Polycrystalline silicon bar crushing system and method

A crushing system and crushing method technology, applied in grain processing, etc., can solve the problems of silicon material surface contamination, single crystal minority carrier lifetime reduction, affecting downstream solar energy lifetime and photoelectric conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

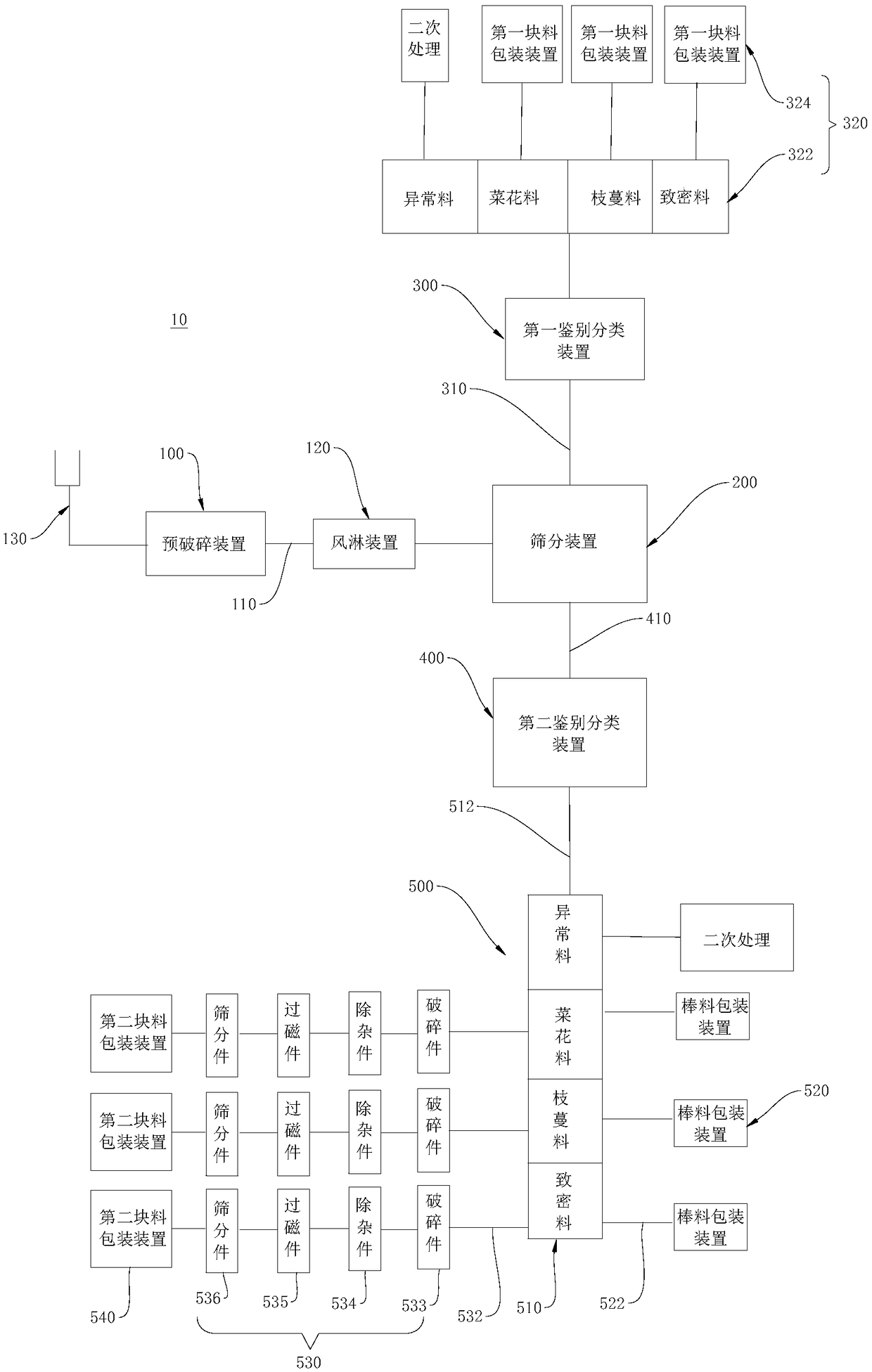

[0044] Please refer to figure 1 , the present embodiment provides a polysilicon rod crushing system 10, which includes a pre-crushing device 100 for primary crushing of polysilicon rods; used to divide the primary crushed polysilicon rods into rods and the screening of the first piece of material Device 200; the first identification and classification device 300 for distinguishing and classifying the first block; the second identification and classification device 400 for distinguishing and classifying the bar; the bar processing device 500, the bar processing device 500 includes at least four bar collection devices 510, and the bar collection device 510 is connected with a bar packaging device 520 and a crushing device 530; wherein, the pre-crushing device 100 and the screening device 200 pass through the first channel 110 Connection; the screening device 200 is connected with the first identification and classification device 300 through the second channel 310; the screening...

Embodiment 2

[0058] This embodiment provides a method for crushing polysilicon rods. The method for crushing polysilicon rods adopts any one of the above-mentioned polysilicon rod crushing systems 10, including:

[0059] Pre-crushing, placing polycrystalline silicon rods into the pre-crushing device 100 for pre-crushing;

[0060] Screening, the primary crushed polysilicon rods are divided into rods and the first block by the screening device 200;

[0061] First classification, using the first identification and classification device 300 to identify and classify the first block;

[0062] The second classification is to identify and classify the bars through the second identification and classification device 400;

[0063] Bar stock processing, the bar stock is packaged or crushed through the bar stock processing device 500 .

[0064] The polysilicon rod crushing method provided by the present invention includes the polysilicon rod crushing system 10 mentioned above, so it also has the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com