Patents

Literature

31 results about "Lift-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lift-off process in microstructuring technology is a method of creating structures (patterning) of a target material on the surface of a substrate (e.g. wafer) using a sacrificial material (e.g., Photoresist). It is an additive technique as opposed to more traditional subtracting technique like etching. The scale of the structures can vary from the nanoscale up to the centimeter scale or further, but are typically of micrometric dimensions.

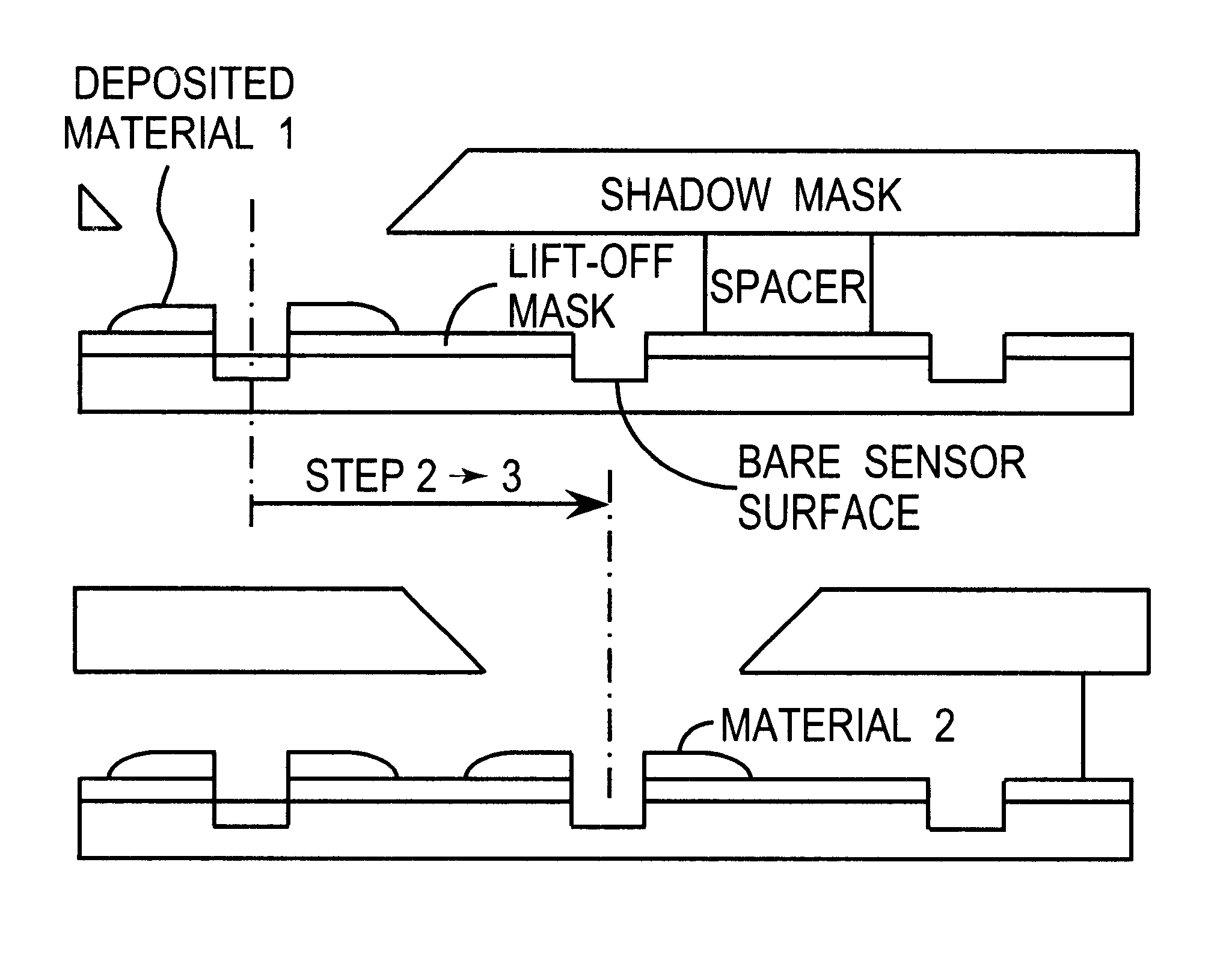

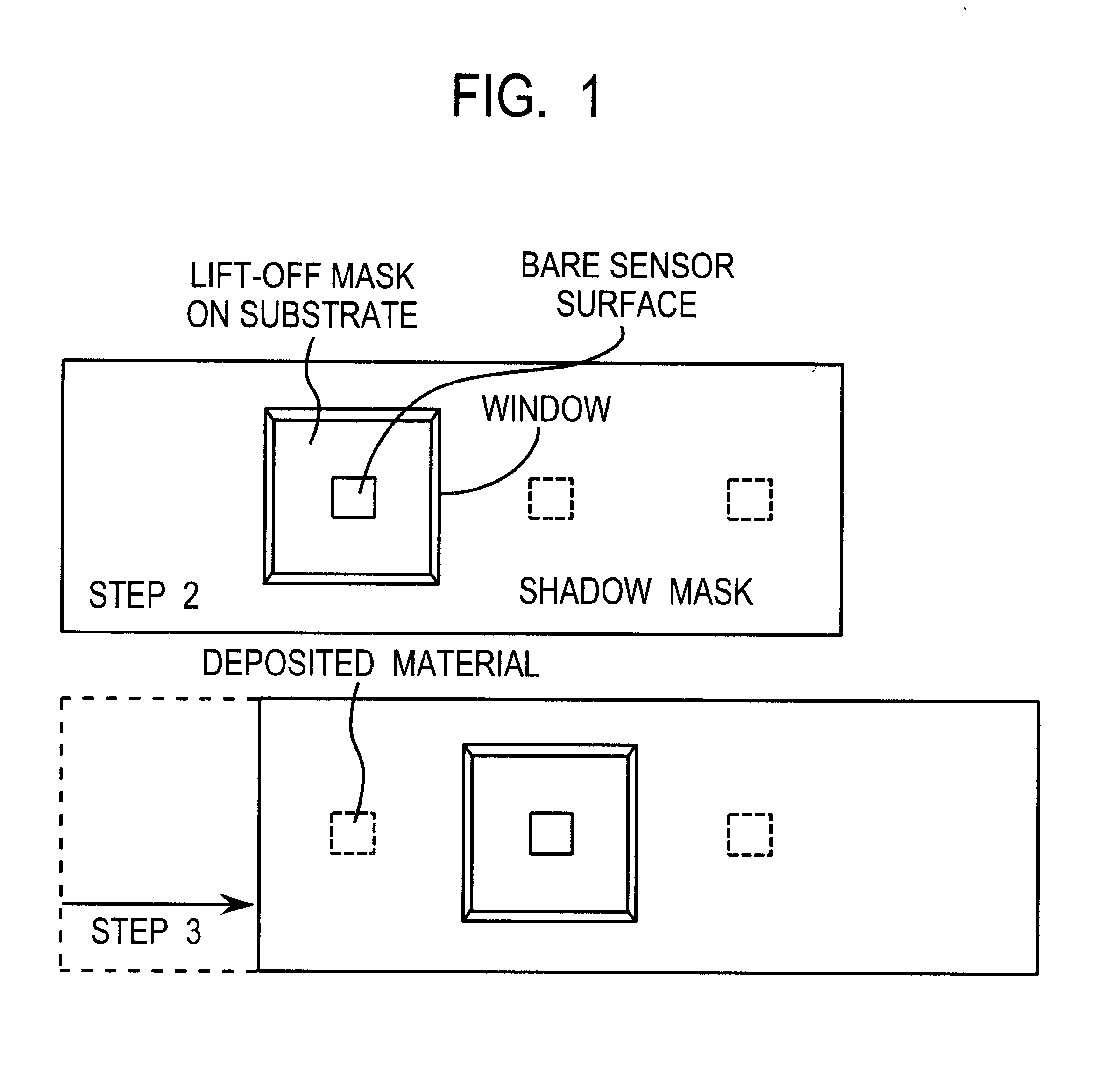

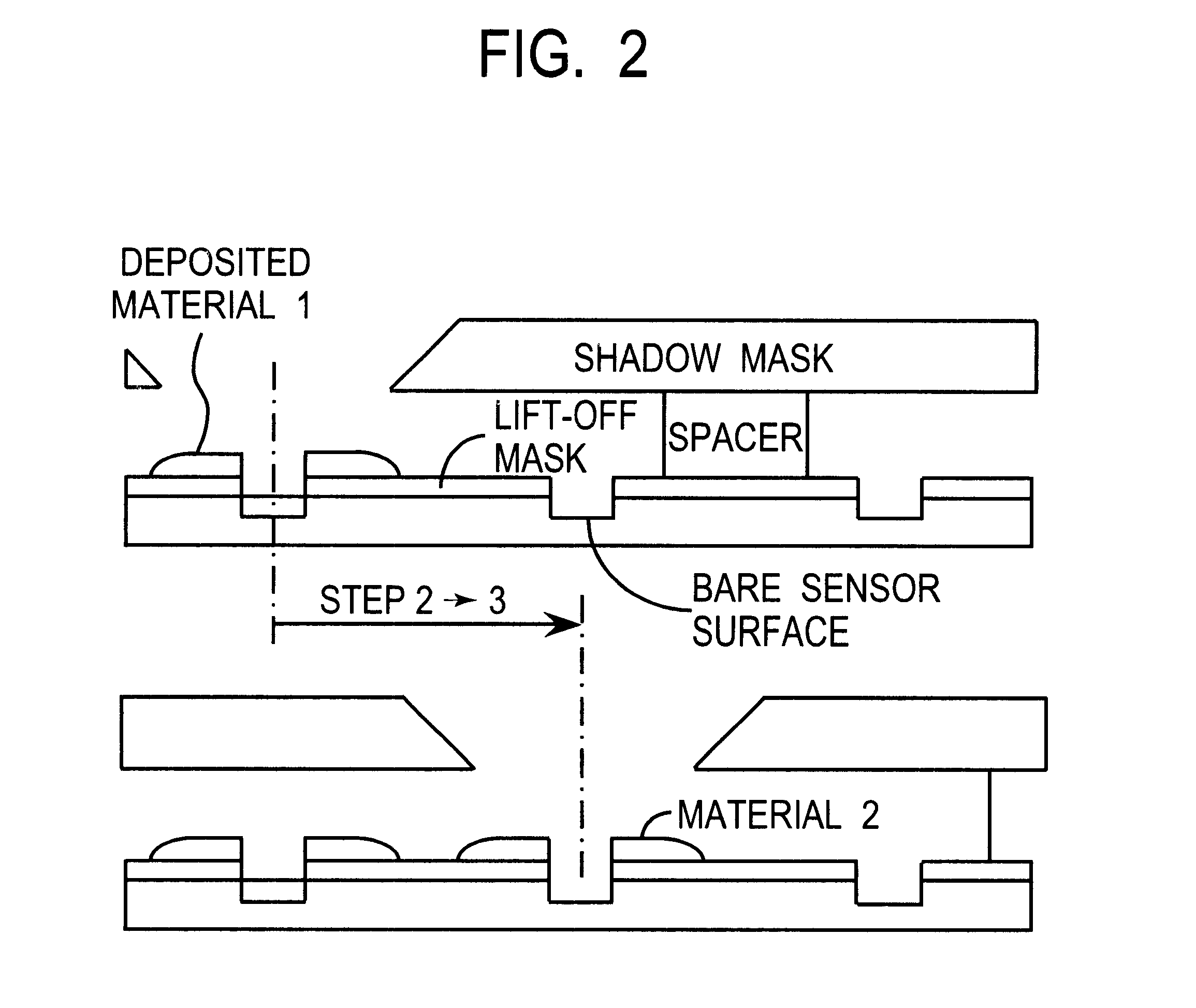

Manufacturing method for integrated sensor arrays

InactiveUS6410445B1Material analysis by electric/magnetic meansPhotomechanical apparatusSensor arrayResist

Method for the fabrication of sensor arrays with individually different sensing surface, where lift off technique and shadow mask technique is used simultaneously. A resist layer with openings at all locations where coatings are intended is applied with lift off technique. Then a shadow mask is used provided with widows only at the openings where deposit is intended for one specific coating. By for instance vapor deposition, coatings are effected where there are openings in the resist and windows in the shadow mask. The shadow mask is moved to the next depositions location and the procedure repeated until all coatings have been effected. The shadow mask is removed as is also the resist giving an improved sensor quality compared to prior-art methods.

Owner:APPLIEDSENSOR SWEDEN

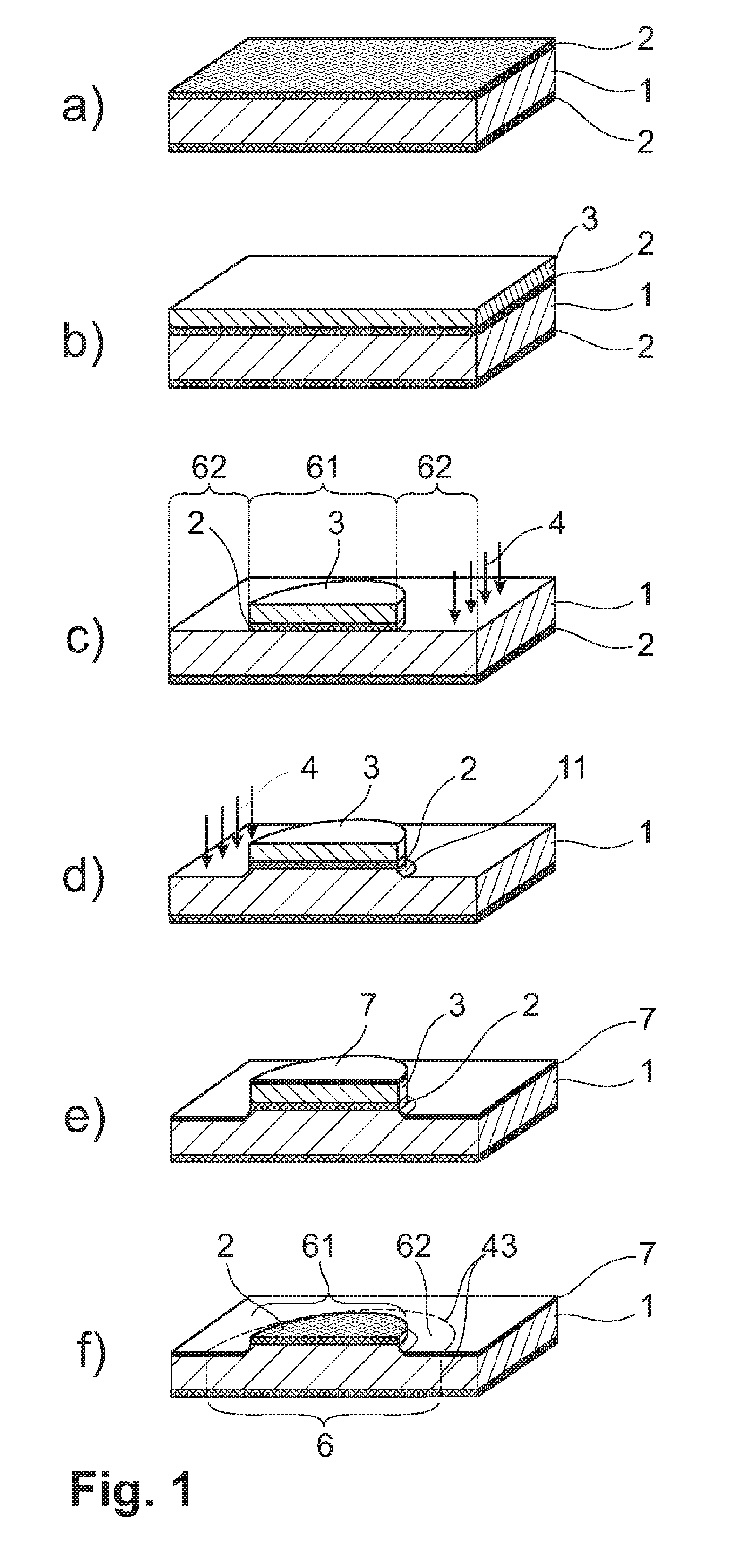

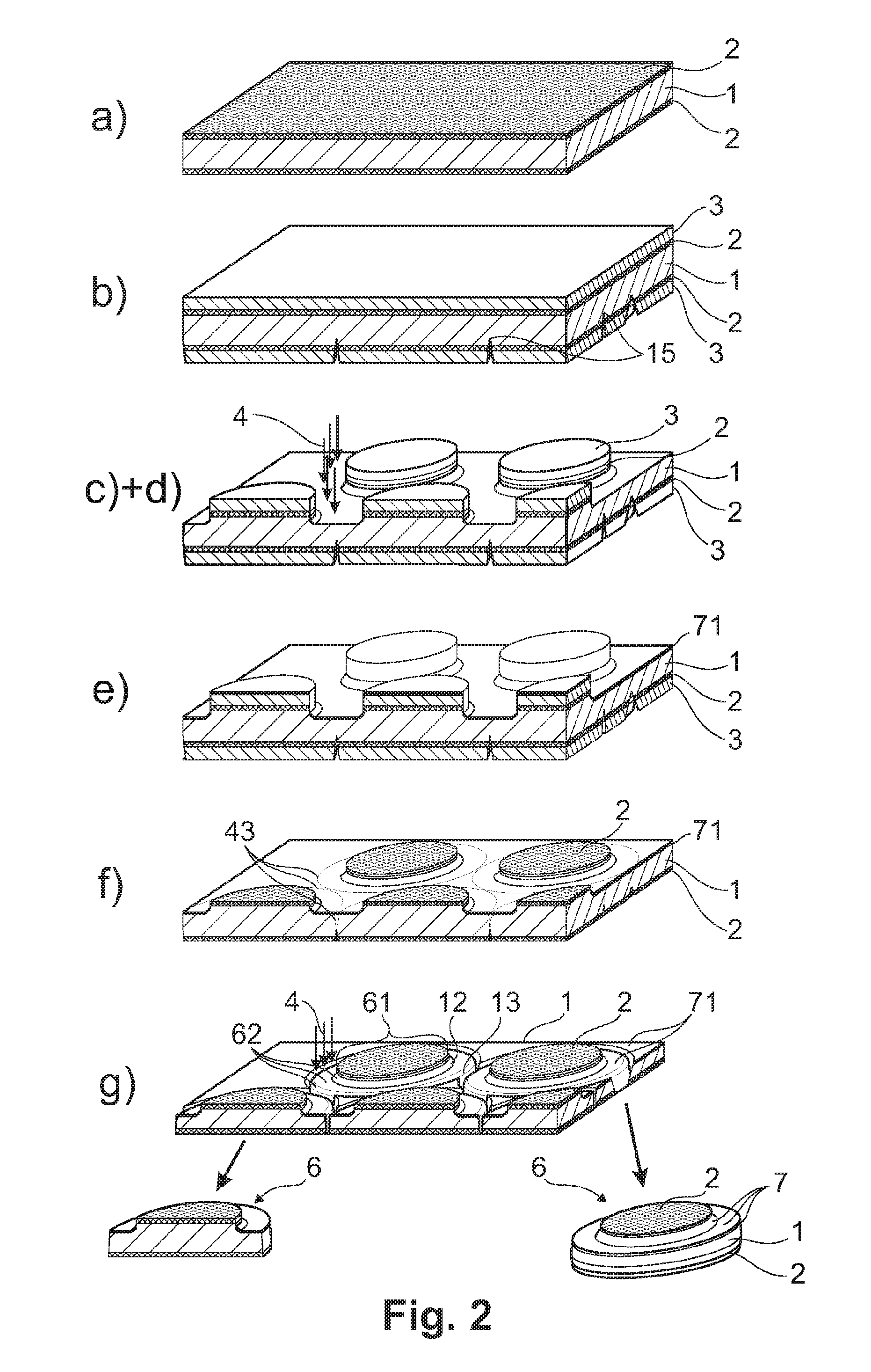

Method for Producing Window Elements that Can Be Soldered into a Housing in a Hermetically Sealed Manner and Free-Form Window Elements Produced in Accordance with Said Method

ActiveUS20160062127A1Improve reliabilityMinimize unwanted extraneous radiationRadiation pyrometryPhotometryHigh energyOptical coating

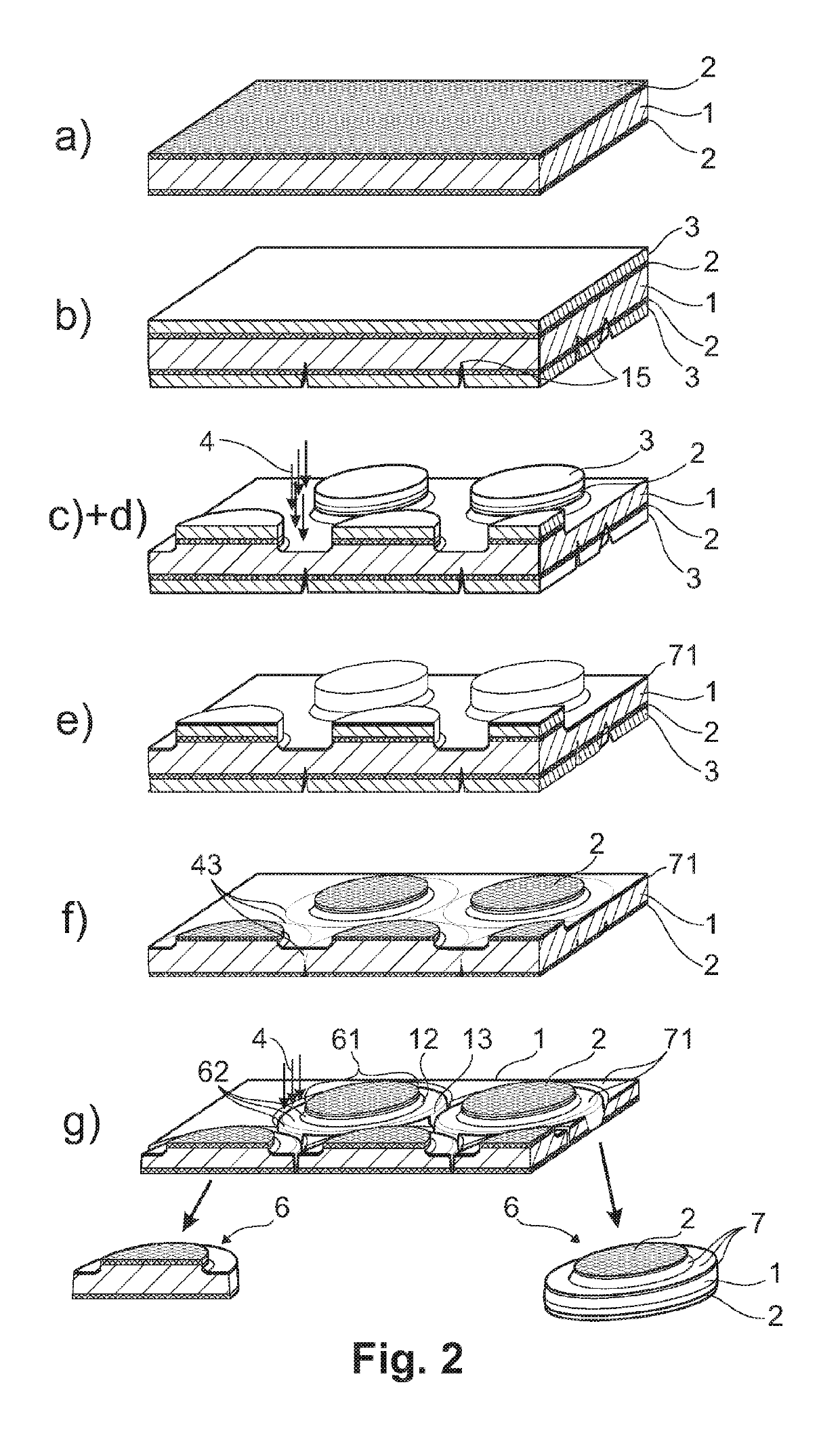

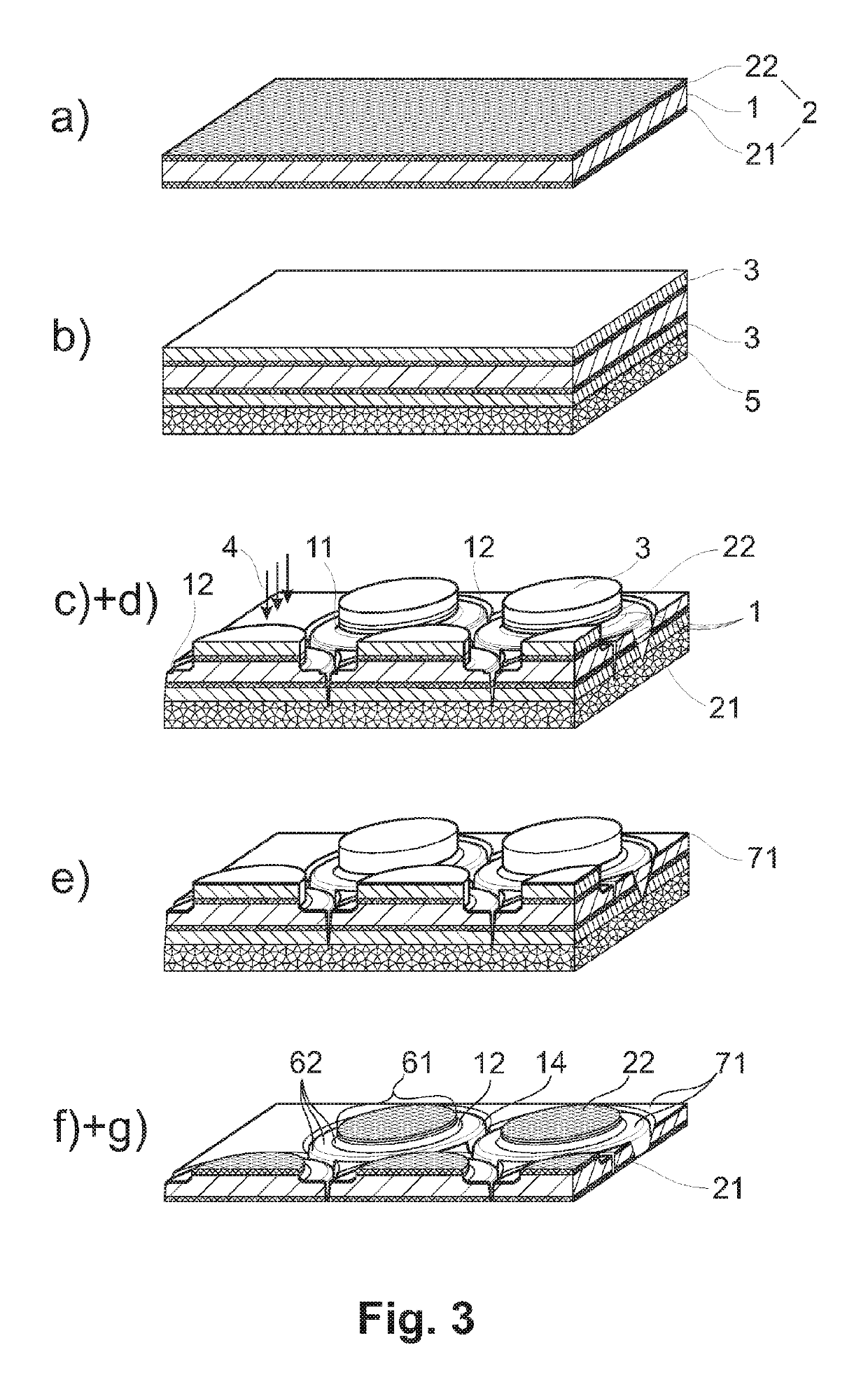

A method for production of window elements which can be soldered into a housing in a hermetically tight manner with optical coating and free-form window elements are disclosed. After application of optical coatings, a protective layer is applied to the optical coating, the two layer systems are selectively removed by means of a machining beam of high-energy radiation for the purpose of ablation of a desired optically active free-form surface for window elements with any geometric shape through a localized machining beam in edge regions of the optically active free-form surface such that the protective layer remains on the optical coating as lift-off mask which is lifted off after applying a metallization for a solder layer by an etching process that acts selectively only on the protective layer but not on the optical coating, and the metallization remains only on the peripheral edge regions circumscribing the free-form surfaces.

Owner:JENOPTIK OPTICAL SYST +1

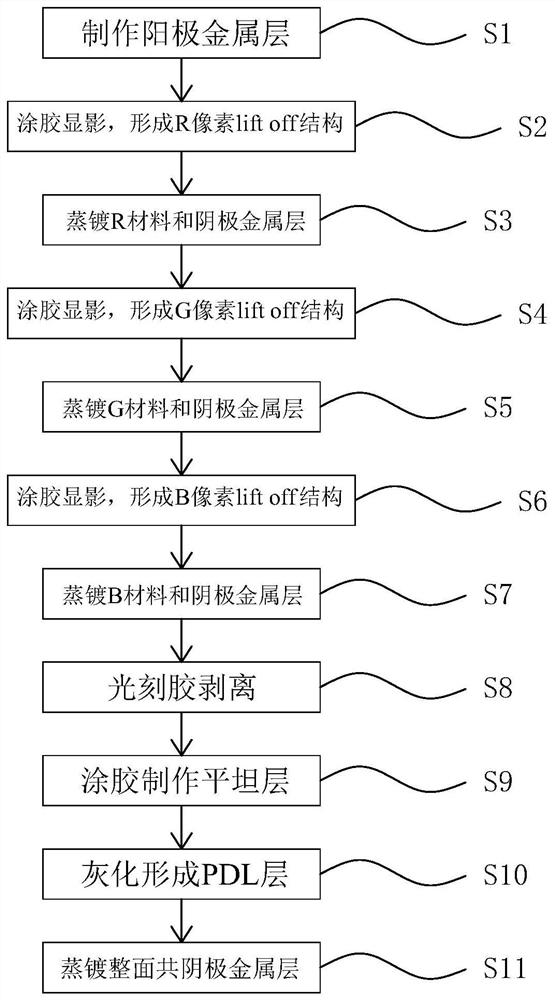

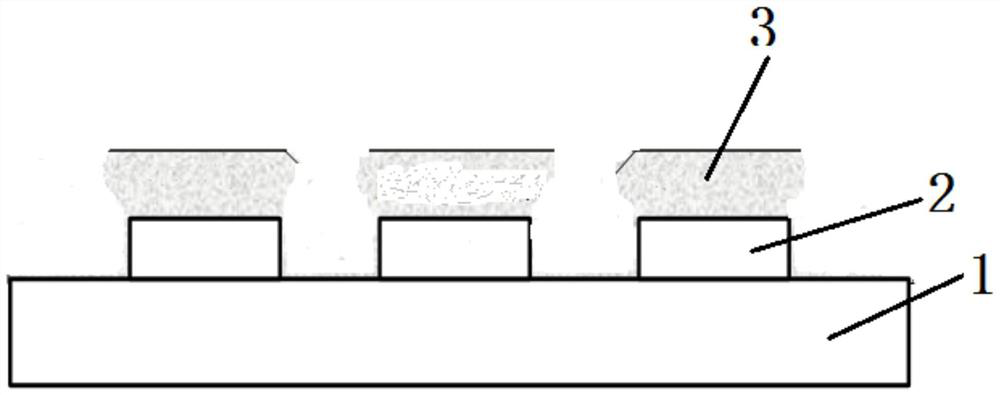

Preparation method of silicon-based OLED panel

ActiveCN112420798ARealize independent self-illuminationIncrease display brightnessSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionPhotoresist

The invention discloses a preparation method of a silicon-based OLED panel. The preparation method comprises the following steps: S1, manufacturing an anode metal layer; S2, conducting gluing and developing to form an R pixel lift off structure; S3, conducting evaporation plating to form an R material and a cathode metal layer; S4, conducting gluing and developing to form a G pixel lift off structure; S5, conducting evaporation plating to form a G material and a cathode metal layer; S6, conducting gluing and developing to form a B pixel lift off structure; S7, conducting evaporation plating toform a B material and a cathode metal layer; S8, stripping a photoresist; S9, conducting gluing to manufacture a flat layer; S10, performing ashing to form a PDL layer; and S11, conducting evaporation plating on a whole-surface common cathode metal layer. According to the preparation method of the silicon-based OLED panel, the self-alignment structure for OLED evaporation plating is prepared by adopting a yellow light process, independent and autonomous luminescence of RGB of PPI 2000 or more can be realized, and the overall display brightness and resolution are greatly improved.

Owner:ANHUI SEMICON INTEGRATED DISPLAY TECH CO LTD

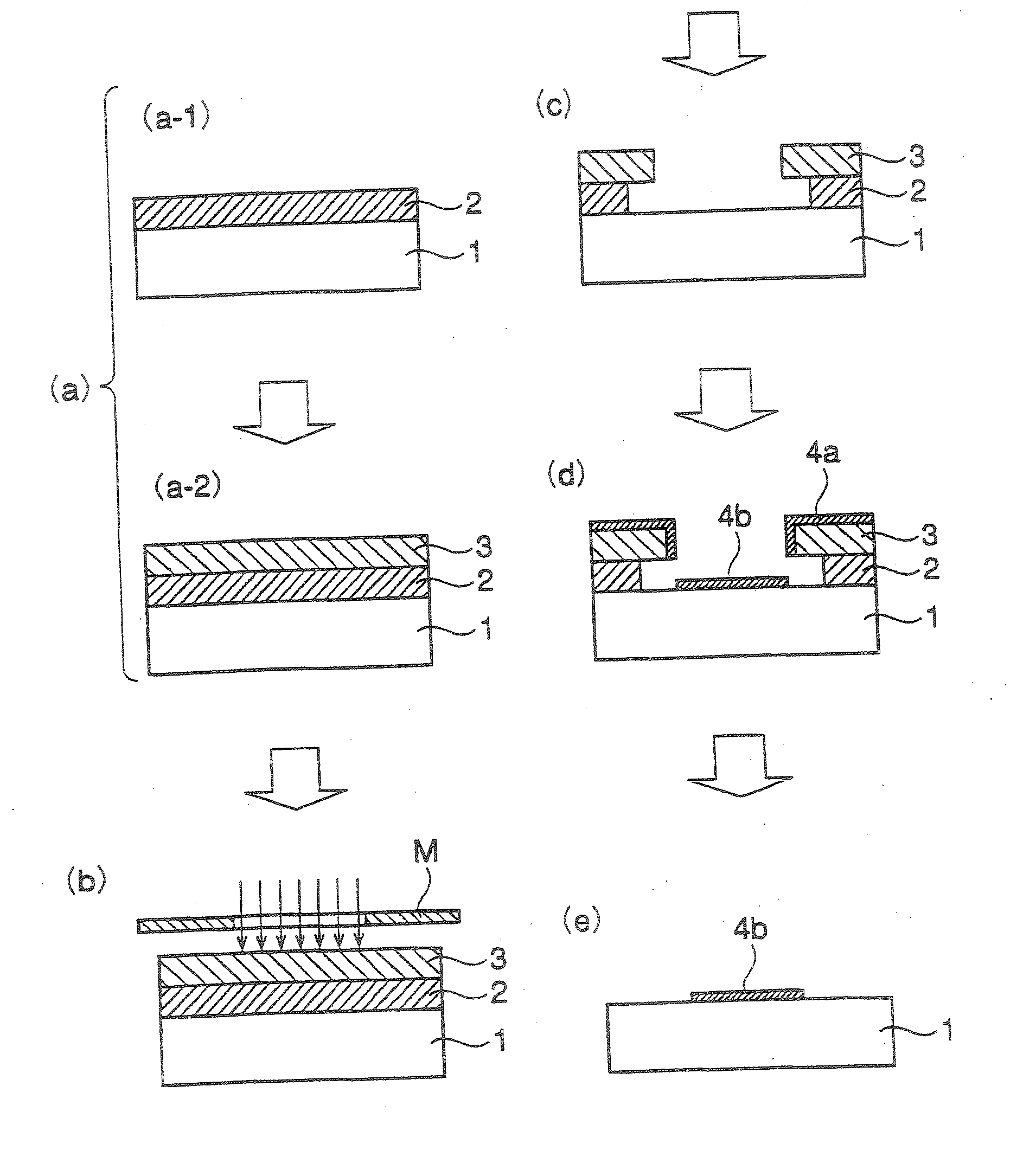

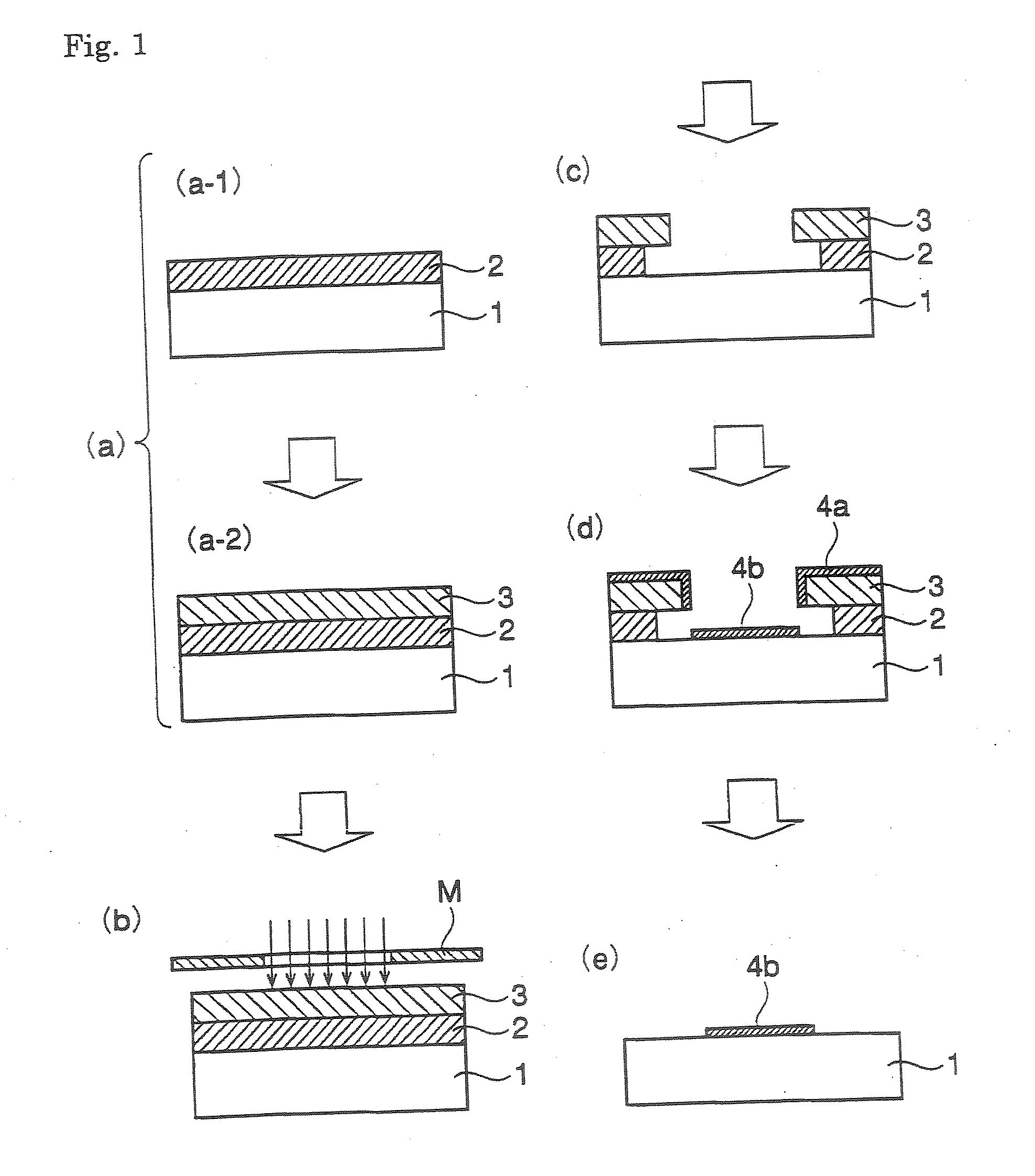

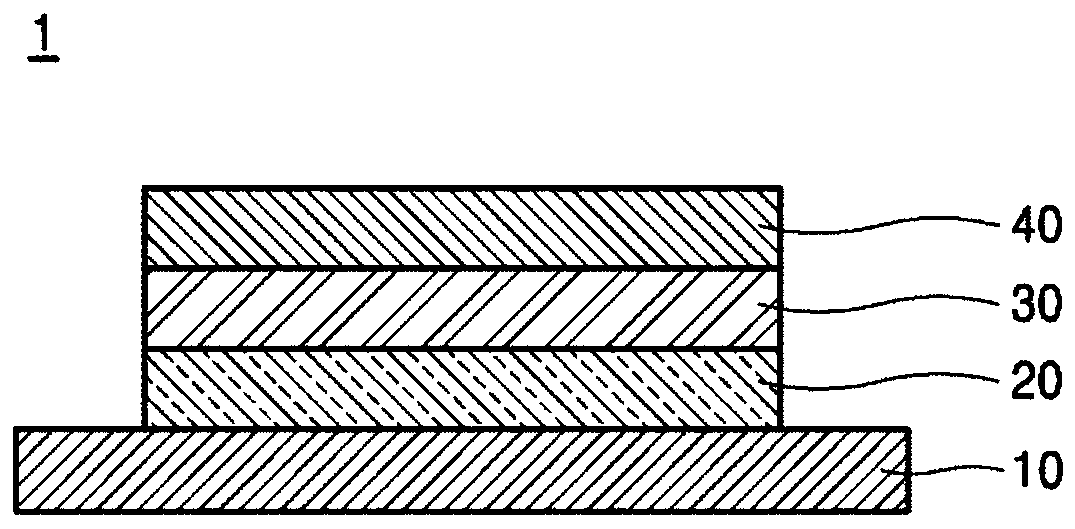

Two-layer film and method of forming pattern with the same

InactiveUS20070248905A1Improve productivityConfirm the undercut profilePhotoprinting processesPhotosensitive material processingResistSingle exposure

The invention concerns a lift-off process for patterning layers that are deposited and / or sputtered. The invention provides a two-layer resist and a patterning method using the resist. The patterning method can readily produce burr-free layers on a substrate. The method comprises the steps of: sequentially applying positive radiation-sensitive resin compositions 1 and 2 to form a two-layer laminate; subjecting the two-layer resist to single exposure and development to produce fine patterns having an undercut cross section; depositing and / or sputtering an organic or inorganic thin layer with use of the resist pattern as a mask; and lifting off the resist pattern to leave a pattern of the thin layer in desired shape.

Owner:JSR CORPORATIOON

Method for removing native oxide and associated residue from a substrate

InactiveUS20130316533A1Electric discharge tubesElectrostatic cleaningPhysical chemistrySilicon tetrafluoride

Owner:APPLIED MATERIALS INC

Manufacturing method of non-invasive graphene nano-scale device

InactiveCN104934301AEasy to makeEasy to manufactureSemiconductor/solid-state device manufacturingNanotechnologyPolymethyl methacrylateScanning electron microscope

The invention belongs to the technical field of electron beam lithography, in particular to a method for manufacturing a graphene nano-scale device with electron beam lithography, a stencil and optical lithography. The method comprises the following steps: coating a silicon nitride membrane of 100-300nm with PMMA (Polymethyl Methacrylate) of 300-600nm in a spinning way for serving as a mask, directly writing an interdigital electrode which is 100-200nm in width and 200-500nm in period with electron beam lithography, and etching the silicon nitride membrane of 100-300nm with RIE (Reactive Ion Etching) to obtain the stencil; evaporating gold of 100nm onto graphene in which silicon is taken as a substrate through thermal evaporation by taking the stencil as a mark plate; and defining a pads region with optical lithography, evaporating the gold through thermal evaporation, and performing lift off. According to a required graphical process condition, an electron beam lithography machine, RIE, an optical lithography machine, a SEM (Scanning Electron Microscope), thermal evaporation and the like are required. Through the tools, graphical processing of a tiny device can be realized, and the non-invasive graphene nano-scale device is manufactured.

Owner:FUDAN UNIV

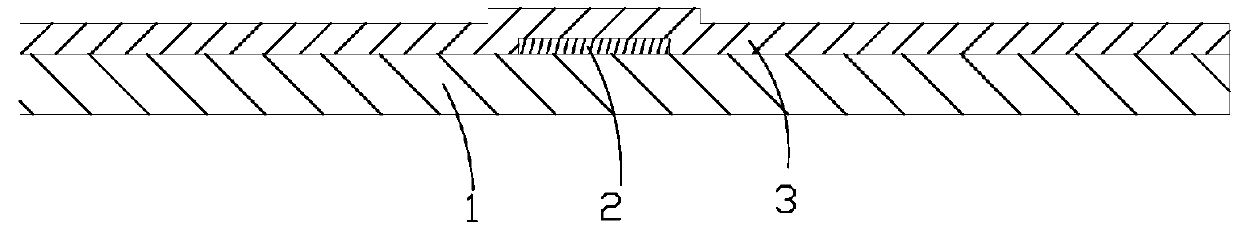

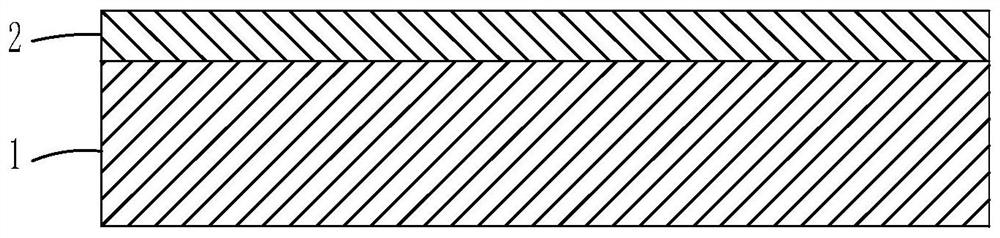

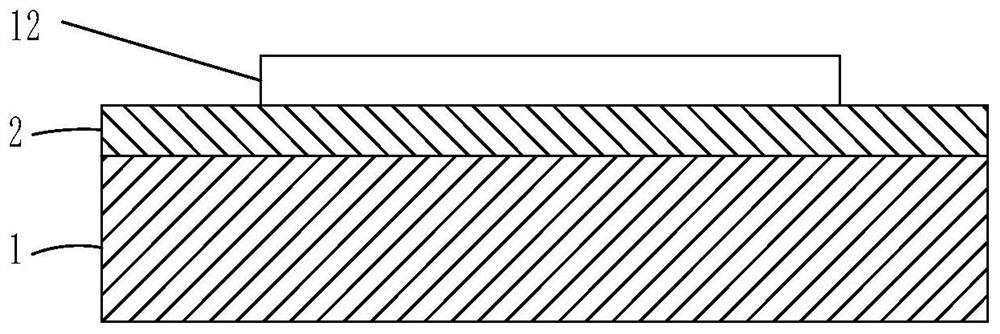

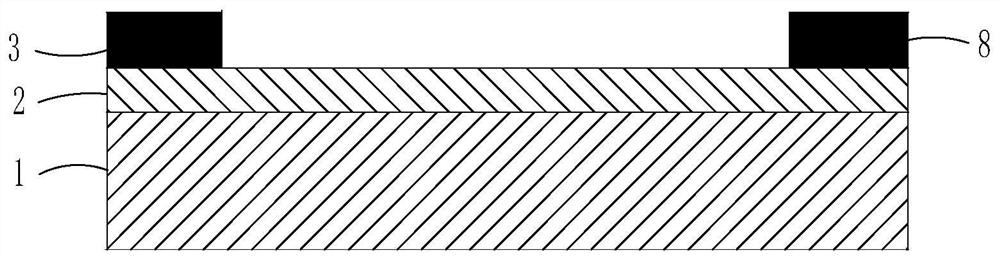

Kind of image-text firework production method

The present invention comprises a pattern-character firework carrier (101), a pattern-character display method, and a pattern-character firework setting-off step. The pattern-character firework carrier (101) is provided with a lifting-off device (201) which is provided with a lifting-off gunpowder bin (1) with lifting-off gunpowder (6) packaged inside, and a pattern-character display control device (301) which is provided with a lattice gunpowder packaging body (2) provided with a firework launching unit (4) and a simultaneous ignition bin (3).The pattern-character display method comprises steps of designing a pattern, converting the pattern into a color lattice graphic (12), arranging fireworks according to the graphic, loading the fireworks, and the like. The setting-off step comprises: igniting a fuse (8), igniting the lifting-off gunpowder (6), lifting off the pattern-character firework carrier (101), exciting the simultaneous ignition device (5), igniting firework launching gunpowder (10), sending firework display gunpowder (9) out of the carrier, simultaneously igniting the firework display gunpowder (9) in the air, and displaying the pattern and character in the air. The method is simple in implementation, low in cost, and capable of allowing the gunpowder to be combined freely. The sky can be made bright and colorful with the fireworks. Affection can be directly expressed.

Owner:SUZHOU ZZH INTPROP SERVICES

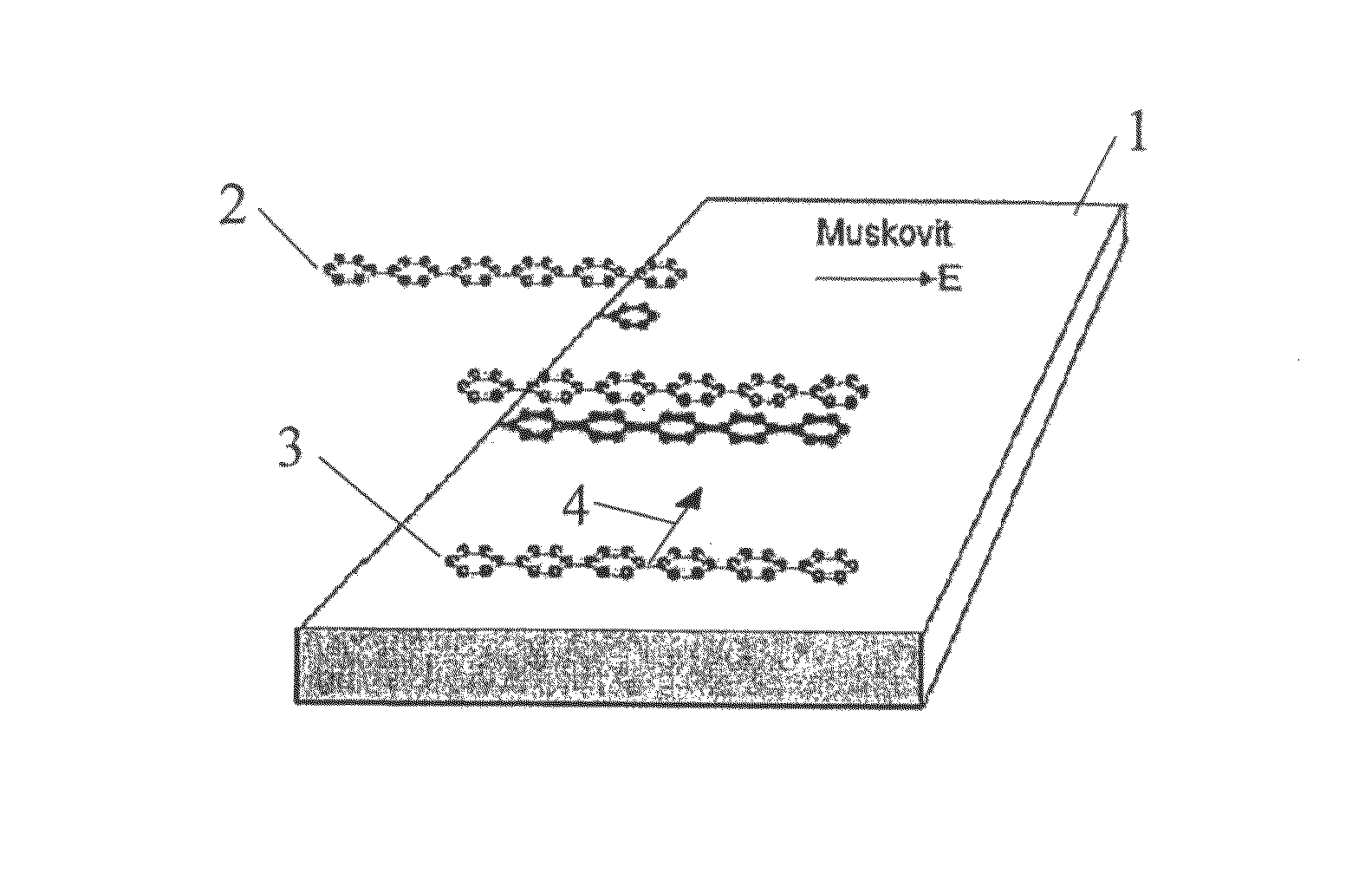

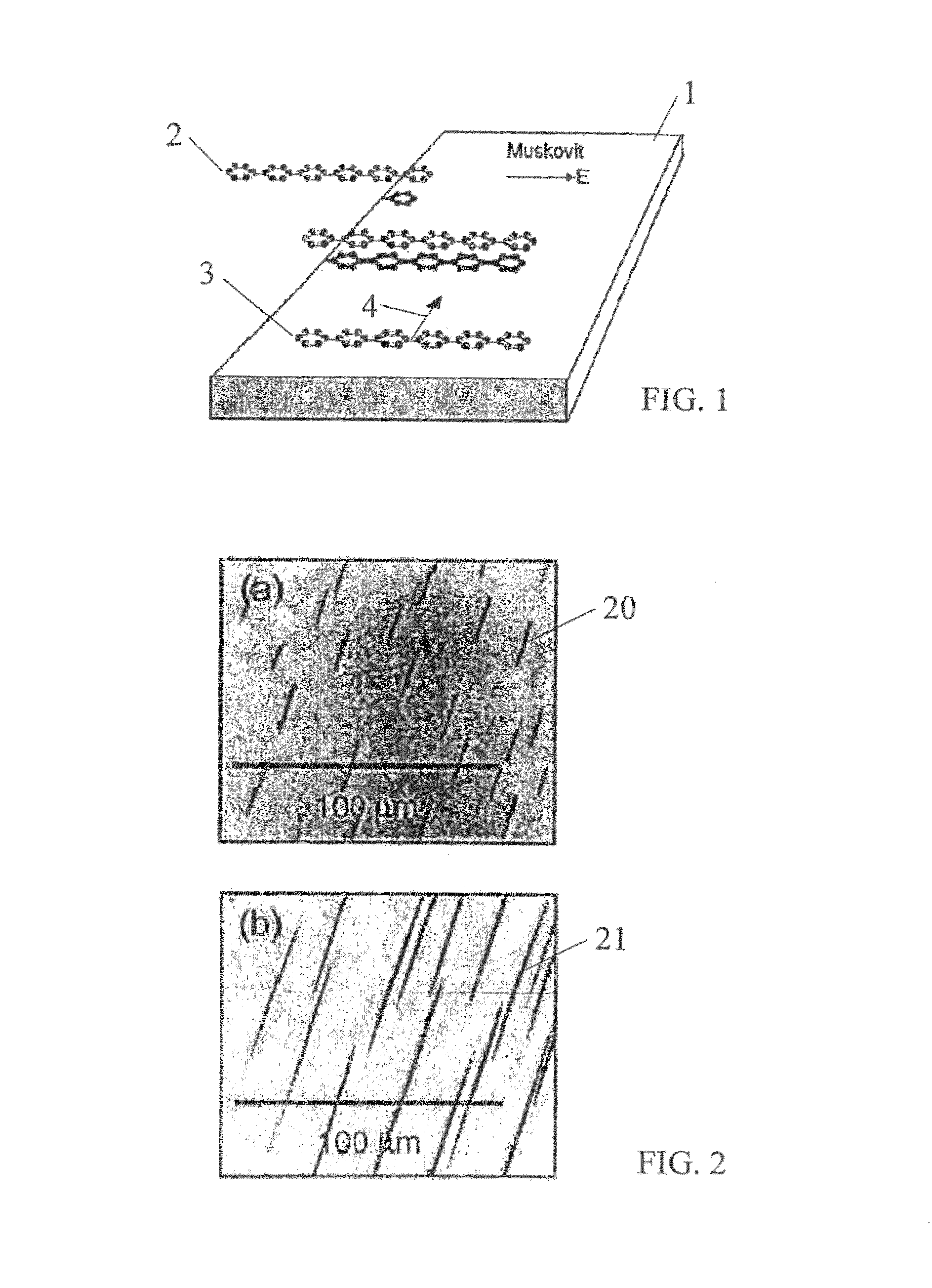

Soft-lift off of organic nanofibers

InactiveUS8034400B2Cheap productionEasy to produceSolid-state devicesSpecial surfacesPolymer scienceDielectric substrate

The invention relates to a method of releasing an ensemble of nanofibers from a dielectric substrate as well as to applications of the method. The organic nanofibers are grown on the substrate and can be released by first providing a polar liquid to a surface of the substrate and subsequently supplying energy to the combined system of nanofibers and liquid. The release may preferably be followed by transferring the released nanofibers to another substrate for application of the nanofibers, including alignment and / or structuring of the nanofibers. The applications includes light emitting, guiding and sensing applications.

Owner:NANOFIBER

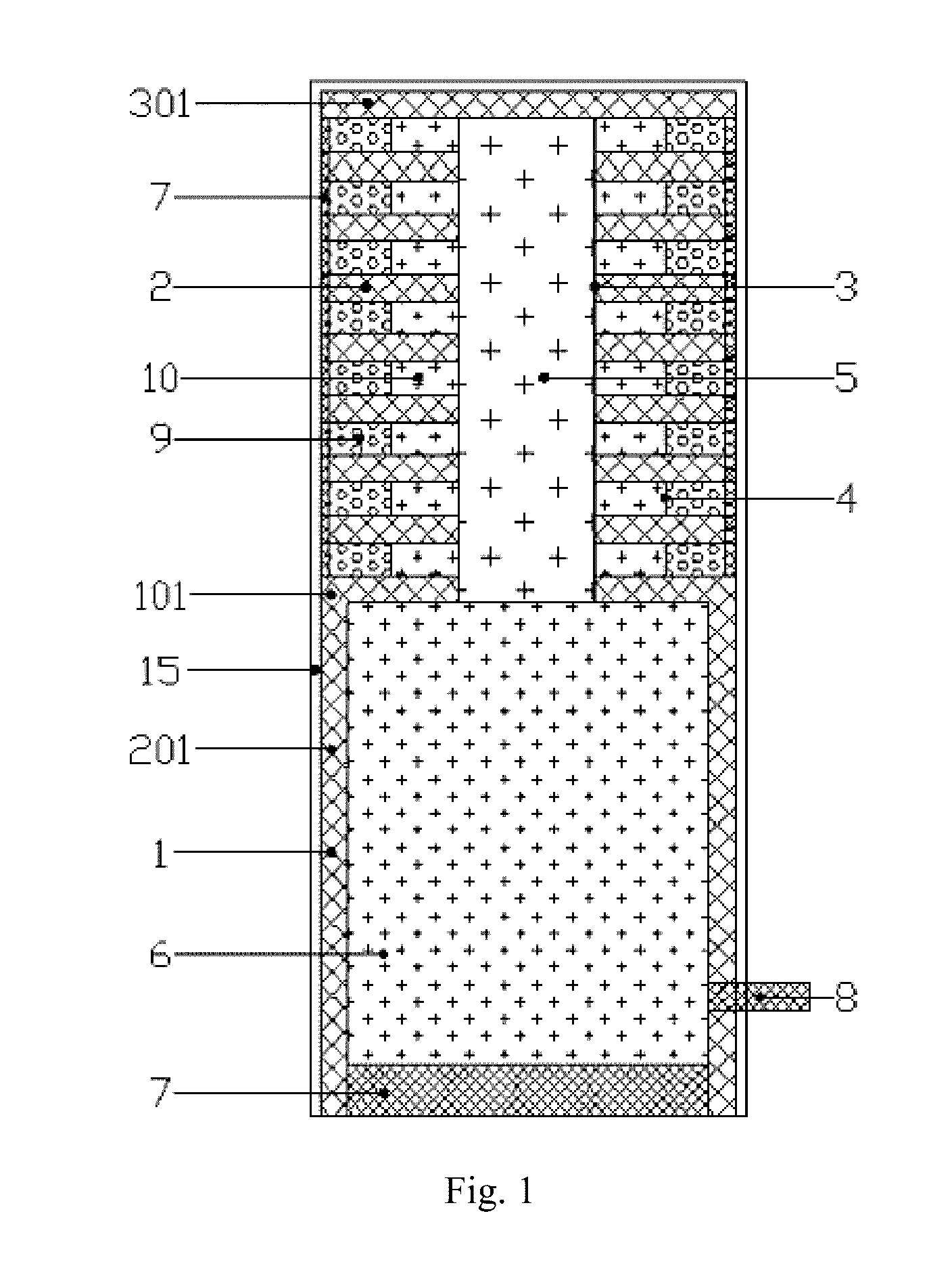

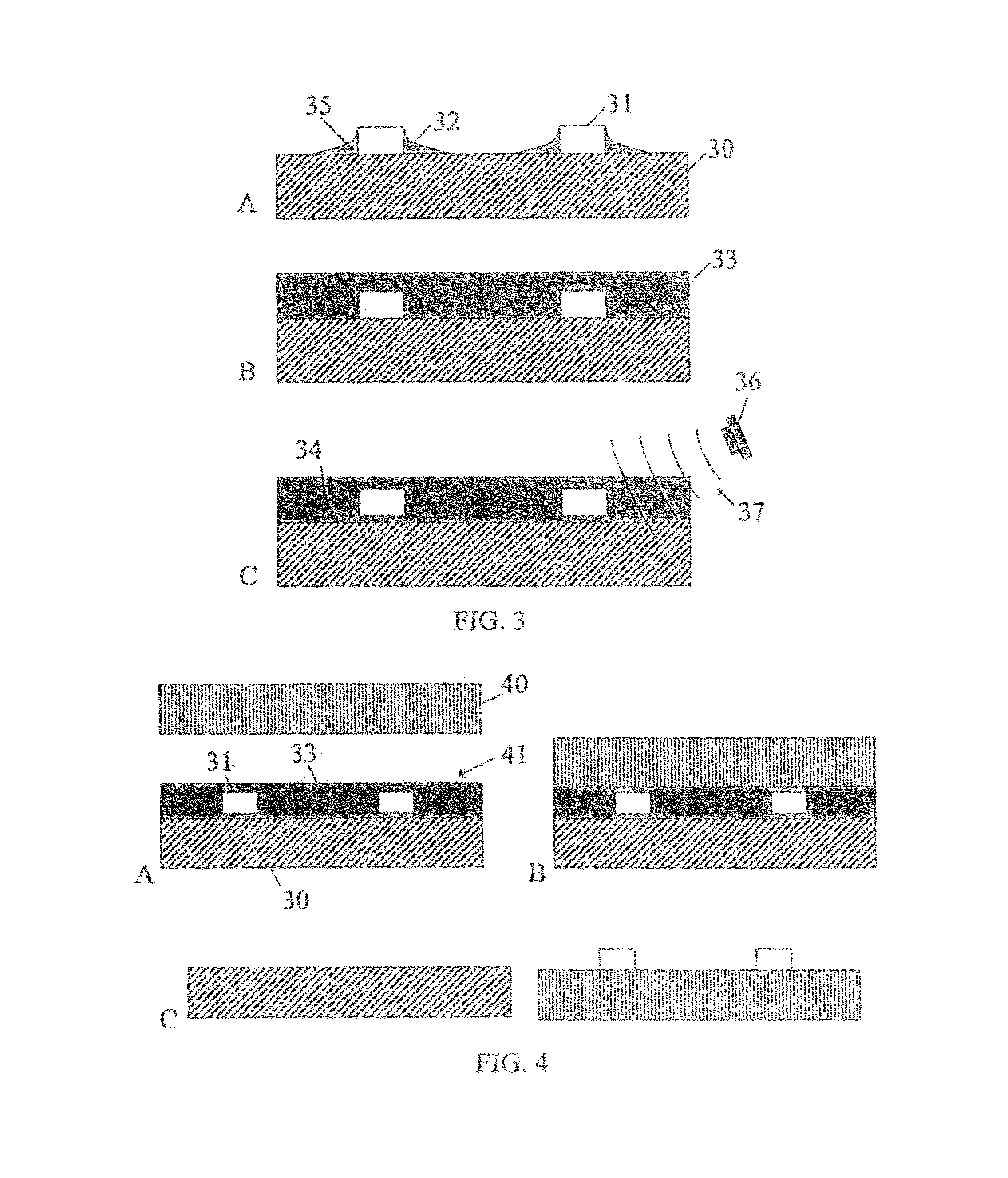

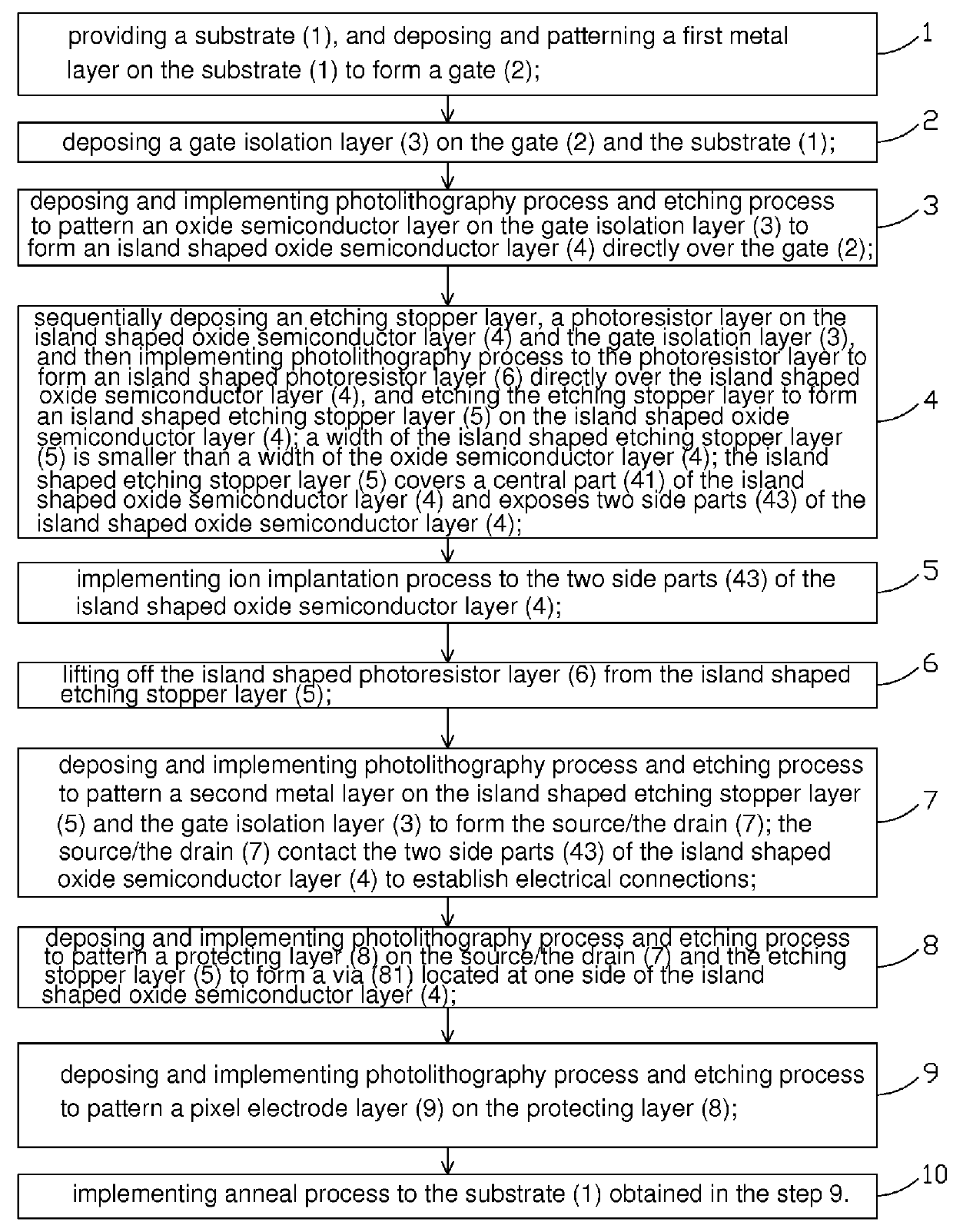

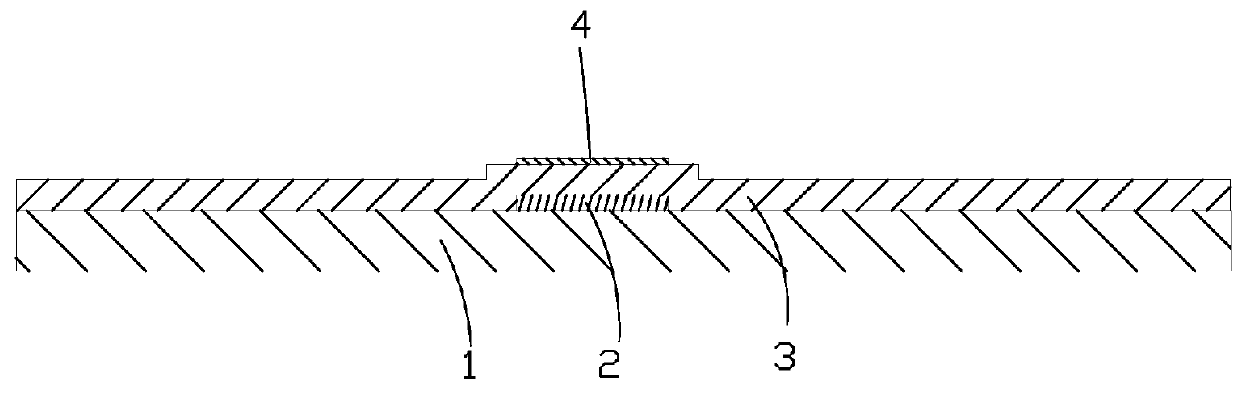

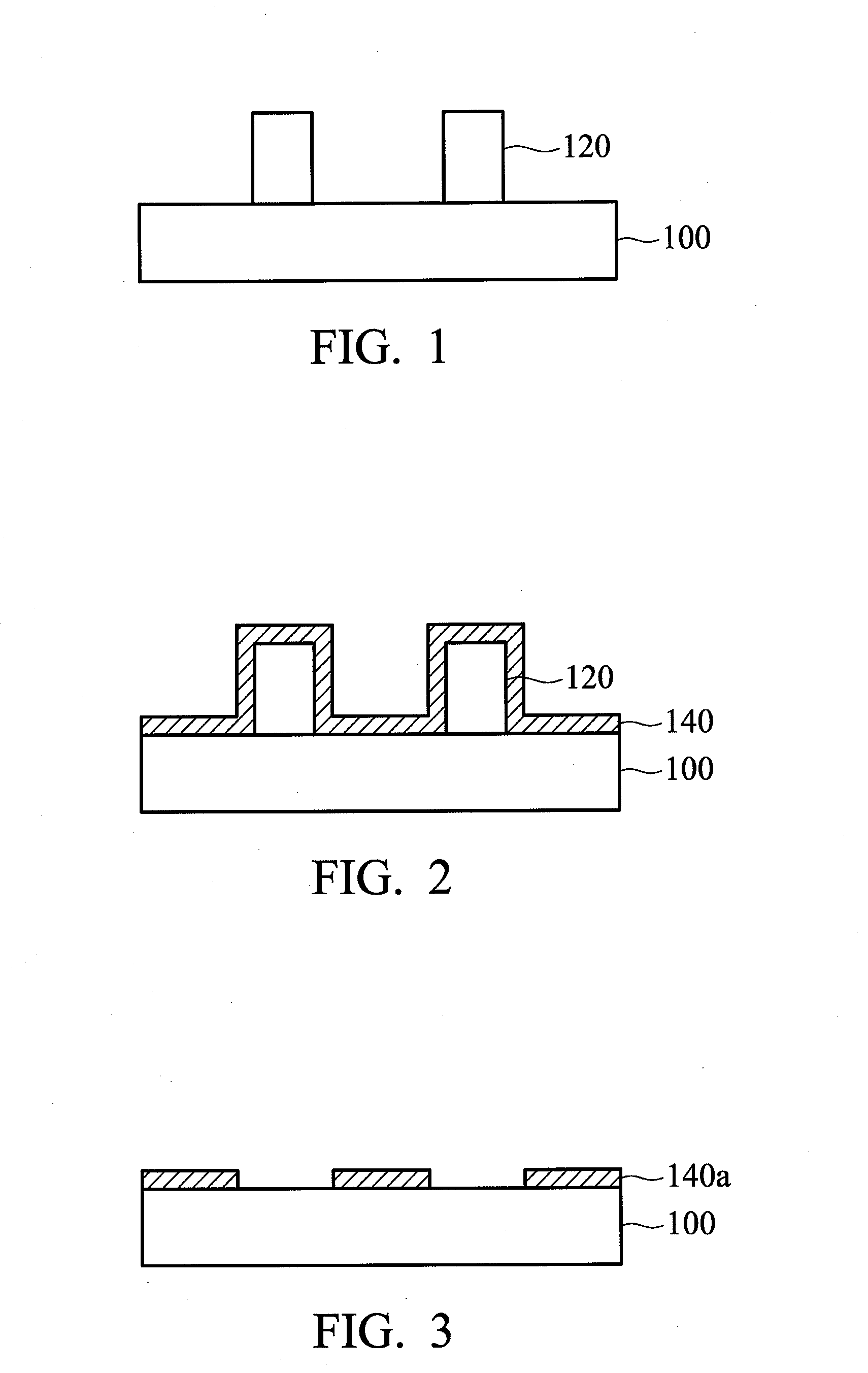

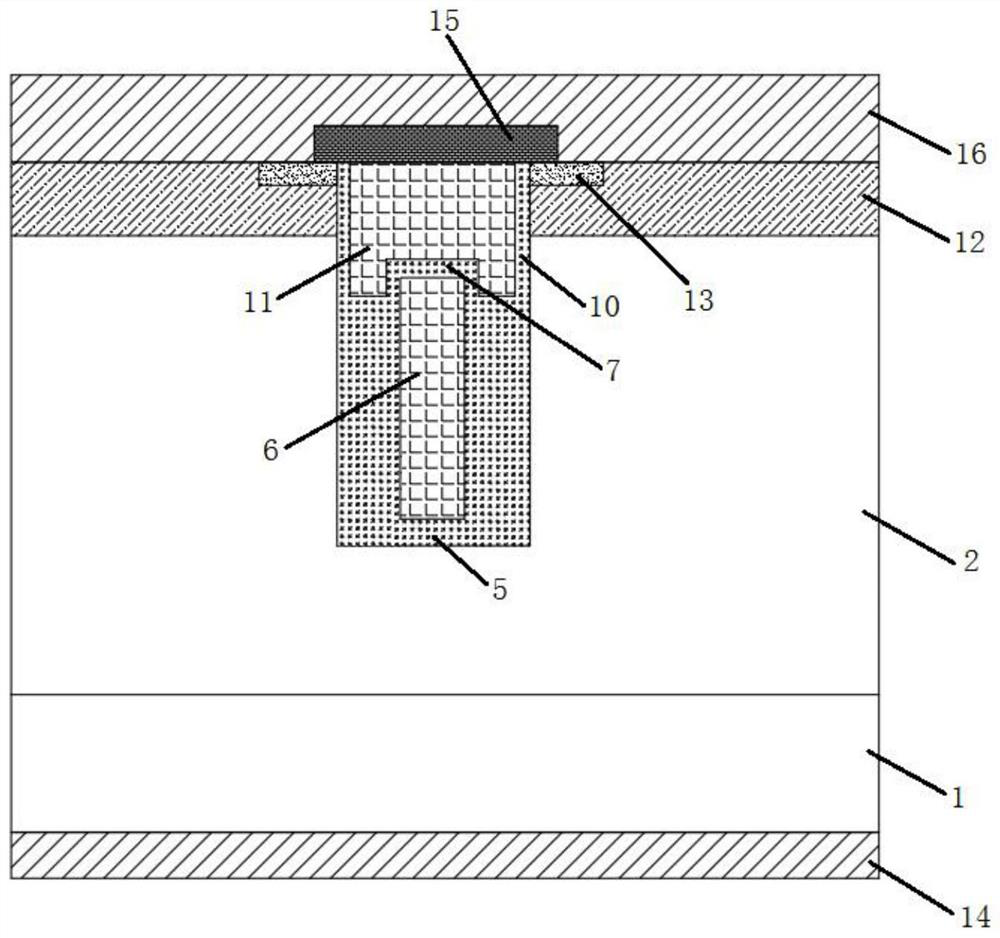

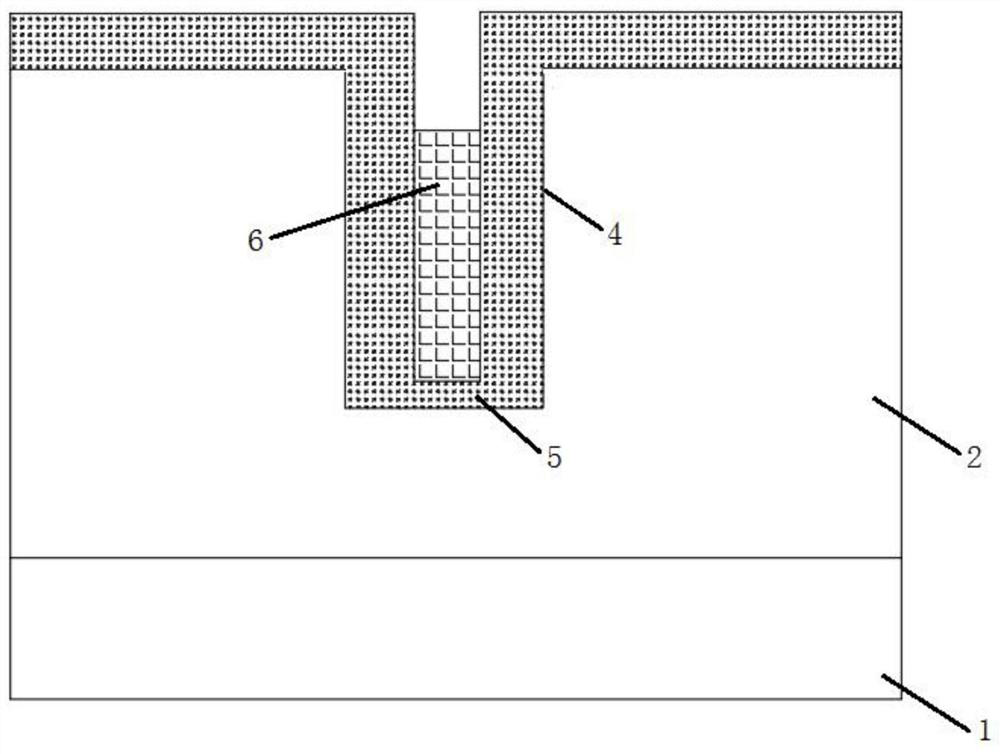

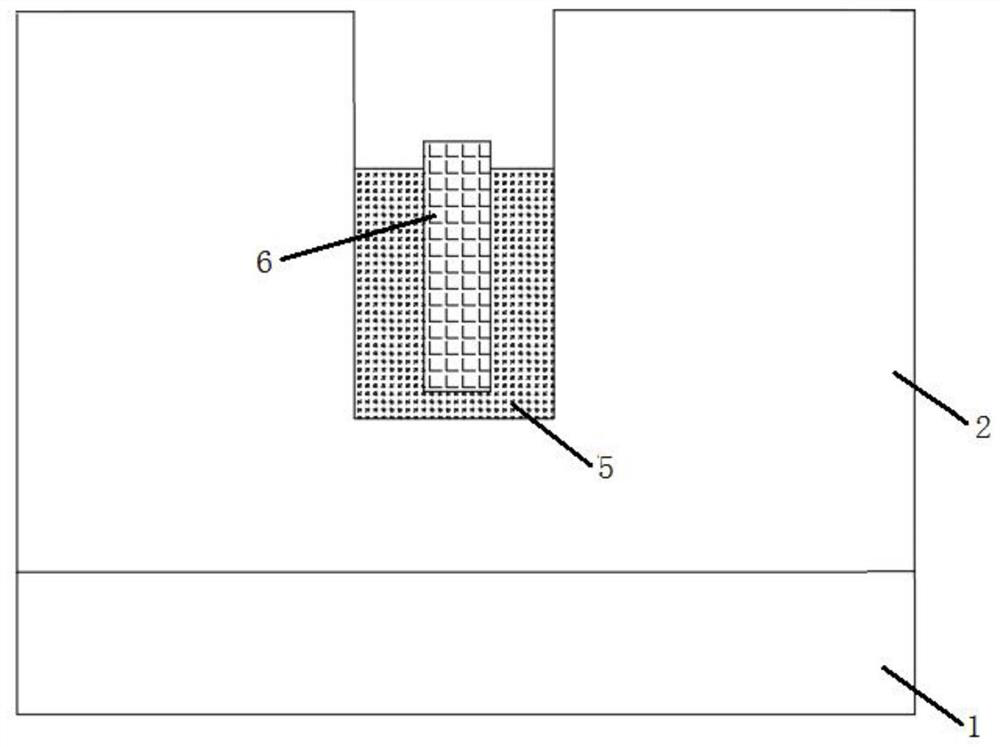

Manufacture method of TFT substrate and sturcture thereof

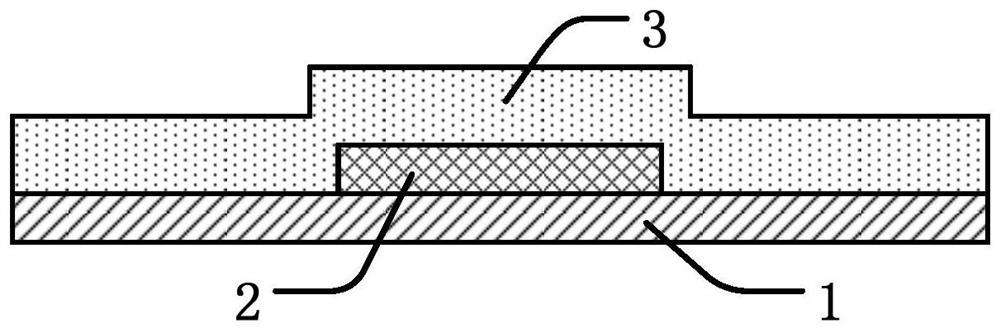

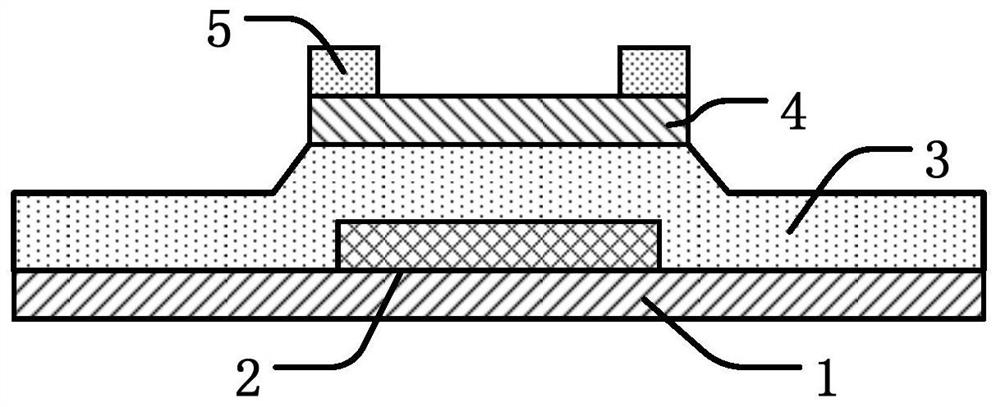

ActiveUS20160056267A1Reduce ohm contact resistance therebetweenReduce the driving voltageTransistorSolid-state devicesElectrical connectionIsolation layer

The present invention provides a manufacture method of an oxide semiconductor TFT substrate, and the method comprises steps of: 1, forming a gate (2) on a substrate (1); 2, deposing a gate isolation layer (3); 3, forming an island shaped oxide semiconductor layer (4); 4, forming an island shaped photoresistor layer (6) and an island shaped etching stopper layer (5), and the island shaped etching stopper layer (5) covers a central part (41) of the island shaped oxide semiconductor layer (4) and exposes two side parts (43) of the island shaped oxide semiconductor layer (4); 5, implementing ion implantation process to the two side parts (43) of the island shaped oxide semiconductor layer (4); 6, lifting off the island shaped photoresistor layer (6); 7, forming a source / a drain (7), and the source / the drain (7) contact the two side parts (43) of the island shaped oxide semiconductor layer (4) to establish electrical connections; 8, deposing and patterning a protecting layer (8); 9, deposing and patterning a pixel electrode layer (9); 10, implementing anneal process.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Fabrication method of asymmetric surface channel field effect transistor and power device

ActiveCN109786233BImprove power densityImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesLift-offAtomic physics

The present application provides a method for fabricating an asymmetric surface-channel field-effect transistor and power device, belonging to the technical field of microwave power devices, comprising the following steps: depositing a metal mask layer; preparing a first photoresist layer; forming a source region pattern and a drain region pattern; depositing a source metal layer and a drain metal layer at the source region pattern and the drain region pattern; lifting off and removing the first photoresist; applying two photoresist layers; photolithographically etching a gate-etching window pattern and a field plate metal window pattern, and etching the metal mask layer at the corresponding location; depositing a gate metal layer and a field plate metal layer, the distance between the two sides of the gate metal layer and the corresponding unetched metal mask layer being different; the effective gate–source spacing of the device is smaller than the effective gate–drain spacing. The method for fabricating the asymmetric surface-channel field-effect transistor, and device having an effective gate–source spacing which is smaller than the effective gate–drain spacing, provided by the present application, are capable of taking into account the saturation current and effectively improving breakdown voltage and operating voltage to increase the power density of the device.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

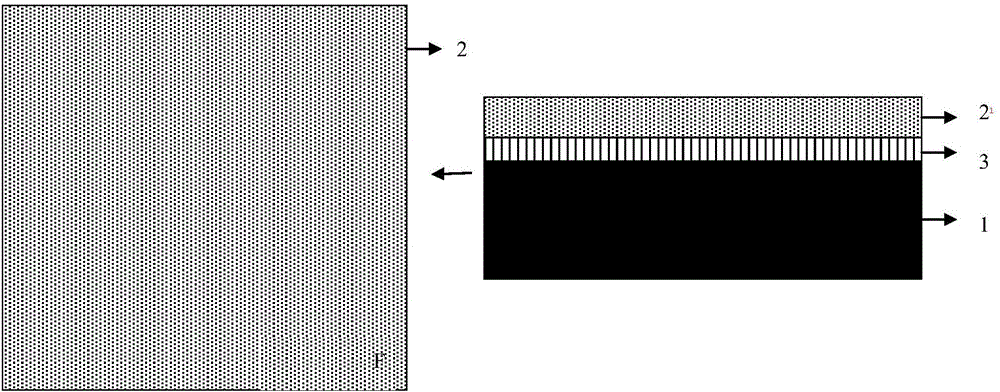

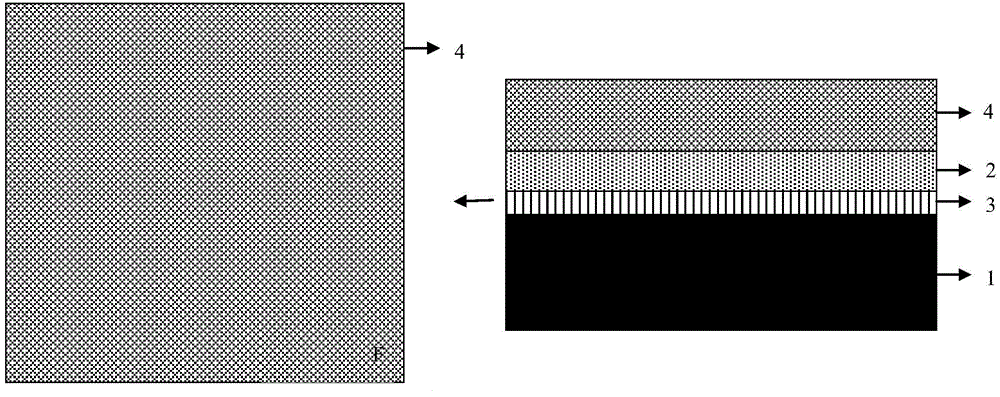

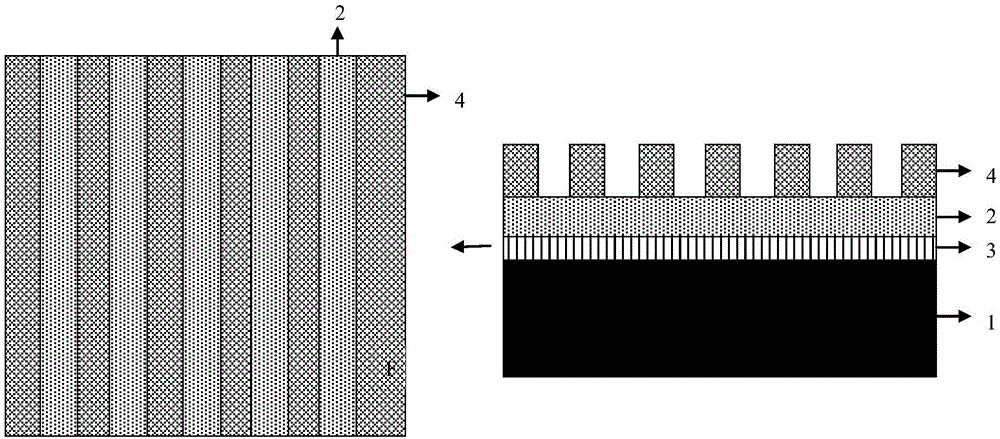

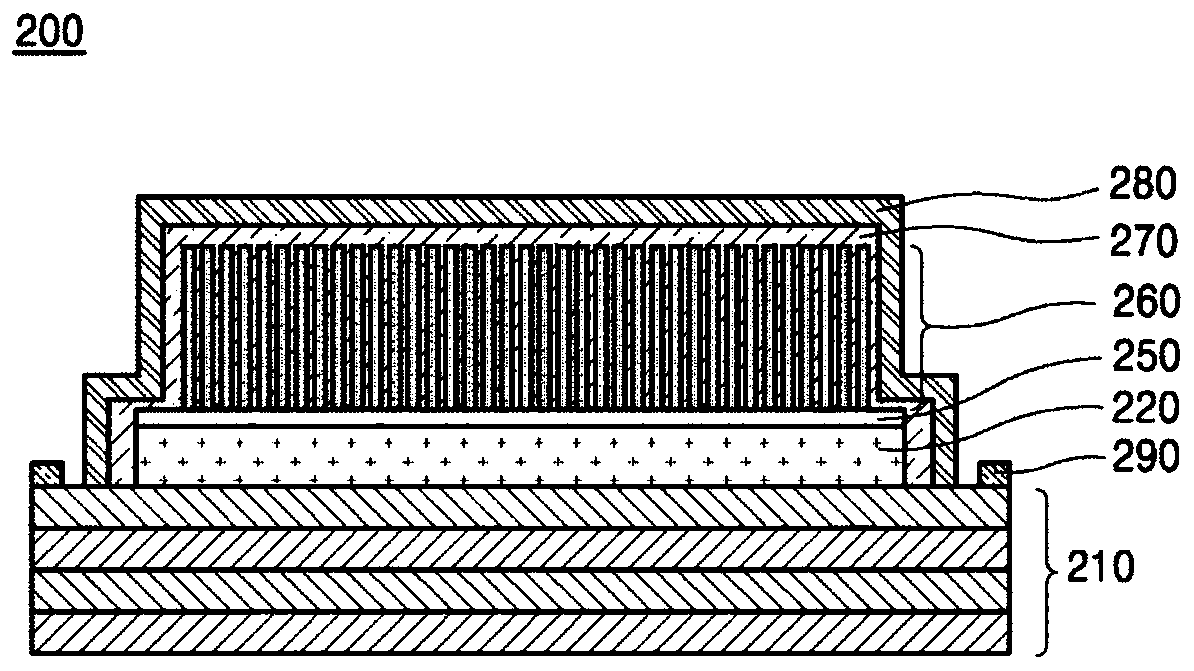

Panel for flexible digital x-ray detector and manufacturing method thereof

ActiveCN110034137AHigh hydrogen contentEfficient separationSolid-state devicesRadiation controlled devicesAmorphous siliconEngineering

A panel for a flexible digital X-ray detector and a method for manufacturing the same are disclosed. The flexible digital X-ray detector reduce device characteristic deterioration caused by X-ray exposure, increase flexibility to the panel by reducing a thickness of the panel yet provide rigidity to maintain the shape of the panel, and reduce residual impurities during a Laser Lift Off (LLO) process. The panel can include a multi-buffer layer in which a silicon oxide (SiOx) layer and a silicon nitride (SiNx) layer are alternately stacked, and a device array layer and a scintillator layer thatare disposed over the multi-buffer layer. During the LLO process, the method for manufacturing the panel includes increasing the hydrogen content using a sacrificial layer including an amorphous silicon (a-Si) layer and a silicon nitride (SiNx) layer disposed at both surfaces of the a-Si layer, such that the amount of residual impurities in the sacrificial layer can be reduced.

Owner:LG DISPLAY CO LTD

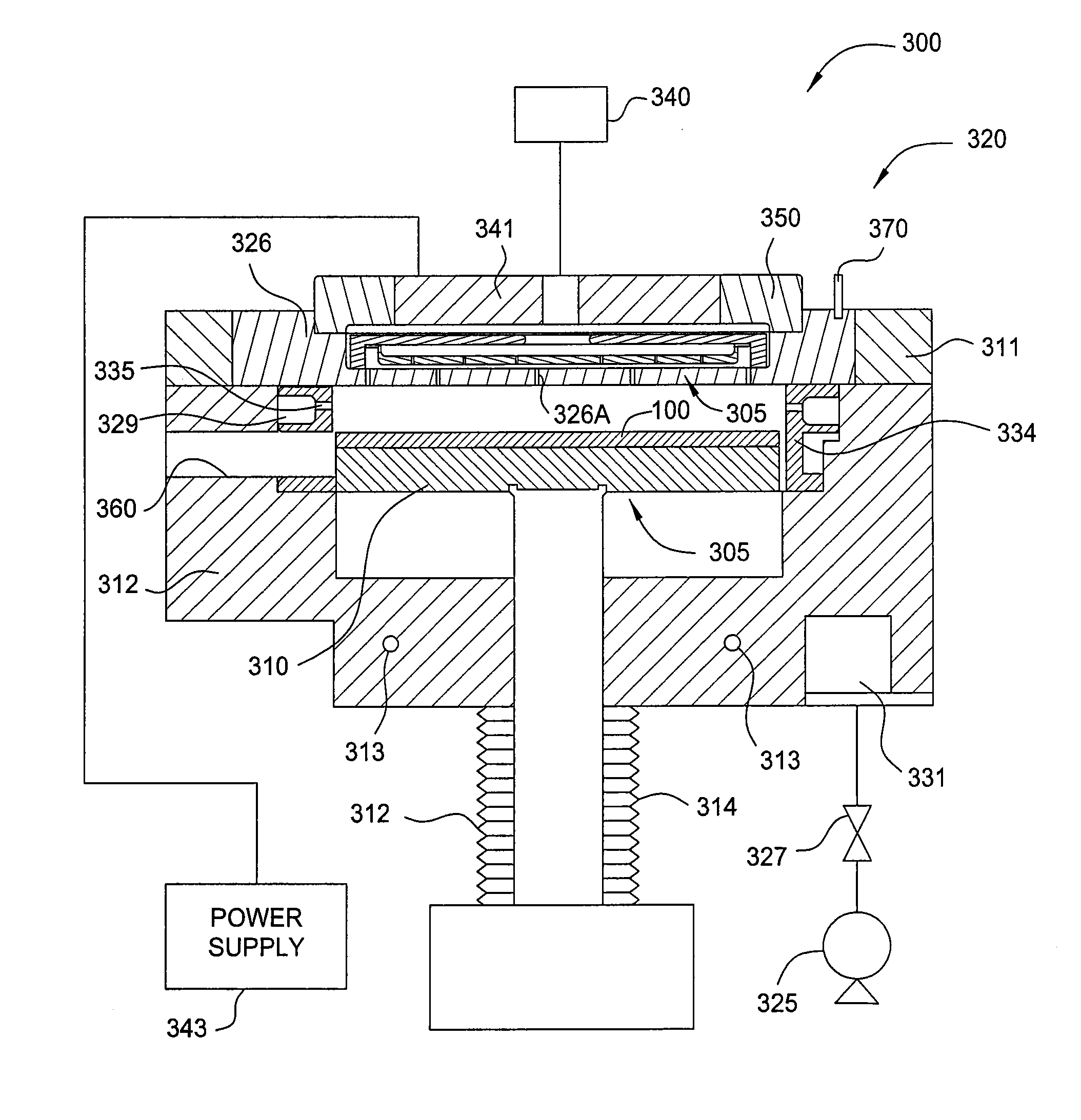

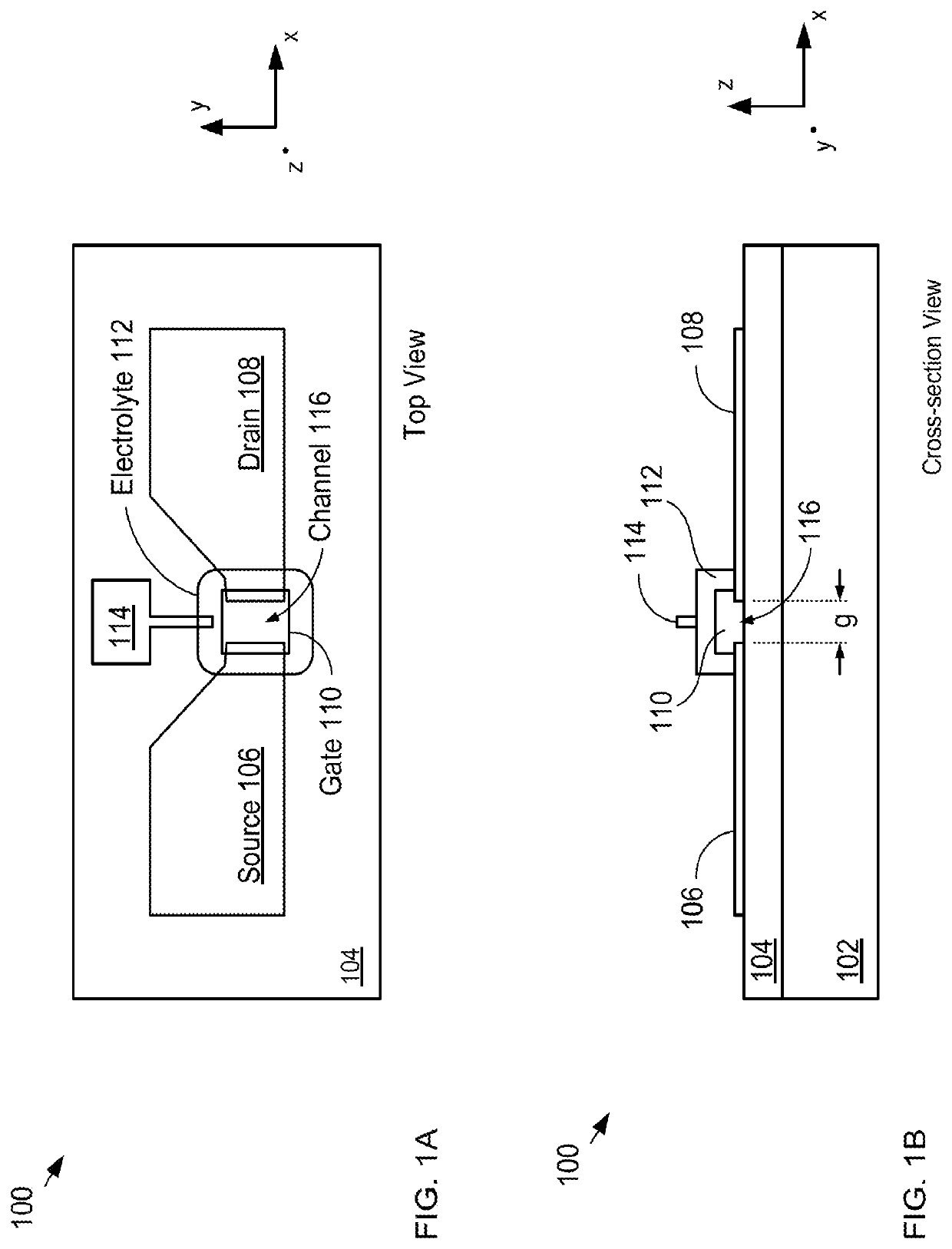

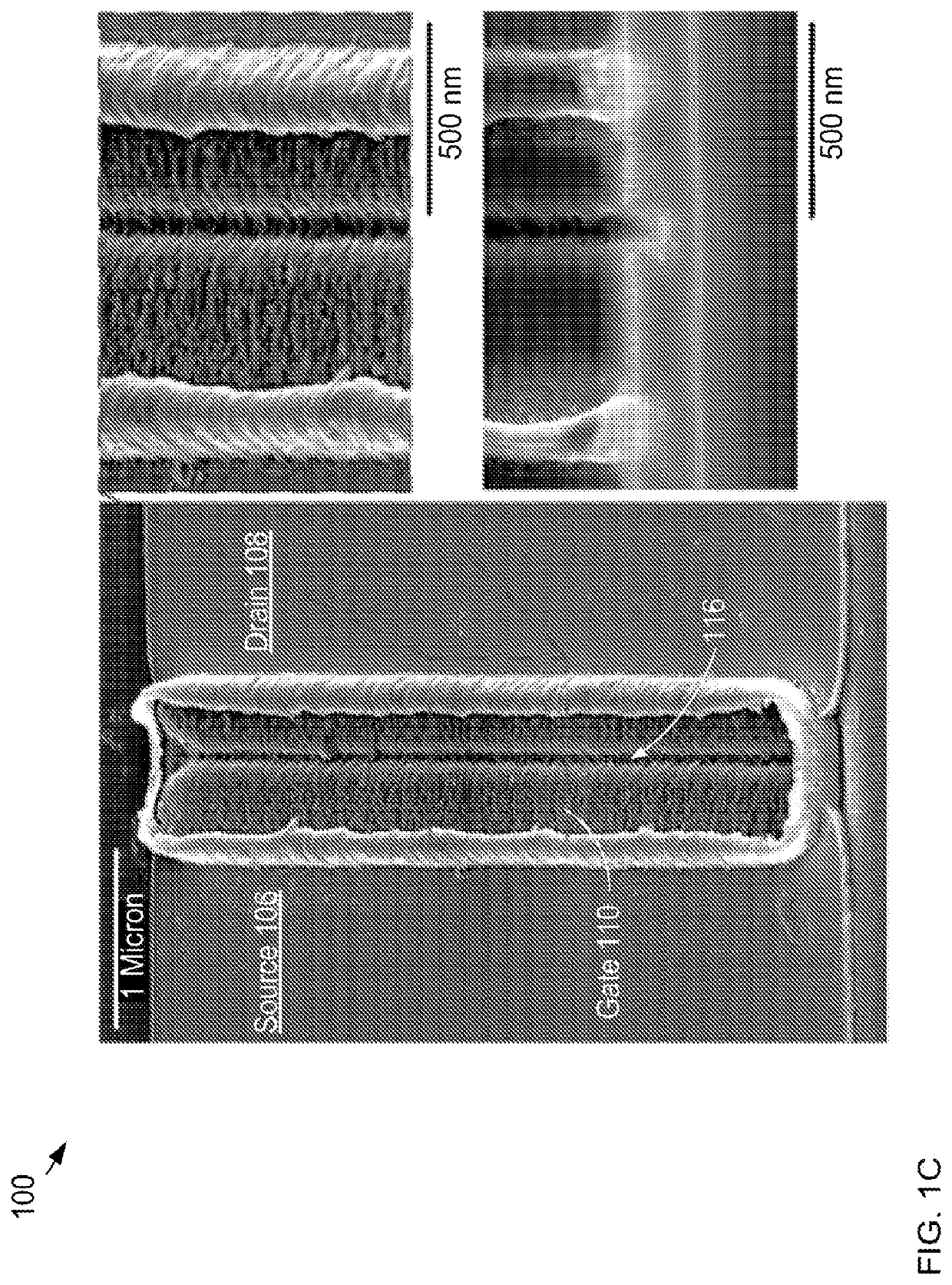

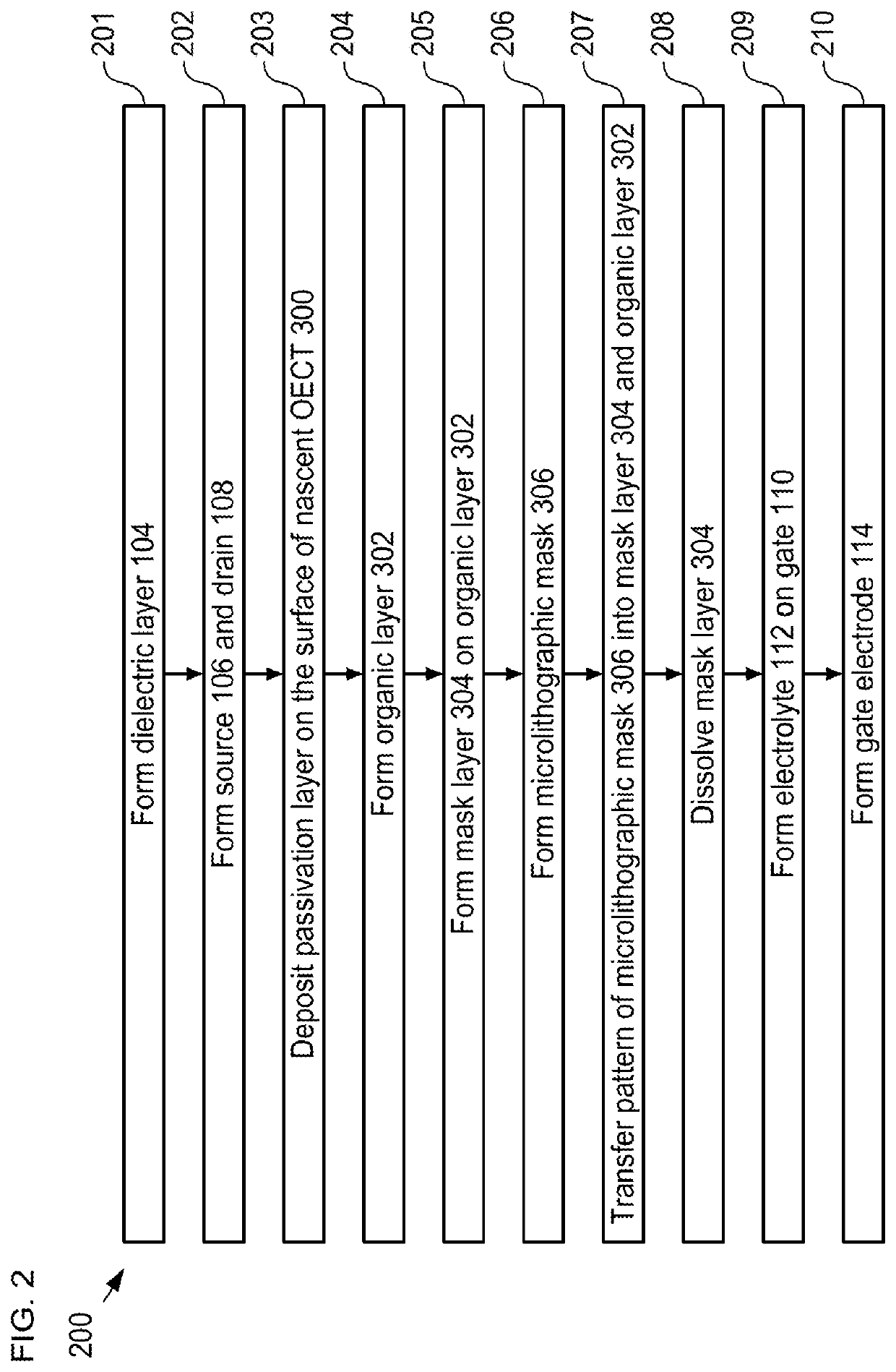

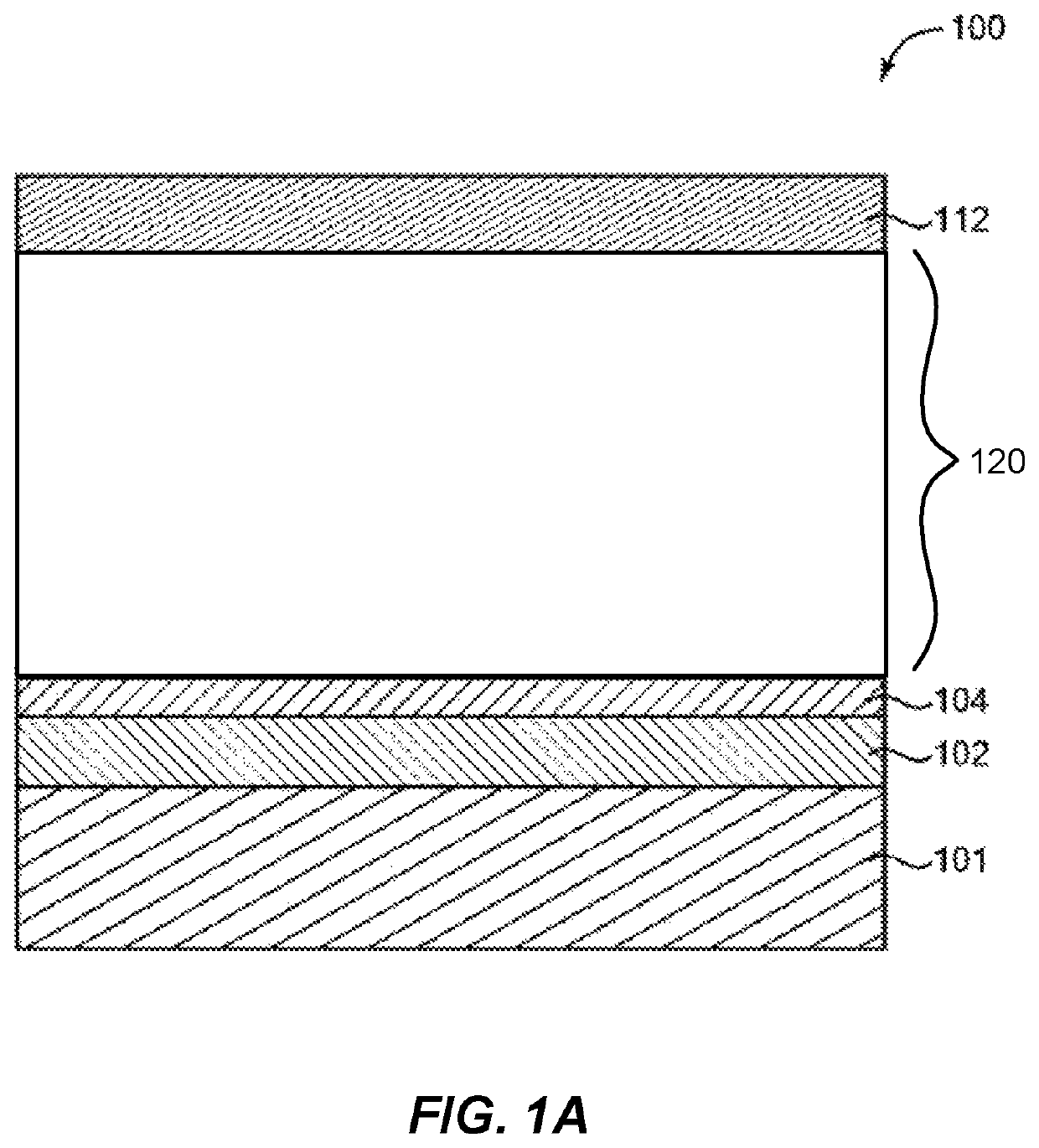

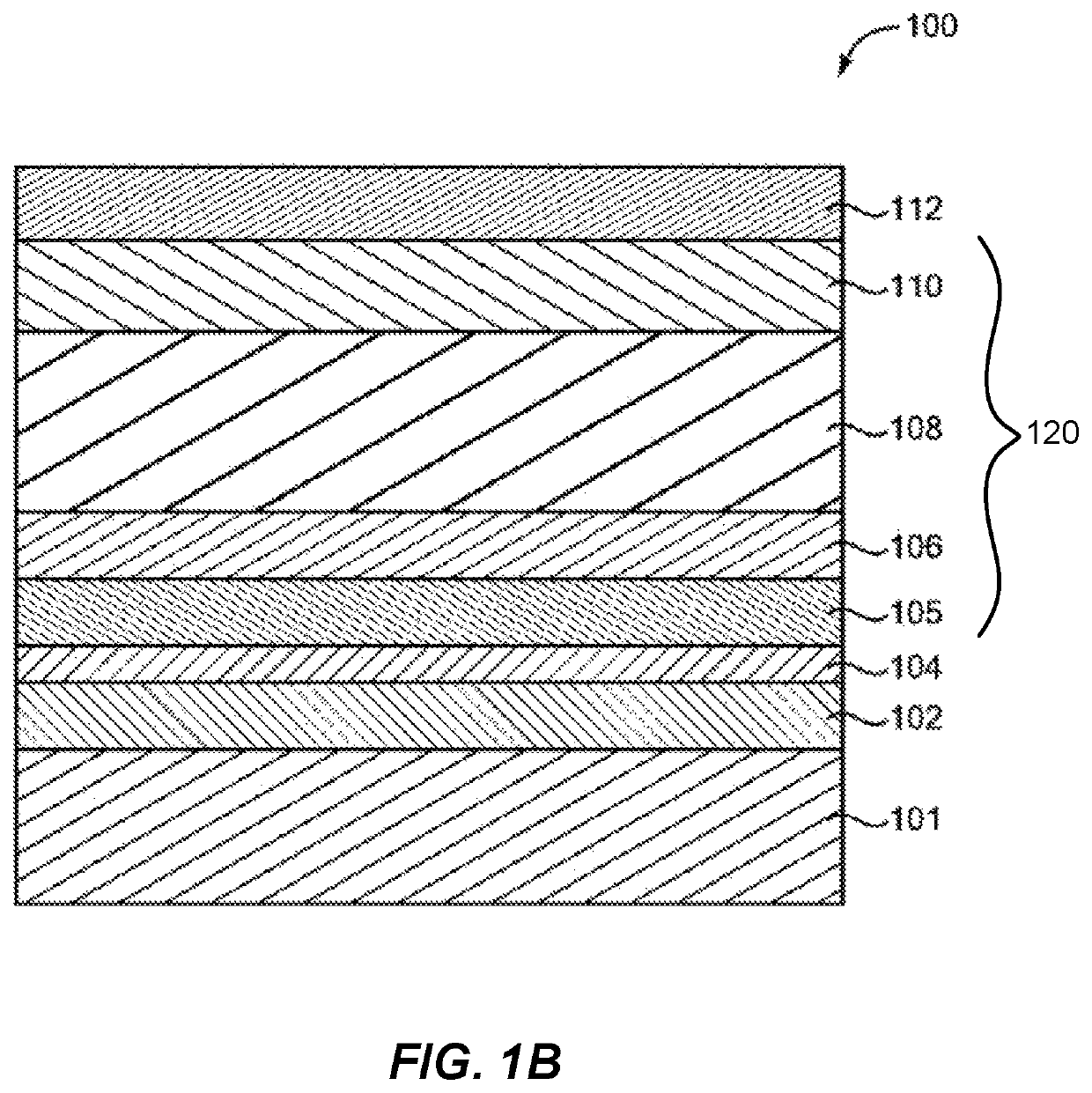

Method for lithograghic patterning of sensitive materials

ActiveUS10581003B2Avoid contactSolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionOrganic semiconductor

Methods for patterning highly sensitive materials, such as organic materials, organic semiconductors, biomolecular materials, and the like, with photolithographic resolution are disclosed. In some embodiments, a germanium mask (304) is formed on the surface of the sensitive material (302), thereby protecting it from subsequent processes that employ harsh chemicals that would otherwise destroy the sensitive material (302). A microlithography mask (306) is patterned on the germanium mask layer (304), after which the germanium exposed by the microlithography mask (306) is removed by dissolving it in water. After transferring the pattern of the germanium mask (304) into the sensitive material (302), the germanium and microlithography masks (304, 306) are completely removed by immersing the substrate in water, which dissolves the remaining germanium and lifts off the microlithography mask material. As a result, the only chemical to which the sensitive material (302) is exposed during the patterning process is water, thereby mitigating or avoiding damage to the material (302).

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

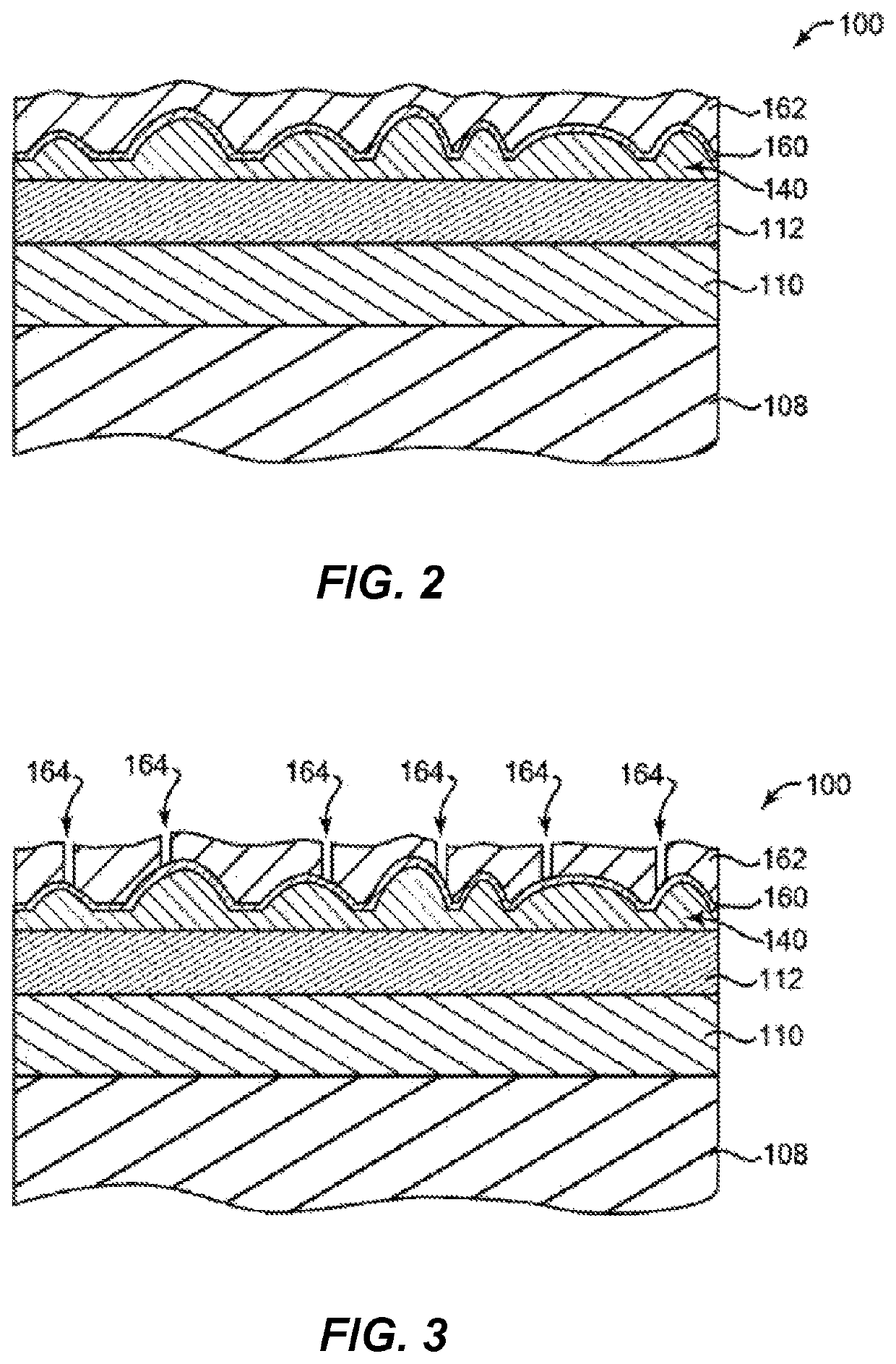

Thin-film semiconductor optoelectronic device with textured front and/or back surface prepared from etching

ActiveUS11038080B2Photovoltaic energy generationSemiconductor devicesLaser etchingPhysical chemistry

Owner:ALTA DEVICES INC

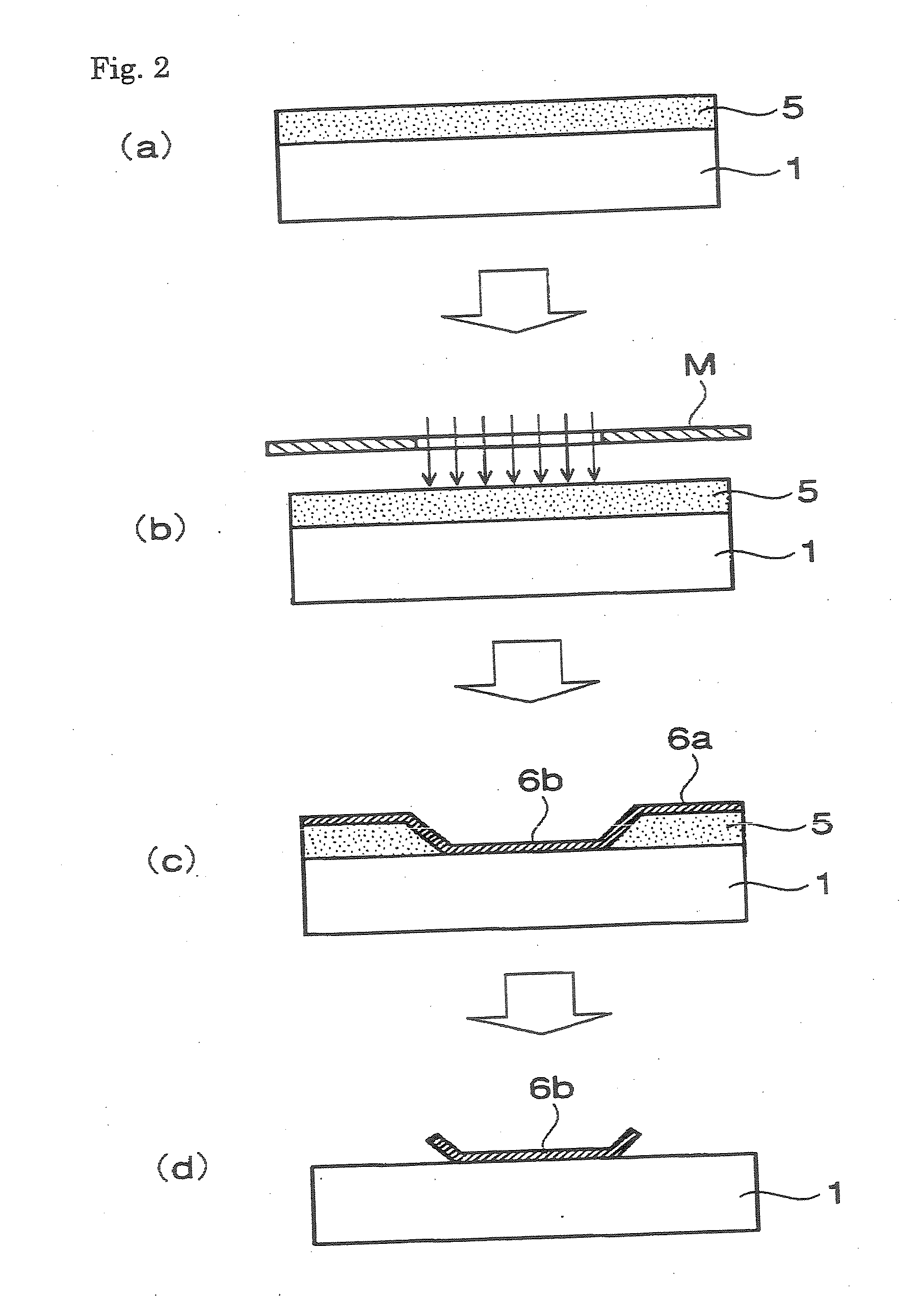

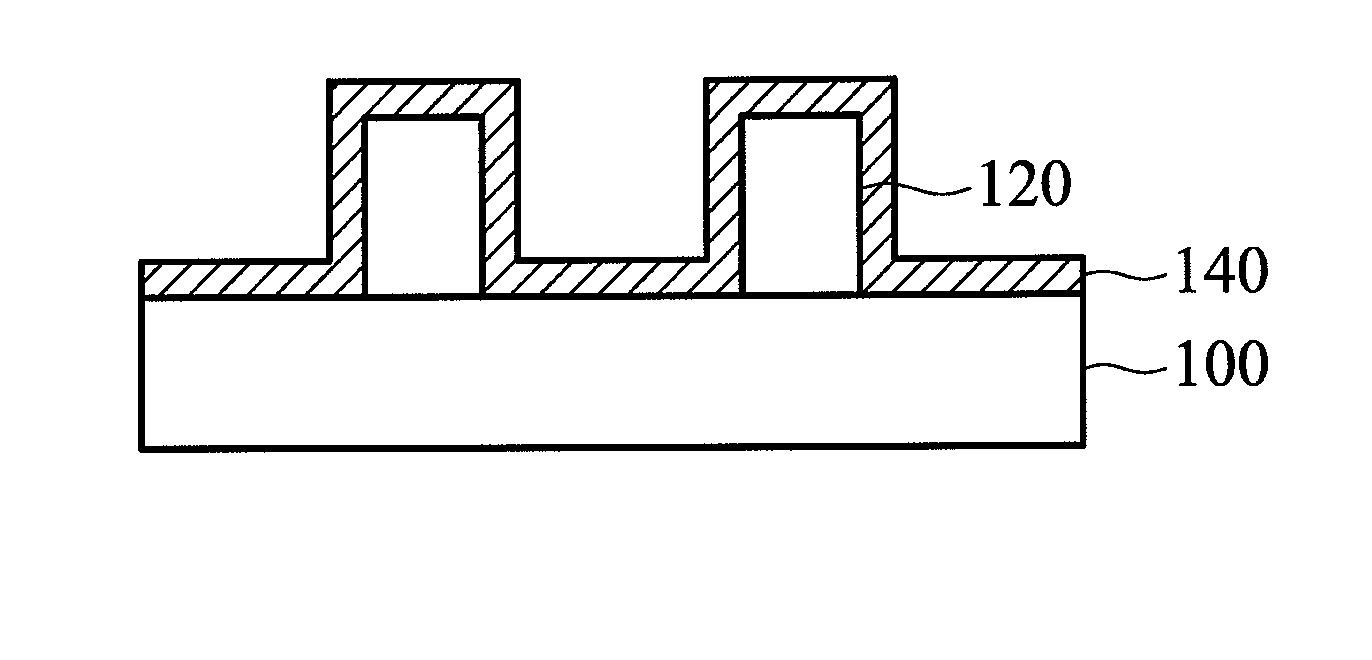

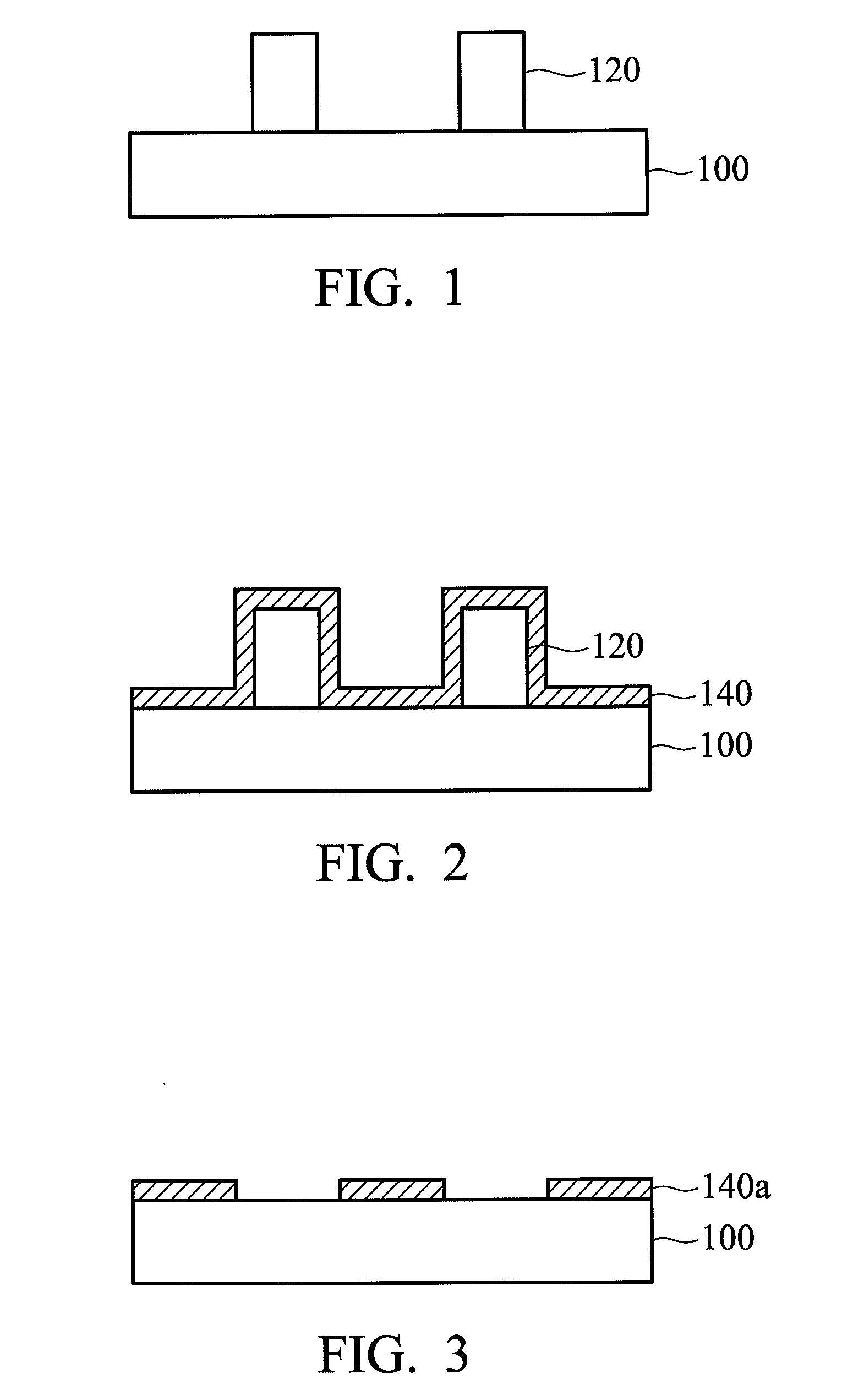

Patterning process for oxide film

ActiveUS20140034605A1Decorative surface effectsSemiconductor/solid-state device manufacturingPhysical chemistryMaterials science

The present disclosure provides a patterning process for an oxide film, including: covering a barrier layer composition on a substrate to form a patterned barrier layer, wherein the barrier layer composition includes an inorganic component and an organic binder with a weight ratio of 50-98:2-50; forming an oxide film on the patterned barrier layer and the substrate, wherein a thickness ratio (D1 / D2) of the barrier layer (D1) to the oxide film (D2) is about 5-2000; and lifting off the barrier layer and the oxide film thereon, while leaving portions of the oxide film on the substrate.

Owner:IND TECH RES INST

Method for producing window elements that can be soldered into a housing in a hermetically sealed manner and free-form window elements produced in accordance with said method

ActiveUS10330941B2Minimizing penetrationSolder connection is firmRadiation pyrometryPhotometryHigh energyOptical coating

A method for production of window elements which can be soldered into a housing in a hermetically tight manner with optical coating and free-form window elements are disclosed. After application of optical coatings, a protective layer is applied to the optical coating, the two layer systems are selectively removed by means of a machining beam of high-energy radiation for the purpose of ablation of a desired optically active free-form surface for window elements with any geometric shape through a localized machining beam in edge regions of the optically active free-form surface such that the protective layer remains on the optical coating as lift-off mask which is lifted off after applying a metallization for a solder layer by an etching process that acts selectively only on the protective layer but not on the optical coating, and the metallization remains only on the peripheral edge regions circumscribing the free-form surfaces.

Owner:JENOPTIK OPTICAL SYST +1

Method for stripping metal film by using positive photoresist as mask

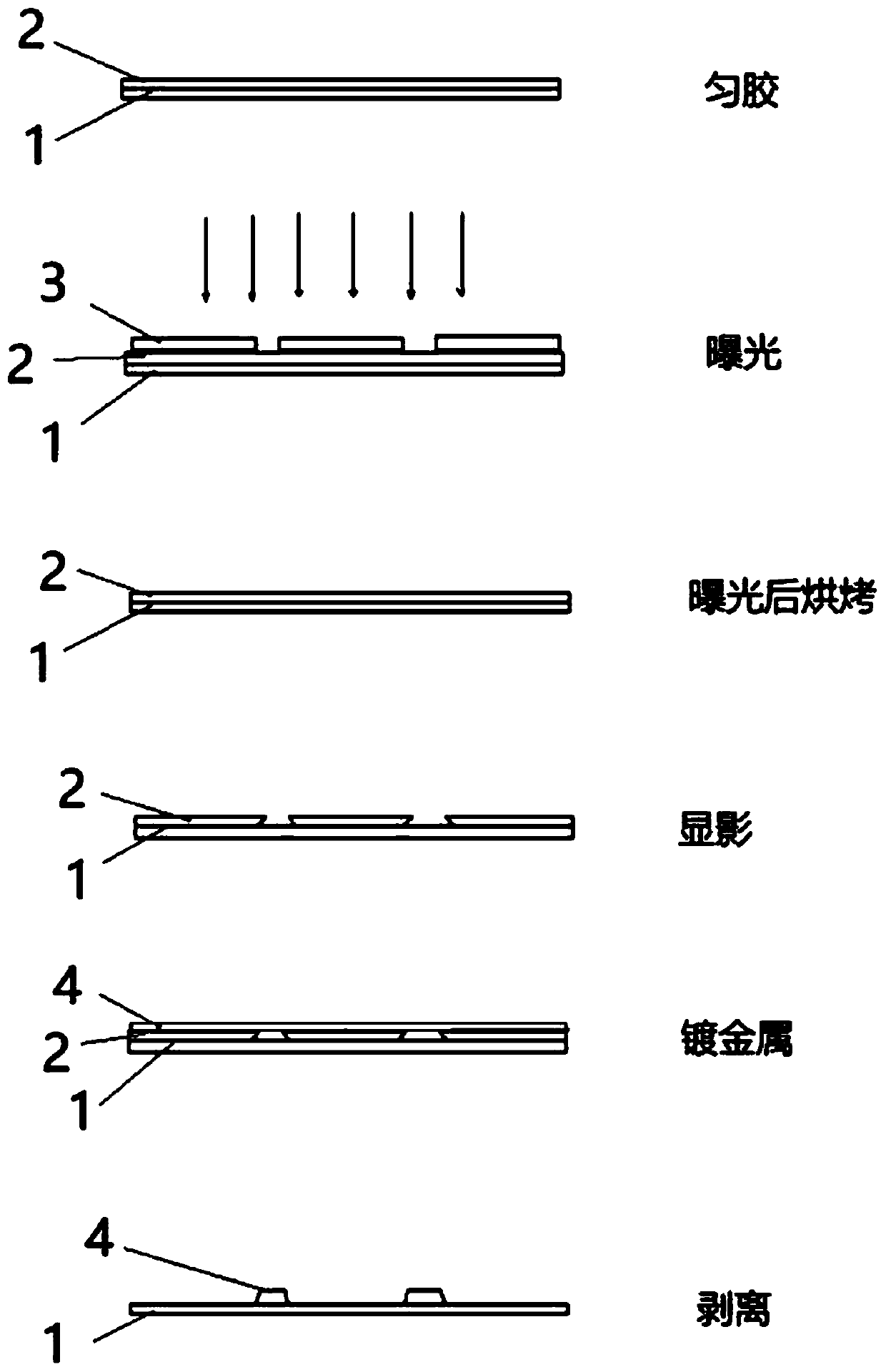

PendingCN111522208ANot easy to lift offLow costSemiconductor/solid-state device manufacturingPhotosensitive material processingOrganic solventChain scission

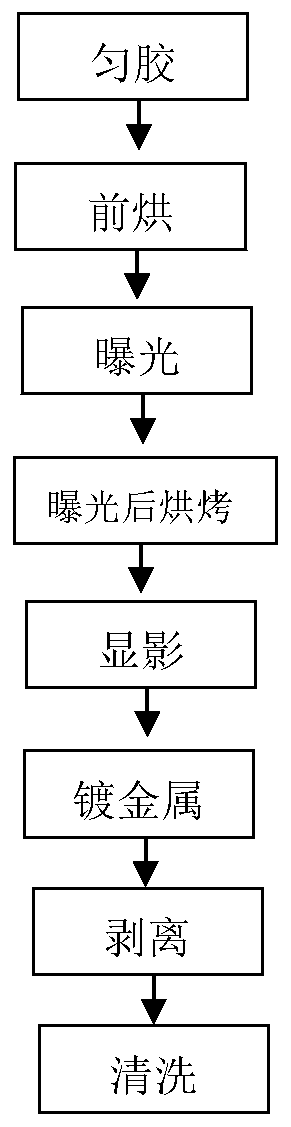

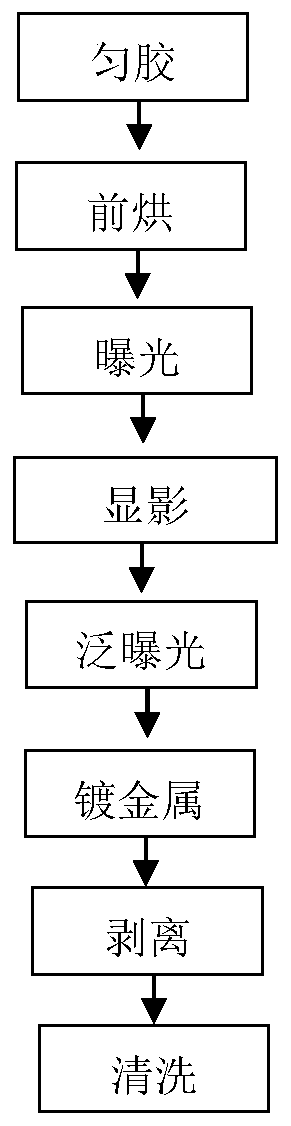

The invention discloses a method for stripping a metal film by using positive photoresist as a mask. Gluing, pre-baking, exposing, developing, cleaning, extensive exposing, metal plating and strippingare conducted on a substrate, specifically, a blue film is attached to the surface of the substrate, then the blue film is torn off, and metal with glue at the bottom is removed through the viscosityof the blue film. And finally, the substrate is placed in an organic solvent, and the residual photoresist on the surface of the substrate and the residual metal on the substrate are removed. According to the invention, the traditional positive photoresist is adopted, the normal exposure energy and exposure time of the positive photoresist are used in a photoetching machine to carry out whole-surface extensive exposure, and then film coating is carried out. Extensive exposure is performed on the positive photoresist; the photoresist crosslinking is changed, the adhesion is reduced, chain scission reaction occurs between molecules, pinholes are formed in the surface of the photoresist, so that the adhesion between the metal film and the surface of the positive photoresist becomes poor, themetal layer with the photoresist at the bottom can be directly torn off by using the blue film, and the defect that metal with a right angle or an approximate right angle after positive photoresist development is not easy to lift off is overcome.

Owner:NJU OPTOELECTRONICS ENG RES INST CO LTD

Display panel and manufacturing method thereof

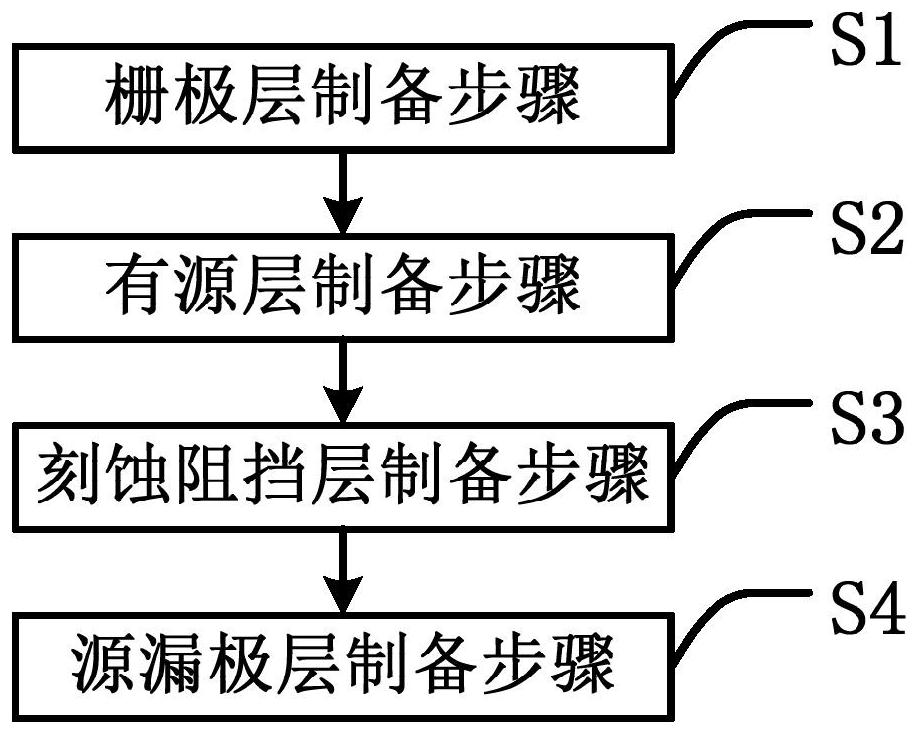

ActiveCN111370311BReduce harmImprove reliabilityTransistorSemiconductor/solid-state device manufacturingEngineeringActive layer

The present application discloses a display panel and a preparation method thereof. The preparation method of the display panel includes the following steps: a gate layer preparation step, an active layer preparation step, an etching barrier layer preparation step, and a source-drain layer preparation step, The active layer preparation step includes a semiconductor layer preparation step and a first patterning treatment step. The technical effect of the present invention is that, by repeatedly using the source-drain photomask, combined with the Lift off technology, the preparation of the device with the etching barrier layer is realized, and the cost of the mask plate is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

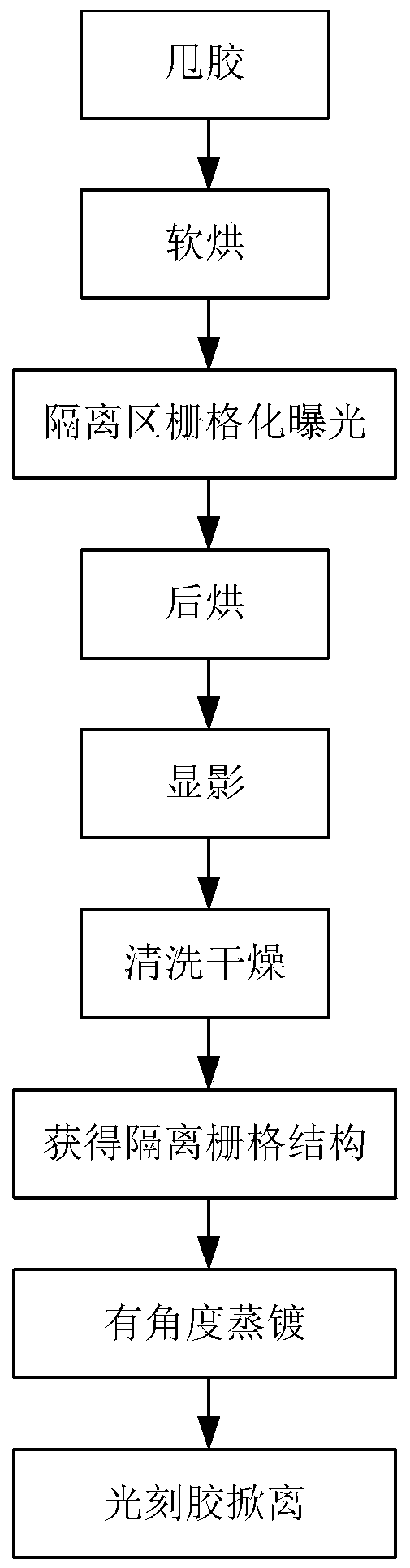

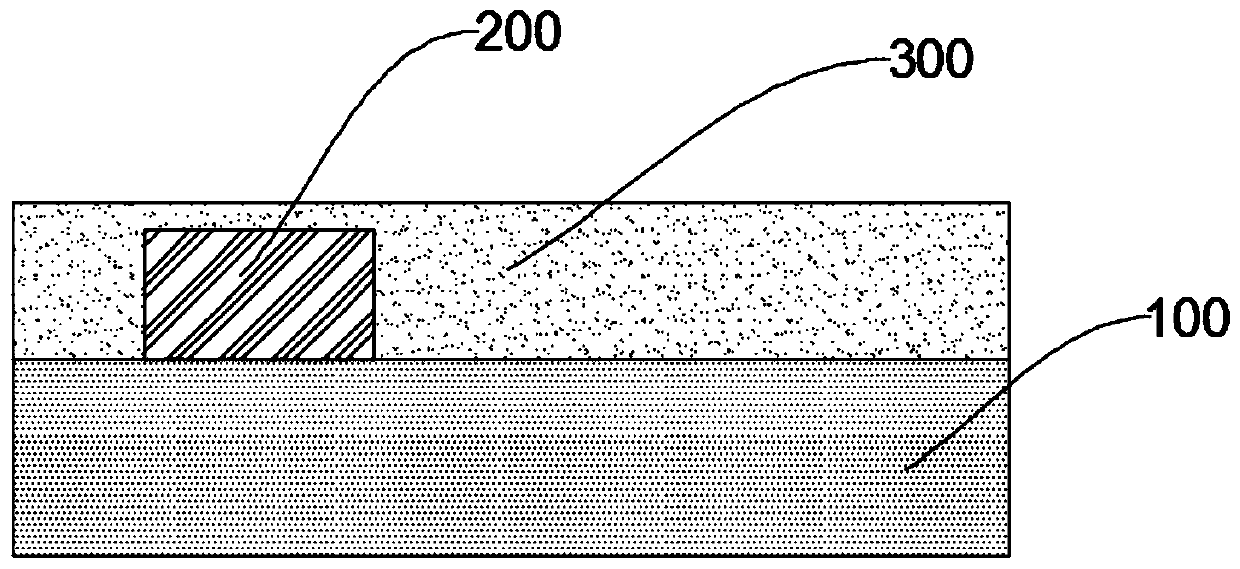

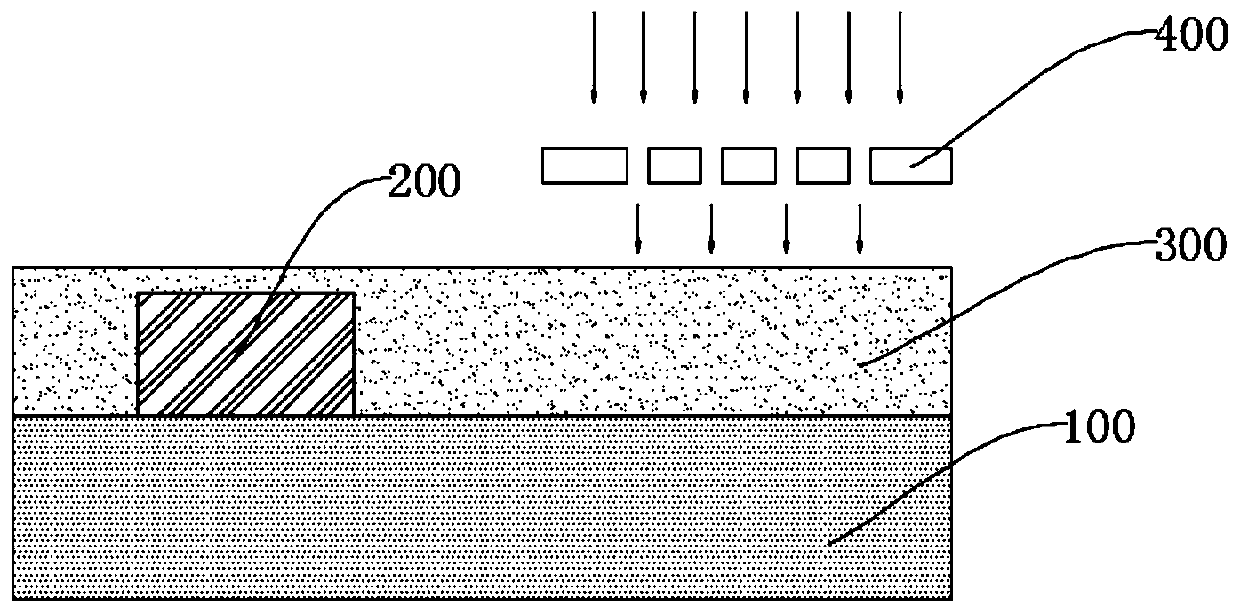

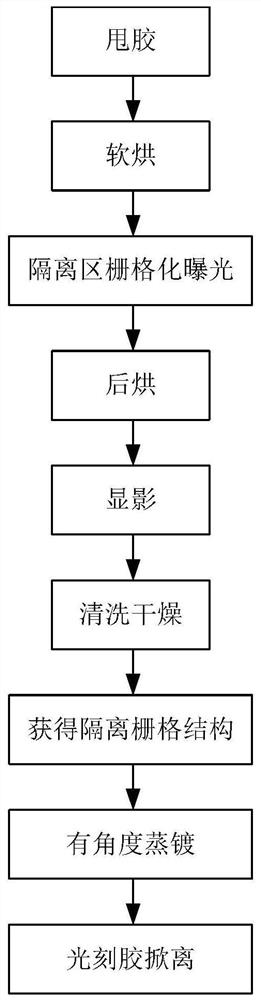

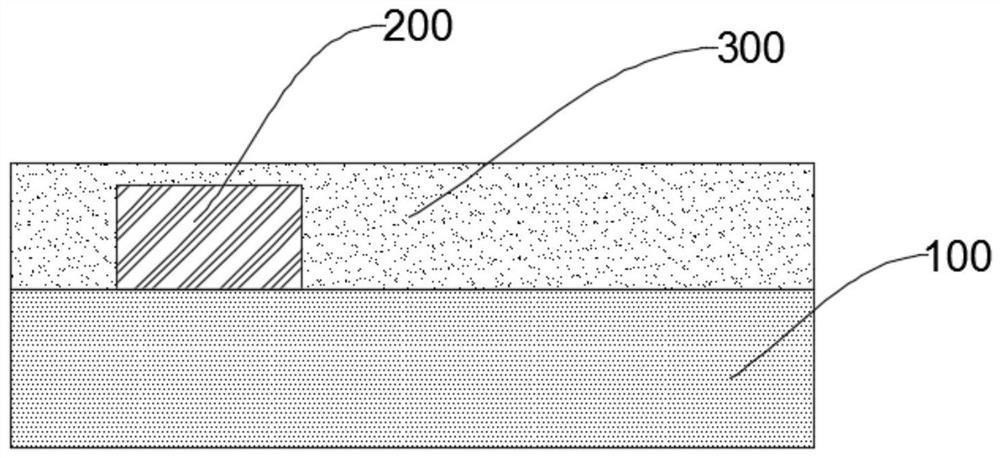

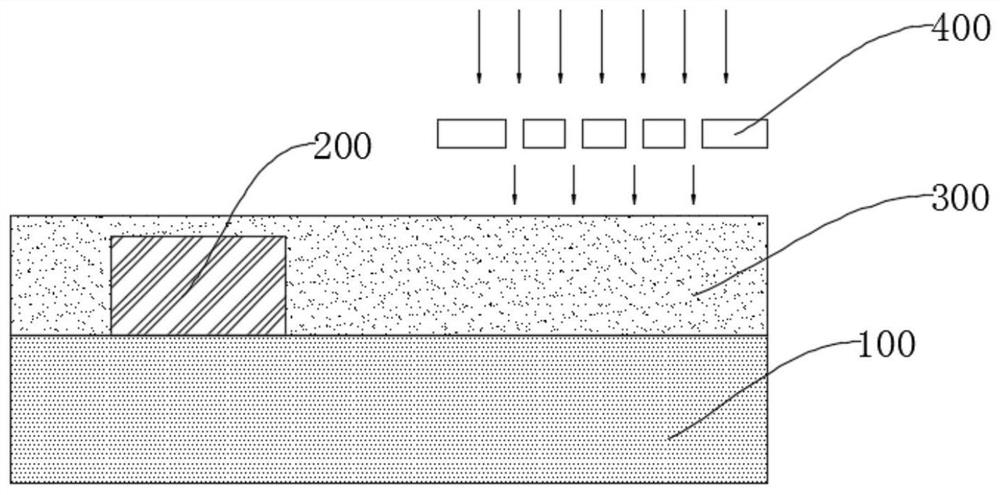

Method for manufacturing isolation structure of semiconductor device and semiconductor device thereof

ActiveCN110661170AGuaranteed contactLaser detailsPhotomechanical apparatusDevice materialPhotoresist

The invention relates to semiconductor manufacturing, in particular to a method for manufacturing the isolation structure of a semiconductor device and a semiconductor device. The manufacturing process of the semiconductor device includes the following steps that: a substrate is provided; a device is formed on the substrate; and a conductive isolation structure is formed on the substrate. The method for forming the conductive isolation structure comprises the following steps that: a photoresist layer is formed on the device and the substrate; a grid structure is formed in the photoresist layer; the grid structure is reserved; a conductive layer is formed on the surfaces of the device, the substrate and the grid structure; and the grid structure is lifted off. According to the method of theinvention, a lift-off process is provided; the photoresist with a lift-off function is subjected to gridding treatment, so that the photoresist can still be in full contact with a solvent after a sample piece is subjected to angled evaporation, and lift-off operation is completed.

Owner:深圳市矽赫科技有限公司

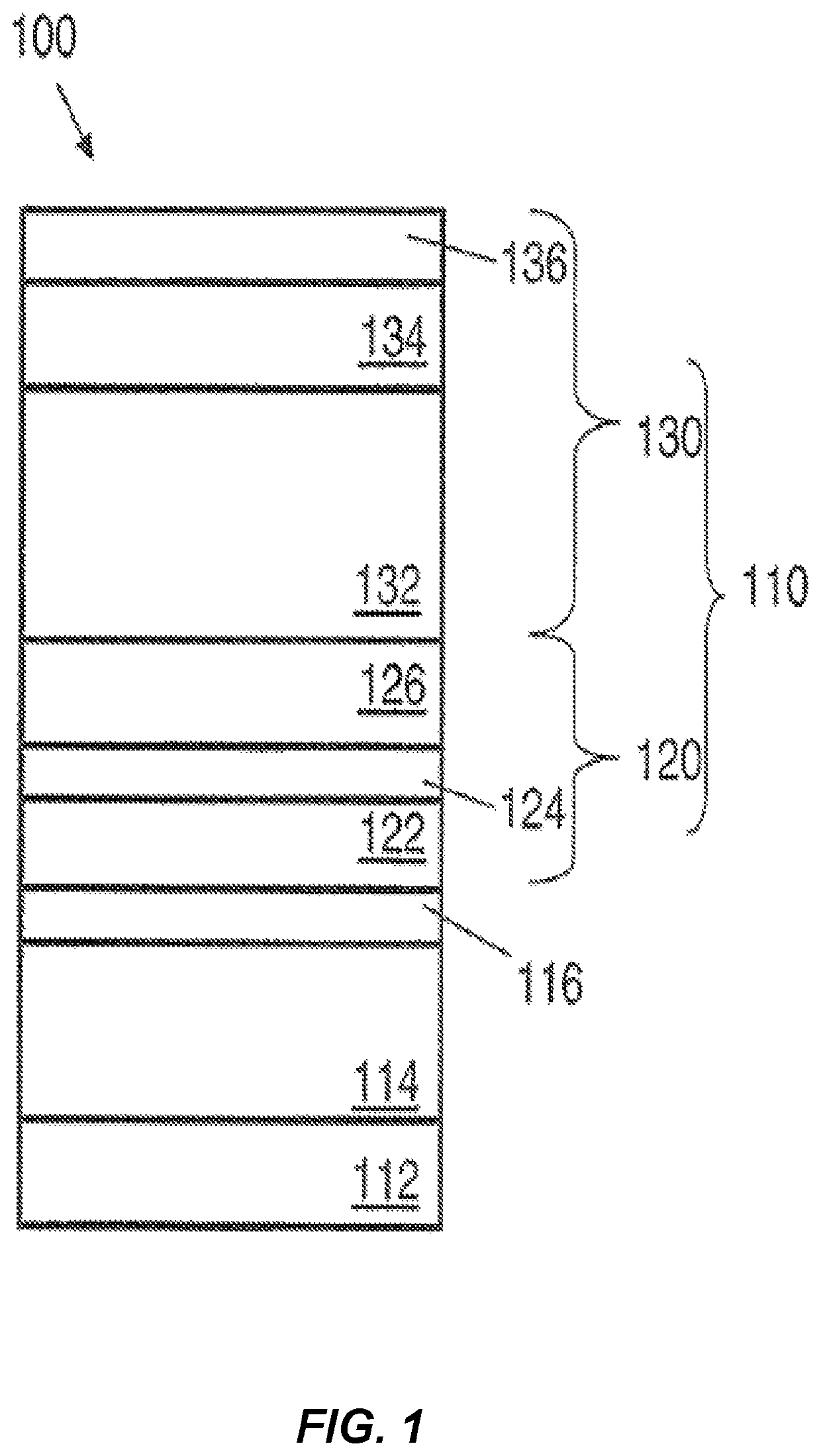

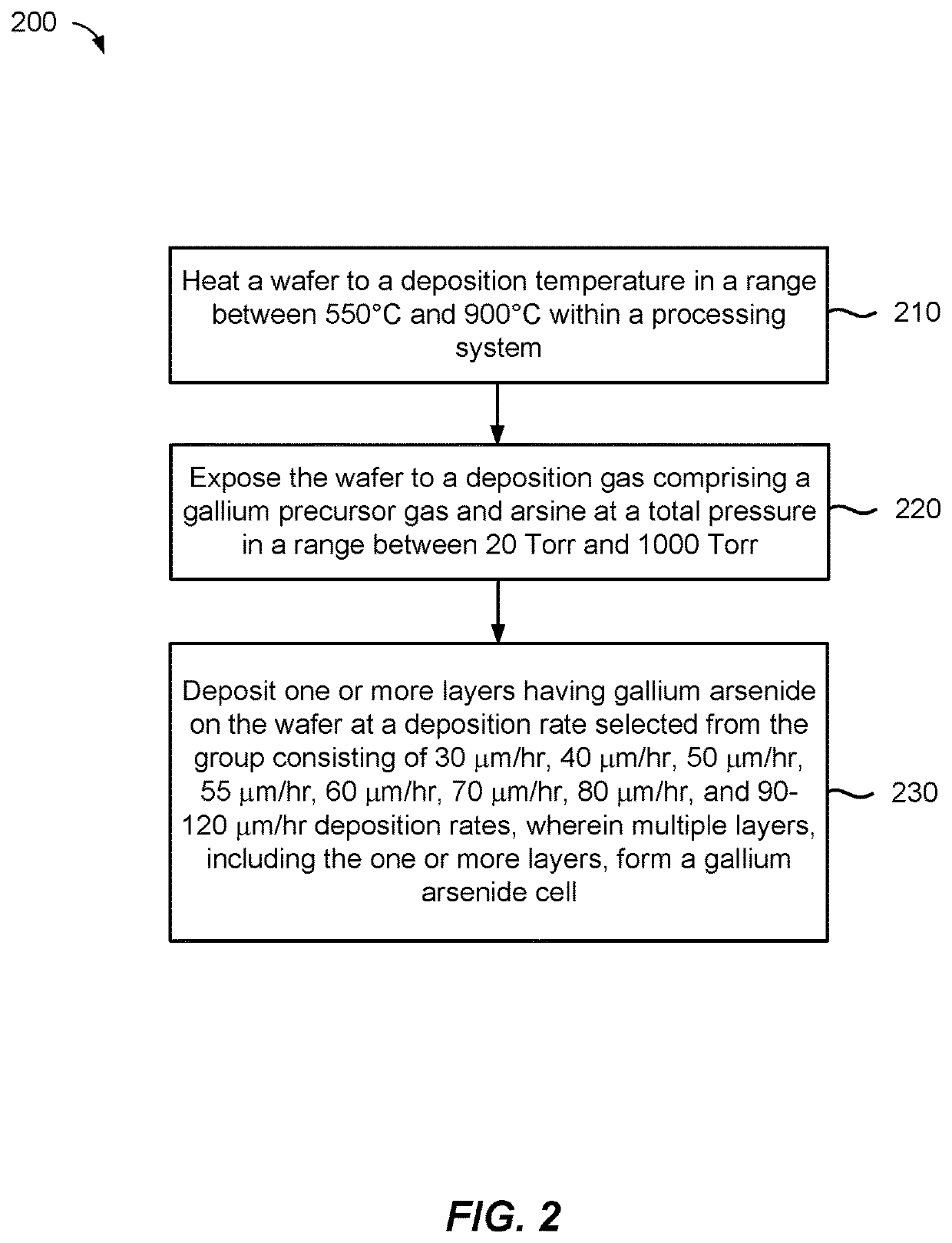

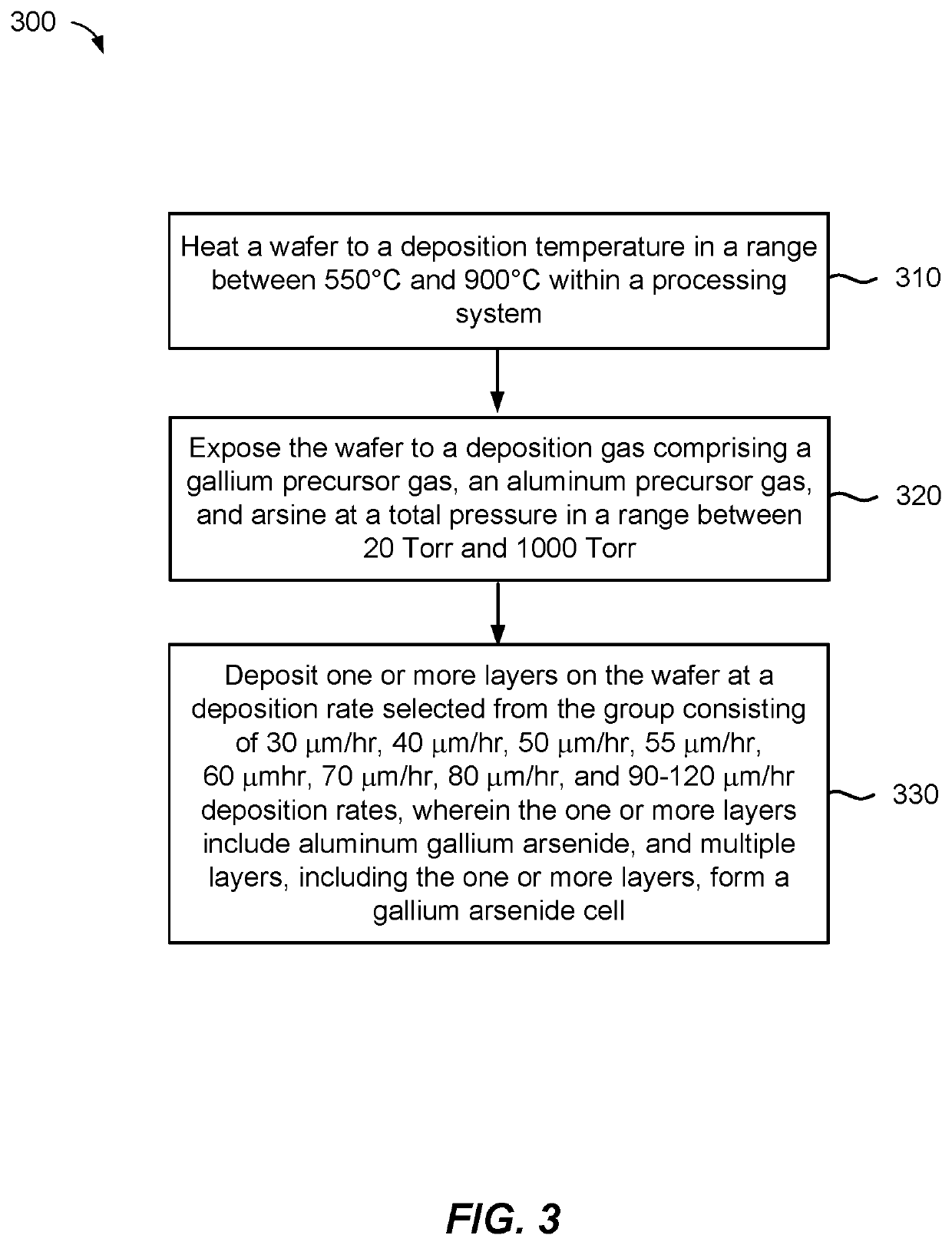

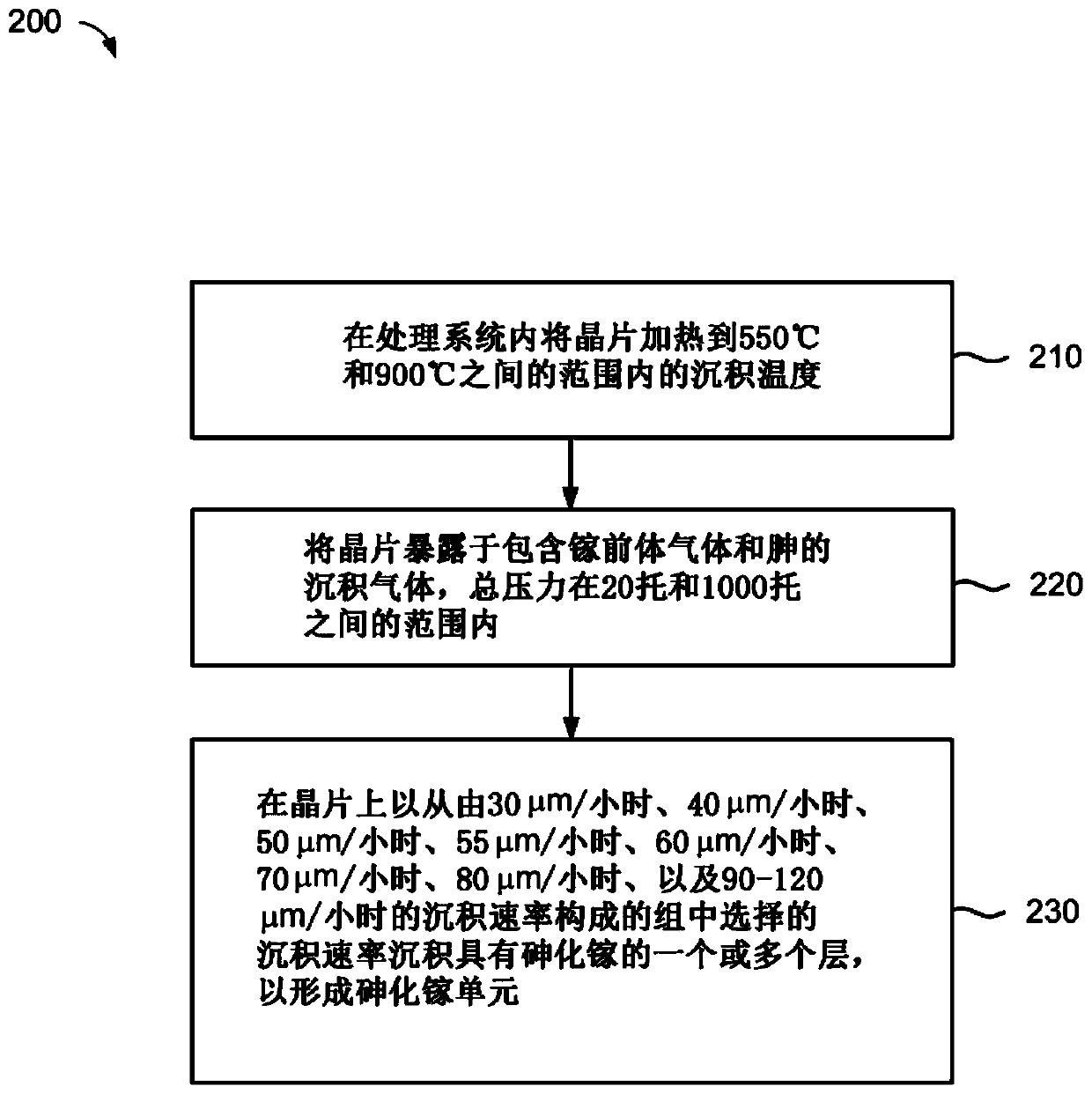

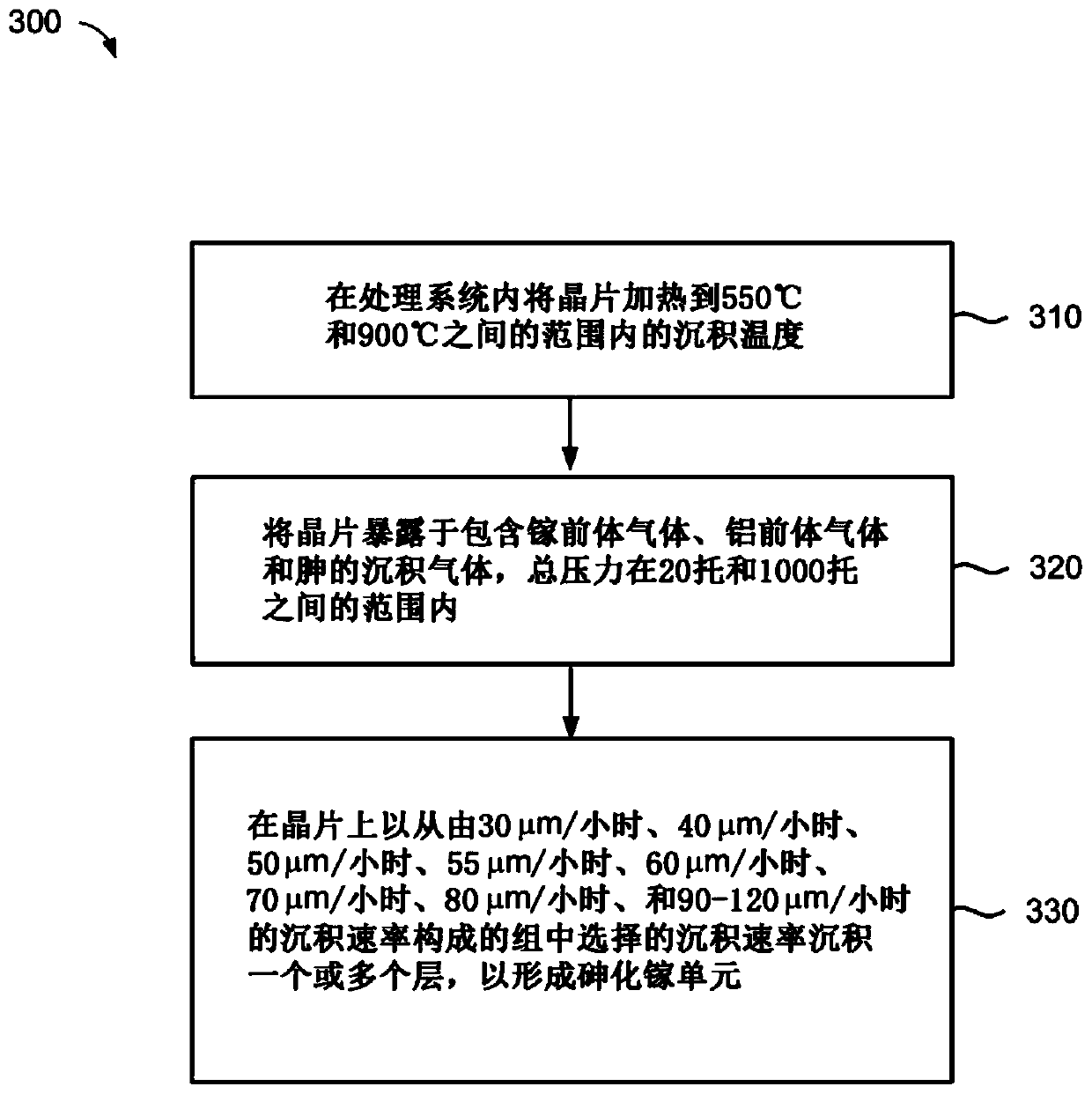

Methods for high growth rate deposition for forming different cells on a wafer

ActiveUS11393683B2Polycrystalline material growthSemiconductor/solid-state device manufacturingIndiumIndium arsenide

Aspects of the disclosure relate to processes for epitaxial growth of Group III / V materials at high rates, such as about 30 μm / hr or greater, for example, about 40 μm / hr, about 50 μm / hr, about 55 μm / hr, about 60 μm / hr, about 70 μm / hr, about 80 μm / hr, and about 90-120 μm / hr deposition rates. The Group III / V materials or films may be utilized in solar, semiconductor, or other electronic device applications. The Group III / V materials may be formed or grown on a sacrificial layer disposed on or over the support substrate during a vapor deposition process. Subsequently, the Group III / V materials may be removed from the support substrate during an epitaxial lift off (ELO) process. The Group III / V materials are thin films of epitaxially grown layers containing gallium arsenide, gallium aluminum arsenide, gallium indium arsenide, gallium indium arsenide nitride, gallium aluminum indium phosphide, phosphides thereof, nitrides thereof, derivatives thereof, alloys thereof, or combinations thereof.

Owner:ALTA DEVICES INC

Display panel and manufacturing method thereof

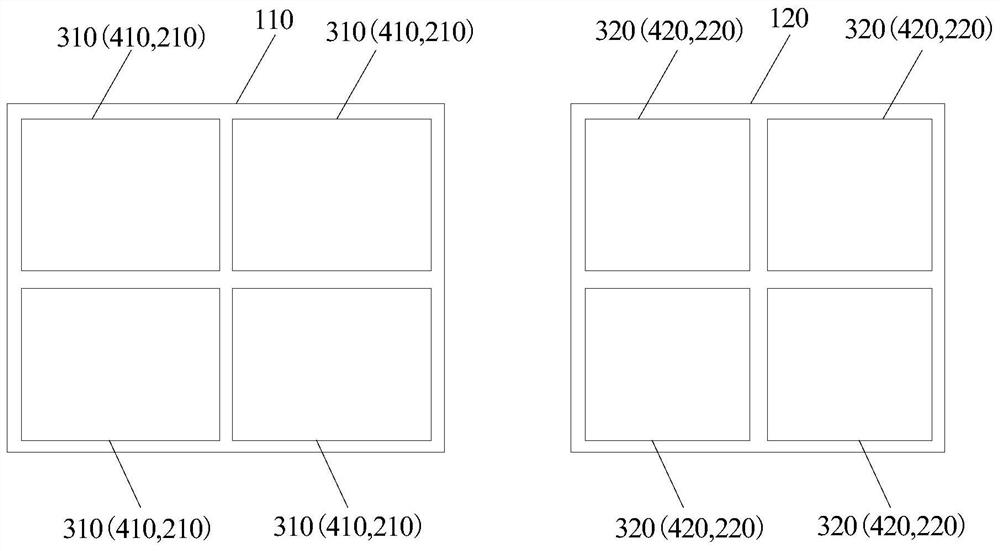

ActiveCN108333819BThere will be no unclean cuttingPerformance impactNon-linear opticsCrystallographyColor film

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

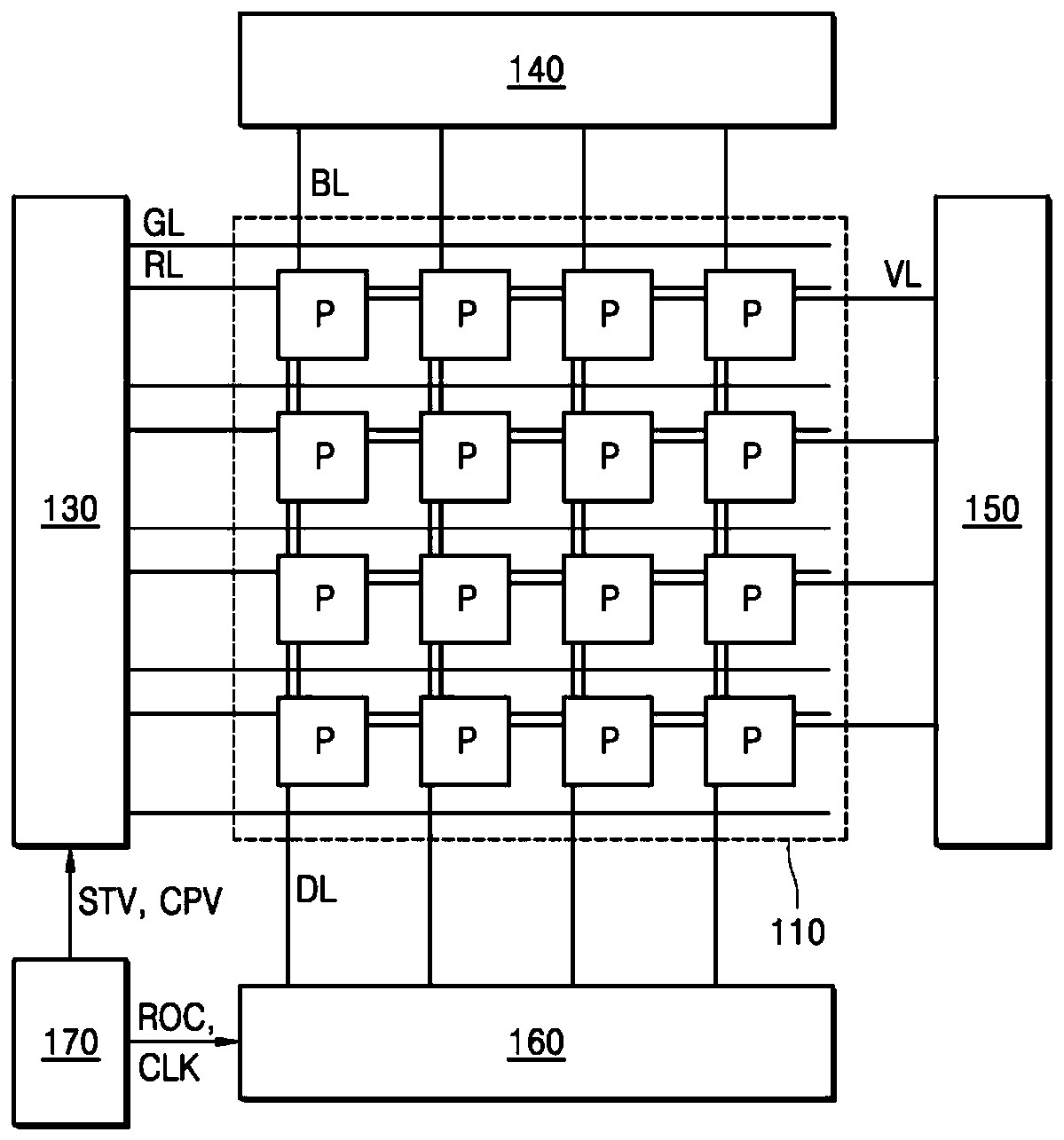

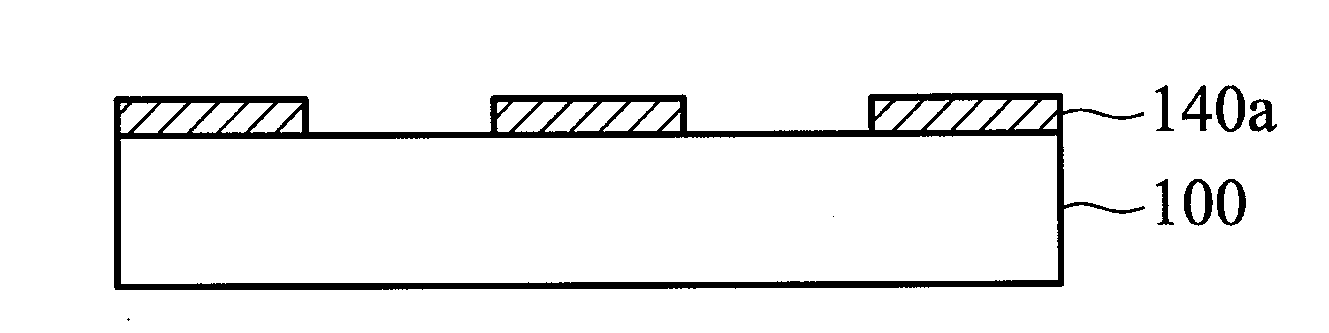

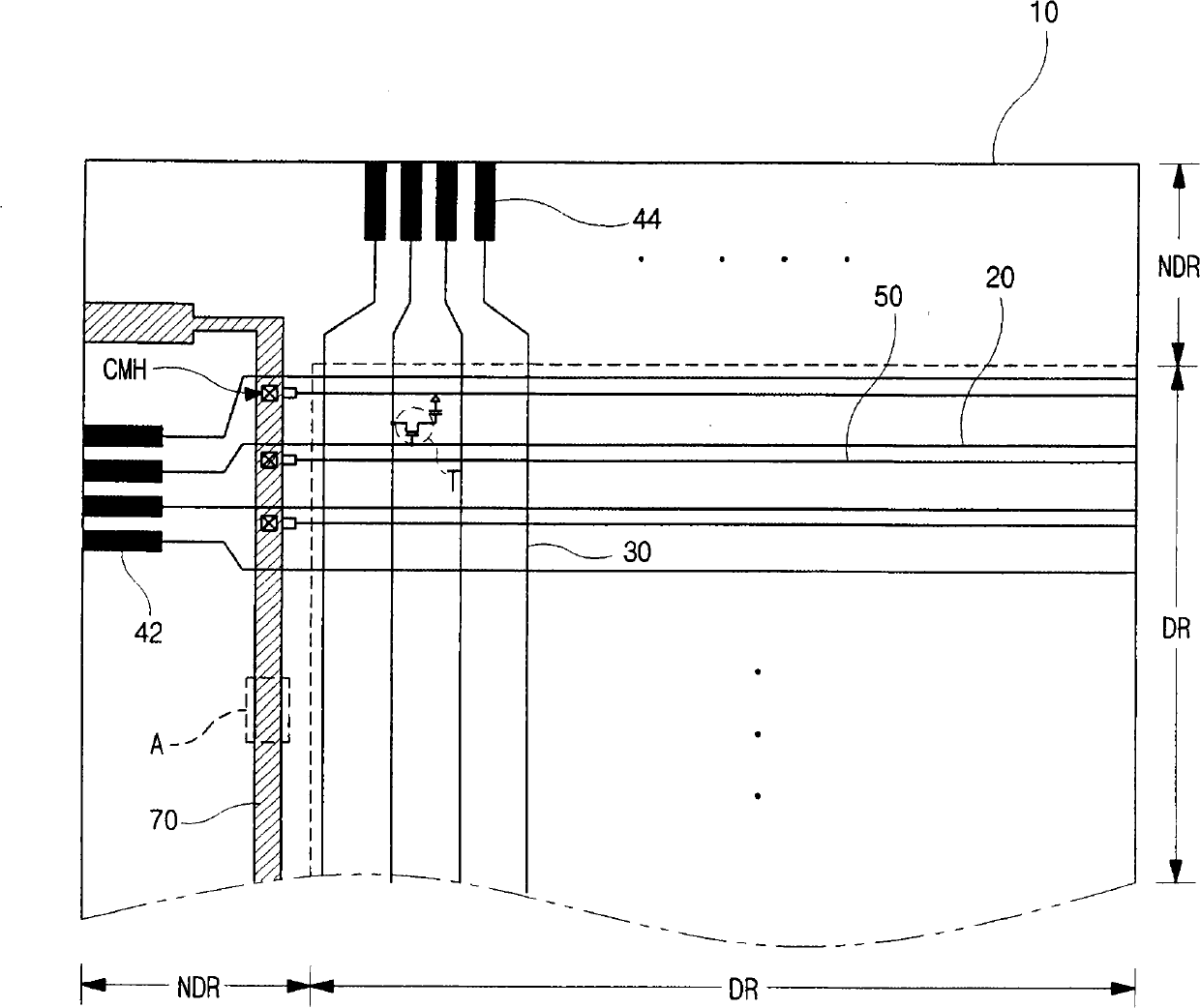

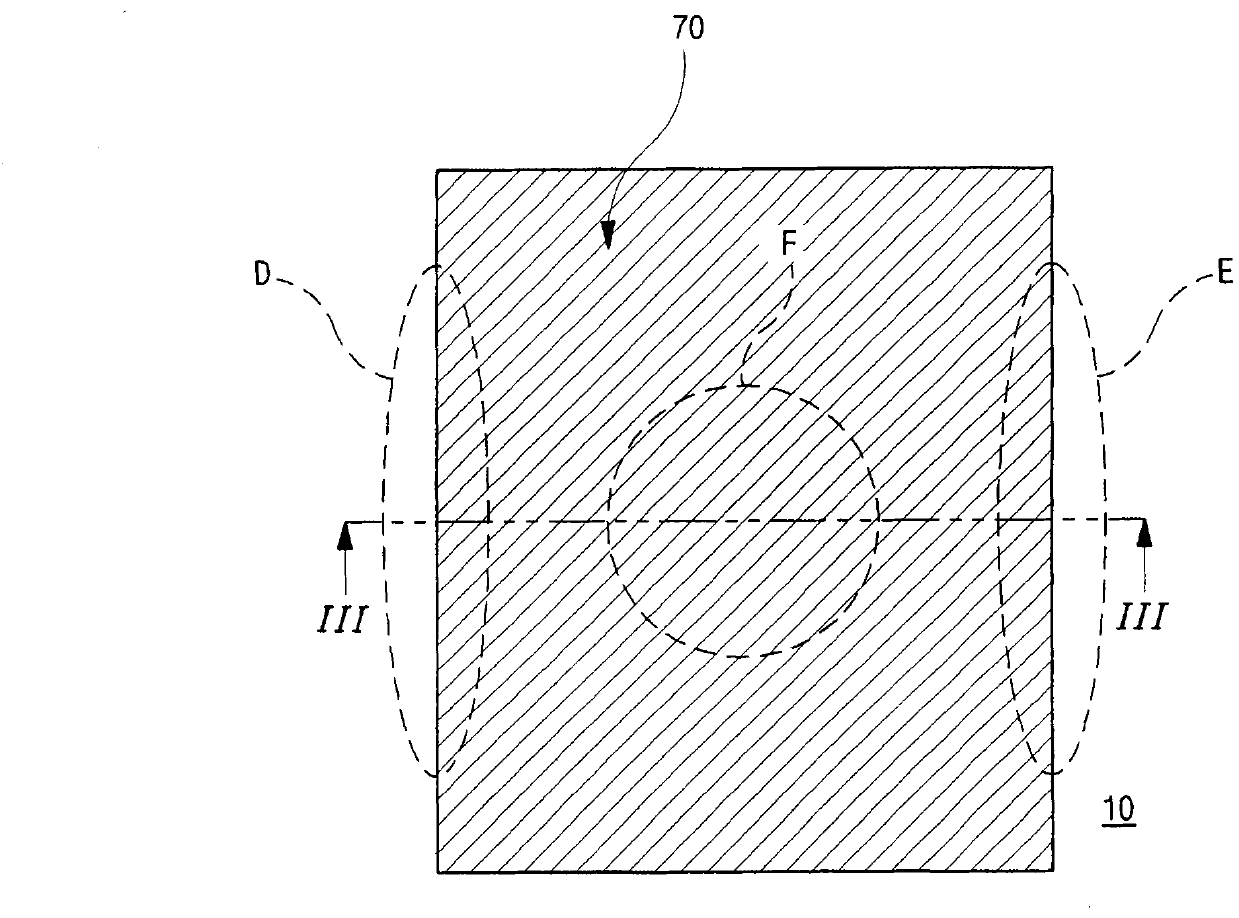

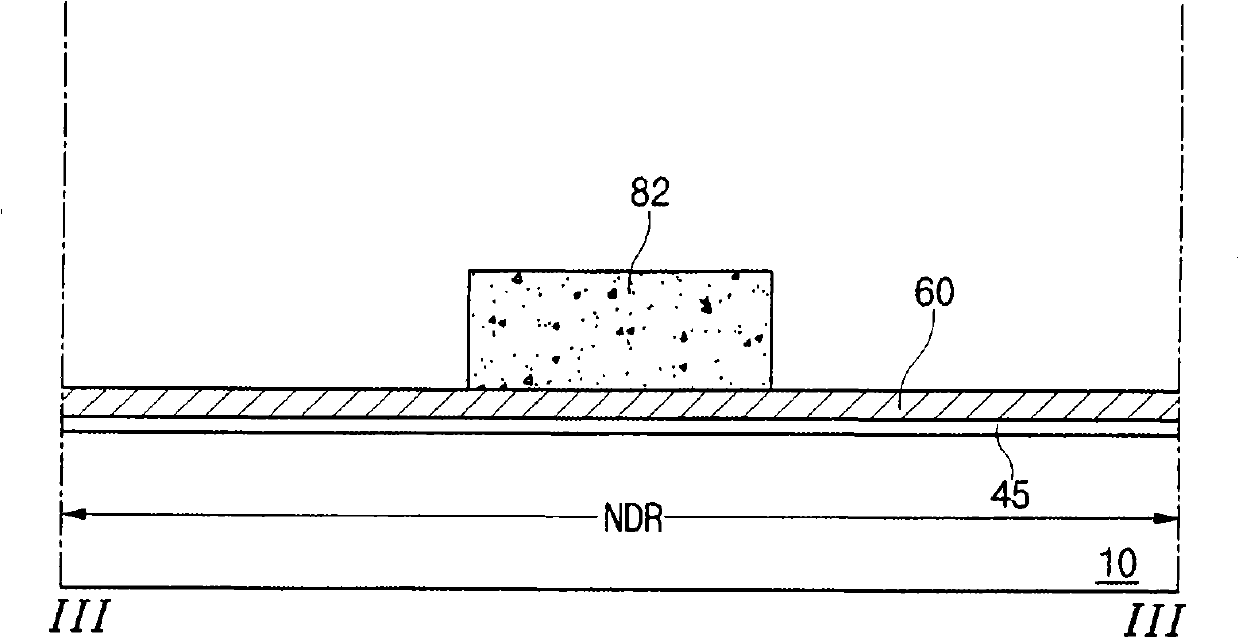

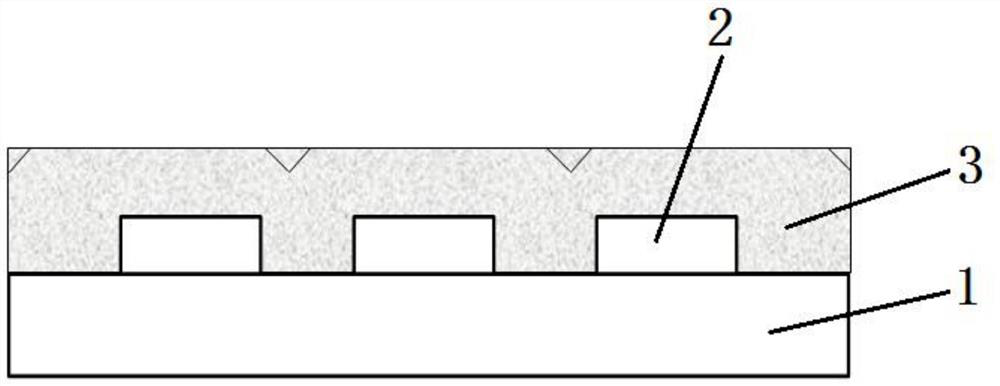

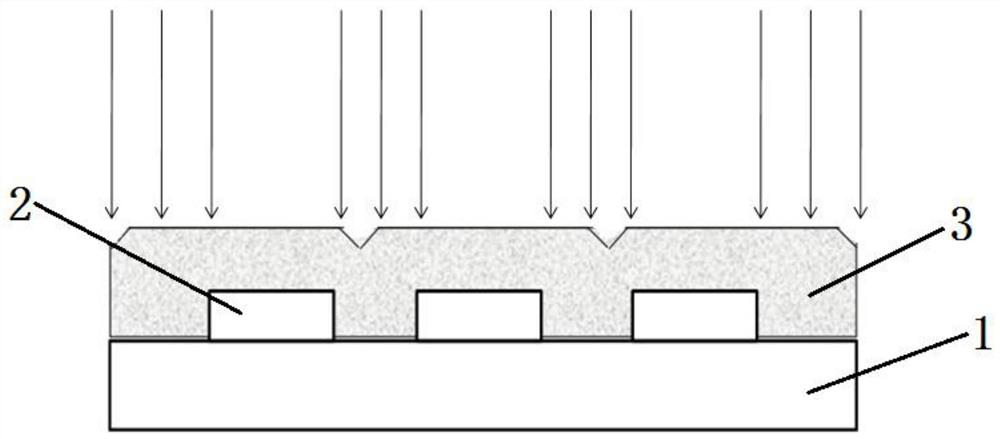

Method of lifting off and fabricating array substrate for liquid crystal display device using the same

ActiveCN101349877BSemiconductor/solid-state device manufacturingPhotosensitive material processingLiquid-crystal displayPhotoresist

The present invention relates a method of lifting off and fabricating array substrate for liquid crystal display device using the same. The method of lifting off includes forming a first material layer on a substrate; forming a photoresist pattern including first and second holes and on the first material layer; patterning the first material layer using the photoresist pattern as a patterning mask to form a material pattern having first and second grooves within the material pattern, the first and second grooves corresponding to the first and second holes, respectively; forming a second material layer on an entire surface of the substrate including the photoresist pattern and the first and second grooves; and removing the photoresist pattern and the second material layer on the photoresist pattern at the same time, wherein a portion of the material pattern between the first and second grooves and portions of the material pattern at sides of the first and second grooves constitute a line as a whole.

Owner:LG DISPLAY CO LTD

Patterning process for oxide film

ActiveUS8906247B2Decorative surface effectsSemiconductor/solid-state device manufacturingPhysical chemistryMaterials science

The present disclosure provides a patterning process for an oxide film, including: covering a barrier layer composition on a substrate to form a patterned barrier layer, wherein the barrier layer composition includes an inorganic component and an organic binder with a weight ratio of 50-98:2-50; forming an oxide film on the patterned barrier layer and the substrate, wherein a thickness ratio (D1 / D2) of the barrier layer (D1) to the oxide film (D2) is about 5-2000; and lifting off the barrier layer and the oxide film thereon, while leaving portions of the oxide film on the substrate.

Owner:IND TECH RES INST

A method for improving the abnormality of the lift OFF process pattern of the thick metal layer

ActiveCN109461652BAvoid glue collapseReduce stressSemiconductor/solid-state device manufacturingGraphicsEngineering physics

Owner:WUXI ZHONGWEI JINGYUAN ELECTRONIC CO LTD

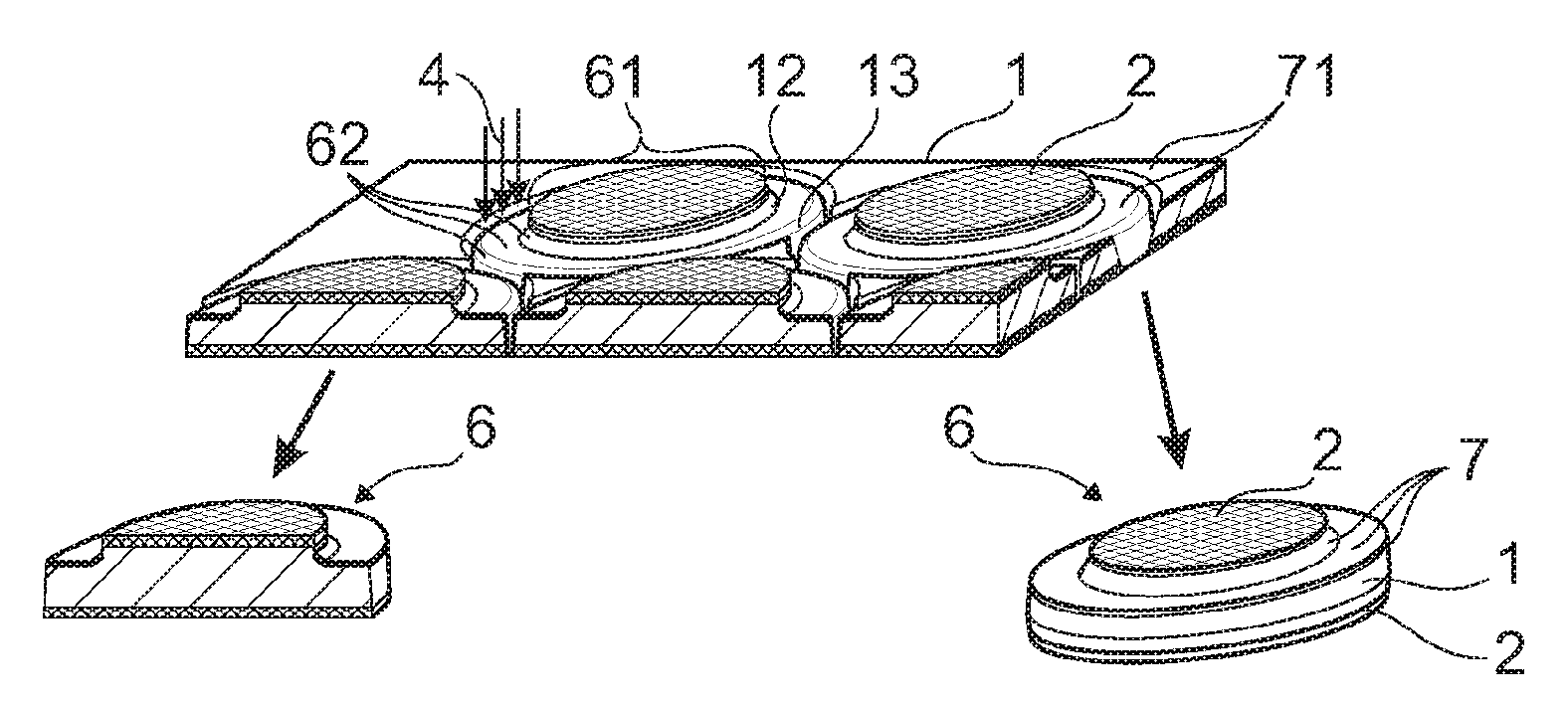

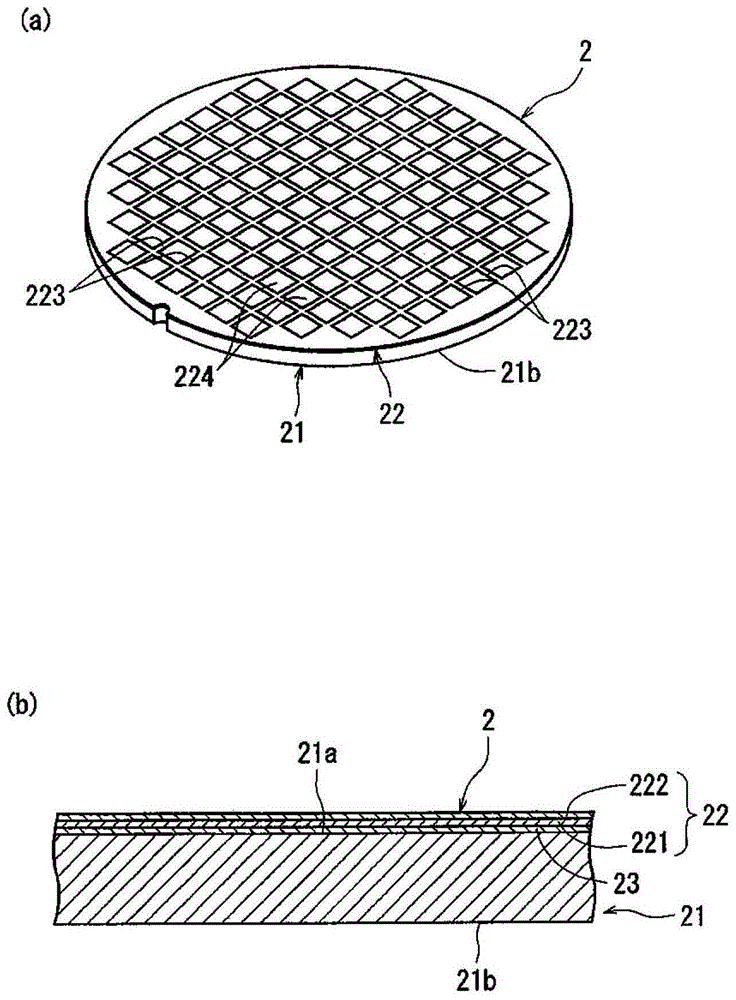

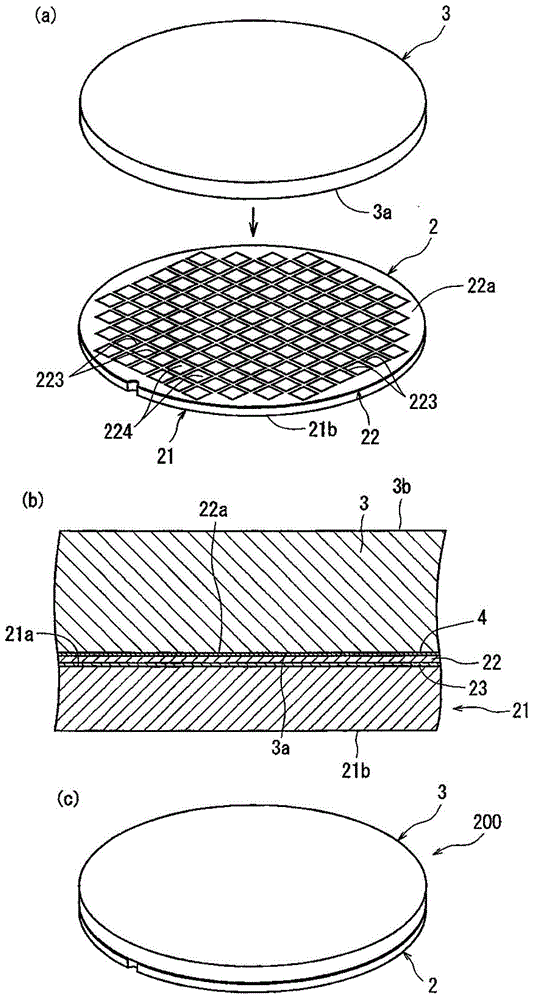

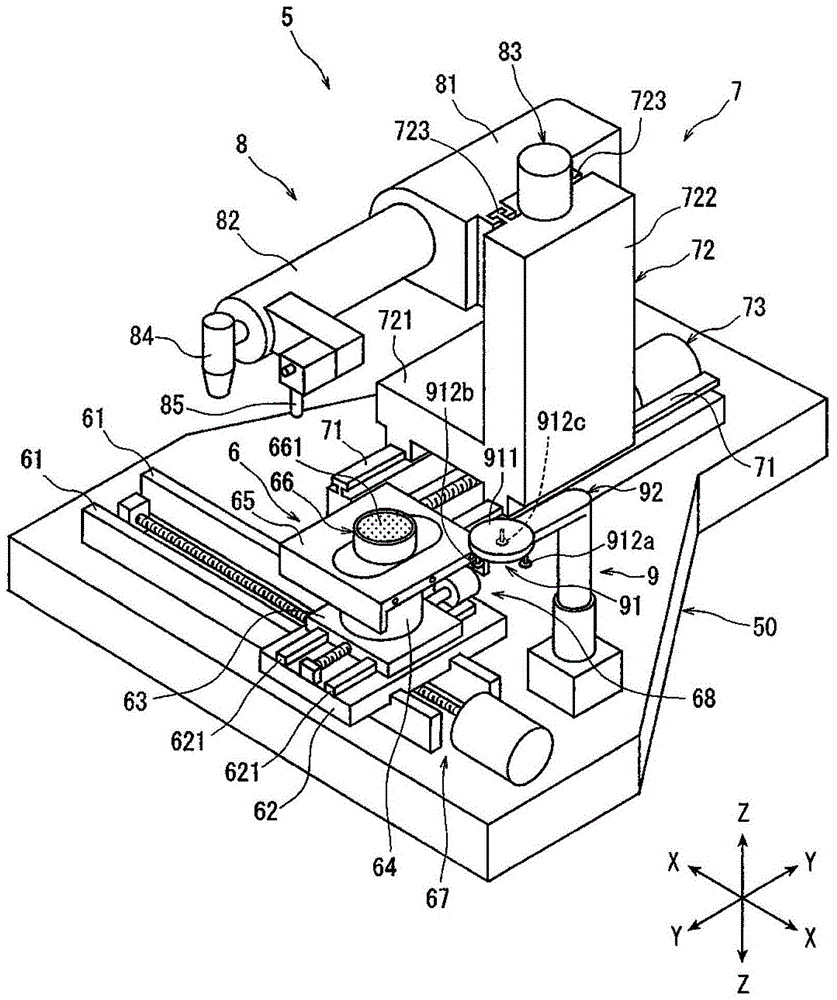

Lift off method

ActiveCN103378232BSolid-state devicesSemiconductor/solid-state device manufacturingWaferingEngineering

The present invention provides a lift-off method capable of reliably peeling off an epitaxial substrate. Provided is a lift-off method for transferring an optical device layer of an optical device wafer to a transfer substrate, which includes a transfer substrate bonding process, bonding the transfer substrate to the surface of the optical device layer of the optical device wafer; a gas layer forming process, The buffer layer is irradiated with pulsed laser light from the back side of the epitaxial substrate of the optical device wafer to form a gas layer at the interface between the epitaxial substrate and the buffer layer; the gas layer detection process detects the outermost gas in the formed gas layer the area of the layer; the epitaxial substrate adsorption process, positioning the suction pad to the area where the outermost gas layer detected by the gas layer detection process in the epitaxial substrate is located, to adsorb the epitaxial substrate; and the optical device layer transfer process, The suction pad holding the epitaxial substrate is moved in a direction away from the epitaxial substrate to peel off the epitaxial substrate, and transfer the optical device layer to the transfer substrate.

Owner:DISCO CORP

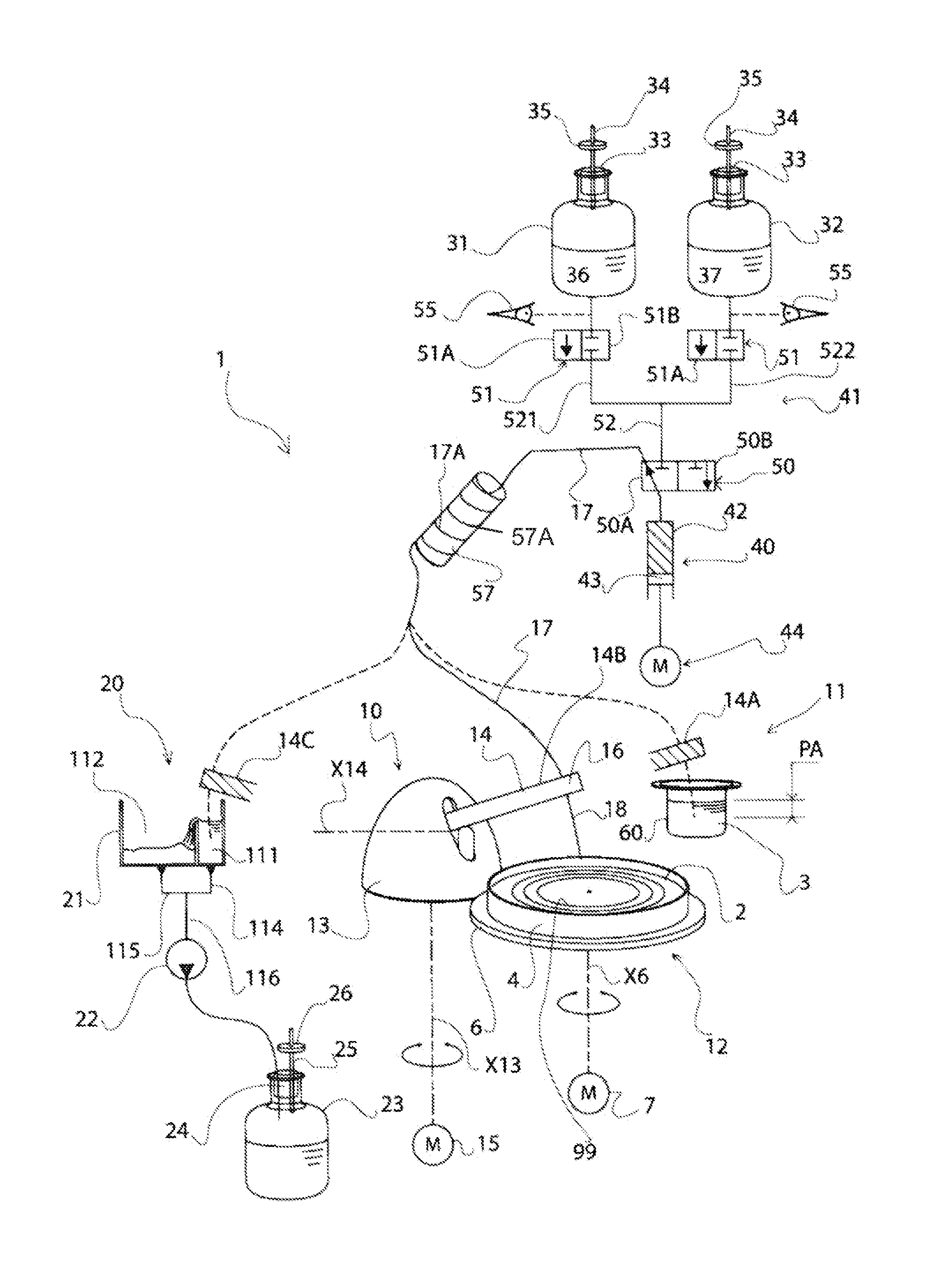

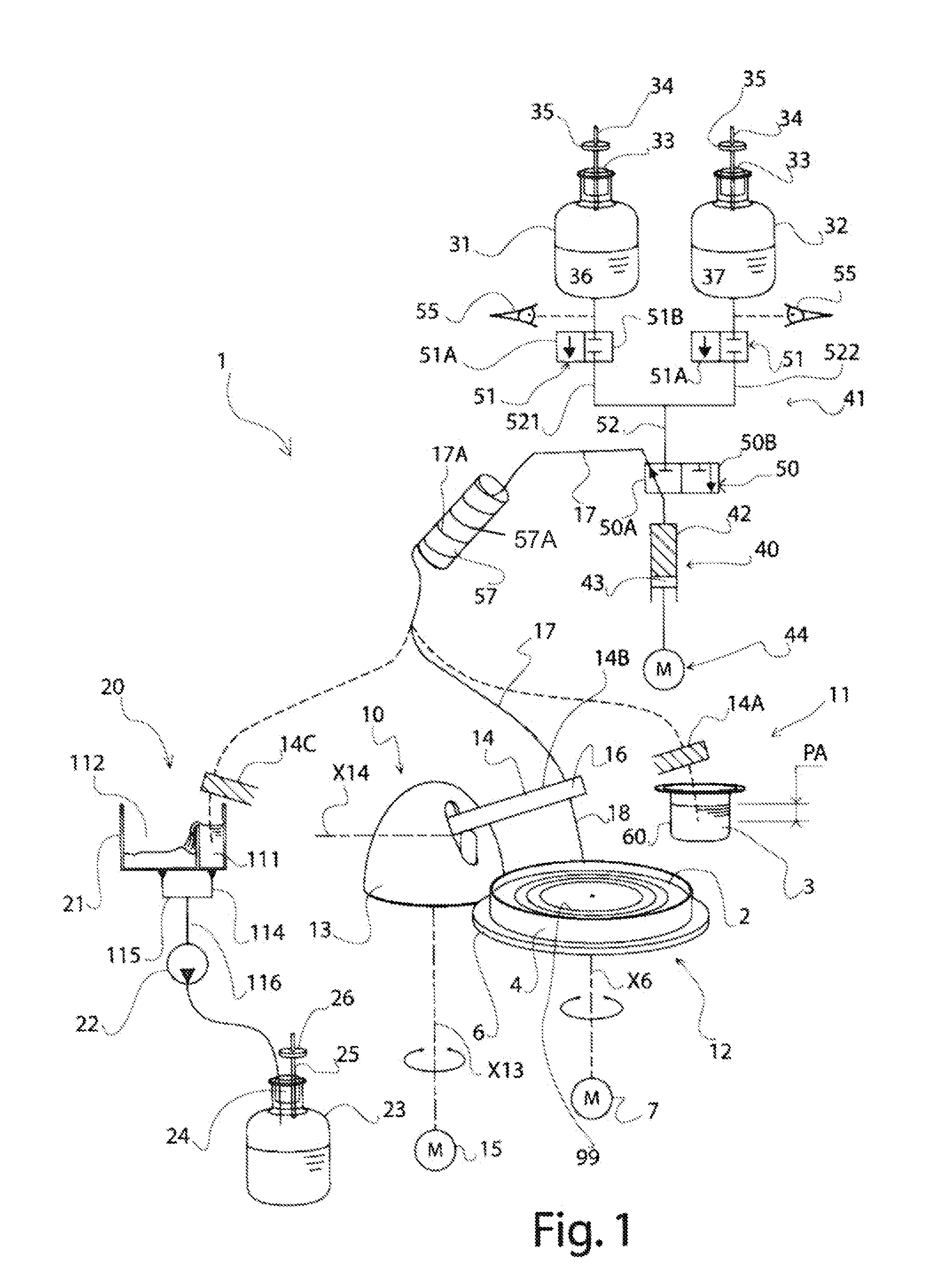

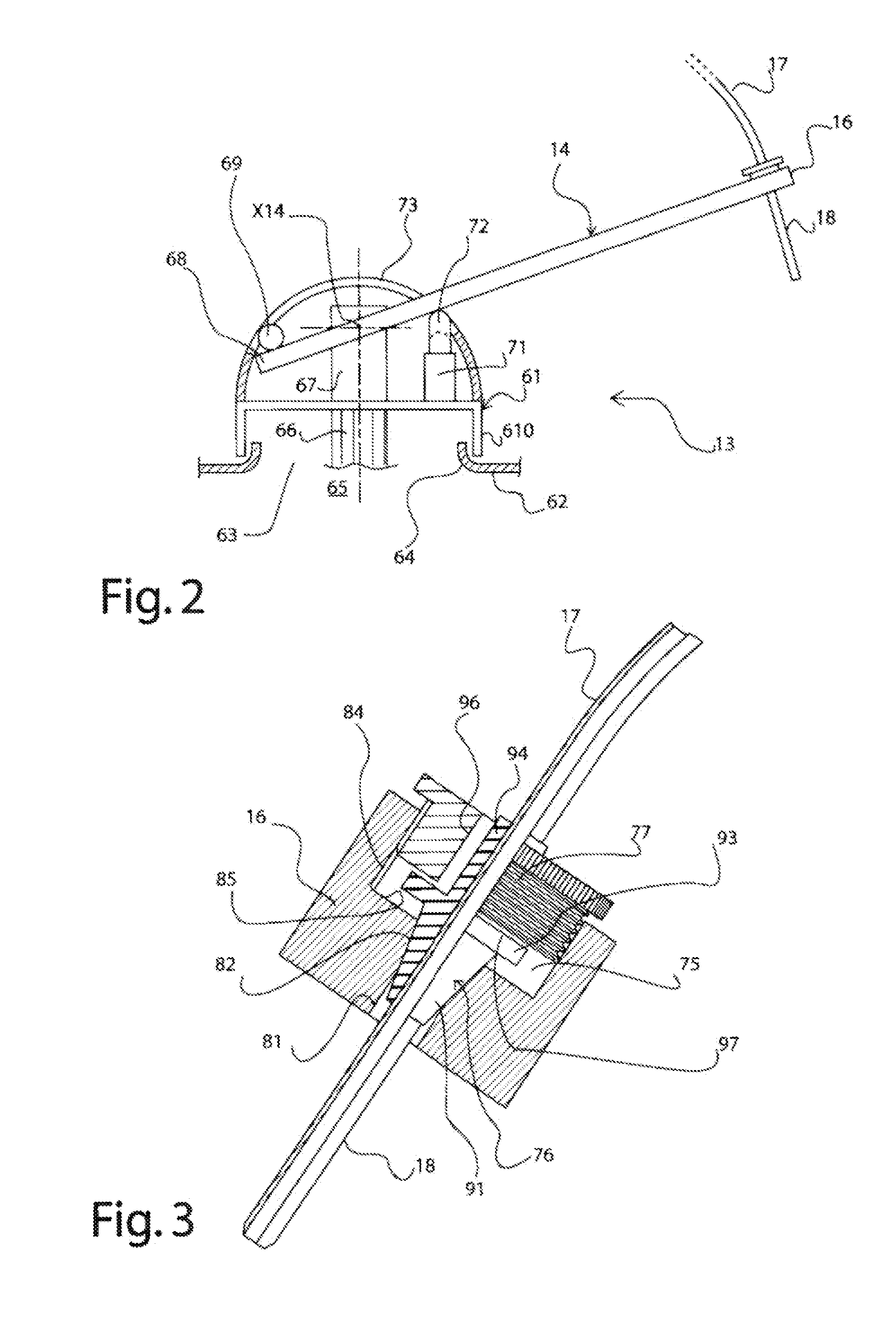

Automatic inoculating system and method for depositing a sample on a substrate in a pattern

ActiveUS20130260038A1Conveniently removedConveniently replacedSpraying apparatusCoatingsDistal portionHorizontal axis

An automatic inoculating system for depositing a sample on a substrate in a predetermined pattern. A turret is rotatable about a vertical axis, and an arm retained by the turret is pivotable about a horizontal axis. A stylus retained at a distal portion of the arm sucks up and dispenses the sample, such as by use of a pumping system in fluidic communication with the stylus. A support rotatably retains the substrate. The arm can be raised and lowered, such as by a cylinder on which the arm rests without a retaining mechanical connection therebetween. The arm can thus freely lift off the cylinder as when the stylus contacts the surface of the substrate. The sample can thus be deposited on the substrate in a predetermined pattern by a dispensing from the stylus in combination with rotation of the turret and the substrate and a pivoting of the arm.

Owner:INTERLAB

A kind of manufacturing method of split gate mosfet

ActiveCN111403289BPrecise thickness controlDoes not affect shapeSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETHigh density

The invention discloses a method for fabricating a split gate MOSFET, comprising: step 1, forming an epitaxial layer on a substrate; step 2, depositing a first oxide layer on a first main surface; step 3, forming a trench; Fourth, remove the first oxide layer; step five, form a second oxide layer in the trench; step six, form a separation gate polysilicon in the trench; step seven, form an isolation oxide layer between polysilicon; step eight, in the trench forming a nitride layer; step 9, forming sacrificial polysilicon in the trench; step 10, removing the nitride layer above the sacrificial polysilicon to form a mask structure; step 11, using the mask structure as an etching mask to remove the inter-polysilicon isolating the second oxide layer above the oxide layer; step 12, removing the nitride layer to lift off the sacrificial polysilicon. In the present invention, the isolation oxide layer between polysilicons that meets the technological requirements can be formed at one time through the high-density plasma chemical vapor deposition method or the low-temperature wet oxidation method.

Owner:捷捷微电(南通)科技有限公司

High growth rate deposition for group iii/v materials

PendingCN110582838ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingIndiumGallium arsenate

Aspects of the disclosure relate to processes for epitaxial growth of Group III / V materials at high rates, such as about 30 [mu]m / hr or greater, for example, about 40 [mu]m / hr, about 50 [mu]m / hr, about 55 [mu]m / hr, about 60 [mu]m / hr, about 70 [mu]m / hr, about 80 [mu]m / hr, and about 90-120 [mu]m / hr deposition rates. The Group III / V materials or films may be utilized in solar, semiconductor, or otherelectronic device applications. The Group III / V materials may be formed or grown on a sacrificial layer disposed on or over the support substrate during a vapor deposition process. Subsequently, theGroup III / V materials may be removed from the support substrate during an epitaxial lift off (ELO) process. The Group III / V materials are thin films of epitaxially grown layers containing gallium arsenide, gallium aluminum arsenide, gallium indium arsenide, gallium indium arsenide nitride, gallium aluminum indium phosphide, phosphides thereof, nitrides thereof, derivatives thereof, alloys thereof,or combinations thereof.

Owner:尤蒂卡黎赛科有限责任公司

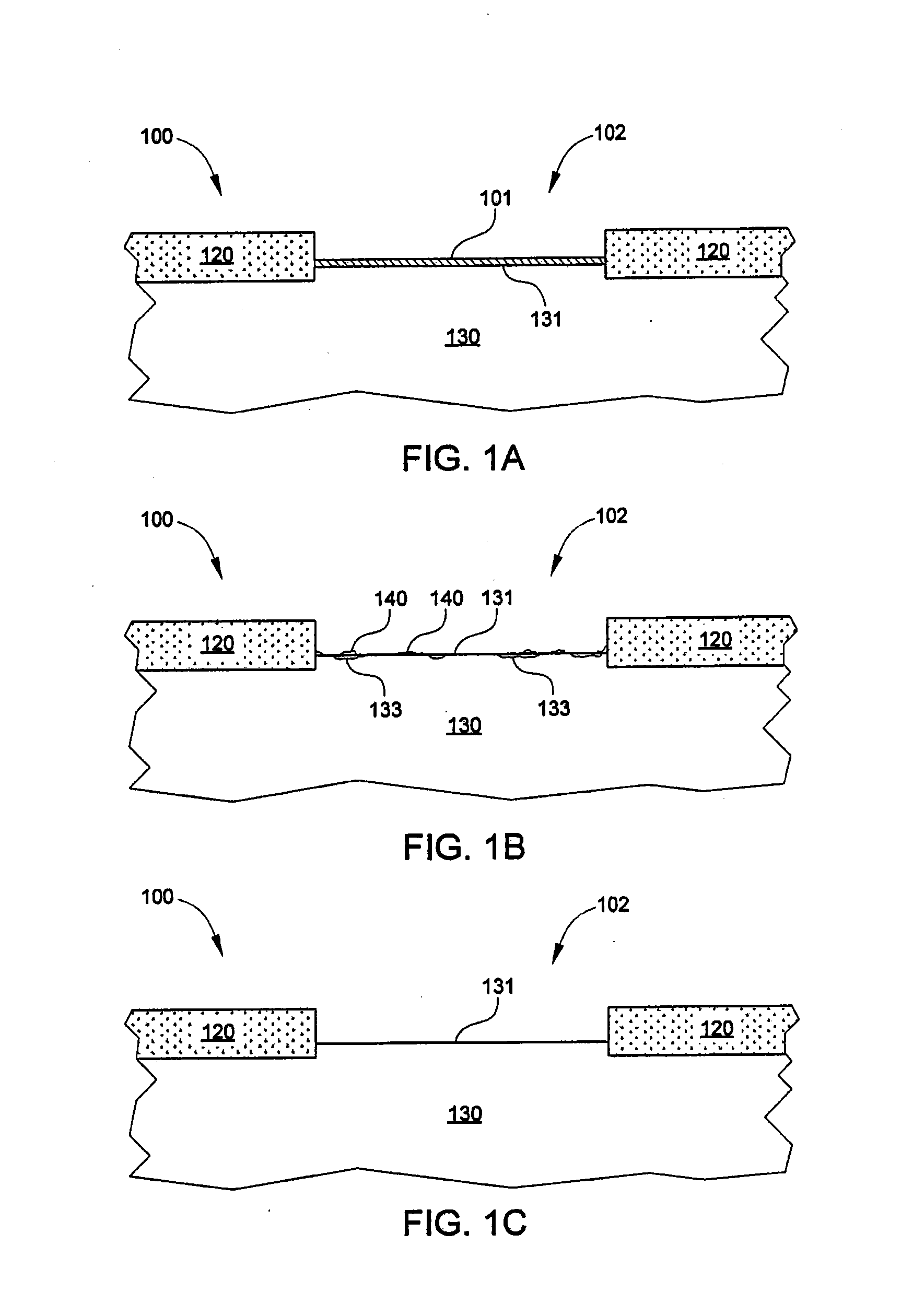

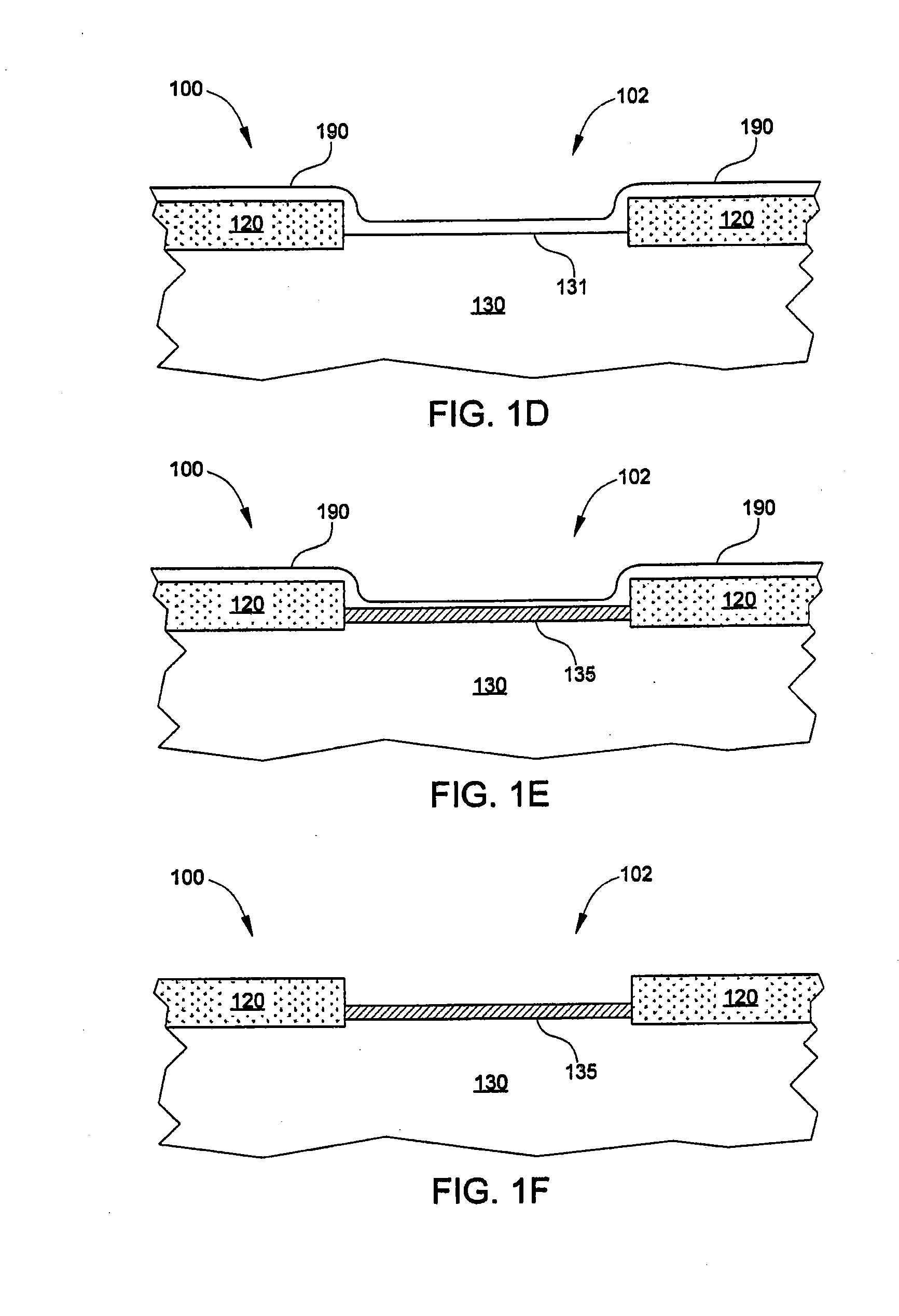

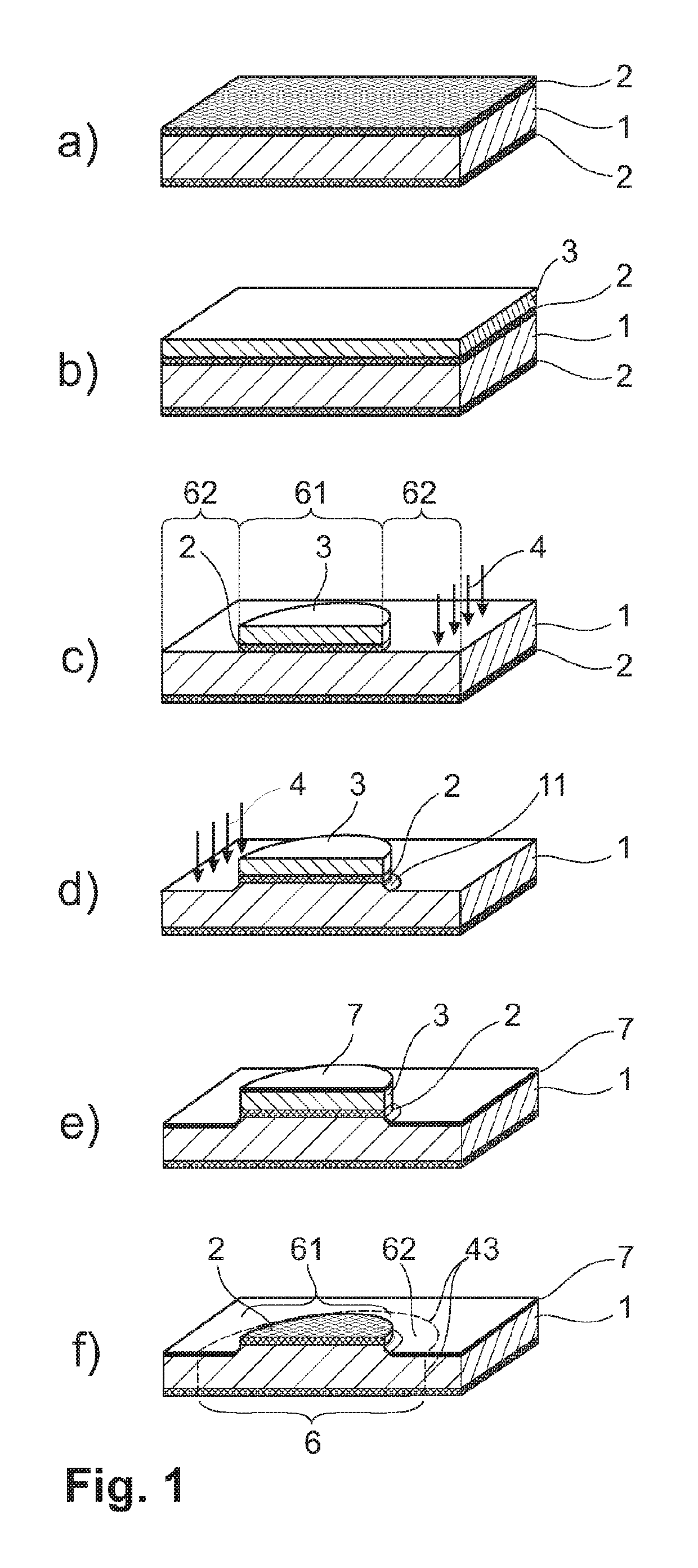

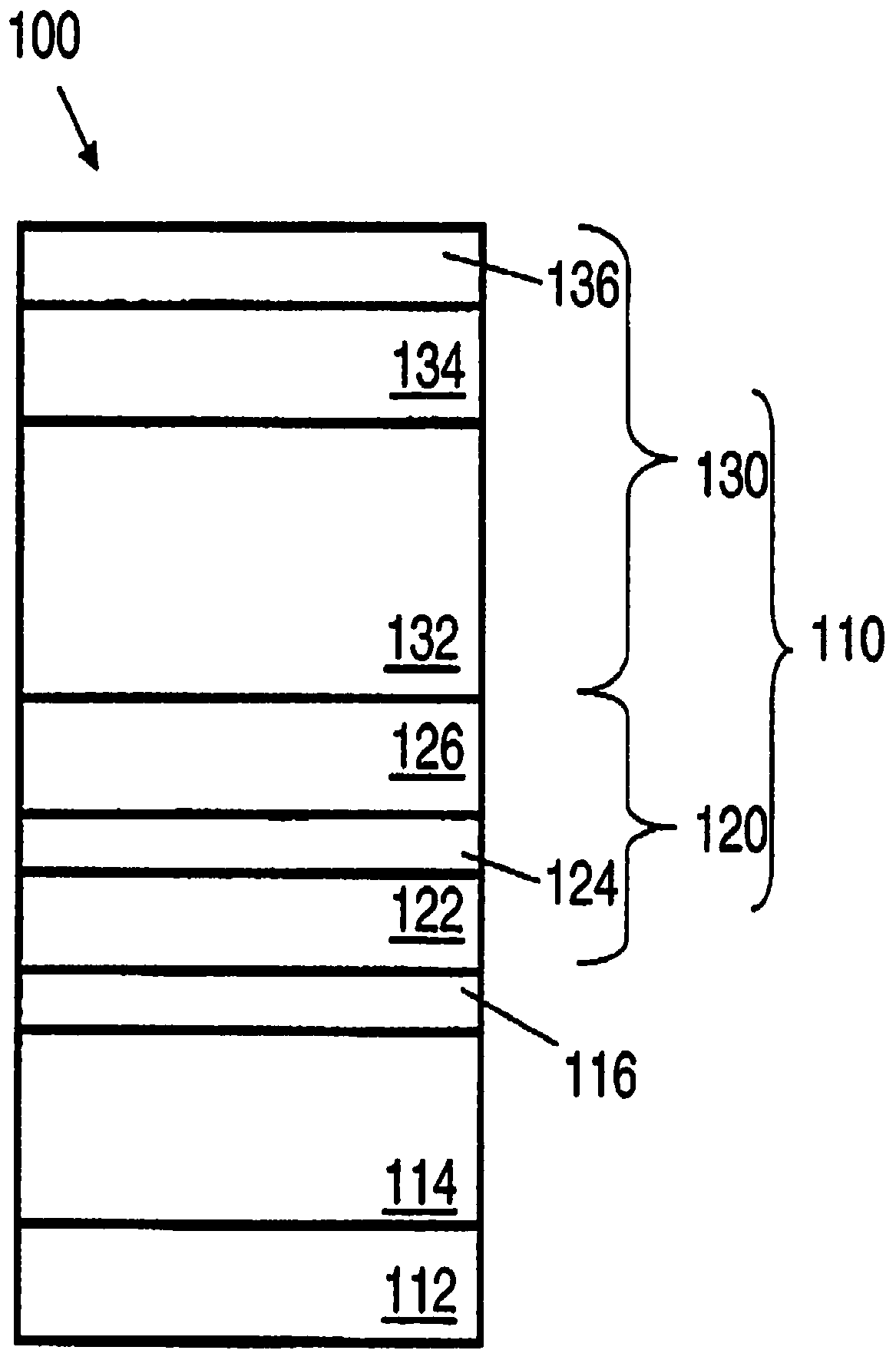

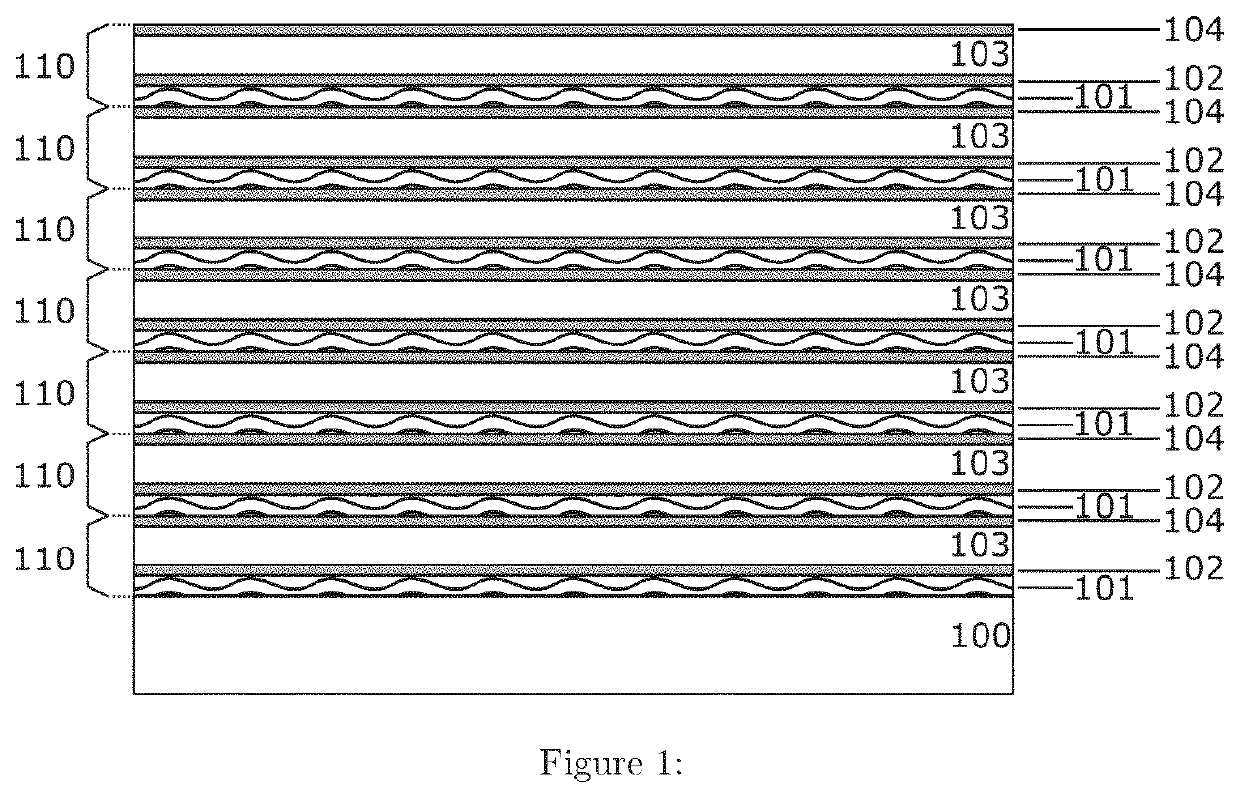

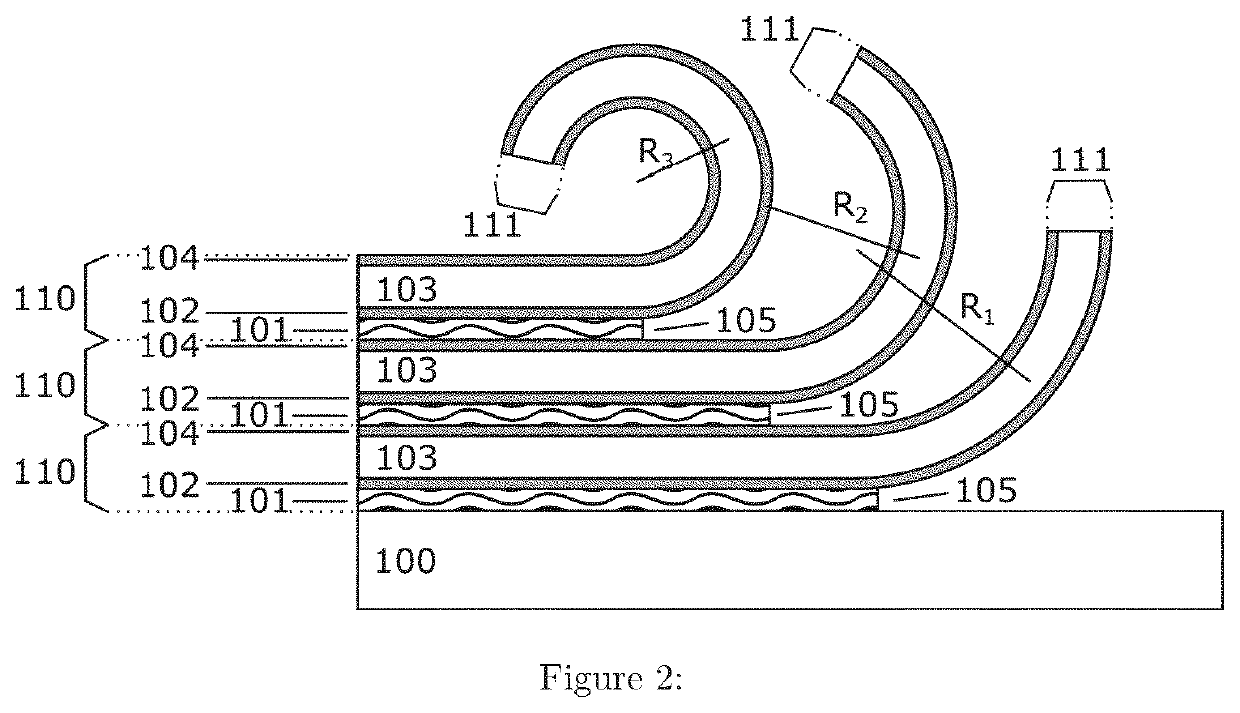

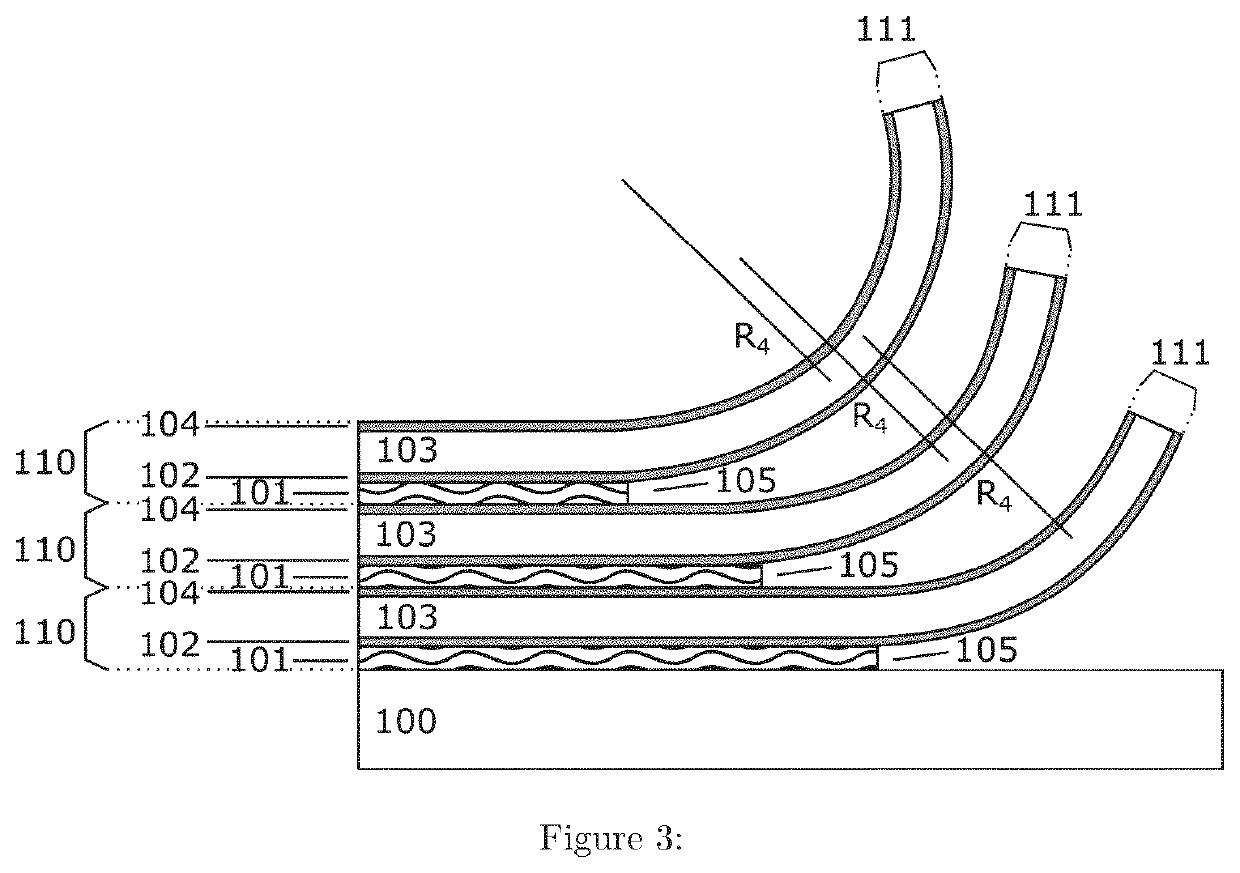

Method and structure for thin-film fabrication

PendingUS20220367275A1Easy to disassembleUse of separateSemiconductor/solid-state device manufacturingPhotovoltaic energy generationThin membraneEngineering

The present invention relates to the epitaxial lift-off of thin-films allowing the reuse of the expensive semiconductor substrates. In particular, it describes a structure and a method for epitaxial lift-off of several thin films from a single substrate (100) using a plurality of dissimilar sacrificial layers (101), strained layers (102, 104), and / or device or component layers (103). The properties of the sacrificial layers (101) and the strained layers (102,104) can be used (i) to facilitate the lift off process, (ii) to control the point of time of release of each released thin film individually and (iii) to aid in separation and sorting of the released thin films. The released device or component layers can comprise various useful structures, such as optoelectronic devices photonic components.

Owner:OKSANEN JANI +1

Method for manufacturing isolation structure of semiconductor device and semiconductor device thereof

ActiveCN110661170BGuaranteed contactLaser detailsPhotomechanical apparatusDevice materialPhotoresist

The invention relates to semiconductor manufacturing, in particular to a method for manufacturing the isolation structure of a semiconductor device and a semiconductor device. The manufacturing process of the semiconductor device includes the following steps that: a substrate is provided; a device is formed on the substrate; and a conductive isolation structure is formed on the substrate. The method for forming the conductive isolation structure comprises the following steps that: a photoresist layer is formed on the device and the substrate; a grid structure is formed in the photoresist layer; the grid structure is reserved; a conductive layer is formed on the surfaces of the device, the substrate and the grid structure; and the grid structure is lifted off. According to the method of theinvention, a lift-off process is provided; the photoresist with a lift-off function is subjected to gridding treatment, so that the photoresist can still be in full contact with a solvent after a sample piece is subjected to angled evaporation, and lift-off operation is completed.

Owner:深圳市矽赫科技有限公司

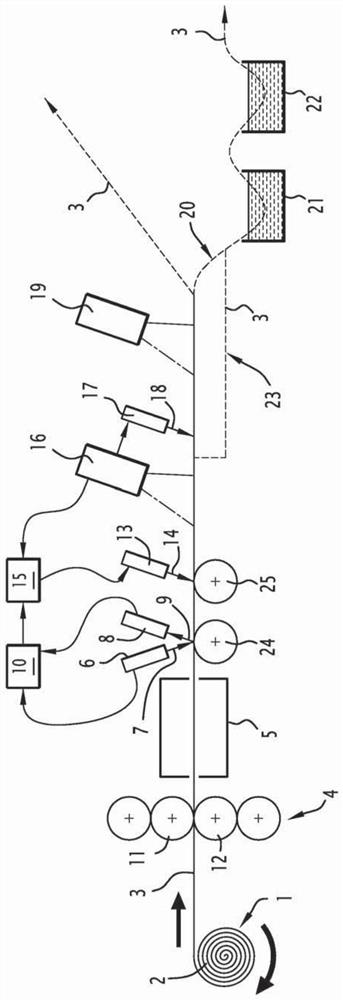

Method for laser stripping mobile metal products and equipment for implementing the method

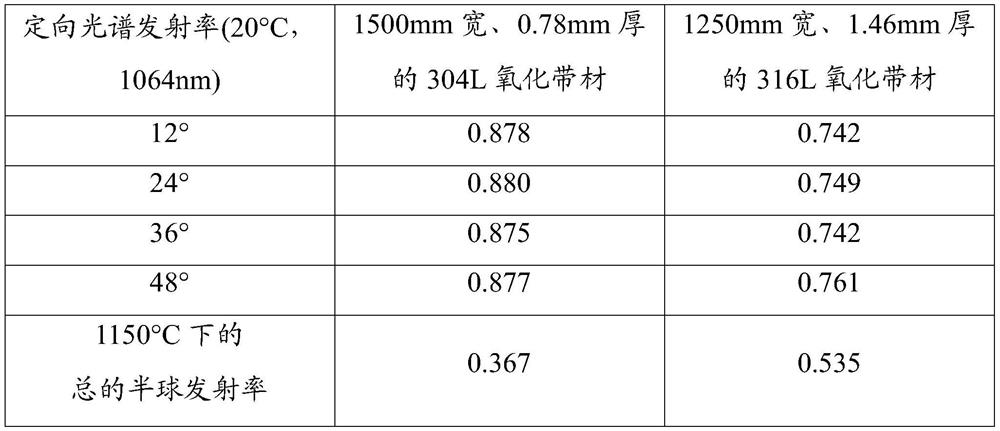

ActiveCN110087818BGood descaling effectWork treatment devicesExtrusion cleaning devicesEmissivityLight spot

The application discloses a method for stripping a mobile metal product (3) having an oxide layer, using laser stripping, the method comprising the following steps: at least one first laser (6) is sent on the product to be stripped ( 3) the light beam (7) reflected on the oxidized surface, said emission beam (9) is intercepted by the sensor (8), which sends the collected information to the processing unit (10); the processing unit (10) calculates the product ( 3) the absorption of the light beam (7) by the surface of the oxidized surface in the direction of said reflected light beam (9) is deduced from this, and this emissivity is compared with the reference value pre-recorded in the processing unit (10) The information is associated; at least one second laser (13) sends a beam (14) onto the surface of the product to peel off the surface, the spot of the beam (14) passing through the spot of the beam (14) on the product ( 3) Optical and / or mechanical scanning methods that move laterally on the surface of the surface, or cover the entire surface to be peeled off by an optical system that converts light spots into lines, and the second laser (13) is controlled by the control unit (15 ) control which receives information provided by the processing unit (10) in order to determine the operation to be imposed on said second laser (13) by comparison with experimental results pre-recorded in the control unit (15) parameters in order to peel off the surface of the product (3); means (16, 17) for inspecting the peeled surface of the product (3) detect the effect of the peeling. The present application also relates to a device for carrying out the method.

Owner:艾普伦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com