Great-core-diameter optical fiber coupler and manufacturing method of great-core-diameter optical fiber coupler

An optical fiber coupler and a manufacturing method technology, which are applied to the coupling of optical waveguides, light guides, optics, etc., can solve the problems that the coupler cannot meet the needs of high-energy laser transmission, the fiber laser energy is uneven, and the fiber is not coaxially costed. Achieve the effect of reducing the difficulty of fiber coupling, reducing the risk of twisting, and reducing the non-axis of the fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

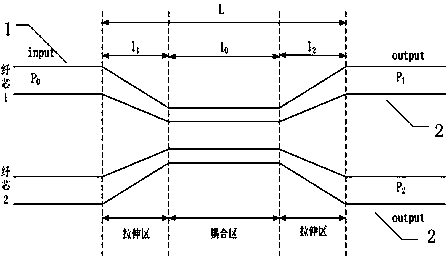

[0026] like figure 1 As shown, the large-core optical fiber coupler of this embodiment includes an input optical fiber 1 and two output optical fibers 2; the core diameter of the optical fiber is in the range of 200-600um, and the input optical fiber 1 and the output optical fiber 2 can have different core diameters. For optical fiber, the fiber core-skin ratio is 1:1.04 or 1:1.25.

[0027] Combined with the geometric structure of large core diameter fiber which is different from that of communication fiber, a theoretical model of large core diameter fiber coupling is established.

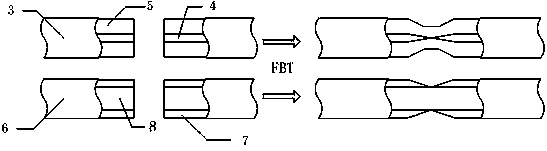

[0028] like figure 2 As shown, usually when the single-mode fiber 3 is coupled, since the core diameter 4 of the fiber is relatively thin (about 9-10um), the core diameter will become thinner and thinner during melting and stretching, and the light propagating in the core will gradually leak into the In the cladding layer 5, an optical fiber transmission medium layer composed of the cladding lay...

Embodiment 2

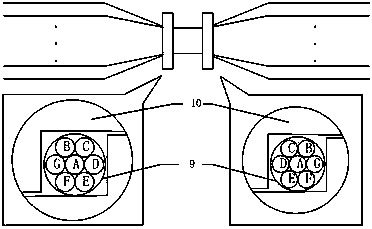

[0032] like image 3 As shown, the two ends of the coupling area are clamped by the fixture with a regular hexagonal cavity. The interior of the structure at both ends is related to the arrangement of seven optical fibers, in which the input optical fiber is in the center, and the six coupling optical fibers are around. The regular hexagons are closely arranged, and the relative positions are in one-to-one correspondence. Bind the arranged optical fibers with thin ropes 6, and then design a way to fix the arrangement of optical fibers by extruding and gluing two pieces of processing parts 7 according to the outer diameter of the seven optical fibers. The processing parts 7 need to be cut by wire To ensure the smoothness of the inner wall, so as not to damage the optical fiber. This kind of stable fiber arrangement with solidified workpieces at both ends of the coupling area can effectively ensure the uniformity of the splitting ratio after the fiber is melted. At the same tim...

Embodiment 3

[0034] like Figure 4 Shown, the microstructure processing of the coupler output end, the external structure includes a metal tube 11 for fixing, but the internal structure is different from the prior art, the difference lies in its ball lens 12 and large core diameter optical fiber 6, the front surface 12a of the lens and the rear surface 12b are spherical, the inner diameter of the front section 11a of the metal tube closely matches the outer diameter of the optical fiber used, the inner diameter of the rear section 11b of the metal tube closely matches the diameter of the ball lens, and the precision of the inner diameter of the metal tube ensures a large The coaxiality between the core fiber and the ball lens. The diameter of the ball lens should be larger than the core diameter of the coupling fiber, and the numerical aperture of the lens is NA1 smaller than the numerical aperture of the output fiber is NA2. Curing is carried out on the clean operating table in the purif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com