Patents

Literature

69results about How to "High energy laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

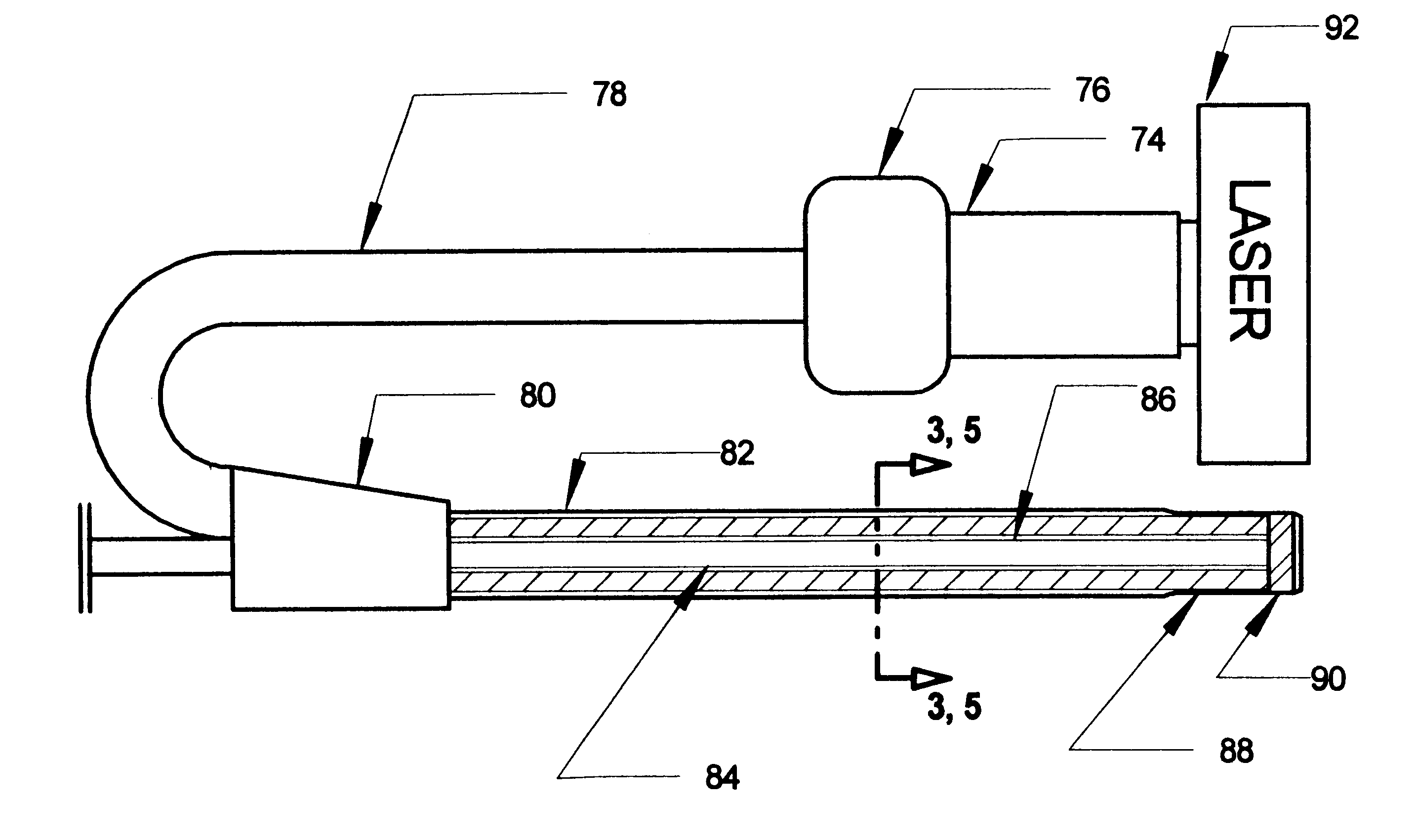

Excimer laser catheter

InactiveUS6440125B1Reduce the possibilityHigh energy laserDiagnosticsCatheterEndovascular therapyAtheroma

A method and apparatus of providing endovascular therapy. The steps include arranging optical fibers within a catheter, the catheter having a tip whose length is at least 1 cm and whose diameter of less than 1 millimeter, connecting an excimer laser to the optical fibers; and delivering laser energy from the excimer laser in excess of 60 fluence at 40 Hertz through the optical fibers. The delivering of the laser energy may be to non-calcified or calcified deposits of an atherosclerotic lesion to ablate the same. The method also includes the step of inserting the catheter through an artery by pushing the same until the tip is in within laser energy striking distance of the atherosclerotic lesion.

Owner:RENTROP PETER

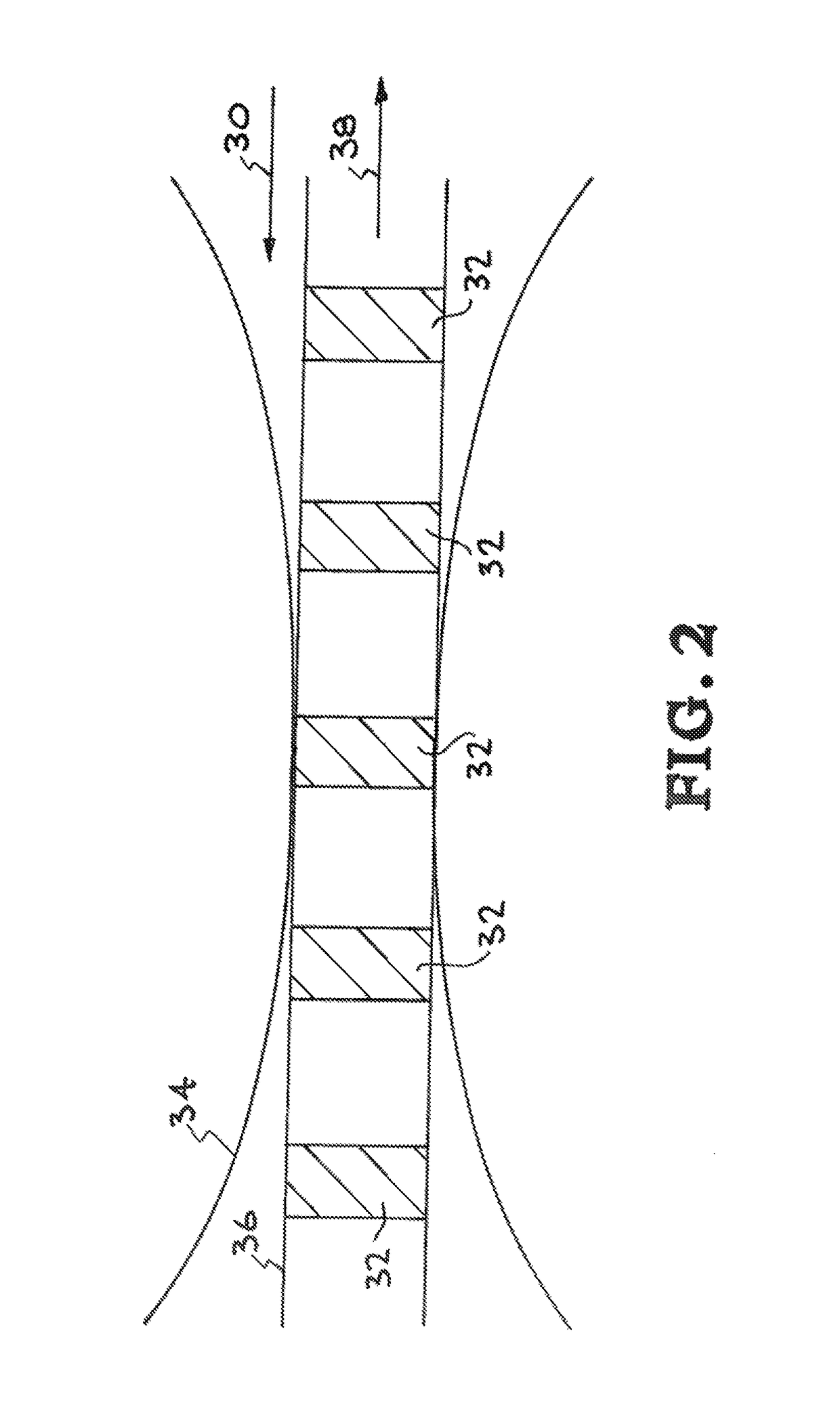

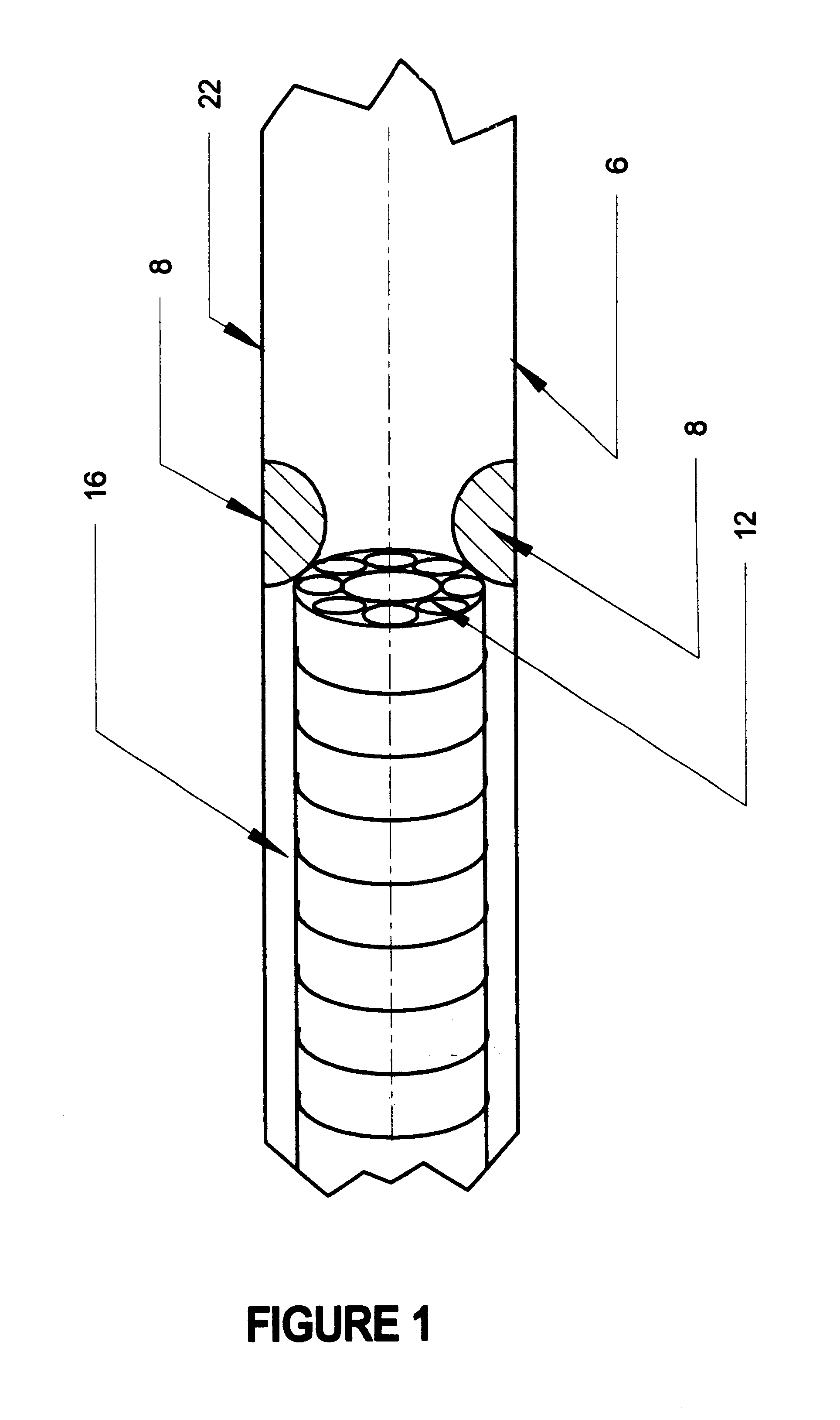

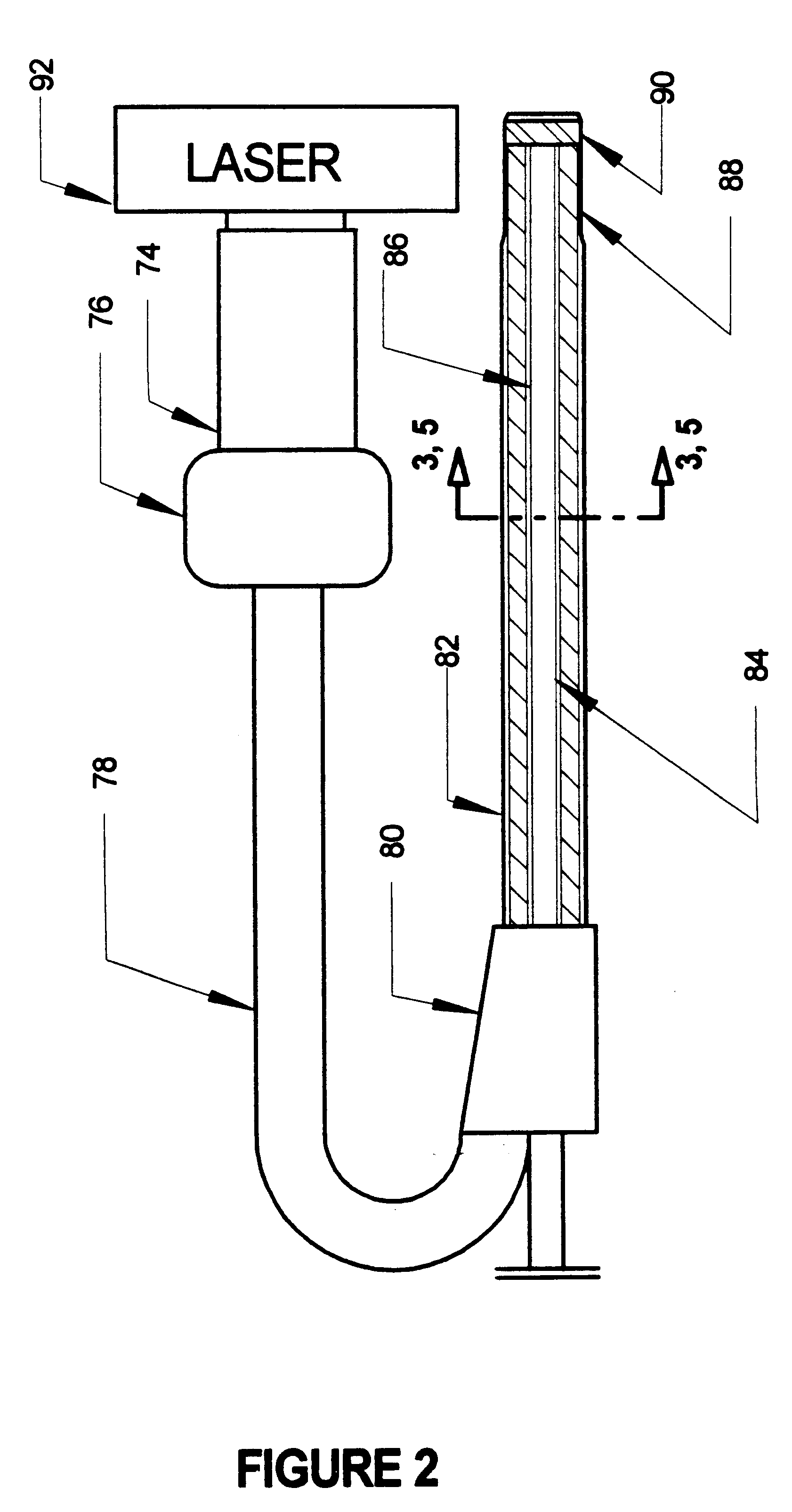

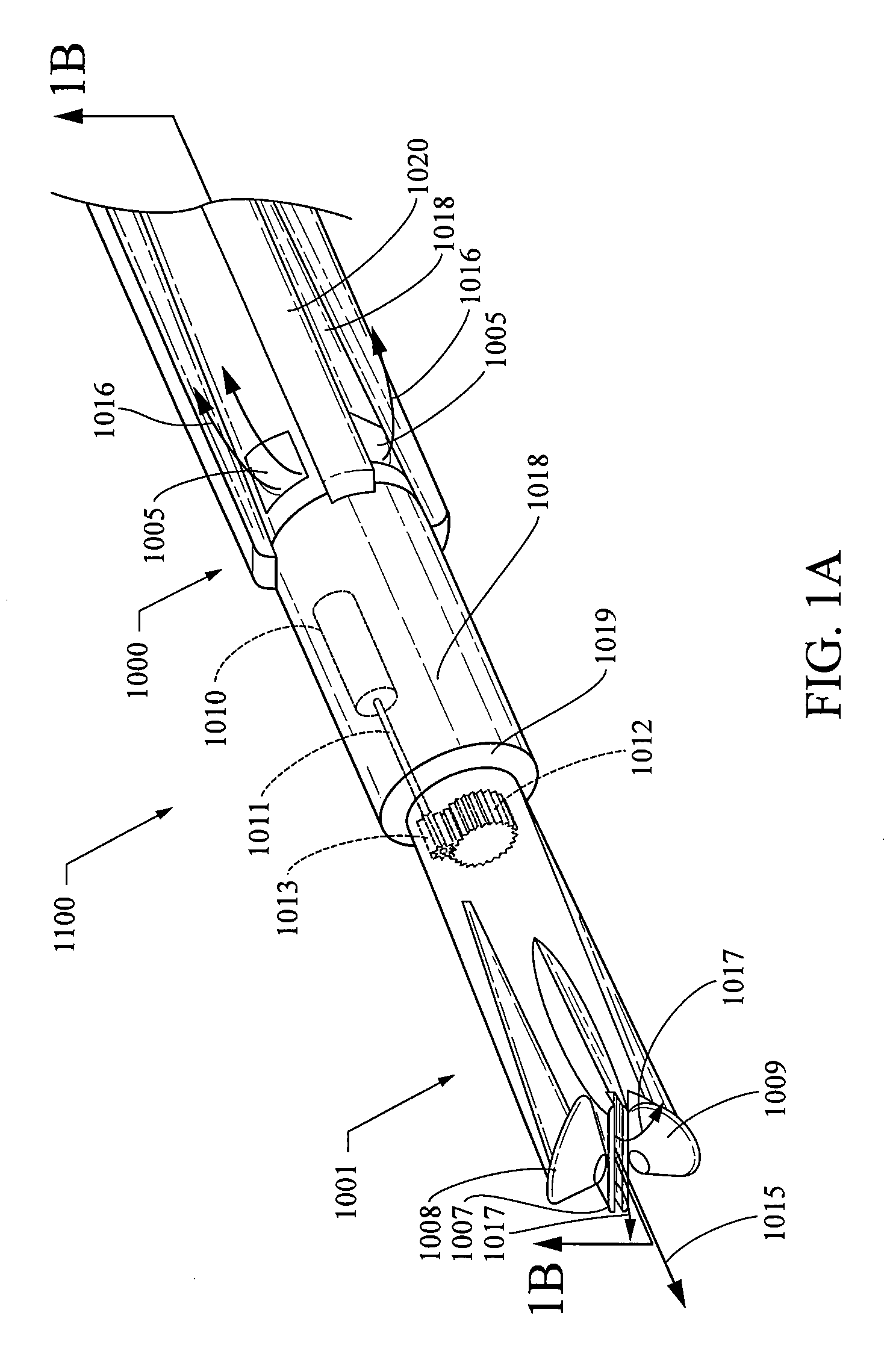

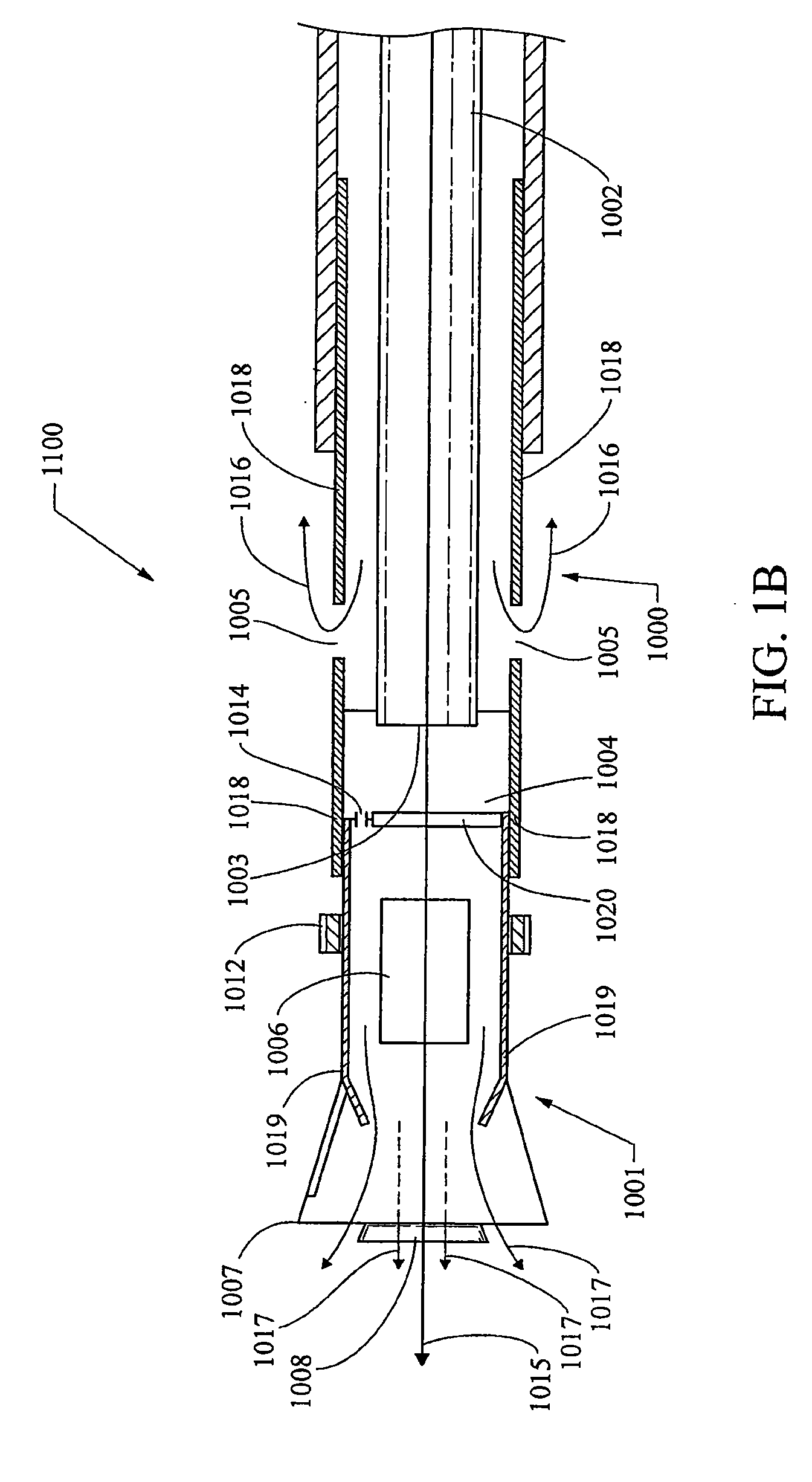

Apparatus for Advancing a Wellbore Using High Power Laser Energy

ActiveUS20100044104A1High energy laserReduce distractionsDrill bitsDisloding machinesLaser opticsHigh power lasers

There is provided a system, apparatus and methods for delivering high power laser energy to advance a borehole deep into the earth using laser energy. In particular, there is provided a laser bottom hole assembly (LBHA) for the delivery of such laser energy to the surfaces of a borehole, which assembly may have laser optics, a fluid path for debris removal and a mechanical means to remove earth.

Owner:FORO ENERGY

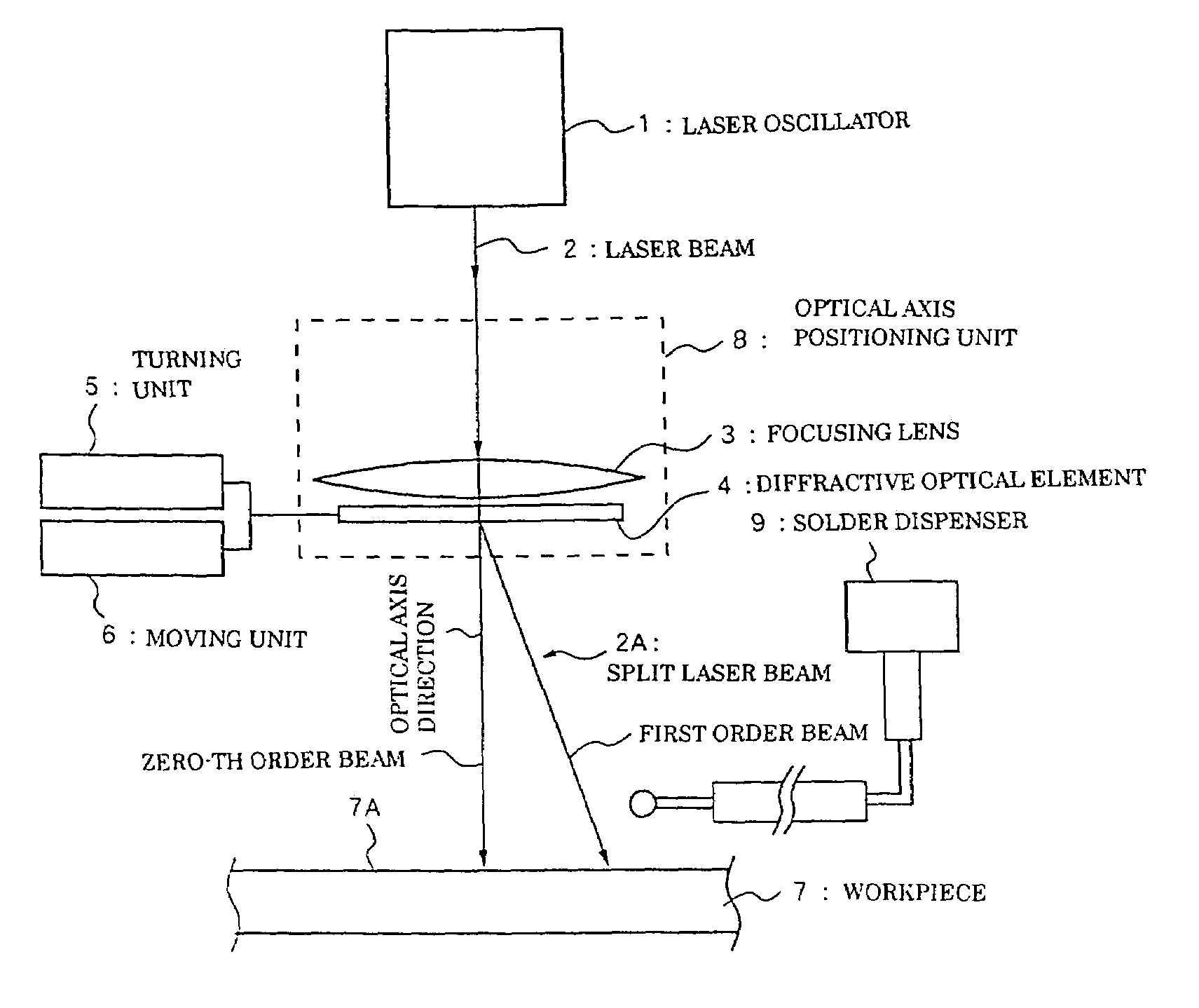

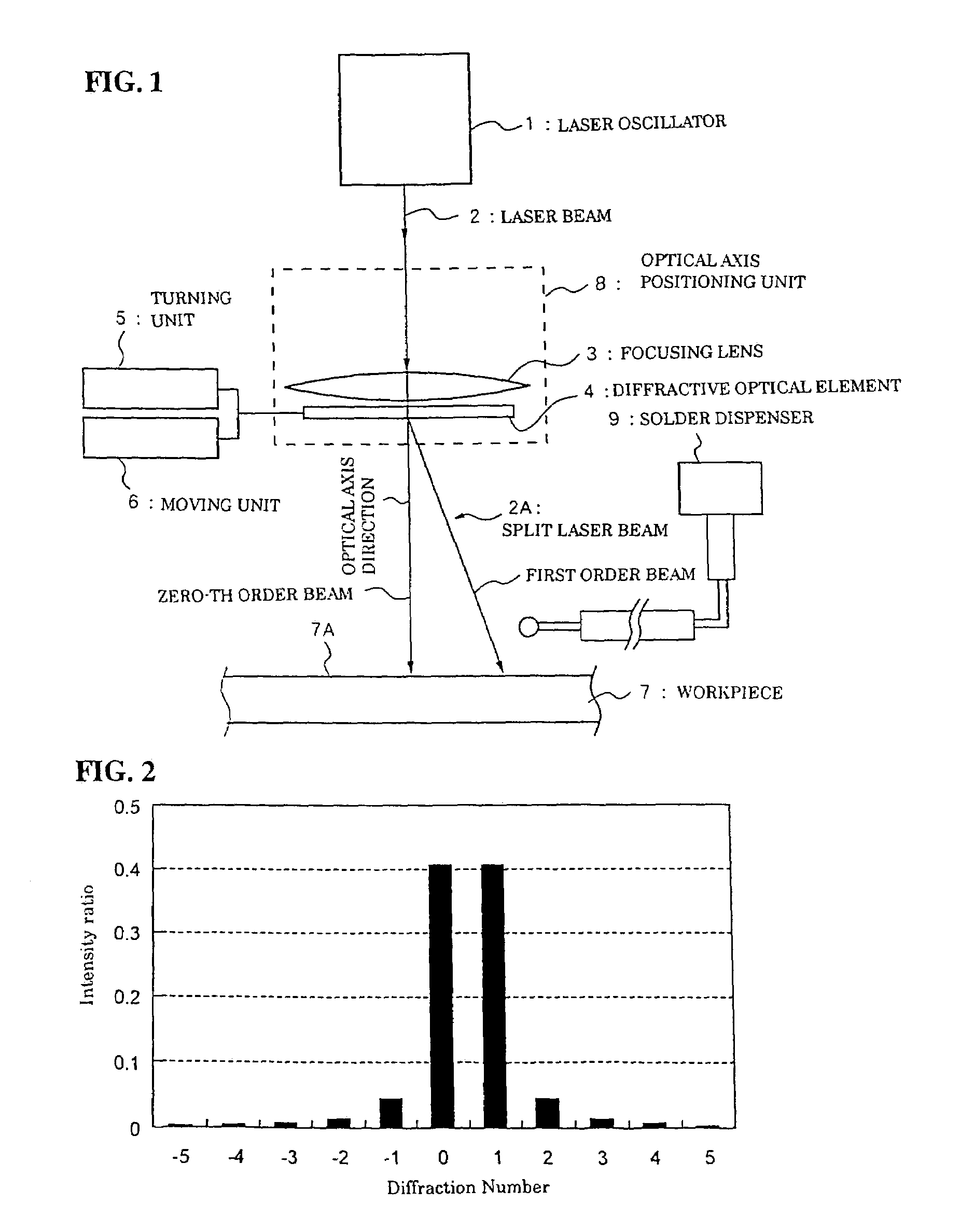

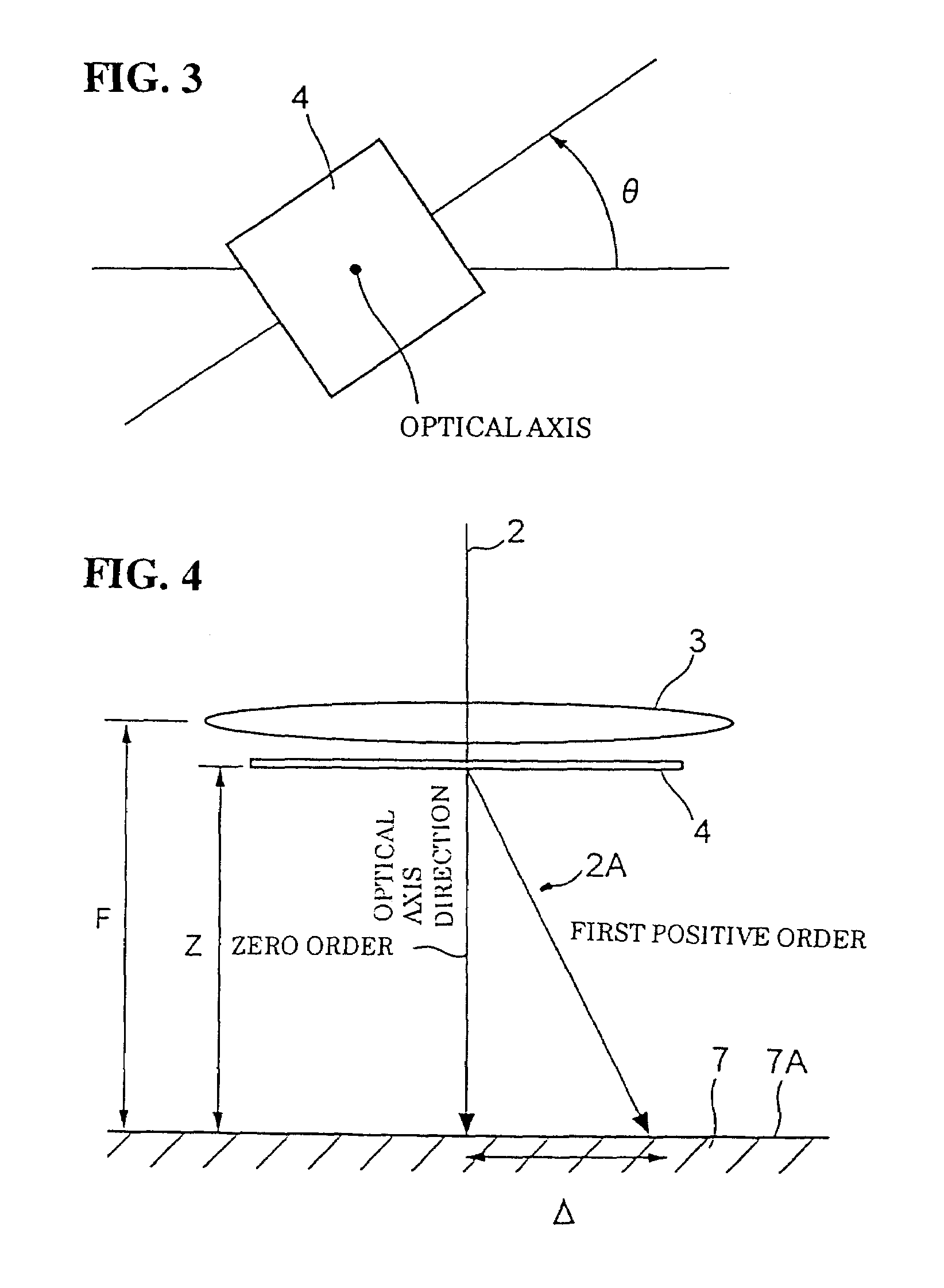

Laser processing method, laser welding method, and laser processing apparatus

ActiveUS7009138B2High energy laserImprove energy efficiencyPrinted circuit assemblingSoldering apparatusLaser processingLight beam

A processing method including steps for splitting a single beam into a plurality of beams including a zero-order diffracted beam, by diffracting the single beam by a diffractive element, for turning an array of focused beam spots obtained from the plurality of beams about the center of the zero-order diffracted beam according to the direction of an array of welding points where parts mounted on a circuit board are welded to the board, for causing a spot interval between focused beam spots in the array to agree with the interval between the plurality of welding points by adjusting the distance from the diffractive element to the board, and for increasing the intensity of the plurality of beams, to a welding intensity, and connecting the parts by simultaneously irradiating the welding points with the focused beam spots in the array having the determined direction and spot interval.

Owner:SEIKO EPSON CORP

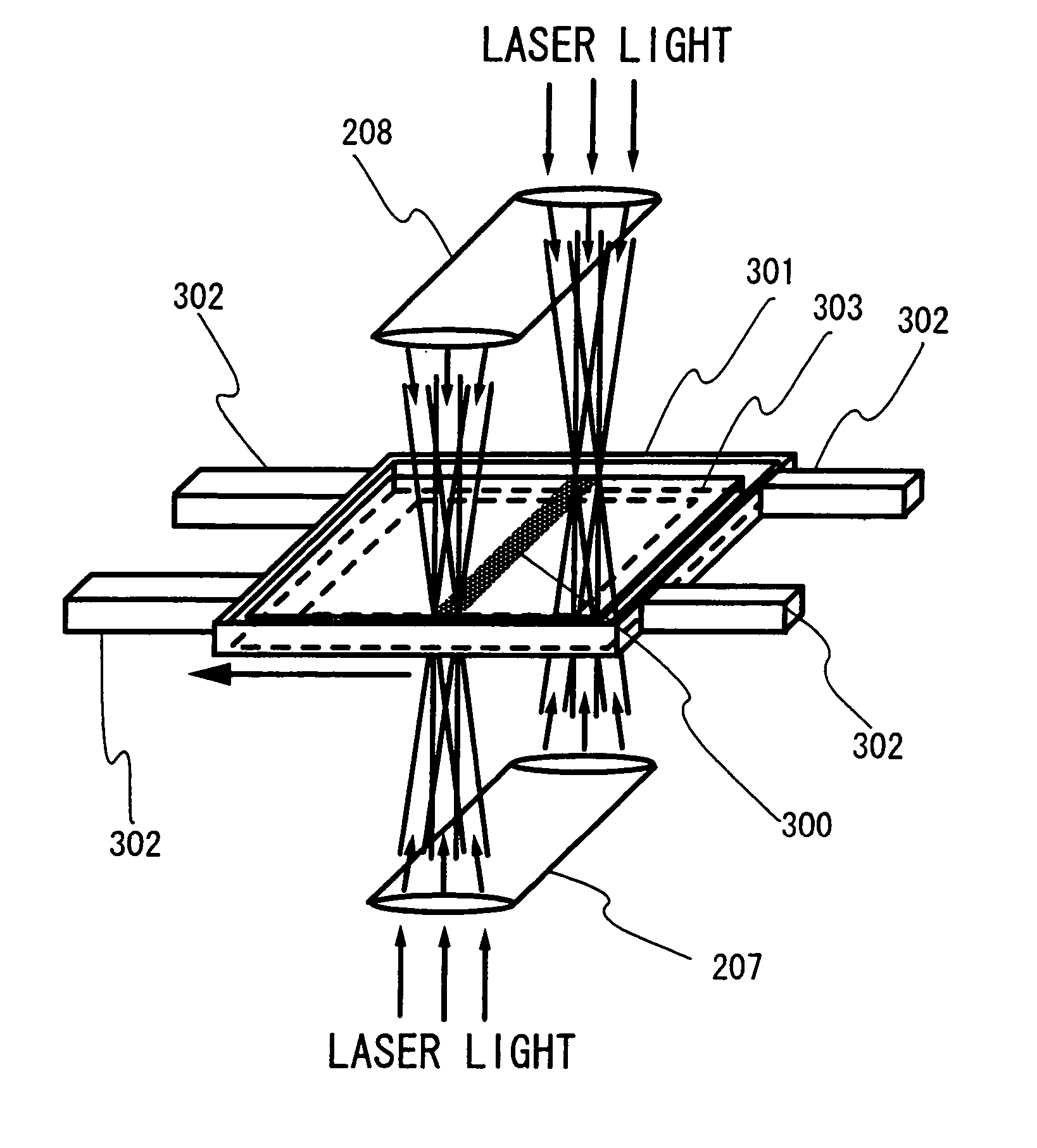

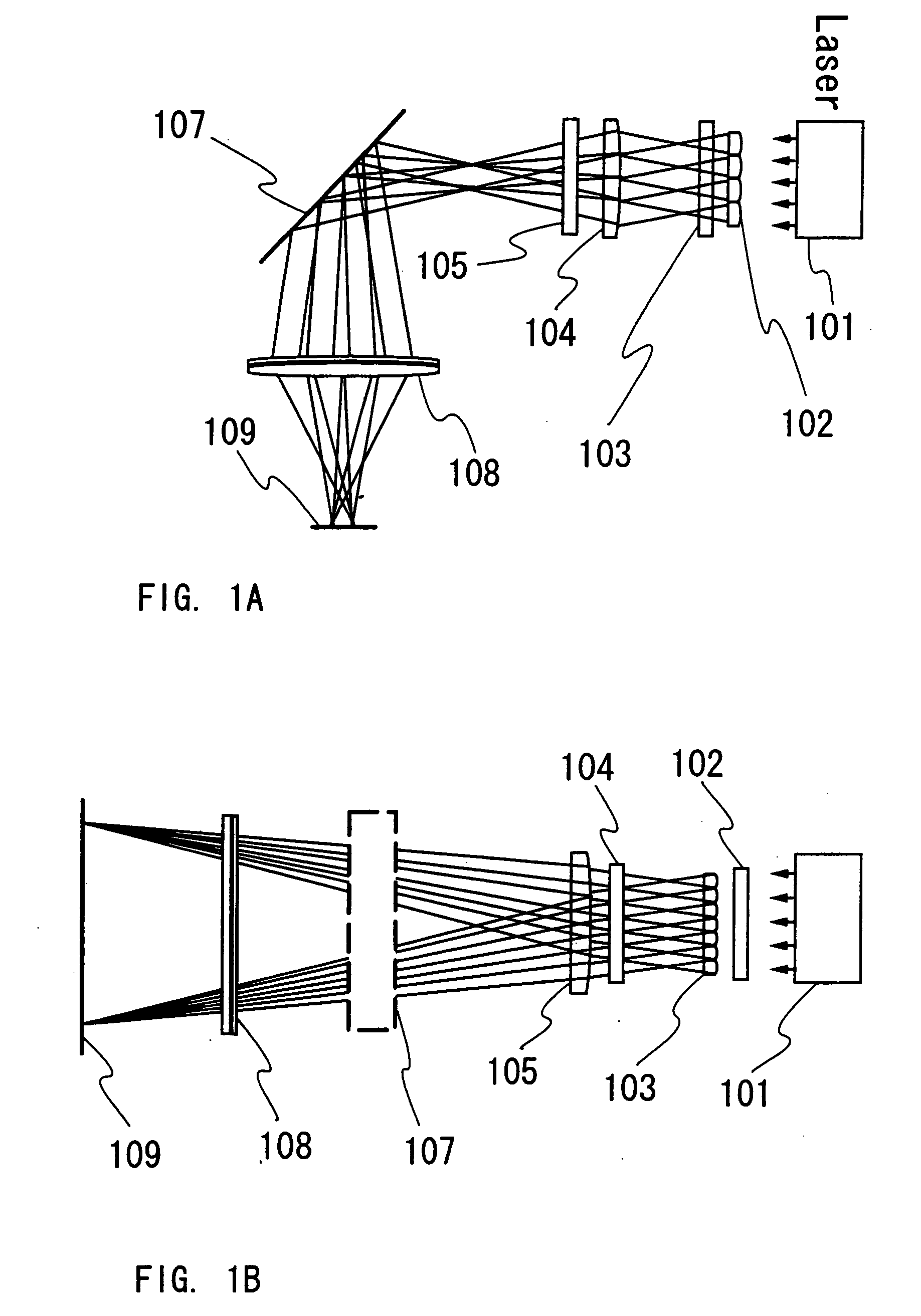

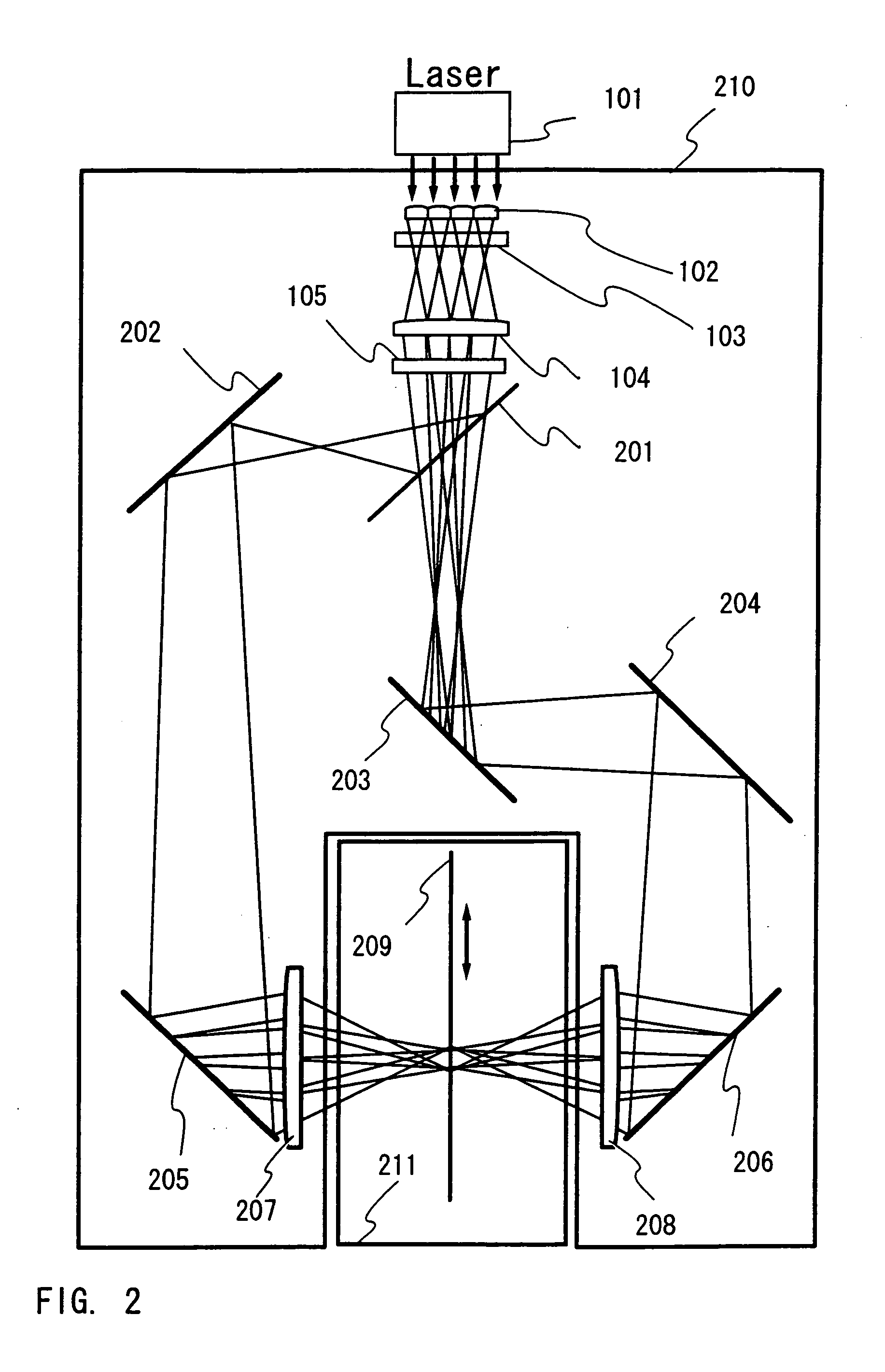

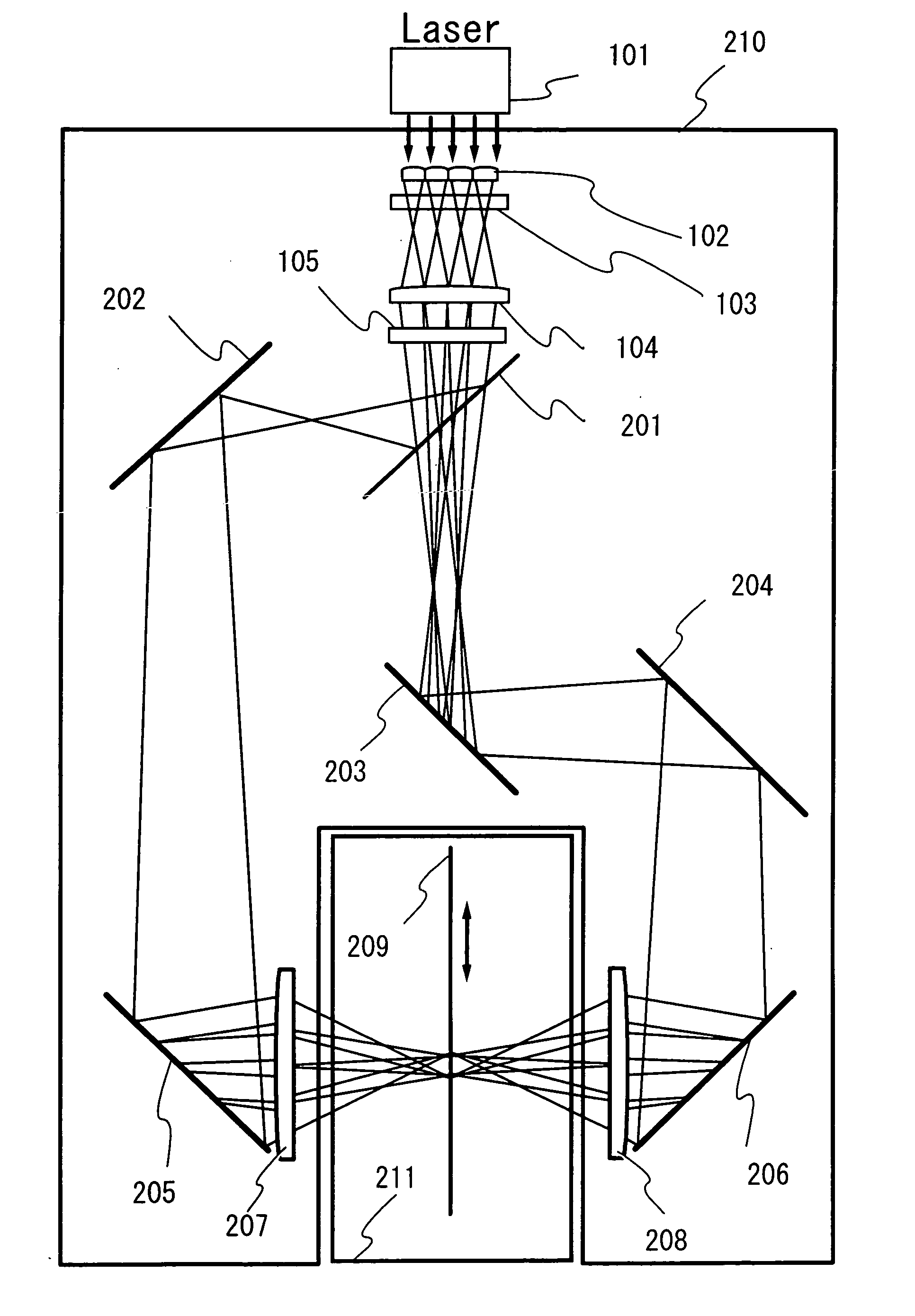

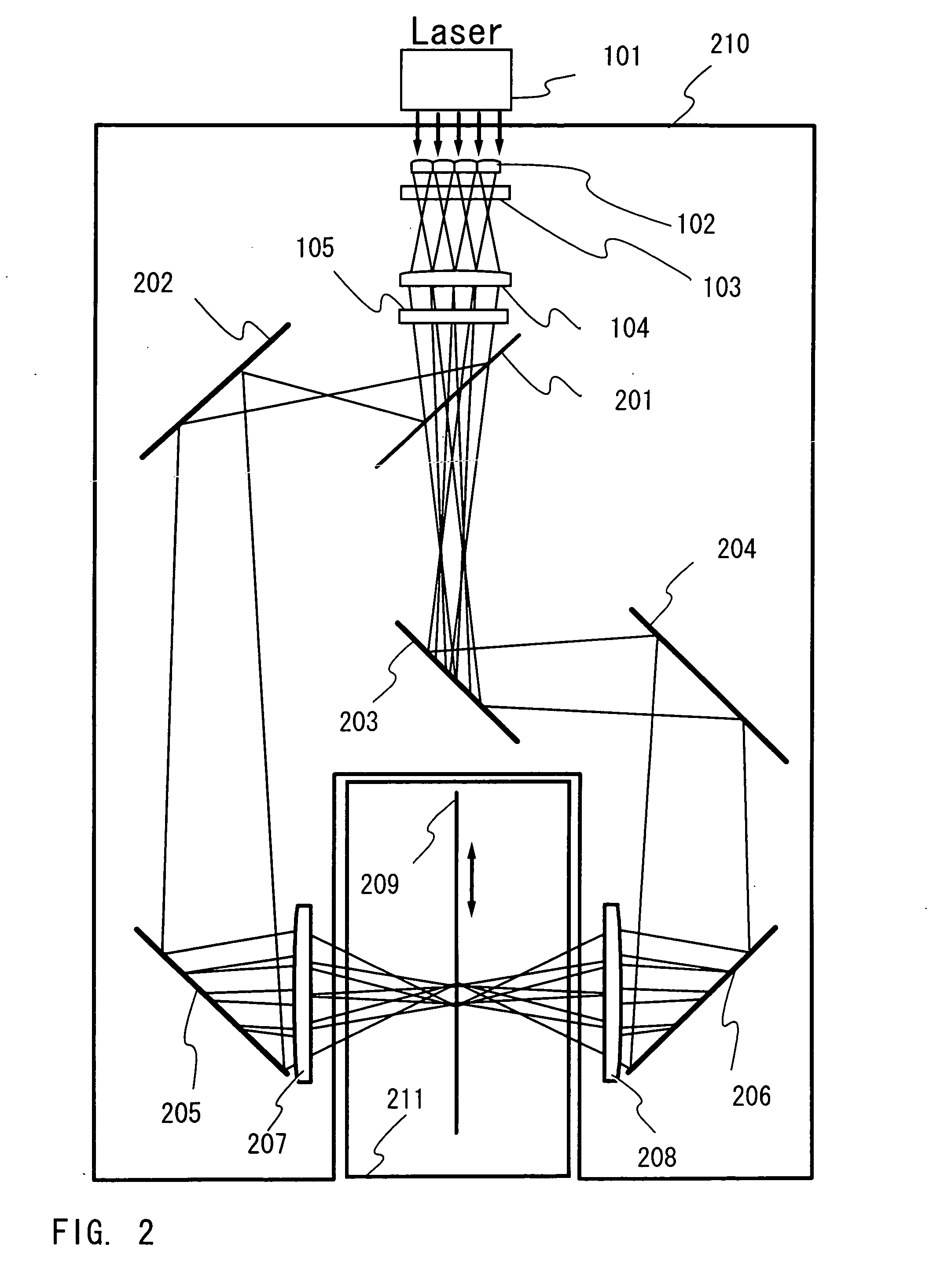

Laser irradiation apparatus laser irradiation method, semiconductor device and method of manufacturing a semiconductor device

InactiveUS6927109B1Reduce hydrogen concentrationHigh energy laserSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconLight beam

To form a polycrystalline silicon film having a grain size of 1 μm or greater by means of laser annealing. A beam emitted from a laser apparatus (101) is split in two by a half mirror. The split beams are processed into linear shapes by cylindrical lenses (102) to (105), and (207), then simultaneously irradiate an irradiation surface (209). If an amorphous silicon film formed on a glass substrate is disposed on the irradiation surface (209), an area will be irradiated by both a linear shape beam entering from a front surface and a linear shape beam that has transmitted through the glass surface. Both linear shape beams irradiate the same area to thereby crystallize the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

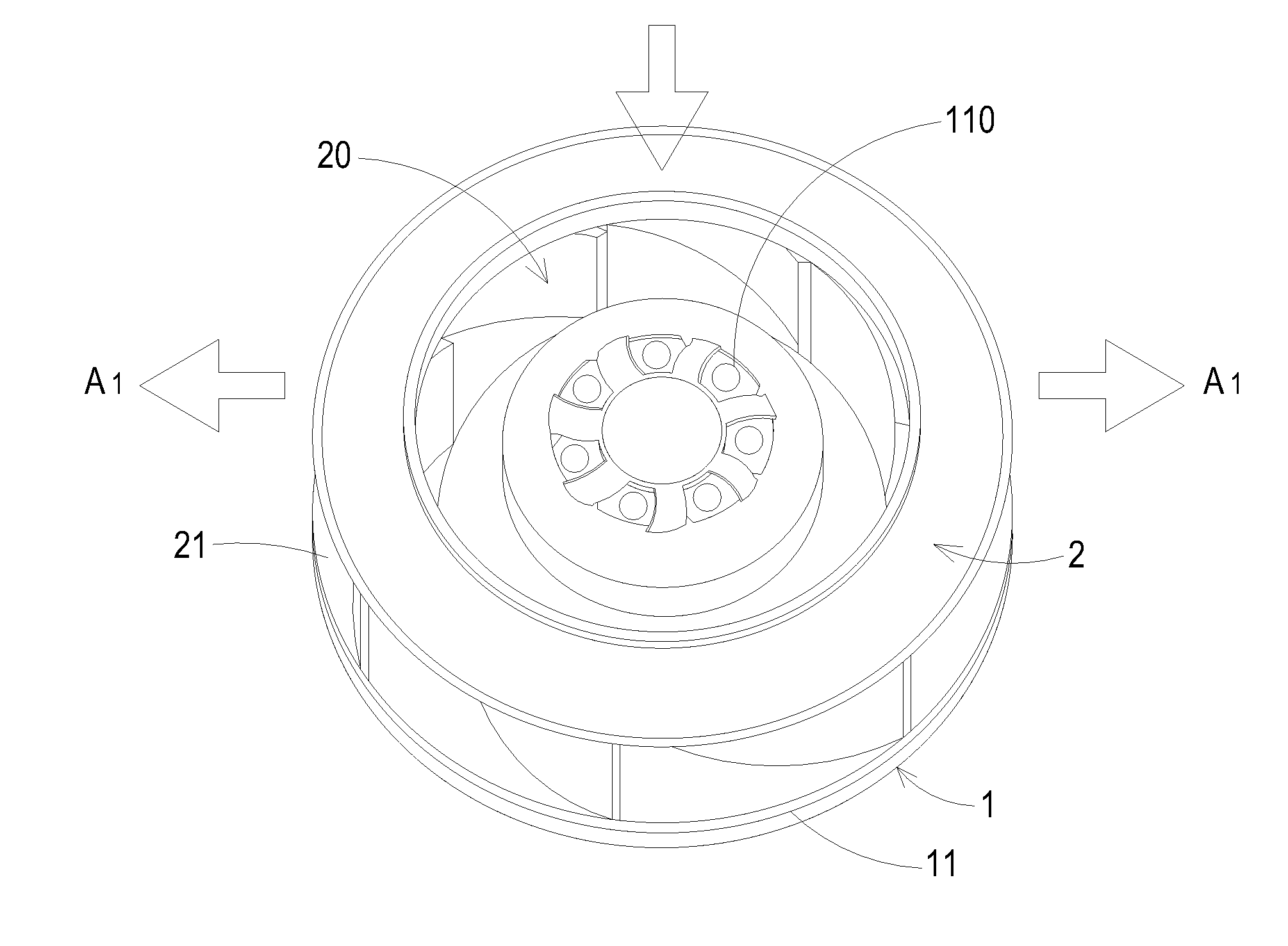

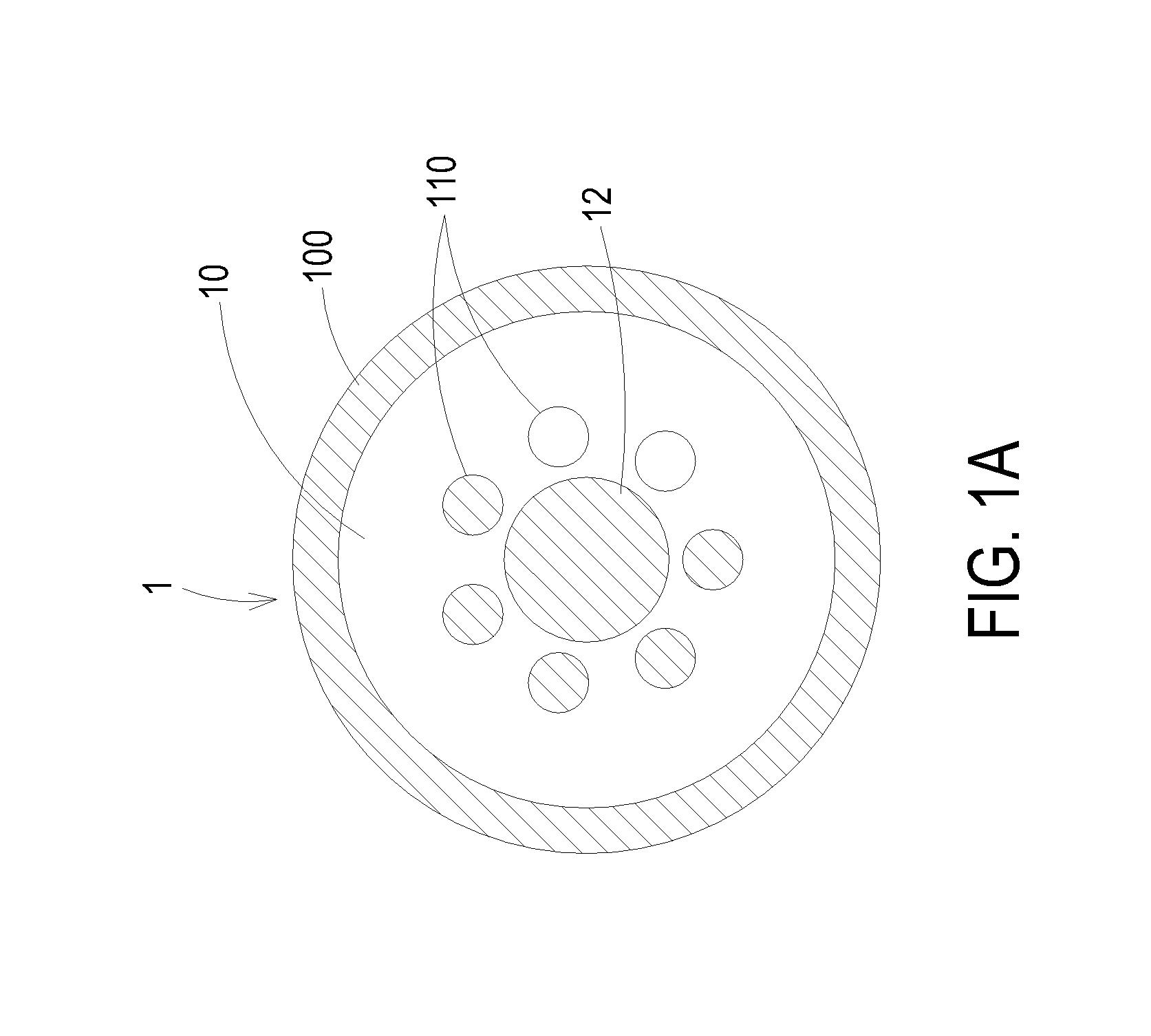

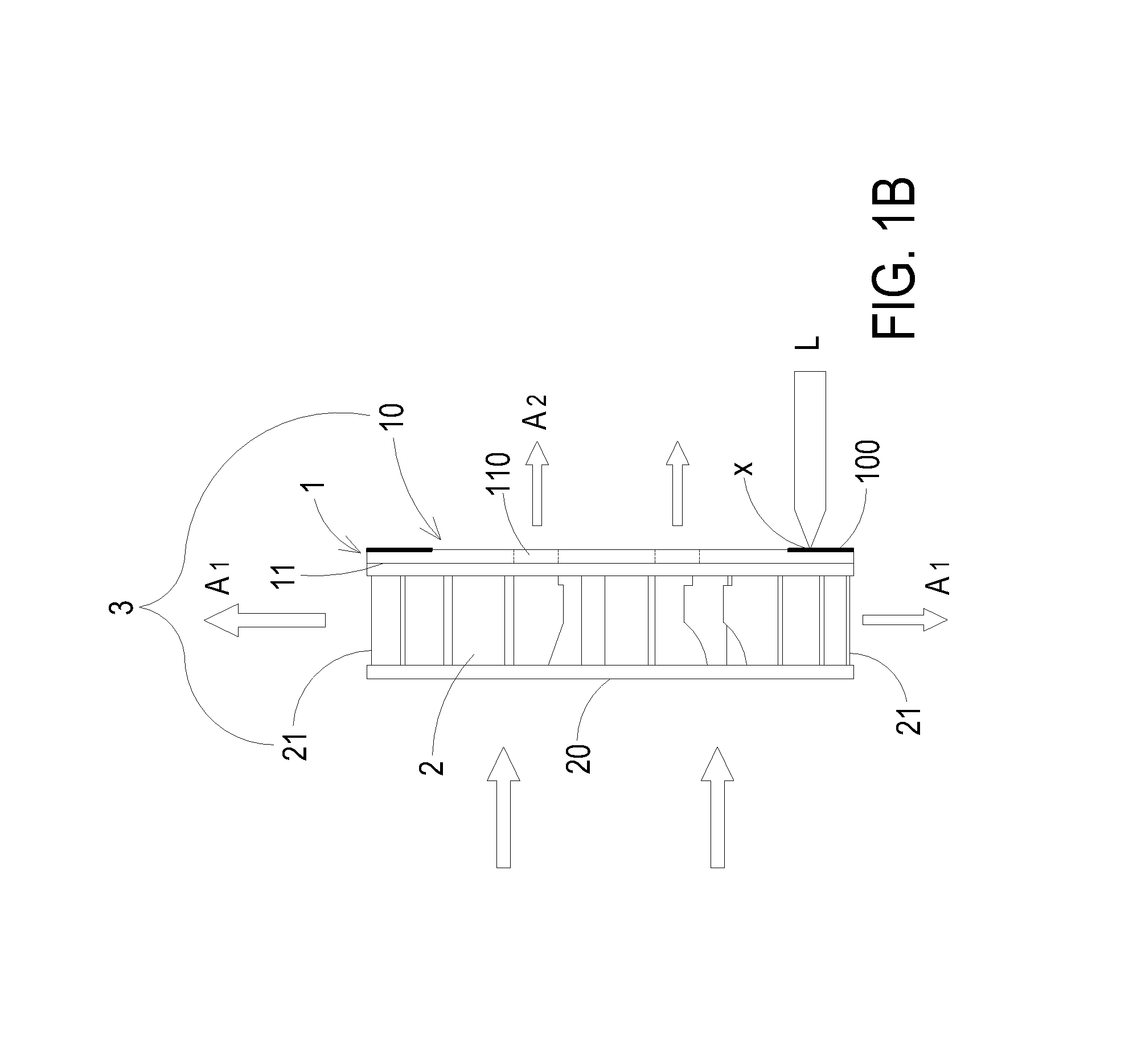

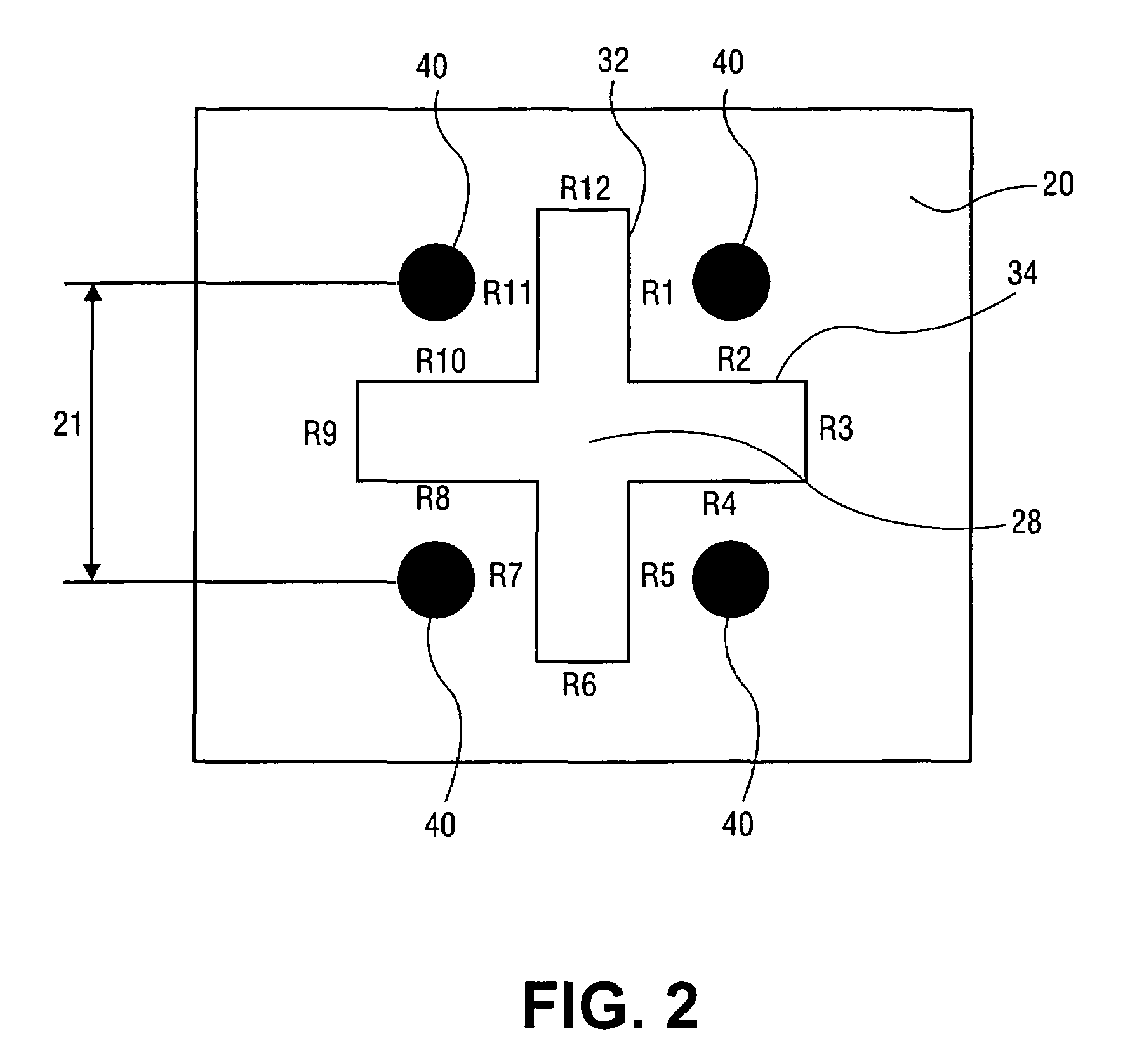

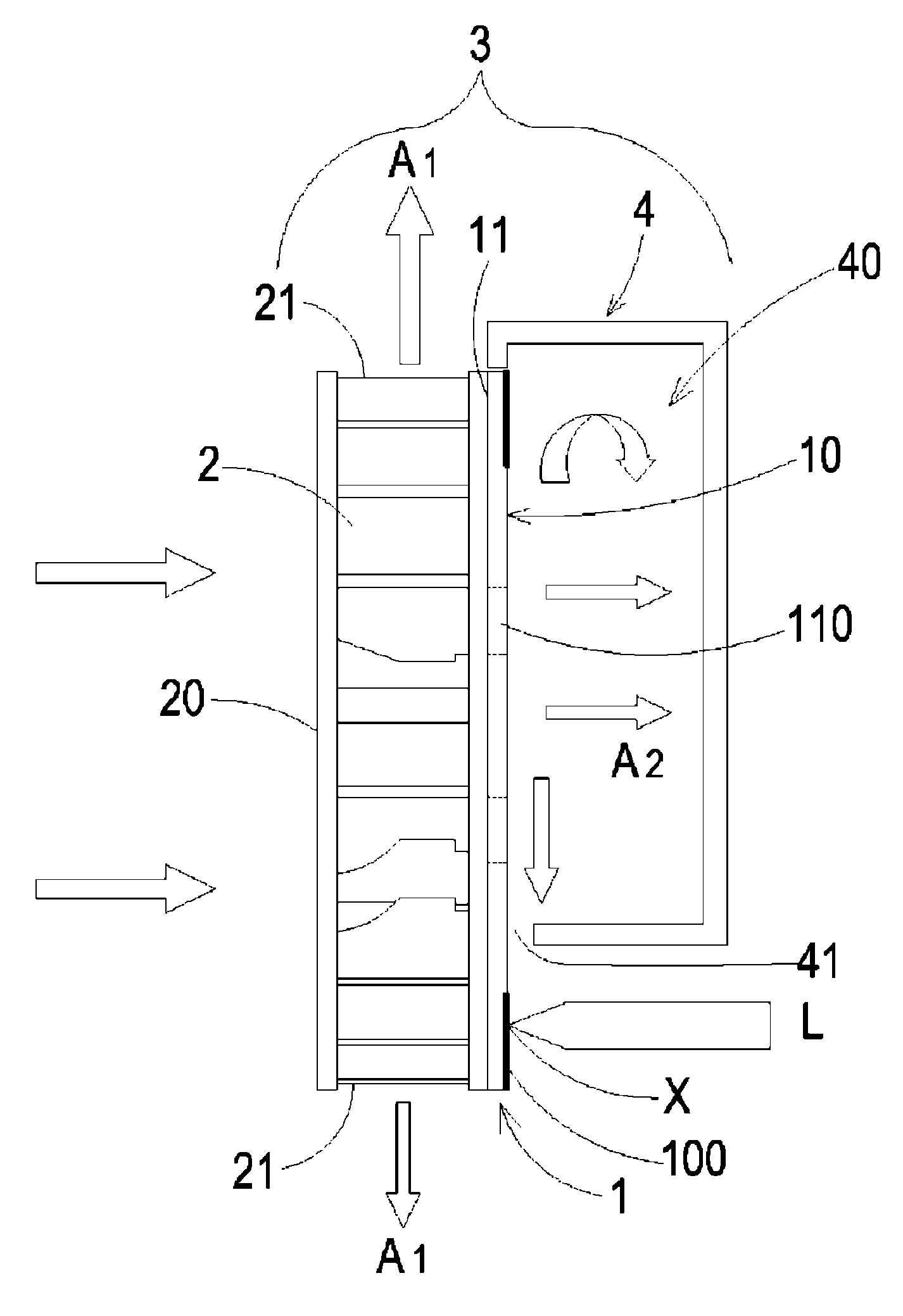

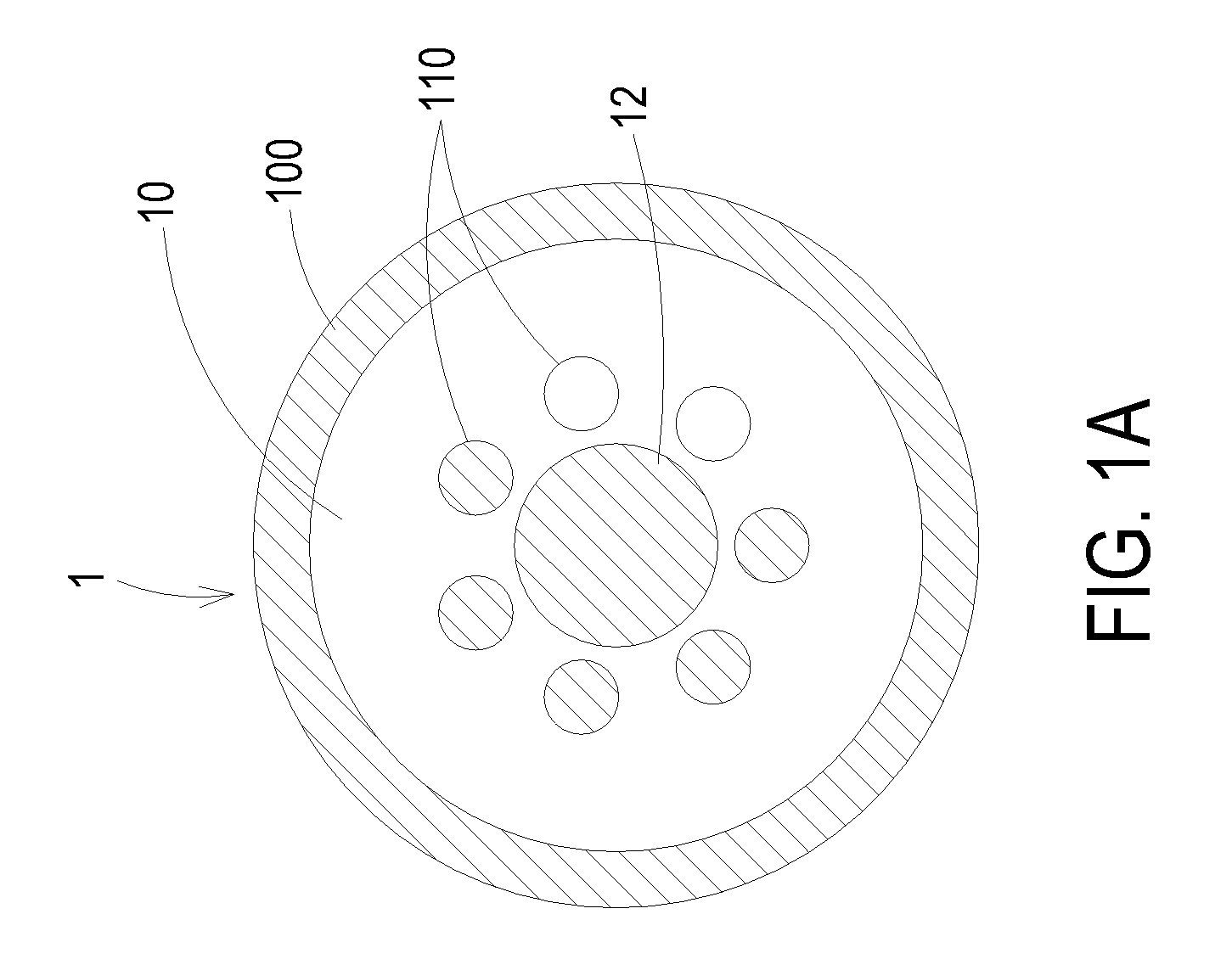

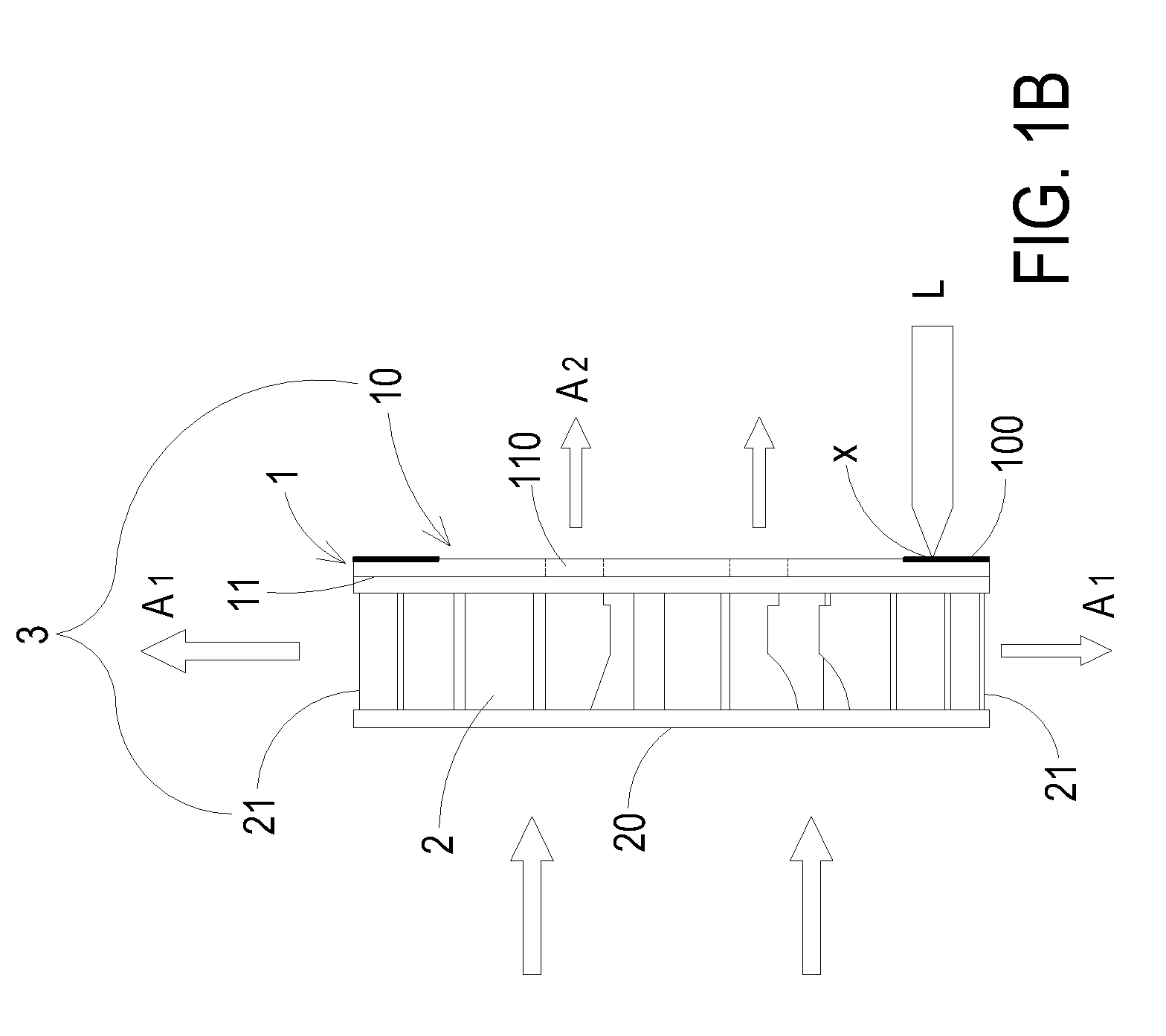

Phosphor wheel heat-dissipating module for laser projection system

A phosphor wheel heat-dissipating module for a laser projection system is provided. The phosphor wheel heat-dissipating module includes a phosphor wheel, a plurality of air vents and an impeller. At least one phosphor agent is coated on an outer-ring portion of a first surface of the phosphor wheel. The air vents run through the phosphor wheel. The impeller is disposed on a second surface of the phosphor wheel, and includes an inlet and a first outlet. A laser beam is projected on the outer-ring portion of the phosphor wheel. When the phosphor wheel is rotated at a high rotating speed, an airflow is inhaled into the impeller through the inlet. A first portion of the airflow is blown out through the first outlet, and a second portion of the airflow is transferred to the first surface of the phosphor wheel through the air vents.

Owner:DELTA ELECTRONICS INC

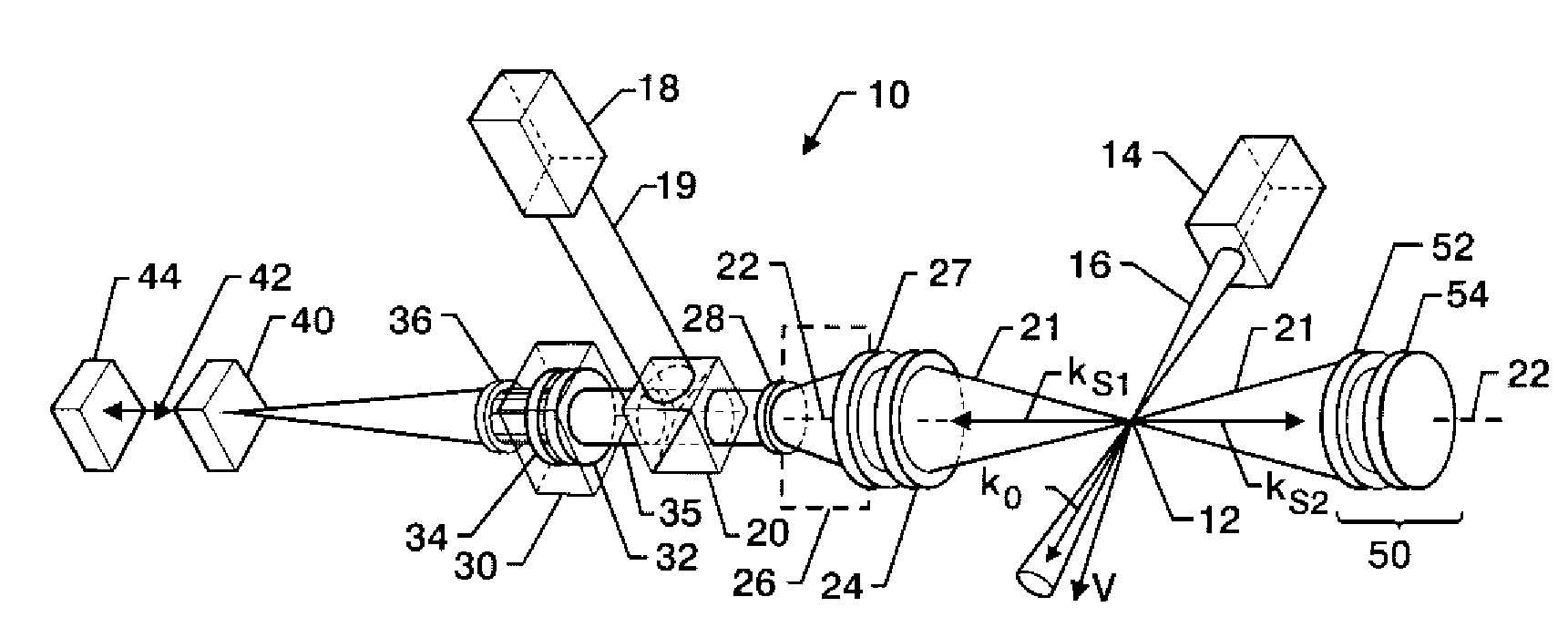

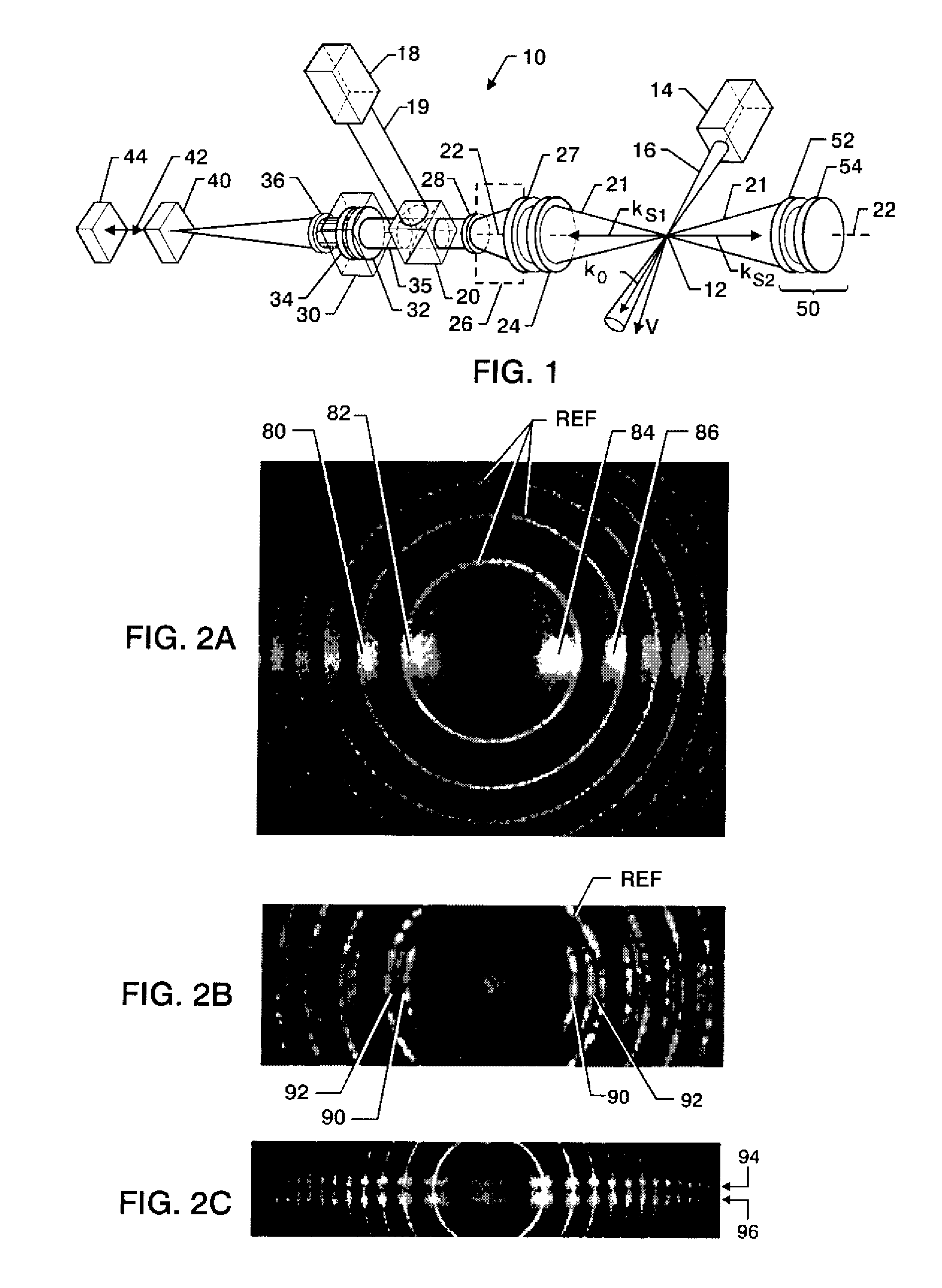

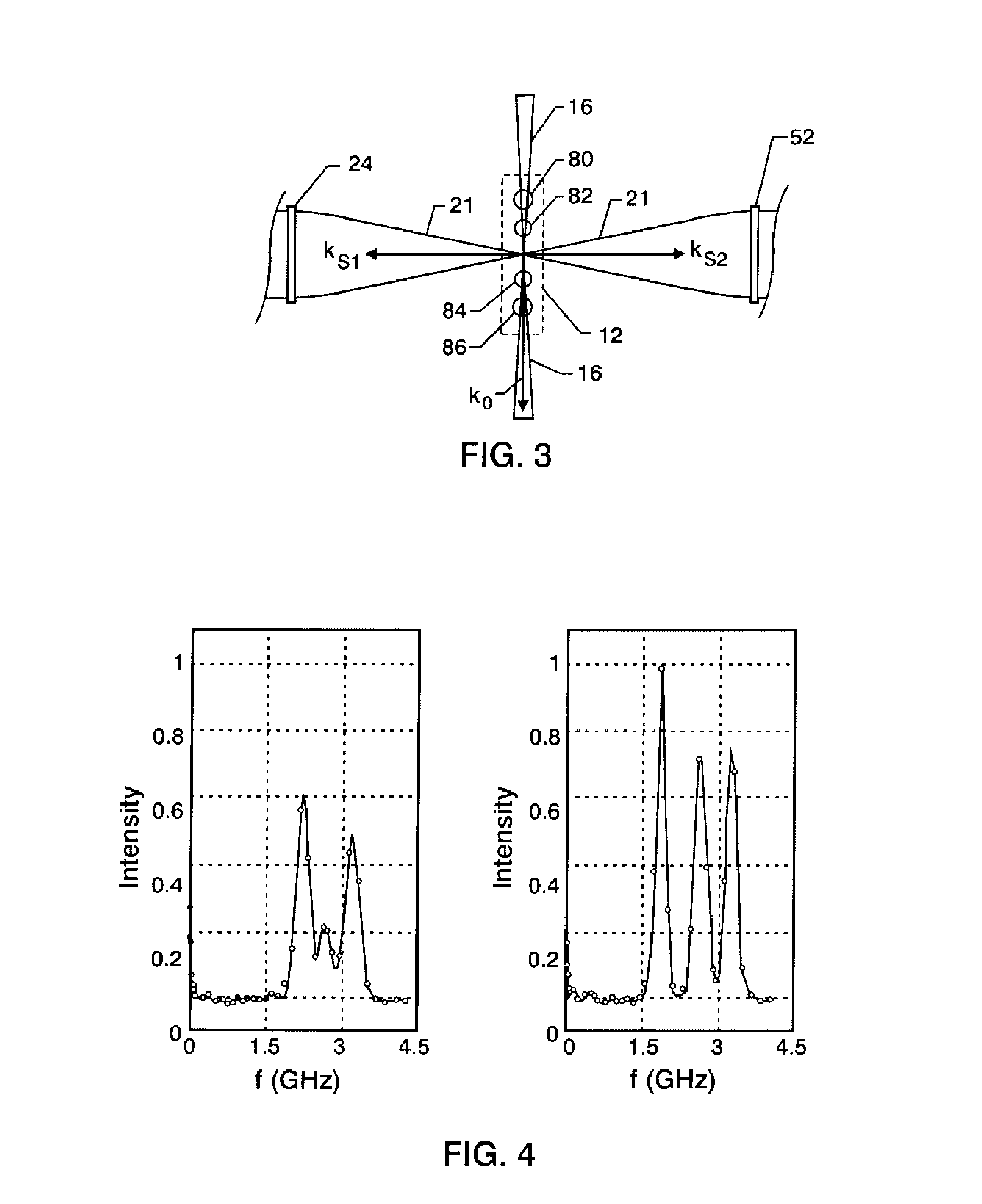

Interferometric Rayleigh Scattering Measurement System

InactiveUS20080043219A1Efficient measurementLow costMaterial analysis by optical meansIndication/recording movementRayleigh scatteringRayleigh Light Scattering

A method and apparatus for performing simultaneous multi-point measurements of multiple velocity components in a gas flow is described. Pulses of laser light are directed to a measurement region of unseeded gas to produce Rayleigh or Mie scattered light in a plurality of directions. The Rayleigh or Mie scattered light is collected from multiple directions and combined in a single collimated light beam. The Rayleigh or Mie scattered light is then mixed together with a reference laser light before it is passed through a single planar Fabry-Perot interferometer for spectral analysis. At the output of the interferometer, a high-sensitivity CCD camera images the interference fringe pattern. This pattern contains the spectral and spatial information from both the Rayleigh scattered light and the reference laser light. Interferogram processing software extracts and analyzes spectral profiles to determine the velocity components of the gas flow at multiple points in the measurement region. The Rayleigh light rejected by the interferometer is recirculated to increase the accuracy and the applicability of the method for measurements at high temperatures without requiring an increase in the laser energy.

Owner:NASA

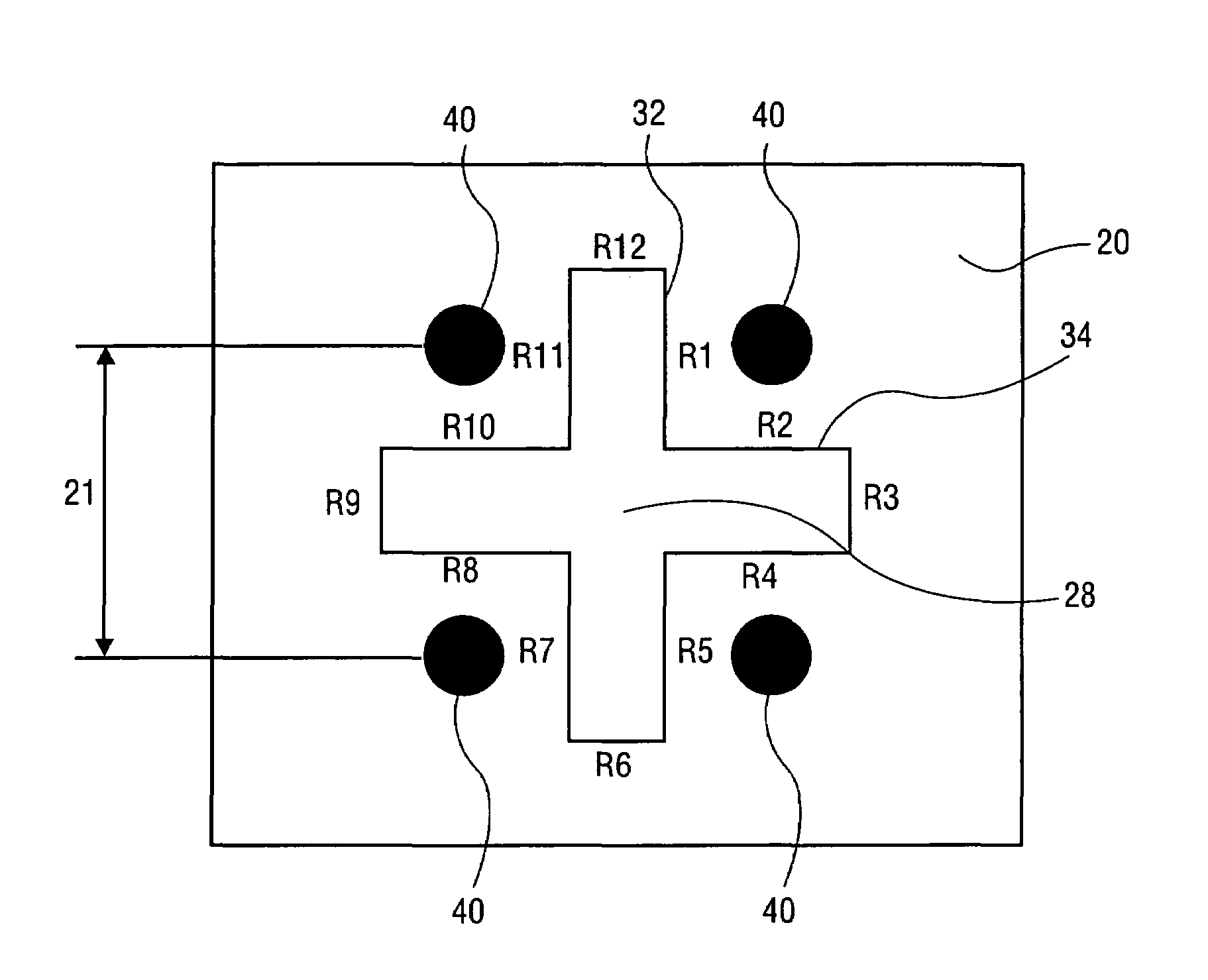

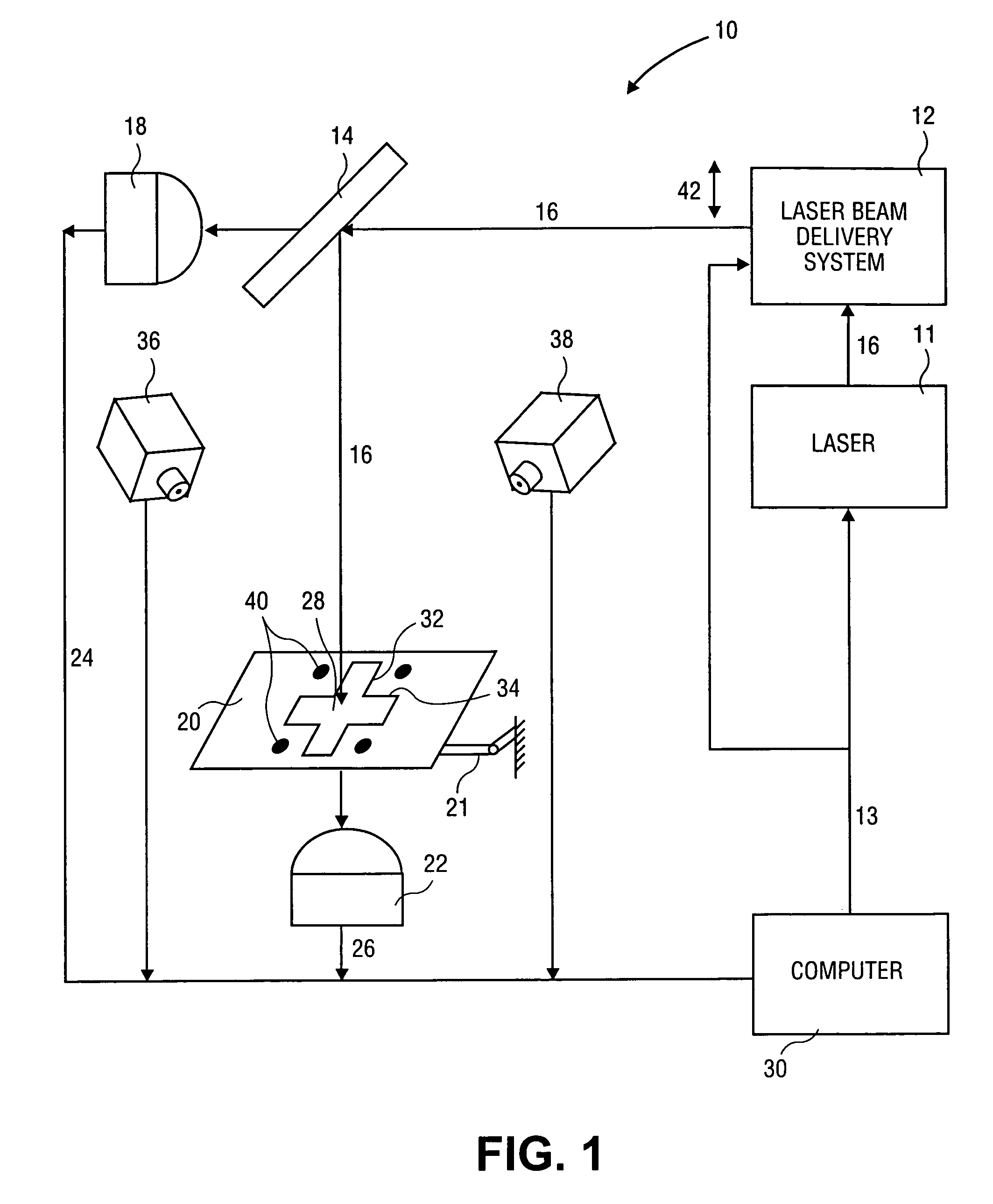

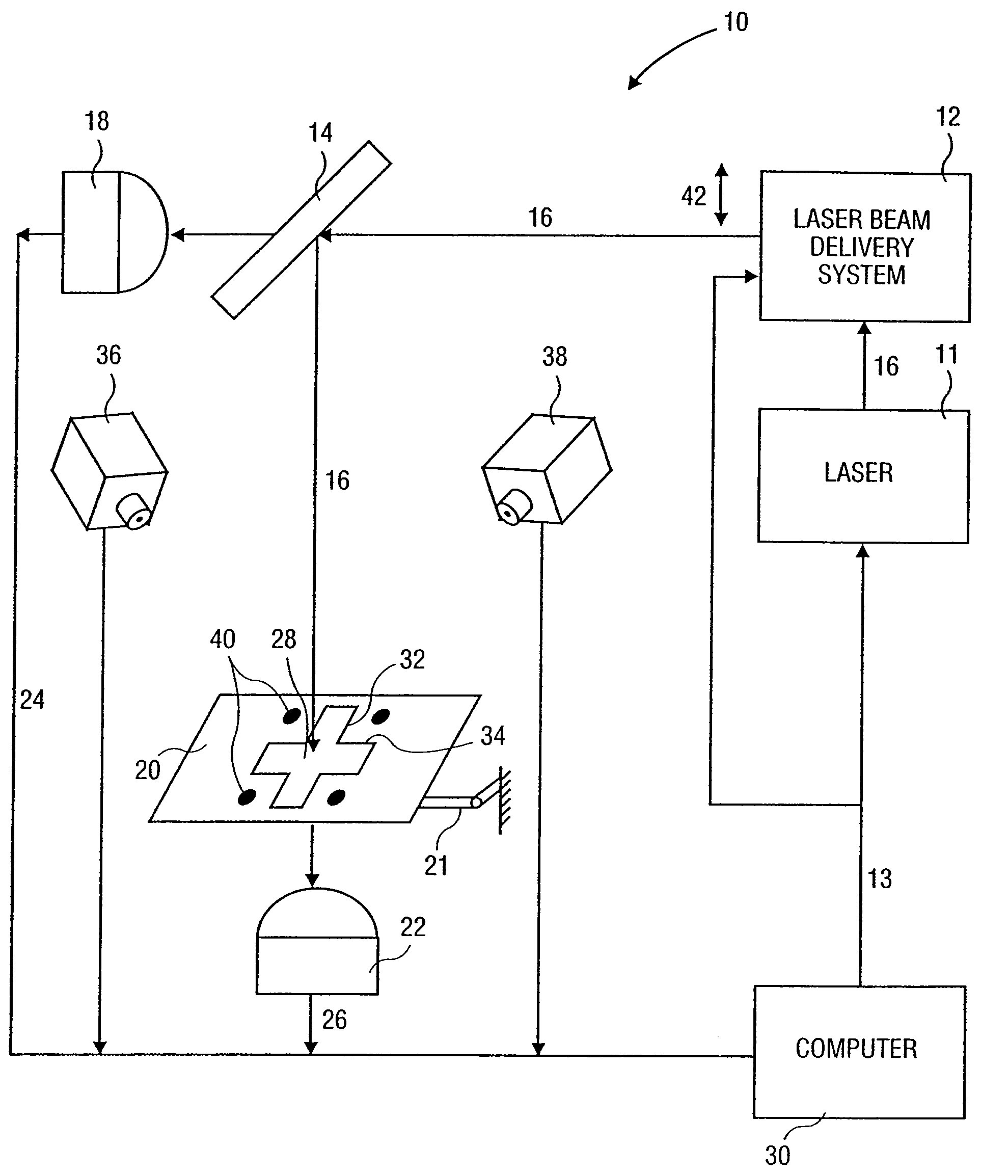

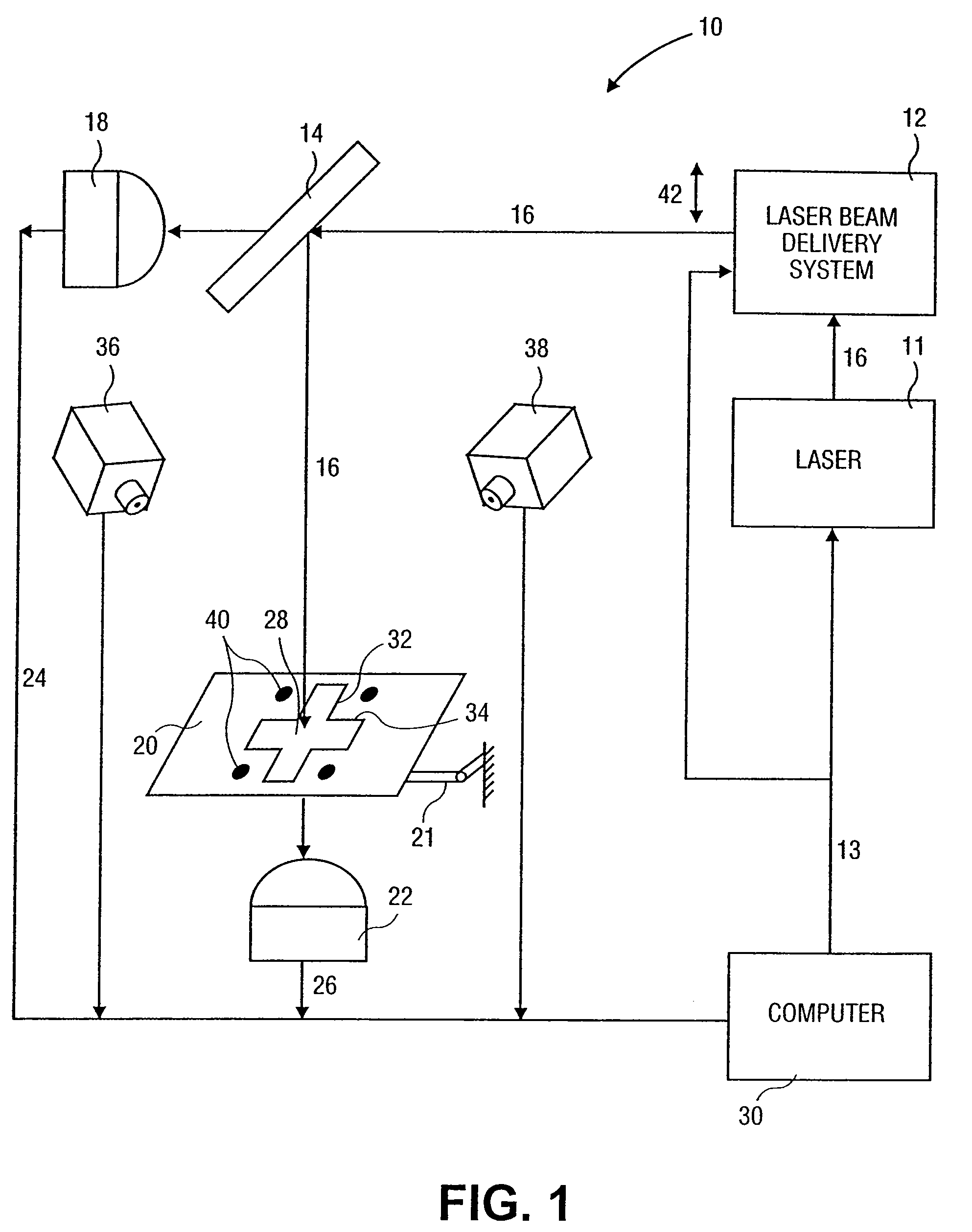

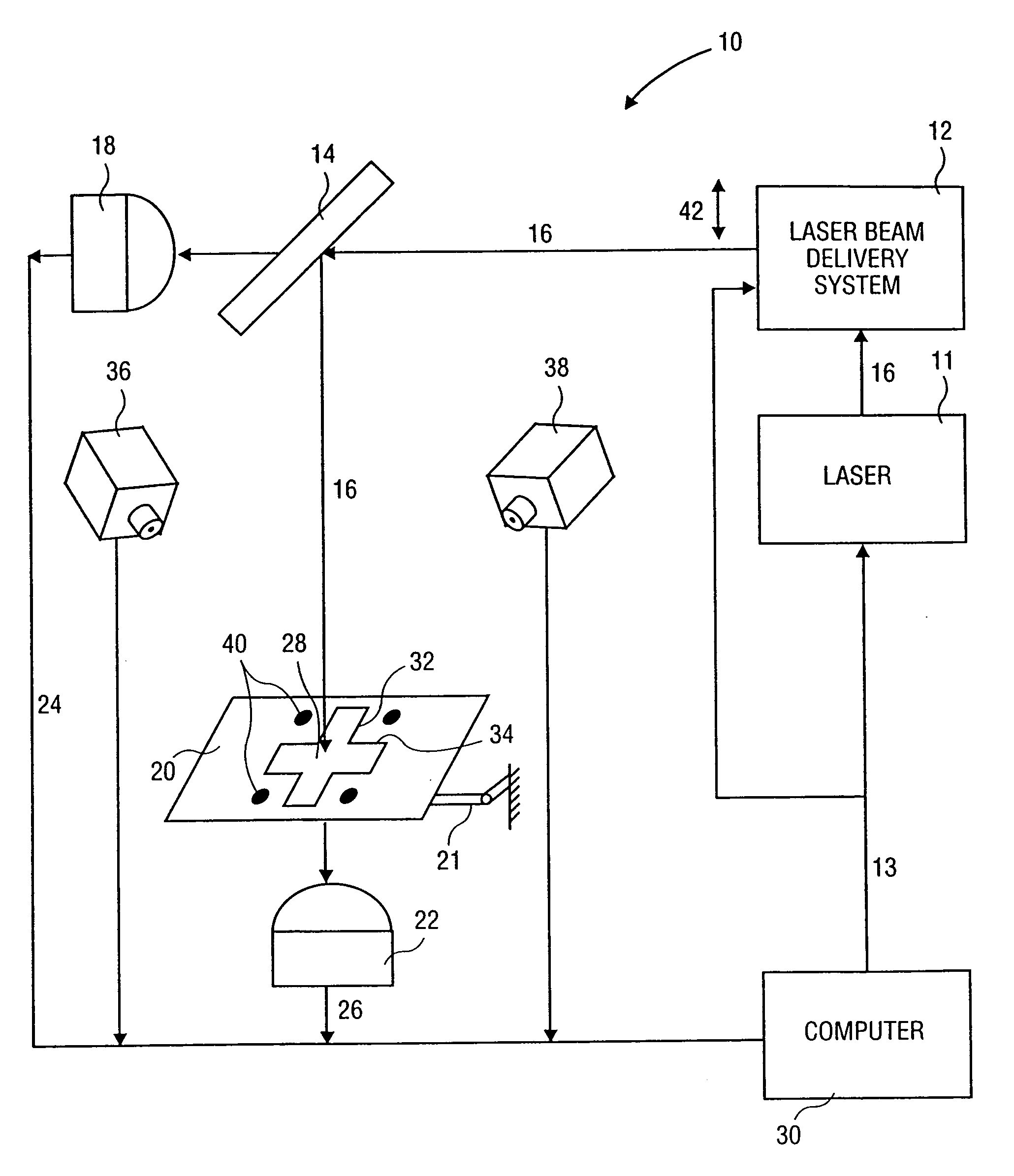

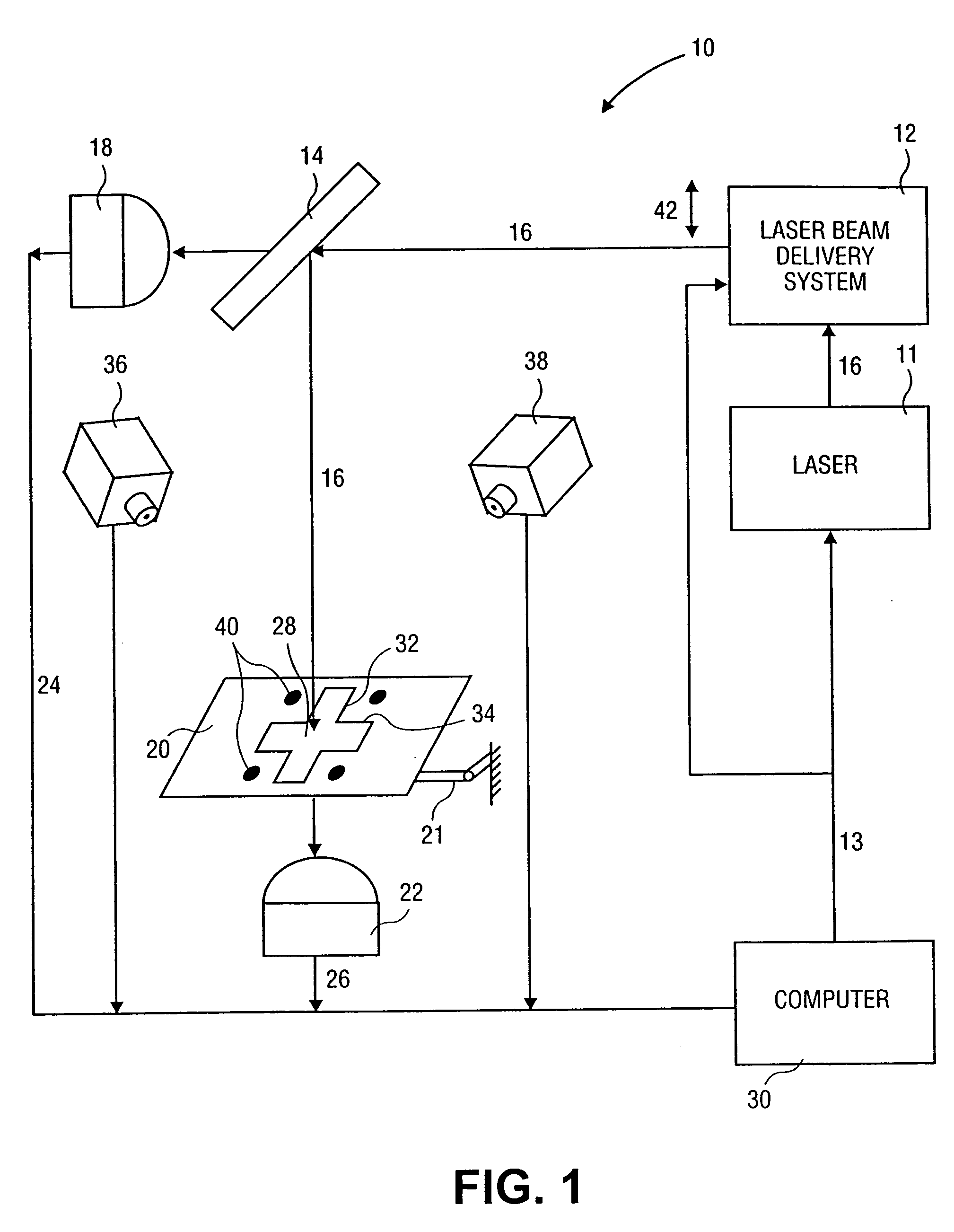

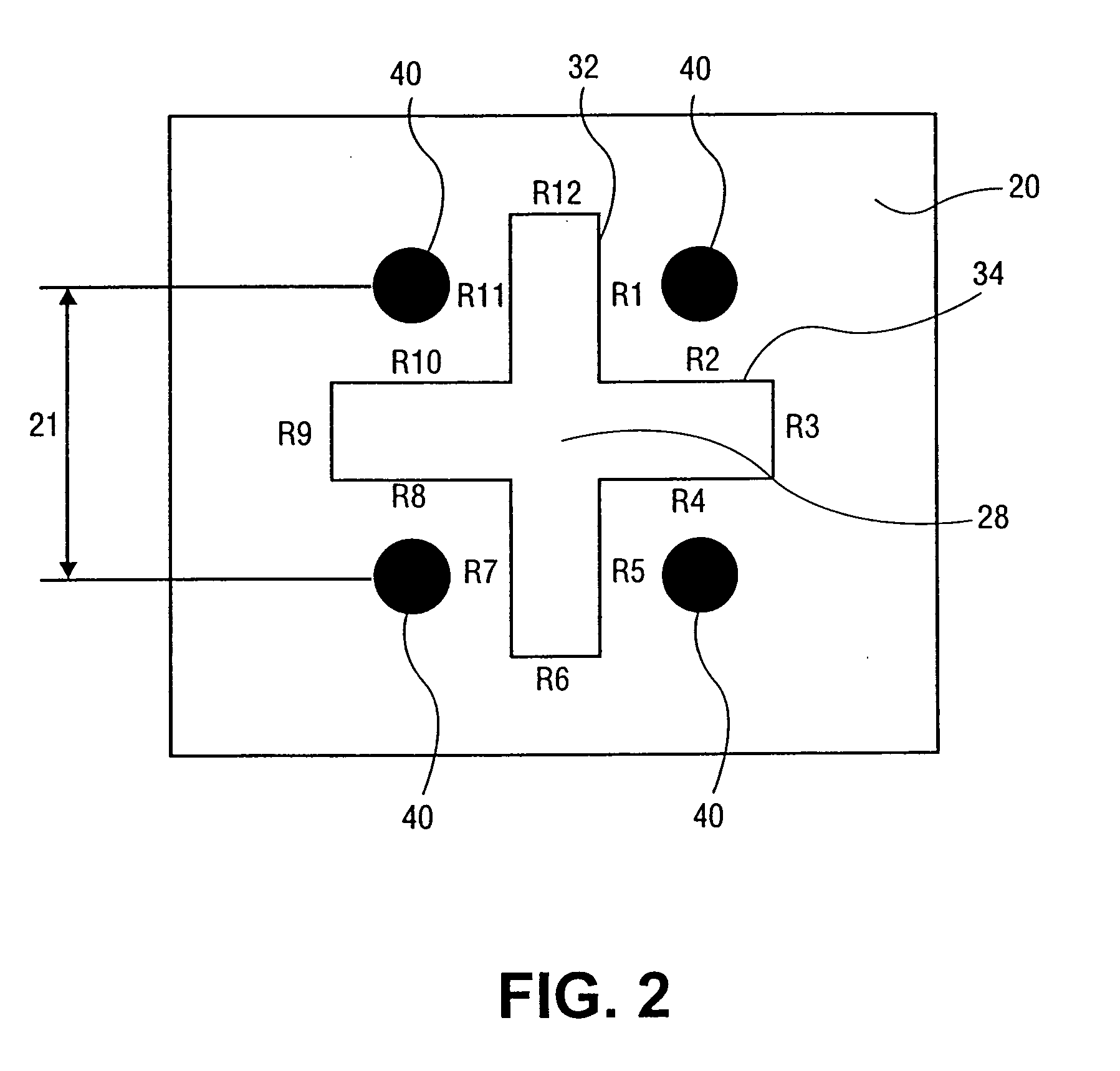

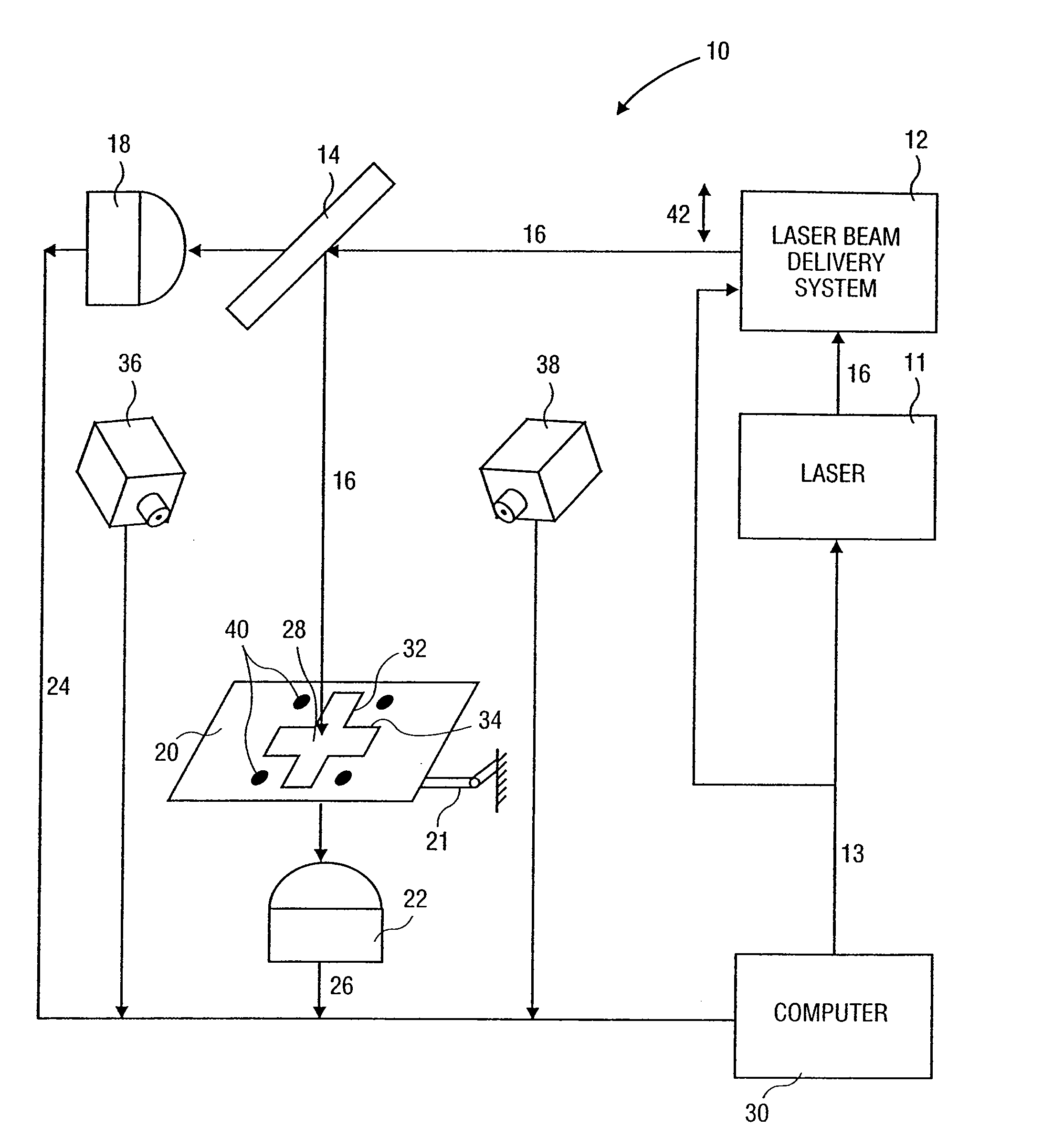

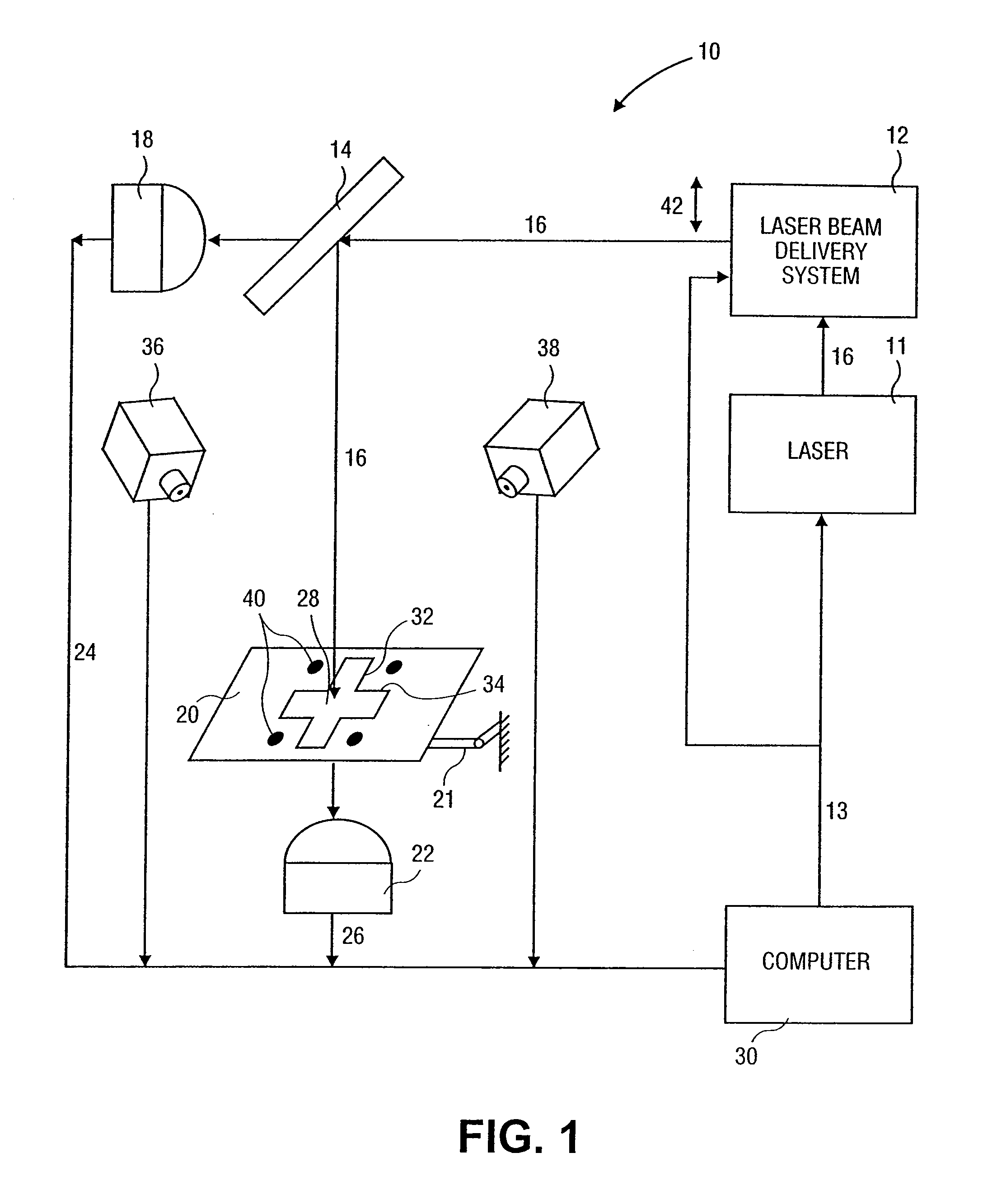

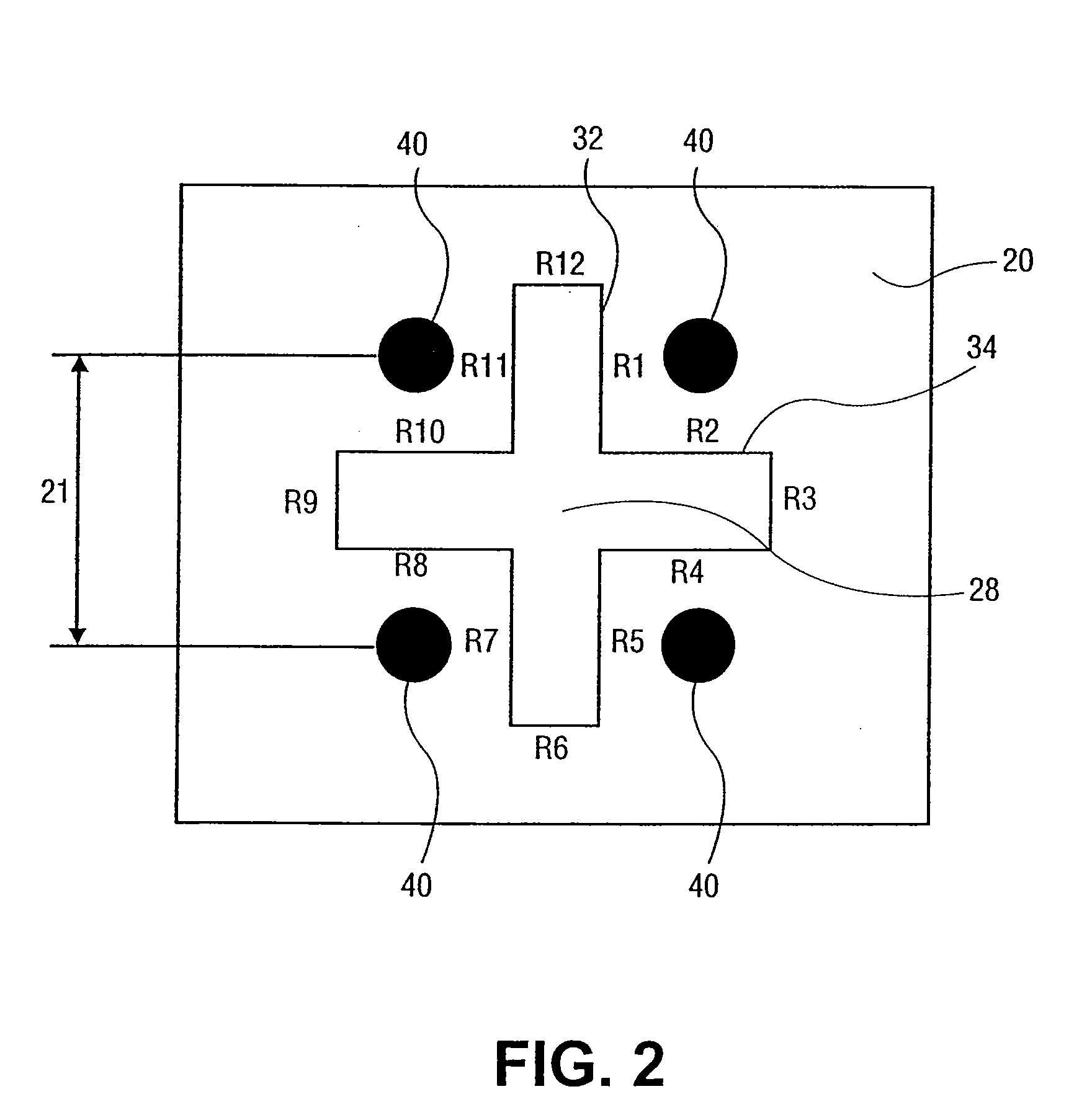

Methods and systems for laser calibration and eye tracker camera alignment

InactiveUS7001376B2Easy alignmentImprove calibration accuracyLaser surgeryLaser detailsPupilLaser beams

The present invention provides methods, systems, and apparatus for calibrating a laser ablation system, such as an excimer laser system for selectively ablating a cornea of a patient's eye. The invention also facilitates alignment of eye tracking cameras that measure a position of the eye during laser eye surgery. A calibration and alignment fixture for a scanning laser beam delivery system having eye tracking cameras may include a structure positionable in a treatment plane. The structure having a feature directing laser energy incident thereon to a calibration energy sensor, at least one reference-edge to determine a characteristic of the laser beam (shape, dimensions, etc.), and an artificial pupil to determine alignment of the eye tracking cameras with the laser system.

Owner:AMO MFG USA INC

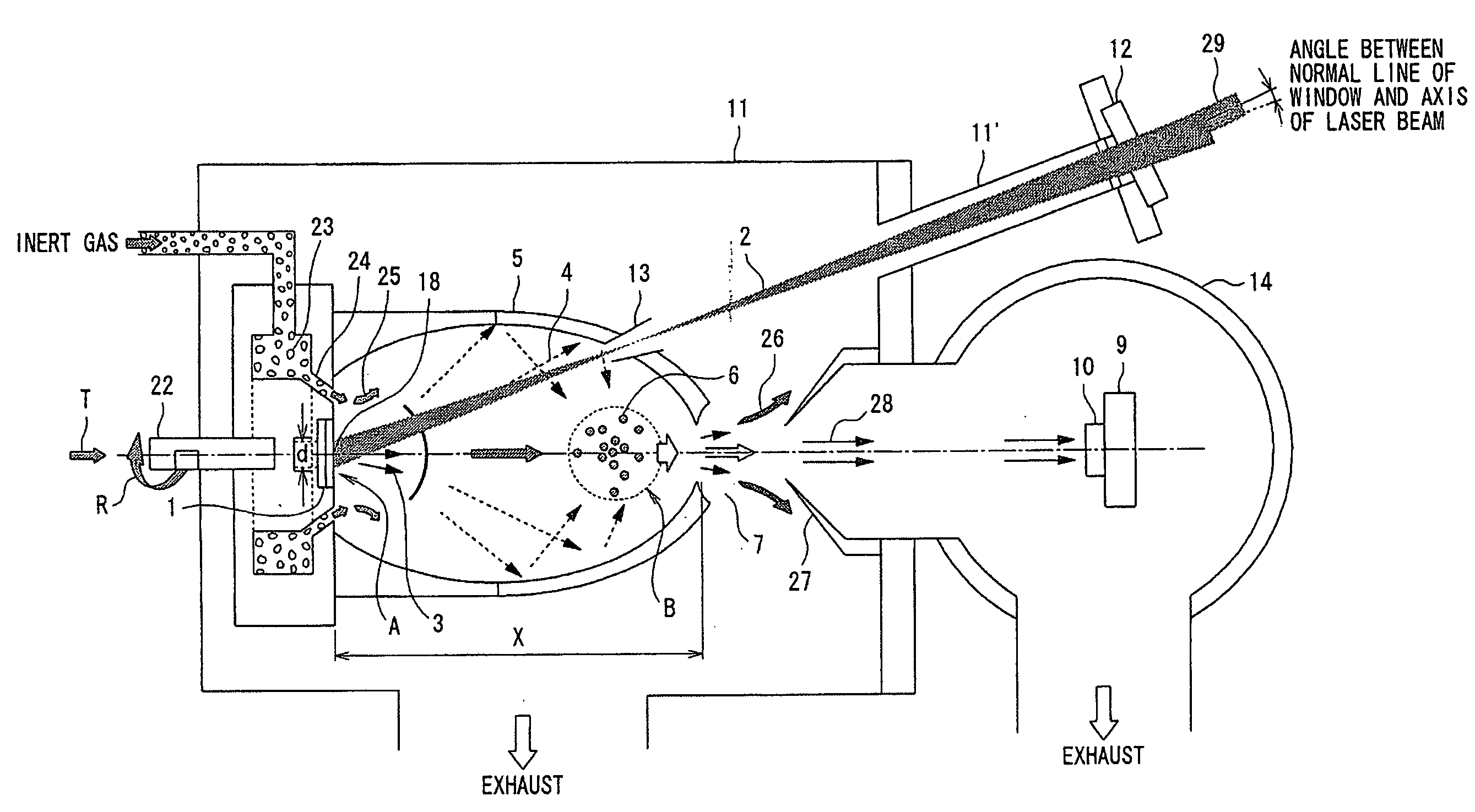

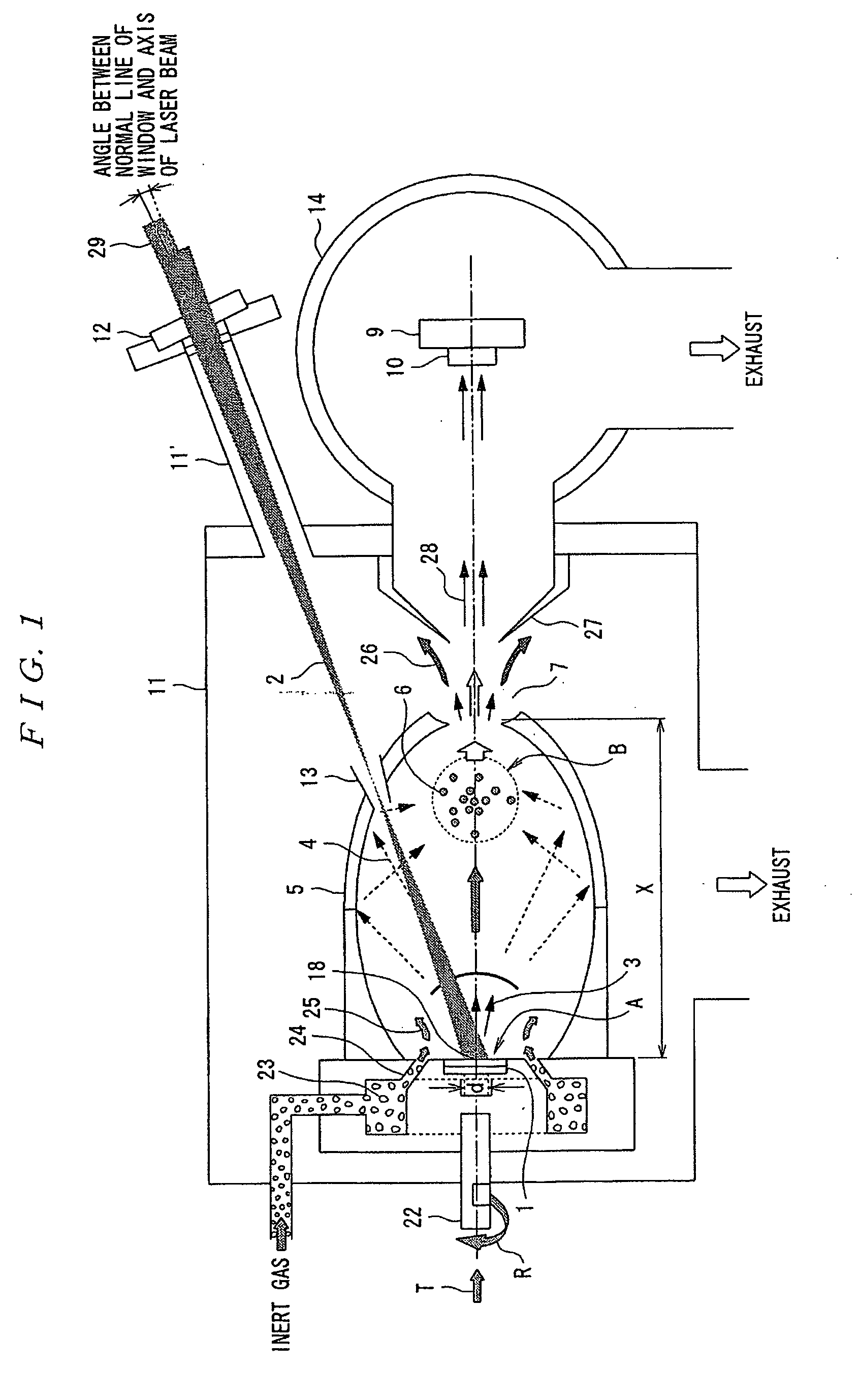

Cluster film formation system and film formation method, and cluster formation system and formation method

InactiveUS20090114848A1Improve the preparation effectImprove productivityVacuum evaporation coatingSputtering coatingEnvironmental geology

The invention provides a cluster film formation system in which, in a cluster formation container 5, target 1 is irradiated with laser beams 2 to generate material vapor, which generates a shock wave 4 of an inert gas, and the shock wave 4 is reflected by a wall of the cluster formation container 5 to confine the material vapor having progressed in a particular region, and atoms or molecules of the material vapor and the inert gas collide with each other mutually to form groups of clusters, which are made to flow out through an outflow window 7, and sprayed deposited on a substrate 9 to form a cluster film 10. Corresponding to augmentation of energy strength of the laser beams 2, a cross section area of the laser beams 2 on the surface of the target is made large, thereby an increase in the amount of generation of the material vapor and efficient generation of the shock wave of the inert gas both are realized, and at the same time, the cluster formation container is enlarged so that the reflected wave of the shock wave meets conditions for confining the material vapor.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Methods and systems for laser calibration and eye tracker camera alignment

InactiveUS7456949B2Easy alignmentIncreasing overall system cost and complexityLaser surgeryPhotometry using reference valuePupilLaser beams

The present invention provides methods, systems, and apparatus for calibrating a laser ablation system, such as an excimer laser system for selectively ablating a cornea of a patient's eye. The invention also facilitates alignment of eye tracking cameras that measure a position of the eye during laser eye surgery. A calibration and alignment fixture for a scanning laser beam delivery system having eye tracking cameras may include a structure positionable in a treatment plane. The structure having a feature directing laser energy incident thereon to a calibration energy sensor, at least one reference-edge to determine a characteristic of the laser beam (shape, dimensions, etc.), and an artificial pupil to determine alignment of the eye tracking cameras with the laser system.

Owner:AMO MFG USA INC

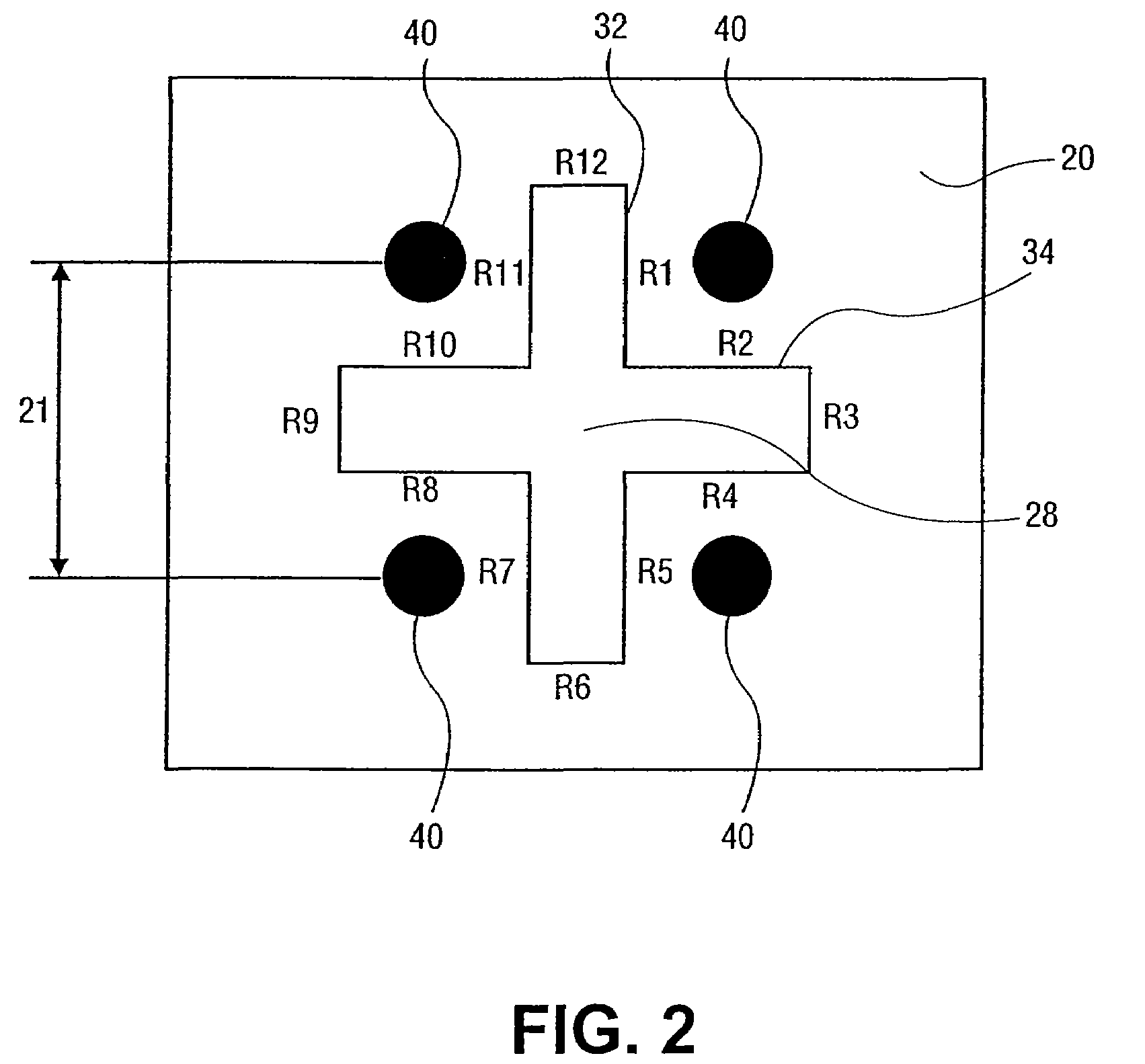

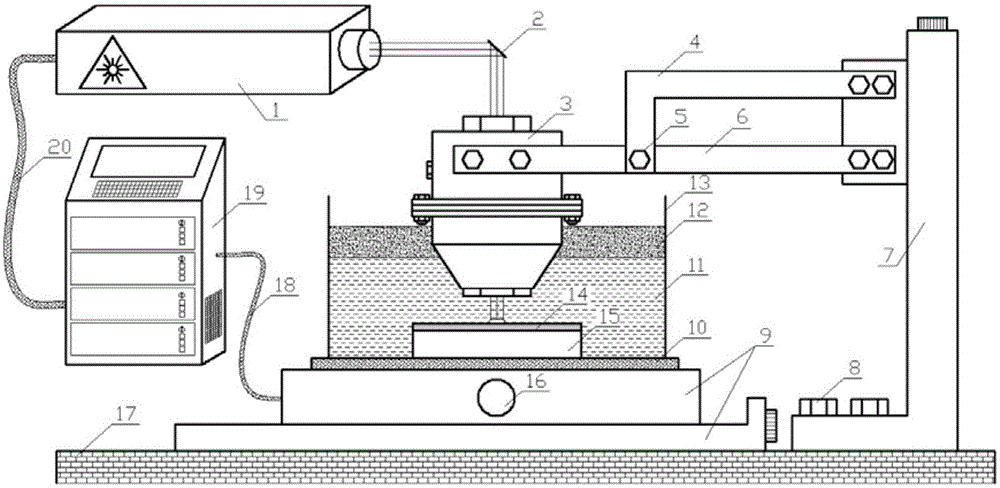

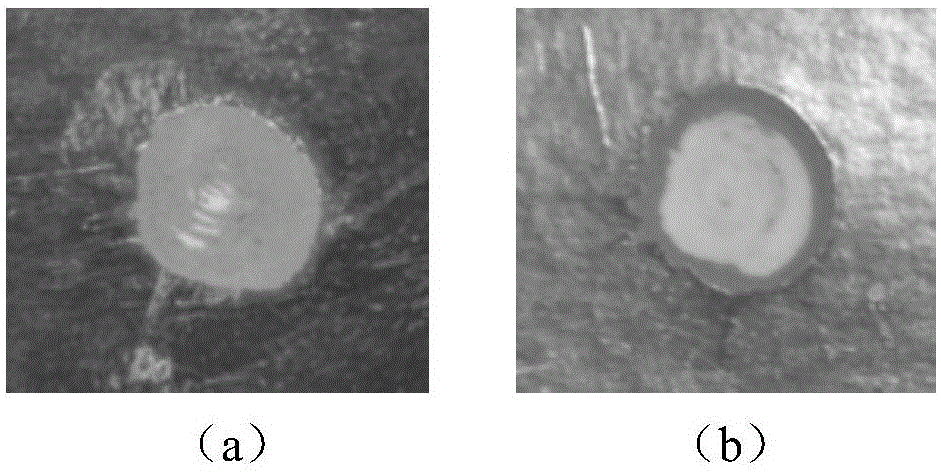

High-light-transmittance deep-freezing laser impact head and laser impact system

The invention relates to a high-light-transmittance deep-freezing laser impact head and laser impact system suitable for deep freezing laser impact technology. The temperature-insulation ceramic / plastic and vacuum temperature-insulation method are utilized to prevent water in air from being adsorbed onto high-transmittance glass due to low temperature and solve the problem that liquid nitrogen vapor can not be light-transmitting, thereby ensuring the light beam quality in the deep-freezing laser impact process. The high-light-transmittance deep-freezing laser impact head is characterized by comprising an upper end cover, a main body, a lower end cover, high-transmittance glass, a heat-insulation ceramic / plastic and other core components. The high-light-transmittance deep-freezing laser impact head ensures the light beam to smoothly reach the sample surface in the deep-freezing laser impact process, effectively enhances the light transmittance of the laser, has the advantage of simple structure, and is easy to implement.

Owner:JIANGSU UNIV

Methods and systems for laser calibration and eye tracker camera alignment

InactiveUS20060103839A1Easy alignmentIncreasing overall system cost and complexityLaser surgeryLaser detailsPupilLaser beams

The present invention provides methods, systems, and apparatus for calibrating a laser ablation system, such as an excimer laser system for selectively ablating a cornea of a patient's eye. The invention also facilitates alignment of eye tracking cameras that measure a position of the eye during laser eye surgery. A calibration and alignment fixture for a scanning laser beam delivery system having eye tracking cameras may include a structure positionable in a treatment plane. The structure having a feature directing laser energy incident thereon to a calibration energy sensor, at least one reference-edge to determine a characteristic of the laser beam (shape, dimensions, etc.), and an artificial pupil to determine alignment of the eye tracking cameras with the laser system.

Owner:AMO MFG USA INC

Methods and Systems for Laser Calibration and Eye Tracker Camera Alignment

InactiveUS20070225692A1Easy alignmentImprove calibration accuracyLaser surgeryPhotometry using reference valuePupilLaser beams

The present invention provides methods, systems, and apparatus for calibrating a laser ablation system, such as an excimer laser system for selectively ablating a cornea of a patient's eye. The invention also facilitates alignment of eye tracking cameras that measure a position of the eye during laser eye surgery. A calibration and alignment fixture for a scanning laser beam delivery system having eye tracking cameras may include a structure positionable in a treatment plane. The structure having a feature directing laser energy incident thereon to a calibration energy sensor, at least one reference-edge to determine a characteristic of the laser beam (shape, dimensions, etc.), and an artificial pupil to determine alignment of the eye tracking cameras with the laser system.

Owner:AMO MFG USA INC

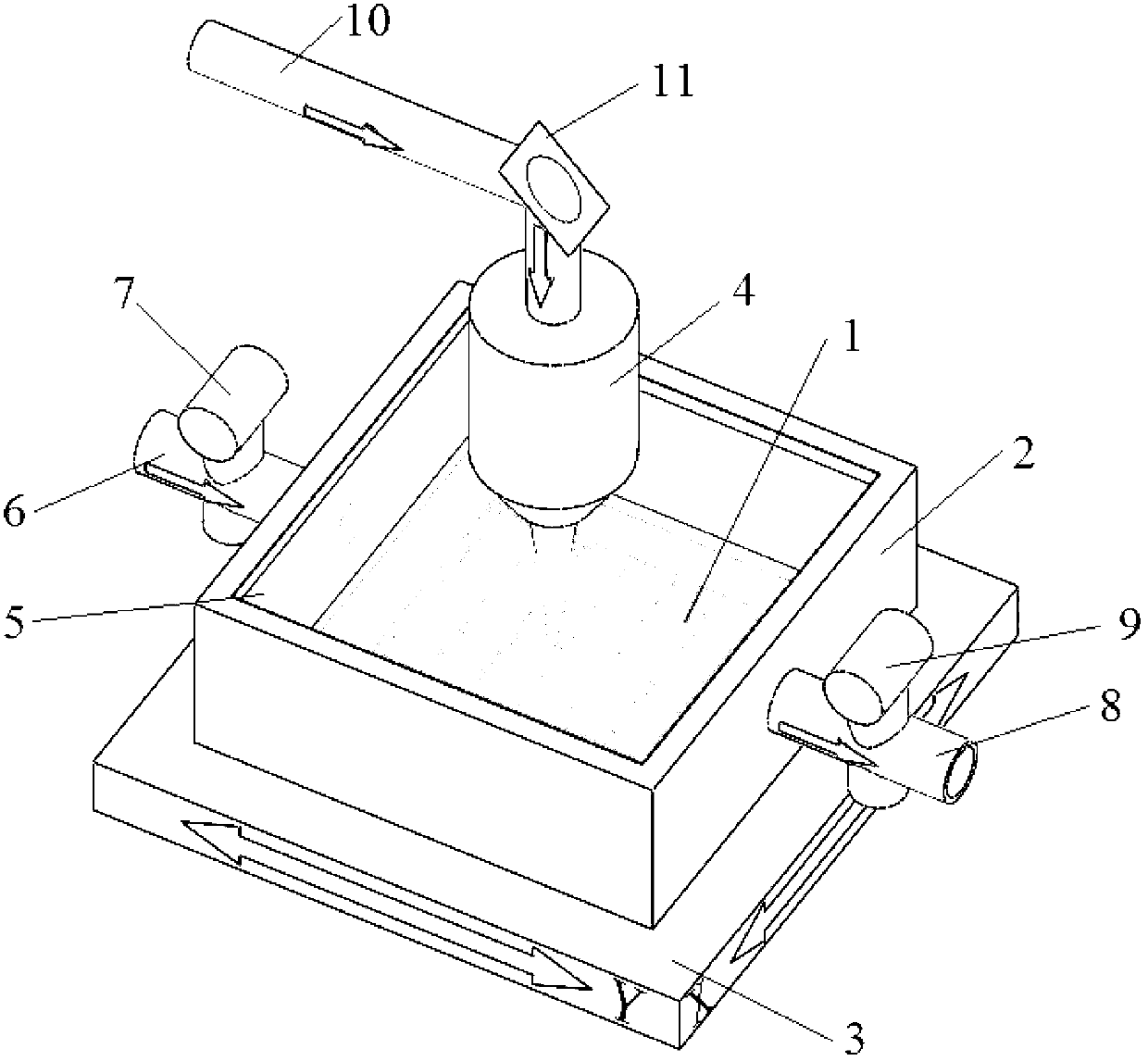

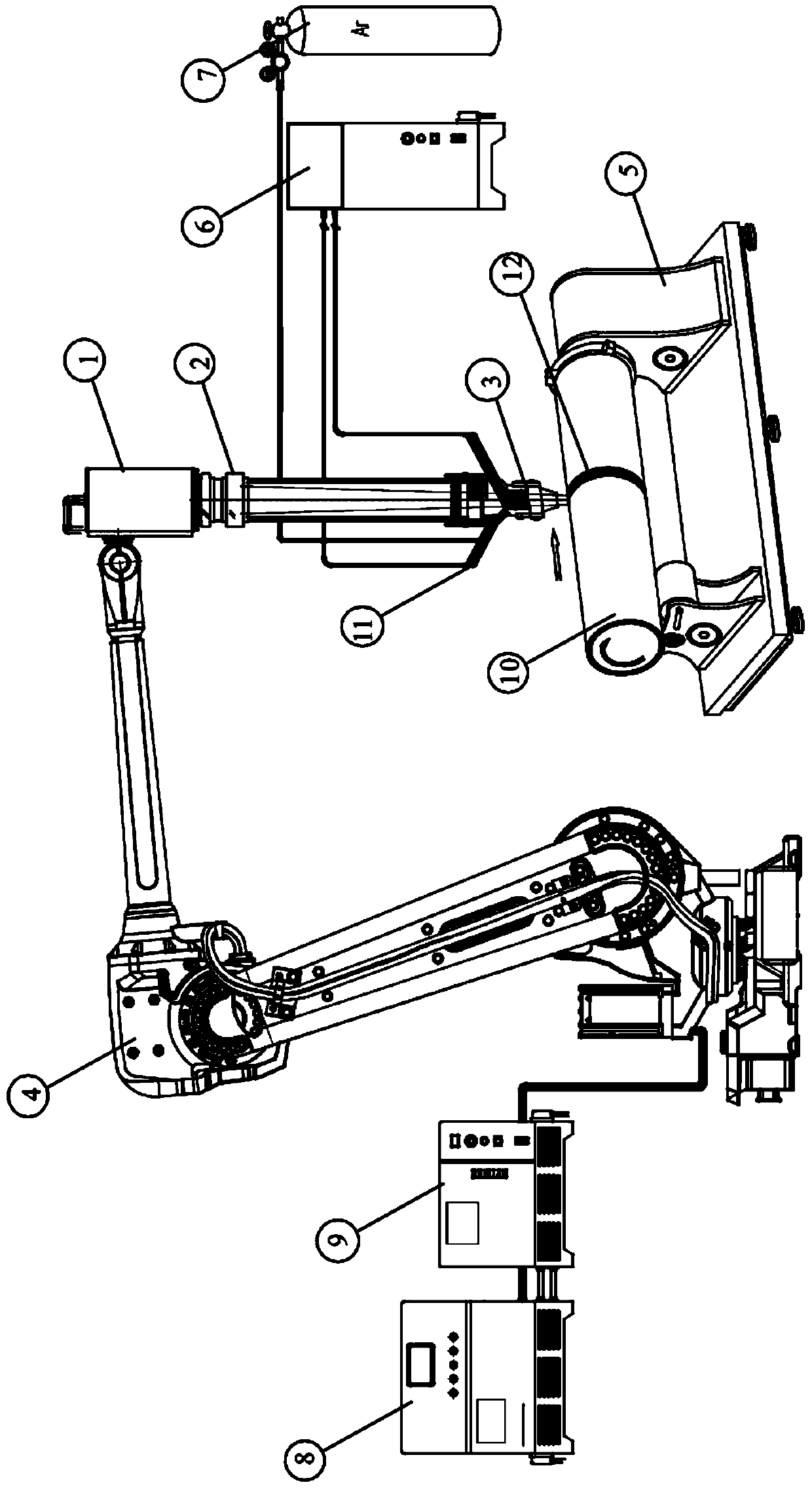

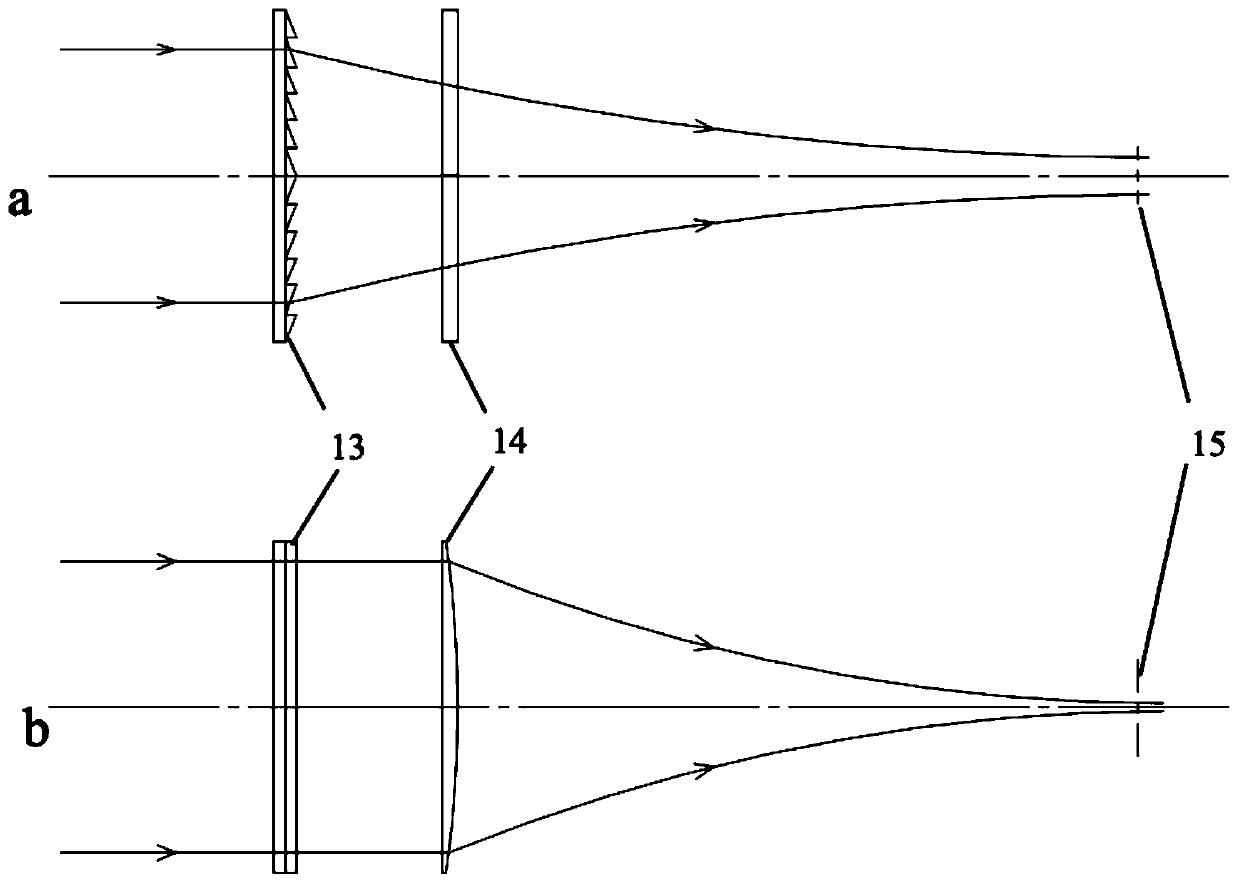

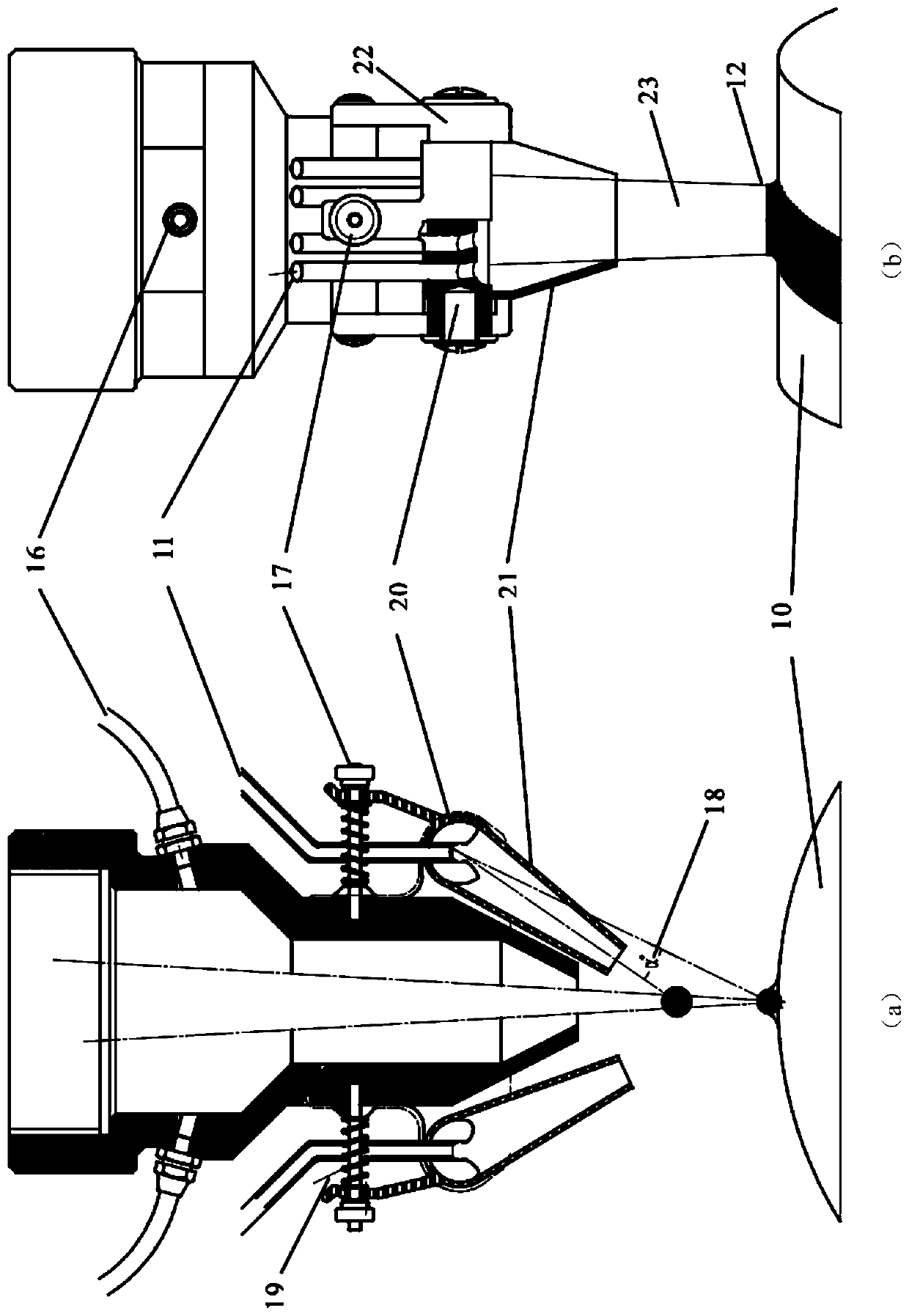

Fast and efficient semiconductor laser cladding device with wide light beam and adjustable powder feeding angle

ActiveCN110144583AIncrease single pass cladding areaReduce the burden of rotationMetallic material coating processesLaser lightSurface modification

The invention belongs to the technical field of laser surface modification, and discloses a fast and efficient semiconductor laser cladding device with a wide light beam and an adjustable powder feeding angle. The fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle comprises a semiconductor laser (1), a light beam shaping and Fresnel focusing system (2), an adjustable wide light band powder feeding head (3), a powder feeder (6), a high-speed machine tool (5), a six-axis linkage robot (4) and a central control system (9), wherein the light beam shaping and Fresnel focusing system (2) is used for shaping a laser light and focusing to form a wide-light-band laser light; the adjustable wide light band powder feeding head (3) is used for conveying powder and the wide-light-band laser light on the surface of a large-scale shaft type workpiece to be processed; and the diameter of a workpiece is larger than 1000mm, and the length of the workpiece is not lower than 10m. According to the fast and efficient semiconductor laser cladding device with the wide light beam and the adjustable powder feeding angle provided by the invention, through improving structures and arrangement manners of key components, outer surface strengthening and surface repairing can be carried out aiming at the large-scale shaft type workpieces such as petroleum pipelines, ocean facilities, natural gas conveying, mining and tunnel piercing, so that the wear resistance and the corrosion resistance of the surface are improved, and the service life is greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

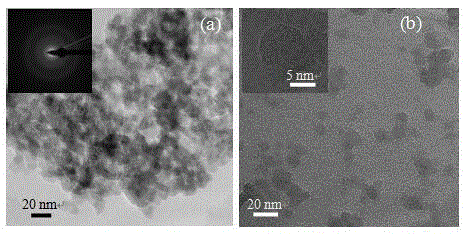

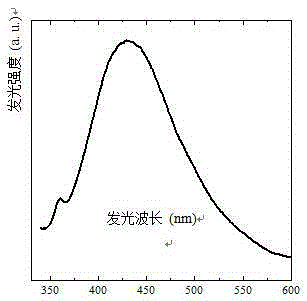

Light-emitting amorphous silicon carbide nanoparticle preparation method

ActiveCN105236410AGuaranteed normal formationSmall diameterMaterial nanotechnologyNanoparticleCarbide

The present invention relates to a light-emitting amorphous silicon carbide nanoparticle preparation method, and belongs to the technical field of photoelectric materials. The method is mainly characterized in that the silicon carbide polycrystalline ceramic sheet surface is subjected to a polishing treatment, focusing is performed onto the polycrystalline ceramic sheet immersed in deionized water by using excimer pulse laser, and during the irradiation process, a three-dimensional controllable platform carries a beaker to slowly translate so as to make the laser irradiation position on the ceramic sheet be continuously changed, such that finally the amorphous silicon carbide nanoparticles suspended in the deionized water and having the diameter of about 10 nm is obtained, wherein the surface is hydrophilic so as to ensure that the amorphous nanoparticles can be stably suspended in the ionized water and do not produce settling. In addition, the amorphous silicon carbide nanoparticles have strong and stable blue light emission, and have good application prospects in the fields of photoelectricity and biomedicine.

Owner:YANGZHOU UNIV

Phosphor wheel heat-dissipating module for laser projection system

ActiveUS9010971B2Effective coolingReduce areaLighting heating/cooling arrangementsProjectorsImpellerPhosphor

A phosphor wheel heat-dissipating module for a laser projection system is provided. The phosphor wheel heat-dissipating module includes a phosphor wheel, a plurality of air vents and an impeller. At least one phosphor agent is coated on an outer-ring portion of a first surface of the phosphor wheel. The air vents run through the phosphor wheel. The impeller is disposed on a second surface of the phosphor wheel, and includes an inlet and a first outlet. A laser beam is projected on the outer-ring portion of the phosphor wheel. When the phosphor wheel is rotated at a high rotating speed, an airflow is inhaled into the impeller through the inlet. A first portion of the airflow is blown out through the first outlet, and a second portion of the airflow is transferred to the first surface of the phosphor wheel through the air vents.

Owner:DELTA ELECTRONICS INC

Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof

ActiveCN111058116AEasy to prepareEasy to operateArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsEngineeringBiology

The invention discloses a skin-core type poly(lactic acid) (PLA) / poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and a preparation method thereof, and belongs to the field of high polymer materials. The preparation method of the skin-core type PLA / PHBV composite fiber specifically includes the steps: 1, respectively drying the raw material PLA in a skin layer and a raw material PHBV in a core layer, wherein moisture content of the PLA and the PHBV is not more than 200 ppm; and 2, weighing the raw materials PLA and PHBV obtained in the step 1 according to a composite spinning ratio to perform compositely spinning, melting spinning, cross air blowing, applying oil, winding, online stretching, and thermoforming to obtain the skin-core type PLA / PHBV composite fiber, wherein the number of holes in a spinning plate used during a spinning process is 24-144. The material prepared according to the method is high in breaking strength, and can be applied to the fields of medical materials, agricultural textile, disposable goods and package materials.

Owner:JIANGNAN UNIV

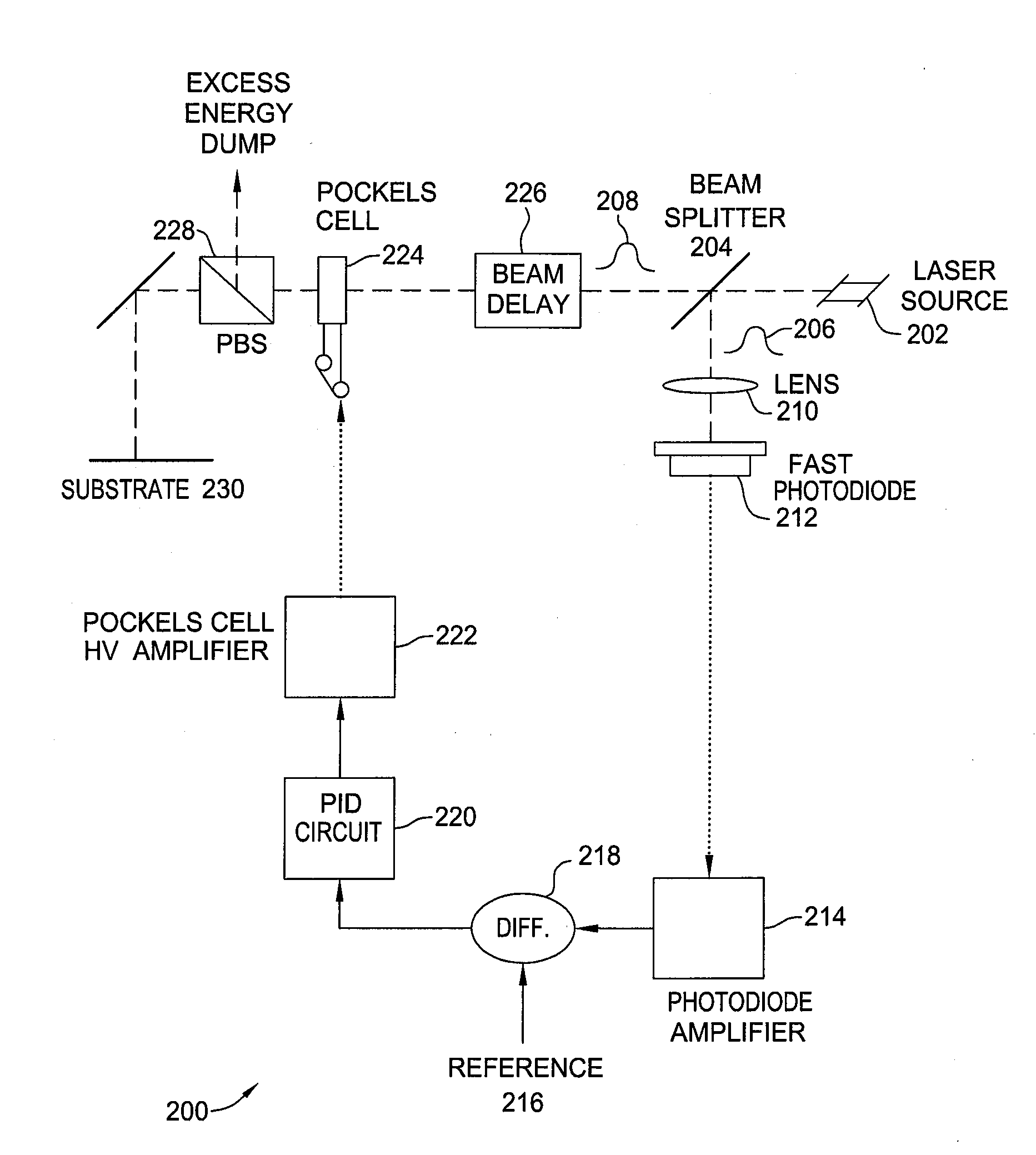

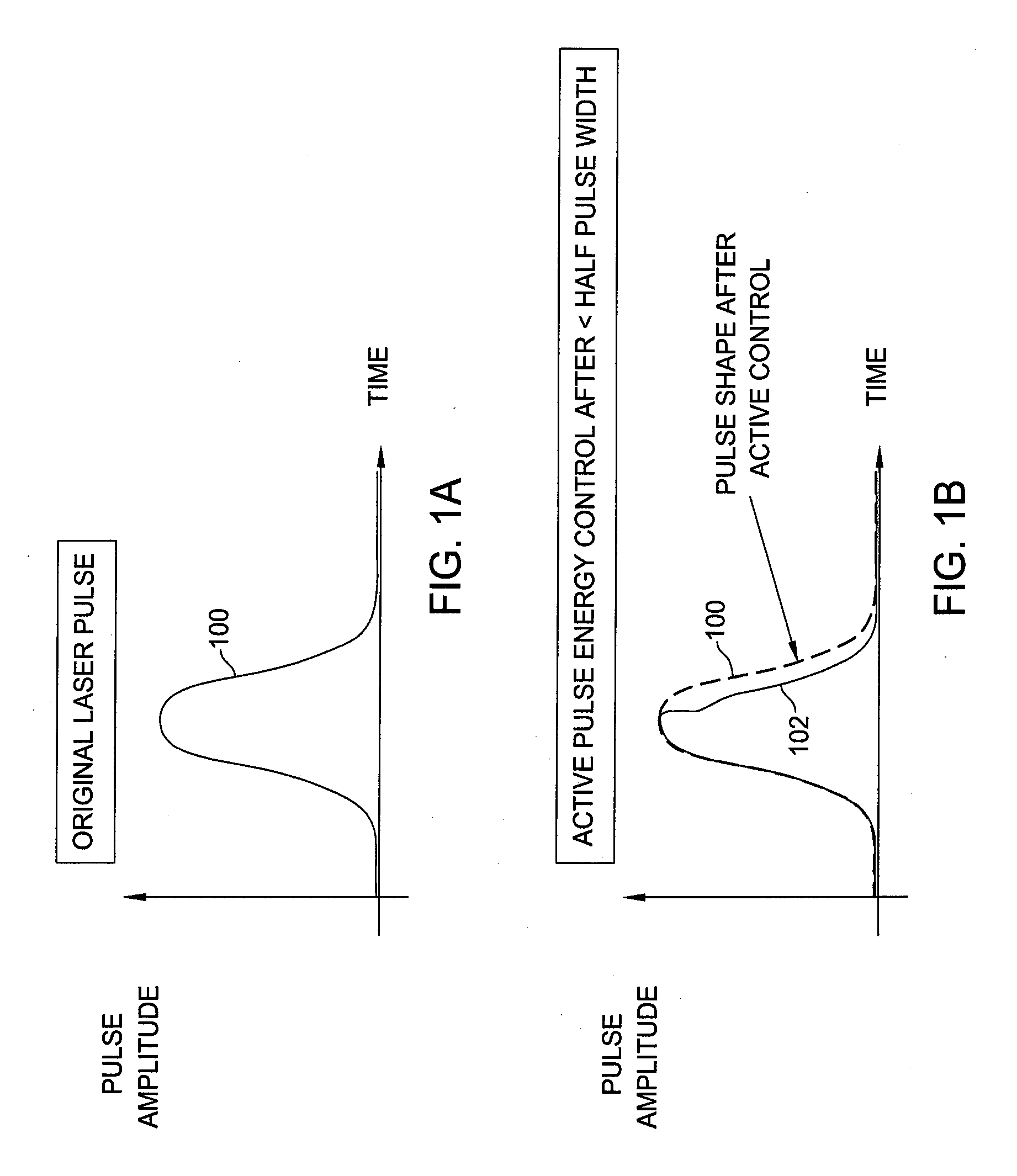

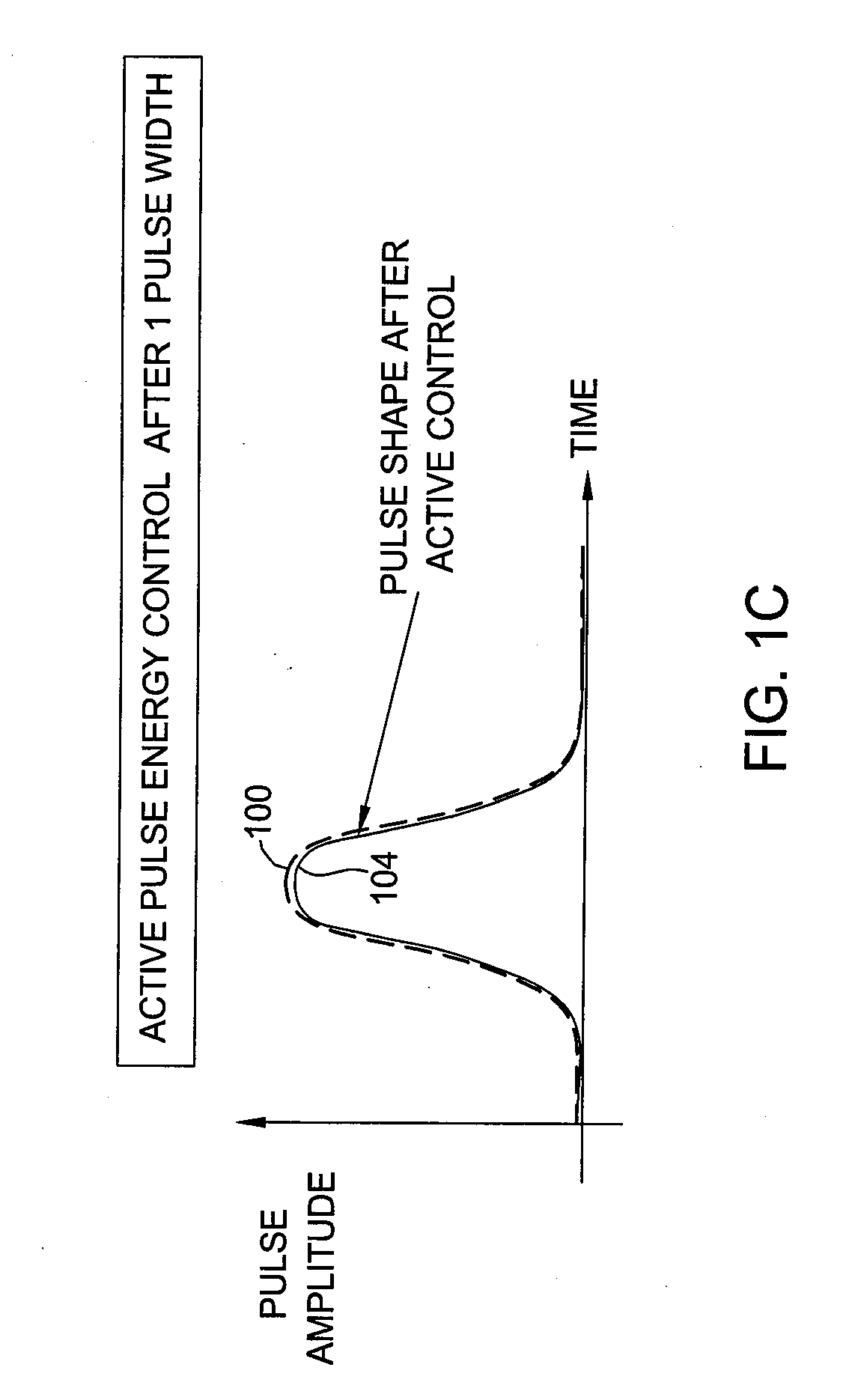

Increased nanosecond laser pulse-to-pulse energy repeatability using active laser pulse energy control

InactiveUS20090046750A1High energy laserReduce variationLaser detailsSemiconductor/solid-state device manufacturingEnergy variationNanosecond laser pulse

A method and apparatus for reducing the pulse-to-pulse laser energy variation (i.e., increasing the pulse-to-pulse laser energy repeatability) from a pulsed laser source are provided. In this manner, laser pulses impingent on a processing plane, such as the surface of a wafer or other substrate, may have substantially the same energy content leading to a more controlled process when compared to conventional processing. The method may be based on in-situ detection of the pulse energy level and the subsequent active adjustment of the transmitted laser pulse energy in a closed-loop control scheme. Furthermore, the active adjustment of the laser pulse energy may occur within a few nanoseconds after the original laser pulse is generated by a pulsed laser source.

Owner:APPLIED MATERIALS INC

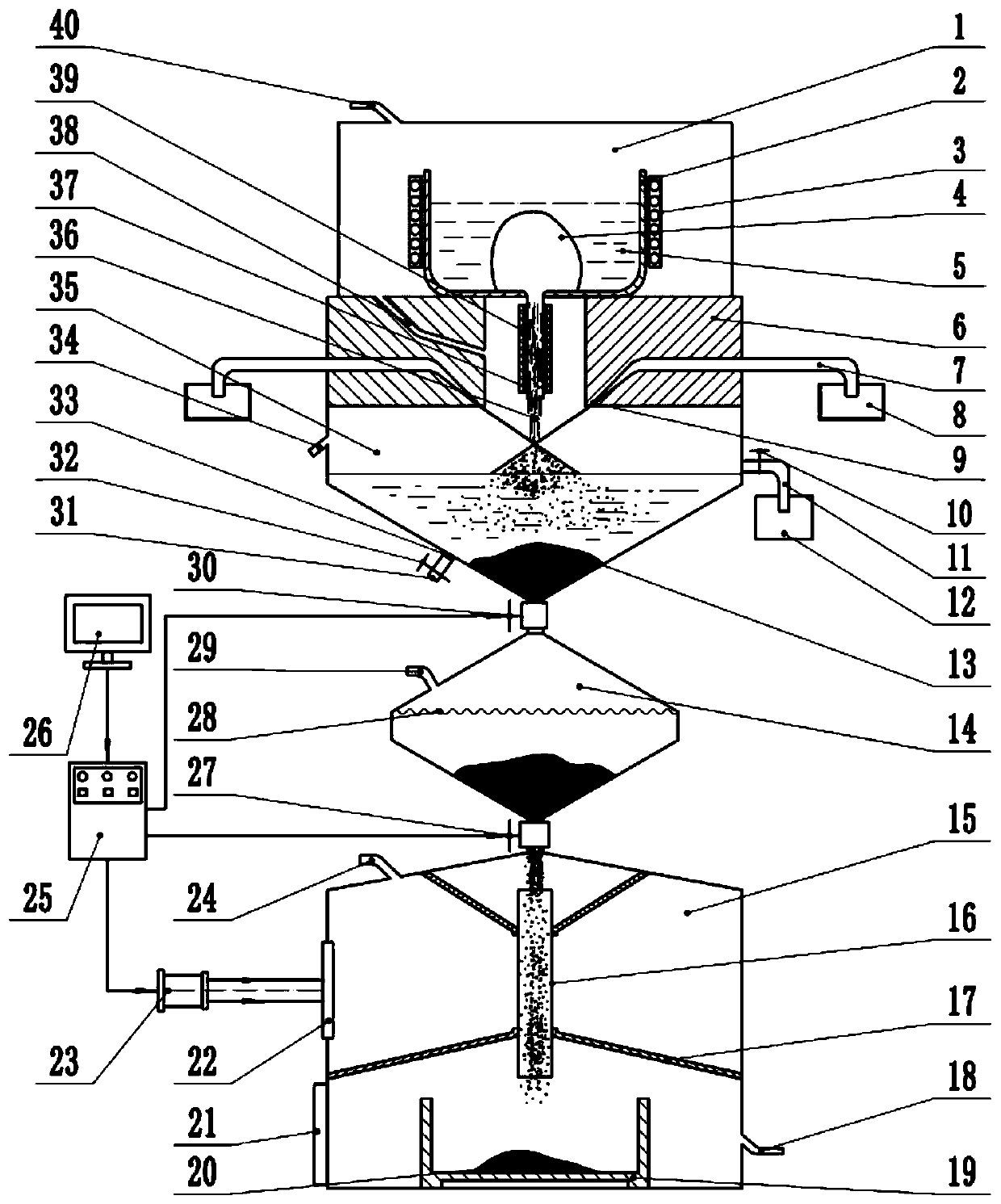

Method and device for preparing spherical metal powder through combined atomization

The invention discloses a method and device for preparing spherical metal powder through combined atomization, and belongs to the technical field of metal powder preparation. The device comprises a metal melting system, a water atomizing system, a powder drying system, a laser spheroidizing system, a powder collecting system, a gas circulating system and a control system. A water atomization method has the characteristics of low cost, high production efficiency and small granularity but the prepared powder is uneven in morphology and high in oxygen content; a laser spheroidizing method is highin laser energy and directivity controllability and can spheroidize irregular powder; and the two methods are combined so that advantages can be combined and disadvantages can be overcome, and the combined method is suitable for preparing spherical metal powder. The method and device have good application prospects in actual production of advanced manufacturing technologies such as 3D printing.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

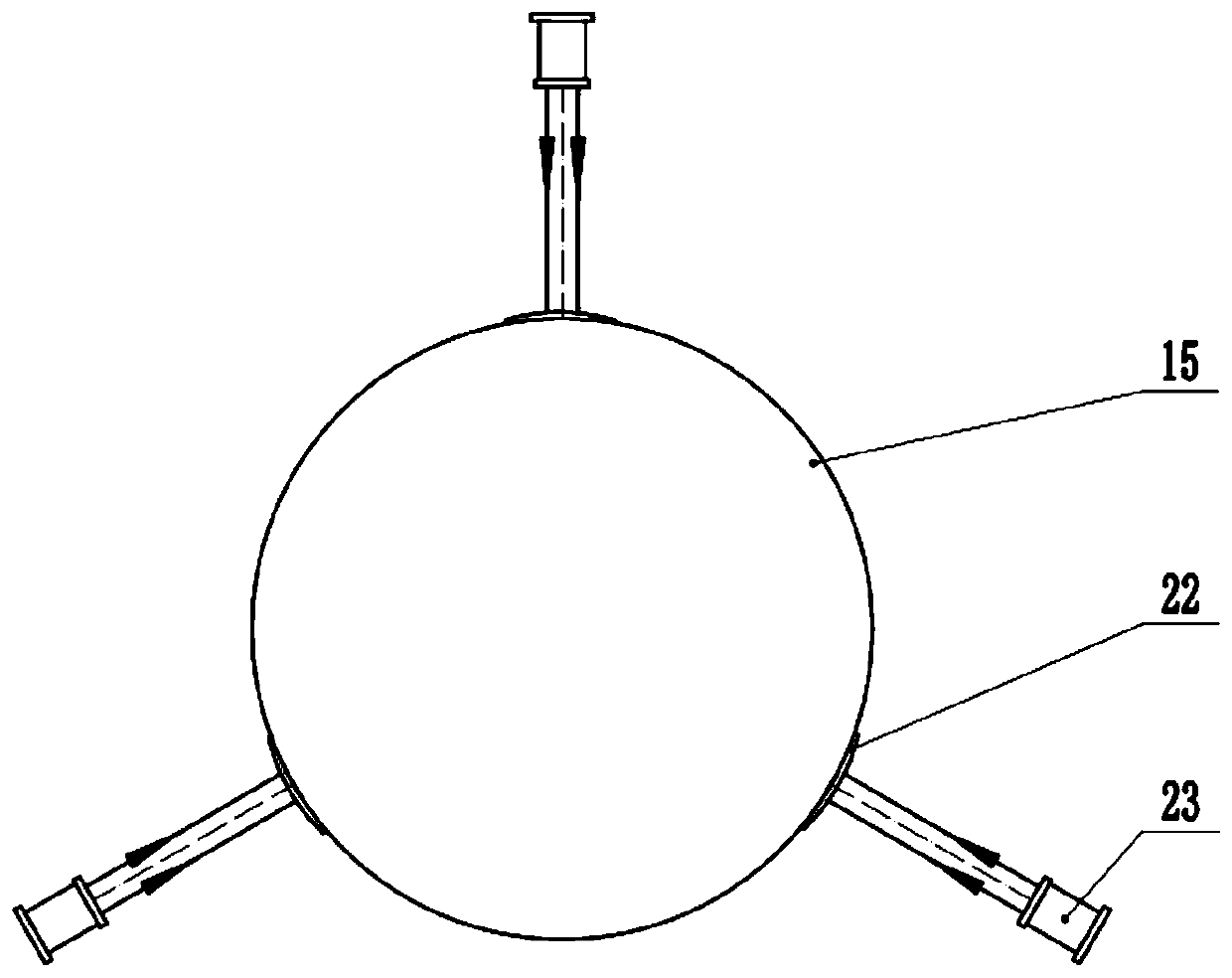

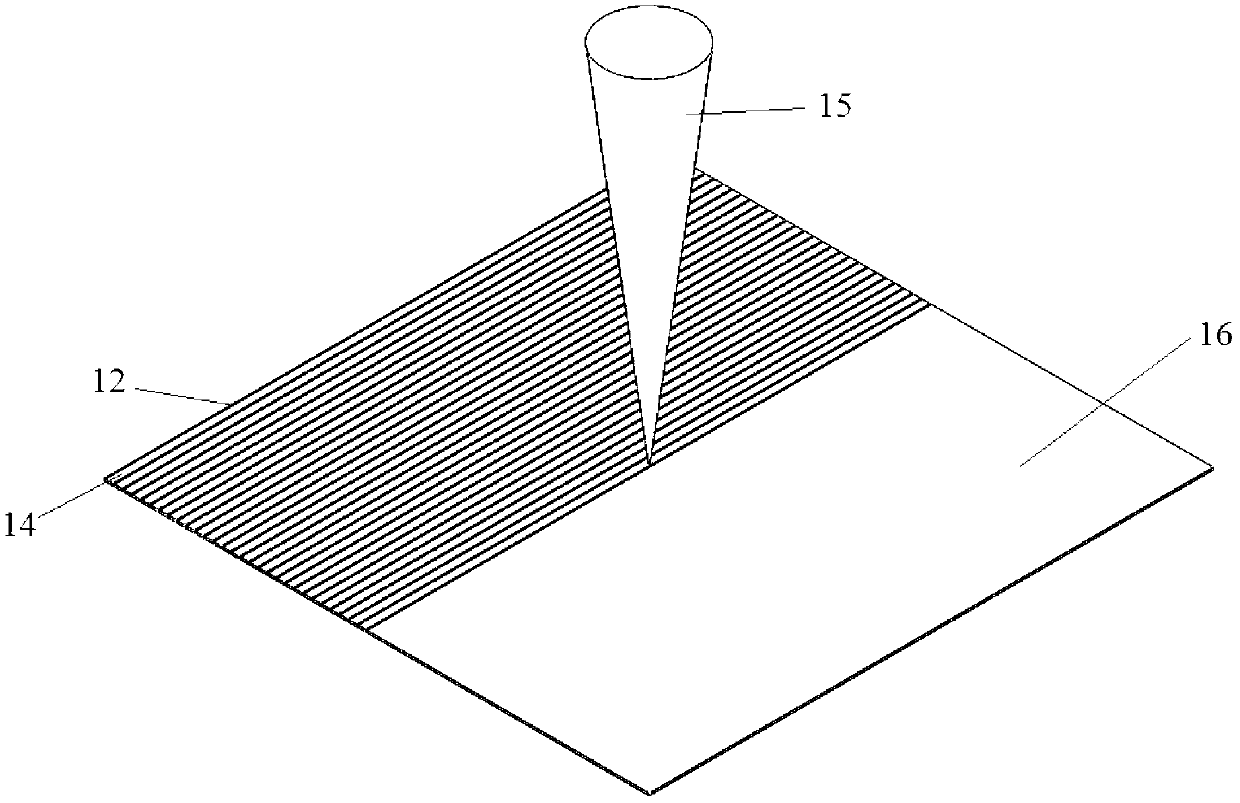

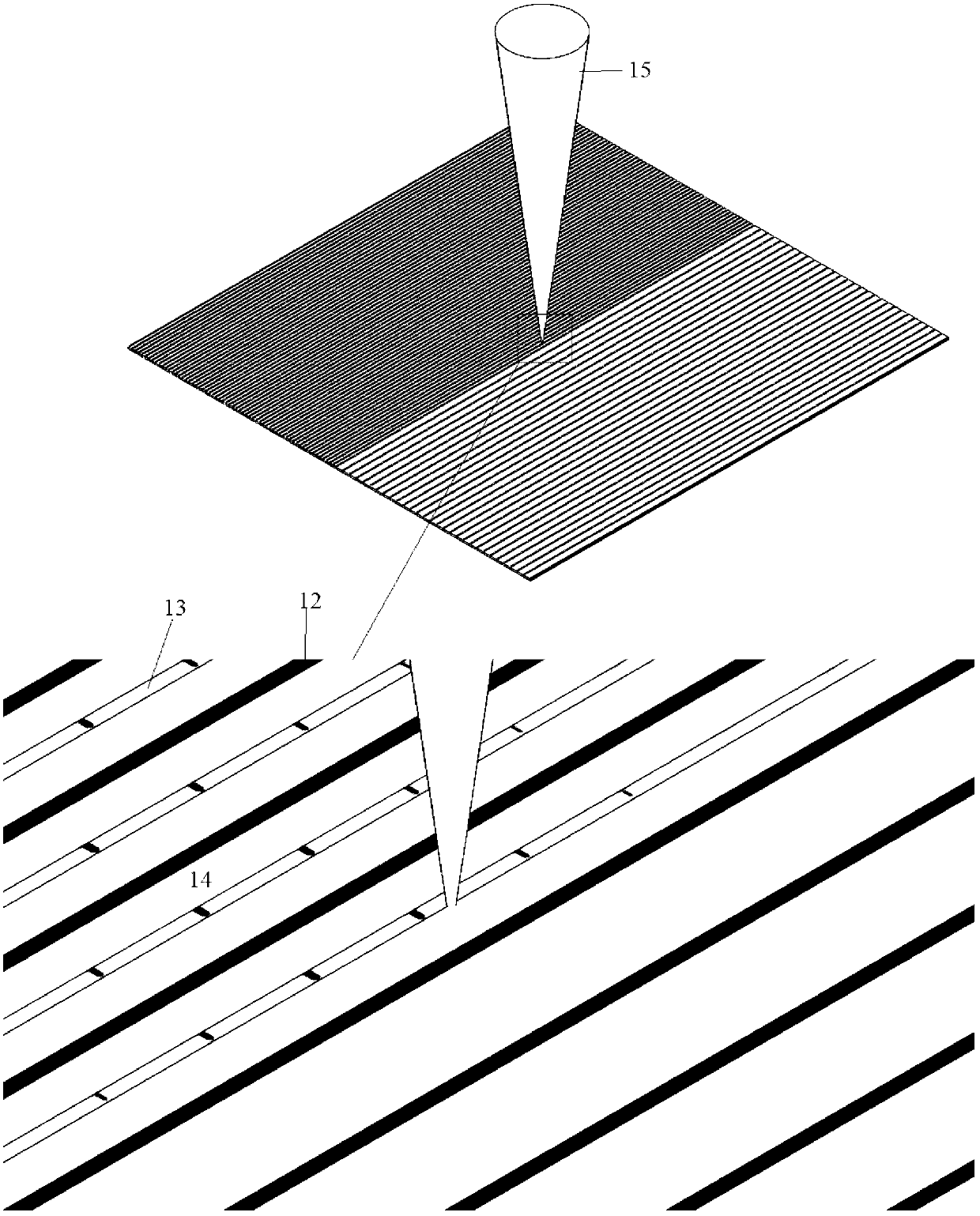

Method for manufacturing vertical multi-junction solar cell piece by laser

ActiveCN103219421AIncrease concentrationHigh energy laserFinal product manufactureSemiconductor devicesSemiconductor materialsRegioselectivity

The invention relates to a method for manufacturing a vertical multi-junction solar cell piece by laser. The method comprises the following steps of placing a semiconductor material in a vacuum chamber installed with a transparent window, wherein the vacuum chamber is installed in a three-dimensional mobile platform; selectively doping in an area to the semiconductor material in impurity atmosphere by laser to form a p type or n type doped stripe sequence, wherein the depletion layer plane of the formed p-n junction or p-i-n junction sequence is vertical to lighting face; and manufacturing the vertical multi-junction solar cell piece by etching an electrode groove on the back. The invention provides a cheap and simple full laser manufacturing process for the vertical multi-junction solar cell piece.

Owner:NANJING TRIZ INST OF LASER APPL TECH CO LTD

Laser irradiation apparatus, laser irradiation method, semiconductor device, and method of manufacturing a semiconductor device

InactiveUS20050247685A1Reduce hydrogen concentrationHigh energy laserSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialAmorphous silicon

To form a polycrystalline silicon film having a grain size of 1 μm or greater by means of laser annealing. A beam emitted from a laser apparatus (101) is split in two by a half mirror. The split beams are processed into linear shapes by cylindrical lenses (102) to (105), and (207), then simultaneously irradiate an irradiation surface (209). If an amorphous silicon film formed on a glass substrate is disposed on the irradiation surface (209), an area will be irradiated by both a linear shape beam entering from a front surface and a linear shape beam that has transmitted through the glass surface. Both linear shape beams irradiate the same area to thereby crystallize the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

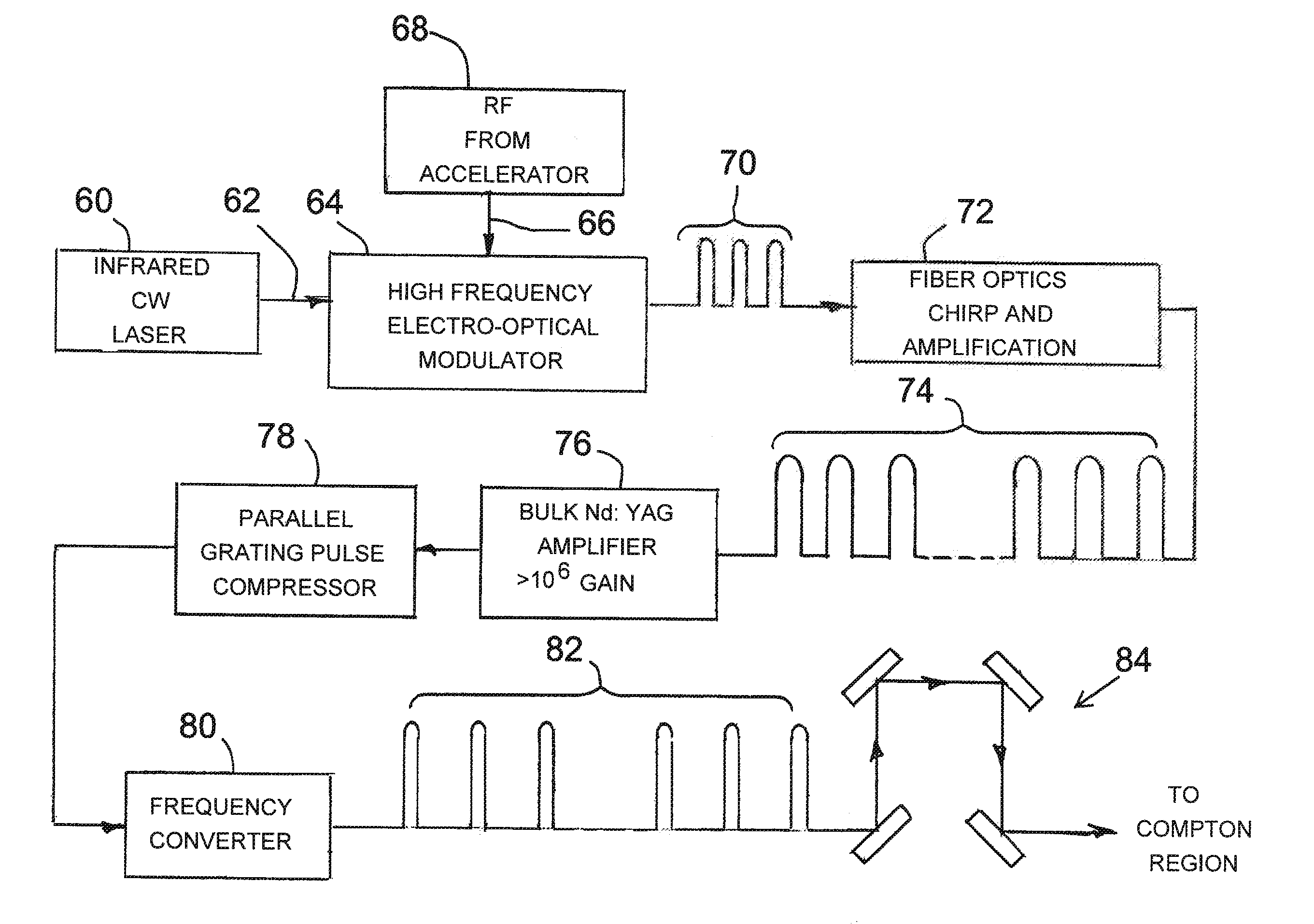

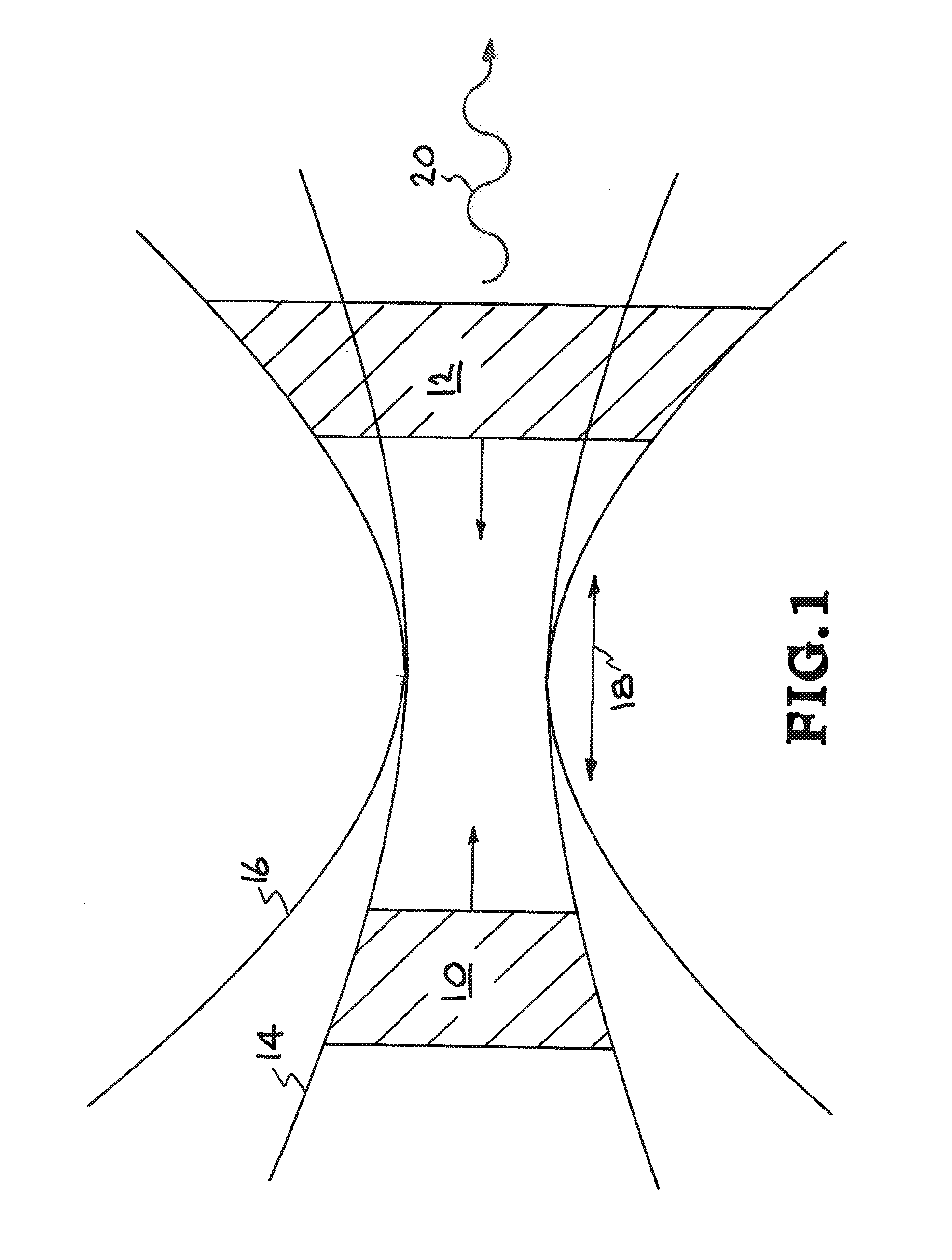

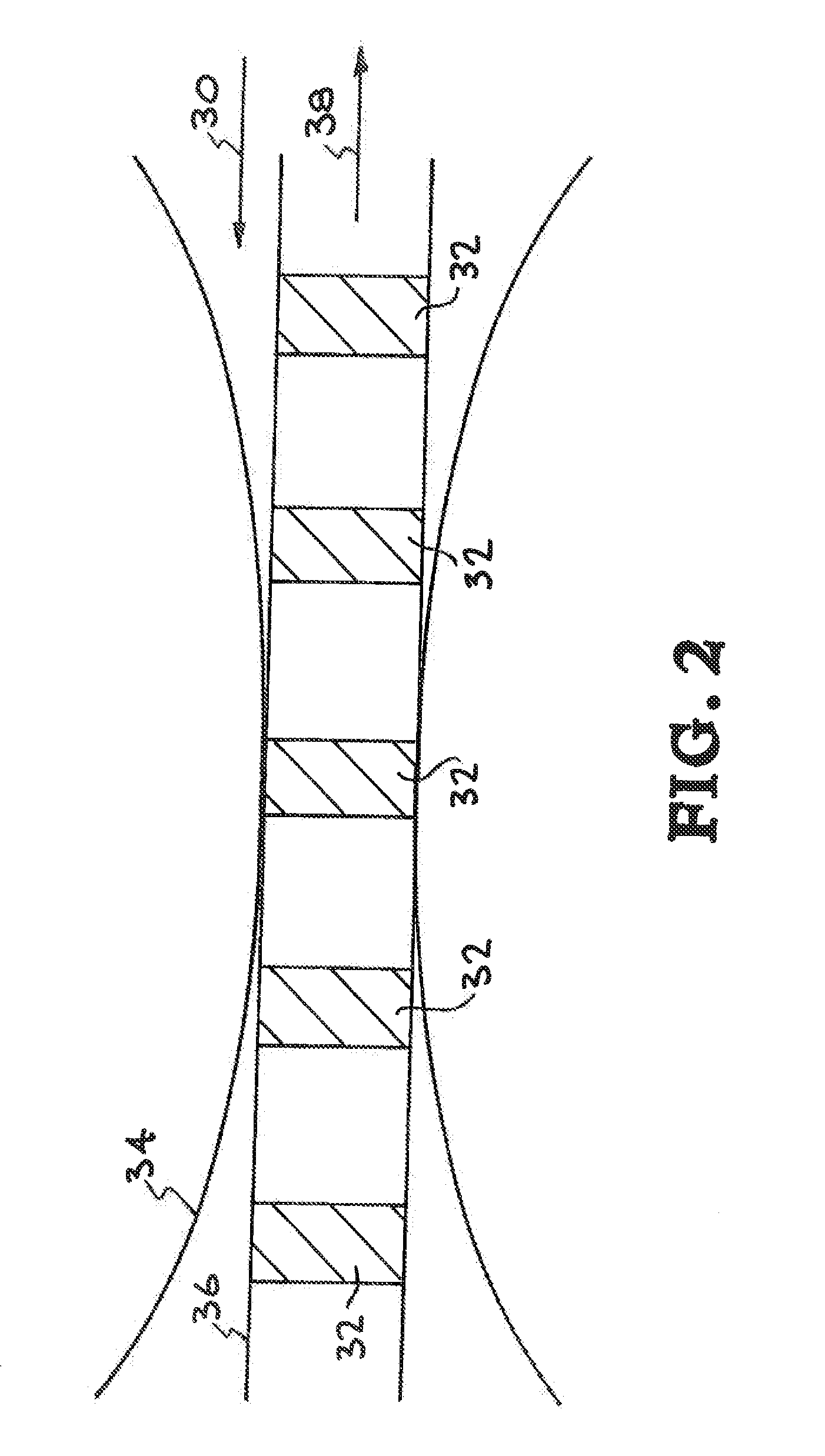

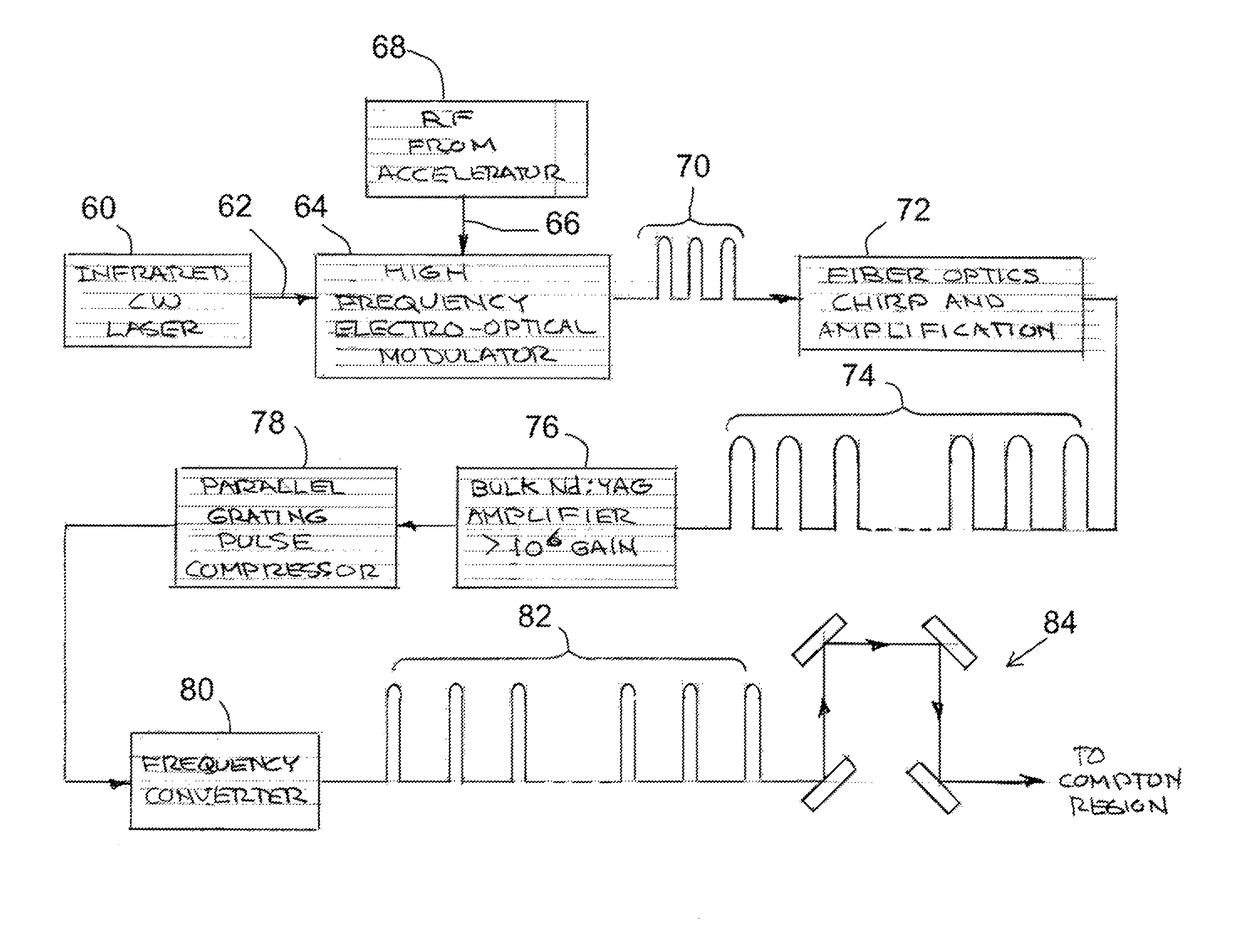

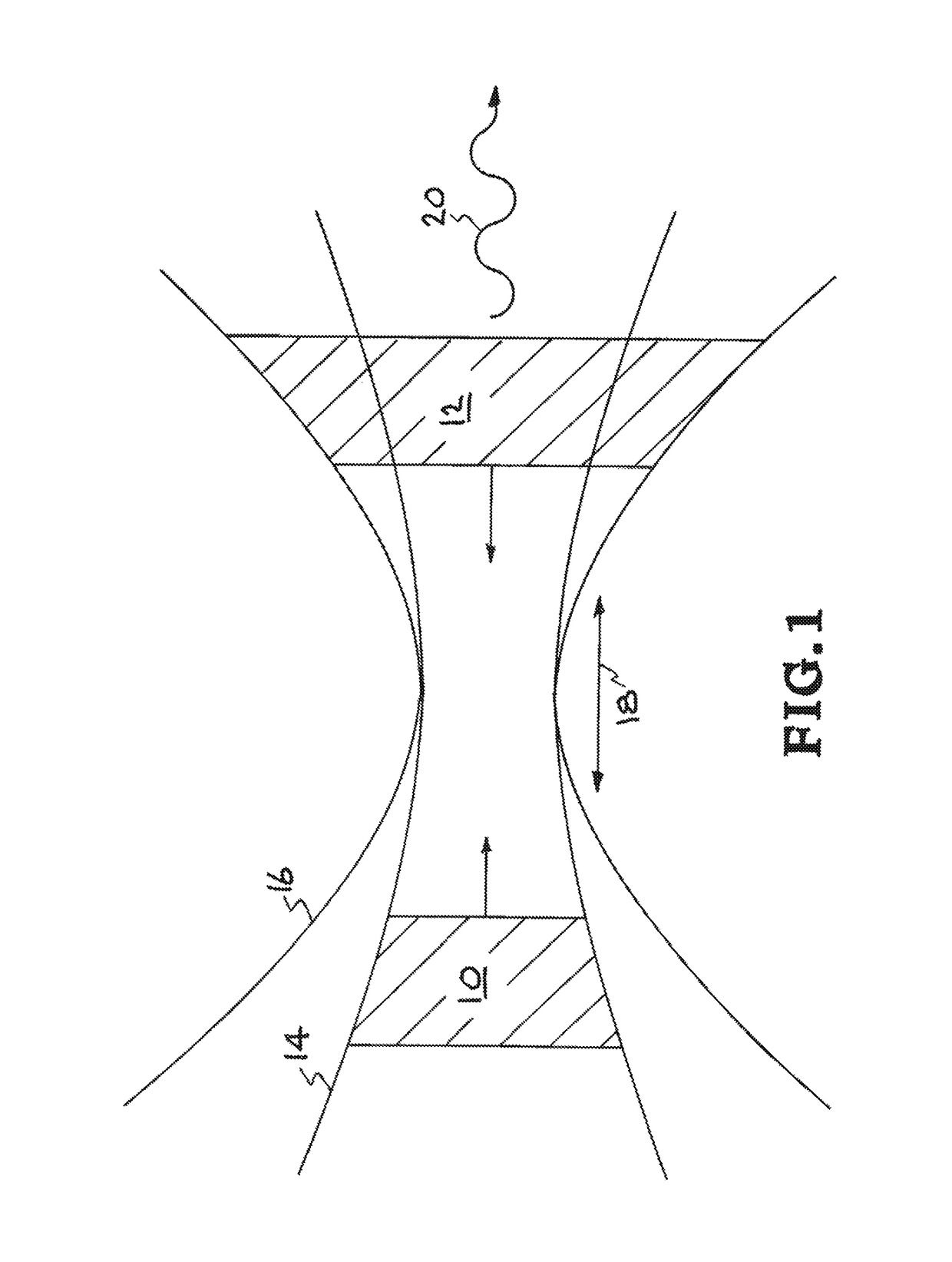

Modulated method for efficient, narrow-bandwidth, laser compton x-ray and gamma-ray sources

ActiveUS20140376697A1Narrow bandwidthIncrease laser energy to Compton photon conversion efficiencyX-ray tube with very high currentX-ray apparatusSoft x rayX-ray

A method of x-ray and gamma-ray generation via laser Compton scattering uses the interaction of a specially-formatted, highly modulated, long duration, laser pulse with a high-frequency train of high-brightness electron bunches to both create narrow bandwidth x-ray and gamma-ray sources and significantly increase the laser to Compton photon conversion efficiency.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Modulated method for efficient, narrow-bandwidth, laser Compton X-ray and gamma-ray sources

ActiveUS9706631B2Narrow bandwidthHigh energy laserX-ray tube with very high currentX-ray apparatusSoft x rayX-ray

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

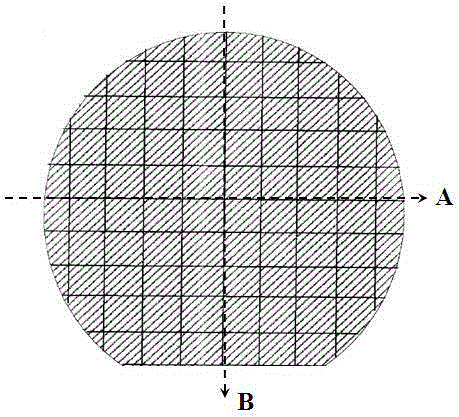

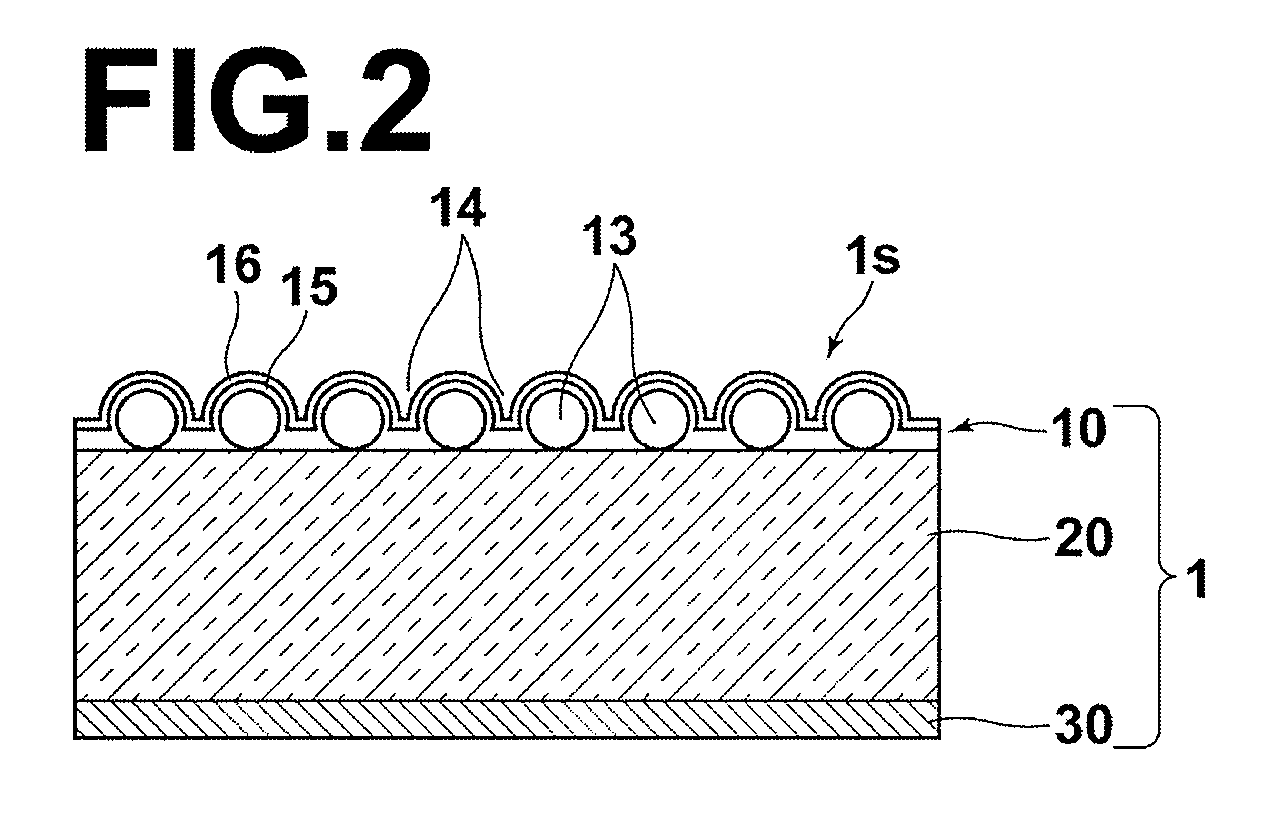

Nitride-based light emitting diode chip and manufacturing method thereof

ActiveCN105185744AReduce absorptionIncrease side wall lightSemiconductor/solid-state device manufacturingLaser beam welding apparatusLight absorbanceGallium nitride

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

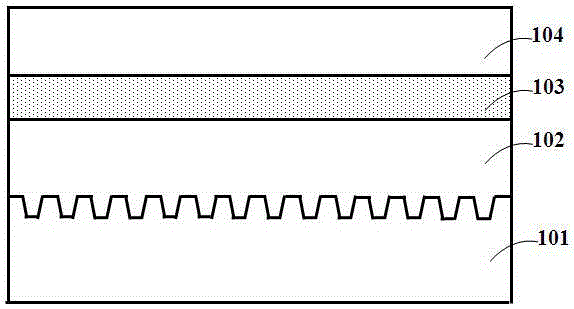

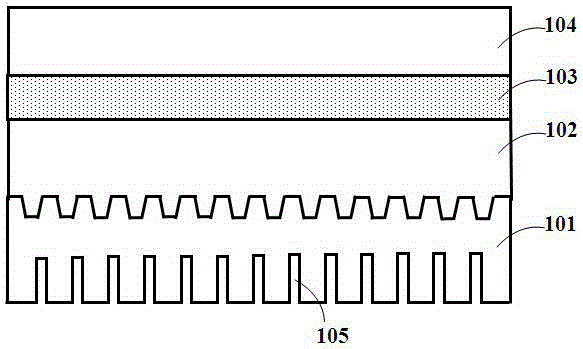

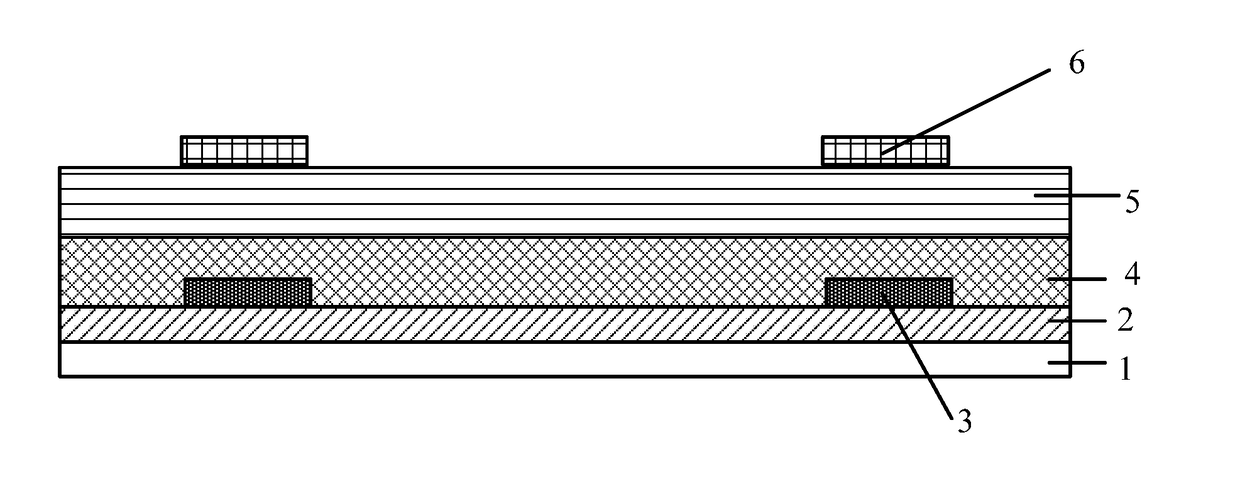

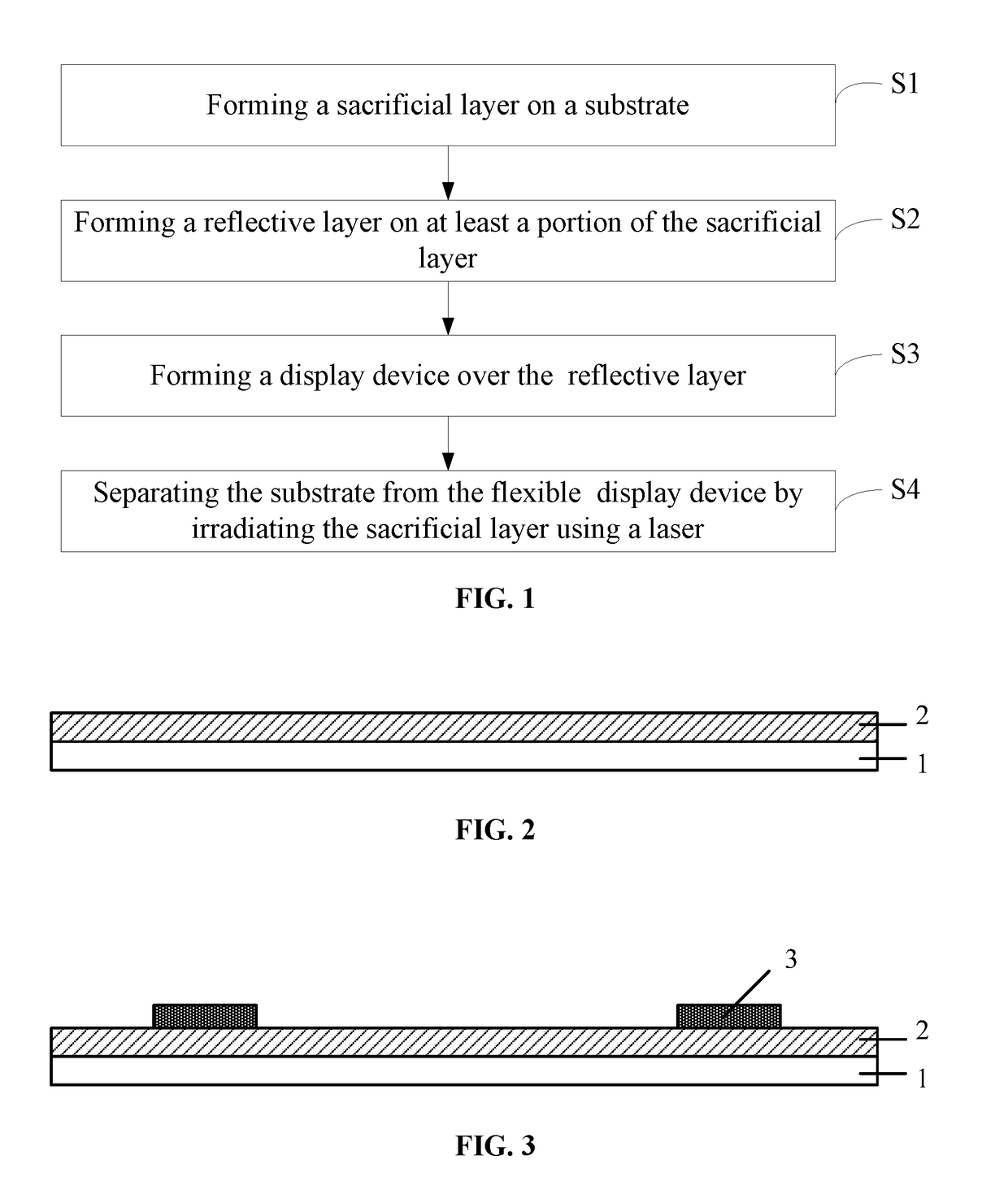

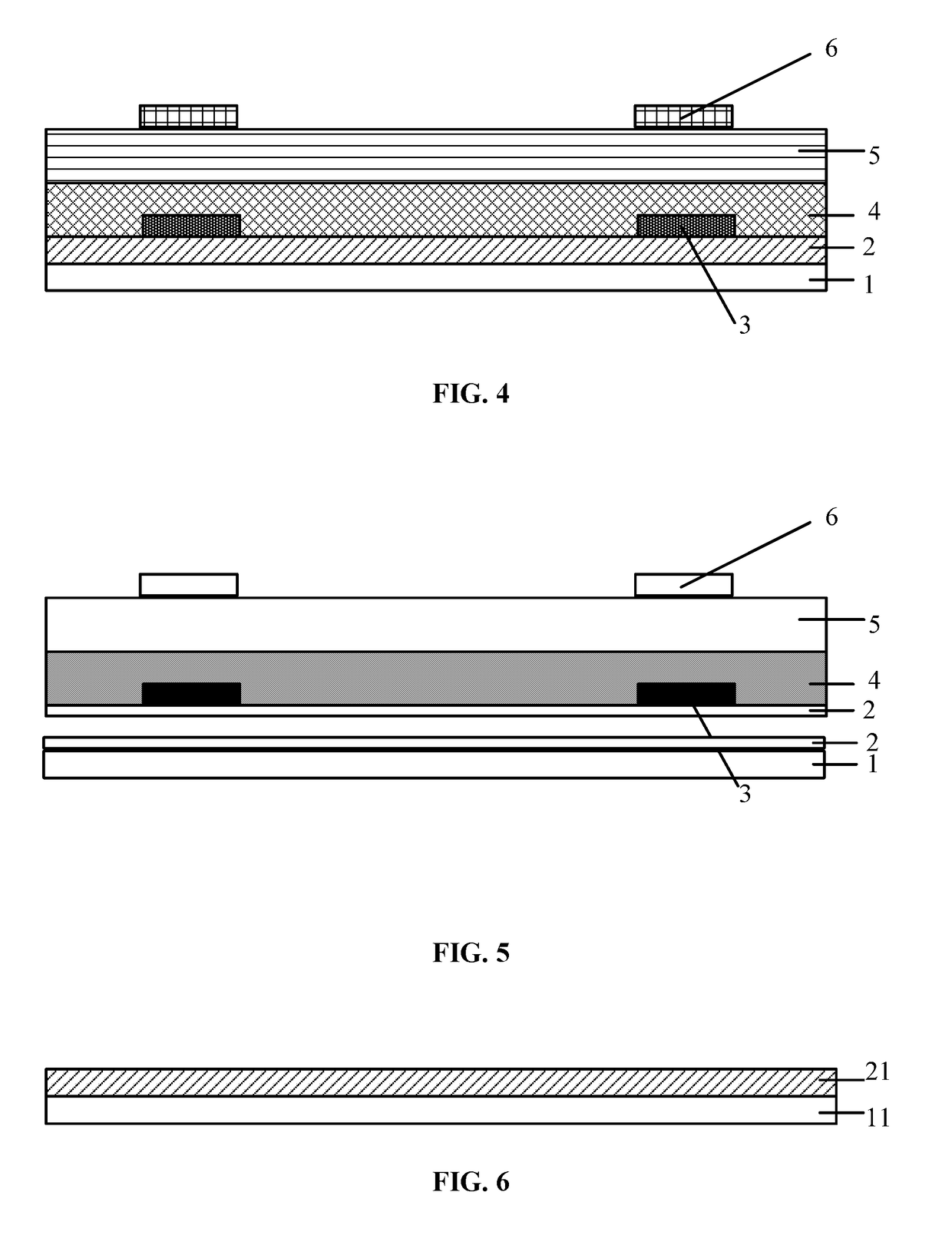

Flexible device and fabrication method thereof, display apparatus

ActiveUS20170120569A1Reduce laser energyHigh energy laserLamination ancillary operationsSynthetic resin layered productsOptoelectronicsReflective layer

A method for fabricating a flexible device is provided. The method includes forming a sacrificial layer on a substrate; and forming a reflective layer to reflect a laser for subsequently de-bonding the sacrificial layer from the rigid substrate back to the sacrificial layer to reduce required de-bonding energy of the laser over at least a portion of the rigid substrate. Further, the method includes forming a flexible device over the reflective layer; and separating the substrate from the sacrificial layer by irradiating the sacrificial layer using the laser.

Owner:BOE TECH GRP CO LTD

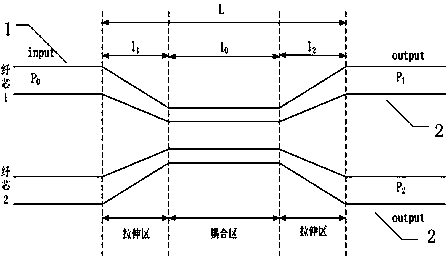

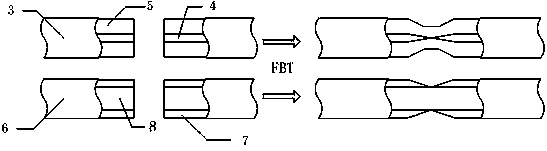

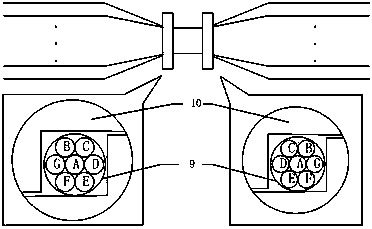

Great-core-diameter optical fiber coupler and manufacturing method of great-core-diameter optical fiber coupler

ActiveCN104345388AHigh energy laserReduce the risk of distortionCoupling light guidesLight spotTransmittance

The invention discloses a great-core-diameter optical fiber coupler, which comprises an input optical fiber and n output optical fibers, wherein the n is greater than or equal to 1 but smaller than or equal to 6, the core diameter of the input optical fiber is 200 to 600mum, the core-to-sheath ratio range of the input optical fiber is 1:1.04 to 1:1.25, the core diameter of each output optical fiber is 200 to 400mum, the core-to-sheath ratio of the output optical fiber is identical to that of the input optical fiber, the input optical fiber and the output optical fibers are fixed and twisted in a coupling region, one end, in the coupling region, of the input optical fiber is the output end of the input optical fiber, the other end of the input optical fiber is the input end of the input optical fiber, one end, in the coupling region, of each output optical fiber is the input end of each output optical fiber, and the other end of each output optical fiber is the output end of the output optical fiber. The great-core-diameter optical fiber coupler has the advantages that the optical fiber coupling difficulty is low, the light splitting ratio of the coupler is uniform, the optical fiber uncoaxiality caused by optical fiber accumulation in the coupling region is reduced, the light spot divergence angle is smaller than 30 degrees, the transmittance is greater than 70 percent, any light splitting ratio can be realized, and the light splitting ratio deviation is + / -7 percent.

Owner:NANJING CHUNHUI SCI & TECH IND

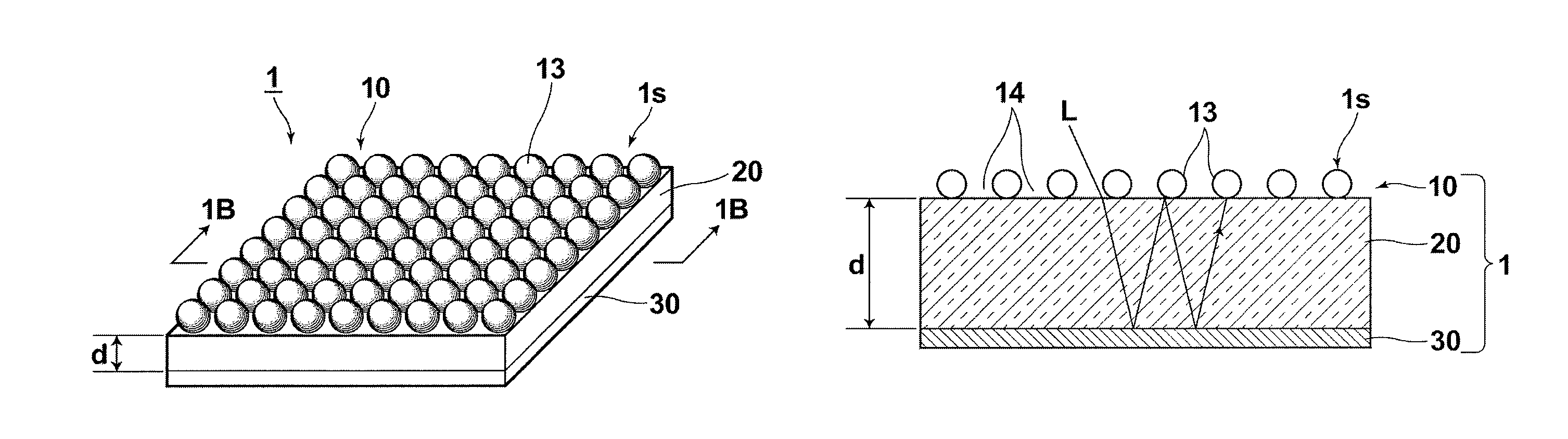

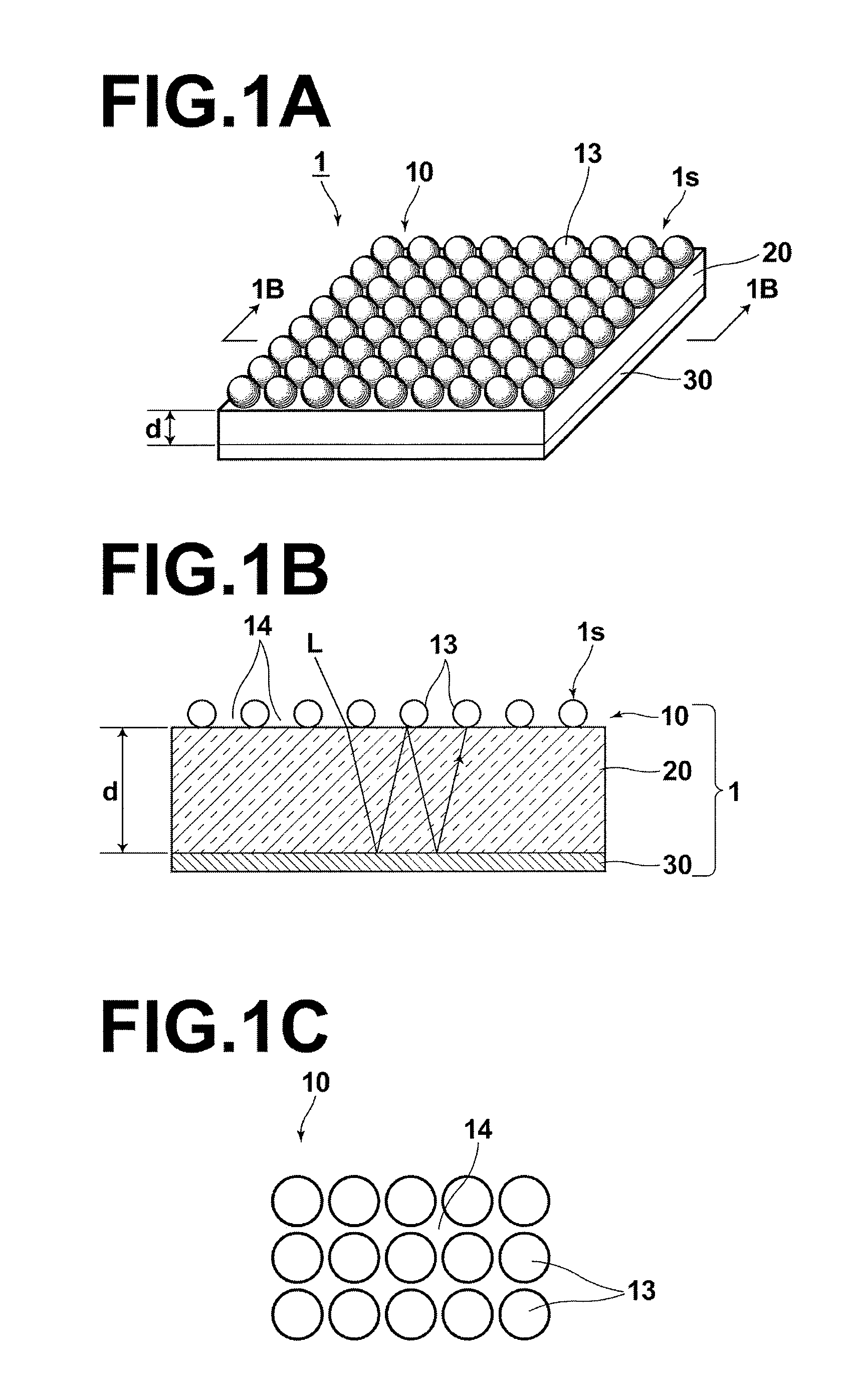

Substrate for mass spectrometry and mass spectrometry method

ActiveUS8008620B2Effectively enhances the electric fieldHigh energy laserIsotope separationMass spectrometersAnalyteResonance

Owner:FUJIFILM CORP

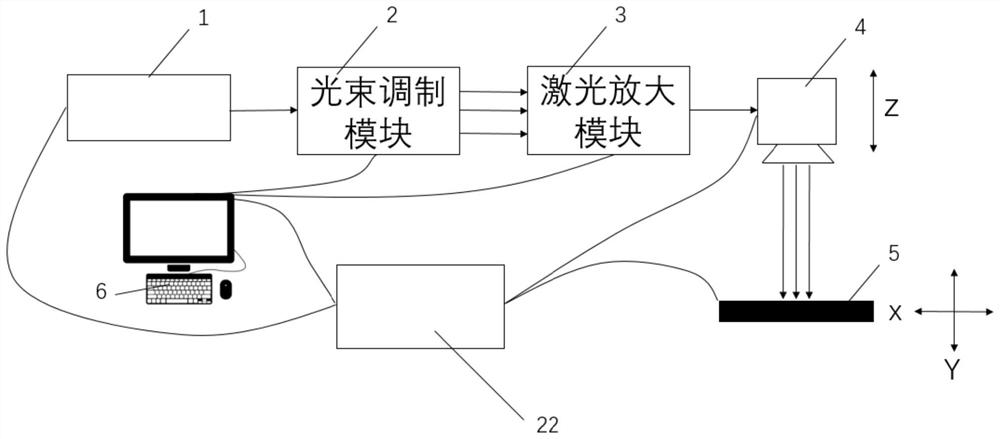

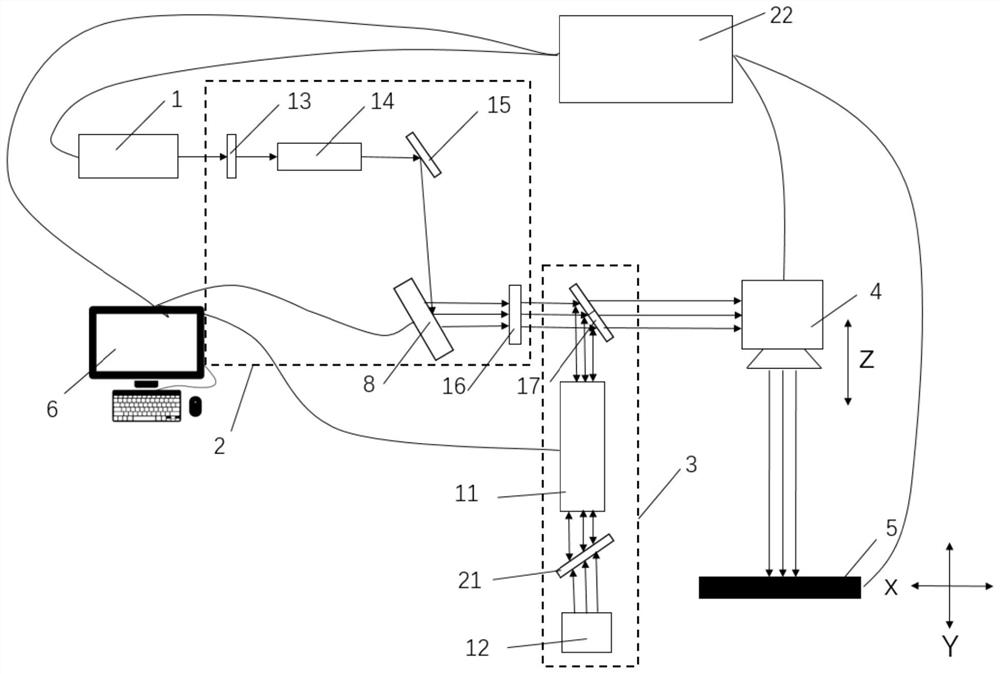

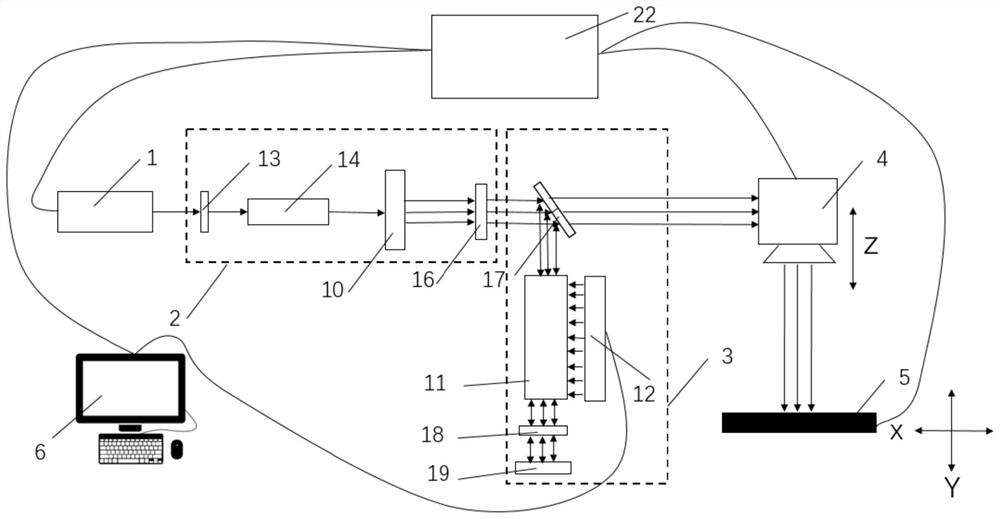

Multi-beam laser amplification scanning processing system and method based on light field regulation and control

InactiveCN111822850AAchieve direct controlReduce lossLaser beam welding apparatusLaser processingLight beam

The invention provides a multi-beam laser amplification scanning processing system and method based on light field regulation and control. The method comprises the following steps: expanding emitted laser; modulating the expanded laser by using a hologram to obtain multi-beam laser with preset light field distribution; carrying out energy amplification on the multi-beam laser to obtain high-powermulti-beam laser; and controlling high-power multi-beam laser to scan and process a workpiece to be processed. The multi-beam laser amplification scanning processing system and method based on light field regulation and control can flexibly regulate and control light beams and carry out power amplification, can realize high-precision, high-quality, high-efficiency and infinite-amplitude laser processing, and have wide application prospects.

Owner:XI AN JIAOTONG UNIV

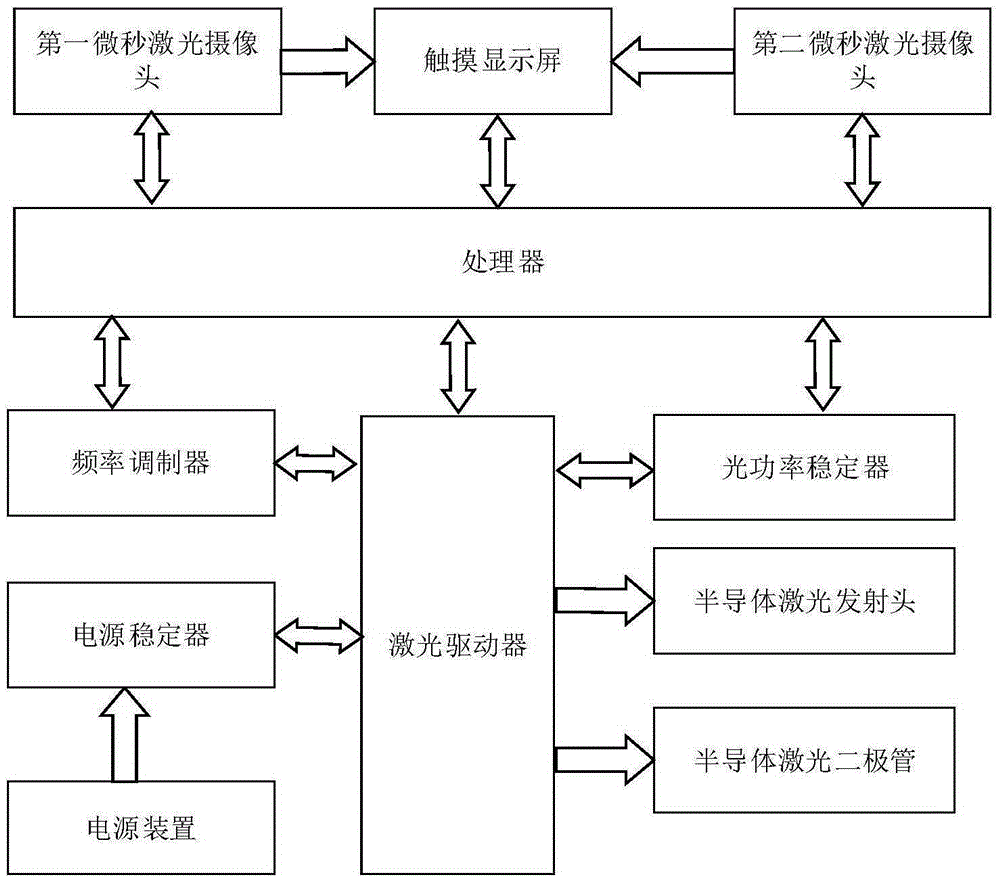

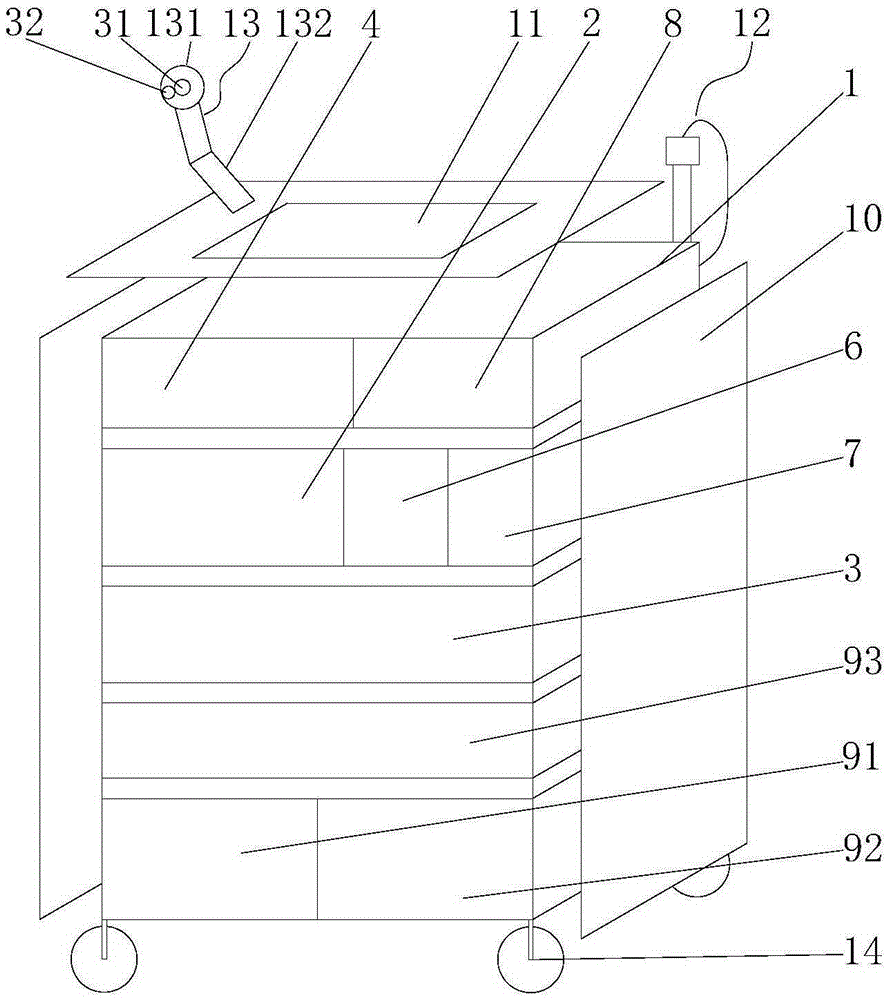

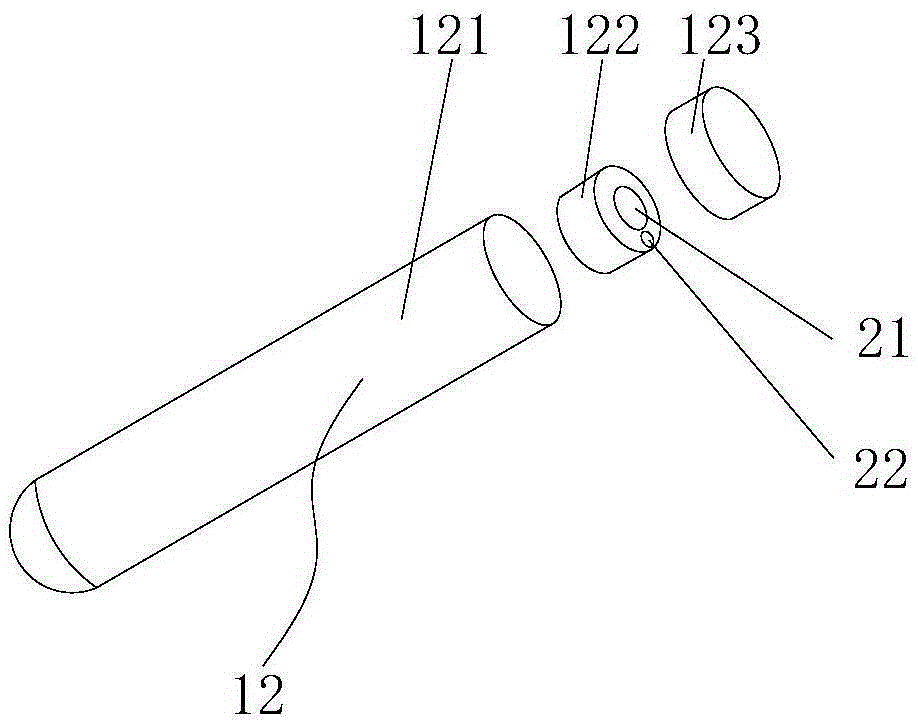

Semiconductor laser therapeutic instrument

The invention relates to a semiconductor laser therapeutic instrument. The semiconductor laser therapeutic instrument comprises a control host and therapeutic heads; the control host comprises a frame, a power source device, a power source stabilizer, a processor, a laser driver, a frequency modulator and a cooling device; and the therapeutic heads comprise a first therapeutic head and a second therapeutic head. According to the semiconductor laser therapeutic instrument of the invention, a whole therapeutic process is a physical therapeutic process, a patient will feel painless, the semiconductor laser therapeutic instrument is non-toxic and side effect-free; weak laser of which the wavelength is 650nm has a biological stimulation effect, and can promote bio-chemical reaction, increase the permeability of cell membranes and the activity of some enzymes, and strengthen metabolism, and therefore, the ribonucleic acid in cells can be synthetized, activity can be strengthened, protein synthesis can be strengthened, and the content of glycogen of an irradiated portion can be increased, and an ATP function can be enhanced, and thus, local blood circulation can be improved, absorption and dissipation of inflammation can be promoted. The semiconductor laser therapeutic instrument of the invention is non-invasive, side effect-free, safe and reliable, and has an obvious therapeutic effect.

Owner:福建省民众医疗科技集团有限公司

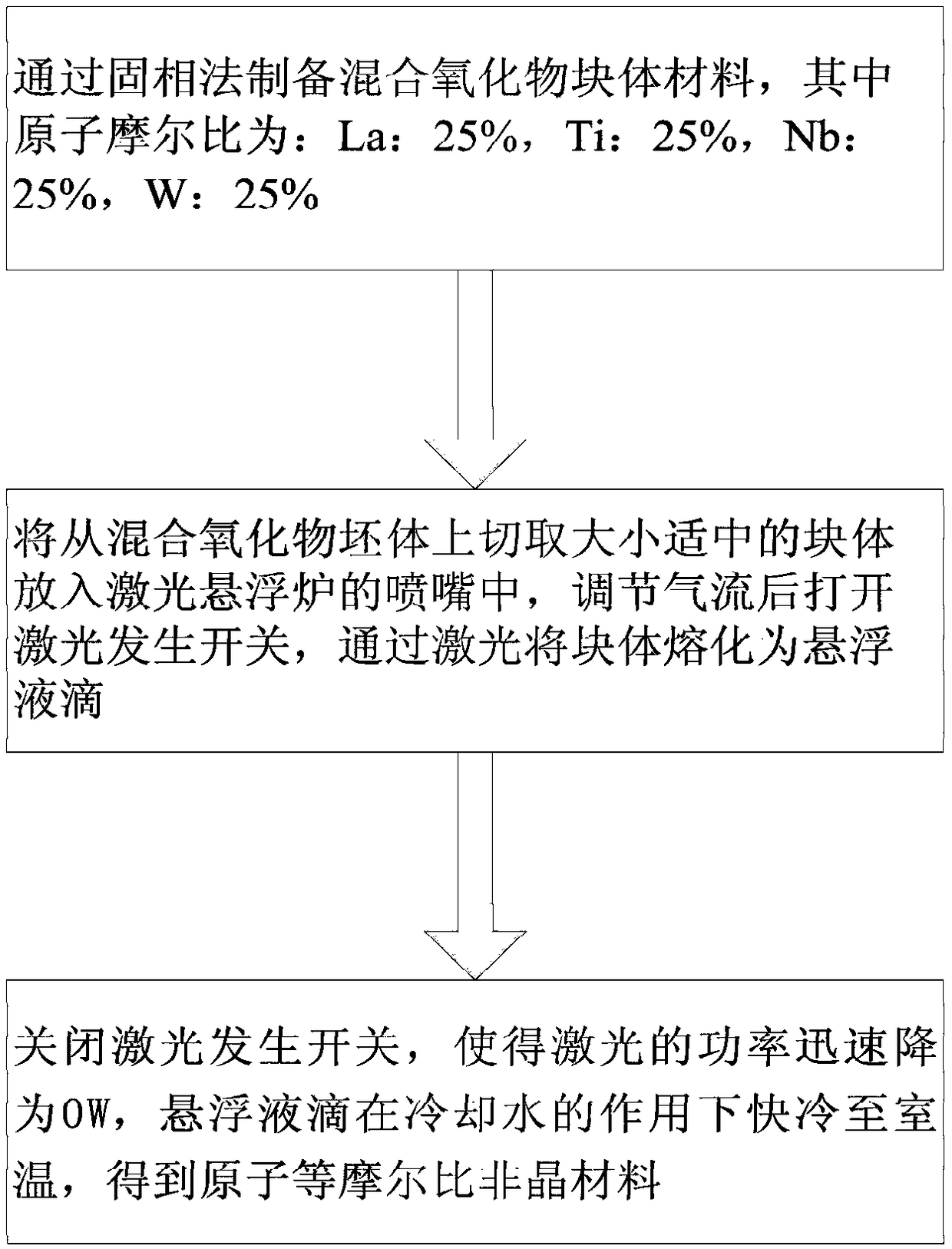

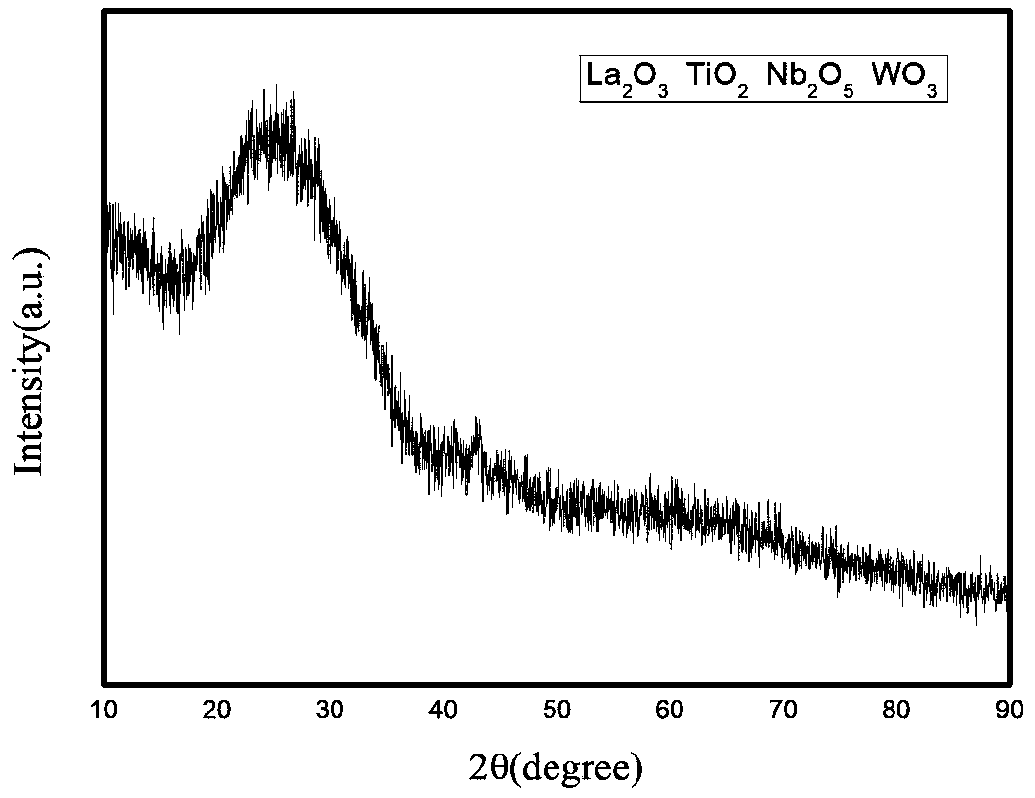

Amorphous material with equal atom mol ratio and preparation method thereof

ActiveCN108706635APromotes the formation of amorphousHigh energy laserTungsten compoundsLanthanumCondensation process

The invention provides an amorphous material with an equal atom mol ratio and a preparation method thereof and belongs to the technical field of preparation of amorphous materials. The amorphous material is prepared from four types of oxide including lanthanum trioxide, titanium dioxide, niobium pentoxide and tungsten oxide and the atom mol ratio is as follows: La accounts for 25 percent, Ti accounts for 25 percent, Nb accounts for 25 percent and W accounts for 25 percent; the preparation method comprises the following steps: 1) mixing the raw materials according to the equal atom mol ratio; drying, pre-firing and carrying out tabletting to prepare a mixed oxide blank; 2) putting the block-shaped blank into a laser suspension furnace and melting a block through laser; then rapidly coolingto room temperature. According to the amorphous material provided by the invention, oxide mixed powder is suspended in the air in a melting, rapid cooling and condensation process and is not in contact with any container; in a cooling process, no heterogeneous nucleation is formed, so that the formation of the amorphous material is facilitated; impurity elements cannot be introduced and the purityof the amorphous material is kept.

Owner:NORTHEASTERN UNIV

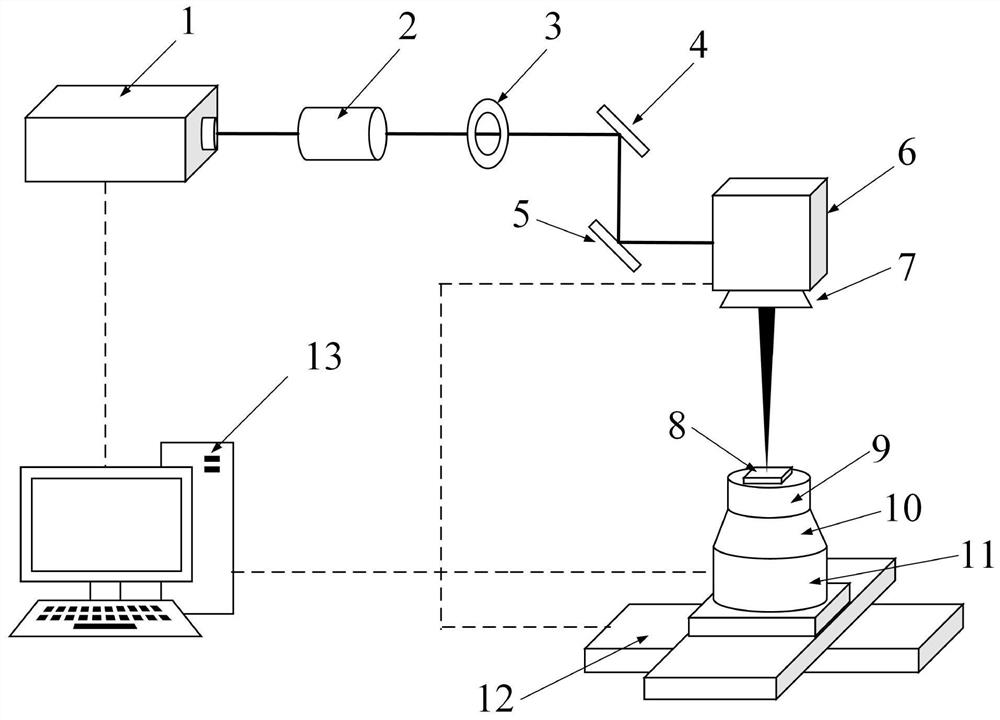

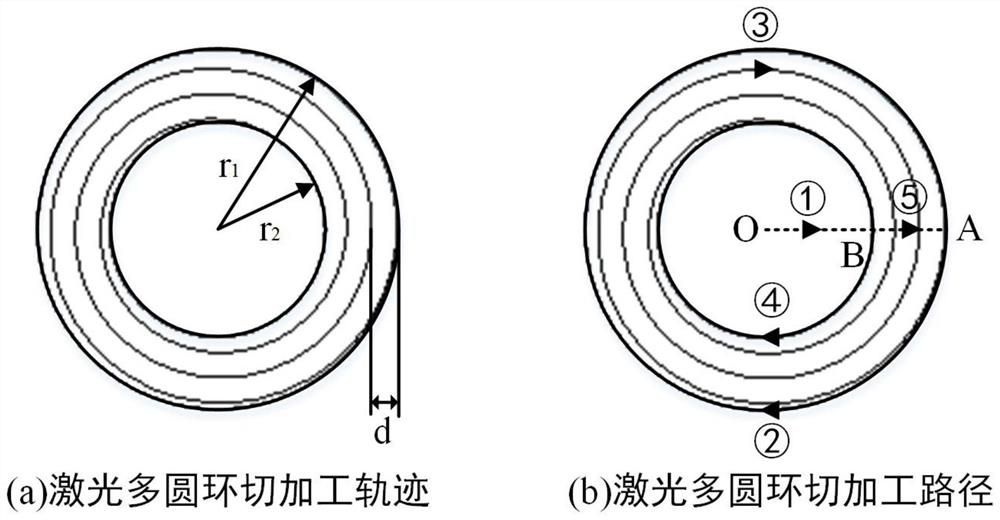

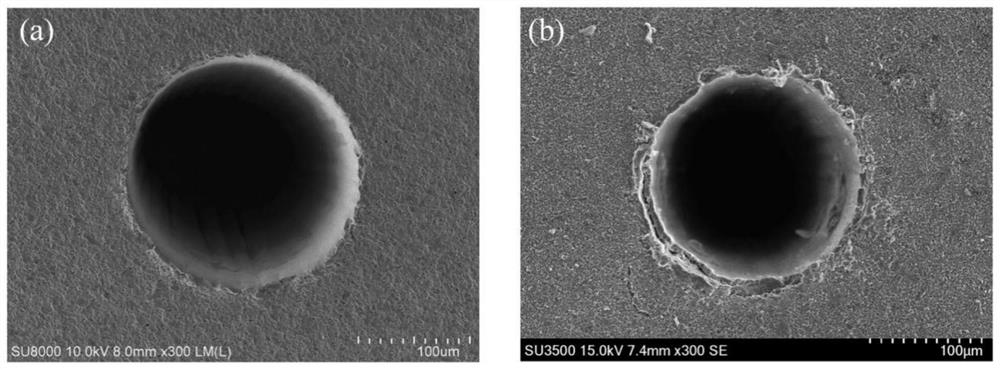

Small-taper high-quality efficient machining device and method for via holes in surface of packaging substrate

InactiveCN112917027AQuality improvementHigh removal rateLaser beam welding apparatusMaterial removalLaser scanning

The invention discloses a small-taper high-quality efficient machining device and method for via holes in the surface of a packaging substrate. According to the method, firstly, an ultrasonic vibration auxiliary laser machining system is built, then the packaging substrate is cleaned and clamped on a clamp for laser drilling, and a precise movement workbench is controlled to focus laser on the upper surface of the packaging substrate; then, the coupling vibration frequency of the packaging substrate is searched through an ultrasonic vibration auxiliary device, and ultrasonic vibration parameters are set; laser processing parameters are set through a computer, a laser scanning track is drawn, and scanning track parameters are set; then, a computer controls a short pulse laser to output laser, an ultrasonic vibration device is started at the same time, and a scanning galvanometer is used for controlling the laser to conduct via hole machining on the packaging substrate along a set path; and after the via holes are machined, the packaging substrate is cleaned to obtain a finished product. According to the method, laser processing is assisted by ultrasonic vibration, and material removal is carried out by adopting a laser multi-ring cutting processing track, so that the taper of the via holes is reduced, and the machining efficiency is greatly improved.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000061.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000071.png)

![Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof Skin-core type poly(lactic acid) (PLA)/poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)] (PHBV) composite fiber and preparation method thereof](https://images-eureka.patsnap.com/patent_img/41133139-793b-474a-9c7b-c3bdf61c5b14/BDA0002293244890000072.png)