Automatic fire-controlling coal stove for tobacco roasting machine

A technology of coal-fired furnace and flue-cured tobacco machine, which is applied in the fields of tobacco, tobacco preparation, application, etc. It can solve the problems that the temperature and humidity cannot be effectively and timely controlled, the quality of tobacco leaves is affected, and the firepower cannot be easily controlled, so as to improve the grade rate of tobacco leaves, The effect of easy operation and labor liberation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

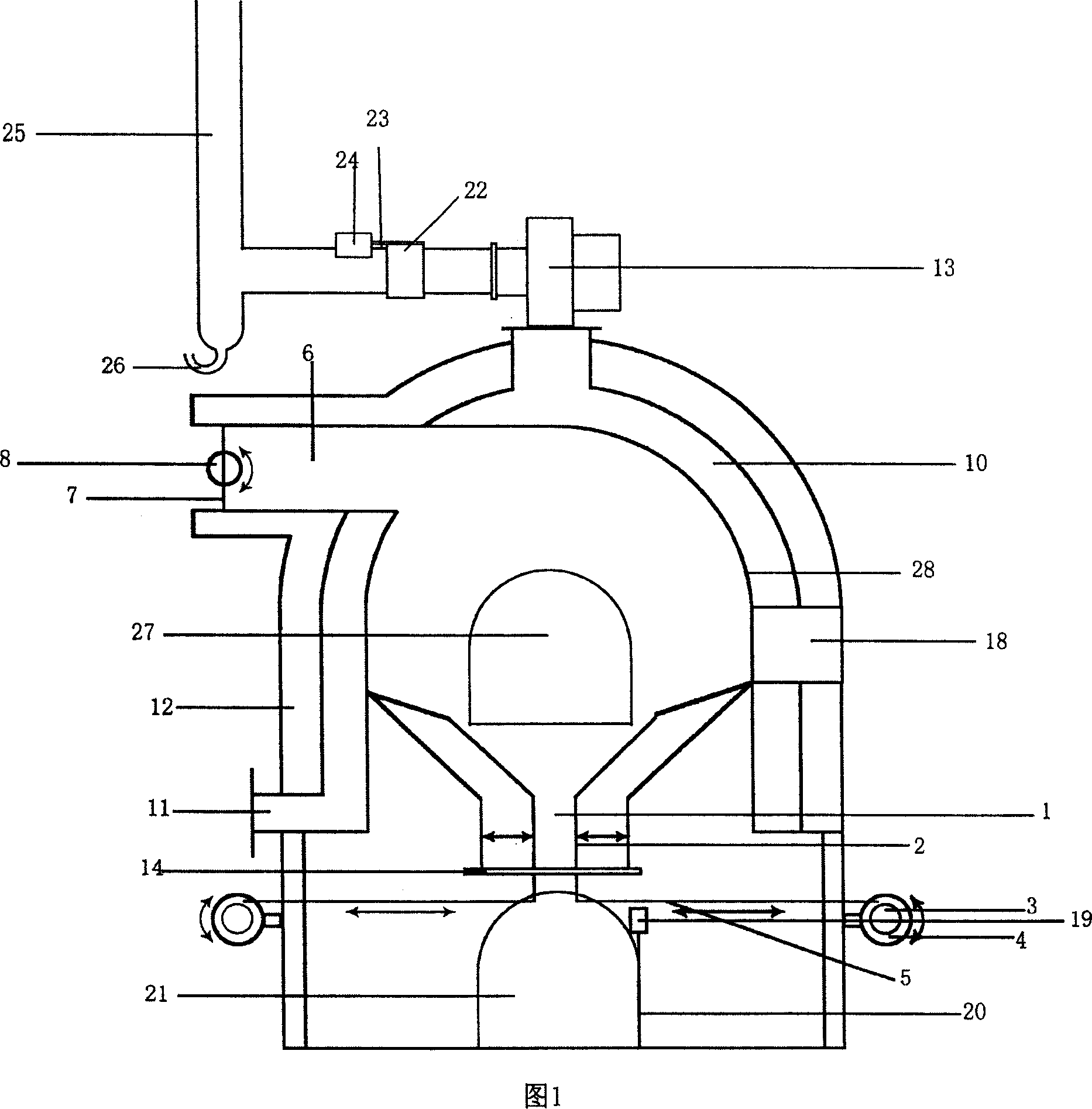

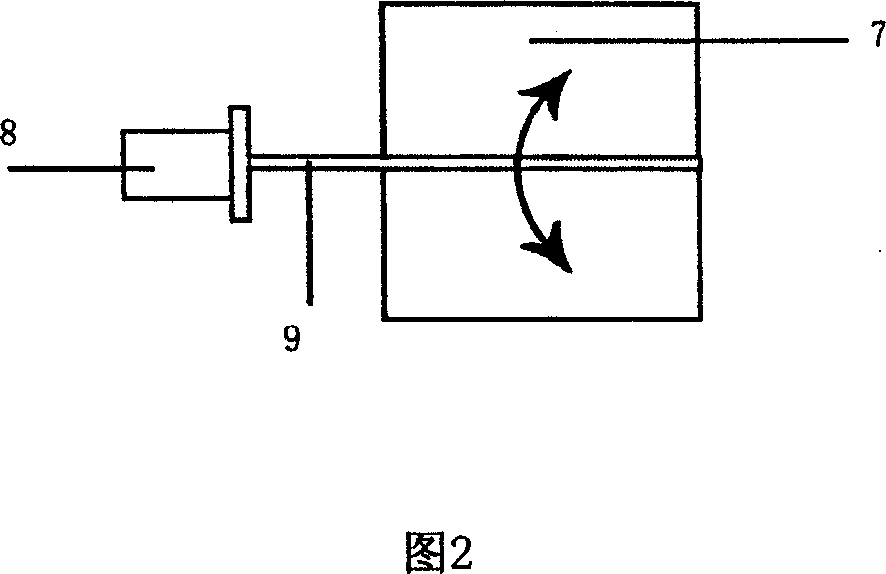

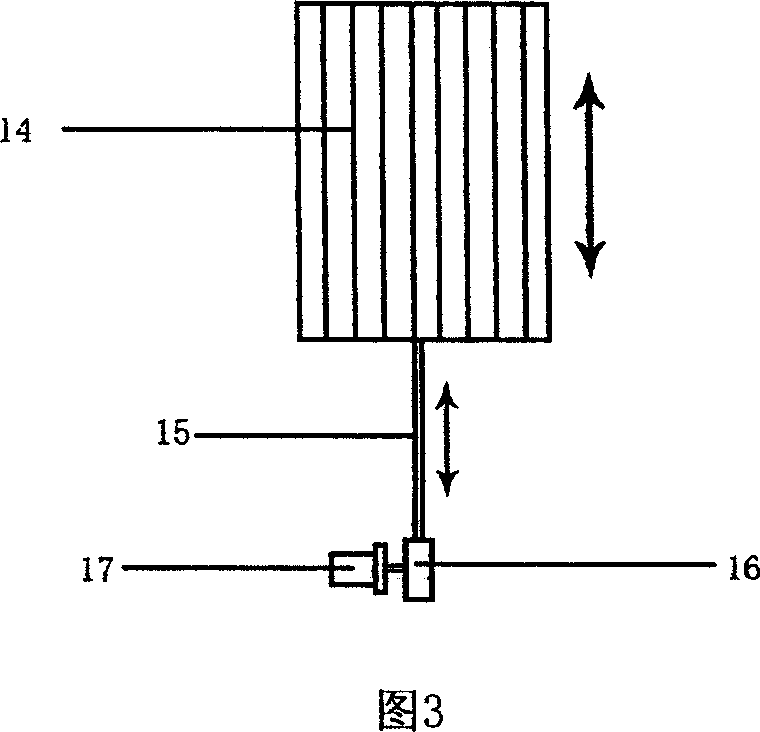

[0010] According to the accompanying drawings, the present invention includes a furnace 1, a furnace wall 28, an insulation layer 12, a grate 14 and a hot air duct 6. The furnace 1 is a furnace in which the volume of the furnace can be controlled by a furnace regulating plate 2, and the furnace regulating plate 2 is controllable. Move, the furnace adjustment plate 2 is connected to one end of the metal rod 5, the other end of the metal rod 5 is connected to the eccentric wheel 4, the eccentric wheel 4 is coaxially connected to the variable speed motor 19, and the eccentric wheel 4 and the variable speed motor 19 are installed at the lower part of the coal-fired furnace body . The upper part of the furnace body surrounded by the furnace regulating plate 2 is an inverted trapezoidal cone, and the lower part is a rectangular three-dimensional shape. A heat supply valve 7 is arranged at the outlet of the hot air passage 6, and the motor drives the heat supply valve shaft 9 to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com