Long Wavelength Induim Arsenide Phosphide (InAsP) Quantum Well Active Region And Method For Producing Same

a technology of indium arsenide phosphide and long wavelength light, which is applied in the direction of lasers, semiconductor devices, semiconductor lasers, etc., can solve the problems of significant lattice mismatch, rapid increase in the value of isub>th /sub>, and the inability of ingaasp quantum well layers to meet 1.5 m wavelength, etc., to suppress the relaxation of layers, reduce the dislocation, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While described below using an example of an edge emitting laser that incorporates InAsP quantum well layers, other device structures can benefit from the invention. For example, a vertical-cavity surface-emitting laser (VCSEL) including high quality InAsP quantum well epitaxial layers can be economically fabricated using the concepts of the invention.

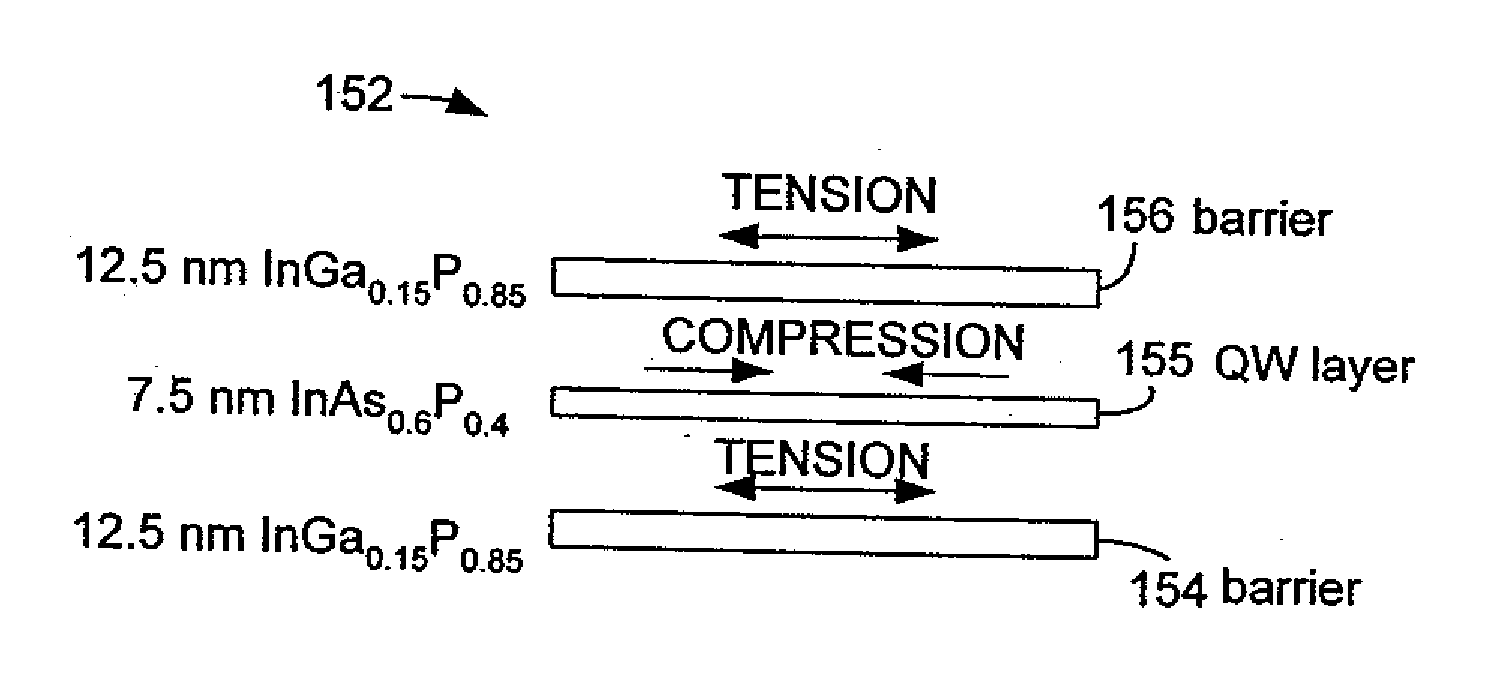

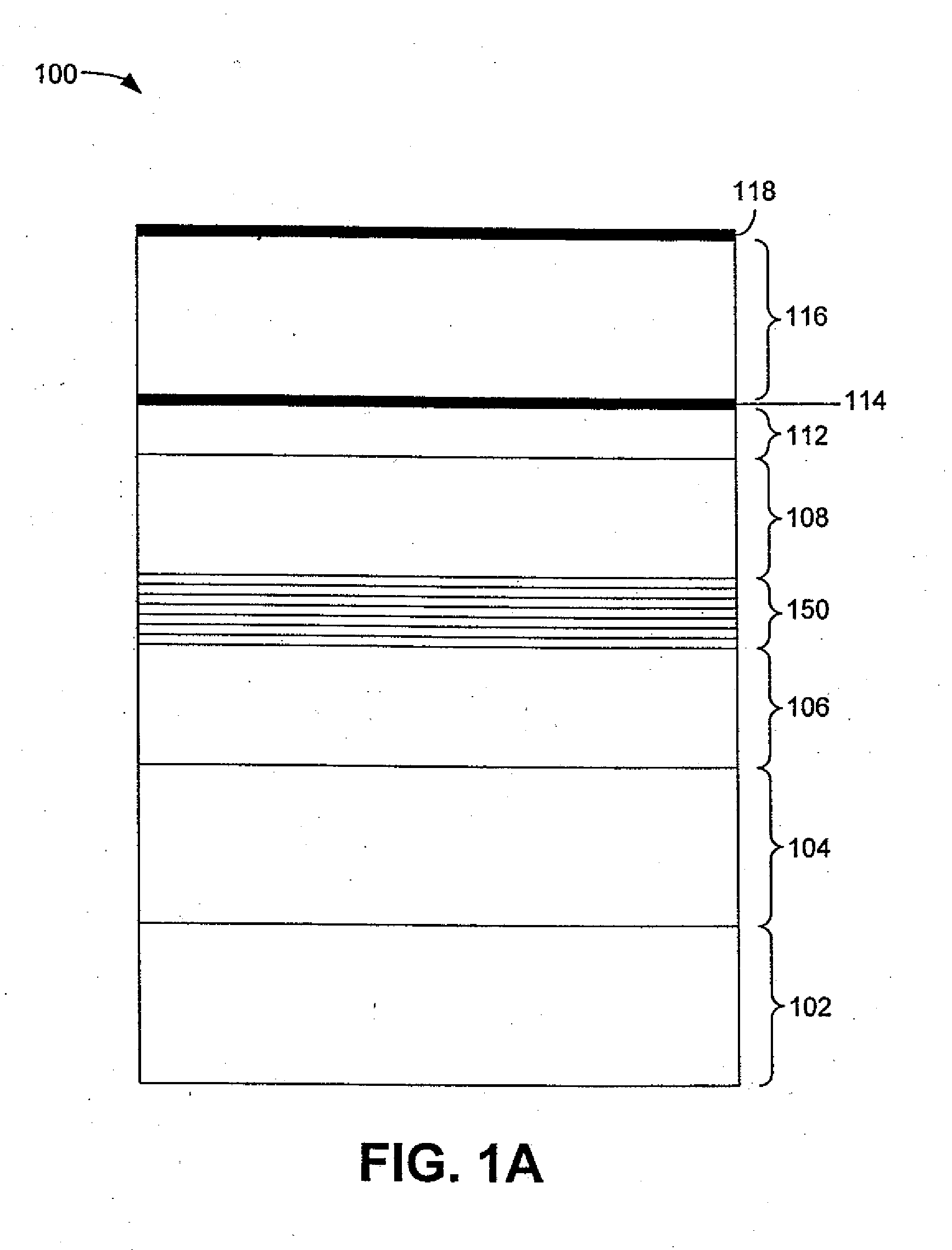

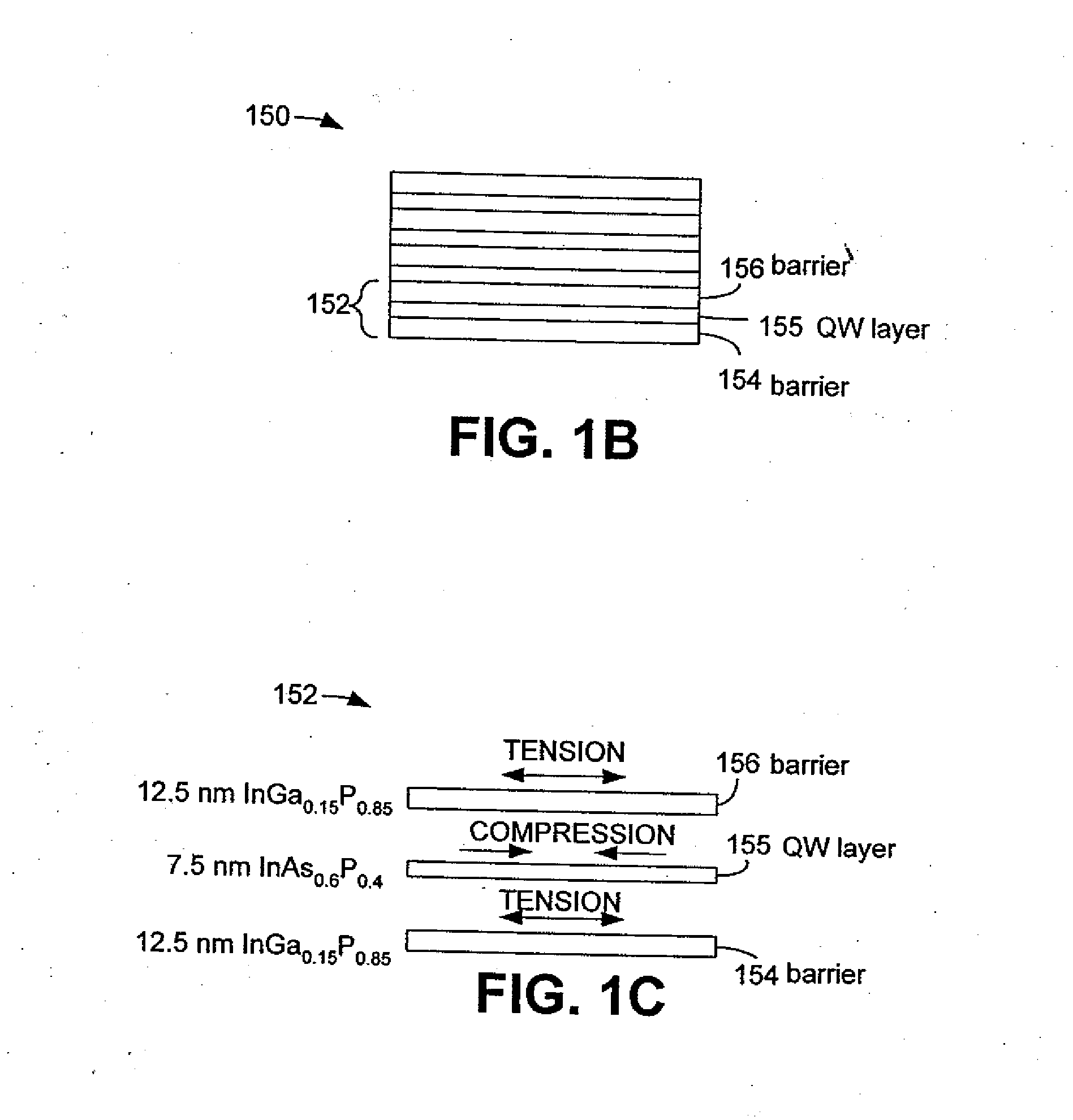

[0021]FIG. 1A is a schematic view illustrating the relevant portions of an exemplary edge emitting laser 100 constructed in accordance with an aspect of the invention. Some of the elements of the laser 100 are omitted for simplicity. The laser 100 comprises an N-type, sulfur (S) doped, indium phosphide (InP) substrate 102 over which an n-type 2 μm thick, selenium (Se) doped, InP cladding layer 104 is formed. The cladding layer 104 is formed using a high bandgap, low refractive index material.

[0022] A lower separate confinement heterostructure (SCH) layer 106 is formed over the cladding layer 104. The lower SCH layer 106 is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com