Double-capsule self-repairing epoxy coating and preparation method thereof

An epoxy coating, self-healing technology, used in microcapsule preparations, microsphere preparation and other directions, can solve the problems of low encapsulation efficiency, inability to provide sufficient structural stability, emulsion droplet fusion, demulsification, etc., to improve the encapsulation efficiency. volume, improve repair efficiency, and prevent the effect of milk droplet fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

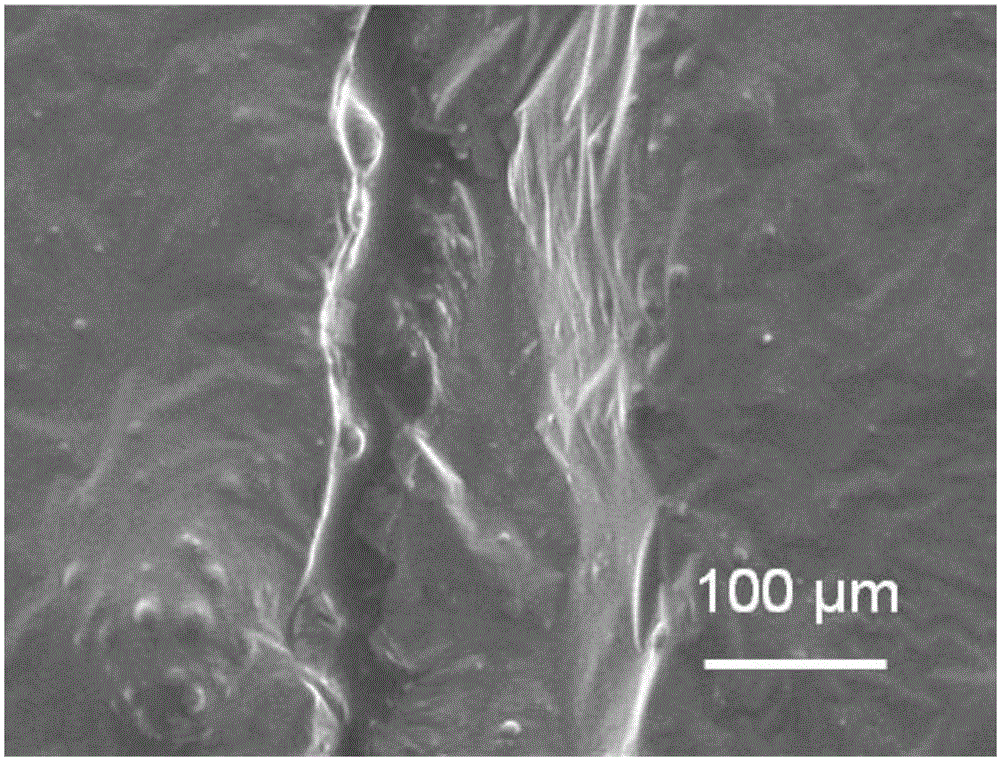

Image

Examples

Embodiment 1

[0028] (1) Add 1 g of polyvinyl alcohol (polymerization degree: 2600) to 100 mL of deionized water, and stir magnetically at 80 °C for 12 h to obtain an aqueous solution of polyvinyl alcohol. Add 30 mg of silica nanoparticles to 6 mL of polyvinyl alcohol aqueous solution for ultrasonic dispersion for 1 min, add 3 g of epoxy resin, mix the oil and water phases, and emulsify at 9000 rpm high-speed shearing to obtain an oil-in-water skin stabilized by silica nanoparticles Pickering emulsion; then add 300 ml of isophorone diisocyanate to the Pickering emulsion, and mix well to obtain a mixed solution. Dissolve 300 mL of tetraethylenepentamine in 3 mL of deionized water, then add it into the mixture, and let it stand at room temperature for 40 min to obtain a suspension of epoxy microcapsules, wash the suspension three times with water, filter, and dry at room temperature for 24 h , to obtain epoxy microcapsules.

[0029] (2) Add 1 g polyisobutylene (molecular weight: 2400) to 100...

Embodiment 2

[0032](1) Add 1 g of polyvinyl alcohol (polymerization degree: 2600) to 100 mL of deionized water, and stir magnetically at 80 °C for 12 h to obtain an aqueous solution of polyvinyl alcohol. Add 30 mg of silica nanoparticles to 6 mL of polyvinyl alcohol aqueous solution for ultrasonic dispersion for 1 min, add 1.8 g of epoxy resin, mix the oil and water phases, and emulsify at a high speed of 3000 rpm to obtain an oil-in-water skin stabilized by silica nanoparticles Crean Lotion. Then add 180 mL of isophorone diisocyanate to the Pickering emulsion, and mix evenly to obtain a mixed solution. After dissolving 150 mL tetraethylenepentamine in 3 mL deionized water, add it to the mixture. Stand at room temperature for 40 min to obtain a suspension of epoxy microcapsules, wash the suspension three times with water, filter, and dry at room temperature for 24 h to obtain epoxy microcapsules.

[0033] (2) Add 1 g polyisobutylene (molecular weight: 2400) to 100 mL xylene, and stir mag...

Embodiment 3

[0036] (1) Add 1 g of polyvinyl alcohol (polymerization degree: 2600) to 100 mL of deionized water, and stir magnetically at 80 °C for 12 h to obtain an aqueous solution of polyvinyl alcohol. Add 30 mg of silica nanoparticles to 6 mL of polyvinyl alcohol aqueous solution for ultrasonic dispersion for 1 min, add 4.2 g of epoxy resin, mix the oil and water phases, and emulsify at 6000 rpm high speed shear to obtain silica nanoparticles stabilized oil-in-water skin Crean Lotion. Add 480 mL of isophorone diisocyanate to the Pickering emulsion, and mix evenly to obtain a mixed solution. Dissolve 450 mL of tetraethylenepentamine in 3 ml of deionized water, and then add it to the mixture. Stand at room temperature for 40 min to obtain a suspension of epoxy microcapsules, wash the suspension three times with water, filter, and dry at room temperature for 24 h to obtain epoxy microcapsules.

[0037] (2) Add 1 g polyisobutylene (molecular weight: 2400) to 100 mL xylene, and stir magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com