Patents

Literature

351results about How to "Reduce heating rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

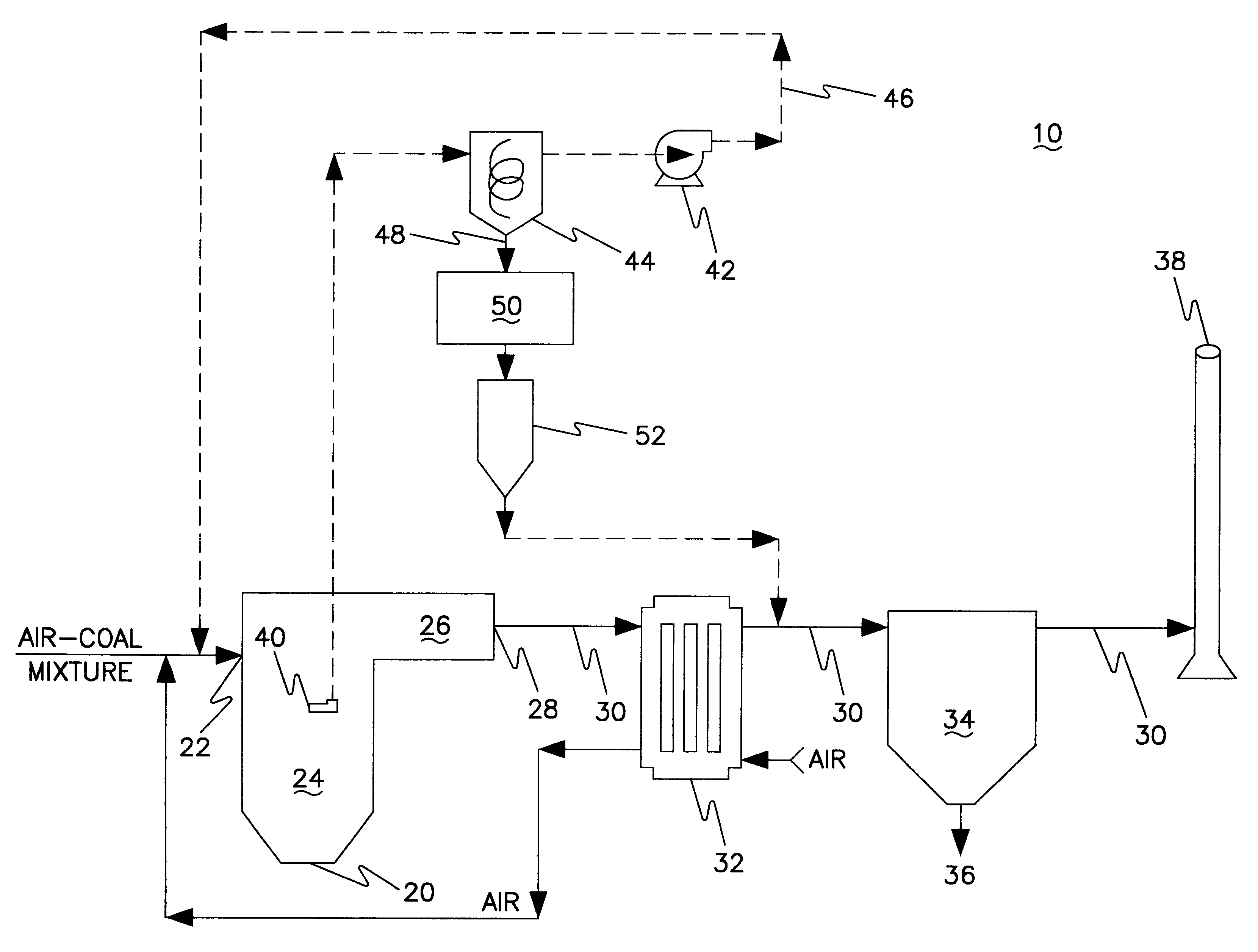

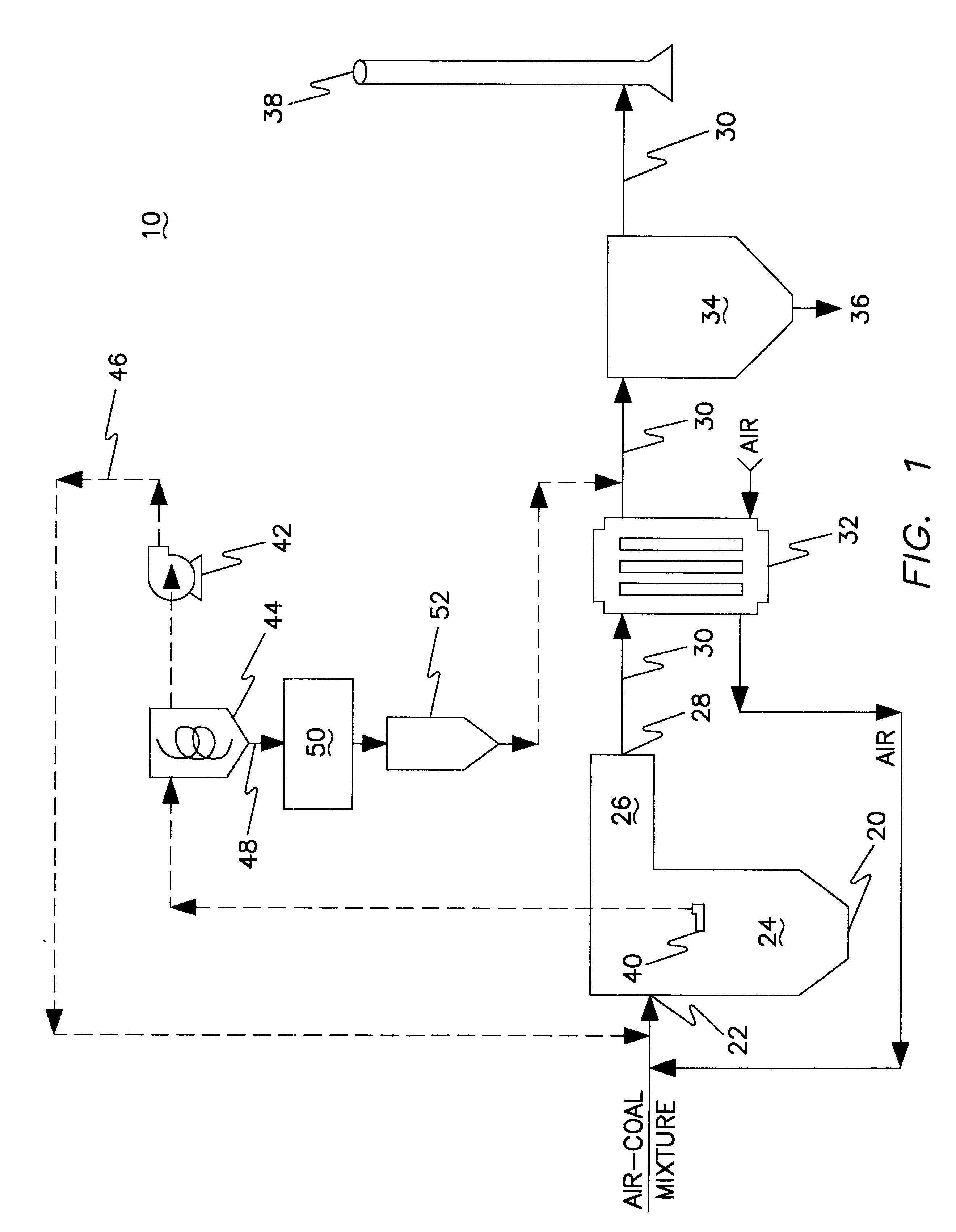

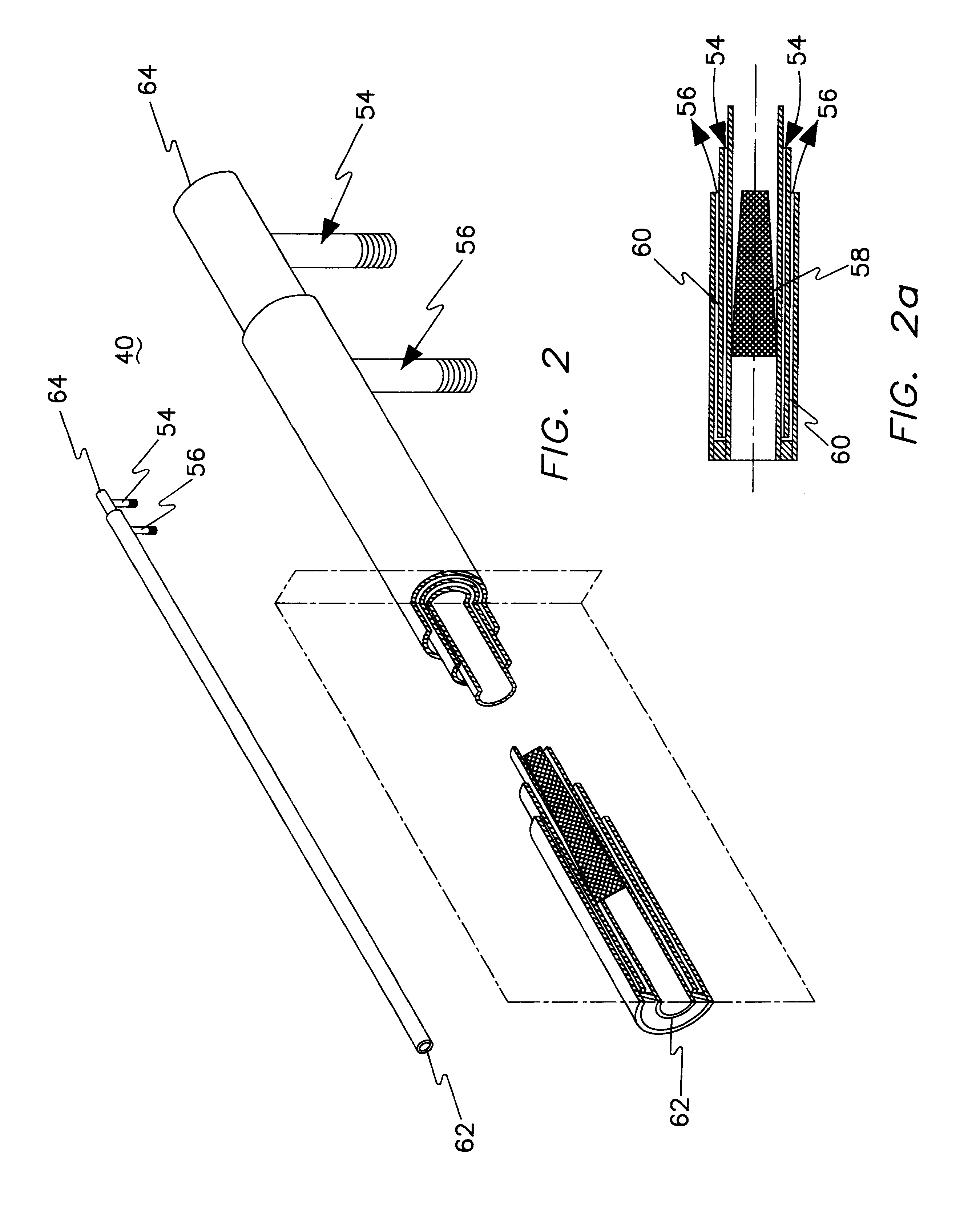

Thief process for the removal of mercury from flue gas

InactiveUS6521021B1Low costQuench oxidationGas treatmentUsing liquid separation agentParticulatesCombustion chamber

A system and method for removing mercury from the flue gas of a coal-fired power plant is described. Mercury removal is by adsorption onto a thermally activated sorbent produced in-situ at the power plant. To obtain the thermally activated sorbent, a lance (thief) is inserted into a location within the combustion zone of the combustion chamber and extracts a mixture of semi-combusted coal and gas. The semi-combusted coal has adsorptive properties suitable for the removal of elemental and oxidized mercury. The mixture of semi-combusted coal and gas is separated into a stream of gas and semi-combusted coal that has been converted to a stream of thermally activated sorbent. The separated stream of gas is recycled to the combustion chamber. The thermally activated sorbent is injected into the duct work of the power plant at a location downstream from the exit port of the combustion chamber. Mercury within the flue gas contacts and adsorbs onto the thermally activated sorbent. The sorbent-mercury combination is removed from the plant by a particulate collection system.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

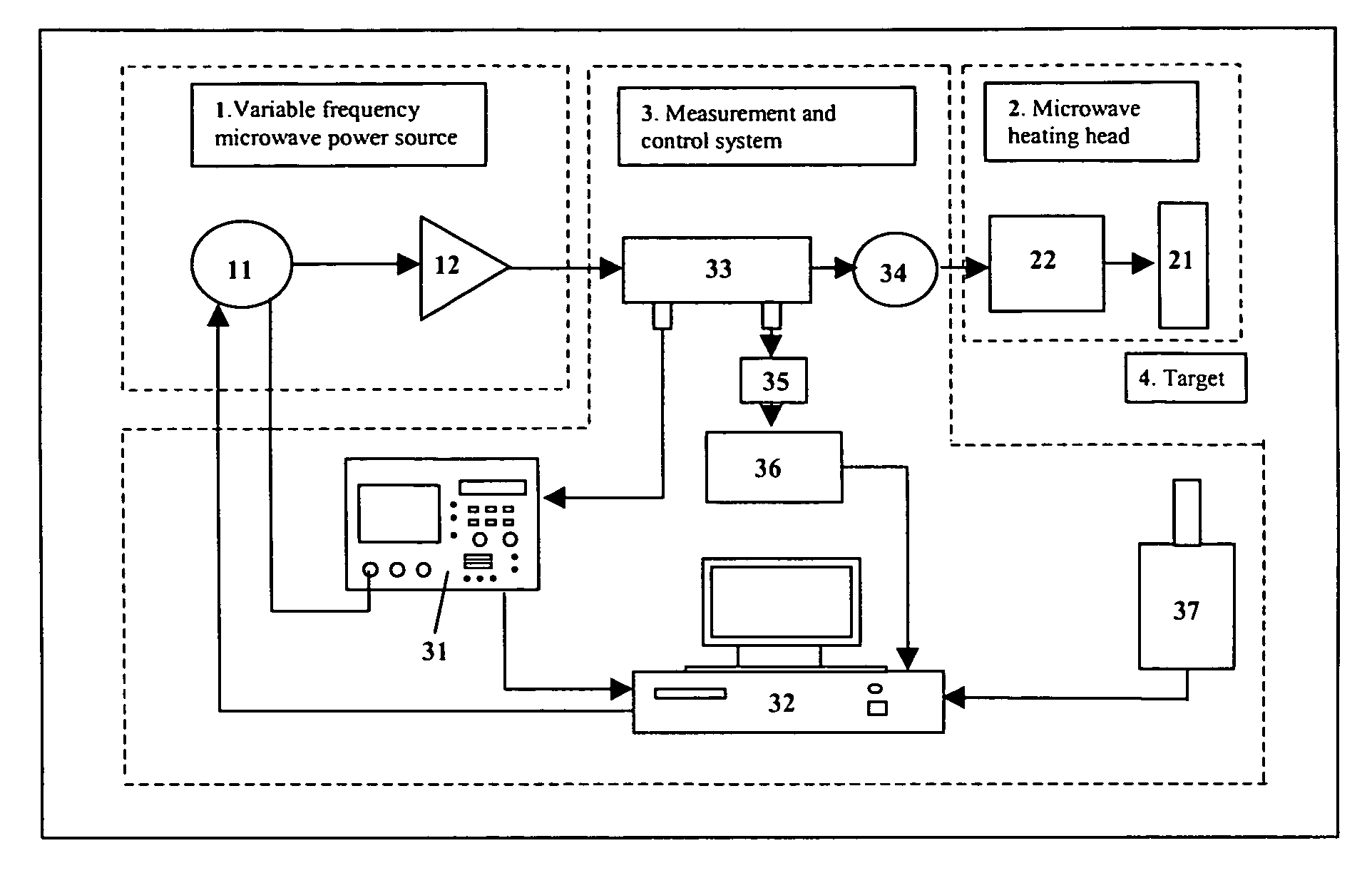

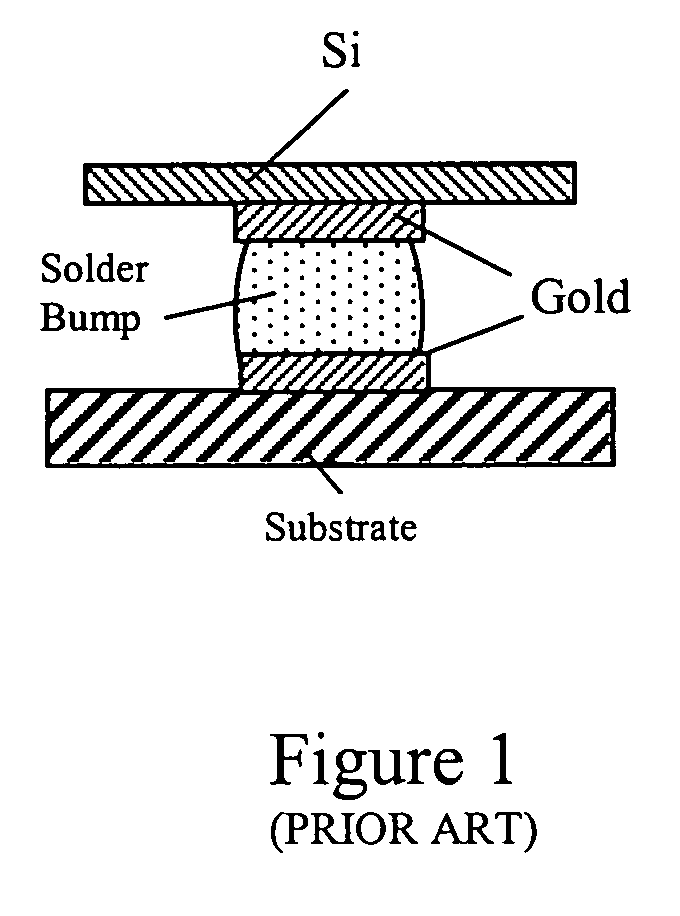

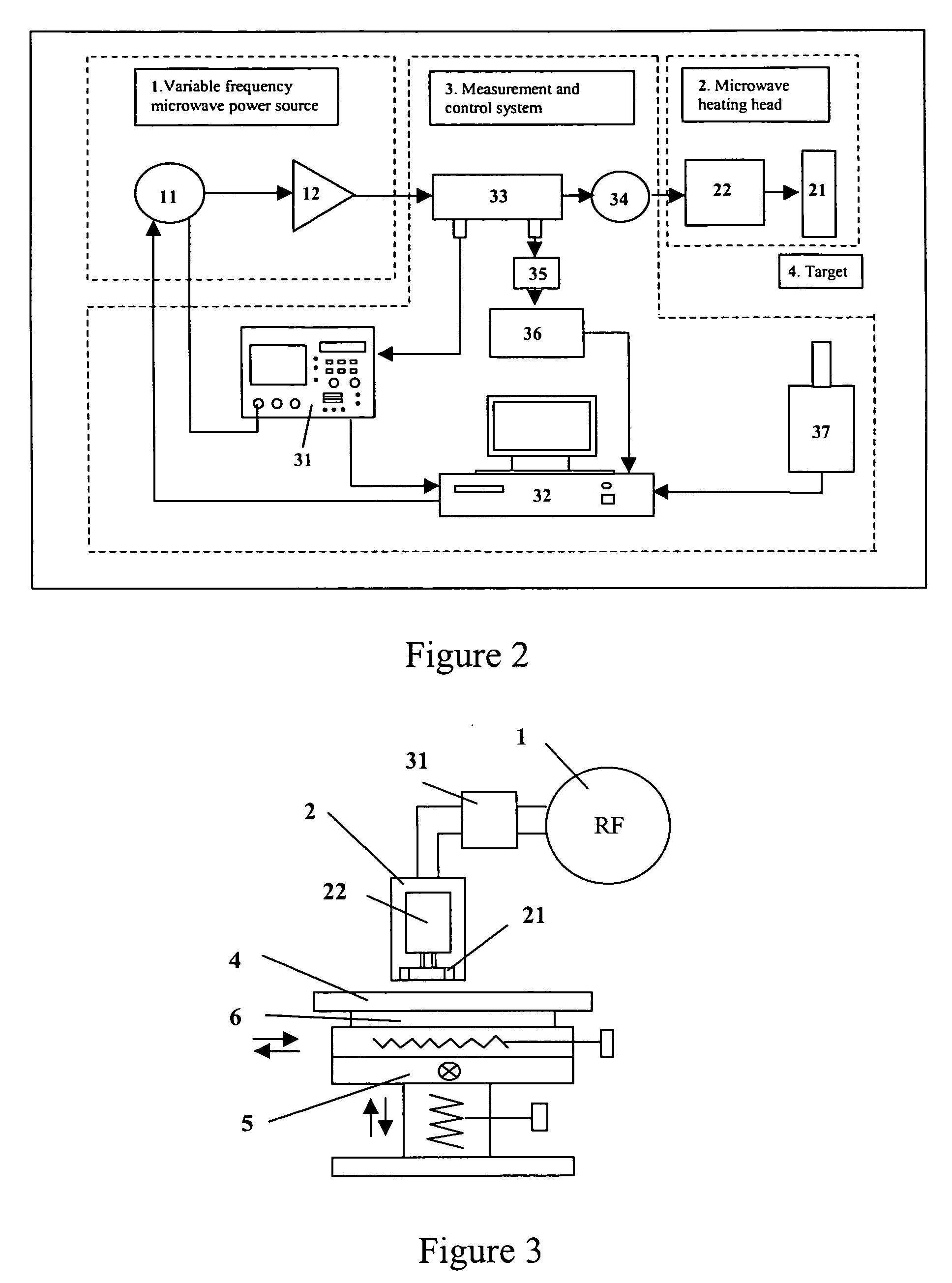

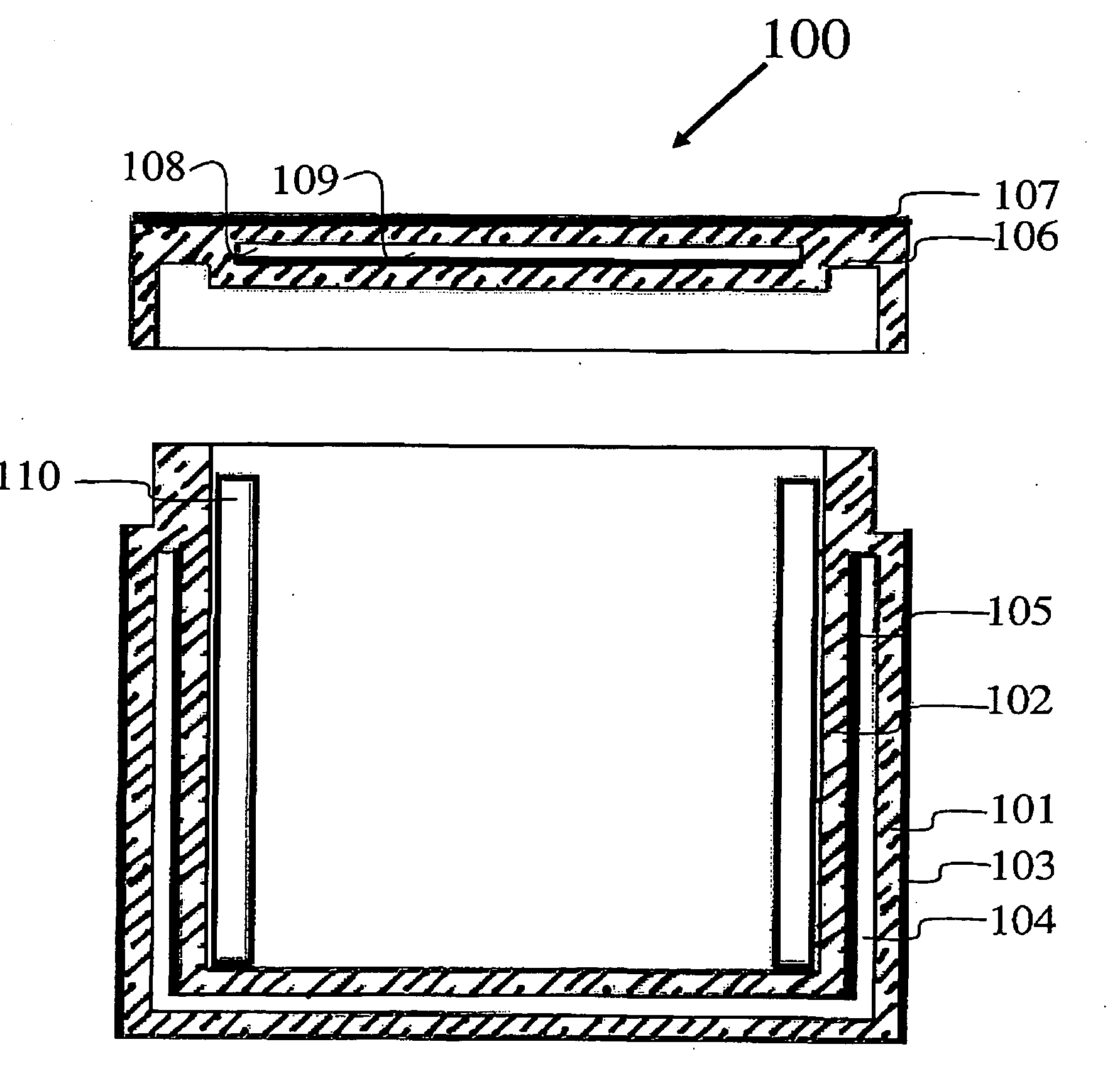

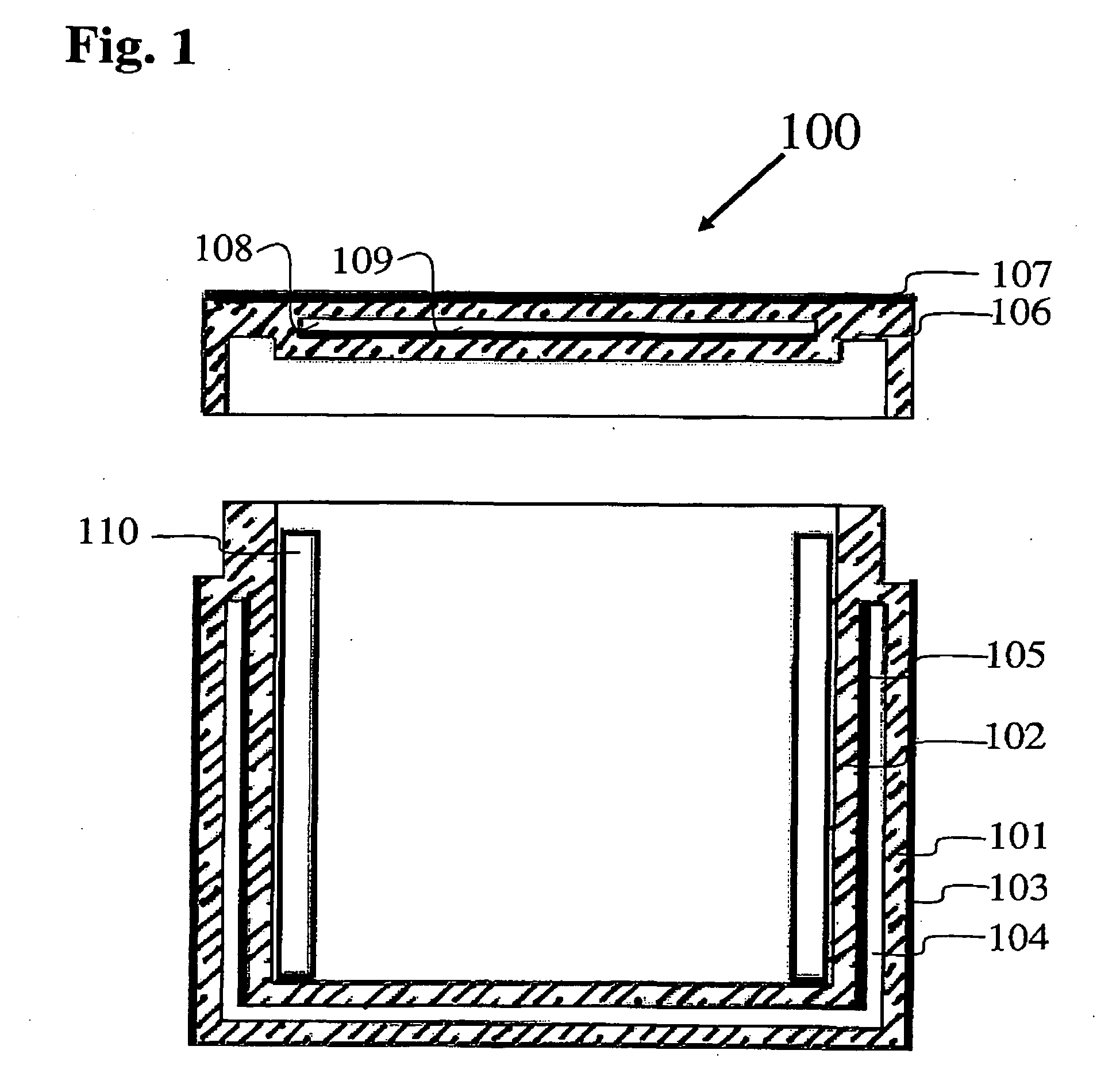

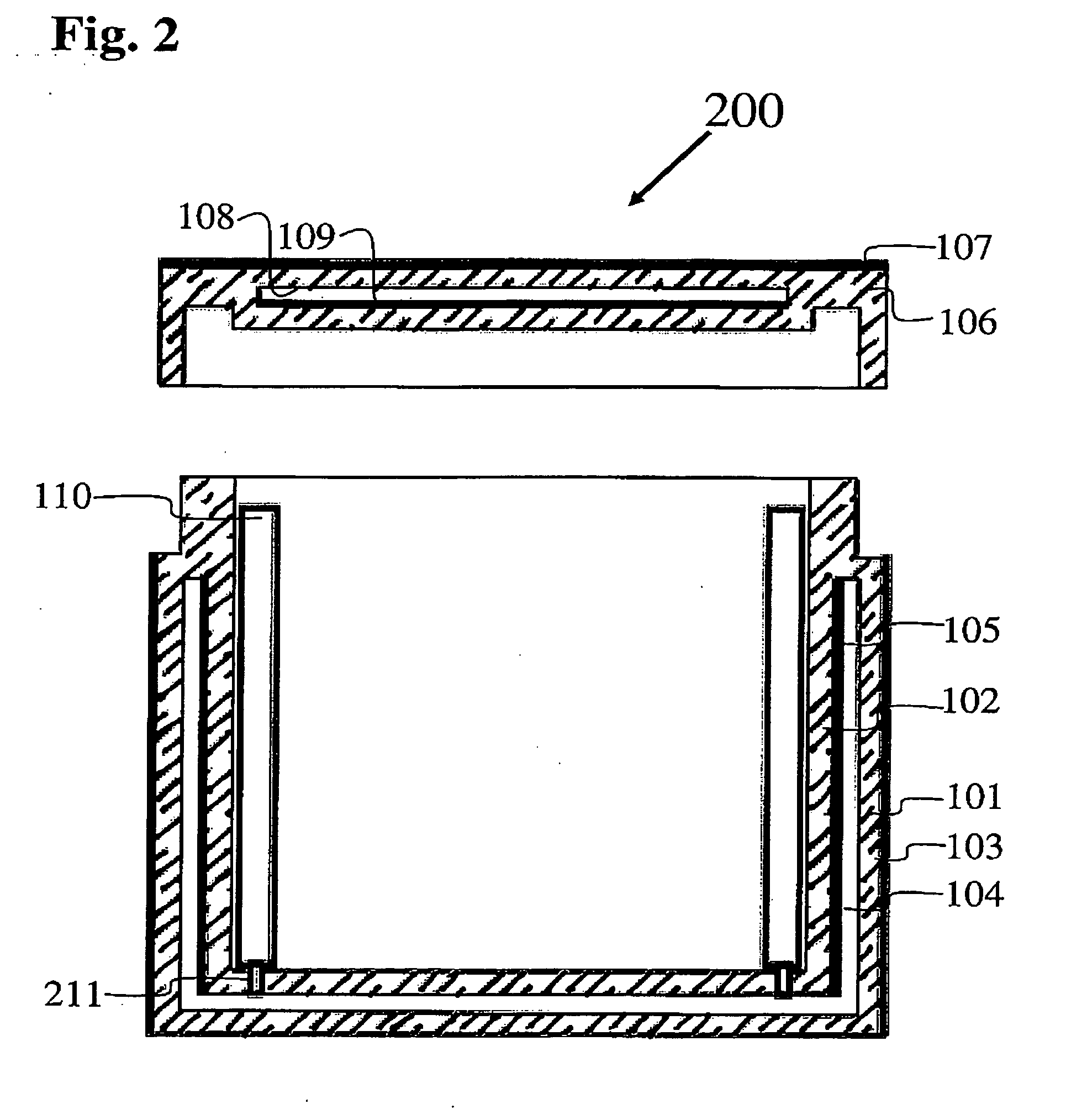

Method and apparatus for rapid thermal processing and bonding of materials using RF and microwaves

ActiveUS20070108195A1Heating fastMicrowave heating is fastSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInterconnection density

A method and apparatus for rapid and selective heating of materials using variable frequency RF and microwaves. The apparatus uses variable frequency solid state electronics as a microwave power source, a novel microwave heating head to couple microwave energy to the target materials and a match-up network to tune the frequency and impedance match between the microwave source and the load. An electronic and computer measurement and control system is employed to monitor and control the microwave heating process. The method teaches the use of inductive microwave coupling for thin conductive materials such as metal film and impurity doped silicon wafers. The method also teaches the use of capacitive microwave coupling for dielectric material such as glass and ceramics. The method further teaches the use of rapid and selective heating of heterostructure for bonding and sealing of mems and integrated circuits. The method and apparatus can provide ultra-high heating speed along with ultra-high heating temperatures for rapid thermal processing of semiconductors and other materials. It also allows the use of bonding materials with high melting temperature for strong bonding and sealing of mems and IC devices. The apparatus further provides for high interconnection density of integrated circuits as connections are made without the use of solder bumps.

Owner:TIAN YONGLAI +1

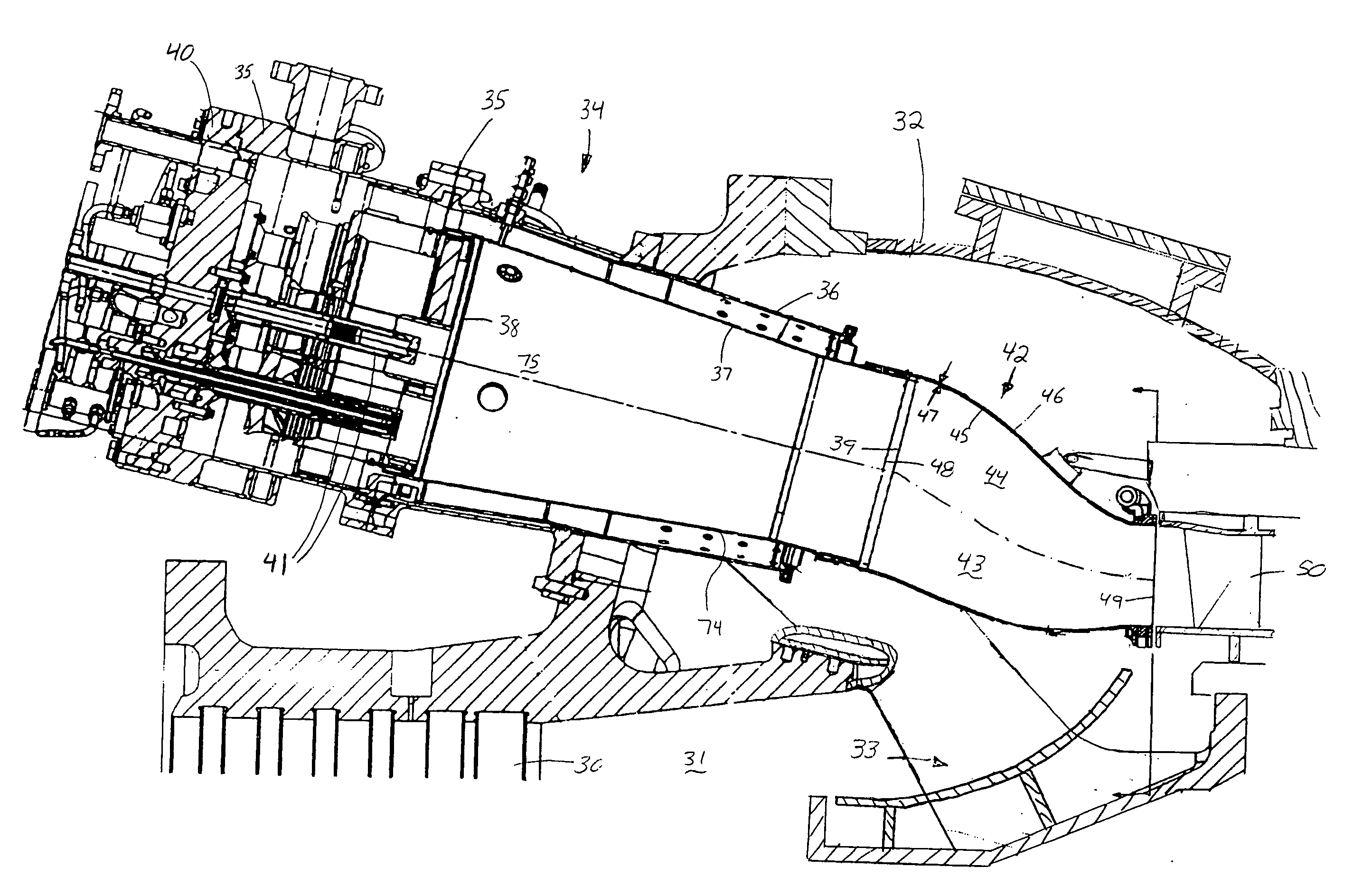

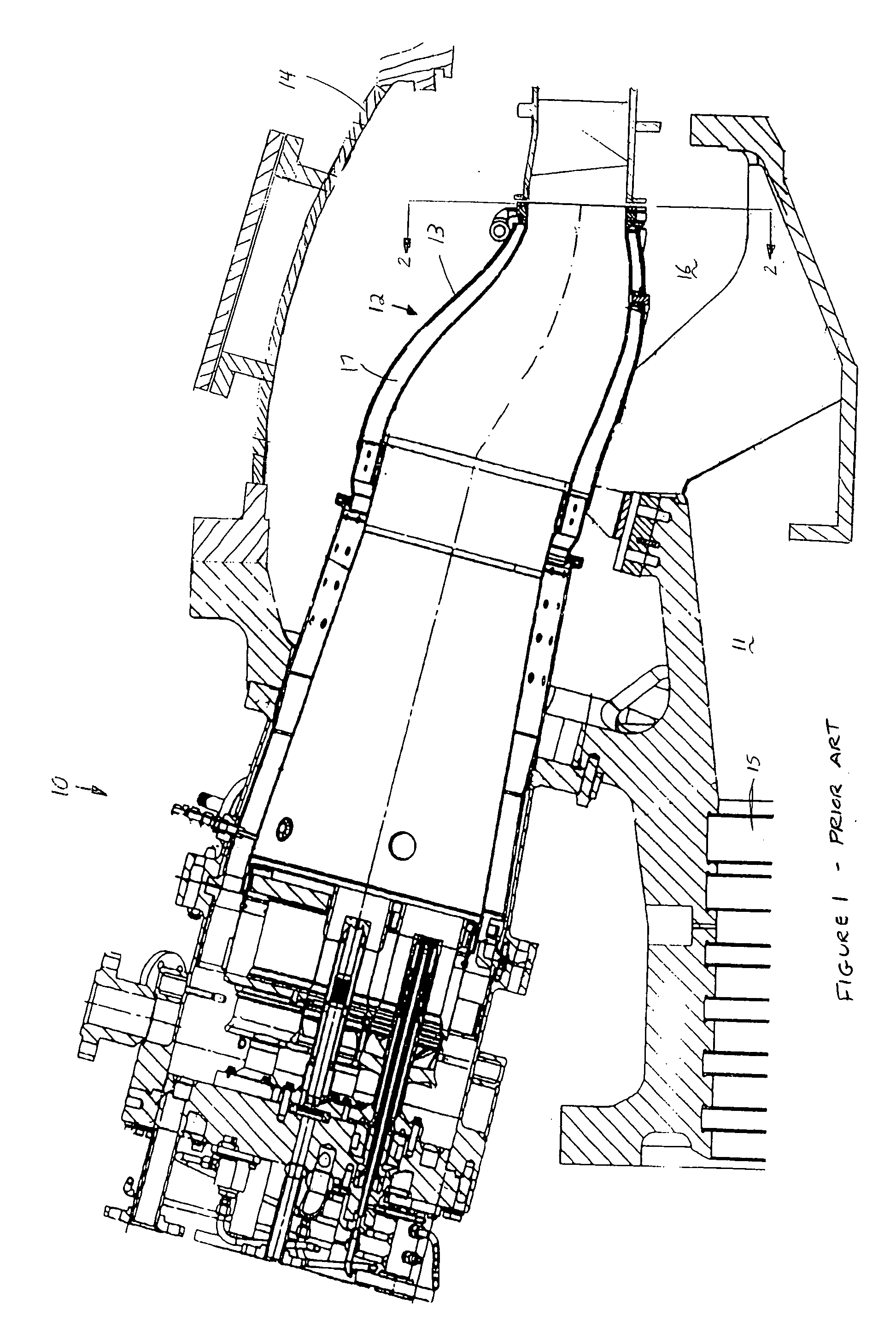

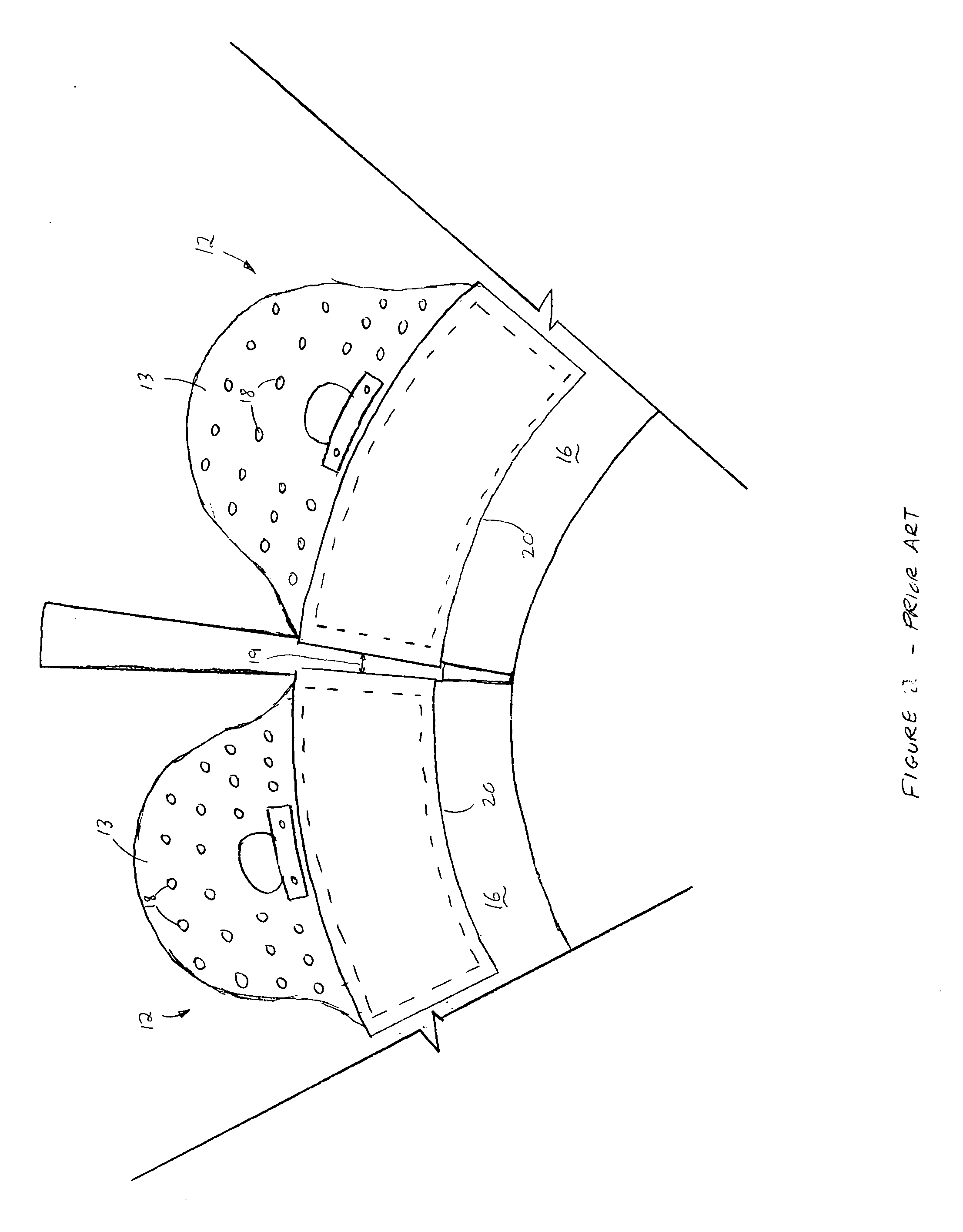

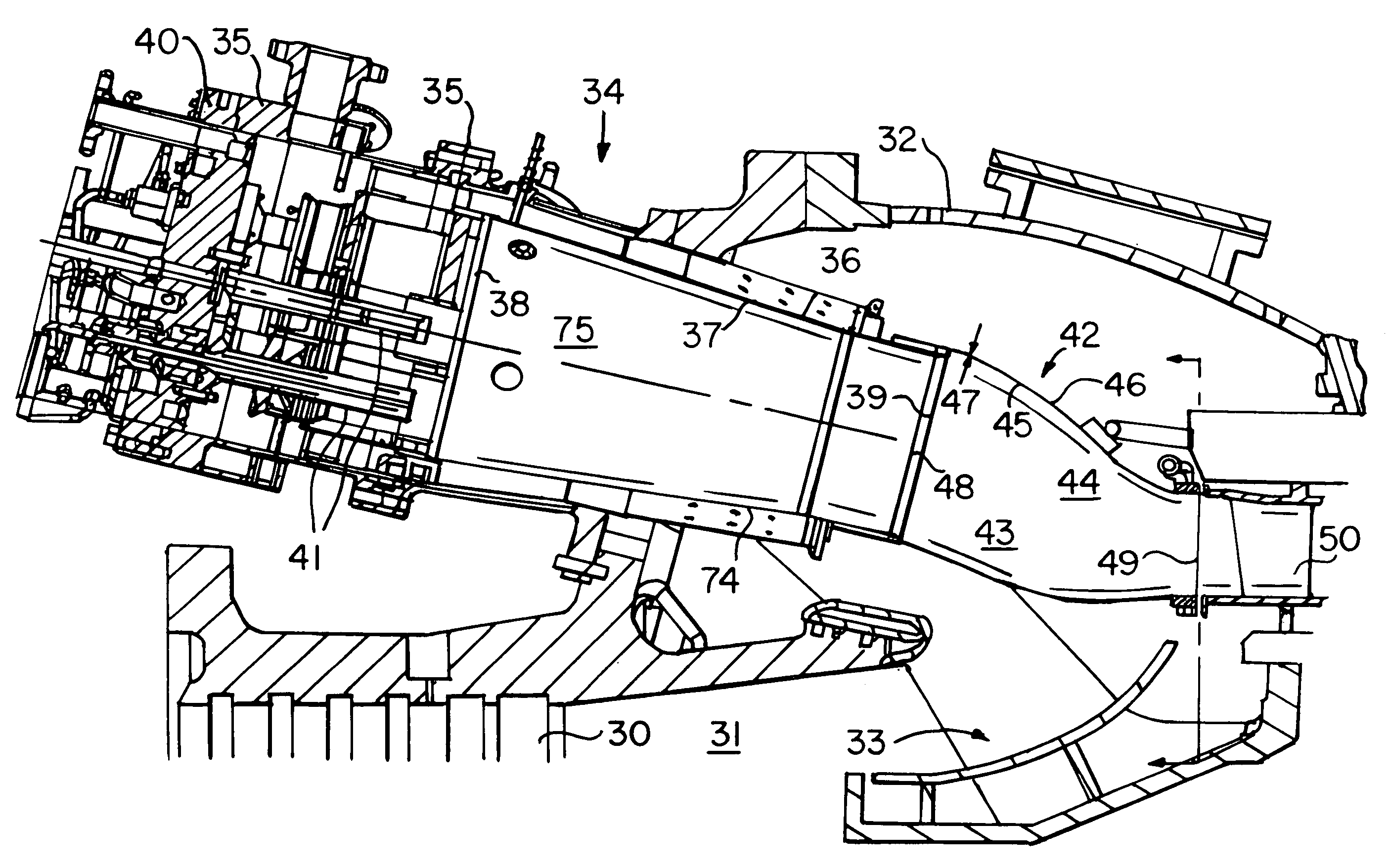

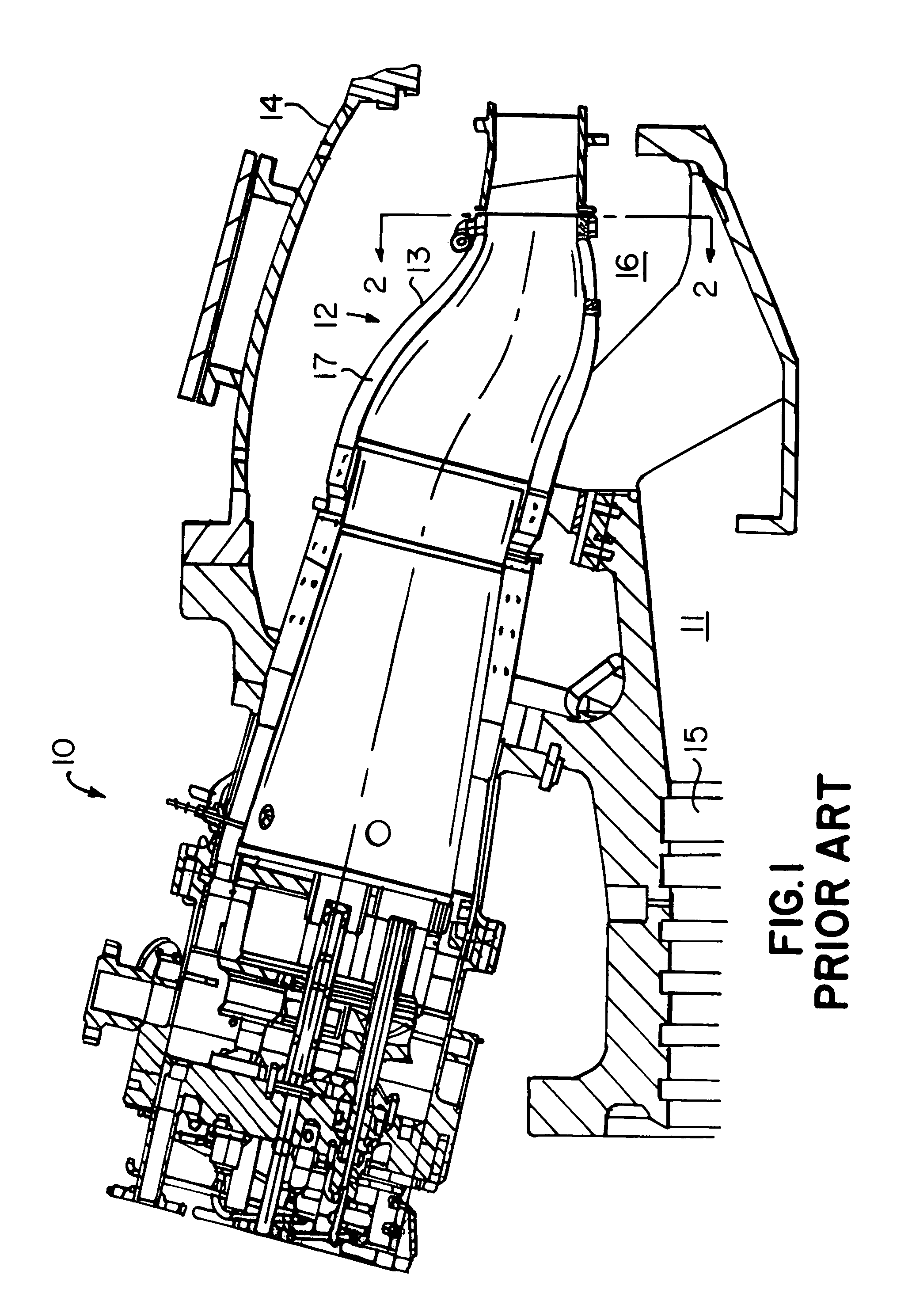

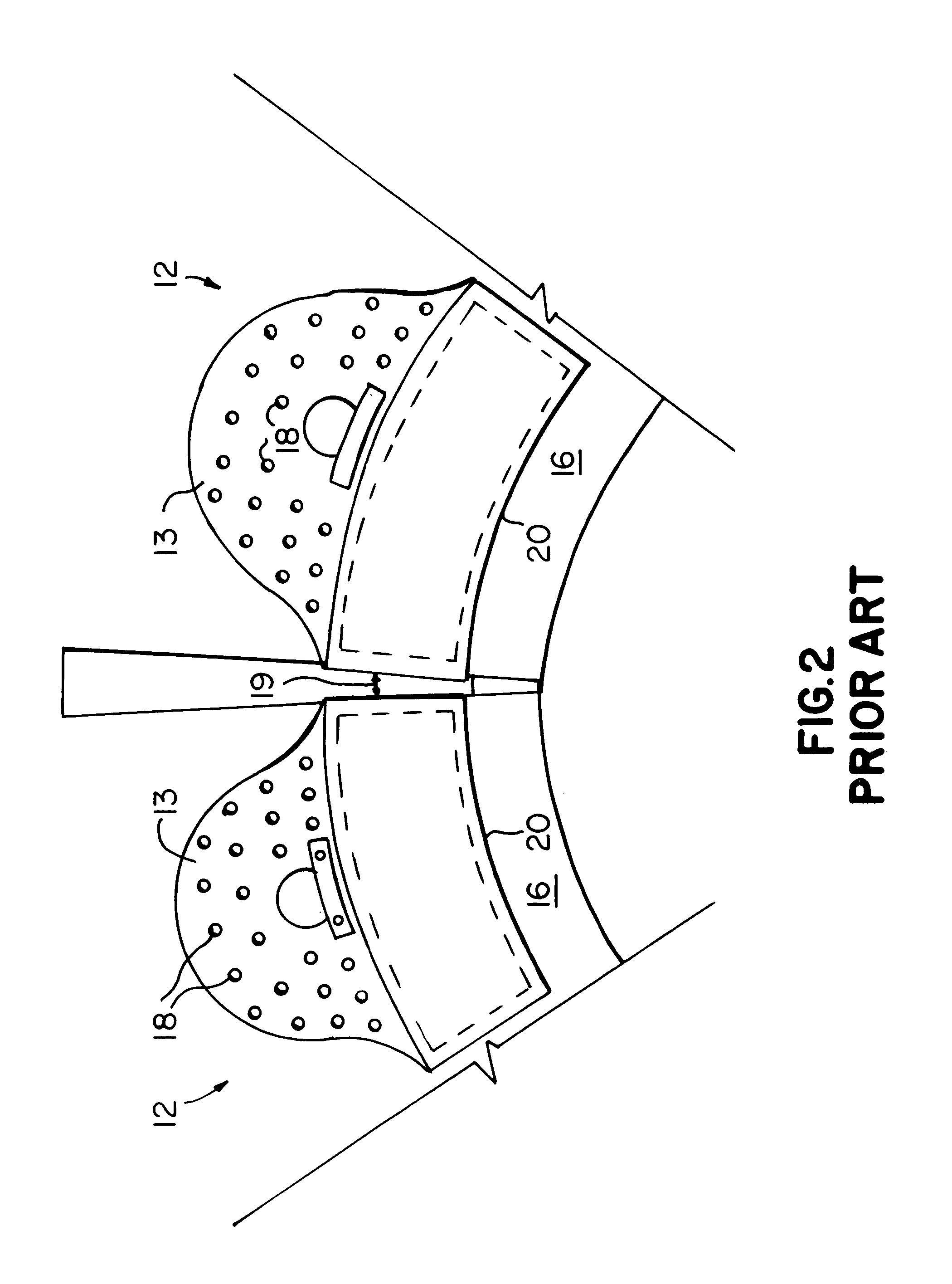

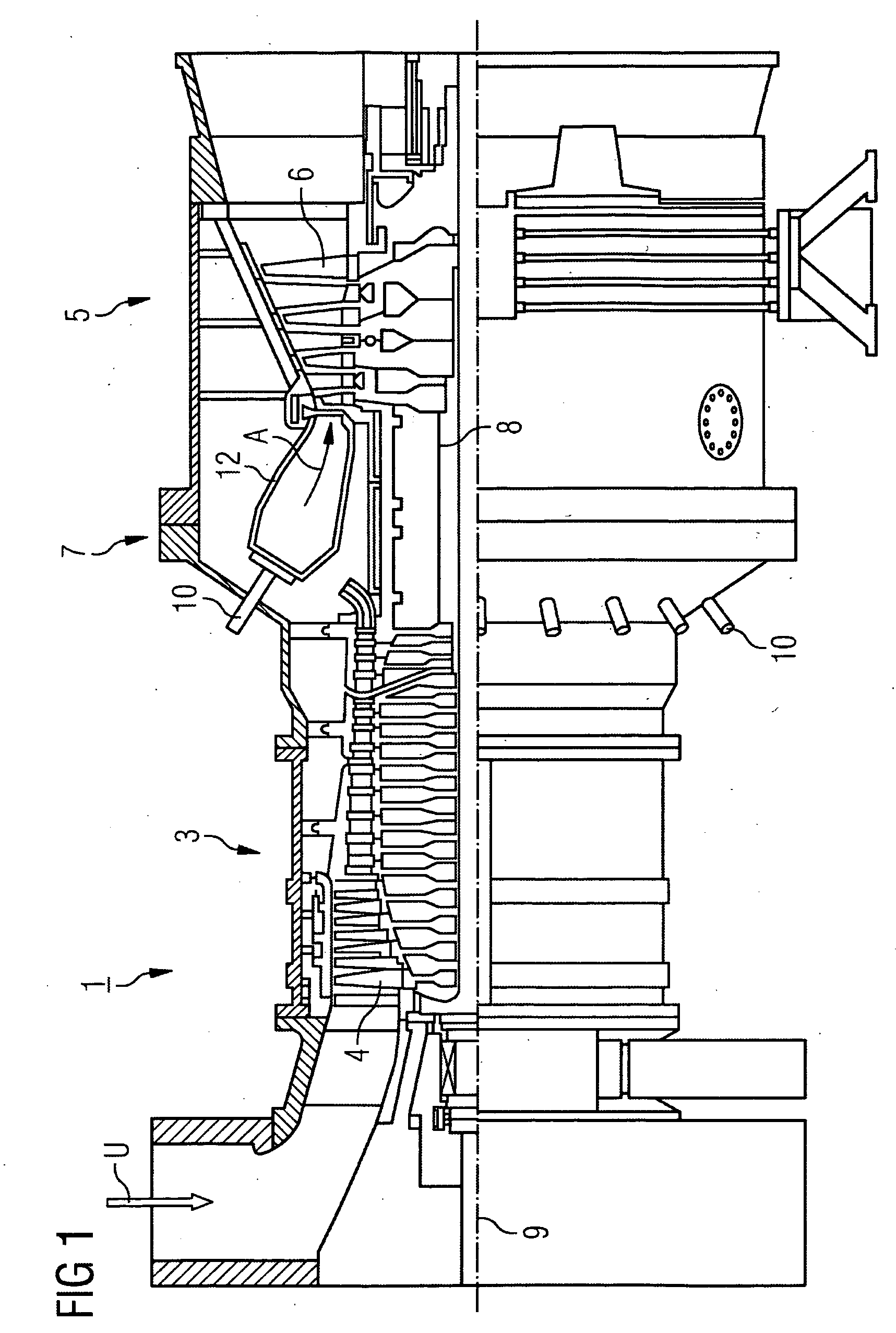

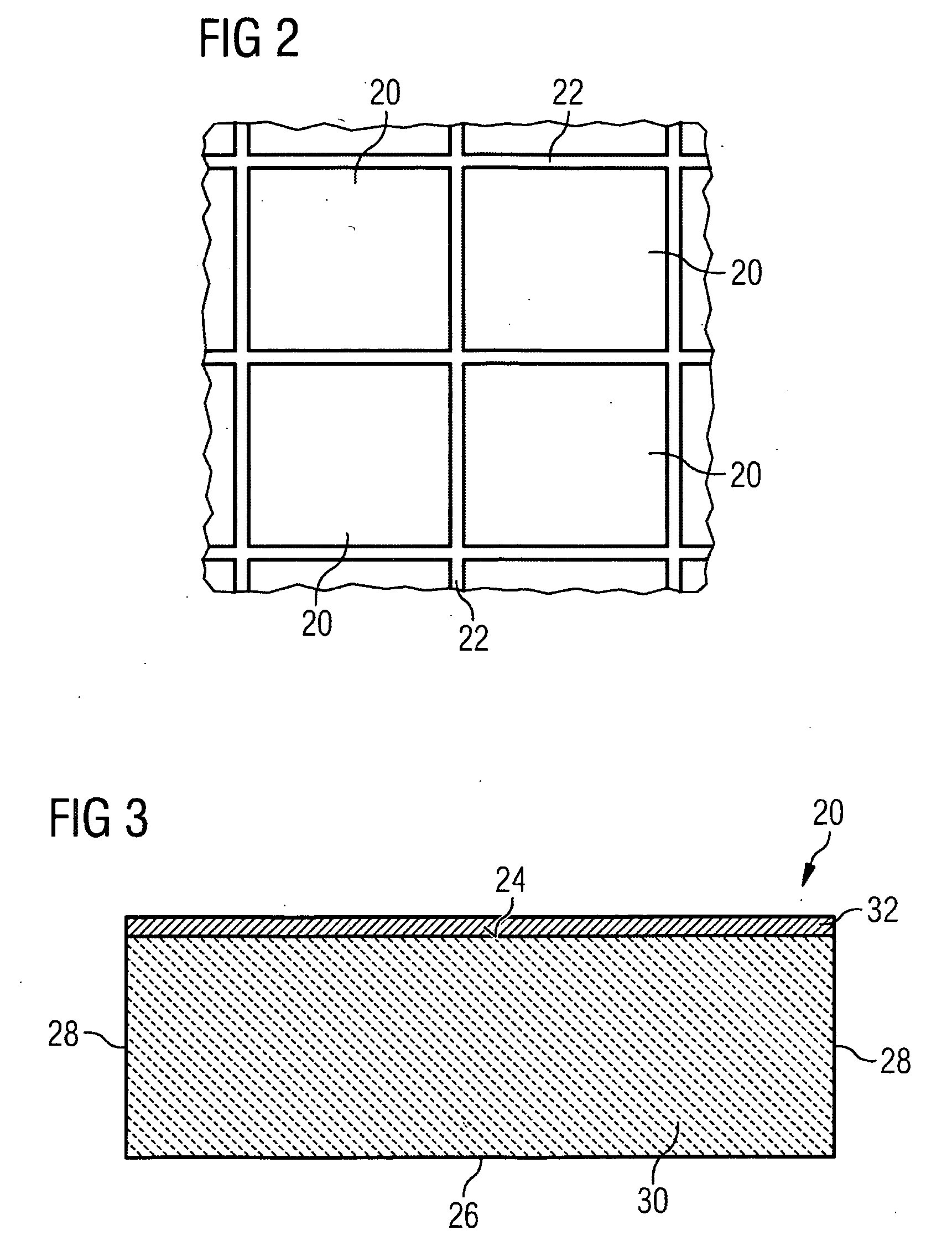

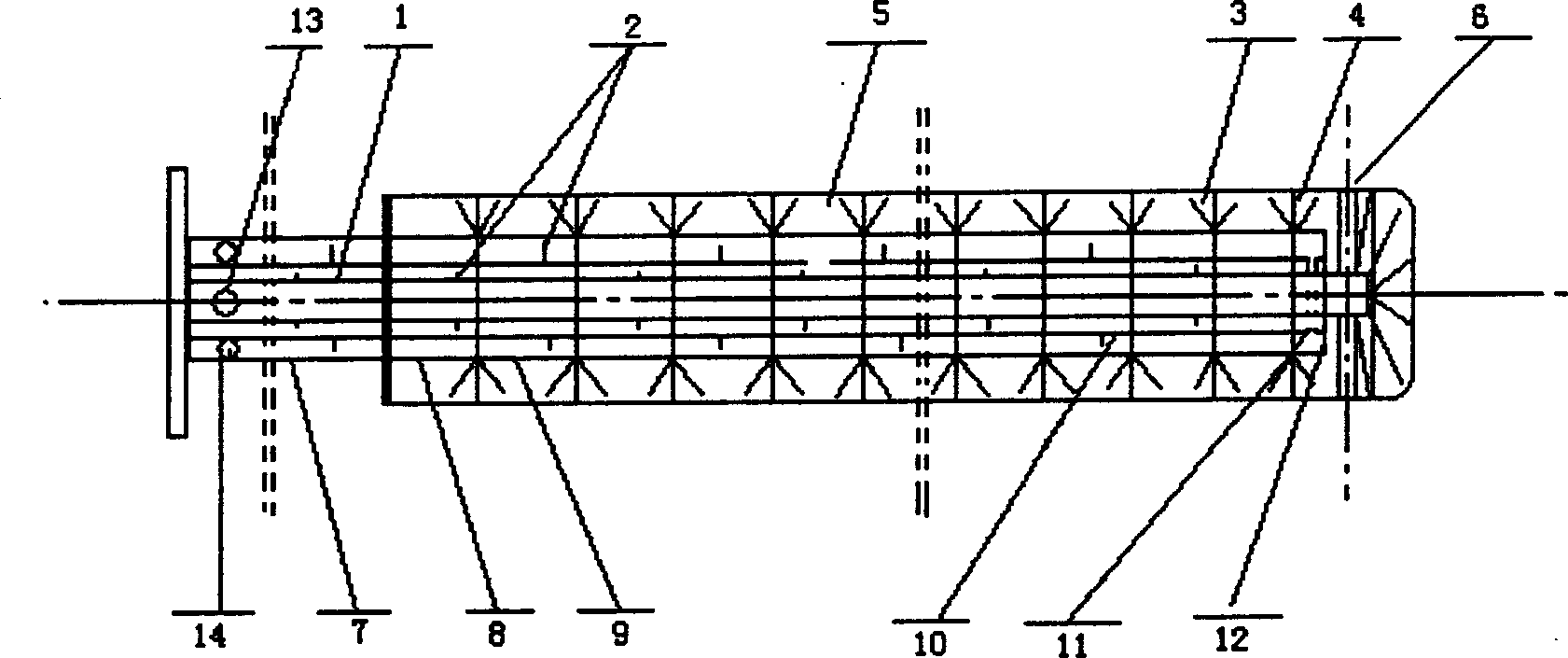

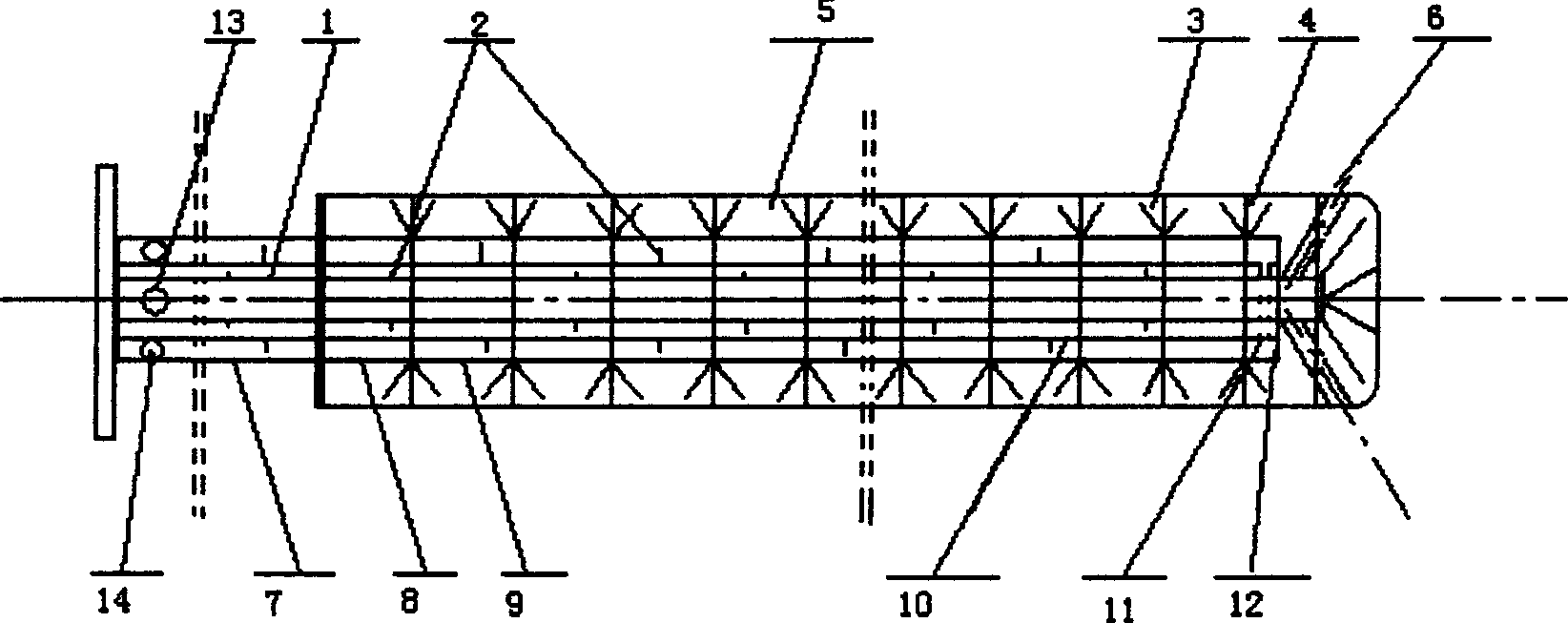

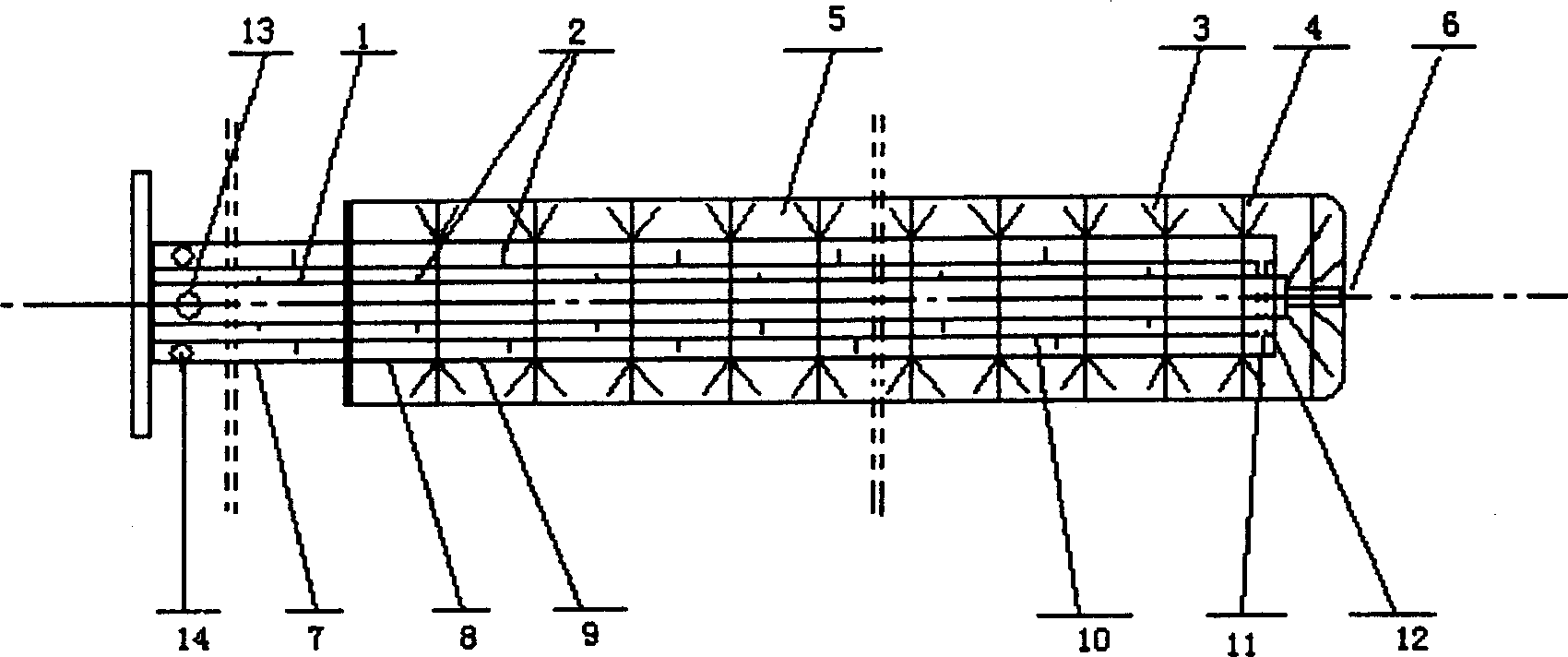

Apparatus and method for reducing the heat rate of a gas turbine powerplant

ActiveUS20050241317A1Reduce total pressure lossHigh supply pressureContinuous combustion chamberGas turbine plantsCombustion systemTurbine

The present invention provides an apparatus and method for reducing the pressure loss of air prior to entering a combustion system, such that, for a known combustion system having a predetermined pressure loss, the resulting fluid entering the turbine has a higher supply pressure that will result in more efficient turbine and increased engine output. Significant enhancements include the addition of a plurality of deflector assemblies to direct the air from a compressor outlet towards an exposed single-wall transition duct to provide direct cooling to a first panel of the transition duct.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Apparatus and method for reducing the heat rate of a gas turbine powerplant

ActiveUS7047723B2Reduce total pressure lossImprove pressure resistanceContinuous combustion chamberGas turbine plantsCombustion systemEngineering

The present invention provides an apparatus and method for reducing the pressure loss of air prior to entering a combustion system, such that, for a known combustion system having a predetermined pressure loss, the resulting fluid entering the turbine has a higher supply pressure that will result in more efficient turbine and increased engine output. Significant enhancements include the addition of a plurality of deflector assemblies to direct the air from a compressor outlet towards an exposed single-wall transition duct to provide direct cooling to a first panel of the transition duct.

Owner:ANSALDO ENERGIA SWITZERLAND AG

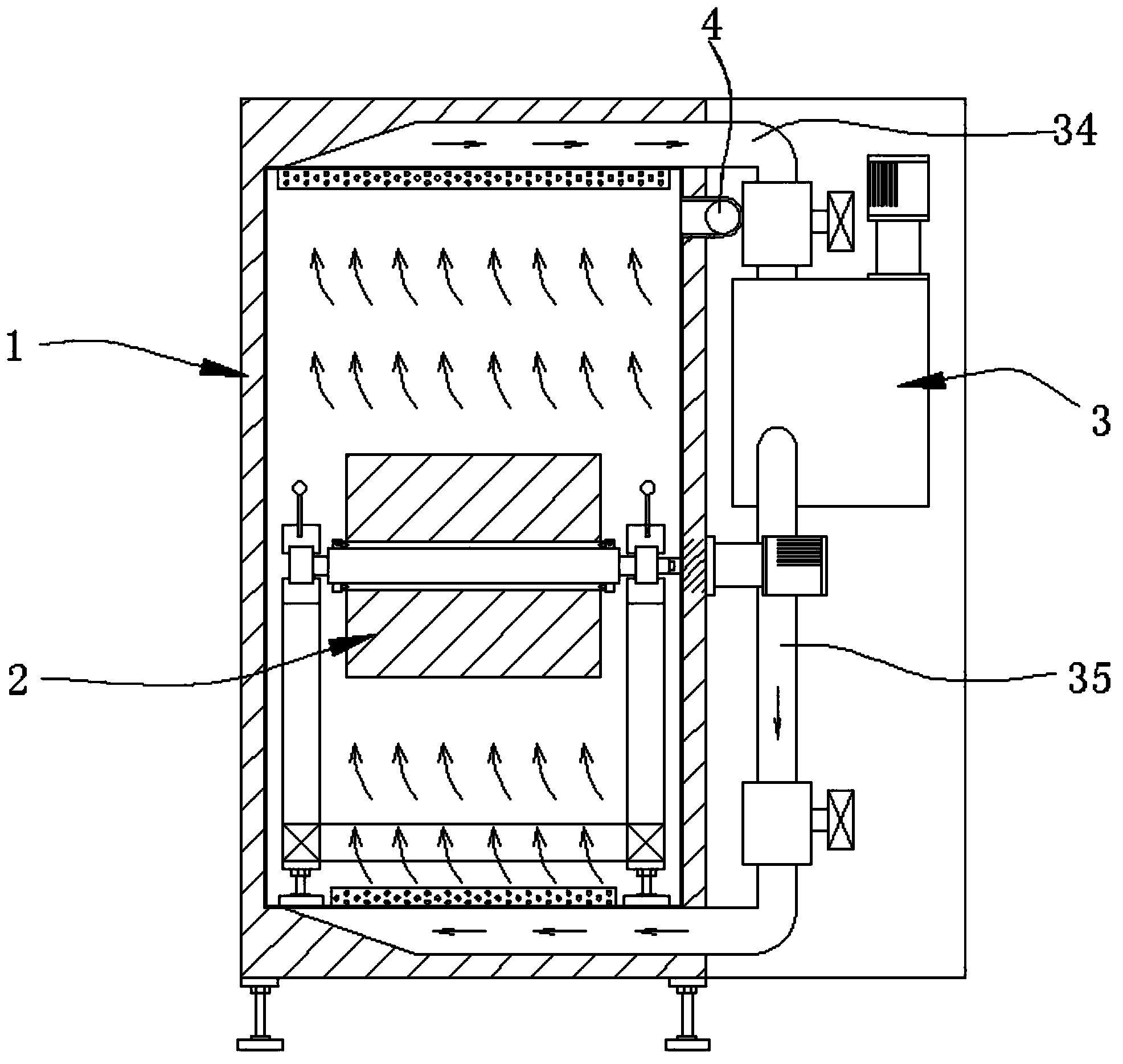

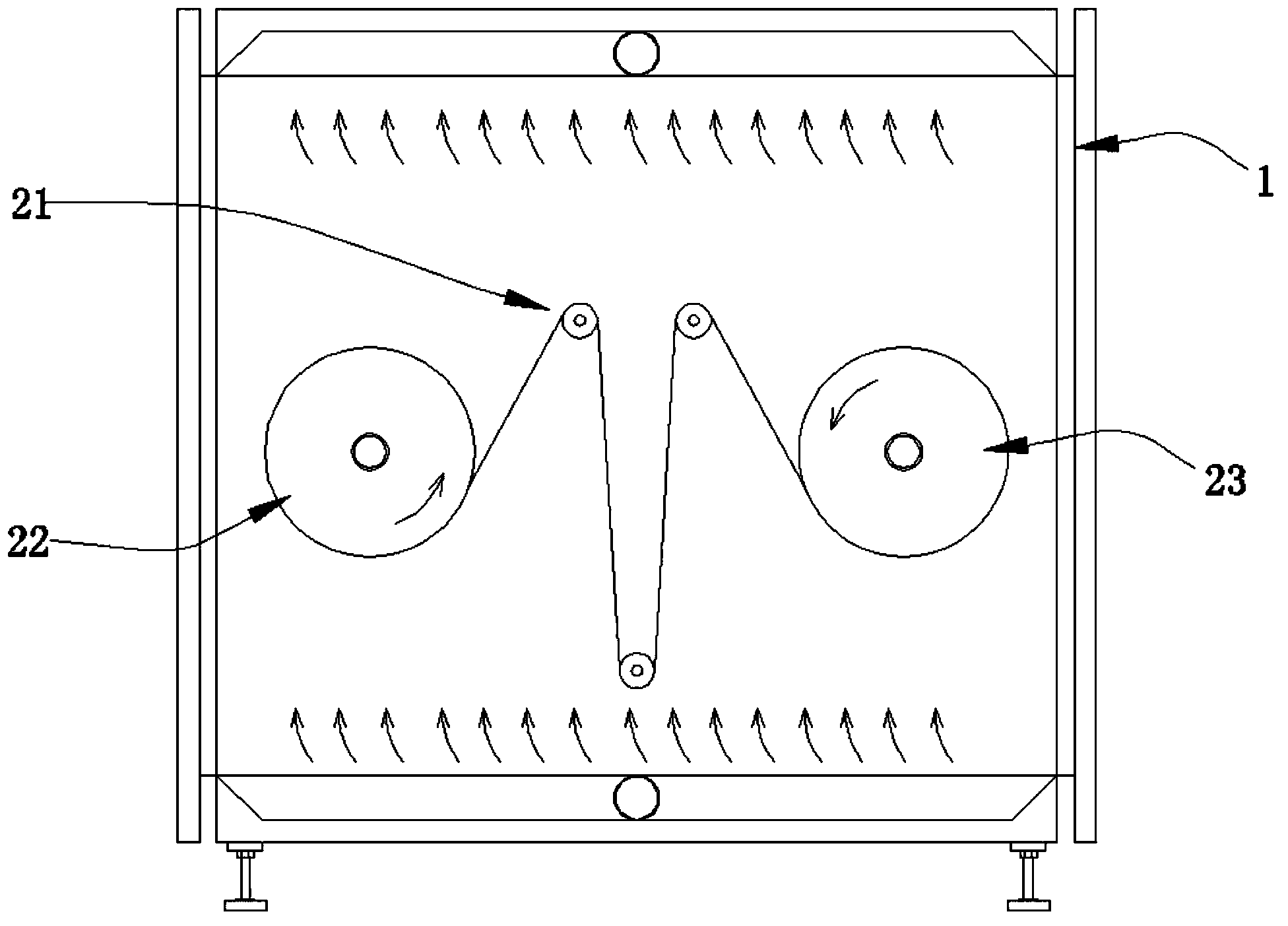

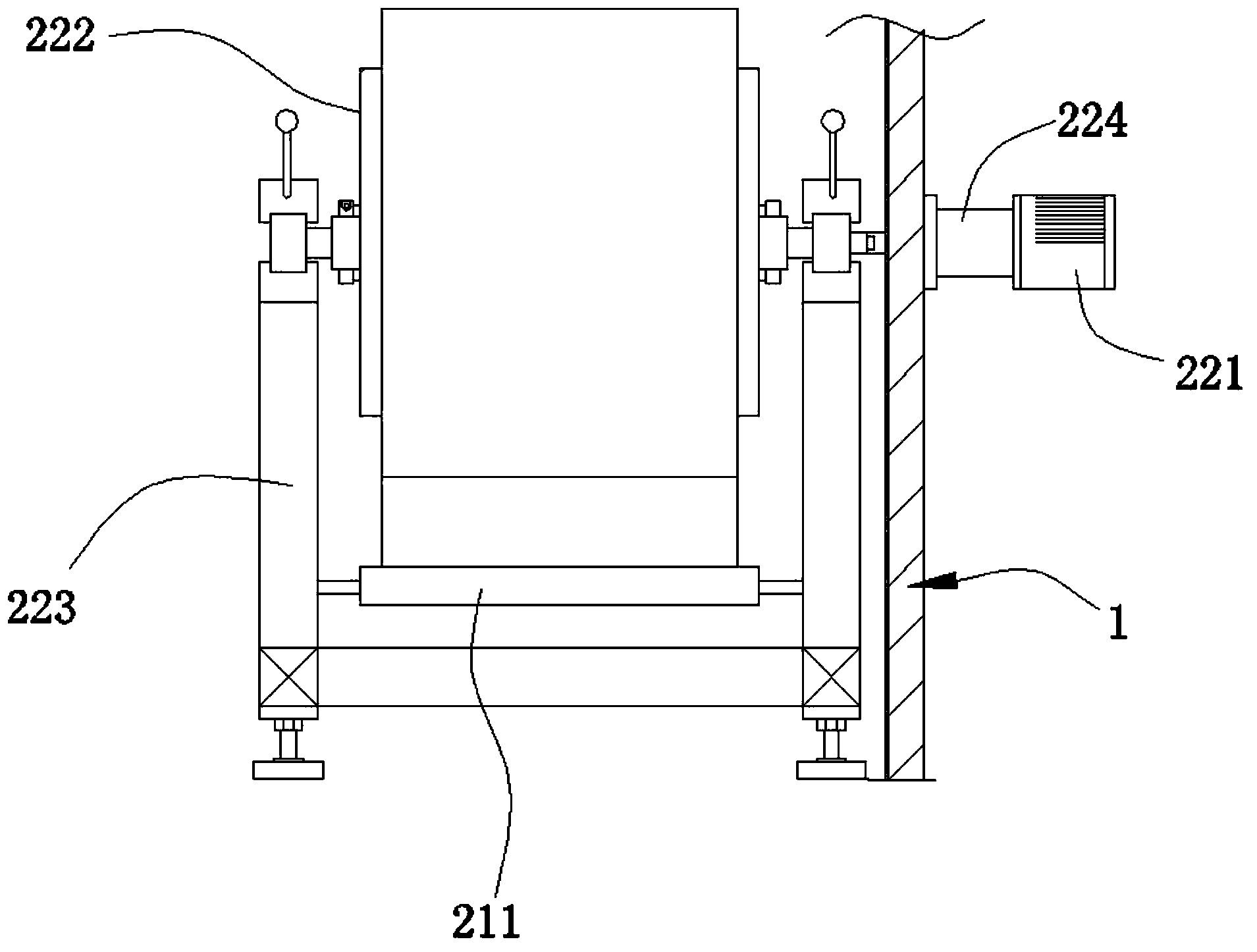

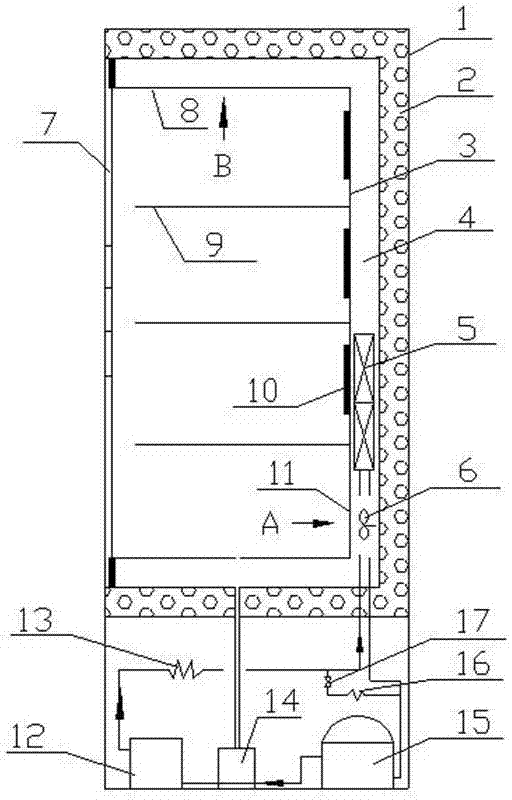

Vacuum drying oven

InactiveCN103836886AReduce heating rateFast heatingDrying using combination processesDrying machines with local agitationPower batteryNitrogen

The invention discloses a vacuum drying oven. The vacuum drying oven comprises a vacuum oven body. The interior of the vacuum oven body is at least provided with a roll material winding and unwinding mechanism. The outer sidewall of the vacuum oven body is at least provided with a wind-powered light emitting device. The vacuum drying oven is simple in structure and reasonable in design; roll materials in the vacuum oven body can be unwound for baking through the roll material winding and unwinding mechanism, so that baking time is effectively shortened, and baking quality is improved. Meanwhile, hot air is delivered to an inner cavity of the vacuum oven body through the wind-powered light emitting device to form a dynamic loop for circulation heating, the heat cycle is fast, the temperature rise rate of the vacuum drying oven can be increased, good temperature uniformity can also be acquired, so that a drying effect is further improved, and product quality is guaranteed. Moreover, nitrogen which has a drying effect can further be led in through a nitrogen pipe, water is pumped out through a vacuum tube, and therefore a breath type drying effect is formed. In this way, drying time is substantially shortened, production efficiency is enhanced, and the vacuum drying oven can be widely popularized and especially applicable to the power battery industry.

Owner:陈伟陵

Madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric

InactiveCN1810889AReduce the chance of occurrenceImprove uniformityNatural dyesDyeing processSodium bicarbonatePhosphate

The present invention is madder dye extracting process and its usage in dyeing mercerized wool and mercerized wool fabric. The madder dye extracting process includes the following steps: washing madder root as material, fermentation at 20-50 deg.c for 20í½30 hr, and extracting madder dye through heating at 70-90 deg.c and condensing evaporated gas for 0.5-1.5 hr. The dyeing process includes two steps: the first step of ecological pre-treatment of mercerized wool or mercerized wool fabric in treating liquid comprising sodium bicarbonate, coconut oil biethyl alcohol acrylamine as detergent and neutral organic phosphate in certain proportion at 20-60 deg.c and bath ratio of 1:20-50 for 10-60 min; and the second step of harmless mordant dyeing of the pre-treated mercerized wool or mercerized wool fabric. The present invention has rich dye resource, good dyeing effect and less damage of mercerized wool.

Owner:HAILAN GRP +1

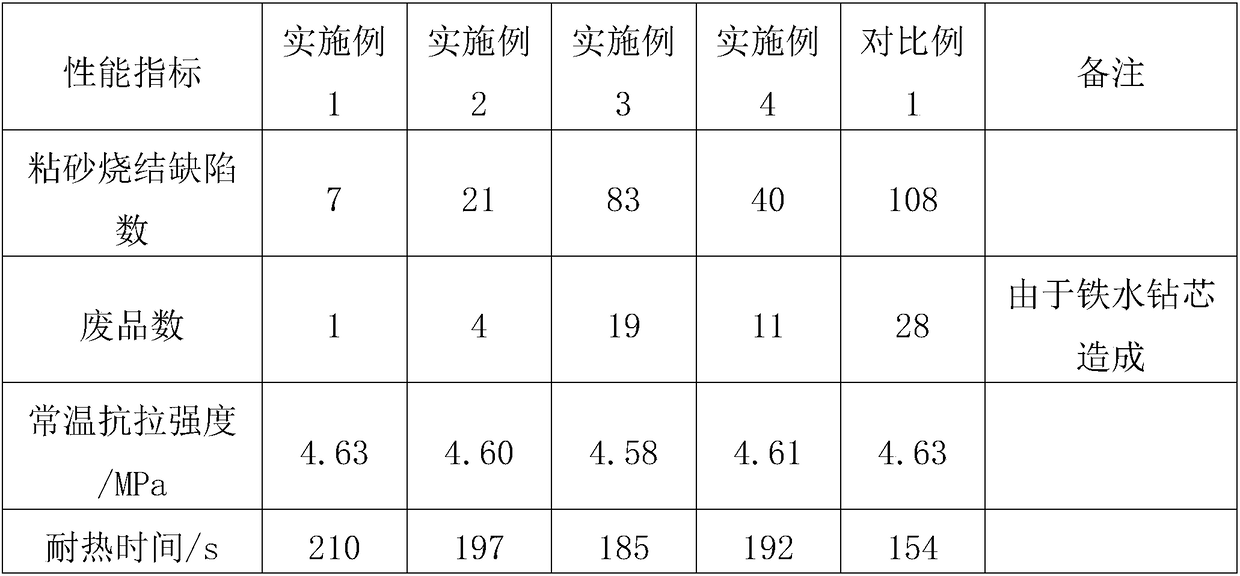

High-temperature resisting precoated sand for casting

InactiveCN108127073AReduce heating rateSlow down decompositionFoundry mouldsFoundry coresHeat resistanceDecomposition

The invention relates to the field of precoated sand, in particular to high-temperature resisting precoated sand for casting. The precoated sand is prepared from the following raw materials, by weight, of 97-98 parts of crude sand, 2-2.5 parts of phenolic resin, 0.3-0.4 part of urotropine, 0.15-0.2 part of calcium stearate, and 0.1-0.3 part of hollow ceramic micro-beads. According to the high-temperature resisting precoated sand for casting, the hollow ceramic micro-beads are added into the raw materials, because the hollow ceramic micro-beads have high temperature resistance and high heat resistance performance, the temperature rising speed and the decomposition speed of sand cores are decreased when molten iron is poured into the sand cores of the precoated sand, and the molten iron is effectively prevented from permeating into the sand cores, so that sand adhering of a casting is reduced, the number of defects of sand-adhering sintering is decreased significantly, and the rate of finished products of the casting is increased greatly.

Owner:LIUZHOU LIUJING TECH CO LTD

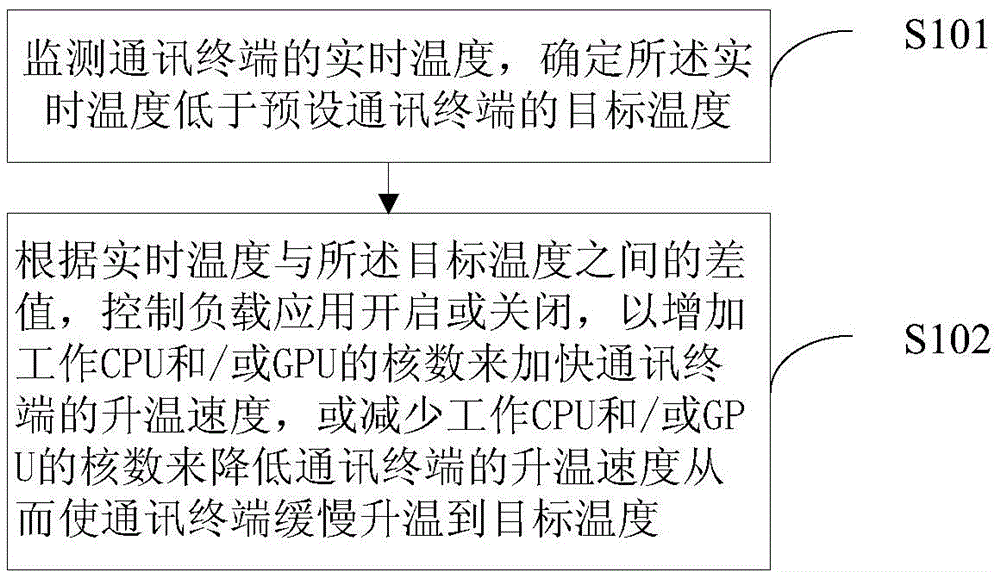

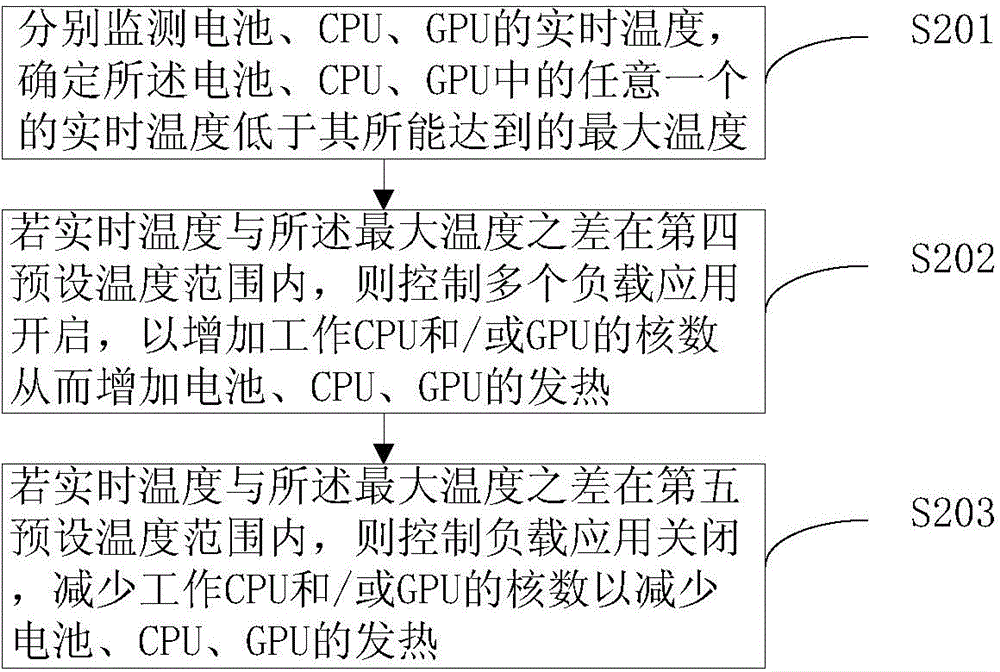

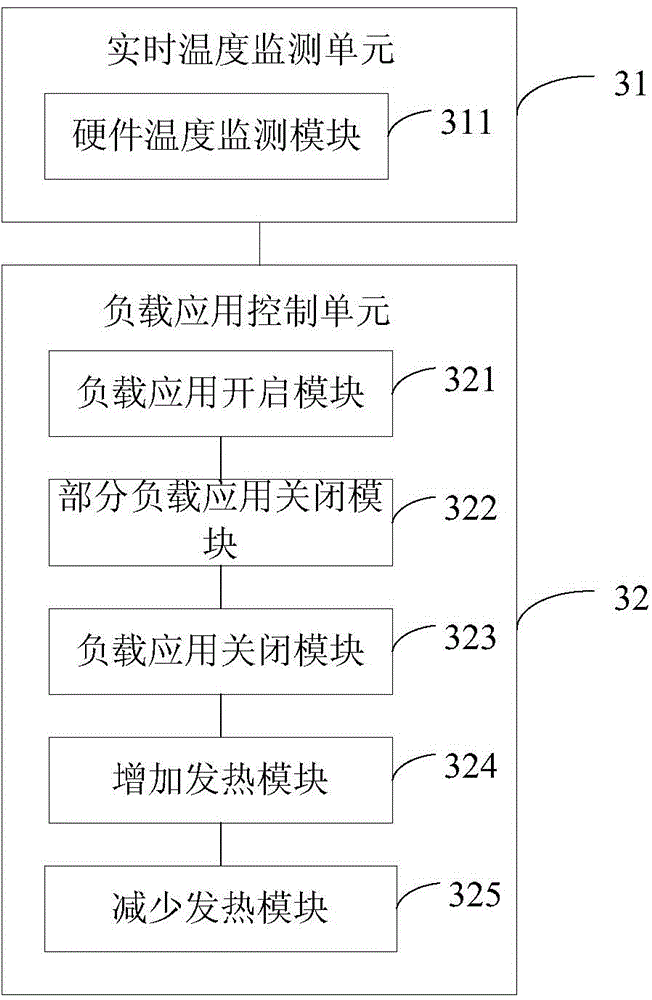

Communication terminal temperature control method and device

ActiveCN104536483AFast heatingReduce heating rateTemperature control using electric meansTemperature controlComputer terminal

The invention relates to the technical field of communication, in particular to a communication terminal temperature control method and device. According to the method and device, the real-time temperature of a communication terminal is monitored, it is determined that the real-time temperature is lower than the target temperature of the preset communication terminal; a load application is controlled to be opened or closed according to the difference value between the real-time temperature and the target temperature, the temperature rising speed of the communication terminal is increased by increasing the core number of a working CPU and / or a working GPU, or the temperature rising speed of the communication terminal is reduced by reducing the core number of the working CPU and / or working GPU so as to enable the temperature of the communication terminal to rise to the target temperature slowly. The load application is controlled to be opened or closed by monitoring the difference value between the real-time temperature and the target temperature of the communication terminal so as to increase or reduce the temperature rising speed of the communication terminal, high-temperature and constant-temperature control of the communication terminal is achieved through utilization of waste gas heat, and the heating bag function is achieved.

Owner:SHANGHAI ZHUO YOU NETWORK TECH

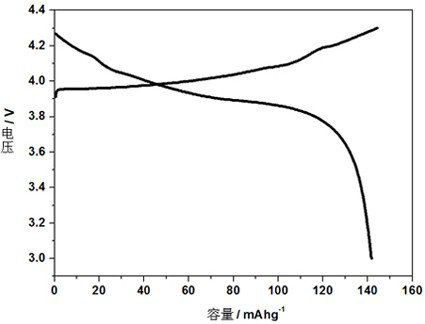

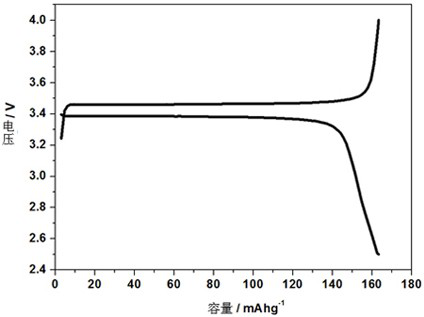

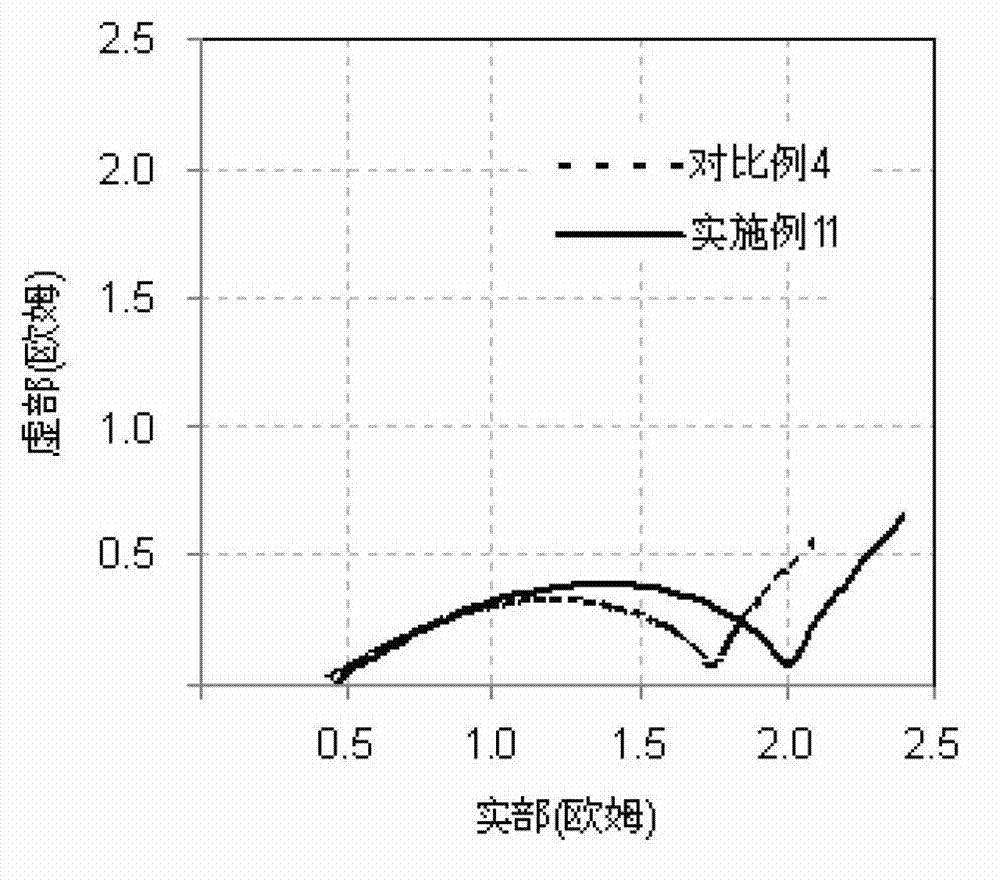

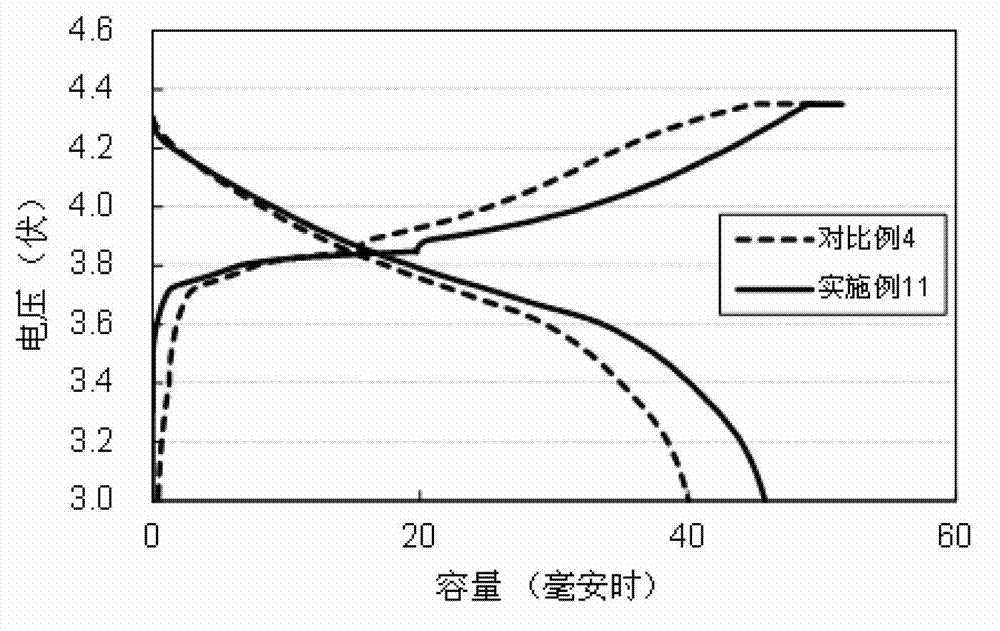

High-safety solid-state electrolyte, preparation method and application thereof

ActiveCN111969245AEasy to makePreparation non-toxicSolid electrolytesLi-accumulatorsIsocyanatePlasticizer

The invention relates to a high-safety solid-state electrolyte and a preparation method thereof, and application in a lithium secondary battery. According to the invention, a solid-state electrolyte precursor solution comprises a lithium salt, an isocyanate-containing compound and a hydroxyl-containing polymer monomer, a solid-state electrolyte is obtained by polymerizing the precursor solution, the polymerization temperature ranges from 20 DEG C to 80 DEG C, the solid-state electrolyte precursor solution further comprises one or more of a plasticizer, an active monomer, an initiator and a catalyst, and the solid-state electrolyte contains polymerizable groups, and can be subjected to a polymerization reaction at a temperature higher than 100 DEG C to form a polymer with a cross-linked network structure, so that the lithium battery does not generate internal short circuit under extremely high temperature conditions such as heat abuse and the like, and the safety performance of the lithium battery is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

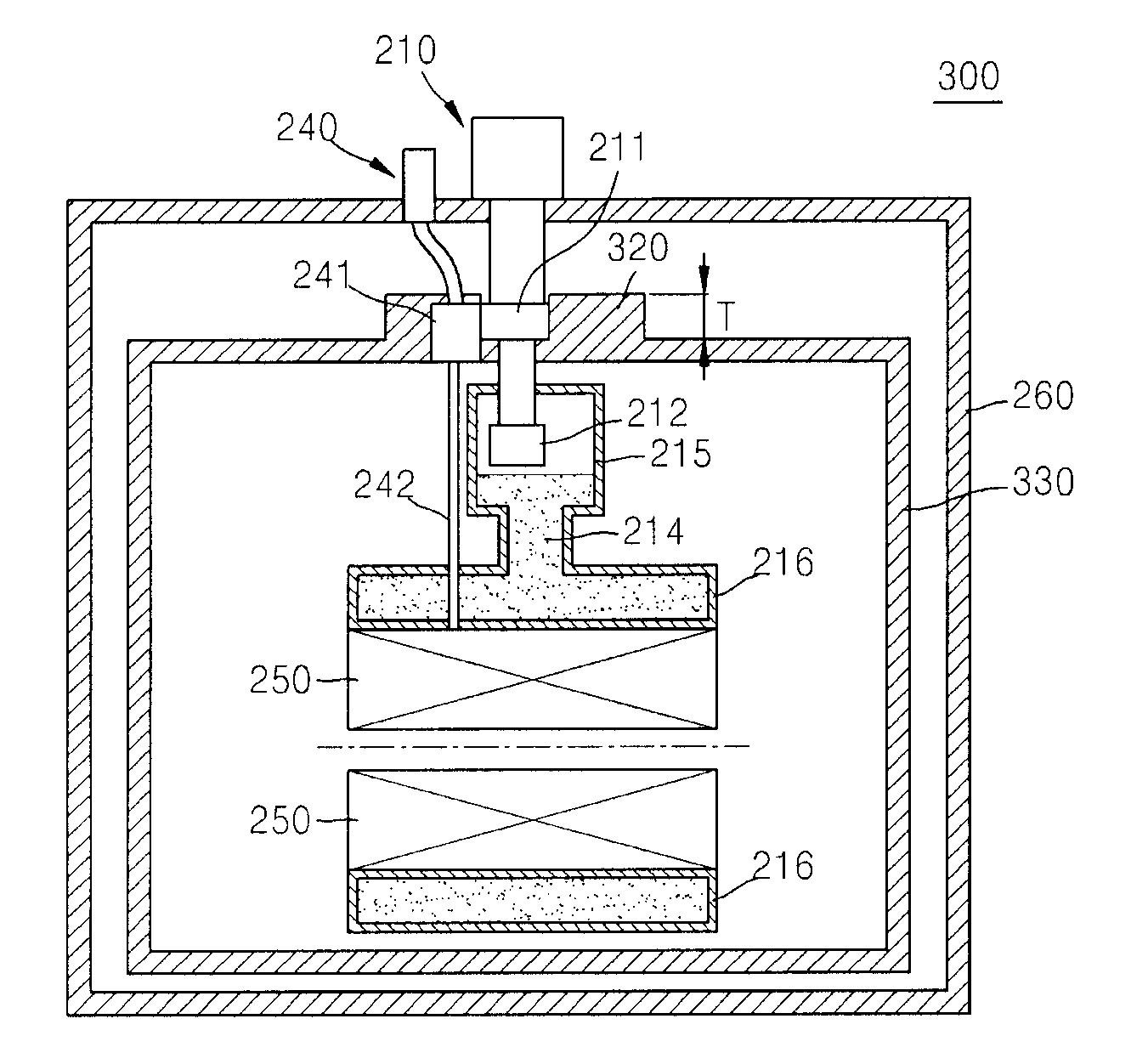

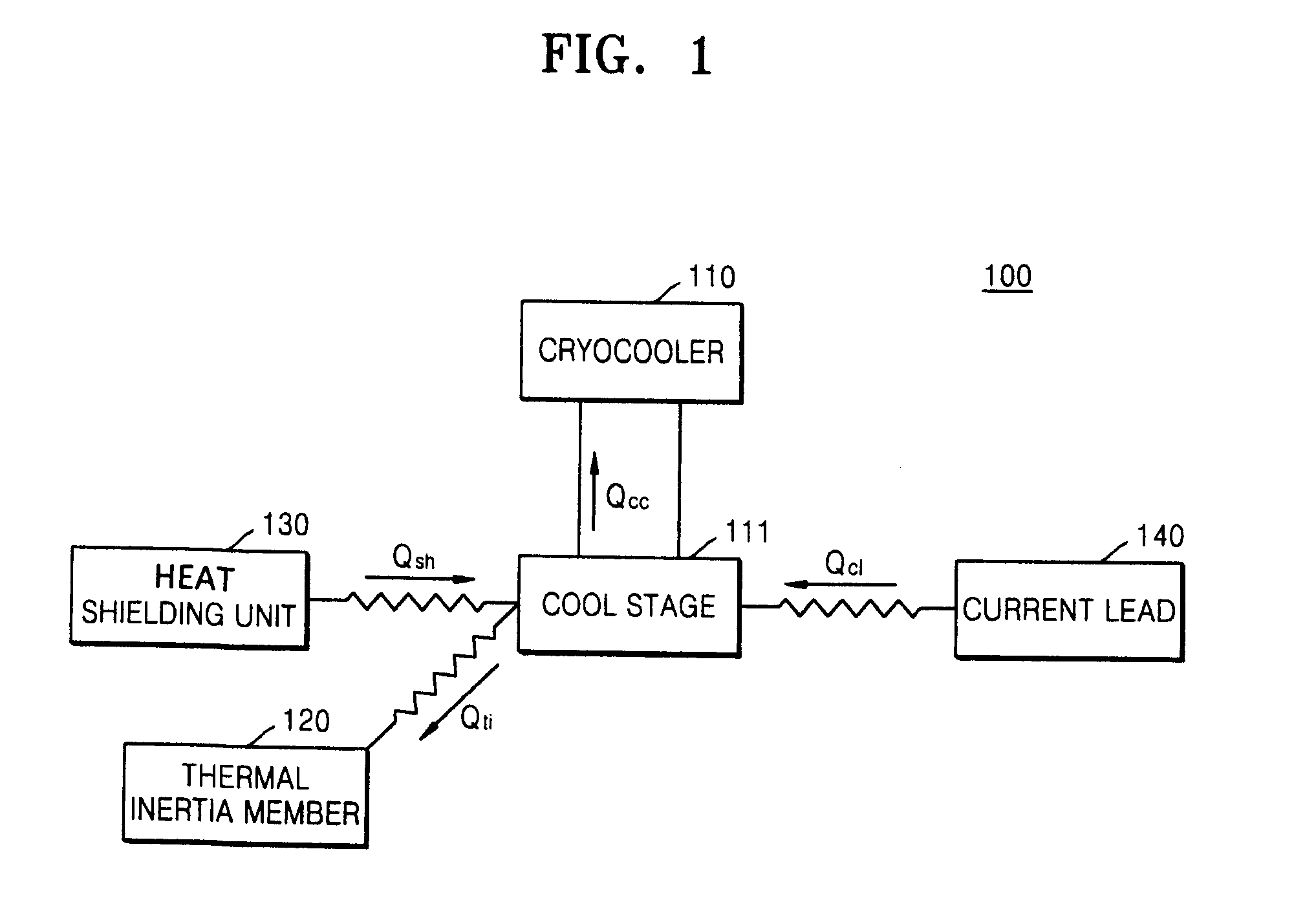

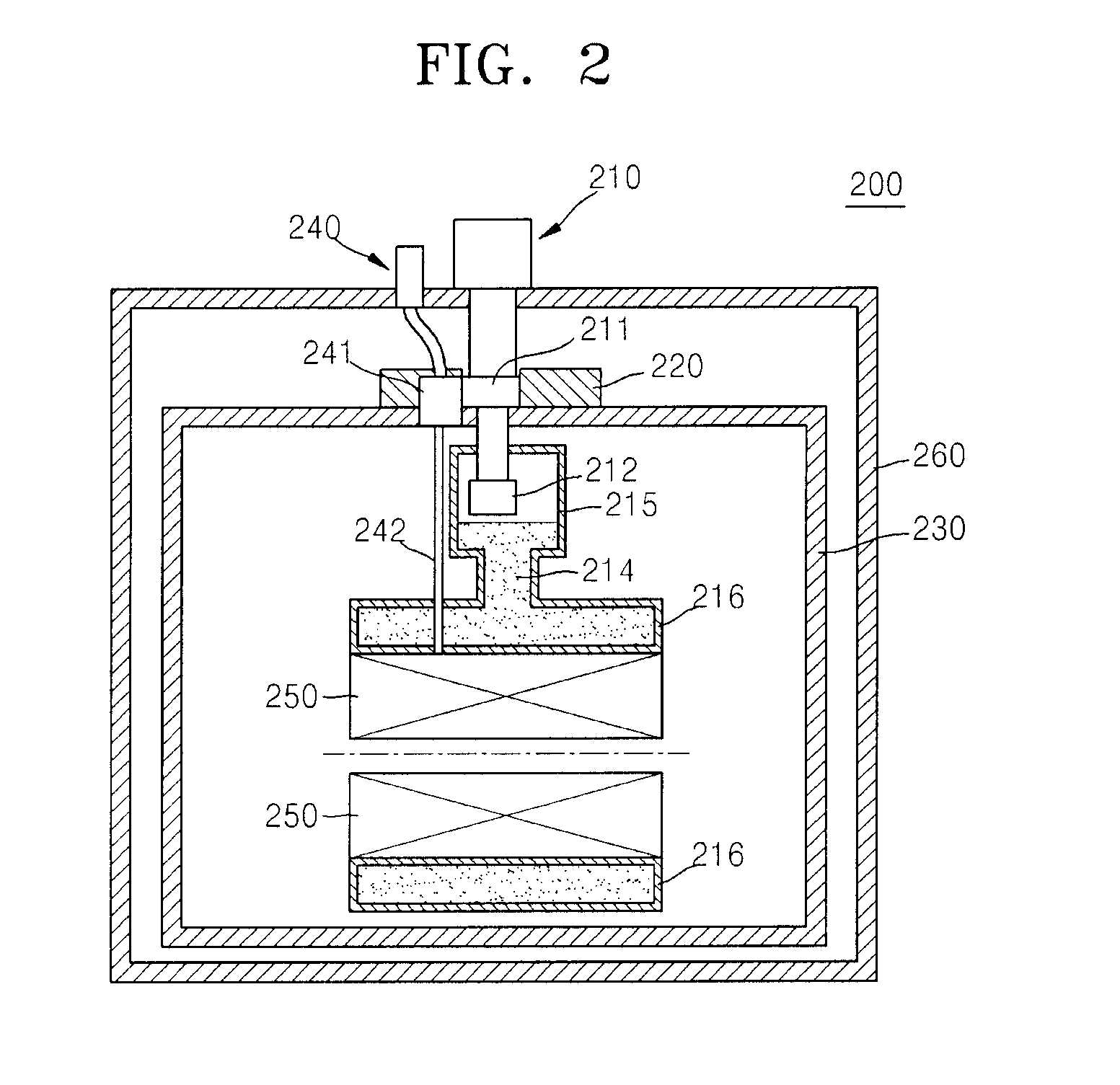

Cryocooler system and superconducting magnet apparatus having the same

InactiveUS20130203603A1Lower temperature riseRate of temperature increase decreaseCompression machinesMagnetsSuperconducting CoilsEngineering

A cryocooler system and a superconducting magnet apparatus having the cryocooler system include a cryocooler having a cool stage that cools a heat shielding unit and a thermal inertia that thermally contacts the cool stage of the cryocooler and has a high heat capacity. The cryocooler system reduces a temperature-increasing rate in a current lead by using the thermal inertia member when the temperature in the current lead is increased due to heat generated when an electrical current applied to a superconducting coil is ramped-up or ramped-down.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for dyeing mercerizing wool or mercerizing wool fabric by yellow chrysanthemum flower dye

InactiveCN101117775AReduce the chance of occurrenceImprove uniformityDyeing processSodium bicarbonatePhosphate

The present invention relates to a method of dyeing mercerized wool or mercerized wool fabrics with yellow chrysanthemum paint, which is taken as the paint, and the dyeing method is divided into two steps including ecological pretreatment and subsequent innocuous mordant dyeing: the first step, treatment conditions: baking soda of 1-3 percent of cloth weight, 1-5 percent coconut oil diethanol amide as detergent of 1-5 percent of cloth weight, 0.2-1.0g / L neutral phosphate, temperature 20-60 DEG C, duration 10-60min, bathing ratio 1 to 20-50; the second step, mordant dyeing: the mercerized wool or mercerized wool fabrics with ecological pretreatment is treated with mordant front dyeing, single bathing or post dyeing. The yellow chrysanthemum resources are rich, easy for expanding plantation, with sound dyeing and less damage to mercerized wool during dyeing.

Owner:HAILAN GRP +1

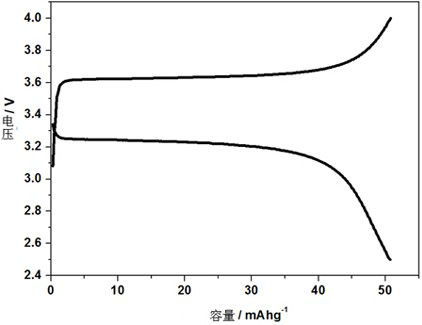

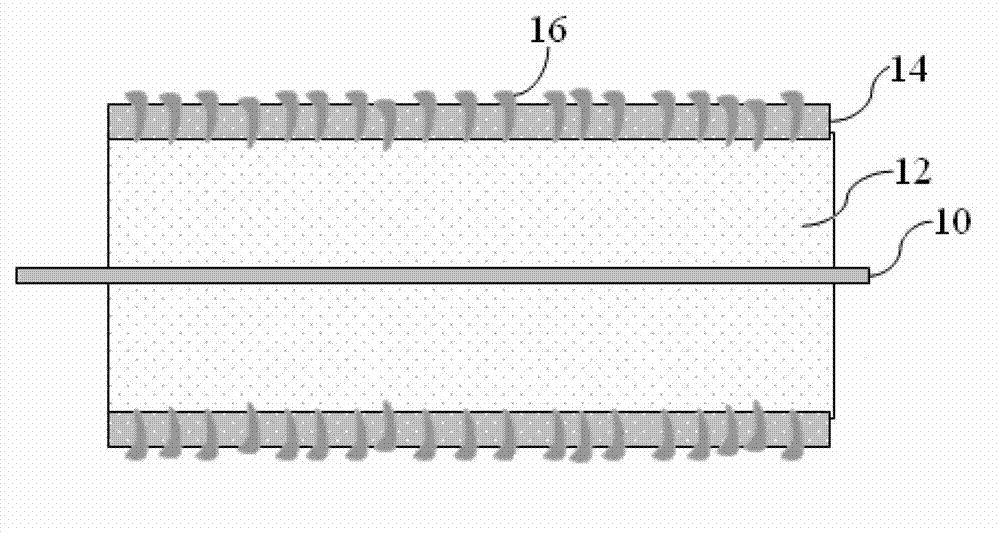

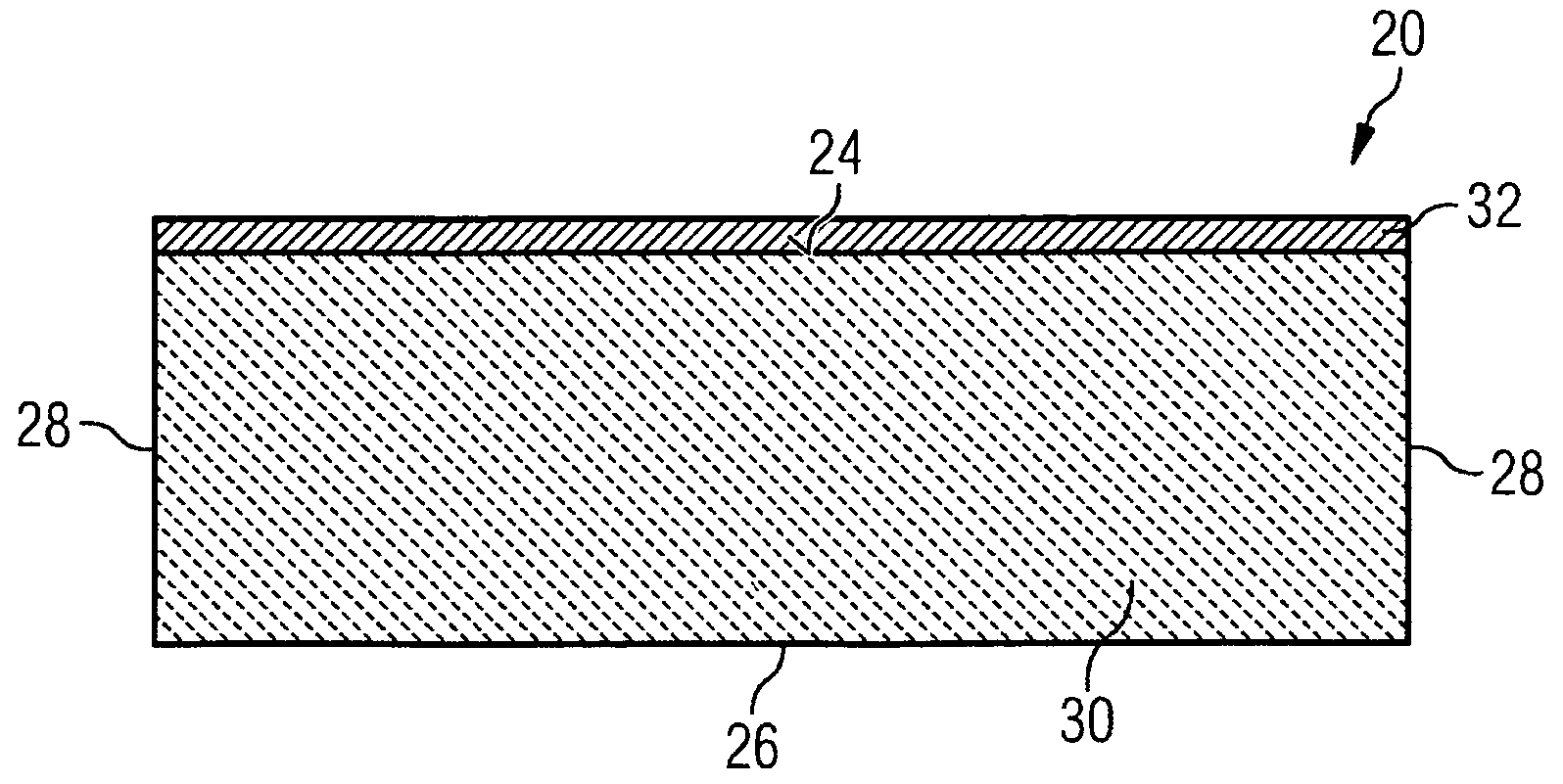

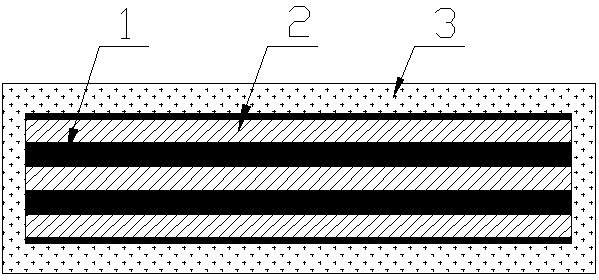

Lithium ion battery anode sheet

ActiveCN103094522AImprove cycle performanceReduce heating rateNon-aqueous electrolyte accumulator electrodesMetallic lithiumElectrical battery

The invention discloses a lithium ion battery anode sheet. The anode sheet comprises an anode current collector, an active substance layer, a high-resistance layer and metallic lithium particles, the active substance layer is coated on the anode current collector, the high-resistance layer is positioned on the active substance layer, the median size of the metallic lithium particles is greater than the thickness of the high-resistance layer, and the metallic lithium particles are distributed in and penetrate through the high-resistance layer. Compared with lithium ion batteries made through using anode sheets in the prior art, the lithium ion battery made through using the anode sheet disclosed in the invention has the advantages of increase of the first coulomb efficiency and the reversible capacity, improved circularity, and great reduction of the short circuit current in the battery, so the generation of the short circuit in the battery is reduced.

Owner:NINGDE AMPEREX TECH

Rice hull ash-paraffin wax phase-change aggregate and preparation method thereof

InactiveCN102303958AImprove packaging efficiencyReduce heating rateSolid waste managementHeat-exchange elementsParaffin waxMaceral

The invention relates to a rice hull ash-paraffin wax phase-change aggregate and a preparation method thereof. The rice hull ash-paraffin wax phase-change aggregate is characterized by comprising three materials including rice hull ash, paraffin wax and mineral powder, wherein the mass of the mineral powder accounts for 35 to 50 percent of the total mass of the rice hull ash, paraffin wax and mineral powder; and the mass ratio of paraffin wax to rice hull ash ranges from 1:1 to 1:5. The method comprises: mixing industrial rice hull ash and paraffin wax, and heating the mixture to allow the paraffin wax to melt into the pores in the rice hull ash, wherein a certain negative pressure is generated in the container by high-low temperature regulation to increase the melt amount of paraffin wax in the rice hull ash; sieving the mixed product of the rice hull ash and paraffin wax to obtain small particles of the mixed product; covering the small particles with powder; and thus, obtaining the rice hull ash-paraffin wax phase-change aggregate. The preparation process of the rice hull ash-paraffin wax phase-change aggregate is simple and low in cost, the paraffin wax content in the aggregate is high, the temperature control effect is desirable, and the adaptability to concrete is high.

Owner:WUHAN UNIV OF TECH +2

Composite molten steel refining additive

This invention provides a molten steel composite refining additive. The said additive by wt.% includes aluminium ash 10-50% (aluminium content at least being 15% of ash wt.), metallurgical furnace slag 10-60%, carbide 5-65%, limestone 1-10% and witherite 1-10%. This additive is used for the oxidable slag tapping process of steel smelting furnace such as electric furnace, converter, etc. and for refining furnace to make the oxidable molten steel proceed polybasic composite oxygen removal, sulphur removal and quick deoxidated impurity inclusion removal, and at the same time, it enhances quick dissolution of added slagging material and quick slag forming.

Owner:重庆工业高等专科学校

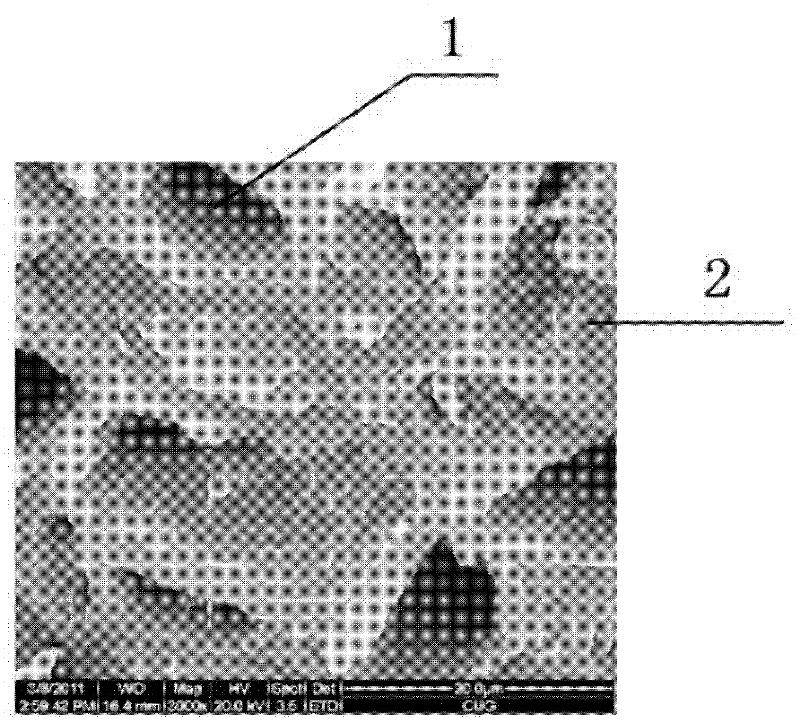

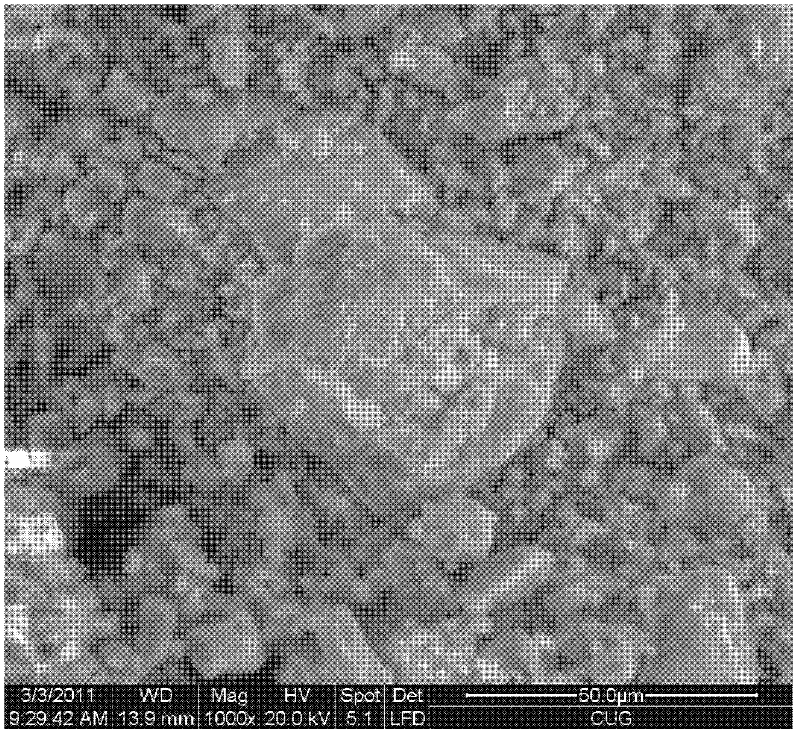

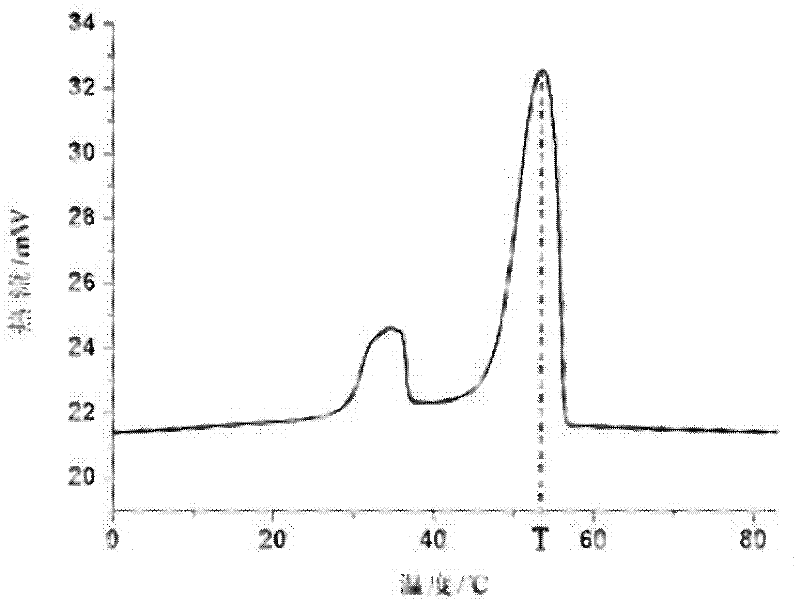

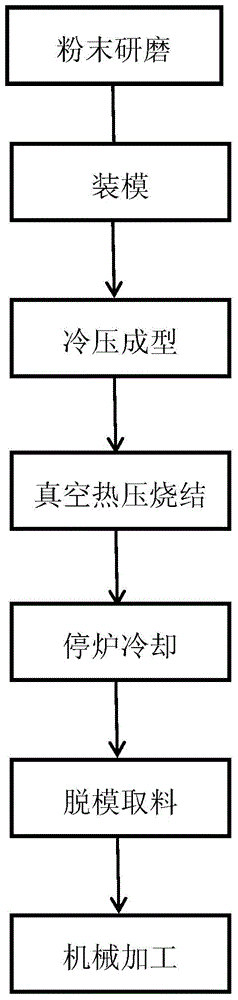

Preparation method of CdTe sputtering target material

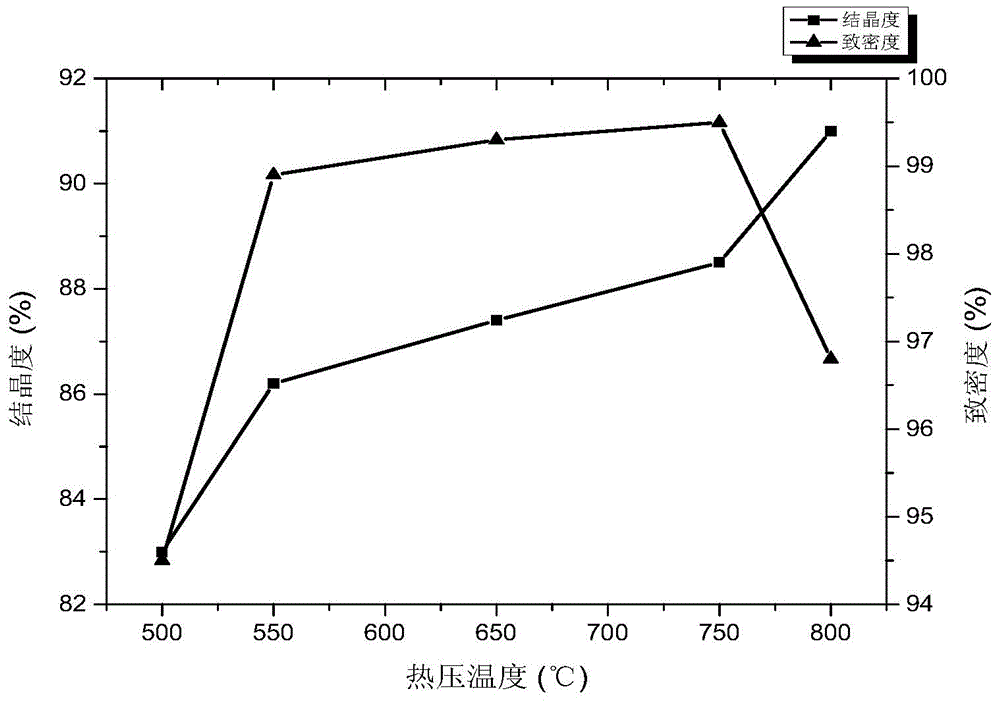

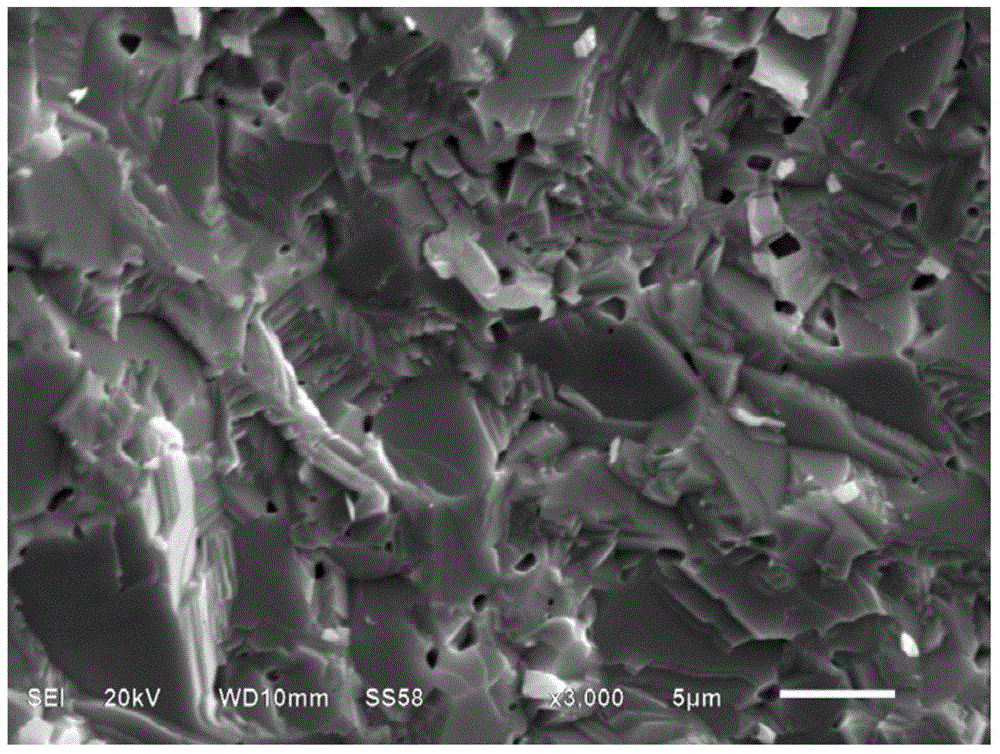

ActiveCN104694889AImprove uniformityAvoid stratificationVacuum evaporation coatingSputtering coatingCrystallinitySolar cell

The invention relates to a preparation method of a CdTe sputtering target material, and belongs to the field of solar cell materials. The preparation method comprises the following steps: (1) crushing and grinding a CdTe block prepared through vacuum melting into powder, and loading the obtained CdTe powder into a mould for cold press moulding; (2) after the cold press moulding is finished, placing into a hot pressed furnace for vacuum hot pressed sintering, wherein the hot pressing temperature is 500-800 DEG C, the pressure is 20-200 MPa, and the temperature pressure keeping time is 30-120 minutes; and (3) after the vacuum hot pressed sintering is finished, stopping the hot pressed furnace for cooling, demoulding for taking a material, and machining. The CdTe sputtering target material obtained through the preparation method disclosed by the invention can achieve the density more than 98%, the average grain size less than 45 nanometers and the target material crystallinity more than 80%.

Owner:有研资源环境技术研究院(北京)有限公司

Energy storage type drug refrigerator

InactiveCN103884144ASuitable temperatureReduce heating rateLighting and heating apparatusDomestic refrigeratorsDrug productMechanical engineering

Provided is an energy storage type drug refrigerator. The energy storage type drug refrigerator mainly comprises a shell, an inner container and a door. The side, opposite to the door, of the inner container serves as the inner side of the inner container, the side, opposite to the shell, of the inner container serves as the outer side of the inner container, the inner side of the inner container is provided with a regenerator, the regenerator is arranged at the junction position of an air duct and the shell, and energy storage materials are arranged in the regenerator. The energy storage materials in the regenerator release heat to perform phase transition (the energy storage materials are changed from liquid into solid) in the cooling process of the refrigerator, the energy storage materials in the regenerator absorb heat to perform phase transition (the energy storage materials are changed from solid into liquid) in the heating process of the refrigerator, the rising speed of the temperature of the refrigerator is lowered, and the start frequency of a compressor is reduced so as to protect the compressor.

Owner:SUZHOU KERT SCI INSTR

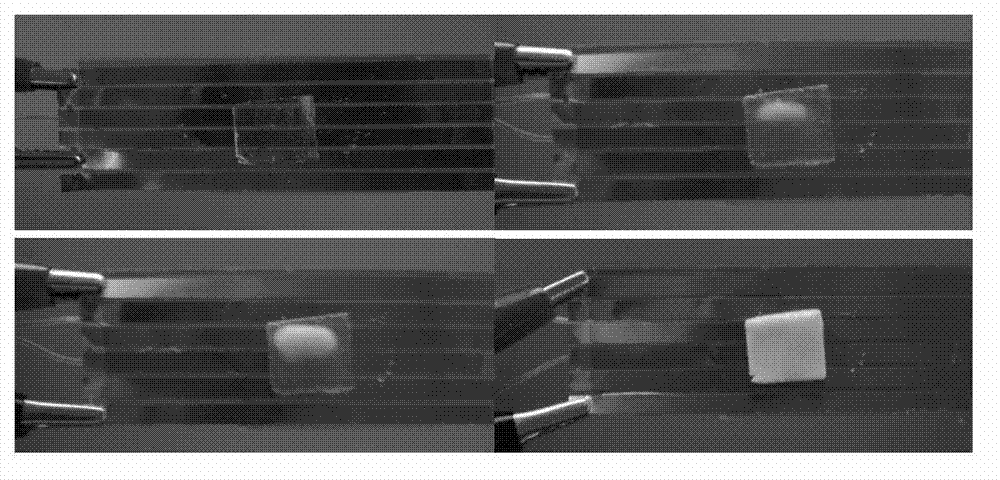

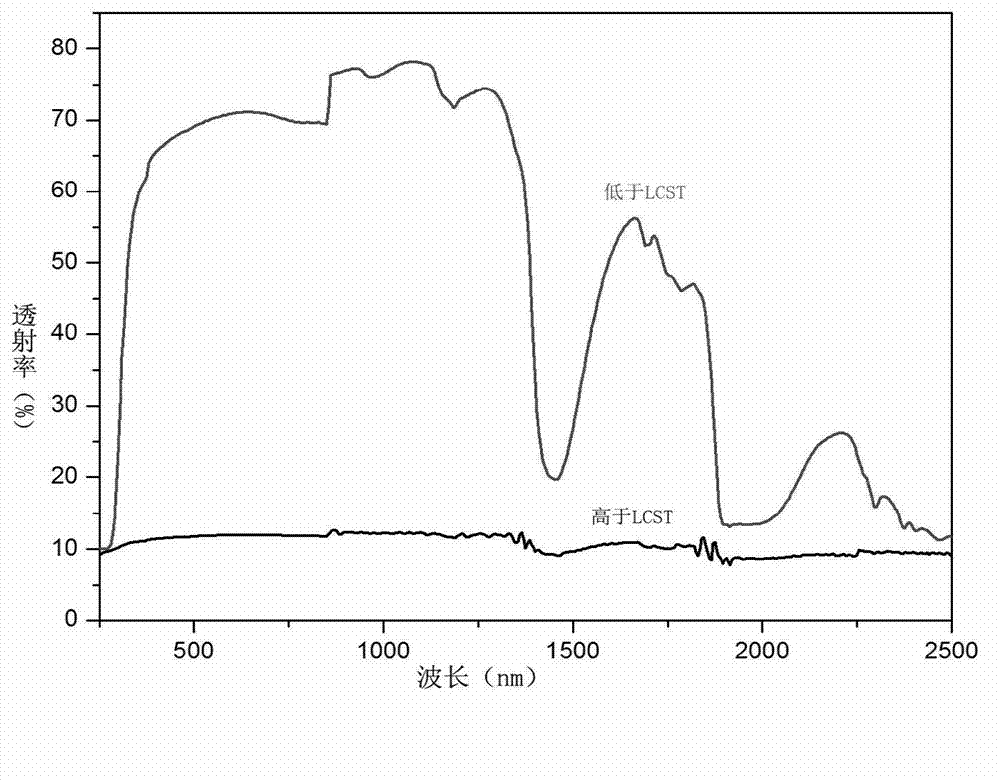

Temperature sensor of photonic crystal and preparation method thereof

ActiveCN103162857ADisplay temperatureReduce the temperatureThermometers using physical/chemical changesSmart hydrogelsPhotonic crystal

A temperature sensor of photonic crystal and a preparation method of the temperature sensor relate to a simple sensor and a preparation method of the sensor. The temperature sensor aims at solving the problems that a sensor existing in the prior art can only transmit signals without the ability of regulating or reacting upon output signal. The temperature sensor is composed of a composition of hydrogel and monodispersed microballoon. The method comprises a step of growing gelatin on the photonic crystal through a in-situ polymerization to gain the photonic crystal or a intelligent hydrogel compound system and product is made as a lump or coated on the a basement so that the temperature sensor is obtained. The temperature sensor has the advantages of not only displaying effectively and quickly temperature situation of detected area but also responding to a temperature field. Heating rate can be slowed effectively and the temperature of the detected area can even be lowered by adjusting and controlling incident intensity.

Owner:HARBIN INST OF TECH

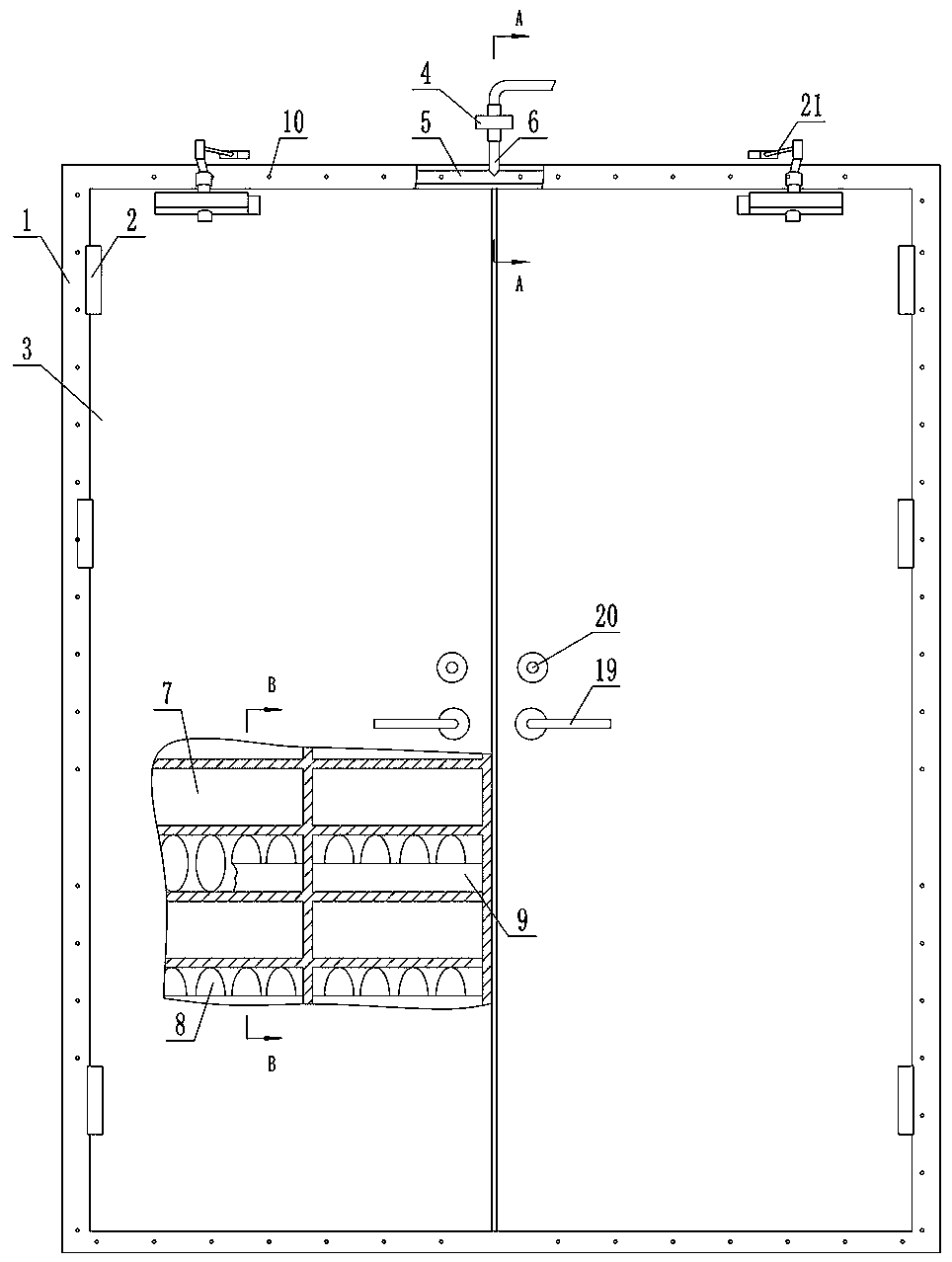

Fireproof safety door

The invention discloses a fireproof safety door. A water spray mechanism is arranged in a door frame, the water spray mechanism comprises water pipes arranged in the orientation of the door frame, thewater pipes communicate with the outside water source through a three-way joint, and a temperature-sensitive device is arranged between the three-way joint and the outside water source; a plurality of latticed empty cavities are formed in a door body, the empty cavities are filled with flame retardants and water bags, wherein the flame retardants and the water bags are separated from each other,the flame retardants comprise spongy layers and rock wool layers arranged on the two sides of the rock wool layers, and the water bags are connected with the inner walls of cavities bodies of the empty cavities of the door body through supporting plates. The water spray mechanism, the flame retardants and the water bags are arranged, when fire happens, on the one hand, water sprayed from the waterspray mechanism forms a water curtain to block flames, and the water curtain further has certain absorption action on smoke dust in air; and on the other hand, the flame retardants can greatly improve the heat-insulating performance of the door body, when the water bags shrink and crack after heated, internal loaded tap water overflows from a through hole of the door body, and the temperature rise speed of the fireproof safety door is effectively reduced.

Owner:SHANGQIU NORMAL UNIVERSITY

Low-heat anti-cracking portland cement

The invention discloses low-heat anti-cracking Portland cement. The cement clinker of the cement consists of the following minerals in percentage by weight: 40 to 70 percent of dicalcium silicate, 10 to 35 percent of tricalcium silicate, 1 to 4 percent of tricalcium aluminate, 15 to 30 percent of tetra calcium aluminoferrite, and 0.1 to 0.8 percent of free calcium oxide, wherein the content of magnesium oxide in the cement is between 3.5 and 5.0 percent, the content of alkali is not more than 0.55 percent, and the content of sulfur trioxide is not more than 3.5 percent. The cement has the main technical indexes that the ignition loss is less than or equal to 3wt%, the specific area is less than or equal to 340m<2> / kg, the stability is qualified, 3-day tensile strength is not required, the 7-day tensile strength is more than or equal to 13MPa, the 28-day tensile strength is between 42.5MPa and 52.5MPa, the 3-day breaking strength is not required, the 7-day breaking strength is more than or equal to 3.5MPa, the 28-day breaking strength is more than or equal to 7.0MPa, the 3-day hydration heat is less than or equal to 220KJ / kg, and the 7-day tensile strength is less than or equal to 250KJ / kg. The cement can be used for remarkably improving the cracking resistance of hydraulic concrete.

Owner:CHINA THREE GORGES CORPORATION

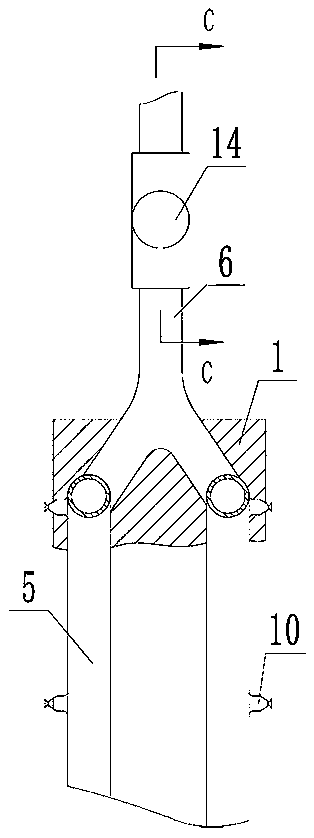

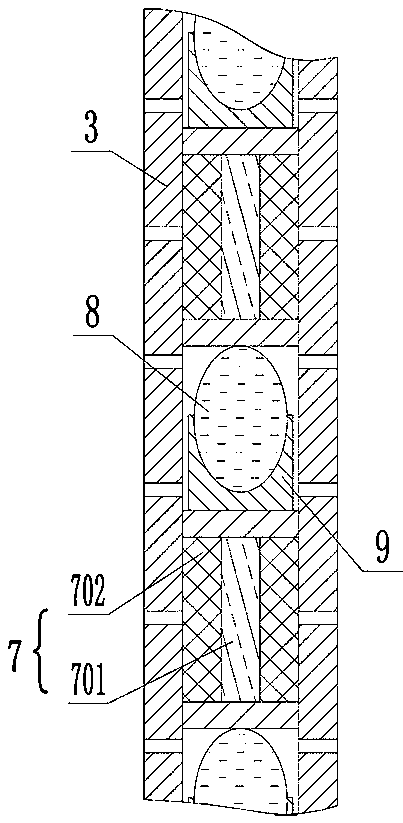

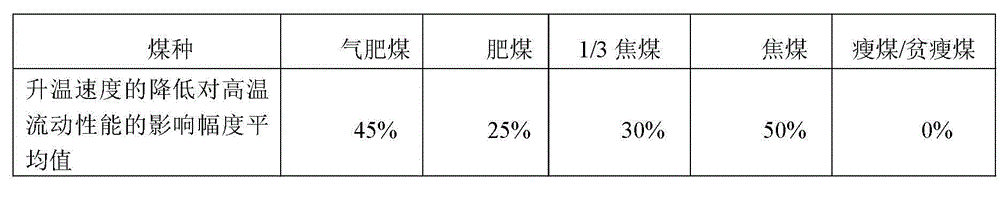

Coking coal blending method of wide carbonization chamber coke oven

The invention discloses a coking coal blending method of a wide carbonization chamber coke oven. The method comprises a step of blending various single coking coals, wherein each single coking coal comprises the following components in percentage by weight: 16-25% of lean coal and meager lean coal, 10-20% of fat coal 1#, 17-29% of 1 / 3 coking coal, 15-20% of coking coal 1#, 6-20% of coking coal 2#, 5-10% of coking coal 3#, 6-10% of gas-fat coal and fat coal 2# and the balance of other random available coking coal of which the volatile component content Vdaf is less than or equal to 35%; the maximum Gieseler fluidity of the compound coal is 600-1,400ddpm; and the volatile components account for 24-27%. The method disclosed by the invention effectively reduces the coal preparation cost, overcomes adverse impact on the high-temperature flowing property of the coking coal caused by the heating speed reduction in a coking process of the wide carbonization chamber coke oven, effectively reduces the graphite accumulation speed on the oven top and improves the coke quality and the coke output.

Owner:武汉钢铁有限公司

Ceramic Component With Surface Resistant To Hot Gas and Method for the Production Thereof

InactiveUS20090181257A1Improve resistance performanceExtended service lifeContinuous combustion chamberPretreated surfacesMetallurgyProduct gas

The invention relates to a ceramic component comprising a surface which is resistant to hot gas, and a method for the production thereof. Said ceramic component comprises a ceramic body and a surface which is resistant to hot gas. According to the invention, the surface which is resistant to hot gas is provided with a poorly reactive mineral coating.

Owner:SIEMENS AG

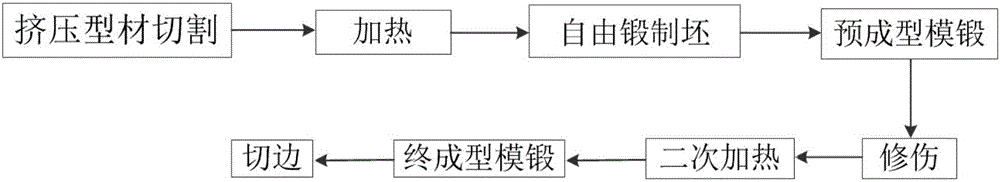

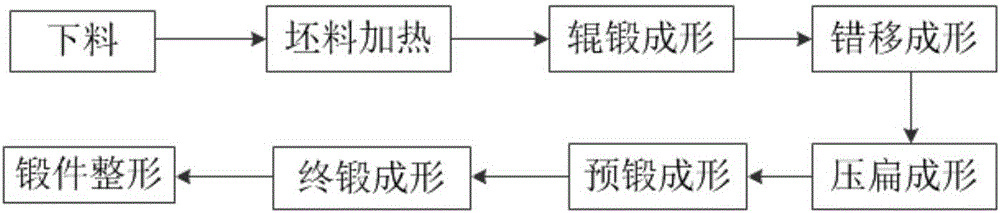

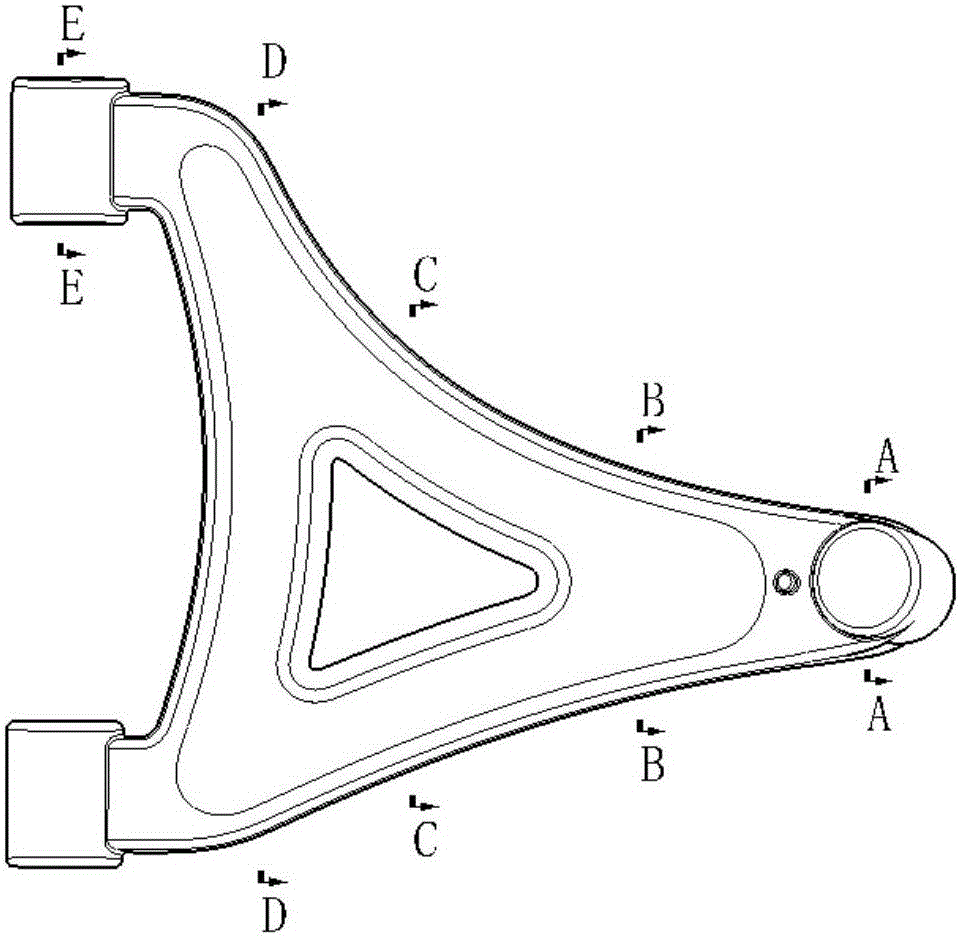

Forging forming method of triangular aluminum alloy control arm

ActiveCN106424529AAvoid Folding DefectsReduce repair workRailway componentsForging/hammering/pressing machinesControl armHeating furnace

The invention discloses a forging forming method of a triangular aluminum alloy control arm and aims at solving the problems in the prior art of low quality of a product, low material utilization ratio and low production efficiency. The forging forming method comprises the following steps: 1, blanking; 2, heating a blank: heating the blank in the first step in an electric induction heating furnace at the heating temperature of 420-480 DEG C, keeping the temperature for 5-8min to enable the blank to be uniformly heated, and finishing dynamic recrystallization after finishing forging to obtain uniform microstructures; 3, roll forgingforming: 1) calculating a roll forging pass n; 2) roll forging forming: comprising the following steps: from (1) first-pass roll forgingforming to (4) fourth-pass roll forging forming; 4, mis-shifted forming; 5, flattening forming; 6, pre-forging forming; 7, finish forging forming: carrying out finish forging forming on the basis of pre-forging forming, designing a die according to a hot forging drawing during finish forging forming, putting a pre-forging into a mold cavity of the finish forging die, and then obtaining a part in finish forging forming under the action of a press; and 8, shaping the forging.

Owner:JILIN UNIV

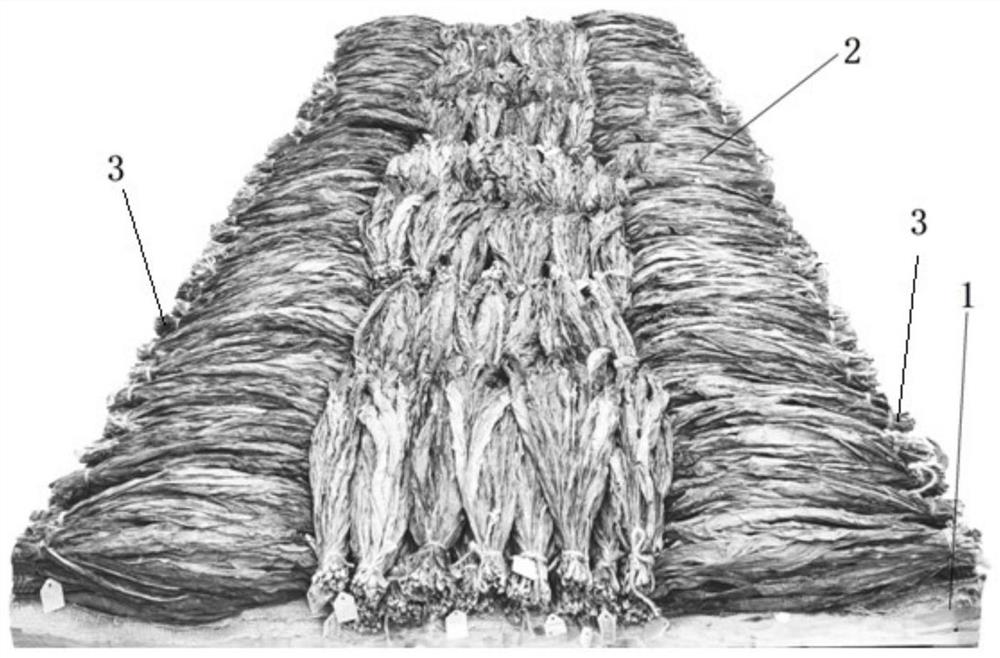

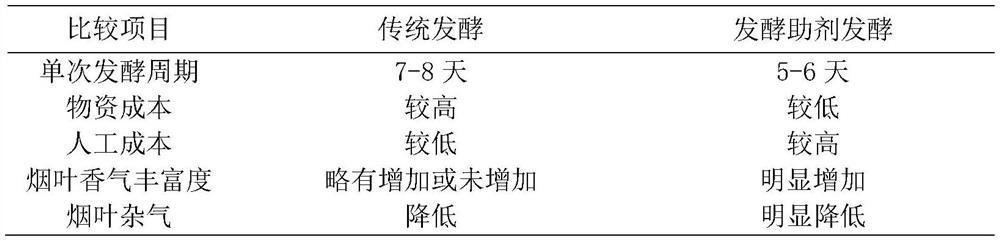

Preparation method of cigar tobacco agricultural fermentation aid and agricultural fermentation method

PendingCN113907403AReduce laborShorten fermentation timeTobacco preparationTobacco treatmentAgricultural scienceAgricultural engineering

The invention discloses a preparation method of a cigar tobacco agricultural fermentation aid and an agricultural fermentation method. The preparation method comprises the steps: 1), mixing a flavoring agent and a coloring agent, and obtaining a stock solution A; 2) uniformly mixing a flavor enhancer with water, heating to boil, and taking supernate to obtain a stock solution B; 3) mixing the stock solution A, the stock solution B and a penetrant in proportion to obtain a mixed solution, adding a bacteria increasing agent into the mixed solution, and uniformly mixing to obtain a fermentation stock solution; and 4) uniformly mixing the fermentation stock solution with water in proportion to obtain the fermentation aid. The agricultural fermentation method comprises the following steps: uniformly spraying a layer of the cigar tobacco leaf agricultural fermentation auxiliary agent on the lower leaves of the cigar wrapper and the cigar core by using a sprayer when each layer of the cigar wrapper and the cigar core is stacked, wherein the cigar tobacco leaf agricultural fermentation aid needs to be uniformly sprayed on the leaves on the middle and upper parts of the cigar cores by using a moisture regaining device, and then the cigar cores are stacked. The method can shorten the fermentation time, and is superior to traditional fermentation in the aspects of appearance quality, physical characteristics and sensory quality of tobacco leaves.

Owner:YUXI TABACOO COMPANY OF YUNNAN PROVINCE

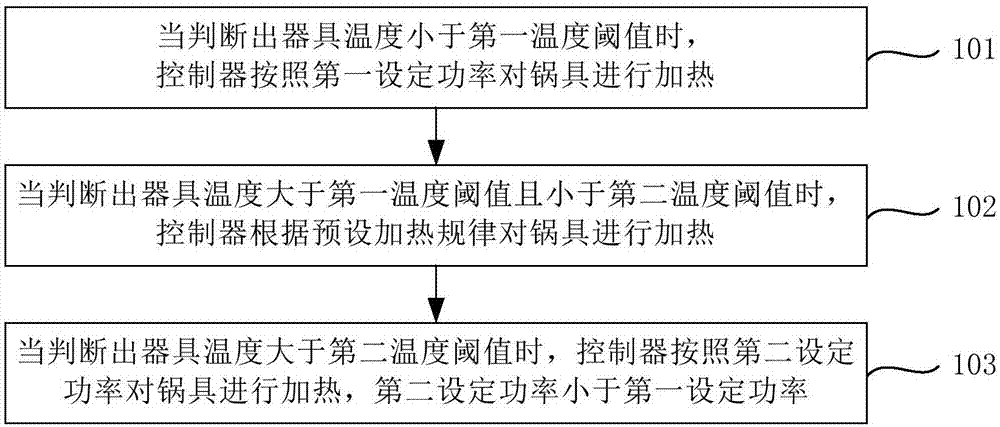

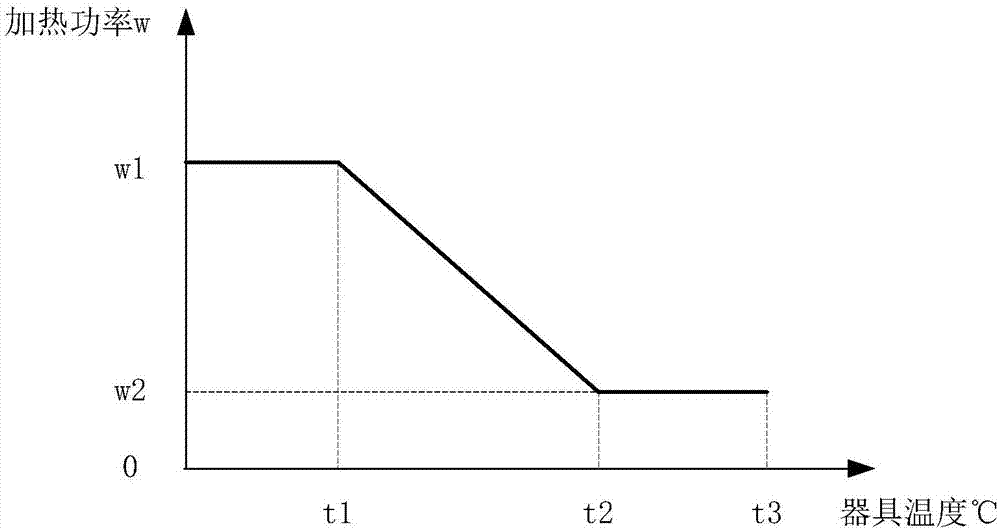

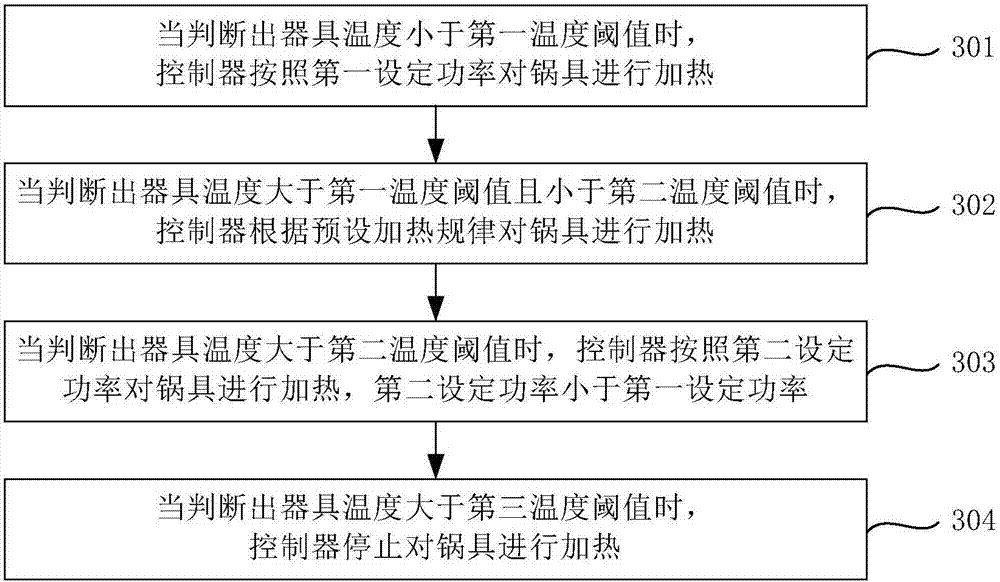

Cooking utensil heating control method and device, electric heating component and electric cooking utensil

InactiveCN107544586AFast heatingReduce heating rateTemperatue controlTime-controlled ignitorsElectricityEngineering

The invention provides a cooking utensil heating control method and device, an electric heating component and an electric cooking utensil. The method comprises the steps of when it is judged that theutensil temperature is smaller than a first temperature threshold value, heating a pot according to first set power; when it is judged that the utensil temperature is larger than the first temperaturethreshold value and smaller than a second temperature threshold value, heating the pot according to a preset heating law; when it is judged that the utensil temperature is larger than the second temperature threshold value, heating the pot according to second set power, wherein the second set power is smaller than the first set power. The cooking utensil control method and device, the electric heating component and the electric cooking utensil can solve the problem in the prior art that the convenience is poor in the cooking process caused by intermittent heating.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Fabric laminated flame-retardant conveyor belt for coal mines

The invention discloses a fabric laminated flame-retardant conveyor belt for coal mines. The fabric laminated flame-retardant conveyor belt for coal mines is characterized in that the framework material, the cover adhesive formulation and the adhesive sticker formulation are improved and a flame-retardant fabric layer having certain flame retardant property is taken as the framework material, and therefore, the safety performance index is satisfied, and the problems of easy deflection and large elongation of an integer core belt. Besides, the rubber-plastic CPE (Chlorinated Polyethylene) is introduced into the cover adhesive formulation so that the flowing property of the cover adhesive at high temperatures can be improved; a flame-retardant lubricant MB-202 is added so that the temperature rise rate can be reduced, and the friction temperature not exceeding 325 DEG C of a roller is guaranteed. In the adhesive sticker formulation, a plurality of adhesives are combined so that the adhesive strength can be improved, and moreover, the scaling problem is solved.

Owner:YANKUANG GRP CO LTD +1

Rapid degreasing and sintering method for photocuring shaped ceramic body

InactiveCN110372398AIncreased intensityEscape without defectAdditive manufacturing apparatusCarbonizationWarming process

The invention relates to a vacuum-air-vacuum rapid degreasing and sintering method for a photocuring shaped ceramic body.The photocuring shaped ceramic bodyis placed in a foamed alumina ceramic platform to be transferred along into a vacuum oven, under the vacuum condition of 1x10<-3> to 5x10<-1>Pa, the temperature is raised to 550 to 650 DEG C and maintained for 1 to 2 h at a heating rate of 0.5to 2 DEG C / min through intermittent heat preservation during heating; after carbonization of the ceramic body is completed, the temperature of the vacuum oven is naturally lowered to 300 to 400 DEG Cand kept for 1 to 2 hours,a vacuum pump is turned off, air is slowly introduced into the vacuum oven at a rate of 0.1 to 1 L / min so that carbon reserved in the ceramic body slowly reacts with oxygen to form carbon dioxide to escape,when holding time is up, the vacuum pump is opened, the temperature is raised to a sintering temperature of the ceramic at a rate of 3 to 5 DEG C / min and maintained, air oxidation after vacuum carbonization prevents the residual small amount of carbonfrom affecting the properties of sintered ceramics.

Owner:WUHAN UNIV OF TECH

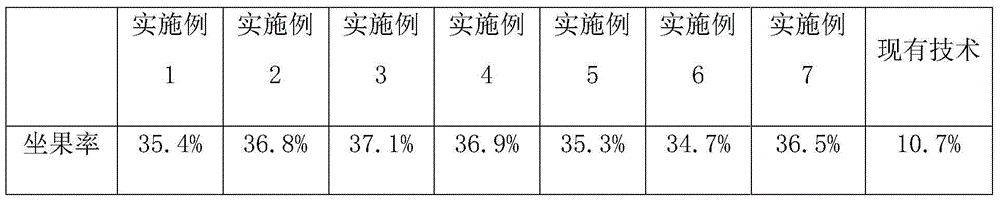

Improving method for fruit setting rate of almond trees

InactiveCN104642044ALow autoflowering rateIncreased autoflowering rateFertilising methodsCultivating equipmentsFruit setAlmond tree

The invention provides an improving method for the fruit setting rate of almond trees. The improving method comprises the following steps: firstly, selecting varieties: selecting the almond trees with freeze resistance and air temperature fluctuation resistance as main cultivars, and selecting the almond trees with the same flowering stage as pollinating varieties, wherein during planting, the quantity proportion of the main cultivars to the pollinating varieties is 3:1; secondly, managing fertilizer and water; applying base fertilizer in autumn, dressing before germinating, and spraying foliage fertilizer at the swelling stage of fruits; irrigating tree bodies at the flowering stage, after flowering, in drought seasons and after fertilizing; thirdly, performing artificial supplementary pollination: dissolving white sugar, urea, borax and pollen in water and uniformly stirring to obtain pollen liquid, feeding the pollen liquid in a sprayer and then spraying the pollen liquid to almond tree flowers; fourthly, spraying a plant growth regulator: before flowering, spraying a mixture of plant mineral elements and the urea to the tree bodies, spraying a mixture of maleic hydrazide, the plant mineral elements and the urea at the full-bloom stage, and spraying a mixture of the plant mineral elements, the urea and monopotassium phosphate after flowering; fifthly, resisting cold. According to the improving method provided by the invention, the fruit setting rate and the yield of the almond trees can be effectively improved.

Owner:陈林美

Light weight portable fire resistant containment system

InactiveUS20110094423A1Restricting heat deliveryEasily withstand fire exposureWallsWing framesFiberPaper document

A lightweight portable fire resistant containment system has an outer shell and an inner shell that fits inside the outer shell, forming an insulating air gap. A lid closes the outer shell, defining a closed storage space. The outer shell, inner shell and lid are fabricated from high temperature resisting ceramic fibers and are bonded together with an inorganic or charred bond to form a light weight integral component. A stainless steel sheet wrap prevents ingress of flame and hot gas into the bonded ceramic fibers of the outer shell and lid. The inner shell outer surface has a metallic infrared reflecting wrap limiting radiation received from the inner surface of the outer shell. The inner surface of the inner shell has an encased ceramic porous body infiltrated with solidified phase change material, absorbing latent heat of fusion from the interior surface of inner shell and limiting temperature exposure of valuable stored documents and photographs.

Owner:DELLORUSSO JR ANTHONY J

Self-cooling iron liquid pretreating spray gun

InactiveCN1818083AGuaranteed cooling strengthReduce heating rateManufacturing convertersPre treatmentEngineering

The invention is about the hot iron pretreatment ejection gun. It can solve the problem of the mismatch of the gun core material and the gun line material. The gun includes: the main duct, the columnar rivet, the V anchorage piece, the ring rivet, the gun line of fireproof material, the spraying mouth, the gun bar, the intensified pipe, the organic coating, the wind cooling duct, the wind cooling jet, the intensified pipe baffle plate, the air intake and the gas nozzle. The gun of the invention has the simple structure and the long life.

Owner:WUHAN IRON & STEEL (GROUP) CORP

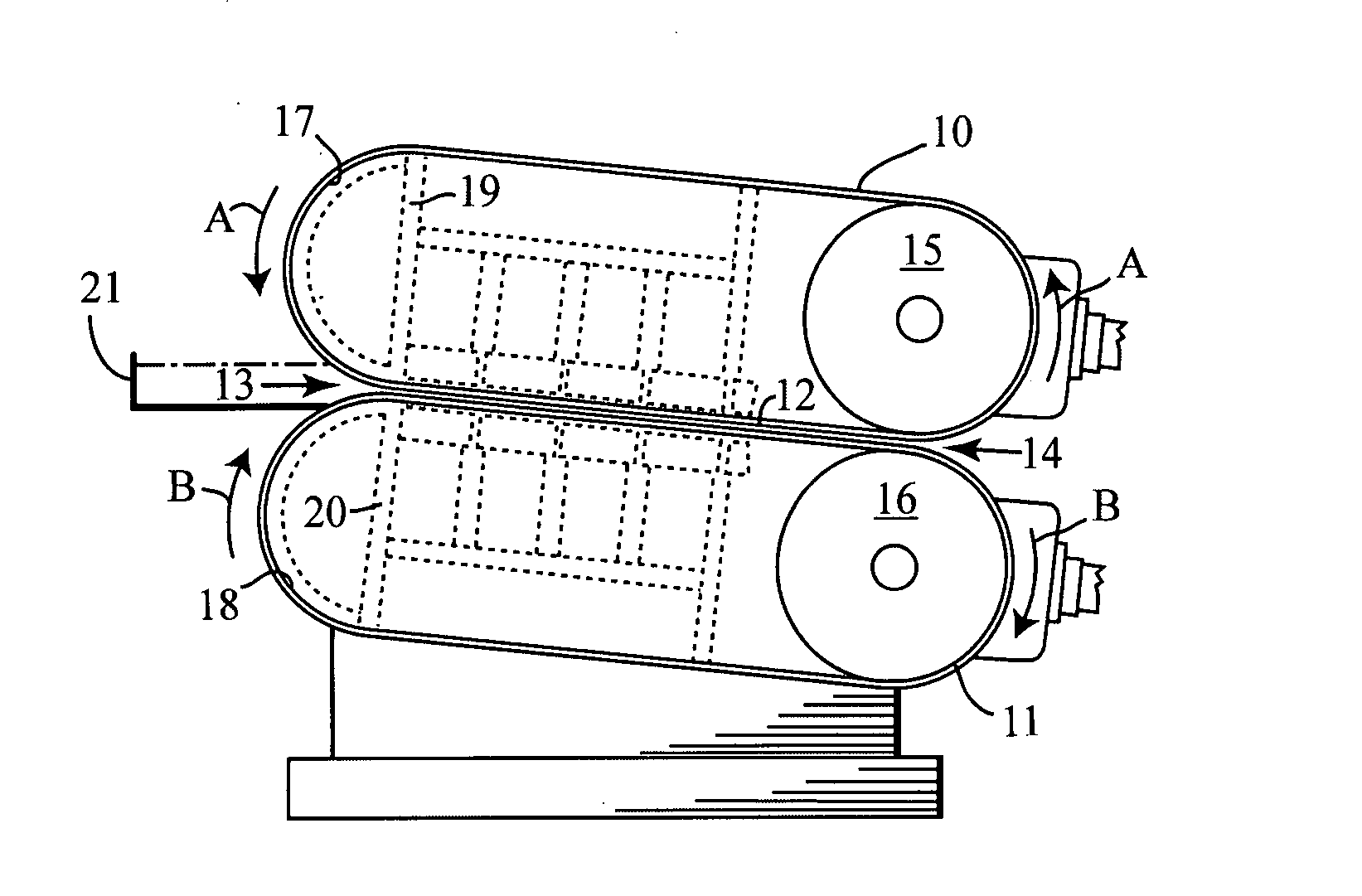

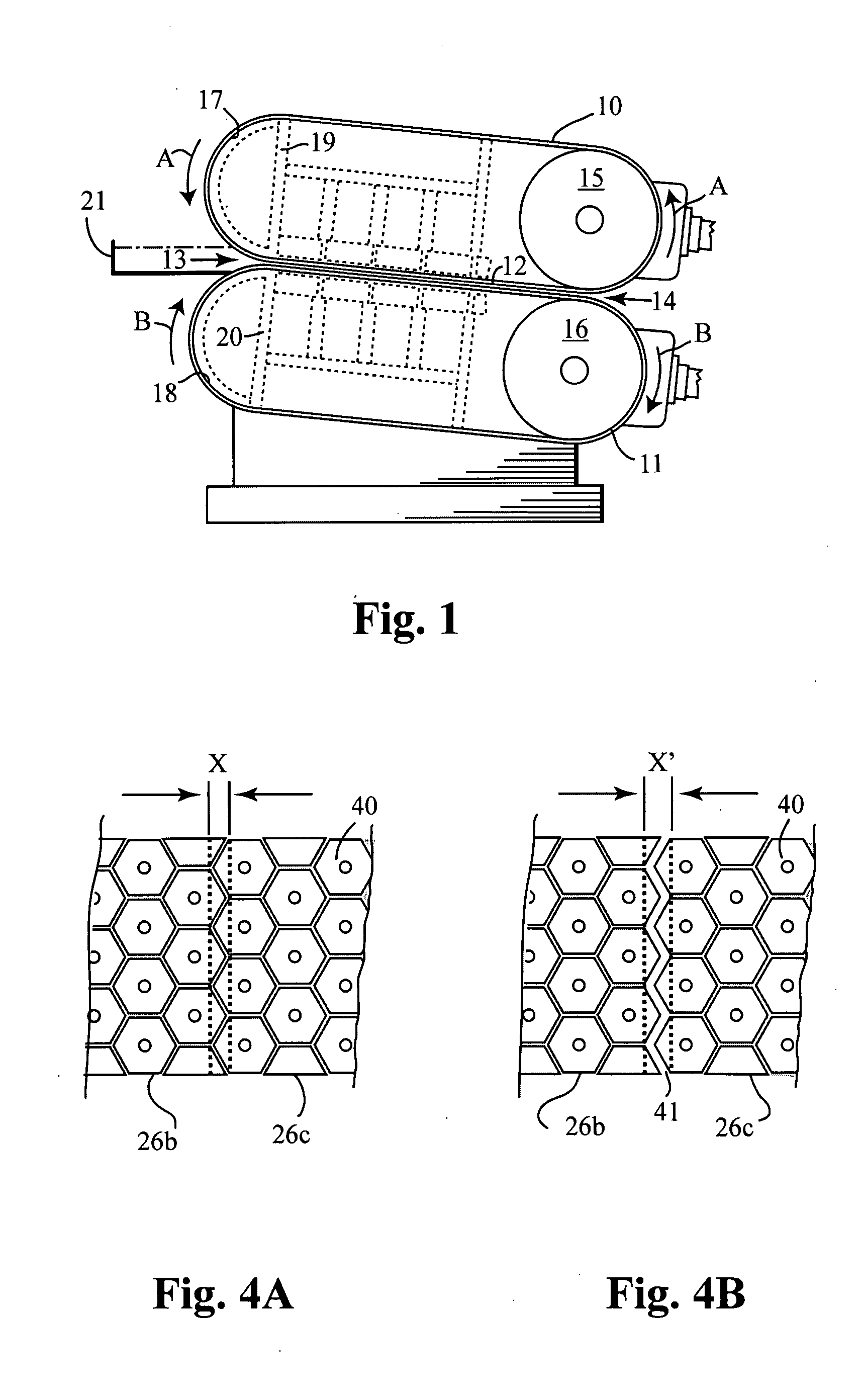

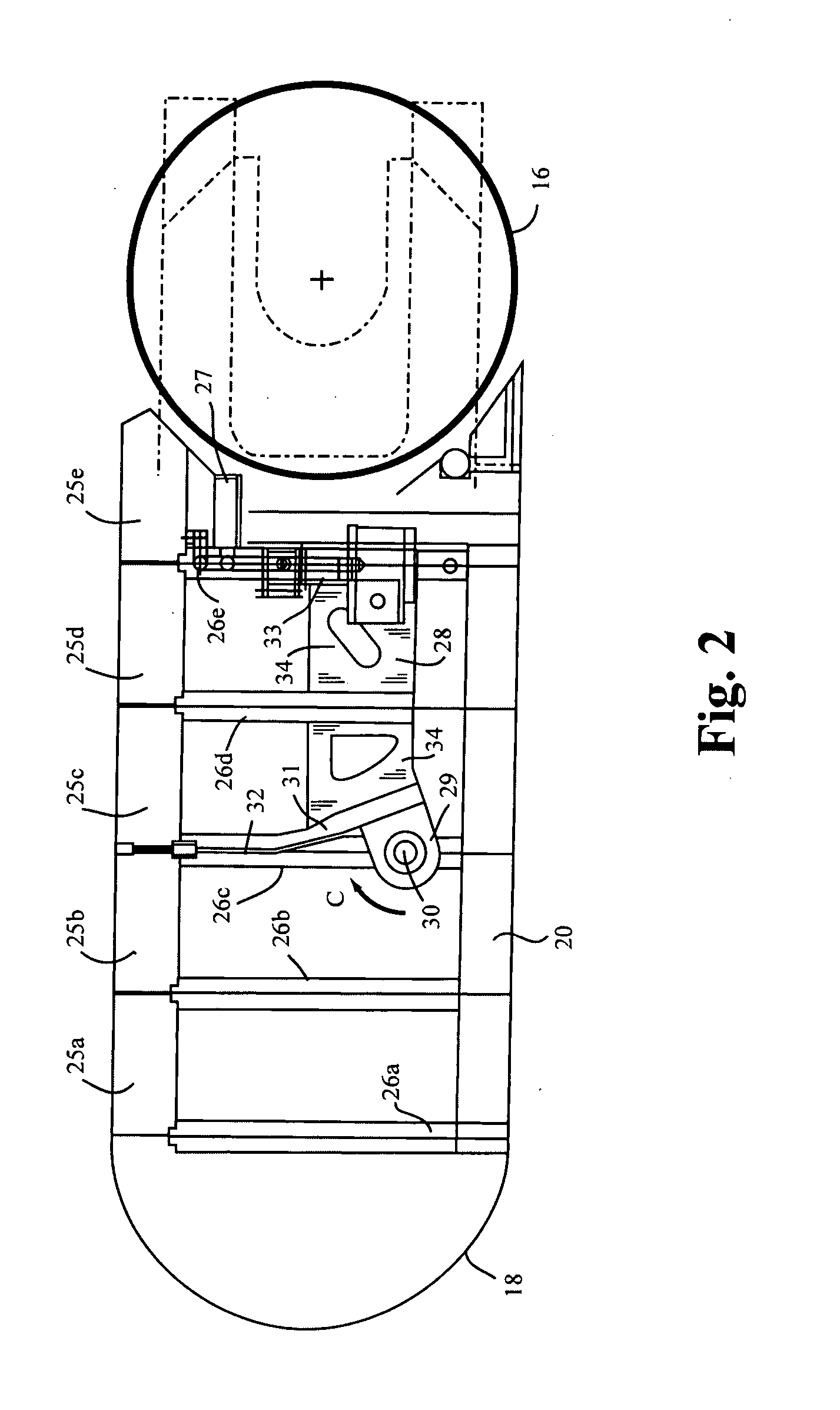

Belt casting machine having adjustable contact length with cast metal slab

A twin-belt casting machine for casting metal strip. The machine is provided with a casting cavity which includes an upstream fixed casting region, in which the belts are in fixed convergent paths in contact with the cast slab, and an adjacent downstream portion in which the belts are adjustable between alignment with the fixed convergent paths and non-alignment therewith (being less convergent or divergent). When the adjustable portions of the paths are moved outwardly relative to the fixed convergent paths, the belts separate from the cast slab at differing predetermined points within the casting cavity. By adjusting the downstream portion of the casting cavity in this manner, the casting machine can operate at essentially constant throughput for a wide range of alloys while ensuring that the cast slab exiting the caster has a temperature within a predetermined range suitable for further rolling to produce sheet product.

Owner:NOVELIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com