Cleaning device for a textile machine

A technology for cleaning devices and textile machines, which can be used in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of impossibility of cleaning fiber materials and achieve the effect of removing and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

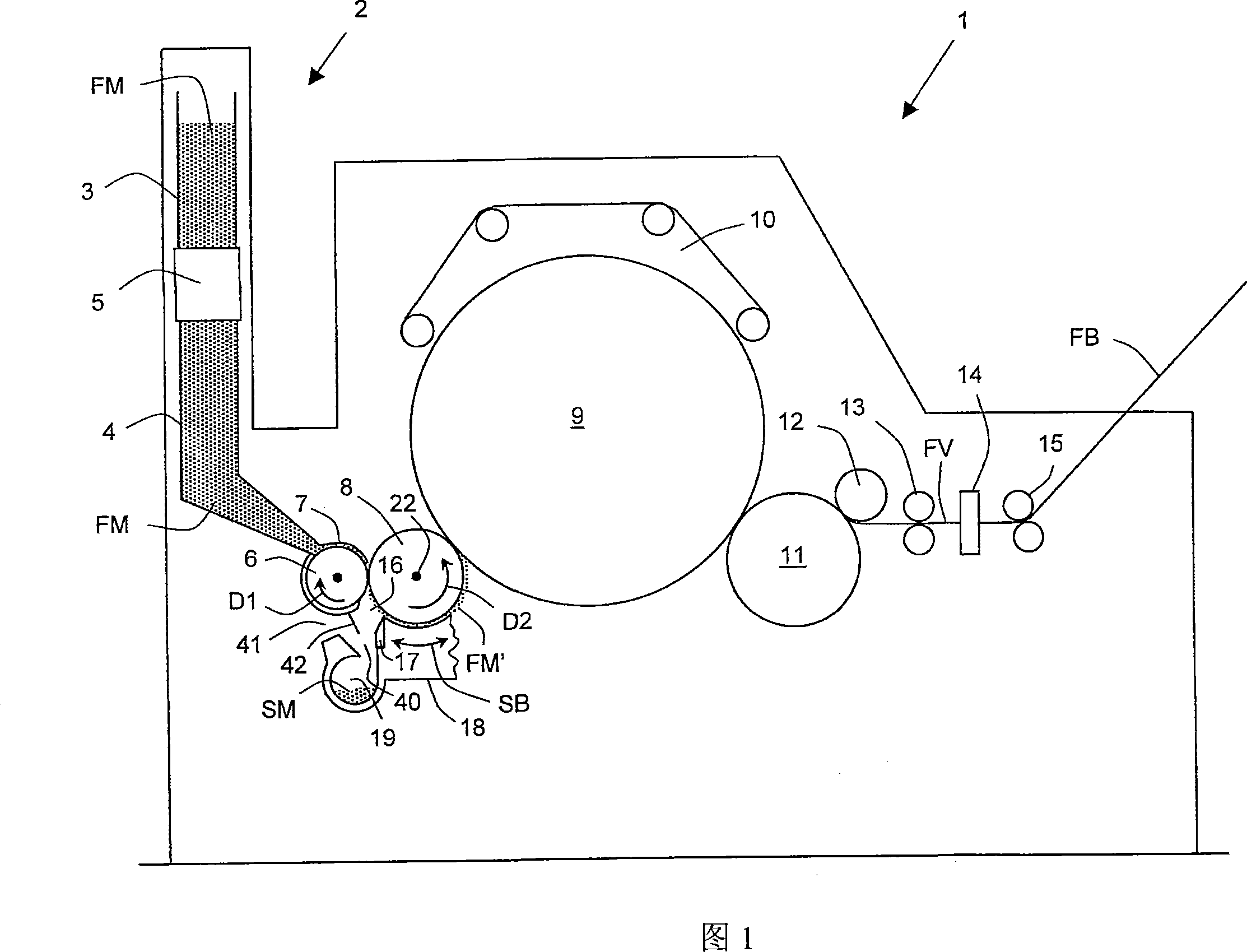

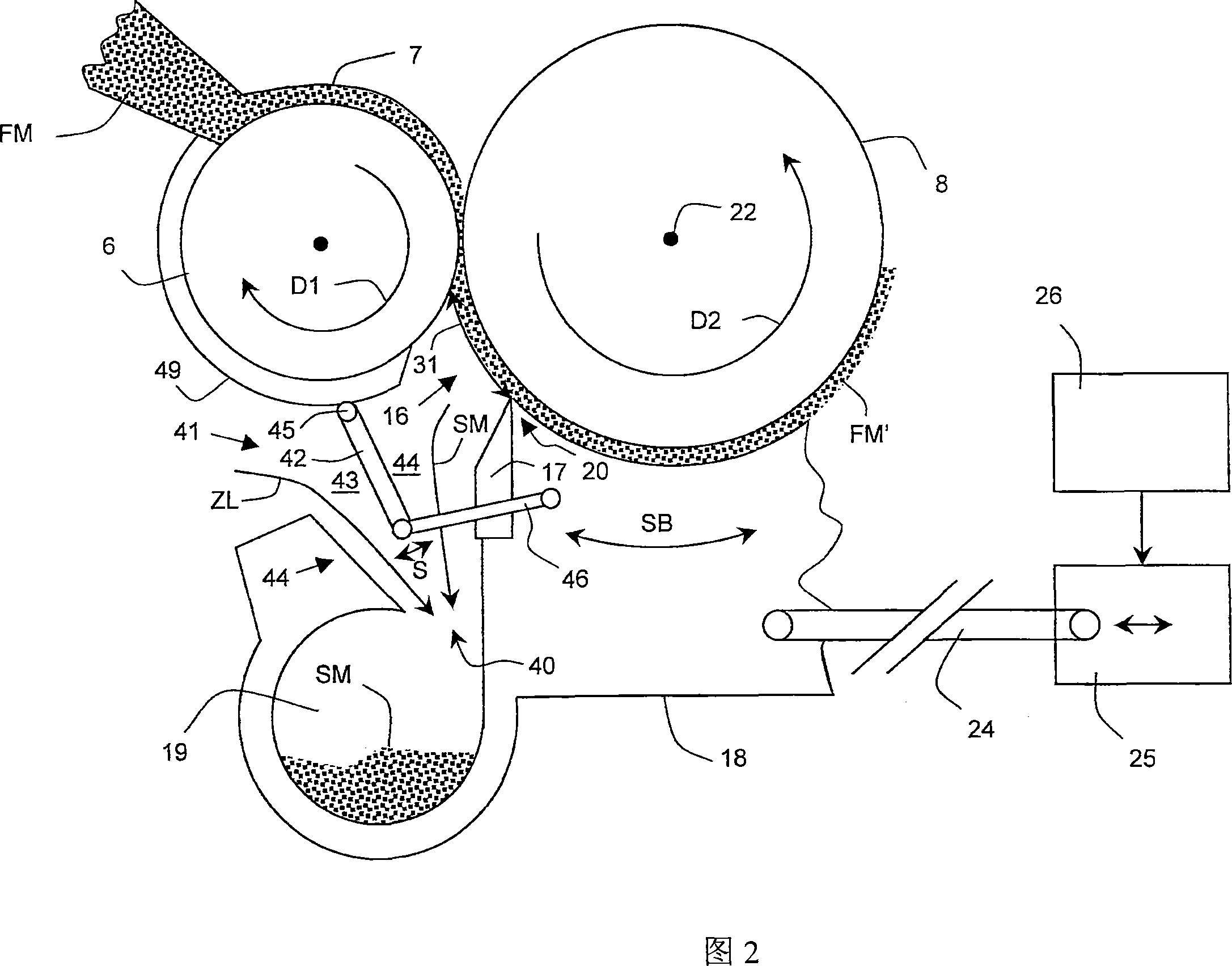

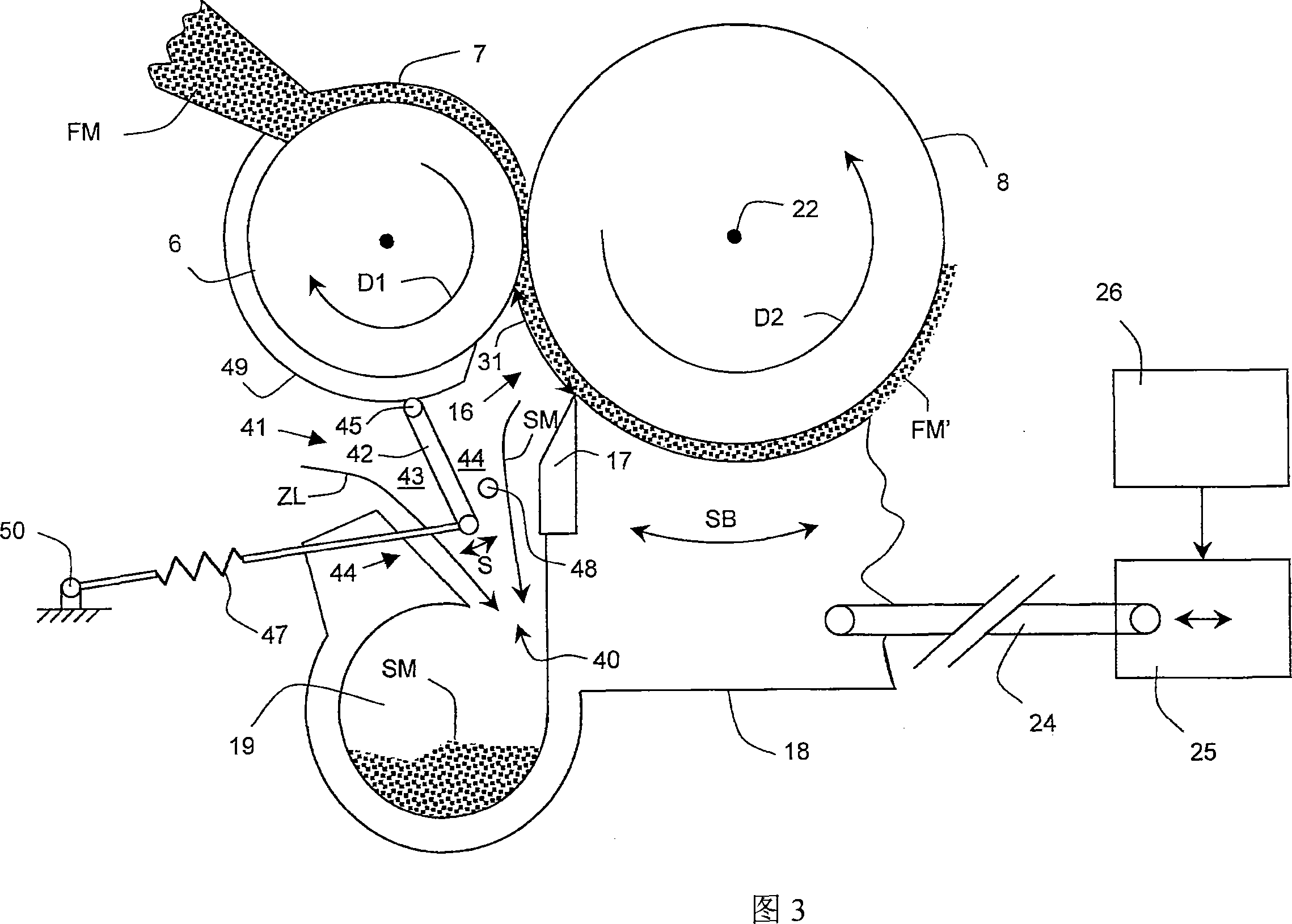

[0041] FIG. 1 shows a carding machine 1 as an example of a textile machine with a cleaning device. However, the invention can also be applied in other textile machines, in particular open-broom machines, such as coarse cleaners, fine cleaners or mixers, and also in spinning preparation machines, such as open-ended spinning machines.

[0042] The card 1 is designed for carding synthetic or natural fibers, in particular staple fibers, and fiber mixtures formed therefrom. The card 1 comprises a feed channel 2 which is only schematically shown here. The fibrous material FM prepared in the blowroom and in the form of coarse cotton tufts is fed into the feed channel 2 via an air flow by means of a pipe system not shown. In this case, the feed chute 2 comprises a feed trough 3 in its upper part, a storage trough 4 in its lower part and an opener device 5 interposed between them.

[0043] By opening the coarse fiber bundles in the opening device 5 , previously firmly bonded individu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com