Patents

Literature

990 results about "Laser excimer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An excimer laser, sometimes more correctly called an exciplex laser, is a form of ultraviolet laser which is commonly used in the production of microelectronic devices, semiconductor based integrated circuits or "chips", eye surgery, and micromachining.

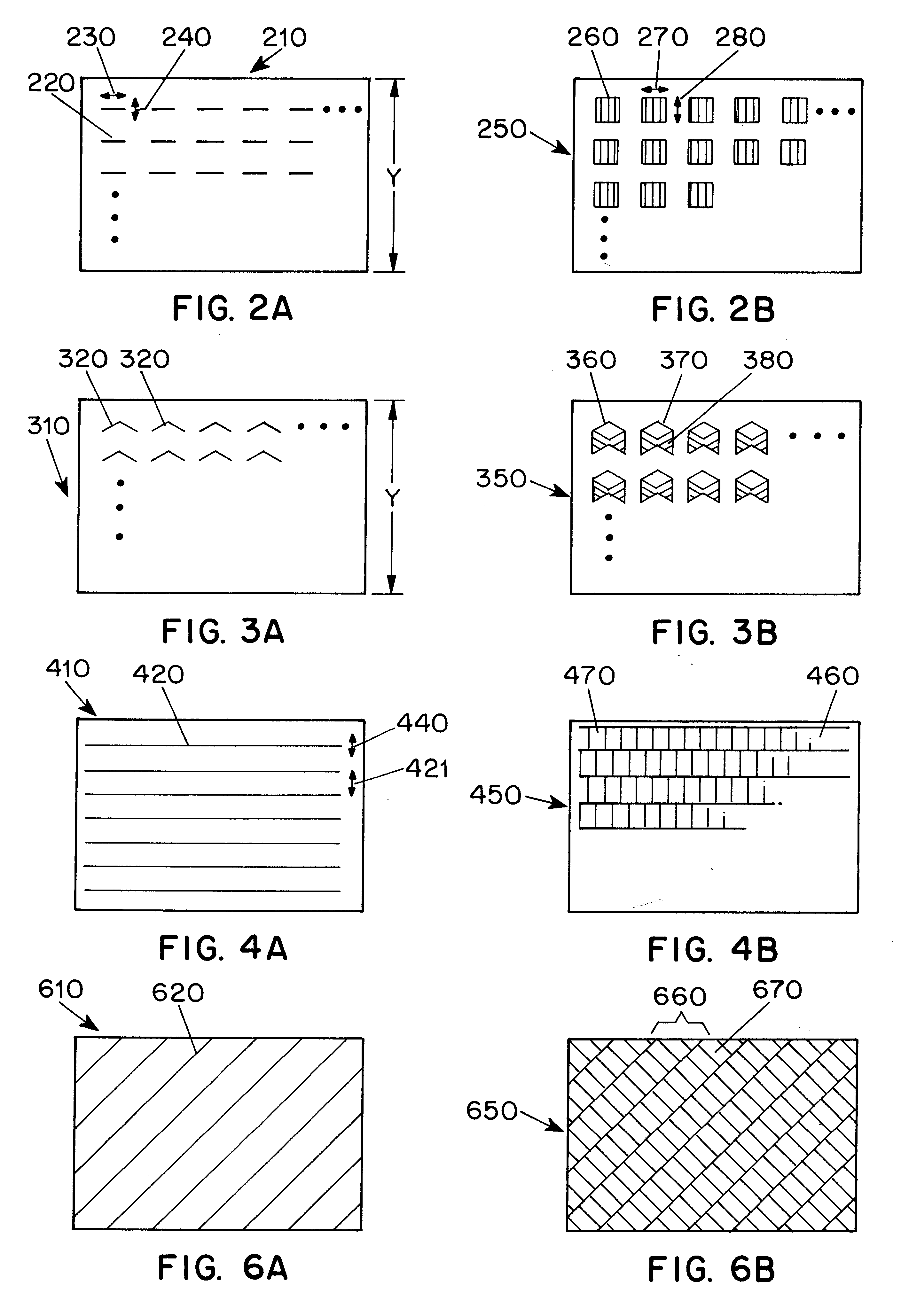

Methods for producing uniform large-grained and grain boundary location manipulated polycrystalline thin film semiconductors using sequential lateral solidification

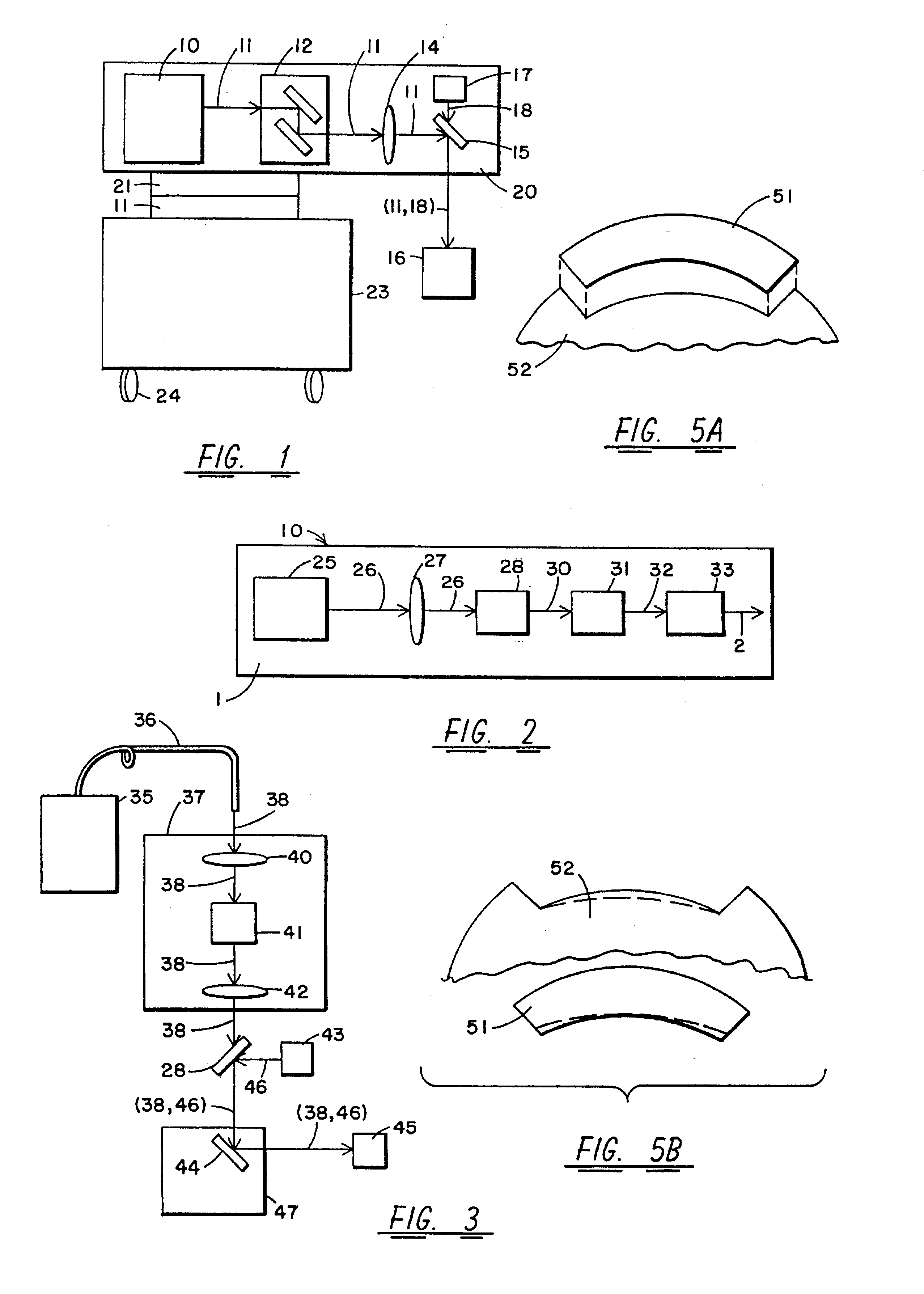

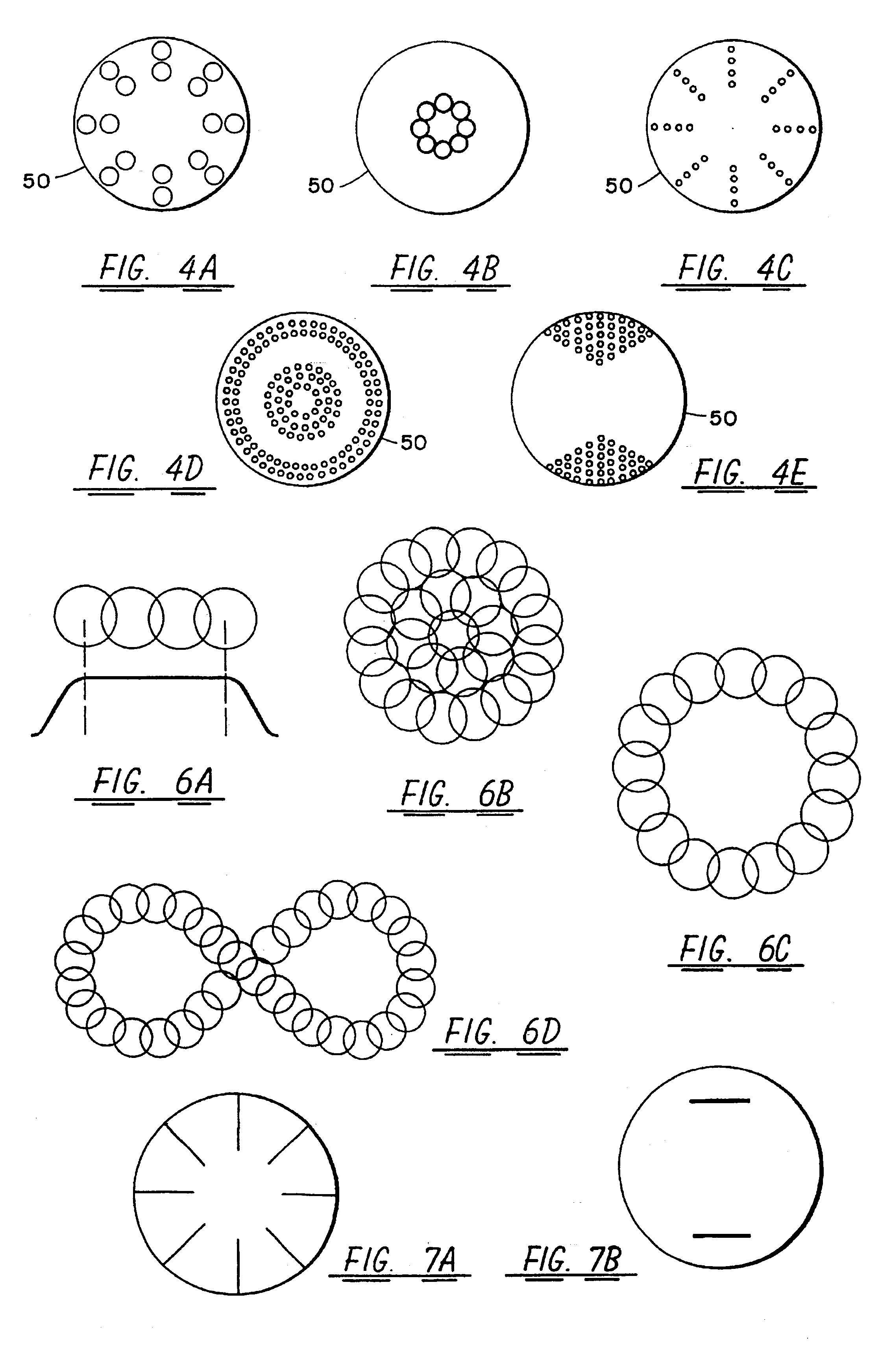

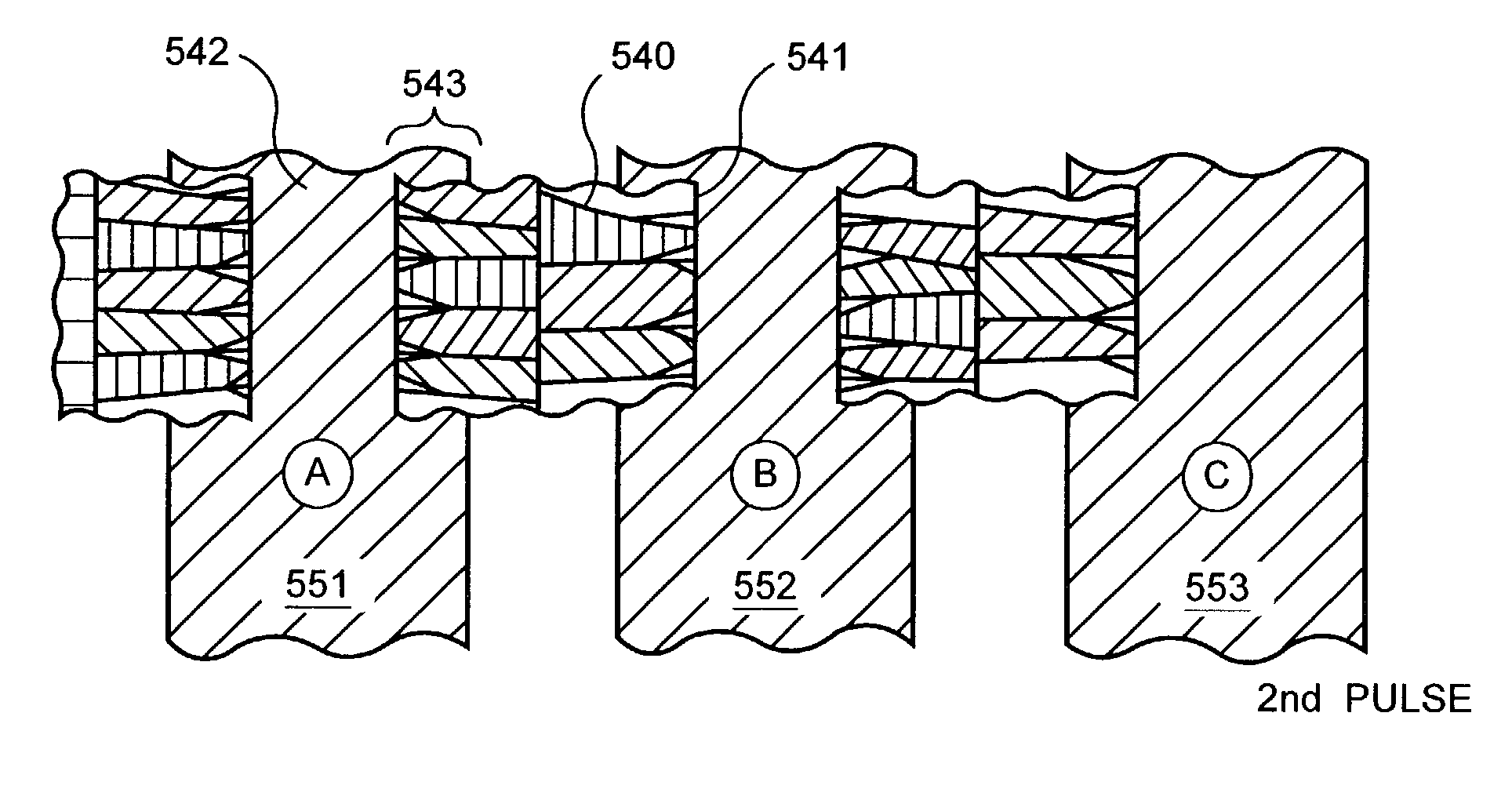

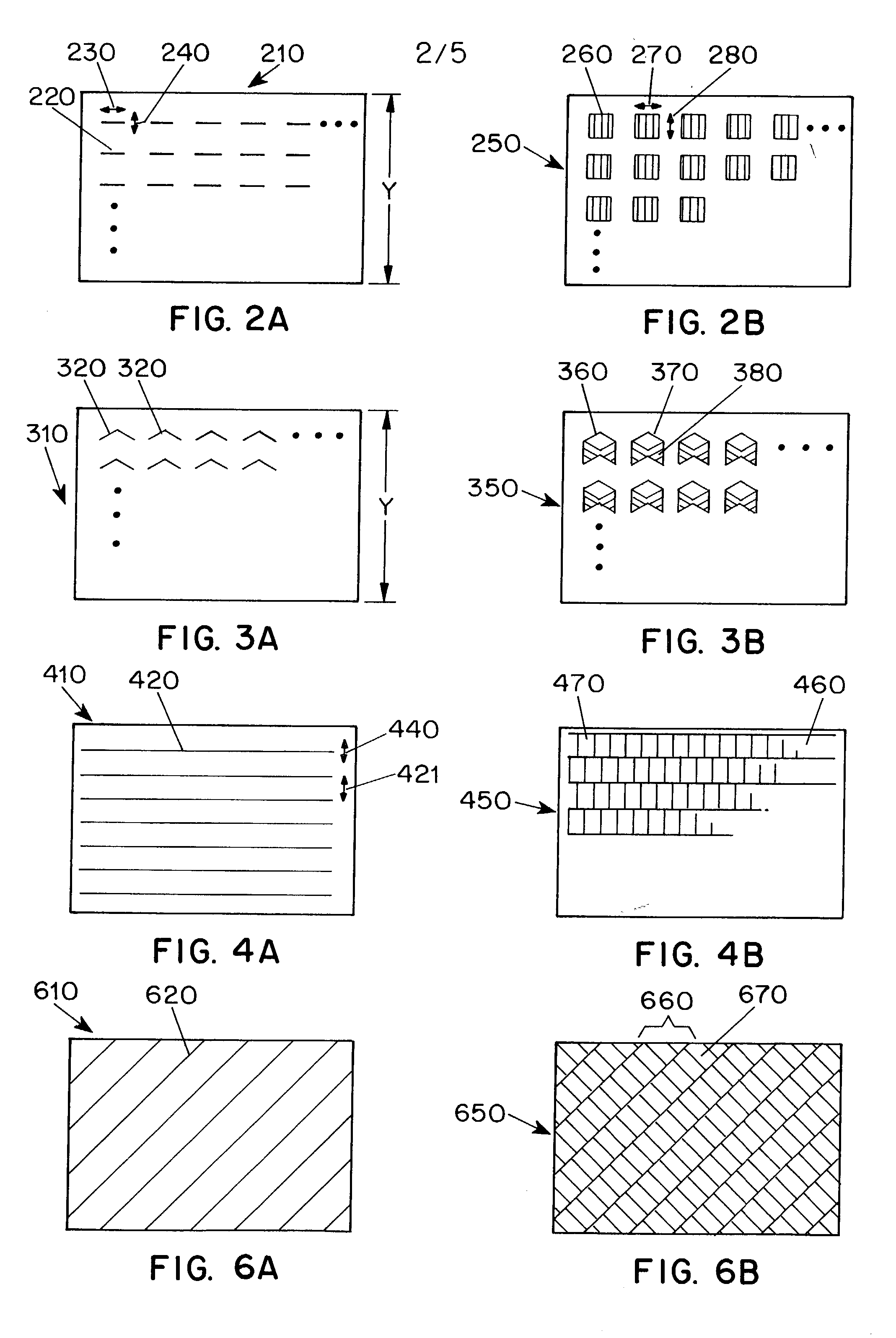

Methods for processing an amorphous silicon thin film sample into a polycrystalline silicon thin film are disclosed. In one preferred arrangement, a method includes the steps of generating a sequence of excimer laser pulses, controllably modulating each excimer laser pulse in the sequence to a predetermined fluence, homoginizing each modulated laser pulse in the sequence in a predetermined plane, masking portions of each homogenized fluence controlled laser pulse in the sequence with a two dimensional pattern of slits to generate a sequence of fluence controlled pulses of line patterned beamlets, each slit in the pattern of slits being sufficiently narrow to prevent inducement of significant nucleation in region of a silicon thin film sample irradiated by a beam let corresponding to the slit, irradiating an amorphous silicon thin film sample with the sequence of fluence controlled slit patterned beamlets to effect melting of portions thereof corresponding to each fluence controlled patterned beamlet pulse in the sequence of pulses of patterned beamlets, and controllably sequentially translating a relative position of the sample with respect to each of the fluence controlled pulse of slit patterned beamlets to thereby process the amorphous silicon thin film sample into a single or polycrystalline silicon thin film.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

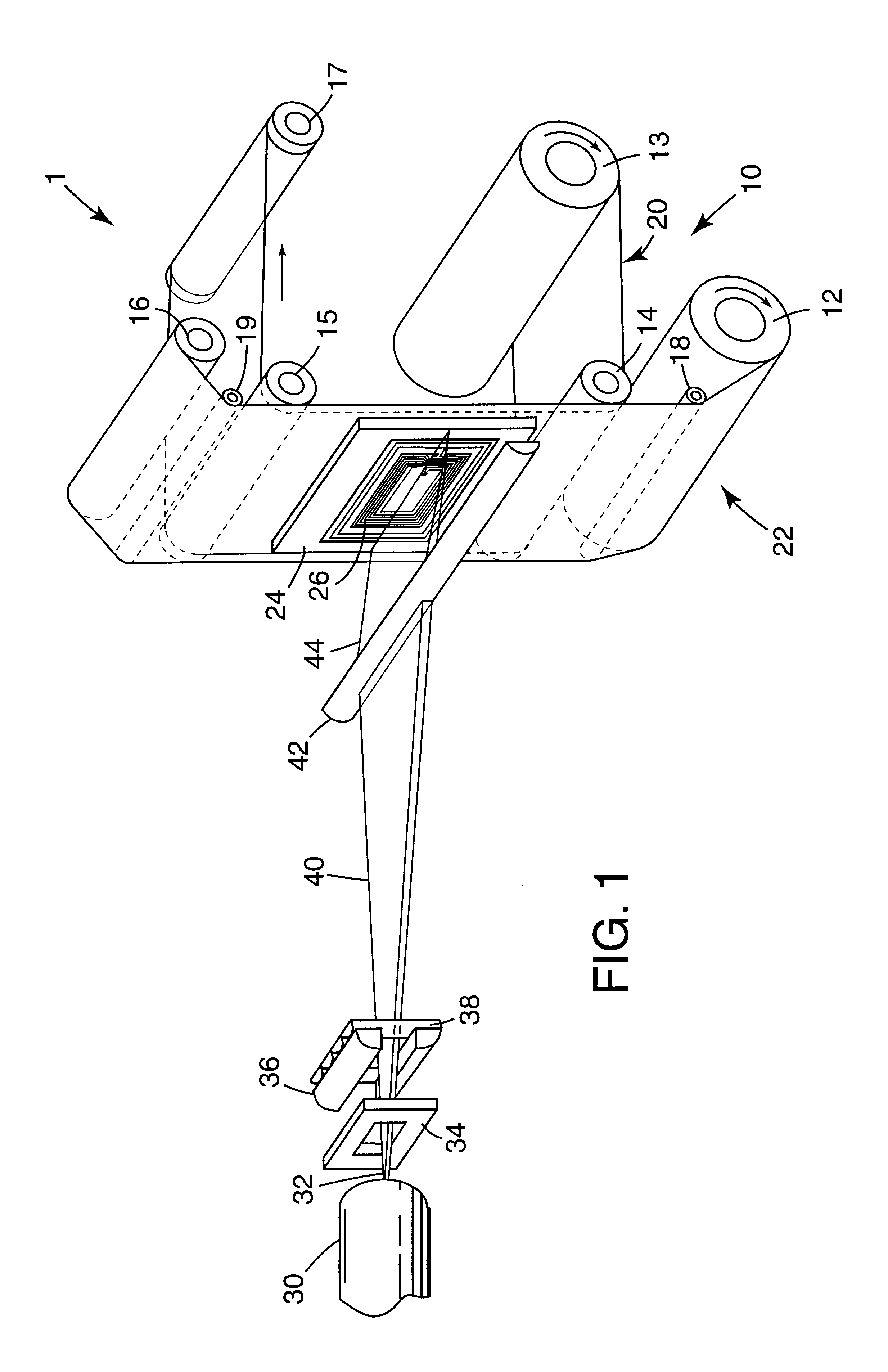

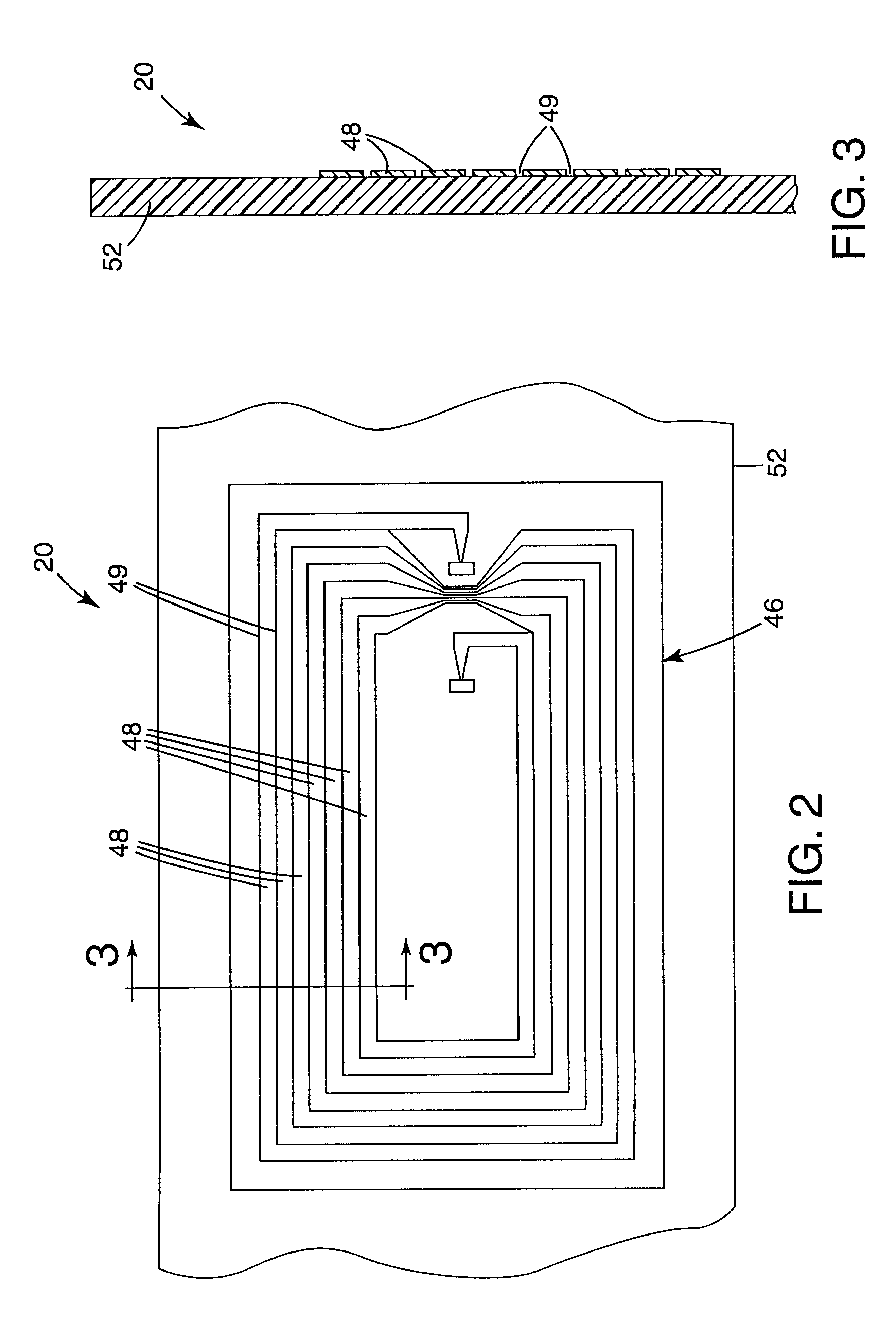

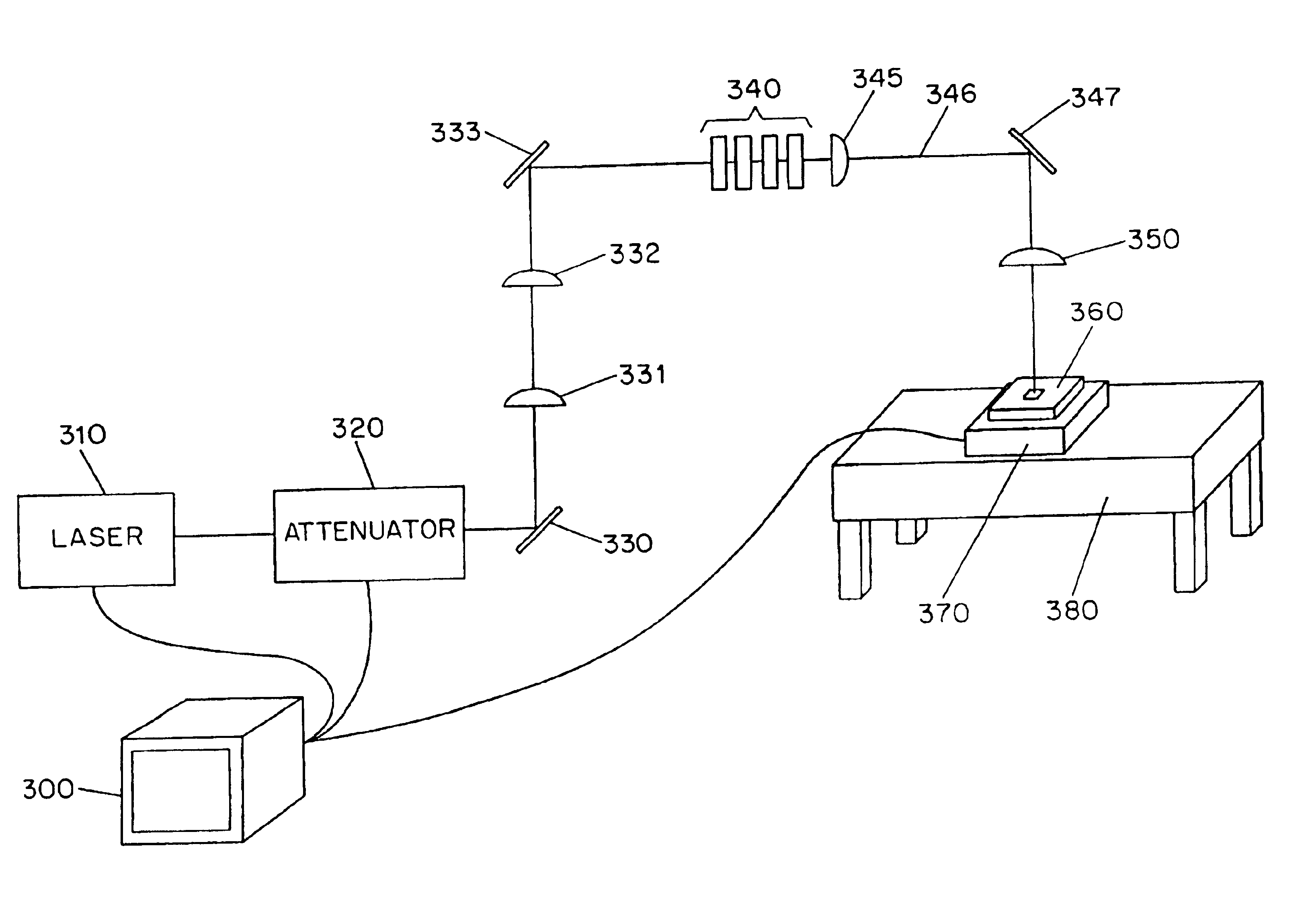

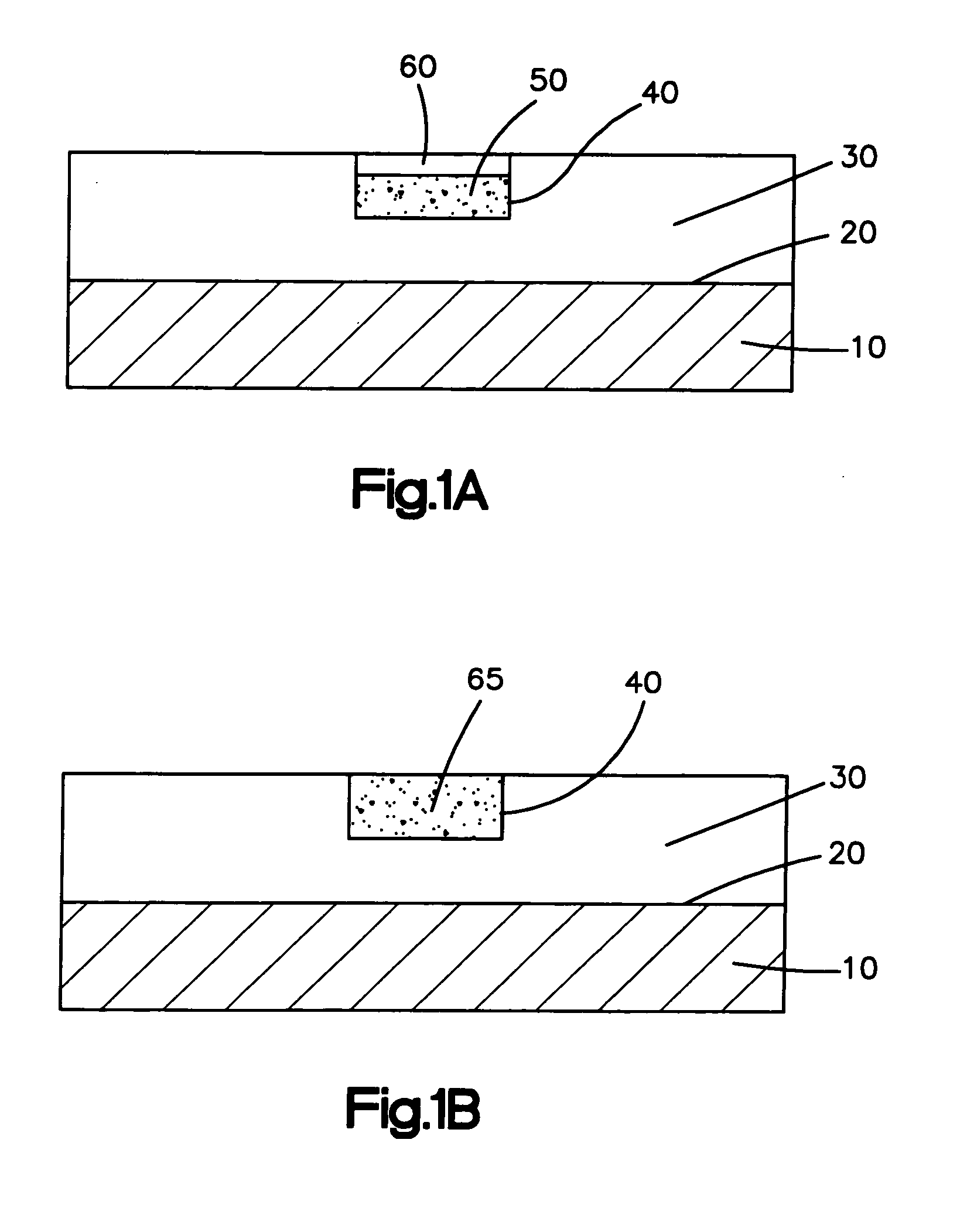

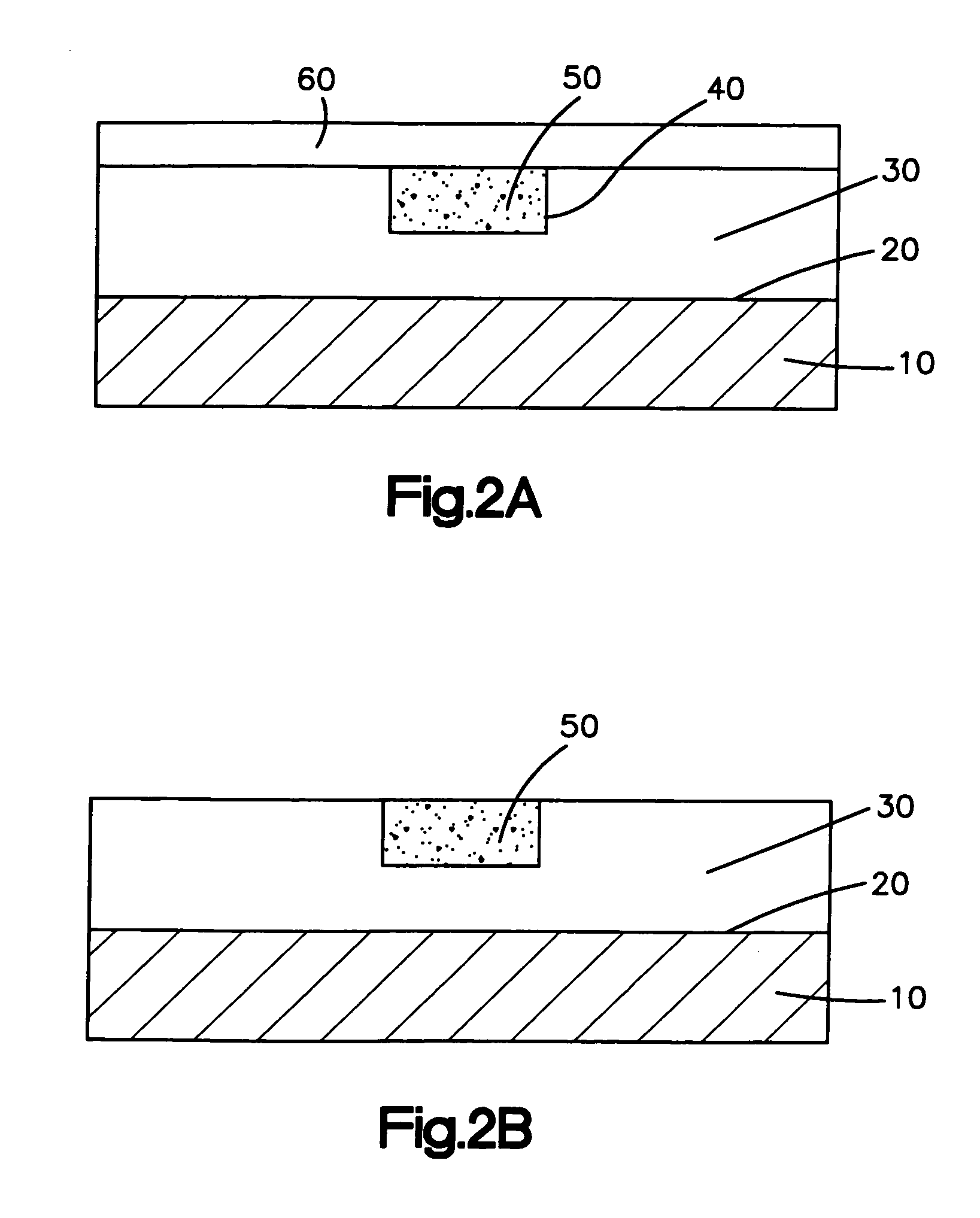

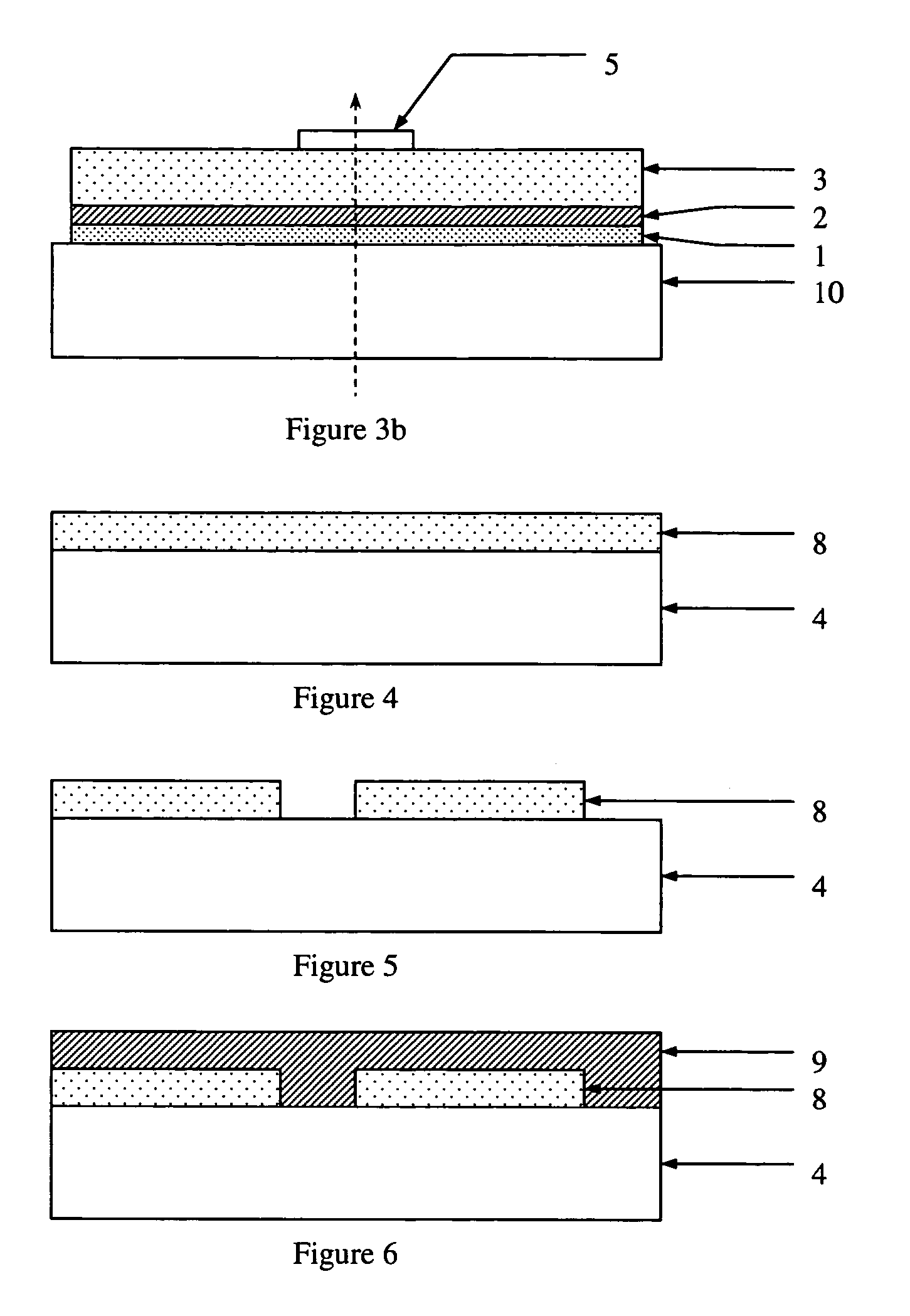

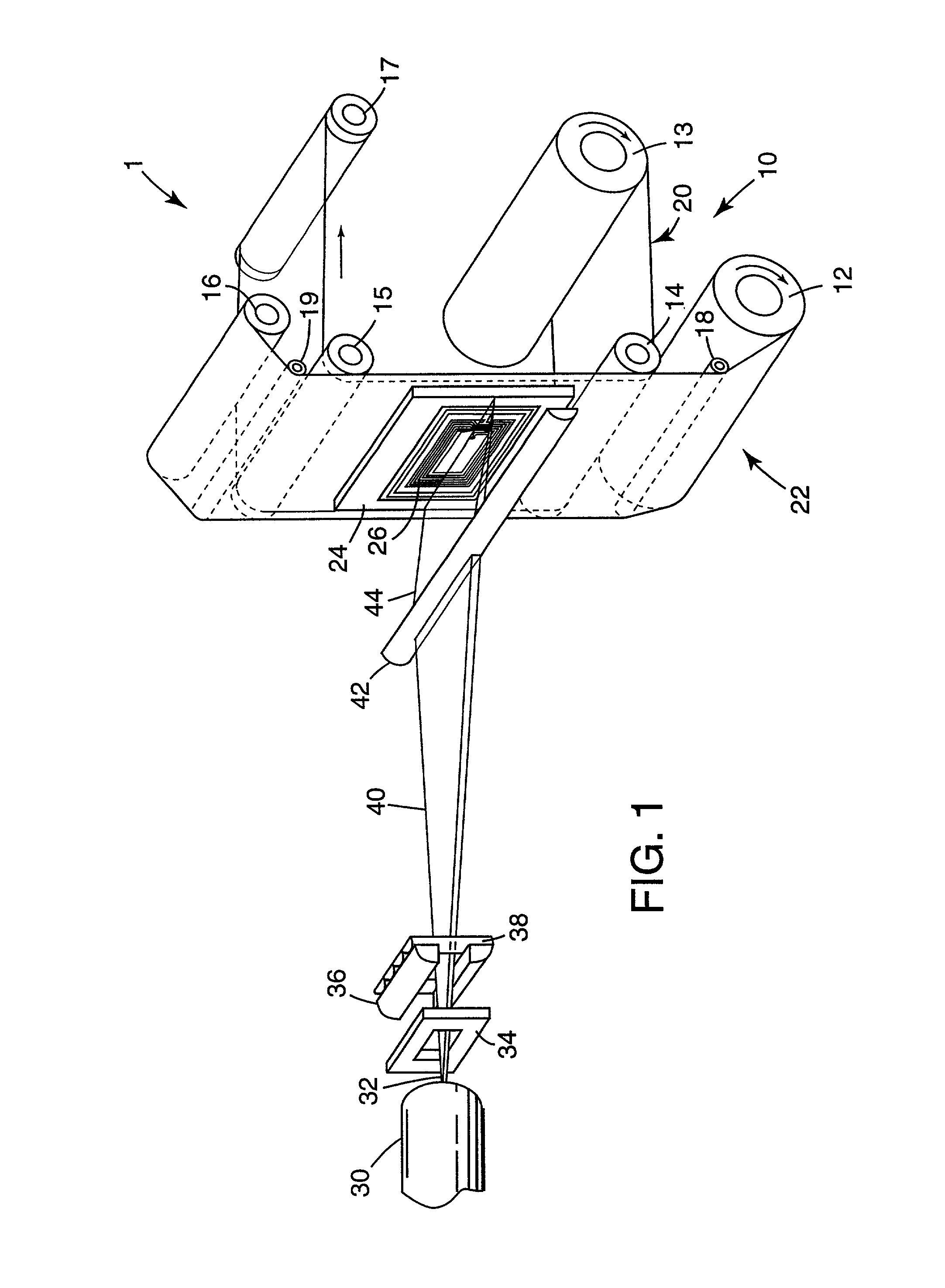

Imaged article on polymeric substrate

InactiveUS6203952B1Increasing the thicknessSmooth peelingAntenna supports/mountingsLoop antennasResistPolymer substrate

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of:A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other;B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating; andC. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation.The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

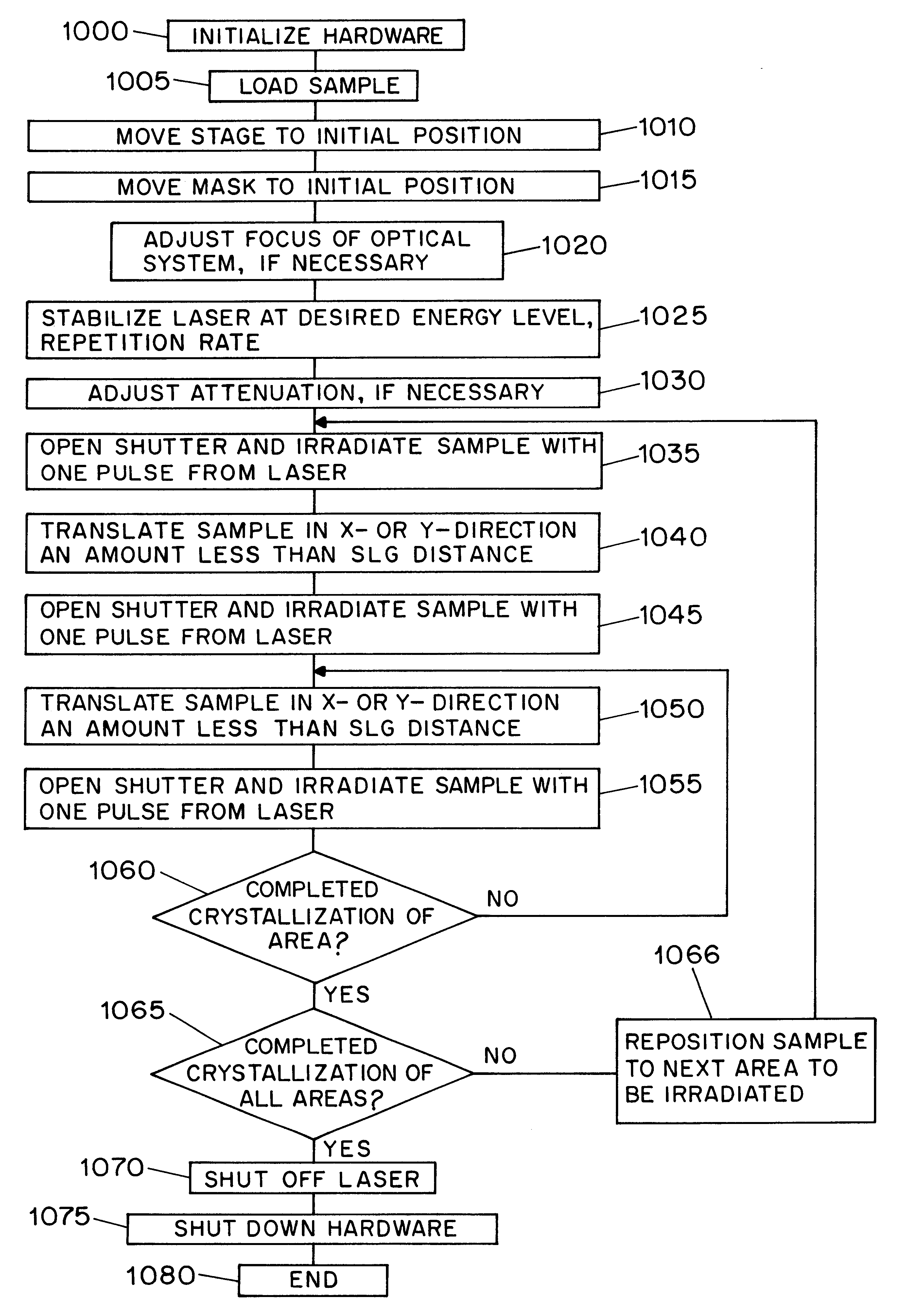

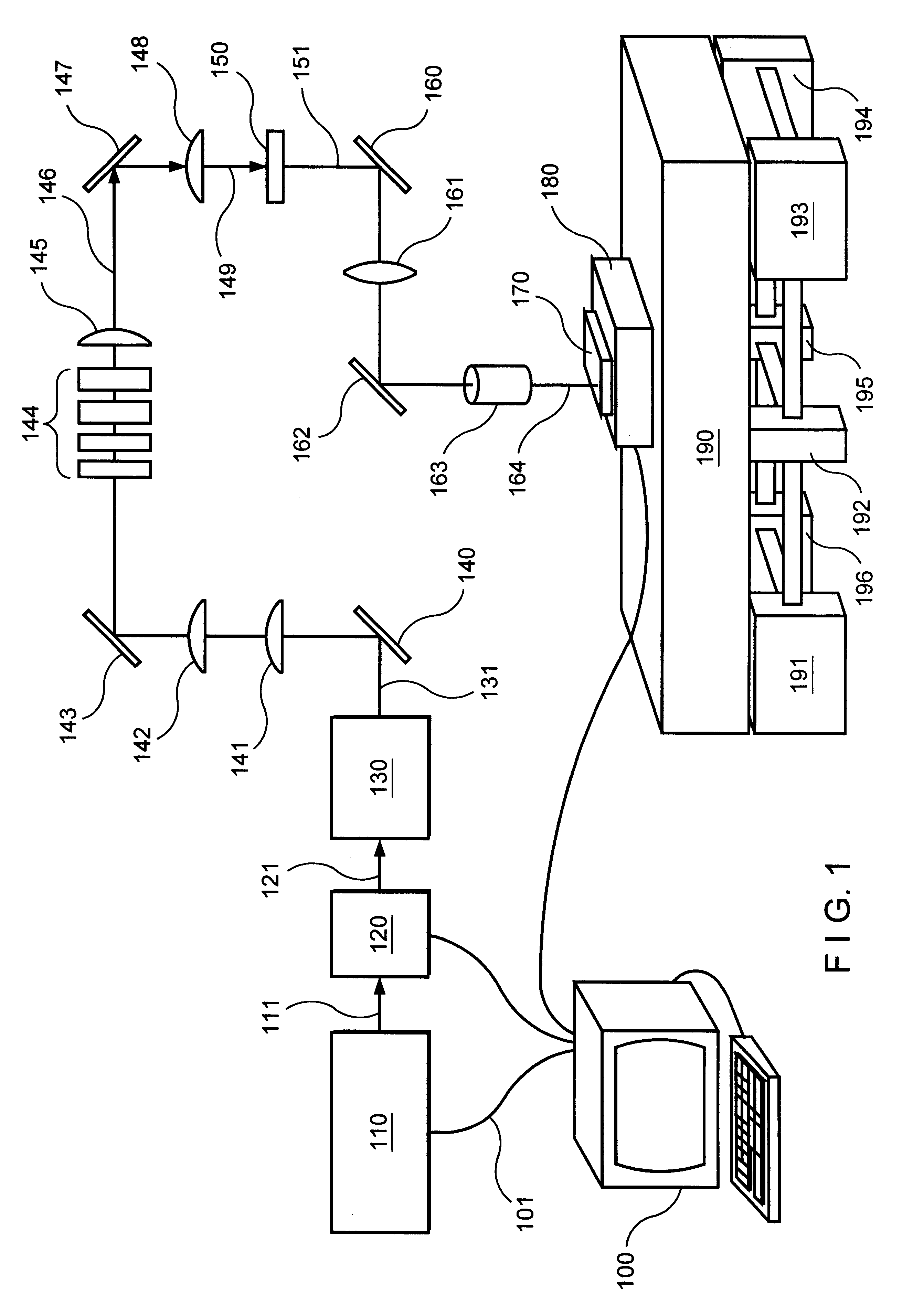

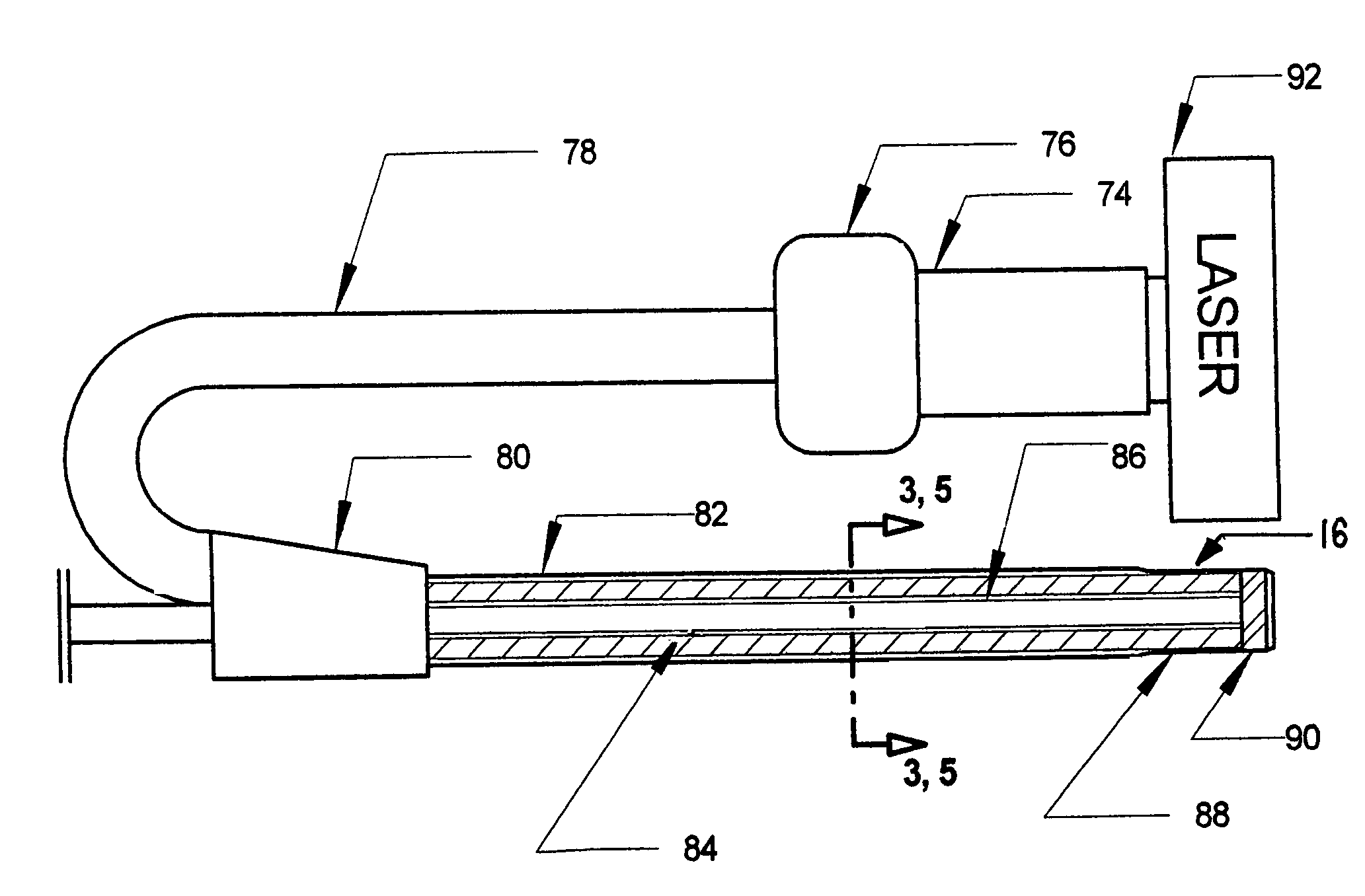

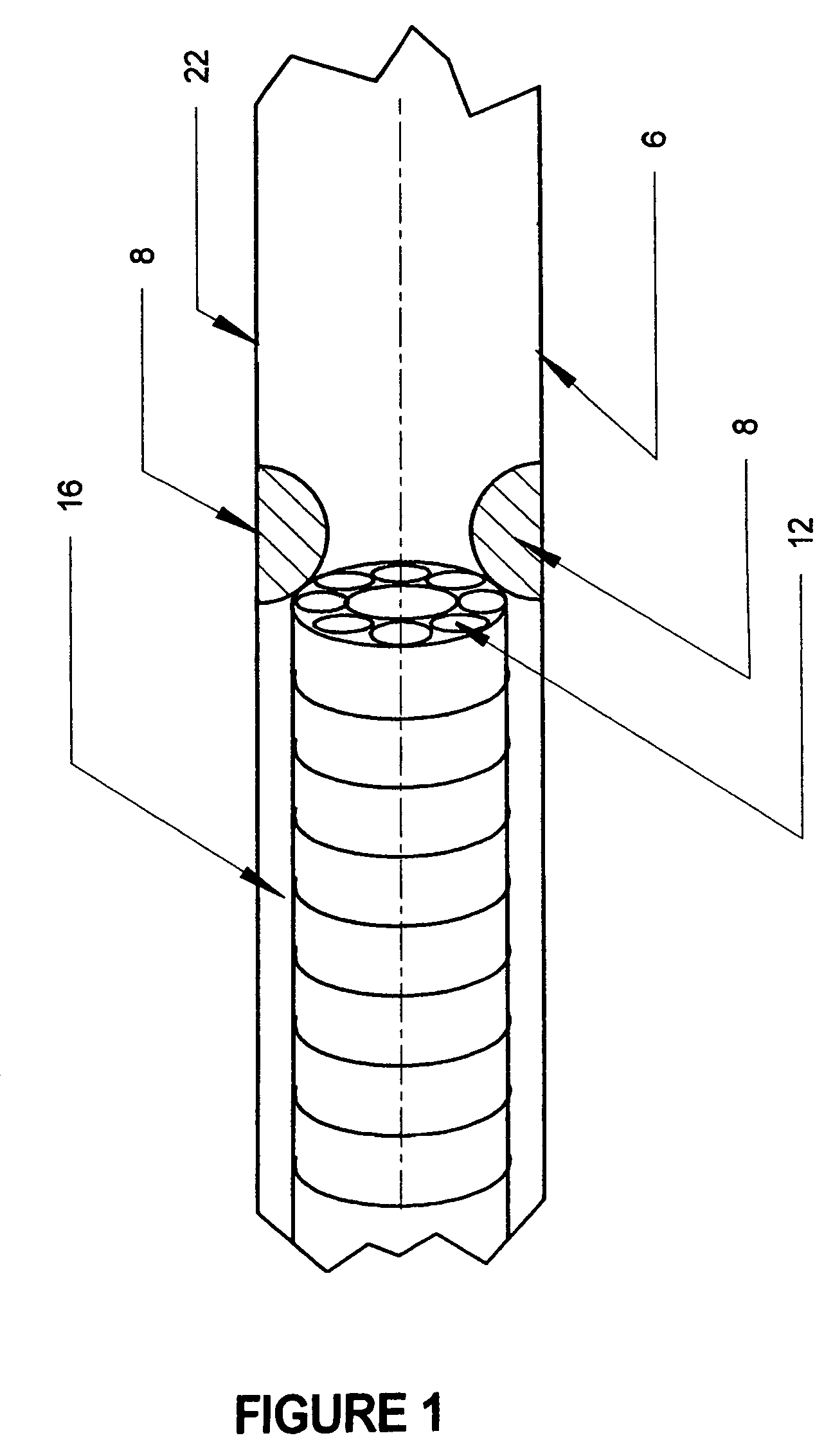

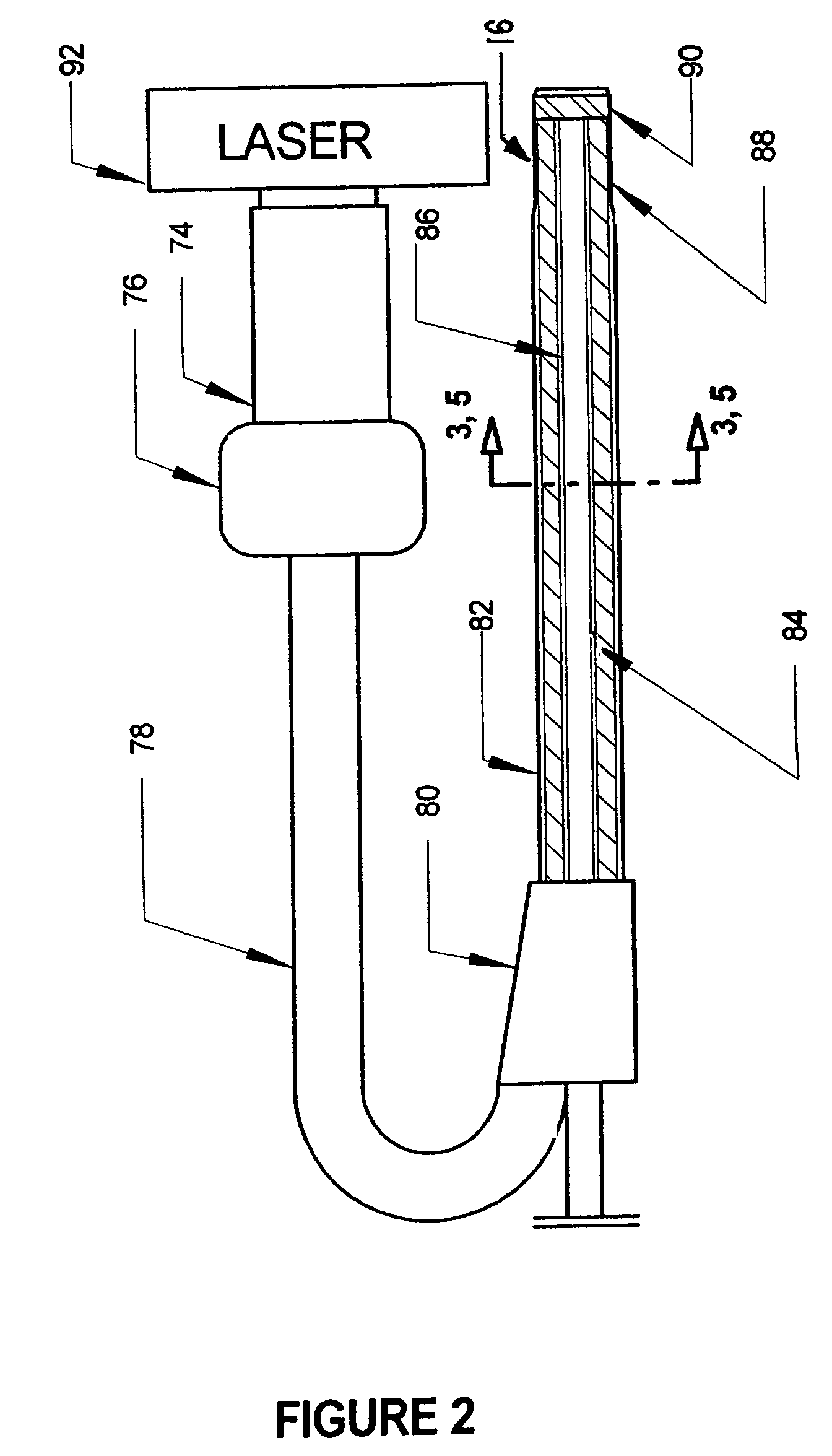

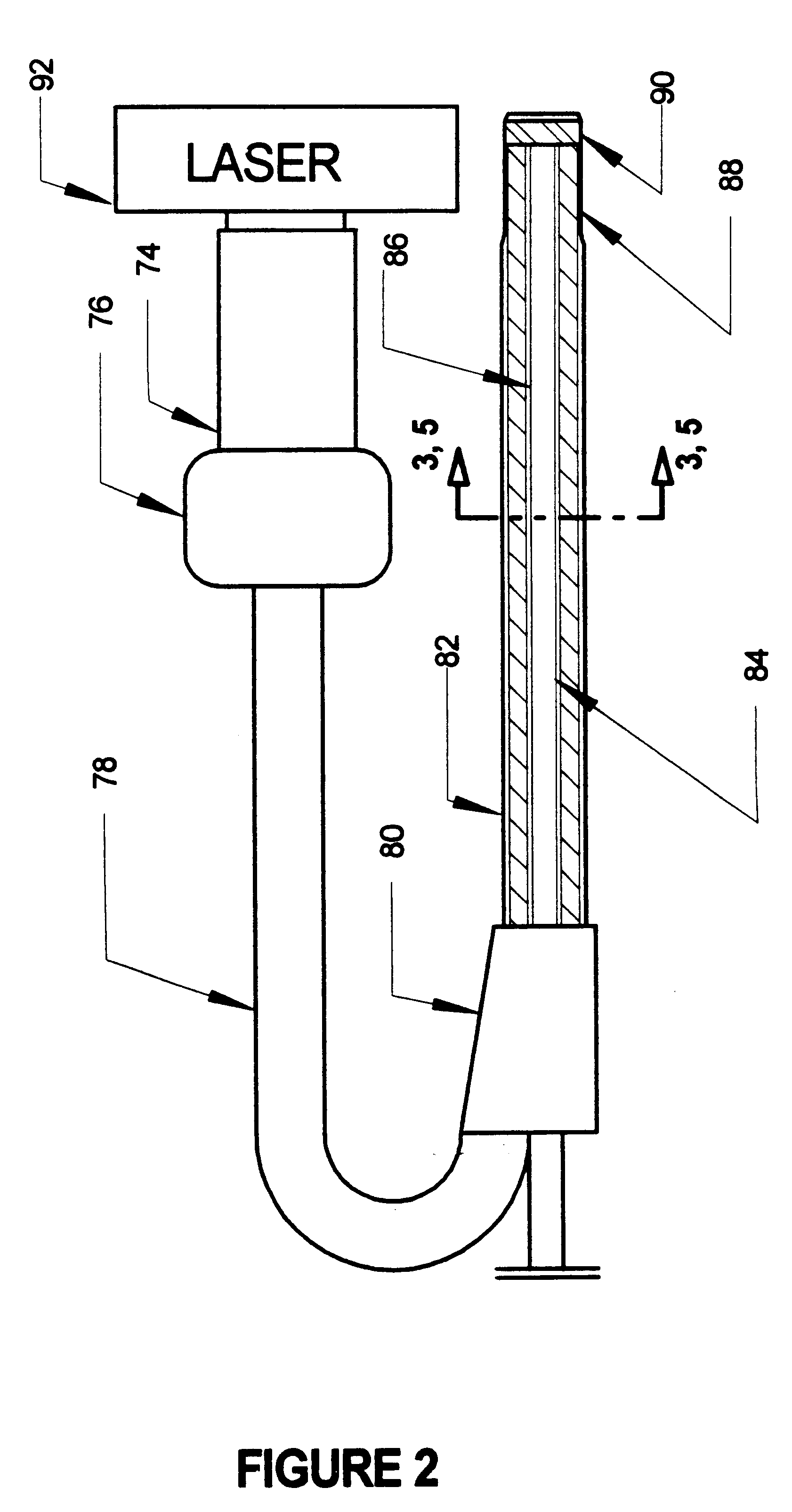

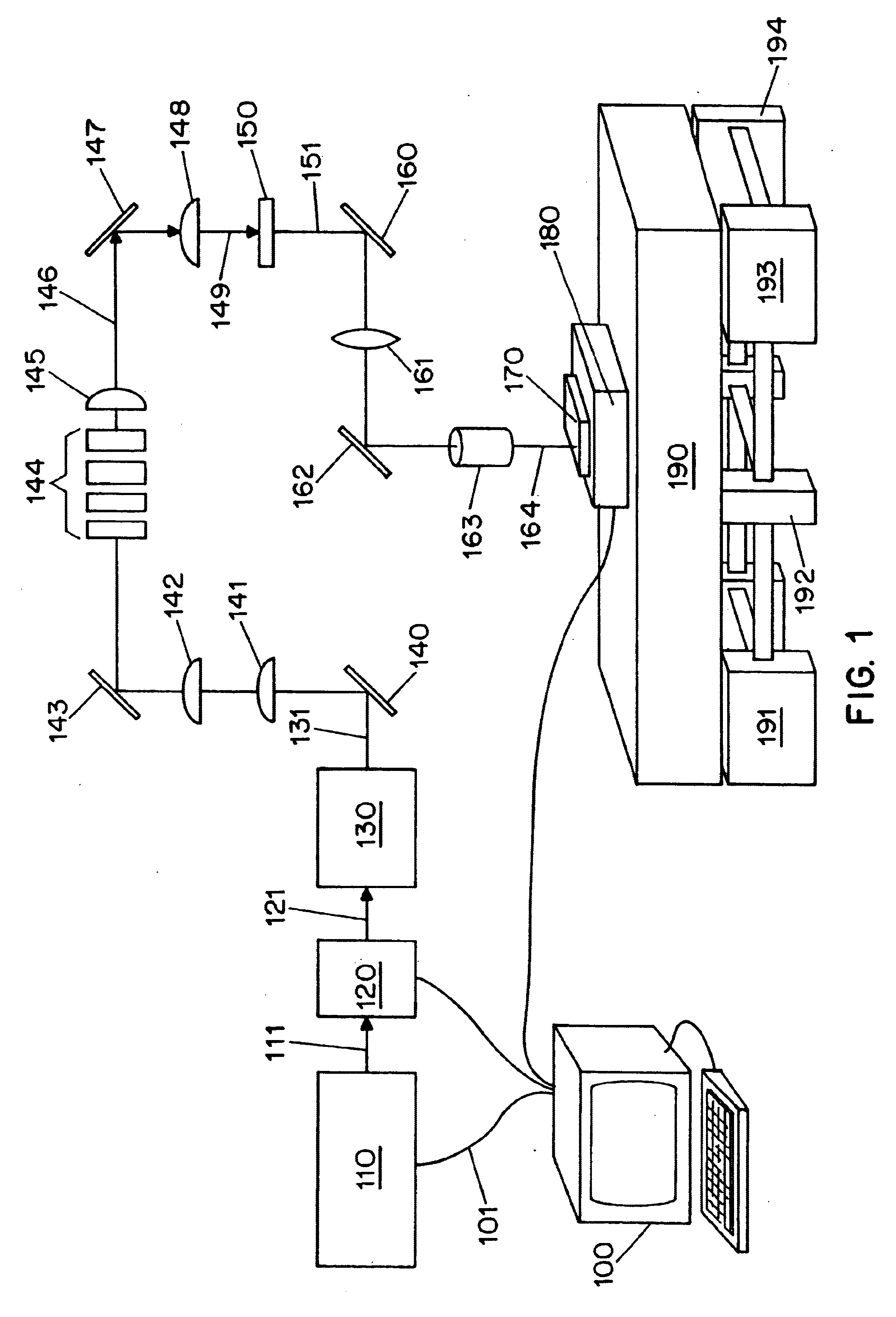

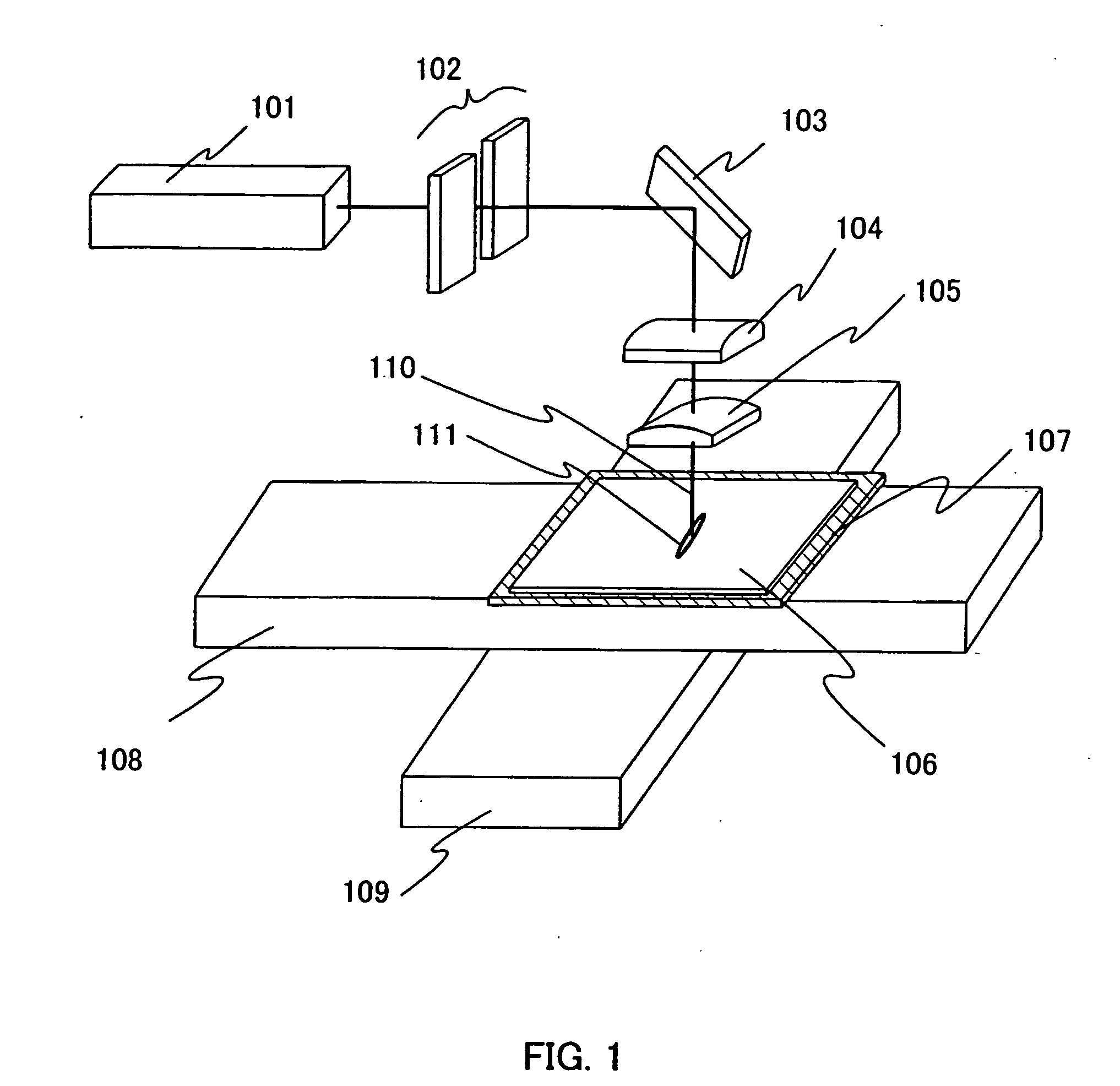

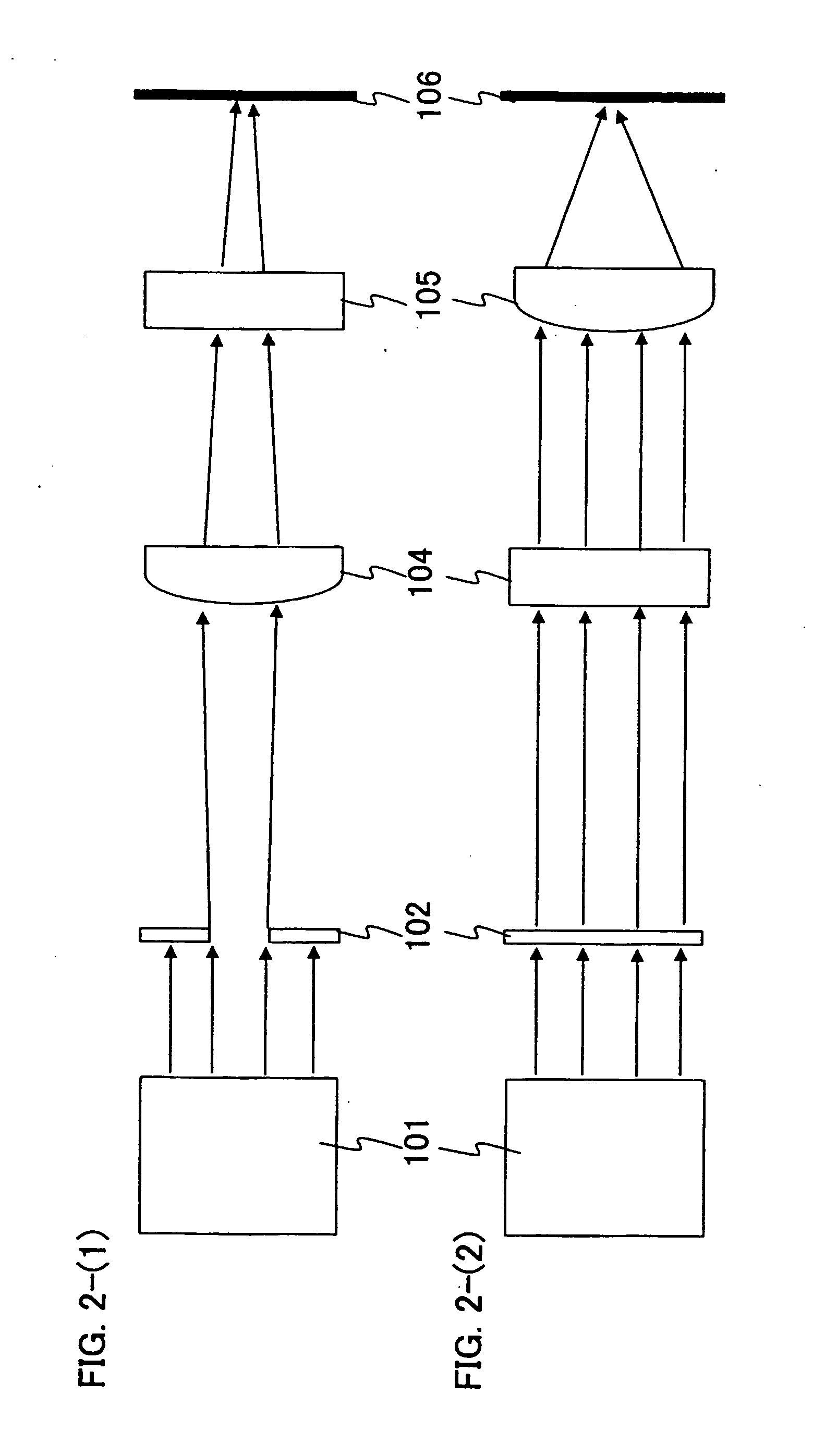

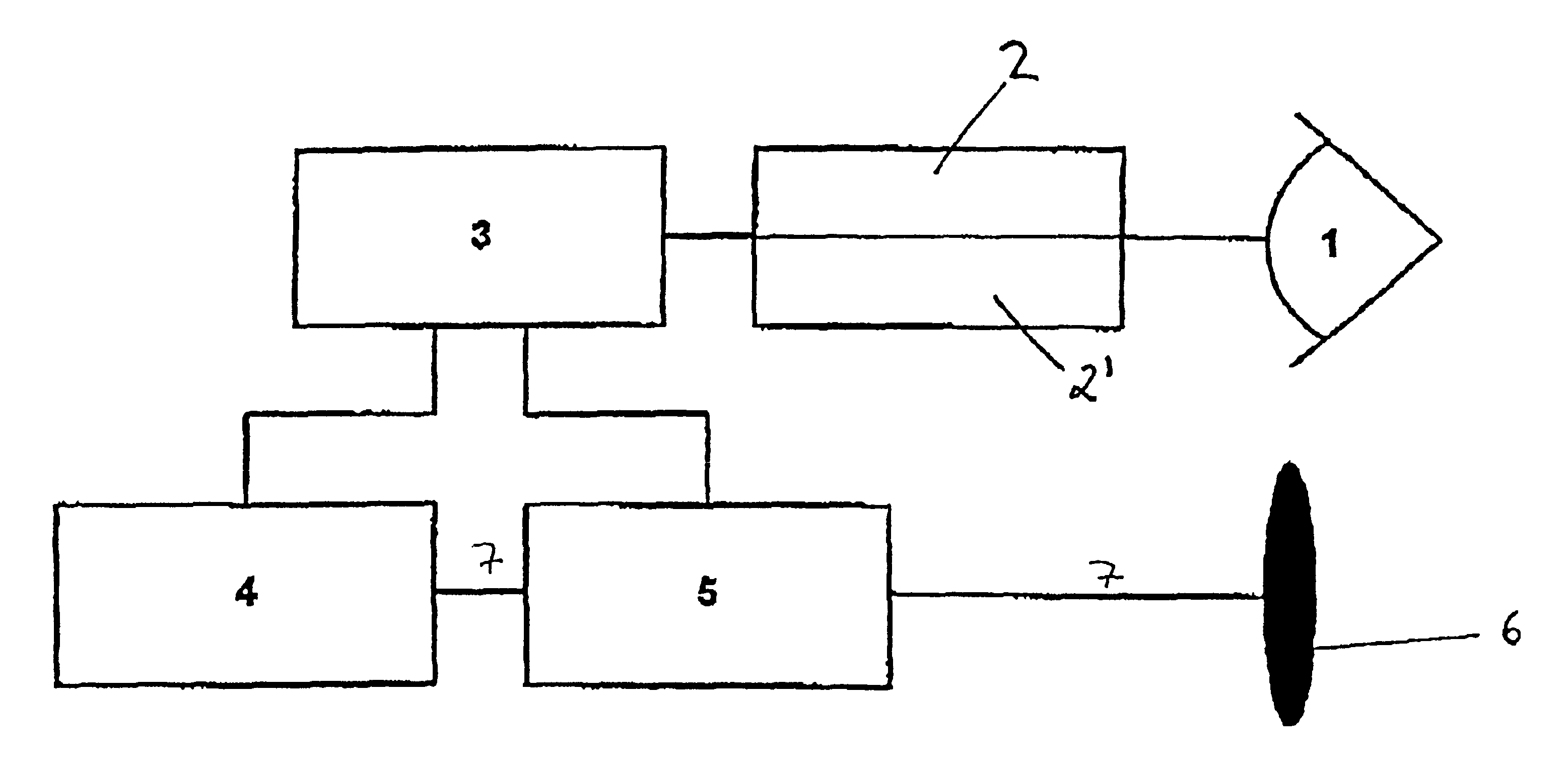

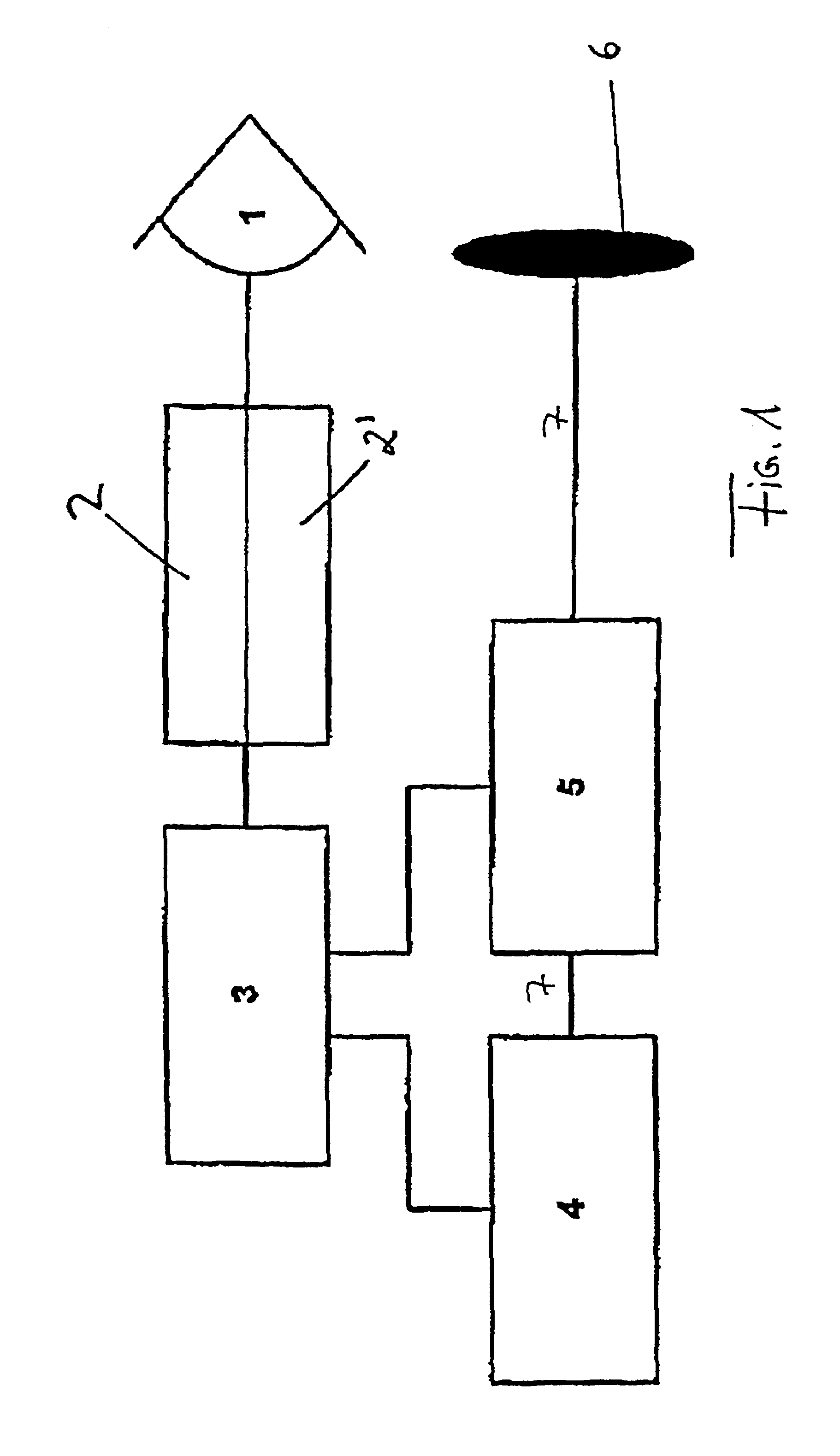

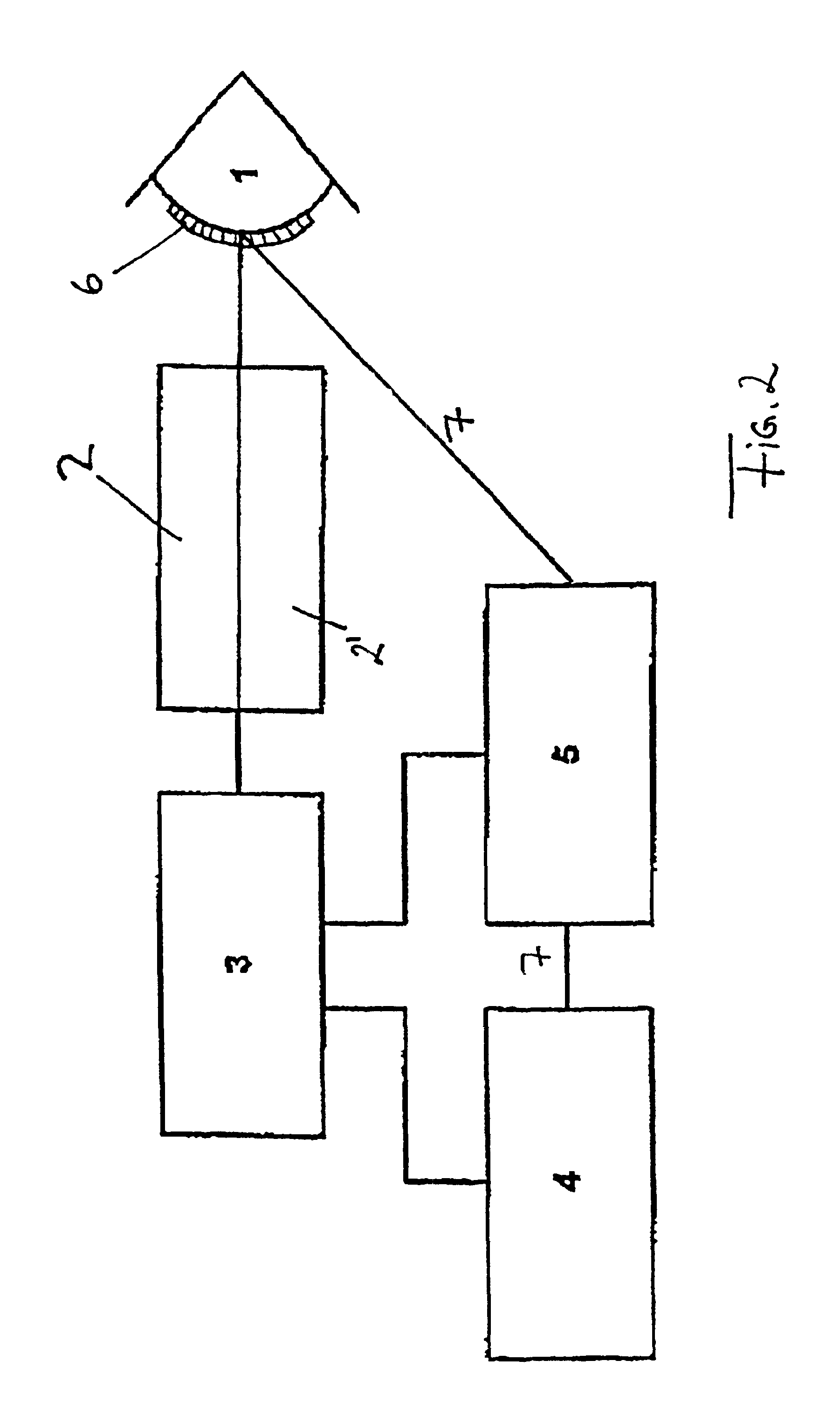

Systems and methods using sequential lateral solidification for producing single or polycrystalline silicon thin films at low temperatures

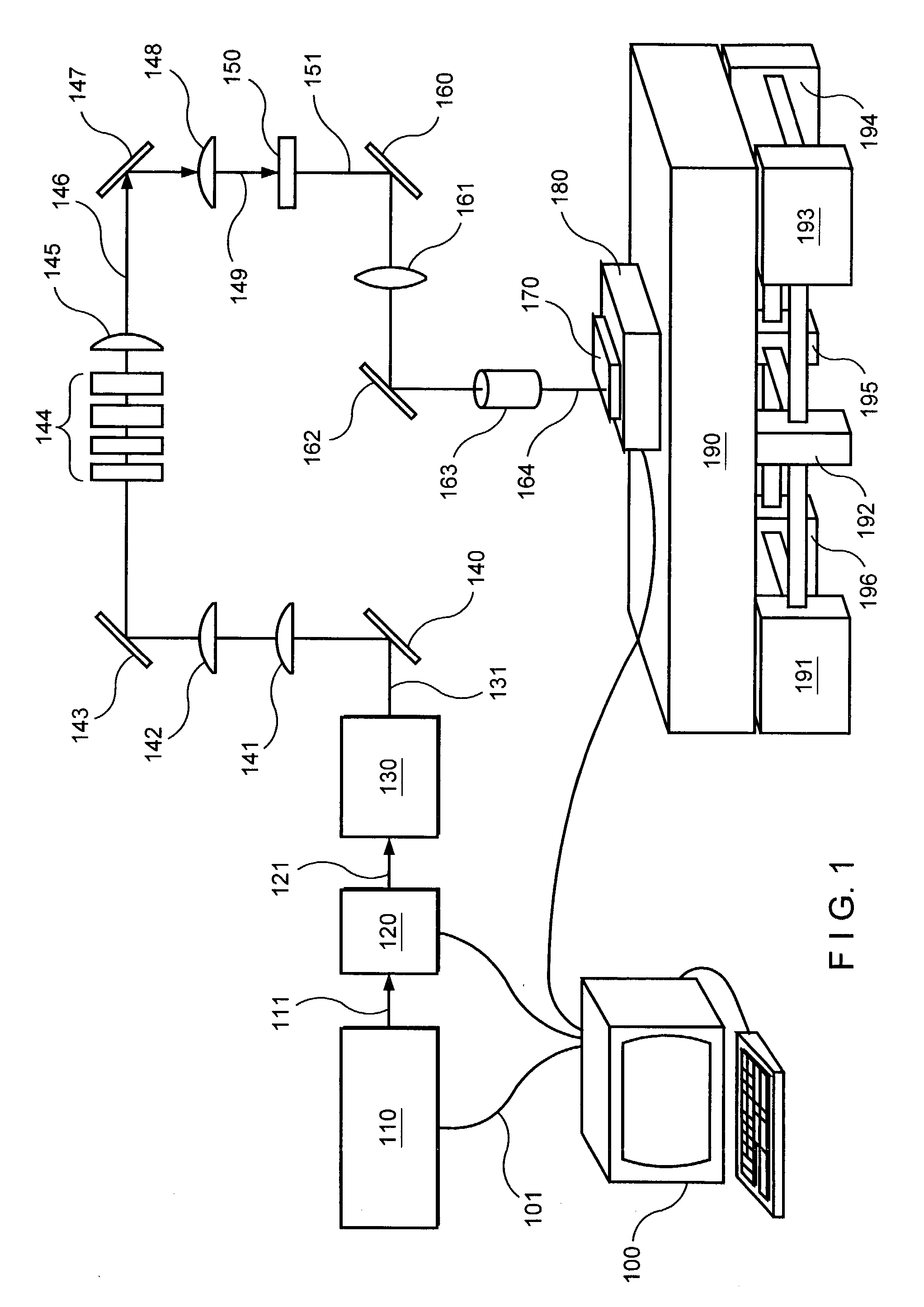

System and methods for processing an amorphous silicon thin film sample into a single or polycrystalline silicon thin film are disclosed. The system includes an excimer laser for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator for controllably modulating fluence of the excimer laser pulses, a beam homoginizer for homoginizing modulated laser pulses in a predetermined plane, a mask for masking portions of the homoginized modulated laser pulses into patterned beamlets, a sample stage for receivingthe patterned beamlets to effect melting of portions of any amorphous silicon thin film sample placed thereon corresponding to the beamlets, translating means for controllably translating a relative position of the sample stage with respect to a position of the mask and a computer for controlling the controllable fluence modulation of the excimer laser pulses and the controllable relative positions of the sample stage and mask, and for coordinating excimer pulse generation and fluence modulation with the relative positions of the sample stage and mask, to thereby process amorphous silicon thin film sample into a single or polycrystalline silicon thin film by sequential translation of the sample stage relative to the mask and irradiation of the sample by patterned beamlets of varying fluence at corresponding sequential locations thereon.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Excimer laser catheter

Owner:RENTROP PETER

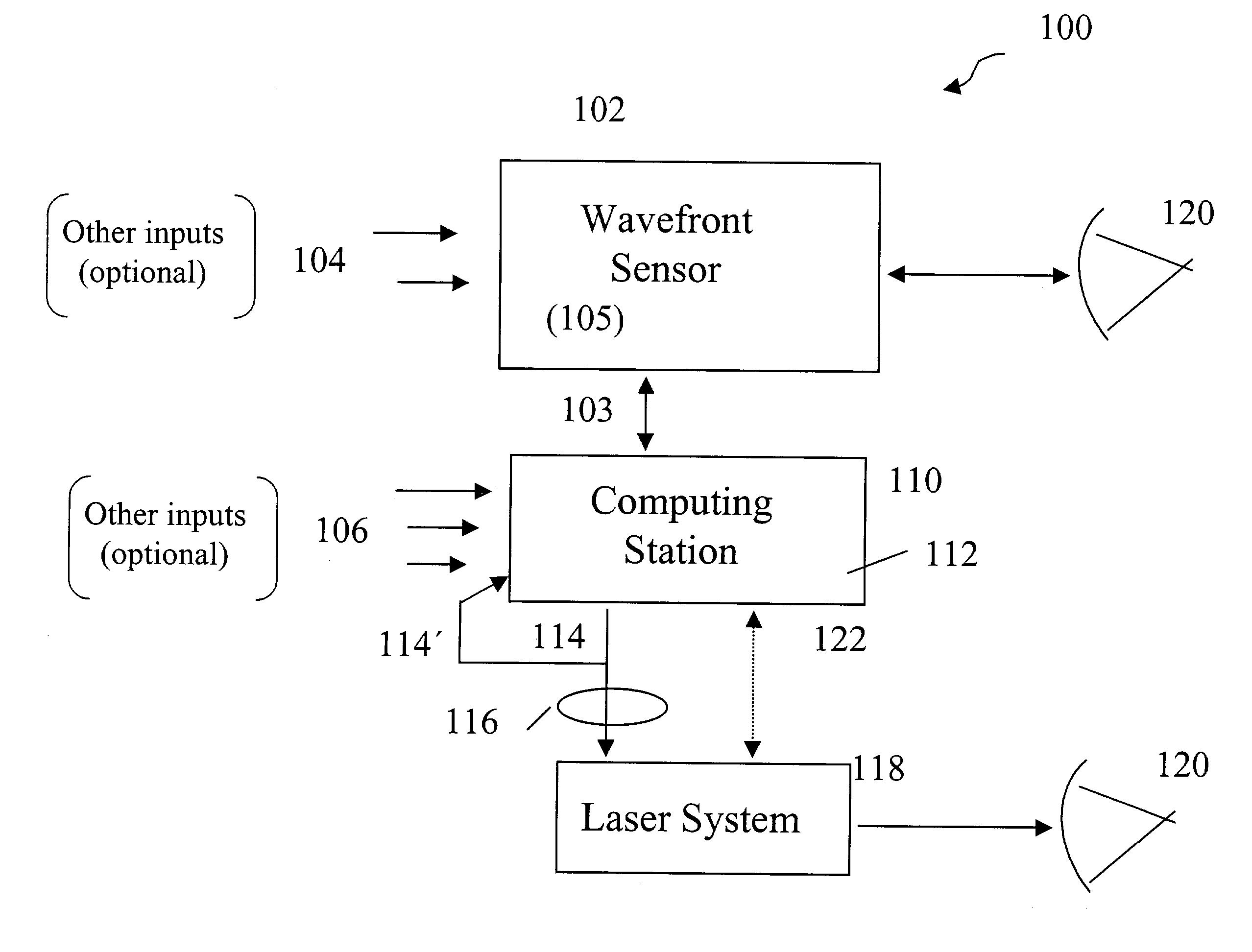

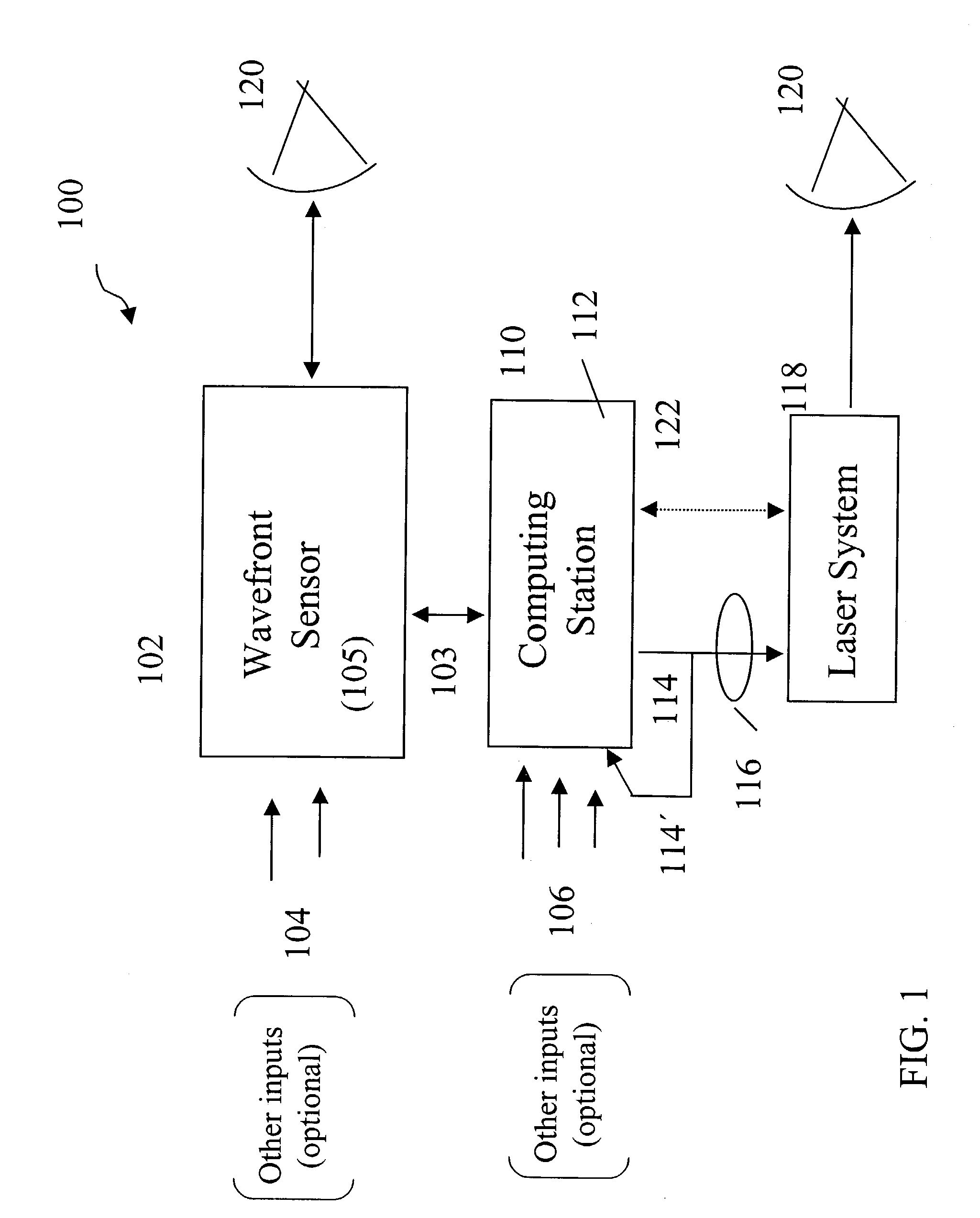

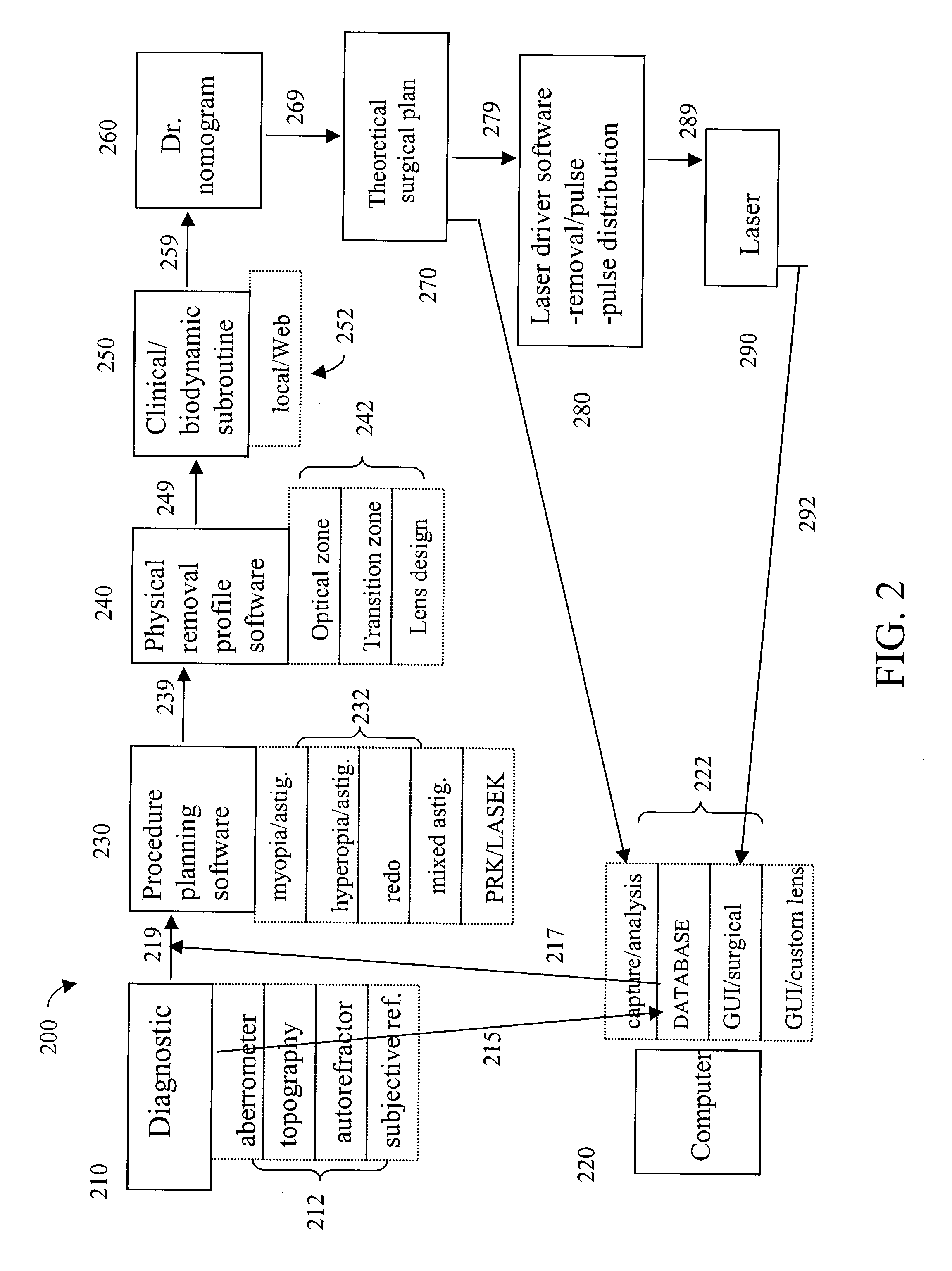

Method and apparatus to guide laser corneal surgery with optical measurement

InactiveUS20070282313A1Faster visual recoveryLess invasiveLaser surgerySurgical instrument detailsRefractive errorPhototherapeutic keratectomy

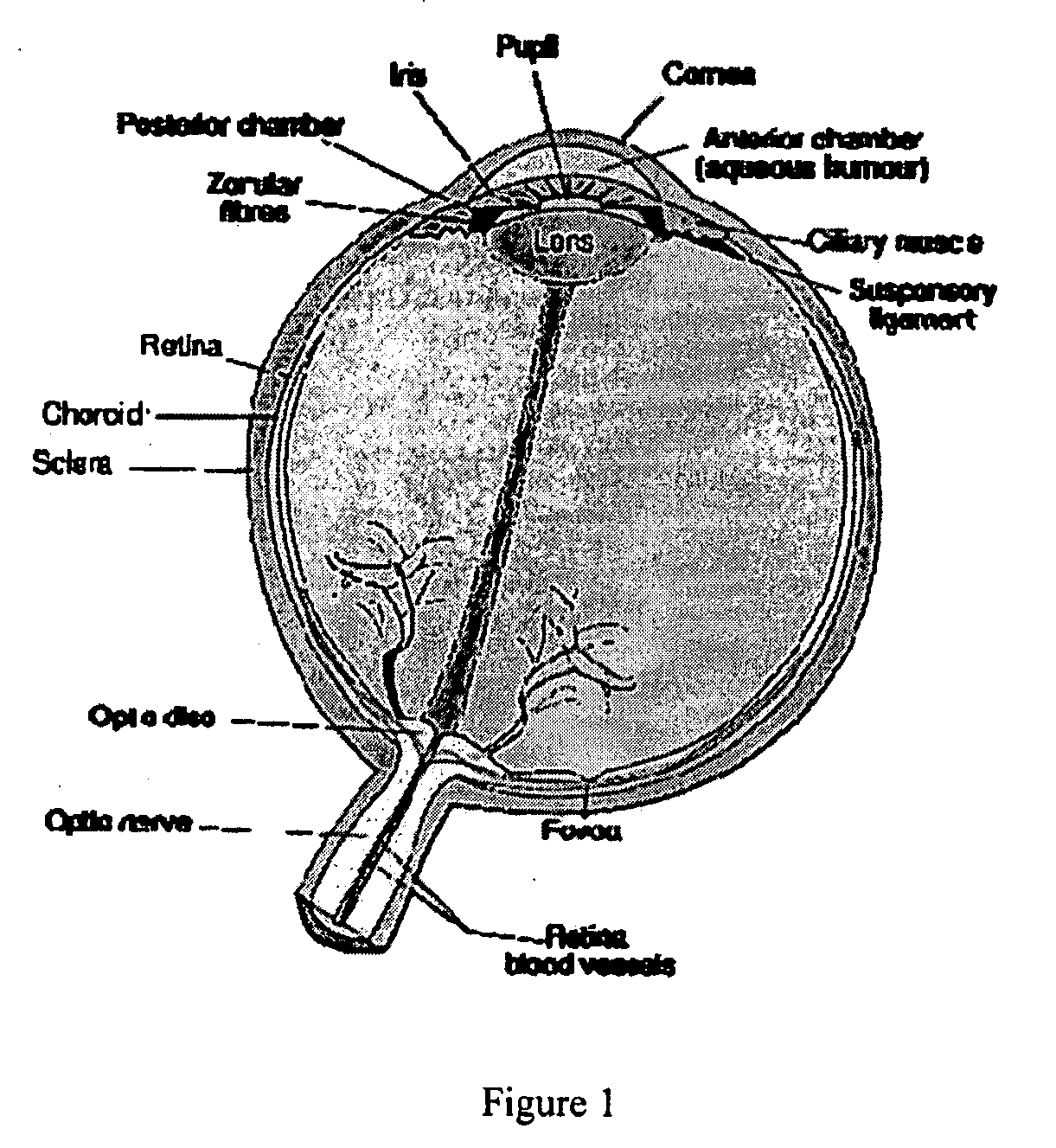

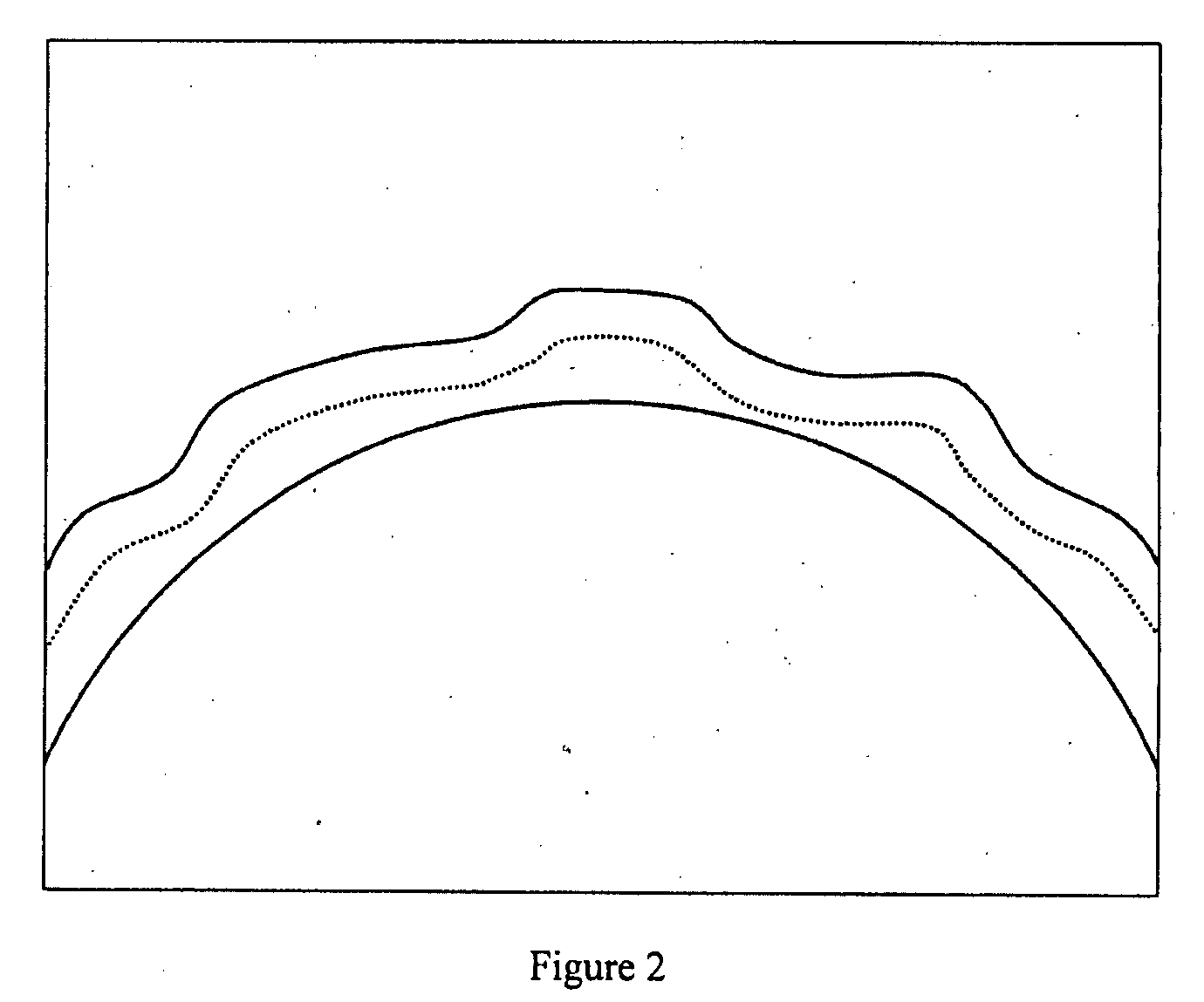

Optical coherence tomography (OCT) is used to map the surface elevation and thickness of the cornea. The OCT maps are used to plan laser procedures for the treatment of an irregular, opacified or weakened cornea, and in the treatment of refractive errors. In the excimer laser phototherapeutic keratectomy (PTK) procedure, the OCT data is used to plan a map of ablation depth needed to restore a smooth optical surface. In the excimer laser photorefractive keratectomy procedure, OCT mapping of epithelial thickness is used to achieve clean laser epithelial removal. In femtosecond laser anterior keratoplasty procedure, OCT data is used to plan the depth of femtosecond laser dissection to remove an anterior layer of the cornea, leaving a smooth recipient bed of uniform thickness to receive a disk of donated corneal tissue. The linkage of an OCT system to a precise laser surgical system enables the performance of new procedures that are safer, less invasive and produce faster visual recovery than conventional surgical procedures.

Owner:UNIV OF SOUTHERN CALIFORNIA

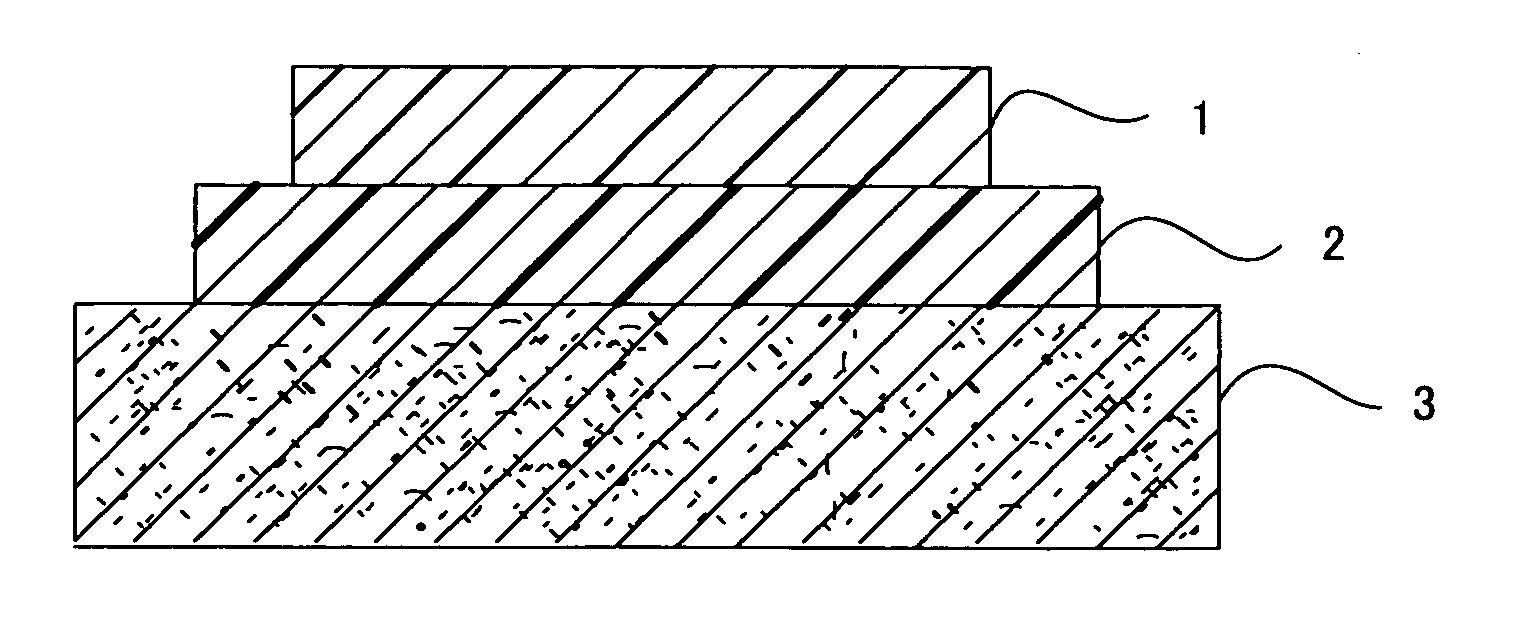

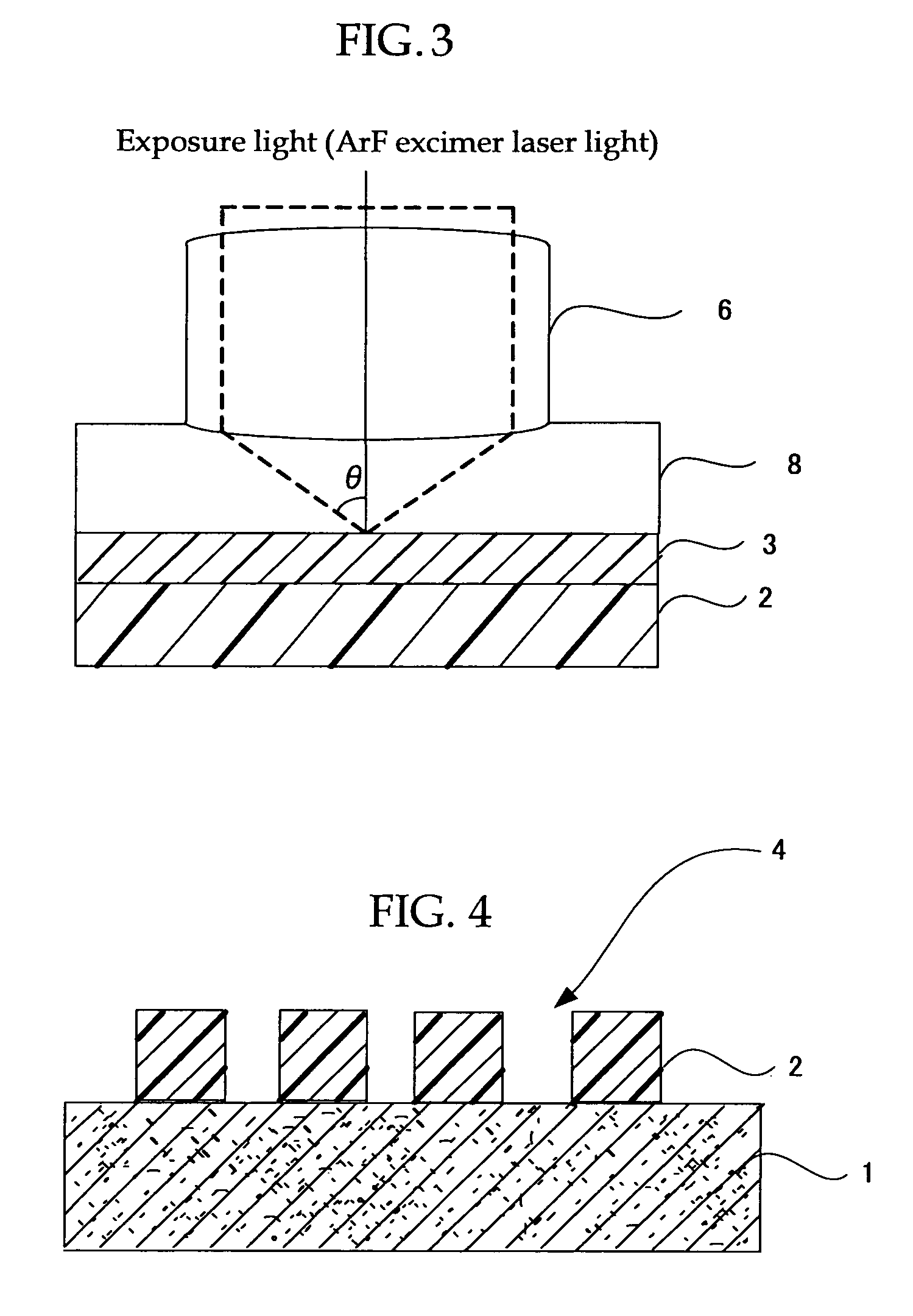

Positive resist composition and patterning process

ActiveUS20080153030A1Good storage stabilityHigh resolutionOrganic chemistryPhotosensitive materialsHigh energyPhotoacid generator

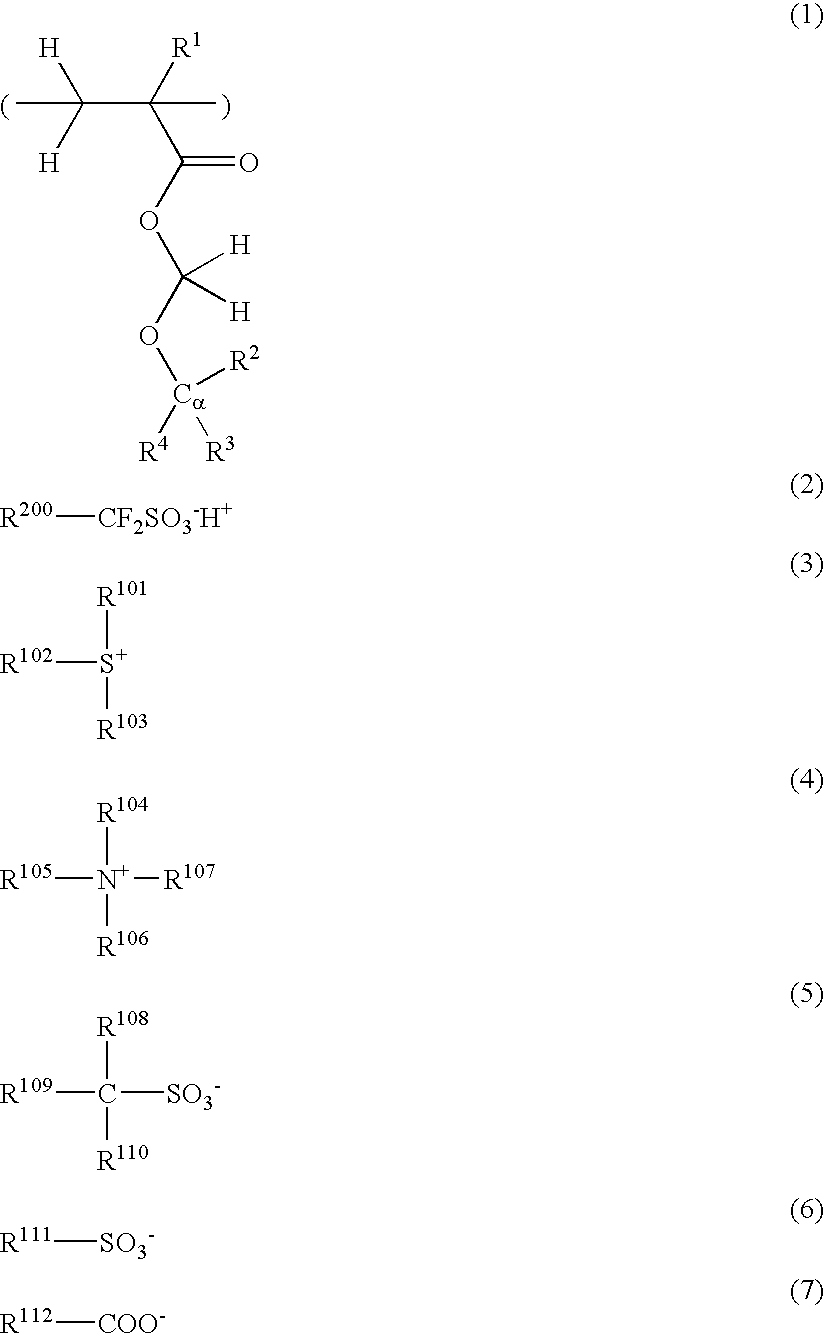

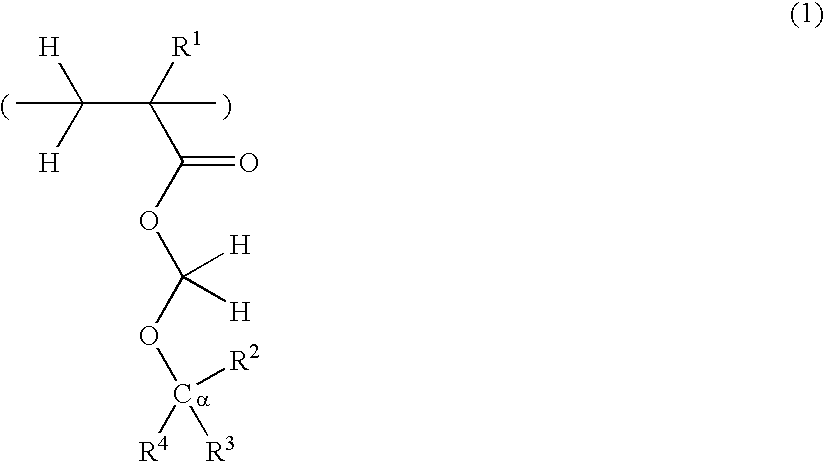

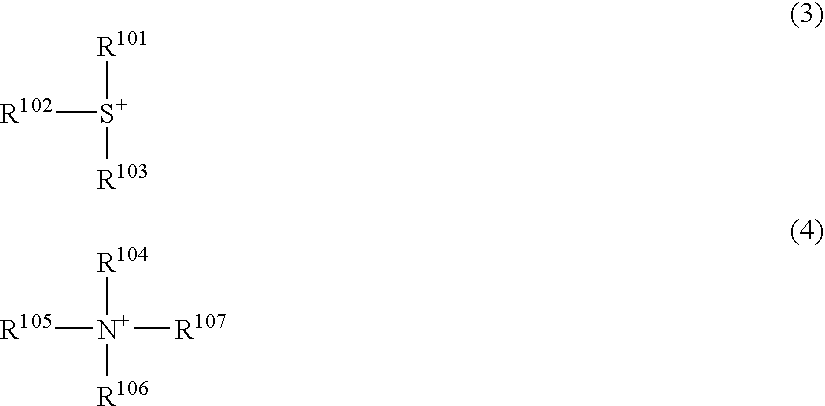

There is disclosed a resist composition that remarkably improves the resolution of photolithography using a high energy beam such as ArF excimer laser light as a light source, and exhibits excellent resistance to surface roughness and side lobe under use of a halftone phase shift mask; and a patterning process using the resist composition. The positive resist composition at least comprises (A) a resin component comprising a repeating unit represented by the following general formula (1); (B) a photoacid generator generating sulfonic acid represented by the following general formula (2) upon exposure to a high energy beam; and (C) an onium salt where a cation is sulfonium represented by the following general formula (3), or ammonium represented by the following general formula (4); and an anion is represented by any one of the following general formulae (5) to (7).

Owner:SHIN ETSU CHEM IND CO LTD

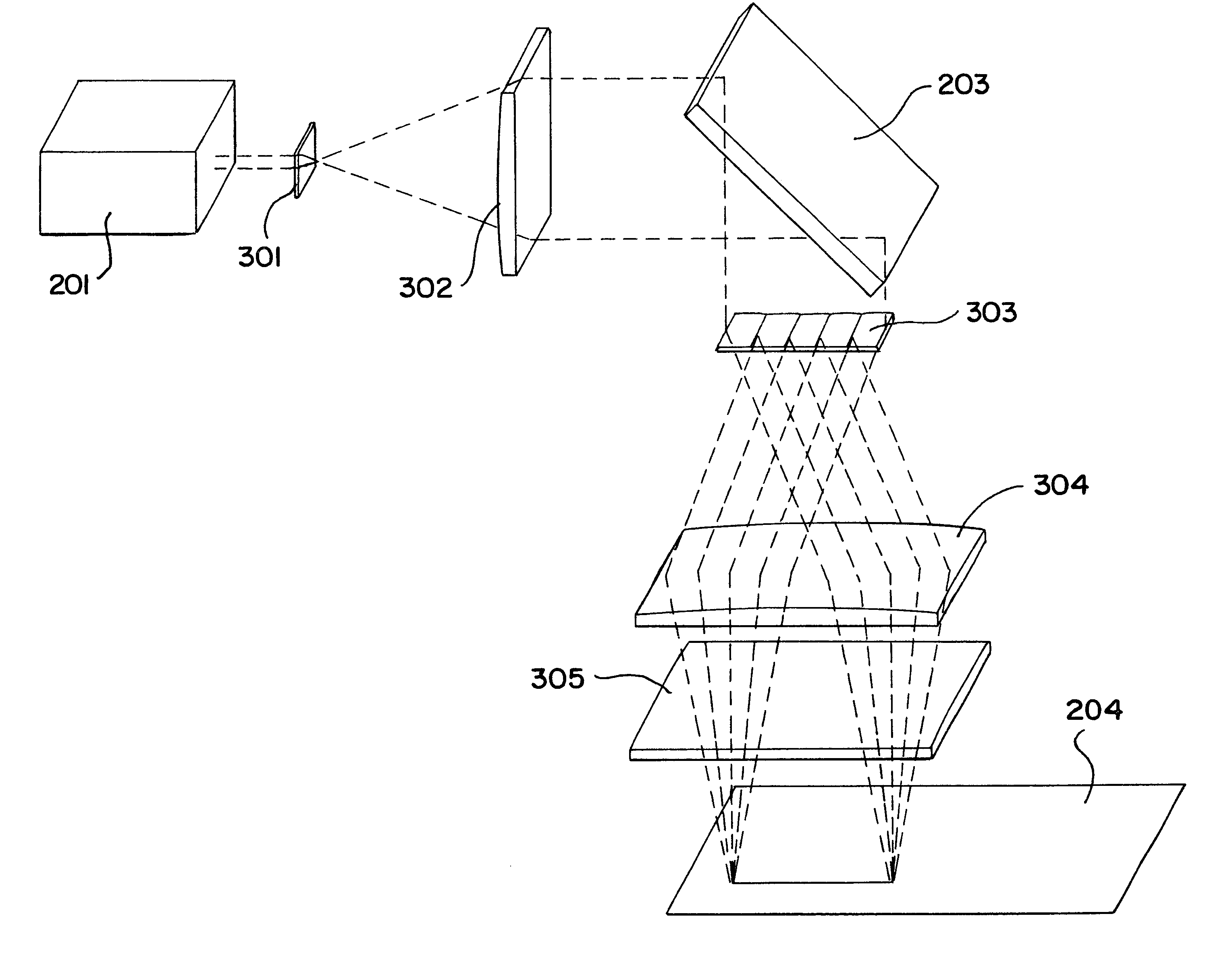

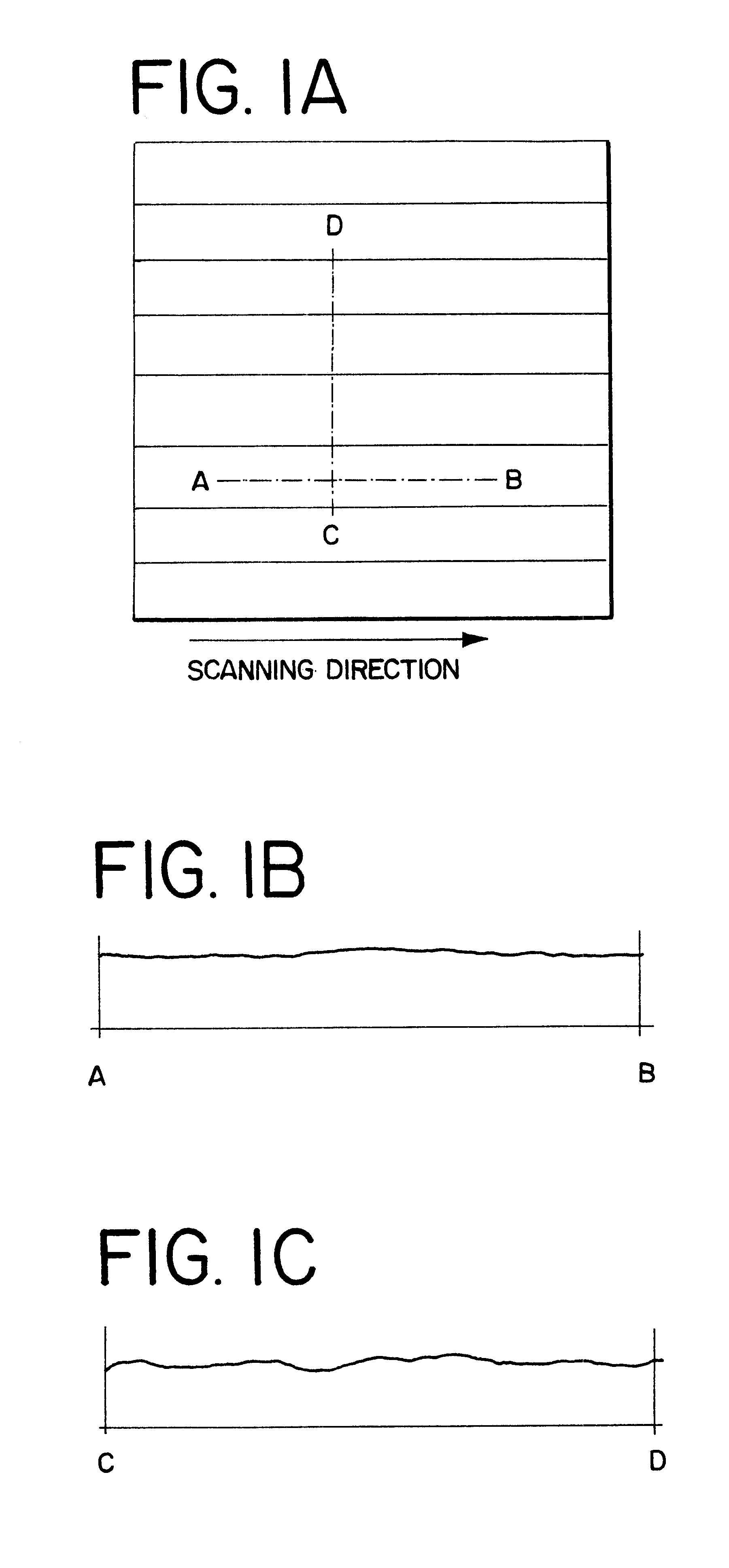

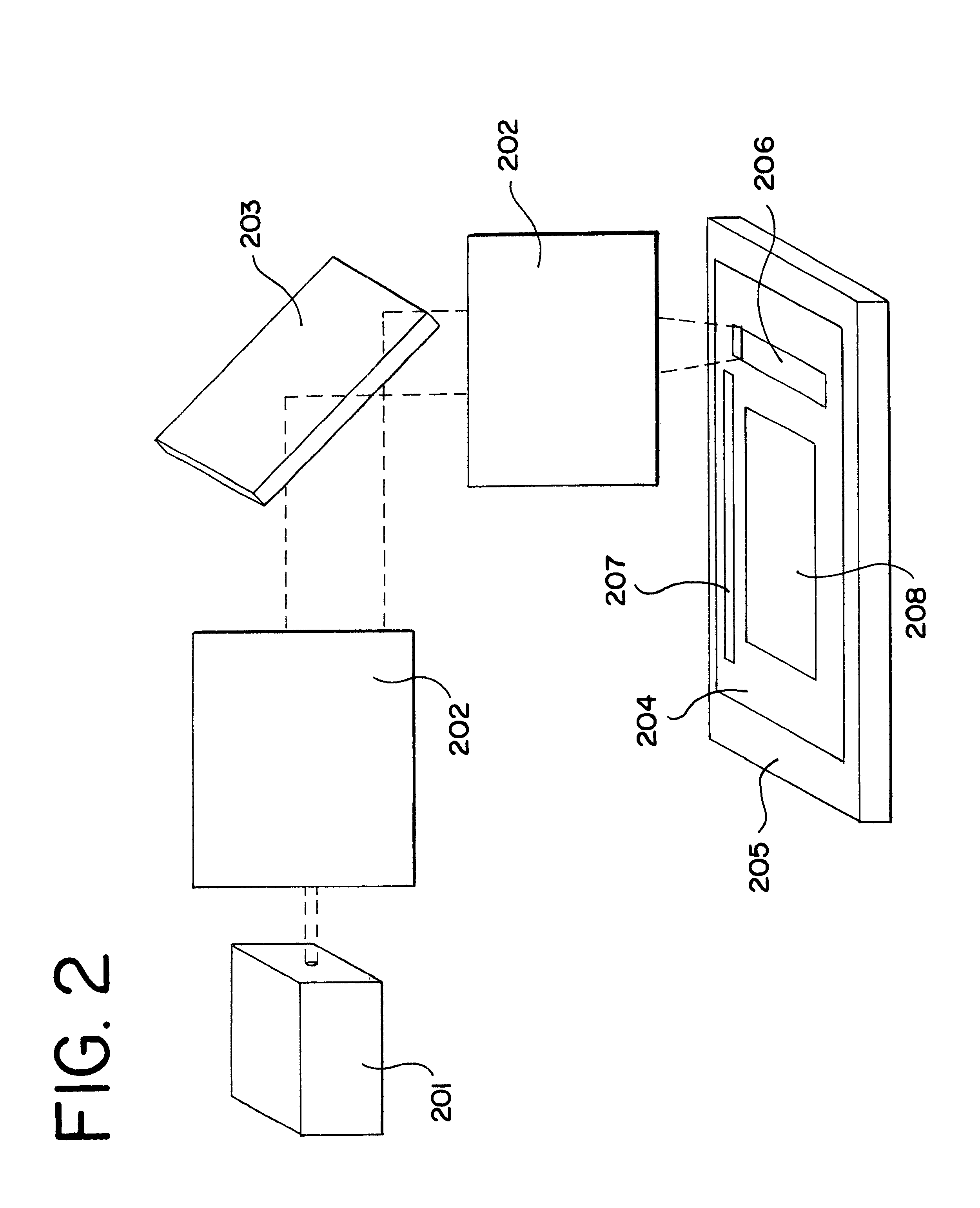

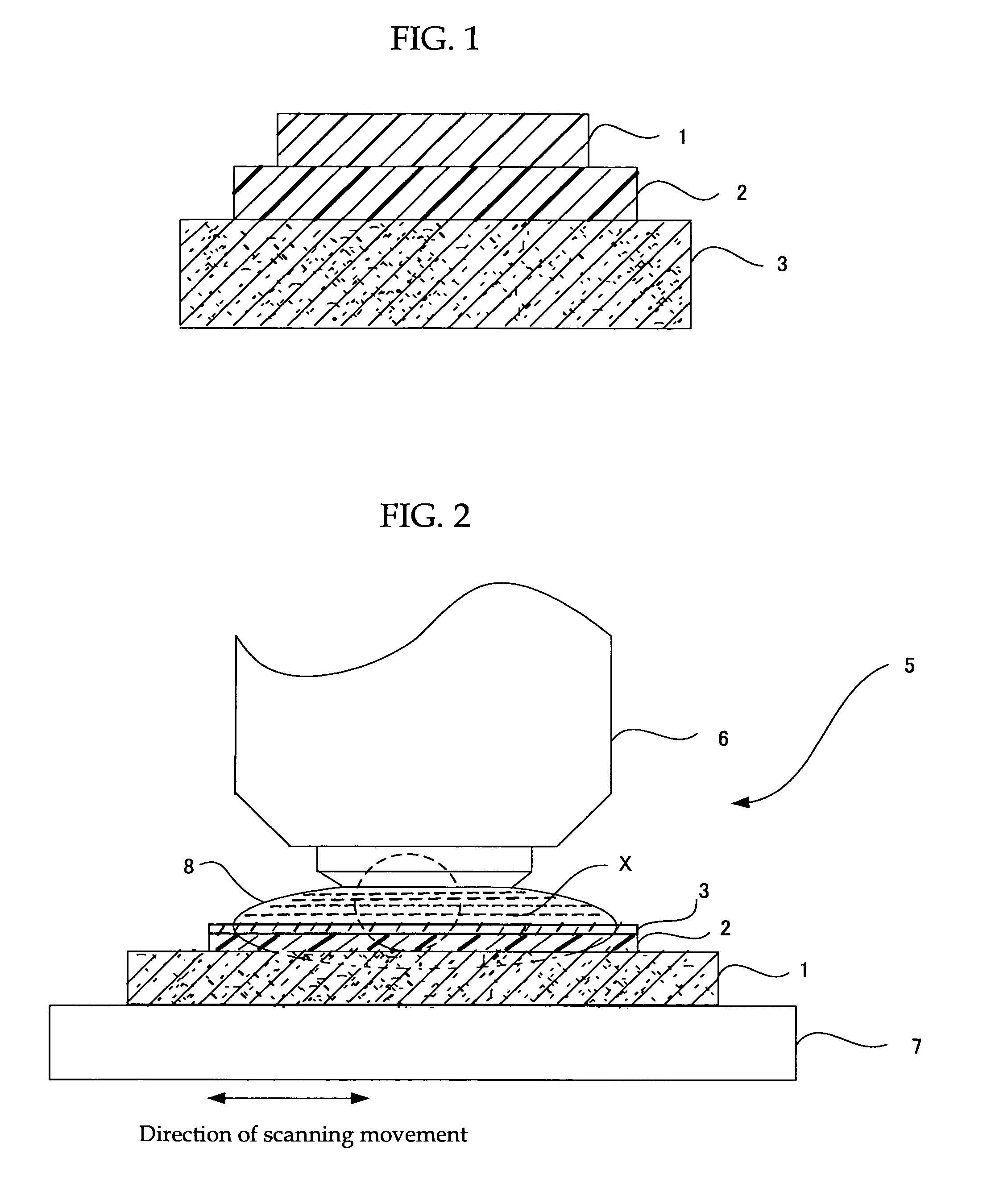

Laser irradiation method, laser irradiation apparatus, and semiconductor device

InactiveUS6535535B1Laser using scattering effectsSolid-state devicesContinuous lightLiquid-crystal display

An object of the present invention is obtaining a semiconductor film with uniform characteristics by improving irradiation variations of the semiconductor film. The irradiation variations are generated due to scanning while irradiating with a linear laser beam of the pulse emission. At a laser crystallization step of irradiating a semiconductor film with a laser light, a continuous light emission excimer laser emission device is used as a laser light source. For example, in a method of fabricating an active matrix type liquid crystal display device, a continuous light emission excimer laser beam is irradiated to a semiconductor film, which is processed to be a linear shape, while scanning in a vertical direction to the linear direction. Therefore, more uniform crystallization can be performed because irradiation marks can be avoided by a conventional pulse laser.

Owner:SEMICON ENERGY LAB CO LTD

Ophthalmic surgery method using non-contact scanning laser

InactiveUSRE37504E1Low-powerLow-cost and effectiveLaser surgeryDiagnosticsSystem parametersOphthalmic surgery

A refractive laser surgery process is disclosed for using compact, low-cost ophthalmic laser systems which have computer-controlled scanning with a non-contact delivery device for both photo-ablation and photo-coagulation in corneal reshaping. The basic laser systems may include flash-lamp and diode pumped UV solid state lasers (193-215 nm), compact excimer laser (193 nm), free-running Er:glass (1.54 microns), Ho:YAG (2.1 microns), Q-switched Er:YAG (2.94 microns), and tunable IR lasers, (750-1100) nm and (2.5-3.2) microns. The advantages of the non-contact, scanning device used in the process over other prior art lasers include being safer, reduced cost, more compact and more precise and with greater flexibility. The theory of beam overlap and of ablation rate and coagulation patterns is also disclosed for system parameters. Lasers are selected with energy of (0.01-10) mJ, repetition rate of (1-10,000), pulse duration of 0.01 nanoseconds to a few hundreds of microseconds, and with spot size of (0.05-2) mm for use with refractive laser surgery.

Owner:LASERSIGHT TECH

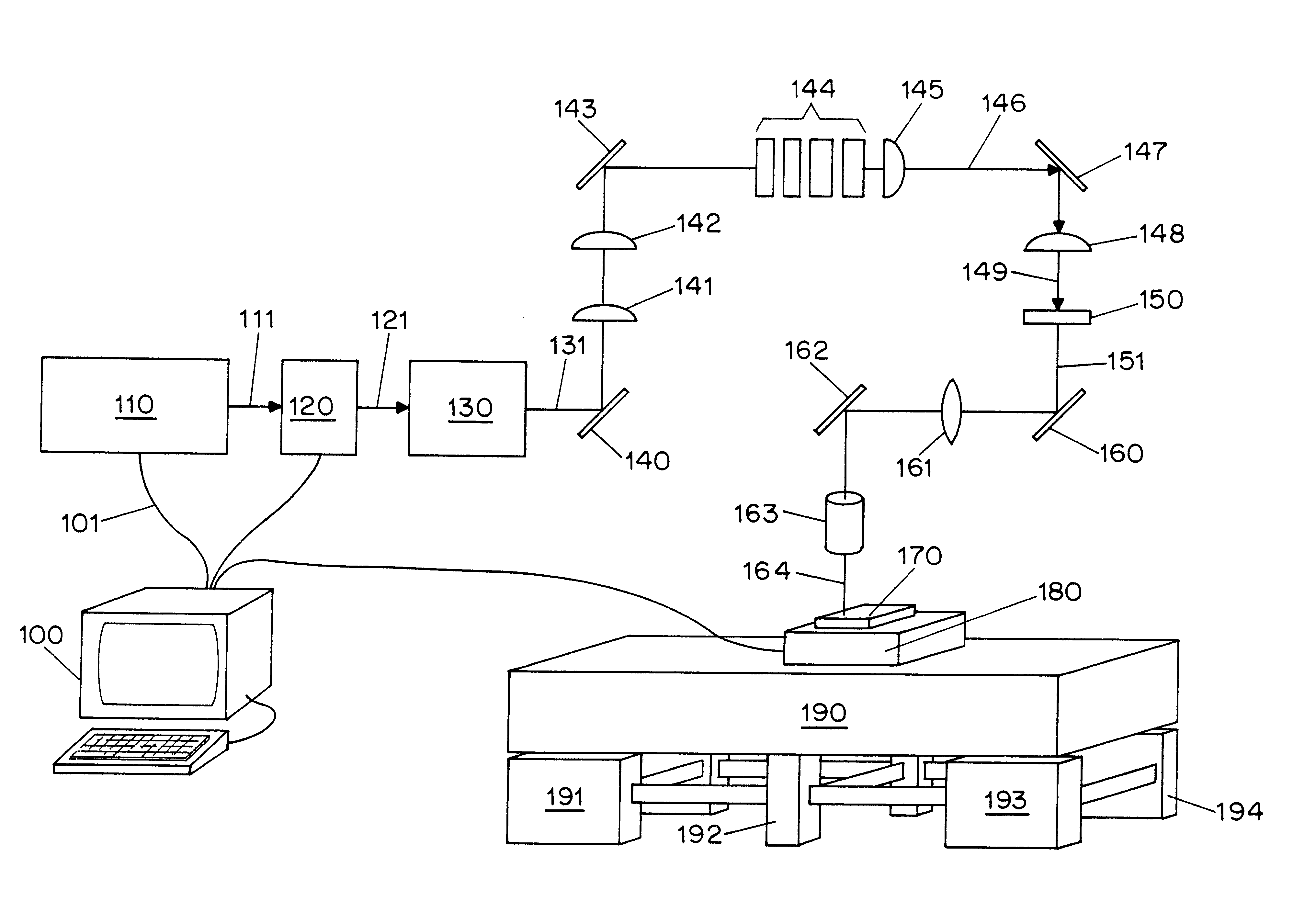

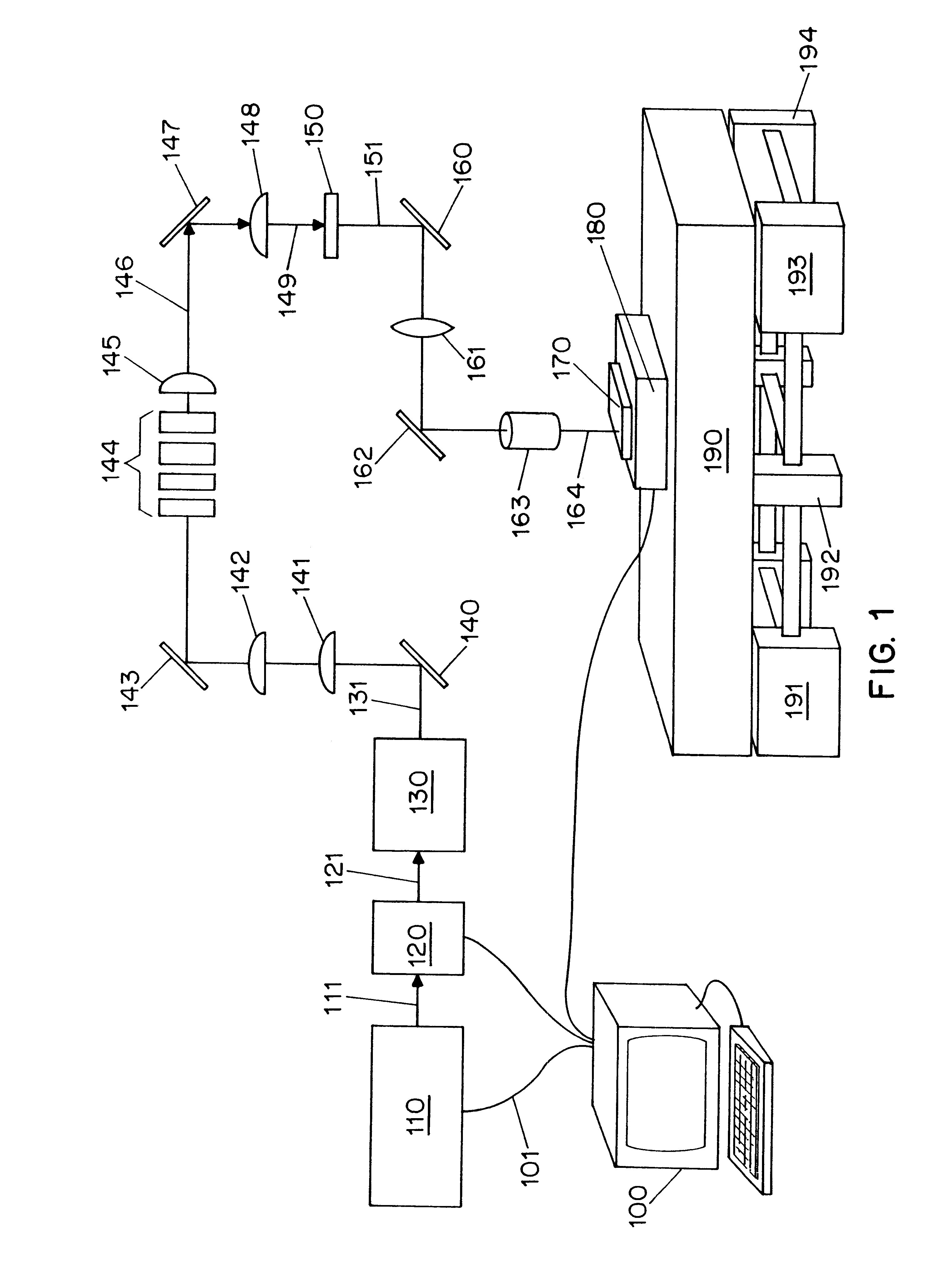

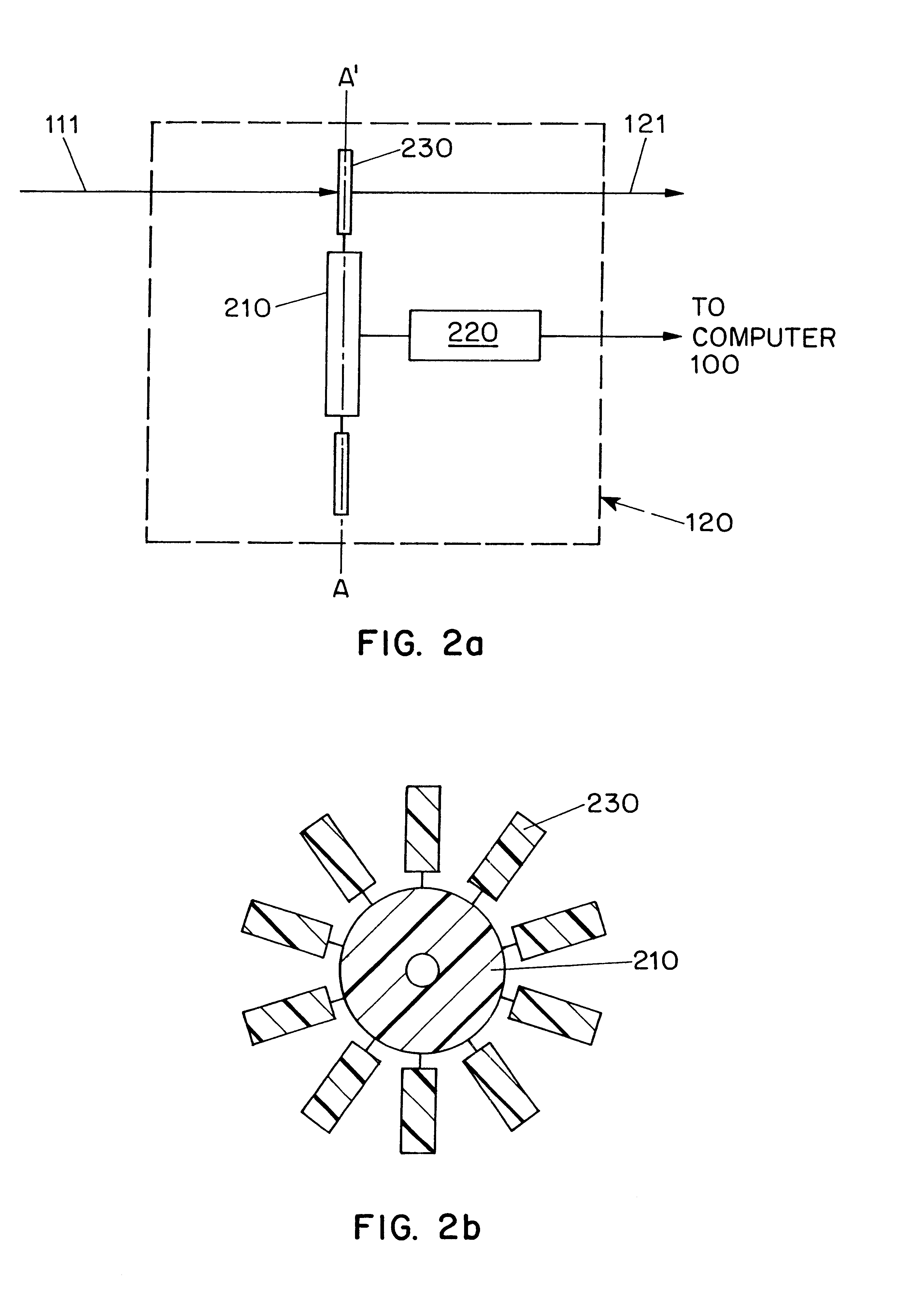

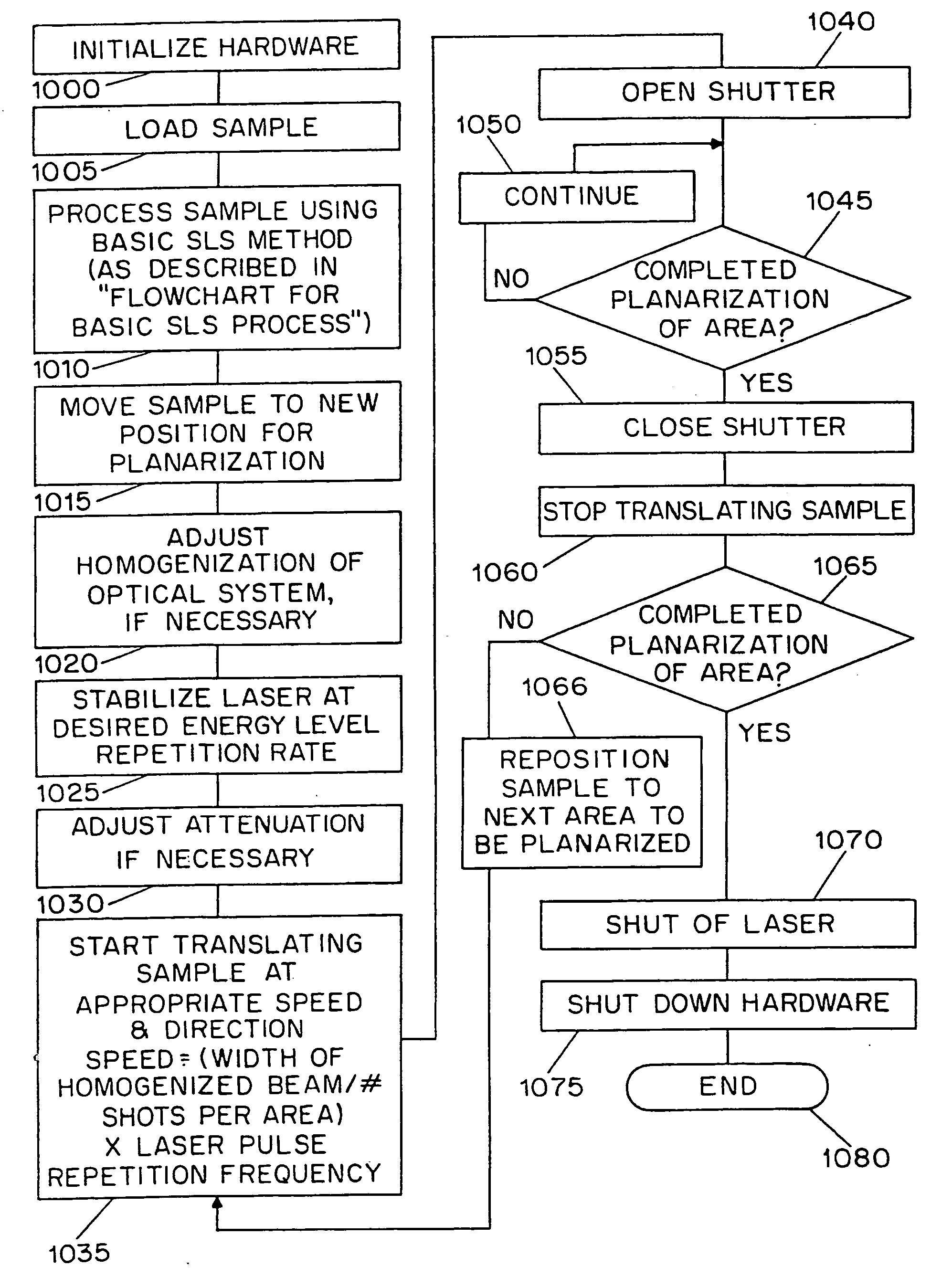

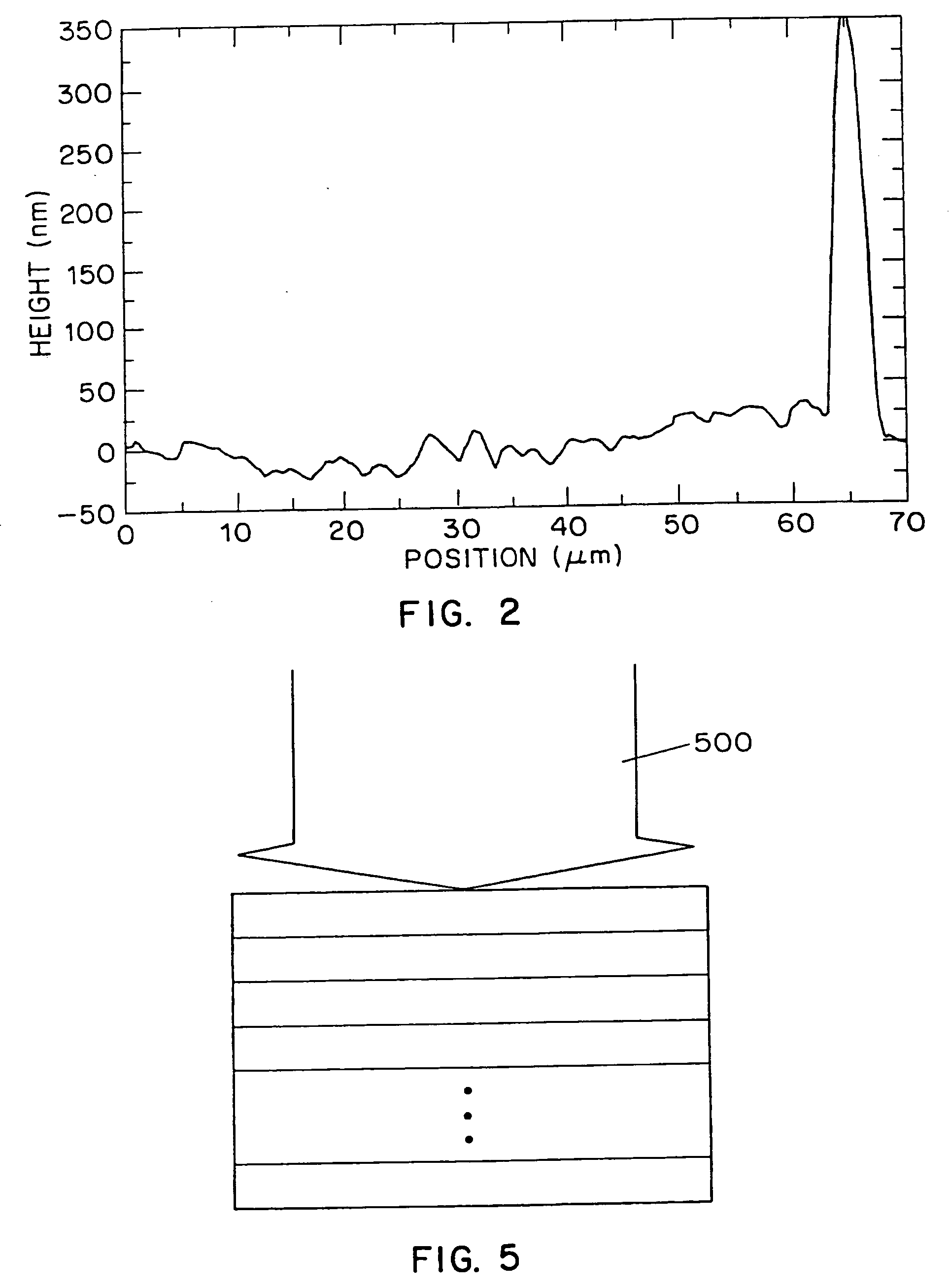

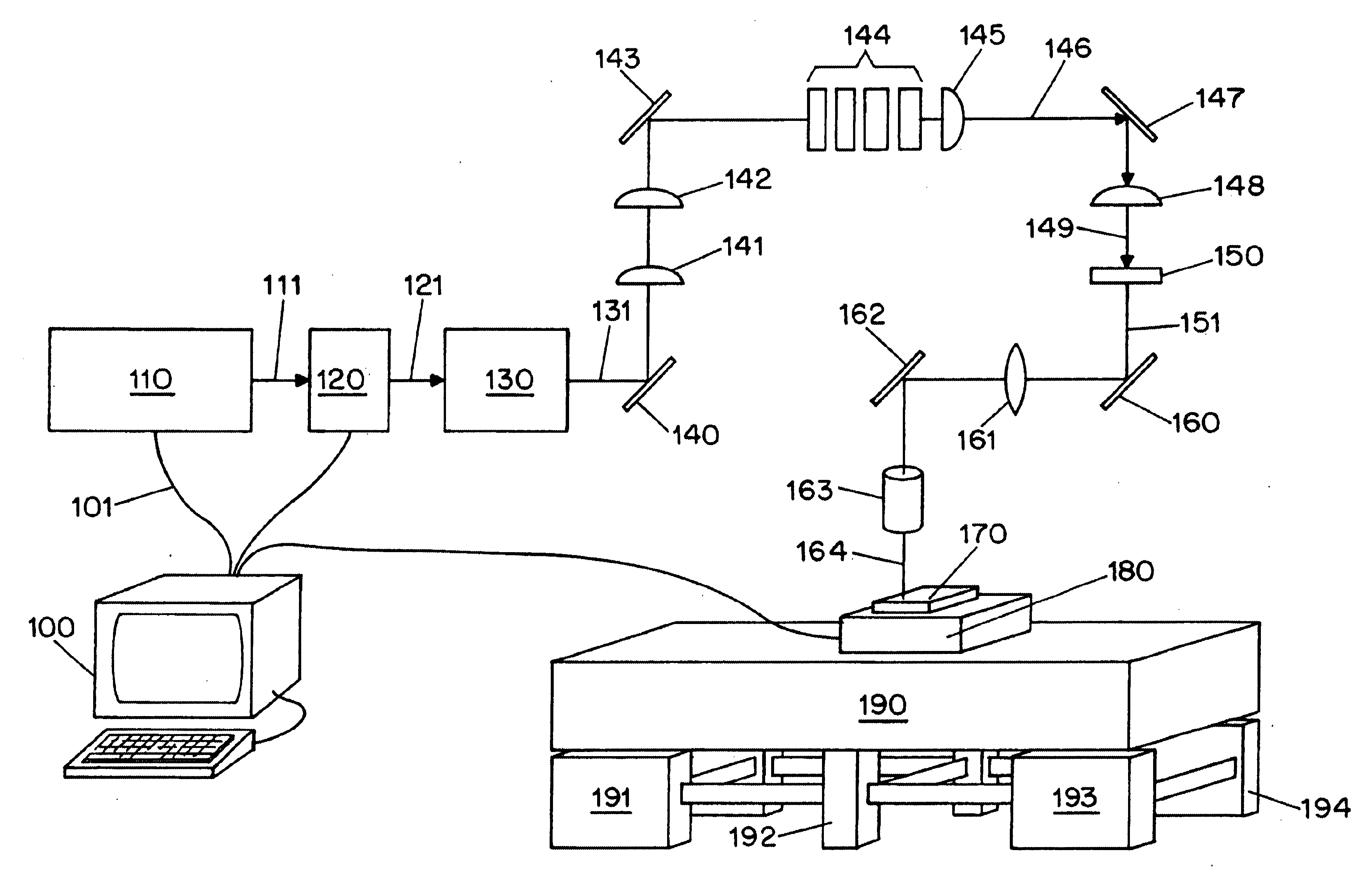

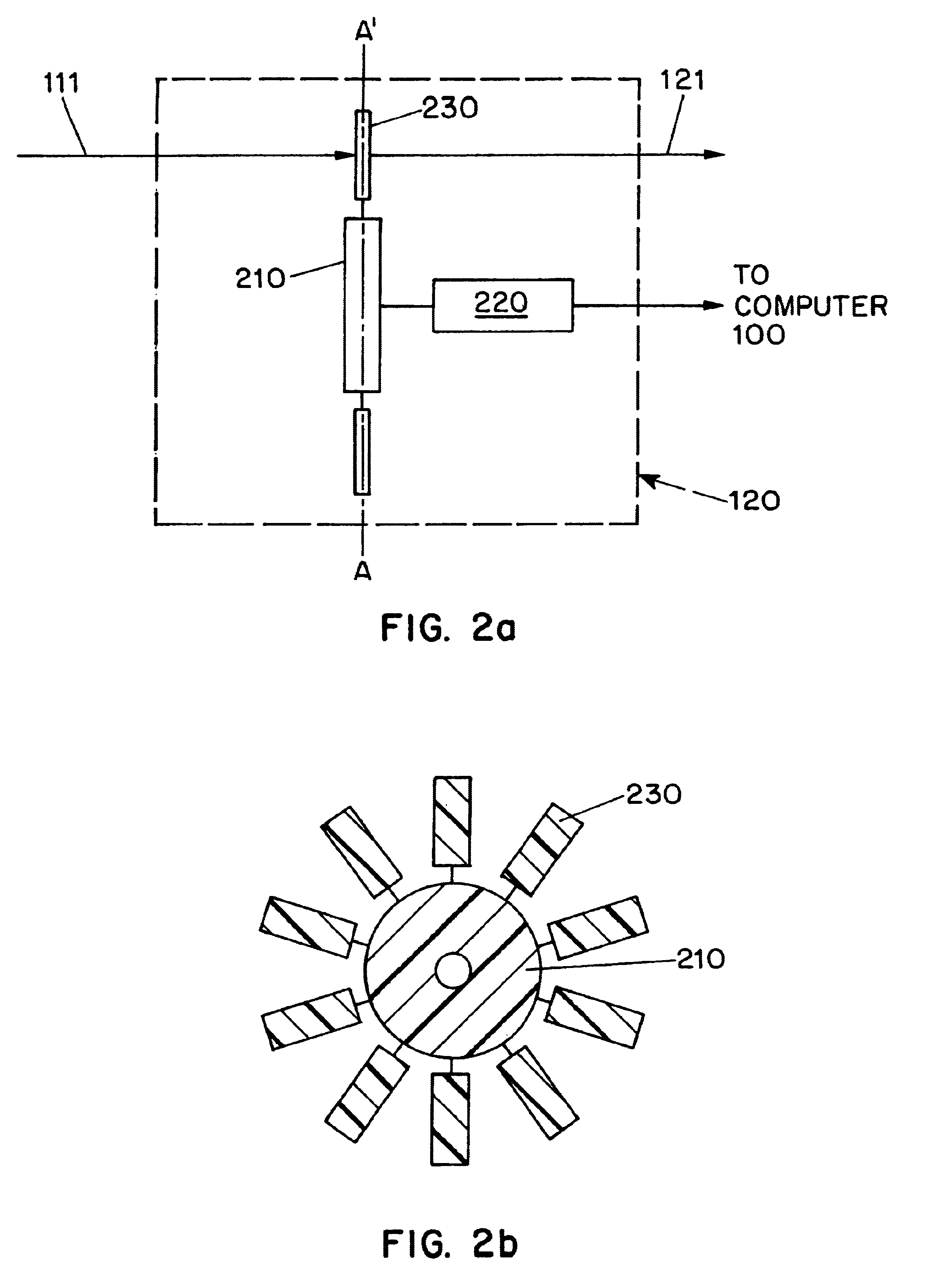

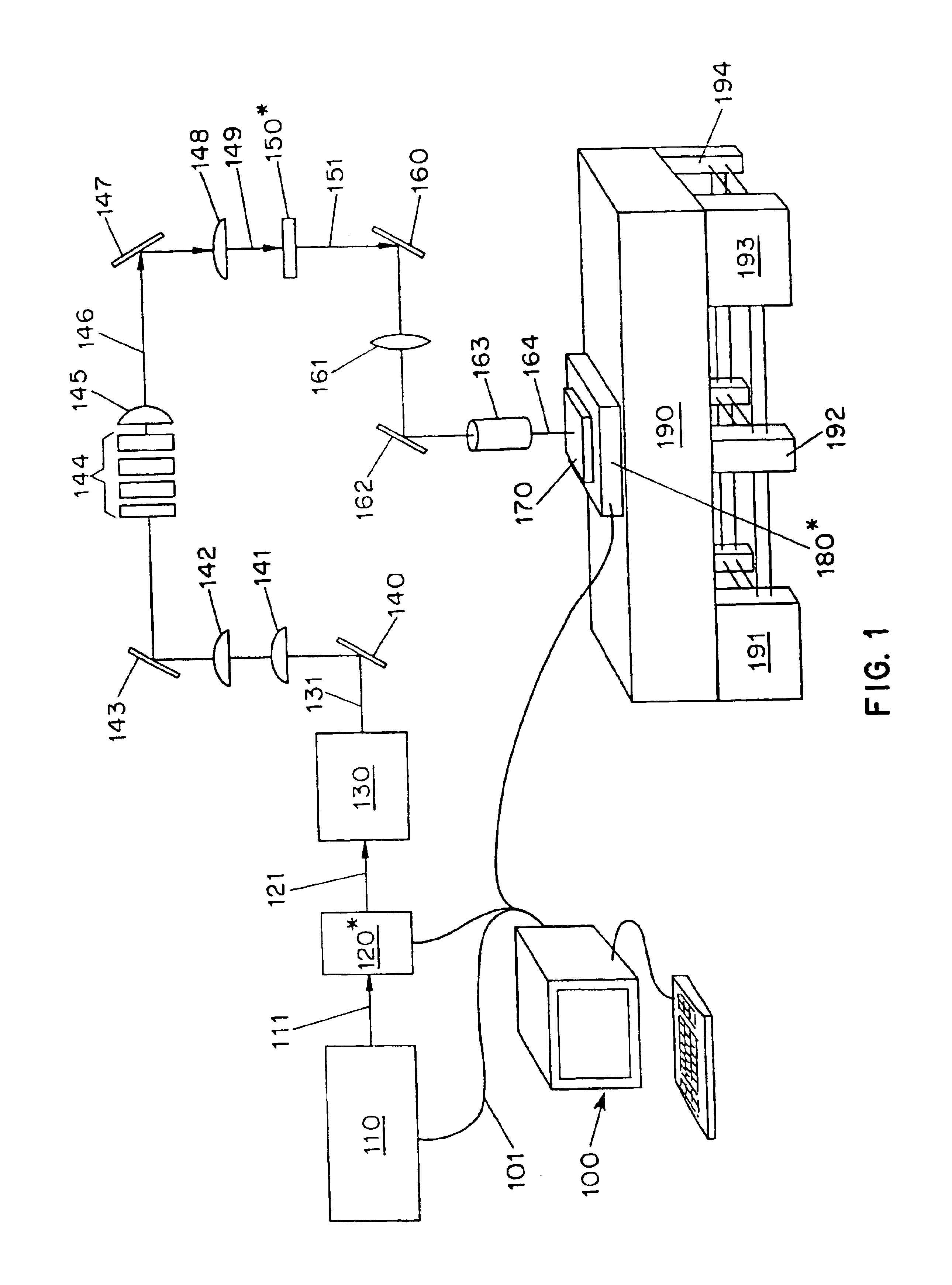

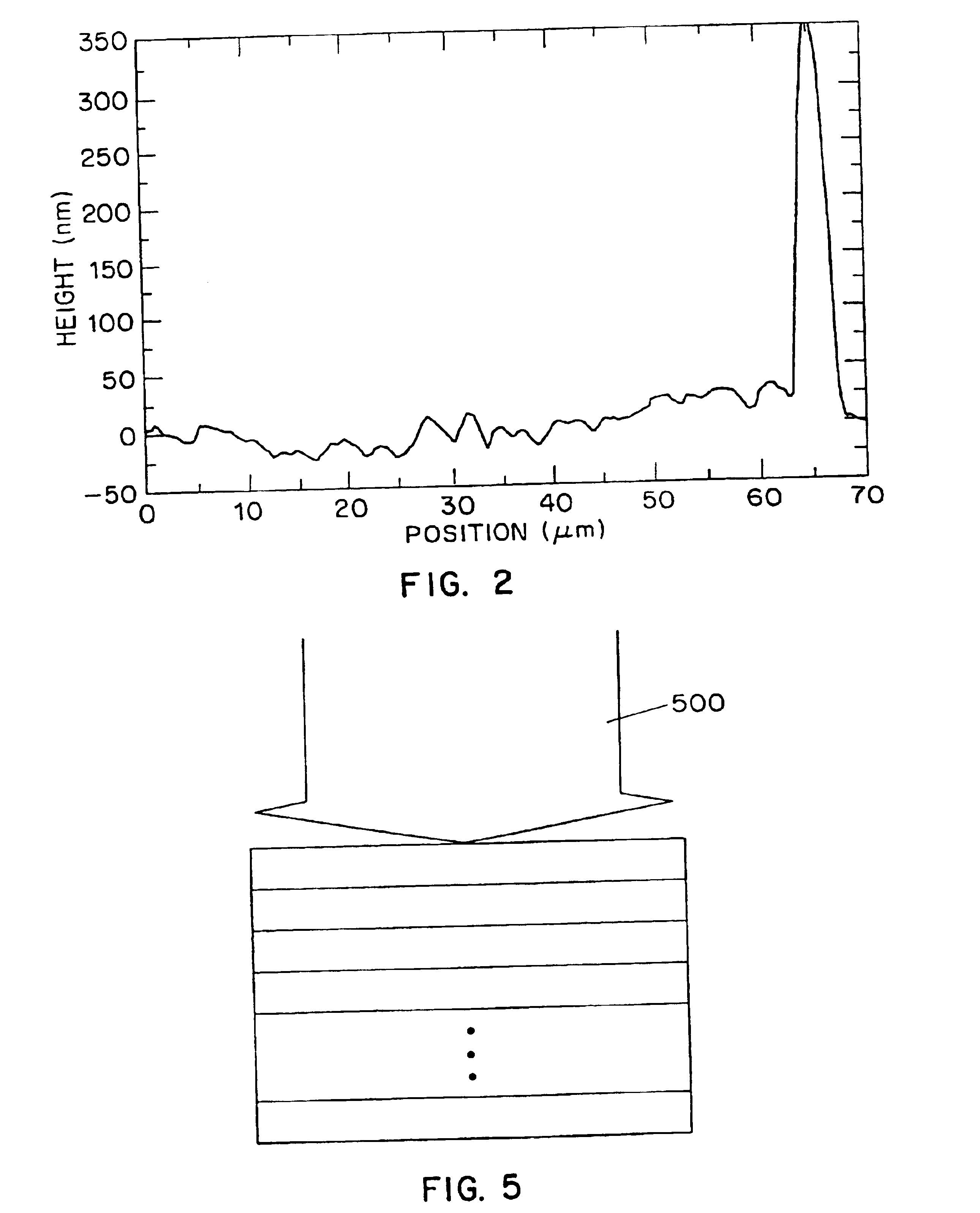

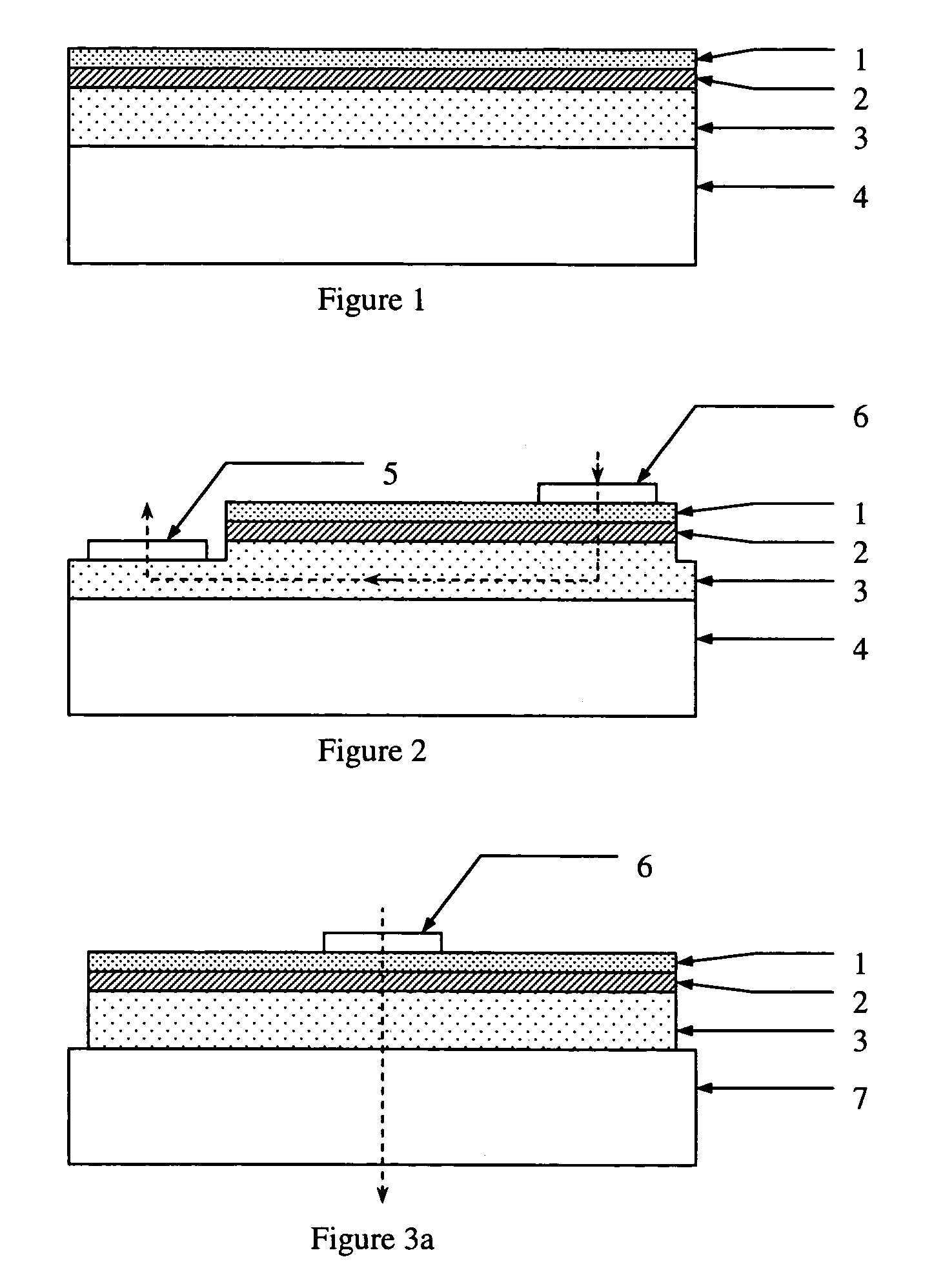

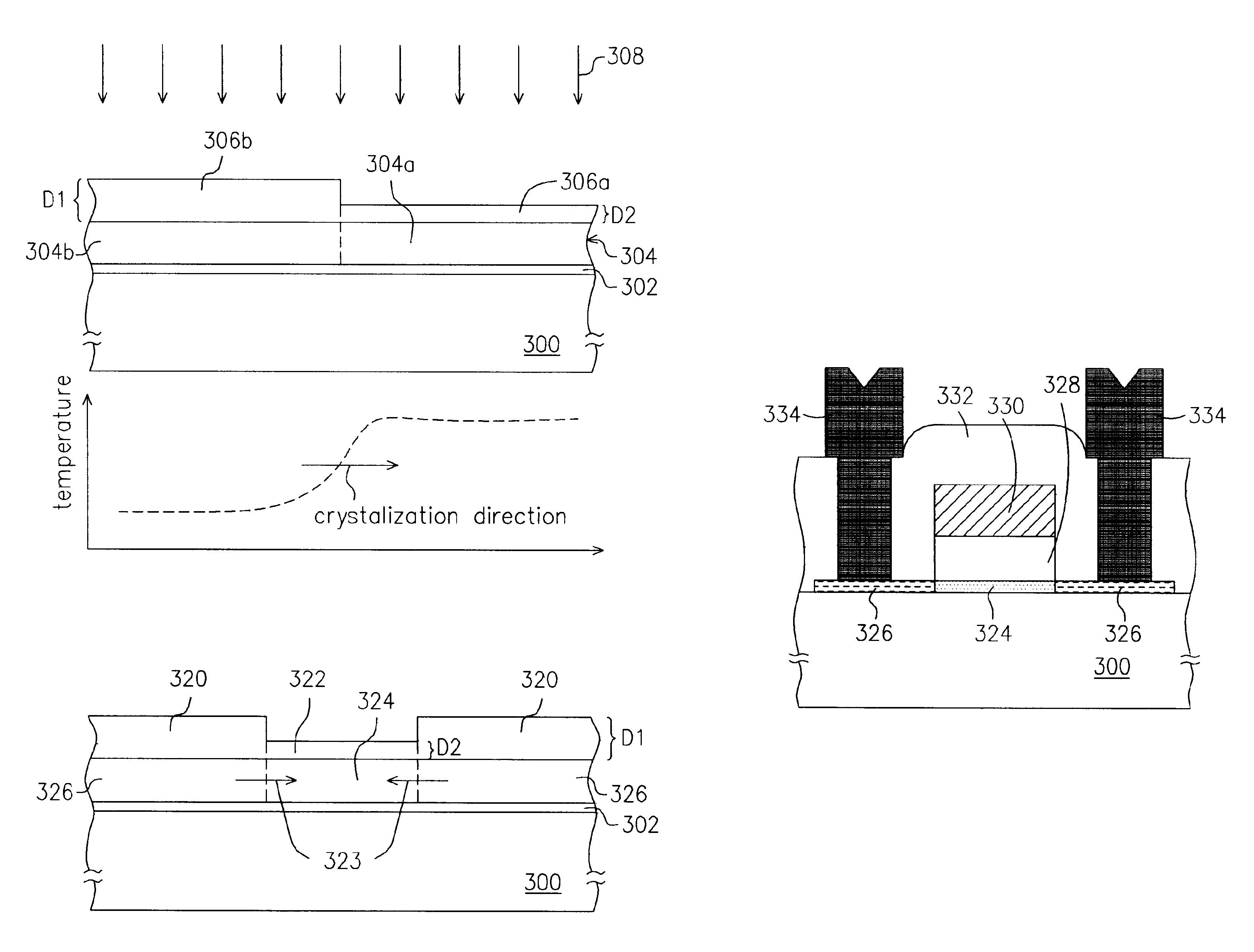

Surface planarization of thin silicon films during and after processing by the sequential lateral solidification method

InactiveUS20050032249A1Reduce surface roughnessAvoid insufficient thicknessSemiconductor/solid-state device manufacturingMetal working apparatusSurface roughnessLight beam

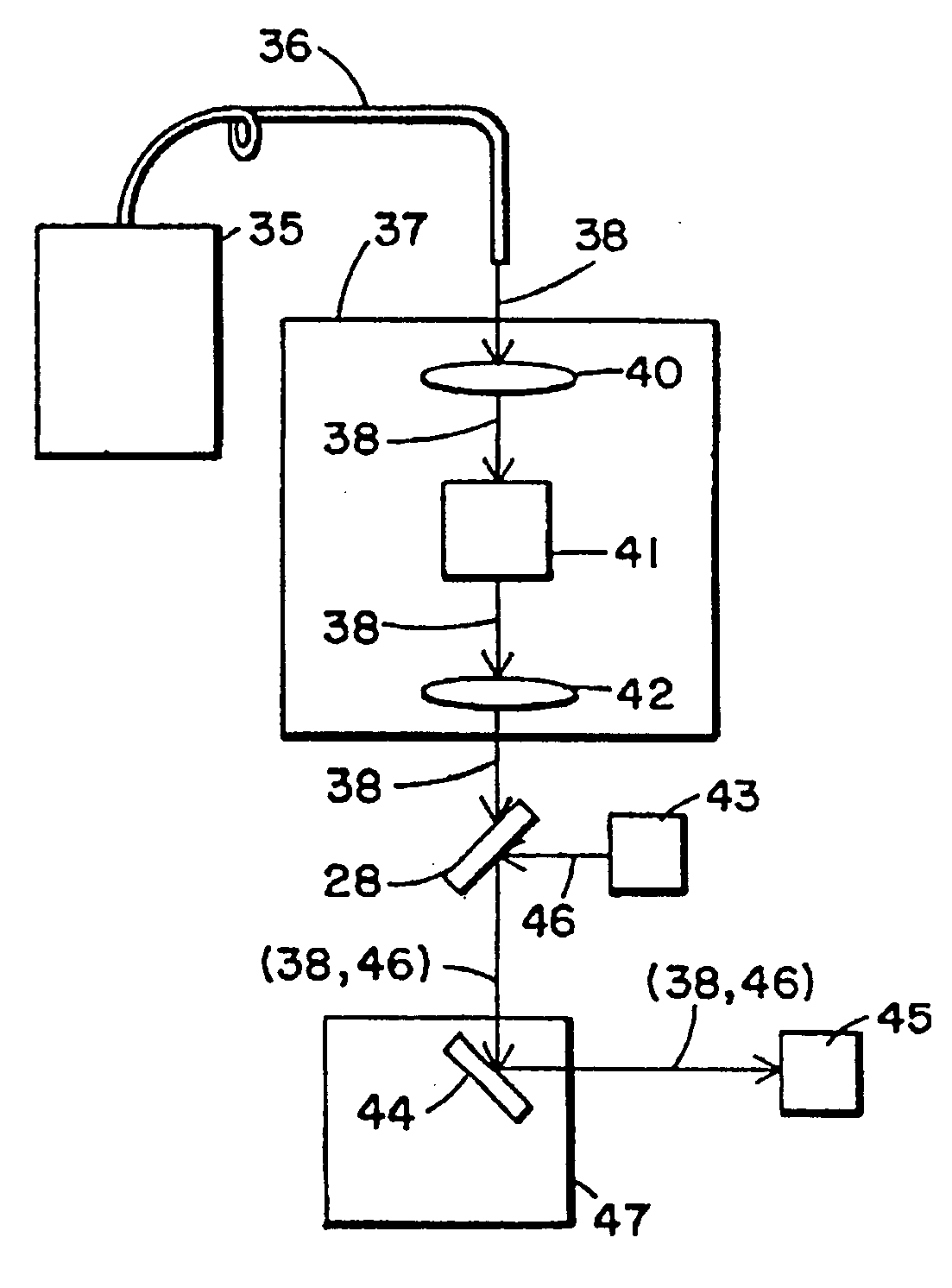

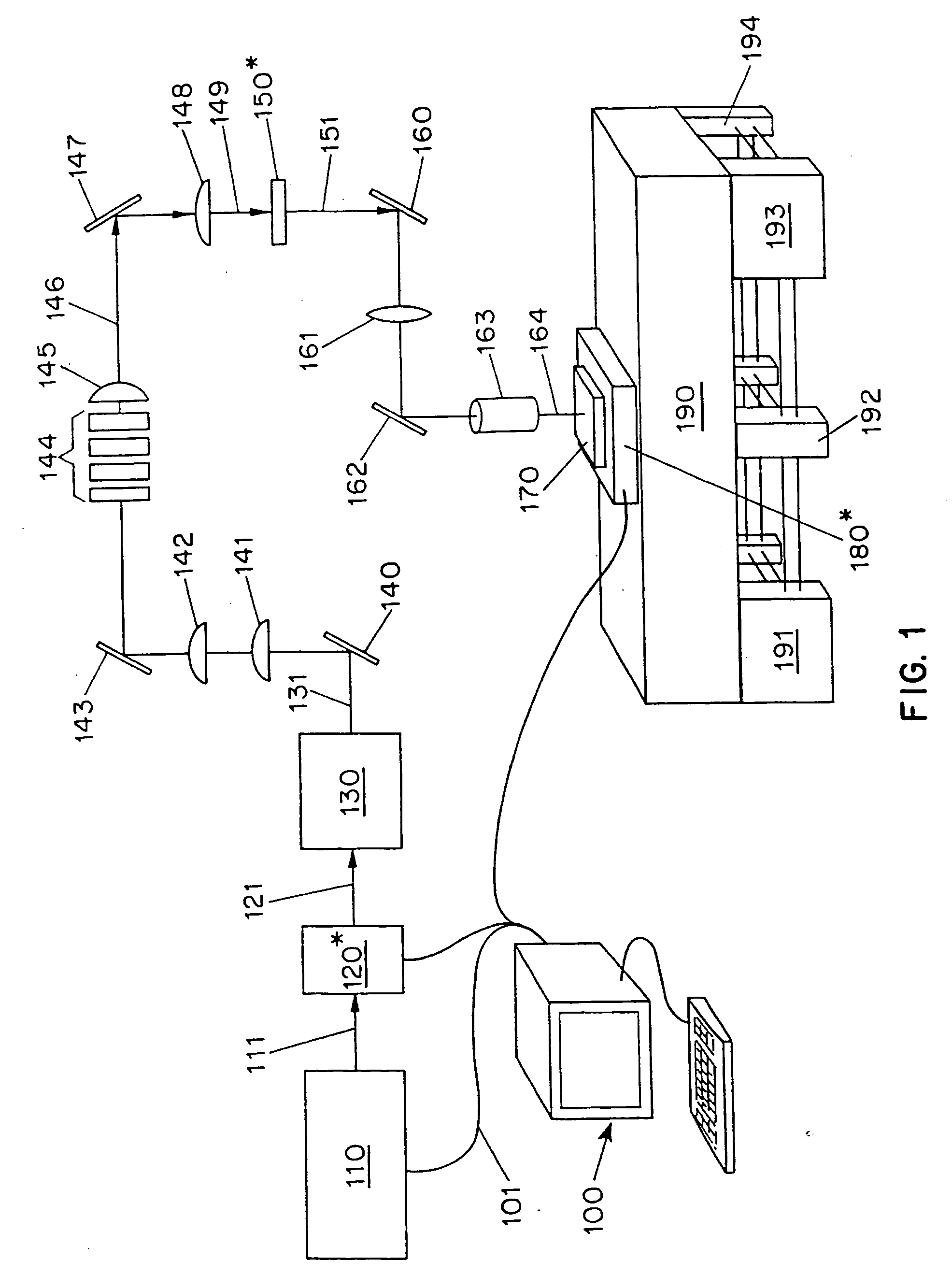

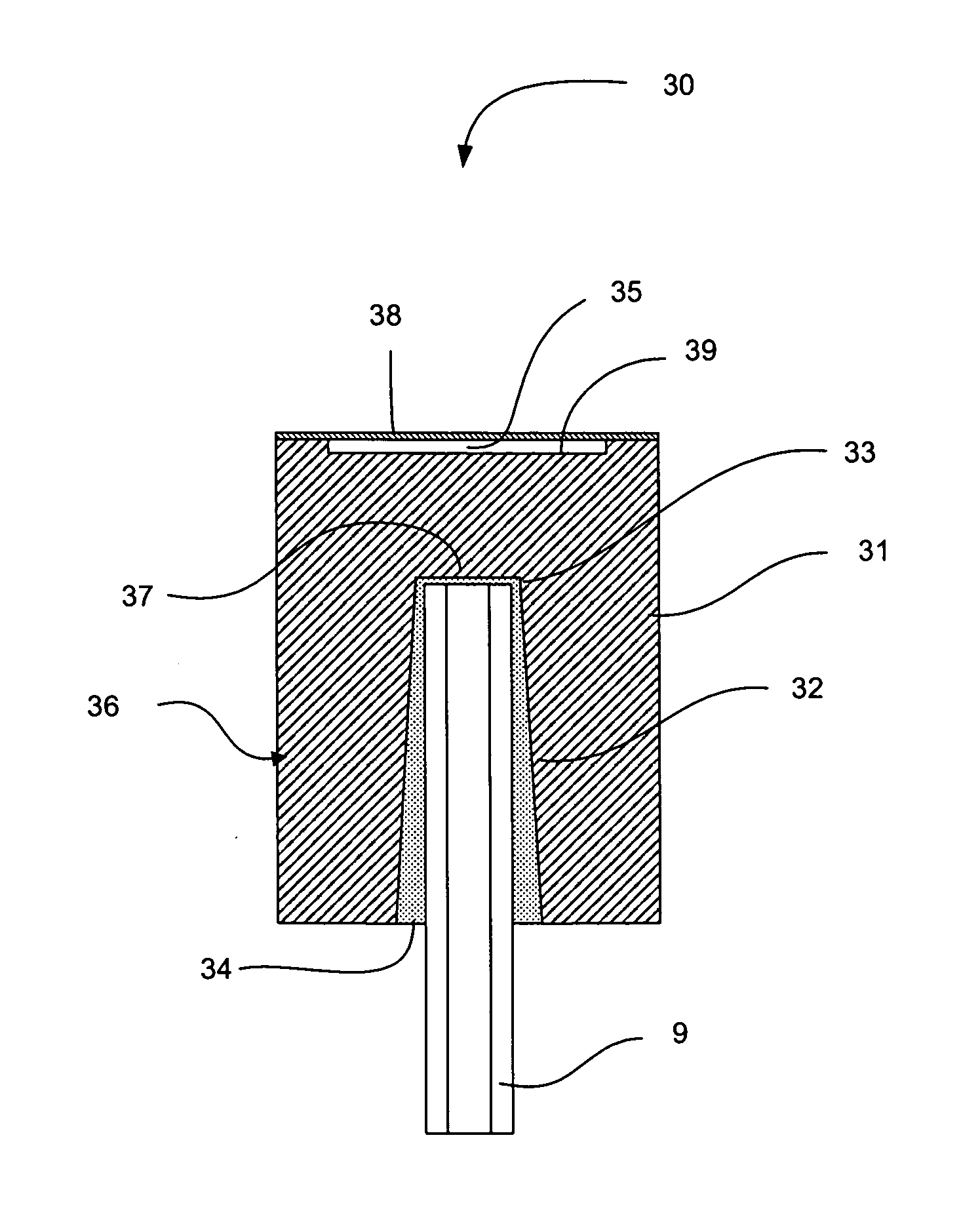

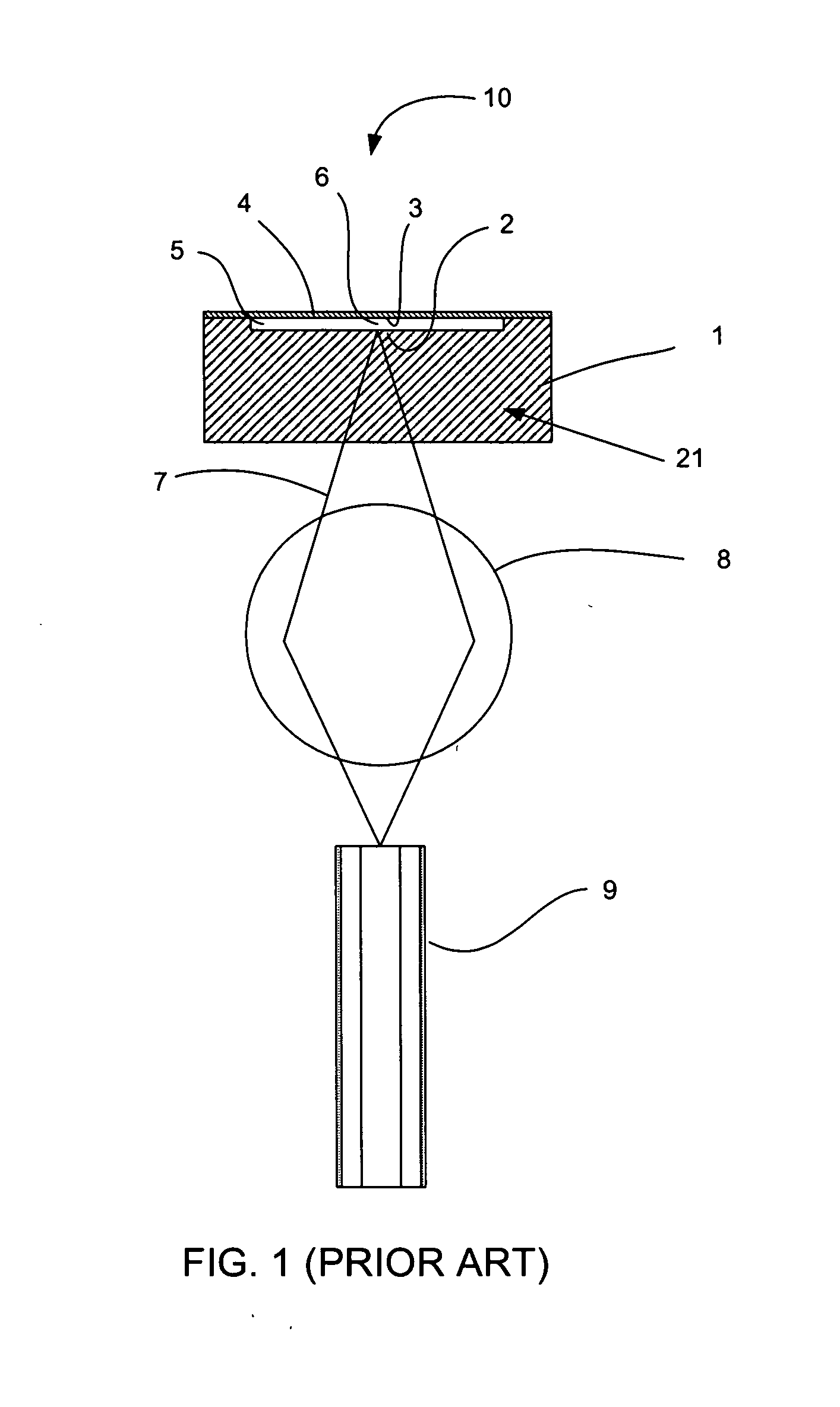

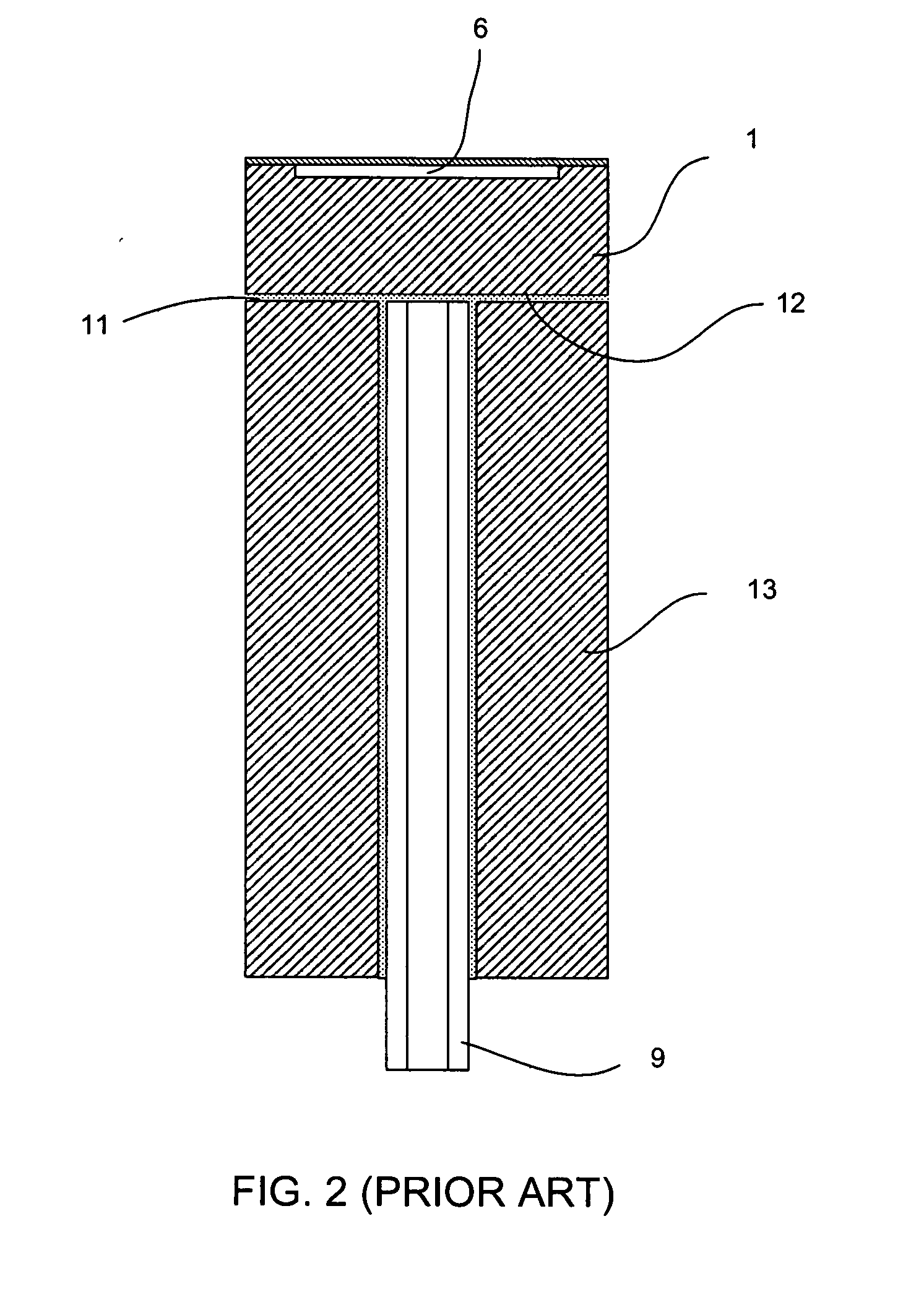

Systems and methods for reducing a surface roughness of a polycrystalline or single crystal thin film produced by the sequential lateral solidification process are disclosed. In one arrangement, the system includes an excimer laser (110) for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator (120) for controllably modulating the fluence of the excimer laser pulses such that the fluence is below that which is required to completely melt the thin film, a beam homoginizer (144) for homoginizing modulated laser pulses in a predetermined plane, a sample stage (170) for receiving homoginized laser pulses to effect melting of portions of the polycrystalline or single crystal thin film corresponding to the laser pulses, translating means for controllably translating a relative position of the sample stage (170) with respect to the laser pulses, and a computer (110) for coordinating the excimer pulse generation and fluence modulation with the relative positions of the sample stage (170) to thereby process the polycrystalline or single crystal thin film by sequential translation of the sample stage (170) relative to the laser pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

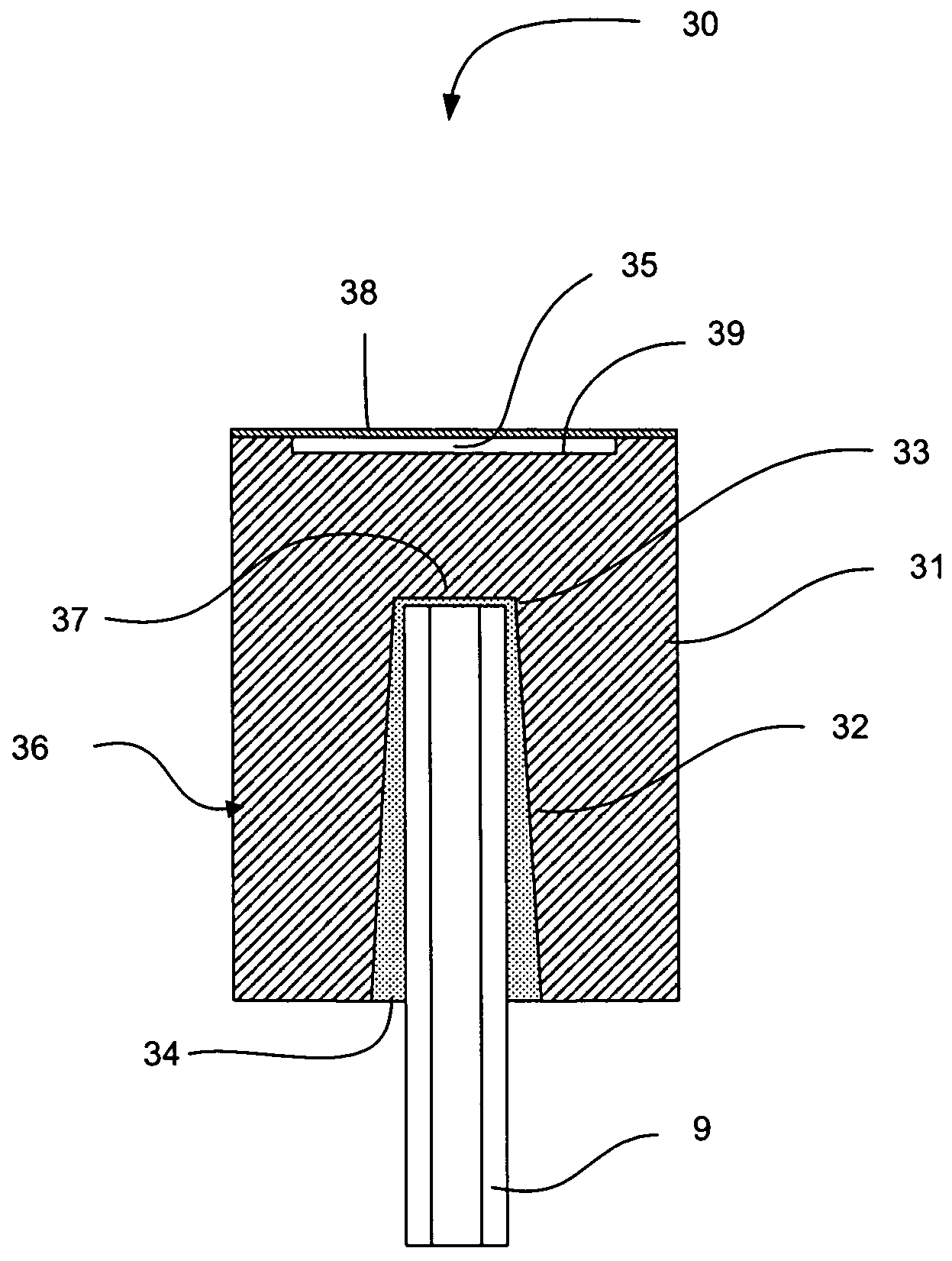

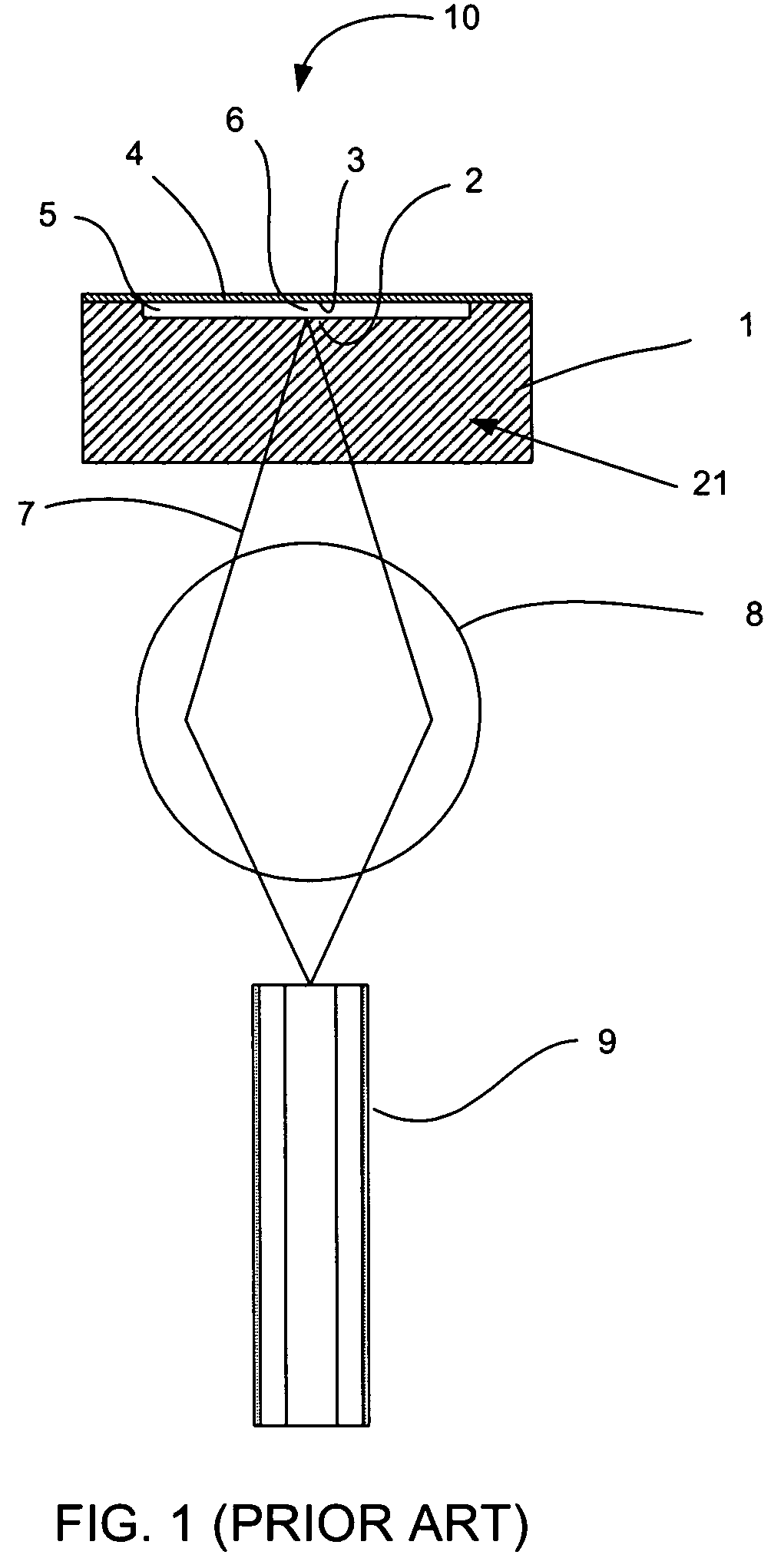

Fiber optic pressure sensor for catheter use

ActiveUS20060133715A1Low costHigh fidelity measurementFluid pressure measurement by electric/magnetic elementsCatheterAdhesiveEngineering

The invention provides a miniature robust fiber optic pressure sensor. The miniature fiber optic sensor comprises a Fabry-Perot chip bonded to an optical fiber. The invention provides a new sensor design that reduces the amount of adhesive required to bond the optical fiber to the Fabry-Perot sensor such that the sensor is less sensitive to moisture. The invention also provides manufacturing methods of the sensor comprising a method based on etching and a method based on using an excimer laser. The invention also provides a chip design that renders the chip less sensitive to thermal changes. The invention also provides a chip design in which a sensor diaphragm has a well-defined thickness. The invention also provides a chip design that protects the chip from etching.

Owner:OPSENS

Methods for producing uniform large-grained and grain boundary location manipulated polycrystalline thin film semiconductors using sequential lateral solidification

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

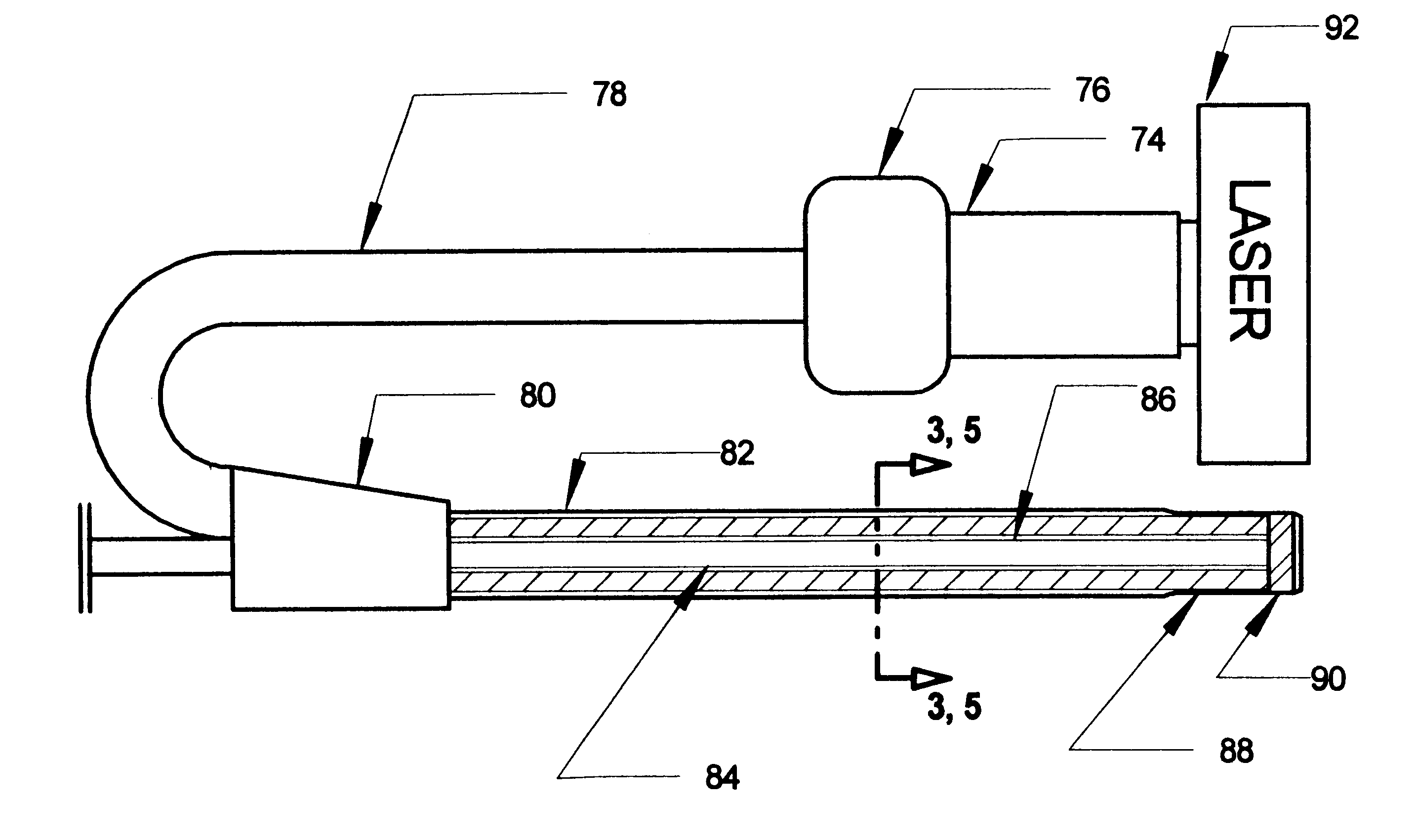

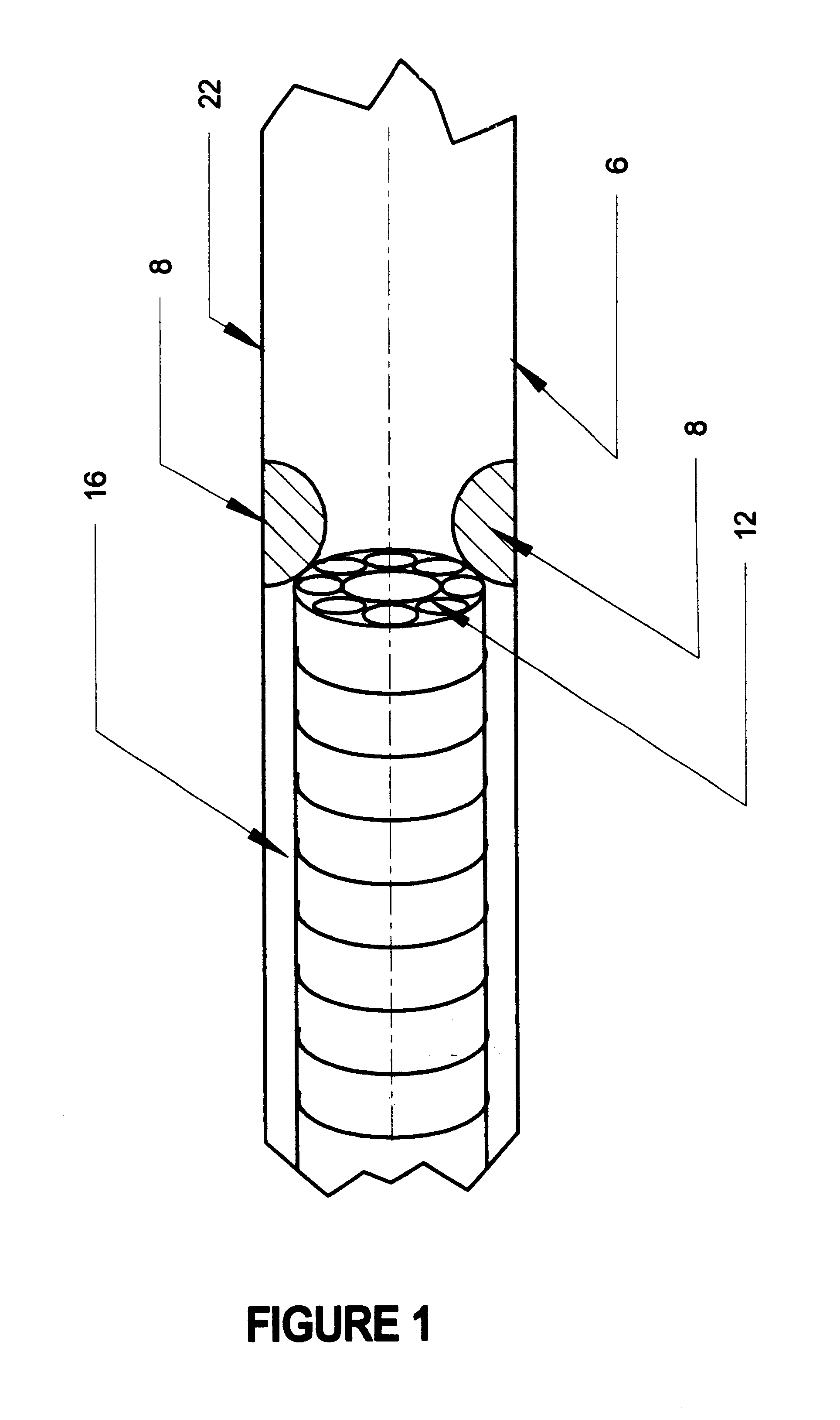

Excimer laser catheter

InactiveUS6440125B1Reduce the possibilityHigh energy laserDiagnosticsCatheterEndovascular therapyAtheroma

A method and apparatus of providing endovascular therapy. The steps include arranging optical fibers within a catheter, the catheter having a tip whose length is at least 1 cm and whose diameter of less than 1 millimeter, connecting an excimer laser to the optical fibers; and delivering laser energy from the excimer laser in excess of 60 fluence at 40 Hertz through the optical fibers. The delivering of the laser energy may be to non-calcified or calcified deposits of an atherosclerotic lesion to ablate the same. The method also includes the step of inserting the catheter through an artery by pushing the same until the tip is in within laser energy striking distance of the atherosclerotic lesion.

Owner:RENTROP PETER

Systems and methods using sequential lateral solidification for producing single or polycrystalline silicon thin films at low temperatures

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Fiber optic pressure sensor for catheter use

ActiveUS7689071B2Low costHigh fidelity measurementFluid pressure measurement by electric/magnetic elementsCatheterAdhesiveMoisture

The invention provides a miniature robust fiber optic pressure sensor. The miniature fiber optic sensor comprises a Fabry-Perot chip bonded to an optical fiber. The invention provides a new sensor design that reduces the amount of adhesive required to bond the optical fiber to the Fabry-Perot sensor such that the sensor is less sensitive to moisture. The invention also provides manufacturing methods of the sensor comprising a method based on etching and a method based on using an excimer laser. The invention also provides a chip design that renders the chip less sensitive to thermal changes. The invention also provides a chip design in which a sensor diaphragm has a well-defined thickness. The invention also provides a chip design that protects the chip from etching.

Owner:OPSENS

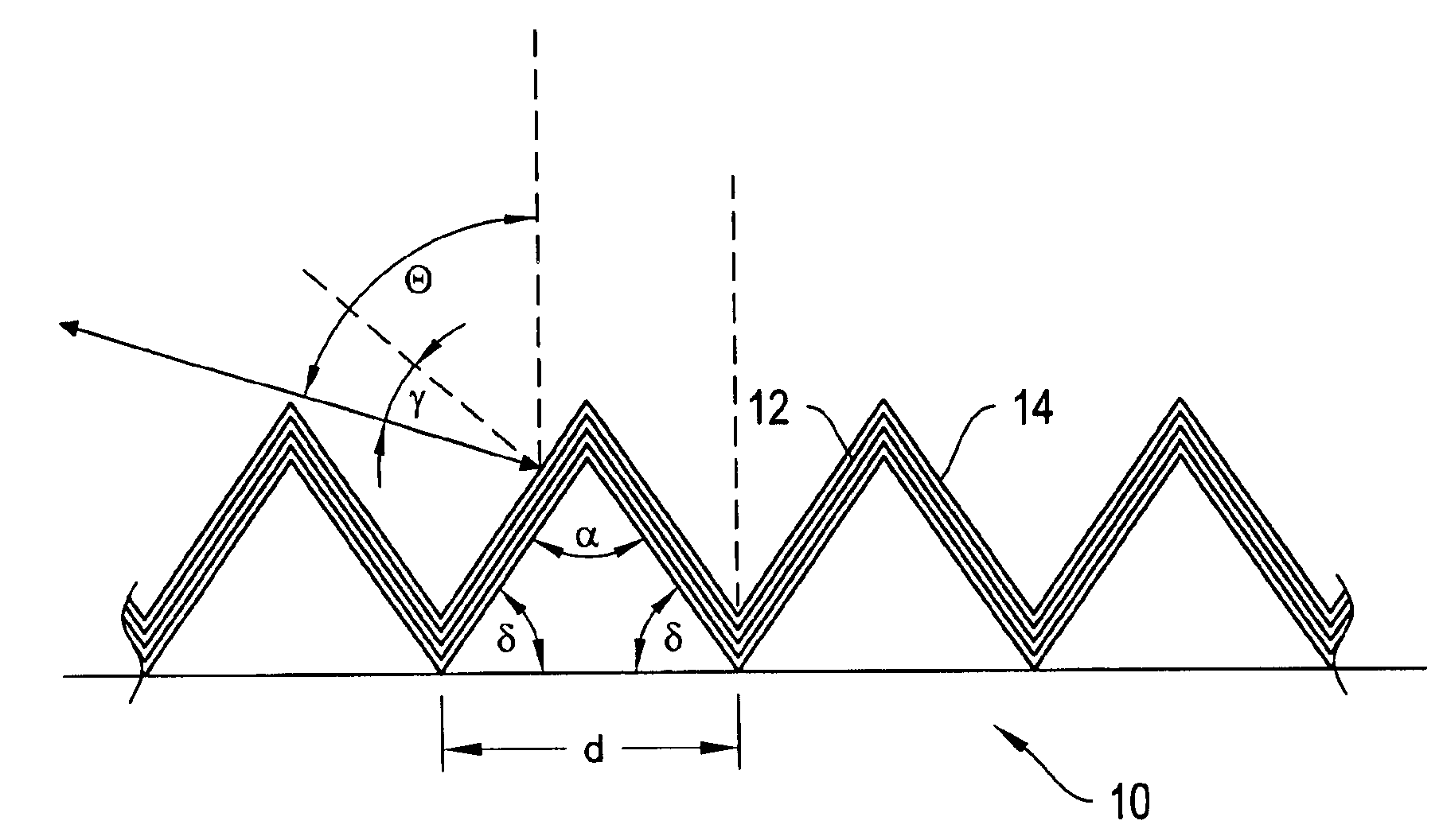

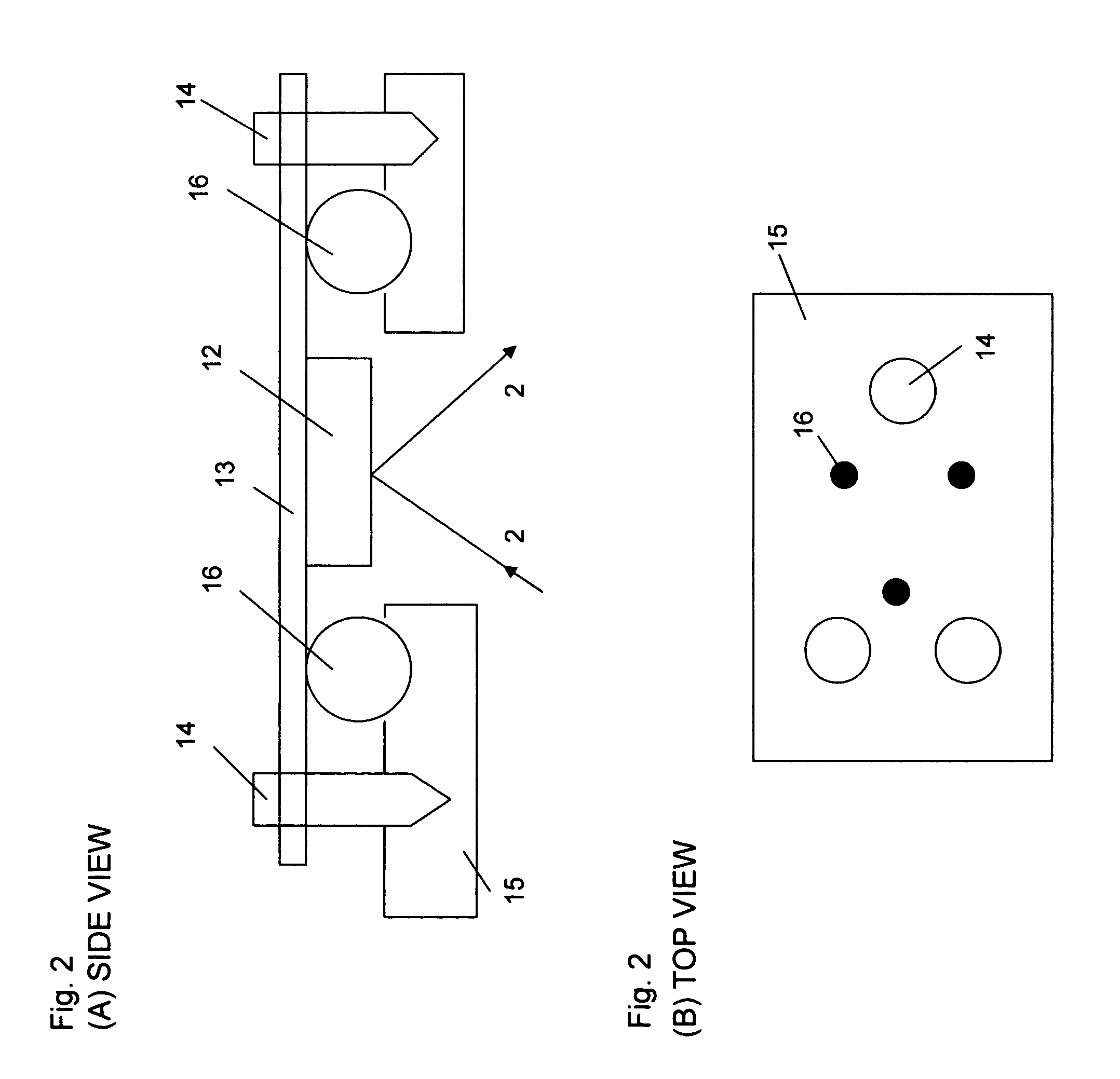

Optical pulse stretching and smoothing for ArF and F2 lithography excimer lasers

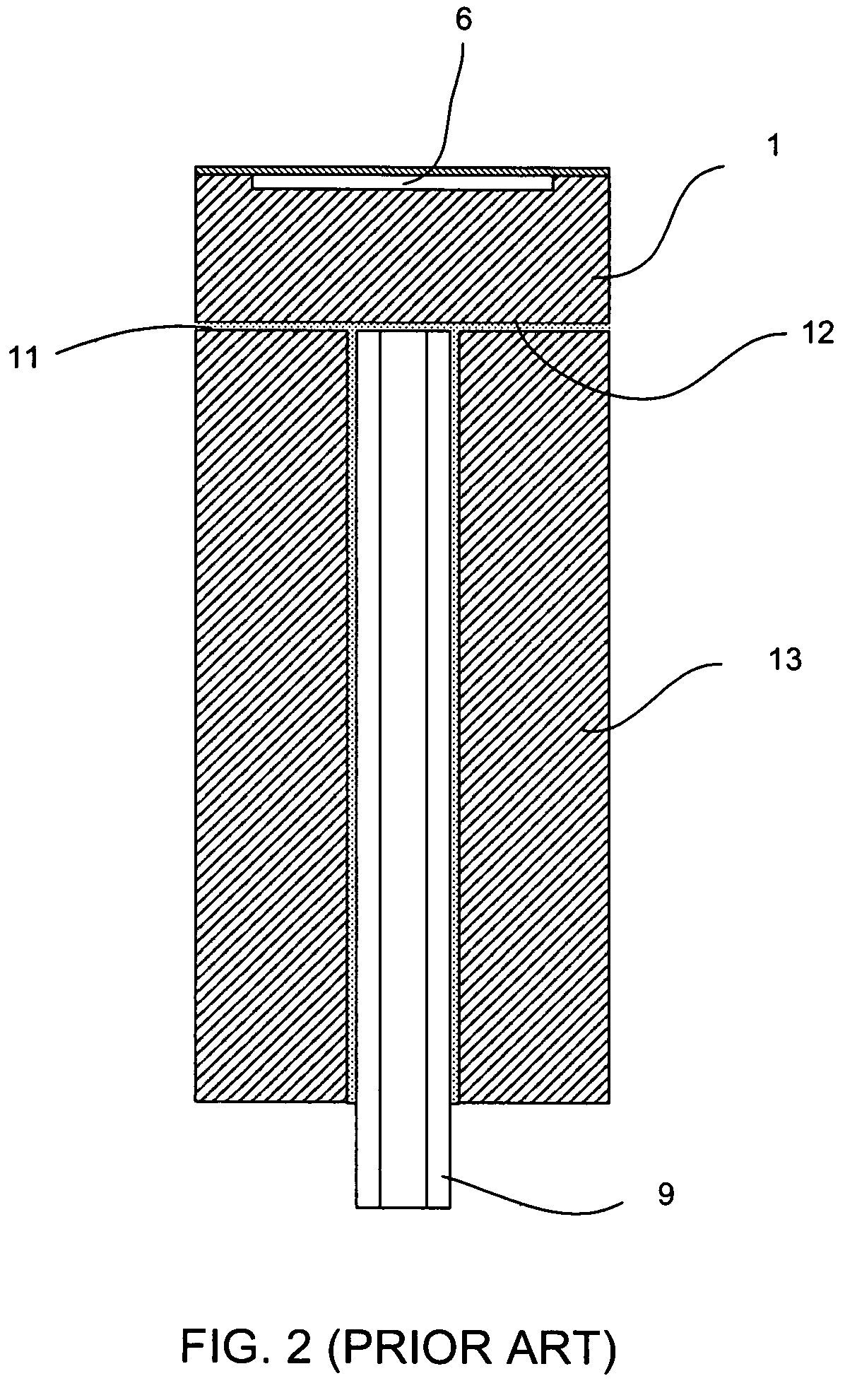

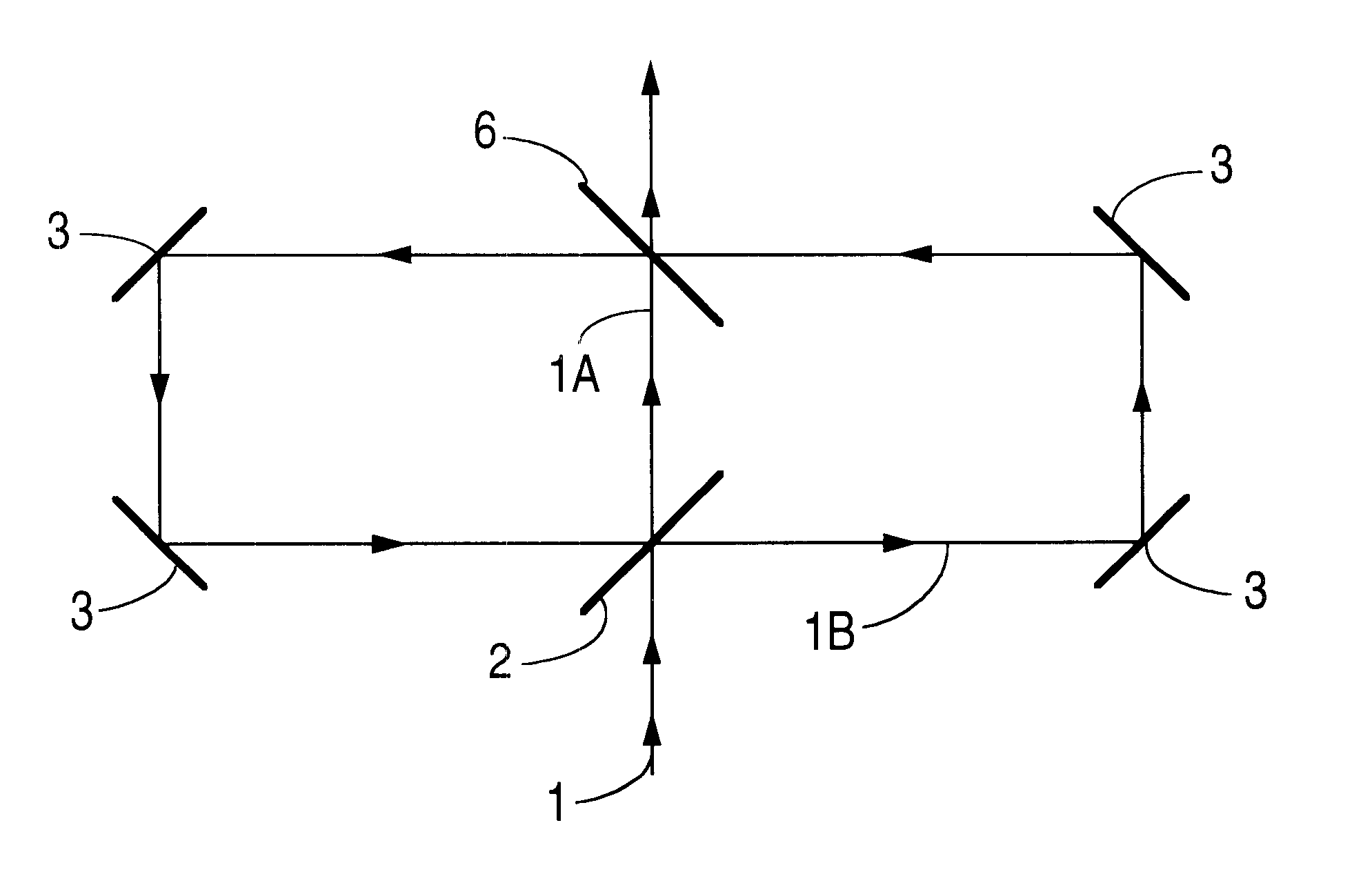

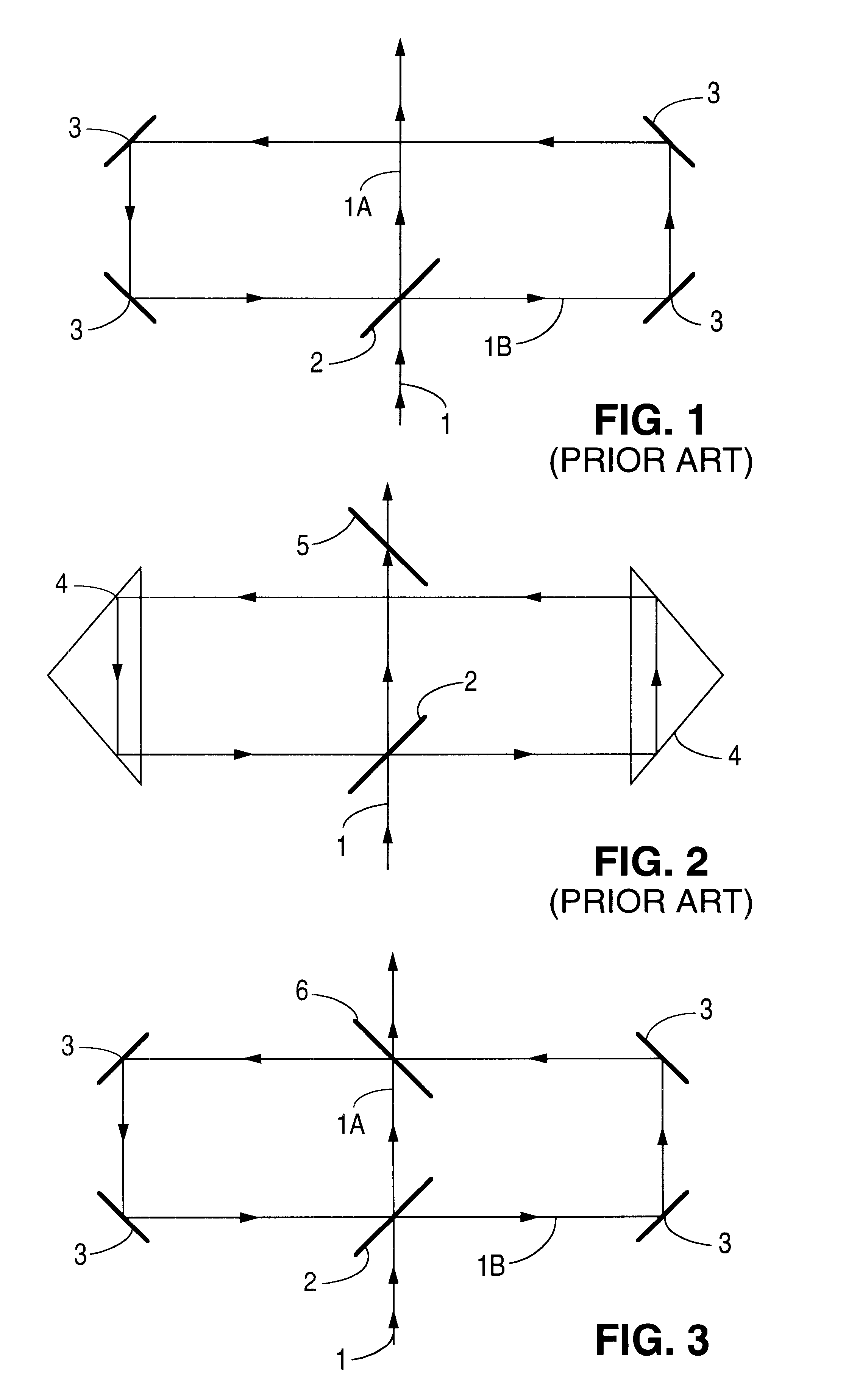

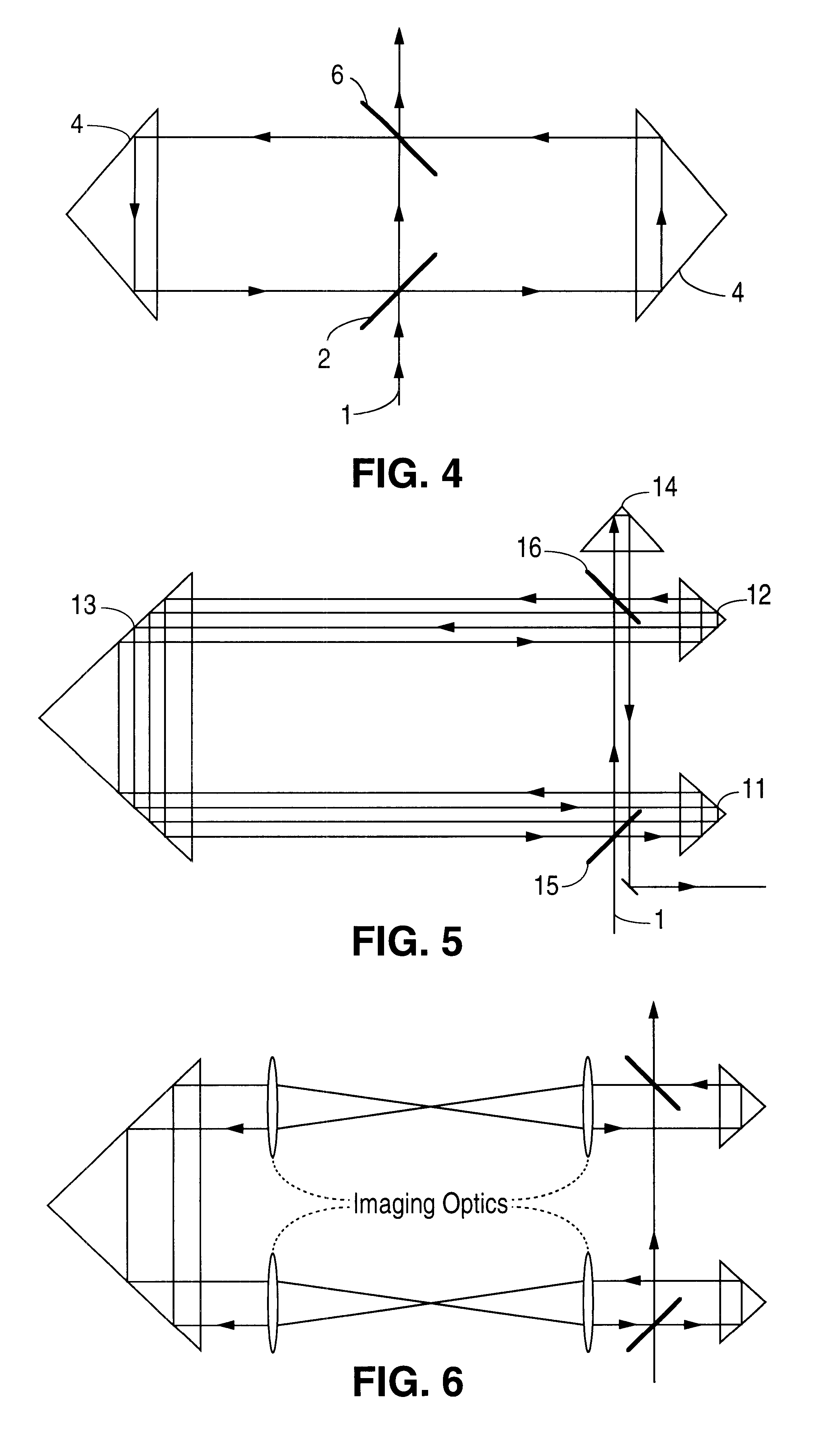

InactiveUS6389045B1Easy to stretchFlat shapeOptical resonator shape and constructionGenerators/motorsOptical reflectionLithographic artist

A method and apparatus are provided for temporally stretching and smoothing of the pulses of an output beam of excimer and lithography lasers. The method and apparatus are based upon providing an optical delay line or circuit having a plurality of optical reflectors and a plurality of beam recombiners or splitters so arranged as to divide the pulse into numerous portions which vary in their travel time through the circuit. As a result, the energy of the incident pulse is greatly stretched and smoothed.

Owner:COHERENT GMBH

Resist cover film-forming material, process for forming resist pattern, semiconductor device and process for manufacturing the same

InactiveUS7608386B2High light transmittanceResist performance can not be impairedPhotosensitive materialsRadiation applicationsResistEngineering

Owner:FUJITSU LTD

Laser irradiation method, laser irradiation apparatus and method for manufacturing semiconductor device

InactiveUS20070178672A1High output powerImprove mobilityPolycrystalline material growthBy zone-melting liquidsNonlinear opticsDevice material

In conducting laser annealing using a CW laser or a quasi-CW laser, productivity is not high as compared with an excimer laser and thus, it is necessary to further enhance productivity. According to the present invention, a fundamental wave is used without putting laser light into a non linear optical element, and laser annealing is conducted by irradiating a semiconductor thin film with pulsed laser light having a high repetition rate. A laser oscillator having a high output power can be used for laser annealing, since a non linear optical element is not used and thus light is not converted to a harmonic. Therefore, the width of a region having large grain crystals that is formed by scanning once can be increased, and thus the productivity can be enhanced dramatically.

Owner:SEMICON ENERGY LAB CO LTD

Surface planarization of thin silicon films during and after processing by the sequential lateral solidification method

InactiveUS6830993B1Reduce surface roughnessAvoid insufficient thicknessSemiconductor/solid-state device manufacturingFrom frozen solutionsLight beamSurface roughness

Systems and methods for reducing a surface roughness of a polycrystalline or single crystal thin film produced by the sequential lateral solidification process are disclosed. In one arrangement, the system includes an excimer laser (110) for generating a plurality of excimer laser pulses of a predetermined fluence, an energy density modulator (120) for controllably modulating the fluence of the excimer laser pulses such that the fluence is below that which is required to completely melt the thin film, a beam homoginizer (144) for homoginizing modulated laser pulses in a predetermined plane, a sample stage (170) for receiving homoginized laser pulses to effect melting of portions of the polycrystalline or single crystal thin film corresponding to the laser pulses, translating means for controllably translating a relative position of the sample stage (170) with respect to the laser pulses, and a computer (110) for coordinating the excimer pulse generation and fluence modulation with the relative positions of the sample stage (170) to thereby process the polycrystalline or single crystal thin film by sequential translation of the sample stage (170) relative to the laser pulses.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

System and method for predictive ophthalmic correction

A system and method for providing a predictive outcome in the form of a predictive best instruction for a therapeutic ophthalmic correction of a patient's vision defects. The predictive best instruction is derived from prospective therapeutic-outcome-influencing, new information that is analyzed in conjunction with optimized, historical therapeutic-outcome information. The instruction is preferably an optimized, custom, photoablative algorithm for driving a photoablative, excimer laser. The instruction can be provided on a fee basis.

Owner:BAUSCH & LOMB INC

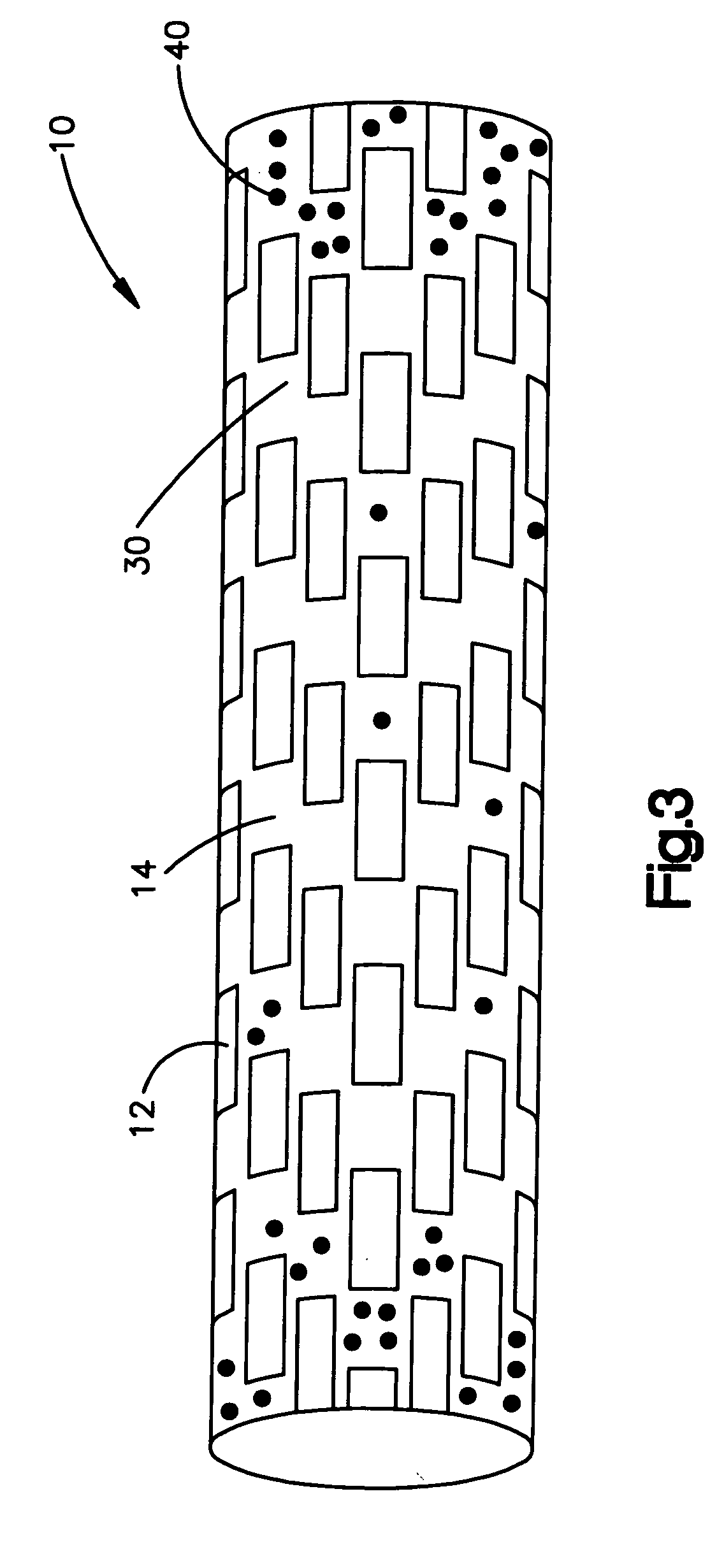

Coated medical device and method for making the same

InactiveUS20050266039A1Efficient methodPrecise positioningStentsOrganic active ingredientsInsertion stentUltrashort laser

The invention pertains to medical devices, such as stents, having a surface and a first coating layer comprising a first polymer disposed on at least a portion of the surface, in which at least one cavity formed in the first coating layer. A biologically active material is deposited into the cavity, and a second coating layer comprising a second polymer is disposed over the biologically active material in the cavity. The cavity may be formed using an excimer laser or ultrashort laser to ablate the first coating layer, and the biologically active material may be deposited in the cavity using a picoliter dispensing system. Methods for making such medical devices are also disclosed.

Owner:BOSTON SCI SCIMED INC

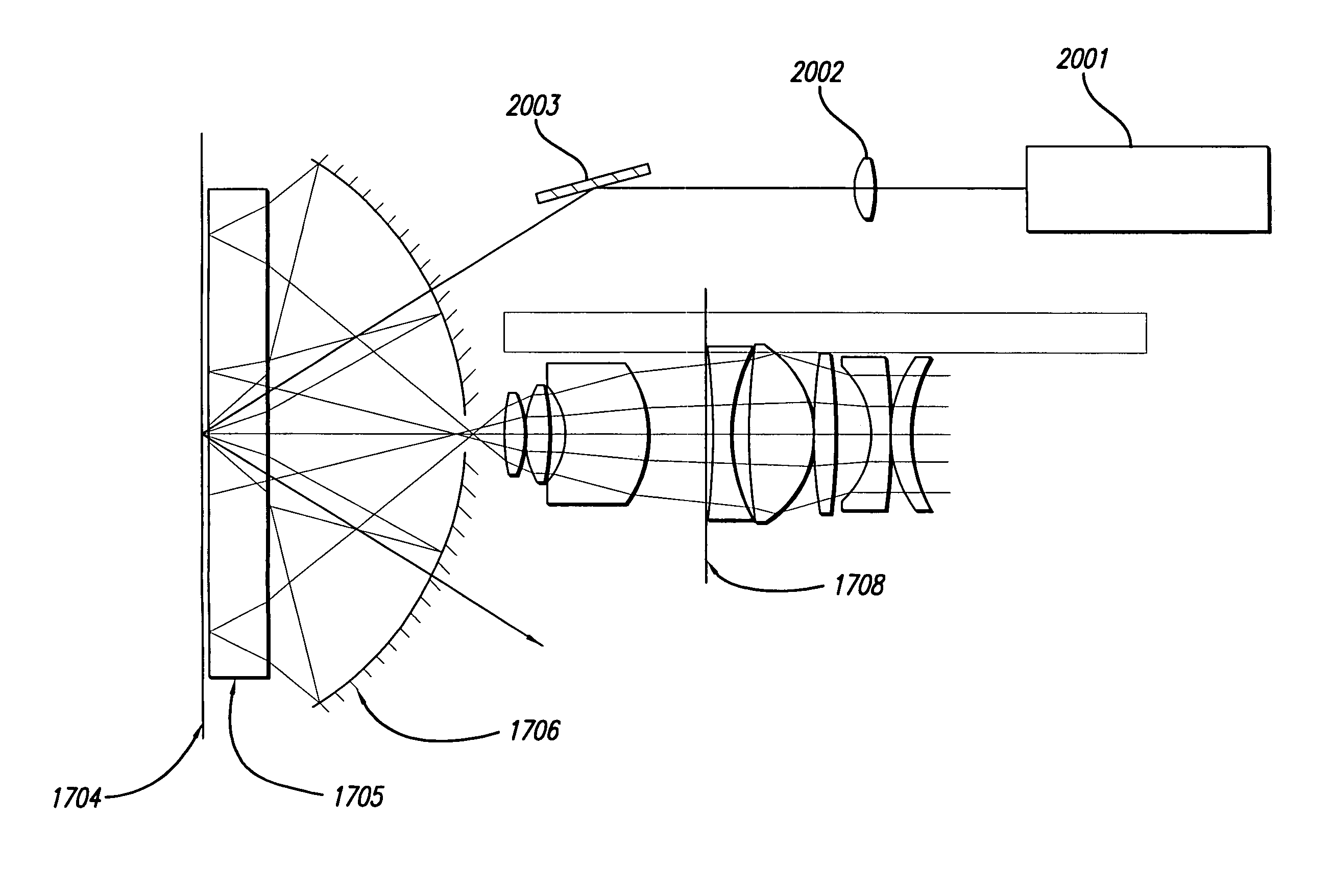

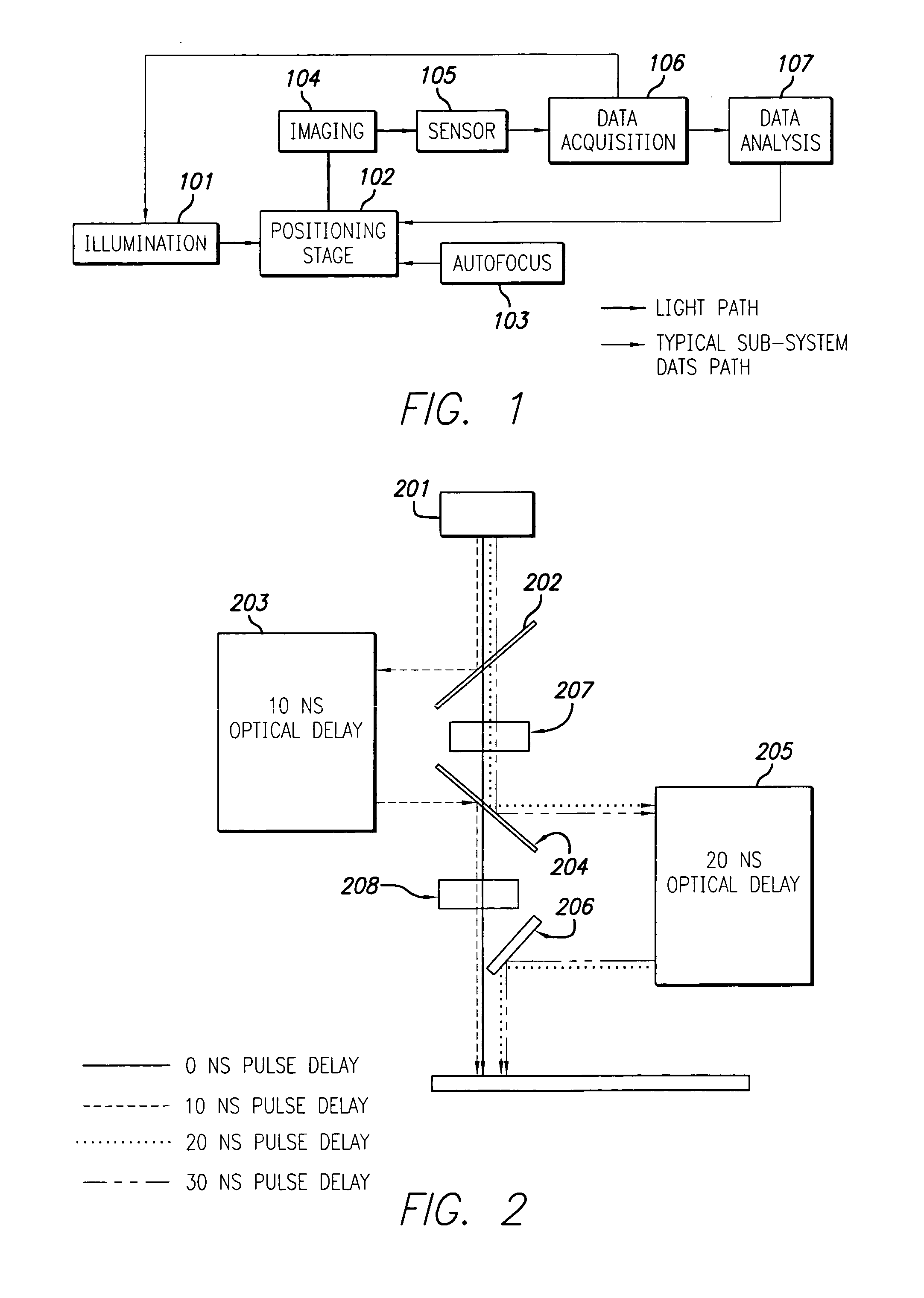

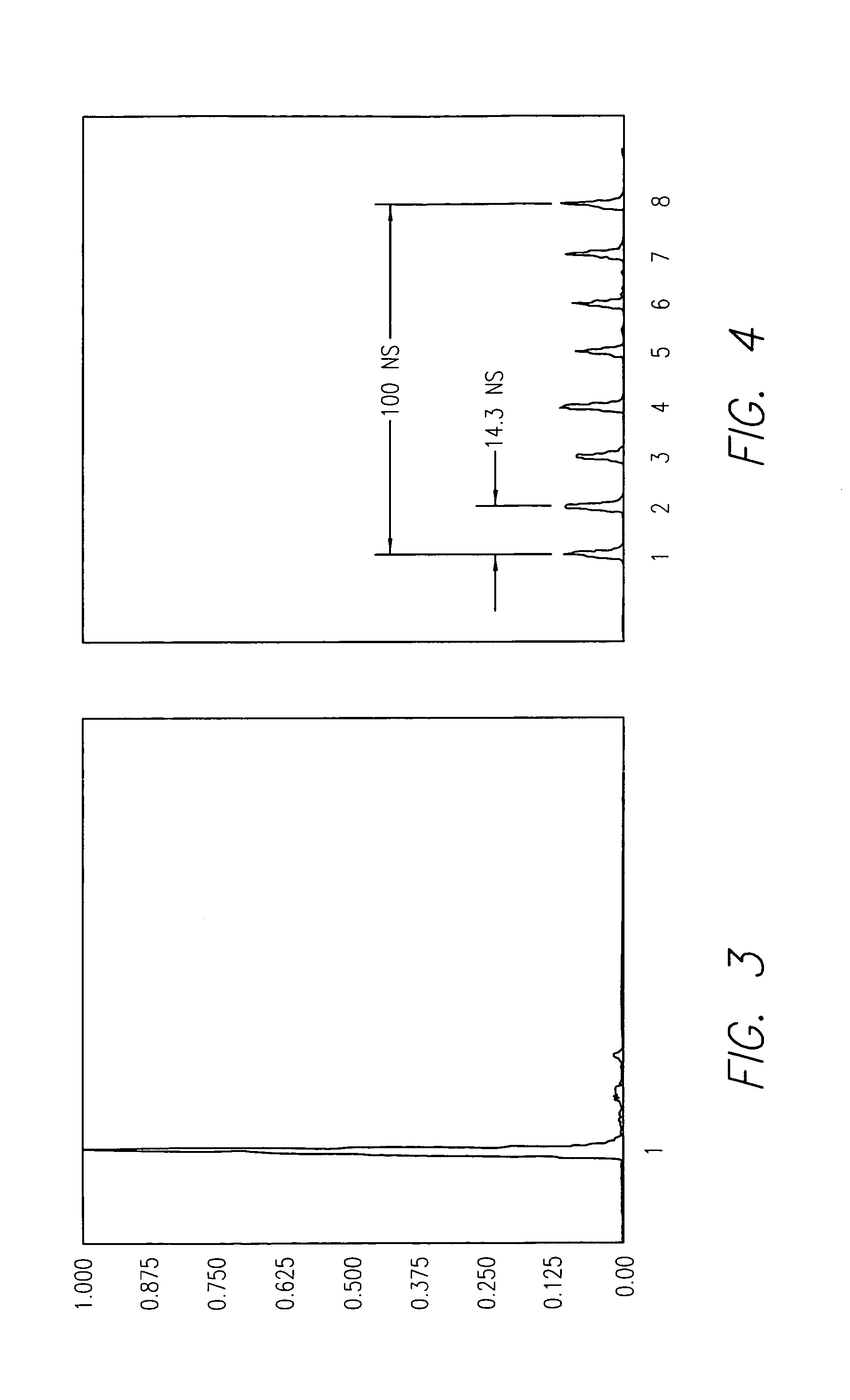

Excimer laser inspection system

A system and method for inspecting a specimen, such as a semiconductor wafer, including illuminating at least a portion of the specimen using an excimer source using at least one relatively intense wavelength from the source, detecting radiation received from the illuminated portion of the specimen, analyzing the detected radiation for potential defects present in the specimen portion.

Owner:KLA TENCOR TECH CORP

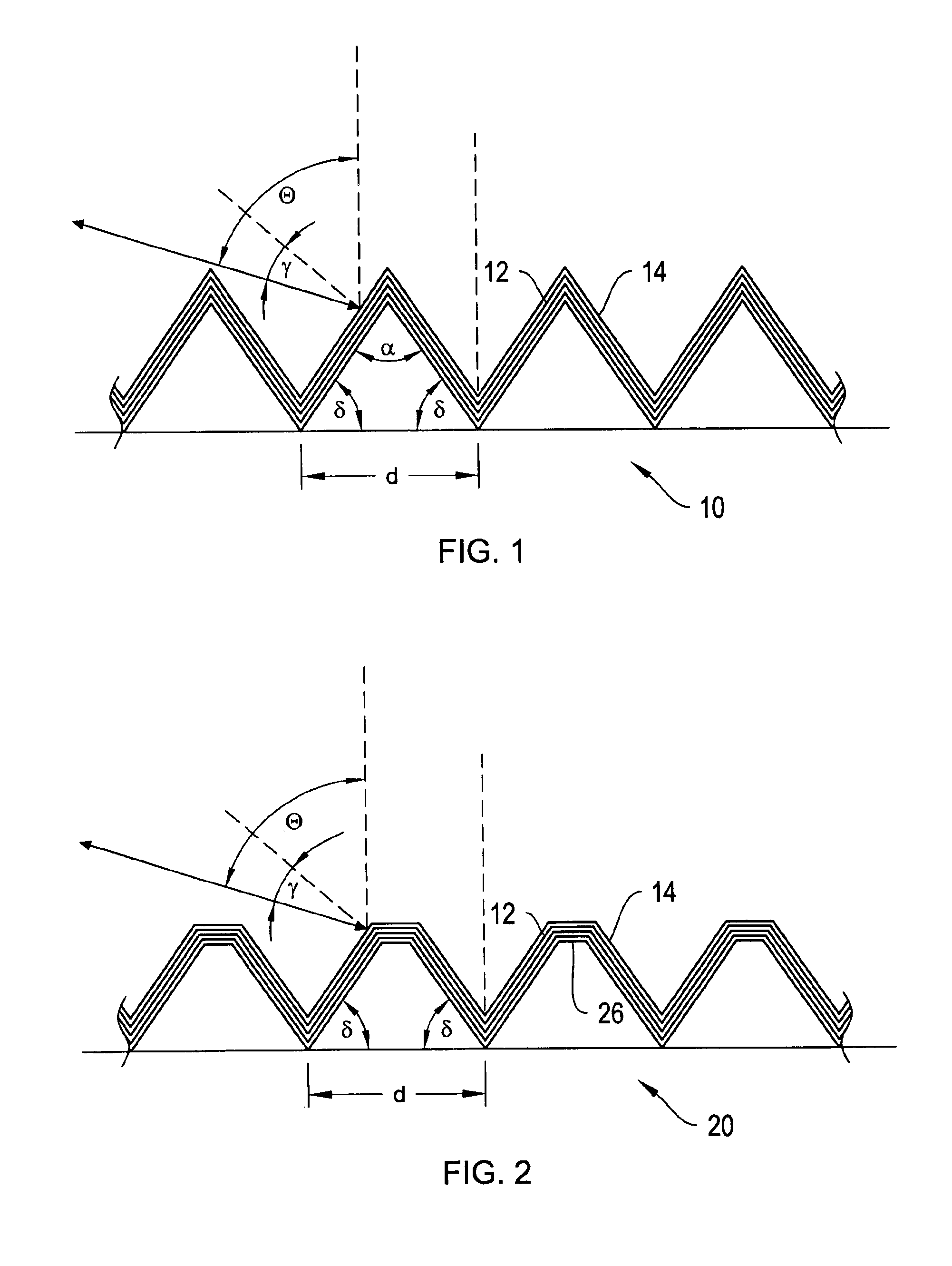

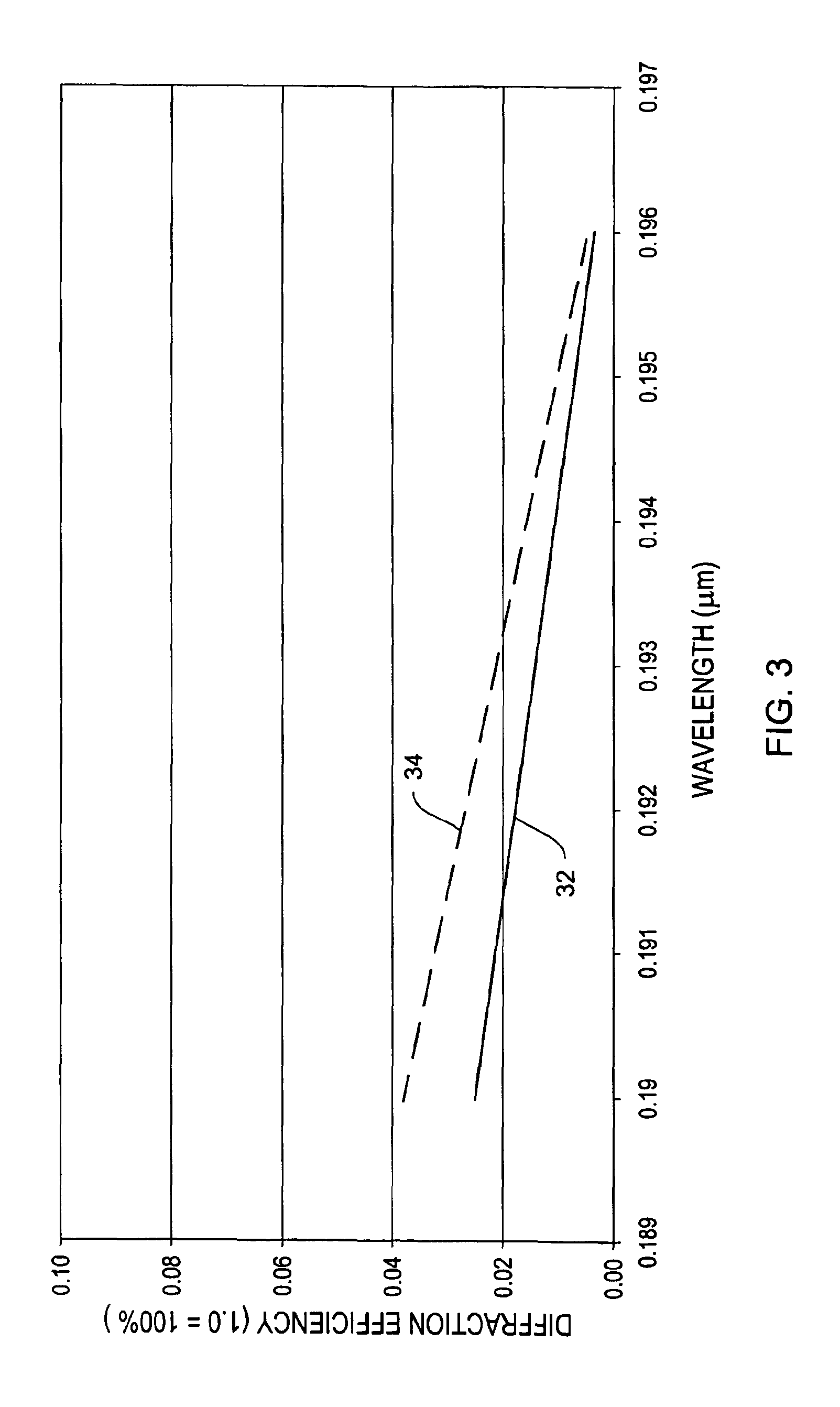

Grating device with high diffraction efficiency

InactiveUS6958859B2High diffraction efficiencyHigh wavelength dispersionDiffraction gratingsElectricityLength wave

A grating structure with a dielectric coating is disclosed that operates efficiently away from the blaze angle in low order with a high diffraction efficiency and high wavelength dispersion. Such grating structure can be employed in Littrow configuration to provide, for example, cavity feedback in excimer lasers.

Owner:LUMELLA

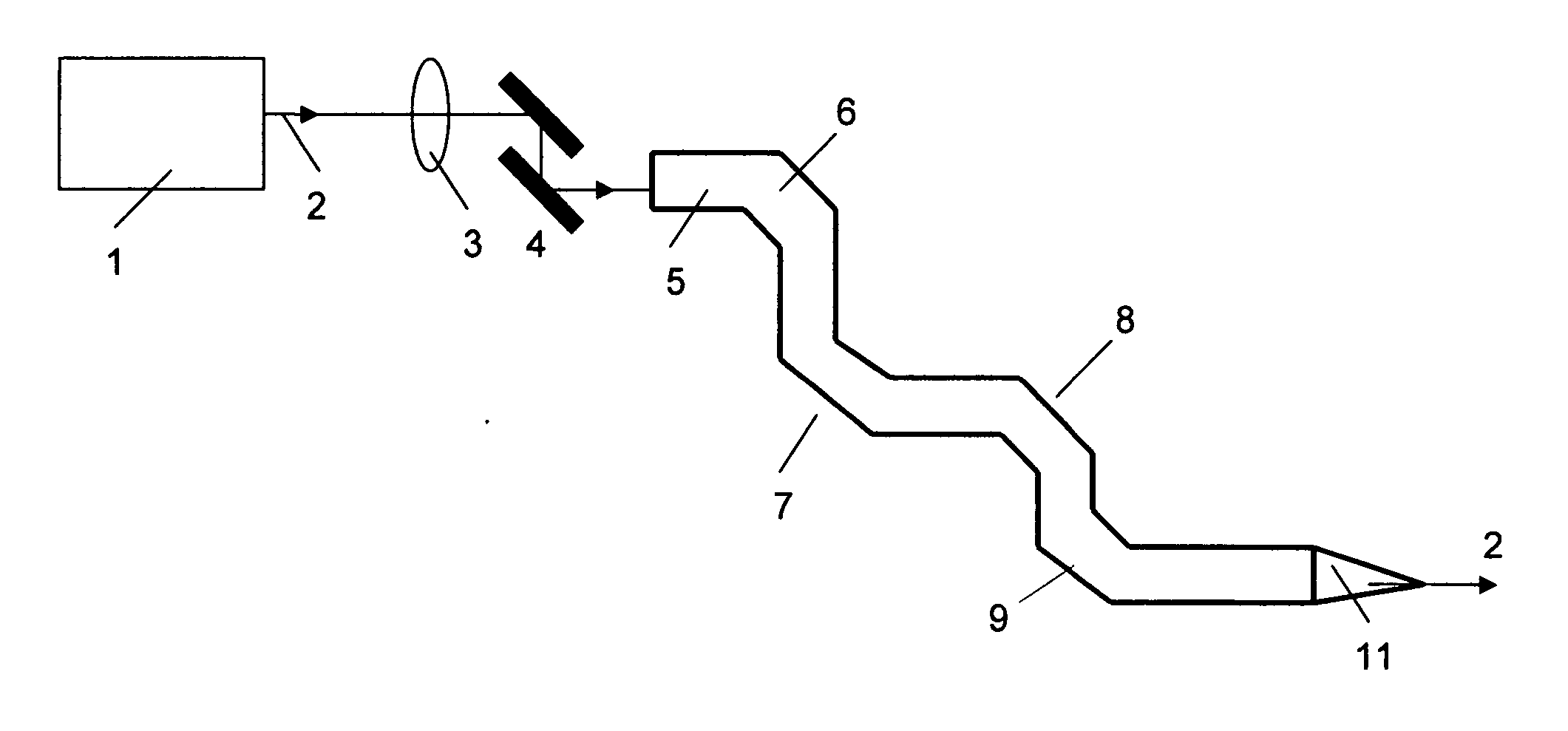

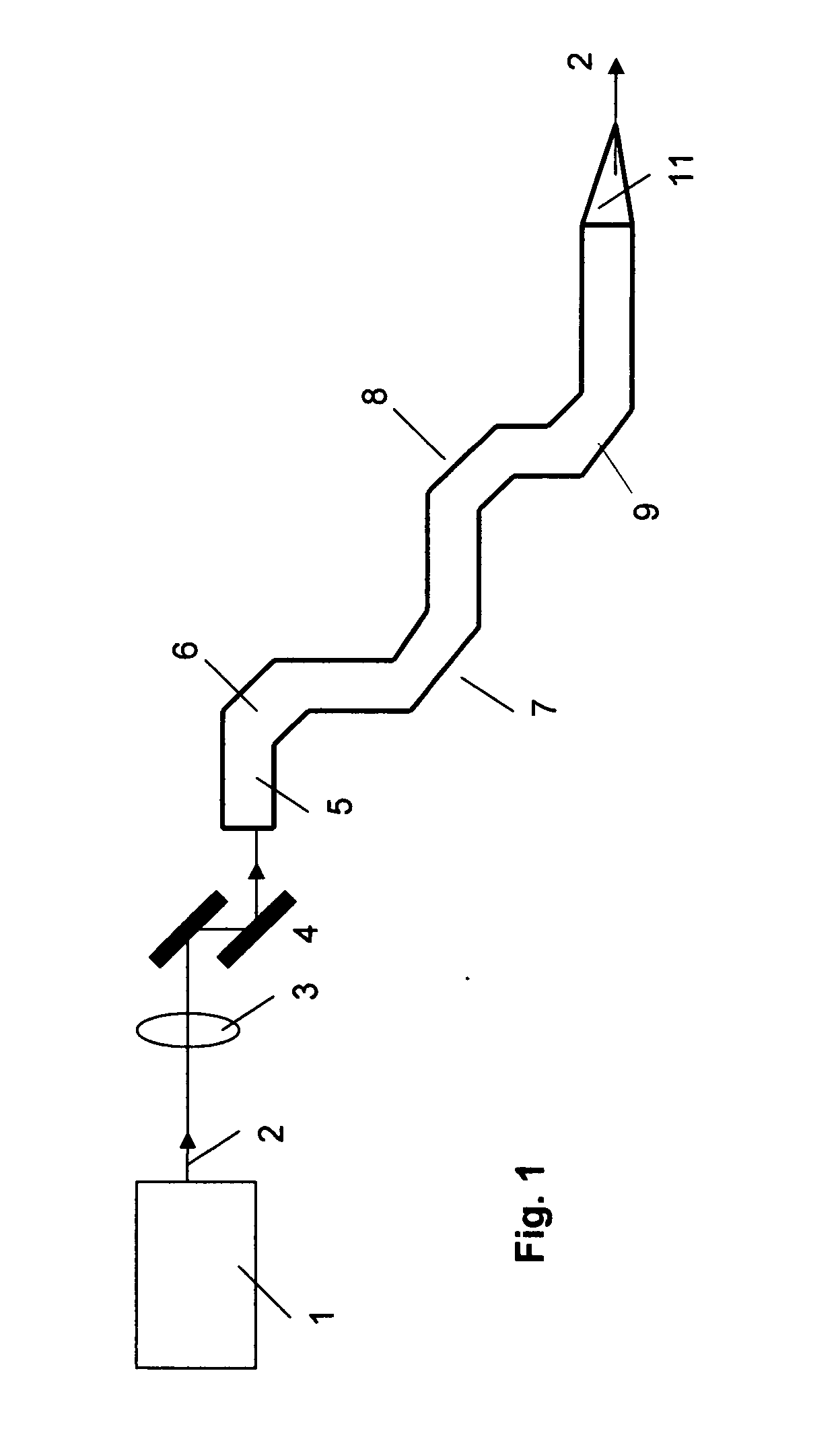

Treatment of eye disorders using articulated-arm coupled ultraviolet lasers

InactiveUS20060129141A1Increase flexibilityIncrease spacingLaser surgerySurgical instrument detailsIntra ocular pressureDisease

Surgical method and apparatus for presbyopia correction and glaucoma by laser removal a portion of the sclera and / or ciliary tissue are disclosed. The disclosed preferred embodiments of the system consists of a beam spot controller, an articulated arm and an attached end-piece. The basic laser beam includes UV laser having wavelength ranges of (0.19-0.36) microns, generated from UV excimer lasers of ArF, XeCl or solid state lasers of Nd:YLF, Nd:YAG, Ti:sapphire with harmonic generation using nonlinear crystals. Presbyopia is treated by ablation of the treated surface tissue in predetermined patterns outside the limbus to increase the accommodation of the eye. Glaucoma is treated by decreasing of intra ocular pressure of the laser surgery.

Owner:NEW VISION

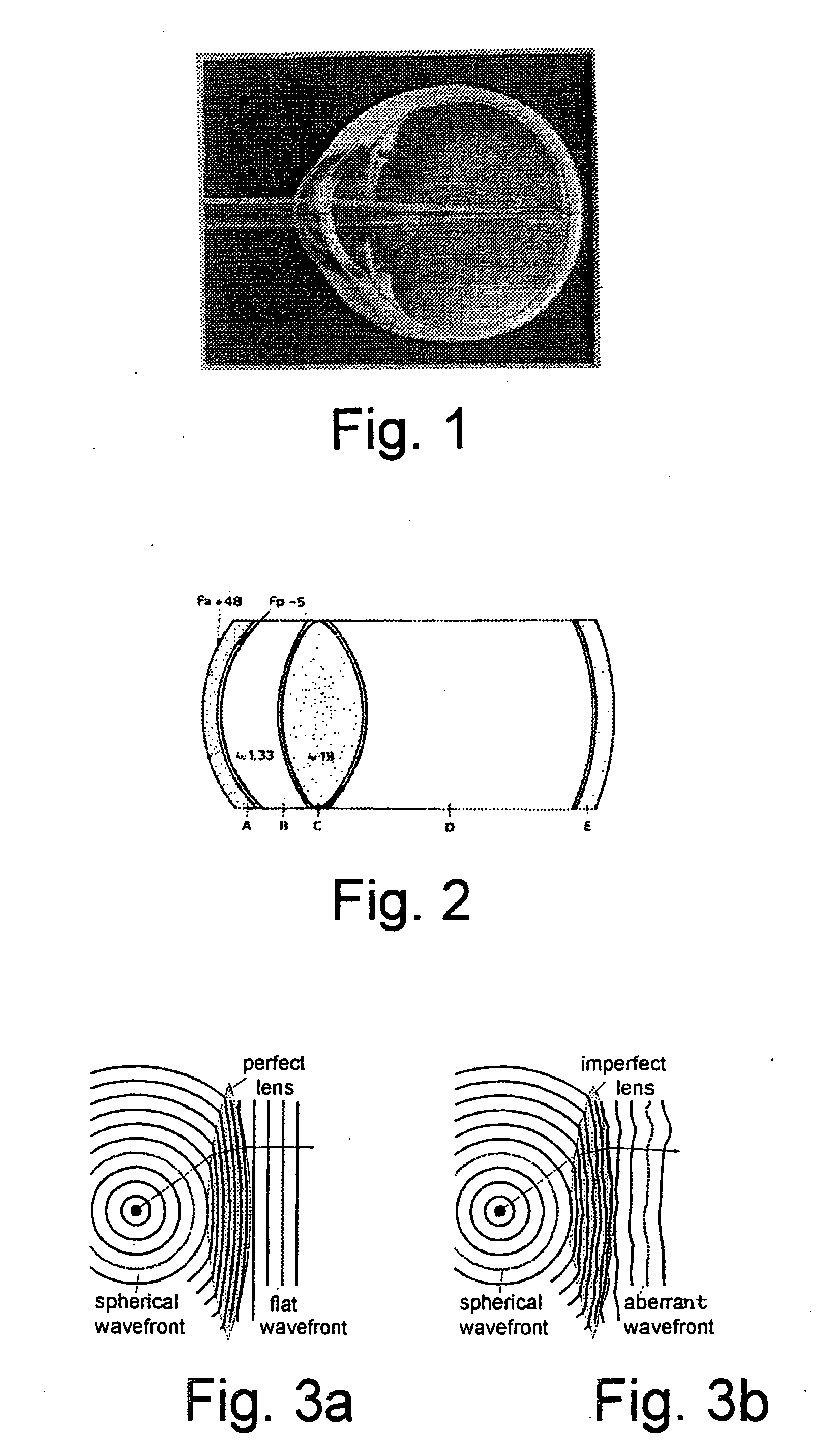

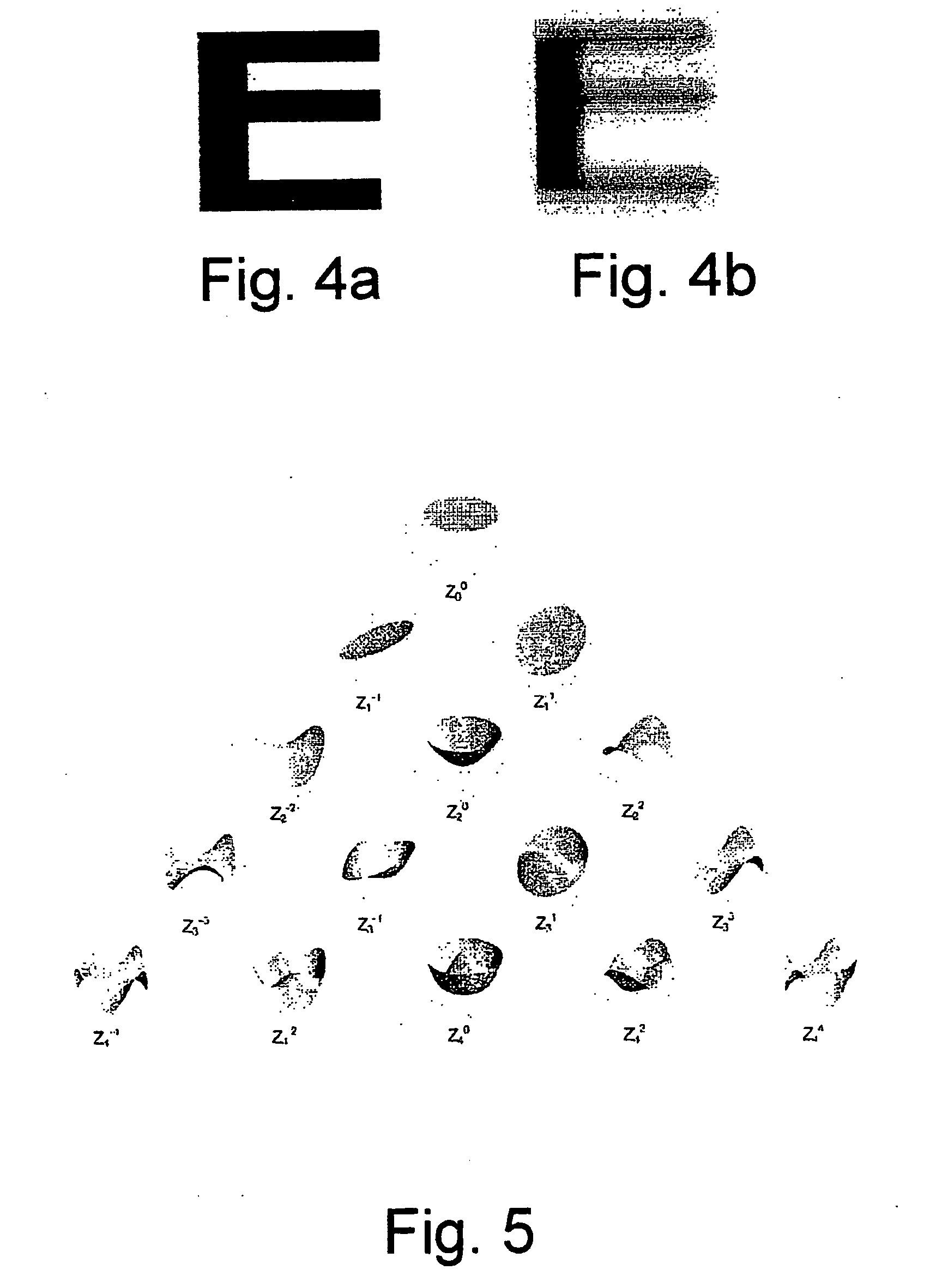

Method and device for performing online aberrometrie in refractive eye correction indices

The invention relates to a method and a device for the complete correction of sight defects in the human eye. Combinations of measuring, and processing methods are described which when applied as disclosed in the invention, make it possible to fully correct sight defects in the human eye. Measuring methods are used which can precisely scan the surface of the cornea and also register other imaging defects in the light path up to the retina. Computer-aided of said measuring results determined when combined with calculation of ideally corrected ocular lenses (for example after cataract operations) or ideally corrected surfaces of the cornea opens up the possibility of manufacturing a patient-specific lens and / or achieving ideal correction of the cornea using preferably a topography-supported spot-scanning-excimer laser system.

Owner:CARL ZEISS MEDITEC AG

Methods of processing of gallium nitride

InactiveUS7015117B2Polycrystalline material growthFrom solid stateThermal energyElectrical conductor

A method for improving thermal dissipation in large gallium nitride light emitting diodes includes replacing sapphire with a better thermal conductor resulting in more efficient removal of thermal energy. A method for achieving a reliable and strong temporary bond between a GaN epitaxial layer and a support wafer. A method for transferring an epitaxial film from a growth substrate to a secondary substrate. An excimer laser initiates film delamination from the growth substrate. The laser beam is shaped by a shadow mask and aligned to an existing pattern in the growth substrate. A method for fabricating a LED that radiates white spectrum light. A phosphor that radiates a white spectrum after excitation in the blue or UV spectrum onto the GaN epitaxial wafer prior to die separation and packaging. A method for depositing a metal substrate onto a GaN epitaxy layer.

Owner:ALLEGIS TECH

Resist composition and patterning process

A resist composition comprising (A) an organic solvent; (B) at least two polymers with weight average molecular weights of 1,000-500,000, which have at least one type of acid labile group and are crosslinked within a molecule and / or between molecules with crosslinking groups having C-O-C linkages; and (C) a photoacid generator is sensitive to high-energy radiation, has excellent sensitivity, resolution, and plasma etching resistance, and provides resist patterns of outstanding thermal stability and reproducibility. Patterns obtained with this resist composition are less prone to overhanging and have excellent dimensional controllability. The resist composition is suitable as a micropatterning material for VLSI fabrication because it has a low absorption at the exposure wavelength of a KrF excimer laser, thus enabling the easy formation of a finely defined pattern having sidewalls perpendicular to the substrate.

Owner:SHIN ETSU CHEM IND CO LTD

Method for patterning thin films

InactiveUS20010006766A1Great throughput and outputReduce impactPhotography auxillary processesAntenna supports/mountingsResistMicroscopic scale

Patterned articles, such as RFID antenna, are made by subablation, a process comprising the steps of: A. providing a substrate having a coating, such as a metal or metal oxide, and an interface comprising the thin region where the coating and the substrate are closest to each other; B. exposing at least one part of the total area of the coating to a flux of electromagnetic energy, Such as a focused excimer laser beam, sufficient to disrupt the interface but insufficient to ablate the coating, and C. removing the parts of the coating in registry with the portion of the interface area that was disrupted, by means such as ultrasonic agitation. The process has advantages over photo-resist processes in that there is no residual chemical resist left on the product and no undercutting of the pattern or image. It has advantages over laser ablation processes in that higher throughput is possible at the same energy level and there is no microscopic debris left on the product surface.

Owner:3M INNOVATIVE PROPERTIES CO

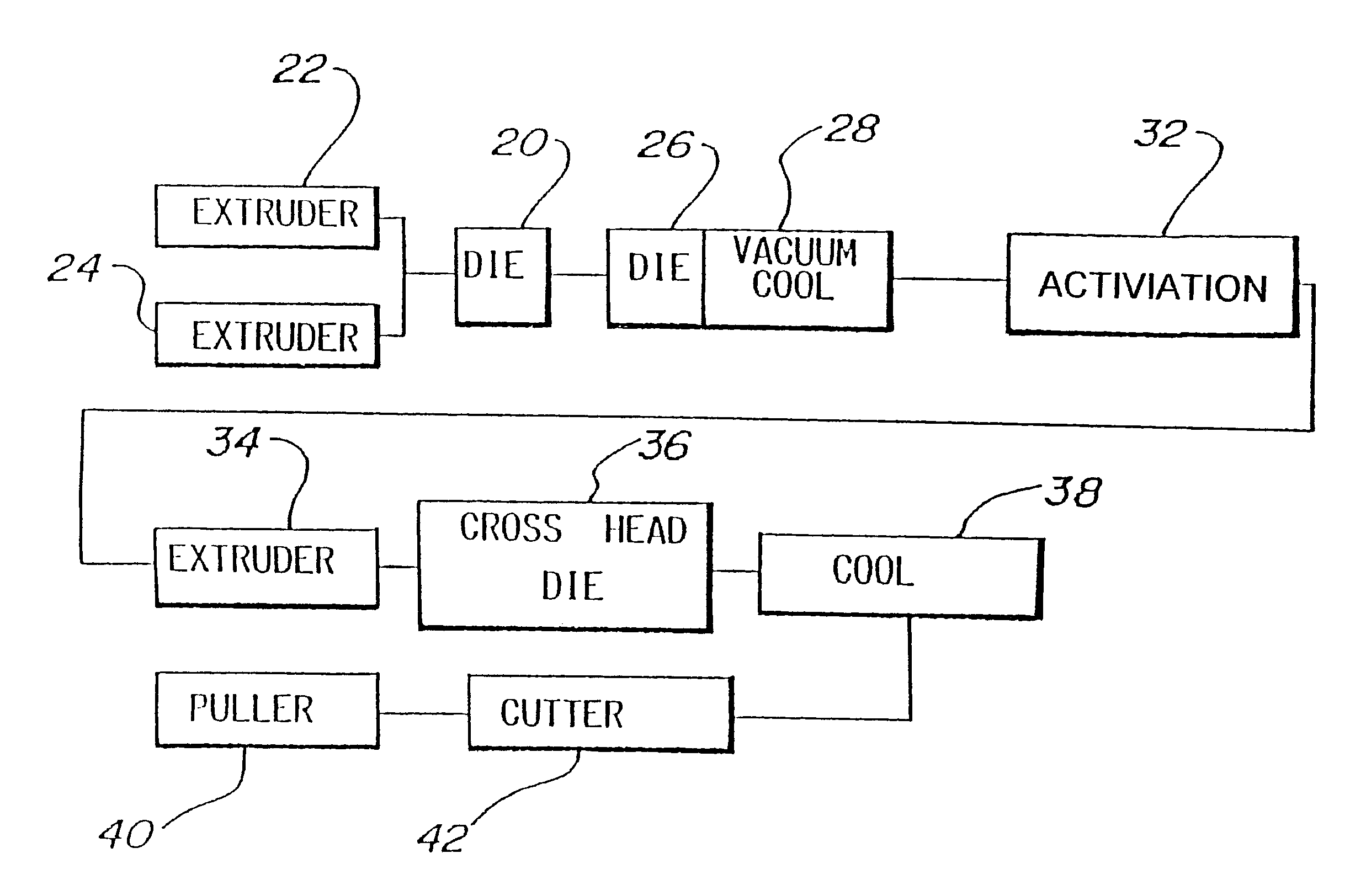

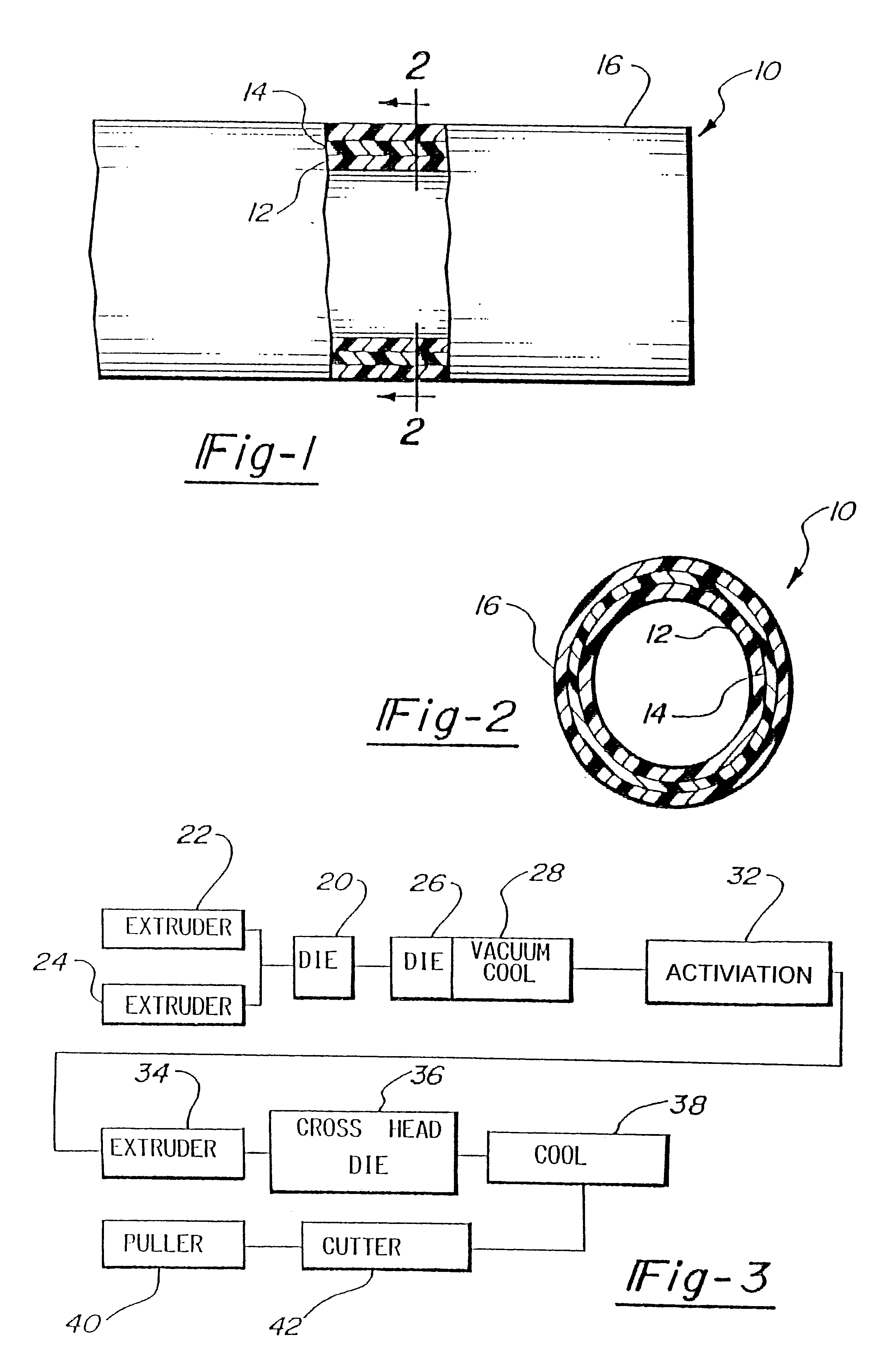

Fluoropolymer composite tube and method of preparation

InactiveUS6517657B1High strengthLamination ancillary operationsSynthetic resin layered productsAdhesiveX-ray

Described herein is a method of preparing a fluoropolymer composite comprising the steps of activating the fluoropolymer substrate and thereafter applying a layer of a different polymer to the activated fluoropolymer substrate. The activation step can be described as a mixed gas plasma discharge or an electrically formed plasma. Also described herein are other methods of surface activation including exposure to excimer laser, gamma rays, x-ray flux, electron beam, sodium naphthalate bath, coupling or curing agents, and others. In particular, described is a fuel pipe comprised of an inner fluorocarbon layer having electrostatic discharge resistance and hydrocarbon evaporative emission resistance chemically bonded to an outer layer of a cross-linked polyethylene polymer. There is no need for additional adhesives. Fluoropolymer layers have excellent chemical resistance.

Owner:MARTINREA IND INC

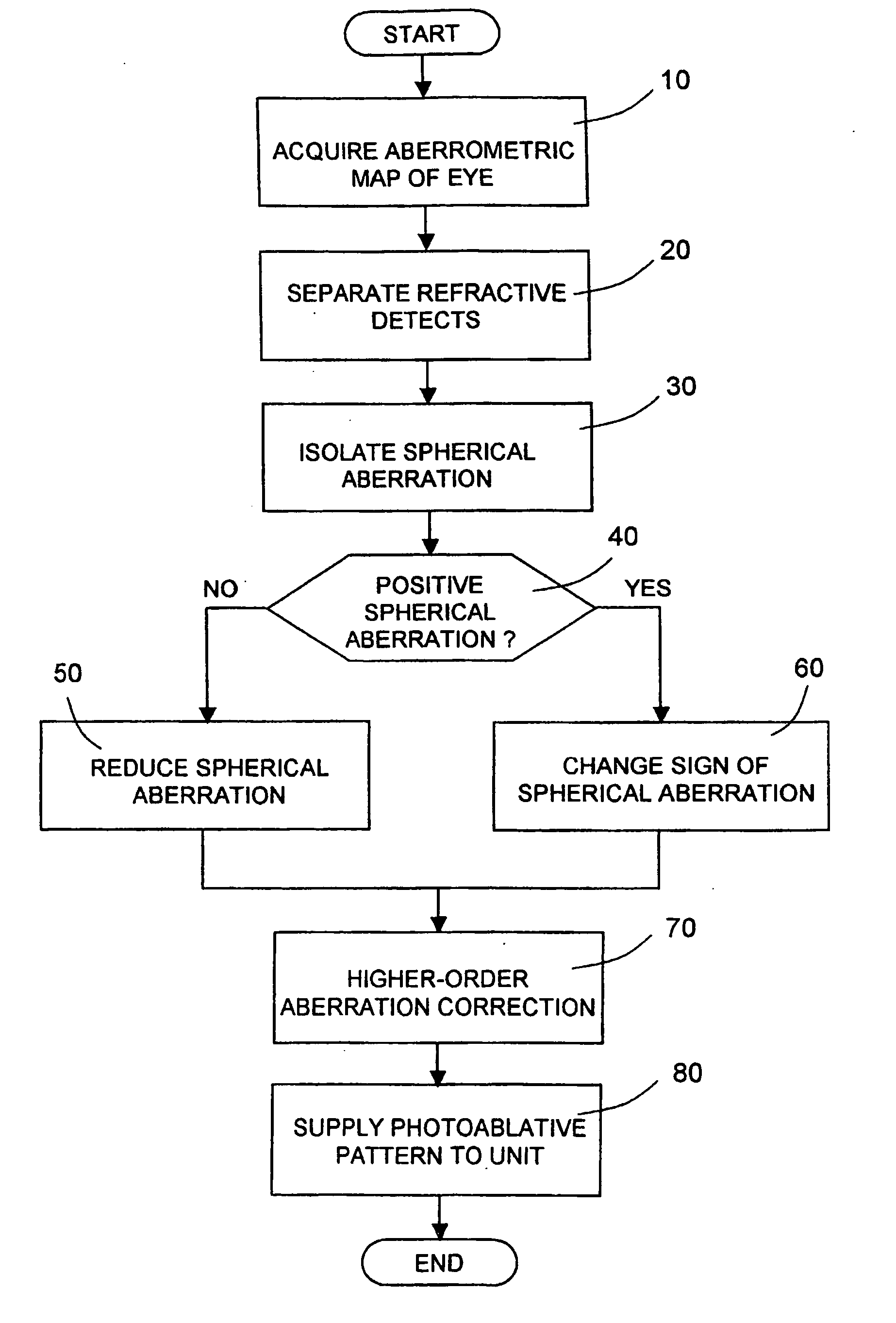

Excimer laser unit and relative control method for performing cornea ablation to reduce presbyopia

ActiveUS20060195074A1Mitigates presbyopiaLaser surgerySurgical instrument detailsPhotoablationHyperopic astigmatism

There are described an excimer laser unit and a method of controlling the unit to perform cornea ablation to reduce presbyopia, wherein the excimer laser unit is controlled to form on the cornea a photoablative pattern inducing a fourth-order ocular aberration, in particular a positive spherical aberration. More specifically, an aberrometric map of the eye is first acquired indicating the visual defects of the eye, which include second-order visual defects such as hypermetropia, astigmatism, and myopia, and higher-order visual defects such as spherical aberration; if the detected spherical aberration is negative, it is reduced by numerically increasing its absolute value to obtain an overcorrect photoablative inducing positive spherical aberration; conversely, if the detected spherical aberration is positive, its sign is changed and its absolute value increased numerically to obtain an overcorrect photoablative pattern inducing positive spherical aberration; and the photoablative pattern so generated is supplied to the excimer laser unit for implementation on the cornea.

Owner:CARL ZEISS MEDITEC AG

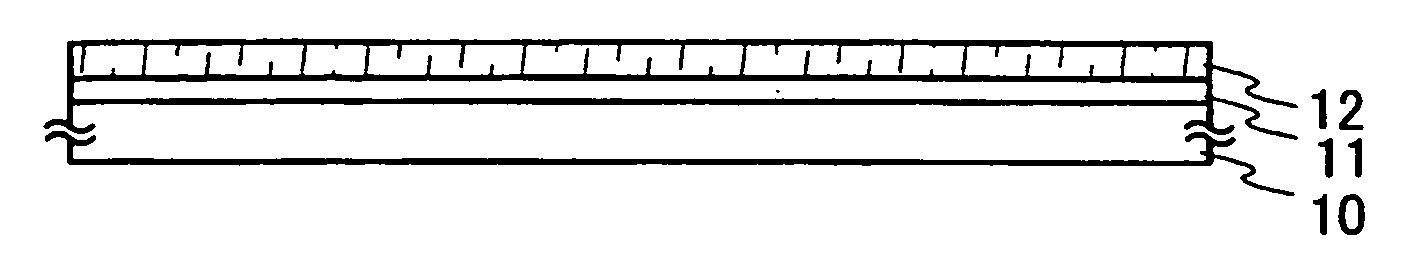

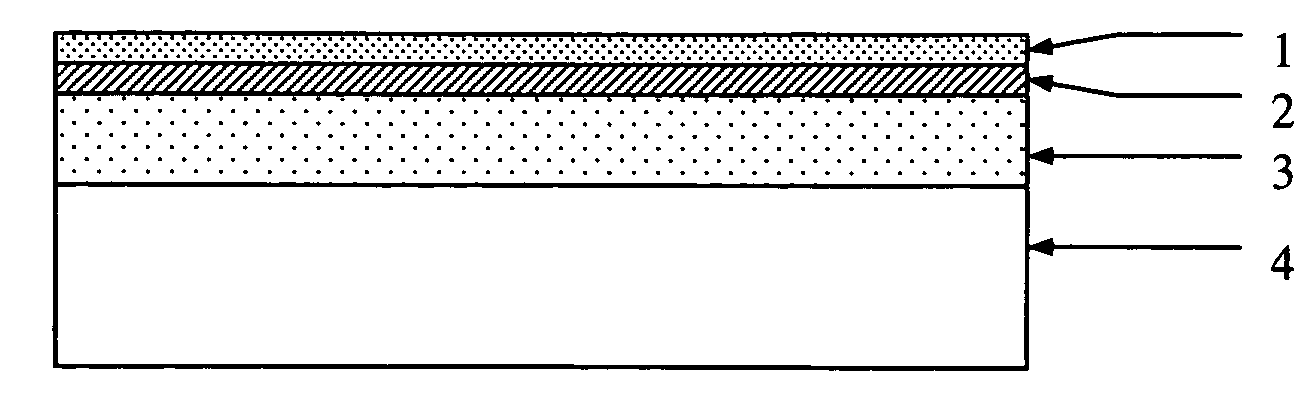

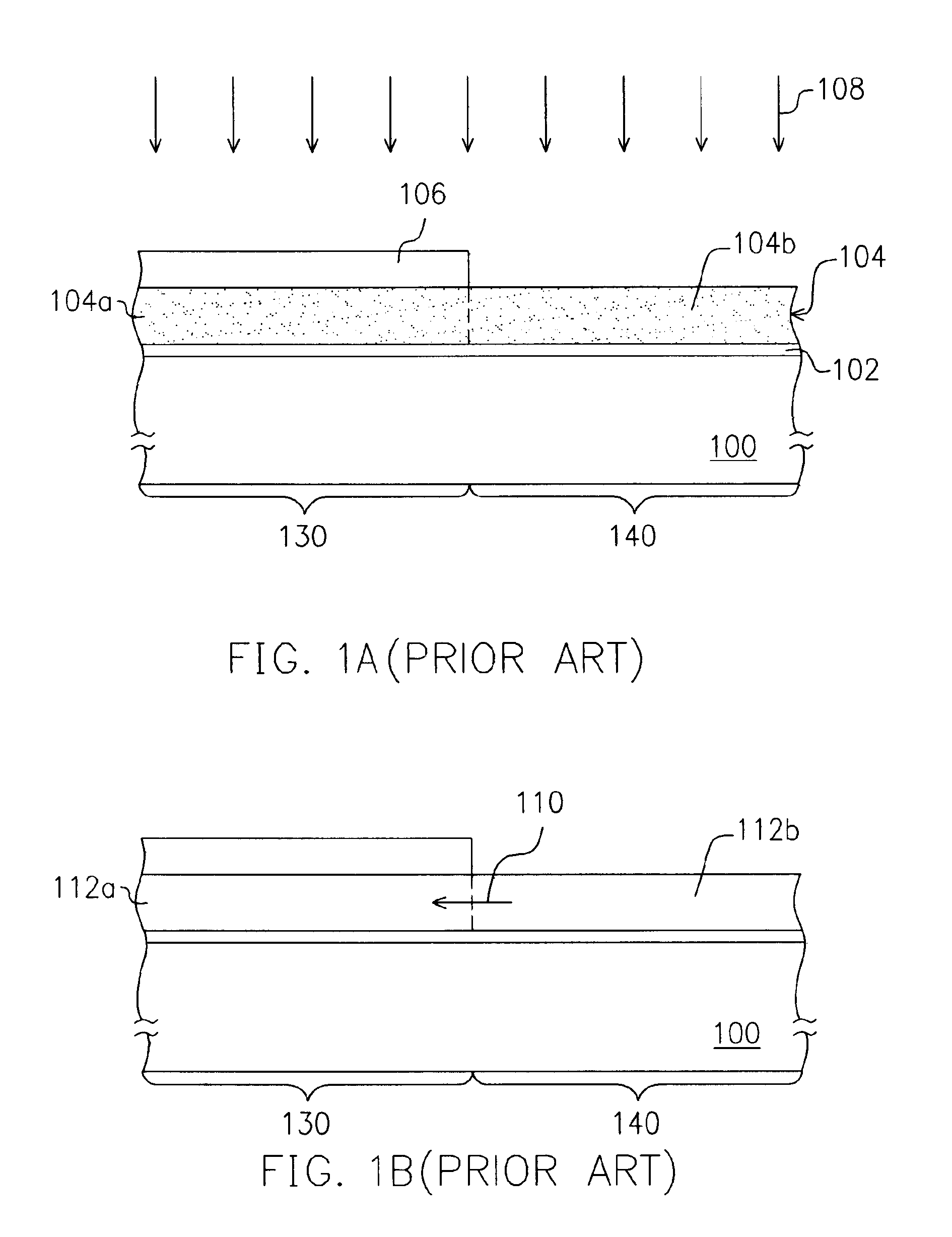

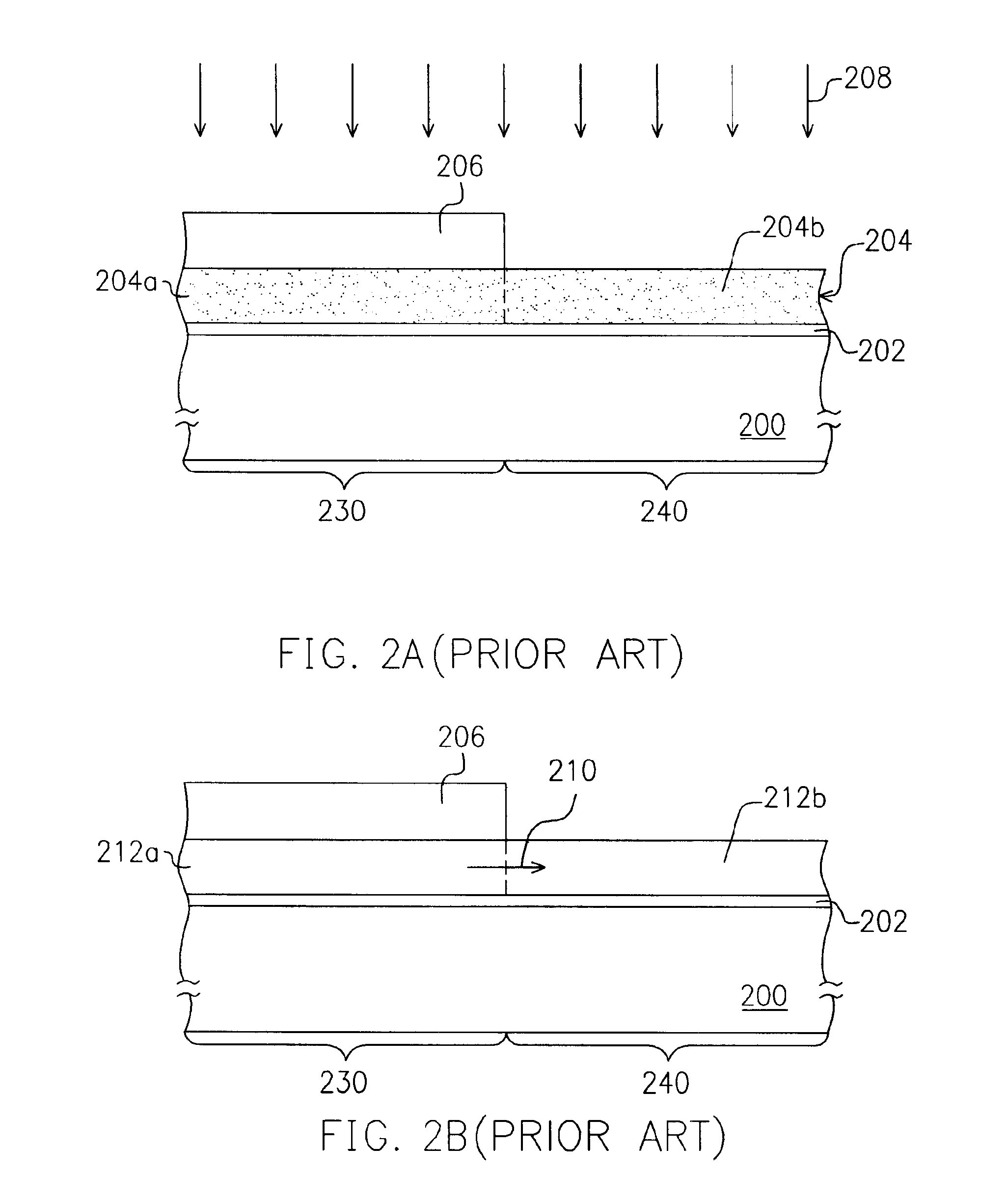

Method of fabricating polysilicon film

InactiveUS6916690B2Increasing lateral temperature gradientInduce lateral crystallizationTransistorSolid-state devicesAmorphous siliconLaser annealing

A method of fabricating polysilicon film is described. An amorphous silicon layer is formed on the substrate, an optical layer is formed on the amorphous silicon layer, wherein the optical has a first region having a first thickness and a second region having a second thickness, and the reflectivity of the first region for an excimer laser is higher than that of the second region. A laser annealing process is then preformed to transform the amorphous silicon layer into a polysilicon film.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com