Method for patterning thin films

a thin film and patterning technology, applied in the direction of loop antennas, printing, thermography, etc., can solve the problems of sudden increase in surface temperature for a short time, inability to achieve the desired effect, and inability to produce debris. , to achieve the effect of reducing process steps, reducing the generation of debris, and high fluen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

[0060] This example illustrated the effect of a different energy source on image characteristics.

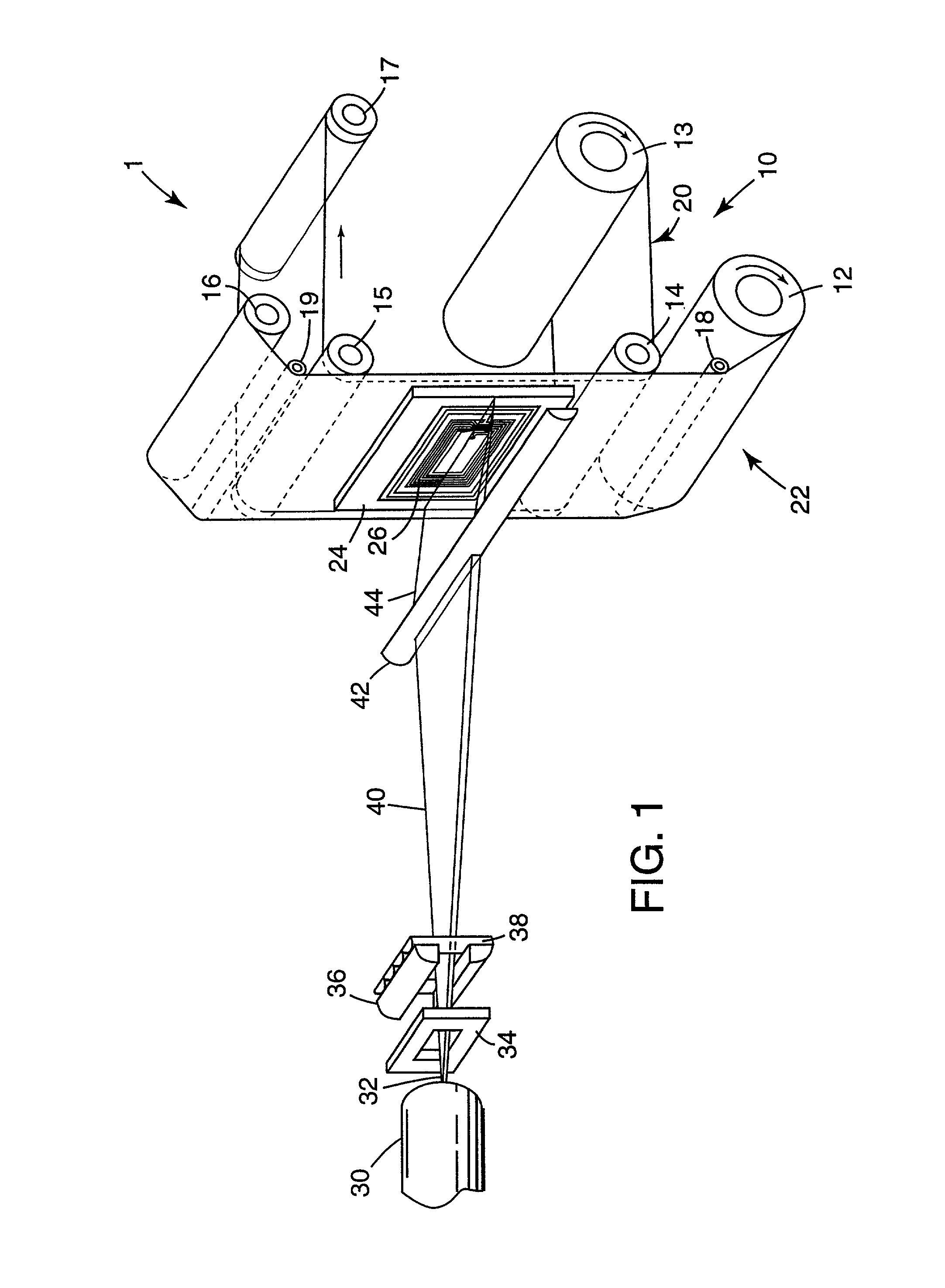

[0061] Example 4 was made in a manner similar to Example 1 except a different energy source and optical train were used, some of the conditions were changed, and a different cleaning method was used. The energy source was an infrared laser (Model 2660 Nd:YAG Infrared Laser available from Excel Technology Inc., Hauppauge, N.Y.) operating at a wavelength of 1.06 .mu.m, a repetition rate of 2000 Hz, an energy per pulse of 0.6 mJ, and a pulse width of 200 ns. The laser light incident on the metal coating was a dot or point, in contrast to the line or narrow rectangle of light in example 1 (as shown in FIG. 1). The optical trail consisted of only a round plano-convex lens with focal length of 10 cm. There was no beam shaper, homogenizer, or cylindrical lens. No mask and no protective web were used. The resulting fluence reaching the metal surface was determined from the energy output of the l...

example 5

[0063] This example illustrated the use of a metal oxide coating on the substrate.

[0064] Example 3 was made as in Example 1 except that a metal oxide coated substrate was used and the energy output was reduced to about 650 mJ. The metal oxide coated substrate consisted of polyester that had been sputter coated with indium tin oxide to achieve a conductivity of 80 Ohms / square and available as No. OFC80 from Courtaulds Performance Films Inc., Canoga Park, Calif. The optical train was configured to shape the incident excimer laser beam into a 150 mm by 0.89 mm rectangle at the metal oxide surface. The energy from the excimer laser was adjusted to achieve a calculated fluence of about 80 mJ / cm.sup.2 in tills rectangle, below the ablation threshold of 90 mJ / cm.sup.2 that is needed to ablate this coating from this substrate for this wavelength. The final beam profile was overlapped by 10% for the successive pulses. The subsequent pattern had good resolution with fine features as small as ...

example 6

[0065] This example illustrated the use of a different substrate class.

[0066] Example 6 was made as in Example 1 except that a different substrate was used and the fluence was reduced. (energy level was about 650 mJ). The metal coated substrate consisted of polyimide (50 .mu.m thick film available as Kapton.TM. E from DuPont Inc., Circleville, Ohio) that had been sputter coated with copper to achieve a coating thickness of approximately 250 nm. The resulting subablation fluence used to disrupt the coating substrate interface was calculated to be 170 mJ / cm / .sup.2, below the ablation threshold of approximately 300 mJ / cm.sup.2 that is needed to ablate the metal from the substrate for this wavelength. The subsequent pattern had good resolution with fine features as small as 75 .mu.m wide lines and spaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ablation threshold fluence | aaaaa | aaaaa |

| ablation threshold fluence | aaaaa | aaaaa |

| focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com