Method for removing green algae in the middle and late culture stages of Porphyra yezoensis

A technology of Porphyra variegata and green algae, applied in gardening methods, herbicides and algicides, botanical equipment and methods, etc., can solve the problems of destroying ecological balance, shrinking porphyra fronds, and heavy workload. Achieve the effect of little influence of natural conditions, expanding the scope of application and improving the grade rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for removing green algae in the later stage of a kind of Porphyra zebra cultivation of the present invention will be described in further detail below.

[0030] The method includes the following steps:

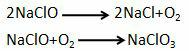

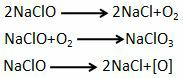

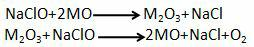

[0031] (1) Take 50ml ~ 100ml of commercially available sodium hypochlorite solution with a concentration of 10%, add clean and disinfected seawater to make the volume to 1L, and then add trisodium phosphate and disodium hydrogen phosphate to the above-mentioned Adjust the pH value in the solution to keep the pH value between 9.0 and 9.5 to ensure the stability of the solution during transportation and storage, and keep it for later use;

[0032] (2) After the laver net curtains are placed in the sea area, that is, during the laver cultivation process from September 21 to April of the following year, they are put into the sea at low tide and operated by smearing;

[0033] (3) During the process of removing green algae, take the solution in step (1), add commerc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com