Patents

Literature

47results about How to "Quality loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encoder and method

ActiveUS20140140359A1Quality lossEfficient codingTime-division multiplexDigital video signal modificationTheoretical computer scienceEncoder

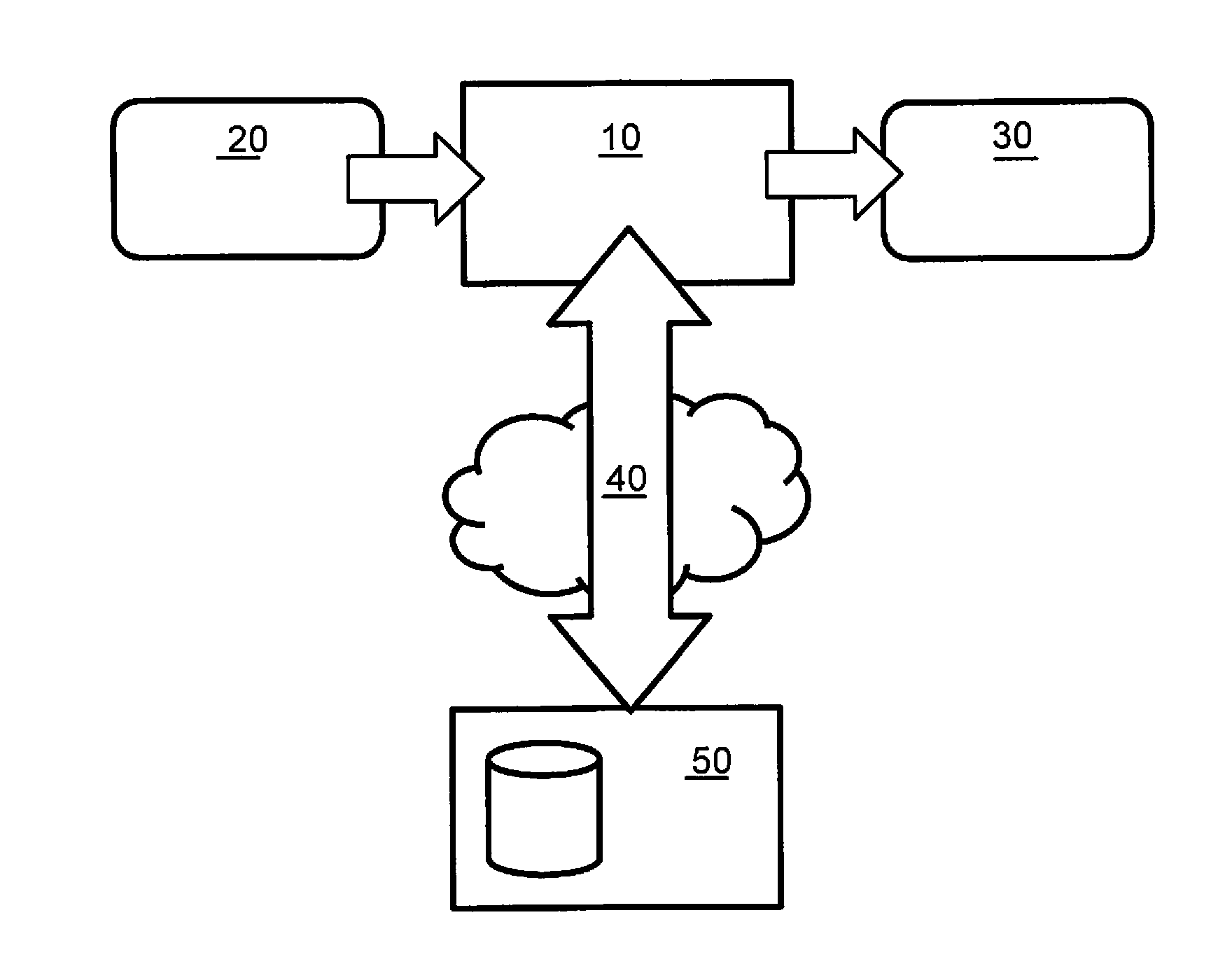

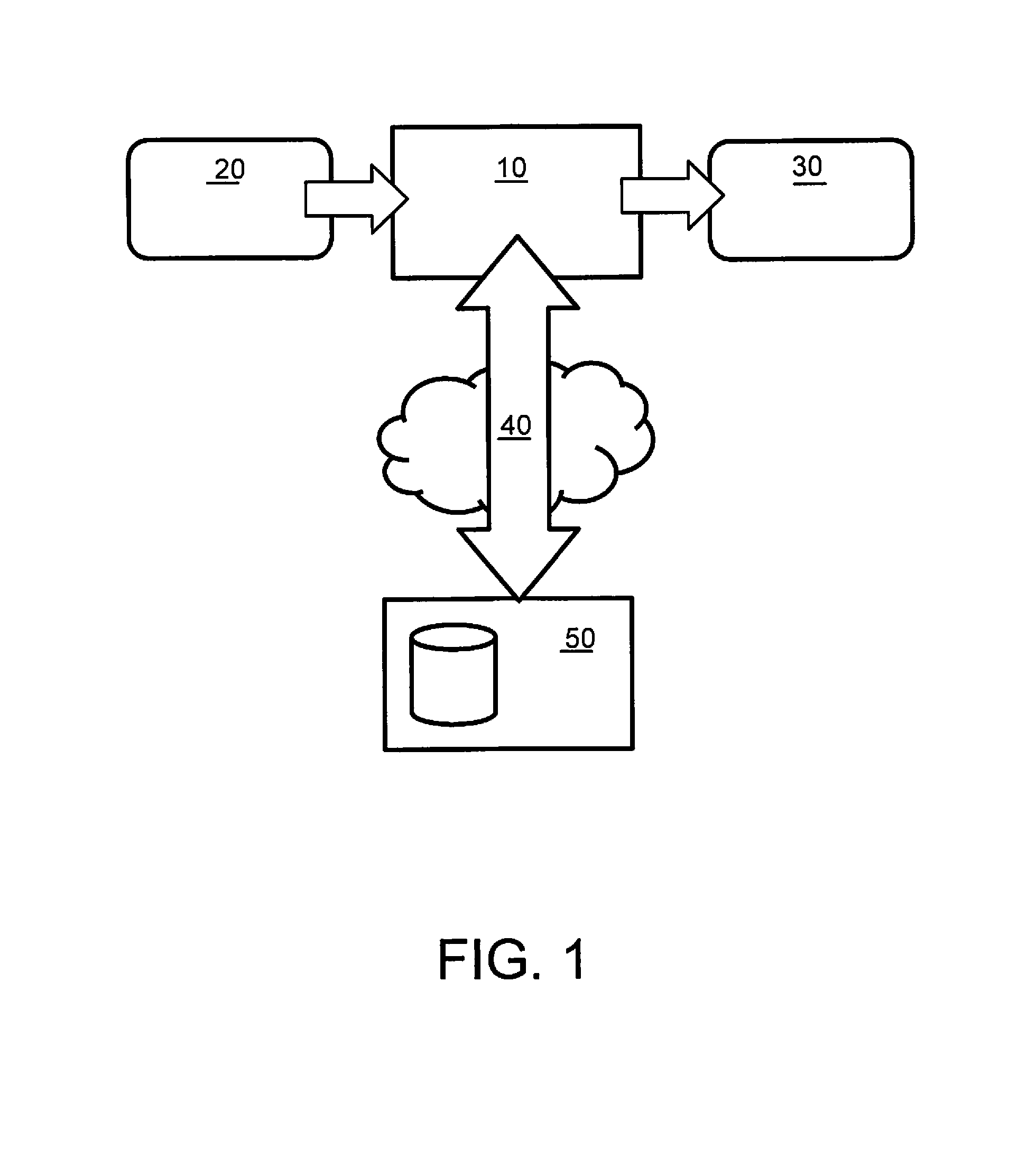

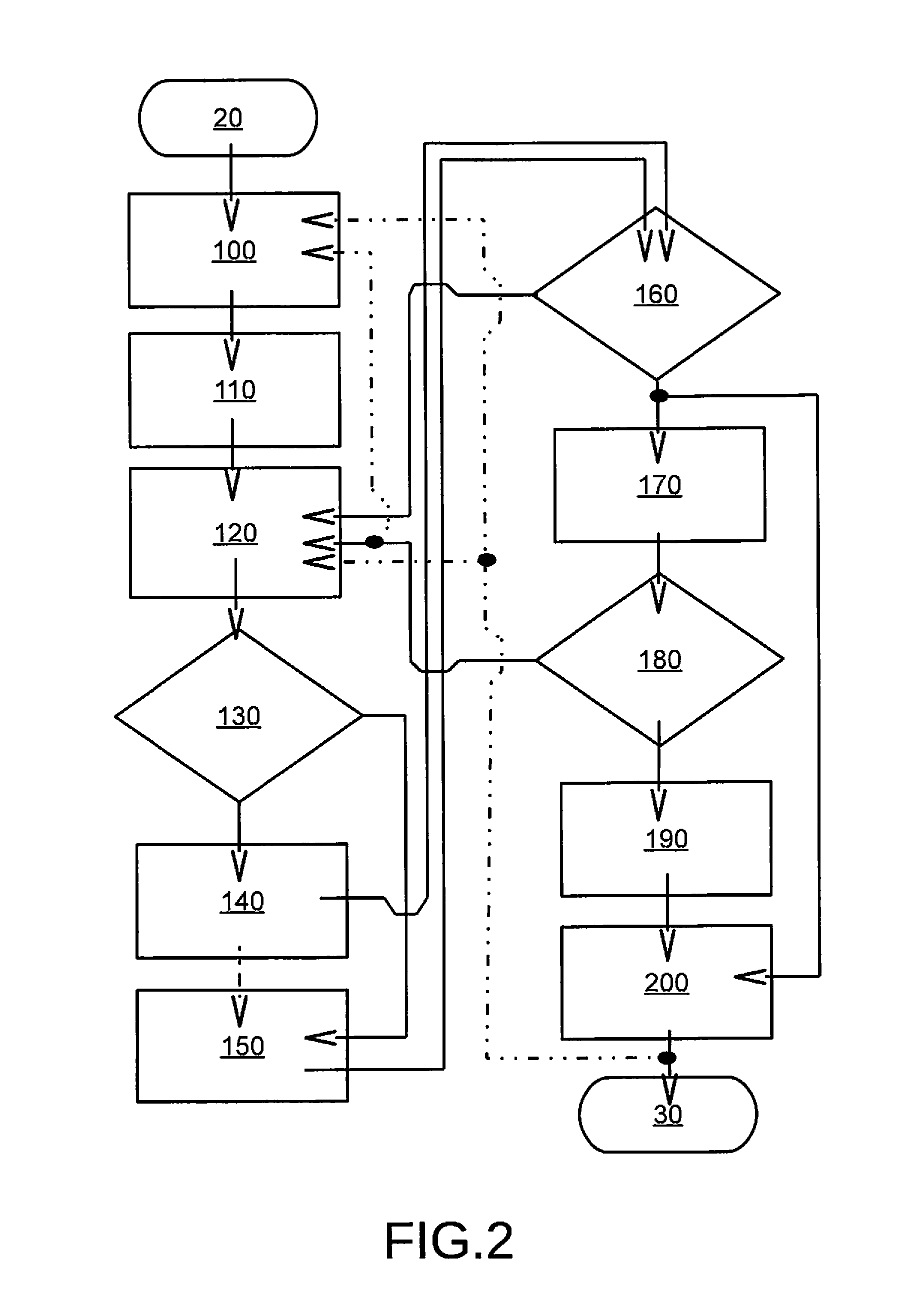

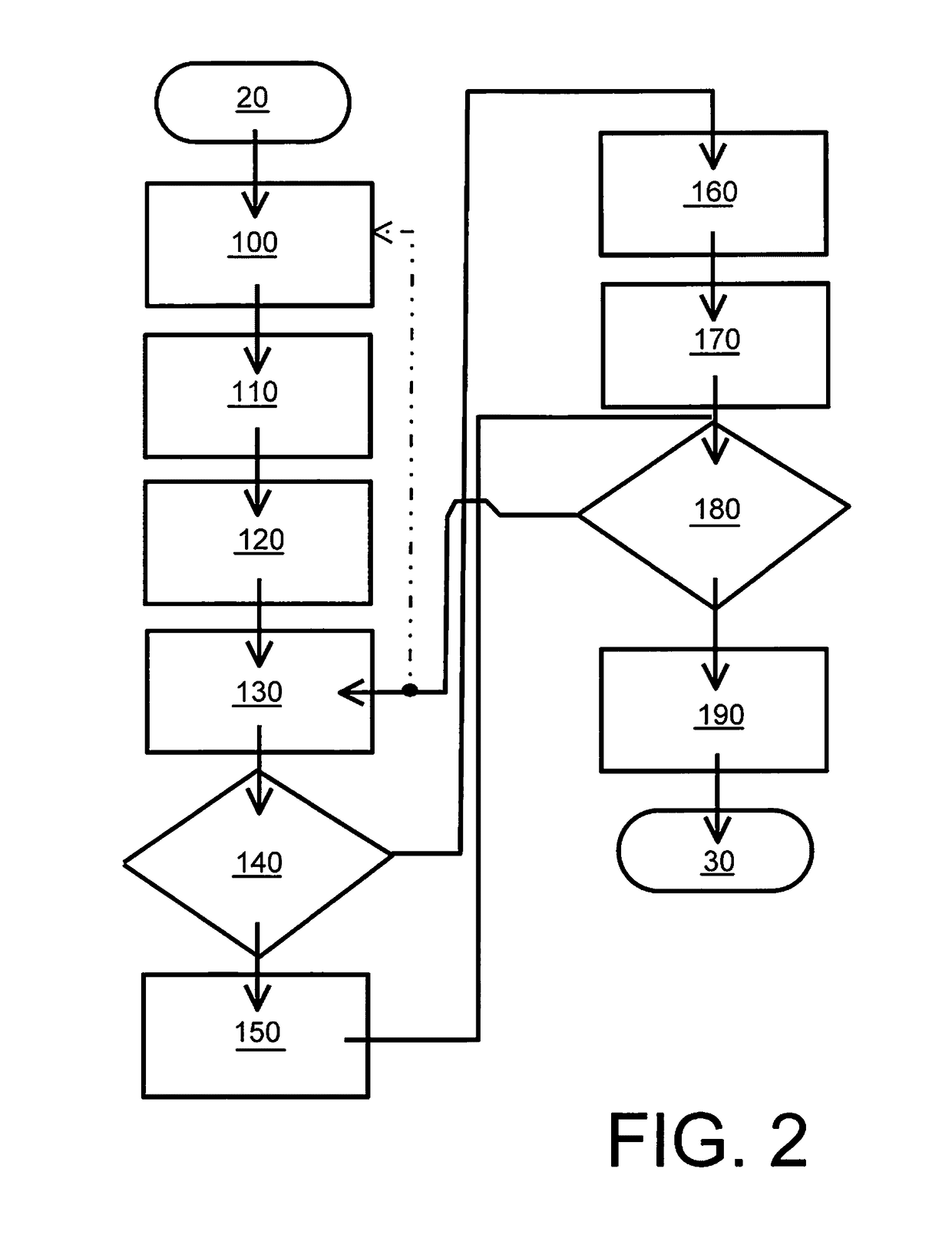

An encoder includes data processing hardware which is operable: to divide input data into a plurality of blocks or packets; to apply a plurality of transformations to content of the blocks or packets to generate corresponding transformed data; to check a quality of representation of the transformed data prior to application of the transformations to determine whether or not the quality of representation of the transformed data satisfies one or more quality criteria; if the quality of representation of the transformed data does not satisfy the one or more quality criteria, to sub-divide and / or to combine the one or more blocks or packets further and repeating the transformation step; and if the quality of representation of the transformed data satisfies the one or more quality criteria, to output the transformed data to provide encoded output data representative of the input data to be encoded.

Owner:GURULOGIC MICROSYST

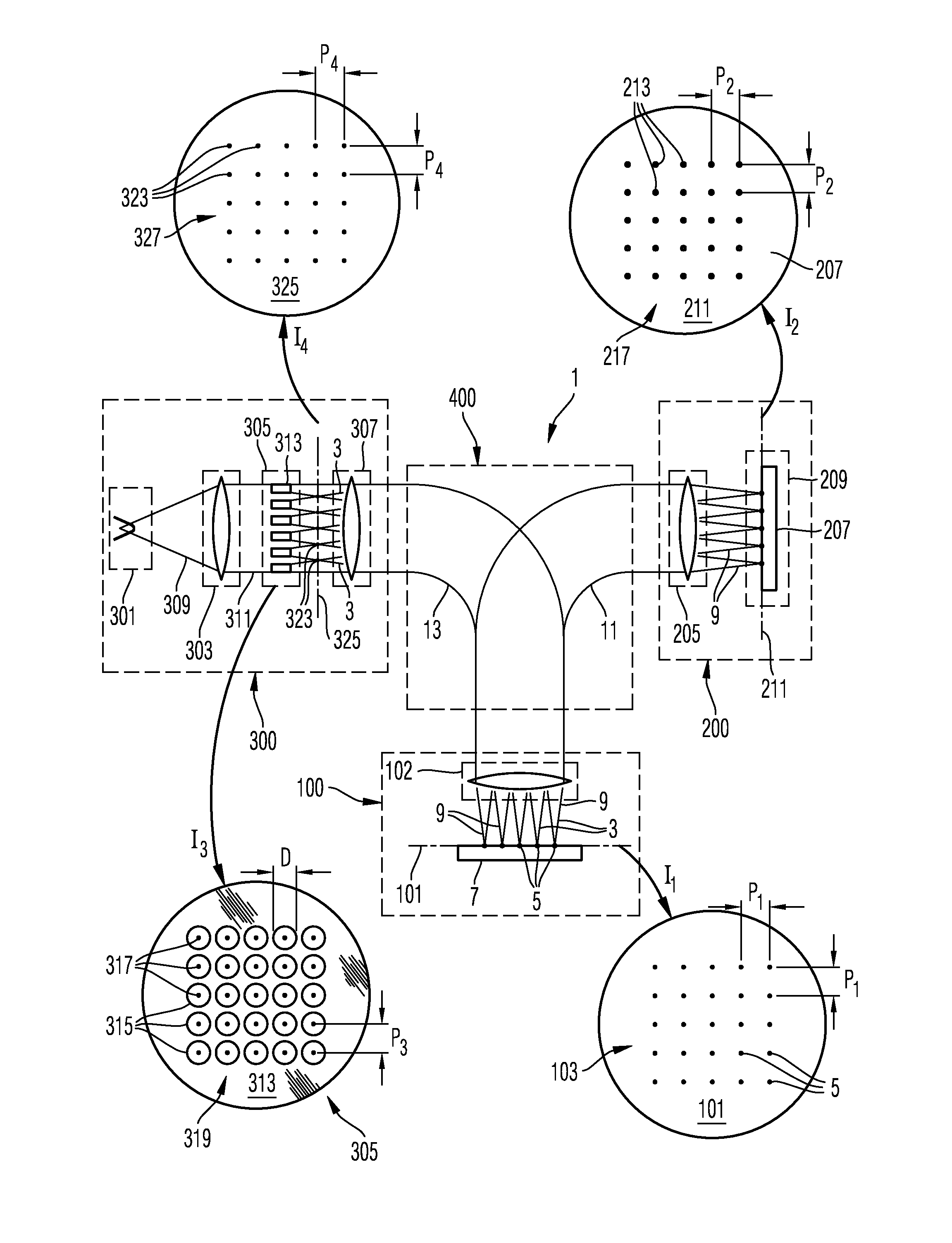

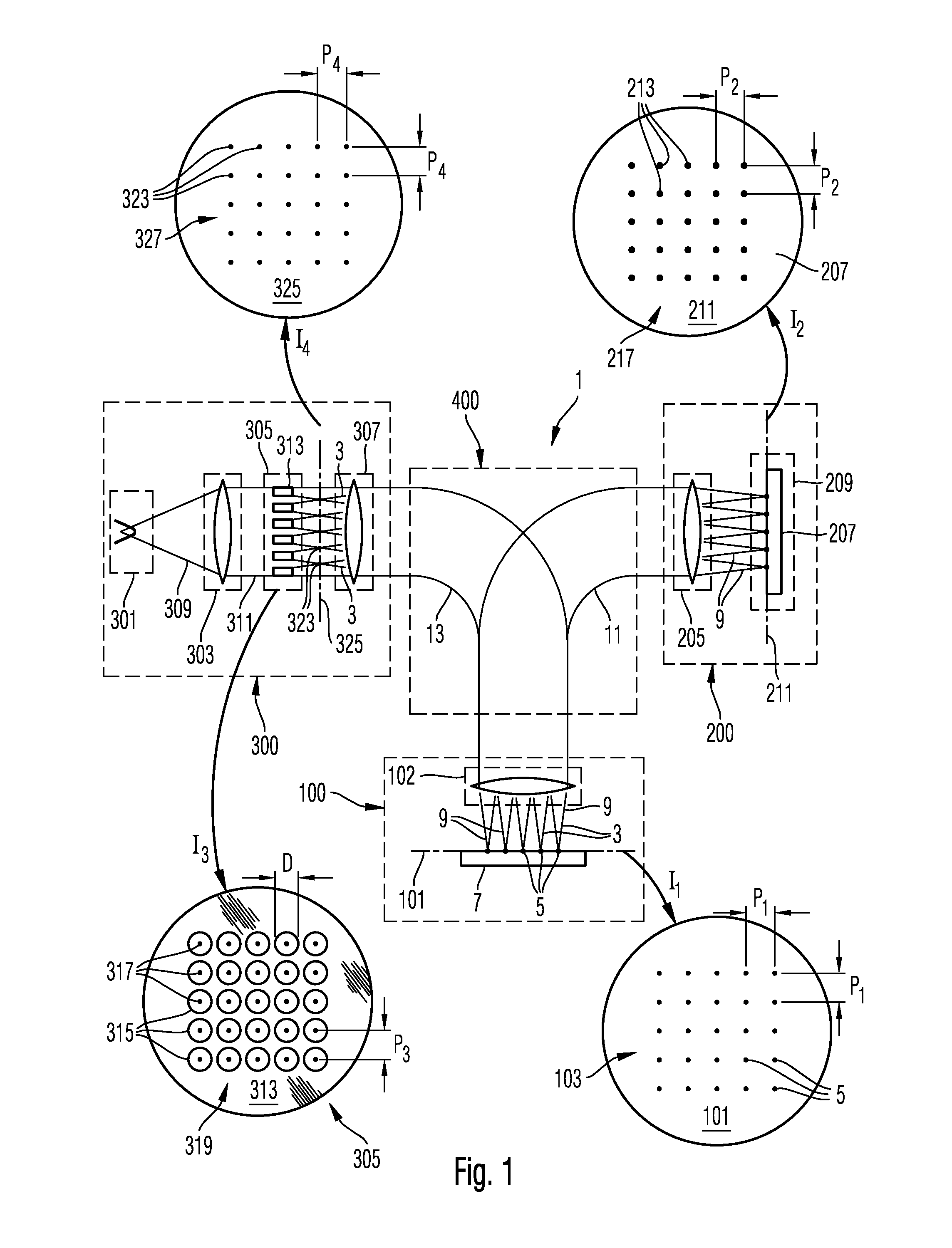

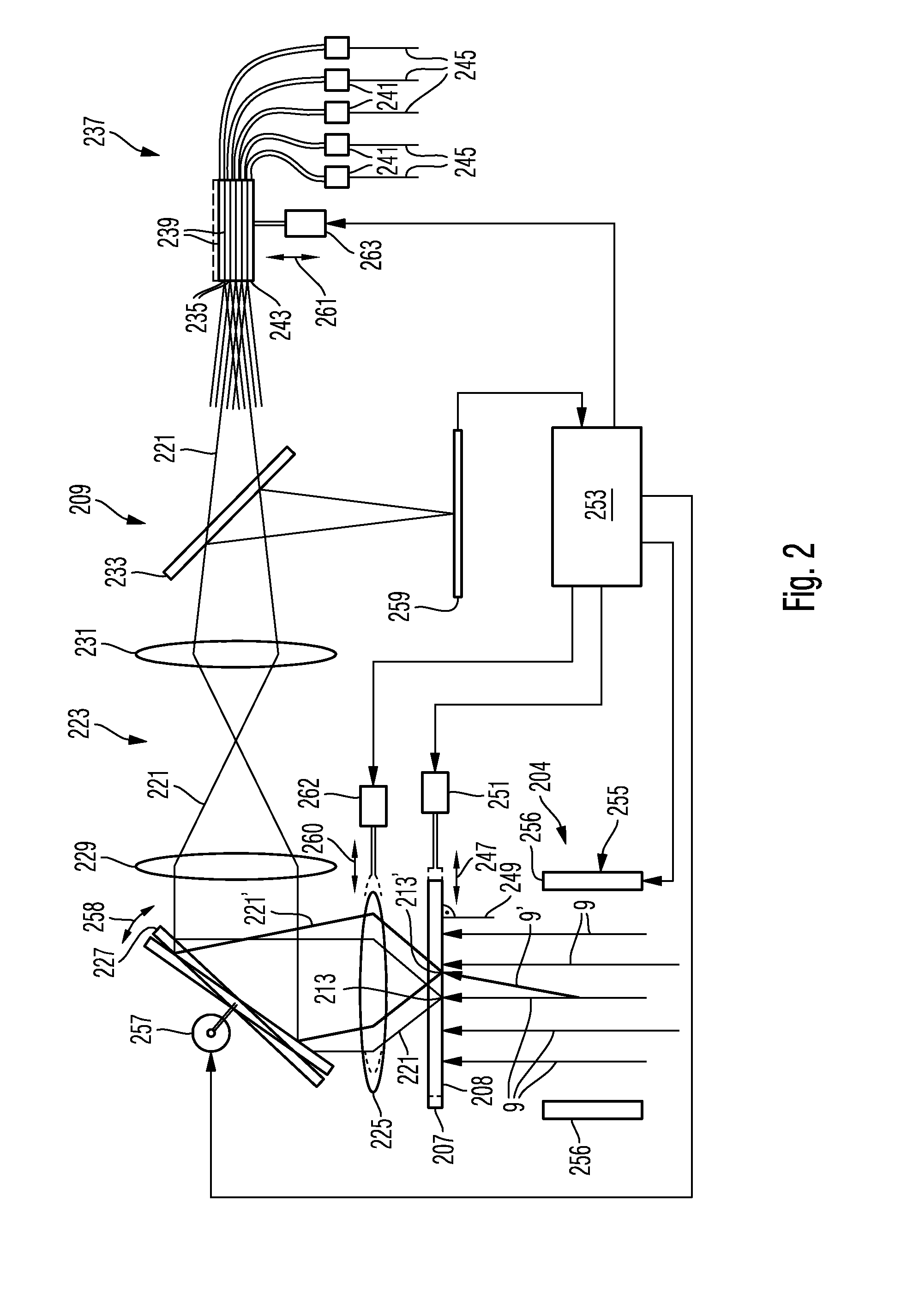

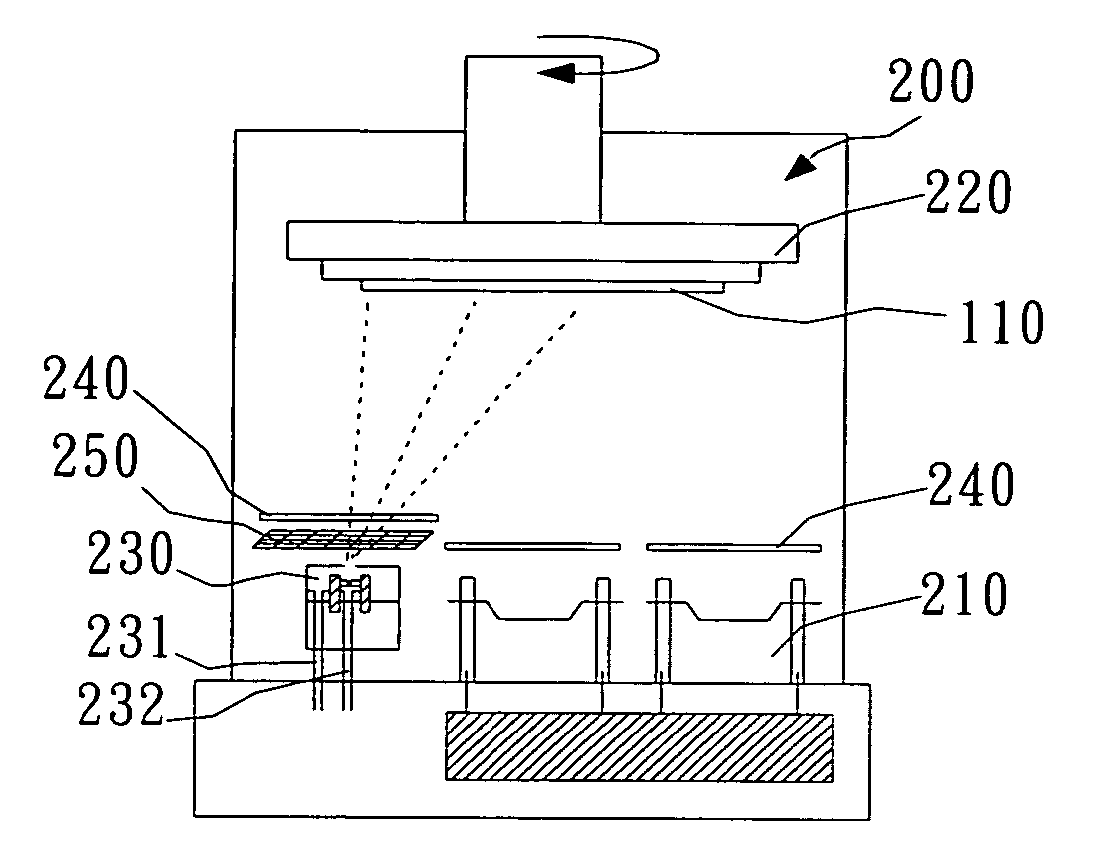

Method of Detecting Electrons, an Electron-Detector and an Inspection System

ActiveUS20150083911A1Less deterioration of qualityExtended operating timeMaterial analysis using wave/particle radiationElectric discharge tubesLight beamOptoelectronics

An electron-detector comprises a scintillator plate 207, electron optics 204 for directing a plurality of electron beams 9 onto the scintillator plate so that the electron beams are incident onto the scintillator plate at locations of incidence disposed at a distance from each other, a light detector 237 comprising a plurality of light receiving areas 235 disposed at a distance from each other, and light optics for generating a first light-optical image of at least a portion of the scintillator plate at a region 243 where the light receiving areas of the light detector are disposed so that, by the imaging, each of the locations of incidence is associated with a light receiving area; and wherein the electron optics comprise an electron beam deflector 255 for displacing the locations of incidence of the electron beams on the scintillator plate in a direction orthogonal to a normal 249 of a surface 208 of the scintillator plate.

Owner:CARL ZEISS MICROSCOPY GMBH

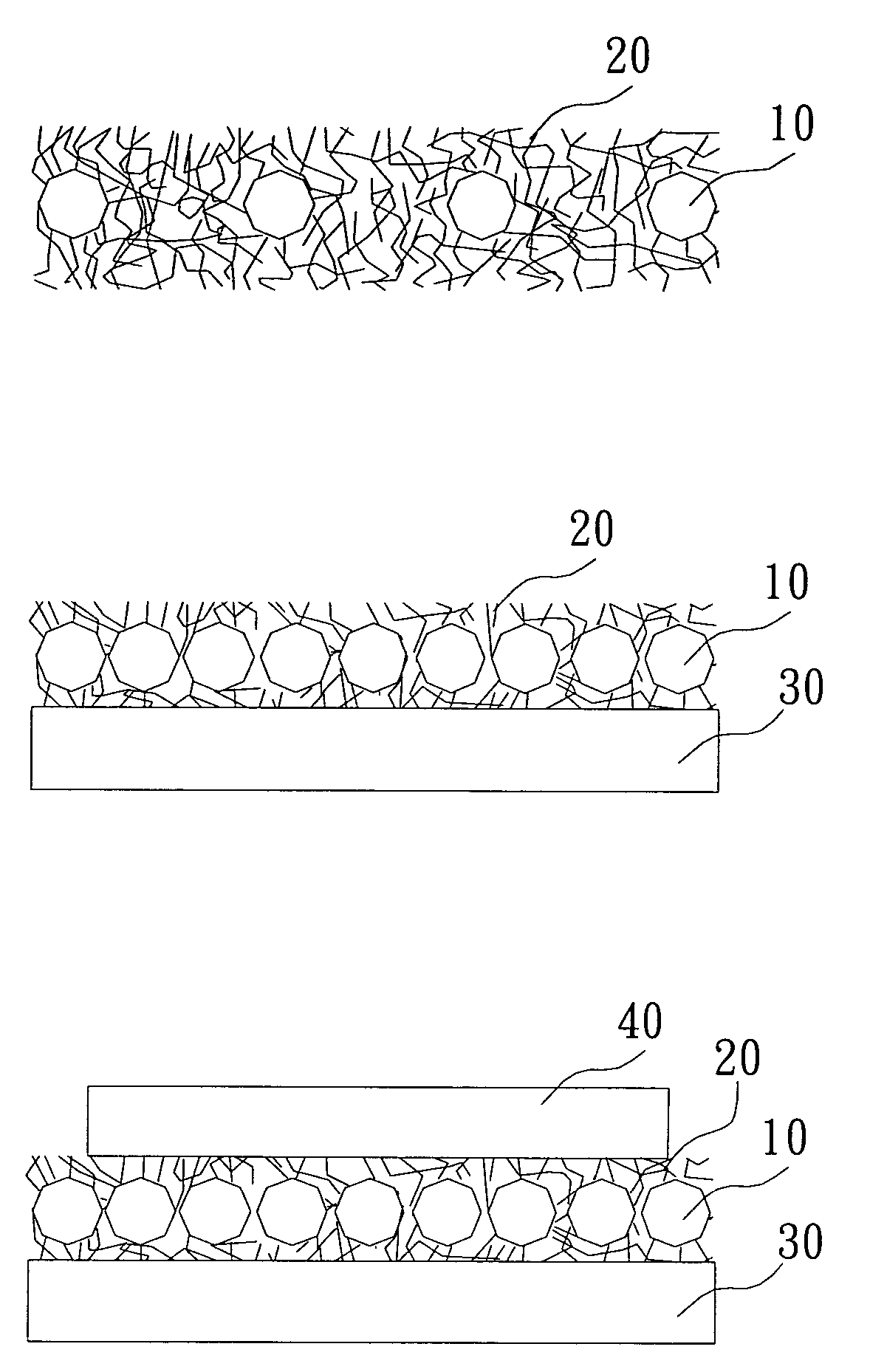

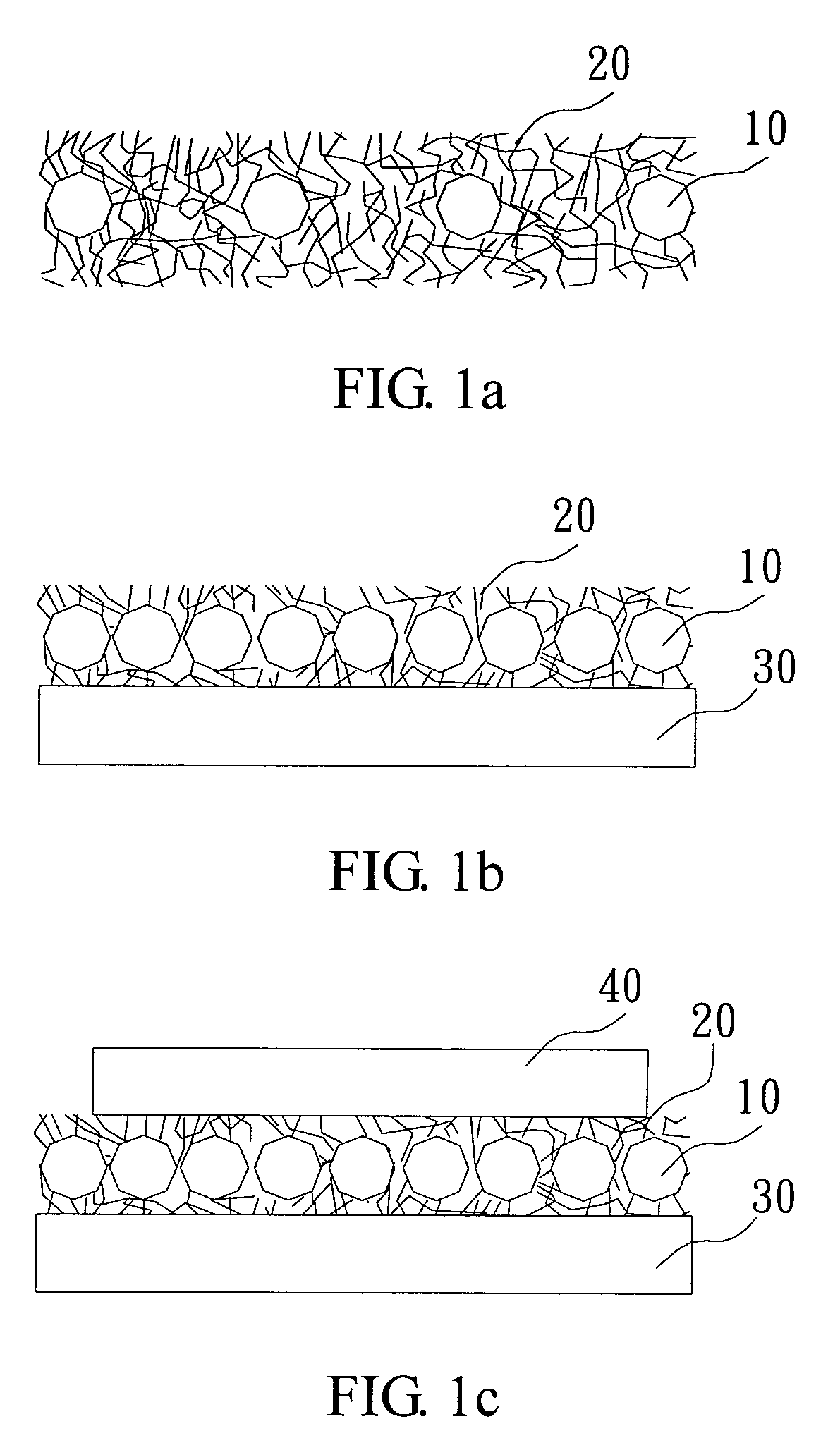

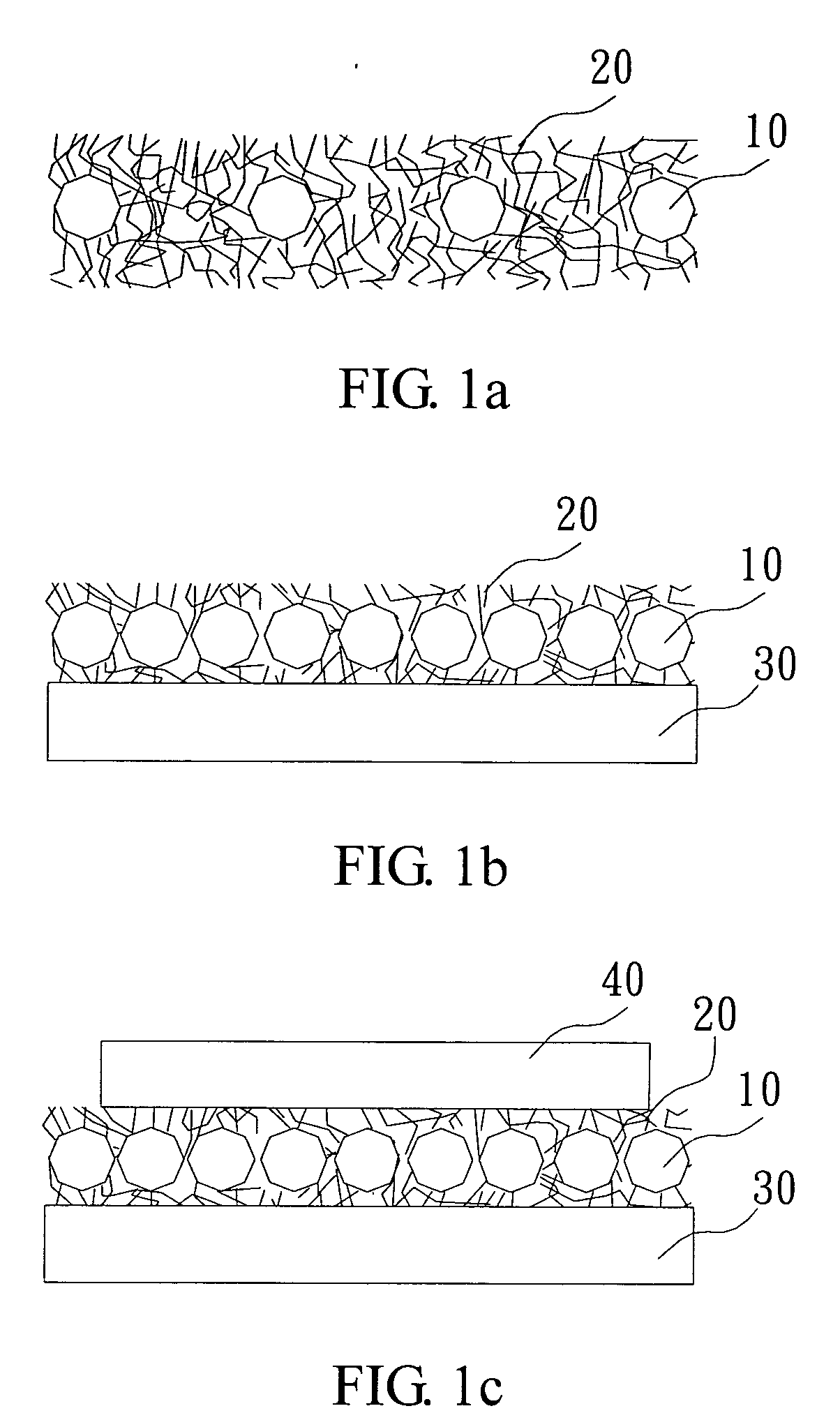

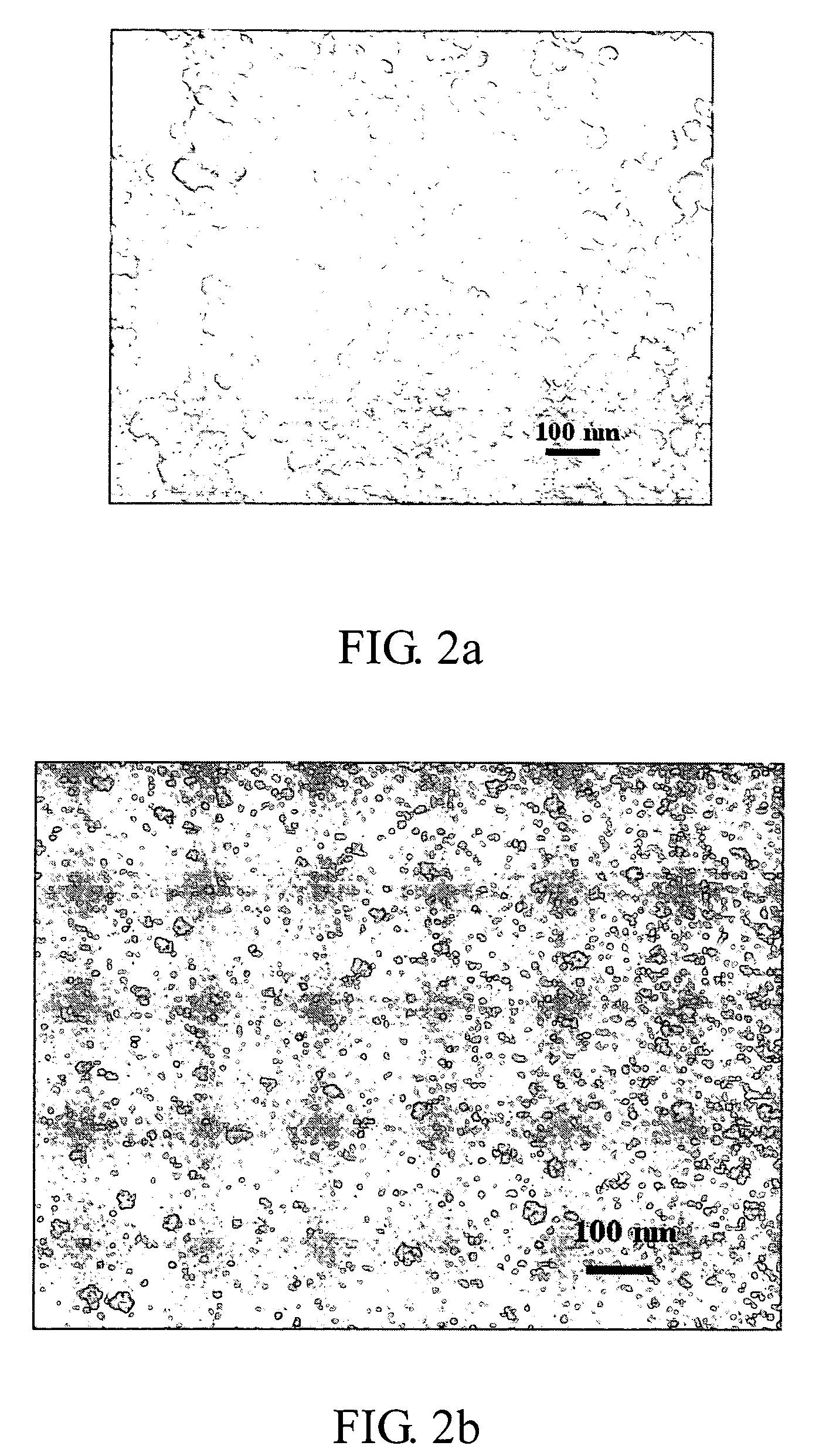

Method of manufacturing a quantum-dot element

ActiveUS7303937B2Quality lossEvenly distributedNanoinformaticsSemiconductor/solid-state device manufacturingQuantum dotSolvent

Owner:IND TECH RES INST

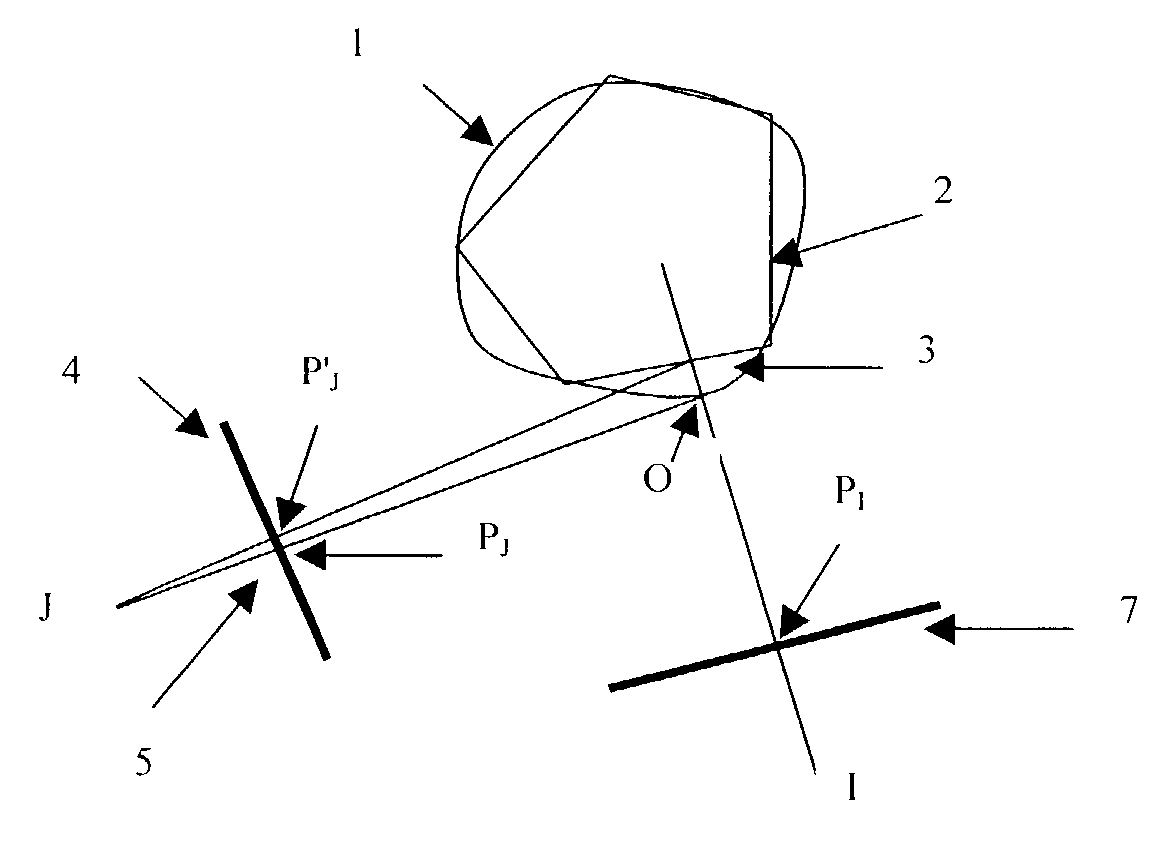

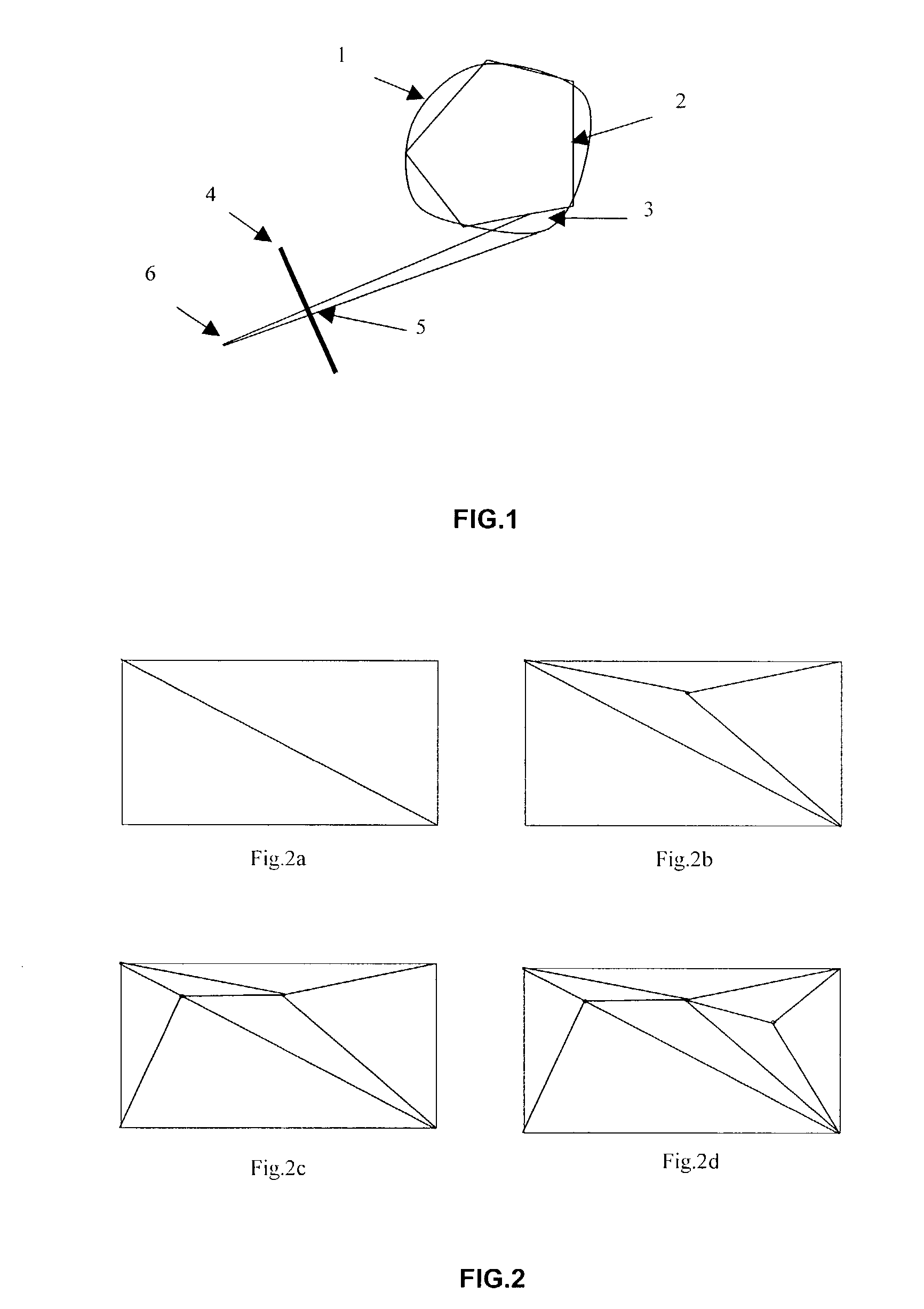

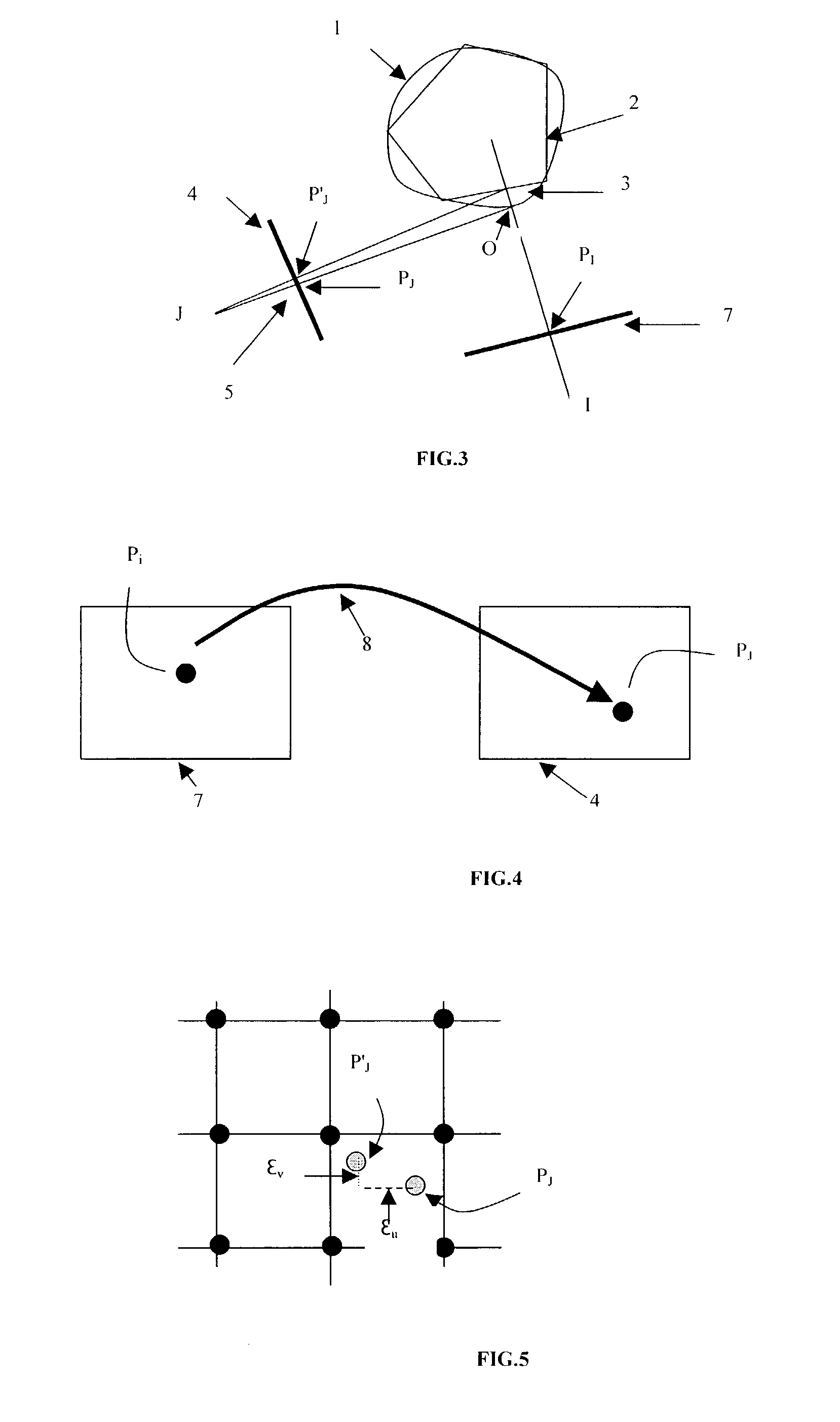

Process for modelling a 3D scene

ActiveUS7113635B2Simplification of depth mapQuality lossCharacter and pattern recognitionSteroscopic systemsComputer graphics (images)Algorithm

A process for modeling a 3D scene is provided which comprises validating the model by determining a maximum permitted distortion (5) on a 2D synthesized image (4), generated by the approximation inherent in the model (2); calculating for a point I of a reference image (7) and on a set of synthesized images (4) representing the 3D point of the scene corresponding to this point I, of the minimum (zi−Δzi1) and maximum (zi+Δzi2) depth values of the depth zi of this point I corresponding to this maximum distortion, calculating a span around the depth zi of this point I, dependant on the minimum value of the error Δzi2 and on the minimum value of the error Δzi1 among the values calculated for the synthesized images of the set.

Owner:MAGNOLIA LICENSING LLC

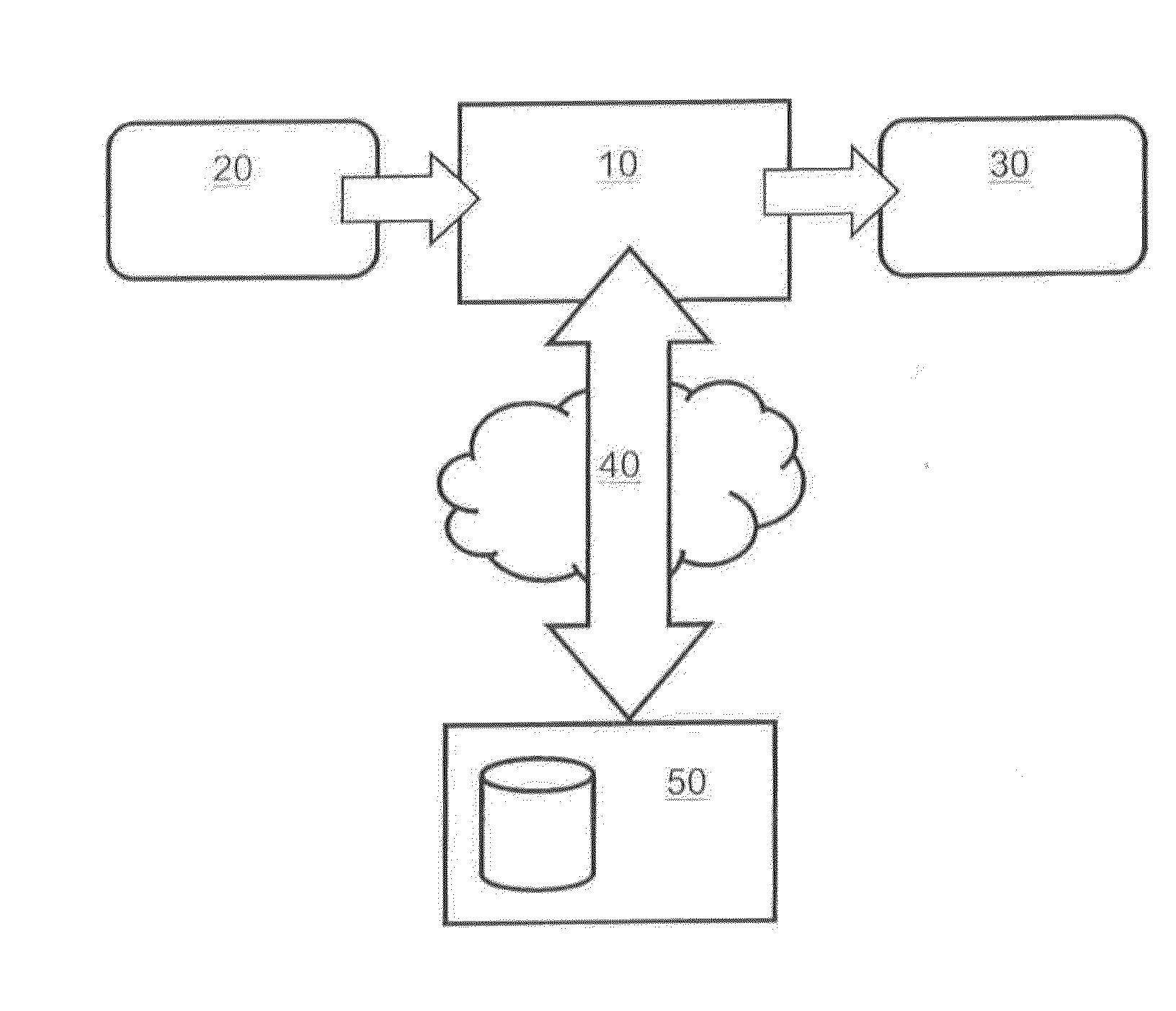

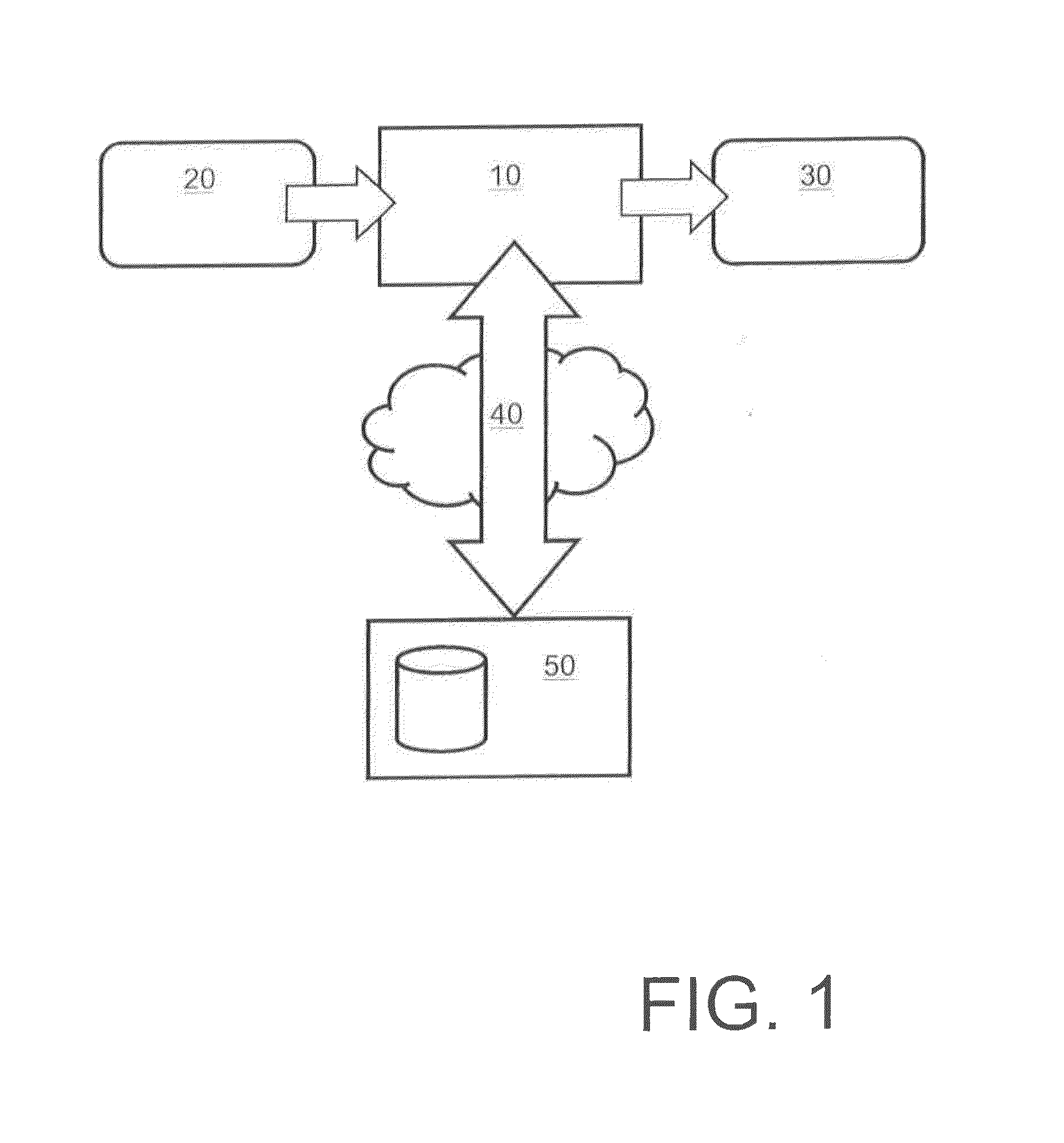

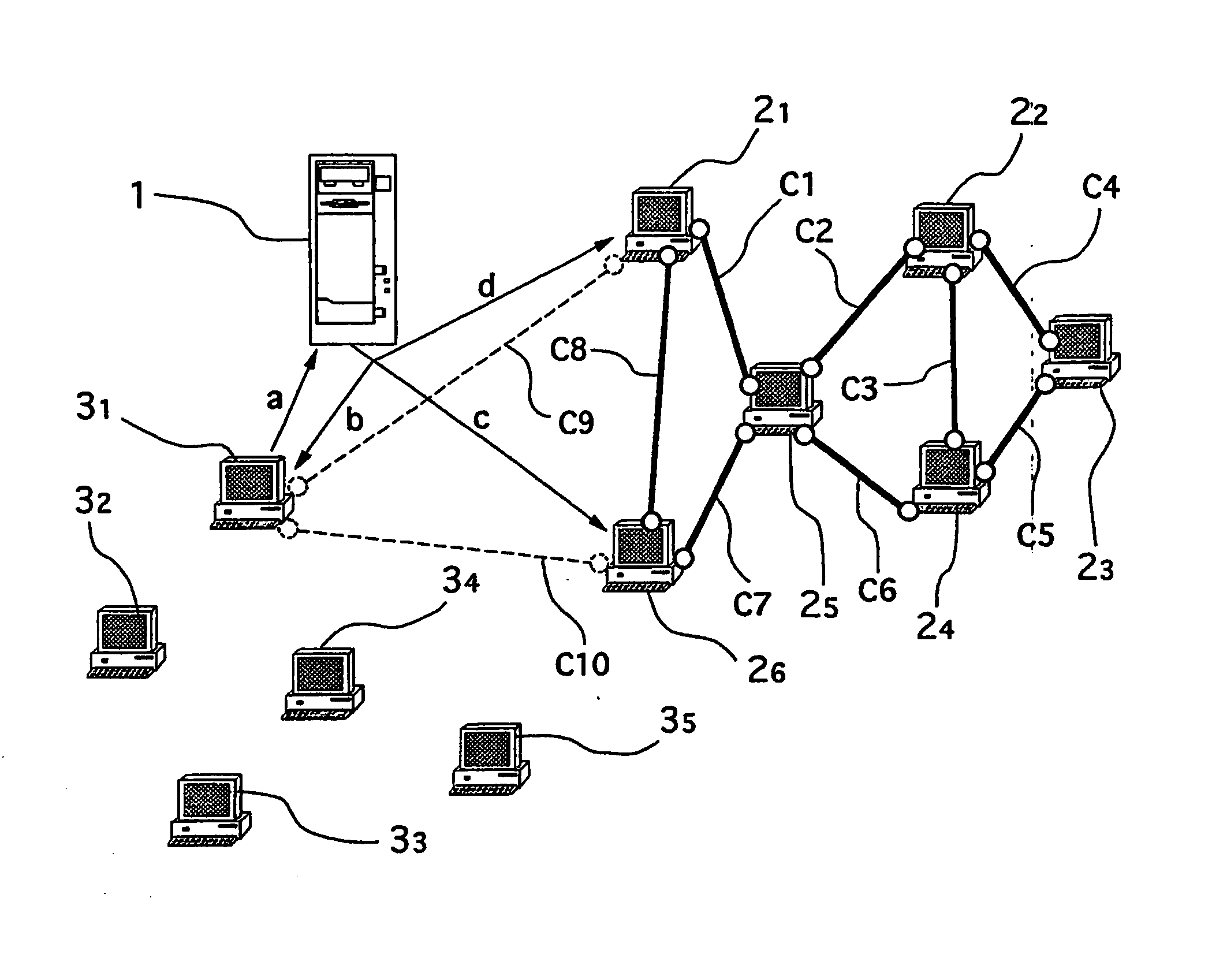

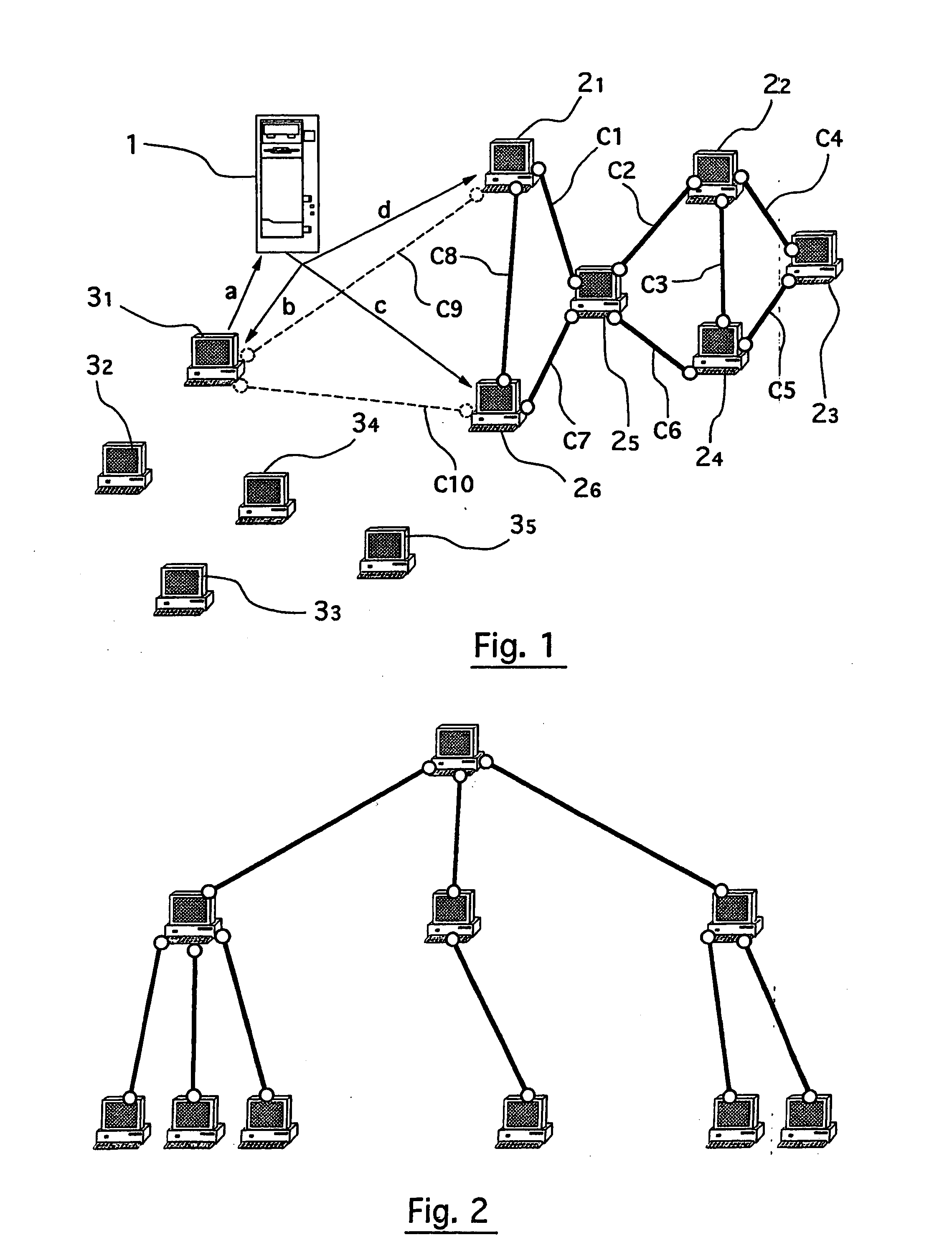

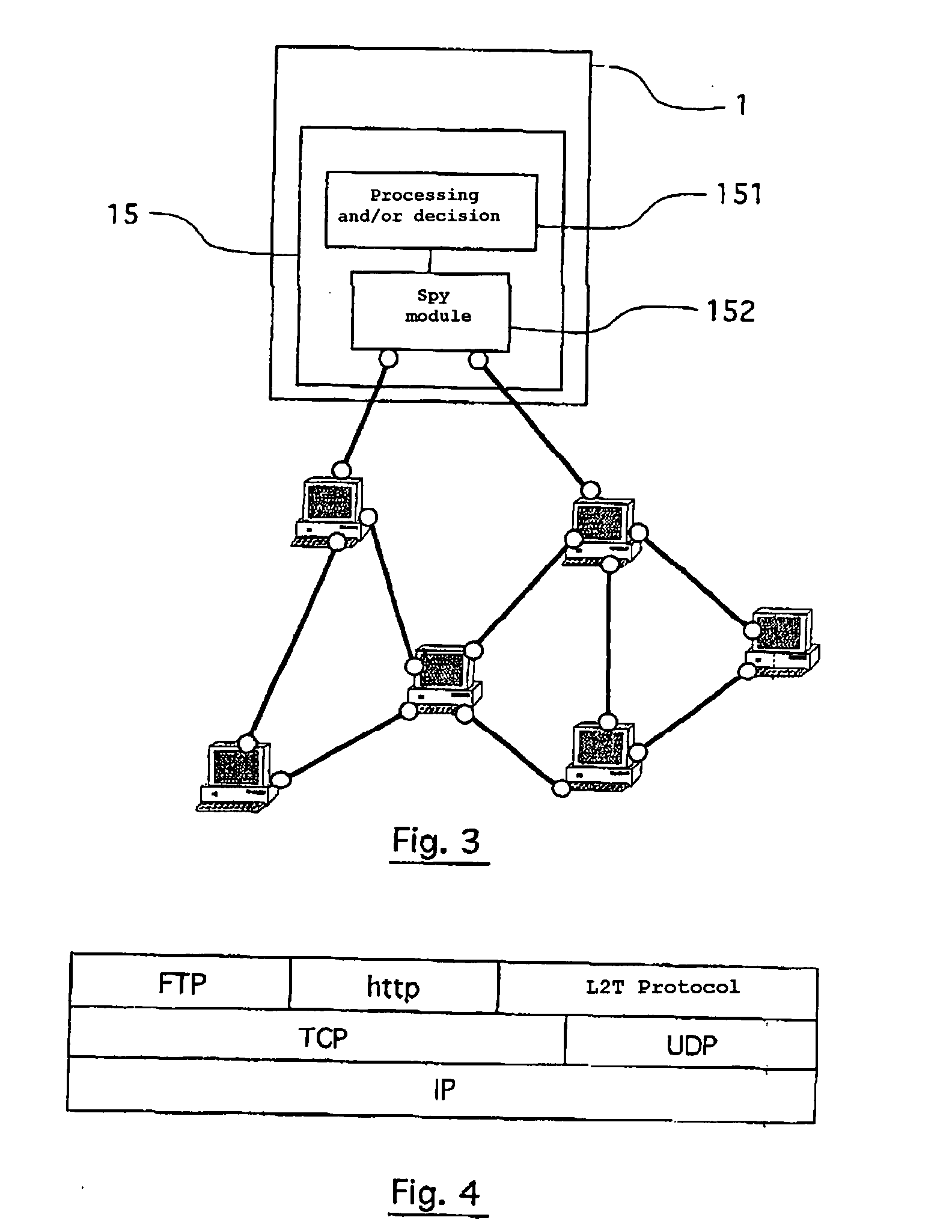

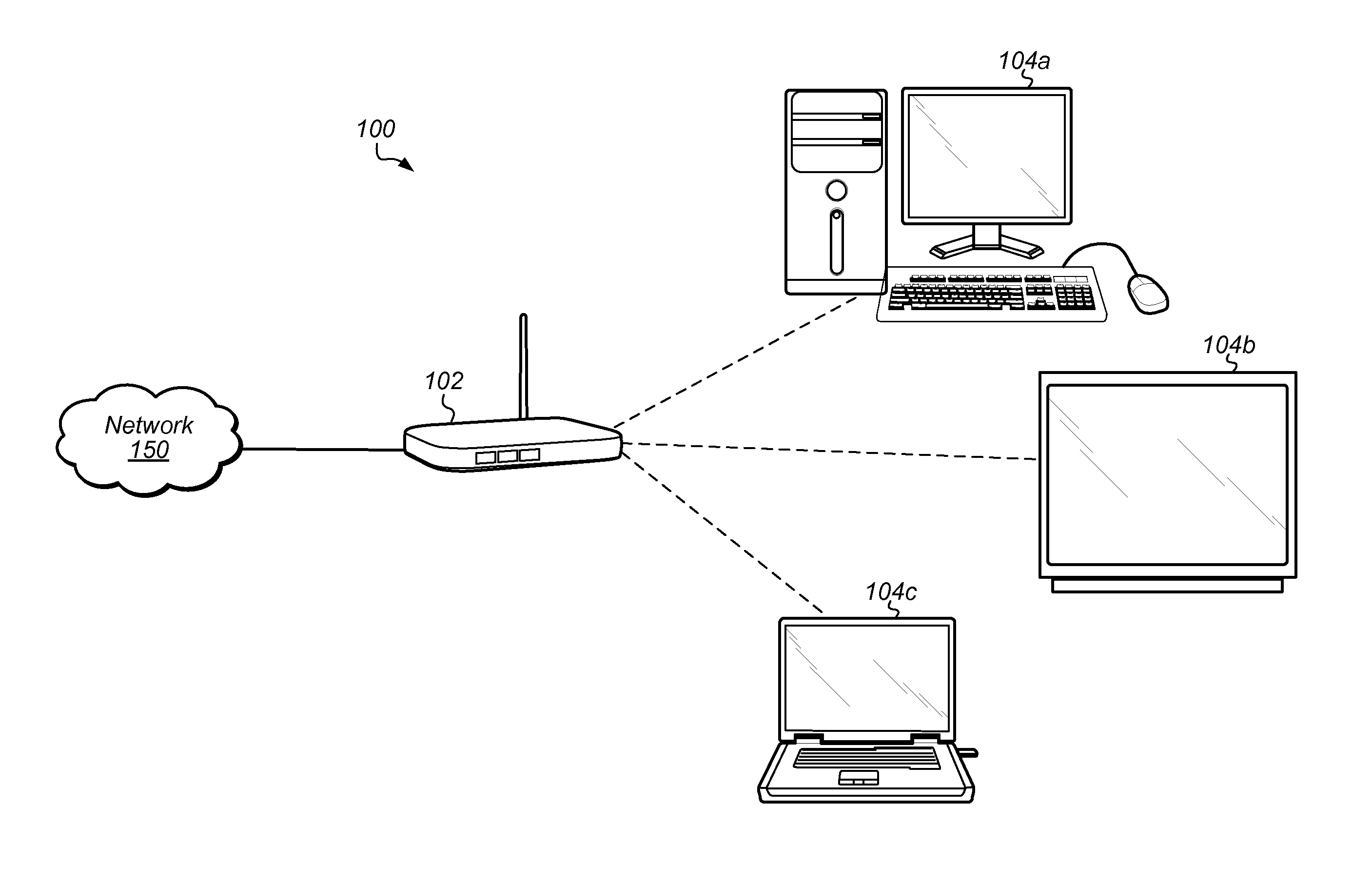

Method for communication and/or machine resource sharing among plurality of members of a community in a communication network

InactiveUS20050138181A1Reduce computing timeQuality lossResource allocationMultiple digital computer combinationsPeer-to-peerComputer science

The invention concerns a method for communication and / or machine resource sharing, in a communication network, among a plurality of members of a community, whereby each member is considered as active or passive depending on whether he is connected or not to the community. The invention is characterised in that the method comprises a step which consists in managing, through at least one central server, a graph of connections between the active members. Said management step itself comprises a step whereby, when one of the passive members (called future active member) wishes to be connected to the community, he sets up a temporary connection with the central server, so that the latter can provide connection instructions to the future active member and to active member(s) to whom the latter has to be connected. Then, the future active member sets up a permanent peer-to-peer connection with each active member indicated by the central server. The inventive technique can be said to be hybrid peer-to-peer, since it combines centralisation of the connection graph among active members, with decentralisation of exchanges between among active members.

Owner:IPDIVA

Method for manufacturing a quantum-dot element

ActiveUS20060046330A1Quality lossEvenly distributedNanoinformaticsSemiconductor/solid-state device manufacturingQuantum dotSolvent

A method for manufacturing a quantum-dot element is disclosed. The method includes the following steps. First, a deposition chamber having at least one atomizer and a substrate-supporting base is provided. The atomizer is connected to a gas inlet and a sample inlet. Afterwards, a sample solution is prepared composed of a plurality of functionalized quantum dots dispersed in a solvent. Simultaneously, a substrate is placed on the substrate-supporting base in the deposition chamber. Finally, the sample solution and a gas are transferred into the atomizer through the sample inlet and the gas inlet respectively for generating quantum-dot droplets, which subsequently deposit on the substrate in the deposition chamber. The quantum-dot element manufactured by the present invention has a uniform distribution of quantum dots that have a small size and, therefore, the quality of the quantum-dot element can be substantially improved.

Owner:IND TECH RES INST

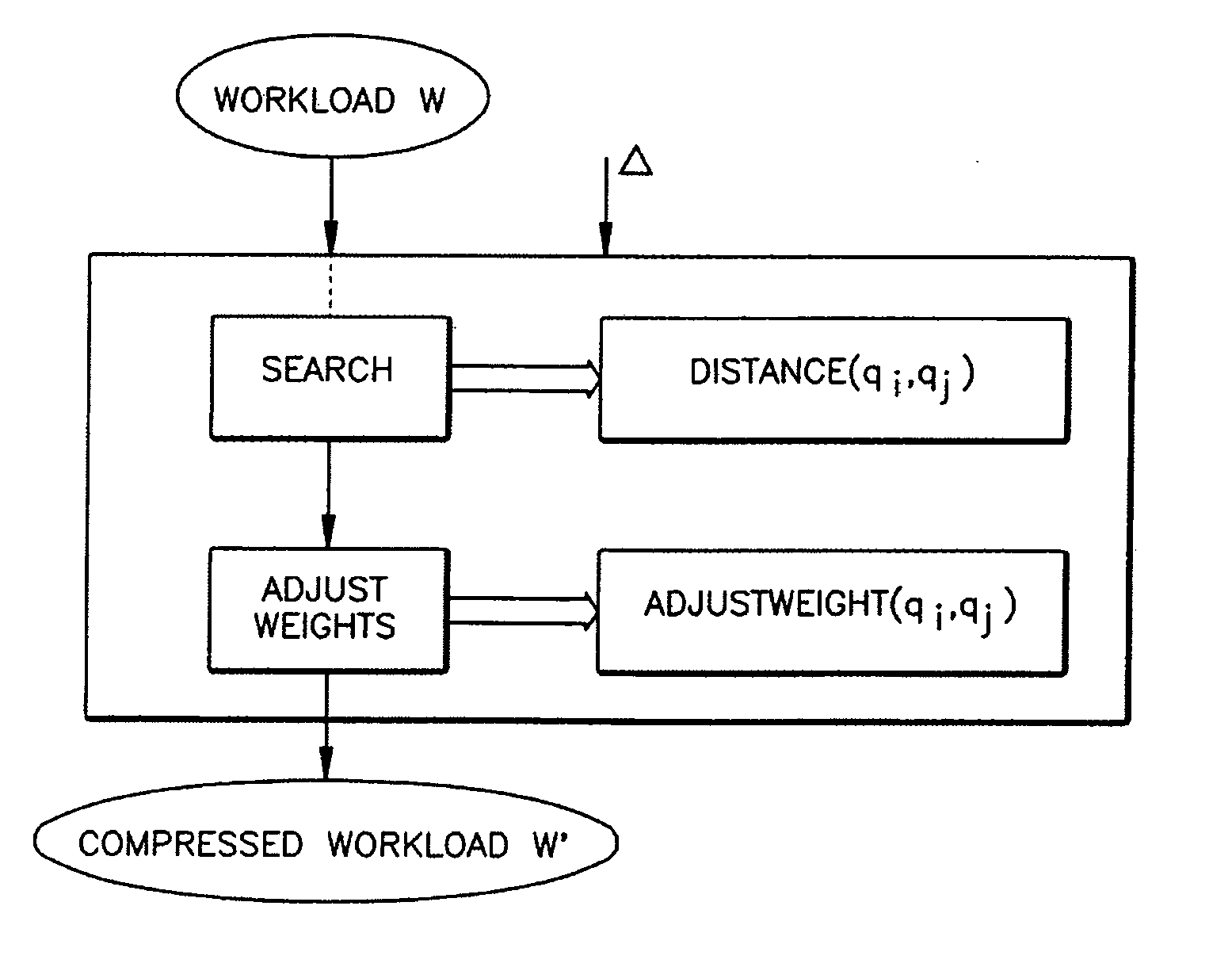

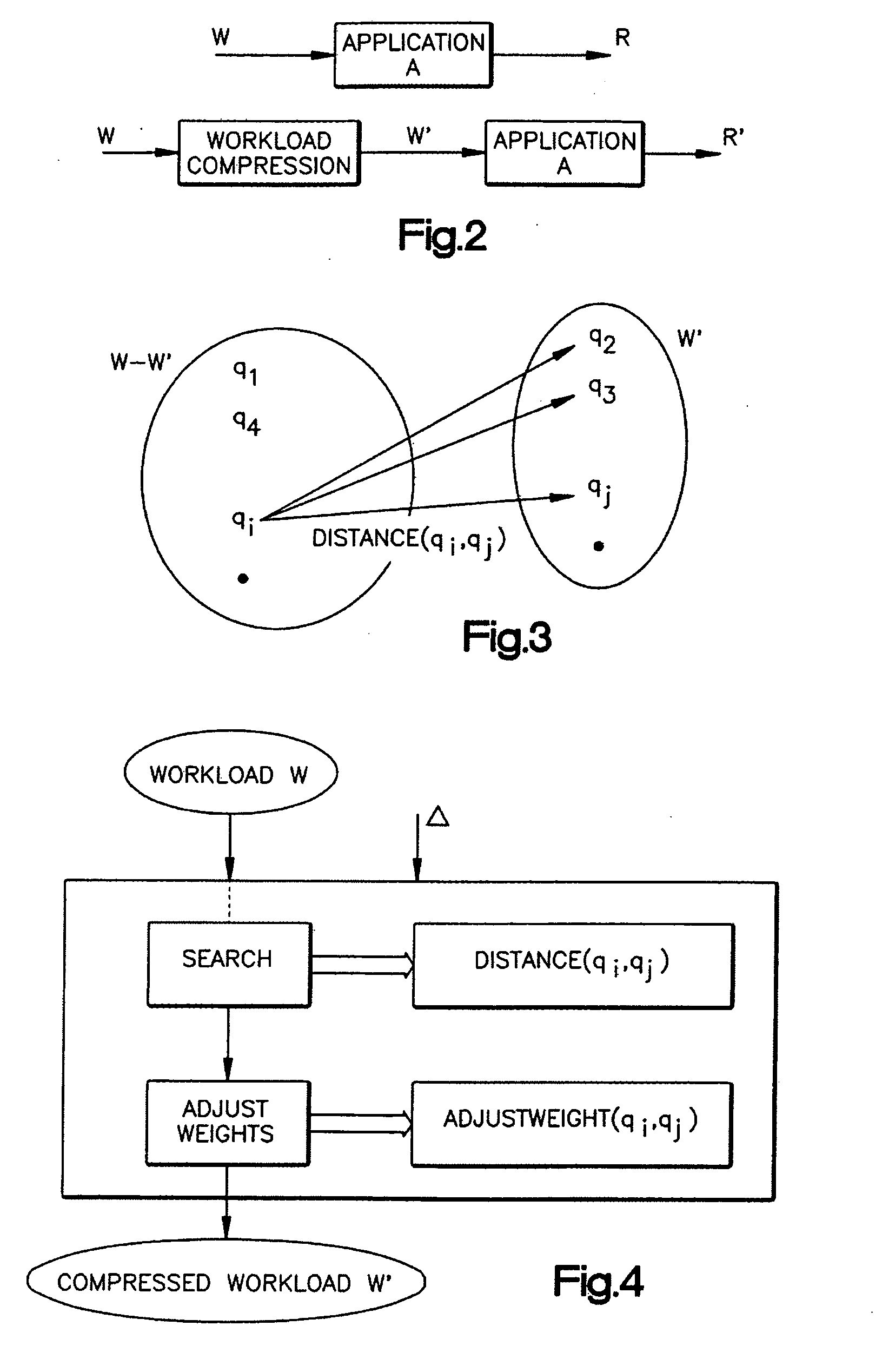

Compressing database workloads

InactiveUS20050102305A1Quality lossData processing applicationsSpecial data processing applicationsRelational databaseApplication specific

Relational database applications such as index selection, histogram tuning, approximate query processing, and statistics selection have recognized the importance of leveraging workloads. Often these applications are presented with large workloads, i.e., a set of SQL DML statements, as input. A key factor affecting the scalability of such applications is the size of the workload. The invention concerns workload compression which helps improve the scalability of such applications. The exemplary embodiment is broadly applicable to a variety of workload-driven applications, while allowing for incorporation of application specific knowledge. The process is described in detail in the context of two workload-driven applications: index selection and approximate query processing.

Owner:MICROSOFT TECH LICENSING LLC

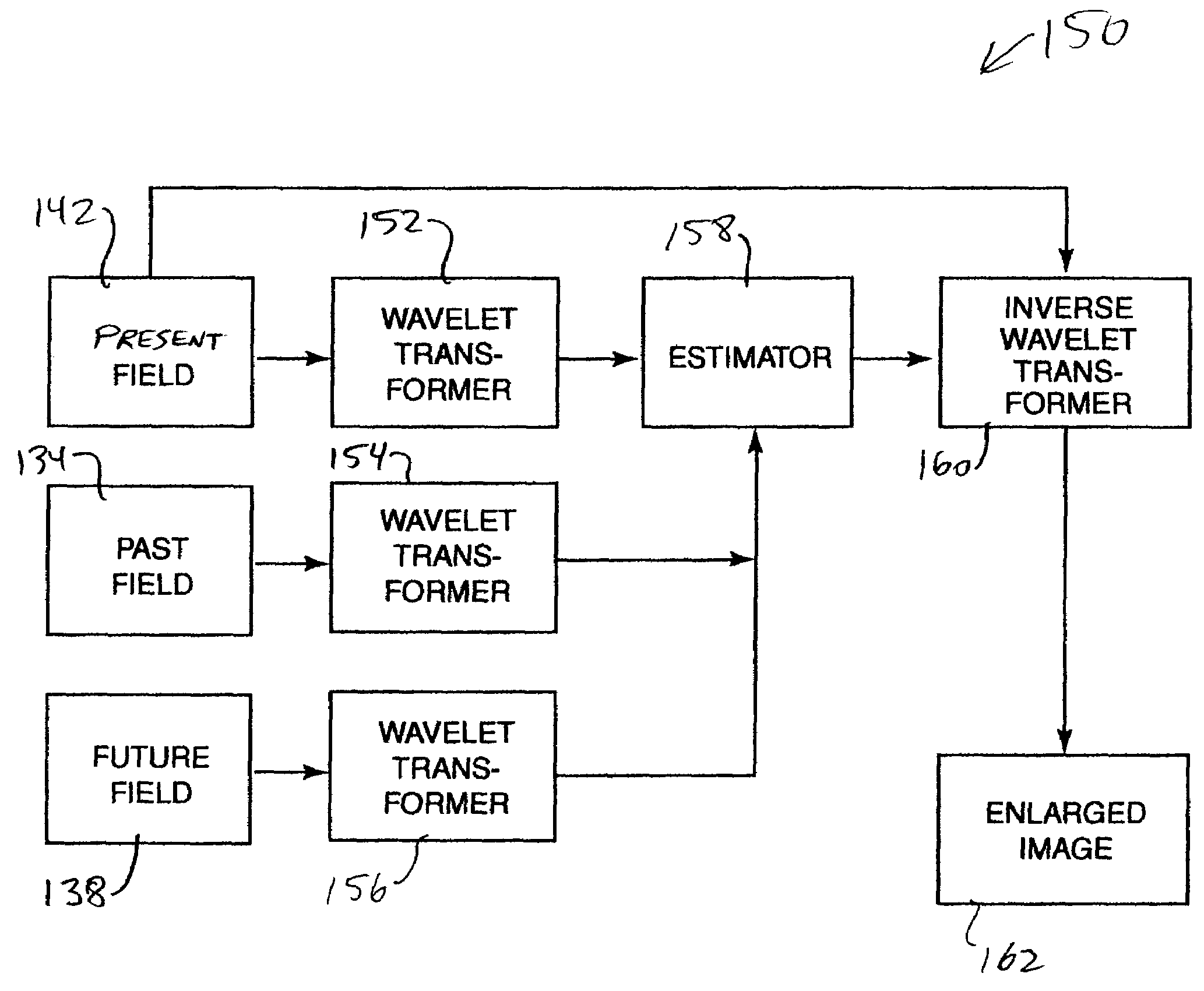

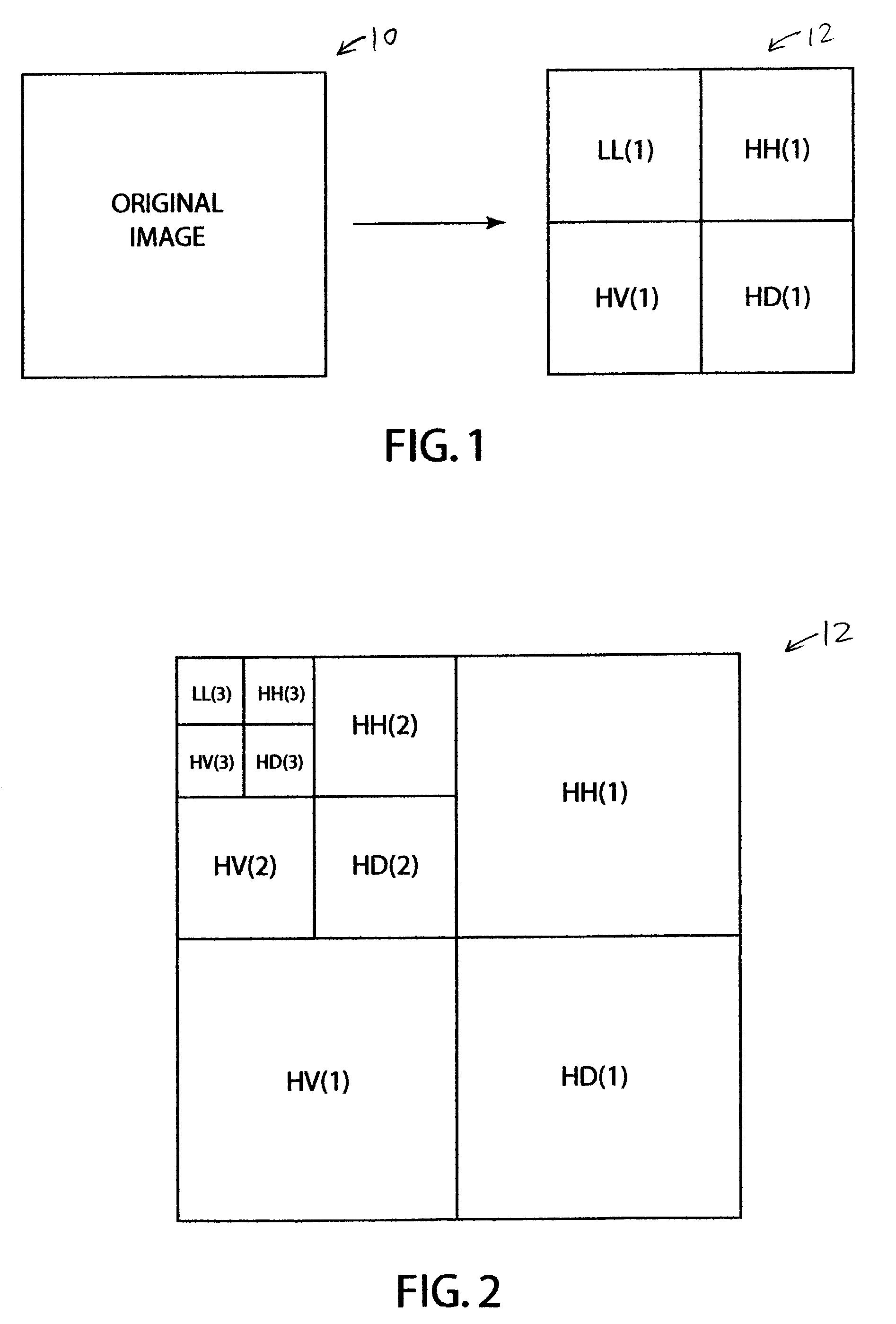

Image enhancement and data loss recovery using wavelet transforms

InactiveUS7085436B2Enhanced and high imageOptimization orderImage enhancementGeometric image transformationOriginal dataVideo sequence

Methods and systems for image and video enhancement and data-loss recovery using wavelet transforms are disclosed. A wavelet transformed image is defined as multiple sections, where one section is the original image, and coefficients are estimated for each other section using information obtained from that section. An inverse wavelet transform on the wavelet transformed image obtains an enlarged image. For obtaining a high resolution video frame, one section is the original video frame, and coefficients are estimated for each other section using information from a lower level wavelet transform of a corresponding section of a past or future frame of the video sequence. For recovery of data lost from transmitted original data, the locality of the lost data is determined in lower and higher levels of a wavelet transform tree, and information at the locality in the lower and higher levels is used to estimate the lost data.

Owner:VISIOPRIME

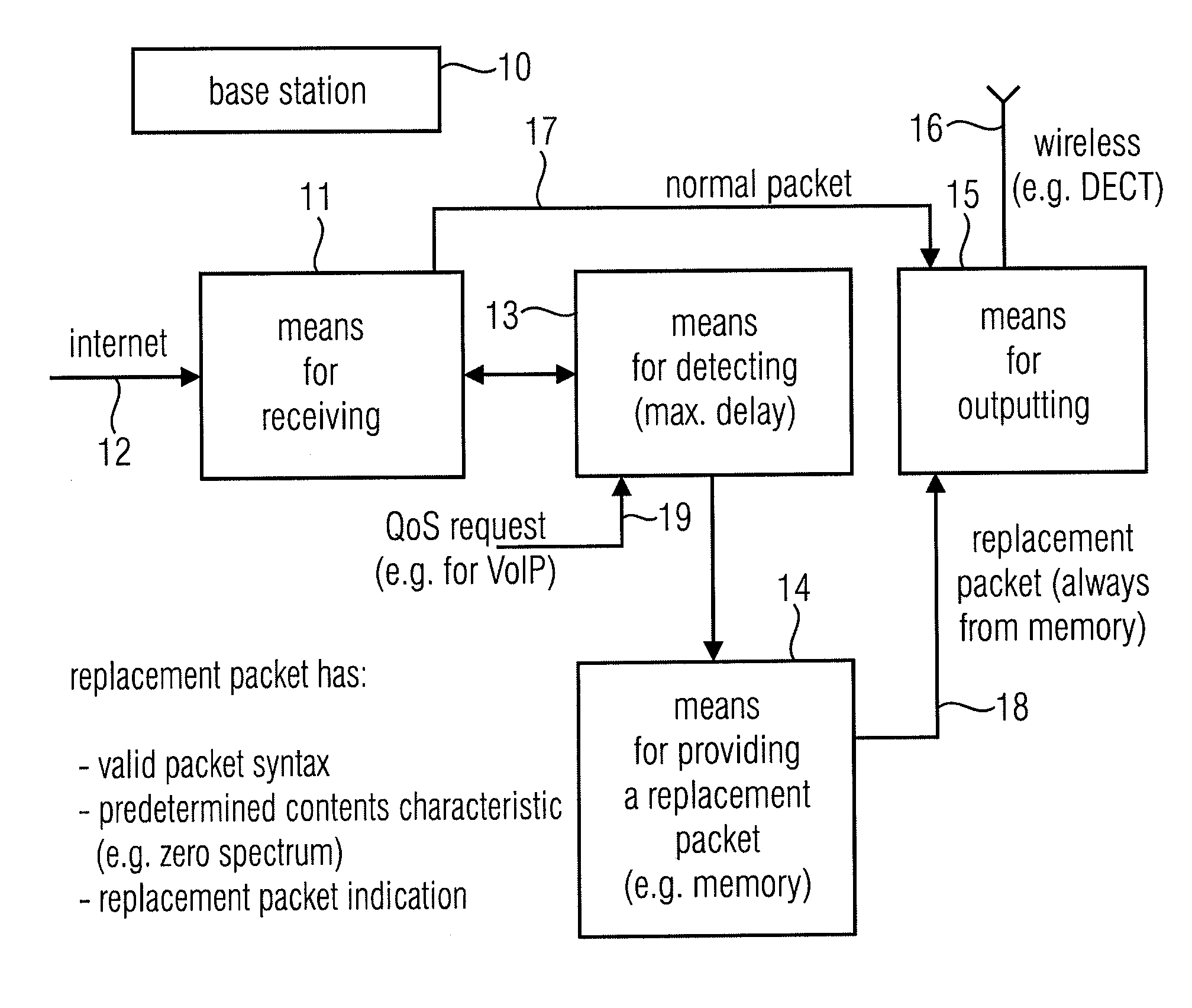

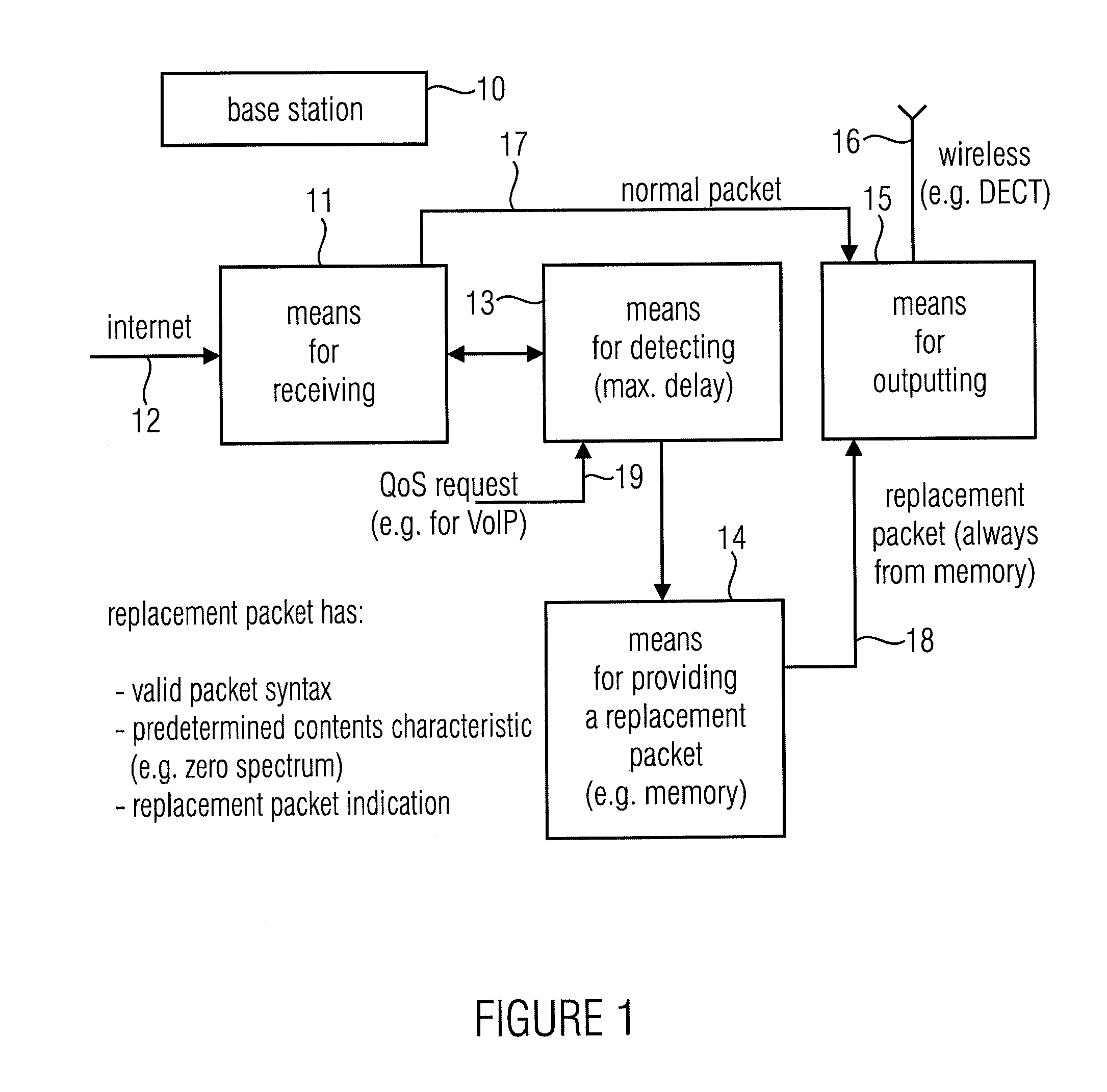

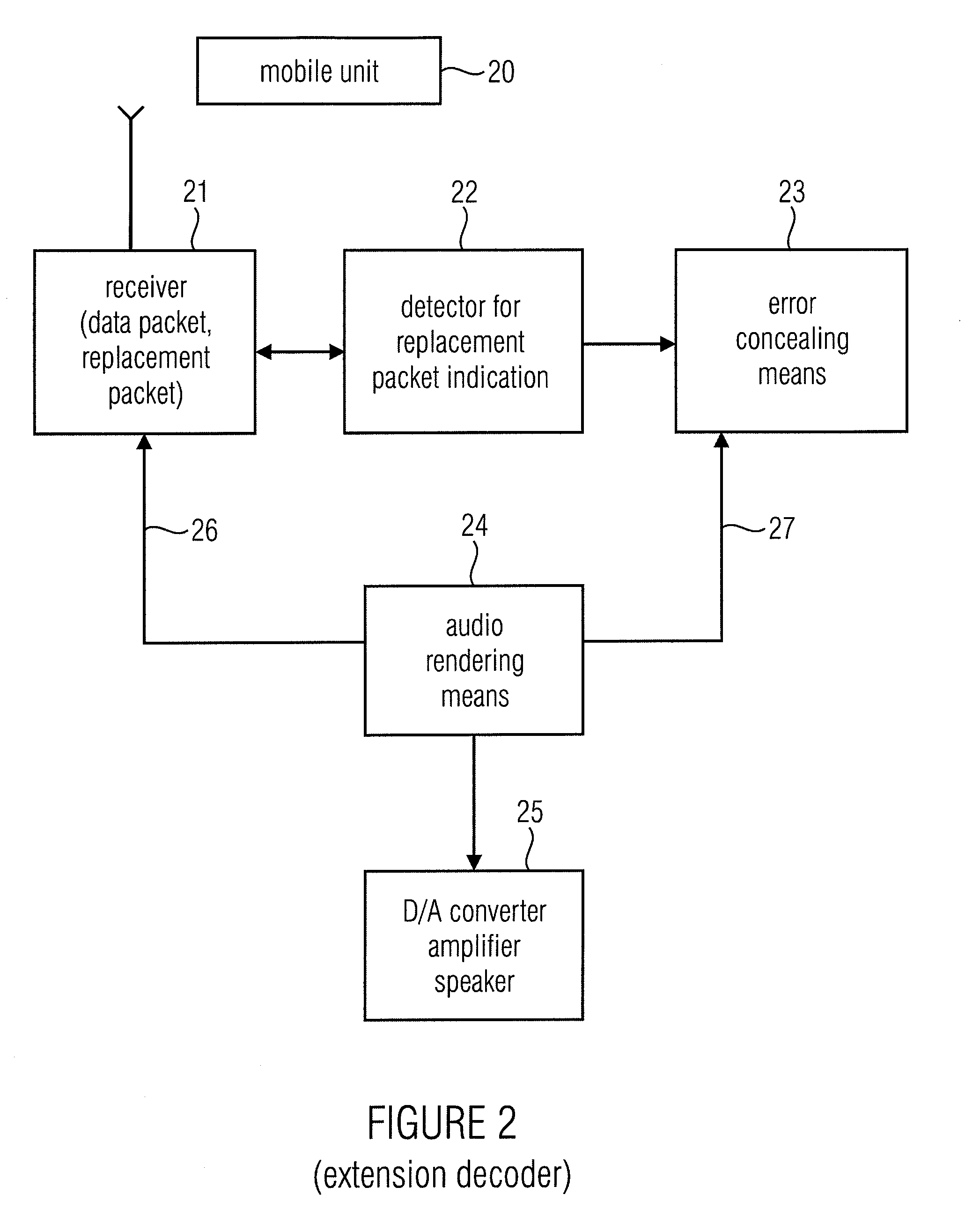

Apparatus and Method for Transmitting a Sequence of Data Packets and Decoder and Apparatus for Decoding a Sequence of Data Packets

ActiveUS20100284281A1Quality lossEasy to decodeTransmission systemsFrequency-division multiplex detailsComputer hardwareError concealment

In the context of packet-oriented data transmission via a network, an apparatus for transmitting a sequence of data packets checks whether a packet is missing or faulty. In this case, a replacement packet is provided which is a valid packet with regard to a packet syntax which, however, has a predetermined contents characteristic. On the decoder side, a basic decoder recognizes the packet as a valid packet and decodes same, whereas an extension decoder can enable an error concealing measure on the basis of an indication in the replacement packet to the fact that this is a replacement packet, in order to provide a higher-quality audio reproduction.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

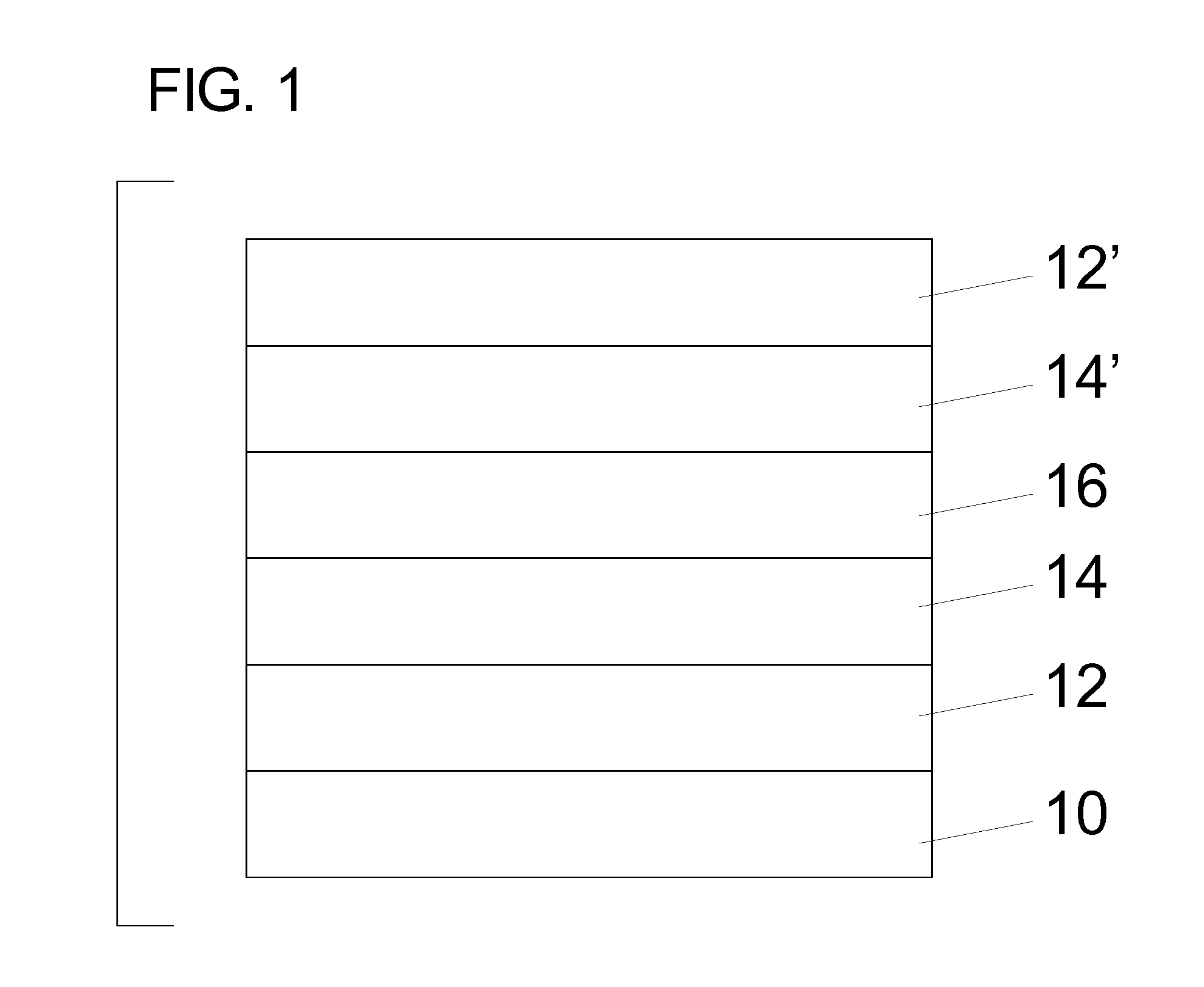

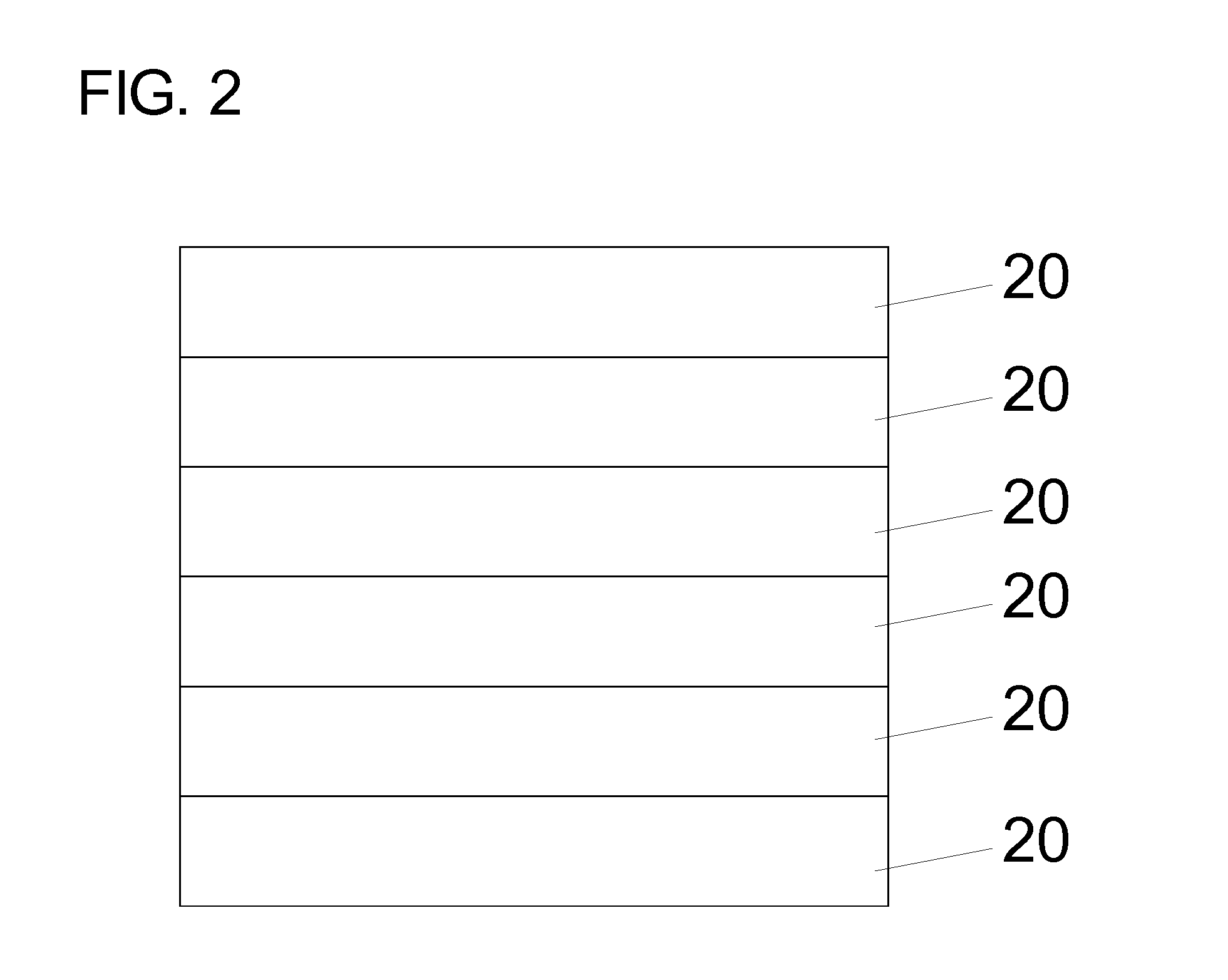

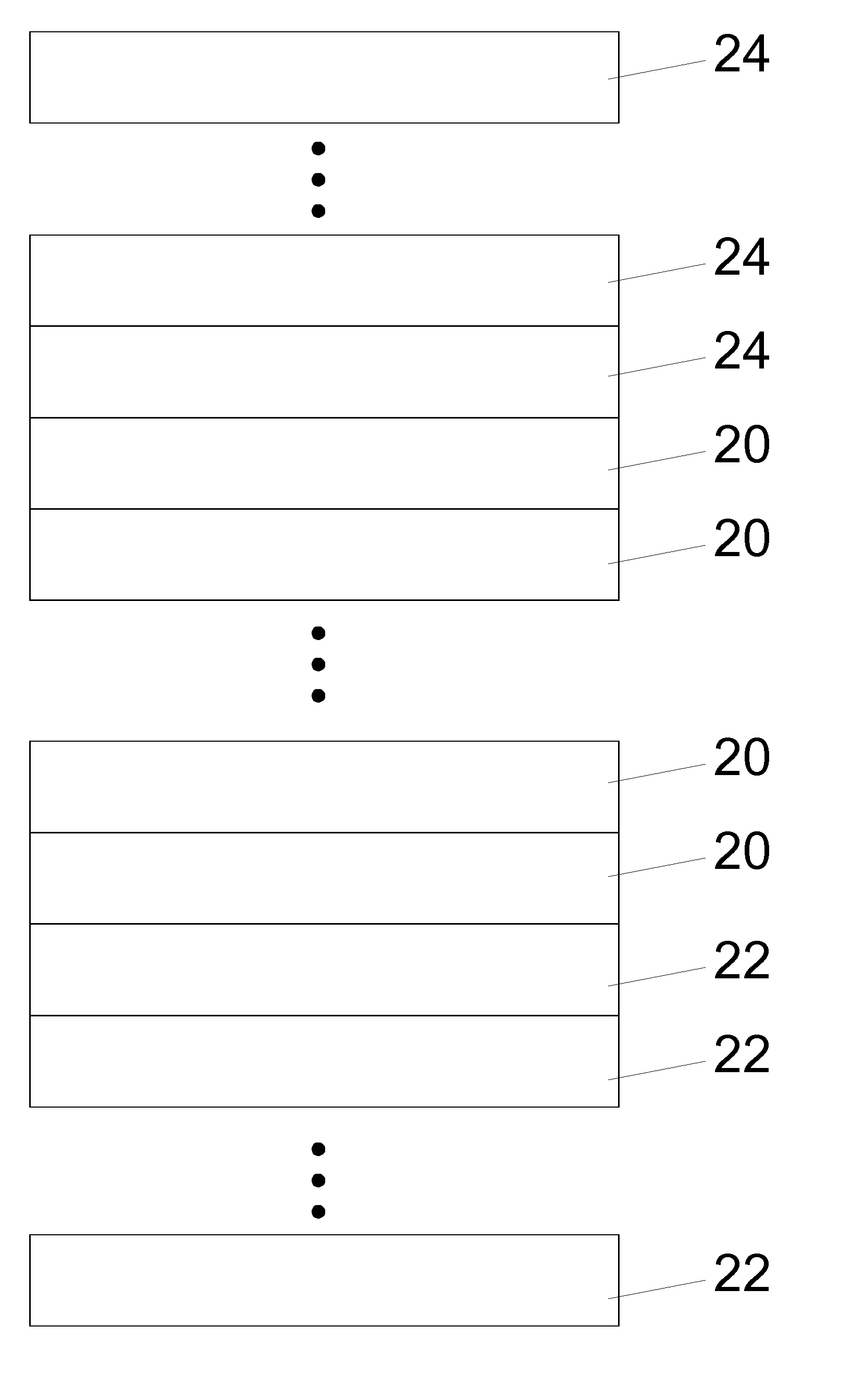

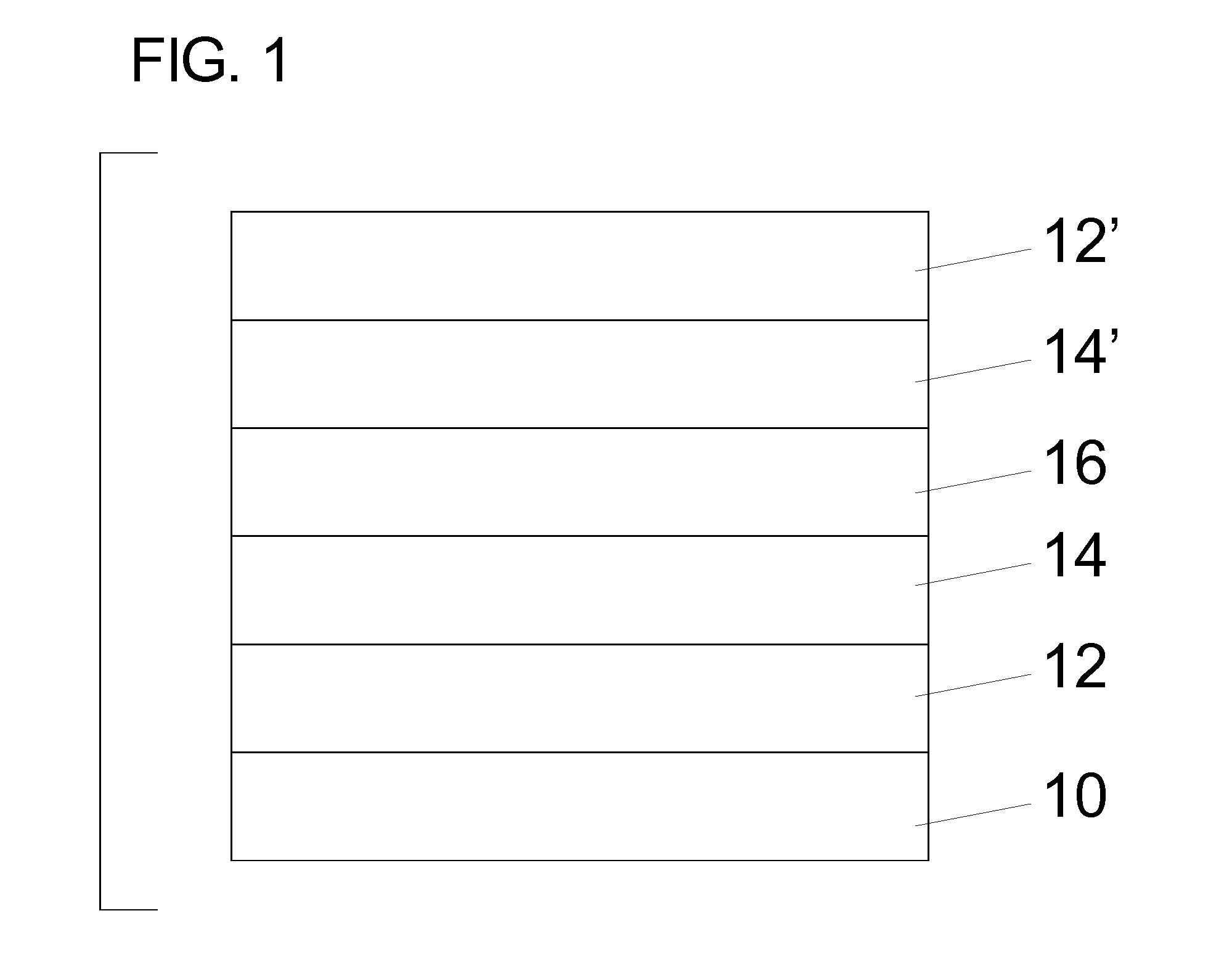

Long Wavelength Infrared Superlattice

InactiveUS20130043458A1Quality lossOvercome lossSemiconductor/solid-state device manufacturingNanoopticsGallium antimonideIndium arsenide

An embodiment of the present invention improves the fabrication and operational characteristics of a type-II superlattice material. Layers of indium arsenide and gallium antimonide comprise the bulk of the superlattice structure. One or more layers of indium antimonide are added to unit cells of the superlattice to provide a further degree of freedom in the design for adjusting the effective bandgap energy of the superlattice. One or more layers of gallium arsenide antimonide are added to unit cells of the superlattice to counterbalance the crystal lattice strain forces introduced by the aforementioned indium antimonide layers.

Owner:SVT ASSOCS

Long Wavelength Infrared Superlattice

InactiveUS20130043459A1Extend the cutoff wavelengthQuality lossSemiconductor/solid-state device manufacturingNanoopticsGallium antimonideIndium arsenide

An embodiment of the present invention improves the fabrication and operational characteristics of a type-II superlattice material. Layers of indium arsenide and gallium antimonide comprise the bulk of the superlattice structure. One or more layers of indium antimonide are added to unit cells of the superlattice to provide a further degree of freedom in the design for adjusting the effective bandgap energy of the superlattice. One or more layers of gallium arsenide antimonide are added to unit cells of the superlattice to counterbalance the crystal lattice strain forces introduced by the aforementioned indium antimonide layers.

Owner:SVT ASSOCS

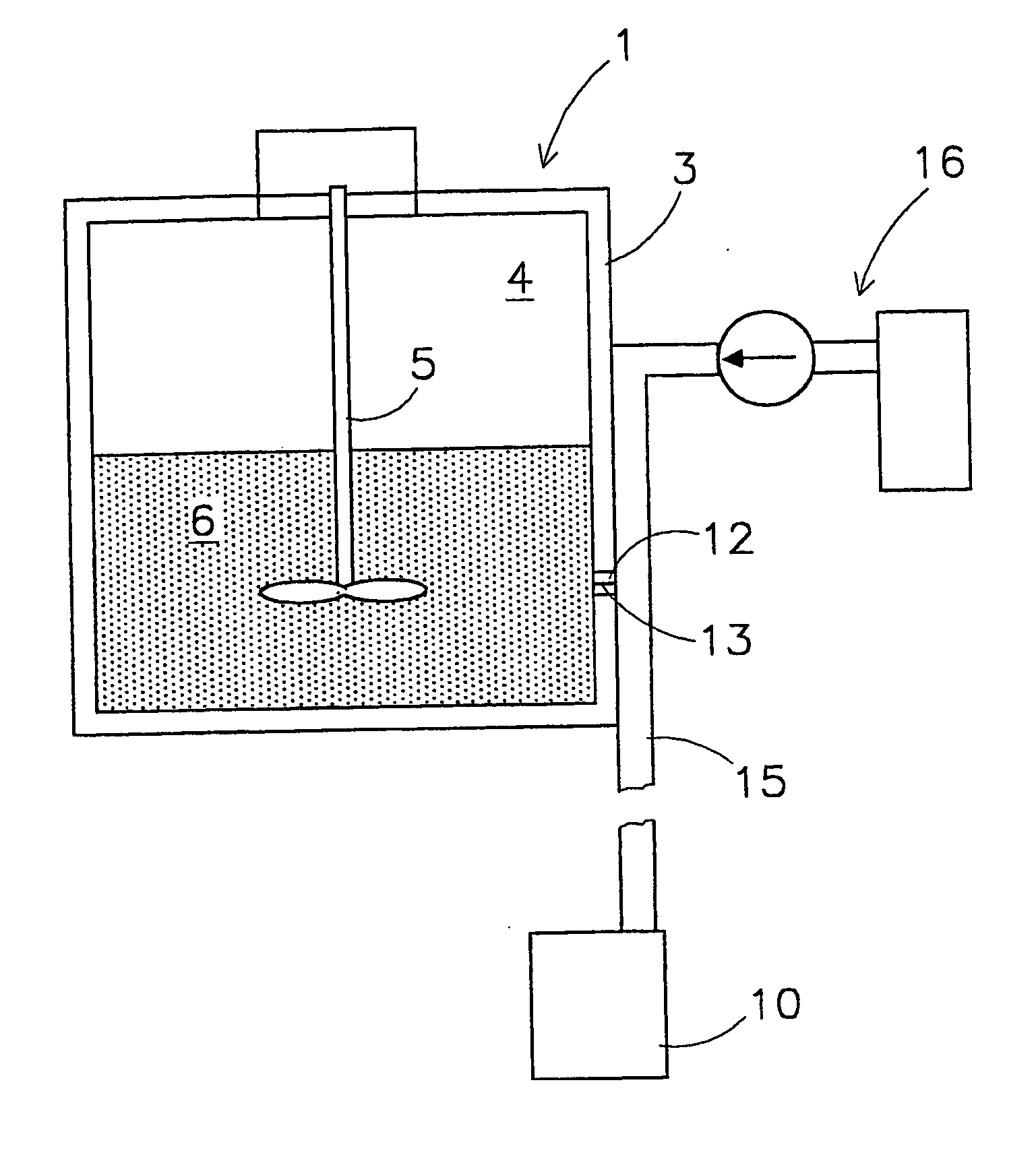

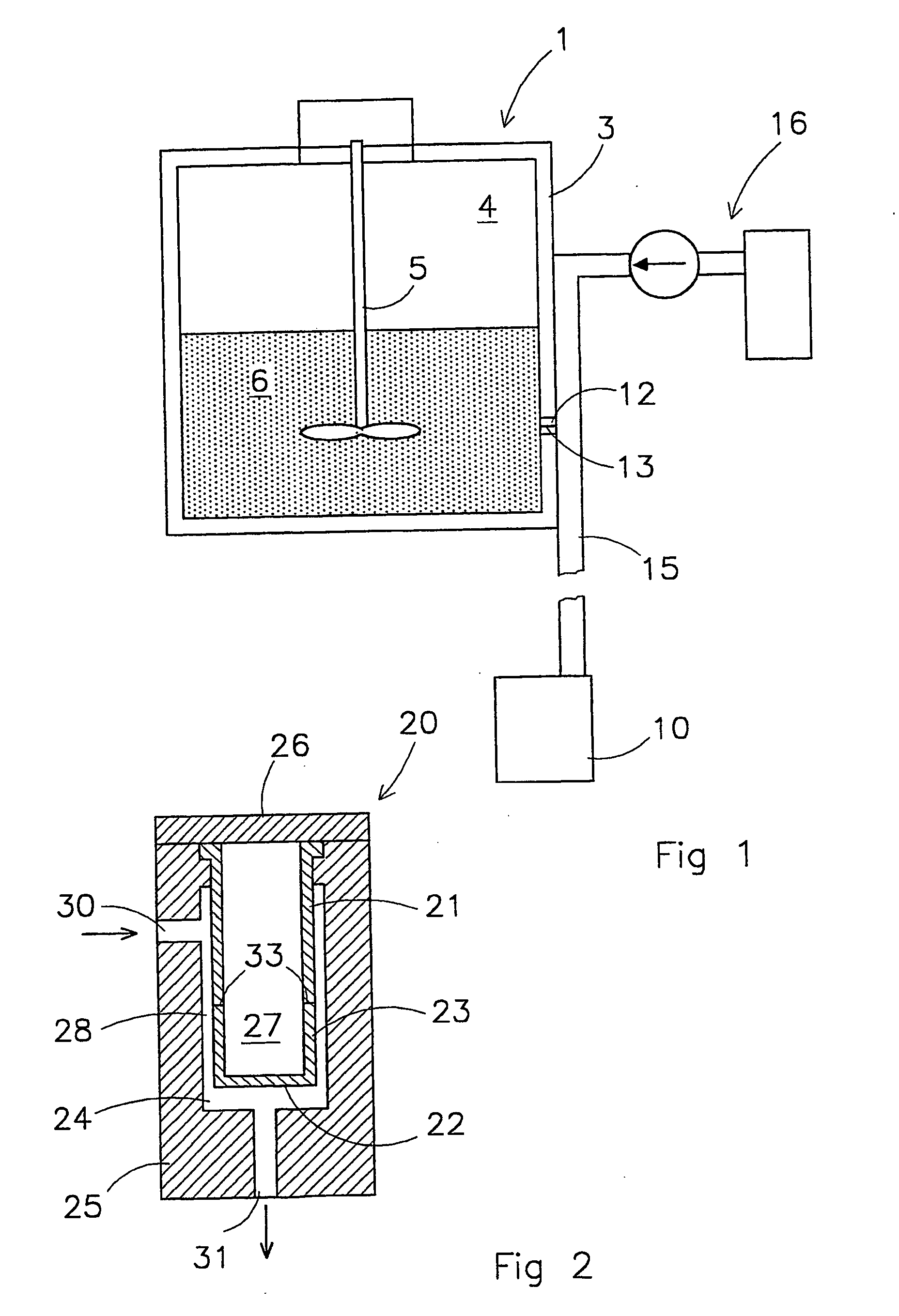

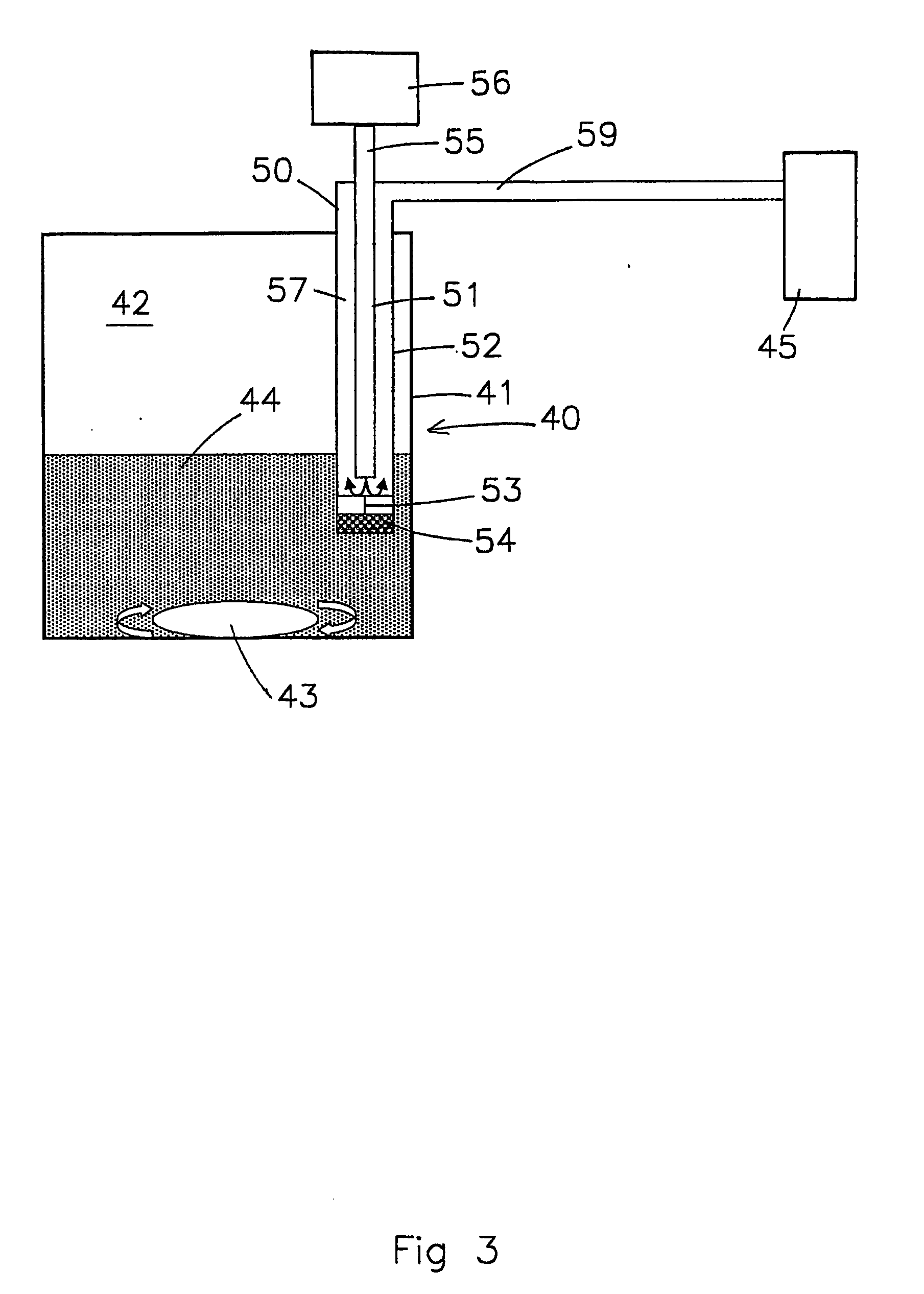

System for chemical experiments

InactiveUS20050169815A1Quality lossSimple designSequential/parallel process reactionsLaboratory glasswaresChemical reactionAnalytical chemistry

A system for performing a chemical experiment comprises a reactor vessel having a wall defining a reaction chamber for receiving one or more fluids performing a chemical reaction. An analysis apparatus is located remote from said reactor vessel for analysing samples of said one or more fluids removed from said reaction chamber. Sampling means and transfer means are provided which are adapted for removing samples of said one or more fluids from said reaction chamber and transferring said samples to said analysis apparatus. The sampling and transfer means comprise a sample removal passage in communication with said reaction chamber and a sample transfer passage connected to said sample removal passage and extending to said analysis apparatus. The sample removal passage establishes an open communication between said reaction chamber and said sample transfer passage and the sample removal passage contains a flow restrictor. A pressure drop over said flow restrictor causes the removal of said samples from the reaction chamber.

Owner:AVANTIUM INT

Encoder and method

ActiveUS20160156367A1Quality lossEfficient codingCode conversionDigital video signal modificationData informationData treatment

An encoder includes data processing hardware operable to: process input data into a plurality of blocks / packets; apply a plurality of transformations to content of the blocks / packets to generate corresponding transformed data; check a quality of representation of the transformed data prior to application of the transformations to determine whether or not the quality of representation of the transformed data satisfies quality criteria; if the quality of representation does not satisfy the quality criteria, to divide and / or combine the one or more individual blocks or packets further and repeating the transformation step; and if the quality of representation of the transformed data satisfies the one or more quality criteria, to select coding methods and encode data representative of the input data to be encoded to provide encoded output data; and communicate in the encoded data information describing the plurality of transformations or combinations of transformations employed when coding the blocks / packets.

Owner:GUROLOGIC MICROSYST OY

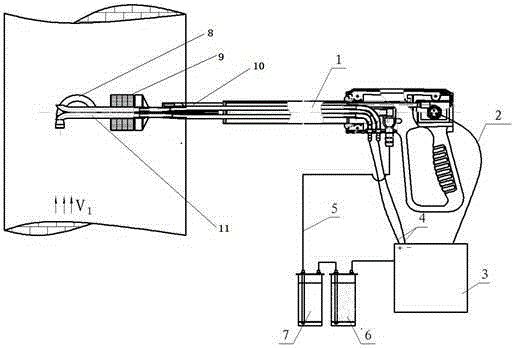

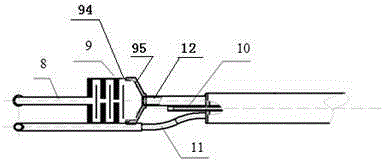

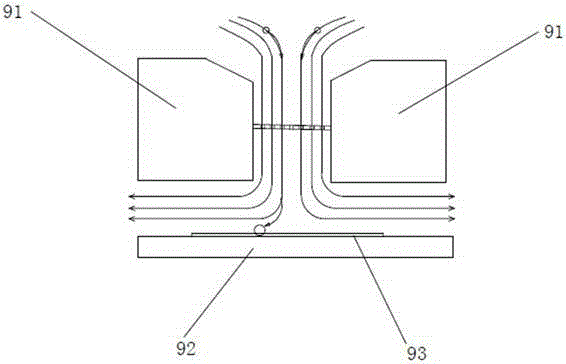

Low-concentration smoke dust sampling device and method

InactiveCN105181402AAvoid depositionAvoid efficiencyWithdrawing sample devicesHydrologyThermocouple device

The invention discloses a low-concentration smoke dust sampling device. The low-concentration smoke dust sampling device comprises a main machine, a sampling gun, a condenser and a drier. The sampling gun comprises a handle, a sampling tube, a pitot tube and a thermocouple, wherein the sampling tube, the pitot tube and the thermocouple are connected with the handle. The gas outlet end of the sampling tube is sequentially connected with the condenser, the drier and the main machine. The thermocouple and the pitot tube are connected with the main machine. A multi-stage sampling head is installed at the head of the sampling tube. A sampling nozzle is arranged at the front end of the multi-stage sampling head. The multi-stage sampling head comprises a shell and three dust collection units arranged in the shell. The dust collection units are sequentially arranged in the flowing direction of smoke. The smoke entering the sampling tube is sequentially in contact with the dust collection units, smoke dust is adsorbed by the dust collection units, and the smoke dust collecting efficiency of the device is improved. The invention further discloses a low-concentration smoke dust sampling method in which the device is adopted. By means of the low-concentration smoke dust sampling device and method, the concentration of the smoke dust is accurately measured under the low-concentration and high-humidity working condition.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

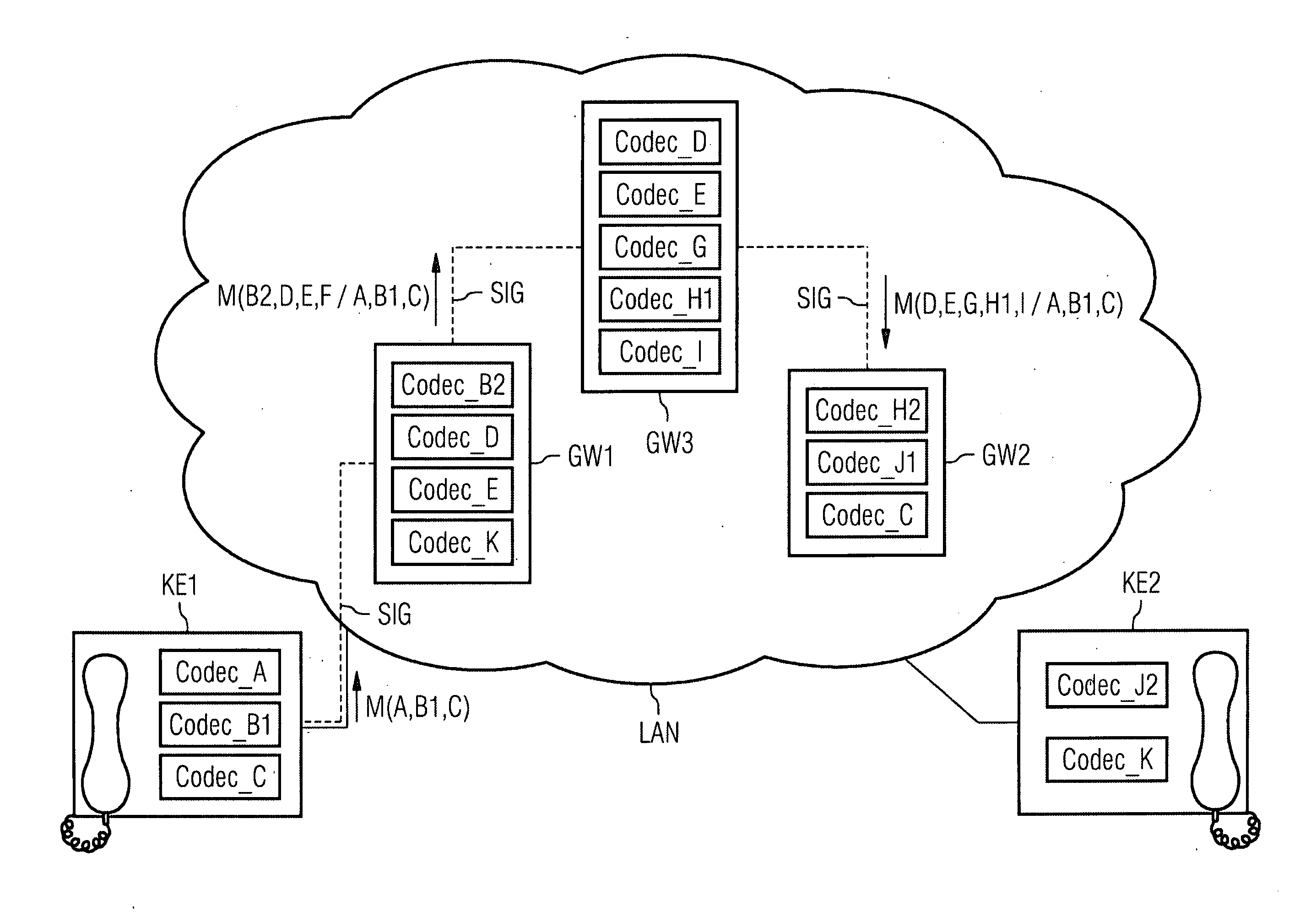

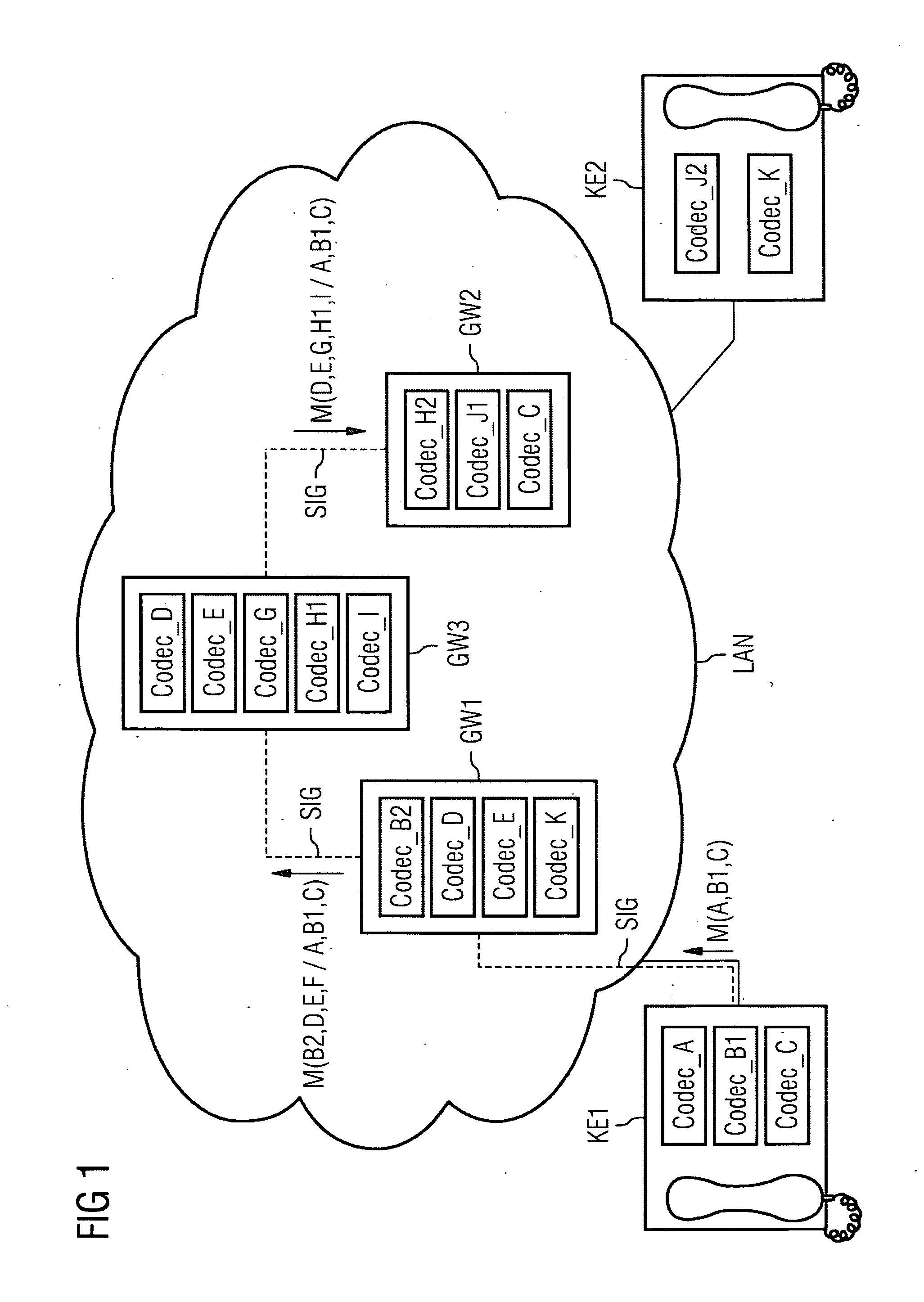

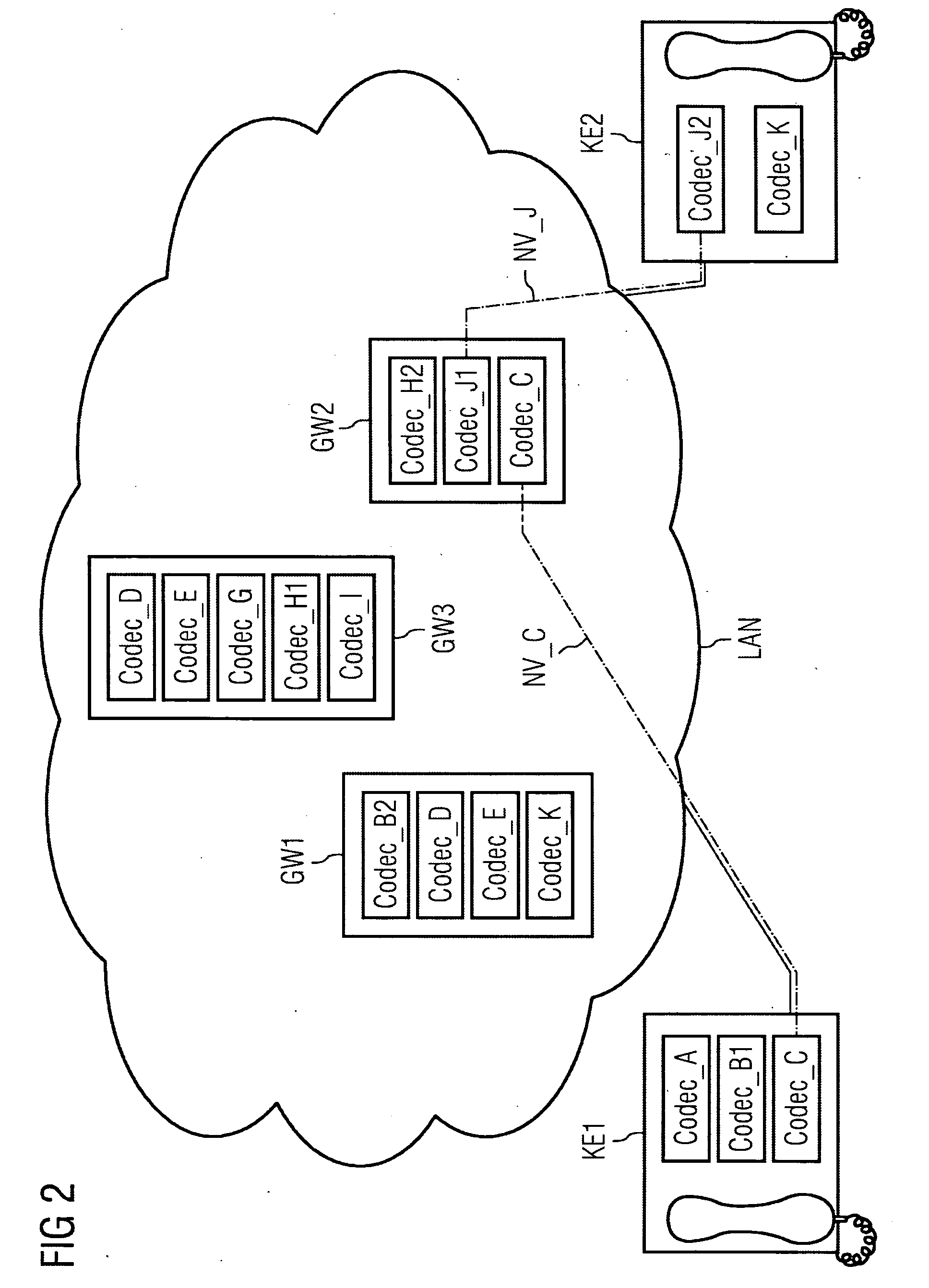

Method, Server Device and Converting Device for Setting Up a Payload-Data Connection

ActiveUS20090303983A1Reduce quality lossLoss of qualityMultiplex system selection arrangementsInterconnection arrangementsData connectionComputer compatibility

There is described a transmission of user data from a source communications device provided with a first encoder for encoding users data to a target communications device provided with a first decoder for decoding said user data via a communication network which is provided with several converting devices comprising additional encoders and additional decoders for carrying out a verification of the converting devices. Via the verification it is determined, whether the first encoder is compatible with the decoder of a given converting device and, whether the first decoder is compatible with the encoder of said converting device. One of the converting devices for which the compatibility is ascertained by the verification is selected for transmitting user data. During transmission of the user data, said user data encoded with the aid of the first encoder is decoded with the aid of the compatible decoder of the converting device and the user data decodable with the aid of the first decoder is encoded with the aid of the compatible encoder of the selected converting device.

Owner:UNIFY GMBH & CO KG

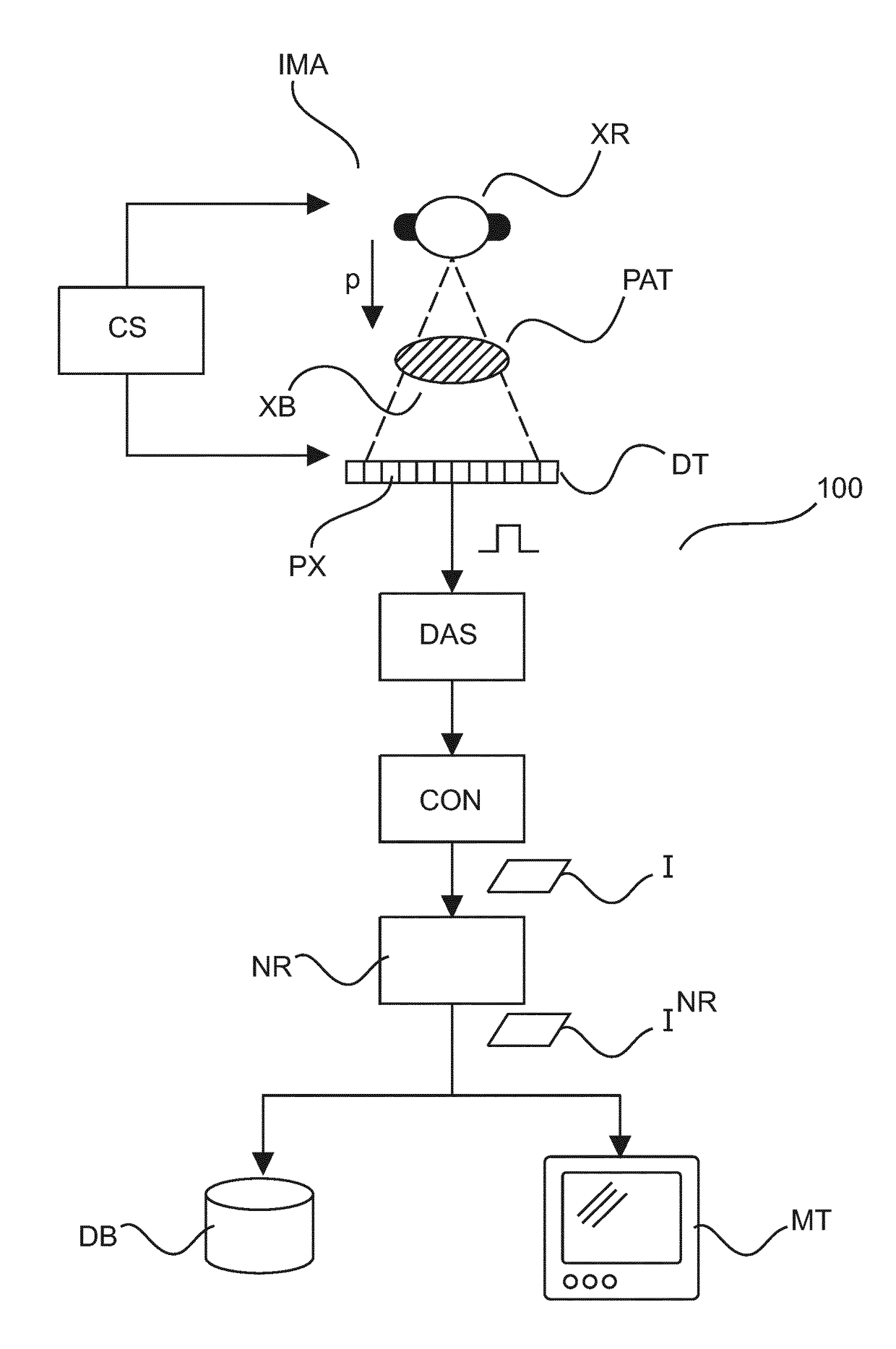

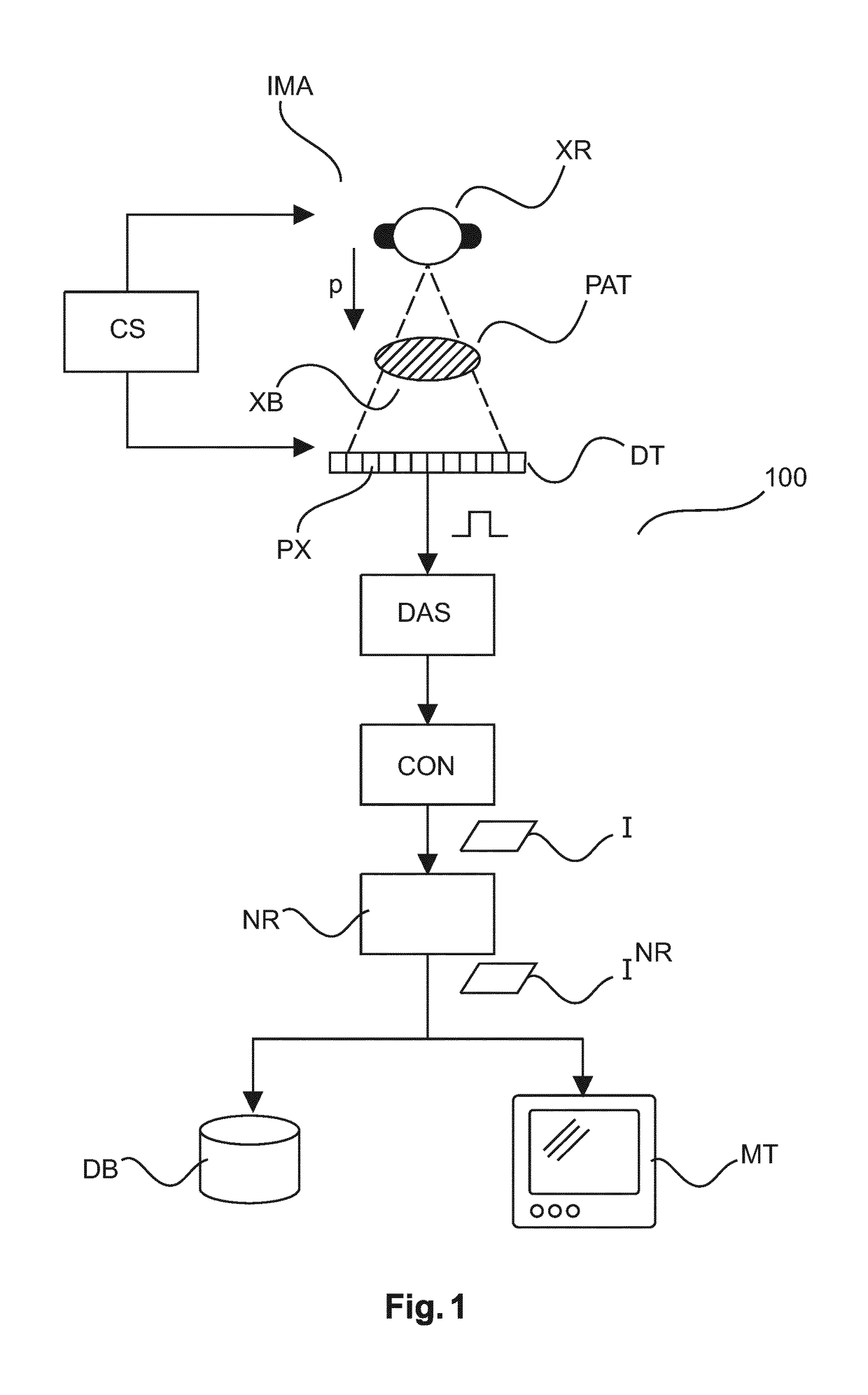

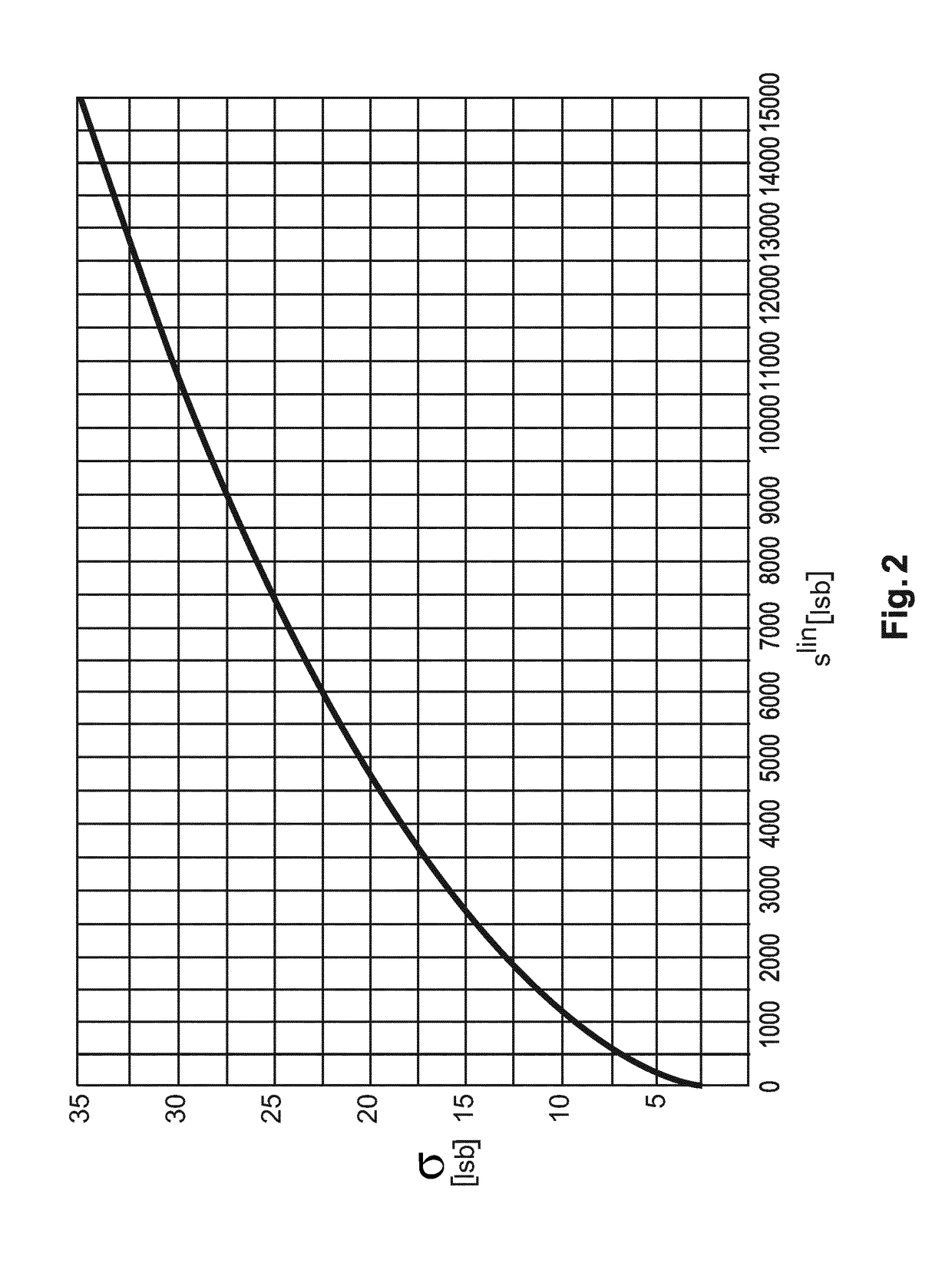

Simulating dose increase by noise model based multi scale noise reduction

ActiveUS20170345132A1Quality lossAmount of control be reduceImage enhancementReconstruction from projectionNoise reductionSpatial frequency

An image processing method and related apparatus. An image is decomposed into spatial frequency components images. The spatial frequency component images are normalized relative to specific noise models, remapped by a noise reduction function and are then combined to obtain a noise reduced version of the image.

Owner:KONINKLJIJKE PHILIPS NV

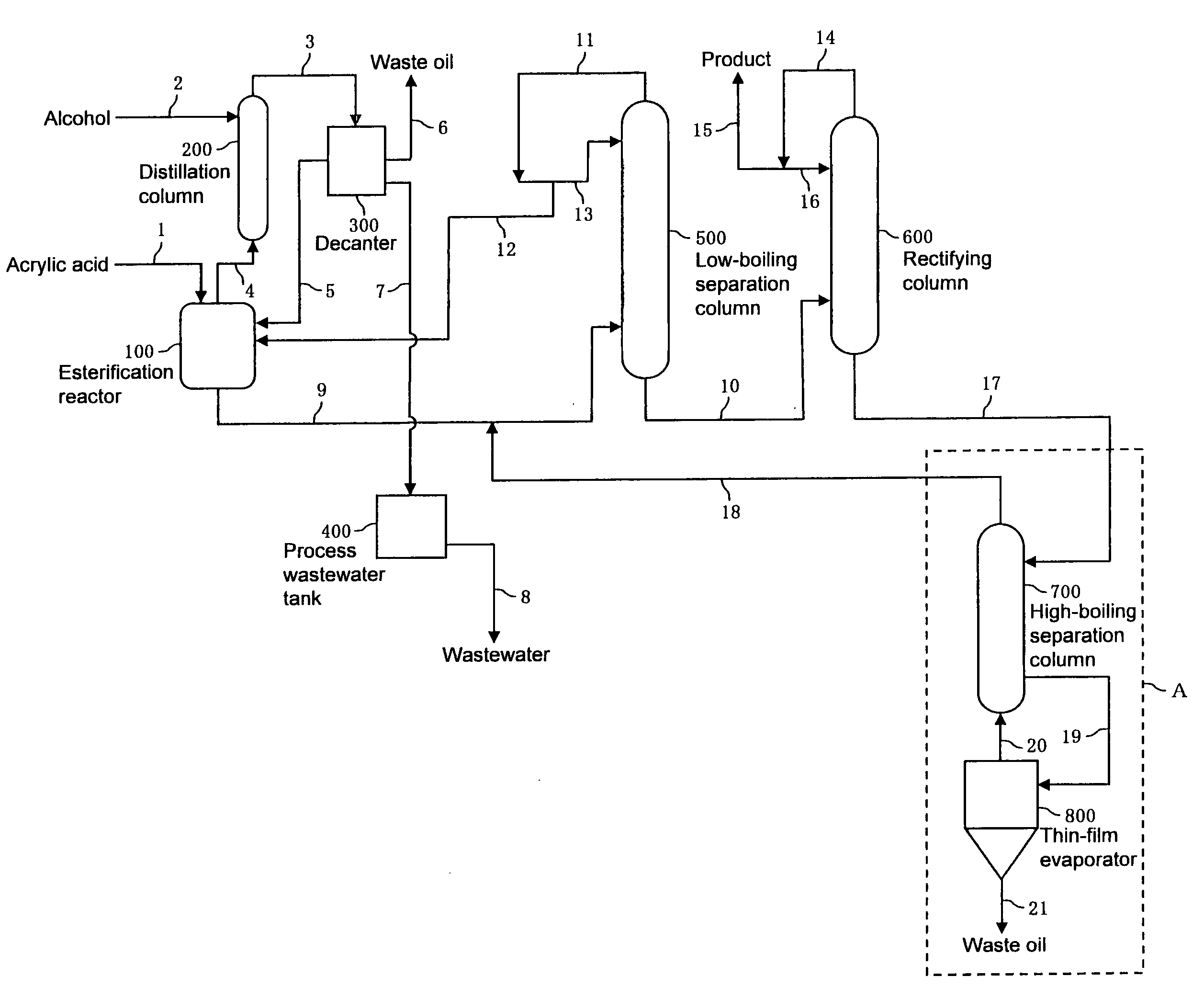

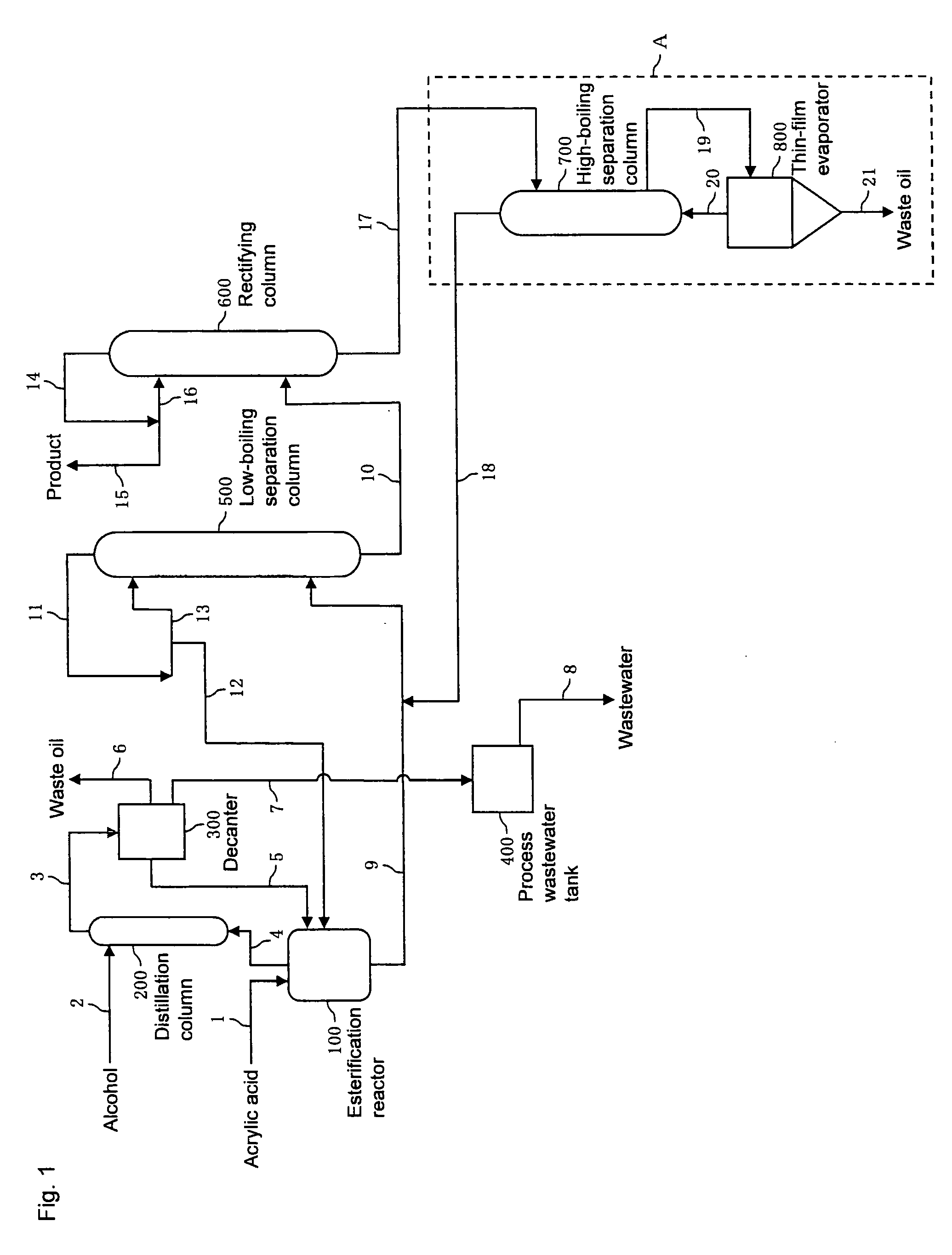

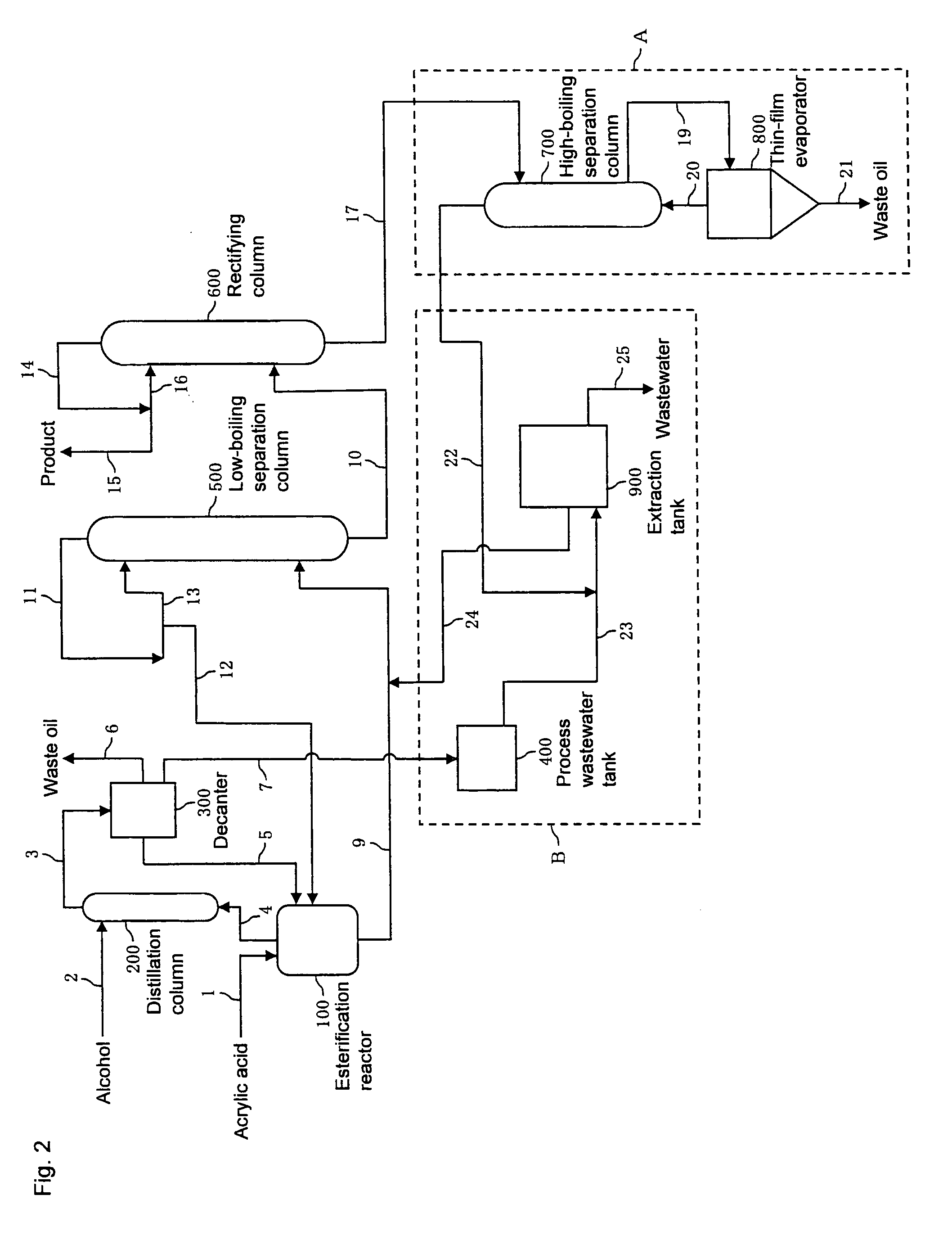

Process for producing acrylic ester

ActiveUS20080015384A1Increase acceptanceIncrease productionOrganic compound preparationCarboxylic acid esters preparationAlcoholBoiling point

A process for producing an acrylic ester with excellent economic efficiency, which can eliminate the conventional problems to maintain the stable quality and the low unit consumption of raw materials, in the process for producing an acrylic ester using acrylic acid containing high-boiling acid components influencing the loss in quality and the unit consumption of raw materials, and an aliphatic or alicyclic alcohol having from 5 to 8 carbon atoms, as raw materials, and using a strongly acidic cation exchange resin as a catalyst. In such a process for producing an acrylic ester, a crude acrylic ester withdrawn from the bottom of a low-boiling separation column is supplied to a rectifying column, a rectified acrylic ester is taken out from the top of the rectifying column, while a high-boiling substance containing an acrylic ester, which is withdrawn from the bottom of the rectifying column, is supplied to a high-boiling separation column and / or a thin-film evaporator to separate it into an acrylic ester component and a high-boiling substance, and the separated acrylic ester component is taken out as a distillate and supplied to the low-boiling separation column for its recovery.

Owner:NIPPON SHOKUBAI CO LTD

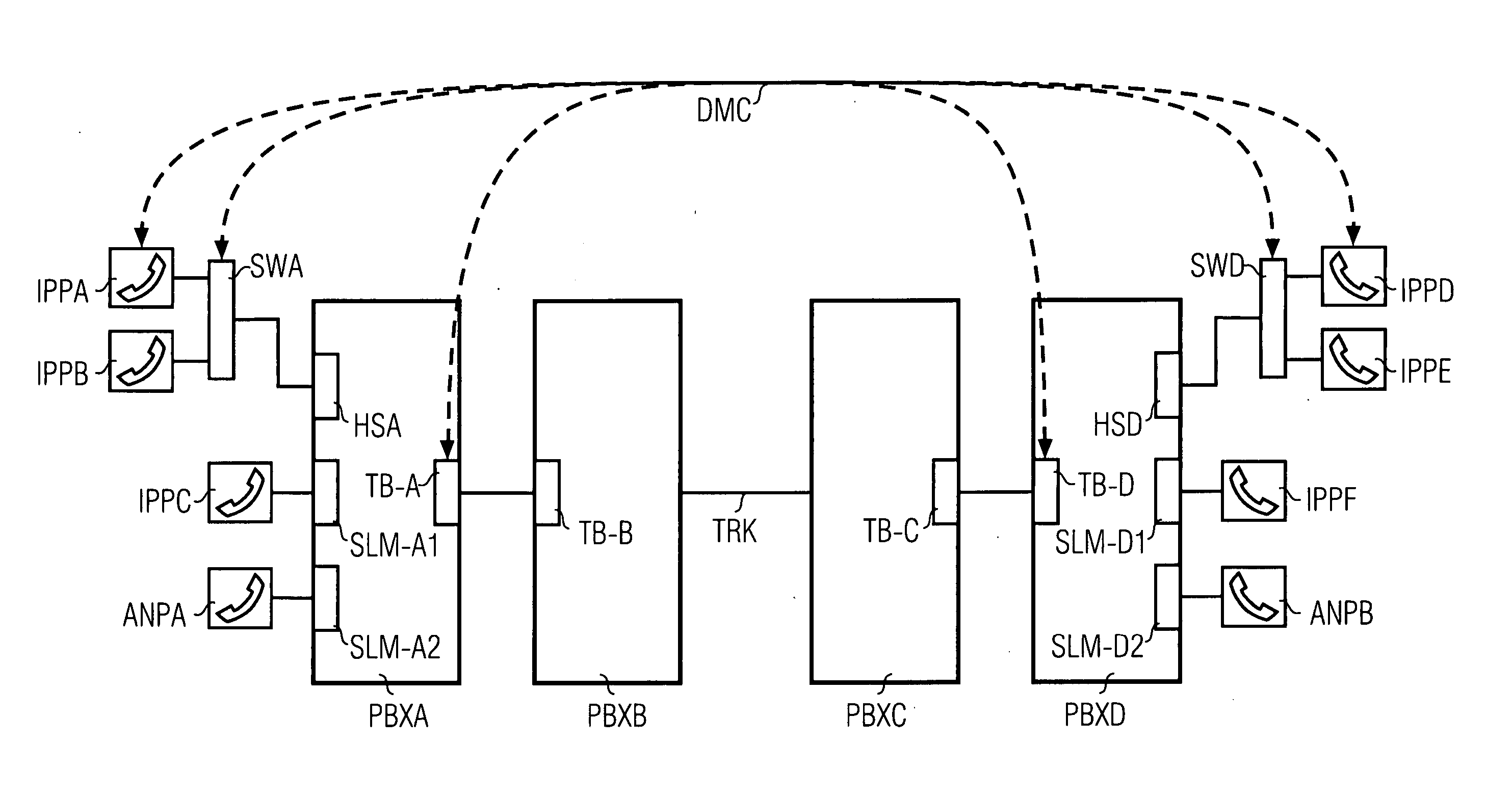

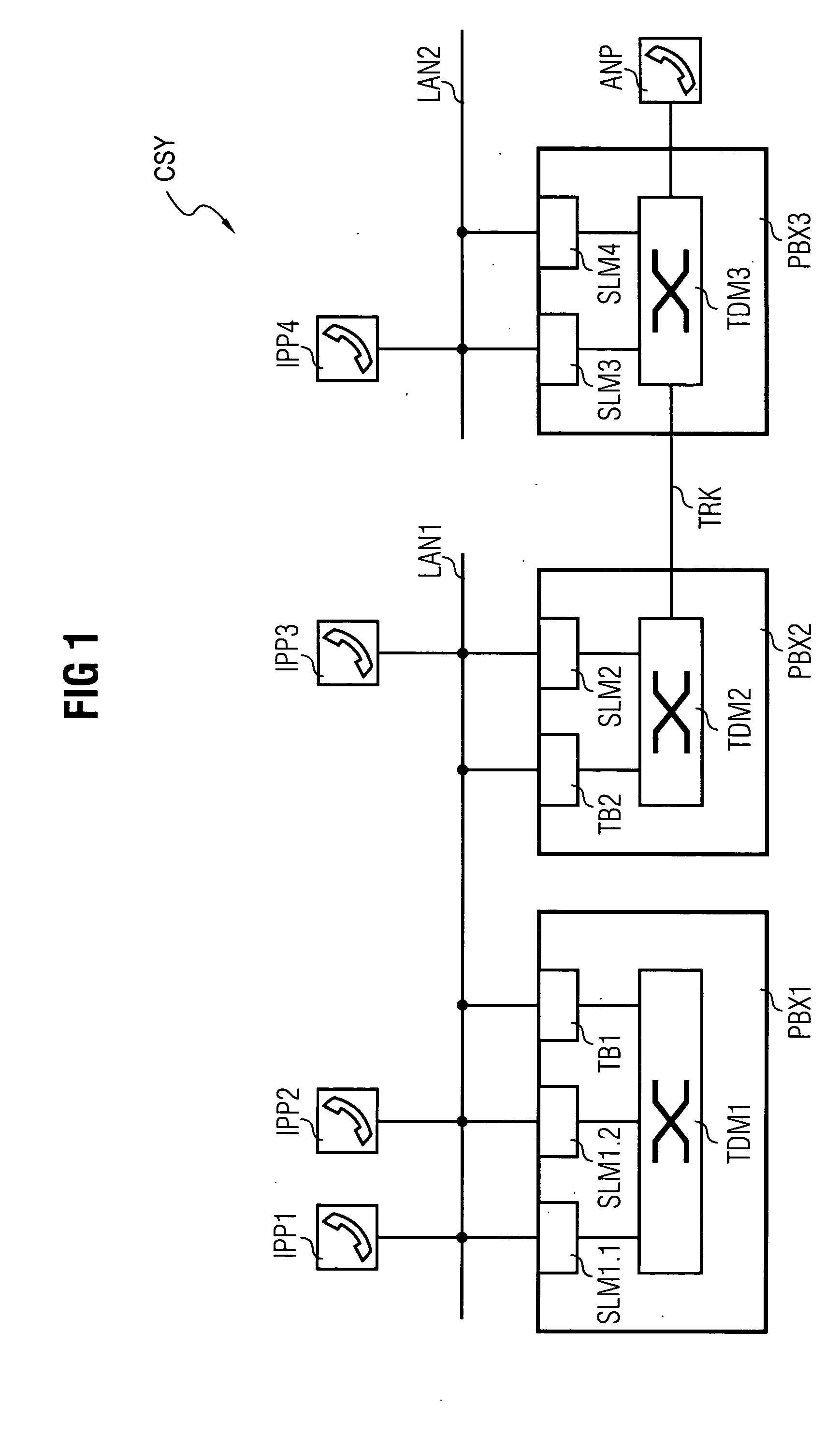

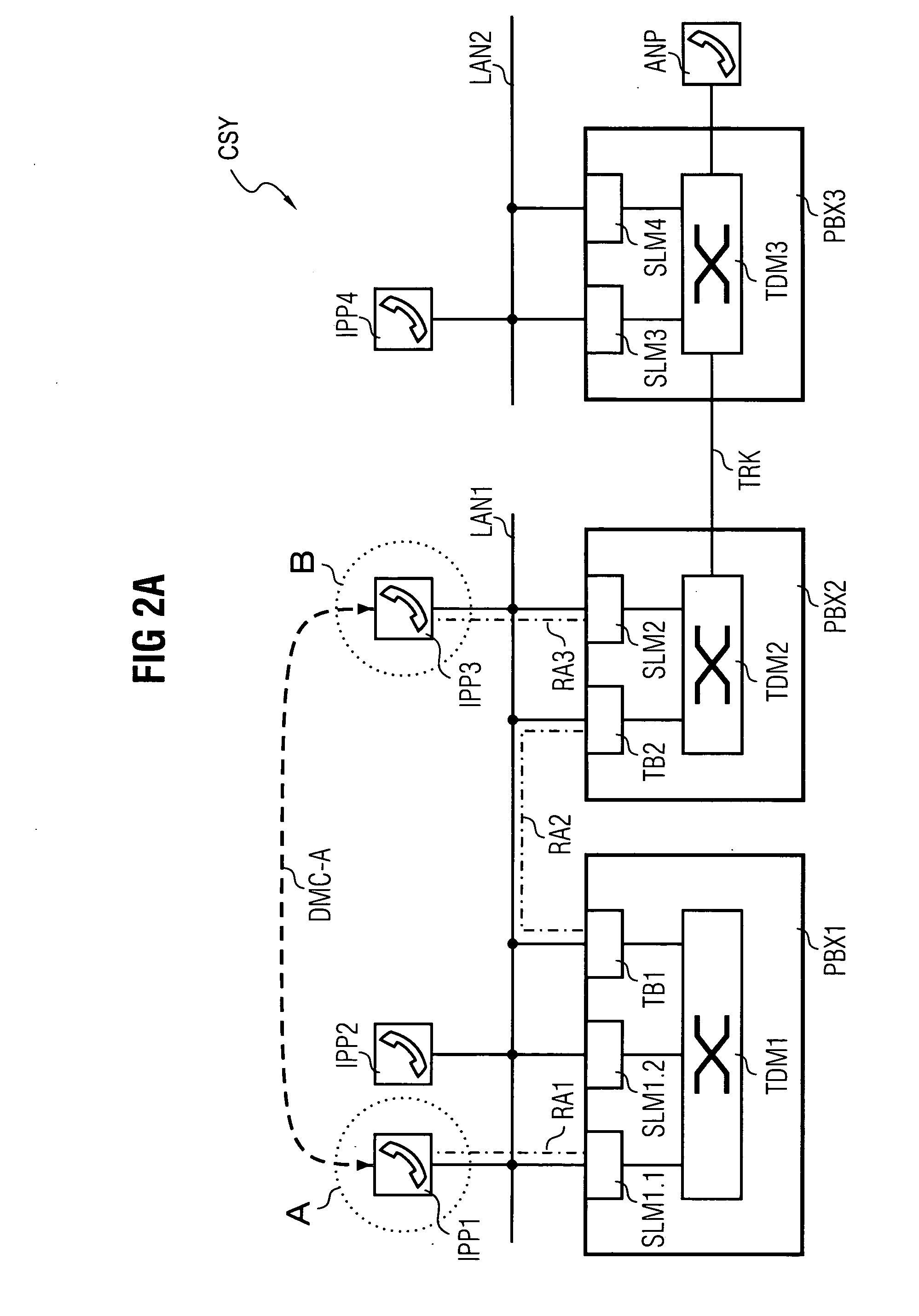

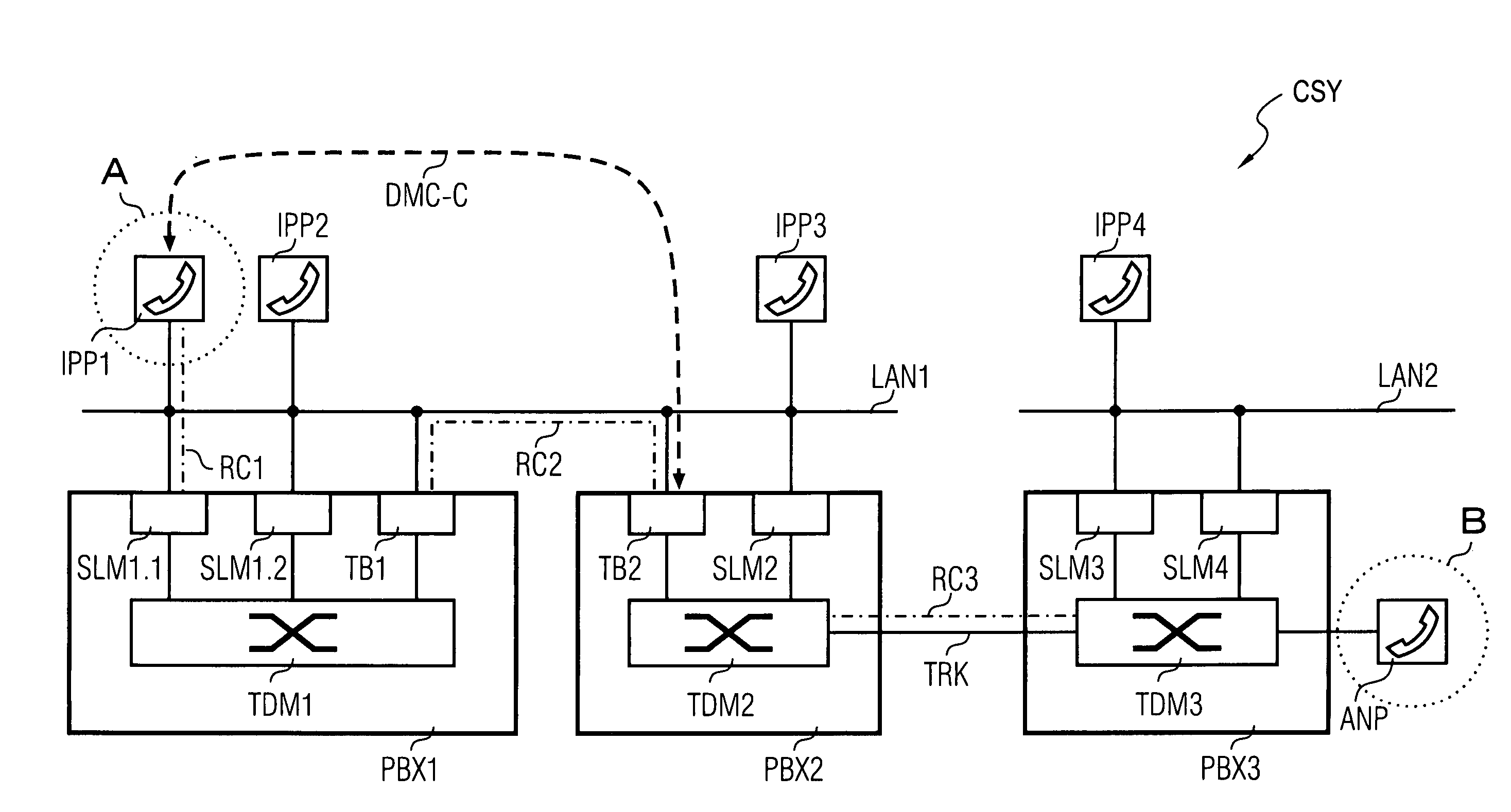

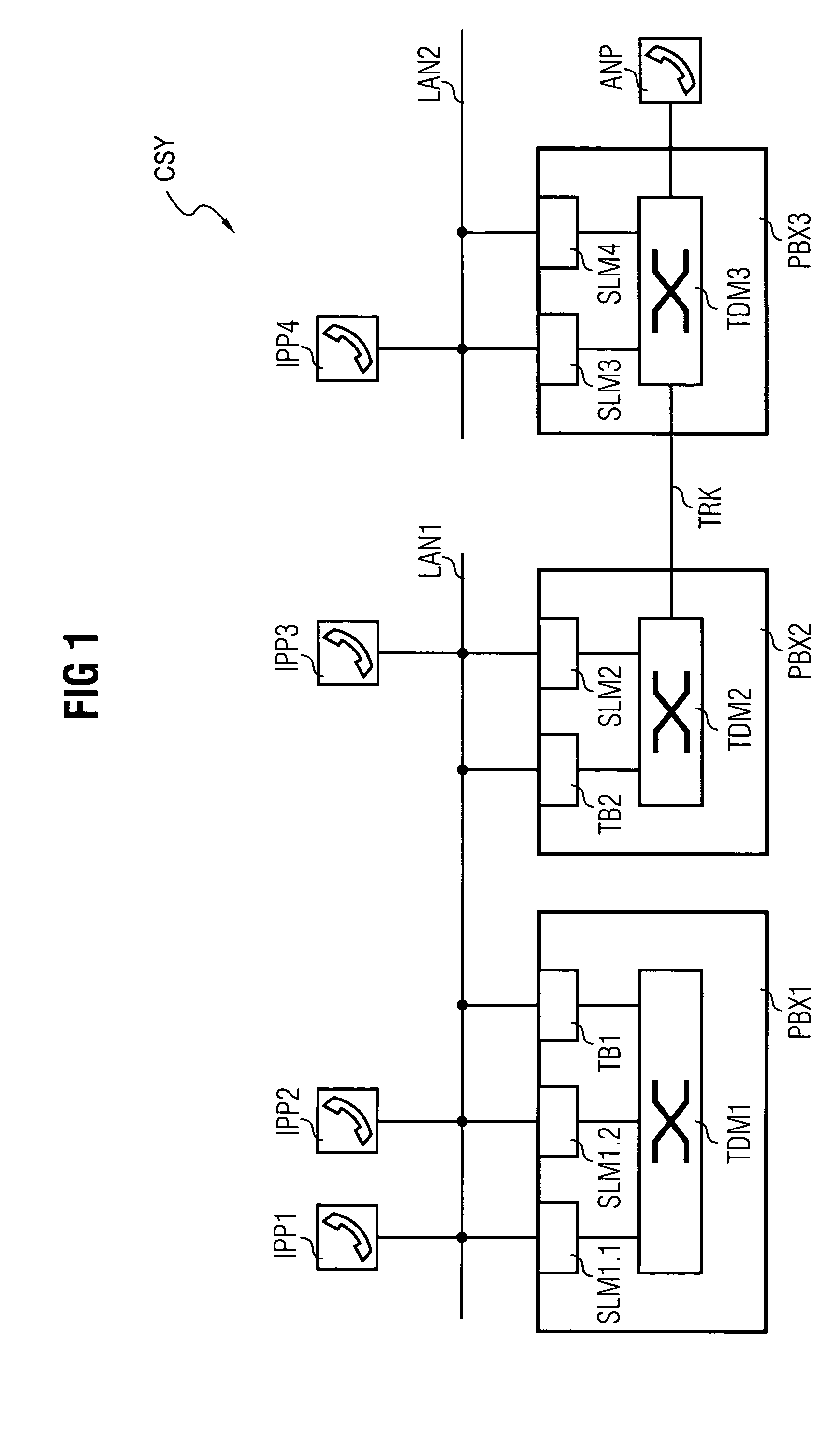

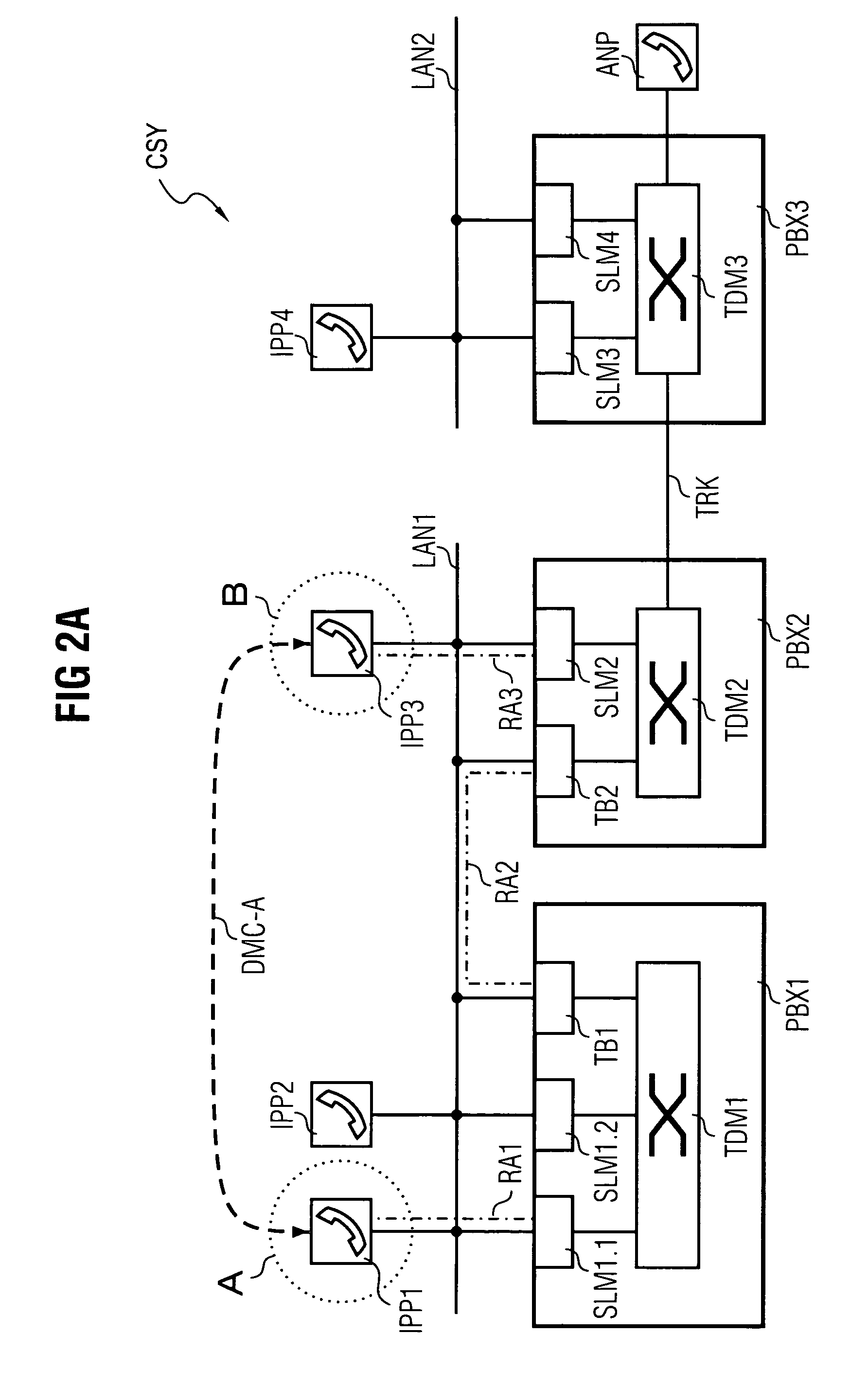

Method for transmitting communication data in a communication system

ActiveUS20050111459A1Loss of dataQuality lossMultiplex system selection arrangementsData switching by path configurationCommunications systemCommunication unit

The invention relates to a method for transmitting communication data in a communication system (CSY) between a calling first communication unit (IPPA) and a called second communication unit (IPPD), wherein, in a first step a primary connection is set up starting from the first communication unit (IPPA) via at least one node unit to the second communication unit (IPPD) with transmission of addressing data of the communication units (IPPA,IPPD) and node units participating in the setup of the primary connection. Following this, the first communication unit (IPPA) and / or a first node unit disposed along the primary connection which have a valid addressing data element are registered as the ingress node. Furthermore, the second communication unit (IPPD) and / or a last node unit disposed along the primary connection which have a valid addressing data element are registered as the egress node. With the embodiment of a secondary connection (DMC) between the egress and the ingress node via a network which is available in the communication system (CSY), communication data is finally transmitted via the secondary connection (DMC).

Owner:UNIFY GMBH & CO KG

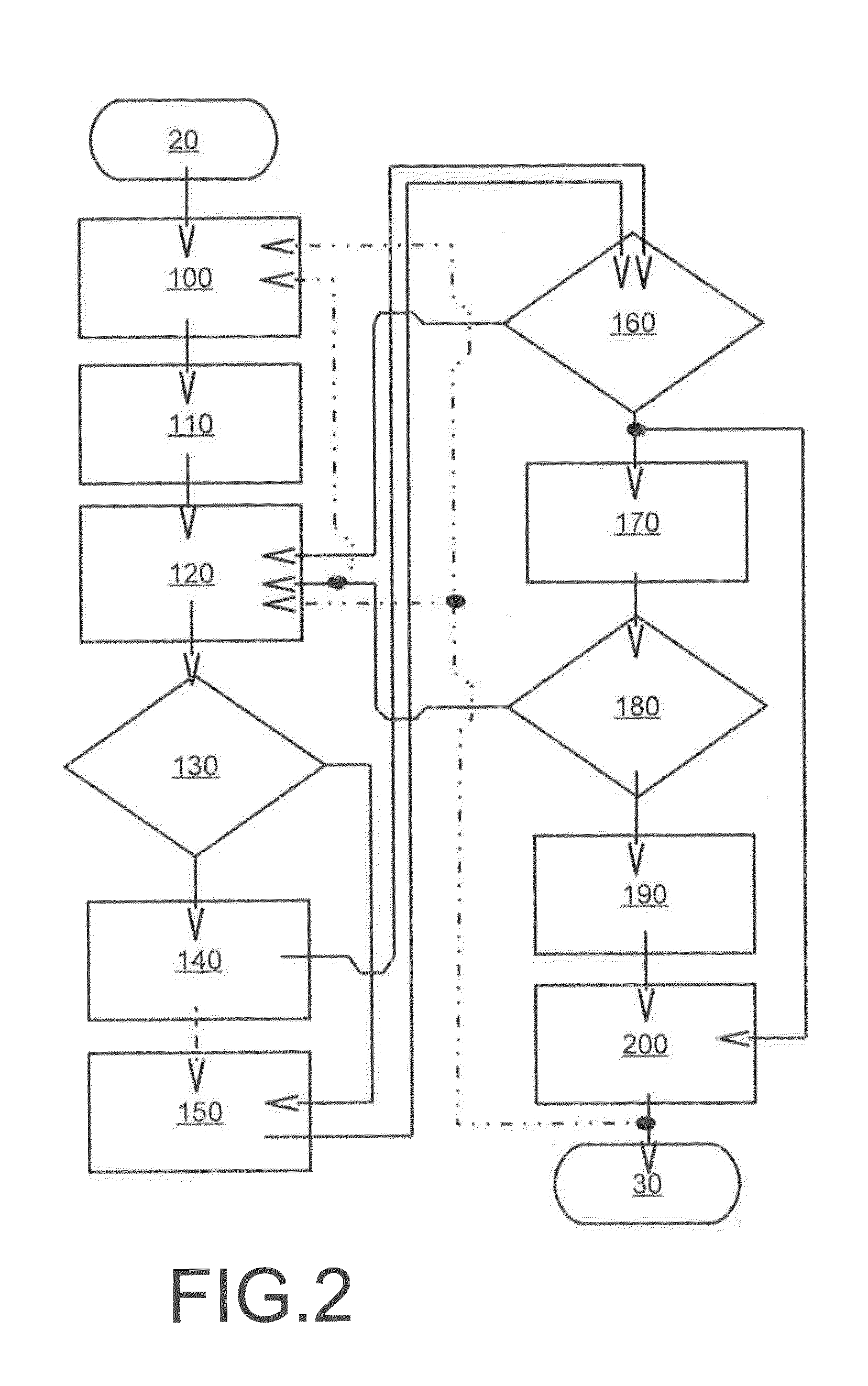

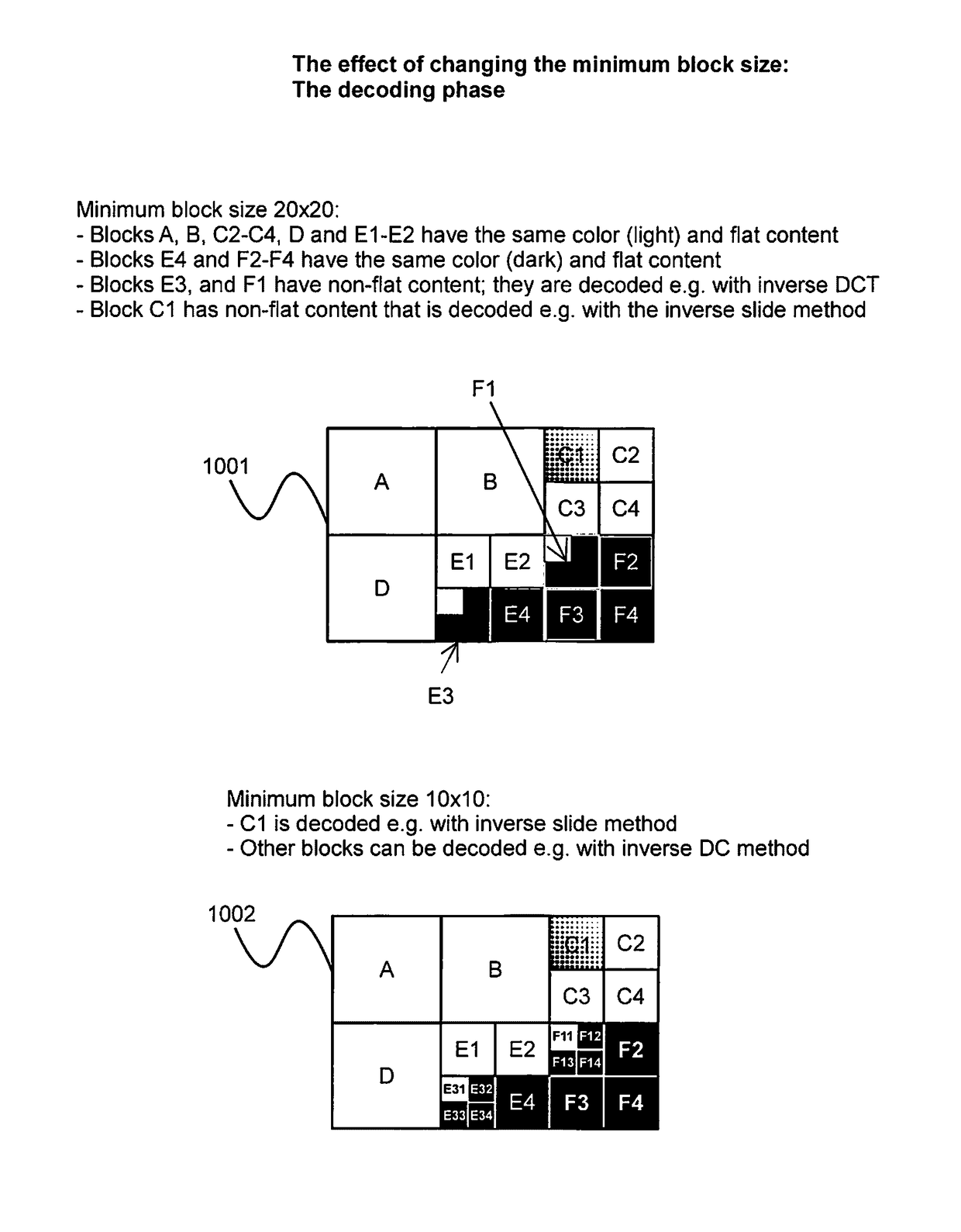

Decoder and method

ActiveUS20170070752A1Quality lossIncrease lossPulse modulation television signal transmissionCode conversionData processingComputer hardware

A decoder is operable to decode input data to generate corresponding decoded output data. The decoder includes data processing hardware which is operable to:(a) process the encoded input data to extract therefrom header information indicative of encoded data pertaining to individual blocks and / or packets included in the encoded input data, and information including data indicative of transformations employed to the individual blocks and / or packets;(b) create an initial set of individual blocks and / or packets based on received header data, and preparing a data field in a data storage arrangement for receiving decoded individual block and / or packet content;(c) split or combine individual blocks and / or packets in the data field according to information indicative of splitting / combining;(d) retrieve information describing the transformations and then applying an inverse of the transformations for decoding the encoded and compressed original block and / or packet data to generate corresponding decoded block and / or packet content for populating said data field; and(e) when the encoded input data has been at least partially decoded, outputting data from the data field as the decoded output data.

Owner:GURULOGIC MICROSYST

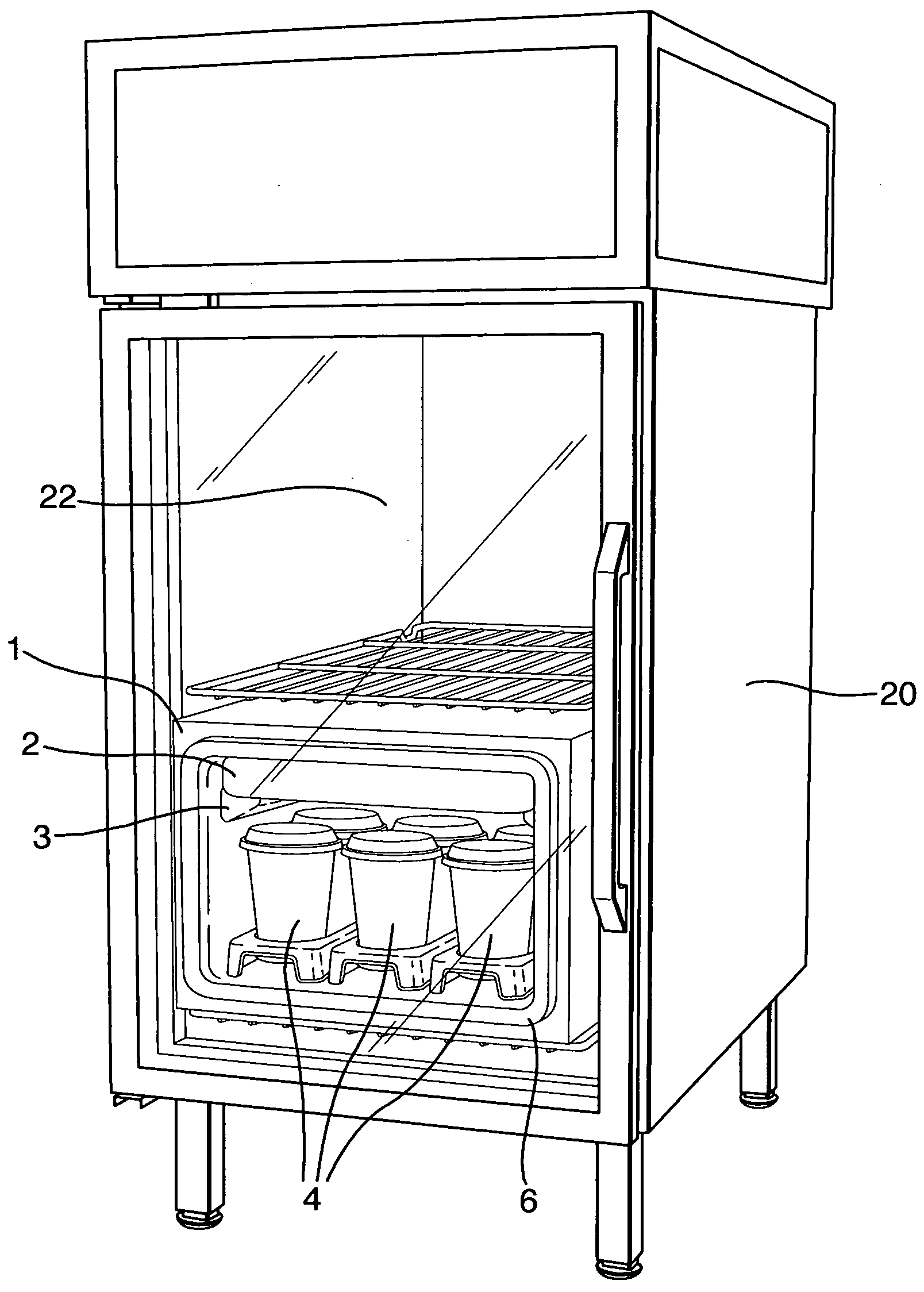

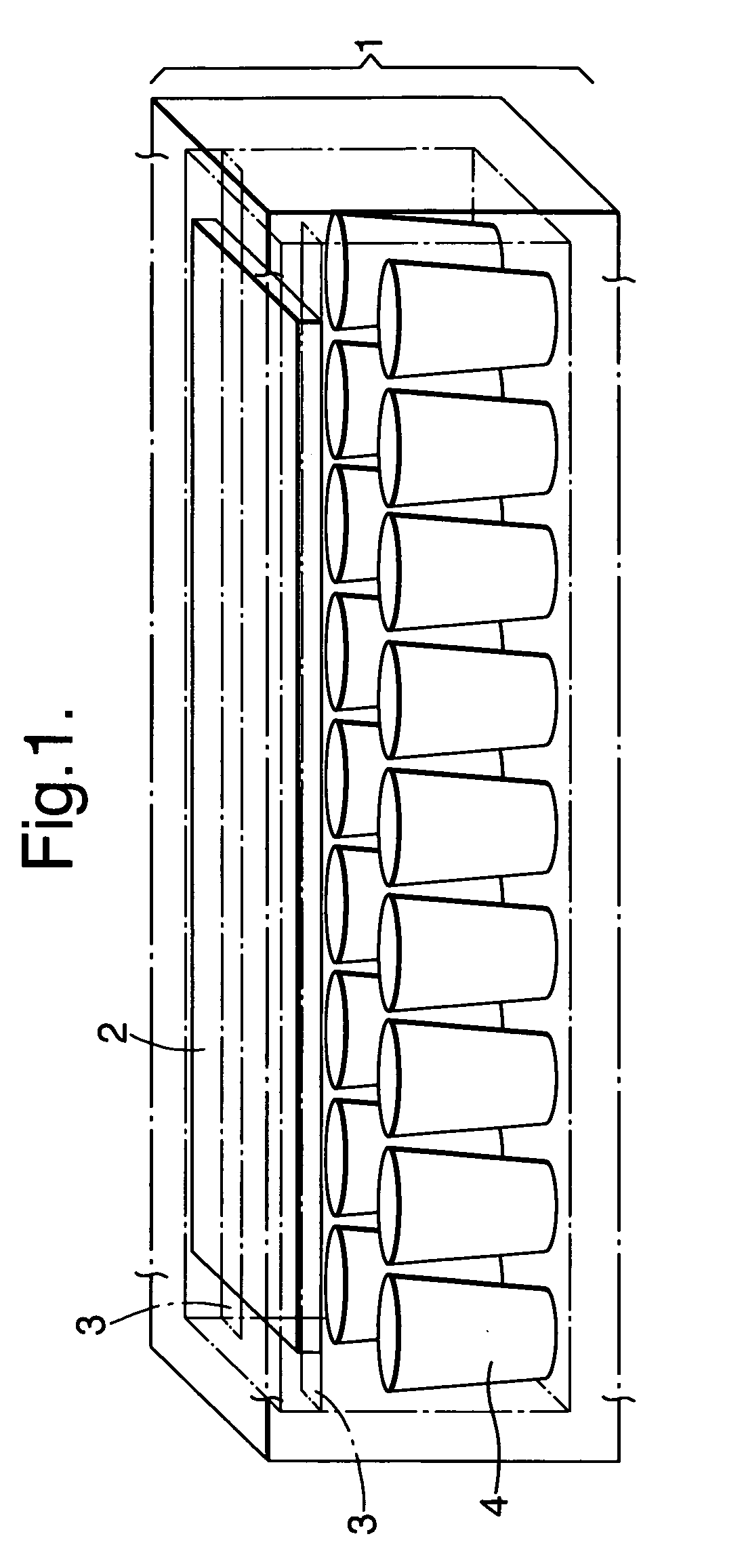

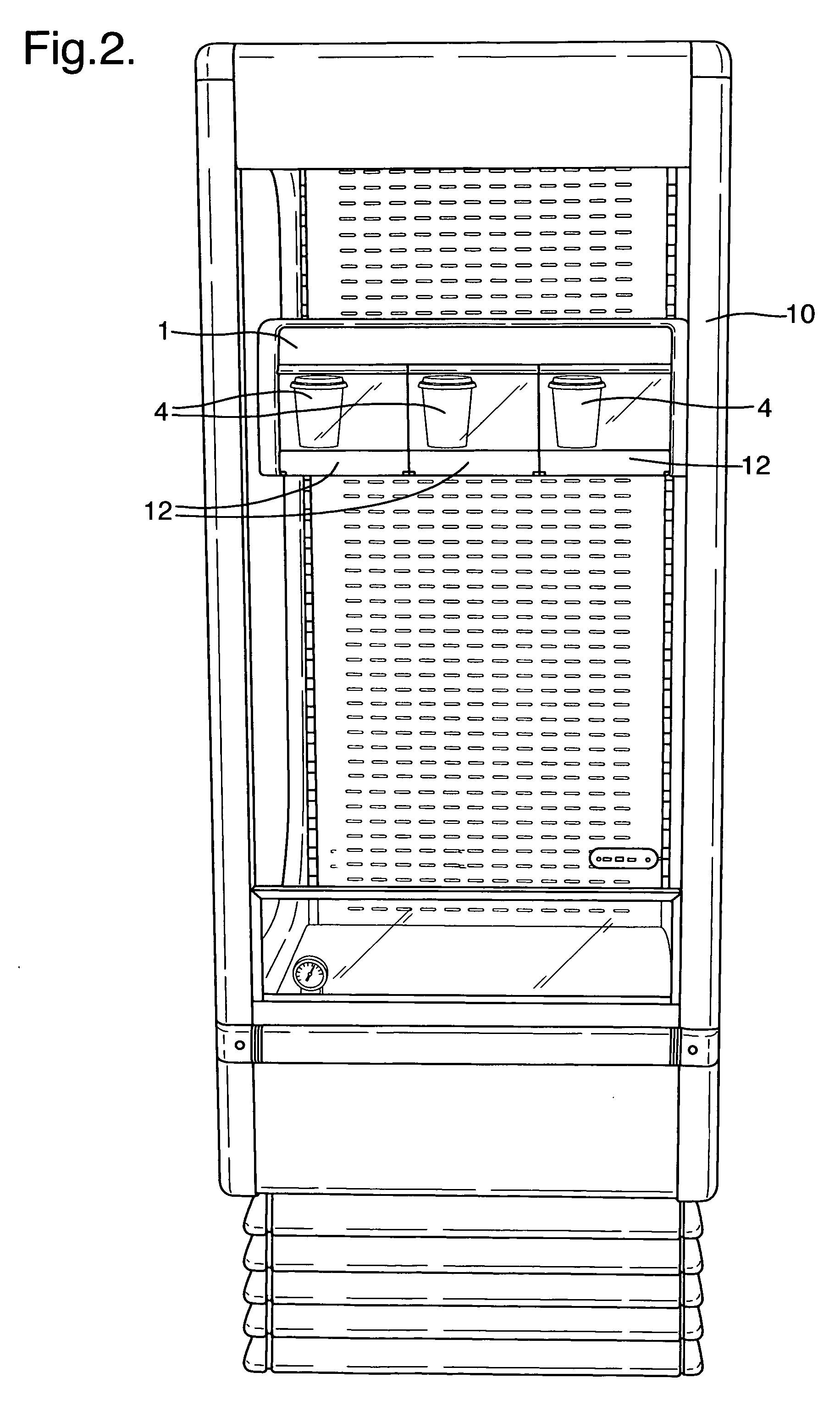

Apparatus and method for displaying and dispensing frozen edible products

ActiveUS20090183515A1Improve visibilityImprove accessibilityShow cabinetsLighting and heating apparatusBiomedical engineeringPassive cooling

An apparatus for displaying and dispensing frozen edible products is provided, comprising a chill cabinet inside which is situated an insulated container equipped with passive cooling means, and which contains one or more frozen edible products. A method for displaying and dispensing frozen edible products from the apparatus is also provided.

Owner:CONOPCO INC D B A UNILEVER

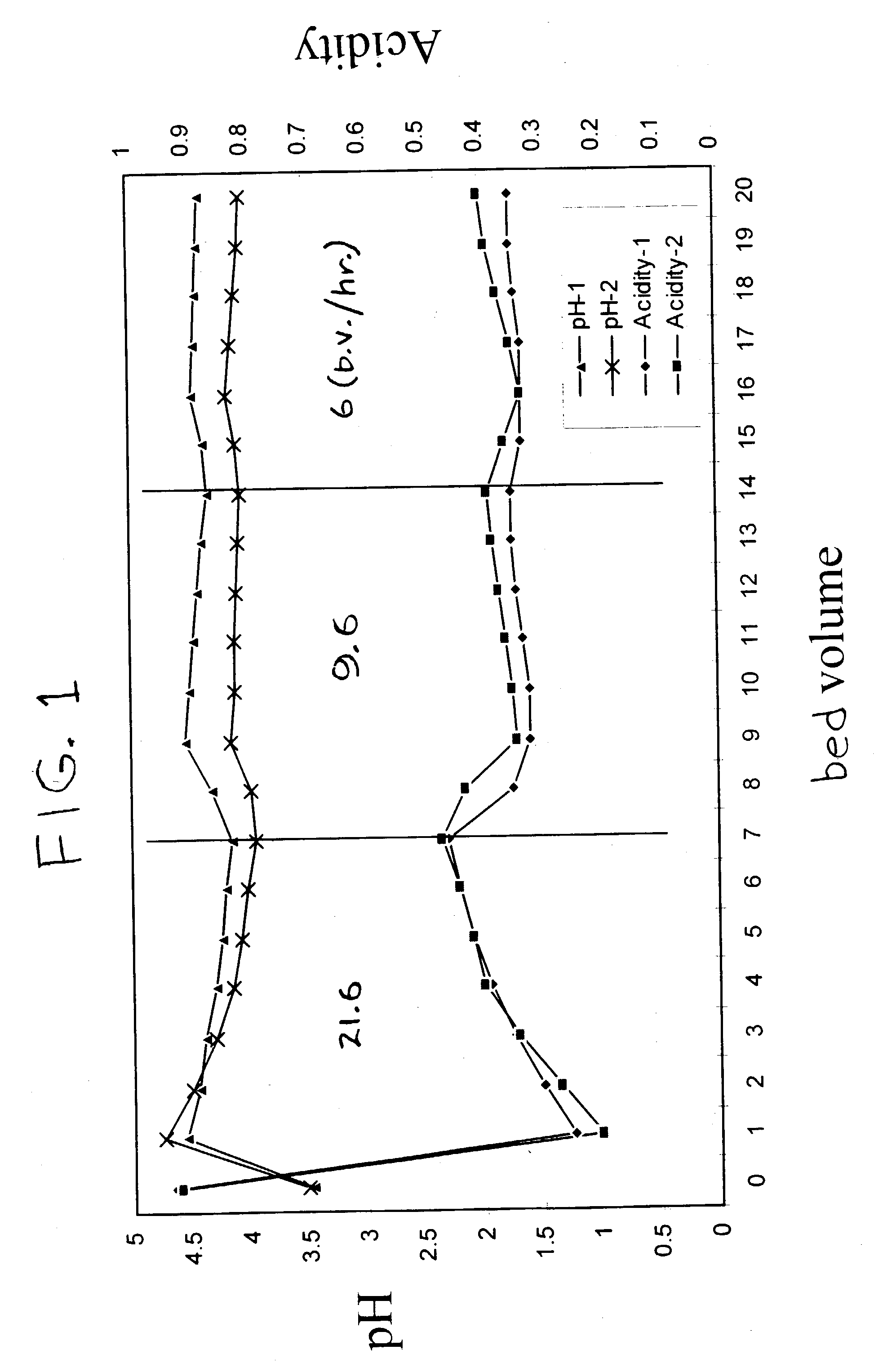

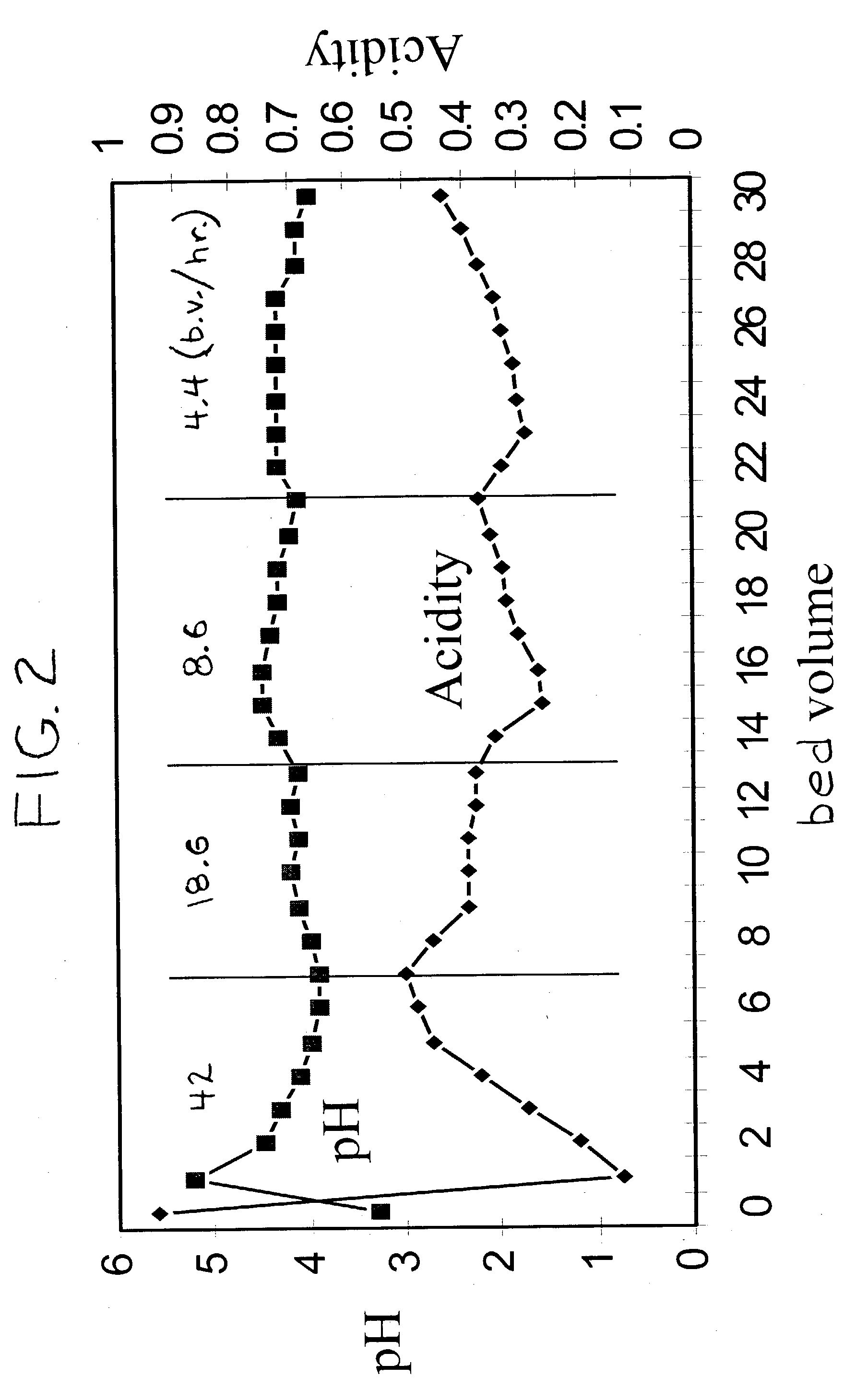

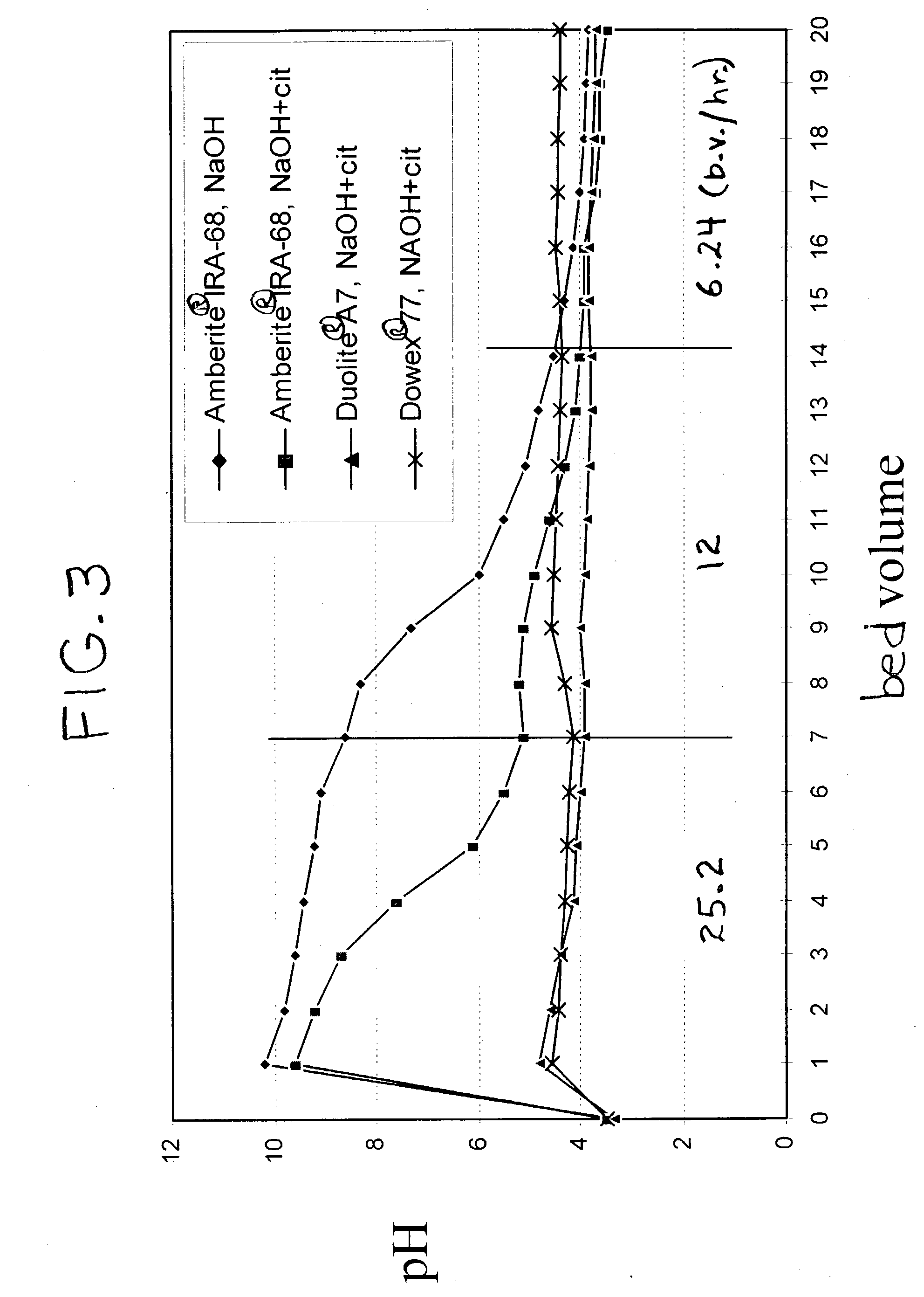

Resin deacidification of citrus juice with high acid maintenance

ActiveUS20040197448A1Less contact timeReduce acidityMilk preparationWort preparationMicroorganismFruit juice

The deacidification of citrus juice with ion exchange resin is described. Maintaining a high acid condition of the juice is achieved by passing the juice through regenerated resin that is preconditioned with an aqueous food-grade acid, preferably citric acid. Additionally or optionally, an early bed volume or multiple early bed volumes of juice flow are at a rapid flow rate. The products obtained also are described, and they may be any deacidified citrus juice or juice blend where the pH of the juice does not rise above that of an acid food pH for the juice during deacidification. In preferred embodiments, the juice product is orange juice. In another preferred embodiment, the conditioning process is used to provide a deacidified citrus juice product while avoiding raising the pH of any portion of the juice to 4.6 or above so as to control microbial growth of the juice.

Owner:TROPICANA PROD INC

Video Stream Protection

InactiveUS20130117791A1Excessive qualityQuality lossClosed circuit television systemsTransmissionComputer graphics (images)Protection system

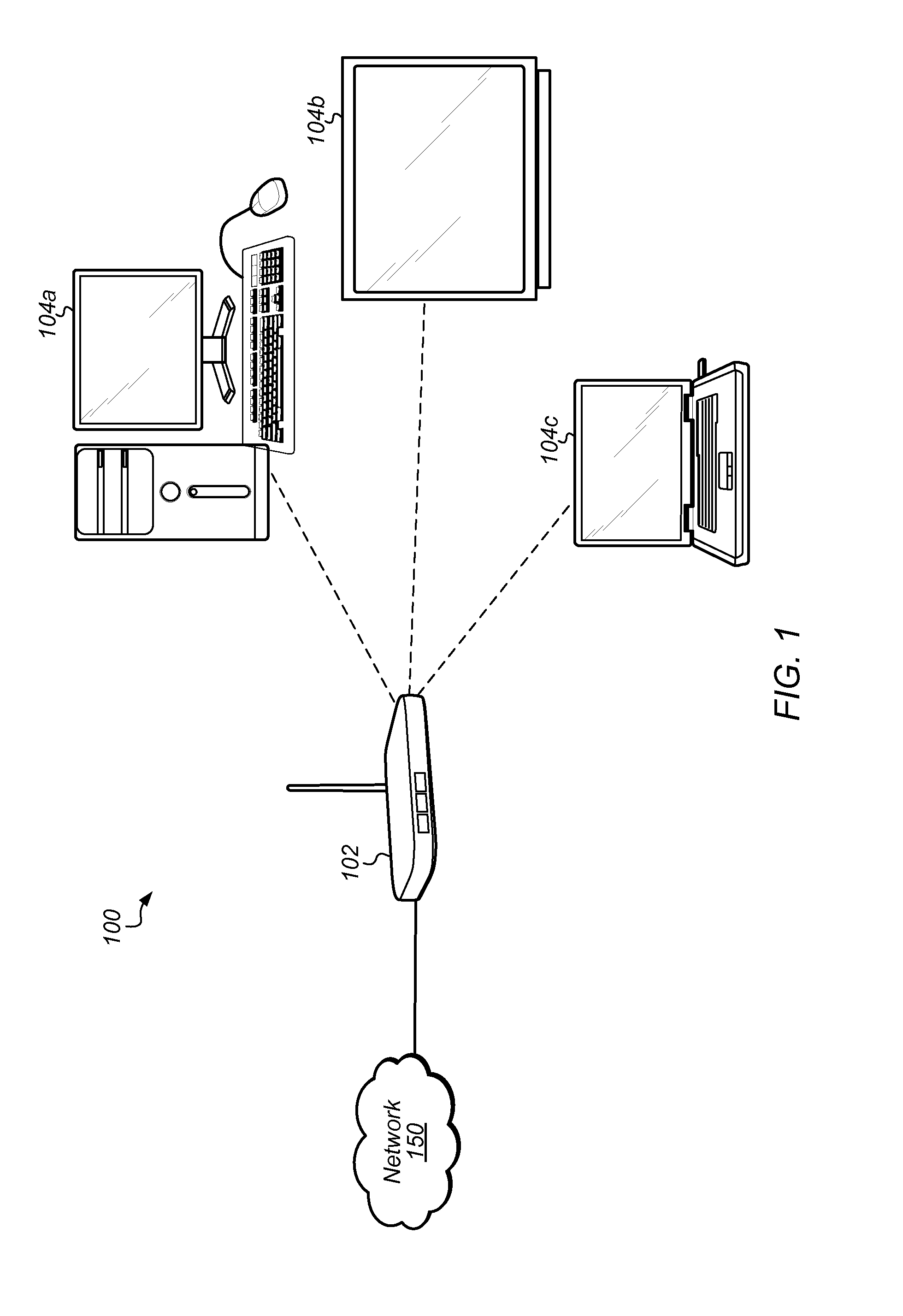

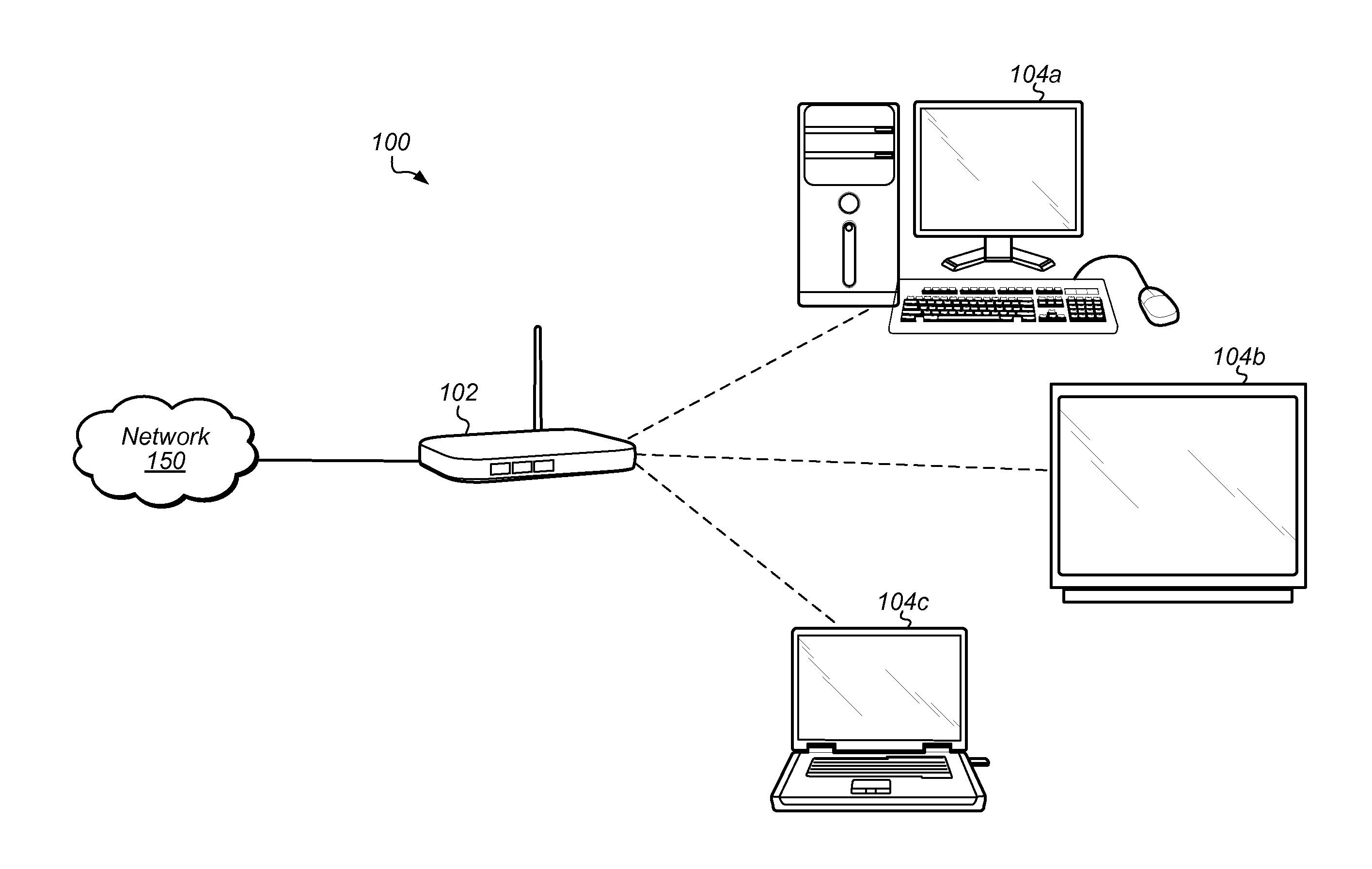

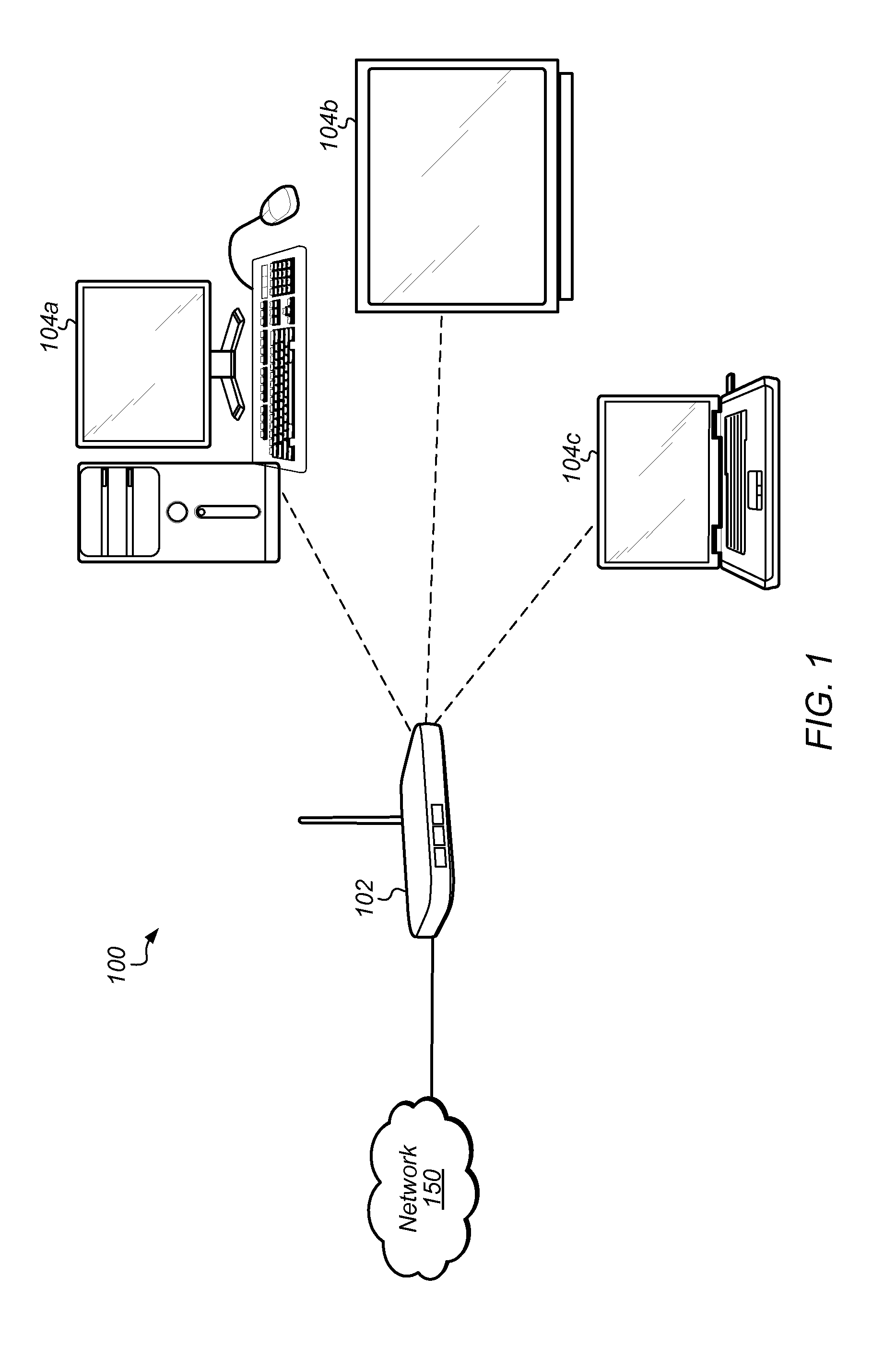

System and method for protecting video stream quality during transmission over a wireless medium. A plurality of video streams may be transmitted to one or more clients in a wireless manner. It may be determined that a size of a transmit queue is above a first threshold. The plurality of video streams may be differentiated, as part of which a video stream may be selected for penalization in order to protect the other video streams of the plurality of video streams. A scheduling penalty may be imposed on the selected video stream based on determining that the size of the transmit queue is above the first threshold and based on differentiating the plurality of video streams.

Owner:QUALCOMM INC

Video stream protection

InactiveUS8695047B2Minimize impactImprove qualityData switching by path configurationClosed circuit television systemsComputer graphics (images)Protection system

System and method for protecting video stream quality during transmission over a wireless medium. A plurality of video streams may be transmitted to one or more clients in a wireless manner. It may be determined that a size of a transmit queue is above a first threshold. The plurality of video streams may be differentiated, as part of which a video stream may be selected for penalization in order to protect the other video streams of the plurality of video streams. A scheduling penalty may be imposed on the selected video stream based on determining that the size of the transmit queue is above the first threshold and based on differentiating the plurality of video streams.

Owner:QUALCOMM INC

Method for transmitting communication data in a communication system

ActiveUS7701927B2Loss of dataQuality lossMultiplex system selection arrangementsData switching by path configurationCommunication unitCommunications system

The invention relates to a method for transmitting communication data in a communication system (CSY) between a calling first communication unit (IPPA) and a called second communication unit (IPPD), wherein, in a first step a primary connection is set up starting from the first communication unit (IPPA) via at least one node unit to the second communication unit (IPPD) with transmission of addressing data of the communication units (IPPA,IPPD) and node units participating in the setup of the primary connection. Following this, the first communication unit (IPPA) and / or a first node unit disposed along the primary connection which have a valid addressing data element are registered as the ingress node. Furthermore, the second communication unit (IPPD) and / or a last node unit disposed along the primary connection which have a valid addressing data element are registered as the egress node. With the embodiment of a secondary connection (DMC) between the egress and the ingress node via a network which is available in the communication system (CSY), communication data is finally transmitted via the secondary connection (DMC).

Owner:UNIFY GMBH & CO KG

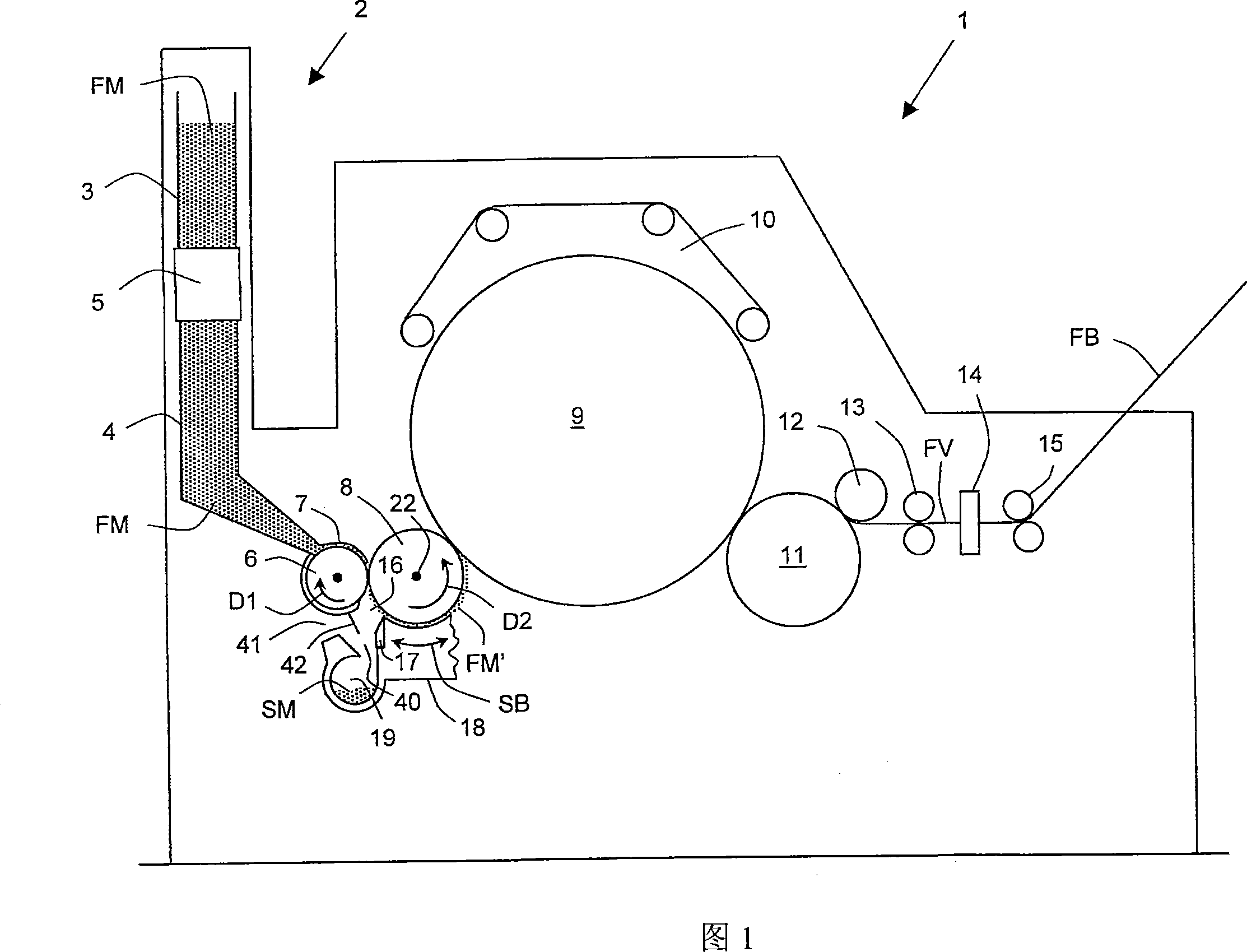

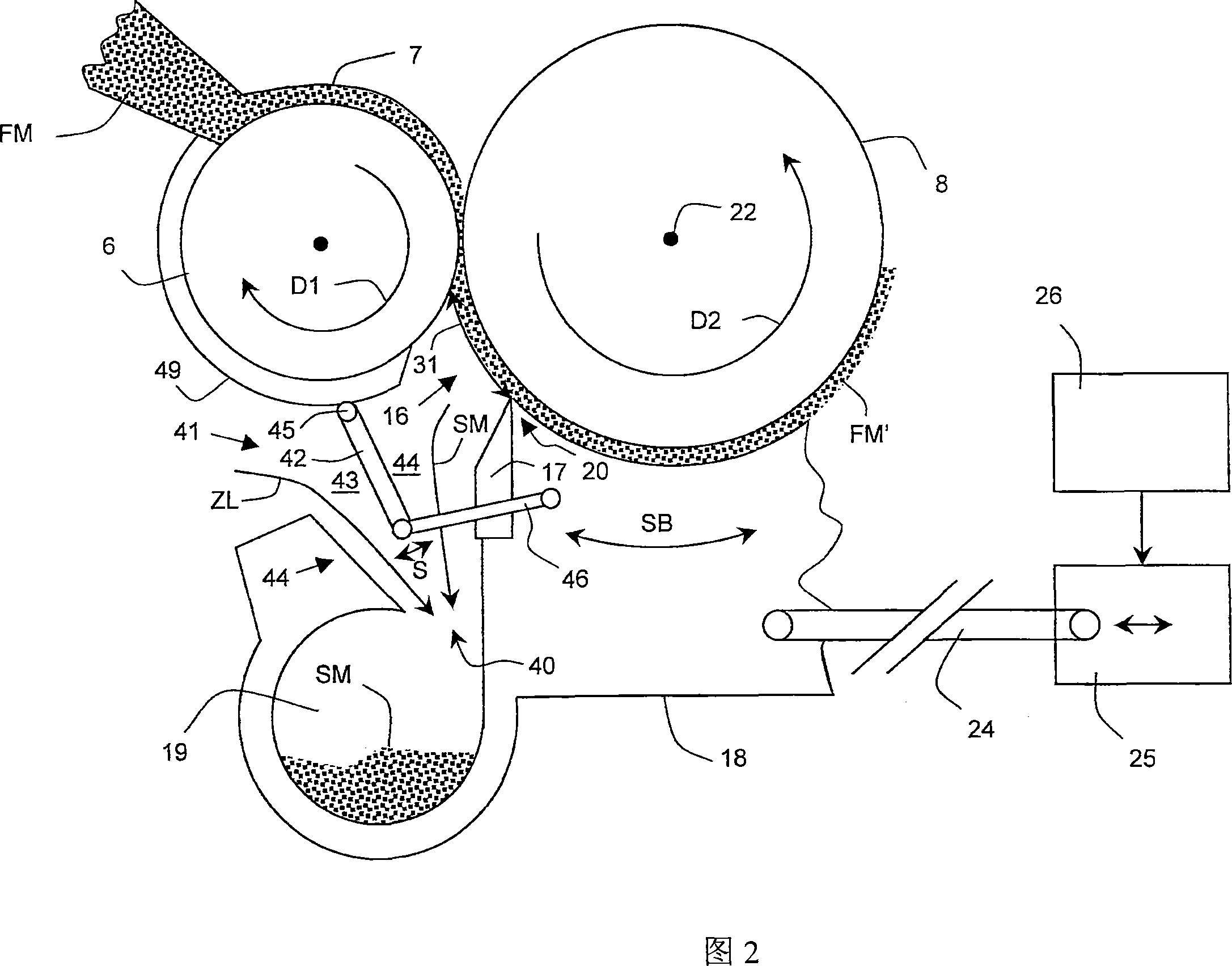

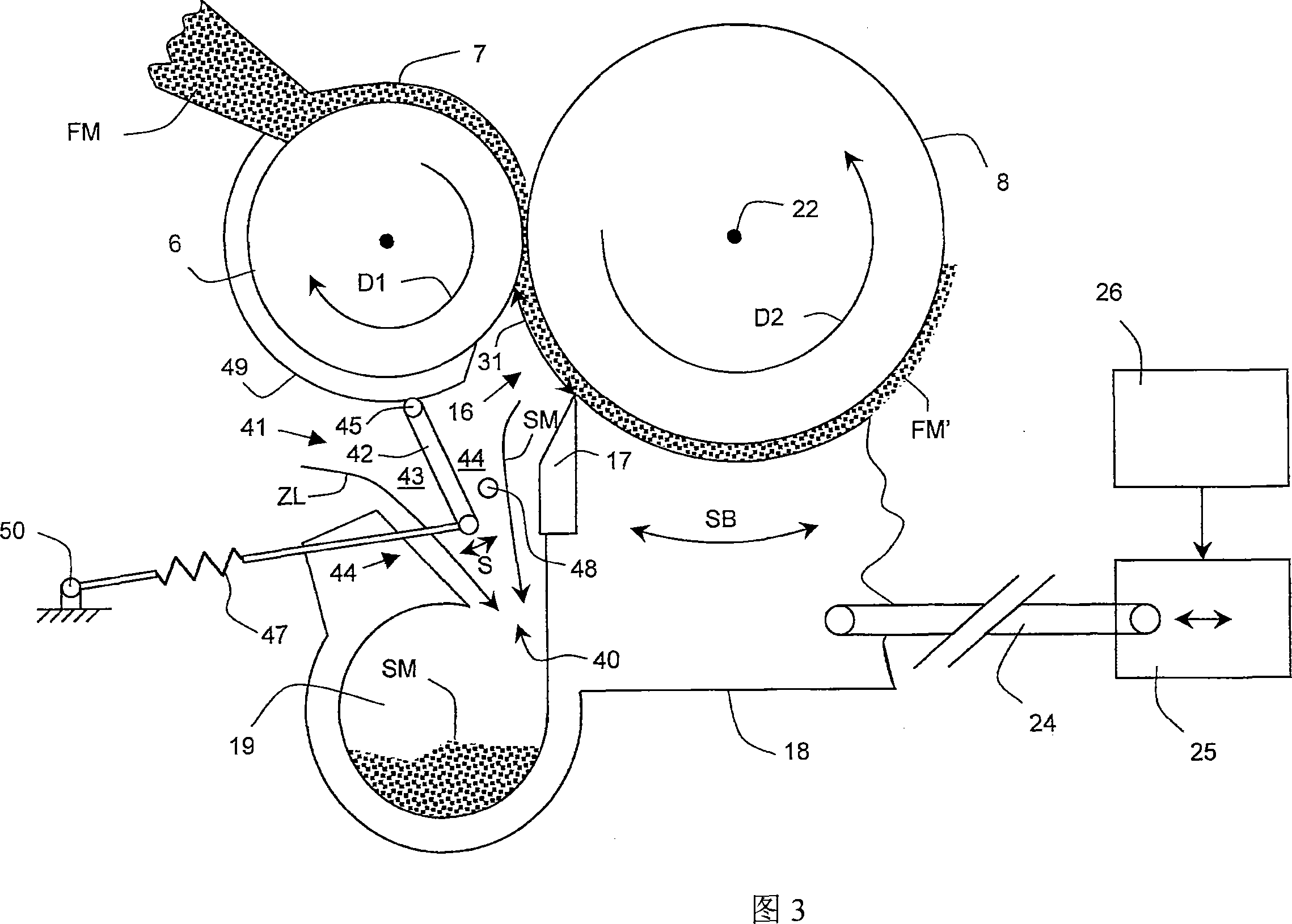

Cleaning device for a textile machine

Disclosed is a cleaning device for a textile machine (1), particularly a carding machine (1) or a blow room machine. Said cleaning device comprises a rotatable opening cylinder (8) for opening delivered fiber material (FM), e.g. a licker-in (8), and at least one dirt outlet (16) for eliminating dirt material (SM) from the delivered fiber material (FM). Said dirt outlet (16) is disposed in a zone located along the periphery of the opening cylinder (8) and is delimited by an edge element (17), e.g. a mote knife (17), at the end pointing in the direction of rotation (D2) of the opening cylinder (8). The edge element (17) is arranged on a support (18) that can be swiveled about a supporting shaft (22) such that the length (31) of the dirt outlet (16) along the periphery of the opening cylinder (8) can be modified. The inventive cleaning device further comprises a dirt discharge duct (40) extending from the dirt outlet (16) to a suction chamber (19) as well as an air inlet (41) that is assigned to the dirt discharge duct (40) and is used for feeding an intake air flow (ZL). A shielding element (42) which blocks the dirt outlet (16) relative to the delivered intake air flow (ZL) is assigned to the dirt discharge duct (40) such that the intake air flow (ZL) is largely prevented from influencing the elimination of dirt material (SM).

Owner:MASCHINENFABRIK RIETER AG

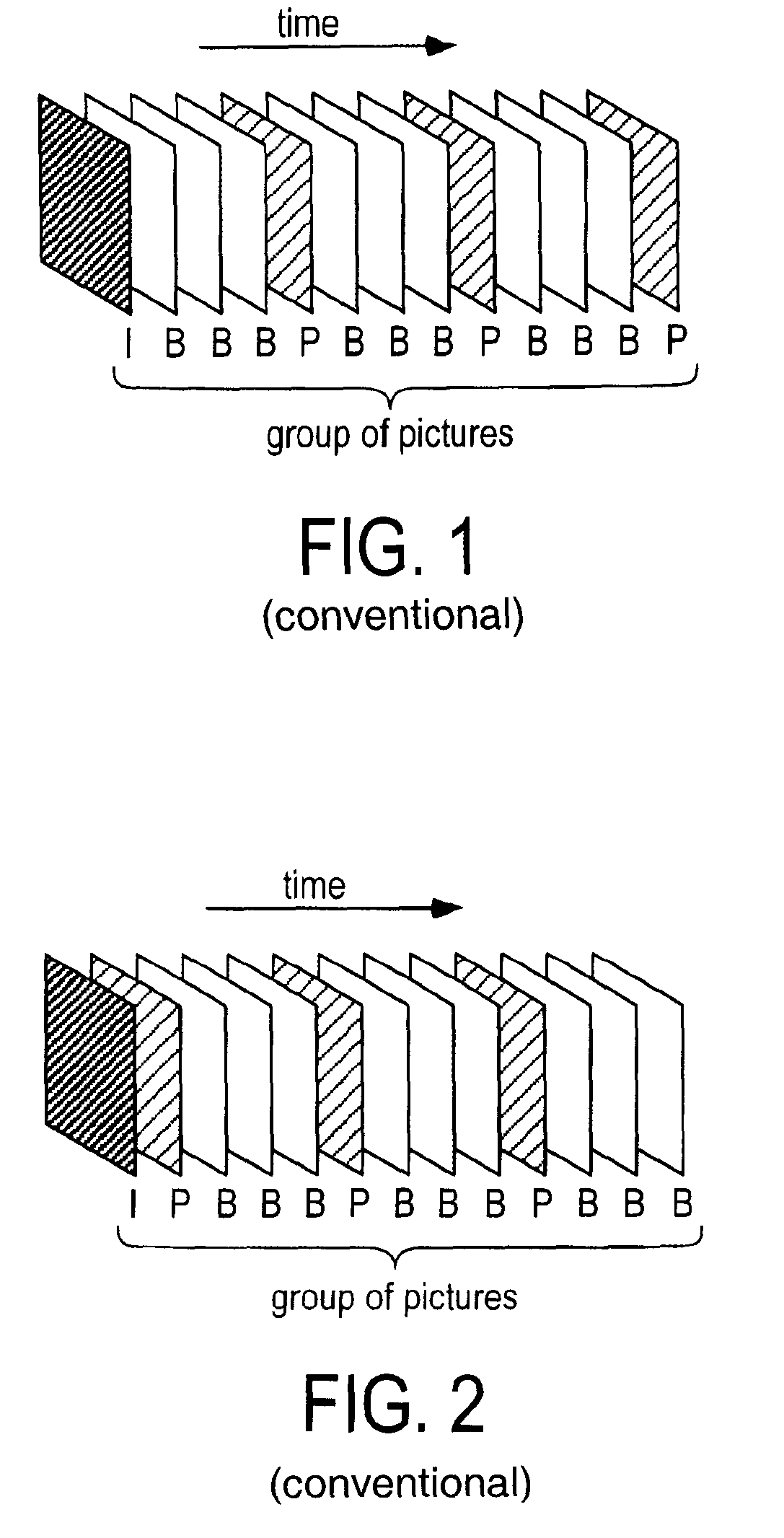

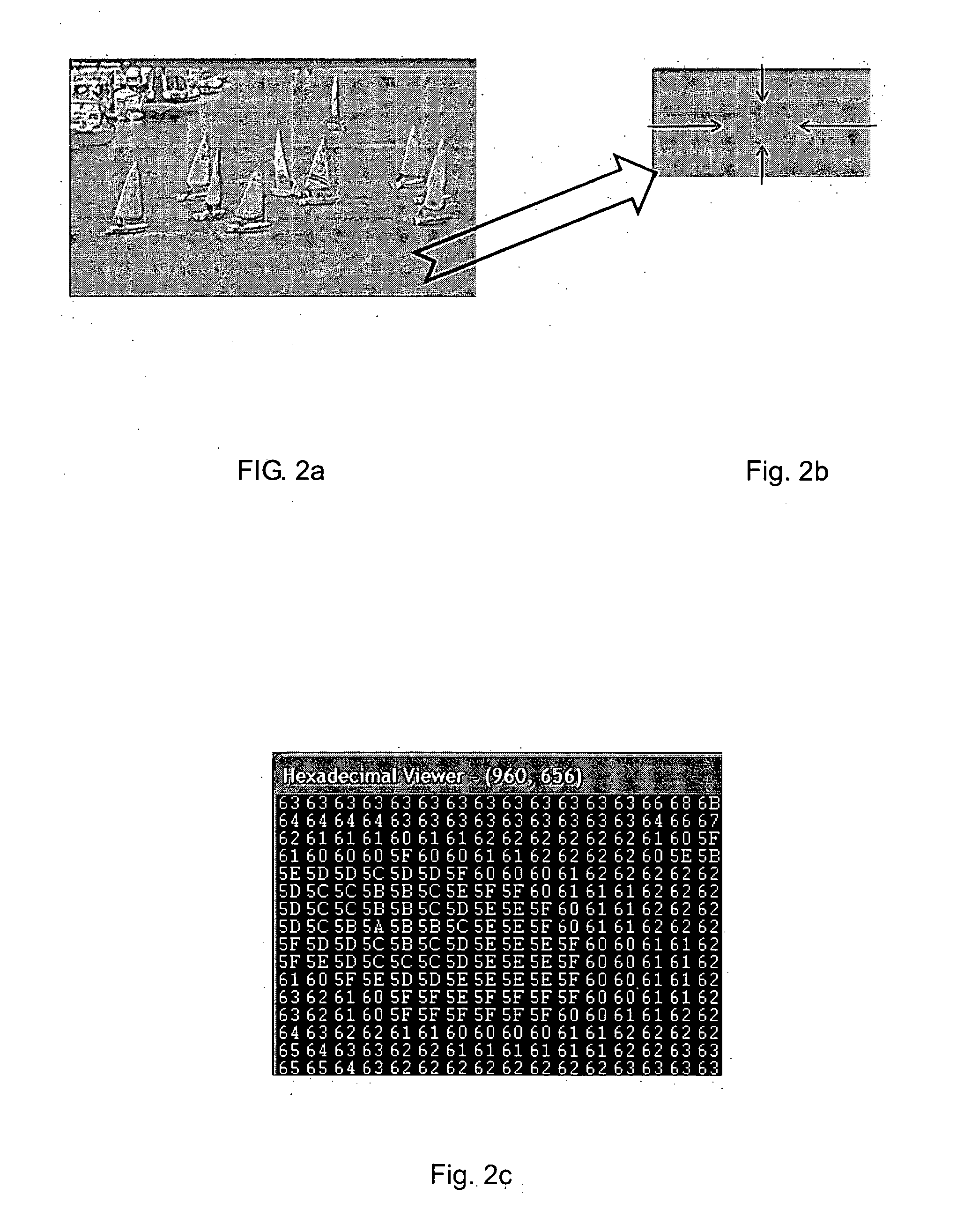

Digital video encoding method

InactiveUS20150139295A1Quality lossColor television with pulse code modulationColor television with bandwidth reductionDigital videoMedia server

A method for encoding a digital video image producing a high resolution is proposed. A source digital video image is segmented into a plurality of video frames and each such frame is segmented into a plurality of blocks composed of pixels. An encoded digital video image is formed from a sequence of the frames. Each subsequent frame is added to the encoded image if the frame is entirely different from the previous frame. If a subsequent frame repeats the previous frame, then a command is added to repeat the previous video frame. If a subsequent frame is not entirely different, then a command is added to the encoded image to repeat the previous frame taking into account the differing blocks. The pixels in the encoded image are formed having a square shape, regardless of their compression ratio. The encoded image can be saved to at least one media server.

Owner:YAROSHENKO VADIM VITALEVICH

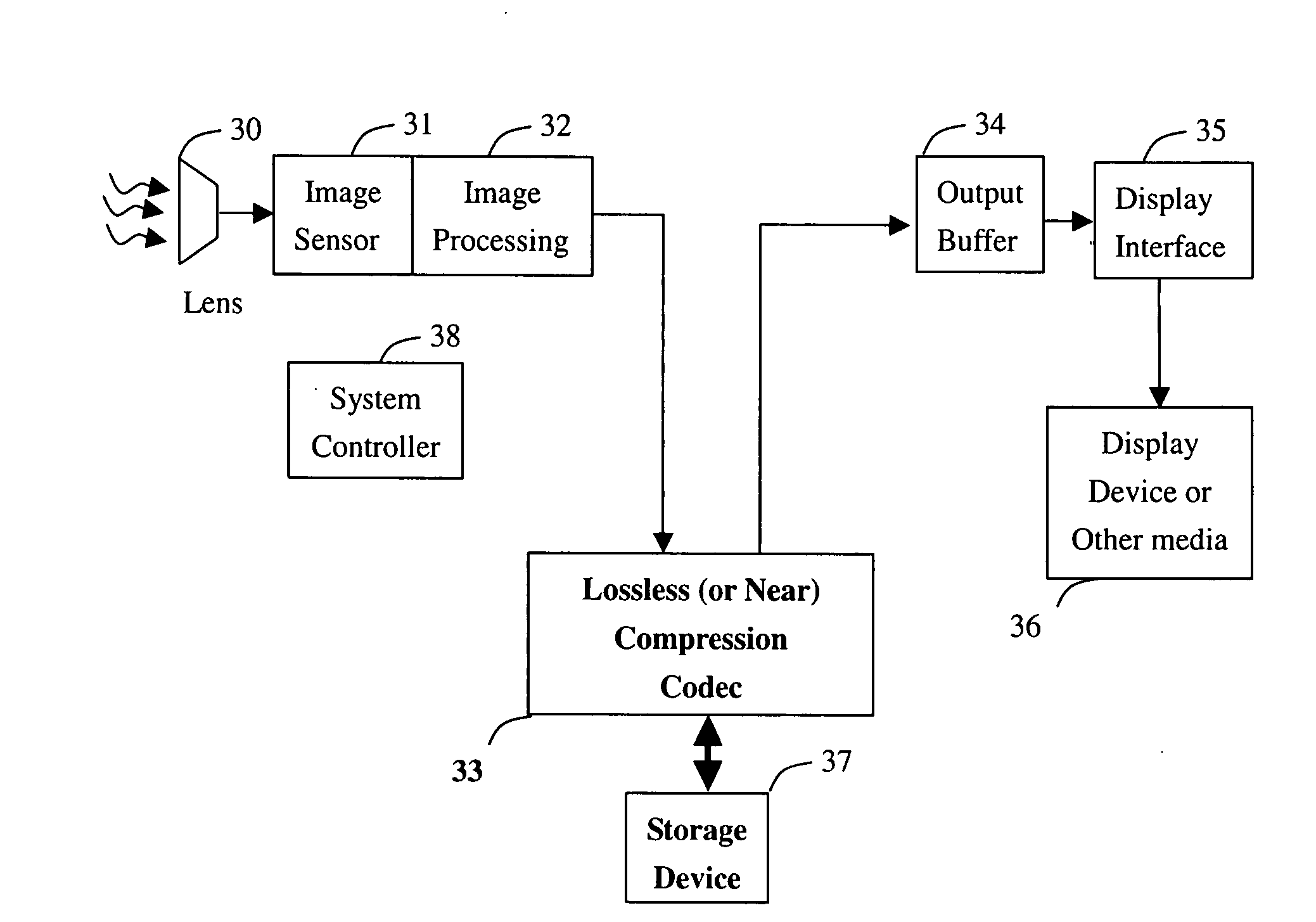

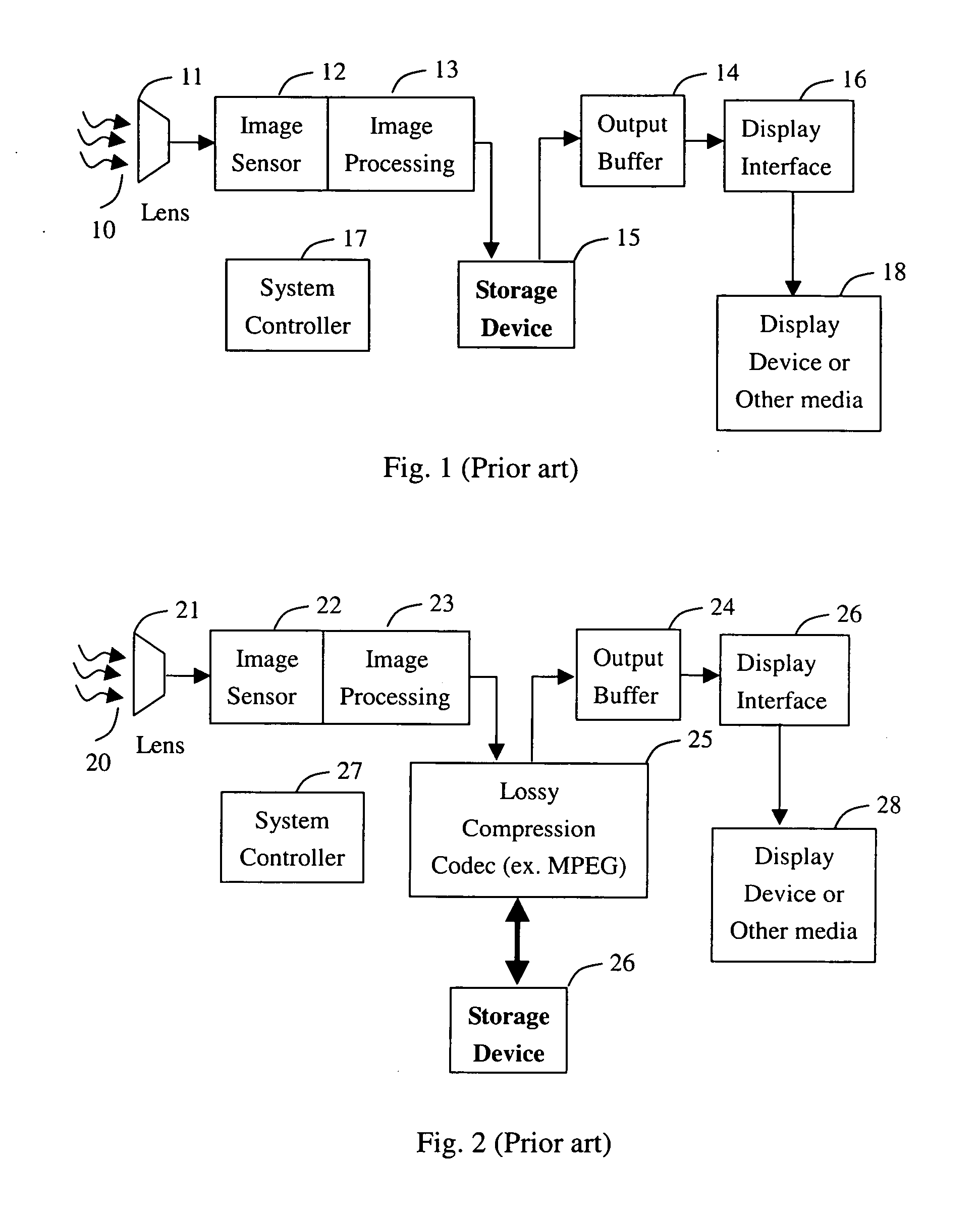

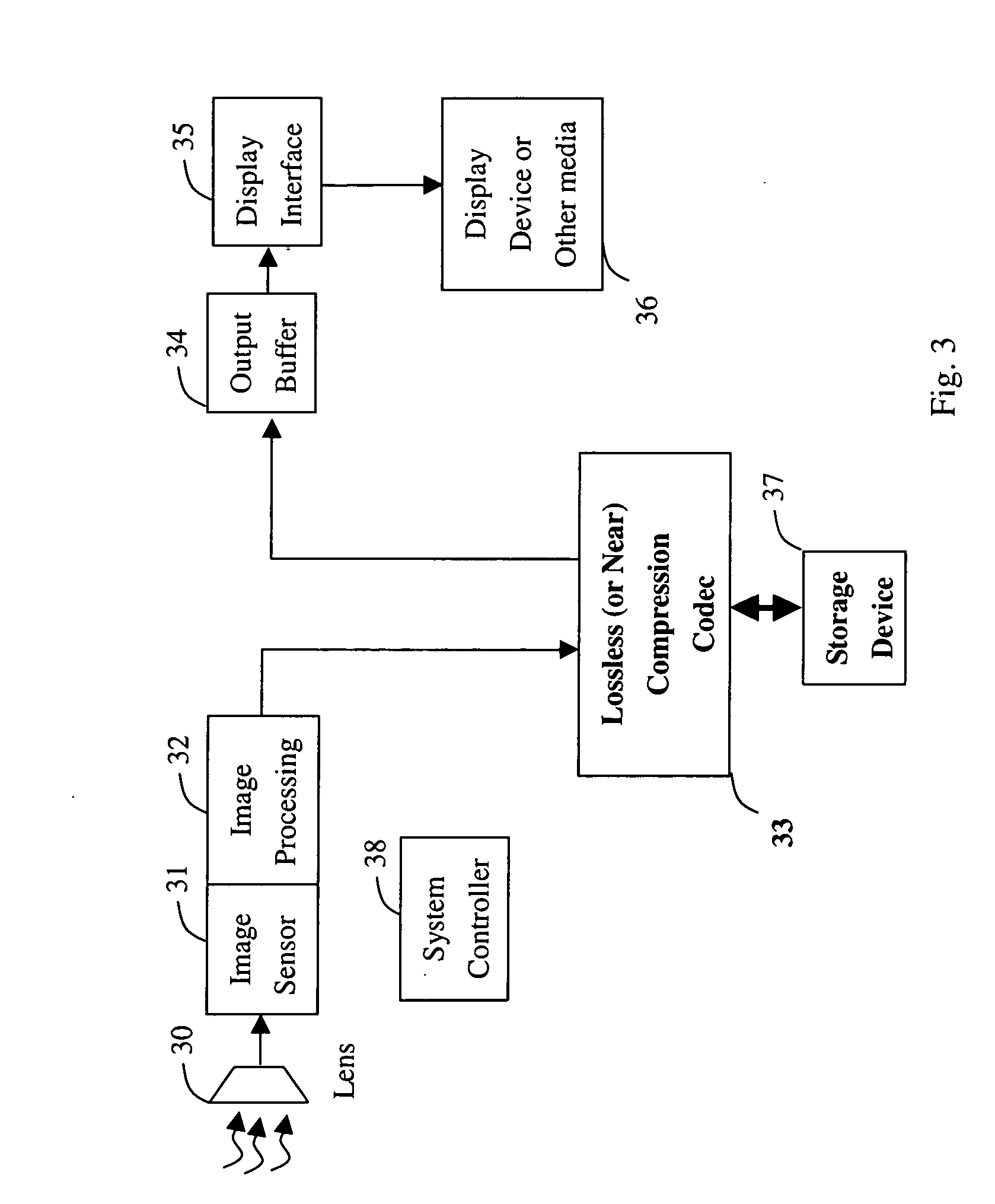

Method and apparatus of video recording and output system

InactiveUS20060275020A1Quality lossLoss rateTelevision system detailsColor television detailsComputer graphics (images)Display device

A video recording and output system applies compression method and apparatus to plurality of images. The majority pixels of video stream which have been compressed and saved into a storage device have no data loss compared to the original raw image data is compressed by a method so named as “lossless” compression algorithm. When outputting the compressed image, a decompression engine is to reconstruct the compressed image into the raw image firstly and output to a display device. Another mechanism of outputting the decompressed image of raw image is to re-compress it into another image format with a certain amount of pixels having data loss compared to original image.

Owner:TAIWAN IMAGINGTEK

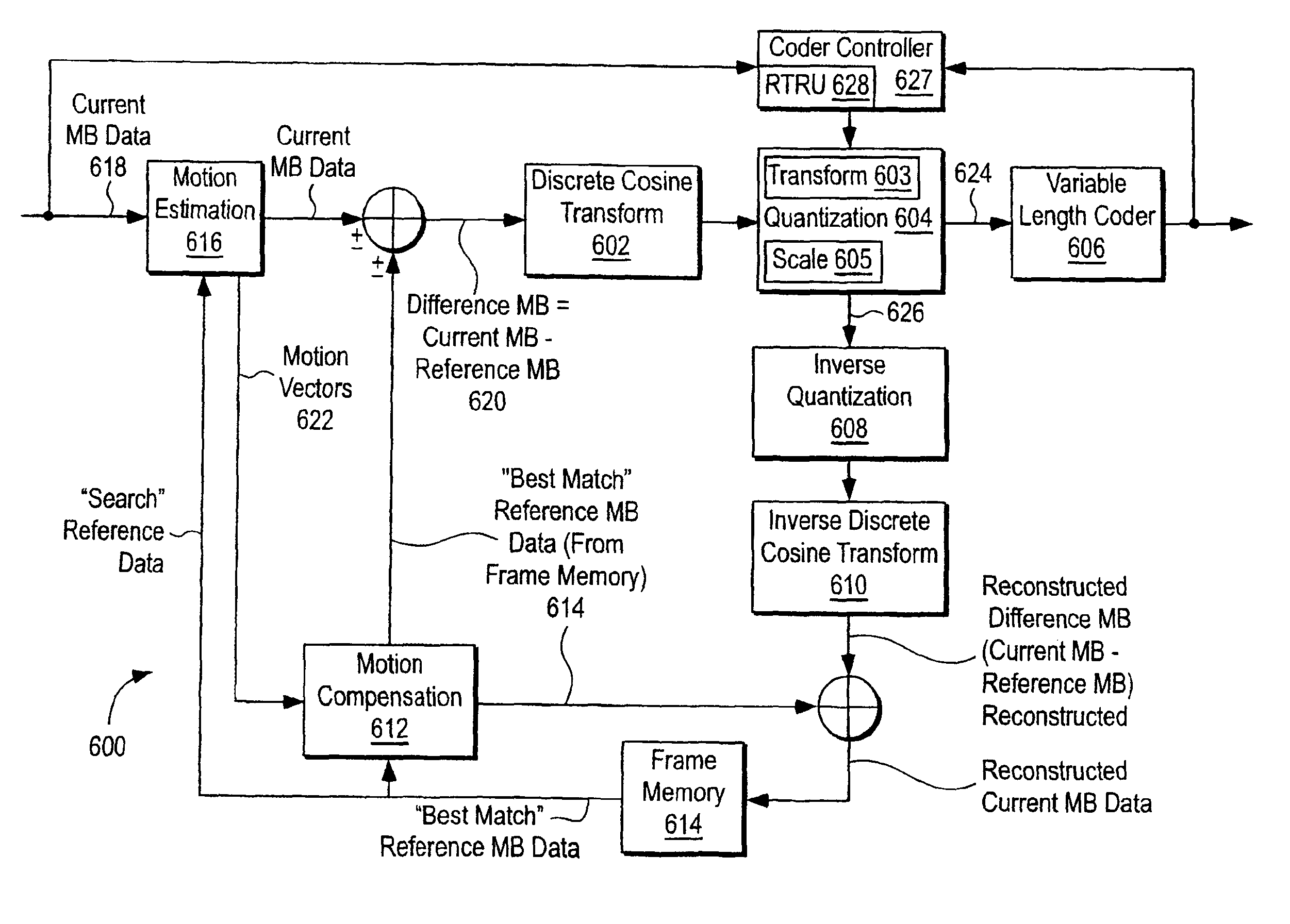

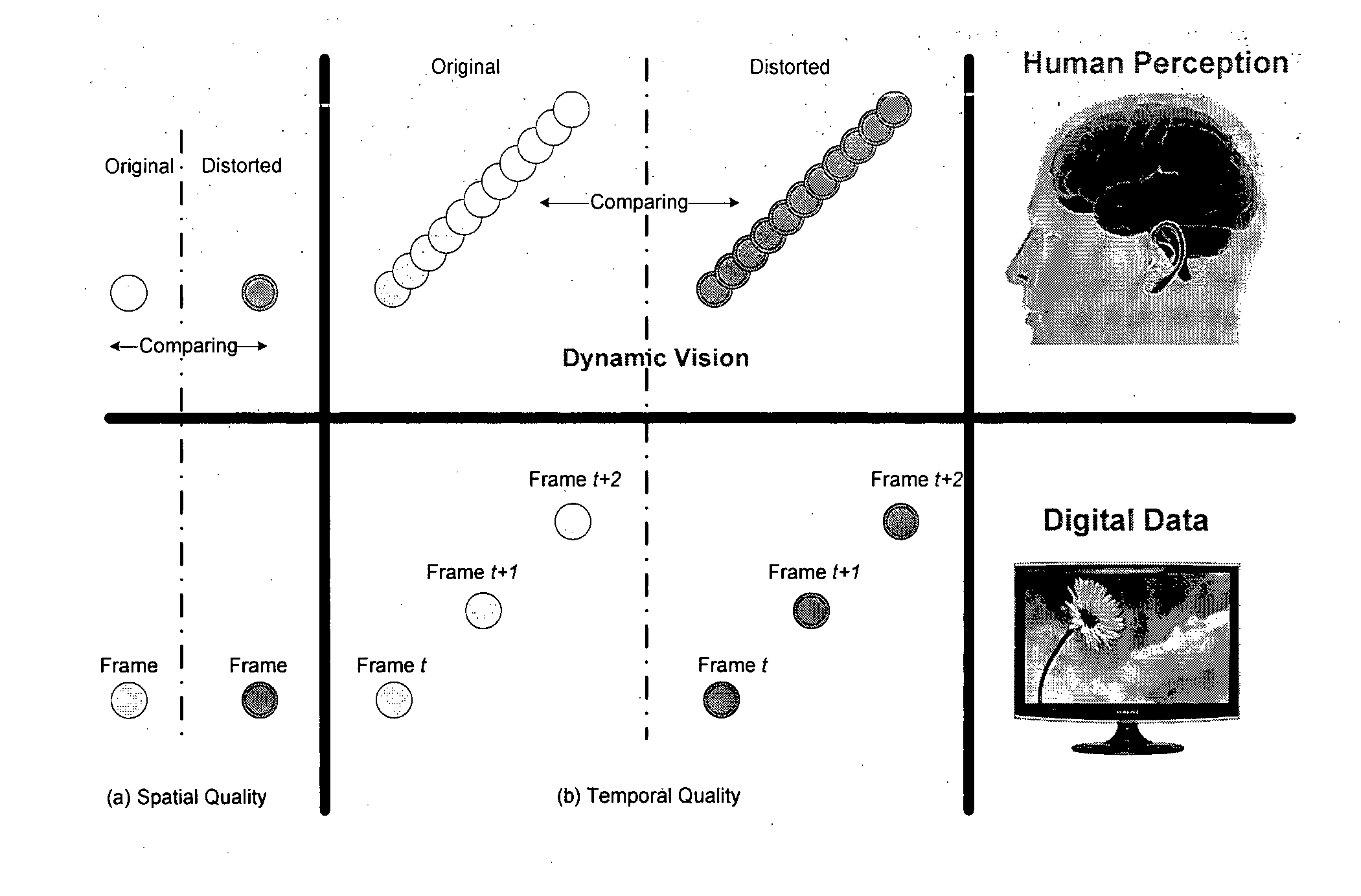

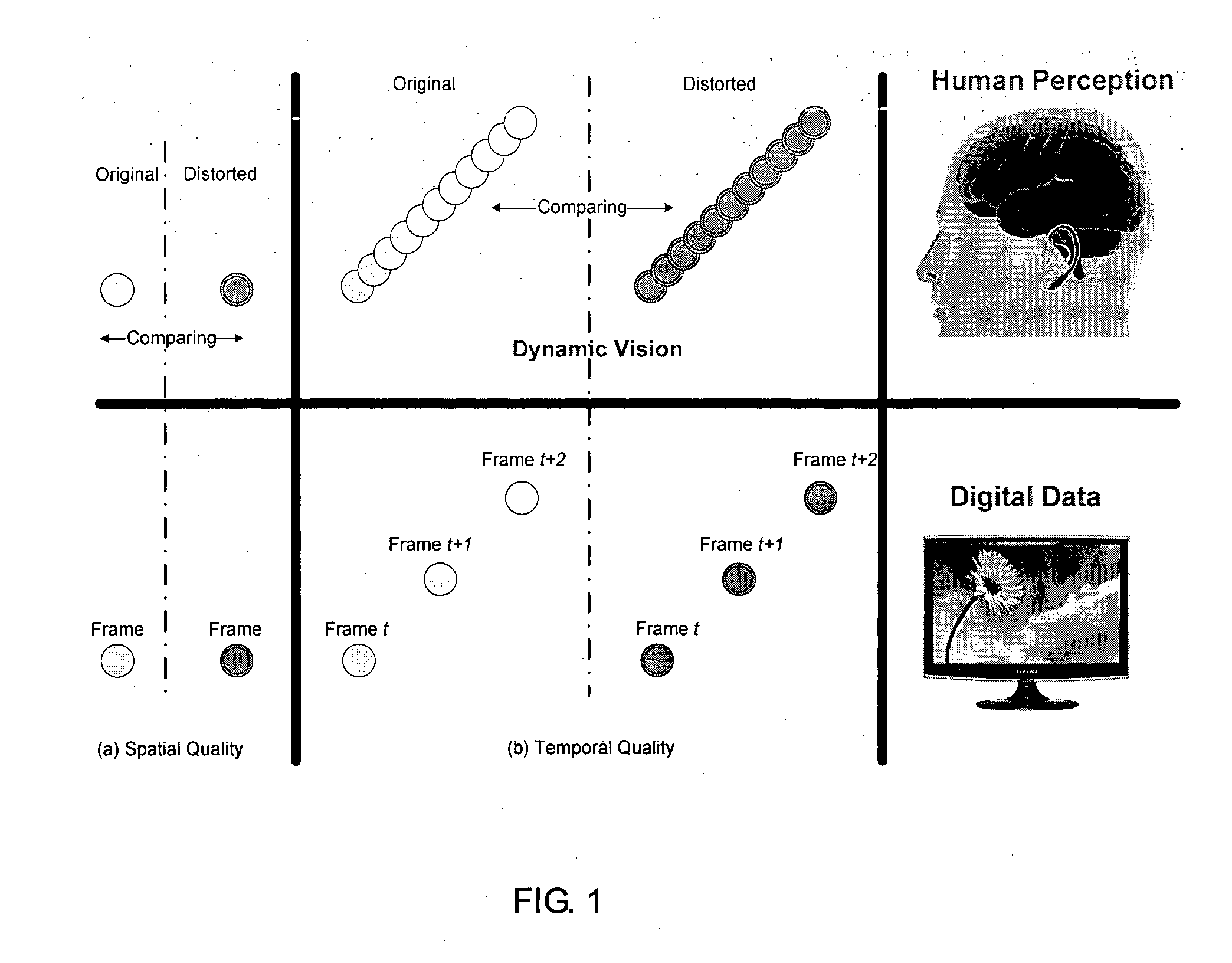

System and method of reduced-temporal-resolution update for video coding and quality control

ActiveUS8325797B2Reduce resolutionLess update informationColor television with pulse code modulationColor television with bandwidth reductionTemporal resolutionImage resolution

A novel system and method of Reduced-Temporal-Resolution Update (RTRU) and quantizing video transform coefficients is provided for use using hybrid coding standards when receiving a frame from within a group of video frames, where the amplitude of the quantization parameter is defined for the quantization of the frame according to a reduced temporal resolution update process; where the amplitude of the quantization parameter for macroblocks in the frame is defined according to a reduced temporal resolution update process; and where a bitstream is composed for transmission and subsequent decoding by a standard compliant decoder.

Owner:GEO SEMICONDUCTOR INC

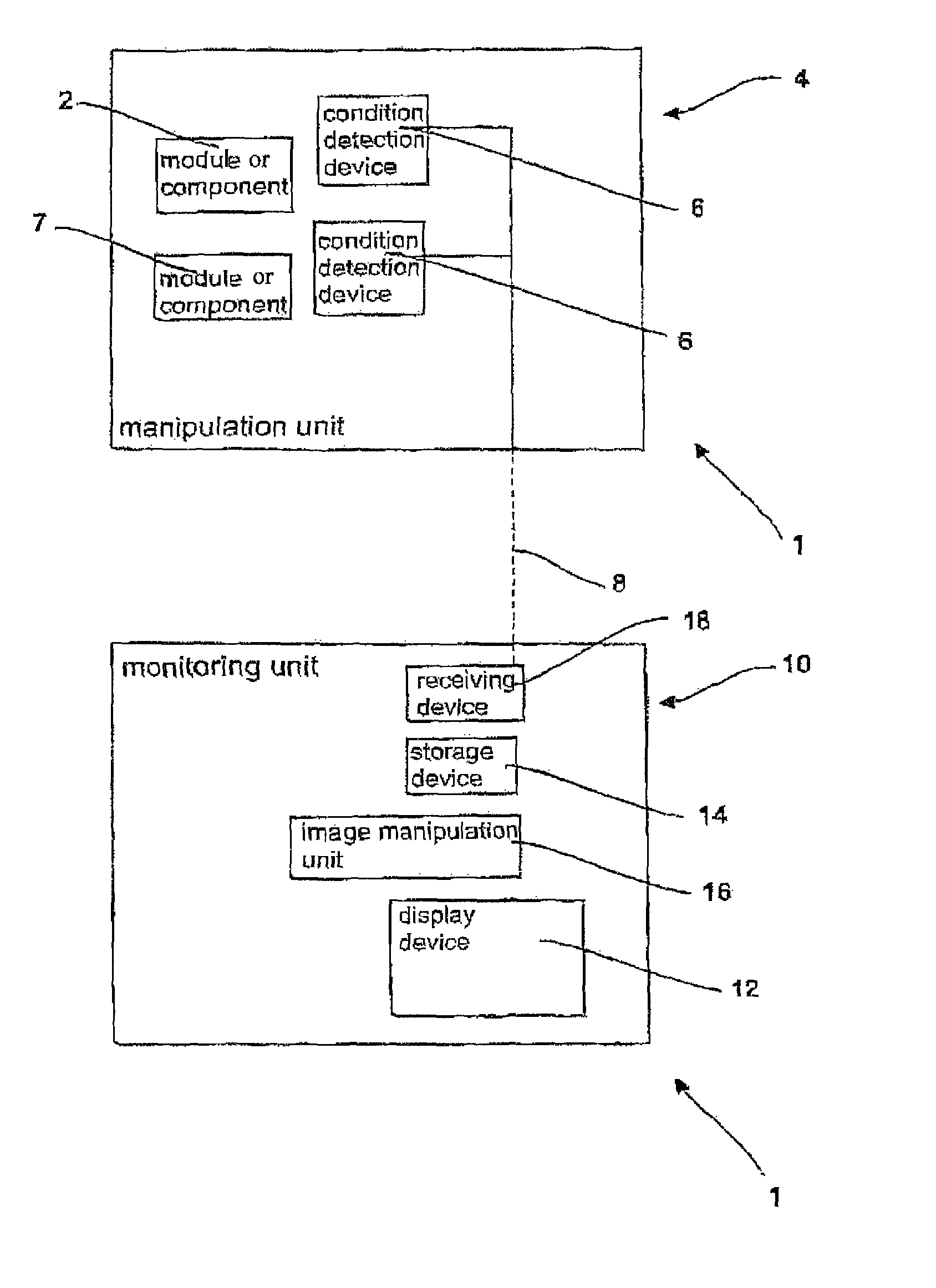

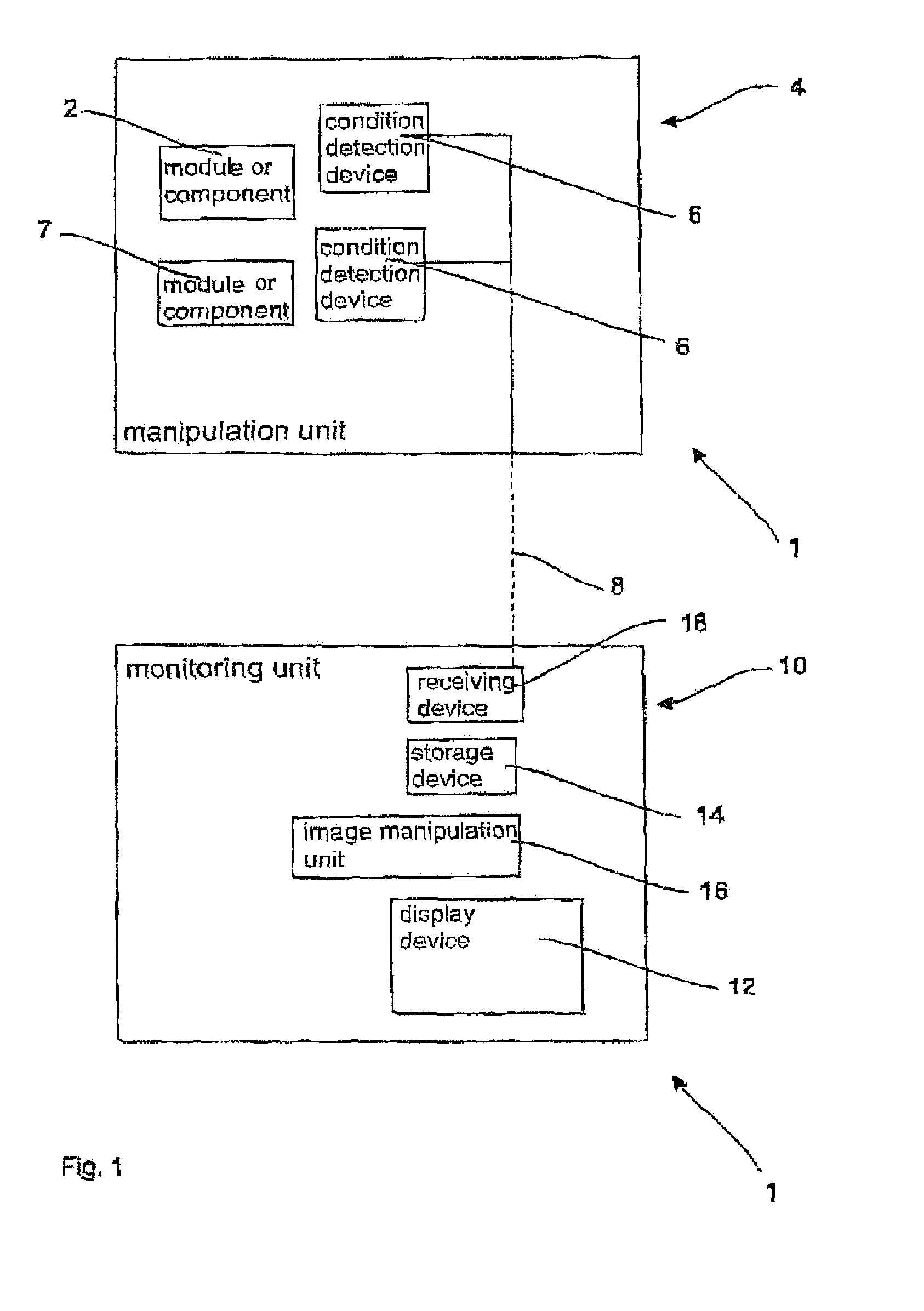

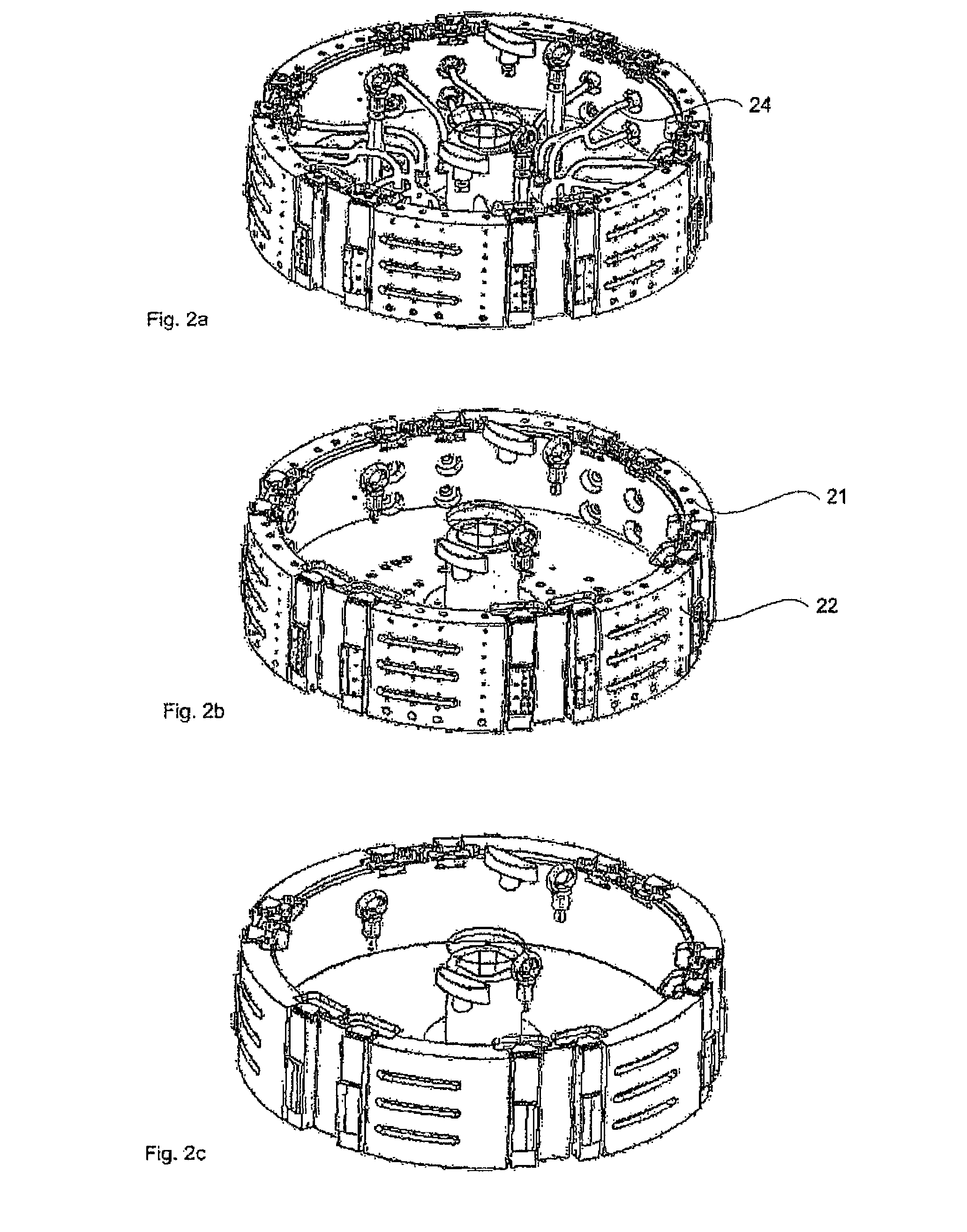

Monitoring unit for a device for manipulating containers

ActiveUS8265781B2Easy to operateImproving the self-descriptiveness of the machineProgramme controlSafety arrangmentsDisplay deviceData storing

A device for manipulating containers, comprising a manipulation unit manipulating the containers in a predetermined manner, this manipulation unit including at least one condition detection unit which detects at least one operating condition of the manipulation unit and sends out condition signals which are characteristic for this operating condition of the manipulation unit, and including a monitoring unit for monitoring the manipulation unit, the monitoring unit including a visual display device for displaying information as well as a storage device in which presentation data for components of the manipulation unit is deposited. According to the invention, the monitoring unit includes an image manipulation unit which as a response to emitted condition signals provides image sequences on the basis of presentation data stored on the storage device, which image sequences may be output via the display device.

Owner:KRONES AG

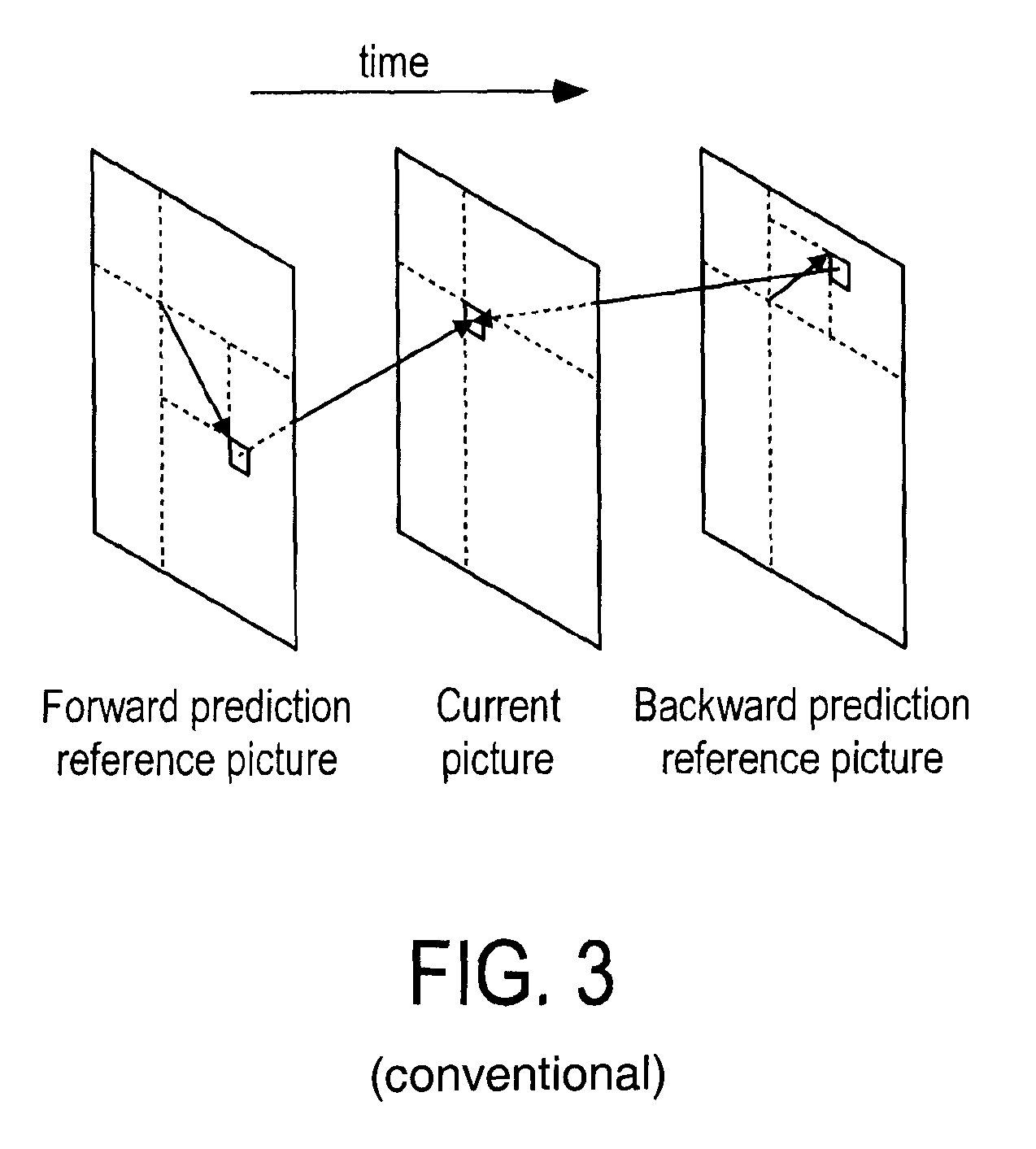

Method and device for determining a motion vector for a current block of a current video frame

InactiveUS20130251045A1Quality of experience dropDifferent qualityColor television with pulse code modulationColor television with bandwidth reductionMotion vectorComputer science

A method for determining a motion vector for a current video frame block comprises determining the motion vector using full search. Then, a number of further motion vectors is counted which is the number of motion vectors of neighbouring blocks which are similar to each other and the motion vector. Then it is ascertained that the number meets or exceeds a threshold and that the motion vector is not similar to at least one of the counted further motion vectors. A search region is determined using counted motion vectors and searched for a local best match of the current block. The motion vector is changed towards referencing the local best match. The search region only comprises candidates referenced by motion vector candidates similar to a yet further motion vector pointing to a centre of the further search region. Then, the motion vector resembles the motion presumed by the HVS.

Owner:THOMSON LICENSING SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com