"Two-step" method of refining outside the furnace to produce low-carbon manganese-silicon alloy

An out-of-furnace refining and silicon alloy technology, which is applied in the field of ferroalloy smelting, can solve problems such as difficult control of production costs and unsustainable continuous and stable production, and achieve the effects of improved product grade rate, low production cost and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The method for producing low-carbon manganese-silicon alloy by two-step refining outside the furnace, the steps are as follows by weight:

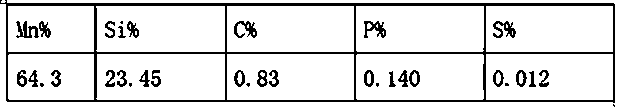

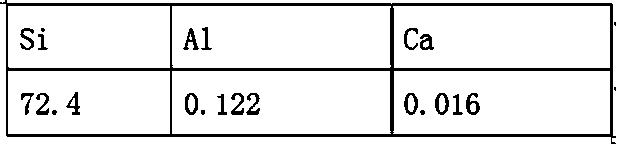

[0016] (1) Using a 25.5MVA submerged arc furnace to produce silicon-manganese alloy products containing 22.4% silicon;

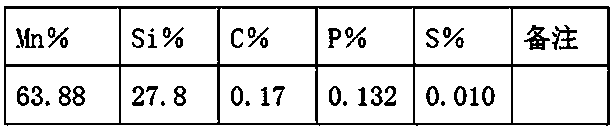

[0017] (2) Heat 9.6 tons of silicon-manganese alloy products containing 22.4% silicon into a 20-ton intermediate frequency furnace, add 0.77 tons of ferrosilicon, and then smelt for 9 minutes at a temperature of 1450 degrees. After the mixed molten iron is completely melted, add 0.25 tons Slagging agent and 0.08 tons of covering agent, refining for 17 minutes, after refining, power outage, sedation for 5 minutes; slag removal, furnace pouring, and finally 9.61 tons of low-carbon manganese-silicon alloy containing 27.34% silicon and 0.17% carbon.

Embodiment 2

[0019] The method for producing low-carbon manganese-silicon alloy by two-step refining outside the furnace, the steps are as follows by weight:

[0020] (1) Using a submerged arc furnace above 25.5MVA to produce silicon-manganese alloy products containing 23.8% silicon;

[0021] (2) Heat 10.4 tons of silicon-manganese alloy products containing 23.8% silicon into a 20-ton intermediate frequency furnace, add 1.15 tons of ferrosilicon, and then smelt with electricity for 7 minutes at a temperature of 1500 degrees. After the mixed molten iron is completely melted, add 0.26 tons Slagging agent and 0.085 tons of covering agent, refining for 20 minutes, after refining, power outage, sedation for 5 minutes; slag removal, furnace pouring, and finally 10.52 tons of low-carbon manganese-silicon alloy containing 28.54% silicon and 0.15% carbon.

Embodiment 3

[0023] The method for producing low-carbon manganese-silicon alloy by two-step refining outside the furnace, the steps are as follows by weight:

[0024] (1) Use 25.5MVA and above submerged arc furnaces to produce silicon-manganese alloy products containing 23.92% silicon;

[0025] (2) Heat 10.2 tons of silicon-manganese alloy products containing 23.92% silicon into a 20-ton intermediate frequency furnace, add 0.67 tons of ferrosilicon, and then smelt for 12 minutes at a temperature of 1650 degrees. After the mixed molten iron is completely melted, add 0.25 1 ton of slagging agent and 0.08 ton of covering agent, refining for 24 minutes, after refining, power outage, sedation for 5 minutes; slag removal, furnace pouring, and finally 10.25 tons of low-carbon manganese-silicon alloy containing 27.15% silicon and 0.18% carbon .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com