Process for physical isolation of regions of a substrate board

a technology of physical isolation and substrate board, which is applied in the manufacture of solid-state devices, semiconductor/solid-state devices, electric devices, etc., can solve the problems of complex preparation of integration supports, difficult to meet the requirements of an increasingly dense integration, and difficult to meet the requirements of isolation constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The purpose of this invention is to propose a process for physical isolation of regions with a substrate board without the difficulties mentioned above.

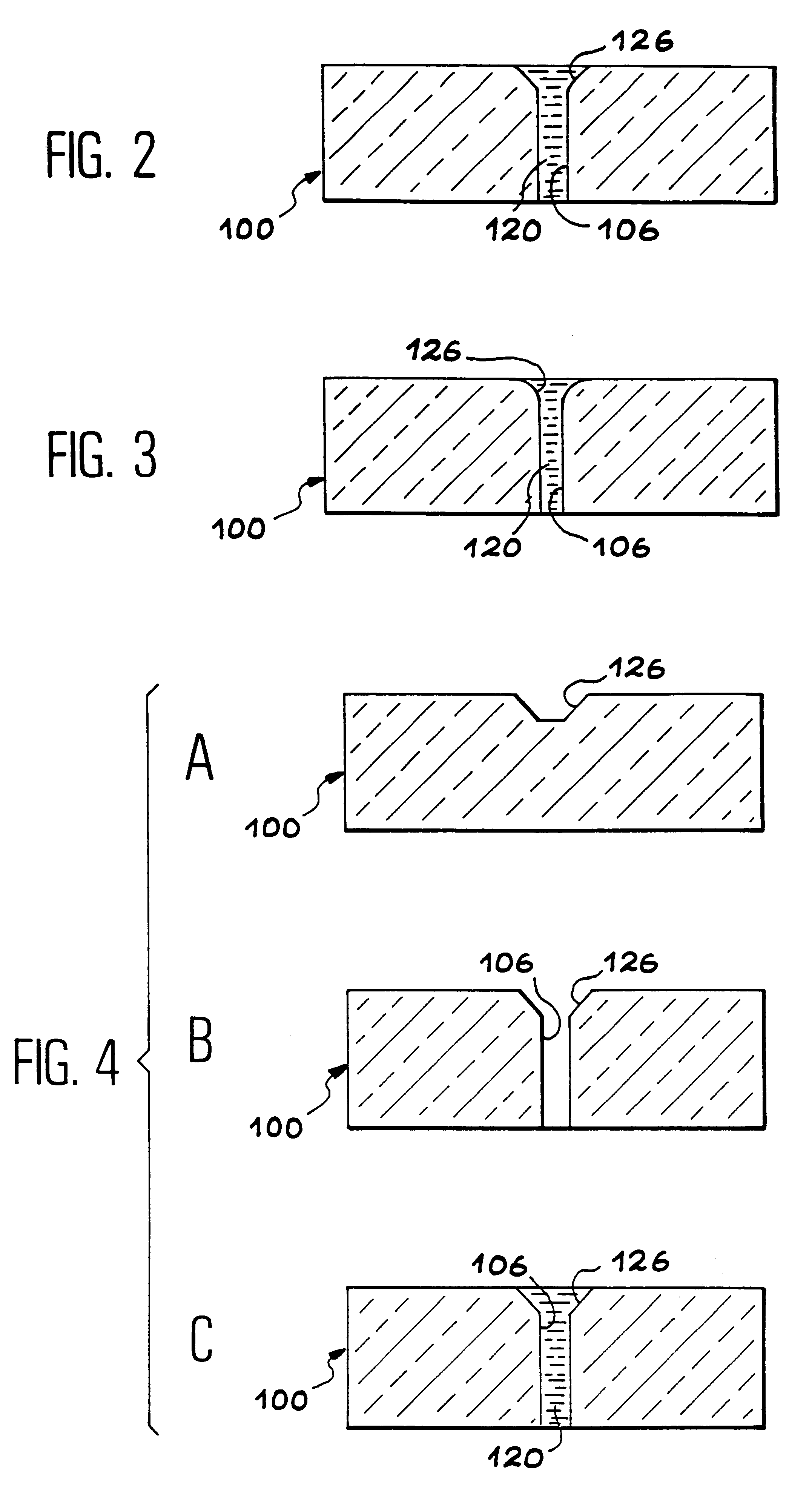

One purpose in particular is to propose this type of process for making an electrical, optical, mechanical and / or magnetic isolation according to the manufacturing requirements of the circuits considered.

Another purpose is to propose such a process particularly suitable for electronic power circuits capable of providing insulation at high voltages.

Another purpose is to propose an isolation system which is easy to use, which can be implemented during or after the placement of components in or on regions of the substrate board, and which is compatible with the constraints of large scale component integration.

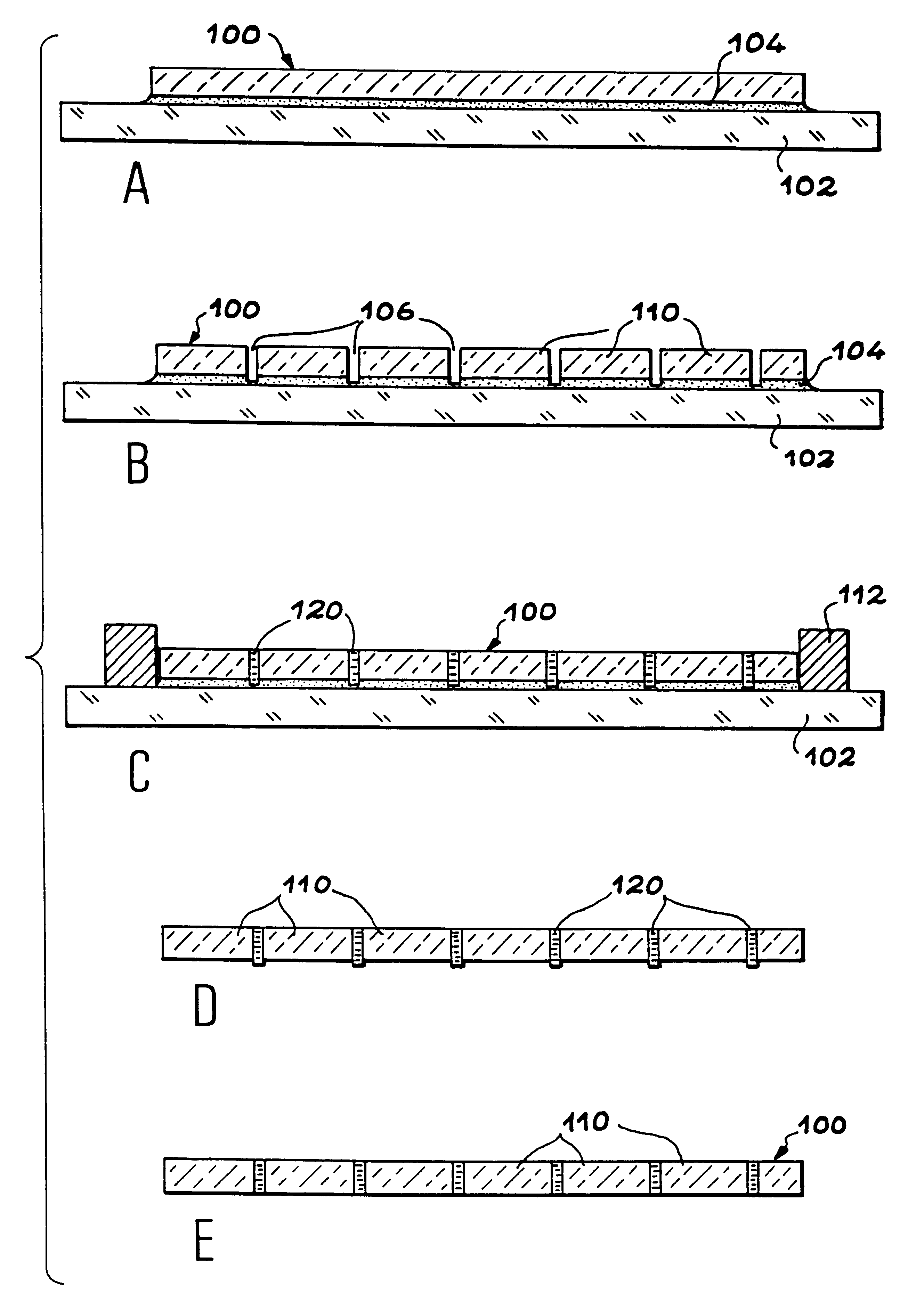

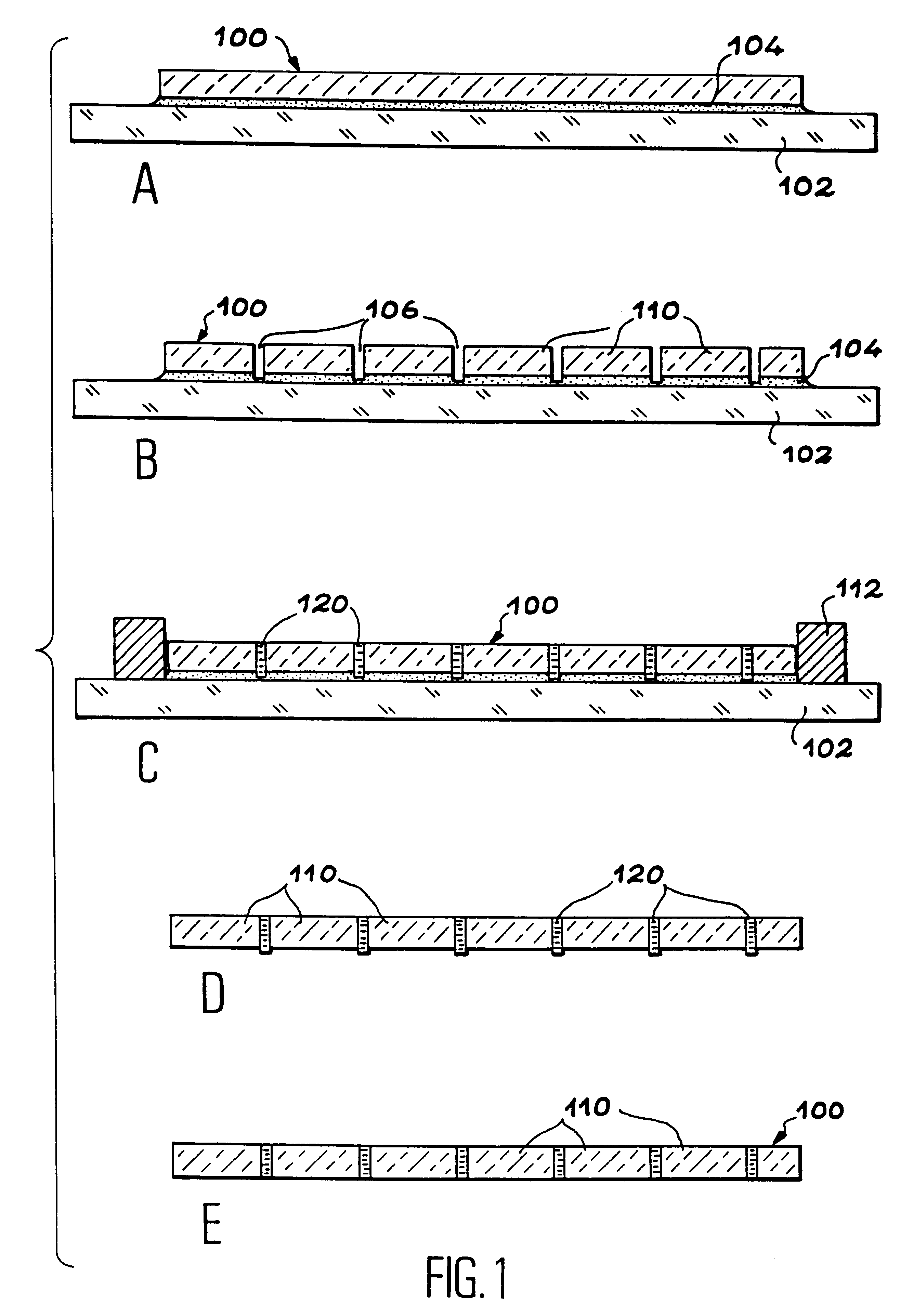

In order to achieve these purposes, the purpose of the invention is more specifically a process for physical isolation of regions of a substrate board comprising the following steps:

a) bonding of the substrate onto a support using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| physical | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com