Method of preparing back coated real leather intimating synthetic leather

A manufacturing method and technology of artificial leather, applied in textiles and papermaking, etc., can solve the problems of long process flow, low grade rate and low production efficiency of artificial leather synthetic leather, and achieve diversified leather styles, high grade rate, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

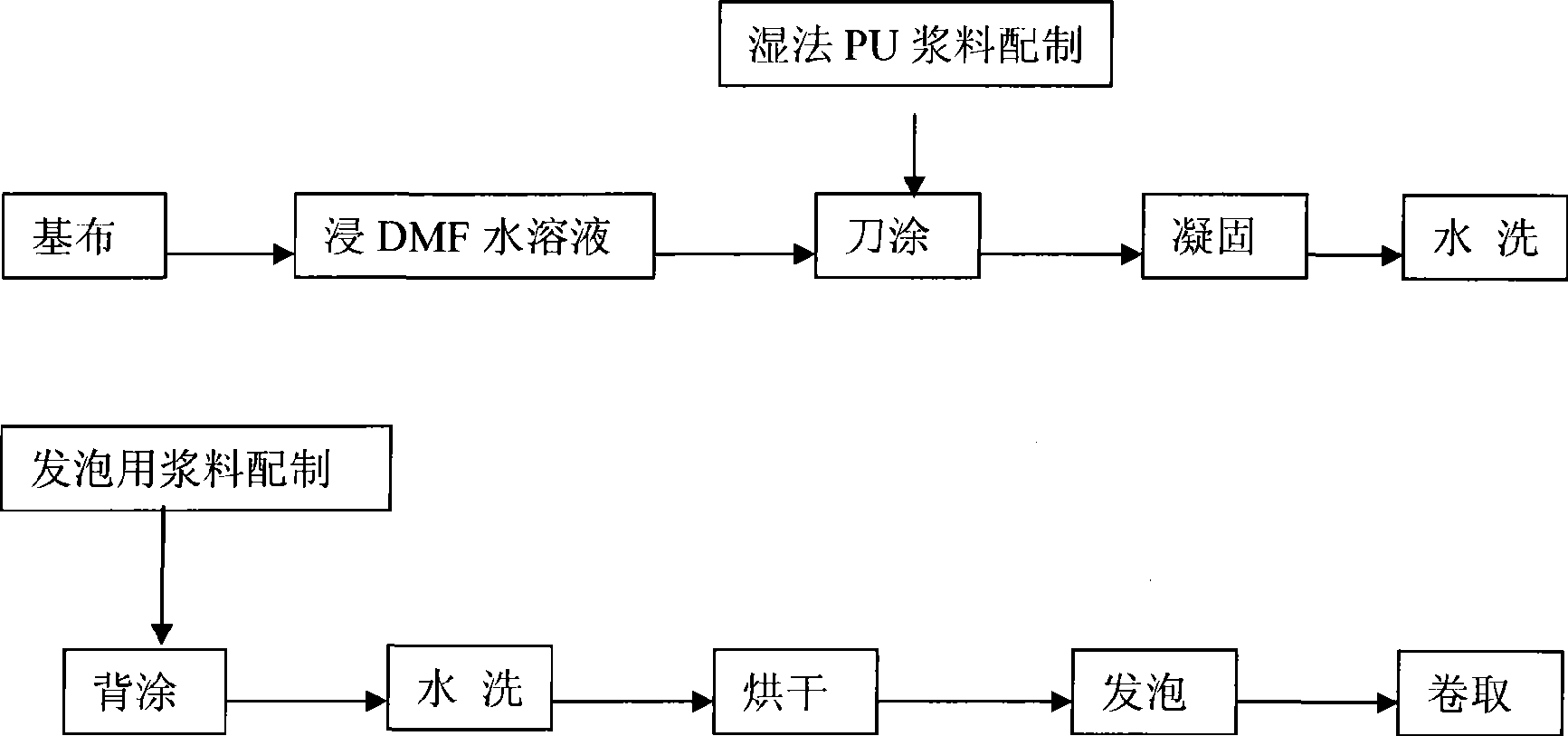

[0036] A kind of manufacture method of back-coated imitation leather synthetic leather:

[0037] (1) Knitted fleece is used as a wet-laid base material.

[0038] (2) Preparation of wet-process single-coating materials: prepare slurry according to the traditional single-coat wet-process PU slurry system, knife-coat to the substrate, solidify, and wash with water.

[0039] (3) Preparation of wet-process back-coated foaming materials;

[0040] According to the formula of the slurry, it is calculated by weight:

[0041] Foaming resin (ST-1030) 100 parts

[0042] 80 parts of dimethylformamide (DMF)

[0043] Foaming agent (461DU40) 0.5 part

[0044] Foaming agent (461DU40) 1.5 parts

[0045] Solvent-based color paste 5 parts

[0046] (4) Back-coat the foaming slurry to the wet base, then dry: 120°C for 3 minutes, foaming: 135°C for 20 seconds for low-temperature foaming;

[0047] (5) Grinding treatment of the back of the wet-process crust leather: 80 mesh sandpaper grinding t...

example 2

[0050] A kind of manufacture method of back-coated imitation leather synthetic leather:

[0051] (1), 0.9mm*220g / m 2 All polyester as base material;

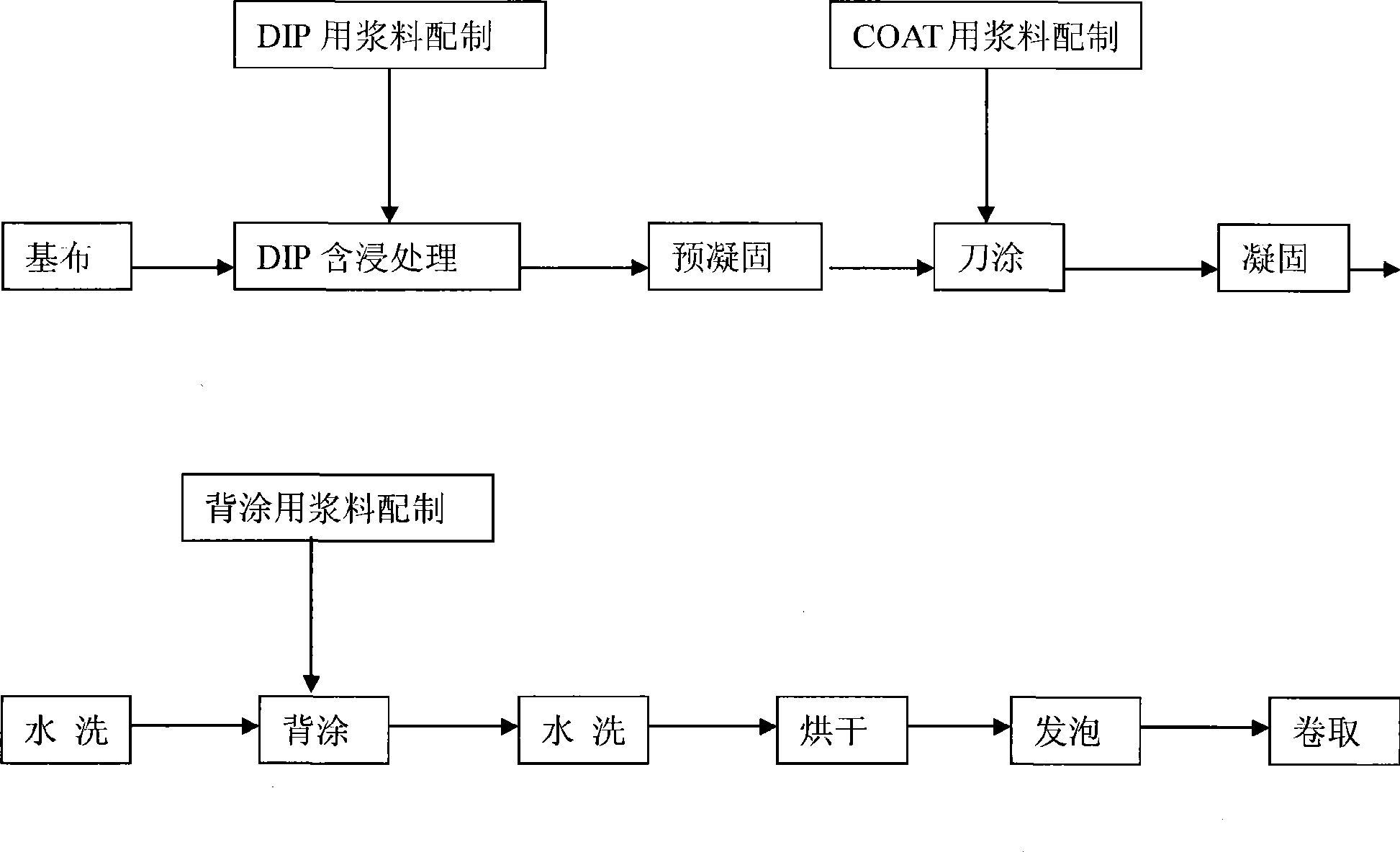

[0052] (2) Knife coating, coagulation, and water washing of wet DC process materials: according to the traditional DC process formula system.

[0053] (3) Preparation of wet-process back-coated foaming materials;

[0054] According to the formula of the slurry, it is calculated by weight:

[0055] Foaming resin (ST-1040) 100 parts

[0056] 80 parts of dimethylformamide (DMF)

[0057] Foaming agent (461DU40) 1 part

[0058] Foaming agent (461DU40) 3 parts

[0059] 2 parts solvent-based color paste

[0060] (4) Back-coat the foaming slurry to the wet base, then dry: 130°C for 3 minutes, foaming: 150°C for 15 seconds;

[0061] (5) Grinding treatment of the back of the wet process crust leather: 150 mesh sandpaper grinding treatment;

[0062] (6) Pattern transfer of dry-process release paper on the front of wet crust leathe...

example 3

[0064] A kind of manufacture method of back-coated imitation leather synthetic leather:

[0065] (1), 0.60mm double-sided raised fabric woven fabric as wet substrate;

[0066] (2) Knife coating, coagulation, and water washing of wet DC materials: according to the traditional DC process formula system.

[0067] (3) Preparation of wet-process back-coated foaming materials;

[0068] According to the formula of the slurry, it is calculated by weight:

[0069] Foaming resin (ST-1040) 100 parts

[0070] 55 parts of dimethylformamide (DMF)

[0071] Foaming agent (461DU40) 0.5 part

[0072] Foaming agent (909DU80) 5 parts

[0073] (4) Back-coat the foaming slurry to the wet base, then dry: 120°C for 2.5 minutes, foaming: 180°C for 10 seconds at high temperature;

[0074](5) Grinding treatment of the back of the wet process leather: 240 mesh sandpaper grinding treatment;

[0075] (6) Pattern transfer of dry-process release paper on the front of wet crust leather.

[0076] illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com