Patents

Literature

330 results about "Disodium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disodium phosphate (DSP), or sodium hydrogen phosphate, or sodium phosphate dibasic, is the inorganic compound with the formula Na₂HPO₄. It is one of several sodium phosphates. The salt is known in anhydrous form as well as forms with 2, 7, 8, and 12 hydrates. All are water-soluble white powders; the anhydrous salt being hygroscopic.

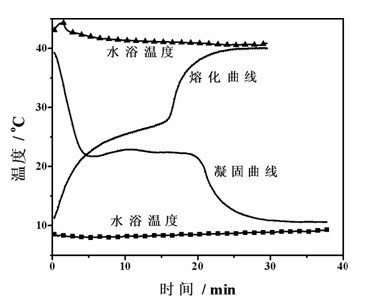

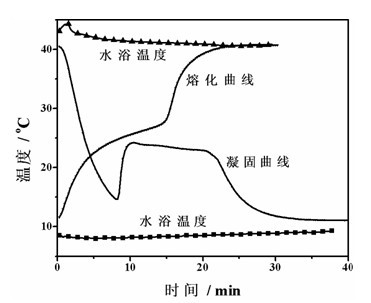

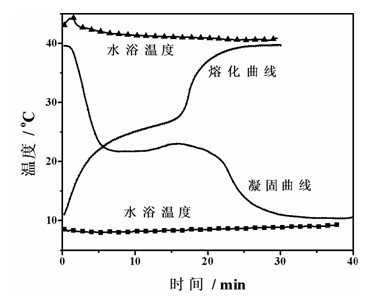

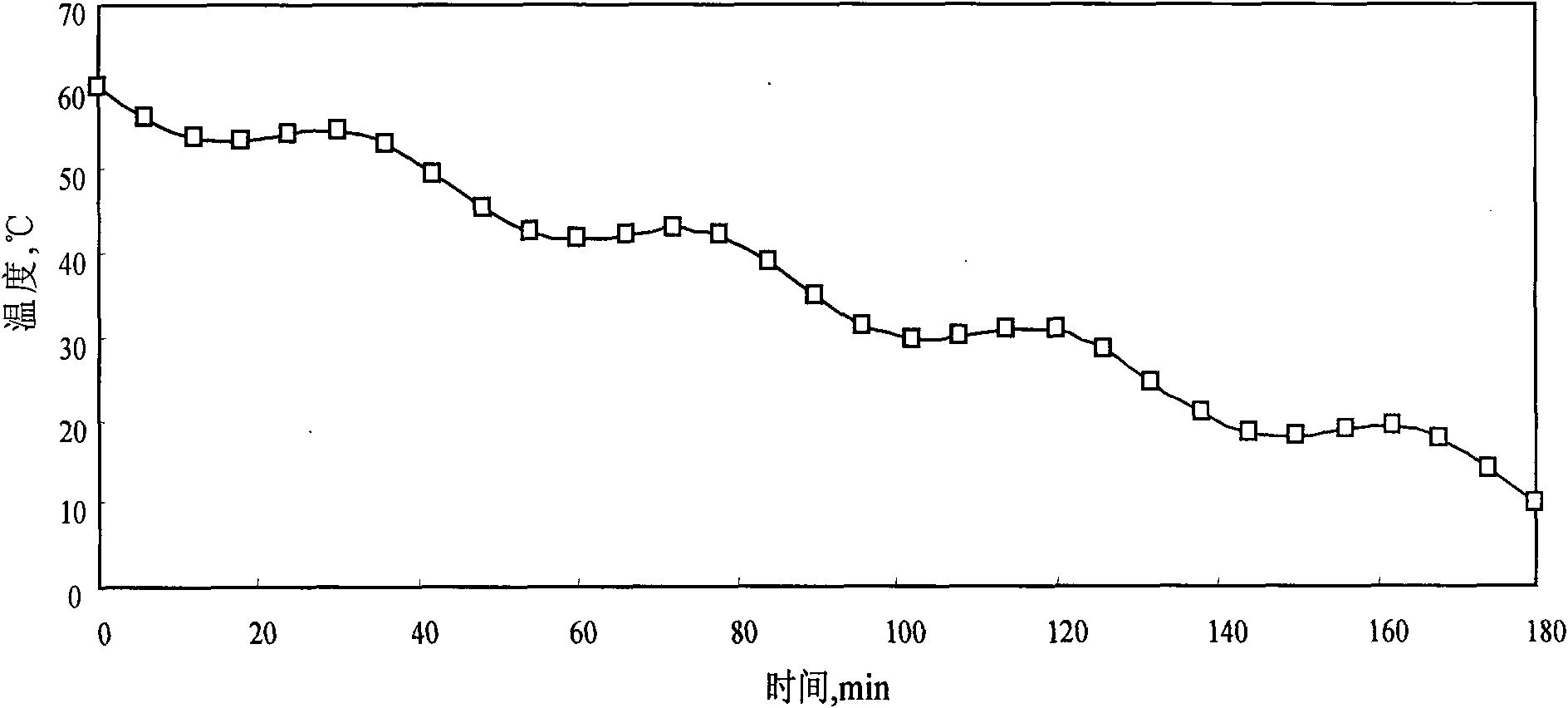

Inorganic phase-change material and preparation method thereof

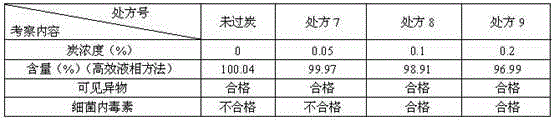

InactiveCN102660231ALatent heat of fusion without decaySimple methodHeat-exchange elementsDisodium phosphateHydrogen phosphate

The invention discloses an inorganic phase-change material and a preparation method thereof. The inorganic phase-change material comprises at least one of a thickening agent and a water-retaining agent, and main thermit, nucleating agent, pH regulator, heat conducting agent, and water, wherein the main thermit is eutectic salt of sodium sulfate decahydrate and sodium hydrogen phosphate docecahydrate. The preparation method comprises the following steps: adding the main thermit in water, stirring in 40-45 DEG C water bath until completely fusing, adding the nucleating agent, the pH regulator, and the heat conducting agent and fully stirring to completely dissolve the nucleating agent and the pH regulator and uniformly disperse the heat conducting agent, then adding at least one of the thickening agent and the water-retaining agent and stirring to uniformly disperse the thickening agent or completely expanse the water-retaining agent, so as to obtain the inorganic phase-change material. The inorganic phase-change material of the invention has the characteristics of noninflammability and no toxicity, the phase change temperature is 21-27 DEG C, the latent heat of phase change is 214 kJ / kg, and the inorganic phase-change material has no attenuation of performance after 1000 weeks of the solidification-fusing cycle.

Owner:WUHAN UNIV

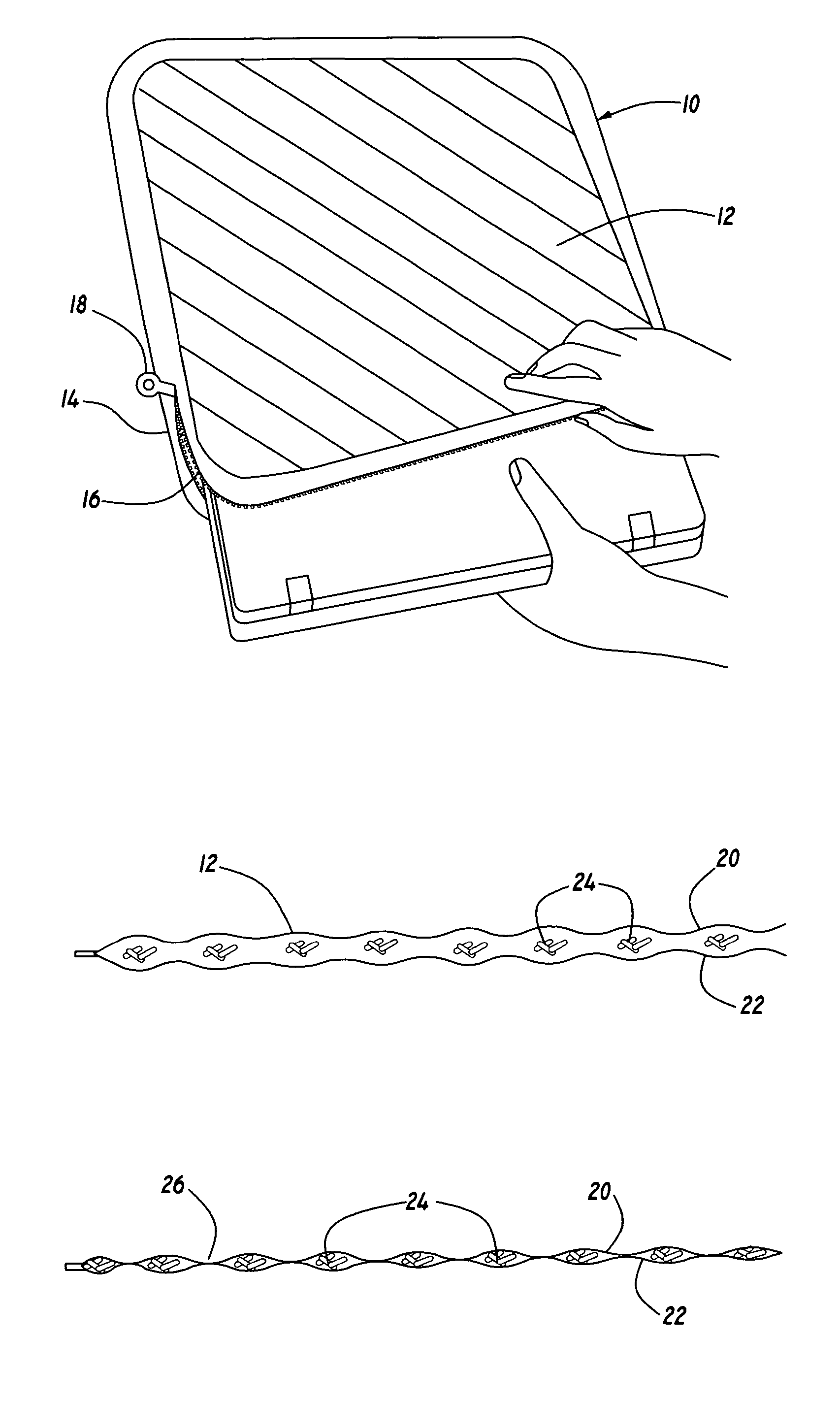

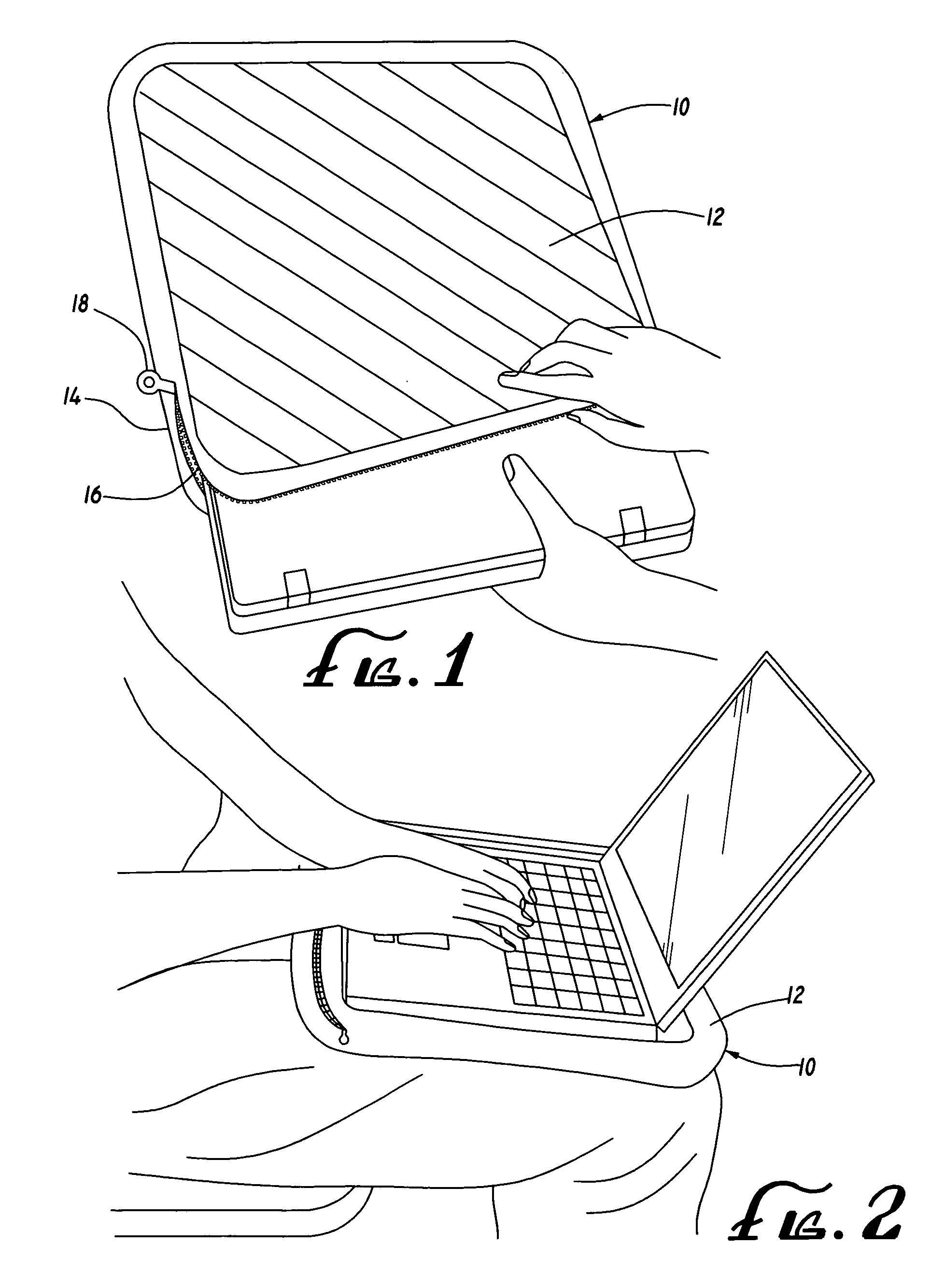

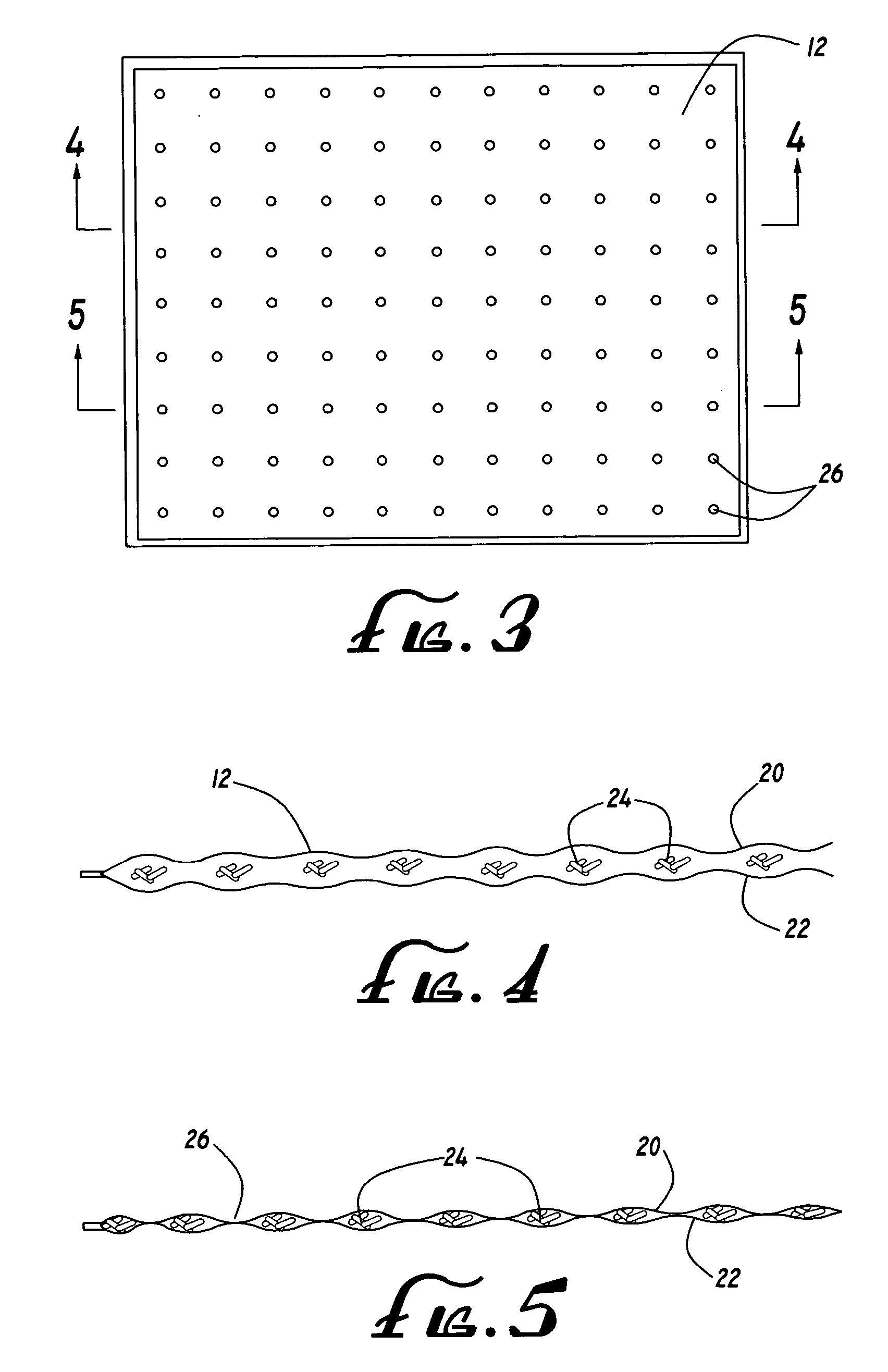

Conductive cooling pad for use with a laptop computer

InactiveUS7324340B2Details for portable computersCooling/ventilation/heating modificationsDisodium phosphateSodium Thiosulfate Pentahydrate

A self contained laptop computer cooling pad that does not require any electrical power to operate and will effectively and efficiently reduce the operating temperature of the computer and reduce the heat being transferred into the user's lap. The cooling pad contains a phase-changing compound such as sodium sulfate decahydrate, sodium carbonate decahydrate, disodium phosphate dodecahydrate or sodium thiosulfate pentahydrate, and may be made of a soft, flexible material that will contain the phase-changing compound and prevent excess shifting within the cooling pad. The cooling pad is placed under the laptop computer when operating the computer to effectively transfer heat away from the computer by conduction and prevent passage onto the user. The cooling pad may be in the form of a sleeve to additionally provide padded storage for the computer when not in use.

Owner:XIONG WEI

Multifunctional composite material with heterostructure and preparation method thereof

InactiveCN102974375AOptimal Control StructureSingle shapeBiocidePhysical/chemical process catalystsMaterials scienceOrganopónicos

Owner:JIANGSU UNIV

Hydrogen Peroxide Toothpaste With Improved Stability

InactiveUS20130108559A1Improve stabilityCosmetic preparationsToilet preparationsPhosphatePhosphoric acid

Aqueous oral care compositions containing hydrogen peroxide and having improved stability, such compositions containing at least 35%, by weight of the composition, of water and further including a peroxide compatible abrasive such as fused silica, calcium pyrophosphate and / or dicalcium phosphate, a gel network, and a protection system containing sodium acid pyrophosphate, disodium phosphate, and / or phosphoric acid.

Owner:THE PROCTER & GAMBLE COMPANY

Chitosan polymer and preparation method thereof

The invention relates to a medical material for surgery, in particular to a chitosan polymer capable of being used as a medical bioengineering scaffold and a carrier carrying active growth factors and a preparation method thereof. In the preparation method, the raw materials comprise natural chitosan powder, gelatin powder, genipin solution and glycerol-2-disodium phosphate powder; the preparation method comprises a preparation stage of the raw materials before synthesis and a synthesis stage; and in the synthesis stage of the chitosan polymer, the natural chitosan is subjected to chemical cross-linking and ion cross-linking with the genipin and the glycerol-2-disodium phosphate respectively, and the gelatinous chitosan polymer is obtained. The method is simple in operation, the adopted materials are natural and nontoxic and are conveniently obtained, and the chitosan polymer produced by using the method has good stability and can be used as the medical bioengineering scaffold and thecarrier carrying the active growth factors.

Owner:赵文 +1

Cleaning and bleaching solutions containing phosphates and/or phosphoric acid and improved processes for their use

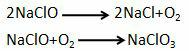

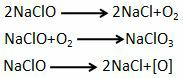

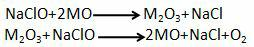

InactiveUS20050075263A1Chlorine stability lossOrganic detergent compounding agentsNon-surface-active detergent compositionsO-Phosphoric AcidDisodium phosphate

The present invention refers to cleaning and bleaching procedures, in which it is used bleaching solutions containing water, disodium phosphate dodecahydrate and / or diphosphonic-1,1-hydroxyethane-1 acid and / or phosphoric acid at the 75% of nutritional value, said solutions can be used for both, household and industrial purposes.

Owner:GOMEZ FERMIN ENECOIZ

Method for removing green algae in the middle and late culture stages of Porphyra yezoensis

InactiveCN102550388AImprove grade rateLittle impact from natural conditionsBiocideAnimal repellantsDisodium phosphatePorphyra

Disclosed is a method for removing green algae in the middle and late culture stages of Porphyra yezoensis. The method is characterized by comprising (1) preparing 50-100ml of 10% sodium hypochlorite solution, adding cleaned and disinfected seawater to reach a volume of 1L, adding trisodium phosphate and disodium phosphate at molar ratio of 3:1 to the above solution, and adjusting pH to 9.0-9.5 for later use; (2) during the culture process after nori mesh screens are placed into the sea (i.e. from September 21 to April of the next year), performing smear operation in the sea; (3) during the process to clear green algae, adding analytical grade citric acid to the solution of step (1) to allow pH value of the solution to be about 5.0-5.5; (4) smearing the solution obtained in step (3) in batches every day to green algae attached to mesh screens, raft frames and cables so that the damaged green algae break under the effect of seawater flow and enter the sea; and (5) smearing with the solution obtained in step (3) once every two months. The method of the invention can remove green algae attached to mesh screens, raft frames and cables in the middle and late culture stages of Porphyra yezoensis.

Owner:SHANGHAI OCEAN UNIV

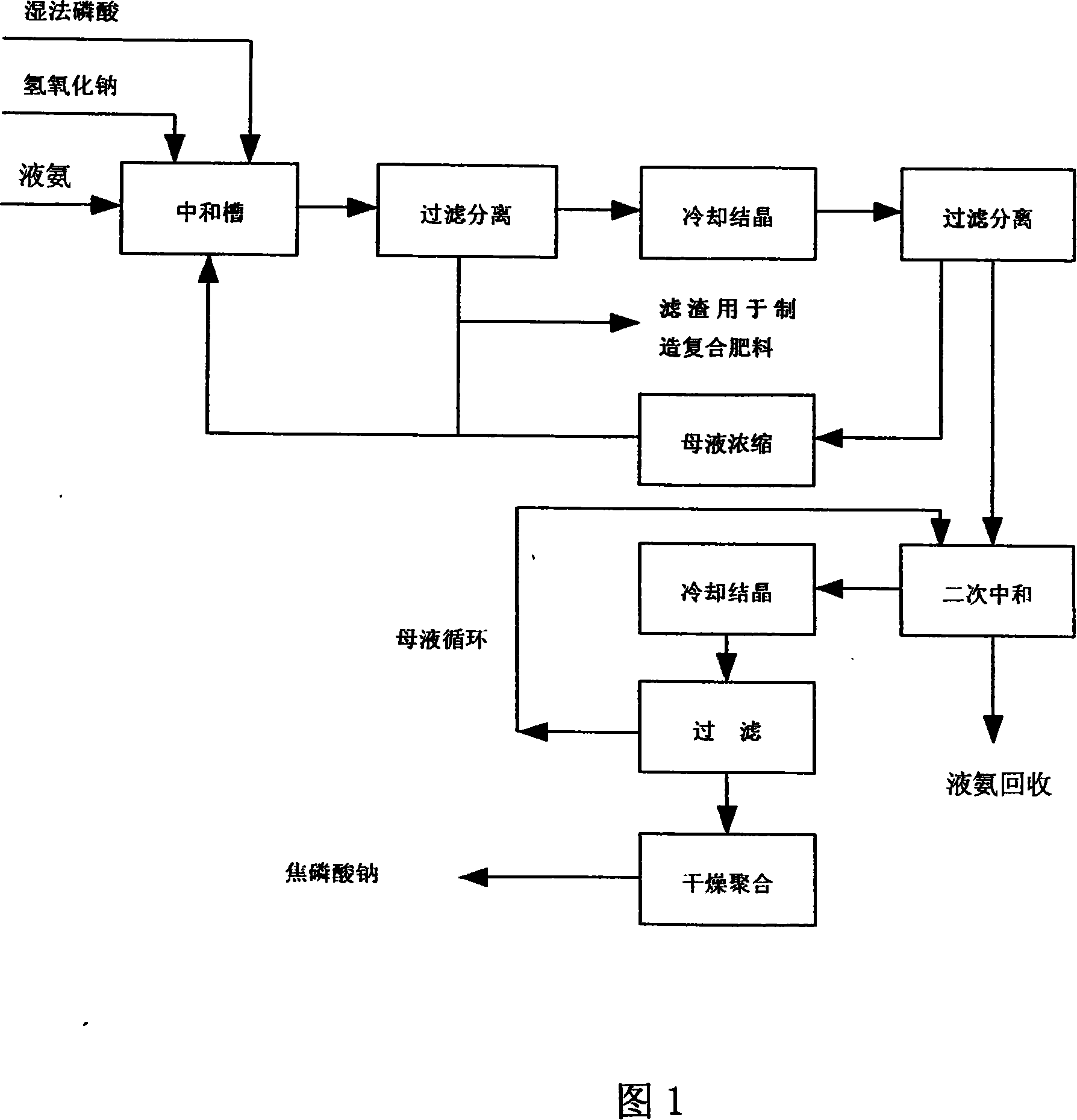

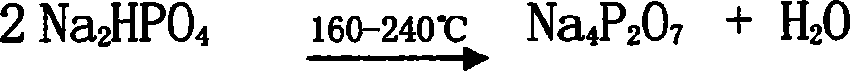

Technique for preparing sodium pyrophosphate from wet method phosphoric acid

InactiveCN101121506AControl impurity contentAvoid easy separationPhosphorus compoundsPhosphoric acidPyrophosphate

Owner:SICHUAN HONGDA

Extraction method of ginger essential oil

Owner:SOUTH CHINA UNIV OF TECH

Methods for coagulating collagen using phosphate brine solutions

InactiveUS7078068B2Shorten drying timePhosphatesPeptide/protein ingredientsDisodium phosphateDipotassium phosphate

Owner:ICL PERFORMANCE PROD

5'-guanosine-disodium phosphate crystallizing method

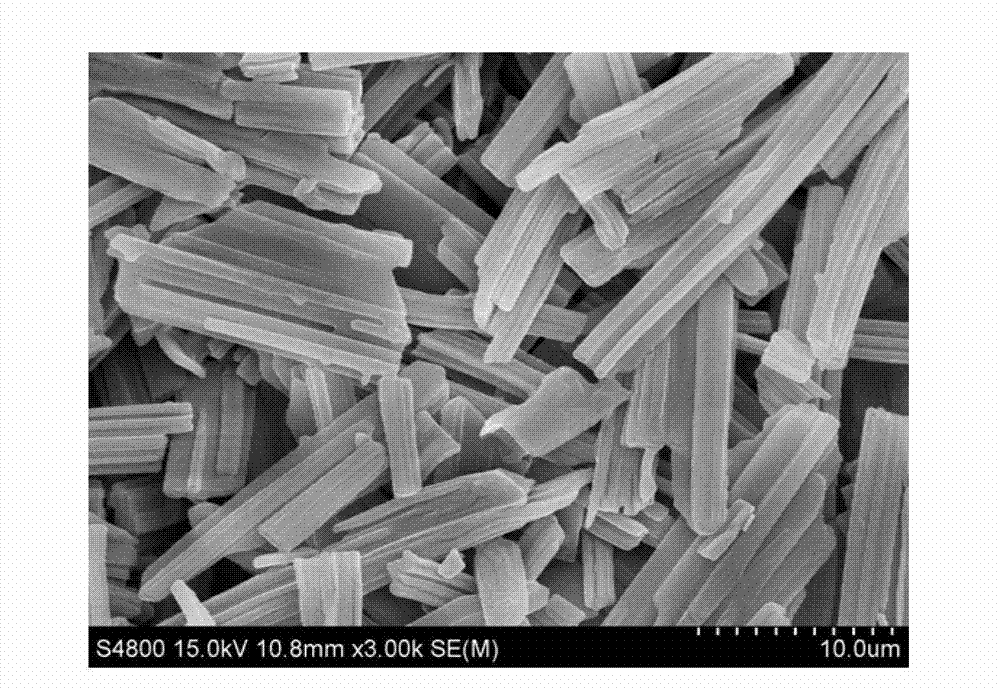

InactiveCN101654469ACrystal stablePromote conversionSugar derivativesSugar derivatives preparationDisodium phosphateNational standard

The invention discloses a 5'-guanosine-disodium phosphate crystallizing method comprising the following steps: adding sodium salt which is 0.2-2 times of 5'-guanosine-disodium phosphate and desolvation with a volume being 0.3-3 times of that of a 5'-guanosine-disodium phosphate solution into a 5'-guanosine-disodium phosphate crude product water solution with concentration of 5-20 percent by weight; controlling the crystallizing temperature of 10-60 DEG C; controlling the mixing rotating speed of 50-300r / min; and after the crystallization is completed, filtering and drying the solution to obtain a 5'-guanosine-disodium phosphate crystal. Due to the adoption of the method, the product quality of the obtained 5'-guanosine-disodium phosphate crystal reaches the national standard, and the 5'-guanosine-disodium phosphate crystal with a stable crystal grain diameter range can be obtained by controlling a crystallizing technical condition and a flow field state. The 5'-guanosine-disodium phosphate crystallizing method has simple operation, good repeatability and shorter crystallizing time and is suitable for the industrial production of the 5'-guanosine-disodium phosphate product.

Owner:SOUTH CHINA UNIV OF TECH +1

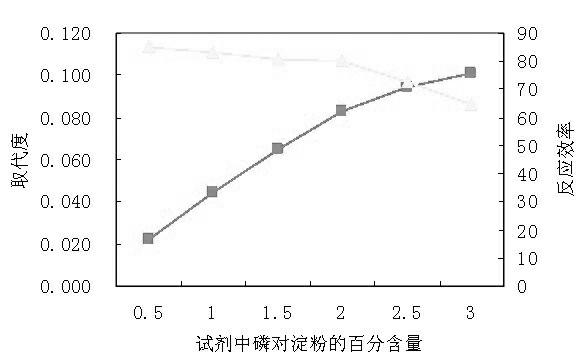

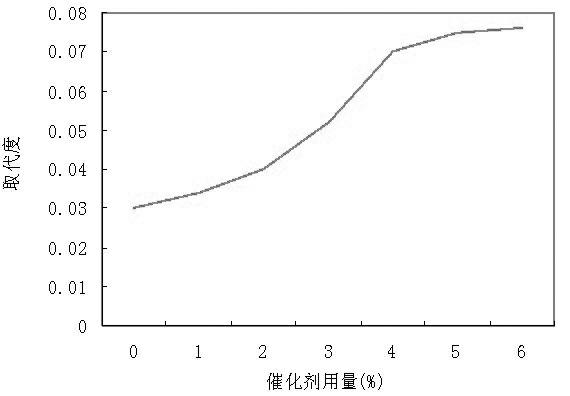

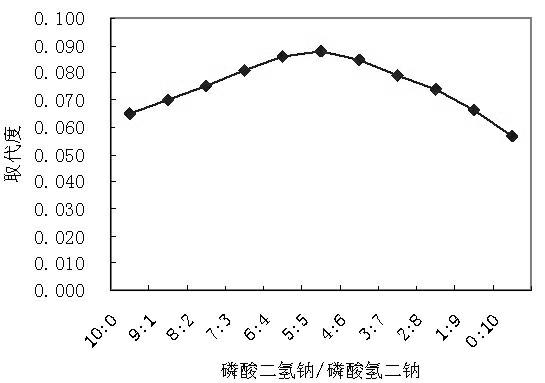

Phosphate starch printing paste and preparation method thereof

InactiveCN102154851AHigh viscosityGood viscosity stabilityDyeing processSODIUM METAPHOSPHATEPhosphoric Acid Esters

The invention discloses a phosphate starch printing paste and a preparation method thereof. Cassava starch is utilized to be reacted with sodium dihydrogen phosphate and sodium hydrogen phosphate in hot air, and urea is adopted as a catalyst to produce phosphate starch. The sodium dihydrogen phosphate and the sodium hydrogen phosphate generate micro sodium metaphosphate at high temperature, and the sodium metaphosphate is crosslinked with the starch, thus the viscosity of the starch is improved. Simultaneously, the urea is used as the catalyst and in esterification with the starch so as to generate hydrophilic carbamic acid ester starch. The phosphate starch produced by adopting the method can be dissolved in cold water; the paste is transparent and has clean color and luster; the sodium metaphosphate is corsslinked with the starch, thus the viscosity and the viscosity stability of the starch are improved, the PVI (polyvinyl isobutyl ether) value is increased, and the preparation method is more suitable for being applied to the printing paste.

Owner:JIANGXI BODA CHEM

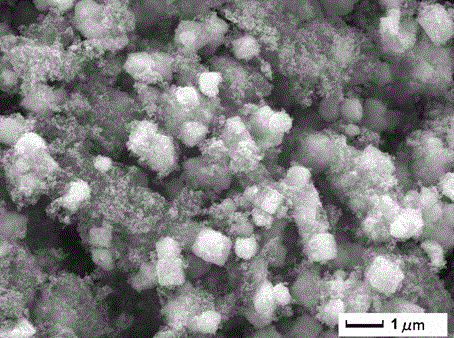

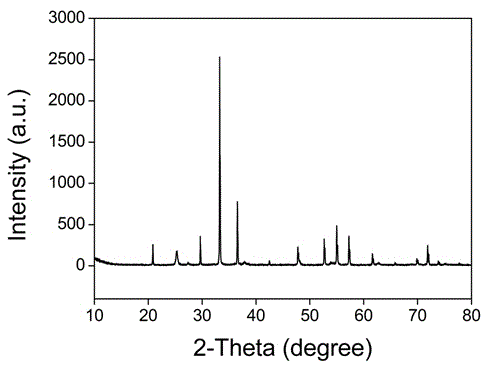

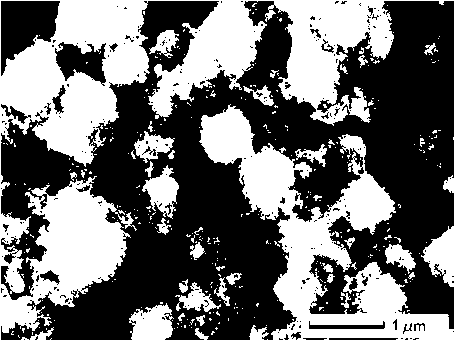

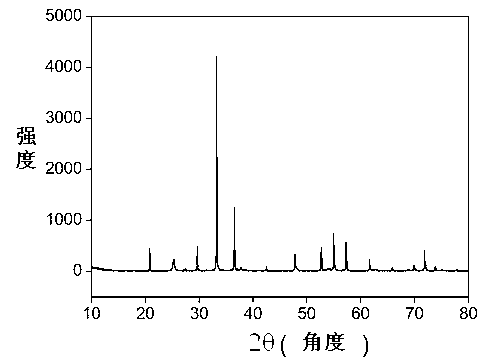

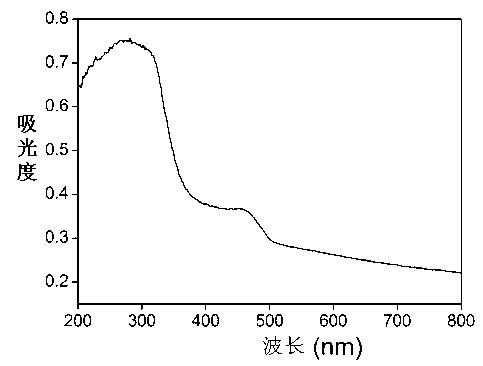

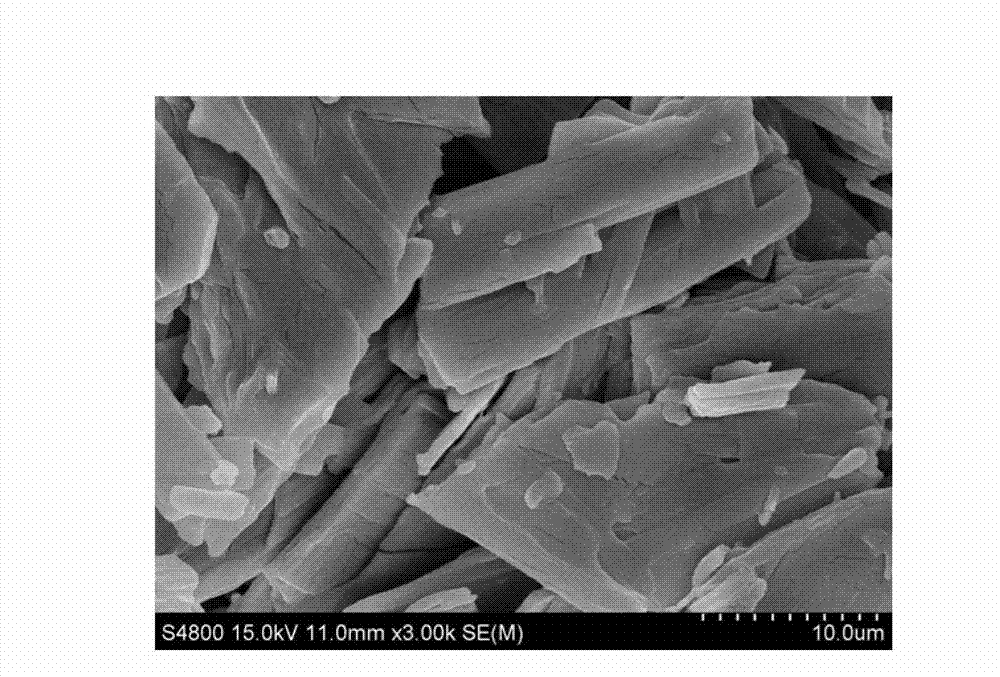

Silver phosphate cuboid/P25 dual-function composition material and preparation method thereof

InactiveCN103120944ARegular topographyUniform particle sizeBiocidePhysical/chemical process catalystsOrganic dyePhosphoric acid

The invention discloses a silver phosphate cuboid / P25 dual-function composition material and a preparation method thereof, which belong to the technical field of composition materials, antibiosis materials, photocatalysis and environmental management. The preparation method comprises the following steps of: dissolving P25 in water and performing ultrasonic dispersion on the P25 to obtain a P25 dispersion solution; dissolving silver nitrate in de-ionized water, and dripping the dissolved silver nitrate in the P25 dispersion solution under a magnetic stirring condition, thus obtaining a mixed solution A; slowly dripping prepared ammonia water in the mixed solution A, thus obtaining a mixed solution B; and stirring the ammonia water and the mixed solution B for a while, slowly dripping a disodium hydrogen phosphate solution in the mixed solution B for unceasingly stirring, pumping and filtering products, repetitively washing the products by absolute ethyl alcohol and de-ionized water for many times, and drying the washed products in a vacuum manner, thus obtaining the silver phosphate cuboid / P25 dual-function composition material. Silver phosphate in the prepared composition material has a regular cubic structure and is uniform in particle size; and the composition material has a good photocatalysis degradation effect on organic dyestuff rhodamine B under visible light irradiation, and has a broad-spectrum sterilizing effect on common bacteria.

Owner:JIANGSU UNIV

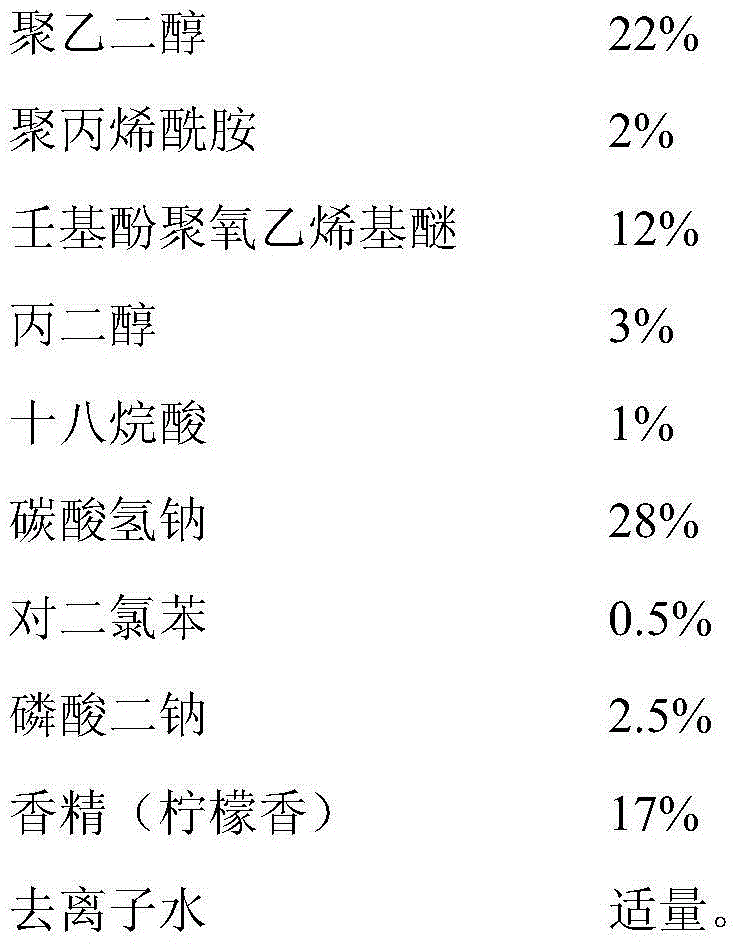

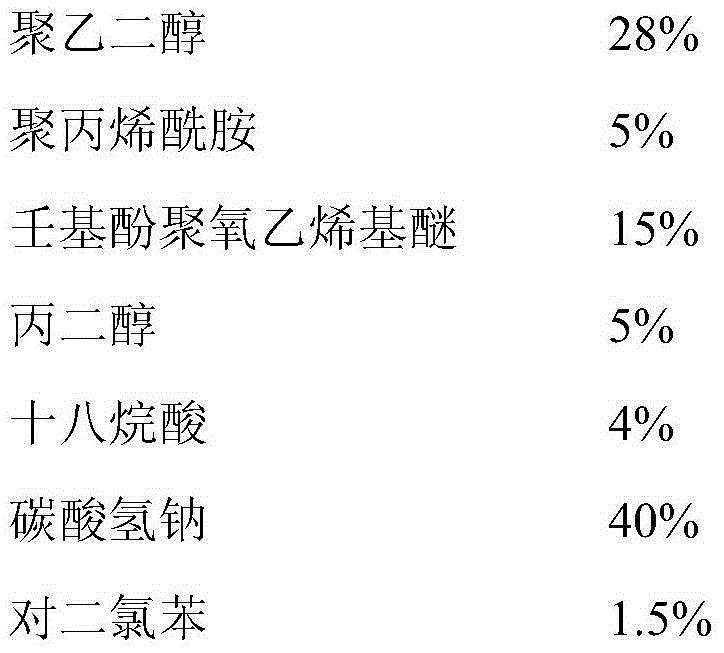

Toilet deodorizing scale inhibitor

InactiveCN104629961AGood scale inhibitionFunction increaseSurface-active non-soap compounds and soap mixture detergentsSodium bicarbonateSorbent

The invention provides a toilet deodorizing scale inhibitor. The toilet deodorizing scale inhibitor comprises polyethylene glycol, polyacrylamide, polyoxyethylene nonylphenyl ether, propanediol, octadecanoic acid, sodium bicarbonate, p-dichlorobenzene, disodium phosphate, an essence (lemon essence) and deionized water. Sodium bicarbonate easily reacts with ammonia to produce an odorless carbonate substance which has the function of deodorizing; the anti-static surfactant can avoid the occurrence of new dirt; polyethylene glycol can form a film on the surface of water to seal and cover residual stink; and propanediol is a good adsorbent to harmful gases such as hydrogen sulfide.

Owner:QINGDAO WATER WORLD ENVIRONMENTAL PROTECTION TECH

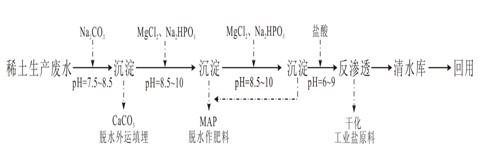

Method for treating waste water generated in ionic rare earth production

InactiveCN102674593ASmall scaleIncrease reaction rateMultistage water/sewage treatmentReverse osmosisMagnesium ammonium phosphate

The invention discloses a method for treating waste water generated in ionic rare earth production. The method includes (1) feeding sodium carbonate into the waste water, keeping the pH (potential of hydrogen) value to range from 7.5 to 8.5, mixing the sodium carbonate with the waste water for 10 to 25 minutes, settling the mixture for 15 to 35 minutes, separating sediment and enabling calcium ion removal rate to reach 98% at least; (2) regulating the pH value of the mixture to range from 8.5 to 9.5 by supernate after sedimentation, simultaneously feeding magnesium chloride and sodium hydrogen phosphate into the mixture according to a ratio of n(Mg):n(N):N(P) of (1.5-2):(1-1.5):(1.2-2), mixing and stirring the mixture for 20 to 30 minutes, settling the mixture for 15 to 30 minutes, separating mud from water; and (3) repeating the step (2) once, regulating the pH value to range from 6 to 9 by the aid of hydrochloride acid after settling and water draining are performed in a secondary MAP (magnesium ammonium phosphate) method, then removing salt by a reverse osmosis membrane, and recycling drained water for production. The quantity of the fed sodium carbonate ranges from 105% to 120% of the molar concentration of calcium ions. Reveres osmosis concentrated liquor is used as an industrial salt raw material to be recycled after being dried. The method has the advantages of low cost, thorough and short reaction process, small size of reaction device, simple equipment and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

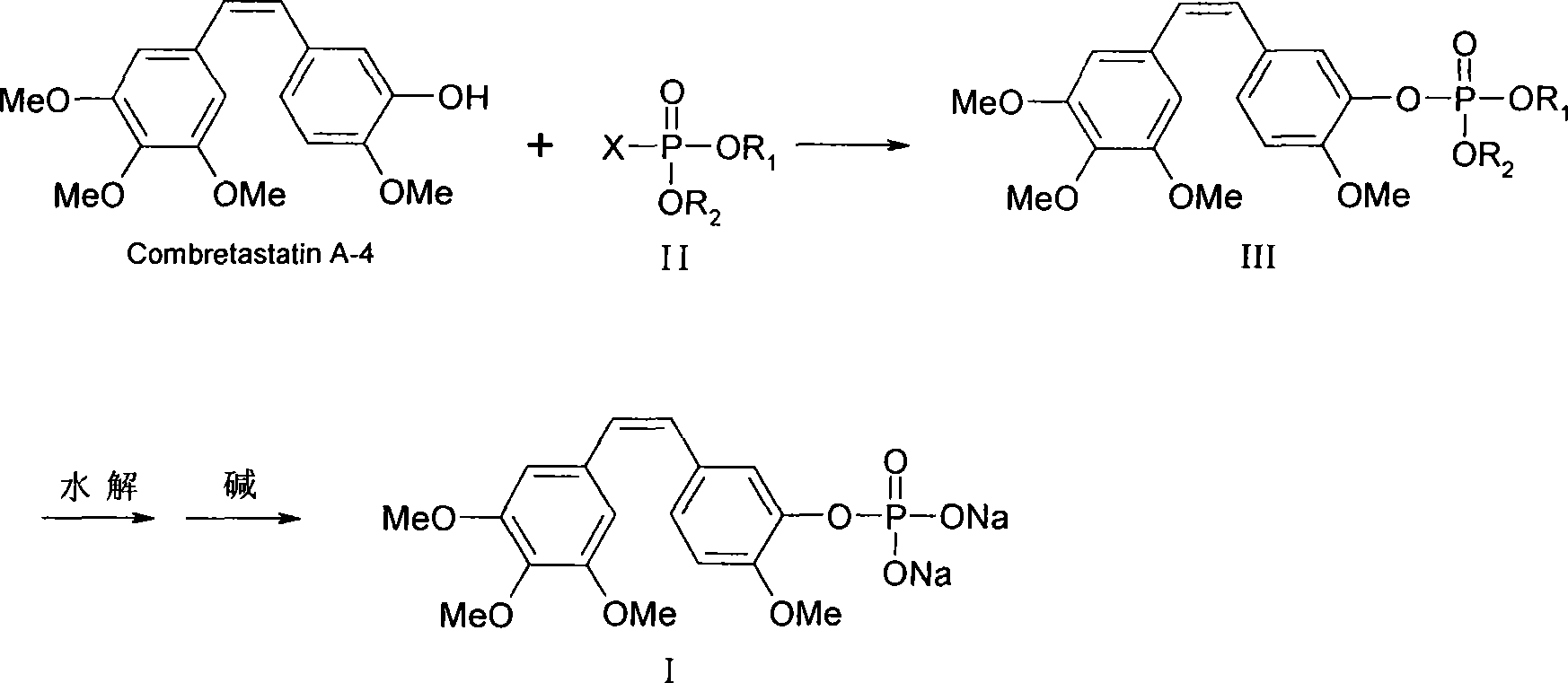

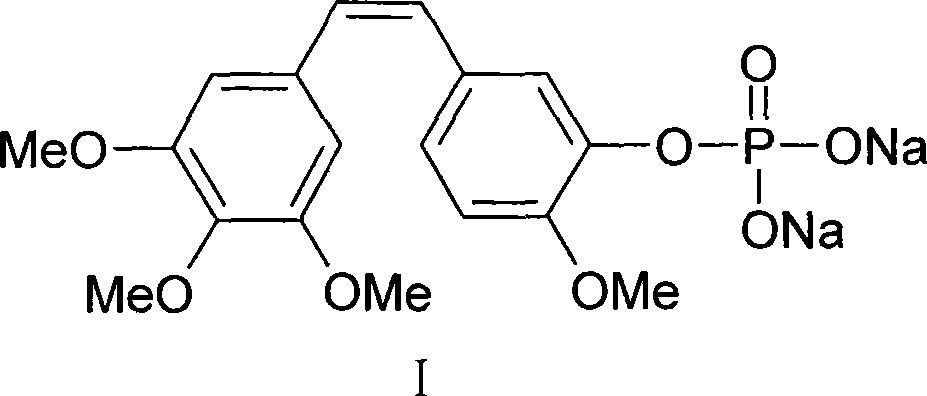

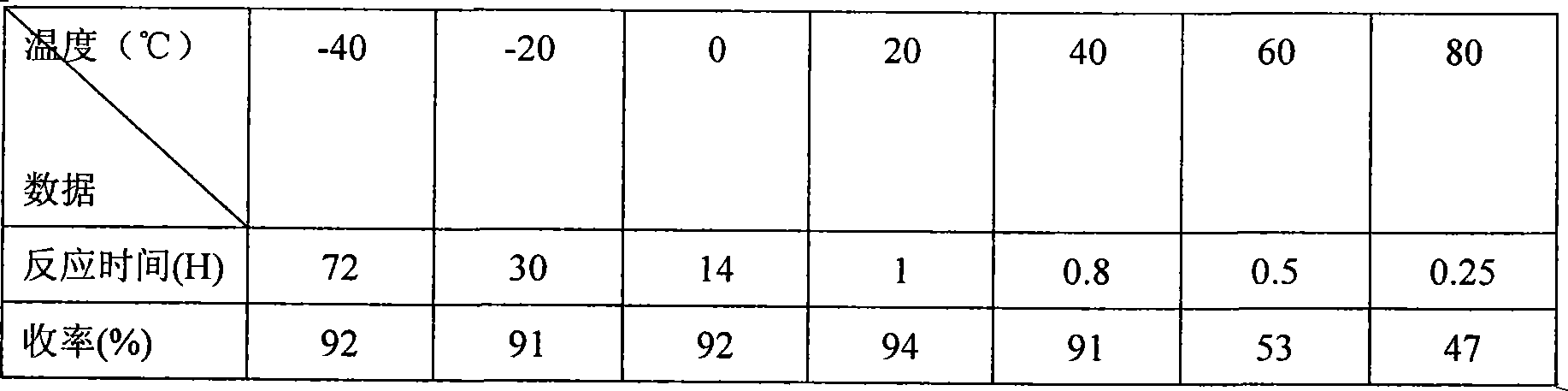

Method for preparing Combretastatin A-4 phosphoric acid ester disodium salt

ActiveCN101220054AMild reaction conditionsThe reaction temperature is constantGroup 5/15 element organic compoundsPhosphoric Acid EstersDisodium phosphate

The invention provides a method for preparation of Combretastatin A-4 disodium phosphate. The method carries out the synthesis according to the synthesizing route shown on the right, wherein X is chlorine or bromine; are selected from tert-butyl, triphenyl methyl, 2-cynaoethyl, benzyl, phenyl, 4-nitrophenyl, 4-nitrobenzyl and 2-nitrobenzyl, R1 and R2 can be identical or different substituting groups. The method adopts bis-alkoxyl phosphoryl halide as the phosphorylation reagent, which is inexpensive and easy to acquire. Catalyst DMAP is added in the reaction to milden the reaction condition and stabilize the reaction temperature. The reaction time is short and the operation is simple. The phosphorylation intermediate needs no purification. The invention also has the advantages of high yield and quality of product and easy industrial production.

Owner:SICHUAN HENGXING BIOMEDICAL

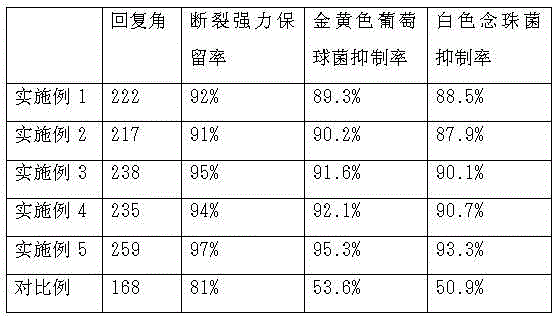

Anti-wrinkle antibiotic finishing agent as well as preparation method and application thereof

ActiveCN104695219AImprove wrinkle resistanceEnhanced inhibitory effectVegetal fibresBiotechnologyCyclodextrin

The invention discloses an anti-wrinkle antibiotic finishing agent as well as a preparation method and application thereof. The anti-wrinkle antibiotic finishing agent comprises 0.8-2.6wt% of azelaic acid, 1.6-3.2wt% of sodium hydrogen phosphate, 2.5-4wt% of carboxymethyl chitosan, 3.3-5.6wt% of hydroxypropyl-beta-cyclodextrin, 3-6wt% of a perilla frutescens ethyl acetate extract, 3.5-7wt% of a rhizoma kaempferiae ethanol extract, 6-12wt% of polyglycerol monooleate and the balance of water. The preparation method comprises the following steps: (1) preparing the perilla frutescens ethyl acetate extract; (2) preparing the rhizoma kaempferiae ethanol extract; and (3) mixing and stirring the components according to the percentage by weight, and shearing, thereby obtaining the anti-wrinkle antibiotic finishing agent. The anti-wrinkle antibiotic finishing agent has the advantages of good anti-wrinkle effect, good antibiotic effect and wide application range.

Owner:SUZHOU INST OF TRADE & COMMERCE

Preparation method of modified starch for wastewater treatment

ActiveCN105347437AEasy to settleCause secondary pollutionOther chemical processesWater treatment compoundsPotato starchPotassium hydroxide

The invention discloses a preparation method of modified starch for wastewater treatment, and belongs to the field of starch. According to the preparation method, a water treatment agent is provided through modification with the modified starch as a natural high-molecular carbohydrate; the modified starch is obtained by modifying potato starch by utilizing a potassium hydroxide and urea mixed solution, a disodium phosphate oxygen and citric acid buffer solution, a cross linking agent; carbon bisulfide and the like; carbon bisulfide is utilized for acting on the starch, so that precipitation is easy; the modified starch has an efficiency of metal ion displacement, so as to remove copper, chromium, zinc, and lots of heavy metal ions in the industrial wastewater; not only can heavy metals be recovered, but also the modified starch is nontoxic and harmless to environments, and is free of secondary pollution to the environments.

Owner:内蒙古世杰化工有限公司

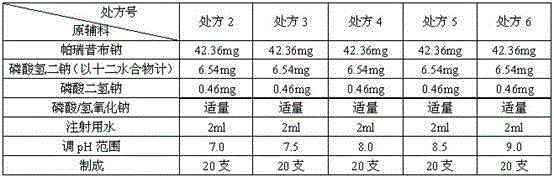

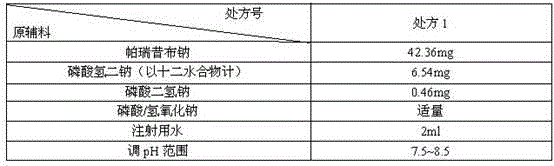

Parecoxib sodium pharmaceutical composition for injection

InactiveCN104414966AHigh yieldReduce market riskNervous disorderAntipyreticUse medicationDisodium phosphate

The invention relates to a stable parecoxib sodium pharmaceutical composition for injection. The pharmaceutical composition specifically comprises parecoxib sodium and an additive for injection, wherein disodium hydrogen phosphate and sodium dihydrogen phosphate are used as buffer agents, and phosphoric acid / sodium hydroxide is used as a pH regulator. The medicine composition is feasible in production process, stable and controllable in quality, low in irritation on the skin, convenient to transport and store and capable of providing reasonable preparation prescription and preparation process for clinical medication, and easily realizes industrialization.

Owner:TIANJIN HANRUI PHARMA

Airplane engine heat exchanger guiding-tube bend filling and technique

InactiveCN101058708AImprove bending qualityStable performance of filling processOther chemical processesHollow article cleaningSodium bicarbonateJet aeroplane

The invention discloses a bending filler and technique of heat exchanger conduit of airplane motor in the machine making domain, which comprises the following steps: allocating raw material proportionally; putting disodium phosphate and sodium bicarbonate in the autoclave; blending 2h; adding stablizier and reinforcer; packing the allocated fill; sealing to reserve. The filling technique of conduit product comprises the following steps: weighing the filler; controlling the temperature after the filler is fused; entering into the working condition; filling the conduit. The cleaning technique is characterized by the following: placing the moulded conduit into cleaning groove; injecting the tap water to heat and stir; controlling the water temperature between 80 and 90 deg. c for 20-30 min; fetching the conduit; draining the solution; repeating 5 times; fetching the conduit to dry; finishing the cleaning process.

Owner:沈阳华铁异型材有限公司 +1

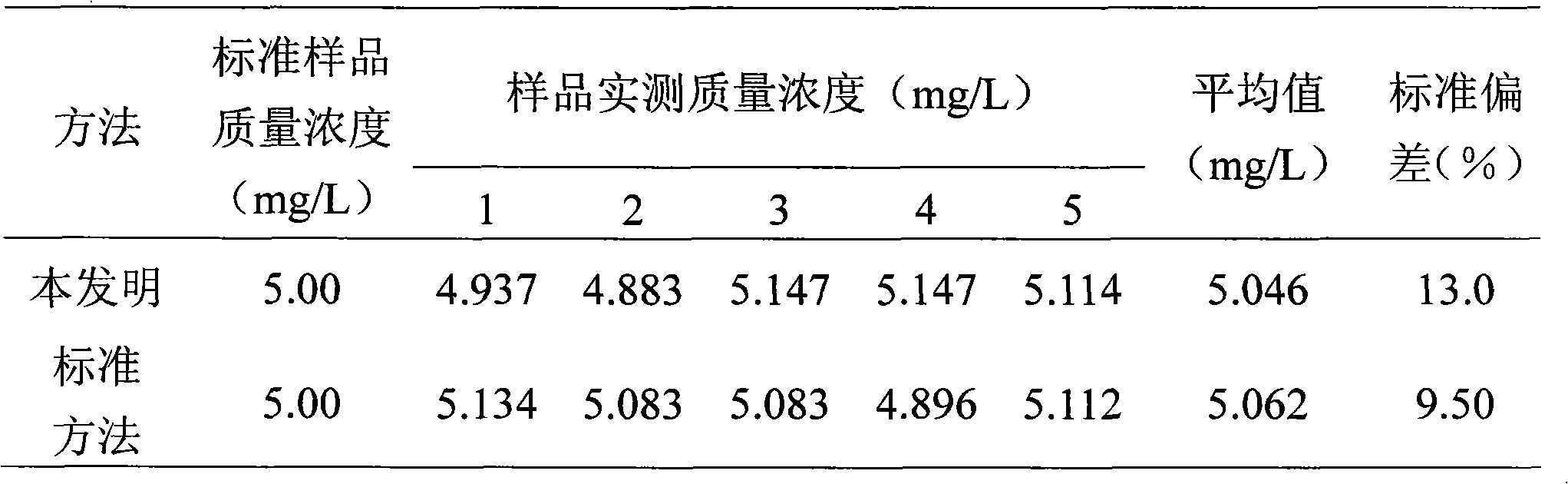

Rapid measurement reagent for manganese concentration in water and use method thereof

ActiveCN101639448AAvoid disadvantages such as short shelf lifeSimple and fast operationMaterial analysis by observing effect on chemical indicatorMass ratioPotassium

The invention relates to a rapid measurement reagent for manganese concentration in water and a use method thereof. The rapid measurement reagent for the manganese concentration in water comprises a reagent A and a reagent B in a mass ratio of 1:1, wherein (1) the reagent A comprises the following components in percentage by weight: 5.0-15.0 anhydrous potassium pyrophosphate, 10.0-30.0 disodium hydrogen phosphate, 0.5-5.0 citric acid and 60-80 anhydrous sodium sulphate; (2) the reagent B comprises the following components in percentage by weight: 5-25 potassium periodate and 75-95 potassium chloride. The use method of the rapid measurement reagent comprises the following steps: adding the reagent A to a water sample to be measured, adding the reagent B after the reagent A is dissolved; standing for 10 minutes; and comparing colors with a standard colorimetric card, a colorimetric disc or a colorimetric meter, and reading the manganese concentration. The invention has the advantages ofsimple and convenient operation, accurate results, low price, convenient transportation and carrying, on-site measurement suitability, and the like.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

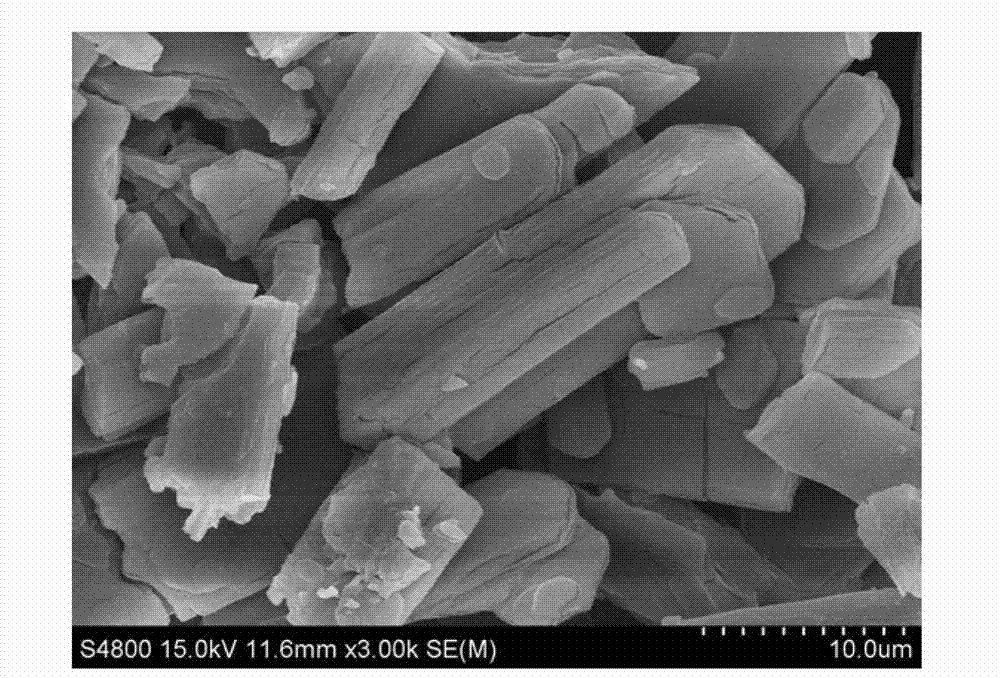

Method for dilution crystallizationelution and crystallization of cytidine 5'-disodium phosphate

InactiveCN102952167AHigh yieldUniform particle sizeSugar derivativesSugar derivatives preparationAnti solventDisodium phosphate

The invention discloses a method for dilution crystallizationelution and crystallization of cytidine 5'-disodium phosphate. An organic solvent of 0.5-3.0 time(s) of aqueous solution of cytidine 5'-disodium phosphate is added as an anti-solvent into the aqueous solution of cytidine 5'-disodium phosphate with the pH value of 7.0-9.0 and the concentration of 10-300g / L, mixing is performed at temperature of 10-40 DEG C and at a controlled speed of 50-230rmp, suction filtration is performed after complete crystallization, the crystal is washed with ethanol, and vacuum drying is performed to obtained the cytidine 5'-disodium phosphate crystal. By adopting the method, the final product quality can be improved significantly, and the yield of the crystalline product can be increased stably. Moreover, the particle size of the crystal can be controlled by changing the mixing speed or temperature for crystallization. The method has the advantages of simpleness in operation and good repeatability and is suitable for industrial production of the cytidine 5'-disodium phosphate.

Owner:NANJING UNIV OF TECH

Anti-shakeout foundry molding sand and preparation method thereof

The invention relates to anti-shakeout foundry molding sand, which is prepared from the following raw materials by weight: 10-15 parts of yellow loam, 4-6 parts of shell powder, 15-20 parts of vermiculite, 13-17 parts of magnesite fine powder, 1-1.5 parts of zinc dialkyl dithio phosphate, 3-4 parts of sulfurized calcium alkyl phenolate, 2-3 parts of aluminum silicate ceramic fibers, 7-10 parts of organic bentonite, 2-3 parts of disodium phosphate dodecahydrate, 1-2 parts of citric acid monomethyl ester, 200-220 parts of clay, a proper amount of water, and 20-30 parts of an auxiliary agent. According to the anti-shakeout foundry molding sand of the present invention, the clay is used so as to provide advantages of suitable particle size, good gas permeability, good fluidity and good dispersion, and the casting surface is smooth, such that the recycling can be achieved; and the aluminum silicate ceramic fibers are used, such that the strength of the clay particles is increased, and advantages of breaking resistance, good collapsibility and shakeout preventing are provided.

Owner:芜湖久弘重工股份有限公司

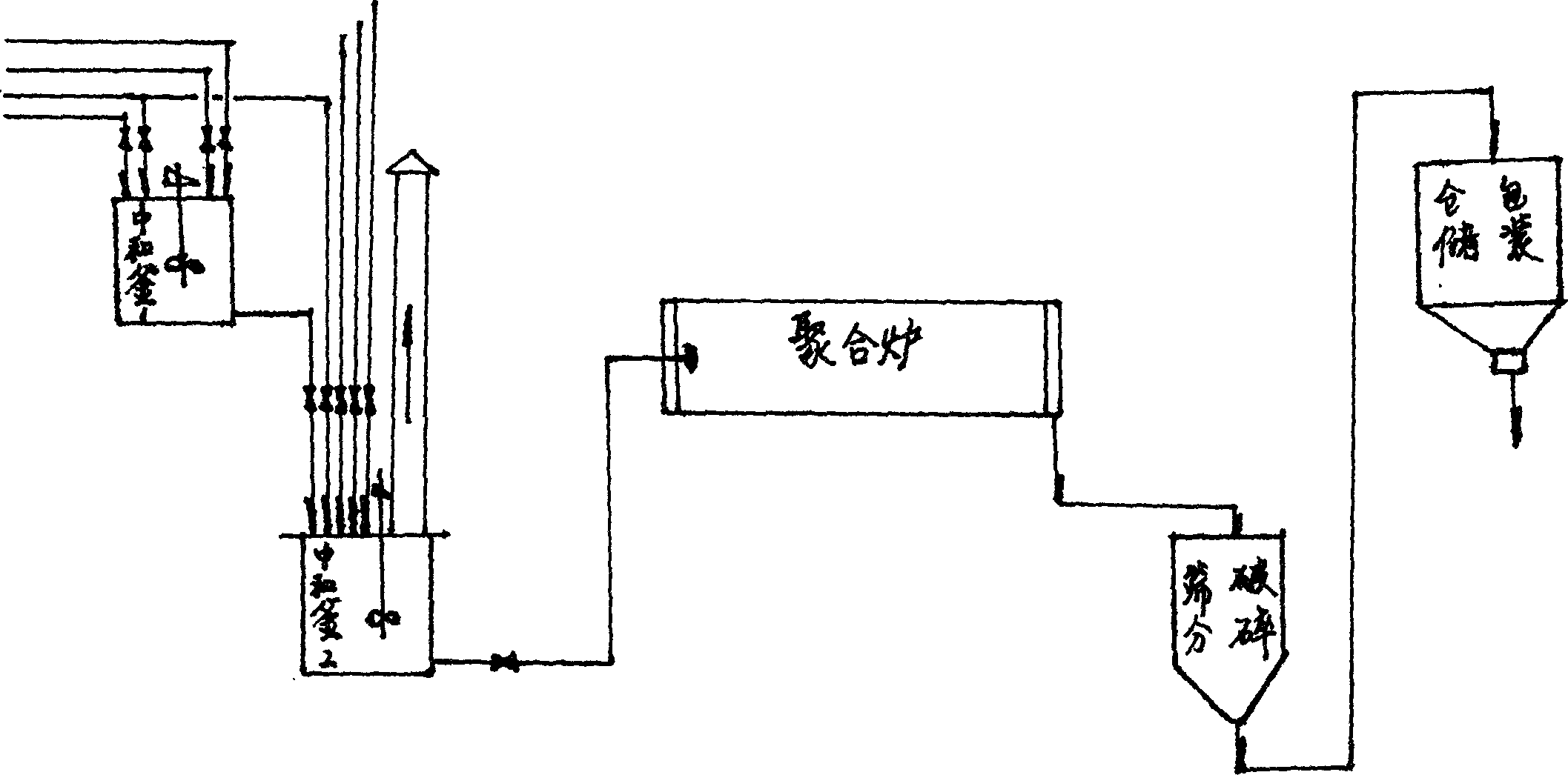

New technique for producing disodium phosphate

A process for preparing sodium tripolyphosphate includes adding waste phosphoric acid to neutralizing reactor, steam heating while adding sodium carbonate under stirring until 82 deg.C and pH=8+ / -1, adding liquid sodium hydroxide until 90 deg.C and pH=12+ / -1, stirring for 5-20 min, depositing, transferring it to another neutralizing reactor, adding waste sodium carbonate, adding phosphoric acid and sodium hydroxide while regulating K=3.0+ / -0.1, adding ammonium nitrate, filtering and dewatering polymerization.

Owner:张立民 +1

Method of manufacture for shelf stable pasteurized cheese shreds

ActiveUS20070154612A1Large specific surface areaImprove melting effectMilk preparationCheese manufactureDisodium phosphateRoom temperature

Shelf stable cheeses, especially shredded cheeses, and the manufacture thereof. Cheeses of the invention have good melting properties, are microbiologically safe and resistant to the growth of mold and pathogens when stored at room temperature, and can maintain physical integrity when subjected to temperature abuse. The cheese may be comprised of a mixture of salts (e.g., sodium chloride, disodium phosphate, sodium hexametophosphate, sodium alginate, titanium dioxide, sorbic acid, and the like), starch (e.g., waxy maize and the like), water, cheese, and cheese for manufacture.

Owner:KRAFT FOODS GRP BRANDS LLC

Composite flocculant

InactiveCN101973613AEfficient removalGood removal effectWater/sewage treatment by flocculation/precipitationHigh concentrationWater treatment system

The invention relates to a composite flocculant, which is formed by mixing ferric trichloride hexahydrate(FeCl3.6H2O), pure water, sodium carbonate(Na2CO3), disodium phosphate dodecahydrate(Na2HPO4.12H2O) and poly dimethyl diallyl ammonium chloride (PDMDAAC); the proportion weight percentages of the five ingredients in turn are 28 to 32 percent, 50 to 56 percent, 6 to 16 percent, 3 percent and 3 percent respectively, preferably 30 percent, 52 percent, 12 percent, 3 percent and 3 percent respectively. The invention has the advantages that: the composite flocculant is low in cost, practical, nontoxic and harmless, can effectively remove high-concentration organic pollutants and suspended matters from a waste water treatment system, has an excellent removal effect on chromaticity and can be used in place of various medicaments.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Method for high density culture of lactic acid bacteria for kraut

InactiveCN1844362AHigh densityReduce proliferationBacteriaMicroorganism based processesHigh concentrationPhosphoric acid

This invention relates to a high cell density cultivation mehtod of a lactic acid bacterium for pickles, wherein: the conventional Lactobacillus plantarum being applied as the seed strain, activated by routine method for enlarging cultivation, inoculated into fermentating culture media prepared by routine method with the characteristic composition of 0.2-0.3% sodium citrate, 0.2-0.3% disodium phosphate, 0.1-0.2% monosodium orthophosphate and pH 6.3-6.6, during the cultivation process, keeping the pH stable between 5.8-6.2 by flowing ammonia soluthion, after 20h post cultivation, adding 500ml-700ml fresh culture meida, centrifuging, adding recombinant protective agent comprising 10-15% skimmed milk, 5-7% glutavene, 2-3% glycerin and 7-8% maltose, and lyophilizing. This method is characterized of high performance and liability, high concentration of active lactic acid bacteria in the culture, and overcoming the damage and death problems of part of microorganism cells during the lyophilizing process.

Owner:JIANGSU UNIV

Preparation method of high-viscoelasticity injection composed of glucosamine and sodium hyaluronate

InactiveCN105982911AChange the high hygroscopicityReduce humidityOrganic active ingredientsInorganic non-active ingredientsDouble saltTherapeutic effect

The invention relates to a preparation method of a high-viscoelasticity injection composed of glucosamine and sodium hyaluronate. The injection mainly includes the components of glucosamine sulfate / sodium chloride double salt and the sodium hyaluronate with sodium dihydrogen phosphate and disodium hydrogen phosphate, as auxiliary materials, being used as a pH regulator. Sodium chloride is employed as an osmotic pressure regulator. The injection is greatly reduced in hygroscopicity and enhanced in flowability, is improved in stability, has good treatment effects, low drug resistance rate and less adverse reaction, and can be used in intra-articular injection therapy on arthritis.

Owner:上海建华精细生物制品有限公司

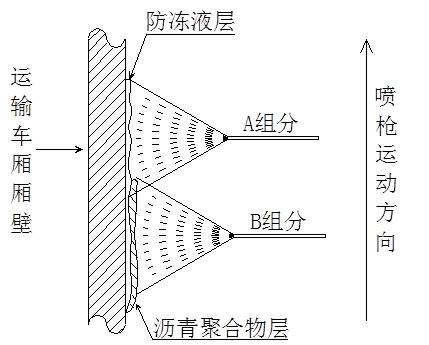

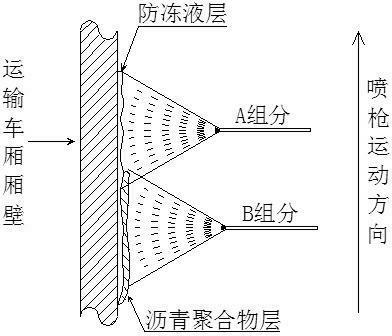

Antifreeze liquid film for pulverized coal transport and preparation method and application thereof

InactiveCN102676060AEasy to useEasy to shapeConjugated diene hydrocarbon coatingsChloropene polymer coatingsLiquid layerPetroleum

The invention relates to an antifreeze liquid film for pulverized coal transport and a preparation method and the application thereof. Industrial calcium chloride, sodium benzoate, sodium hydrogen phosphate, sodium nitrite, triethanolamine and ethanol are used as raw materials to prepare an antifreeze liquid component A. Anionic emulsified petroleum asphalt, anionic emulsified neoprene latex, anionic emulsified styrene-butadiene latex, defoaming agent and industrial water are used as raw materials to prepare asphalt polymer film forming agent component B. The component A and the component B are respectively sprayed on wall faces of a carriage by a spray gun, the component B meeting the component A can automatically precipitate to form a solid asphalt polymer film attached onto an antifreeze liquid layer of the component A, so that the antifreeze liquid film for pulverized coal transport is formed. The antifreeze liquid film effectively prevents antifreeze liquid from flowing from the wall surface of the carriage to the bottom, moisture in transported coal is prevented from dispersing to the carriage wall, and gathering and the like of a great quantity of antifreeze liquid at the carriage bottom can be reduced. Further, utilization of the antifreeze liquid film saves energy resources, shortens wagon transfer time and lowers transport cost.

Owner:TAIYUAN UNIV OF TECH

Stable recombination human interferon alpha 1b water solution

The invention relates to a stabilized recombinant human interferon alpha1b water solution, where the water solution with a total volume of 1000ml contains, therapeutic effective dose of interferon alpha1b, 2.5-27.0g of sodium chloride, 0.15-0.60g of citric acid, 1.5-6.0g of dodecahydro-disodium phosphate, and 5-20g of human blood albumin.

Owner:BEIJING TRI PRIME GENE PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com