Patents

Literature

920 results about "Thin-film-transistor liquid-crystal display" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

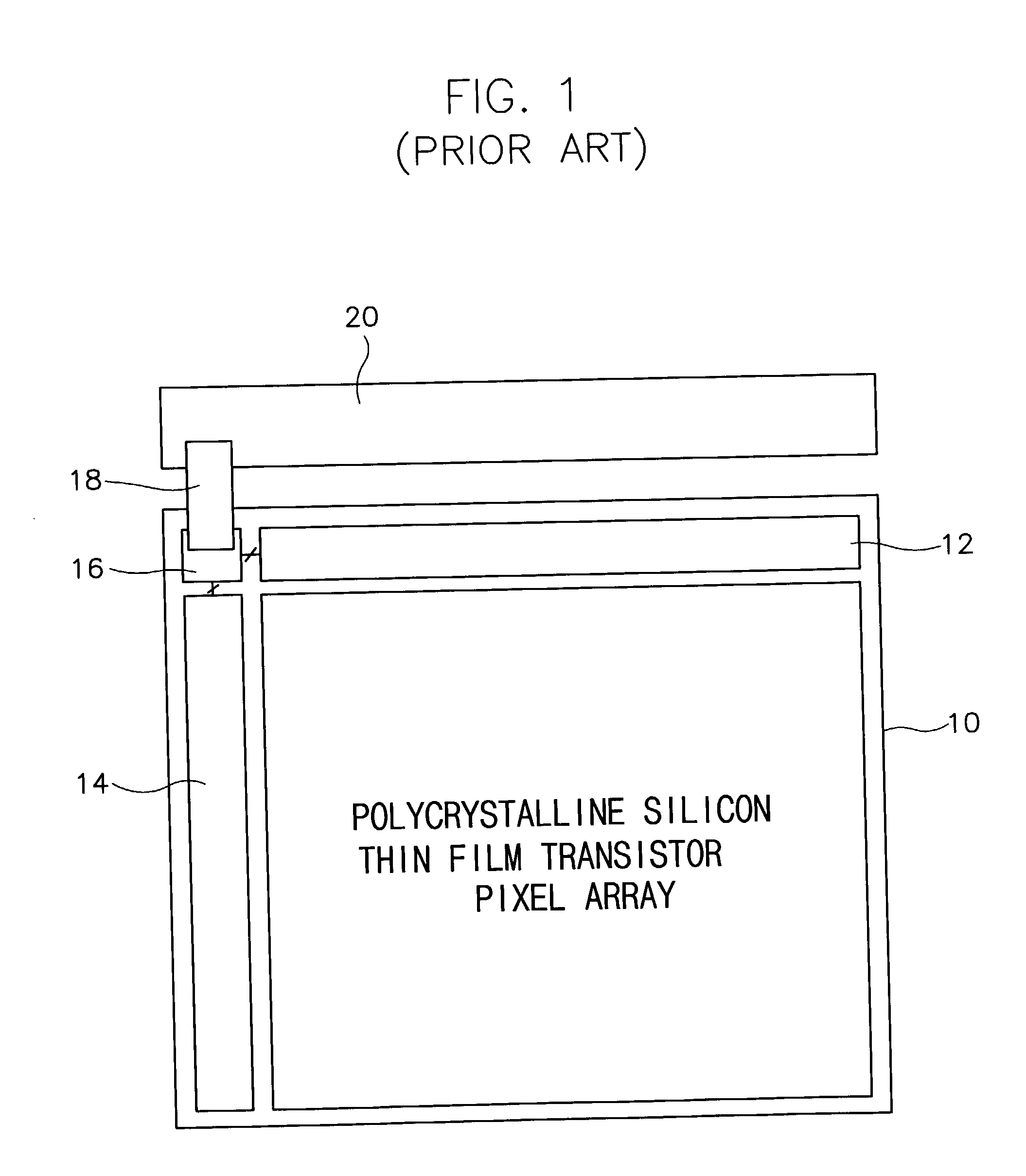

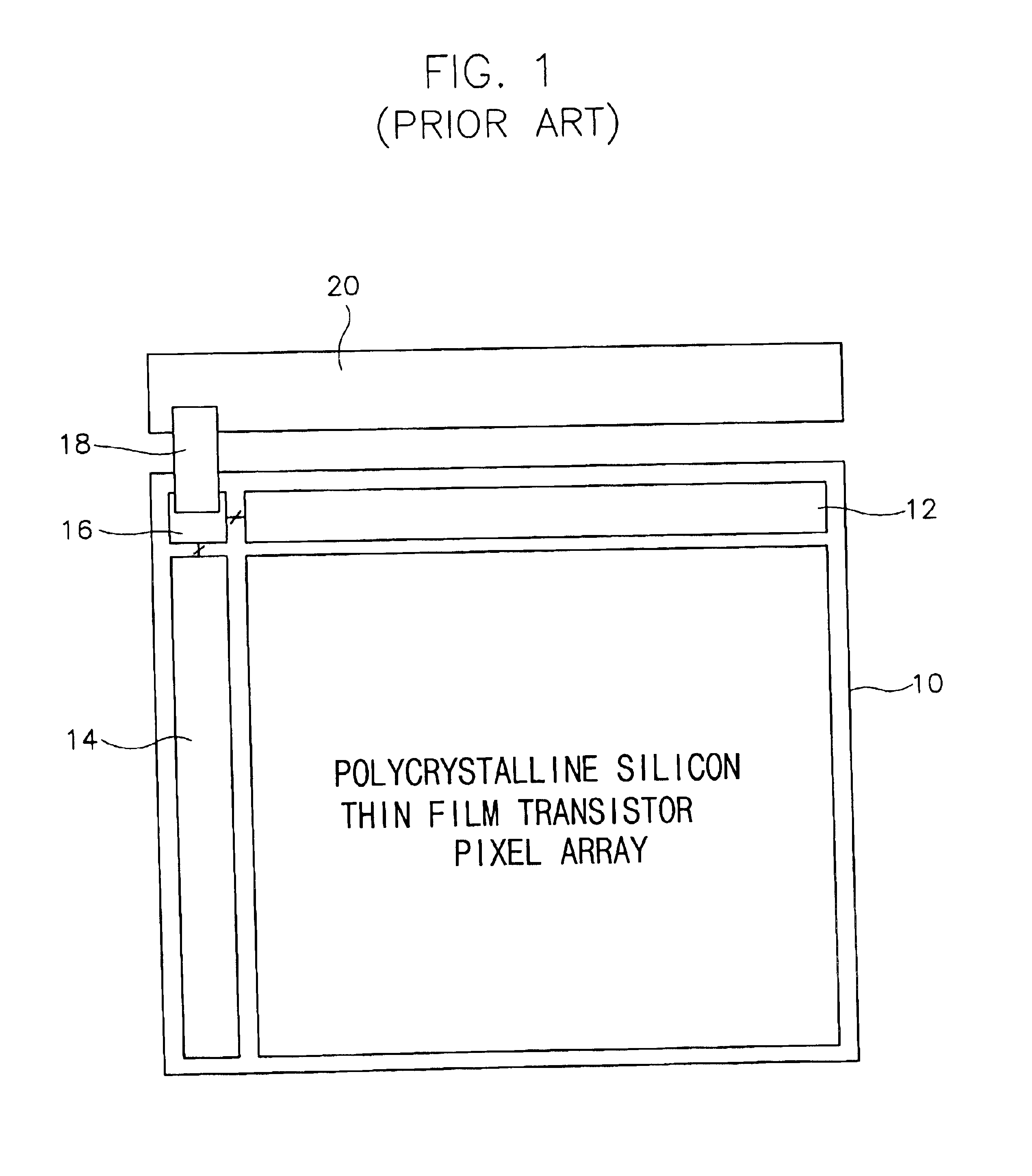

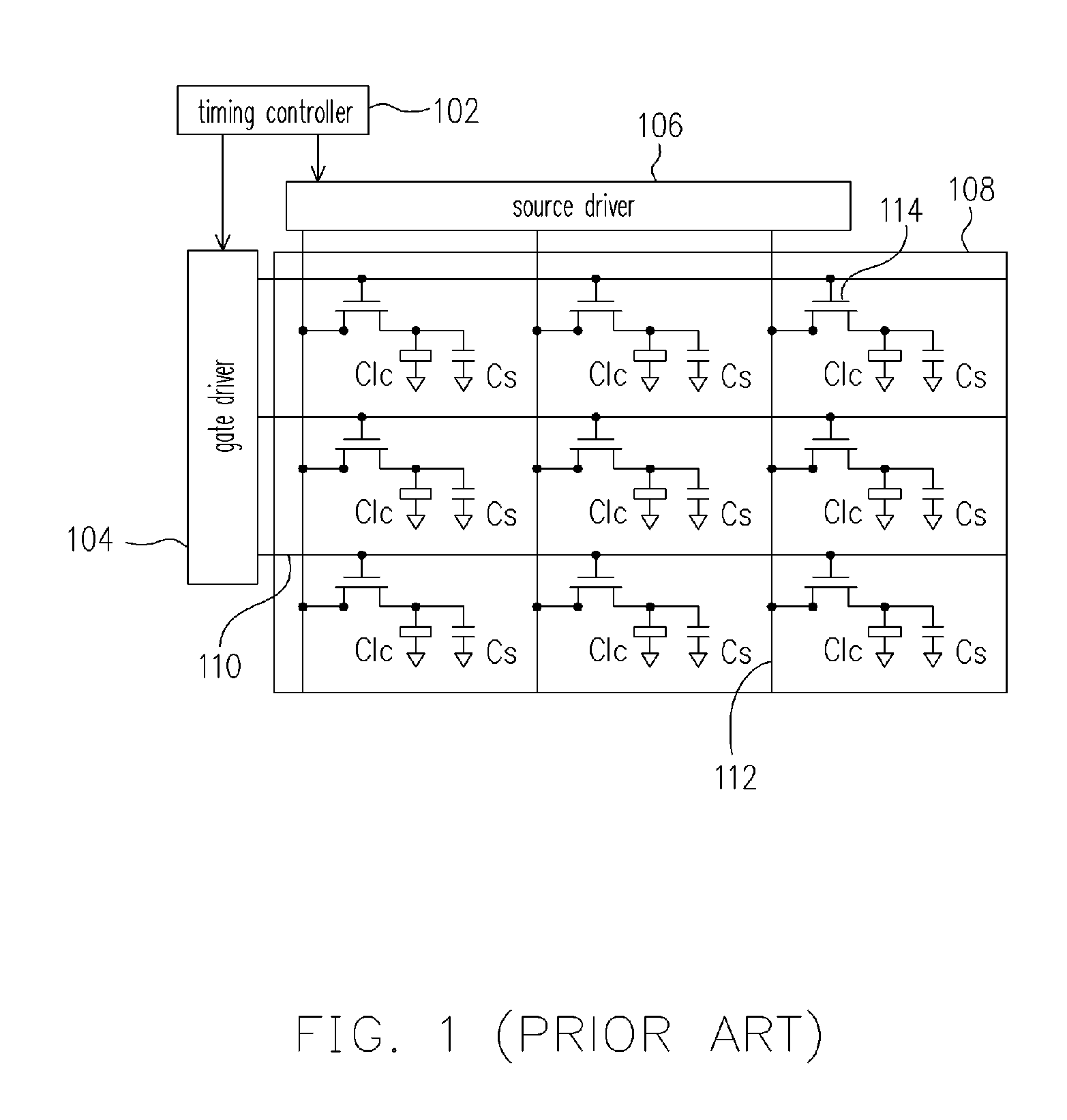

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

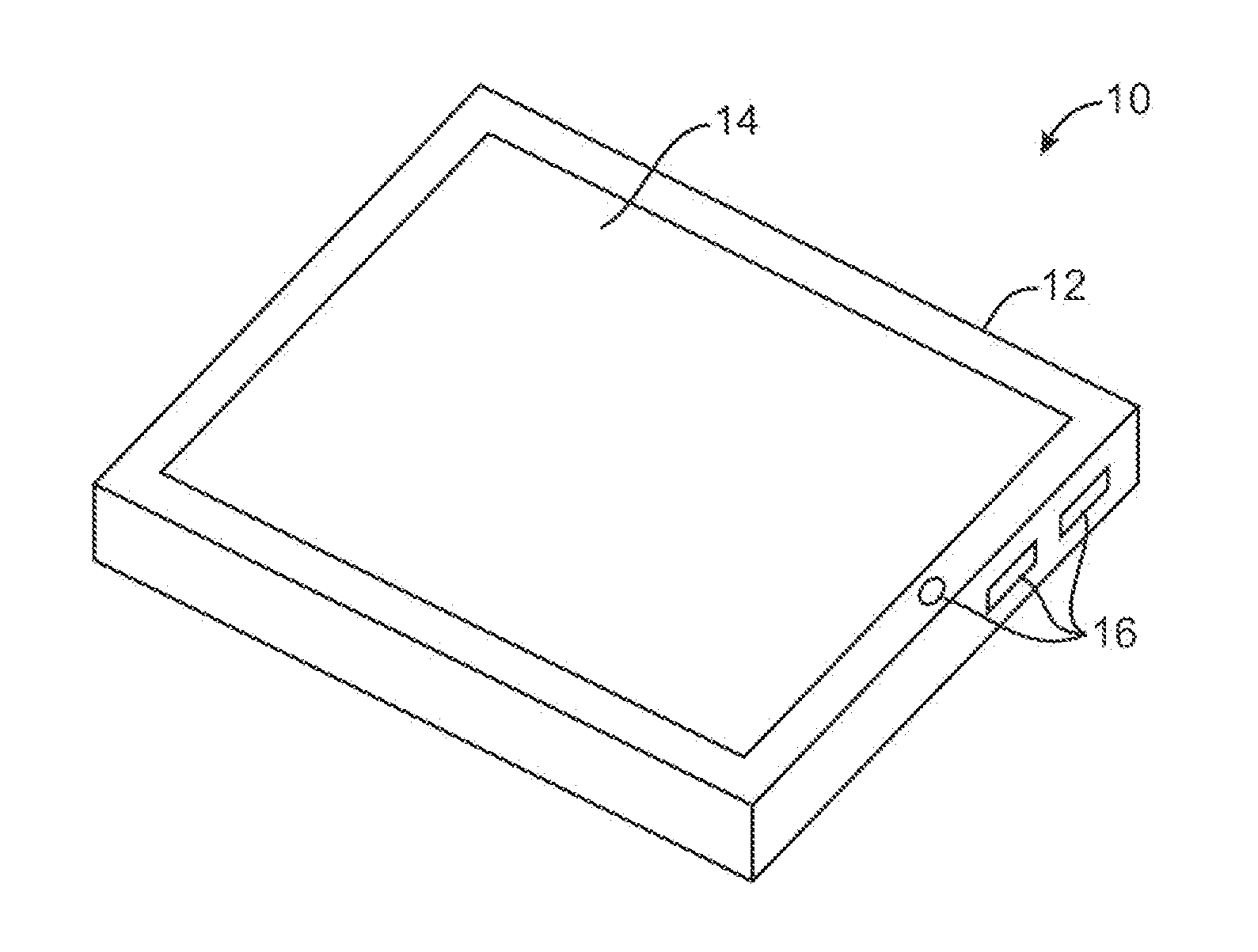

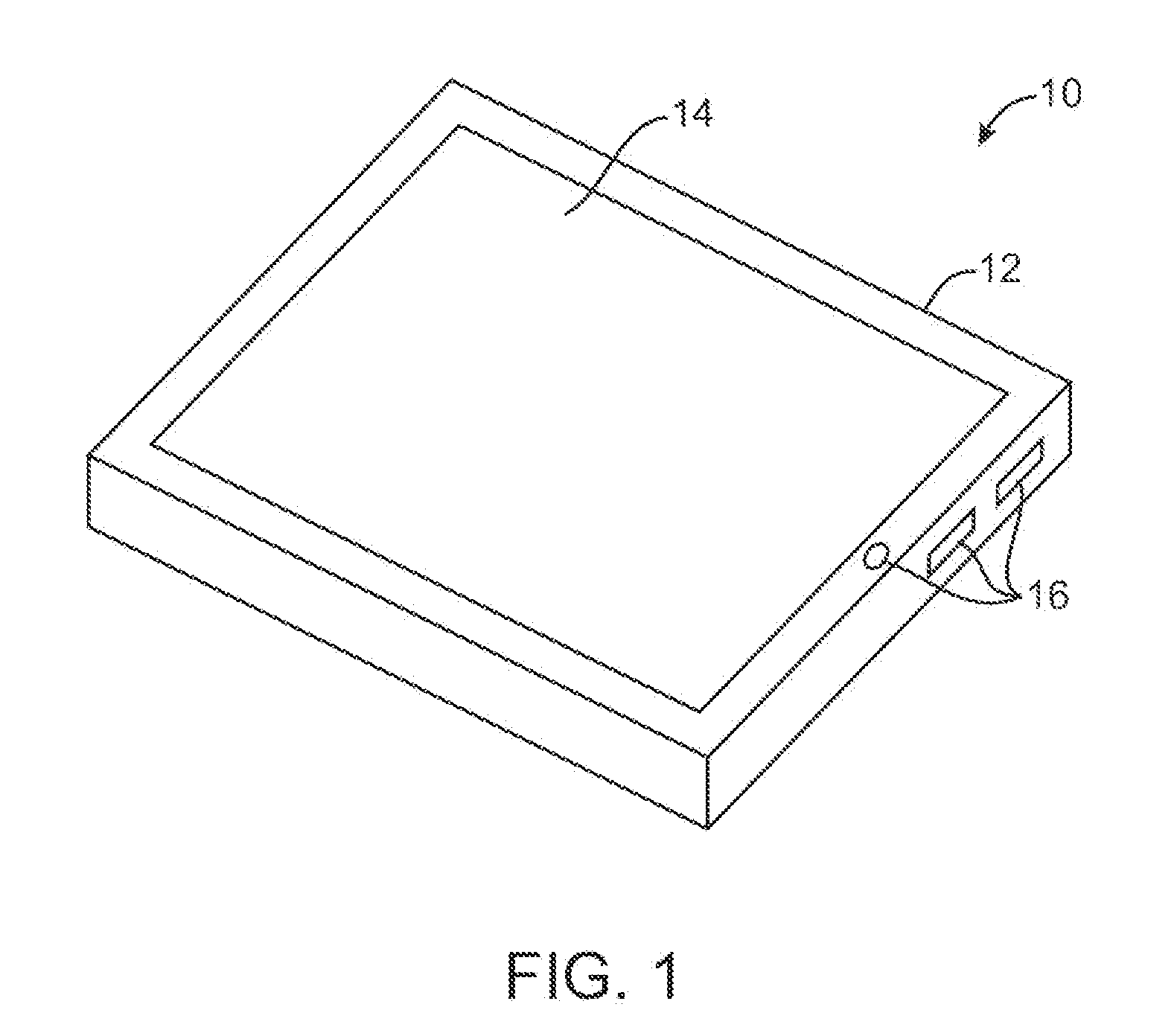

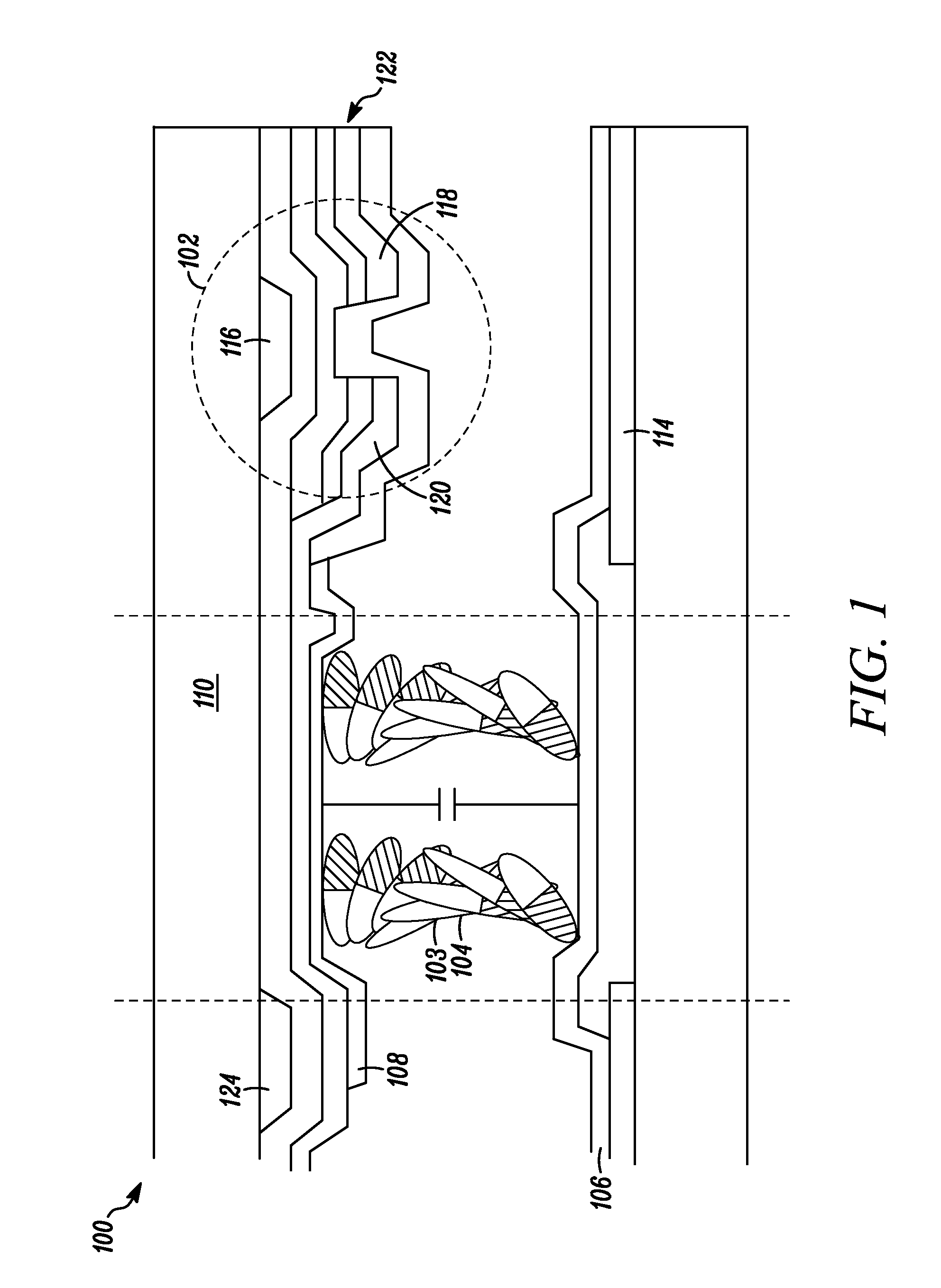

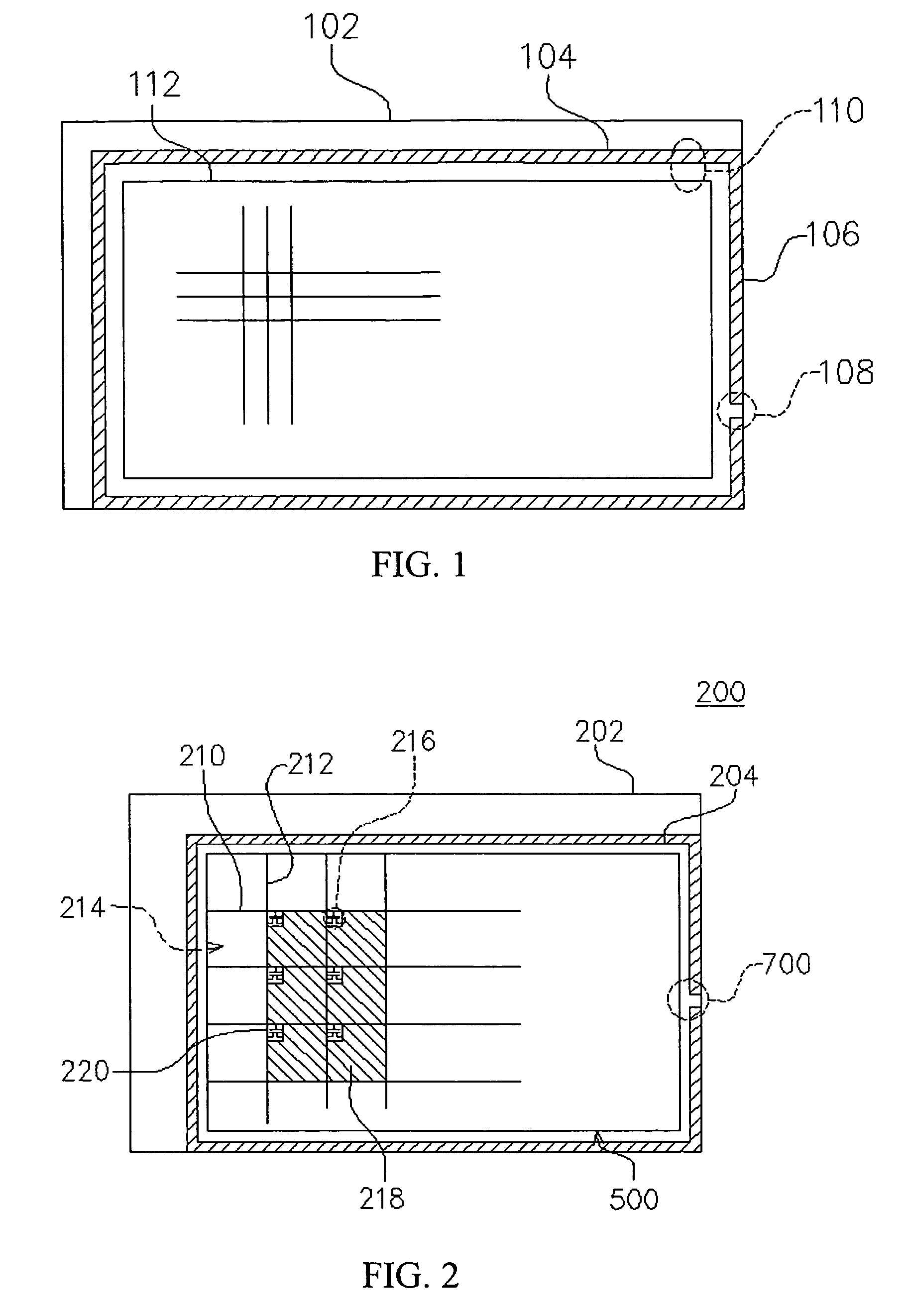

Electric field shielding for in-cell touch type thin-film-transistor liquid crystal displays

ActiveUS20110285640A1Avoid disruptionReduce stepsNon-linear opticsInput/output processes for data processingLiquid-crystal displayDisplay device

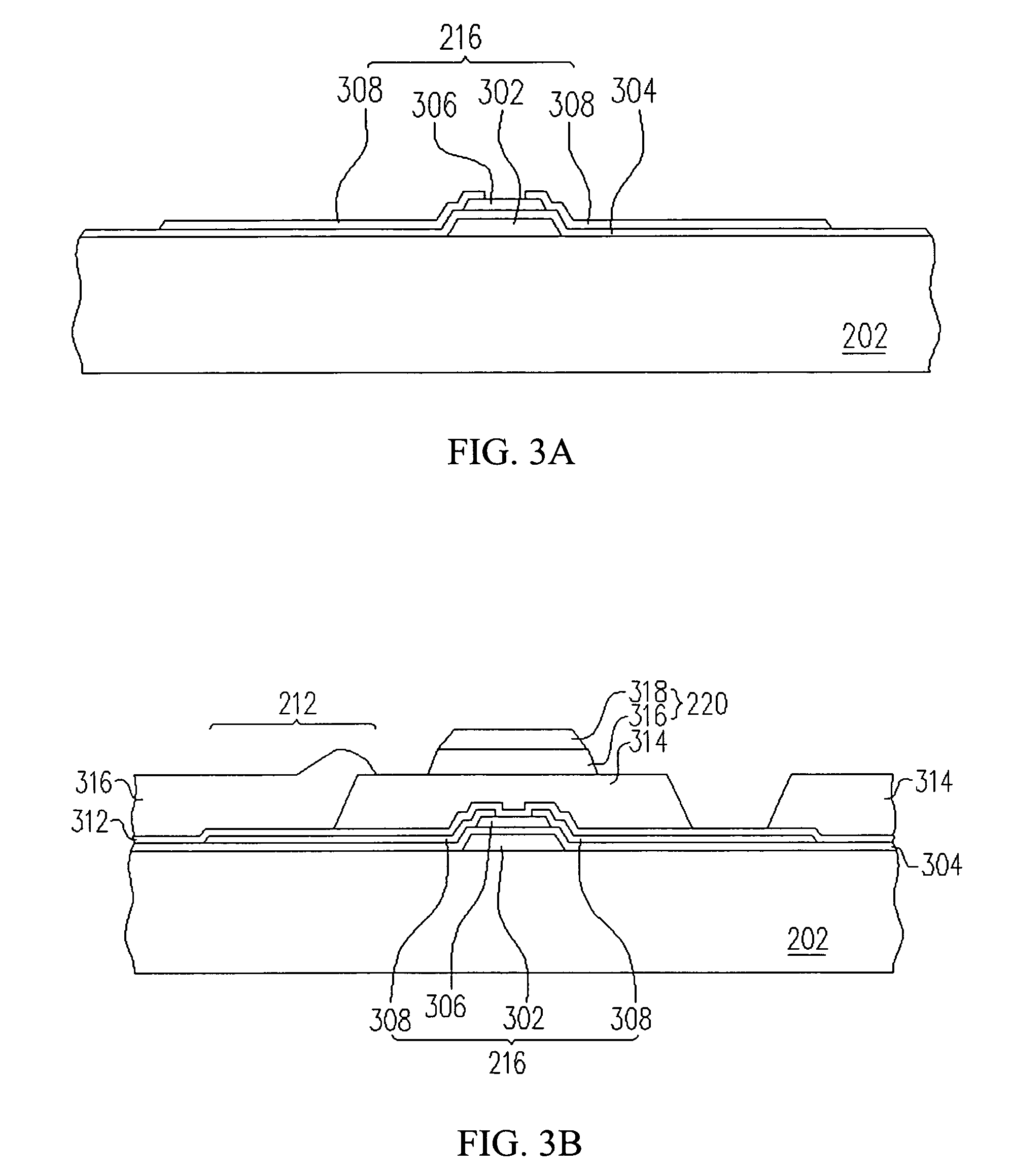

Displays such as liquid crystal displays may be used in electronic devices. During operation of a display, electrostatic charges on the surface of the display may give rise to electric fields. One or more electric field shielding layers may be provided in the display to prevent the electric fields from disrupting operation of the liquid crystals material in the display. The shielding layers may be formed at a location in the stack of layers that make up the display that is above the liquid crystal material of the display. Touch sensors and thin film transistors may be located below the shielding layer.

Owner:APPLE INC

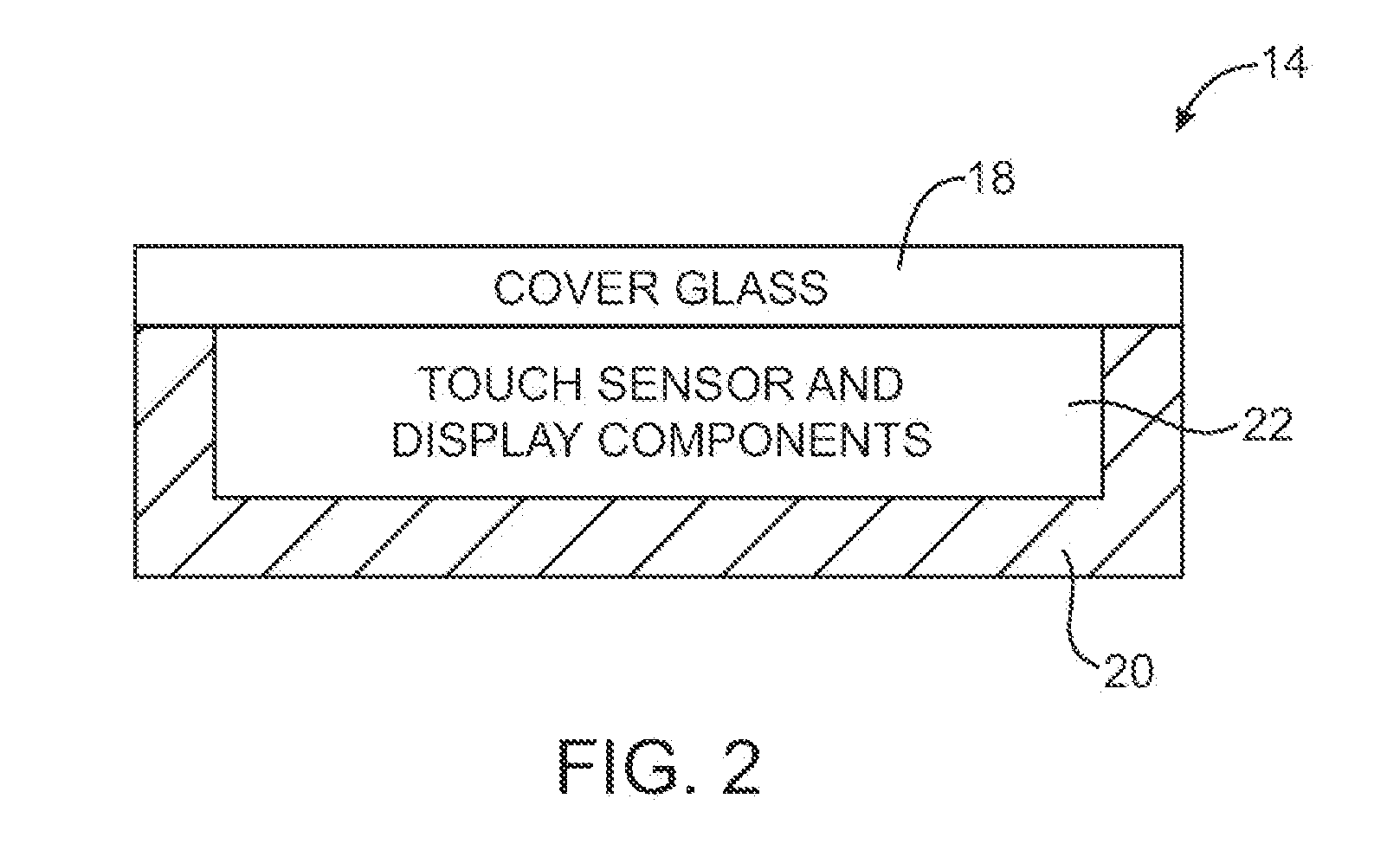

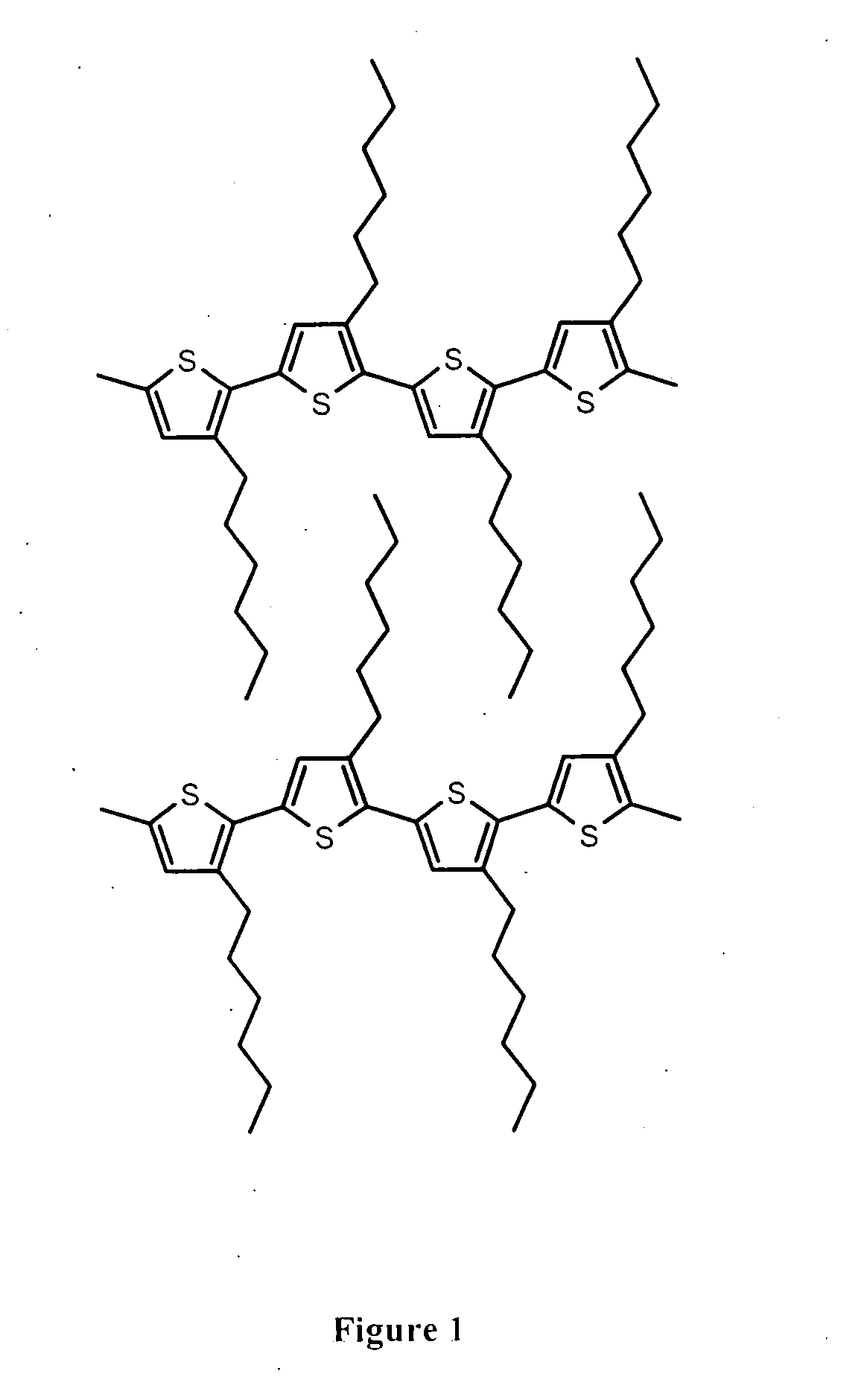

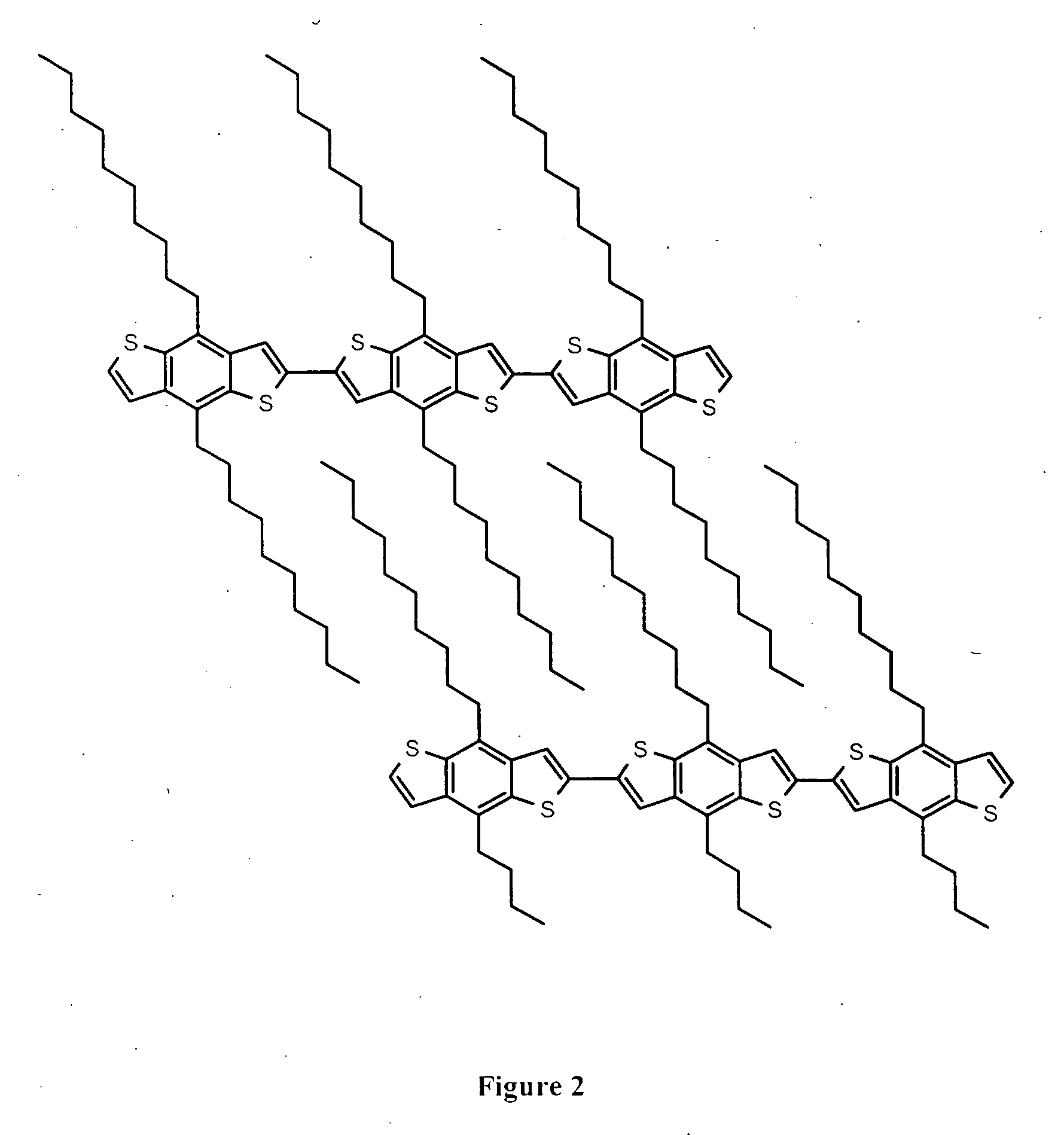

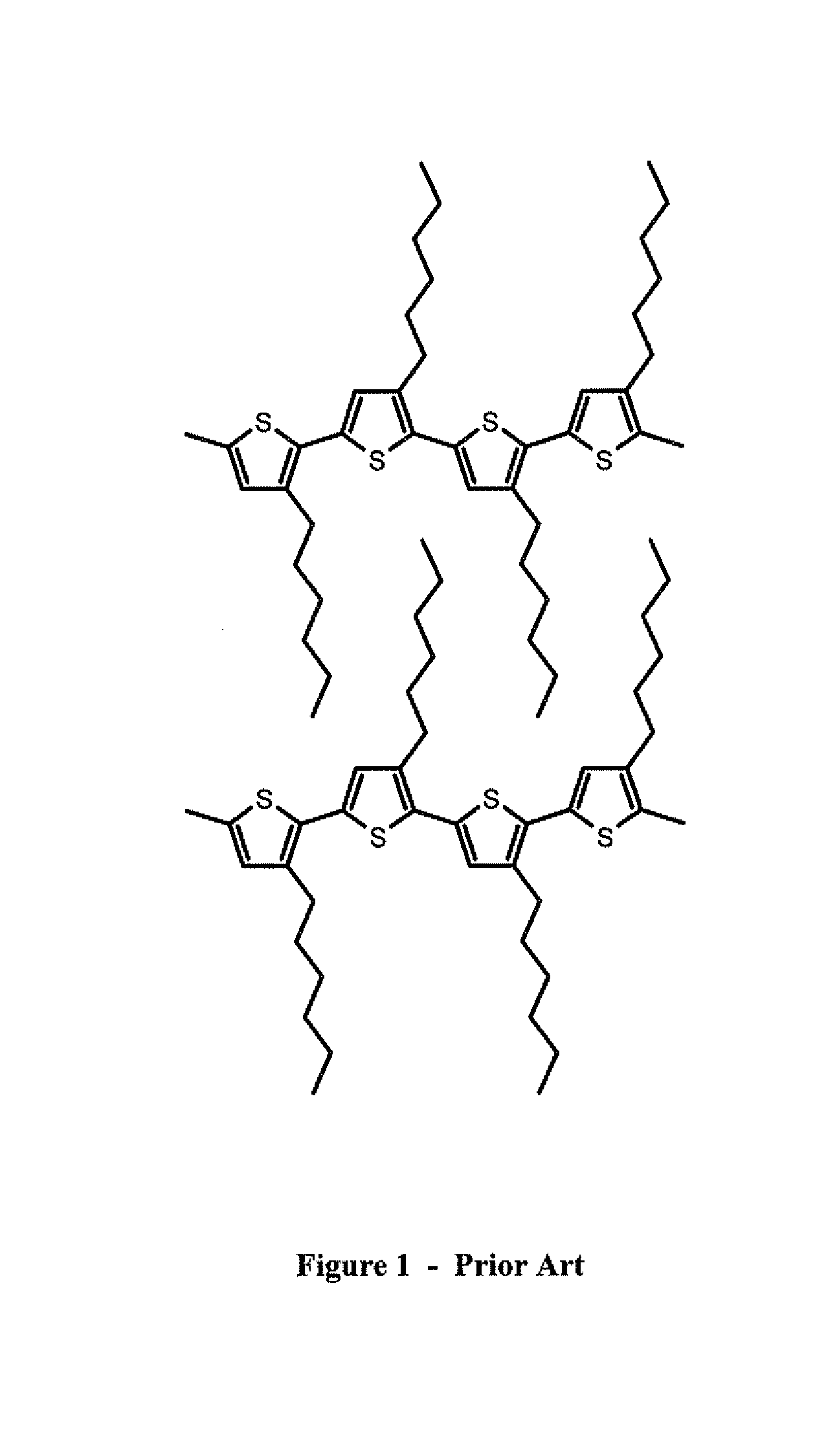

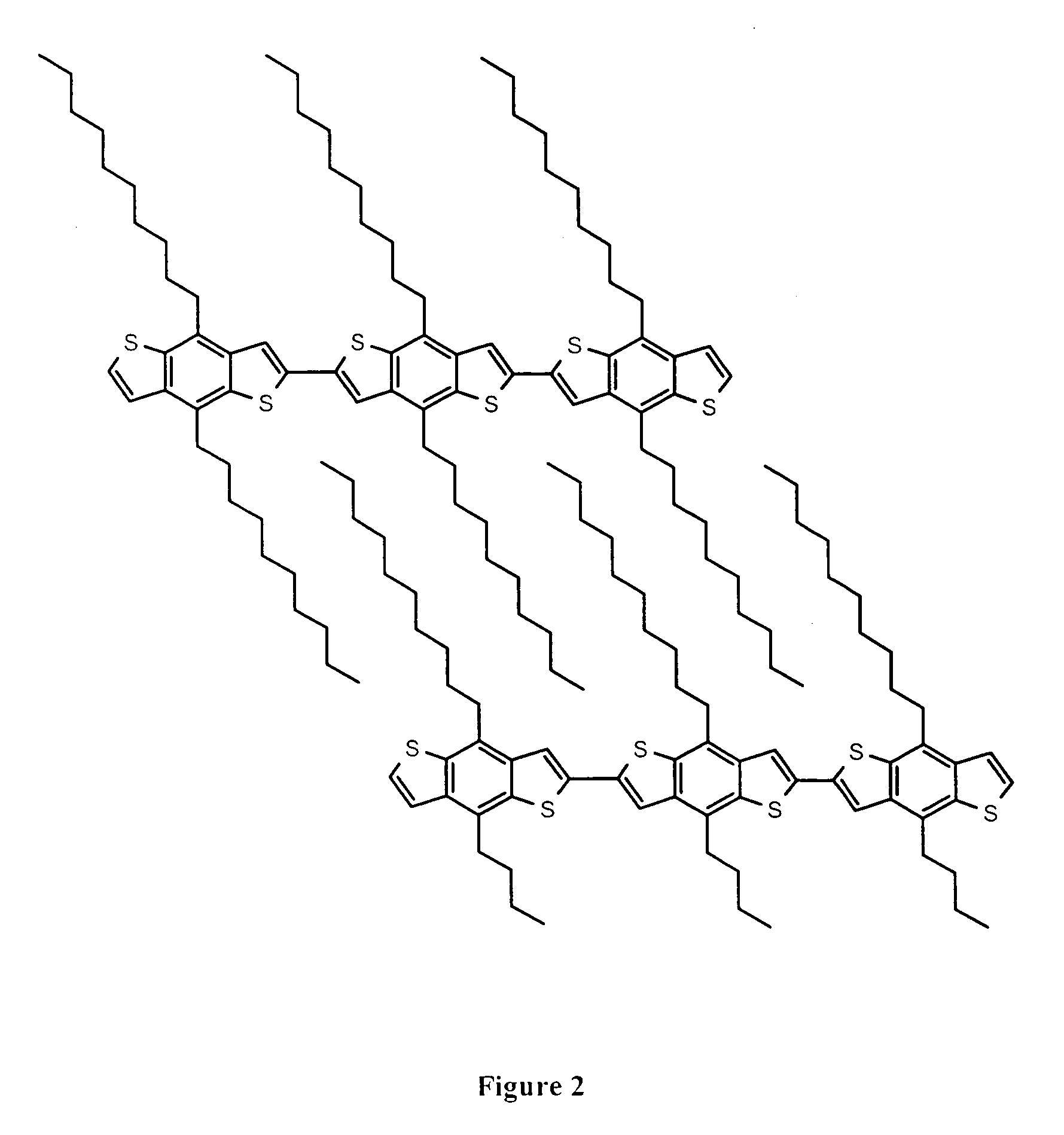

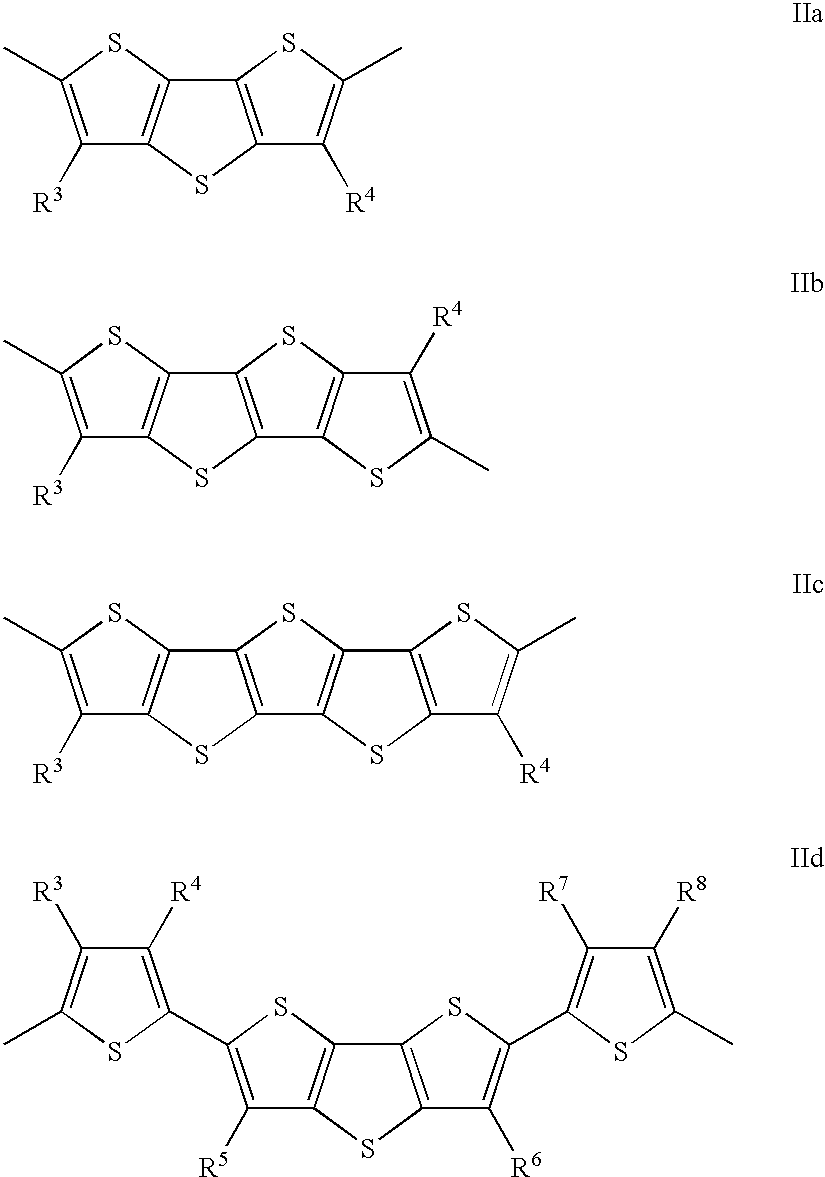

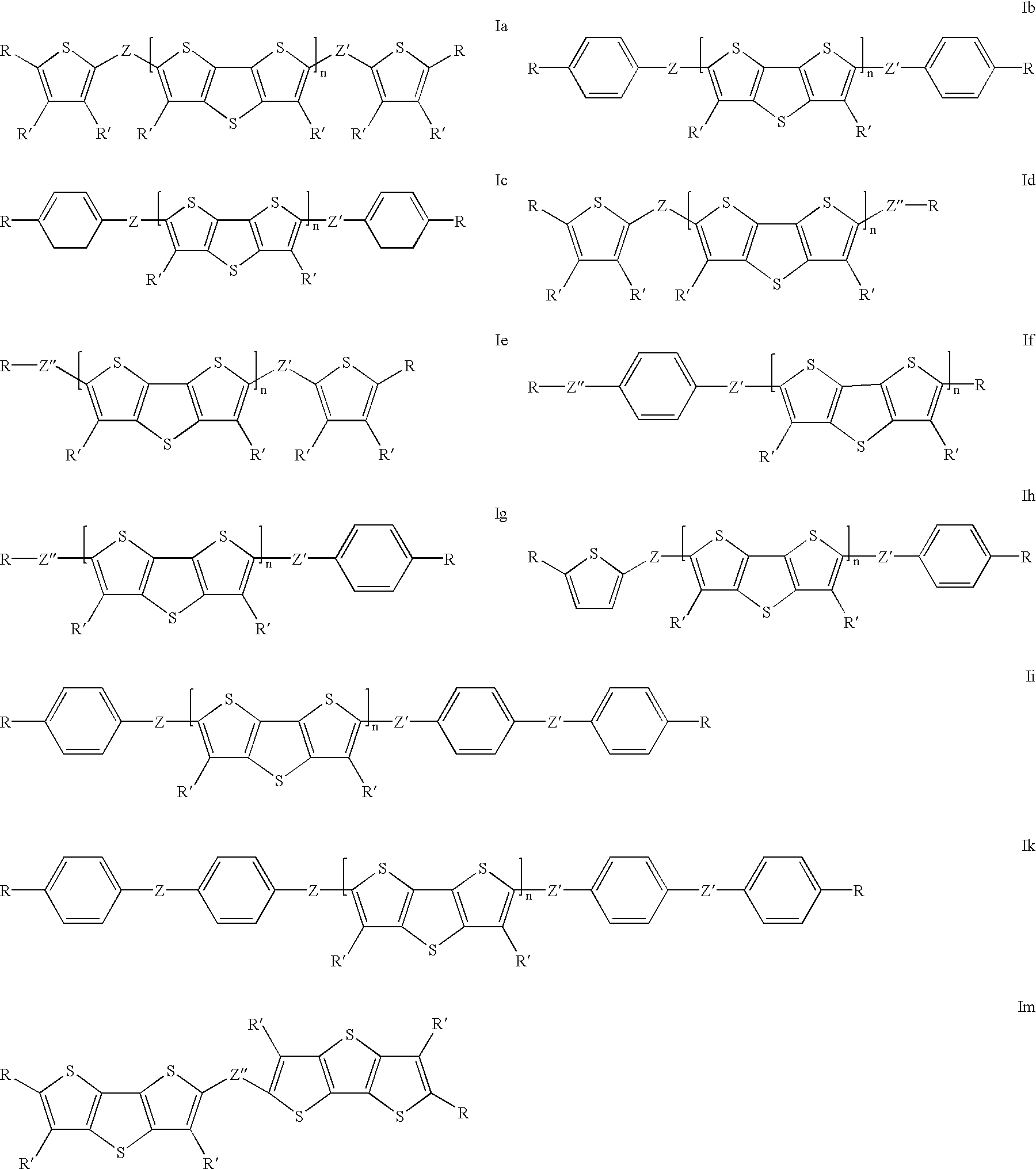

Poly(benzodithiophenes)

InactiveUS20050082525A1Liquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

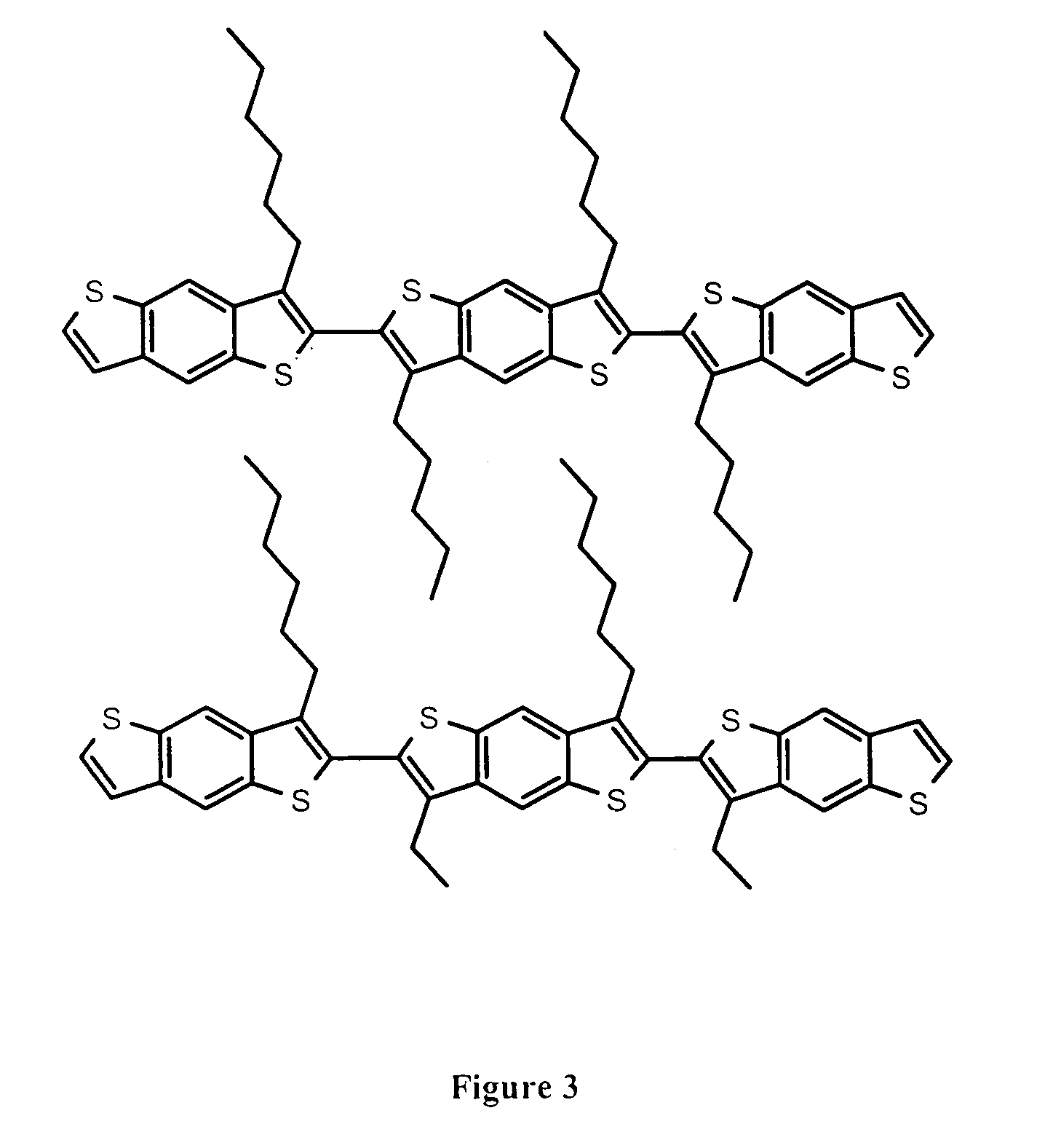

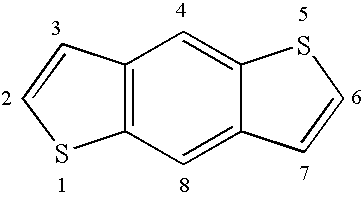

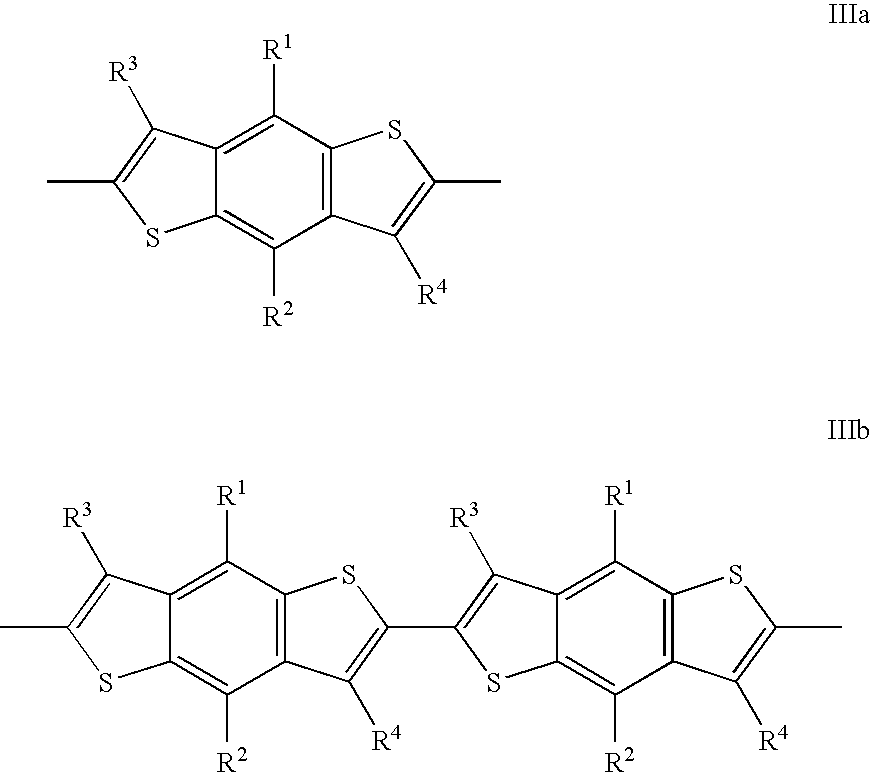

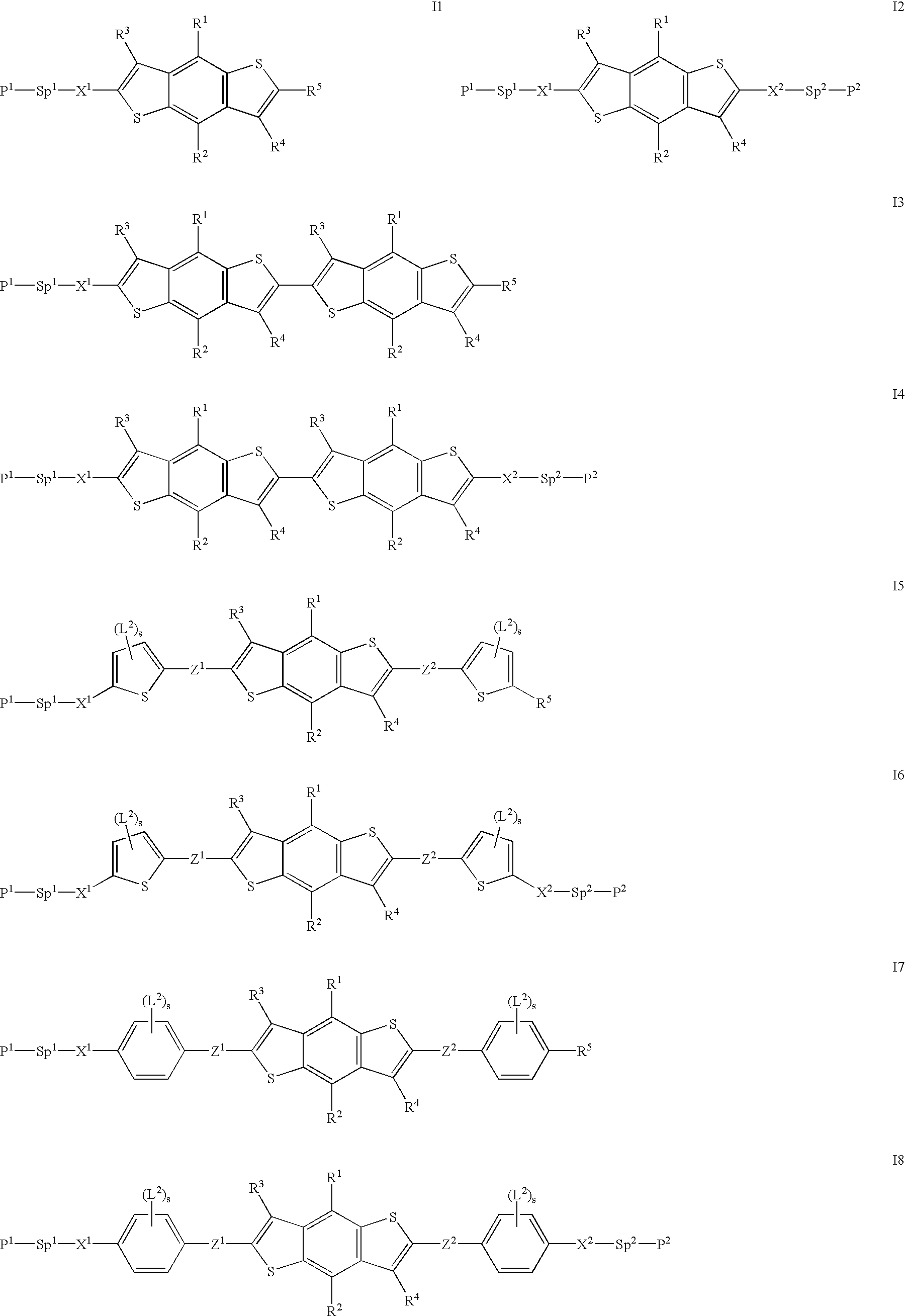

Disclosed are novel poly(benzodithiophenes), their use as semiconductors or charge transport materials in optical, electro-optical or electronic devices, for example, liquid crystal displays, optical films, organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag.

Owner:RAYNERGY TEK INC

Poly(benzodithiophenes)

InactiveUS7524922B2Liquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

Disclosed are novel poly(benzodithiophenes), their use as semiconductors or charge transport materials in optical, electro-optical or electronic devices, for example, liquid crystal displays, optical films, organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag.

Owner:RAYNERGY TEK INC

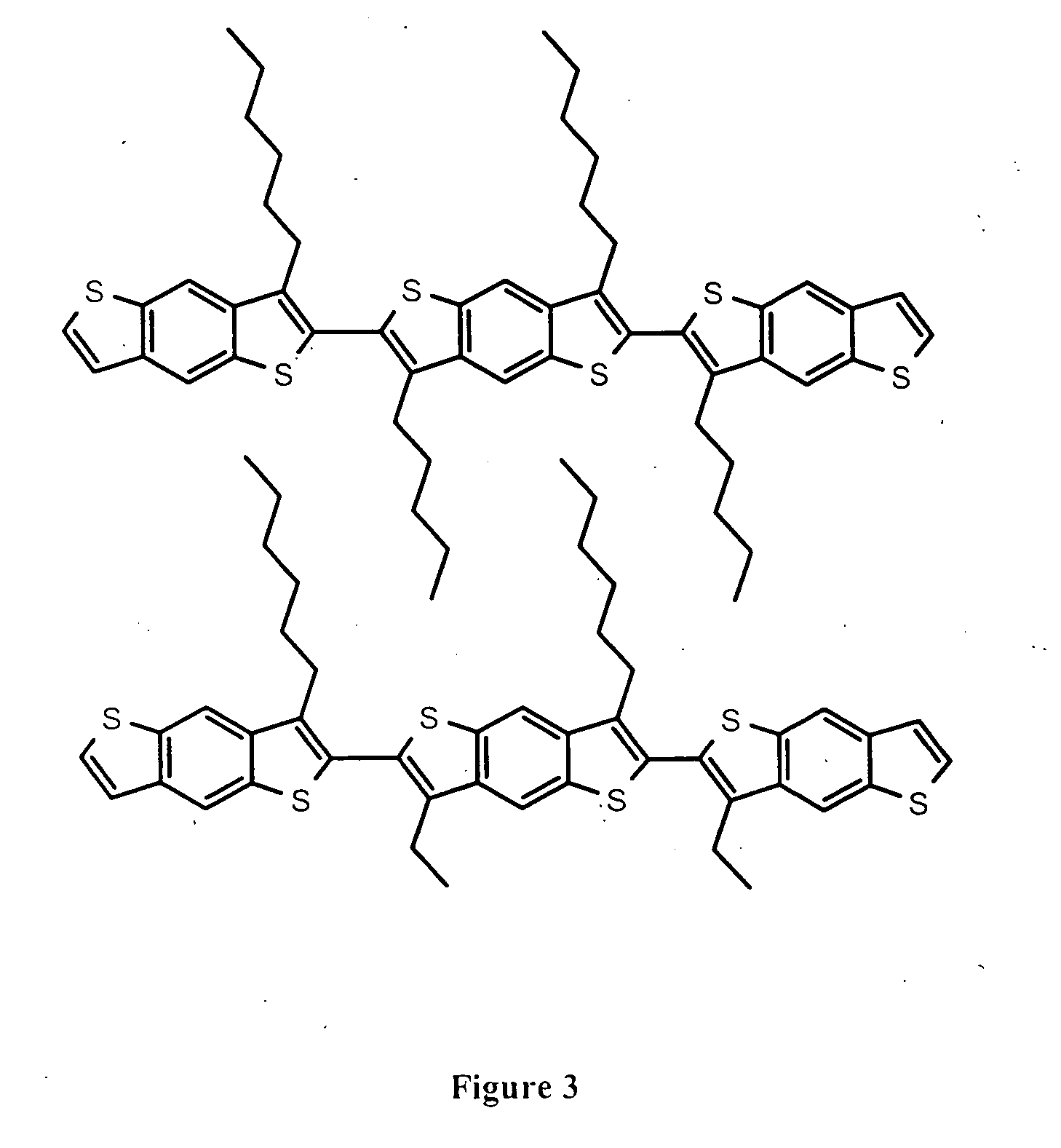

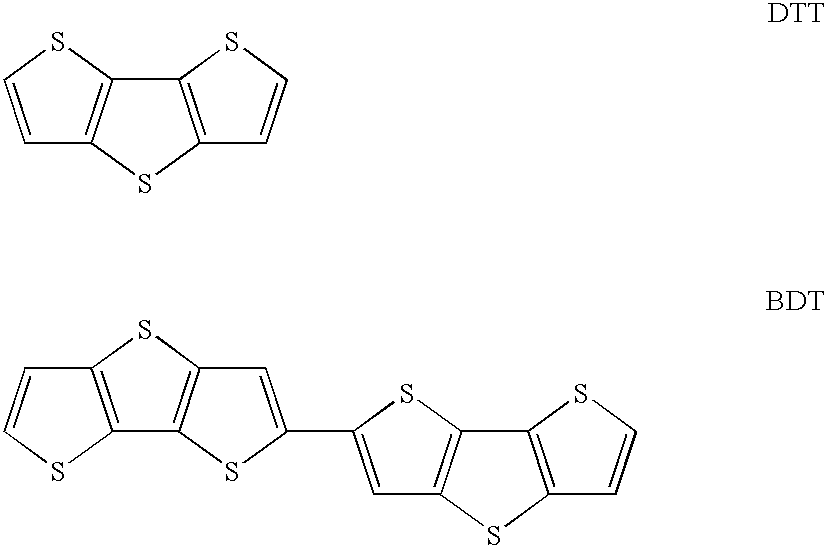

Reactive mesogenic benzodithiophenes

InactiveUS6913710B2High carrier mobilitySimple materialLiquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

The invention relates to new reactive mesogenic benzodithiophene derivatives, their use as semiconductors or charge transport materials, in optical, electro-optical or electronic devices like for example liquid crystal displays, optical films, organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag comprising the reactive mesogenic benzodithiophenes.

Owner:MERCK PATENT GMBH

Molybdenum sputtering targets

InactiveUS20060042728A1High purityImprove performanceVacuum evaporation coatingSputtering coatingDevice materialThin-film-transistor liquid-crystal display

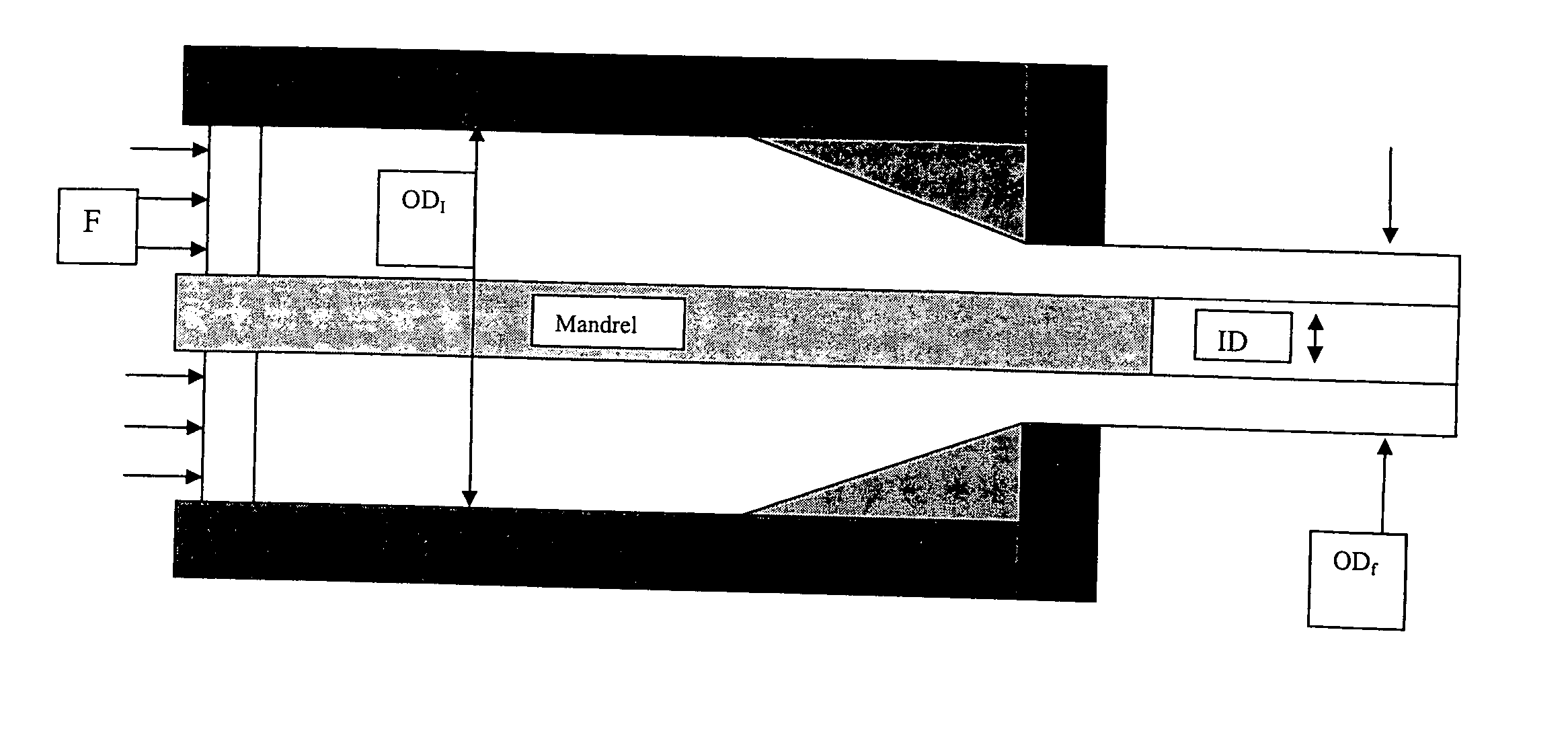

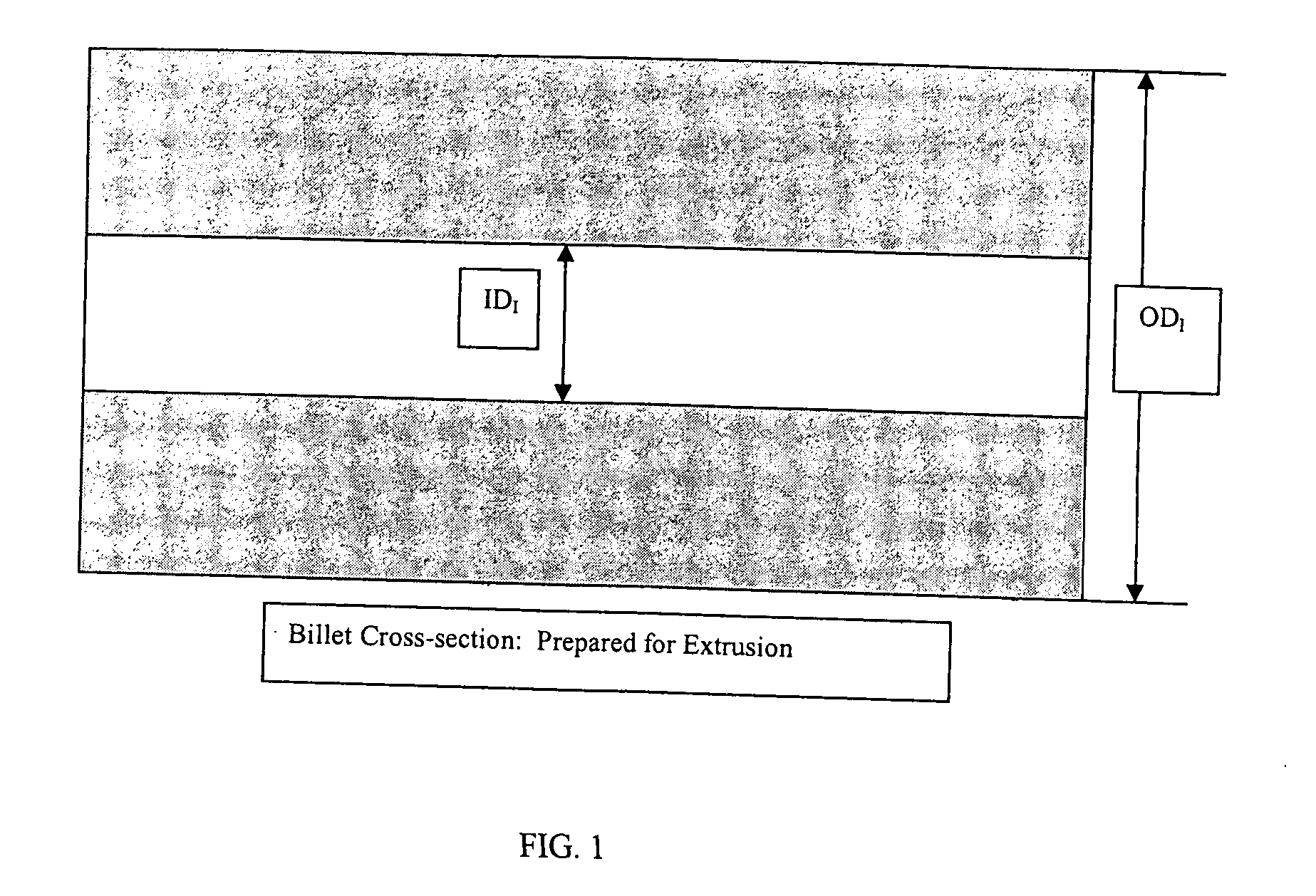

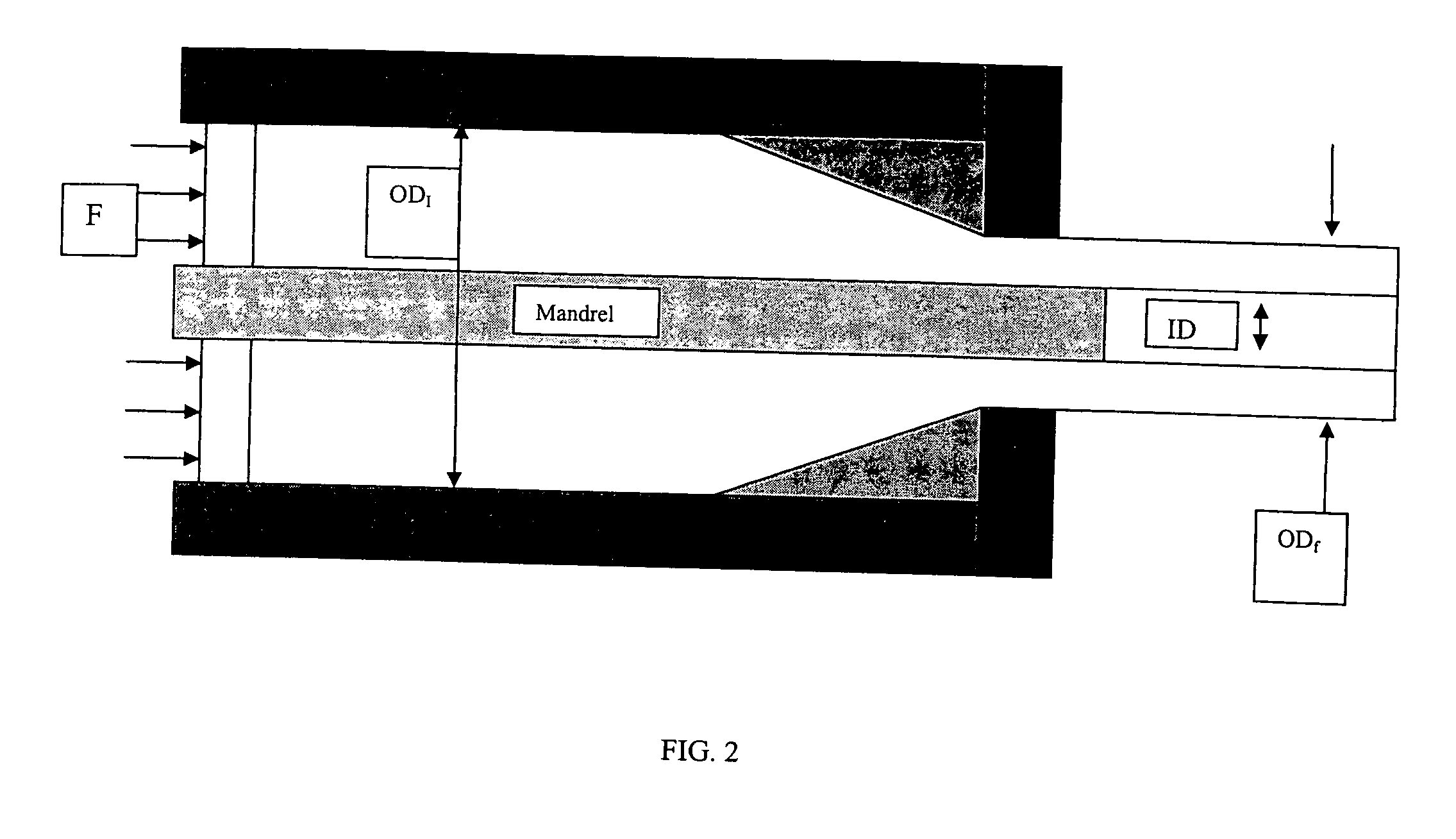

Molybdenum, sputtering targets and sintering characterized as having no or minimal texture banding or through thickness gradient. The molybdenum sputtering targets having a fine, uniform grain size as well as uniform texture, are high purity and can be micro-alloyed to improved performance. The sputtering targets can be round discs, square, rectangular or tubular and can be sputtered to form thin films on substrates. By using a segment-forming method, the size of the sputtering target can be up to 6 m×5.5 m. The thin films can be used in electronic components such as Thin Film Transistor—Liquid Crystal Displays, Plasma Display Panels, Organic Light Emitting Diodes, Inorganic Light Emitting Diode Displays, Field Emission Displays, solar cells, sensors, semiconductor devices, and gate device for CMOS (complementary metal oxide semiconductor) with tunable work functions.

Owner:H C STARCK INC

Thienothiophene derivatives

InactiveUS6818260B2Liquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

The invention relates to new thienothiophene derivatives, their use as semiconductors or charge transport materials, in optical, electrooptical or electronic devices like for example organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in photovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag comprising the thienothiophene derivatives.

Owner:MERCK PATENT GMBH

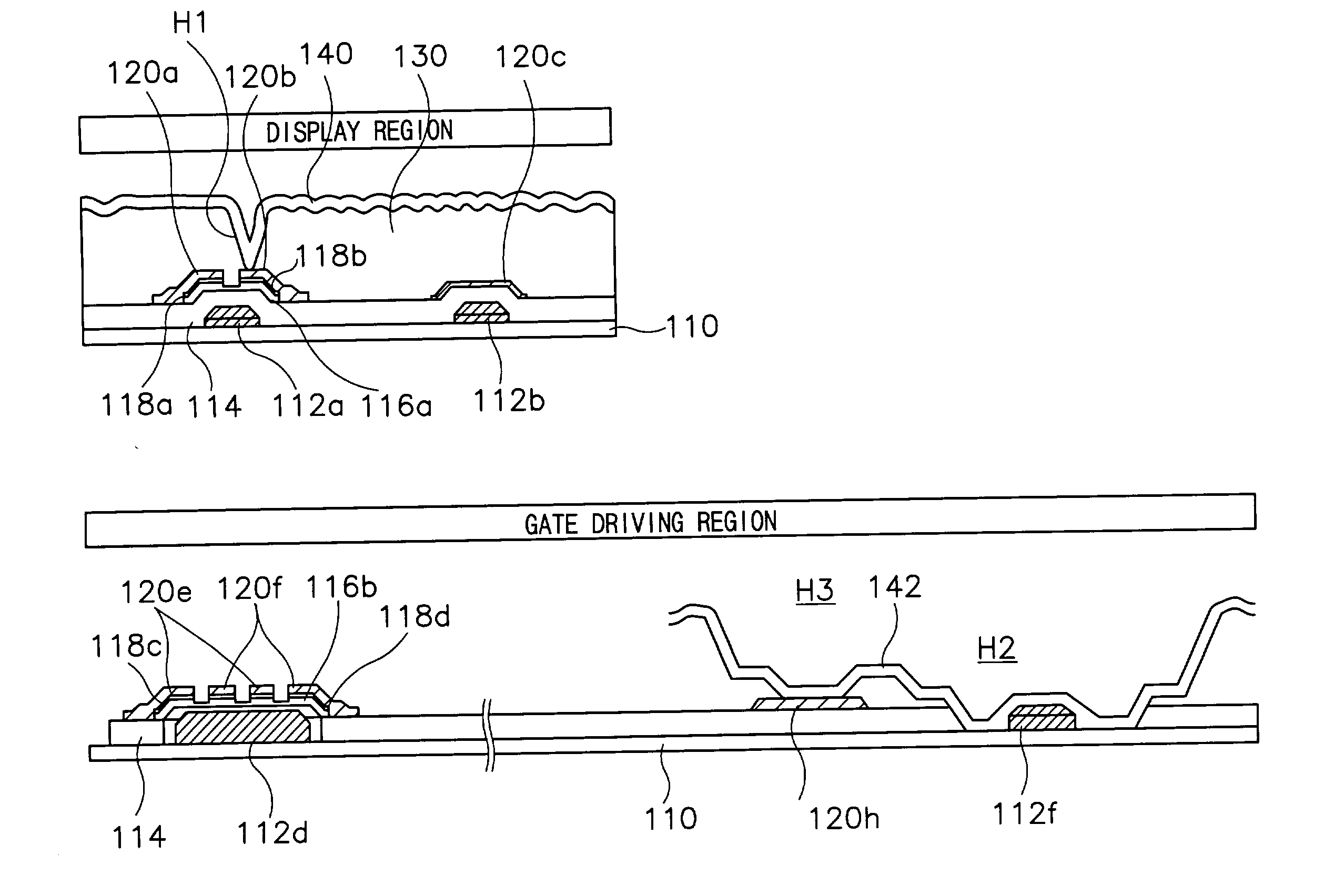

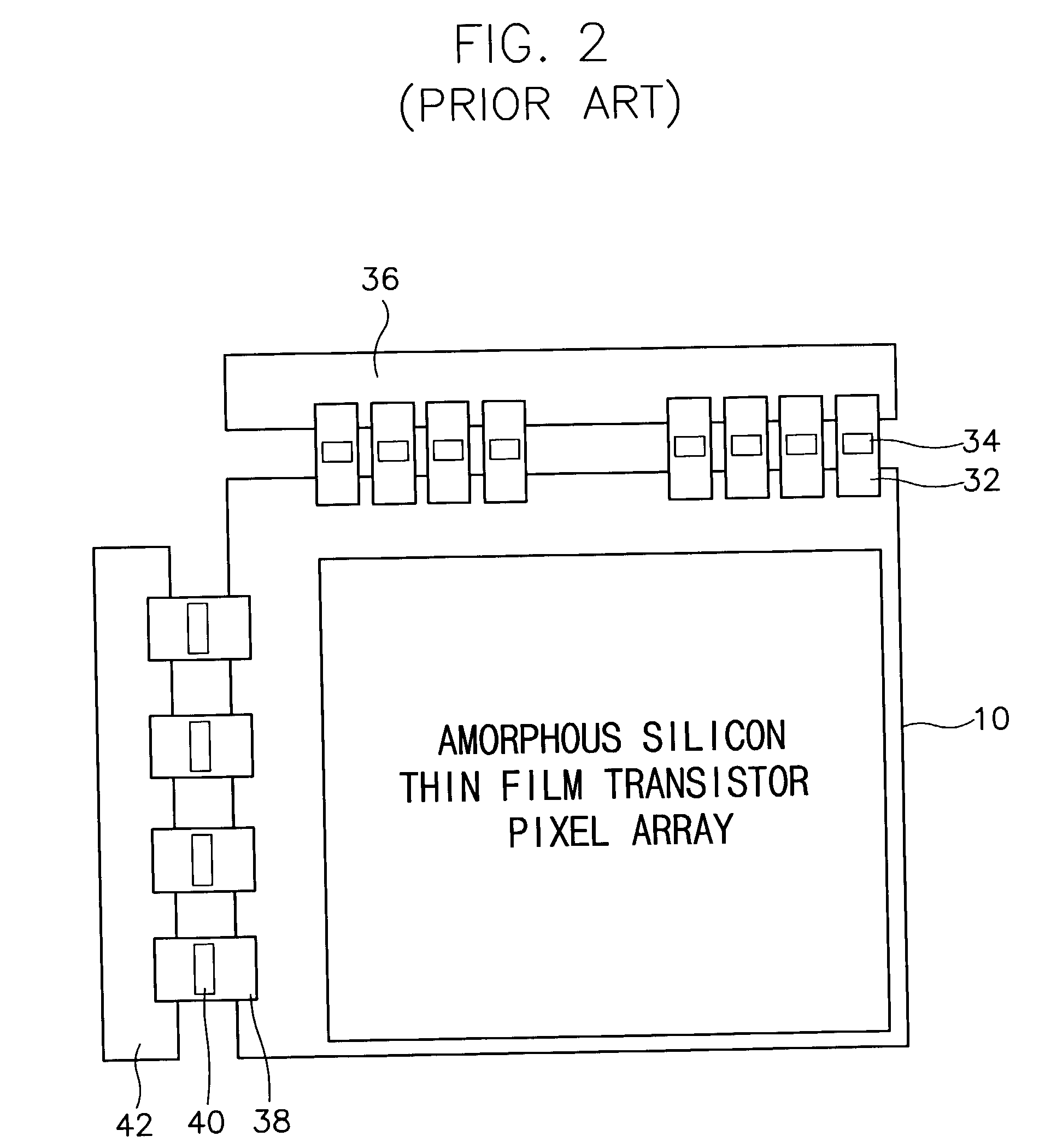

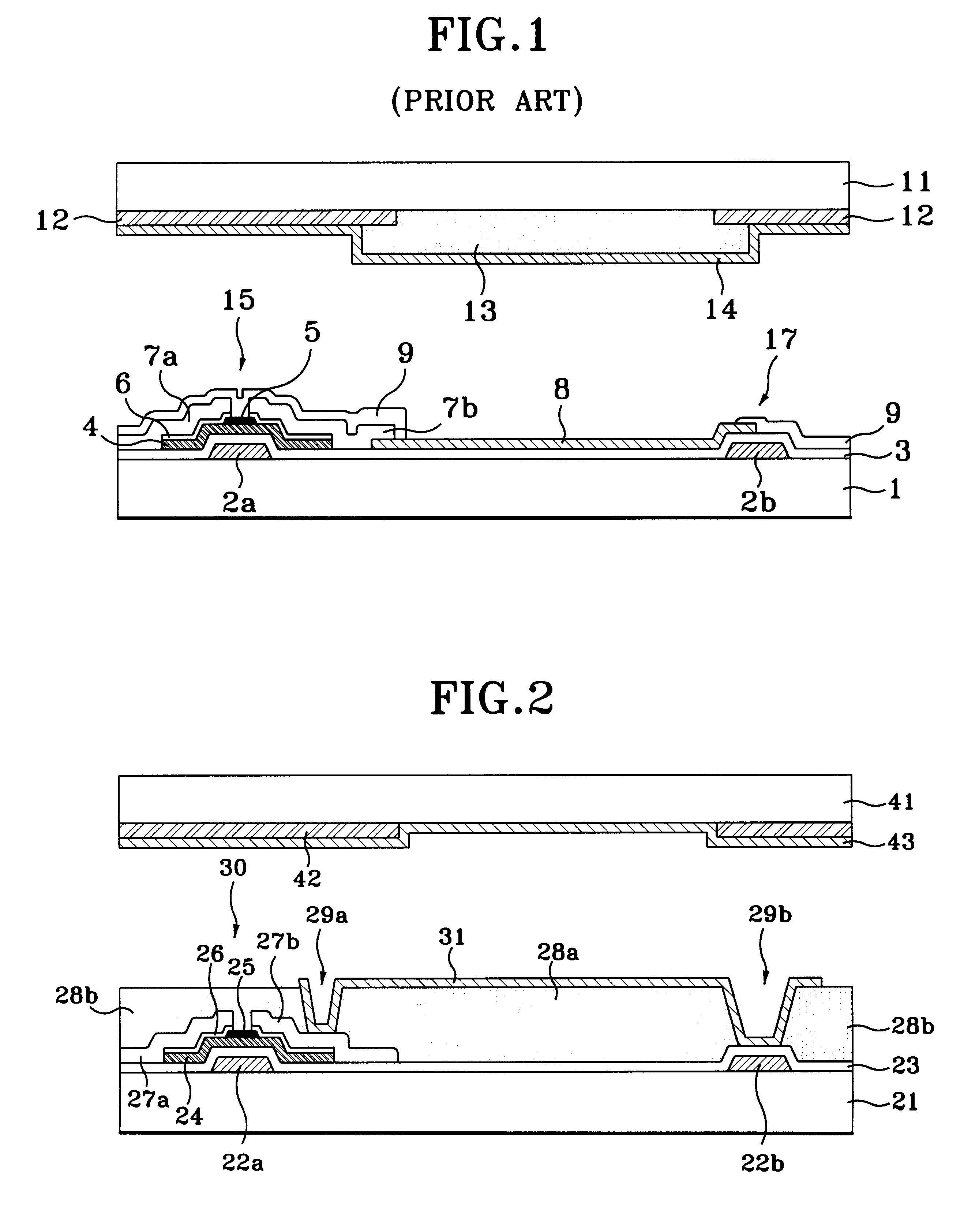

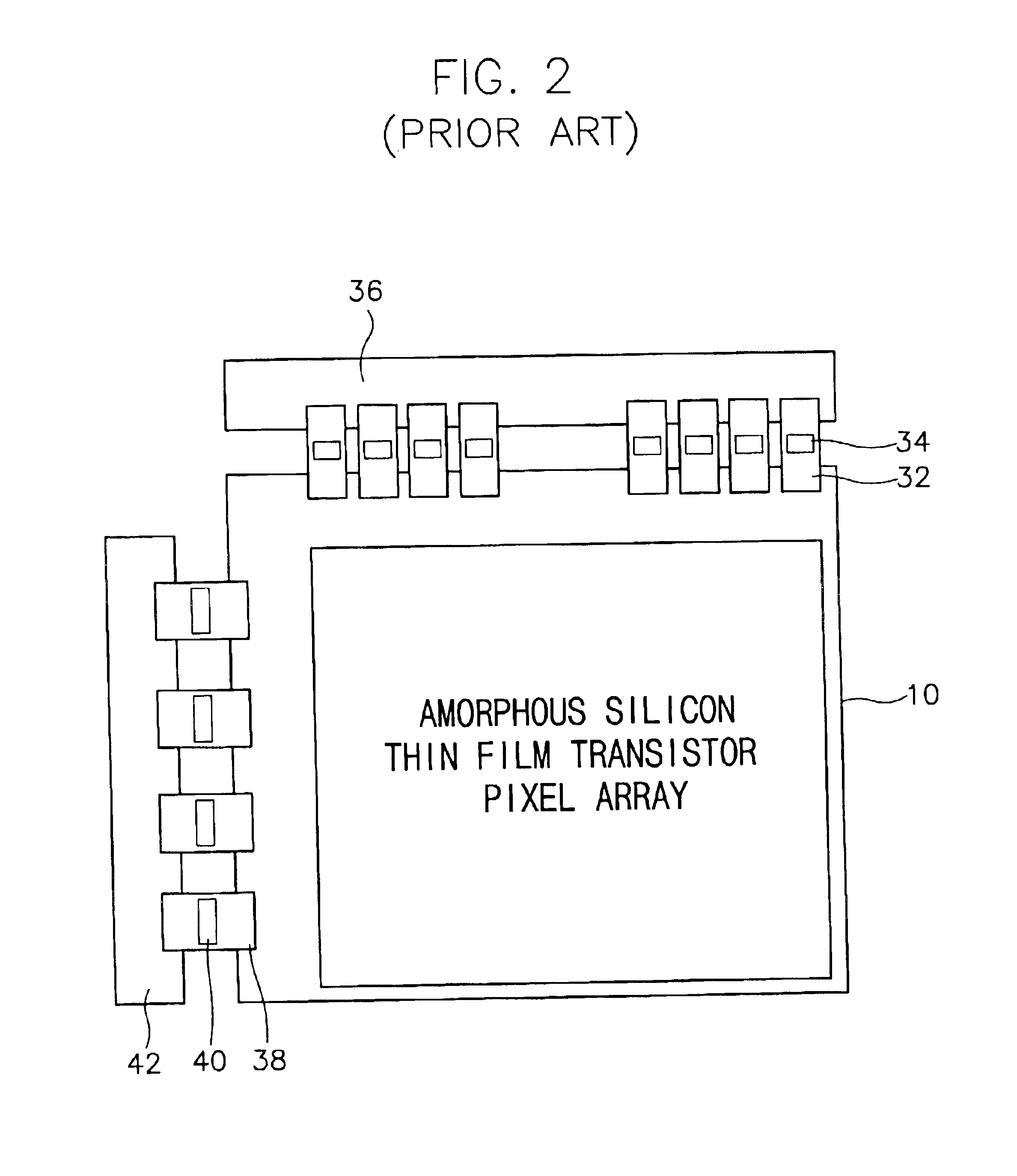

Amorphous silicon thin film transistor-liquid crystal display device and method of manufacturing the same

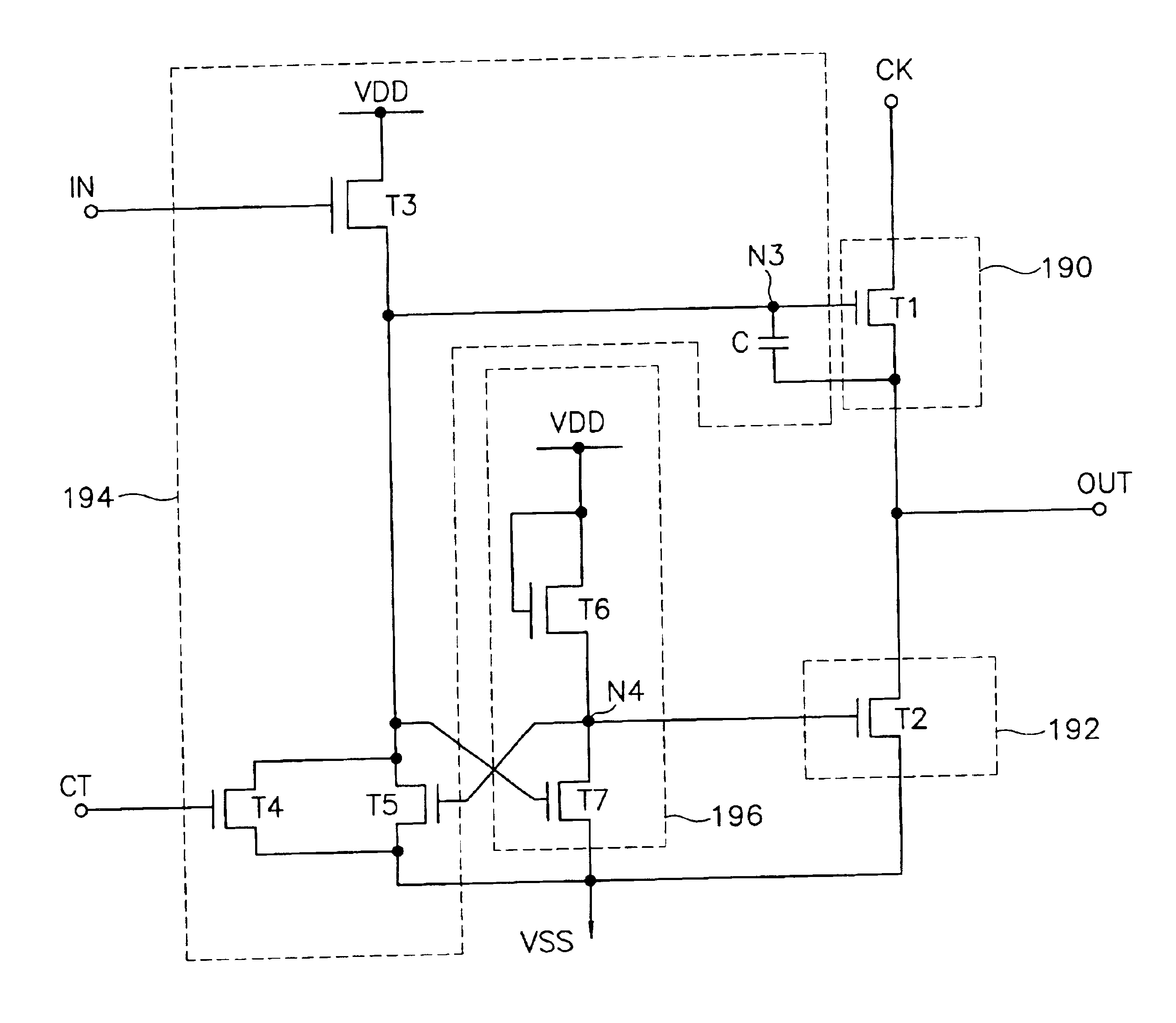

InactiveUS20030222311A1Reduce in quantitySimple manufacturing processTransistorStatic indicating devicesShift registerLiquid-crystal display

In an amorphous silicon thin film transistor-liquid crystal display device and a method of manufacturing the same, gate patterns including a gate line and a gate electrode are formed on an insulation substrate having a display region and a driving circuit region on which a plurality of shift registers are formed, a gate insulating film, active layer patterns and data patterns including source and drain electrodes are formed successively on the substrate, a passivation layer on the substrate has a first contact hole exposing a drain electrode of the display region and second and third contact holes respectively exposing a gate electrode and source and drain electrodes of a first transistor of each of the shift registers, an electrode patterns on the passivation layer include a first electrode connected to the drain electrode of the display region through the first contact hole and a second electrode connecting the gate electrode to the source and drain electrodes of the first transistor through the second and third contact holes, and the gate driving circuit including the shift registers and the wirings are integrated on the insulating substrate without an additional process, thereby simplifying the manufacturing process.

Owner:SAMSUNG DISPLAY CO LTD

Etchant for thin film transistor liquid crystal display device

ActiveCN101265579AReduced stabilityGuaranteed stabilitySemiconductor/solid-state device manufacturingSurface treatment compositionsLiquid-crystal displayThin-film-transistor liquid-crystal display

Owner:DONGJIN SEMICHEM CO LTD

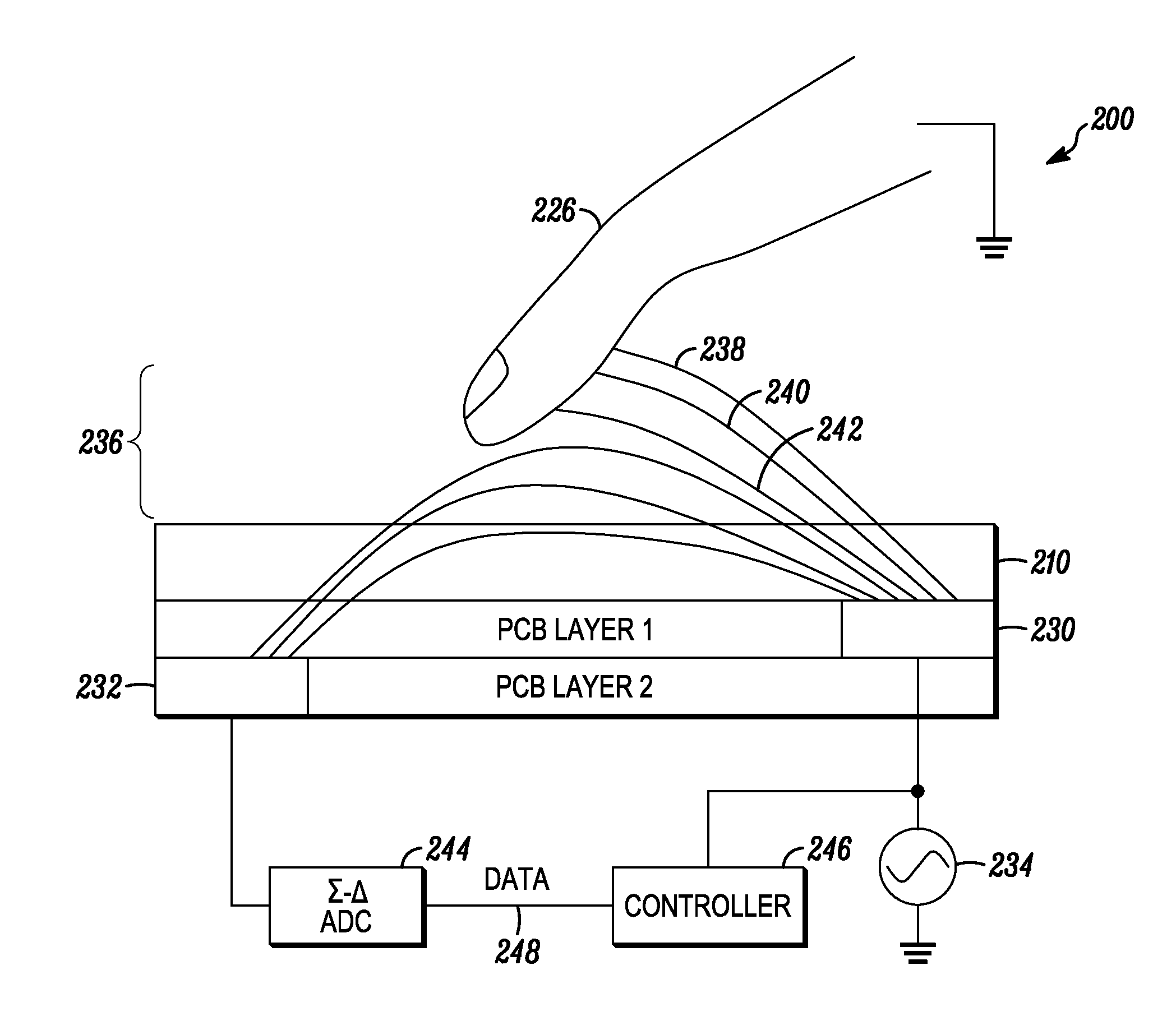

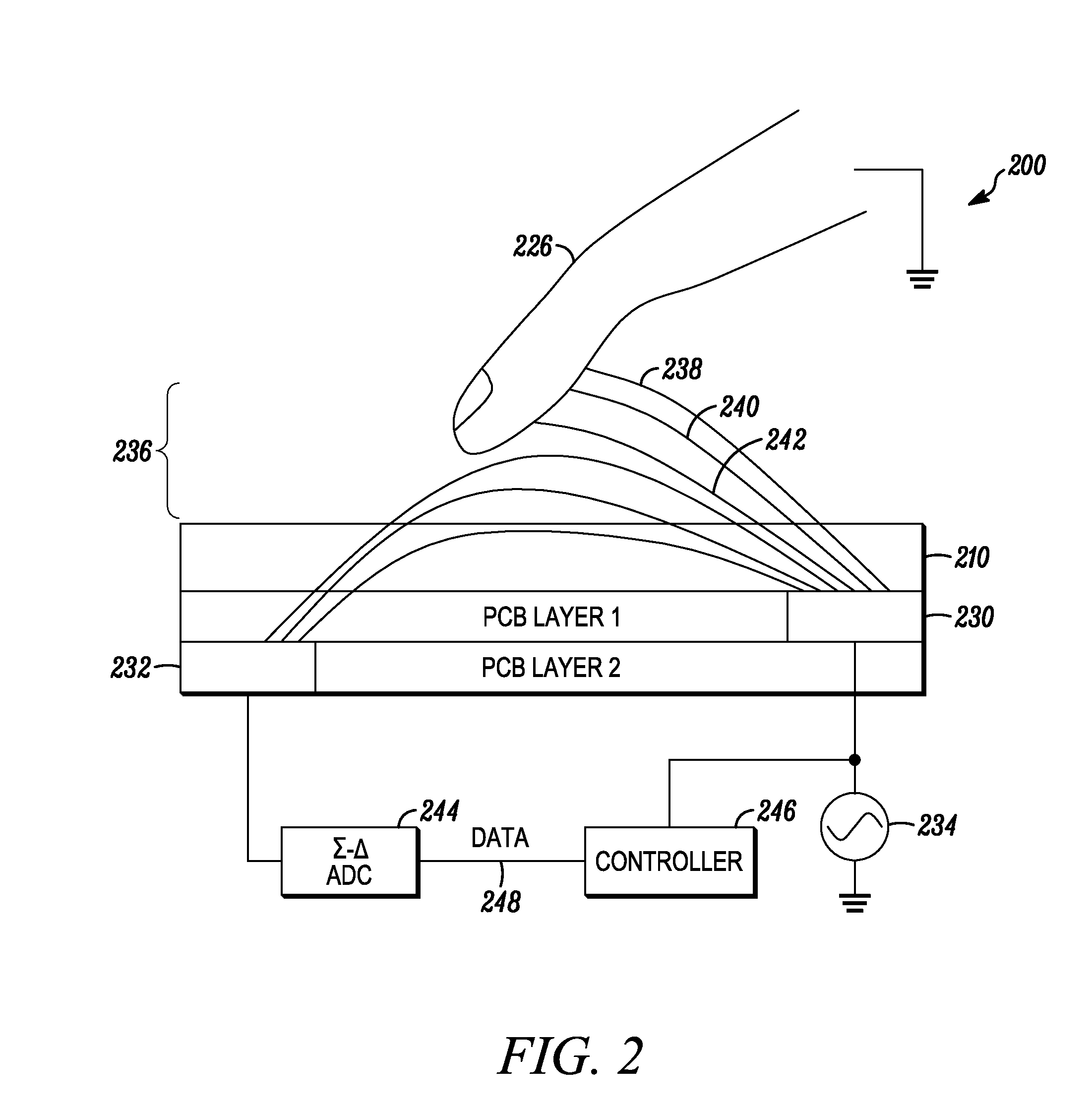

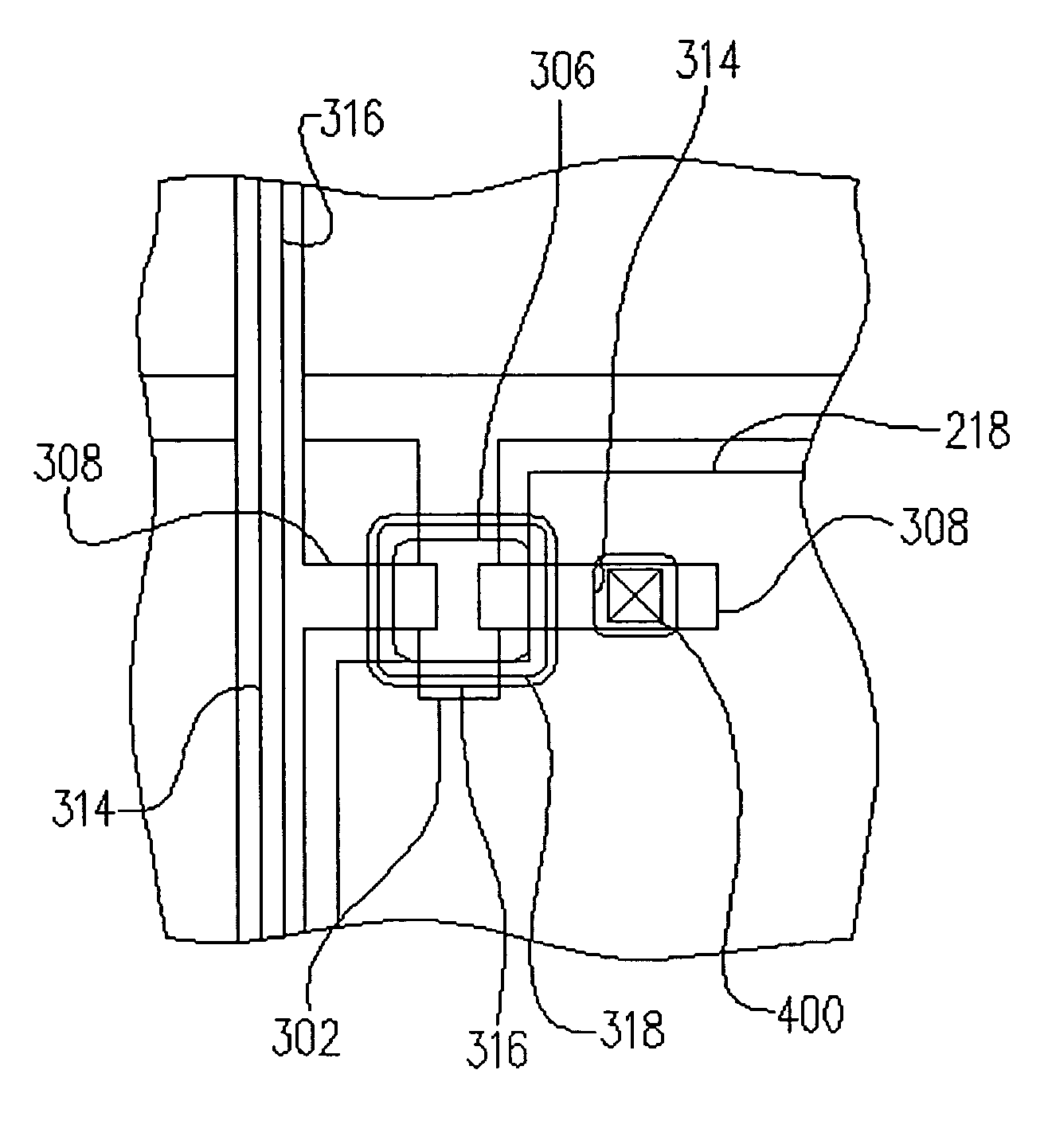

Integrated capacitive sensing devices and methods

InactiveUS20090079707A1Improve experienceLarge thicknessInput/output processes for data processingLiquid-crystal displayDisplay device

Disclosed are touch screen devices and methods of sensing an object near the surface of a touch screen device. A capacitive sensor is integrated into display electronics by flipping the traditional thin film transistor liquid crystal display (TFT) stack-up which has a bottom gate structure so that it is an inverted bottom gate structure. Accordingly, the gate structure is near the top of the display and the gate drive lines are re-used as excitation lines in addition to their function as display lines. The excitation lines therefore drive excitation to generate an induced electric field at the surface of the display device. Additionally, other lines are used as sensor lines so that sensor signals are input to the device controller to determine the position of an object at the surface of the display device. Accordingly, the excitation lines are scanned to detect the presence of a finger or other object.

Owner:MOTOROLA MOBILITY LLC

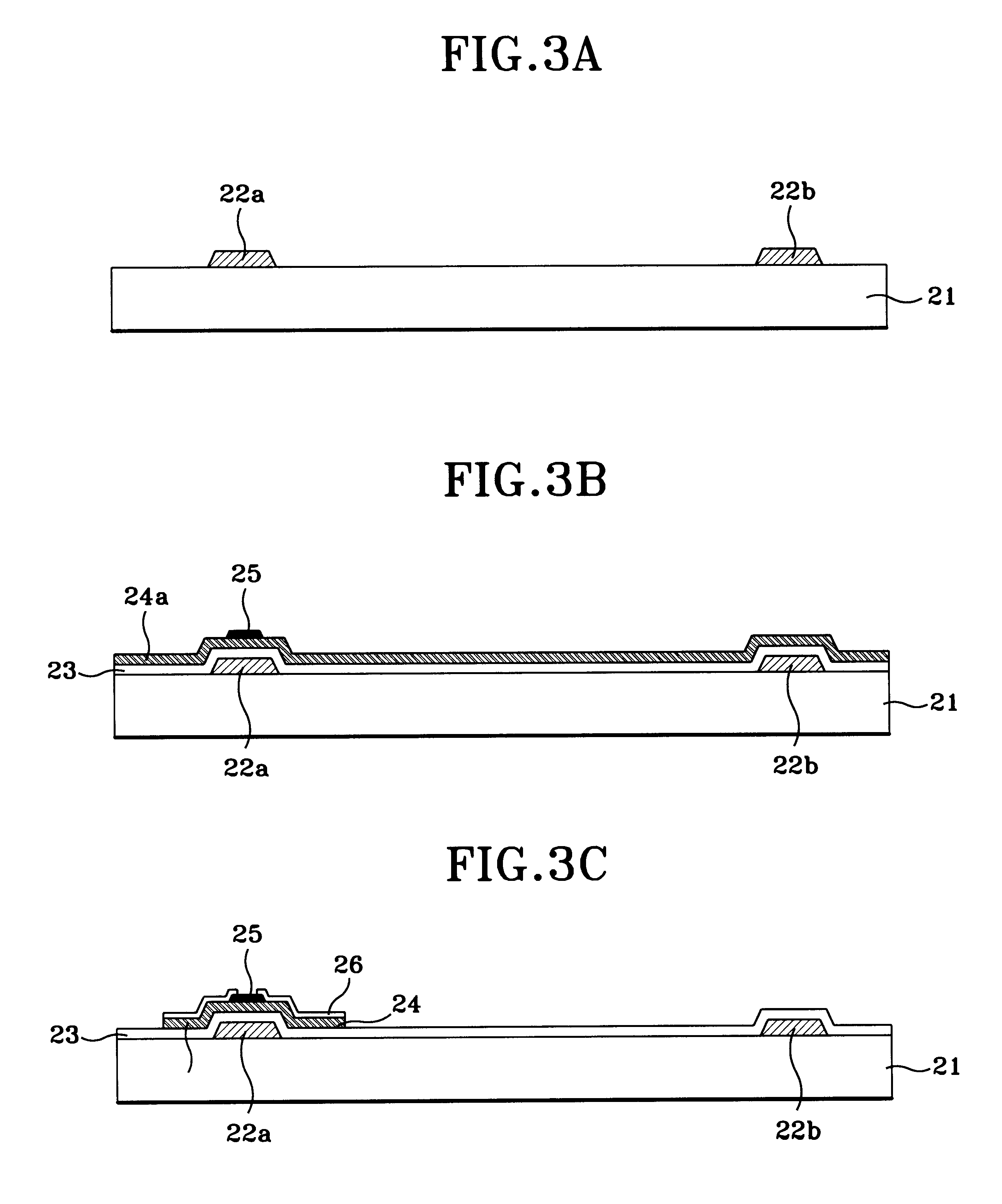

Thin film transistor liquid crystal display and method for manufacturing the same

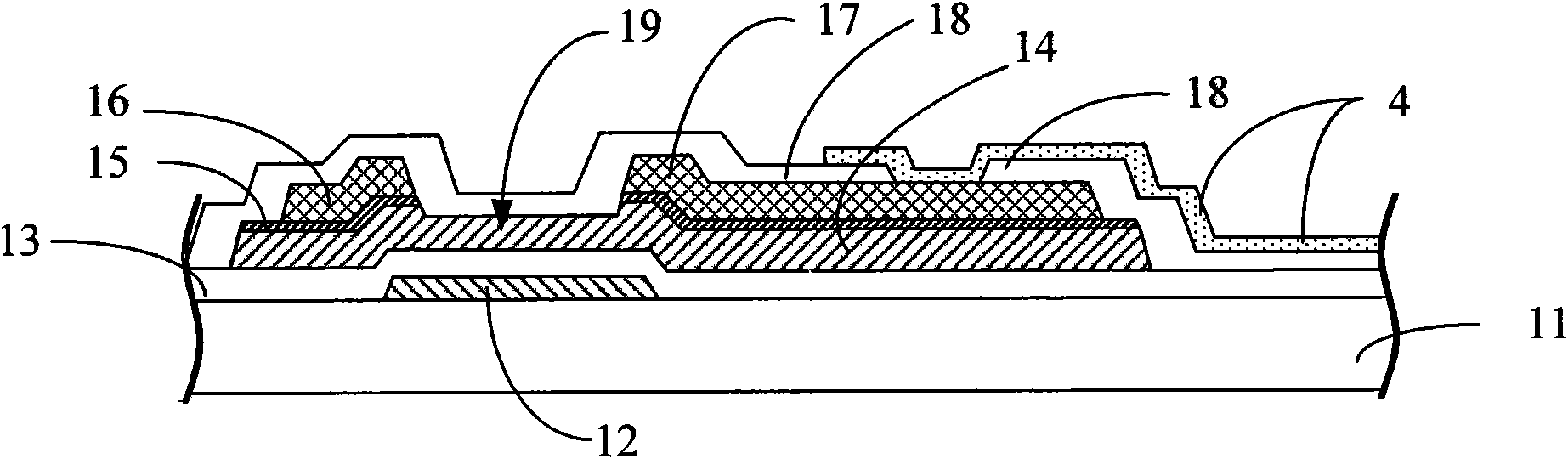

InactiveUS6191835B1Simple processLow investment costNon-linear opticsLiquid-crystal displayThin-film-transistor liquid-crystal display

A color filter layer covering both a thin film transistor and a pixel electrode which are formed on a lower substrate. A portion of the color filter layer positioned on the thin film transistor serves a protection layer of the thin film transistor and the other portion of the color filter layer serves a conventional color filter layer which were conventionally formed on an upper substrate opposite to the lower substrate. Therefore, the process number for the LCD is decreased and thus the manufacturing cost of the LCD is reduced.

Owner:BOE HYDIS TECH

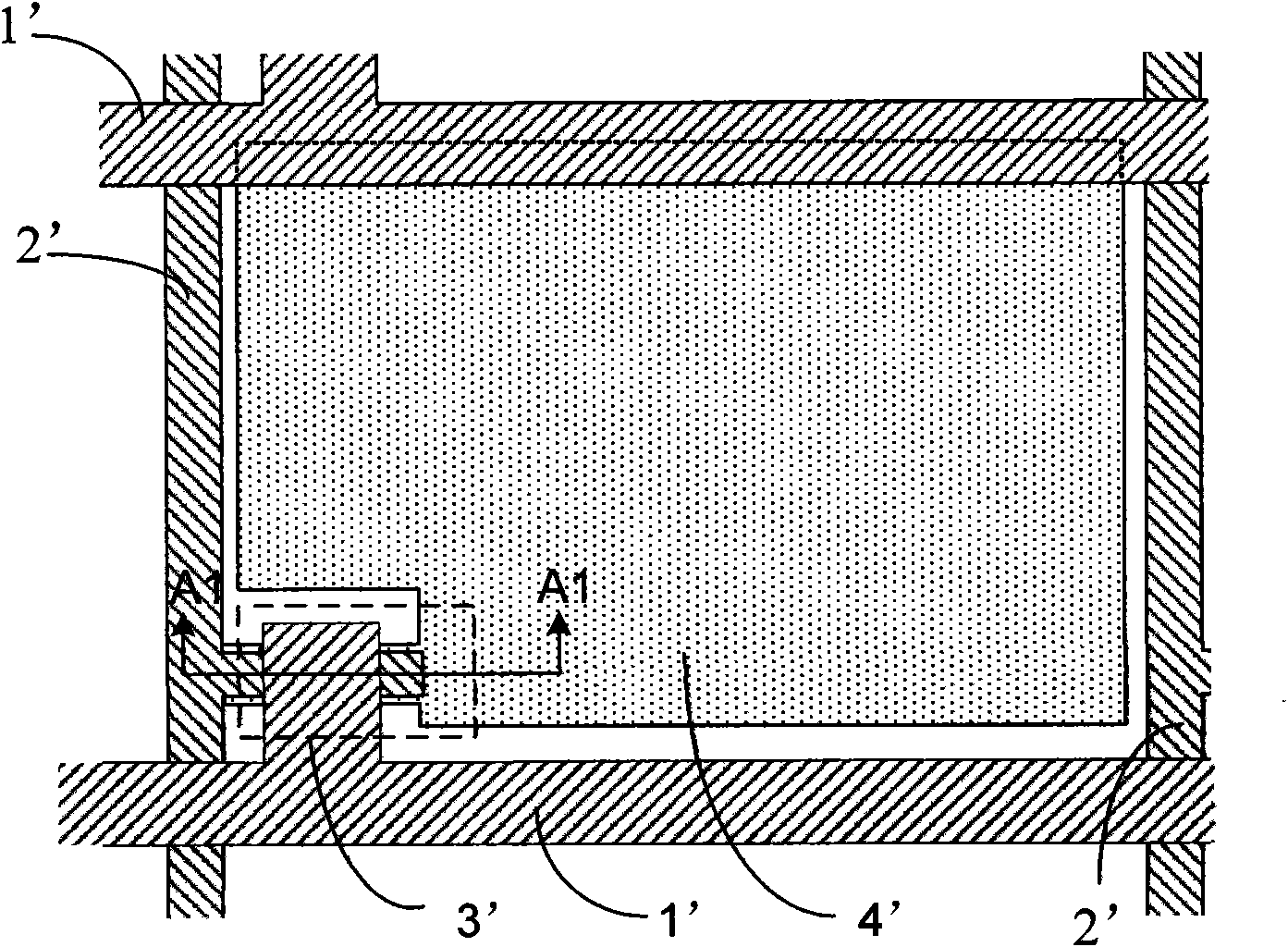

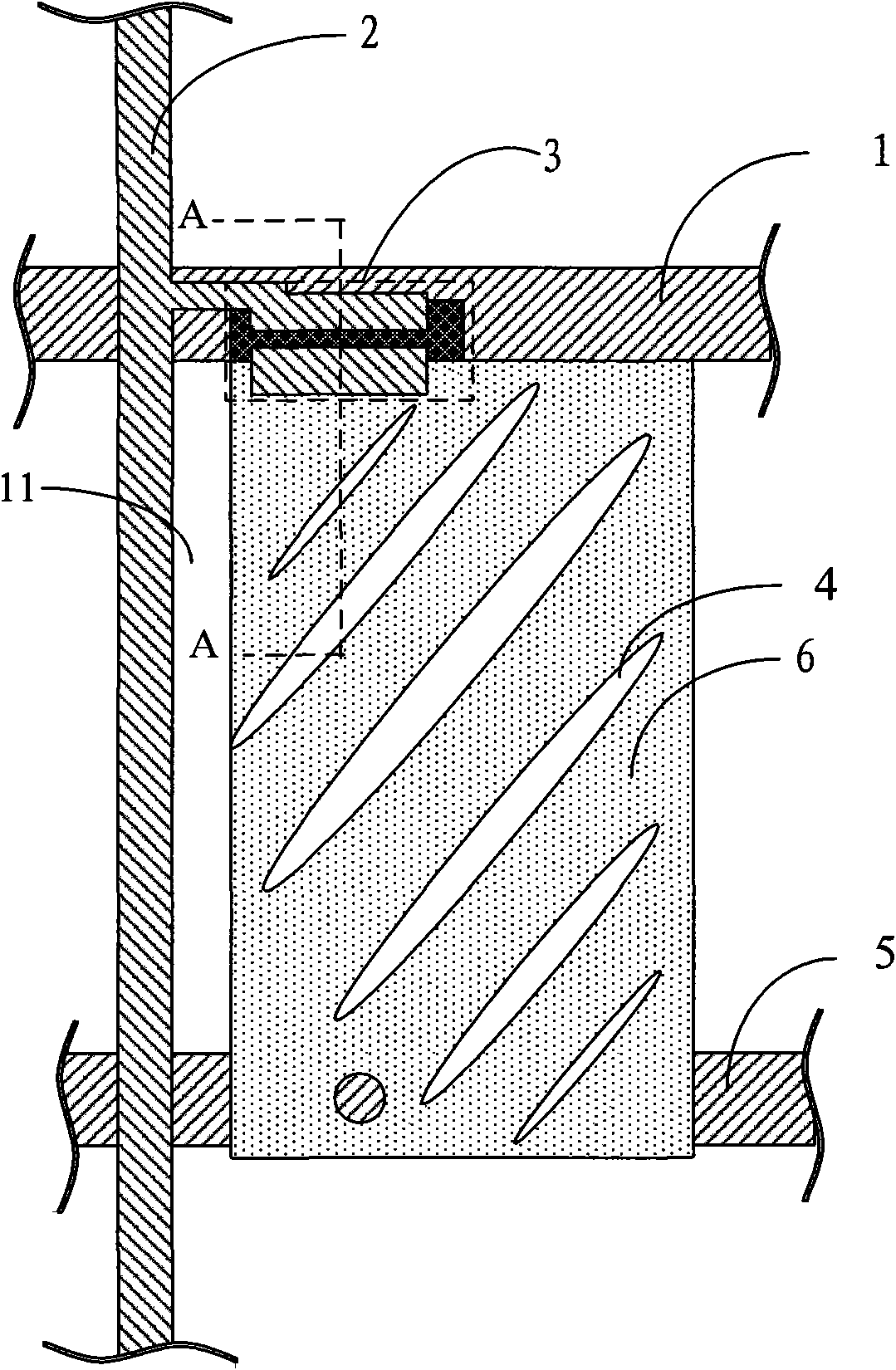

Thin film transistor liquid crystal display

A thin film transistor (TFT) liquid crystal display (LCD) panel, its array substrate, and its manufacturing method. Color filters are integrated on the TFT array, and color filter stacks are formed on the thin film transistors to replace a black matrix, thereby reducing manufacturing time and costs. The color filter stacks can be placed at the border of the display area of the panel to reduce light leakage. The border of the display area has a liquid crystal injection hole. To allow the size of the liquid crystal injection hole to be increased, and to reduce the light leakage at the hole, color filter blocks and overlapping metal layers can be used at the border of the display area. The color filter stacks and other dielectric layers need to be away from the welding points of repair structures to prevent dielectric layer bursts during a repair process. Storage capacitors can use the feature described above so that the color filters are positioned away from the overlapping portions. Welding is used to improve the electrical contact between the metal layers and the pixel electrode.

Owner:INNOLUX CORP

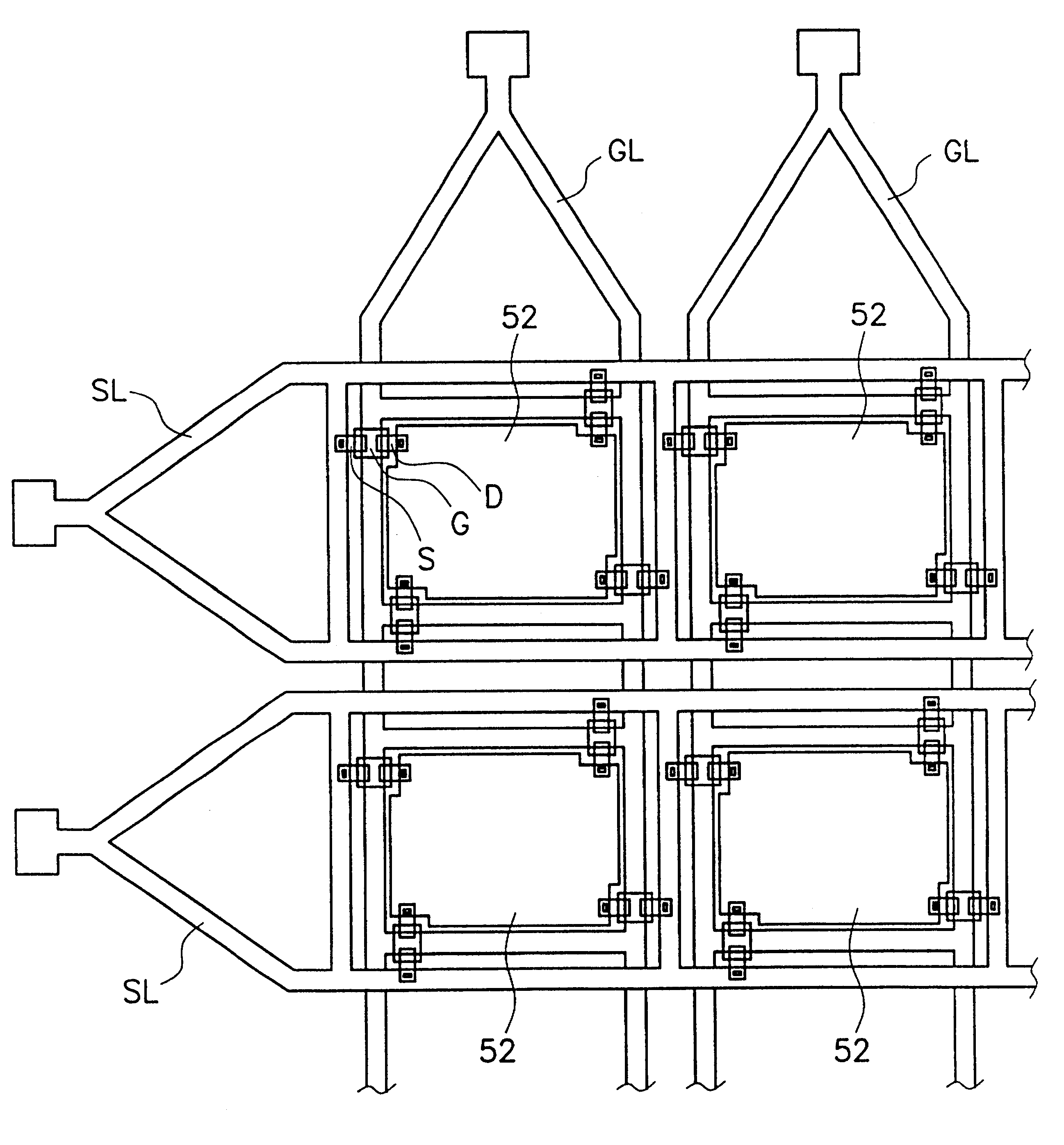

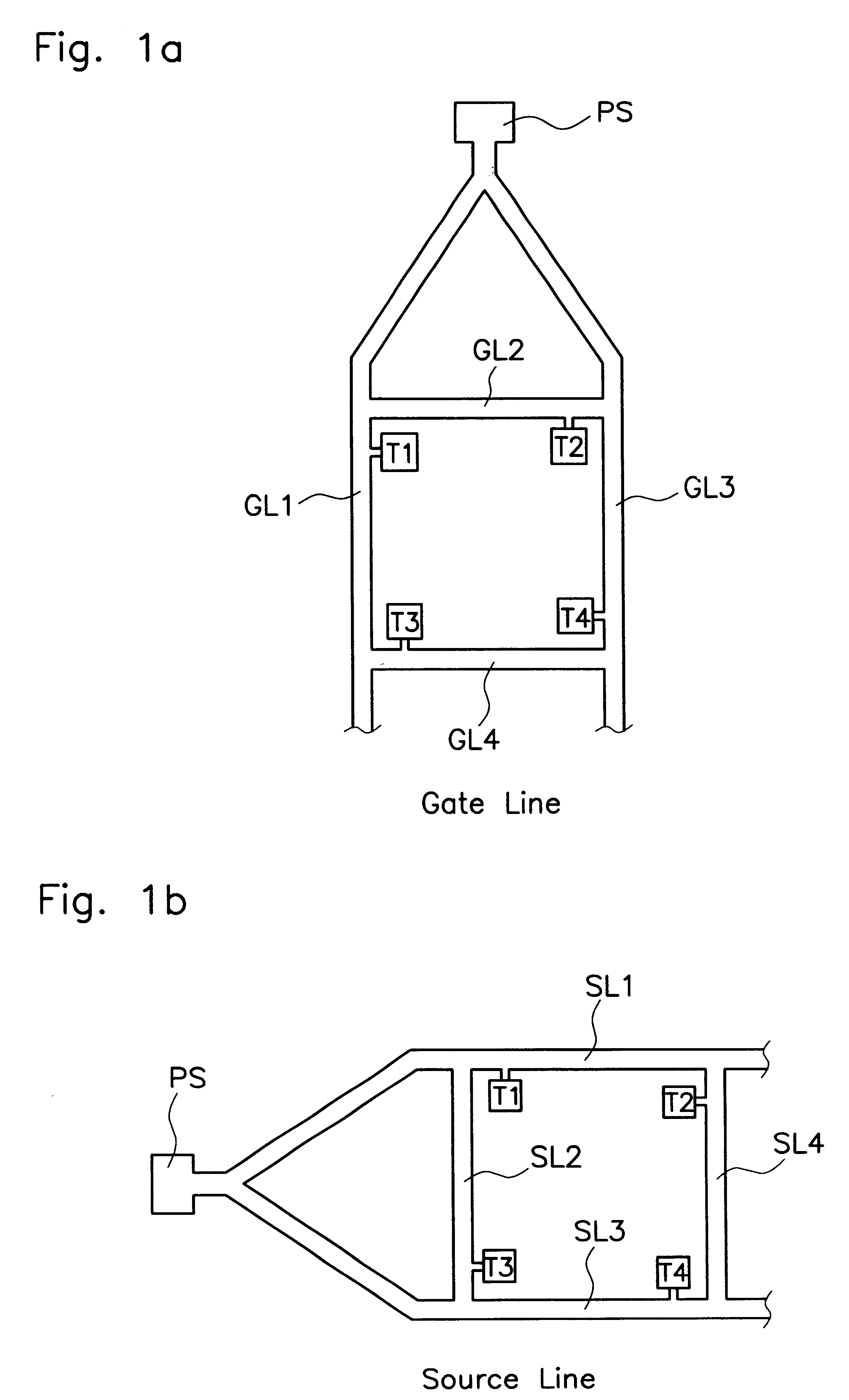

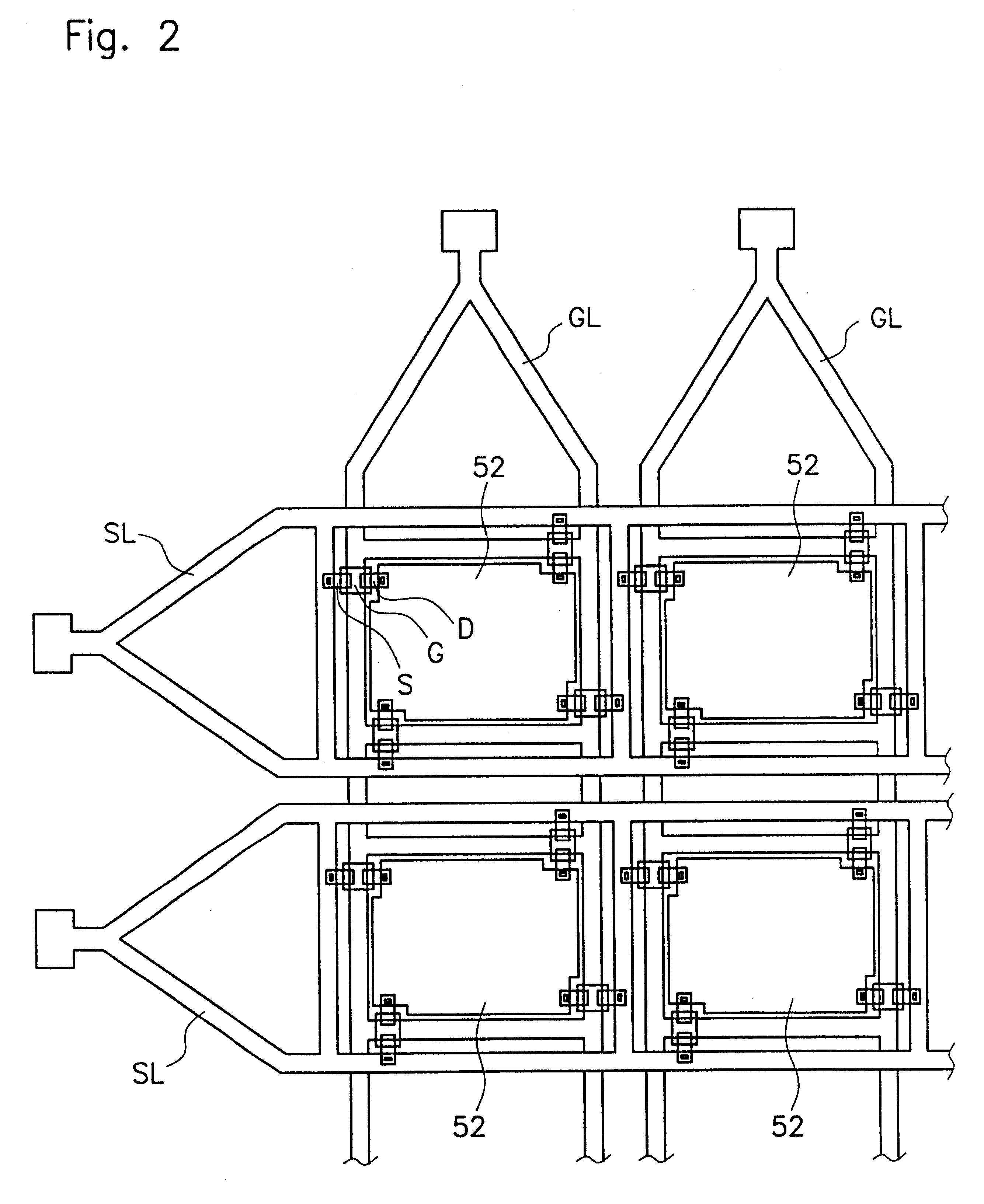

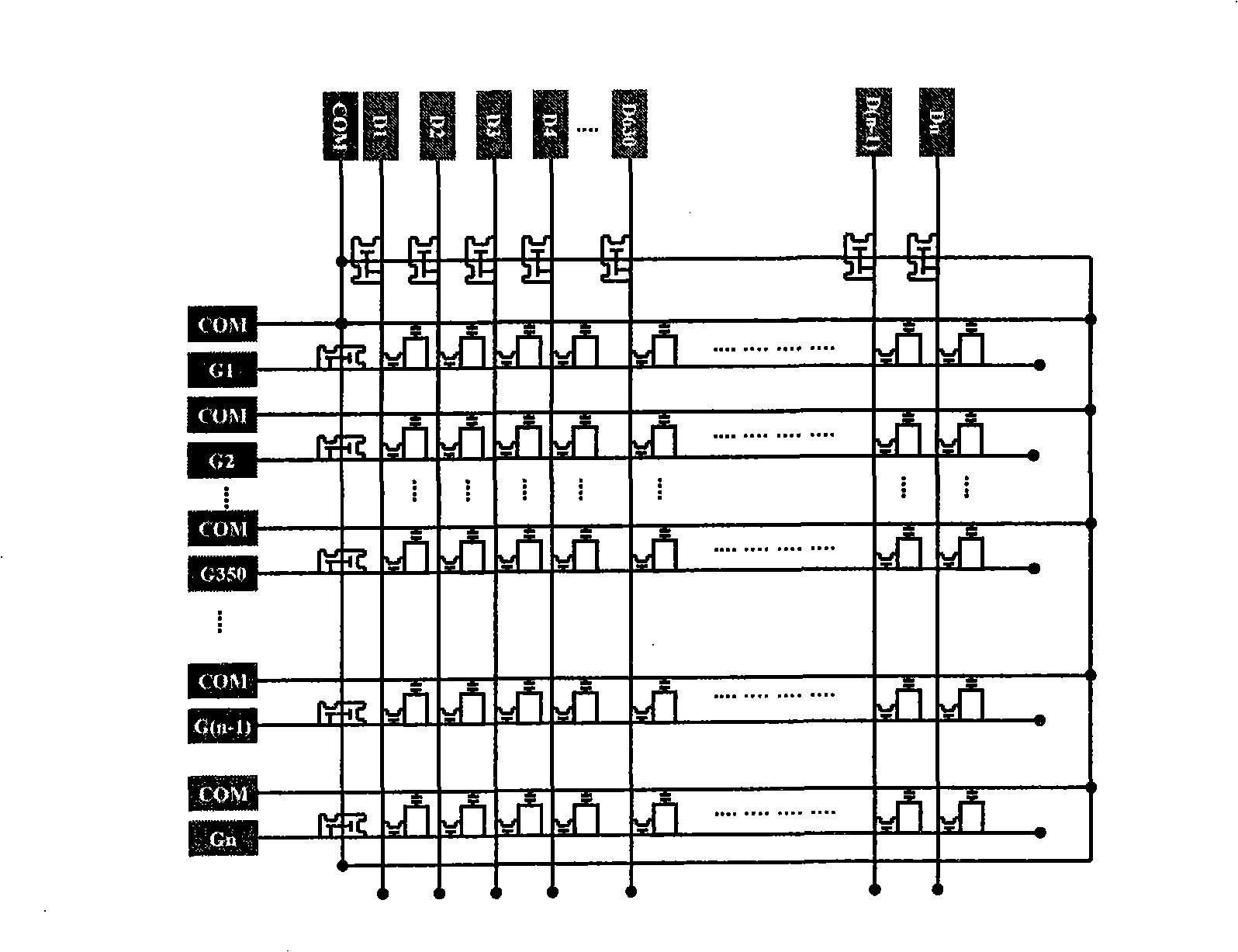

Thin film transistor liquid crystal display including at least three transistors associated with an unit pixel

A thin film transistor liquid crystal display according to the present invention provides against cut-off of lines for supplying a predetermined "ON'- or "OFF'-signal to thin film transistors and improves "ON'-current characteristic of the thin film transistors arranged in parallel. The thin film transistor liquid crystal display comprises primary lines and secondary lines to supply scanning signals and data signals respectively wherein each of said primary and secondary lines are branched and a thin film transistor is electrically coupled to each of the branched lines such that at least two transistors are turned on and off simultaneously when one of primary lines and one of secondary lines are applied with scanning signals and data signals respectively. Particularly, the primary and secondary lines are patterned in a trapezoid shape to define a lattice having two vertical sides and two horizontal sides for a unit pixel electrode.

Owner:SAMSUNG DISPLAY CO LTD

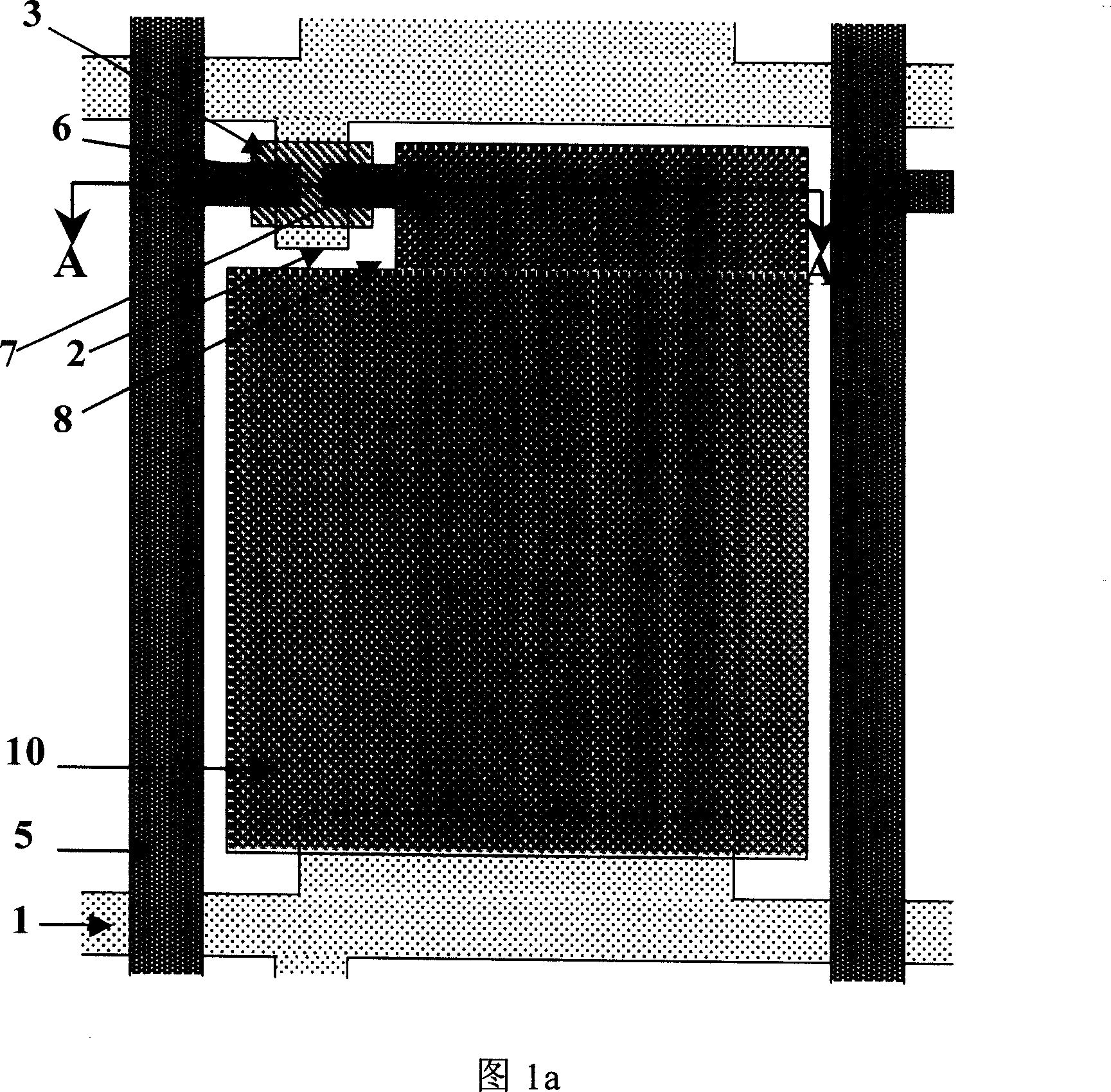

LCD and making method thereof

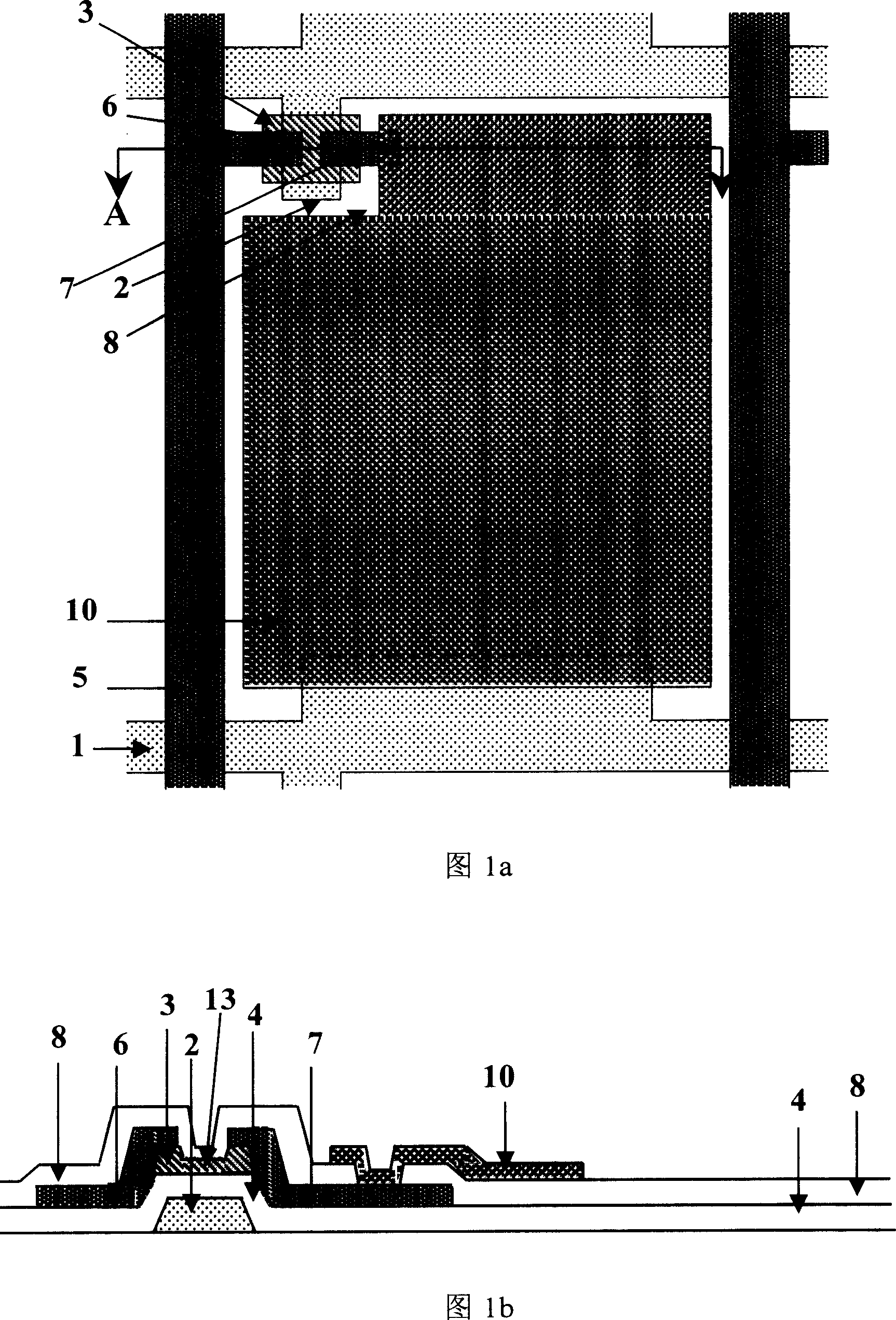

InactiveCN101334564AShorten the lengthLower resistanceSolid-state devicesNon-linear opticsLiquid-crystal displayThin-film-transistor liquid-crystal display

The invention provides a liquid crystal display array substrate structure of a film transistor, comprising a substrate and a first metal layer which comprises a gate electrode scanning line, and a gate electrode which are formed on the substrate; a gate electrode insulation layer that is formed on the gate electrode scanning line and the gate electrode; an active layer which is formed on the gate electrode insulation layer; a second metal layer which comprises a data line, a source electrode, a drain electrode and a public electrode line which are formed on the gate insulation layer, wherein, the source electrode and the drain electrode are partly carried on the active layer; a passivation layer which is formed on the data line, the source electrode, the drain electrode and the public electrode line and is formed into a contact hole on the drain electrode; a pixel electrode which is formed on the passivation layer and is connected with the drain electrode by the contact hole on the drain electrode. The invention also provides a preparation method used for a TFT LCD array substrate structure, which improves a state that the public electrode line is originally parallel to the gate electrode scanning line to be a state that the public electrode line is parallel to the data line, reduces the length of each public electrode line in the display area, and reduces the resistance of each public electrode line.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

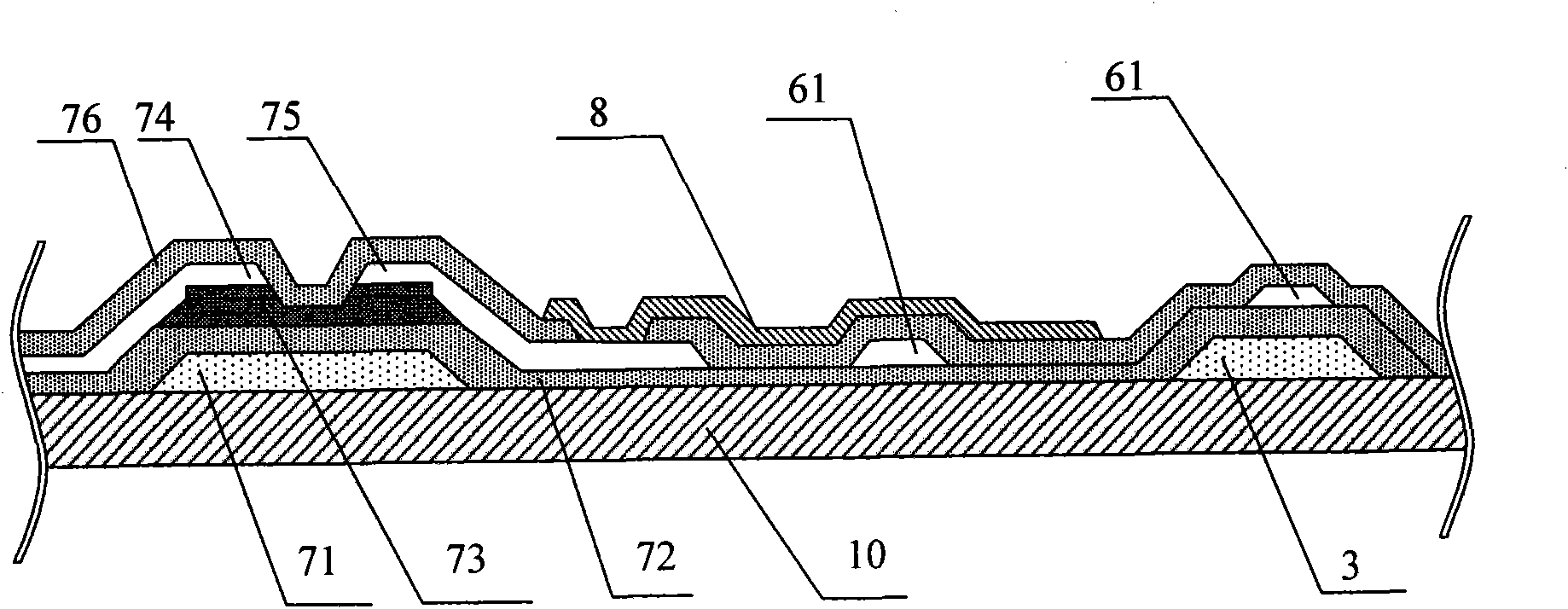

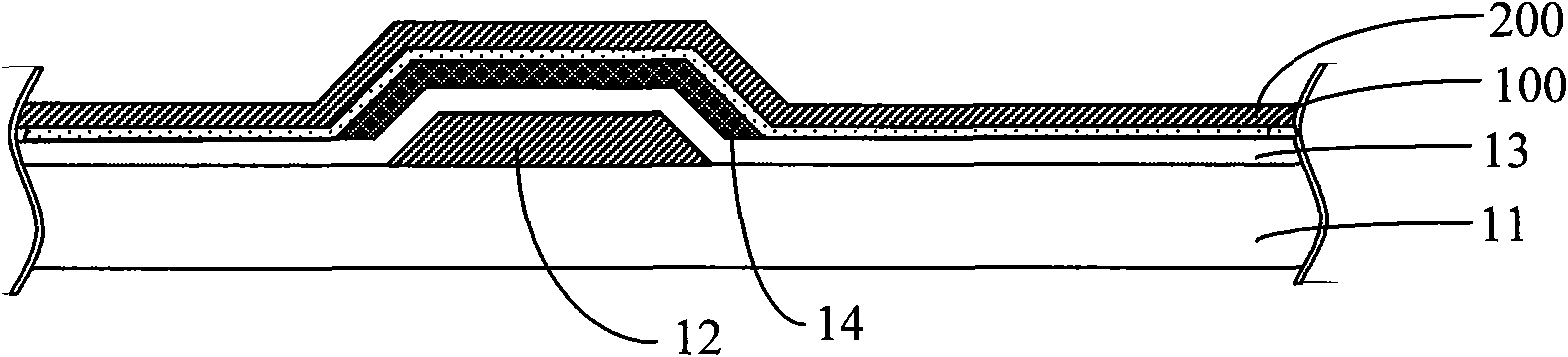

TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array base plate and manufacturing method thereof

ActiveCN101894807ASimplify processing difficultyImprove yield rateSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayComposition process

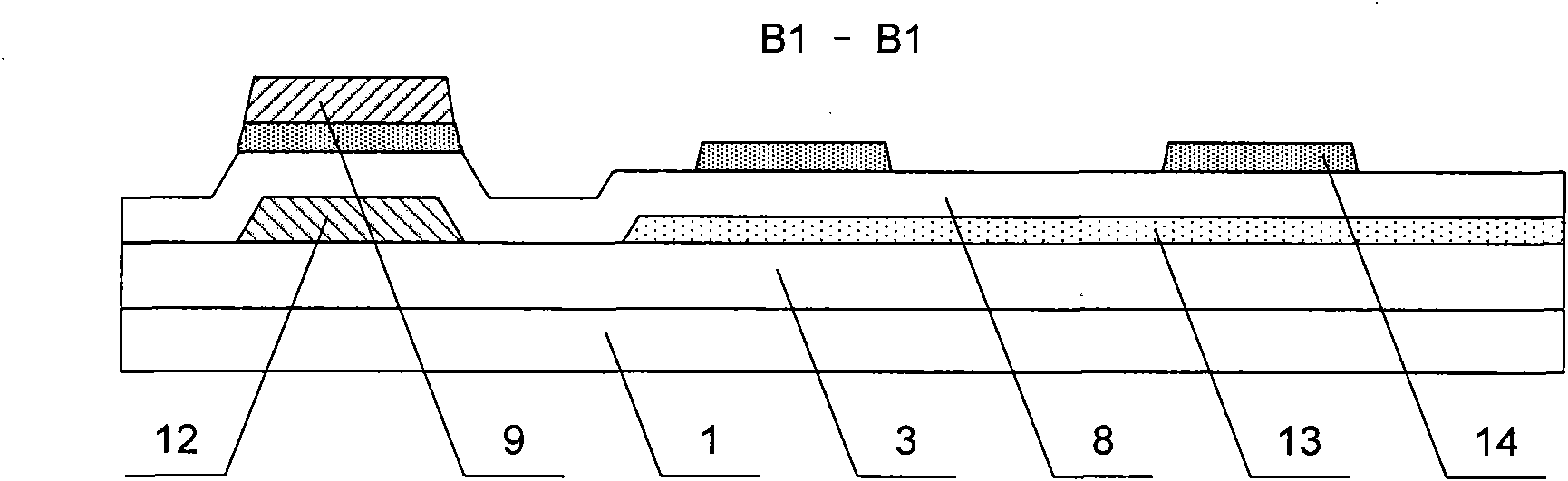

The invention discloses a TFT-LCD (Thin Film Transistor-Liquid Crystal Display) array base plate and a manufacturing method thereof. The manufacturing method comprises the steps of: sequentially depositing a transparent conductive thin film, a source-drain metal thin film and a doped semiconductor thin film on a transparent base plate; forming a figure which comprises a doped semiconductor layer, a source electrode, a drain electrode, a data line and a pixel electrode by a first composition process; depositing the semiconductor thin film; forming a figure which comprises a TFT channel and a semiconductor layer by a second composition process; depositing an insulating thin film and a grid metal thin film; and forming a figure which comprises a grid line and a grid electrode by a third composition process. In the invention, three composition processes are used for manufacturing the TFT-LCD array base plate with a top grid structure. Compared with the traditional three composition processes for manufacturing the array base plate, the manufacturing method of the invention does not need a lift-off peeling process, largely simplifies the process difficulty, and enhances the product yield.

Owner:BOE TECH GRP CO LTD +1

Amorphous silicon thin-film transistor liquid crystal display

InactiveUS6922217B2Reduce in quantitySimple manufacturing processTransistorStatic indicating devicesShift registerLiquid-crystal display

In an amorphous silicon thin film transistor-liquid crystal display device and a method of manufacturing the same, gate patterns including a gate line and a gate electrode are formed on an insulation substrate having a display region and a driving circuit region on which a plurality of shift registers are formed, a gate insulating film, active layer patterns and data patterns including source and drain electrodes are formed successively on the substrate, a passivation layer on the substrate has a first contact hole exposing a drain electrode of the display region and second and third contact holes respectively exposing a gate electrode and source and drain electrodes of a first transistor of each of the shift registers, an electrode patterns on the passivation layer include a first electrode connected to the drain electrode of the display region through the first contact hole and a second electrode connecting the gate electrode to the source and drain electrodes of the first transistor through the second and third contact holes, and the gate driving circuit including the shift registers and the wirings are integrated on the insulating substrate without an additional process, thereby simplifying the manufacturing process.

Owner:SAMSUNG DISPLAY CO LTD

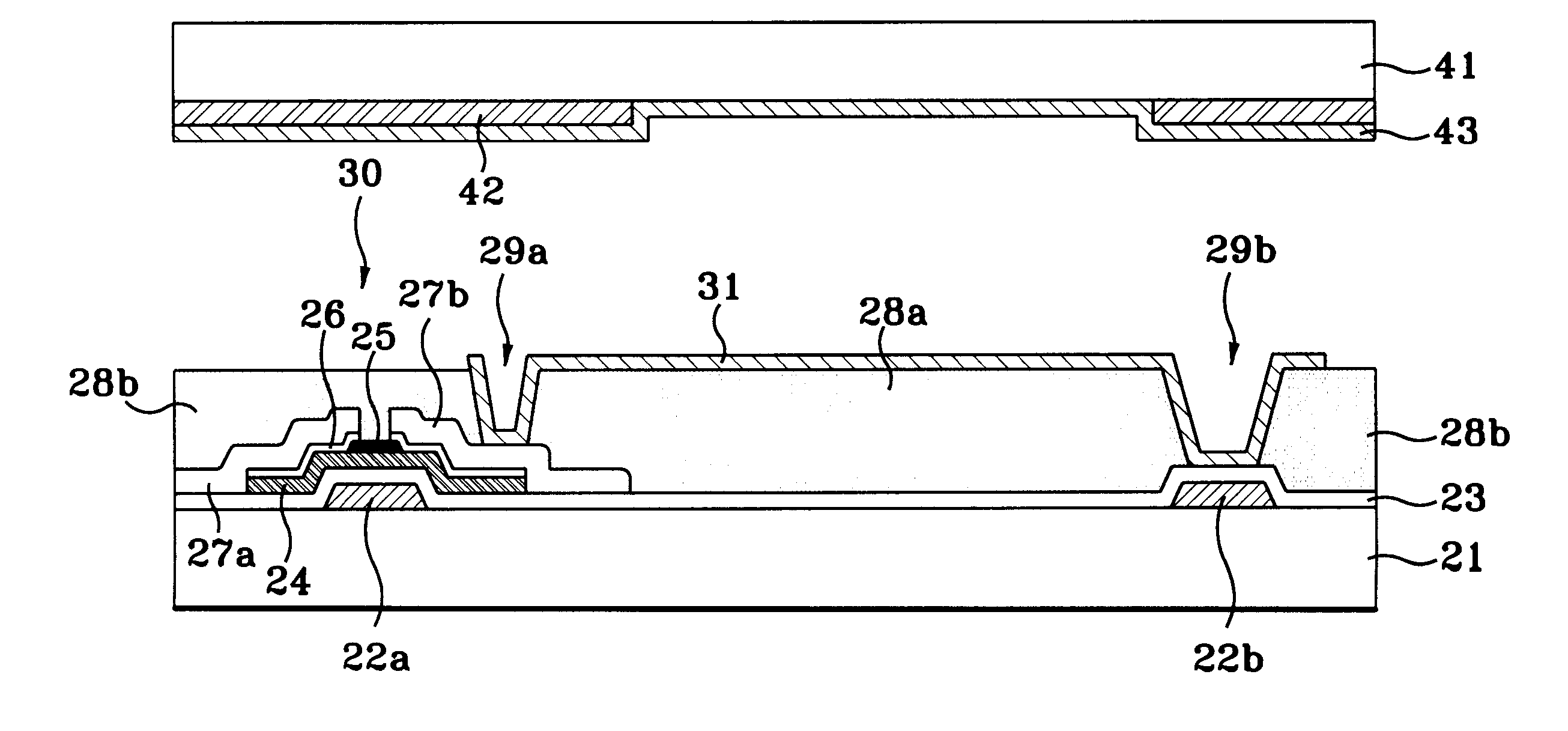

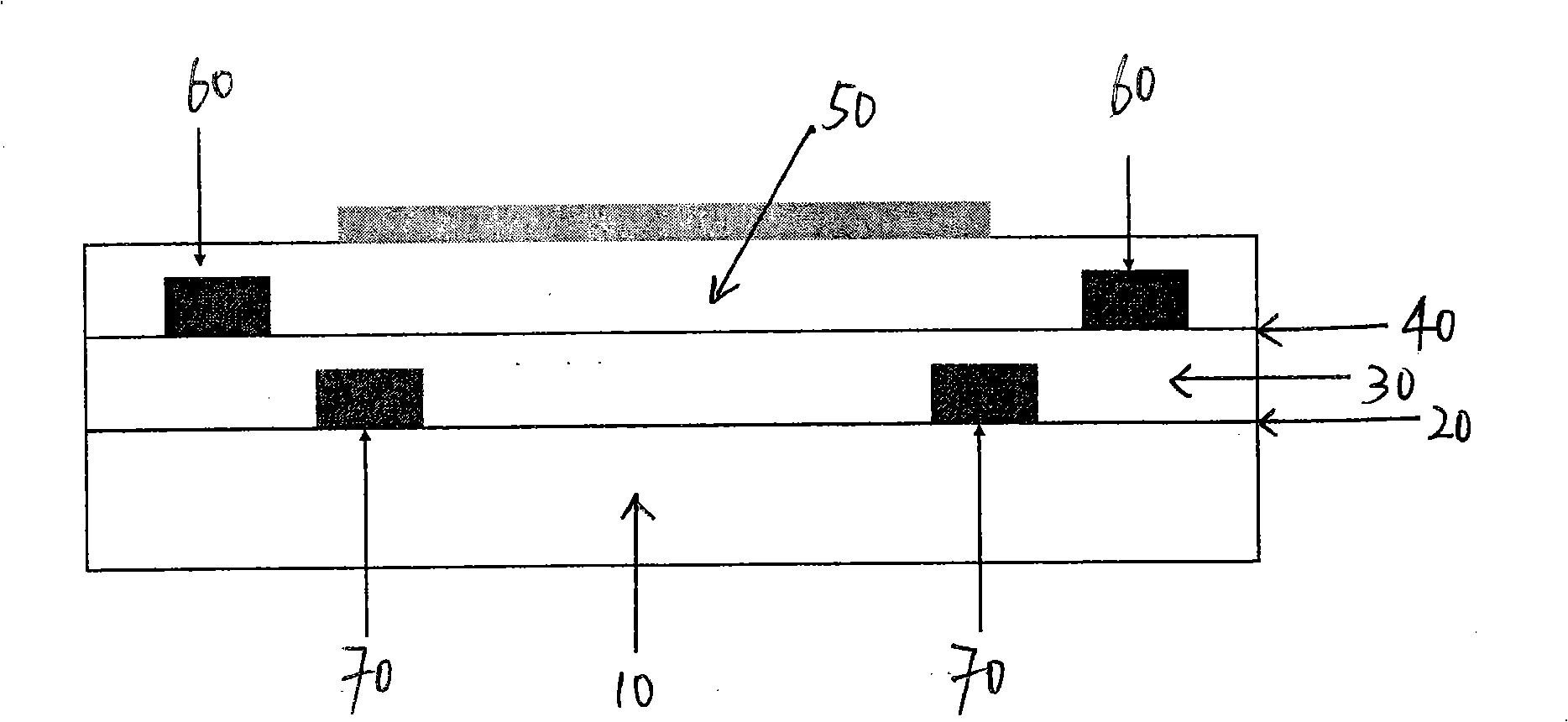

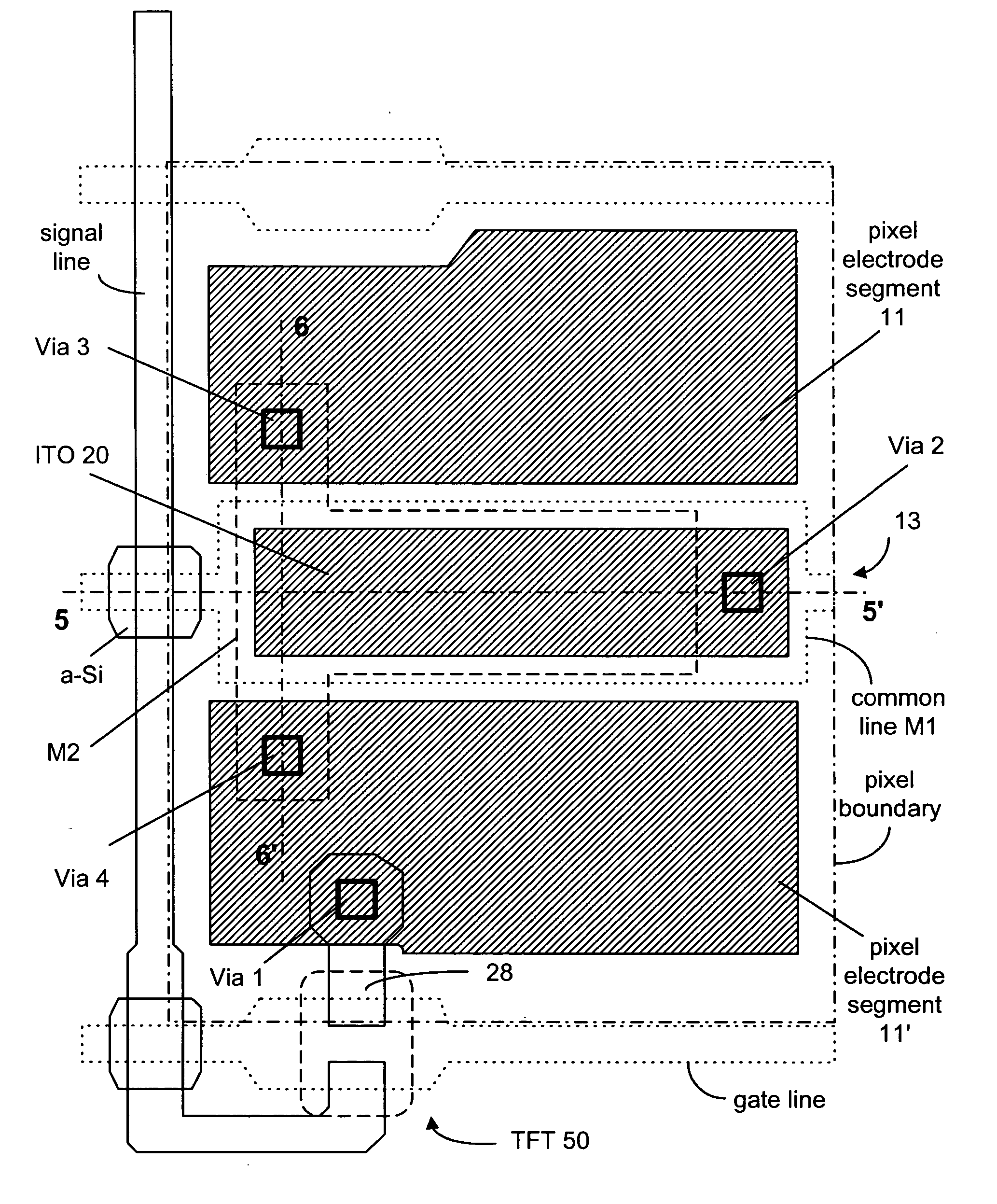

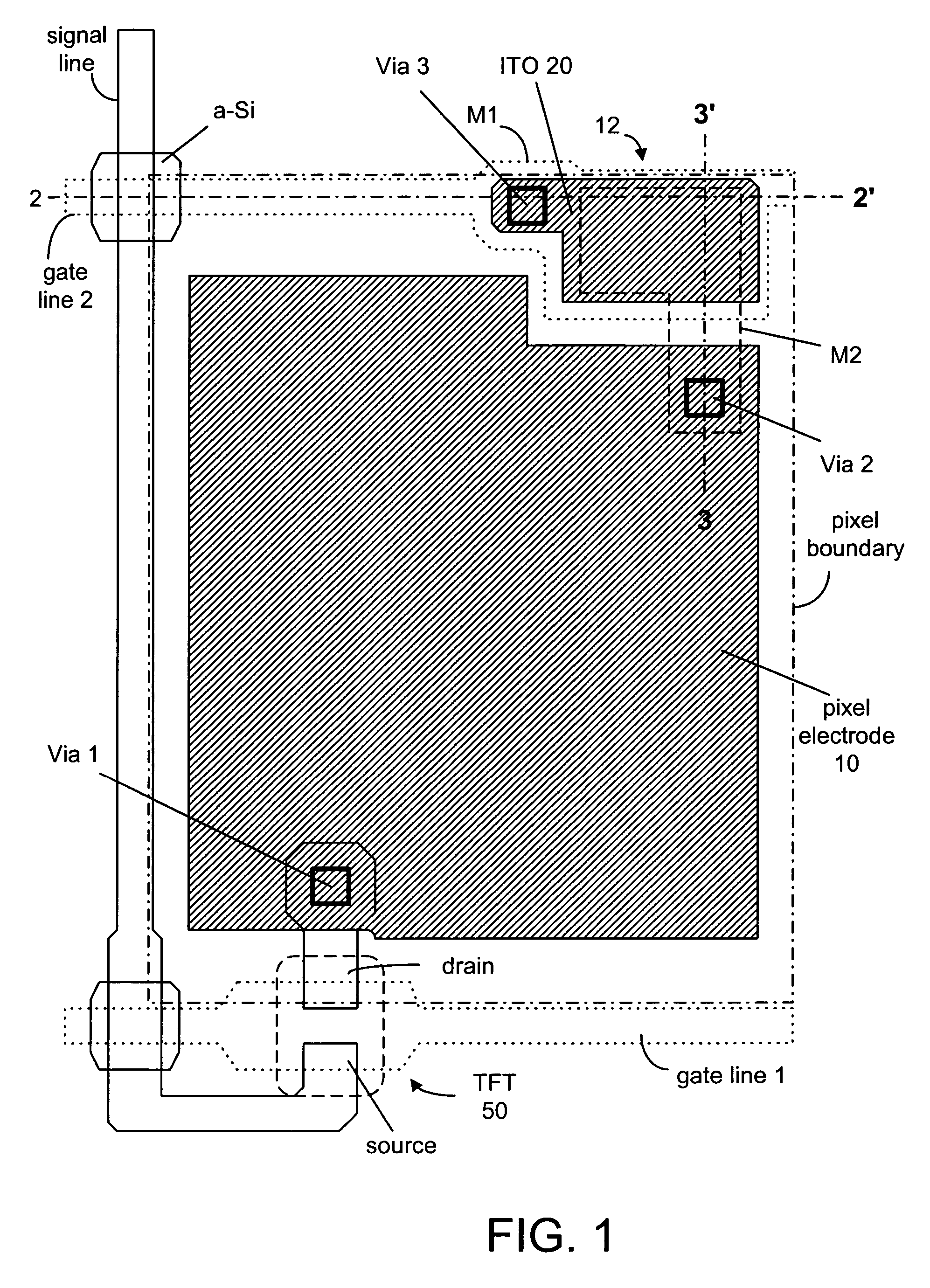

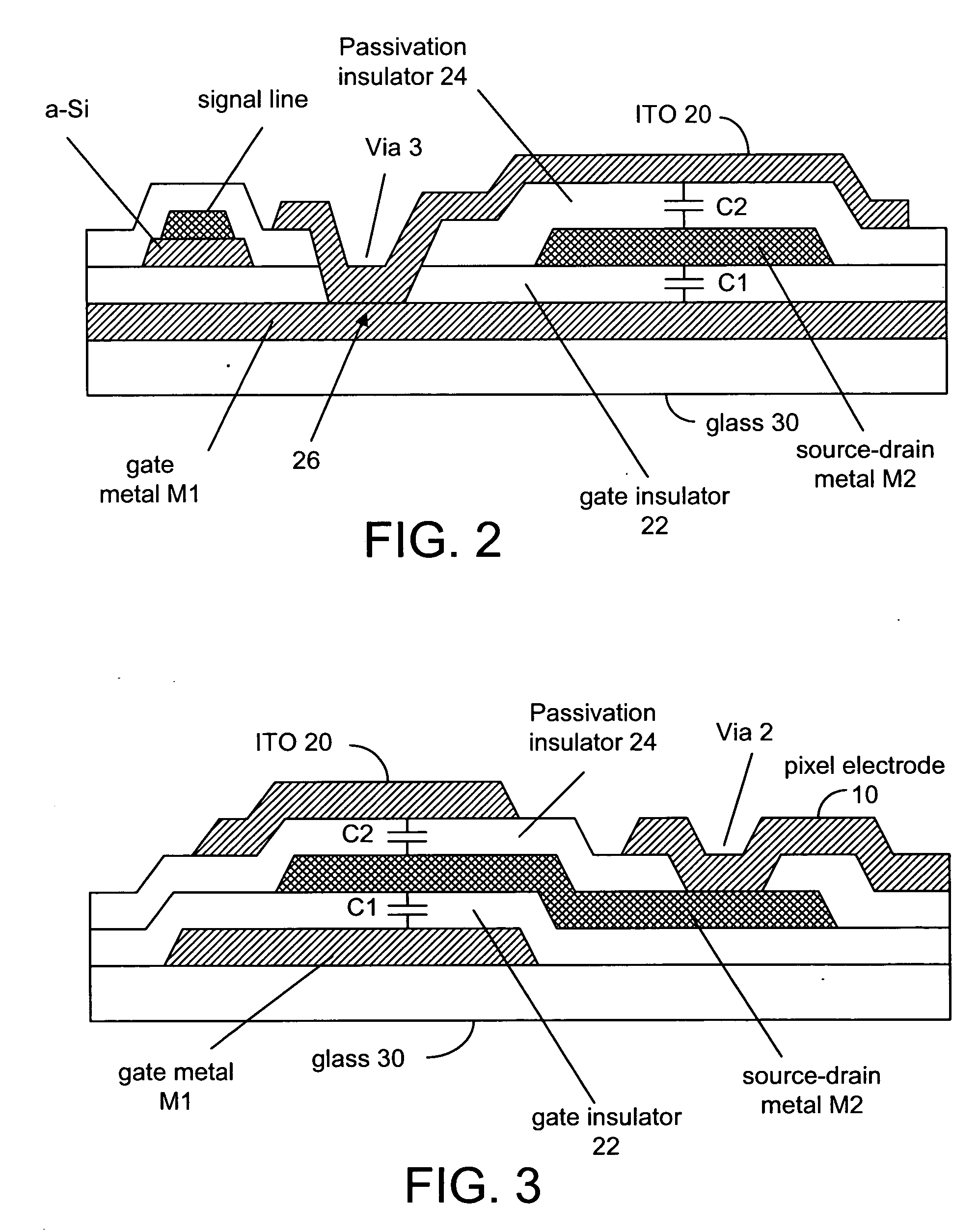

Stacked storage capacitor structure for a thin film transistor liquid crystal display

ActiveUS20060119753A1Increase capacitanceImprove overall utilizationTransistorStatic indicating devicesLiquid-crystal displayGate insulator

A stacked storage capacitor structure for use in each pixel of a TFT-LCD, wherein a first storage capacitor is formed by a first metal layer, a gate insulator layer and a second metal layer. The second capacitor is formed by the second metal layer, a passivation insulator layer and an ITO layer. The first metal layer and the ITO layer are joined together through a via hole which is etched in one insulator etching step during the overall fabrication process through both the gate insulator and the passivation insulator layers. As such, the two capacitors are connected in parallel in a stacked configuration. With the stacked storage capacitor structure, the charge storage capacity is increased without significantly affecting the aperture ratio of a pixel. The ITO and the pixel electrode can be different parts of an indium tine oxide layer deposited on the passivation insulator layer.

Owner:AU OPTRONICS CORP

Liquid crystal display

InactiveUS20070091043A1Static indicating devicesNon-linear opticsLiquid-crystal displayElectrical polarity

A liquid crystal display includes an array pixel including a plurality of pixels arranged in a matrix. The plurality of pixels include a set of pixels including a pair of center pixels adjacent to each other, and a pair of first-color pixels and a pair of second-color pixels obliquely facing each other across the center pixels. Each pixel includes a pixel electrode and a thin film transistor. The liquid crystal display further includes a plurality of gate lines extending in a row direction for transmitting a gate signal to the pixels, and a plurality of data lines extending in a column direction for transmitting data signals to the pixels. The pixels are subject to polarity inversion.

Owner:SAMSUNG ELECTRONICS CO LTD

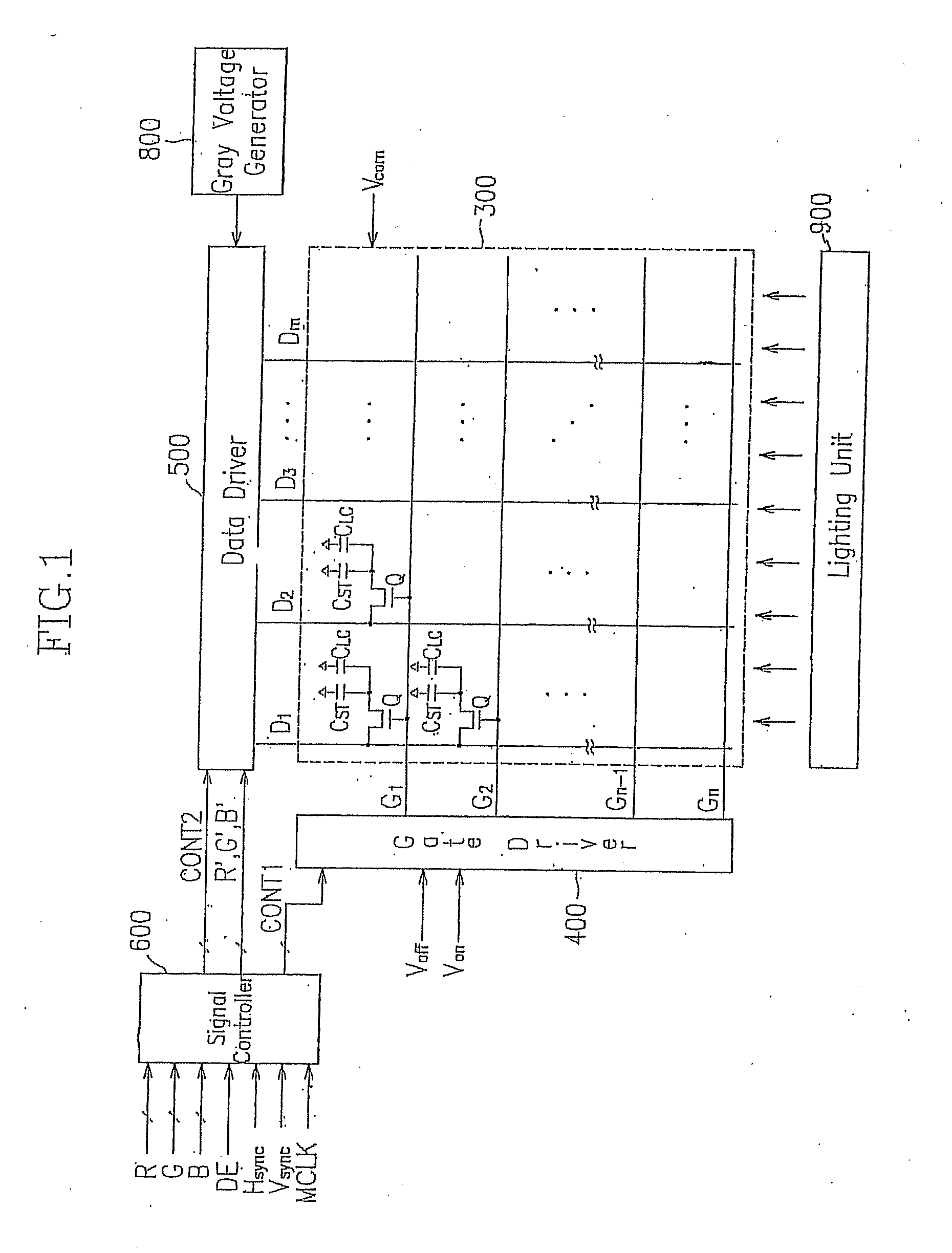

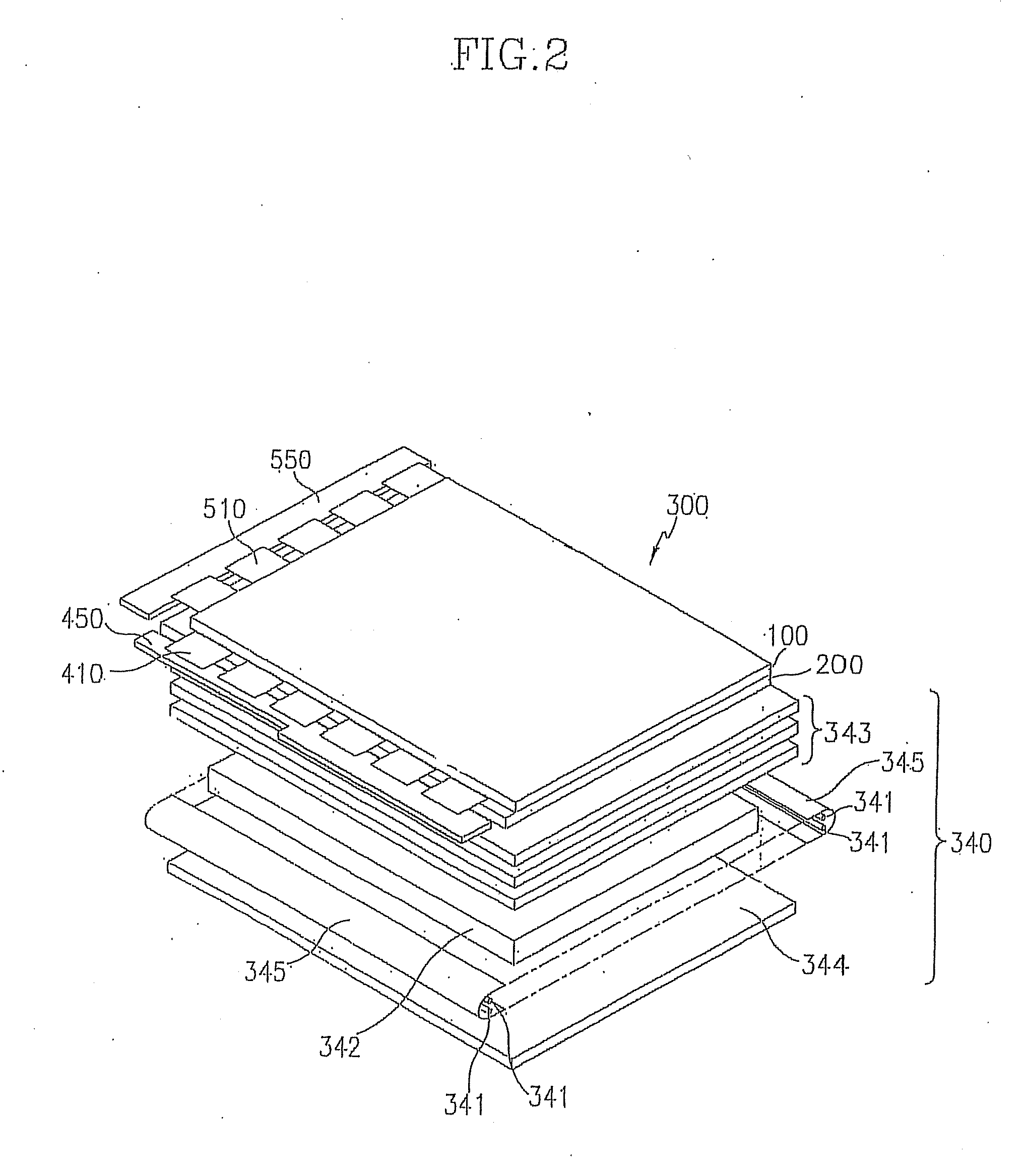

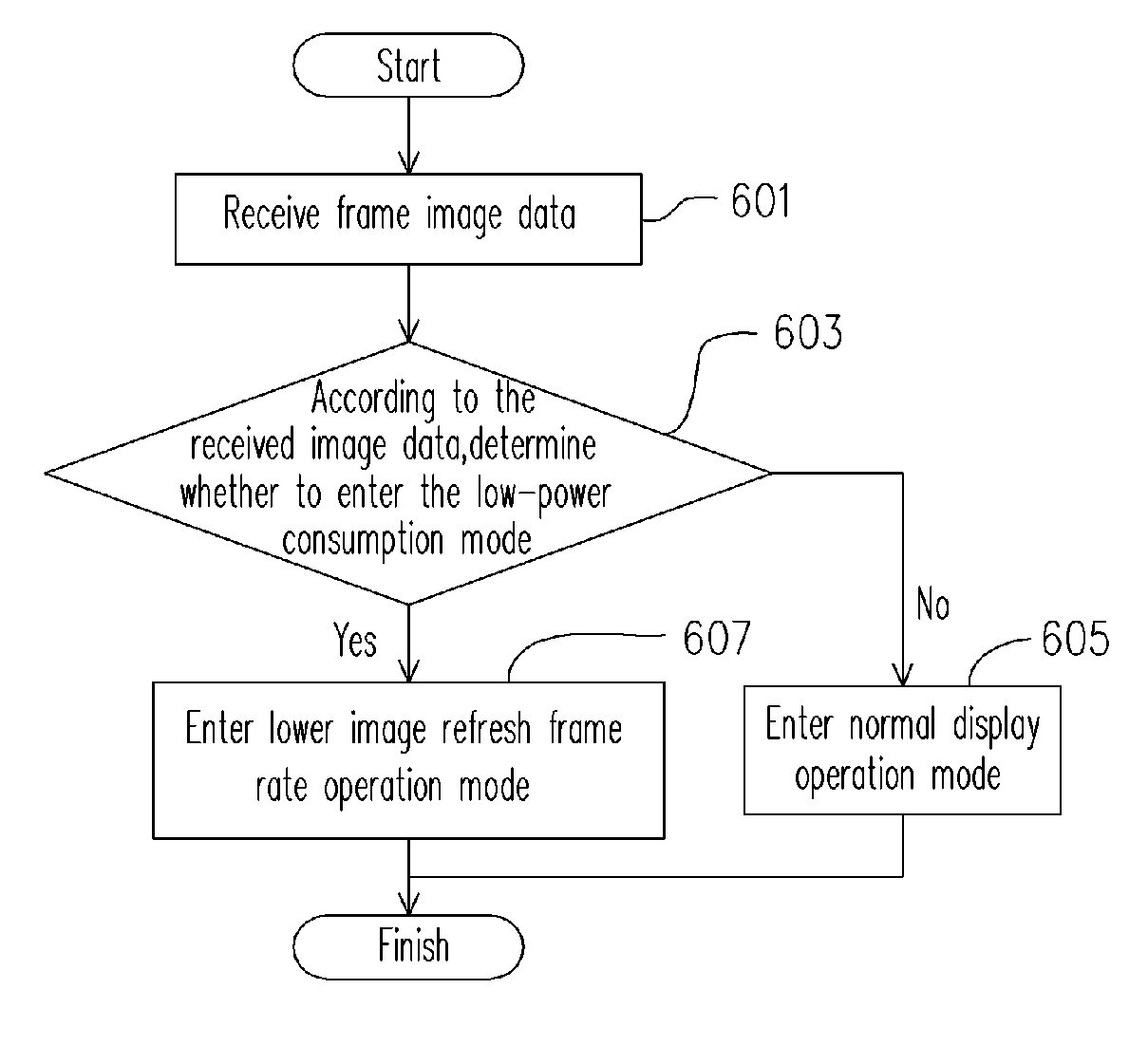

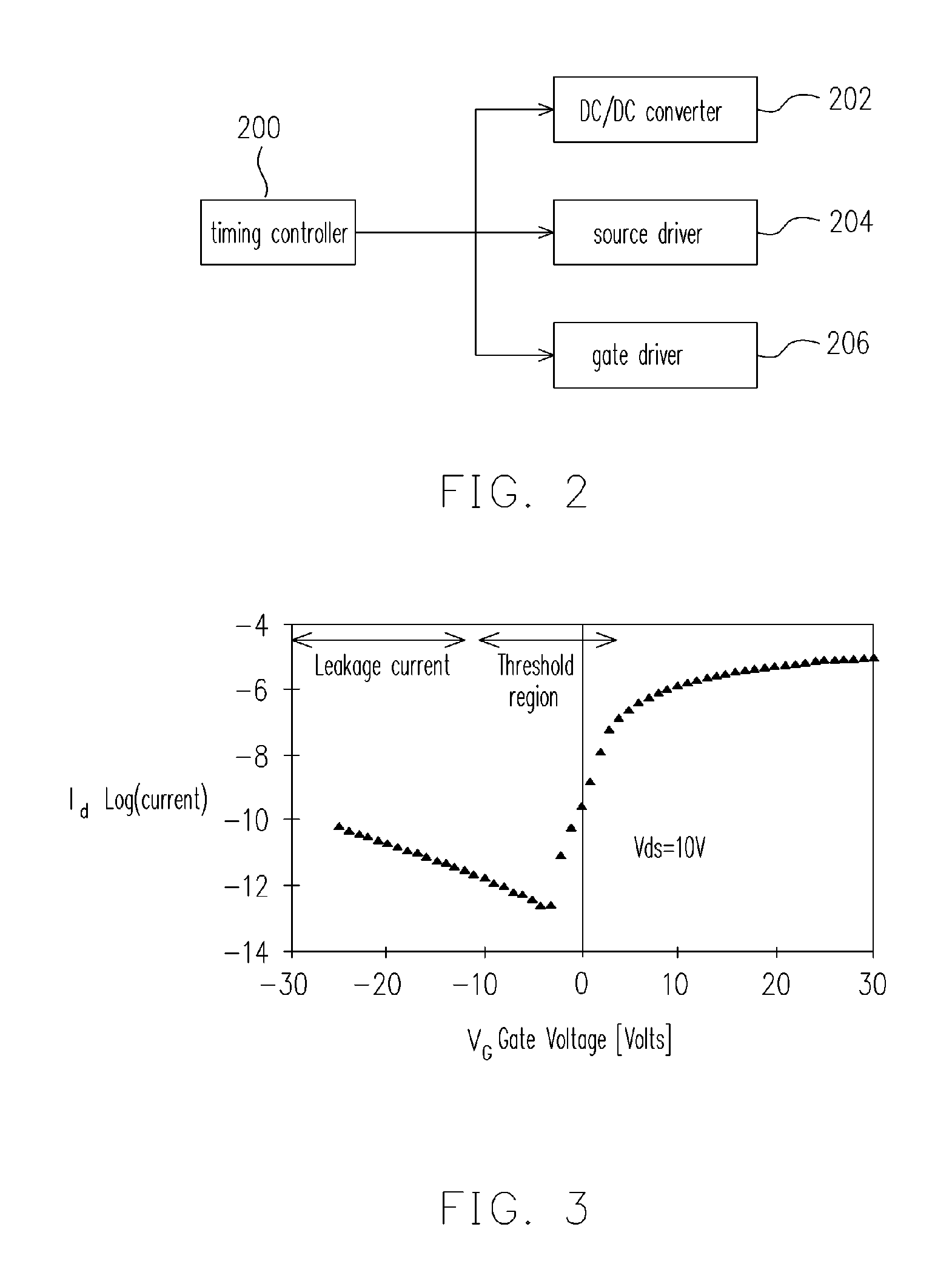

Power saving method for thin film transistor liquid crystal display

InactiveUS20060267972A1Reduce power consumptionSave powerCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayEngineering

A power saving method for a thin film transistor liquid crystal display is provided. The method is suitable for a thin film transistor liquid crystal display (TFT LCD). During image display period, different refresh frame rate are used accordingly to the different variation rates of the image frame data.

Owner:AU OPTRONICS CORP

Thin film transistor liquid crystal display (TFT-LCD) array substrate as well as manufacturing method and test method thereof

ActiveCN101770122AAugmented Test Analysis PathwayImprove analytical performanceSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayThin-film-transistor liquid-crystal display

Owner:BOE TECH GRP CO LTD +1

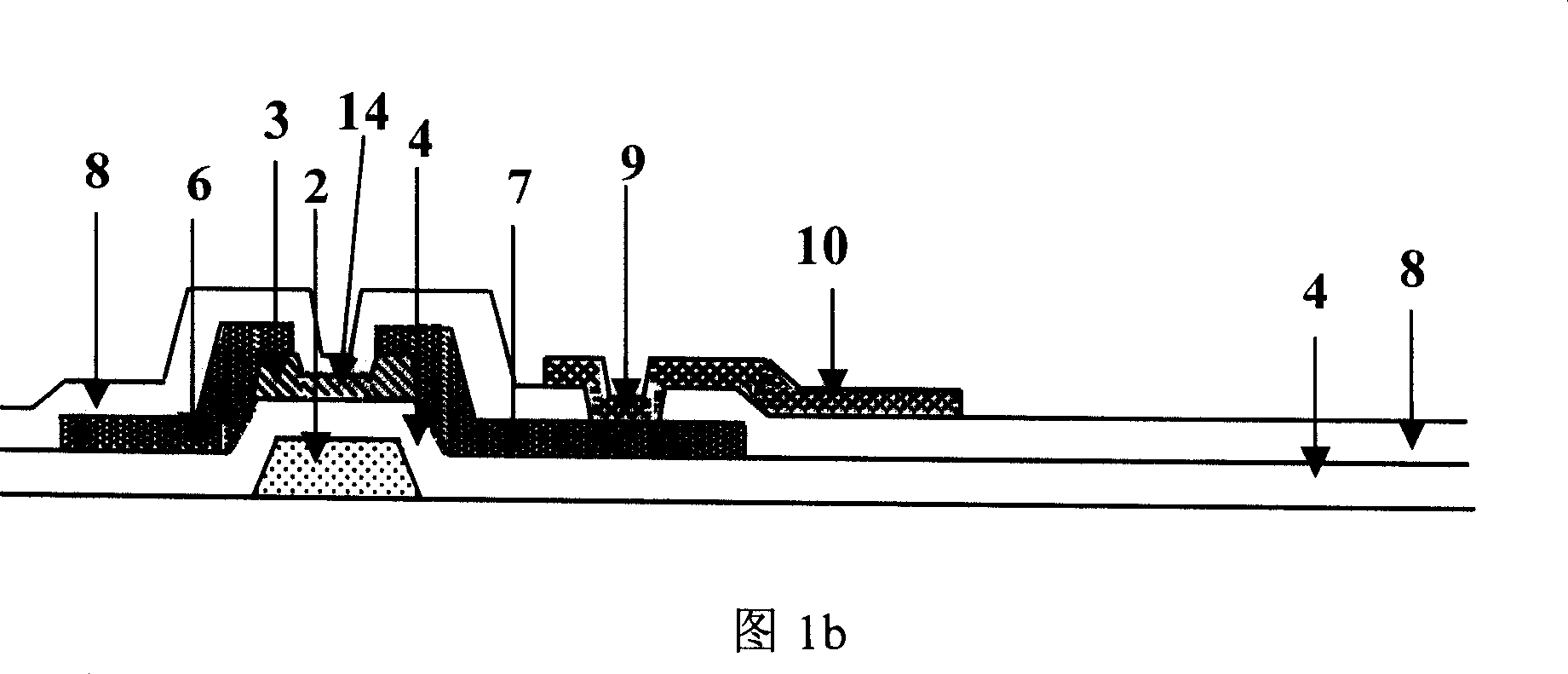

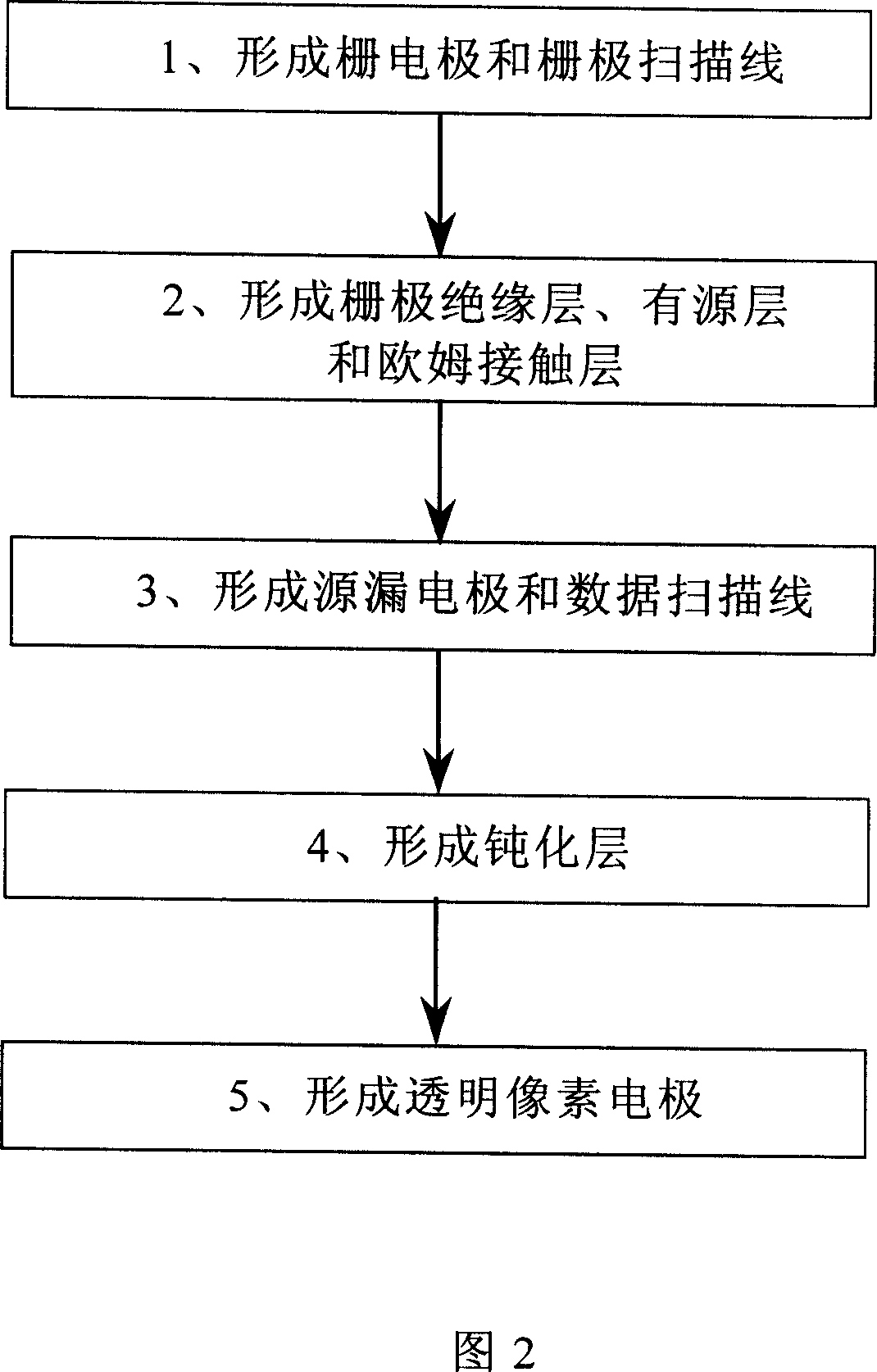

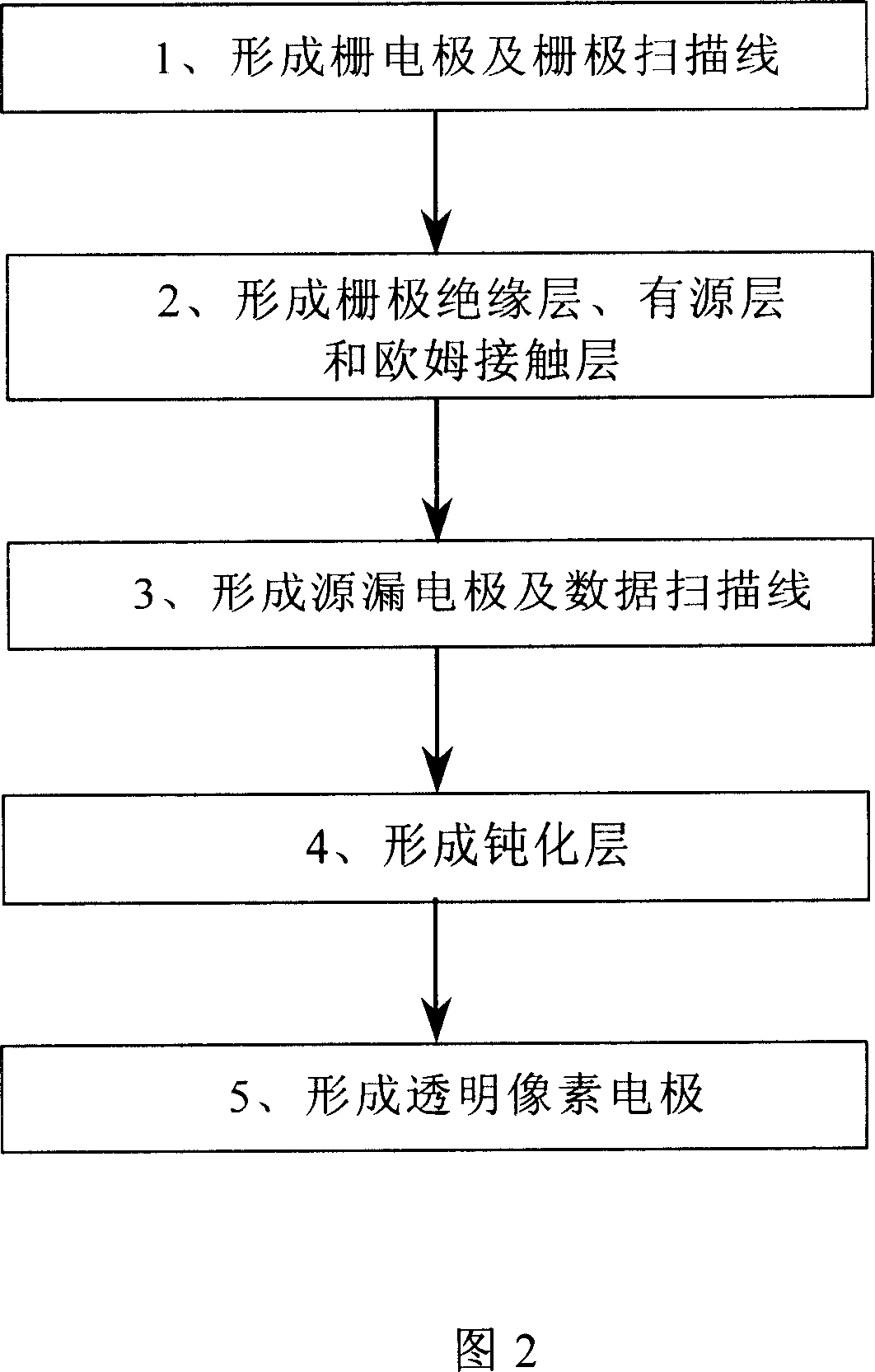

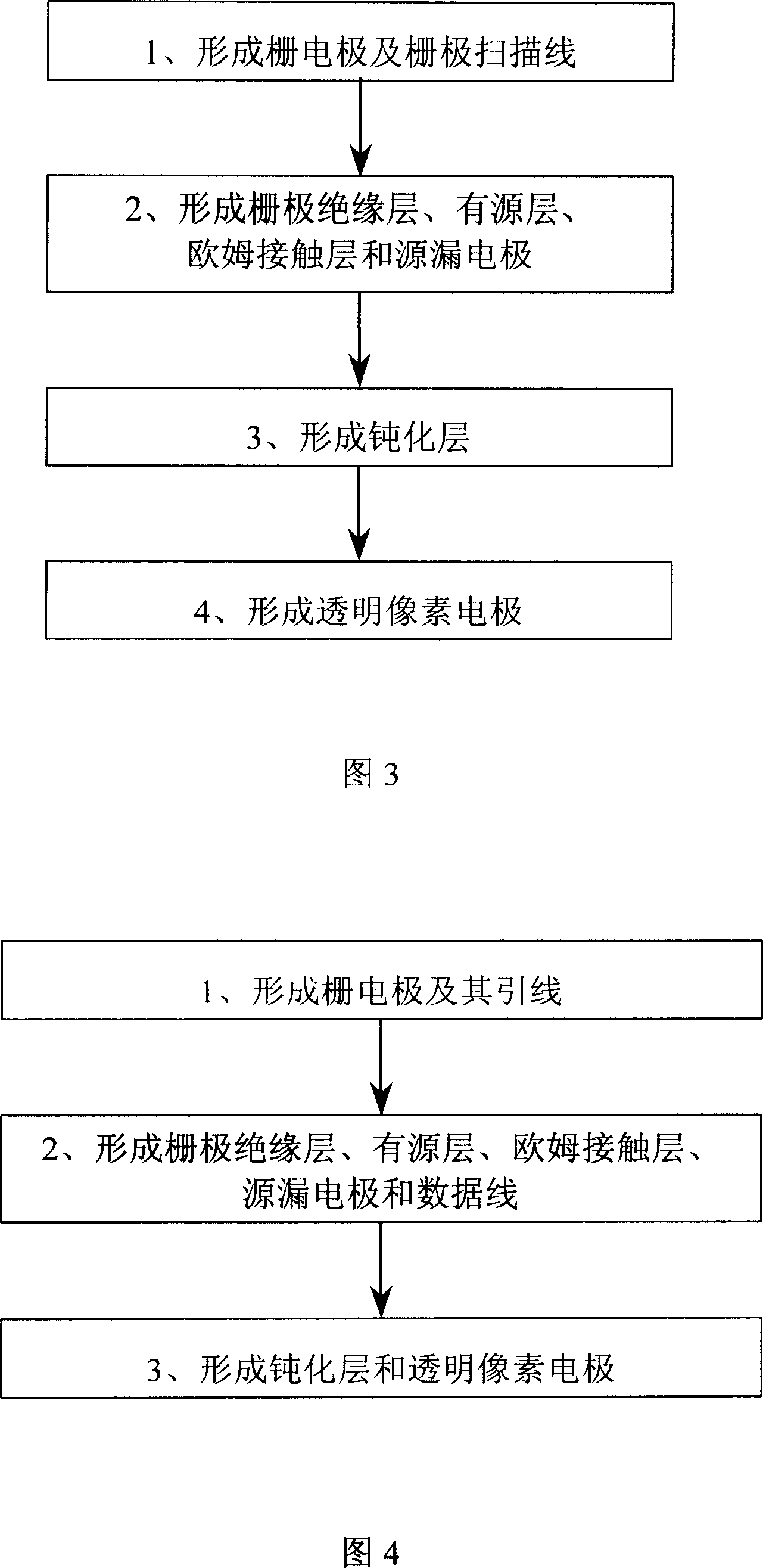

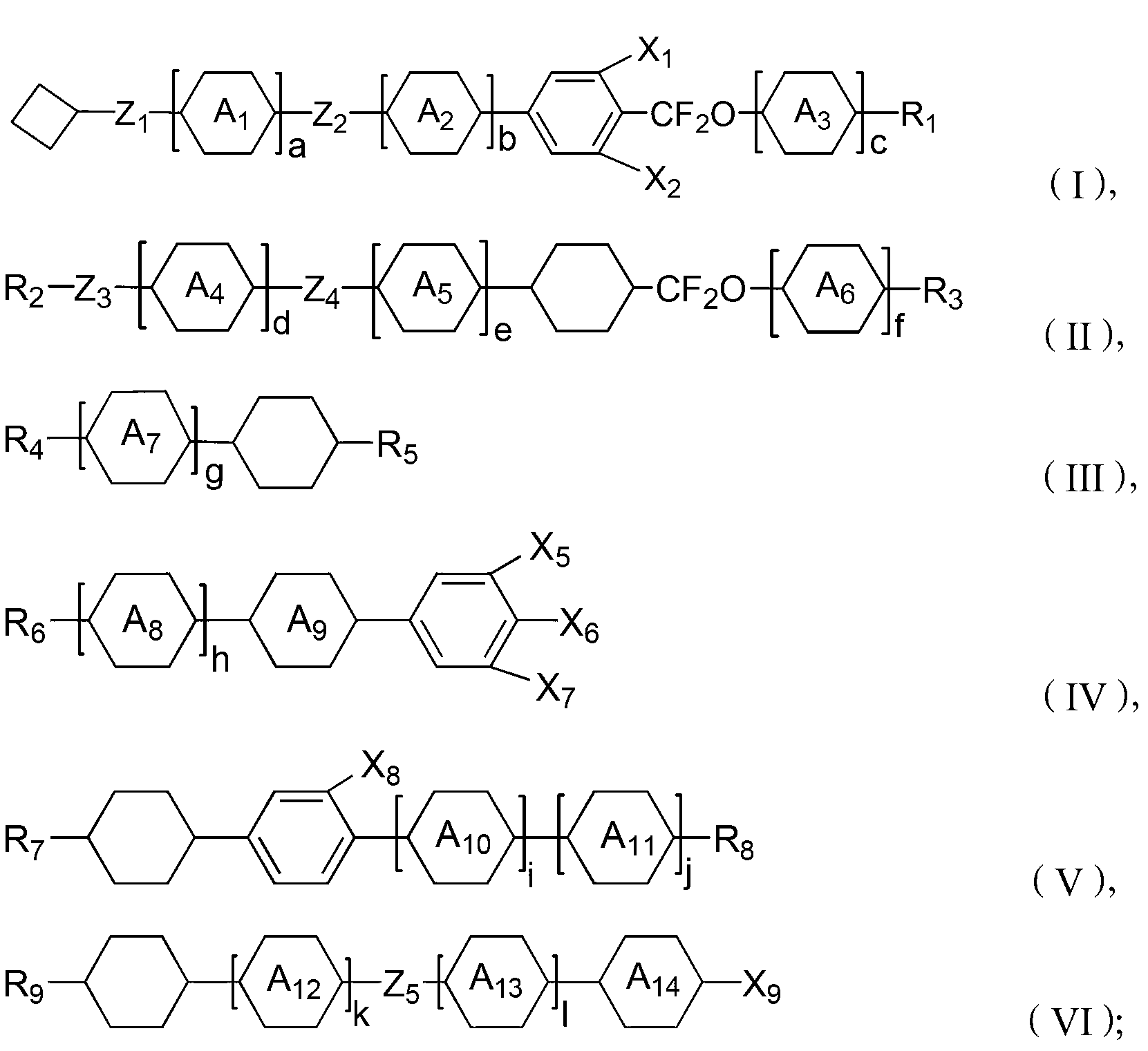

Manufacturing method for array substrate of thin film transistor LCD

ActiveCN101034262ALow costSimple manufacturing processSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusInsulation layerThin-film-transistor liquid-crystal display

The invention opens a manufacturing method of the thin film transistor liquid crystal display array substrate. Including the following steps: first, forms the first metal film on the substrate; uses the version of the first layer metal film define the design of the first metal film and to form grid scan line and grid electrode. Next, the first insulating layer, the active layer, ohmic contact layer and the second layer metal film were deposited above the metal grid in turn; The use of the second block mask, namely, a gray-first definition of the second mask layer metal film patterns, forms a source of leakage and data scanning lines; Secondly forms the active layer island and conductive thin film transistor device channel. Then it forms the second insulation film on the second metal layer. Finally, the use of the third block mask, that is the second block of gray-definition version of the second mask layer insulation film, forms a second layer insulation film designs, makes some part of the second layer and the second layer of metal insulation layer exposed, and the other part was the protection of light-sensitive materials. Here a transparent conductive film deposits on it, and then removes light sensitive materials and their attachment -the electro-conductive film, finally forms the design of the electric conduction thin film.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

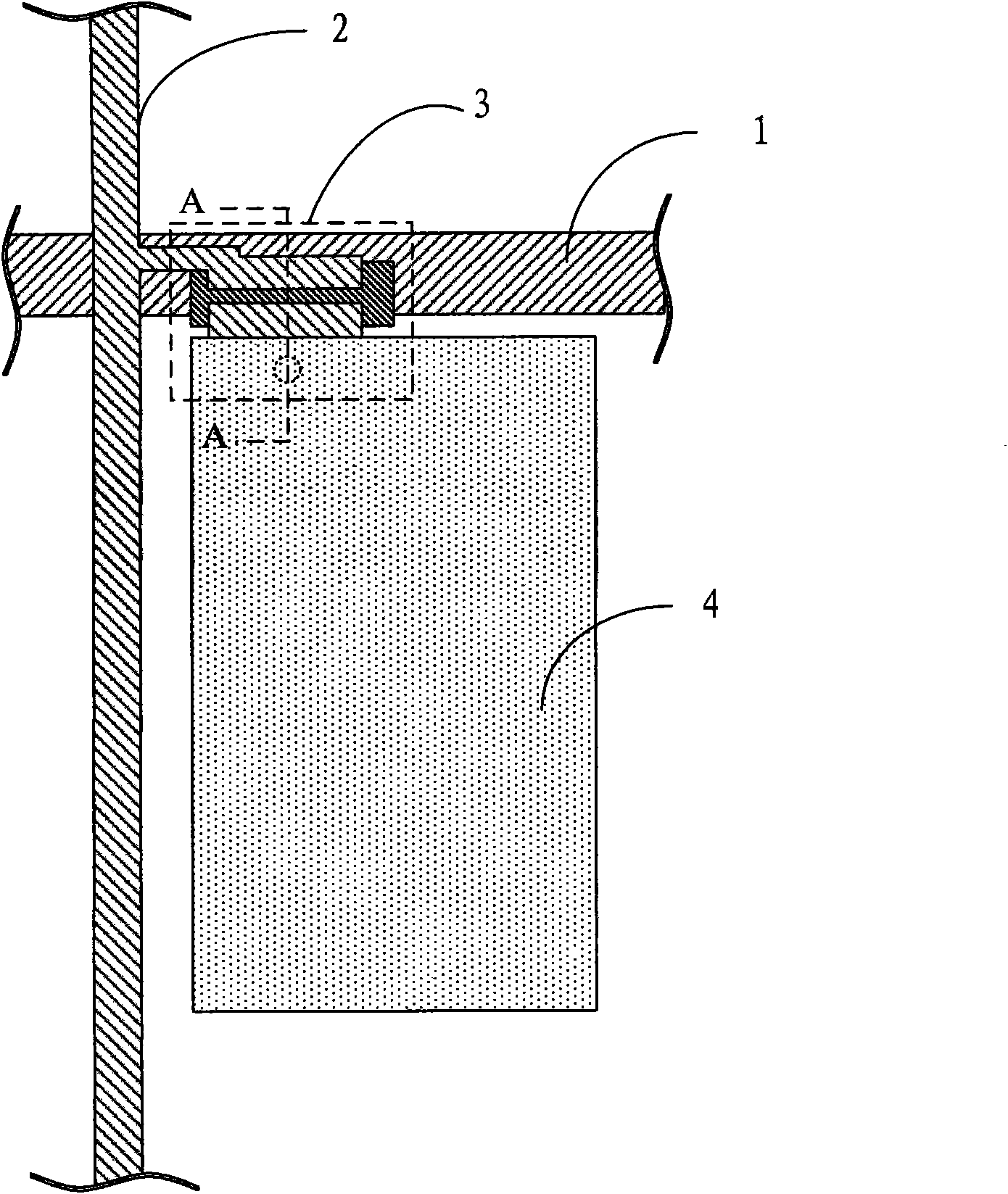

Thin film transistor liquid crystal display

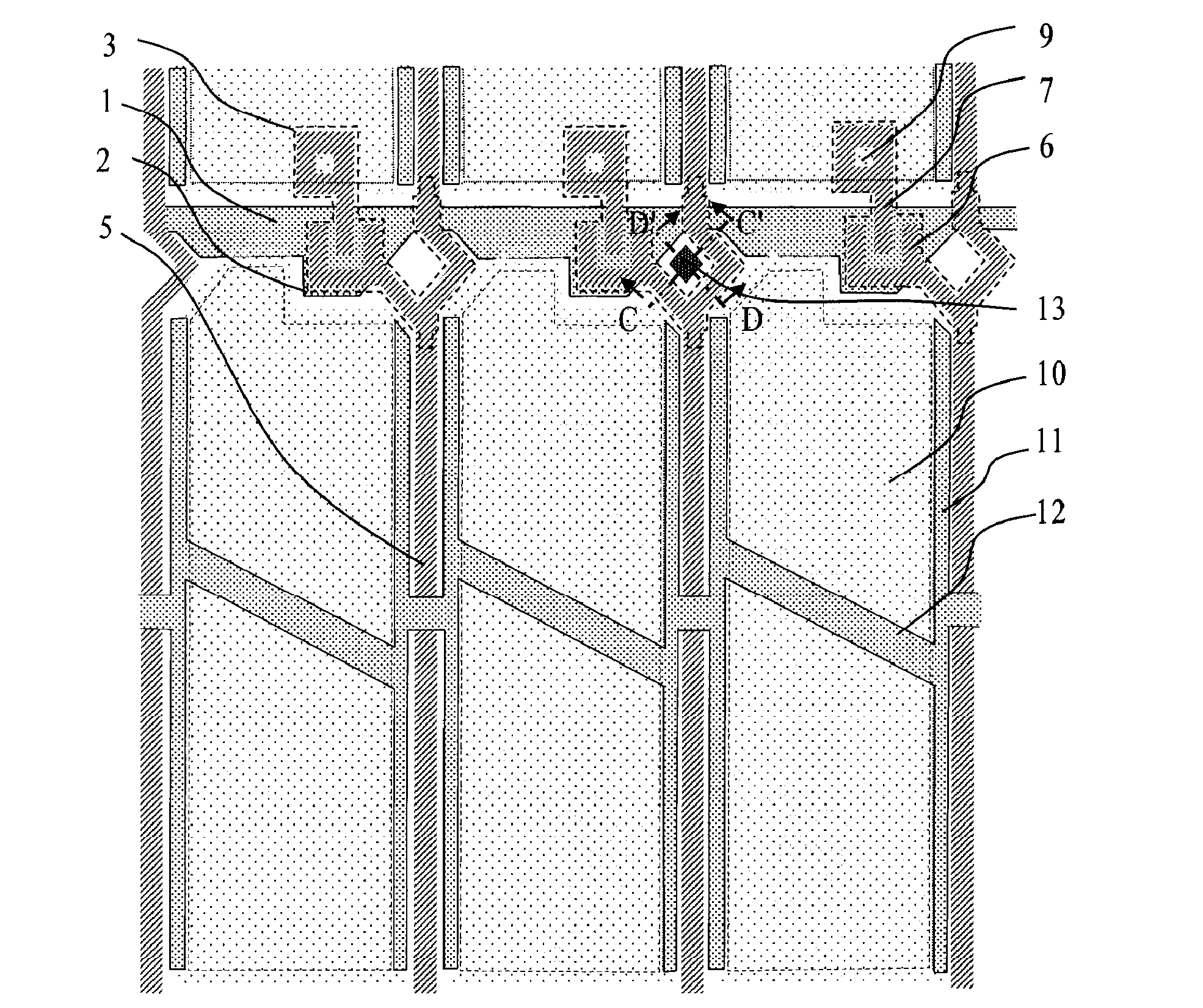

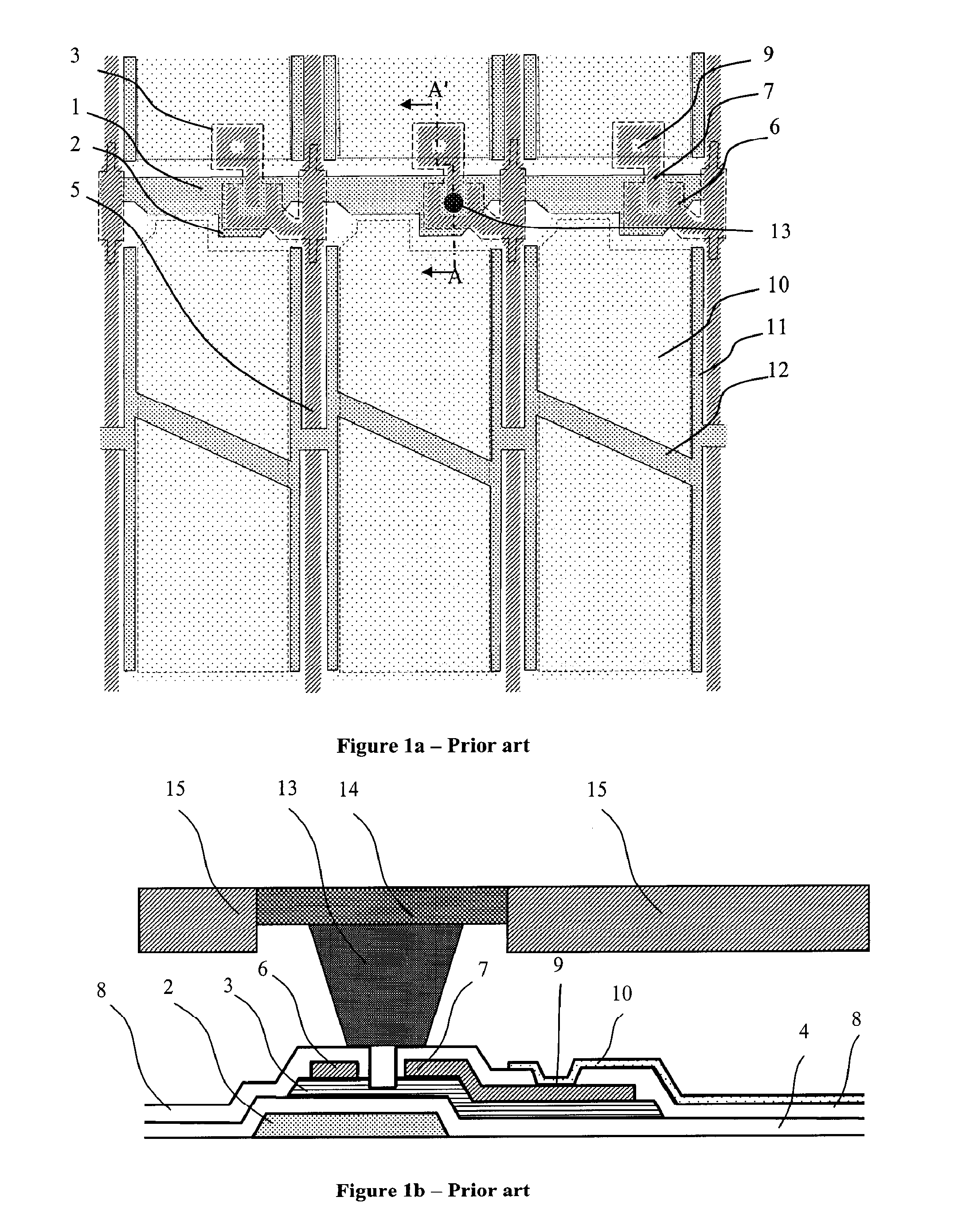

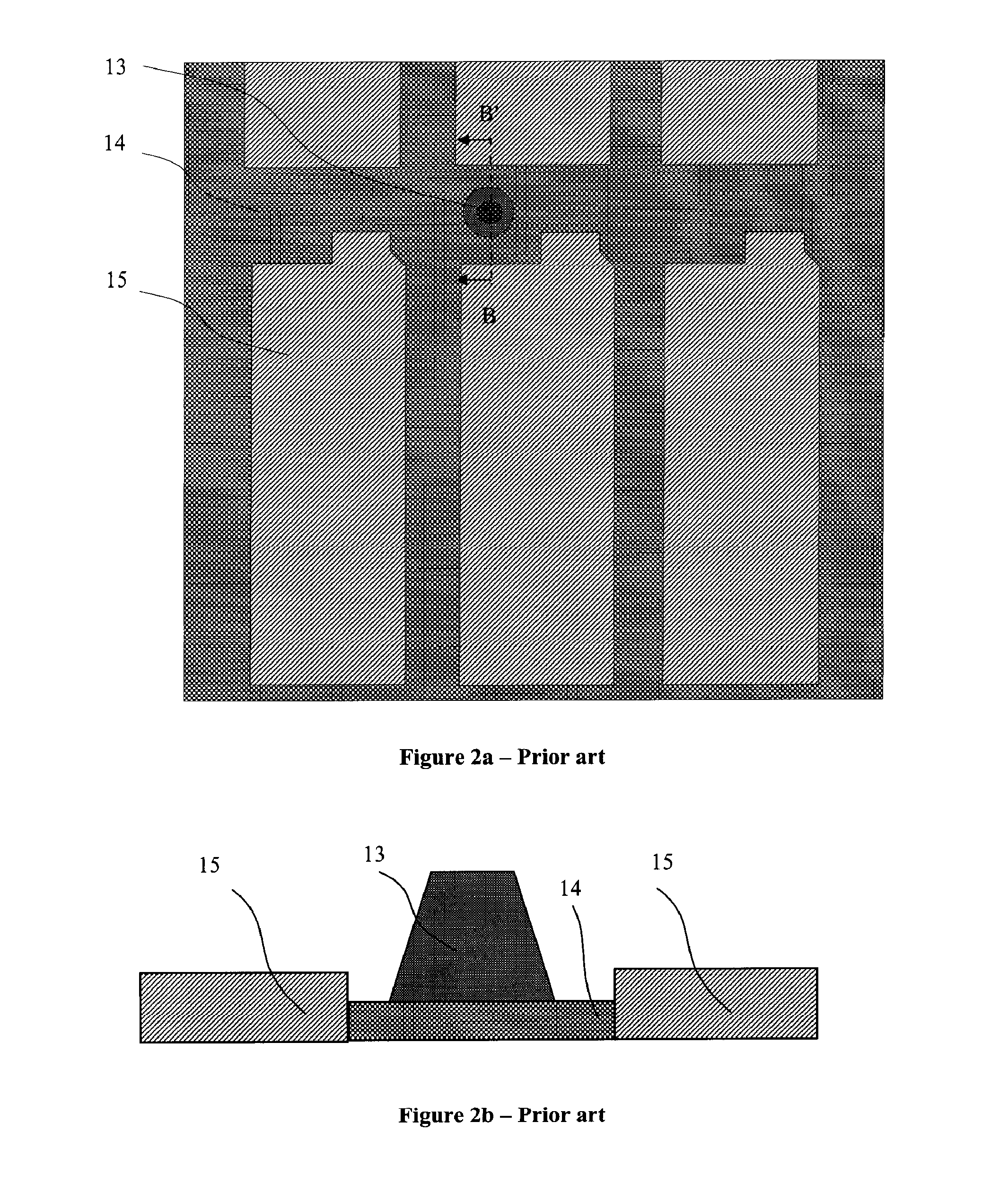

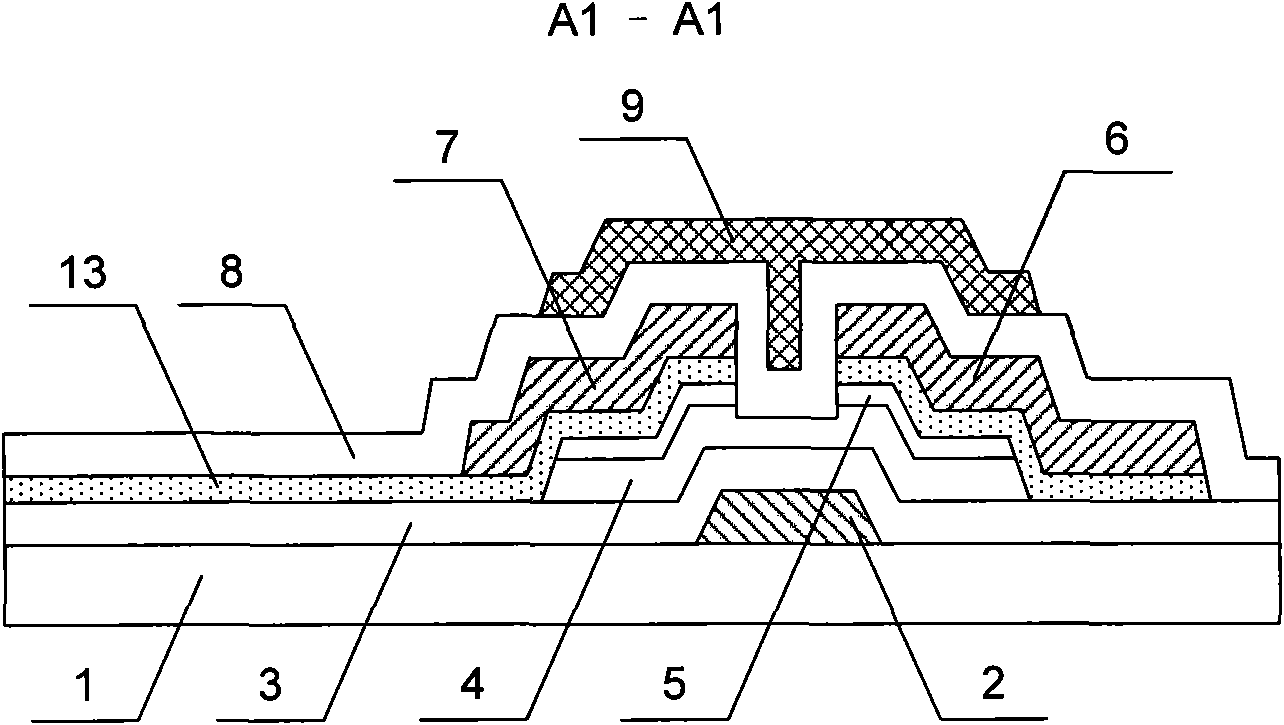

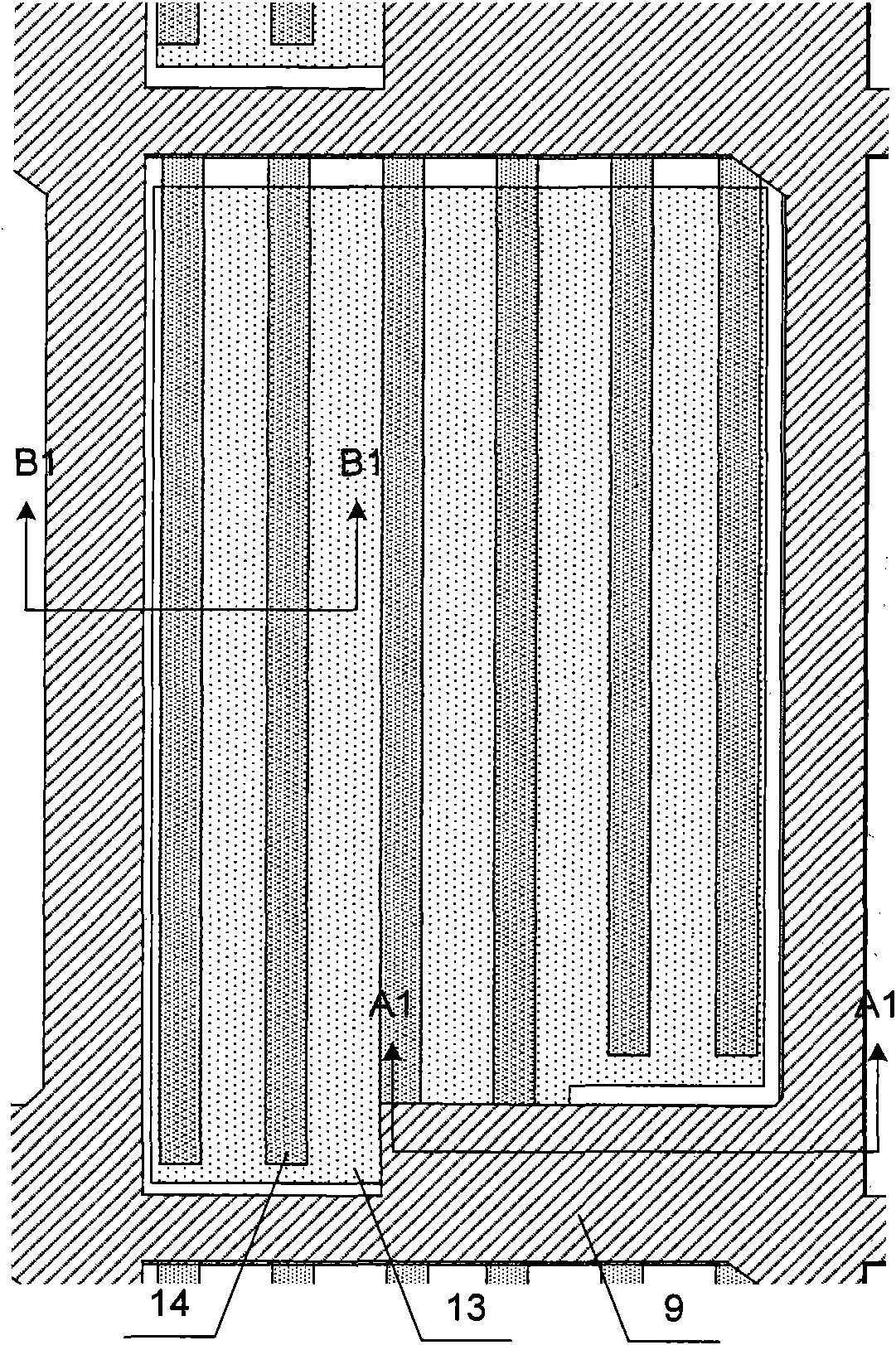

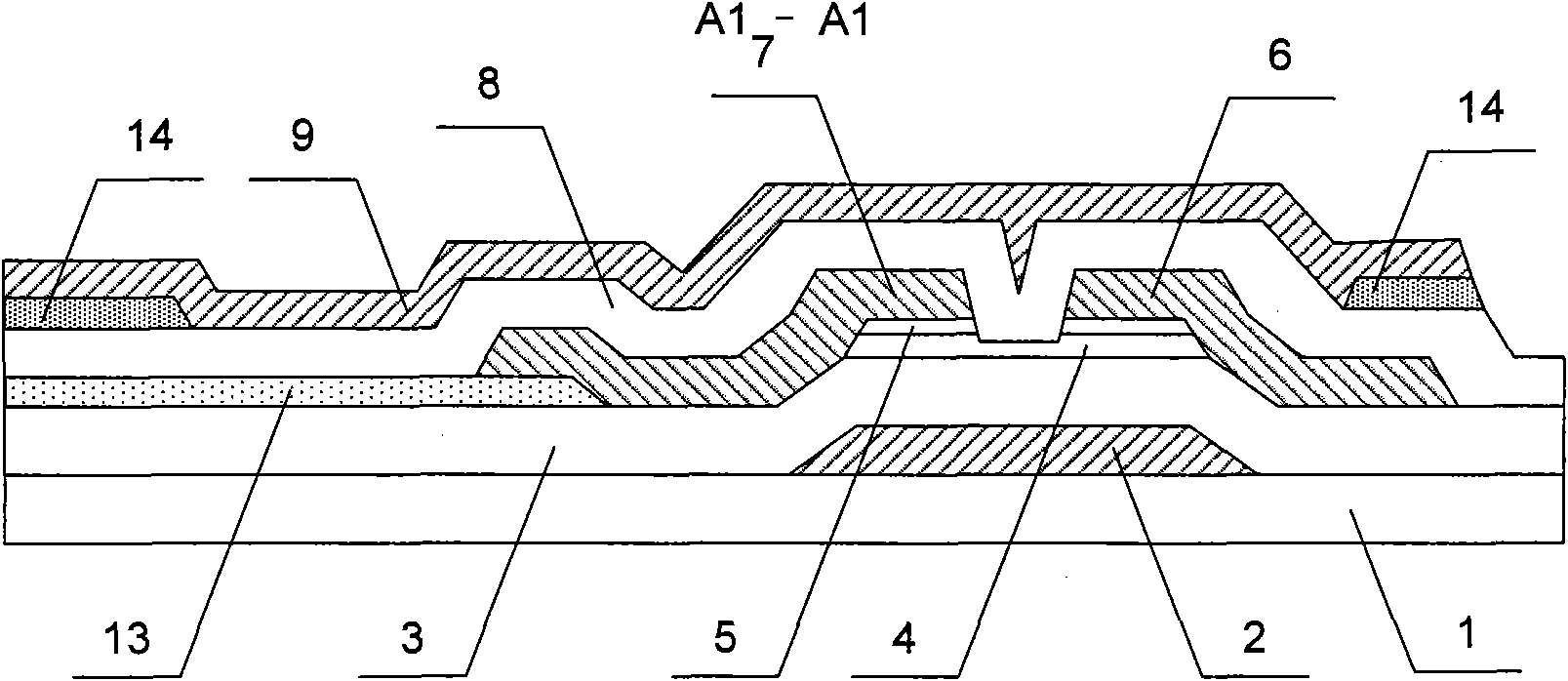

ActiveUS20080123007A1Stable configurationNon-linear opticsLiquid-crystal displayThin-film-transistor liquid-crystal display

A thin film transistor liquid crystal display (TFT LCD), including a TFT array substrate, a color filter substrate and a post spacer disposed between the TFT array substrate and the color filter substrate. The TFT array substrate includes a gate line, a data line, and a TFT disposed in a pixel area defined by the gate line and the data line crossing with each other, and the TFT comprises a source / drain electrode. The post spacer is located in a region at least partially surrounded by the source / drain electrode, the data line and the gate line.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

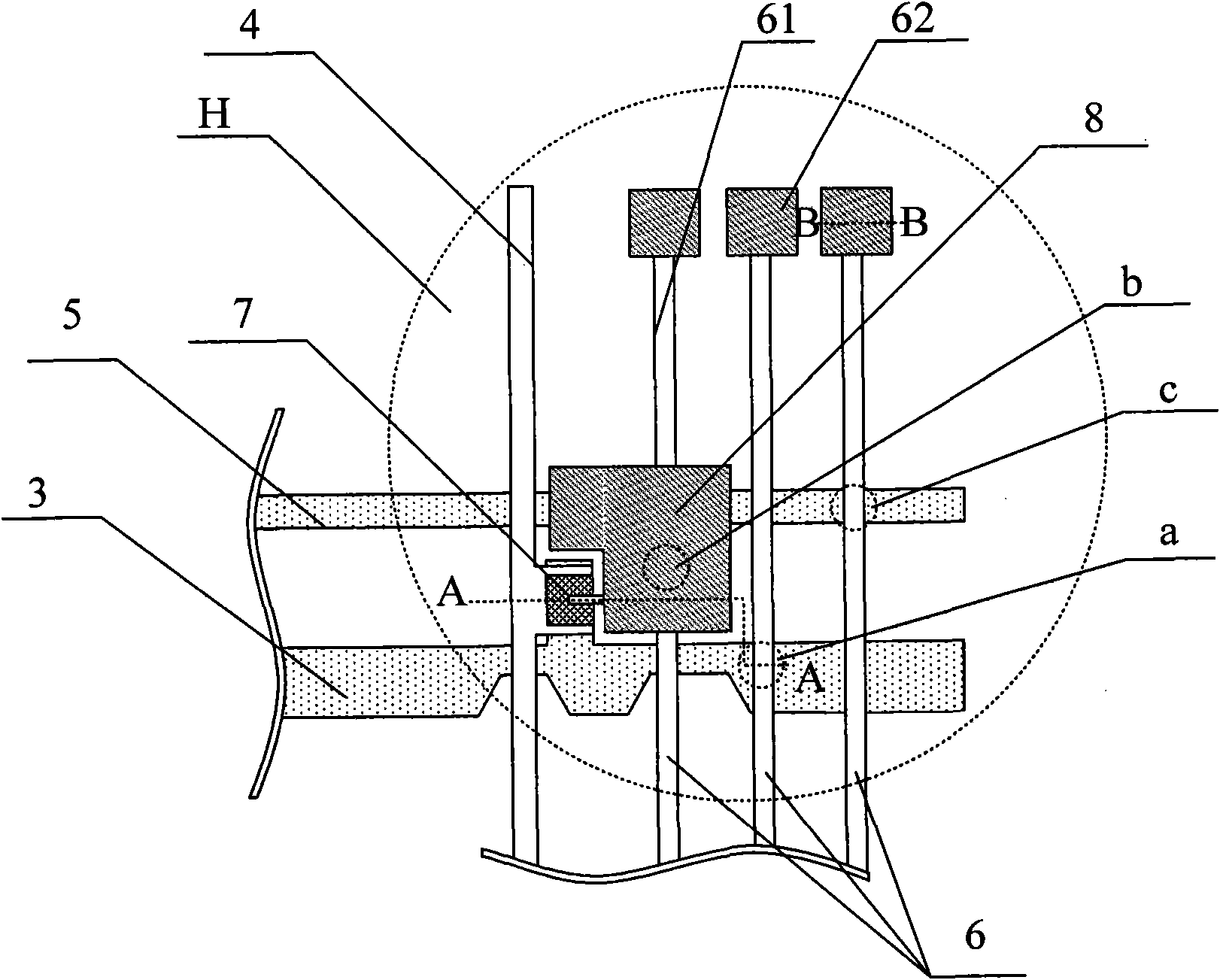

Array base board structure of thin film transistor liquid crystal display and its producing method

ActiveCN1987622ASimple manufacturing processImprove efficiencyTransistorStatic indicating devicesLiquid-crystal displayScan line

Through enlarging contact area between transparent pixel electrode and drain electrode of thin film transistor (TFT), structure of array base plate (ABP) of TFT LCD form favorable connection. The method for preparing ABP of TFT LCD includes three steps of photoetching technology with masks: first, using first ordinary mask defines pattern of first layer of metal thin film so as to form grid scan lines, and grid electrode; then, using second mask i.e. graytone, semitransparent mask defines patterns of second layer of metal thin film and active layer to form channels of data scan lines, silicon island, source / drain electrodes and TFT; finally, using third ordinary mask defines second layer of insulation film i.e. pattern of passive film, and using lift off stripping technique forms patterns of transparent conductive film, i.e. transparent pixel electrodes. The invention reduces number of mask, and number of photoetching process, and simplifies procedure for preparing ABP of TFT LCD.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

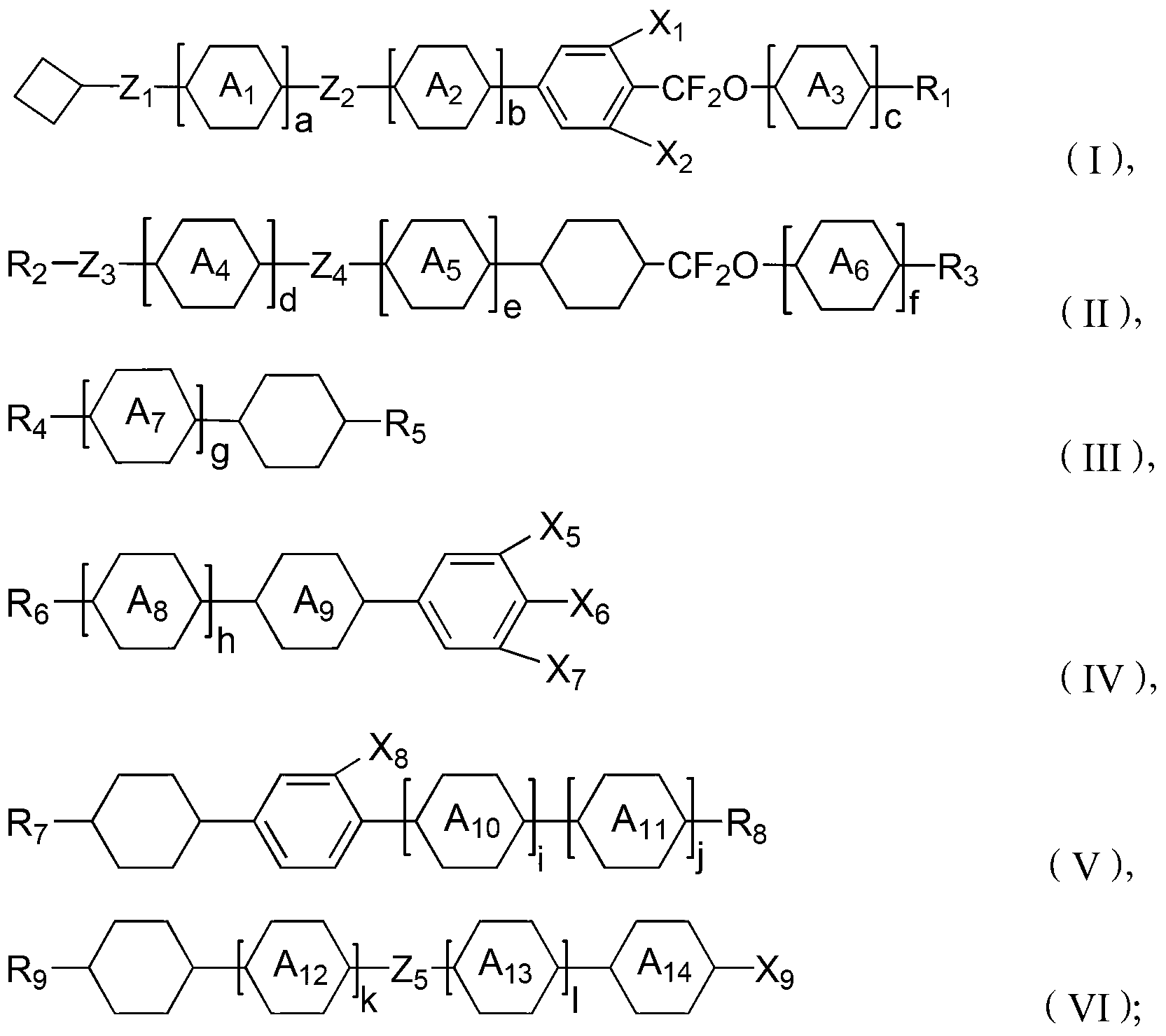

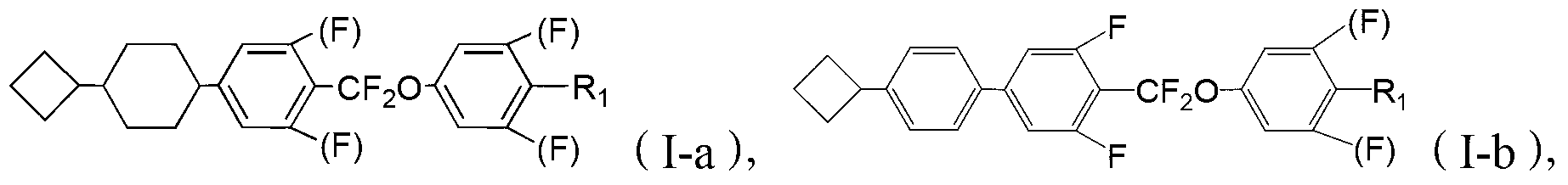

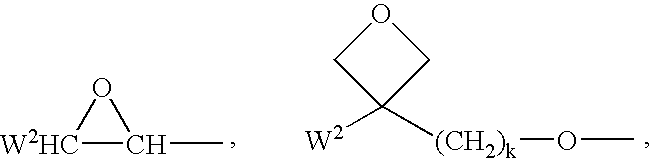

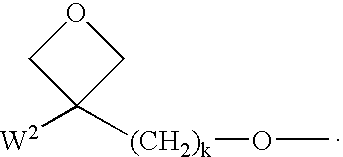

Liquid crystal composite containing difluorooxymethylene bridge polar monomer compound

ActiveCN103305231AQuick responseShort response timeLiquid crystal compositionsLiquid-crystal displayDisplay device

The invention discloses a liquid crystal composite containing a difluorooxymethylene bridge polar monomer compound. The liquid crystal composite comprises the following components in percentage by weight: 1%-40% of compounds shown in a general formula I, 1%-40% of compounds shown in a general formula II, 5%-70% of compounds shown in a general formula III, 1%-60% of compounds shown in a general formula IV, 0%-20% of compounds shown in a general formula V and 0%-20% of compounds shown in a general formula VI. The liquid crystal composite disclosed by the invention has the characteristics of high response speed, low driving voltage and high resistivity and voltage conservation rate, has the capability of improving the viewing angle of a liquid crystal display by heightening the pretilt angle of a liquid crystal in a display and is suitable for a fast-responsive TFT-LCD (Thin Film Transistor Liquid Crystal Display).

Owner:BEIJING CHENGZHI YONGHUA DISPLAY TECHNOLOGY CO LTD

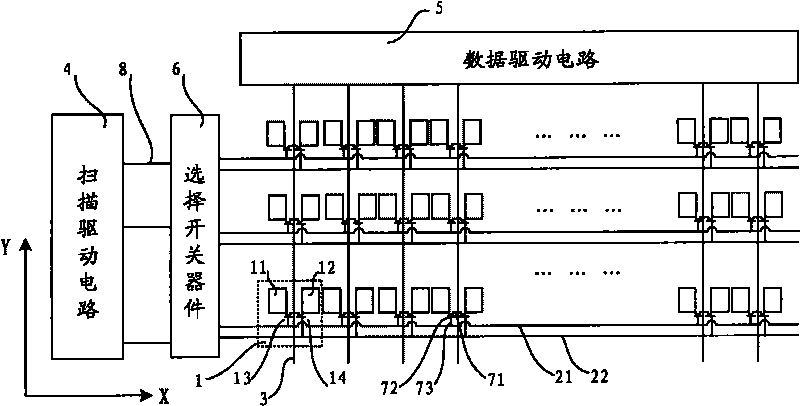

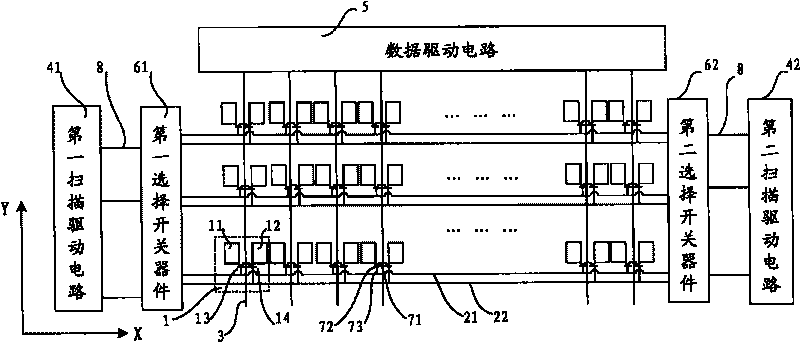

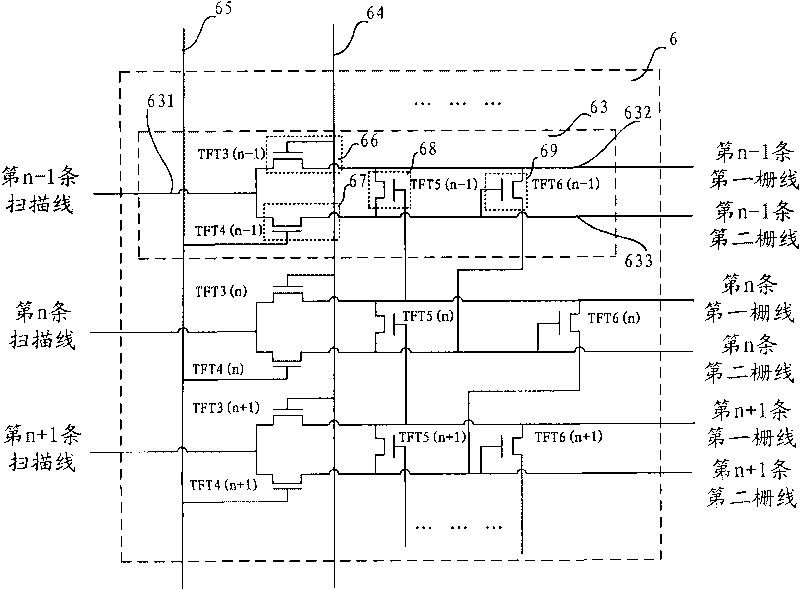

TFT-LCD (Thin Film Transistor Liquid Crystal Display) array base plate and drive method thereof

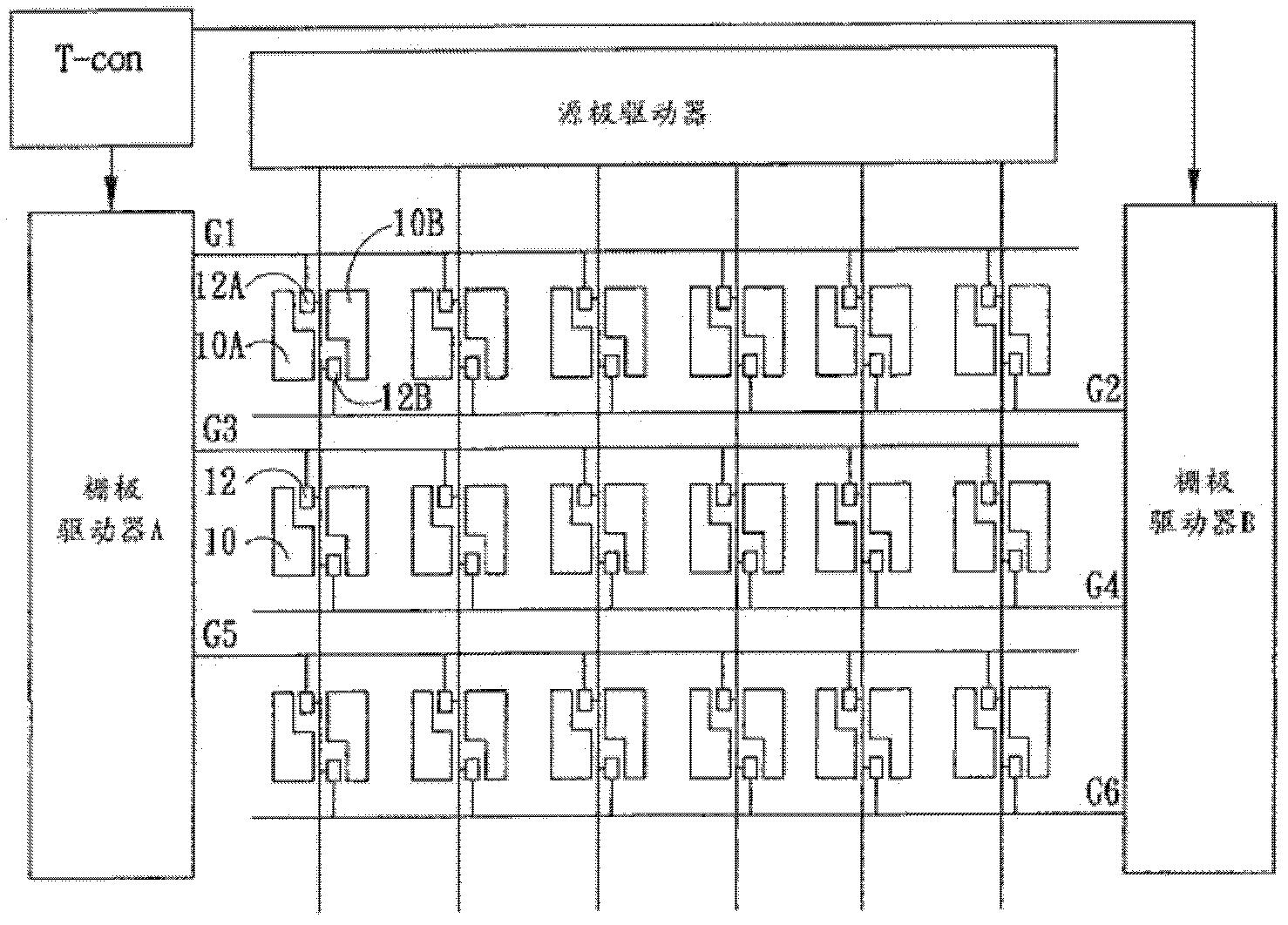

ActiveCN101762915AReduce manufacturing costIncrease widthStatic indicating devicesSolid-state devicesThin-film-transistor liquid-crystal displayEngineering

The invention relates to a TFT-LCD array base plate and a drive method thereof. The array base plate comprises a base plate, wherein the base pate is provided with pixel areas which are ranged in a matrix way; each pixel area is provided with a first pixel electrode, a first film transistor, a second pixel electrode and a second film transistor, the first pixel electrode and the first film transistor are positioned in an odd line, and the second pixel electrode and the second film transistor are positioned in an even line; a first grid line and a second grid line are arranged in each pixel area, the first grid line is connected with a grid electrode of the first film transistor, and the second grid line is connected with a grid electrode of the second film transistor; and a data line is arranged in each pixel area and respectively connected with a source electrode of the first film transistor and a source electrode of the second film transistor. The invention reduces the quantity of the data lines and data drive chips or pins thereof or reduces the quantity of the grid lines and scanning drive chips or pins thereof and lowers the production cost of a TFT-LCD.

Owner:BOE TECH GRP CO LTD +1

Polymerisable charge transport compounds

InactiveUS20040175638A1Facilitating intermolecular charge-hopping mechanismsHigh carrier mobilityLiquid crystal compositionsOrganic chemistryOrganic field-effect transistorDisplay device

The invention relates to polymerisable charge transport compounds, their use as semiconductors or charge transport materials, in optical, electrooptical or electronic devices like for example organic field effect transistors (FET or OFET) for thin film transistor liquid crystal displays and integrated circuit devices such as RFID tags, electroluminescent devices in flat panel displays, and in plotovoltaic and sensor devices, and to a field effect transistor, light emitting device or ID tag comprising the polymerisable charge transport compounds.

Owner:MERCK PATENT GMBH

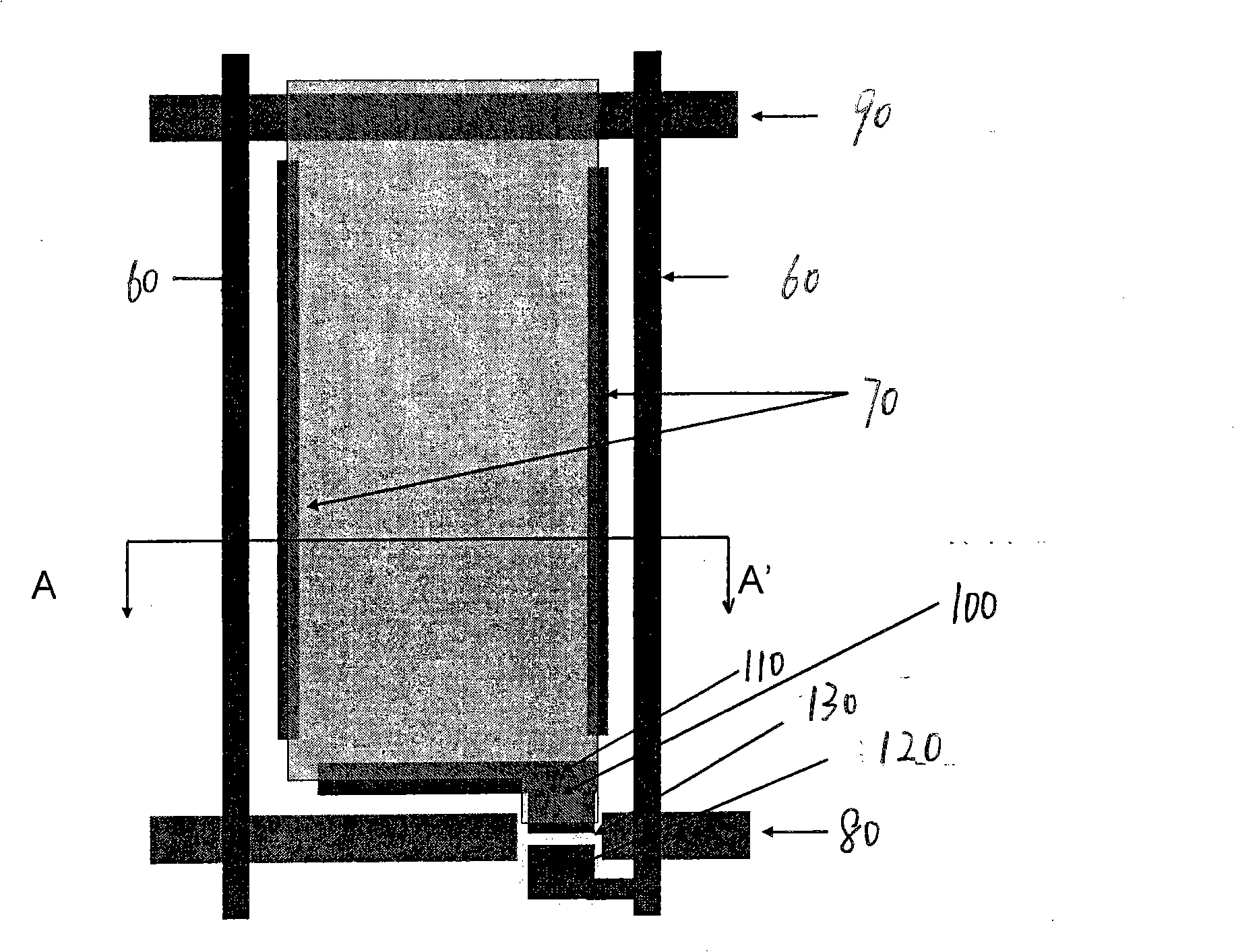

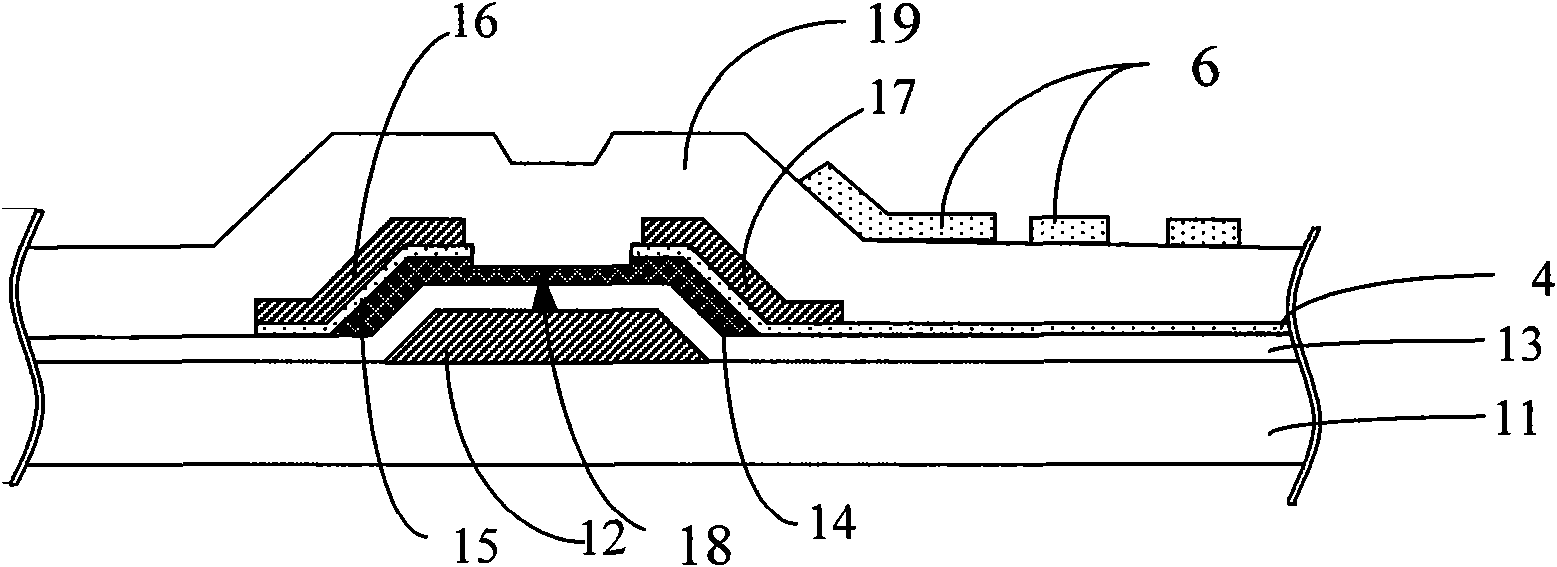

TFT-LCD (Thin Film Transistor Liquid Crystal Display) array base plate and manufacturing method thereof

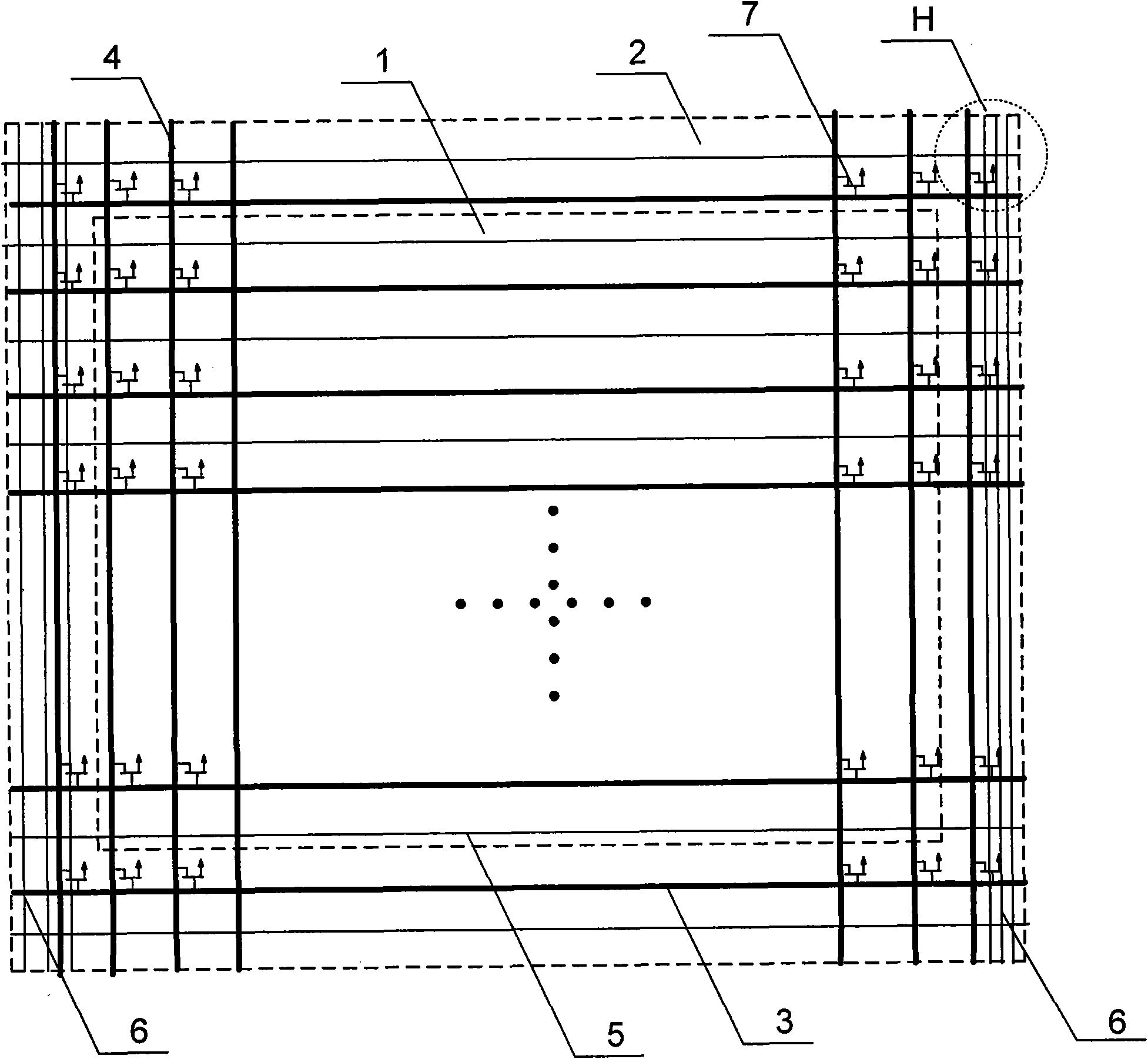

InactiveCN101887897AIncrease opening ratioIncrease display brightnessTransistorSolid-state devicesCapacitanceEngineering

The invention relates to a TFT-LCD (Thin Film Transistor Liquid Crystal Display) array base plate and a manufacturing method thereof. The array base plate comprises a grid line and a data line, wherein a pixel electrode and a thin film transistor are formed in a pixel region limited by the grid line and the data line, and a shielding layer is formed above a TFT channel region of the thin film transistor. The manufacturing method comprises the following steps of: depositing a grid metal thin film to form the figures of the grid line and a grid electrode; depositing a grid insulating layer, a semiconductor thin film and a doped semiconductor thin film to form the figure of an active layer; depositing a transparent conductive thin film and a source and drain metal thin film to form the figures of a pixel electrode, the data line, a source electrode, a drain electrode and the TFT channel region; and depositing a passivation layer and a shielding thin film to form the figures of the shielding layer, a grid line interface through hole and a data line interface through hole, wherein the shielding layer is positioned above the TFT channel region. The invention avoids the generation of leakage current under the condition of not increasing a production process and improves the size of capacitance storage in unit area.

Owner:BOE TECH GRP CO LTD +1

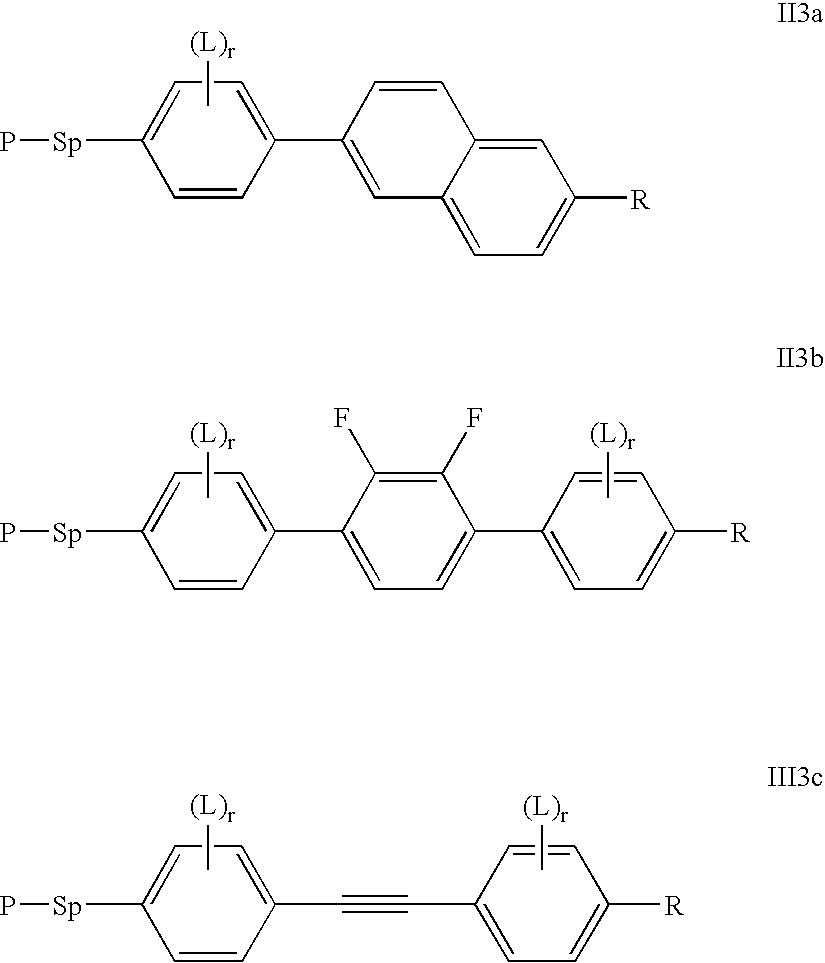

Resourceful treatment method of waste thin film transistor liquid crystal monitor

InactiveCN101690936ALow running costHigh recovery rateSolid waste disposalElectronic waste recyclingHazardous substanceFluorescence

The invention relates to a resourceful treatment method of waste thin film transistor liquid crystal monitors. The method comprises the following steps: sending liquid crystal display panels in a semi-sealed disassembly table to disassemble and remove mercury-containing fluorescent tubes so as to classify and separately recycle metal materials, plastics and glass and reach the aim of recycling resources; at the same time separating mercury-containing fluorescent tubes, organic polarizing film and liquid crystal and separately collecting and processing so as to realize the harmless and safe disposal of hazardous substances. The invention can be widely used for the resourceful recovery treatment of TFT-LCD computer monitors, LCD TVs and other liquid crystal products with similar structure and functions and is characterized by low operating cost and high recovery rate.

Owner:TSINGHUA UNIV

Thin film transistor liquid crystal display (TFT-LCD) array substrate and manufacturing method thereof

InactiveCN102156368AReduce widthImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingThin-film-transistor liquid-crystal displayEngineering

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate and a manufacturing method thereof. The array substrate comprises a grid line and data lines which are formed on a substrate and define a pixel region, wherein a pixel electrode, a TFT and common electrodes are formed in the pixel region. The array substrate also comprises a black matrix which is prepared from conductive film materials and is connected with the common electrodes. The manufacturing method comprises the following steps: forming a graph comprising the grid line, the data lines, the pixel electrode and the TFT; and forming a graph comprising the common electrodes and the black matrix. The array substrate and the manufacturing method have the following beneficial effects: the black matrix can not only effectively shelter the light leakage region but also serve as the connection bus of the common electrodes by arranging the graph comprising the black matrix on the array substrate and connecting the black matrix with the common electrodes, thus effectively overcoming the technical defects of high production cost of the existing structure and common electrode delay.

Owner:BOE TECH GRP CO LTD +1

Array substrate and display device

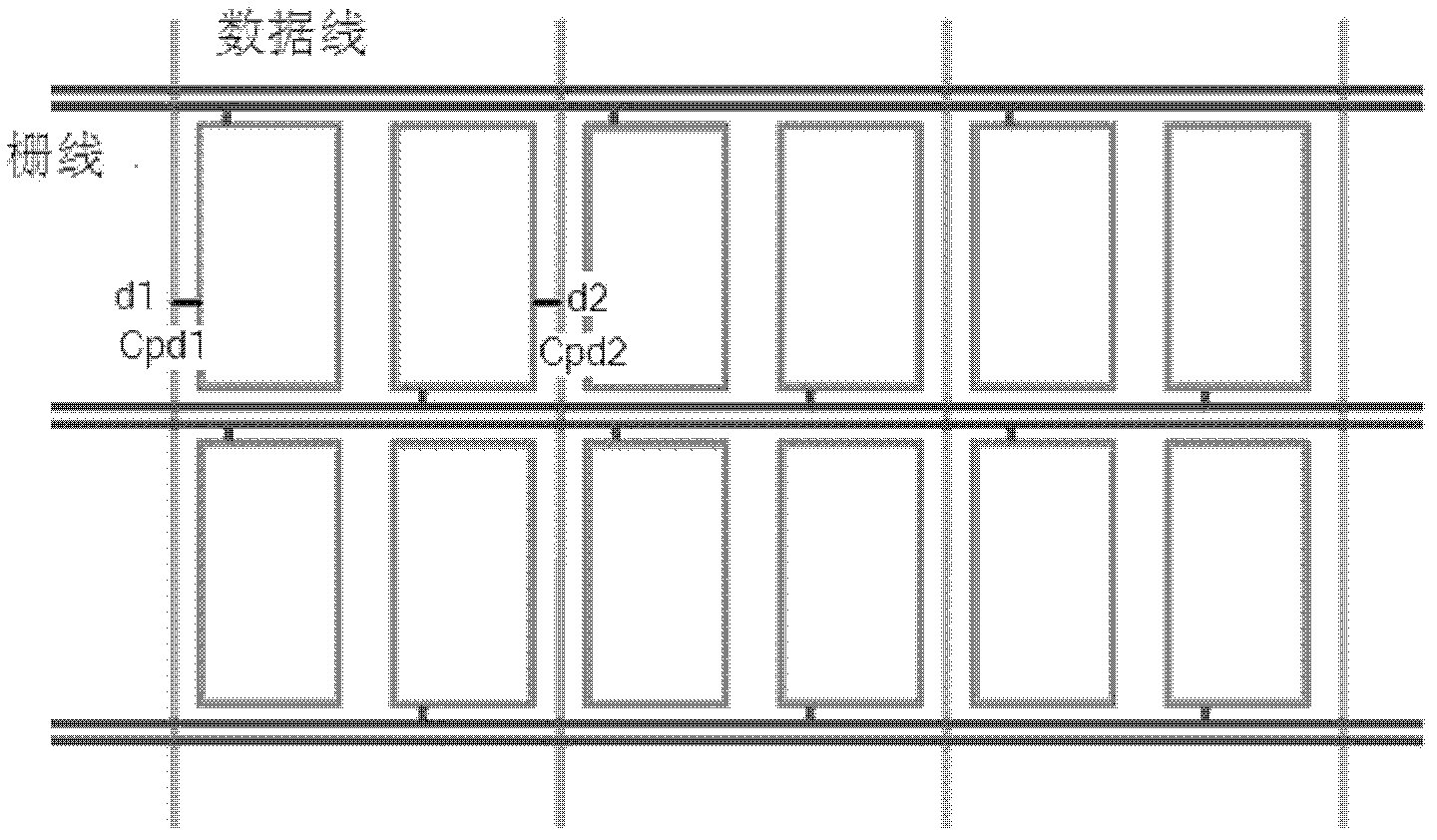

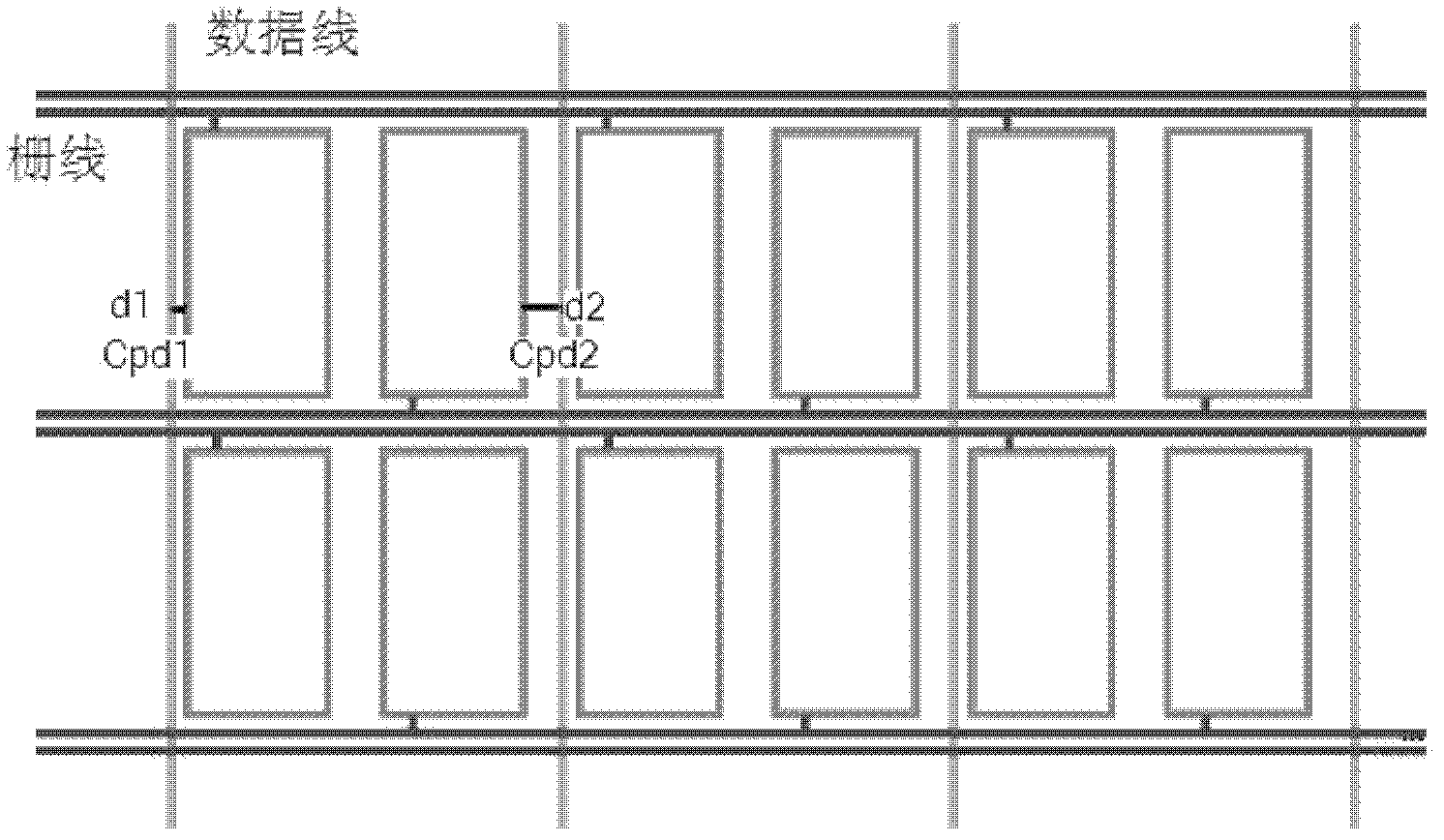

InactiveCN102629053AUnbalanced effects can be balancedNarrow frameStatic indicating devicesSolid-state devicesDisplay deviceThin-film-transistor liquid-crystal display

The invention discloses an array substrate and a display device, and relates to the technical field of TFT-LCDs (Thin Film Transistor Liquid Crystal Display). The array substrate comprises an active pixel region and a terminal region; the active pixel region comprises pixel units, grid lines, data lines and grid electrode leads; and two rows of pixel units are arranged between each two adjacent data lines. The array substrate is characterized in that each grid electrode lead is arranged between each two rows of pixel units; the grid electrode leads are correspondingly connected with the grid lines. According to the array substrate and the display device comprising the same, which are disclosed by the invention, the grid electrode leads are arranged in the active pixel region, so that the unbalanced influence of the data lines on pixels can be balanced and a border is narrowed.

Owner:BOE TECH GRP CO LTD +1

FFS (Fringe Field Switching) type TFT-LCD (Thin Film Transistor Liquid Crystal Display) array substrate and manufacturing method thereof

ActiveCN101957529AEtching precisionGuaranteed parametersSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayComposition process

The invention discloses an FFS (Fringe Field Switching) type TFT-LCD (Thin Film Transistor Liquid Crystal Display) array substrate and a manufacturing method thereof. The method comprises the following steps of: depositing a first metal film on a transparent substrate, and forming a pattern comprising a grid line, a grid electrode and a common electrode line through a first pattern composition process; depositing a grid insulating layer, an active layer film and a second metal film, and retaining the active layer film and the second metal film in a data line region, a source electrode region,a drain electrode region and a TFT channel region through a second pattern composition process; depositing a first transparent conducting film, and forming a pattern comprising a source electrode, a drain electrode, a TFT channel and a pixel electrode through a third pattern composition process; and depositing a passivation layer, forming a pattern comprising a connecting hole through a fourth pattern composition process, carrying out photoresist ashing process, depositing a second transparent conducting layer, and forming a pattern comprising a common electrode through an off-ground stripping process. The invention can reduce the excessive etching degree of the TFT channel and can ensure the display performance of a liquid crystal display.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com