Method for manufacturing active area of broadband spectrum indium arsenide/indium phosphide quantum dot laser

A technology of indium arsenide and indium quantum, which is applied in lasers, phonon exciters, laser components, etc., can solve the problems of low luminous efficiency of quantum dots and achieve good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

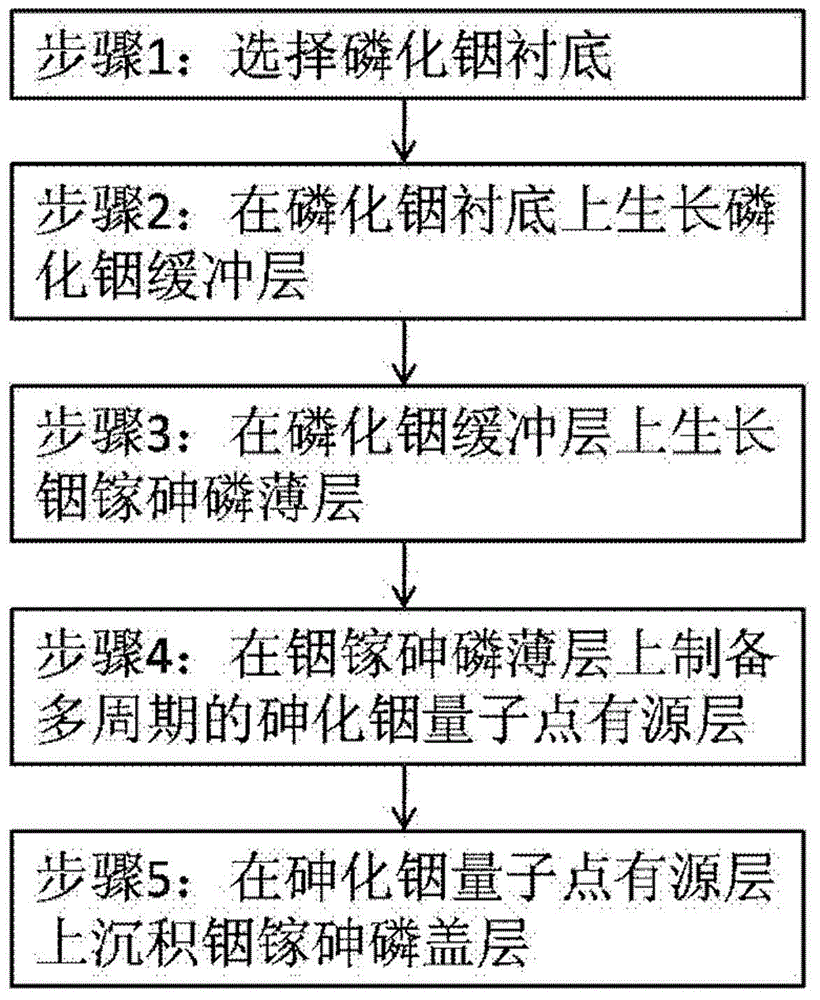

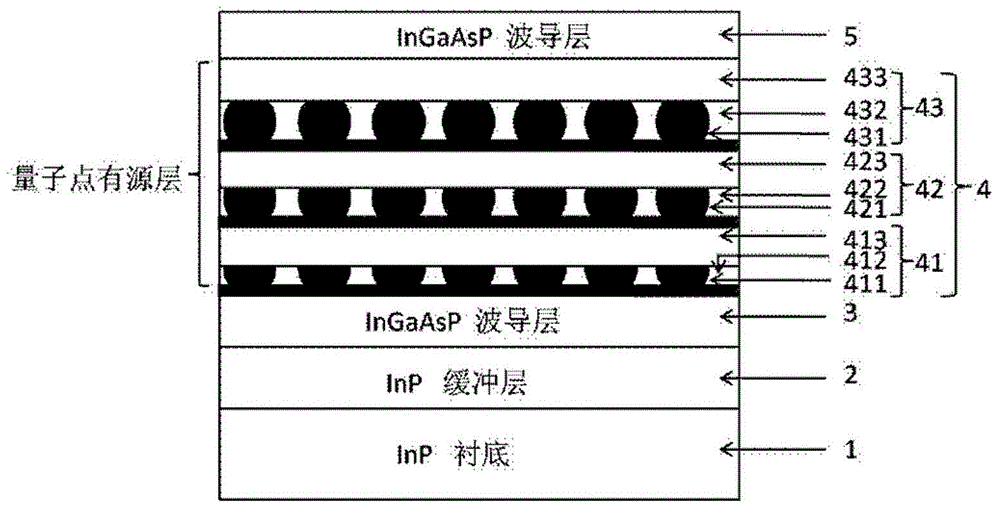

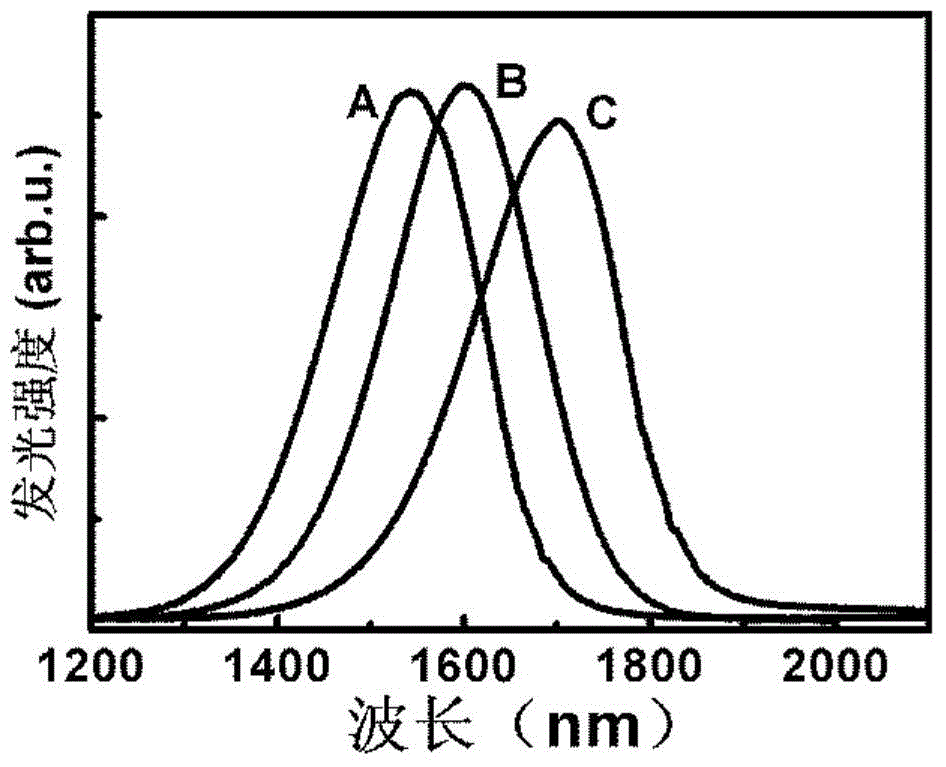

[0030] refer to figure 1 and figure 2 , a method for making an active region of a wide-spectrum indium arsenide / indium phosphide quantum dot laser, comprising the steps of:

[0031] Step 1: Select an indium phosphide substrate 1;

[0032] Step 2: growing an indium phosphide buffer layer 2 on the indium phosphide substrate 1; the growth temperature of the indium phosphide buffer layer 2 is 645°C; the growth thickness is 300nm, and the molar ratio of group V and group III sources is 200 ;

[0033] Step 3: growing a lattice-matched InGaAsP thin layer 3 on the InP buffer layer 2; the growth temperature of the InGaAsP thin layer 3 is 645°C, and its growth rate is 0.5nm / s, V The / III ratio was 150. This layer serves as the lower barrier layer of the active region;

[0034] Step 4: Prepare a multi-period indium arsenide quantum dot active layer 4 on the indium gallium arsenide phosphorus thin layer 3, the indium arsenide quantum dot active layer 4 includes three periods of indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com