Patents

Literature

175results about How to "Realize green manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid die forging and rolling compound formation method for GH4033 high-temperature alloy irregular-section large ring piece

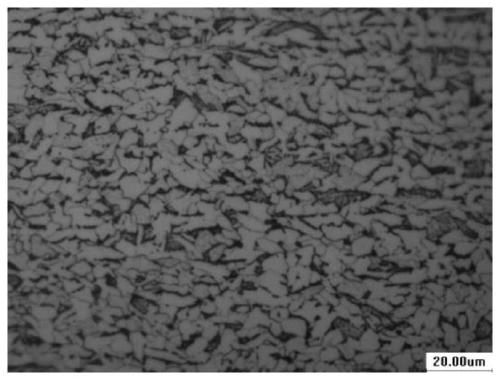

The invention relates to a liquid die forging and rolling compound formation method for a GH4033 high-temperature alloy irregular-section large ring piece. The method comprises the following steps of: 1) smelting; 2) performing liquid die forging, namely fixing a liquid die forging mold on an indirect extrusion casting machine, pouring a quantitative amount of alloy solution into the liquid die forging mold at the pouring temperature of between 1350 and 1450 DEG C, pressurizing at the speed of 40 to 50 mm / s, filling for 1 to 6 seconds at the specific pressure of 300 to 400 MPa, keeping the pressure for 50 to 90 seconds, and thus obtaining a similarly final section ring blank; 3) homogenizing; 4) performing afterheat isothermal rolling, namely cooling the homogenized similarly final section ring blank to the temperature of between 1100 and 1140 DEG C, and performing afterheat isothermal rolling on a radial shaft compound ring rolling machine; 5) performing thermal treatment, namely performing solid solution instant thermal treatment, keeping the ring blank at the temperature of between 900 and 1000 DEG C for 1 to 2 hours, performing air cooling, then heating to the temperature of 1080 DEG C, keeping the temperature for 8 hours, performing air cooling to the temperature of 750 DEG C, keeping the temperature for 16 hours, and performing air cooling; and 6) finishing.

Owner:SOUTHWEST UNIVERSITY

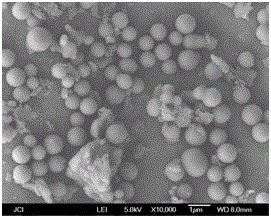

Method for preparing carbon microspheres through hydrothermal carbonization of biomass

The invention discloses a method for preparing carbon microspheres through hydrothermal carbonization of a biomass. The method comprises the following steps: stirring and mixing camellia seed husk powder which serves as a raw material and deionized water, treating the mixture ultrasonically, transferring the treated mixture into a stainless steel reactor, introducing an inert gas into the stainless steel reactor to remove oxygen, putting the stainless steel reactor into an air blowing drying box, carrying out reaction at a constant temperature, cooling the product of reaction to room temperature, pouring out the upper-layer liquid, tanking out the solid, clearing the solid ultrasonically with deionized water and ethanol in sequence until the washing liquid is colorless, extracting with ultrasonic waves and microwaves in the solution of ethanol in water, filtering the mixture in vacuum, and drying in a vacuum drying box to obtain the carbon microspheres. The method disclosed by the invention has the advantages that the raw material for preparing the carbon microspheres is a biomass waste which is wide in source and low in cost, the process of preparing the carbon microspheres is simple and is friendly to environment, no poisonous and harmful reagents are adopted in the whole preparation process, and the prepared poisonous carbon microspheres are uniform in size and can be used conveniently. In addition, the method is low in production cost and can realize large-scale production.

Owner:NANCHANG HANGKONG UNIVERSITY

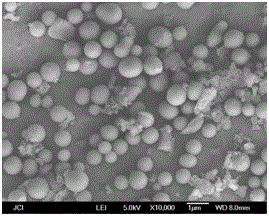

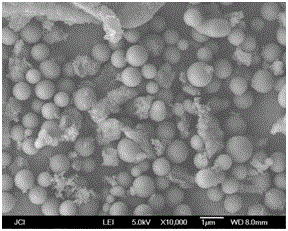

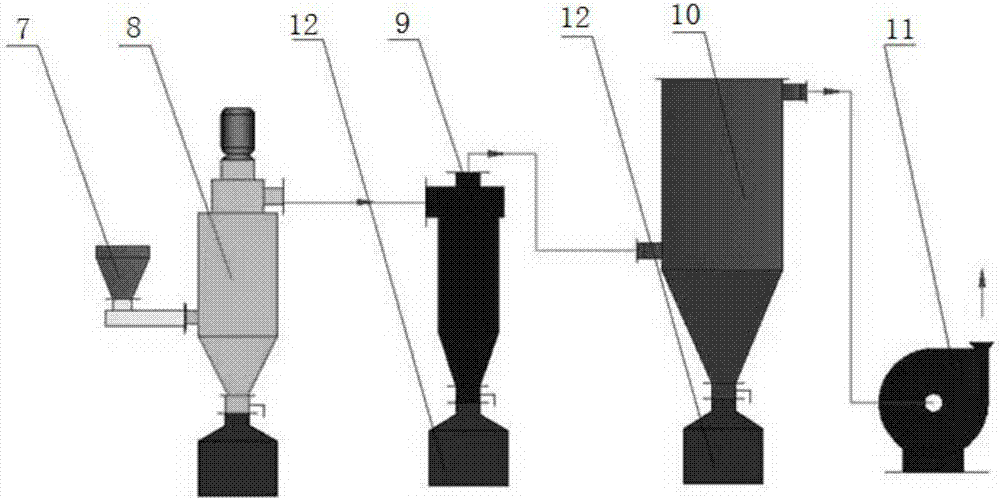

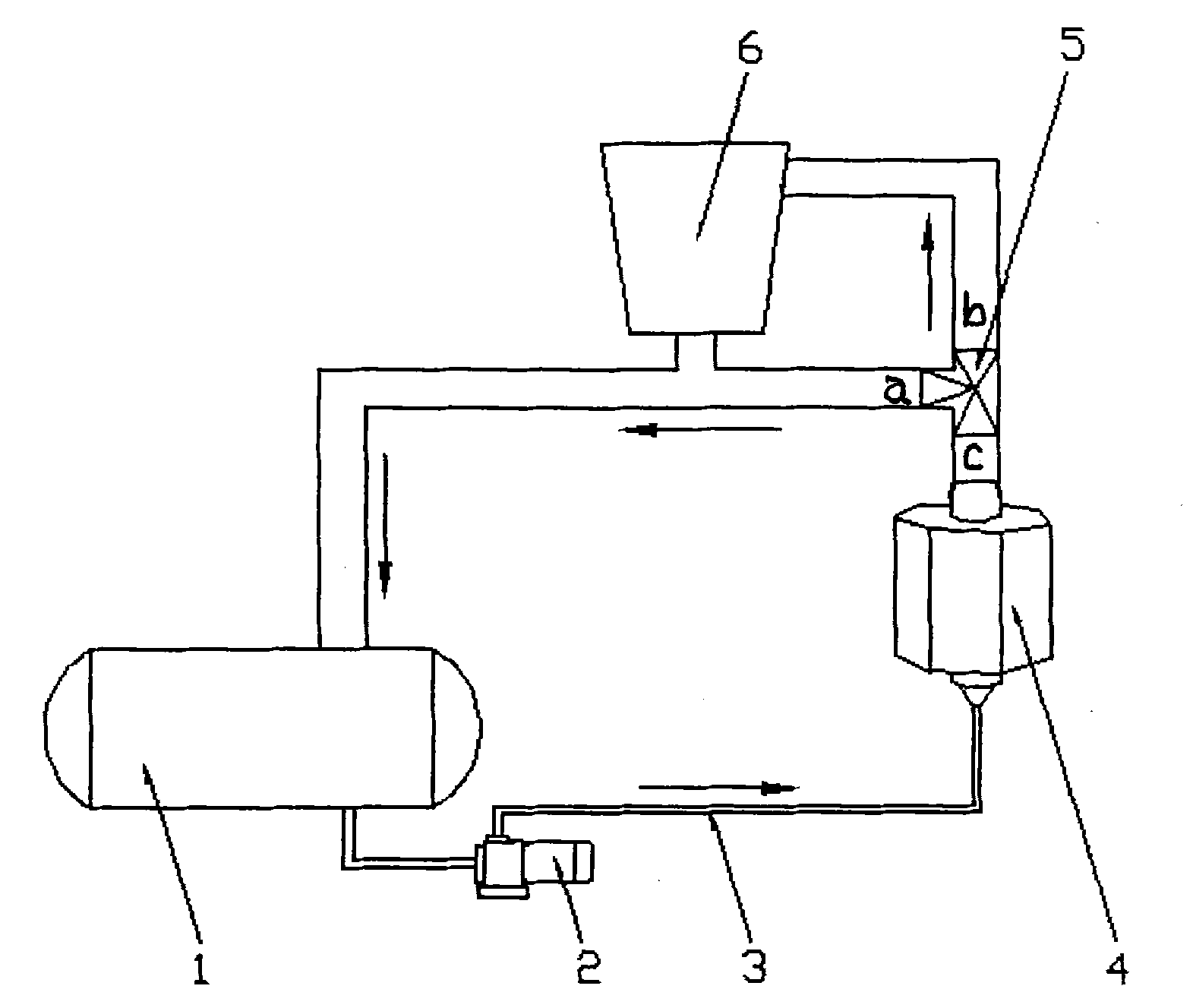

Preparation method of Hastelloy X alloy powder for 3D printing

InactiveCN106956008AAppropriate ratioImprove purityAdditive manufacturing apparatusAlloyUltrasonic vibration

The invention relates to a preparation method of Hastelloy X alloy powder for the 3D printing technology. The preparation method specifically comprises the steps of the vacuum electrode induction melting gas atomization technology, ultrasonic vibration screening, inert gas shielding airflow grading, vacuum degassing treatment and the like to prepare the Hastelloy X alloy powder suitable for the 3D printing technology. Compared with the prior art, the Hastelloy X alloy powder has the characteristics of low impurity content, low oxygen content, high degree of sphericity and the like, meets the performance requirements to powder material from different 3D printing technologies, and promotes the application development of the 3D printing technology.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

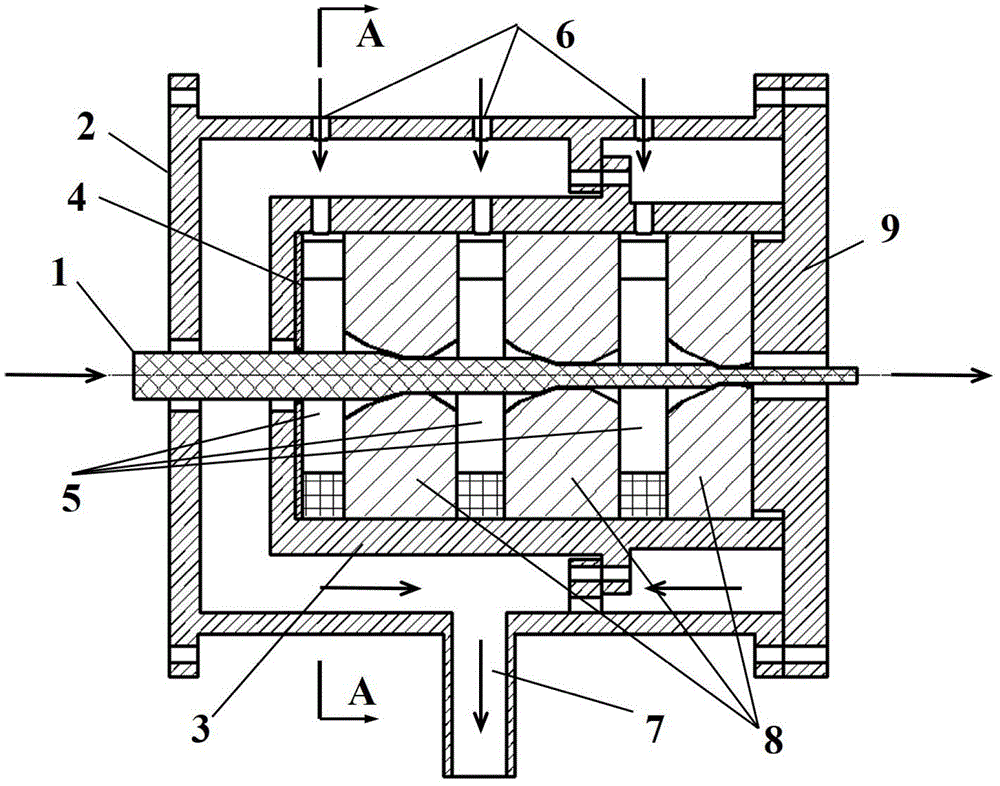

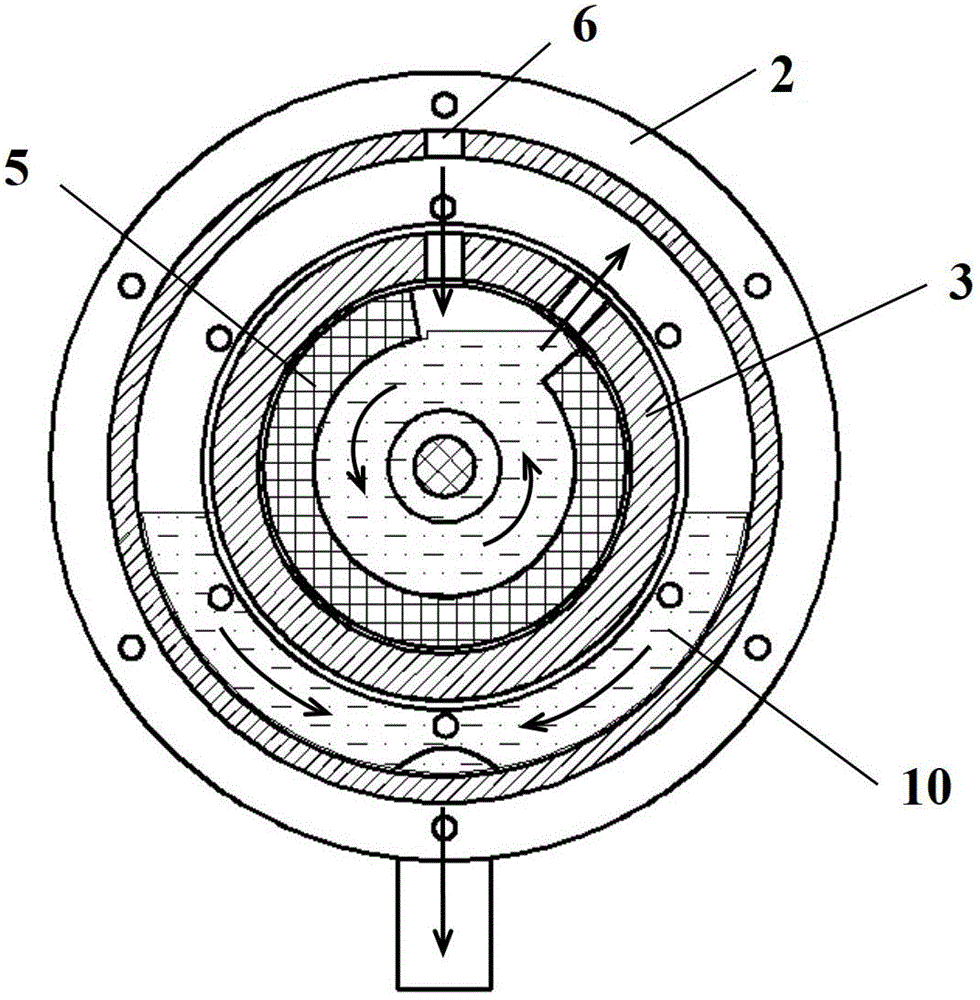

Multi-pass metal drawing device based on water lubrication drawing

The invention discloses a multi-pass metal drawing device based on water lubrication drawing. The multi-pass metal drawing device comprises a support, a drawing cavity which is fixed in the support, a sealing ring, a mold group and a lubrication chamber group which are arranged in the drawing cavity, and a cover plate which is fixed on the support, wherein the mold group is an ultra-smooth nano diamond composite coating mold; a drawing cavity lubricant inlet is aligned with the center line of a support lubricant inlet; the sealing ring, the lubrication chamber group and the mold group are sequentially placed in the drawing cavity along the drawing direction of a pipeline material; and the opening direction of a lubrication chamber is aligned with the drawing cavity lubricant inlet and outlet. The multi-pass metal drawing device can ensure that the contact area between the pipeline material and the mold group is completely immersed in a lubricant during drawing, then the excellent water lubrication property of a diamond film is brought into play, and a drawing area is effectively lubricated and cooled, so that the service life of the mold is prolonged, and the processing surface quality and the surface smooth finish and cleanliness are improved; and meanwhile, the characteristics of safety and non-pollution of a water base lubricant also ensure that a processing environment is greatly improved.

Owner:SHANGHAI JIAO TONG UNIV +2

Cutter abrasion repairing method

InactiveCN104759624AHigh repair valueGuaranteed machining accuracyIncreasing energy efficiencyHeat inorganic powder coatingMilling cutterData acquisition

The invention discloses a cutter abrasion repairing method. The cutter abrasion repairing method comprises the steps of firstly preprocessing an abraded cutter, clamping and positioning the preprocessed abraded cutter, enabling an image acquisition system to conduct data acquisition on the positioned abraded cutter and transmit acquired data to a computer so as to form an abraded cutter three-dimensional model, reading the cutter three-dimensional model into a computer before the cutter is abraded, calculating the cutter three-dimensional model required to be compensated through Boolean operation, filling a repair material in the cutter three-dimensional model required to be compensated, using laser direct-sintering technology to sinter and repair the abraded position, and finally cleaning and grinding the repaired cutter so as to complete cutter repair. The cutter abrasion repairing method can be applied to repair of high-cost and high-repair-value cutters including integral cutters, blades, drill tools, large milling cutters and the like, facilitate resource saving and reduction of production cost and achieve green manufacture.

Owner:SHAOXING UNIVERSITY

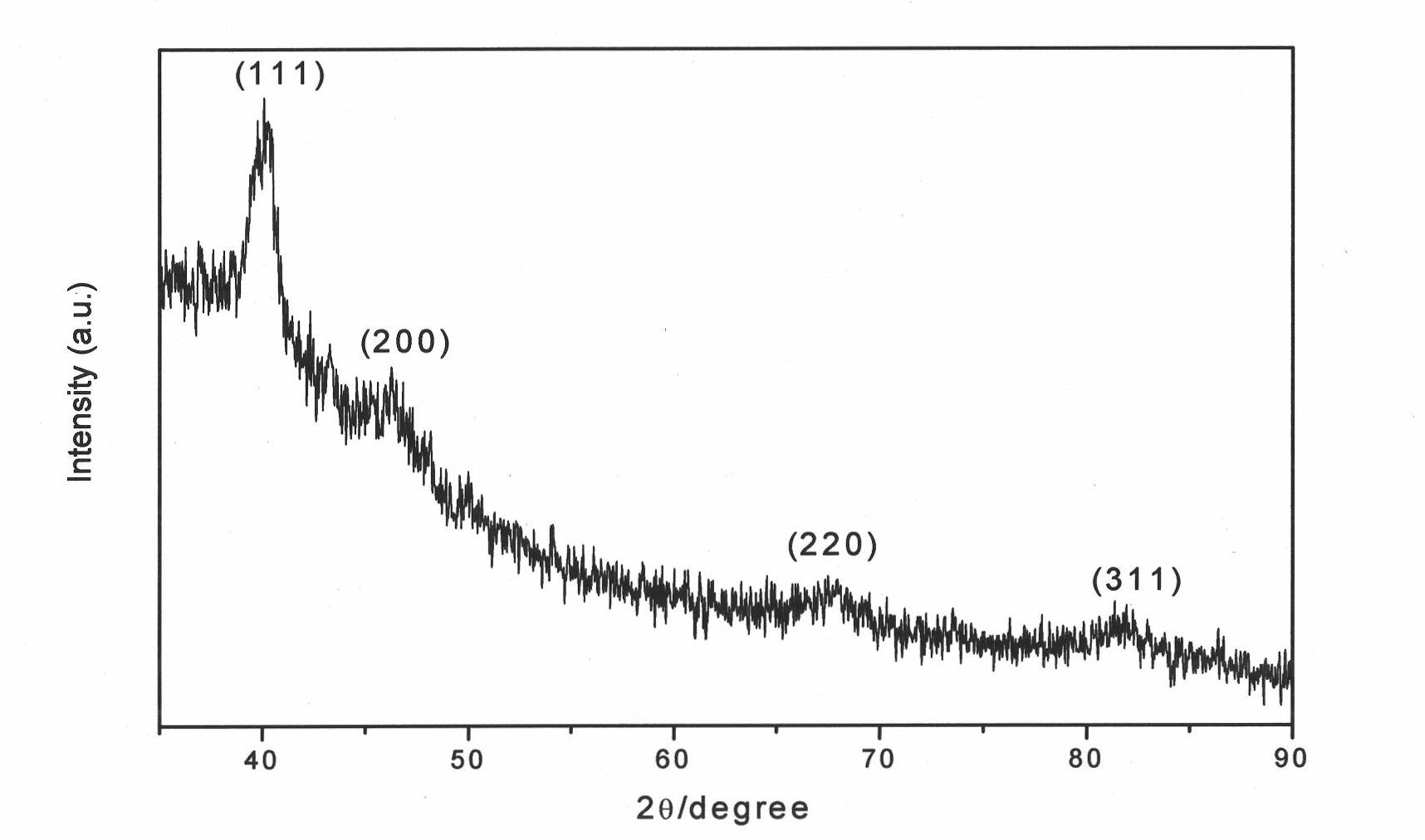

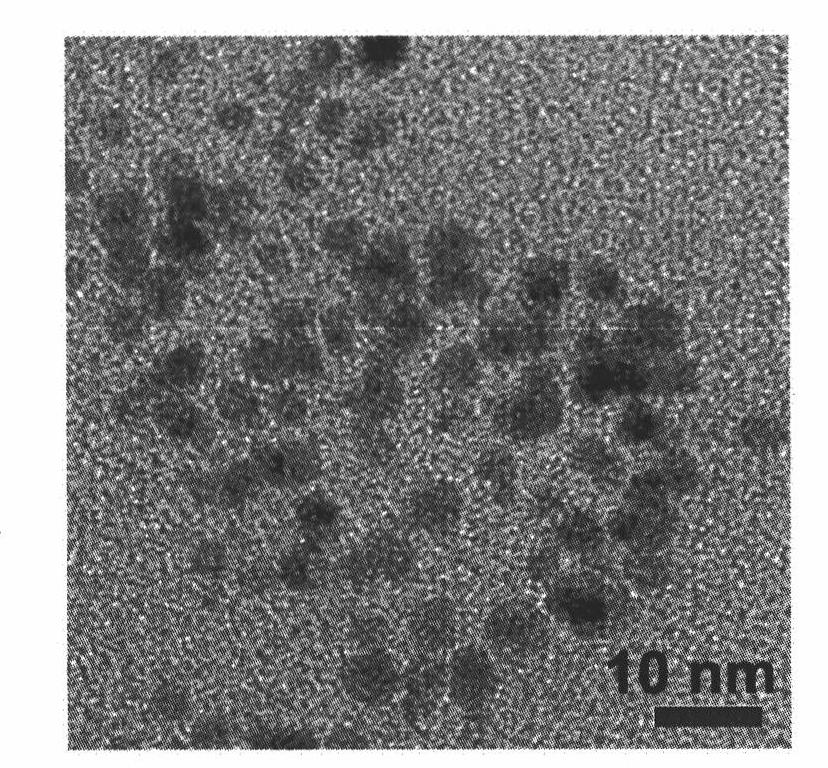

Nanometer palladium catalyst for hydrogenation of anthraquinone and preparation method thereof

InactiveCN101804346AImprove hydrogenation efficiencyReduce dosageCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthranilNanoparticle

The invention relates to a nanometer palladium catalyst for hydrogenation of anthraquinone and a preparation method thereof, relating to a palladium catalyst. The invention provides the nanometer palladium catalyst for the hydrogenation of anthraquinone and the preparation method thereof, wherein natural plants are taken as a reducing agent and a carrier. The nanometer palladium catalyst is prepared by dispersing nanometer palladium granules on a Cape jasmine carrier, and based on weight percent, the loaded palladium accounts for 1.2-3.6 percent of Cape jasmine, and the size of the nanometer palladium granules is 3-10 nm. Cape jasmine lixivium is prepared by dipping Cape jasmine in water, and the nanometer palladium catalyst is prepared by preparing palladium chloride into palladium chloride and Cape jasmine mixing solution by using the Cape jasmine lixivium, reducing and drying to obtain the nanometer palladium catalyst loaded on the Cape jasmine, i.e. the nanometer palladium catalyst for the hydrogenation of anthraquinone.

Owner:XIAMEN UNIV

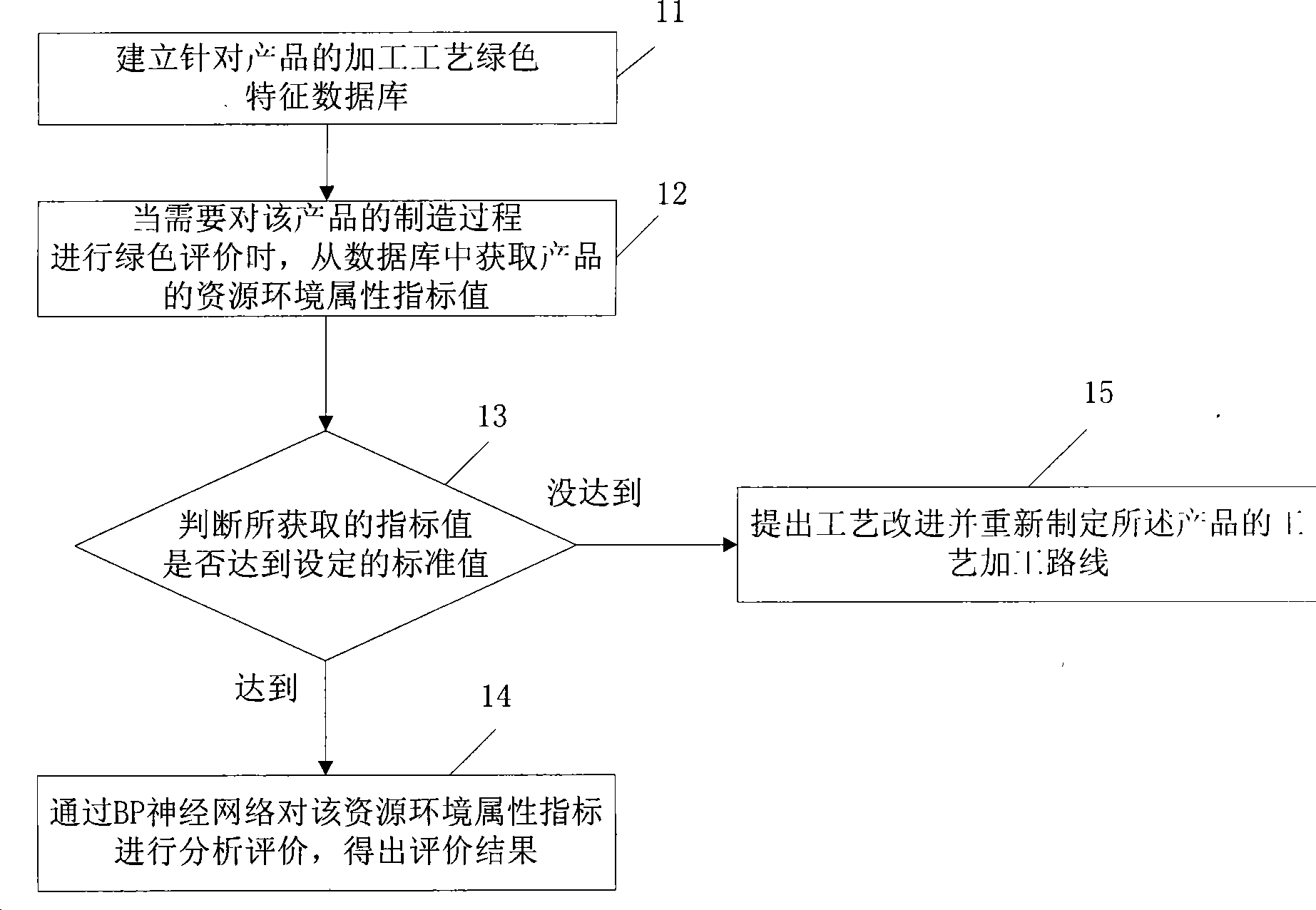

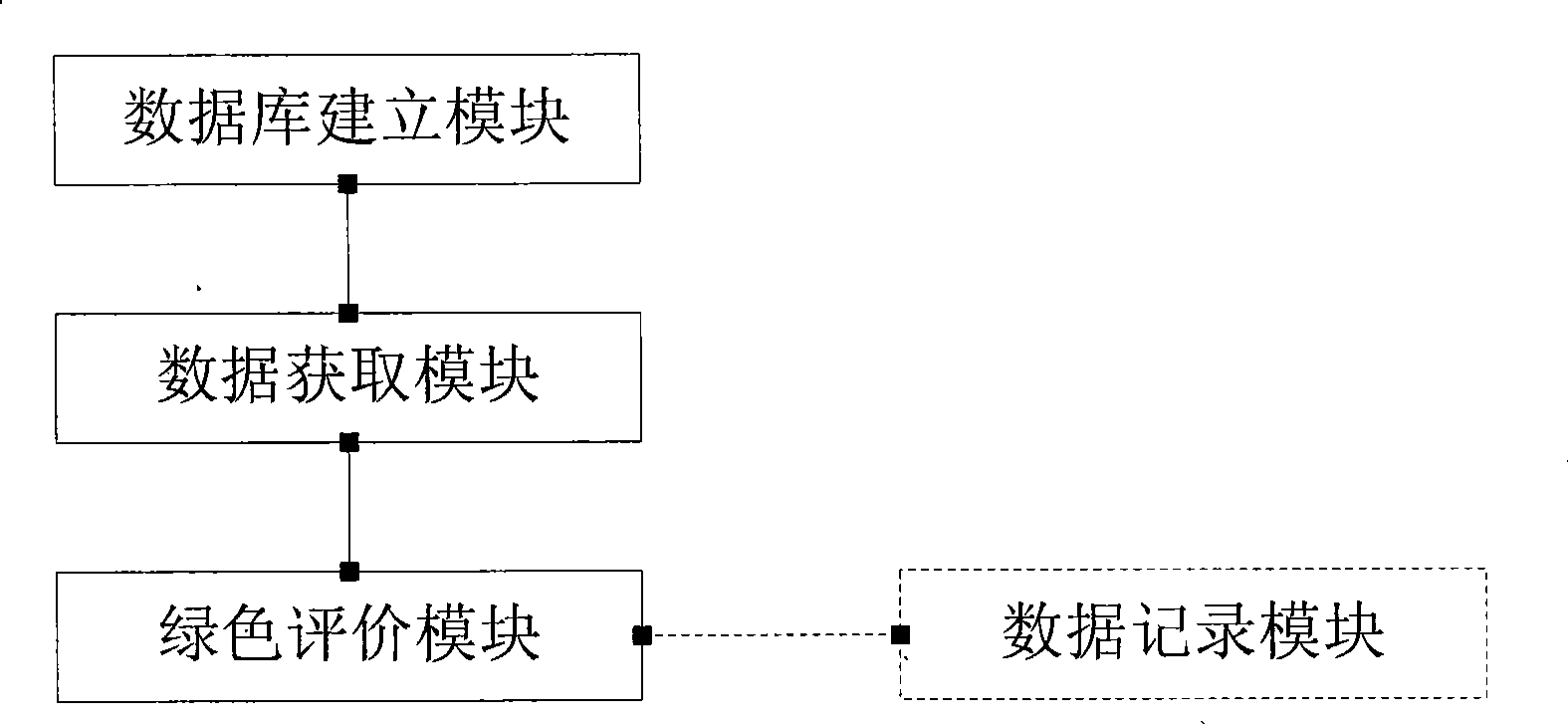

Green appraising method and device in manufacture course of products

InactiveCN101419690AIncrease profitSmall negative impact on the environmentBiological neural network modelsEnvironment effectResource utilization

The embodiment of the invention provides a pollution-free evaluation method in product manufacturing process and a device thereof. The method specifically comprises the following steps: establishing a pollution-free characteristic database for a processing technique of the product; acquiring resource environment attribute index values generated in the product manufacturing process from the database when the product manufacturing process needs pollution-free evaluation; and then judging whether the resource environment attribute index values reach preset standard values; if reaches, calling index values quantizing rule from the database, and analyzing and evaluating the resource environment attribute by a BP neural network. In such way, resource consumption and environmental impact condition in the product manufacturing process can be analyzed and evaluated, thus being capable of taking corresponding measures to reduce the negative environmental impact produced in the product manufacturing process, improving the resource utilization rate, and realizing pollution-free product manufacturing.

Owner:WUHAN UNIV OF SCI & TECH

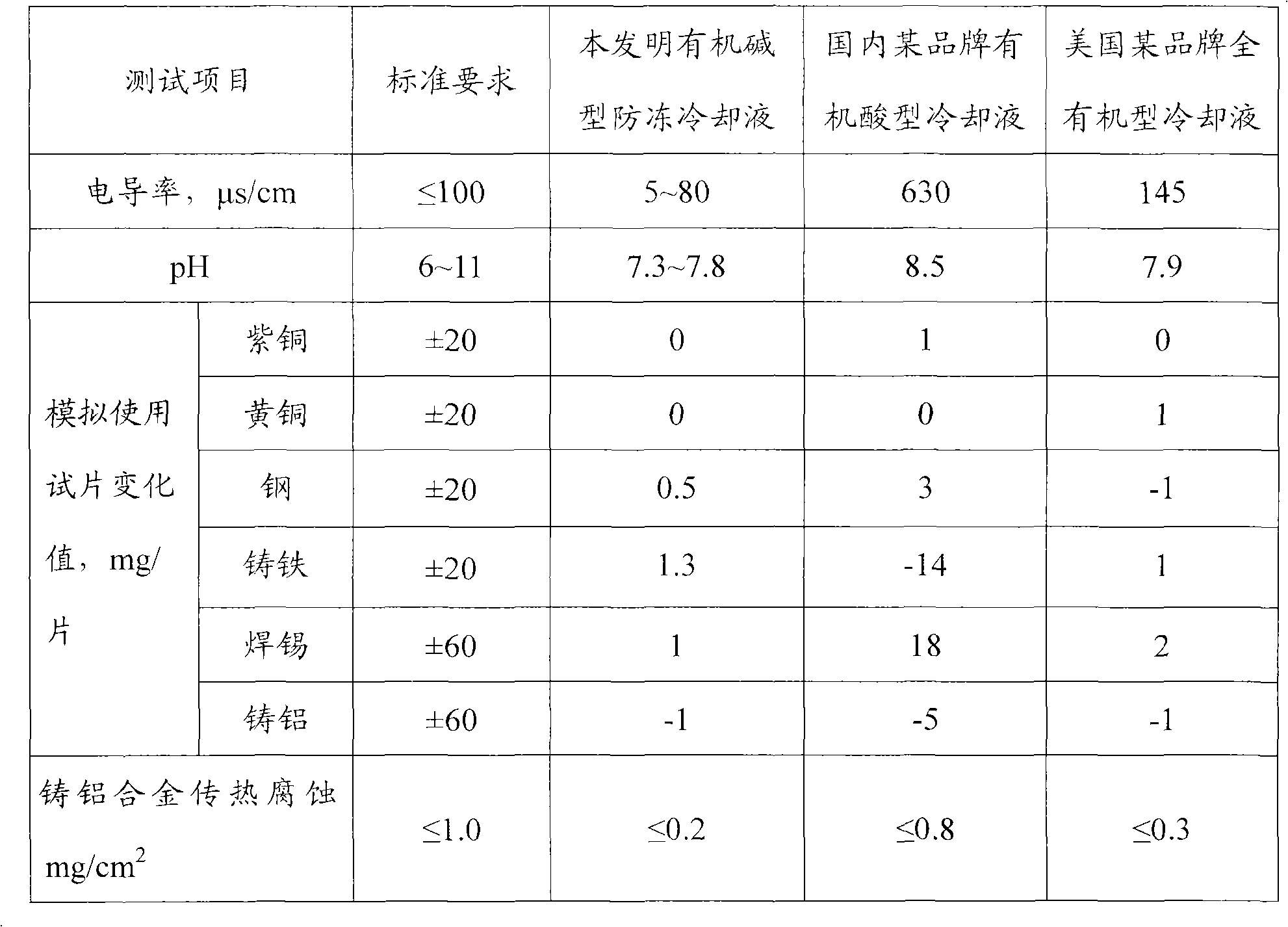

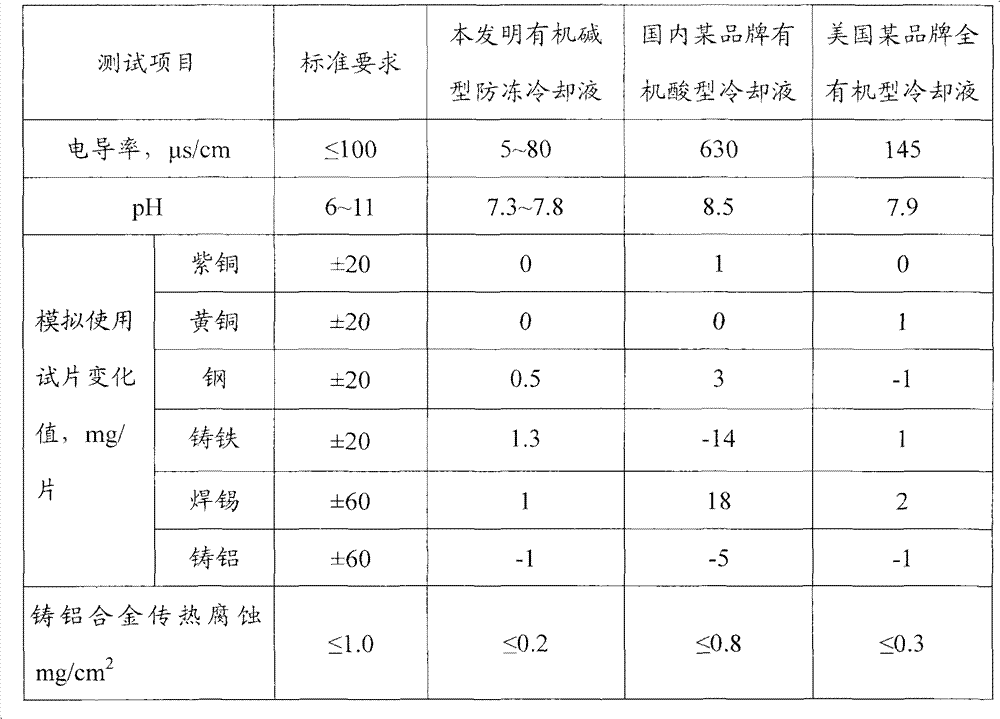

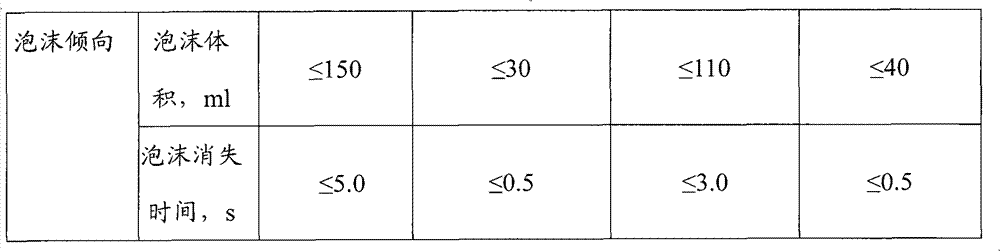

Low-conductivity super-long-acting organic base type anti-freezing cooling liquid

InactiveCN102174313APrevent corrosion of metal partsStorage stableHeat-exchange elementsCycloalkaneChemistry

The invention provides low-conductivity super-long-acting organic base type anti-freezing cooling liquid, which comprises the following components in percentage by weight: 15 to 96 percent of anti-freezing agent, 0.05 to 1.5 percent of natural alkaloid, 0.5 to 2.5 percent of hetero-cycloalkane, 0.01 to 0.3 percent of azole component, and the balance of deionized water. In invention, since the natural alkaloid is matched with nonionic organic compounds, the prepared anti-freezing cooling liquid has the characteristics of low freezing point, high boiling point, no scale formation, corrosion protection, high heat efficiency and the like; in addition, the prepared anti-freezing cooling liquid also has ultra-low conductivity which can reach 5 mus / cm and is a few hundredths of the conductivity of a common water cooling medium because the anti-freezing cooling liquid does not contain the components of inorganic salts, organic carboxylic acid and the like. The anti-freezing cooling liquid with ultra-low conductivity can effectively slow up the corrosion on metal parts of a cooling system, and meet the requirement of special conditions such as the cooling of a wind generator set and the like on the insulation safety of the anti-freezing cooling liquid. The anti-freezing cooling liquid realizes environmental protection and ultra-long-acting service, and is particularly suitable for special equipment such as a wind generator set, an imperial sedan engine and the like.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

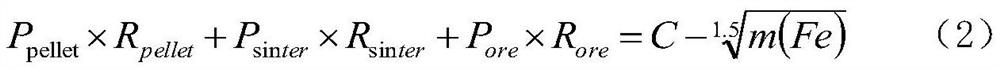

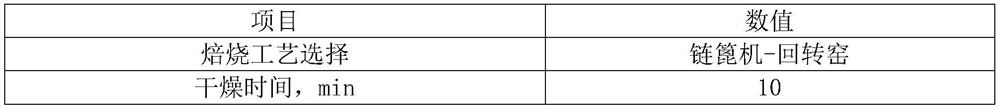

Methods for preparing and using pre-reduced fluxed pellets by taking steel slag as part of raw materials

InactiveCN111910072ARealize green manufacturingAchieve recyclingBlast furnace detailsProcess efficiency improvementBlast furnace smeltingFly ash

The invention relates to a method for preparing pre-reduced fluxed pellets by taking steel slag as part of raw materials. The method comprises the following steps of (1) screening the steel slag, screening out steel slag particles with the particle size of 2-4 mm, and grinding the rest steel slag into steel slag powder; (2) drying fly ash, and grinding the fly ash into fly ash powder; (3) mixing the steel slag powder, the fly ash powder, iron oxide red, iron ore concentrate powder and a composite binder in a mixer; (4) taking the steel slag particles with the particle size of 2-4mm as a pelletizing core, and continuously putting the steel slag particles into a pelletizer for pelletizing to obtain green pellets; and (5) carrying out drying, preheating and roasting to obtain finished pelletsof the pre-reduced fluxed pellets. After the technical scheme is adopted in blast furnace production, the cost of blast furnace production is reduced, so that the market competitiveness of an iron-making process is enhanced, meanwhile, cyclic utilization of secondary resources of an iron and steel plant can be realized, then application of high-added-value products is realized, and further, greenmanufacturing of blast furnace smelting is realized.

Owner:ANGANG STEEL CO LTD

GH4169 high-temperature alloy special-cross-section large annular piece liquid forging and rolling composite forming method

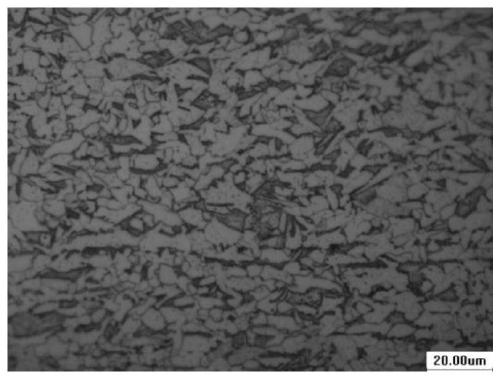

InactiveCN102689156AIncrease productivityHigh material utilizationMetal rollingHeat conservationEngineering

The invention discloses a GH4169 high-temperature alloy special-cross-section large annular piece liquid forging and rolling composite forming method which comprises the following steps: 1) smelting; 2) liquid forging: fixing a liquid forging mold on an indirect squeezing casting machine, pouring an alloy solution in constant volume into the liquid forging mold, wherein the pouring temperature is 1350-1400 DEG C, the pressurization speed is 35-40mm / s, the type filling time is 1-6 seconds, and the specific pressure is 350-400MPa; and keeping the pressure under the pressure for 35-90 seconds, thereby obtaining a near terminal cross section annular blank; 3) homogenizing: cooling the near terminal cross section annular blank to 1150-1160 DEG C, performing heat preservation for 20-30 hours, then rising the temperature to 1180-1190 DEG C, and performing heat preservation for 110-130 hours; 4) residue heat isothermal rolling: reducing the temperature of the near terminal cross section annular blank after homogenization to 1010-1120 DEG C, and carrying out residue heat constant temperature rolling on a radial and axial composite rolling annular machine; 5) heat treatment: performing heat preservation on the annular blank at a temperature of 715-725 DEG C for 8 hours, and then cooling to 615-625 DEG C in a furnace at a speed of 50 DEG C / h, performing heat preservation for 8 hours, and carrying out air cooling; and 6) finishing.

Owner:SOUTHWEST UNIVERSITY

Electroslag casting production method for waterwheel blade green compact

An electroslag casting production method for a waterwheel blade green compact is characterized by comprising the following steps: confirming the outline of the blade green compact according to the intelligent three-dimensional expanded size of a water turbine blade; producing a crystallizer and a consumable electrode of the blade green compact; preparing the qualified blade green compact of the electroslag casting water turbine by optimizing electroslag casting process parameters and the anti-cracking heat treatment process. The method has the advantages that the detects of the conventional blade green compact of the water turbine can be overcome; a near-net forming green compact producing process is provided for the water turbine blade formed through heated-die pressing process; the produced blade green compact material is high in degree of purity, uniform in chemical constituents, compact in structure, free of defects such as looseness, slag inclusion and hole shrinkage, favorable in mechanical property, and higher in fatigue resistance performance, anti-cracking performance and expansibility, and can reach the mechanical property of forge pieces made of the same material and meet the requirements of flaw detection indexes.

Owner:SHENYANG RES INST OF FOUNDRY

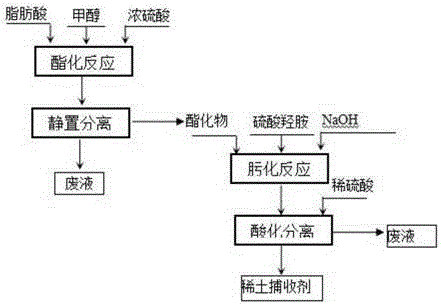

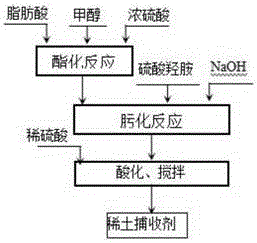

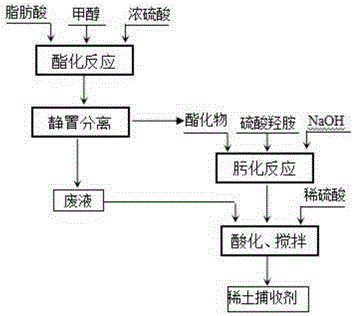

Green preparation method for hydroxyl oxime acid rare-earth flotation agents

ActiveCN106008266AEmission reductionRealize green manufacturingOrganic compound preparationCarboxylic acid esters preparationWater dischargeEconomic benefits

The invention provides a green preparation method for hydroxyl oxime acid rare-earth flotation agents. The green preparation method comprises the steps of fatty acid esterification, fatty acid ester oximation and acidification. After the fatty acid esterification and before the fatty acid ester oximation, waste liquid is not treated, and a fatty acid esterification mixed product is totally added into a reaction kettle for performing oximation directly. The invention also provides another green preparation method for the hydroxyl oxime acid rare-earth flotation agents. The green preparation method comprises the steps of fatty acid esterification, fatty acid ester separation and purification, fatty acid ester oximation and acidification; when the step of fatty acid ester acidification is performed, the waste liquid obtained by separating and purifying the fatty acid ester is added. A hydroxyl oxime acid rare-earth collecting agent is synthesized by adopting the process provided by the invention, the waste water discharge during a synthesizing process can be reduced; the green preparation of the hydroxyl oxime acid rare-earth flotation agents can be realized; the economic benefit of an enterprise can be greatly improved; meanwhile, the flotation agents obtained by the method provided by the invention have excellent flotation performance.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Method for extracting L-isoleucine through whole membrane technology

ActiveCN106220521AIncrease incomeSimple processOrganic compound preparationMicroorganismsFlocculationFiltration membrane

The invention belongs to the technical field of base acid production, and discloses a method for extracting L-isoleucine through whole membrane technology. The method comprises the following steps: step 1) filtering through a micro-filtration membrane and removing impurities through flocculation; step 2) filtering through an ultra-filtration membrane, step 3) concentrating through a reverse osmosis membrane; step 4) concentrating and crystallizing. The membrane technology is combined with the flocculation agent to remove the impurities, the process is simple and feasible, and the yield and the purity of the product are greatly improved.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

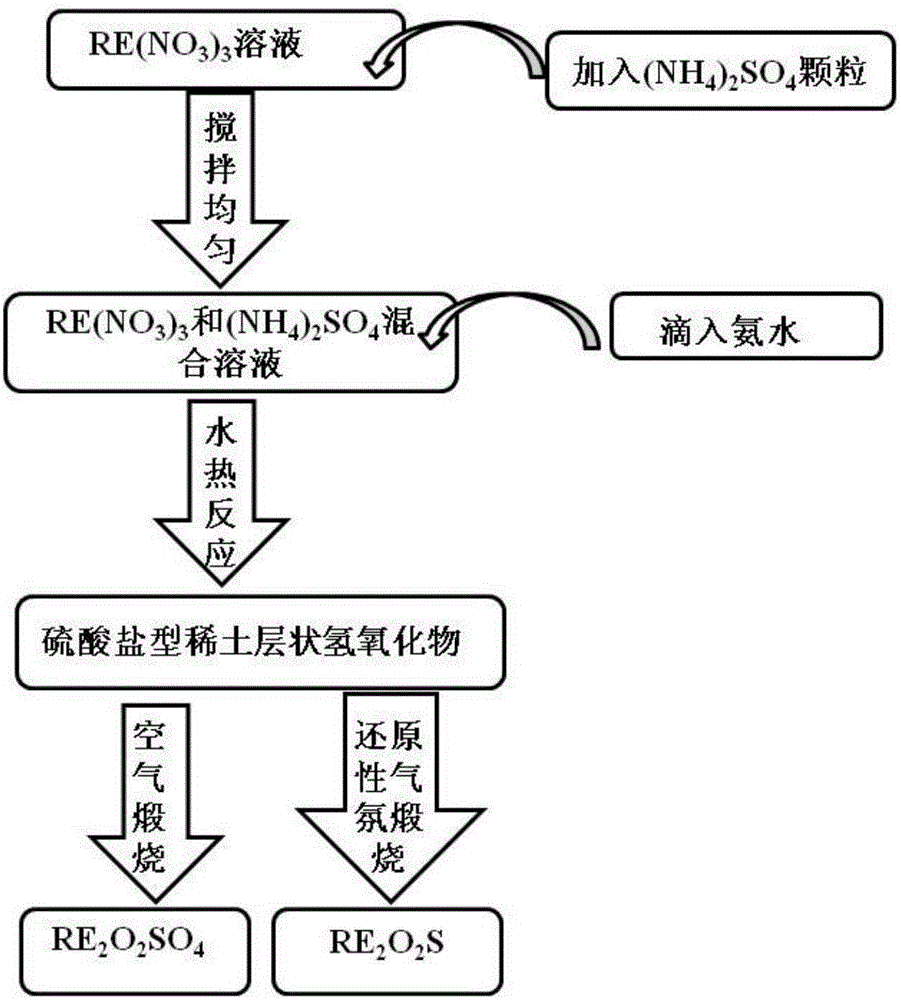

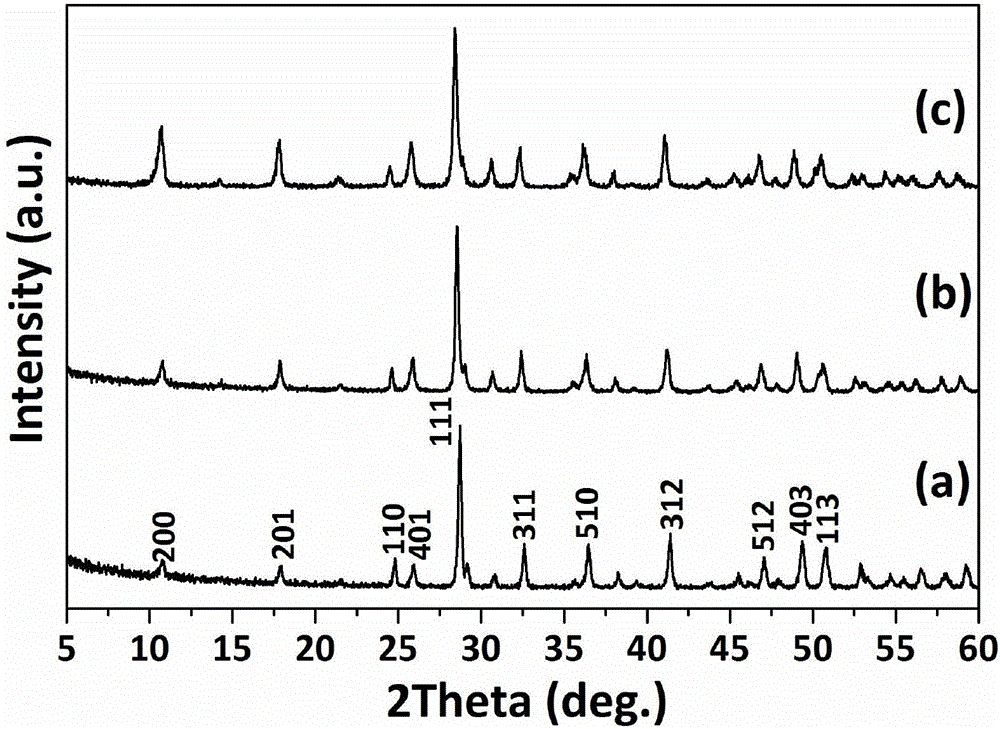

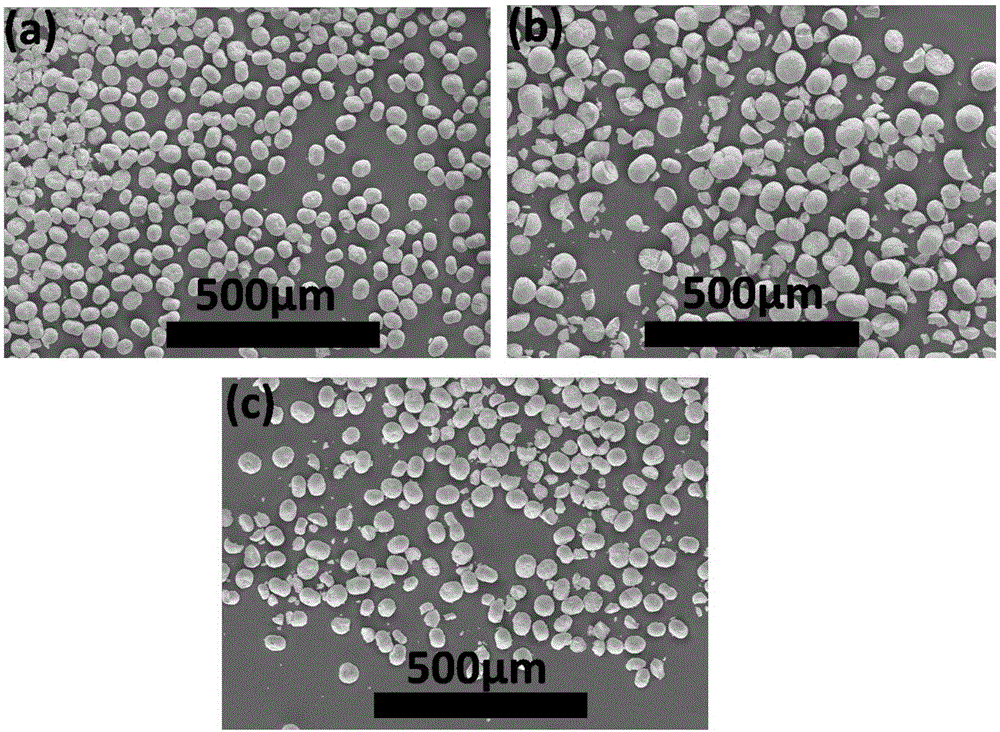

Preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor

ActiveCN106520121ASolve the discharge problemRealize green manufacturingLuminescent compositionsOxygenUp conversion

The invention provides a preparation method of rare earth-doped gadolinium oxysulfide and oxygen-containing gadolinium sulphate up-conversion phosphor, and belongs to the field of material science. The method comprises the following steps that 1, Gd(NO3)3.6H2O, Yb(NO3)3.6H2O and Ln(NO3)3.6H2O are mixed, deionized water is added, and a RE(NO3)3 solution is obtained; 2, ammonium sulfate is dissolved into the RE(NO3)3 solution, stirring is conducted, stirring continues, ammonia water is added, the pH value is regulated, and suspension is obtained; 3, the suspension is subjected to a hydrothermal reaction for 1-72 h at the temperature of 100 DEG C to 150 DEG C and then naturally cooled to room temperature, and a reaction product is obtained; 4, the reaction product is centrifugally separated, washed and dried, and a white powder precursor is obtained; 5, the white powder precursor is calcined, and the rare earth ion-doped Gd2O2S or Gd2O2SO4 up-conversion phosphor is obtained. According to the method, the problems of usage of sulfur-containing raw materials and discharge of harmful by-products in a conventional method are effectively solved, and the method is a green and environment-friendly preparation technique.

Owner:NORTHEASTERN UNIV

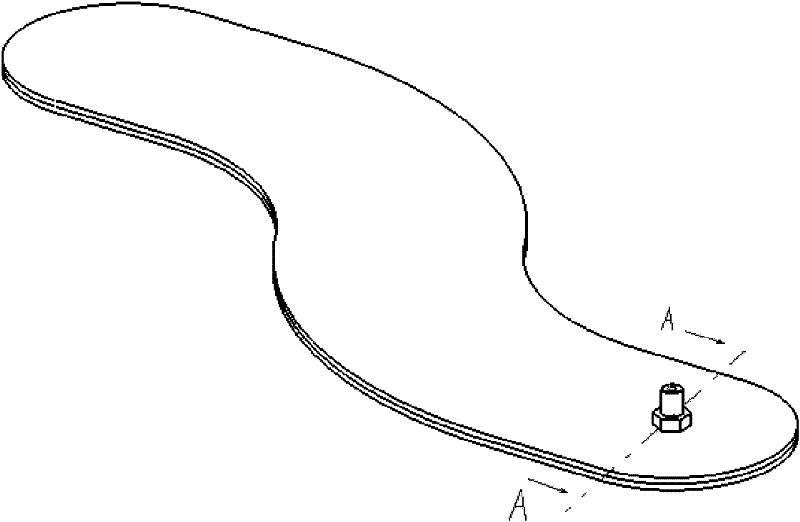

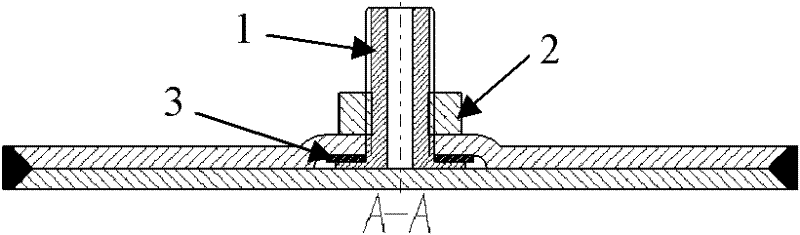

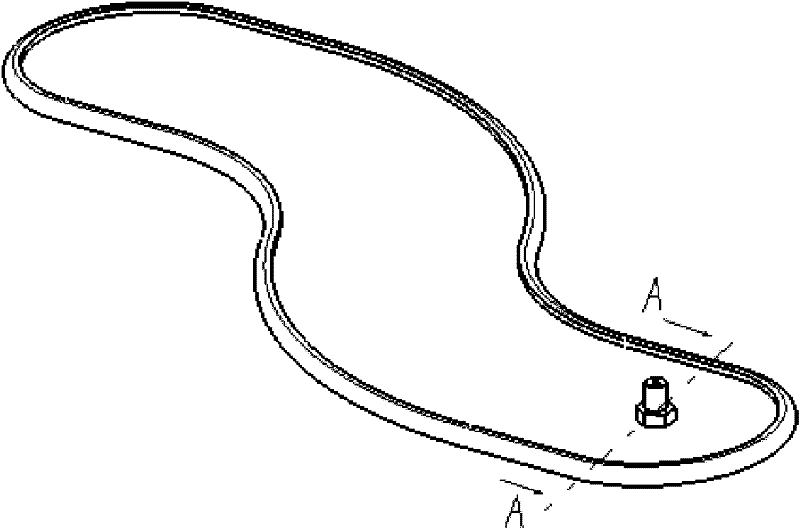

Flexible manufacturing method of thin-wall complex bent pipes

The invention discloses a flexible manufacturing method of thin-wall complex bent pipes. The method comprises the following steps: dividing a bent pipe into two workpieces in mirror symmetry, calculating an extension drawing of the two workpieces, and reserving appropriate flanging quantity; welding line and process supplementary region used for pressurization, mounting a pipe joint (1) used for pressurization on one workpiece; and pressurizing and bulging with gas or liquid by virtue of the pipe joint (1) after direct butt welding or flanging welding is carried out on the two workpieces, or correcting shape by utilizing a local bulging tool directly or manually, wherein the bent pipe can be composed of one section or multiple sections, also can be a special pipe or variable-cross-section pipe and also can be a variable-bend-radius pipe. The flexible manufacturing method of the thin-wall complex bent pipe can be used for changing the processing mode of bent pipe die moulding, flexible manufacturing of the thin-wall bent pipe in a complex shape can be realized, and the production cost can be reduced.

Owner:JILIN UNIV

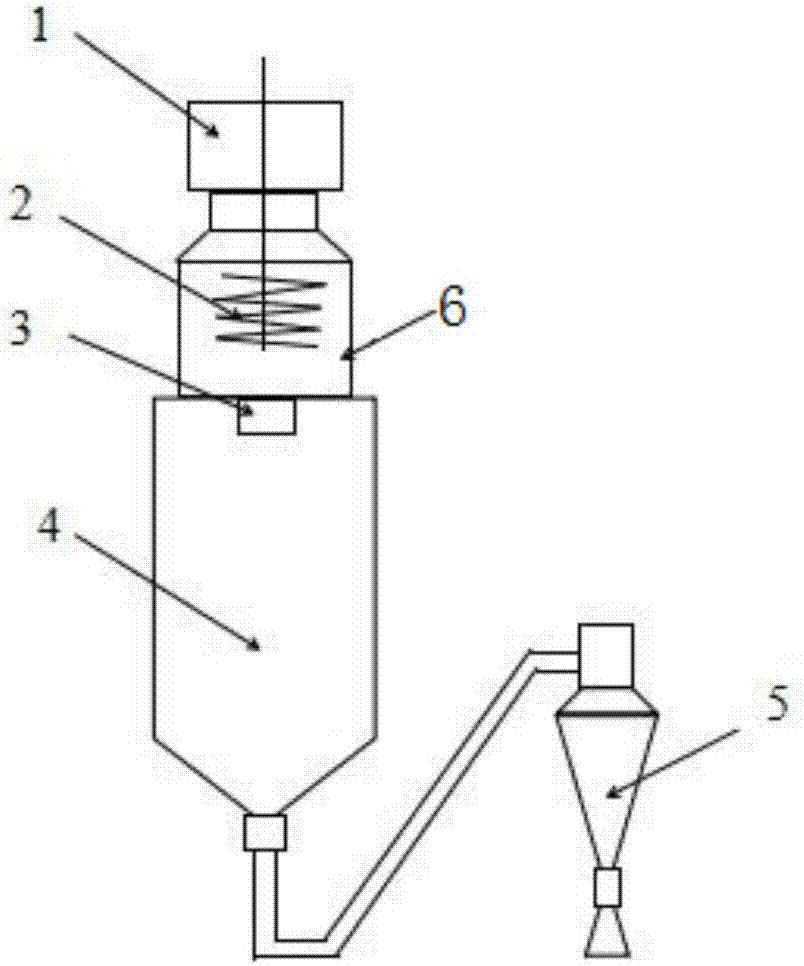

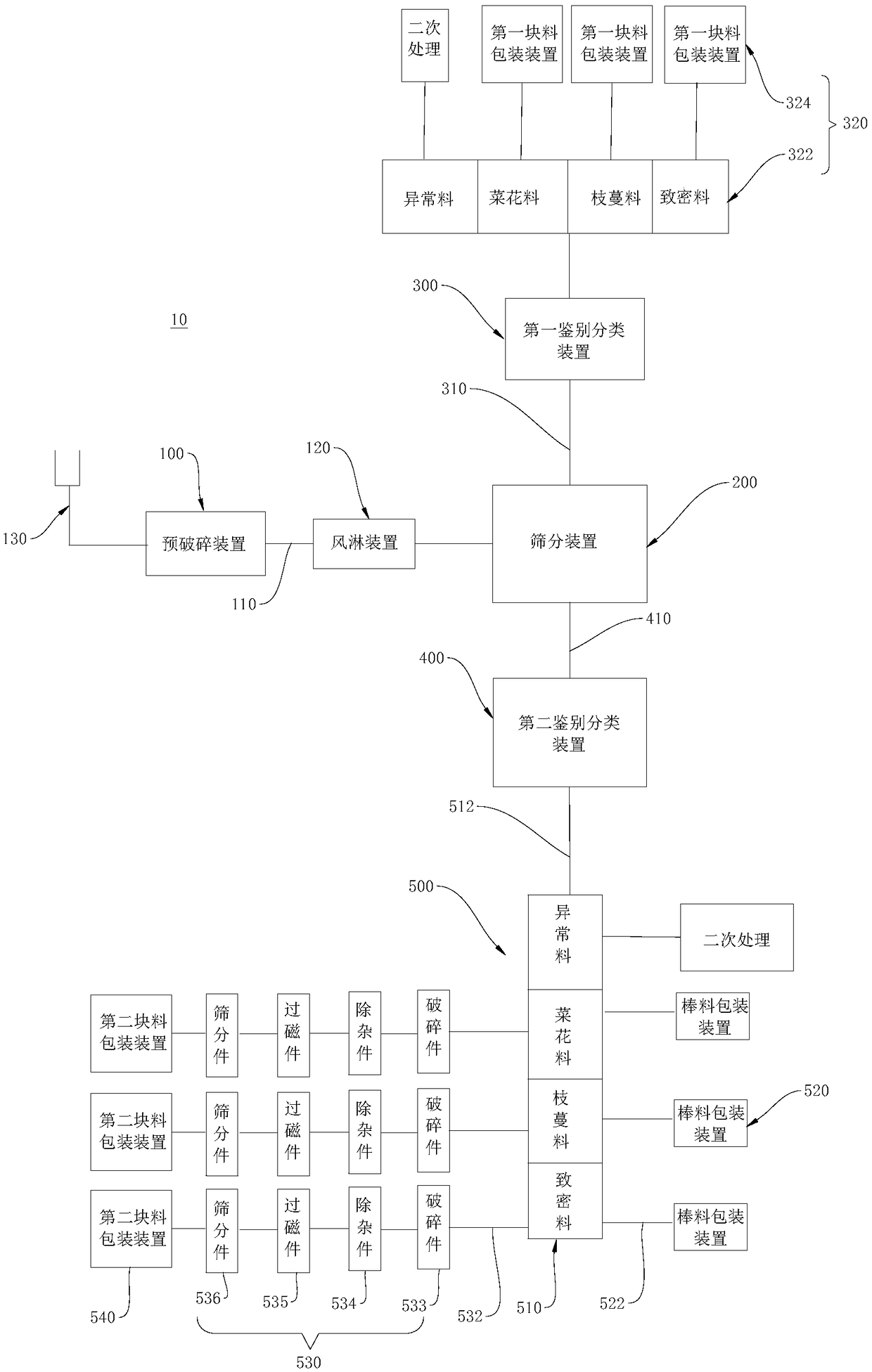

Polycrystalline silicon bar crushing system and method

The invention relates to the field of polycrystalline silicon production, in particular to a polycrystalline silicon bar crushing system and method. According to the provided polycrystalline silicon bar crushing system, polycrystalline silicon bars are subjected to pretreatment, a screening device is used for separating the bars from blocks, the blocks enter a first identifying and classifying device and are distinguished according to different kinds of the blocks; the bars enter a second identifying and classifying device, are distinguished according to different kinds of the bars and enter different bar collection devices of a bar treatment device, and when a user needs the bars, the bars are led into a bar packaging device to be packaged; and when the user needs the blocks, the blocks are led into a crushing device to be crushed. According to the provided polycrystalline silicon bar crushing system, the operation time of operators is saved, pollution caused by manmade operation is avoided, efficiency is improved, and cost is saved. According to the provided polycrystalline silicon bar crushing method, the above polycrystalline silicon bar crushing system is included, and therefore the above beneficial effects are achieved.

Owner:ASIA SILICON QINGHAI

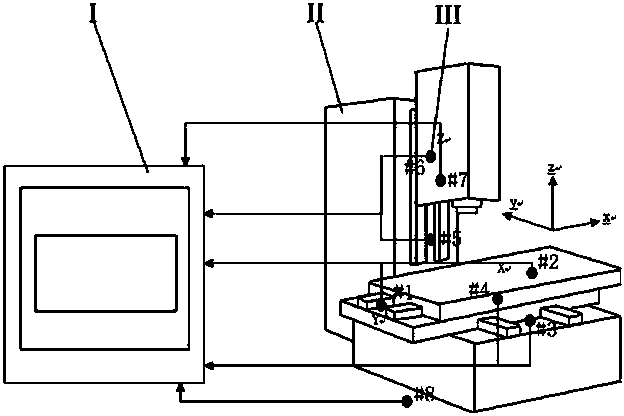

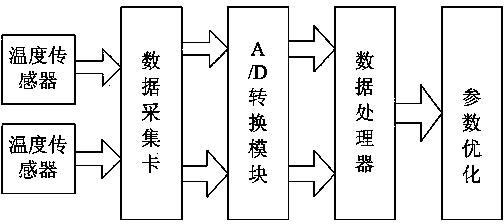

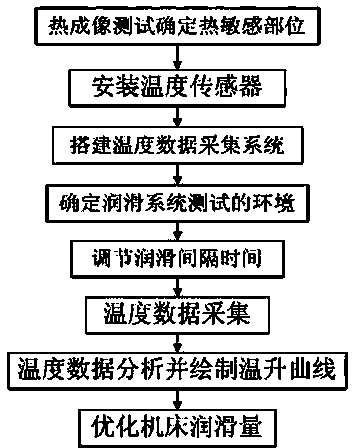

Machining center lubricity test system and optimization method

InactiveCN103639848AAvoid settingDoes not affect mobilityMeasurement/indication equipmentsMaintainance and safety accessoriesEngineeringMachine tool

The invention relates to a machining center lubricity test system and an optimization method and belongs to the field of testing of machining center lubrication systems. Thermosensitive parts of a spindle system and a feed system are identified by thermal imaging testing of the spindle system and the feed system, and temperature sensors are mounted at the thermosensitive parts. A test system of a machining center lubrication system is set up; the lubrication amount is adjusted by adjusting a lubrication time interval of a machining center; the spindle system and the feed system of the machining center move continuously in different lubrication amount states; and simultaneously, temperature data at the thermosensitive parts is acquired. The lubrication amount of the spindle system and the feed system of the machining center is optimized based on temperature rises of the thermosensitive parts. The invention provides the test system and the optimization method for optimizing the lubrication amount of the machining center lubrication system; the problem of unreasonable lubrication amount setting of the machining center lubrication system at present is solved; the movement performance of a machine tool can be improved; the use cost of the machine tool is lowered; and the pollution of lubricating oil is reduced.

Owner:通用技术集团沈阳机床有限责任公司

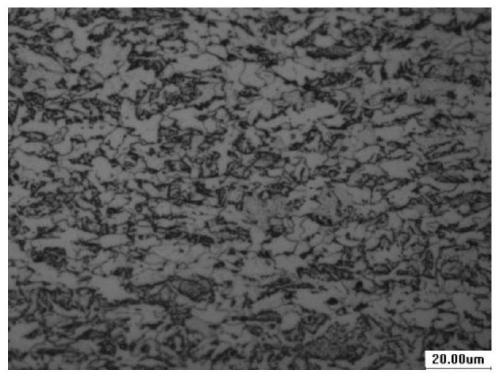

Liquid die forging/rolling composite forming method for magnesium alloy irregular-section large-size ring piece

The invention relates to a liquid die forging / rolling composite forming method for a magnesium alloy irregular-section large-size ring piece, which comprises the following steps: smelting, liquid die forging, homogenizing, excess heat isothermal rolling, heat treatment and finishing, wherein in the liquid die forging process, after a liquid die forging die is fixed onto an indirect extrusion casting machine, the smelted magnesium alloy solution is quantitatively cast into the liquid die forging die, and kept under the specific pressure of 140-200 MPa for 35-150 seconds to obtain the similar end-section ring blank, wherein the casting temperature is 680-740 DEG C, the pressurization speed is 50-100 mm / s, and the cavity filling time is 1-6 seconds; and in the excess heat isothermal rolling process, when the homogenized similar end-section ring blank is cooled to 300-400 DEG C, isothermal rolling is carried out on a radial / axial composite ring rolling machine. The method provided by the invention can simplify the blank making process of the alloy ring piece, lower the cost, enhance the production efficiency, effectively improve the microstructure state of the liquid die forging die magnesium alloy ring piece, and enhance the comprehensive mechanical properties.

Owner:SOUTHWEST UNIVERSITY

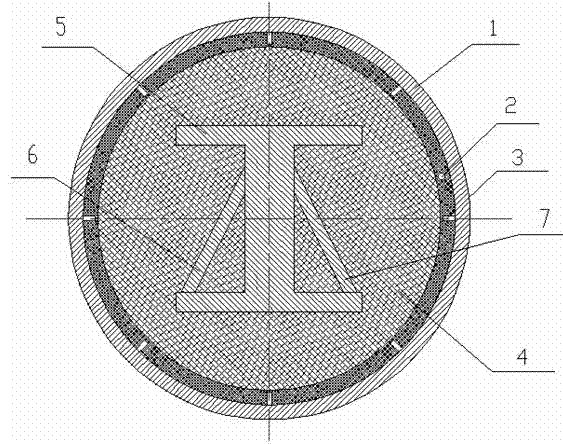

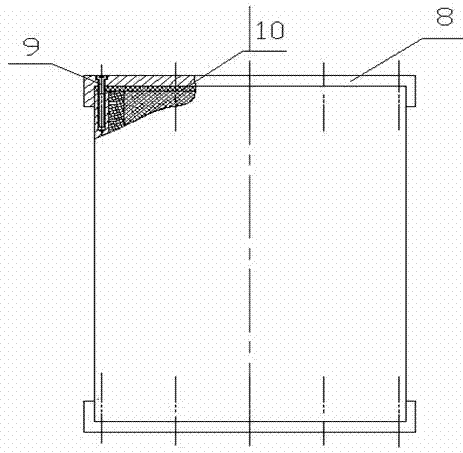

Injection molded steel-tube sea sand recycled concrete column with built-in stiffening member

The invention relates to an injection molded steel-tube sea sand recycled concrete column with a built-in stiffening member. The injection molded steel-tube sea sand recycled concrete column comprises an injection molded steel tube which is filled with sea sand recycled concrete. Two ends of the injection molded steel tube are respectively provided with an end cover. A FRP section steel stiffening member is also arranged inside the sea sand recycled concrete. The internal surface of the injection molded steel tube has good elastoplasticity and strength as well as corrosion resistance. According to the invention, sea sand is directly applied in the recycled concrete of the injection molded steel tube, and it is unnecessary to process sea sand. The sea sand recycled concrete is poured into the injection molded steel tube to form the injection molded steel-tube recycled concrete column, and then two ends of the injection molded steel tube are sealed by the use of seal covers with plastic washers. The injection molded steel tube provides tightening force for the recycled concrete such that sea sand and the recycled concrete are tightly combined. In addition, as a corrosion resistant layer inside the injection molded steel tube has good elastoplasticity and strength and has fracture resistance and compressive strength 3.5 times higher than a common steel tube, the corrosion resistant layer can play a role in corrosion prevention and isolation and can be used to make the injection molded steel tube and the recycled concrete to be more tightly combined. Thus, the injection molded steel-tube sea sand recycled concrete column has better functional effects.

Owner:GUANGDONG UNIV OF TECH

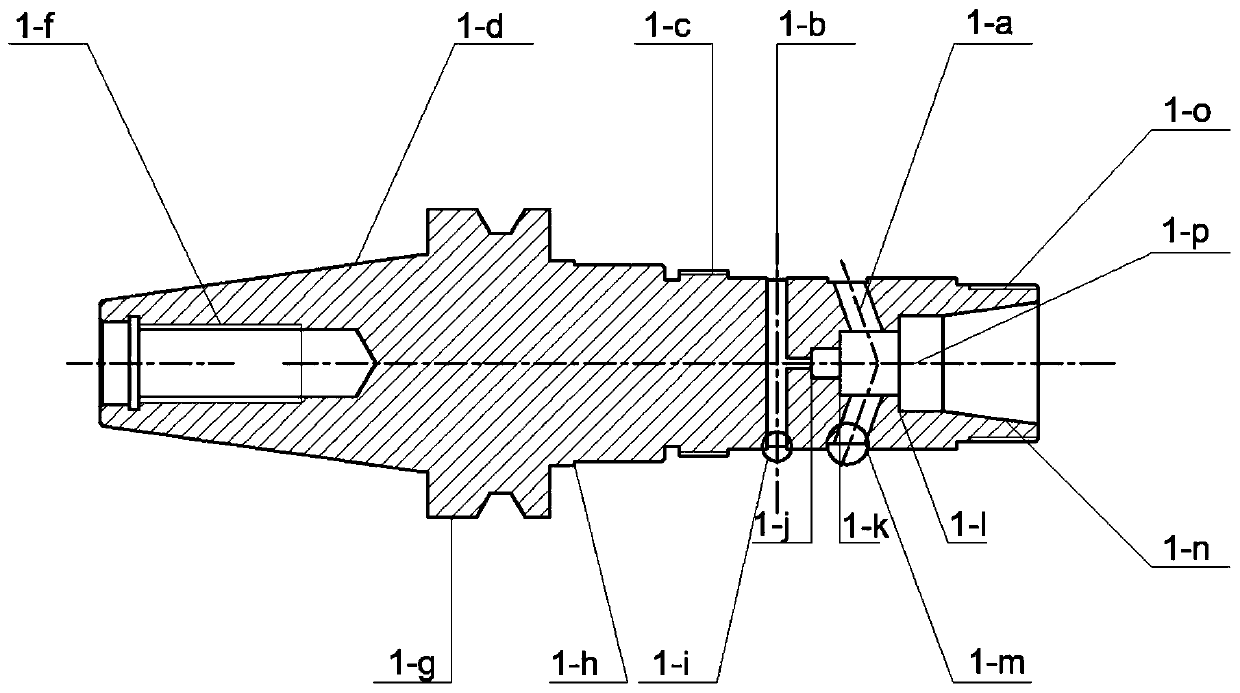

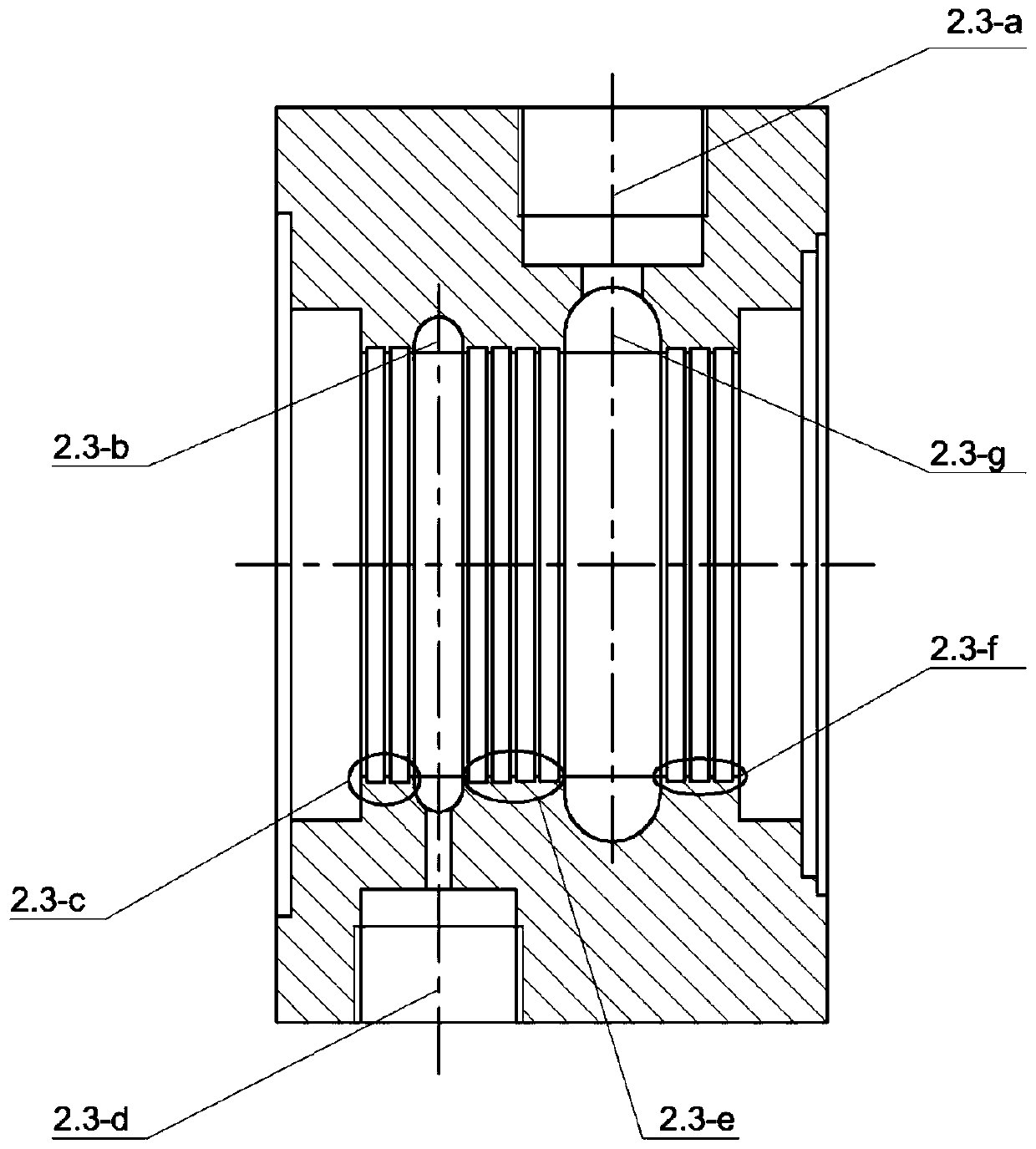

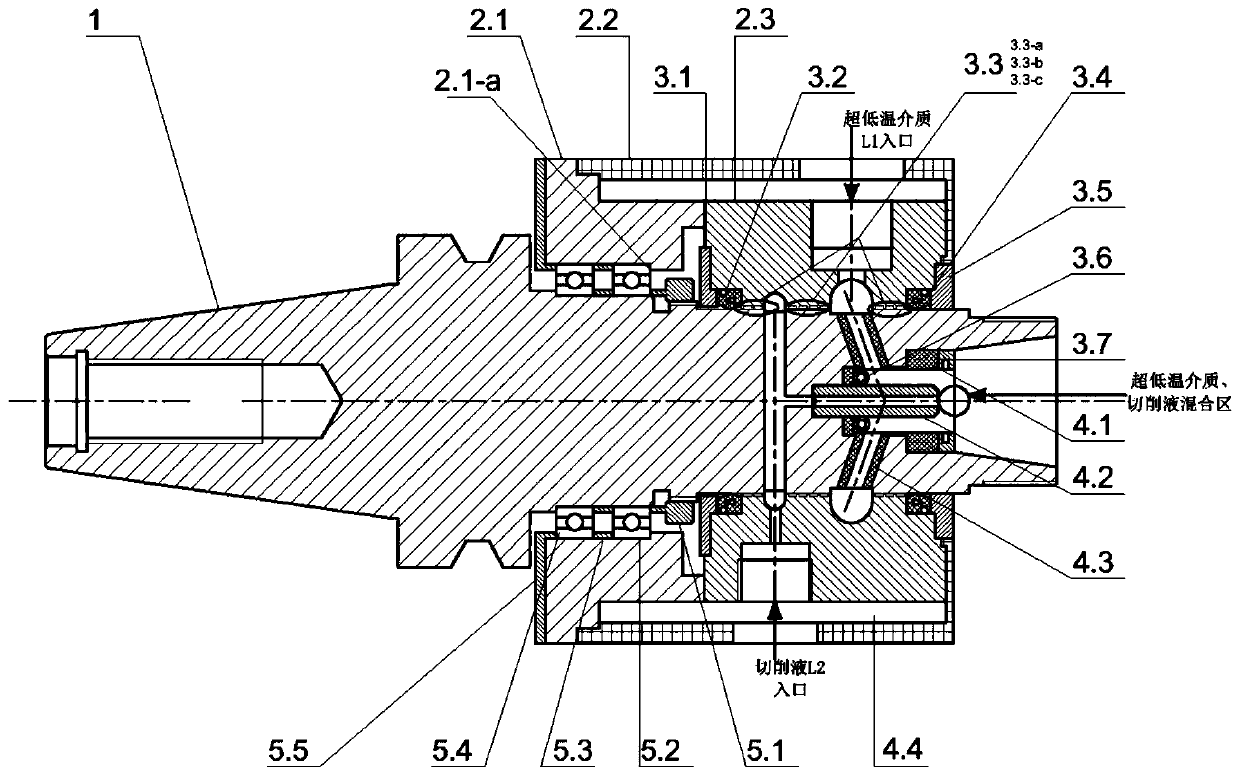

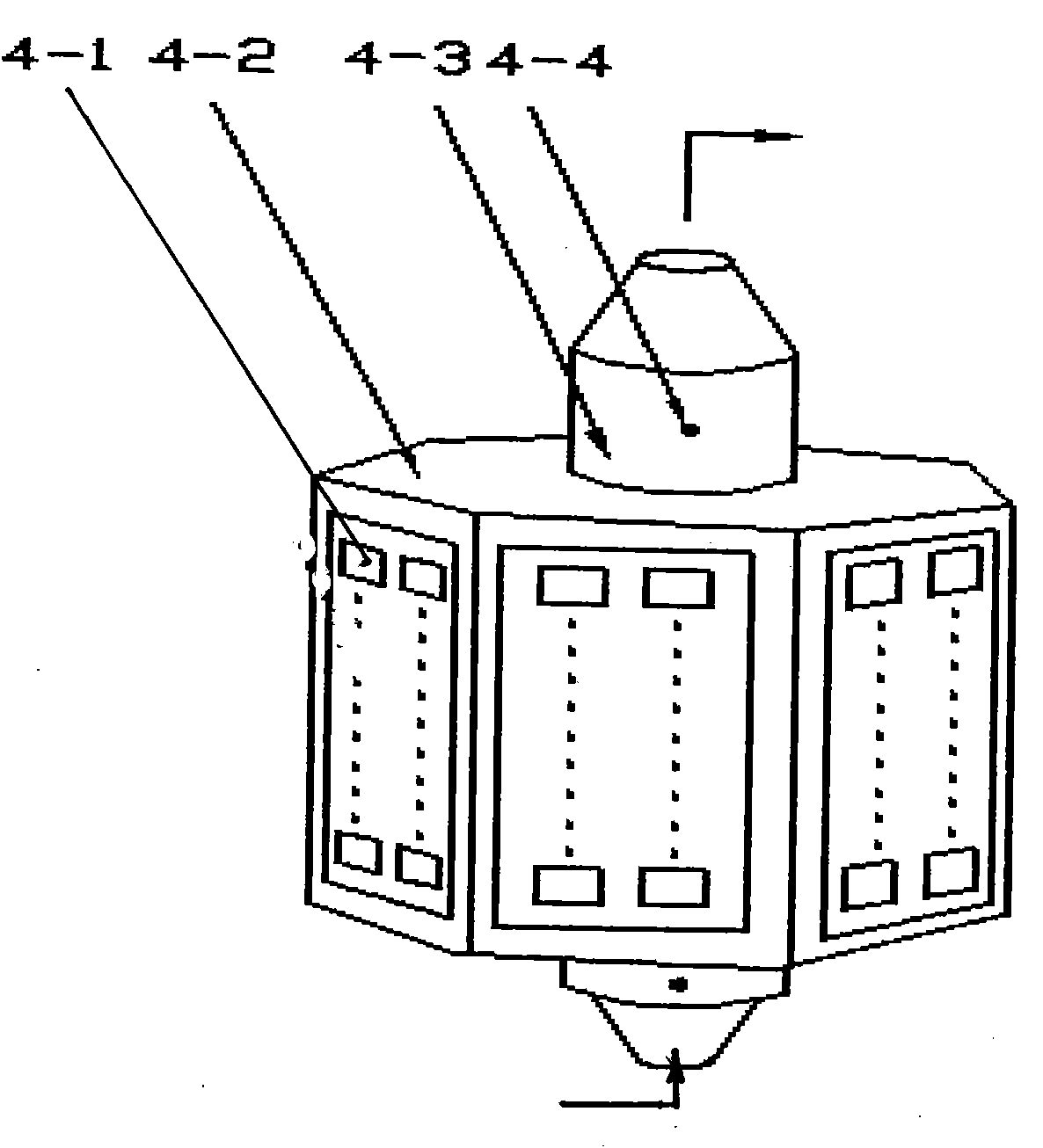

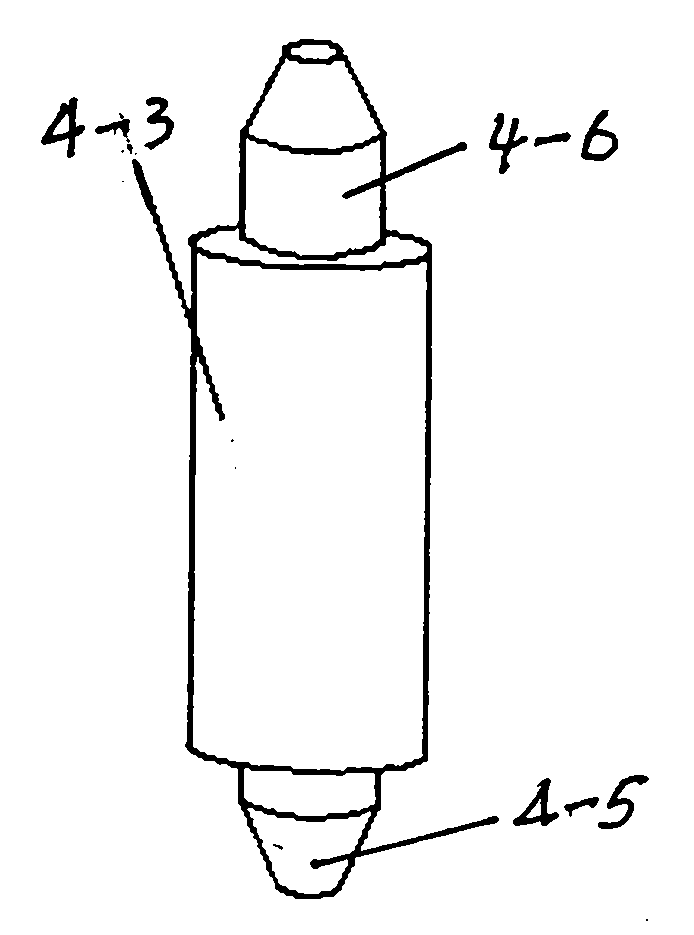

Knife handle suitable for low-temperature minimal quantity lubrication

ActiveCN110883591ASolve problems not suitable for low temperature MQL cuttingOvercome tightnessMilling cuttersAdverse effect compensationNumerical controlCooling effect

The invention provides a knife handle suitable for low-temperature minimal quantity lubrication, and belongs to the technical field of cooling and lubrication of numerical control machine tools. The knife handle comprises a knife handle body, a peripheral static structure, a multi-layer sealing structure, a heat insulation structure and a bearing supporting structure. The problems that in the minimal quantity lubrication technology, the cooling performance is insufficient, and lubrication is insufficient in the low-temperature cooling machining technology are solved, the oxygen isolation protection effect of an ultralow-temperature medium, the cooling effect of the ultralow-temperature medium and the anti-attrition lubrication effect of minimal quantity lubrication are integrated, and therefore a good machining effect is achieved on the aspect of materials difficult to machine. The knife handle can be used for machining the materials difficult to machine through a traditional numericalcontrol machine tool, the application range of an outer rotating inner knife handle is widened, the cutting heat of the materials difficult to machine in the cutting machining process is effectivelyreduced, the service life of a knife is prolonged, traditional cutting fluid is replaced, and green manufacturing is achieved.

Owner:DALIAN UNIV OF TECH

Green preparation method of polyimide gas separation membrane

ActiveCN107376672ANo pollution in the processAvoid harmSemi-permeable membranesGas treatmentSeparation factorN dimethylformamide

The invention belongs to the technical field of membrane separation and in particular relates to a green preparation method of a polyimide gas separation membrane. The membrane preparation process comprises the following process steps: (1) synthesis of water-soluble polyimide: dissolving the prepared hydroxypolyimide in N,N-dimethylformamide, adding a sulfonation or carboxylation reagent and K2CO3, reacting at the temperature of 56 DEG C for 20 hours, and dissolving a product in a mixed solution of methanol and dichloromethane for recrystallization, so as to obtain water-soluble polyimide; (2) preparation of a polyimide gas separation membrane: taking water as a solvent, dissolving the water-soluble polyimide in water to prepare a casting solution, uniformly performing knife coating on a tetrafluoroethylene plate, standing at a room temperature for 12 hours, and drying in a drying oven at the temperature of 50 DEG C for 6 hours, thereby obtaining the product polyimide gas separation membrane. According to the method disclosed by the invention, the organic solvent is replaced with water for film mulching in the film preparation process based on a green film preparation technology, so that no volatile organic vapor is produced. The prepared polyimide gas separation membrane is excellent in permeability of CO2 gas and high in separation factor of CO2 / N2.

Owner:JIANGNAN UNIV

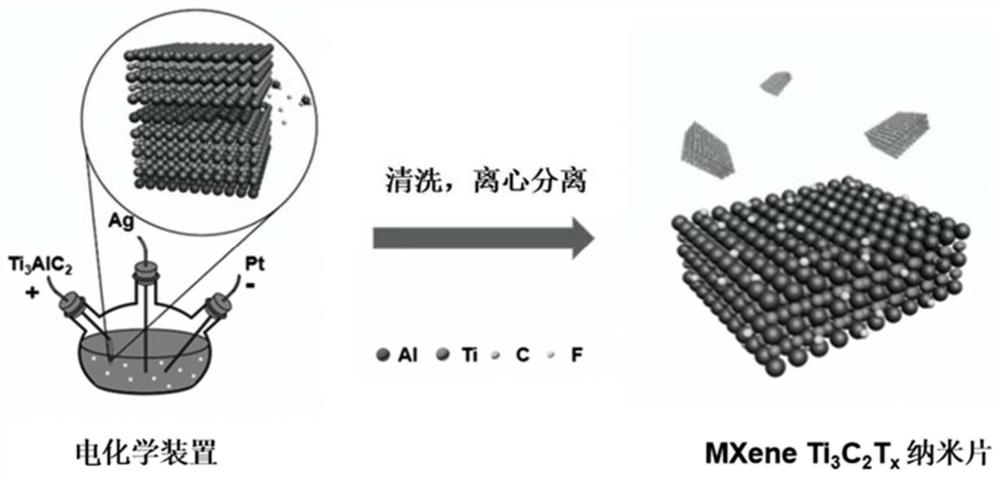

Method for electrochemically preparing MXene

PendingCN111661848ARealize green manufacturingThe preparation process is safe and non-toxicElectrolysis componentsCarbon compoundsElectrolytic agentStrong acids

The invention provides a method for electrochemically preparing MXene. The method comprises the following steps: preparing an MAX base material into a working electrode, fixing the working electrode in an electrolytic tank, adding an electrolyte, which is fluorine-containing anion liquid to serve as an etching agent, into the electrolytic tank to make the working electrode immersed into the electrolyte, taking a working electrode as a positive electrode, applying a voltage to make the fluorine-containing anion liquid ionized to generate .F free radicals, and enabling the .F free radicals to etch A-layer atoms in the MAX base metal; and after the electrolysis is finished, separating the electrolyte containing an MXene dispersion to obtain the MXene material. According to the electrochemicalstripping method, the mild, green and pollution-free ionic liquid is adopted as the electrolyte, hydrofluoric acid with high corrosivity and other byproducts such as strong acid and strong alkali cannot be generated in the electrochemical stripping process, the preparation process is safe and non-toxic, the electrochemical pressurization range is small, the safety is high, and green preparation of MXene is realized.

Owner:SHENZHEN HANGUANG TECH CO LTD

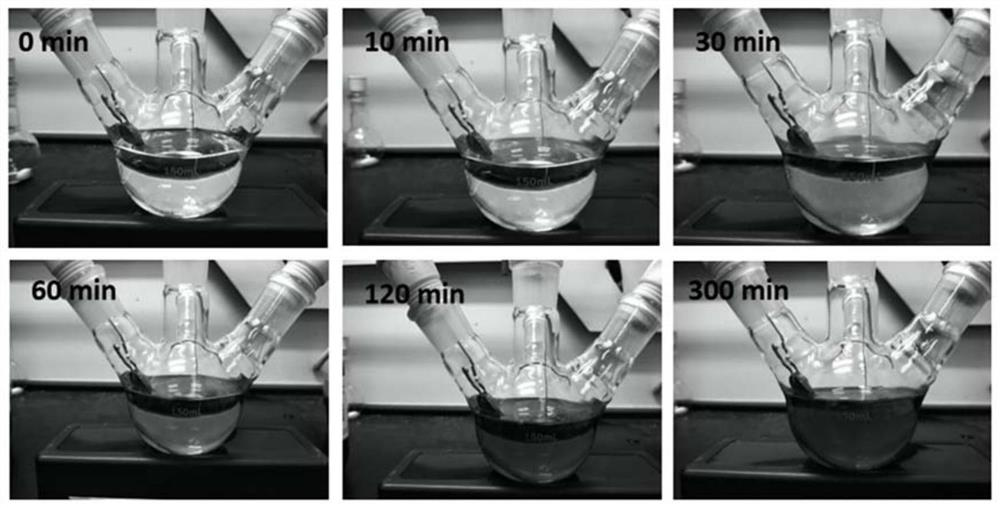

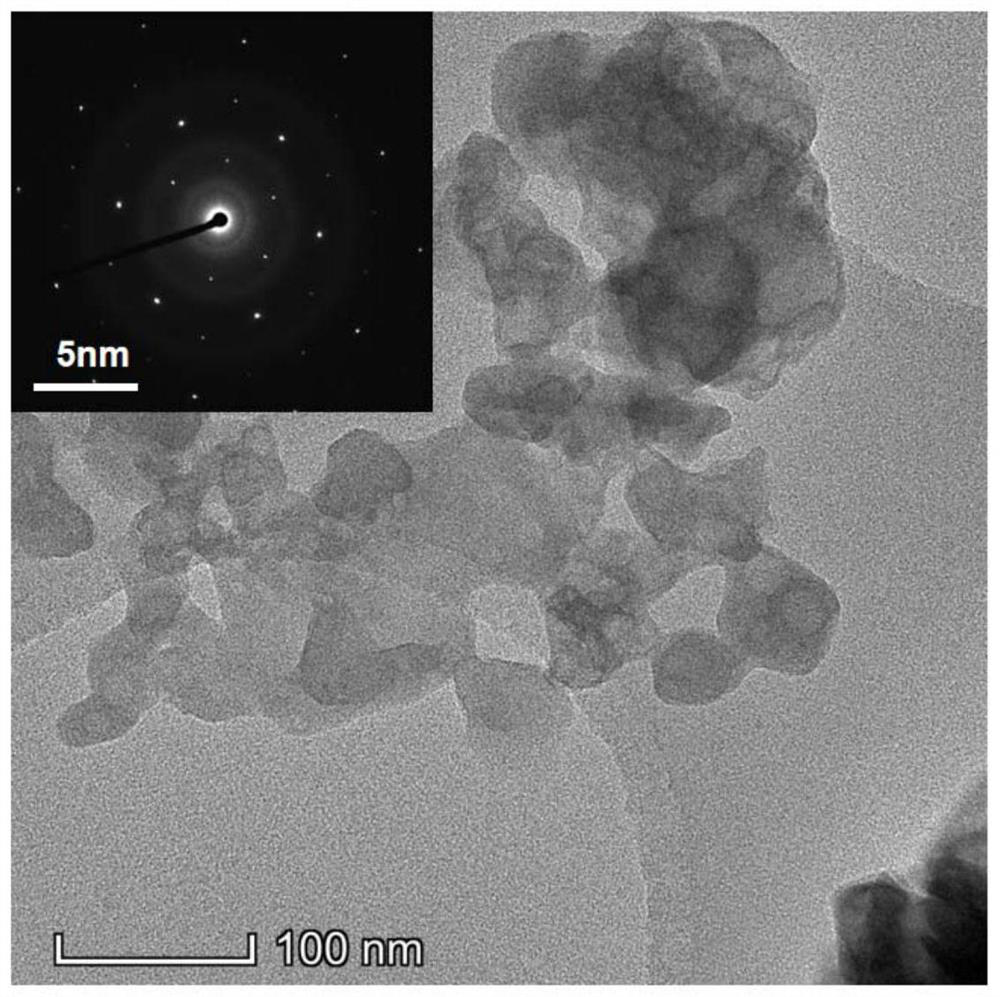

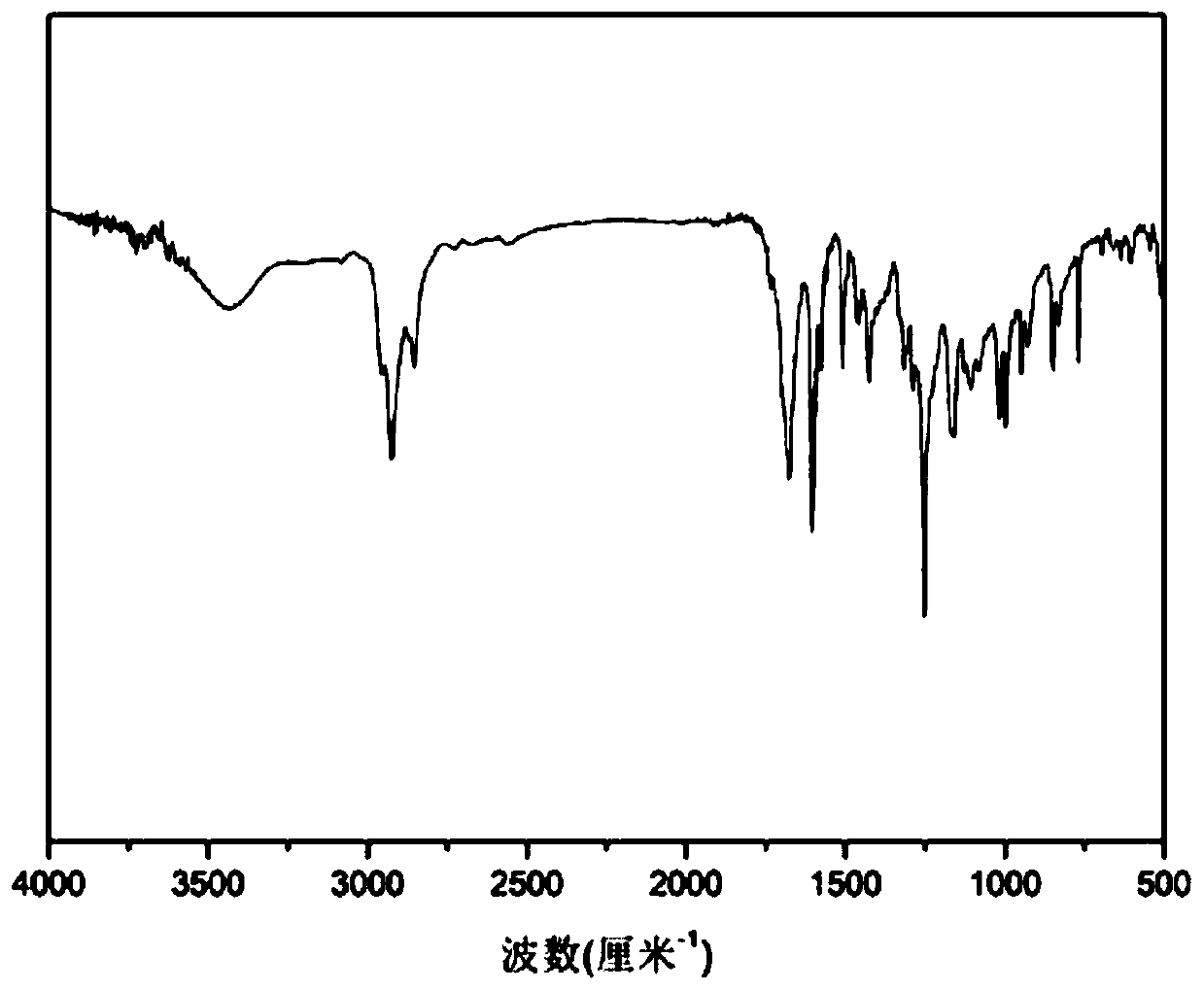

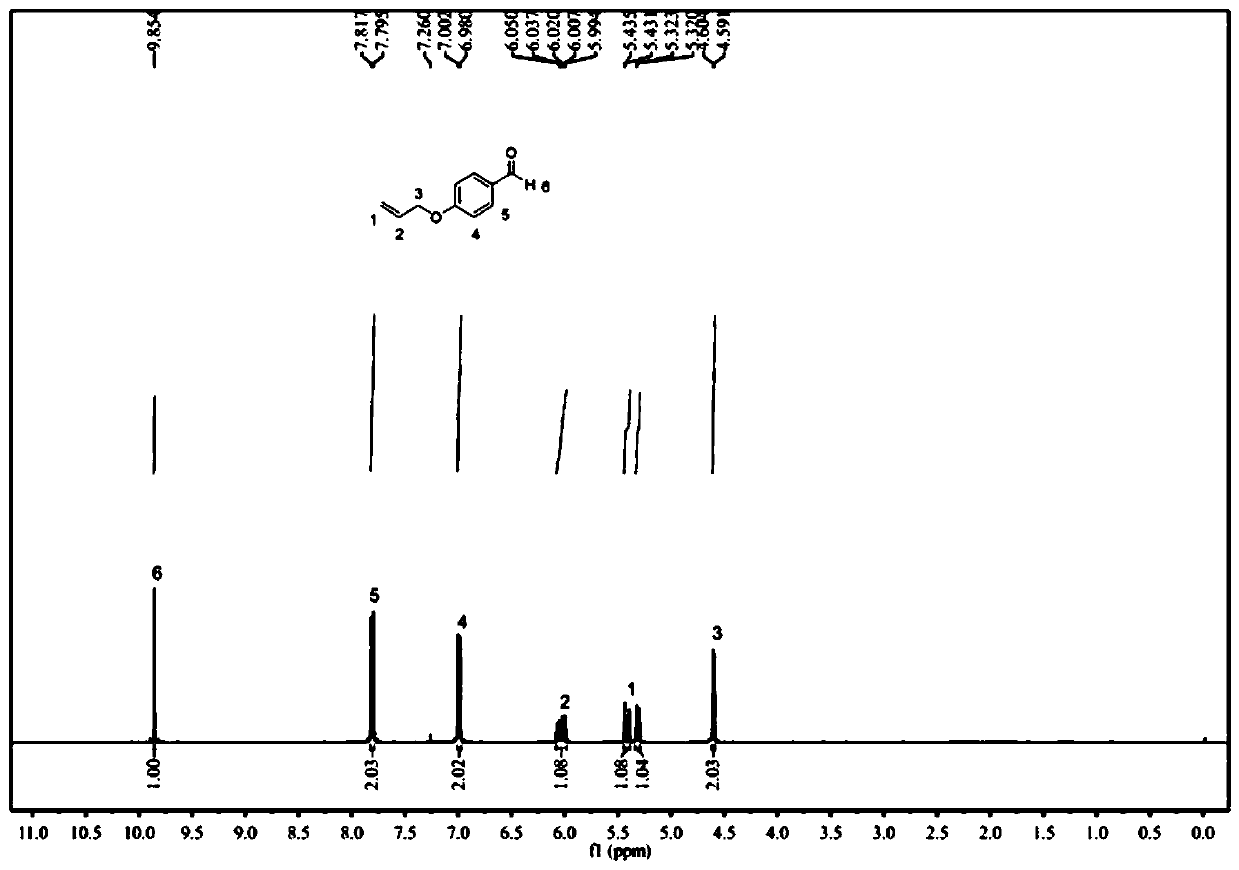

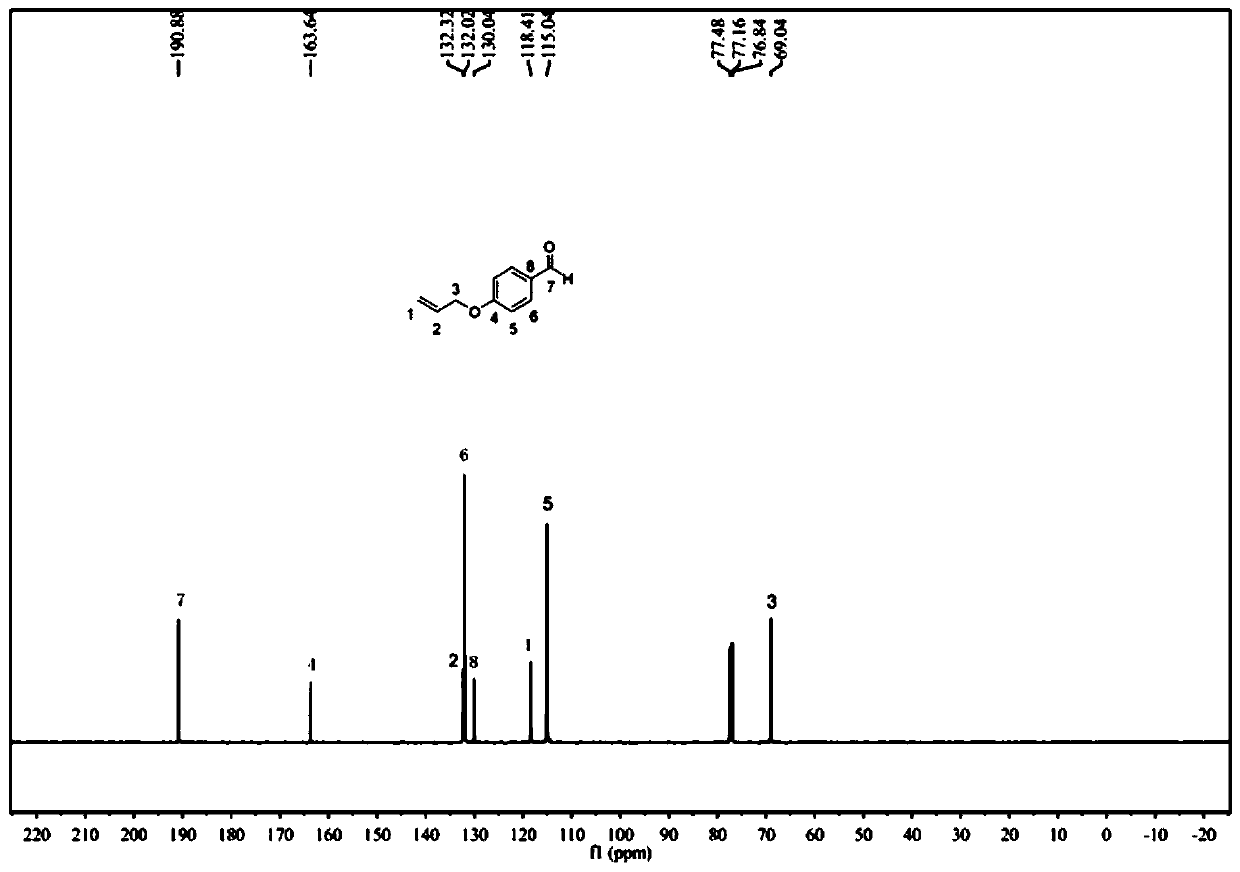

Carboxylic ester structure containing diene monomer and polyester thereof, and sulfur-containing polyester

InactiveCN110183328AThe synthesis process is simpleAbundant raw materialsOrganic compound preparationCarboxylic acid esters preparationSolventChemistry

The invention discloses a carboxylic ester structure containing diene monomer and polyester thereof, and sulfur-containing polyester. The monomer is prepared through the following steps: 1) with one selected from the group consisting of vanillin, syringaldehyde, p-hydroxybenzaldehyde, 3-fluoro-4-hydroxybenzaldehyde, 3-bromo-4-hydroxybenzaldehyde and 3-methyl-4-hydroxybenzaldehyde as a raw material, dissolving the raw material into an organic solvent, then allowing an obtained solution to react with alkenyl halide under the action of a catalyst, and allowing a reaction product to be recrystallized or separated through a chromatography column so as to obtain an olefine aldehyde monomer; and 2) with the olefine aldehyde monomer as a raw material, allowing the olefine aldehyde monomer to reactunder the action of a catalyst and a promoter without a solvent or after the olefine aldehyde monomer is dissolved in an organic solvent, and allowing a reaction product to be recrystallized or separated through a chromatography column so as to obtain the carboxylic ester structure containing diene monomer. The polyester provided by the invention is prepared under the action of a Hoveyda-Grubbs catalyst and p-benzoquinone. The sulfur-containing polyester provided by the invention is prepared by a reaction of the polyester and a dimercaptan compound. The invention relates to a novel monomer and a polymer. The preparation processes for the monomer and the polymer provided by the invention have the characteristics of rich raw material sources, simple preparation process, no generation of flammable and explosive low-boiling-point volatile matters, greenness, environmental friendliness and universality.

Owner:GUIZHOU UNIV

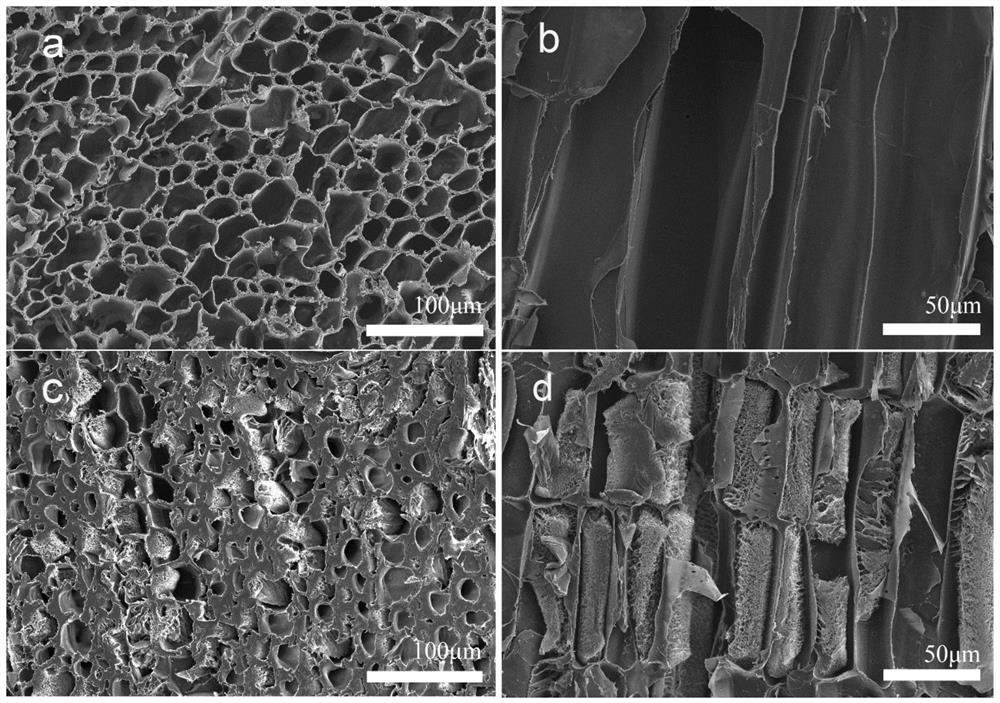

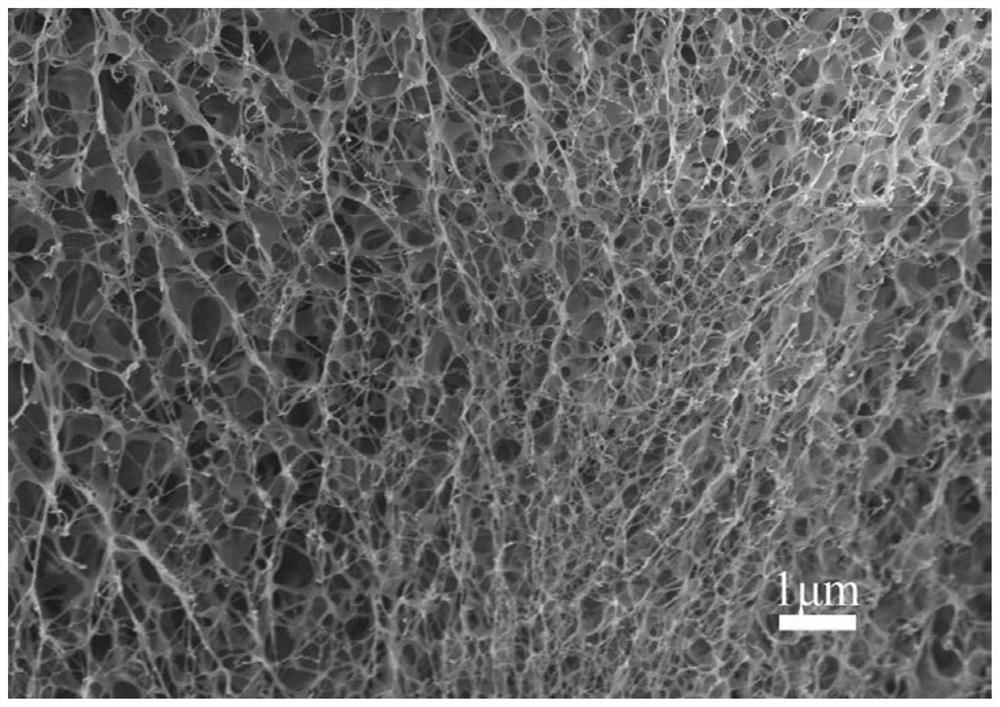

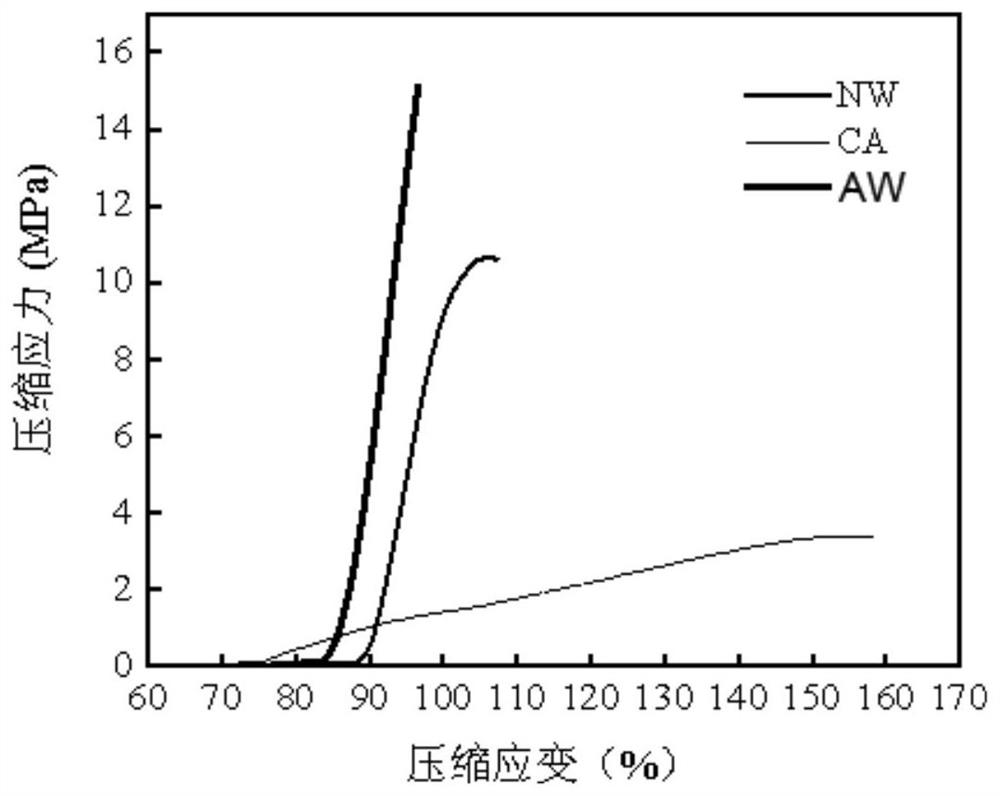

High-strength anisotropic aerogel type wood structure and preparation method thereof

ActiveCN114670299AHigh porosityHigh specific surface energyRadiation/waves wood treatmentWood treatment detailsFiberPolymer science

The invention discloses a high-strength anisotropic aerogel type wood structure and a preparation method thereof. The method comprises the following steps: cutting log wood into wood blocks according to the direction of a cross section or a longitudinal section, performing pretreatment through purification and drying processes, and keeping the water content at 5-50%; immersing the obtained wood block in a wood dissolving system; the infiltrated wood block is subjected to ultrasonic treatment, so that fiber parts on the inner walls of the cell cavities are dissolved out and filled into cell cavity pore channels; the dissolved wood is placed in a regeneration solvent to be subjected to regeneration treatment for 0.1-100 hours; and the obtained wood block is placed in a replacement solvent, drying treatment is conducted, and the aerogel type wood is obtained. According to the aerogel type wood structure, an original anisotropic micro-channel of wood is reserved, and meanwhile the micro-channel is filled with a large number of nanometer networks with the size within 100 nm; the elasticity modulus of the prepared aerogel type wood structure is 156.2 + / -18 MPa, and the elasticity modulus of natural wood is 99.07 MPa.

Owner:SOUTH CHINA UNIV OF TECH

Ti microalloying 540MPa-level high reaming steel belt and production method thereof

The invention discloses a Ti microalloying 540MPa-level high reaming steel belt and a production method thereof. The steel belt comprises, by mass percent, 0.07%-0.11% of C, 1.00%-1.30% of Mn, not larger than 0.015% of S, not larger than 0.020% of P, 0.05%-0.12% of Si, 0.015%-0.040% of Als, 0.020%-0.040% of Ti, not larger than 0.0050% of N, 0.30%-0.36% of Ceq and the balance iron and inevitable impurities. The production method comprises the procedures of converter smelting, LF refining, continuous casting, heating, rough rolling, finish rolling, cooling and coiling. Low carbon, conventional manganese and titanium alloy components are adopted for design, through a cooling path and medium-temperature coiling control, the obtained steel belt is suitable for producing Japanese automobile axlefront brackets and other automobile stamped parts, the body weight can be reduced easily, and fuel consumption can be reduced.

Owner:TANGSHAN STAINLESS STEEL +1

Method for heating titanium strip cleaning acid liquor by using microwave heater

The invention relates to a method for heating titanium strip cleaning acid liquor by using a microwave heater. In the method, the titanium strip cleaning acid liquor flowing through microwave heating equipment is directly heated in a non-contact mode by the microwave heating equipment through microwave energy radiated by the microwave heater, so that the acid liquor reaches the temperature needed by the technology in a circulating state, and a titanium strip passes through a pickling bath at a certain speed for pickling. The method has the advantages of capacities of directly heating the titanium strip cleaning acid liquor, having no heat exchange process, improving the thermal efficiency, achieving zero carbon emission, reducing the energy consumption and solving the problems of environmental pollution and energy waste brought by the use of boilers.

Owner:KUNMING UNIV OF SCI & TECH +1

Low-conductivity super-long-acting organic base type anti-freezing cooling liquid

InactiveCN102174313BMeet insulation safety requirementsReduce corrosionHeat-exchange elementsOrganic baseCarboxylic acid

The invention provides low-conductivity super-long-acting organic base type anti-freezing cooling liquid, which comprises the following components in percentage by weight: 15 to 96 percent of anti-freezing agent, 0.05 to 1.5 percent of natural alkaloid, 0.5 to 2.5 percent of hetero-cycloalkane, 0.01 to 0.3 percent of azole component, and the balance of deionized water. In invention, since the natural alkaloid is matched with nonionic organic compounds, the prepared anti-freezing cooling liquid has the characteristics of low freezing point, high boiling point, no scale formation, corrosion protection, high heat efficiency and the like; in addition, the prepared anti-freezing cooling liquid also has ultra-low conductivity which can reach 5 mus / cm and is a few hundredths of the conductivity of a common water cooling medium because the anti-freezing cooling liquid does not contain the components of inorganic salts, organic carboxylic acid and the like. The anti-freezing cooling liquid with ultra-low conductivity can effectively slow up the corrosion on metal parts of a cooling system, and meet the requirement of special conditions such as the cooling of a wind generator set and the like on the insulation safety of the anti-freezing cooling liquid. The anti-freezing cooling liquid realizes environmental protection and ultra-long-acting service, and is particularly suitable for special equipment such as a wind generator set, an imperial sedan engine and the like.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

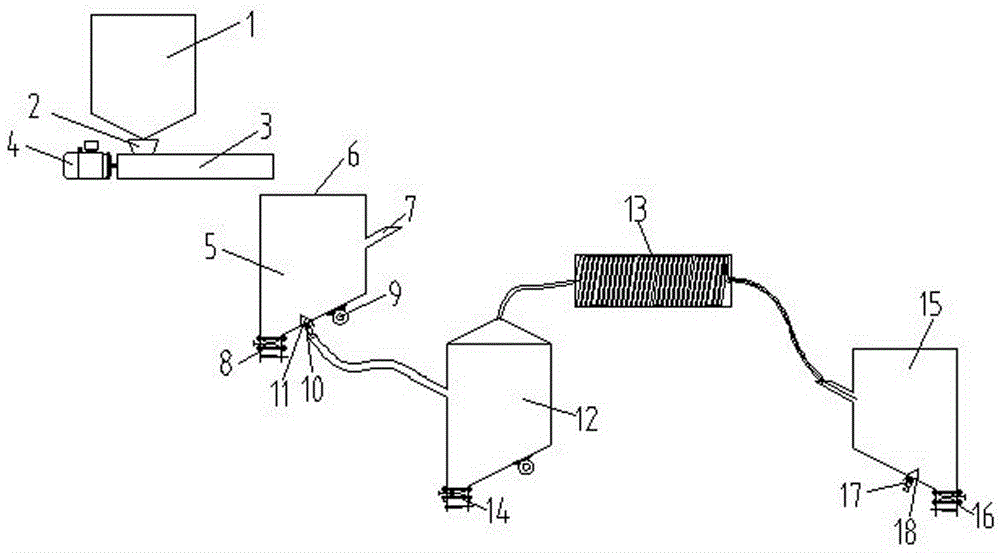

Production process and equipment for extracting rosewood essential oil from rosewood chips

InactiveCN104818118AIncrease productionQuality improvementEssential-oils/perfumesRosewoodCellulose breakdown

The invention discloses a production process and equipment for extracting rosewood essential oil from rosewood chips. The method comprises the steps of catalyzing the rosewood chips, water and cellulase inside a dip vat to obtain a liquid; during catalyzation of the rosewood chips, the water and the cellulase inside the dip vat, vibrating the dip vat through an ultrasonic vibrator mounted on the dip vat to even the rosewood chips and the water; filtering the liquid, distilling water of the filtered liquid through a distilling tank, and conveying the distilled liquid to a condenser for liquefaction to obtain rough essential oil; conveying the rough essential oil into a purification tank, and performing extraction through petroleum ether extracting agent to obtain the rosewood essential oil. The production process and equipment for extracting the rosewood essential oil from the rosewood chips can improve the production efficiency, reduce energy consumption and improve the quality of the essential oil.

Owner:SHAOXING UNIVERSITY

Laser cladding gear reconstruction and repair method

InactiveCN109371393ASmall dilutionSmall heat affected zoneMetallic material coating processesGear grindingAngle grinder

The invention relates to a laser cladding gear reconstruction and repair method. The laser cladding gear reconstruction and repair method aims to prolong the service life of products and effectively save the production cost. The laser cladding gear reconstruction and repair method comprises the following steps of cleaning a scrapped gear with kerosene to remove surface impurities; wiping a tooth surface clean with cloth to reveal primary colors, and polishing an area to be repaired with an angle grinder and a file to reveal metallic luster; using absolute ethyl alcohol to carry out secondary cleaning, thoroughly removing residual oil stains on the tooth surface, and then carrying out air drying treatment; adopting metal powder to carry out local cladding treatment on damaged portions of gear surfaces through a laser cladding device, wherein the cladding area slightly exceeds a repairing area, and the cladding thickness exceeds the tooth surfaces by 1-1.5mm; and using a gear grinding machine to grind off gear surface allowance and complete tooth surface shaping and restoration.

Owner:阳泉煤业集团华越机械有限公司煤机装备研究院

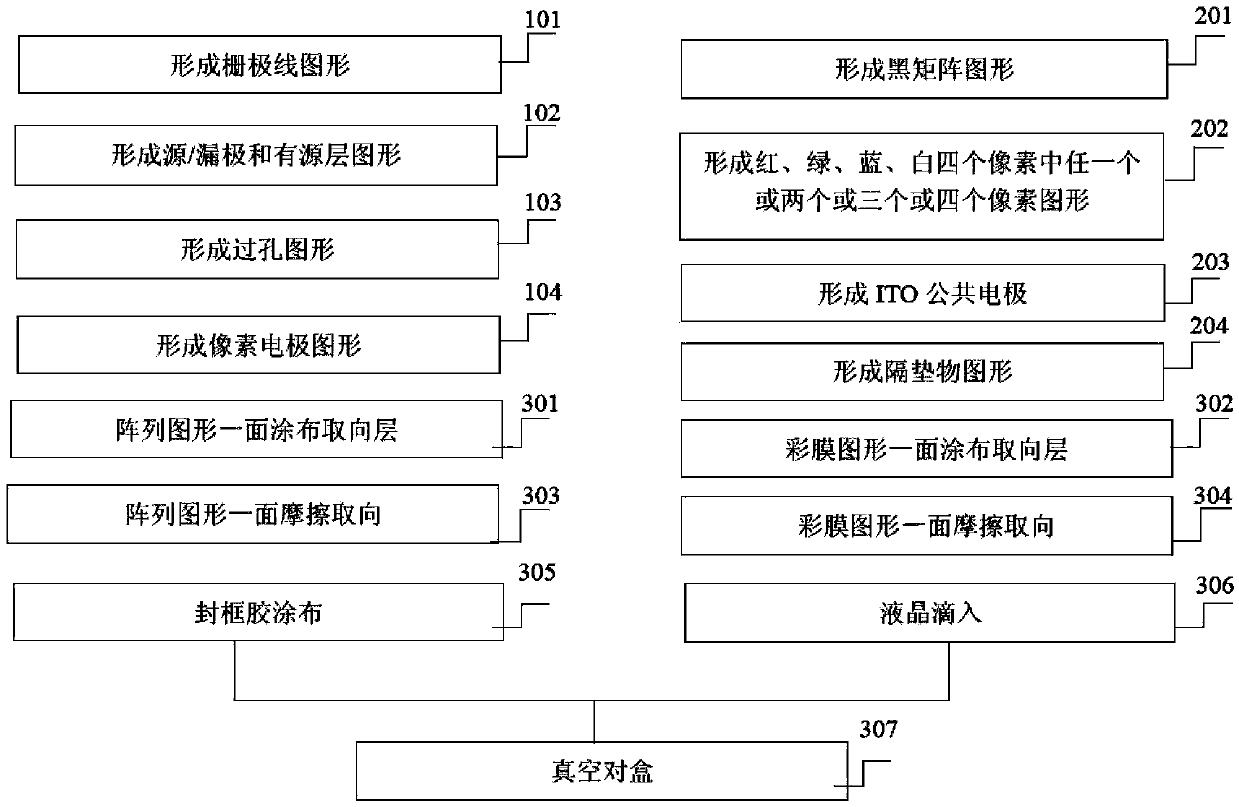

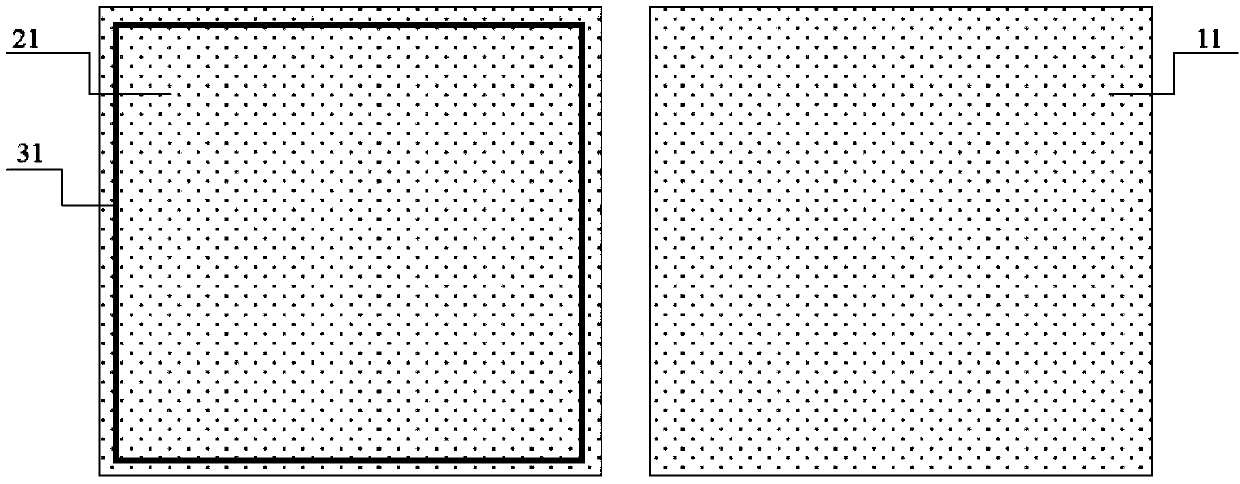

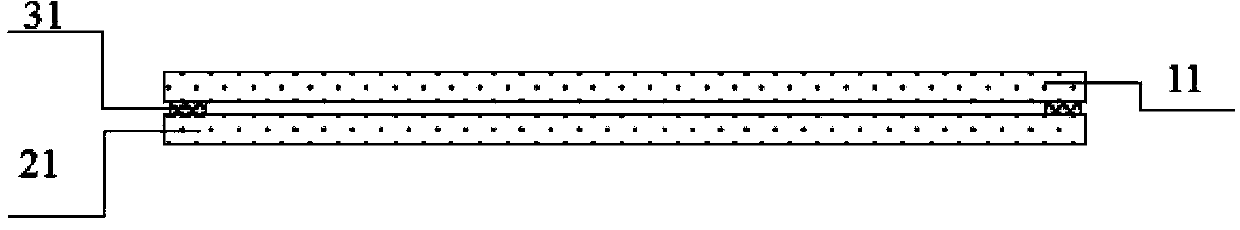

Method for manufacturing thin film transistor liquid crystal displayer (TFT-LCD)

ActiveCN103869519AAvoid pollutionThinning process omittedSolid-state devicesNon-linear opticsLiquid-crystal displayColor film

The invention discloses a method for manufacturing a thin film transistor liquid crystal displayer (TFT-LCD). The method for manufacturing the TFT-LCD includes: laminating a first substrate and a second substrate so as to form a mother substrate; forming an array figure on the first substrate; forming a color film figure on the second substrate; cutting the mother substrate and separating the first substrate from the second substrate; turning over the first substrate and the second substrate after being separated and forming a box. By adopting the method for manufacturing the TFT-LCD, an ultrathin thin TFT-LCD is manufactured, a subsequent thinning process is omitted, and accordingly various badness, cost increases and environmental pollution, which are caused by the subsequent process, are avoided, and furthermore green manufacturing of products is achieved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com