Patents

Literature

314results about How to "Improve roast quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

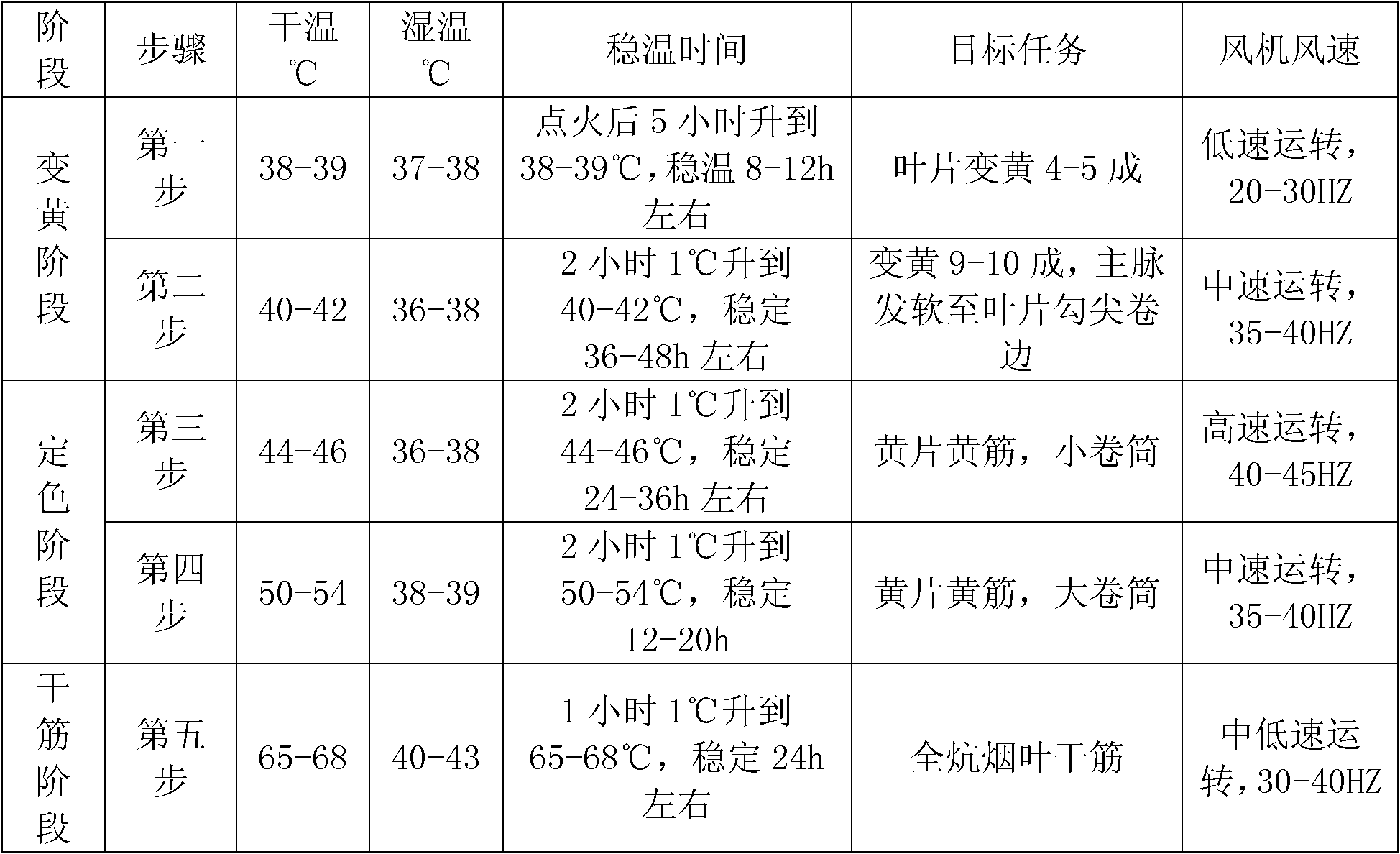

Three-section and five-step bulk curing process for flue-cured tobacco

InactiveCN102488310ALow hardware requirementsReduce construction costsTobacco preparationEngineeringFlue

The invention discloses a three-section and five-step bulk curing process for flue-cured tobacco, and belongs to the technical field of tobacco modulation. The process mainly comprises three curing stages, namely a yellowing stage, a fixation stage and a stem drying stage, and is characterized in that: the yellowing stage and the fixation stage are also decomposed into two key temperature and humidity steps respectively; by increasing a key temperature and humidity step of the stem drying stage, three curing stages and five key temperature and humidity steps are set for the entire curing process; according to variation condition of tobacco leaves and by controlling the temperature and humidity of a curing room in the temperature and humidity ranges required by corresponding steps of the five key temperature and humidity steps, the aim of adjusting and controlling flue-cured tobacco curing process is fulfilled, a better effect is achieved, poor curing of green miscellaneous tobacco and the like is obviously reduced, the proportion of yellow tobacco and high-grade tobacco is increased, the structure is loose, the oil content is increased, and the internal and external appearance quality and the availability of the tobacco are obviously improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

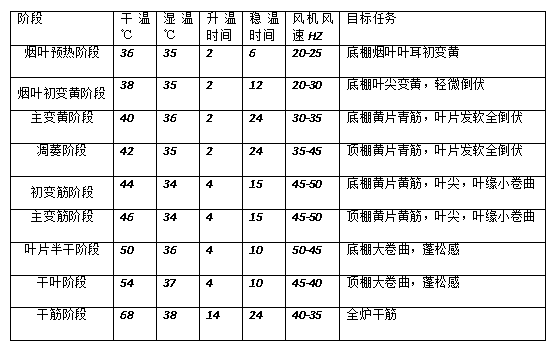

Scattered-tobacco stacking low-humidity slow flue curing process for flue-curing tobacco bulk curing barn

InactiveCN103829363AImprove roast qualityAvoid the phenomenon of more blue veinsTobacco preparationCentrifugal fanChemistry

The invention discloses a scattered-tobacco stacking low-humidity slow flue curing process for a flue-curing tobacco bulk curing barn. The process comprises 9 stages of a preheating stage, a primary yellowing stage, a main yellowing stage, a withering stage, a primary stem changing stage, a main stem changing stage, a leaf half-drying stage, a leaf drying stage and a stem drying stage. Different from the traditional curing method, the process is characterized in that a centrifugal fan is used for replacing an axial flow fan to perform forced ventilation and moisture removing, and a low-humidity method is used throughout the curing process instead of relative-high-humidity curing of the traditional curing method; meanwhile, the withering stage is added after leaf yellowing, so that the tobacco leaf water content achieves an appropriate level, and tobacco leave color fixation is facilitated; the stem changing stage time is prolonged, so that the tobacco stem yellowing and the tobacco leaf dehydration color fixation are facilitated.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

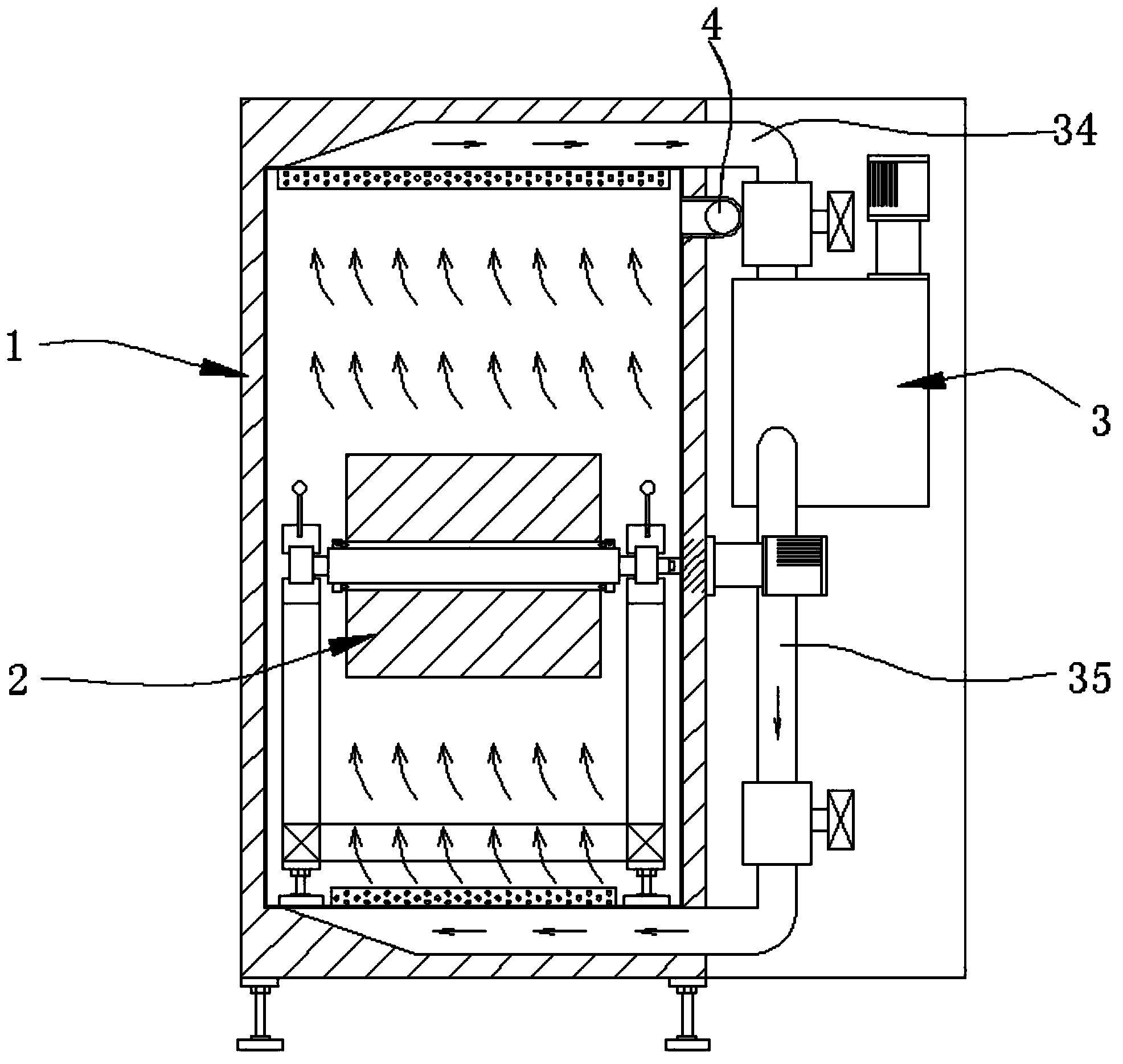

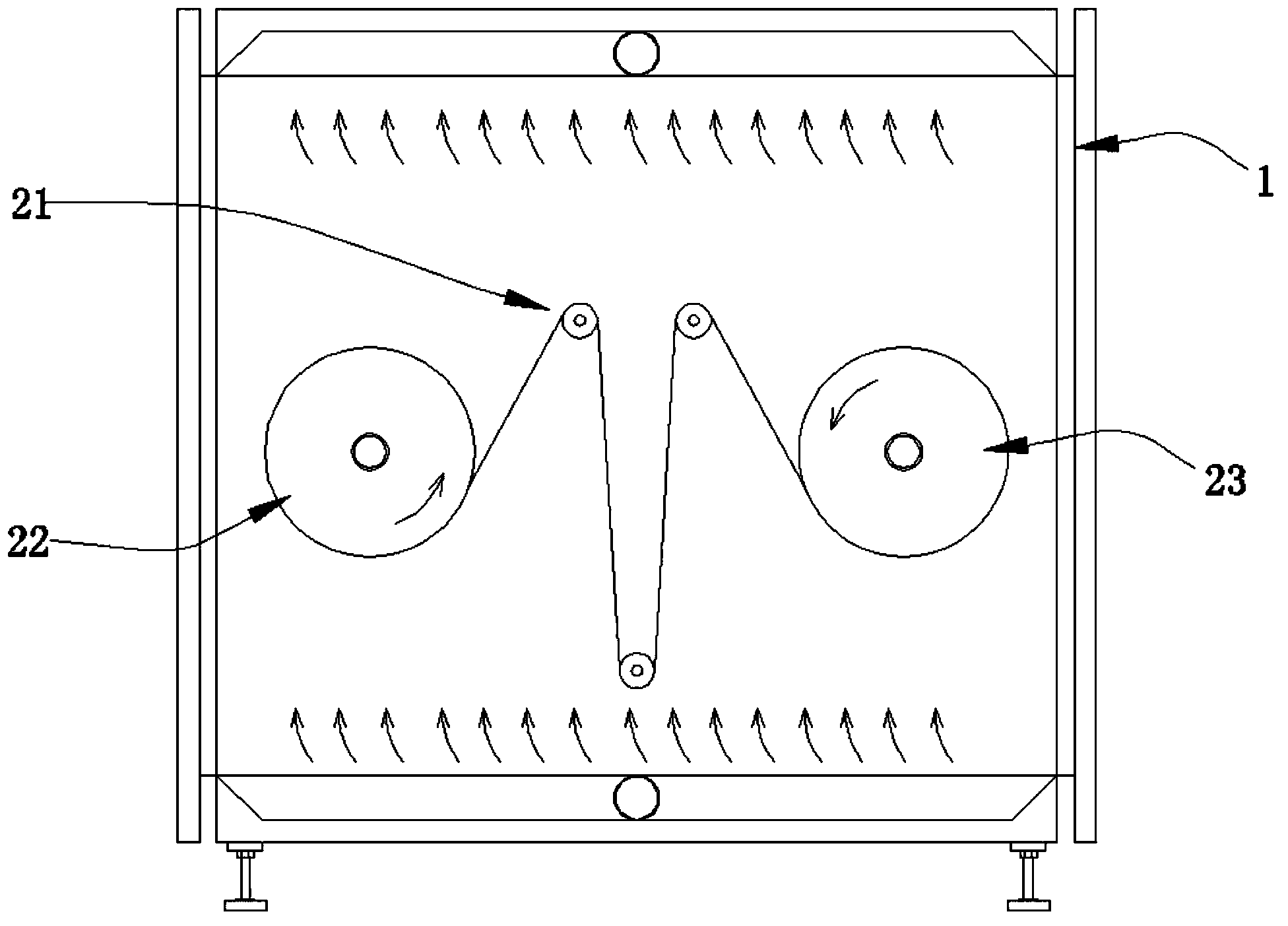

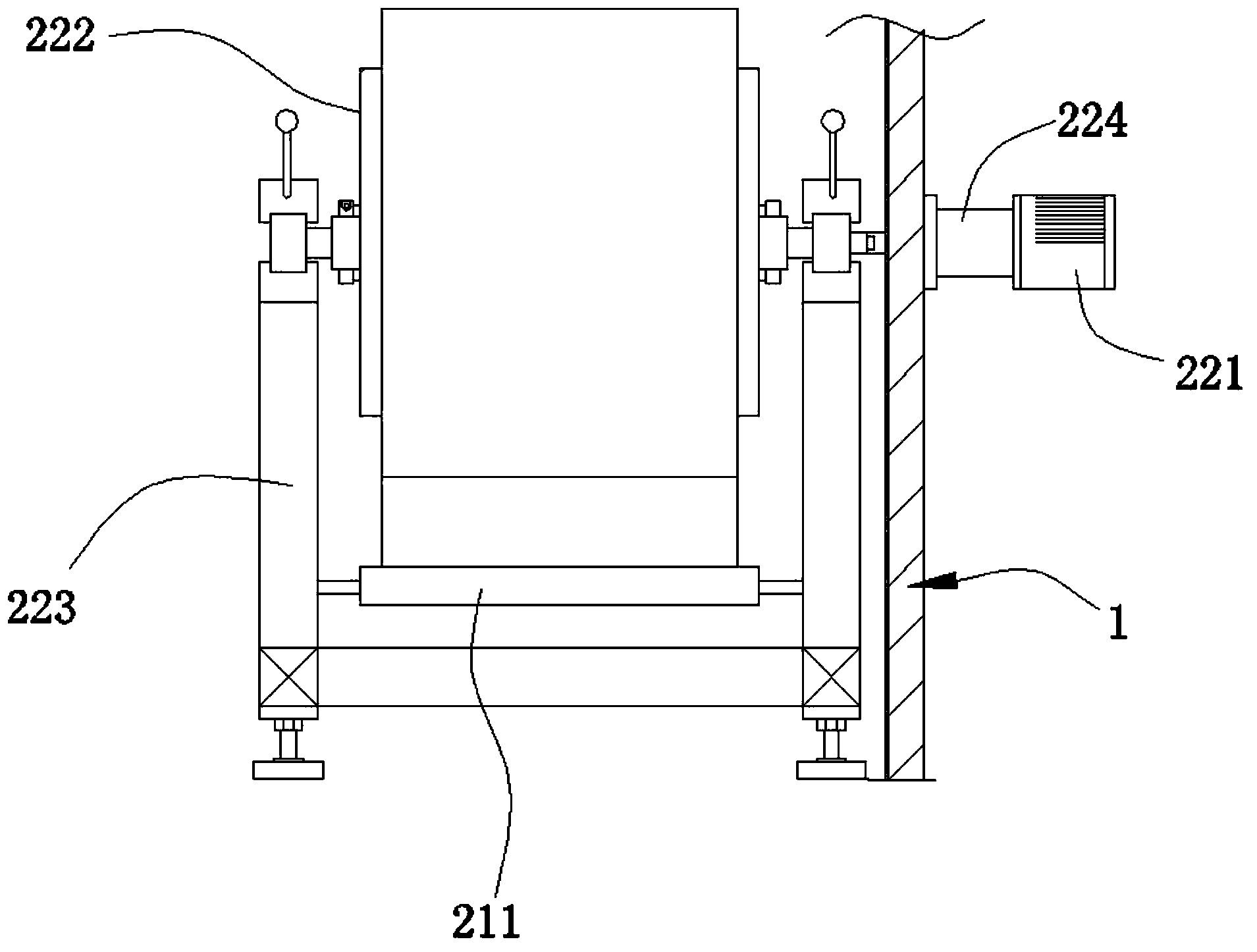

Vacuum drying oven

InactiveCN103836886AReduce heating rateFast heatingDrying using combination processesDrying machines with local agitationPower batteryNitrogen

The invention discloses a vacuum drying oven. The vacuum drying oven comprises a vacuum oven body. The interior of the vacuum oven body is at least provided with a roll material winding and unwinding mechanism. The outer sidewall of the vacuum oven body is at least provided with a wind-powered light emitting device. The vacuum drying oven is simple in structure and reasonable in design; roll materials in the vacuum oven body can be unwound for baking through the roll material winding and unwinding mechanism, so that baking time is effectively shortened, and baking quality is improved. Meanwhile, hot air is delivered to an inner cavity of the vacuum oven body through the wind-powered light emitting device to form a dynamic loop for circulation heating, the heat cycle is fast, the temperature rise rate of the vacuum drying oven can be increased, good temperature uniformity can also be acquired, so that a drying effect is further improved, and product quality is guaranteed. Moreover, nitrogen which has a drying effect can further be led in through a nitrogen pipe, water is pumped out through a vacuum tube, and therefore a breath type drying effect is formed. In this way, drying time is substantially shortened, production efficiency is enhanced, and the vacuum drying oven can be widely popularized and especially applicable to the power battery industry.

Owner:陈伟陵

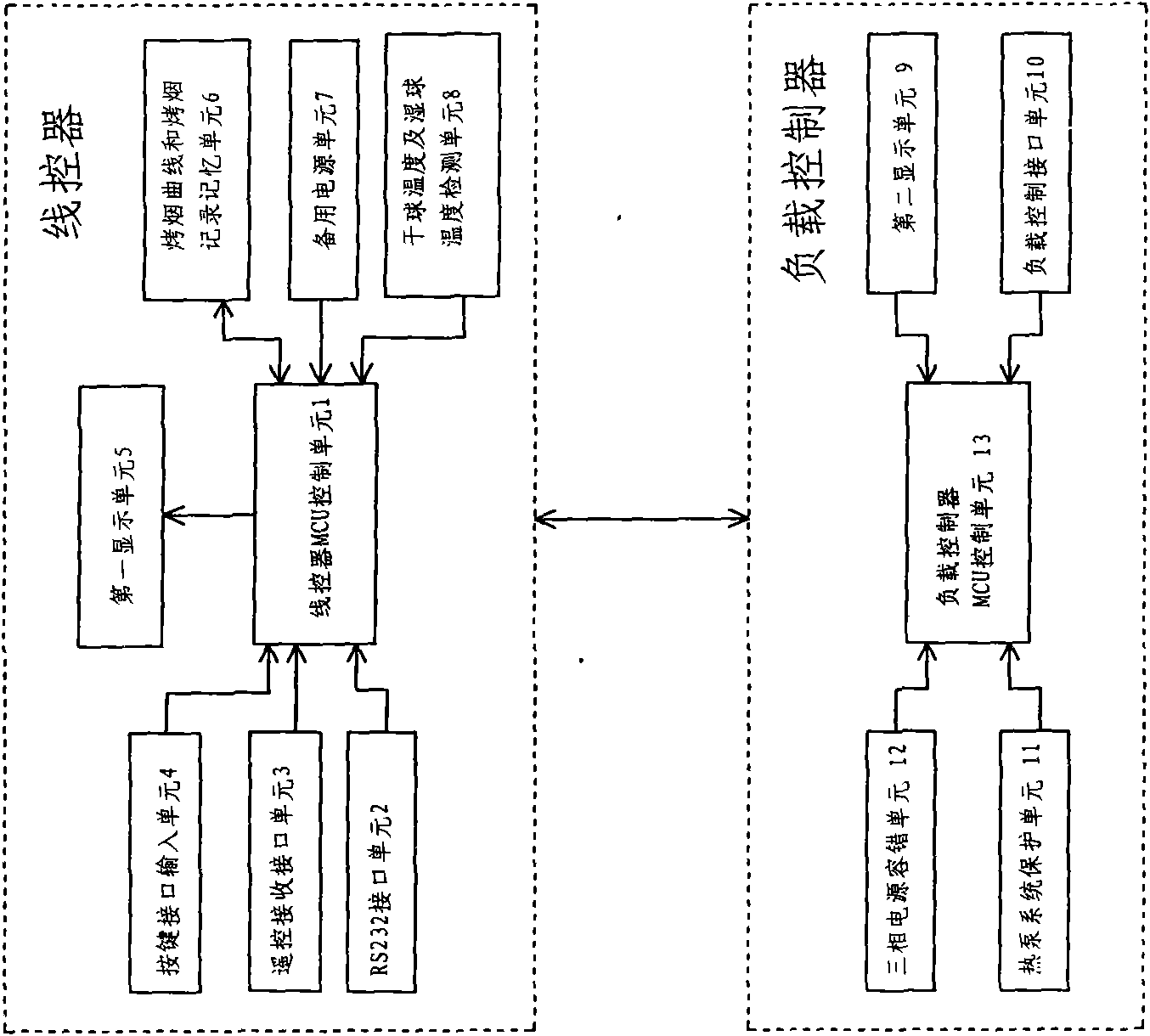

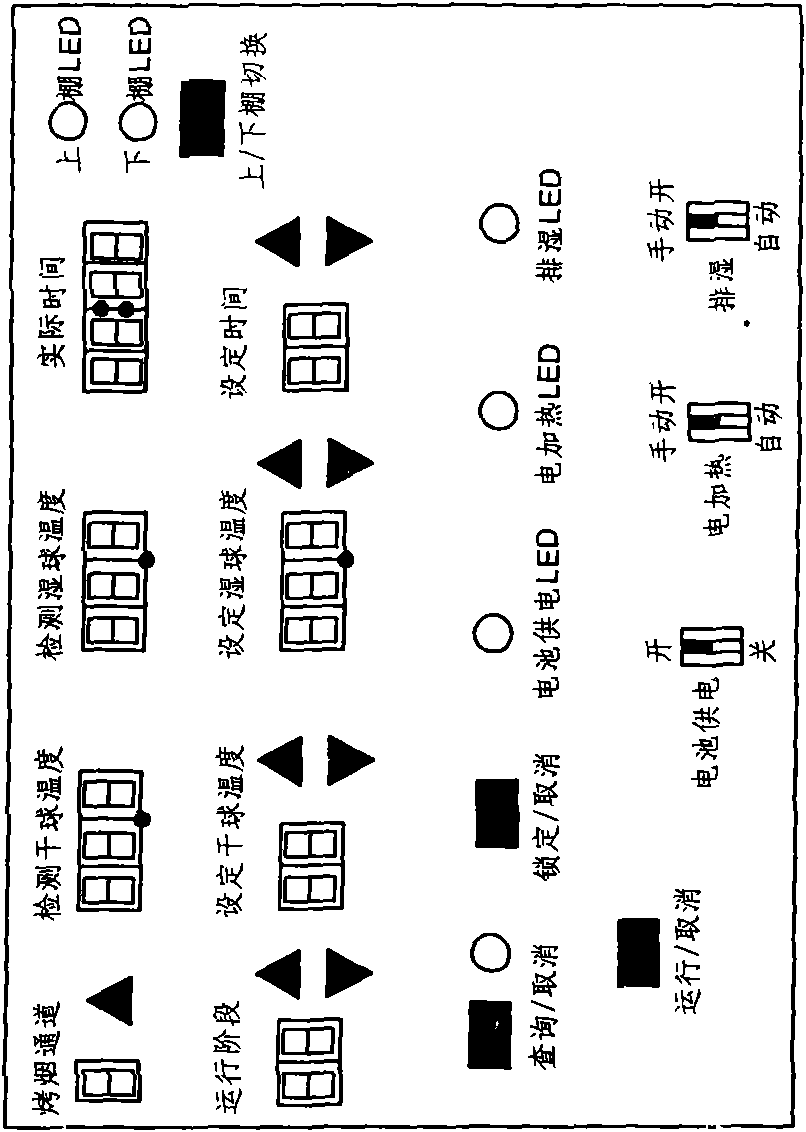

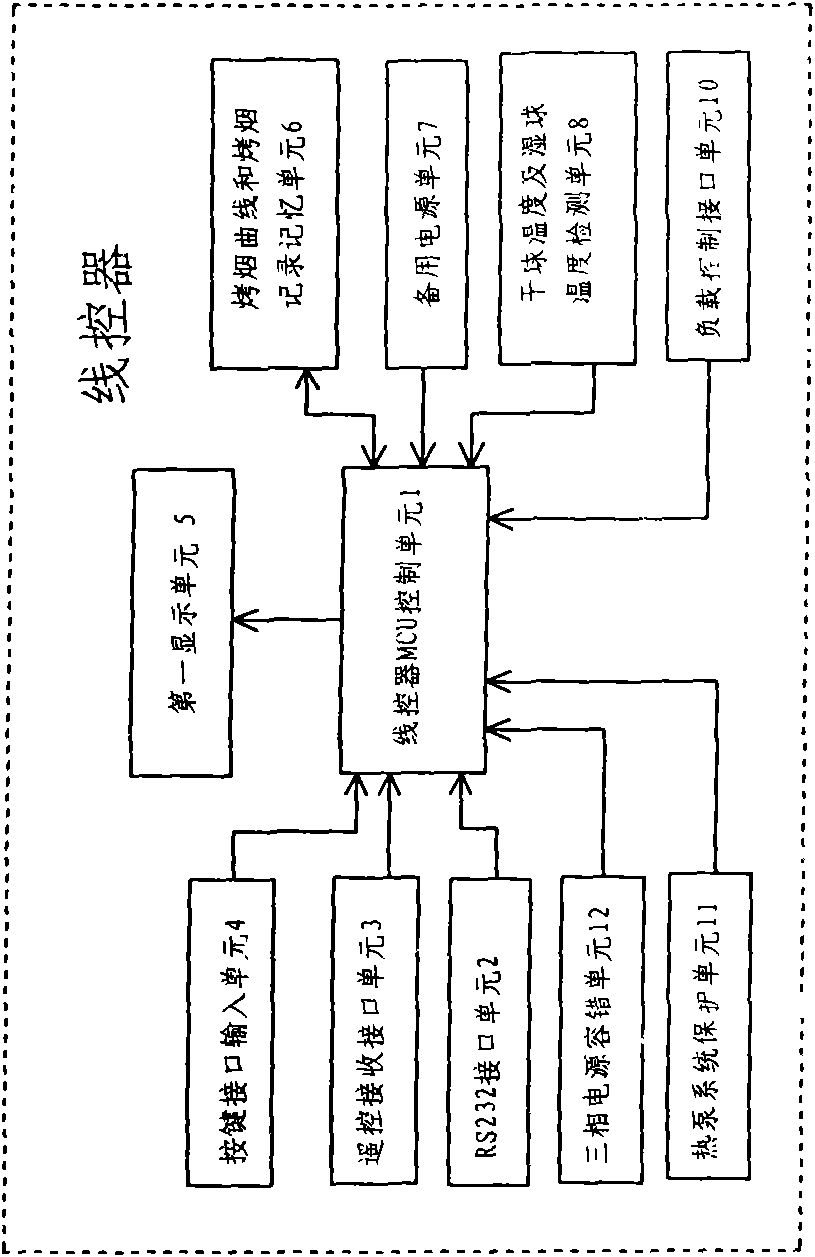

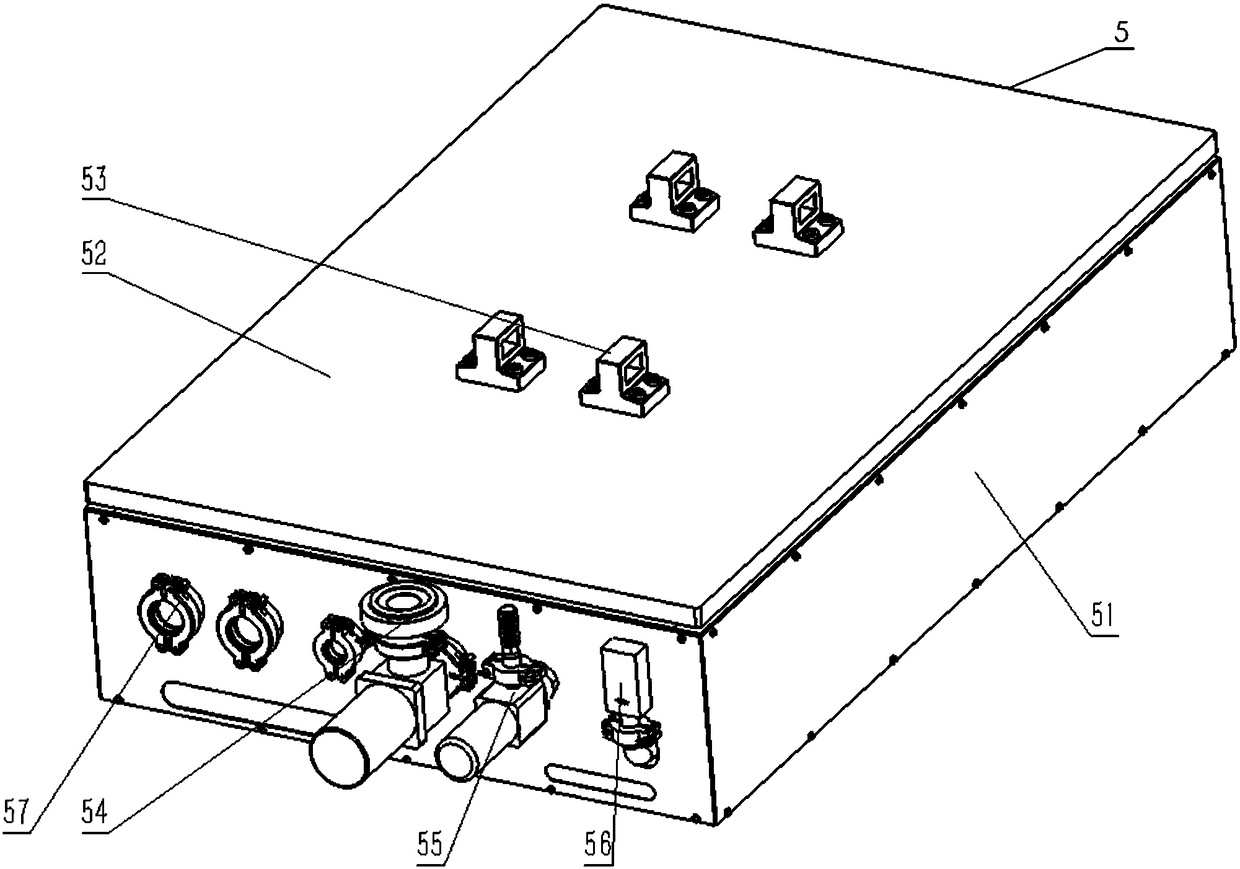

Air conditioning controller special for curing tobacco and control method thereof

InactiveCN101526256ALow baking work intensityReduce heat lossTobacco preparationSpace heating and ventilation safety systemsWork statusElectric heating

The invention relates to an air conditioning controller special for curing tobacco and a control method thereof. The special air conditioning controller for curing tobacco comprises a wire controller; the wire controller comprises an input unit and an MCU of the wire controller, which are connected; the MCU of the wire controller is respectively connected with a first display unit, a cured tobacco curve, a tobacco-curing recording memory unit, a spare power supply unit, a dry-bulb temperature and wet-bulb temperature detection unit, a load control interface unit, a heat pump system protective unit and a three-phase power fault tolerant unit; and the MCU of the wire controller receives a control instruction from the input unit so as to control the working states of a heat pump and an electric heating and dehumidifying device. The air conditioning controller utilizes the heat pump heating technology and a heat recovery device in the process of curing tobacco, can reduce the air pollution and save energy, can also improve the curing quality of the tobacco and reduce the working intensity of curing tobacco, control the dry-bulb temperature and the wet-bulb temperature in a curing room precisely and greatly improve the automation degree and the control precision.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

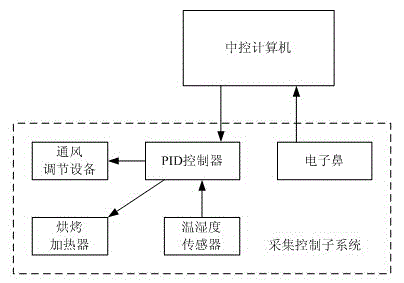

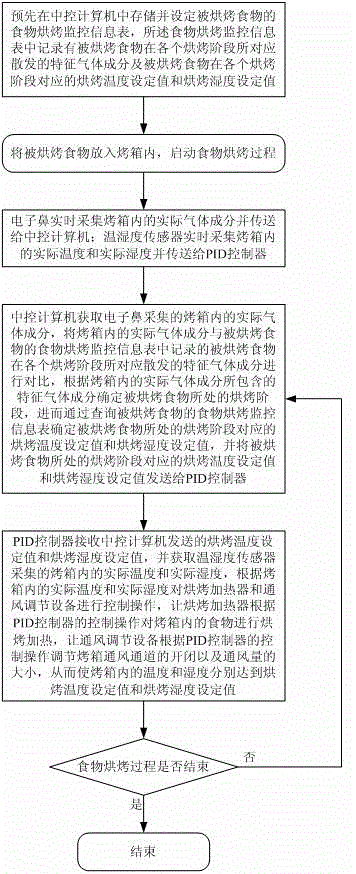

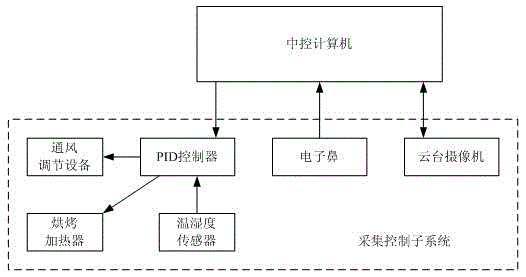

Automatic baking monitoring system and method

InactiveCN102722201ARealize adaptive adjustment monitoringImprove accuracySimultaneous control of multiple variablesProportion integration differentiationMonitoring system

The invention provides an automatic baking monitoring system and method which are used for monitoring a food baking process in an oven. The system mainly comprises a central control computer and an acquisition control subsystem which is in data communication with the central control computer, wherein the acquisition control subsystem comprises a baking heater, ventilation adjustment equipment, a humidity and temperature sensor, a proportion integration differentiation (PID) controller and an electronic nose. By using the automatic baking monitoring system and the automatic baking monitoring method, actual temperature, actual humidity and actual gas components in the food baking process in the oven can be automatically acquired in real time through circulating judgment and control; a baking stage of foods can be accurately judged in real time according to the actual gas components in the oven; the temperature and the humidity in the oven are correspondingly adjusted to be equal to a baking temperature set value and a baking humidity set value which correspond to the baking stage of the foods; adaptive adjustment monitoring of the food baking process is realized; and the accuracy and the baking quality of a baking process are improved.

Owner:CHONGQING UNIV

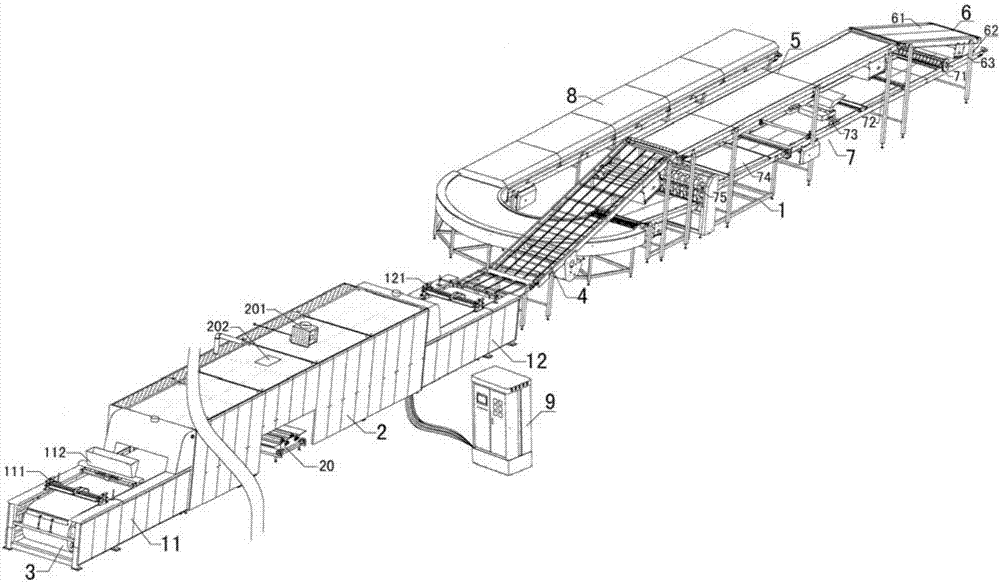

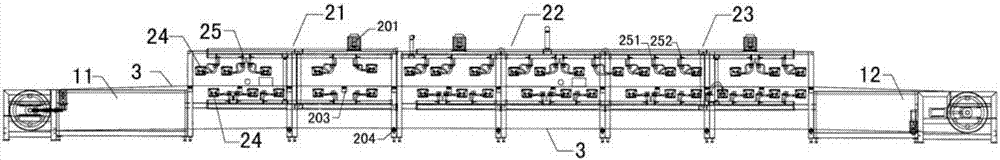

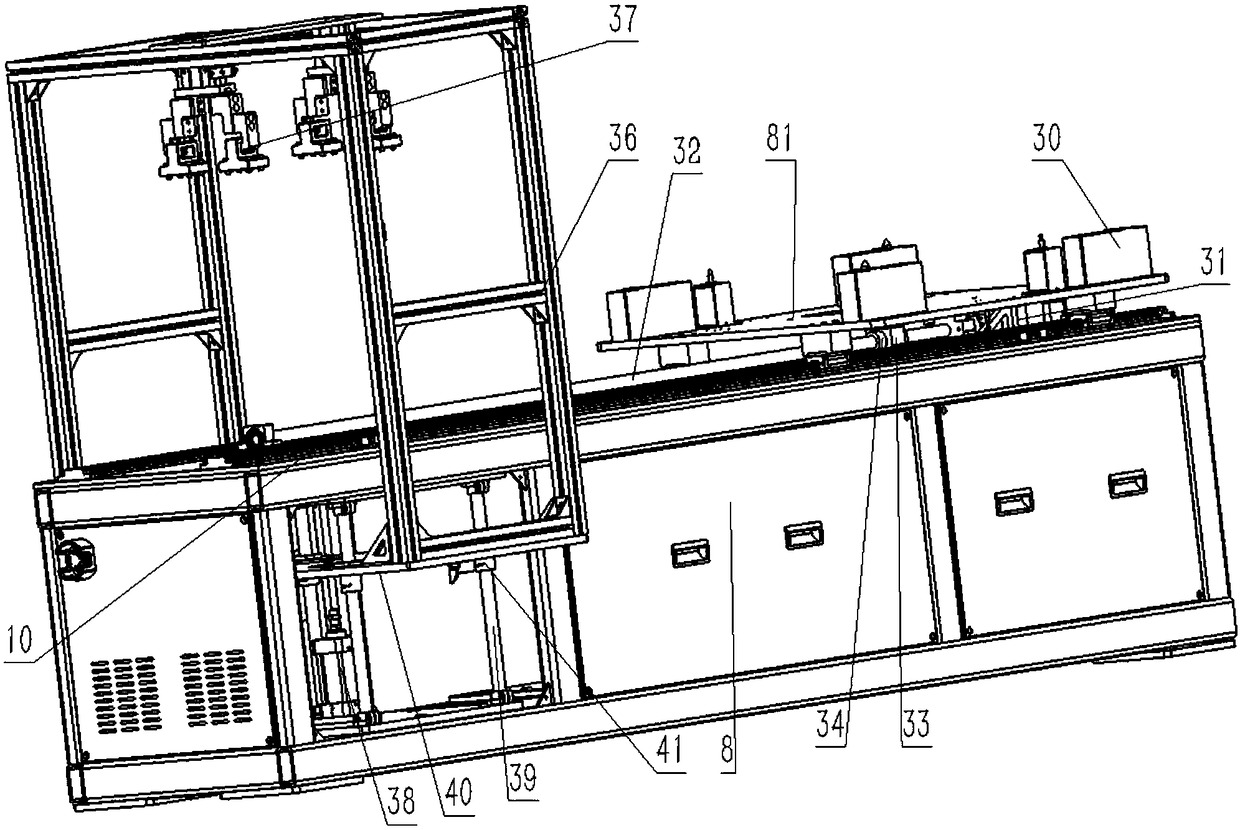

Full-automatic pocket cake baking production line and production processing method

InactiveCN107212037AGood conditionGreat tasteBaked article fillingBaking surface cleaning/greasingProgrammable logic controllerMolding machine

The invention discloses a full-automatic pocket cake baking production line and production processing method. The full-automatic pocket cake baking production line comprises a furnace inlet platform, a furnace outlet platform, a tunnel oven, a steel belt, a net chain conveying belt, a cooling transmission belt, a turning and rolling mechanism, a sandwich forming mechanism, a sterilization mechanism, a frame and a PLC (programmable logic controller) control box, the cooling transmission belt and the sandwich forming mechanism are arranged on the upper layer and the lower layer of the frame, the turning and rolling mechanism is connected with the cooling transmission belt and the sandwich forming mechanism, the tunnel oven is provided with a preheating area, a baking coloring area and a moisture control area, so that baking quality is controlled, a first pneumatic oil spray machine, a grouting machine, a second pneumatic oil spray machine, an automatic steel belt cleaning mechanism, an arc-shaped turning plate, a cutting slitting machine, a turnover mechanism, a paste machine, a laminating mechanism, a continuous forming separation mechanism and the sterilization mechanism are sequentially arranged on the production line, the PLC control box is connected with devices of the production line in a controlled manner, and intelligent control is achieved.

Owner:福建省亿焙机械有限公司

High-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating

The invention discloses a high-temperature walking beam furnace beam and column insulation lining slag-adhesion-preventing coating. The coating comprises the raw materials of, by weight: 55-60% of the bauxite clinker, 5-10% of magnesium aluminate spinel, 5-10% of calcined anthracite, 2-5% of flake graphite, 3-6% of silicon carbide, 4-6 % of alpha-Al2O3 powder, 4-6% silica micro-powder, 5-7% of calcium aluminate cement, 0.5-1.5% of metal silicon powder, 2.5-3.5% of water-soluble epoxy resin and water-soluble curing agent, 0.05-0.10% of explosion-proof fiber, 0.1-0.15% of sodium hexametaphosphate, 0.05-0.10% of an organic reducing agent, and 0. 04-0.07% of an organic silane coupling agent. With the slag-adhesion-preventing coating, the comprehensive targets are achieved, that service lives of the furnace beam and the column insulation lining are prolonged, furnace energy consumption and insulation lining surface slag adhesion amount are reduced, furnace maintenance cost is reduced, and high-temperature-oriented silicon steel production efficiency is improved.

Owner:武汉钢铁有限公司

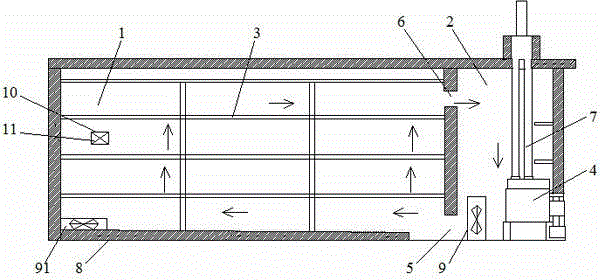

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

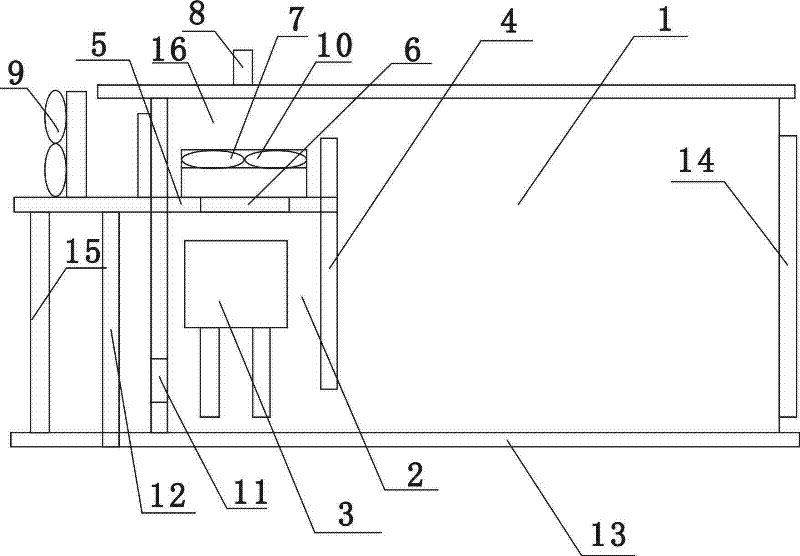

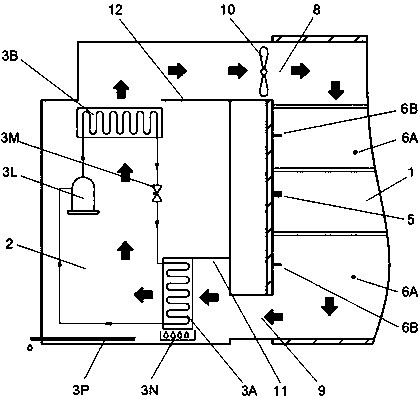

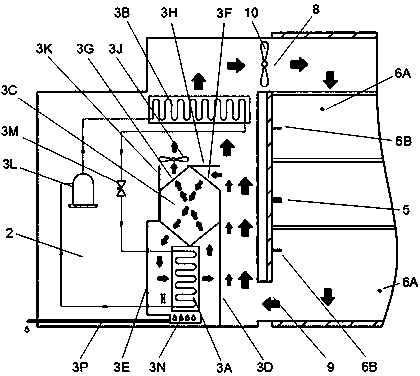

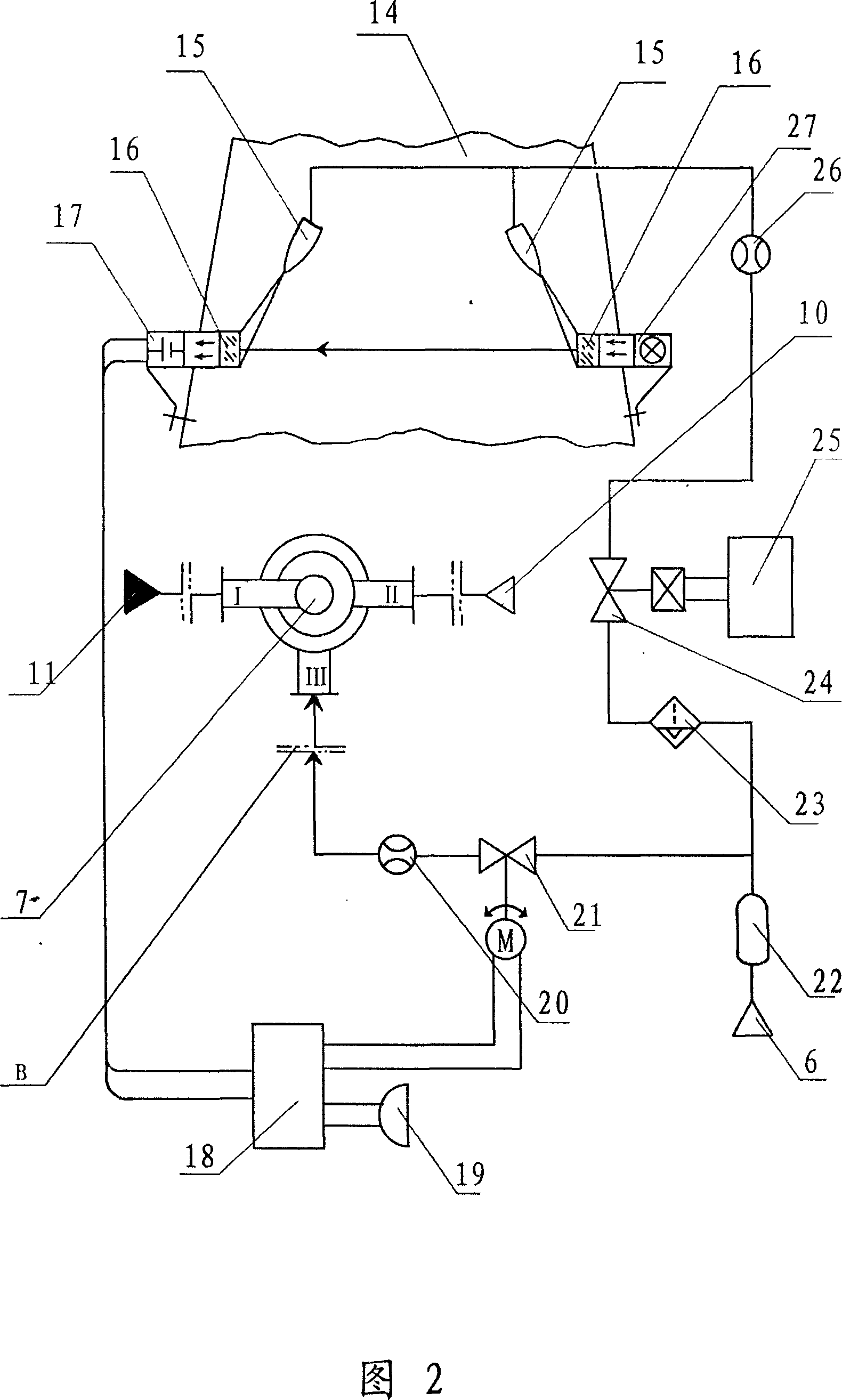

High-efficiency and energy-saving intensive tobacco flue-curing house

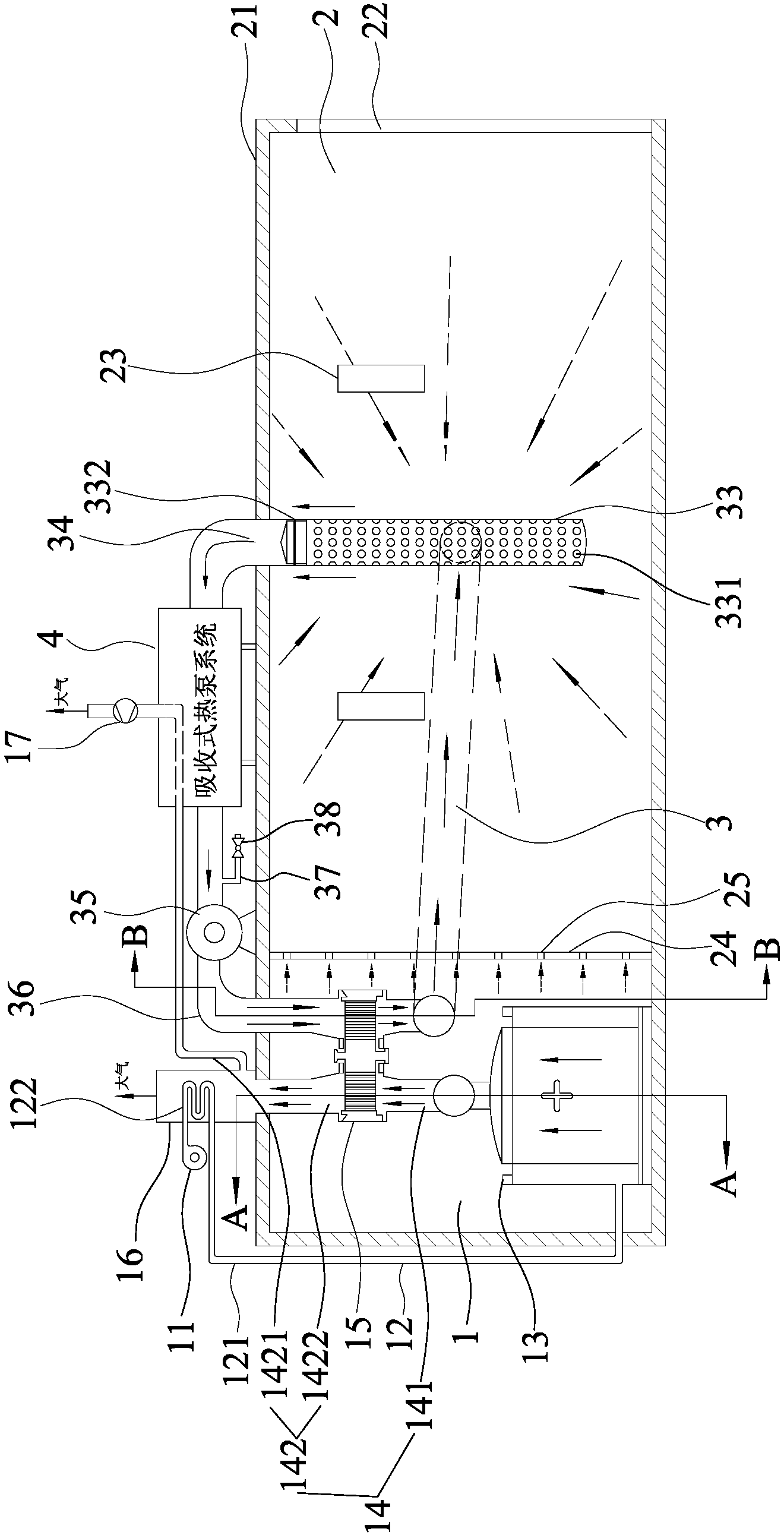

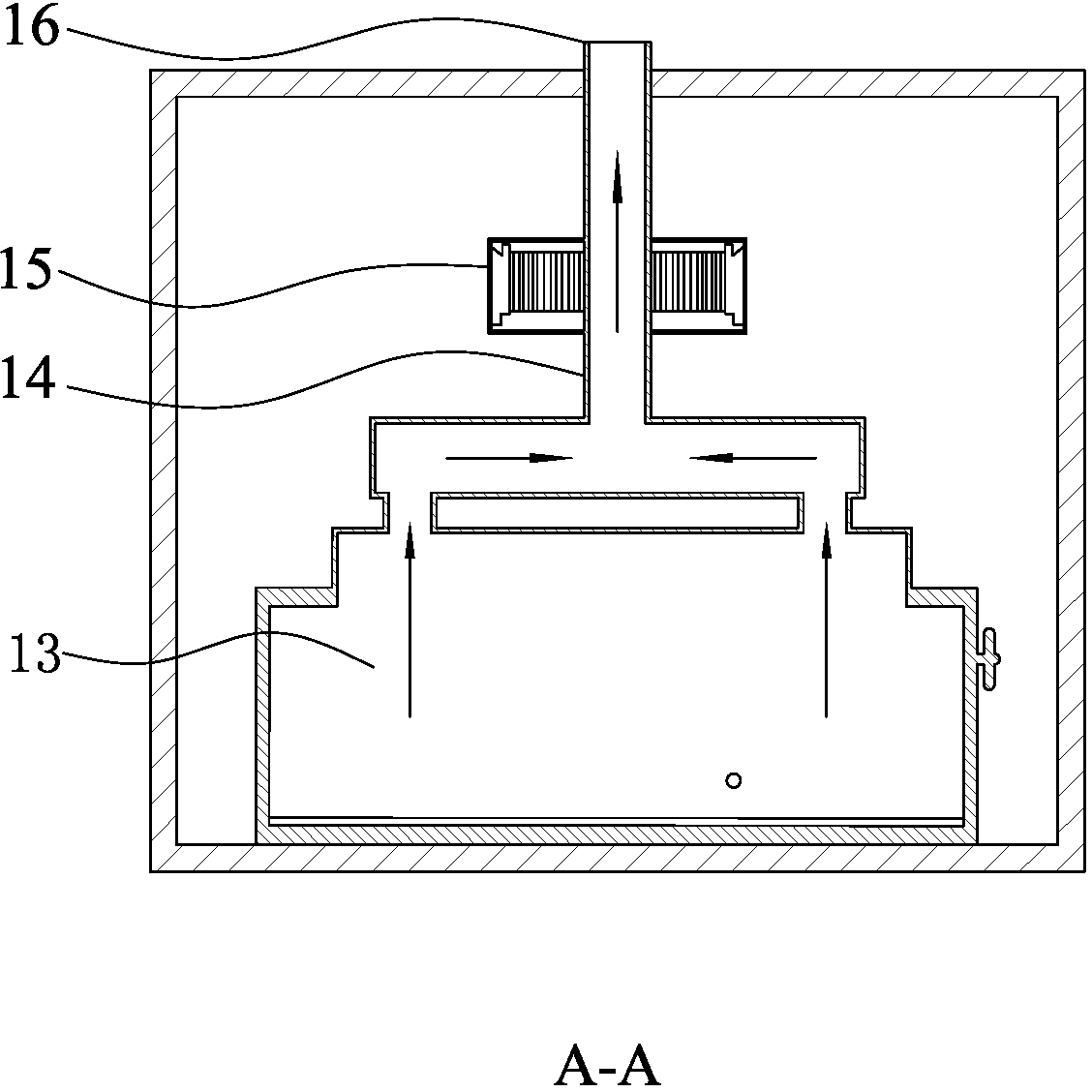

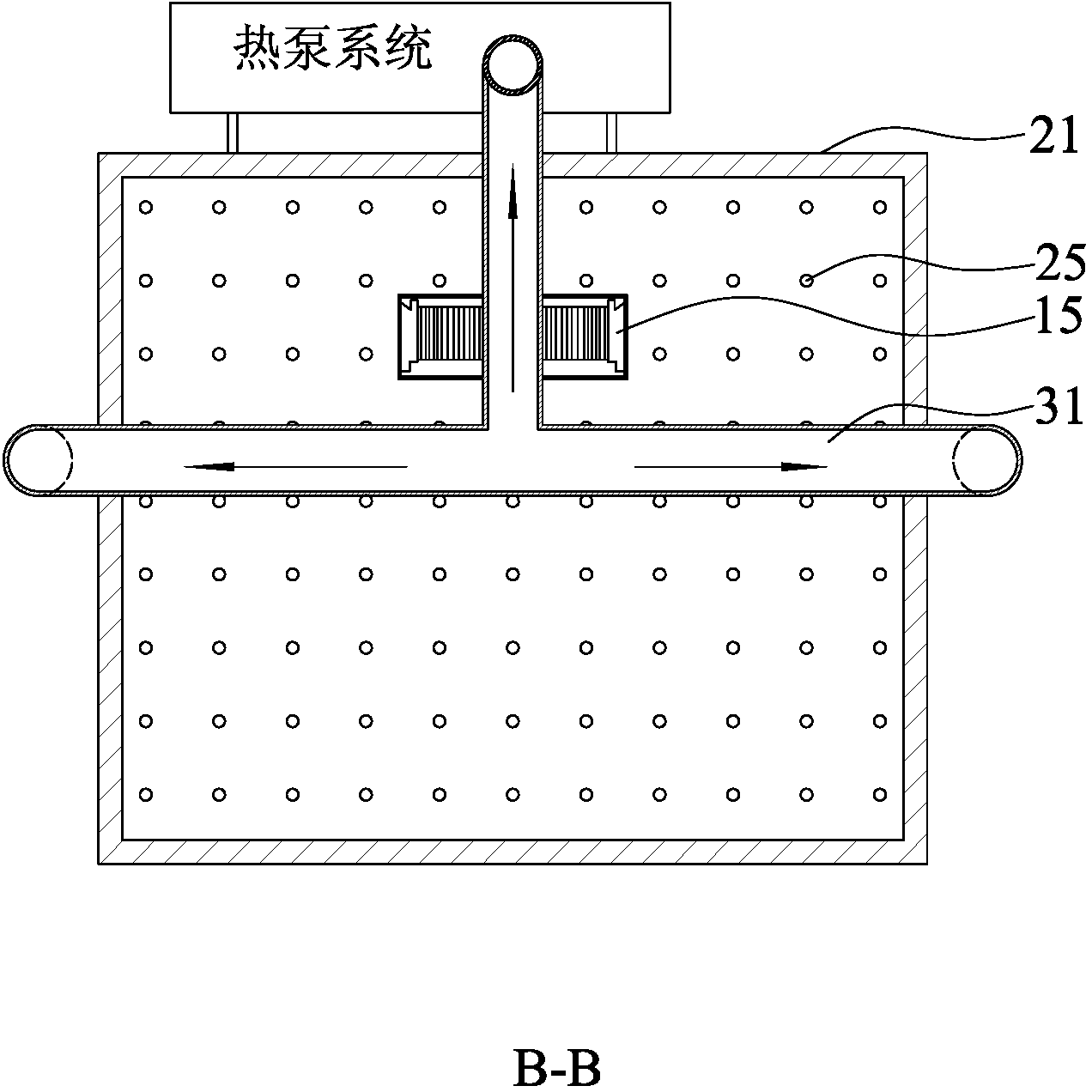

ActiveCN102697157AImprove combustion efficiencyImprove energy utilizationTobacco preparationFinal product manufactureHigh energyAbsorption heat pump

The invention discloses a high-efficiency and energy-saving intensive tobacco flue-curing house, which comprises a heat supply chamber, a baking chamber, a hot air circulating system and an absorption type heat pump system, wherein the hot air circulating system is connected with the heat supply chamber, the baking chamber and the absorption type heat pump system sequentially by a pipeline; and the absorption type heat pump system is arranged on the top of the baking chamber. According to the high-efficiency and energy-saving intensive tobacco flue-curing house, the heat exchange efficiency and energy utilization rate are improved by utilizing a technology of performing heat exchange by a rotary air heat exchanger, a technology of preheating air required by the combustion of a hearth by recovered smoke waste heat, a technology that the recycled smoke waste heat is used as a heat source of the absorption type heat pump system and the like; a baking effect of the tobacco flue-curing house is improved by utilizing technologies of supplying air from two sides of a side wall air distribution board and exhausting the air from the center of a central air draft pipe; and a humidity-discharging effect and an energy-saving effect are improved by utilizing a technology of performing deep dehumidification and recovering humidity-discharging waste heat by the heat pump system. Therefore, the high-efficiency and energy-saving intensive tobacco flue-curing house has the characteristics of high heat exchange efficiency, high energy utilization rate, good baking effect and good humidity-discharging effect, is particularly suitable for low-cost and large-scale production, and can be widely applied to the technical field of tobacco flue-curing.

Owner:JIMEI UNIV

Curing process of flue-curing barn

InactiveCN102499431AEffective reflection of qualityStable color fixationTobacco preparationOperabilityDry-bulb temperature

The invention discloses a curing process of a flue-curing barn, and belongs to the technical field of a tobacco curing. The process comprises the following steps: an ignition and temperature control stage: heating and roasting by utilizing an air source heat pump unit independently; tobacco leaf yellowing stage: heating and roasting by utilizing the air source heat pump unit independently; tobacco leaf color fixing stage: heating by utilizing the air source heat pump unit independently when a dry-bulb temperature is between 44 and 50 DEG C, and heating by using a coal burning boiler independently when the dry-bulb temperature rises to over 50 DEG C; and a tobacco leaf stem drying stage: heating by using the coal burning boiler independently. The curing process has the advantages of safetyand insurance, strong operability, stability of tobacco leaf color fixation, good leaf shrinkage, great improvement of flavor quantity of tar and tobacco leaves, is simple to operate; and the technical scheme of the roasting process has strong operability, so that the tobacco leaf curing quality and superior leaf ratio can be remarkably improved, the tobacco leaf dry matter consumption is reduced, and the roasting effects of saving energy, reducing emission, increasing quality and improving efficiency can be achieved.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

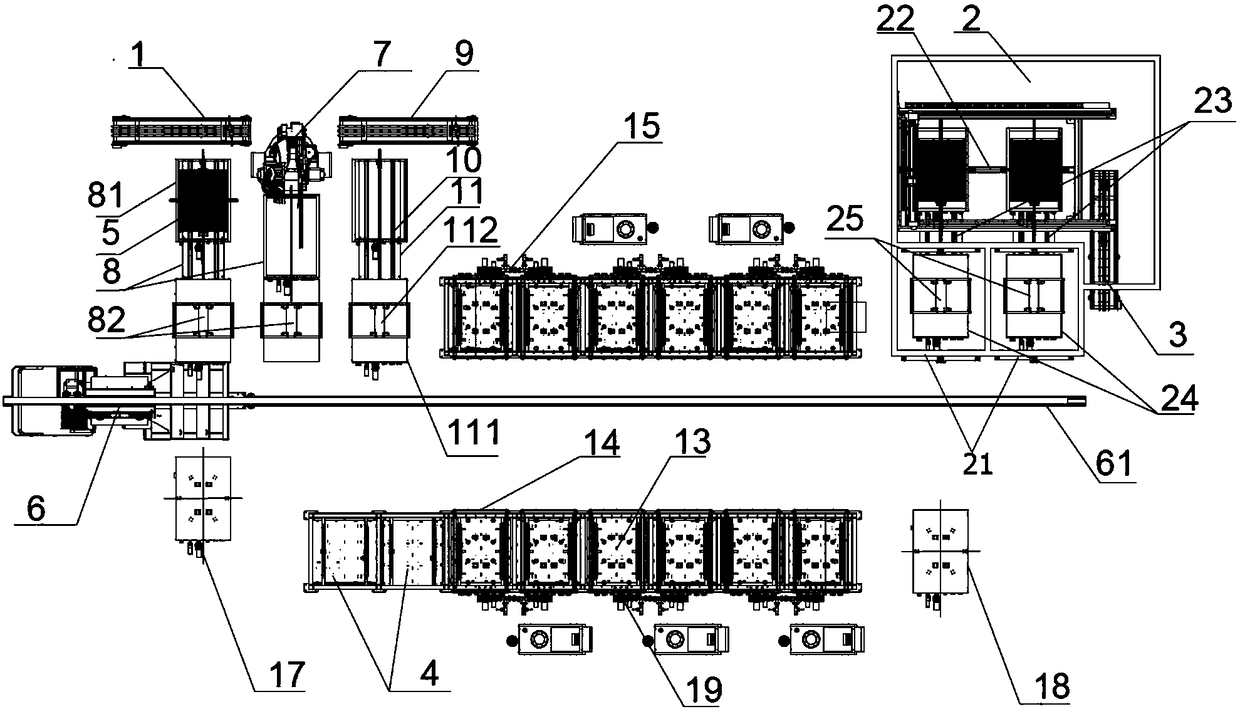

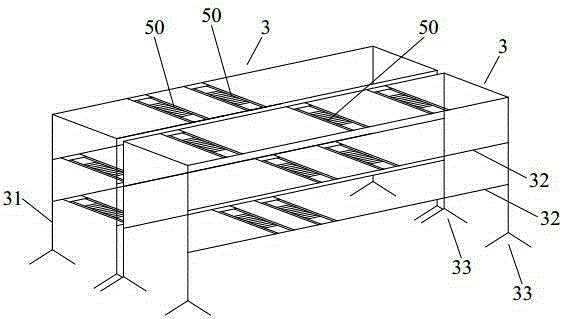

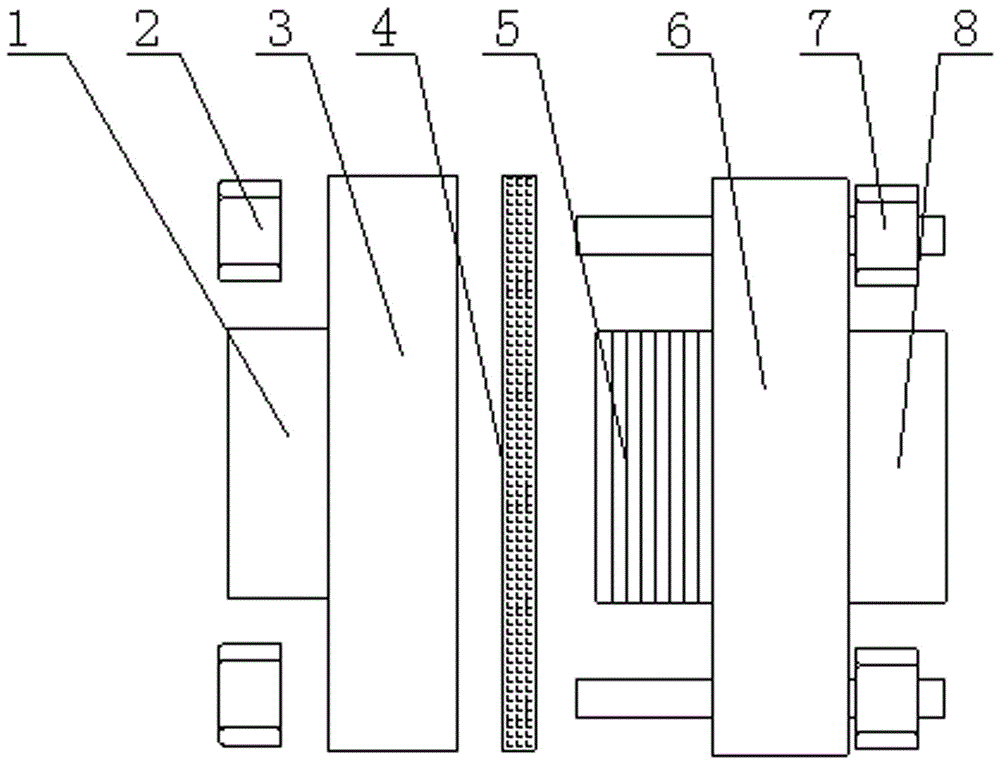

Full-automatic movable drying line

ActiveCN108168220AGuaranteed stabilityQuality assuranceFinal product manufactureDrying solid materials without heatComputer control systemVacuum pumping

The invention provides a full-automatic movable drying line. The full-automatic movable drying line is sequentially provided with a battery feeding input line, a battery feeding system, a stereo storage rack-type roasting system, a battery discharging system located inside a drying chamber and a battery discharging output line with one end communicating with the drying chamber in time order. The full-automatic movable drying line further comprises movable drying boxes, a stacking machine used for transferring the movable drying boxes between all the systems, and an upper computer control system. The whole line is debugged by an upper computer, each system operates independently and cannot interfere with one another, and stability of the whole line is guaranteed. A vacuum environment is provided for the stereo storage rack-type roasting system through each independent movable drying box, vacuum pumping time is correspondingly shortened, and drying efficiency is effectively improved. Thecable contact position of a movable drying box heating device is located outside the vacuum range, and vacuum point discharge in the vacuum environment is effectively avoided. The battery dischargingsystem is located inside the drying chamber, there is no need to dry the whole workshop, and cost is greatly reduced. Continuous operation can be achieved, operating is stable, the sealing property is good, unmanned operation is realized in the whole course, roasting quality is improved, roasting time is shortened, roasting cost is reduced and therefore the battery quality is effectively guaranteed.

Owner:HENAN DINGNENG ELECTRONICS TECH

Secondary roasting furnace for carbon products and roasting method of secondary roasting furnace

InactiveCN102381696AEliminate environmental pollutionLower fuel consumptionChemical industryFlueAsphalt

The invention discloses a roasting furnace, and particularly relates to a secondary roasting furnace for carbon products. The secondary roasting furnace is structurally characterized in that two rows of furnace chambers are symmetrically arranged on two sides of a furnace central line in a furnace body, each row of furnace chambers consists of a plurality of single chamber bodies, each single furnace chamber body is divided into n-1 material tanks by n flame paths, each material tank comprises flame path walls on two sides, transverse walls at two ends and a material tank bottom, a light heat-insulation furnace cover for sealing is arranged on the top of each material tank, volatile matter balancing channels are arranged on upper portions of the flame path walls, volatile matter flowing channels are arranged on upper portions of the transverse walls, ends of the two rows of furnace chambers are connected by communicating flame paths, volatile matter flowing control gate discs are inserted into the volatile matter flowing channels from tops of the transverse walls, smoke vents are disposed on upper surfaces of the transverse walls and communicated with smoke discharge devices, the smoke discharge devices are communicated with a main smoke flue, and flame path gate discs are arranged among the flame path walls of the adjacent single furnace chamber bodies. Asphalt volatile matters generated during roasting are guided to the high-temperature flame paths to be completed burned, and environmental pollution due to the fact that asphalt smoke is discharged into the atmosphere is thoroughly eliminated.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

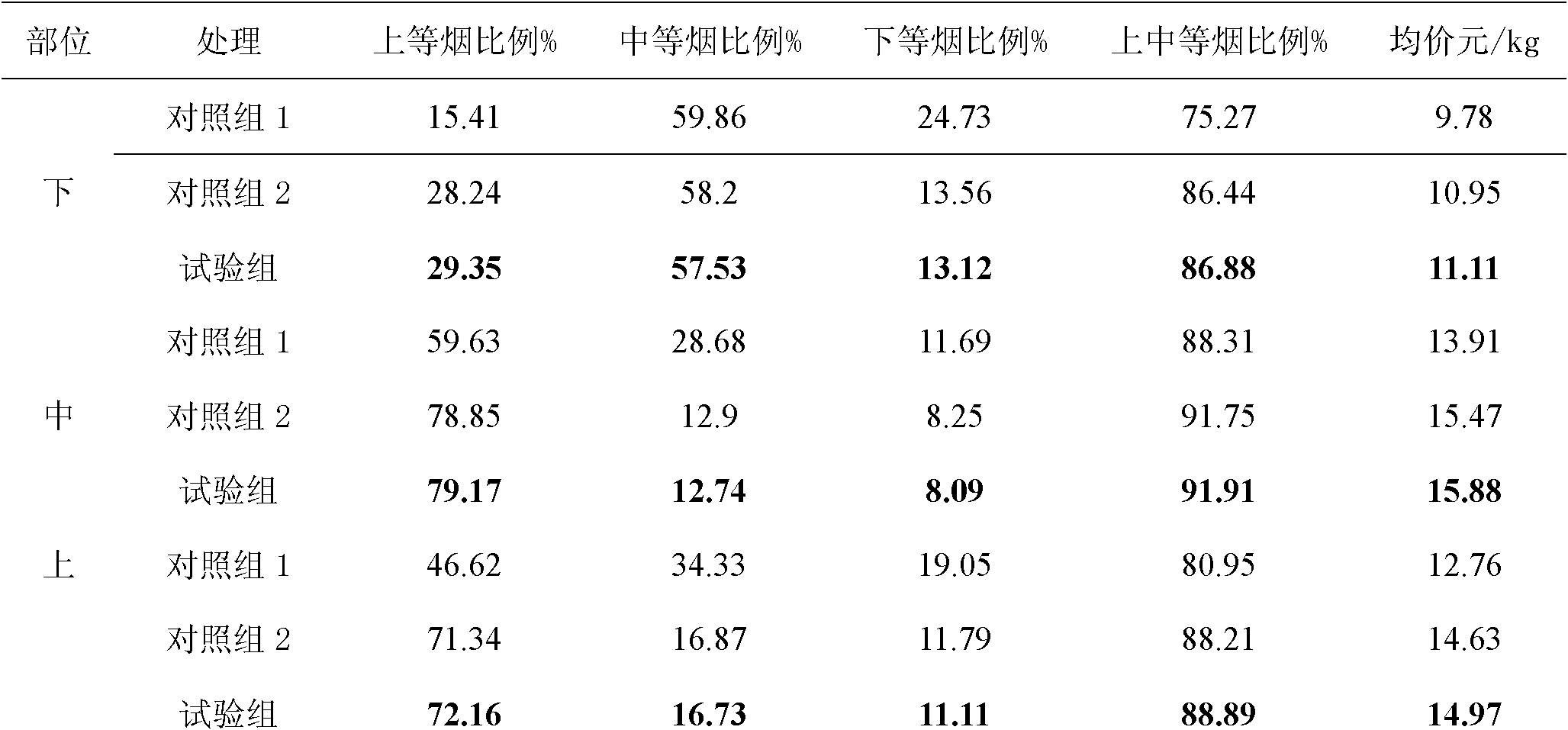

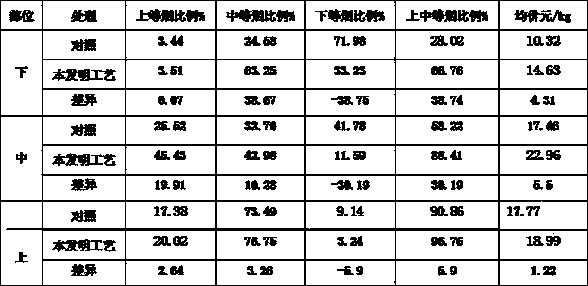

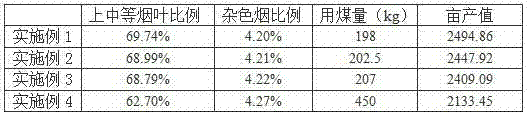

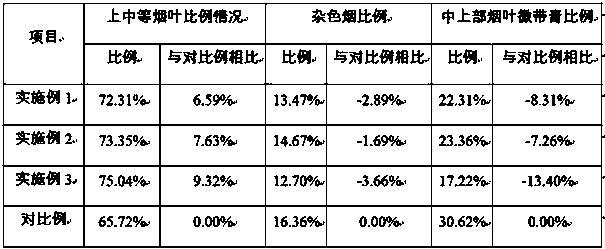

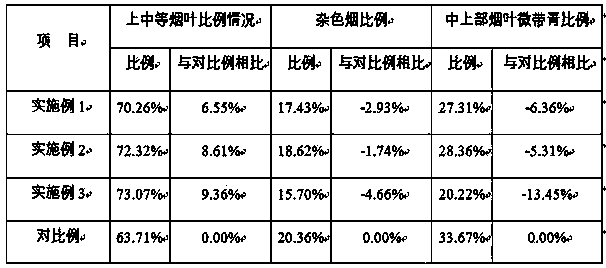

Method for roasting high-temperature drought premature tobacco leaves

The invention discloses a method for roasting high-temperature drought premature tobacco leaves. The method mainly includes the step of the early stage of yellowing, the step of the middle stage of yellowing, the steps o f the later stage of yellowing, the step of the early stage of color fixing, the step of the later stage of color fixing, and the step of the stem drying stage. According to the method, roasting losses of the high-temperature drought premature tobacco leaves are reduced by adjusting the roasting technological parameters, and the roasting quality of the tobacco leaves is remarkably improved. The proportion of the better-than-average tobacco leaves is obviously increased, the proportion of the variegated tobacco leaves is decreased, and the proportion of the tobacco leaves which are slightly greenish in the middle upper portions is greatly decreased.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

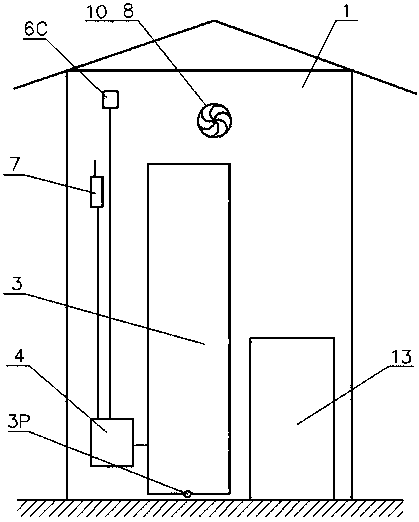

Flue-curing method for fresh tobacco leaves

InactiveCN106820240AFast BindingImprove roast qualityTobacco preparationEngineeringTobacco processor

The invention discloses a flue-curing method for fresh tobacco leaves. The flue-curing method includes steps of weaving and binding the fresh tobacco leaves, hanging the fresh tobacco leaves in tobacco flue-curing chambers and carrying out flue-curing on the fresh tobacco leaves. The flue-curing method is characterized in that the fresh tobacco leaves are woven and bound by two rod racks, binding wires are arranged on the rod racks, butted side surfaces arranged on the two rod racks are butted to one another, and a plurality of spaced tobacco leaf mounting spaces are formed on the two rod racks, so that the ends of the fresh tobacco leaves can be bound into the tobacco leaf mounting spaces by the binding wires, the fresh tobacco leaves are in suspension states, contact between the tobacco leaves and the rod racks can be reduced during flue-curing, and the flue-curing uniformity can be improved. The flue-curing method has the advantages that the flue-curing method can be implemented easily, conveniently and quickly and is favorable for improving the flue-curing quality of tobacco leaves, the fresh tobacco leaves can be quickly woven and bound, and the like.

Owner:YANGTZE NORMAL UNIVERSITY

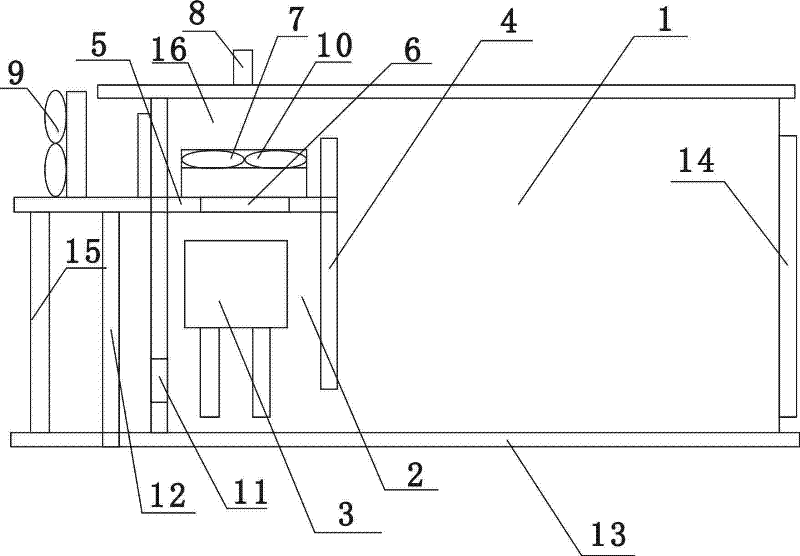

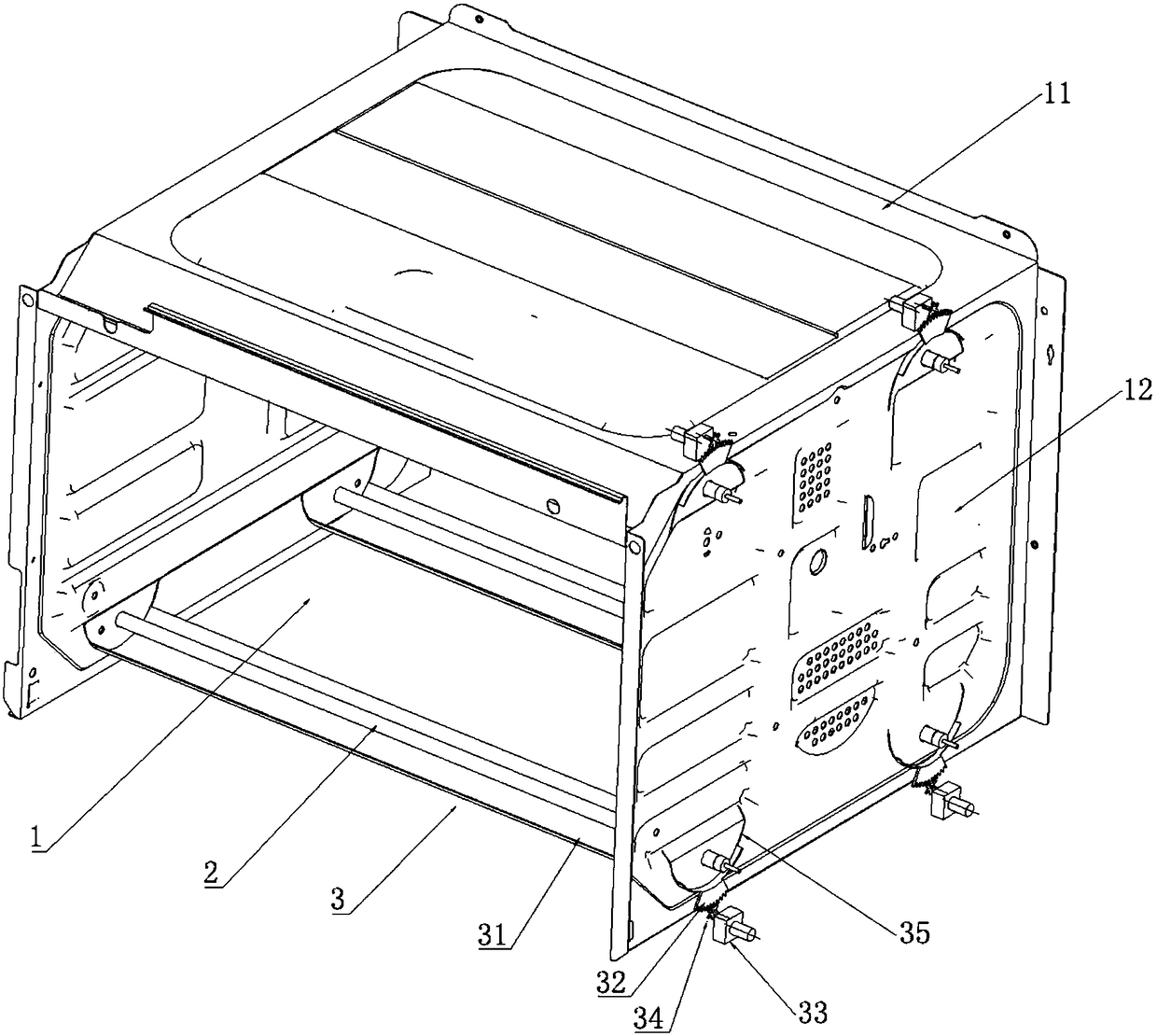

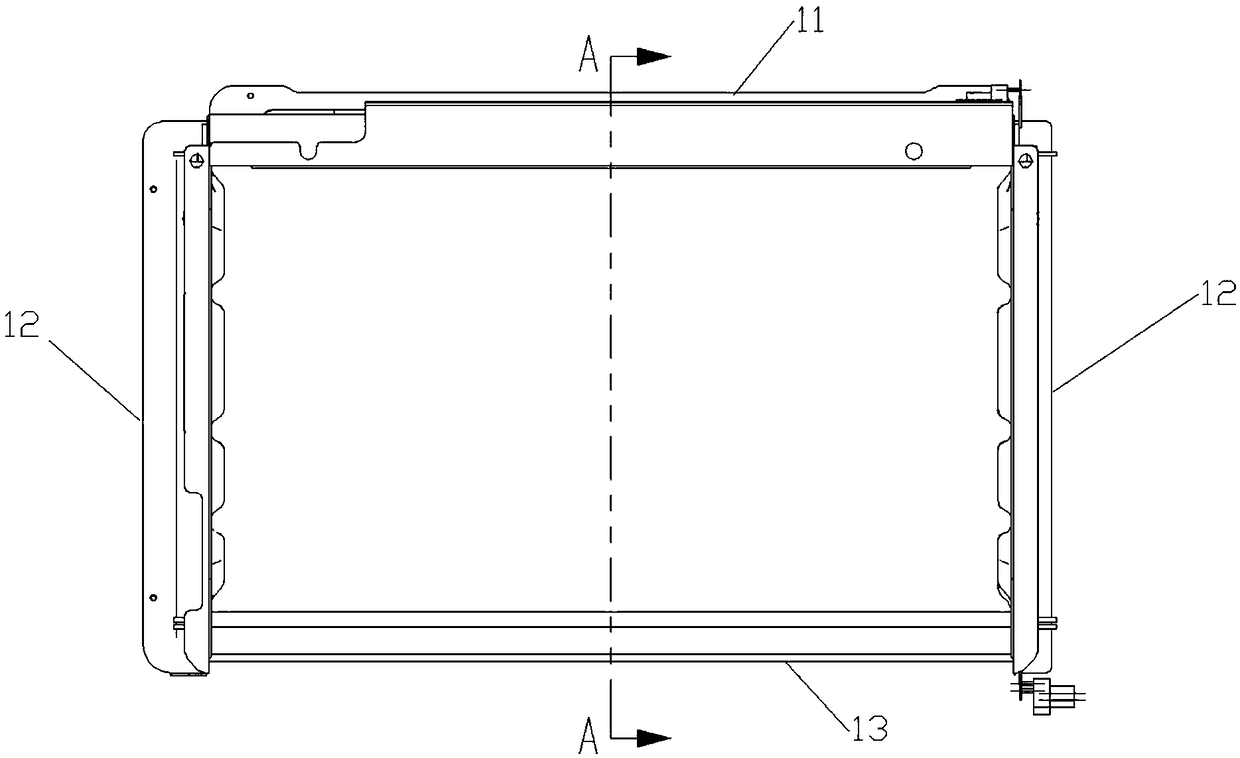

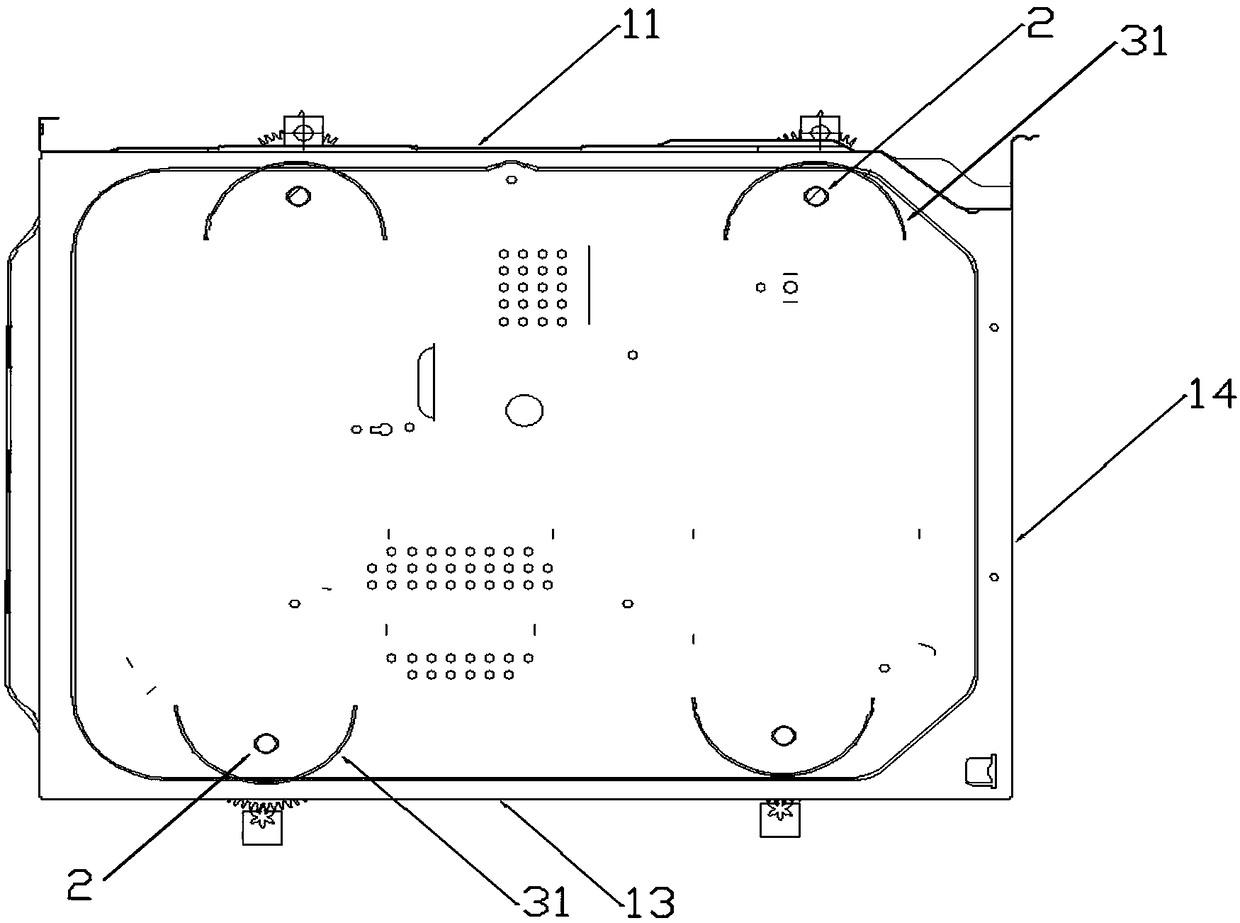

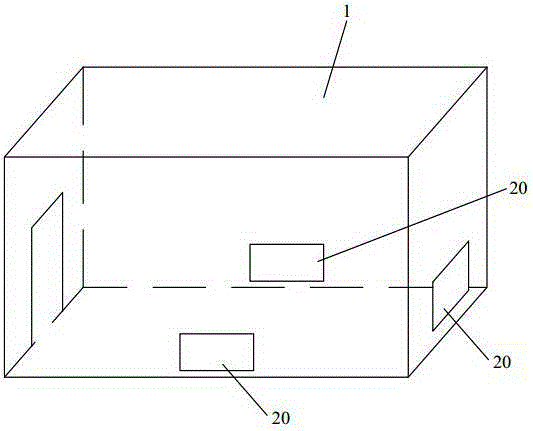

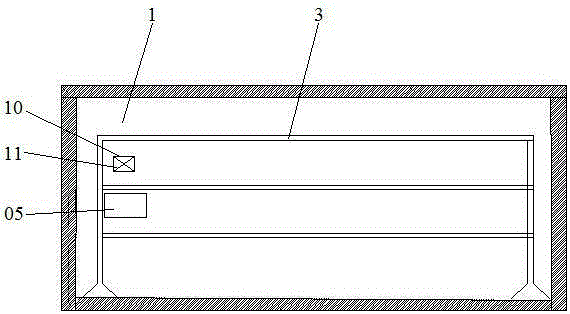

Oven with rotatable reflection cover and control method thereof

PendingCN108392094AEvenly bakedThere will be no problem of partial burntRoasters/grillsHeating timeFood material

The invention relates to the field of kitchen electrical appliances and discloses an oven with a rotatable reflection cover. The oven comprises a cavity (1), heating tubes (2) and rotatable reflectioncover assemblies (3). The heating tubes (2) correspond to the rotatable reflection cover assemblies (3) one to one to form a heating roasting assembly for reflecting heat to different angles, and theheating roasting assembly is arranged in the cavity (1). The invention further discloses a control method of the oven with the rotatable reflection cover. Roasting parameters such as heating time ofthe heating tubes (2) and rotation angles of the reflection cover (31) are determined according to the area and weight of food materials, and the food materials placed in the cavity (1) are roasted. According to the oven with the rotatable reflection cover, the rotation angle of the reflection cover (31) can be adjusted according to the difference of the area and weight of the food materials, thetemperature uniformity of the food materials is improved, and the cooking efficiency and quality are improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

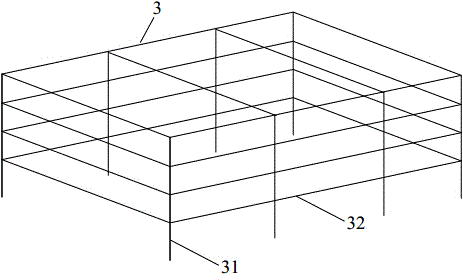

Heating piece tobacco baking chamber for waste heat recycling

InactiveCN105286072AHigh performance ratioIncrease heating capacityTobacco preparationFinal product manufactureCooking & bakingProcess engineering

The invention relates to the technical field of tobacco-baking equipment, in particular to a heating piece tobacco baking chamber for waste heat recycling. The heating piece tobacco baking chamber for waste heat recycling comprises a tobacco baking room provided with two tobacco hanging racks, each tobacco hanging rack comprises vertically arranged vertical rods and transversely arranged transverse rods, and the lower portions of the vertical rods are provided with supporting feet; the transverse rods are provided with tobacco clamps; the two tobacco hanging racks are arranged side by side; the tobacco baking room further comprises heating piece devices arranged on walls. One side of the tobacco baking room is further provided with waste heat recycling equipment. By means of the heating piece tobacco baking chamber, tobacco baking efficiency and quality are remarkably improved; hot air emitted by the heating piece devices is utilized to conduct baking, the heating piece devices are utilized, no additional heating device is needed, and the cost of the additional heating device is omitted; besides, the heating piece devices are small in size, space is saved, and the tobacco leaves can be baked effectively.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

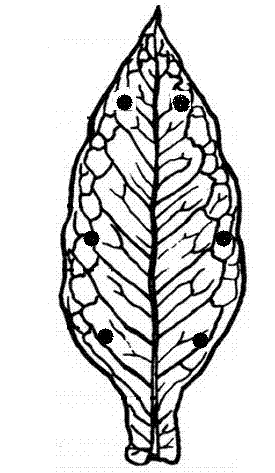

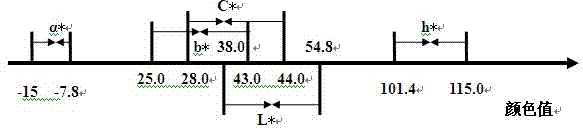

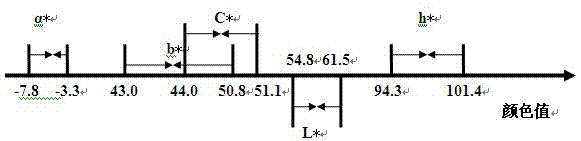

Method for judging tobacco leaf yellowing degree and baking progress in tobacco backing and yellowing stage

InactiveCN103499526AResolutionSolve the problem that there is no clear quantitative index for the baking processColor/spectral properties measurementsChlorophyllinChlorophyll content

The invention discloses a method for detecting and judging the tobacco leaf yellowing degree and the baking progress in a tobacco baking and yellowing stage. The method comprises the following steps of placing representative tobacco leaves into a sampling window when the tobacco leaves are baked and packaged; measuring color indexes of 10 representative tobacco leaves extracted from the sampling window through a colorimeter in need of judging the yellowing degree of the tobacco leaves in the tobacco leaf yellowing stage, measuring the chlorophyll content, the carotenoid content and a ratio of the chlorophyll content to the carotenoid content at the same time, and taking average values. According to the method disclosed by the invention, the problem that definite indexes and a measuring method for the tobacco leaf yellowing degree and the baking progress of the tobacco baking and yellowing stage are always deficient is solved. According to the method, the indexes are definite; objective judgment indexes are obtained; the baking progress can be quantized; the error caused by vision is alleviated. Tobaccos are monitored by the method, and the colors of the baked tobacco leaves are uniform and consistent; the comprehensive quality is improved; the tobacco leaf baking quality can be improved. The method is suitable for tobacco enterprises.

Owner:GUIZHOU TOBACCO SCI RES INST

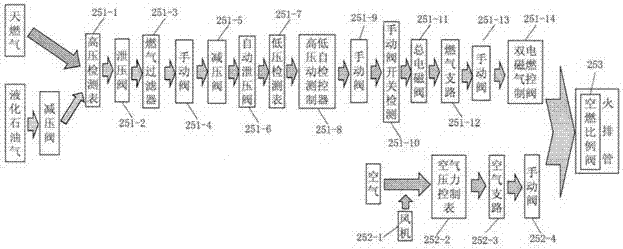

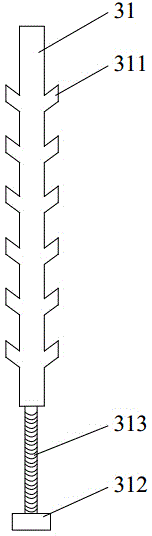

Liquefied petroleum gas tobacco curing house

InactiveCN104957745AImprove heating efficiencyEasy to useTobacco preparationDrying gas arrangementsFlueCuring of tobacco

The invention relates to the technical field of tobacco curing equipment, in particular to a liquefied petroleum gas tobacco curing house. The liquefied petroleum gas tobacco curing house comprises a hot air chamber provided with a heating device, and a tobacco curing chamber provided with a tobacco hanging rack, a circulation flue is formed between the tobacco curing chamber and the hot air chamber through an air inlet and an air return opening, and the heating device is connected with a heat exchange pipe. A first draught fan is arranged at the part, close to the air inlet, of the lower portion of the hot air chamber, and a second draught fan blowing upwards is arranged on the part, opposite to the first draught fan, of the lower portion of the tobacco curing chamber. The tobacco hanging rack comprises vertical rods arranged vertically and transverse rods arranged transversely, and a plurality of clamping parts used for being connected with the transverse rods in a clamping mode are arranged on the vertical rods. The novel tobacco curing house further comprises motors arranged on the lower portions of the vertical rods respectively and transmission rods connected with the motors, and the upper portions of the transmission rods are connected with the bottoms of the vertical rods. The heating device is a liquefied petroleum gas fuel heating device. Liquefied petroleum gas serves as fuel of the liquefied petroleum gas fuel heating device, environmental friendliness and cleanness are achieved, and the liquefied petroleum gas tobacco curing house has the advantages of being clean, sanitary, safe, cheap, high in heating efficiency, convenient to use and the like.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

Intelligent dual-power tobacco flue-curing barn

ActiveCN108477660AImprove reliabilityAchieve quality improvement and loss reductionTobacco preparationFinal product manufactureSpectrum analyzerEngineering

The invention belongs to the technical field of tobacco leaf flue-curing, and discloses an intelligent dual-power tobacco flue-curing barn which comprises a tobacco flue-curing chamber, a heating chamber, a heat pump unit, a biomass fuel furnace, a field control instrument, an infrared spectrum analyzer, a temperature and humidity detection system and data transmission equipment. The heating chamber is adjacent to the tobacco flue-curing chamber, an air inlet and a return air inlet are formed in the upper portion and the lower portion of a heat-insulation wall, a circulating fan is arranged inthe heating chamber and directly faces the air inlet, a heat pump evaporator of the heat pump unit is arranged on the lower portion of the heating chamber and directly faces the return air inlet, a heat pump condenser of the heat pump unit is arranged on the upper portion of the heat pump evaporator, the biomass fuel furnace is arranged in the heating chamber and is positioned on a side of the heat pump unit, the infrared spectrum analyzer is arranged in the tobacco flue-curing chamber, probes of the infrared spectrum analyzer directly face tobacco leaves, probes of the temperature and humidity detection system are arranged in the tobacco flue-curing chamber, the data transmission equipment is arranged in the heating chamber, and the infrared spectrum analyzer, the temperature and humidity detection system, the data transmission equipment, the circulating fan and the heat pump unit are electrically connected with the field control instrument. The intelligent dual-power tobacco flue-curing barn has the advantages of simple structure, energy conservation, consumption reduction, intelligent regulation and control, quality improvement and aroma enhancement.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Baking technology effectively avoiding phenomenon that dust is hung on tobacco leaves at upper portion

InactiveCN108208905ASolve the phenomenon of hanging grayImprove roast qualityTobacco preparationEngineeringTobacco leaf

The invention provides a baking technology effectively avoiding the phenomenon that dust is hung on tobacco leaves at the upper portion. A tobacco stem tobacco weaving mode is adopted, and according to the tobacco leaf change state in the baking process, the baking process is divided into 9 stages: the stage when leaves become 70-80% yellow and leaf tips and leaf edges become soft, the stage whenthe leaves become 90% yellow and the tobacco leaves at the middle temperature layer start to hook the tips and curl the edges, the stage when yellow leaves have green tendons and the tobacco leaves atthe middle temperature layer reach small dug cylinders, the stage when branch veins of the tobacco leaves are totally yellow and the leaves at the middle temperature layer are 2 / 3 dried, the stage when the yellow leaves have yellow tendons and the leaves are totally dried, the stage when the tobacco tendons state to be dried, the stage when bases of the tobacco tendons become brown and tobacco tendons are shrunk and become brown, the stage when the leaves are 2 / 3 or above dried, and the stage when the tobacco tendons are totally dried. 9 key temperatures and precise humidity control points are mainly set, the time and speed change of the temperatures and the humidity is precisely controlled, the phenomenon that due to imbalance of the time and temperature change of the tobacco leaves, thedust is hung on the tobacco leaves at the upper portion, and the baking quality of the tobacco leaves is improved.

Owner:WEIFANG TOBACCO MONOPOLY BUREAU

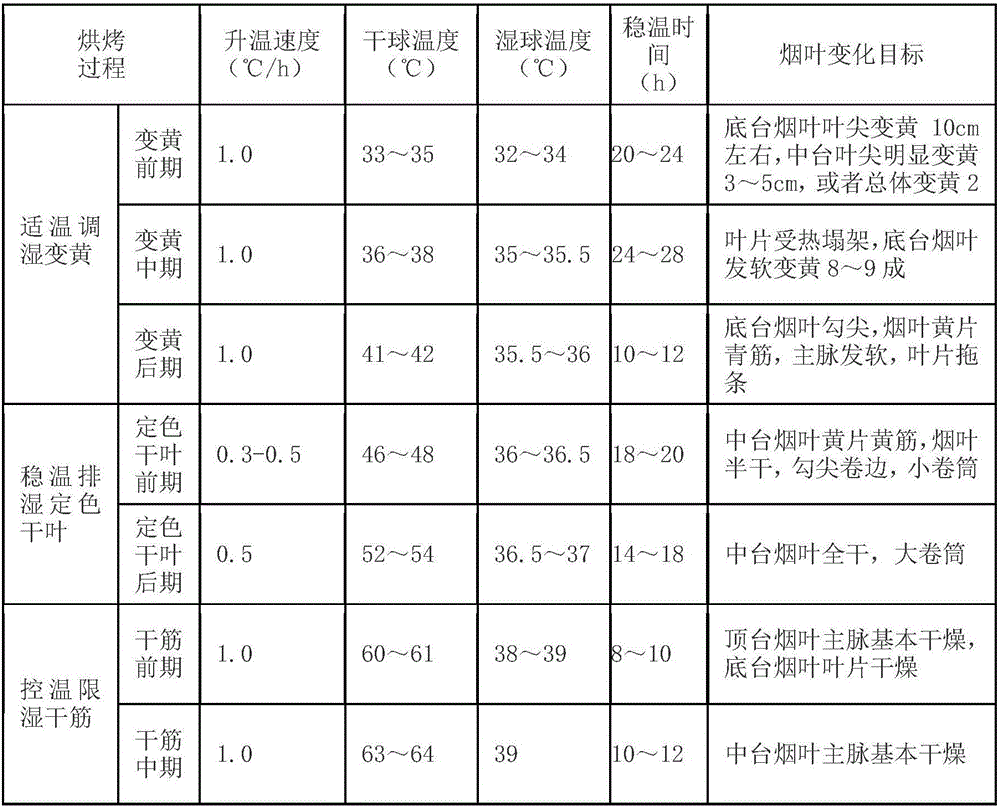

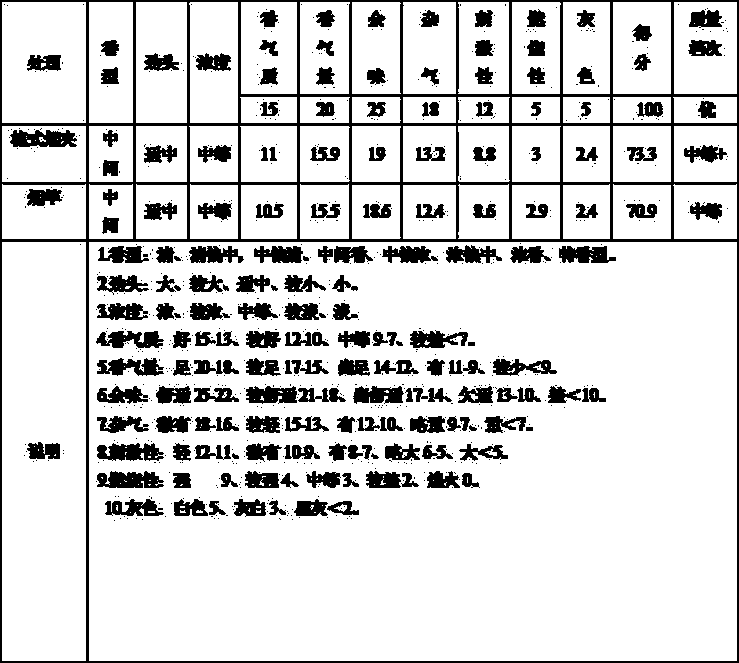

Intensive type bakery baking yellow and baking fragrant baking process for honghuadajinyuan tobacco

InactiveCN106387976AImprove roast qualityBright colorsTobacco preparationProcess engineeringTobacco leaf

The invention discloses an intensive type bakery baking yellow and baking fragrant baking process for honghuadajinyuan tobacco. The baking process comprises three steps of conducting humidity adjustment on the tobacco at a proper temperature until the tobacco becomes yellow; conducting humidity elimination, color determination and leaf drying on the tobacco at a stable temperature; and conducting temperature controlling, humidity limiting and stems drying. Compared with the prior art, the intensive type bakery baking yellow and baking fragrant baking process for honghuadajinyuan tobacco has the advantages that the baking process improves greatly the quality of baking; the color of tobacco leaf is bright and shining; the amount of oil and fragrance of the tobacco are adequate; the quality of the fragrance is good; and the penetrating force of the fragrance is strong.

Owner:XICHANG COLLEGE

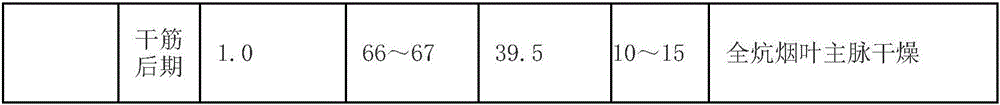

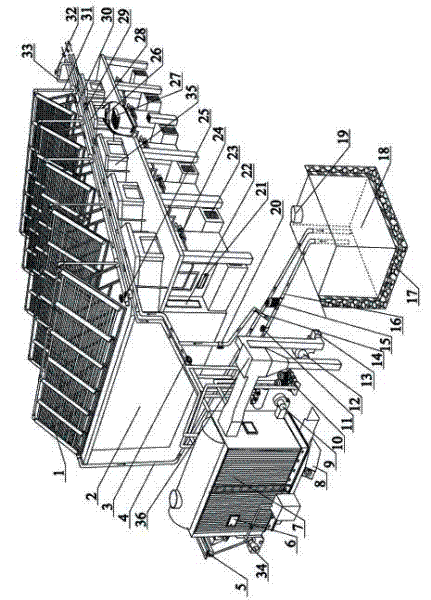

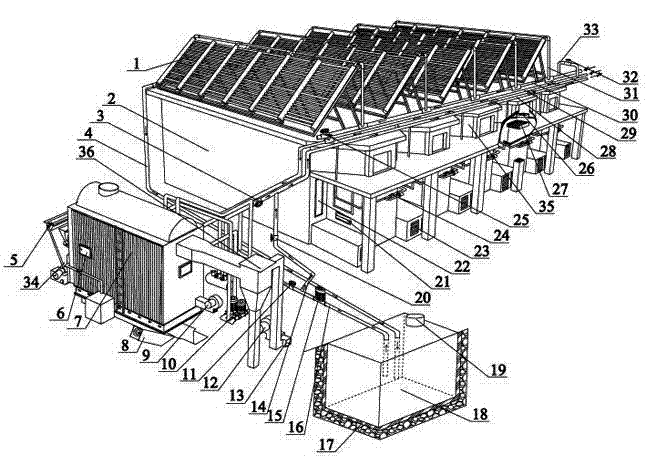

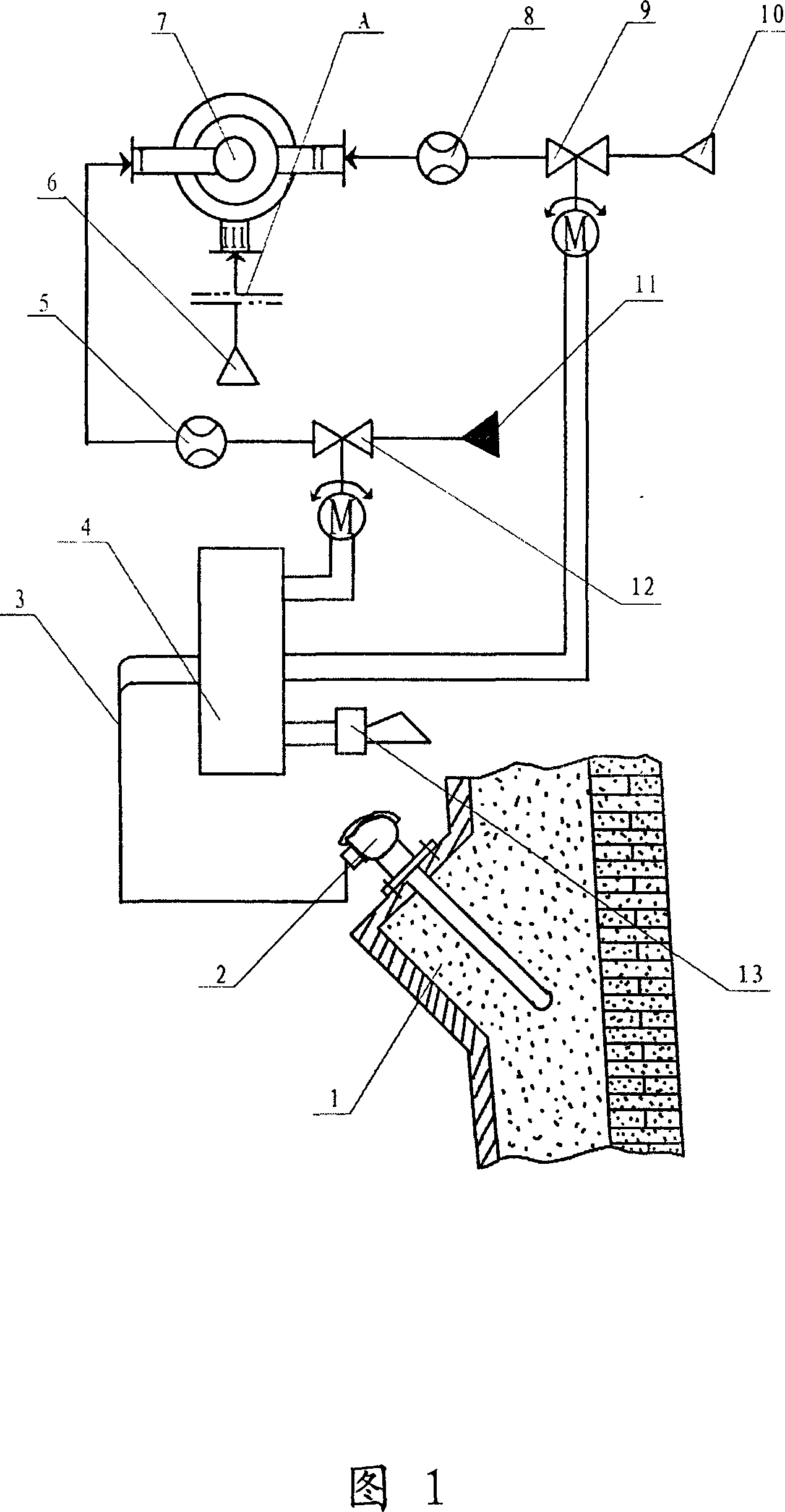

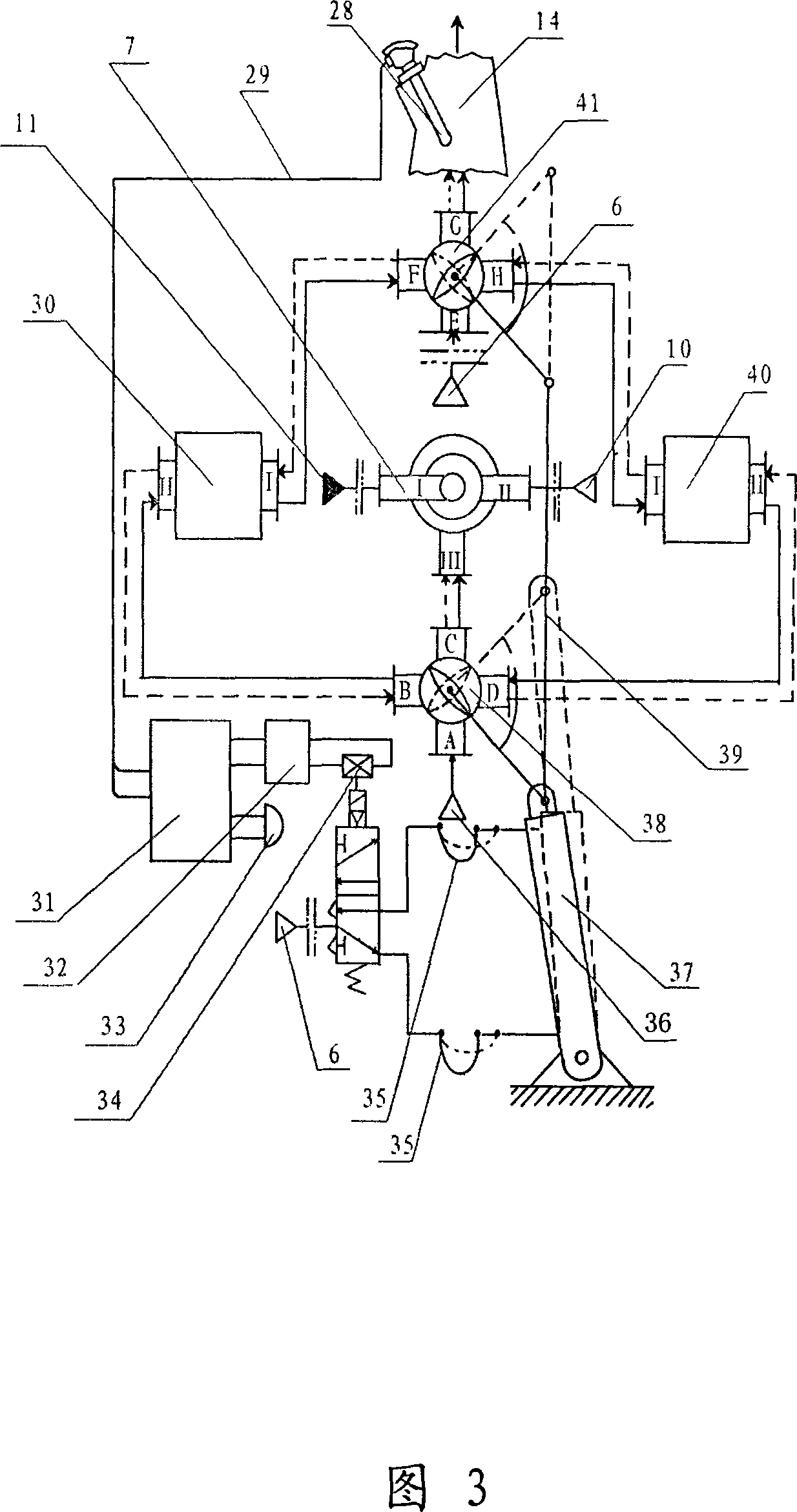

Hot-water centralized heating tobacco flue-curing device adopting combination of solar energy and biomass fuels

InactiveCN102160681ATo achieve the purpose of curing tobacco leavesSave energyTobacco preparationThermodynamicsSolar water

Owner:HENAN AGRICULTURAL UNIVERSITY

Roasting method of high-temperature droughty unripe tobacco leaves

ActiveCN103689782AReduce bake lossImprove roast qualityTobacco preparationIntermediate stageTobacco processor

The invention discloses a roasting method of high-temperature droughty unripe tobacco leaves. The roasting method comprises the following six steps: a yellowing early stage, a yellowing middle stage, a yellowing later stage, a color-fixing front stage, a color-fixing later stage and a stem drying stage. With the roasting method disclosed by the invention, roasting loss of high-temperature droughty unripe tobacco leaves is reduced by regulating roasting process parameters, and roasting quality of the tobacco leaves is improved. Moreover, a proportion of middle and upper grades of tobacco leaves is obviously increased, the proportion of variegated tobacco leaves is reduced, and the proportion of tobacco leaves which are greenish on middle upper parts is obviously lowered, and good effect is achieved.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

Method for improving curing quality of tobacco leaves affected by Cold Dew

ActiveCN105341986AHigh activityPay attention to moisturizingTobacco preparationChemistryCuring of tobacco

The invention discloses a method for improving the curing quality of tobacco leaves affected by Cold Dew. In the method, tobacco leaves with whitened tobacco stems and most setae falling off as well as faint yellow color are adopted, the tobacco loading density inside a curing barn is 42-45 kg / m<3>, and the tobacco loading volume at least occupies 95% of the total volume of the curing barn; the curing process with low temperature and limited low-humidity yellowing as well as the room-temperature drying is adopted, and specifically comprises a preheating stage, a yellowing stage, a color setting stage and a stem drying stage, and curing is carried out till the main veins of the tobacco leaves in the whole curing barn become dry, wherein the temperature rising speed in each curing stage is controlled to be 1 DEG C / 1-2 h. The method is particularly suitable for the tobacco leaves planted in a delayed manner due to various reasons, and the tobacco leaves growing in tobacco areas with high altitude, low temperature and long growth period of flue-cured tobaccos, wherein the harvesting and curing of the tobacco leaves are finished during the Autumnal Equinox and the Frost's Descent, the material metabolism, synthesis and degrading of the substances inside the tobacco leaves become slow, the leaves become thick, the tissues are coarse, and the fading and yellowing are slow. The method is simple and easy to operate, the curing quality of the tobacco leaves affected by cold dews can be improved, the loss is reduced, and the income of the tobacco growers is increased.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Method for improving curing quality of tender mature-delay tobacco leaves

The invention discloses a method for improving the curing quality of tender mature-delay tobacco leaves. According to the method, the tobacco leaf harvesting standards include that tobacco leaves are mature to be yellowing in green and have yellow leaf tips, the smoke filling density in a curing room is 38-40 kg / m<3> and the curing room is filled with smoke accounting for 85-90% of the volume. Through the three-stage baking process, the method specifically includes the yellowing stage, the color fixing stage and the vein drying stage till main veins of tobacco leaves in the whole curing room are cured to be dry. In the later period of the yellowing stage, the wind speed among tobacco leaves in the curing room reaches 0.3-0.4 m / s in the high wind speed layer, reaches 0.25-0.35 m / s in the medium wind speed layer and reaches 0.2-0.3 m / s in the low wind speed layer. The curing method is particularly suitable for lower tobacco leaves formed under the conditions of high water and fertilizer, high densities, inharmonious nutrients and too much nitrogen, leaves are fat, high in water content, high in moisture holding capacity and little in dry substance, nitrogen compounds are mainly contained, and the problems that tobacco leaves have no maturity delay capacity in the field and can get rotted before being mature are solved. The method is easy to operate, the curing quality of tender mature-delay tobacco leaves can be improved, loss can be reduced, and income of tobacco farmers is increased.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

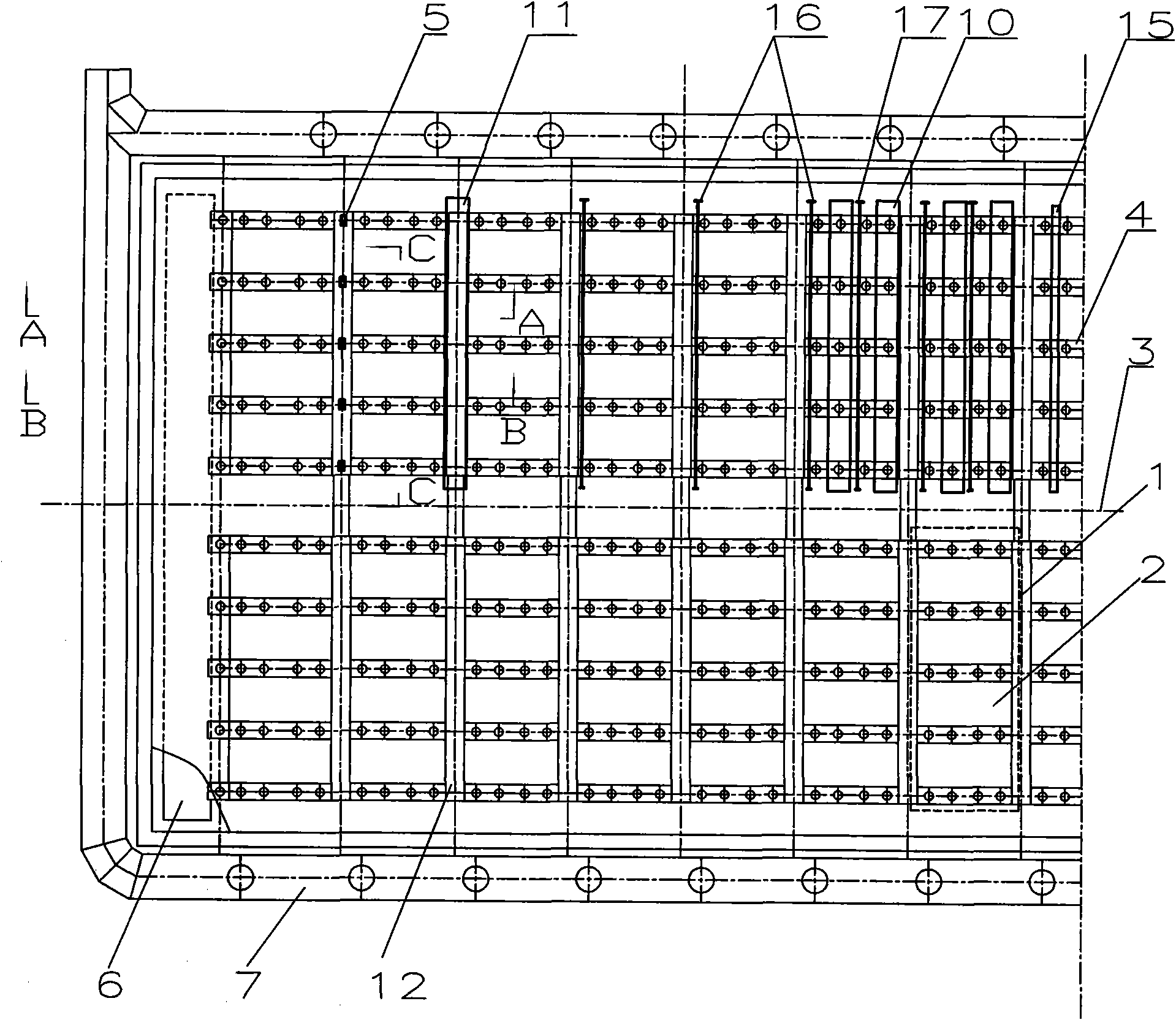

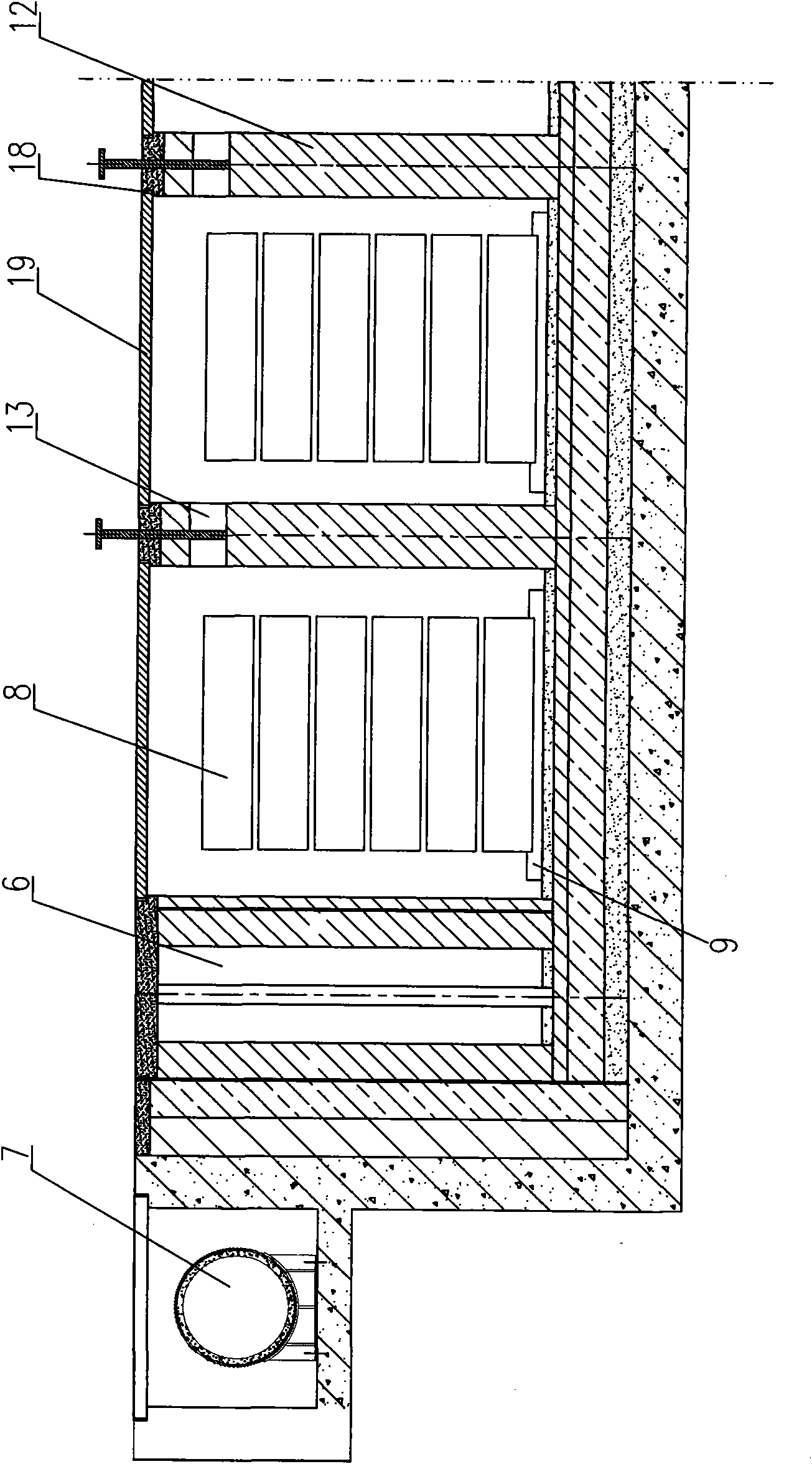

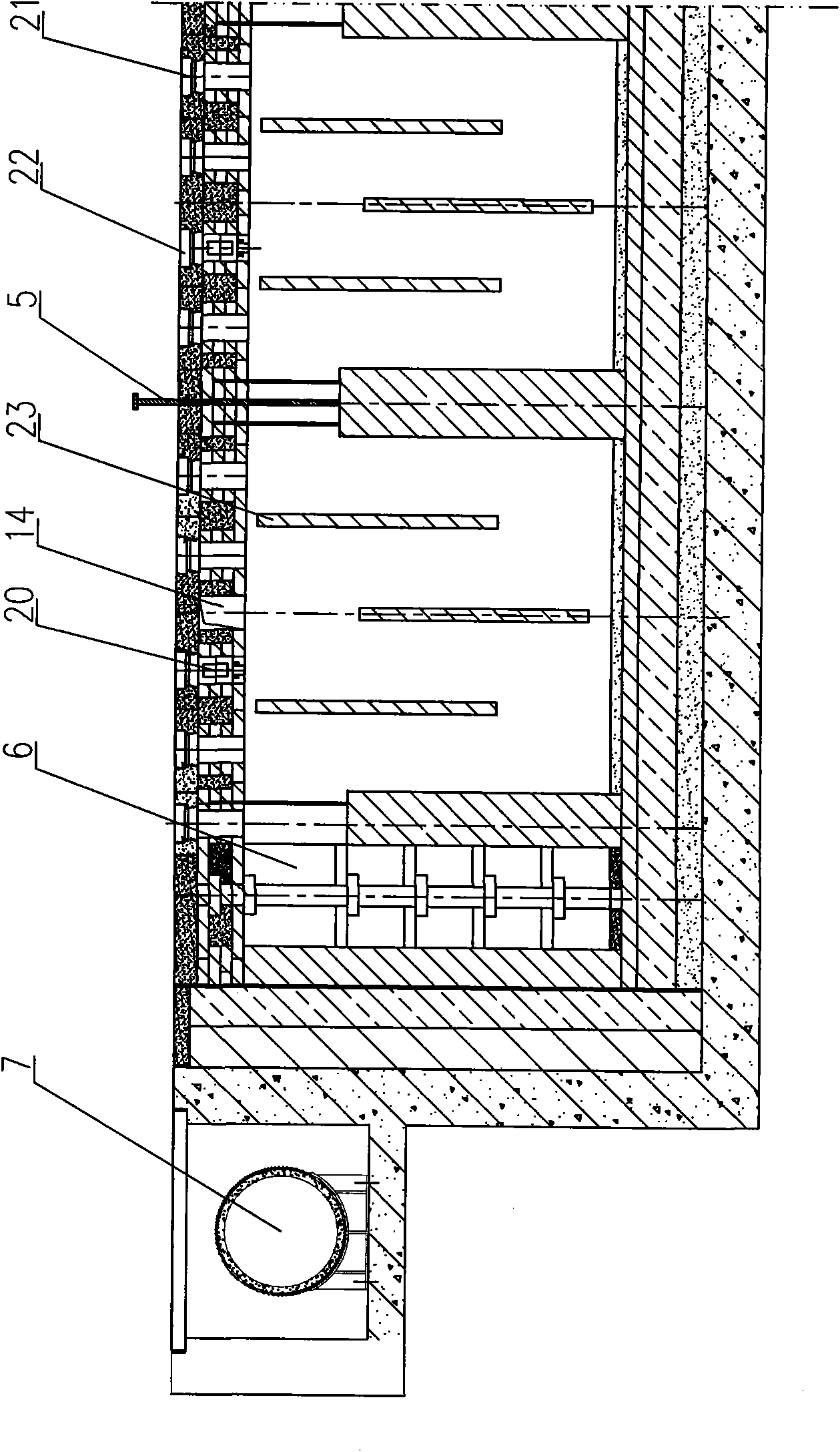

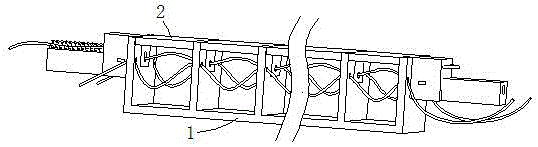

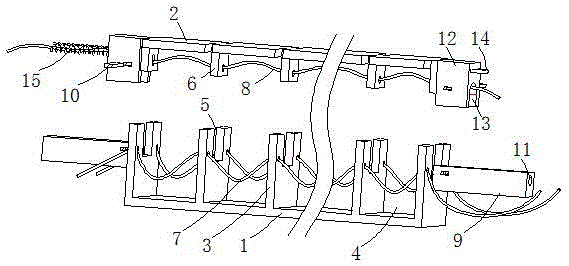

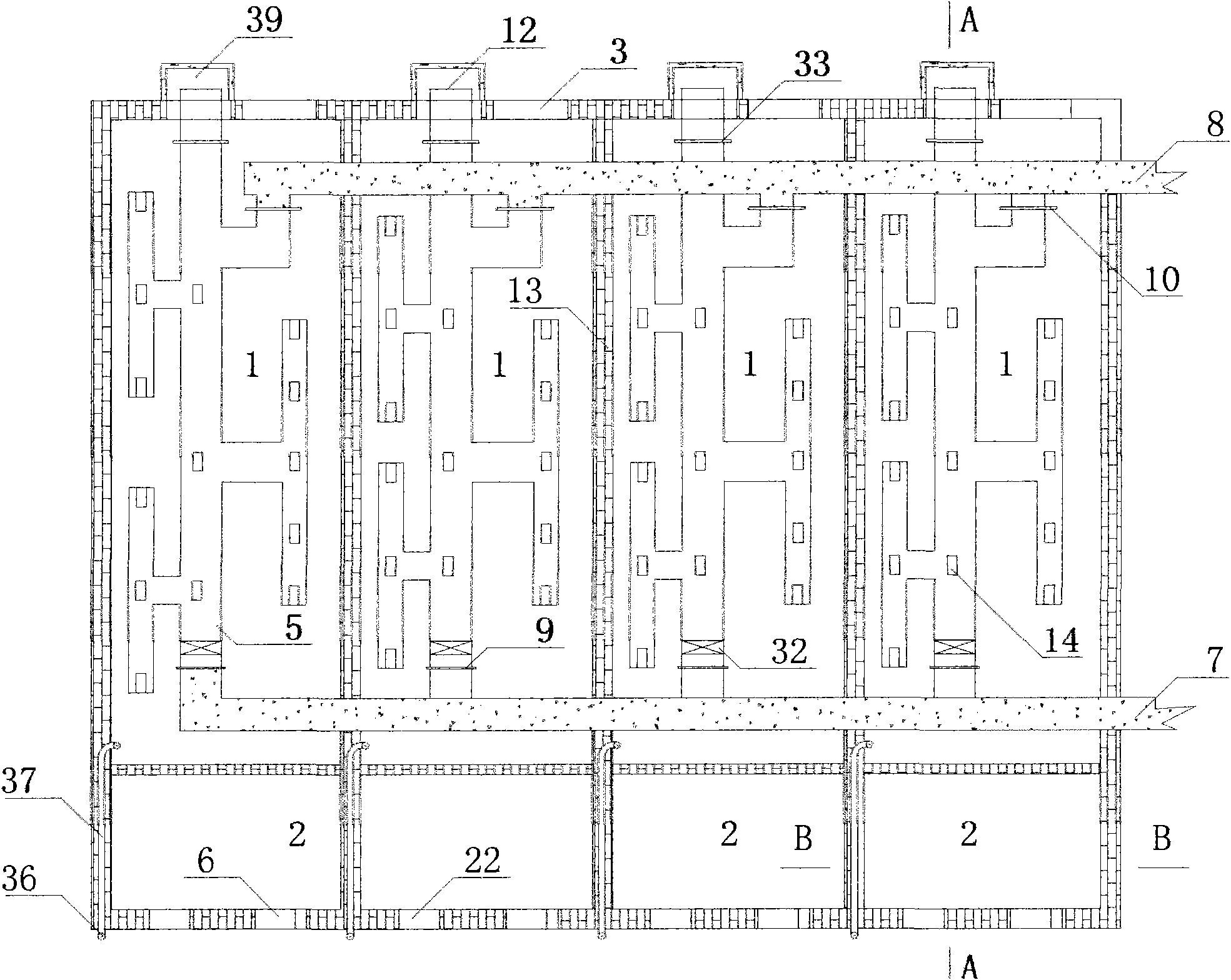

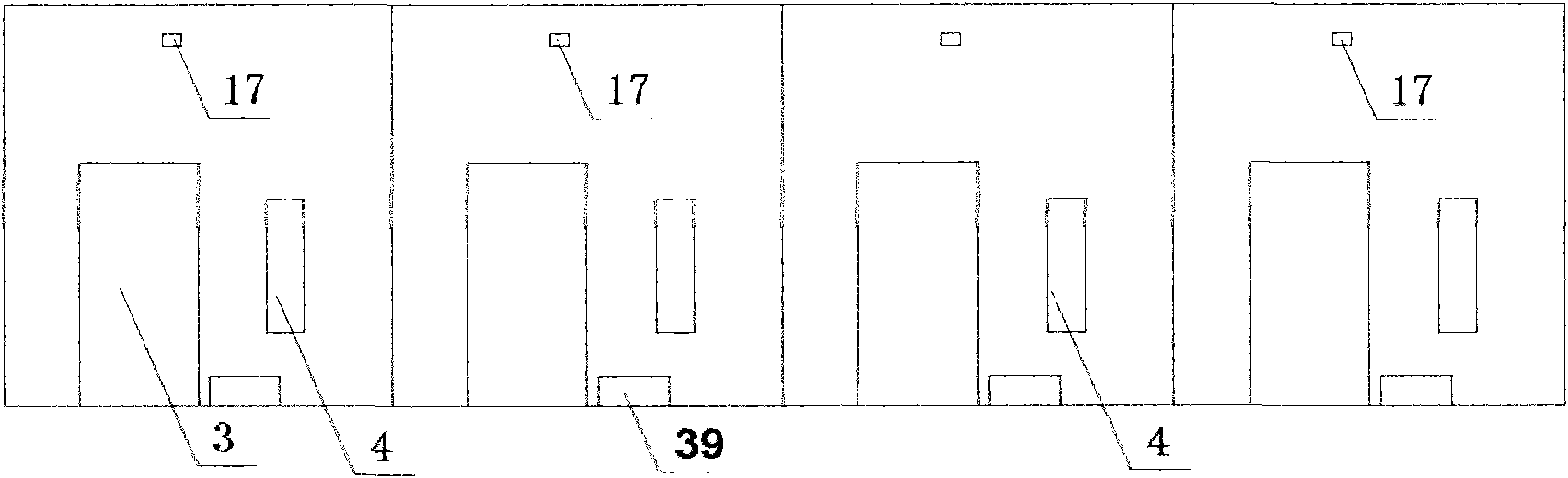

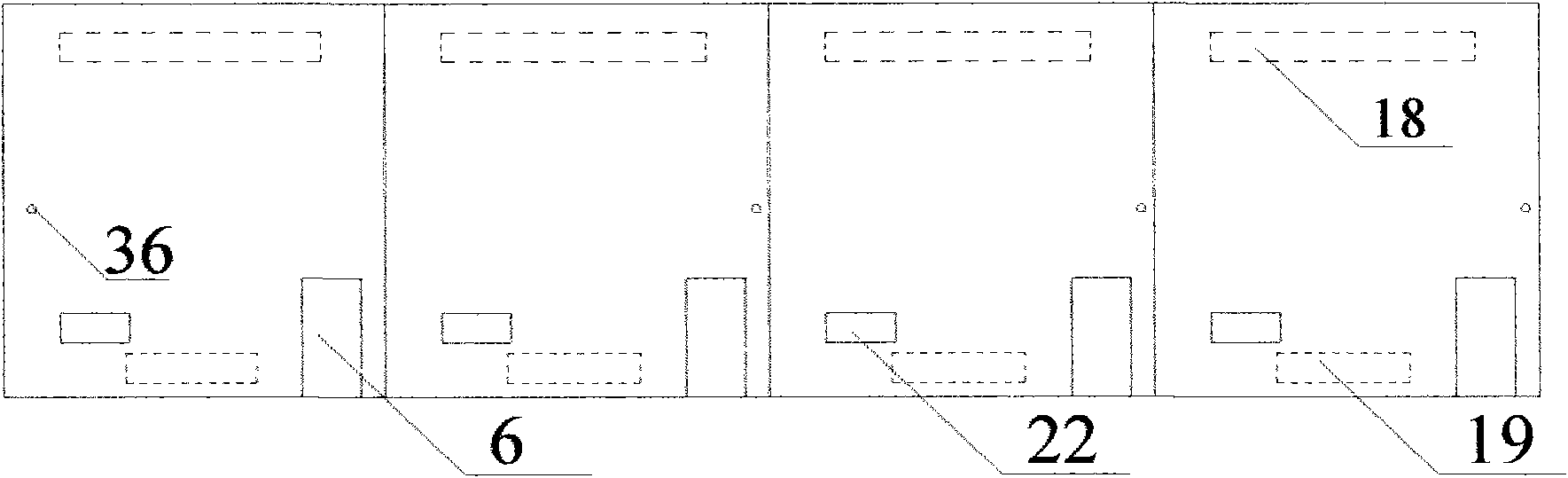

Waste heat-sharing integral-body compact flue-curing barn and operating-using method thereof

InactiveCN101843358AReduce baking costsBaking remoisture cost reductionTobacco preparationEngineeringMoisture

The invention relates to a waste heat-sharing integral-body compact flue-curing barn, which consists of a plurality of tobacco-curing chambers connected as a whole, wherein the adjacent tobacco-curing chambers are spaced through a longitudinally arranged public partition wall; the back ends of the tobacco-curing chambers are provided with heating chambers corresponding to the tobacco-curing chambers; the tobacco-curing chambers and the heating chambers are spaced through a transverse public partition wall; the inside of the tobacco-curing chambers is provided with moisture-removing channels, as well as waste-heat heating channels and waste-heat dampening channels hermetically communicating all the tobacco-curing chambers; the waste-heat heating channels and the waste-heat dampening channels are in H-shaped communication with the moisture-removing channels respectively; the moisture-removing channels lead to outside; the tobacco-curing chambers are provided with moisture removal air inlets inside; and the front ends of the tobacco-curing chambers are provided with tobacco loading / unloading doors, tobacco change observation windows and reduced-pressure heat-exchange air outlets. The waste heat-sharing integral-body compact flue-curing barn has the advantages of scientific structure, reasonable layout, convenient operation, good performance and capability of simplifying and improving architectural structure of the flue-curing barn, reducing construction cost, saving energy, reducing consumption, reducing curing cost and labor, improving the utilization rate of heat energy circulation and stably improving the quality of flue-cured tobacco.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

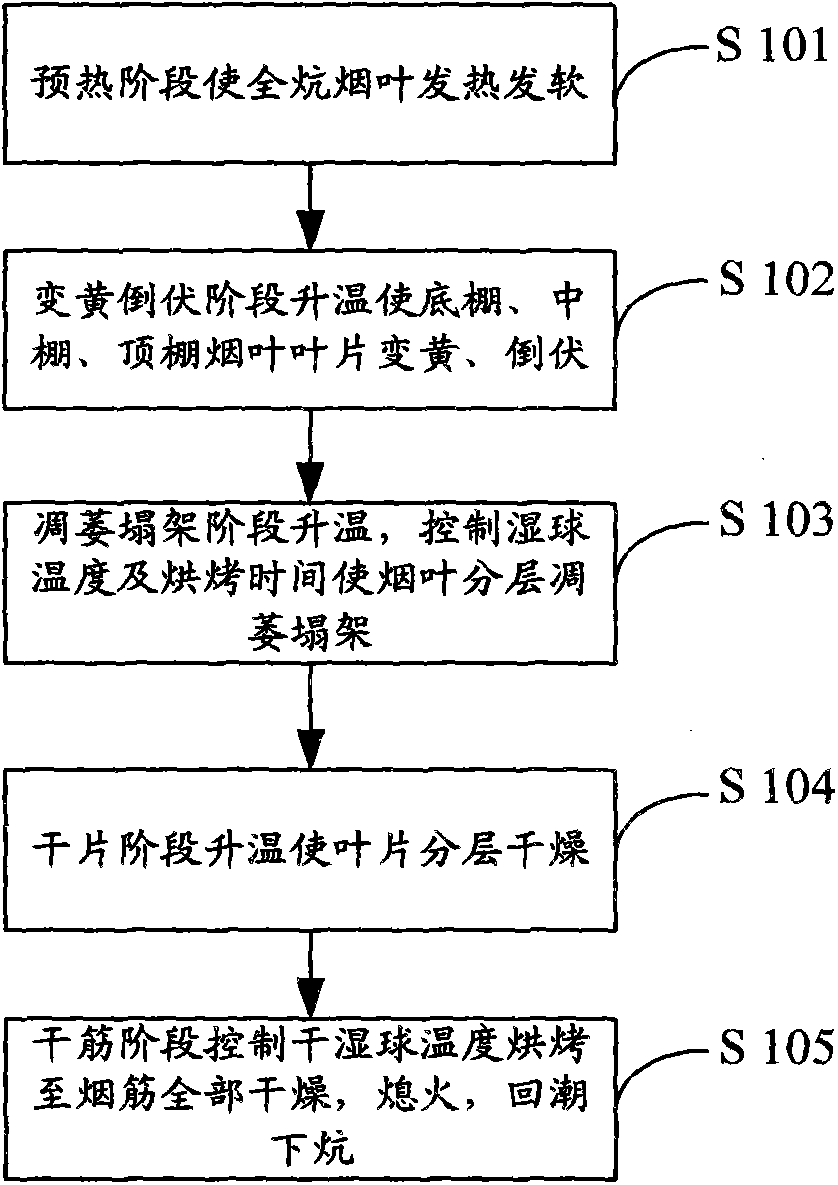

Airflow lift type flue-cure tobacco scattered leaf cuttage layered curing method

InactiveCN103431513AGood colorHigh oil contentTobacco preparationRoom temperatureTemperature difference

The invention discloses an airflow lift type flue-cure tobacco scattered leaf cuttage layered curing method. The method comprises the following steps of: at a preheating stage, raising the temperature of tobacco leaves from room temperature to proper temperature as soon as possible to promote softening of the leaves; at a yellowing and lodging stage, raising temperature to yellow and lodge the tobacco leaves at a bottom shed, a middle shed and a top shed in layers; at a withering and collapsing stage, raising the temperature, controlling the wet bulb temperature and the curing time, withering and collapsing the tobacco leaves at the bottom shed, the middle shed and the top shed in layers by using vertical temperature difference and safely fixing color; at a slice drying stage, controlling dry and wet bulb temperature to dry the tobacco leaves in layers; at a stem drying stage, controlling the dry and wet bulb temperature to cure until the tobacco stems are fully dried, flaming out, dampening and discharging from a kang. According to the method, the yellowing and lodging stage, the withering and collapsing stage and the slice drying stage are stepped in the curing process and are divided into two obvious processes respectively to perform the layered curing; the method is easy, convenient and safe to operate; the layered curing can be performed aiming at the bottom shed, the middle shed and the top shed of a curing house; black tobaccos, yellow slices and green stems are obviously reduced; the color and the oil of the tobacco leaves are increased; the tobacco leaf curing quality is obviously improved.

Owner:HENAN AGRICULTURAL UNIVERSITY +2

Baking process for intensive baking room

InactiveCN103622149AIncrease aromaImprove roast qualityTobacco preparationAir velocityProcess engineering

The invention discloses a baking process for an intensive baking room. A comb type cigarette clamp is adopted for installing cigarettes, and ten temperature and humidity accurate control points are set. According to the technical scheme, operation is easy and safe, the baking process is quantized accurately, baking loss caused by human baking errors is greatly reduced, the baking step is simplified, automatic baking can be achieved by setting the dry-bulb temperatures, the wet-bulb temperatures, the temperature increase speed and the temperature stabilization time of ten key temperature points and the parameters of the air speed of a fan in the baking process, and therefore the operability is high and the labor cost is saved. Meanwhile, the baking quality of tobacco is improved through accurate control of the dry-bulb temperatures, the wet-bulb temperatures, the temperature increase speed, the temperature stabilization time and the parameters of the air speed of the fan, and the baked tobacco is bright in appearance color, sufficient in oil content, loose in structure, good in aroma and sufficient in amount.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

Automatic observing and controlling method for roasting heat accumulating type steel ladle and the device using the method

InactiveCN101121200AImprove roast qualityPrevent from being baked throughCasting safety devicesVolumetric Mass DensitySmoke

The present invention discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature. The present invention also discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature; the present invention can ensure the sufficient burning of fuel and the heating quality of the ladle; the present invention can thoroughly remove the defect that the smoke and dust will pollute the environment and the energy-saving effect is obvious.

Owner:江苏兴利来特钢有限公司

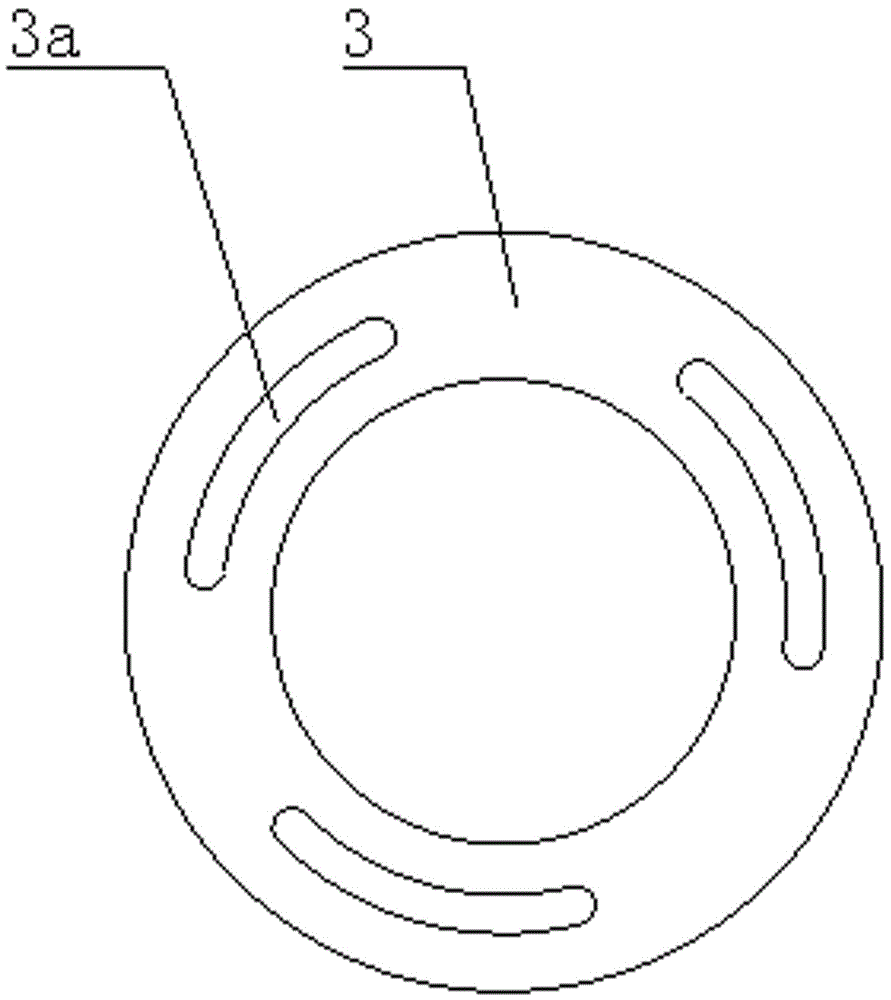

Flange fast and firm in connection

ActiveCN106224667AQuick and efficient installationEasy to installFlanged jointsFoundry mouldsEngineeringFlange

The invention relates to a flange fast and firm in connection. The flange fast and firm in connection comprises a first flange body, a second flange body, a sealing gasket, a fastening bolt and a nut. The corresponding positions of the first flange body and the second flange body are each provided with at least two arc-shaped holes. The fastening bolt sequentially penetrates the arc-shaped holes in the first flange body and the arc-shaped holes of the second flange body and is connected with the nut in a threaded manner. The sealing gasket is arranged between the first flange body and the second flange body. The side, close to the first flange body, of the second flange body is provided with an annular connecting block. An external thread is machined on the outer side of the annular connecting block. A connecting groove matched with the annular connecting block is formed in the first flange body. An internal thread matched with the external thread of the annular connecting block is machined on the inner wall of the connecting groove. According to the flange fast and firm in connection, the first flange body and the second flange body are connected through the thread of the connecting block firstly and thereafter connected through the bolt when connected, and the two connecting manners are matched mutually, so that connection of the first flange body and the second flange body is firmer and more stable, and the problems of leakage and the like caused by infirm connection are reduced greatly.

Owner:YANCHENG FENGGONG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com