Method for manufacturing thin film transistor liquid crystal displayer (TFT-LCD)

A liquid crystal display and thin film transistor technology, which is applied in the field of manufacturing ultra-thin thin film transistor liquid crystal displays, can solve problems such as bumps, increased manufacturing costs, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

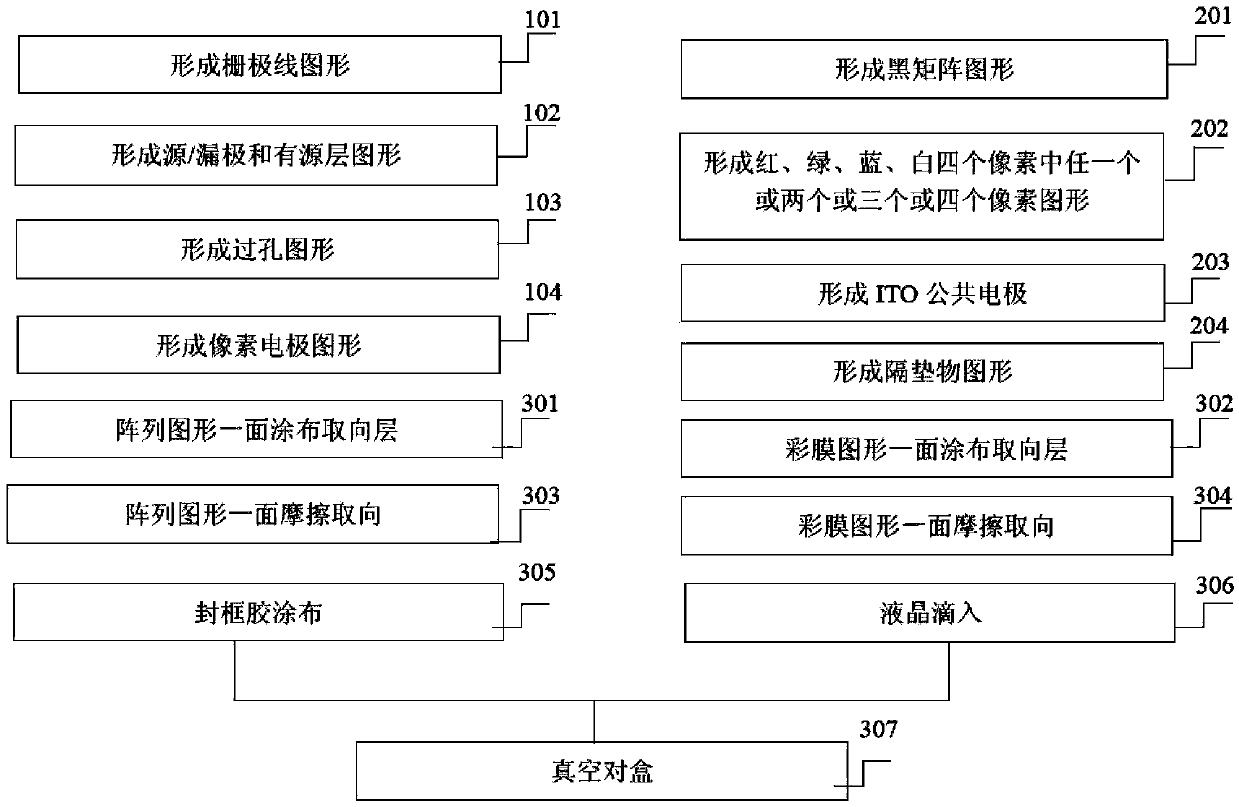

[0035] figure 1 It shows the basic process flow of manufacturing TFT-LCD in the prior art, including: array pattern formation and color filter pattern formation, and three major process flows of array substrate and color filter substrate bonding to form a liquid crystal cell.

[0036] The formation process of the array pattern can adopt the four-time mask process commonly used in this field, including:

[0037] Step 101: forming a gate line pattern;

[0038] Step 102: forming source / drain and active layer patterns;

[0039] Step 103: forming a via pattern;

[0040] Step 104: forming a pixel electrode pattern.

[0041] The forming process of color film graphics may include:

[0042] Step 201: forming a black matrix pattern;

[0043] Step 202: forming any one or two or three or four pixel graphics of red, green, blue and white pixels;

[0044] Step 203: forming an ITO common electrode;

[0045] Step 204: Form a spacer pattern.

[0046] The liquid crystal cell forming pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com