LCD and making method thereof

A technology of liquid crystal display and thin film transistor, which is applied in the direction of optics, instruments, electrical components, etc., can solve the problems of reducing the aperture ratio of the display unit, and achieve the effect of reducing the number of cross points, reducing the distance, and increasing the aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

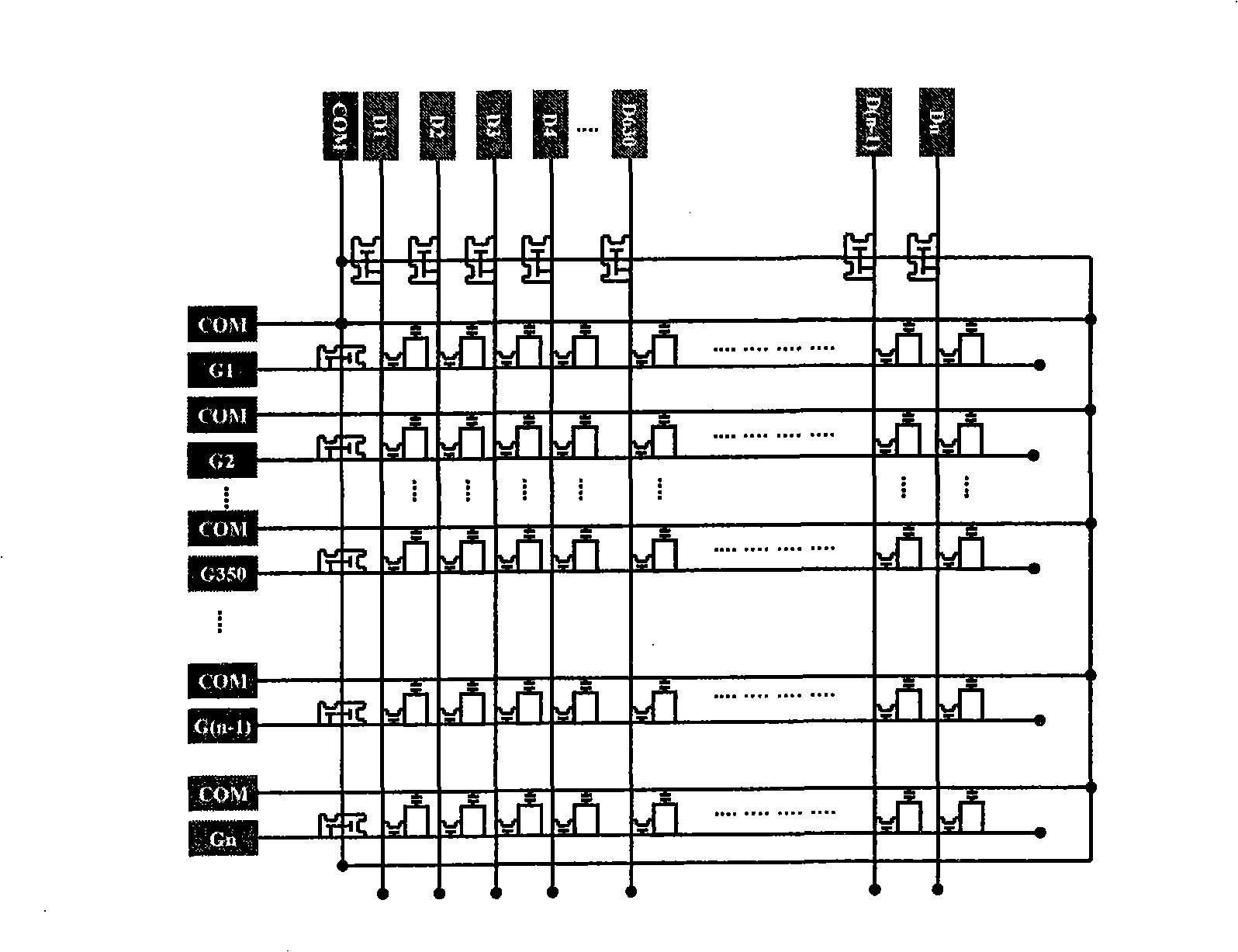

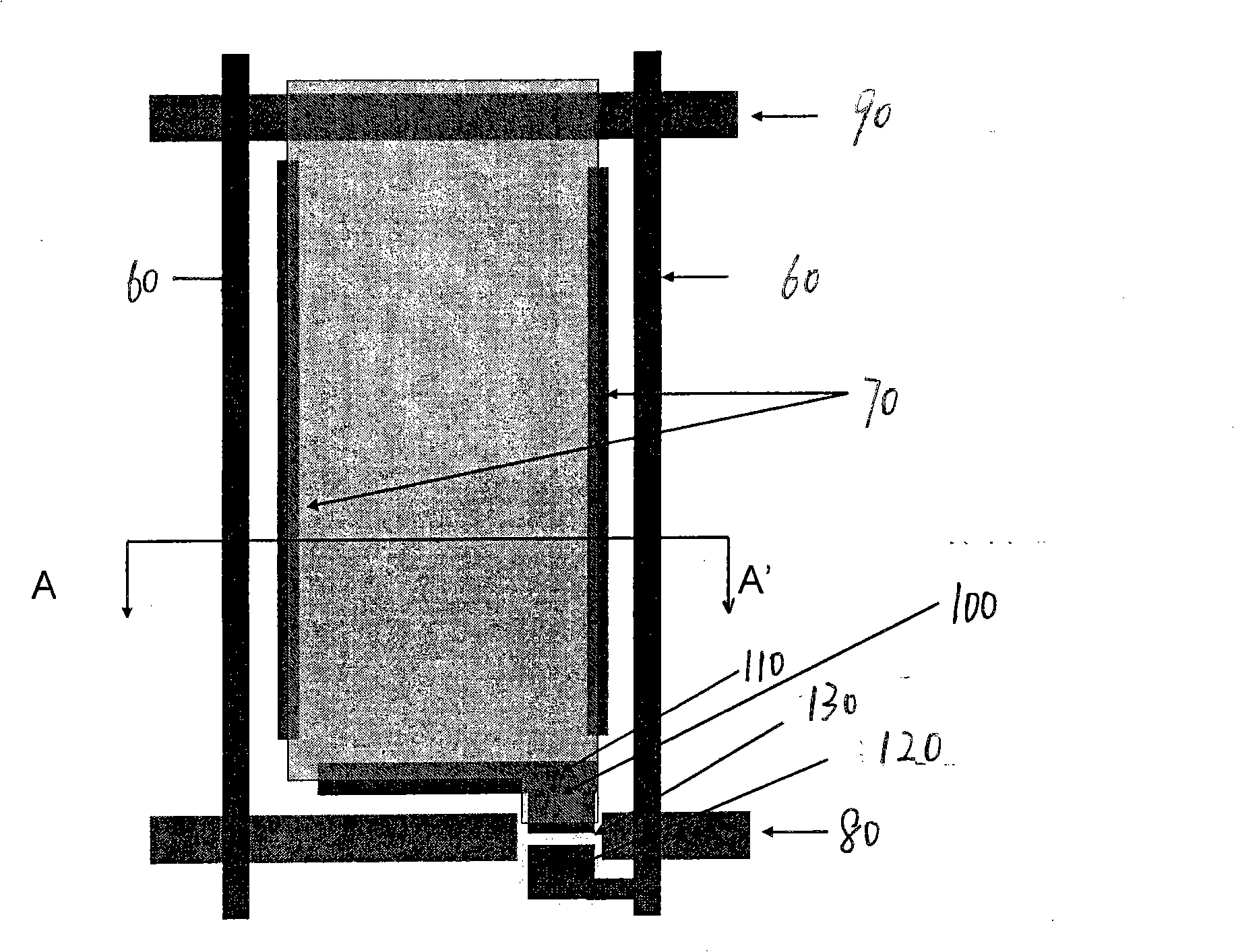

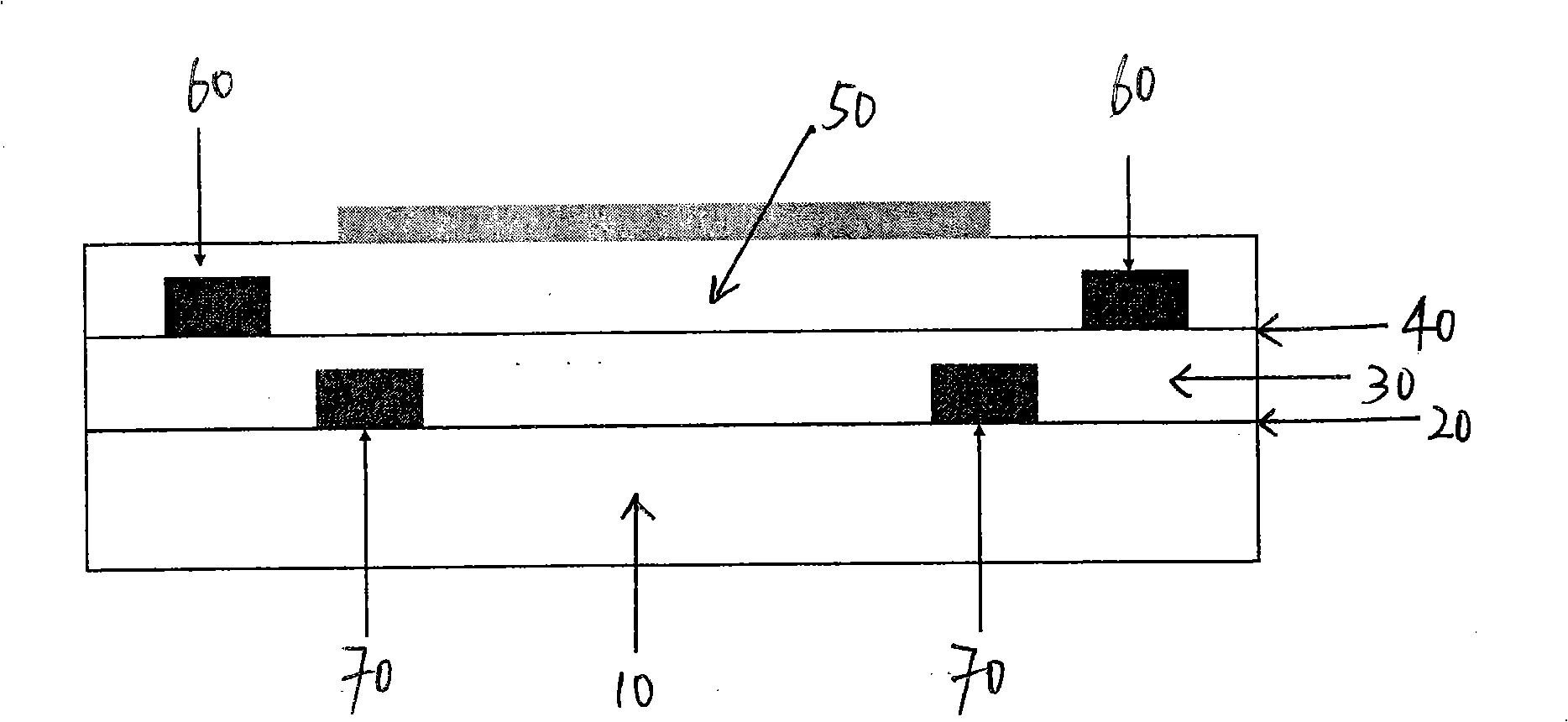

[0043] Figure 4 A schematic diagram of the structure of the array substrate of the present invention is given. Such as Figure 4 As shown, there are two kinds of metal layers on the array substrate of the TFT LCD. The first metal layer forms a group of gate scanning lines, and the second metal layer forms a group of data lines and common electrode lines arranged parallel to each other and perpendicular to the gate scanning lines. Connected scan lines and data lines define display elements within the display area. The potential of the gate scanning line is introduced by the terminal part (formed by the first metal layer) on the left side of the array substrate, the potential of the data line is introduced by the terminal part (formed by the second metal layer) on the upper side of the array substrate, and the common electrode line Potentials are simultaneously introduced from the upper and lower sides of the array substrate. On the upper side of the array substrate, the co...

Embodiment 2

[0057] In addition to the above-mentioned array substrate structure, the following different structural designs can also be implemented on the basis of the above structure according to actual needs.

[0058] Such as Figure 6 As shown, the common electrode potential is guided to the opposite side of the data line terminal from the data line terminal module through the first layer of metal. Then lead the potential of the common electrode on the first layer of metal to the common electrode line formed by the second layer of metal in the display area through the contact hole. The contact hole is composed of a via hole on the first metal layer, a via hole on the second metal layer, and a transparent conductive layer respectively covering the two via holes.

Embodiment 3

[0060] Such as Figure 7 As shown, the common electrode lines 9 parallel to the data lines can be placed in the center of the display unit in addition to being placed on one side of the display unit. This design can reduce the interference between the data line and the common electrode line, and reduce the probability of short circuit on the same layer that may be caused between the data line and the common electrode line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com