Method for preparing low-density and long-wavelength indium arsenide/gallium arsenide (InAs/GaAs) quantum dots

A long-wavelength, low-density technology, applied in the field of molecular beam epitaxy, can solve the problems of limited extraction efficiency, small quantum dot size, lack of space constraints for carriers, etc., achieving the effect of easy control of density and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

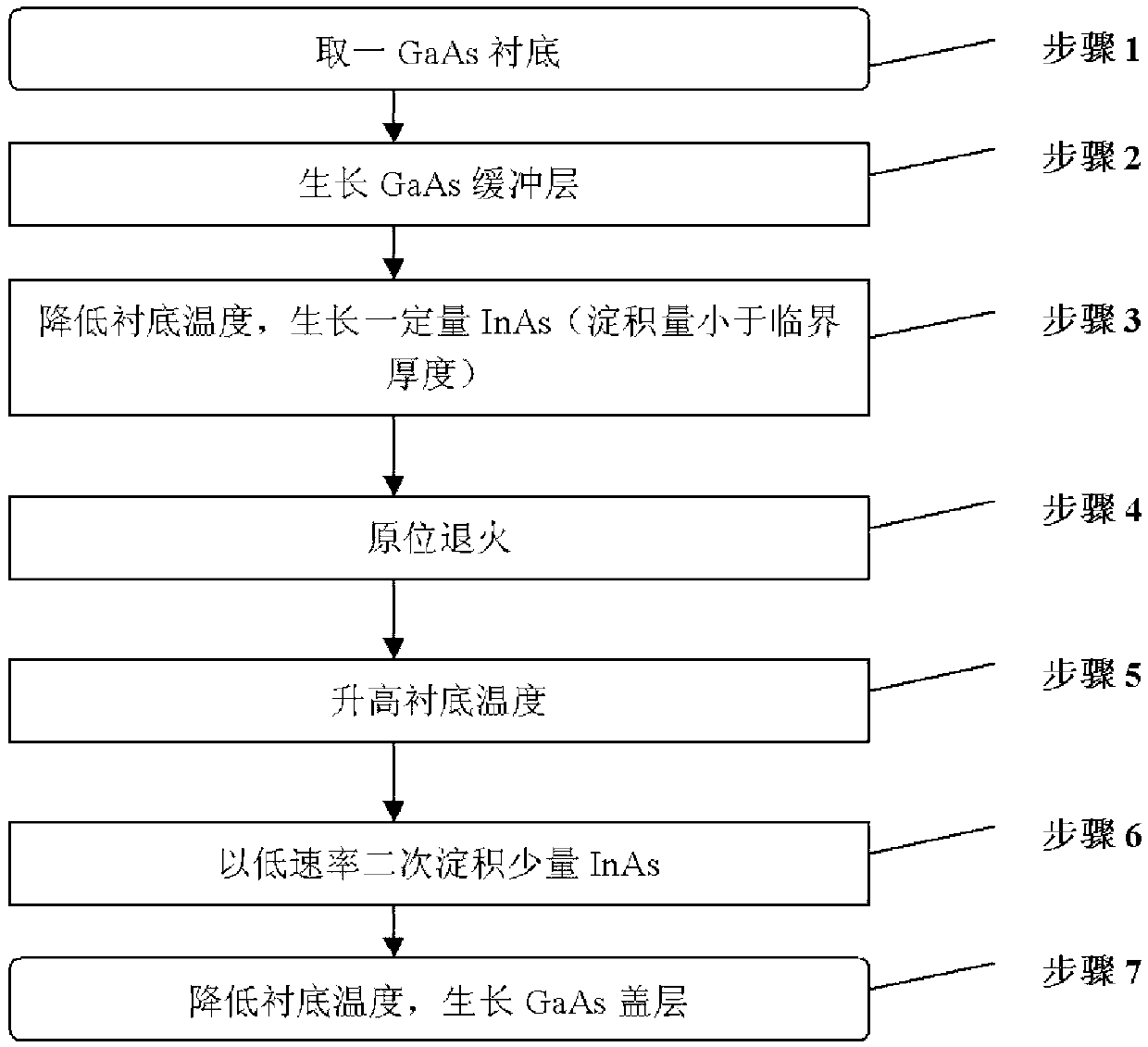

[0024] see figure 1 As shown, the present invention provides a method for preparing low-density, long-wavelength InAs / GaAs quantum dots, comprising the steps of:

[0025] Step 1: Take a liner, put the substrate into the molecular beam epitaxy equipment after pretreatment such as degassing, and the substrate material is GaAs;

[0026] Step 2: Deposit a growth buffer layer on the substrate; grow a GaAs buffer layer on the GaAs substrate and other epitaxial layers that match the substrate lattice; in this step, the substrate temperature is 580°C, and the thickness of the GaAs buffer layer is Unlimited, unlimited growth rate.

[0027] Step 3: Deposit and grow an InAs layer on the buffer layer, suspend the deposition and growth when the critical thickness is not reached, the temperature of the deposition and growth InAs layer is 470°C-490°C, the growth rate is 0.01-0.1ML / s, pause The deposited and grown InAs layer is 0.05-0.5ML less than the critical thickness; the substrate temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com