Patents

Literature

130 results about "Indium arsenide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indium arsenide, InAs, or indium monoarsenide, is a semiconductor composed of indium and arsenic. It has the appearance of grey cubic crystals with a melting point of 942 °C. Indium arsenide is used for construction of infrared detectors, for the wavelength range of 1–3.8 µm. The detectors are usually photovoltaic photodiodes. Cryogenically cooled detectors have lower noise, but InAs detectors can be used in higher-power applications at room temperature as well. Indium arsenide is also used for making of diode lasers.

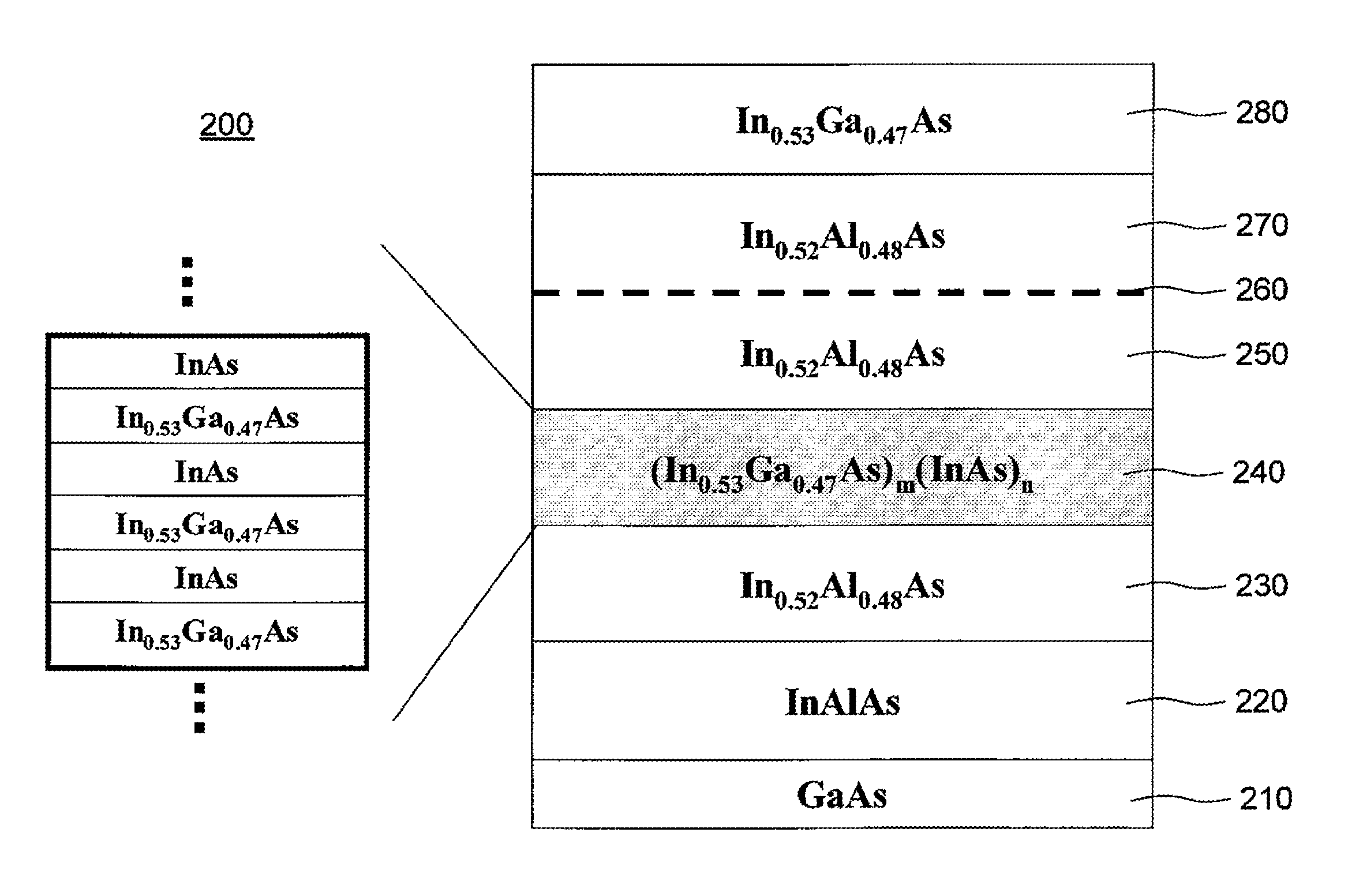

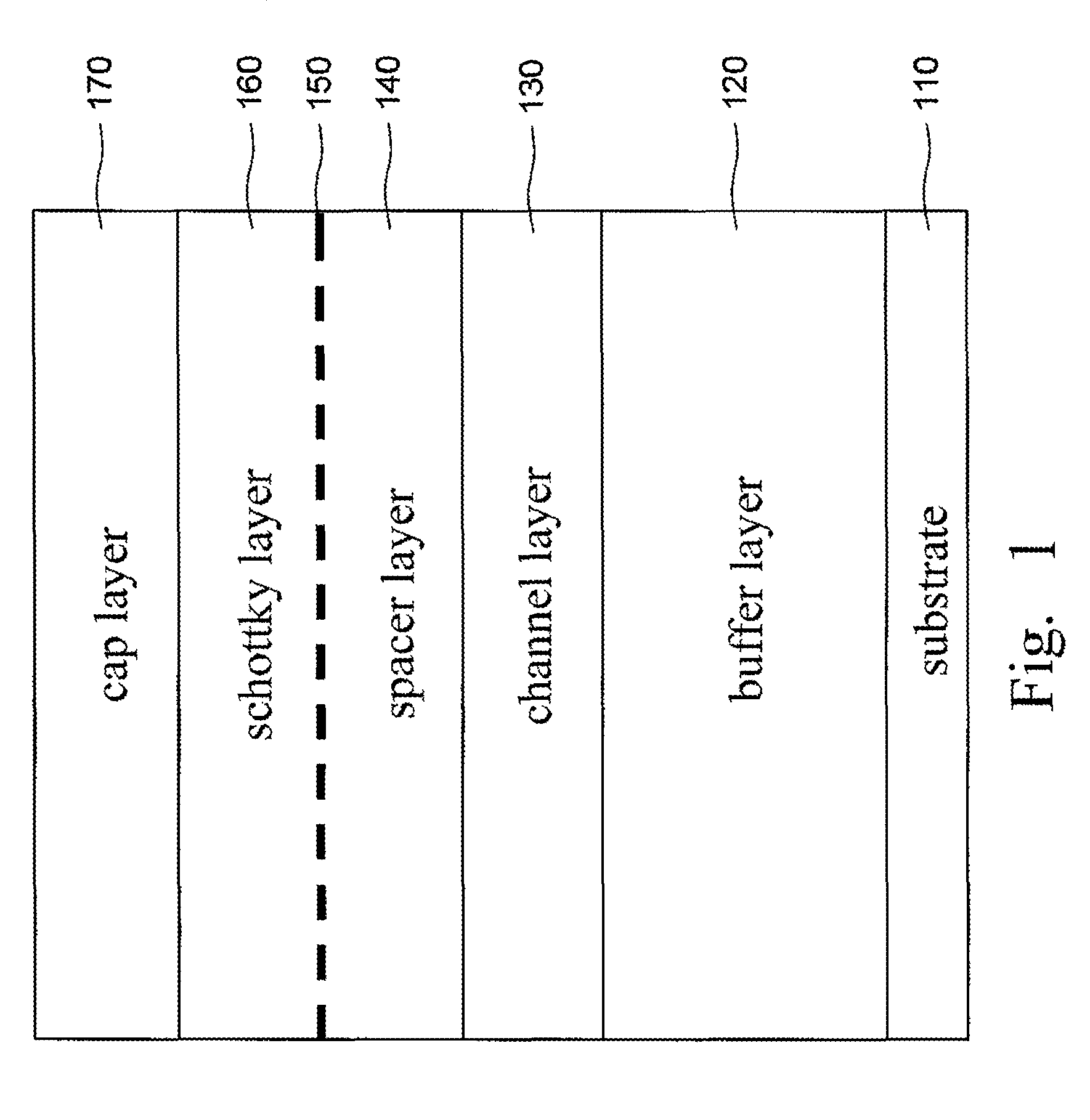

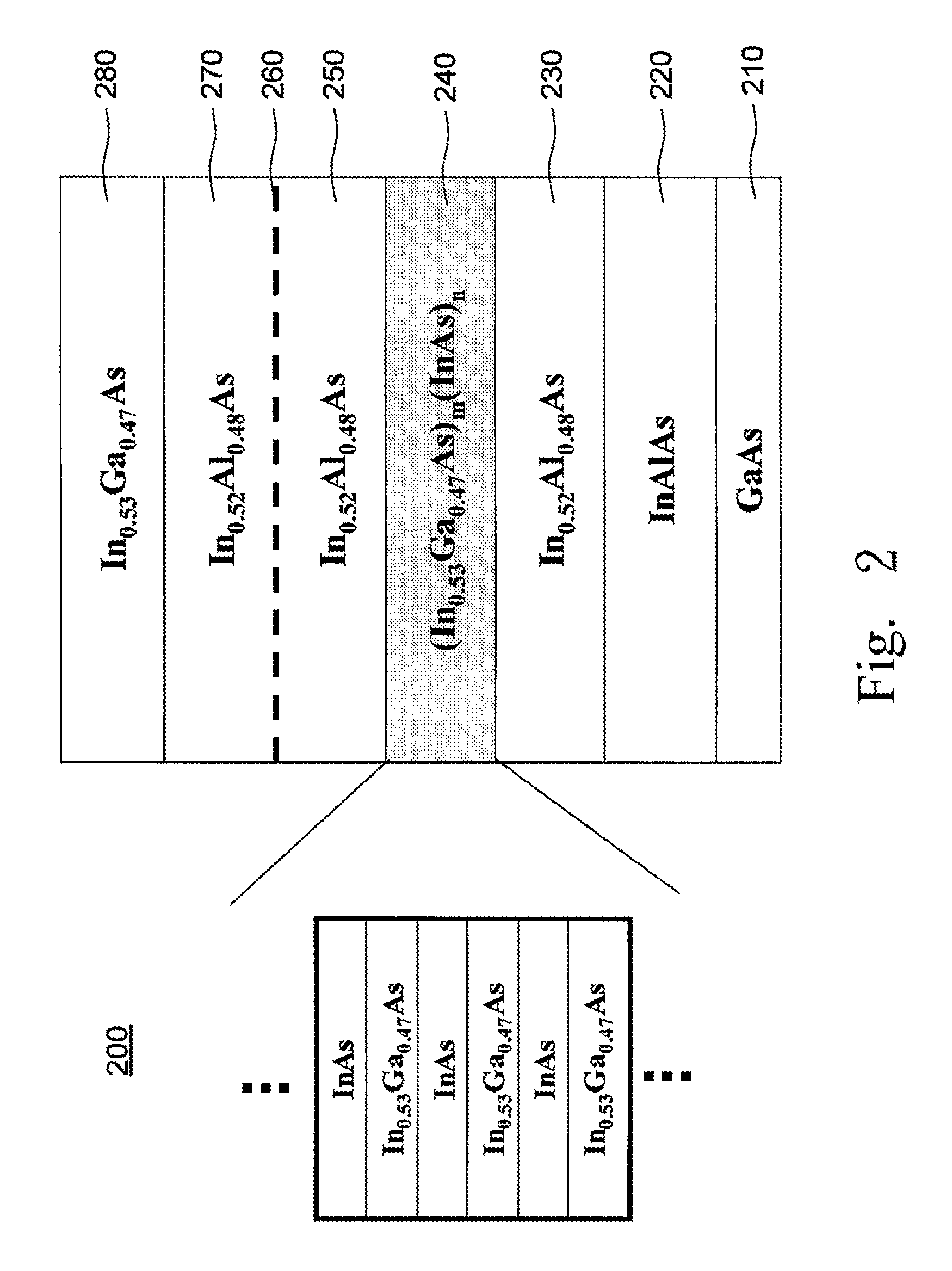

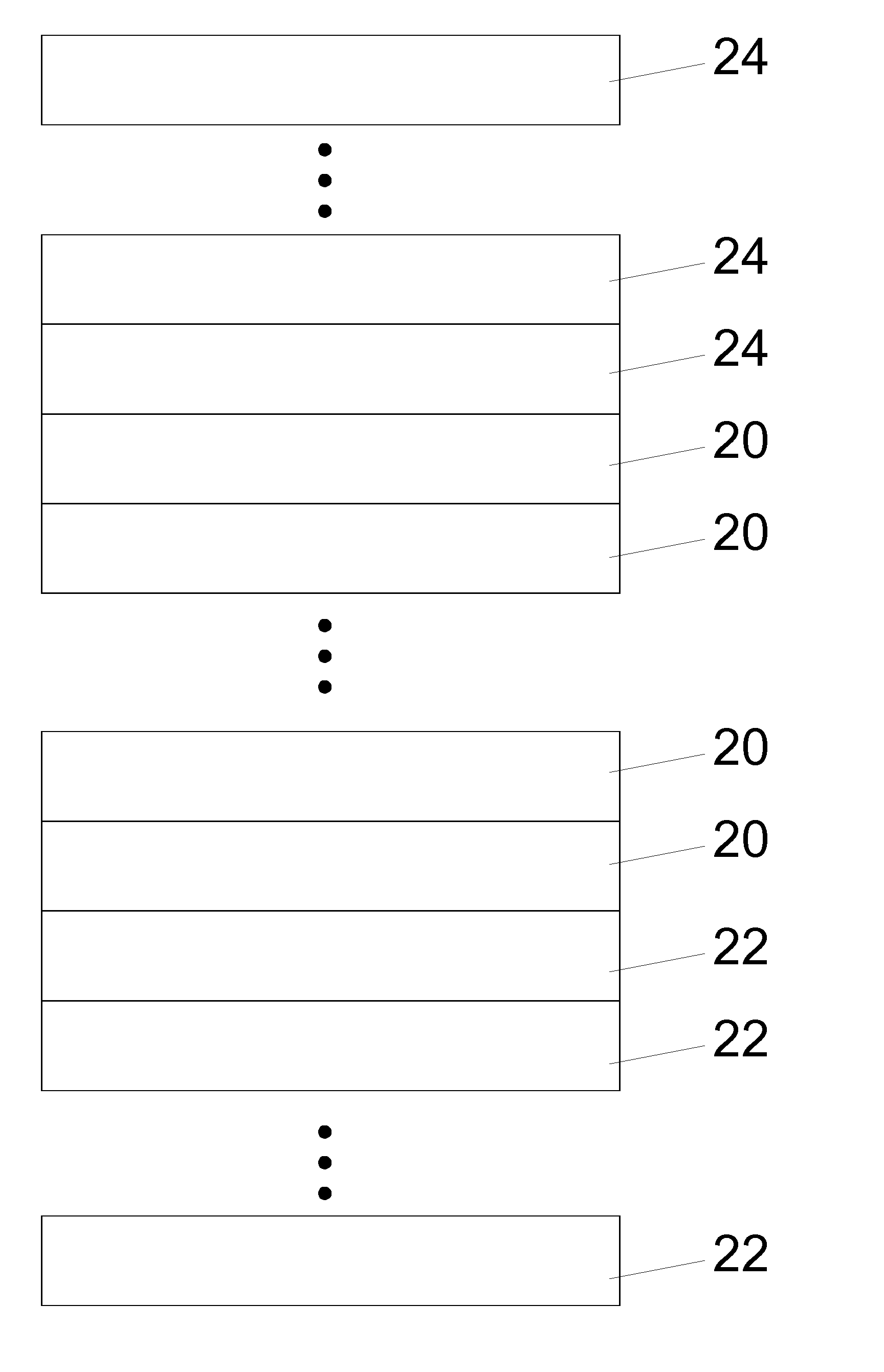

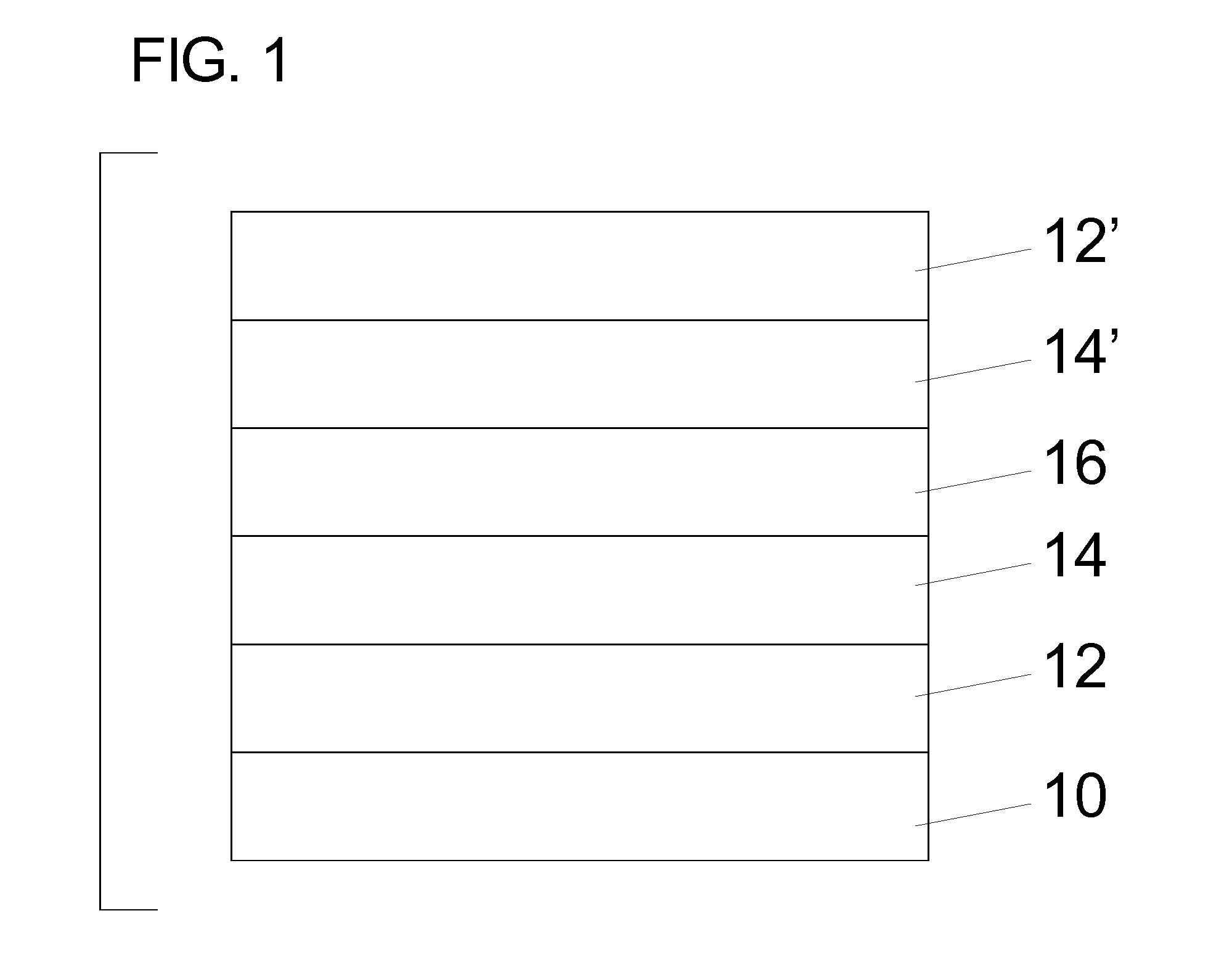

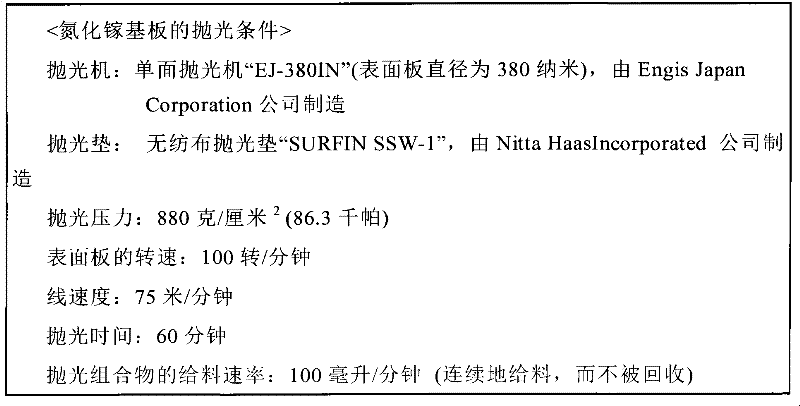

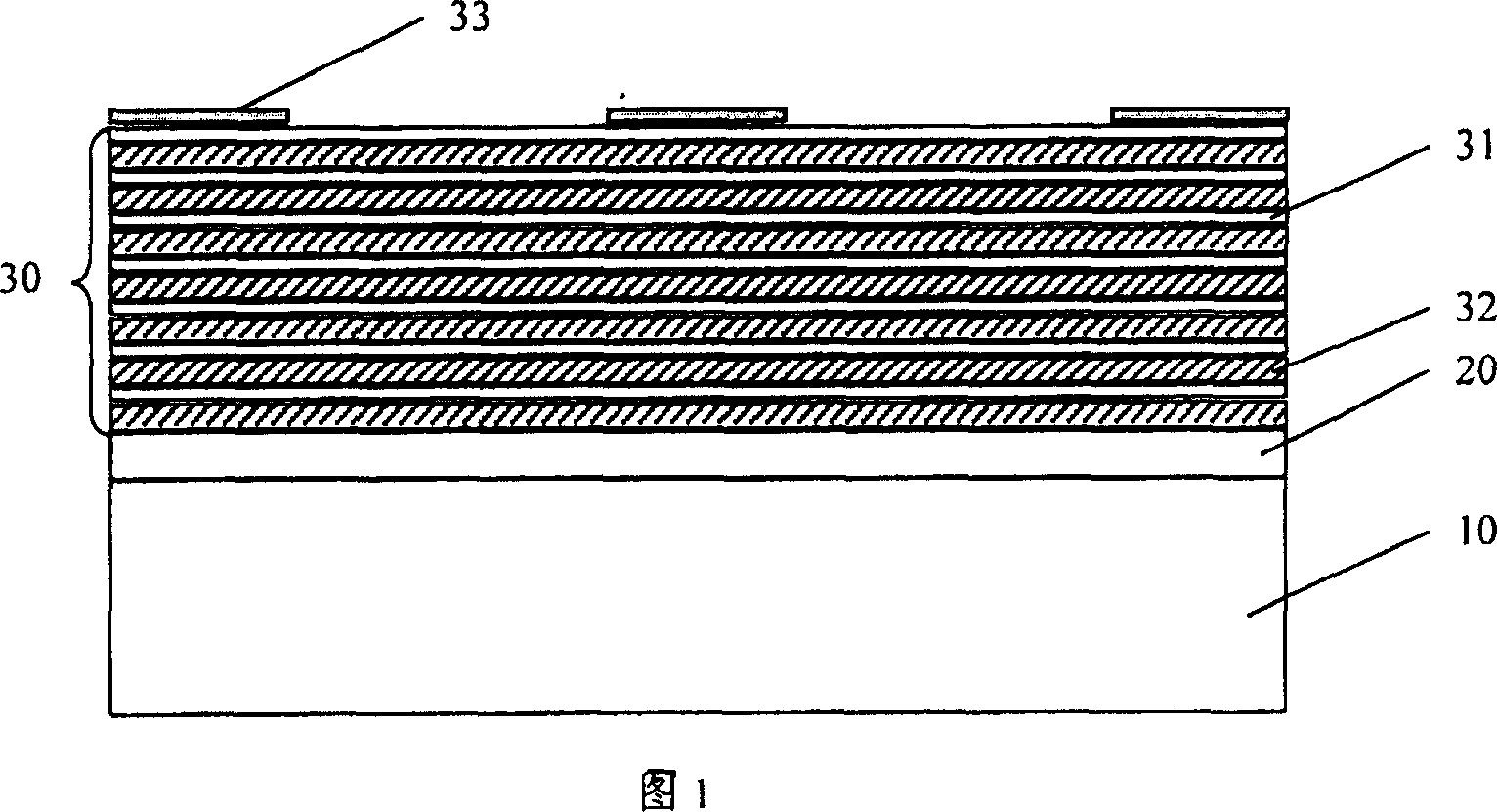

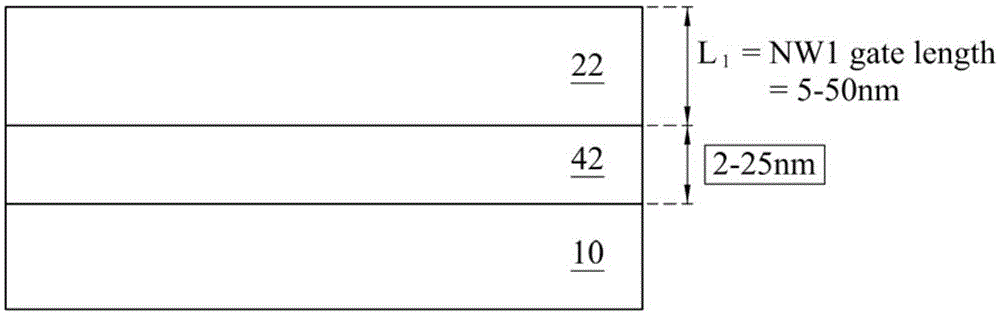

High electron mobility transistor and method for fabricating the same

ActiveUS8169002B2Improve high-frequency characteristicHigh electron mobilityTransistorNanoinformaticsIndium arsenideIndium gallium arsenide

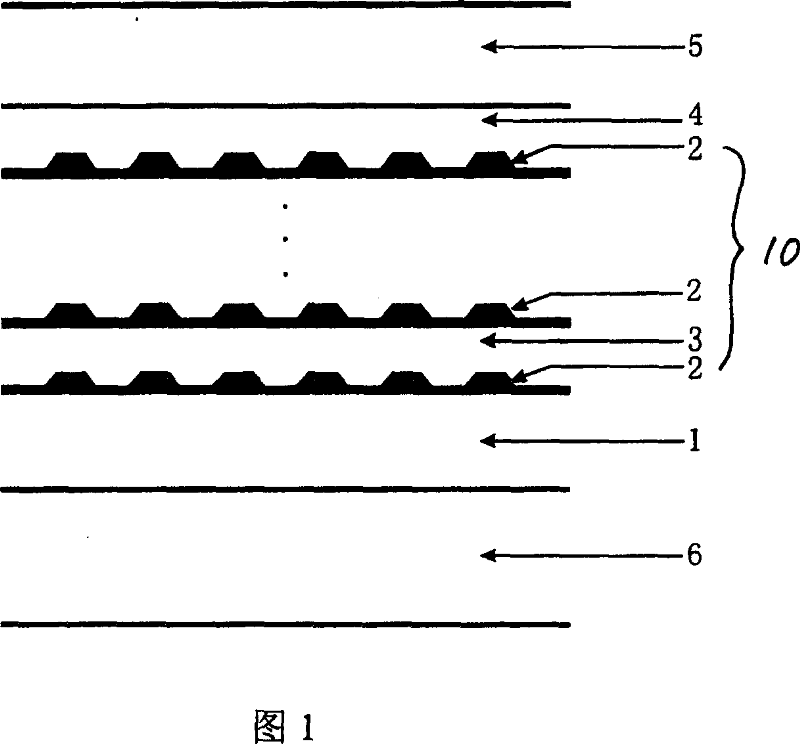

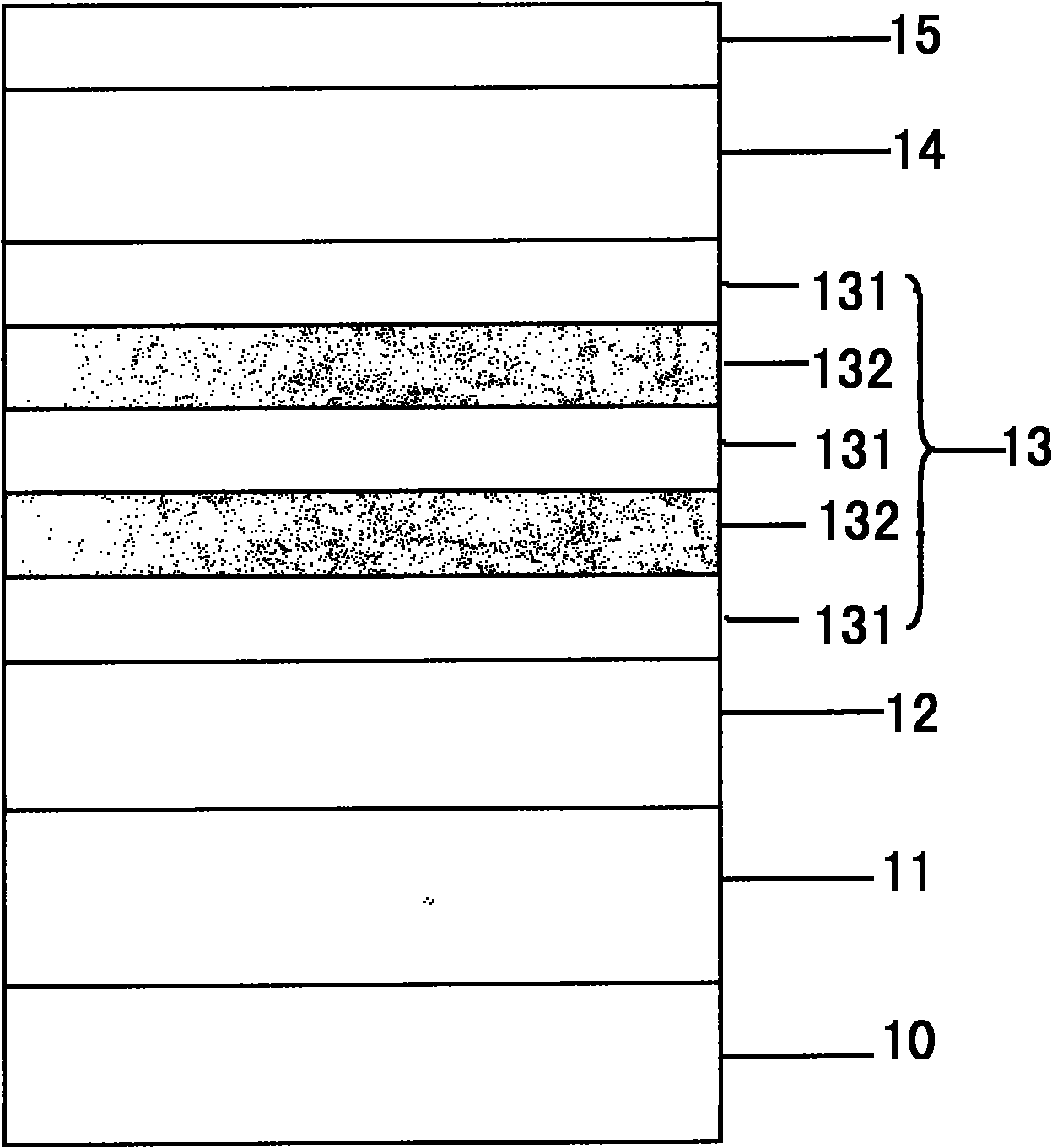

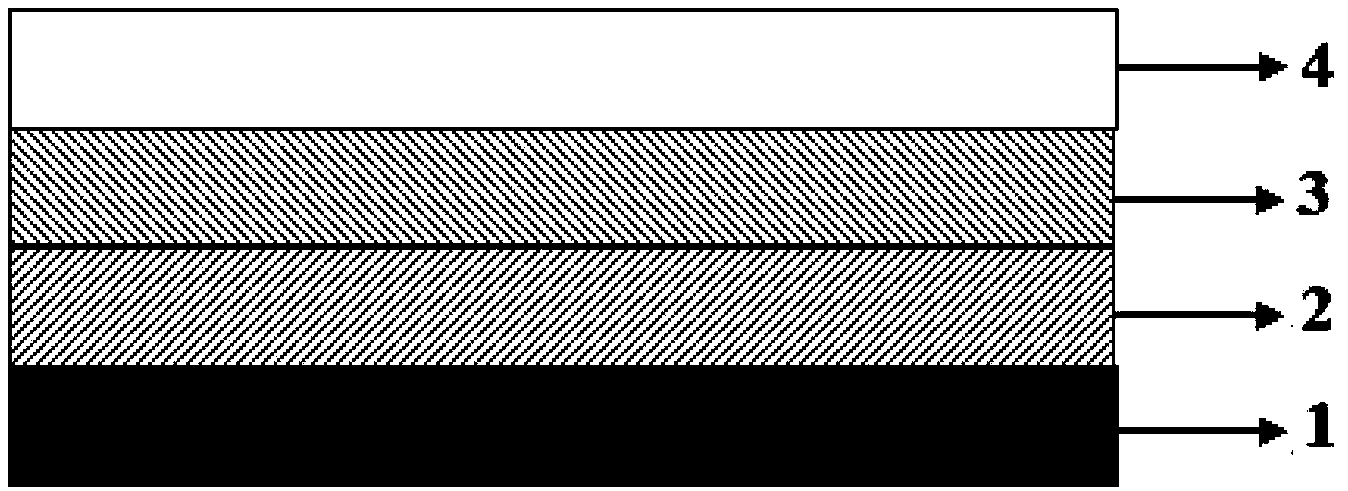

A high electron mobility transistor includes a substrate, a buffer layer, a channel layer, a spacer layer, a schottky layer and a cap layer. The buffer layer is formed on the substrate. The channel layer is formed on the buffer layer, in which the channel layer comprises a superlattice structure formed with a plurality of indium gallium arsenide thin films alternately stacked with a plurality of indium arsenide thin films. The spacer layer is formed on the channel layer. The schottky layer is formed on the spacer layer. The cap layer is formed on the schottky layer.

Owner:YLTLINK TECH CORP

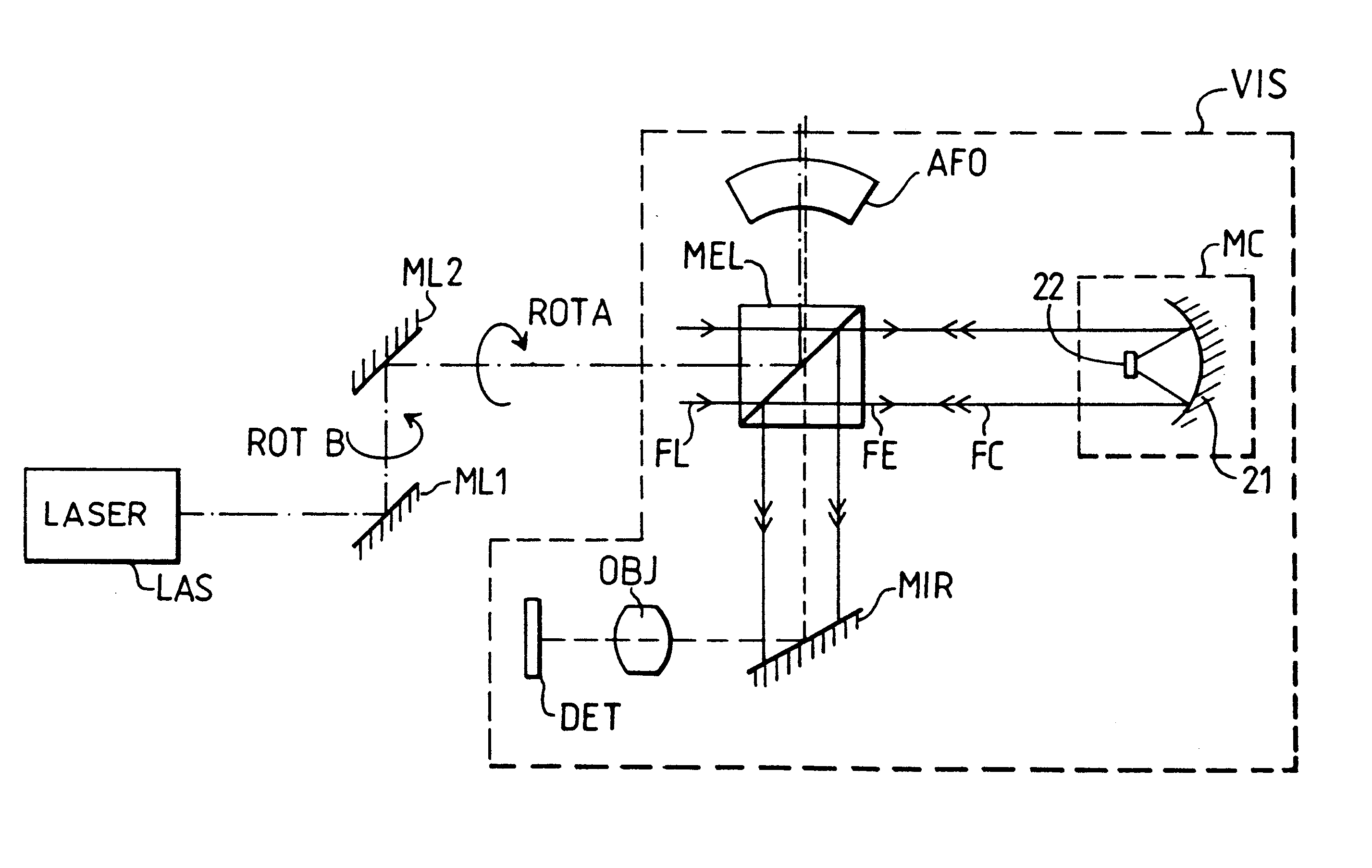

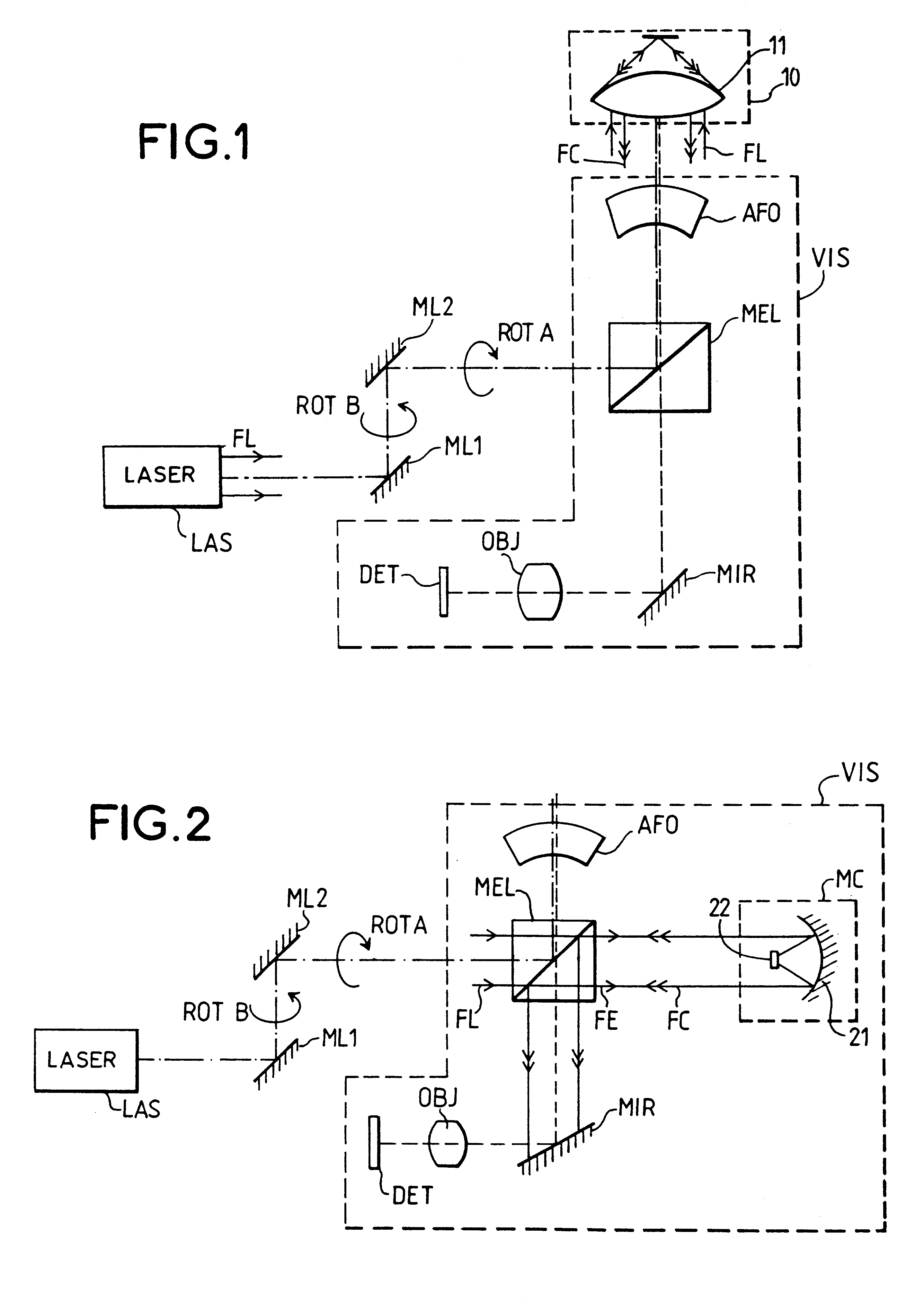

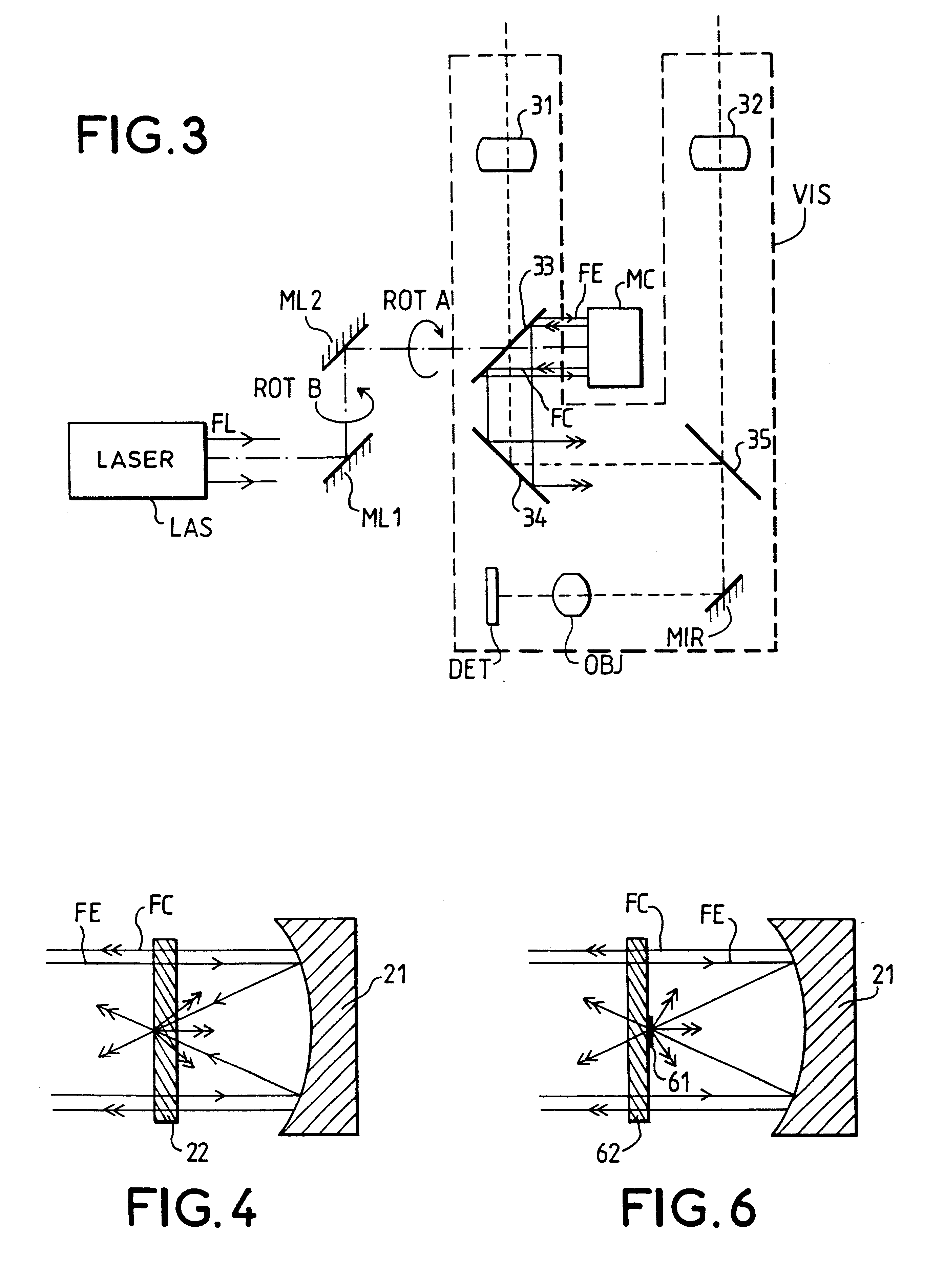

Device for harmonizing a laser emission path with a passive observation path

InactiveUS6307623B1Good flexibilityAngle measurementAiming meansSemiconductor materialsSpectral bands

A device for harmonizing a laser beam path with an observation path for a target includes a laser that generates a laser beam; a first optical element that directs a first part of the laser beam toward the target along the laser beam path while directing a second part of the laser beam toward a conversion device; and a second optical element that directs a converted beam from the conversion device to a sensor that receives the converted beam and an image from the target. The conversion device includes a photoluminescent material that converts the second part of the laser beam into a converted radiation having a wavelength within a spectral band of the sensor, and an optical assembly that focuses the second part of the laser beam into the photoluminescent material and that collects at least a portion of the converted radiation to form the converted beam. The photoluminescent material can include photoluminescent ions such as erbium ions, or a semiconductor material such as indium arsenide. The photoluminescent material can include two materials, wherein the first material has a photoluminescence lifetime greater than a pulse duration of the pulsed laser beam, and the second material has an emission spectrum of photoluminescence covering at least a portion of a sensitivity spectral band of the sensor. The conversion device can also include a non-linear material that frequency converts the second part of the laser beam into an intermediary radiation having a wavelength shorter than the laser beam, and where the photoluminescent material converts the intermediary radiation into the converted radiation.

Owner:THOMSON CSF SA

Polishing Composition and Polishing Method Using The Same

InactiveUS20110223840A1Improve polishing ratePigmenting treatmentOther chemical processesZeta potentialIndium

Owner:FUJIMI INCORPORATED

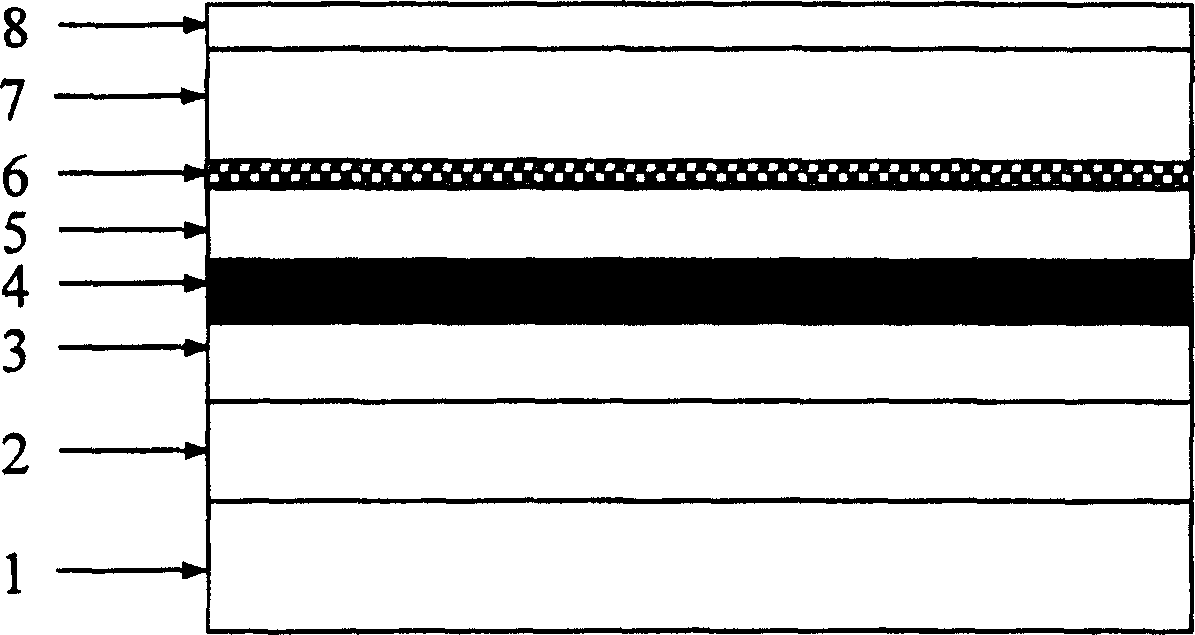

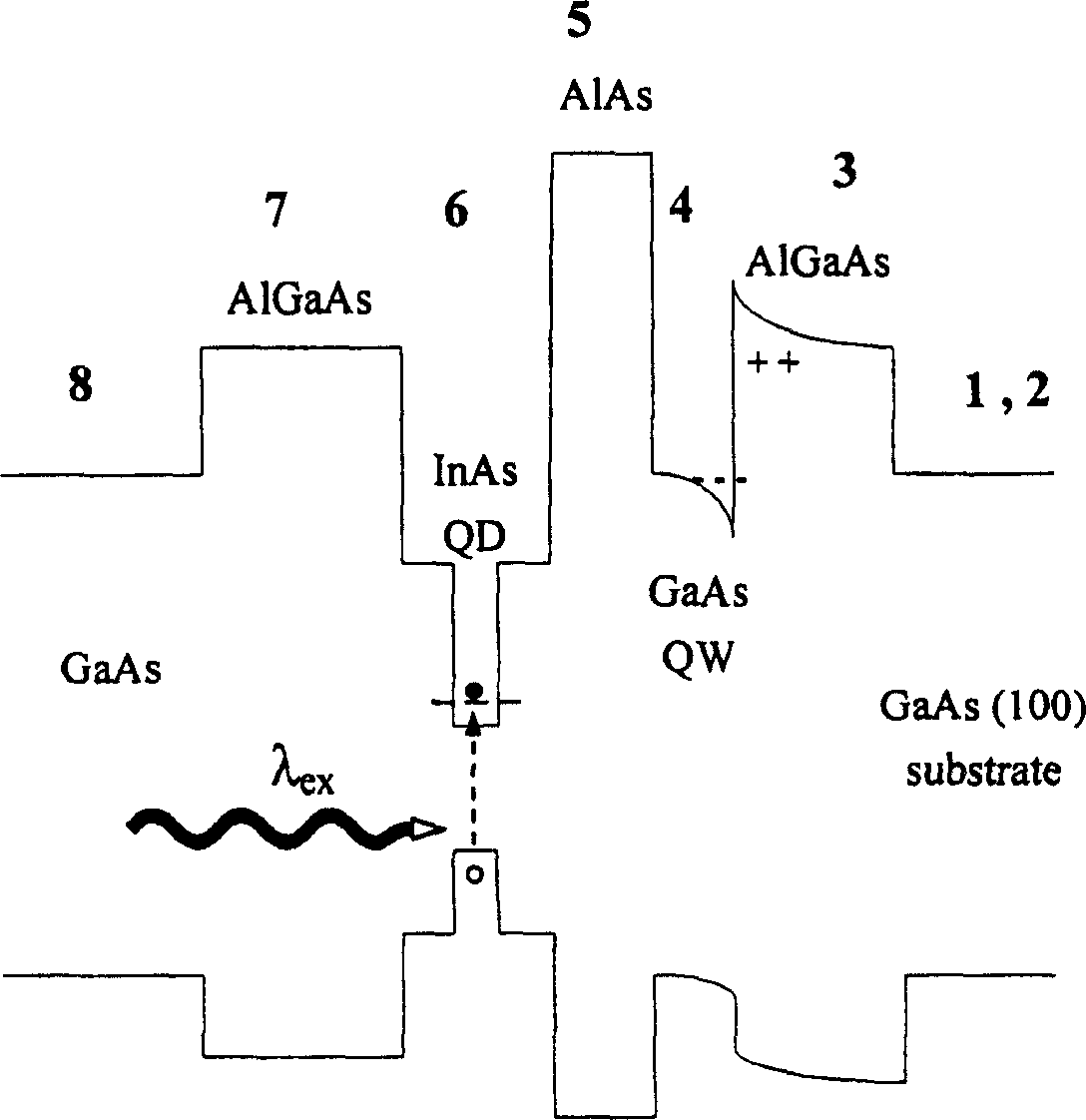

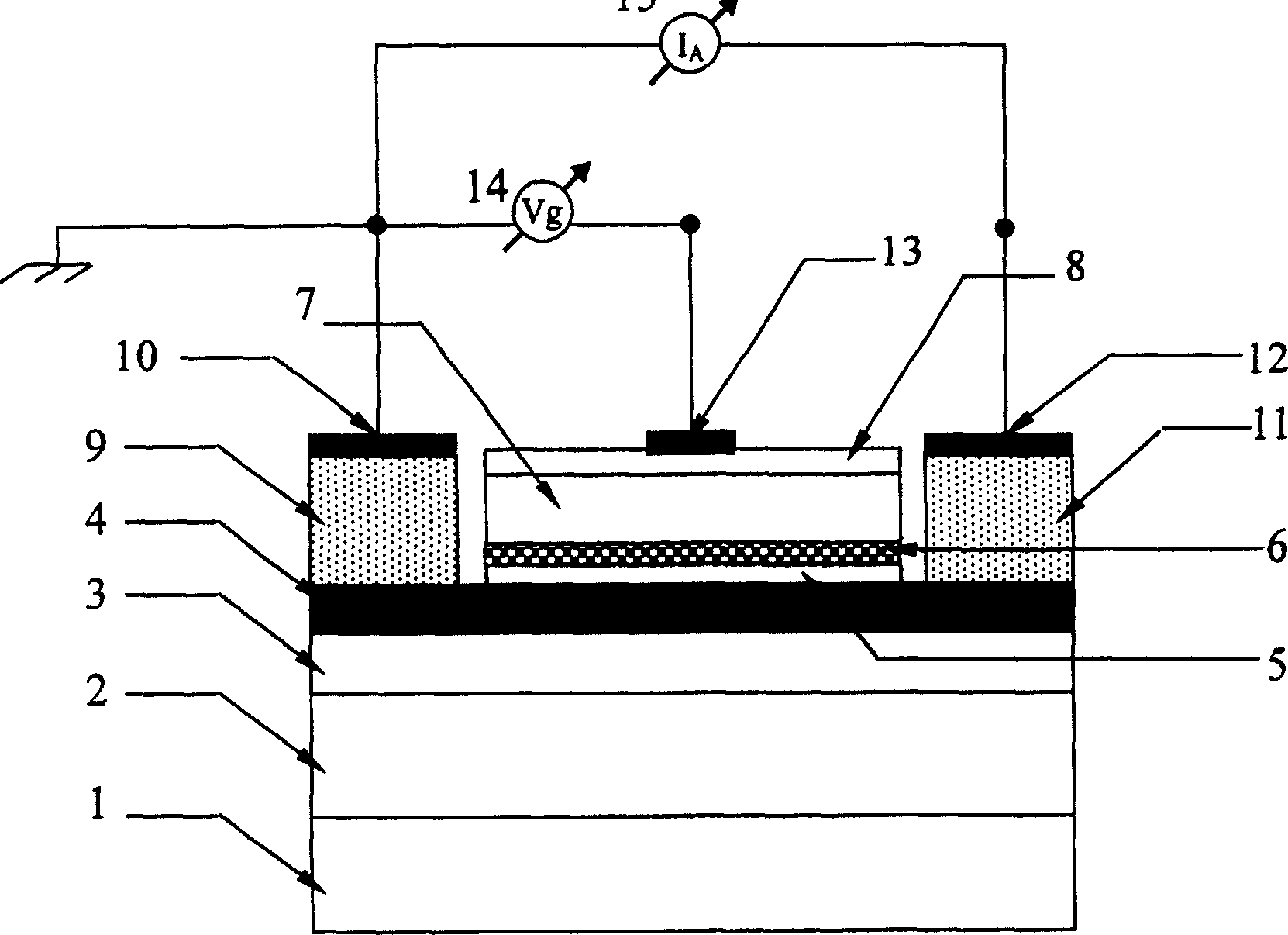

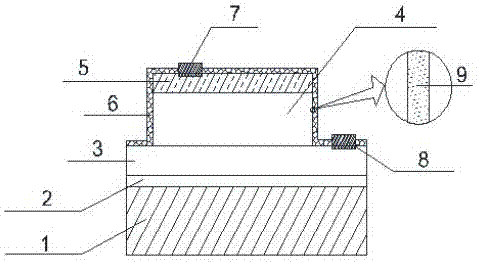

Optical detection field effect transistor containing quantum point and manufacturing method

InactiveCN1832208AImprove response efficiencySimple structureFinal product manufactureSemiconductor devicesGratingIndium arsenide

This invention relates to an optical detection field effect transistor containing quantum points and its manufacturing method characterizing: 1, longitudinally integrating a compound semiconductor optical detector and a metal-semiconductor field effect transistor to grow on a same substrate material, 2, separating the active region mesa of InAs quantum points under the grating and the source / drain region to connect the modulated conduction channel under the quantum points with the source / drain to constitute a conducting loop to realize the effective integration of optical devices and electric appliances.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

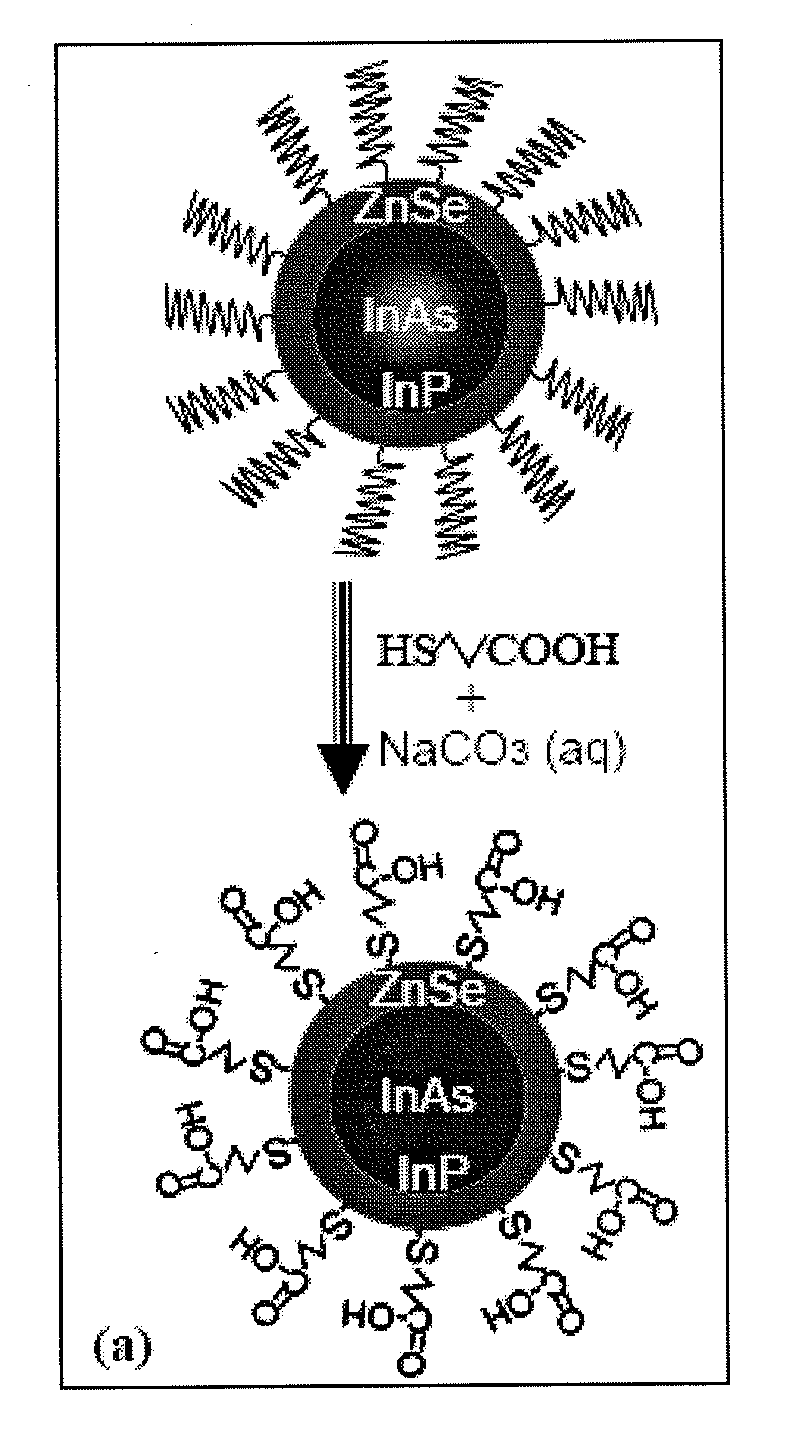

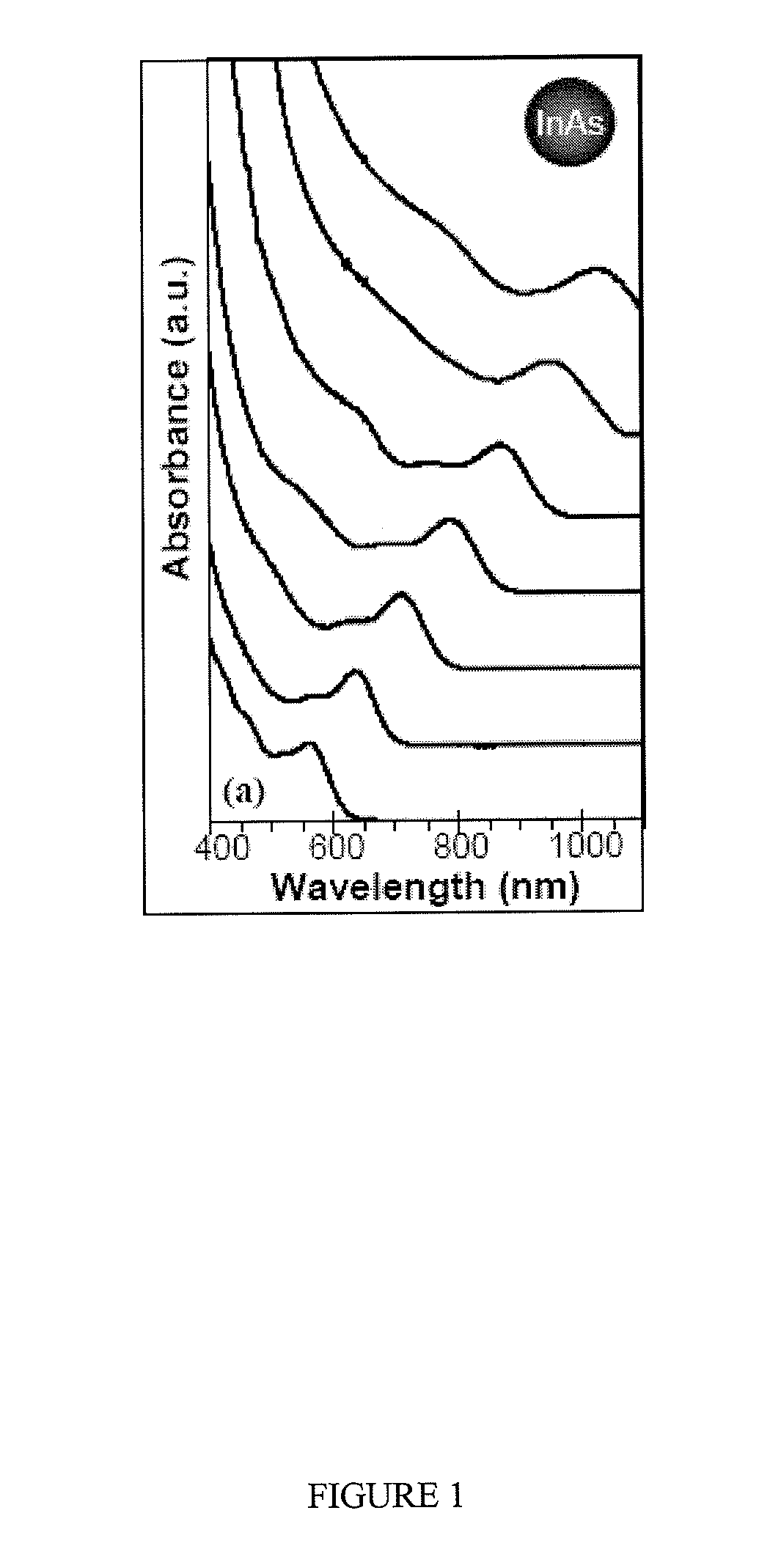

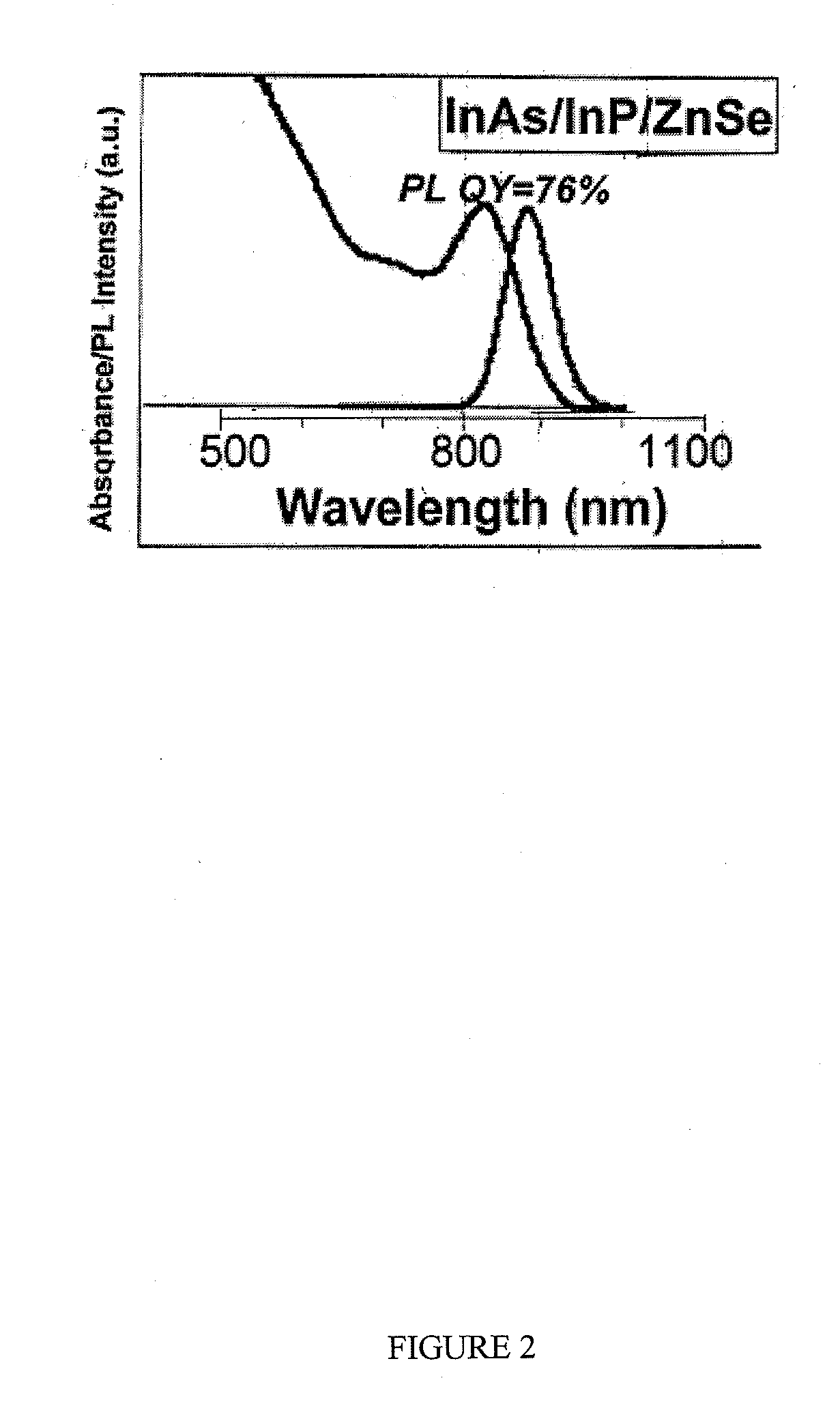

Indium arsenide nanocrystals and methods of making the same

InactiveUS20100090164A1Stable against photo-oxidationHigh electroluminescence efficiencyMaterial analysis by optical meansThin material handlingPhotoluminescenceIndium arsenide

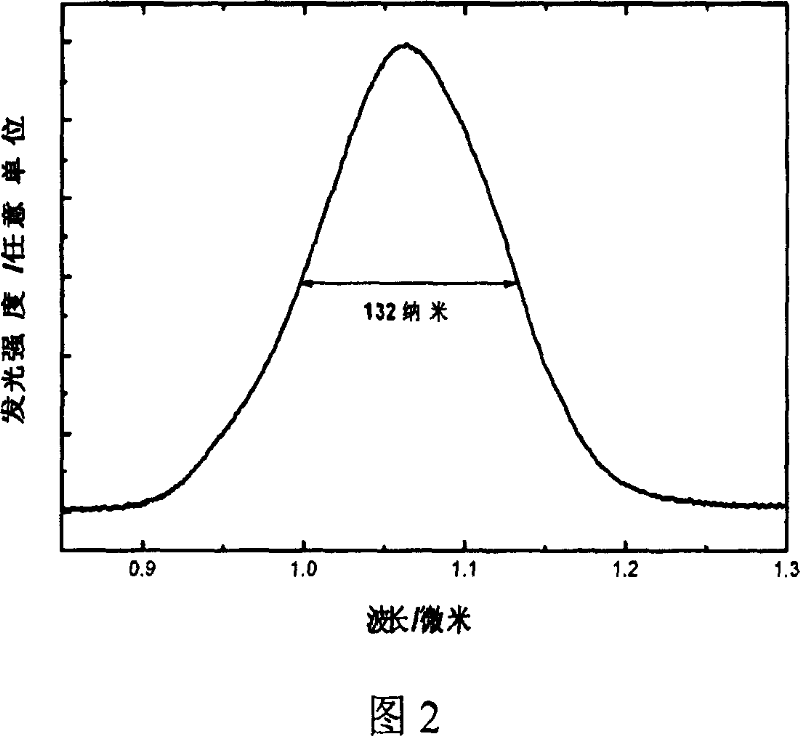

The present invention provides high quality monodisperse or substantially monodisperse InAs nanocrystals in the as-prepared state. In some embodiments, the as-prepared substantially monodisperse InAs nanocrystals demonstrate a photoluminescence of between about 700 nm and 1400 nm.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

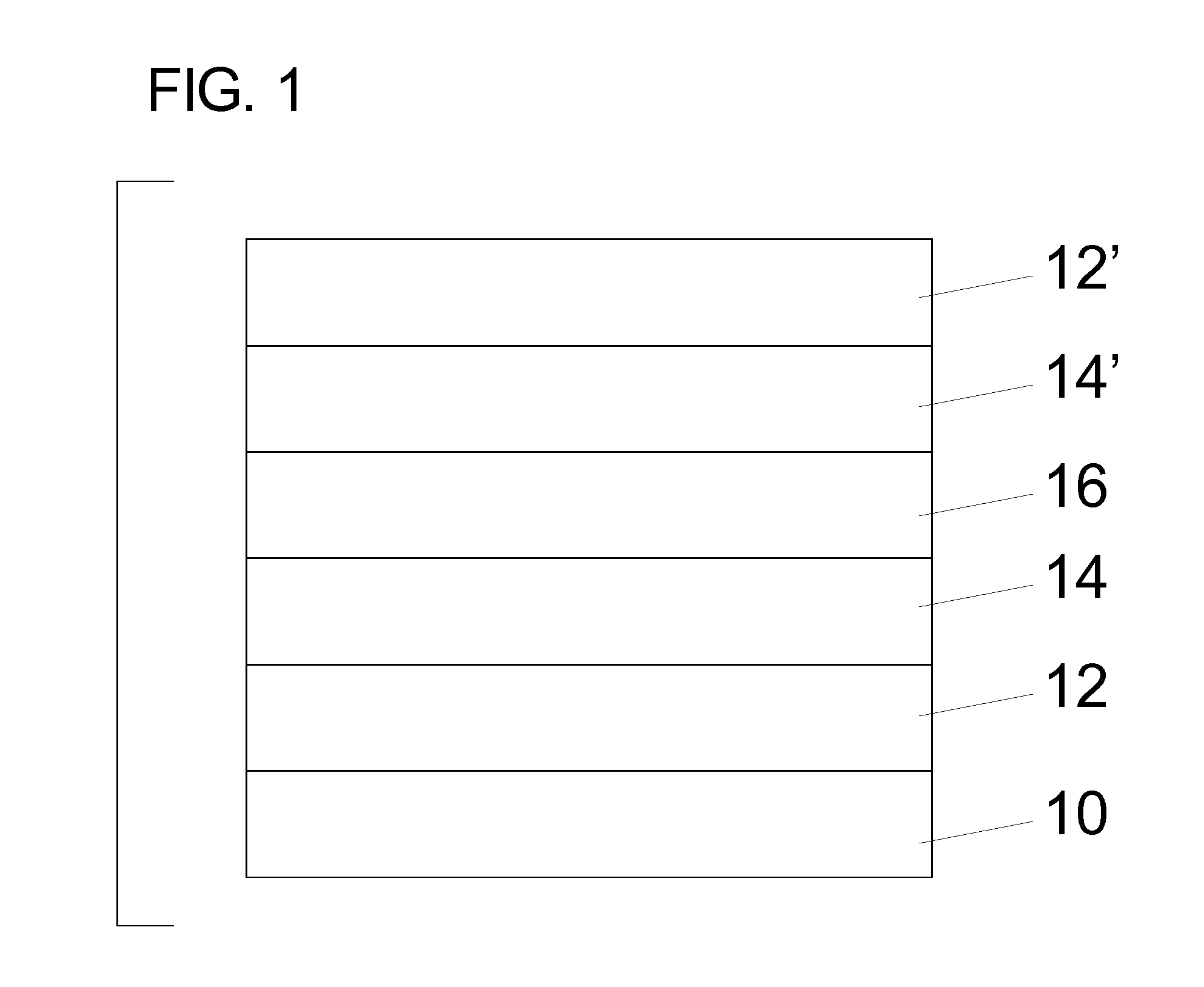

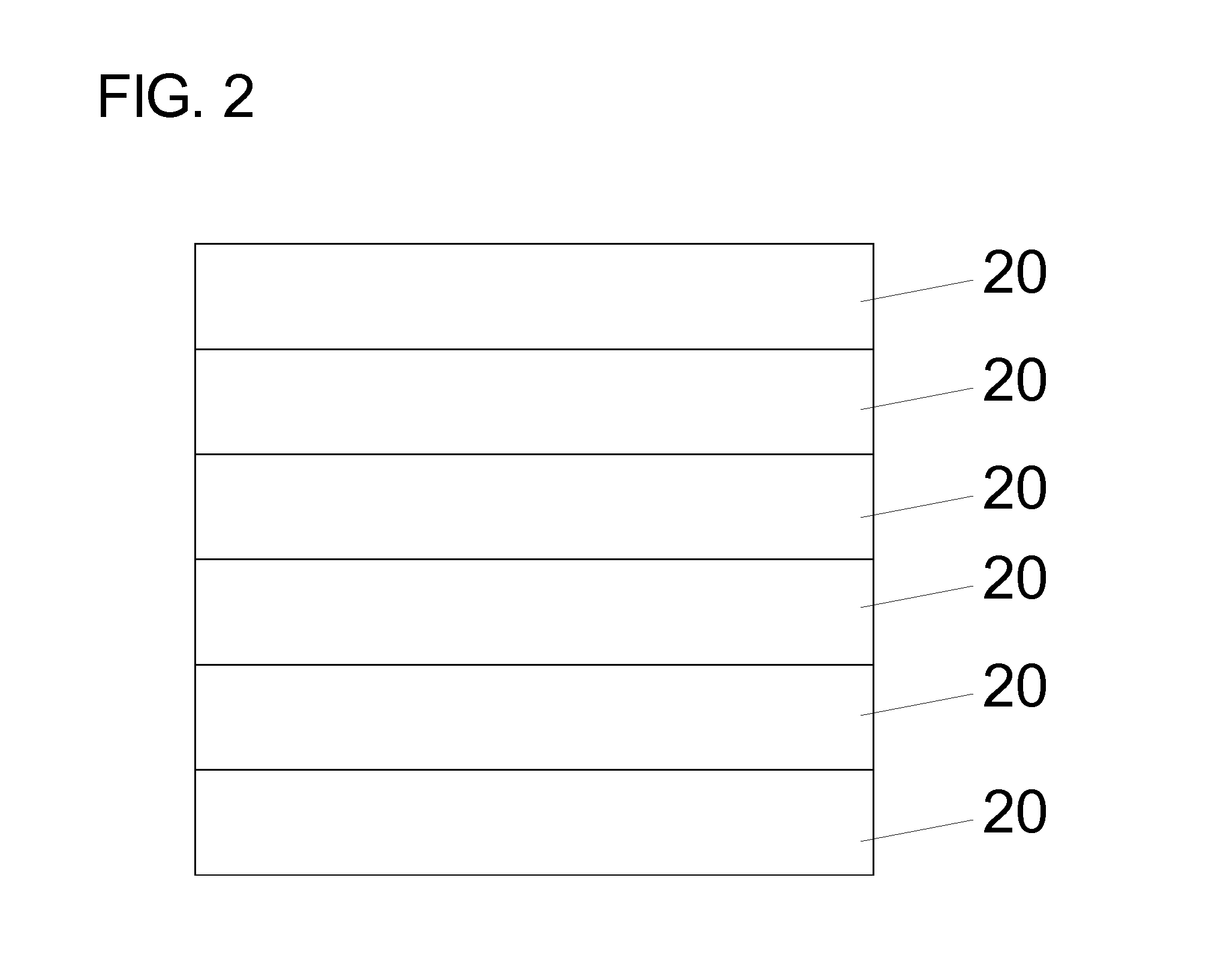

Long Wavelength Infrared Superlattice

InactiveUS20130043458A1Quality lossOvercome lossSemiconductor/solid-state device manufacturingNanoopticsGallium antimonideIndium arsenide

An embodiment of the present invention improves the fabrication and operational characteristics of a type-II superlattice material. Layers of indium arsenide and gallium antimonide comprise the bulk of the superlattice structure. One or more layers of indium antimonide are added to unit cells of the superlattice to provide a further degree of freedom in the design for adjusting the effective bandgap energy of the superlattice. One or more layers of gallium arsenide antimonide are added to unit cells of the superlattice to counterbalance the crystal lattice strain forces introduced by the aforementioned indium antimonide layers.

Owner:SVT ASSOCS

Long Wavelength Infrared Superlattice

InactiveUS20130043459A1Extend the cutoff wavelengthQuality lossSemiconductor/solid-state device manufacturingNanoopticsGallium antimonideIndium arsenide

An embodiment of the present invention improves the fabrication and operational characteristics of a type-II superlattice material. Layers of indium arsenide and gallium antimonide comprise the bulk of the superlattice structure. One or more layers of indium antimonide are added to unit cells of the superlattice to provide a further degree of freedom in the design for adjusting the effective bandgap energy of the superlattice. One or more layers of gallium arsenide antimonide are added to unit cells of the superlattice to counterbalance the crystal lattice strain forces introduced by the aforementioned indium antimonide layers.

Owner:SVT ASSOCS

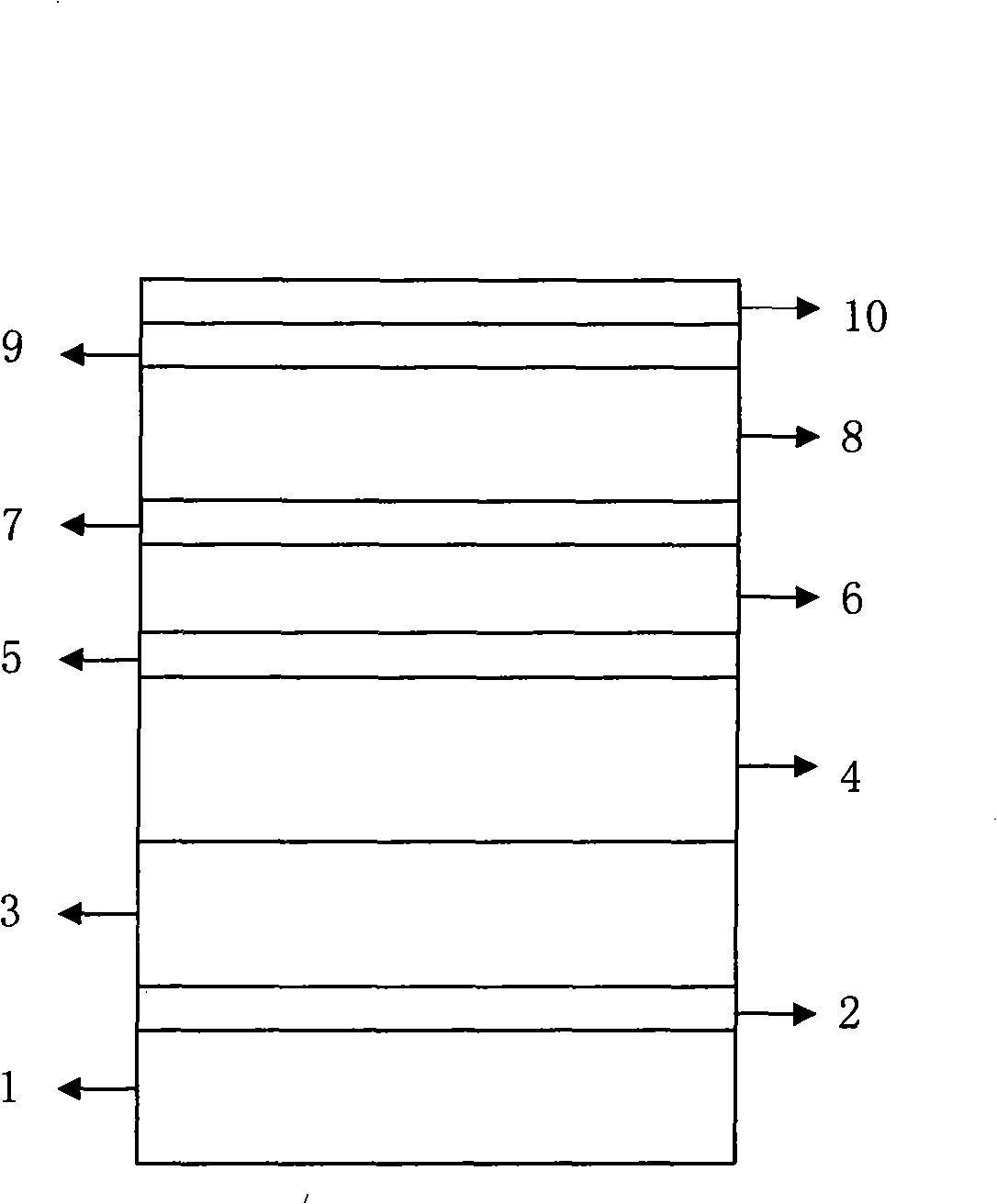

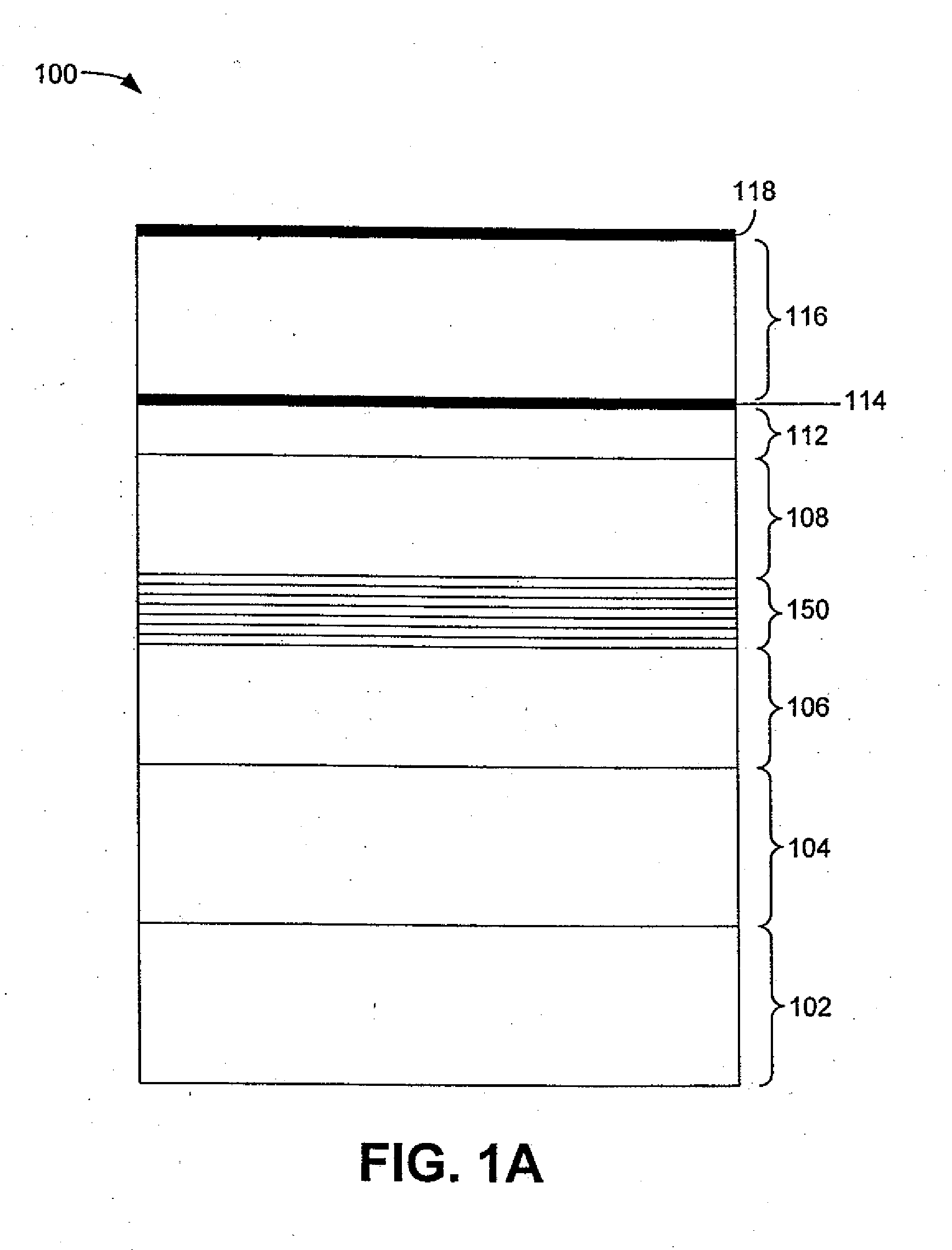

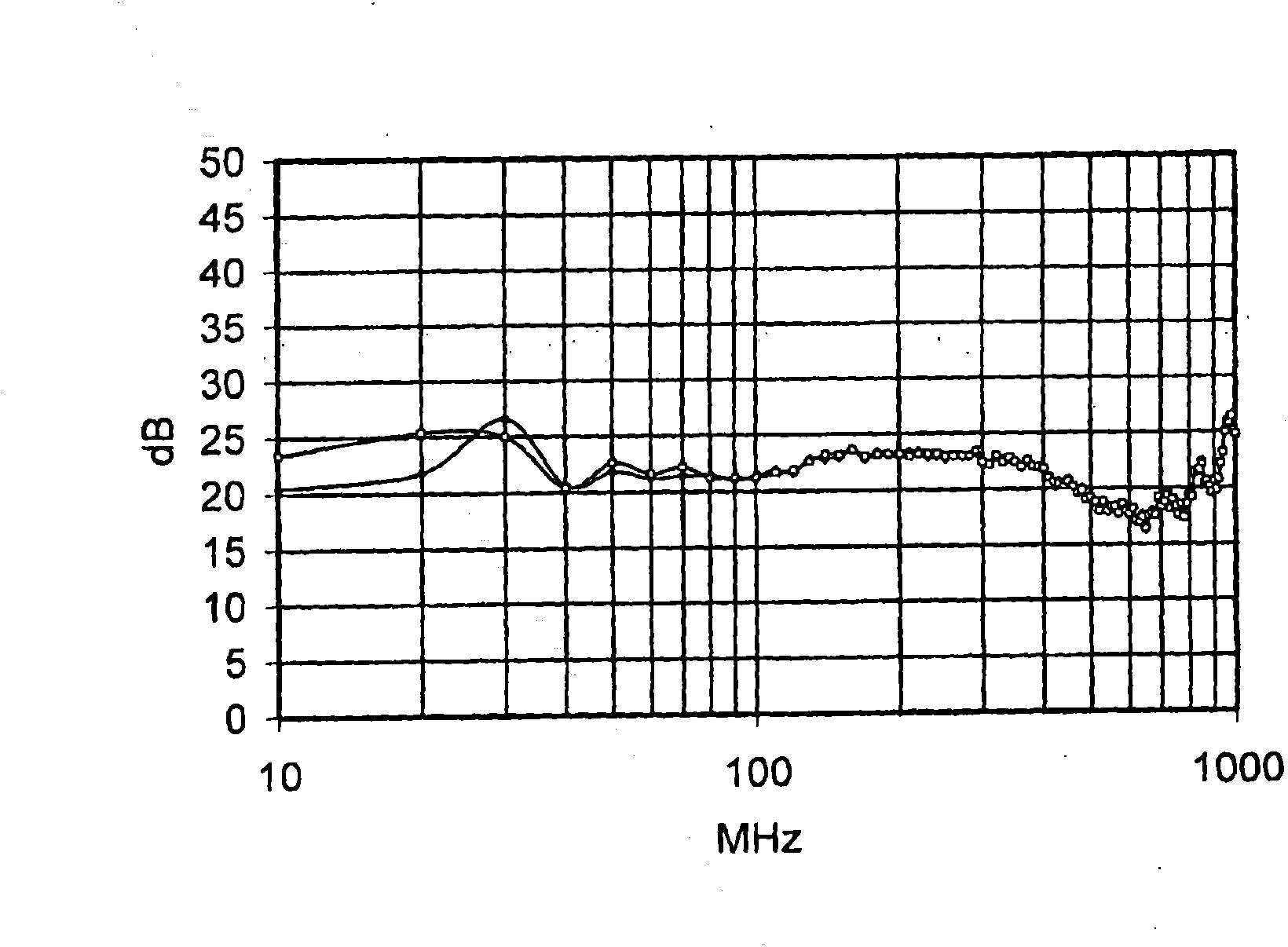

808nm large-power quantum well laser in non-aluminum active region of asymmetric structure

ActiveCN101340060AIncreased light confinement factorReduce leakageOptical wave guidanceLaser detailsIndium arsenideWaveguide

The invention provides an aluminum-free active region 808nm high-power quantum-well laser with asymmetric structure. From the bottom to the top, the structure of the laser sequentially comprises a substrate, a buffer layer, an N-type lower limiting layer, a lower waveguide layer, a quantum-well layer, an upper waveguide layer, a potential barrier limiting layer, a P-type upper limiting layer, a transition layer and an ohmic contact layer, wherein, the upper waveguide layer and the lower waveguide layer are made of aluminum-free material Indium gallium phosphide, the quantum-well layer made of gallium indium arsenide phosphide material, the waveguide layer and the quantum-well layer form the aluminum-free active region, and one layer potential barrier limiting layer which is made of P-type aluminum gallium indium phosphide material and 50nm-150nm thick and has a band gap wider than that of the upper limiting layer is arranged between the upper limiting layer and the upper waveguide layer. The laser of the invention can increase the optical limiting factor of the P-type material region, reduce the optical leakage towards the P-type material region, reduce optical absorption loss of a current carrier at the highly doped area, and improve the work efficiency of the laser; the structure of the invention also improves the limiting effect of the active region on the carrier, reduce the leakage of the carrier and is favorable to the decrease of the threshold current.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

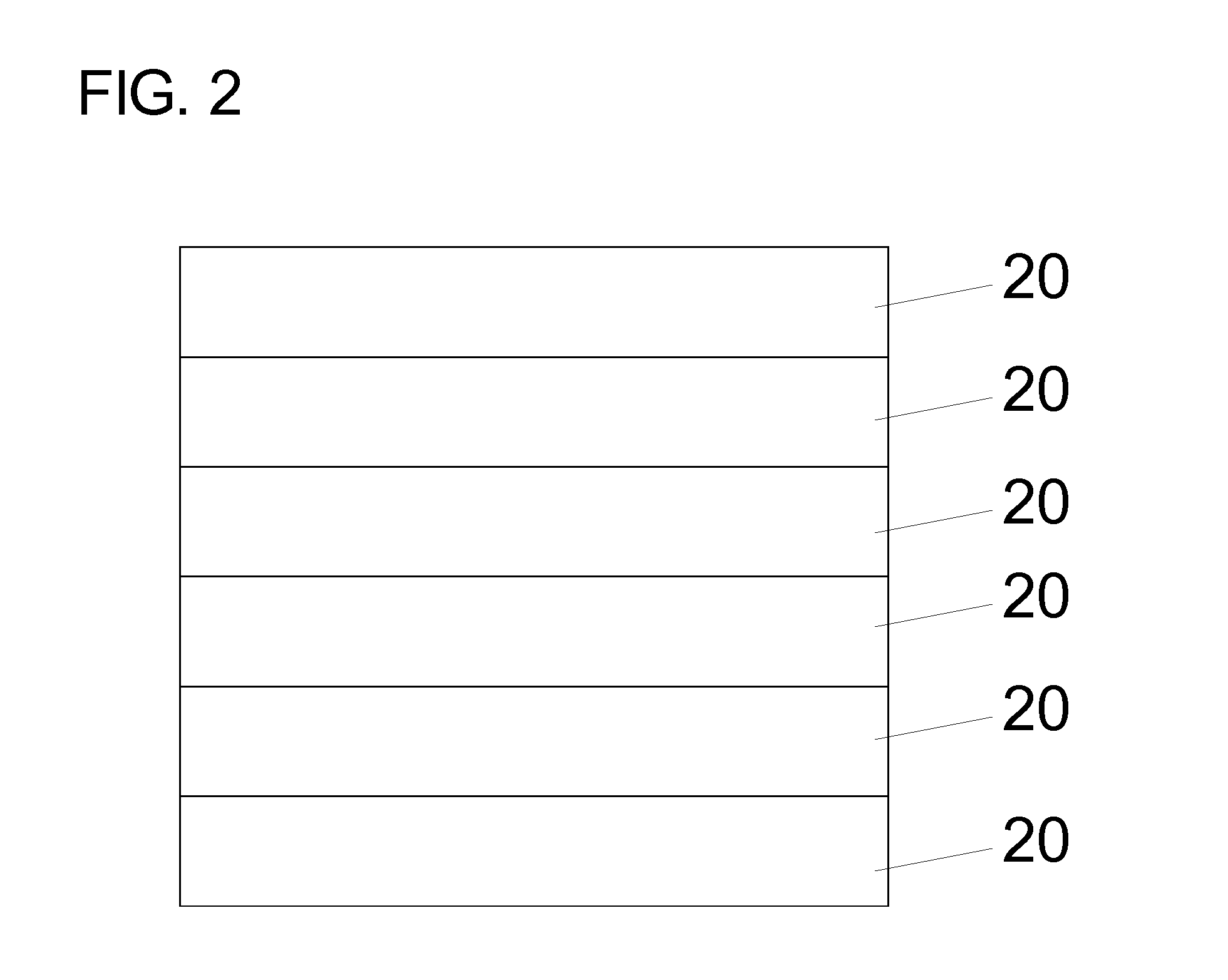

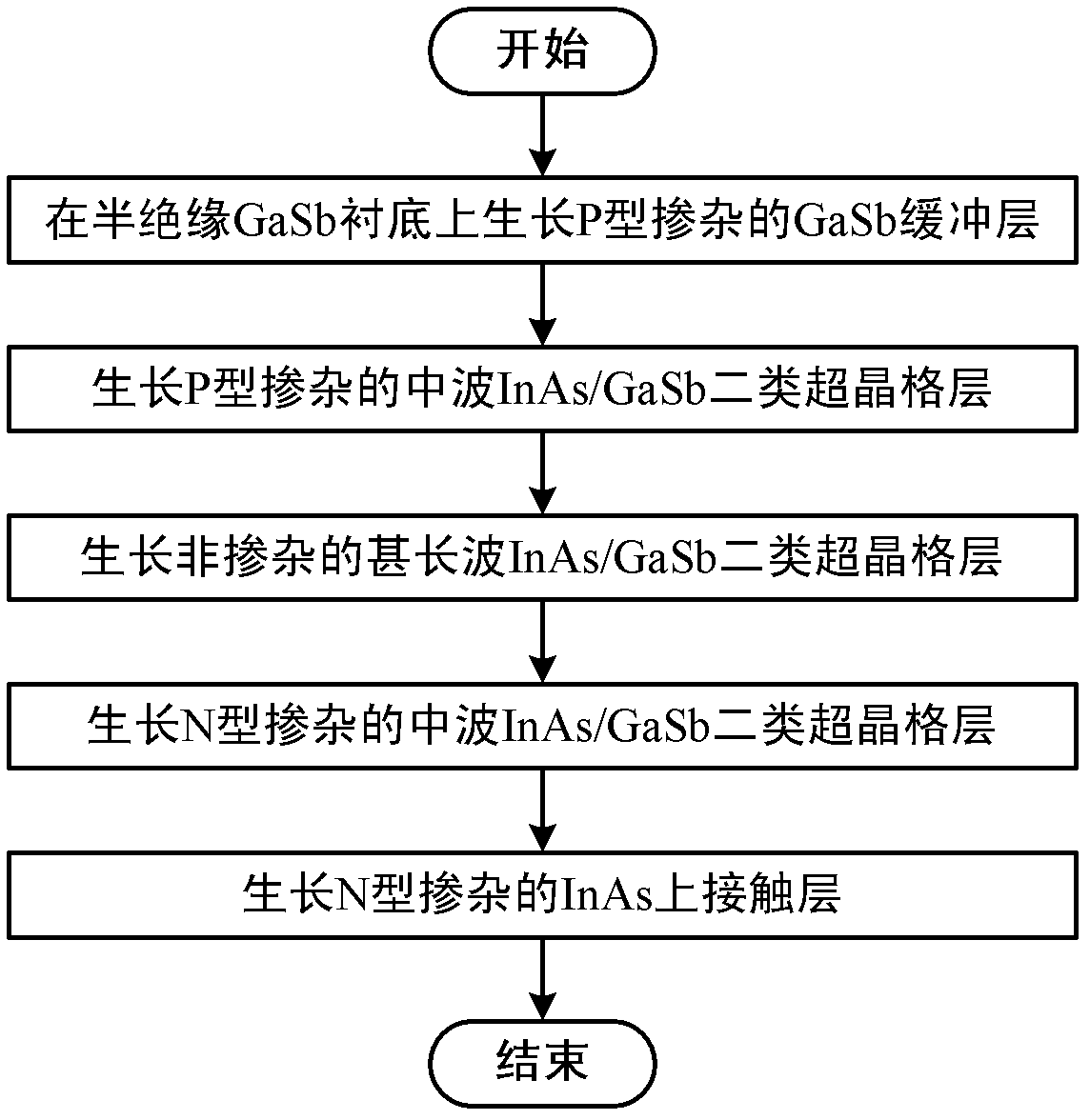

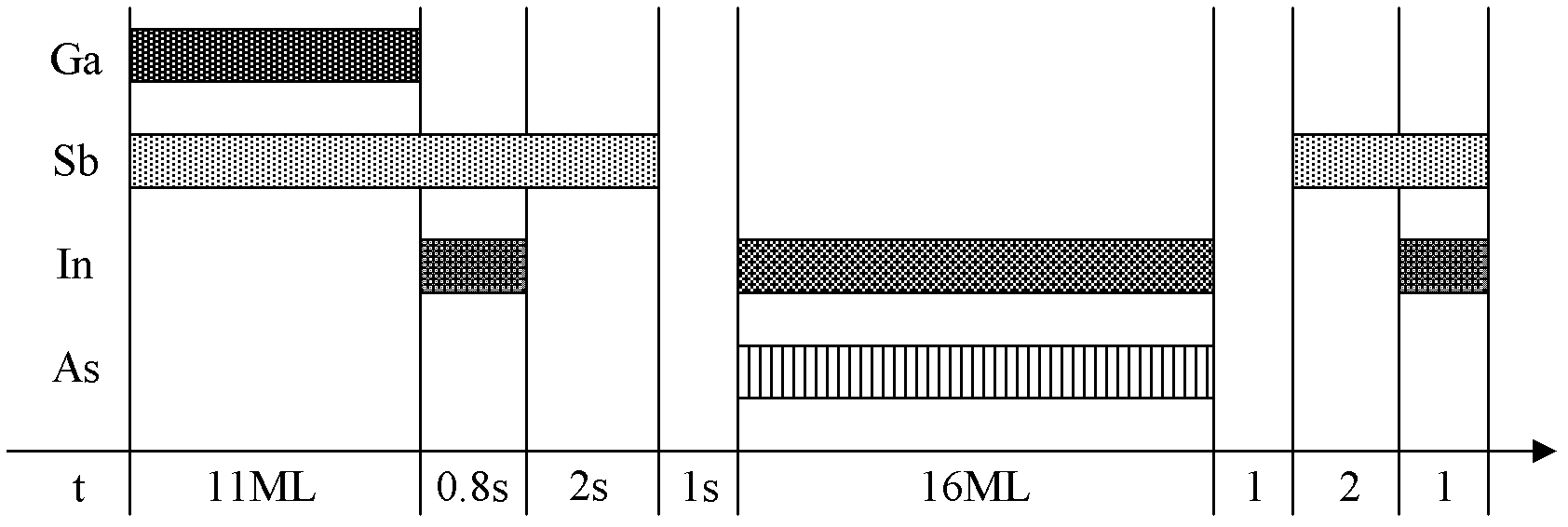

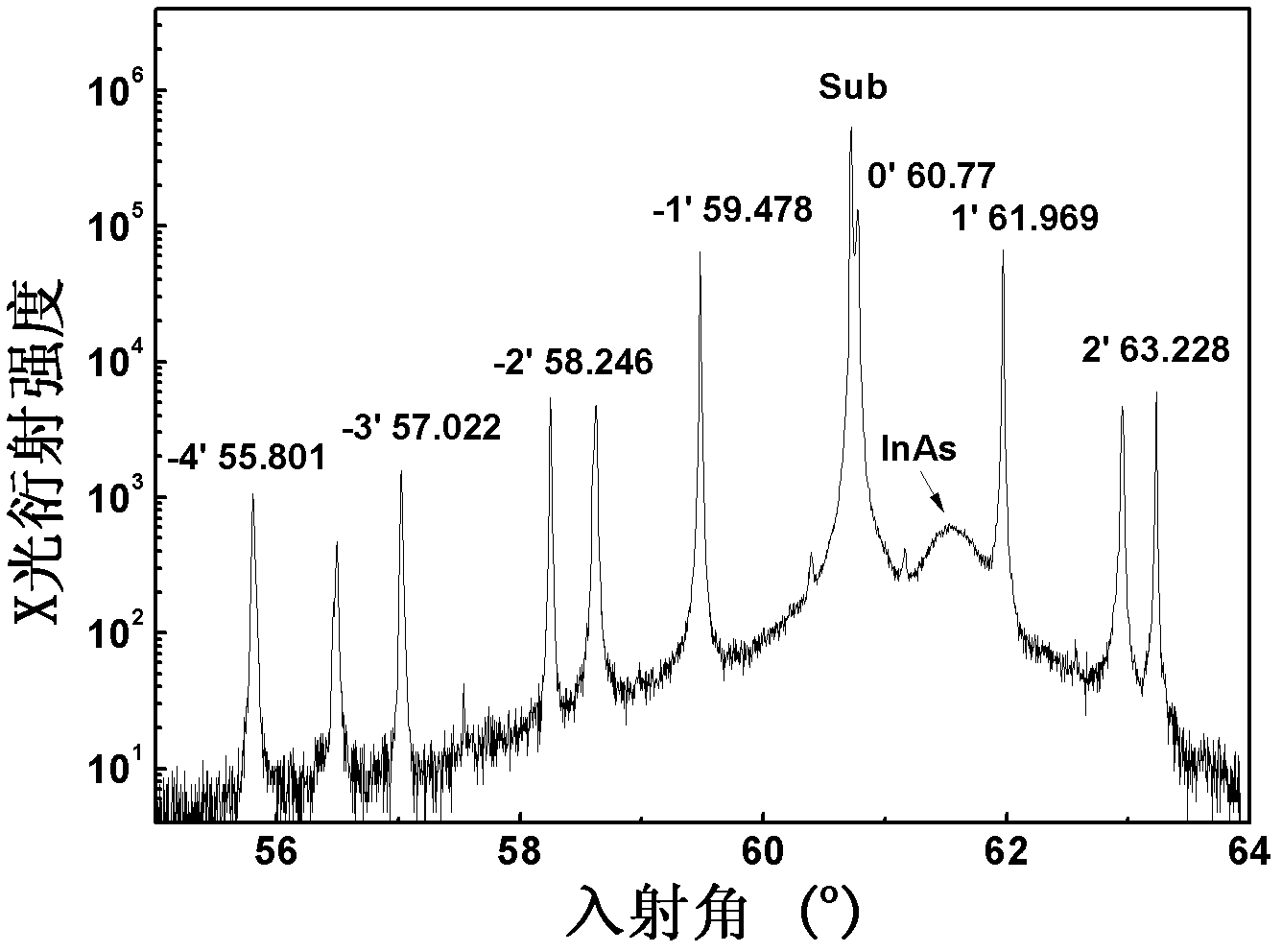

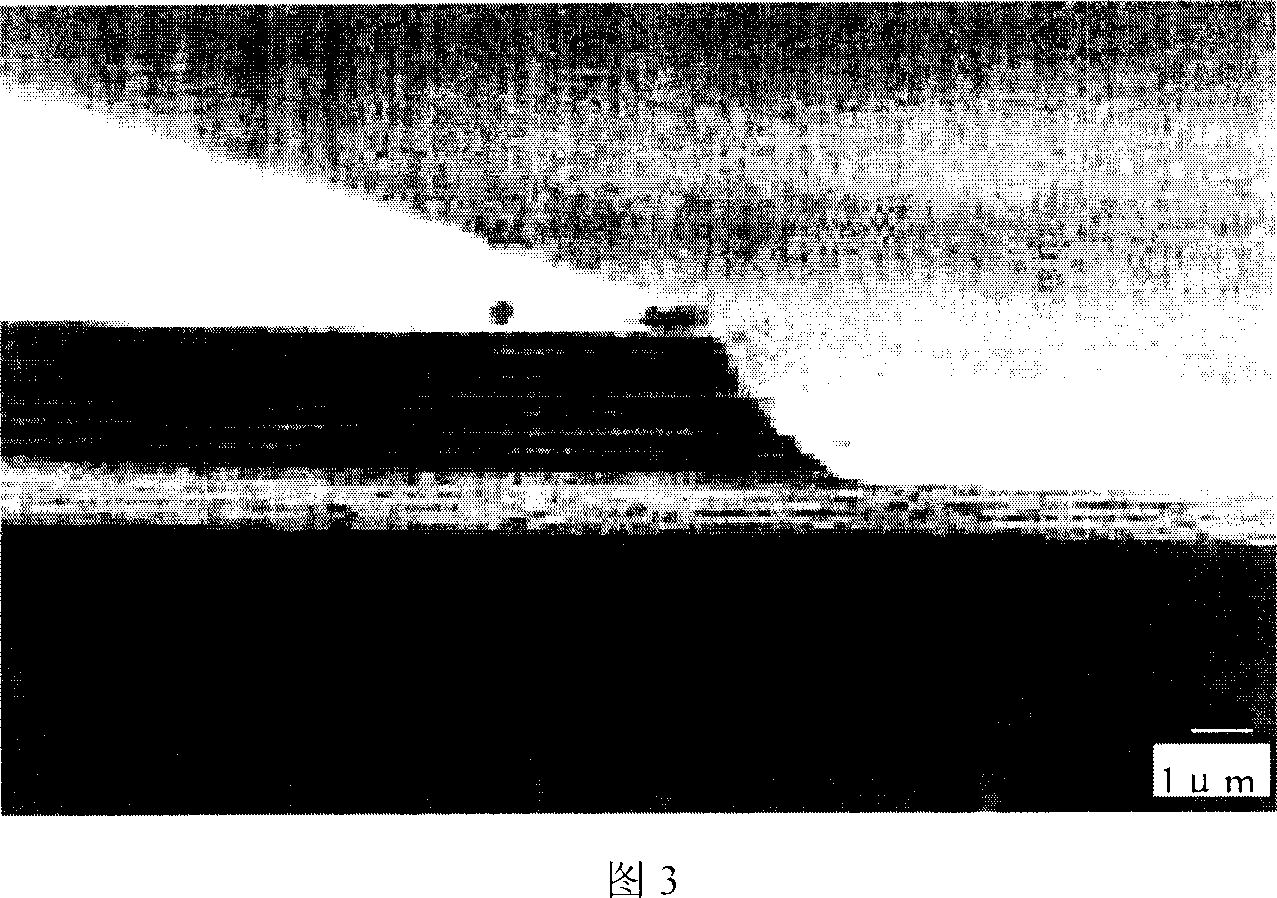

Method for producing very-long wave indium arsenide (InAs)/gallium antimonide (GaSb) second class superlattice infrared detector material

InactiveCN102544229AReduce dark currentExcellent optical propertiesFinal product manufactureSemiconductor devicesGallium antimonideInterface design

The invention discloses a method for producing a very-long wave indium arsenide (InAs) / gallium antimonide (GaSb) second class superlattice infrared detector material, which comprises the step that: a P type doped GaSb buffer layer, a P type doped medium wave InAs / GaSb second class superlattice layer, a non-doped very-long wave InAs / GaSb second class superlattice layer, a N type doped medium wave InAs / GaSb second class superlattice layer and an N type doped InAs upper contact layer are sequentially grown on a semi-insulating GaSb substrate, so the very-long wave InAs / GaSb second class superlattice infrared detector material is obtained. After the method is utilized, because 'Sb-soak' and 'grow interruption' which are well designed are added in an interface design, the quality of the superlattice material is further improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

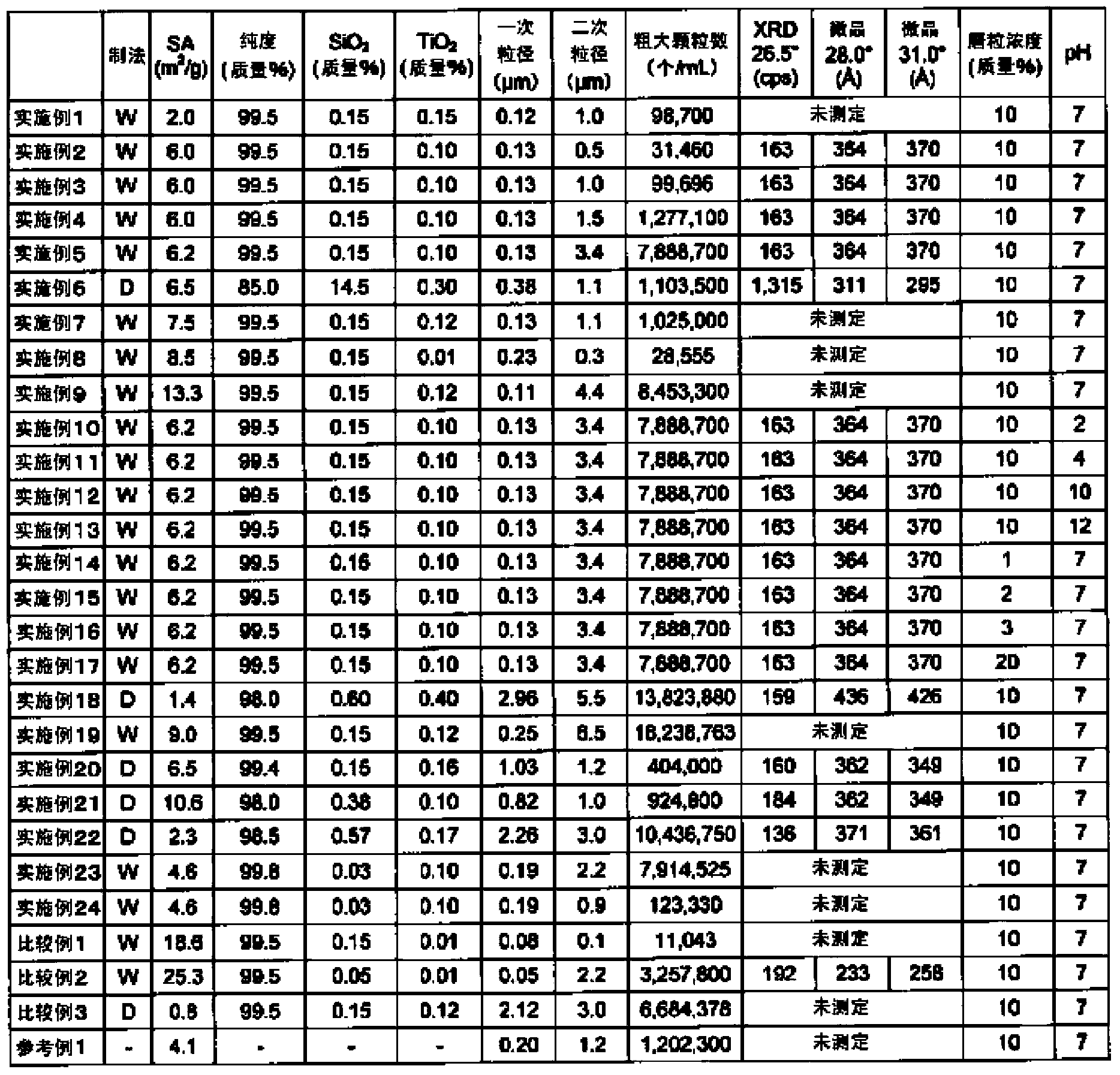

Polishing material and polishing composition

ActiveCN103402705ASuitable for useOther chemical processesLapping machinesIndium arsenideSilicon oxide

Provided is a polishing composition which contains a polishing material and water. The polishing composition contains the polishing material in an amount of 0.1% by mass or more. The polishing material contains zirconium oxide particles. Each zirconium oxide particle has a specific surface area of 1-15 m2 / g. It is preferable that the zirconium oxide particles has a purity of 99% by mass or more. For example, the polishing composition is used for the purpose of polishing hard-brittle materials such as sapphire, silicon nitride, silicon carbide, silicon oxide, glass, gallium nitride, gallium arsenide, indium arsenide and indium phosphide.

Owner:FUJIMI INCORPORATED

Method for growing wide spectrum indium arsenide/aluminium gallium arsenide quantum point material

InactiveCN101038866AExcellent luminous propertiesLaser detailsFinal product manufactureIndium arsenideQuantum

The invention provides a growth method of wide spectrum InAs / GaAlAs quantum dot material, which is a growth method of burying self-organization quantum dot material based on molecular beam epitaxy device, wherein the method includes: choosing a substrate; preparing an GaAlAs buffer layer, as a lower barrier layer for an active region to be mentioned, on the substrate; preparing the active region, working as core part and spectrum emission region of the InAs / GaAlAs quantum dot material, on the GaAlAs buffer layer; preparing low temperature GaAlAs cover layer, as an upper barrier layer for the active region, on the active region; preparing a high temperature GaAlAs cover layer which is the outmost layer of the InAs / GaAlAs quantum dot material for protection, in this manner, the growth of material can be completed.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

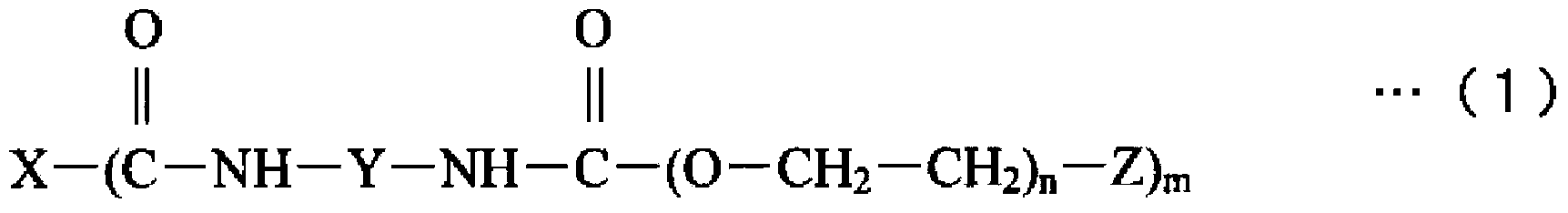

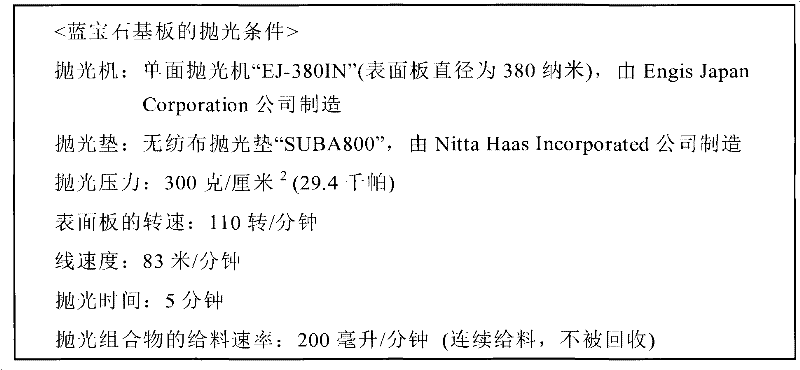

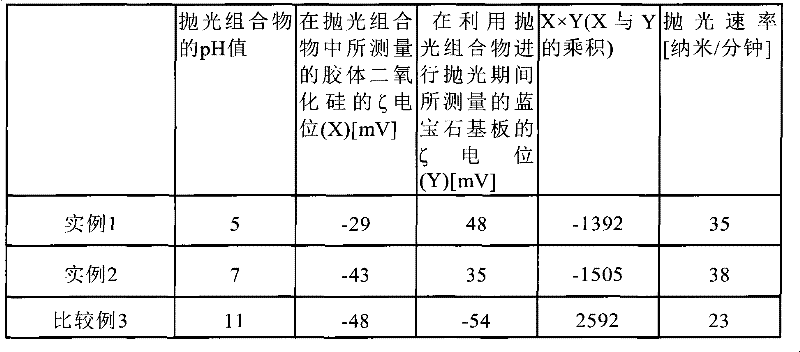

Polishing composition and polishing method using the same

A polishing composition contains at least abrasive grains and water and is used in polishing an object to be polished formed of a substrate material for optical devices, a substrate material for power devices, or a compound semiconductor material. The abrasive grains have a zeta potential satisfying the relationship XY!<=0, where X [mV] represents the zeta potential of the abrasive grains measured in the polishing composition and Y [mV] represents the zeta potential of the object to be polished measured during polishing using the polishing composition. The abrasive grains are preferably of aluminum oxide, silicon oxide, zirconium oxide, diamond, or silicon carbide. The object to be polished is preferably of sapphire, gallium nitride, silicon carbide, gallium arsenide, indium arsenide, or indium phosphide.

Owner:FUJIMI INCORPORATED

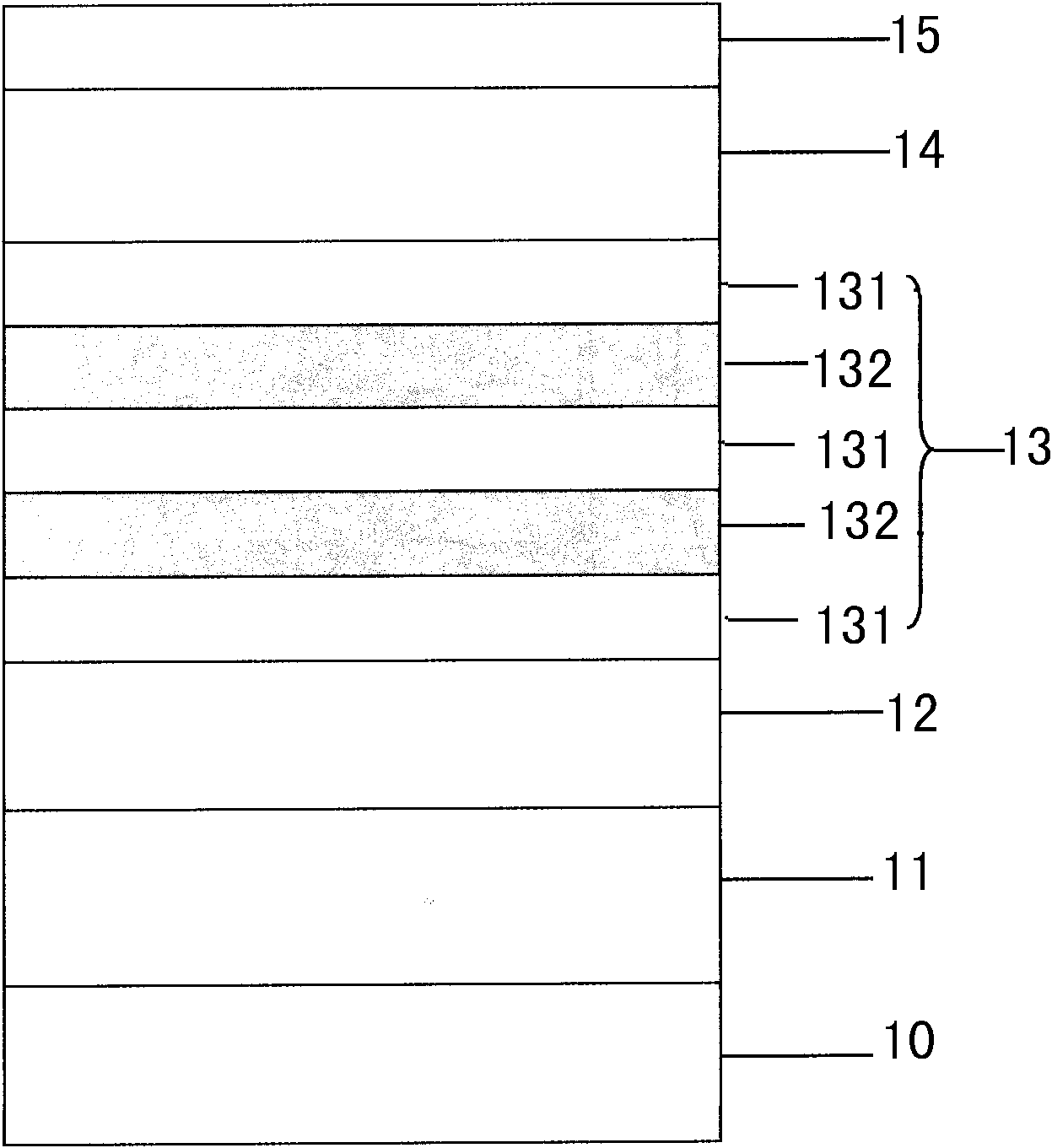

Method for growing indium arsenide/indium gallium arsenide quantum well material on indium phosphide substrate

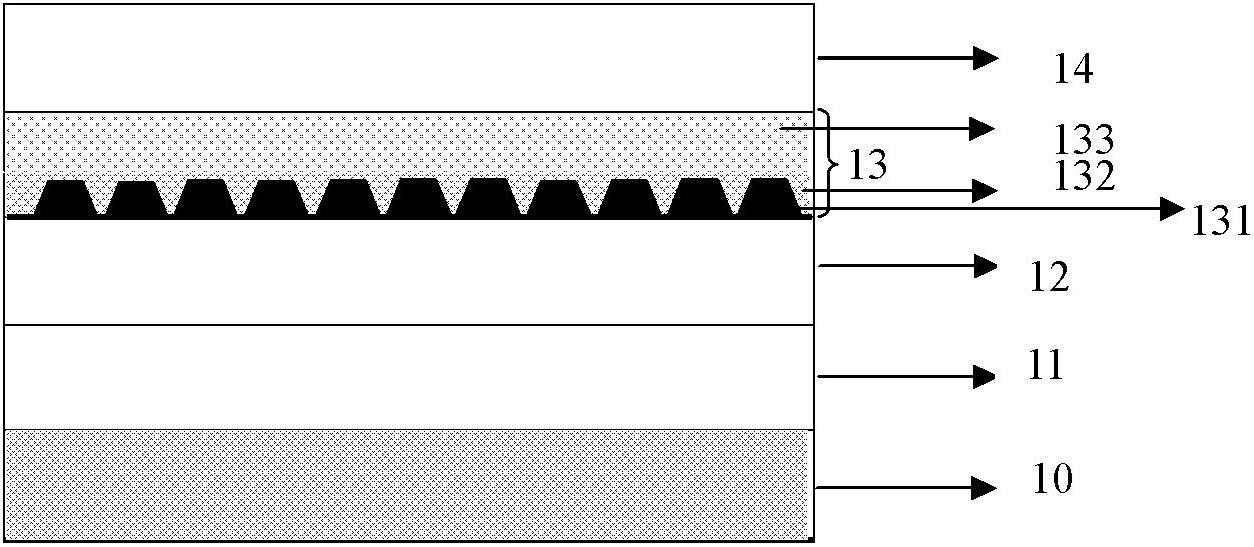

ActiveCN102208756AReduce defectsIncrease the transition wavelengthLaser detailsSemiconductor lasersQuantum wellIndium arsenide

The invention discloses a method for growing indium arsenide / indium gallium arsenide quantum well material on an indium phosphide substrate. The method comprises the following steps of: 1, selecting the substrate; and 2, sequentially growing a buffer layer, a lower waveguide layer, a dual-quantum well structure, an upper waveguide layer and a cover layer to finish growing the indium arsenide / indium gallium arsenide quantum well material on the indium phosphide substrate. In the method, an InAs quantum well with a proper thickness is grown at relatively lower temperature to realize the functions of reducing shortcomings and increasing a transition wavelength to 2.3 mu m under high strain condition.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Indium arsenide antimony and indium gallium arsenide antimony two-waveband infrared detector and manufacturing method thereof

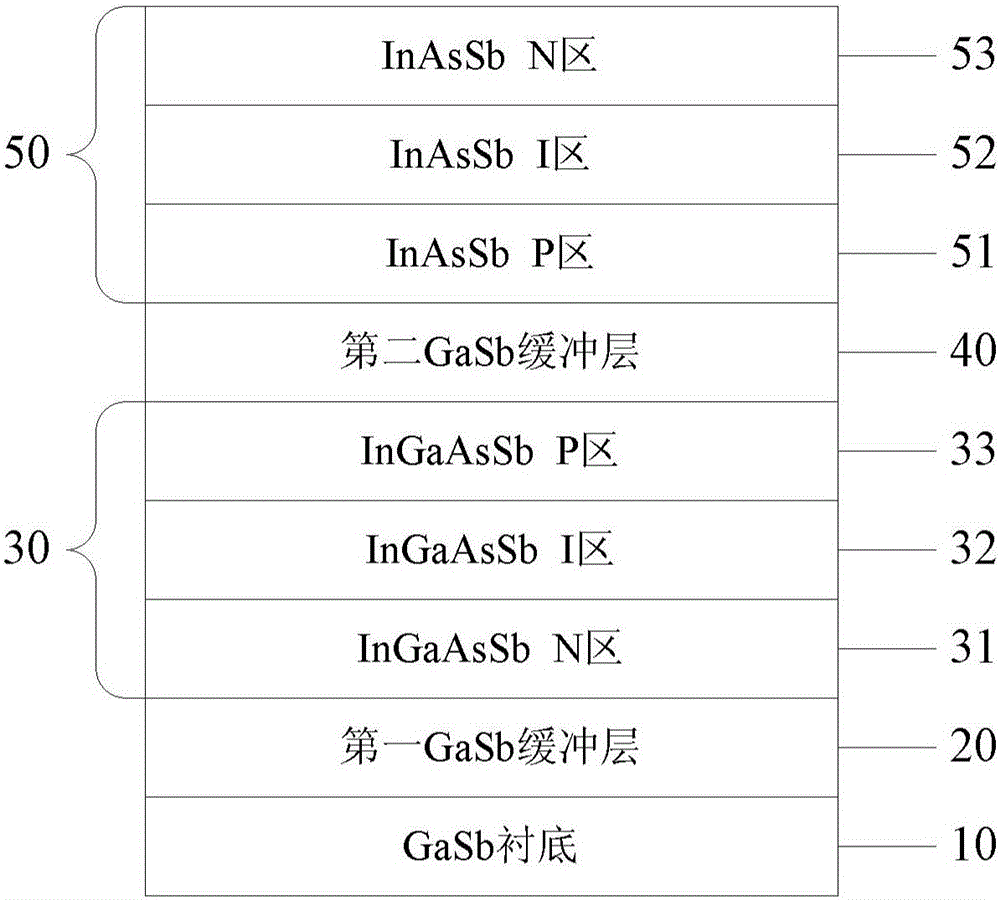

ActiveCN106298993AGuaranteed uniformityGuaranteed accuracyFinal product manufactureSemiconductor devicesIndiumIndium arsenide

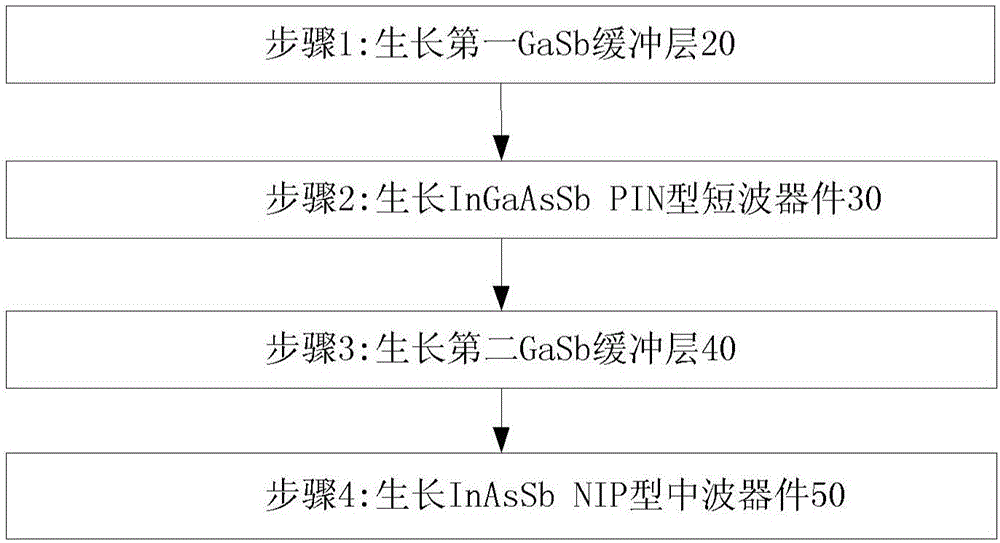

The invention provides an indium arsenide antimony and indium gallium arsenide antimony two-waveband infrared detector and a manufacturing method thereof. The indium arsenide antimony and indium gallium arsenide antimony two-waveband infrared detector structurally comprises a GaSb substrate, a first GaSb buffer layer grown on the GaSb substrate, an InGaAsSb PIN type short-wave device grown on the first GaSb buffer layer, a second GaSb buffer layer grown on the InGaAsSb PIN type short-wave device and an InAsSb NIP type middle-wave device grown on the second GaSb buffer layer. The indium arsenide antimony and indium gallium arsenide antimony two-waveband infrared detector can realize signal detection on an infrared middle-wave waveband and a short-wave waveband.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

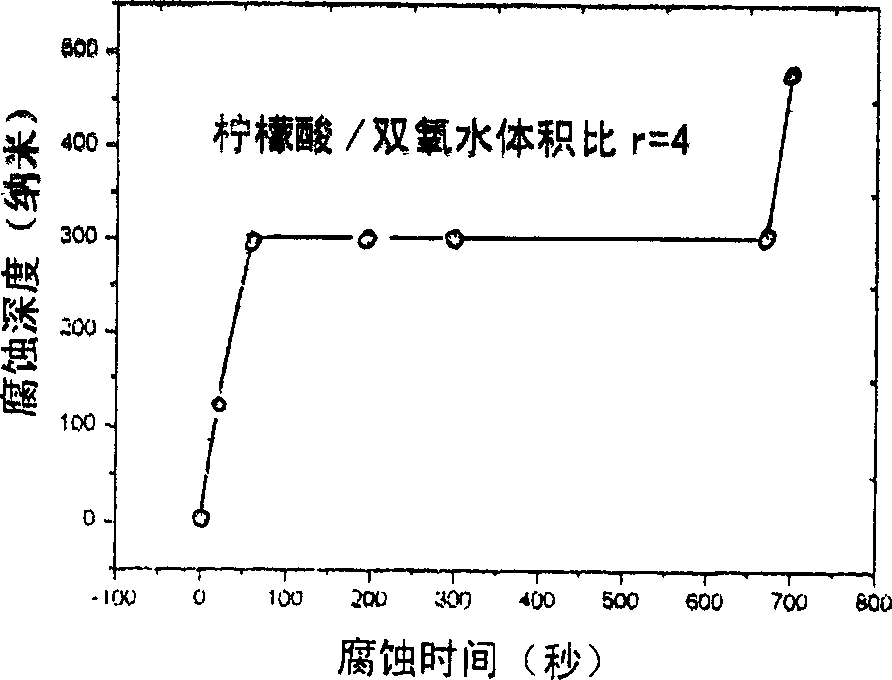

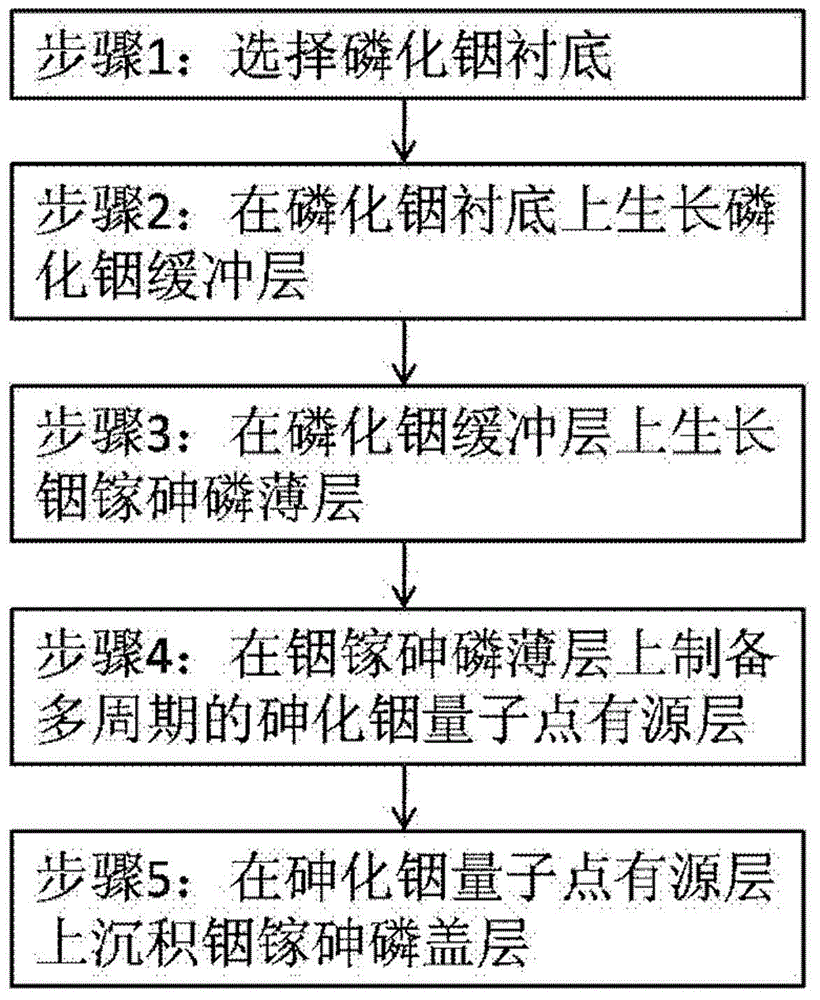

Chemical corrosion liquid in high selection ratio of gallium arsenide in aluminum arsenide / gallium arsenide

This invention relates to a chemical corrosive with high selectivity towards gallium arsenide among gallium arsenide / aluminium arsenide mixture. It uniquely contains citric acid solution and oxydol with a volume ratio of 4:1 and is compatible with gallium arsenide integration technique. Besides, it also has the advantages of nontoxic solution and simple technique.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

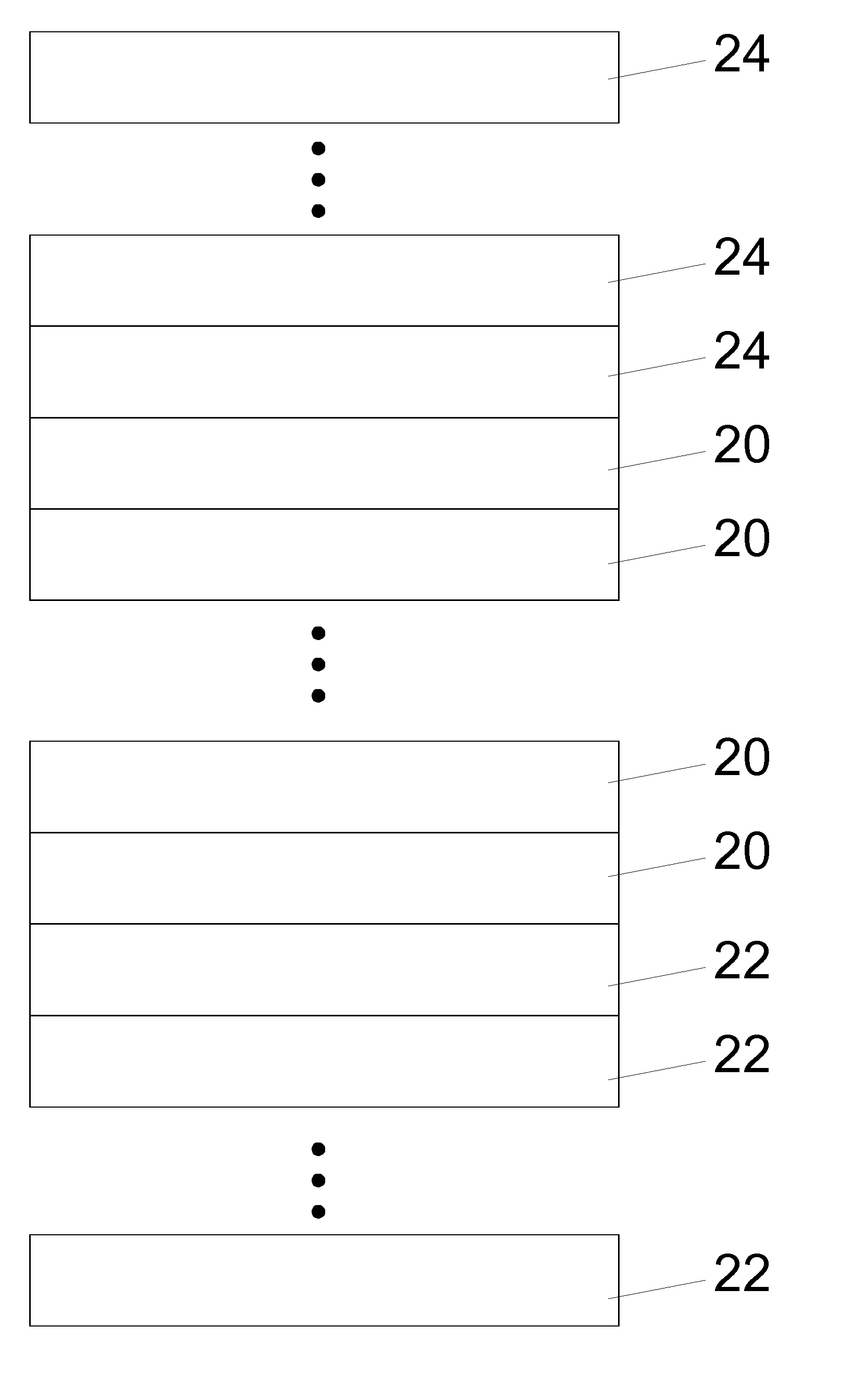

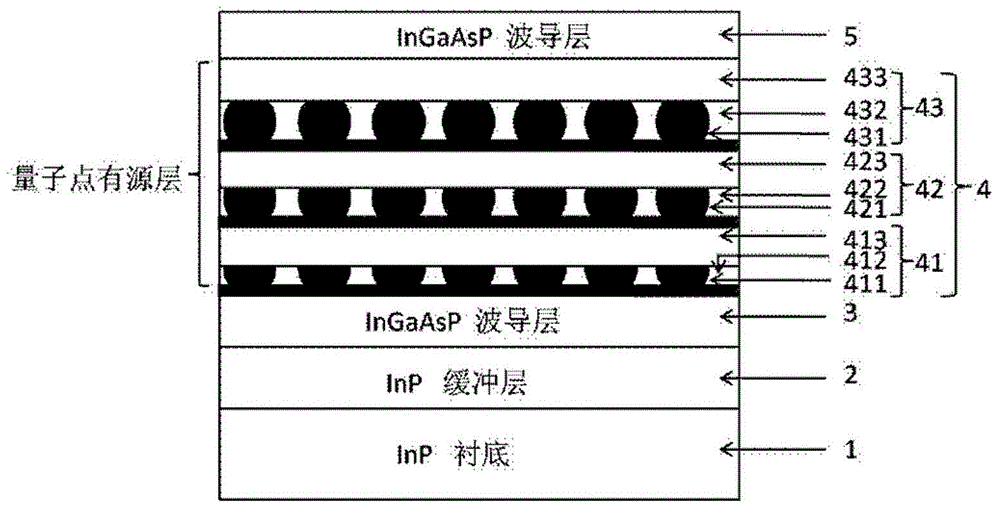

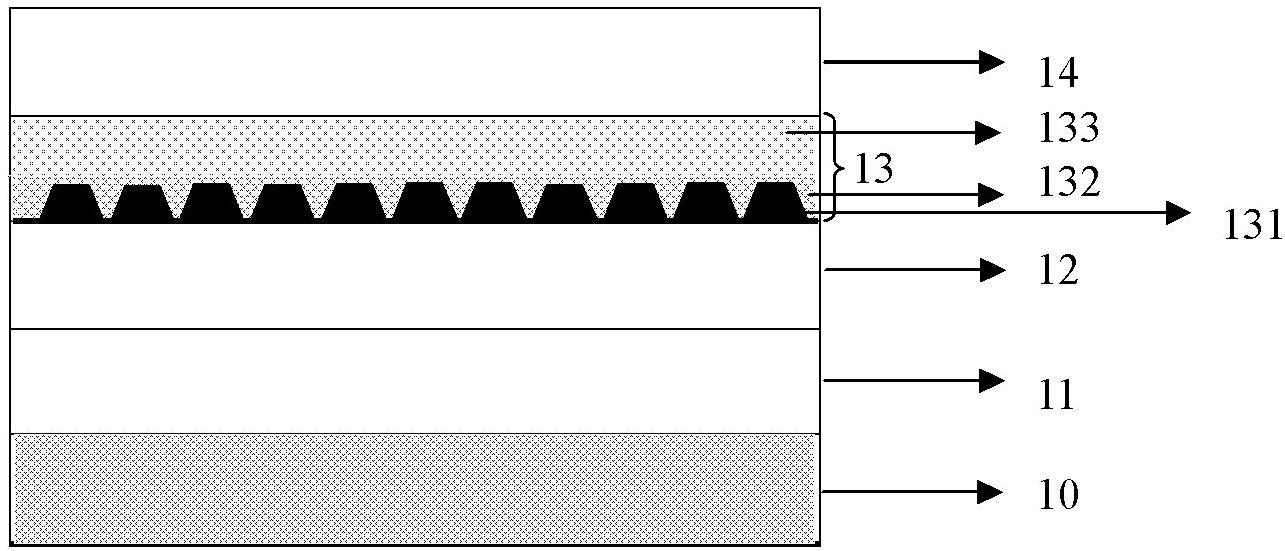

Method for manufacturing active area of broadband spectrum indium arsenide/indium phosphide quantum dot laser

ActiveCN104600564AGood optical performanceLaser detailsSemiconductor lasersIndium arsenideThin layer

Disclosed is a method for manufacturing an active area of a broadband spectrum indium arsenide / indium phosphide quantum dot laser. The method for manufacturing the active area of the broadband spectrum indium arsenide / indium phosphide quantum dot laser includes following steps: step 1, selecting an indium phosphide substrate; step 2, growing an indium phosphide buffer layer on the indium phosphide substrate; step 3, growing an indium gallium arsenide phosphide thin layer with matched lattices on the indium phosphide buffer layer; step 4, preparing a polycyclic indium arsenide quantum dot active layer on the indium gallium arsenide phosphide thin layer, setting the indium gallium arsenide phosphide thin layer as a lower barrier layer of the indium arsenide quantum dot active layer; step 5, depositing an indium gallium arsenide phosphide cover layer on the indium arsenide quantum dot active layer, and setting the indium gallium arsenide phosphide cover layer as an upper barrier layer of the indium arsenide quantum dot active layer. The method for manufacturing the active area of the broadband spectrum indium arsenide / indium phosphide quantum dot laser regulates and controls the height of quantum dots by changing the thickness of the first cover layer, obtains different light wavelengths in different periods, and achieves good optical performance and luminescence spectrum larger than 300nm in width by enabling the polycyclic quantum dots to simultaneously emit light.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

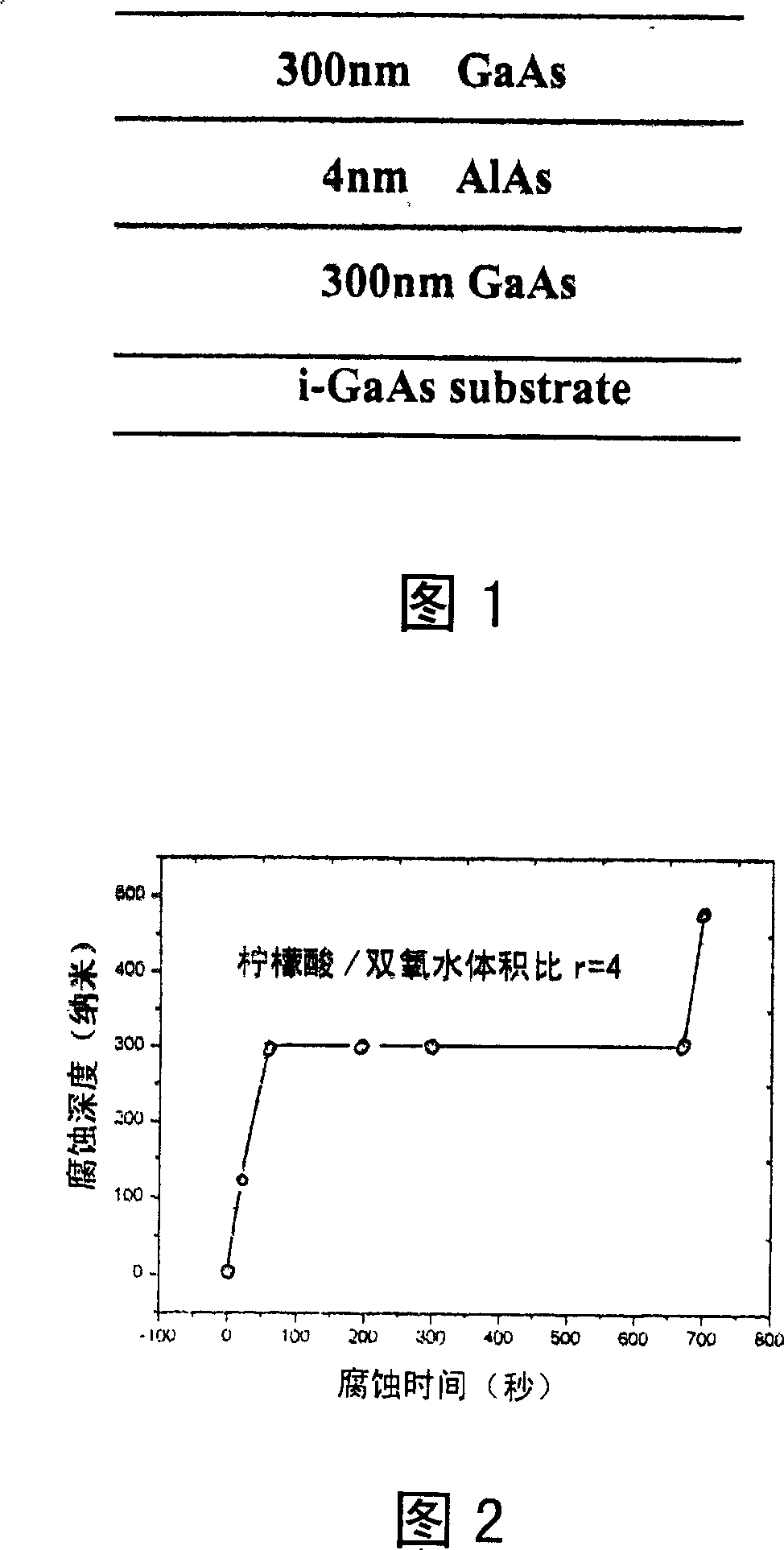

Wet etching method for gallium arsenide/aluminum arsenide distributed Bragg reflector

A type of damp corrupting method of gallium arsenide / aluminium arsenide distributing Prague reflector that characterized in that it includes following steps: (A) on the underlay, the gallium arsenide cushion layer is generated extendedly by method of molecule beam extension; (B) generating several period distribution Prague reflector on the gallium arsenide cushion layer; (C) photoetching the distribution Prague reflector to form photosensitive resist pattern, light possesses width of photosensitive resist in the photosensitive resist pattern; (D) eating off the part of the distribution Prague reflector by cauterization solution; (E) cauterization solution and selective cauterization solution are alternatively used to etch the distribution Prague reflector, so the required cauterization depth can be achieved precisely.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Abrasive and polishing composition

InactiveUS20140051335A1Easy to usePigmenting treatmentOther chemical processesIndium arsenideSilicon oxide

Provided is a polishing composition containing an abrasive and water. The abrasive content in the polishing composition is no less than 0.1% by mass. The abrasive contains zirconium oxide particles. The zirconium oxide particles have a specific surface area of from 1 to 15 m2 / g. The zirconium oxide particles preferably have a purity of no less than 99% by mass. The polishing composition is used in, for example, polishing a hard and brittle material, such as sapphire, silicon nitride, silicon carbide, silicon oxide, glass, gallium nitride, gallium arsenide, indium arsenide, and indium phosphide.

Owner:FUJIMI INCORPORATED

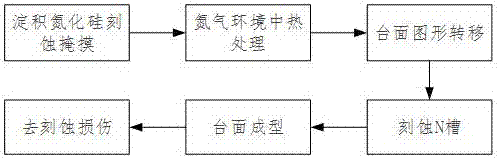

Method for improving extended wavelength gallium indium arsenide detector etching damage

InactiveCN107994094ARepair damageQuality improvementFinal product manufactureSemiconductor devicesIndium arsenideMaterial quality

The invention discloses a method for improving extended wavelength gallium indium arsenide detector etching damage which is provided with a whole set of chip preparation etching processes. The methodincludes the steps: (1) depositing a mask etched by silicon nitride; (2) performing heat treatment in the nitrogen environment; (3) transferring table top images; (4) etching an N groove; (5) forminga table top; (6) removing etching damage. The method has the advantages that the mask etched by the silicon nitride is deposited, the heat treatment is performed in the nitrogen environment, materialdamage can be repaired, complex center density is reduced, material quality is improved, dark current of devices is reduced, hole carrier density can be increased, P-electrode ohmic contact stabilityis facilitated, resistance is reduced, a table top forming process includes gas is etched by the aid of chlorine methane, hydrogen decomposed by the methane in the plasma etching process can passivatedangling bonds formed by etching, and non-radiative recombination center density in materials is reduced. According to an etching damage removing process, damage layers of etching surfaces can be removed, the non-radiative recombination center density is reduced, subsequent passivation effects are enhanced, and the method is applicable to preparation of a high-performance short wave infrared gallium indium arsenide detector.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

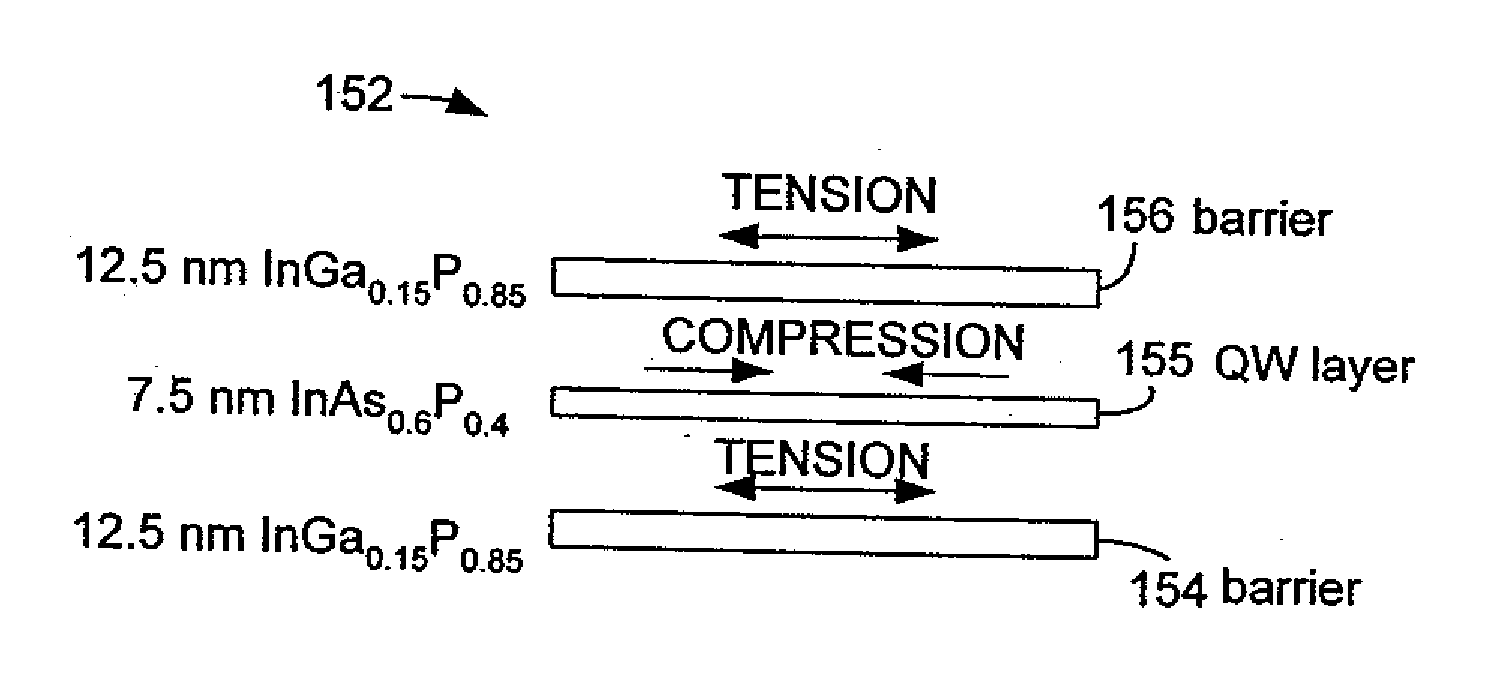

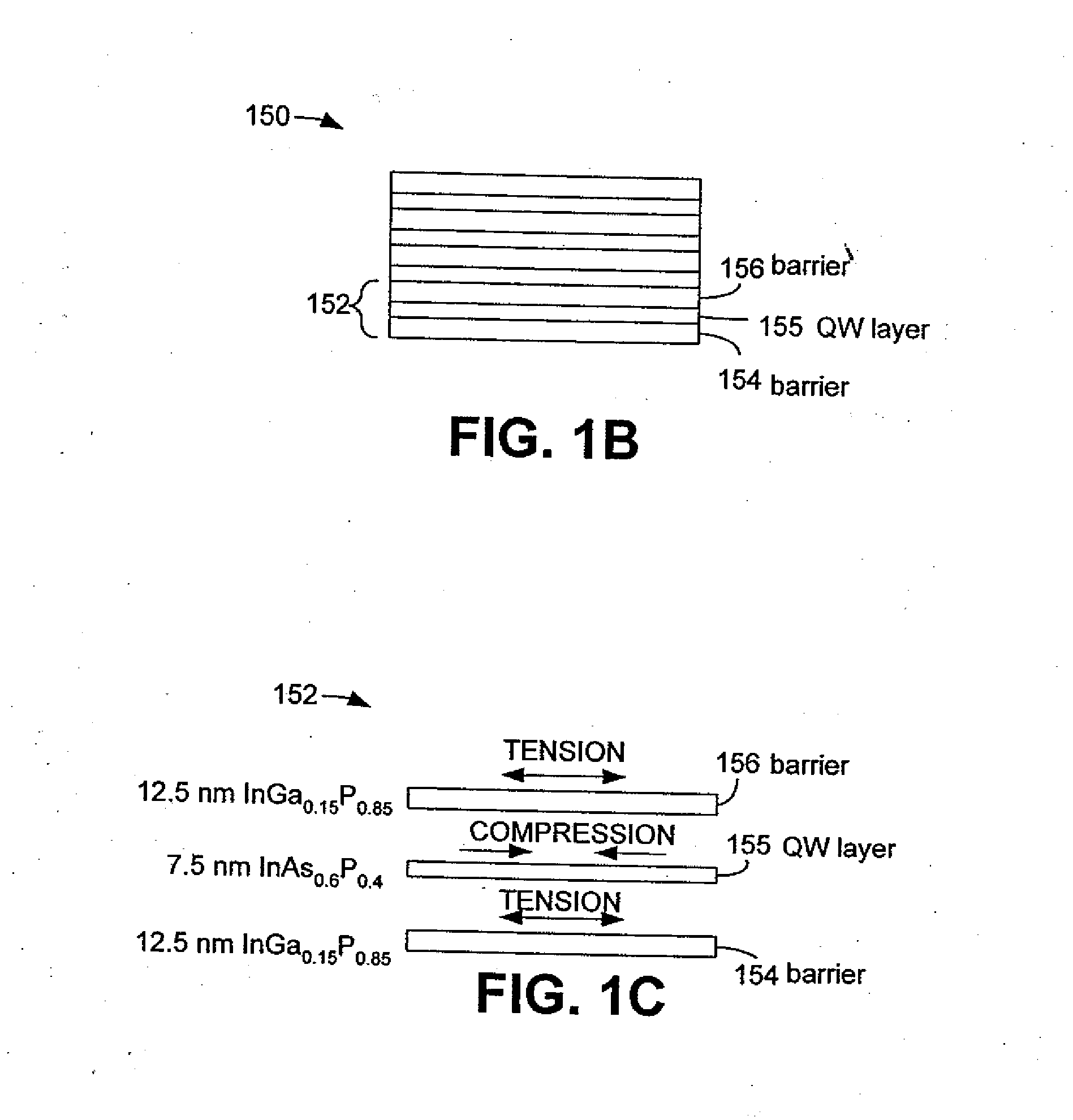

Long Wavelength Induim Arsenide Phosphide (InAsP) Quantum Well Active Region And Method For Producing Same

InactiveUS20070241322A1Quality improvementLess dislocationLaser detailsSemiconductor/solid-state device manufacturingQuantum wellIndium arsenide

Owner:BOUR DAVID P +2

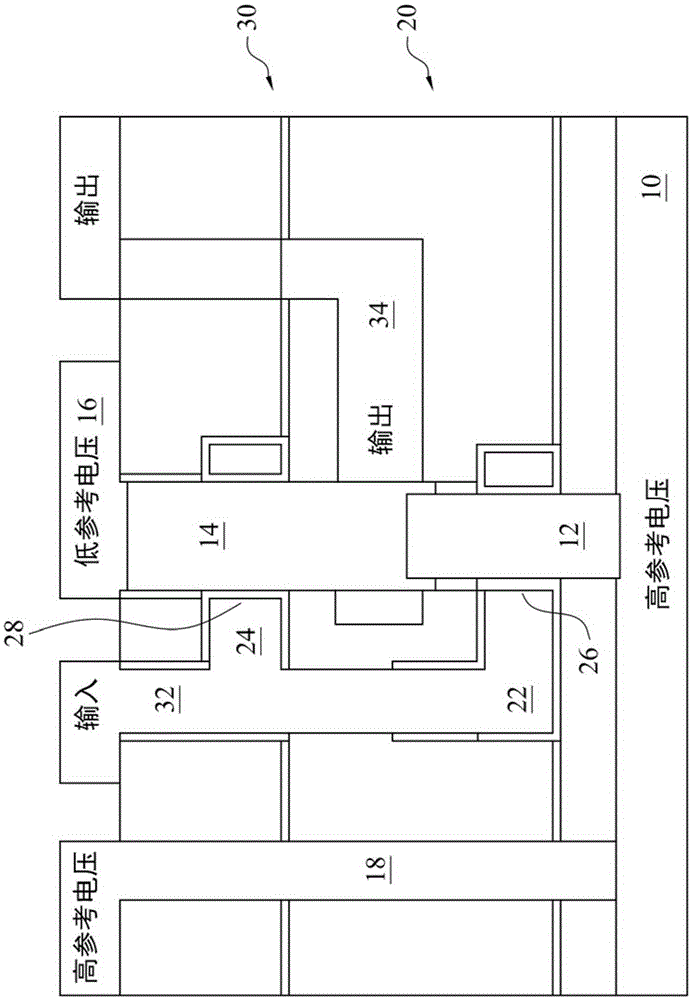

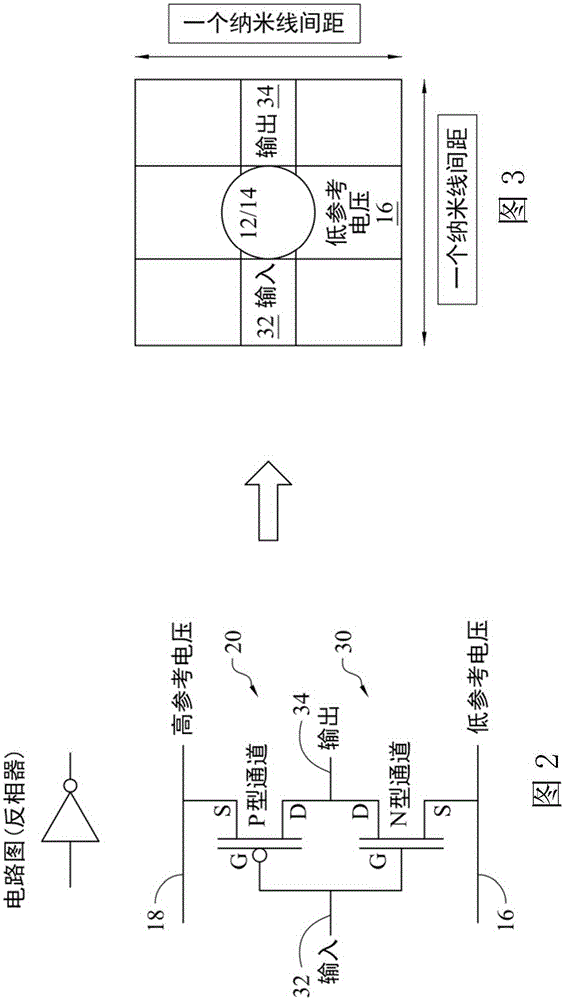

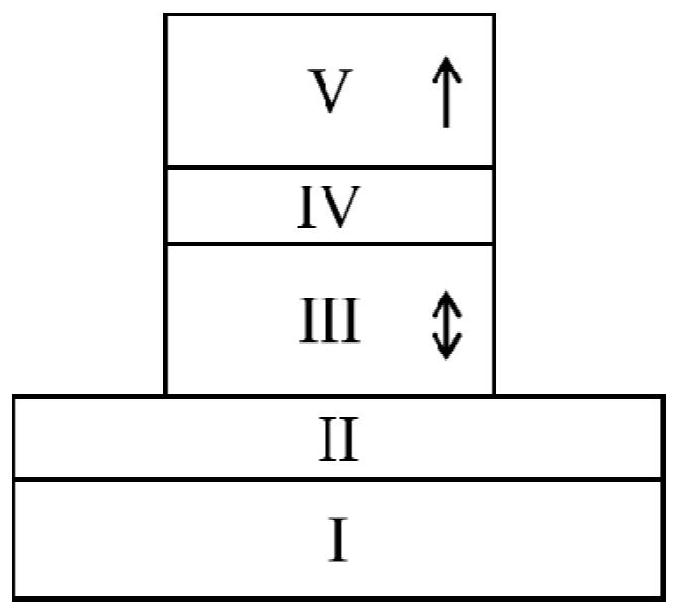

Complementary Cmos Structure And Method

The invention discloses a complementary cmos structure and a method thereof. Selective deposition techniques are used to form a column having a lower portion that includes one type of semiconductor (e.g. germanium) and an upper portion of another type of semiconductor (e.g. indium arsenide. The lower portion of the column provides a channel region for a transistor of one type, while the upper column provides a channel region for a transistor of another type. This provides a complementary pair that occupies a minimum of integrated circuit surface area. The complementary transistors can be utilized in a variety of circuit configurations. Described are complementary transistors where the lower transistor is p-type and the upper transistor is n-type. The method is advantageous in that complementary transistors are provided, wherein the complementary transistors employ a minimum integrated circuit superficial area.

Owner:TAIWAN SEMICON MFG CO LTD

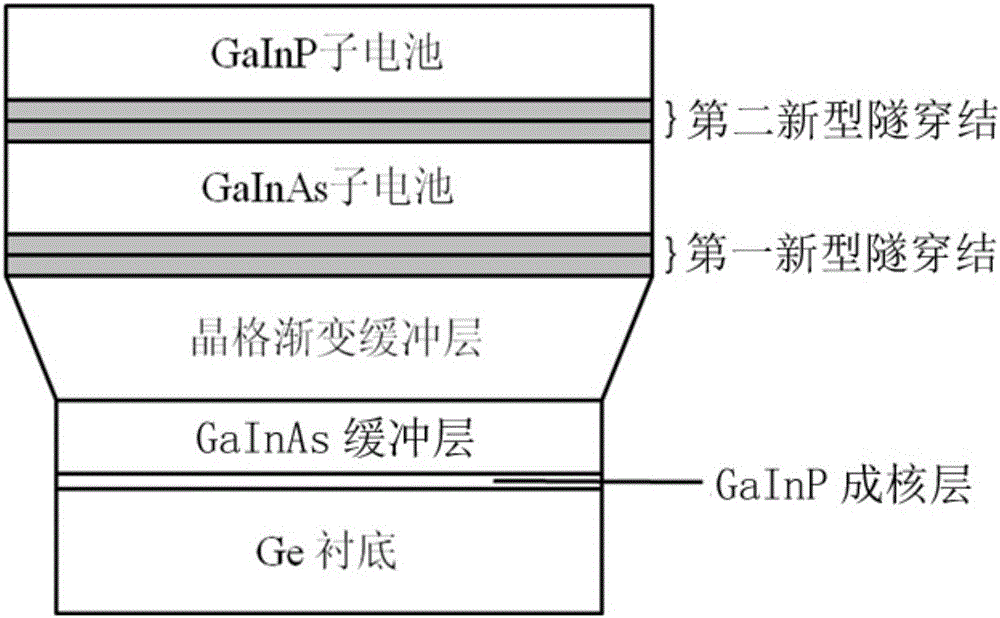

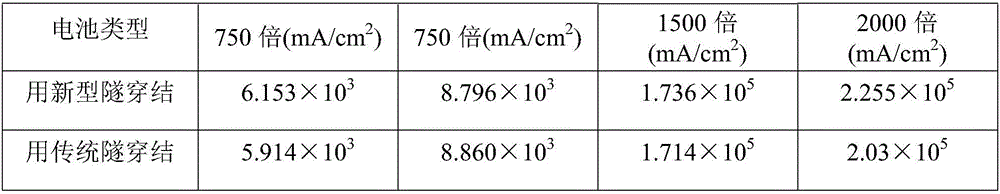

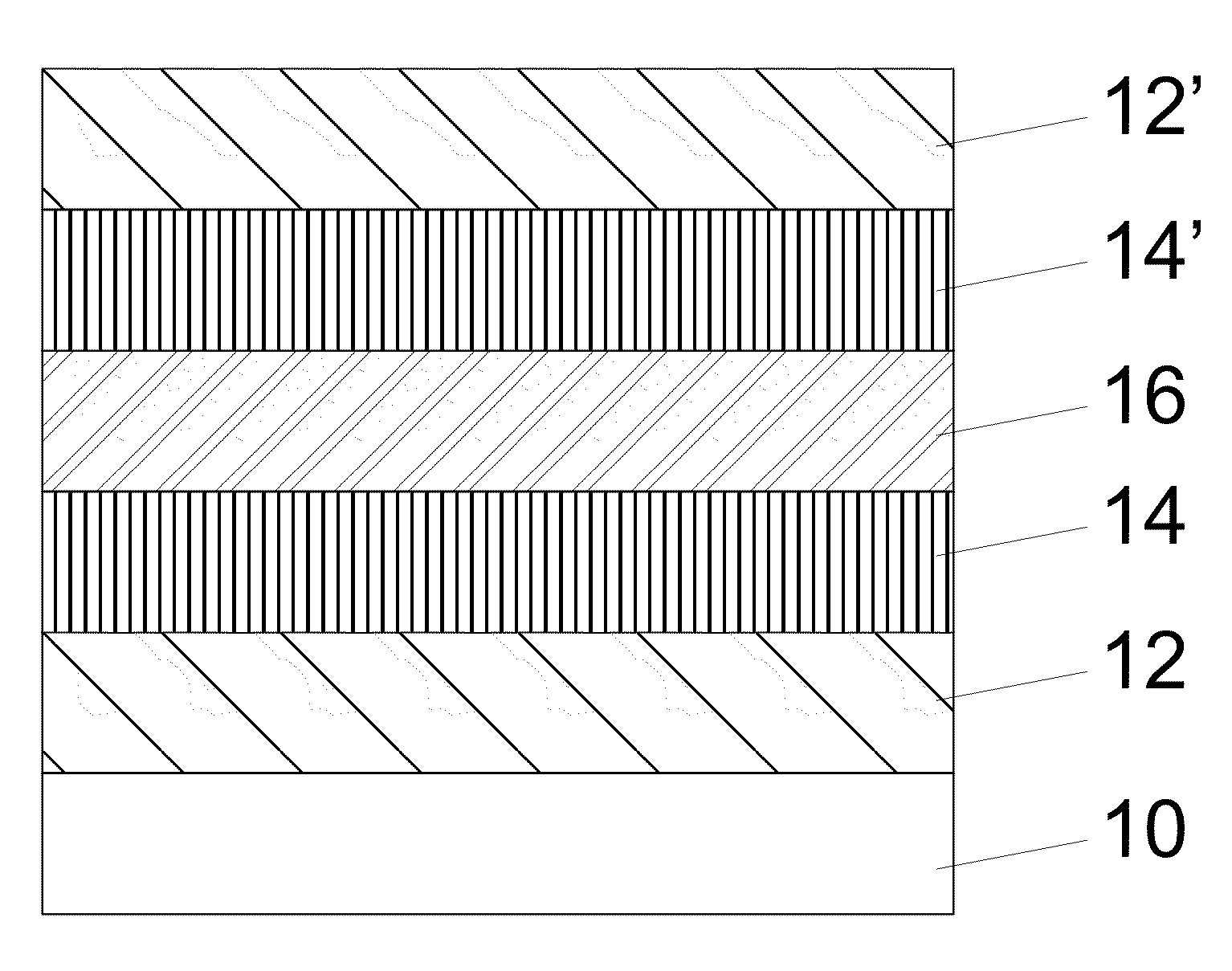

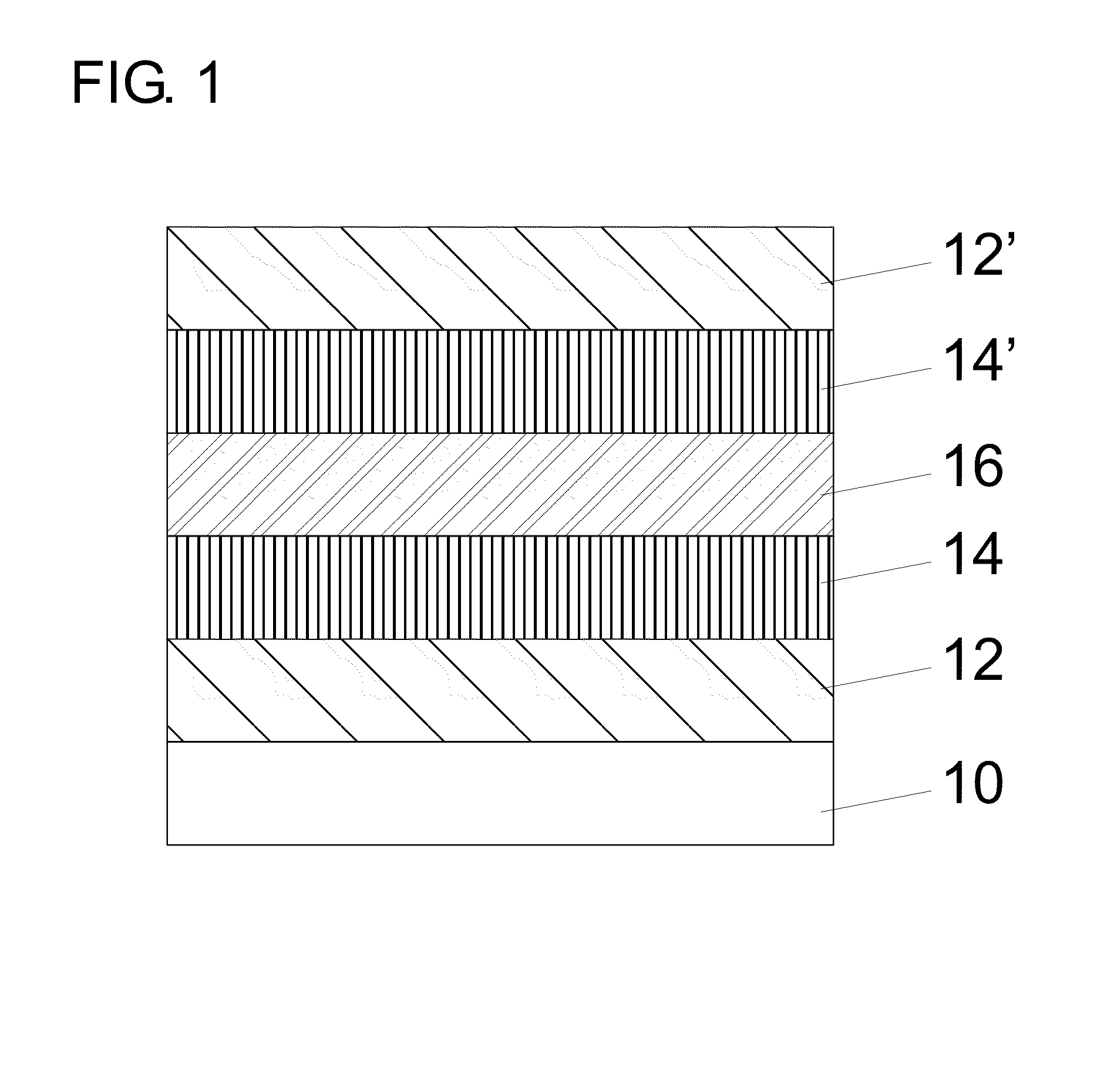

Lattice mismatch solar cell containing novel tunneling junction and preparation method thereof

ActiveCN106024924AImprove crystal qualityActs as a dislocation barrierFinal product manufacturePhotovoltaic energy generationIndiumLattice mismatch

The invention discloses a lattice mismatch solar cell containing a novel tunneling junction and a preparation method thereof. A Ge monocrystal is used as a substrate, and a GaInP nucleation layer, a GaInAs buffer layer, a lattice gradient buffer layer, a first novel tunneling junction, a GaInAs sub cell, a second novel tunneling junction and a GaInP sub cell are grown on the surface of the substrate sequentially from bottom to top. The first novel tunneling junction and the second novel tunneling junction include a layer of degenerate p-type gallium indium nitrogen arsenide (Ga<1-y>In<y>N<x>As<1-x>) and a layer of degenerate n-type gallium indium arsenide (Ga<1-z>In<z>As), the lattice constants of the two layers of materials are respectively consistent with the materials of the adjacent semiconductor layers or the mismatching degree is less than 3%, and the thickness of each layer is 5-100nm. The novel tunneling junction adopted in the invention has better conductivity and light transmission than general tunneling junctions. More importantly, as a rigid material, the novel tunneling junction can filter a lot of threading dislocation and mismatch dislocation, reduce non-radiative recombination, prolong the service life of minority carriers and improve the photoelectric conversion efficiency.

Owner:ZHONGSHAN DEHUA CHIP TECH CO LTD

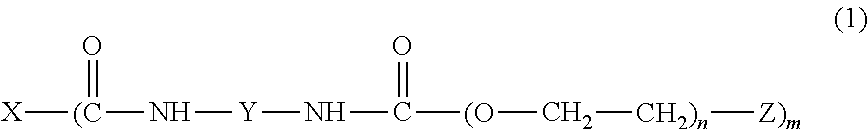

Quantum dot hybrid transparent polyimide fluorescent film and preparation method

The invention discloses a quantum dot hybrid transparent polyimide fluorescent film and a preparation method. The quantum dot hybrid transparent polyimide fluorescent film comprises 0.0001-2.0wt% of quantum dots, 85-99wt% of polyimide and 0-5wt% of additive. The quantum dots are one or more of carbon quantum dots, silicon quantum dots, germanium quantum dots, cadmium sulfide quantum dots, cadmiumselenide quantum dots, cadmium telluride quantum dots, zinc selenide quantum dots, lead sulfide quantum dots, lead selenide quantum dots, indium phosphide quantum dots and indium arsenide quantum dots. Polyimide is prepared by polymerization and imidization reaction of alicyclics, a fluorine-containing bifunctional (multifunctional) organic acid anhydride monomer and an organic amine monomer. Thequantum dot hybrid polyimide fluorescent film has high light transmittance, high quantum efficiency, low dielectric constant and loss and can be applied to the technical field of LED (light-emitting diode) luminescence and display.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

Long wavelength infrared superlattice

ActiveUS8426845B2Extend the cutoff wavelengthTotal current dropNanoinformaticsSemiconductor/solid-state device manufacturingGallium antimonideIndium arsenide

An embodiment of the present invention improves the fabrication and operational characteristics of a type-II superlattice material. Layers of indium arsenide and gallium antimonide comprise the bulk of the superlattice structure. One or more layers of indium antimonide are added to unit cells of the superlattice to provide a further degree of freedom in the design for adjusting the effective bandgap energy of the superlattice. One or more layers of gallium arsenide are added to unit cells of the superlattice to counterbalance the crystal lattice strain forces introduced by the aforementioned indium antimonide layers.

Owner:SVT ASSOCS

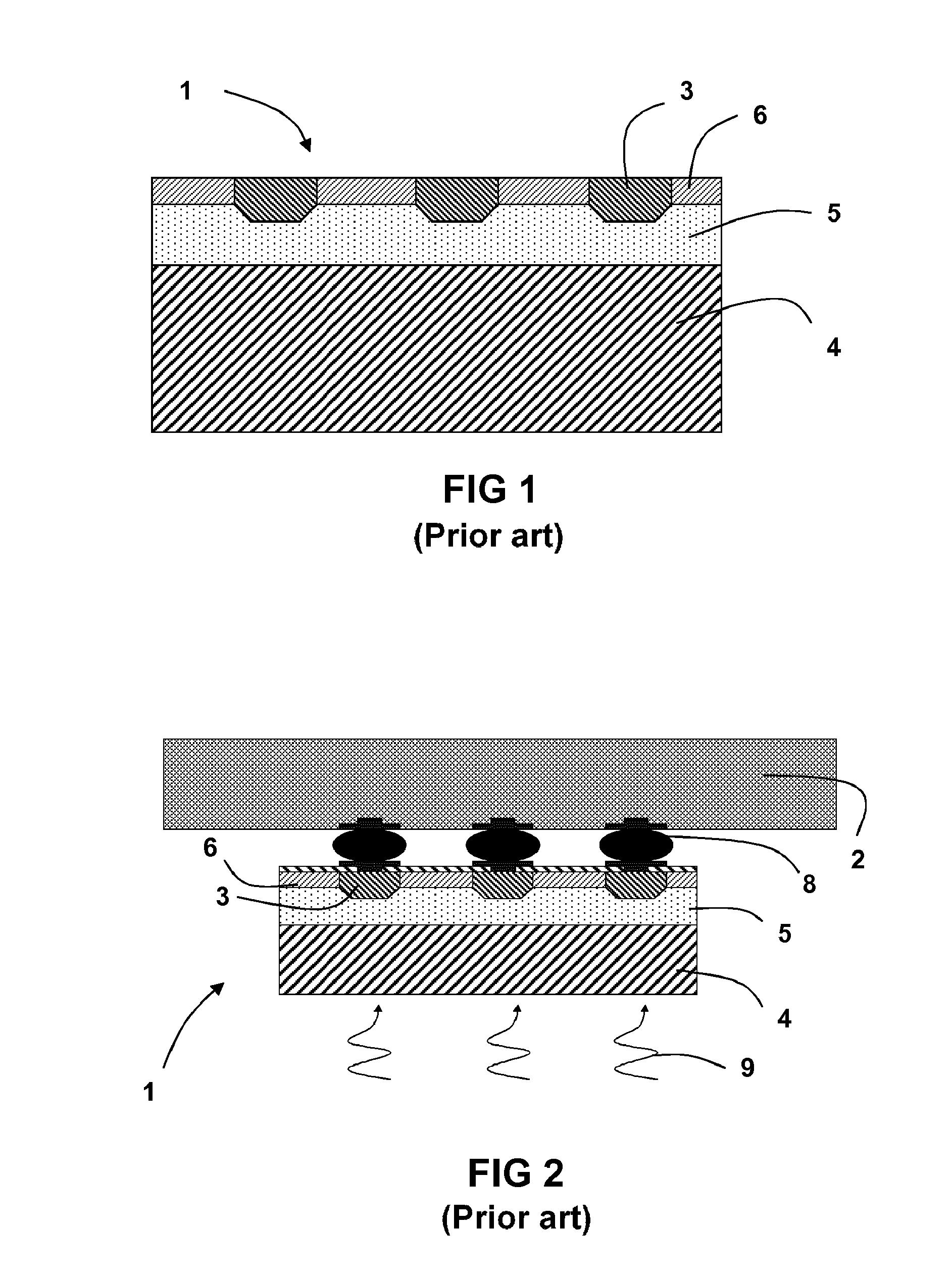

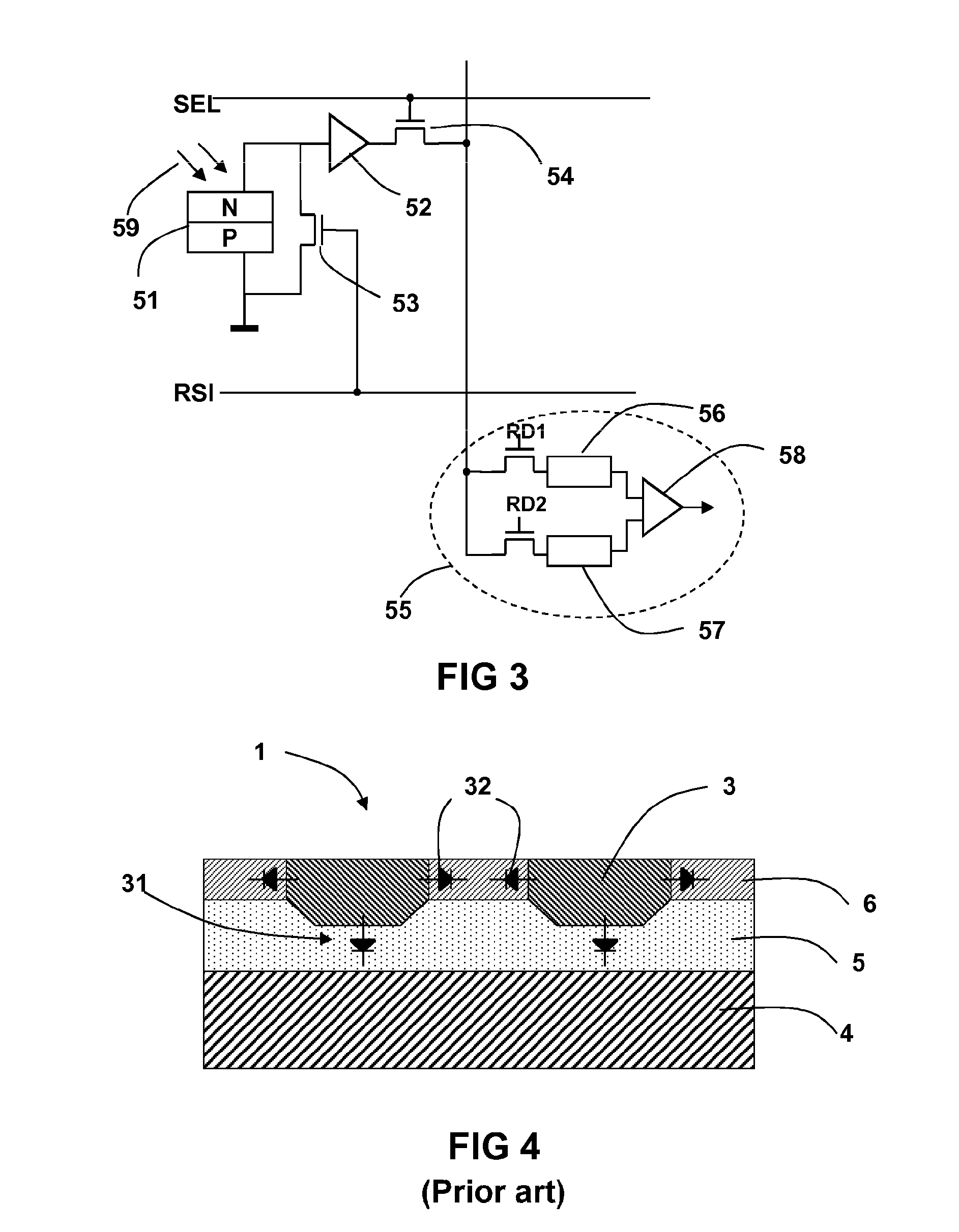

Photodiode array having a charge-absorbing doped region

ActiveUS20150372047A1Solid-state devicesSemiconductor/solid-state device manufacturingCharge carrierIndium arsenide

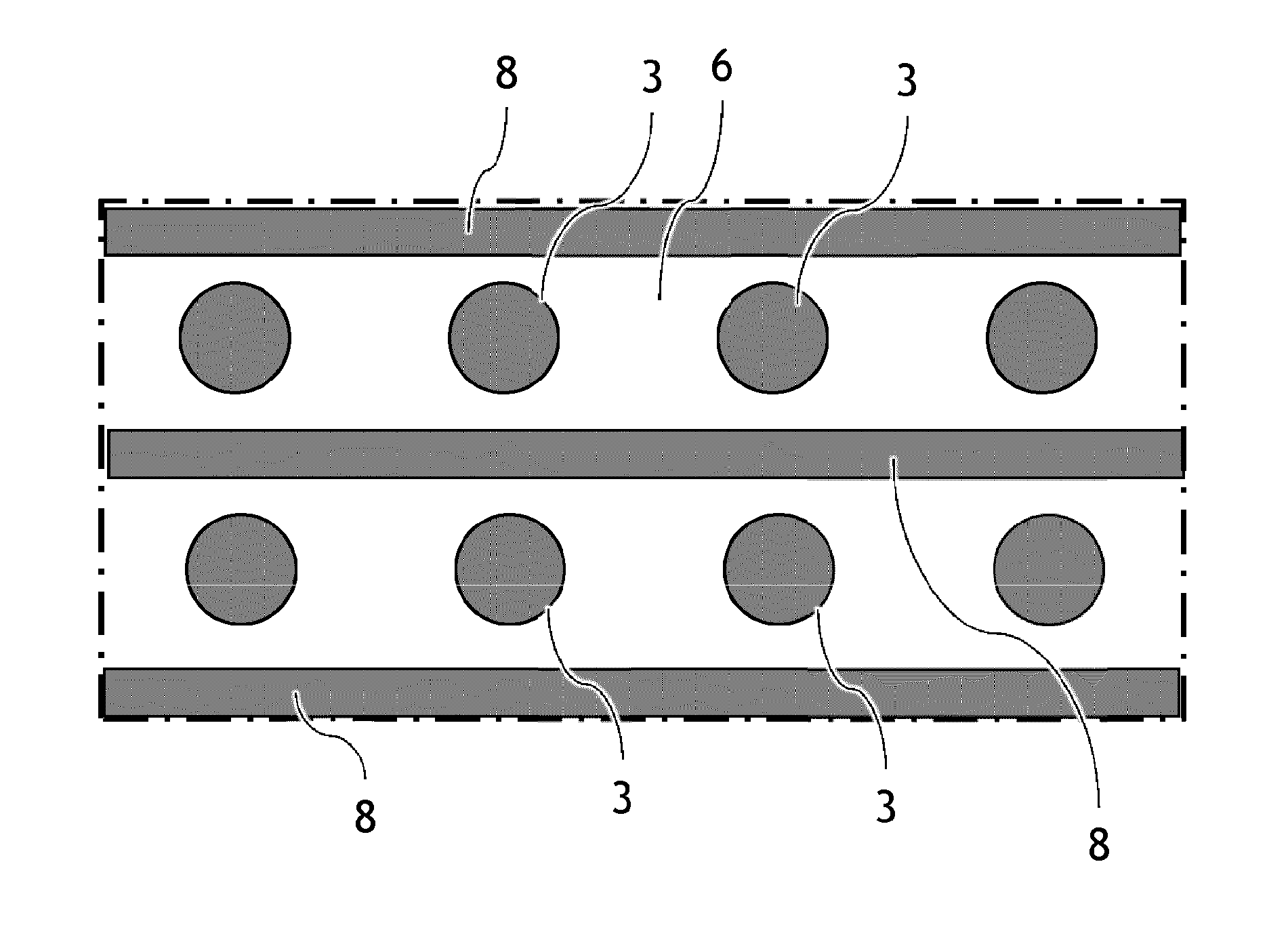

The invention concerns a photodiode array, and the method for producing same, comprising—a cathode comprising at least one substrate layer (4) made from a material from the indium phosphide family and one active layer (5) made from a material from the gallium indium arsenide family, and characterised in that the array further comprises at least two sorts of doped regions of the same type at least partially formed in the active layer (5):—first doped regions (3) forming, with the cathode, photodiodes for forming images,—at least one second doped region (8) absorbing excess charge carriers so as to discharge them.

Owner:NEW IMAGING TECH

InGaAs (Indium Gallium Arsenide) or GaAs (Gallium Arsenide) infrared detector with wide detection bands

InactiveCN103383977ASuppress misfit dislocationsReduce surface recombinationSemiconductor devicesIndiumLattice mismatch

The invention discloses an InGaAs (Indium Gallium Arsenide) or GaAs (Gallium Arsenide) infrared detector with wide detection bands and belongs to the field of optoelectronic materials and devices. The InGaAs or GaAs infrared detector solves the problem that the performance of the existing InGaAs infrared detectors decreases obviously due to the fact that defects are produced by lattice mismatch. The InGaAs or GaAs infrared detector comprises a buffering layer, an absorbing layer and a covering layer which are grown on a GaAs substrate sequentially; the buffering layer is InAsP (Indium Arsenide Phosphorus) doped with Si (Silicon) and the thickness of the buffering layer is 0.5 to 1.5 microns; the absorbing layer is In0.82Ga0.18As with low doped Si and the thickness of the absorbing layer is 2.5 to 3.5 microns; the covering layer is InAlAs (Indium Aluminum Arsenide) doped with Be (Beryllium) and the thickness of the covering layer is 0.5 to 1.5 microns. The InGaAs or GaAs infrared detector with the wide detection bands has the structure which is high in quantum efficiency and high in detection rate and can meet the requirements of front light entering, back light entering and flip chip packaging.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

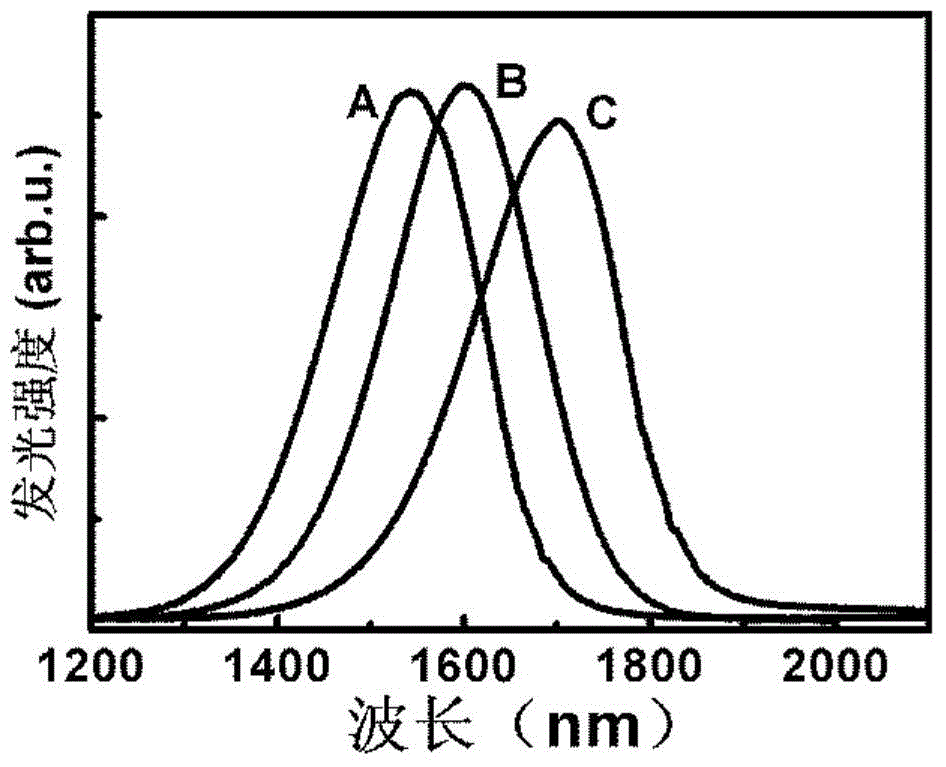

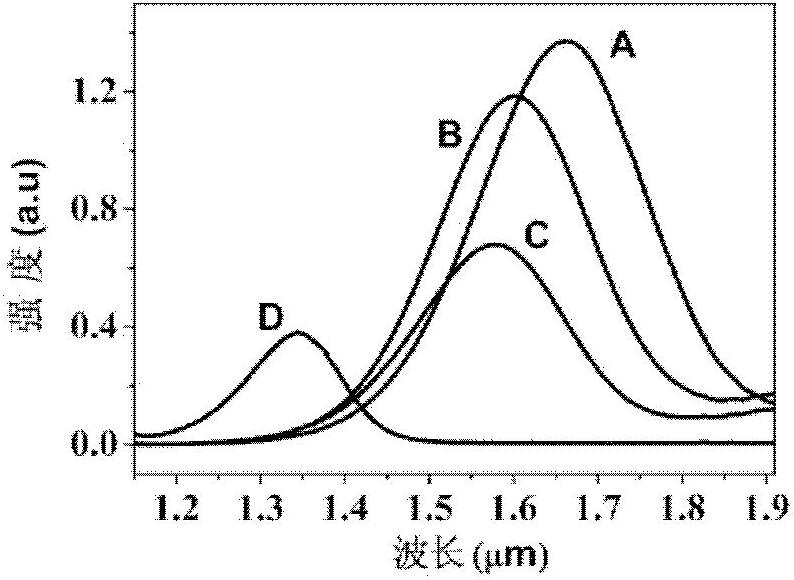

Method for manufacturing active area of indium arsenide/indium phosphide quantum dot laser

ActiveCN102684070ARealize controllable adjustmentGood optical performanceLaser detailsSemiconductor lasersIndiumOptical property

The invention provides a method for manufacturing an active area of an indium arsenide / indium phosphide quantum dot laser. The method comprises the following steps of: step 1, selecting an indium phosphide substrate; step 2, epitaxially growing an indium phosphide buffering layer on the indium phosphide substrate; step 3, depositing a lattice matched indium-gallium-arsenic-phosphorus thin layer on the indium phosphide buffering layer; step 4, epitaxially growing a multi-periodical indium arsenide quantum dot active layer; and step 5, depositing an indium-gallium-arsenic-phosphorus cover layeron the indium arsenide quantum dot active layer. According to the method provided by the invention, the purposes of keeping good optical properties and tuning the light-emitting wavelength are achieved by changing a five-group protection source flow to restrain an As / P exchange effect, controlling the appearance of a quantum dot and combining a two-step cover layer growth process in a growth pause interval of an indium arsenide / indium phosphide quantum dot. The method provided by the invention can be used for controllably adjusting the InAs / InP quantum dot light-emitting wave in a range of 1.3-1.7 microns (num) to 400 nm.

Owner:JIANGSU HUAXING LASER TECH CO LTD

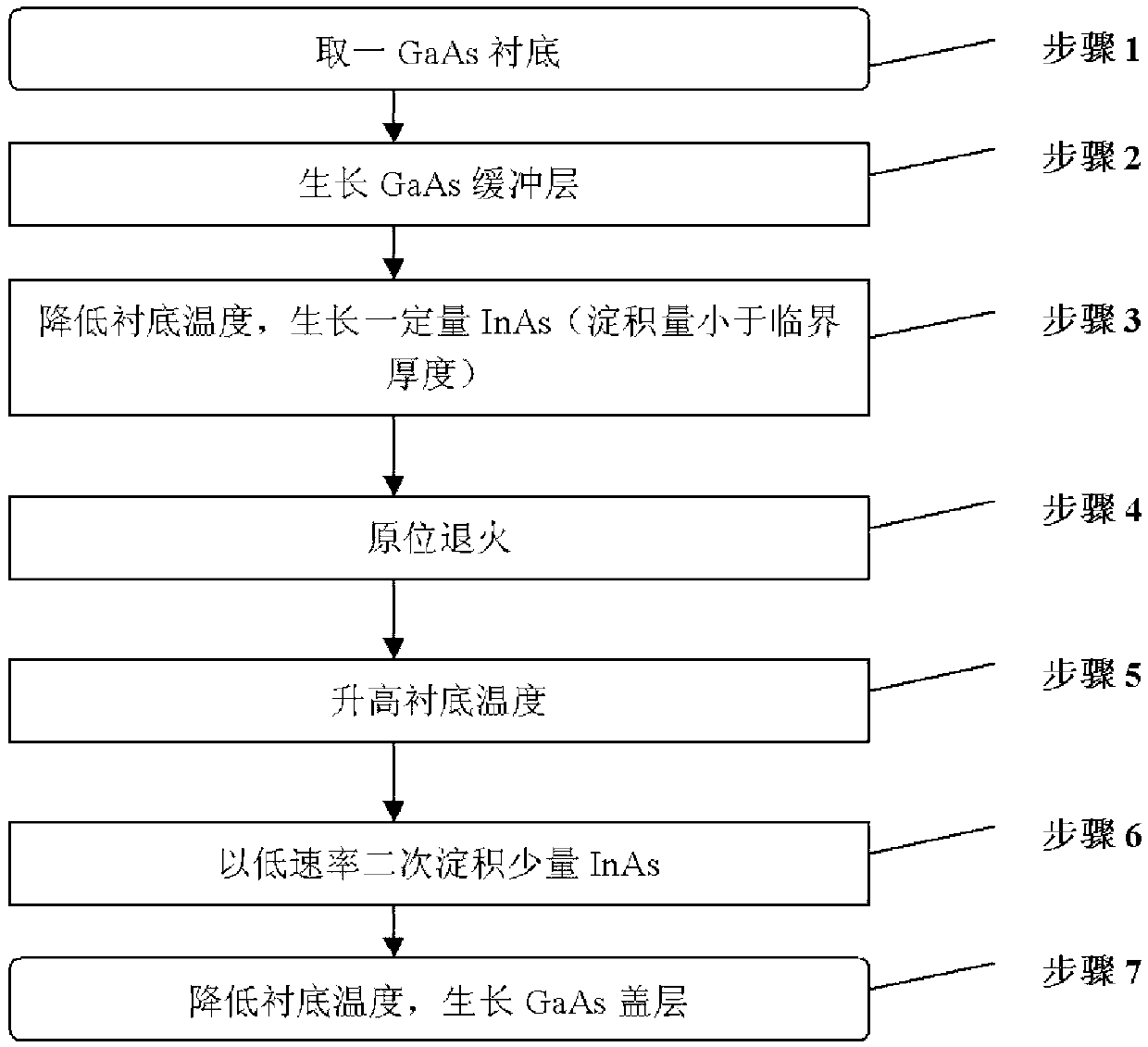

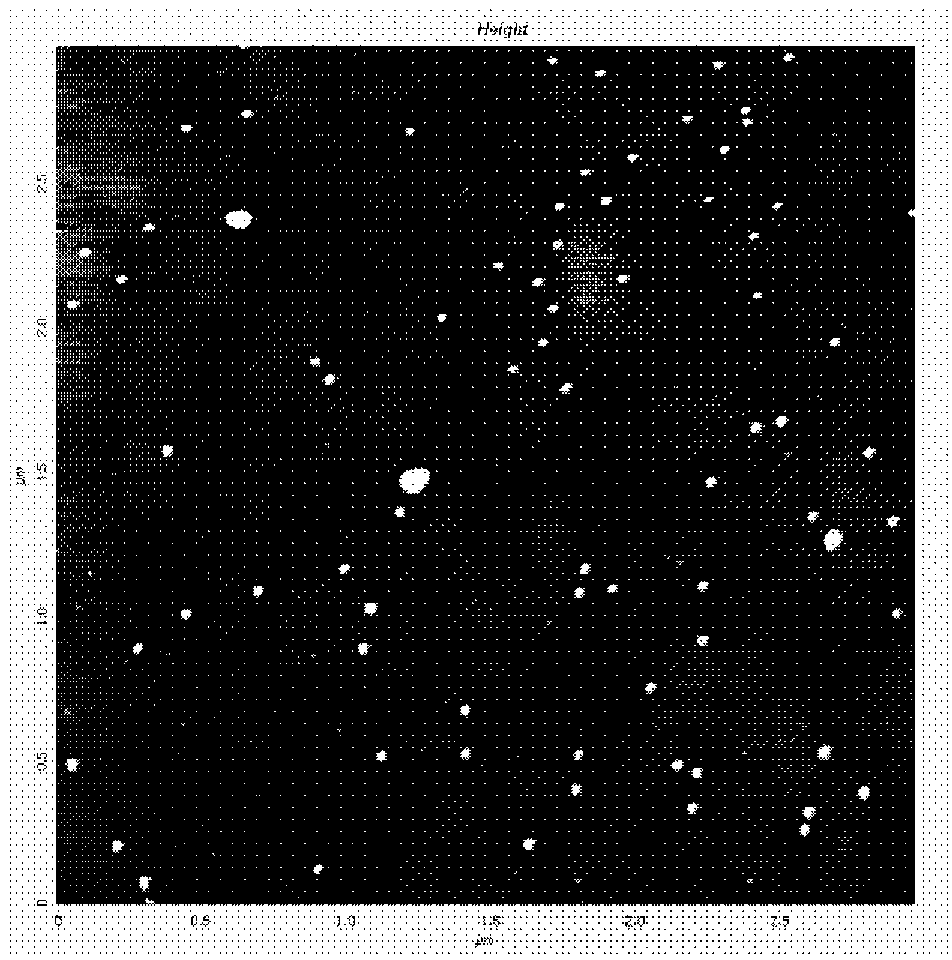

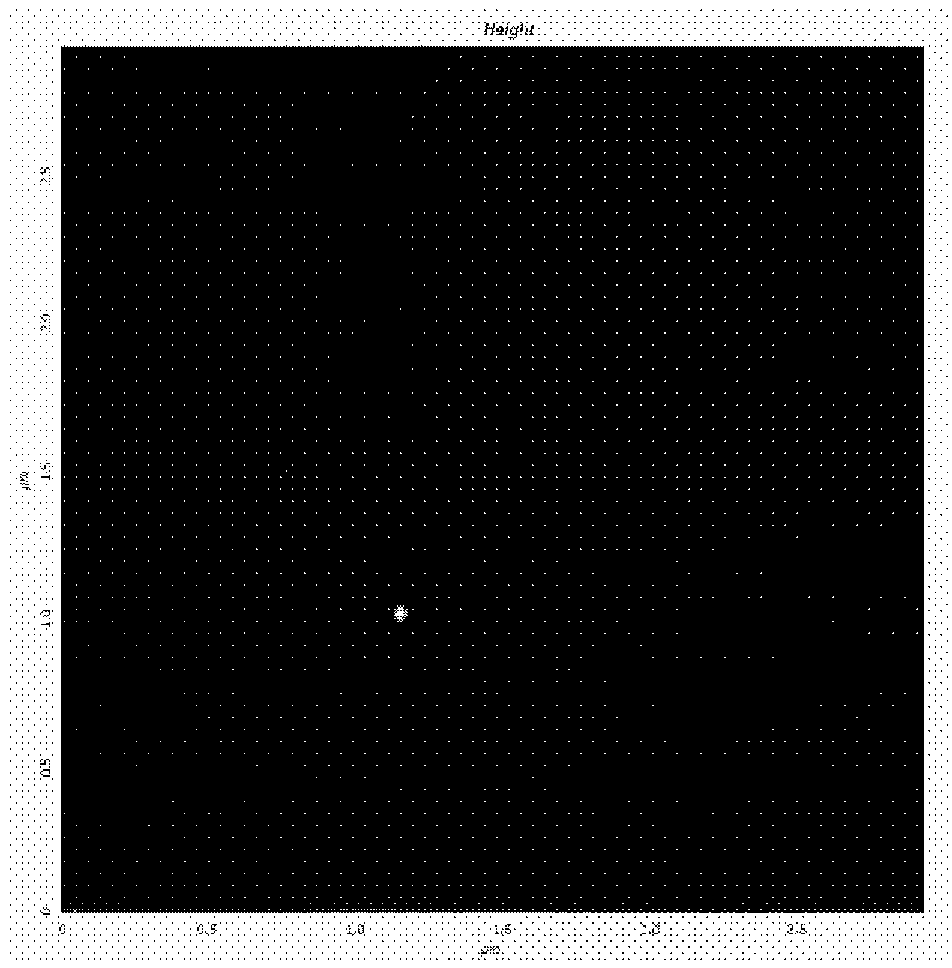

Method for preparing low-density and long-wavelength indium arsenide/gallium arsenide (InAs/GaAs) quantum dots

InactiveCN103137789ALow densityDensity is easy to adjustRenewable energy productsSemiconductor devicesMicrometerIndium arsenide

The invention provides a method for preparing low-density and long-wavelength indium arsenide / gallium arsenide (InAs / GaAs) quantum dots. The method includes a first step of picking up a substrate, a second step of depositing and growing a buffer layer on the substrate, a third step of depositing and growing an InAs layer on the buffer layer, suspending deposition and growth when the InAs layer does not reach the critical thickness, a fourth step of annealing the substrate with the growing InAs layer, a fifth step of rising temperature of the substrate after annealing, a sixth step of growing the InAs layer through secondary deposition, a seventh step of depositing and growing a GaAs cover layer on the InAs layer which grows through the secondary deposition, and obtaining the low-density and long-wavelength InAs / GaAs quantum dot structure. The method can be used for preparing the low-density InAs / GaAs quantum dots with room temperature luminous long-wavelength longer than 1.3 micrometers.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Energy-shielding plastics film

ActiveCN103402758APromote absorptionDoes not cause localized heatingLamination ancillary operationsMagnetic/electric field screeningIndiumIndium arsenide

A plastics film with improved energy-shielding properties, suitable for application on a transparent or translucent surface, such as glass, and which is at least 50% transparent for visible light, further characterized in that it includes at least one plastic carrier layer with on top thereof as a functional layer a metallic layer consisting of antimony and / or arsenic together with indium and / or gallium, wherein the plastics film contains a total of indium (In), gallium (Ga), antimony (Sb) and arsenic (As) together, which are present as an alloy, such as indium andmonide, gallium andmonide, indium arsenide, indium gallium arsenide and / or gallium arsenide, of at least 4.0 ppm by weight and at most 25.0 ppm by weight. A glass plate to which the film is attached, is described as are objects provided with the glass plate. Methods are described for the production of the film, the glass plate and the objects.

Owner:MICHIELS GROUP BVBA

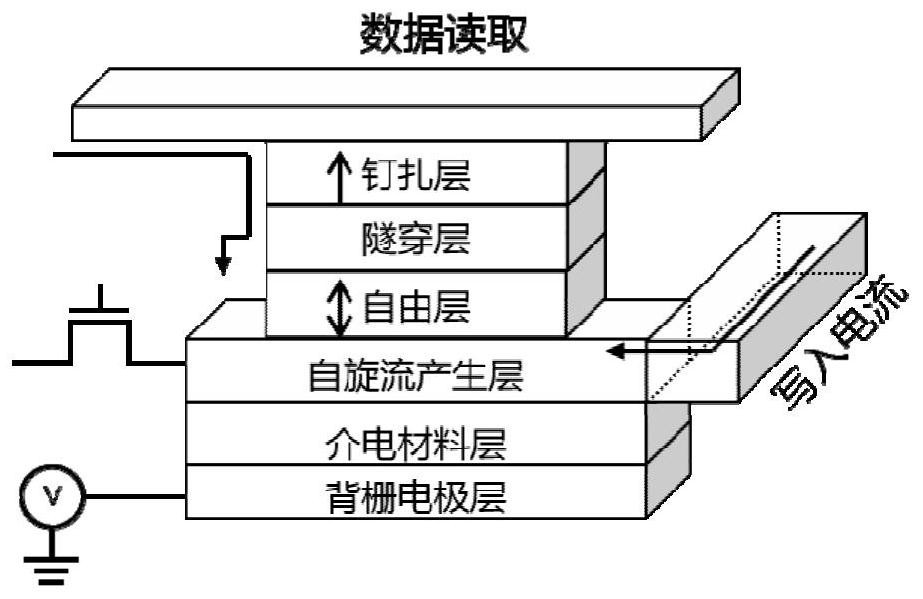

Magnetic random access memory based on III-V group narrow bandgap semiconductor

ActiveCN112054116AReduce power consumptionIncrease power consumptionMagnetic-field-controlled resistorsSolid-state devicesSemiconductor materialsIndium

The invention relates to a magnetic random access memory based on an III-V group narrow bandgap semiconductor, the magnetic random access memory is characterized by sequentially comprising a substratewafer, a dielectric layer, a spin orbit torque acting layer and an MTJ structure layer from bottom to top, and the dielectric layer is made of a cadmium telluride CdTe or zinc telluride ZnTe material; and the spin orbit torque acting layer is made of a III-V group narrow bandgap semiconductor indium antimonide InSb or indium arsenide InAs with high mobility. The structure based on the III-V semiconductor material not only can be matched with an existing semiconductor CMOS process, but also can provide spin orbit coupling strength higher than that of a traditional heavy metal SOT material, andtherefore the problem of power consumption of device write-in current is effectively solved. In addition, the spin orbit coupling strength can be regulated and controlled by applying the back gate voltage, so that the power consumption of the device is further improved. And through electric field control, the programmable and storage integrated capability of the modified device array can be improved.

Owner:SHANGHAI TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com