Thin film transistor liquid crystal display (TFT-LCD) array substrate as well as manufacturing method and test method thereof

A technology of array substrate and manufacturing method, which is applied in the field of TFT-LCD array substrate and its manufacturing and testing, can solve problems such as inability to test signals in the liquid crystal panel, achieve the effect of enhancing the test analysis method and improving the comprehensive analysis ability

Active Publication Date: 2010-07-07

BOE TECH GRP CO LTD +1

View PDF0 Cites 45 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a TFT-LCD array substrate and its manufacturing method and testing method. By addin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

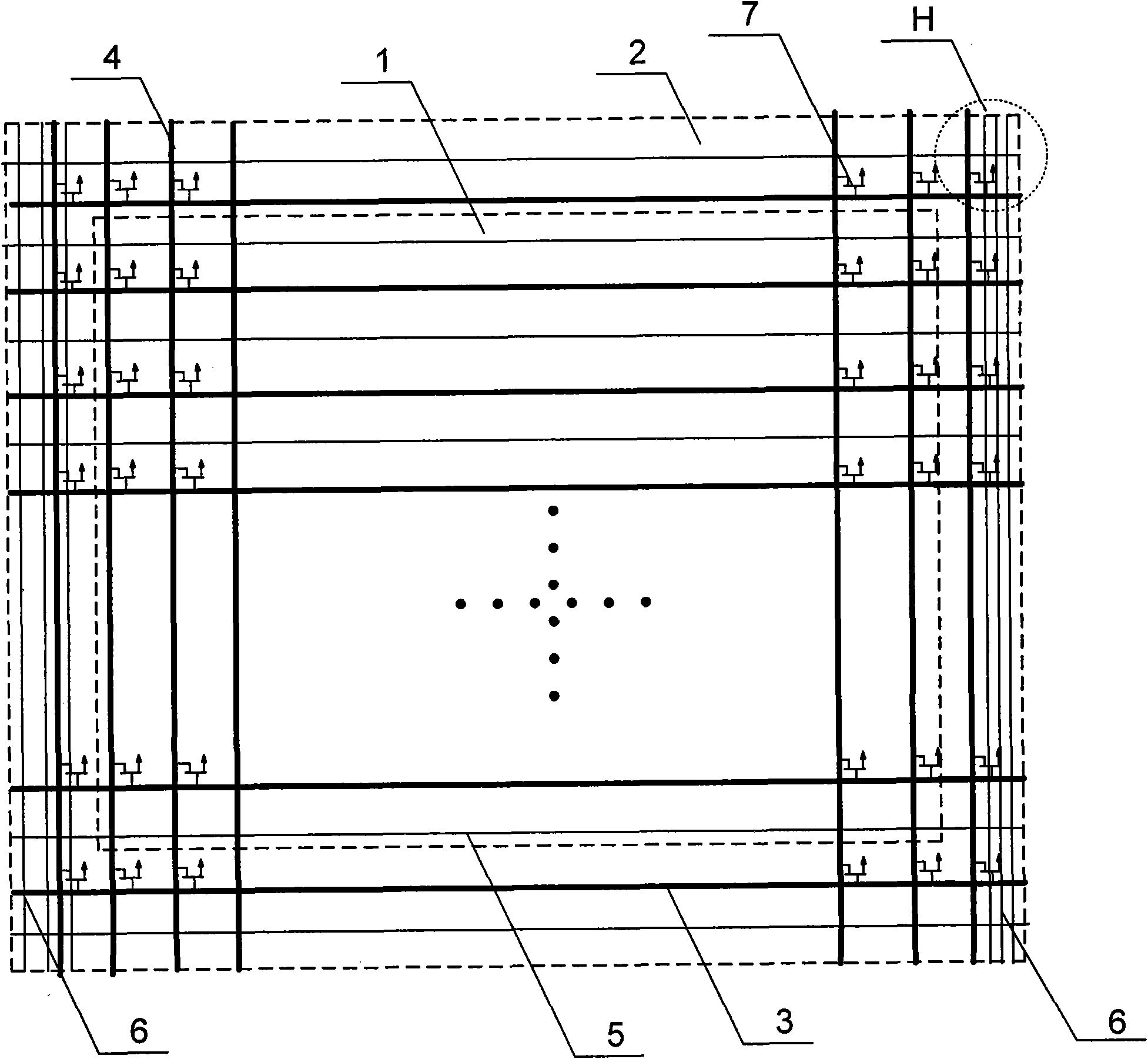

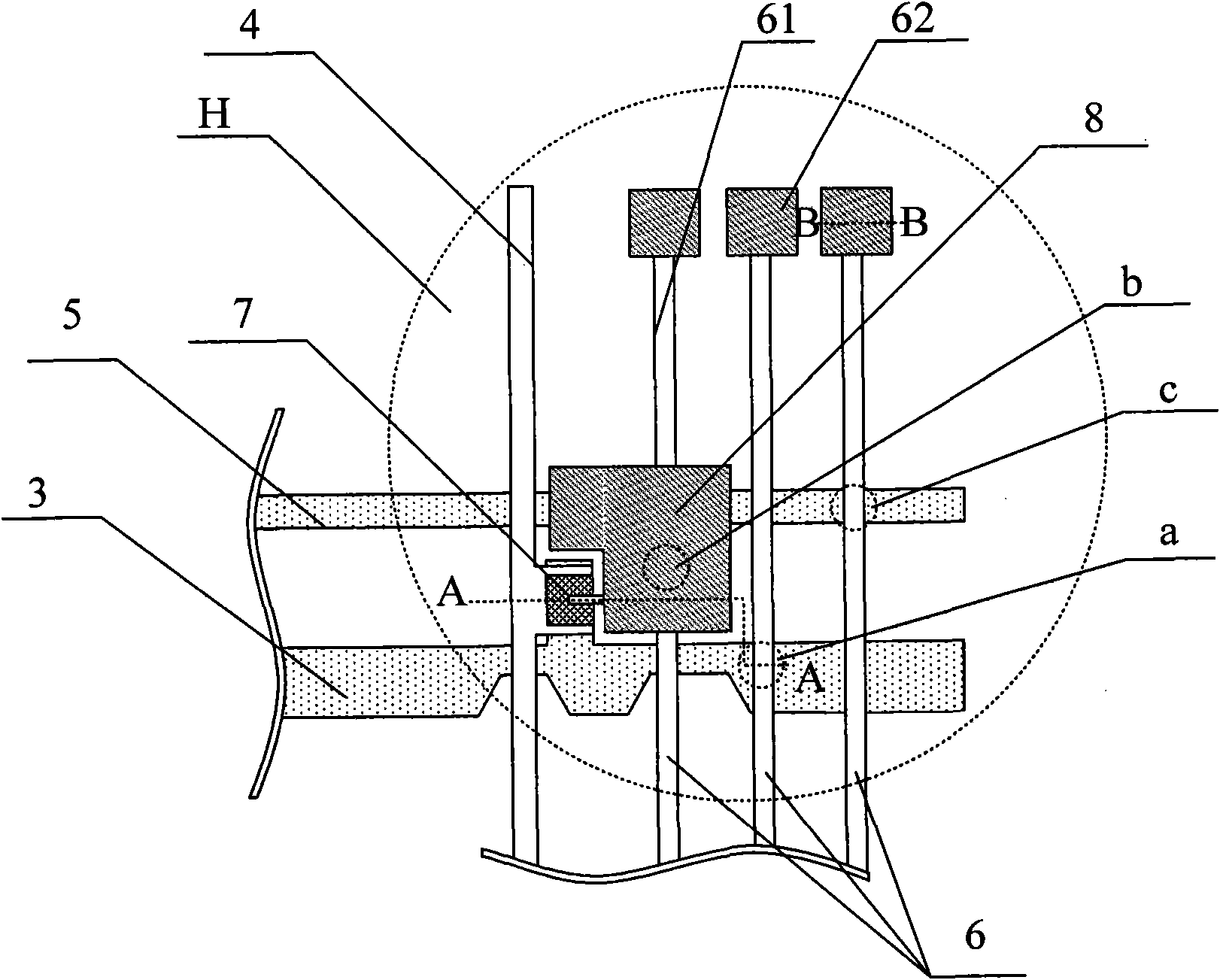

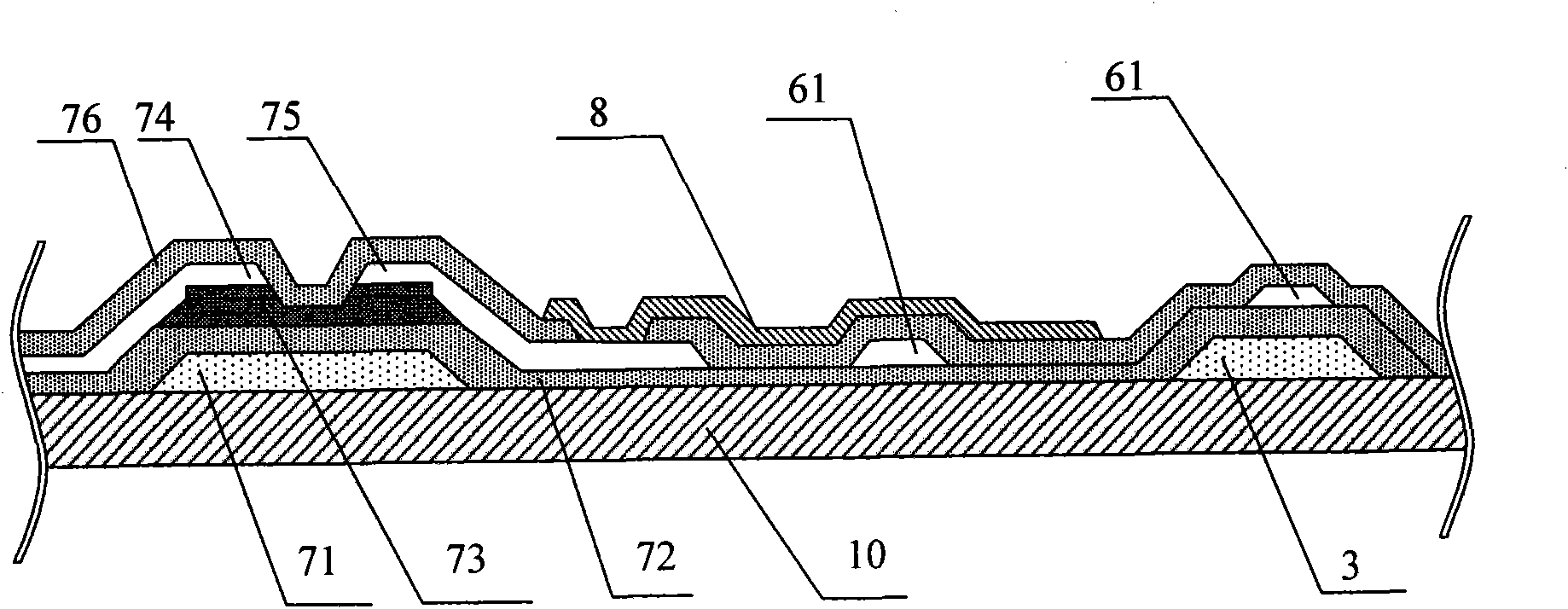

The invention relates to a thin film transistor liquid crystal display (TFT-LCD) array substrate as well as a manufacturing method and a test method thereof. TheTFT-LCD array substrate comprises a display area and a peripheral area, wherein the peripheral area is internally provided with at least one first testing line and/or at least one second testing line; the first testing lines are parallel to data lines; gate lines and/or pixel electrodes are overlapped with the at least one first testing line; the second testing lines are parallel to the gate lines; and the data lines are overlapped with the at least one second testing line. The invention effectively overcomes the technical defect that a signal inside a liquid crystal display panel can not be tested in the prior art by installing the test lines in the peripheral area.

Description

technical field [0001] The invention relates to a liquid crystal display device and its manufacturing method and testing method, in particular to a TFT-LCD array substrate and its manufacturing method and testing method. Background technique [0002] The main structure of Thin Film Transistor Liquid Crystal Display (hereinafter referred to as: TFT-LCD) includes a liquid crystal panel, a backlight and a driving circuit board. Finish. The liquid crystal panel is an opto-mechanical unity, and its basic principle is to use the electric field formed in the liquid crystal panel to control the deflection of the liquid crystal molecules, so that it produces different transmitted light under different electric fields. As a unified whole, it can be considered that the liquid crystal panel is the load of the driving circuit, and the liquid crystal molecules are the load of the electric field formed in the liquid crystal panel, and the three are a unified whole. [0003] The array sub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02F1/1362G02F1/13H01L21/84H01L27/12

Inventor 赵继刚徐宇博

Owner BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com