Patents

Literature

48results about How to "Improve grade rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

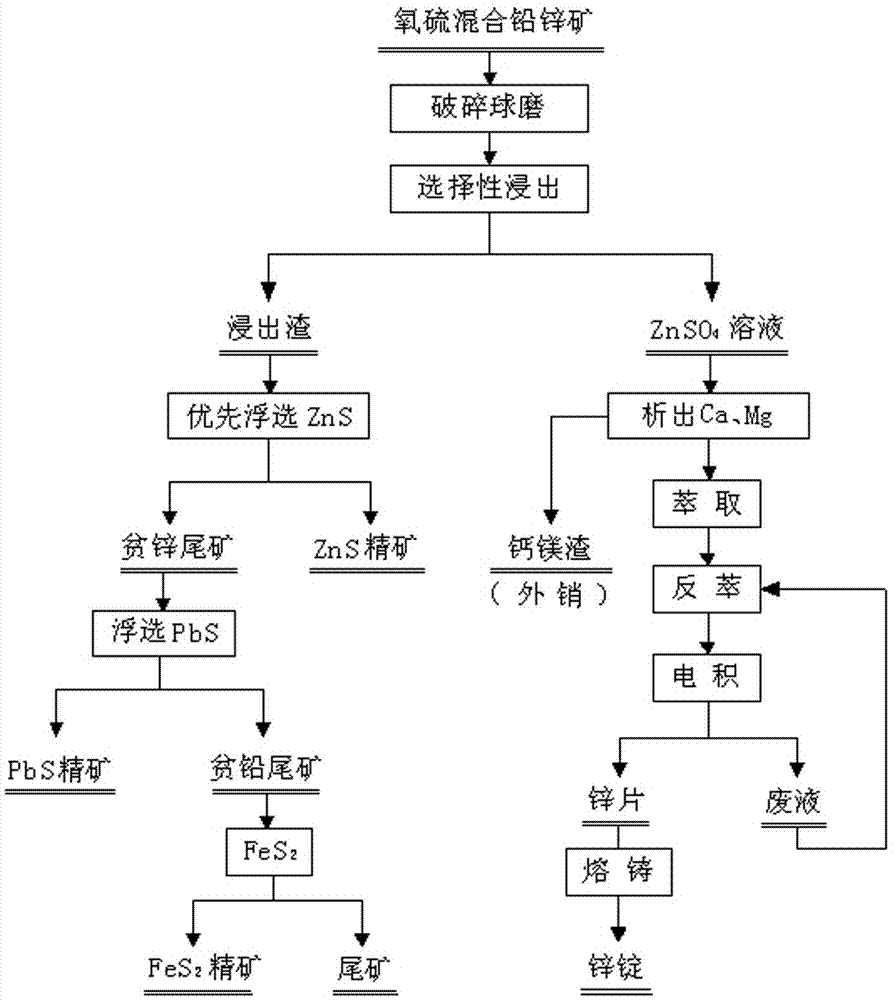

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

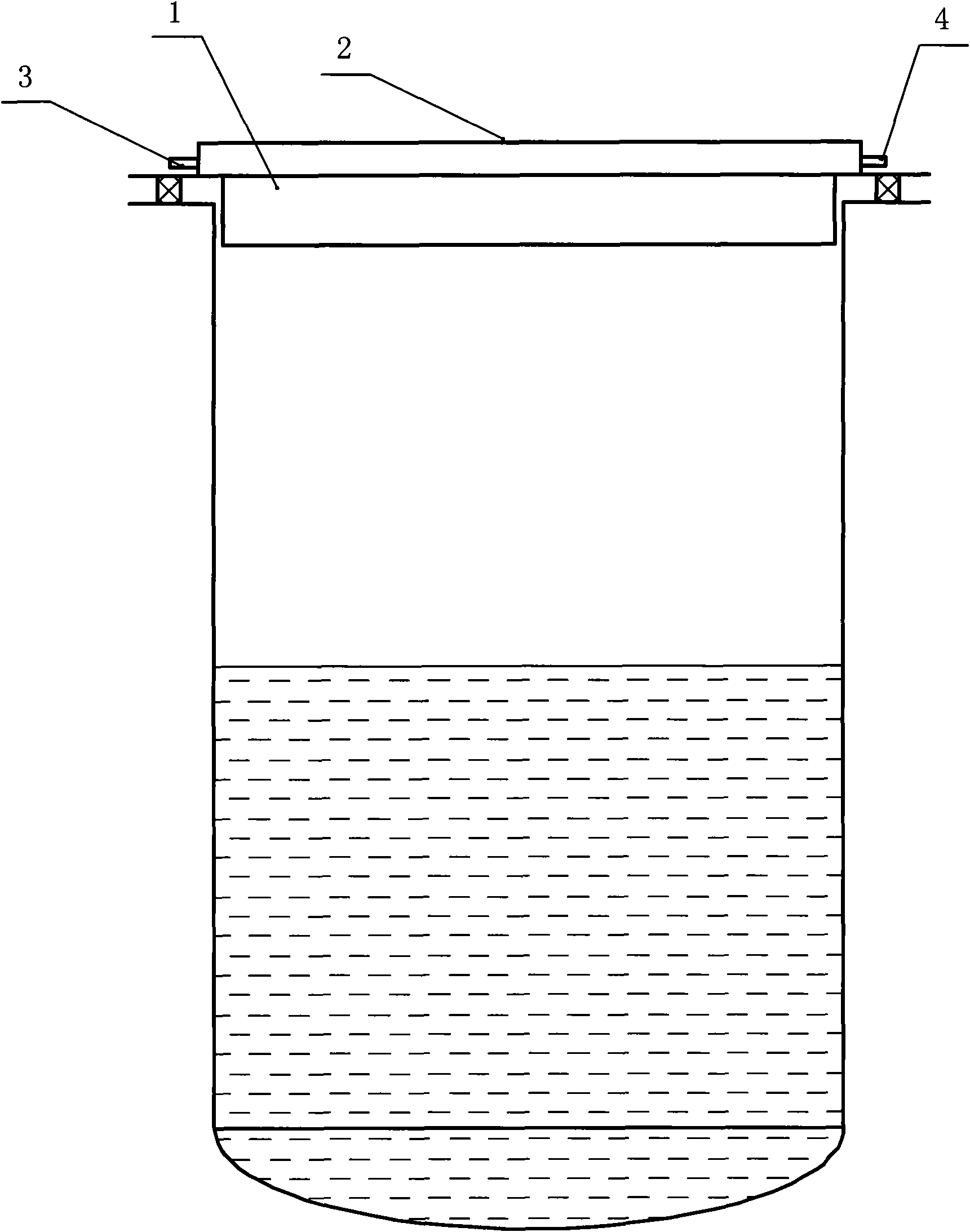

Treatment method of standard exceeding of content of chlorine in titanium sponge

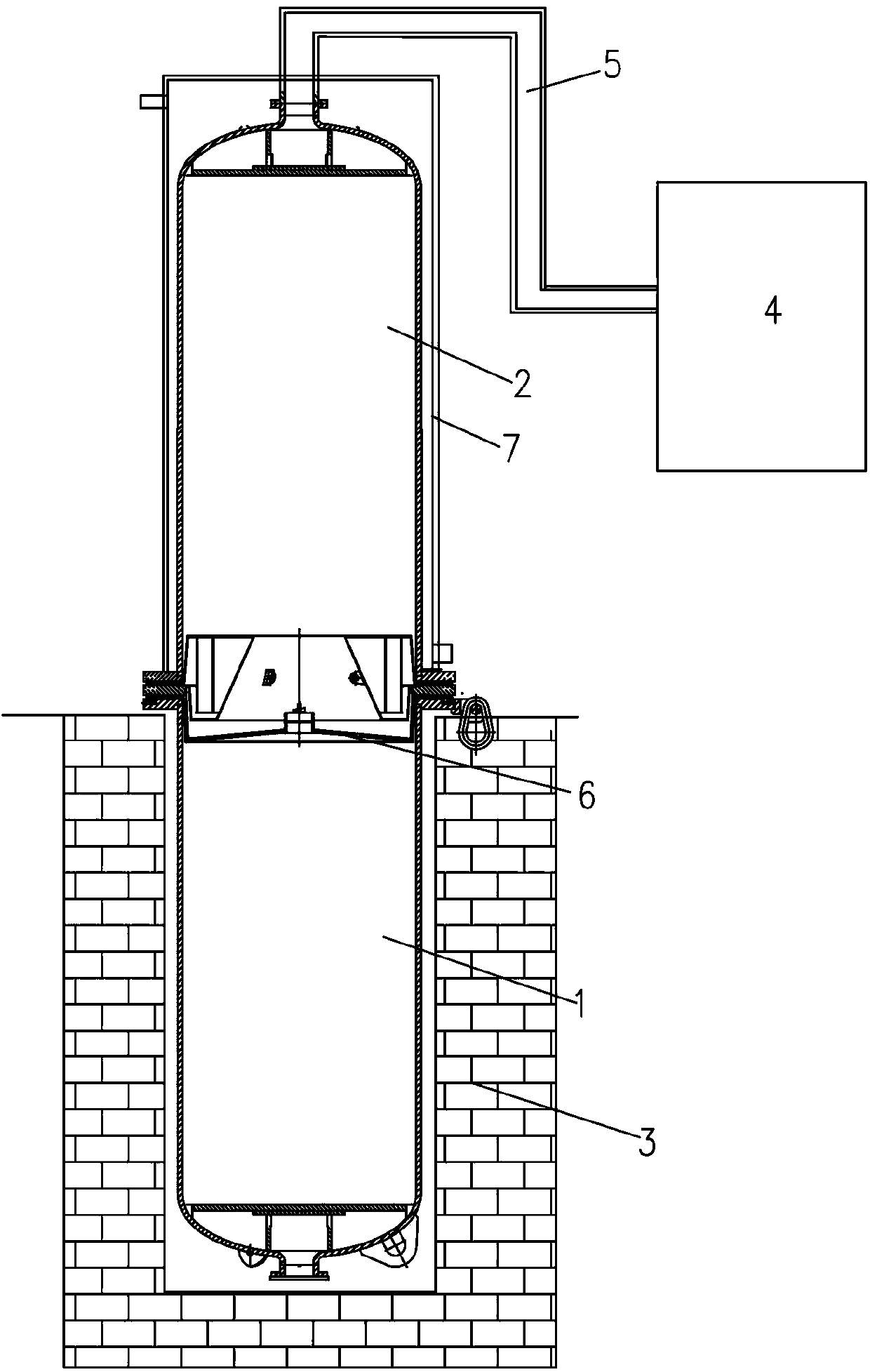

The invention provides a treatment method of standard exceeding of content of chlorine in titanium sponge. The titanium sponge is titanium sponge produced by adopting a magnesiothermic reduction method. The treatment method comprises the following steps: placing the titanium sponge in a reactor, vacuumizing the reactor until the vacuum degree in the reactor is not more than 100Pa; heating the reactor to ensure that the titanium sponge in the reactor is firstly subjected to low-temperature degassing of a temperature phase of 150-200 DEG C and intermediate temperature degassing of four constant temperature phases of 200-300 DEG C, 350-400 DEG C, 450-500 DEG C and 500-550 DEG C to remove water and gas impurities in magnesium chloride hydrate in the titanium sponge; and after degassing is ended, continuously raising the temperature to 900-1020 DEG C for vacuum distillation to remove magnesium chloride in the titanium sponge. According to the method, the content of chlorine in the titanium sponge, which exceeds the standard, can be effectively reduced, and the grade rate of the titanium sponge is increased.

Owner:PANGANG GROUP TITANIUM INDAL

Cleaning treatment process for cow leather

The invention discloses a cleaning treatment process for cowhide, which orderly comprises process steps of soaking, liming, reliming, non-ammonium deliming softening and so on. The process is mainly characterized in that: soaking enzyme is mainly adopted in the step of the soaking, which greatly reduces the use level of a surfactant and the content of COD and BOD. Compared with the prior hair burning method, the liming and the reliming are characterized in that: a hair-saving liming process changes the process thought; the liming expansion is performed after hair saving and hair filtration, which reduces the content of ammonia nitrogen, the COD, the BOD and solid waste in wastewater. And waste liquid after the liming realizes recycling and achieves zero discharge. A non-ammonium deliming softening system is adopted, which reduces the content of the ammonia nitrogen in the wastewater. The use level and the discharge of sulfide and lime which are used to produce leather by the cowhide are reduced by 50 percent or so, an ammonium salt deliming process is saved, the content of the ammonia nitrogen is reduced by more than 90 percent, and the COD and suspended substances are reduced by more than 85 percent.

Owner:ZIBO DAHUAN JIUBAOEN LEATHER

Full grain leather polishing mending cream

InactiveCN102702982AImprove polishabilityHigh pad resistancePolishing compositionsLeather surface finishingAdhesiveMicrosphere

The invention provides a full grain leather polishing mending cream, which comprises the following components in mass percent: 2-20% of thermal expansion hollow microspheres, 10-30% of modified protein adhesive, 10-30% of fischer tropsch wax emulsion, 1-10% of silicon resin emulsion, 0.1-2% of thickener, 0.1-2% of preservative, 10-30% of water, and 15-45% of multiple curable aqueous hyperbranched polyurethane inorganic nanometer material hybrid coating agent. The invention uses the multiple curable aqueous hyperbranched polyurethane inorganic nanometer material hybrid coating agent which has high cushion resistance performance and is suitable for polishing. At the same time, silicon resin with cushion resistance and smoothness and high melting point wax is added to improve the polishing property of the mending cream greatly. By applying the full grain leather polishing mending cream provided by the invention to the slight mending of full grain leather, brush complement and polishing of coarser grain can greatly improve the rate of finished leather and added value, and increase the economic benefit of enterprise.

Owner:ZHEJIANG DONGHUA IND

Environment-friendly ecological board and production process thereof

InactiveCN105291207AHigh glossImprove flatnessWood veneer joiningWood layered productsWater basedEnvironmental resistance

The invention provides an environment-friendly ecological board and a production process thereof. The production process comprises: performing hot-press gluing on one side of an artificial board and impregnated bond paper into an impregnated bond paper decorative artificial board, and cooling the impregnated bond paper decorative artificial board till a room temperature for later use, wherein hot pressing is performed for 5-15 minutes at a temperature ranging from 100 to 150 DEG C and under a pressure ranging from 0.3 to 1.5MPa; coating both sides of a substrate with a cold-pressing glue and performing cold pressing on the substrate and the obtained impregnated bond paper decorative artificial board, wherein the cold-pressing glue is a water-based isocyanate adhesive; cold pressing is performed for over 30 minutes under a pressure ranging from 0.1 to 1Mpa; relieving the pressure, and aging for 5 or more hours followed by cutting edges, thereby obtaining the finished environment-friendly ecological board. The invention provides the environment-friendly ecological board that is few in production steps and high in finished product yield and grade rate, and the production process thereof.

Owner:张建明

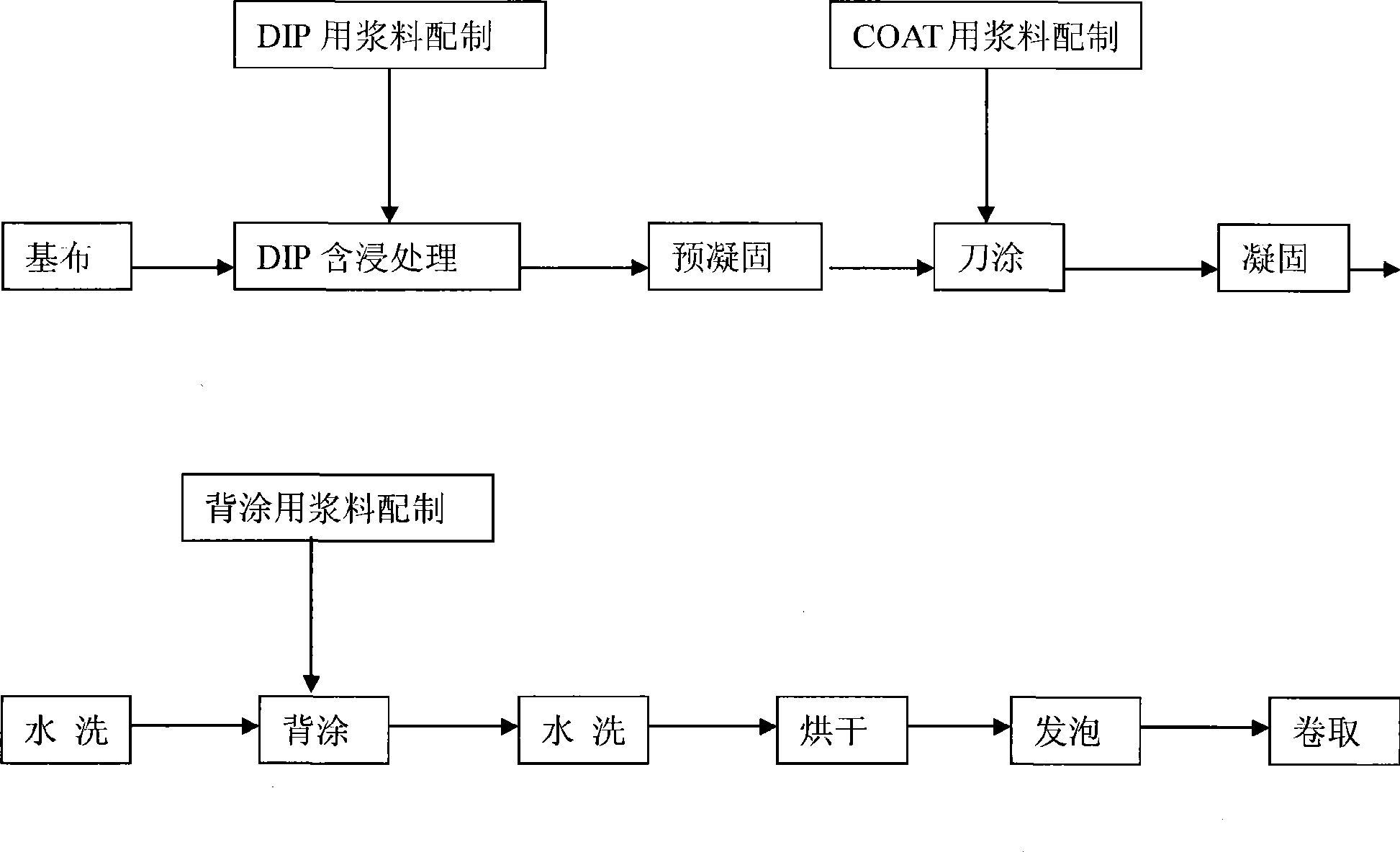

Method of preparing back coated real leather intimating synthetic leather

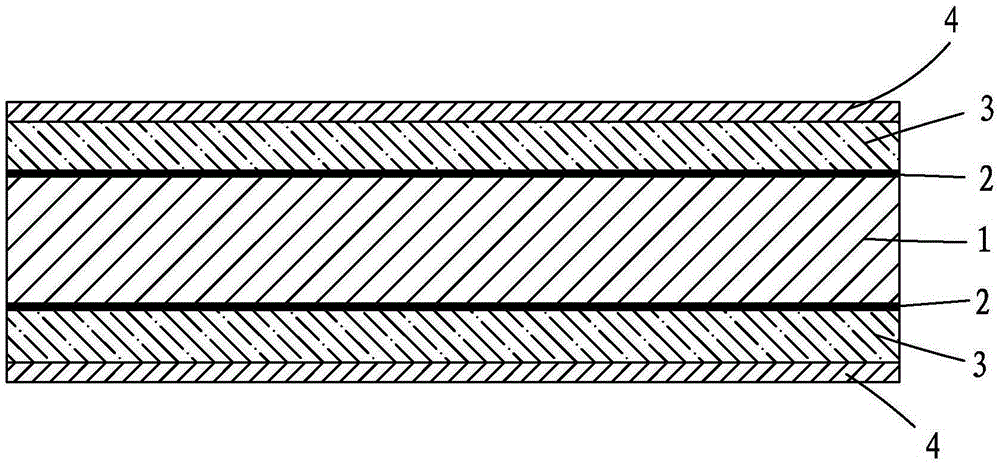

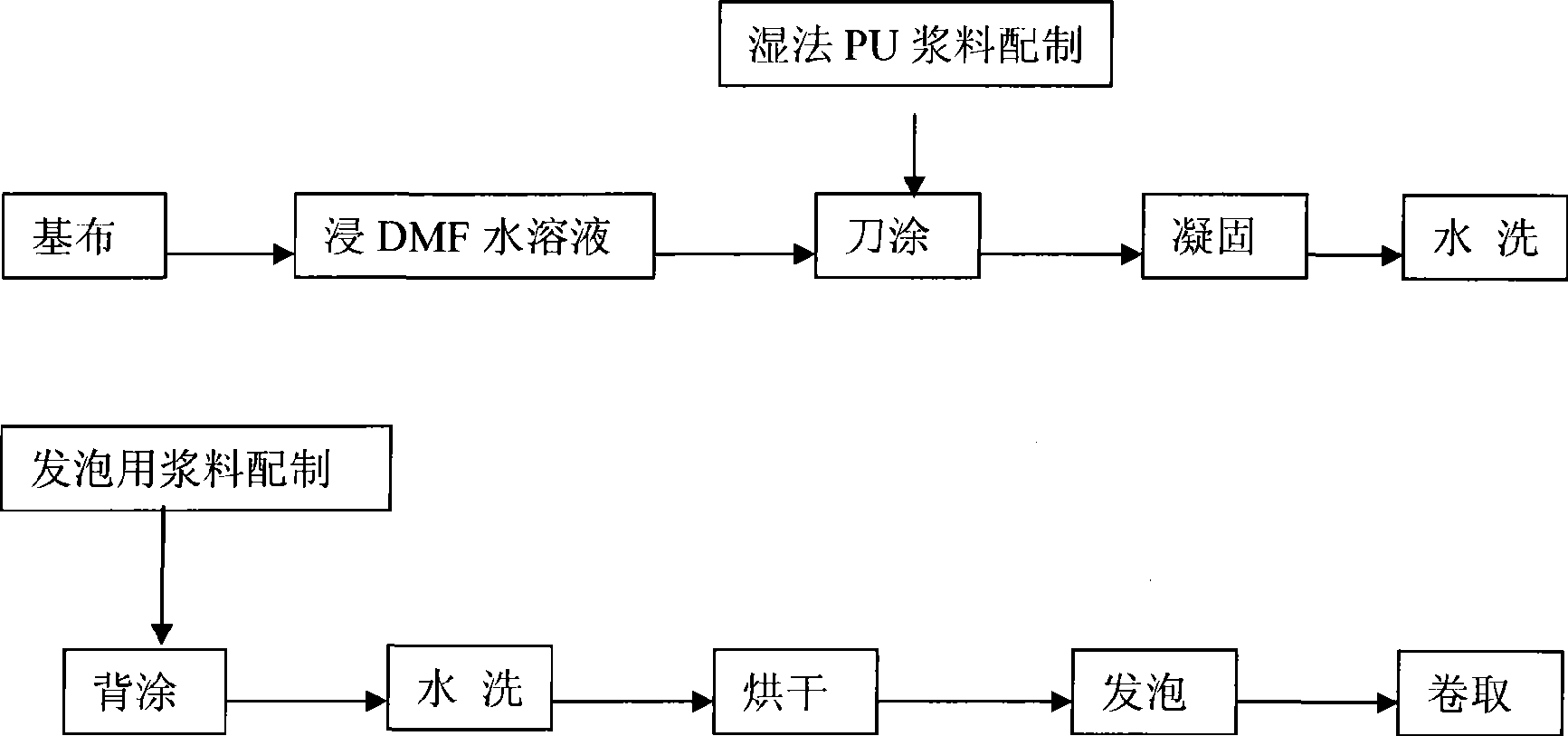

The invention discloses a method for manufacturing back-coated skin-imitated synthetic leather. The method comprises: coating wet-process PU slurry onto the surface of base cloth to form a base green body; after solidifying and washing the base green body, coating foaming slurry on the back of the base green body; washing and drying the base green body and foaming the base green body to form wet-process crust leather; and finally grinding the back of the wet-process crust leather and carrying out dry-process release paper pattern transfer to the front of the wet-process crust leather, wherein the foaming slurry comprises foaming resin ST-1030 or ST-1040, dimethylformamide (DMF), a foaming agent and so on. The method uses the prior synthesis device and research on special foaming slurry to carry out once forming process of the skin-imitated synthetic leather, namely, the method simplifies the prior post processing processes for producing skin-imitated synthetic leather such as pile coating, real leather powder coating and suede foaming into a wet-process once forming process.

Owner:ANHUI ANLI MATERIAL TECH

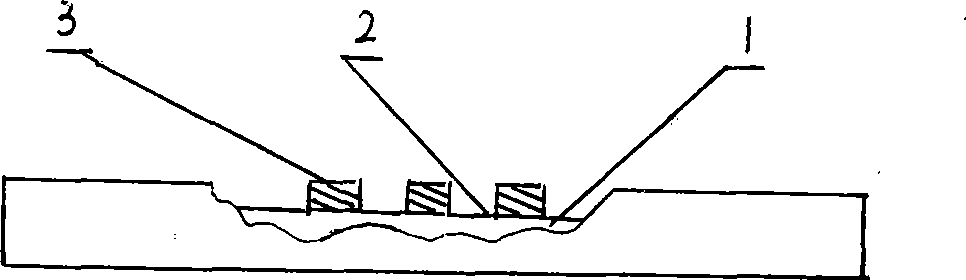

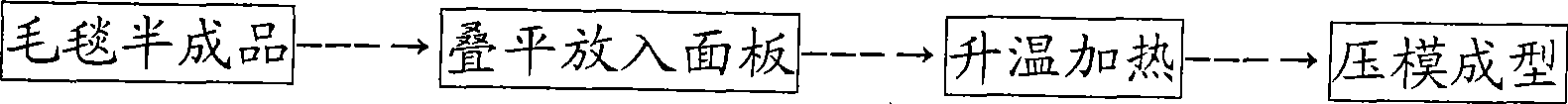

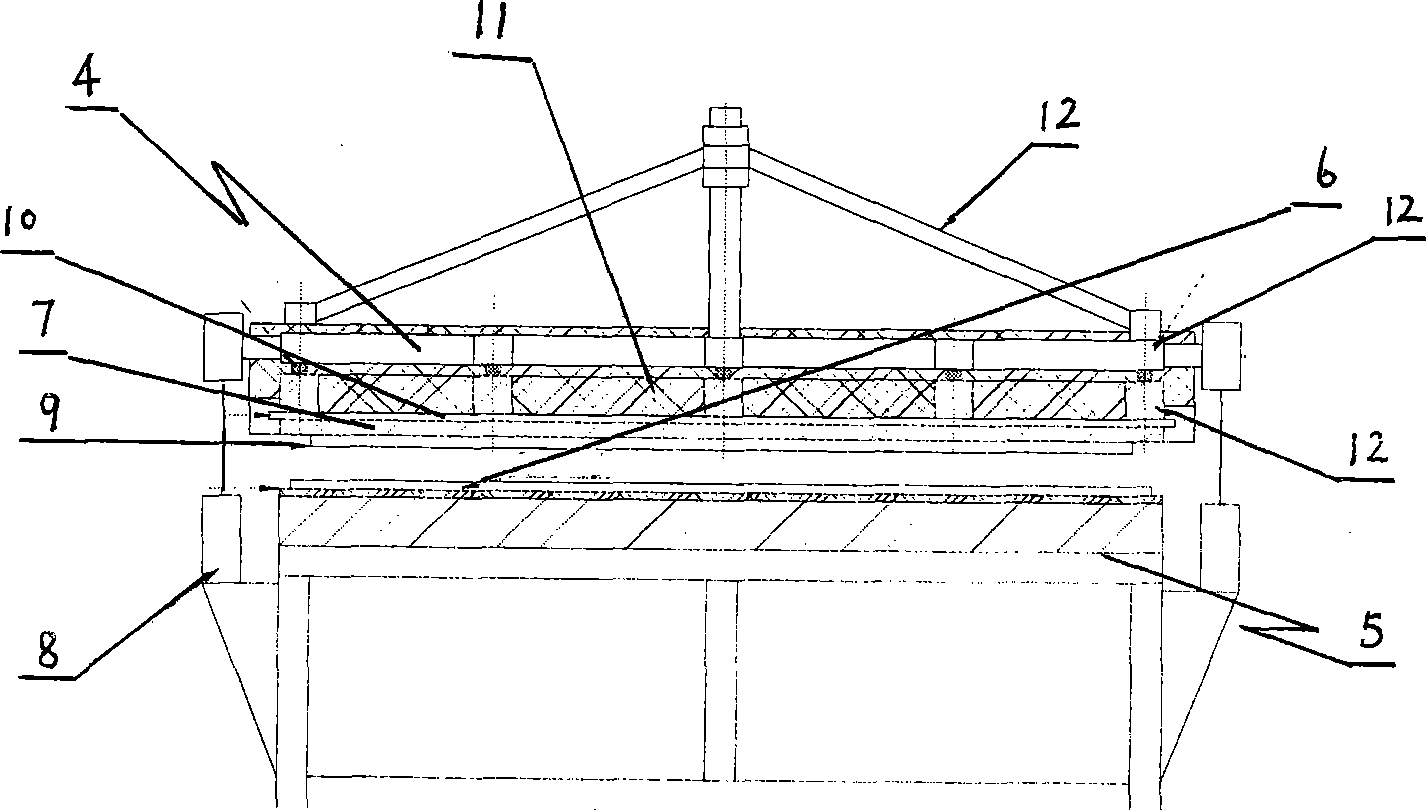

Embossing blanket products and production technique thereof, special device

InactiveCN101416836AEnhance luxury and aestheticsRaise the gradePattern makingEmbossing decorationsWork in processElectric heating

The invention discloses a production technology of an embossed blanket product for improving the grade and class rate of a blanket. The product comprises a blanket bottom surface which is different in patterns consisting of a concave surface and a convex surface; the production technology comprises the steps: a half-finished blanket is conducted with adjustment of printing, and then put into an embossing machine to form an embossed blanket product by heating and embossing for certain time duration. A special device comprises that: the both sides of an upper machine frame and a lower machine frame are provided with an oil tank; a large sheet is arranged on the upper machine frame; tools with different dimensions are arranged under the large sheet; the interior of the large sheet is provided with an electric heating tube above which is provided with a thermal-insulating layer; and the upper machine frame is provided with a reinforcing rib. The production technology has the advantages that: the fuzzy appearing of the surface of the blanket product can be changed, defects of little spots and colorization on the surface of the blanket can be overcome so as to form natural beautiful elegant embossed patterns, improve the luxurious and aesthetic degrees of the blanket product, further increase the class of the blanket products and create economic value.

Owner:姚寿昌

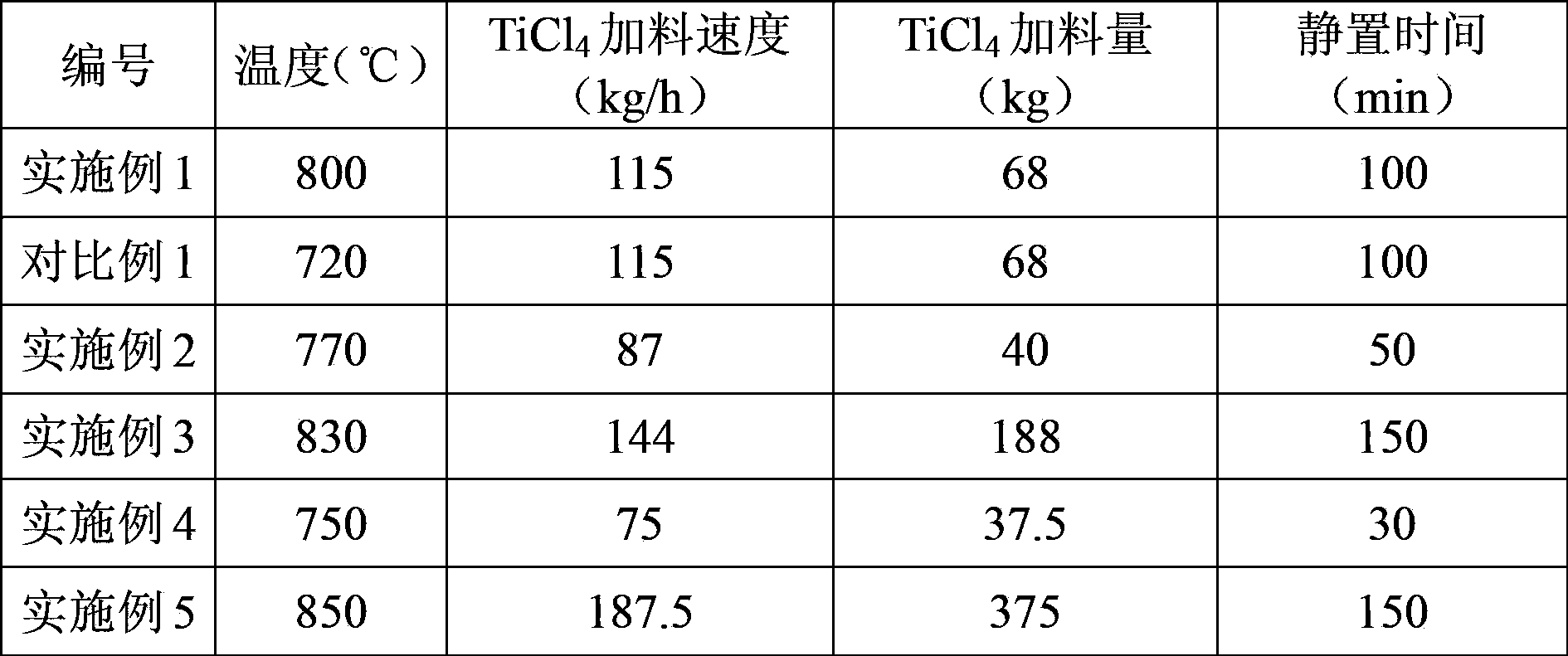

Magnesium refining method and titanium sponge preparation method

The invention discloses a magnesium refining method, and the magnesium refining method includes contact of a melted magnesium material and titanium tetrachloride and then standing, and is characterized in that the contact temperature is 750-850 DEG C. The invention also provides a titanium sponge preparation method which is characterized by comprising refining of the melted magnesium material and contact of the refined melted magnesium material with titanium tetrachloride under technical conditions of magnesiothermy reduction production of sponge titanium, and a method for refining of the melted magnesium material is the magnesium refining method provided by the invention. By using the magnesium refining method provided by the invention, high purity magnesium can be obtained, and by using titanium sponge preparation method for production of the sponge titanium, a sponge titanium product with high qualification rate and high grade rate can be obtained.

Owner:PANGANG GROUP TITANIUM INDAL

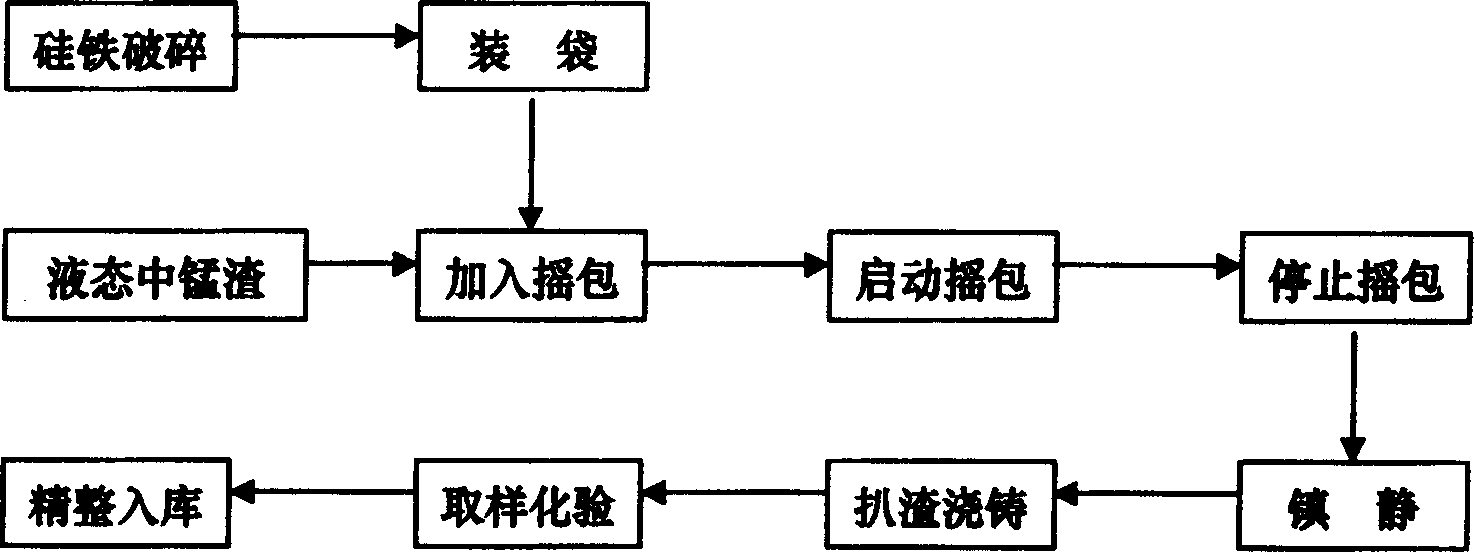

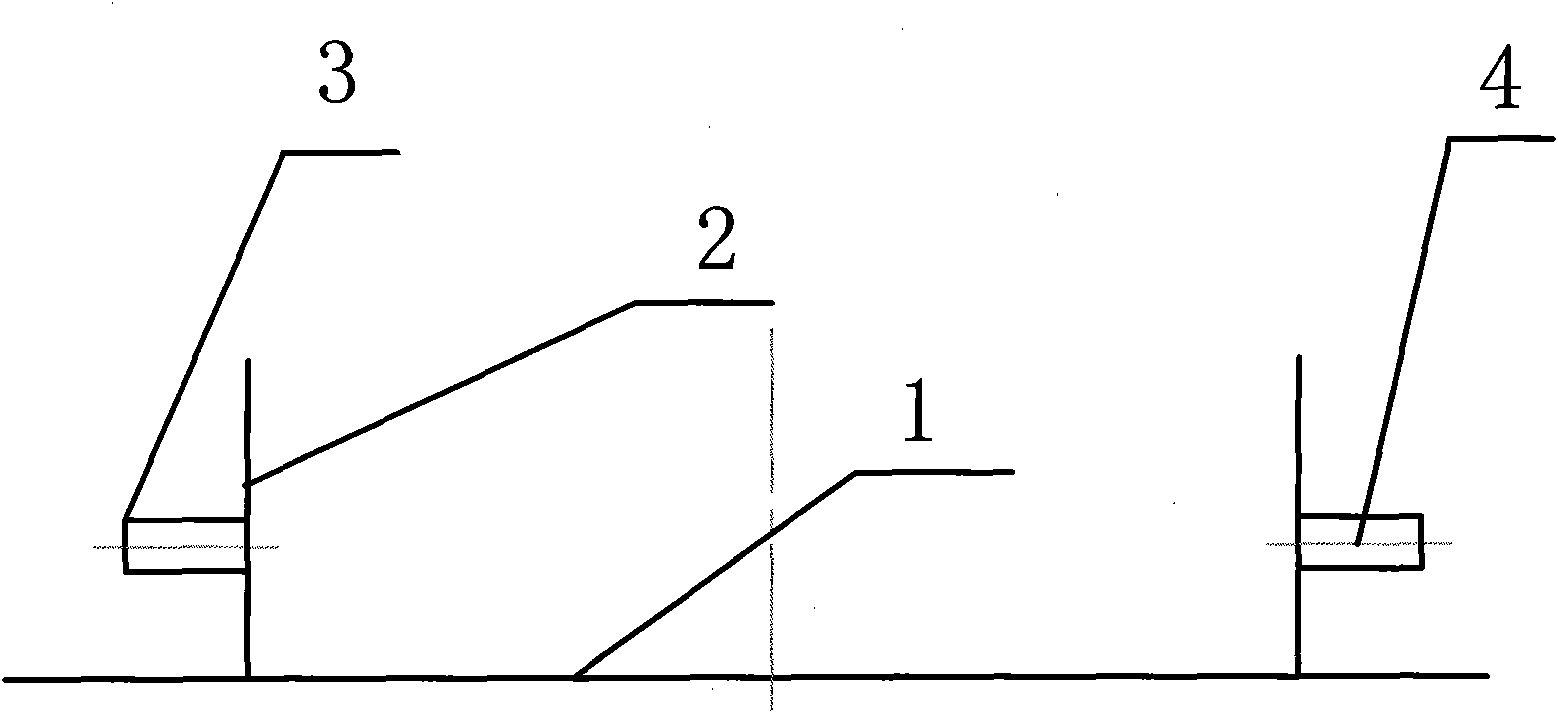

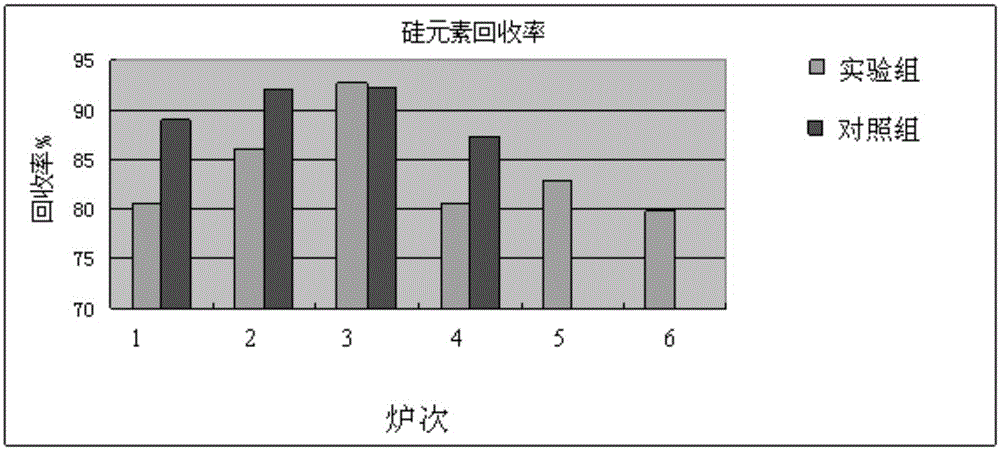

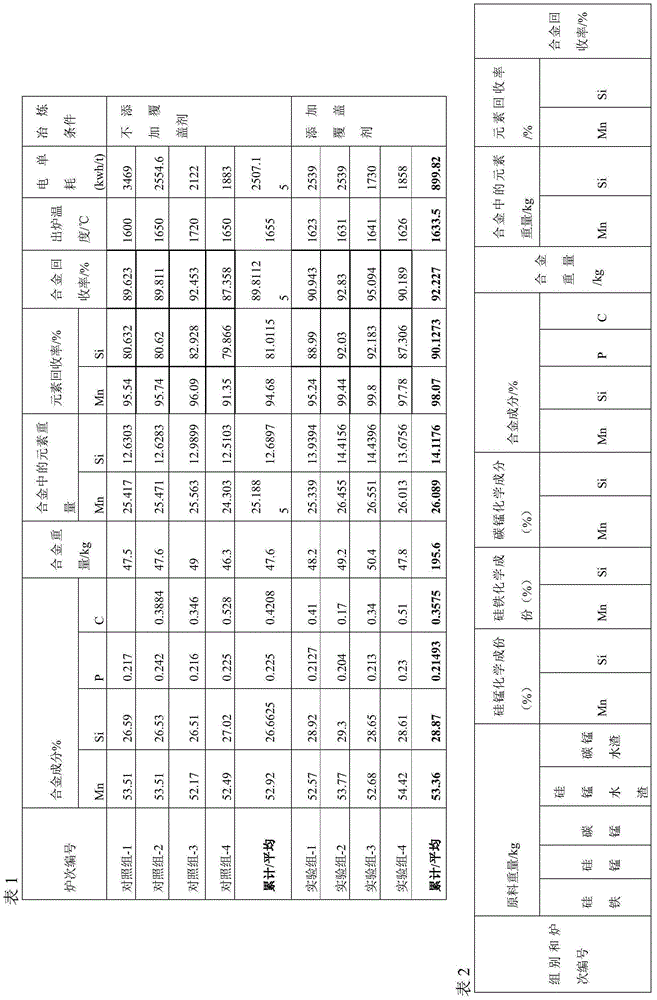

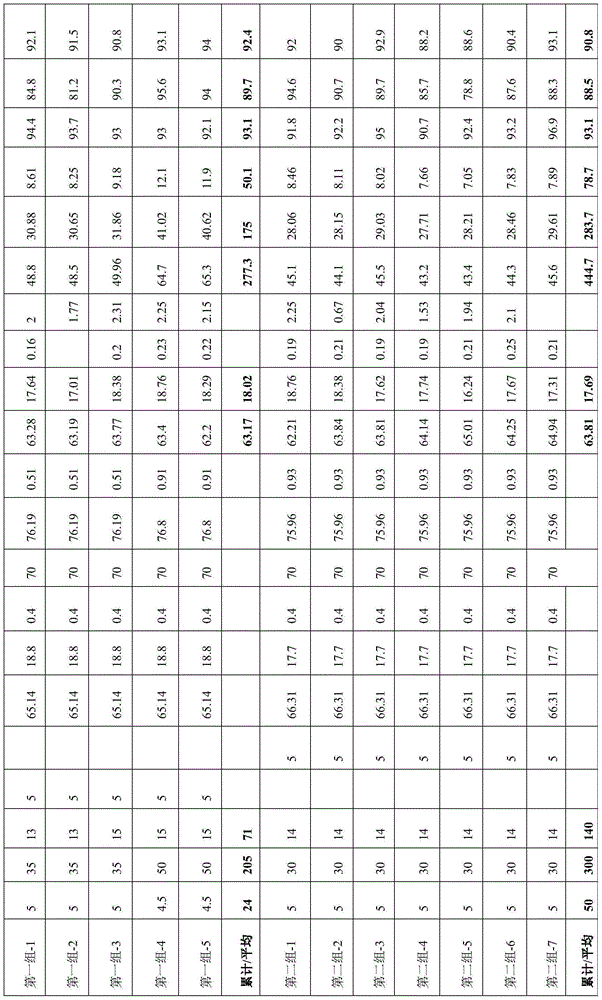

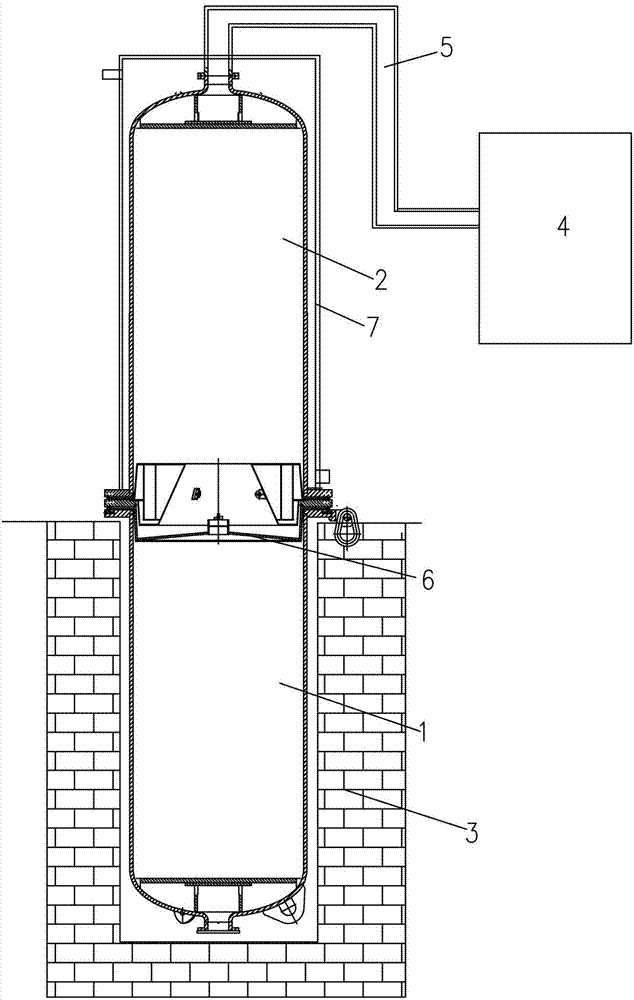

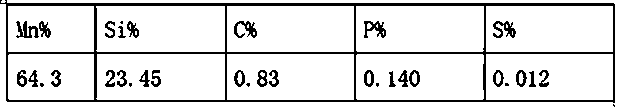

Out-of-furnace process for producing high-silicon manganese silicon

This invention relates to a production method for high SiMnSi by an external furnace method including 1, preparing materials: crusing FeSi powder into the size of 0-10mm, taking Mn slags from a solution with 18-20%Mn and 1.0-1.2 alkali to be put standby under 1480-1510deg.C, 2, inpouring the FeSi and the Mn slags into a waving bag in the proportion of 1:6-9, starting the bag for 9-17 minutes and keeping still for 9-12 minutes then raking up slags to be cast and arranged then to be sent to the storeroom.

Owner:HUNAN FERROALLOY GRP CO LTD

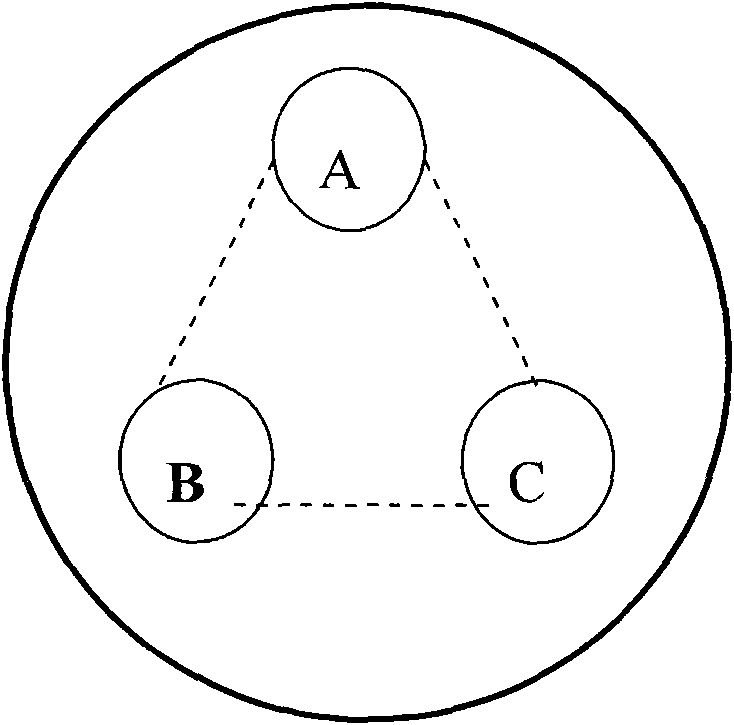

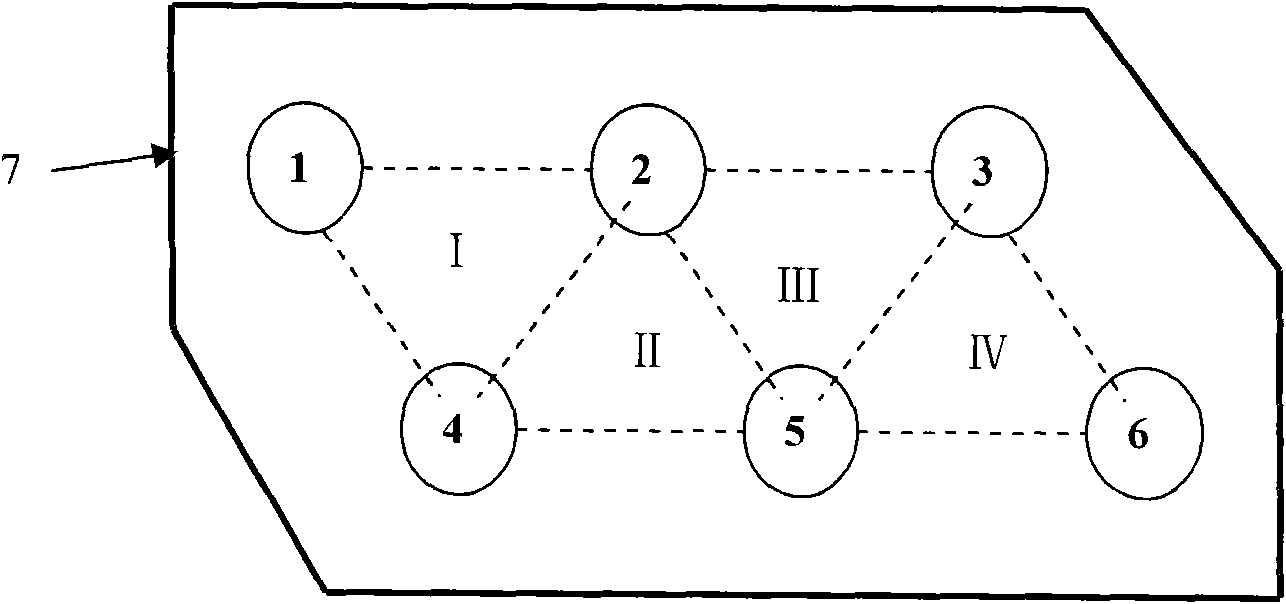

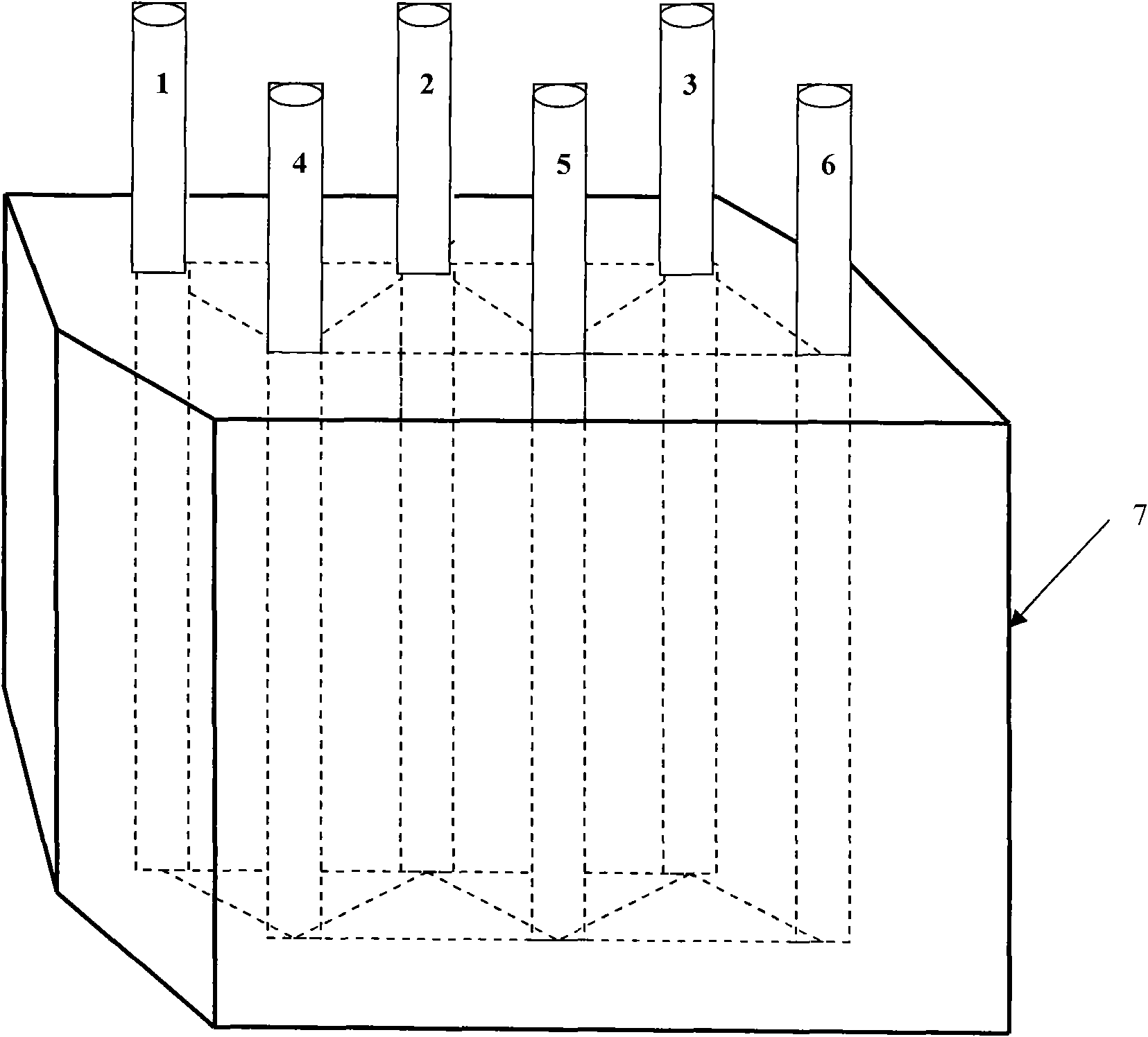

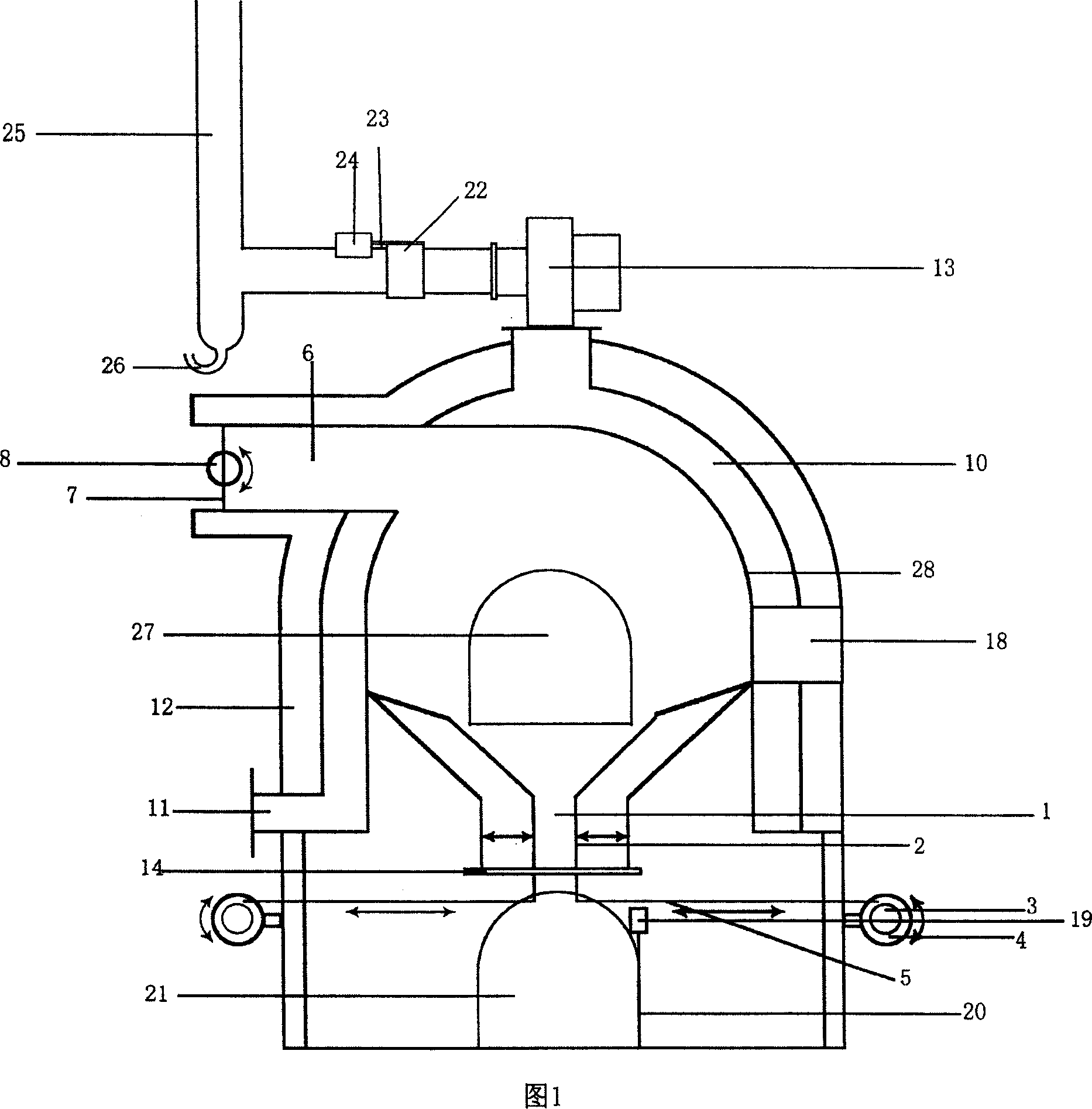

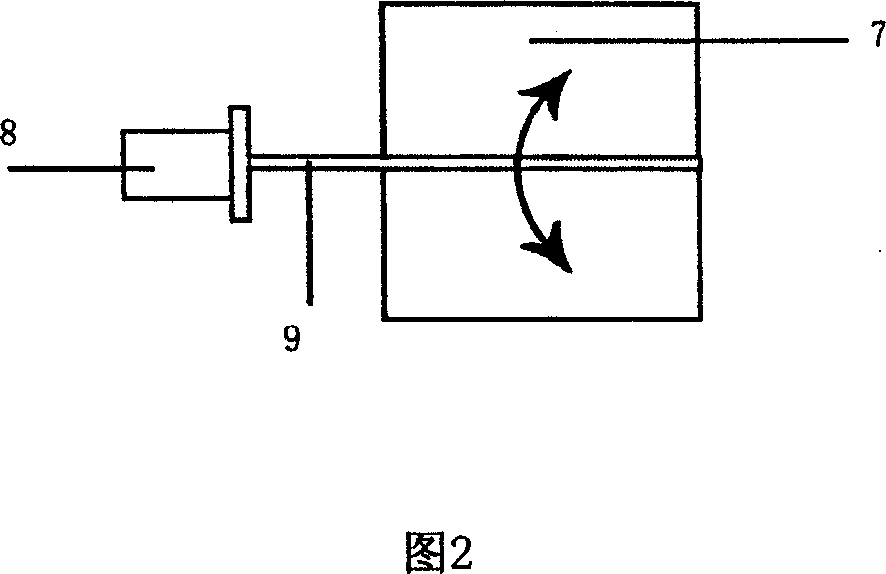

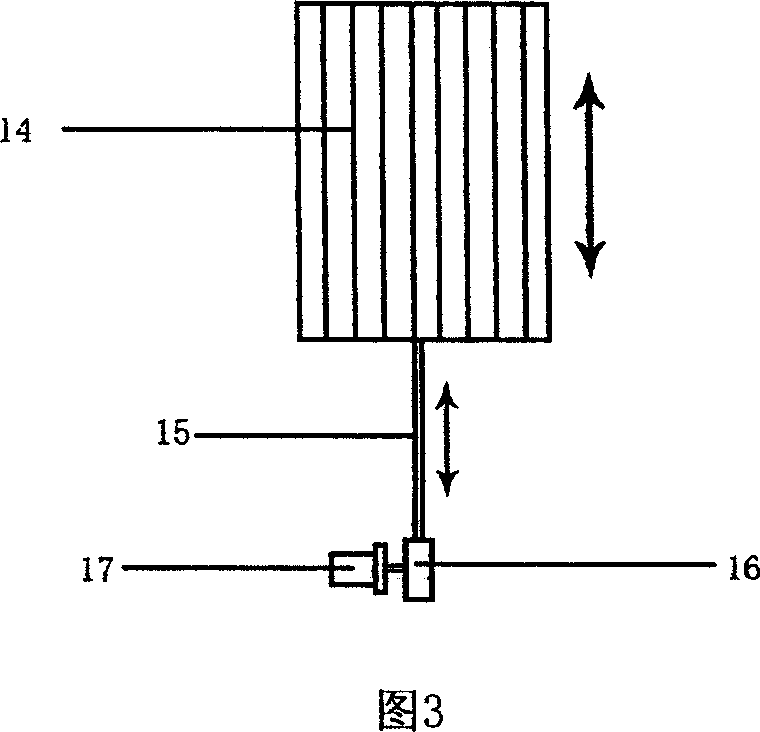

Six phase electrode electric melting furnace

InactiveCN101619928AImproved arc stabilityReduce burning lossCrucible furnacesElectric heating for furnacesFurnace temperatureIsoetes triquetra

The invention provides a six phase electrode electric melting furnace, relating to an electric melting magnesium smelting device, solving the problems of slow temperature rise of furnace temperature, high energy consumption and low yield which exist in current three phase electrode electric melting furnace. In the six phase electrode electric melting furnace, the furnace body is a six-prism body; the six phase electrode is inserted and arranged in the furnace body; the first electrode, the second electrode and the third electrode are arranged in a row with uniform spacing; the fourth electrode, the fifth electrode and the sixth electrode are arranged in a row with uniform spacing; the two rows of electrodes as a whole form a parallelogram; four equilateral triangle hot zones are respectively formed by the first, second, fourth electrodes, the second, fourth, fifth electrodes, the second, third, fifth electrodes, and the third, fifth, sixth electrodes. In the smelting process, the six phase electrode electric melting furnace forms four triangle hot zones, thus achieving concentrated heat, rapid heating of magnesium stones, steady reaction, dramatic lowering of electricity consumption, high speed of temperature rise of furnace temperature which can reach 3500 DEG C, uniform and stable product quality, energy saving and consumption lowering, high yield and good benefit.

Owner:大石桥市金益特种镁质材料厂

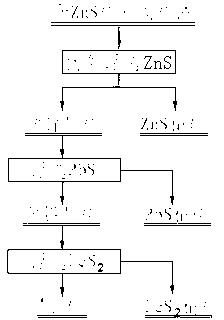

Flotation method of vulcanizing lead and zinc by weak acid full pulp

ActiveCN103157560AImprove leaching rateThe leaching rate is easy to improveFlotationHydrogenVulcanization

The invention discloses a flotation method of vulcanization lead and zinc by weak acid full pulp. Weak acid full pulp flotation is conducted to the vulcanization lead and zinc in ores or slag comprising the vulcanization lead and zinc according to the flotation technology, the flotation technology comprises that ore grinding and pulp mixing are conducted to the ores or the slag in the vulcanization lead and zinc, the weak acid pulp with the potential of hydrogen (PH) value of 1 to 7 is prepared, and then the weak acid full pulp flotation is conducted so that ZnS concentrate, PbS concentrate and FeS2 concentrate are made. The flotation method of the vulcanization lead and zinc by the weak acid full pulp has the advantages of being small in device investment, low in energy consumption, small in consumption of flotation reagents, capable of obtaining zinc sulfide with a higher concentrate grade, and high in lead and zinc recovery rate.

Owner:云南金鼎锌业有限公司

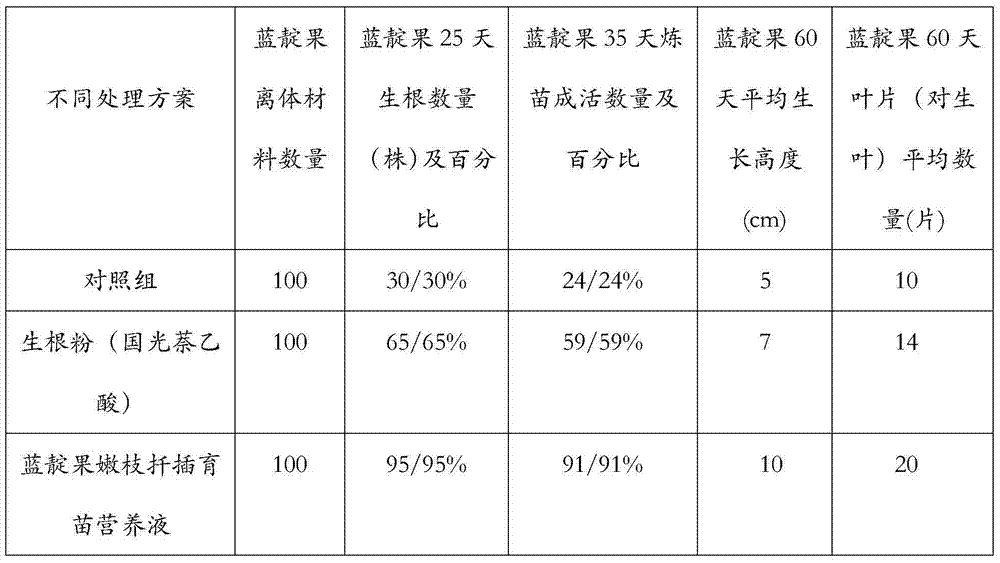

Cutting seedling nutrient solution of lonicera edulis twigs as well as preparation method and application method thereof

InactiveCN103880559AOvercome thinnessSeedling growth rate increasedFertilising methodsFertilizer mixturesPhosphatePotassium

The invention discloses a cutting seedling nutrient solution of lonicera edulis twigs as well as a preparation method and an application method thereof. The cutting seedling nutrient solution includes the following components: 180-220 ml / L honey, 0.9-1.1 ml / L liquid organosilicone, 90-110 ml / L edible vinegar, 45-55 ml / L red orchid extracting solution, 360-440 mg / L pimacol, 36-44 mg / L indolebutyric acid, 9-11 mg / L dichlorphenoxyacetic acid (2, 4-D), 0.9-1.1 g / L potassium dihydrogen phosphate, 0.09-0.11 mg / L iron, 0.045-0.055 mg / L born, 0.036-0.044 mg / L manganese, 0.036-0.044 mg / L copper and 0.027-0.033 mg / L zinc, the cutting seedling nutrient solution disclosed by the invention can be used for preventing decay of a lower notch during a seedling breeding process of the lonicera edulis twigs and promoting quick rooting of an in vitro material.

Owner:QINGDAO QINGXI BANYAN MODERN AGRI DEV

Radiating method in sponge titanium producing process by magnesium method

The invention relates to a radiating method in a sponge titanium producing process by a magnesium method, comprising the following steps: a radiating device is arranged on a large cover of a reactor,and cooling media are continuously led into the radiating device in a reducing process to radiate in the large cover of the reactor. By using the method, when sponge titanium is reduced, because a reaction liquid level has high temperature (generally about 950 DEG C), heat directly radiates on the large cover of the reactor by heat radiation, the temperature of the large cover of the reactor quickly rises, the cooling media are continuously led into a cooling medium inlet of the radiating device and flow out of a cooling medium outlet, thereby realizing effective heat exchange and achieving the radiating effect of the radiating process in the sponge titanium production.

Owner:ZUNYI TITANIUM

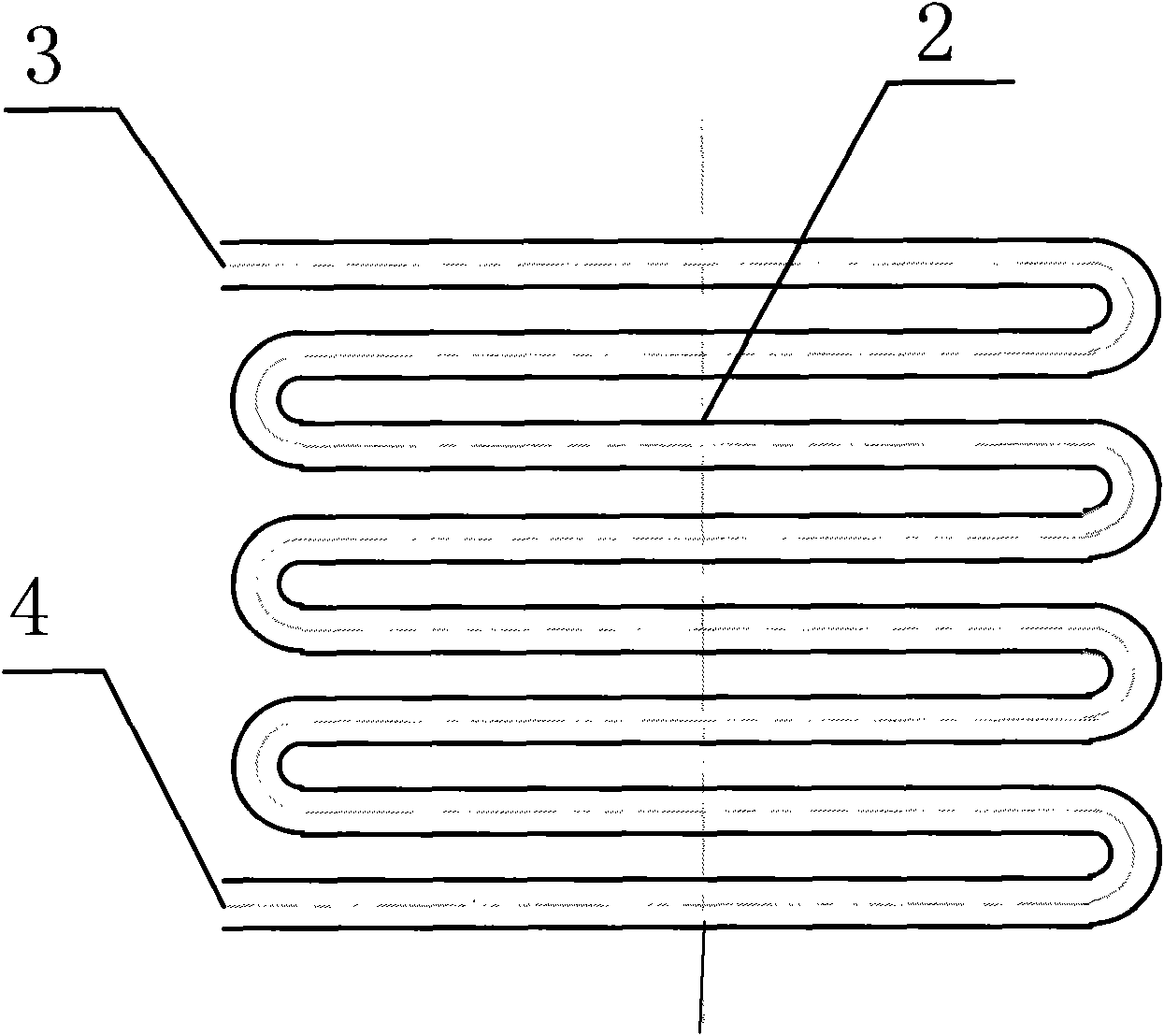

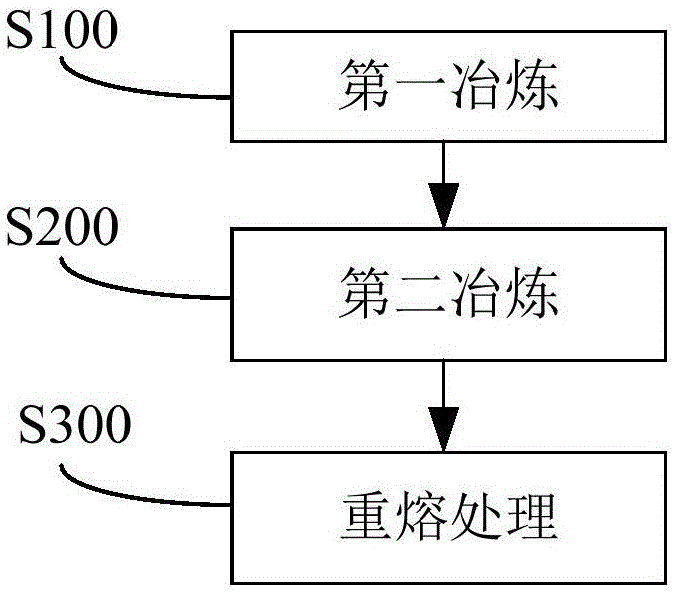

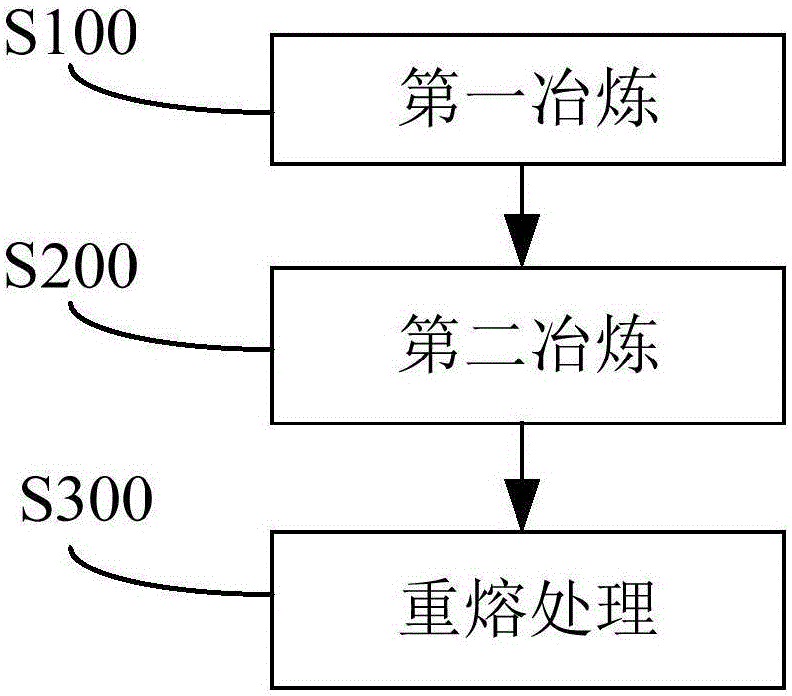

Method for preparing high-silicon silicon-manganese alloy

InactiveCN105112662AImprove grade rateSolve difficult to control, high coke consumptionSmelting processElectricity

The invention discloses a method for preparing a high-silicon silicon-manganese alloy. According to the embodiment of the invention, a manganese-containing raw material is subjected to primary smelting to obtain a liquid-state non-standard manganese-silicon alloy; a silicon-containing raw material is subjected to secondary smelting to obtain a liquid-state silicon mixture, wherein in the secondary smelting, graphite carbon rods are used for fluxing; and the liquid-state non-standard manganese-silicon alloy and the liquid-state silicon mixture are subjected to alloying treatment to obtain the high-silicon silicon-manganese alloy. By using the method disclosed by the invention for producing the high-silicon silicon-manganese alloy, the coke consumption is low, the electricity consumption is low, the cost is remarkably reduced, and the obtained high-silicon silicon-manganese alloy is high in grade and product competitiveness; and moreover, by using the graphite carbon rods for fluxing during a smelting process, the smelting time is remarkably reduced, and the production energy consumption is further reduced.

Owner:云南文山斗南锰业股份有限公司

Automatic fire-controlling coal stove for tobacco roasting machine

InactiveCN101053443AImprove roast qualityImprove grade rateTobacco preparationFire controlElectric machinery

The present invention relates to an automatic fire control coal-fired furnace of tobacco baking machine, including firing space, furnace wall, heat-insulating layer, fire grate and hot air duct, wherein the characterized in that: said firing space is surrounded by firing space adjusting plate and it has controllable variable capacity of firing space, the motion of firing space adjusting plate can be controlled for adjusting the fire to small, medium and big. One end of metal rod connect with firing space adjusting plate, and another end connect with eccentric wheel which connect with speed variable motor with same axle, eccentric wheel and speed variable motor are mounted lopsided downward of external coal-fired furnace. The present invention can greatly enhancing baking quality of tobacco, and it can guarantee the safety of burning in firing space and utilize sufficiently coal-fired heat energy through using naked fire baking and taking calorific radiation heat energy of firing space by circulating air duct, which not only can save coal by 20%, but also greatly enhance gradation rate of tobacco, therefore it can implement full-automatic and simply operation and liberate labor force.

Owner:上海森林印务有限公司 +2

Cleaning method for metal chromium piece

ActiveCN107779884ANo pollution in the processImprove cleaning qualityPhotography auxillary processesElectrolysis componentsCleaning methodsWater temperature

The invention relates to a cleaning method for a metal chromium piece. The cleaning method comprises the following steps: producing a metal chromium piece by virtue of an electrolytic method, stripingthe metal chromium piece from a cathode plate, detecting the lead content of the metal chromium piece, directly putting the metal chromium piece into a water circulating type roller cleaning machinewhen the lead content of the metal chromium piece is less than or equal to 0.002%, cleaning by virtue of a clean water roller, adding a proper amount of nitric acid or oxalic acid into clean water inthe cleaning process when the lead content in the metal chromium piece is more than or equal to 0.002%, and cleaning; and controlling the water temperature at 30-80 DEG C in the cleaning process of the water circulating type roller cleaning machine, carrying out automatic water washing in an automatic cleaning slot by virtue of a full-automatic ultrasonic cleaning machine through clean water, controlling the ultrasonic frequency at 50Hz, then putting the metal chromium piece into a washing slot, carrying out water washing with clean water, finally putting the metal chromium piece into drying equipment, drying, and carrying out packaging. The cleaning method has the advantages that a cleaning process is simple, the operation is easy, the operational environment of workers is improved, the operational difficulty is reduced, the grade ratio of a metal chromium piece product is increased, and the energy conservation, the energy conservation and the environmental protection are realized.

Owner:锦州钒业有限责任公司

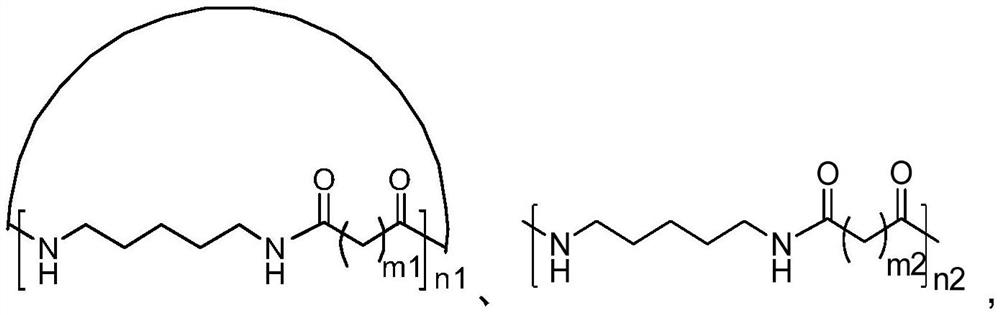

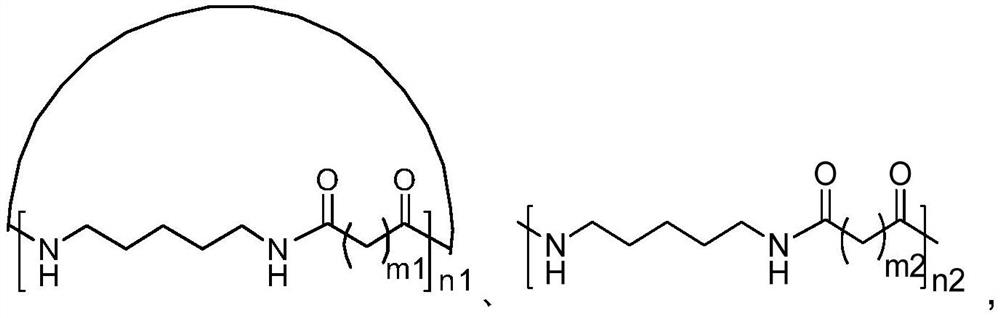

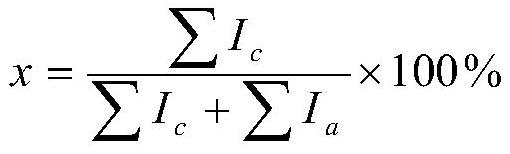

Polyamide 56 fiber with low boiling water shrinkage rate and preparation method and application of polyamide 56 fiber

ActiveCN112410916AEmission reductionReduce the greenhouse effectMelt spinning methodsArtifical filament manufactureYarnPolymer science

The invention belongs to the technical field of polyamide materials, and provides polyamide 56 pre-oriented yarn and textured yarn with low boiling water shrinkage rates and preparation methods and application of the polyamide 56 pre-oriented yarn and textured yarn. The production raw materials of a polyamide 56 fiber comprise 1,5-pentamethylene diamine and adipic acid; or polyamide resin 56 is obtained through polymerization by taking 1,5-pentamethylene diamine and the adipic acid as monomers; wherein the boiling water shrinkage rate of the polyamide 56 fiber is below 9%, and the polyamide 56fiber comprises the polyamide 56 pre-oriented yarn with the low boiling water shrinkage rate and the polyamide 56 textured yarn with the low boiling water shrinkage rate. The polyamide 56 fiber has relatively good mechanical properties, dyeing uniformity and dimensional stability, and the preparation method of the polyamide 56 fiber does not need to modify existing polyamide fiber elasticizing equipment, so that the production cost is reduced.

Owner:CATHAY R&D CENT CO LTD +1

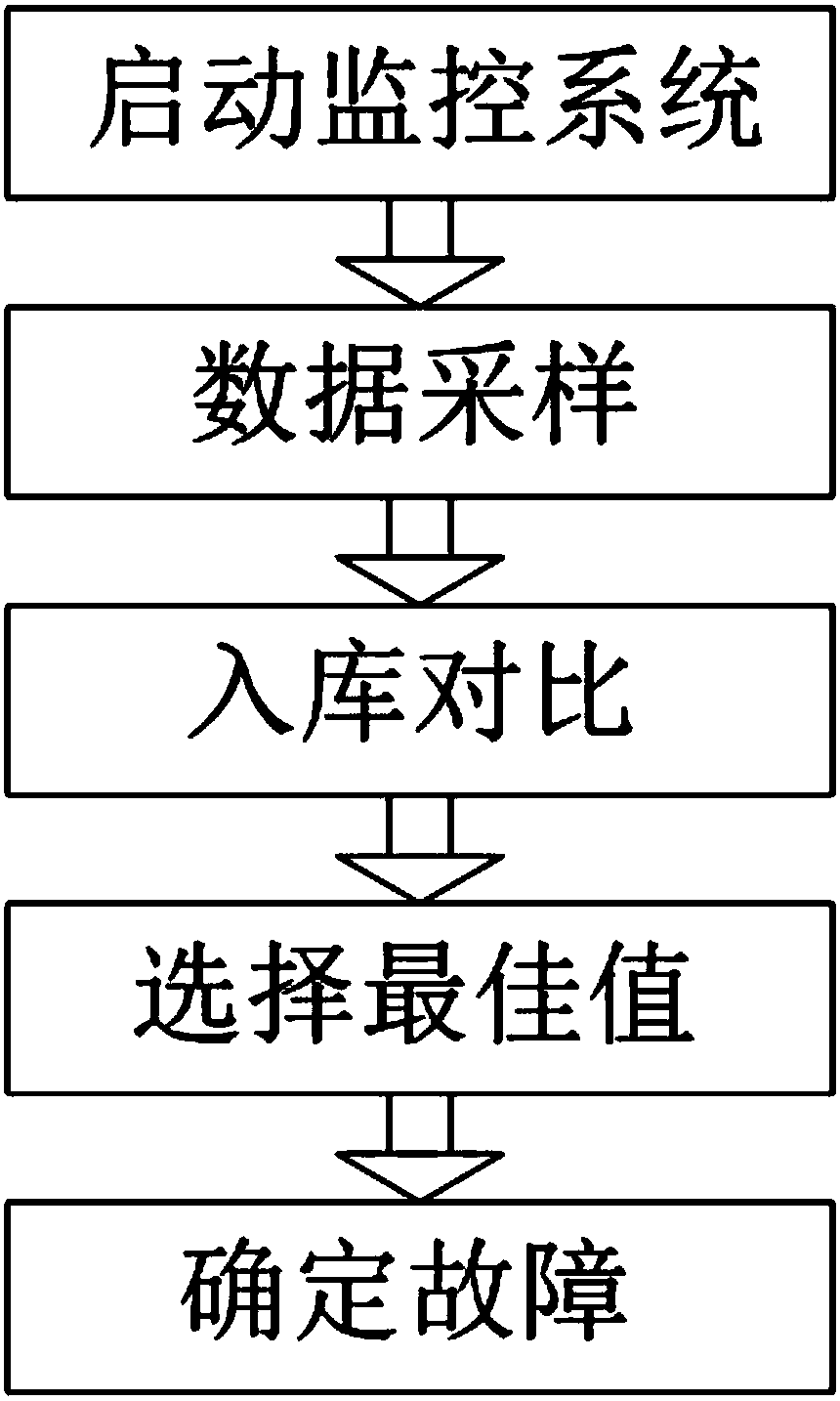

Computer monitoring system control method for electric melting furnace

InactiveCN107942909AHigh degree of automationIncrease productionProgramme control in sequence/logic controllersComputer monitorComputer monitoring

The invention discloses a computer monitoring system control method for an electric melting furnace, wherein the method belongs to the field of computer monitoring technology. The computer monitoringsystem control method for the electric melting furnace comprises the steps of S1, starting a monitoring system, inputting initial technological parameters in an upper computer according to field actual production, starting an electric magnesium melting furnace computer monitoring system, wherein the initial technological parameters comprise granularity of raw material, melting time length, producing equipment, voltage amplitude and melting current magnitude; S2, data sampling, performing A / D conversion on current sampling data from a current transformer by a programmable controller, furthermore sampling each button amount and output amount data of a control motor, and transmitting the sampling data to the upper computer through a communication module by means of network; and S3, performingwarehousing comparison, writing the current sampling data, each button amount and the output amount data of the control motor into a database by supervisory control and data acquisition software of an upper computer, wherein the current sampling data, each button amount and the output amount data of the control motor are transmitted by a lower computer, and generating a current amplitude trend picture in field actual production and a field actual production process picture.

Owner:XUZHOU ZHONGKUANG KAIRUI TECH CO LTD

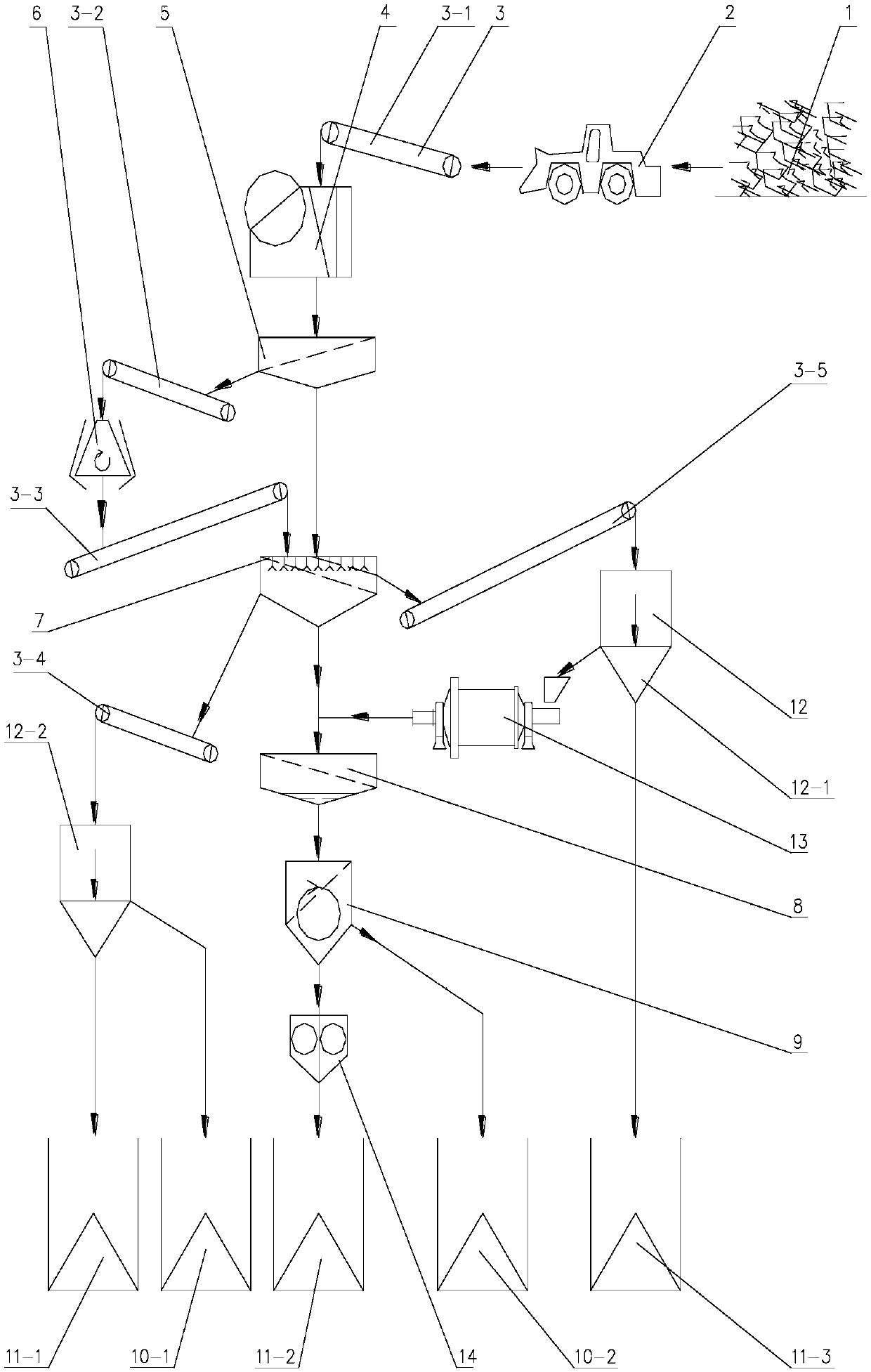

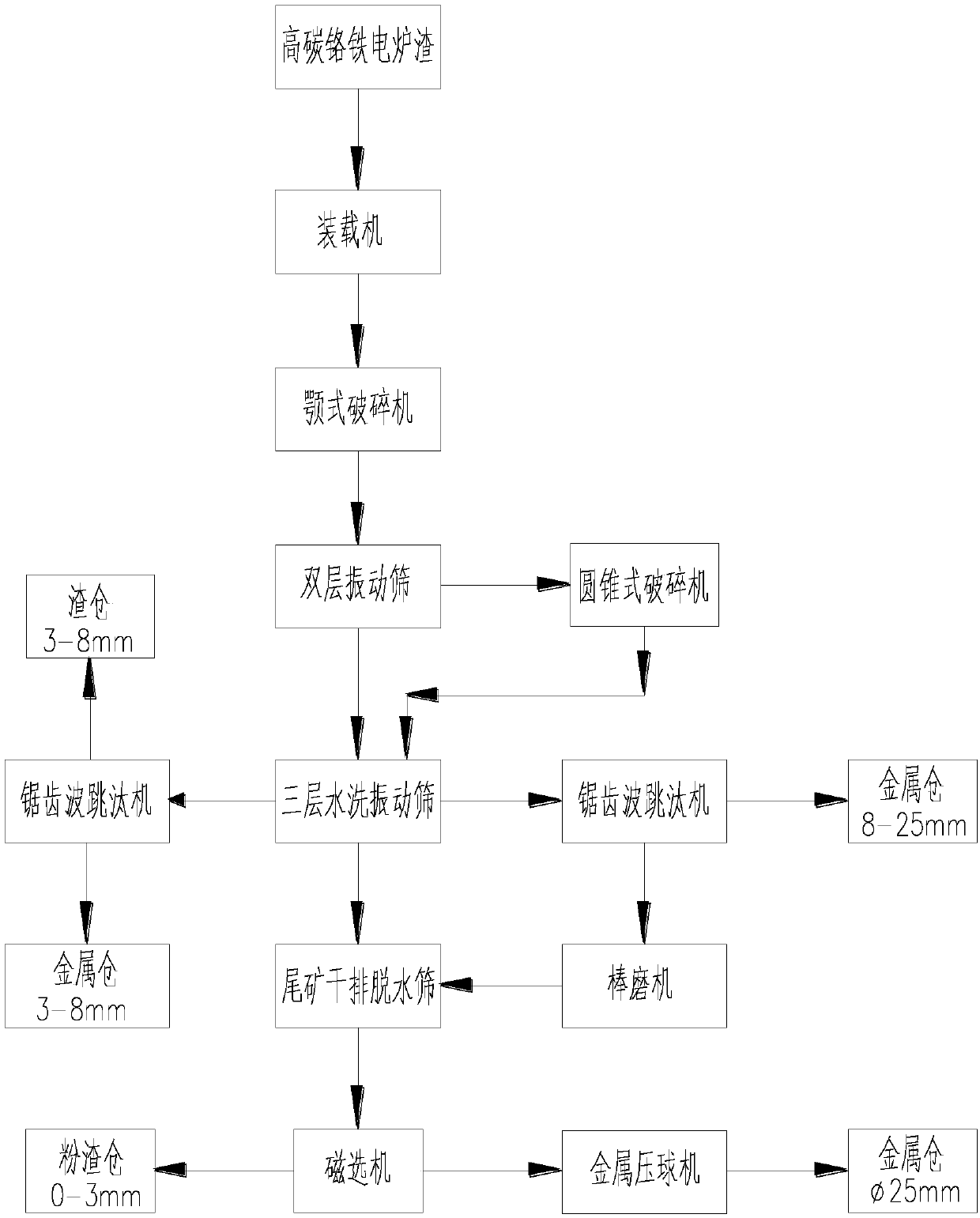

Recovery system for metal in slag of high-carbon ferro-chrome electric furnace

PendingCN107604111AHigh metal recovery rateIncrease productionRecycling and recovery technologiesProcess efficiency improvementSmall footprintSieve

The invention provides a recovery system for metal in slag of a high-carbon ferro-chrome electric furnace, and relates to a slag separation and recovery system suitable for large and medium-sized high-carbon ferro-chrome electric furnace industries. The recovery system for metal in slag of the high-carbon ferro-chrome electric furnace comprises a conveyor, a jaw crusher, a double-layer vibrating sieve, a cone crusher, a three-layer washing sieve, a tailing dry-discharging and dewatering sieve, a magnetic separator, a slag bin, a metal bin, a sawtooth wave jigger, a rod mill and a ball press machine. The recovery system for metal in slag of the high-carbon ferro-chrome electric furnace has the characteristics of being novel in structure, easy and convenient to machine, small in occupied area, capable of relieving labor intensity, high in production efficiency, capable of reducing labor cost and being matched with environmental protection facilities and the like, and thus is a novel recovery system for metal in slag of the high-carbon ferro-chrome electric furnace which is economical and practical.

Owner:大连重工机电设备成套有限公司 +1

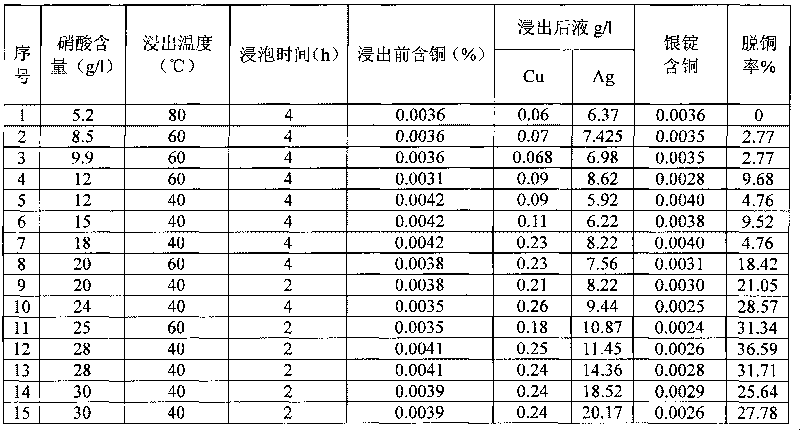

Method for increasing quality of cathode silver power

The invention discloses a method for increasing quality of cathode silver power, aiming to solve the problem that the copper impurity in the cathode silver power exceeds standard. The method comprises the following steps: preparing cathode silver power by controlling the compositions of electrolyte to comprise 90-120g / l of Ag, 8-10g / l of HNO3 and less than 35-60g / l of Cu, and using 20-28g / l of dilute nitric acid to dissolve, soak and rinse the cathode silver power when the copper content in the electrolyte is more than 35g / l, wherein the soaking temperature is 40-50 DEG C, the soaking time is 2h, and the rinsing temperature is 80-90 DEG C. By using the method of the invention, the cost of the 1# cathode silver is reduced and the mass of the product silver ingot is increased. The method has the advantages of low operating intensity, simple equipment, low production cost, capability of not changing the original processing equipment, and the like.

Owner:BAIYIN NONFERROUS GROUP

Repair process for incomplete textile fabric

InactiveCN101285240AEasy to operateSolve the problem of surface marksKnittingYarnStructural engineering

The invention provides a method for repairing imperfect fabric. The method comprises the following steps of: a. the repairing method for replacing broken yarns of the fabric, b. the repairing method for bridging the hole of the damaged fabric; c. the repairing method for threading by a repairing needle, wherein, a. the repairing method for replacing broken yarns of the fabric comprises the main steps that: one end of an auxiliary yarn threads through the original position of the picked broken yarn by a cuspidal plier, sent forwards to the other end of the picked broken yarn along the direction of the broken yarn by the assistance of the plier and pulled out; one end of a section of a right yarn is embedded into the auxiliary yarn thrum; at the same time, two kinds of yarns are twisted according to the twisting directions of the yarns, then a right yarn after being twisted is led to the original position of the broken yarn of the fabric by drawing the auxiliary yarn; the auxiliary yarn is taken off, a new repaired yarn realizes the same tightness with the prior fabric yarn through extending and adjusting the new repaired yarn; and finally, the thrum is remained on the back of the fabric, thereby completing the repair by replacement. The method for repairing imperfect fabric improves product quality and grade product rate on the premise of increasing no input cost.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD +1

Method for preparing silicomanganese with high silicon

The invention discloses a method for preparing silicomanganese with high silicon. The method comprises the following steps: smelting manganese-containing raw materials for the first time to obtain liquid non-standard silicomanganese; smelting silicone-containing raw materials and a covering agent for the second time to obtain a liquid silicon mixture; alloying the liquid non-standard silicomanganese and the liquid silicon mixture to obtain the silicomanganese with high silicon. According to the method, the perrin process is carried out to smelt the silicomanganese with high silicon, and a certain of silicon-containing raw materials and reasonable covering agent are added to the manganese-containing raw materials, thus solving the problems in the prior art that the conditions of a furnace for producing the silicomanganese with high silicon by the one-step method are difficult to control, the coke consumption is high, the electricity consumption is high, and the grade rate is low.

Owner:云南文山斗南锰业股份有限公司

A method of clean high-absorption chrome tanning

This invention is a method of sanitary high-absorption chrome tanning. Its character is using treated waste water releasing from tannery instead of tap water and well water in the whole process. In the prophase, tanning cutting technique is utilized. In the acid soaking process, it is treated with amino resin tanning agent.

Owner:SICHUAN UNIV

Emulsifying method of polyurethane micro-powder, polyurethane micro-powder emulsion, leather mending agent and application thereof

PendingCN111072996AImprove performanceImprove healing effectLeather surface finishingEmulsionActive agent

The invention discloses an emulsifying method of polyurethane micro-powder, a polyurethane micro-powder emulsion, a leather mending agent and application of the leather mending agent, and the emulsifying method comprises the following steps: mixing nonionic surfactants with different HLB values to obtain a compound emulsifier; adding the polyurethane micro-powder into the composite emulsifier to obtain a polyurethane micro-powder suspension; dropwise adding deionized water into the polyurethane micro-powder suspension; dropwise adding a curing agent into the polyurethane micro-powder suspension, adjusting the pH value of the system to 7.5-9, and stirring to obtain the polyurethane micro-powder emulsion; according to the invention, the problem that in the prior art, polyurethane micro-powder is difficult to form a stable body in a water phase or a solvent phase is solved; the technical problem that the application of the polyurethane micro-powder emulsion in leather finishing is limitedin the prior art is solved, the polyurethane micro-powder emulsion is formed and applied to the leather mending agent, the performance of the leather mending agent is improved, and meanwhile, if theleather mending agent containing the polyurethane micro-powder is applied to the grain surface of crust leather, the mending effect can be remarkably improved.

Owner:XINGYE LEATHER TECH CO LTD

Reaction-controllable solvent-free polyurethane resin as well as preparation method and use method thereof

The invention relates to the field of resin synthesis, in particular to reaction-controllable solvent-free polyurethane resin as well as a preparation method and a use method thereof. The invention relates to a reaction-controllable solvent-free polyurethane resin, which is a double-component resin and is composed of a component A and a component B, the component A and the component B are both prepared from main materials and auxiliary materials; the main material in the component A is prepared from the following raw materials in percentage by mass: 5%-15% wt of a chain extender, 50-500 ppm of a catalyst, 1%-5% wt of catalyst composite micro powder for controlling the reaction rate and the balance of polyol; the auxiliary material is a functional auxiliary agent; the main material in the component B is a prepolymer obtained by reaction of polyol and isocyanate; and the main material in the component B is prepared from 55 wt% to 65 wt% of polyhydric alcohol and 35 wt% to 45 wt% of isocyanate. The method has the advantages that the reaction is controllable, and the grade rate of the product can be improved.

Owner:JIAXING HEXIN CHEM IND

Titanium tetrachloride charging method for production of sponge titanium

The invention discloses a titanium tetrachloride charging method for production of sponge titanium. The charging method of the sponge titanium is improved to reduce the influence of magnesium ingots as a raw material on the quality of the sponge titanium, particularly to completely avoid degradation of the sponge titanium caused by over-standard of the Mn and reduce the content admixture iron. The Fe content of a product is in a range of 0.01-0.02wt% and the top-grade product rate is improved. The method is simple without cost increase, easy to operate, obvious in economic benefit, and suitable for being popularized and applied in the sponge titanium industry.

Owner:朝阳金达钛业股份有限公司

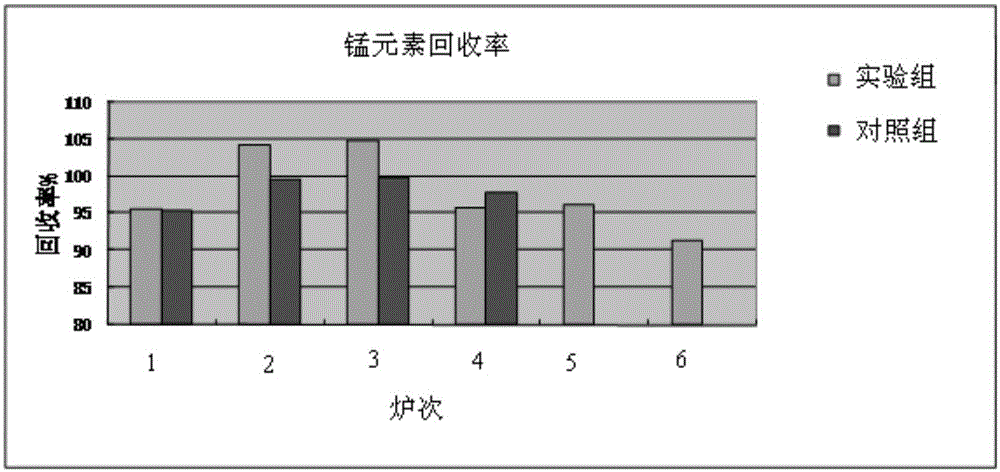

Method for washing electrolytic manganese polar plate

InactiveCN103628089ASimple methodEasy to operatePhotography auxillary processesElectrolysis componentsWater savingElectrolysis

The invention provides a method for washing an electrolytic manganese polar plate. The method comprises the following steps: putting a passivated electrolytic manganese polar plate into an ultrasonic washing groove; putting the electrolytic manganese polar plate into a water washing groove to be washed by clean water; conveying the electrolytic manganese polar plate into an air drying groove to be aired; drying in a drying oven and blowing in an air blowing groove by strong air; conveying the electrolytic manganese polar plate into a stripping region to be finished; putting the stripped electrolytic manganese polar plate into an anode liquid immersion groove to be immersed and then putting into a plate washing groove to be activated by a plate washing solution; conveying the electrolytic manganese polar plate into the ultrasonic washing groove to be washed by the clean water and putting into the water washing groove to be washed by the clean water; and finally, conveying the electrolytic manganese polar plate into the air drying groove to be aired by the strong air and conveying the electrolytic manganese polar plate into a plate reserving region for later use. The method has the advantages that the method is simple and easy to operate; impurities on the surfaces of the electrolytic manganese polar plate and the stripped polar plate are removed effectively and the washing effect is good; the electrolytic manganese polar plate does not need to be washed by a lot of industrial water to realize water saving, energy conservation and environmental protection; the grade rate of a product is also improved and the grade rate of a C-grade product can be up to 60%-63%; the washing effect is good, the falling of an electrolytic manganese sheet is reduced to the greatest extent and the yield of the product is improved.

Owner:CITIC JINZHOU METAL

Treatment method of standard exceeding of content of chlorine in titanium sponge

The invention provides a treatment method of standard exceeding of content of chlorine in titanium sponge. The titanium sponge is titanium sponge produced by adopting a magnesiothermic reduction method. The treatment method comprises the following steps: placing the titanium sponge in a reactor, vacuumizing the reactor until the vacuum degree in the reactor is not more than 100Pa; heating the reactor to ensure that the titanium sponge in the reactor is firstly subjected to low-temperature degassing of a temperature phase of 150-200 DEG C and intermediate temperature degassing of four constant temperature phases of 200-300 DEG C, 350-400 DEG C, 450-500 DEG C and 500-550 DEG C to remove water and gas impurities in magnesium chloride hydrate in the titanium sponge; and after degassing is ended, continuously raising the temperature to 900-1020 DEG C for vacuum distillation to remove magnesium chloride in the titanium sponge. According to the method, the content of chlorine in the titanium sponge, which exceeds the standard, can be effectively reduced, and the grade rate of the titanium sponge is increased.

Owner:PANGANG GROUP TITANIUM INDAL

A kind of cleaning method of metal chrome sheet

ActiveCN107779884BNo pollution in the processImprove cleaning qualityPhotography auxillary processesElectrolysis componentsWater temperatureOxalic acid

The invention relates to a cleaning method for a metal chromium piece. The cleaning method comprises the following steps: producing a metal chromium piece by virtue of an electrolytic method, stripingthe metal chromium piece from a cathode plate, detecting the lead content of the metal chromium piece, directly putting the metal chromium piece into a water circulating type roller cleaning machinewhen the lead content of the metal chromium piece is less than or equal to 0.002%, cleaning by virtue of a clean water roller, adding a proper amount of nitric acid or oxalic acid into clean water inthe cleaning process when the lead content in the metal chromium piece is more than or equal to 0.002%, and cleaning; and controlling the water temperature at 30-80 DEG C in the cleaning process of the water circulating type roller cleaning machine, carrying out automatic water washing in an automatic cleaning slot by virtue of a full-automatic ultrasonic cleaning machine through clean water, controlling the ultrasonic frequency at 50Hz, then putting the metal chromium piece into a washing slot, carrying out water washing with clean water, finally putting the metal chromium piece into drying equipment, drying, and carrying out packaging. The cleaning method has the advantages that a cleaning process is simple, the operation is easy, the operational environment of workers is improved, the operational difficulty is reduced, the grade ratio of a metal chromium piece product is increased, and the energy conservation, the energy conservation and the environmental protection are realized.

Owner:锦州钒业有限责任公司

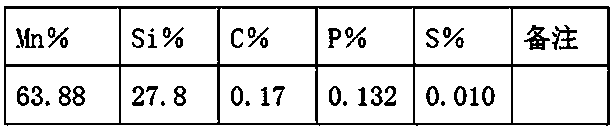

"Two-step" method of refining outside the furnace to produce low-carbon manganese-silicon alloy

The invention discloses a method for producing low carbon manganese-silicon alloy through external refining by adopting a two-step method. The method comprises the following steps: adopting a submerged arc furnace of 25500 KVA or above to produce a silicon manganese alloy product containing 22-24% of silicon; loading the silicon manganese alloy product containing 22-24% of silicon into a 20-ton intermediate frequency furnace, adding silicon iron of which the weight is 5%-15% that of the silicon manganese alloy product in the intermediate frequency furnace, electrifying the intermediate frequency furnace for smelting for 5-15 minutes, adding a slagging element of which the weight is 2.4% that of the silicon manganese alloy product and a covering agent of which the weight is 0.8% that of the silicon manganese alloy product for refining for 15-25 minutes after the temperature reaches 1400 degrees or above, cutting off the power after the completion of refining, and leaving to stand for 5 minutes; and slagging off, tapping and pouring, so as to finally obtain the low carbon manganese-silicon alloy in which the content of Si is higher than or equal to 27% and the content of C is lower than or equal to 0.2%. According to the method for producing low carbon manganese-silicon alloy through external refining by adopting the two-step method, the production scale is large, the product quality is stable, the operation is stable, the production cost is low, the cost is reduced by RMB 461 per ton, and the product grade ratio reaches 95% or above.

Owner:国家电投集团贵州金元绥阳产业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com