Three-section and five-step bulk curing process for flue-cured tobacco

A process and stage technology, applied in the field of intensive baking room baking process, to achieve the effect of quantitative baking links, strong operability, and conducive to mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

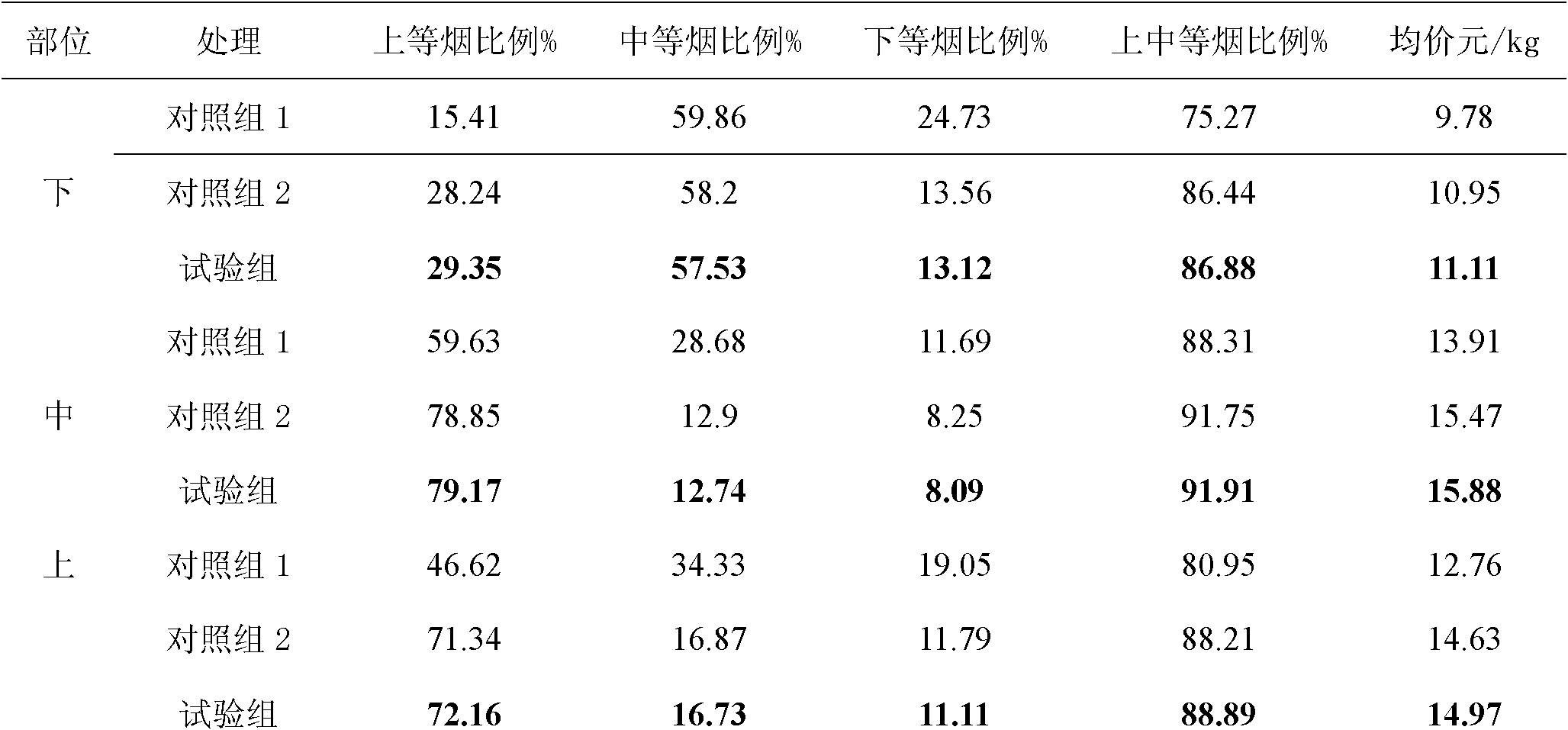

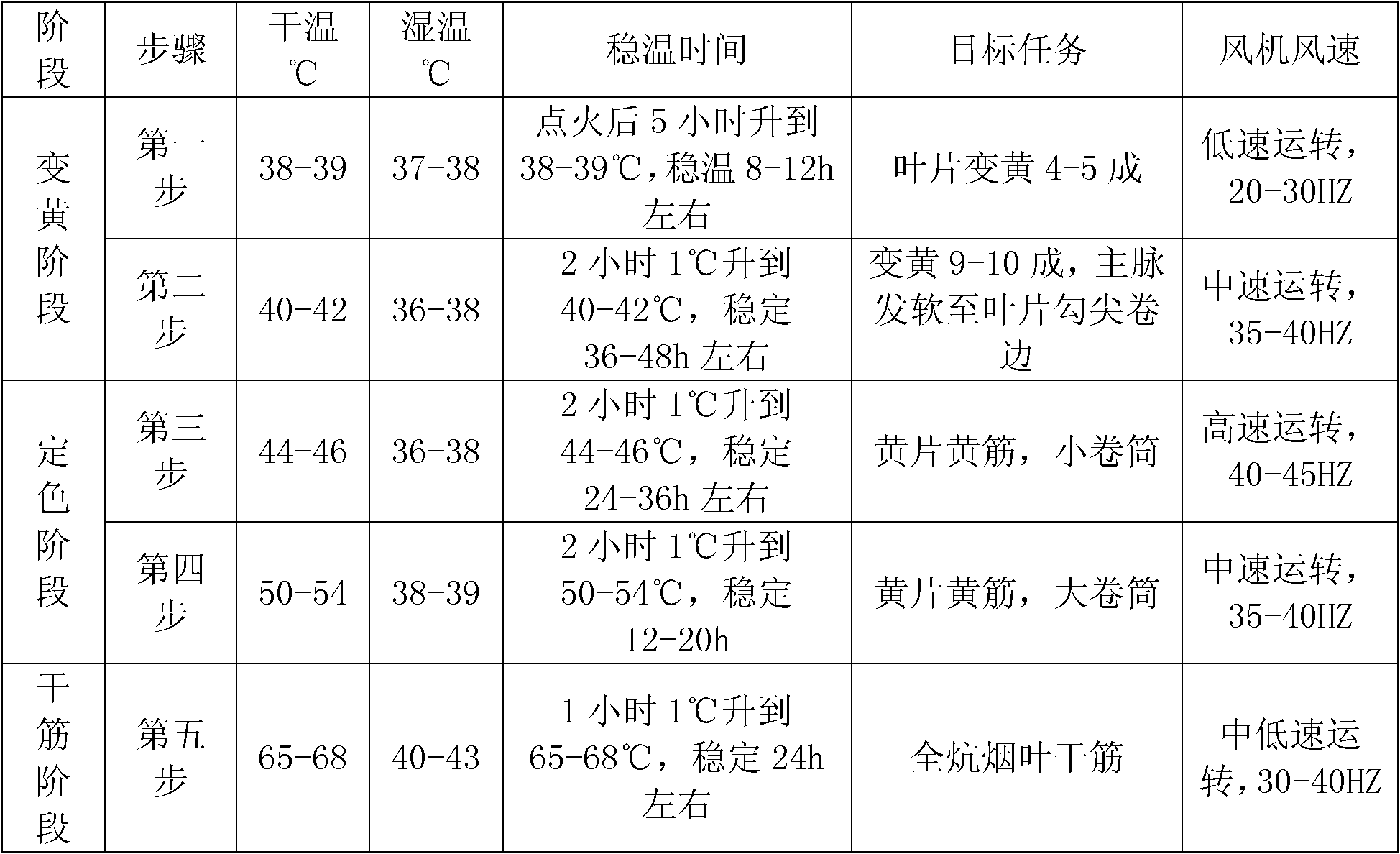

[0019] As can be seen from Table 1, the process steps of the present invention mainly include three baking stages of yellowing stage, color fixing stage and gluten drying stage, which are divided into five major steps. Humidity control steps, two key temperature and humidity control steps in the color fixing stage, and one key temperature and humidity control step in the gluten drying stage. In actual operation, you only need to operate according to the control conditions in the table. In detail, it is:

[0020] The first step of the yellowing stage:

[0021] Operation requirements: After loading the tobacco leaves into the furnace, close the doors, windows and air inlets, ignite the fire, raise the dry bulb temperature to 38-39°C within 5 hours, and control the wet bulb temperature at 37-38°C at the same time, stabilize the temperature for 8-12 hours, so that the tobacco leaves The blades turn yellow by 40-50%, the fan runs at low speed, and the fan with frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com