Manufacturing method of non-invasive graphene nano-scale device

A nano-device and manufacturing method technology, applied in the field of electron beam lithography, can solve the problem of damaging graphene lattice and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Make a 100-200nm wide, 200-500nm period, with a total finger size of 200 μm x 140 μm Stencil, and non-damaging graphene nanodevices fabricated by Stencil lithography:

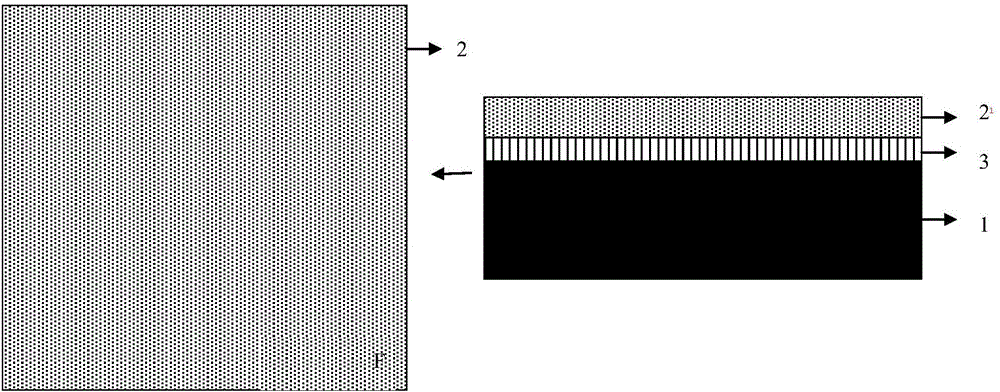

[0057] (1) Use LPCVD to grow 300nm silicon nitride on the silicon substrate. The result is as figure 1 shown.

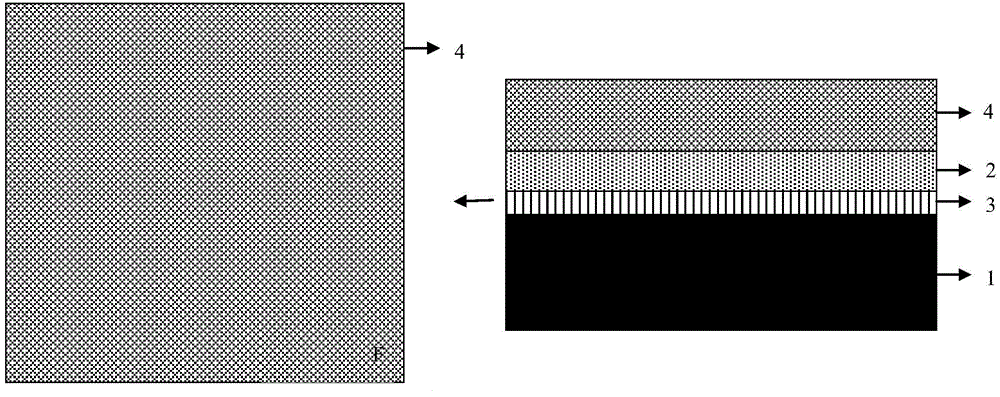

[0058] (2) Spin-coat 300-600 nm PMMA on silicon nitride. The result is as figure 2 shown.

[0059] (3) Bake the spin-coated PMMA silicon wafer in an oven at a temperature of 180°C for 60 minutes or more.

[0060] (4) Measure the thickness of the PMMA glue with a step meter. If the required height is reached, go to (5), otherwise return to step (2).

[0061] (5) Using the above PMMA as a masking layer, design a pattern, expose it by electron beam direct writing, and conduct a dose test.

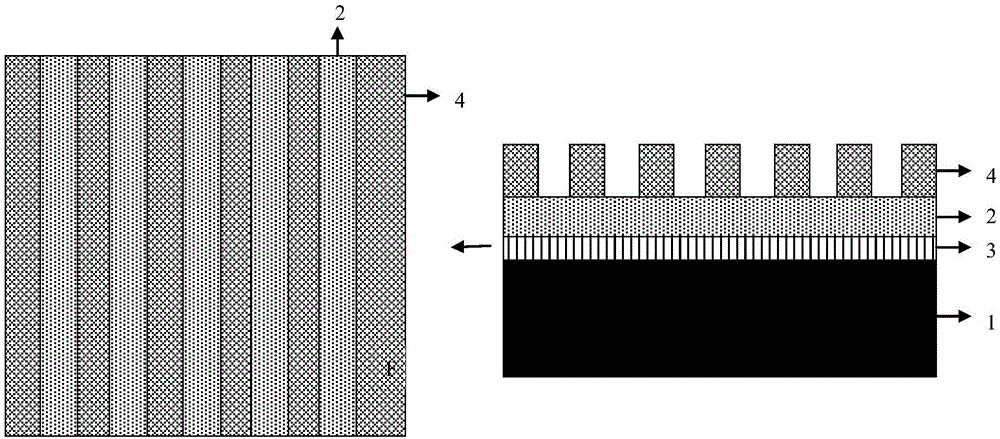

[0062] (6) Develop with developer IMBK and IPA, IMBK:IPA=1:3, developing temperature 23°C, time 1min. The result is as image 3 As indicated, fix with isopropanol for 30 seconds, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com