Amorphous material with equal atom mol ratio and preparation method thereof

A technology of amorphous materials and equimolar ratio, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve problems such as unfavorable amorphous formation, affecting amorphous properties, difficult sample vitrification, etc., to promote amorphous Formation of crystals, maintenance of purity, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

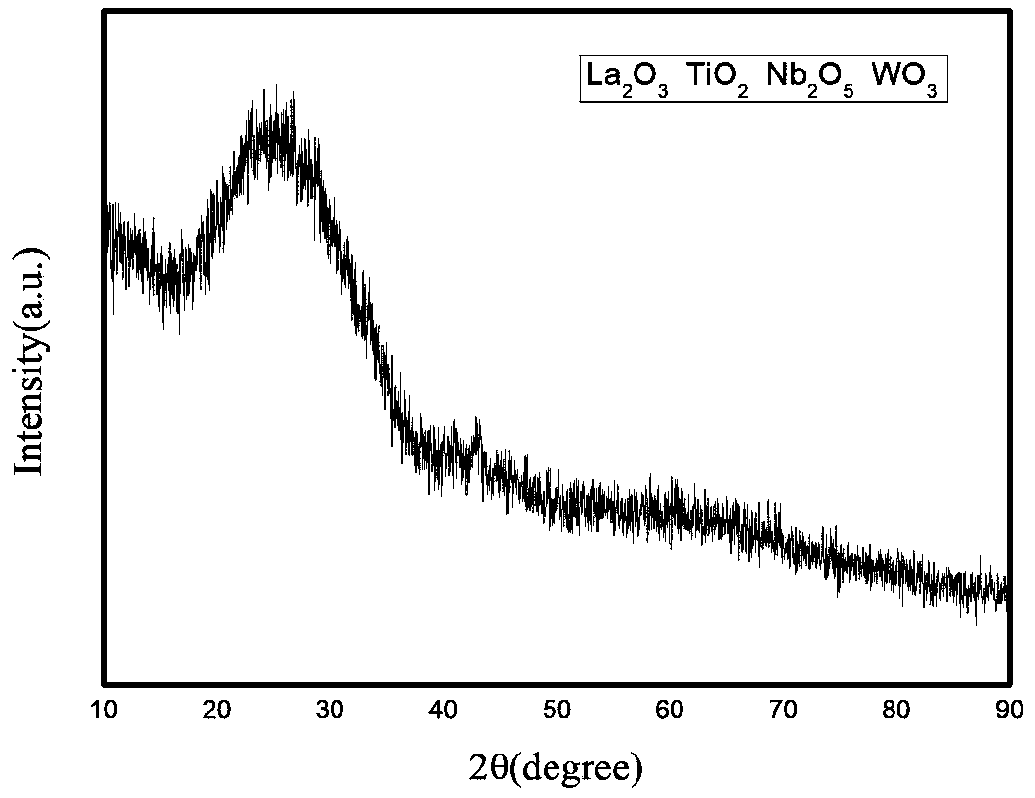

[0036] An equimolar ratio mixed oxide amorphous, made of dilanthanum trioxide (La 2 o 3 ), titanium dioxide (TiO 2 ), niobium pentoxide (Nb 2 o 5 ), tungsten oxide (WO 3 ) The amorphous formed by four kinds of oxides, the atomic molar ratio is: La: 25%, Ti: 25%, Nb: 25%, W: 25%.

[0037] The dilanthanum trioxide (La 2 o 3 ) purity of 4N, titanium dioxide (TiO 2 ) purity of 3N, niobium pentoxide (Nb 2 o 5 ) purity of 4N, tungsten oxide (WO 3 ) purity is 3N.

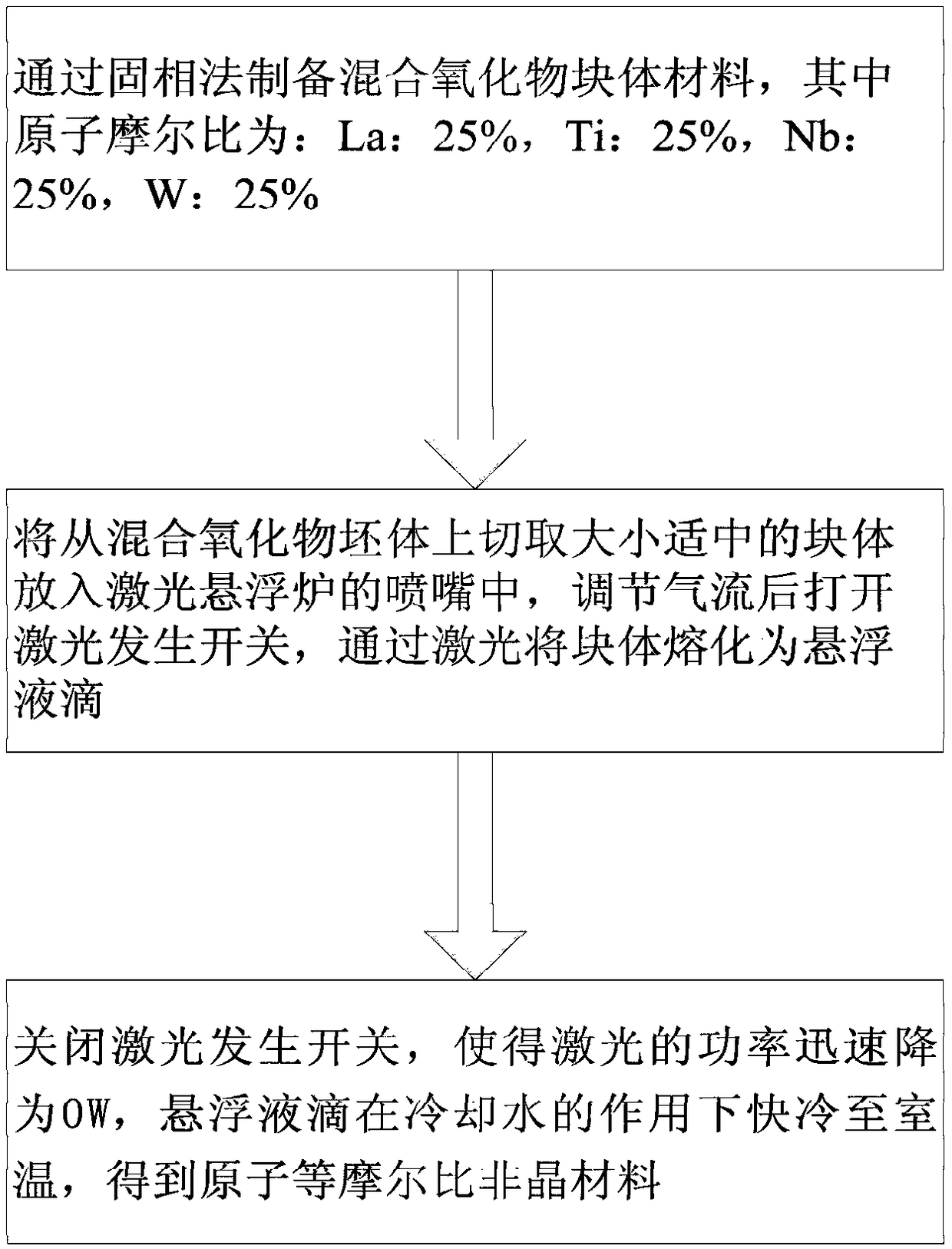

[0038] A kind of preparation method of equimolar ratio mixed oxide amorphous, concrete steps are as follows:

[0039] Step 1, solid phase synthesis:

[0040] (1) According to the atomic molar ratio La: 25%, Ti: 25%, Nb: 25%, W: 25%, LaO 3 / 2 (La 2 o 3 ), TiO 2 , NbO 5 / 2 (Nb 2 o 5 ), WO 3 Mix, and add absolute ethanol, the absolute ethanol should be submerged in powder wet grinding for 3 hours to obtain mixed powder;

[0041] (2) Dry the mixed powder at 80°C for 20 minutes, pass through a sieve, and grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com