Patents

Literature

65 results about "Amorphous Crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Information storage medium using ferroelectric, method of manufacturing the same, and information storage apparatus including the same

InactiveUS20090168238A1Avoid damageDifferent record carrier formsBalustradesEngineeringAmorphous Crystals

Provided is an information storage medium using a ferroelectric, including a substrate having an amorphous crystal structure, an electrode layer formed on the substrate, and a ferroelectric layer in a (001) direction formed on the electrode layer.

Owner:POHANG UNIV OF SCI & TECH +1

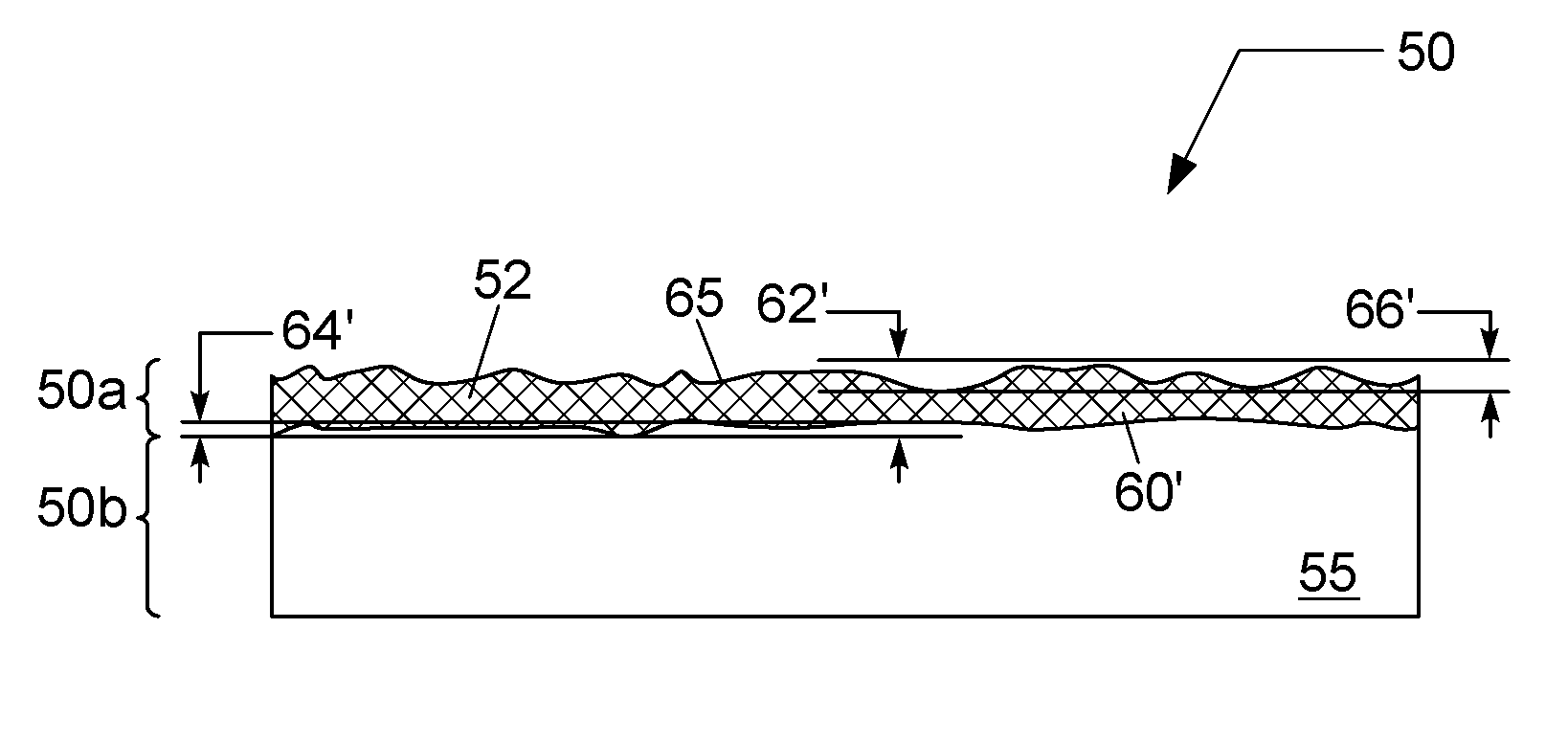

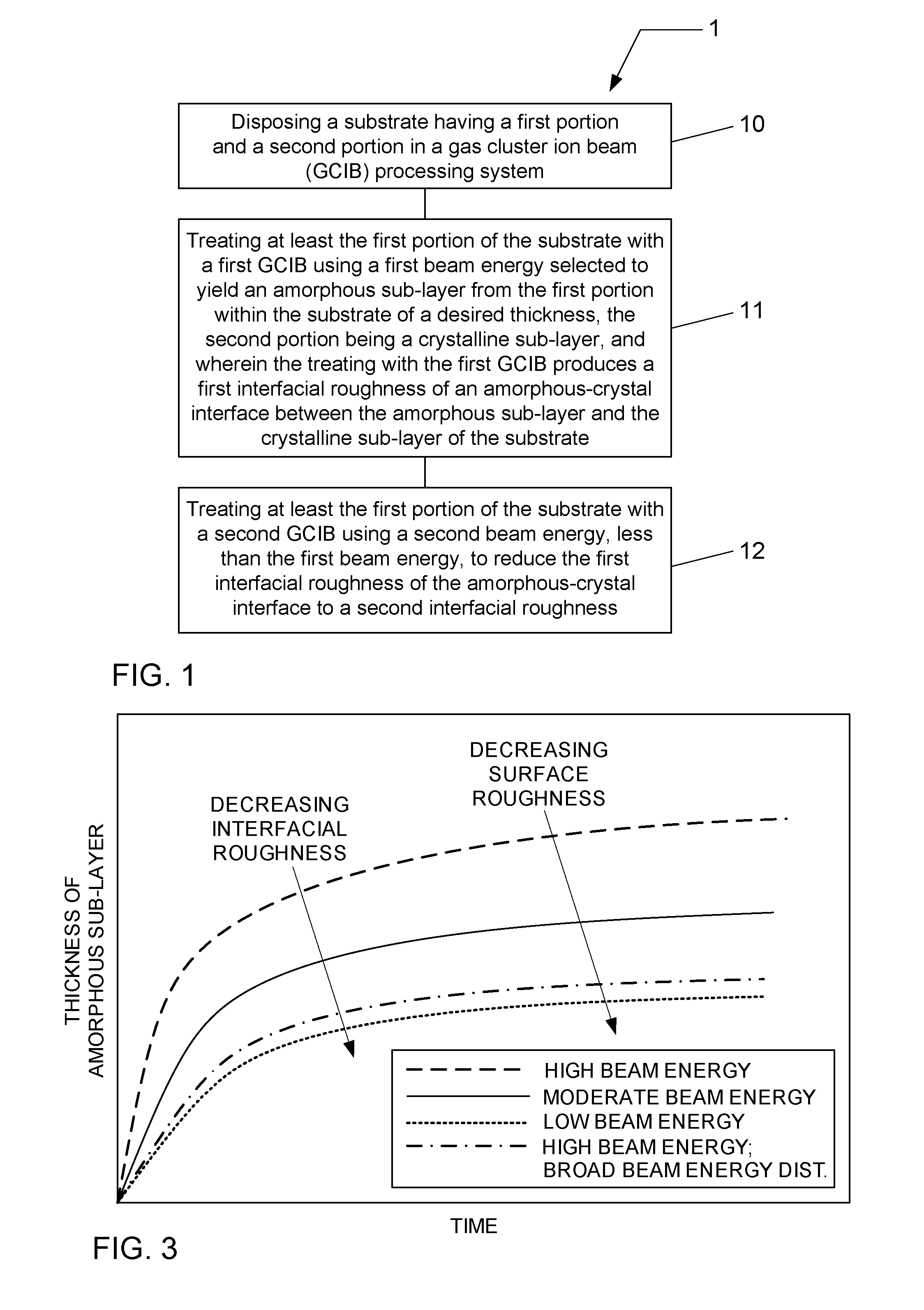

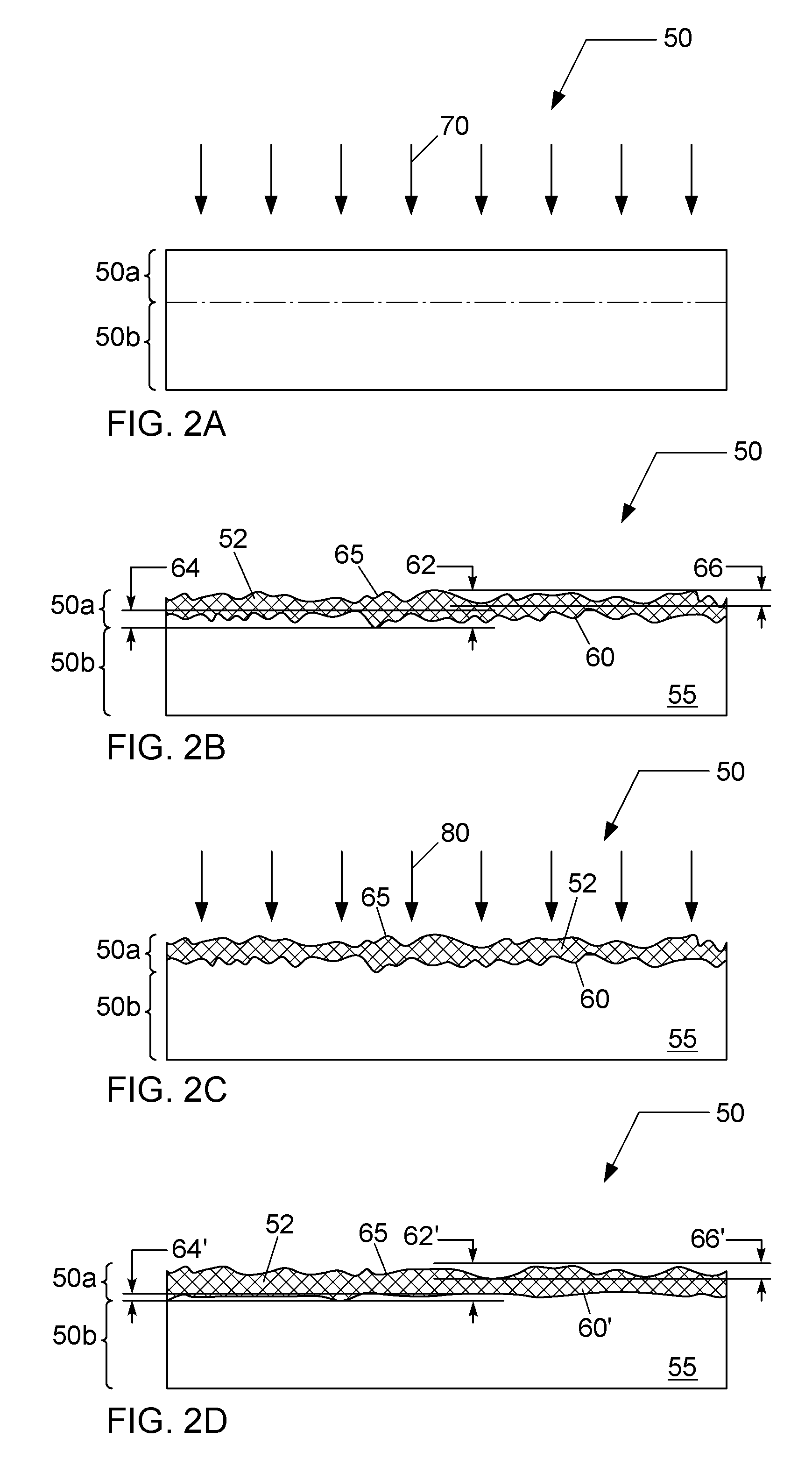

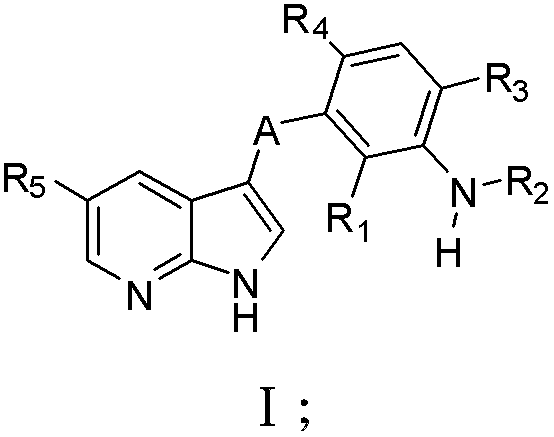

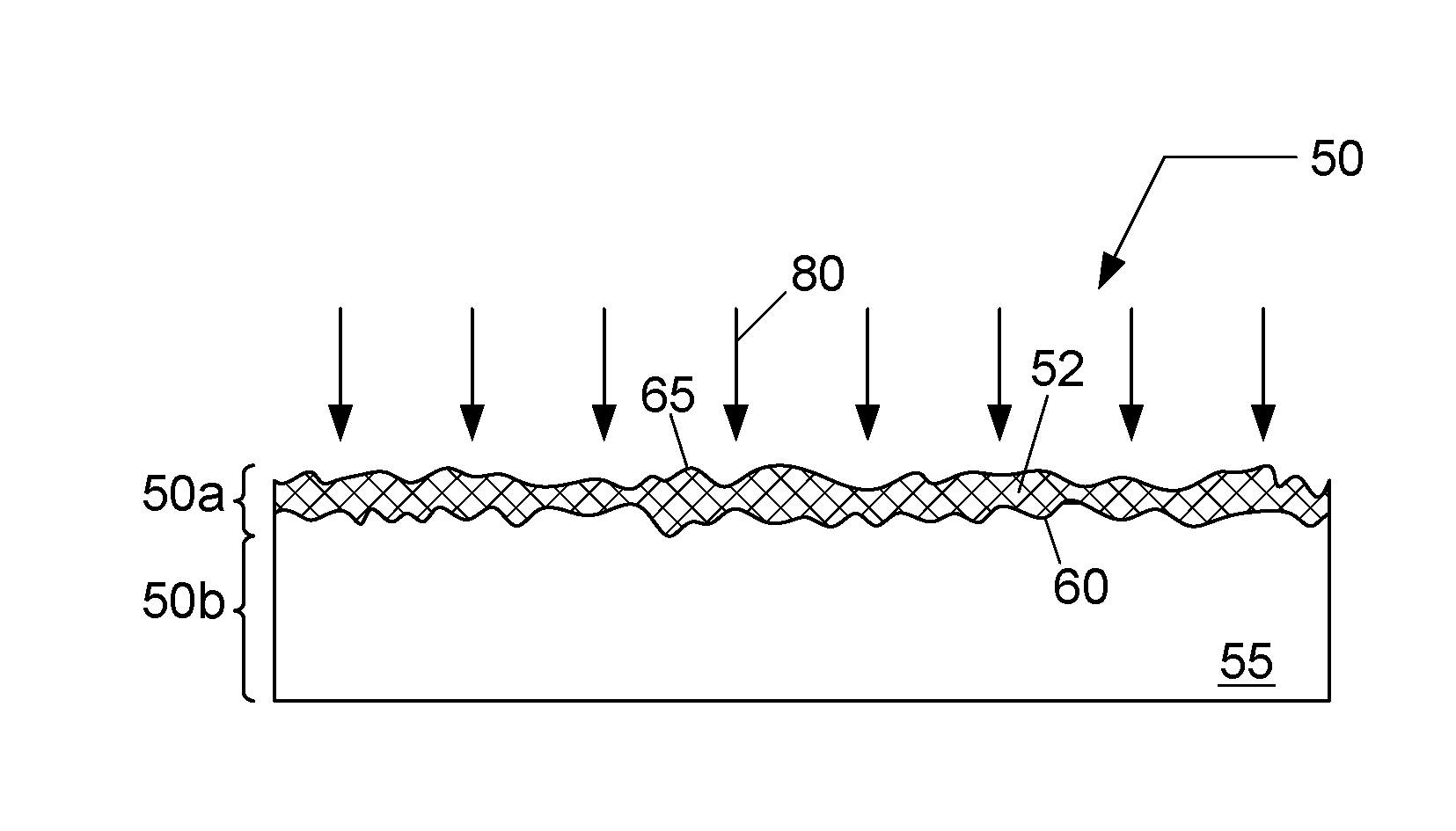

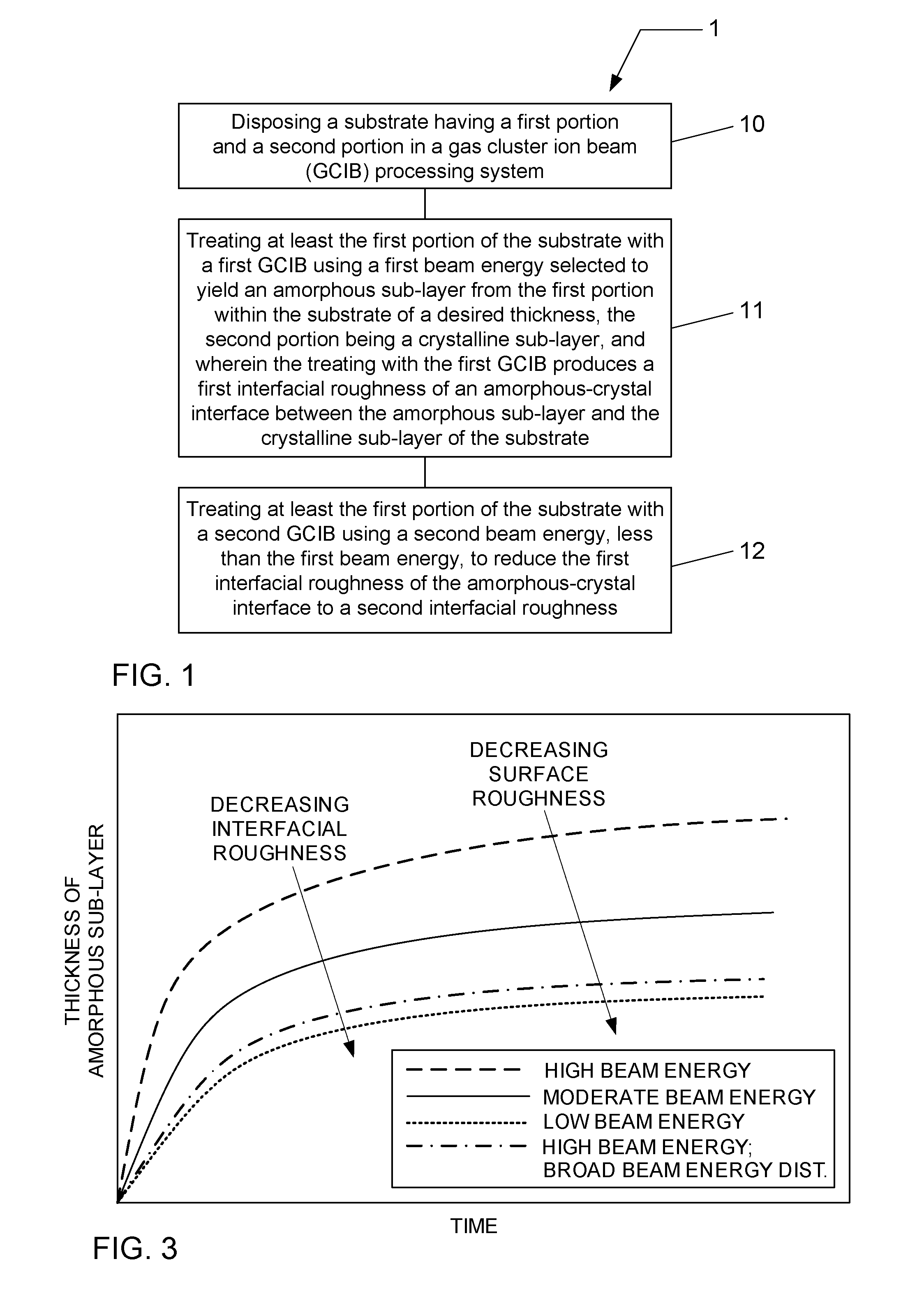

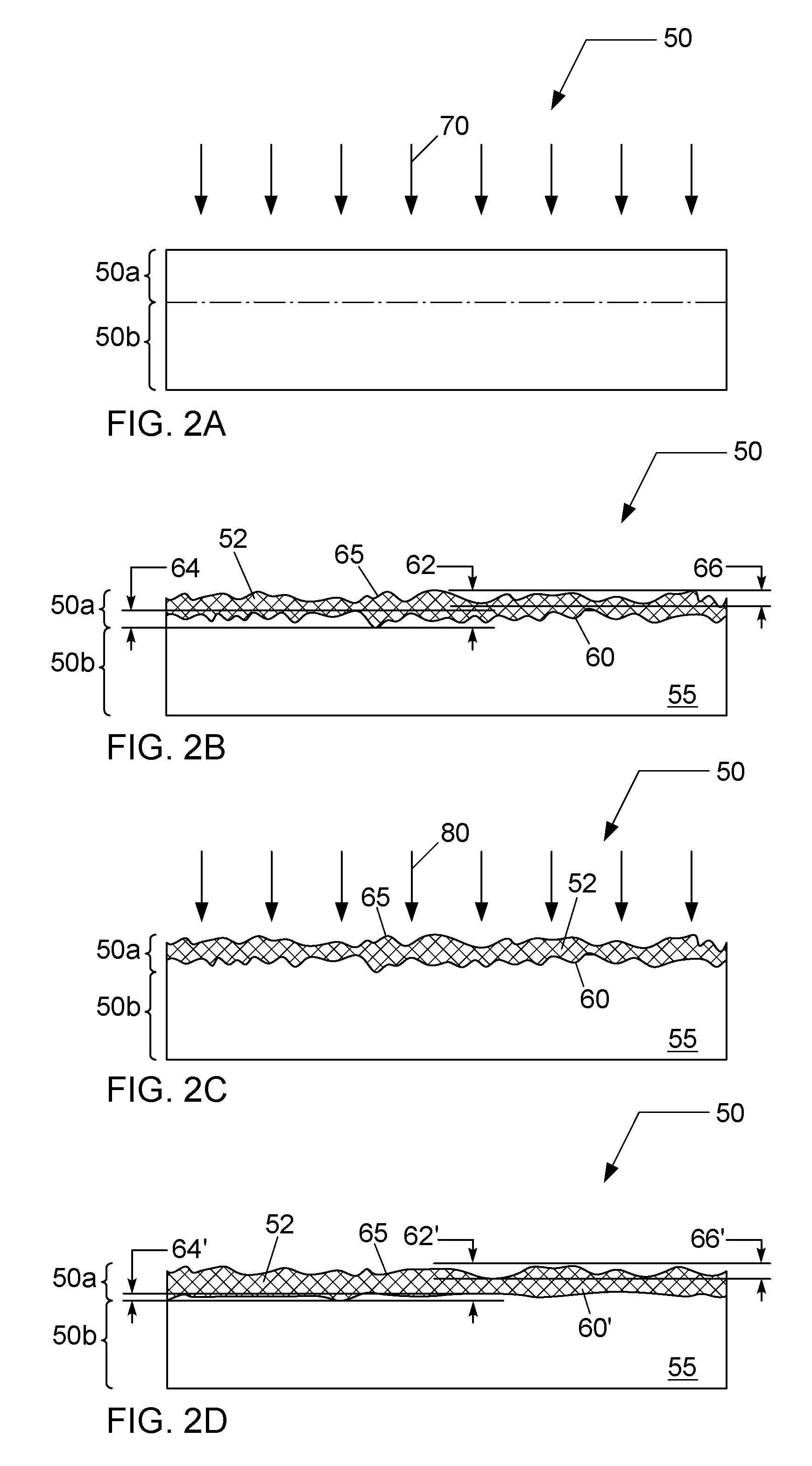

Gcib process for reducing interfacial roughness following pre-amorphization

InactiveUS20120252222A1Reduce interfacial roughnessReduce roughnessSemiconductor/solid-state device manufacturingBeam energyGas cluster ion beam

A method for amorphizing a layer on a substrate is described. In one embodiment, the method includes treating the substrate with a first gas cluster ion beam (GCIB) using a first beam energy selected to yield an amorphous sub-layer within the substrate of a desired thickness, which produces a first interfacial roughness of an amorphous-crystal interface between the amorphous sub-layer and a crystalline sub-layer of the substrate. The method further includes treating the substrate with a second GCIB using a second beam energy, less than the first beam energy, to reduce the first interfacial roughness of the amorphous-crystal interface to a second interfacial roughness.

Owner:TEL EPION

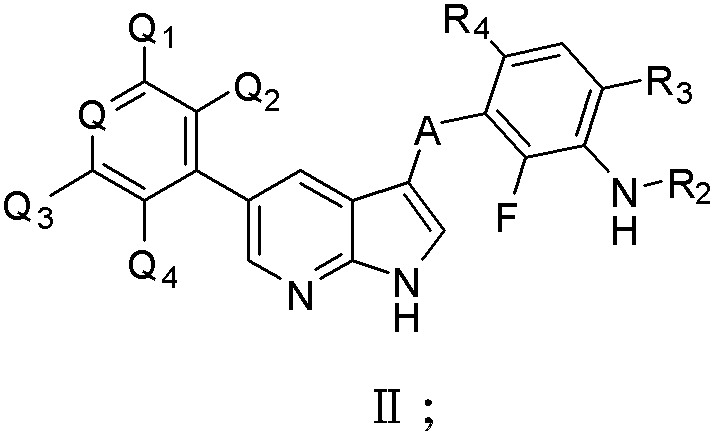

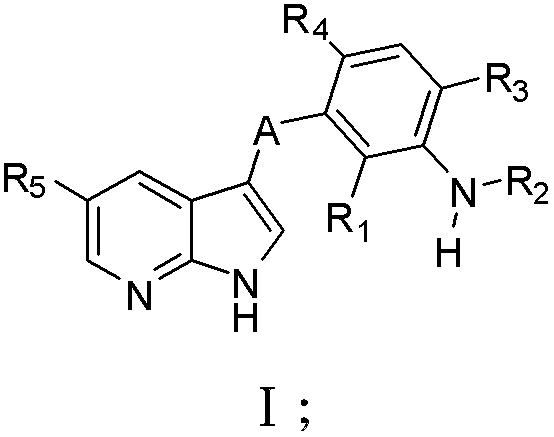

Protein kinase inhibitor and application thereof

InactiveCN102603734AEasy to prepareLittle side effectsOrganic active ingredientsNervous disorderDiseasePTK Inhibitors

The invention discloses a protein kinase inhibitor which is in a mode of a compound shown in a general formula I or pharmaceutically acceptable salt and prodrug thereof, and an isomer and polycrystalline or metamict crystal mode. The invention also relates to a method for preparing a medicament for treating cell excessive multiplification diseases by applying the protein kinase inhibitor.

Owner:CGENETECH (SUZHOU CHINA) CO LTD

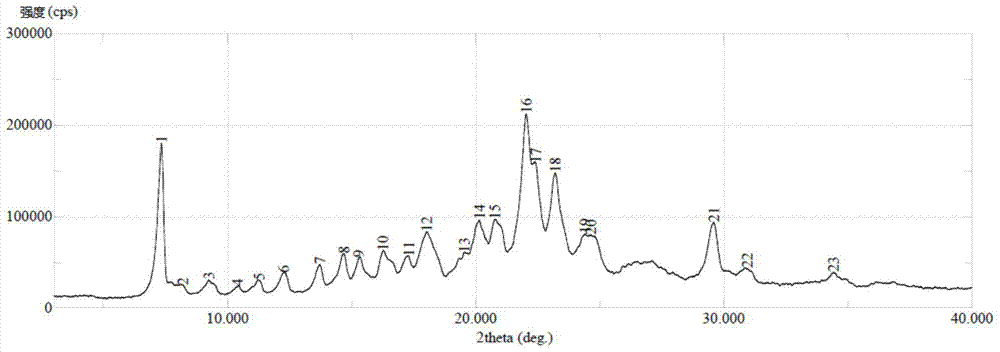

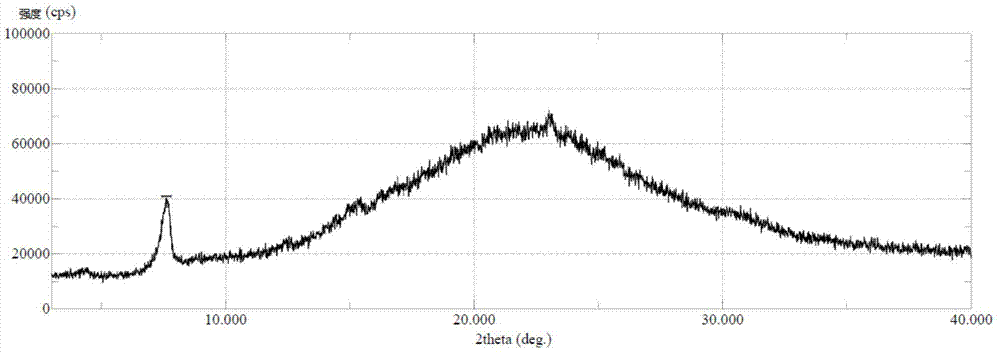

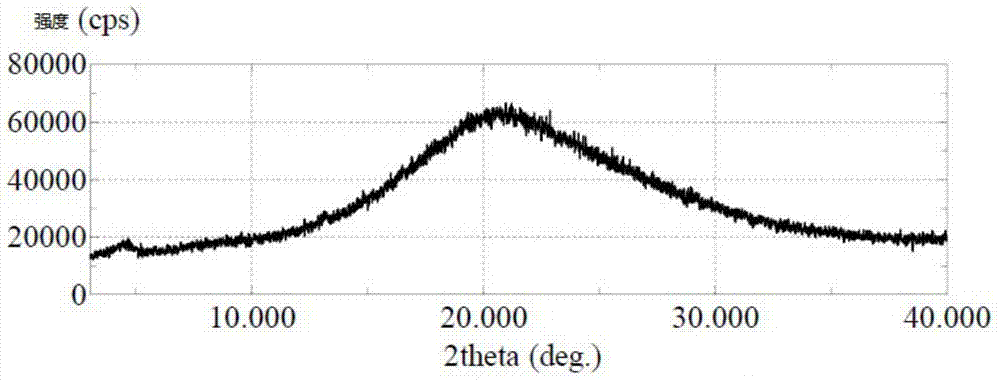

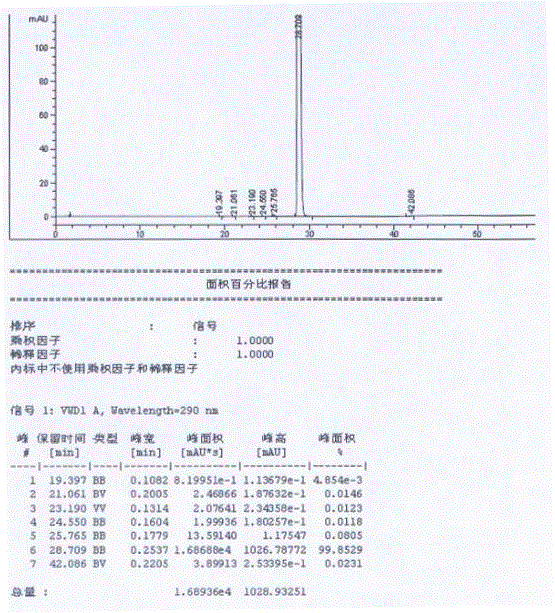

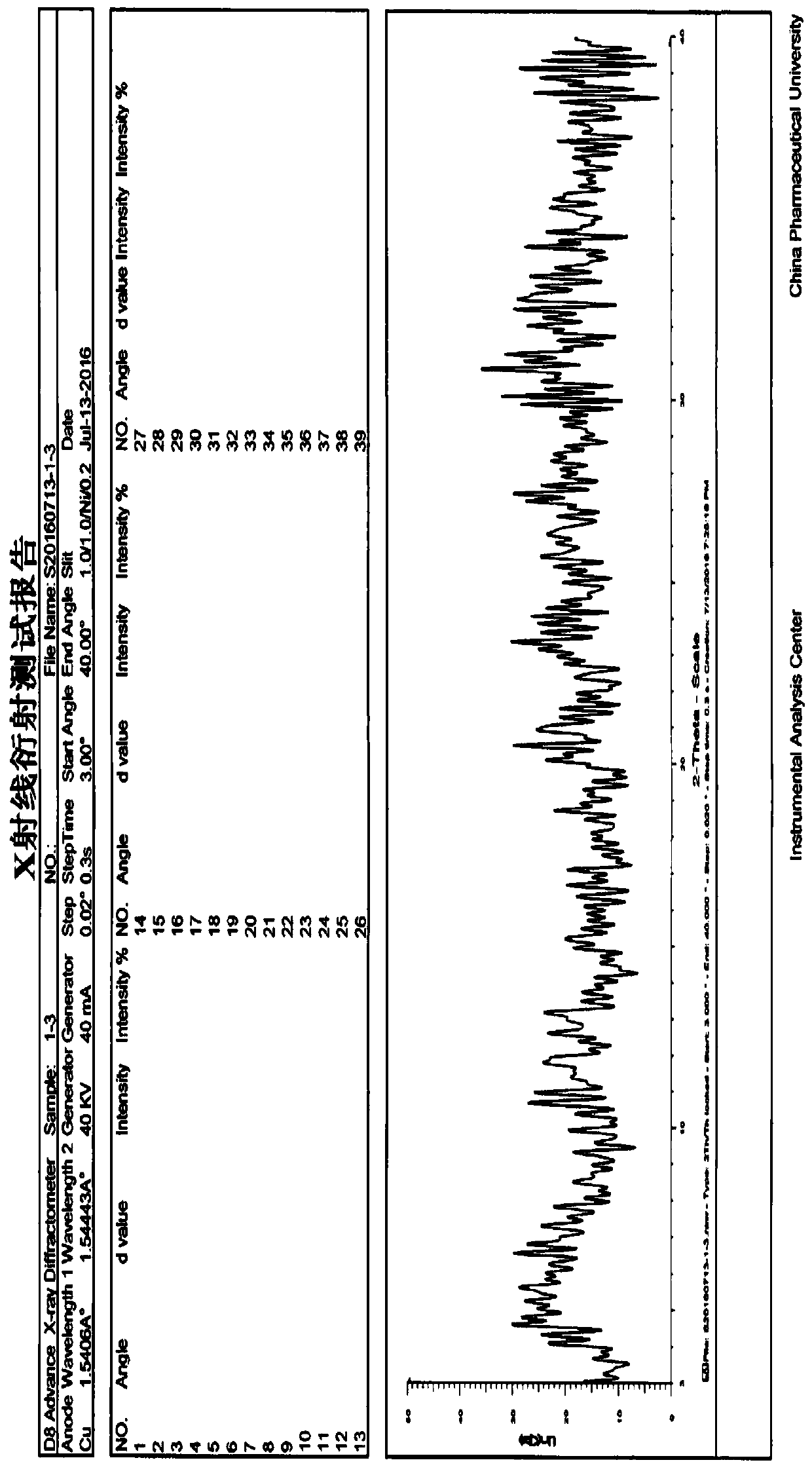

Crystal form of sorafenib tosylate, and preparation method thereof

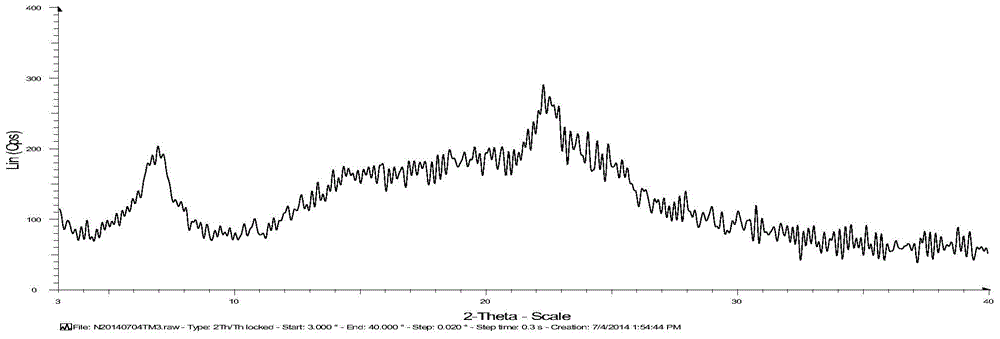

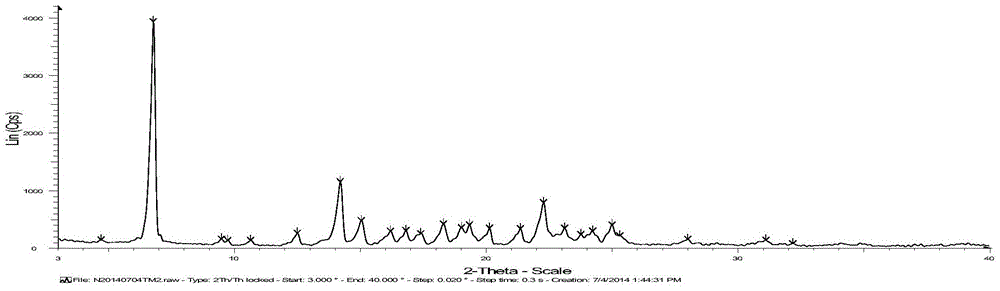

InactiveCN104761492AHigh crystal purityHigh crystallinityOrganic chemistry methodsSulfonic acids salts preparationX-rayPowder diffraction

The invention provides a crystal form of sorafenib tosylate, and a preparation method thereof. The X-ray powder diffraction pattern of sorafenib tosylate of crystal form B has diffraction peaks when the values of 2theta are about 7.34DEG, 18.03DEG, 20.15DEG, 20.77DEG, 22.04DEG, 22.43DEG and 23.21DEG; and the X-ray powder diffraction pattern of sorafenib tosylate of crystal form C has diffraction peaks when the values of 2theta are about 7.61DEG and 13-33DEG. The sorafenib tosylate of crystal form C is prepared through reduced pressure heating of the sorafenib tosylate of crystal form B. The invention also provides a preparation method of amorphous crystals of sorafenib tosylate through reduced pressure heating of the sorafenib tosylate of crystal form B or C. The sorafenib tosylate crystals prepared in the invention have the advantages of good stability, high crystallization purity, simple preparation process, and suitableness for industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

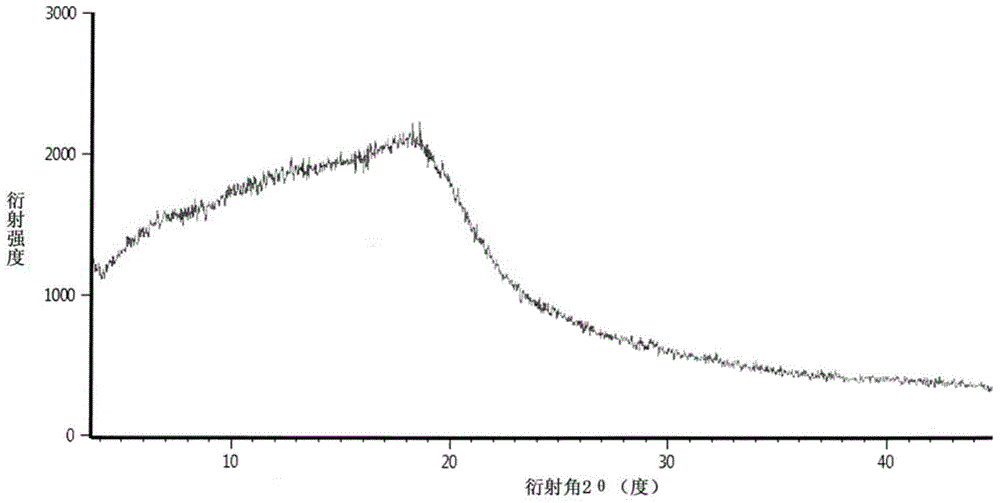

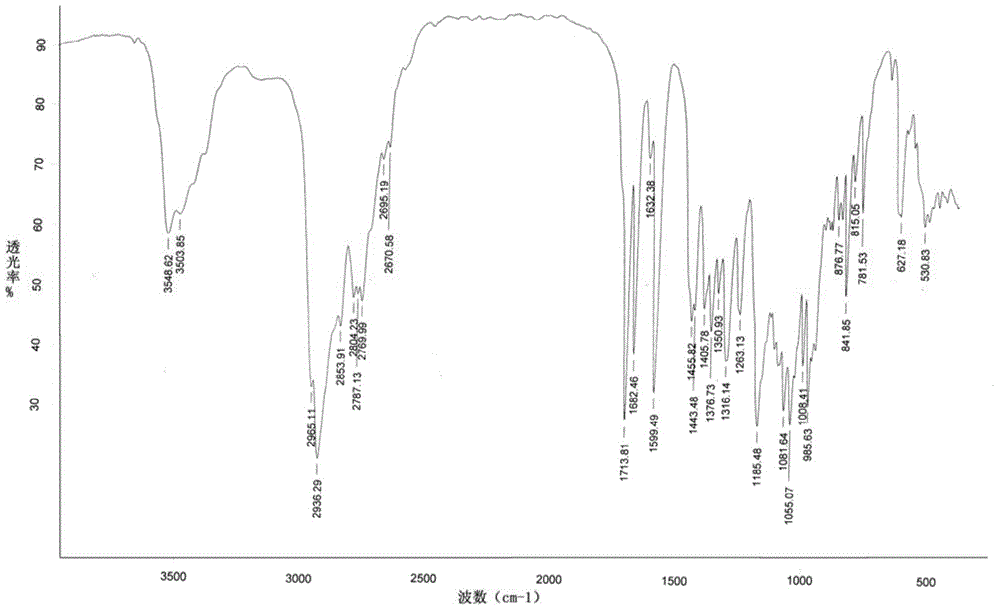

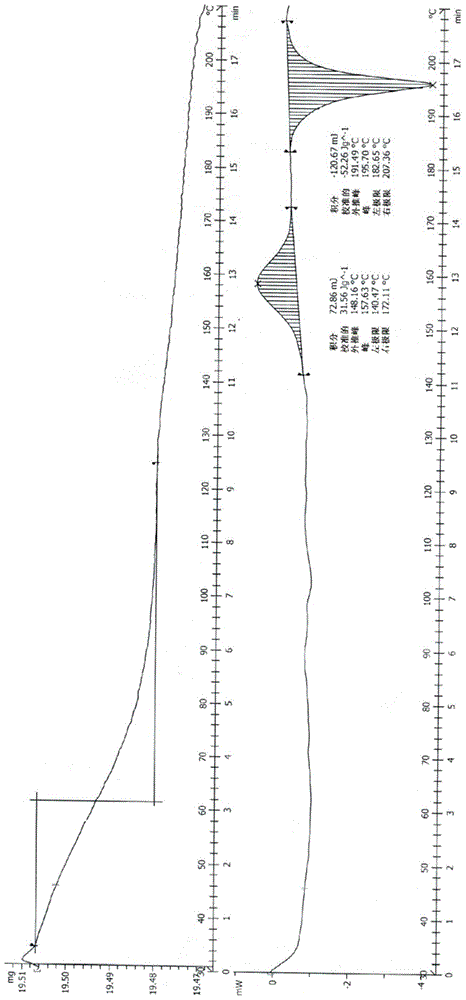

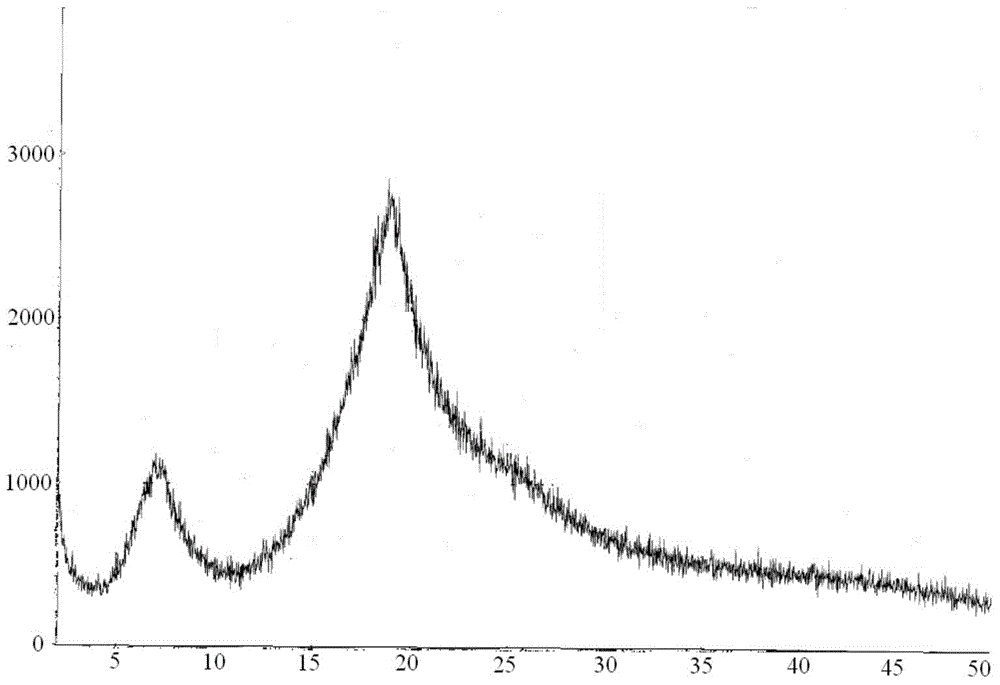

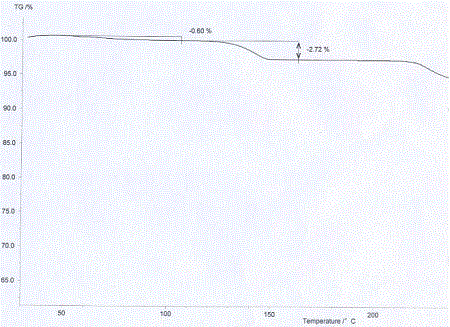

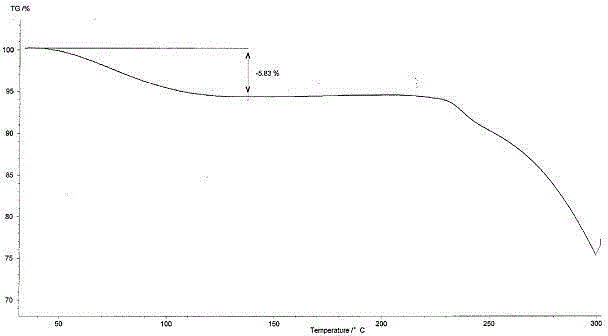

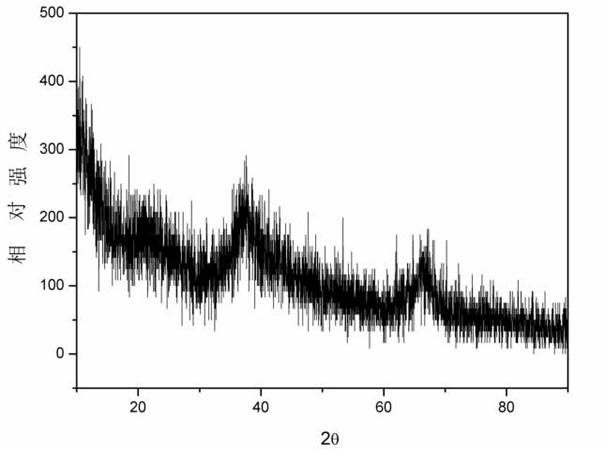

Amorphous crystal of tylonolide, and preparation method thereof

InactiveCN103554203AReduce usageResidue reductionSugar derivativesSugar derivatives preparationSolubilityBioavailability

The invention relates to an amorphous crystal of tylonolide, and a preparation method thereof. The TG-DSC spectrum of the amorphous crystal of tylonolide has an endothermic peak between 185DEG C and 210DEG C, and has an exothermic peak between 140DEG C and 175DEG C; and the XRPD atlas of the amorphous crystal of tylonolide contains no identifiable diffraction peak shapes. The invention also provides the preparation method of the amorphous crystal of tylonolide. The tylonolide having a new crystal form has the advantages of good dissolvability, good stability, good bioavailability, simple preparation, no need of a special apparatus, low production cost, and suitableness for the industrialized production.

Owner:QILU ANIMAL HEALTH PROD

Manufacturing technology for preparing purified water containing water-soluble silicon

ActiveCN104098169APure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentDiseaseHigh concentration

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

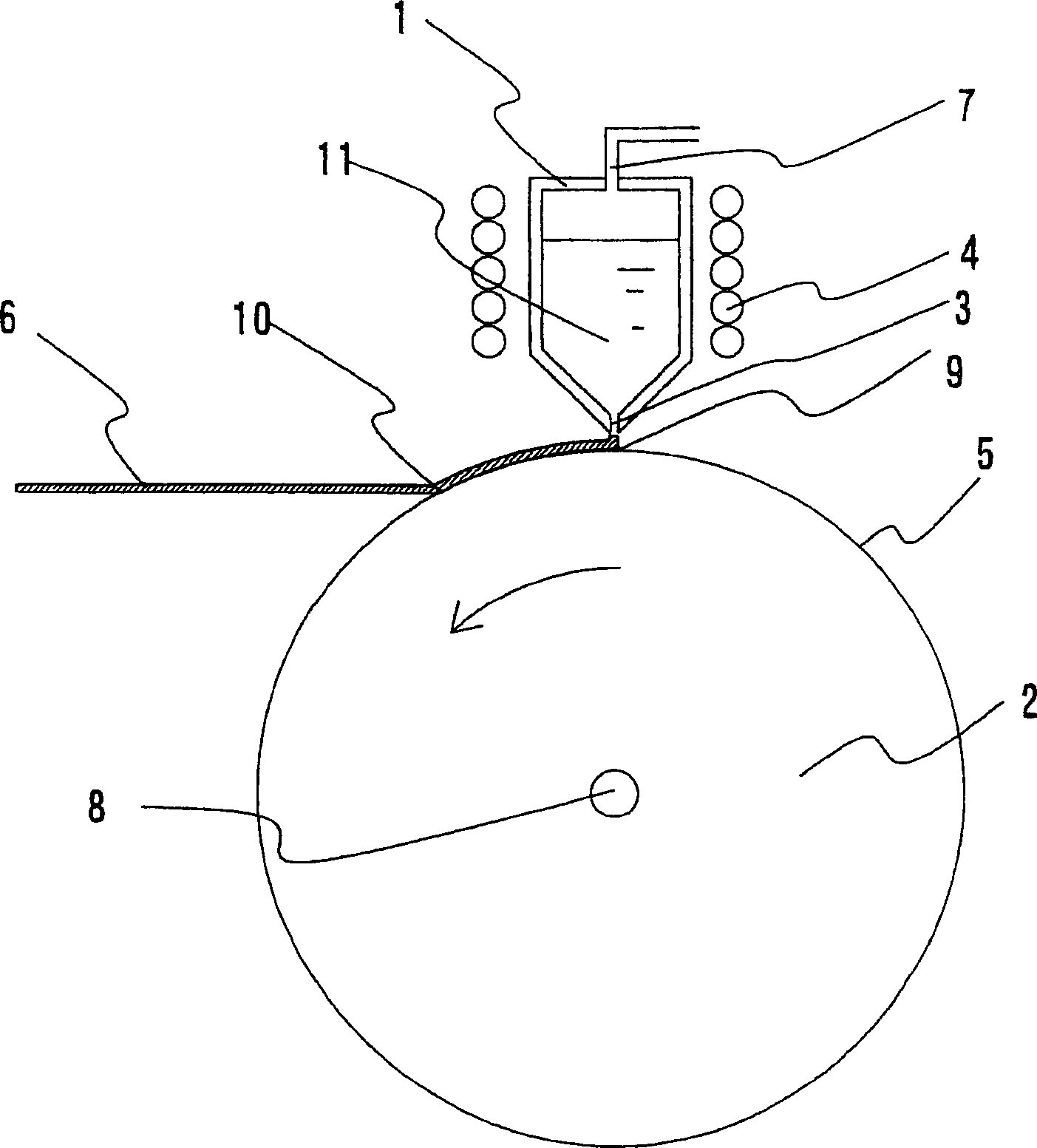

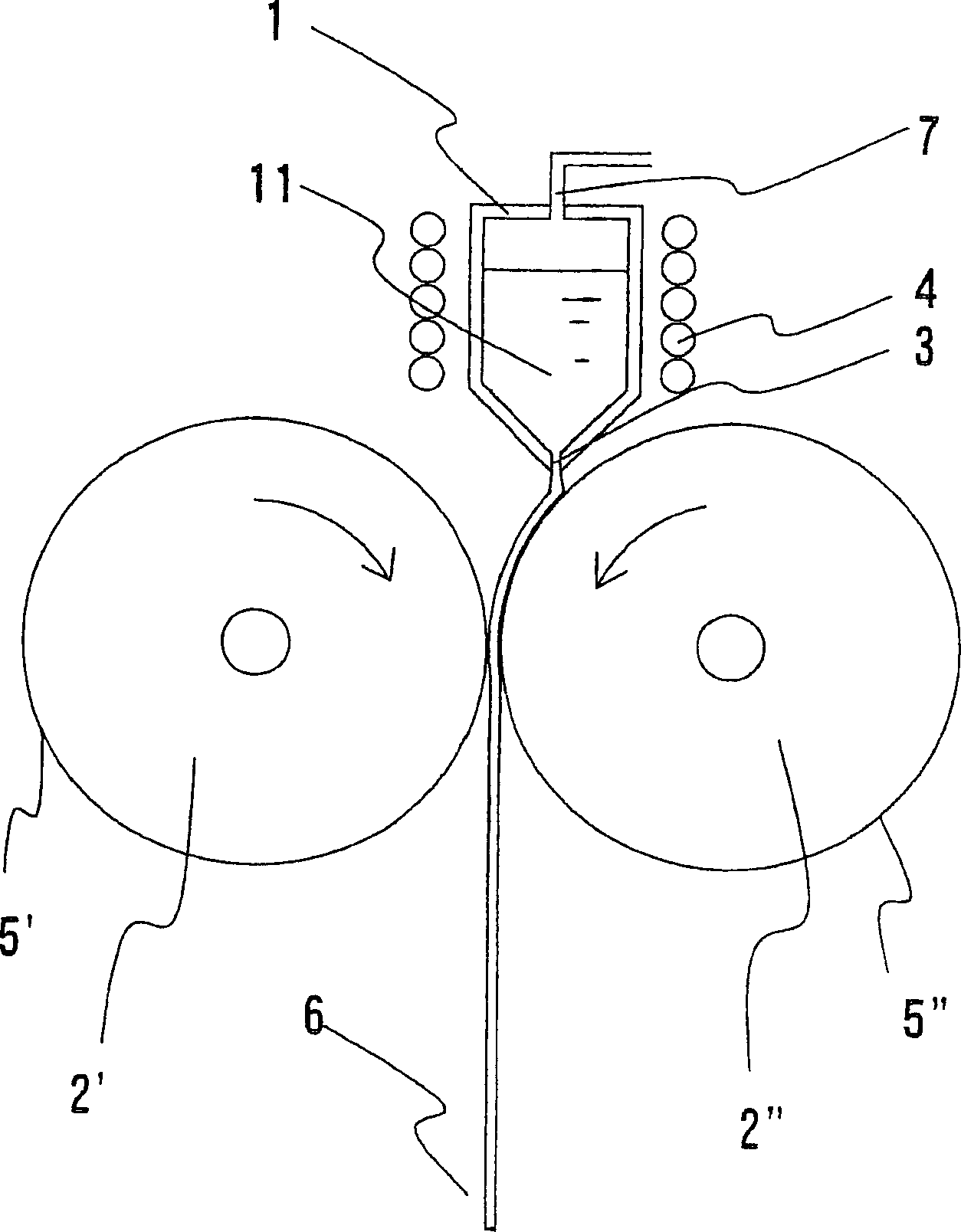

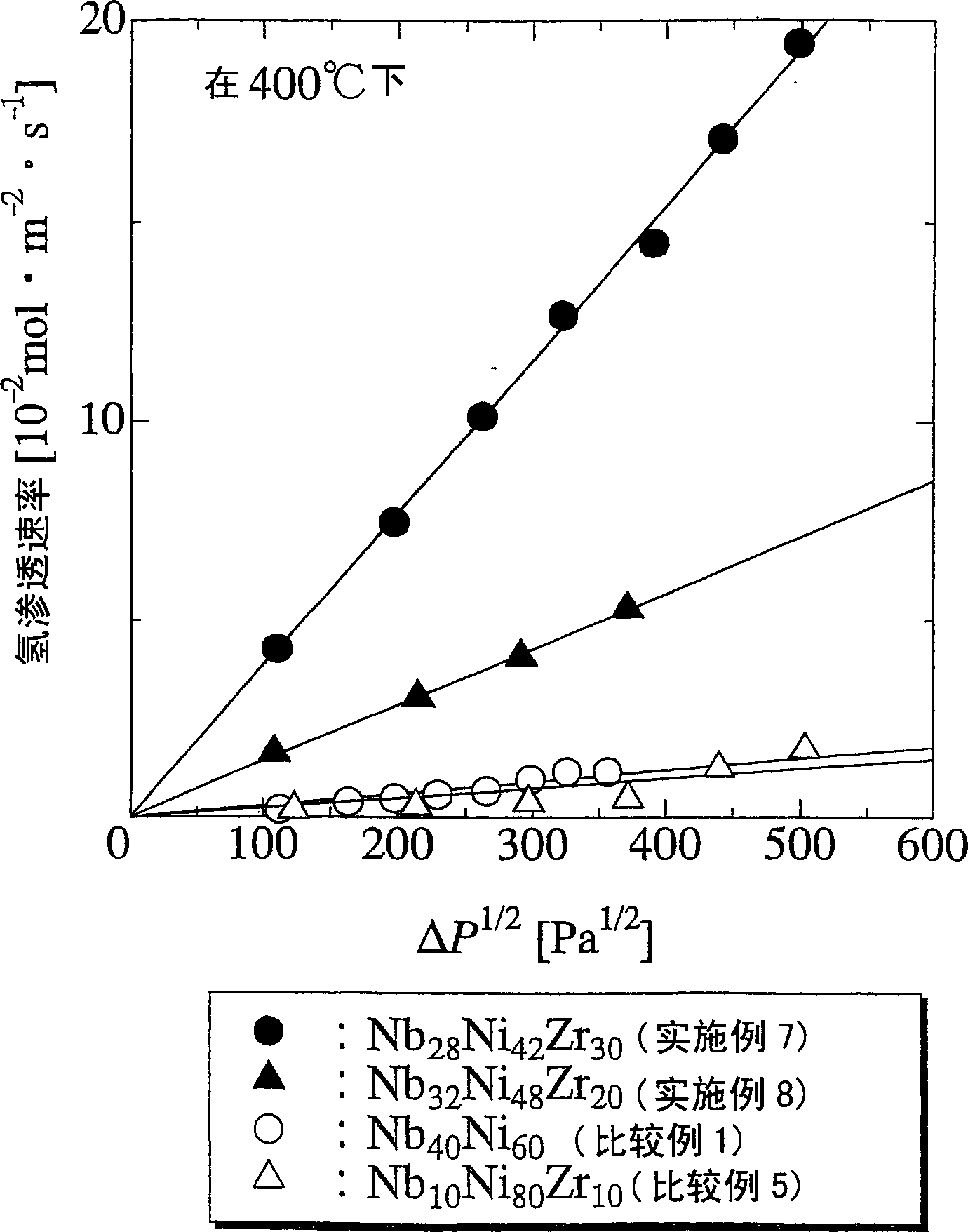

Hydrogen separation membrane and process for producing the same

InactiveUS20060070524A1Excellent in resistance to hydrogen embrittlement hydrogenImprove hydrogen permeabilityMembranesSemi-permeable membranesNiobium alloyHydrogen permeation

A hydrogen permeation membrane having excellent hydrogen permeability and hydrogen embrittlement resistance, and a production method thereof. This membrane is made of a niobium alloy foil having an amorphous crystal structure, the niobium alloy foil comprising 5 to 65 atomic % of at least one member selected from the group consisting of Ni, Co and Mo as a first additive element and 0.1 to 60 atomic % of at least one member selected from the group consisting of V, Ti, Zr, Ta and Hf as a second additive element together with the balance of Nb as an indispensable constituent element wherein 0.01 to 20 atomic % of Al and / or Cu may be contained as a third additive element. This alloy foil can be produced through a method comprising preparing a metal mixture of the above formulation, heating the metal mixture to the melting point or higher in an inert gas so as to melt the same and forming the melt into a film (foil) according to a liquid quenching technique.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

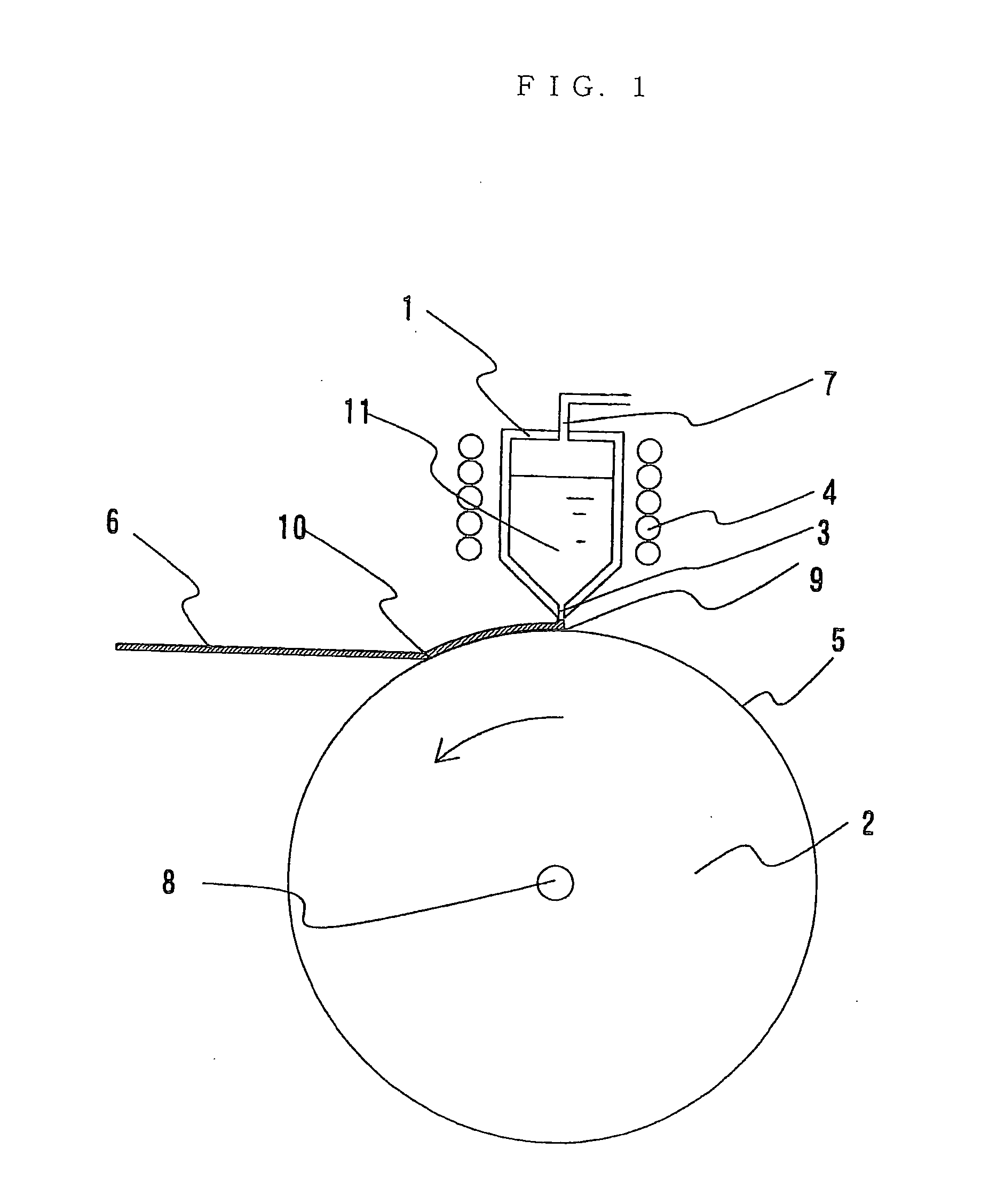

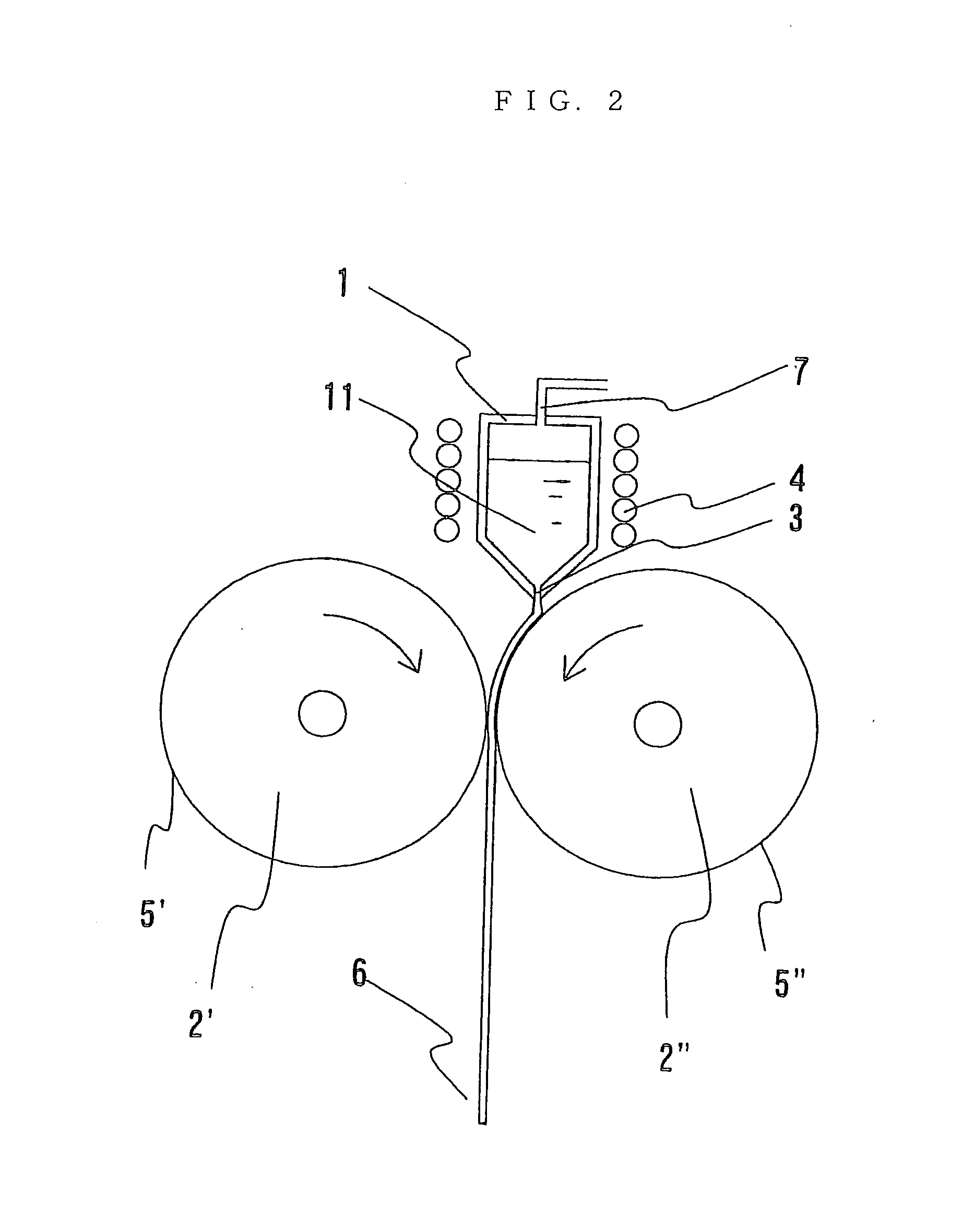

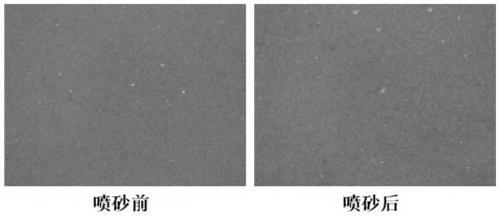

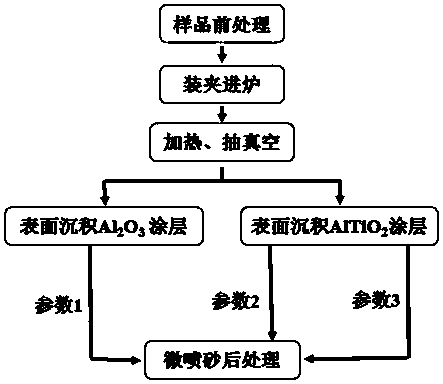

Method of reducing friction coefficient of coating through micro sand blasting after-treatment

ActiveCN111101101AReduce coefficient of frictionImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingCoated surfaceFrictional coefficient

The invention discloses a method of reducing the friction coefficient of a coating through micro sand blasting after-treatment. In order to achieve the purposes that the problem that large particles exist on the surface of the arc ion plating coating is solved, and the friction coefficient of the coating is reduced, an oxide coating with the small thickness is deposited on the surface of a substrate which is covered with the coating, the feature that amorphous crystal grains of the oxide coating are small is utilized to overcome the defect that the surface of the coating is uneven, then the large particles which are caused by arc ion plating and exist on the surface of the coating are removed through micro sand blasting after-treatment, and therefore the surface can be flat and smooth, andthe friction coefficient of the coating is reduced. Sand grains continuously impact on the surface of the coating in the micro sand blasting after-treatment process, and the pressure stress can be effectively improved. Meanwhile, the existence of the oxide can have an effect that the impact force borne by the main coating of the substrate is buffered, and the damage of the coating is reduced. A compact oxide film is formed by the oxide at the high temperature, specifically, the oxide remains on the surface of the coating after sand blasting operation is accomplished, the diffusion of elementsand the heat can be avoided, the wear of the coating is reduced, and the service life of the coating substrate is remarkably prolonged.

Owner:湖南六方晶科技有限责任公司

A production process for preparing purified water containing water-soluble silicon

ActiveCN104098169BPure qualityUniform meltingScale removal and water softeningMultistage water/sewage treatmentHigh concentrationDisease

The invention belongs to the technical field of medicine production, and particularly relates to a manufacturing technology for preparing purified water containing water-soluble silicon by adding the water-soluble silicon into the purified water. The manufacturing technology comprises the following steps: (1) selecting raw materials: selecting water-soluble silicon amorphous crystal particles or powder and purified water for later use; (2) preparing a high-concentration water-soluble silicon solution; (3) preparing a low-concentration water-soluble silicon solution; (4) filtering; (5) sterilizing; (6) storing; (7) labeling, and warehousing and storing at a cool and shady place. The water-soluble silicon solution prepared by the invention, once added into daily food and drink, has beneficial functions on growth, disease preventing, health caring and health improvement of a human body, is applicable to purified water silicon adding of families, schools, small groups and the like, and is applicable to industrial continuous production.

Owner:叶卫斌

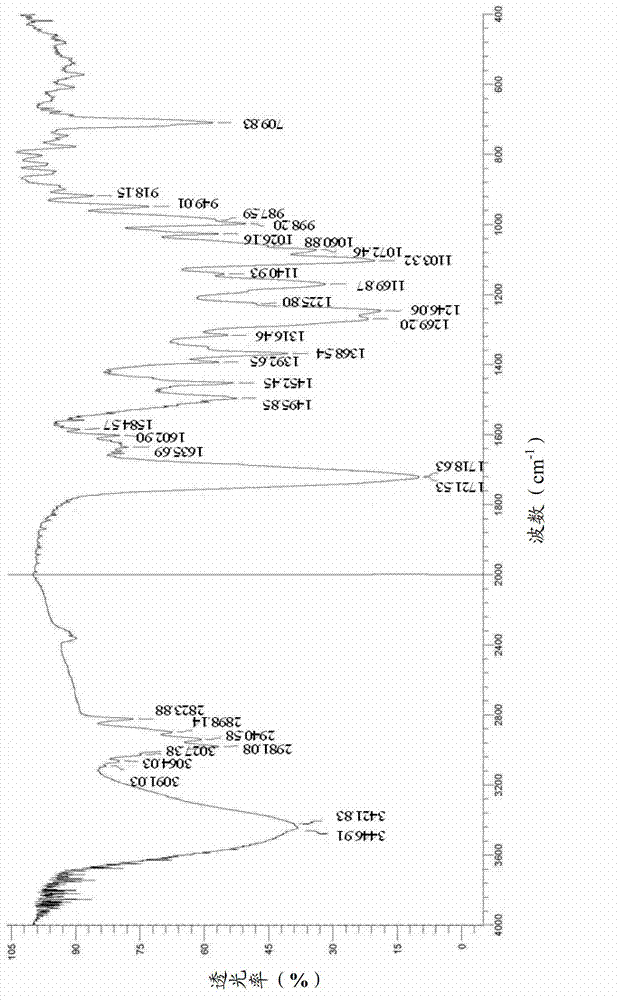

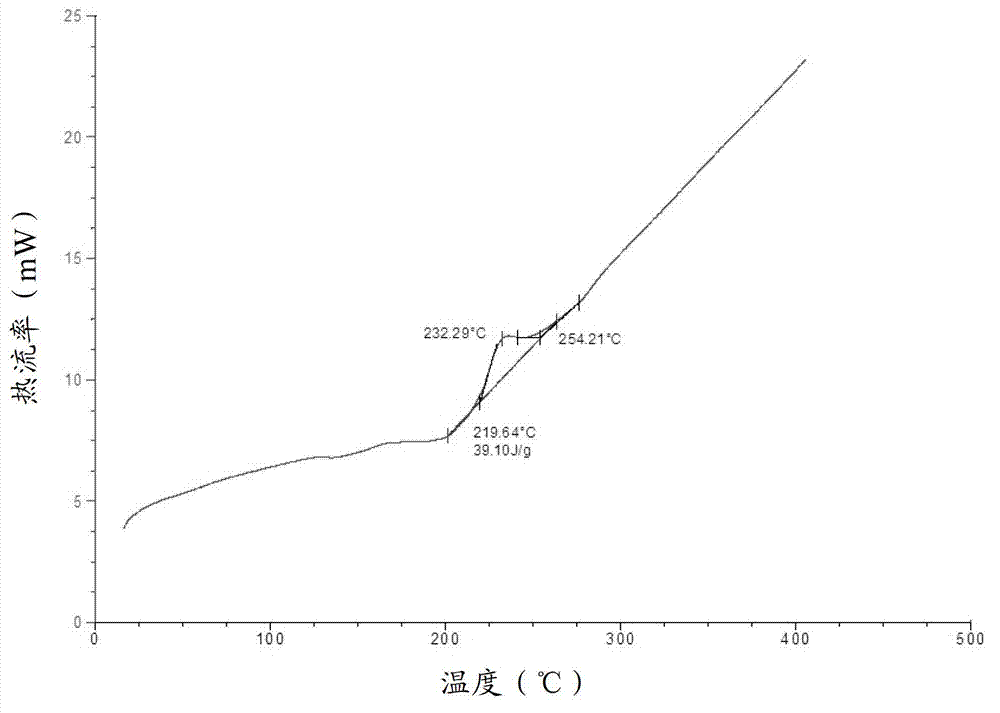

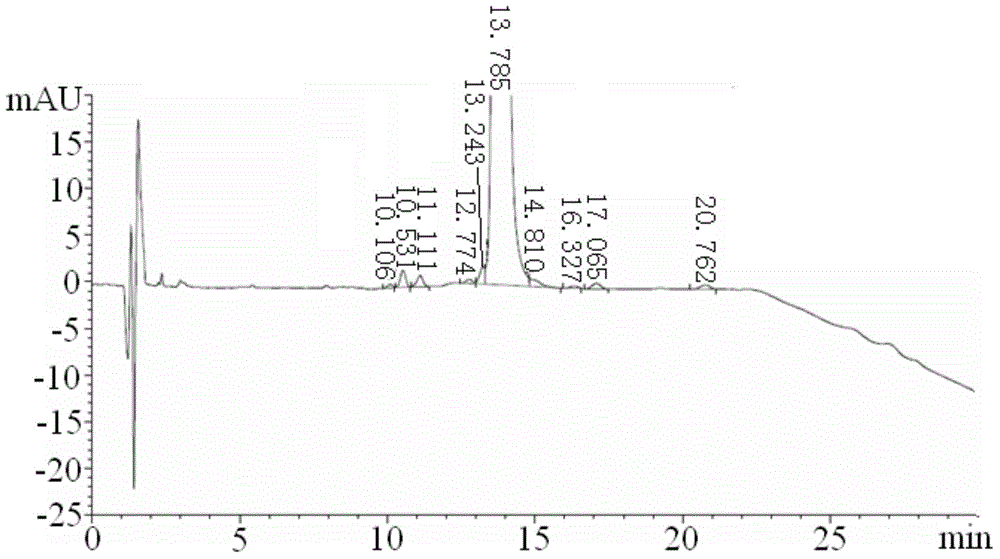

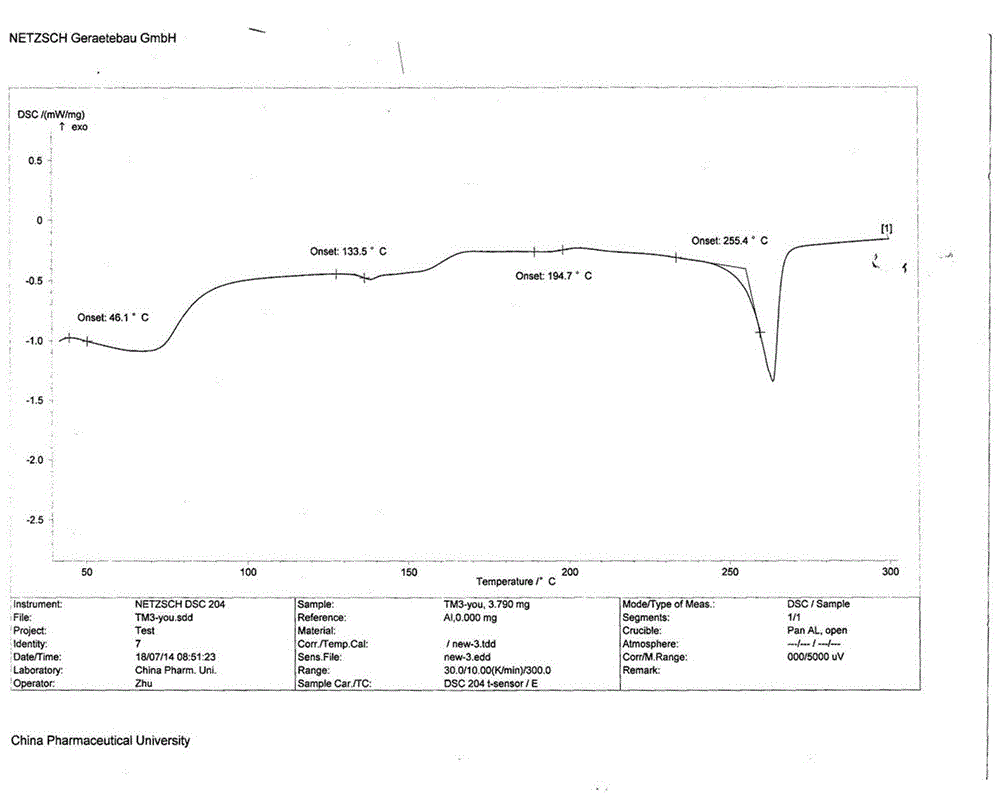

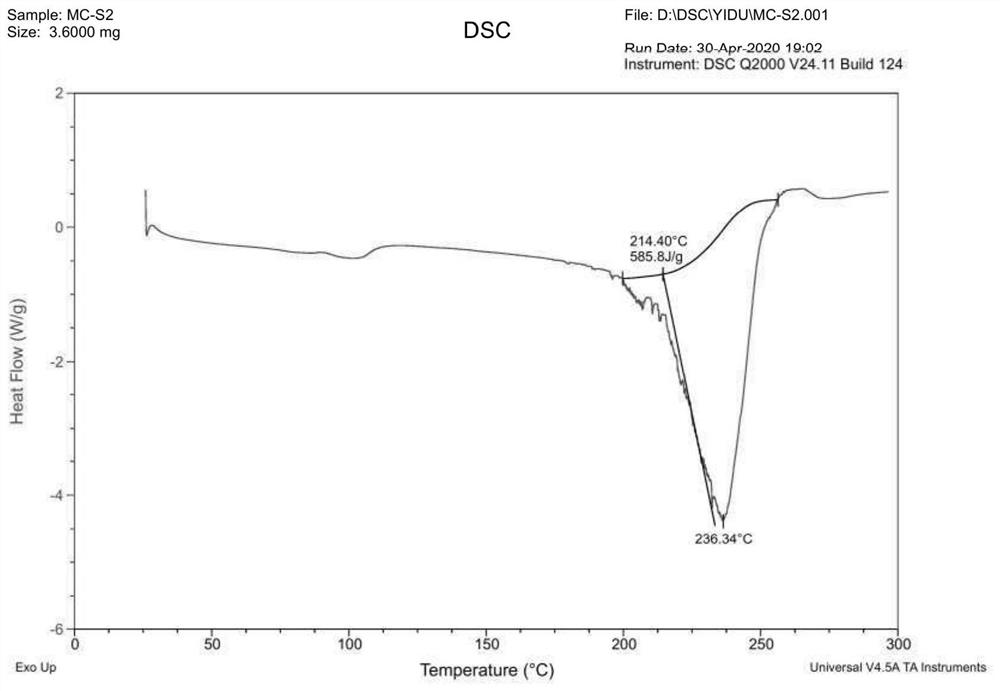

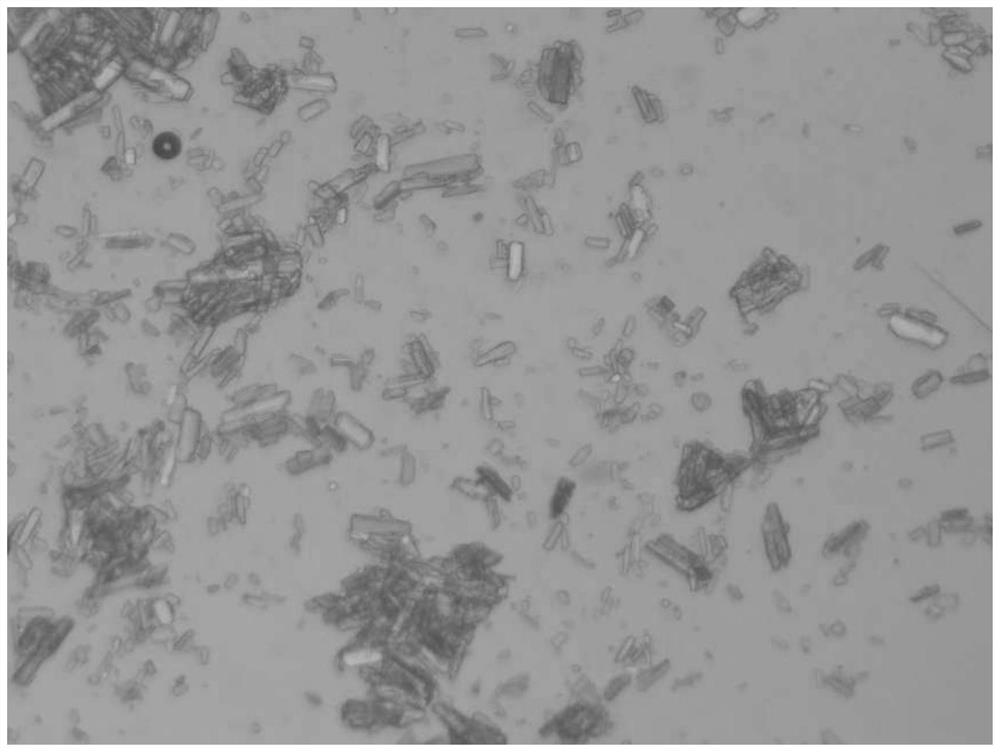

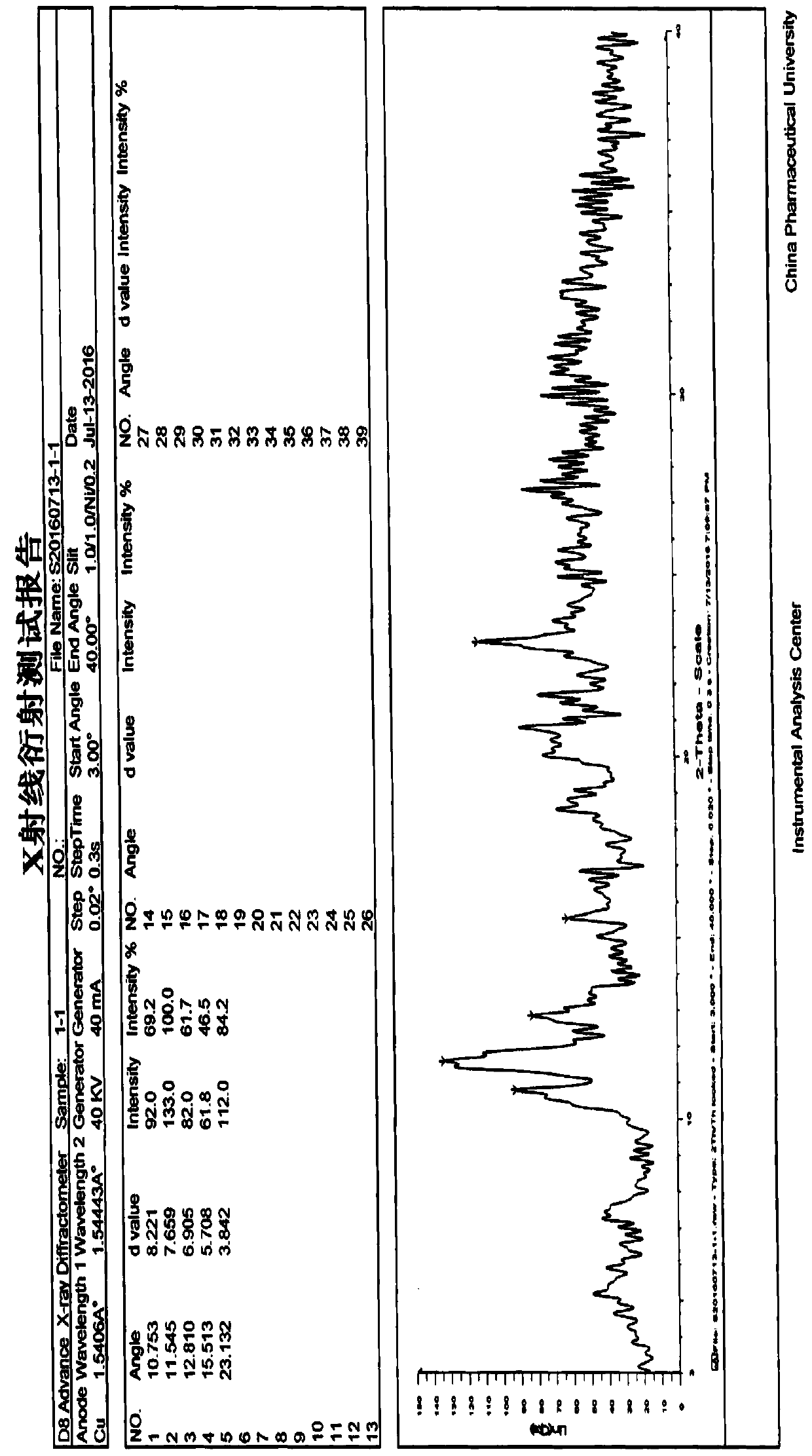

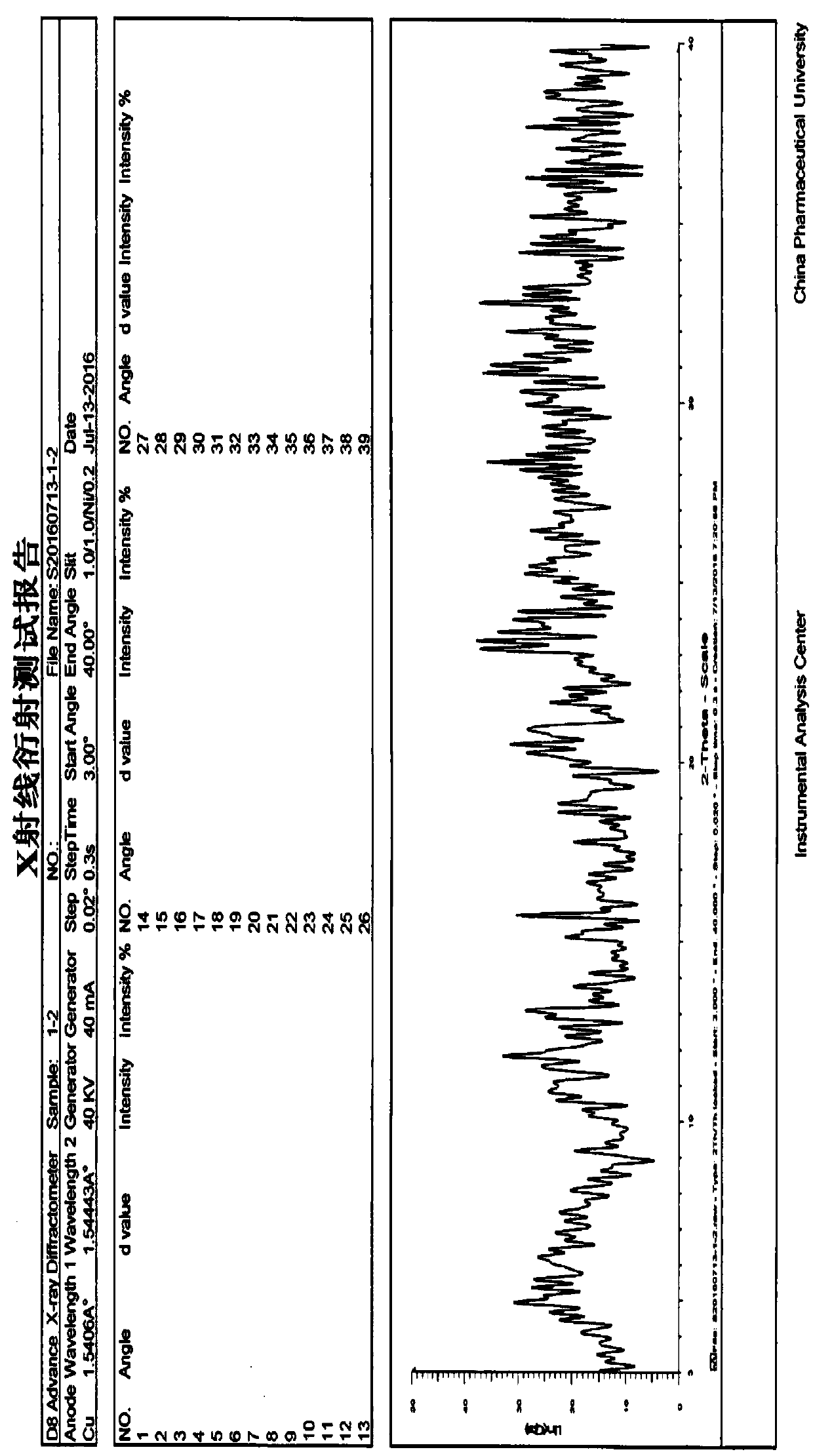

Cabazitaxel amorphous crystal and preparation method thereof

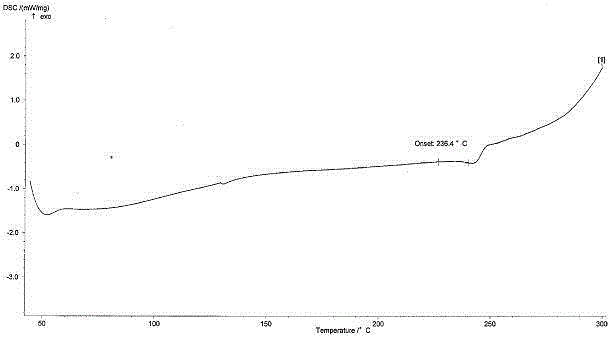

ActiveCN103044364AImprove stabilityReduce organic residuesOrganic active ingredientsOrganic chemistryDifferential scanning calorimetryAmorphous Crystals

The invention relates to the field of cabazitaxel crystal forms and preparation methods thereof, in particular to a cabazitaxel amorphous crystal and a preparation method thereof. A DSC (differential scanning calorimetry) map of the cabazitaxel amorphous crystal has an exothermic peak at 210-260 DEG C. The cabazitaxel amorphous crystal is a novel crystal form of cabazitaxel, and has good stability. The preparation method simplifies operation steps, does not require special equipment, is low in production cost, and is suitable for industrial production.

Owner:重庆兴泰濠制药有限公司

Method for preparing carfilzomib amorphous crystal

InactiveCN104402973AReduce moisture contentImprove stabilityPeptide preparation methodsDevitrificationOrganic solvent

The invention provides a method for preparing a carfilzomib amorphous crystal. The method comprises the following steps: dissolving carfilzomib in an organic solvent to obtain a carfilzomib solution; concentrating the carfilzomib solution to obtain the carfilzomib amorphous crystal. The method has the advantages that as the solvent is organic, no water is needed, and the organic solvent is easy to remove during concentration, no residual can be generated in the product, the moisture content is extremely low, no crystal water is formed, and the obtained carfilzomib amorphous crystal is relatively high in stability. The carfilzomib amorphous crystal is prepared by dissolving carfilzomib and directly concentrating and drying the carfilzomib solution, that is, the processes of crystal growth and devitrification are not avoided, so that the obtained carfilzomib crystal is amorphous. Therefore, the method is simple, high in operability, and suitable for large-scale industrialized production.

Owner:CHONGQING TAIHAO PHARM CO LTD

Preparation method of new crystal form of dexrabeprazole sodium

InactiveCN104910135ANo changeGood crystal stabilityOrganic chemistry methodsAlkaline waterFiltration

Owner:NANJING KEFEI PINGSHENGHUI PHARMA CO LTD +2

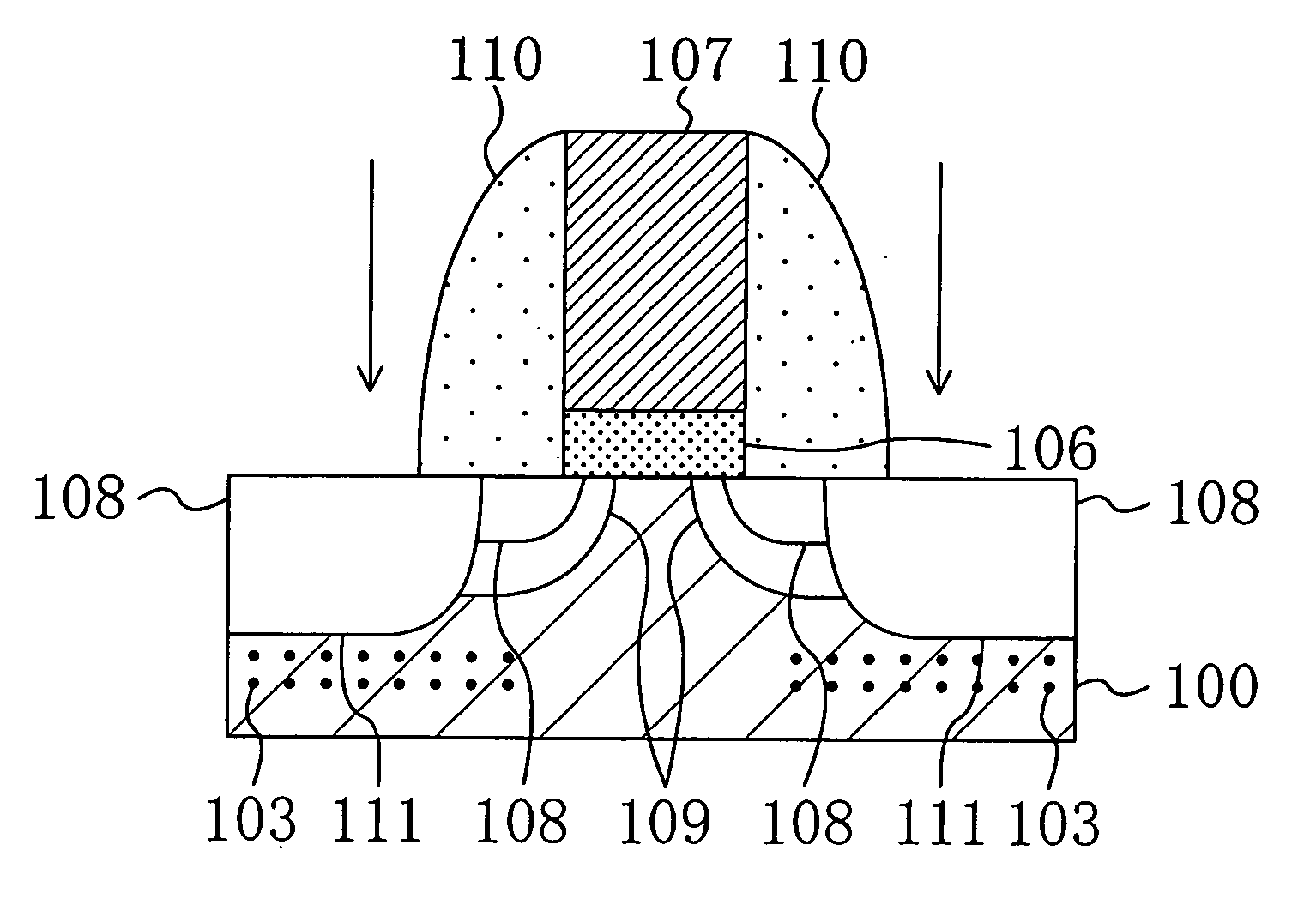

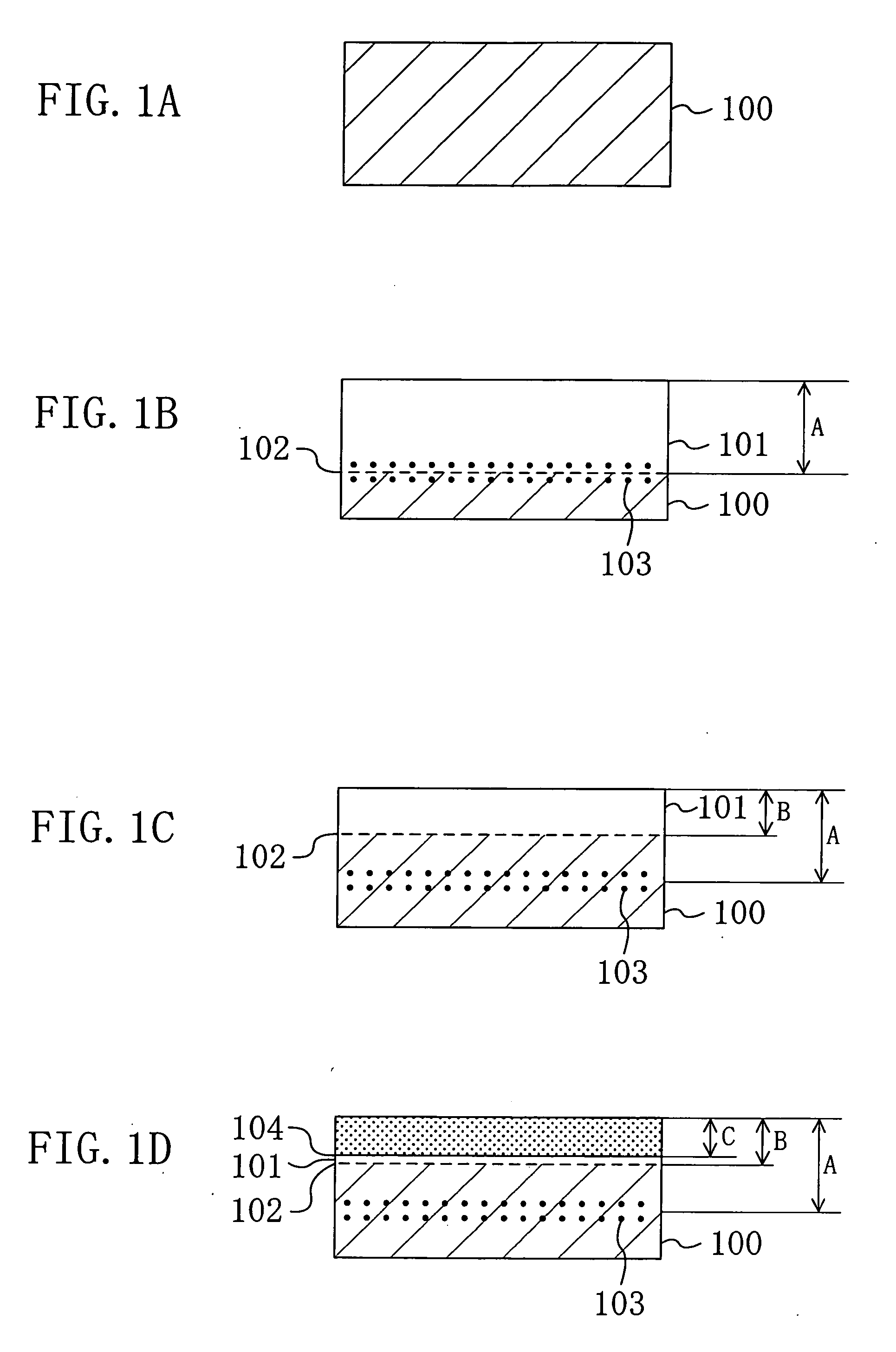

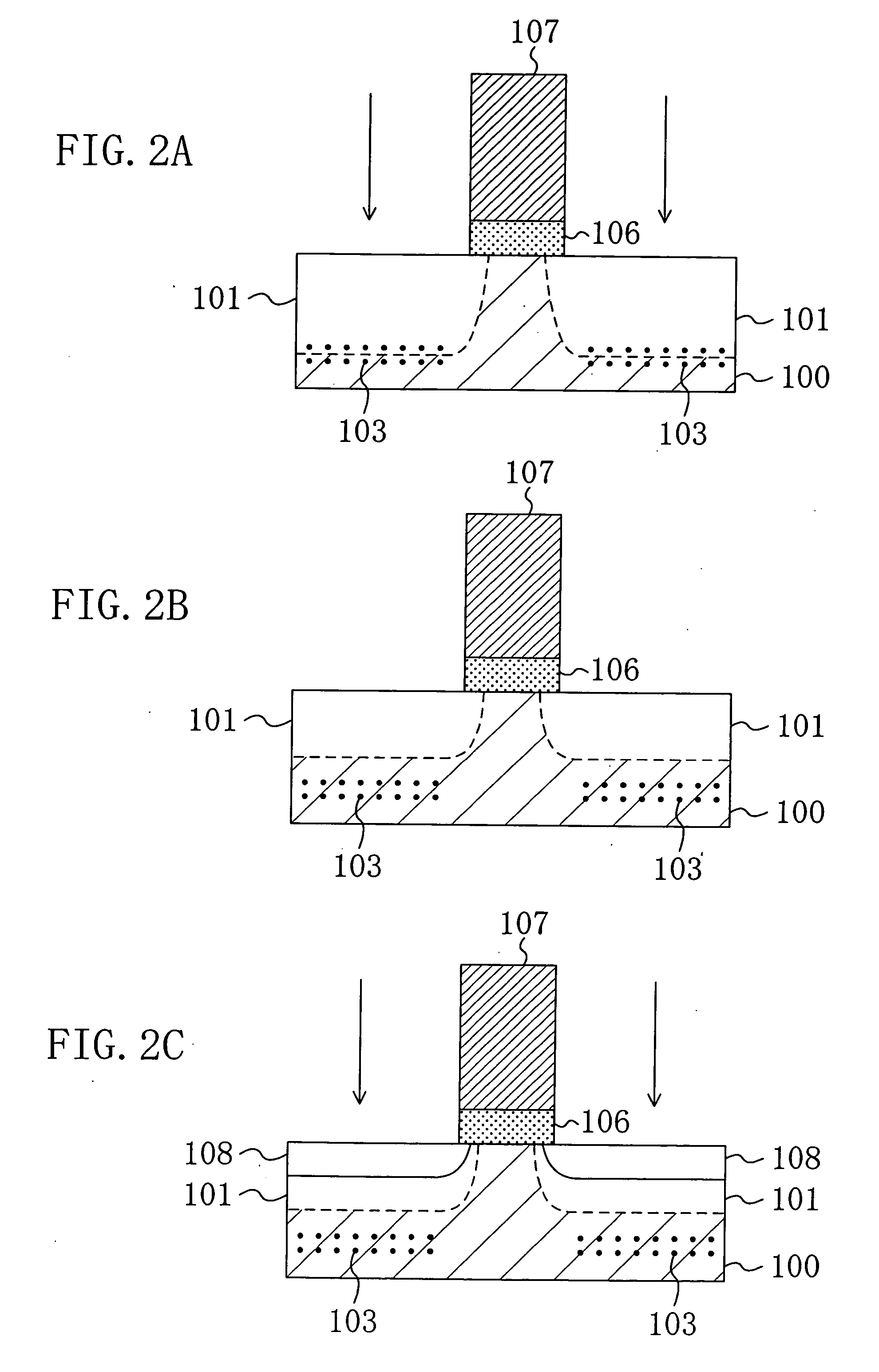

Manufacturing method of a semiconductor device

ActiveUS20070054444A1Reduce the impactReduce leakage currentTransistorSemiconductor/solid-state device manufacturingDevice materialCrystal structure

An amorphous layer 101 is formed in a region from a surface of a silicon substrate 100 to a first depth A. At this time, defects 103 are generated near an amorphous-crystal interface 102. By heat treatment, the crystal structure of the amorphous layer 101 is restored in a region from the first depth A to a second depth B that is shallower than the first depth A. The resultant amorphous layer 101 extends from the surface of the silicon substrate 100 to the second depth B. The defects 103 remain at the first depth A. By ion implantation, a pn junction 104 is formed at a third depth C that is shallower than the second depth B.

Owner:GK BRIDGE 1

Hydrogen separation membrane and process for producing the same

A hydrogen permeation membrane exhibiting excellent hydrogen permeability and hydrogen embrittlement resistance, and a process for producing the same. This membrane is constituted of a niobium alloy foil having an amorphous crystal structure, the niobium alloy foil comprising 5 to 65 atomic % of at least one member selected from the group consisting of Ni, Co and Mo as a first additive element and 0.1 to 60 atomic % of at least one member selected from the group consisting of V, Ti, Zr, Ta and Hf as a second additive element together with the balance of Nb as an indispensable constituent element wherein 0.01 to 20 atomic % of Al and / or Cu may be contained as a third additive element. This alloy foil can be produced through a process comprising preparing a metal mixture of the above formulation, heating the metal mixture to the melting point or higher in an inert gas so as to melt the same and forming the melt into a film (foil) according to a liquid quenching technique.

Owner:FUKUKA METAL FOIL & POWDER CO LTD +1

Method for preparing amorphous crystalline albendazole

InactiveCN102452987AHigh dissolution rateImprove bioavailabilityOrganic chemistryInorganic saltsAcetic acid

The invention discloses a method for preparing amorphous crystalline albendazole, comprising the following steps: dissolving albendazole in methanoic acid, acetic acid or hydrochloric acid, and raising the temperature to 80-100 degrees centigrade and preserving the temperature for 0.5-1 h; adding active carbon into them for decoloration and filtering them, and regulating the pH value of the filter liquid to 6-7 with alkaline, and pump filtering the filter liquid; washing the filter cake to remove off inorganic salt and drying the cake to obtain amorphous crystalline albendazole. In comparison with the prior art, the method disclosed by the invention transfers the original A crystal form into an amorphous crystal form so as to largely raise the dissolution of the albendazole and further raise the bioavailability. The method is simple and is convenient to operate. The prepared finished product has a stable quality. The method is suitable for industrialized production.

Owner:GUILIN PHARMA

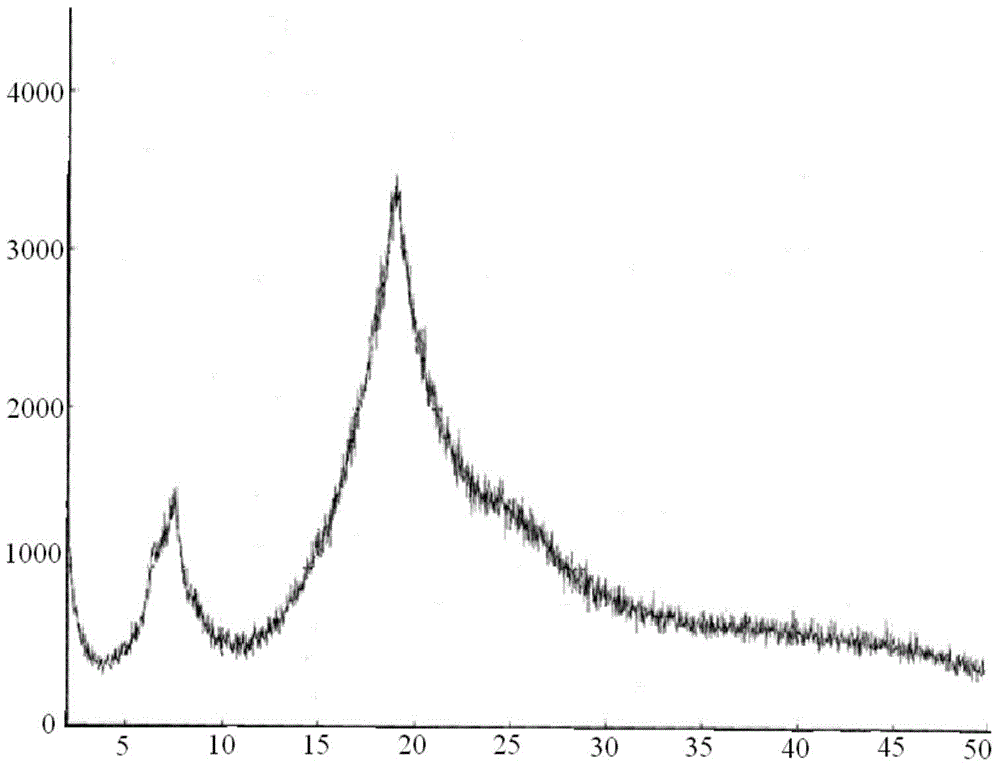

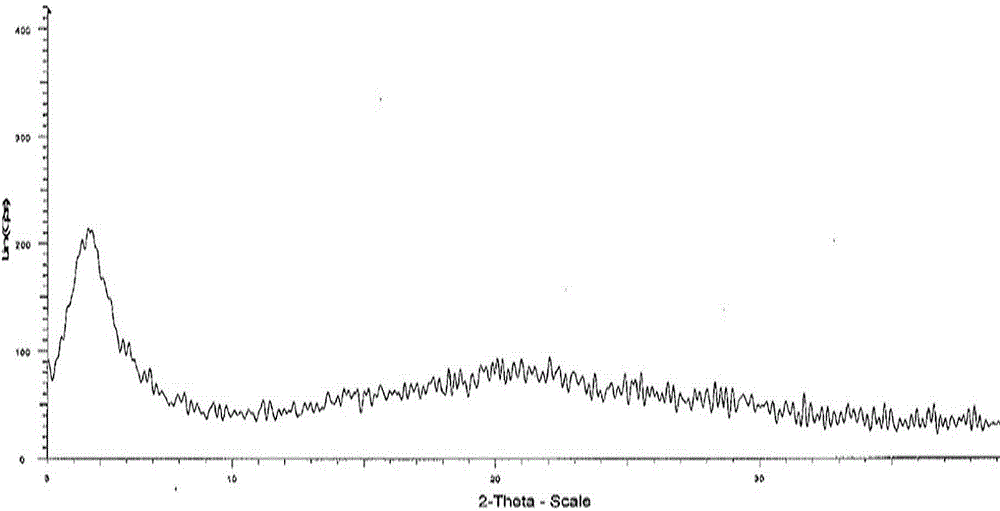

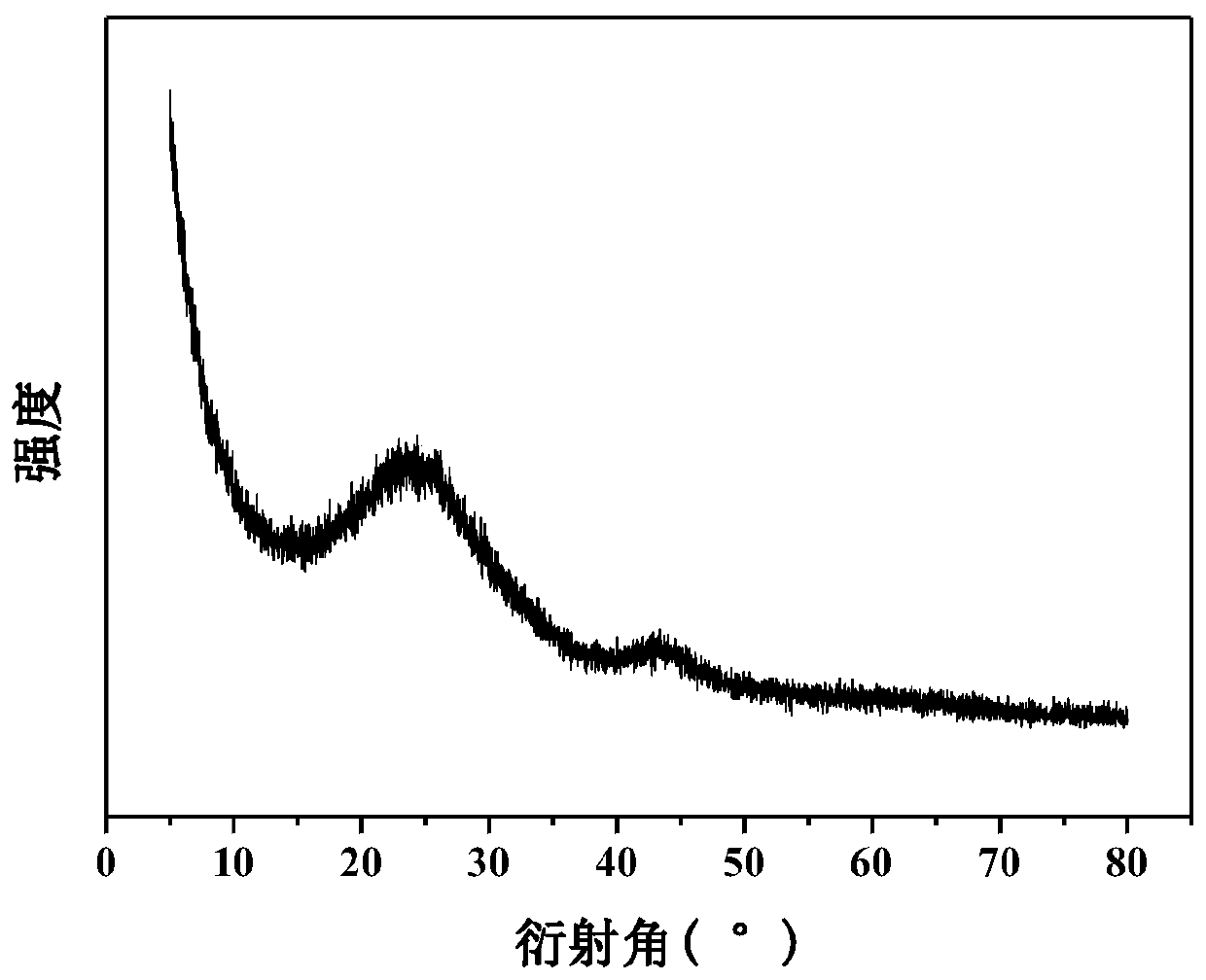

Telmisartan amorphous crystal and preparation method thereof

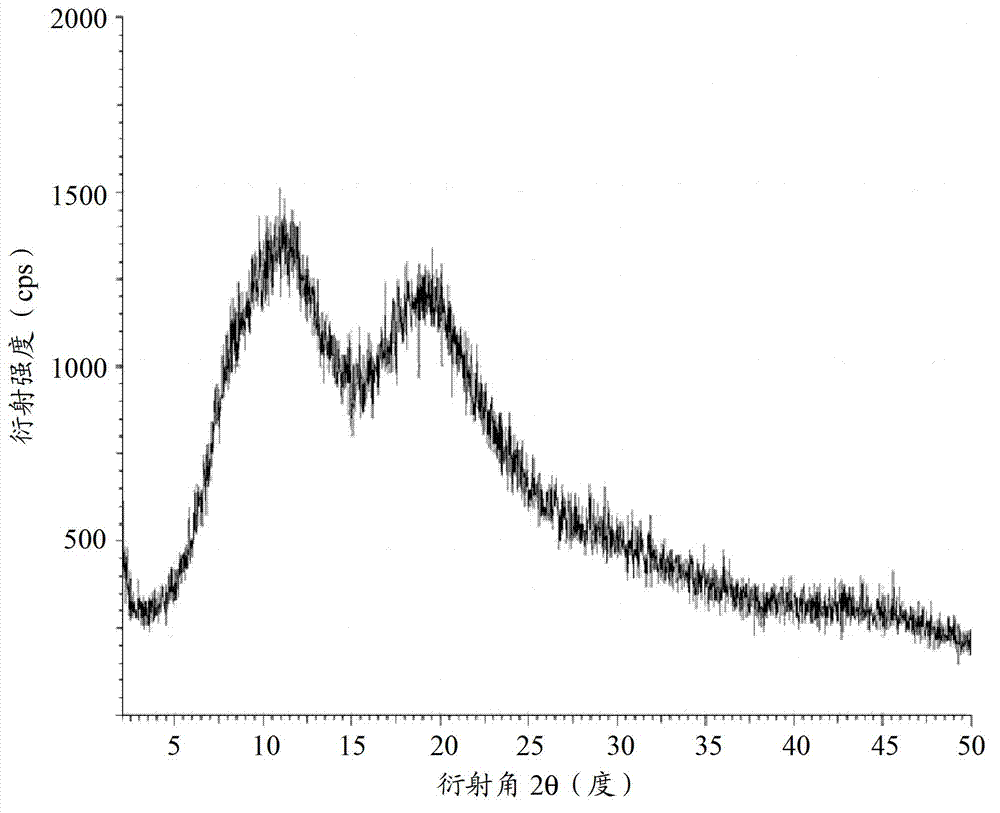

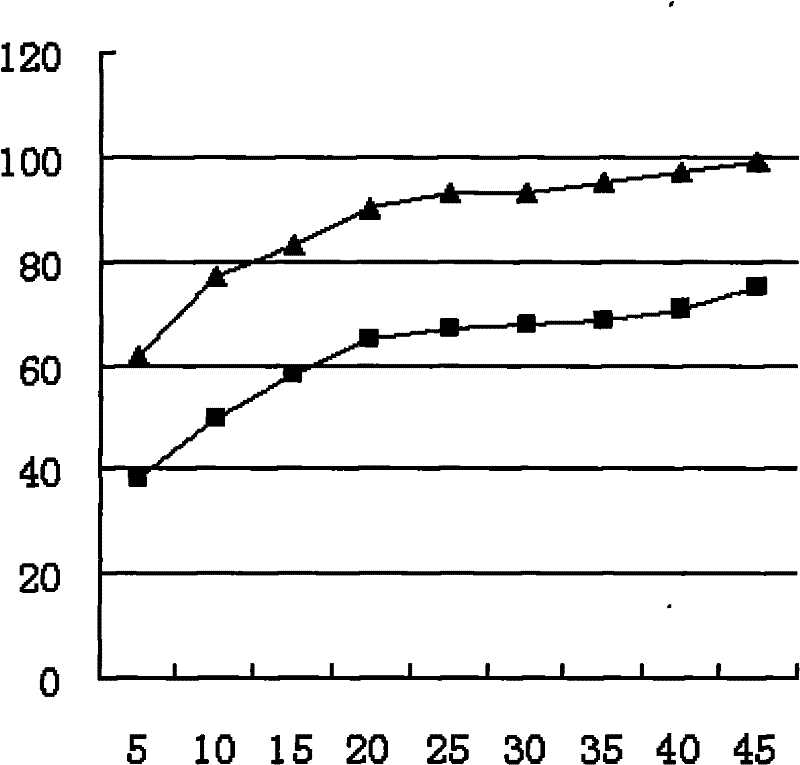

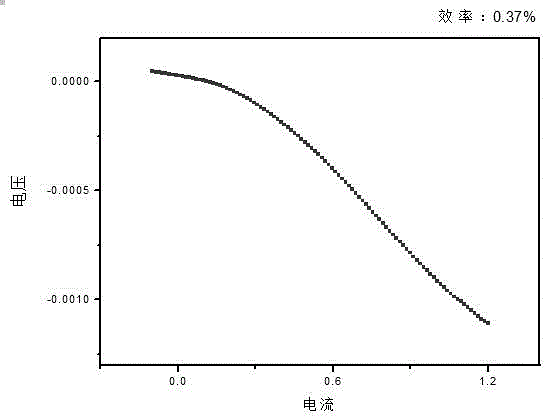

ActiveCN104557724AHigh dissolution rateThe preparation method is safeOrganic chemistryOrganic solventAlcohol

The invention discloses a telmisartan amorphous crystal and a preparation method thereof. An X-ray powder diffraction spectrum of the telmisartan amorphous crystal is as shown in figure 1, and no peak exists on a specific 2 theta characteristic peak position. The preparation method of the telmisartan amorphous crystal comprises the following steps of: a, mixing a crude telmisartan product and an organic solvent, wherein the organic solvent is alcohol; b, adding an alkali, and salifying and dissolving telmisartan under heating; c evaporating out the solvent, selectively metering and adding water at the same time, and adding acid at a temperature below 40 DEG C till no precipitate is separated out; d carrying out centrifugal separation on the precipitate product, and drying a detergent. The telmisartan amorphous crystal is provided by adopting the organic solvent with very low toxicity. The preparation method disclosed by the invention is safe, simple and high in operability; in addition, the obtained product is single in crystal form and can be used for preparing a medicament which contains amorphous telmisartan due to good dissolvability.

Owner:JIANGSU ZHONGBANG PHARMA

Carbon-selenium composite material, positive pole of lithium-selenium battery, and application of positive pole

InactiveCN108502844AIncrease pressure differenceEnhanced capillary actionMaterial nanotechnologyElectrode carriers/collectorsAmorphous seleniumElectrochemical response

The invention belongs to the field of energy storage, and particularly relates to a carbon-selenium composite material, a positive pole of a lithium-selenium battery, and an application of the positive pole. The carbon-selenium composite material is of an amorphous crystal phase, has a uniform structure, and consists of hollow porous nano carbon spheres and amorphous selenium distributed in the inner pore channels of the hollow porous nano carbon spheres. In the carbon-selenium composite material provided by the invention, selenium can enter the porous channels of the porous carbon as much aspossible, so that selenium cannot run off from the positive pole in an electrode reaction, so that higher utilization rate and reversibility can be achieved in an electrochemical reaction.

Owner:WUHAN UNIV OF TECH

Angiotensin receptor antagonist as well as NEP inhibitor drug crystal form and preparation thereof

The invention relates to an amorphous crystal form of a latest-generation cardiotonic agent valsartan ((2R, 4S)-5-biphenyl-4-group-5-(3-carboxyl-propionyl-amino)-2-methyl-ethyl valerate) trisodium and a preparation method of the cardiotonic agent.

Owner:JIANGSU CAREFREE PHARM CO LTD

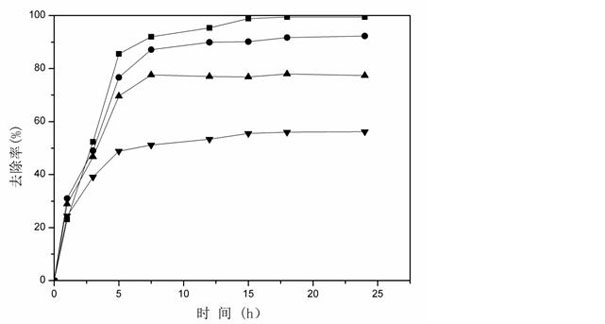

Method for preparing manganese polysilicate doped manganese dioxide adsorbent

InactiveCN101791535AUniform and dense particlesImprove self stabilityOther chemical processesSilicon compoundsSorbentPhysical chemistry

The invention discloses a method for preparing a manganese polysilicate doped manganese dioxide adsorbent, which relates to a method for preparing an adsorbent and application thereof. The method solves the problems that manganese dioxide has poor removal capacity and poor settleability to dimethylamine. The method for preparing the manganese polysilicate doped manganese dioxide adsorbent comprises the following steps of: firstly, preparing a product A; secondly, preparing a product B; and thirdly, adding deionized water into the product B until the product B is pyrolyzed into particles, then removing suspended matters, and drying the particles to obtain the manganese polysilicate doped manganese dioxide adsorbent. The manganese polysilicate doped manganese dioxide adsorbent is applied to water treatments to remove the dimethylamine in water. The adsorbent prepared by the method is an amorphous crystal, and the specific surface area of the adsorbent is 152.79 m<2> / g which is 3 times that of commercially available manganese dioxide. The manganese polysilicate doped manganese dioxide adsorbent can effectively remove the dimethylamine in the water, and has the characteristics of high self stability, simple and convenient method, no need of high-temperature drying, easy recycling and no generation of secondary pollutions.

Owner:HARBIN INST OF TECH

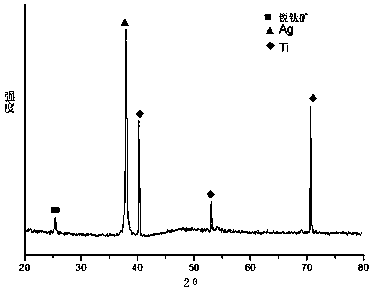

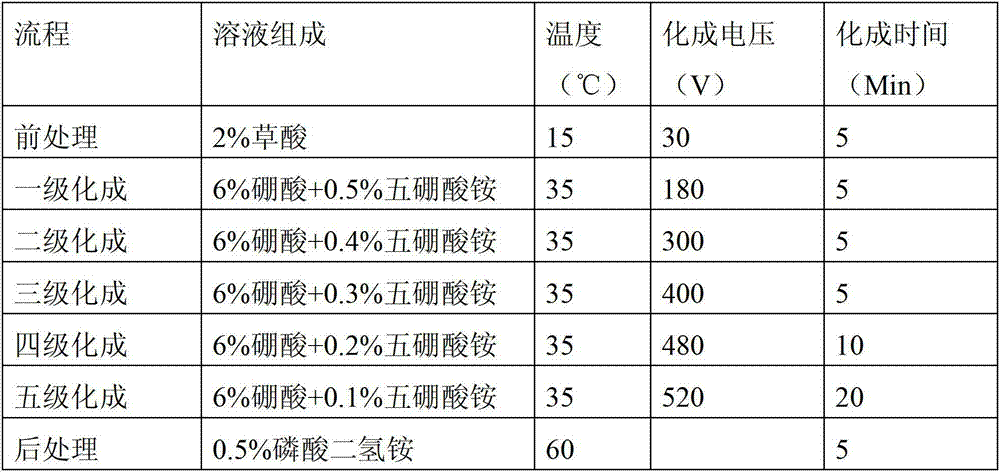

Preparation method of silver-modified crystal form titanium dioxide nanotube layer

InactiveCN108815571ARealize the combinationImprove the deposition effectMaterial nanotechnologySurface reaction electrolytic coatingApatiteBiocompatibility Testing

The invention relates to a preparation method of a silver-modified crystal form titanium dioxide nanotube layer. The preparation method comprises the following three steps: constructing one titanium dioxide nanotube layer on a medical pure titanium surface through constant-voltage anodic oxidation; putting a prepared titanium dioxide nanotube array layer into a centrifugal tube filled with a silver nitrate solution and centrifuging to obtain a titanium dioxide nanotube array layer which is loaded with silver nitrate through centrifugal adsorption; decomposing the silver nitrate in the titaniumdioxide nanotube array layer which is loaded with the silver nitrate through the centrifugal adsorption through heat treatment, and transforming titanium dioxide to an anatase type titanium dioxide nanotube array layer from an amorphous crystal form. According to the preparation method provided by the invention, a prepared silver-modified crystal form titanium dioxide array realizes the combination of a nanotube shale, a specific crystal form type and silver modification; the silver-modified crystal form titanium dioxide array layer has good apatite deposition capability and antibacterial performance in an induction process of simulated body fluid, so that the aims of improving the biocompatibility of the medical titanium surface and carrying out surface modification of the antibacterialperformance on the medical titanium surface are realized.

Owner:HEBEI UNIV OF TECH

Method for manufacturing amorphous oxidation film aluminum foil

InactiveCN102891012AReduce lossCapacitor electrodesAluminium oxides/hydroxidesChemical synthesisMetallurgy

A method for manufacturing an amorphous oxidation film aluminum foil relates to a method for manufacturing a capacitor aluminum foil. The method for manufacturing the amorphous oxidation film aluminum foil comprises the steps of: A, selecting a middle and high pressure corrosive aluminum foil, wherein the thickness of the middle and high pressure corrosive aluminum foil is 75 microns-120 microns, and a corrosive foil of which the aperture is more than 0.05 microns is corroded, and B, carrying out a low-temperature chemical synthesis technology, and forming an AL2O3 formed foil of amorphous crystal. The compact amorphous AL2O3 oxidation film is formed by the method provided by the invention. The method is small in loss, and suitable for changes of pressure drops at two ends of a capacitor.

Owner:朱健雄

Superhard waterproof plated film lenses of spectacles

InactiveCN104880742AImprove wear resistanceLow wear resistanceOptical partsOptical elementsIodideGram

The invention discloses superhard waterproof plated film lenses of spectacles. Each lens sequentially comprises, from top to bottom, an optical resin lens, an anti-reflection film layer, a combination film layer and a superhard water-proof film layer. The superhard water-proof film layer is prepared in a way that N-perfluoro-1-octanesulfonyl fluoride aminopropyltriethoxysilane is adopted to serve as a main raw material; 130-220ml isopropanol and 15-20g water are added to every 100 grams of N-perfluoro-1-octanesulfonyl fluoride aminopropyltriethoxysilane, and then uniform stirring is performed; 7-10g acid solutions are added to the above solution in a stirring state, and sealing reaction is conducted for 5-8 hours at the temperature of 50-65 DEG C; the filtered solution is filtered and dried, and then amorphous crystals are formed; the crystals are crushed to be 10-18 in mesh, and perfluoro octyl group quaternary amines iodide is added to the crushed crystals. Through the design of combination of multiple film layers, the superhard waterproof plated film lenses of spectacles exhibit excellent wear resistance and low reflectivity.

Owner:李国荣

GCIB process for reducing interfacial roughness following pre-amorphization

InactiveUS8440578B2Reduce roughnessReduce first interfacial roughnessSemiconductor/solid-state device manufacturingBeam energyGas cluster ion beam

A method for amorphizing a layer on a substrate is described. In one embodiment, the method includes treating the substrate with a first gas cluster ion beam (GCIB) using a first beam energy selected to yield an amorphous sub-layer within the substrate of a desired thickness, which produces a first interfacial roughness of an amorphous-crystal interface between the amorphous sub-layer and a crystalline sub-layer of the substrate. The method further includes treating the substrate with a second GCIB using a second beam energy, less than the first beam energy, to reduce the first interfacial roughness of the amorphous-crystal interface to a second interfacial roughness.

Owner:TEL EPION

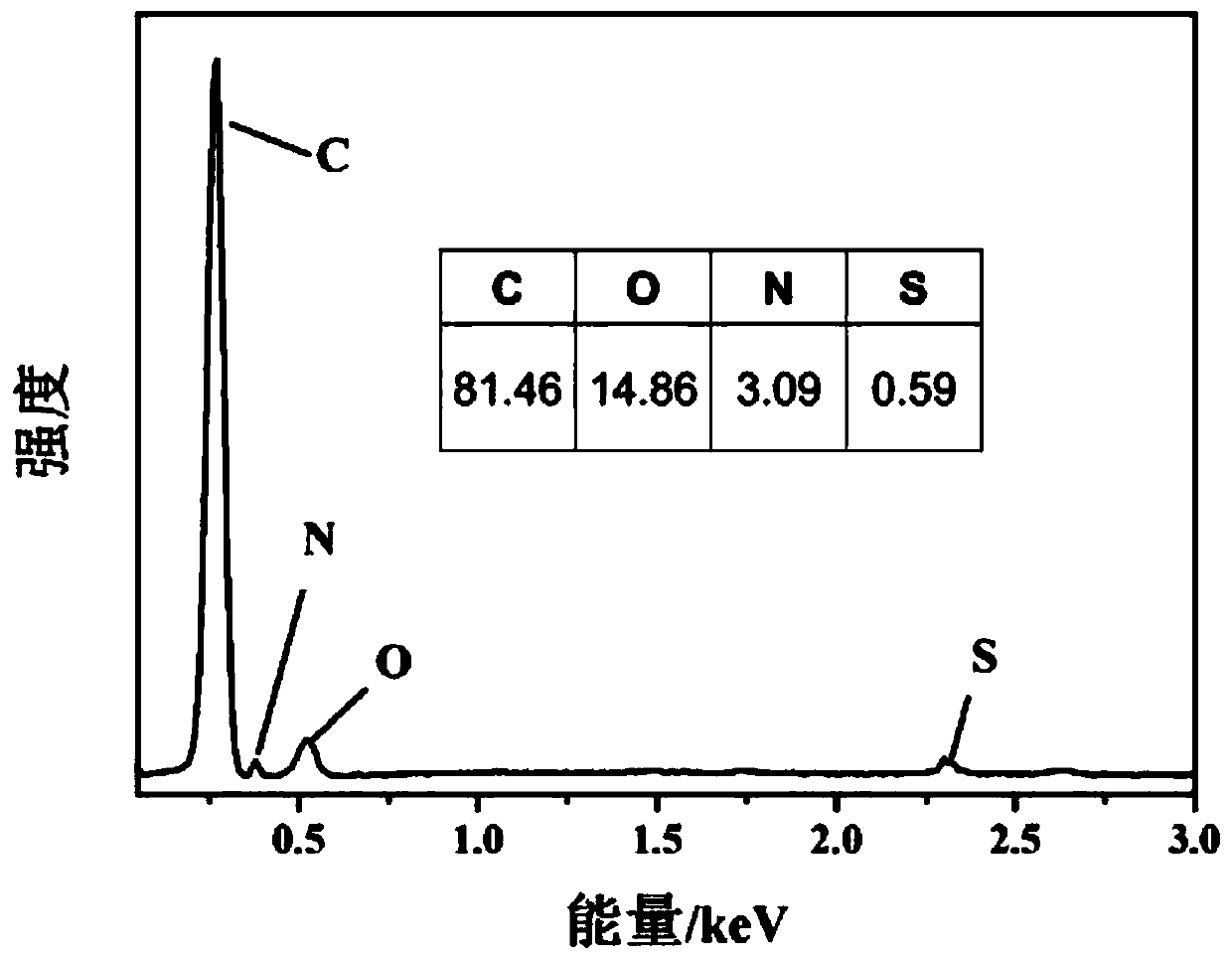

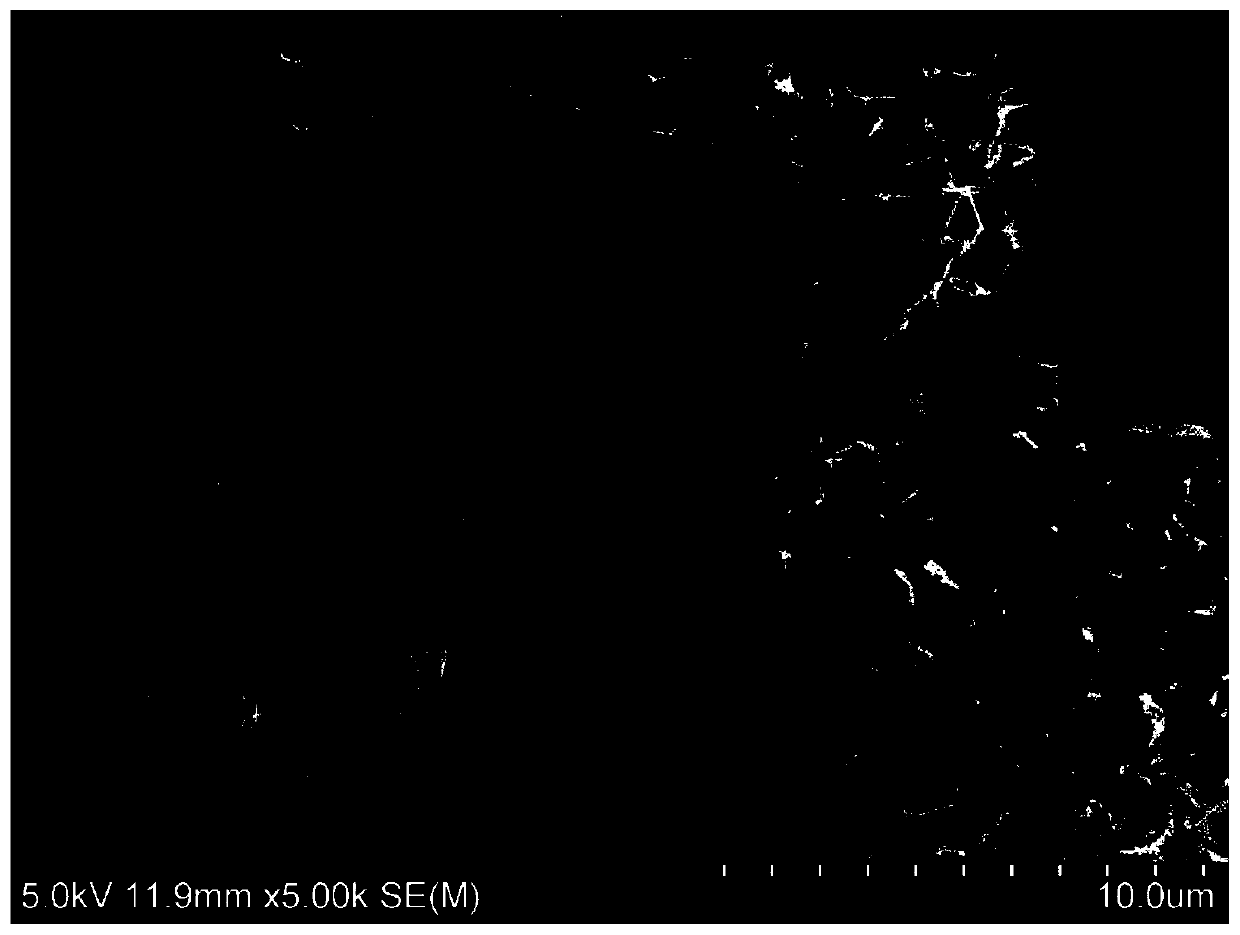

N, S co-doped bagasse nanosheet-shaped mesoporous structure biomass charcoal and preparation method thereof

The invention discloses N, S co-doped bagasse nanosheet-shaped mesoporous structure biomass charcoal and a preparation method thereof. The appearance of the biomass charcoal is of a sheet-shaped porous structure, the thickness of each sheet is 5-50 nm, the pore diameter of each sheet is 6-20 nm, the surface of each sheet is similar to a honeycomb, a large number of nanosheets with mesoporous structures are stacked together, and the crystal form structure of the biomass charcoal is an amorphous charcoal structure. The preparation method is as follows: removing impurities on the surface of bagasse and drying; adding a potassium hydroxide solution, carrying out hydrothermal treatment to obtain a gray flocculent precursor, carrying out carbonization treatment under the protection of nitrogen to obtain bagasse nanosheet-shaped mesoporous structure biomass charcoal, grinding and mixing the bagasse nanosheet-shaped mesoporous structure biomass charcoal serving as a substrate and thiourea serving as a doping agent, and carrying out doping treatment under nitrogen to obtain the N and S co-doped bagasse nanosheet-shaped mesoporous structure biomass charcoal. The method is simple in step, lowin raw material cost, low in technical difficulty, economical and environmentally friendly, and the obtained product is stable in structure, is an amorphous crystal structure material, and has a goodapplication prospect in the fields of environmental remediation, soil improvement, energy storage and shielding / wave-absorbing materials.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

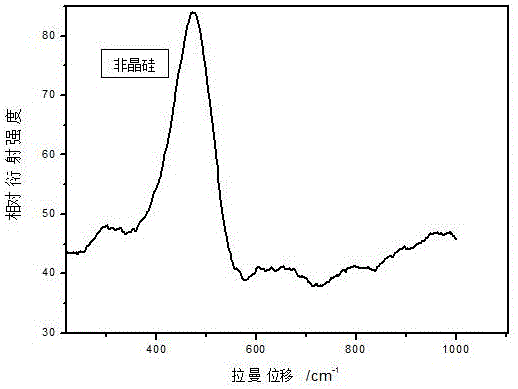

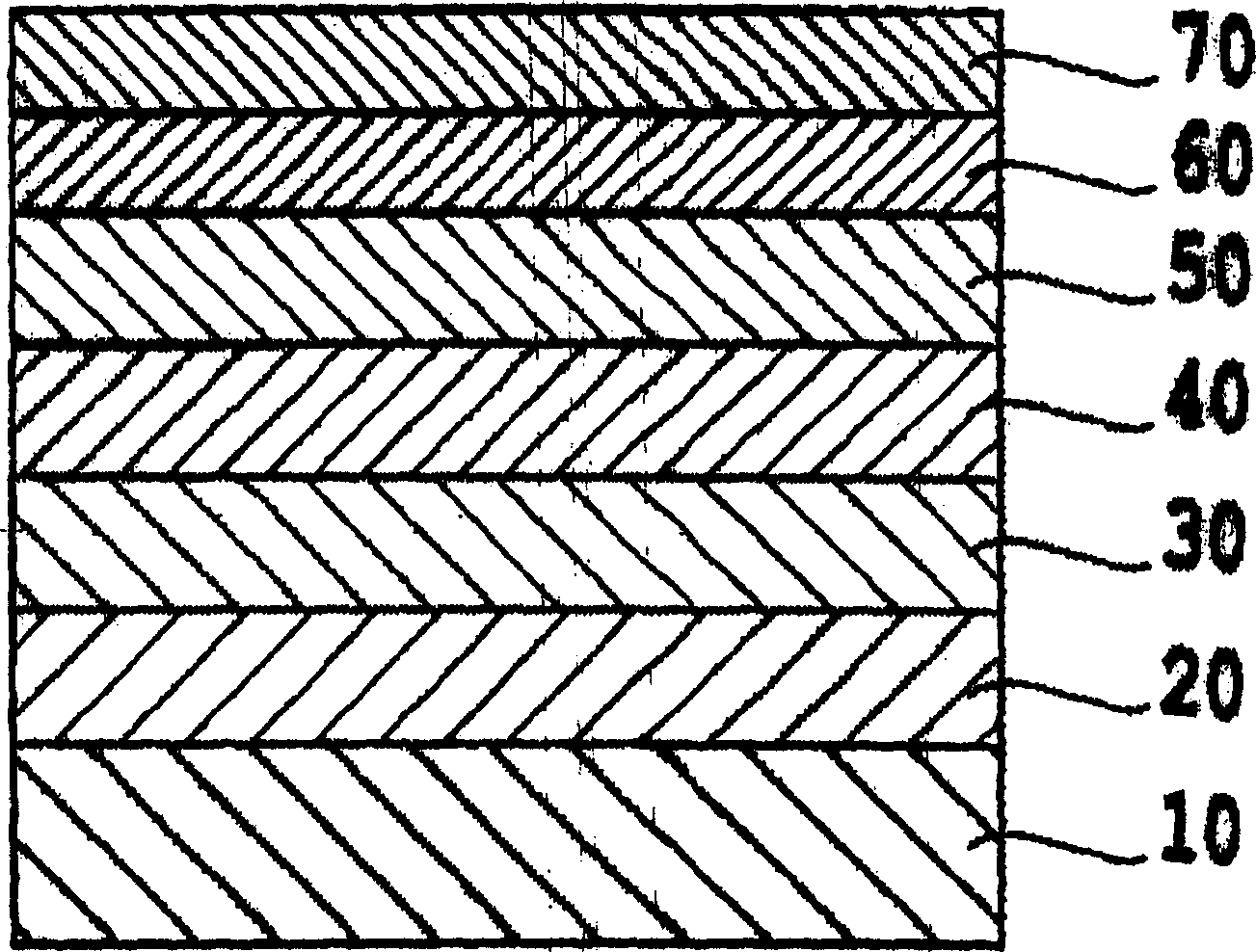

Heterojunction solar cell device production method based on amorphous silicon thin films

InactiveCN106449815AShort recovery timeDoping controlPhotovoltaic energy generationSemiconductor devicesHeterojunctionSilver paste

The invention discloses a heterojunction solar cell device production method based on amorphous silicon thin films. A monocrystalline silicon surface, which is uniformly provided with silver paste in a coated manner and is annealed, is provided with an i-type amorphous silicon thin film and a p-type amorphous silicon thin film in a deposited manner by adopting a plasma chemical vapor deposition method, and an anode conductive electrode layer is produced by adopting a magnetron sputtering method. Transmission and acquisition of photocarriers are effectively enhanced by the produced amorphous-crystal heterojunction, and at the same time, the deposited i-type amorphous silicon thin film is used as the buffer thin layer of the heterojunction thin film, and then objects of acquiring carriers and improving optical conversion efficiency are achieved. The heterojunction solar cell device based on the amorphous silicon thin films has advantages of large area, high efficiency, low costs, good stability, and applicability in photovoltaic devices used for power generation.

Owner:SHANGHAI UNIV

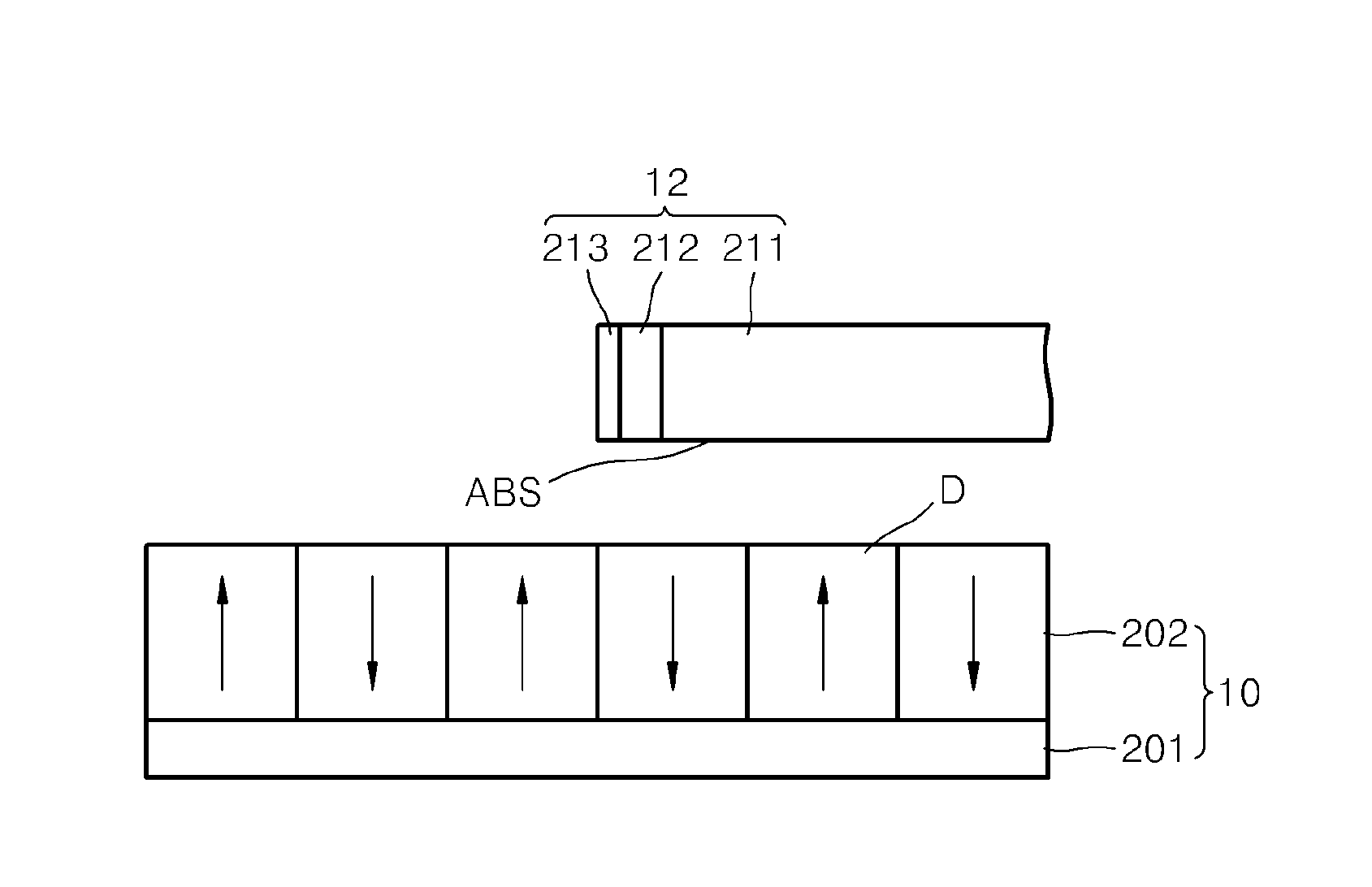

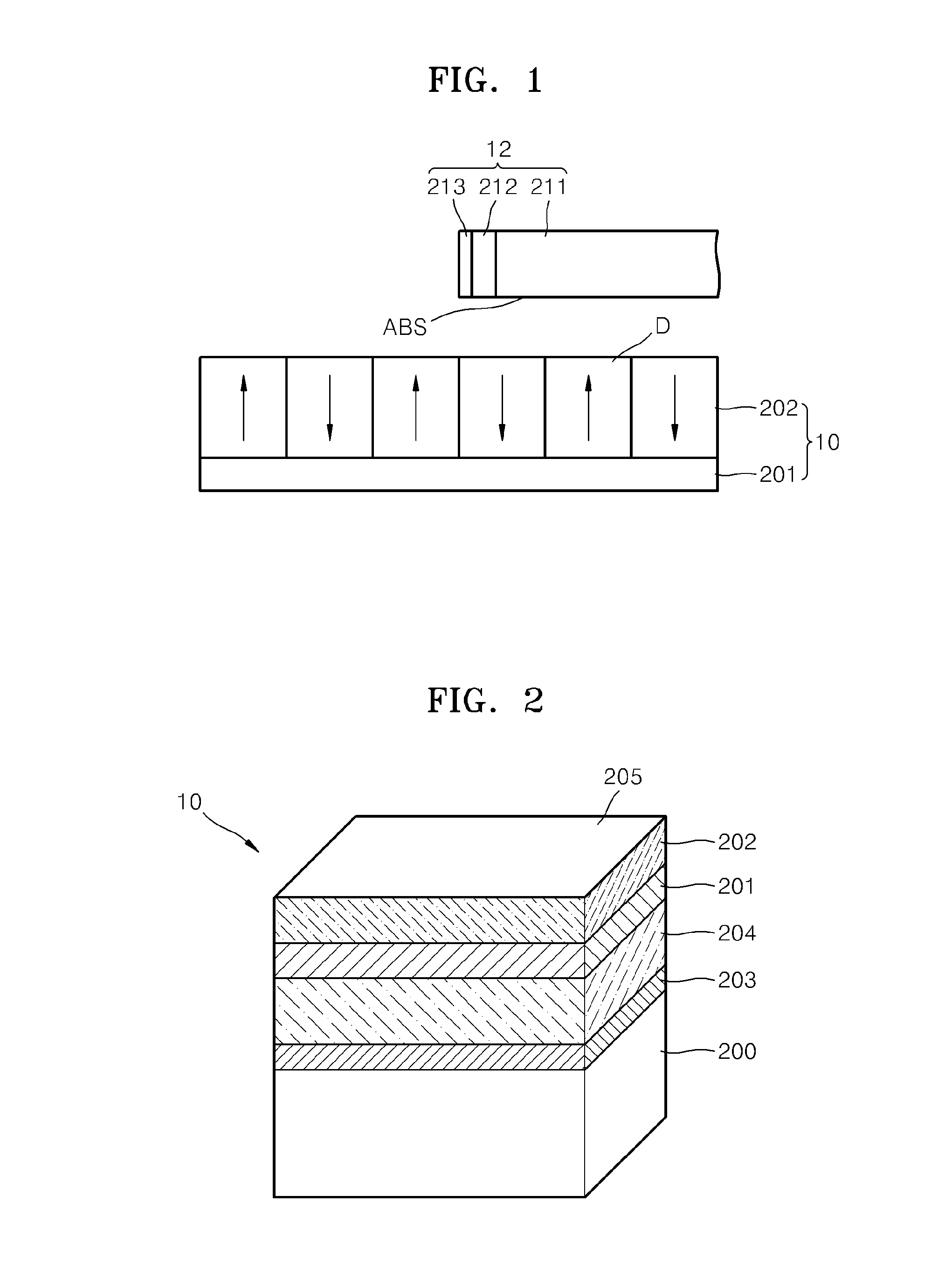

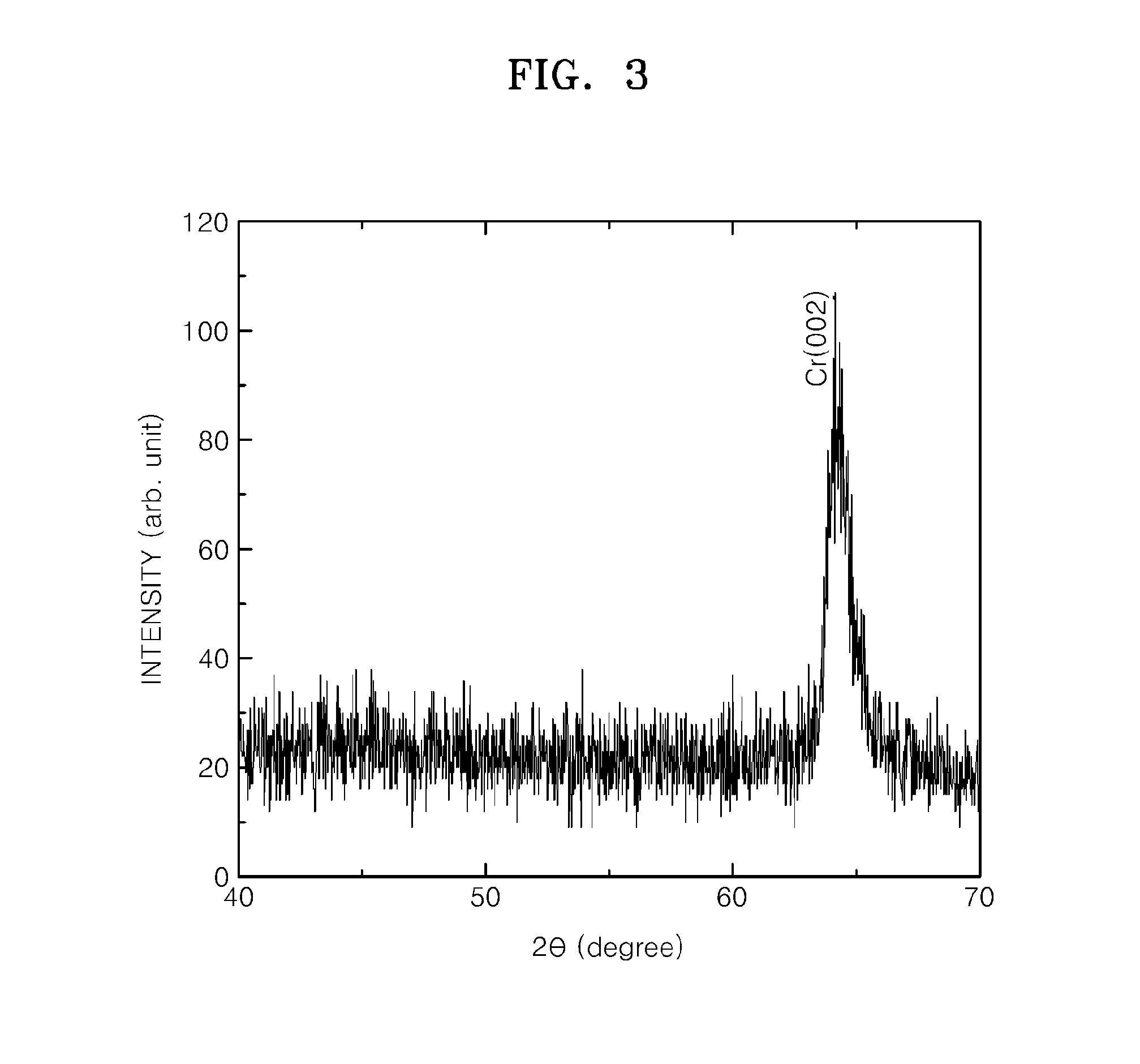

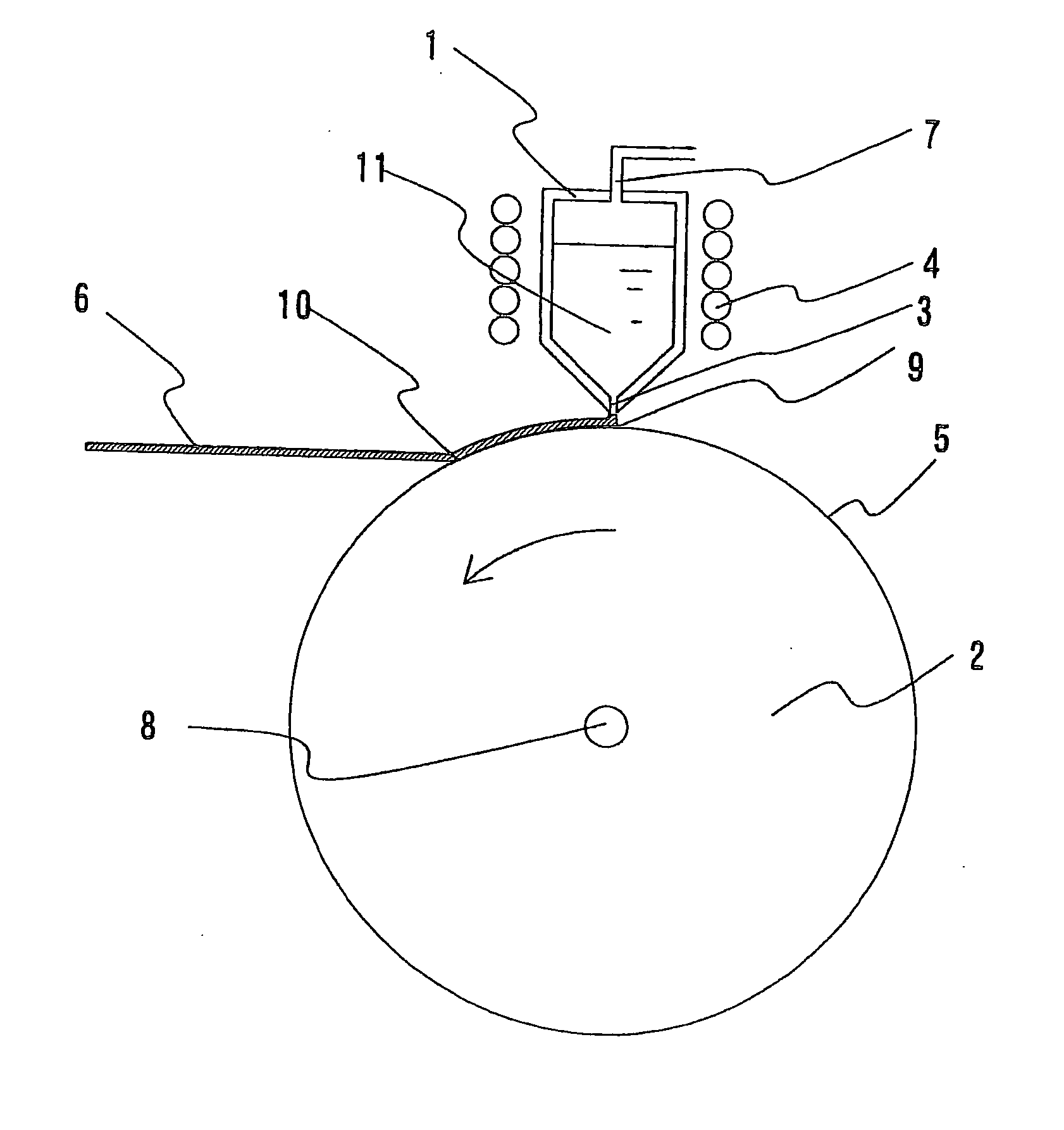

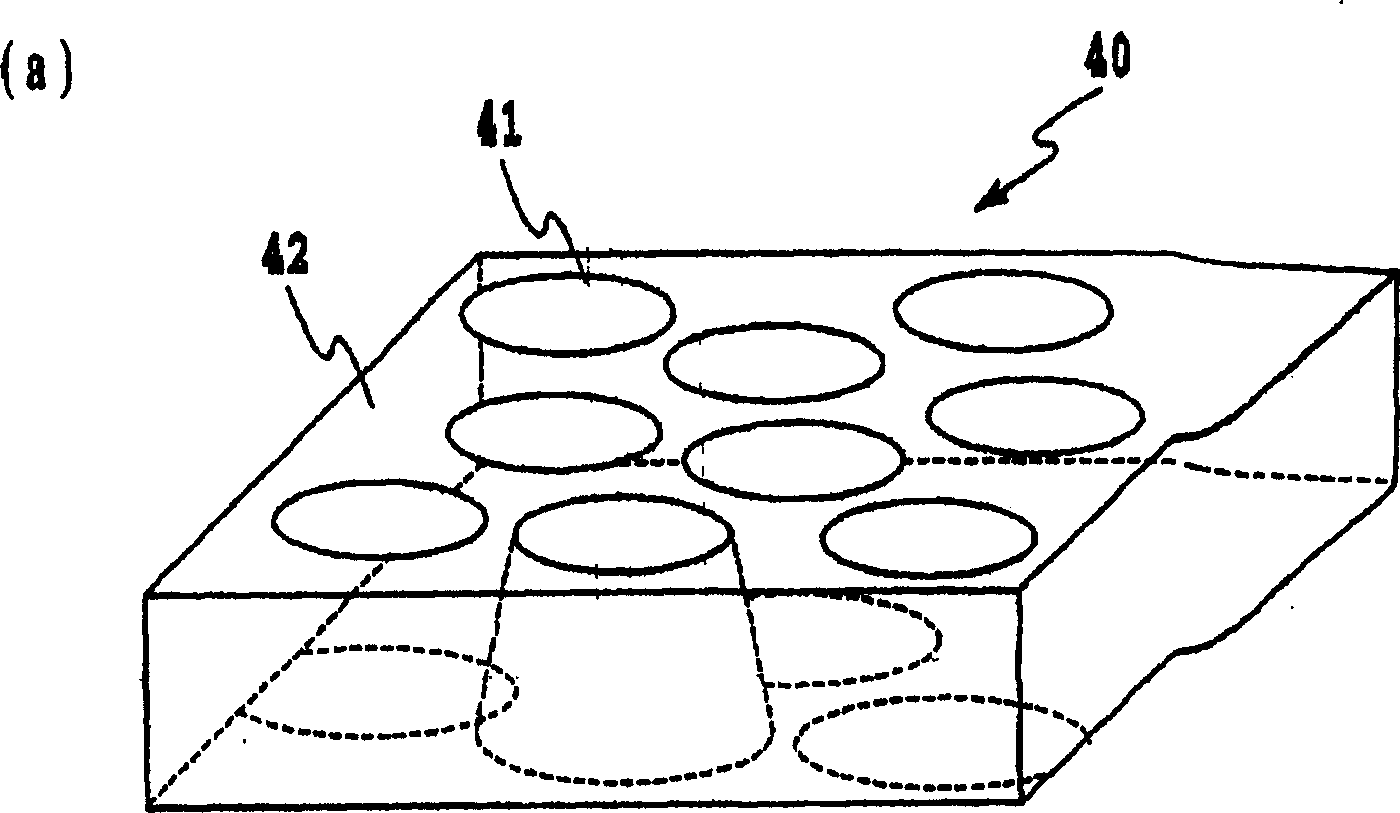

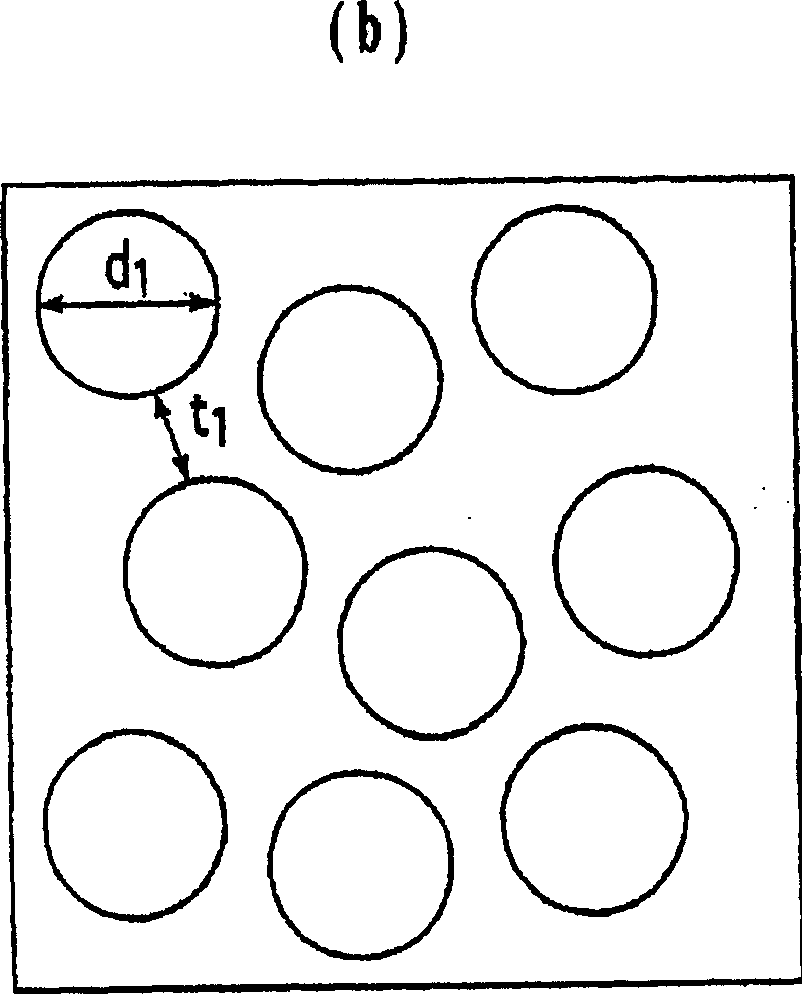

Perpendicular magnetic recording medium, method for preparing the same and magnetic recording equipment

ActiveCN1734566ABase layers for recording layersRecord information storageRecording densityNon magnetic

The object of the present invention is to provide a perpendicular medium, which can suppress the dispersion of alignment and reduce the size of magnetic clusters in the magnetic recording layer by forming the isolation structure of the bottom layer by a simple method like the conventional process for producing continuous film medium. Perpendicular media also have a higher recording density due to the thinner underlying film. A perpendicular magnetic recording medium comprises at least one underlayer and a magnetic recording layer sequentially laminated on a non-magnetic substrate. The bottom layer is composed of crystal grains and amorphous grain boundaries, and the shape of the grains satisfies the following relationship: (area of the bottom region at the initial stage of growth) > (area of the top region).

Owner:FUJI ELECTRIC CO LTD

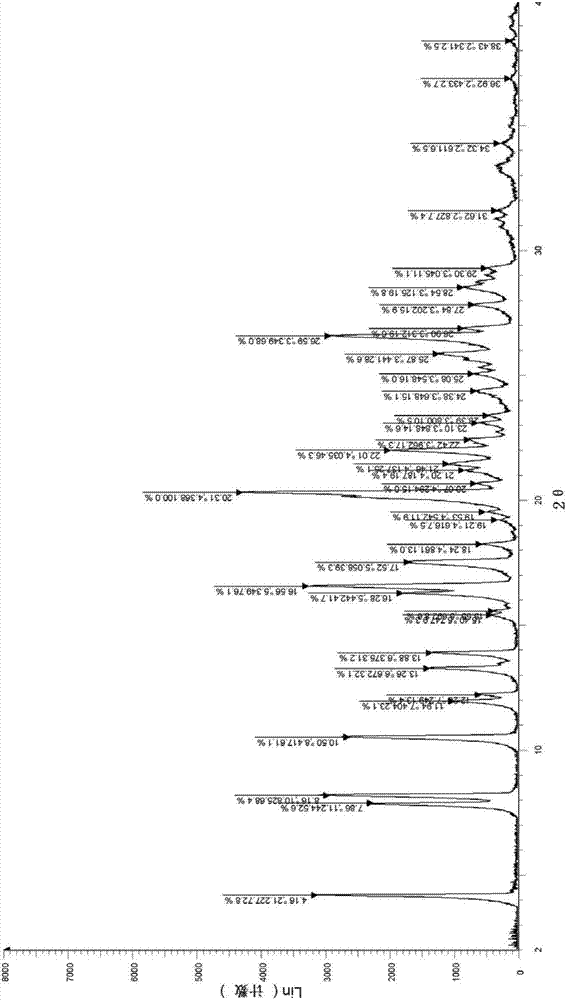

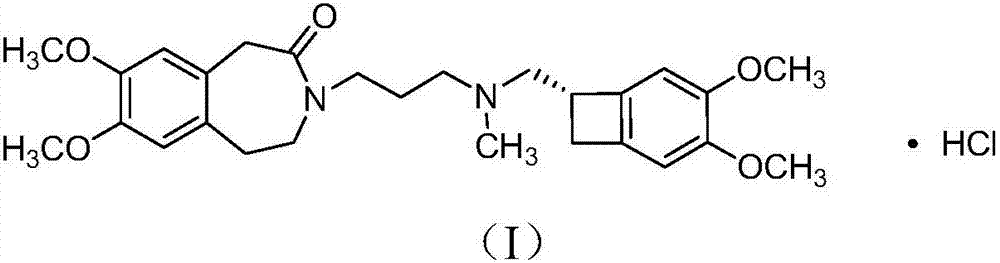

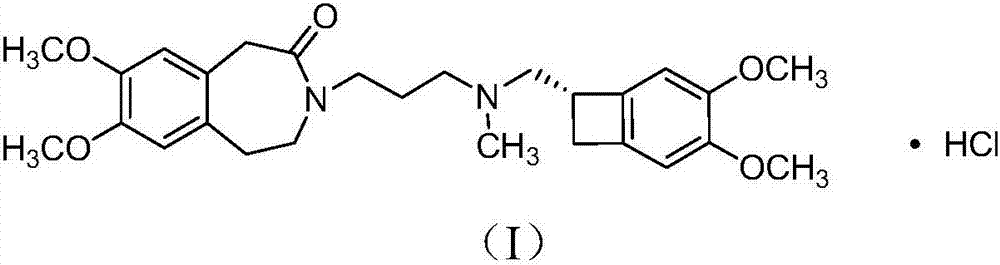

Method for preparing ivabradine hydrochloride alpha crystal form

The present invention relates to a method for preparing an ivabradine hydrochloride alpha crystal form, particularly to a preparation method of an ivabradine hydrochloride alpha crystal form represented by a formula I, wherein the amorphous crystal form or other crystal forms of the ivabradine hydrochloride are subjected to high temperature stirring crystal transformation in toluene, butyl acetate or 4-methyl-2-pentanone and other high boiling point poor solvents. According to the present invention, with the application of the method to prepare the ivabradine hydrochloride alpha crystal form, the operation process is simple, the product yield is high, and the product is easy to dry. The formula I is defined in the specification.

Owner:JIANGSU HENGRUI MEDICINE CO LTD +1

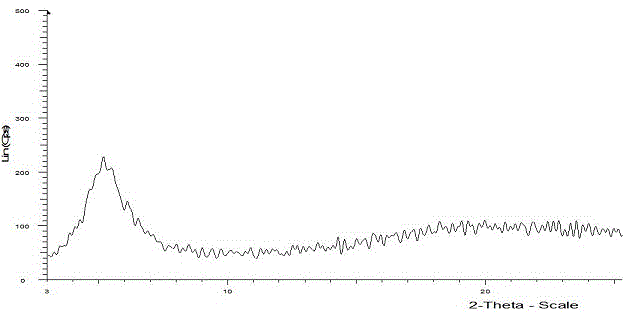

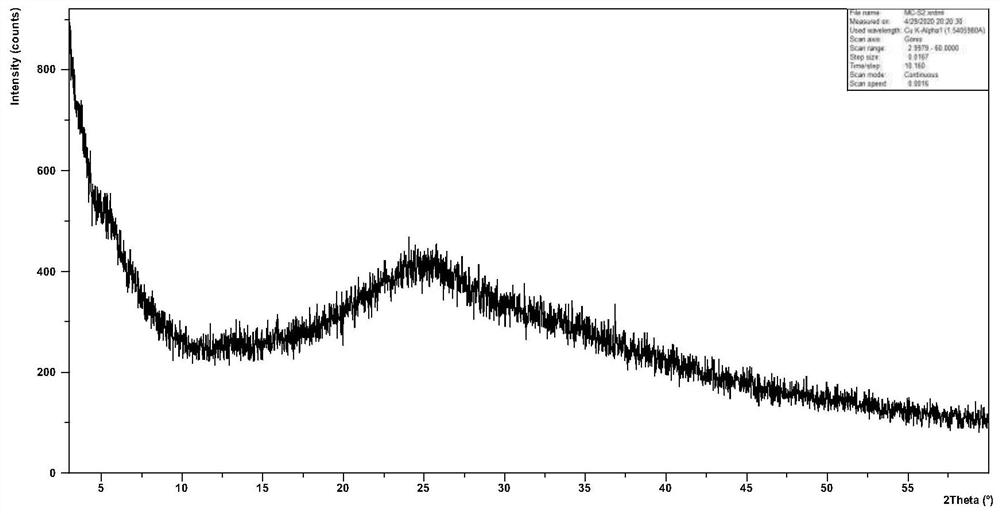

Amorphous crystal form of acetylcholine chloride and preparation method thereof

PendingCN111635327AImprove product qualityQuality is easy to controlOrganic compound preparationOrganic chemistry methodsEthyl acetateN-Butyl Alcohol

The invention relates to the technical field of medicine crystal forms, in particular to an amorphous crystal form of methylcholine chloride and a preparation method of the amorphous crystal form. Inan X-ray powder diffraction pattern of the amorphous acetylcholine chloride crystal form, an amorphous characteristic steamed bun peak exists when 2 theta is equal to 20-35 when the X-ray powder diffraction pattern is expressed by 2 theta + / -0.2 degrees. The preparation method comprises the following steps: dissolving a crude product of acetylcholine chloride in acetonitrile or n-butyl alcohol, and dropwise adding ethyl acetate, acetone or tetrahydrofuran to obtain the amorphous crystal form of acetylcholine chloride. The amorphous crystal form has better wet stability, thereby being beneficial to production and quality control of bulk drugs.

Owner:北京磐谷英汇科技有限公司

Amorphous crystal form of voriconazole disodium phosphate

The invention discloses an amorphous crystal form of voriconazole disodium phosphate. The chemical purity and the crystal form purity of the amorphous voriconazole disodium phosphate are both lager than 98%. In addition, the invention also discloses a preparation method of the amorphous voriconazole disodium phosphate, and further discloses a pharmaceutical composition containing the amorphous voriconazole disodium phosphate and an application of the composition in preparing medicines for treating fungal infection.

Owner:天地人和生物科技有限公司

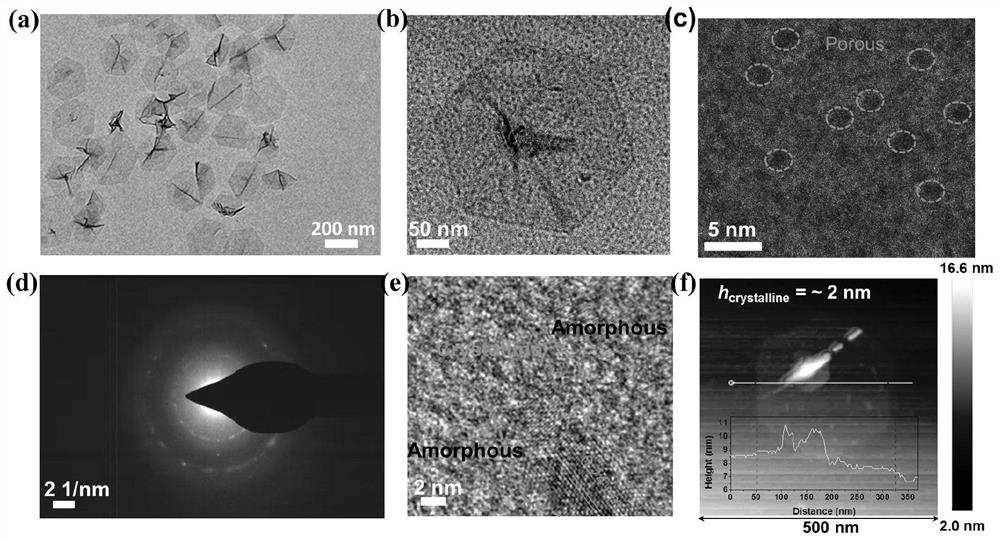

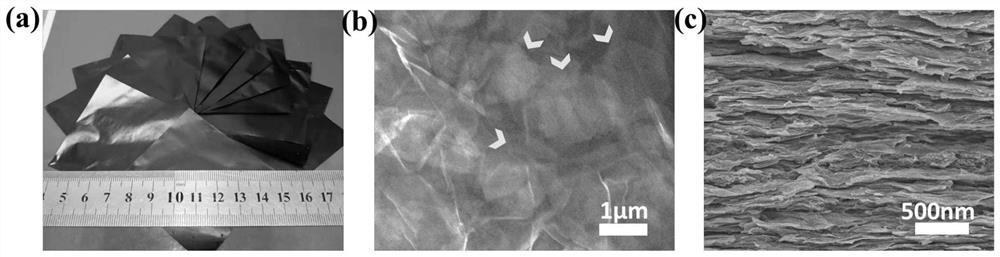

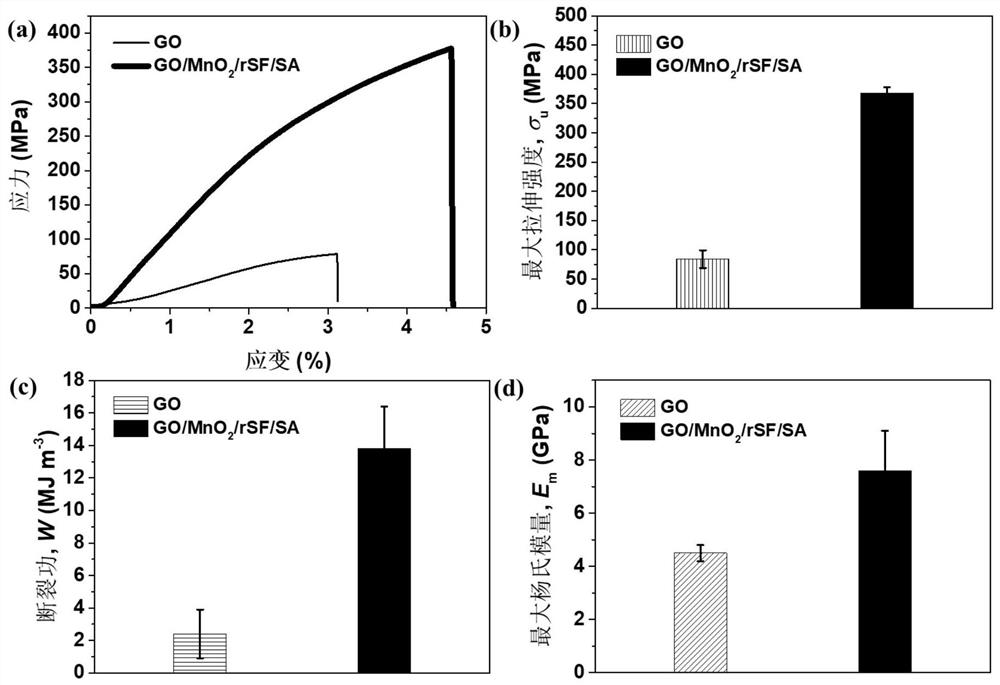

Shell-imitated light-weight high-strength composite material and preparation method thereof

The invention belongs to the technical field of composite material preparation, and relates to a preparation method of a shell-like light-weight high-strength composite material, which comprises the following steps: (1) taking a leaf-shaped amorphous crystal heterogeneous manganese dioxide nanosheet prepared by an oxidation-reduction method and graphene oxide obtained by a Hummers oxidation methodas main construction units, and combining with a small amount of biomacromolecules, preparing a high-strength composite film material through an evaporation-induced self-assembly method; and (2) a large number of composite film materials are assembled into a whole through layer-by-layer brushing of a cross-linking agent, and the light high-strength block layered micro-nano composite material is obtained in combination with a hot-pressing process. The preparation process is simple and convenient to operate, the process is green and environmentally friendly, and the strength of the finally prepared block composite material is far superior to that of most other graphene oxide-based block composite materials.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com