Nanometer composition particle of poly-o-phenyldiamine and silver and its prepn process

A technology of poly-o-phenylenediamine and composite particles, which is applied in the field of preparation of semiconductive poly-o-phenylenediamine and metal nano-composite particles, can solve problems such as the preparation method of nano-composite particles that have not been seen, and achieve simple and easy operation Bank and silver consumption are less, and the output scale is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Accurately weigh 6.48g (0.06mol) o-phenylenediamine monomer and add it to glacial acetic acid, place it in a water bath at 40°C, and stir to promote its dissolution. Weigh 13.68g (0.06mol) of ammonium persulfate according to the oxidant monomer ratio of 1:1, transfer it to a 100mL beaker and add 6mL of deionized water to fully dissolve it. Add the oxidizing agent solution into the glacial acetic acid solution of the o-phenylenediamine monomer, and continue the reflux reaction for 72 hours. After the reaction is finished, filter and dry to obtain doped black powdery poly-o-phenylenediamine.

[0022] The yield of the o-phenylenediamine polymer obtained in this example was 2.59 g, and the yield was 40.0%. The electrical conductivity of the polymer powder measured by the tablet method is 1.8×10 -10 S / cm.

Embodiment 2

[0024] Accurately weigh 6.48g (0.06mol) o-phenylenediamine monomer and add it to glacial acetic acid, place it in a water bath at 40°C, and stir to promote its dissolution. Weigh 27.36g (0.12mol) of ammonium persulfate according to the oxidant monomer ratio of 2:1, transfer it to a 100ml beaker and add 6ml of deionized water to fully dissolve it. Add the oxidizing agent solution into the glacial acetic acid solution of the o-phenylenediamine monomer, and continue the reflux reaction for 72 hours. After the reaction is finished, filter and dry to obtain doped black powdery poly-o-phenylenediamine.

[0025] The yield of the o-phenylenediamine polymer obtained in this example was 5.15 g, and the yield was 79.4%. The electrical conductivity of the polymer powder measured by the tablet method is 3.0×10 -10 S / cm.

Embodiment 3

[0027] Accurately weigh 6.48g (0.06mol) o-phenylenediamine monomer and add it to glacial acetic acid, place it in a water bath at 40°C, and stir to promote its dissolution. Weigh 41.04g (0.18mol) of ammonium persulfate according to the oxidant monomer ratio of 3:1, transfer it to a 100ml beaker and add 6ml of deionized water to fully dissolve it. Add the oxidizing agent solution into the glacial acetic acid solution of the o-phenylenediamine monomer, and continue the reflux reaction for 72 hours. After the reaction is finished, filter and dry to obtain doped black powdery poly-o-phenylenediamine.

[0028] The output of the o-phenylenediamine polymer obtained by this embodiment is 4.61g, and the yield is 71.2%, and the electrical conductivity is less than 1×10 -12 S / cm.

PUM

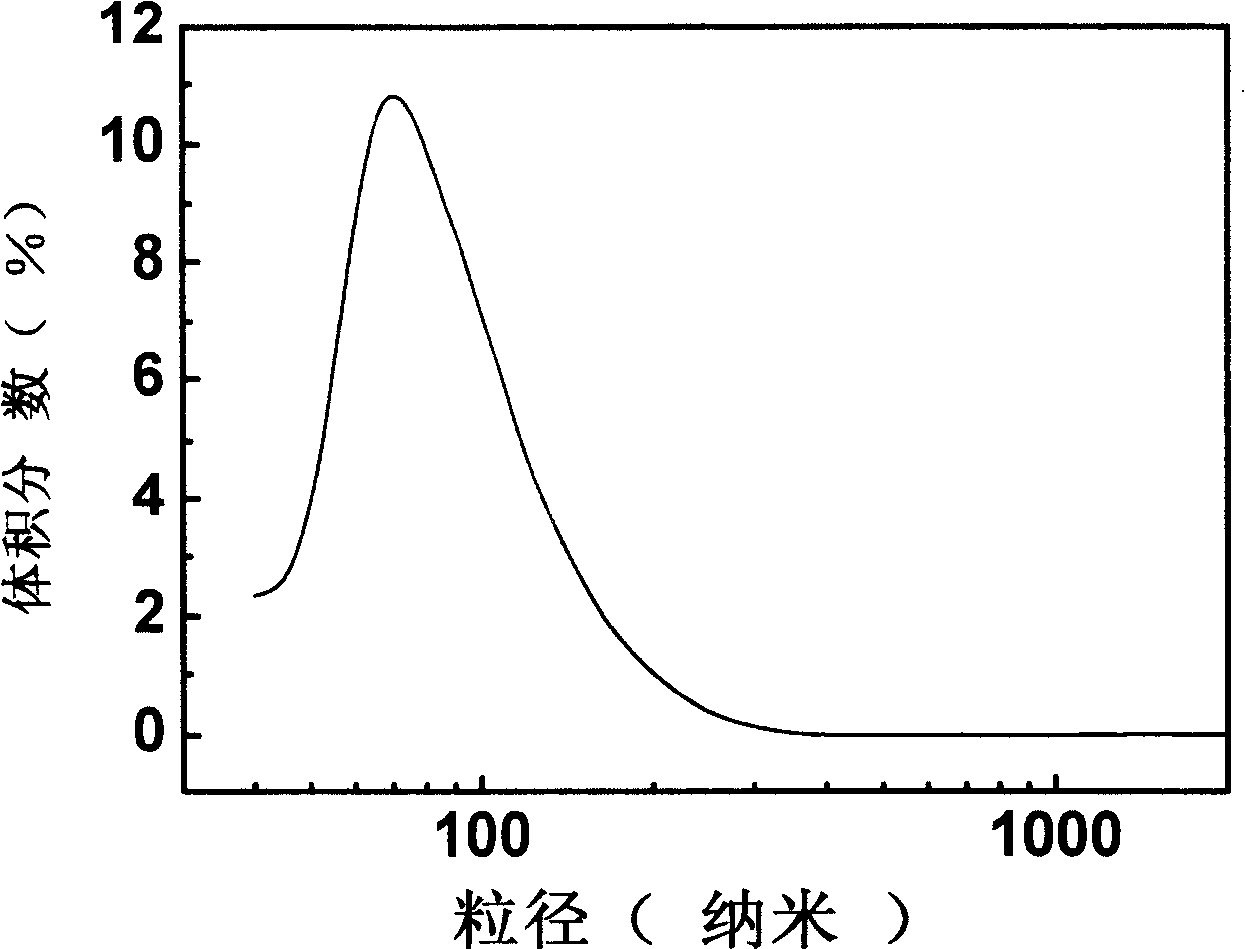

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com