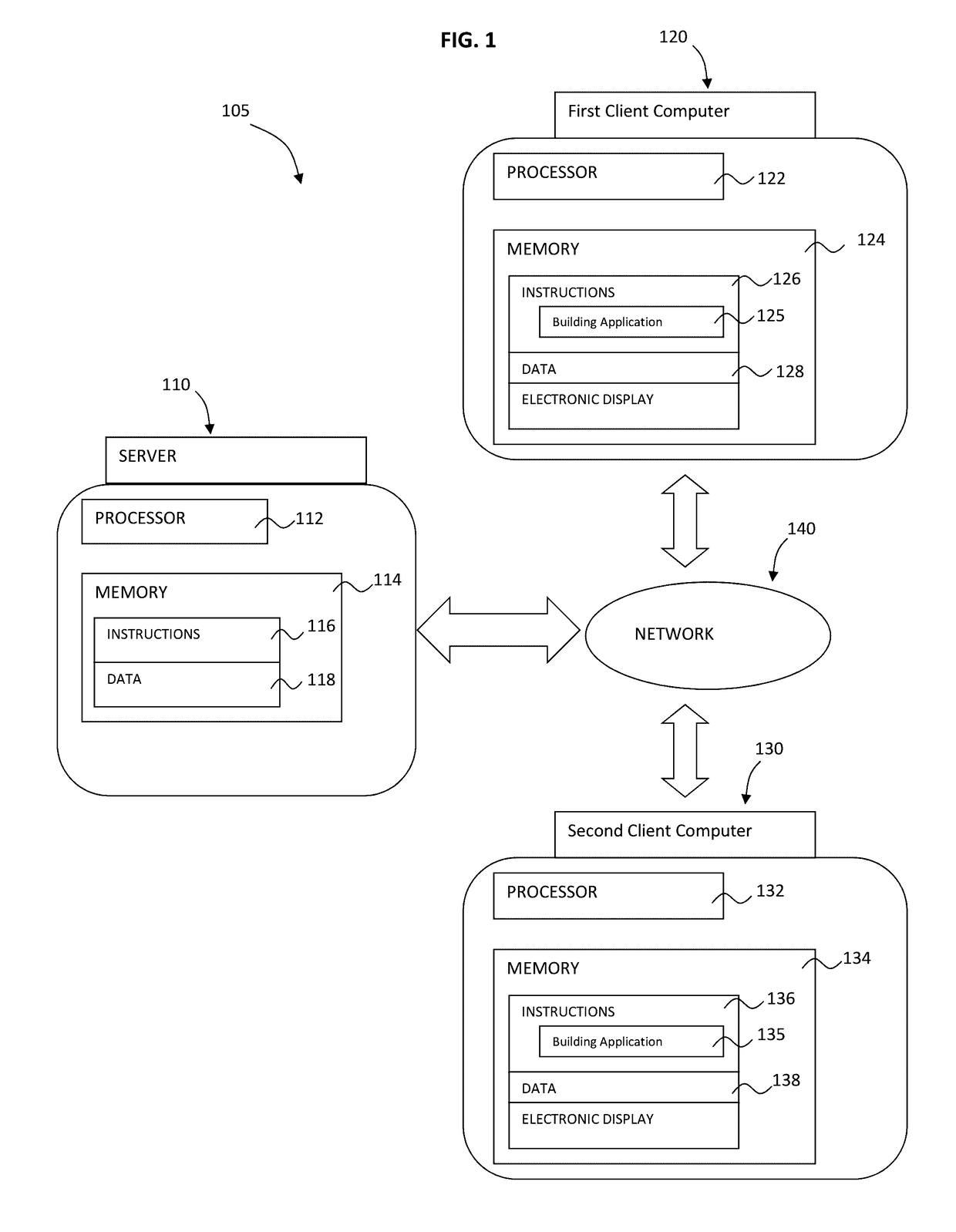

Patents

Literature

591 results about "High energy beam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

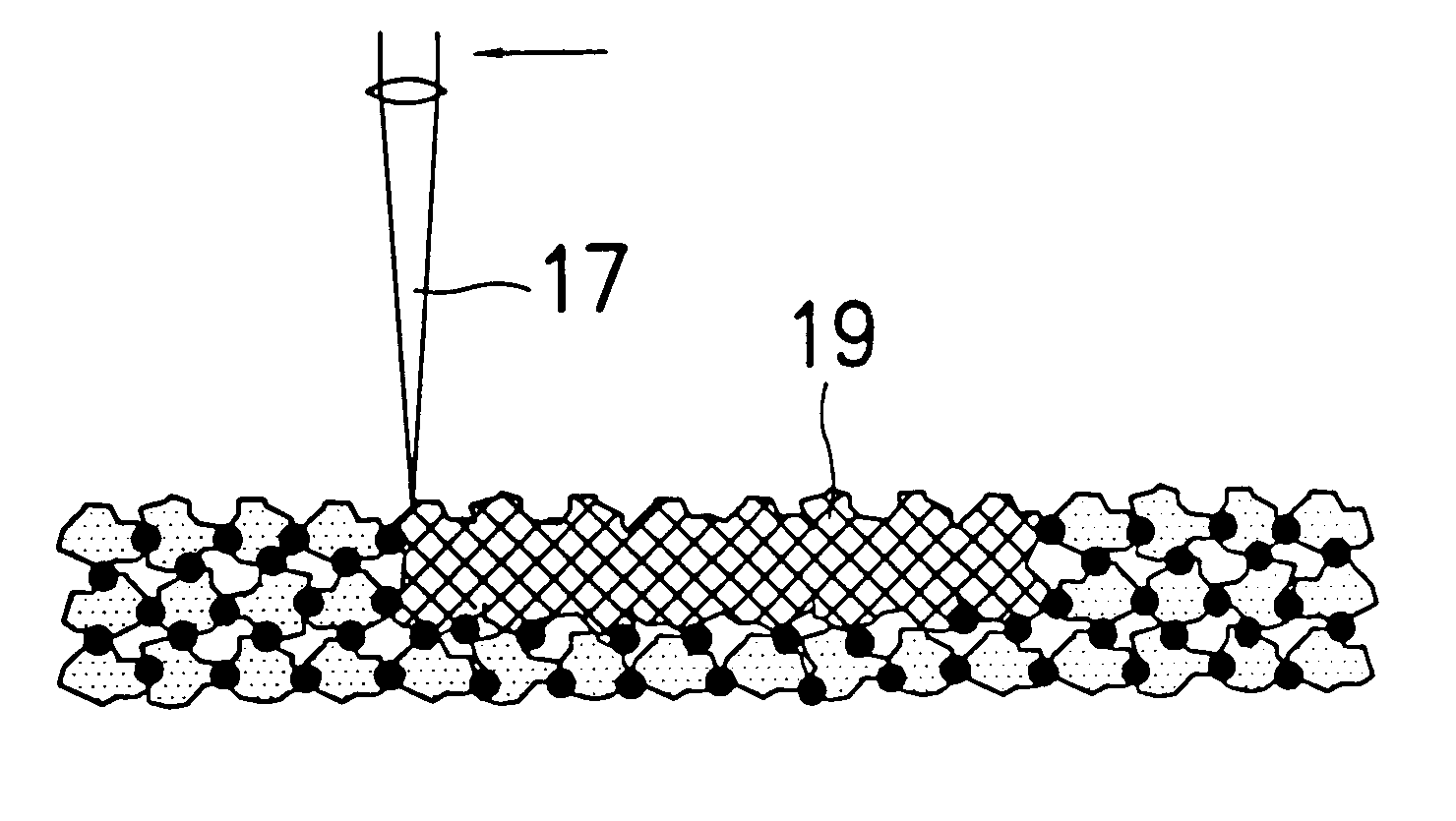

Method for rapid forming of a ceramic work piece

InactiveUS6217816B1Rapid productionPrevent dislocationAdditive manufacturing apparatusFeeding arrangmentsHeat fusionLaser beams

An inorganic binder and a dissolving agent are put into ceramic powder. They are mixed to form a plastic green mixture. Then the said mixture is formed into a thin green layer. Preferably, this thin green layer will be preheated and dried such that the thin green layer will be hardened due to the bonding effect of the inorganic binder. A portion of the thin green layer exposed under a directed high-energy beam is sintered, preferably by a laser beam, to cause ceramic molecules to bond together locally due to heat fusion. By controlling the scanning path of the high-energy beam, a two-dimensional thin cross section of the ceramic part in arbitrary form can be produced. A second thin ceramic layer can be built onto the first thin ceramic layer and bonded to it by the same method. After multiple repetitions of this procedure a three dimensional ceramic part can be fabricated layer upon layer. The green portion, which is not scanned by the high-energy beam, will be removed with suitable method. A ceramic part can be rapidly produced in this way.

Owner:NAT SCI COUNCIL

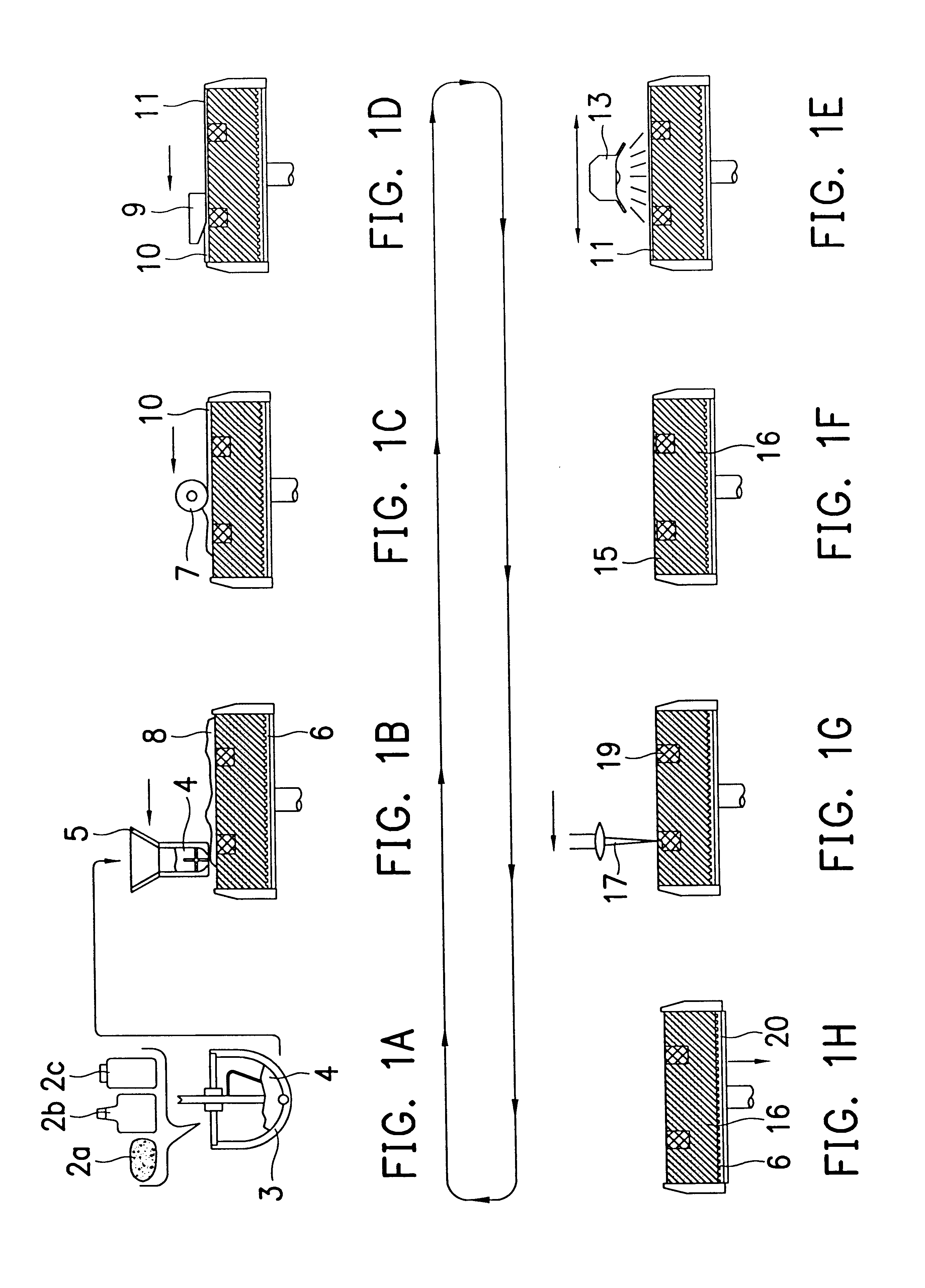

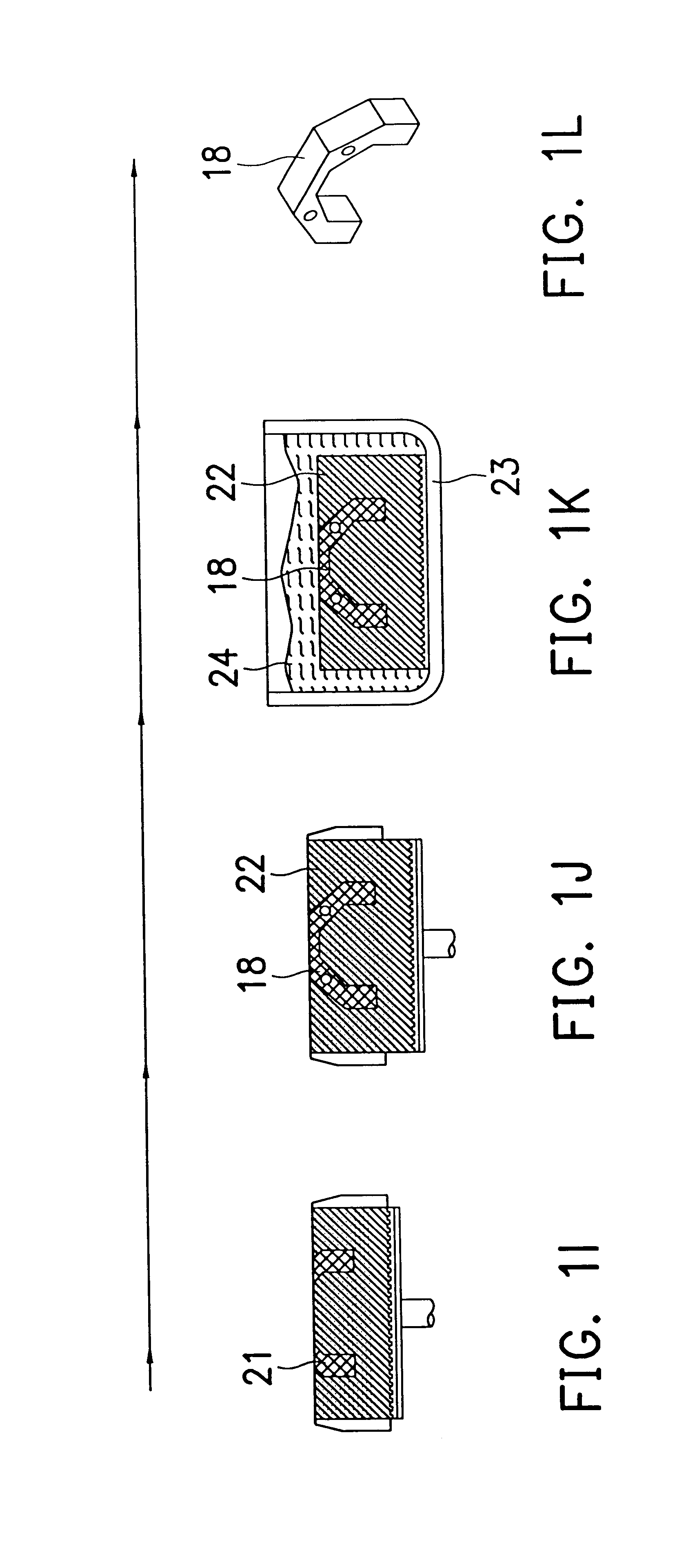

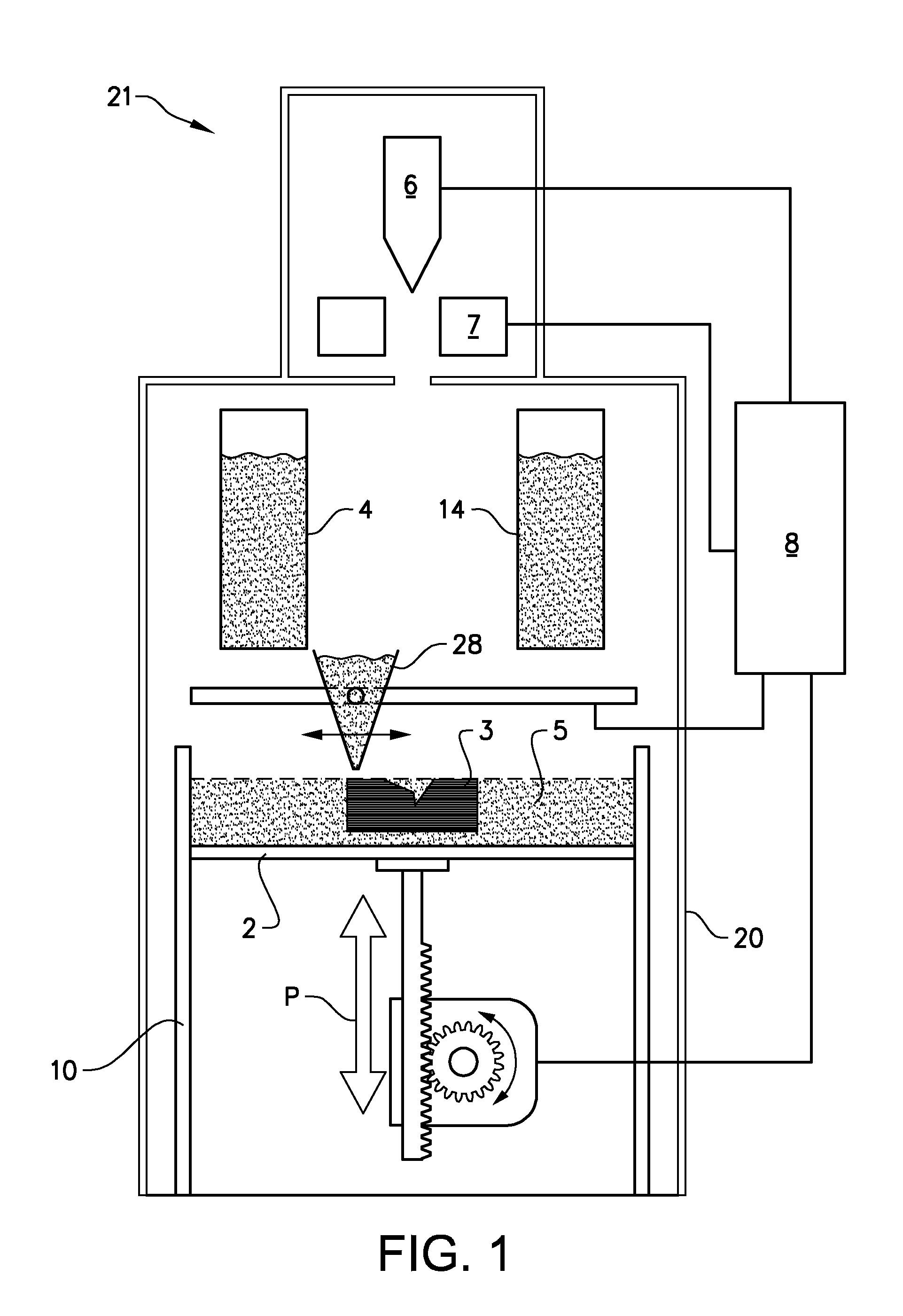

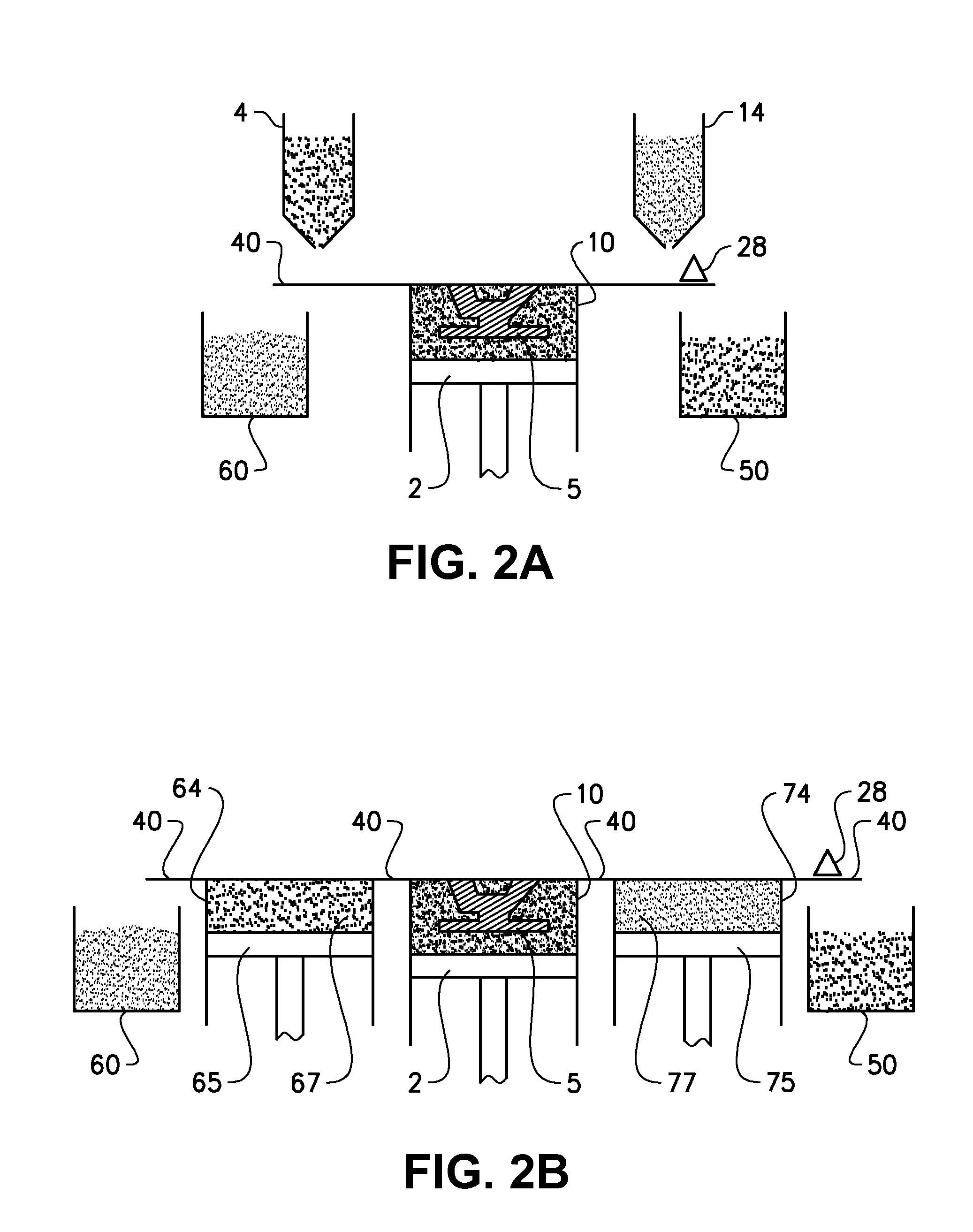

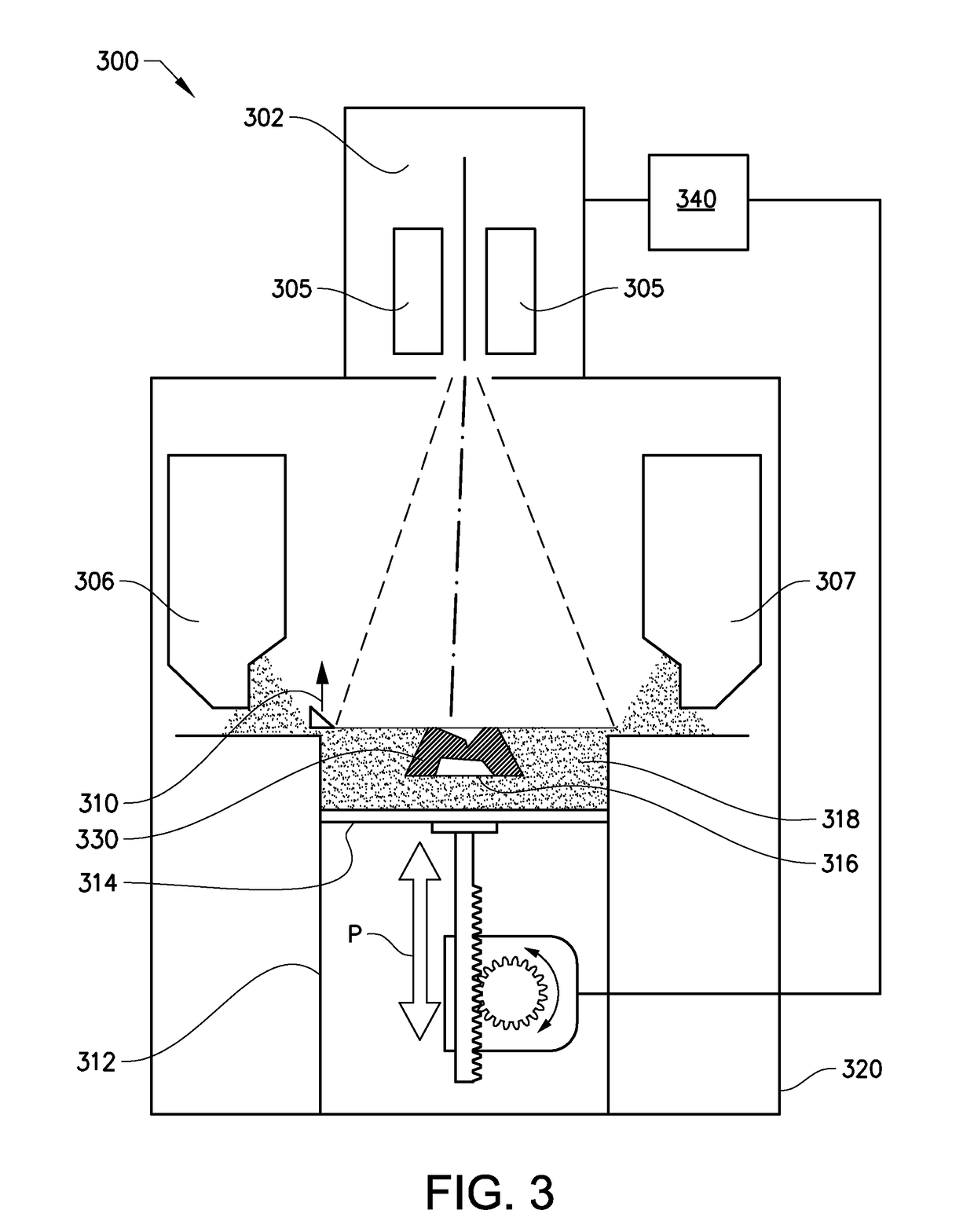

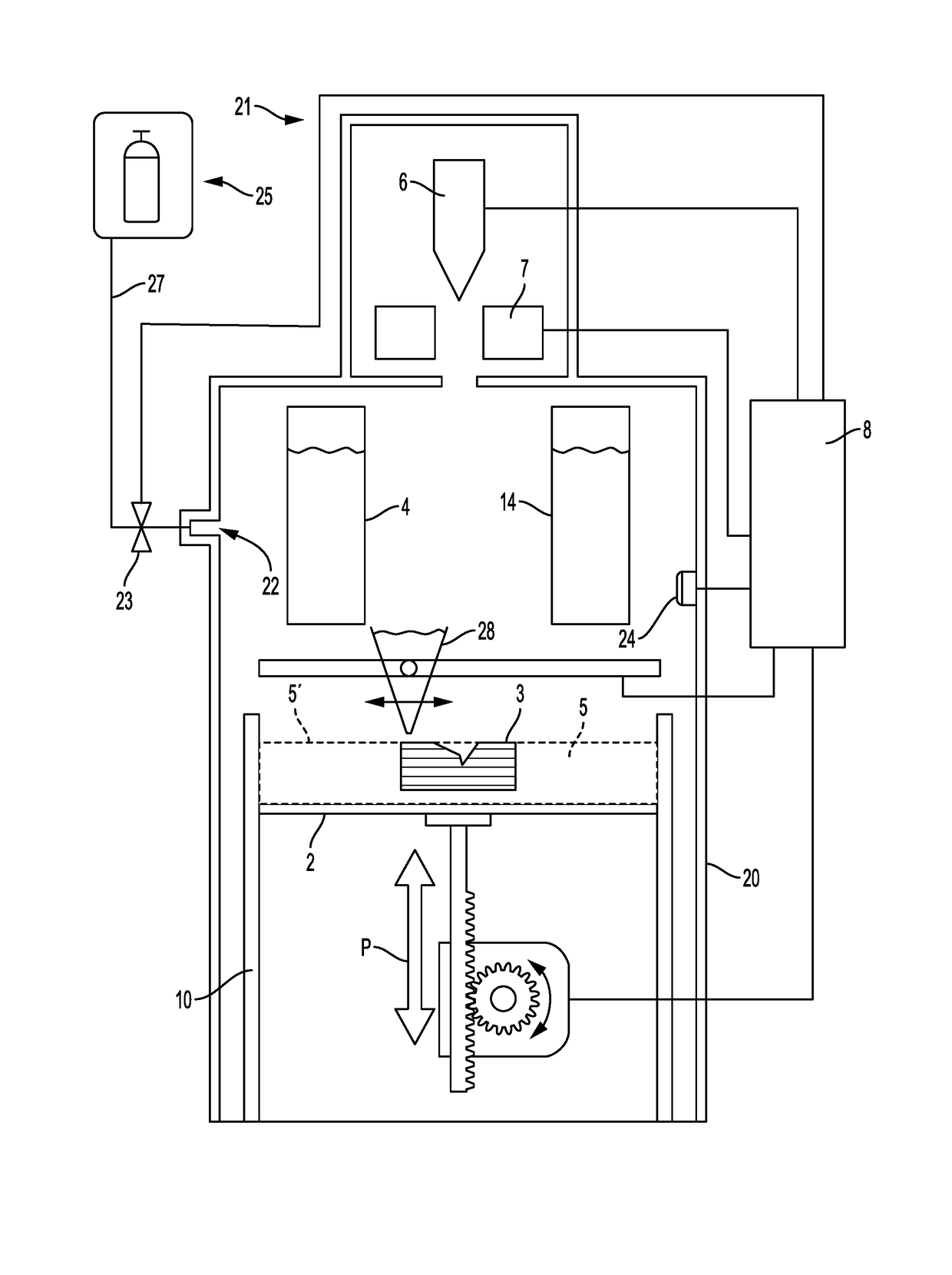

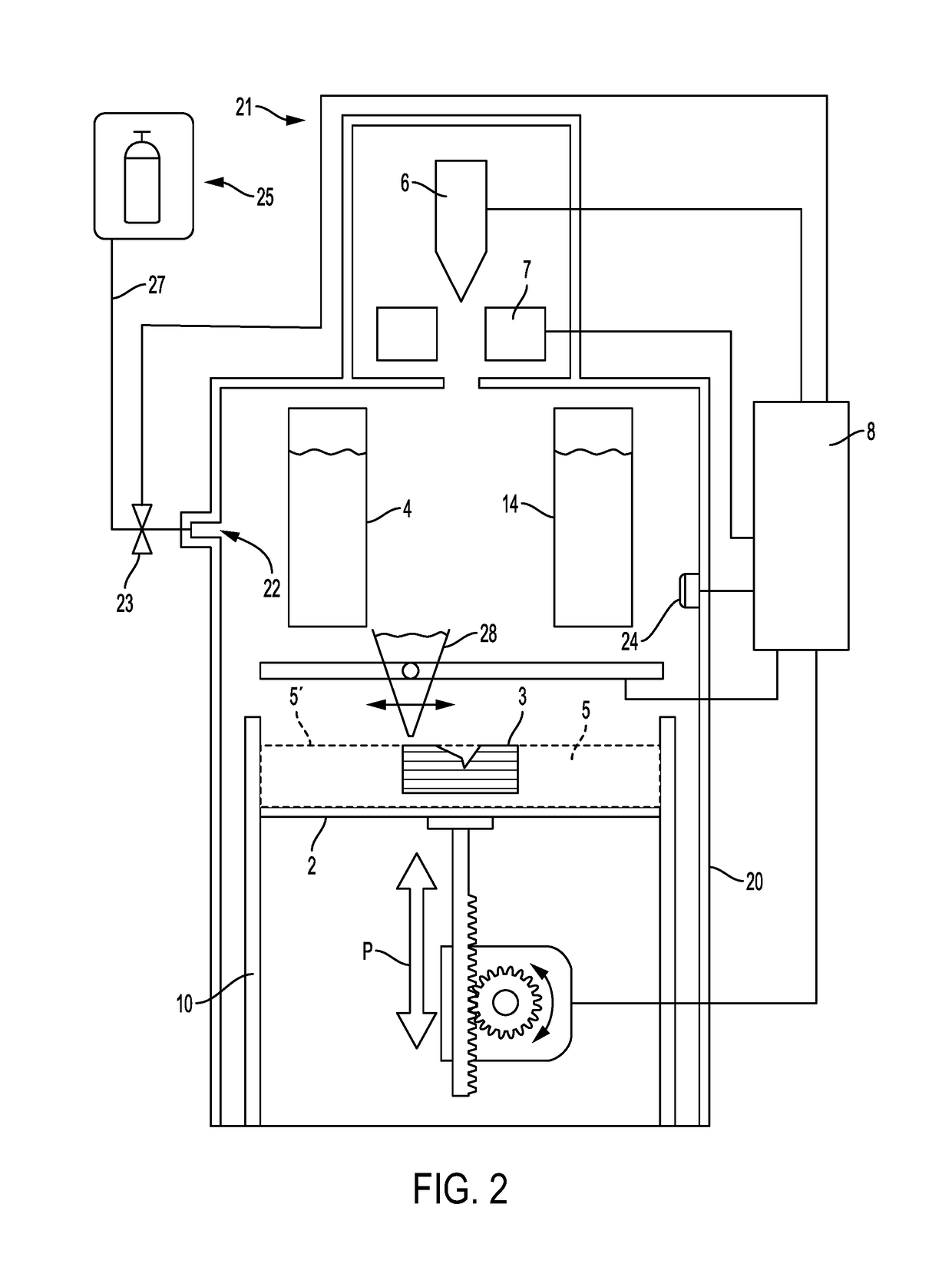

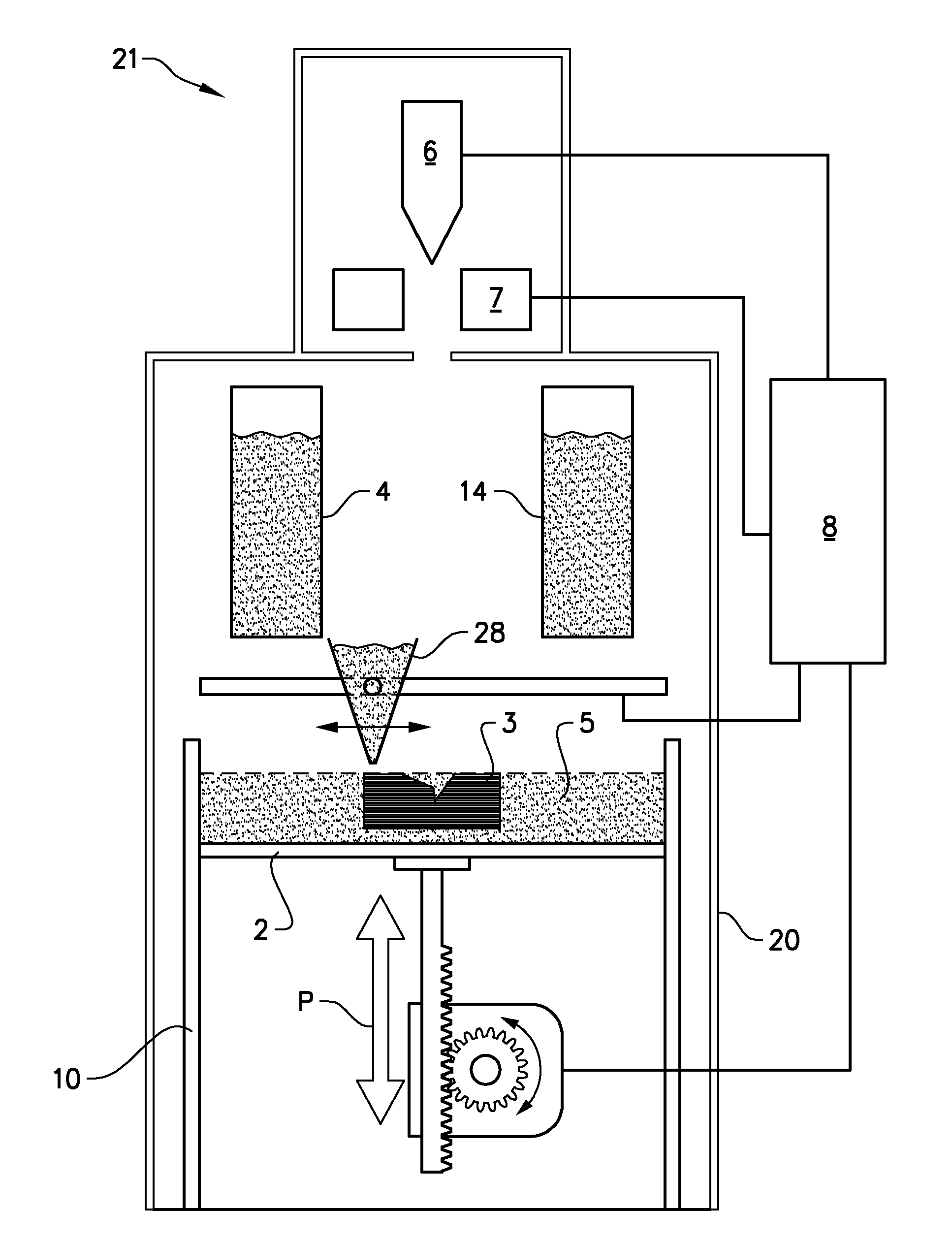

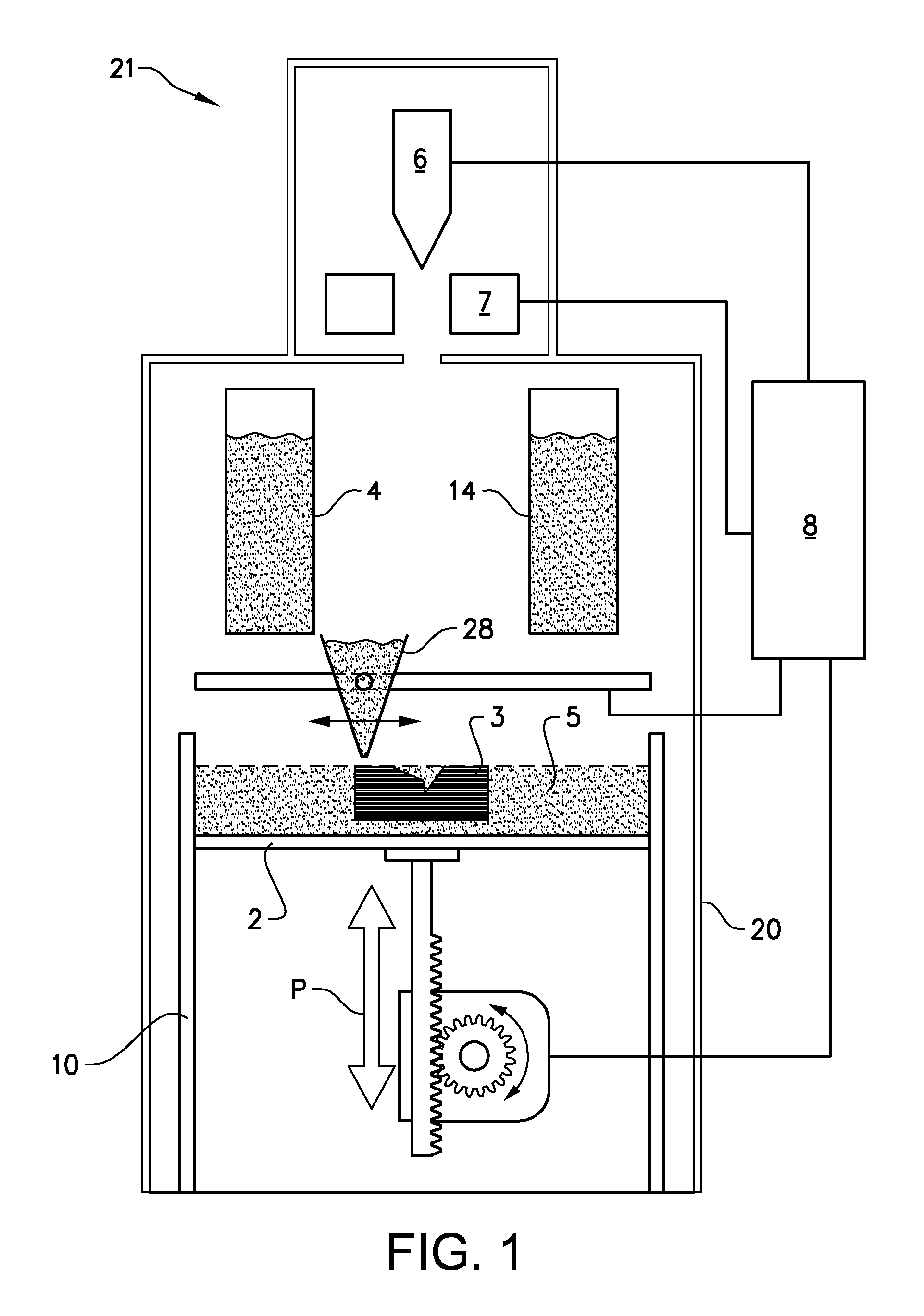

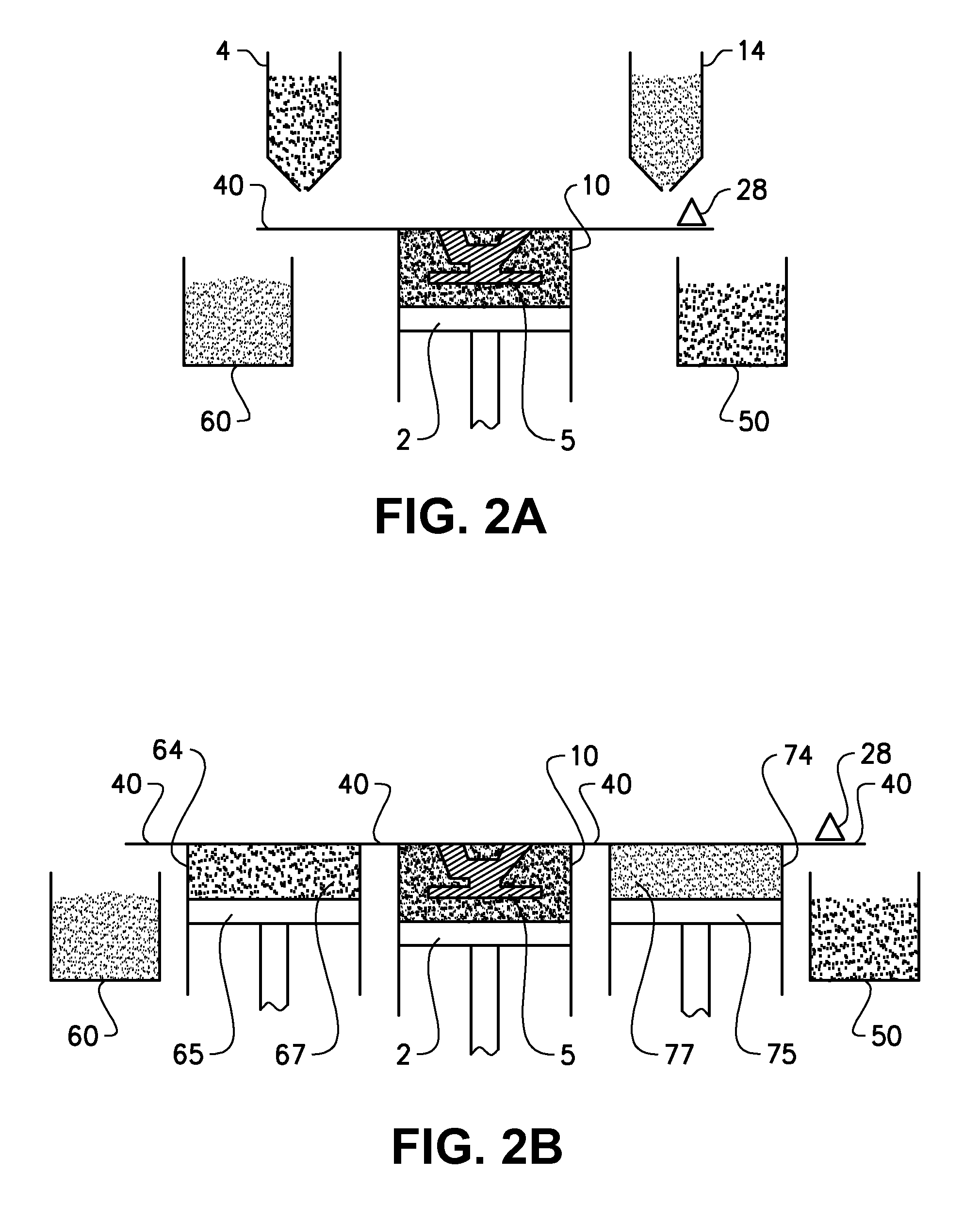

Powder distribution in additive manufacturing of three-dimensional articles

ActiveUS20150071809A1Additive manufacturing apparatusTransportation and packagingMetallurgyAdditive layer manufacturing

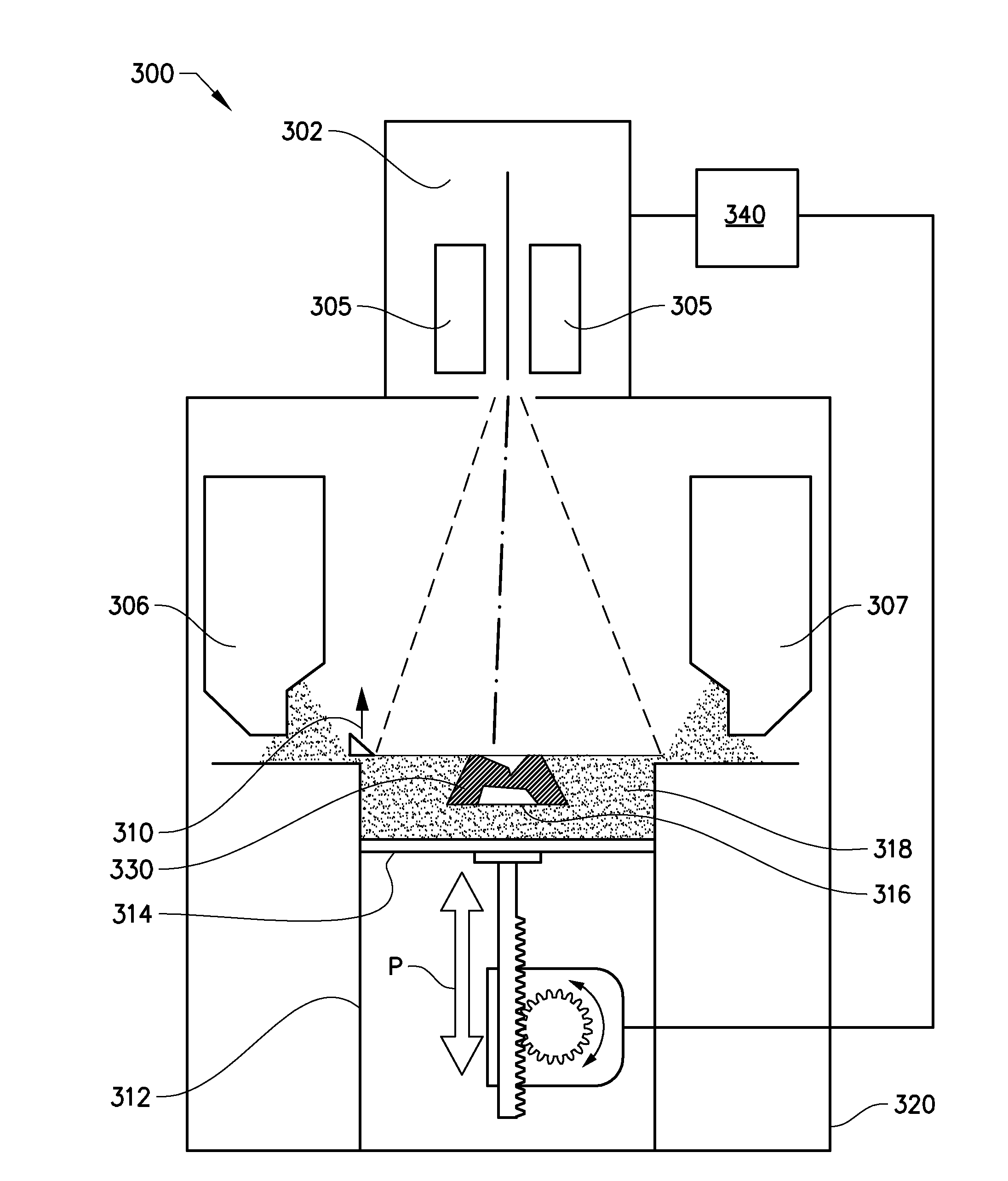

The present invention relates to a method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Said method comprising the steps of: providing at least a first and second powder tank, providing a first type of powder in said first powder tank having a first particle size distribution, providing a second type of powder in said second powder tank having a second particle size distribution, providing a first sub-layer of said first type of powder on said work table, providing a second sub-layer of said second type of powder on top of said first layer of said first type of powder, fusing said first and second sub-layers simultaneously with a high energy beam from a high energy beam source for forming a first cross section of said three-dimensional article.

Owner:ARCAM AB

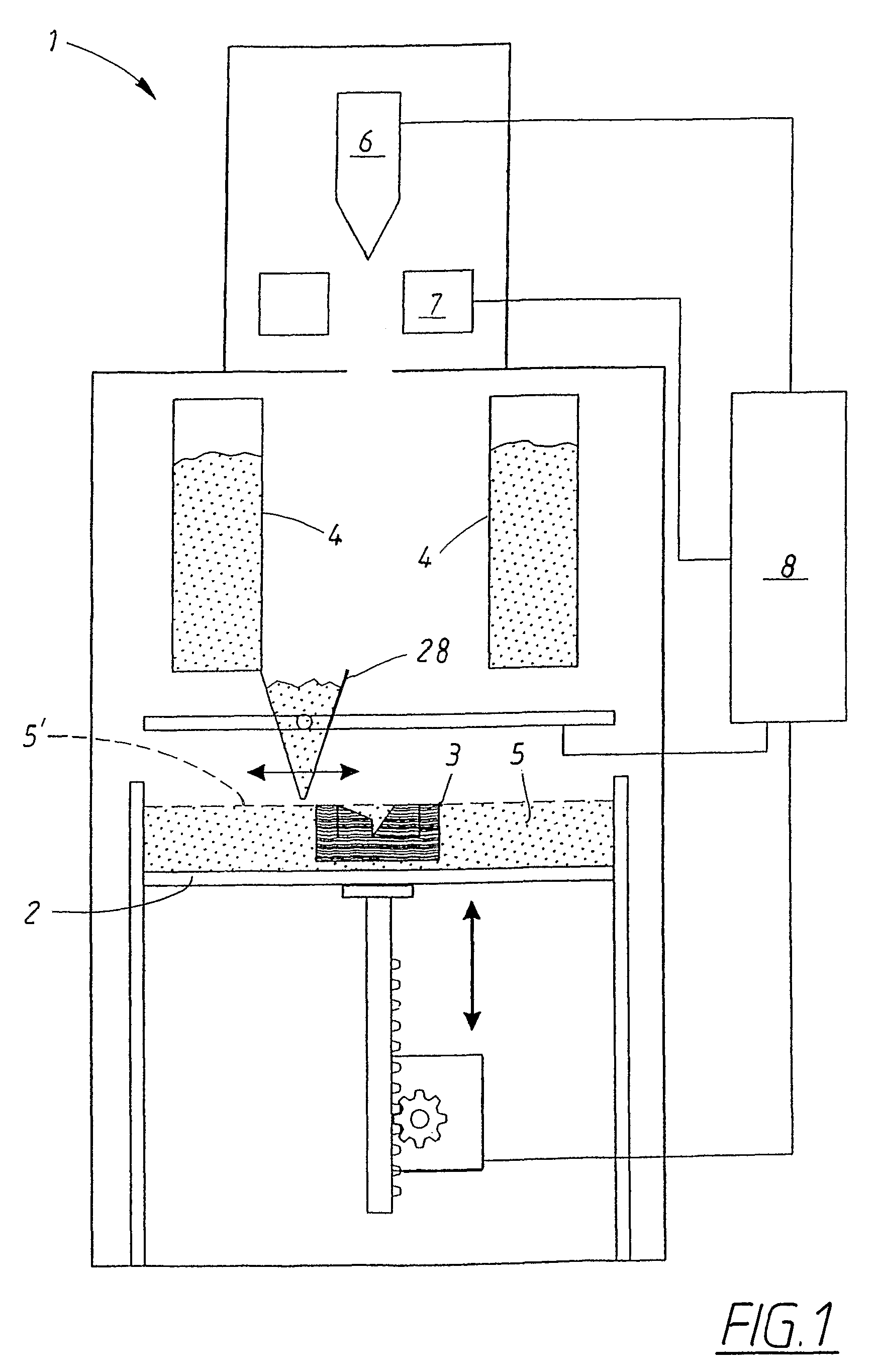

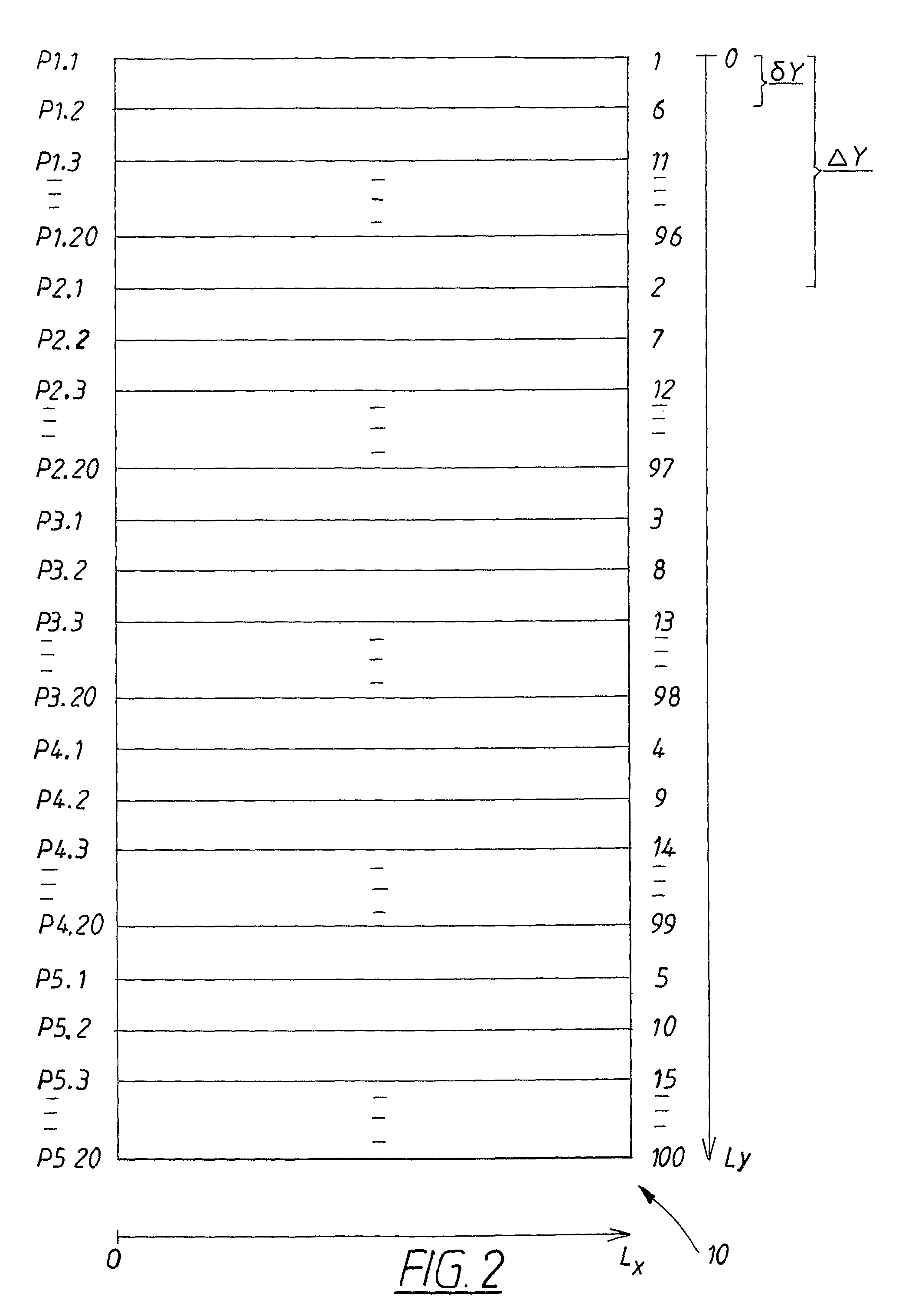

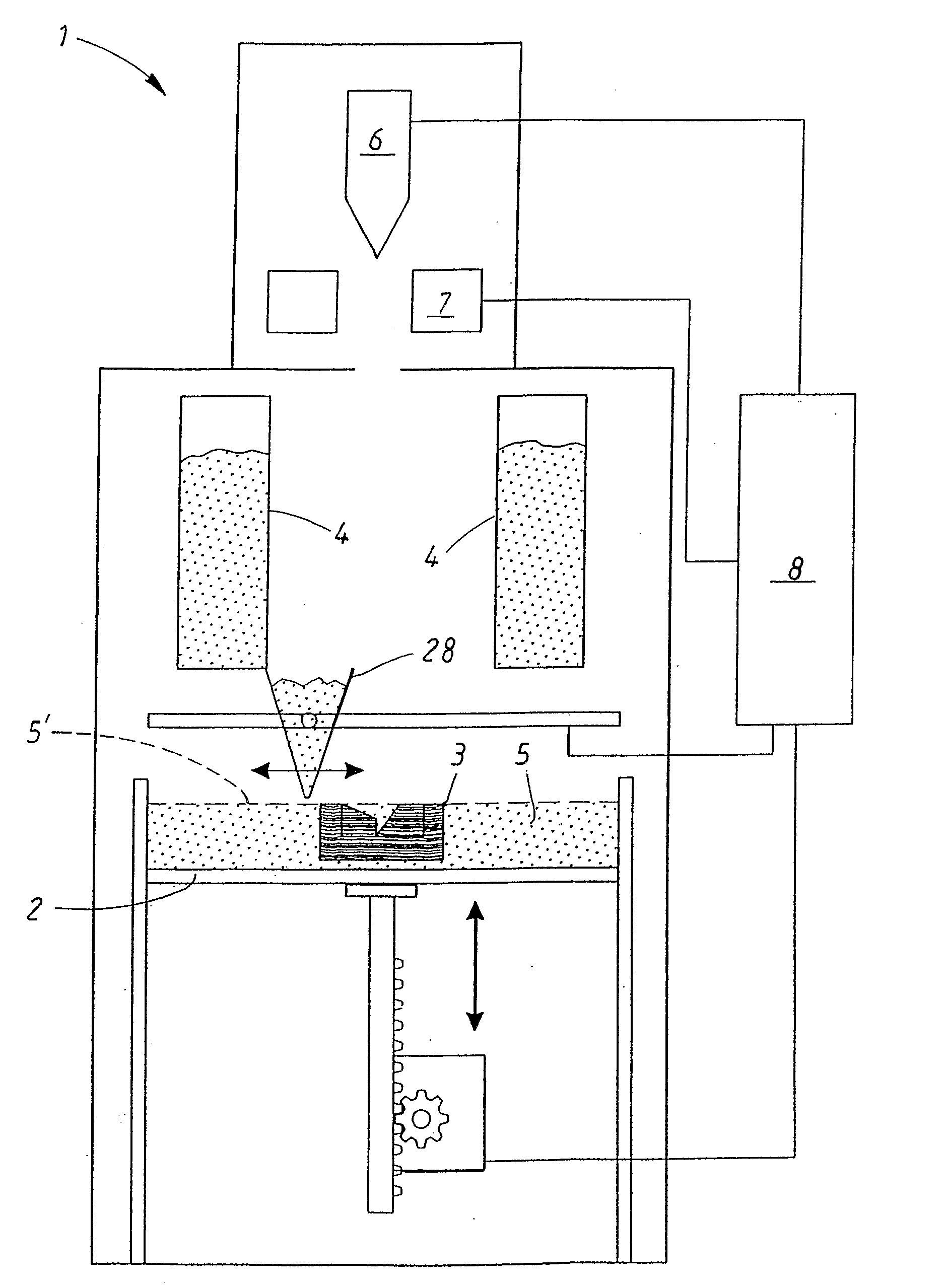

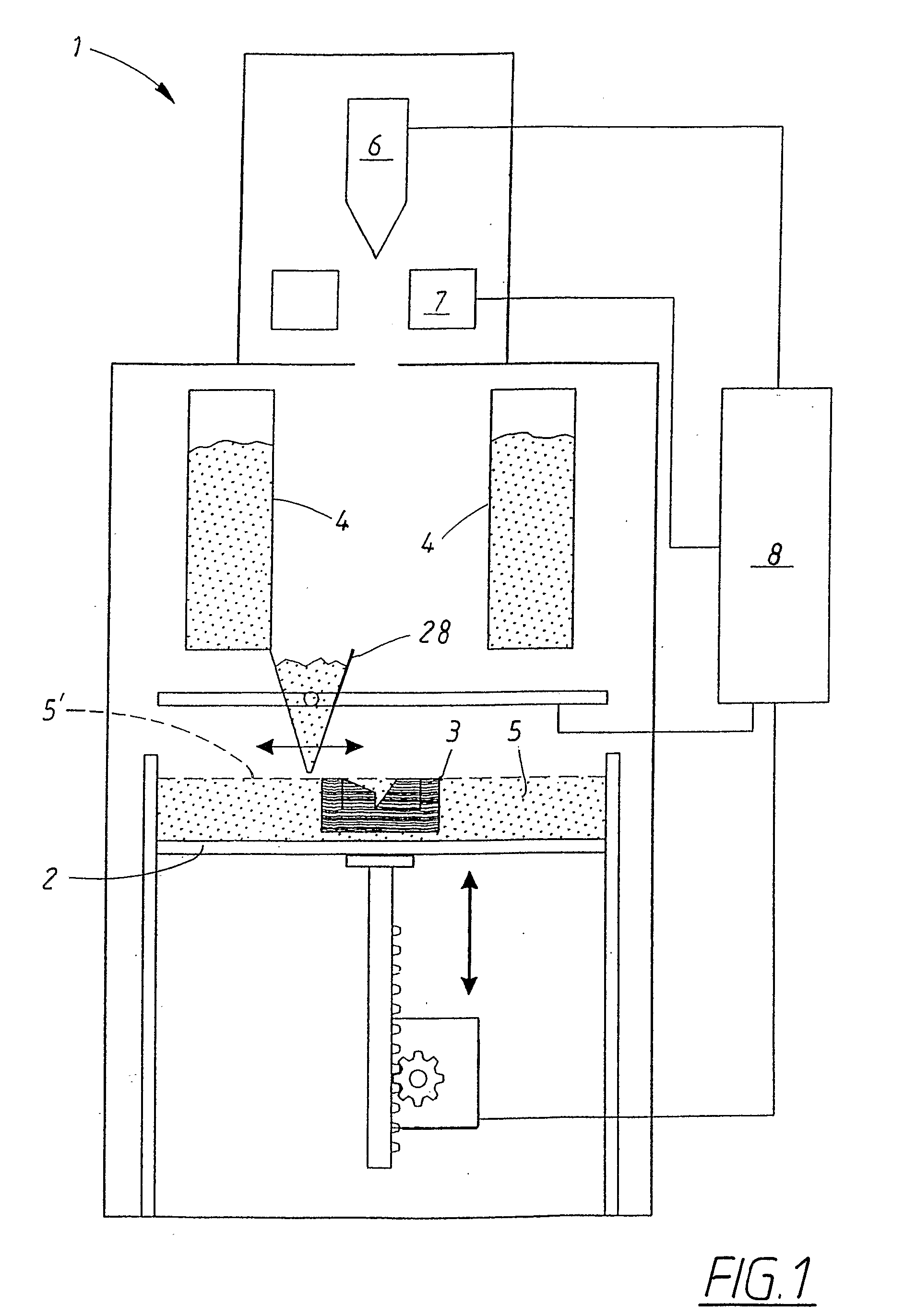

Method and apparatus for producing three-dimensional objects

ActiveUS20120100031A1Equally distributedAdditive manufacturing apparatusIncreasing energy efficiencyHigh energy beamMaterials science

Owner:ARCAM AB

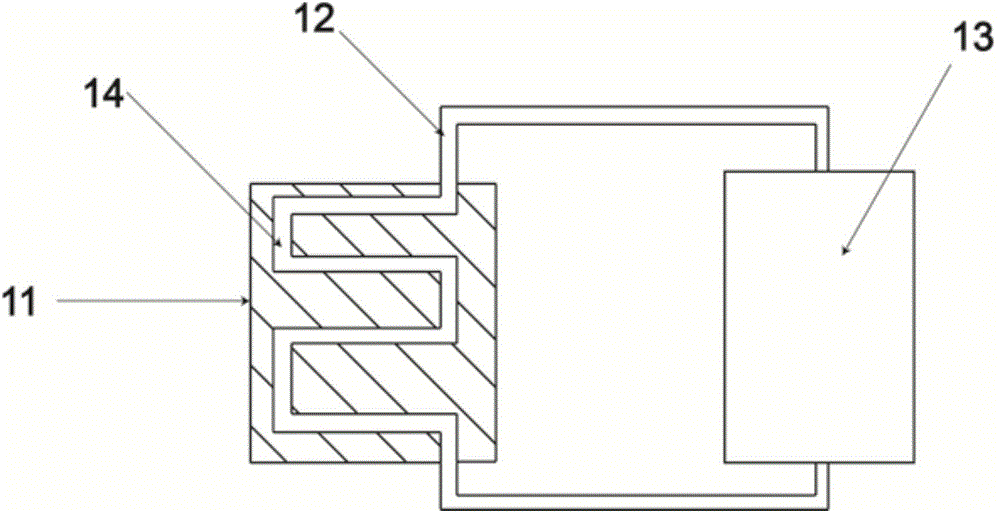

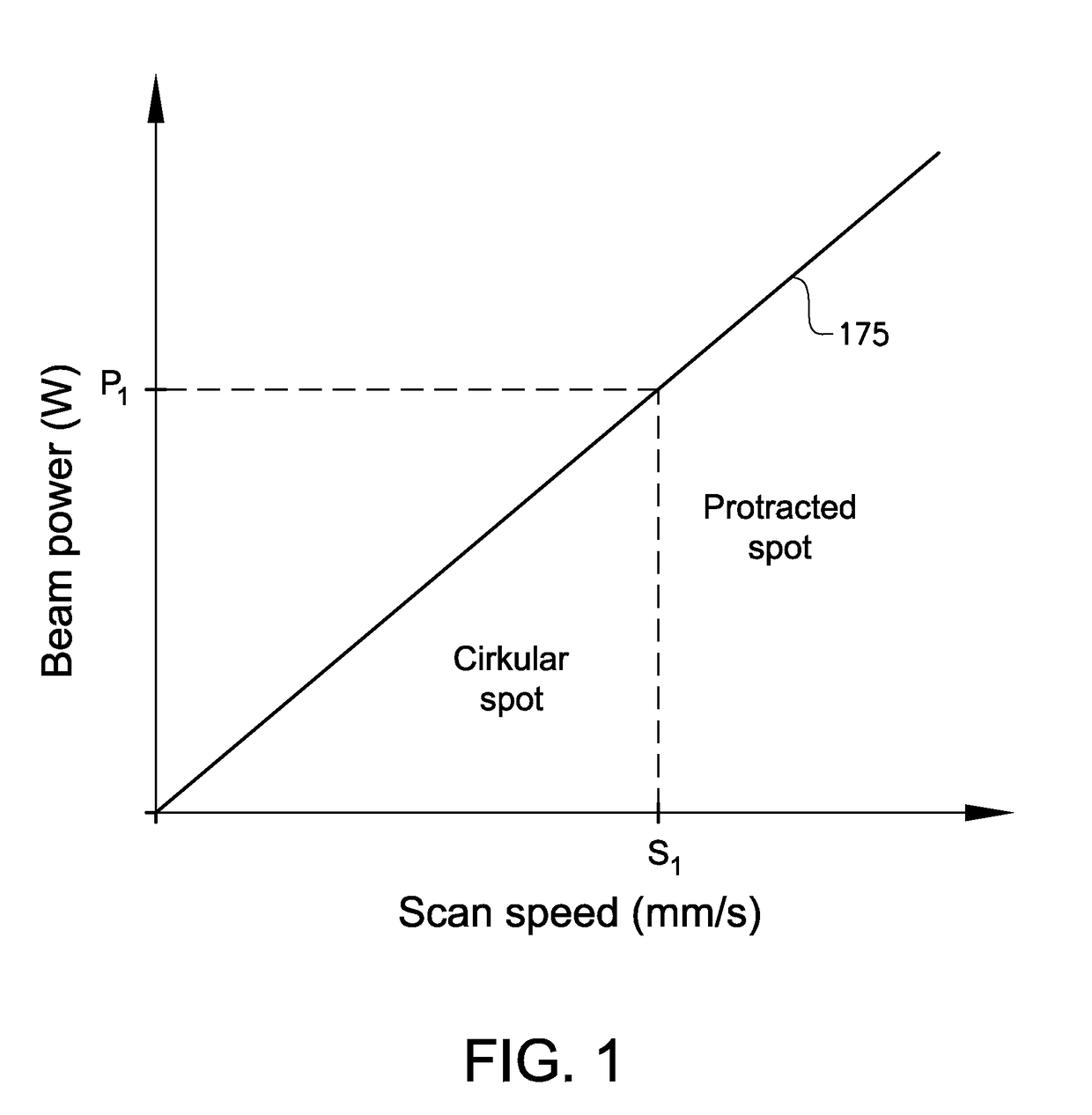

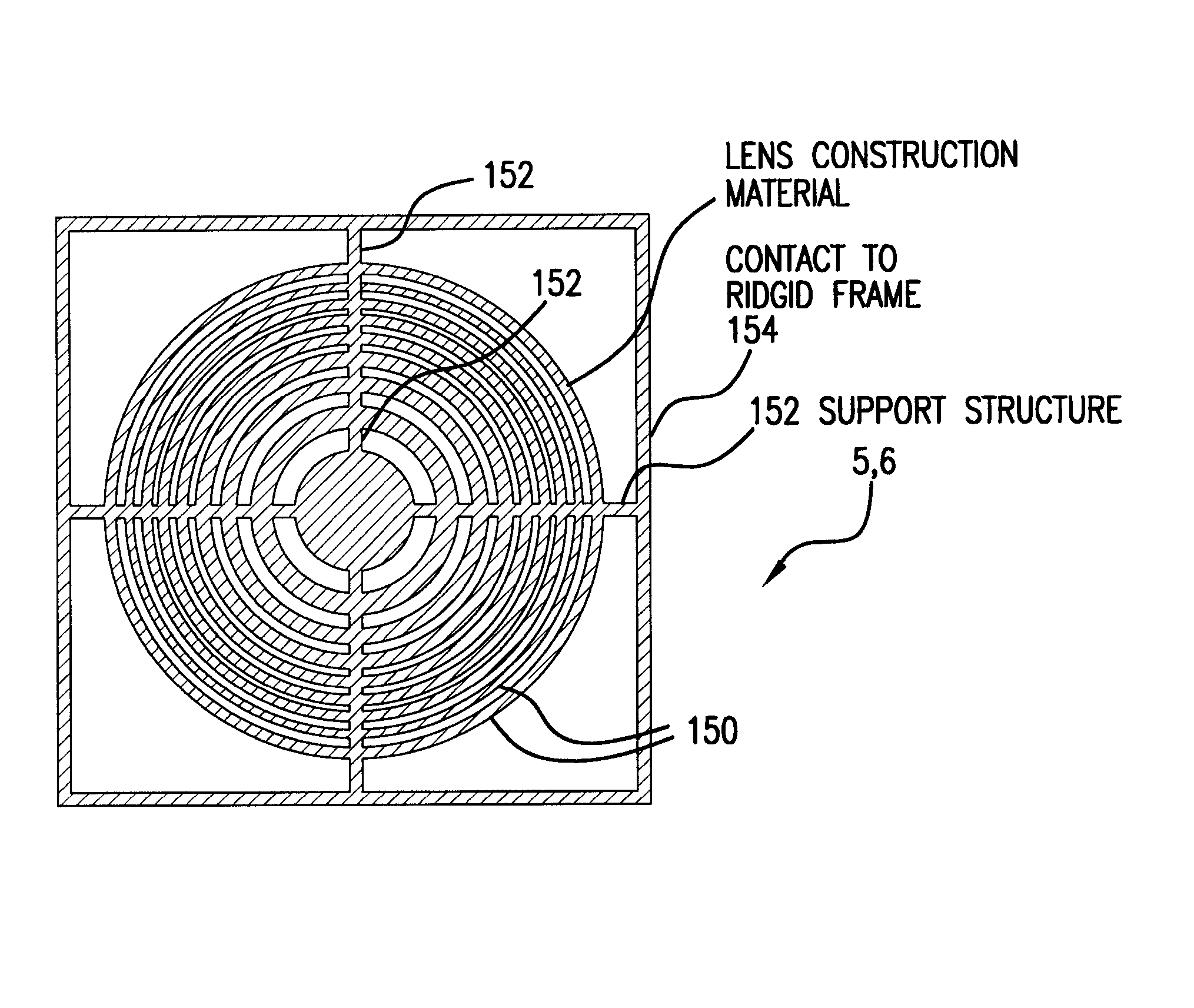

Method for fusing a workpiece

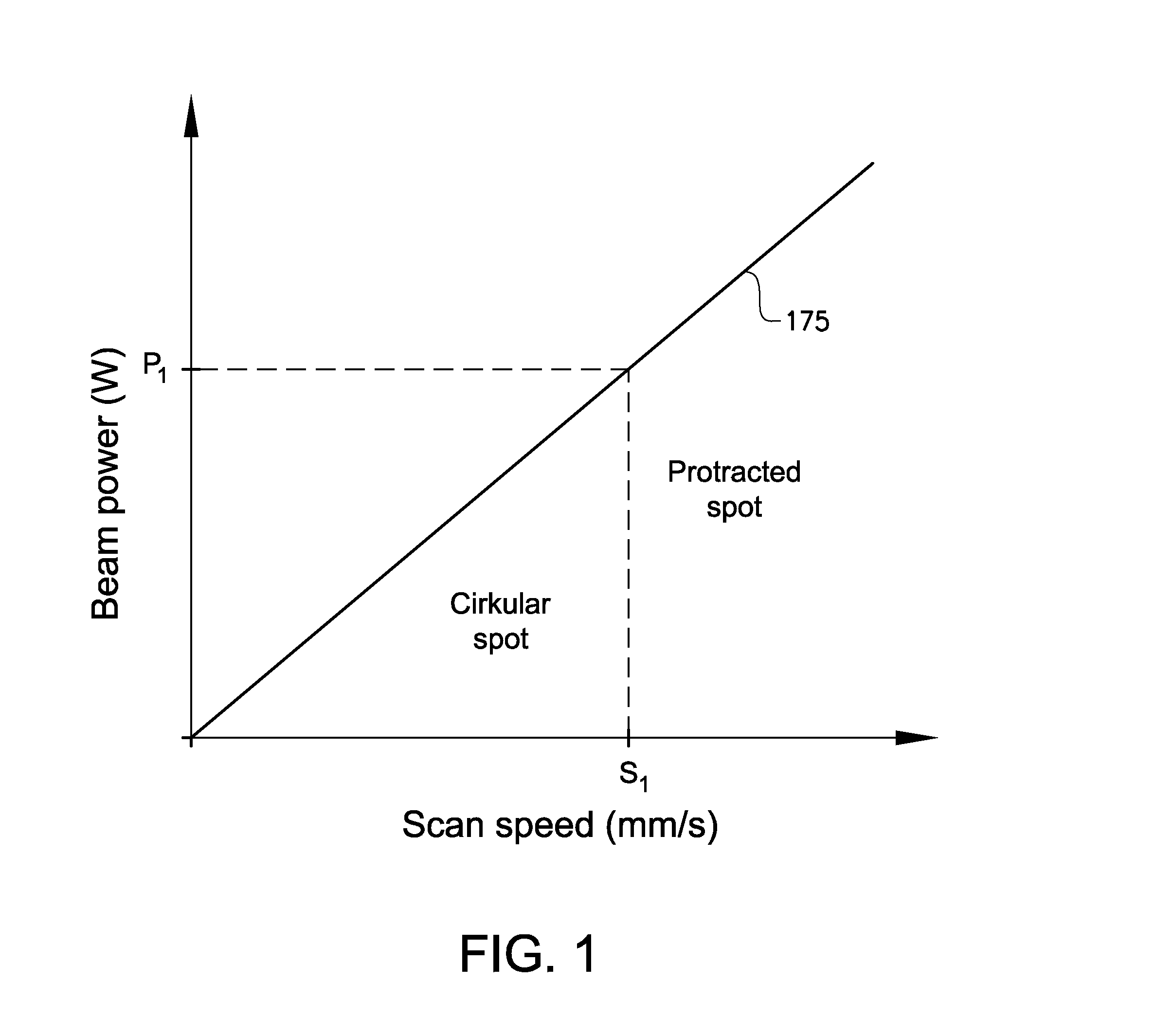

InactiveUS20150283613A1Increase powerSolve the slow scanning speedAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringHigh energy beam

Various embodiments of the present invention relate to a method for welding a workpiece comprising the steps of: making a first weld at a first position on said workpiece with a high energy beam, deflecting the high energy beam with at least one deflection lens for making a second weld at a second position on said workpiece, focusing the high energy beam on said workpiece with at least one focusing lens, shaping the high energy beam on said workpiece with at least one astigmatism lens so that the shape of the high energy beam on said workpiece is longer in a direction parallel to a deflection direction of said high energy beam than in a direction perpendicular to said deflection direction of said high energy beam. The invention is also related to the use of an astigmatism lens and to a method for forming a three dimensional article.

Owner:ARCAM AB

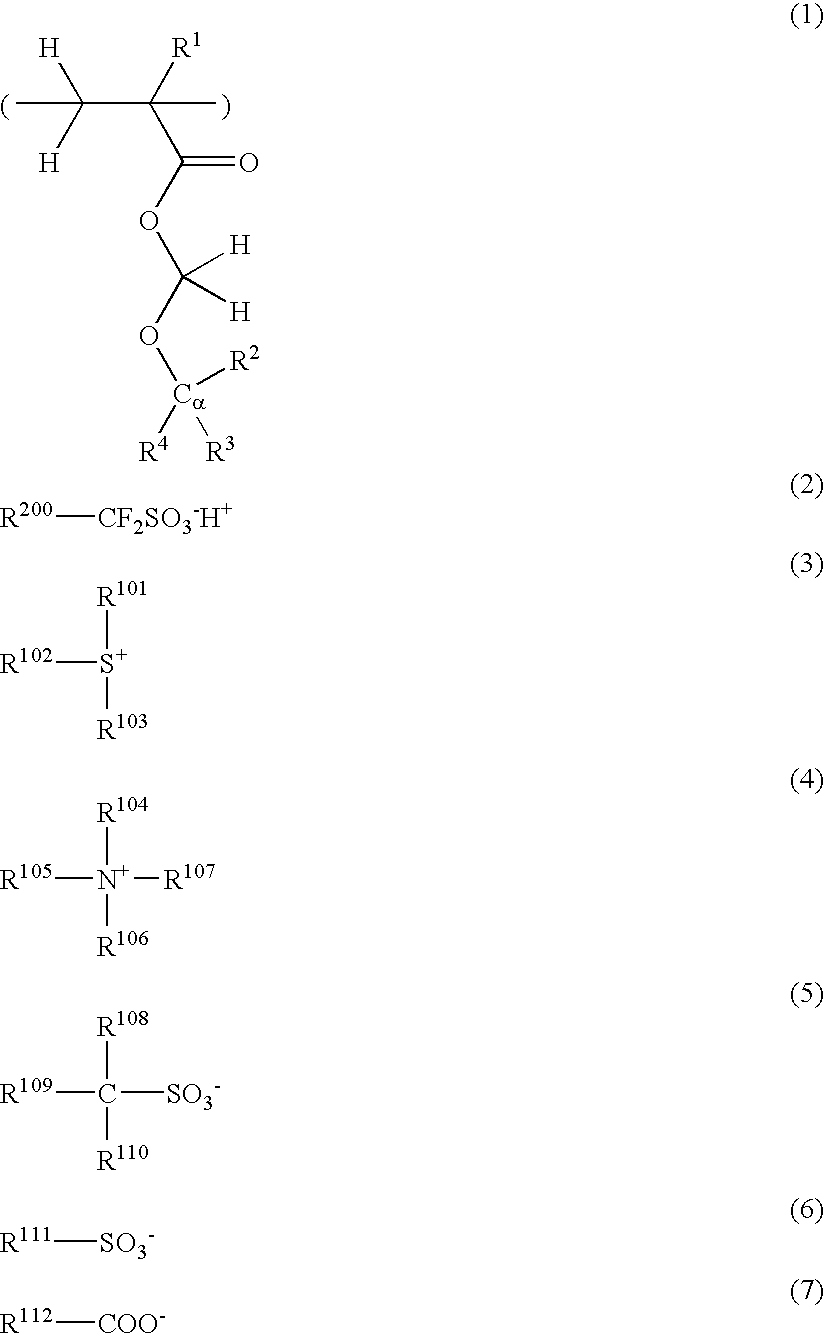

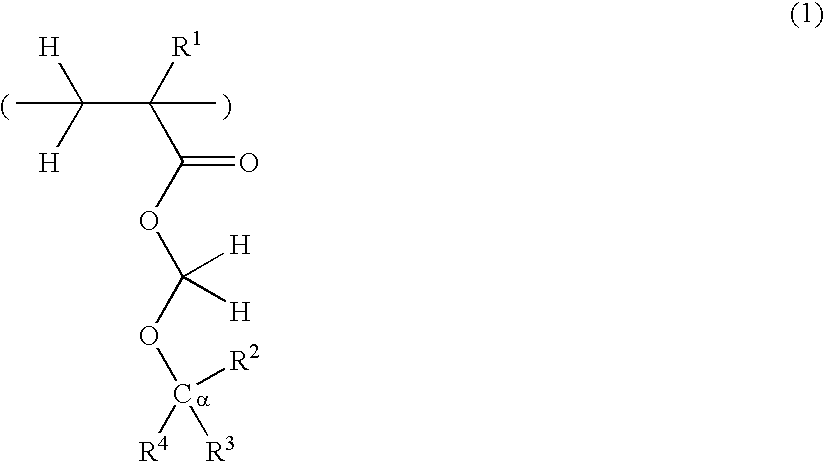

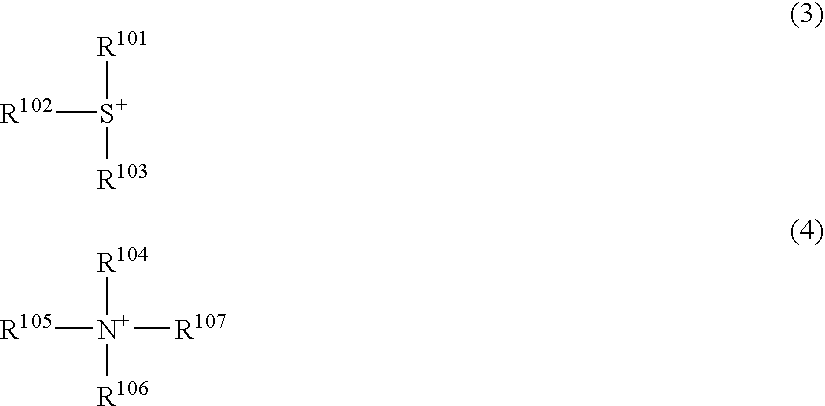

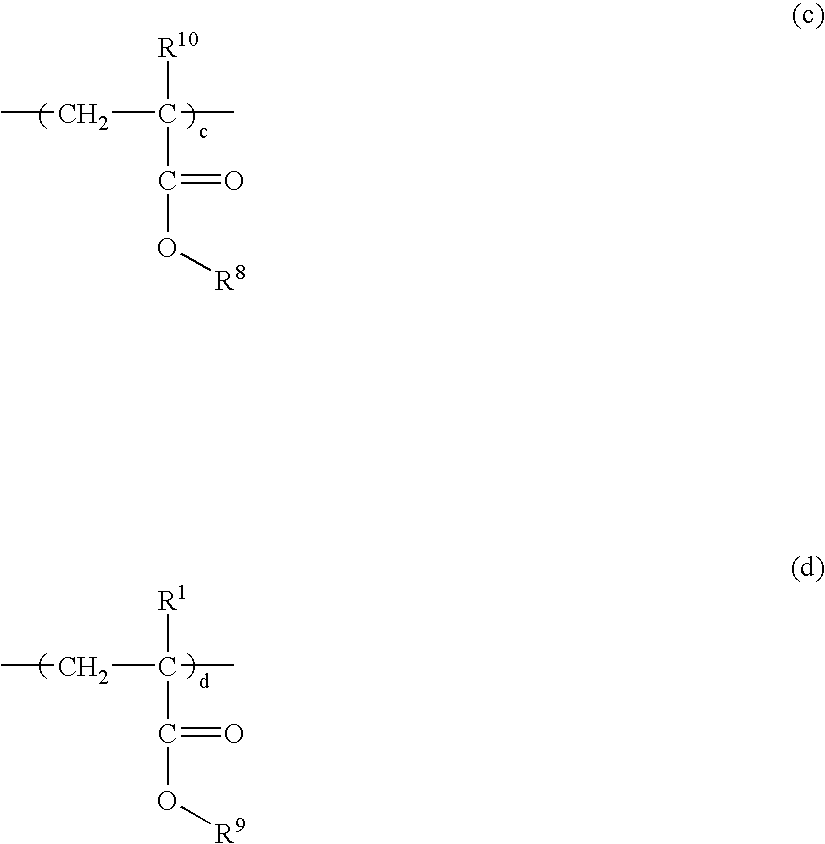

Positive resist composition and patterning process

ActiveUS20080153030A1Good storage stabilityHigh resolutionOrganic chemistryPhotosensitive materialsHigh energyPhotoacid generator

There is disclosed a resist composition that remarkably improves the resolution of photolithography using a high energy beam such as ArF excimer laser light as a light source, and exhibits excellent resistance to surface roughness and side lobe under use of a halftone phase shift mask; and a patterning process using the resist composition. The positive resist composition at least comprises (A) a resin component comprising a repeating unit represented by the following general formula (1); (B) a photoacid generator generating sulfonic acid represented by the following general formula (2) upon exposure to a high energy beam; and (C) an onium salt where a cation is sulfonium represented by the following general formula (3), or ammonium represented by the following general formula (4); and an anion is represented by any one of the following general formulae (5) to (7).

Owner:SHIN ETSU CHEM IND CO LTD

Method and device for producing three-dimensional objects

ActiveUS8187521B2Large gradientImprove conductivityElectric discharge tubesAuxillary shaping apparatusIrradiationHigh energy beam

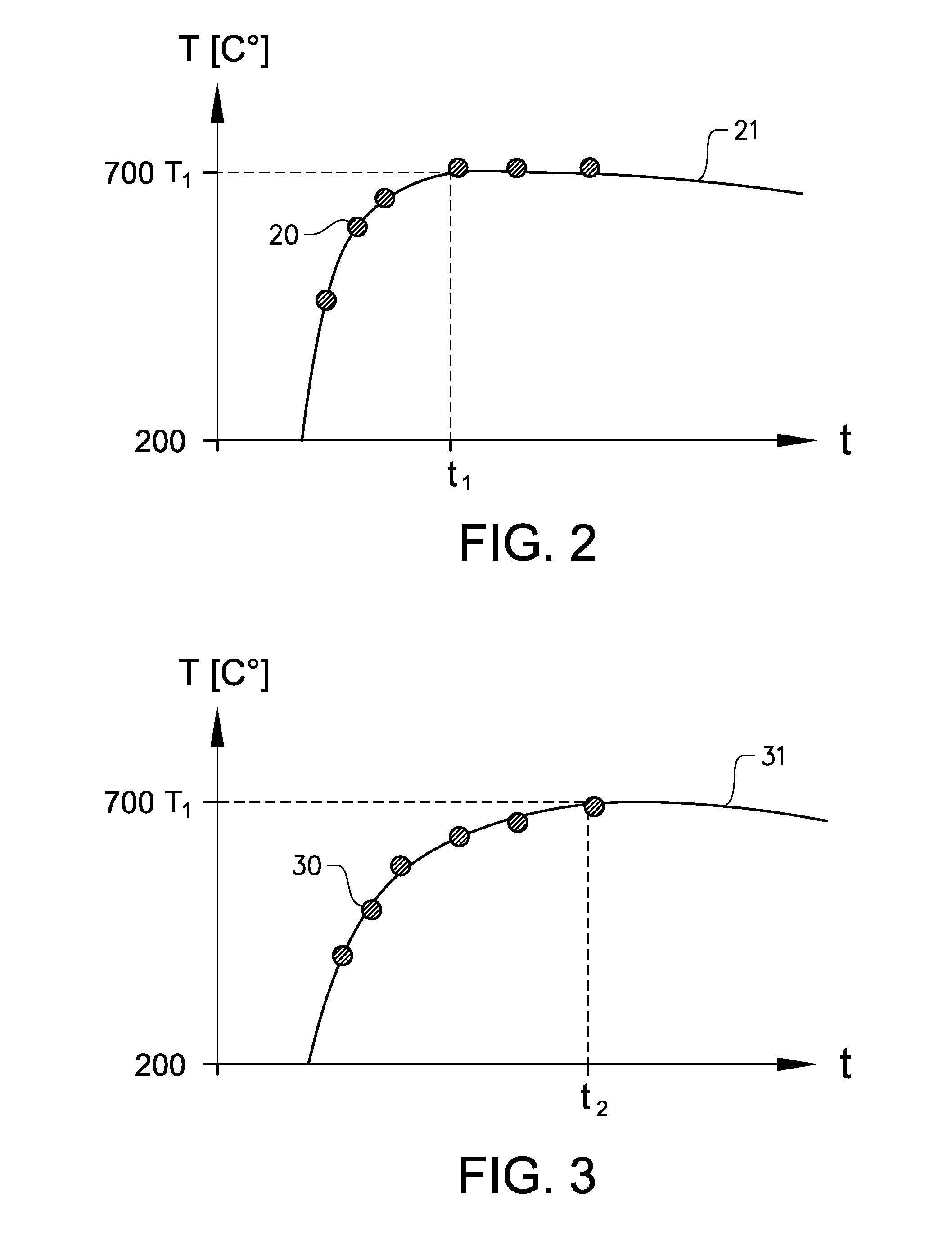

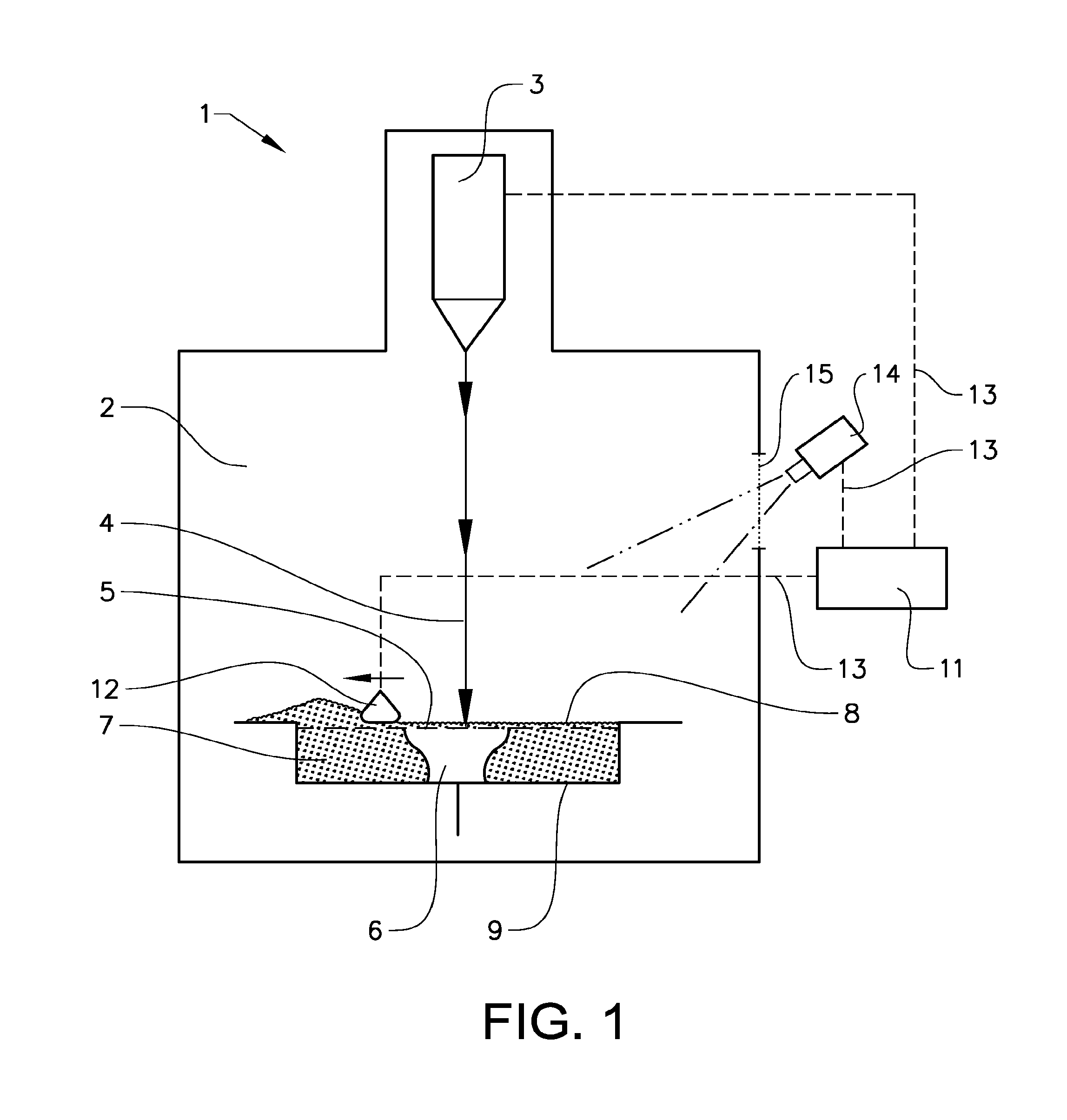

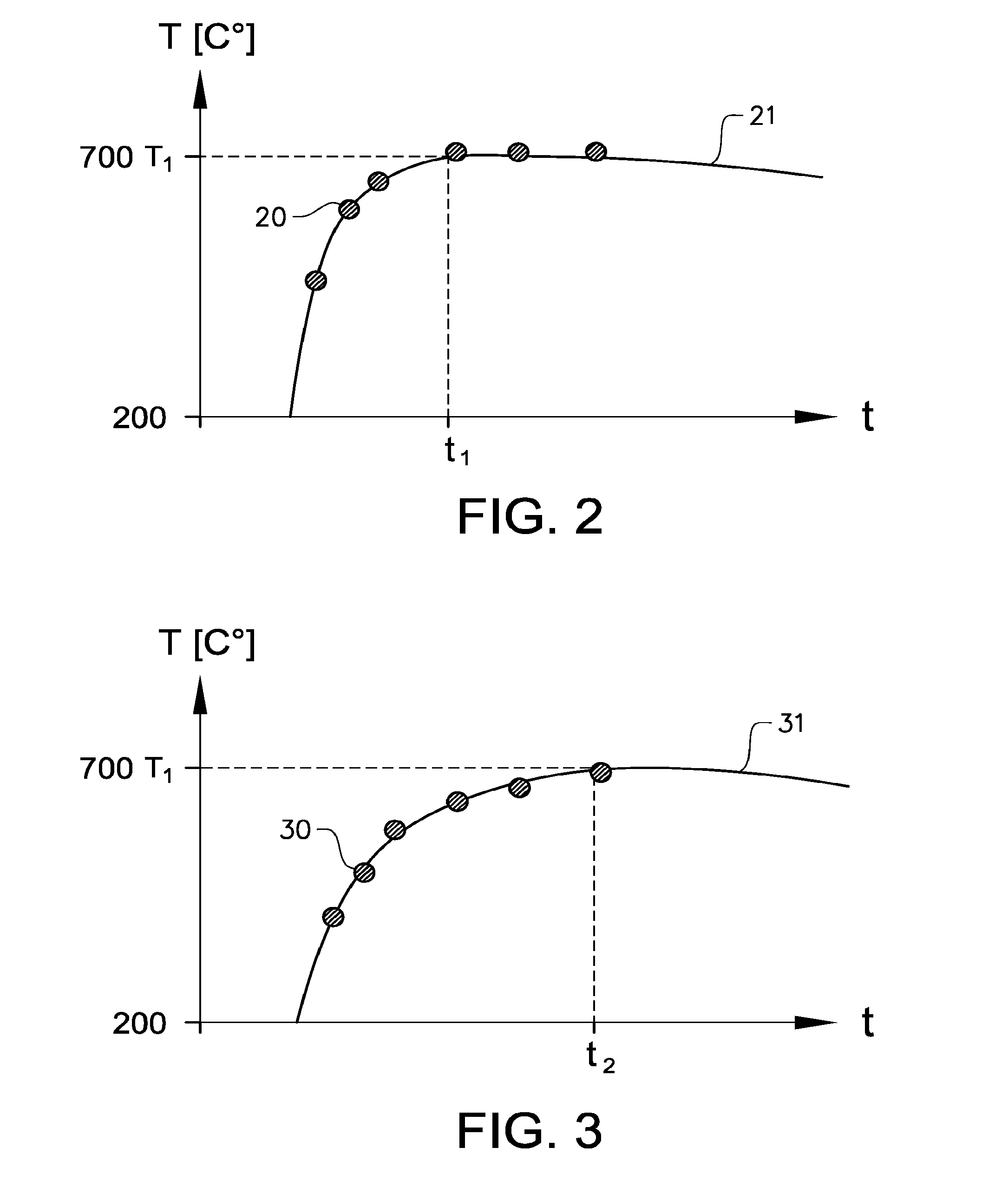

A method for producing three-dimensional objects from a powder material which is capable of solidification by irradiation with a high-energy beam is disclosed. The method comprises homogeneously pre-heating the powder material by scanning with the high-energy beam along predetermined paths over a pre-heating area so that consecutive paths are separated by a minimum security distance which is adapted to prevent undesirable summation effects in the pre-heating area, and then solidifying the powder material by fusing together the powder material. Apparatus for producing such three-dimensional objects is also disclosed.

Owner:ARCAM AB

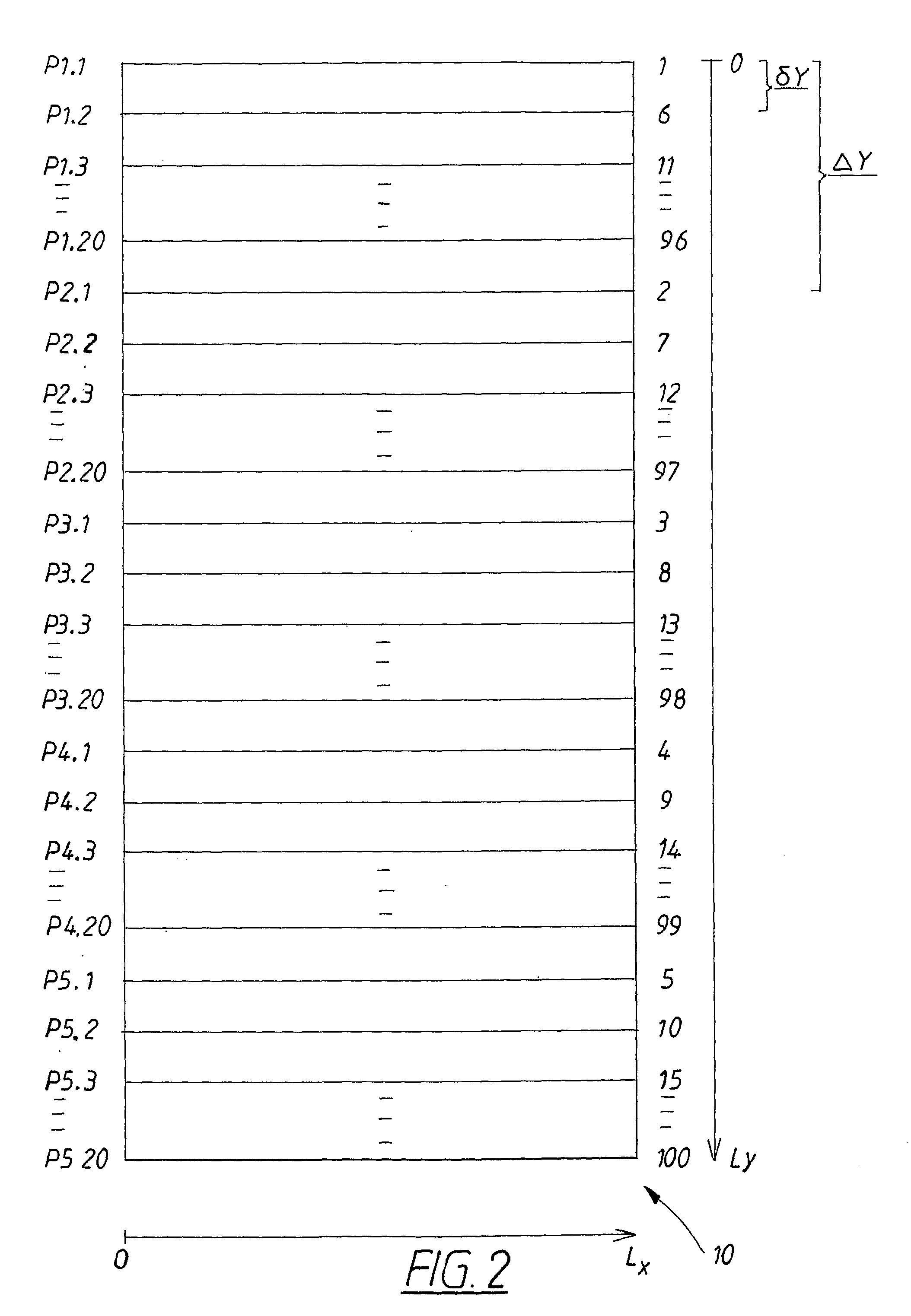

Method and device for producing three-dimensional objects

ActiveUS20100007062A1Large temperature gradientImprove conductivityElectric discharge tubesAuxillary shaping apparatusIrradiationHigh energy beam

A method for producing three-dimensional objects from a powder material which is capable of solidification by irradiation with a high-energy beam is disclosed. The method comprises homogeneously pre-heating the powder material by scanning with the high-energy beam along predetermined paths over a pre-heating area so that consecutive paths are separated by a minimum security distance which is adapted to prevent undesirable summation effects in the pre-heating area, and then solidifying the powder material by fusing together the powder material. Apparatus for producing such three-dimensional objects is also disclosed.

Owner:ARCAM AB

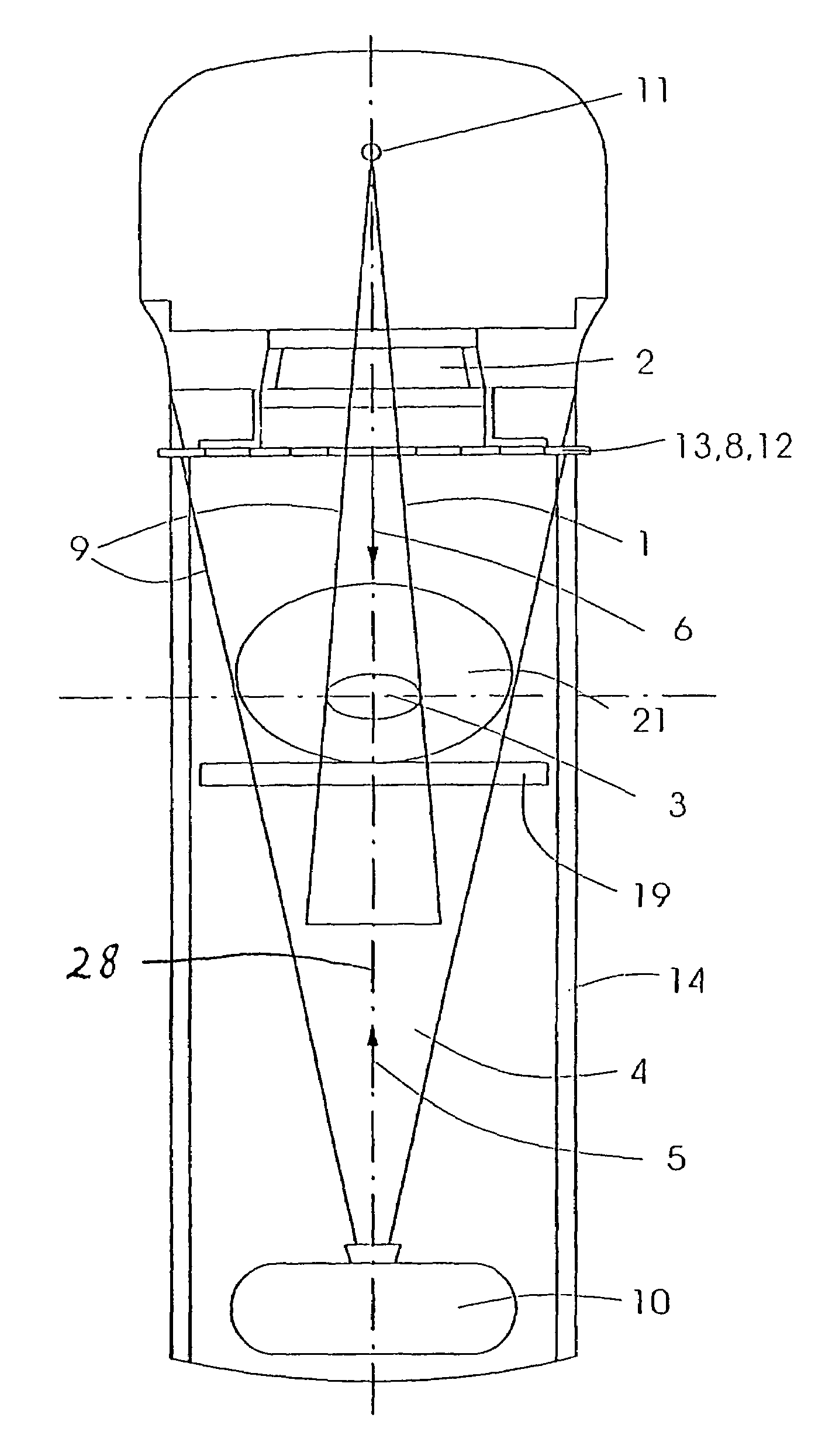

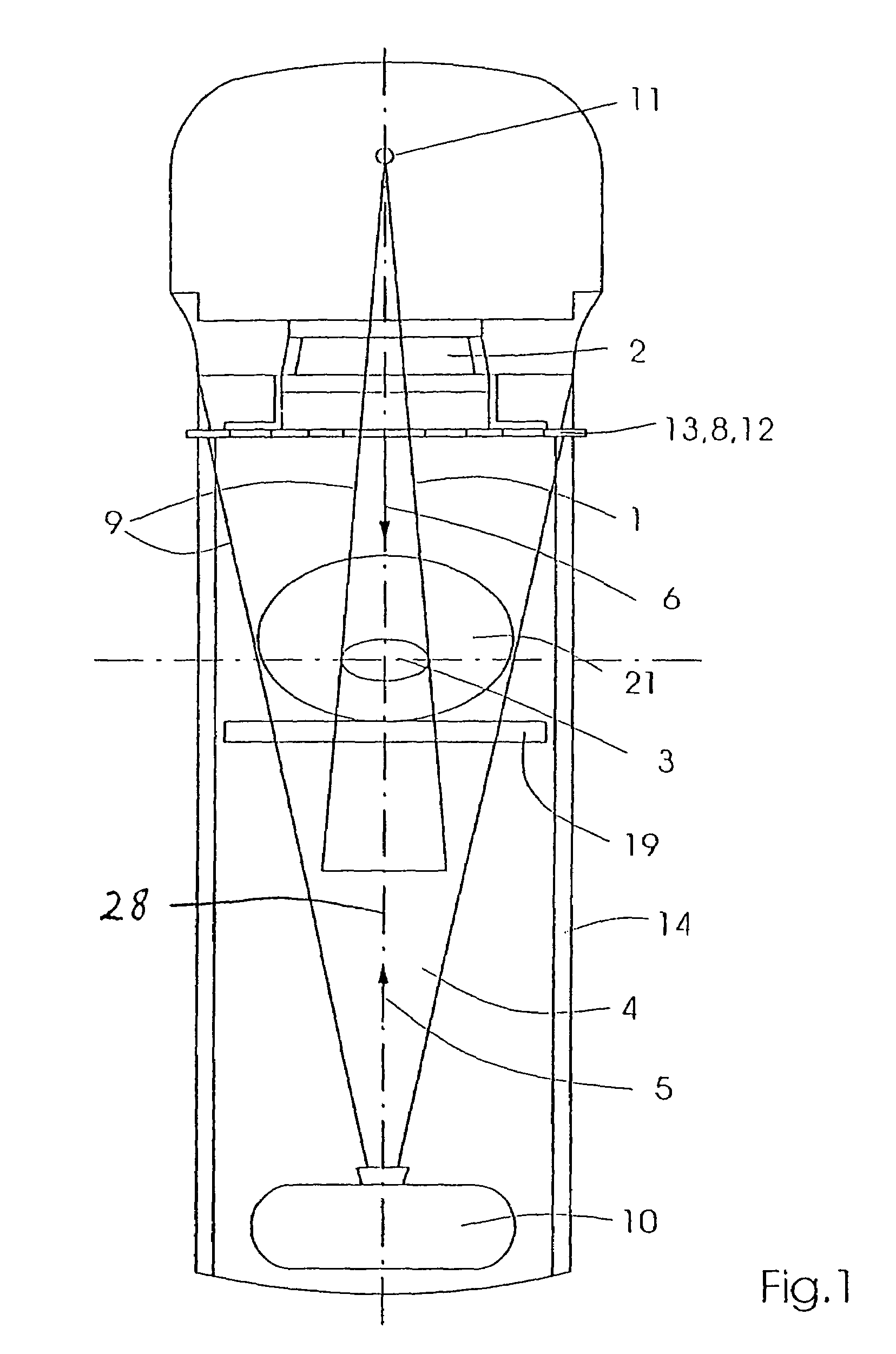

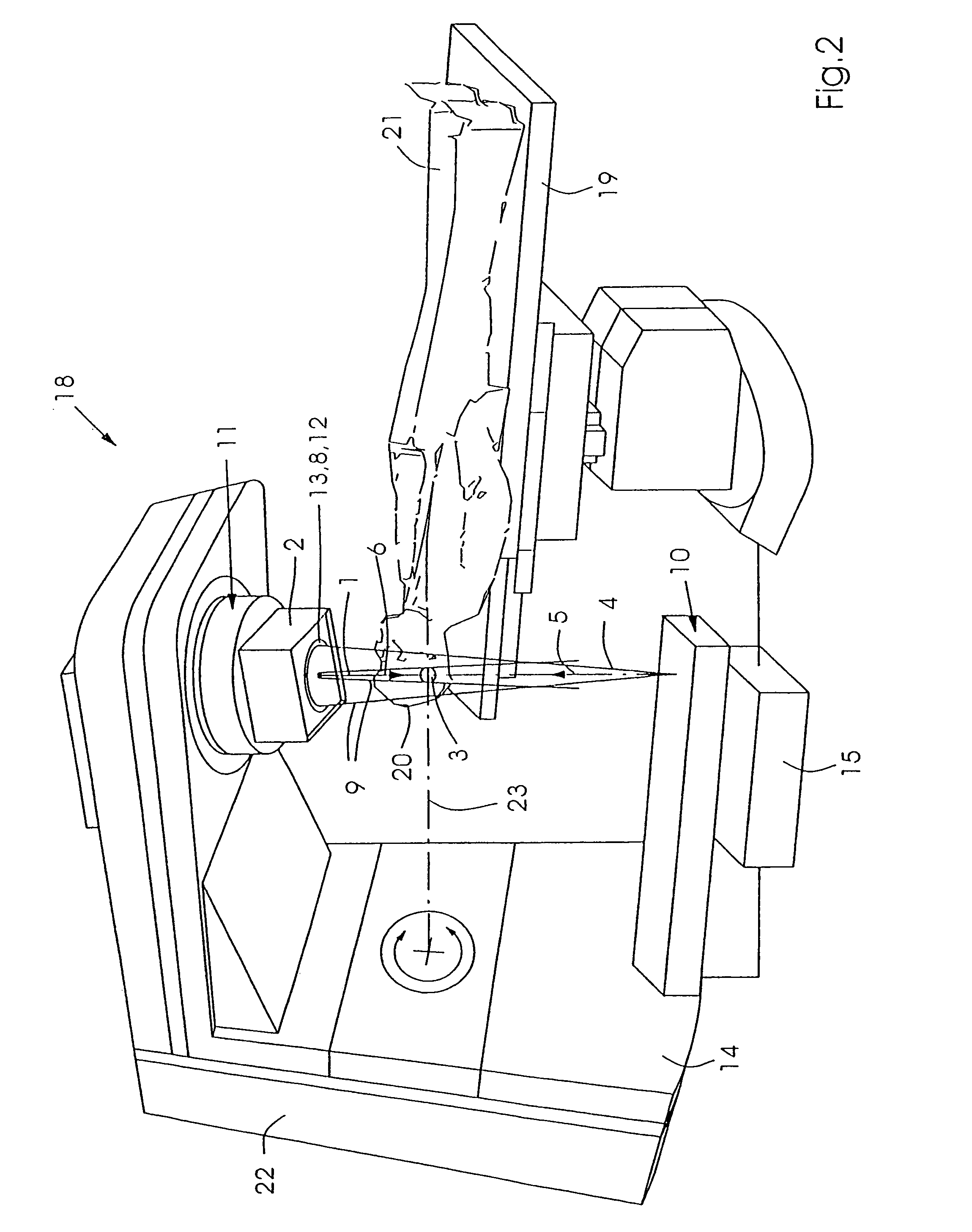

Device for performing and verifying a therapeutic treatment and corresponding computer program and control method

InactiveUS6993112B2Avoid radiationReduce in quantityIrradiation devicesX-ray/gamma-ray/particle-irradiation therapyBeam sourceTherapeutic treatment

The invention relates to a device for performing and verifying therapeutic radiation. An x-ray beam (4) is arranged across from a target volume (3) of the beam source (11) for the high-energy beam (1) in such a way that the beams (1, 4) run in essentially opposite directions (5, 6). The invention also relates to a computer program and a control method for operating said device. The inventive device makes it possible to exactly verify areas (16, 16′, 16″) that are subjected to different levels of radiation, the entire anatomy of the target volume (3), and the surroundings thereof in addition to the contour of the therapy beam (1). The x-ray beam (4) detects the anatomy and position of the patient (21) within the range of the target volume (3) before the high-energy beam (1) is applied and the shape of the applied high-energy beam (1) is then detected and areas (16, 16′, 16″) that are subjected to different levels of radiation as well as at least one partial segment of the target volume (3) during the emission breaks of the high-energy beam (1). The detected data is used for correcting the treatment plan.

Owner:DEUTES KREBSFORSCHUNGSZENT STIFTUNG DES OFFENTLICHEN RECHTS

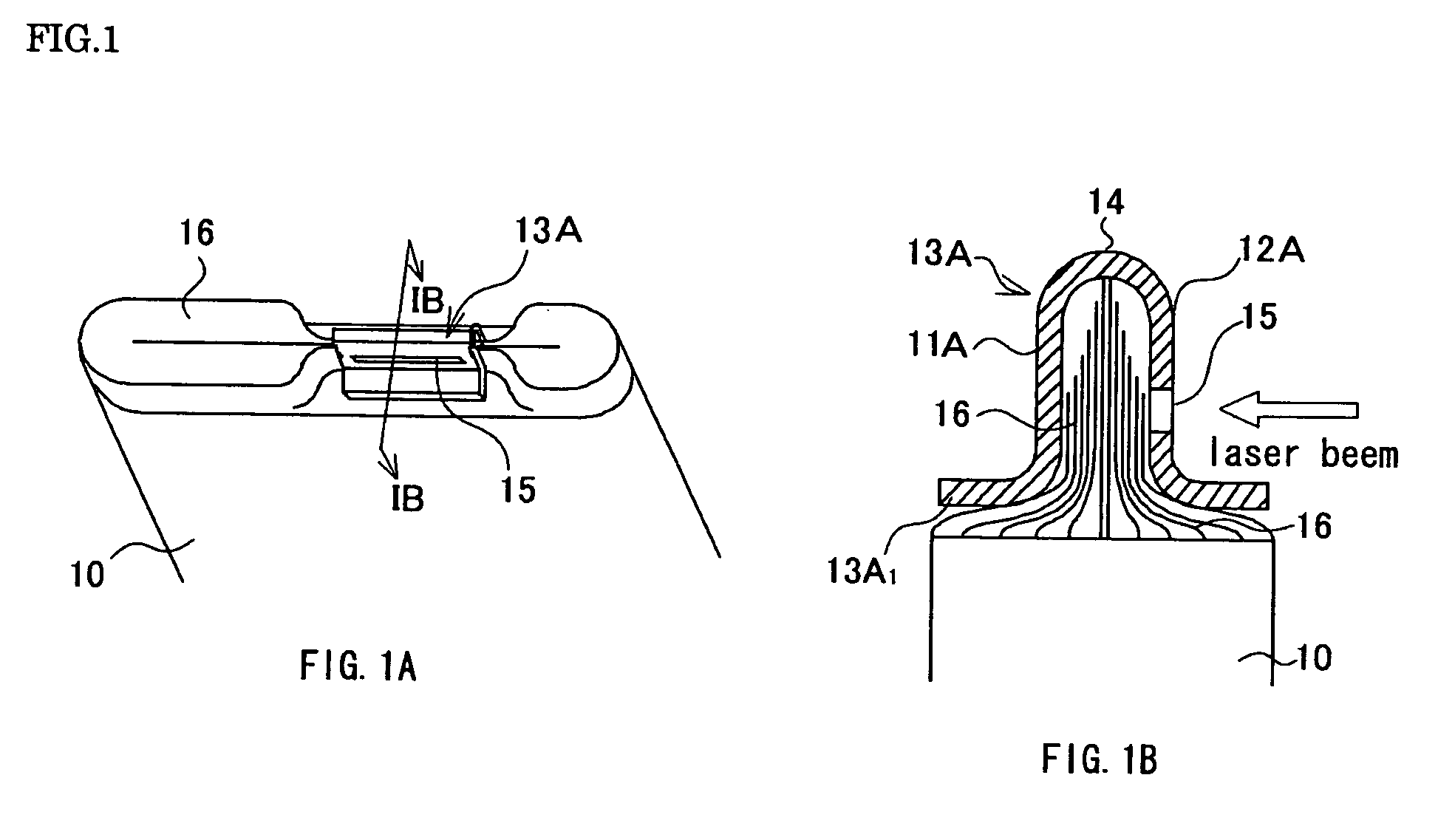

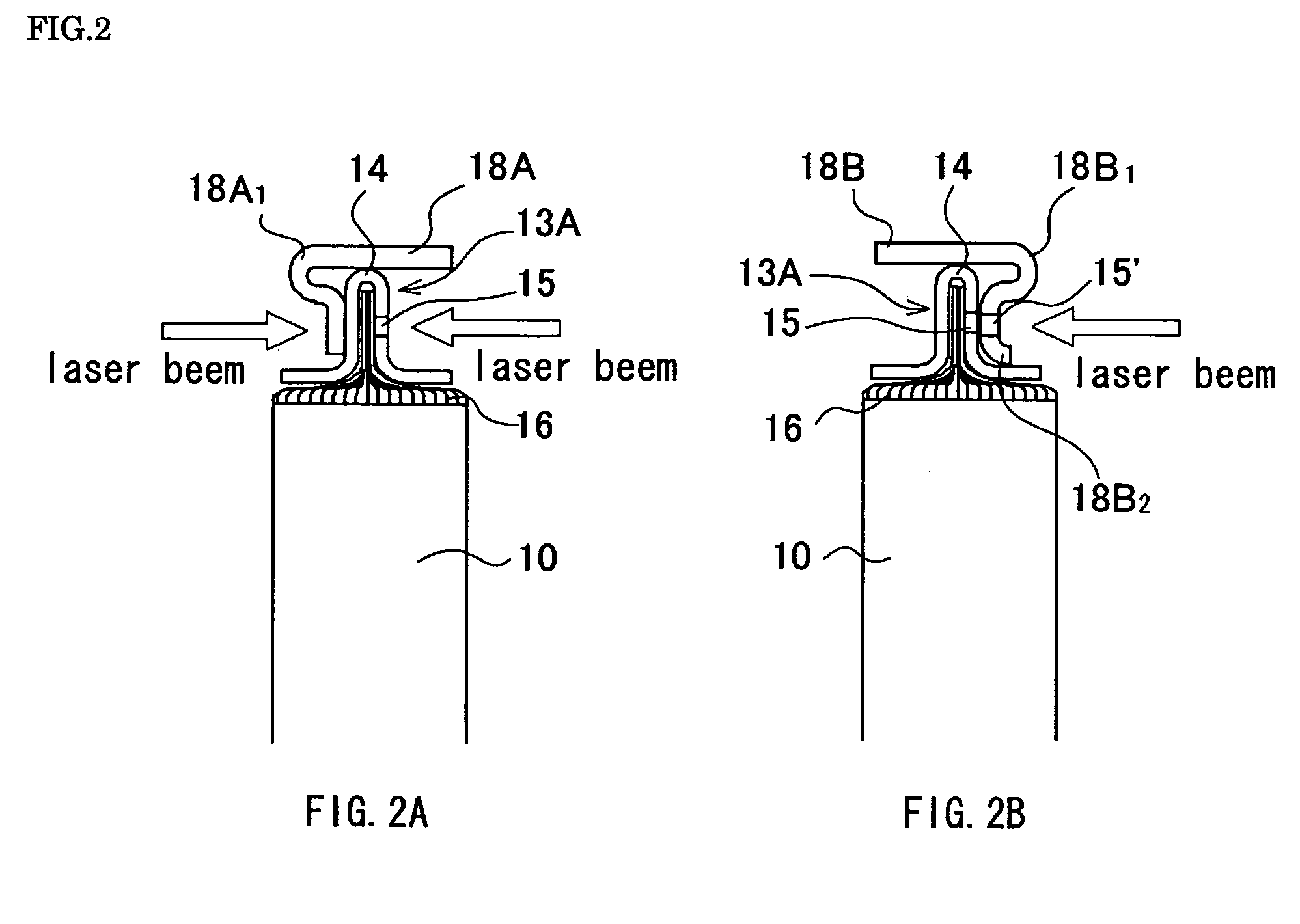

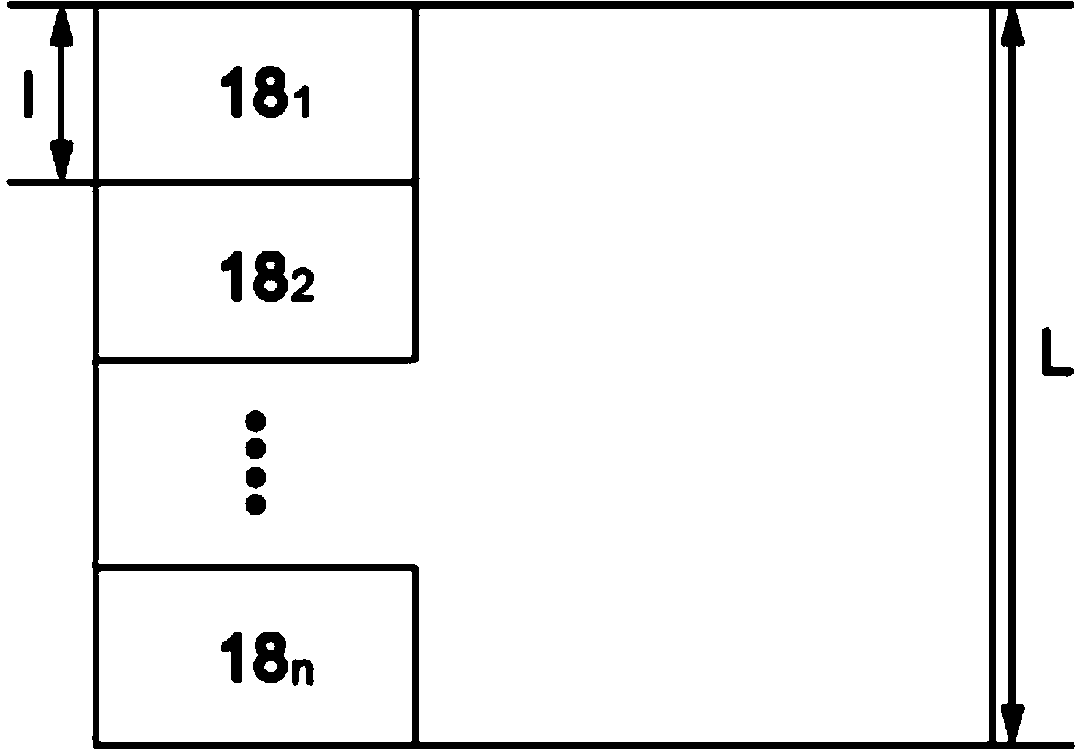

Prismatic battery

ActiveUS20070117009A1Reduce the possibilityNon-aqueous electrolyte accumulatorsCell electrodesElectric vehicleHigh energy beam

A prismatic battery according to one embodiment of the present invention includes a flat electrode group 10 stacked or rolled by mutually positive and negative electrodes with a separator therebetween, a pressing plate 13A, a current collecting body 18A or 18B and a plurality of exposed sections 16, at least one end of the positive and negative electrodes substrates in a width direction being uncoated with a positive or negative electrode mixture. The pressing plate 13A is welded to the exposed sections 16. The pressing plate 13A includes opposing surfaces with a space therebetween provided by folding back a metal plate, and includes a slit 15 along a folded back section at least to one of the opposing surface's side. The exposed sections 16 are inserted into a gap of the pressing plate 13A, and the exposed sections 16 and the pressing plate 13A are welded by a high energy beam from a transverse direction through the slit 15. This provides a prismatic battery for large current application in electric vehicles and hybrid electric vehicles.

Owner:SANYO ELECTRIC CO LTD

Method and apparatus for producing three-dimensional objects

ActiveUS20160303687A1Equally distributedAdditive manufacturing apparatusIncreasing energy efficiencyLight beamMechanical engineering

Owner:ARCAM AB

Additive manufacturing apparatus and method

ActiveUS20160136731A1Additive manufacturing apparatusDirt cleaningManufactured apparatusProcess engineering

An additive manufacturing apparatus for building objects by layerwise consolidation of material. The apparatus includes a build chamber containing a working area, a high energy beam for consolidating material deposited in the working area in layers and a flow device for generating a gas flow across at least a part of the working area from a gas inlet to a gas outlet. The gas inlet and gas outlet are arranged to be movable within the build chamber.

Owner:RENISHAW PLC

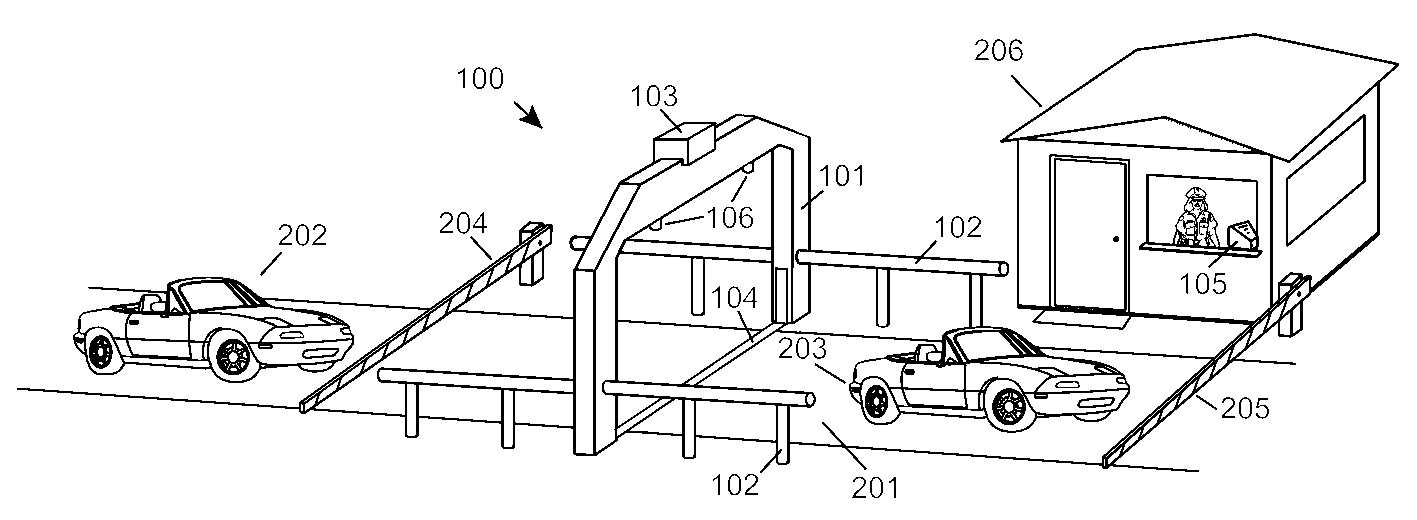

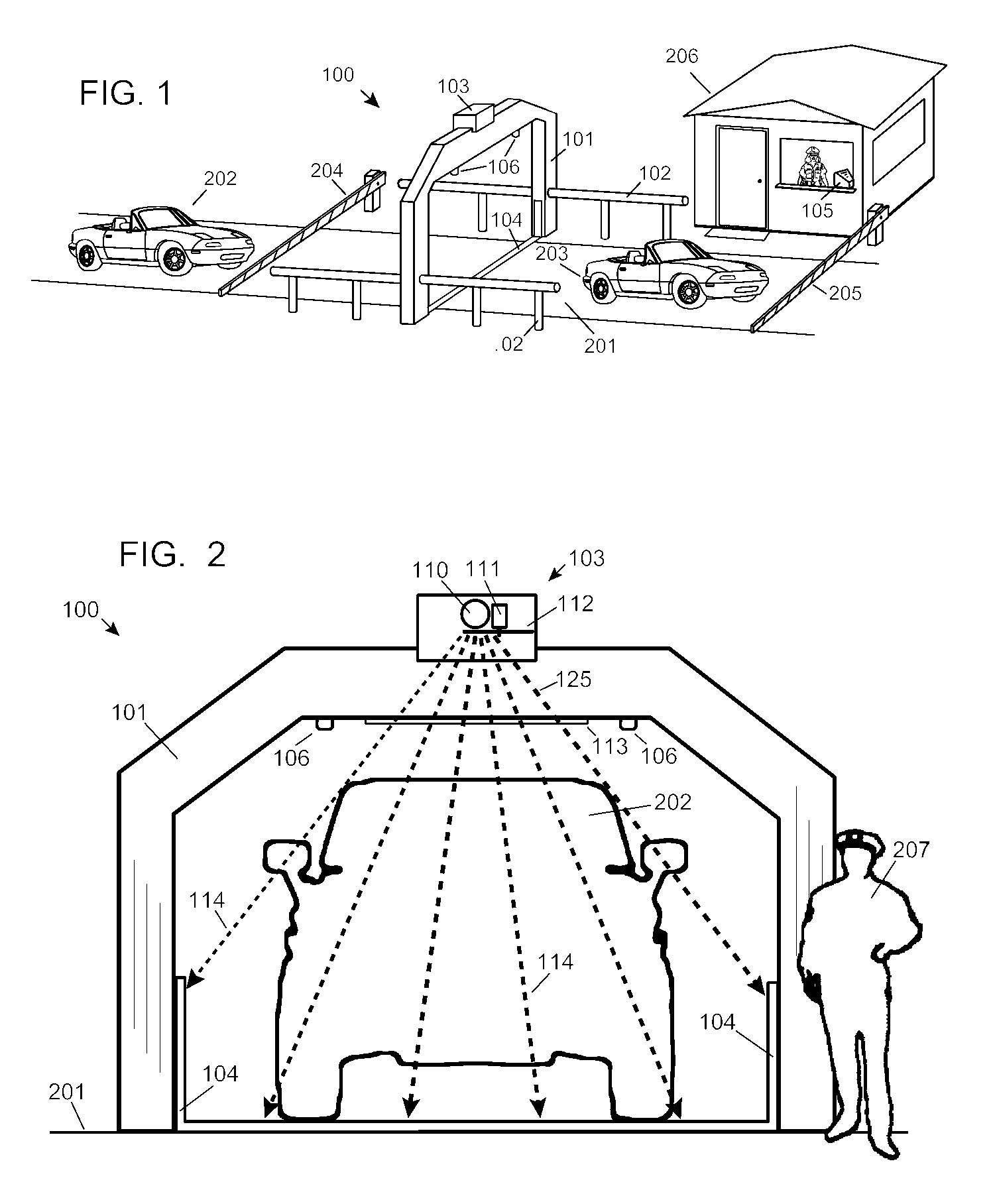

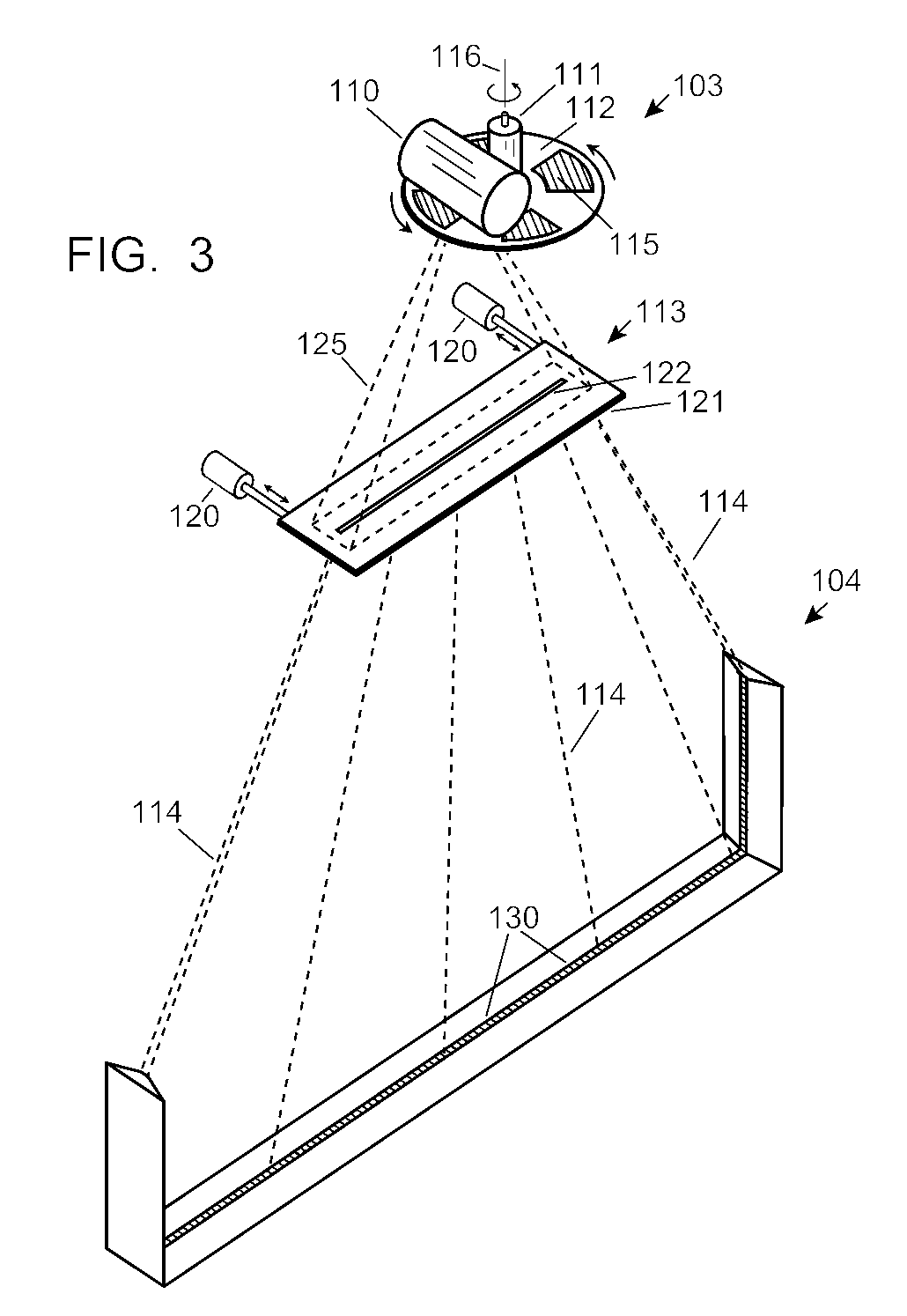

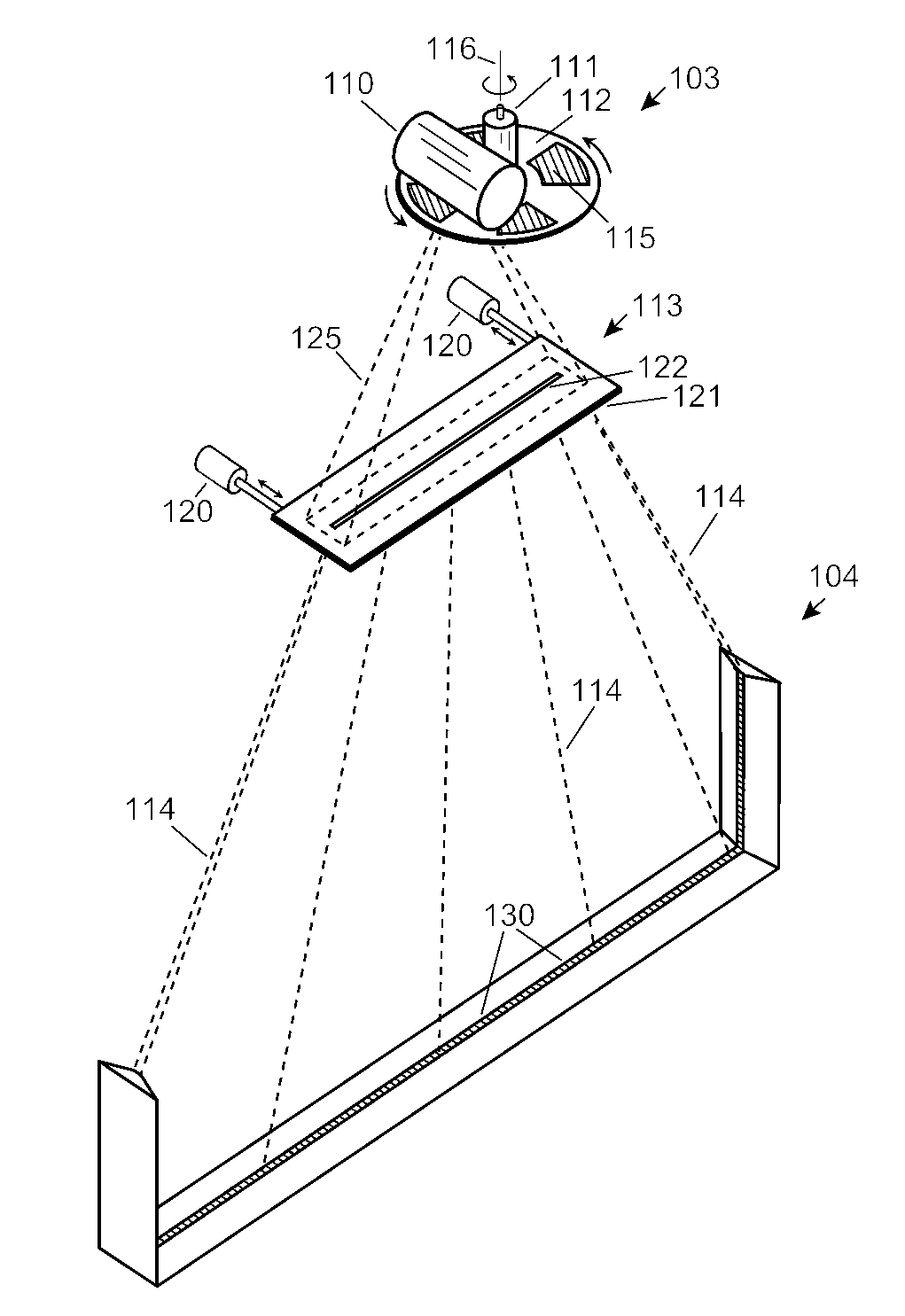

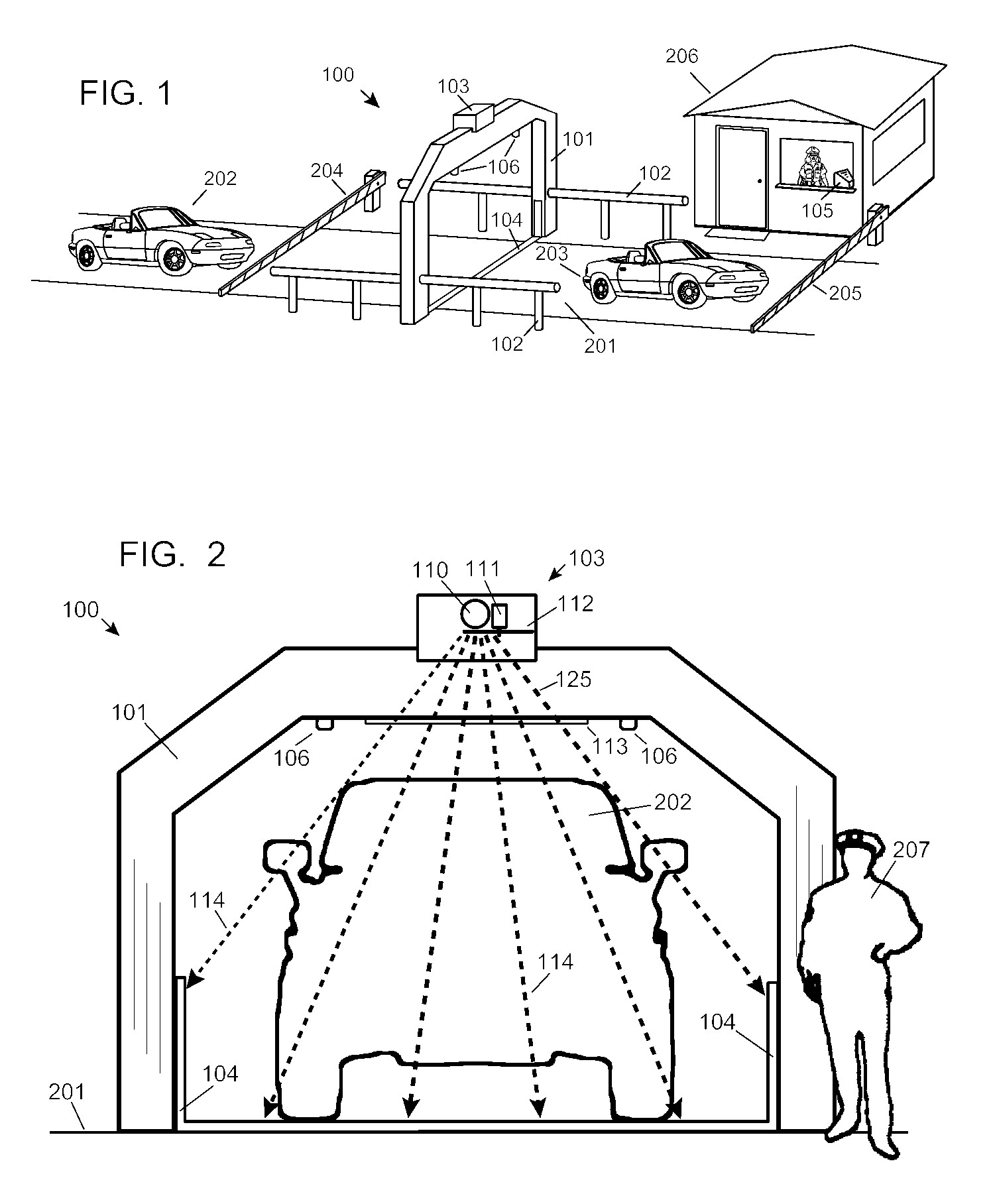

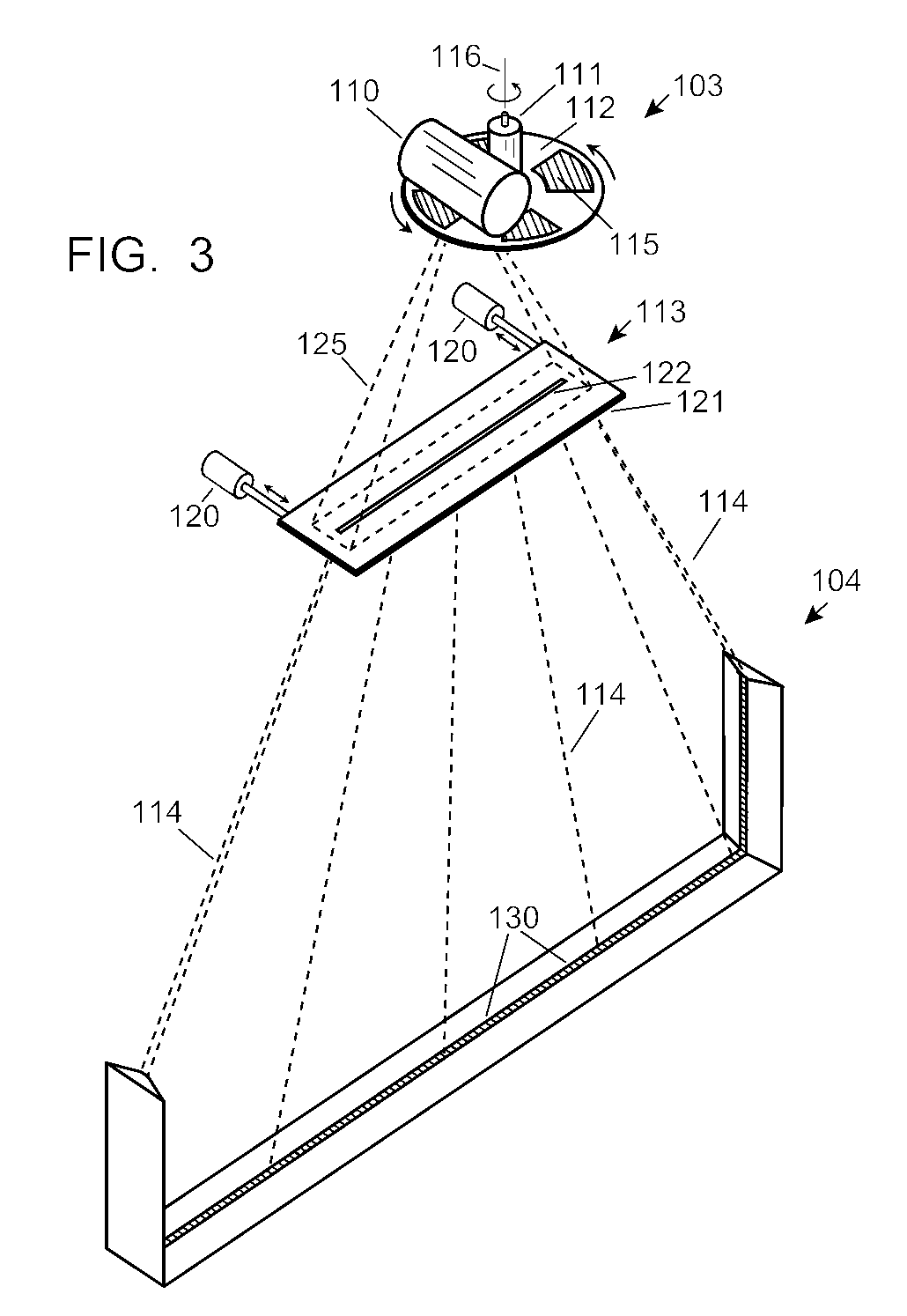

Automobile scanning system

ActiveUS7742568B2Easy to checkUniform exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

Automobile Scanning System

ActiveUS20090086907A1Easy to checkUniform radiation exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

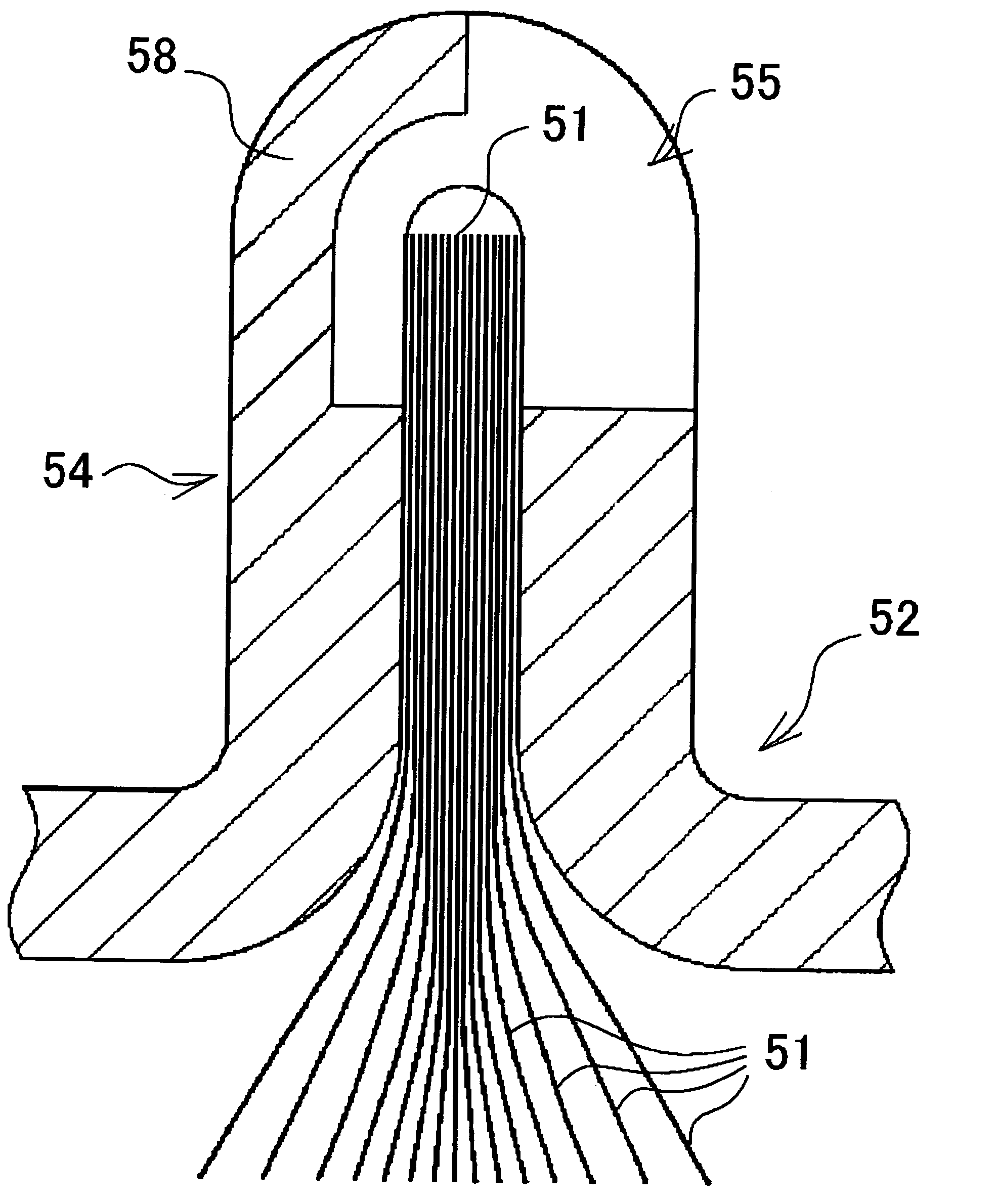

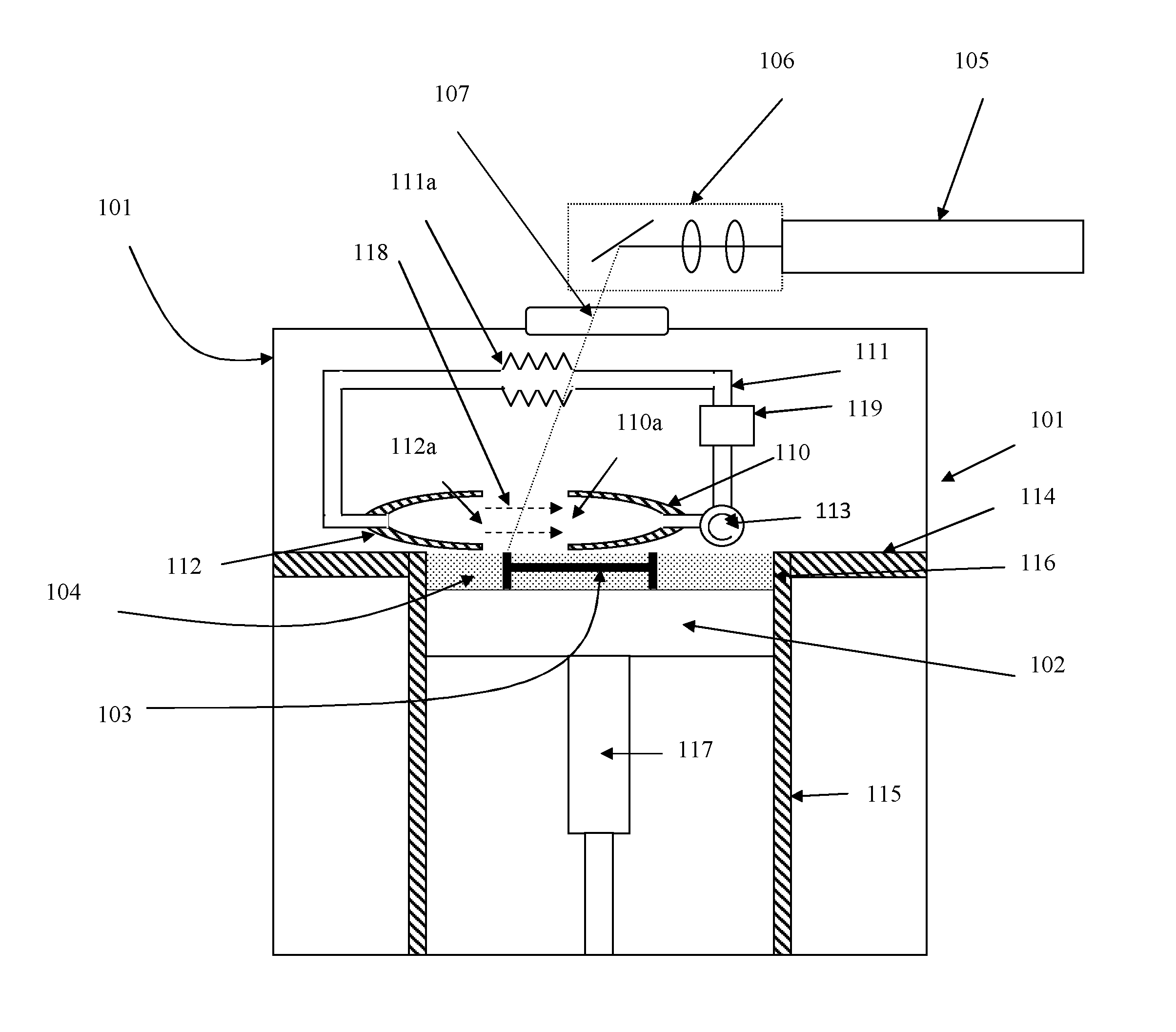

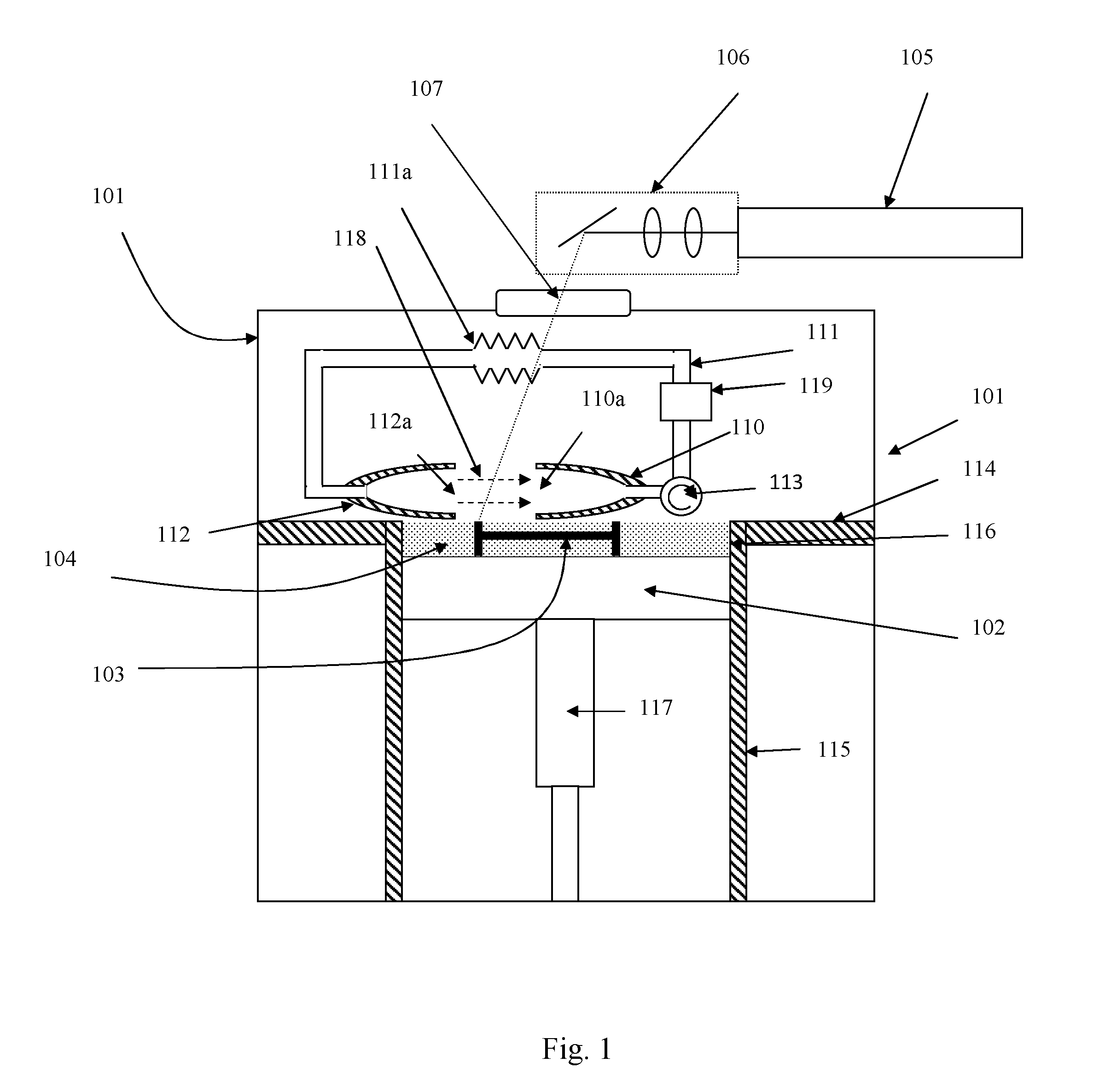

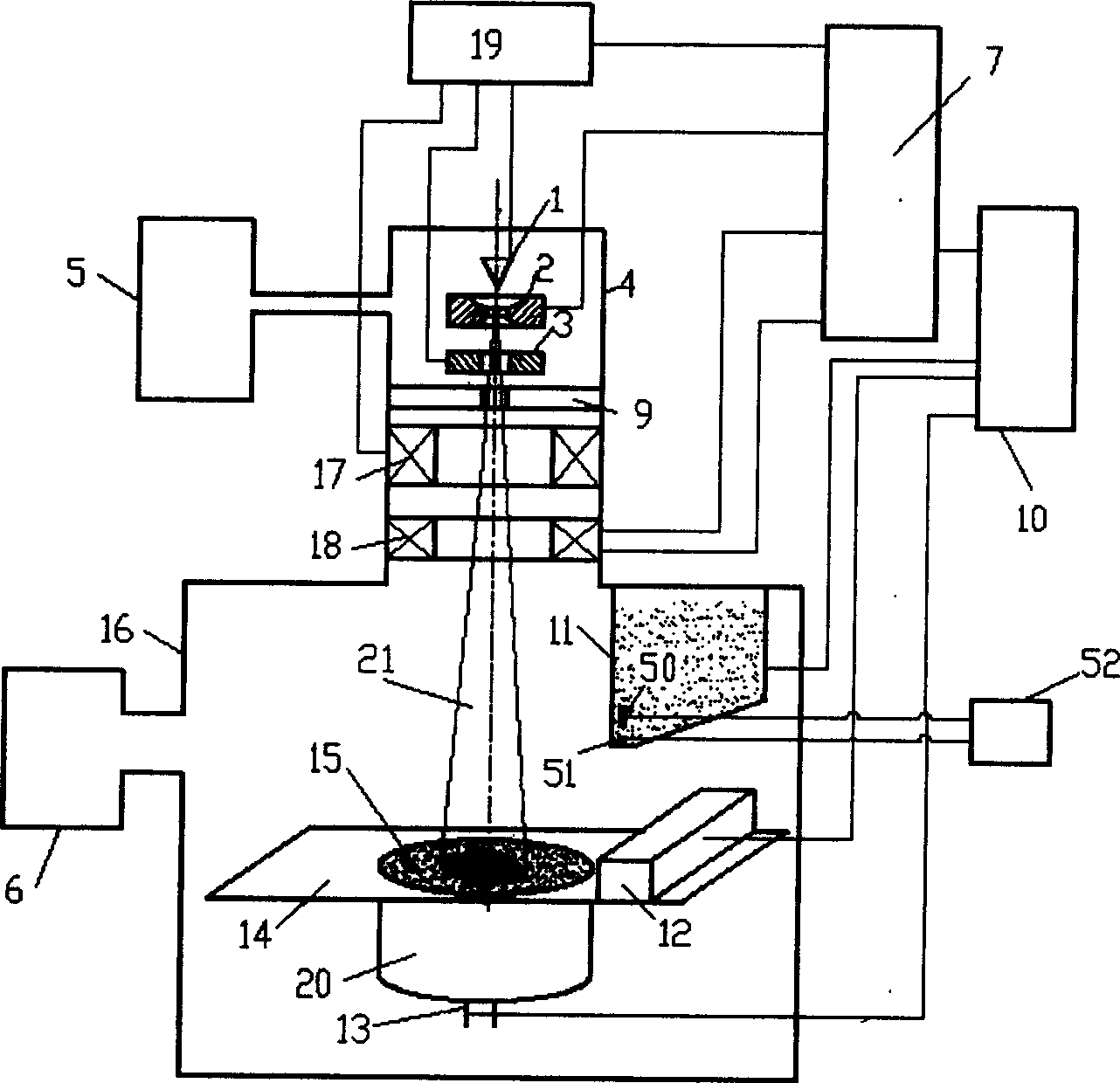

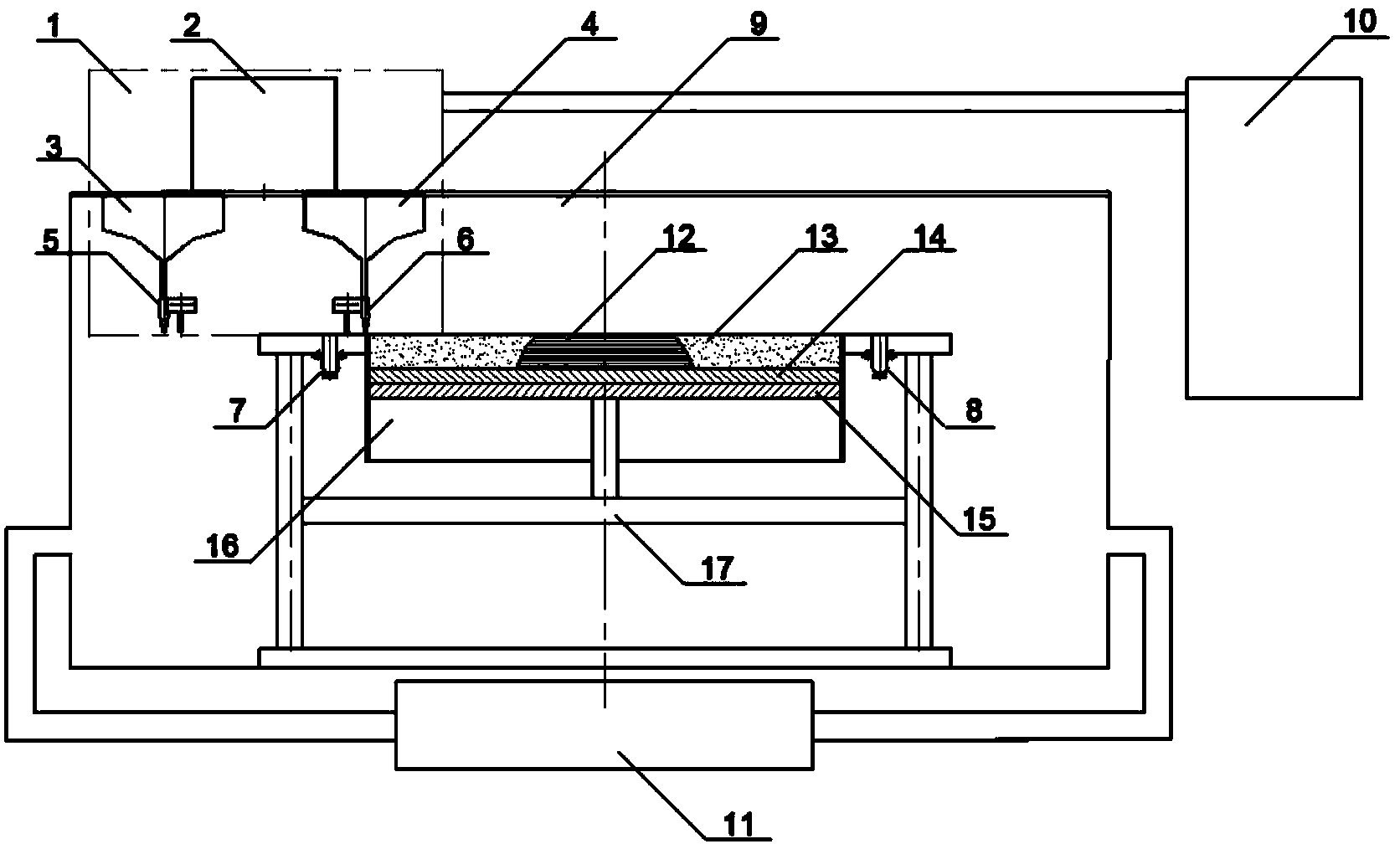

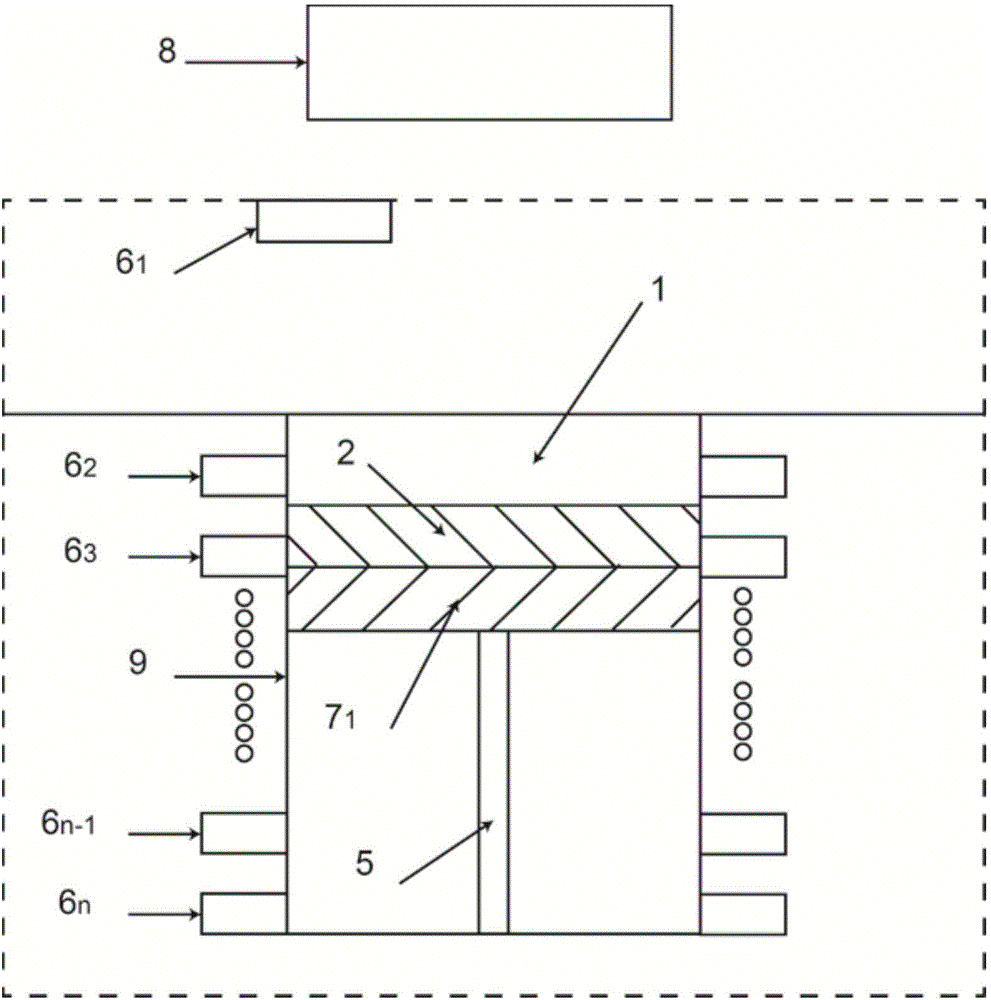

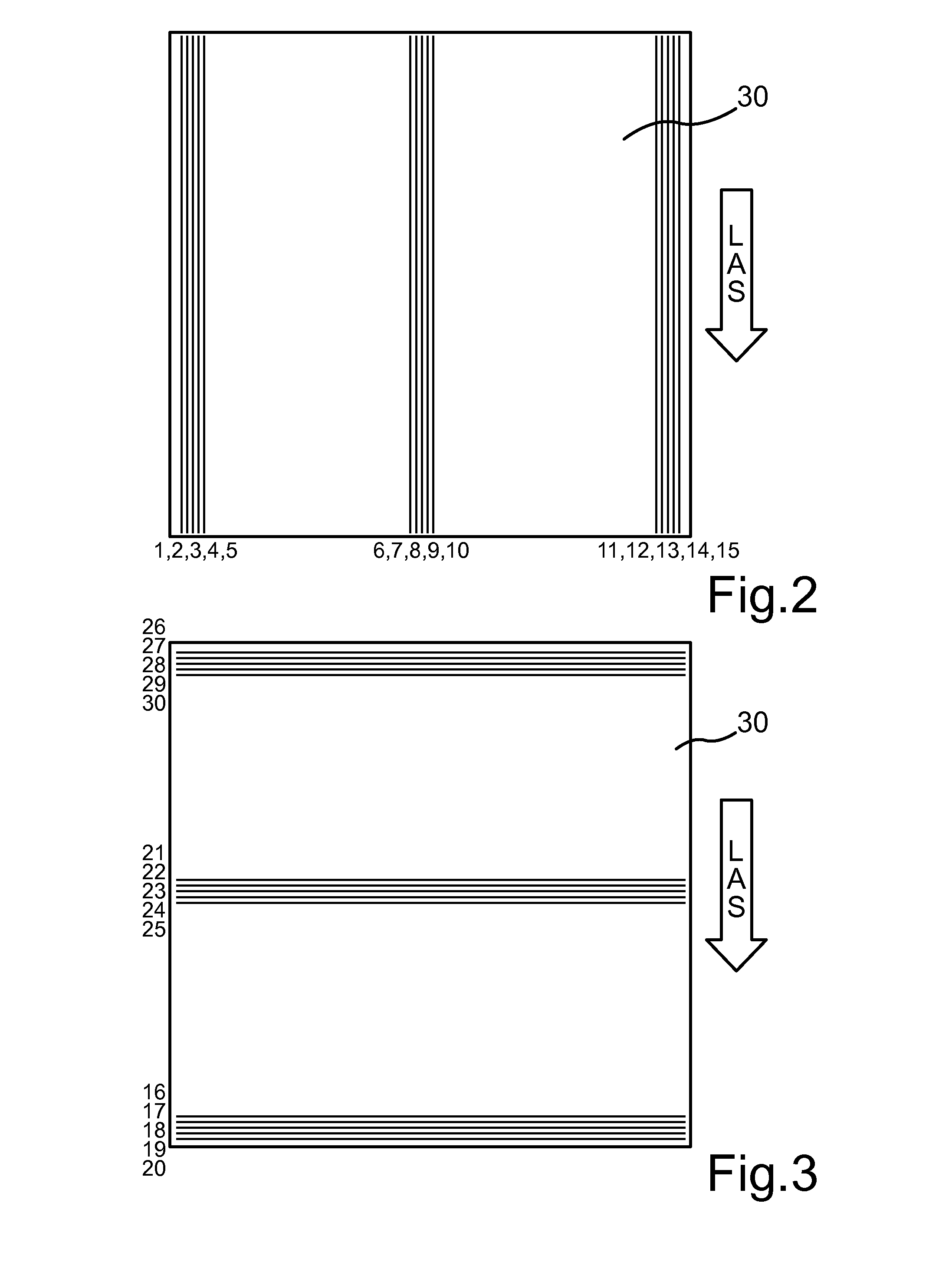

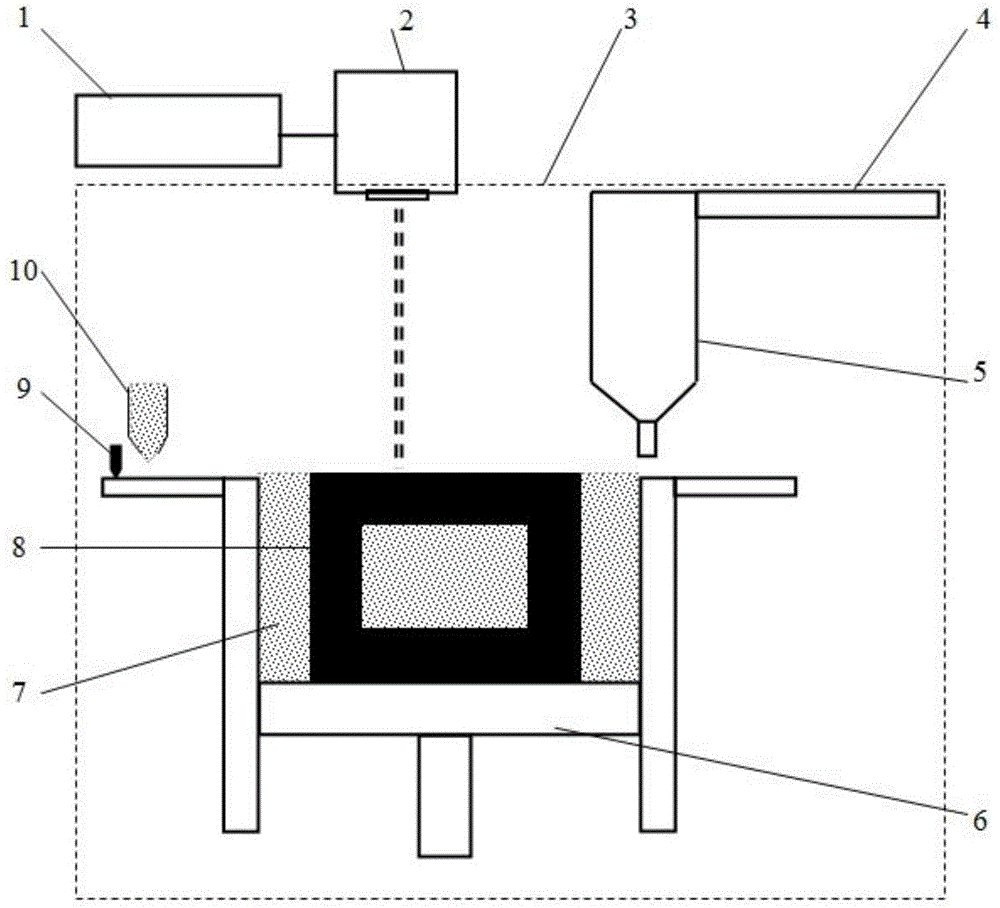

Synchronous sintering process for electronic beam selection zone and three dimension layered producing device

ActiveCN1648802AHigh speedHigh precisionComputer controlElectron beam welding apparatusRapid scanHeat stress

The present invention relates to technology and apparatus with high energy beam to sinter or melt and deposit material successively to realize laminated solid manufacture. The present invention features that the electronic beam scan controller controls the electronic beam to scan fast in pattern projection mode for heating powder homogeneously. Each scanning of the electronic beam has short time in the selected area, so that the scan initiating point has no great temperature change generated during the whole scanning course. Through one or several frames of scanning, the material in the forming area has temperature synchronously raised to reach the sintering or re-melting temperature for deposition onto the forming area before synchronous cooling. The present invention has greatly reduced heat stress and raised forming precision and quality.

Owner:TSINGHUA UNIV

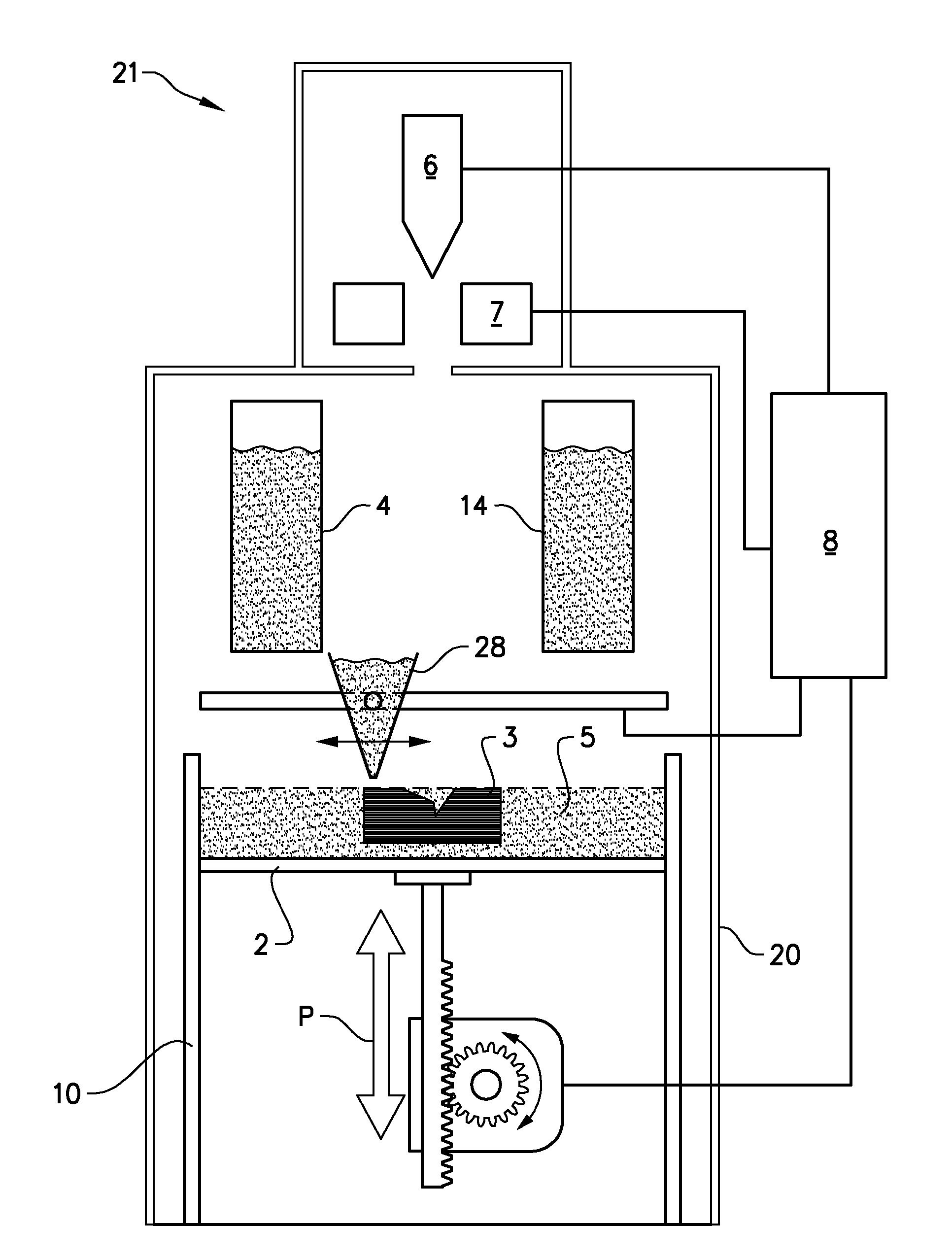

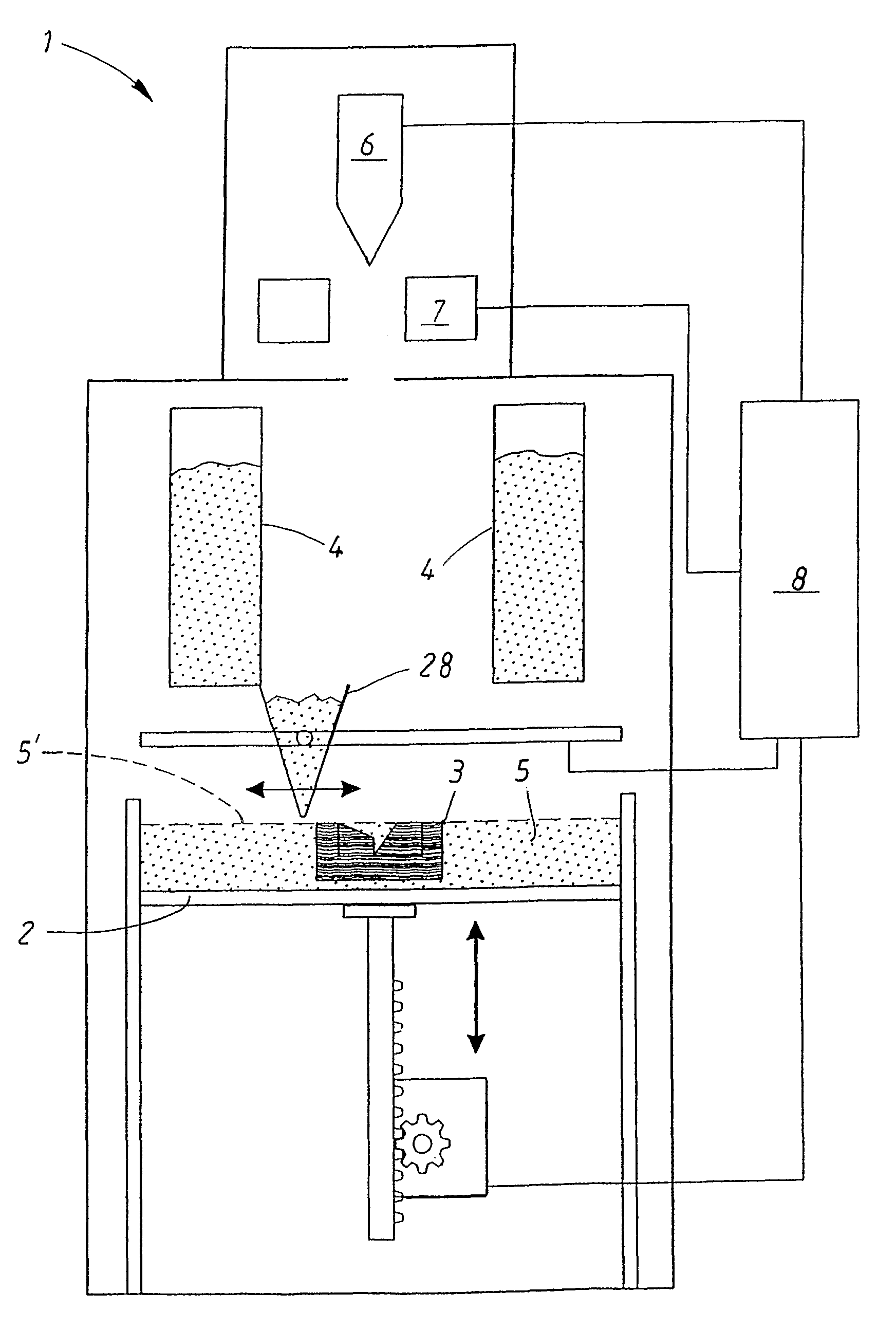

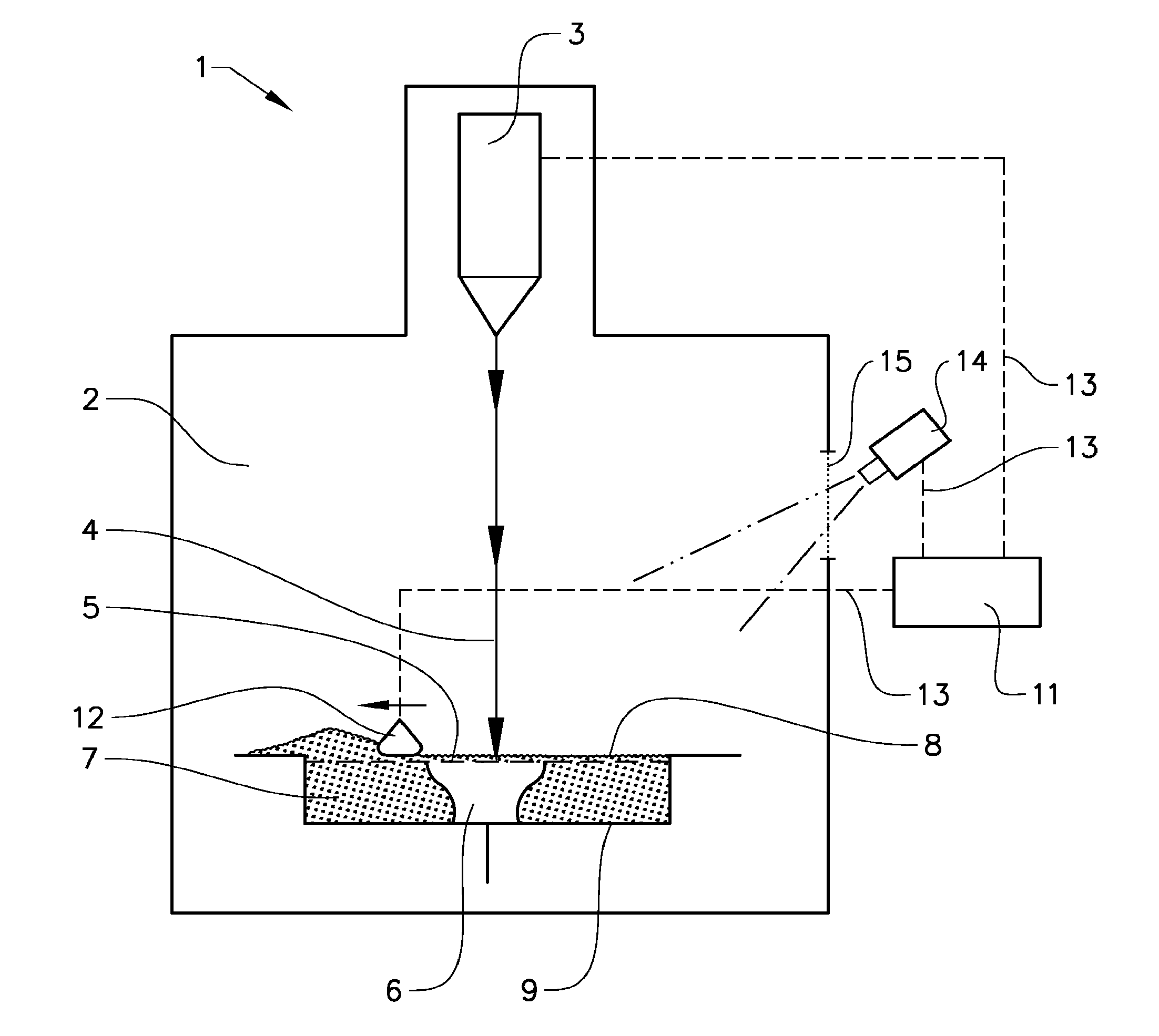

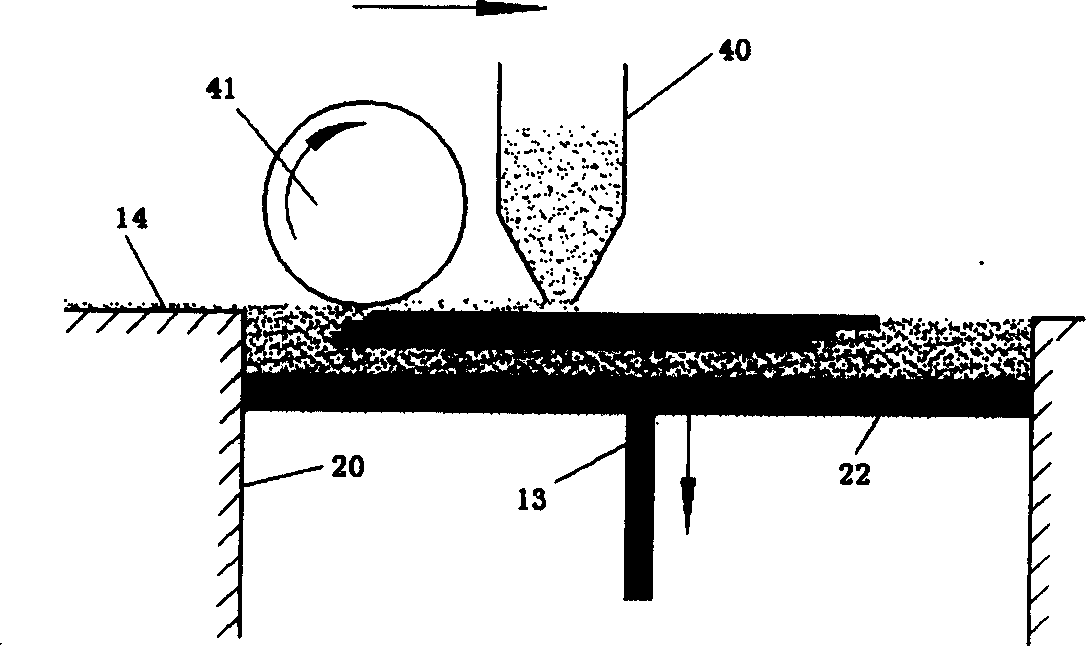

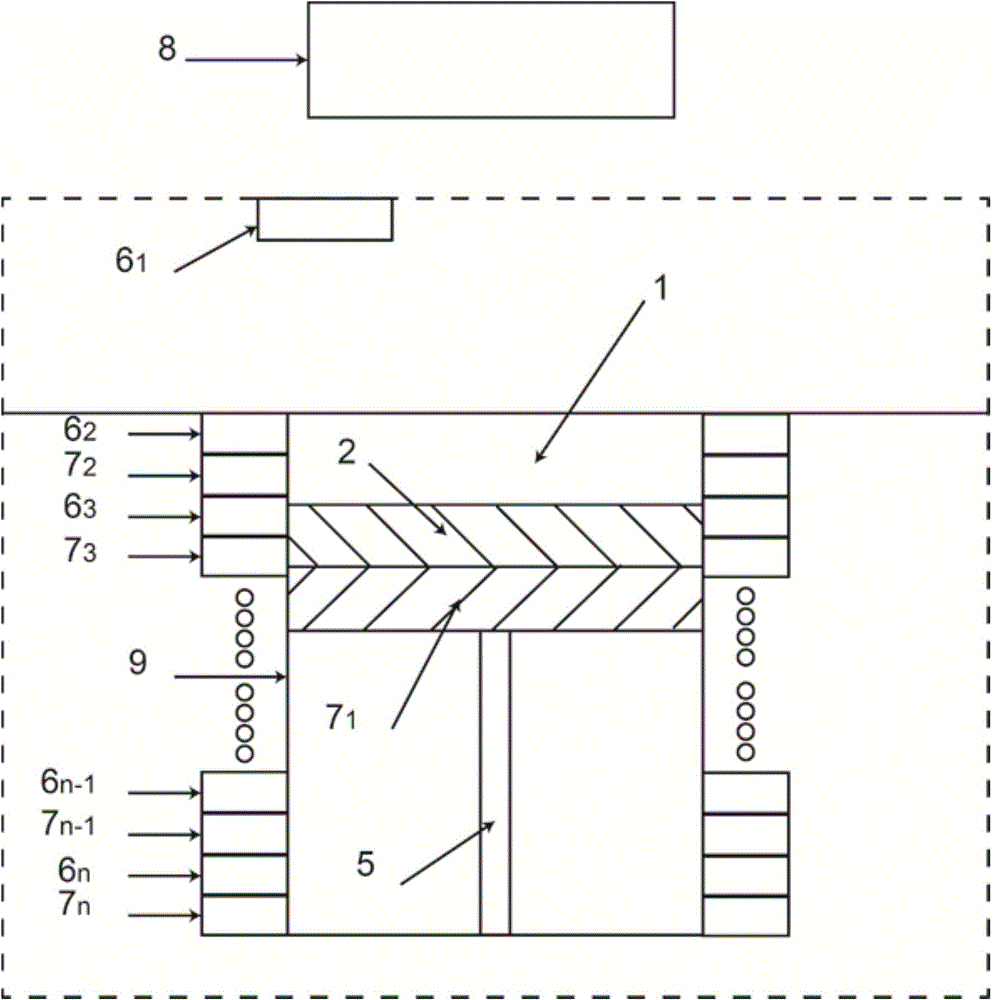

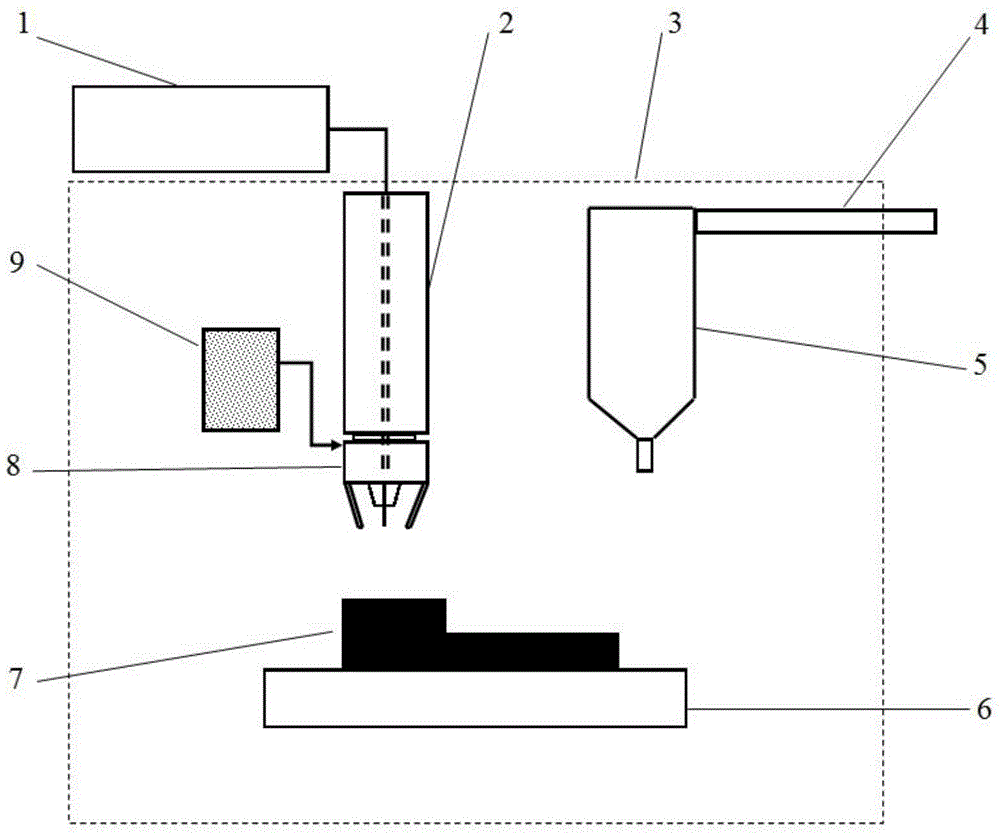

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

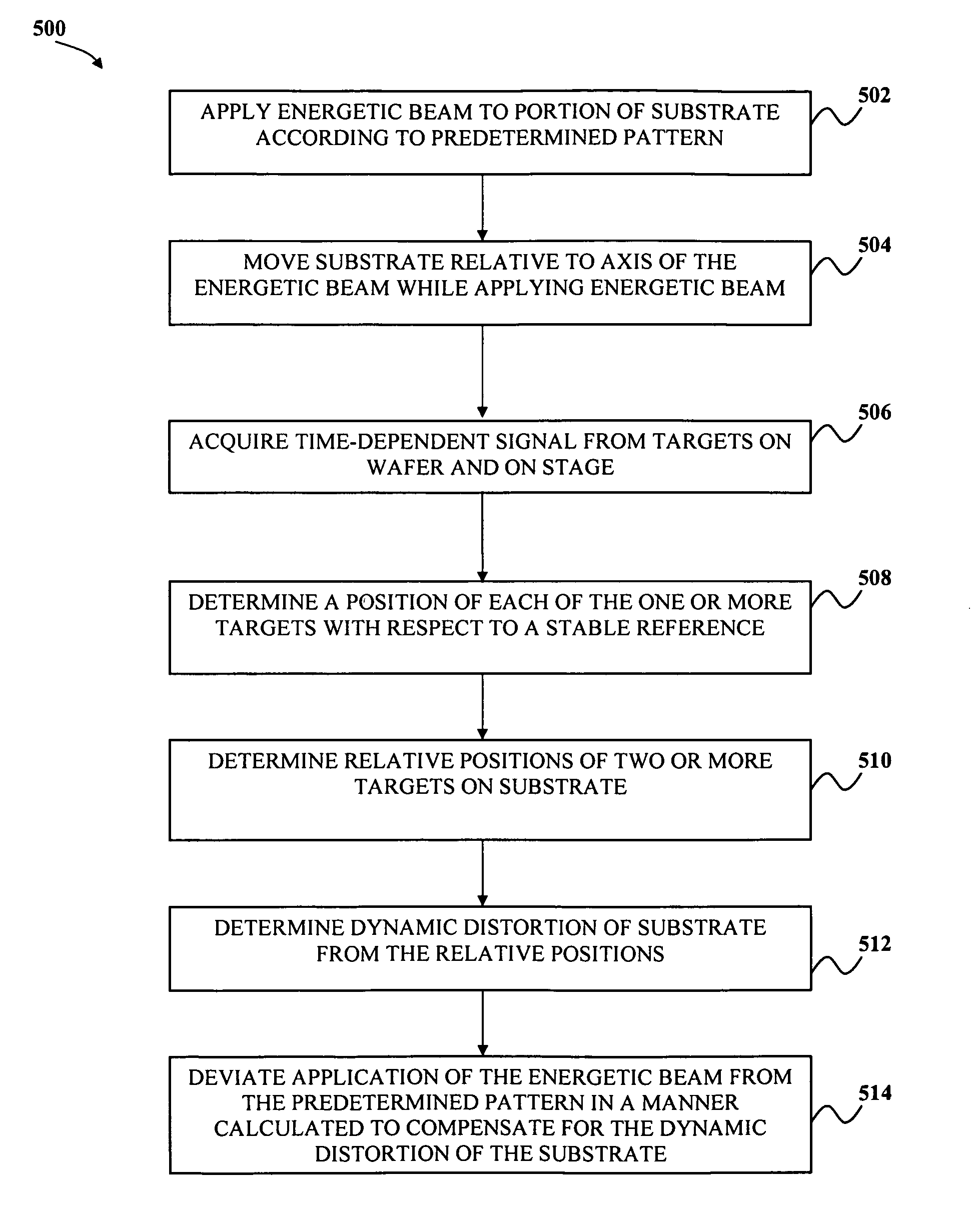

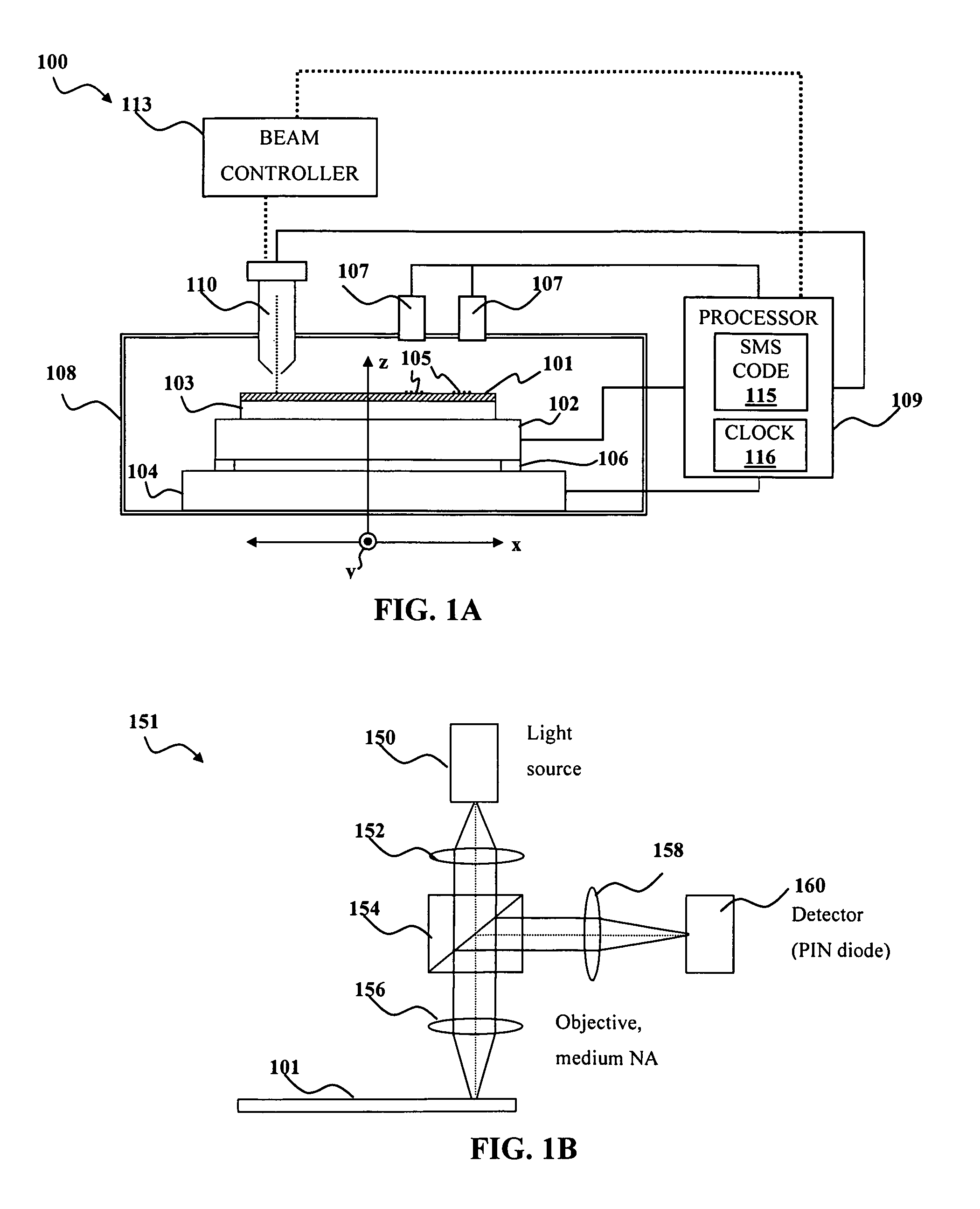

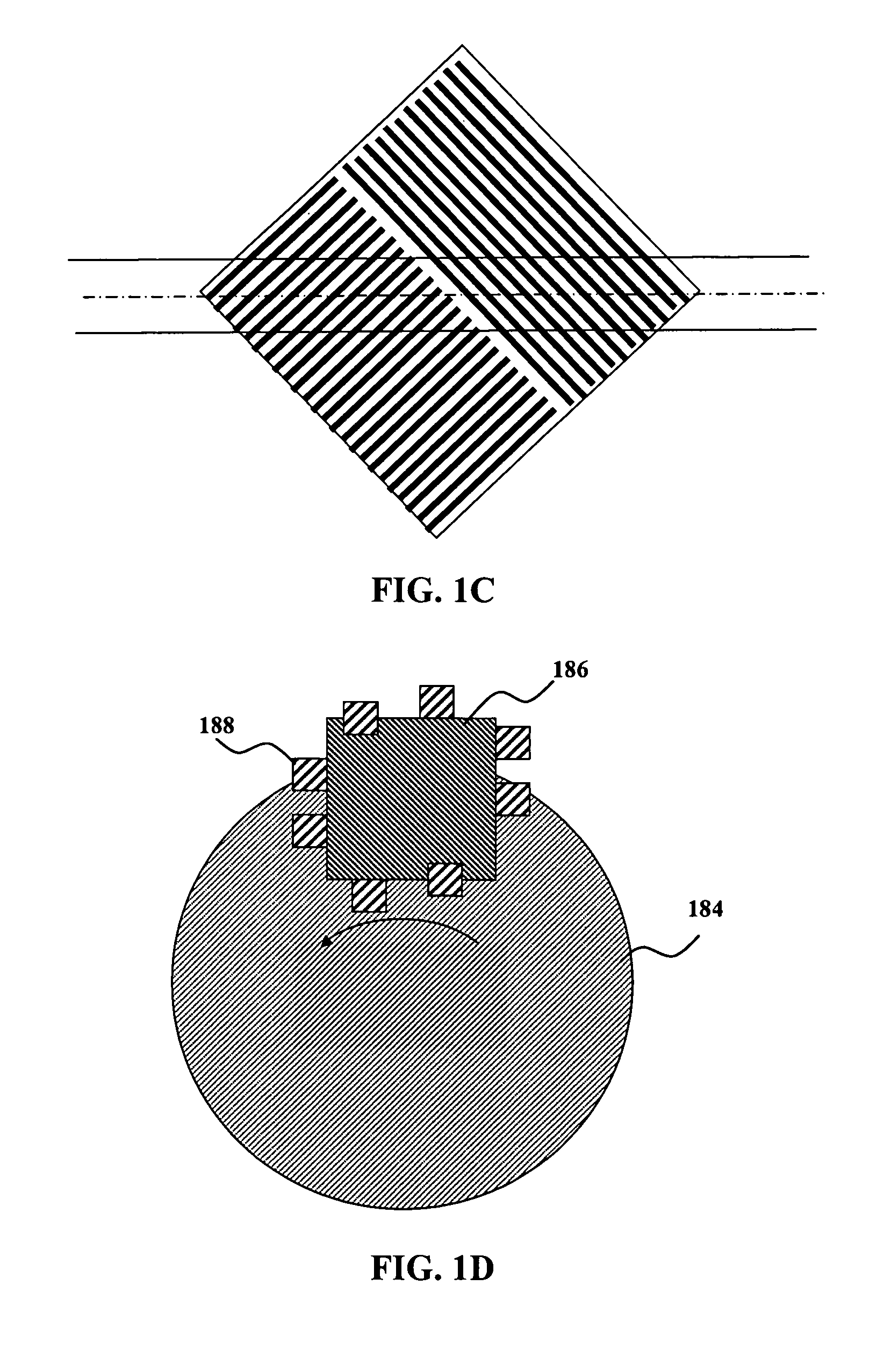

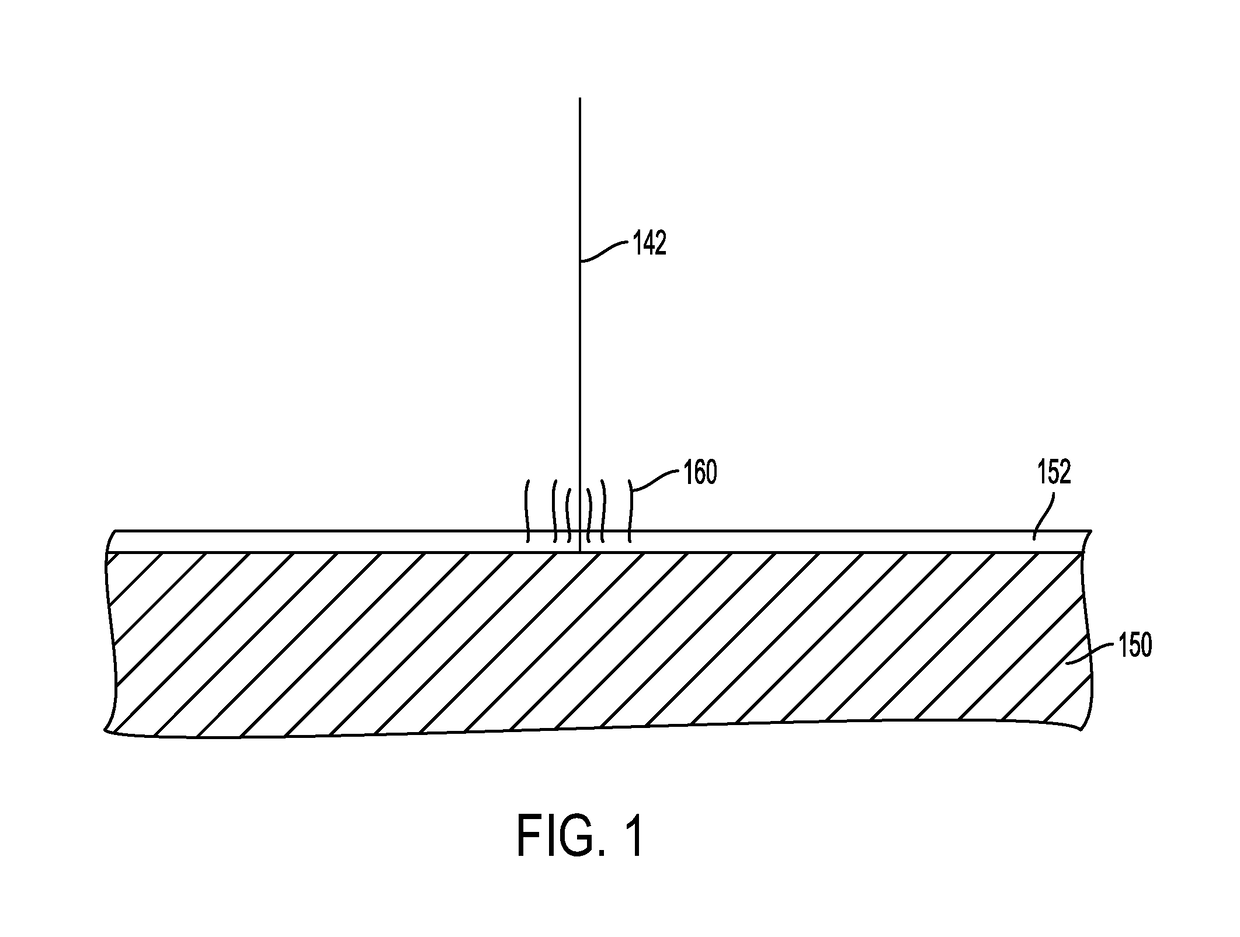

Dynamic tracking of wafer motion and distortion during lithography

ActiveUS7897942B1Smooth movementThe effect is accurateThermometer detailsBeam/ray focussing/reflecting arrangementsLithographic artistLight beam

A substrate processing apparatus and method for dynamic tracking of wafer motion and distortion during lithography are disclosed. An energetic beam may be applied to a portion of a substrate according to a predetermined pattern. The relative positions of one or more targets on the substrate may be determined while applying the energetic beam to the portion of the substrate. A dynamic distortion of the substrate may be determined from the relative positions while applying the energetic beam to the portion of the substrate. Application of the energetic beam may be deviated from the predetermined pattern in a manner calculated to compensate for the dynamic distortion of the substrate.

Owner:KLA CORP

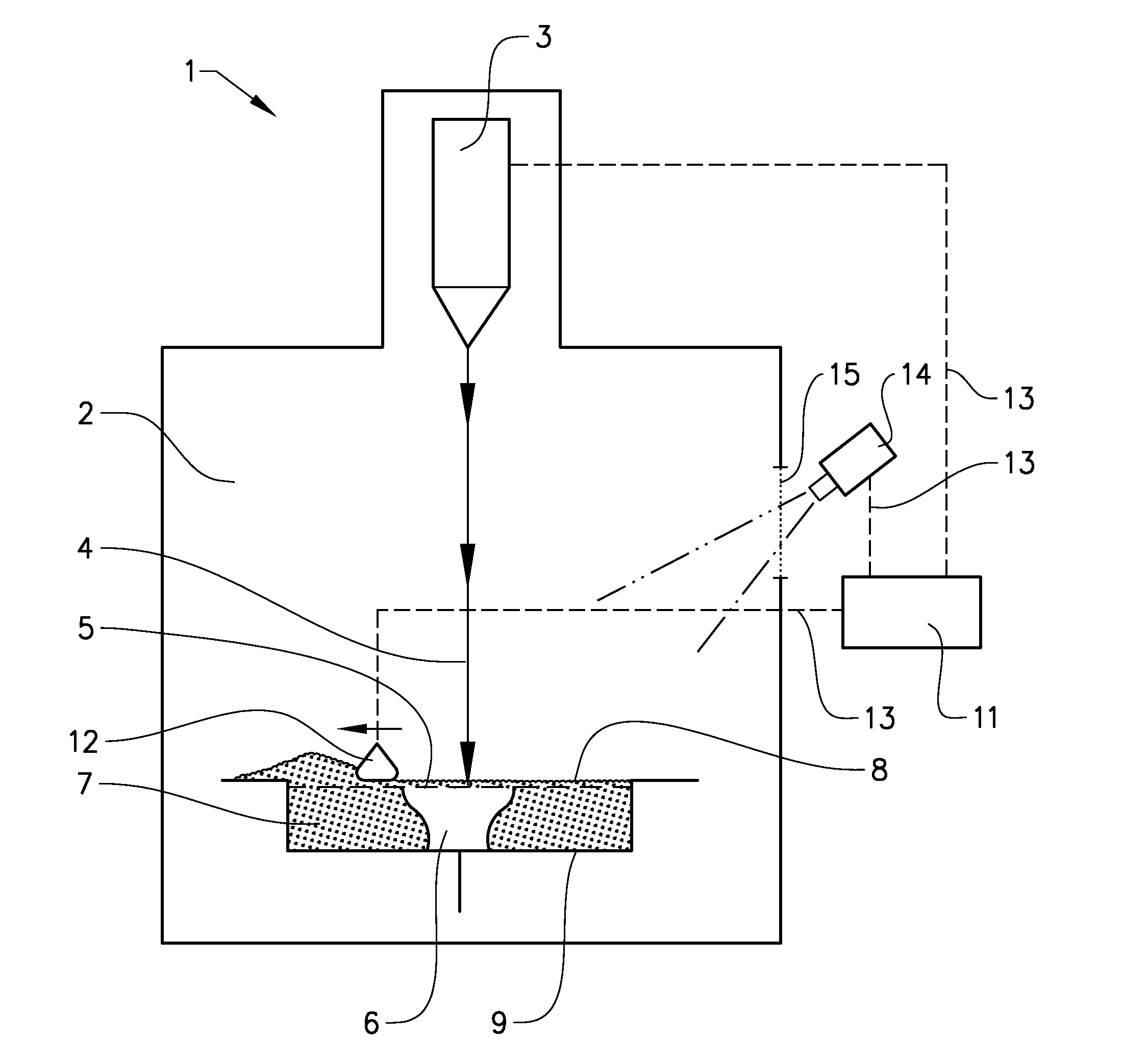

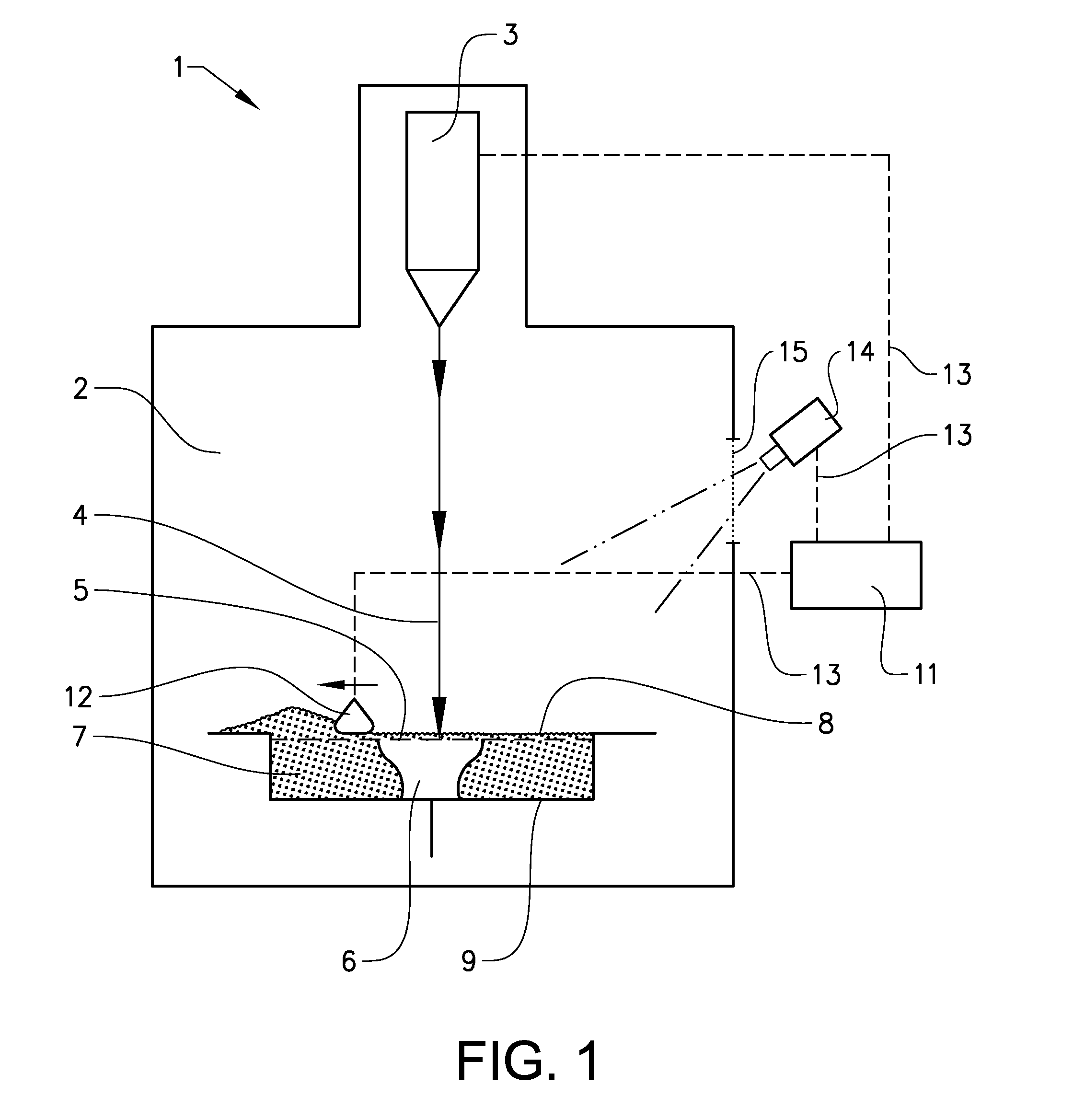

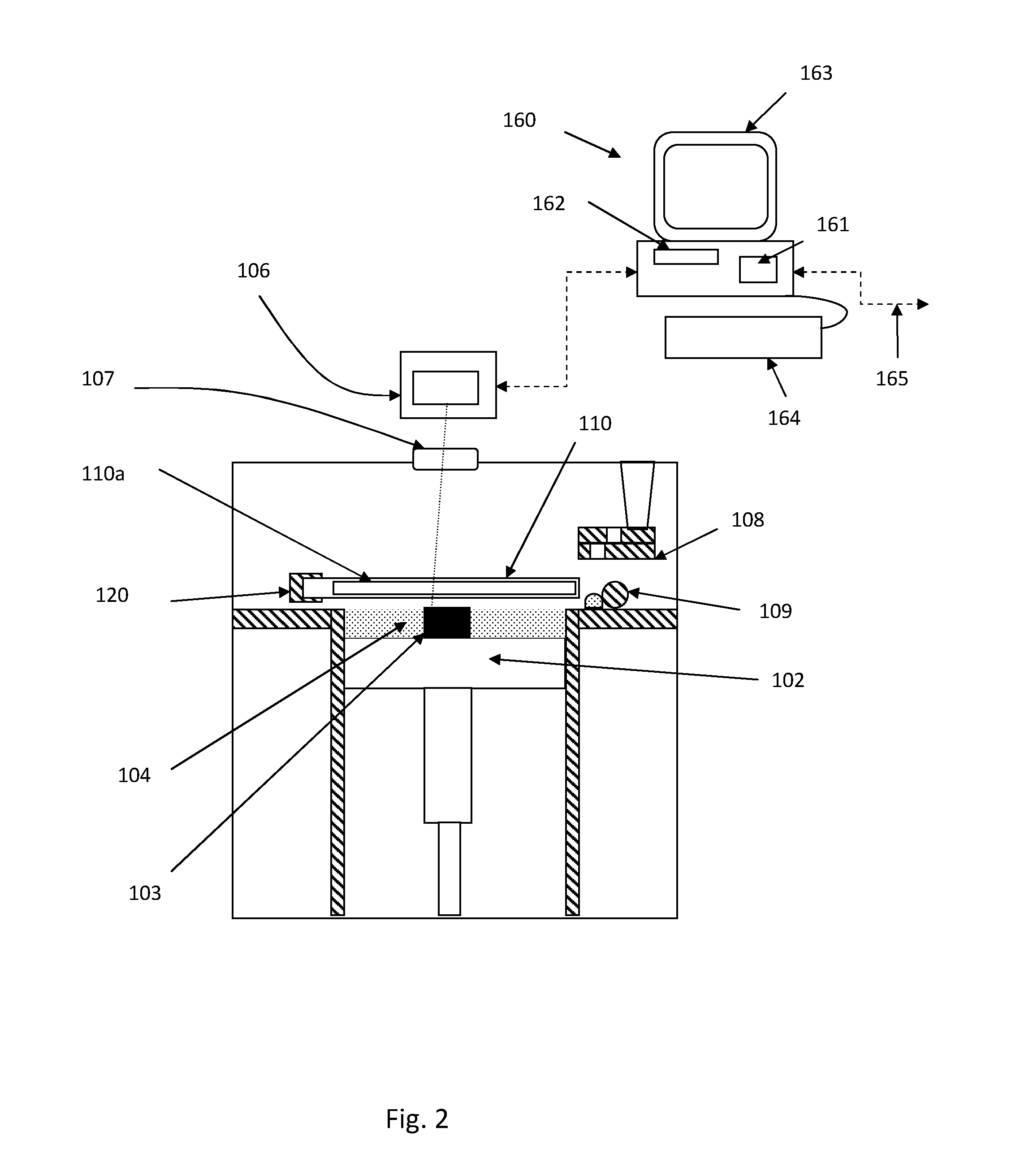

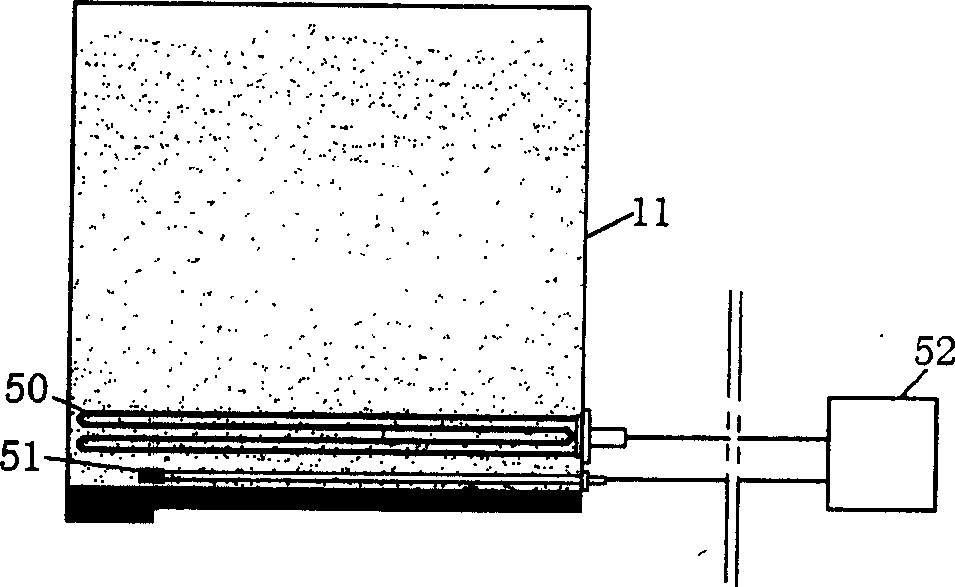

High energy beam area-selecting fusing method and device capable of controlling temperature gradient in shaping area

ActiveCN104959604AEnsure directional solidification conditionsReal-time monitoring of temperature gradientsAdditive manufacturing apparatusTemperature controlHeat flow

The invention discloses a high energy beam area-selecting fusing method and device capable of controlling temperature gradient in a shaping area, and a temperature measurement module and a temperature control module are added to a shaping assembly of the device. When the device is used for manufacturing high-energy beam additive, the temperature gradient interval in a molten pool can be calculated in real time utilizing the boundary temperature, acquired by the temperature measurement module, of a shaping area, proper hot-fluid conditions can be applied to the shaping area through the temperature control module to control temperature gradient intervals of the molten pool and the shaping area, so the molten pool can always satisfy conditions of directional solidification, high precision and performance directional solidified metal members and monocrystalline metal members having different sizes and structures can be efficiently manufactured. By adopting the high energy beam area-selecting fusing method and device capable of controlling the temperature gradient in a shaping area, not only the temperature gradient of the shaping area can always satisfy directional solidification conditions, but also the temperature gradient distribution in stages of a shaping process can be flexibly changed according to actual process needs, so various of functional / structural gradient members can be manufactured.

Owner:HUAZHONG UNIV OF SCI & TECH

Apparatus, method, and computer program product for fusing a workpiece

ActiveUS20170189964A1Increase powerSolve the slow scanning speedAdditive manufacturing apparatusAuxillary shaping apparatusEngineeringAstigmatism

Various embodiments of the present invention relate to a method for welding a workpiece comprising the steps of: making a first weld at a first position on said workpiece with a high energy beam, deflecting the high energy beam with at least one deflection lens for making a second weld at a second position on said workpiece, focusing the high energy beam on said workpiece with at least one focusing lens, shaping the high energy beam on said workpiece with at least one astigmatism lens so that the shape of the high energy beam on said workpiece is longer in a direction parallel to a deflection direction of said high energy beam than in a direction perpendicular to said deflection direction of said high energy beam. The invention is also related to the use of an astigmatism lens and to a method for forming a three dimensional article.

Owner:ARCAM AB

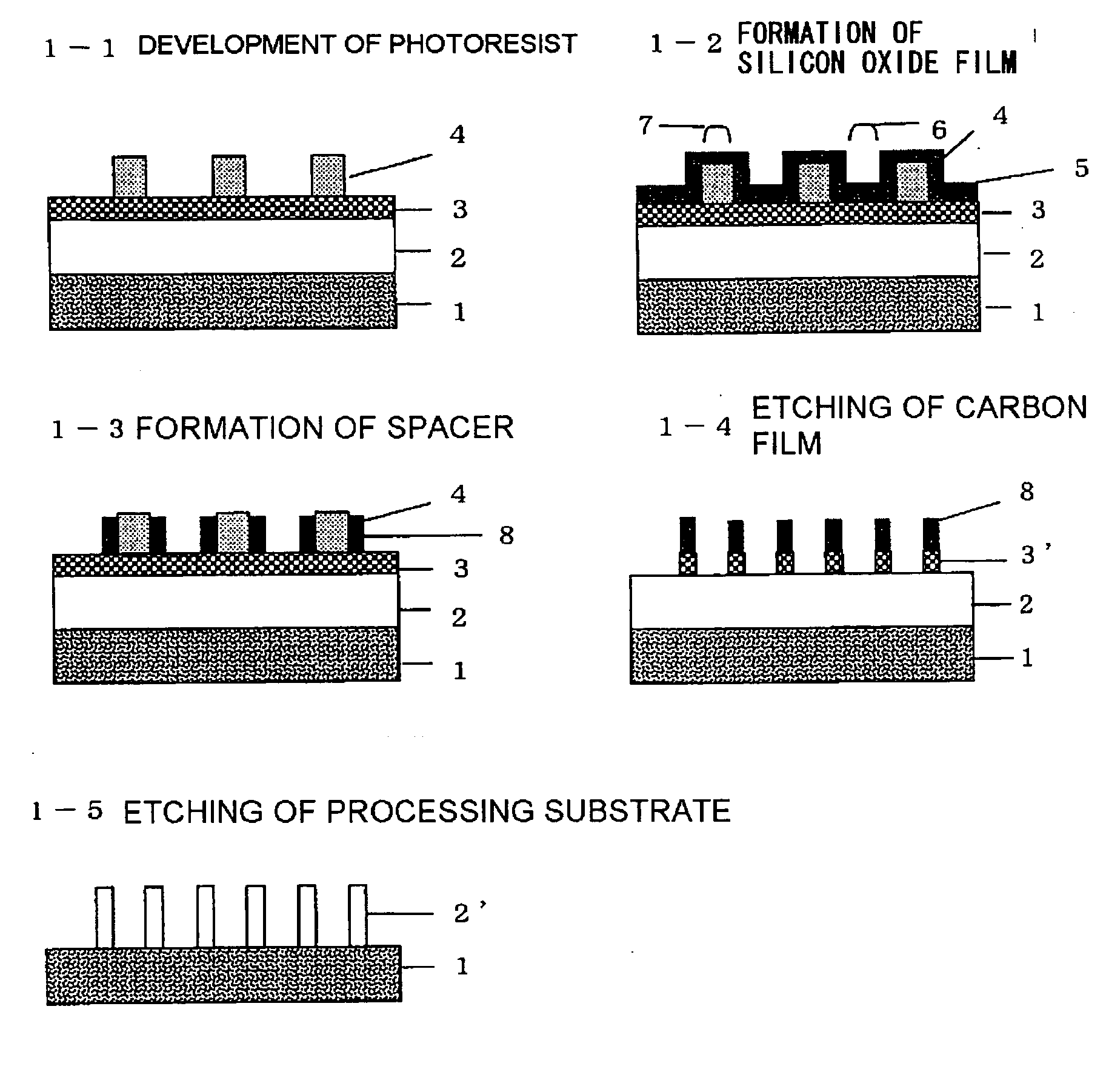

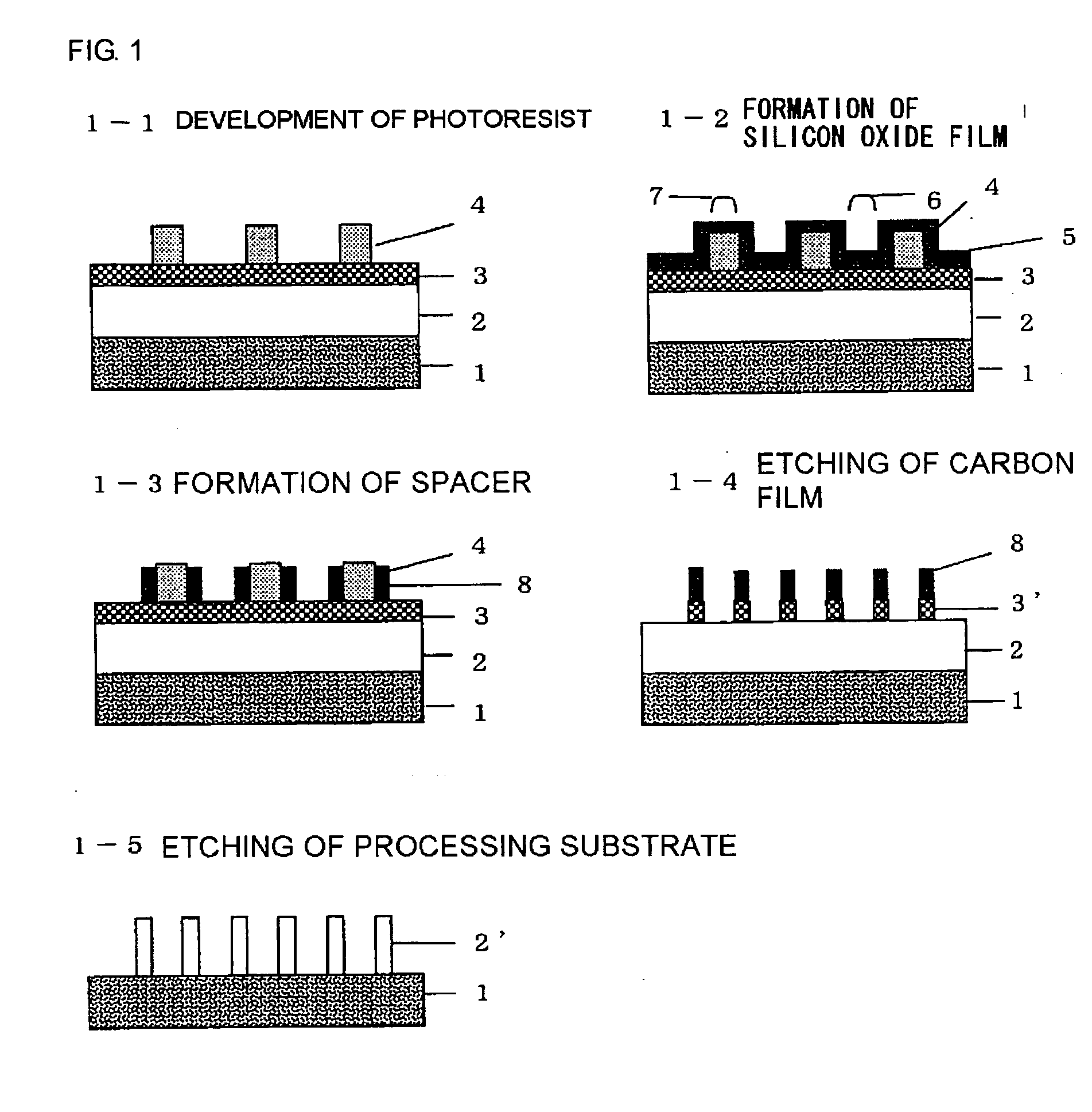

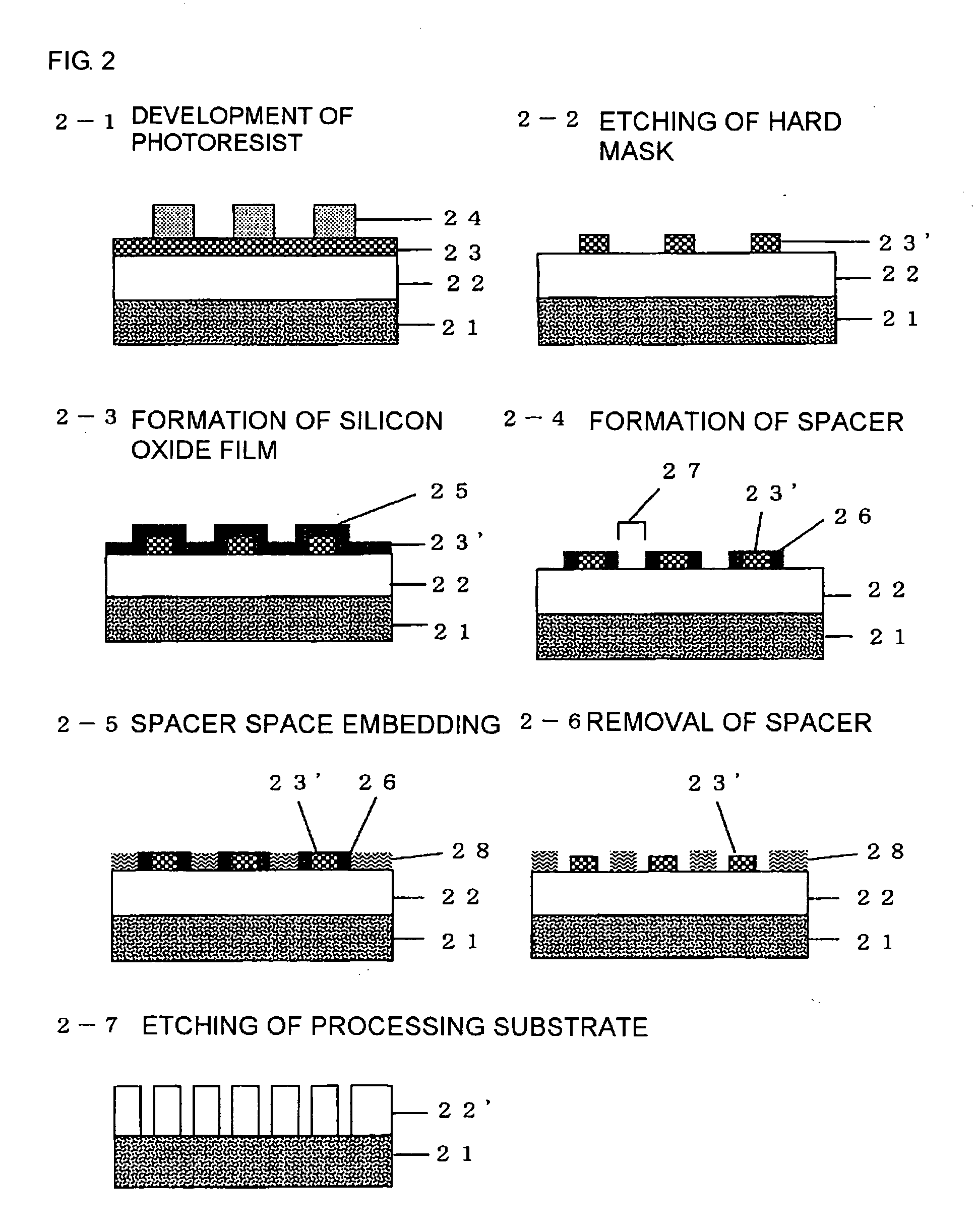

Patterning process

ActiveUS20100055621A1Deterioration of profile be avoidedInhibit deteriorationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusResistYoung's modulus

There is disclosed a patterning process including steps of at least: forming a photoresist film on a substrate; exposing the photoresist film to a high energy beam; developing by using a developer; forming a photoresist pattern; and then forming a spacer on the photoresist pattern sidewall, thereby forming a pattern on the substrate, a patterning process, wherein at least the photoresist pattern having the hardness of 0.4 GPa or more or the Young's modulus of 9.2 GPa or more as a film strength is formed, and a pattern is formed on the substrate by forming a silicon oxide film as the spacer on the photoresist pattern sidewall. There can be provided a patterning process without causing a deformation of a resist pattern and an increase in LWR at the time of forming a silicon oxide film on a photoresist pattern.

Owner:SHIN ETSU CHEM IND CO LTD

Method for additive manufacturing

ActiveUS20170341141A1Affect propertyEasily ionizedAdditive manufacturing apparatusSolid state diffusion coatingHydrogenChemical reaction

A method for forming a three-dimensional article through successive fusion of parts of a metal powder bed is provided, comprising the steps of: distributing a first metal powder layer on a work table inside a build chamber, directing at least one high energy beam from at least one high energy beam source over the work table causing the first metal powder layer to fuse in selected locations, distributing a second metal powder layer on the work table, directing at least one high energy beam over the work table causing the second metal powder layer to fuse in selected locations, introducing a first supplementary gas into the build chamber, which first supplementary gas comprising hydrogen, is capable of reacting chemically with or being absorbed by a finished three-dimensional article, and releasing a predefined concentration of the gas which had reacted chemically with or being absorbed by the finished three dimensional article.

Owner:ARCAM AB

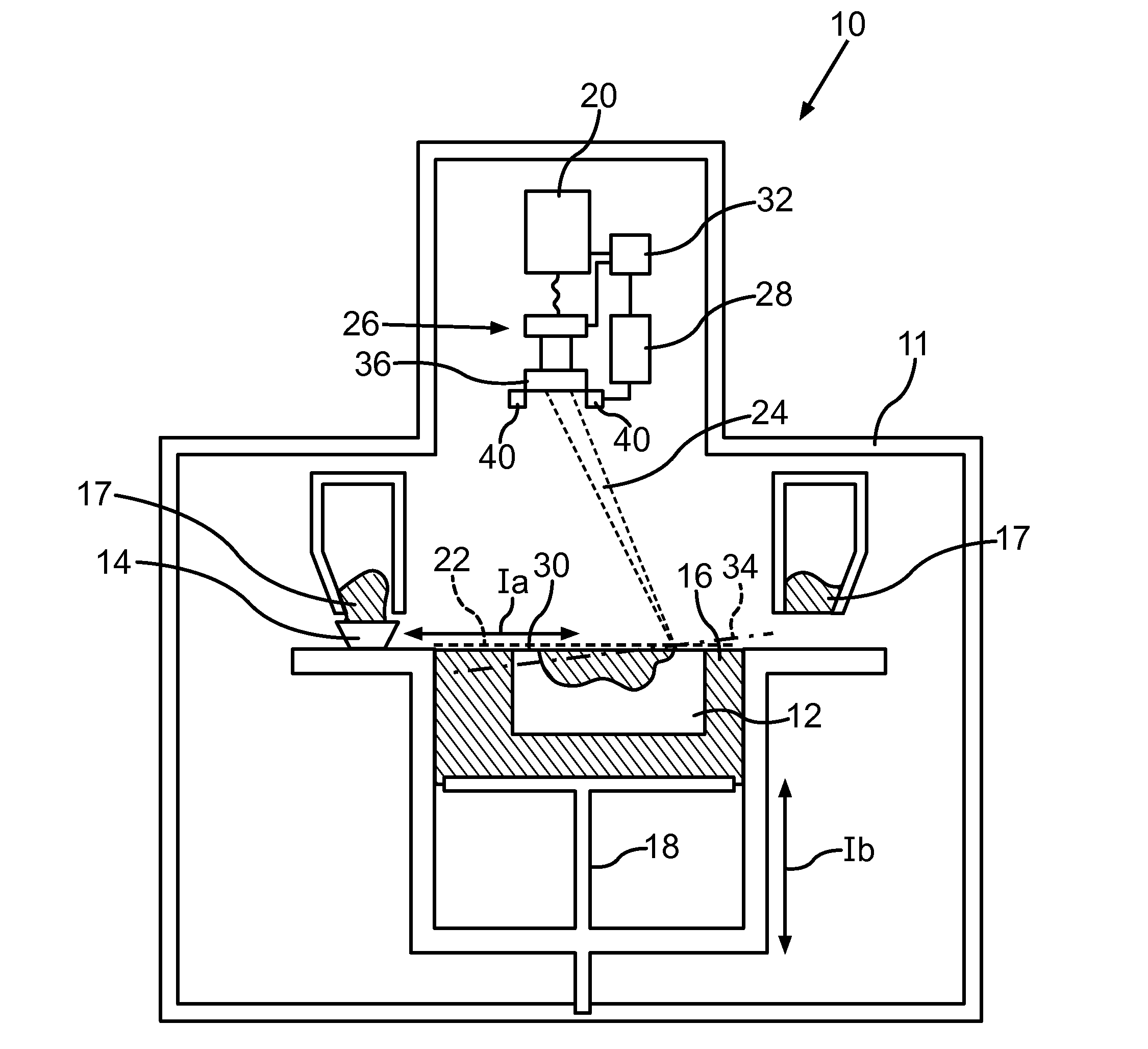

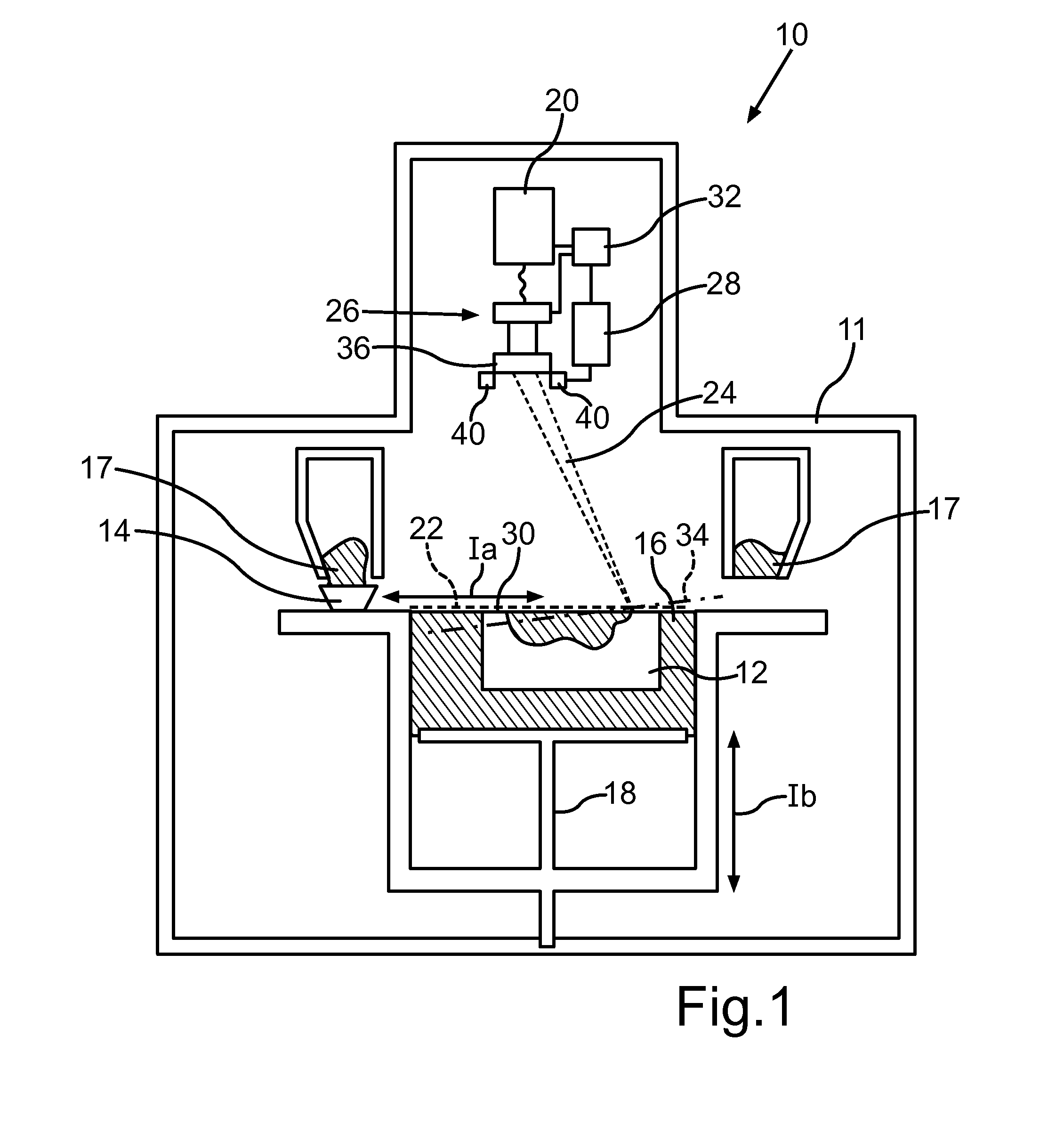

Device for the additive manufacture of a component

InactiveUS20160175935A1Free from damageRapid and simple for determiningAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyHigh energy beam

The invention relates to a device (10) for the additive manufacture of a component (12), comprising at least one coating device (14) for producing a powder layer (16) on a construction platform (18); at least one radiation source (20), in particular a laser, for producing a high-energy beam (24), by means of which the powder layer (16) in a construction surface area (22) can be melted and / or sintered locally to form a component layer (30); at least one deflection device (26), by means of which the high-energy beam (24) can be deflected onto different regions of the powder layer (16) and can be focused on the construction surface area (22); at least one measurement system (28), by means of which a cross-sectional geometry of the high-energy beam (24) on the powder layer (16) and / or the component layer (30) can be determined; and at least one equilibration device (32).

Owner:MTU AERO ENGINES GMBH

Powder distribution in additive manufacturing of three-dimensional articles

ActiveUS9505057B2Additive manufacturing apparatusTransportation and packagingPowder bedMechanical engineering

The present invention relates to a method for forming a three-dimensional article through successive fusion of parts of at least one layer of a powder bed provided on a work table. Said method comprising the steps of: providing at least a first and second powder tank, providing a first type of powder in said first powder tank having a first particle size distribution, providing a second type of powder in said second powder tank having a second particle size distribution, providing a first sub-layer of said first type of powder on said work table, providing a second sub-layer of said second type of powder on top of said first layer of said first type of powder, fusing said first and second sub-layers simultaneously with a high energy beam from a high energy beam source for forming a first cross section of said three-dimensional article.

Owner:ARCAM AB

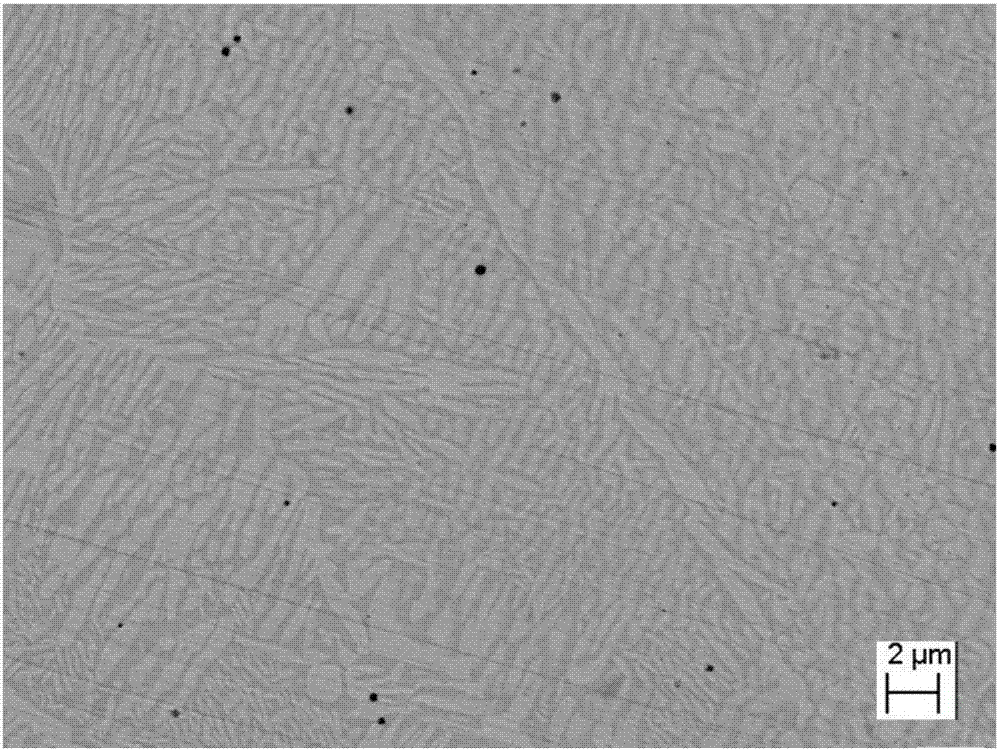

High-energy beam-ultrasonic composite additive manufacturing method for metal materials

InactiveCN104525944AHigh dimensional accuracyHigh performance controlIncreasing energy efficiencyHigh energyMechanical property

The invention discloses a high-energy beam-ultrasonic composite additive manufacturing method for metal materials and belongs to the field of additive manufacturing (3D printing) of metal materials. The method comprises the steps that based on the technical principle of layer-by-layer accumulation of additive manufacturing, metal forming materials are melted through high-energy beams; after the metal forming materials are melted / solidified layer by layer to accumulate to a certain number of layers, the solidified layers are subjected to ultrasonic peening to have compressive plastic deformation, so the internal stress and the internal defects of formed parts are eliminated, and crystalline grains are refined; afterwards, the process of layer-by-layer melting / solidifying accumulation and the process of ultrasonic peening are continued until the whole forming process of metal members is completed. According to the method, real-time layer-by-layer treatment is performed on the solidified layers through ultrasonic peening, so the internal stress and the internal defects can be effectively reduced or eliminated, the crystalline grains can be refined, and the mechanical property of the metal members through additive manufacturing can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

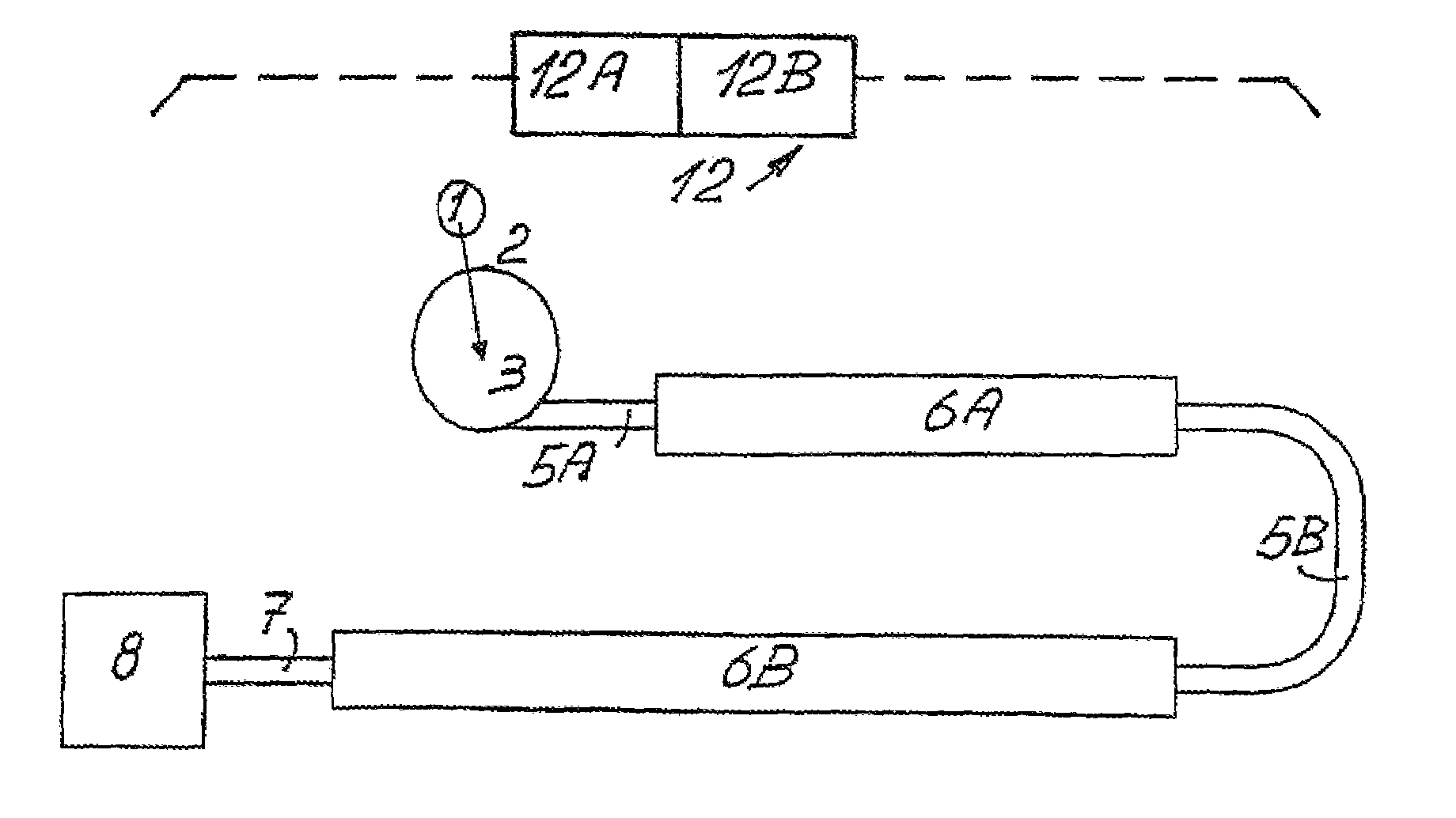

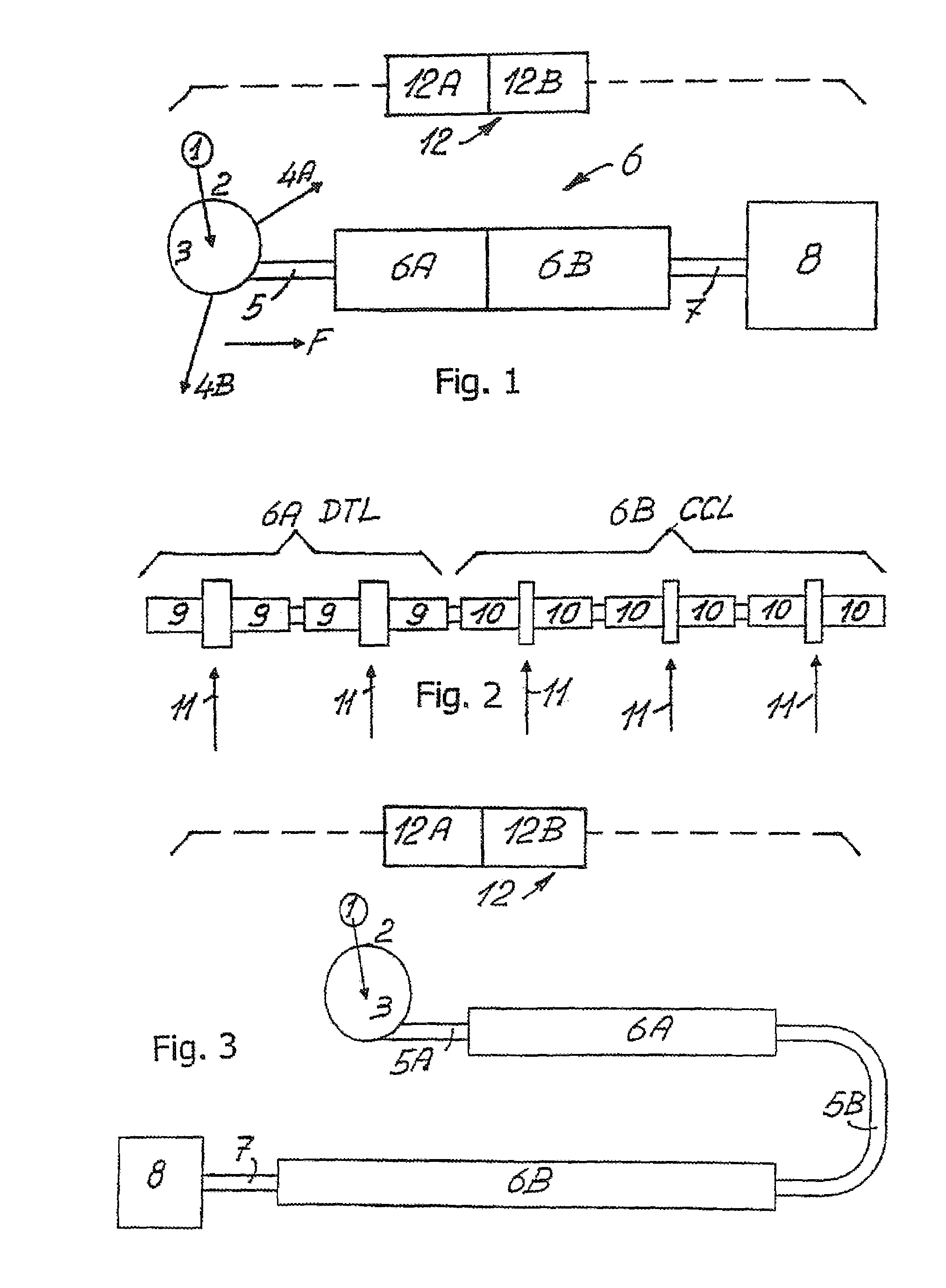

Proton accelerator complex for radio-isotopes and therapy

InactiveUS7554275B2Reduce maintenanceLarge energyMagnetic resonance acceleratorsTransit-time tubesRadio isotopesEngineering

A complex of proton accelerators, includes the following functionally interconnected components: a proton source, a cyclotron, at least one target, located either internally or externally to the cyclotron, a medium energy beam transport magnetic channel, a radiofrequency linear accelerator, a high energy beam transport channel towards an area dedicated to the irradiation of tumors with proton beams, as well as a modular system for supplying radio frequency power capable of feeding, independently two or more accelerating modules of the linac. An integrated computerized system controls the complex of accelerators so to carry out, either in alternation or simultaneously, both the production of radioisotopes—for medical, industrial and therapeutical purposes—and the therapeutical irradiation of, even deep seated tumors. The complex of accelerators produces proton beams which, applying the recently developed ‘spot scanning’ technique, are more suited for the tumor irradiation than the ones produced by cyclotrons and synchrotrons.

Owner:FOND PER ADROTERAPIA ONCOLOGICA TERA

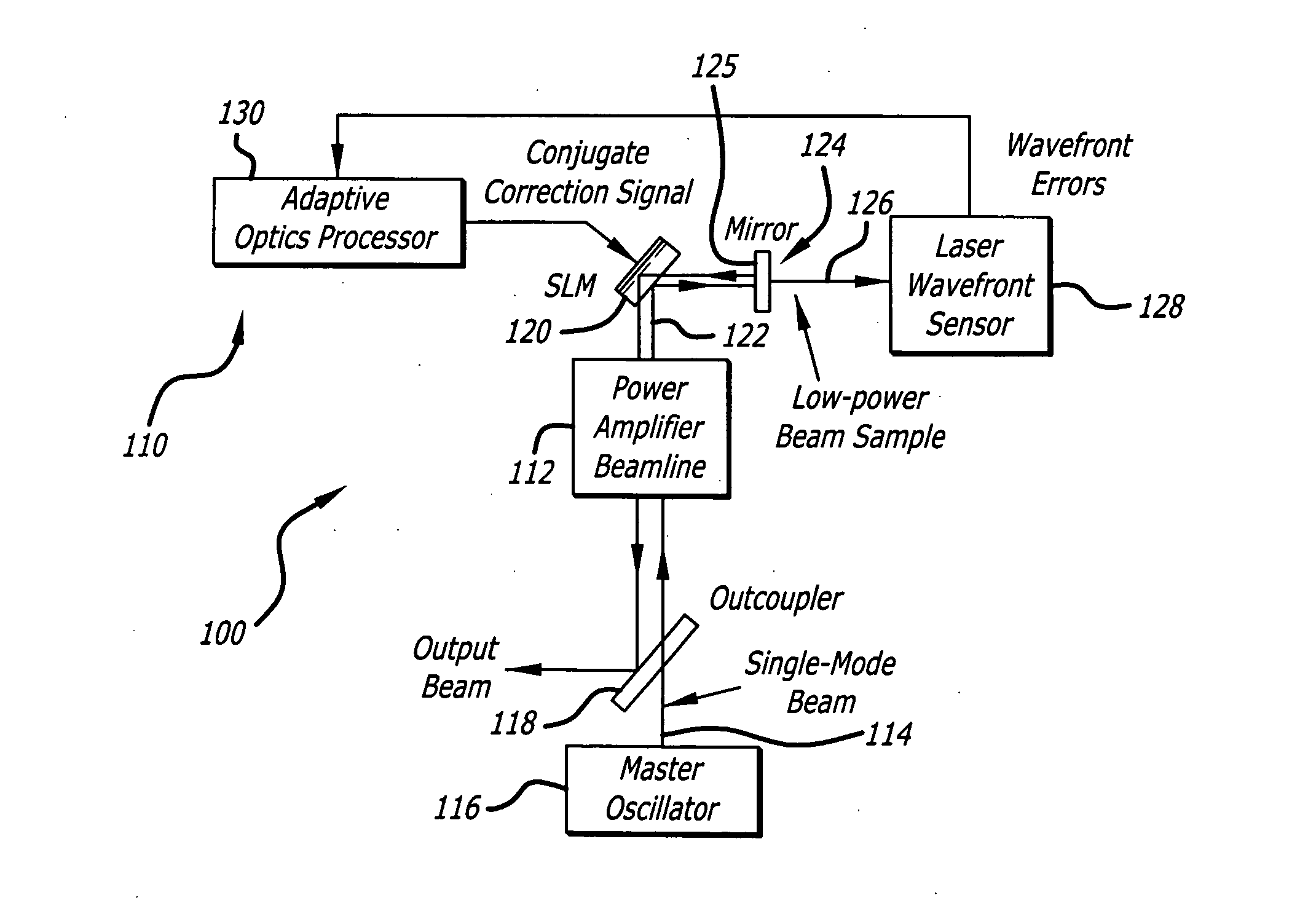

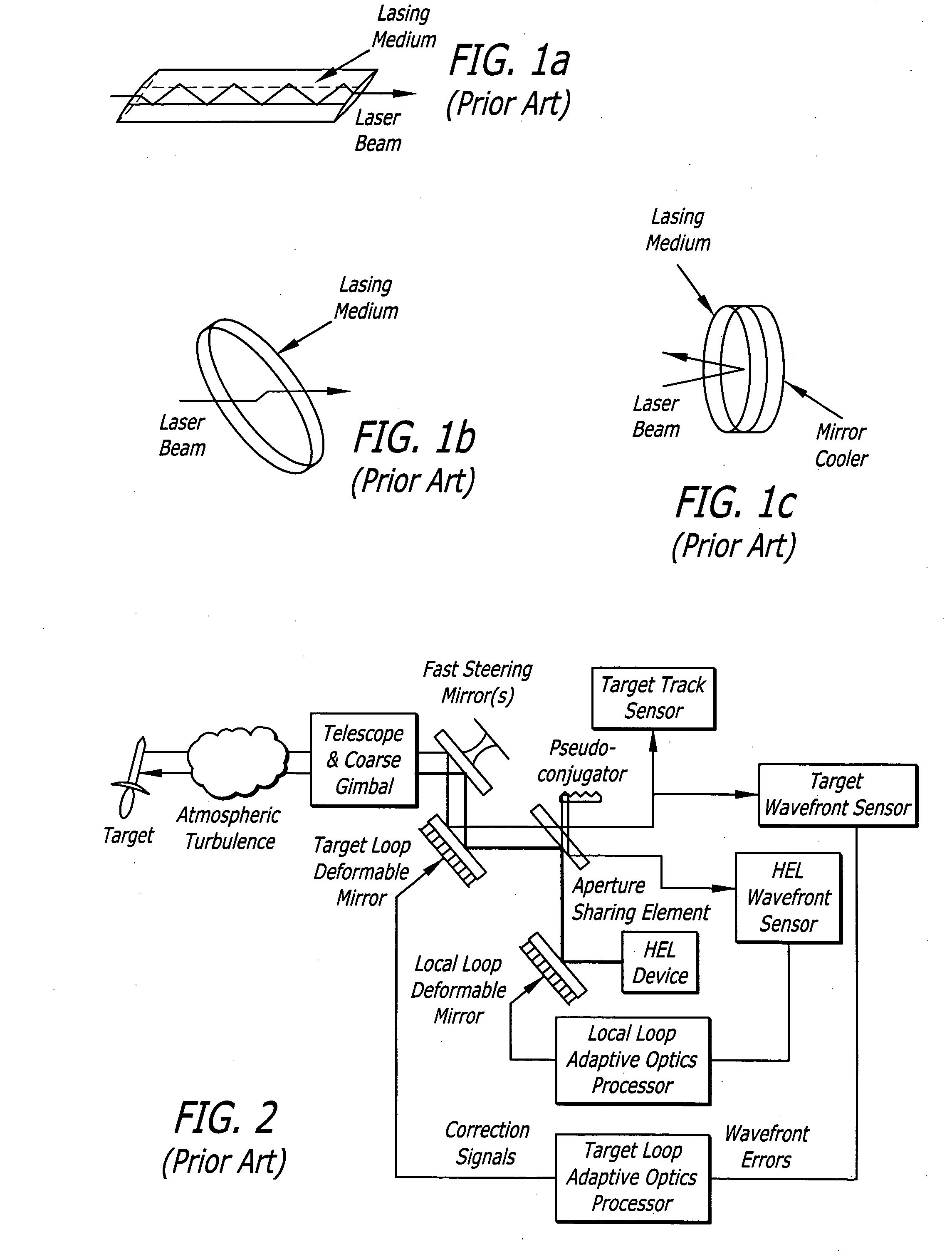

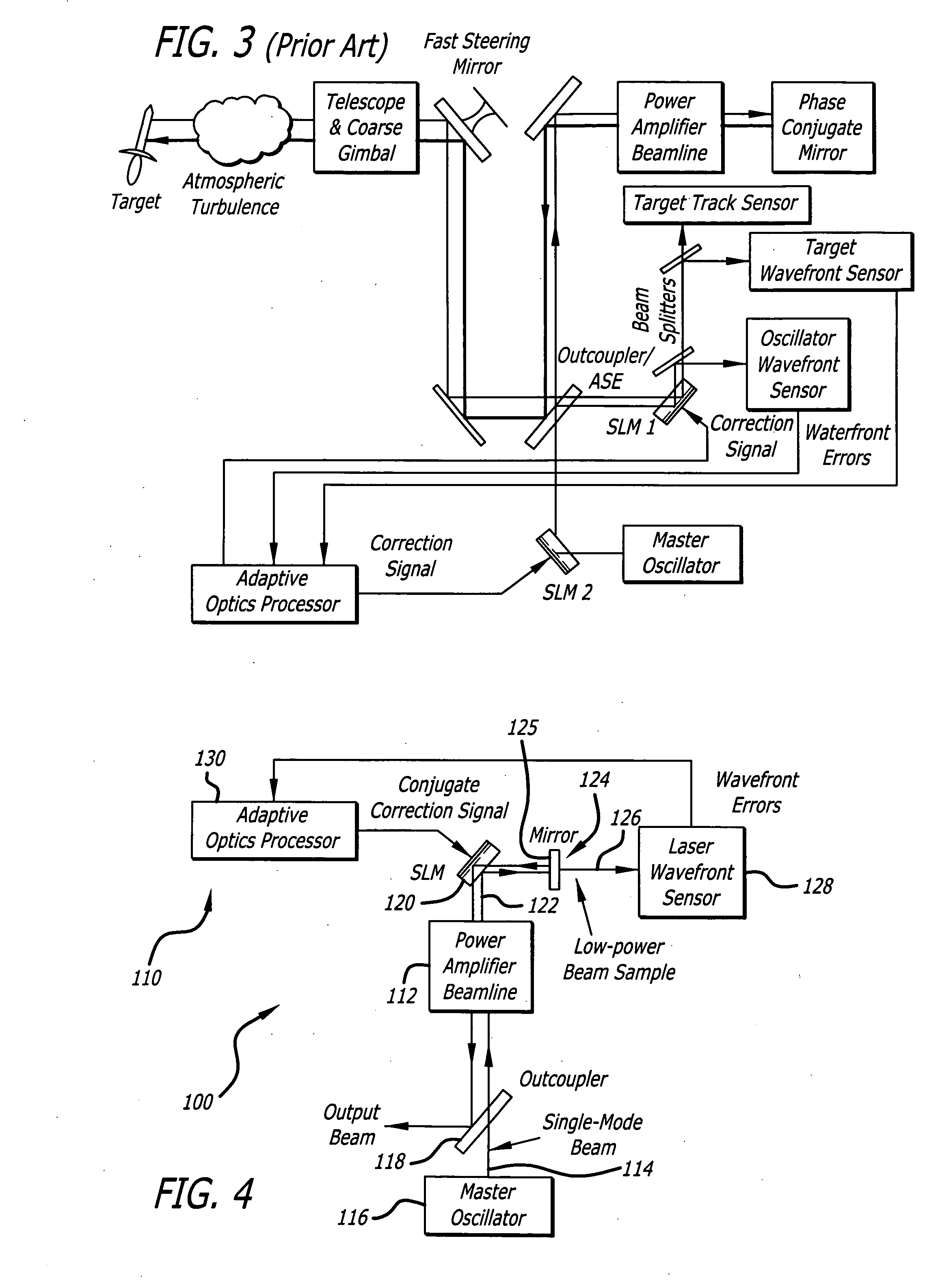

Linear adaptive optics system in low power beam path and method

InactiveUS20100232007A1Aberration correctionDirection controllersDirected energy weaponsDielectricWavefront sensor

A system and method for providing a wavefront corrected high-energy beam of electromagnetic energy. In the illustrative embodiment, the system includes a source of a first beam of electromagnetic energy; an amplifier for amplifying said beam to provide a second beam; a sensor for sensing aberration in said second beam and providing an error signal in response thereto; a processor for processing said error signal and providing a correction signal in response thereto; and a spatial light modulator responsive to said correction signal for adjusting said beam to facilitate a correction of said aberration thereof. In more specific embodiments, the source is a laser and the sensor is a laser wavefront sensor. A mirror is disposed between said modulator and said sensor for sampling said beam. The mirror has an optical thin-film dielectric coating on at least one optical surface thereof. The coating is effective to sample said beam and transmit a low power sample thereof to said means for sensing aberration. The processor is an adaptive optics processor. The spatial light modulator may be a micro electro-mechanical system deformable mirror or an optical phased array. In the illustrative embodiment, the source is a master oscillator and the amplifier is a power amplifier beamline. An outcoupler is disposed between the oscillator and the amplifier.

Owner:RAYTHEON CO

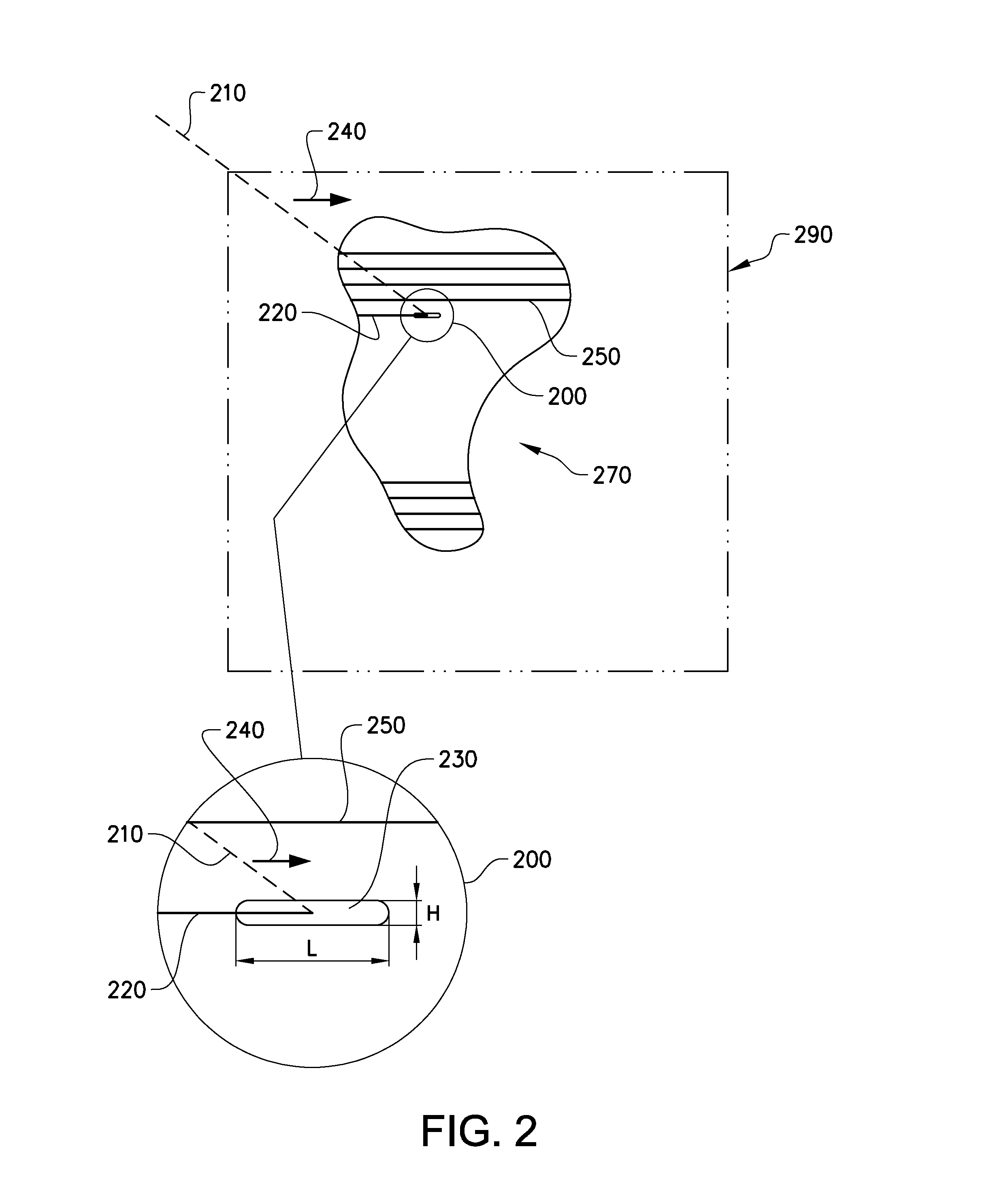

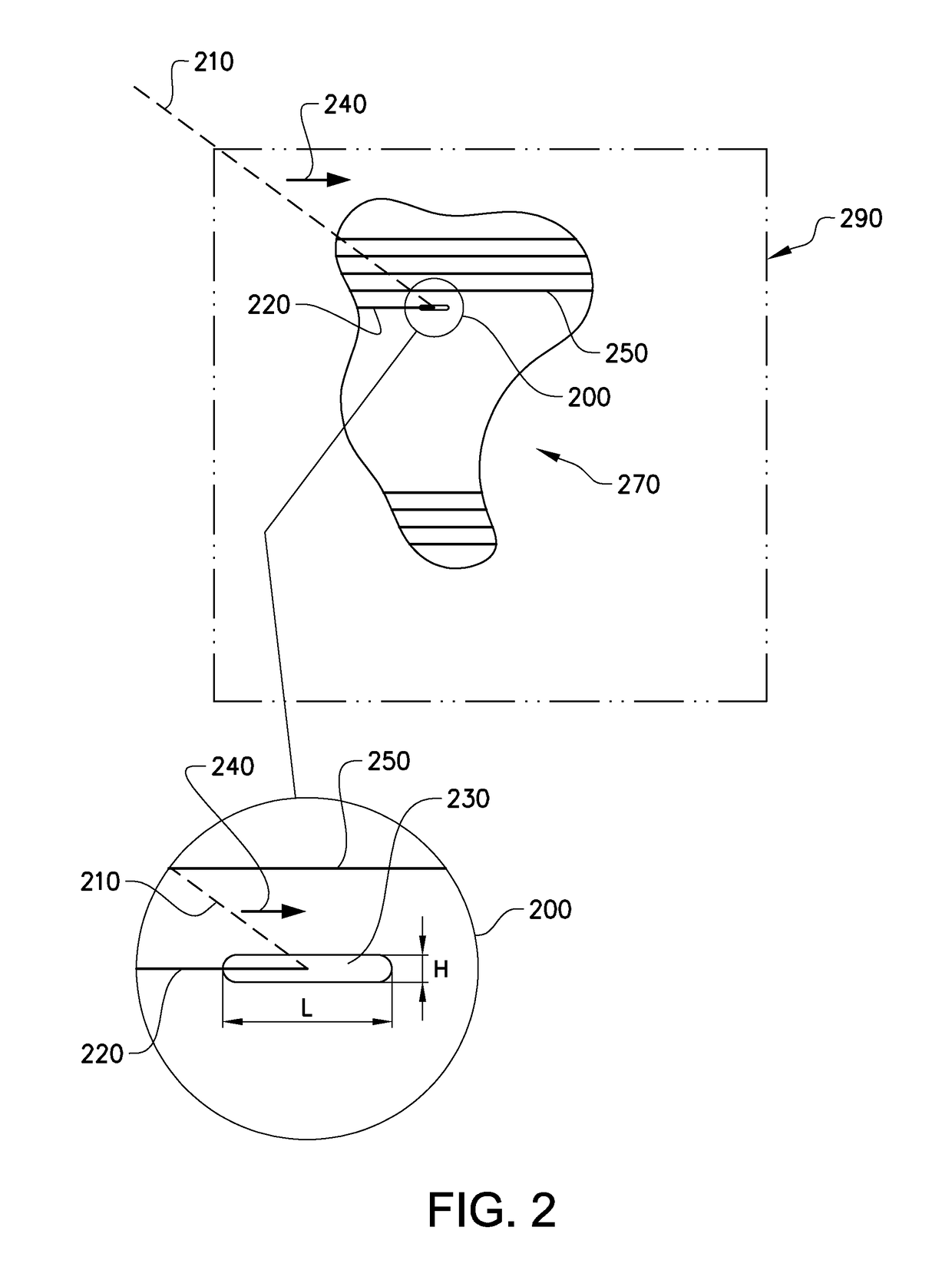

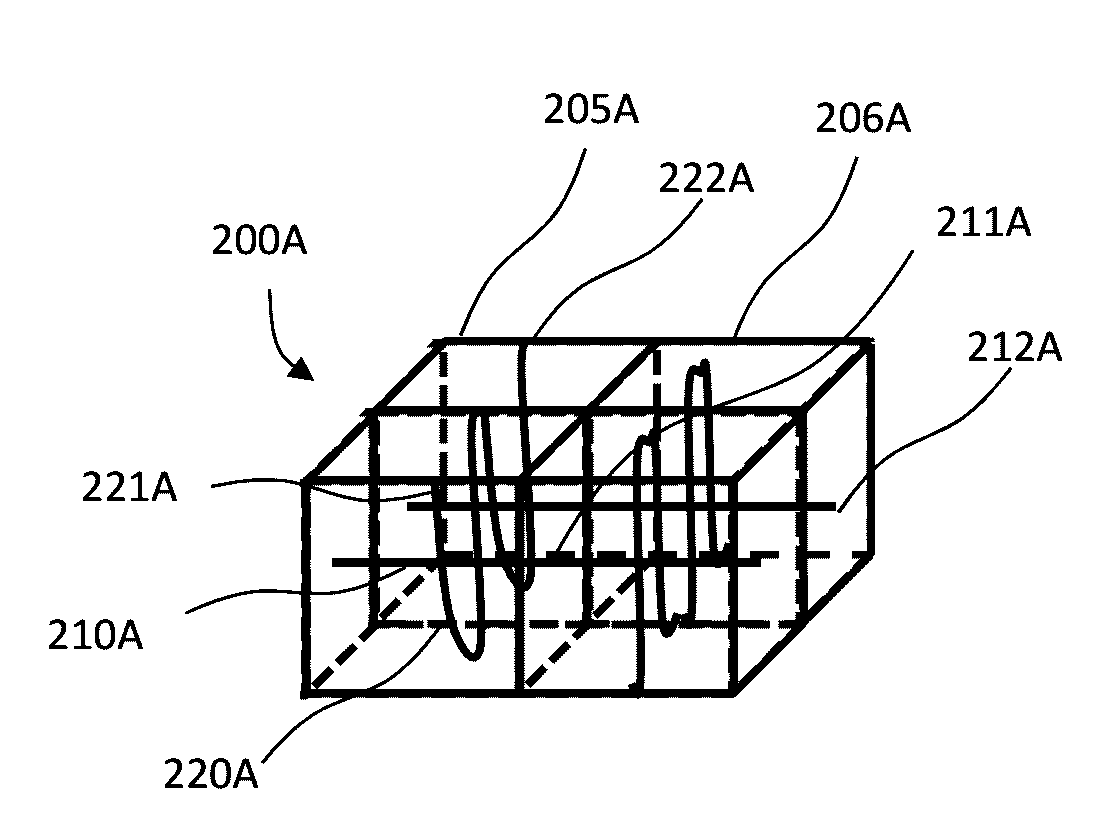

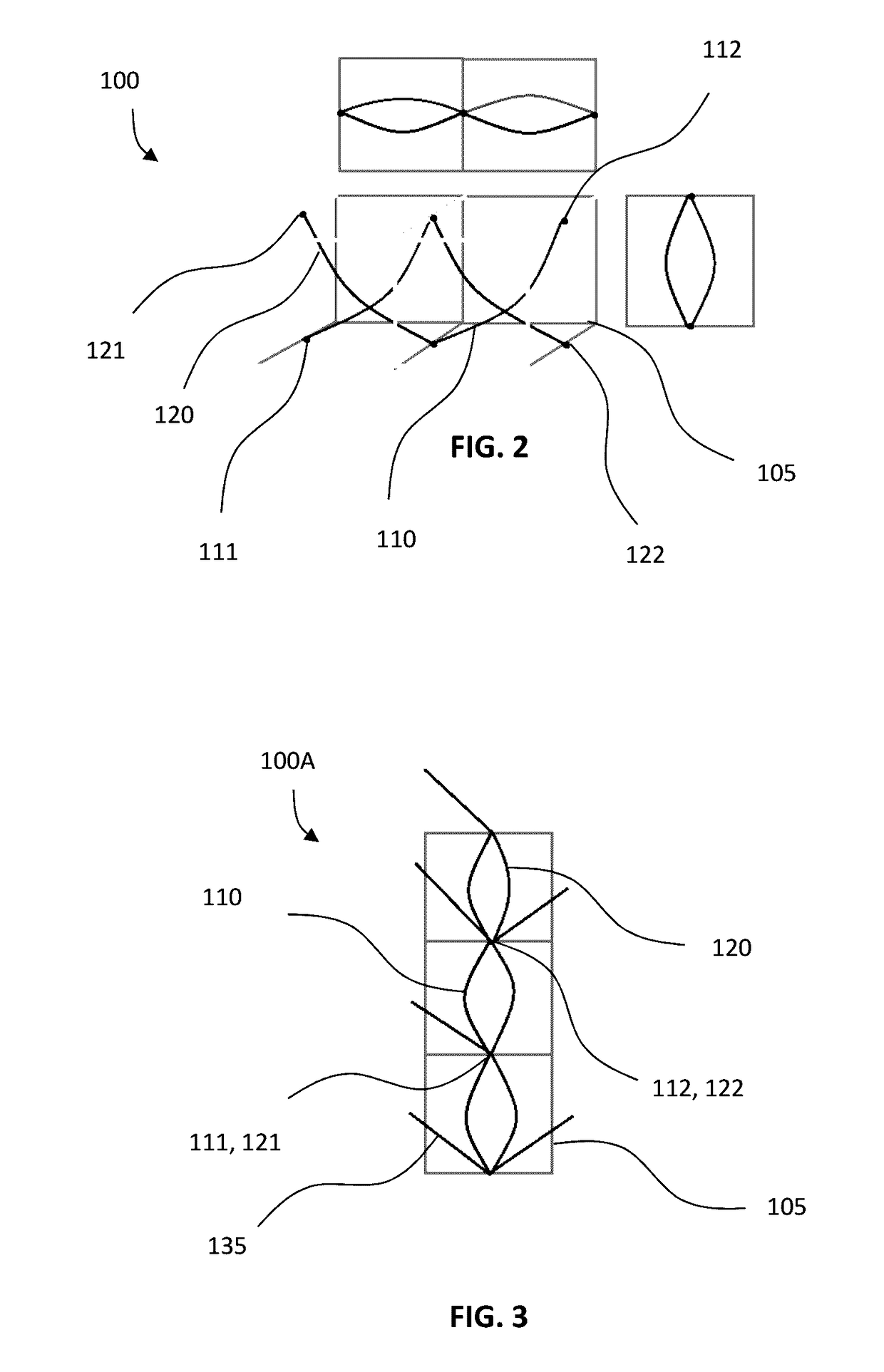

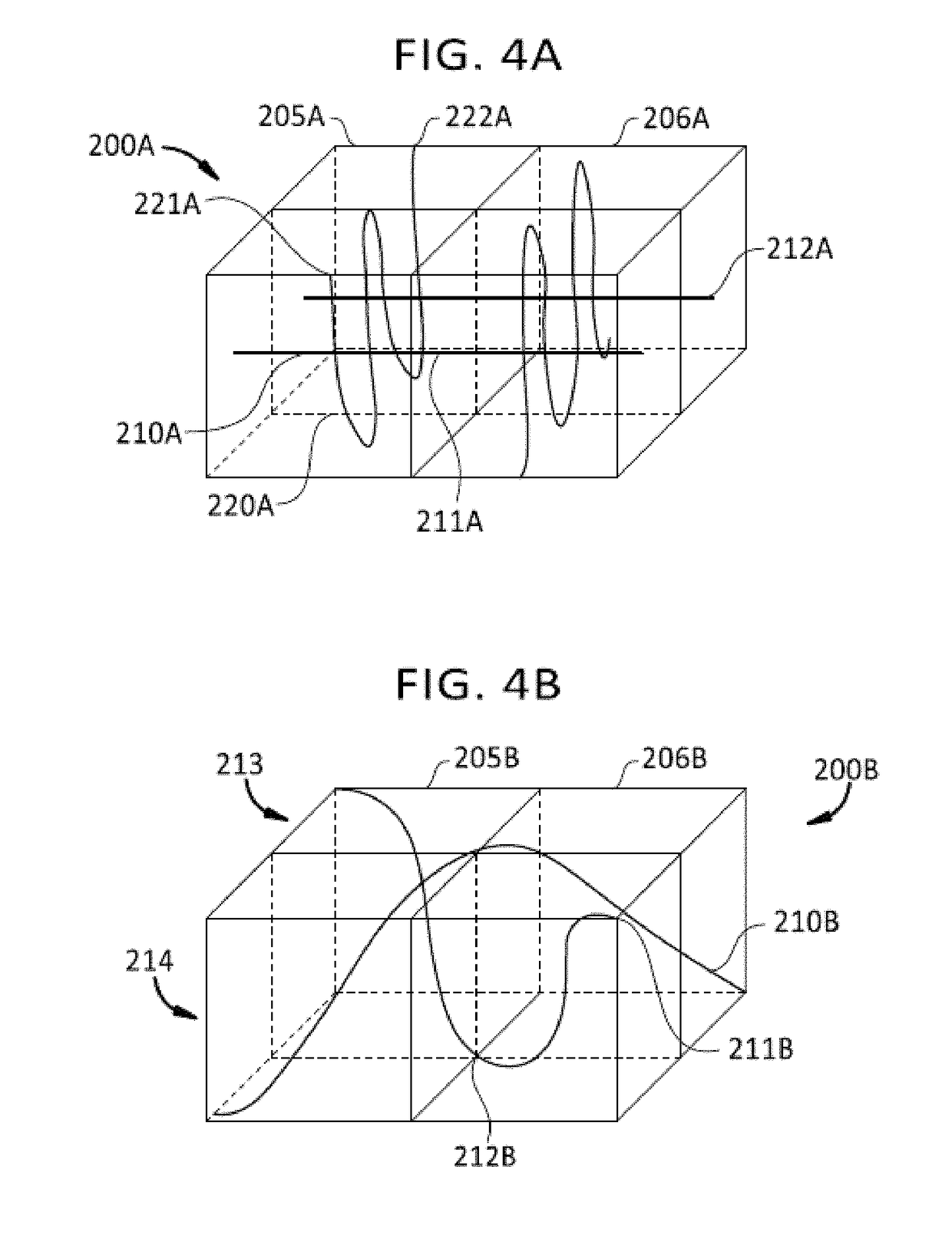

Porous structures produced by additive layer manufacturing

ActiveUS20170165790A1Bone ingrowth may be facilitatedPromote bone ingrowthAdditive manufacturing apparatusCeramic shaping apparatusOptoelectronicsAdditive layer manufacturing

A three-dimensional structure is formed when layers of a material are deposited onto a substrate and scanned with a high energy beam to at least partially melt each layer of the material. Upon scanning the layers at predetermined locations at least a first segment overlapping a second segment and underlapping a third segment is formed.

Owner:HOWMEDICA OSTEONICS CORP

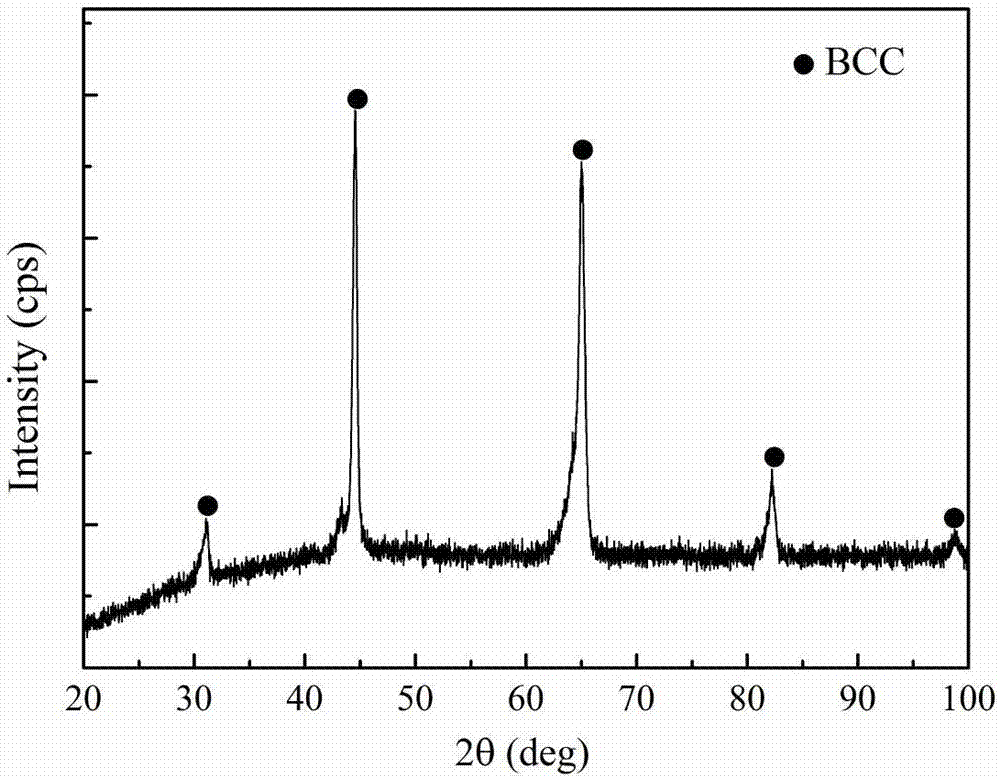

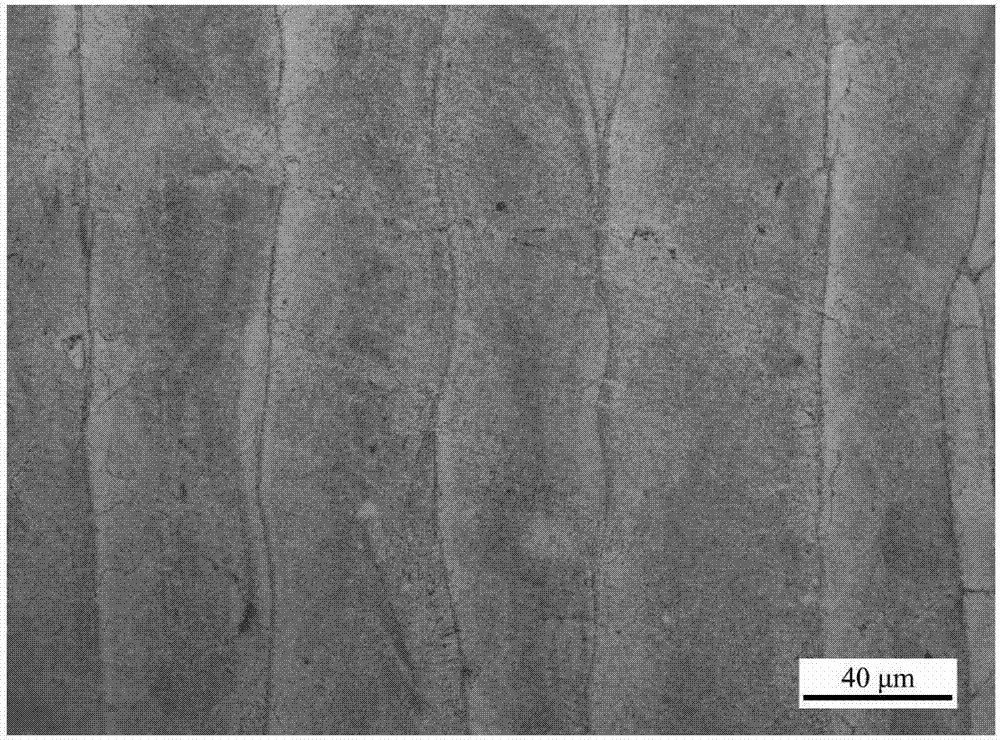

Method for forming high-entropy alloy by using added material manufacturing technology

ActiveCN107130124AHigh densityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyHigh entropy alloys

The invention relates to the technical field of metal alloy formation and manufacturing, and provides a high-entropy alloy powder material system and an added material manufacturing method thereof. Based on such multiple added material manufacturing technologies as powder machine selective high-energy beam melting formation and coaxial powder feeding near net forming, an AlCoCuFeNi high-entropy alloy powder composition and an added material manufacturing process are determined through experiments. The method has the following beneficial effects: high-entropy alloy powder and an alloy component prepared by adopting the added material manufacturing technology have simple body centered cubic structures, and are high in compactness and excellent in mechanical performance; and meanwhile, the preparation process is low in cost, easy to operate and high in production efficiency. The material and the preparation process can directly perform added material manufacturing to form high-entropy alloy parts.

Owner:UNIV OF SCI & TECH BEIJING

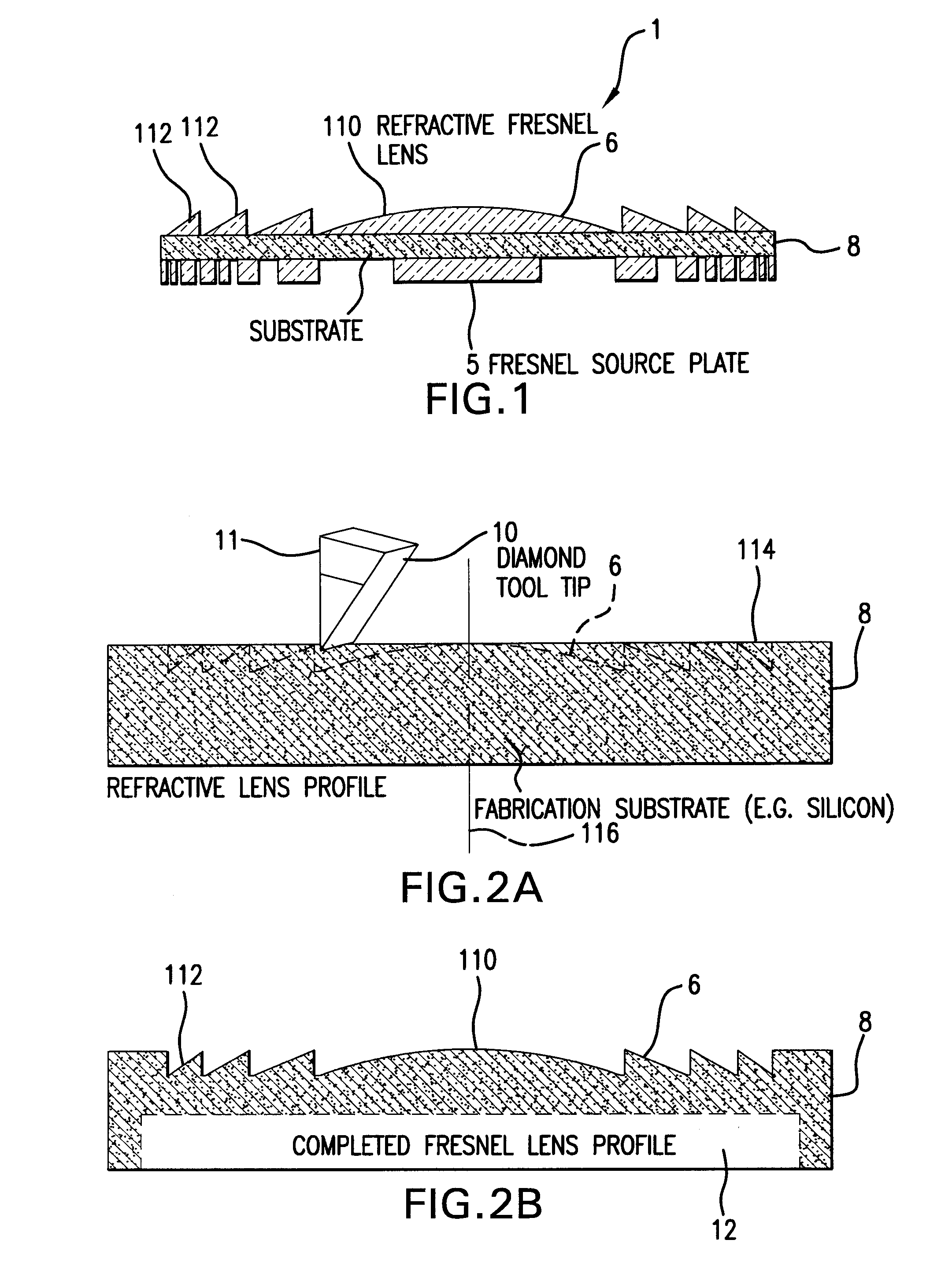

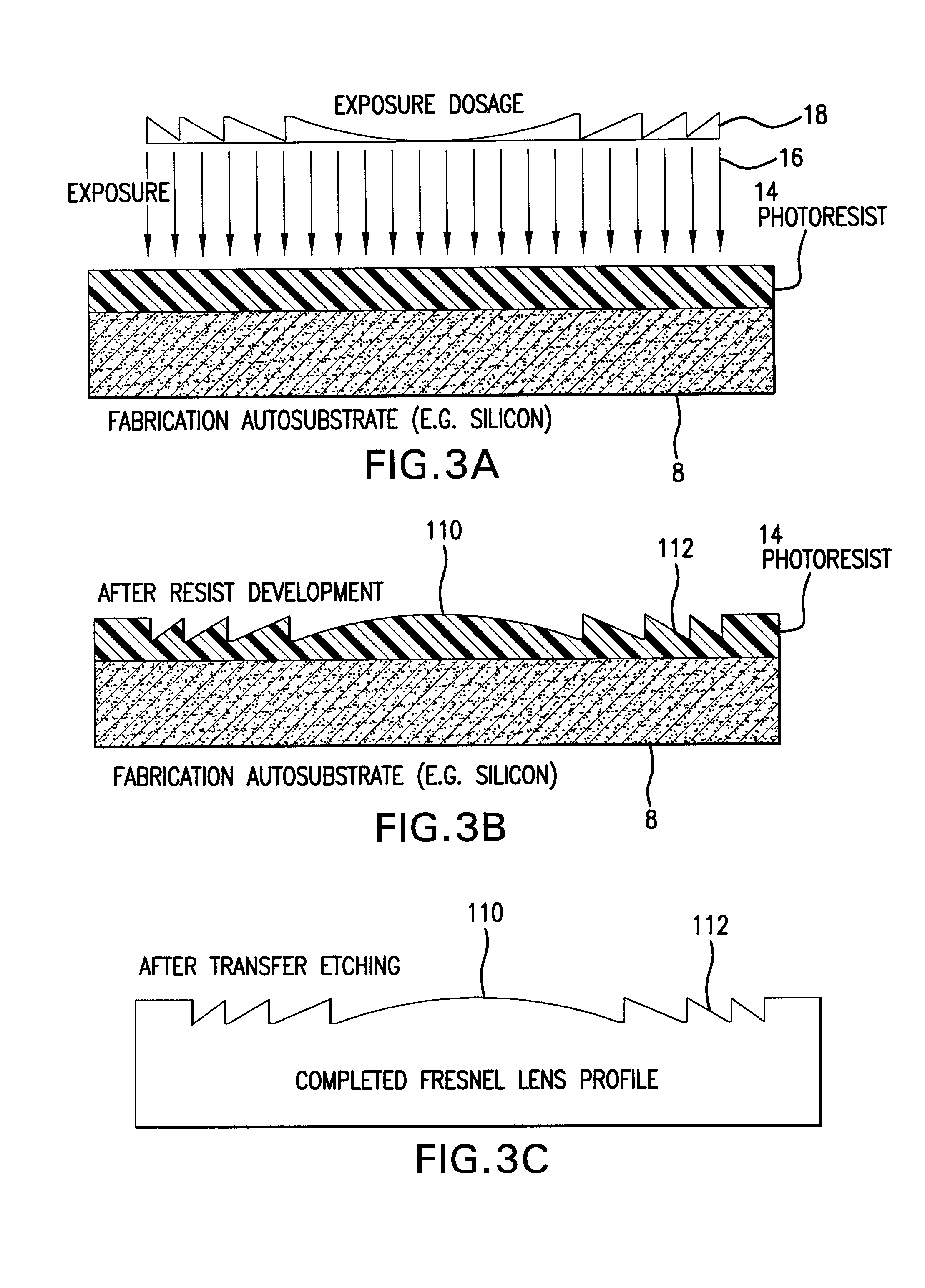

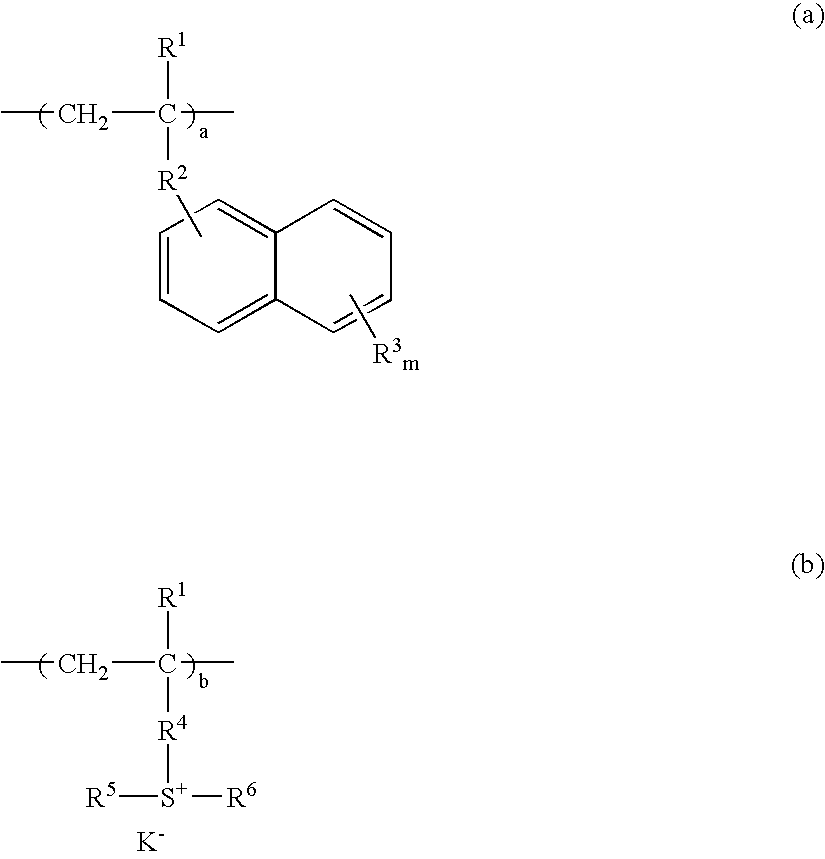

Fabrication Methods for Micro Compound Optics

Methods for fabricating refractive element(s) and aligning the elements in a compound optic, typically to a zone plate element. The techniques are used for fabricating micro refractive, such as Fresnel, optics and compound optics including two or more optical elements for short wavelength radiation. One application is the fabrication of the Achromatic Fresnel Optic (AFO). Techniques for fabricating the refractive element generally include: 1) ultra-high precision mechanical machining, e.g,. diamond turning; 2) lithographic techniques including gray-scale lithography and multi-step lithographic processes; 3) high-energy beam machining, such as electron-beam, focused ion beam, laser, and plasma-beam machining; and 4) photo-induced chemical etching techniques. Also addressed are methods of aligning the two optical elements during fabrication and methods of maintaining the alignment during subsequent operation.

Owner:XRADIA

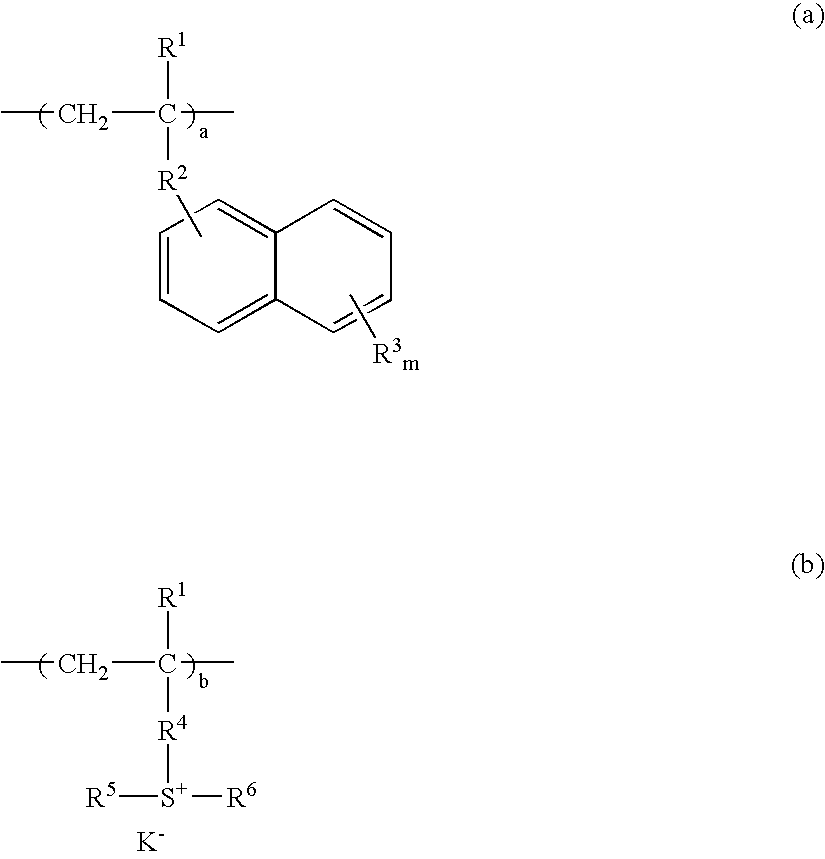

Resist composition and patterning process using the same

ActiveUS20070111140A1High sensitivityHigh resolutionPhotosensitive materialsRadiation applicationsPolymer chemistryHigh energy beam

There is disclosed a resist composition which shows high sensitivity and high resolution on exposure to high energy beam, provides reduced Line Edge Roughness because swelling at the time of development is reduced, provides minor amounts of residue after development, has excellent dry etching resistance, and can also be used suitably for the liquid immersion lithography; and a patterning process using the resist composition. There can be provided a resist composition which comprises, at least, a polymer including repeating units represented by the following general formulae (a) and (b).

Owner:SHIN ETSU CHEM IND CO LTD

Porous structures produced by additive layer manufacturing

ActiveUS20180361510A1Bone ingrowth may be facilitatedPromote bone ingrowthStentsAdditive manufacturing apparatusEngineeringMechanical engineering

A three-dimensional structure is formed when layers of a material are deposited onto a substrate and scanned with a high energy beam to at least partially melt each layer of the material. Upon scanning the layers at predetermined locations a tube device having a first tube and a second tube intersected with the first tube is formed.

Owner:HOWMEDICA OSTEONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com