sandstone aggregate storage and transportation system, a totally-enclosed concrete mixing and conveying system, an integrated sandstone separation and filter pressing workshop, an environment-friendly standard-reaching reinforcement cage processing workshop, an environment-friendly standard-reaching prefabricated part pouring and forming workshop, an intelligentsteam curing system, an intelligent water curing system, an intelligent finished product stacking, storing and shipping system, an informatization and intelligence management system and a production ancillary facility system. A highly-integrated, intelligent, systematic and environment-friendly precast concrete component production factory-like comprehensive solution and a design method based on the solution are provided; and the processes that comprehensive treatment is carried out on pollution sources such as noise, dust, solid waste and waste water are included, technologies such as the Internet of Things, big data and cloud computing are fused, technical means such as an application programming interface (API) are utilized, environmental protection is achieved, secondary utilization ofall materials is achieved, and the recycle environment-friendly requirement is met.

Owner:中电建成都混凝土制品有限公司

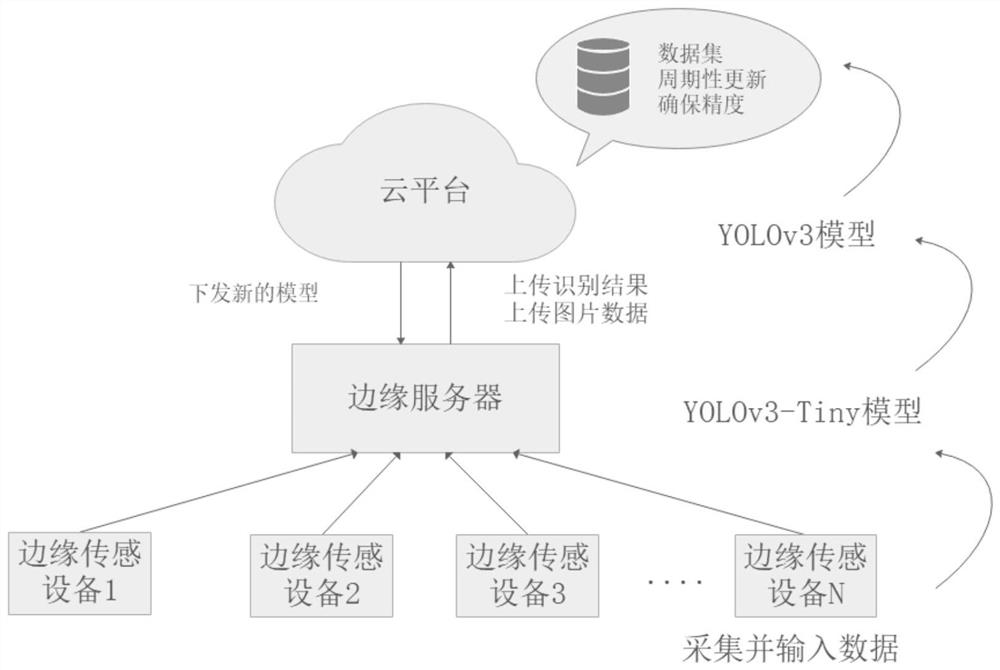

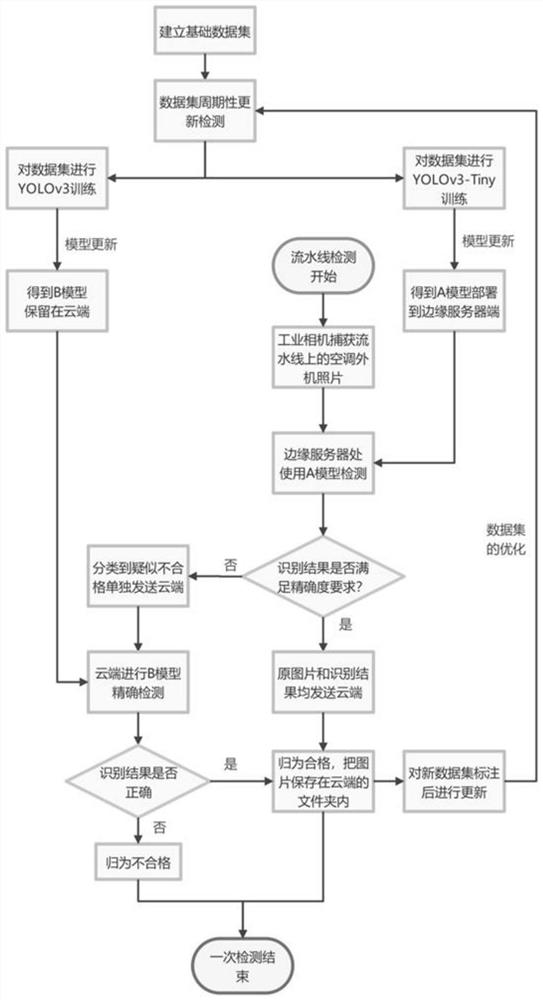

Product appearance detection method based on cloud edge collaborative model optimization and implementation system thereof

PendingCN112788110ARelieve pressureIncrease credibilityCharacter and pattern recognitionTransmissionEdge serverData set

The invention relates to a product appearance detection method based on cloud edge collaborative model optimization and an implementation system thereof. The detection method comprises the following steps: S1, establishing a basic data set; s2, training a YOLOv3-tiny model and a YOLOv3 model, and respectively deploying the YOLOv3-tiny model and the YOLOv3 model at an edge server and a cloud platform; s3, detecting and recognizing, by the YOLOv3-tiny model, the picture, when the picture is detected to be qualified, sending the picture and a detection resultto the cloud platform, and executing the S5, if the detection result is unqualified, determining that the result is suspected to be unqualified, sending the result to the cloud platform, and performing S4; s4, performing secondary detection on the suspected unqualified pictures on the cloud platform; if the secondary detection is not qualified, outputting a result, and ending the process, and if the secondary detection is qualified, performing S5; and S5, storing the qualified picture in the cloud platform, outputting a result, and ending. According to the method, the problems of accuracy, flexibility, time delay and data utilization rate are solved by using a working mode of cloud edge collaboration.

Owner:SHANDONG UNIV

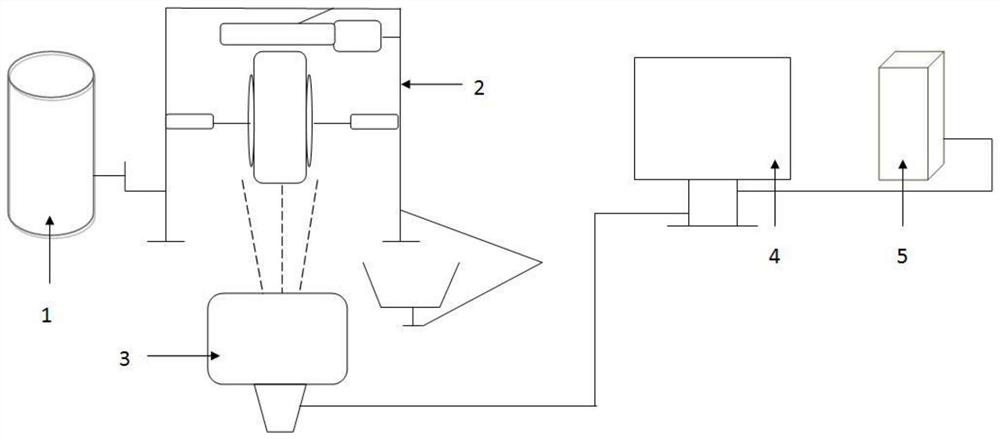

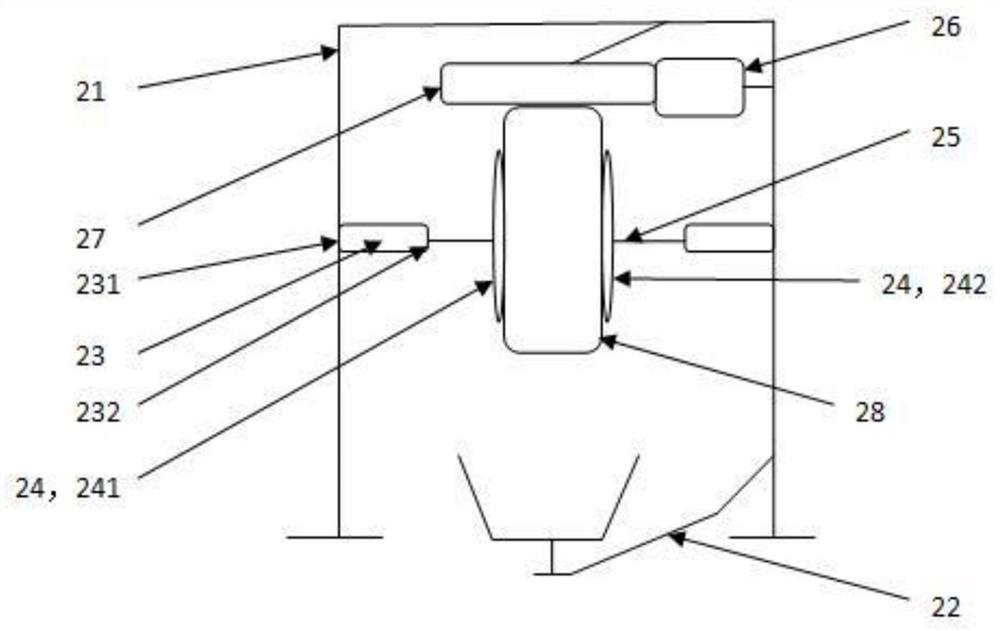

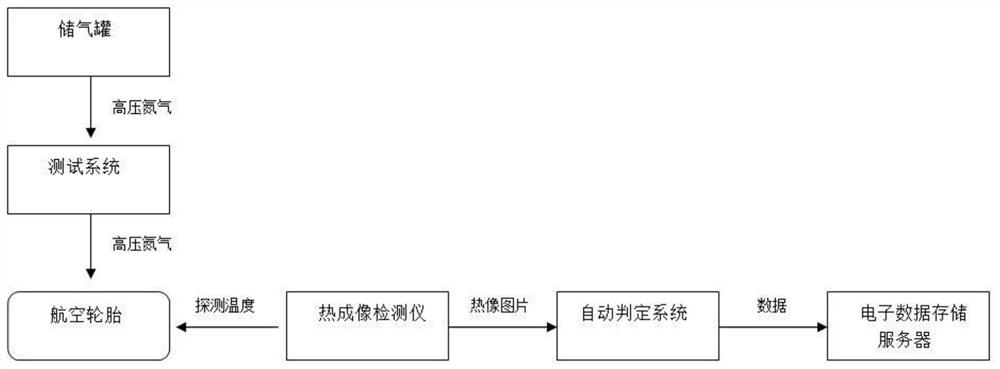

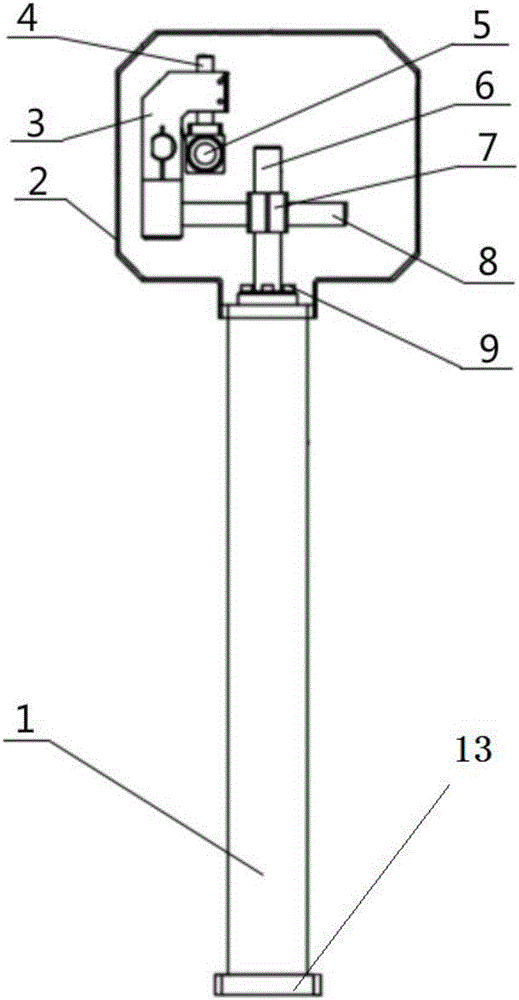

Aircraft tire penetrability damage thermal imaging detection system and method

InactiveCN112461895ANo damageImprove detection accuracyMaterial flaws investigationAviationElectronic data

The invention discloses an aircraft tire penetrability damage thermal imaging detection system which comprises: an air storage tank for filling a tire with a pressure medium at a certain temperature,an inflating device capable of communicating with the tire, a test board connected with the aircraft tire, a thermal imaging detector arranged at a position a certain distance away from the aircraft tire, and an automatic judgment system and a electronic data storage server which are connected with the thermal imaging detector. The air storage tank is connected with the air charging device throughan air conveying pipeline; the inflating device is connected with an aircraft tire connected in the test board; and the automatic judgment system is connected with the electronic data storage serverthrough a data line. The invention belongs to the technical field of tire detection, and solves the problems of low detection precision, low efficiency and low automation degree of penetration damageof aircraft tires.

Owner:QINGDAO SENTURY TIRE CO LTD

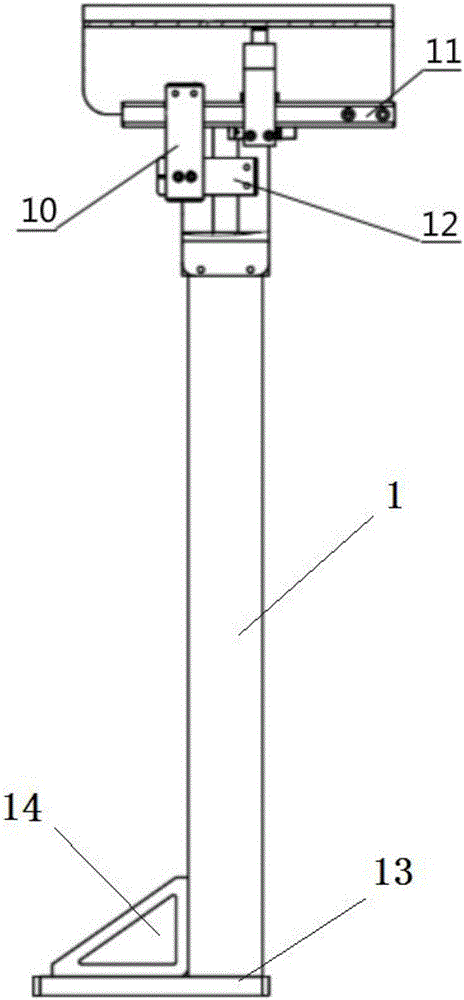

Detection device for end surface defects of piston pin

InactiveCN106290381ARealize quality managementSolve the detection speed is slowOptically investigating flaws/contaminationComputer moduleCcd camera

The invention discloses a detection device for end surface defects of a piston pin. The detection device is provided with two independent detection modules, and the two independent detection modules are used for detecting two end surfaces of the piston pin respectively. The detection device is structurally characterized in that a vertical adjusting pillar is mounted at the top end of a fixed support seat through a plurality of screws and connected with a horizontal adjusting pillar through fixed adjusting blocks, the horizontal adjusting pillar is connected with a mounting plate, the mounting plate is connected with a camera fixing plate through a connecting block, and a lens adjusting block is mounted on the camera fixing plate and connected with a CCD camera through a lens fixing pillar. The end surface defects of the piston pin can be detected, non-contact dynamic detection is realized in a visual identity manner, and the working efficiency is greatly improved while the measurement accuracy is guaranteed.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD +1

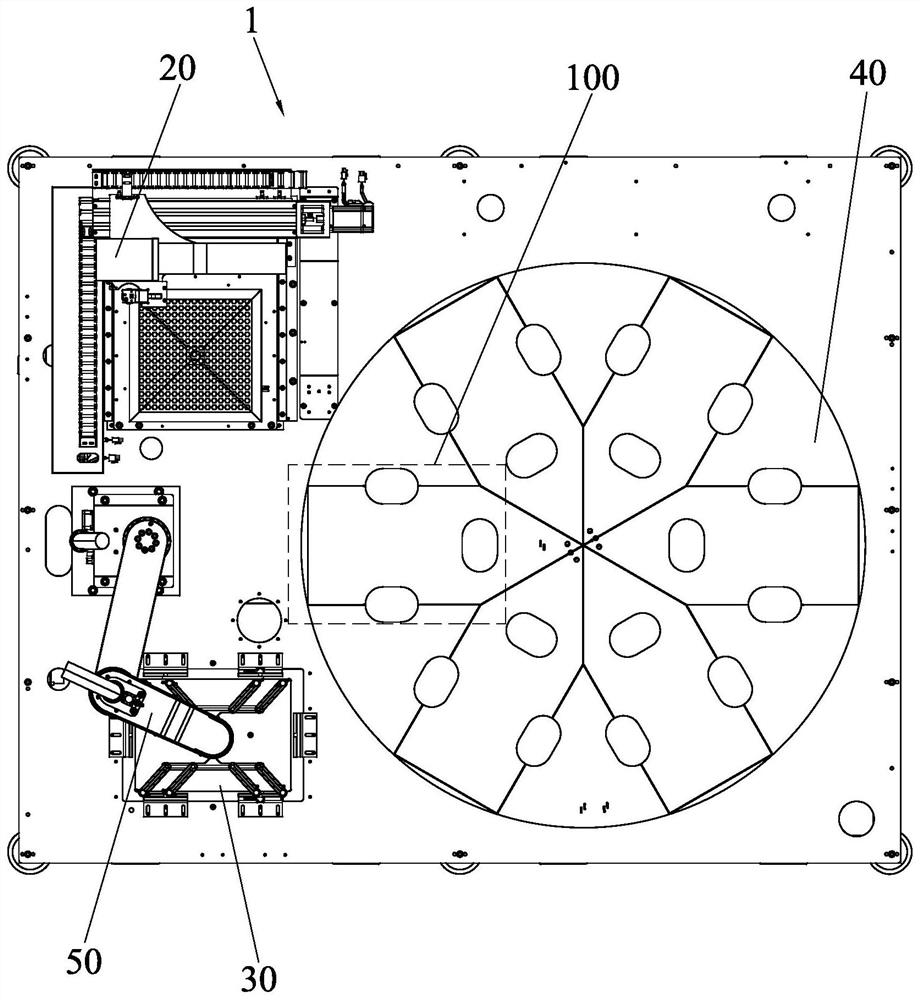

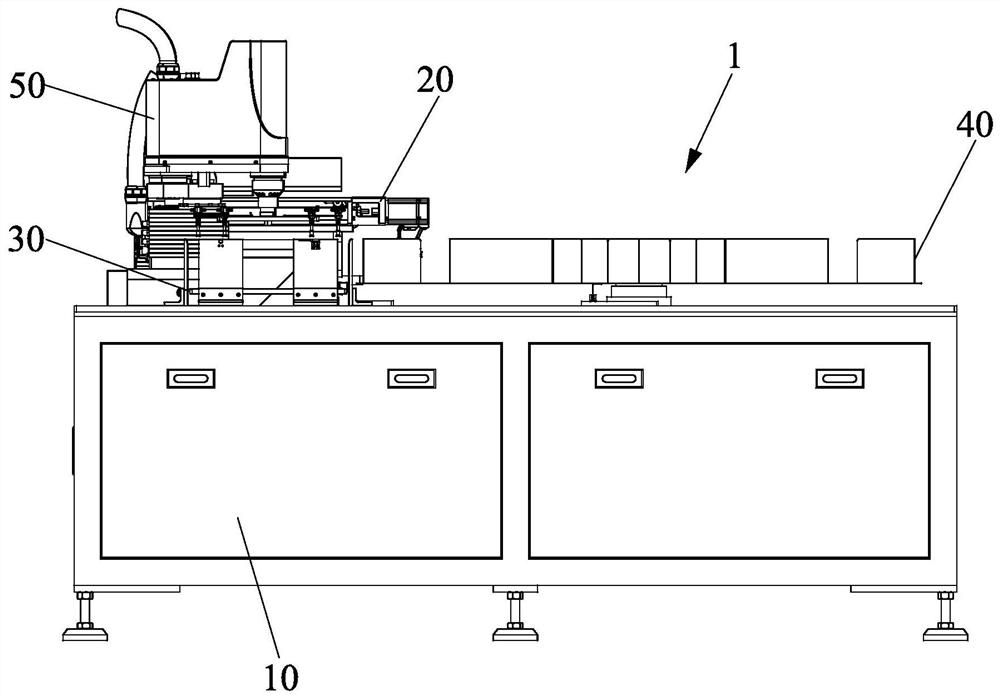

Automatic feeding and discharging machine for punching

PendingCN110328711AReliable grabbingPrecise feeding positionMetal working apparatusPrinted circuit boardEngineering

The invention discloses an automatic feeding and discharging machine for punching. The machine comprises a rack, a feeding and discharging mechanism and a mechanical arm mechanism. The feeding and discharging mechanism comprises a feeding assembly and a discharging assembly, the feeding assembly and the discharging assembly are arranged on the front end of the rack side by side in an up and down sliding manner, the mechanical arm mechanism is arranged above the rack, and comprises mechanical arms and a suction cup jig, the mechanical arms are arranged on the rack and can move above the feedingand discharging mechanism, the suction cup jig can be rotatably arranged below the mechanical arms, the suction cup jig is provided with multiple air channels which are independently arranged, duringfeeding, the mechanical arm drives the suction cup jig to suck a product or tray from the position above the feeding assembly, during discharging, the mechanical arms drive the suction cup jig to place the product or tray to the position above the discharging assembly, automation of the punching process of a printed circuit board can be achieved, intelligent manufacturing is achieved, labor forceis saved, production efficiency is improved, the product machining quality is stabilized, and the economic benefits are improved.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

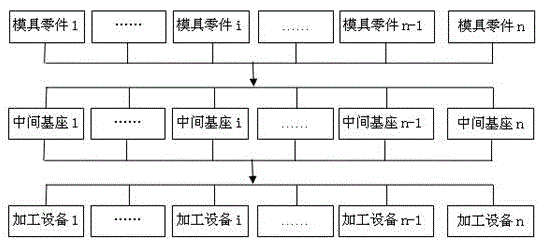

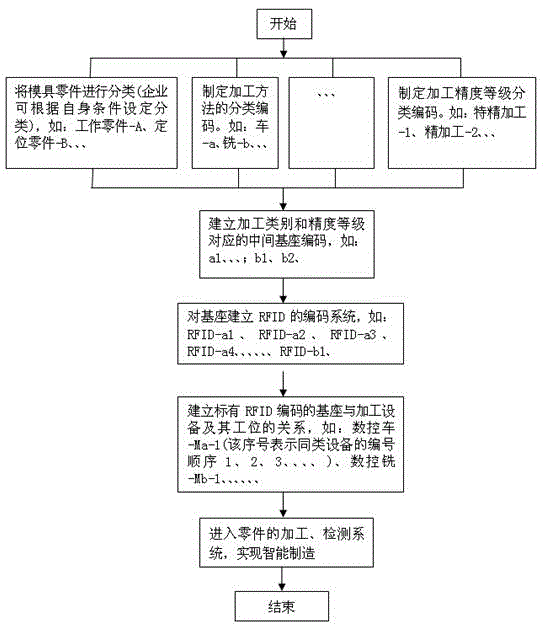

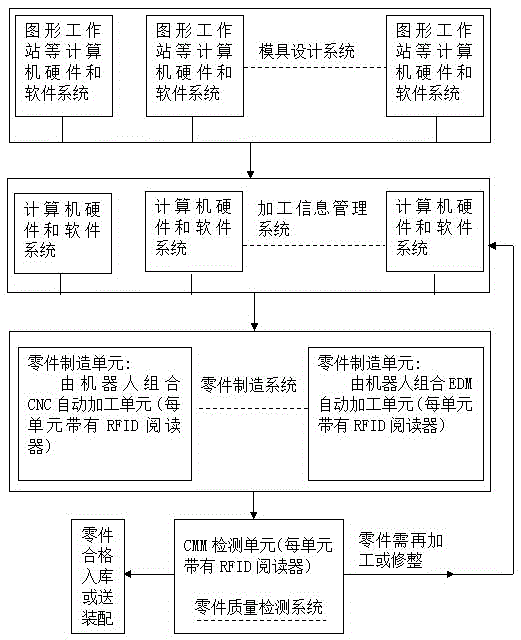

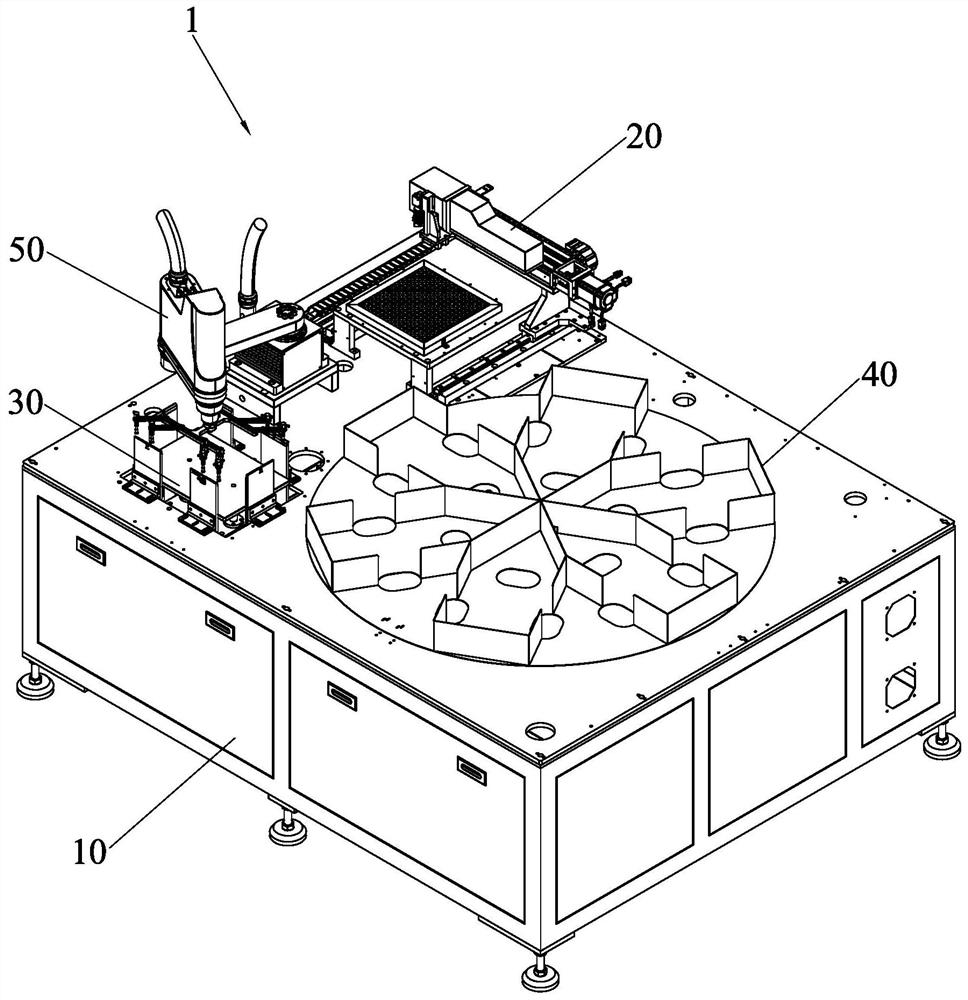

Full-automatic die manufacturing system and method

InactiveCN105414910ARealize intelligent manufacturingIncrease productivityOther manufacturing equipments/toolsEngineeringManufacturing systems

The invention discloses a full-automatic die manufacturing system and method. The manufacturing system comprises a die design system, a machining information management system, a part manufacturing system and a part quality detection system. The die design system is used for designing the structures of dies and parts of the dies and sending part information to the machining information management system. The machining information management system is used for sending machining information of the dies to all part manufacturing units in the part manufacturing system. All machining stations of all the part manufacturing units are provided with radio frequency identification device (RFID) readers. The machining information management system is used for sending commands. All the part manufacturing units receive and transfer the machining information through the RFID readers. The part quality detection system is used for detecting the parts machined by all the part manufacturing units and feeding the information of the machined parts back to the machining information management system through the RFID readers. Whether re-machining is needed or not is determined by the machining information management system. According to the full-automatic die manufacturing system and method, the production efficiency is high, the convenience and practicability are achieved, and intelligent manufacturing of the dies is achieved.

Owner:GUANGDONG UNIV OF TECH

Laser punching equipment

PendingCN111687551AEasy to identifyImprove consistencyPrinted circuitsMetal working apparatusPunchingEngineering

The invention discloses a laser punching equipment. The laser punching equipment comprises a machine frame, a laser punching mechanism, a lifting platform mechanism, a material transfer mechanism andan upper camera. The laser punching mechanism comprises a laser workbench, a mobile module, a laser device and a camera module. The lifting platform mechanism is arranged on a machine frame workbench.The material transfer mechanism comprises a robot and a suction disk jig. A robot is arranged on the machine frame workbench. The suction disk jig is arranged at the bottom end of a rotary arm of therobot. The upper camera is arranged on the part, corresponding to the upper part of the lifting platform, of the machine frame and is used to recognize materials on a lifting platform. With the laserpunching equipment, the operational accuracy and the production efficiency can be improved, equipment operation is automatic, one person can operate multiple devices, the human cost is reduced, and intelligent manufacturing can be implemented.

Owner:厦门柔性电子研究院有限公司 +2

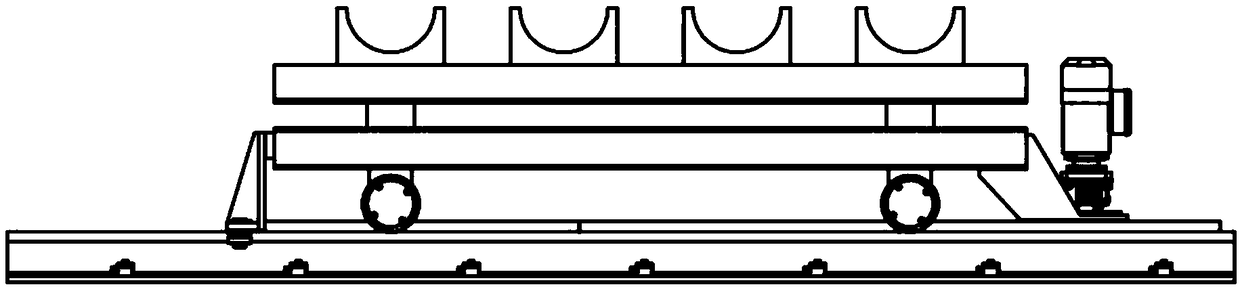

Automatic production line and technology for laminar flow roller manufacturing

PendingCN109434478ASimple production processHigh degree of automationOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses an automatic production line and technology for laminar flow roller manufacturing. The automatic production line comprises a shaft head surfacing device used for repairing a laminar flow roller, a high-speed laser cladding device used for surface reinforcement of the laminar flow roller, a turning device used for processing the laminar flow roller, a mechanical hand which is matched with the shaft head surfacing device, the high-speed laser cladding device and the turning device and is used for feeding and discharge, a tray used for placing and transferring the laminarflow roller, and an automatic forklift. According to the automatic production line, the structure is adopted, shaft head surfacing, surface reinforcement and cutting processing are integrated, the technological process is improved, laminar flow roller manufacturing and remanufacturing are intelligent, production efficiency is high, product quality is stable, and continuous operation can be achieved.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

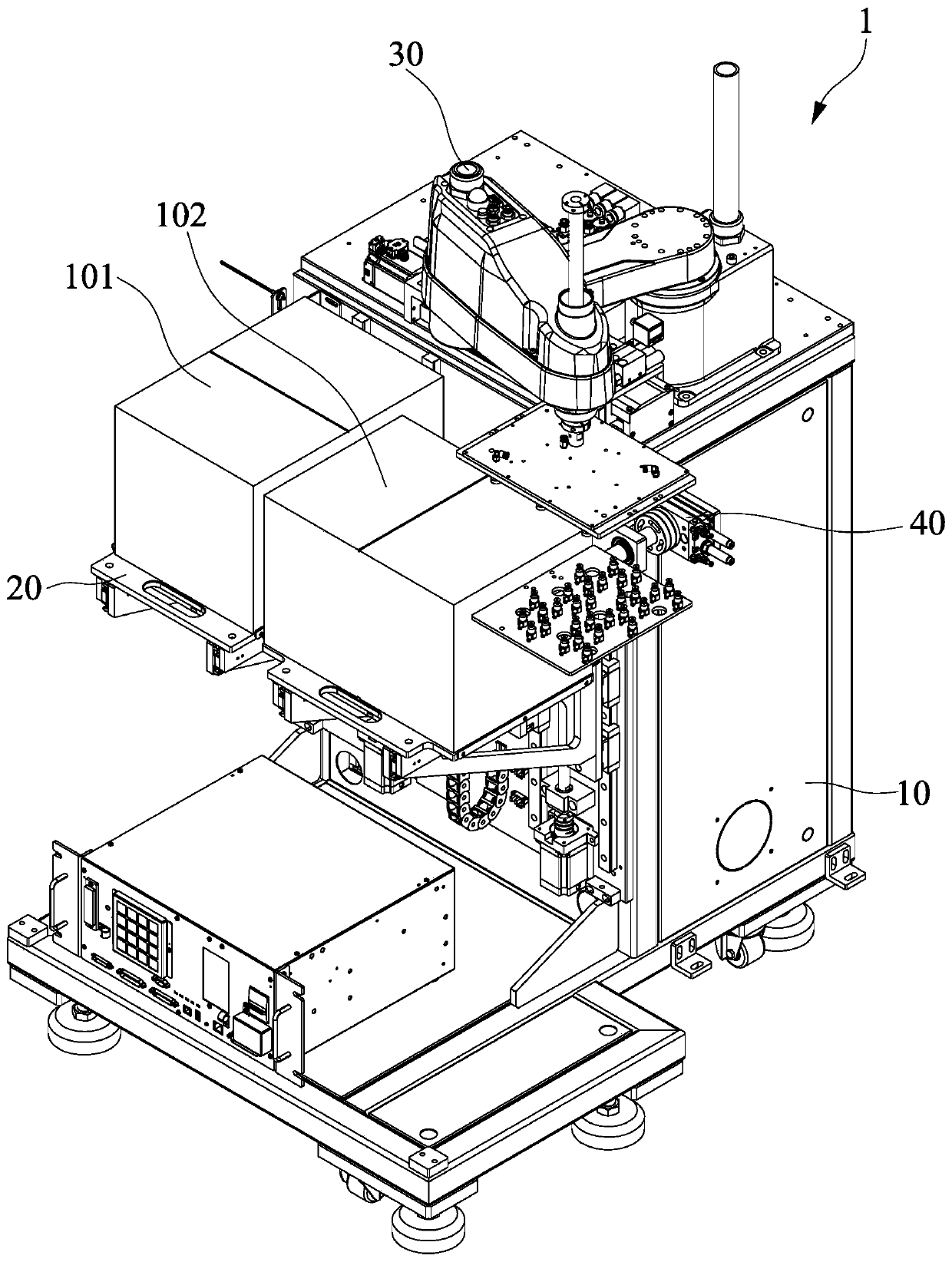

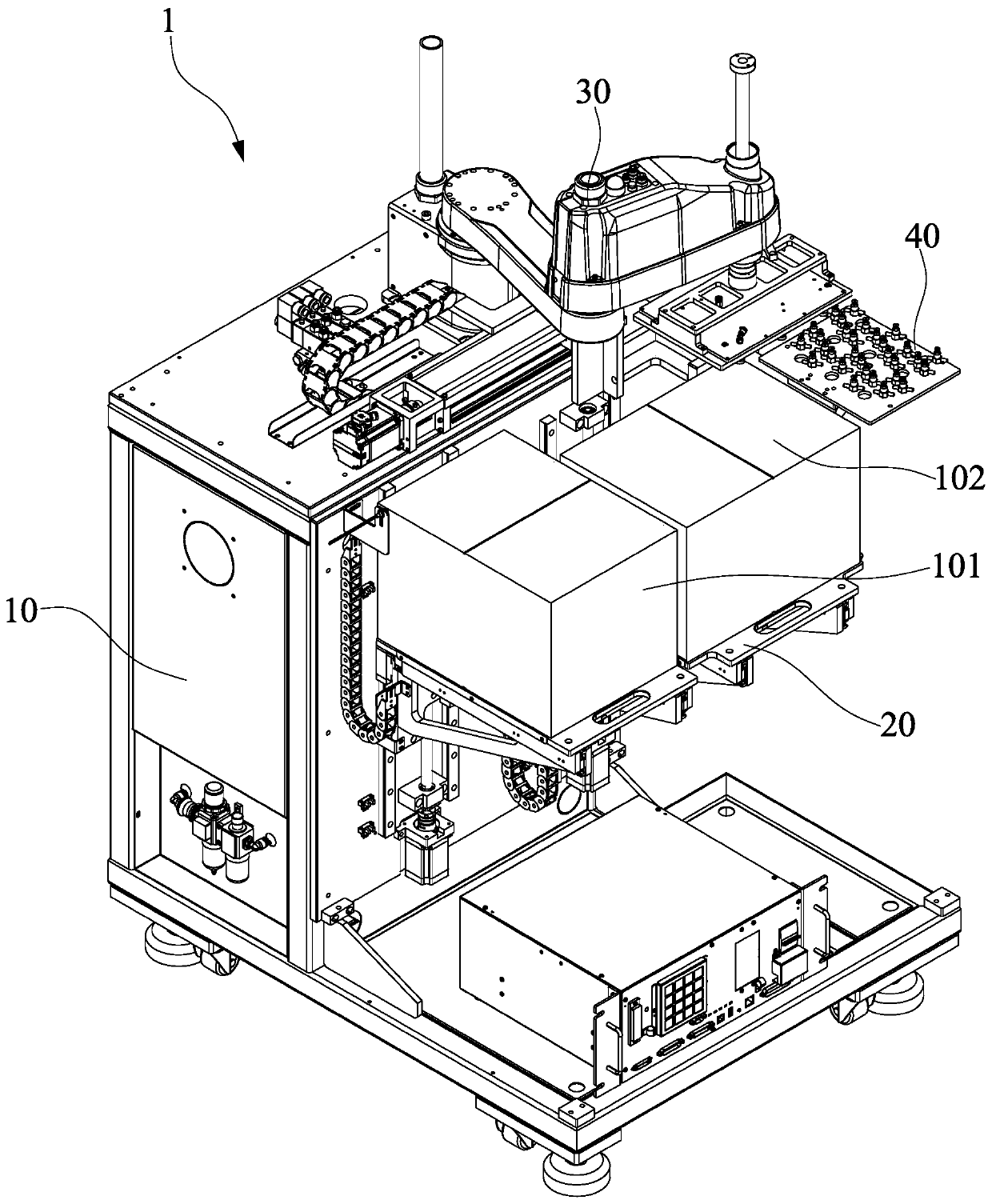

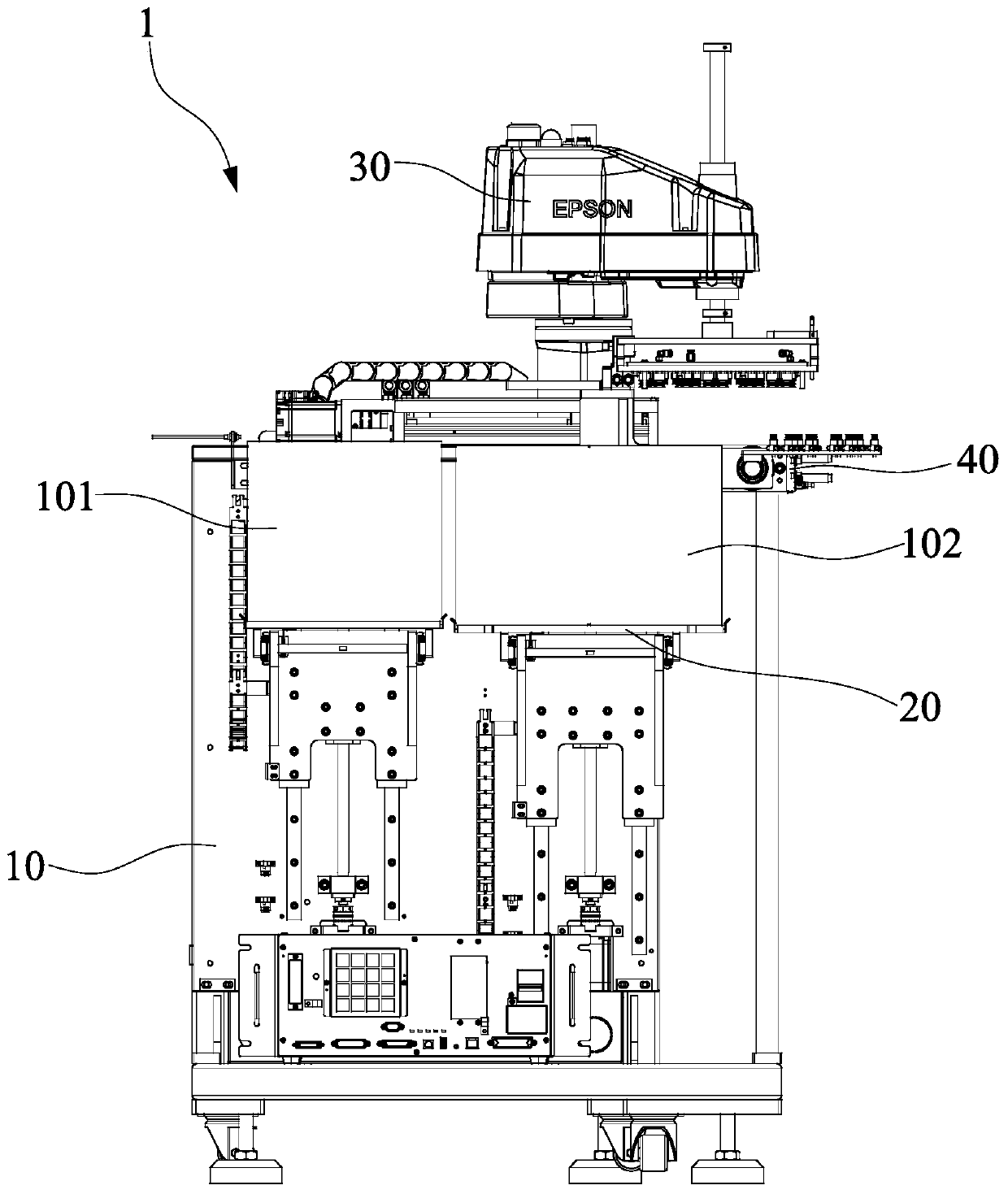

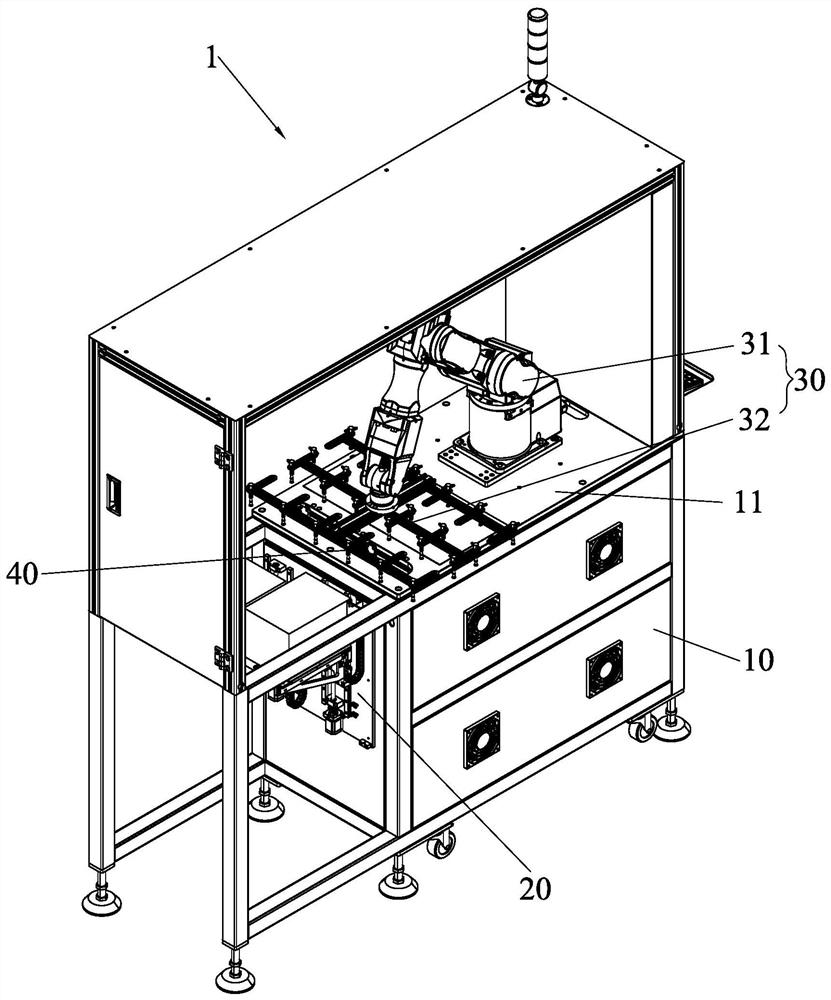

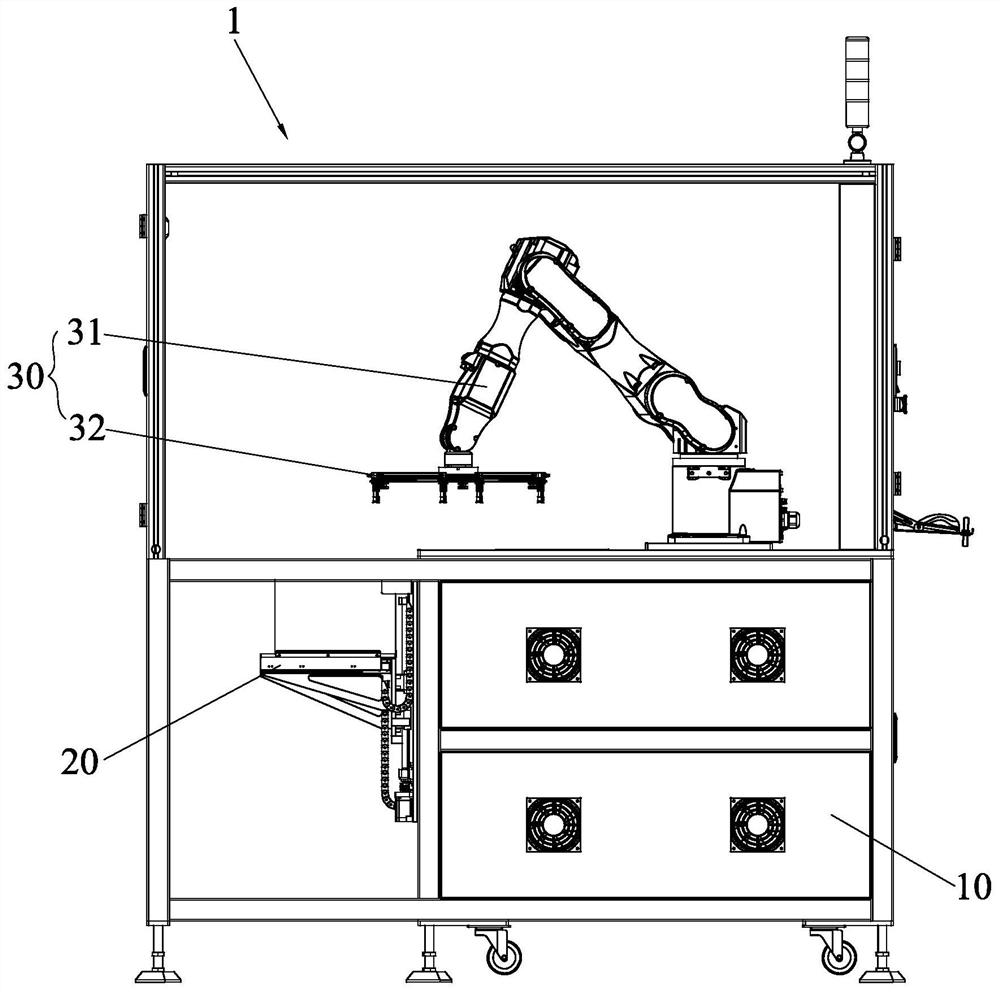

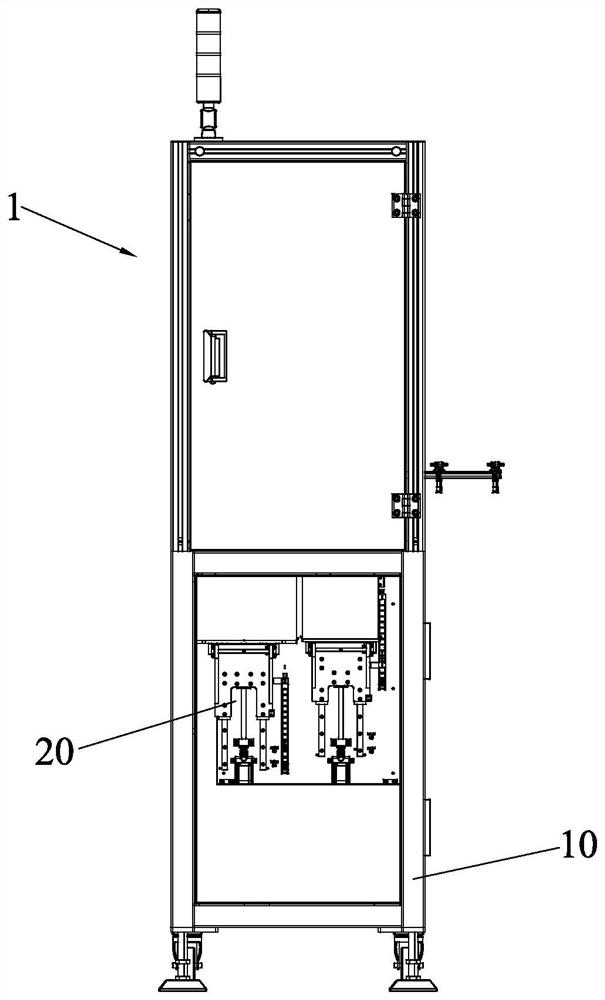

Automatic feeding and discharging equipment and automatic feeding and discharging method

PendingCN112794062ARealize intelligent manufacturingIncrease productivityControl devices for conveyorsReciprocating motionControl engineering

The invention discloses automatic feeding and discharging equipment and an automatic feeding and discharging method. The equipment comprises a rack, a feeding and discharging mechanism and a material moving mechanism, wherein the feeding and discharging mechanism and the material moving mechanism are arranged on the rack; the feeding and discharging mechanism comprises a feeding assembly and a discharging assembly; the feeding assembly and the discharging assembly are arranged on a mechanism mounting plate side by side; the feeding assembly comprises a Y-axis linear module, a Y-axis linear guide rail and a lifting bracket; the Y-axis linear module can drive a lifting bracket to reciprocate along the Y-axis linear guide rail; the discharging assembly and the feeding assembly are the same in structure; and the material moving mechanism comprises a robot and a material suction jig connected with the robot. By adopting the automatic feeding and discharging equipment disclosed by the invention, automatic feeding and discharging can be achieved; manual operation is replaced; intelligent manufacturing is achieved; production efficiency is improved; one person can operate a plurality of devices, so manpower investment is reduced; in addition, the equipment runs stably; and product quality is effectively guaranteed.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

Grinding capacity design method based on grit chip thickness distribution constraint

ActiveCN108334673AAchieve expected processing resultsAvoid consumptionDesign optimisation/simulationComplex mathematical operationsEngineeringElectrical and Electronics engineering

The invention discloses a grinding capacity design method based on grit chip thickness distribution constraint, comprising the steps of (1) setting target grit chip thickness distribution according toprocessing results, giving set grinder surface grit parameter and grinding capacity, and initializing the grinding capacity; (2) subjecting grinder surface grit parameters and grinding capacity to grit chip thickness distribution calculation so as to obtain grit chip thickness distribution; (3) comparing the grit chip thickness distribution of step (2) to the set target grit chip thickness distribution of step (1); if differences are large, adjusting grit grinding capacity, performing the cycle of the steps (2) and (3), and stopping calculating until the differences between the grit chip thickness distribution of step (3) and the set grit chip thickness distribution of step (1) meet a set standard, so that the grinding capacity is an optimization result. The grinding capacity is optimizedin order to perform processing, so that effective expected processing purposes can be met.

Owner:HUAQIAO UNIVERSITY

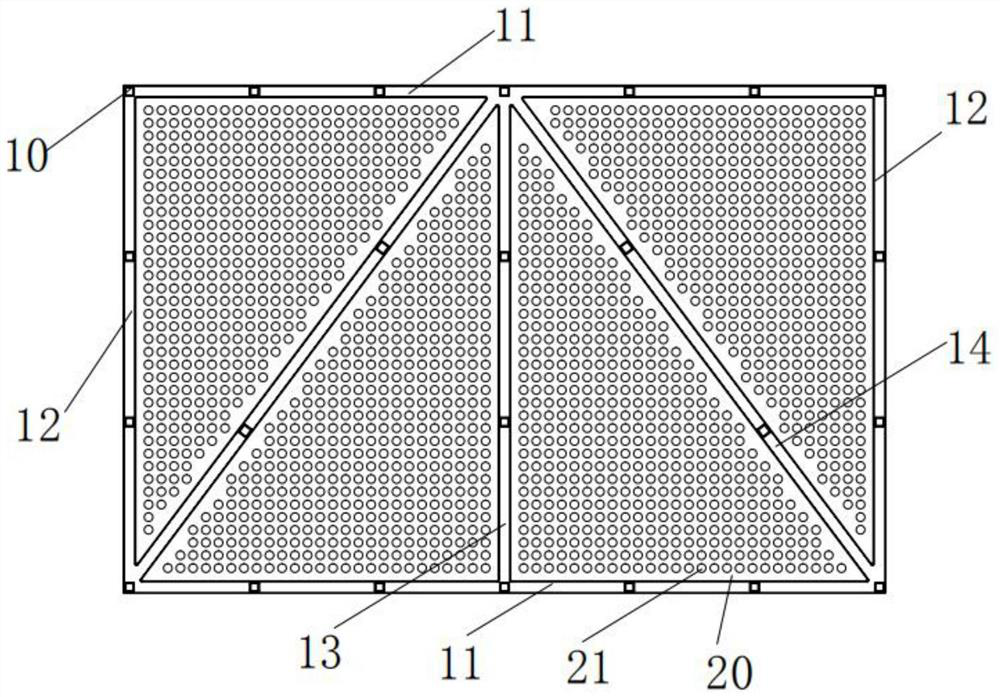

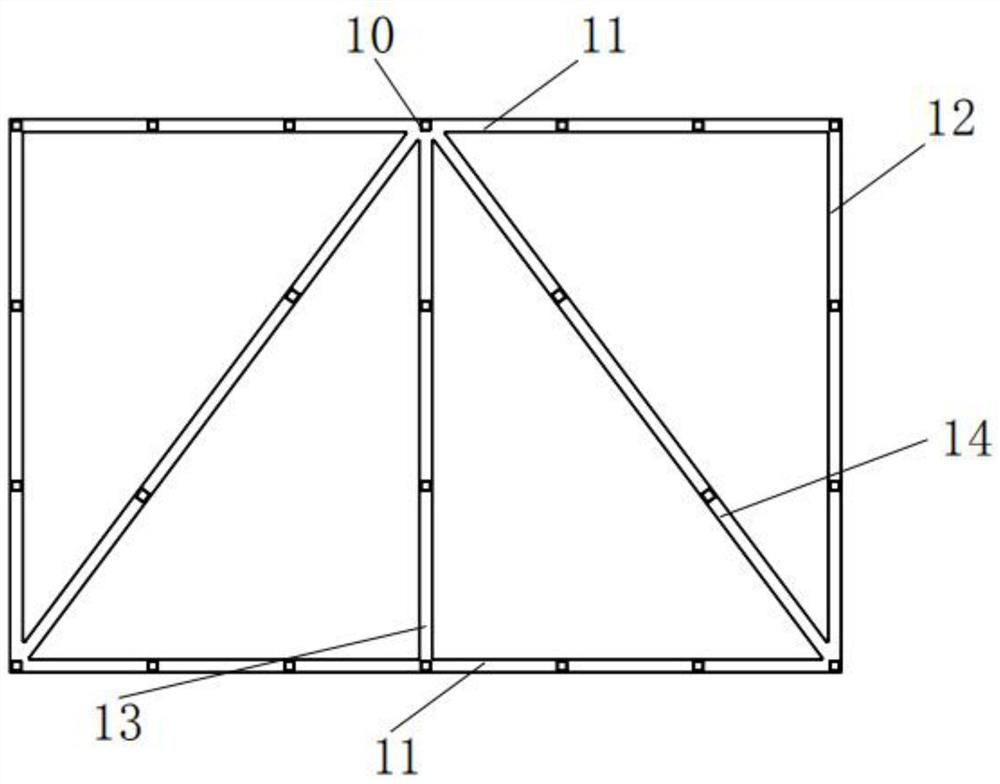

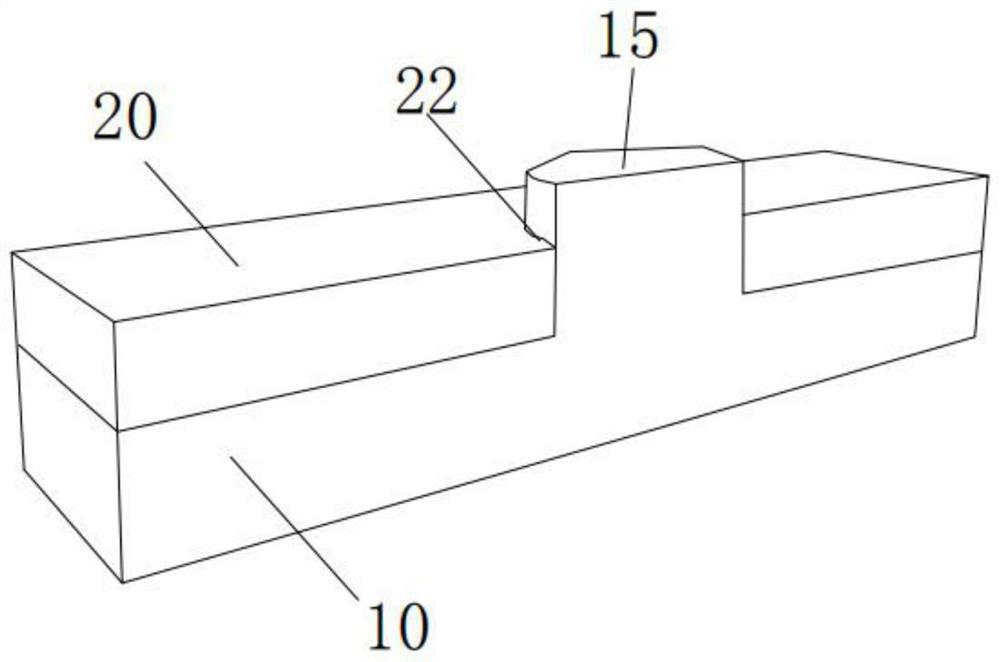

Climbing frame mesh sheet and production method thereof

PendingCN113123624AStrong resistance to deformationAchieve recyclabilityBuilding material handlingDomestic netsCompression moldingGlass fiber

The invention discloses a climbing frame mesh sheet and a production method thereof. The climbing frame mesh sheet comprises a frame and a mesh body, wherein the frame comprises two first supporting rods and two second supporting rods which are perpendicular to each other, wherein the first supporting rods and the second supporting rods form a rectangular structure, a mesh sheet is a rectangular sheet, the mesh sheet is fixedly connected to the surface of the frame, and the frame and the mesh sheet are both made of long glass fiber reinforced polypropylene. According to the climbing frame mesh sheet, the frame and the mesh sheet are made of long glass fiber reinforced polypropylene, so that a climbing frame has the characteristics of high strength, high deformation resistance and high recoverability, in addition, the frame and the mesh sheet are welded and fixed into an integral structure, the product material of the climbing frame mesh sheet is a material and is free of metal fasteners, the whole climbing frame mesh sheet can be crushed, recycled and reused, feeding, hot melting, mixing, spreading, compression molding and product taking can be automatically completed in the production process, intelligent manufacturing and green and environment-friendly for a factory is achieved, 100% recovery of products is achieved, and the environment-friendly policy is met.

Owner:HENGSHUI YOUJIETE PETROLEUM EQUIP TECH CO LTD

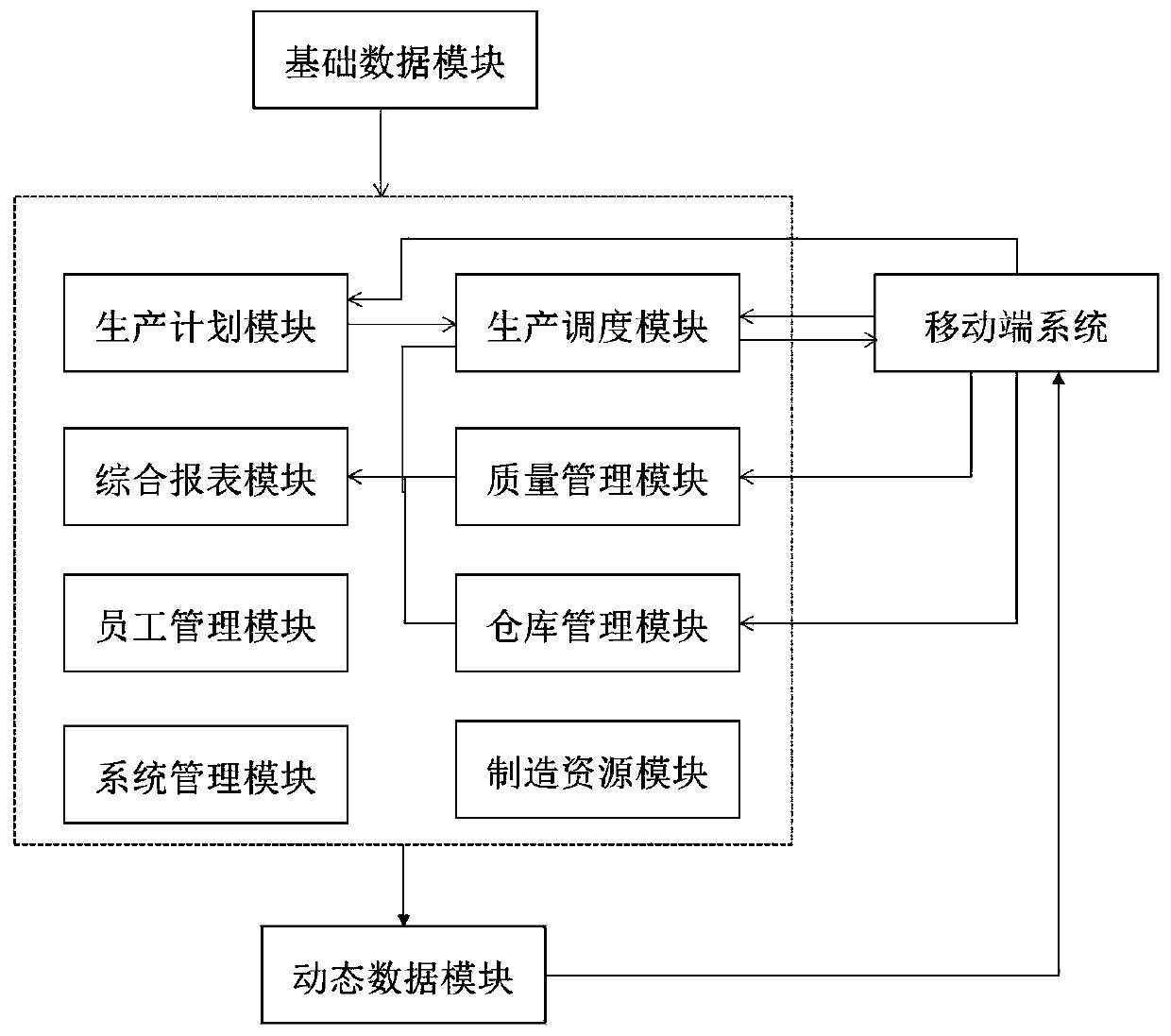

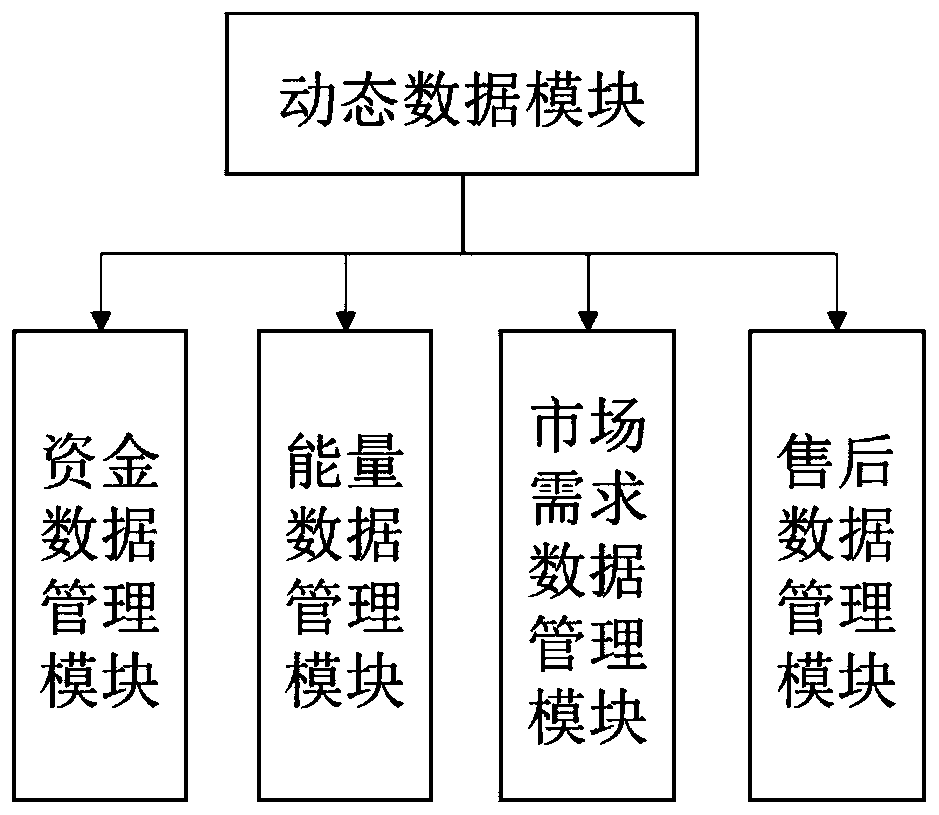

Intelligent manufacturing system for computer production

ActiveCN110689217ARealize intelligent manufacturingEfficient configurationResourcesLogisticsSystems managementMobile end

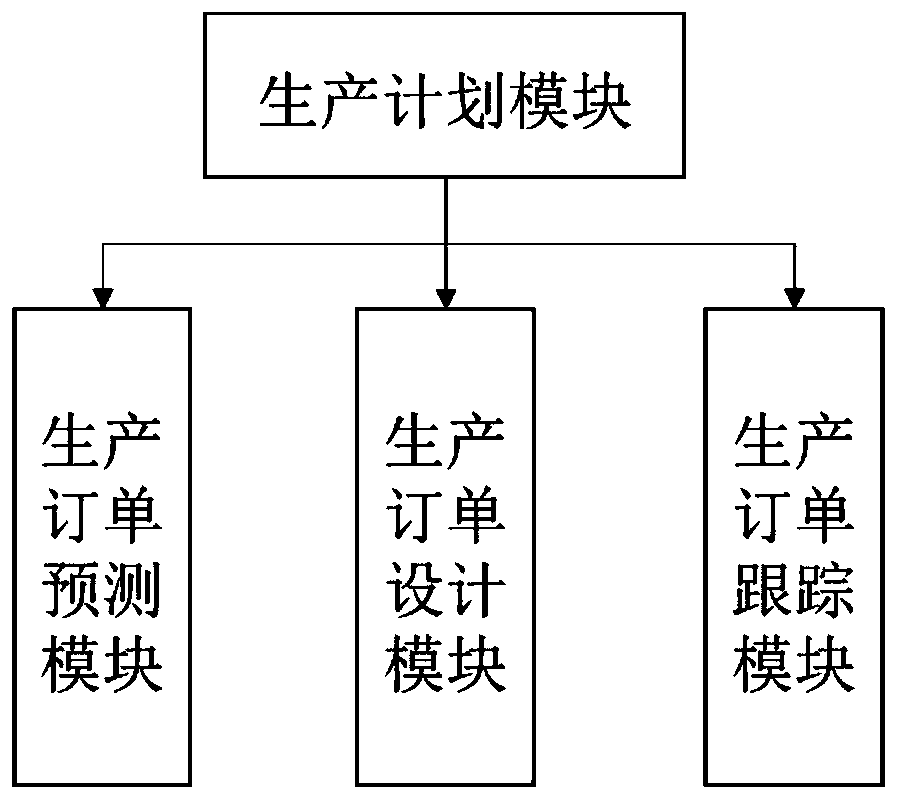

The invention provides an intelligent manufacturing system for computer production. The intelligent manufacturing system comprises a basic data module, a production planning module, a production scheduling module, a quality management module, a manufacturing resource module, an employee management module, a warehouse management module, a comprehensive report module, a system management module, a dynamic data module and an equipped mobile terminal system. The dynamic data module comprises a fund data management module, an energy data management module, a market demand data management module andan after-sales data management module; a computer production intelligent manufacturing knowledge base is constructed through data of the dynamic data module, the production planning module achieves intelligent optimization design of computer manufacturing content by conducting intelligent learning on the knowledge base, and therefore efficient operation of all links is effectively configured, andautomatic production scheduling with the highest benefit and the lowest cost is achieved.

Owner:WUHAN PANSHENG DINGCHENG TECH CO LTD

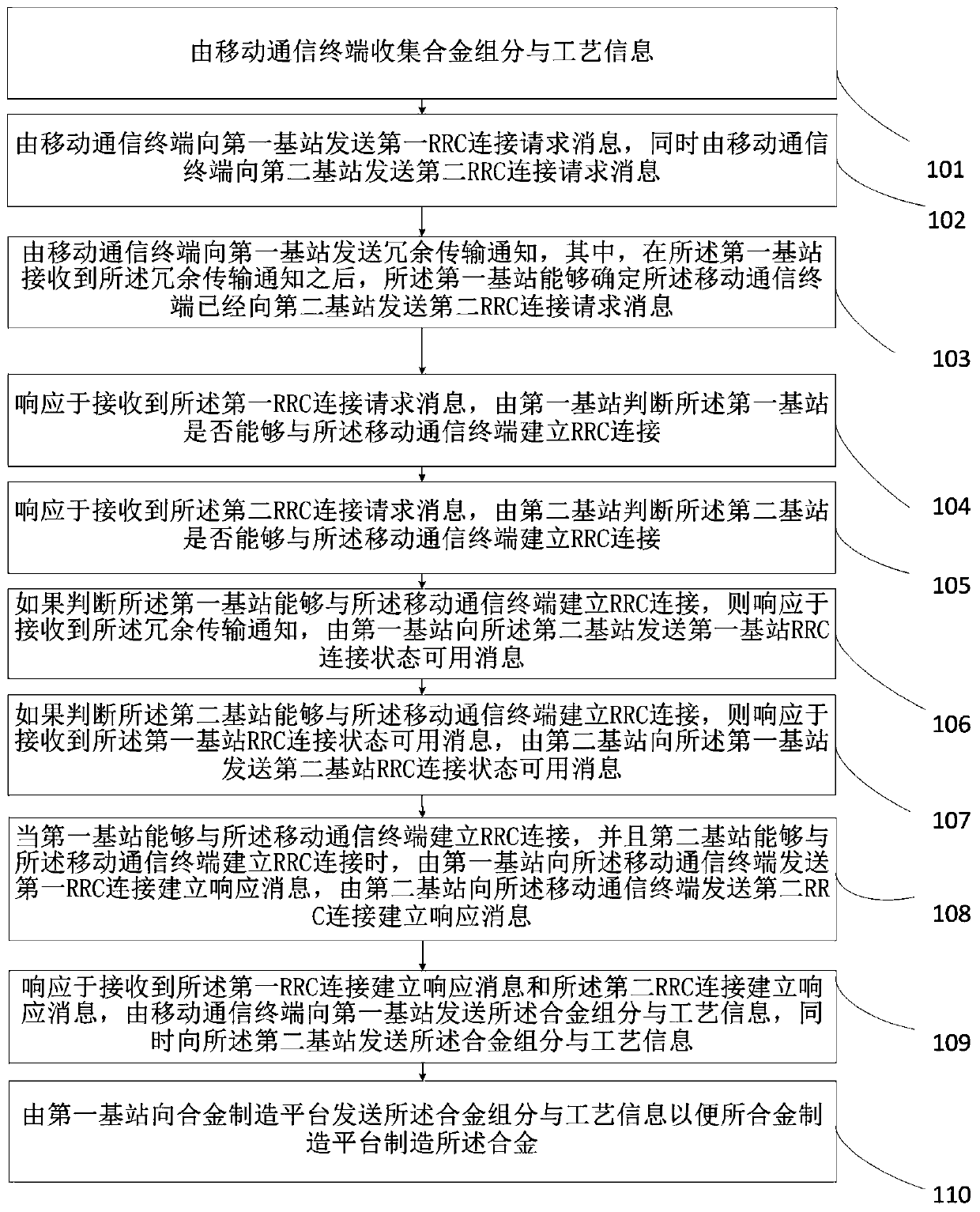

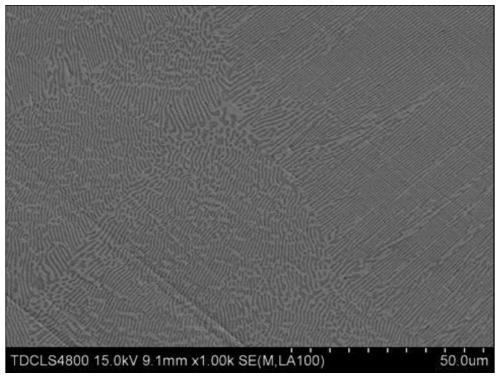

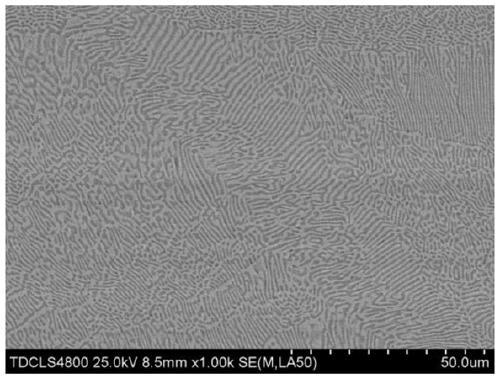

Internet-of-Things based preparation method and preparation system of light green gold alloy for jewelry and horologe industry

ActiveCN110468299AImprove quality stabilityReduce manufacturing costConnection managementTransmissionGold alloysComputer terminal

The invention discloses an Internet-of-Things based preparation method of a light green gold alloy for the jewelry and horologe industry. The preparation method comprises the following steps of collecting alloy component and process information at a mobile communication terminal; transmitting a first RRC connection request message to a first base station from the mobile communication terminal andmeanwhile transmitting a second RRC connection request message to a second base station from the mobile communication terminal; making a response to the received first RRC connection request message and judging whether the first base station can establish RRC connection with the mobile communication terminal or not through the first base station; making a response to the received second RRC connection request message and judging whether the second base station can establish RRC connection with the mobile communication terminal or not through the second base station; transmitting a first base station RRC connection status available message from the first base station to the second base station if judging that the first base station can establish RRC connection with the mobile communicationterminal; and transmitting a second base station RRC connection status available message from the second base station to the first base station if judging that the second base station can establish RRC connection with the mobile communication terminal.

Owner:深圳市金辉源投资有限公司

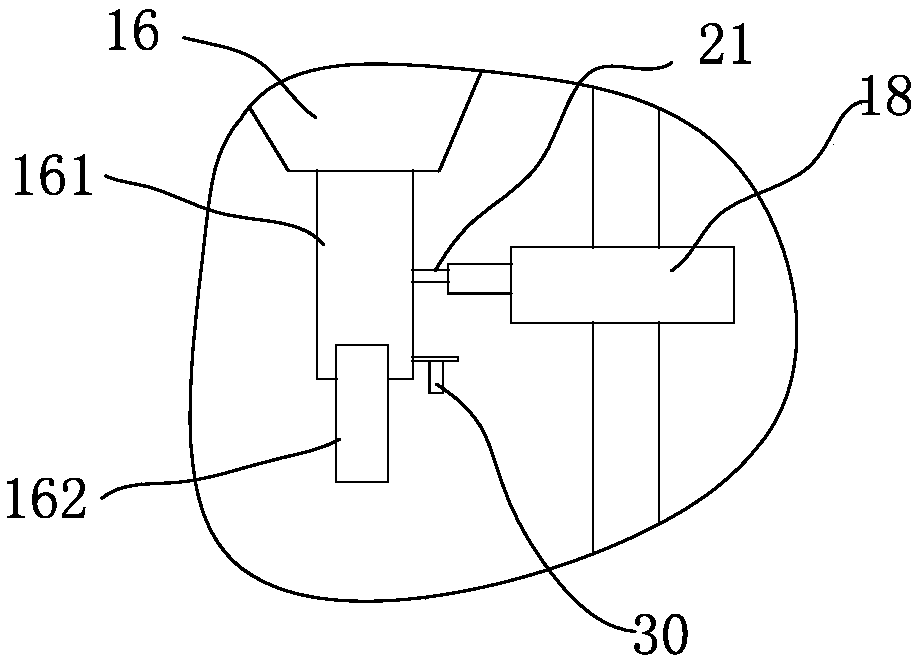

Image digital acquisition device capable of reducing jitter

InactiveCN112261286AReduce jitterSolve the problem that it is easy to make the refraction plate shakeTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention relates to the technical field of image digitization equipment, and discloses an image digitization acquisition device capable of reducing jitter, which comprises a shell, an adjusting knob is rotatably connected to the outer side of the shell, a gear is rotatably connected to the outer side of the adjusting knob, and a connecting rod is rotatably connected to the outer side of the gear. One end of the connecting rod is slidably connected with a sliding way, one end of the connecting rod is rotatably connected with a reflecting device, a pressing block is arranged in the shell, afirst connecting shaft is slidably connected in the pressing block, and a sliding groove is formed in the surface of the first connecting shaft. According to the image digitization acquisition devicecapable of reducing jitter, through connection of the shell and the pressing block, motion compensation can be carried out on jitter of the camera, the problem that the refraction plate is prone to jitter when the angle of the refraction plate is adjusted is solved, the practicability is greatly improved, and the advantage of intelligent manufacturing is achieved; and therefore, image blurring caused by camera vibration is effectively overcome.

Owner:温州卡度琳广告设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com