Method for growing indium arsenide/indium gallium arsenide quantum well material on indium phosphide substrate

A technology of indium arsenide and indium phosphide, which is applied in the field of semiconductor laser manufacturing, can solve the problems of volatile InAs quantum well materials, quality of defective materials, degradation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

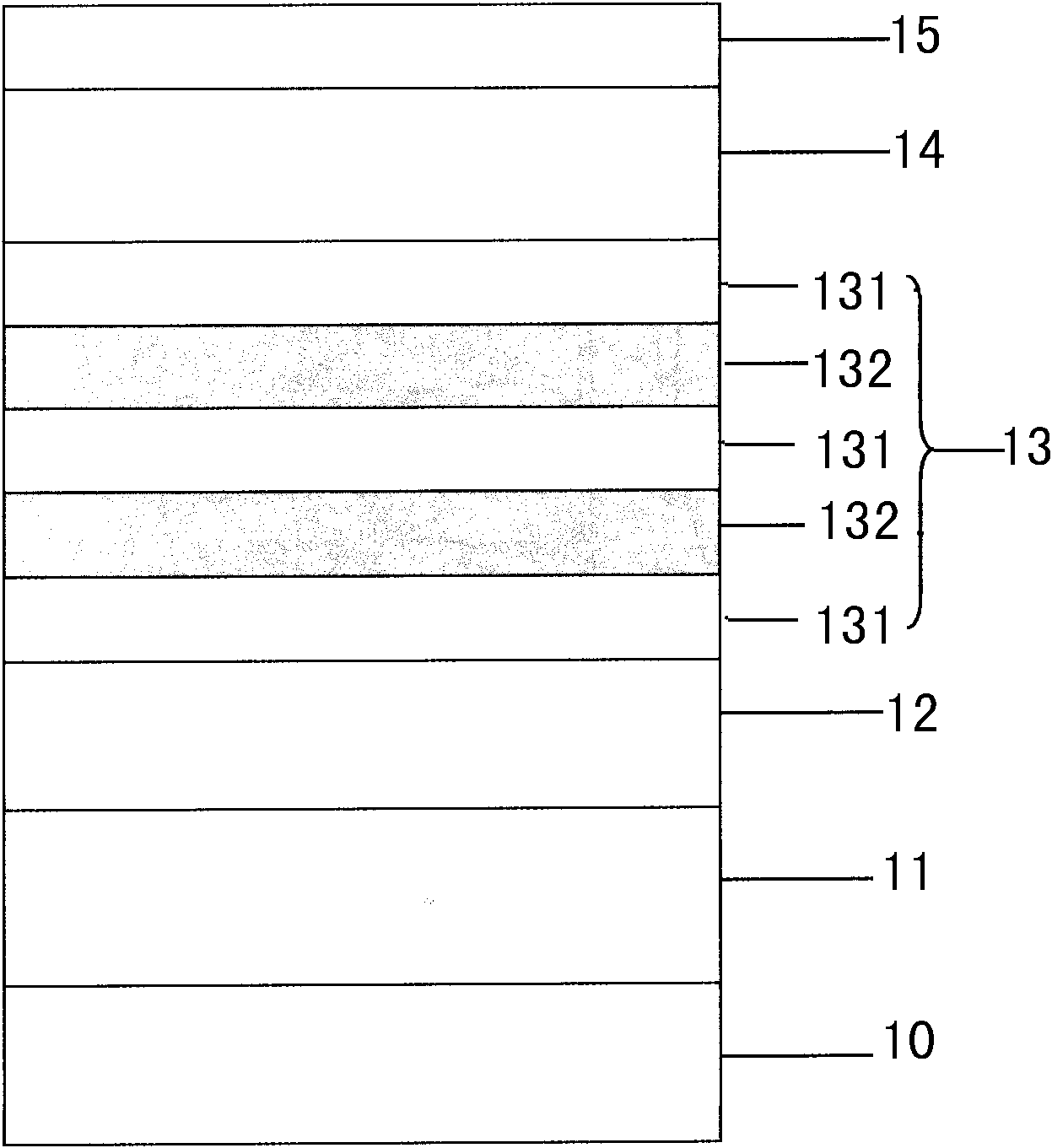

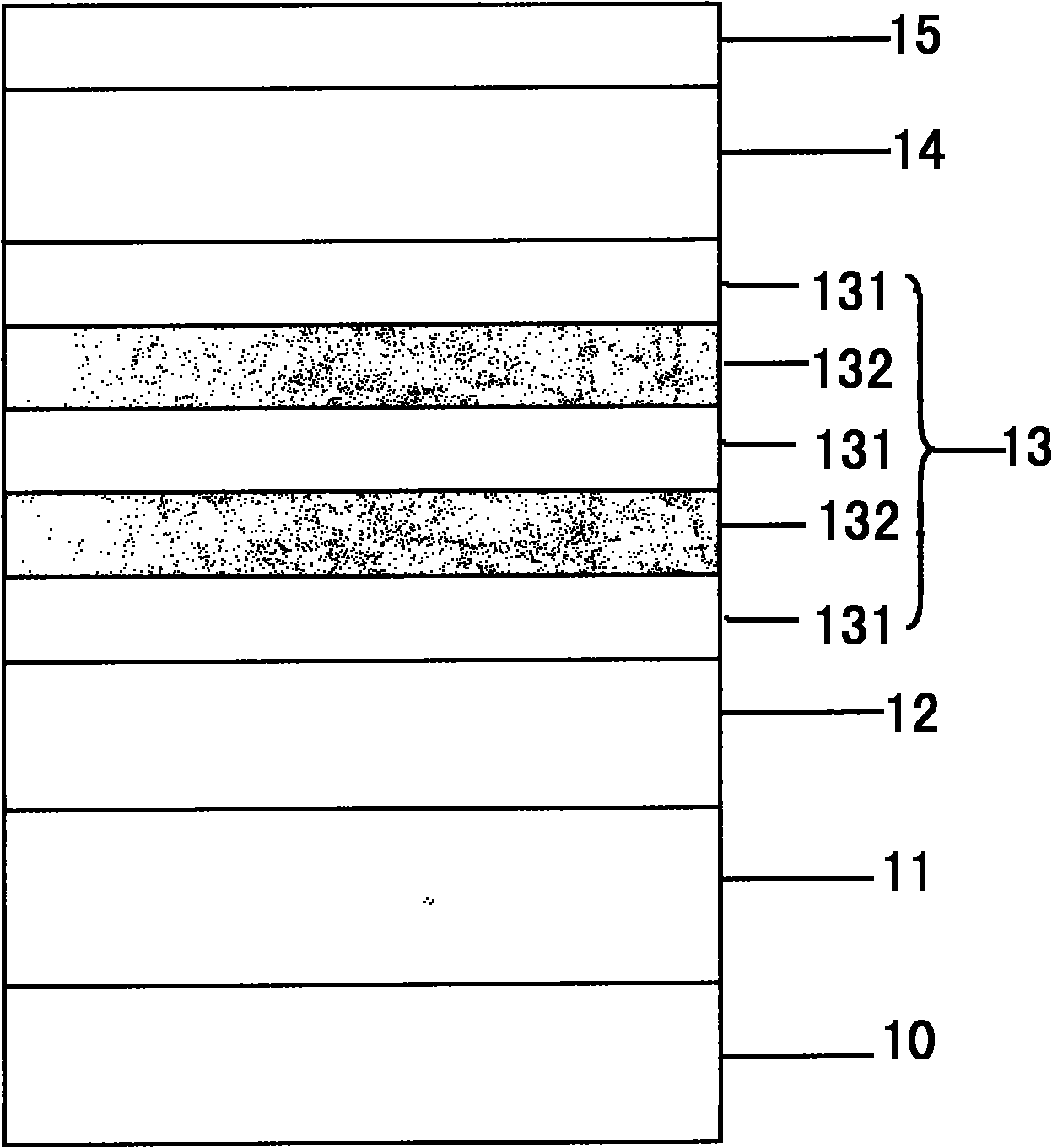

[0032] see again figure 1 As shown, a method of growing indium arsenide / indium gallium arsenide quantum well material on an indium phosphide substrate of the present invention comprises the following steps:

[0033] Step 1: select a half-insulated InP single wafer as the substrate 10;

[0034] Step 2: Using the metal organic compound vapor deposition method, a buffer layer 11, a lower waveguide layer 12, a double quantum well structure 13, an upper waveguide layer 14 and a capping layer 15 are sequentially grown on the substrate 10, and the indium phosphide layer is completed. Fabrication of indium arsenide / indium gallium arsenide quantum well materials grown on substrates.

[0035] The buffer layer 11 is an intrinsic InP buffer layer with a deposition thickness of 200 nm and a growth temperature of 610° C.

[0036] The material of the lower waveguide layer 12 is In 0.72 Ga 0.28 As 0.61 P 0.39 , the wavelength corresponding to its band gap is 1.3 μm, its deposition thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Deposition thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com