Patents

Literature

335 results about "Electron optics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electron optics is a mathematical framework for the calculation of electron trajectories along electromagnetic fields. The term optics is used because magnetic and electrostatic lenses act upon a charged particle beam similarly to optical lenses upon a light beam.

Electron beam exposure system

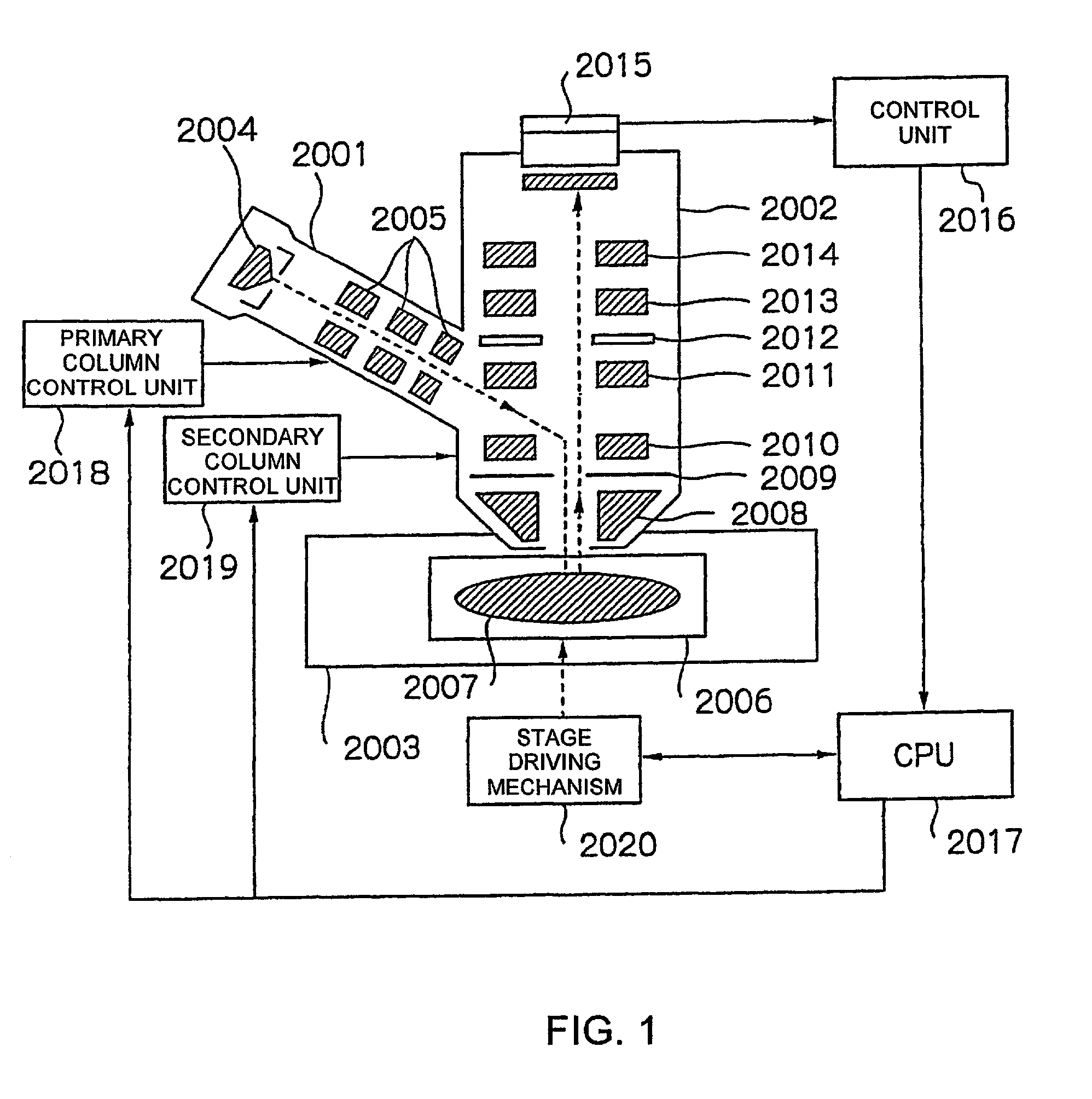

ActiveUS6897458B2Improve performanceHigh resolutionParticle separator tubesCamera film strip handlingVIT signalsElectron optics

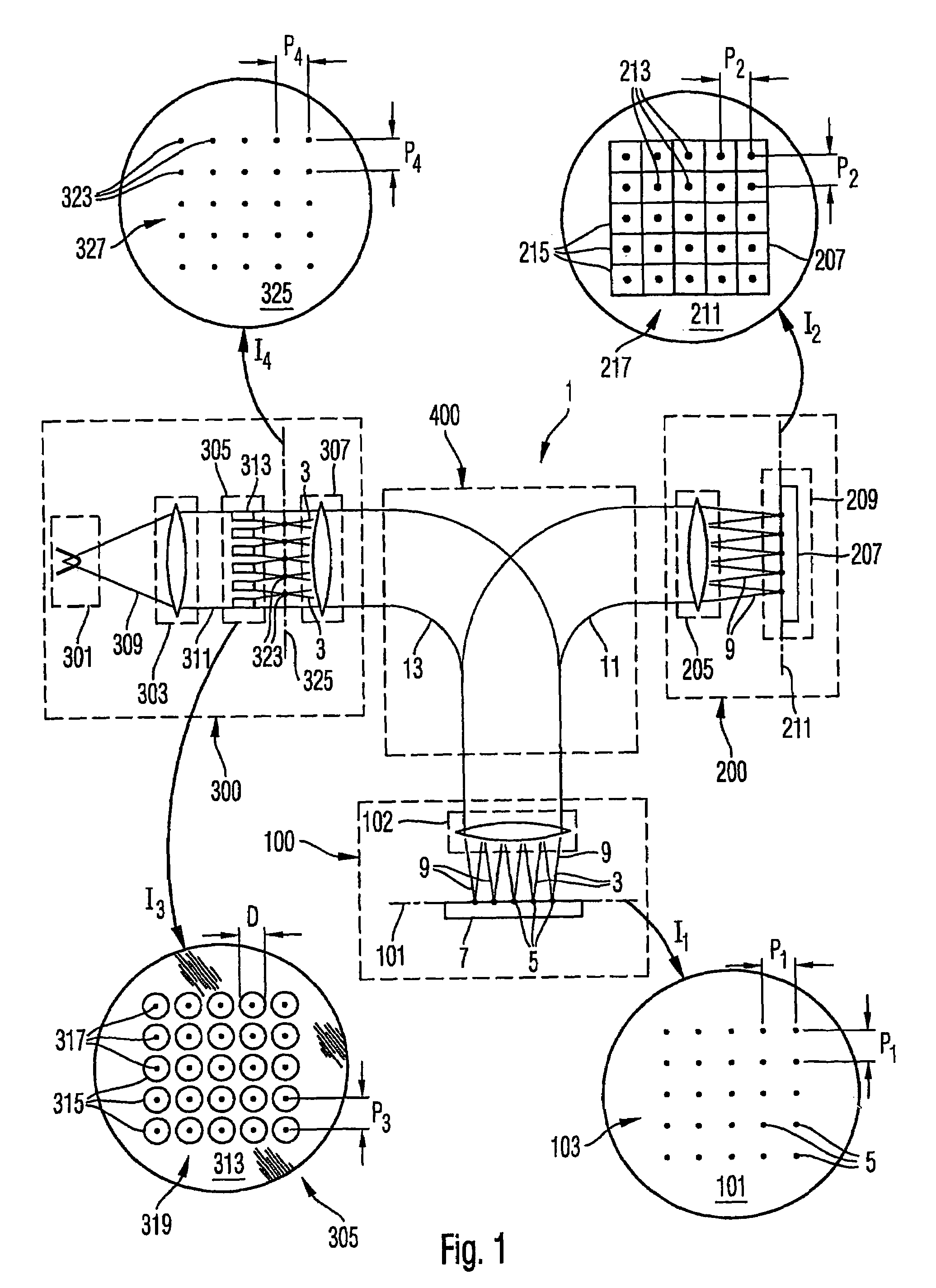

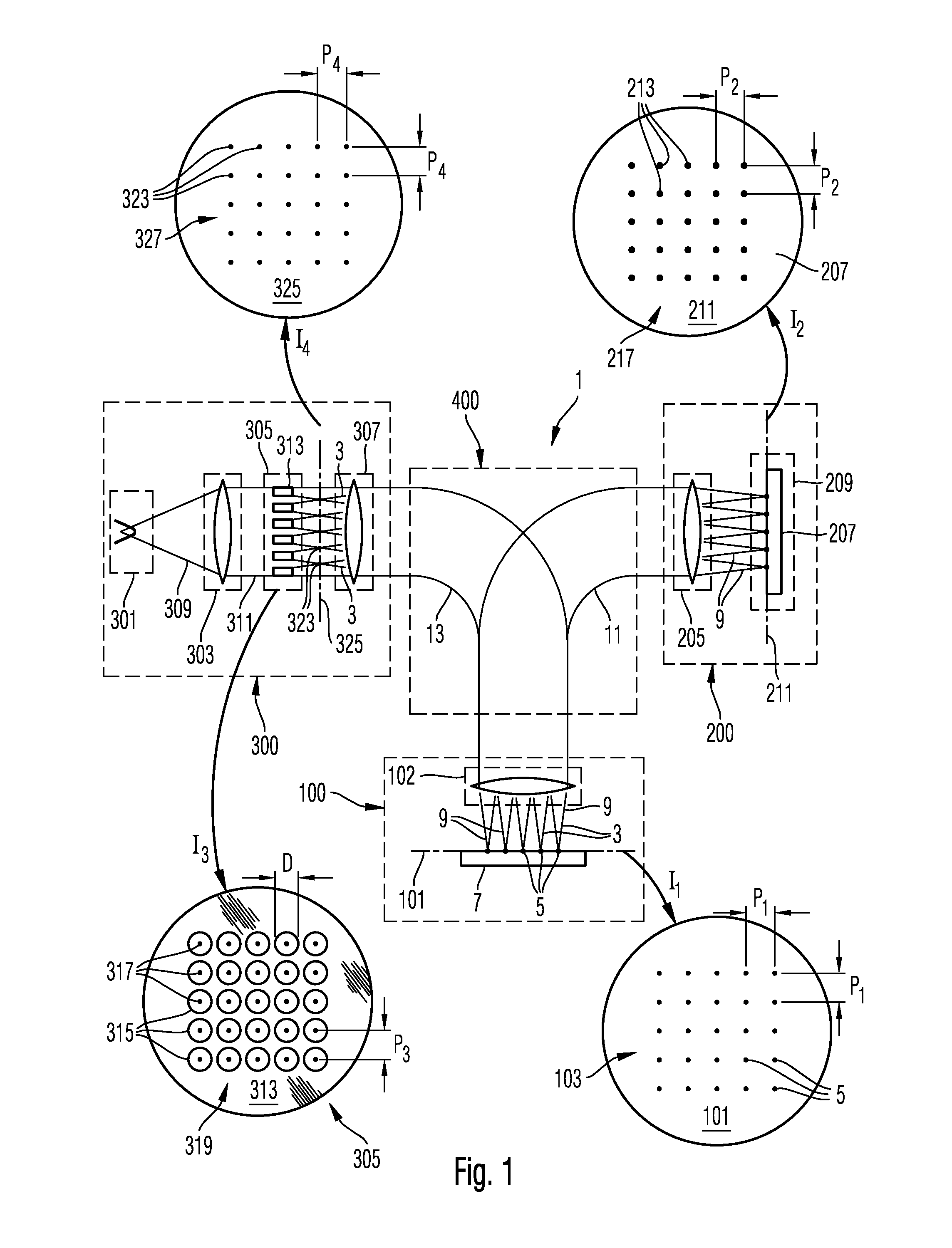

The invention relates to an electron beam exposure apparatus for transferring a pattern onto the surface of a target, comprising:a beamlet generator for generating a plurality of electron beamlets;a modulation array for receiving said plurality of electron beamlets, comprising a plurality of modulators for modulating the intensity of an electron beamlet;a controller, connected to the modulation array for individually controlling the modulators,an adjustor, operationally connected to each modulator, for individually adjusting the control signal of each modulator;a focusing electron optimal system comprising an array of electrostatic lenses wherein each lens focuses a corresponding individual beamlet, which is transmitted by said modulation array, to a cross section smaller than 300 nm, anda target holder for holding a target with its exposure surface onto which the pattern is to be transferred in the first focal plane of the focusing electron optical system.

Owner:ASML NETHERLANDS BV

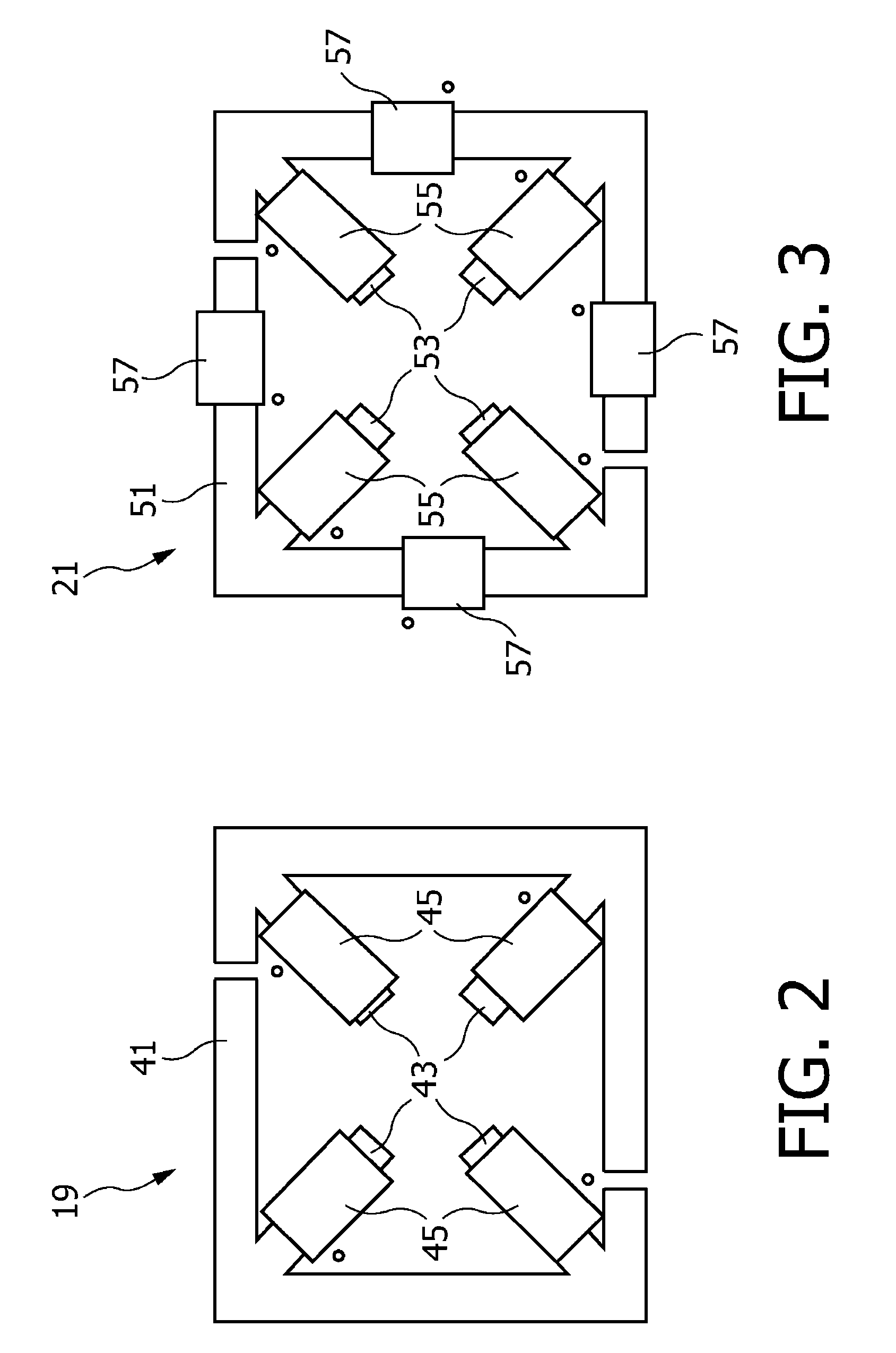

Particle-optical systems and arrangements and particle-optical components for such systems and arrangements

ActiveUS7244949B2High accuracy of focusingMaintain propertiesStability-of-path spectrometersSemiconductor/solid-state device testing/measurementSecondary electronsAtomic physics

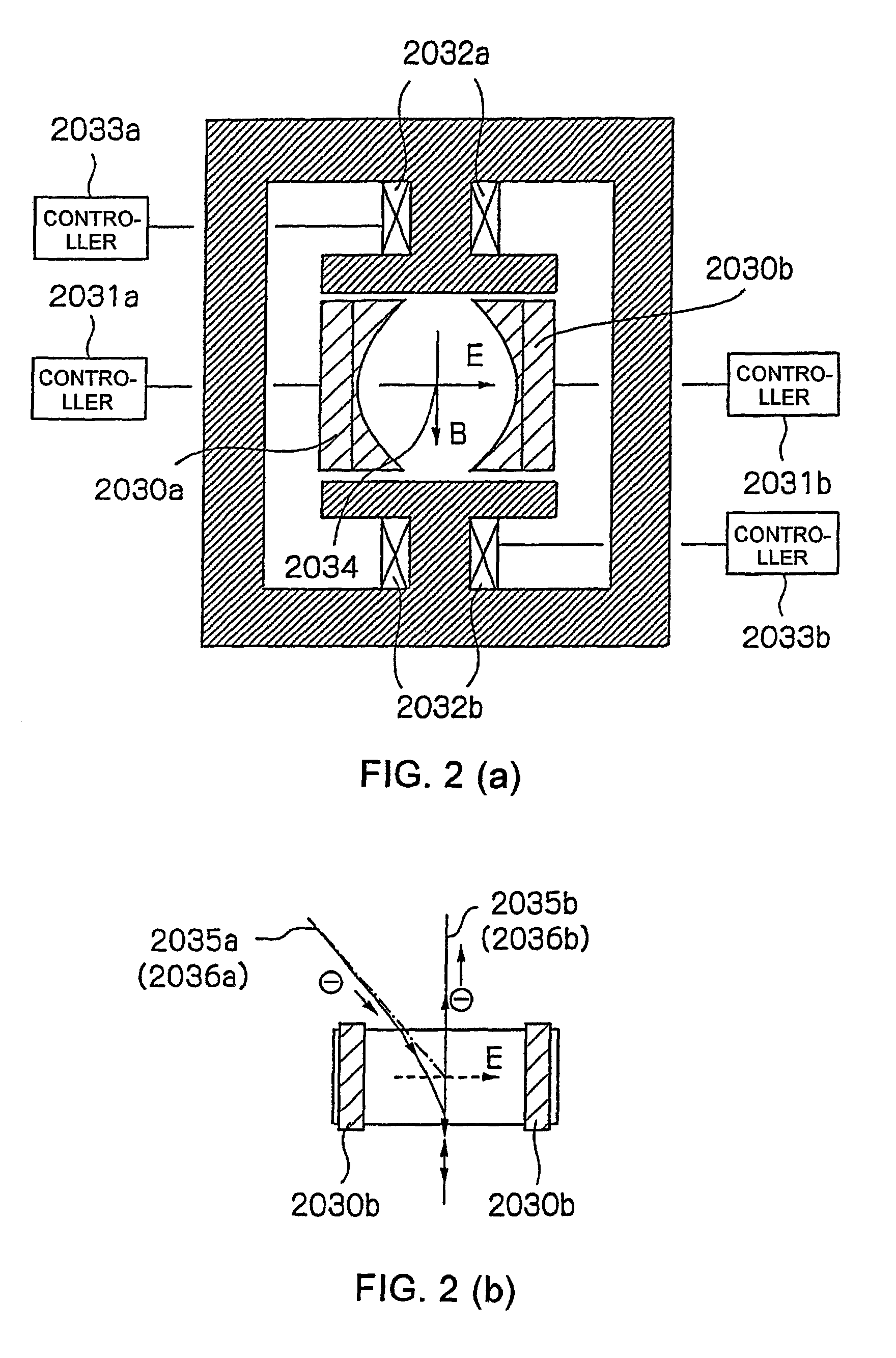

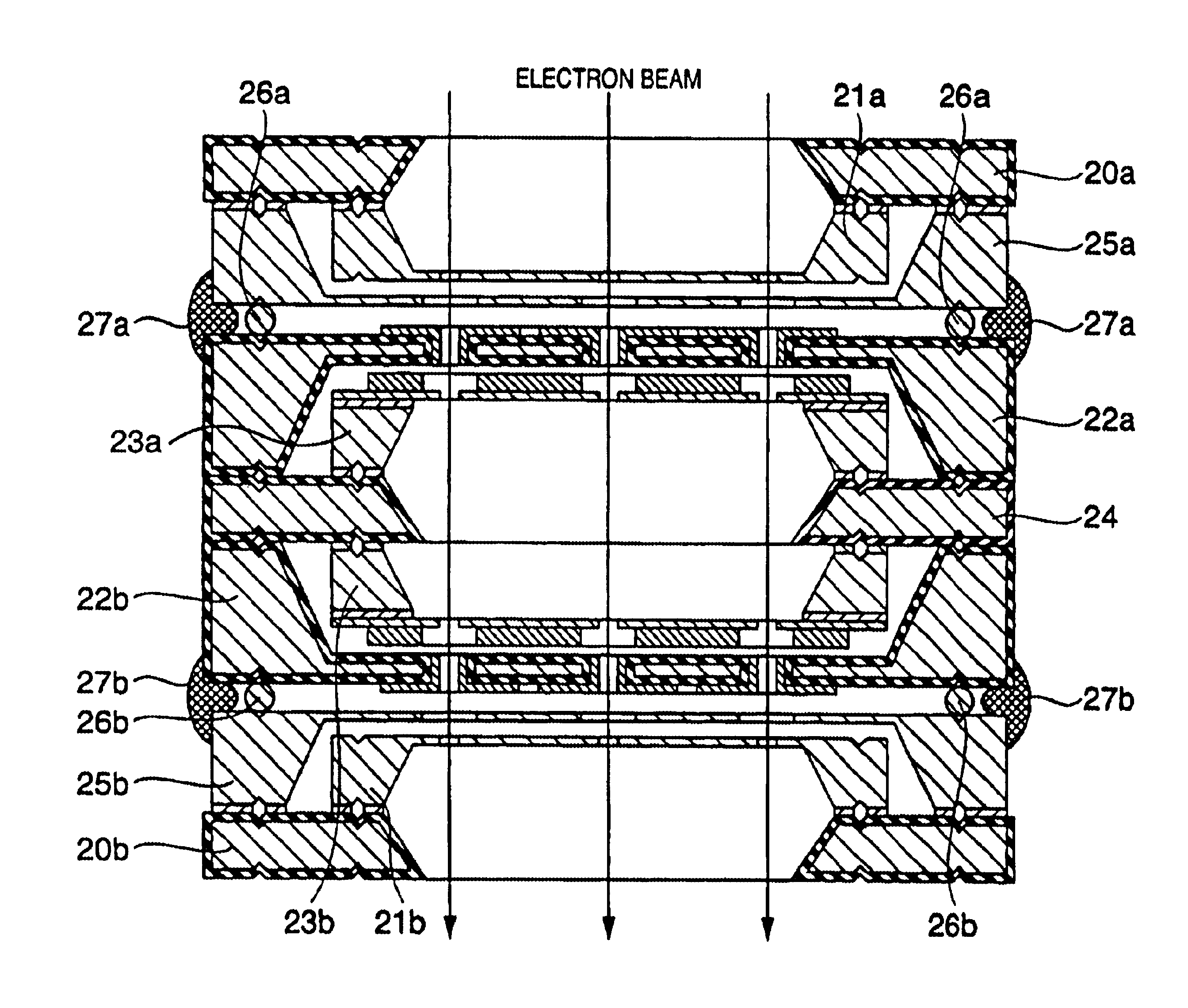

An electron-optical arrangement provides a primary beam path for a beam of primary electrons and a secondary beam path for secondary electrons. The electron-optical arrangement includes a magnet arrangement having first, second and third magnetic field regions. The first magnetic field region is traversed by the primary beam path and the secondary beam path. The second magnetic field region is arranged in the primary beam path upstream of the first magnetic field region and is not traversed by the secondary beam path. The first and second magnetic field regions deflect the primary beam path in substantially opposite directions. The third magnetic field region is arranged in the secondary beam path downstream of the first magnetic field region and is not traversed by the first beam path. The first and third magnetic field regions deflect the secondary beam path in a substantially same direction.

Owner:CARL ZEISS MICROSCOPY GMBH +1

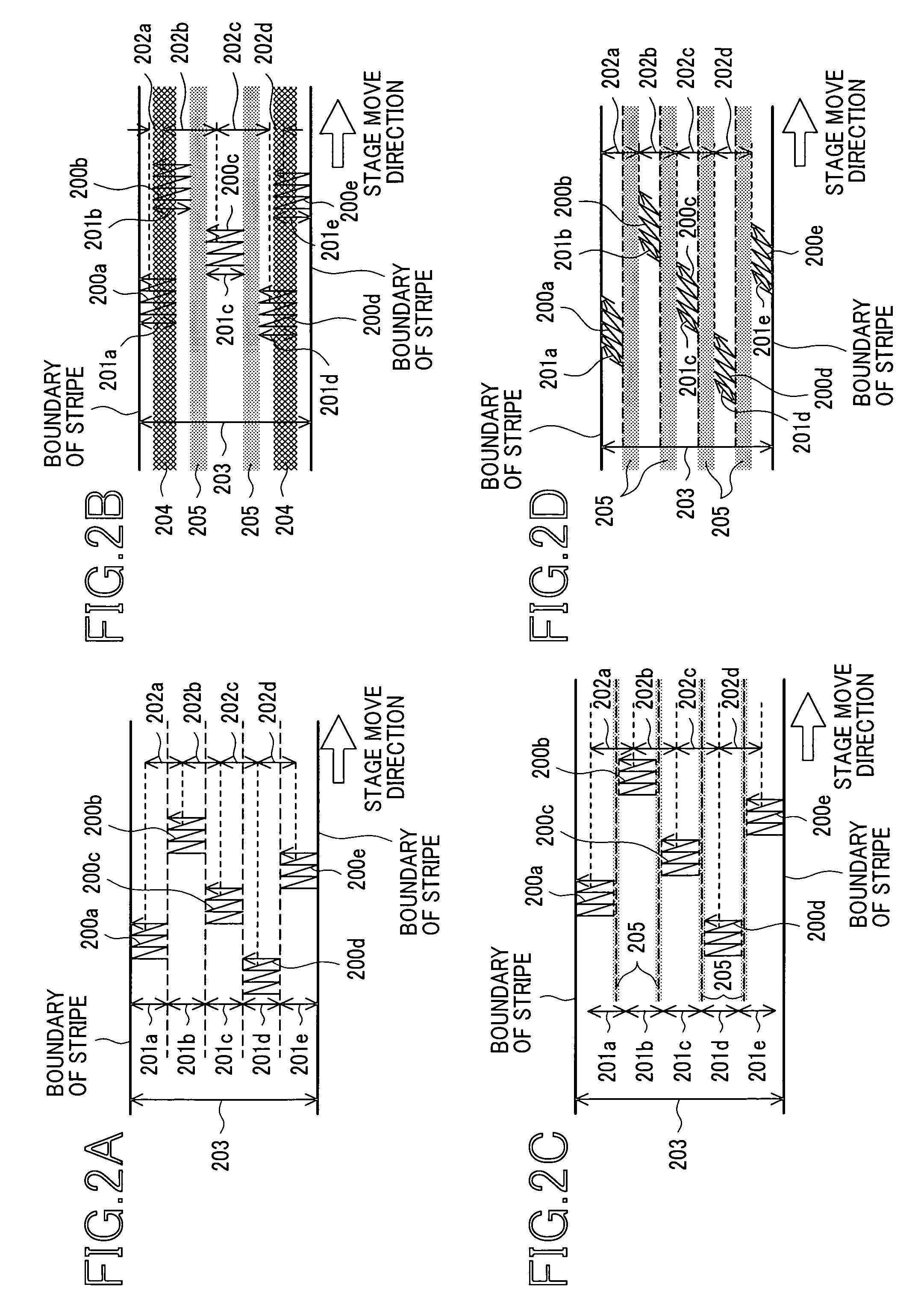

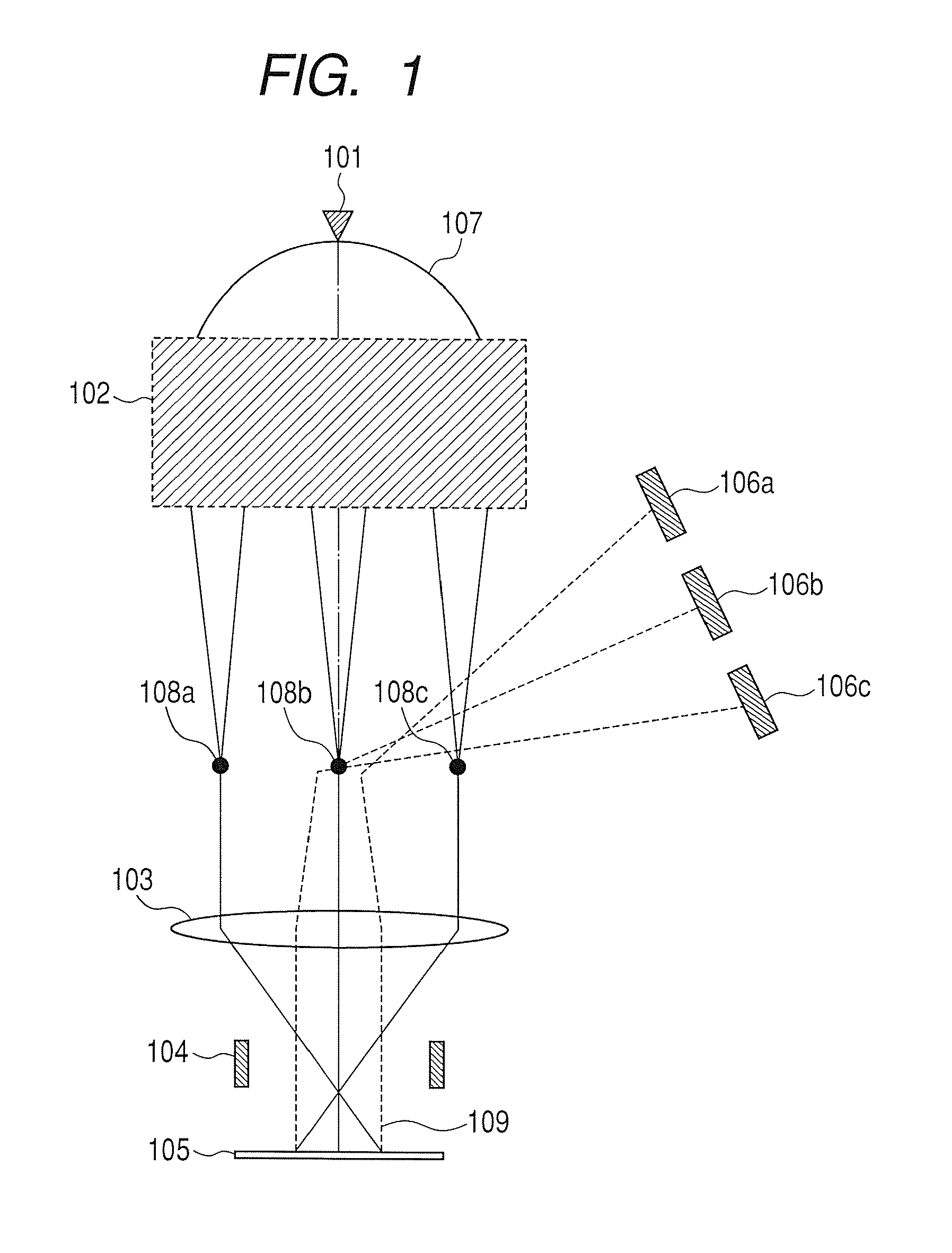

Multi-beam multi-column electron beam inspection system

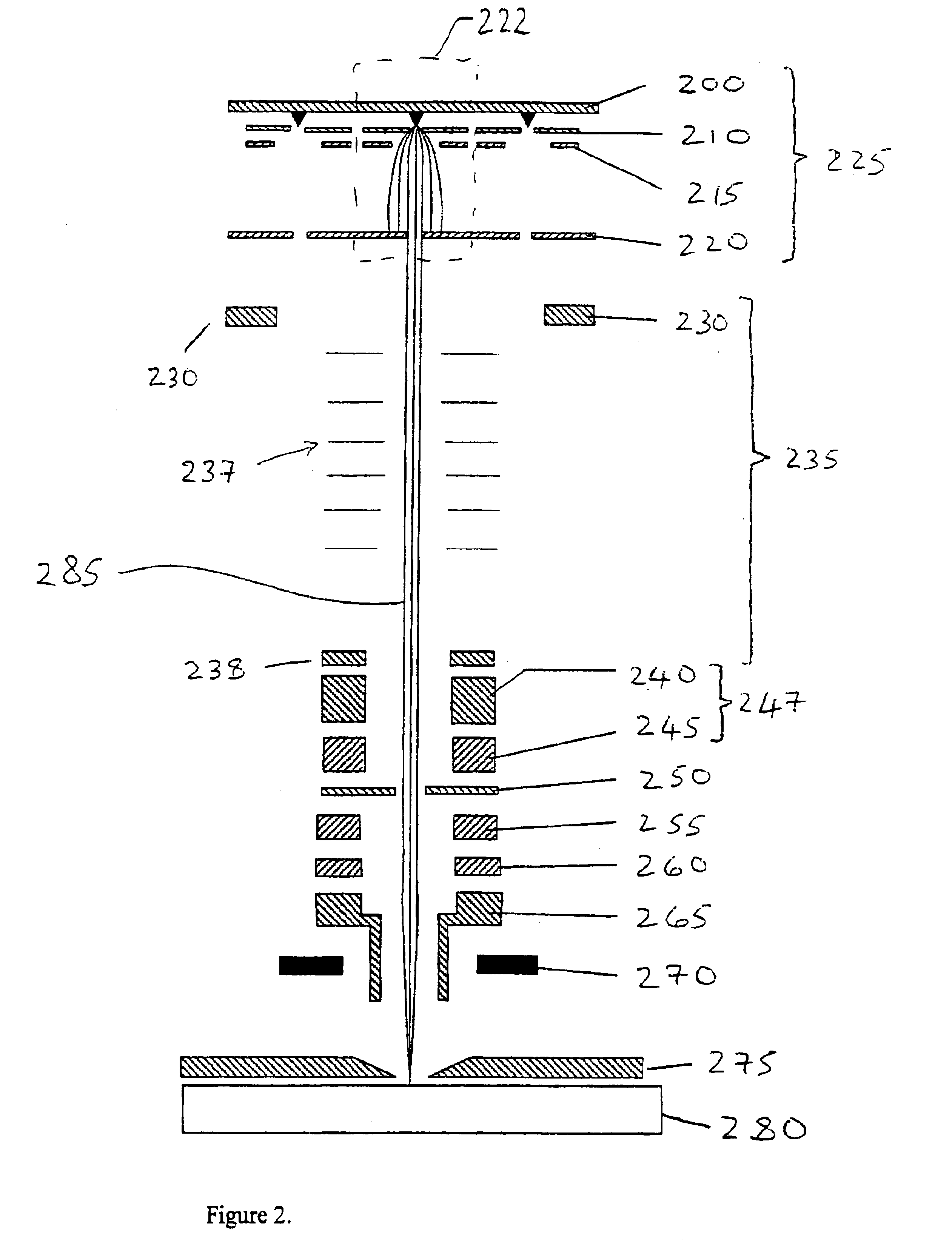

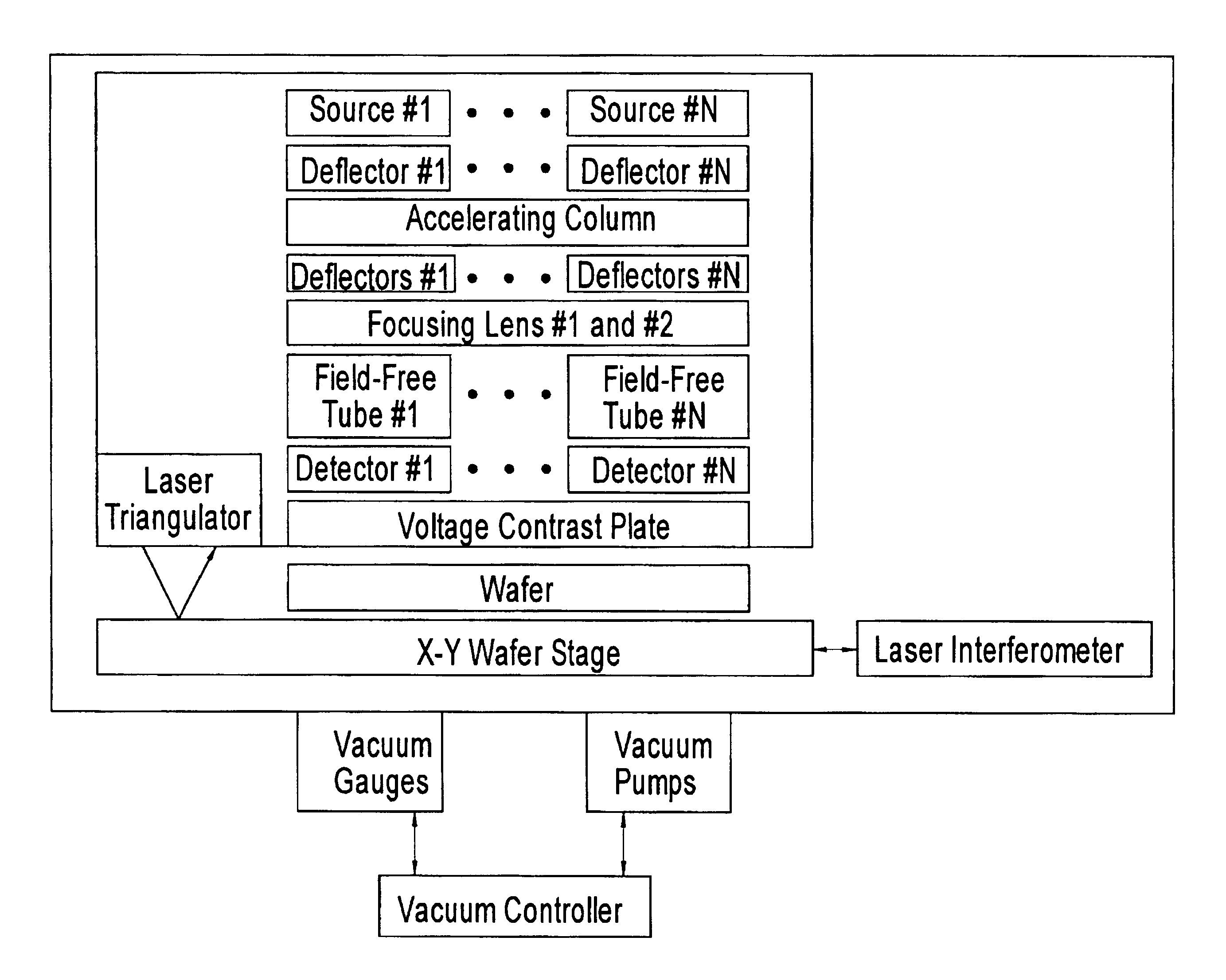

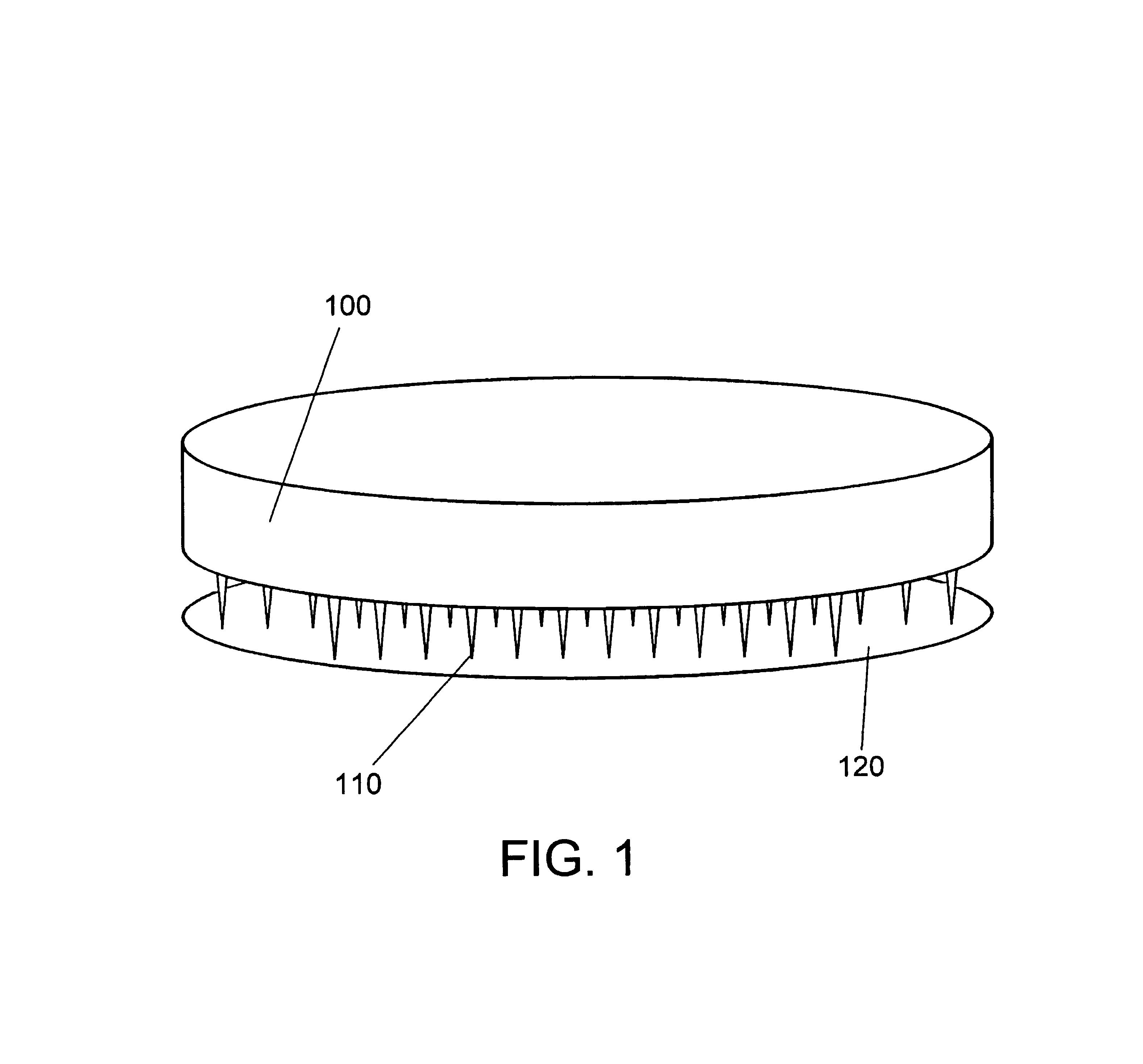

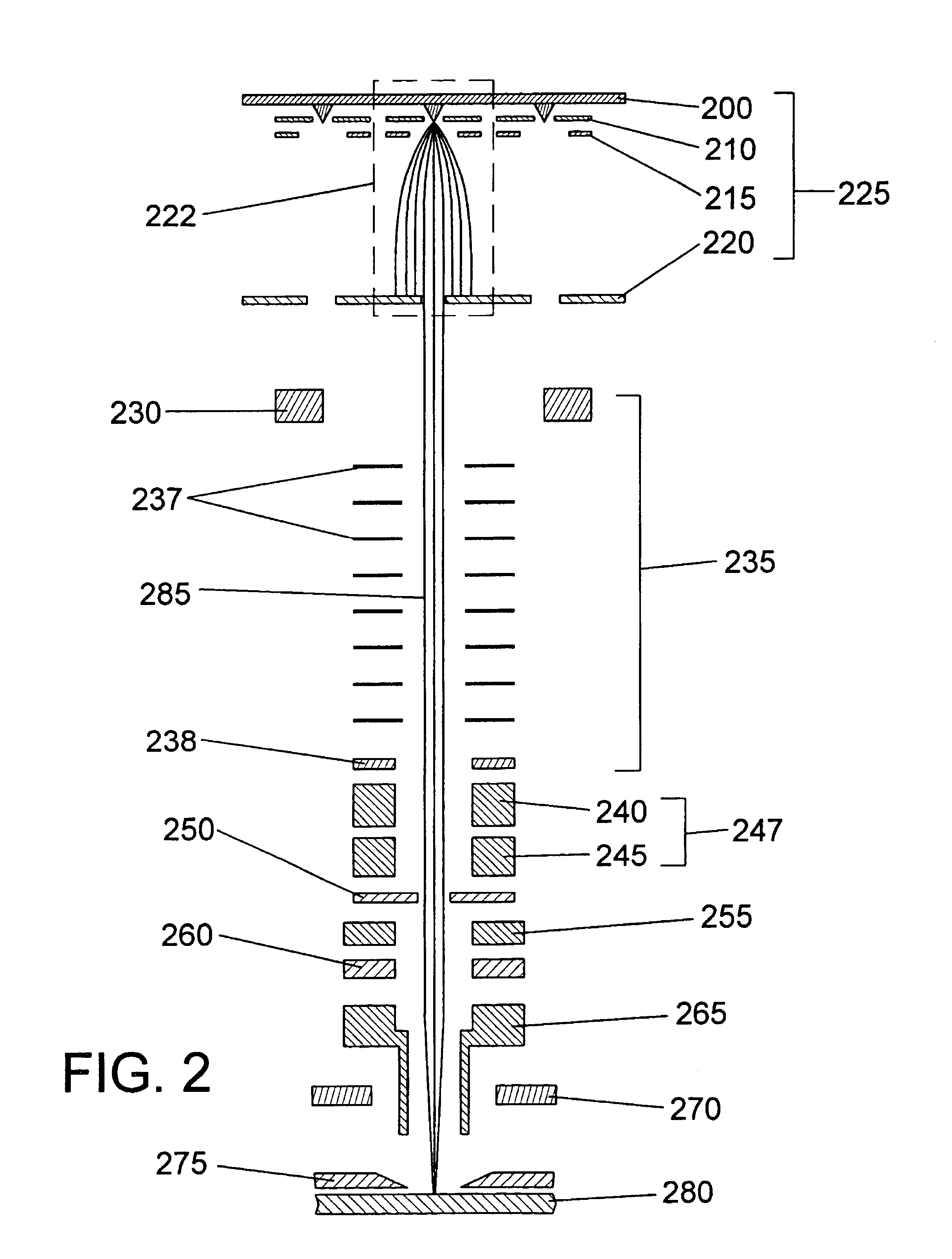

InactiveUS6844550B1Material analysis using wave/particle radiationRadiation/particle handlingSystems designData stream

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

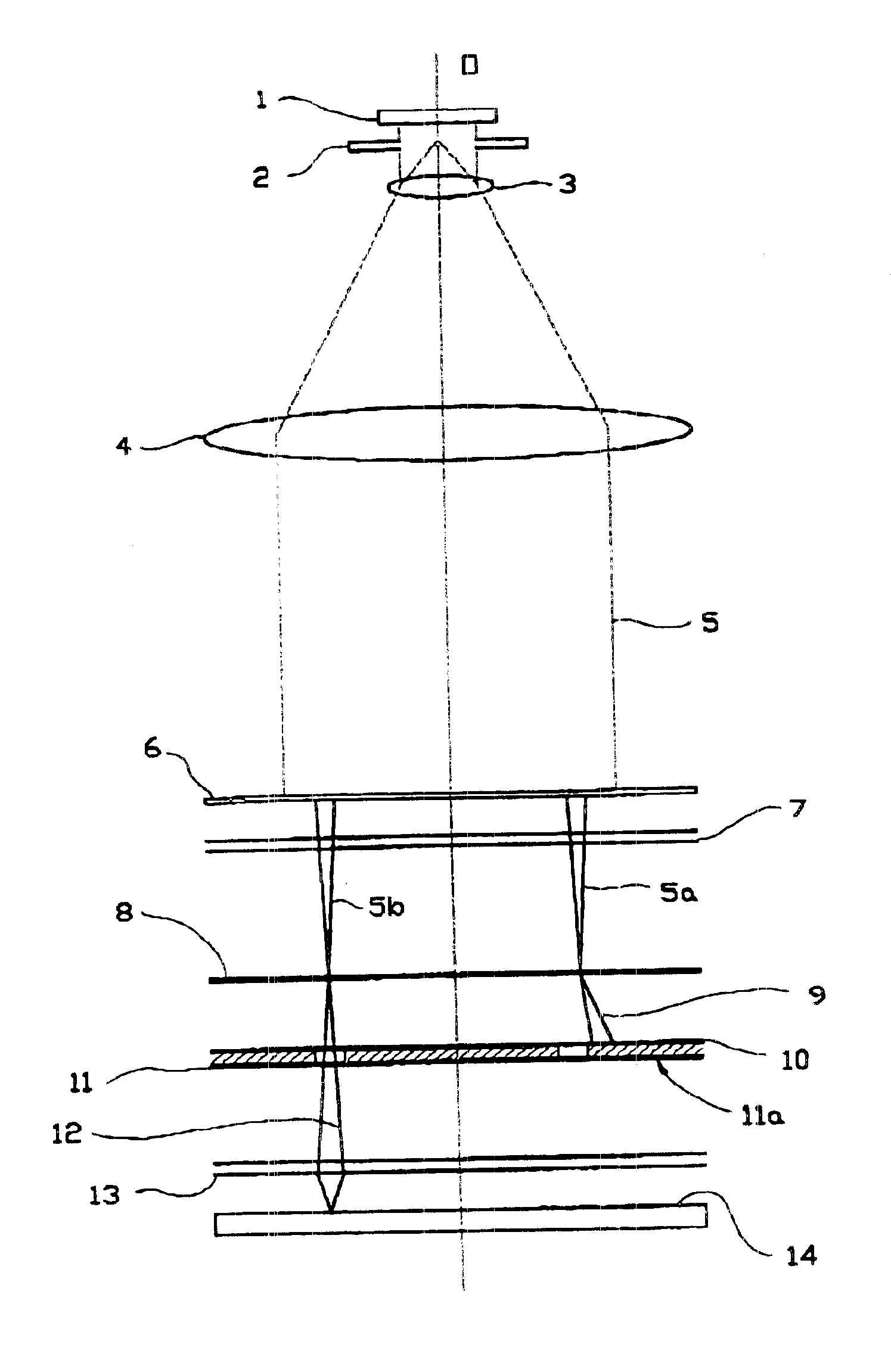

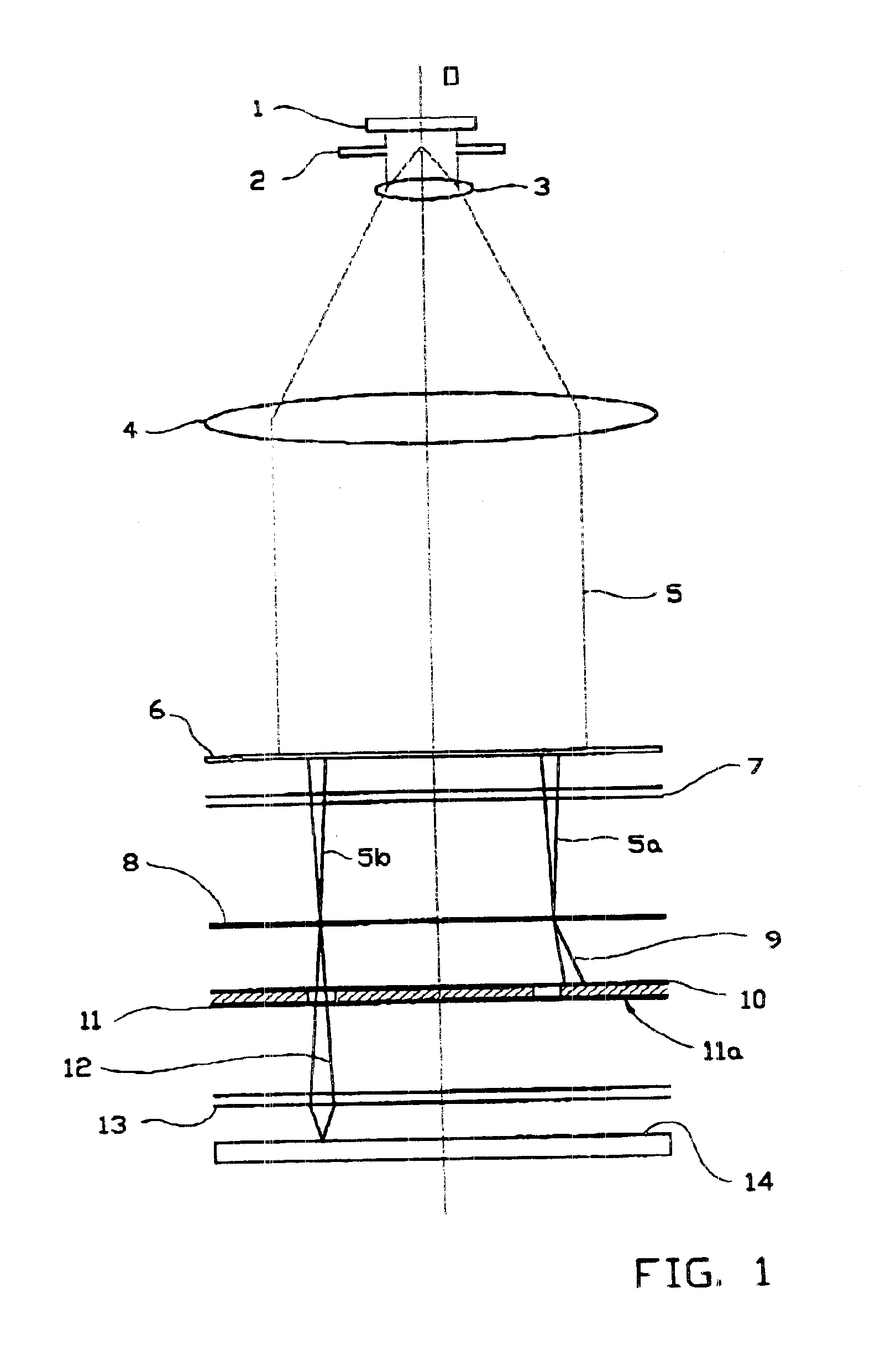

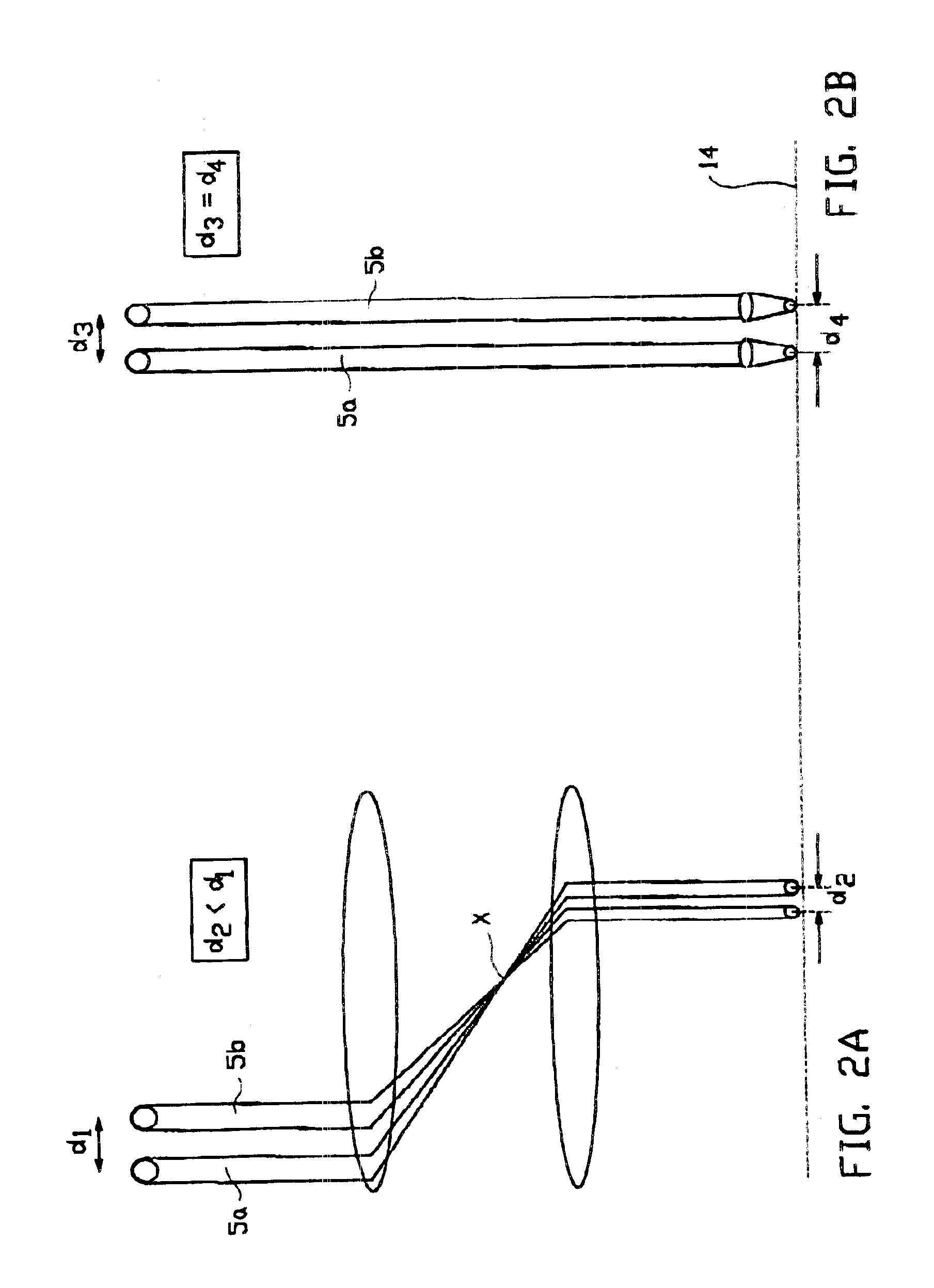

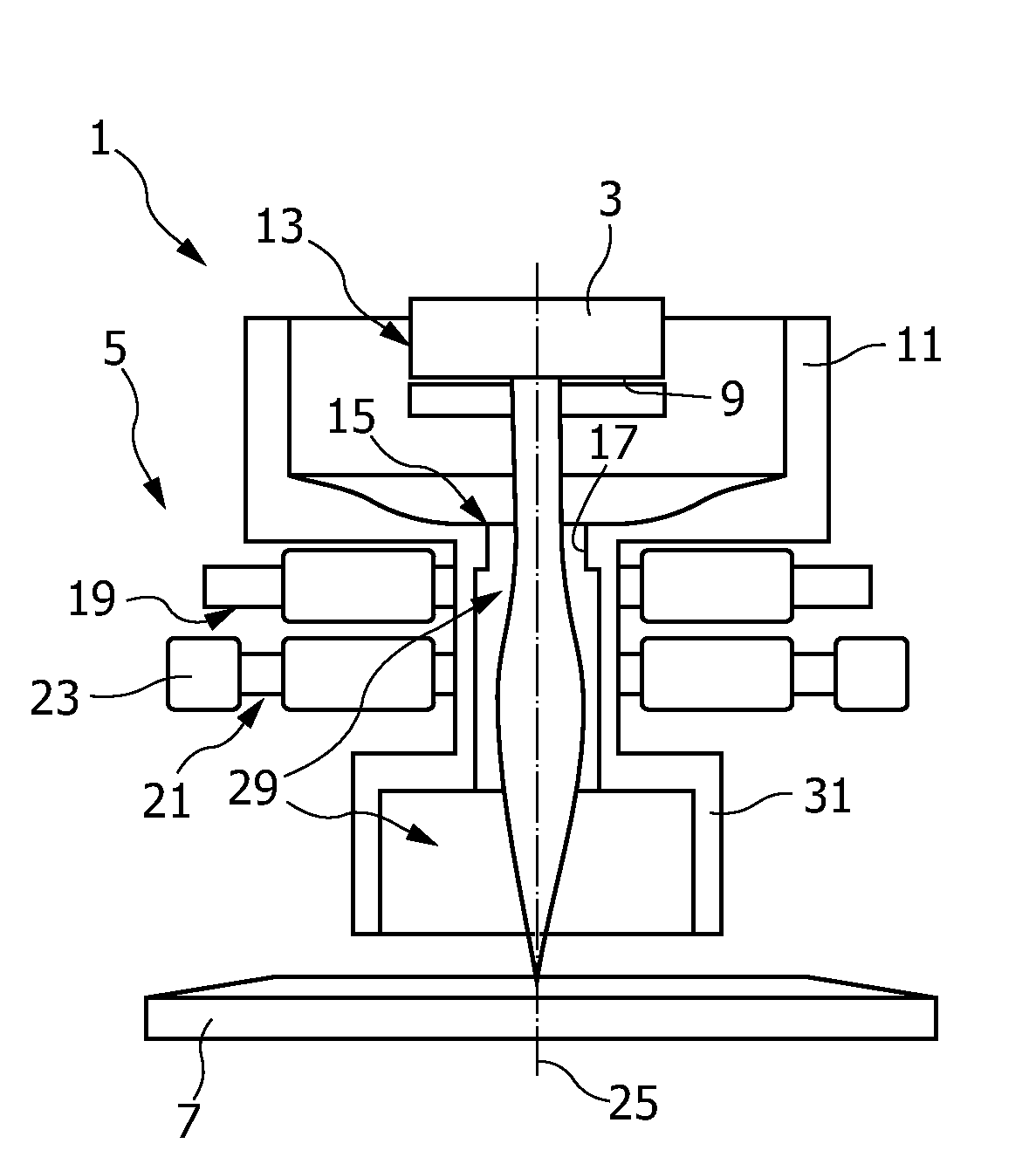

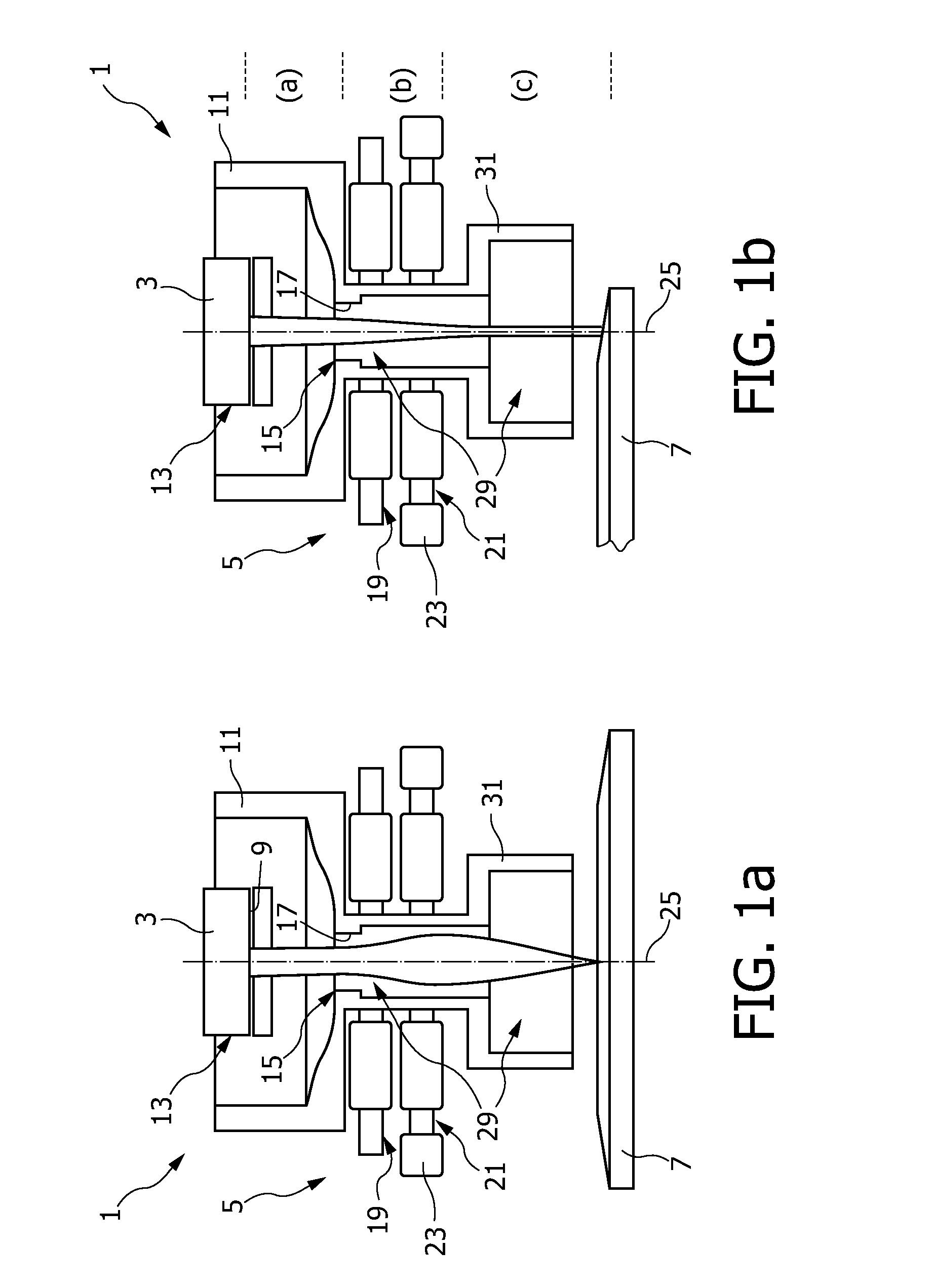

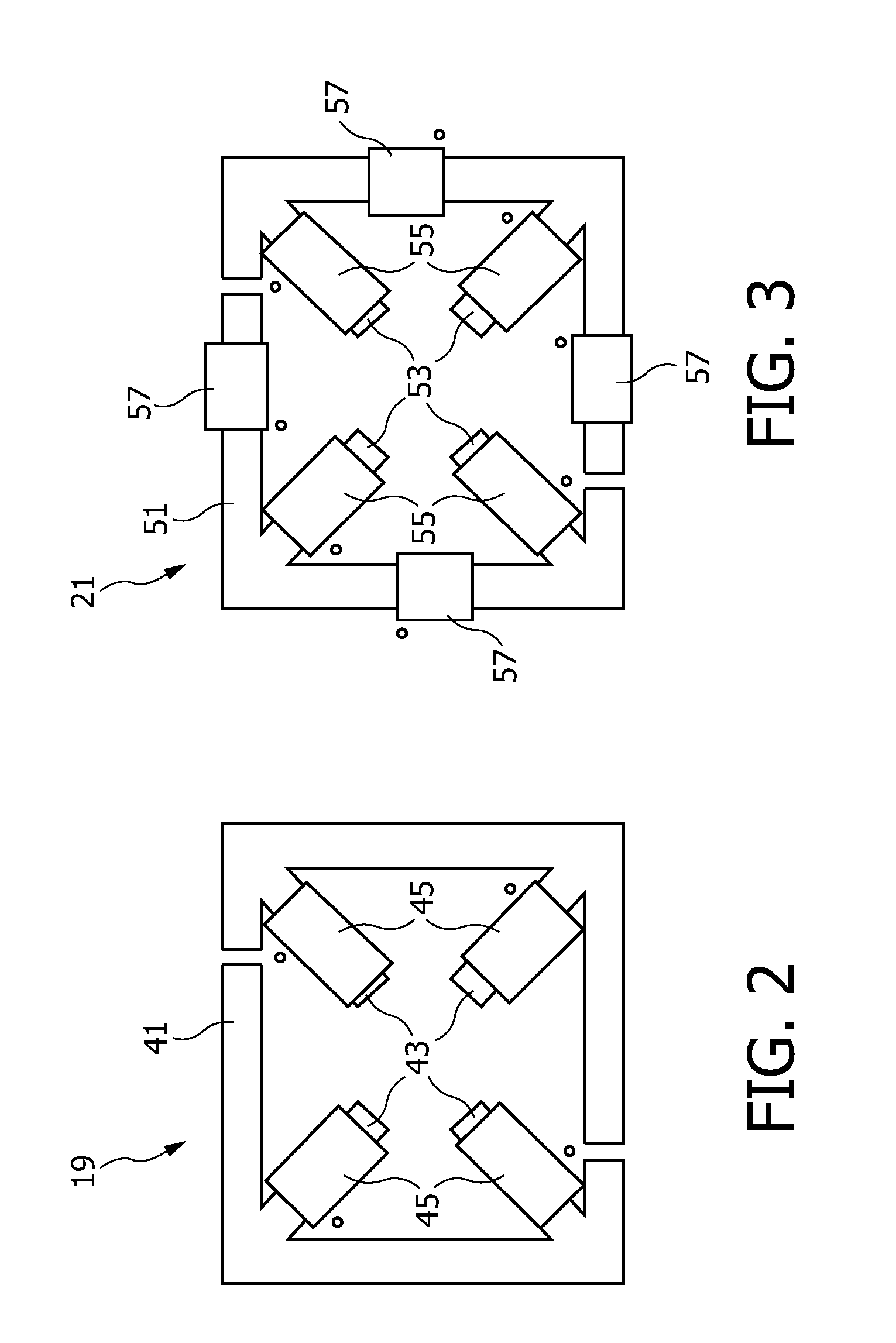

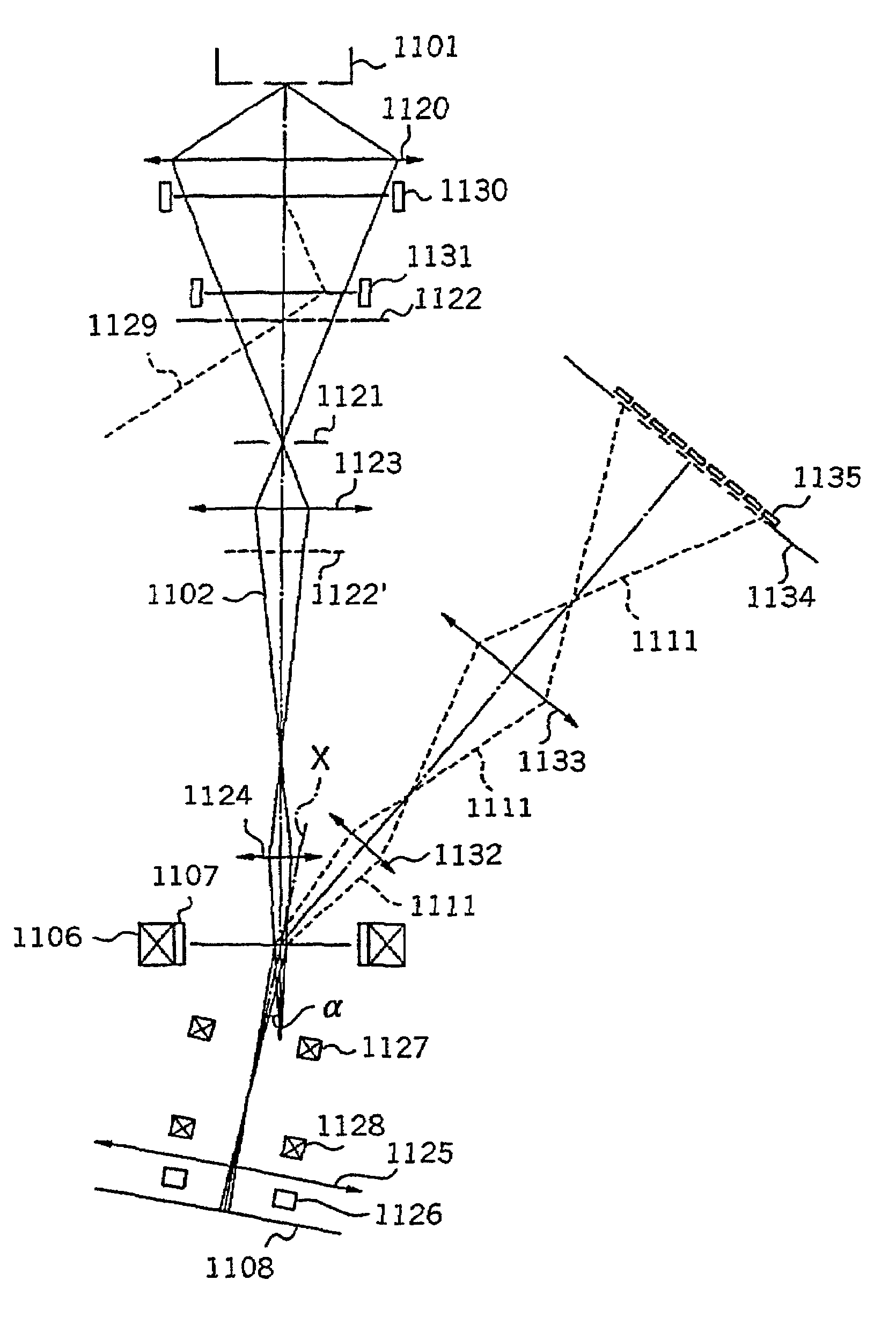

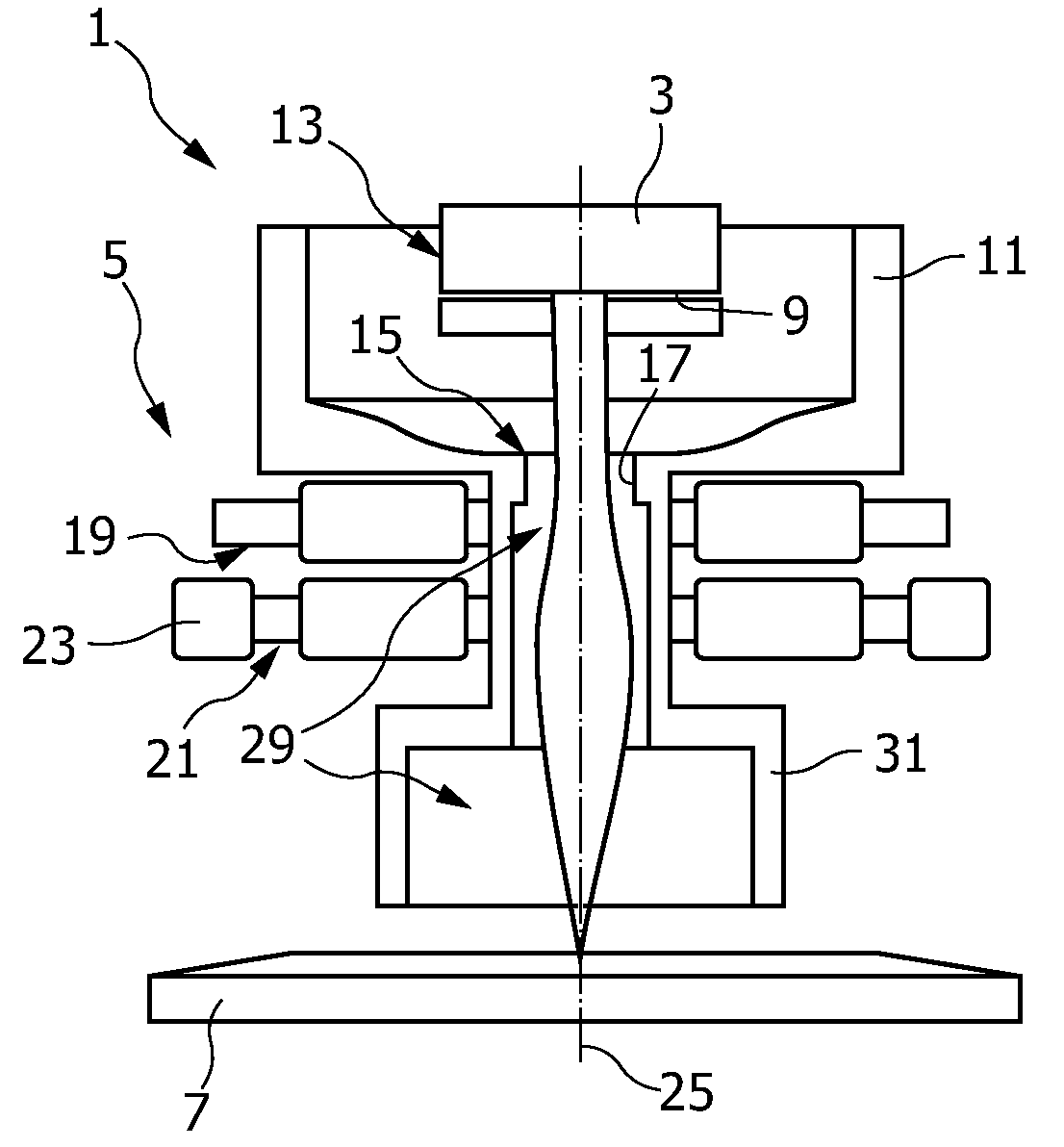

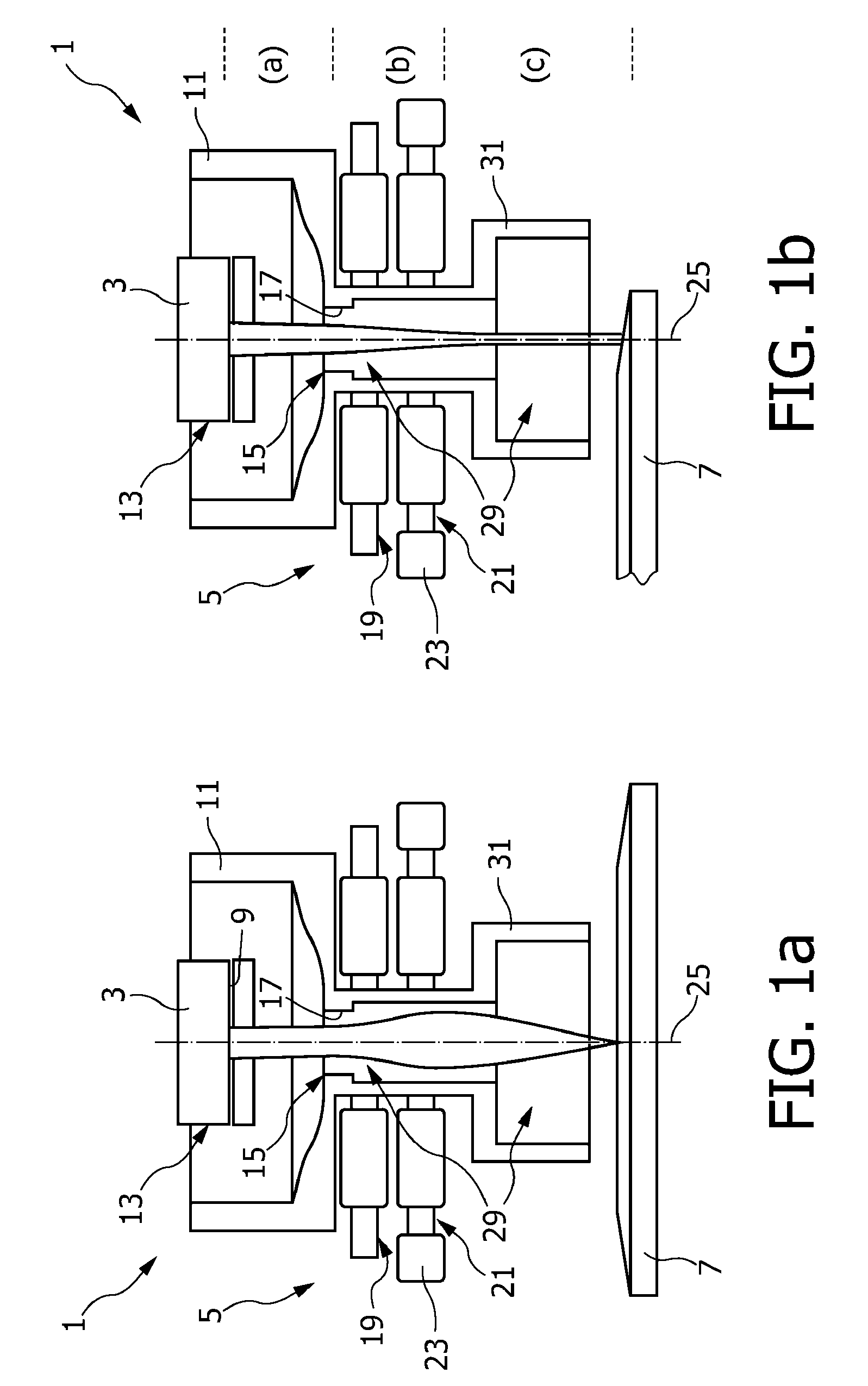

Electron optical apparatus, x-ray emitting device and method of producing an electron beam

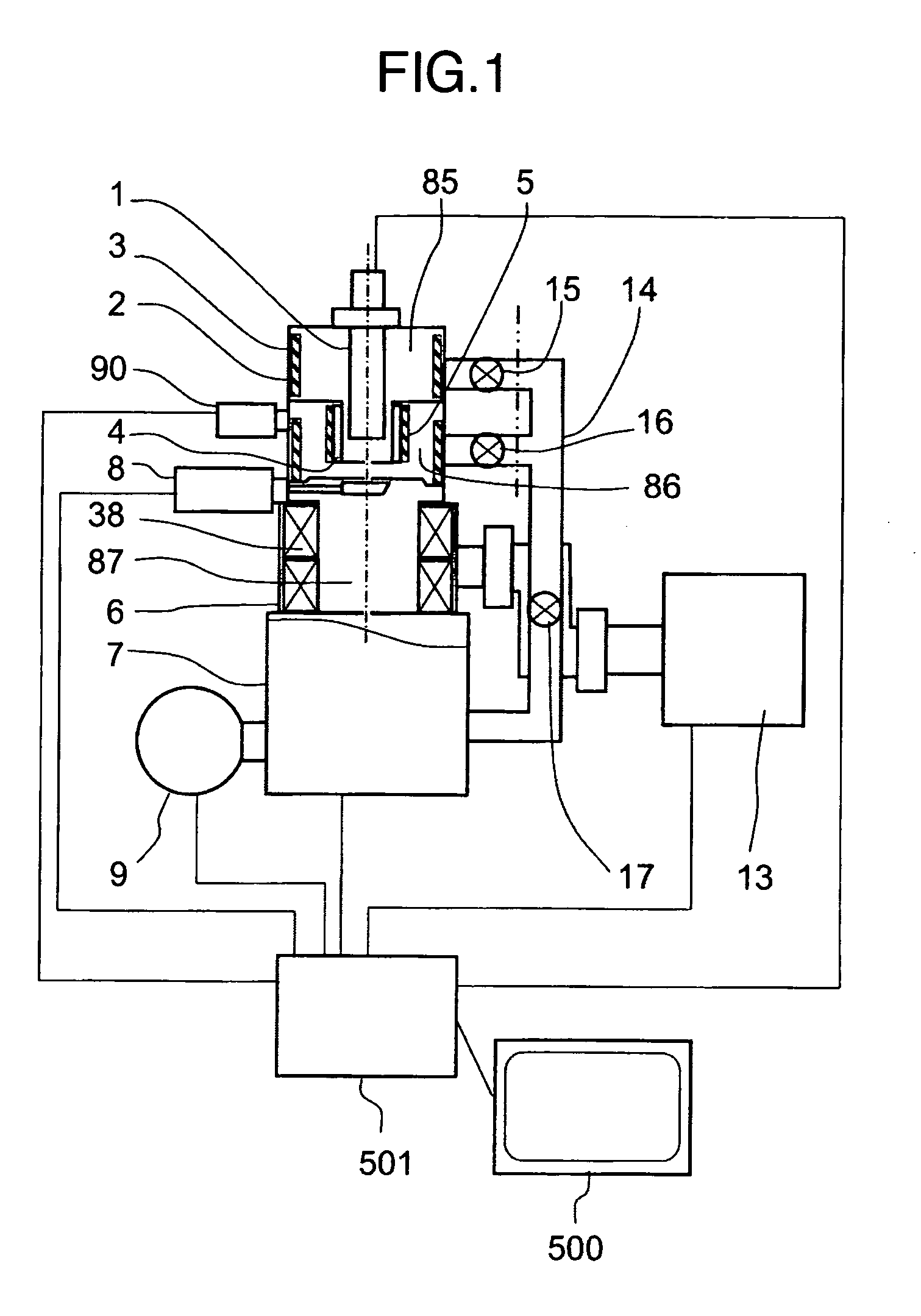

ActiveUS20100020937A1Shorten the lengthSave spaceCathode ray concentrating/focusing/directingOptical axisX-ray

It is described an electron optical arrangement, a X-ray emitting device and a method of creating an electron beam. An electron optical apparatus (1) comprises the following components along an optical axis (25): a cathode with an emitter (3) having a substantially planar surface (9) for emitting electrons; an anode (11) for accelerating the emitted electrons in a direction essentially along the optical axis (25); a first magnetic quadrupole lens (19) for deflecting the accelerated electrons and having a first yoke (41); a second magnetic quadrupole lens (21) for further deflecting the accelerated electrons and having a second yoke (51); and a magnetic dipole lens (23) for further deflecting the accelerated electrons.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Charged particle beam apparatus

InactiveUS20060231773A1Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsGetterFree space

A small-sized charged particle beam apparatus capable of maintaining high vacuum even during emission of an electron beam is provided. A nonevaporative getter pump is placed upstream of differential pumping of an electron optical system of the charged particle beam apparatus, and a minimum number of ion pumps are placed downstream, so that both the pumps are used in combination. Further, by mounting a detachable coil on an electron gun part, the inside of a column can be maintained under high vacuum with a degree of vacuum in the order of 10−8 Pa.

Owner:HITACHI HIGH-TECH CORP

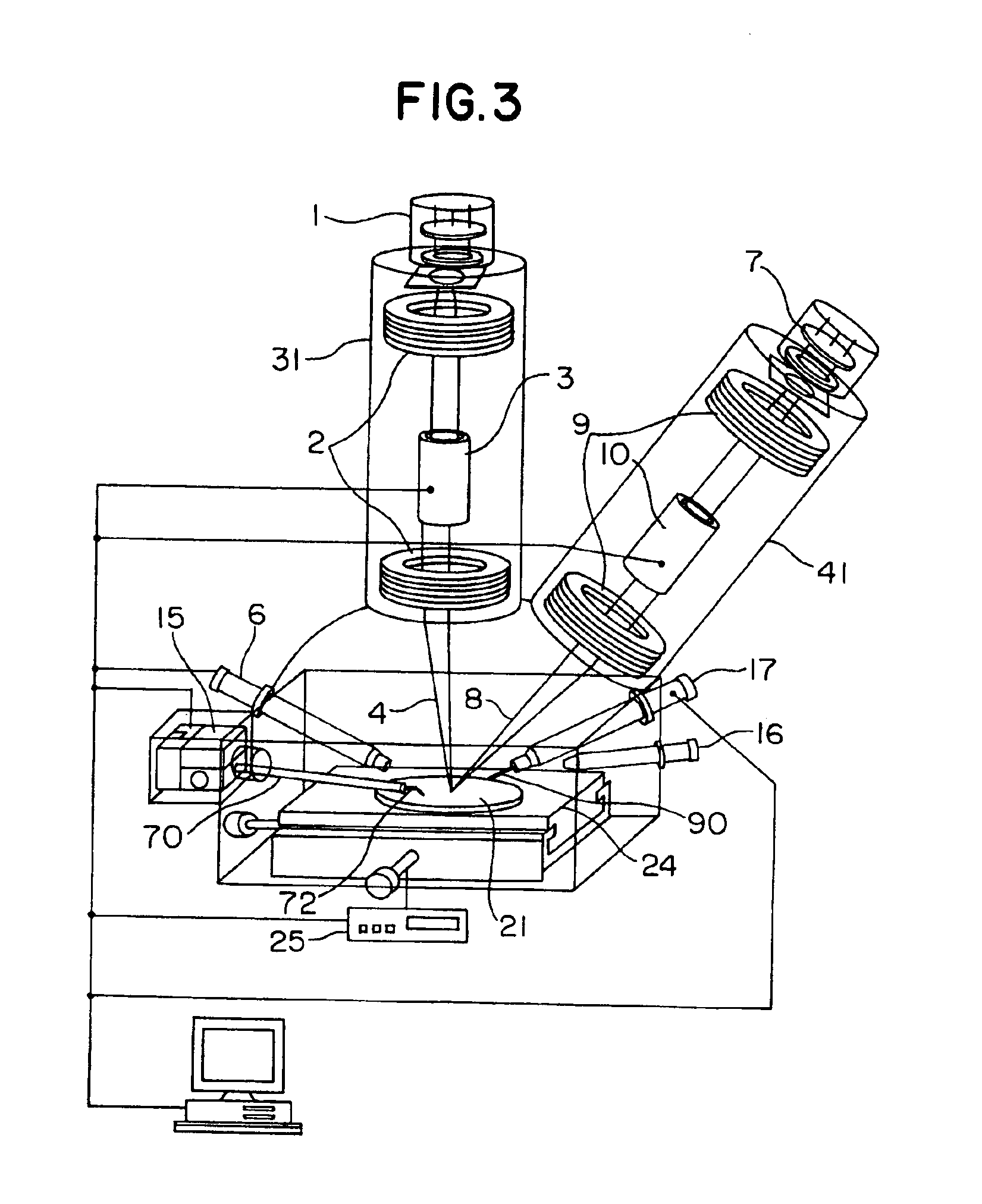

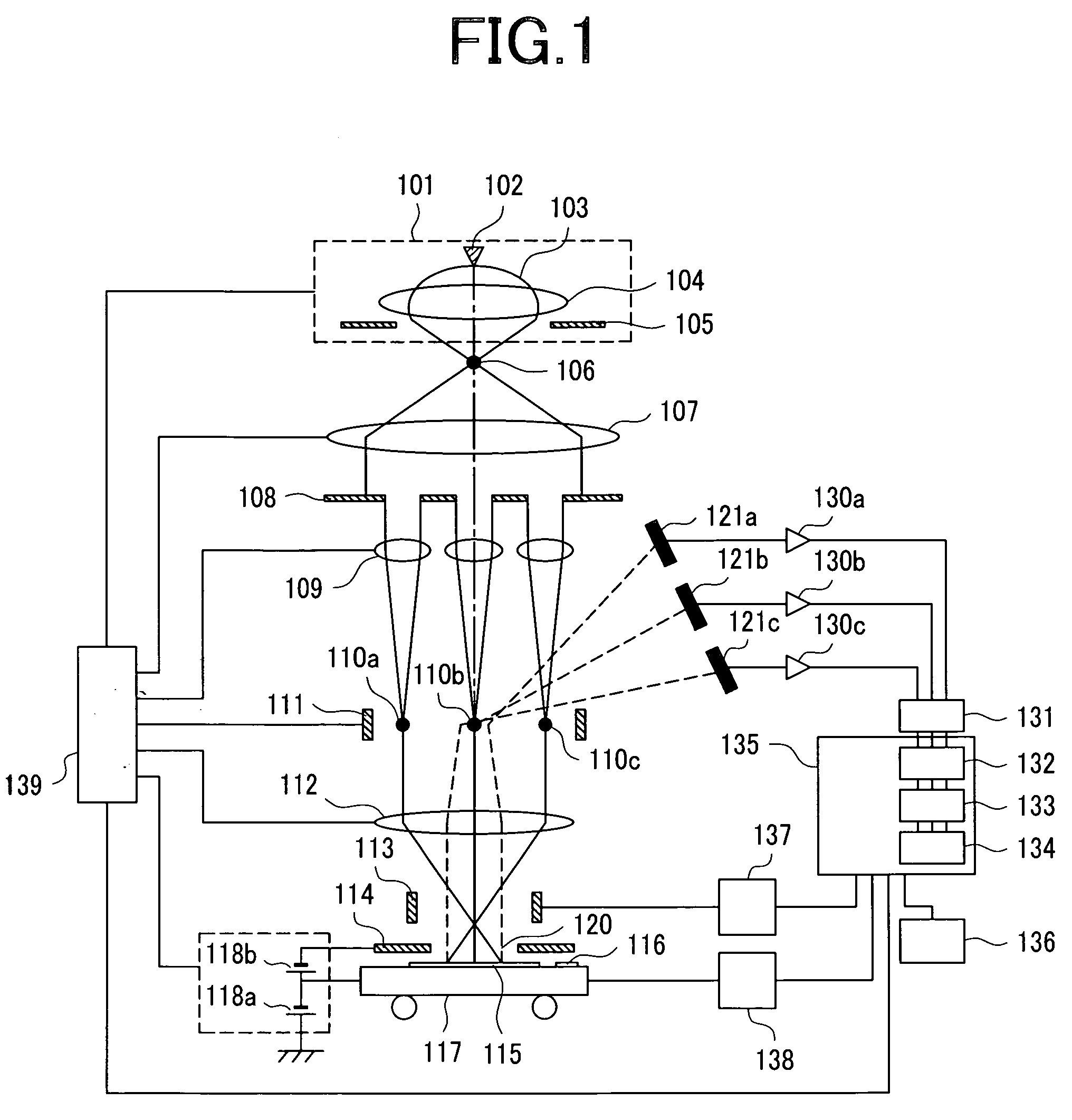

Electron beam inspection system and inspection method and method of manufacturing devices using the system

InactiveUS6992290B2Inspection speed is fastImprove inspection speedMaterial analysis using wave/particle radiationElectric discharge tubesLine sensorSecondary electrons

An electron beam inspection system of the image projection type includes a primary electron optical system for shaping an electron beam emitted from an electron gun into a rectangular configuration and applying the shaped electron beam to a sample surface to be inspected. A secondary electron optical system converges secondary electrons emitted from the sample. A detector converts the converged secondary electrons into an optical image through a fluorescent screen and focuses the image to a line sensor. A controller controls the charge transfer time of the line sensor at which the picked-up line image is transferred between each pair of adjacent pixel rows provided in the line sensor in association with the moving speed of a stage for moving the sample.

Owner:EBARA CORP

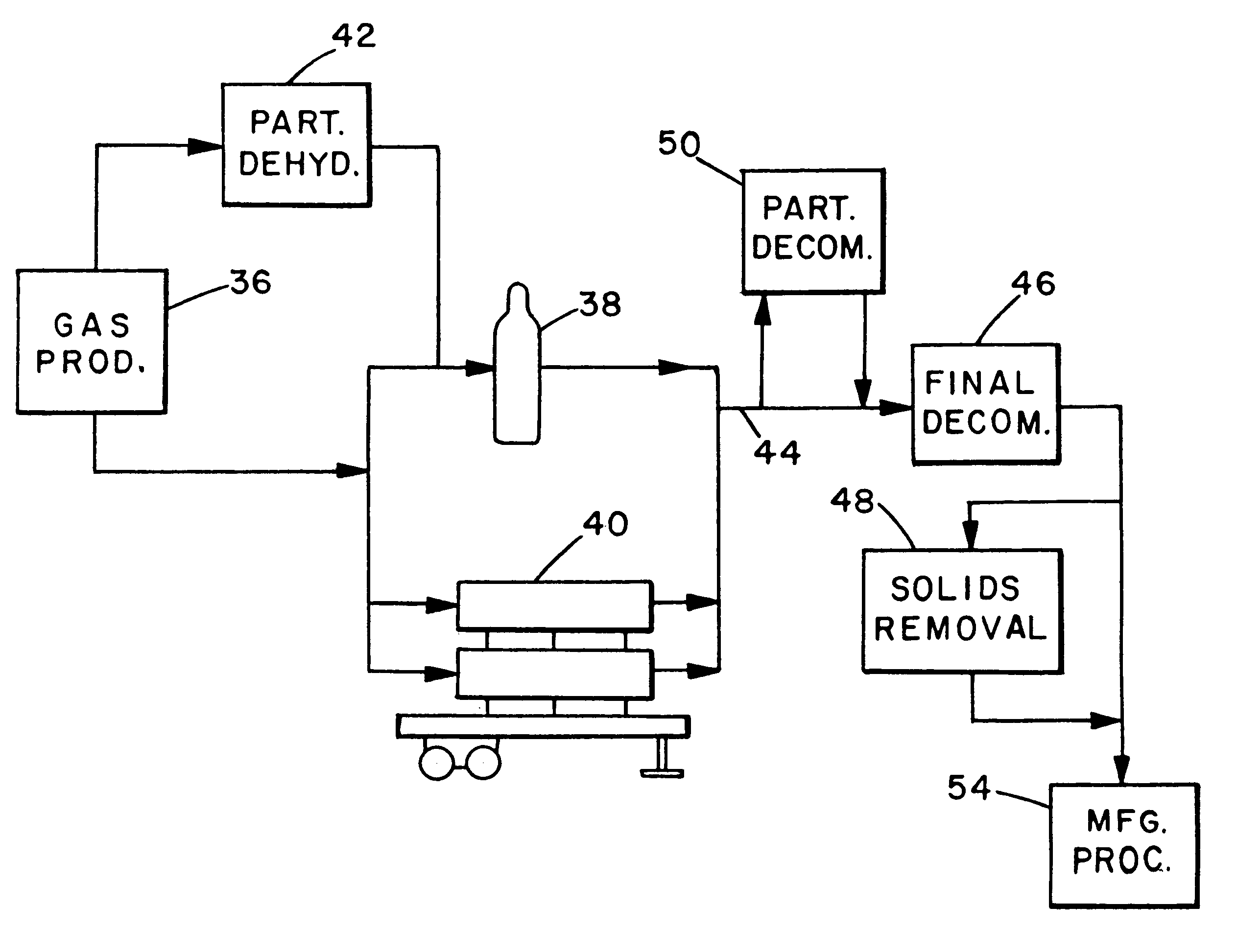

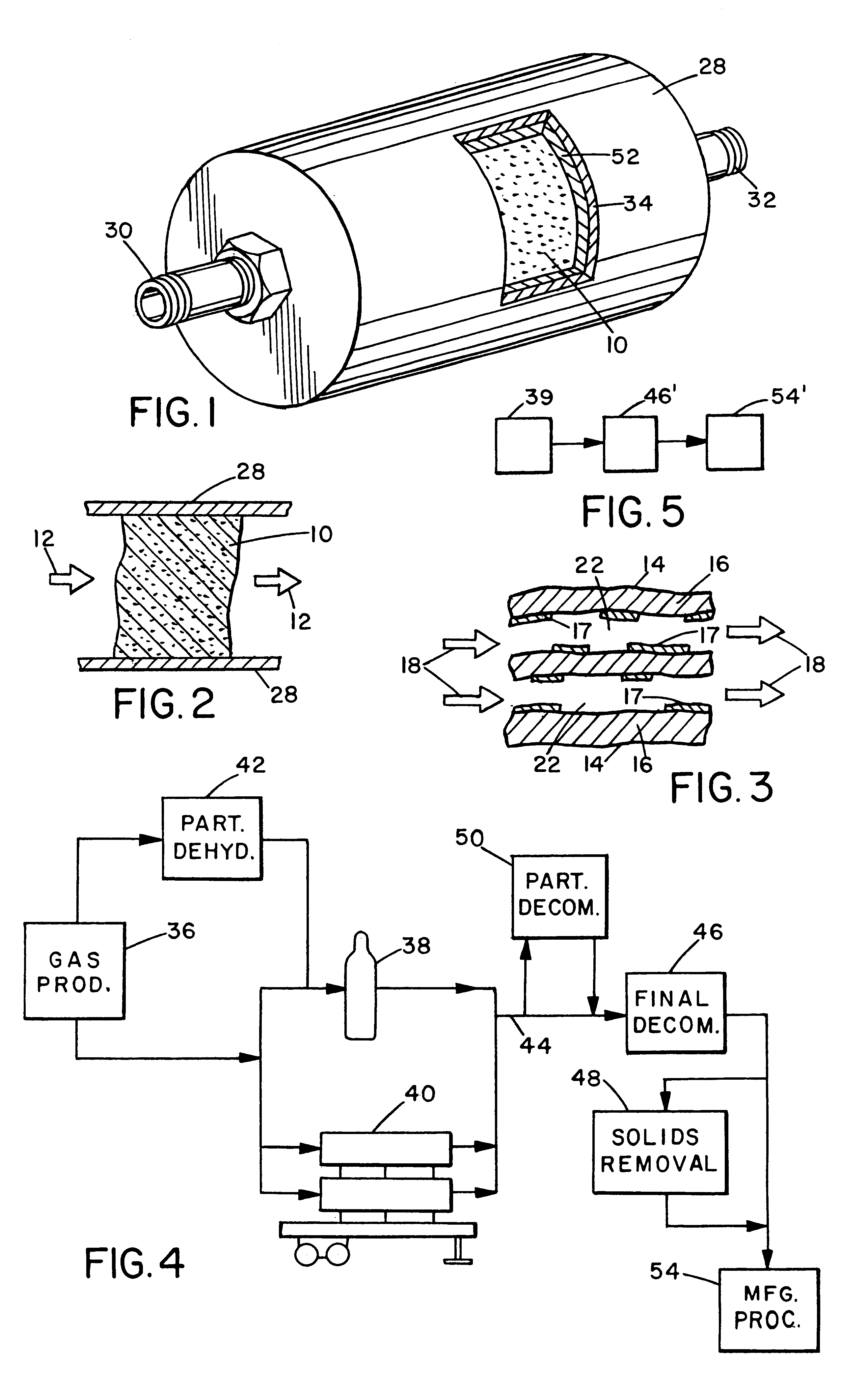

Method and apparatus for purification of hydride gas streams

A process and apparatus for the decontamination of gaseous contaminants (especially oxygen, carbon dioxide and water vapor) from hydride gases (including their lower alkyl analogs) down to <=100 ppb contaminant concentration are described. The critical component is a high surface area metal oxide substrate with reduced metal active sites, which in various physical forms is capable of decontaminating such gases to <=100 ppb, <=50 ppb or <=10 ppb level without being detrimentally affected by the hydride gases. The surface area of the substrate will be >=100 m2 / g, and preferably 200-800 m2 / g. Oxides of various metals, especially manganese or molybdenum, can be used, and mixtures of integrated oxides, or one type of oxide coated on another, may be used. The substrate is preferably retained in a hydride-gas-resistant container which is installed in a gas supply line, such as to a gas- or vapor-deposition manufacturing unit. The invention provides final decontamination for hydride gas streams intended for gas- or vapor-deposition formation of high purity LED, laser (especially blue laser), electronic, optical or similar products, and can be used in combination with upstream preliminary decontamination process and / or upstream or downstream solid particulate removal units.

Owner:SAES PURE GAS

Method and apparatus for processing a micro sample

InactiveUS6927391B2Reduce resolutionGood for observationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementHigh fluxIon beam

Owner:HITACHI LTD

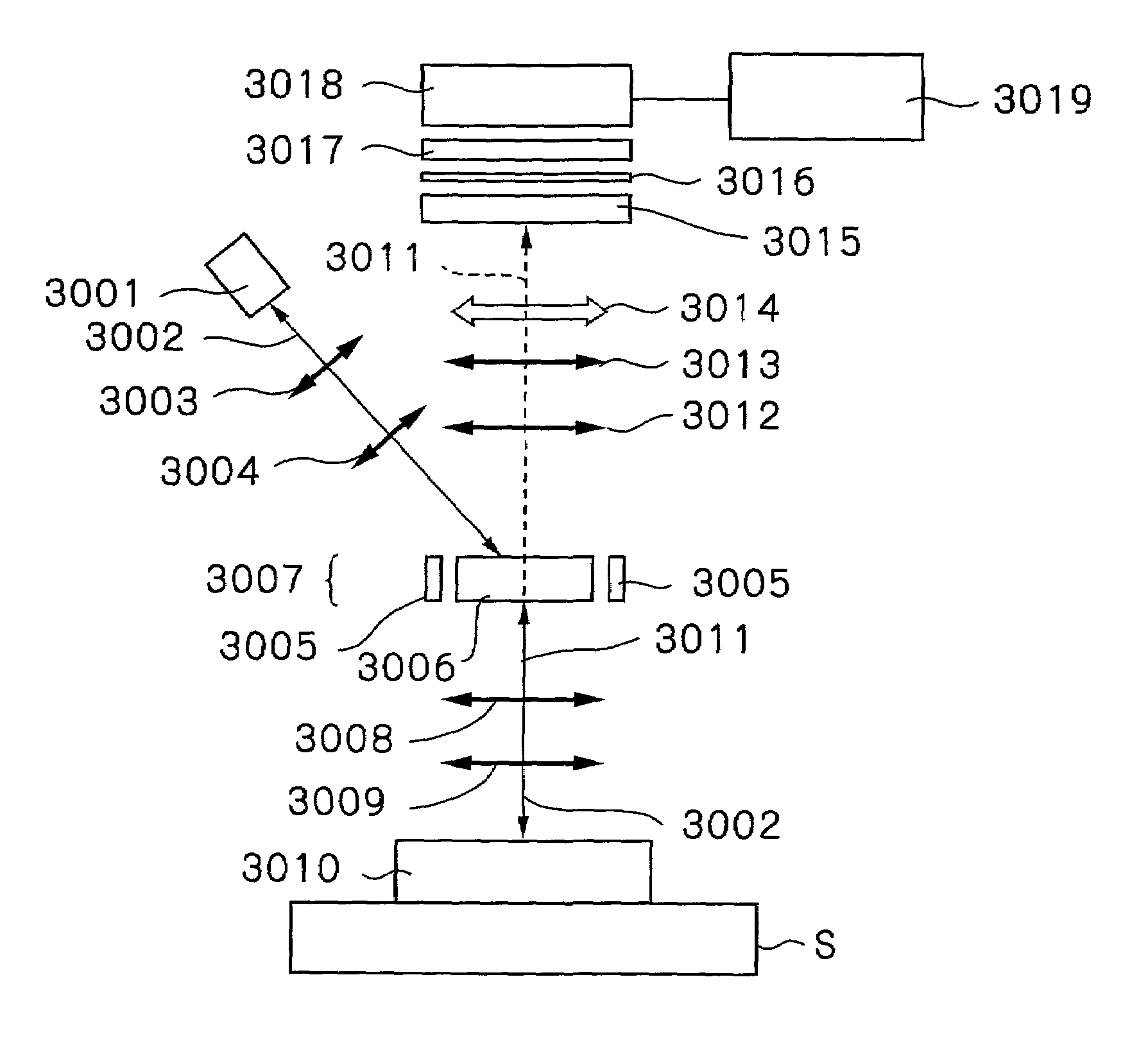

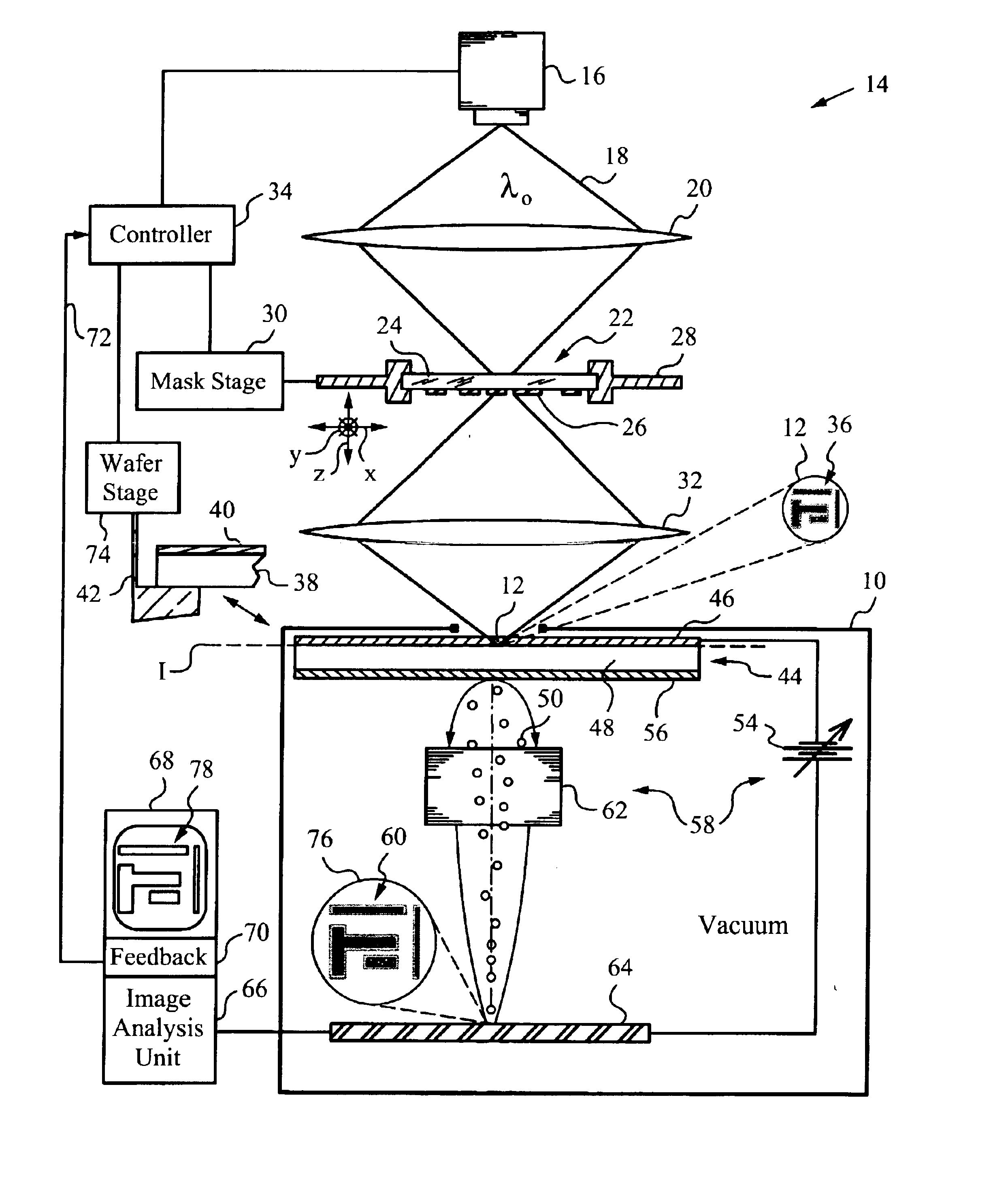

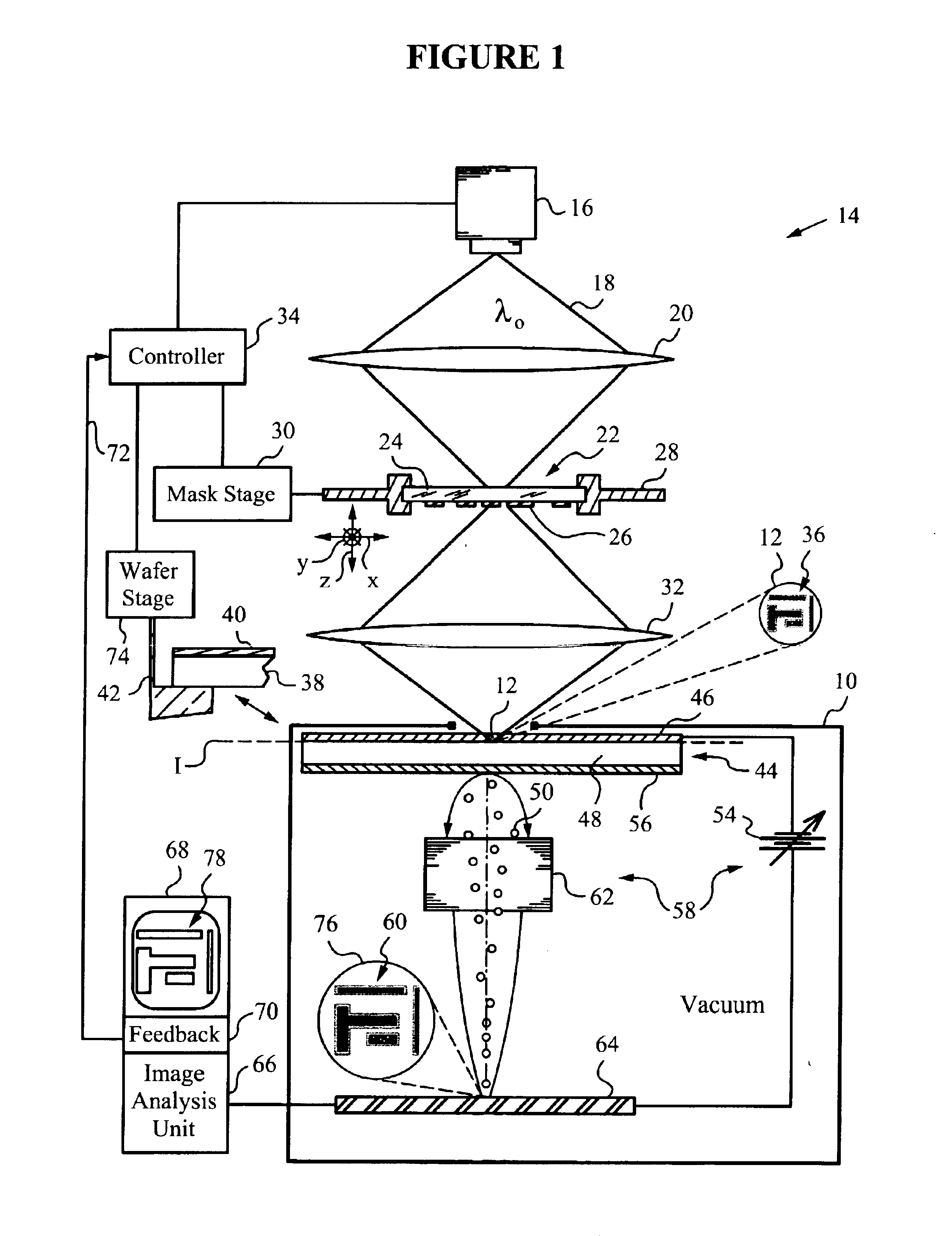

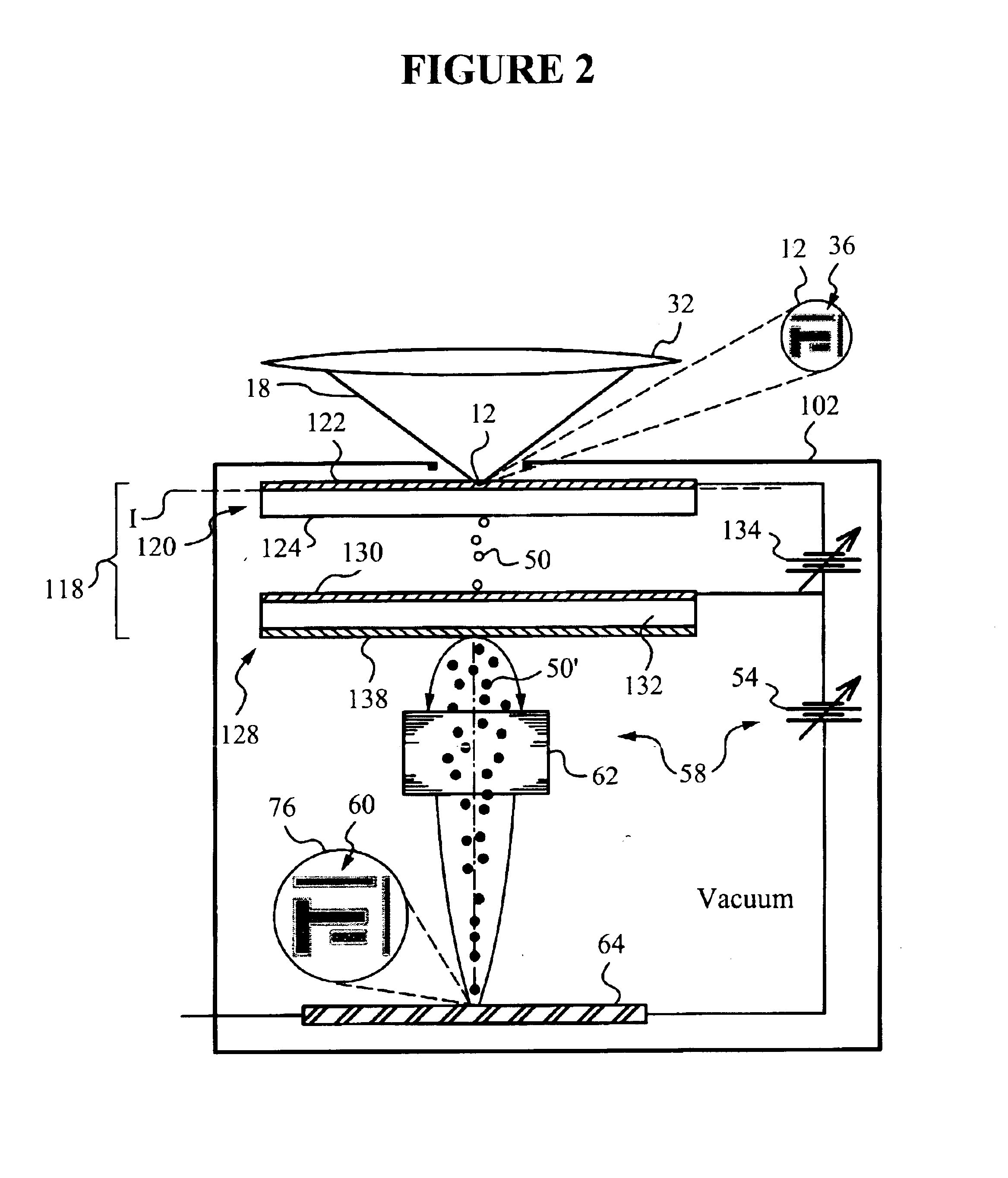

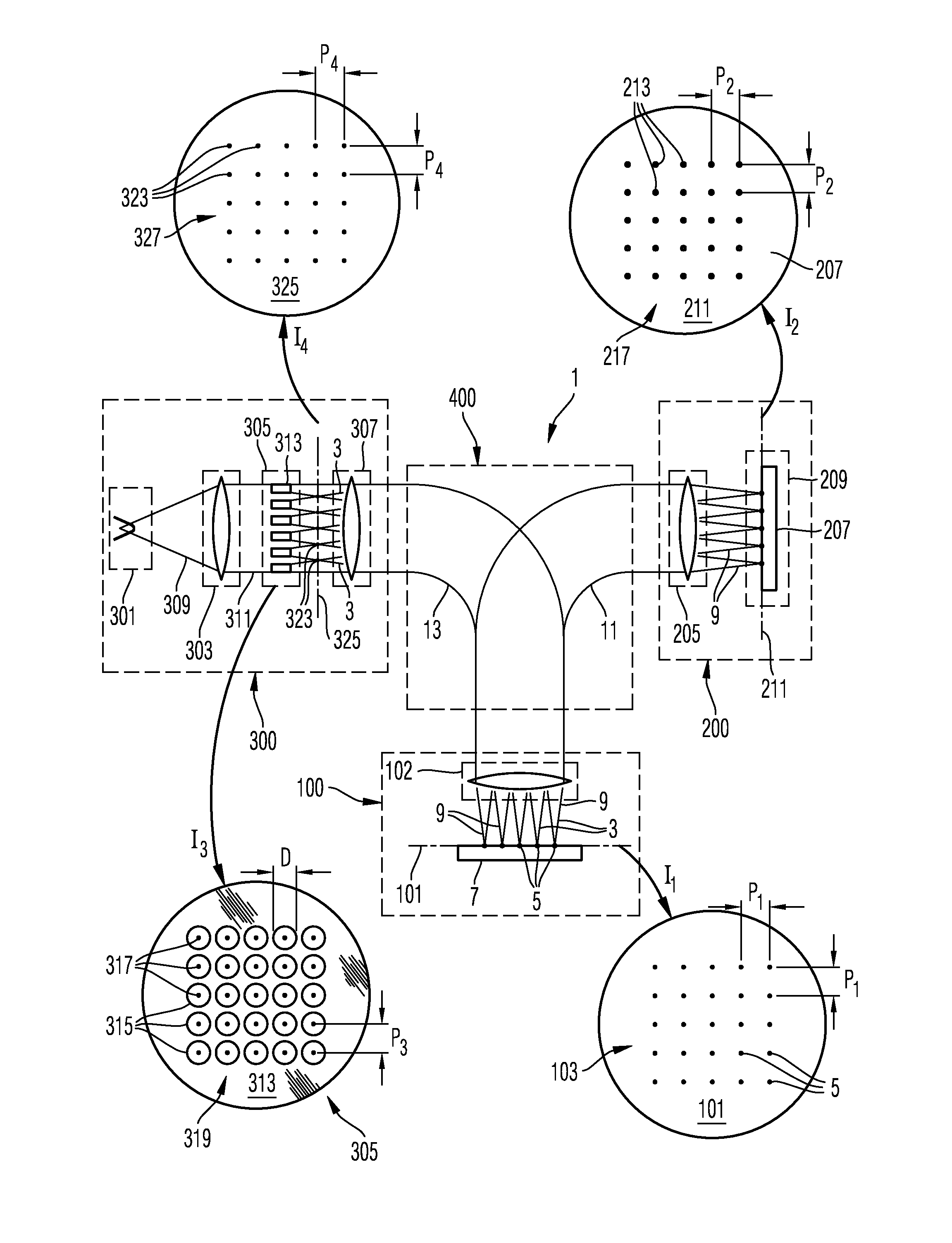

System and method for aerial image sensing

ActiveUS6906305B2Tight energy spreadImprove throughputMaterial analysis using wave/particle radiationSolid-state devicesCharge currentSpatial image

A system to sense an aerial image produced by optical equipment used in, for example, semiconductor fabrication. In one embodiment, the system includes a photo-electron emission device which, in response to an aerial image projected thereon, emits electrons in a pattern corresponding to the light intensity distribution produced by the aerial image. Electron optics provides an enlarged pattern of the pattern in which the electrons are emitted. A sensing unit senses the enlarged pattern. In another embodiment, the system employs a photo-conducting layer to project the aerial image thereon. The photo-conducting layer, in response to the projection of the aerial image thereon, produces local charge depletion corresponding to the light intensity distribution. A steering device delivers electrons to the photo-conducting layer to produce local re-charging currents in proportion to the local charge depletion. A pattern corresponding to the aerial image may be obtained from the re-charging currents.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

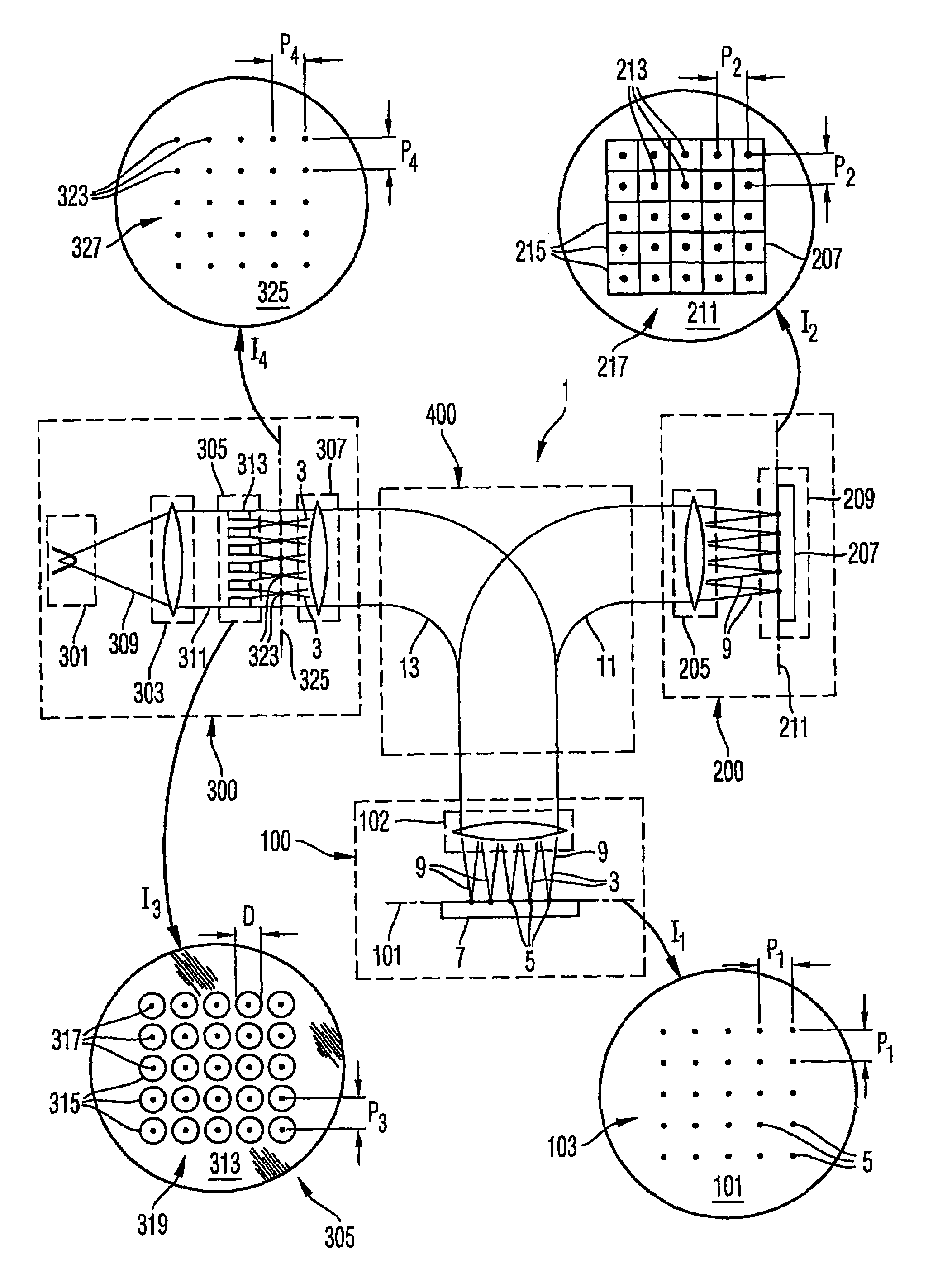

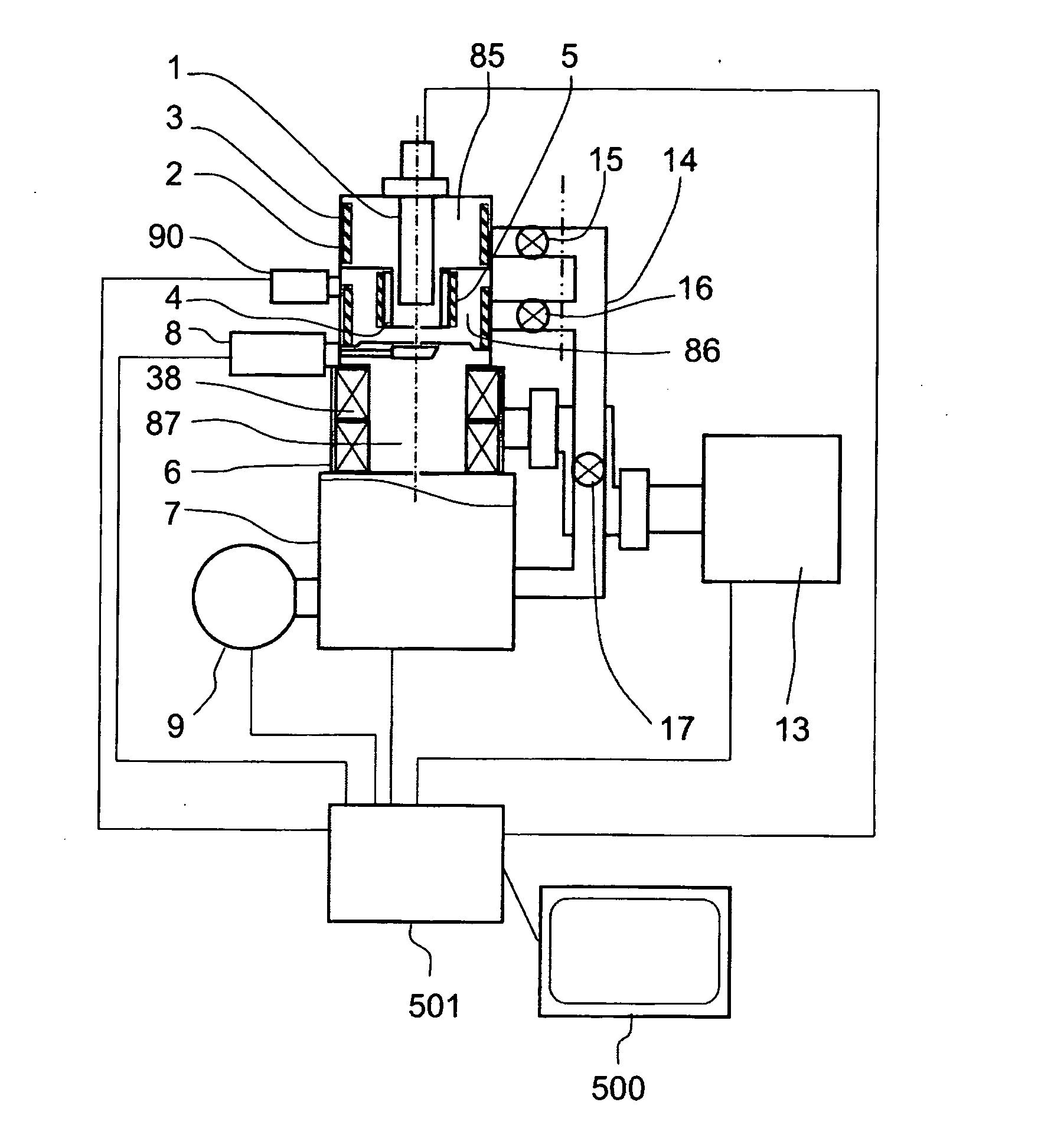

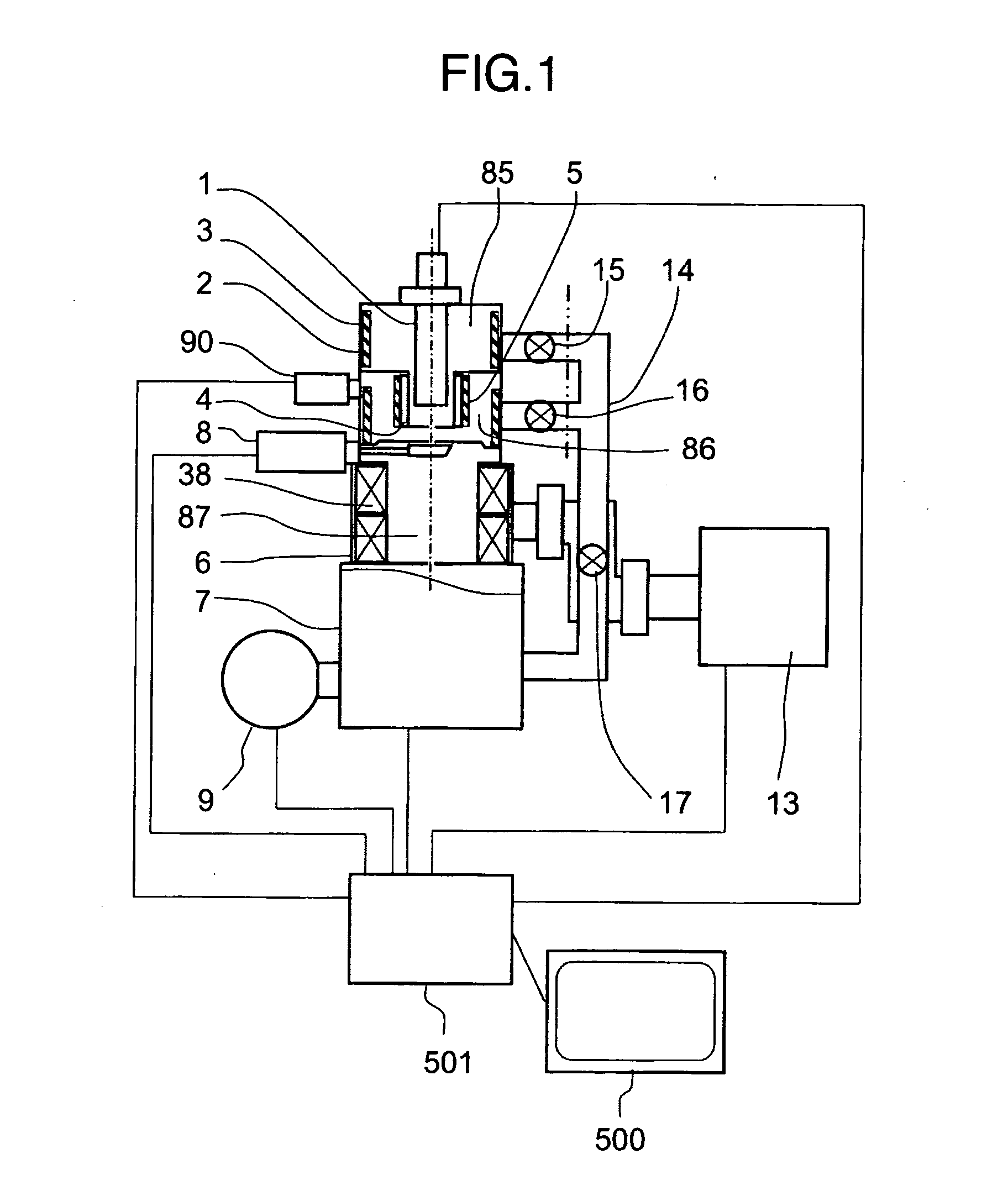

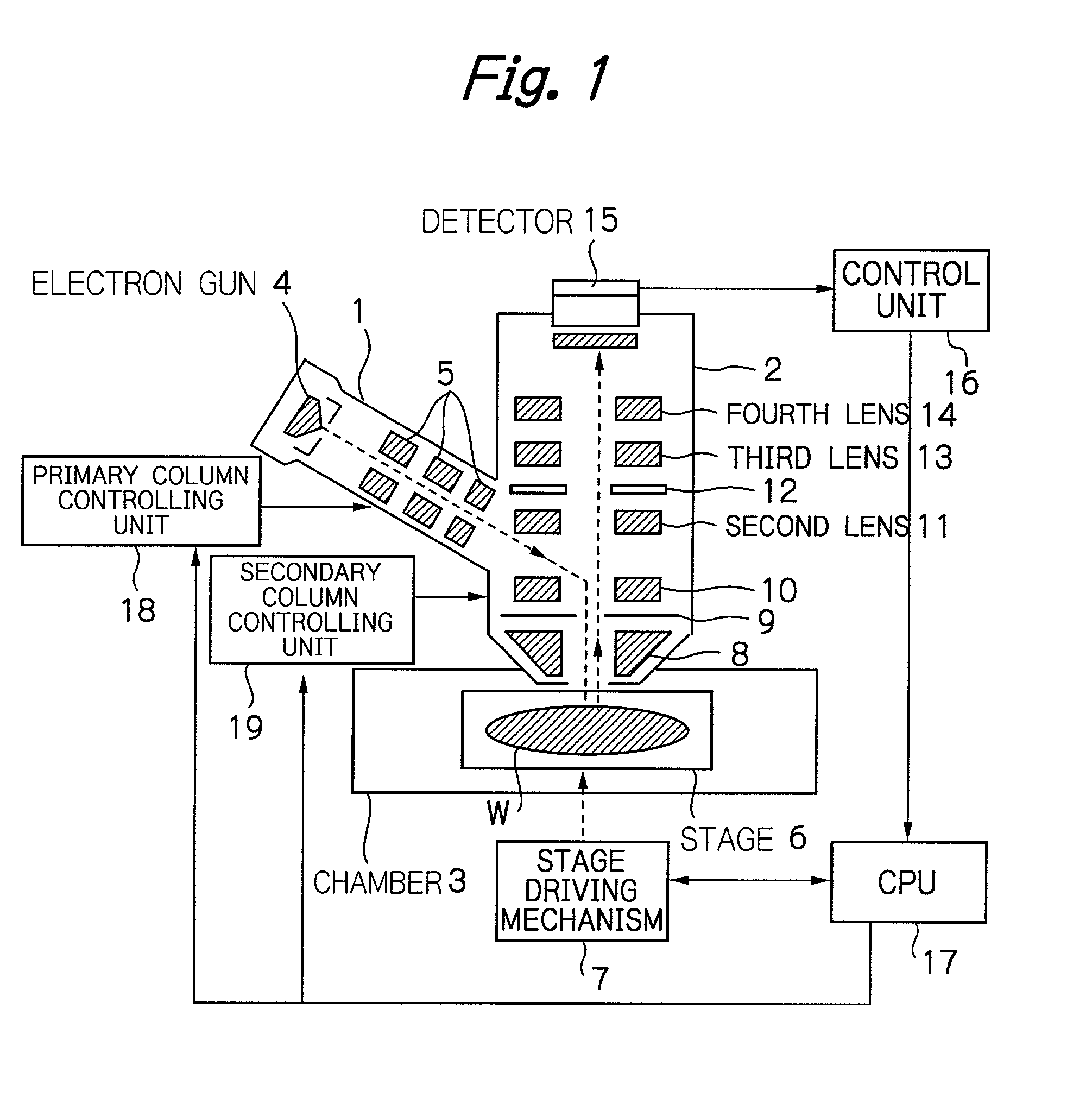

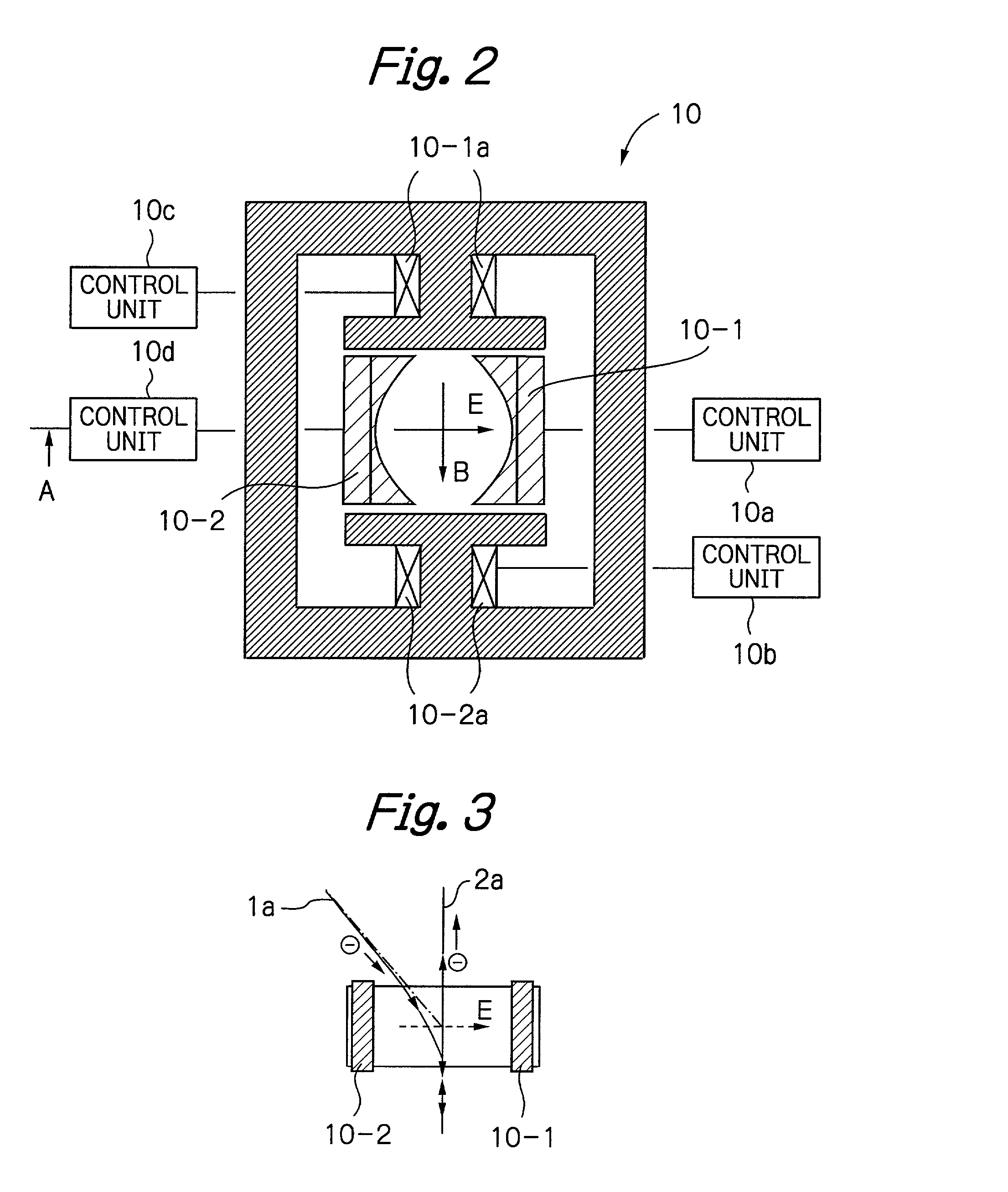

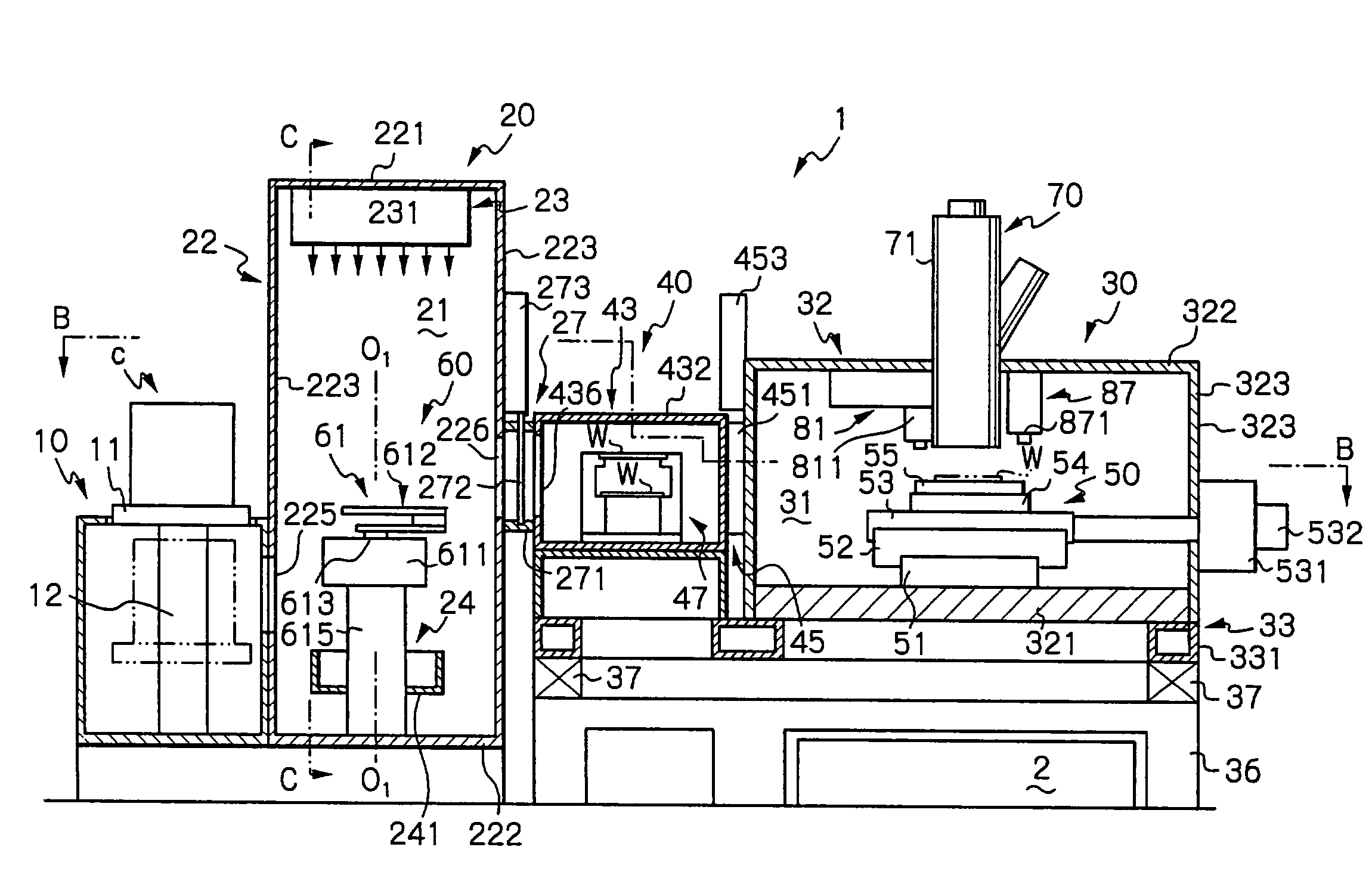

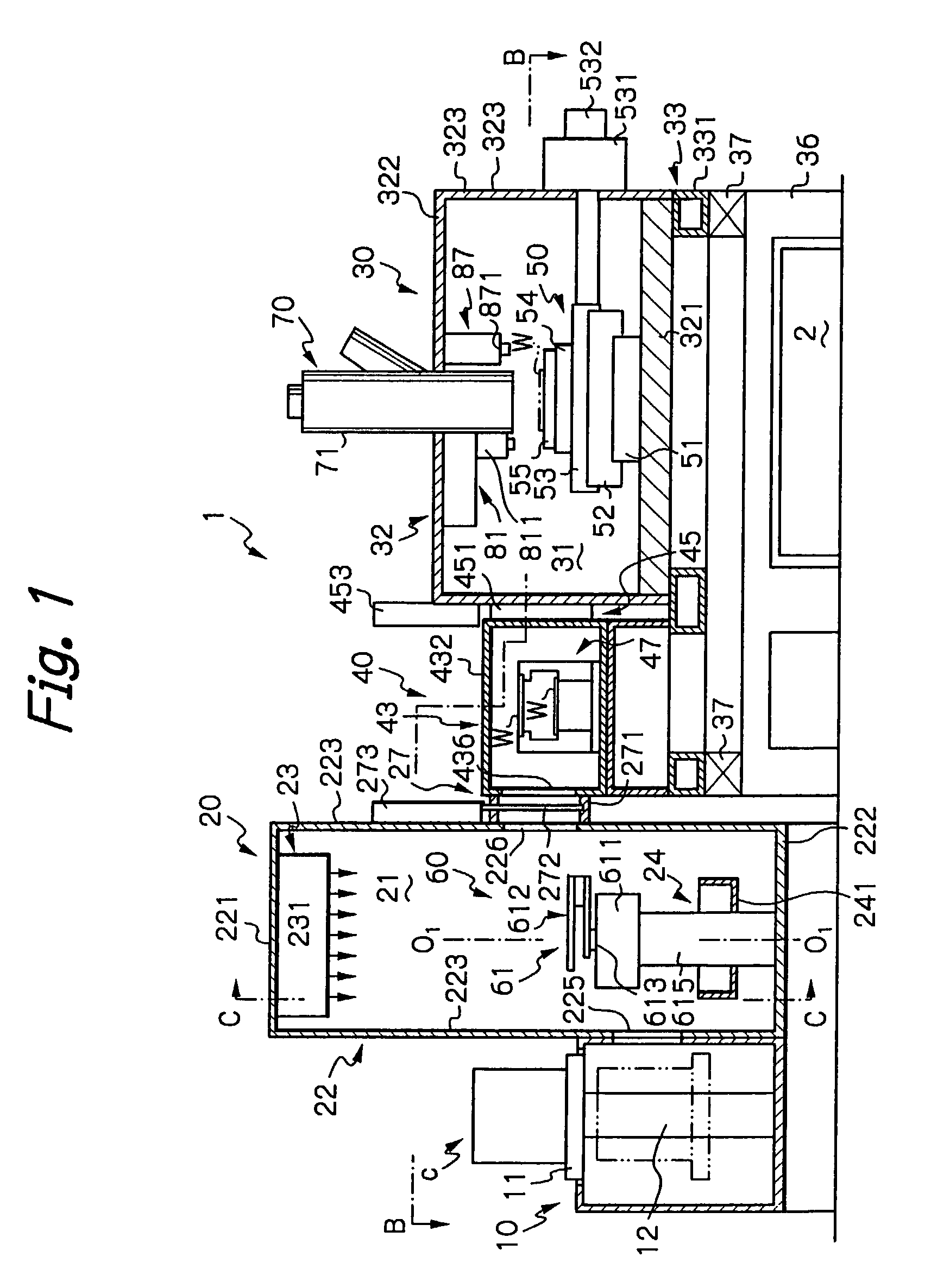

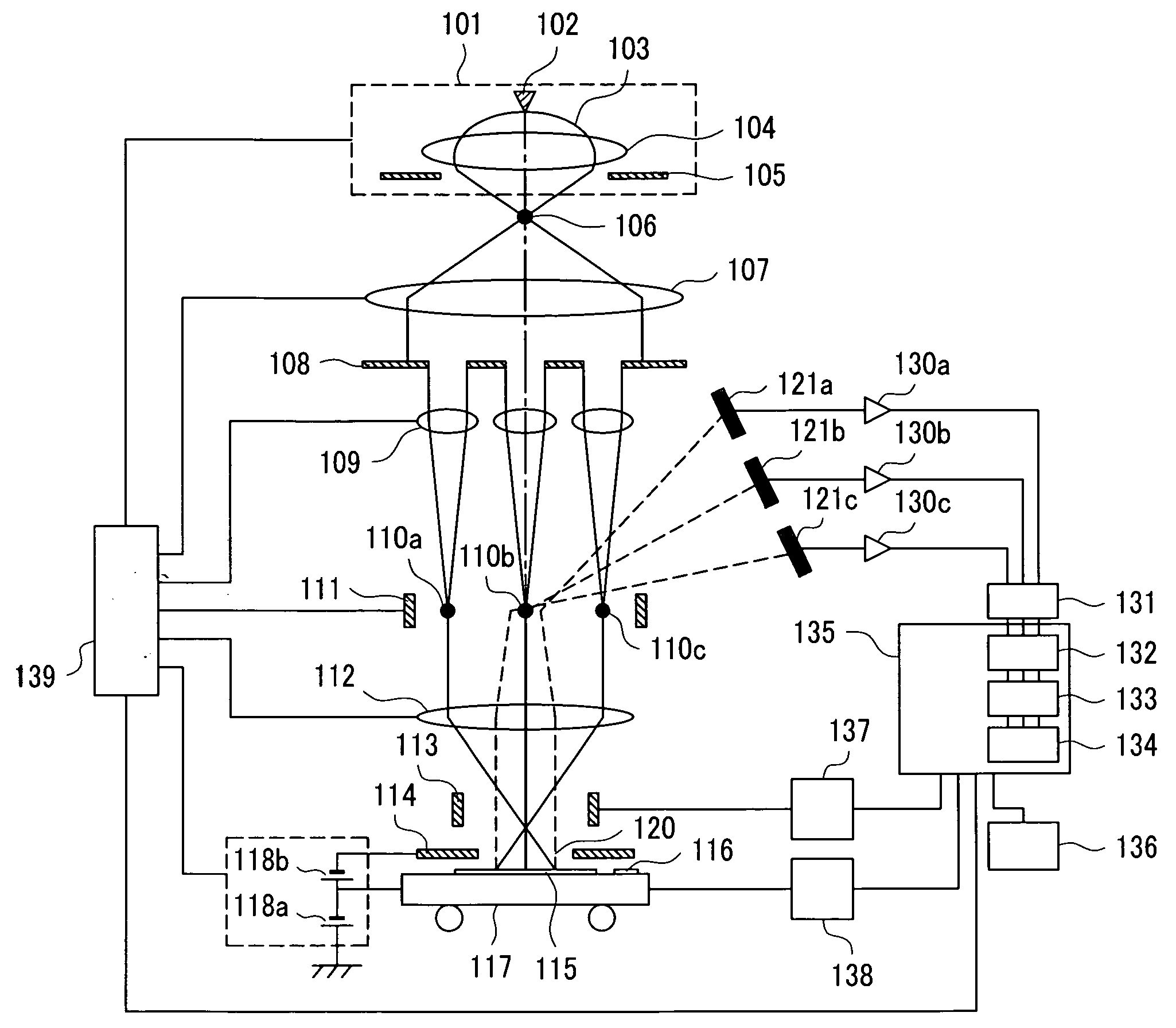

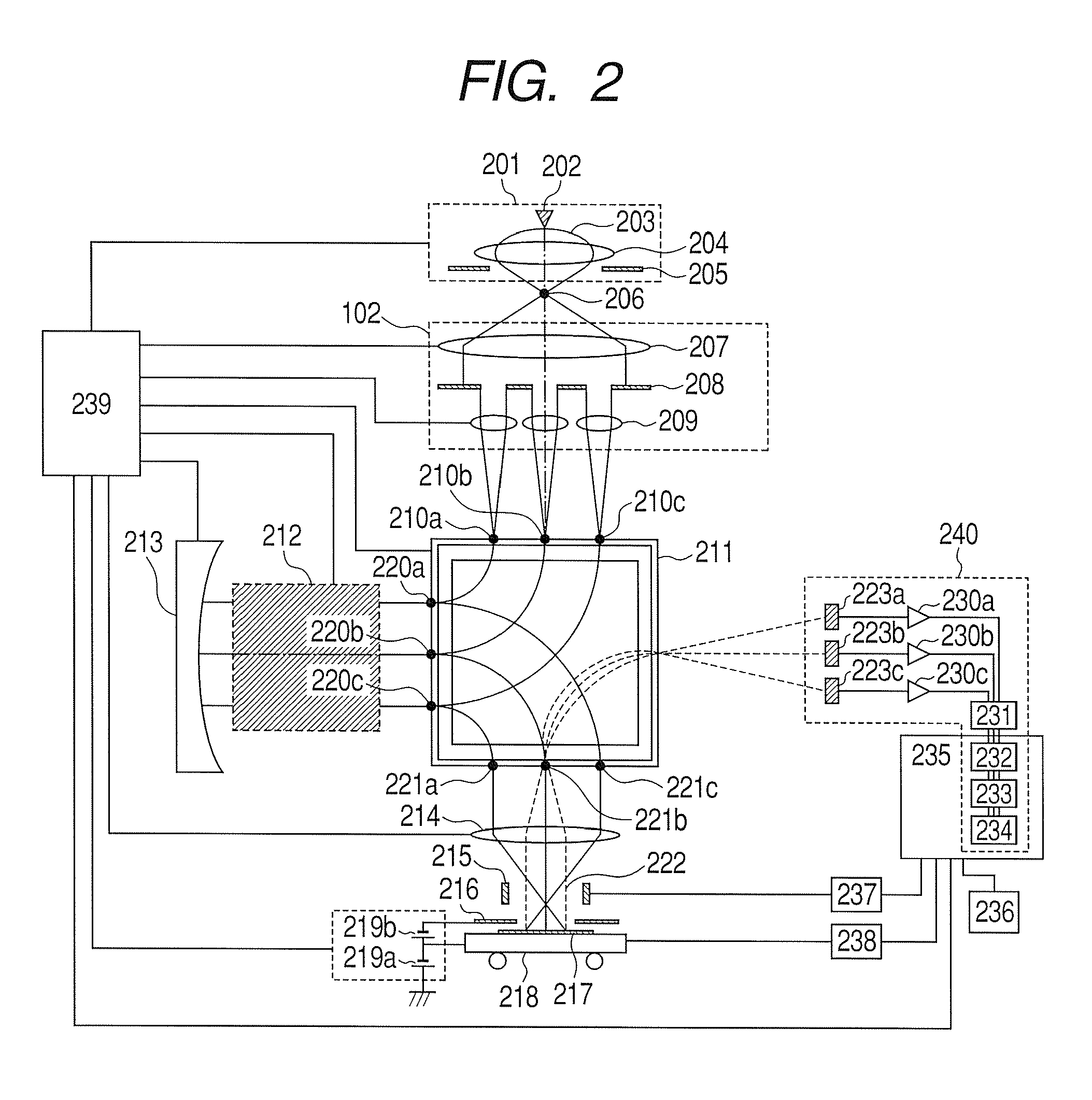

Electron beam apparatus and device fabrication method using the electron beam apparatus

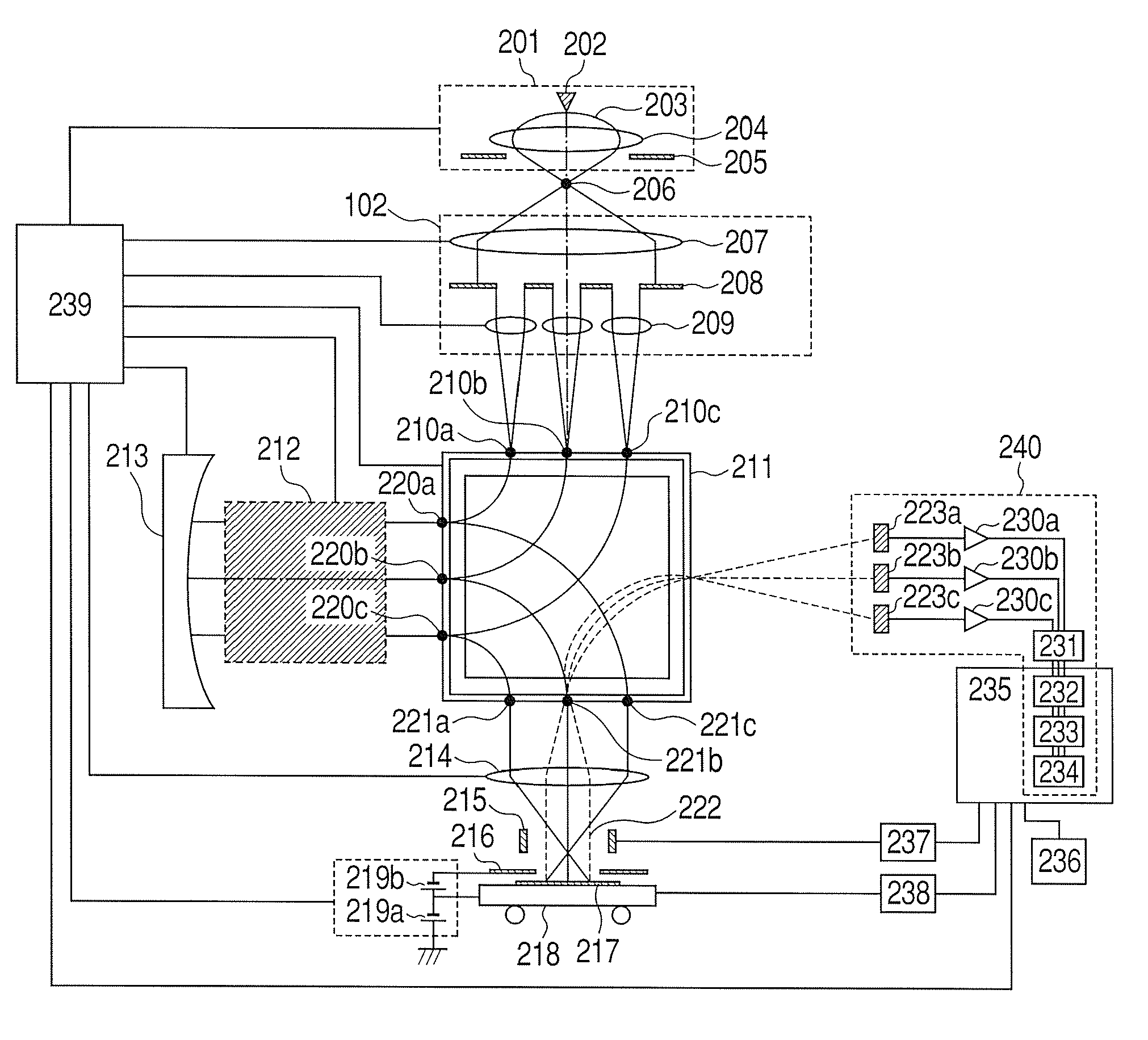

InactiveUS7244932B2Improve throughputImprove accuracyThermometer detailsStability-of-path spectrometersSecondary electronsThroughput

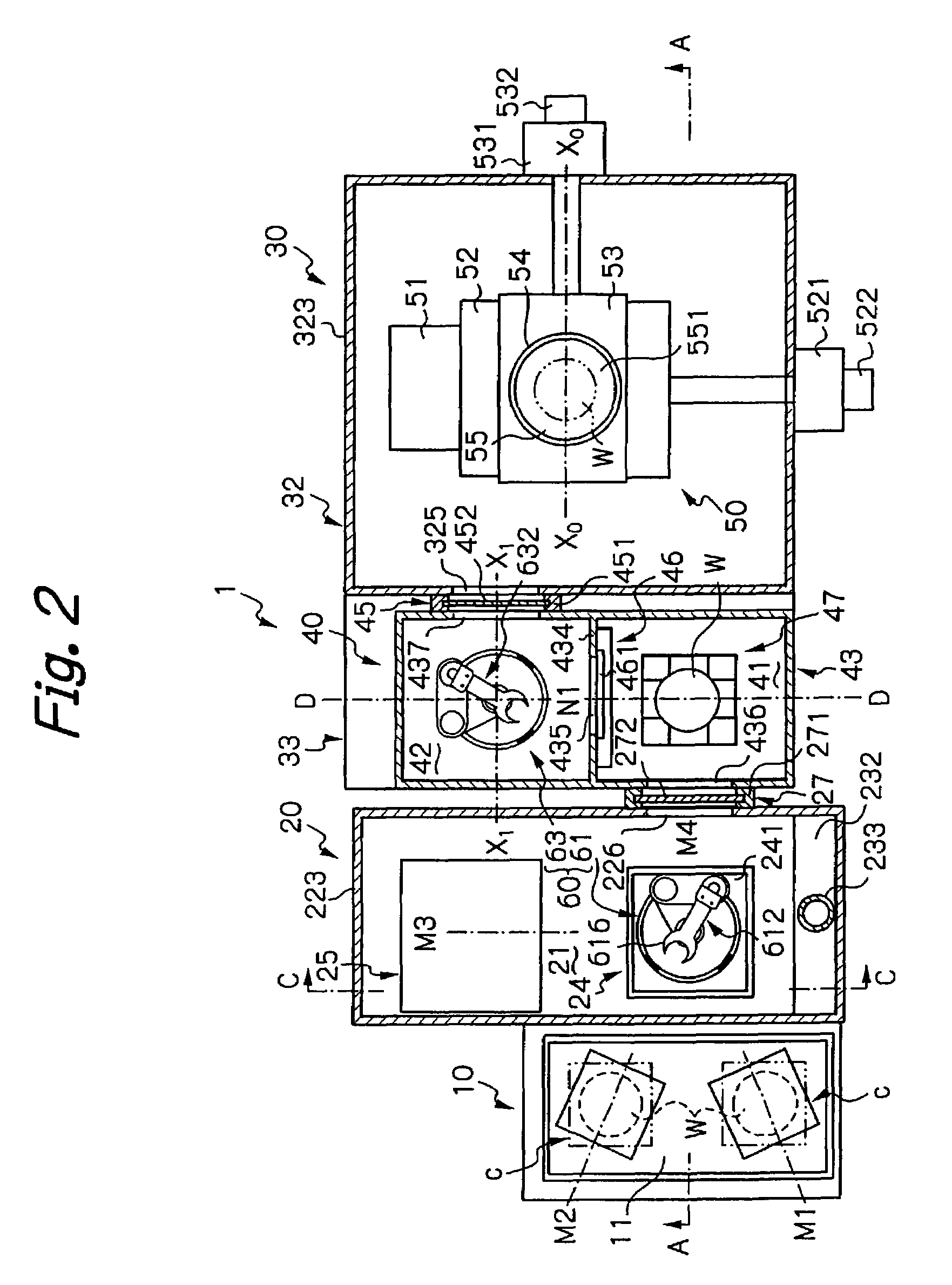

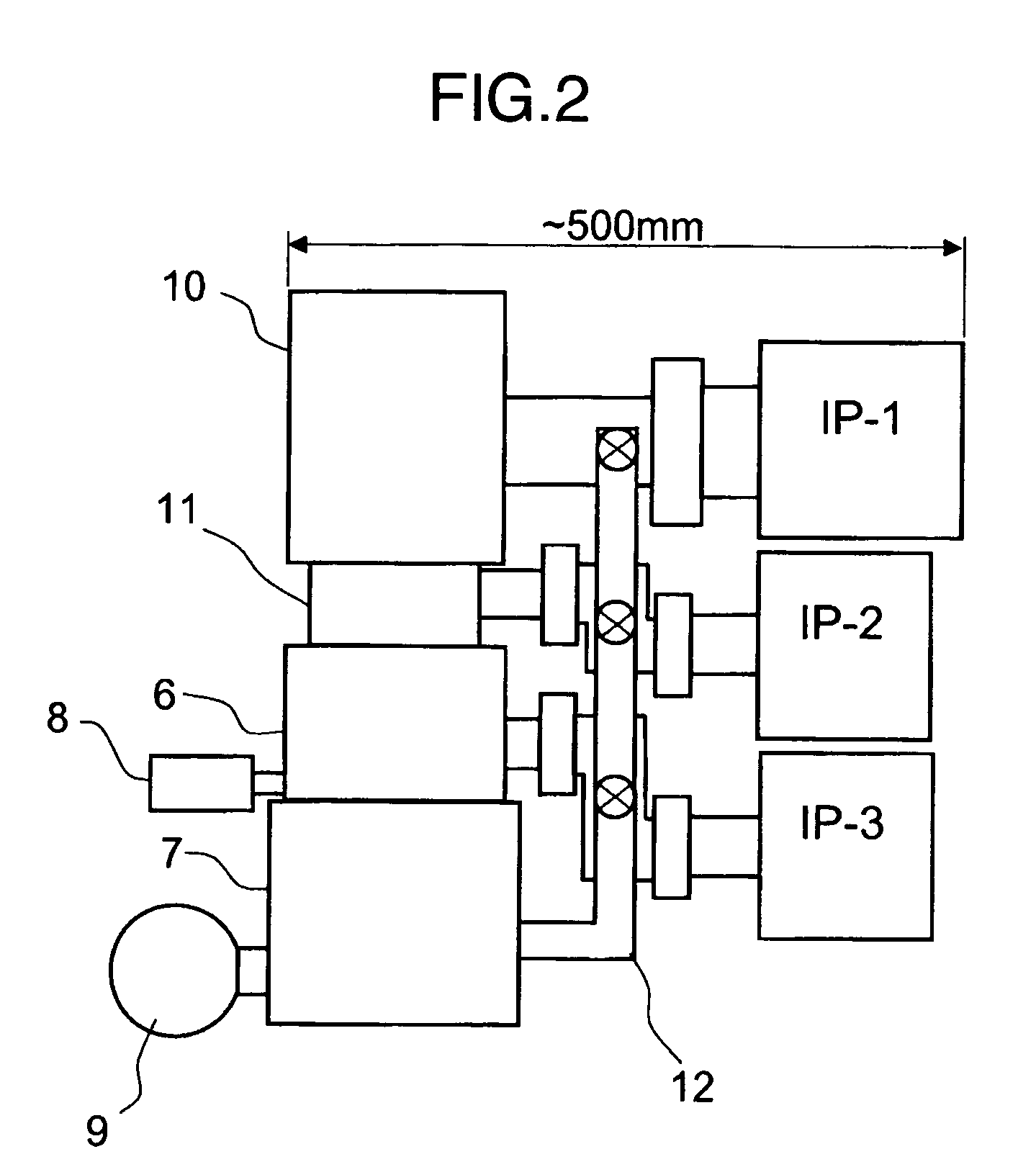

The purpose of the invention is to provide an improved electron beam apparatus with improvements in throughput, accuracy, etc. One of the characterizing features of the electron beam apparatus of the present invention is that it has a plurality of optical systems, each of which comprises a primary electron optical system for scanning and irradiating a sample with a plurality of primary electron beams; a detector device for detecting a plurality of secondary beams emitted by irradiating the sample with the primary electron beams; and a secondary electron optical system for guiding the secondary electron beams from the sample to the detector device; all configured so that the plurality of optical systems scan different regions of the sample with their primary electron beams, and detect the respective secondary electron beams emitted from each of the respective regions. This is what makes higher throughput possible. To provide high accuracy, the apparatus is configured such that the axes of its optical systems can be aligned, and aberrations corrected, by a variety of methods.

Owner:EBARA CORP

Charged particle beam apparatus

InactiveUS7582885B2Improve efficiencyEasy maintenanceBeam/ray focussing/reflecting arrangementsBeam/ray deflecting arrangementsRemoving coilGetter

Owner:HITACHI HIGH-TECH CORP

Charged particle beam apparatus and specimen inspection method

ActiveUS20090001267A1Thermometer detailsBeam/ray focussing/reflecting arrangementsDisplay deviceElectric field

In a multi-charged-particle-beam apparatus, when an electric field and voltage on a surface of a specimen are varied according to characteristics of the specimen, a layout of plural primary beams on the surface of the specimen and a layout of plural secondary beams on each detector vary. Then, calibration is executed to adjust the primary beams on the surface of the specimen to an ideal layout corresponding to the variation of operating conditions including inspecting conditions such as an electric field on the surface and voltage applied to the specimen. The layout of the primary beams on the surface of the specimen is acquired as images displayed on a display of reference marks on the stage. Variance with an ideal state of the reference marks is measured based upon these images and is corrected by the adjustment of a primary electron optics system and others.

Owner:HITACHI HIGH-TECH CORP

Sheet beam-type testing apparatus

InactiveUS7049585B2Inhibition of attachmentMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingBeam source

Owner:EBARA CORP

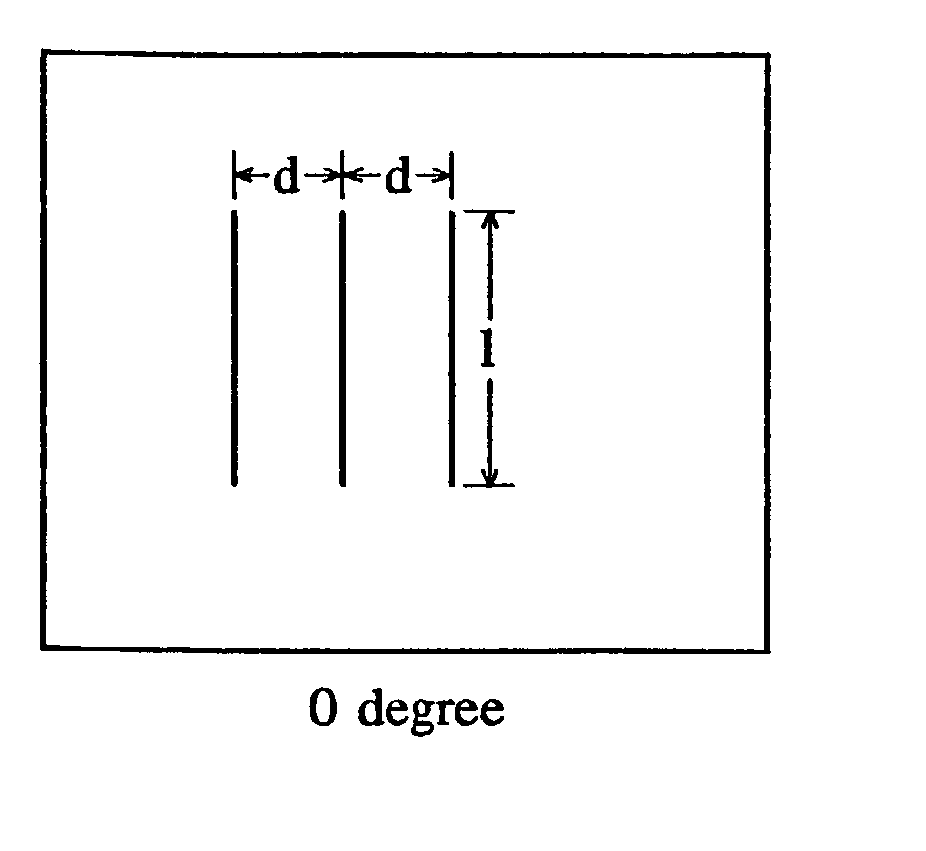

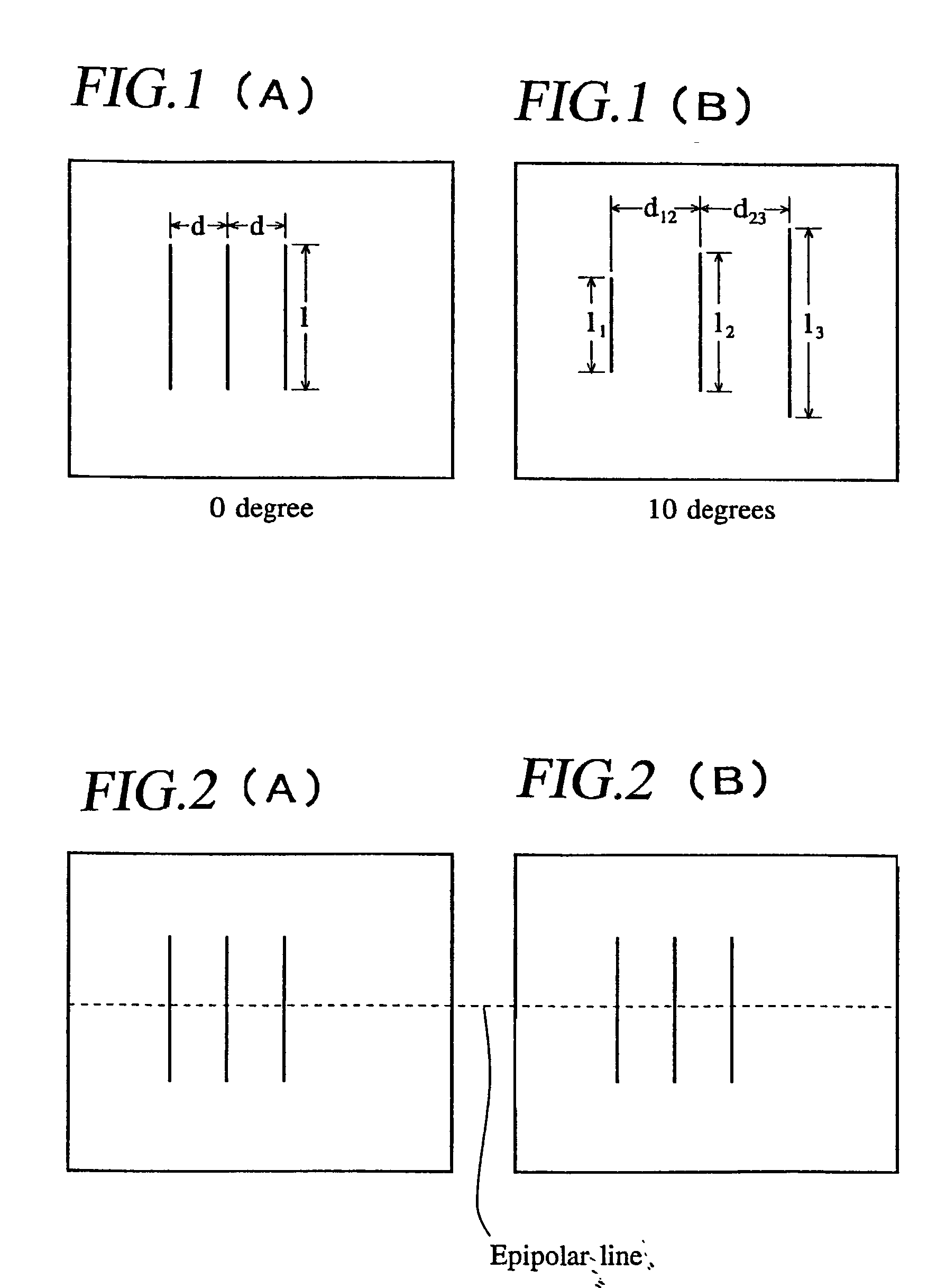

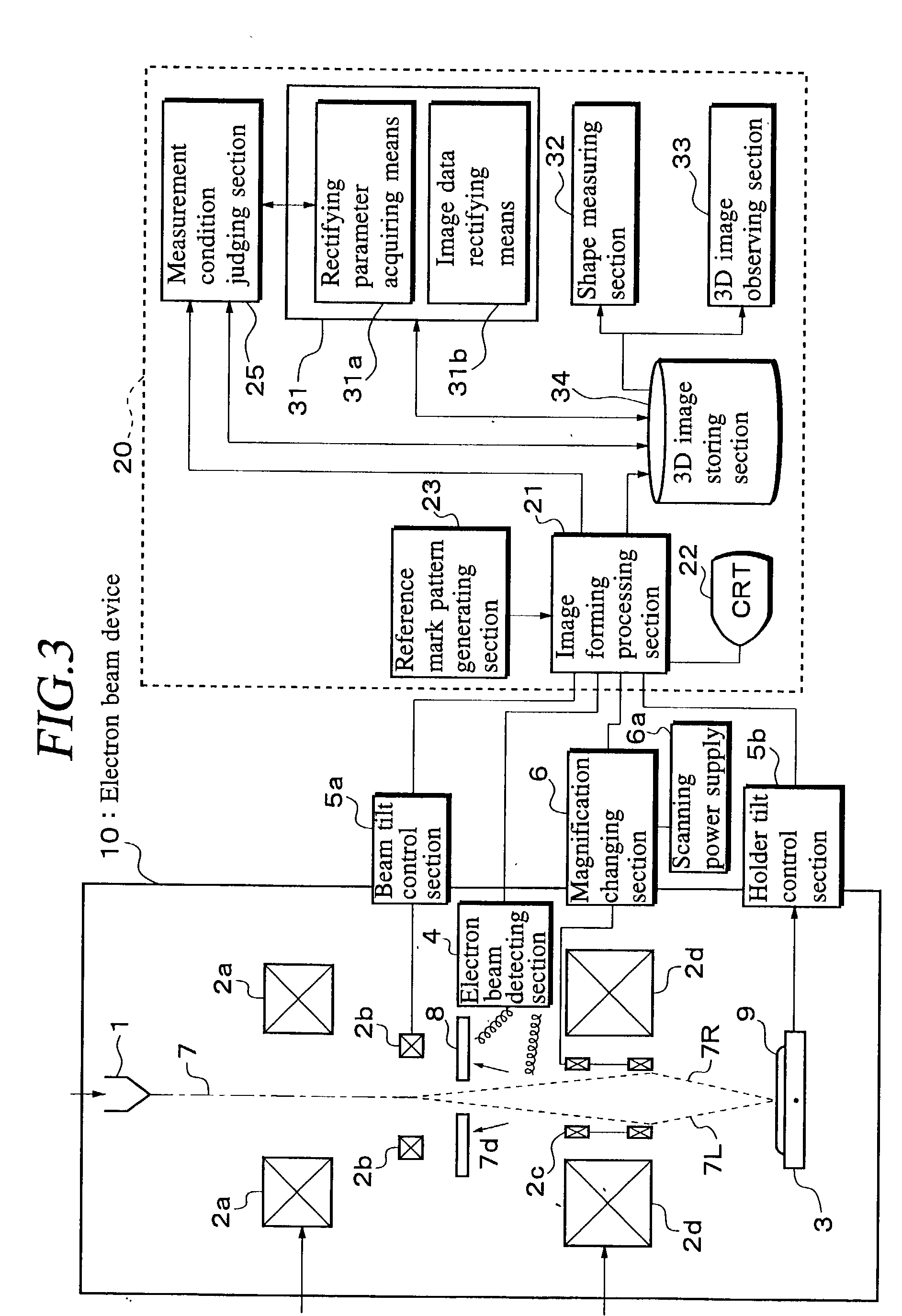

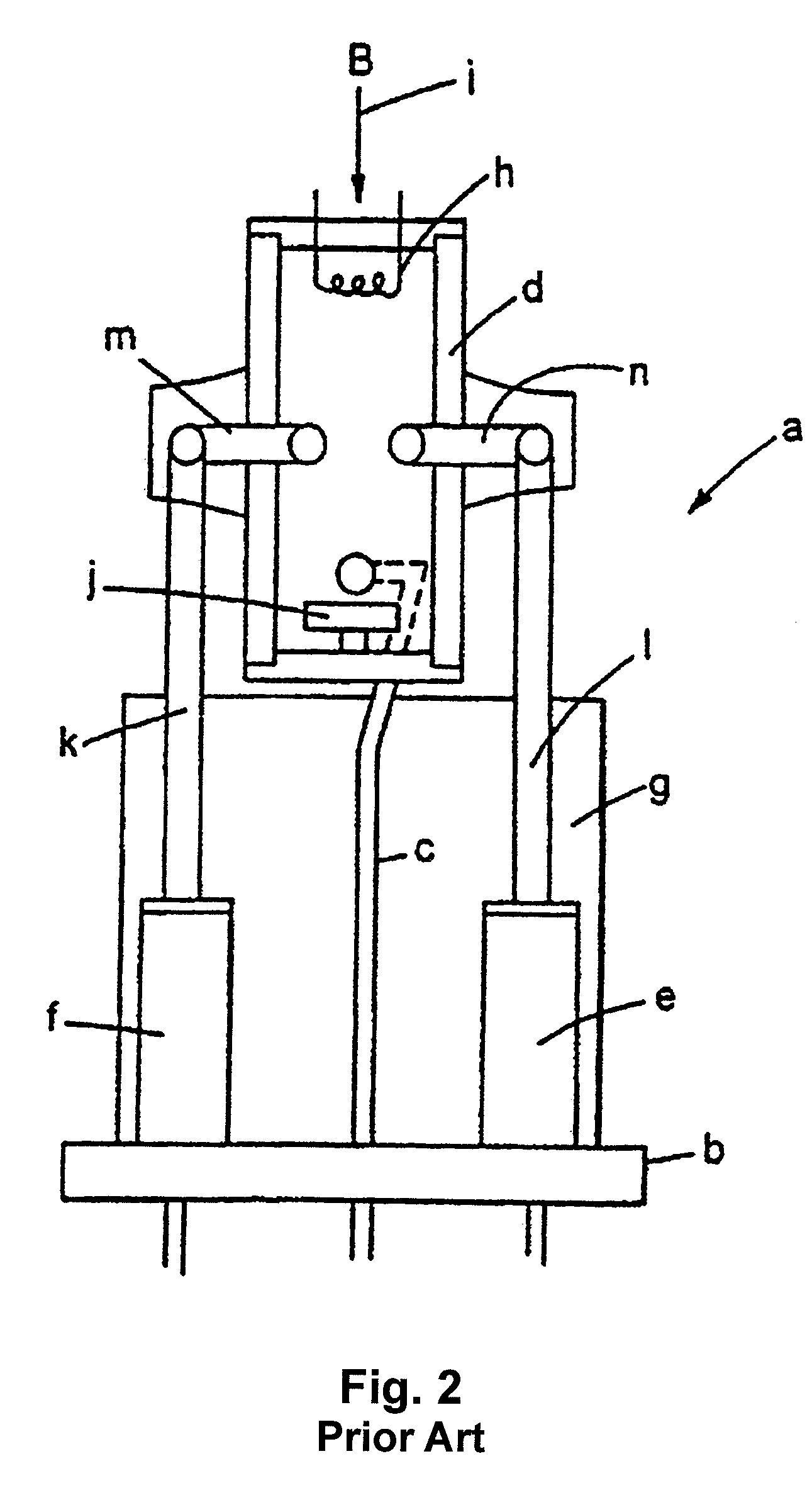

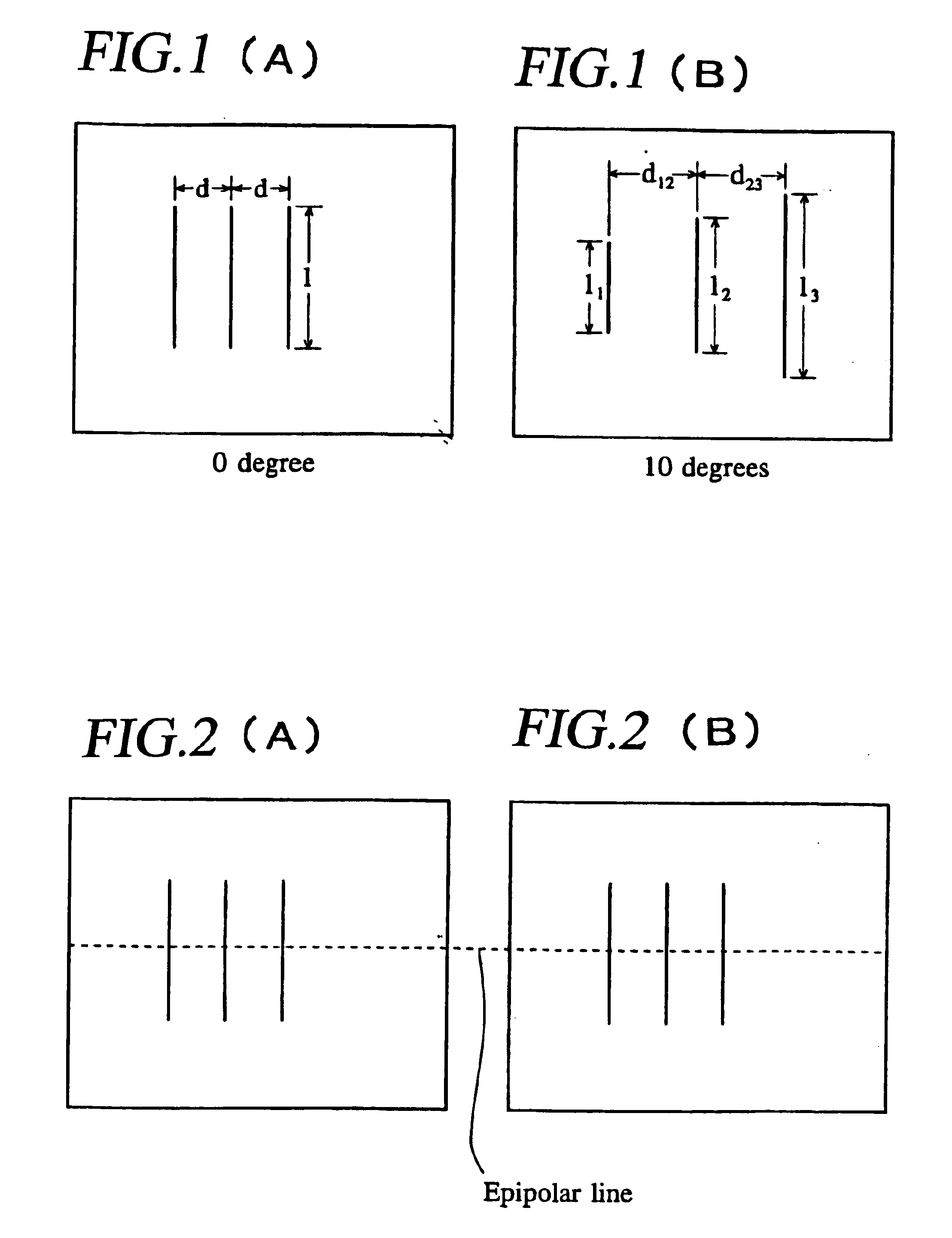

Electron beam device and method for stereoscopic measurements

InactiveUS20020179812A1Accurate rectifying parametersMaterial analysis using wave/particle radiationMicrobiological testing/measurementBeam sourceParticle physics

An electron beam device according to the present invention is made up of an electron beam source for emitting an electron beam, an electron optical system for irradiating the electron beam onto a specimen, a specimen holder for holding the specimen, a specimen tilting section for producing relative tilt angles between the specimen holder and the electron beam, an electron beam detecting section for detecting electron beam emitted from the specimen, and a data correcting section for correcting the three-dimensional detection data to have specified relationship under the condition of a relative tilt angle between the specimen holder and the electron beam.

Owner:KK TOPCON

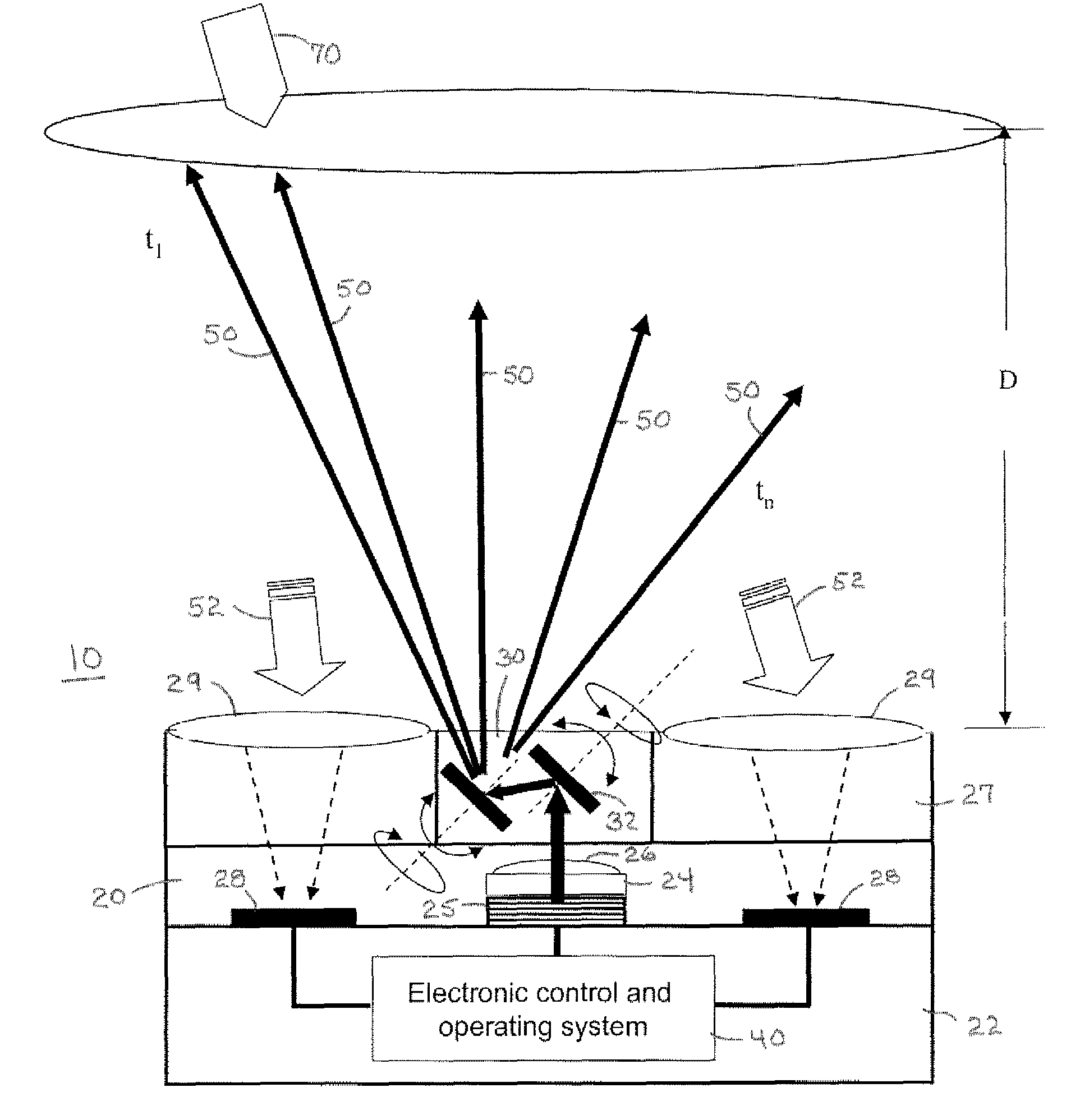

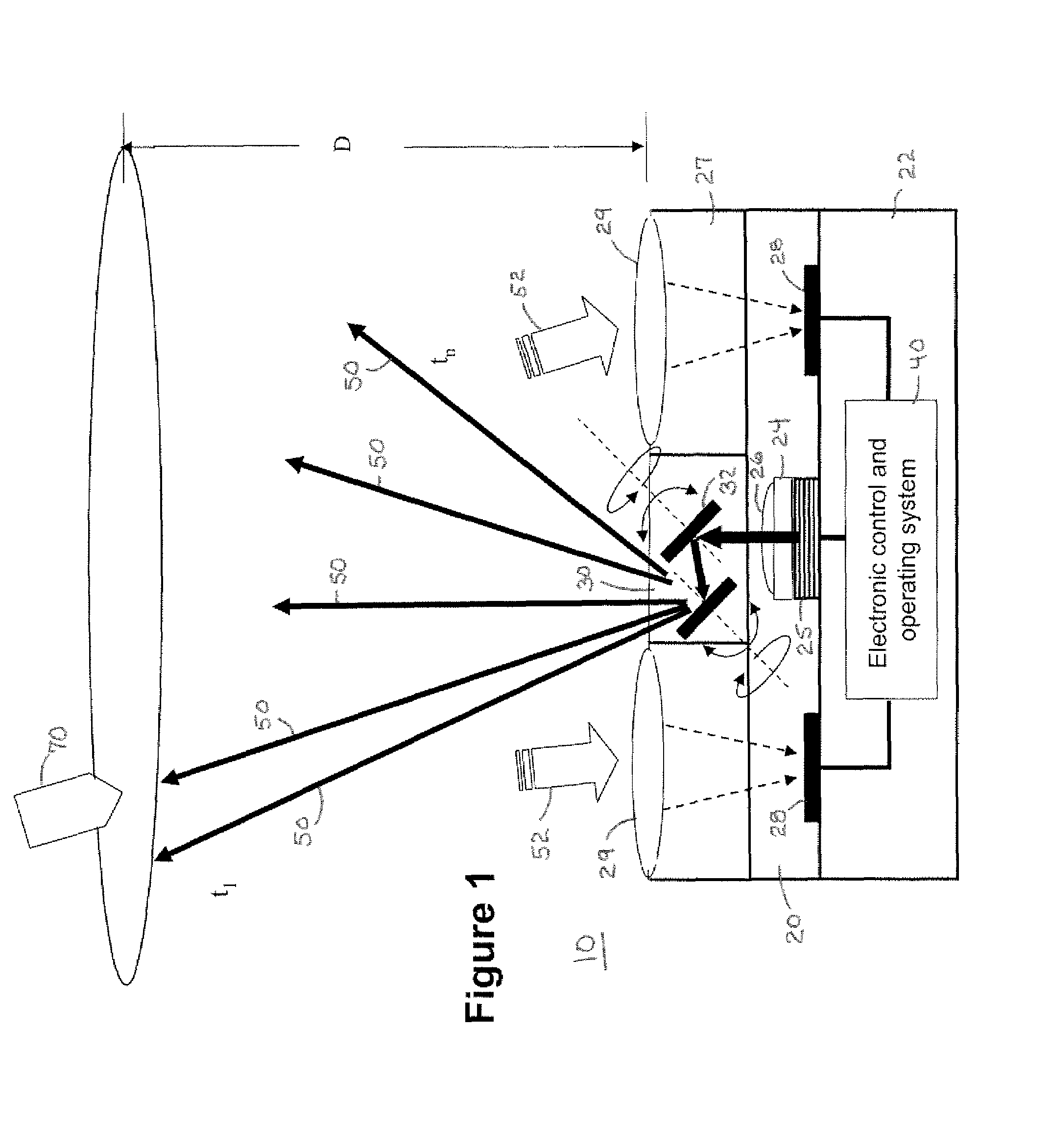

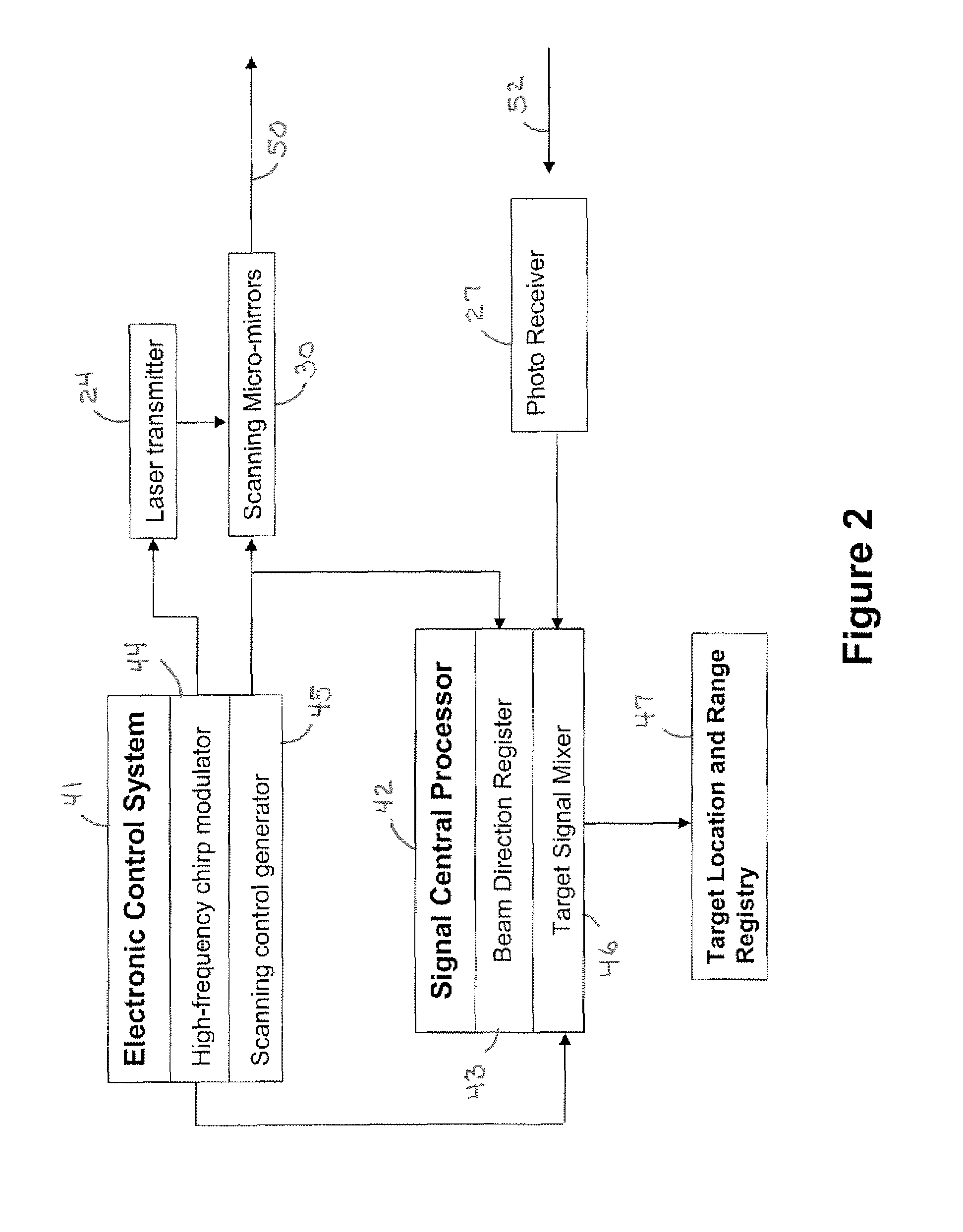

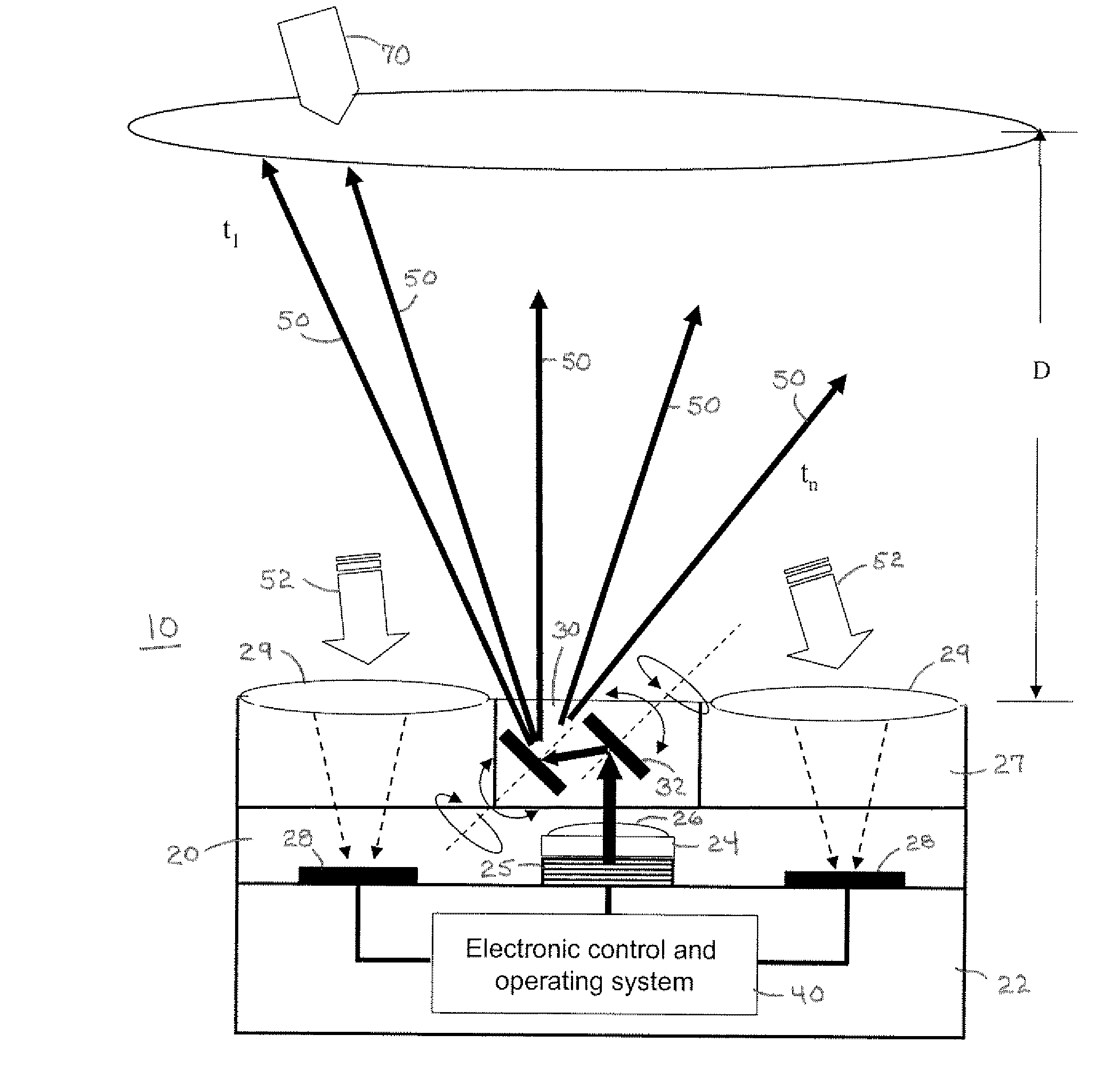

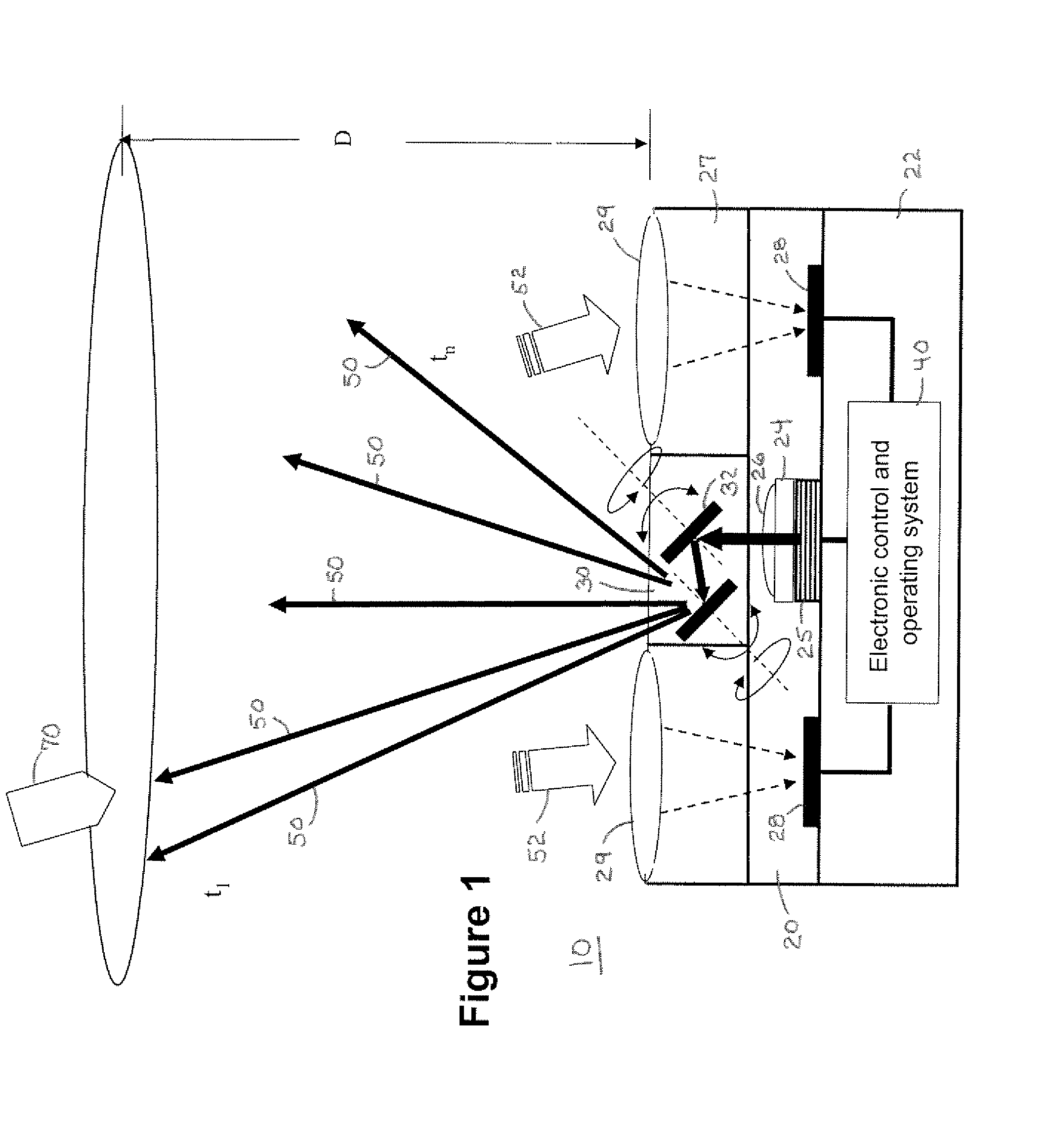

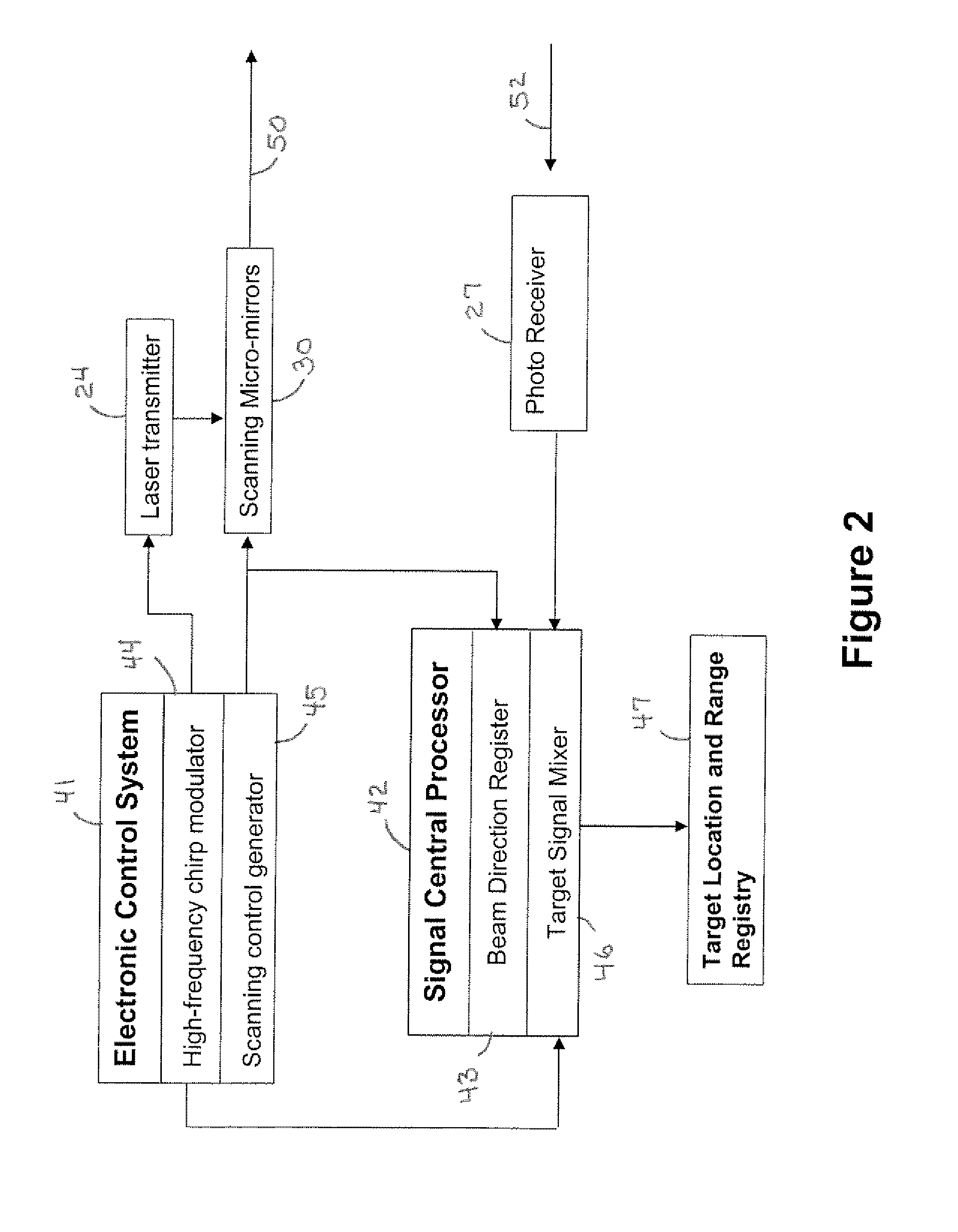

Micro-mirror optical tracking and ranging system

InactiveUS7576837B2Light inexpensiveCheap manufacturingOptical rangefindersElectromagnetic wave reradiationTransceiverEngineering

A micro-mirror optical tracking and ranging system comprises an optical transceiver having a Micro-Electro-Optical Mechanical System (MEOMS) micro-mirror beam steering system and an electronic control and operating system for processing electronic signals. An optical transceiver and MEOMS micro-mirror beam steering system comprises two oppositely installed micro-mirrors controlled so that they spin and tilt synchronously and project a laser beam out in a wide solid angle and interval in a substantially conically shaped scanning pattern. Such an optical transmitter system provides a steered frequency-modulated continuous-wave (FMCW) laser beam. When a laser beam waveform reflects off of an object within the scanned patter it is detected by the optical receiver an electronic control and operating system processes the detected laser beam waveform by mixing it with the original transmitted laser beam waveform and calculates the precise distance and location of the object.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

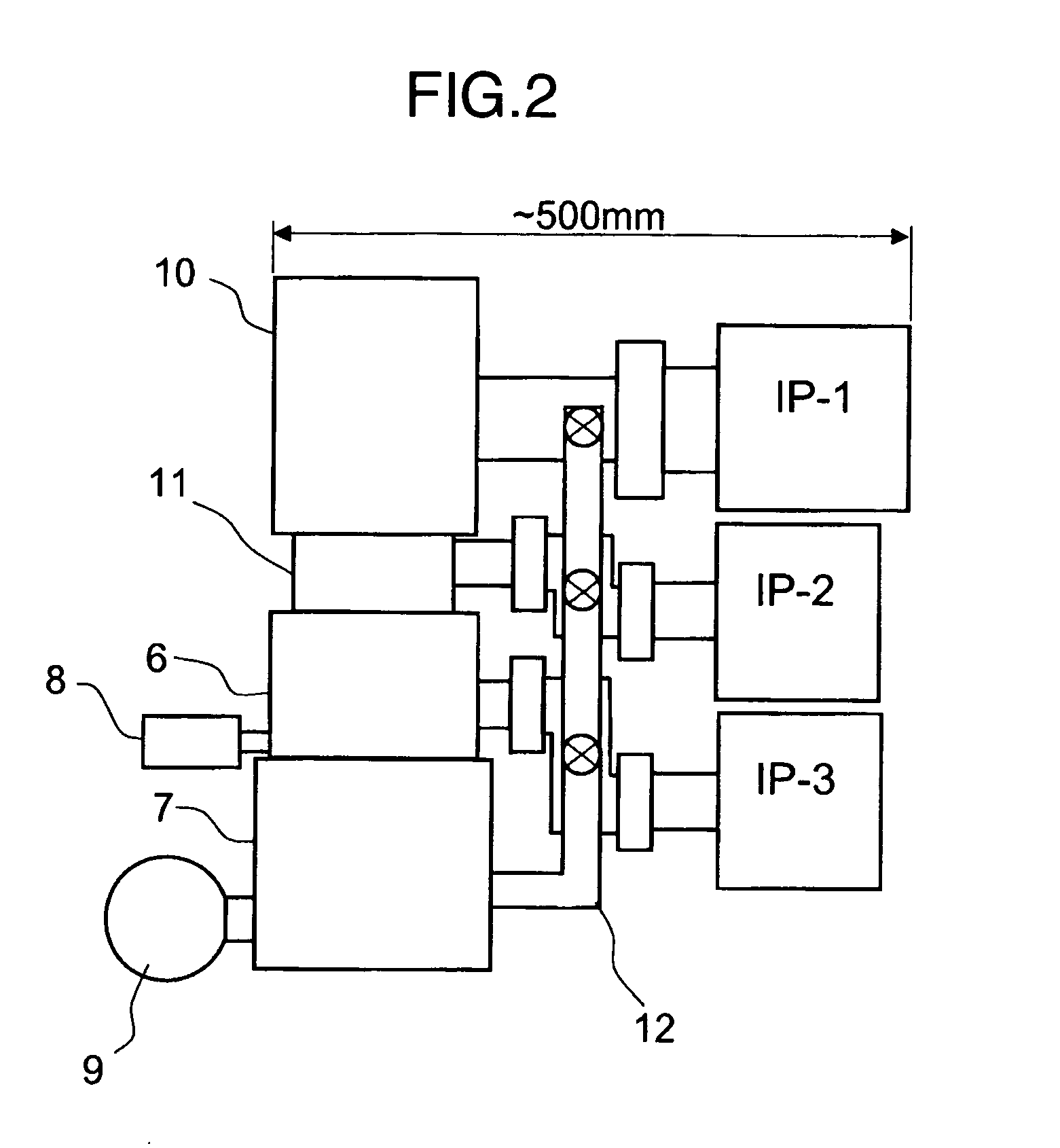

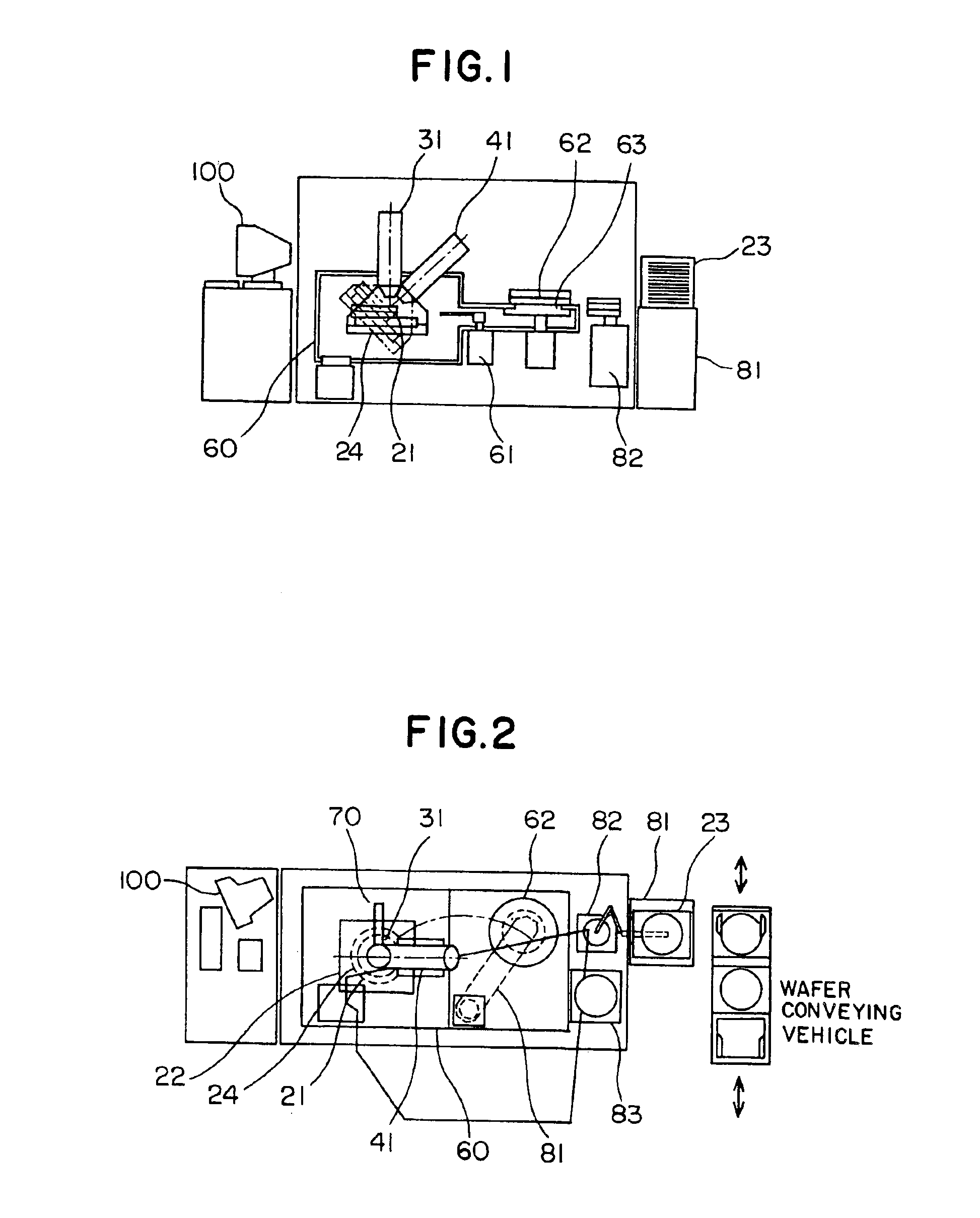

Multi-beam multi-column electron beam inspection system

ActiveUS6977375B2Material analysis using wave/particle radiationRadiation/particle handlingData streamSecondary electrons

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

Charged particle beam apparatus

ActiveUS20100065753A1High sensitivityHigh inspection rateThermometer detailsMaterial analysis using wave/particle radiationMulti beamMolecular physics

With a multi-beam type charged particle beam apparatus, and a projection charged particle beam apparatus, in the case of off-axial aberration corrector, there is the need for preparing a multitude of multipoles, and power supply sources in numbers corresponding to the number of the multipoles need be prepared. In order to solve this problem as described, a charged particle beam apparatus is provided with at least one aberration corrector wherein the number of the multipoles required in the past is decreased by about a half by disposing an electrostatic mirror in an electron optical system.

Owner:HITACHI HIGH-TECH CORP

Electron optical apparatus, X-ray emitting device and method of producing an electron beam

ActiveUS7839979B2FocusEnhanced speed componentCathode ray concentrating/focusing/directingOptical axisX-ray

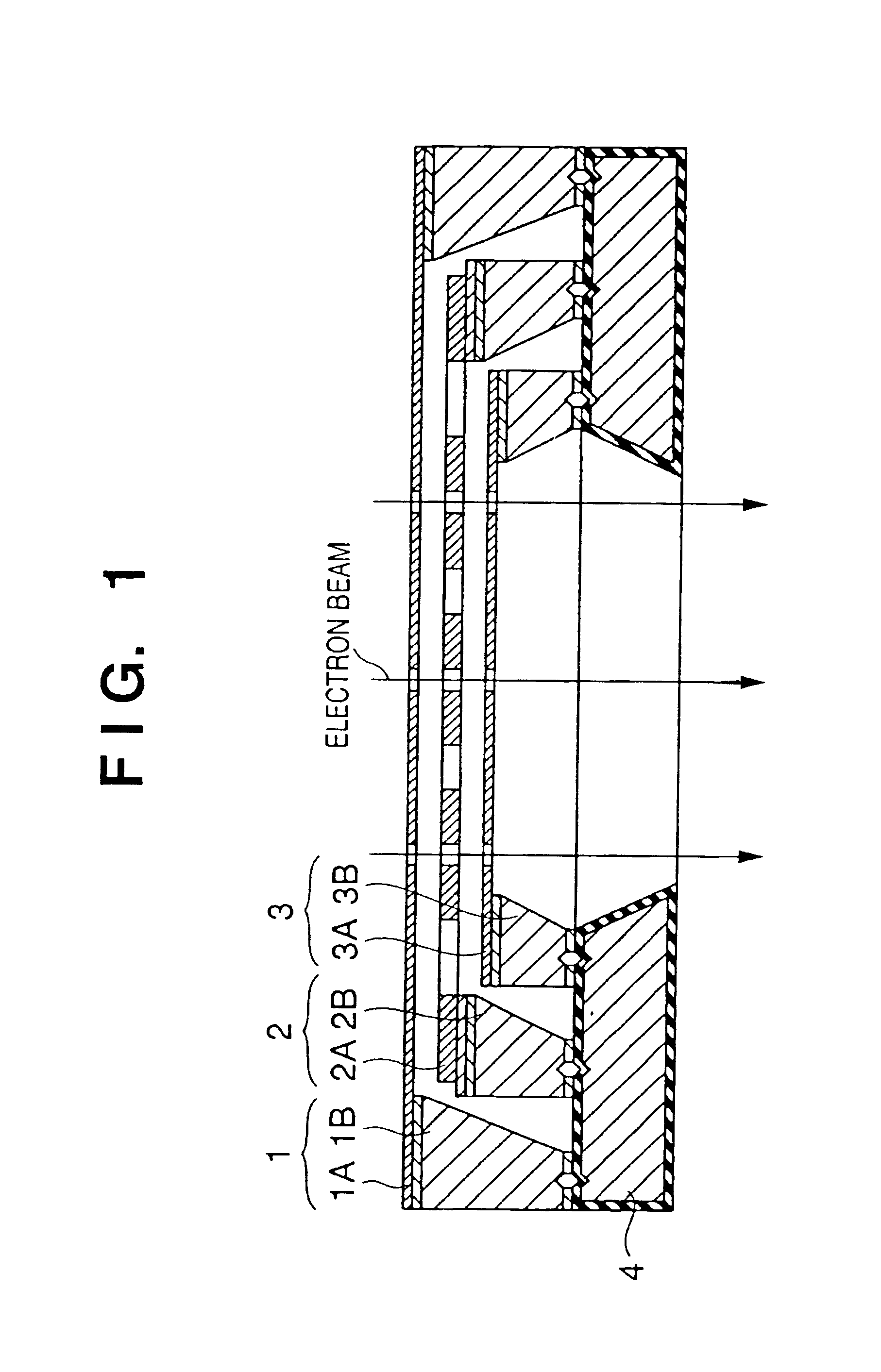

It is described an electron optical arrangement, a X-ray emitting device and a method of creating an electron beam. An electron optical apparatus (1) comprises the following components along an optical axis (25): a cathode with an emitter (3) having a substantially planar surface (9) for emitting electrons; an anode (11) for accelerating the emitted electrons in a direction essentially along the optical axis (25); a first magnetic quadrupole lens (19) for deflecting the accelerated electrons and having a first yoke (41); a second magnetic quadrupole lens (21) for further deflecting the accelerated electrons and having a second yoke (51); and a magnetic dipole lens (23) for further deflecting the accelerated electrons.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Novel non-crystalline oxides for use in microelectronic, optical, and other applications

InactiveUS20020024108A1Oxide/hydroxide preparationTantalum compoundsCrystalline oxideField-effect transistor

The invention relates to non-crystalline oxides of formulas (I) and (II), and methods of forming the same, along with field effect transistors, articles of manufacture, and microelectronic devices comprising the non-crystalline oxides.

Owner:NORTH CAROLINA STATE UNIV

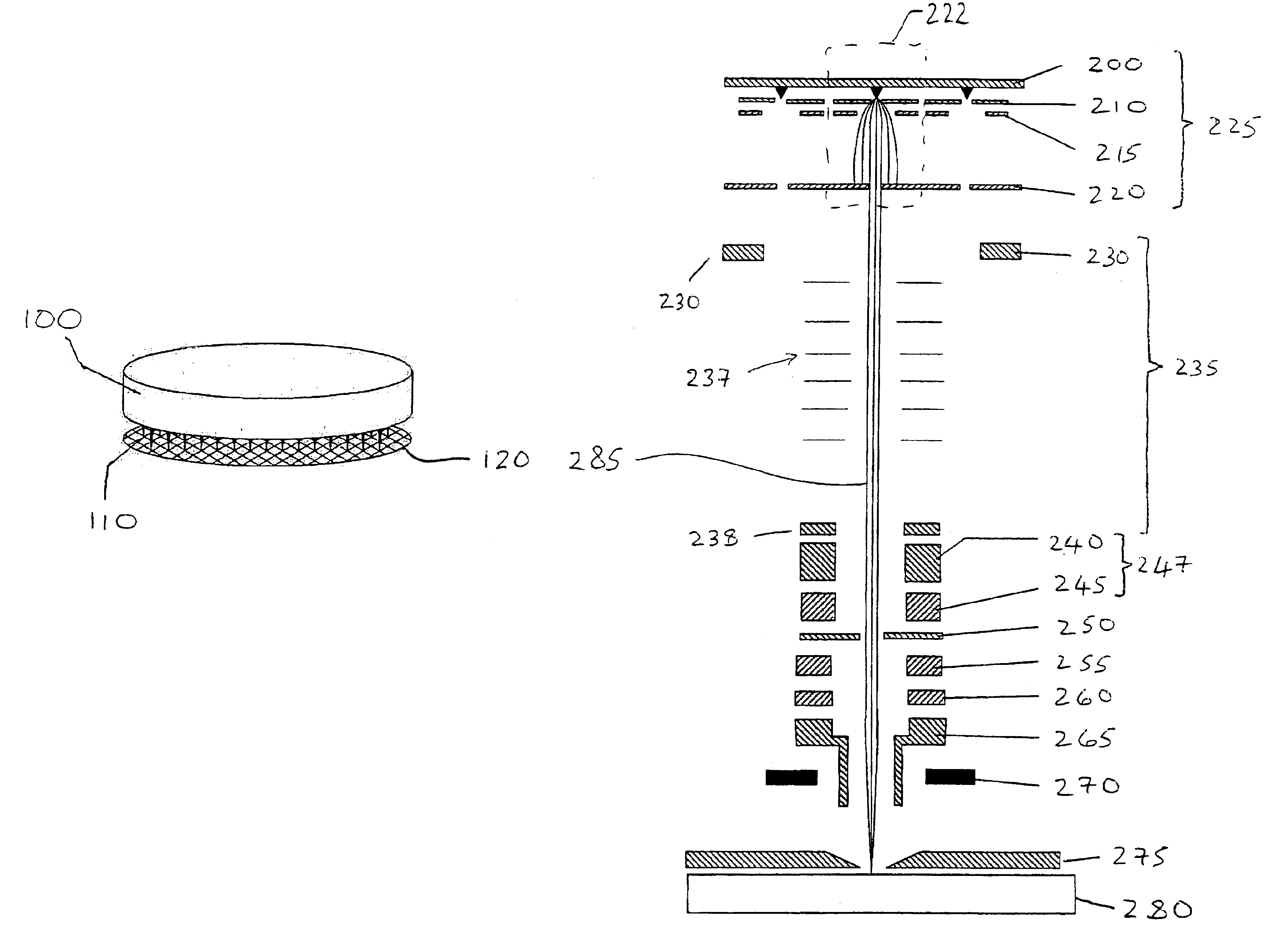

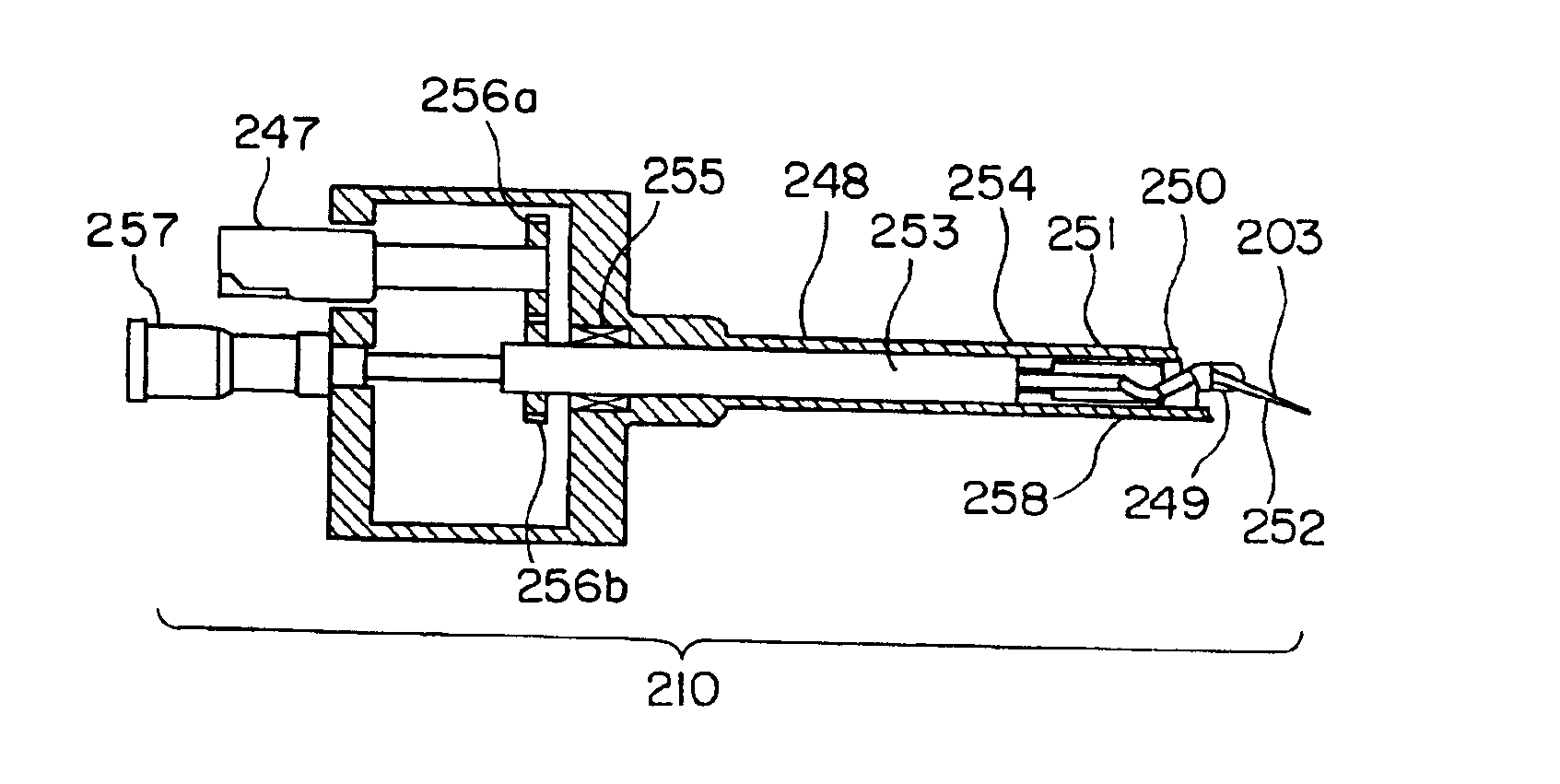

Method of Detecting Electrons, an Electron-Detector and an Inspection System

ActiveUS20150083911A1Less deterioration of qualityExtended operating timeMaterial analysis using wave/particle radiationElectric discharge tubesLight beamOptoelectronics

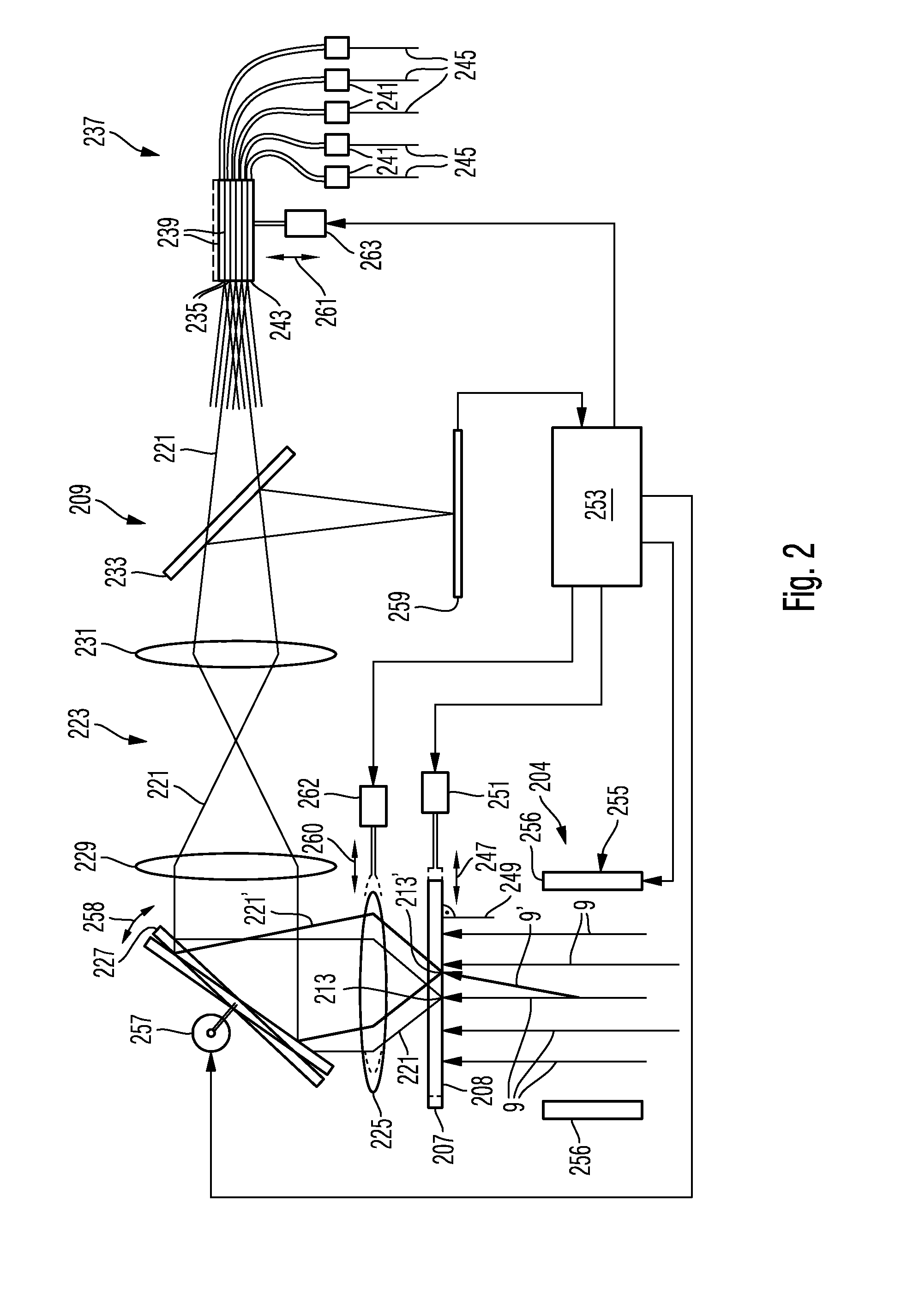

An electron-detector comprises a scintillator plate 207, electron optics 204 for directing a plurality of electron beams 9 onto the scintillator plate so that the electron beams are incident onto the scintillator plate at locations of incidence disposed at a distance from each other, a light detector 237 comprising a plurality of light receiving areas 235 disposed at a distance from each other, and light optics for generating a first light-optical image of at least a portion of the scintillator plate at a region 243 where the light receiving areas of the light detector are disposed so that, by the imaging, each of the locations of incidence is associated with a light receiving area; and wherein the electron optics comprise an electron beam deflector 255 for displacing the locations of incidence of the electron beams on the scintillator plate in a direction orthogonal to a normal 249 of a surface 208 of the scintillator plate.

Owner:CARL ZEISS MICROSCOPY GMBH

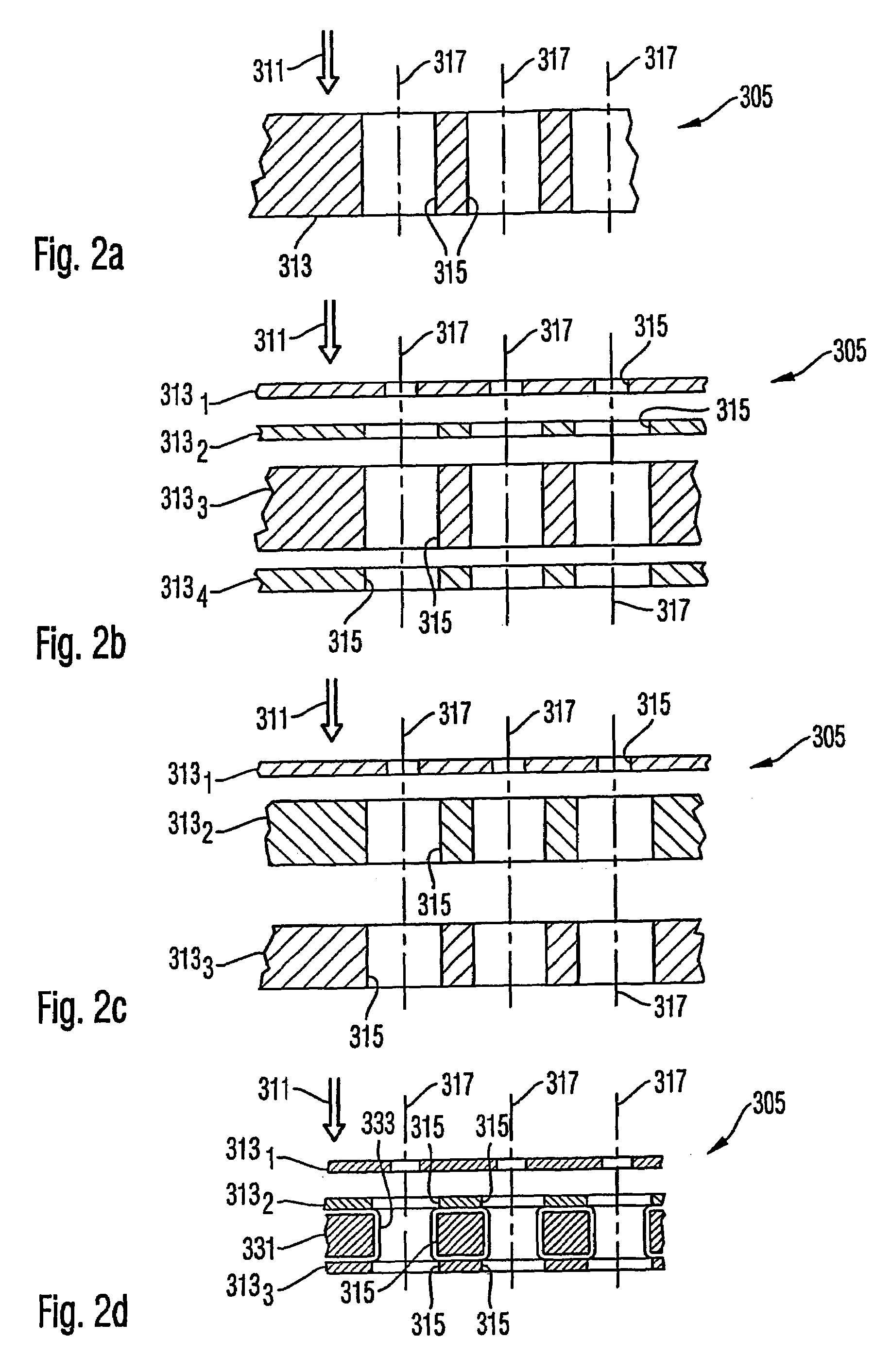

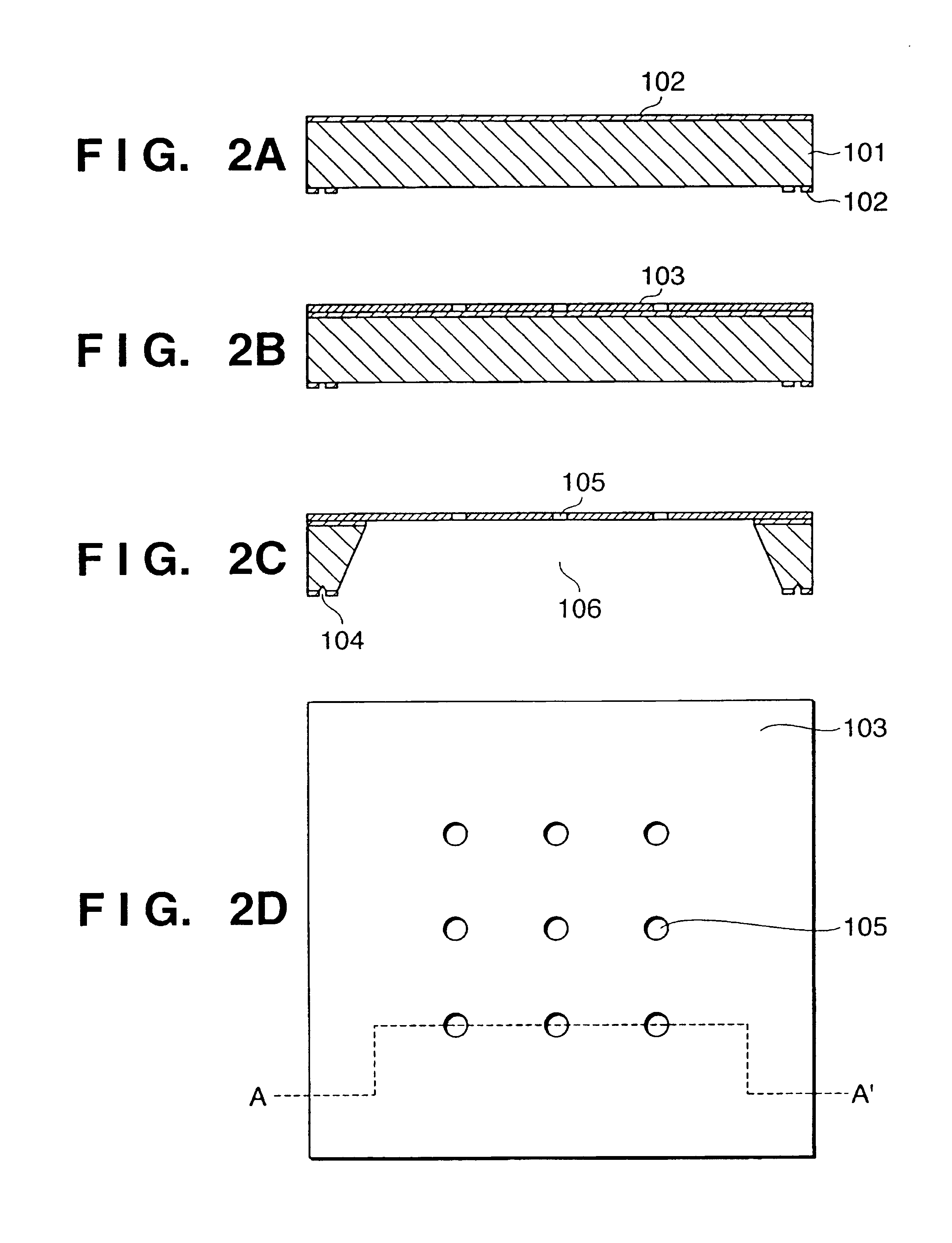

Electron optical system array, method of fabricating the same, charged-particle beam exposure apparatus, and device manufacturing method

InactiveUS6872950B2Improve accuracyImprove reliabilityStability-of-path spectrometersNanoinformaticsElectron lensesAtomic physics

This invention relates to an electron optical system array having a plurality of electron lenses. The electron optical system array includes a plurality of electrodes arranged along the paths of a plurality of charged-particle beams. Each of the plurality of electrodes has a membrane in which a plurality of apertures are formed on the paths of the plurality of charged-particle beams, and a support portion which supports the membrane. At least two of the plurality of electrodes are arranged to form a nested structure.

Owner:CANON KK

Micro-mirror optical tracking and ranging system

InactiveUS20080174762A1Improve spatial resolutionLight inexpensiveOptical rangefindersElectromagnetic wave reradiationTransceiverBeam steering

A micro-mirror optical tracking and ranging system comprises an optical transceiver having a Micro-Electro-Optical Mechanical System (MEOMS) micro-mirror beam steering system and an electronic control and operating system for processing electronic signals. An optical transceiver and MEOMS micro-mirror beam steering system comprises two oppositely installed micro-mirrors controlled so that they spin and tilt synchronously and project a laser beam out in a wide solid angle and interval in a substantially conically shaped scanning pattern. Such an optical transmitter system provides a steered frequency-modulated continuous-wave (FMCW) laser beam. When a laser beam waveform reflects off of an object within the scanned patter it is detected by the optical receiver an electronic control and operating system processes the detected laser beam waveform by mixing it with the original transmitted laser beam waveform and calculates the precise distance and location of the object.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Interference-free optical detection for Raman spectroscopy

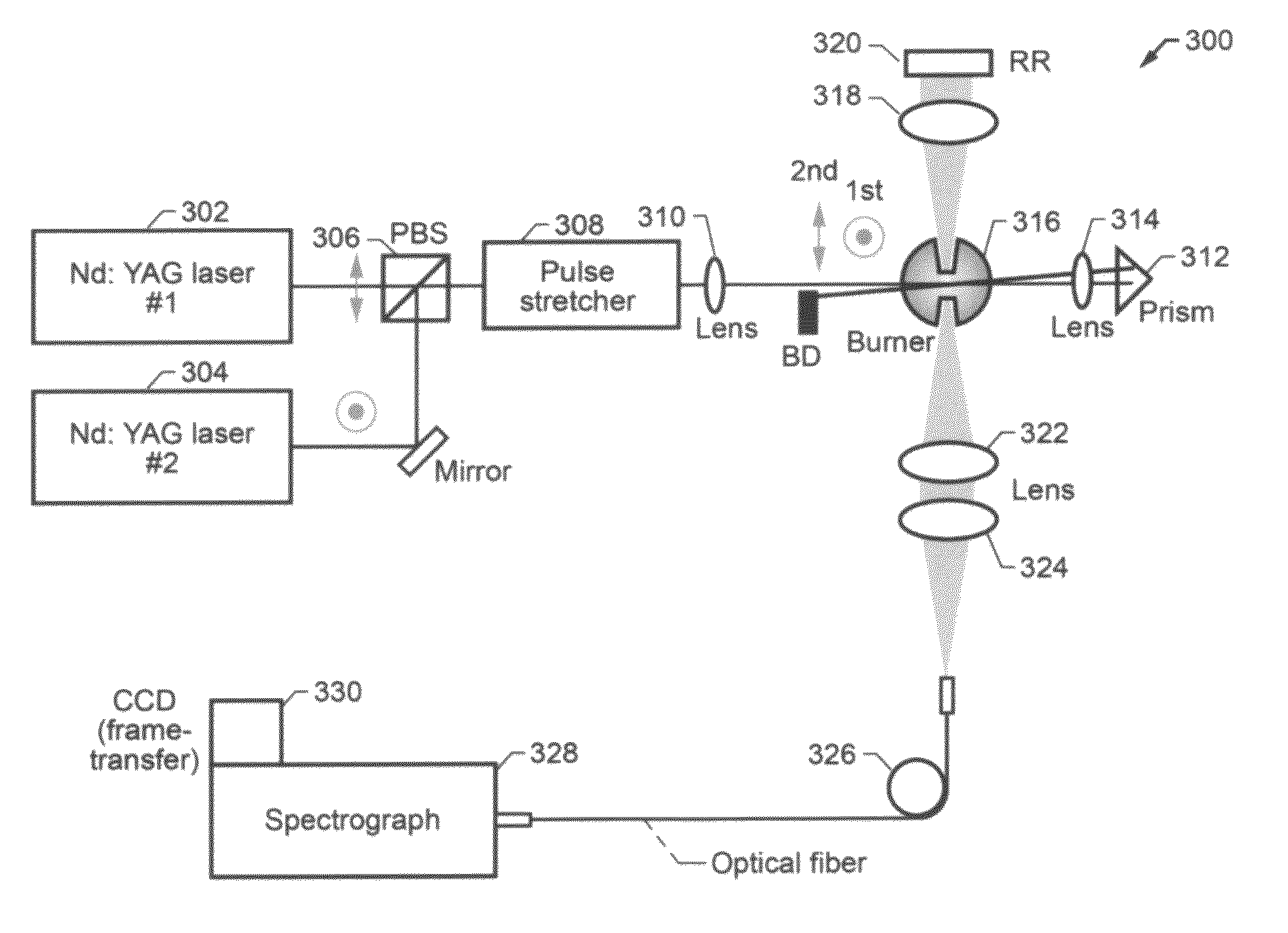

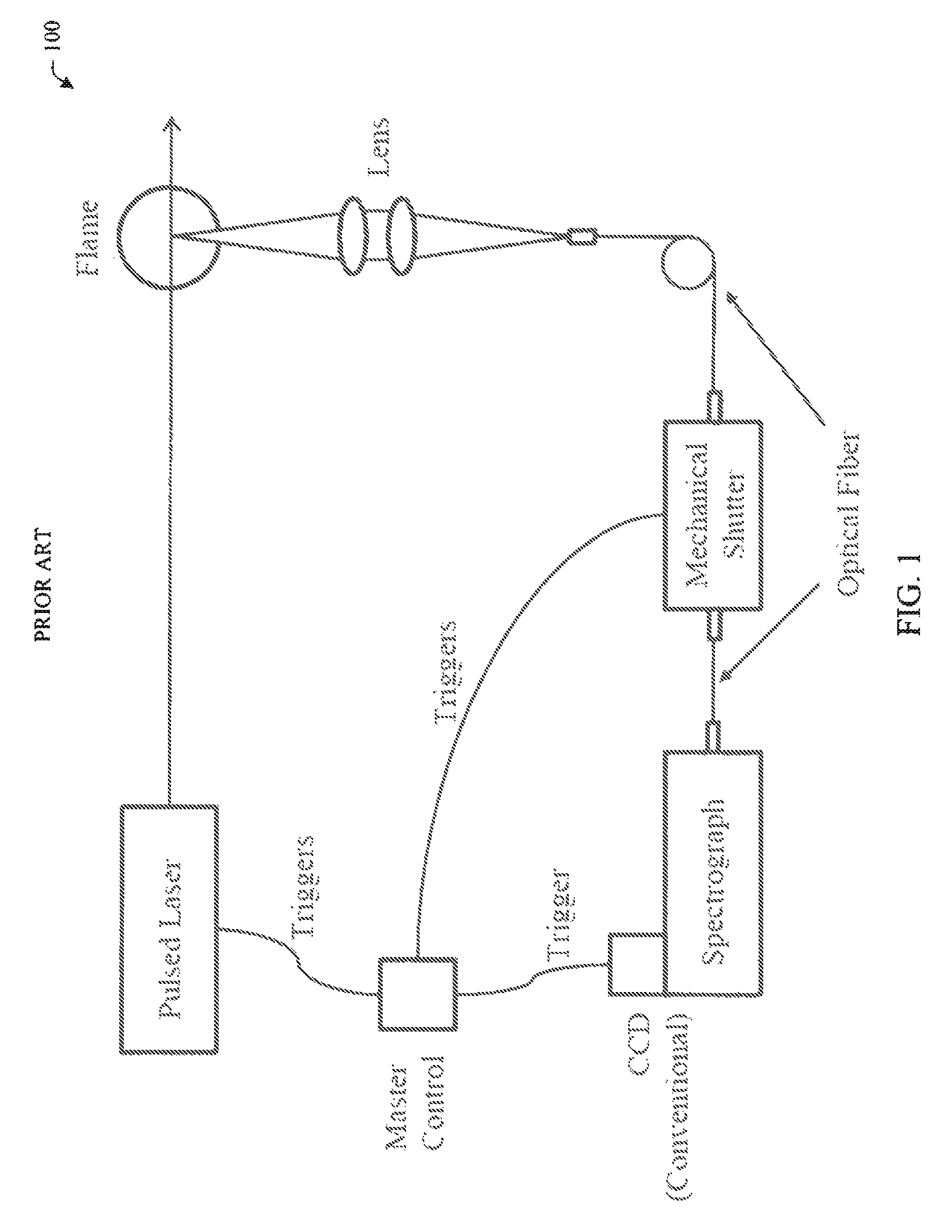

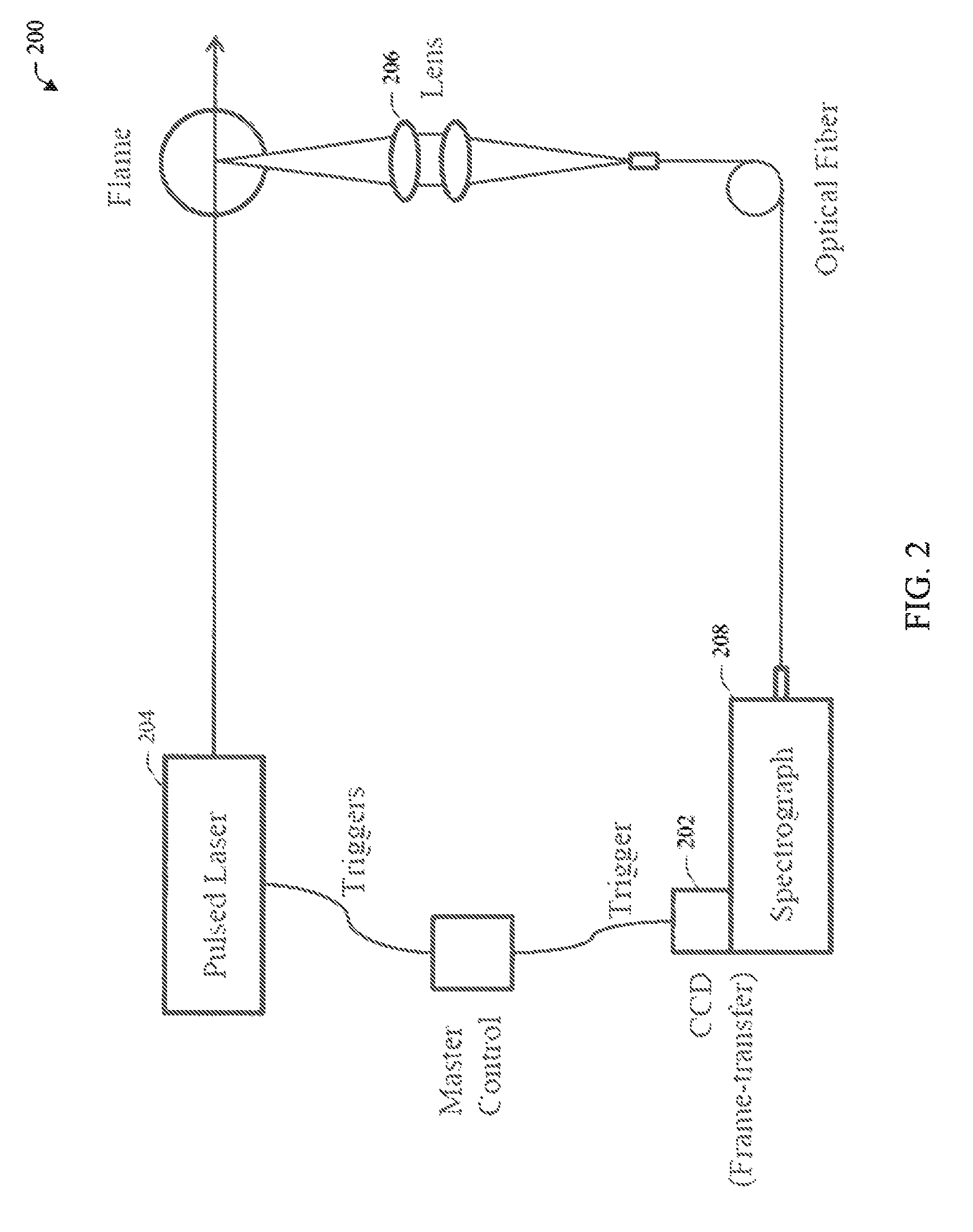

InactiveUS8310671B1Short temporal gatingIncrease luminous fluxRadiation pyrometrySpectrum investigationCombustionBackground noise

An architecture for spontaneous Raman scattering (SRS) that utilizes a frame-transfer charge-coupled device (CCD) sensor operating in a subframe burst gating mode to realize time-resolved combustion diagnostics is disclosed. The technique permits all-electronic optical gating with microsecond shutter speeds (<5 μs), without compromising optical throughput or image fidelity. When used in conjunction with a pair of orthogonally-polarized excitation lasers, the technique measures time-resolved vibrational Raman scattering that is minimally contaminated by problematic optical background noise.

Owner:NASA

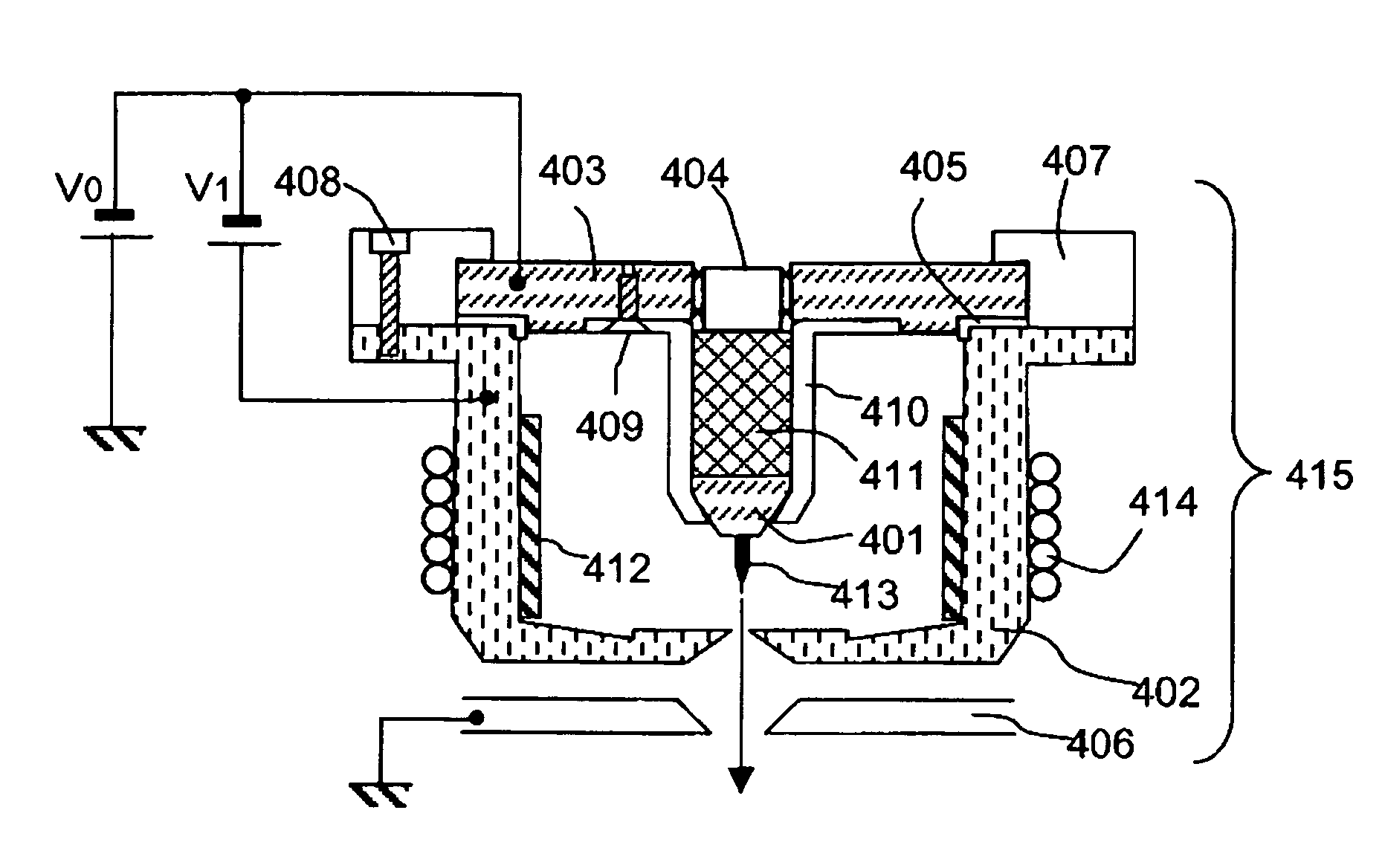

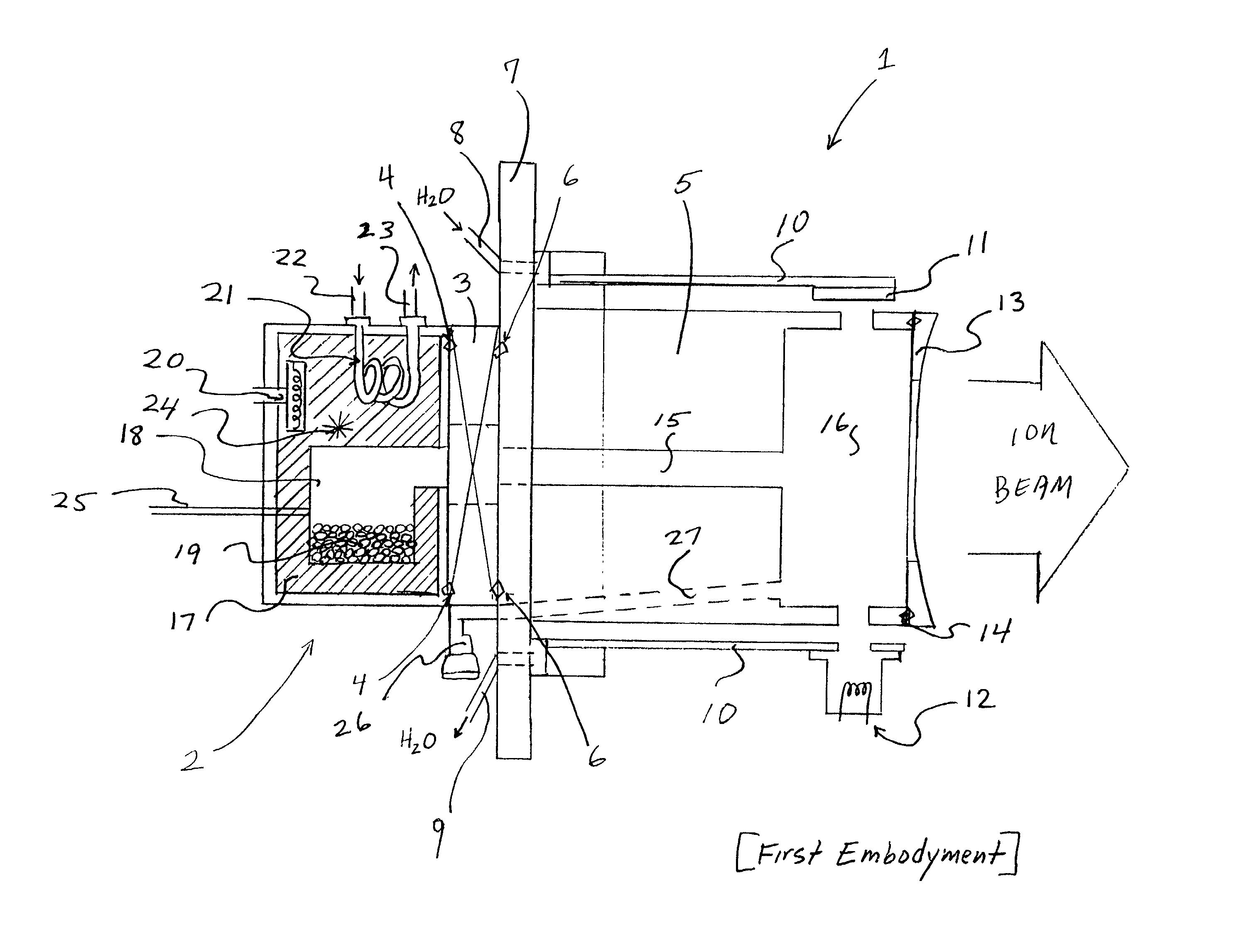

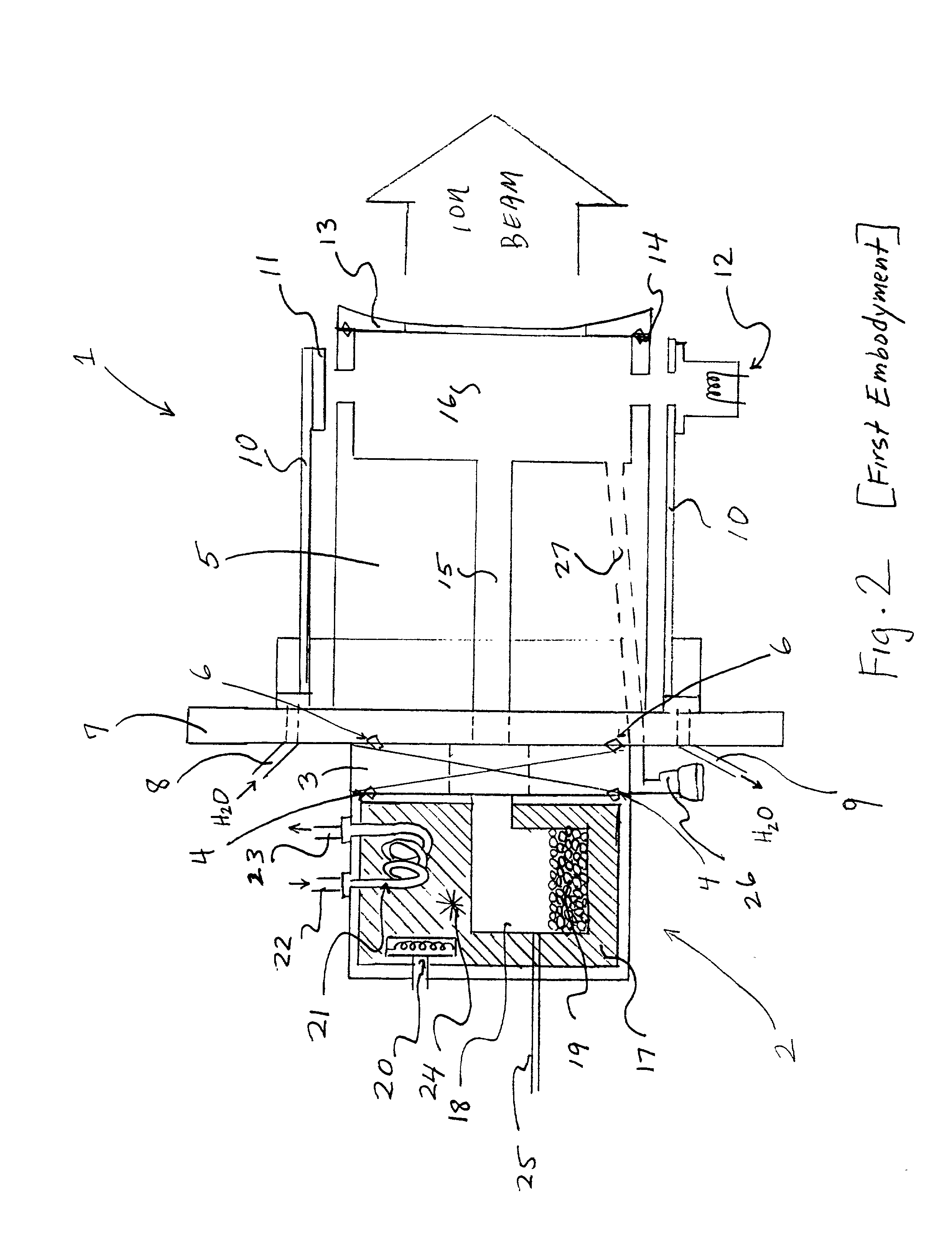

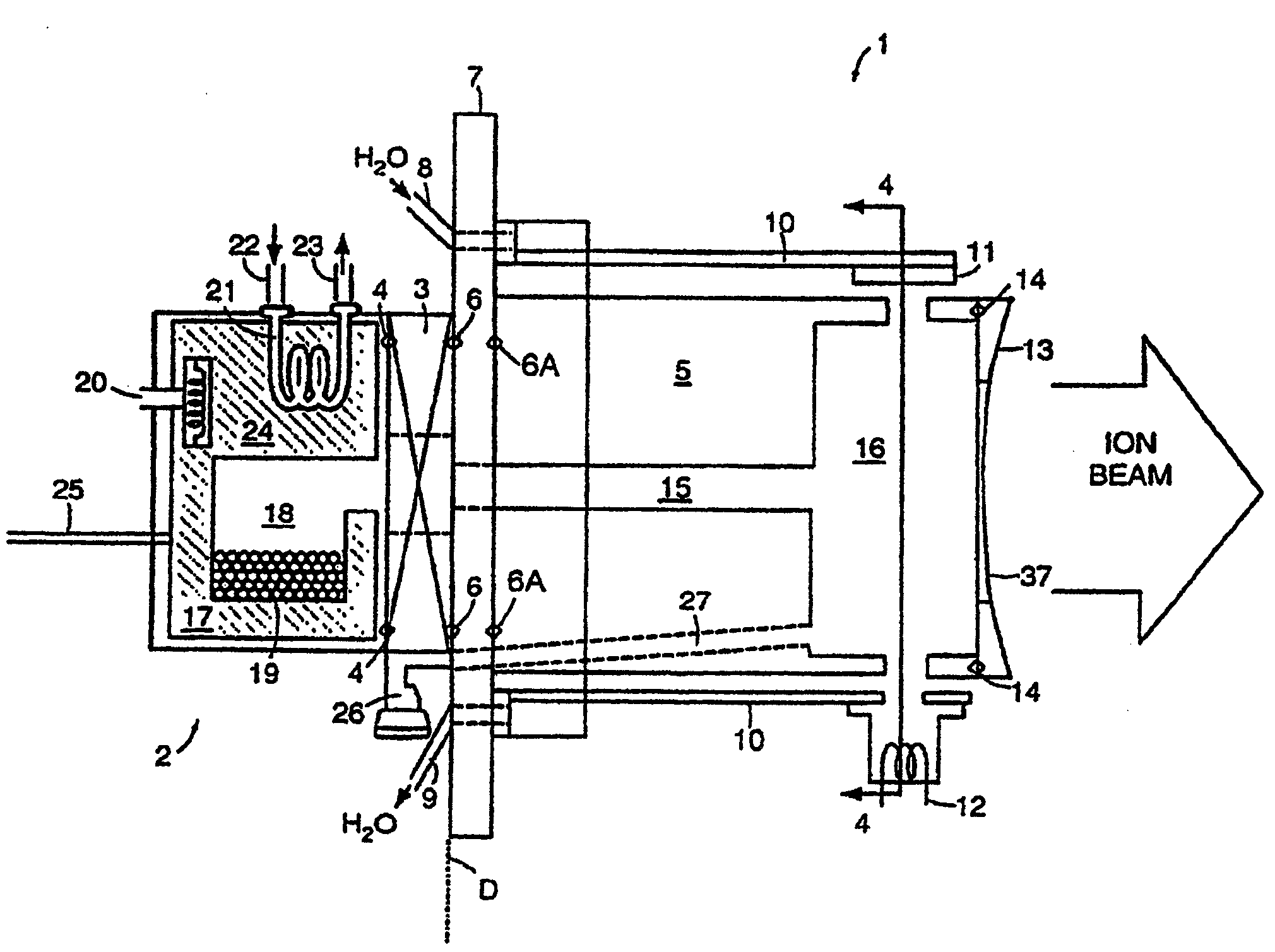

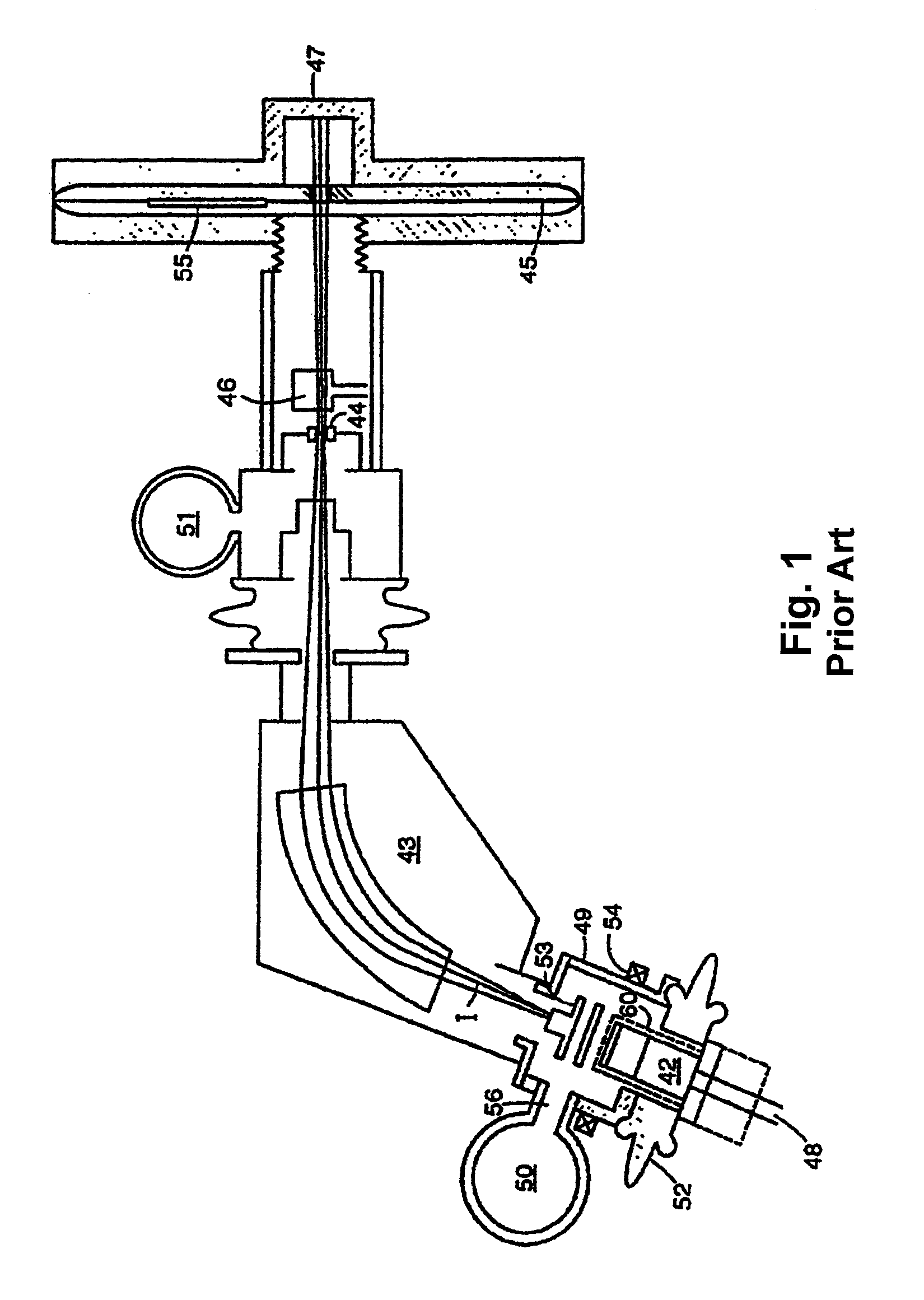

Electron beam ion source with integral low-temperature vaporizer

InactiveUS20020070672A1Maximizes conductanceMinimizes conductanceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energy beamIon implantation

An ion source for ion implantation system and a method of ion implantation employs a controlled broad, directional electron beam to ionize process gas or vapor, such as decaborane, within an ionization volume by primary electron impact, in CMOS manufacturing and the like. Isolation of the electron gun for producing the energetic electron beam and of the beam dump to which the energetic beam is directed, as well as use of the thermally conductive members for cooling the ionization chamber and the vaporizer, enable use with large molecular species such as decaborane, and other materials which are unstable with temperature. Electron optics systems, facilitate focusing of electrons from an emitting surface to effectively ionize a desired volume of the gas or vapor that is located adjacent the extraction aperture. The components enable retrofit into ion implanters that have used other types of ion sources. Demountable vaporizers, and numerous other important features, realize economies in construction and operation. Achievement of production-worthy operation in respect of very shallow implants is realized.

Owner:SEMEQUIP

External cathode ion source

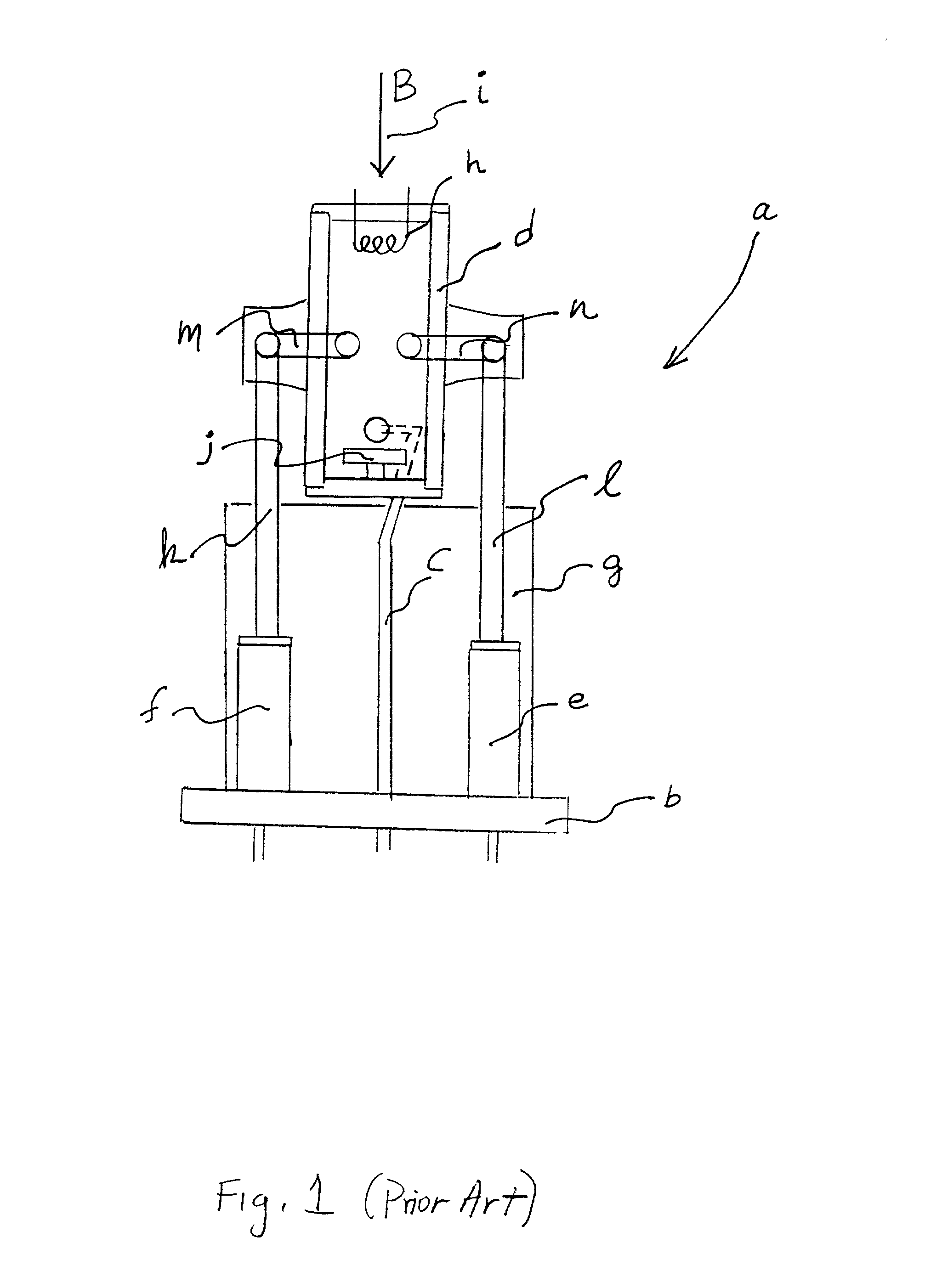

An ion source is disclosed for use in fabrication of semiconductors. The ion source includes an electron emitter that includes a cathode mounted external to the ionization chamber for use in fabrication of semiconductors. In accordance with an important aspect of the invention, the electron emitter is employed without a corresponding anode or electron optics. As such, the distance between the cathode and the ionization chamber can be shortened to enable the ion source to be operated in an arc discharge mode or generate a plasma. Alternatively, the ion source can be operated in a dual mode with a single electron emitter by selectively varying the distance between the cathode and the ionization chamber.

Owner:SEMEQUIP

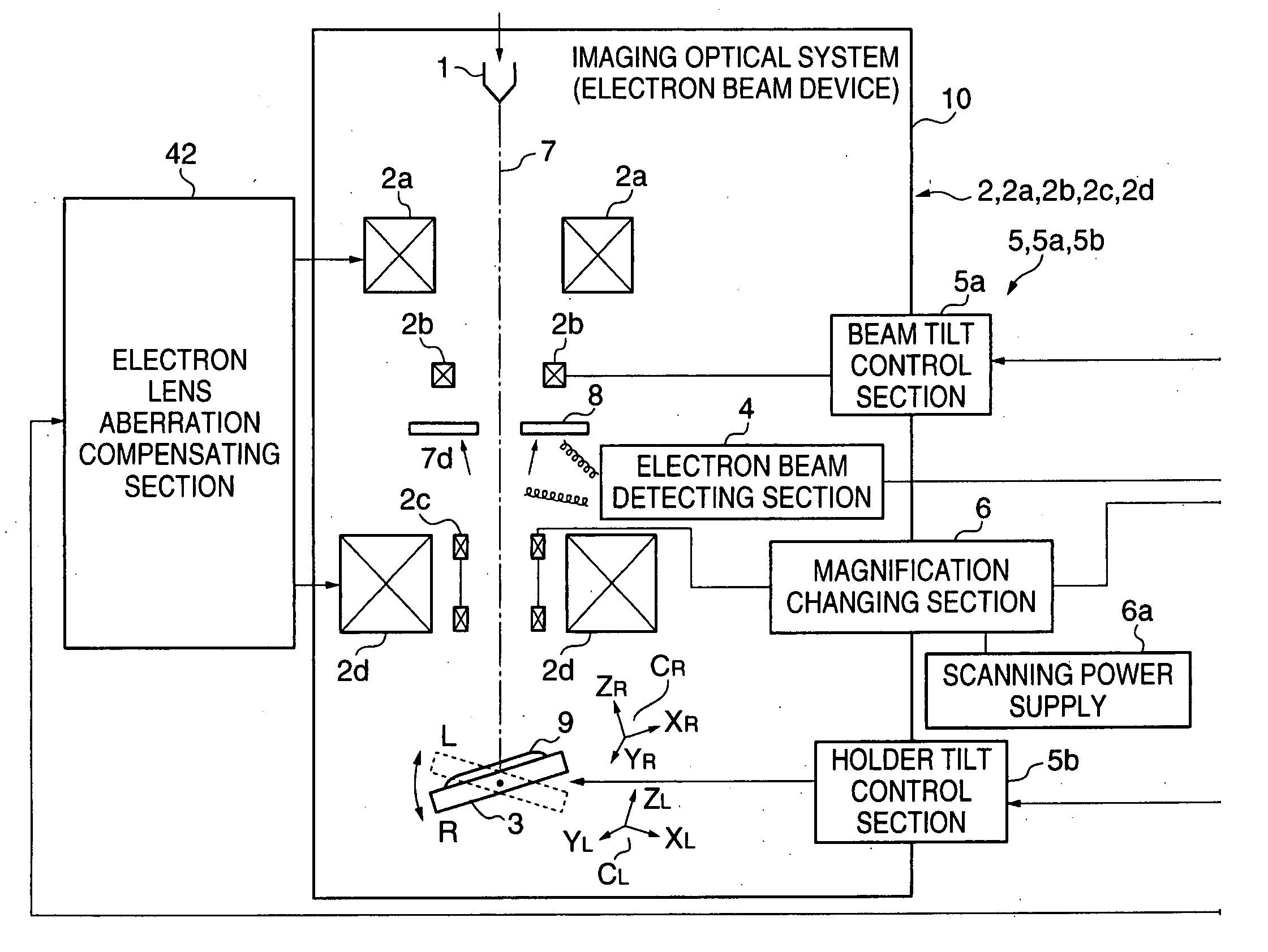

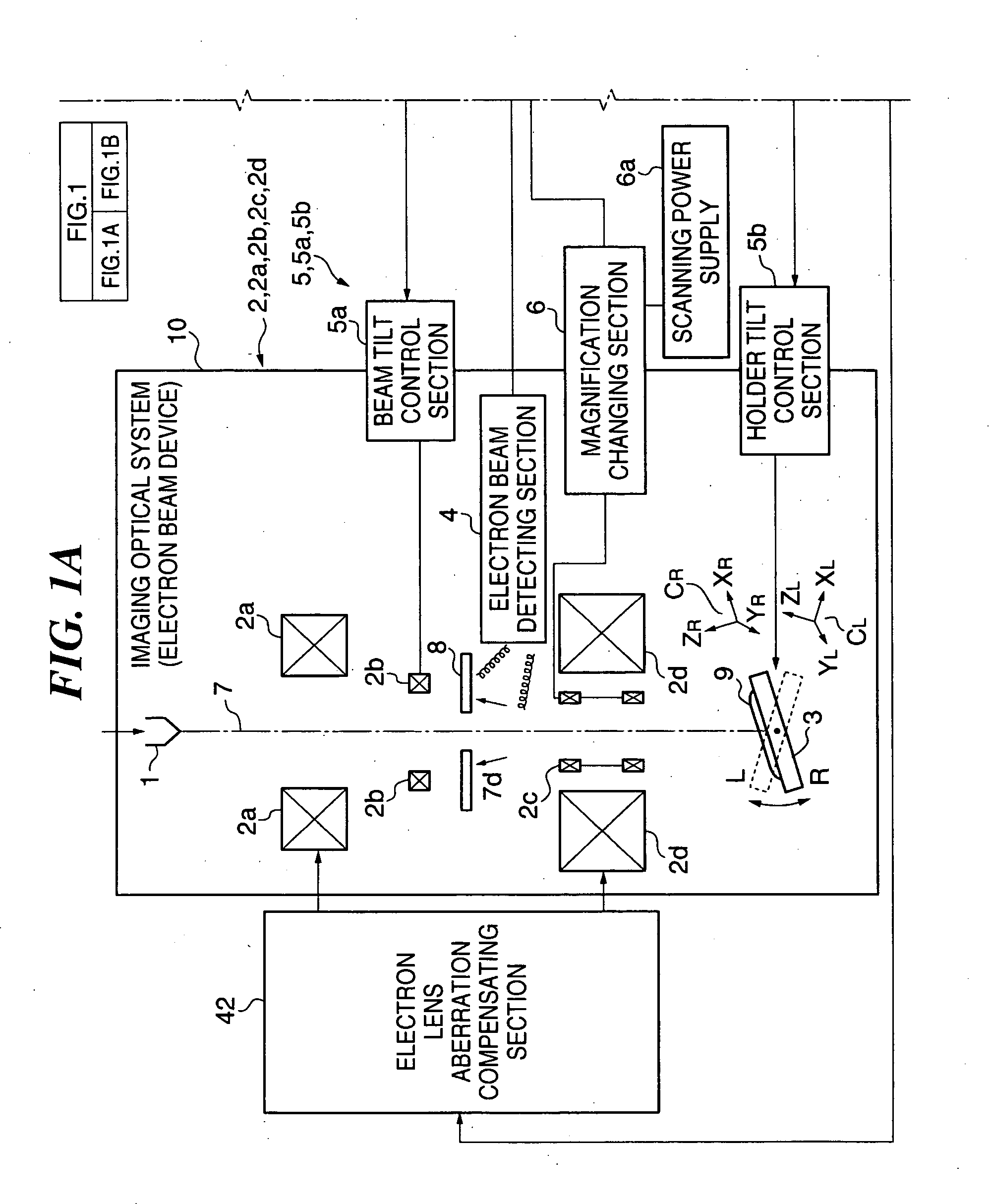

Electron beam device and method for stereoscopic measurements

InactiveUS6852974B2Improve accuracyImage recognition of the reference mark can be carried out smoothlyMaterial analysis using wave/particle radiationMicrobiological testing/measurementBeam sourceAtomic physics

An electron beam device according to the present invention is made up of an electron beam source for emitting an electron beam, an electron optical system for irradiating the electron beam onto a specimen, a specimen holder for holding the specimen, a specimen tilting section for producing relative tilt angles between the specimen holder and the electron beam, an electron beam detecting section for detecting electron beam emitted from the specimen, and a data correcting section for correcting the three-dimensional detection data to have specified relationship under the condition of a relative tilt angle between the specimen holder and the electron beam.

Owner:KK TOPCON

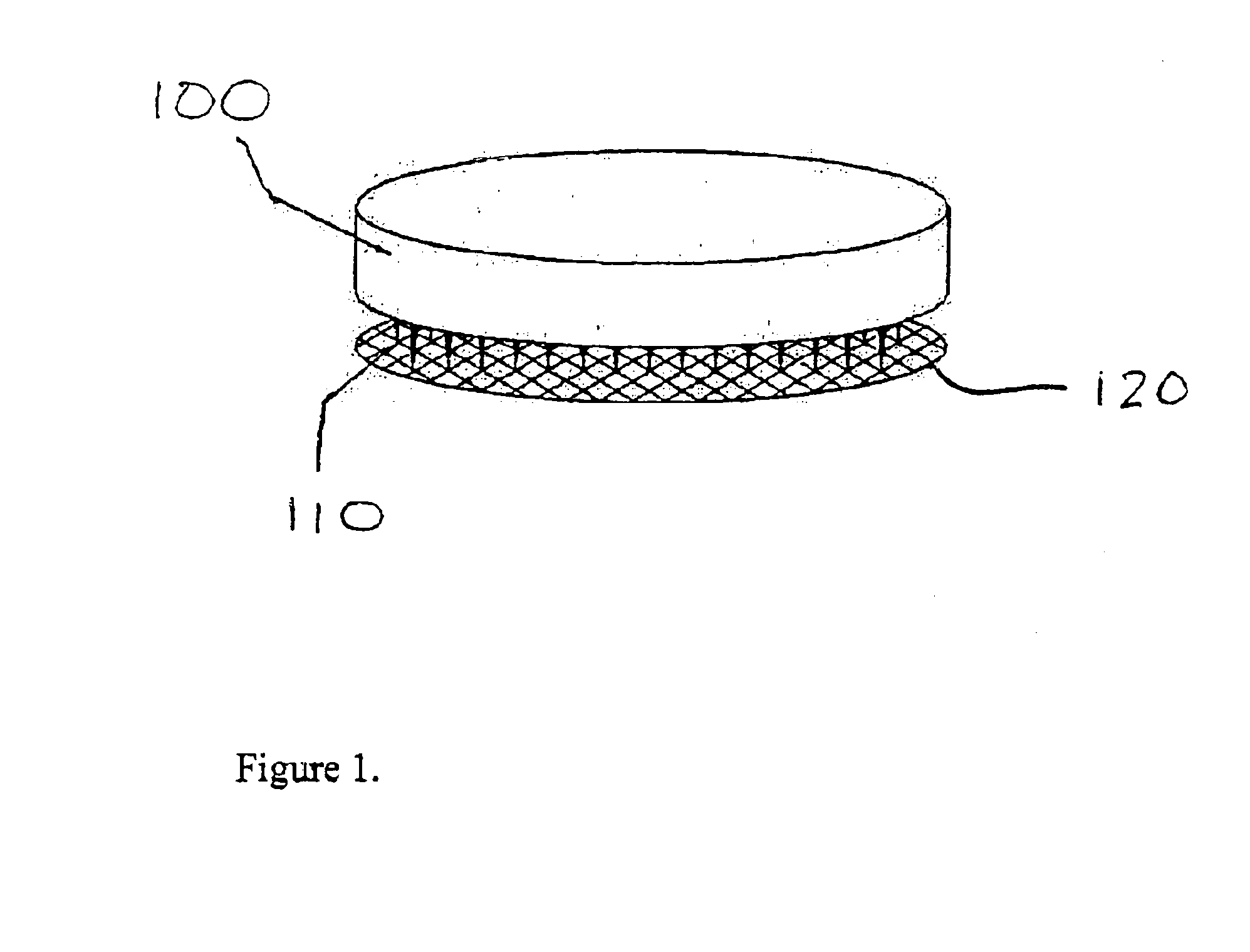

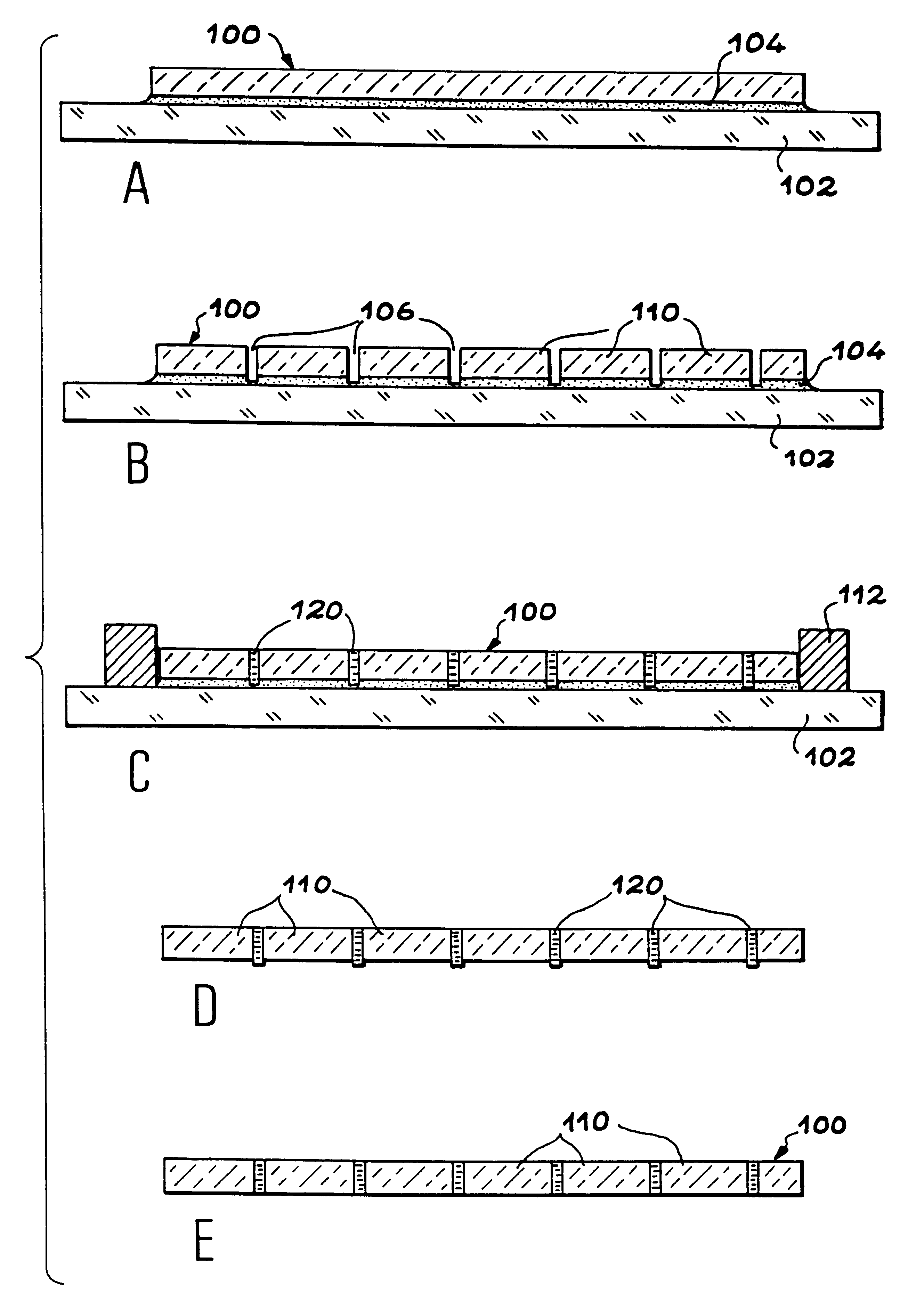

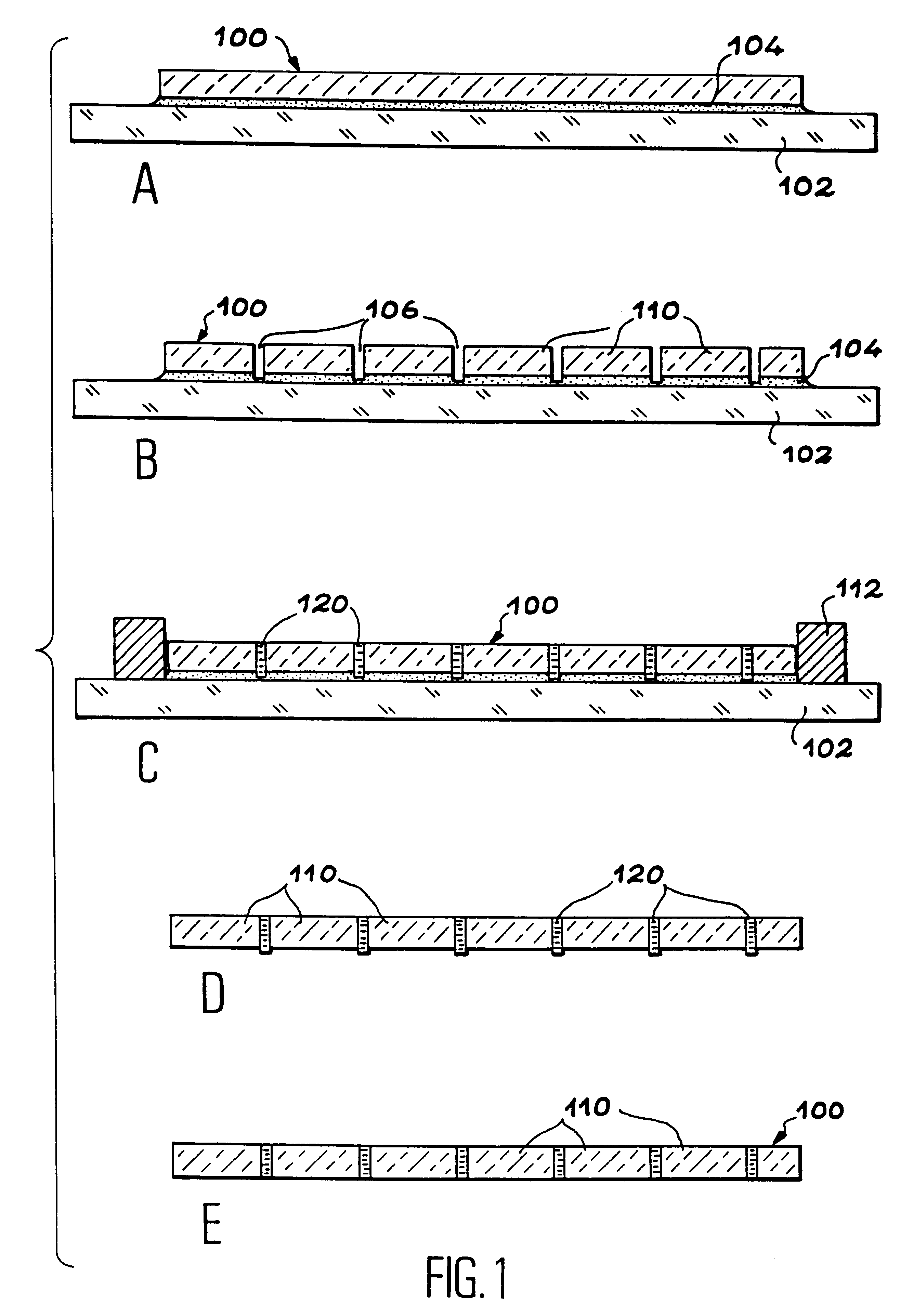

Process for physical isolation of regions of a substrate board

InactiveUS6303462B1Solid-state devicesSemiconductor/solid-state device manufacturingMaterials scienceSolid-state

Process for physical isolation of regions (110) of a substrate board (100) comprising the following steps:a) formation of trenches (106) in the substrate, delimiting regions of the substrate (110),b) placement of a liquid bonding material (120) in the trenches, which can solidify and bond to the substrate board (100) when in the solid state,c) solidification of the bonding material.Application to isolation of electronic, optical, mechanical or magnetic components.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

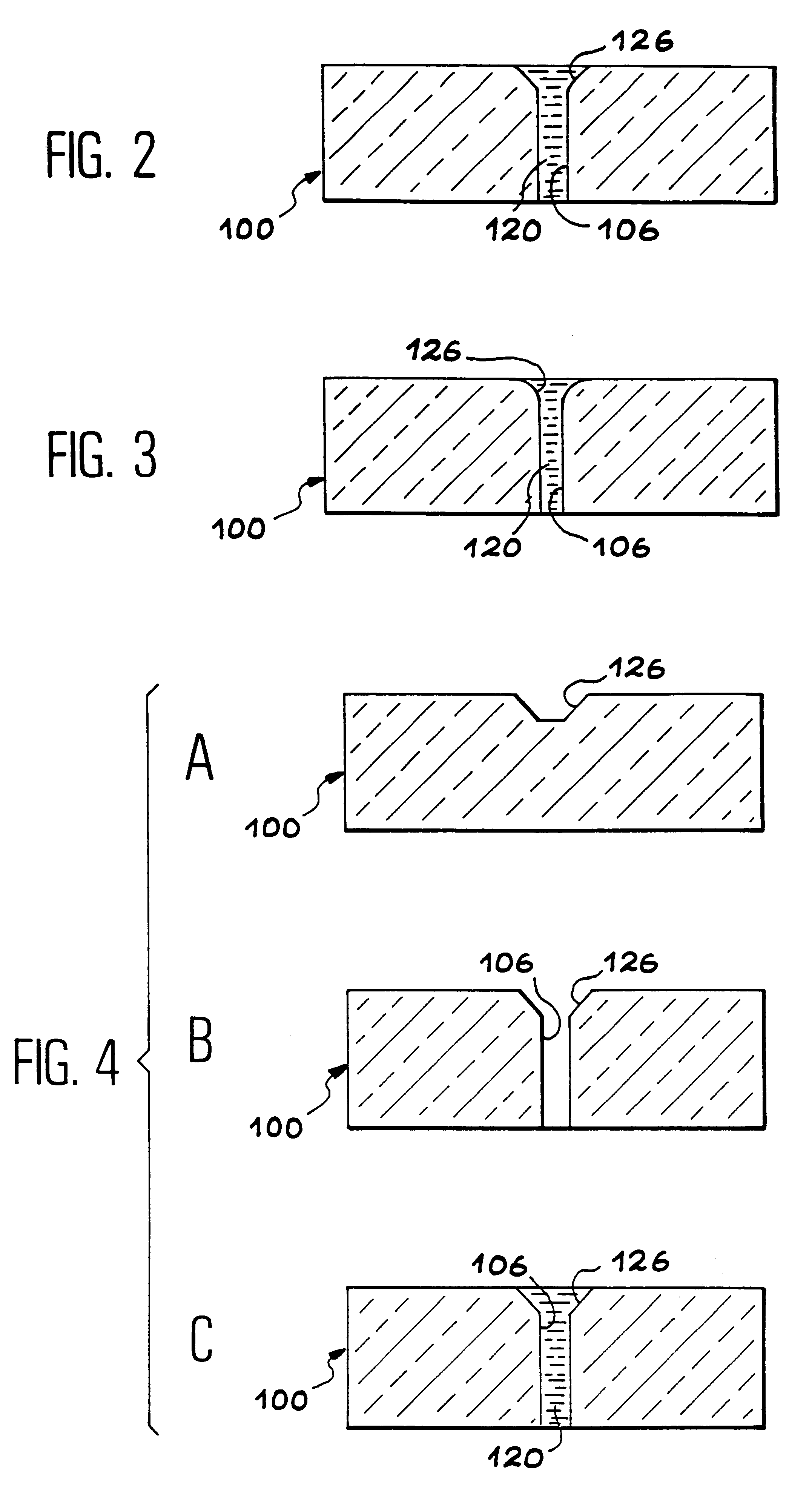

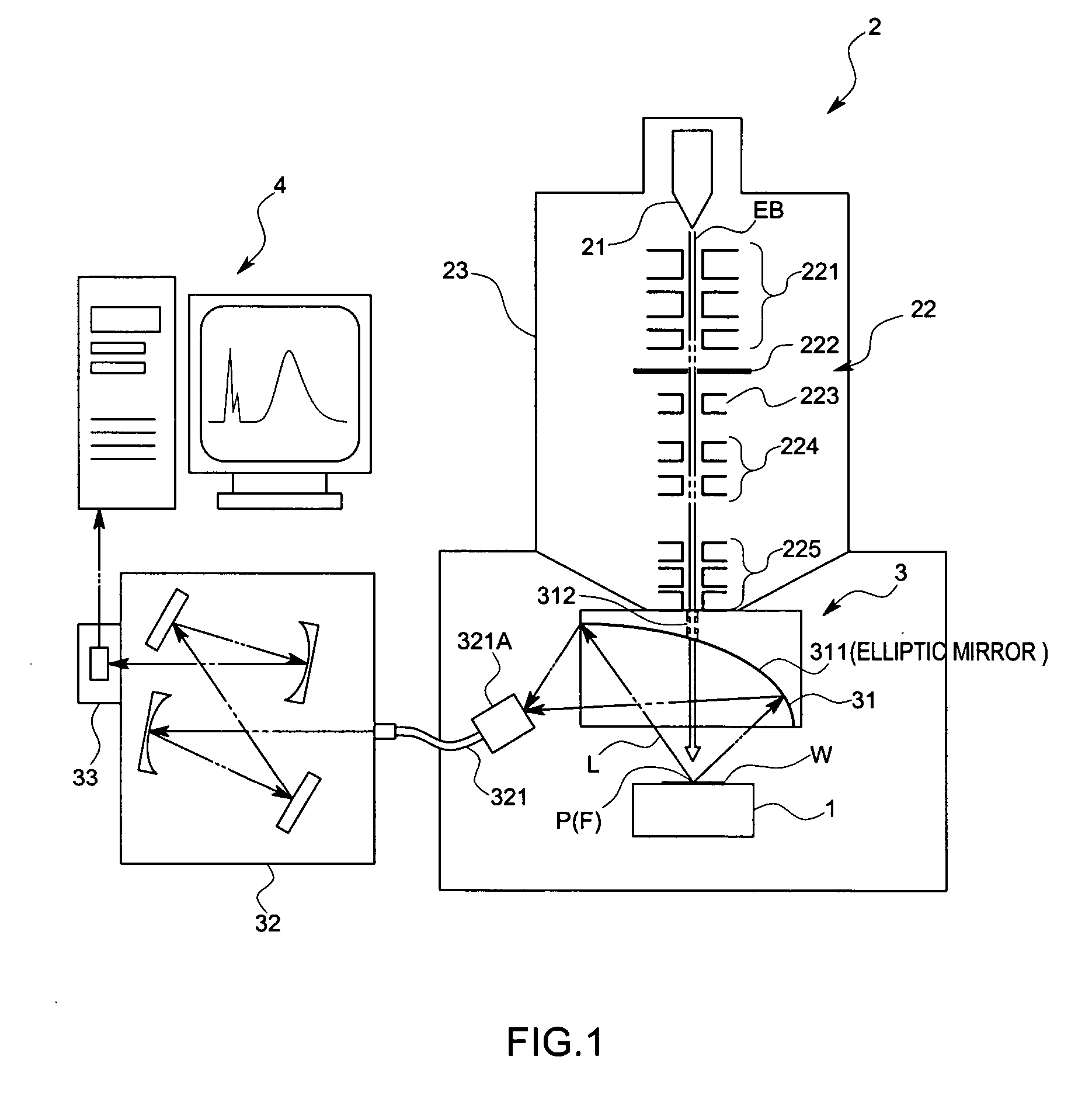

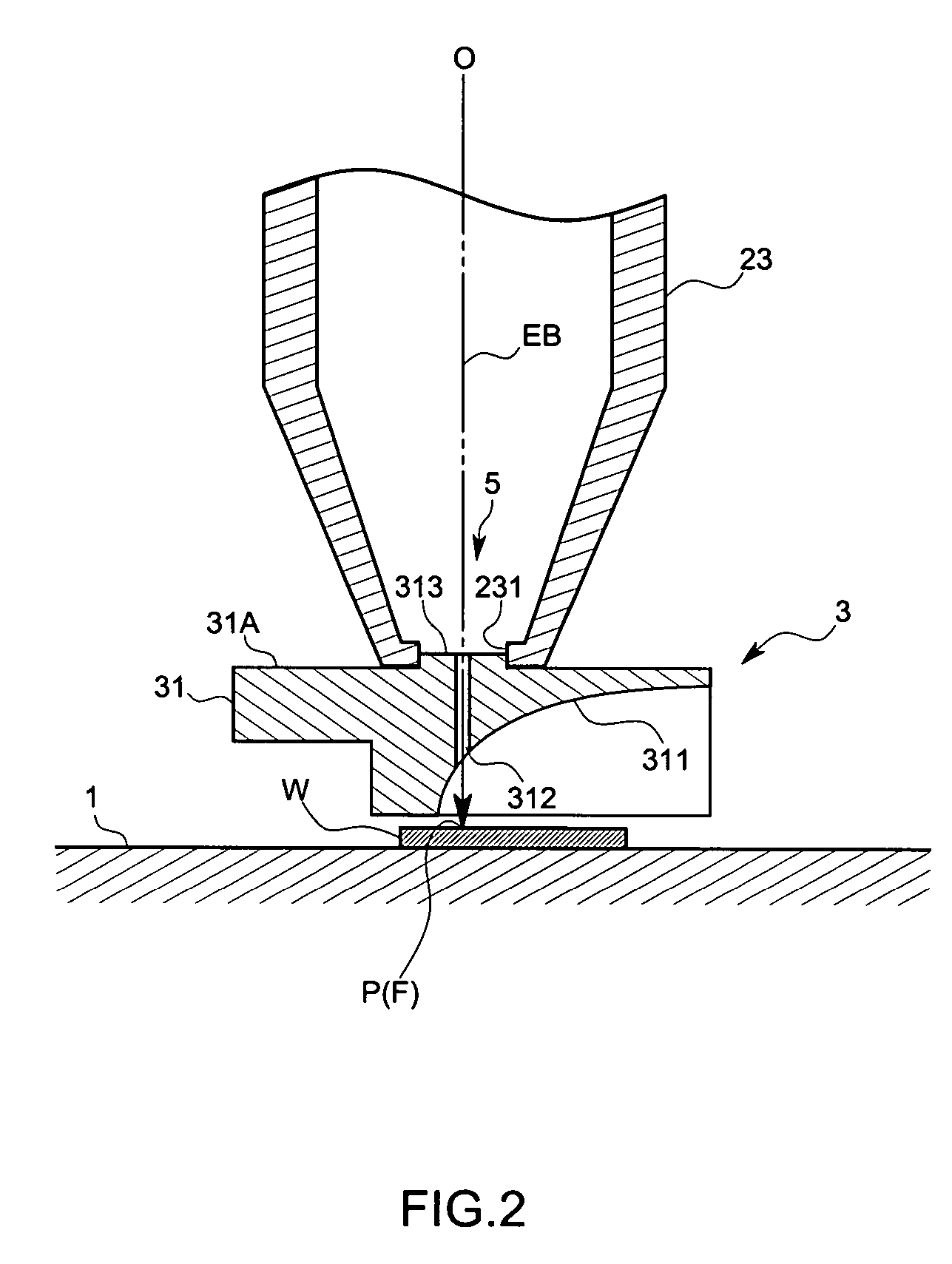

Sample measuring device

InactiveUS20070023655A1Shorten working distanceMaterial analysis using wave/particle radiationElectric discharge tubesSample MeasureMeasurement device

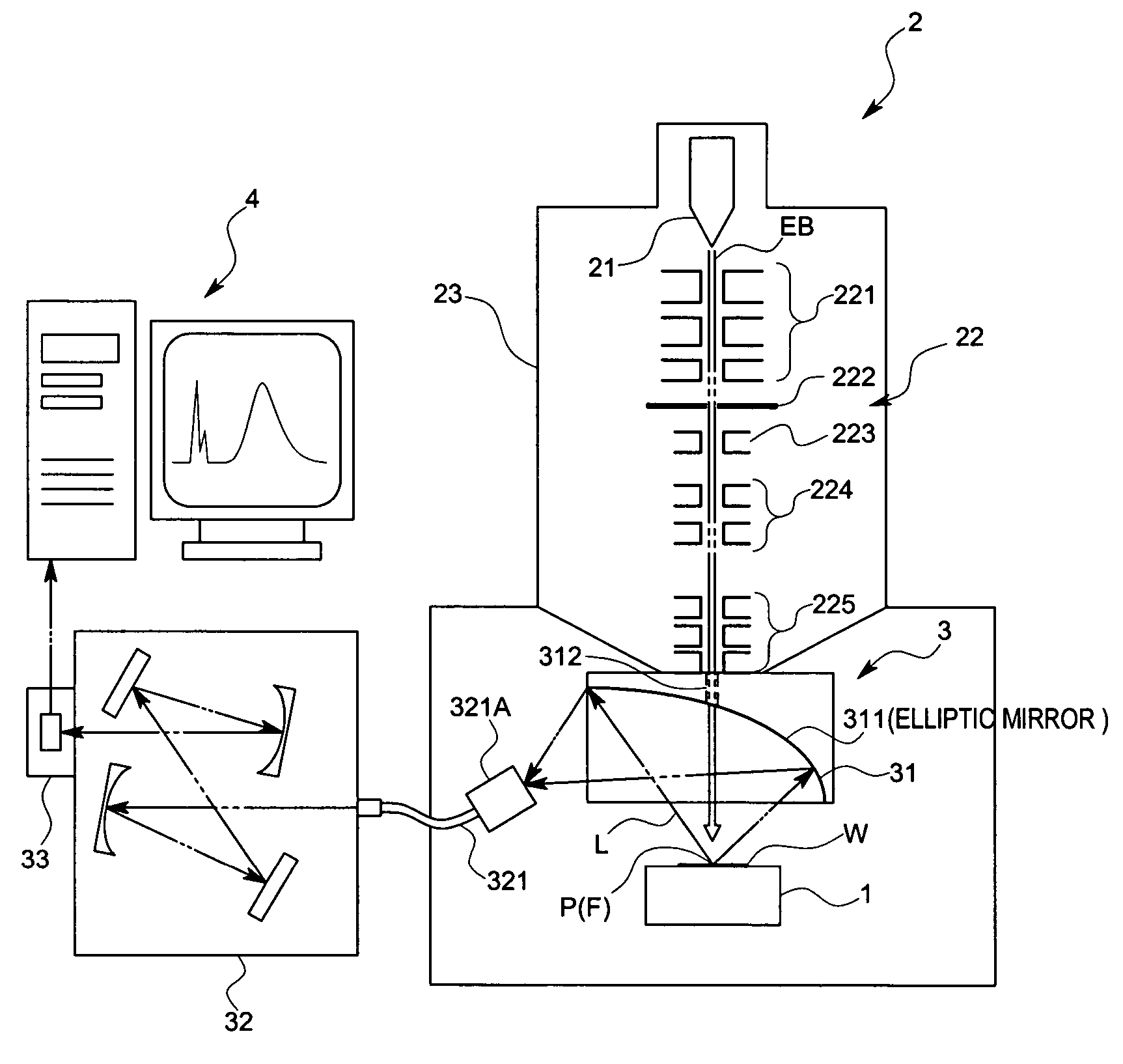

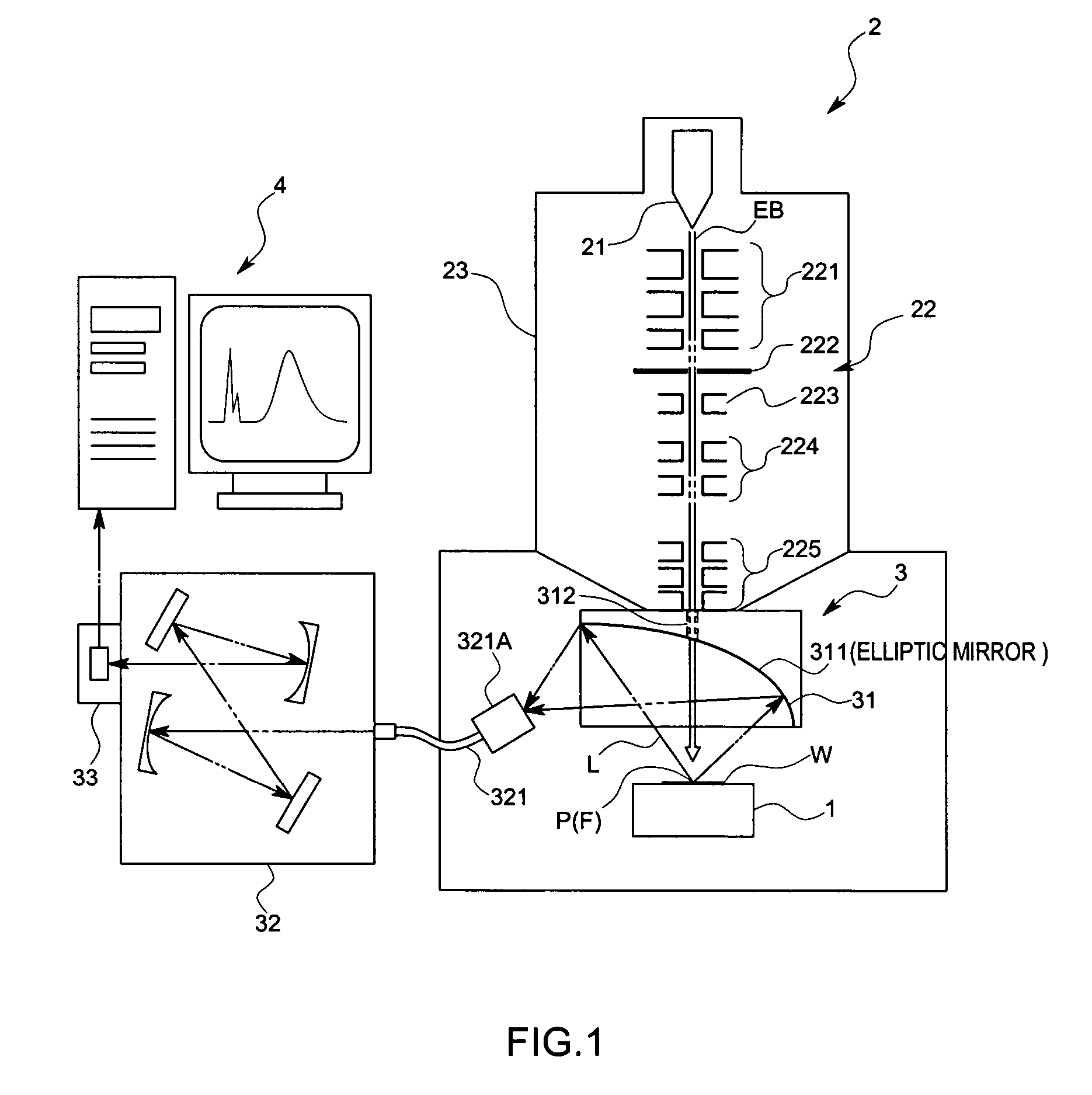

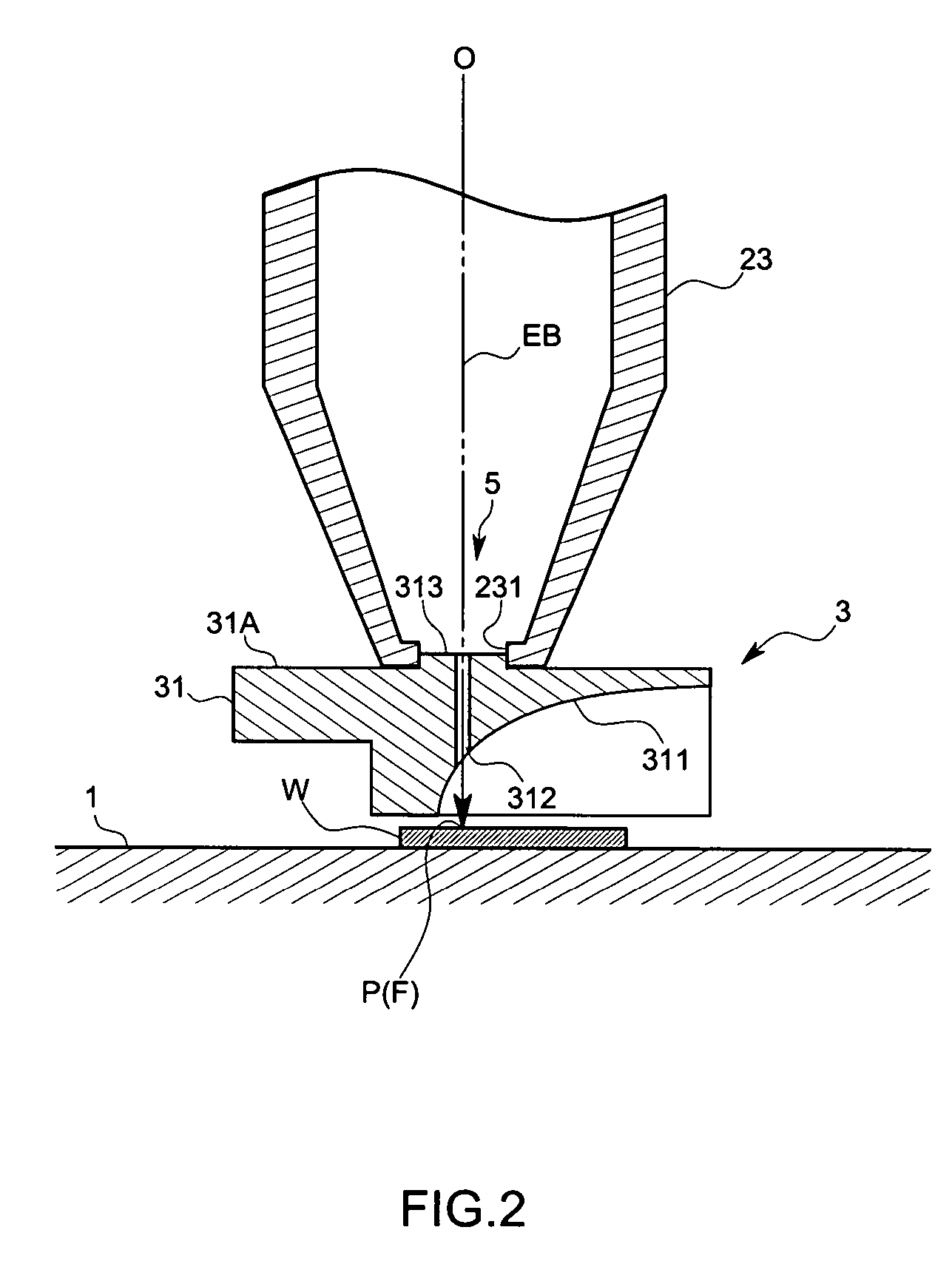

An object of this invention is to make it easy to adjust a position of the energy beam to irradiate and a position of a focal point of a light collecting mirror part, and to prevent displacement of the light collecting part due to vibration with a simple arrangement. A sample measuring device in accordance with this invention is to measure light generated from a sample W by irradiating electron beams EB on the sample W, and comprises a electron optical column part 23 that converges the electron beams EB, and a light collecting mirror part 31 that is arranged between the electron optical column part 23 and the sample W and that has an energy beam path 312 to pass the electron beams EB converged by the electron optical column part 23 and to irradiate the electron beams EB on the sample W and a mirror face 311 whose focal point F is set on an axis of the energy beam path 312 and that collects the light L generated from the sample W by means of the mirror face 311, wherein the light collecting mirror part 31 is supported by the electron optical column part 23 so that the axis of the electron beams EB coincides with the focal point F.

Owner:HORIBA LTD

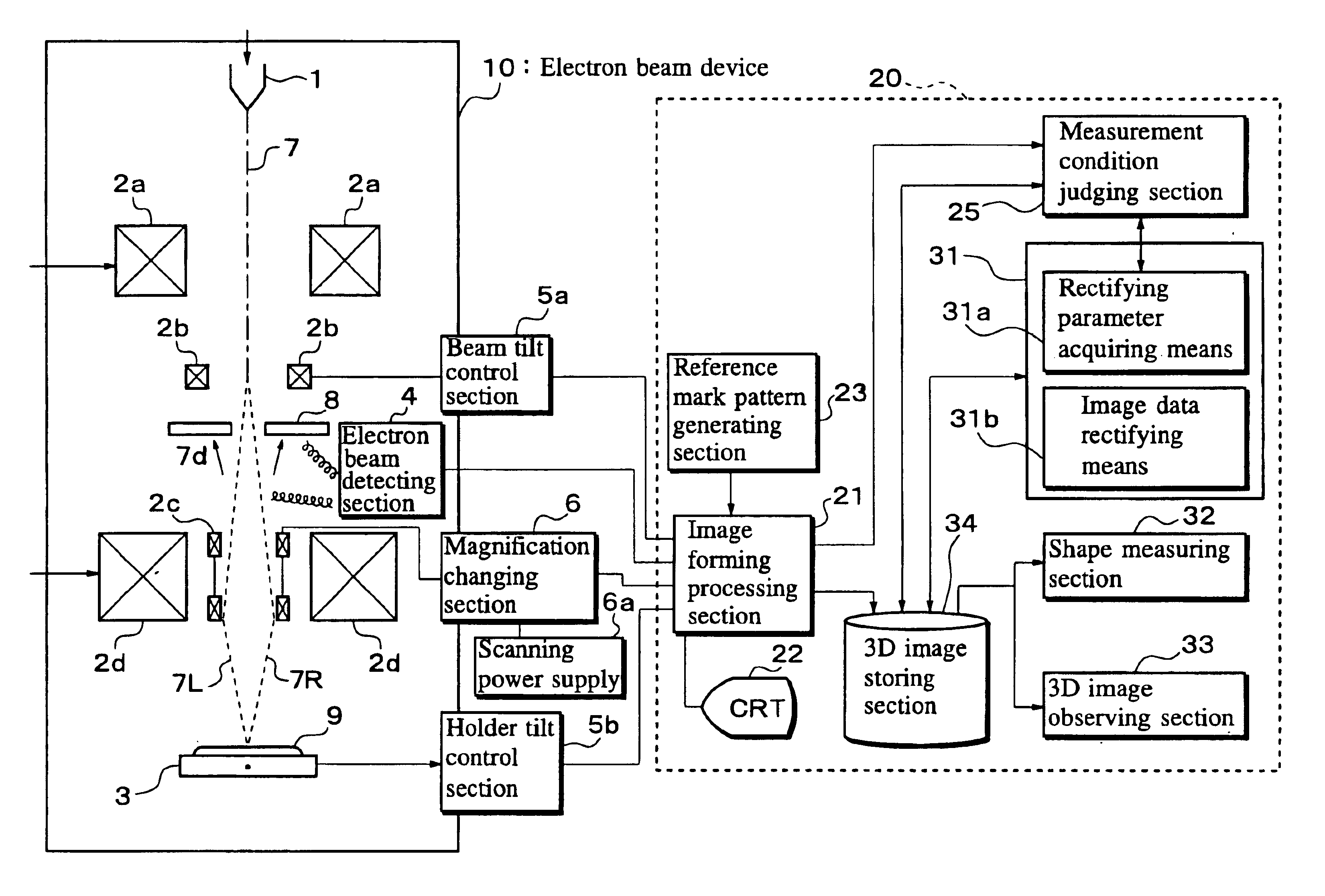

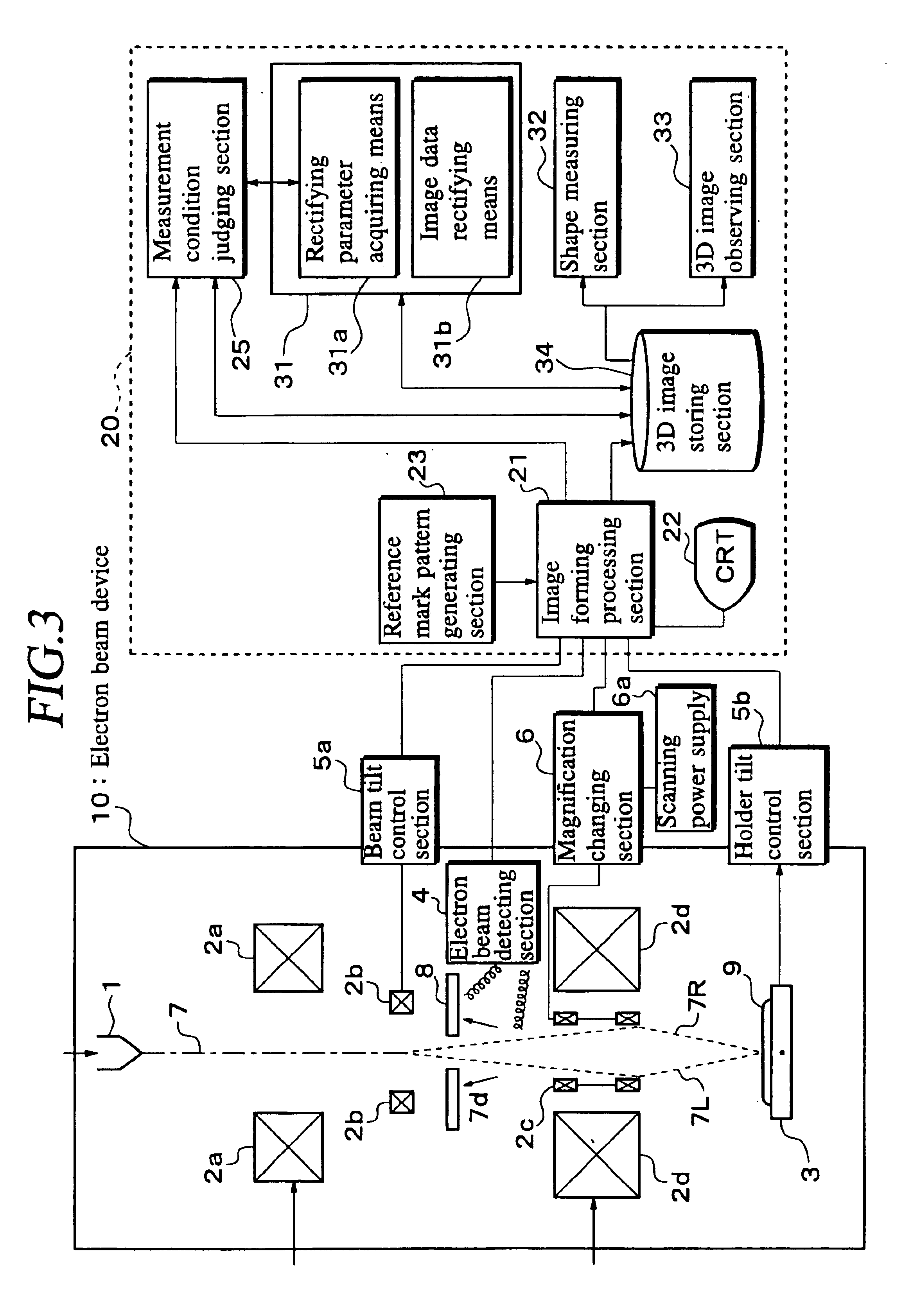

Electron beam system and electron beam measuring and observing method

InactiveUS20050161601A1Reduce aberrationImprove accuracyMaterial analysis using wave/particle radiationImage analysisTemplate basedStereo image

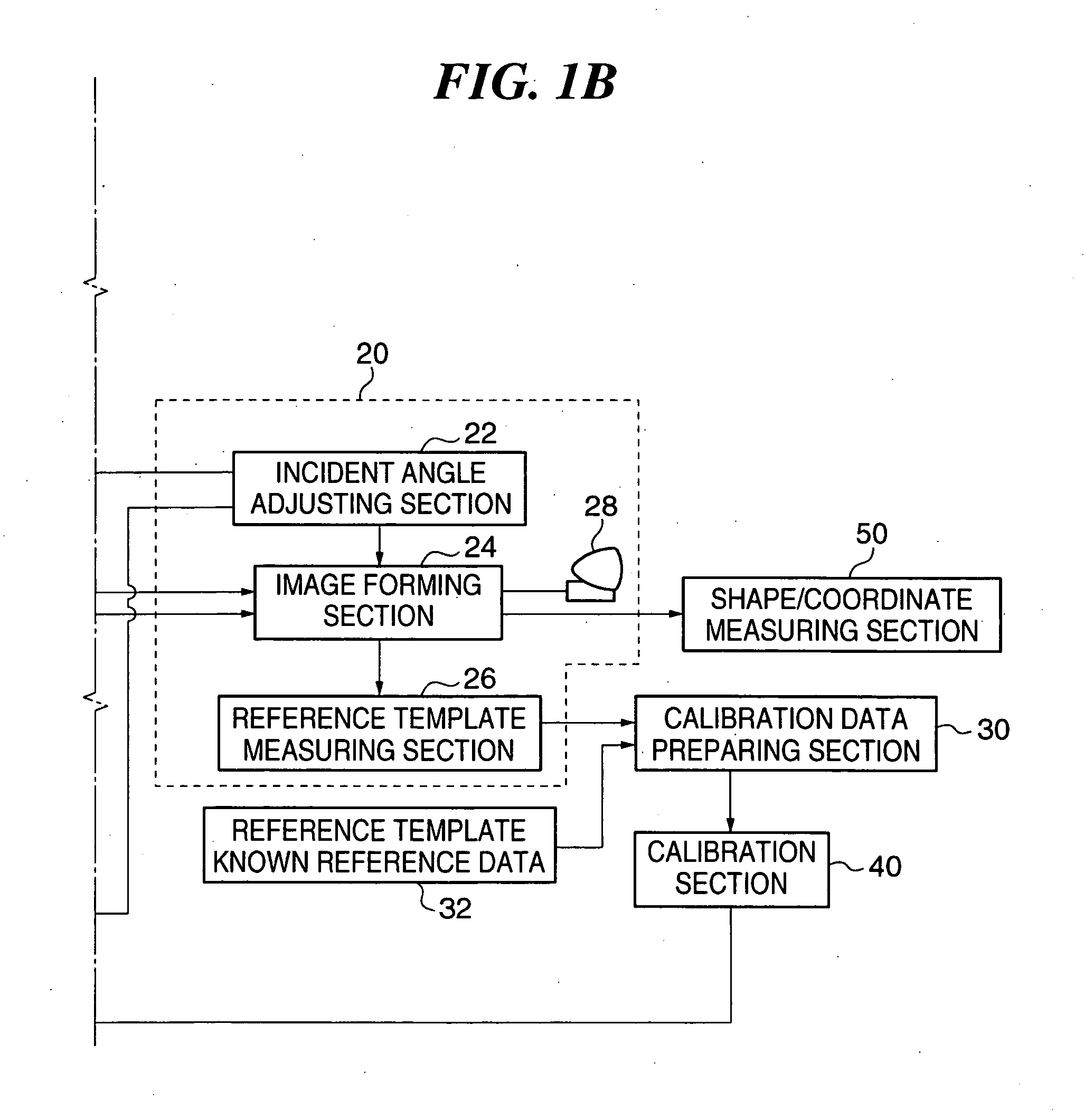

This invention provides an electron beam measuring device capable of performing three-dimensional image measurement of a sample with high precision, irrespective of the tilt angle and height of the sample, by adjusting an electron optical system of a scanning charged-particle beam device so as to be suitable for image measurement. The electron beam measuring device includes a measuring section 20 adapted to tilt a reference template held by a sample holder 3 and an irradiated electron beam 7 relative to each other by means of a sample tilting section 5, to find the shape or coordinate values of the reference template based on a stereo image photographed by an electron beam detecting section 4, a calibration data preparing section 30 for comparing the measuring results at the measuring section 20 with known reference data to prepare calibration data for a stereo image photographed by the electron beam measuring device, and a calibration section 40 for performing a calibration based on the calibration data so as to reduce aberration in an image of the sample detected by the electron beam detecting section 4. Based on the stereo image calibrated by the calibration section 40, the shape or coordinate values of the sample 9 are found.

Owner:KK TOPCON

Sample measuring device

InactiveUS7589322B2Shorten working distanceMaterial analysis using wave/particle radiationElectric discharge tubesSample MeasureAtomic physics

An object of this invention is to make it easy to adjust a position of the energy beam to irradiate and a position of a focal point of a light collecting mirror part, and to prevent displacement of the light collecting part due to vibration with a simple arrangement. A sample measuring device in accordance with this invention is to measure light generated from a sample W by irradiating electron beams EB on the sample W, and comprises a electron optical column part 23 that converges the electron beams EB, and a light collecting mirror part 31 that is arranged between the electron optical column part 23 and the sample W and that has an energy beam path 312 to pass the electron beams EB converged by the electron optical column part 23 and to irradiate the electron beams EB on the sample W and a mirror face 311 whose focal point F is set on an axis of the energy beam path 312 and that collects the light L generated from the sample W by means of the mirror face 311, wherein the light collecting mirror part 31 is supported by the electron optical column part 23 so that the axis of the electron beams EB coincides with the focal point F.

Owner:HORIBA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com