Plastic fiber separator

A plastic fiber and separator technology, which is applied in plastic recycling, transportation and packaging, chemical instruments and methods, etc., can solve the problems affecting the separation of plastic fibers, sewage overflowing to the motor, and lack of water collection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] see Figure 1-4 , in the embodiment of the present invention, a plastic fiber separator, including

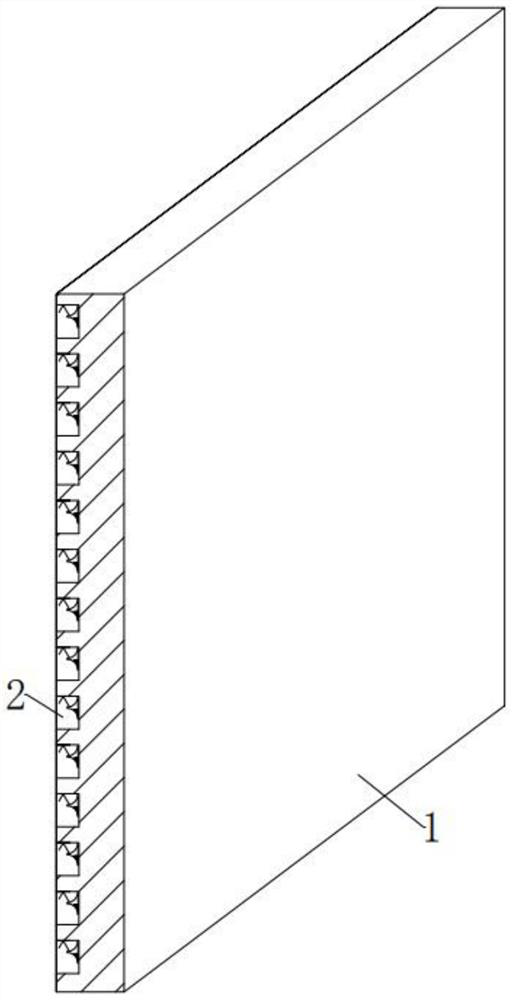

[0047] Shell 1, the inner position of the left outer surface of the shell 1 is arranged in an up-down and vertical direction, and several water-collecting components 2 that can collect sewage are embedded;

[0048] The water collection assembly 2, the water collection assembly 2 includes a water collection shell 201, a pretreatment assembly 202 that can preliminarily close the inlet before the capacity of the water collection shell 201 is saturated, and a pretreatment assembly 202 that can close the inlet of the water collection shell 203 to prevent the collected sewage from overflowing. Water sealing component 203;

[0049] The water collecting shells 201 are embedded in the inner position of the left outer surface of the casing 1 in the vertical and vertical directions, and are equally adjacent to each other;

[0050] A pretreatment assembly 202 is movably installed ...

Embodiment 2

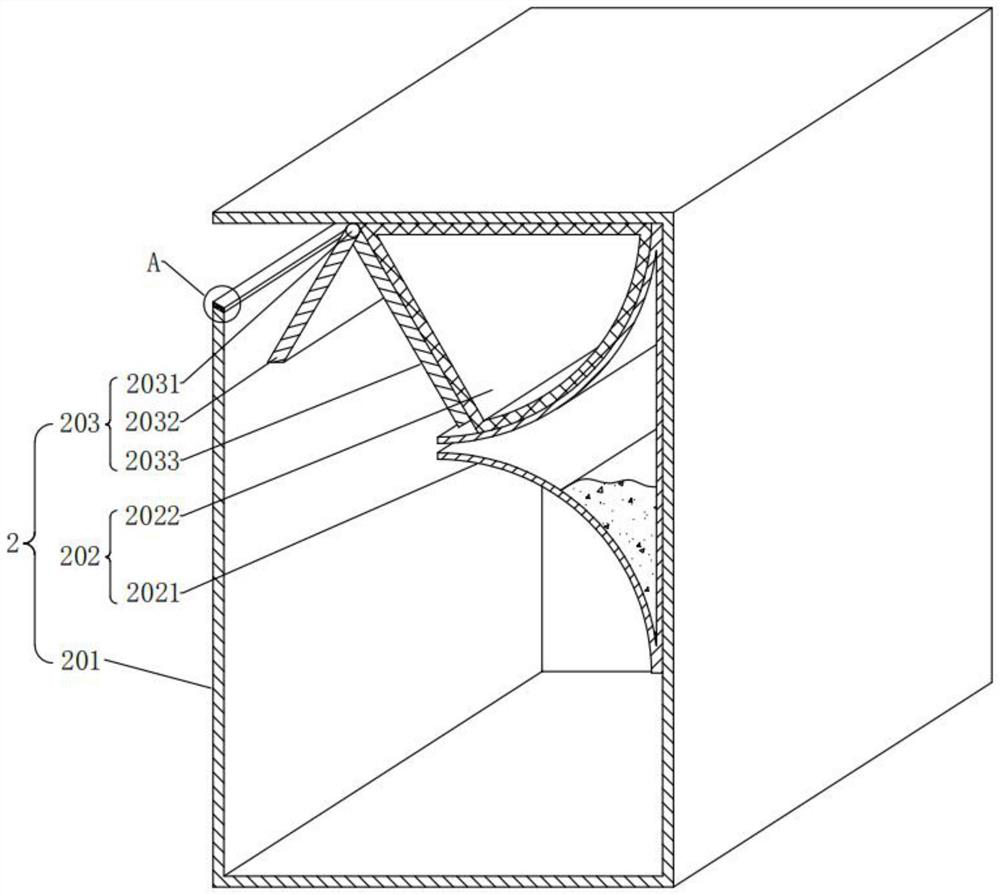

[0058] see image 3 , Figure 5-6 , the difference between the embodiment of the present invention and the embodiment 1 is that the preprocessing component 202 includes:

[0059] The collection tank 2021, the collection tank 2021 is fixedly installed at the position between the right inner wall of the water collecting shell 201 and the top end. Right vertical shape, the material of the collection tank 2021 is copper;

[0060] The collection tank 2021 here has a shape that is hollow inside, concave at the upper left end, convex at the lower left end, and vertical at the right on a longitudinal section, and the material is made of copper. When the internal sewage water level line rises to the gap of the collection tank 2021, it means that the sewage is about to fill the water collecting shell 201. At this time, the sewage will enter the collection tank 2021 through the gap and come into contact with the quicklime powder in the collection tank 2021. A large amount of heat caus...

Embodiment 3

[0071] see image 3 and Figure 7 , the difference between the embodiment of the present invention and the embodiment 1 is that the water sealing component 203 includes:

[0072] As for the rotating shaft 2031, the left end of the top inner wall of the water collecting shell 201 is rotatably installed with the rotating shaft 2031 in the front-rear horizontal direction.

[0073] In the embodiment of the present invention, the water sealing component 203 further includes:

[0074] Left plate 2032, the left plate 2032 is fixedly installed around the lower left outer surface of the rotating shaft 2031, the length of the left plate 2032 is equal to the distance between the rotating shaft 2031 and the magnetic plate 2011, the left plate 2032 has different magnetism from the magnetic plate 2011, The angle between the plate 2032 and the vertical plane is 30° under normal conditions;

[0075] The length of the left plate 2032 here is equal to the distance between the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com