Method of lifting off and fabricating array substrate for liquid crystal display device using the same

A technology of substrates and grooves, which is applied in semiconductor/solid-state device manufacturing, photolithography on patterned surfaces, and optics, and can solve problems such as deteriorating image display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

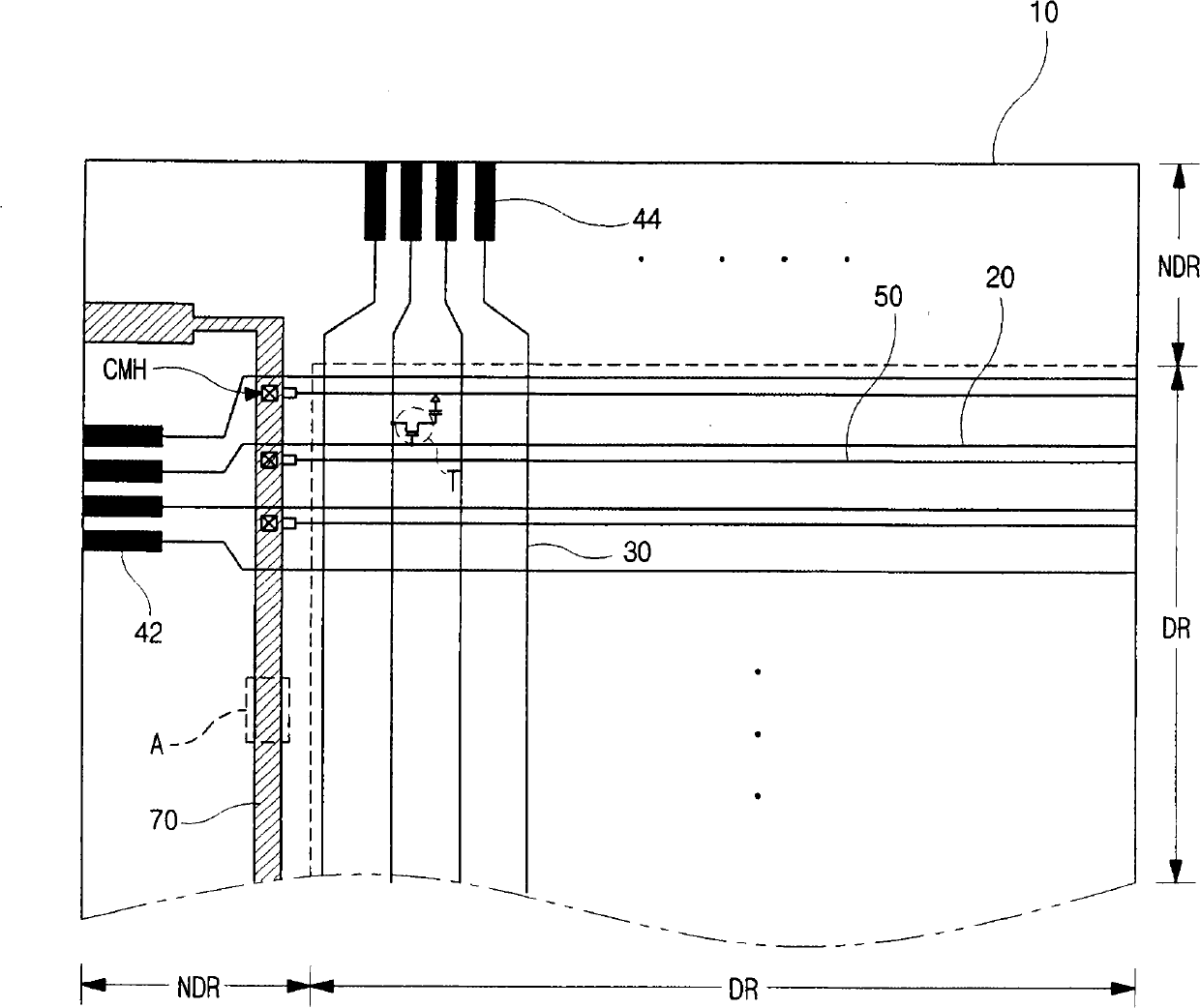

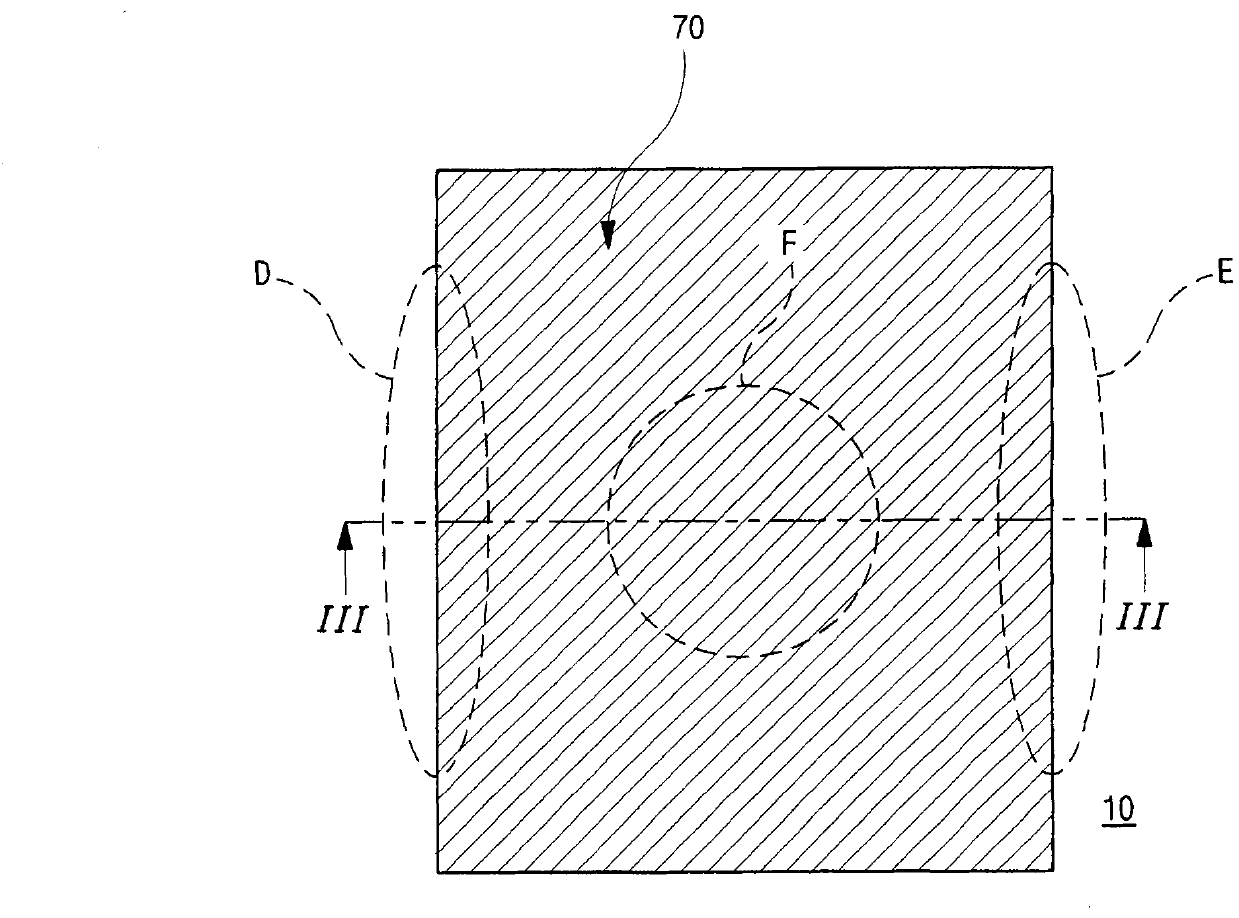

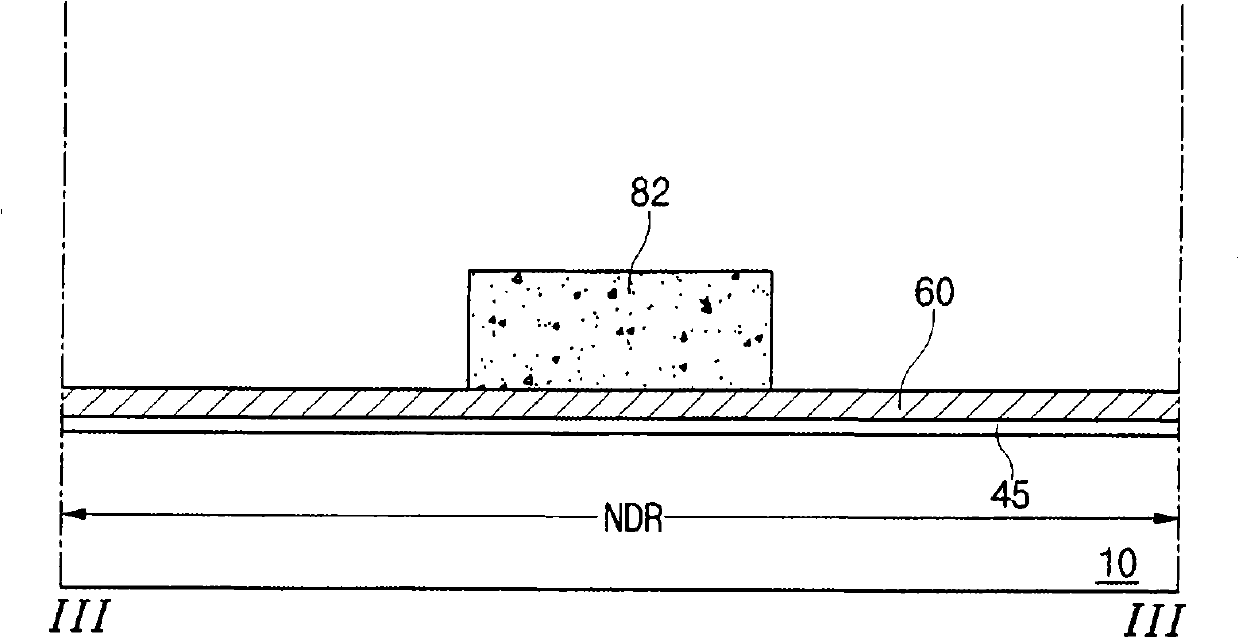

[0042] Figure 4 is a plan view showing a part of a line according to the invention comprising grooves, while Figures 5A-5C is a cross-sectional view, shown taken from the Figure 4 The manufacturing process of the site in the line V-V.

[0043] like Figure 4 As shown, a plurality of first trenches 172 and a plurality of second trenches 174 are formed on line 170 . Each of the first groove 172 and the second groove 174 has a strip shape or a rectangular shape. The line 170 may be one of a common connection line, a gate pad, a data pad, an electrostatic protection circuit line, an MPS line, and a dummy line. Line 170 has a relatively large width. For example, line 170 has a width greater than about 200 microns. A plurality of first trenches 172 are arranged in a first row and spaced apart from each other. A plurality of second trenches 174 are arranged in a second row and spaced apart from each other. After the line 170 is formed through the lift-off process, the pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com