Rice hull ash-paraffin wax phase-change aggregate and preparation method thereof

A technology of rice husk ash and paraffin, which is applied in the field of rice husk ash-paraffin phase change aggregate, can solve the problems of large water demand and affect the popularization and application of concrete, and achieves lower temperature peak, good work adaptability, delayed heating and cooling effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

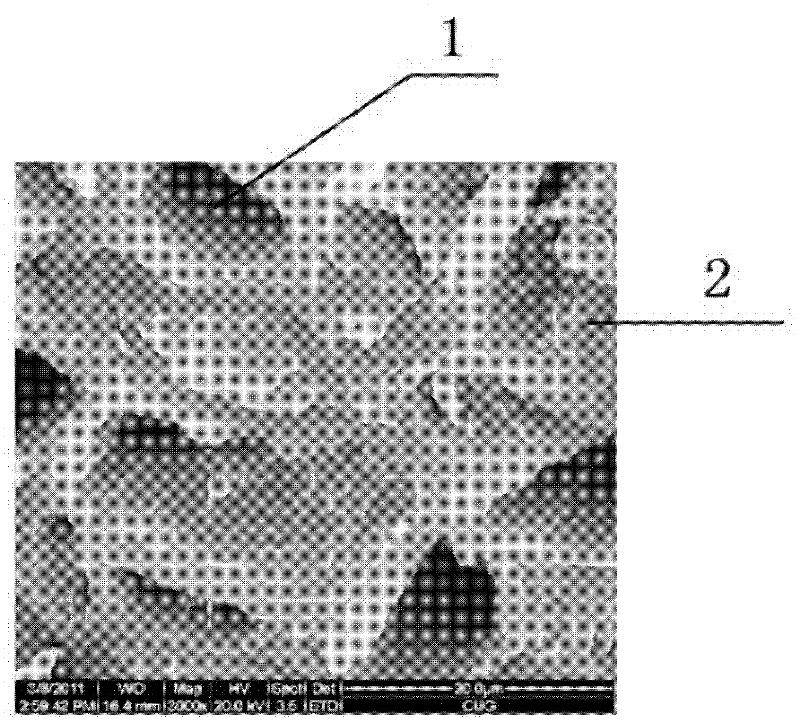

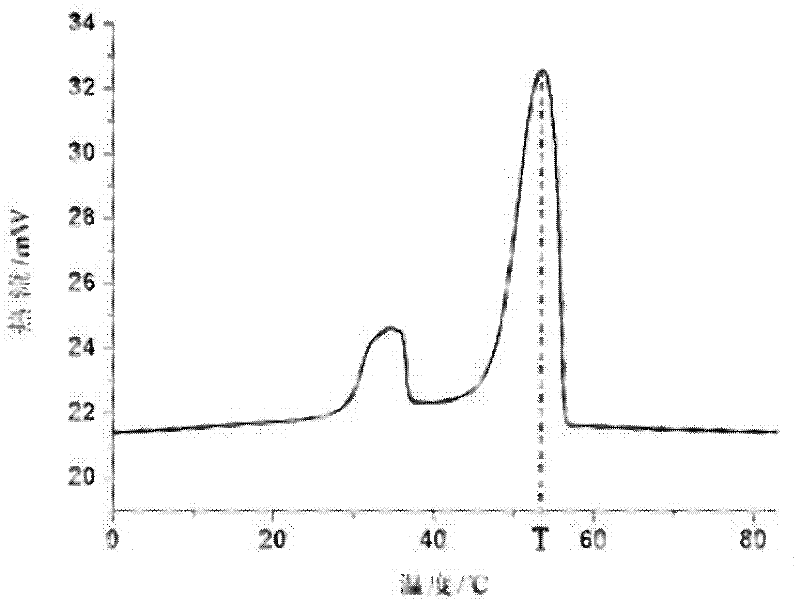

[0053] Take 3Kg of rice husk ash with a particle size of less than 1.18mm, and 3Kg of paraffin particles with a particle size of not more than 2.36mm (the temperature corresponding to the highest peak of the endothermic peak of phase transition is 52°C), mix them evenly, and place them in a metal container to seal . Then place the metal container in a high temperature environment of 78°C for 10 hours, open the release valve of the metal container, release the air for 5 seconds, and close the valve to balance the air pressure in the container and the high temperature environment.

[0054] Then the metal container was transferred to another 42°C low temperature environment for 6 hours. In a lower environment, a negative pressure state is formed in the metal container, which is more conducive to the entry of paraffin into the pore structure of the rice husk ash.

[0055] Take out the metal container, disperse the composite product of rice husk ash and paraffin into particles wit...

Embodiment 2

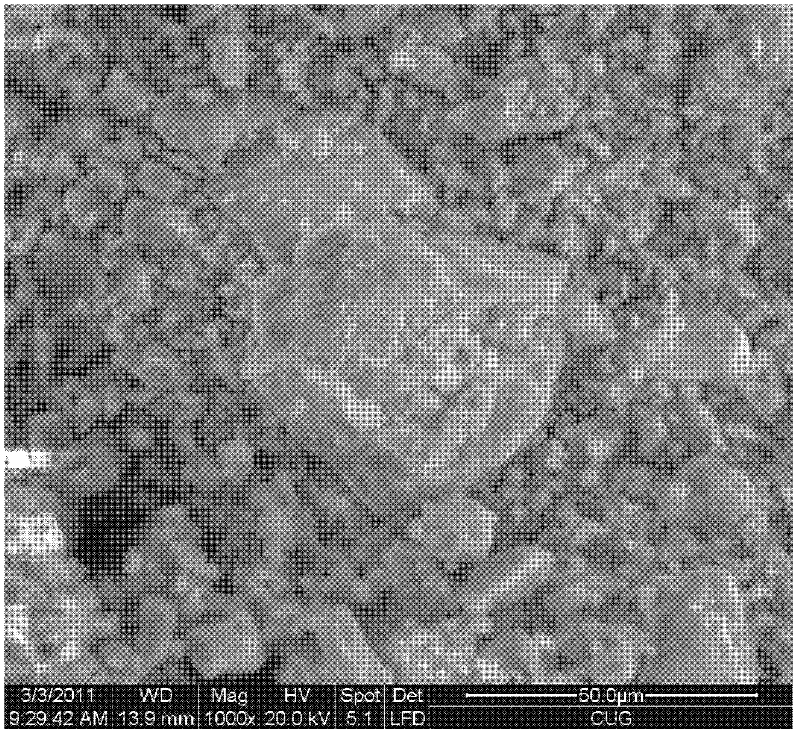

[0059] Take 3Kg of rice husk ash with a particle size of 1.18mm, and 2Kg of paraffin wax particles with a particle size of no more than 2.36mm (the temperature corresponding to the highest peak of the endothermic peak of phase transition is 48°C), mix them evenly, and place them in a metal container to seal . Then place the metal container in an oven at 160°C to keep it warm.

[0060] After heating for 6 hours, open the vent valve of the metal container, vent for 5 seconds, and close the valve. In order to balance the air pressure in the container with the air pressure in the oven at 160°C.

[0061] The metal container was transferred to another oven at 72°C for 2 hours. In a lower environment, a negative pressure state is formed in the metal container, which is more conducive to the entry of paraffin into the pore structure of the rice husk ash.

[0062] Take out the metal container, disperse the composite product of rice husk ash and paraffin into particles with a particl...

Embodiment 3

[0066] Take 3Kg of rice husk ash with a particle size of less than 1.18mm, and 2.4Kg of paraffin wax particles with a particle size of not more than 2.36mm (the temperature corresponding to the highest peak of the endothermic peak of phase transition is 48°C), mix them evenly, and place them in a metal container seal. Then place the metal container in an oven at 120°C to keep it warm.

[0067] After heating for 8 hours, open the vent valve of the metal container, vent for 5 seconds, and close the valve. In order to balance the air pressure in the container with the air pressure in the oven at 120°C.

[0068] The metal container was transferred to another oven at 58°C for 4 hours. In a lower environment, a negative pressure state is formed in the metal container, which is more conducive to the entry of paraffin into the pore structure of the rice husk ash.

[0069] Take out the metal container, quickly sieve the composite product of rice husk ash and paraffin into a clean en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com