Patents

Literature

386results about How to "Completely broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

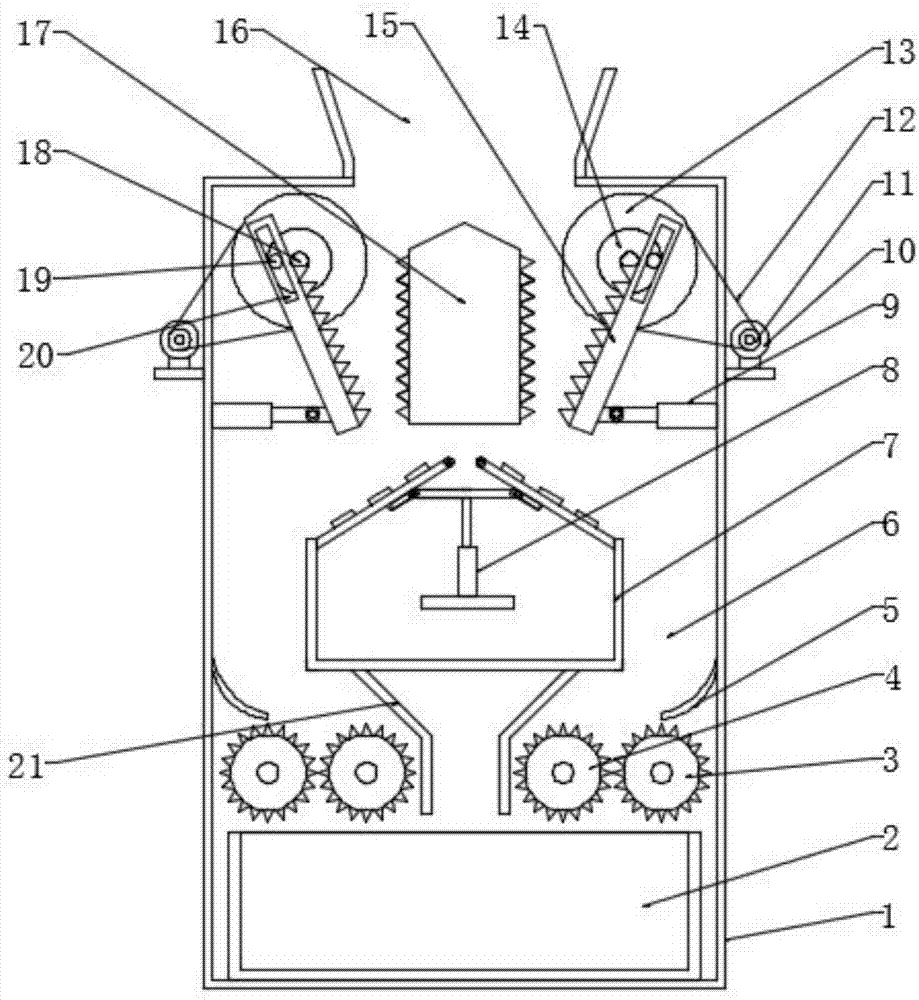

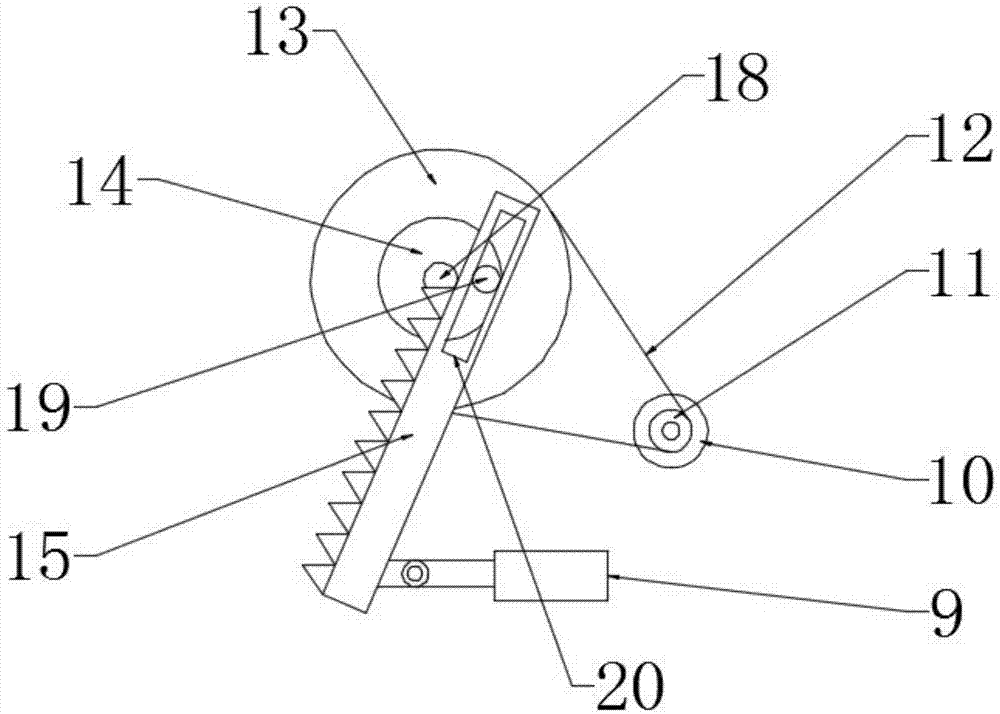

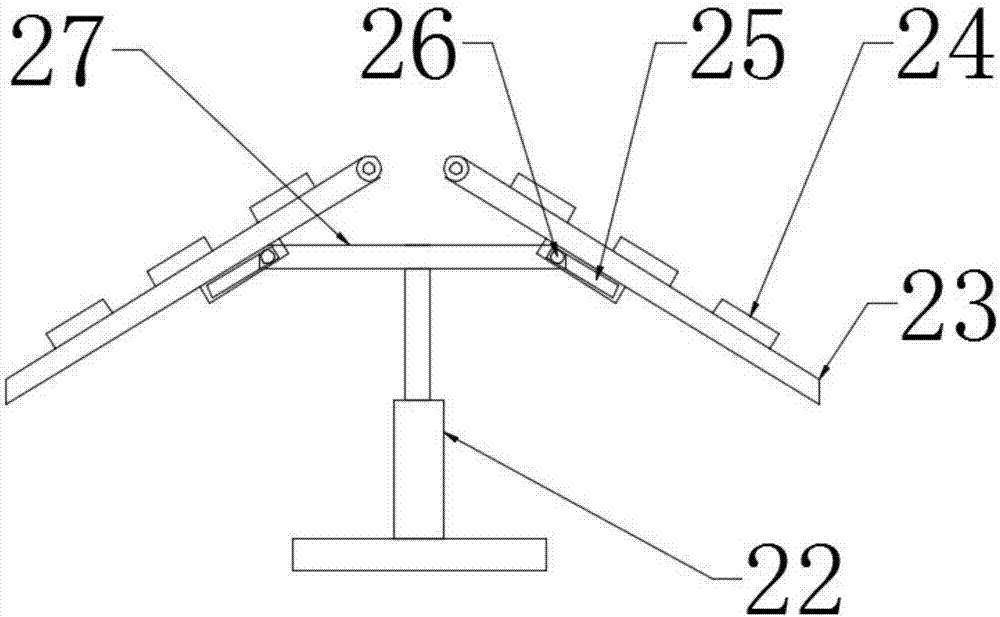

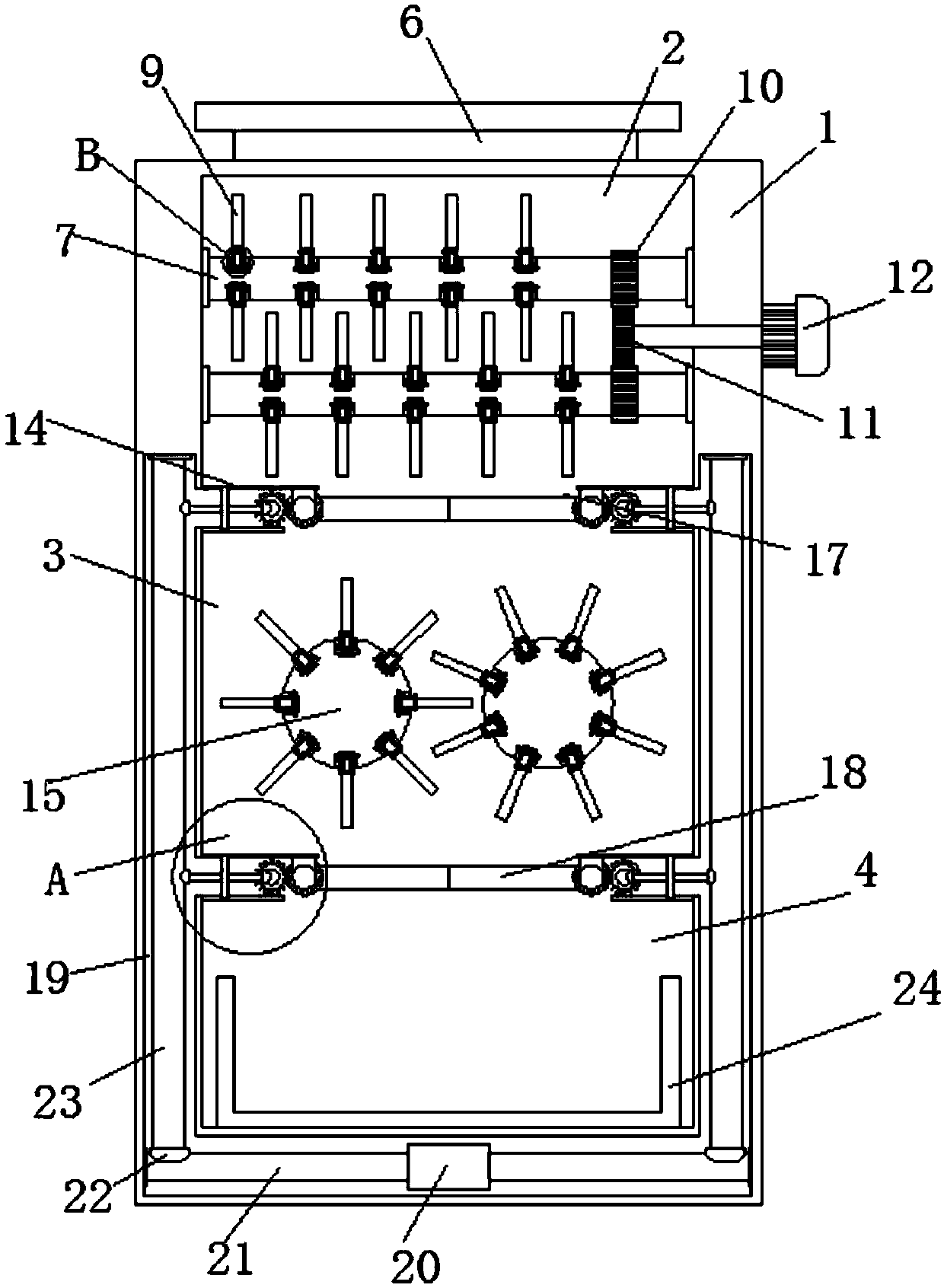

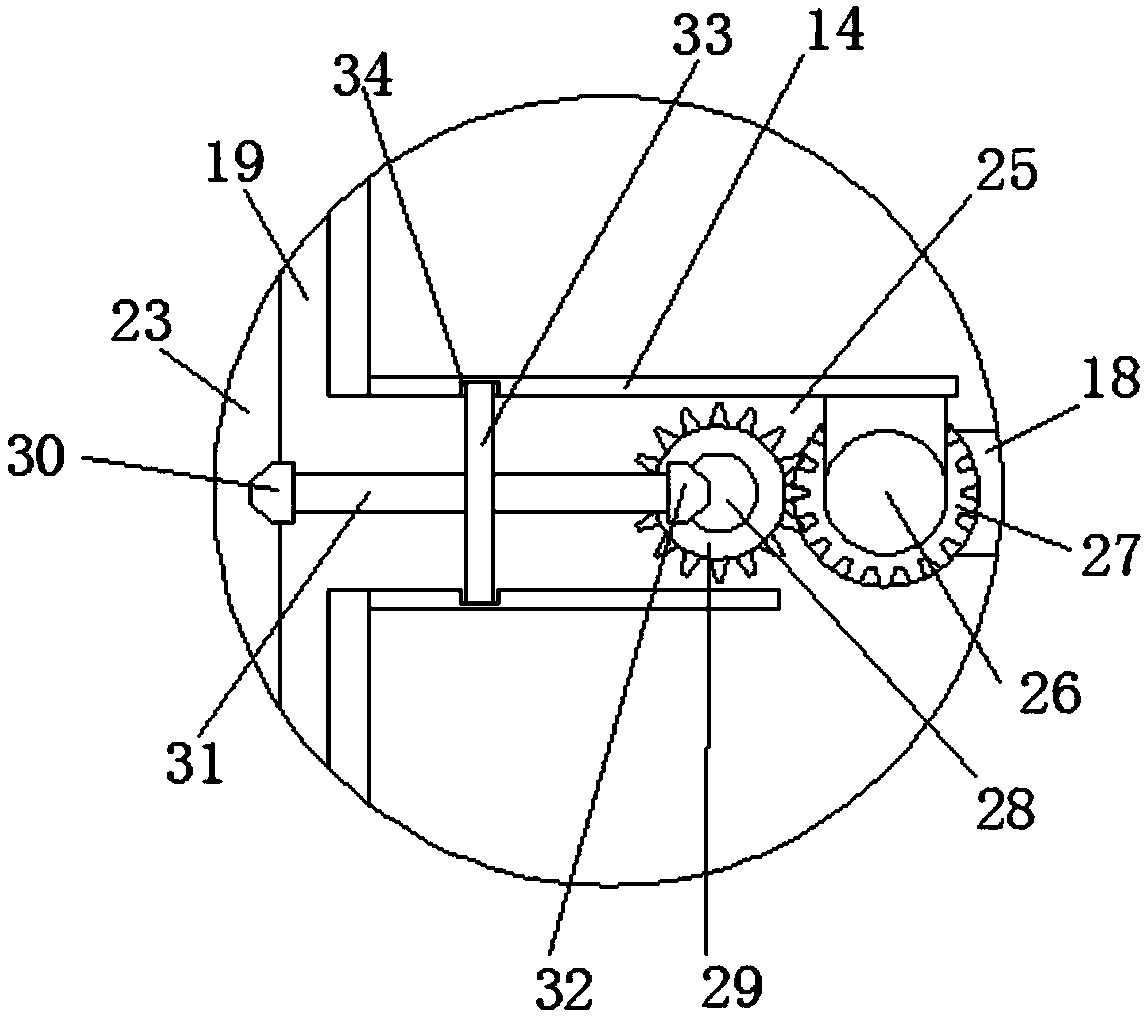

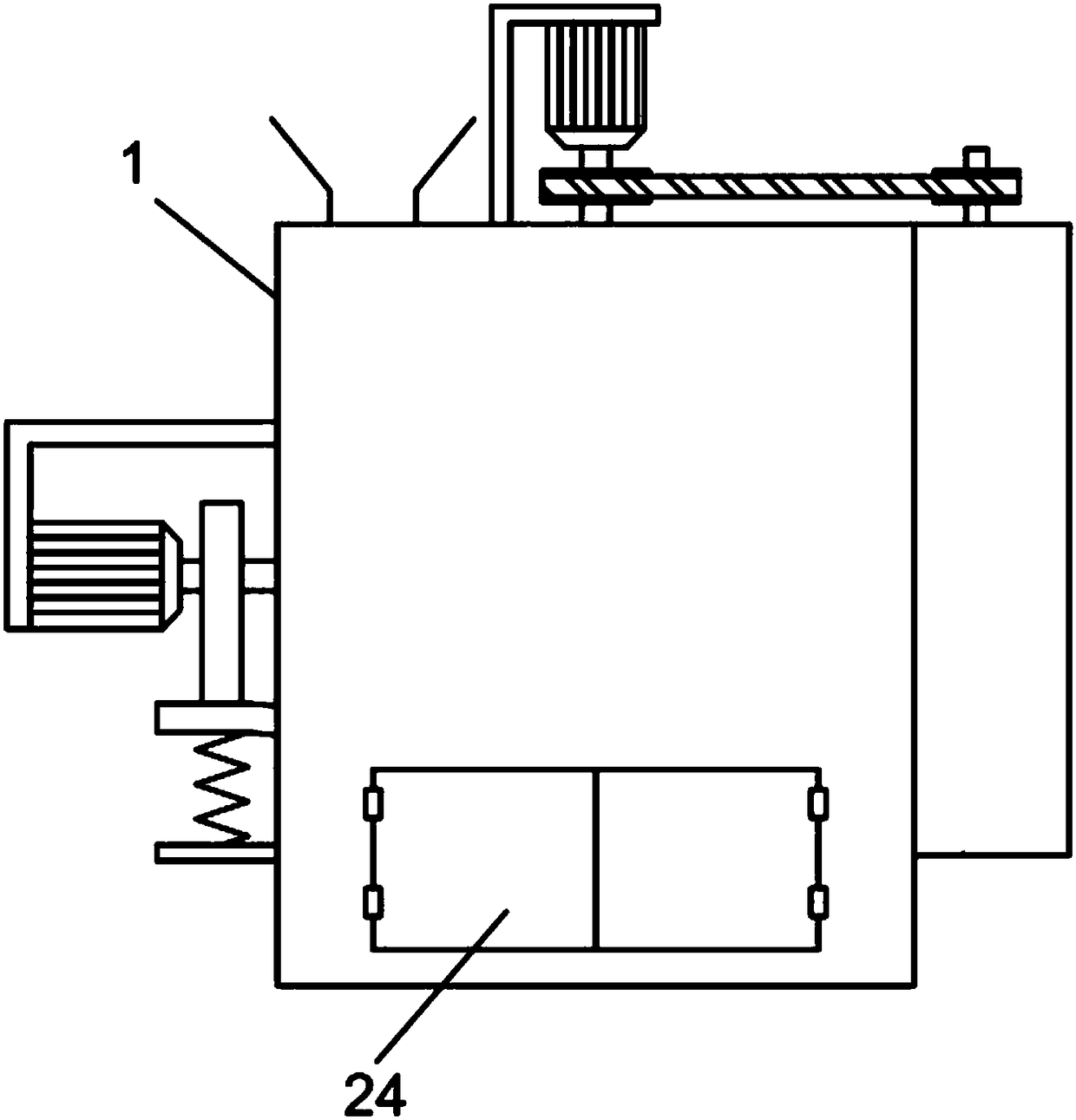

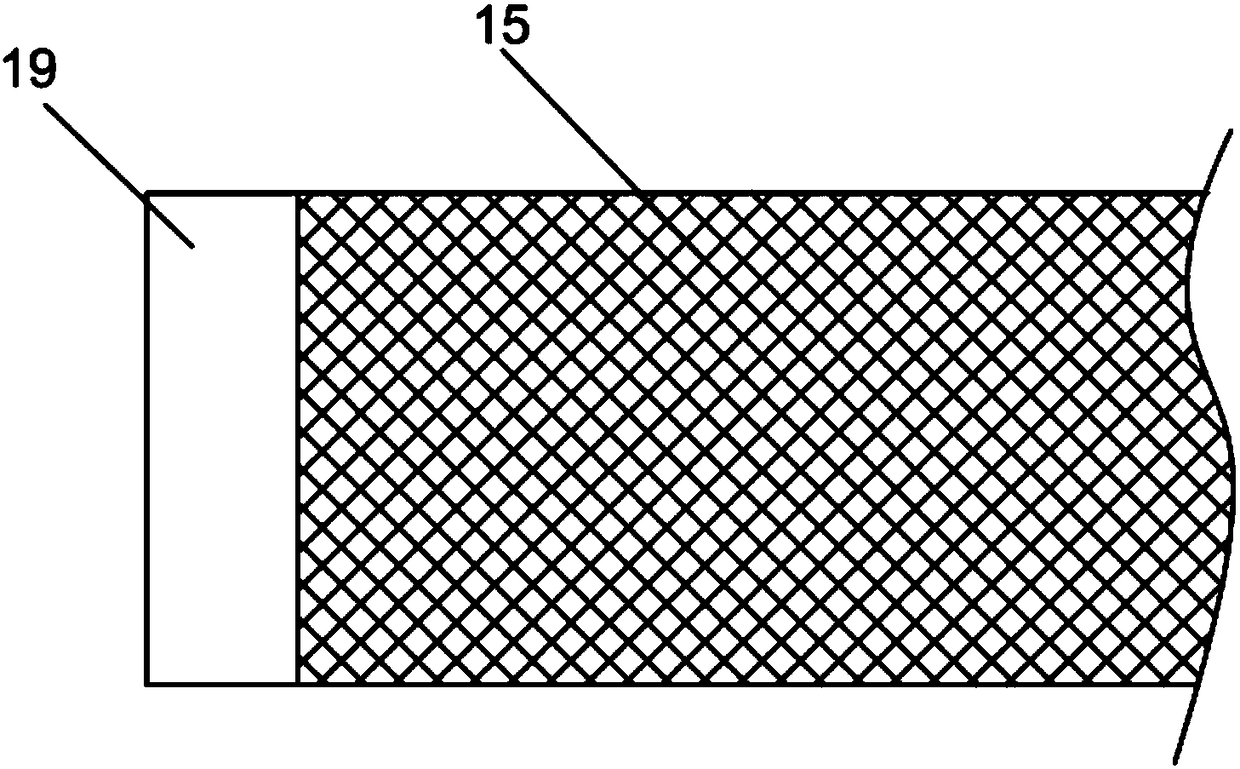

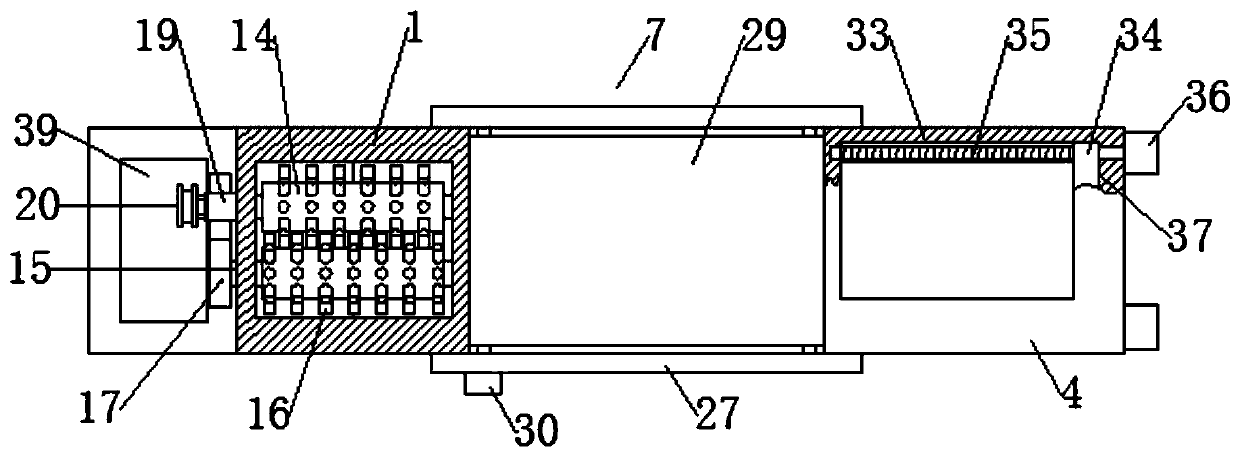

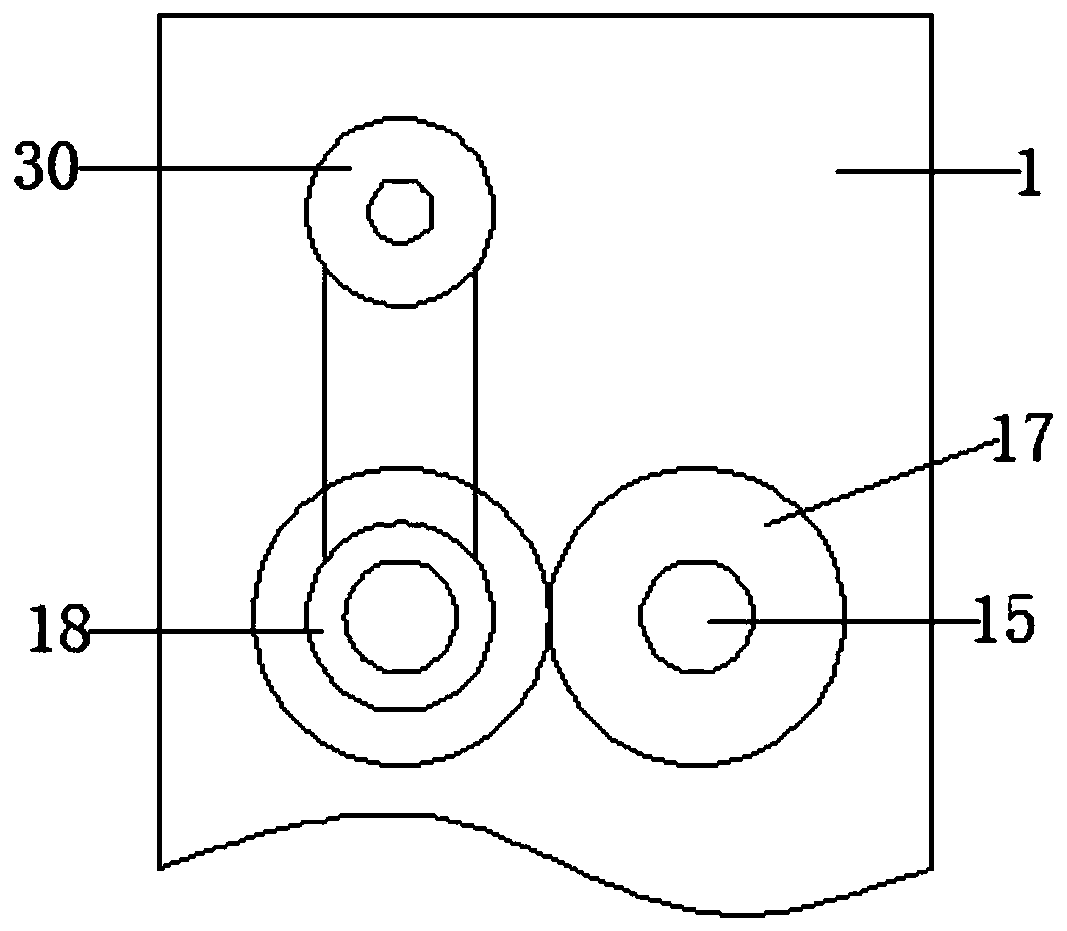

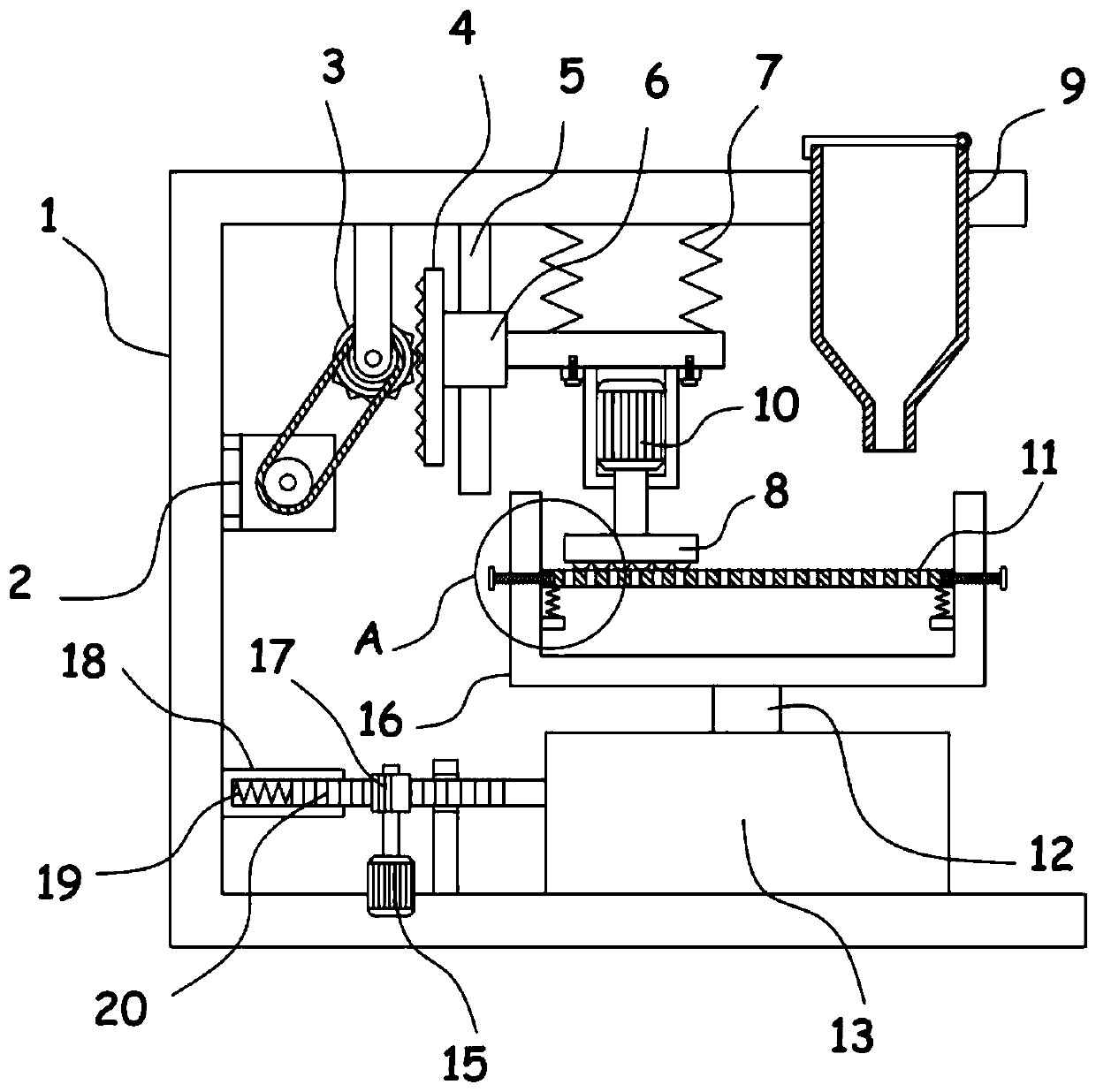

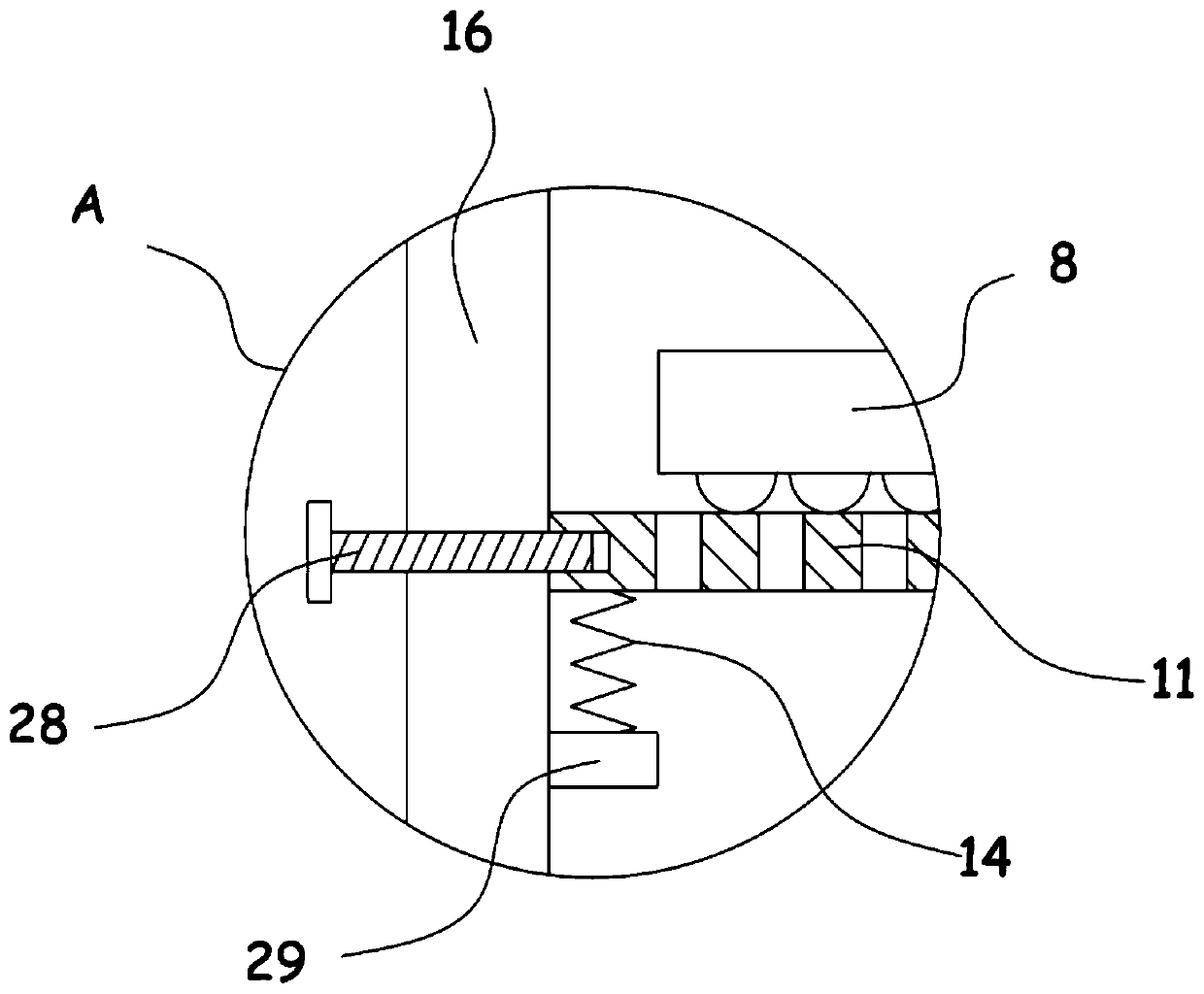

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

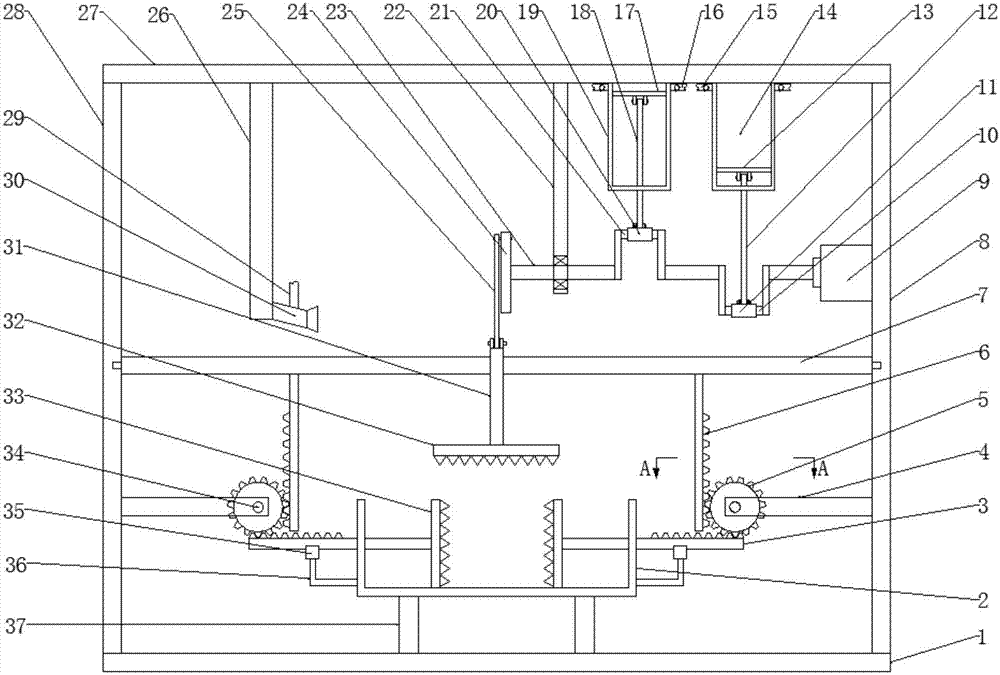

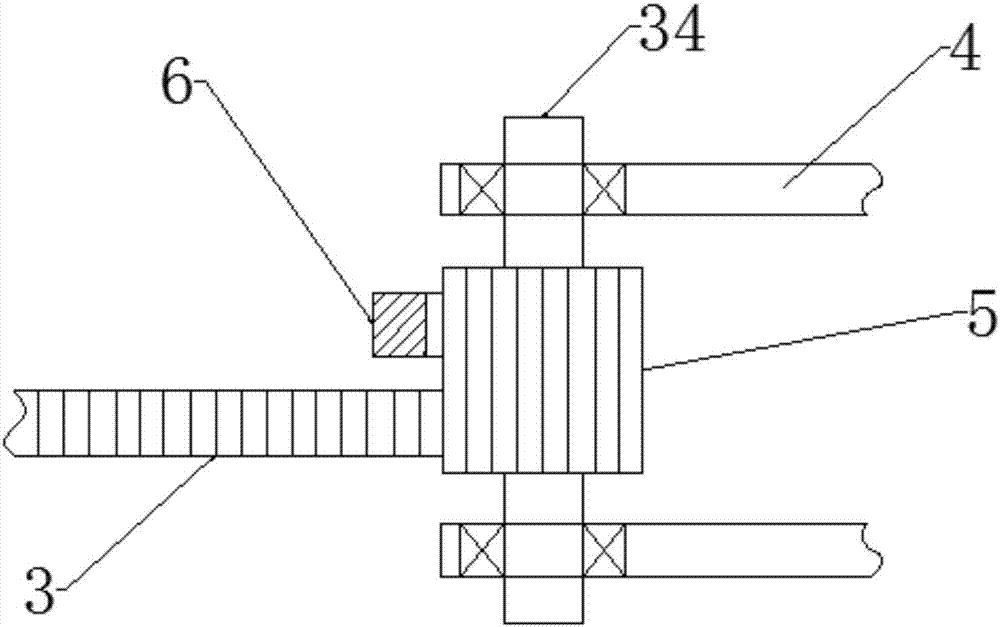

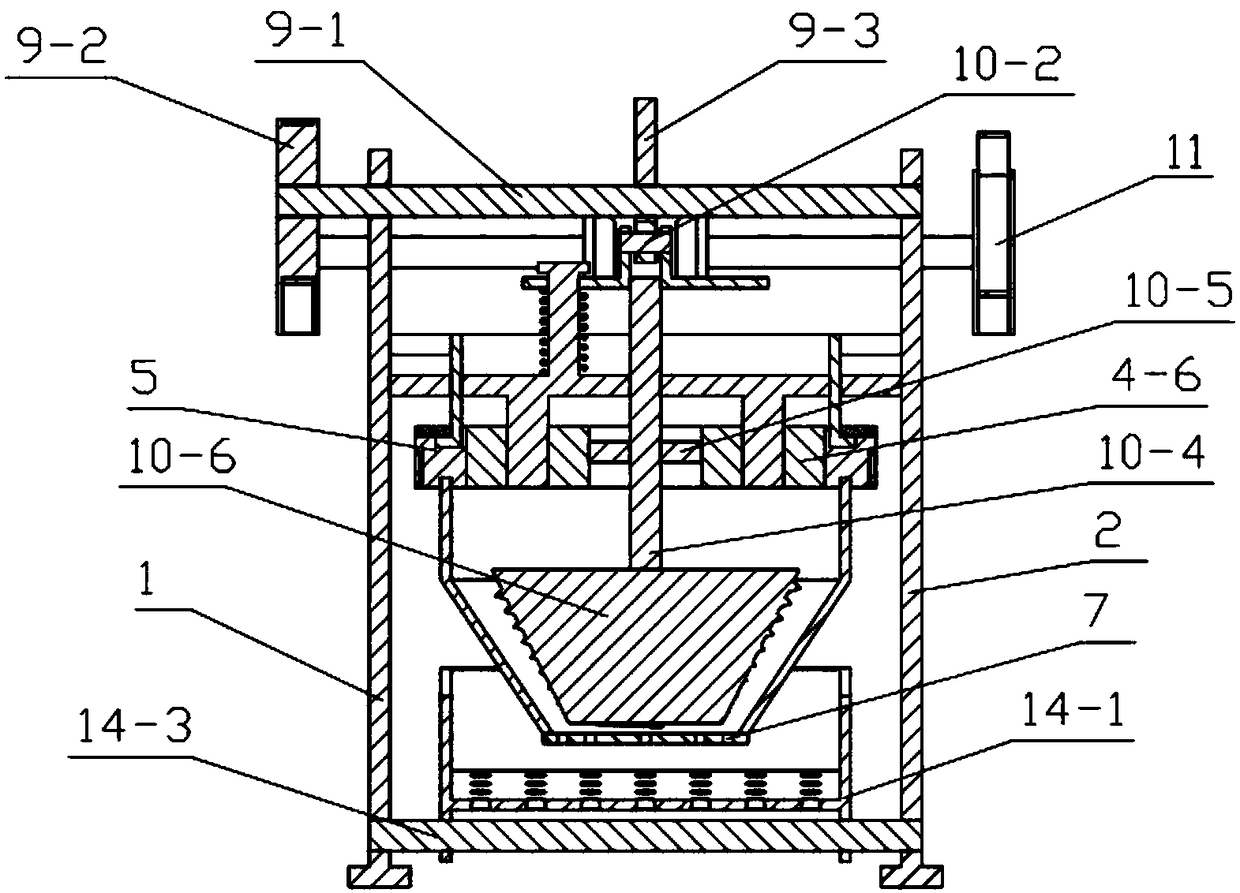

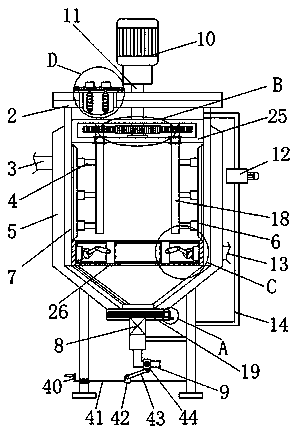

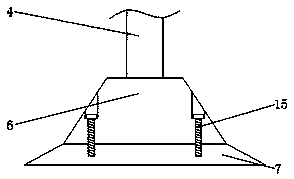

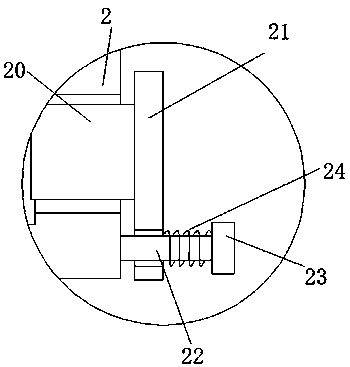

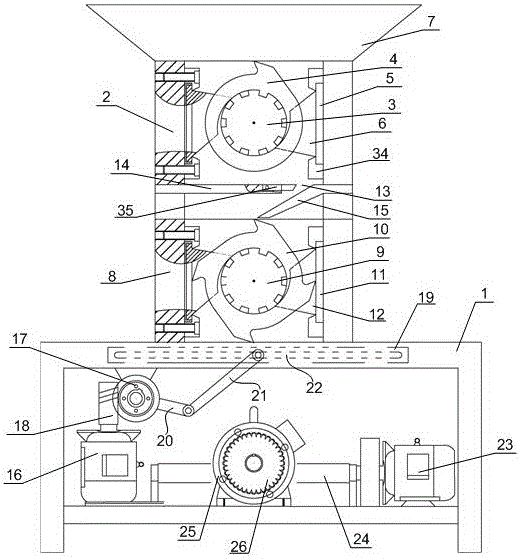

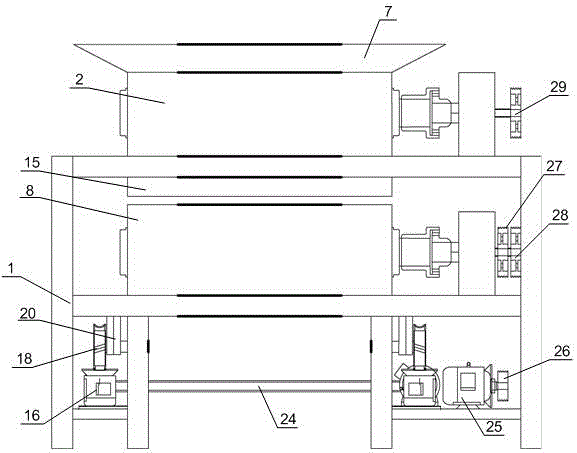

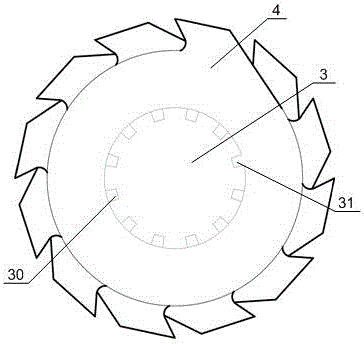

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

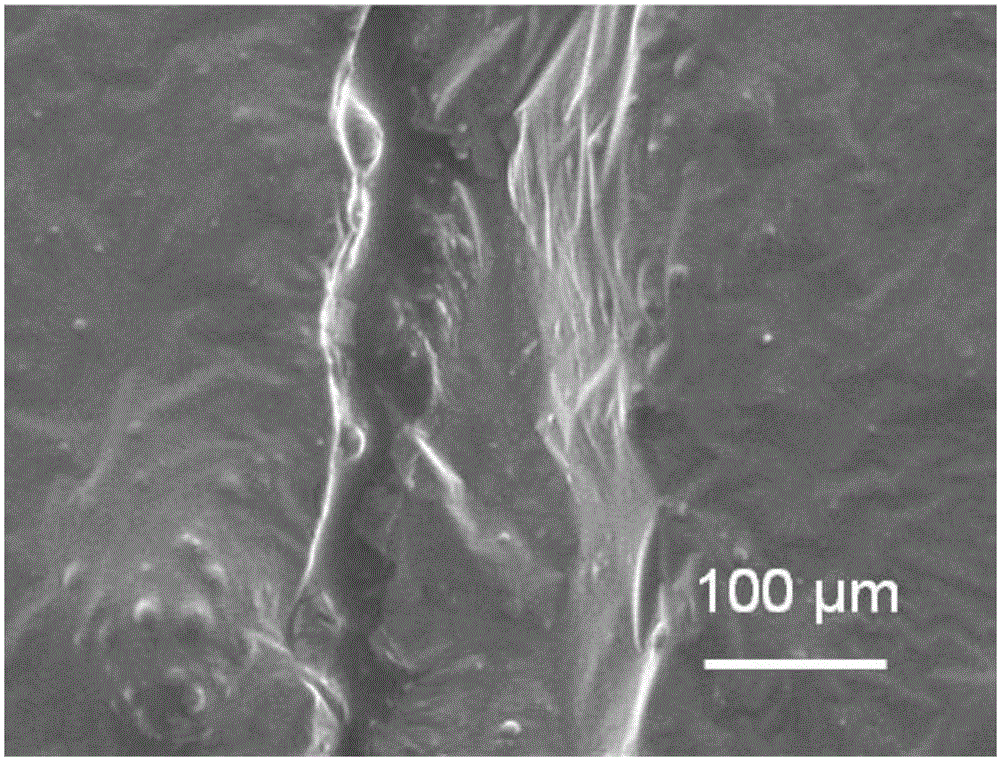

Double-capsule self-repairing epoxy coating and preparation method thereof

InactiveCN105833811ASimple preparation processIncrease productivityMicroballoon preparationMicrocapsule preparationChemistrySilicon dioxide

The invention discloses a double-capsule self-repairing epoxy coating and a preparation method thereof. The preparation method mainly uses Pickering emulsion droplet template method and conducts an interface polymerization of interface isophorone diisocyanate and tetraethylenepentamine in water-oil of epoxy interface to prepare epoxy microcapsule and tetraethylenepentamine microcapsule; and the two microcapsules are added to epoxy resin microcapsules for the formation of double-capsule self-repairing epoxy coating. The Pickering emulsion droplet template method ensures the stability of the emulsion, prevents emulsion droplet blending, improves package amount and efficiency of the microcapsule core material; Pickering emulsion improves the repair efficiency of the double-capsule self-repairing epoxy coating; the introduction of nano silica particles and nano clay in the capsule walls of the epoxy microcapsule and tetraethylenepentamine microcapsule improves the mechanical strength and thermal stability of the microcapsule wall, but also improves the brittleness of the microcapsule and the releasing efficiency of the microcapsule core material, so as to ensure the repair performance of the double-capsule self-repair coating.

Owner:SOUTH CHINA UNIV OF TECH

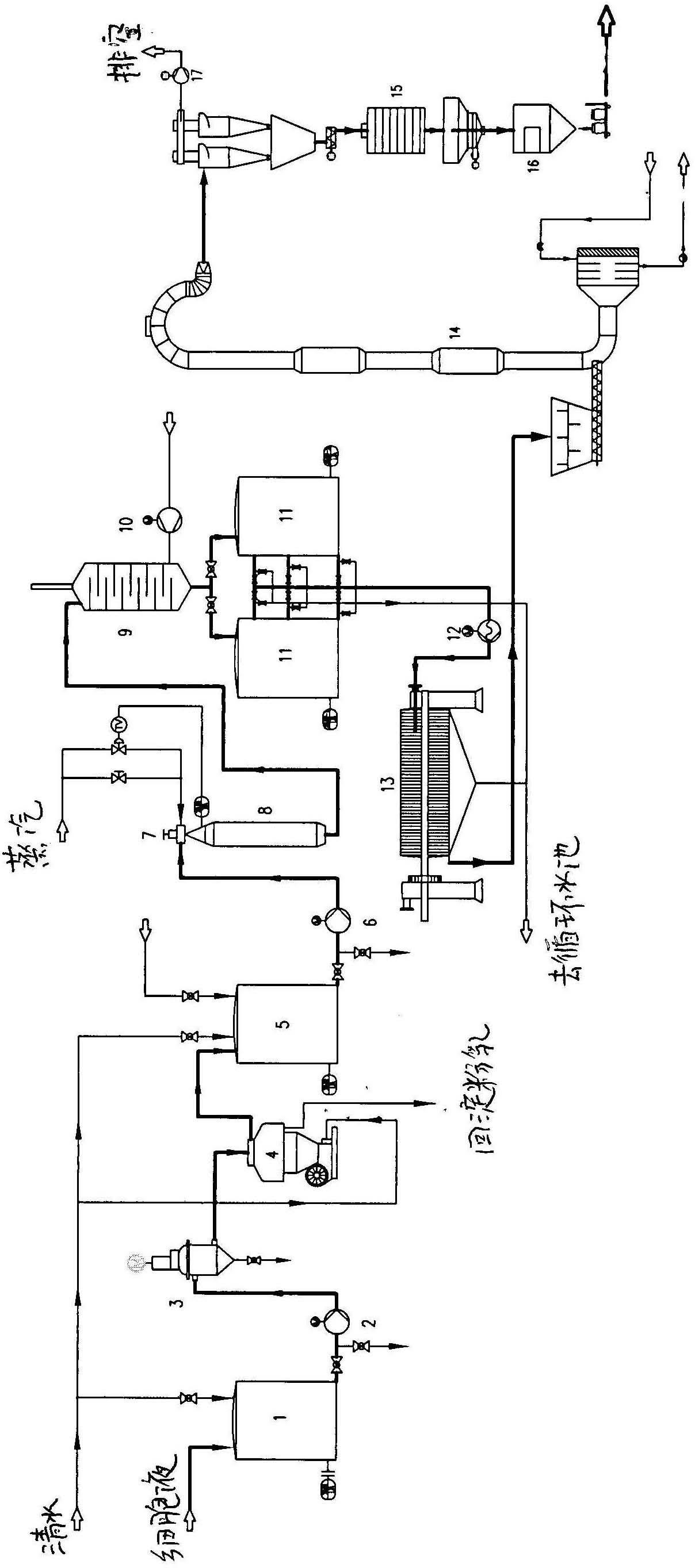

Production process of docosahexenoic acid grease by bioenzyme method wall-breaking

InactiveCN101307341APrevent oxidationCompletely brokenUnicellular algaeMicroorganism based processesLiquid mediumOil oxidation

The invention relates to a method for making docosahexaenic acid (DHA) grease through adopting bio-enzyme method wall breaking, comprising the following steps that: Crypthecodinium cohnii(Seligo)Javornicky is taken as starting strain; alga cell is obtained through carrying out continuous cultivation of Crypthecodinium cohnii(Seligo)Javornicky in liquid medium; and then DHA grease is extracted from the alga cell through bio-enzyme method wall breaking. The method has the advantages that: alga cell wall breaking is complete with the wall-breaking rate reaching more than 95 percent; the method does not need a drying step, and can prevent the oxidation of DHA crude oil, thereby ensuring that the peroxide value of extracted grease is extremely low (i.e. the POV value is less than 0.5); moreover, the yield of the extracted grease is more than 90 percent of total oil, while the refining yield is more than 70 percent of crude oil.

Owner:罗盖特生物营养品(武汉)有限公司

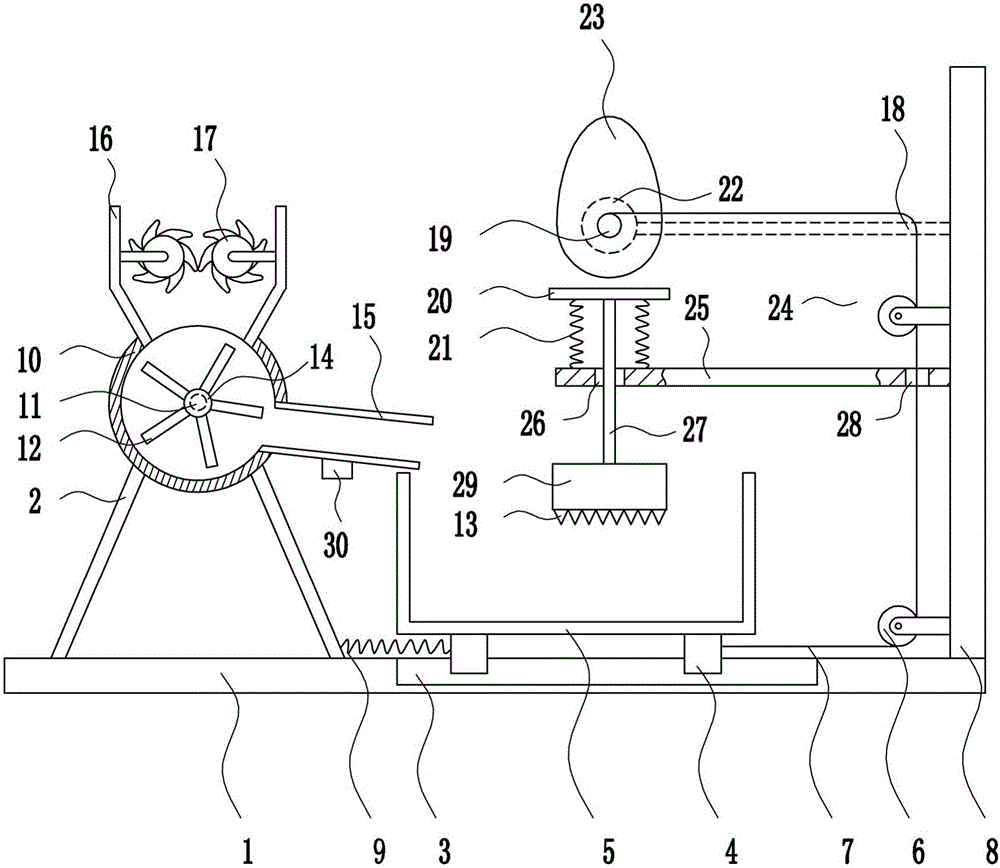

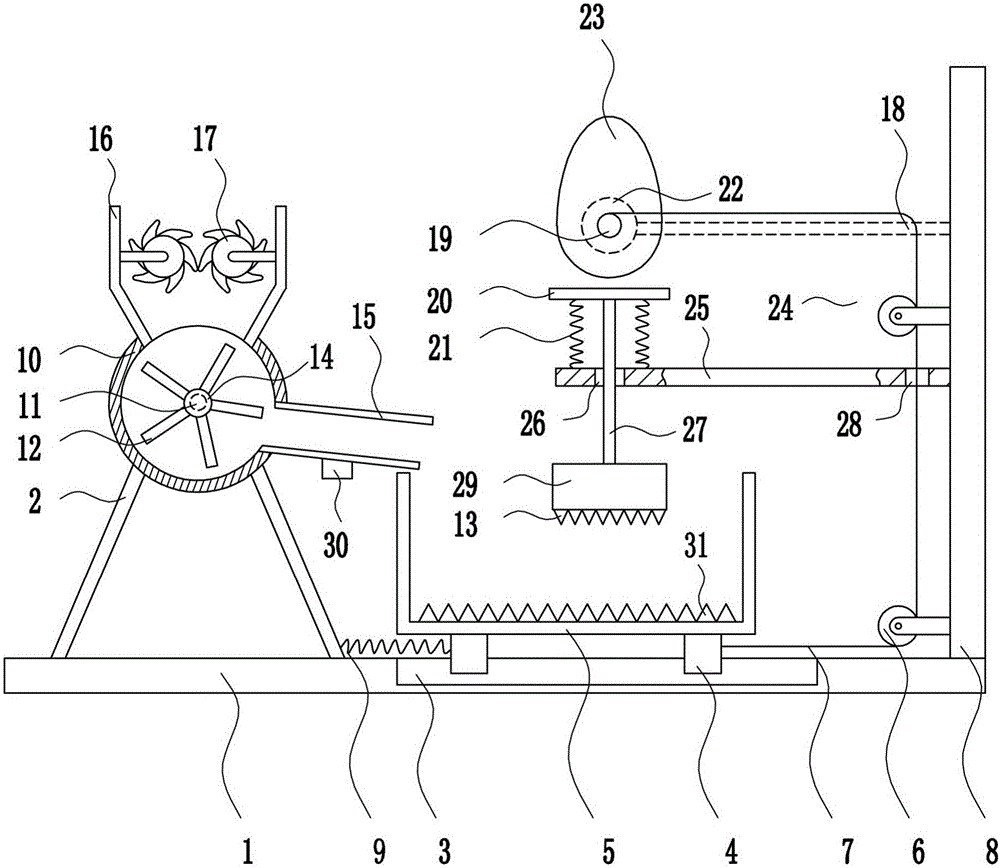

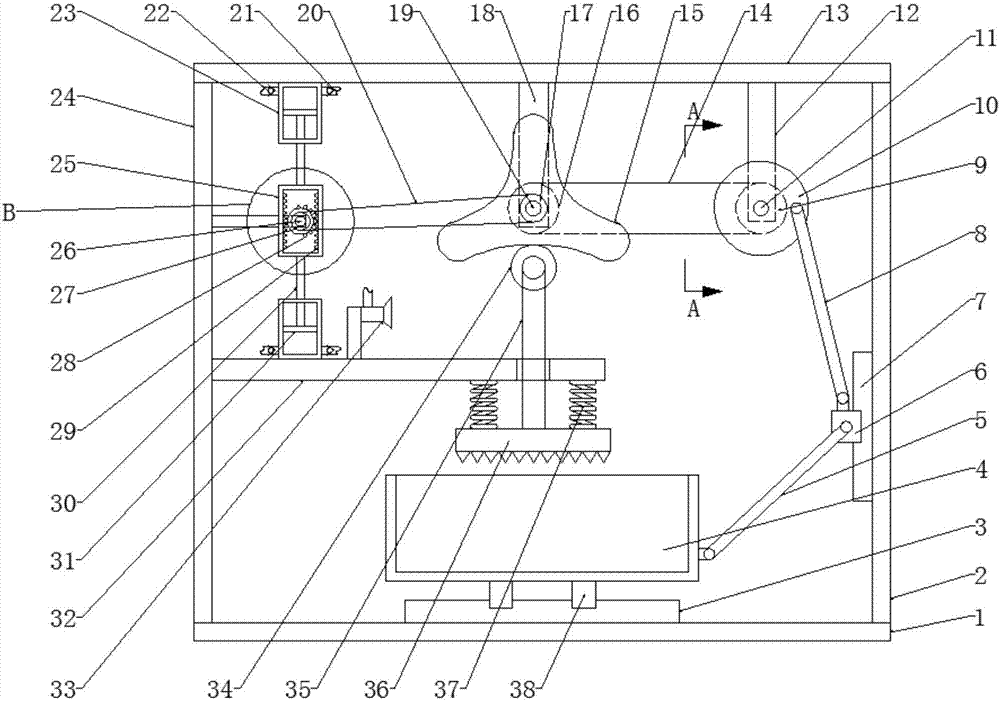

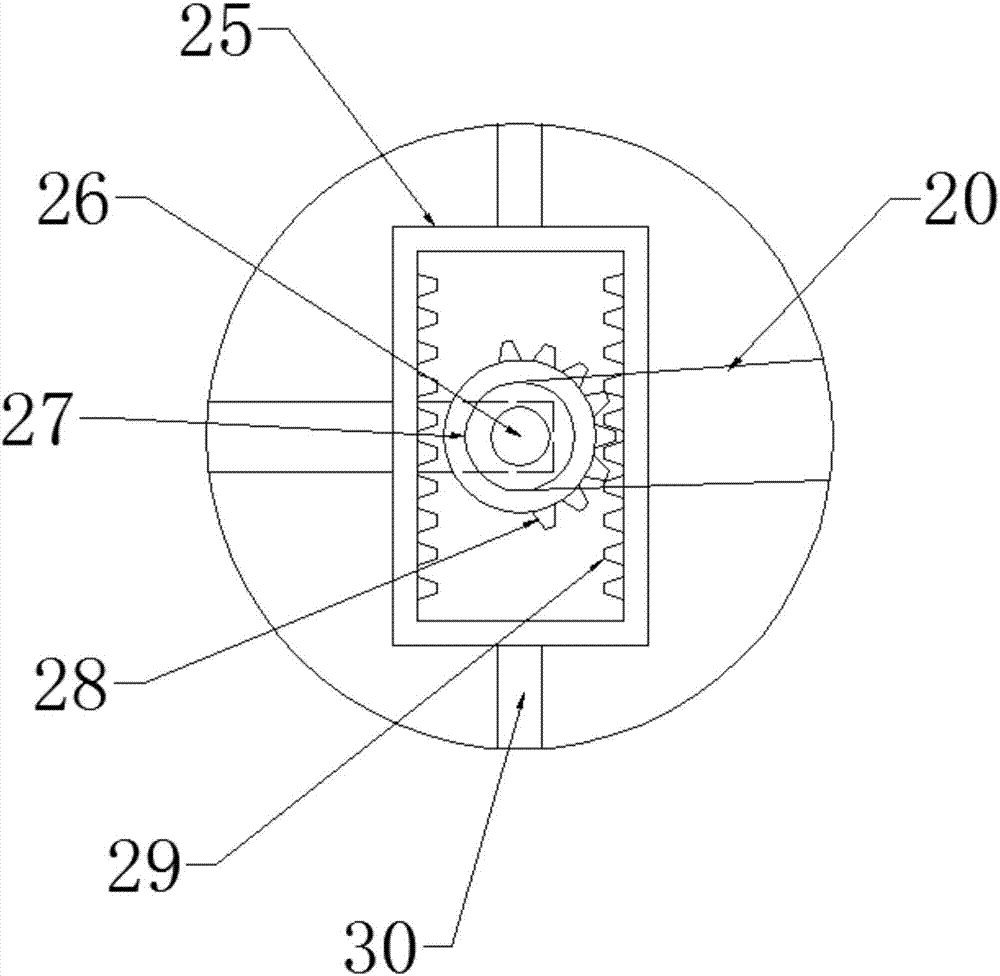

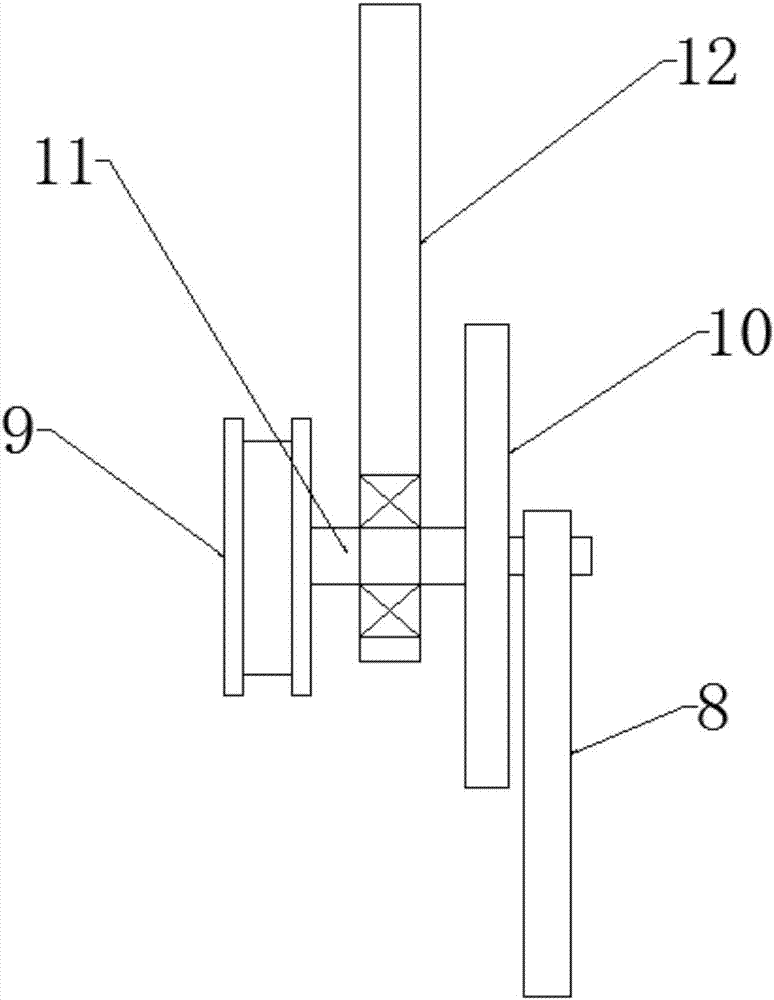

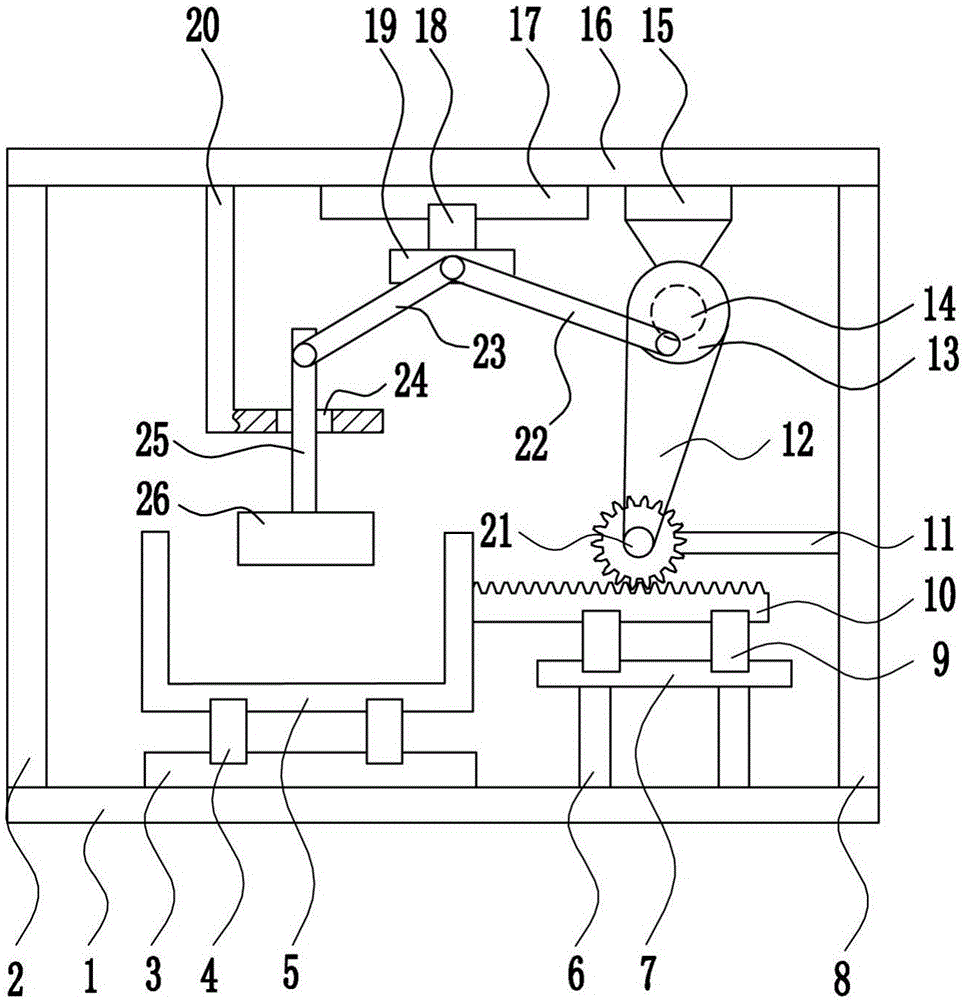

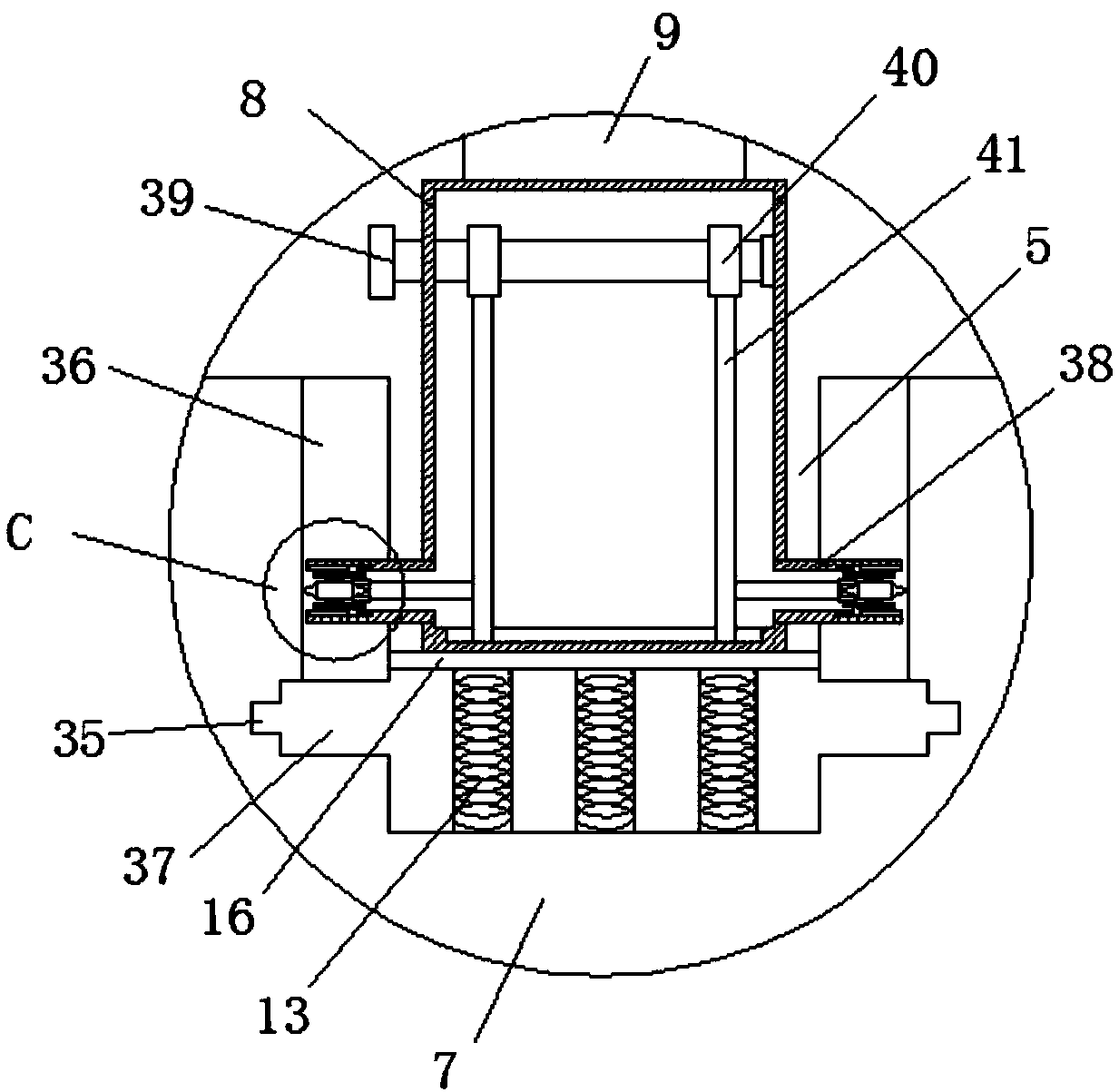

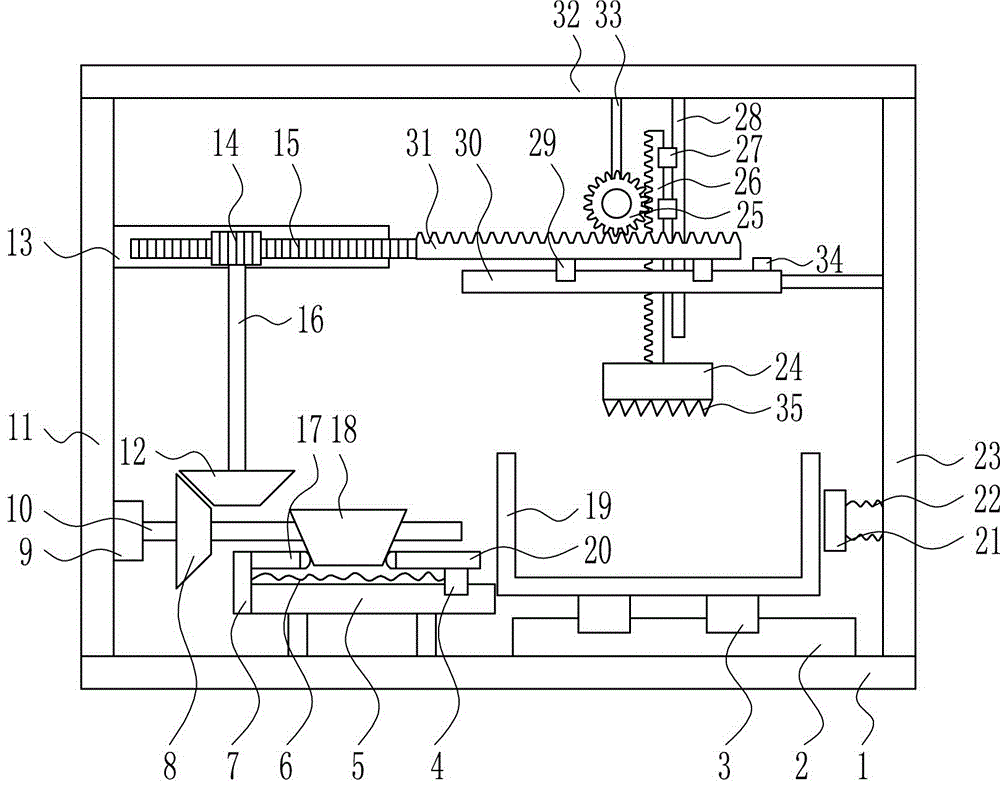

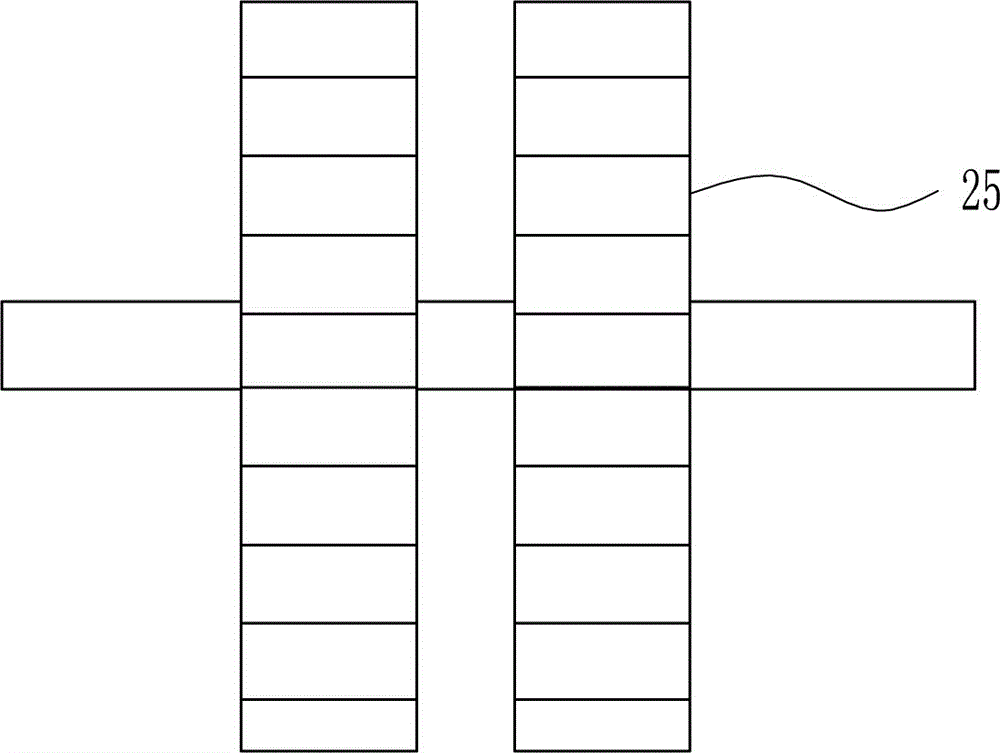

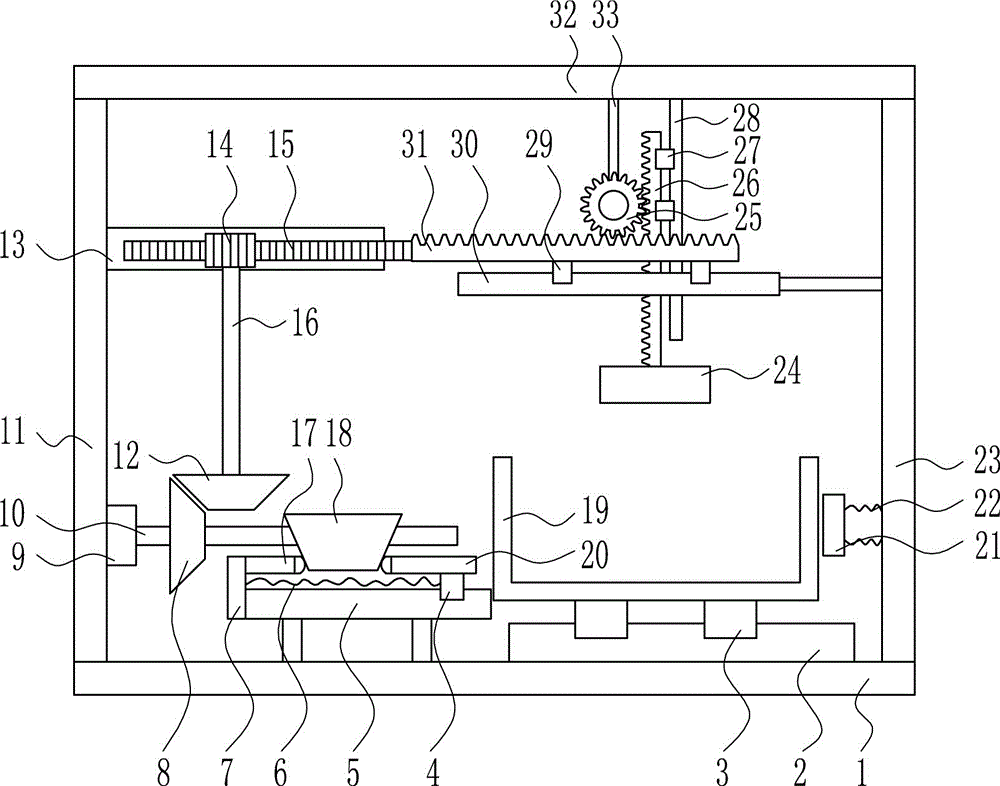

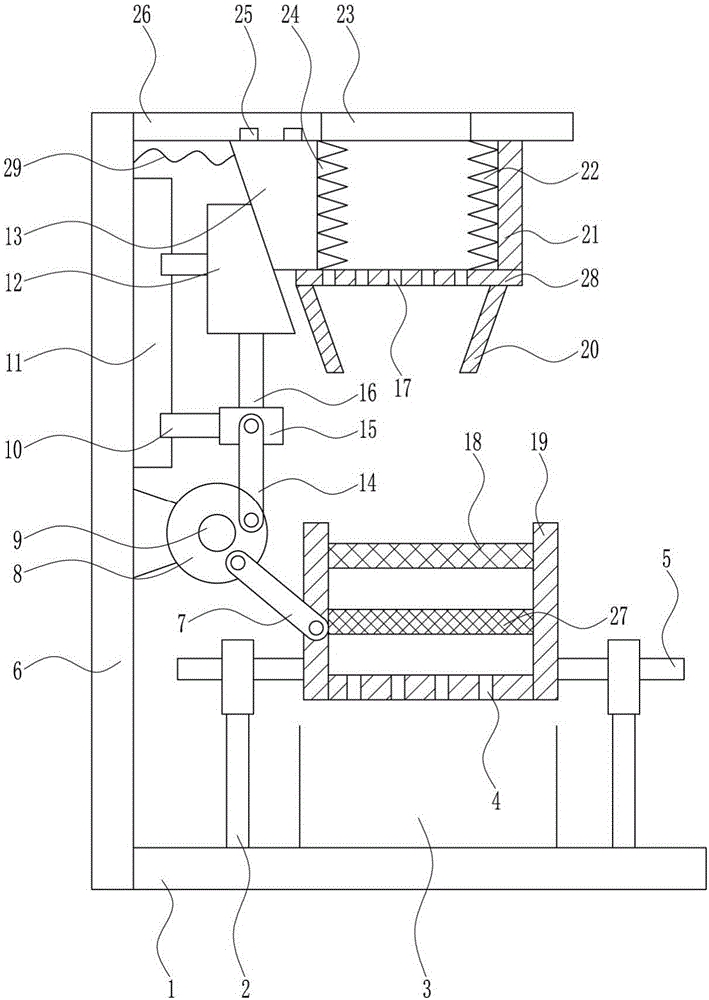

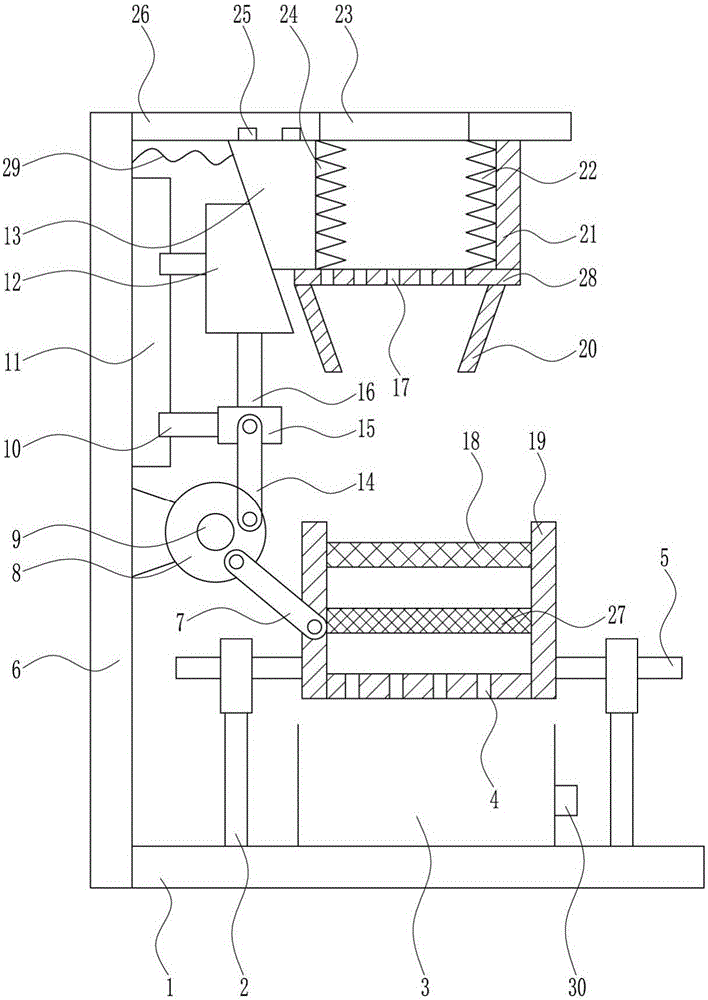

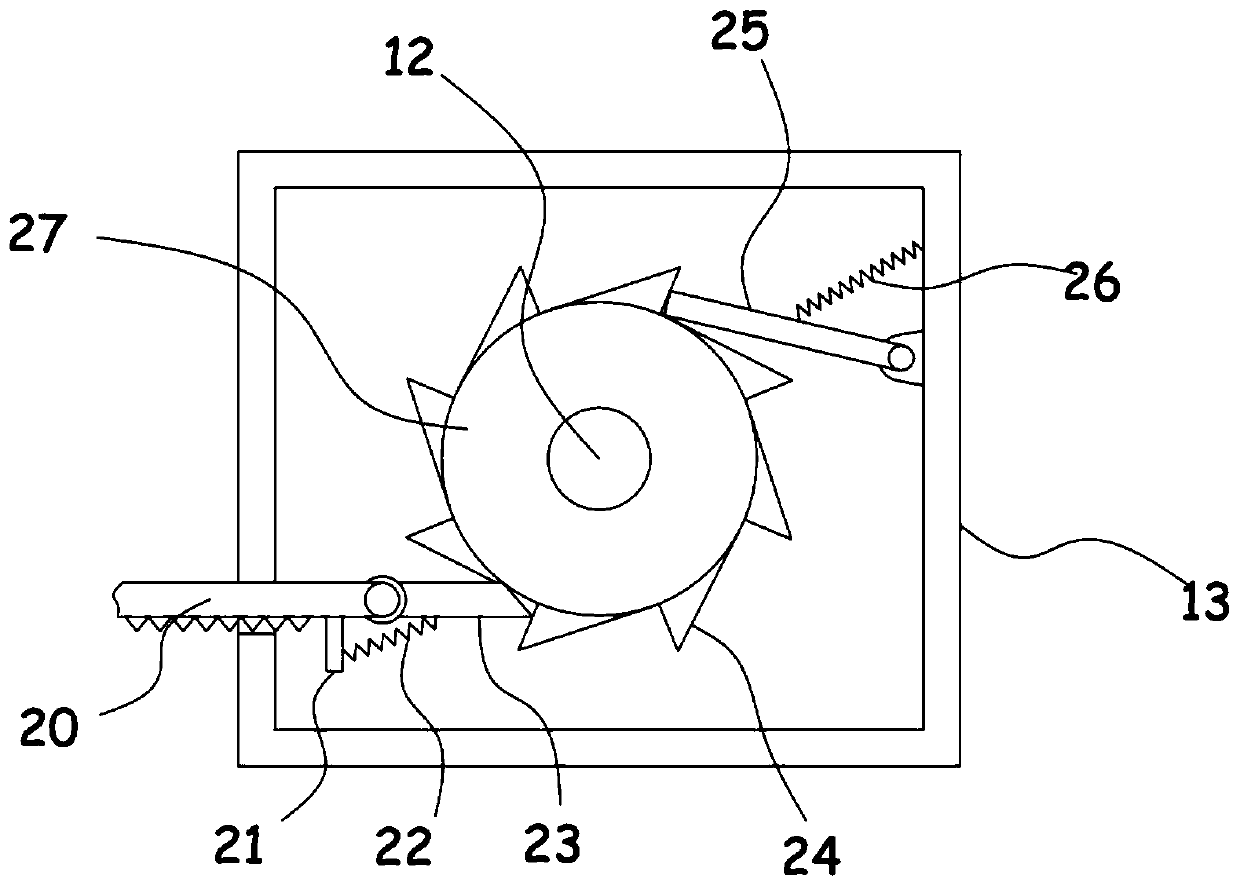

Efficient breaking device of waste bricks serving as wall material for building

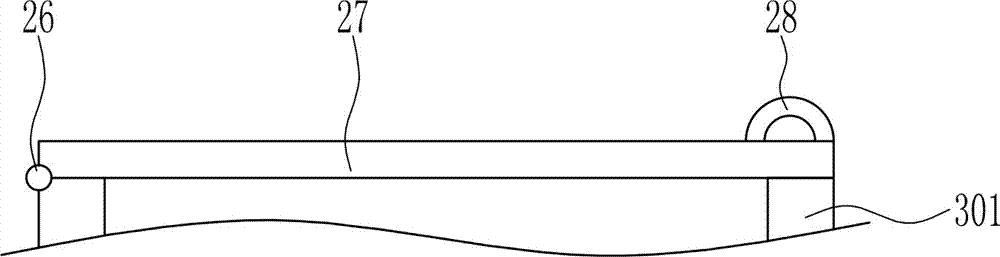

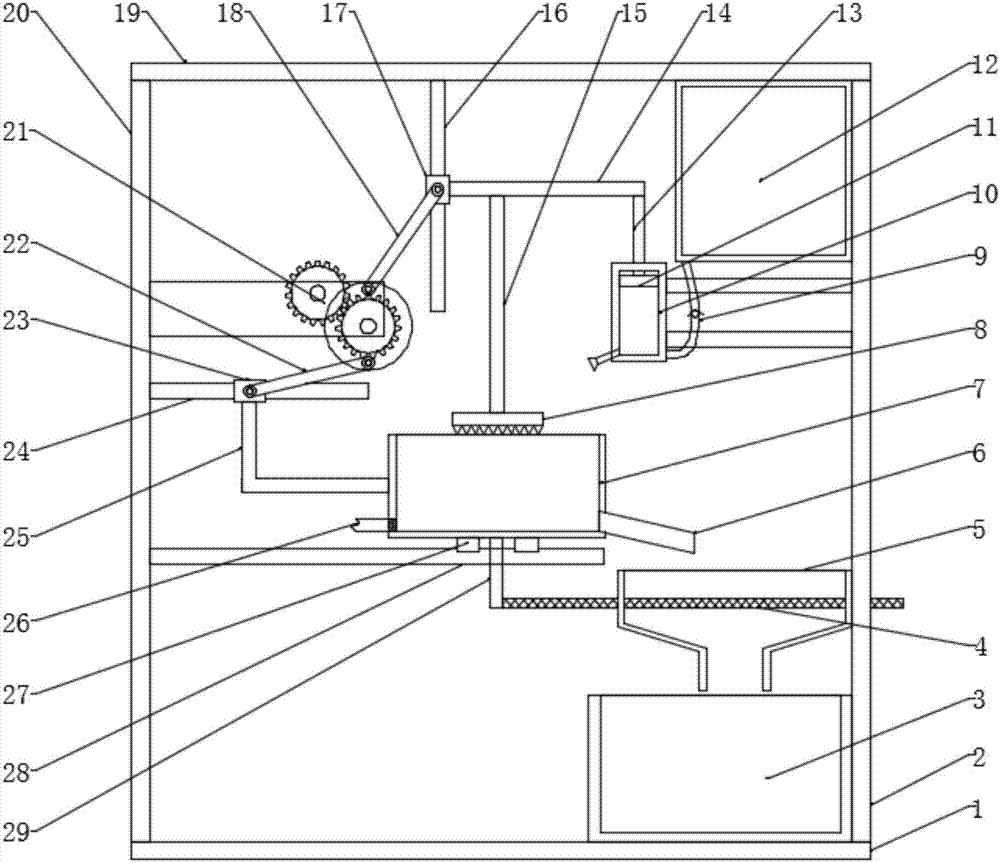

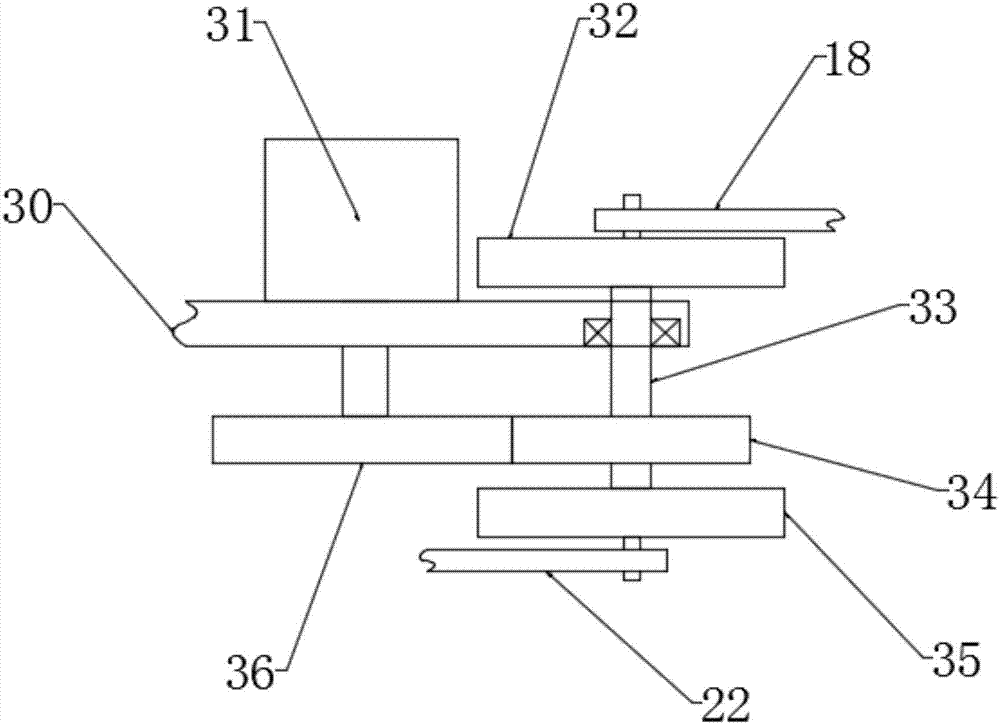

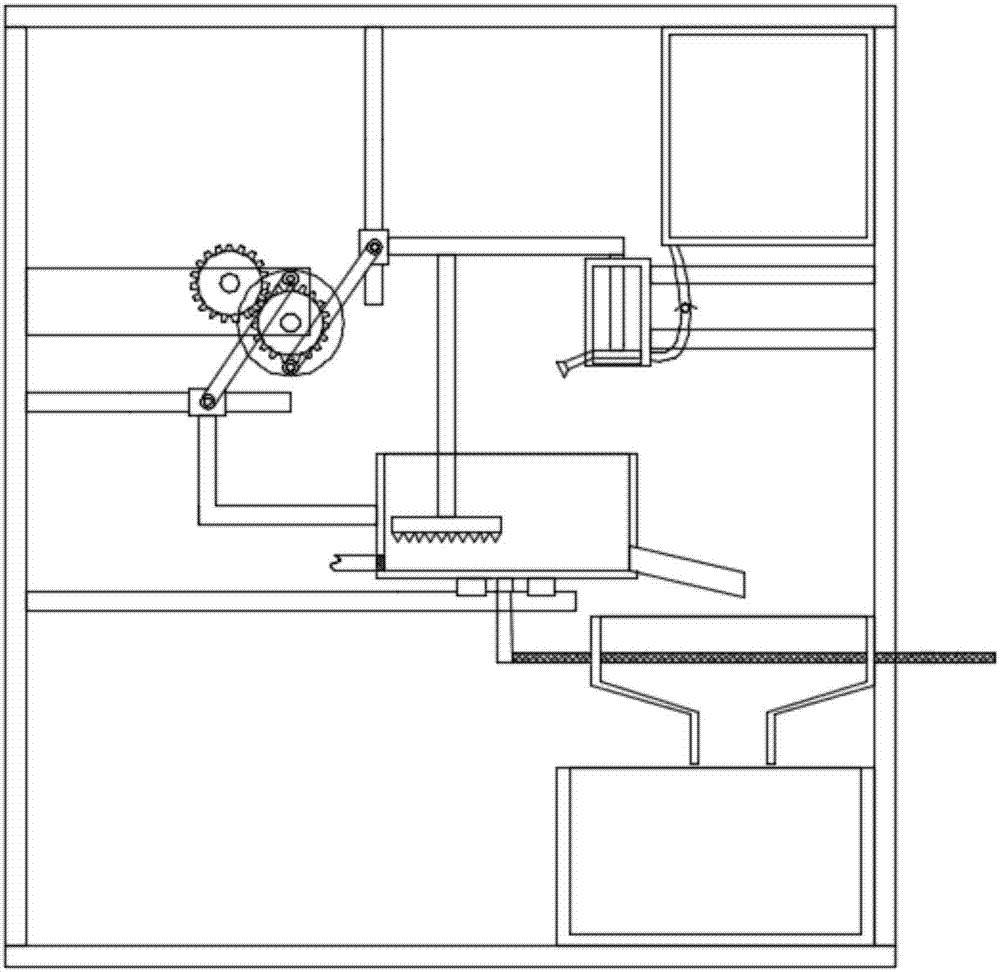

InactiveCN107377064AReduce labor intensityBroken fastUsing liquid separation agentGrain treatmentsCircular discBrick

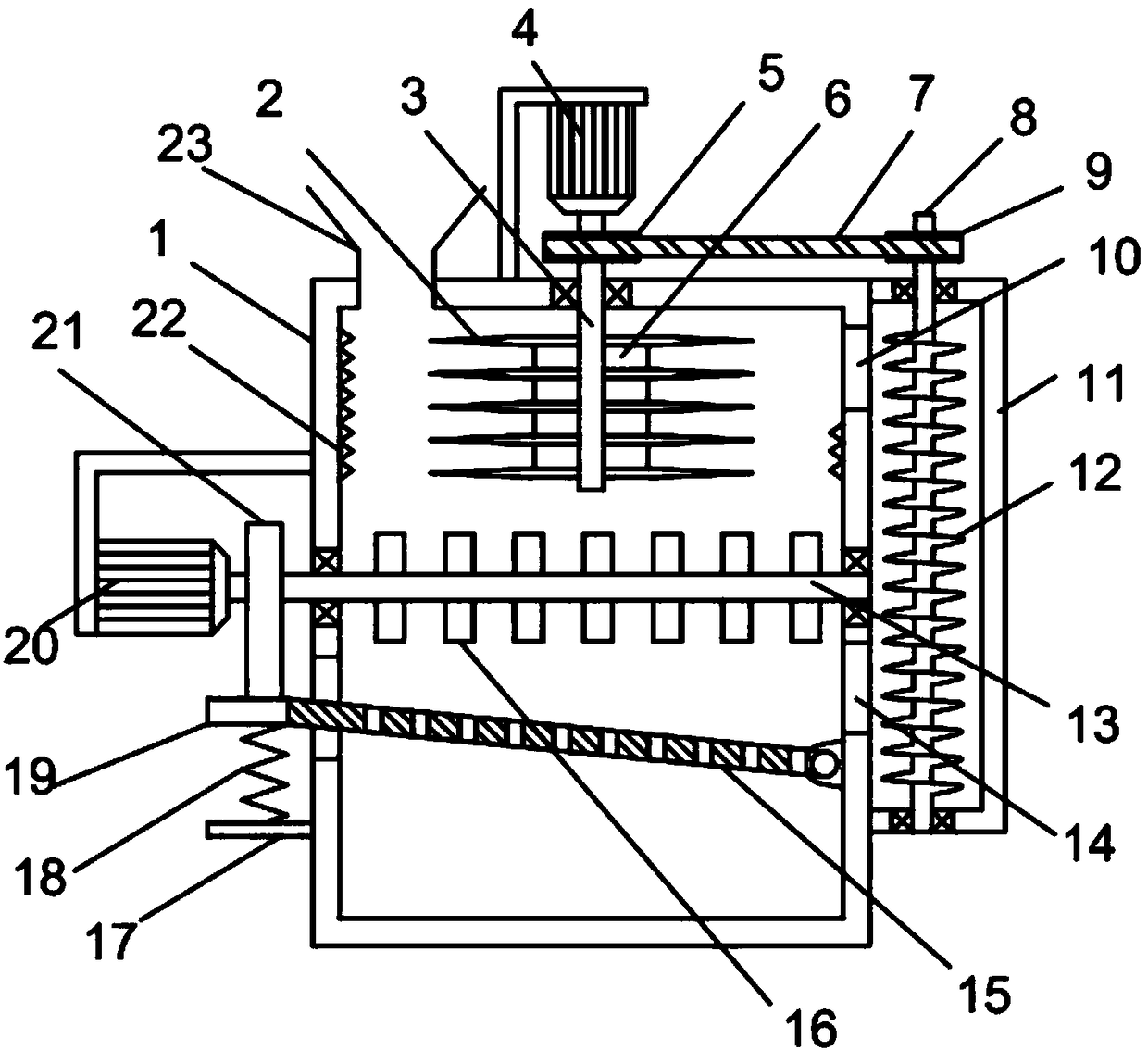

The invention discloses a high-efficiency crushing device for waste bricks of building wall materials, which comprises a bottom plate, a crushing frame, a first crushing plate, a first rack, a gear, a second crushing plate, a first connecting rod, a guide rod, a second rack, second connecting rod, disk, crankshaft, motor, first connecting rod journal, second connecting rod journal, first piston rod, second piston rod and nozzle, the present invention is provided with motor, crankshaft, circle The plate, the first connecting rod and the second connecting rod are used to crush waste bricks from top to bottom through the cooperation of the above parts, and the crushing speed is fast. There are guide rods, second racks, gears and first racks. Cooperate with the first crushing plate to crush the waste bricks from the left and right sides, making the crushing more thorough and even, improving the crushing efficiency and reducing the labor intensity of the staff. There are first connecting rod journal and second connecting rod journal , the first piston rod, the second piston rod and the nozzle, through cooperation to achieve continuous water spraying and dust reduction, to avoid affecting the health of the staff.

Owner:伍超群

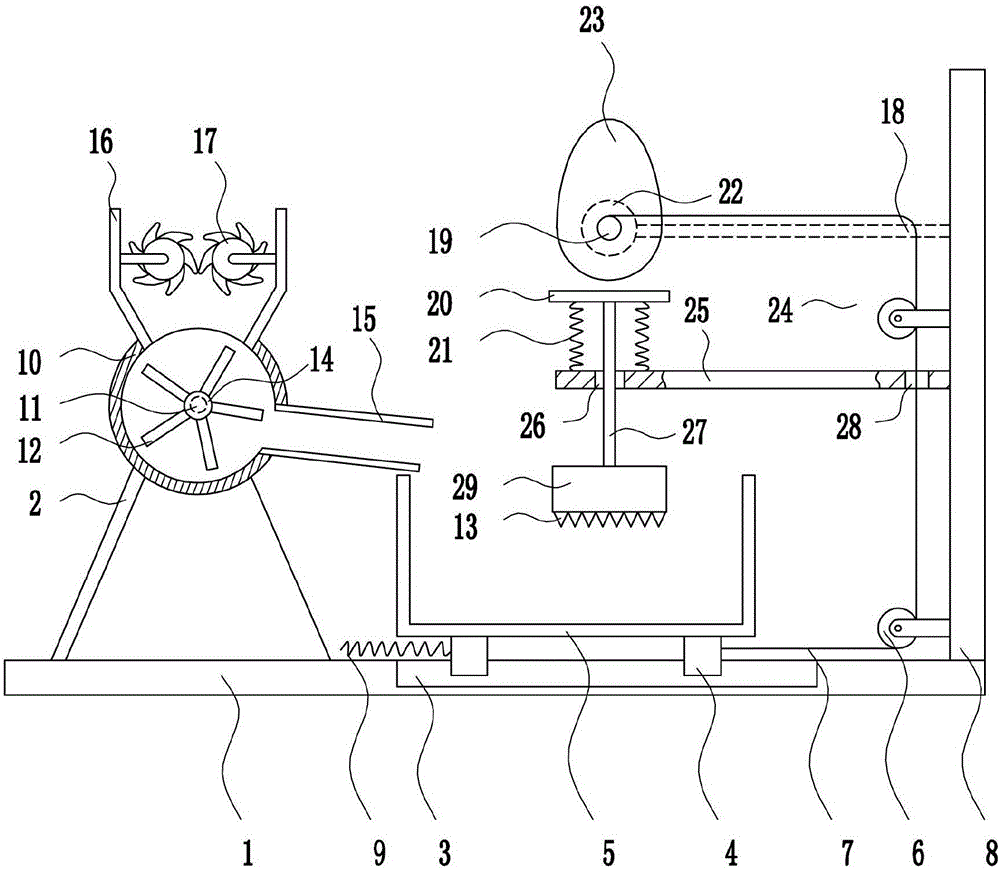

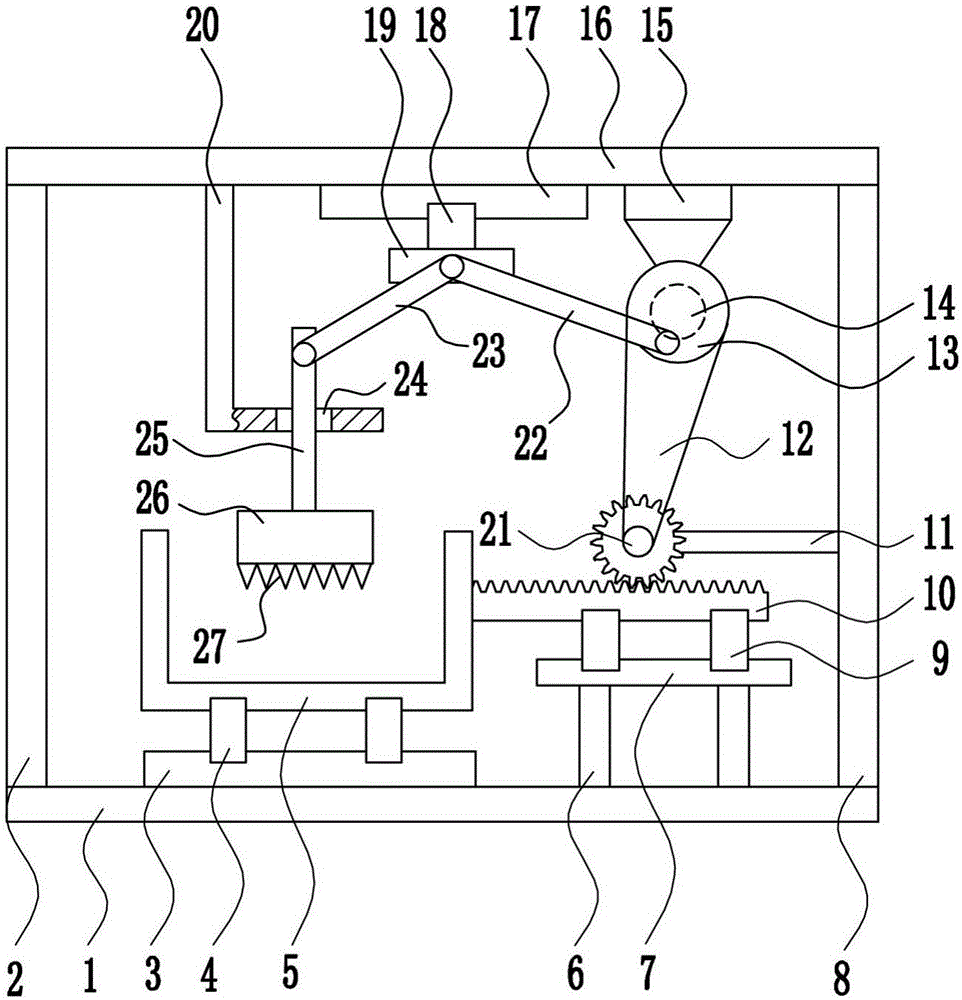

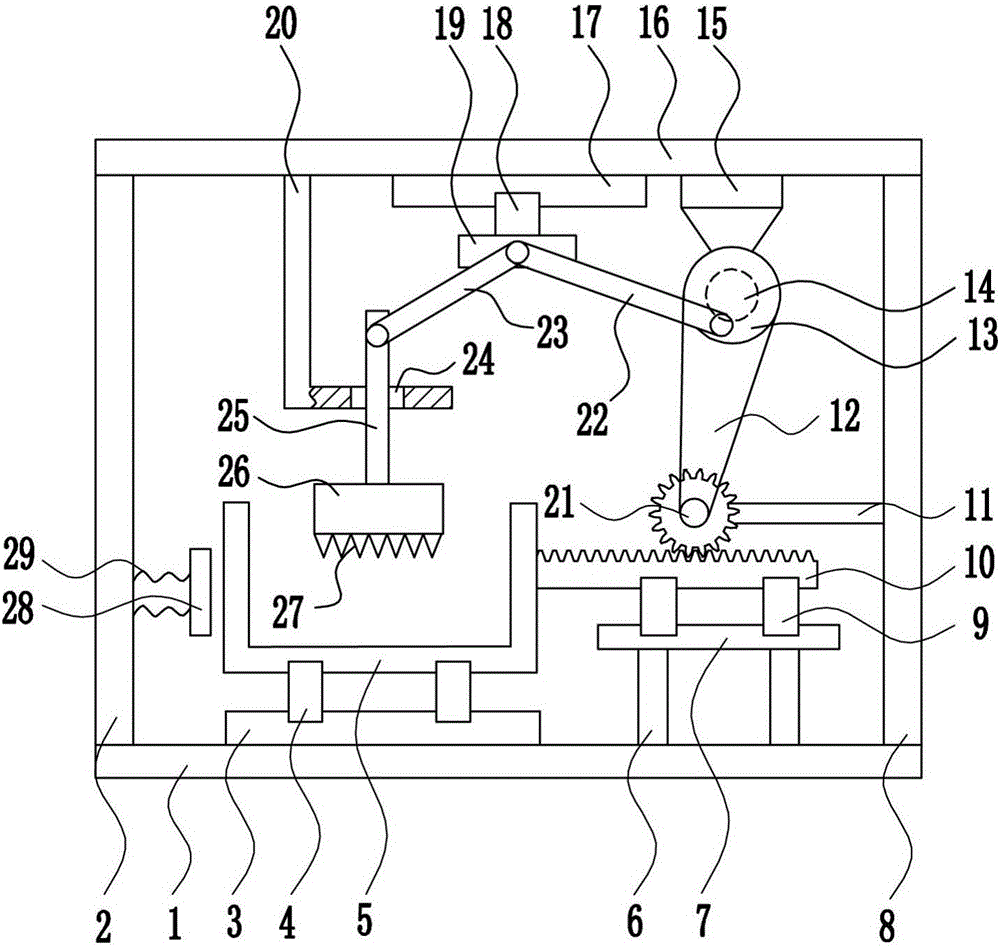

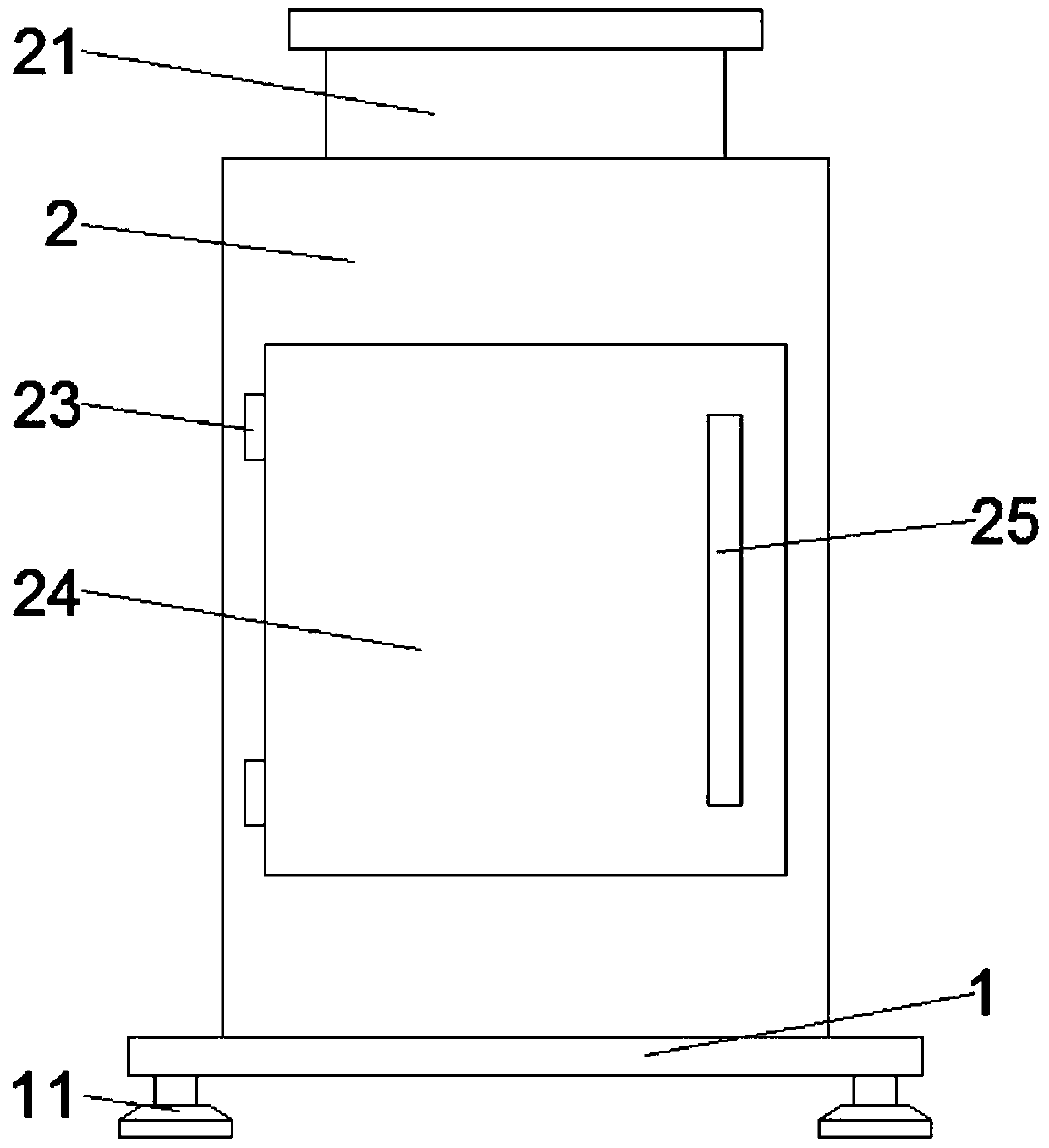

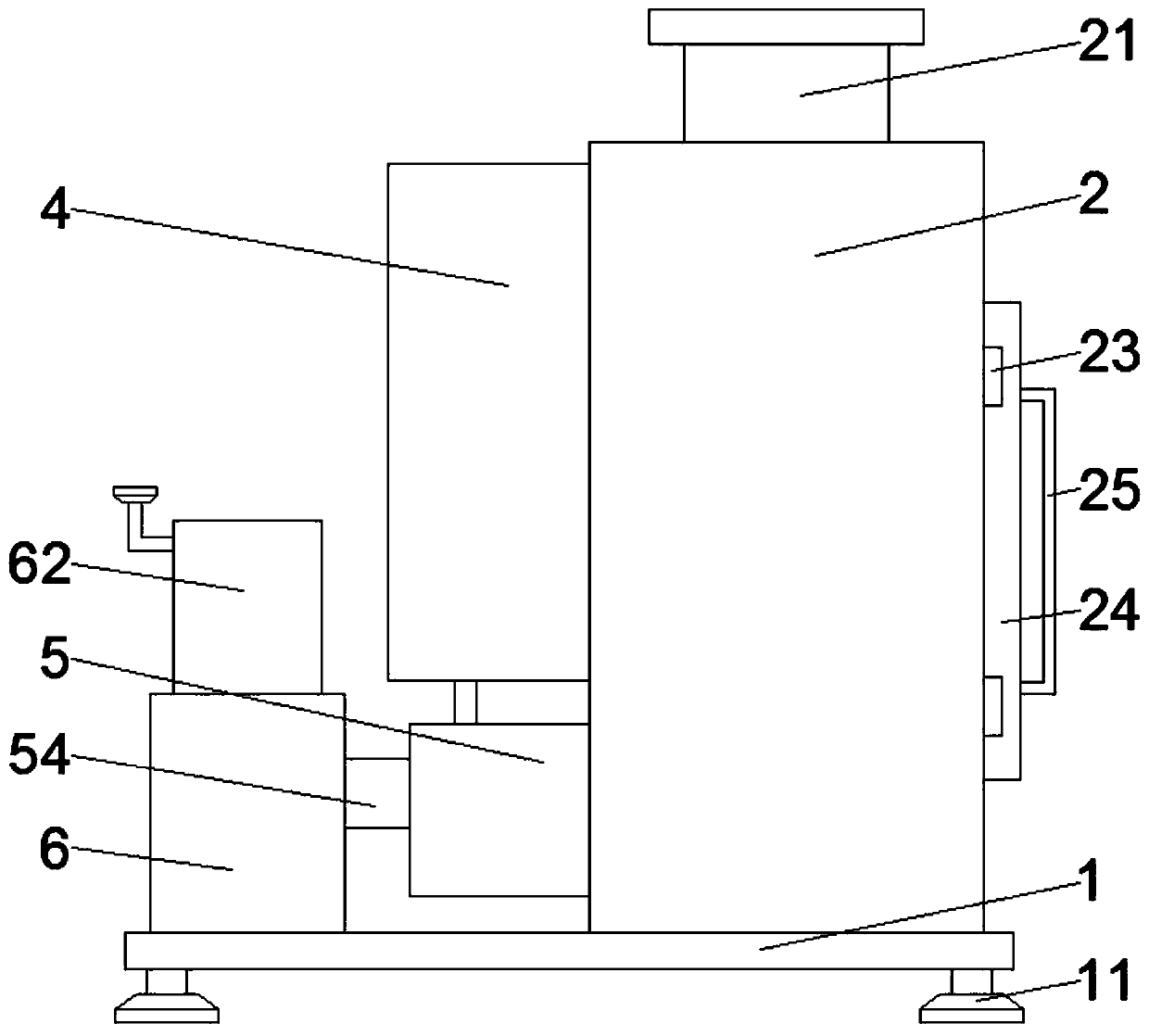

Efficient treatment device for waste vamps for shoe factory

The invention relates to a waste vamp treatment device for a shoe factory and particularly relates to an efficient treatment device for waste vamps for the shoe factory. The invention aims to solve the technical problem of providing the efficient treatment device for waste vamps for the shoe factory, wherein the device crushes thoroughly and uniformly and is simple in structure. In order to solve the technical problem, the invention provides the efficient treatment device for waste vamps for the shoe factory. The device comprises a bottom plate, a mounting base, a slide rail, a slide block, a first fixed pulley, a guy wire, a right rack, a first spring, a spherical housing, a first motor, blades, a first cone-shaped gear, a rotating disc, a discharge pipe, a feeding hopper, electric crushing wheels, a supporting rod, a reel, a pressure plate, second springs, a second motor, a camp, a second fixed pulley, a guide plate, a lifting rod and a pressure block. The device provided by the invention achieves the effects of crushing thoroughly and uniformly and being simple in structure, so that the waste vamps are quickly and efficiently treated, and the production benefit of an enterprise is increased.

Owner:临沂临港投资管理有限公司

Agglomerated cement recycling and crushing device for building

InactiveCN107321424ABroken comprehensiveCompletely brokenUsing liquid separation agentCement productionCircular discEngineering

The invention discloses an agglomerated cement recycling and crushing device for a building. The device comprises a bottom plate, a crushing frame, a motor, a disc-shaped cam, a first belt pulley, a second belt pulley, a roller, a first connecting rod, a crushing plate, a spring, a third belt pulley, a first rotating shaft, a disc, a second connecting rod, a second sliding block, a second sliding rail, a third connecting rod and a dust falling mechanism. The device is provided with the disc-shaped cam, the roller, the first connecting rod, the spring and the crushing plate, through cooperation of the parts, agglomerated cement in the crushing frame is crushed through the crushing plate, the crushing speed is high, and the labor intensity of workers is relieved. The first belt pulley, a first belt, the third belt pulley, the disc, the second connecting rod and the third connecting rod are arranged, through cooperation of the parts, the crushing frame moves leftwards and rightwards, thus the cement in the crushing frame can be comprehensively crushed through the crushing plate, crushing is more through and uniform, and the crushing efficiency is improved. The dust falling mechanism is arranged, continuous water spraying is realized, dust falling is carried out, and influence on the health of the workers is avoided.

Owner:陈仲义

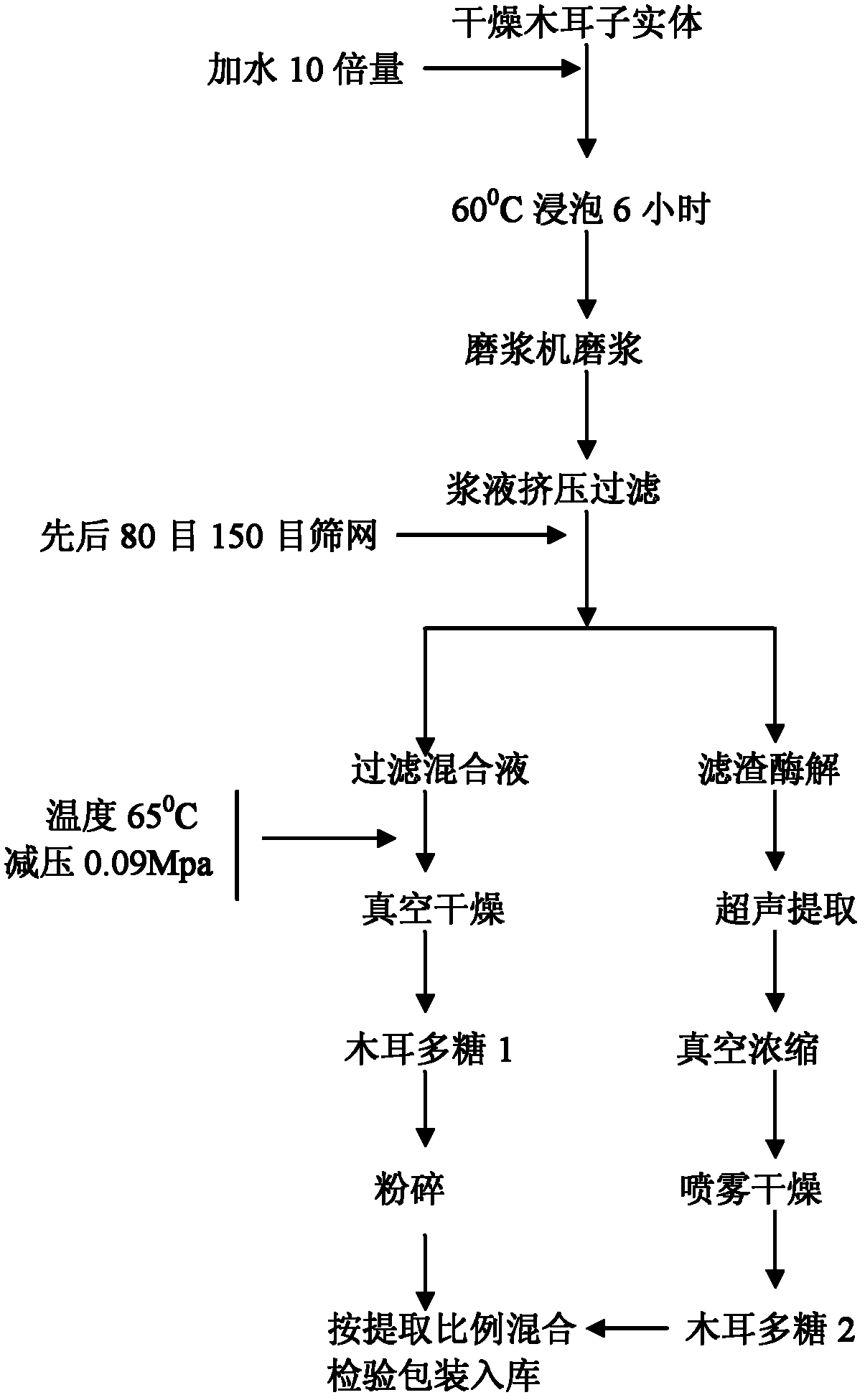

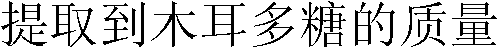

Comprehensive extraction process for auricularia auricula polysaccharide

The invention relates to extraction of active ingredients of Chinese medicines, in particular to a comprehensive extraction process for auricularia auricula polysaccharide. In the comprehensive extraction process for the auricularia auricula polysaccharide, the auricularia auricula polysaccharide is extracted by cooperating a super micron-milling technology, ultrasonic waves and complex enzyme, the dissolution rate of the auricularia auricula polysaccharide can be greatly improved by combining specific extraction process conditions, and the comprehensive extraction process has the advantages of short reaction time, mild reaction conditions, thorough breaking of cell walls, and high dissolution rate of the polysaccharide. Through comprehensive research, the comprehensive extraction process is easy to operate, and ensures that ingredients are retained comprehensively and the extraction yield is greatly improved.

Owner:吉林省美罗国际生物科技集团股份有限公司

Quick waste garbage crushing device for biomedicine pharmacy

The invention relates to a waste garbage crushing device for the biomedicine pharmacy, in particular to a quick waste garbage crushing device for the biomedicine pharmacy. The provided quick waste garbage crushing device for the biomedicine pharmacy is thorough in crushing, high in crushing speed and convenient to operate. The provided quick waste garbage crushing device for the biomedicine pharmacy comprises a bottom plate, a left frame, a first slide rail, first slide blocks, a crushing frame, a bracket, a second slide rail, a right frame, second slide blocks, a rack, a gear, a flat belt, a large belt wheel and the like. The left side of the top of the bottom plate is provided with the left frame and the first slide rail. The quick waste garbage crushing device for the biomedicine pharmacy has the effects of being thorough in crushing, high in crushing speed and convenient to operate, and waste garbage produced in the biomedicine pharmacy can be quickly crushed, so that the waste garbage produced in the biomedicine pharmacy is processed appropriately.

Owner:江苏诺德环保工程有限公司

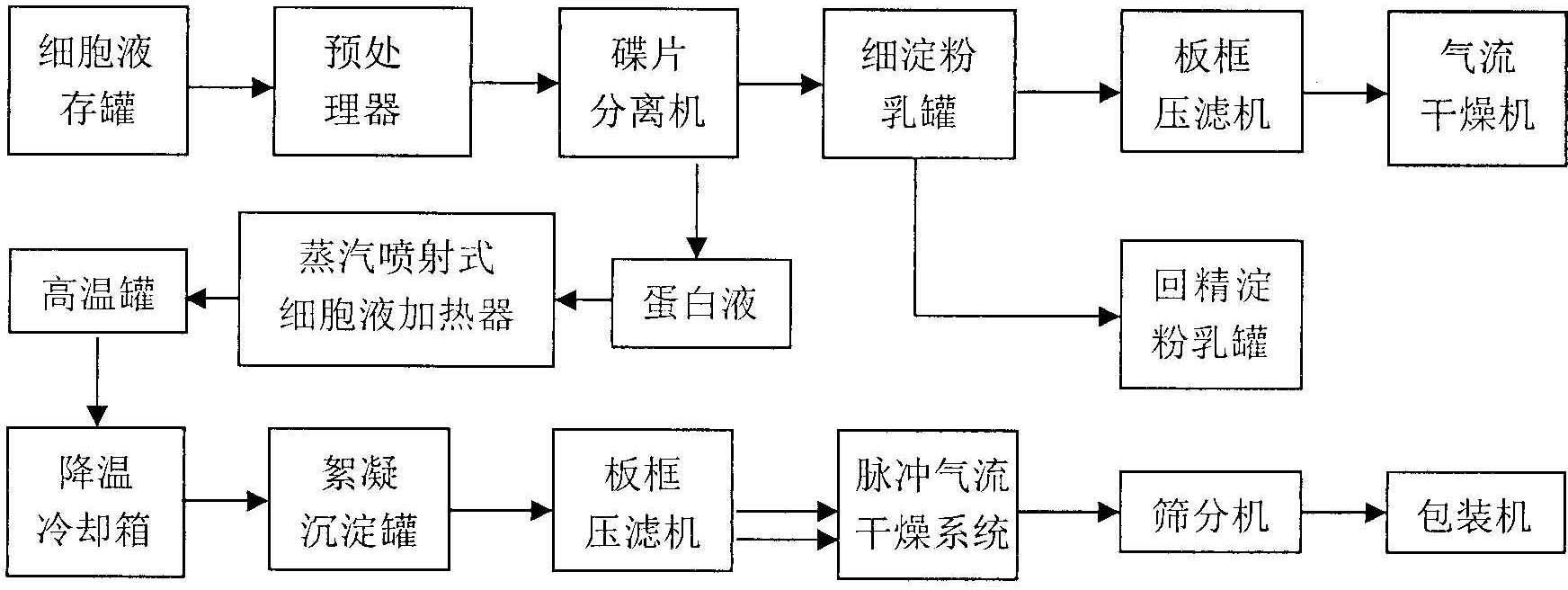

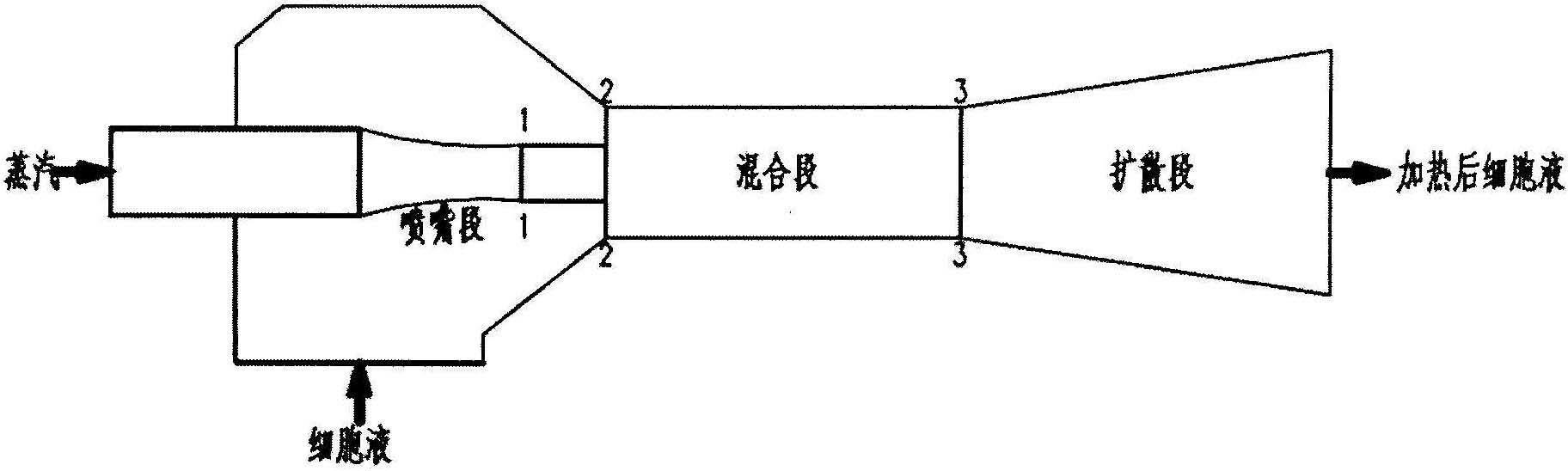

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

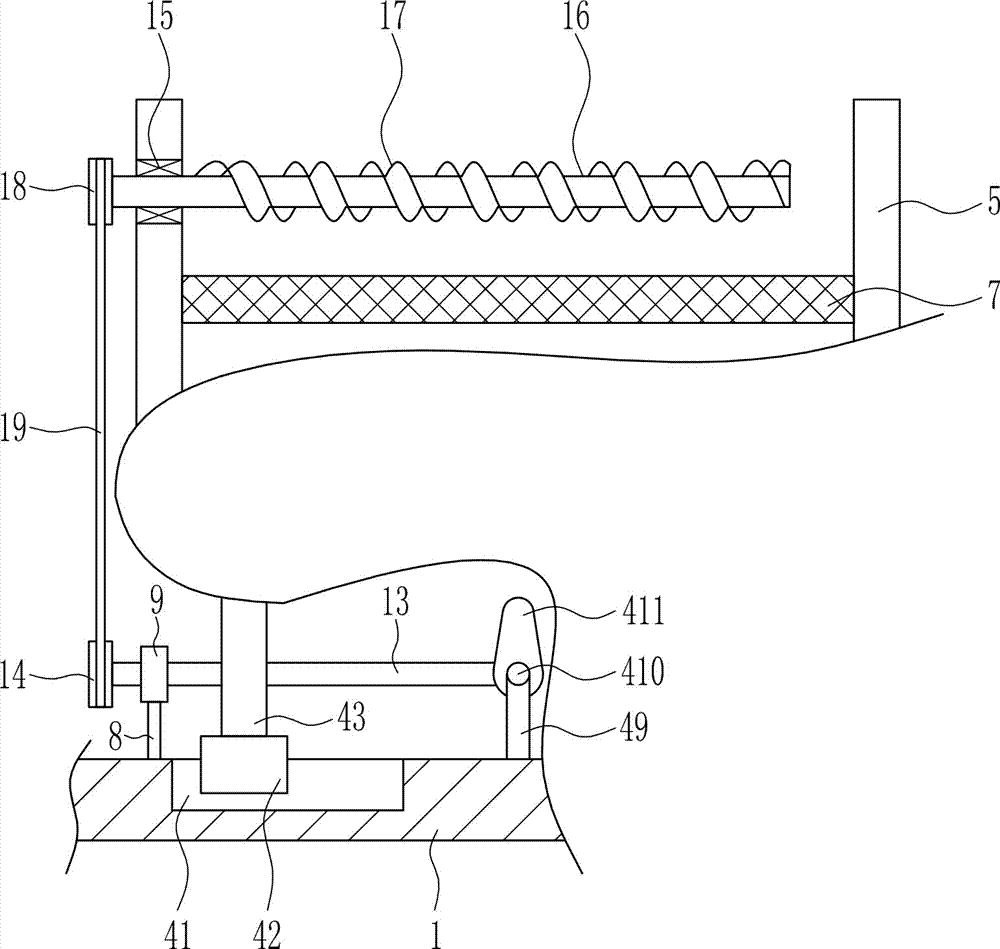

Plastic product recycling machine

InactiveCN108015927ACompletely brokenReduce recycling efficiencyPlastic recyclingGrain treatmentsEngineeringPlastic recycling

The invention discloses a plastic product recycling machine. The plastic product recycling machine comprises a shell, wherein the shell is of a hollow structure; the interior of the shell is divided into a first crushing cavity, a second crushing cavity and a collecting cavity through two partition plates which are arranged in parallel; discharge ports are formed in the partition plates; the firstcrushing cavity, the second crushing cavity and the collecting cavity communicate with one another through the discharge ports; two first rotating rollers which are arranged in parallel are connectedin the first crushing cavity in a rotating mode; and a plurality of cutting blades are arranged on the two first rotating rollers and are arranged in a staggered mode. According to the plastic product recycling machine, waste plastic can be fully crushed so that the plastic can be crushed more thoroughly, the space, occupied by the plastic, of a collecting box can be decreased, and the phenomenonthat the collecting box is frequently replaced can be avoided; and meanwhile, the cutting blades on the rotating rollers can be conveniently replaced, and the phenomenon that the plastic recycling efficiency is reduced due to the fact that the crushing efficiency is influenced by blade passivation can be avoided.

Owner:YINGSHANG LONGYUYANG IND & TRADE

Waste wood block rapid crushing device for construction

The invention relates to a wood block crushing device, in particular to a waste wood block rapid crushing device for construction. The technical effect that the waste wood block rapid crushing device for construction with complete crushing, rapid crushing and convenient operation is provided is achieved. In order to achieve the technical effect, the provided waste wood block rapid crushing device for construction comprises a bottom plate, a first sliding rail, first sliding blocks, a second sliding block, a second sliding rail, a first spring, a fixing plate, a first bevel gear, a motor, a first rotary shaft, a left rack and the like. The left rack, the second sliding rail, the first sliding rail and a right rack are sequentially arranged at the top of the bottom plate from left to right. The fixing plate is arranged on the left side of the second sliding rail. A round head fixed rod is arranged on the upper portion of the right side of the fixing plate. The second sliding block is slidably connected to the second sliding rail. A round head movable rod is arranged on the second sliding block. The effects of complete crushing, rapid crushing and convenient operation are achieved.

Owner:广东振裕再生资源有限公司

Method for extracting schizochytrium aggregatum oil

InactiveCN102199485ASimple processOperational securityFatty-oils/fats productionOil and greaseAlkaline protease

The invention discloses a method for extracting schizochytrium aggregatum oil. The method comprises the following steps of: taking schizochytrium aggregatum mud as a raw material, homogenizing, carrying out alkali extraction, centrifuging and extracting with an organic solvent to obtain the schizochytrium aggregatum oil. The method specifically comprises the steps of: diluting the raw material byutilizing a sodium citrate buffering solution, homogenizing and then carrying out high-temperature treatment, then carrying out alkali extraction, carrying out enzymolysis on the raw material subjected to alkali extraction by adopting neutral protease and alkali protease in sequence, centrifuging and then separating clear oil, and extracting missible oil by adopting the organic solvent, and therefore the oil extraction rate is greatly improved and reaches up to more than 90 percent. The method disclosed by the invention has the advantages of simple process, safety in operation and less pollutions and is suitable for large-scale production; cells can be completely crushed by utilizing the homogenizing treatment; various enzymes in the cells can be prevented from degrading oil by adopting the high-temperature treatment; and the treatment on the missible oil is added, and the oil extraction rate is increased by extraction with the organic solvent, standing delamination and other manners.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

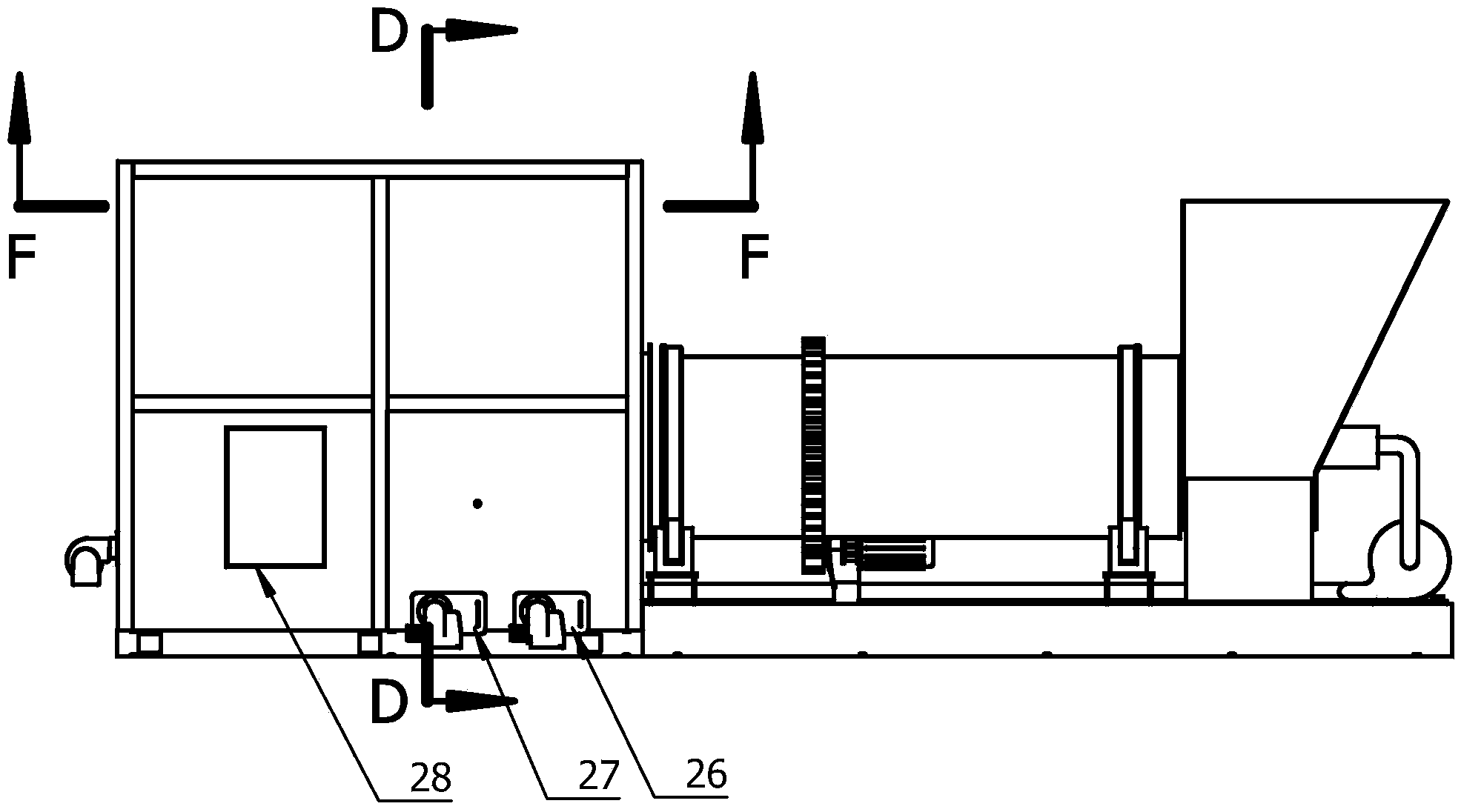

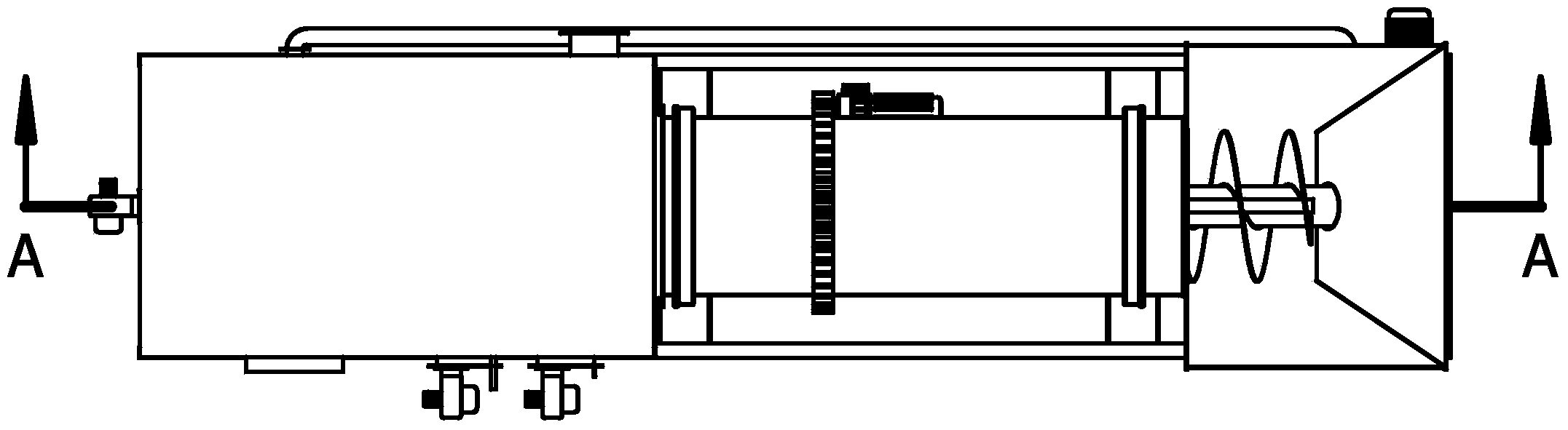

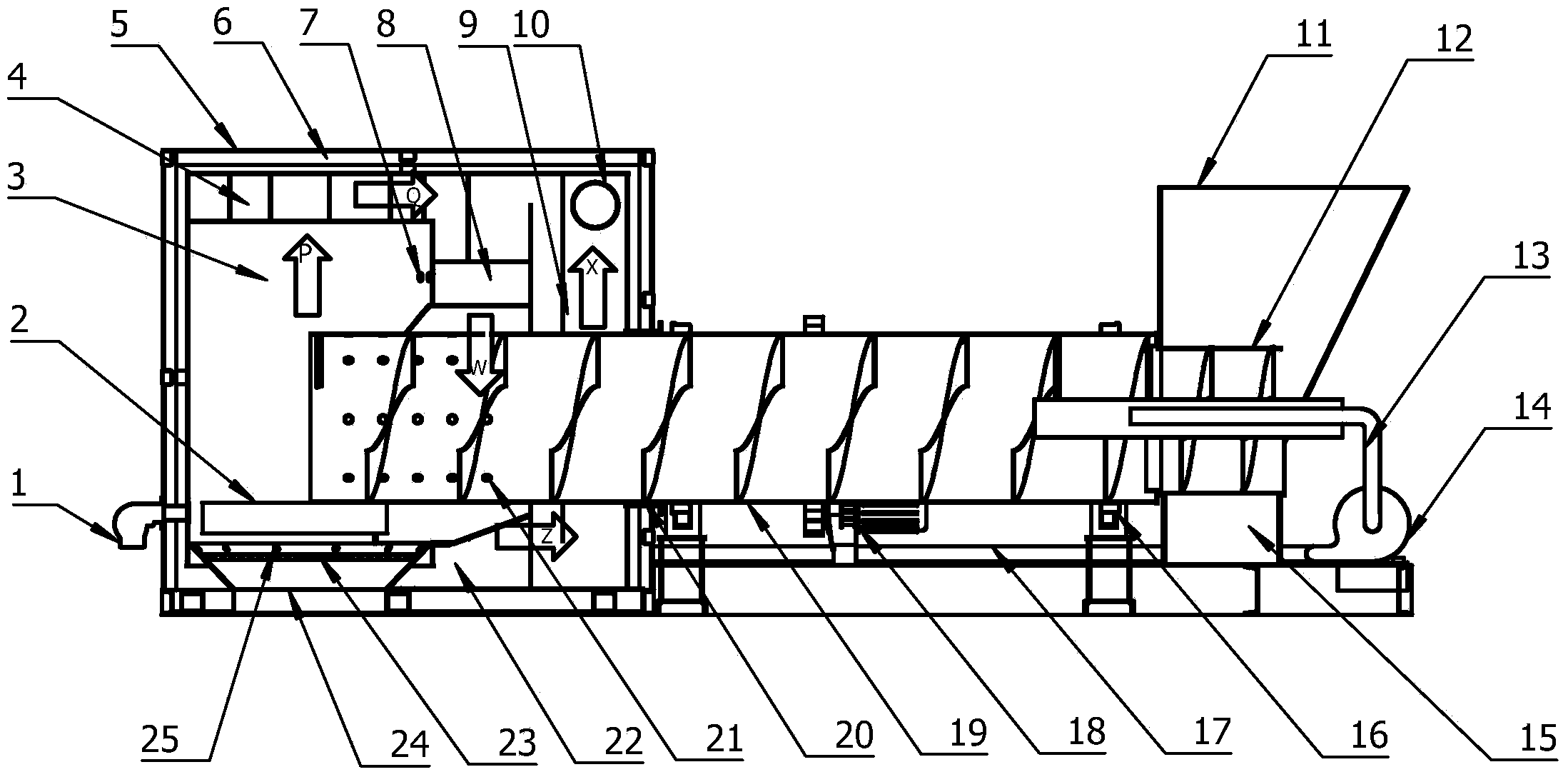

Rotary vertical garbage incinerator

InactiveCN104235856AEasy to manufactureSimplify the installation processIncinerator apparatusCombustion chamberFlue gas

The invention discloses a rotary vertical garbage incinerator, and relates to waste treatment equipment. The rotary vertical garbage incinerator comprises a shell, a combustion chamber positioned in the shell, and a feeding device, wherein the combustion chamber comprises a primary combustion chamber, an annular flue gas pyrolysis chamber, a secondary combustion chamber and a tertiary combustion chamber; space between the shell and each stage of combustion chamber is filled with a vermiculite refractory material; the feeding device comprises a hopper, a rotary drying and feeding drum and a transmission system; the rotary drying and feeding drum is arranged on a drying and feeding drum support mechanism, and is connected with the output end of the transmission system; a feeding spiral plate is arranged in the rotary drying and feeding drum; one end of the drum is connected with the hopper; the other end of the drum extends into the primary combustion chamber, and is provided with drying holes, which are communicated with the primary combustion chamber, on the part in the primary combustion chamber. The rotary vertical garbage incinerator does not need separate garbage pretreatment equipment, drying equipment or secondary combustion equipment, has the advantages of simple structure, low use and maintenance costs, high incineration efficiency and wide application range, and is ideal equipment for garbage incineration.

Owner:杨学勤

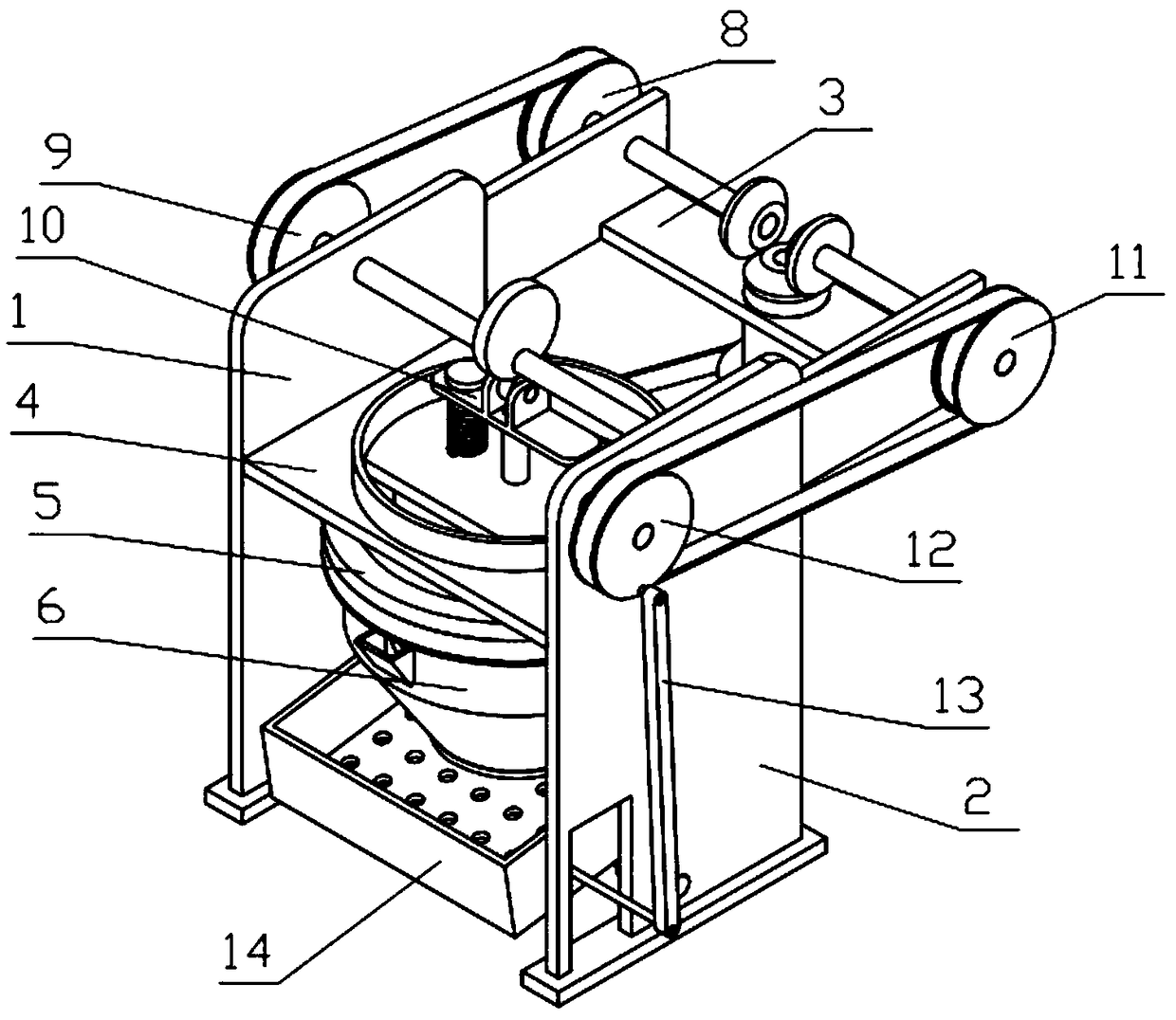

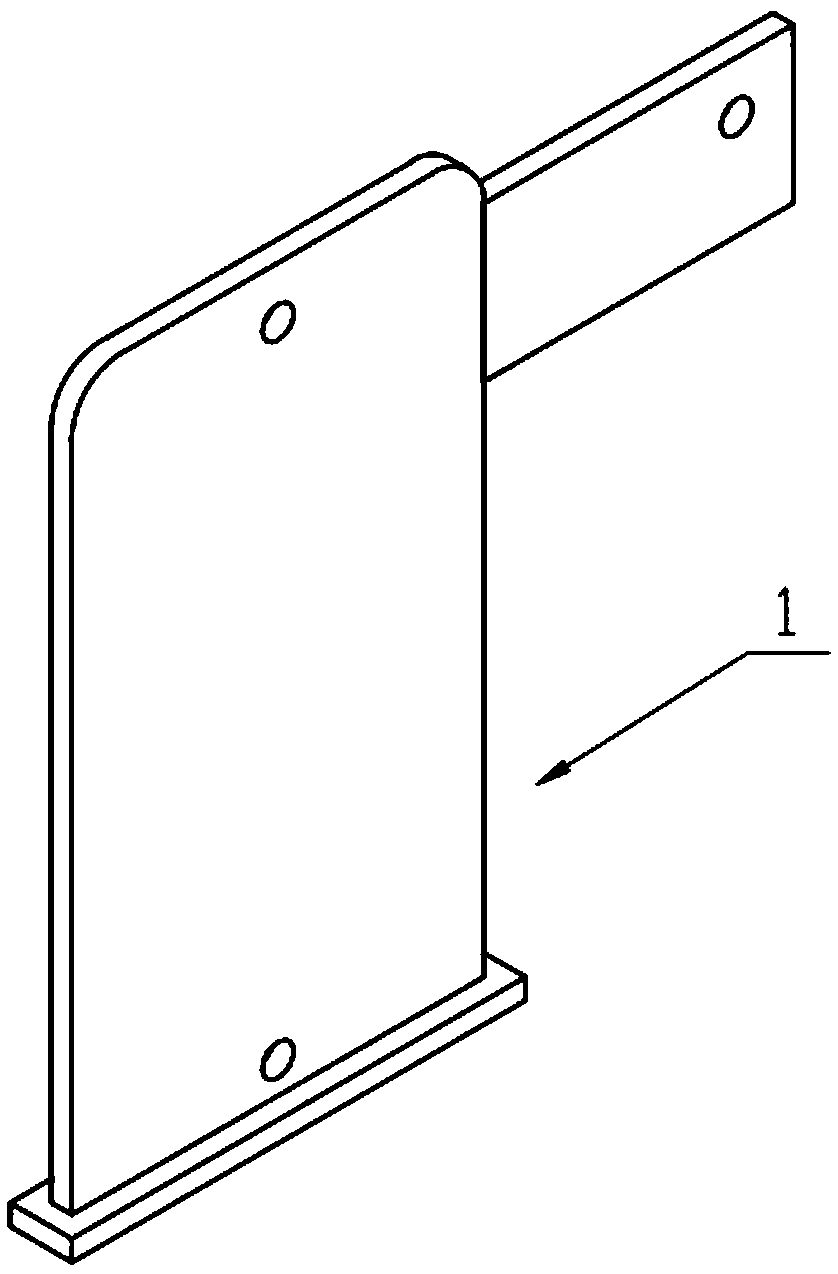

Device for preparing reclaimed sand through waste concrete

The invention relates to a device for preparing reclaimed sand, in particular to a device for preparing reclaimed sand through waste concrete. The device for preparing reclaimed sand through waste concrete comprises a side support I, a side support II, a power mechanism, a planetary gear mechanism, a gear ring, a crushing cylinder, a sieve plate, a transmission mechanism I, a pushing mechanism, acrushing mechanism, a transmission mechanism II, a crank mechanism, connecting rods and a sieve box. The planetary gear mechanism comprises a supporting plate, a supporting cylinder, a planetary gearbase plate, a sliding column, two rotary columns and planetary gears, wherein the supporting cylinder is fixedly connected to the supporting plate, the planetary gear base plate is fixedly connected to the inner circle of the supporting cylinder, the lower end of the sliding column is fixedly connected to the planetary gear base plate, the upper ends of the two rotary columns are fixedly connectedto the planetary gear base plate, and the planetary gears are rotatably connected to the two rotary columns. Concrete can be completely crushed in two directions through the crushing cylinder and thecrushing mechanism, and the completely-crushed concrete is screened through the sieve box.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

Construction engineering construction waste crushing device

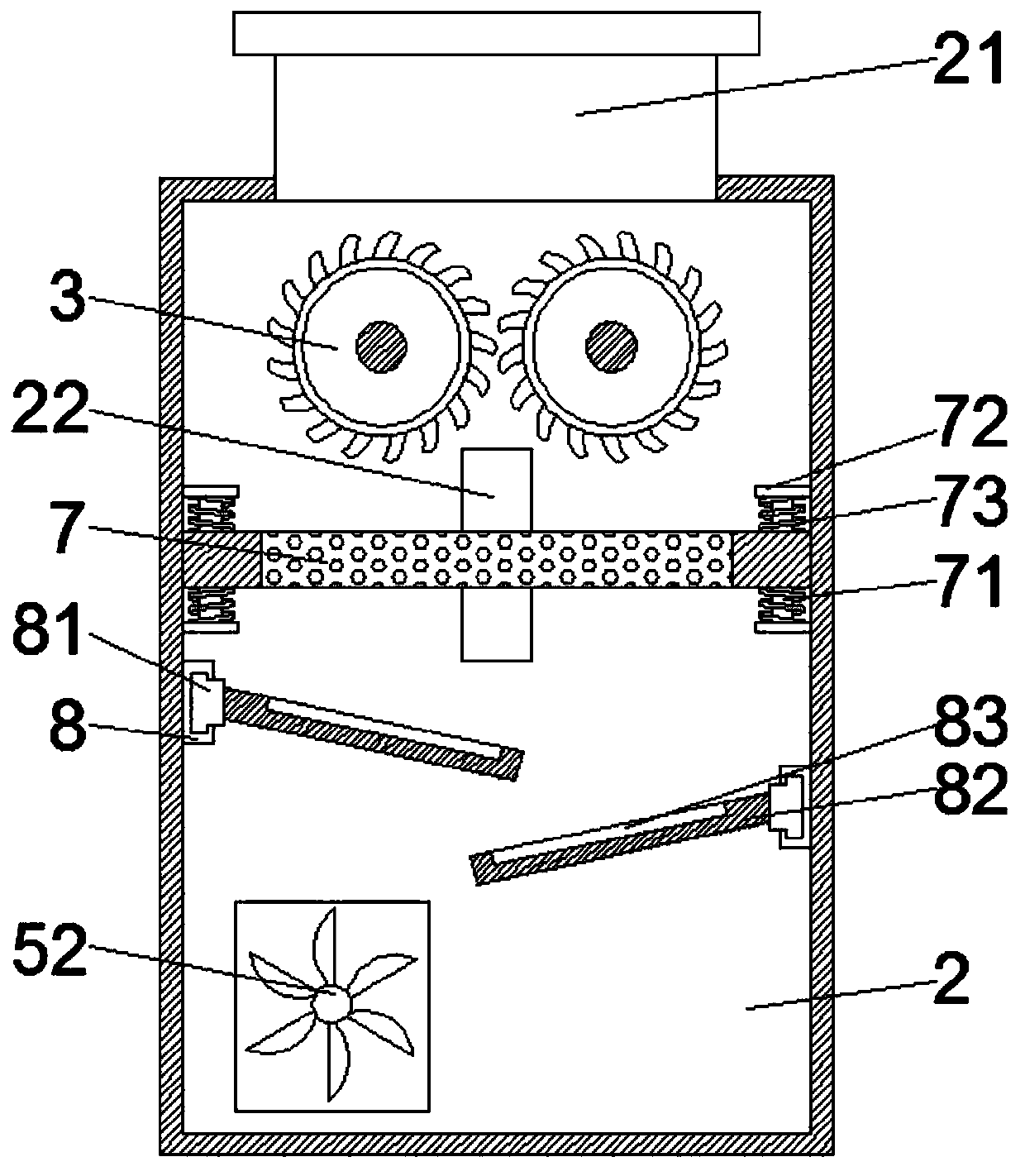

InactiveCN110918614ACompletely brokenImprove working environmentSievingConstruction waste recoveryGear wheelElectric machinery

The invention discloses a construction engineering construction waste crushing device. The device comprises a bottom plate and a box body, wherein a fixed shell is mounted at the upper part of the rear end of the box body, crushing rollers are symmetrically arranged bilaterally in the upper part in the box body, transmission rods are symmetrically mounted at the front ends and the rear ends of thecrushing rollers, the front transmission rod penetrates through the box body to be rotatably connected to the inner wall of the fixed shell, a motor is mounted at the front end of the fixed shell, the rear end of the motor penetrates through the fixed shell to be fixedly connected with the left side transmission rod, the outer surfaces of the transmission rods are sleeved with full gears, the full gears are positioned in the fixed shell, a first belt pulley is arranged on the outer surface of the left side transmission rod in a sleeve mode, and is positioned in the fixed shell, a half gear sleeves the outer surface of the right side transmission rod, a rack is vertically arranged in the fixed shell, the rack meshes with the half gear, a fixing block is mounted at the lower end of the rack, a telescopic device is arranged at the lower end of the fixing block, and a first spring sleeves the outer surface of the telescopic device. According to the device, metal waste with value in use inconstruction waste can be recycled through magnets.

Owner:邓卓

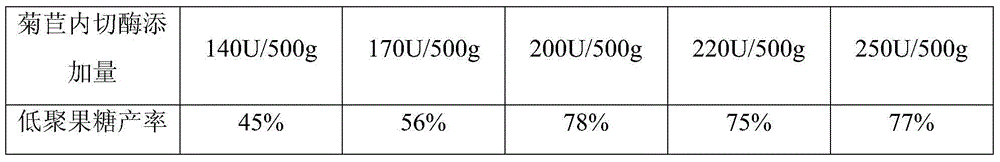

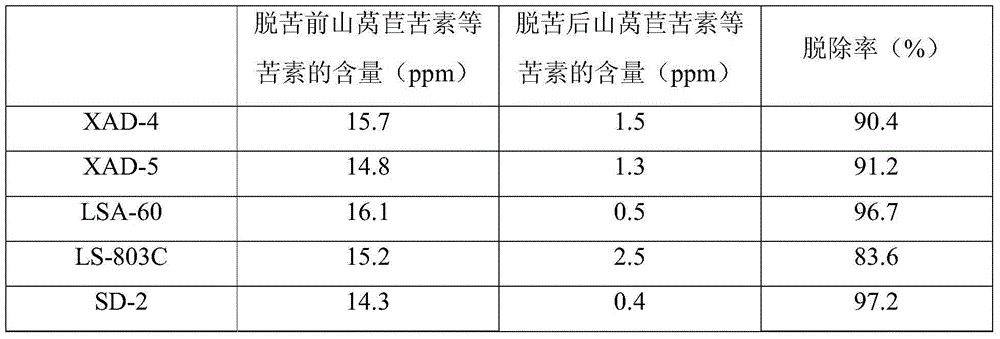

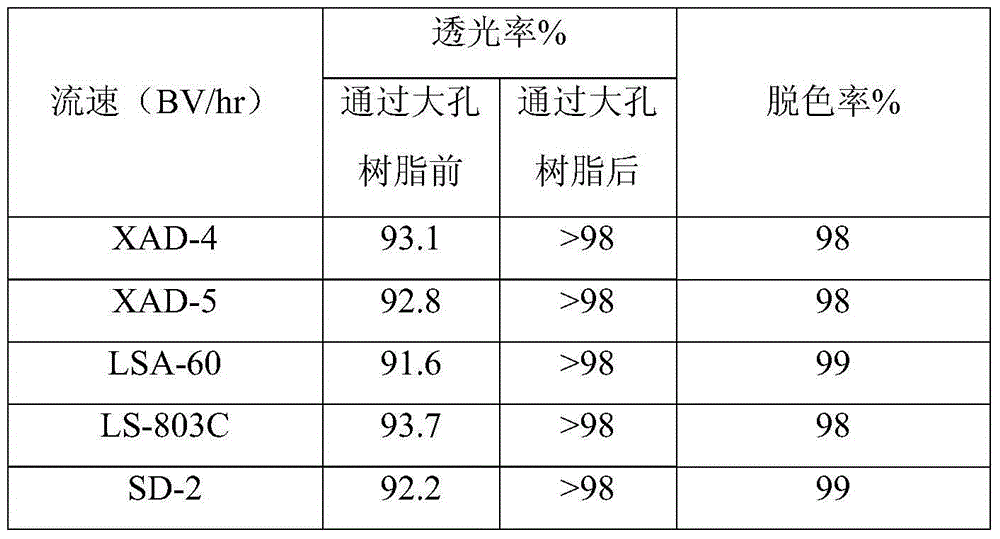

Preparation and purification method of fructo-oligosaccharide

The invention discloses a preparation and purification method of fructo-oligosaccharide and belongs to the field of a natural substance extraction technology. The method provided by the invention comprises the following steps: (1) washing chicory and triturating, and processing with pectase to obtain a mixture; (2) boiling the mixture obtained in the step (1), adding inulase, carrying out enzymolysis and carrying out suction filtration; (3) letting a solution obtained in the step (2) pass through a charcoal column, and collecting an effluent; (4) letting a mixed liquor obtained in the step (3) pass through a nonpolar macroporous resin column and collecting an effluent; and (5) processing a fructo-oligosaccharide mixed liquor c obtained in the step (4) with a nanofiltration membrane, and collecting a filtrate to obtain a fructo-oligosaccharide solution with its purity being greater than 96%. Content of fructo-oligosaccharide in the finally-obtained fructo-oligosaccharide solution is high. In addition, the method provided by the invention has a good effect of removing bitter principle and bitter peptide, is convenient to operate, and has a wide industrial application prospect.

Owner:QINGHAI WEIDE SPECIAL SUGAR

Coffee active ingredient extracting device

InactiveCN109699795AAvoid affecting the effect of concentrationAdequate responseRotary stirring mixersMixer accessoriesBiochemical engineeringBULK ACTIVE INGREDIENT

The invention discloses a coffee active ingredient extracting device. The device comprises a reaction kettle body, wherein the reaction kettle body is provided with a feeding hopper, the lower end ofthe reaction kettle body is in a tapered shape, the outer wall of the lower end of the reaction kettle body is provided with a hollow heating chamber, a motor is arranged above the feeding hopper, a first stirring rod is connected to the lower end of the motor, the first agitating rod extends away from the end of the motor toward the reaction vessel body, and one end extended from the first agitating rod is sleeved with a mounting plate. The coffee active ingredient extracting device is internally provided with an agitating structure, which can stir the material, avoids material deposition onthe bottom of the device, and enhances the concentration effect, the agitating structure can drive the blade to rotate when rotating, the rotating blade can scrape off the material on the inner wall to prevent the material from sticking to the inner wall and improve the effect of the concentrated material, a crushing plate is used for crushing, so that the coffee beans can fully react, and the efficiency is improved.

Owner:刘恒铄

Grain coarse crushing device for agricultural production

InactiveCN108393154AAchieve fragmentationIncrease granularitySievingScreeningDrive shaftSpiral blade

The invention discloses a grain coarse crushing device for agricultural production. The grain coarse crushing device comprises a crushing box, a first motor is fixedly installed at the top of the crushing box vertically, an output shaft of the first motor is coaxially and fixedly provided with a driving shaft extending into the crushing box, the surface of the driving shaft is fixedly provided with a driving belt wheel in a sleeved manner, the right end of a screen plate is hinged to the inner wall of the right side of the crushing box, the left end of the screen plate is fixedly provided withan extending plate extending to the exterior of the crushing box, and a fixing plate is fixedly installed on the outer wall of the left side of the crushing box; and a movable door is rotationally installed on the side wall of the crushing box through a hinge. According to the grain coarse crushing device, the grain particle crushing effect is achieved through rotation of a crushing blade, the rotating shaft is used for driving a longitudinal pulling plate to rotate to pull grains to the crushing blade to achieve secondary crushing, a spiral blade circulates the grains in a lifting barrel tothe crushing box to achieve the repeated crushing effect, the grain refining degree is greatly improved, crushing is more thorough, and the crushing efficiency is high.

Owner:COMMON TECH DEV CO LTD

Crushing device of walnut shells of traditional Chinese medicinal materials

Owner:XUANCHENG HUAKEXUAN PAPAYA BIOTECH CO LTD

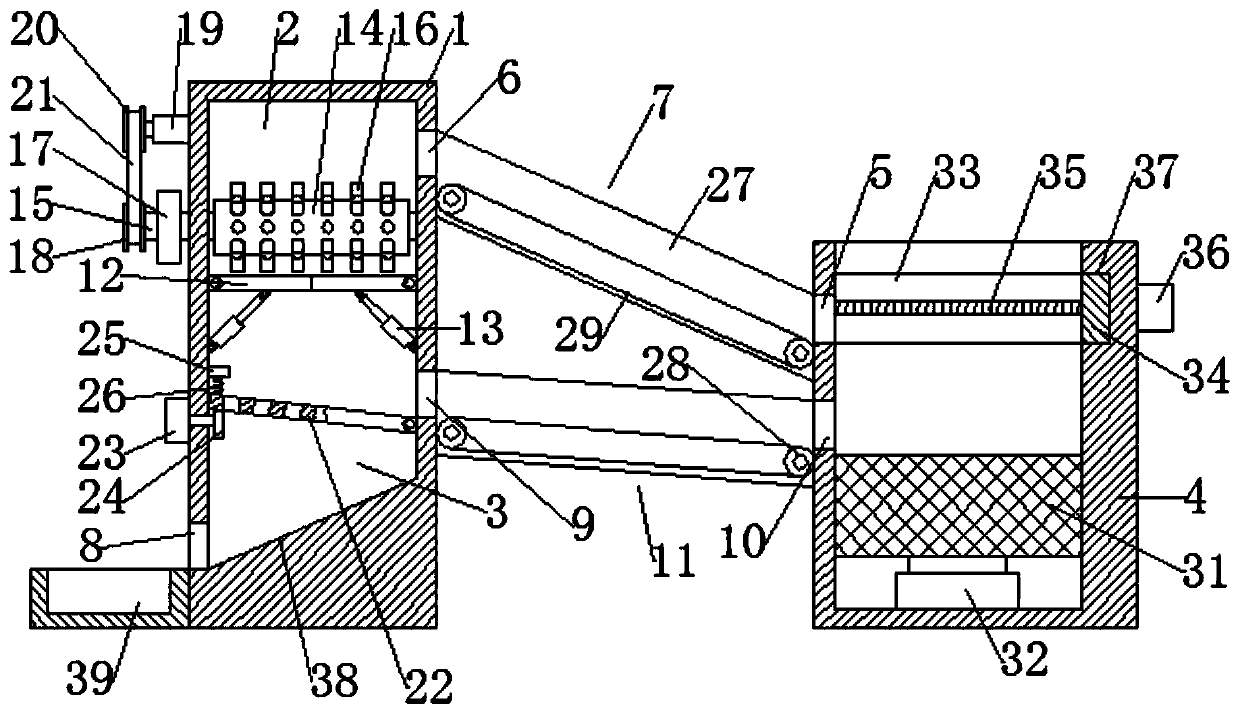

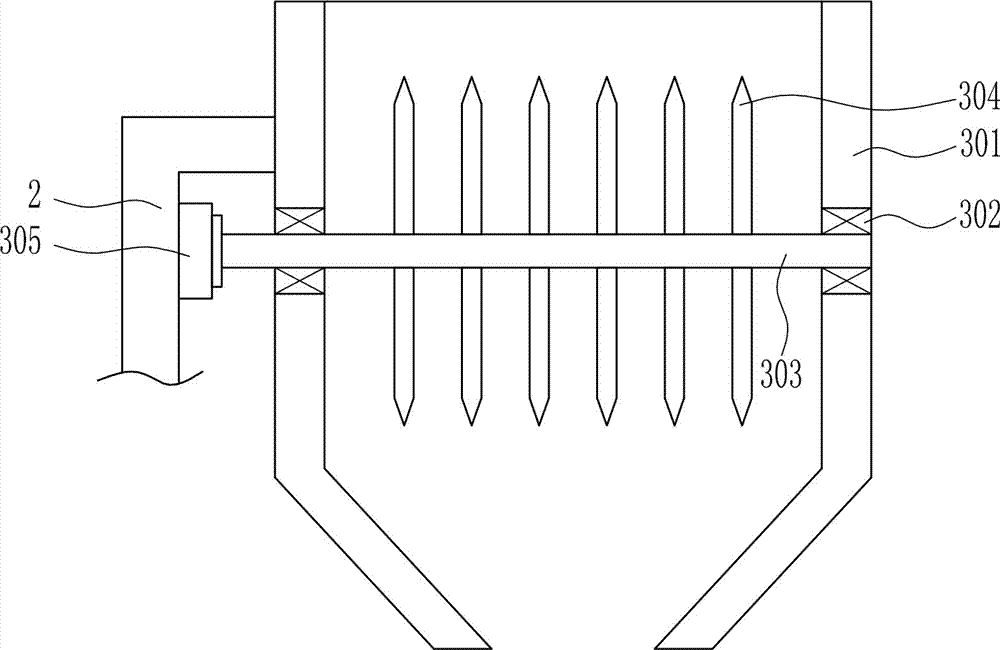

Secondary breaker for whole waste tire

The invention discloses a secondary breaker for a whole waste tire. The secondary breaker comprises a rack, a primary breaking chamber and a secondary breaking chamber; the primary breaking chamber comprises a first box body, a first movable cutter assembly and first fixed cutter assemblies relatively mounted on the two sides of the first movable cutter assembly are arranged in the first box body, the first movable cutter assembly comprises a first movable cutter shaft and a plurality of first movable blades mounted on the first movable cutter shaft, and each first fixed cutter assembly comprises a first fixed cutter positioning plate fixed to the inner side wall of the first box body; a plurality of first fixed blades are arranged on each first fixed cutter positioning plate, and cutter openings of the first fixed blades located on the two sides of the first movable cutter assembly are opposite in direction; the multiple first movable cutter blades and the multiple first fixed blades are arranged in a crossed manner, and a hopper is arranged on an opening in the upper end of the primary breaking chamber; a partition plate with a discharging opening is arranged between the first box body and a second box body, and a sliding way is arranged at the lower end of the discharging opening; the rack is further provided with a screening mechanism and a transmission mechanism.

Owner:WUHAN UNIV OF SCI & TECH

Construction waste treatment device and method

InactiveCN110479418ACompletely brokenImprove crushing effectGrain treatmentsWaste materialLarge particle

The invention discloses a construction waste treatment device. The construction waste treatment device comprises a treatment box, a crushing mechanism is arranged in a crushing cavity, a screening mechanism is arranged in a screening cavity, the left side wall of a waste material groove is provided with a material conveying port, a first conveyor belt is connected between the material conveying port and a feeding port, the left side wall of the treatment box is provided with a discharging port, a second conveyor belt is connected between a material returning port and a material receiving port,and the waste material groove is internally provided with a feeding mechanism used for sending construction waste materials in the waste material groove into the material conveying port; and after the construction waste materials are broken by the crushing mechanism, the construction waste materials fall down to the screening cavity, unqualified construction waste materials with large particles are blocked by the screening mechanism, transferred to the second conveyor belt by the screening mechanism through the material returning port, and returned to the waste material groove again through the material receiving port and wait for entering the crushing cavity to be smashed again next time, the effect of construction waste material smashing is good, and the construction waste materials aresmashed more thoroughly.

Owner:ZHENGZHOU TECHN COLLEGE

Recycled plastic preliminary crushing equipment

The invention relates to crushing equipment in particular to recycled plastic preliminary crushing equipment. In order to solve the technical problem, the recycled plastic preliminary crushing equipment is provided and can thoroughly crush plastics and make crushed plastics be convenient to collect. The recycled plastic preliminary crushing equipment comprises a bottom plate and the like; an L-shaped supporting rod is disposed on the left side of the bottom plate; a crushing device is disposed on the upper portion of the right side of the L-shaped supporting rod; a shaking device is disposed in the middle of the bottom plate; a screening frame is disposed at the top of the shaking device; a discharging outlet is formed in the lower portion of the right wall of the screening frame; and a screen is disposed in the screening frame. The recycled plastic preliminary crushing equipment achieves the effects that the plastics can be thoroughly crushed and the crushed plastics can be conveniently collected, and a user can pull a push rod to achieve left-right movement so that a second push plate can rightwards push out the plastics at the bottom in the screening frame and the crushed plastics can fall into a crushed plastic collecting box through the discharging outlet.

Owner:江苏百安达新材料有限公司

Construction waste crushing and screening device

InactiveCN107335498AAvoid cloggingAffect healthSievingUsing liquid separation agentCircular discGear wheel

The invention discloses a crushing and screening device for construction waste, which comprises a bottom plate, a left side plate, a right side plate, a top plate, a transmission mechanism, a first connecting rod, a second connecting rod, a first sliding sleeve, a vertical sliding rod, a horizontal Rod, third connecting rod, crushing plate, second sliding sleeve, L-shaped rod, crushing frame, slide block, slide rail, discharge pipe, fourth connecting rod, screen mesh, screen box and collection frame, the present invention provides There is a transmission mechanism. The transmission mechanism includes a mounting plate, a motor, a first disc, a mounting shaft, a first gear, a second disc and a second gear. Through the cooperation of the above components, the crushing plate can crush the construction waste in the crushing frame. The structure is simple and the working efficiency is high. At the same time, the crushing frame moves left and right, and the garbage in the crushing frame is constantly turned, so that the crushing is more uniform and thorough, and the crushing efficiency is further improved. There is a fourth connecting rod, a screen and a screen box. The above components work together to drive the screen to move left and right to prevent the screen from being blocked and improve the screening efficiency.

Owner:陈婷

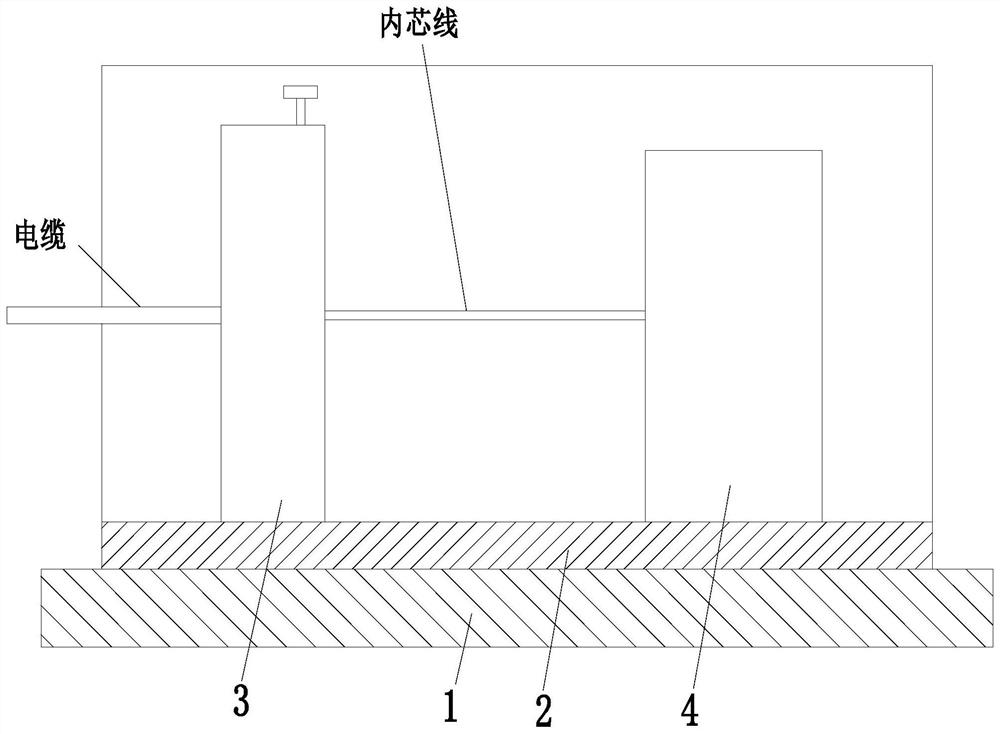

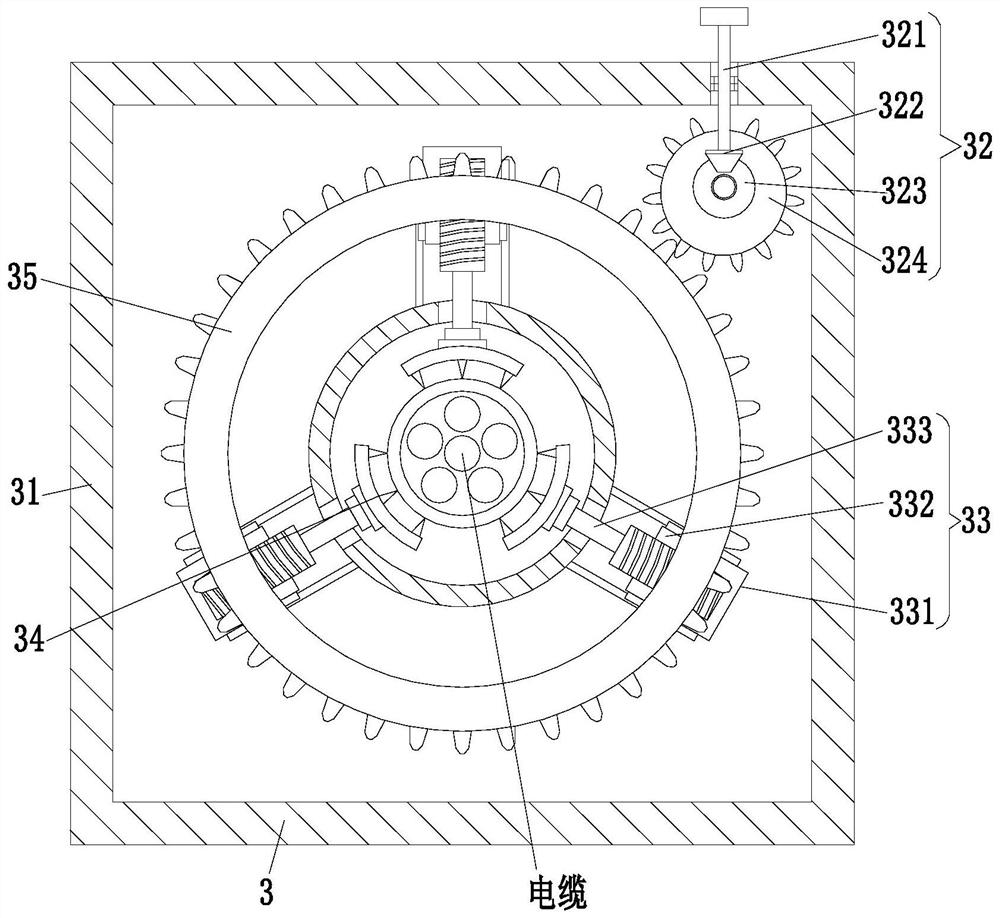

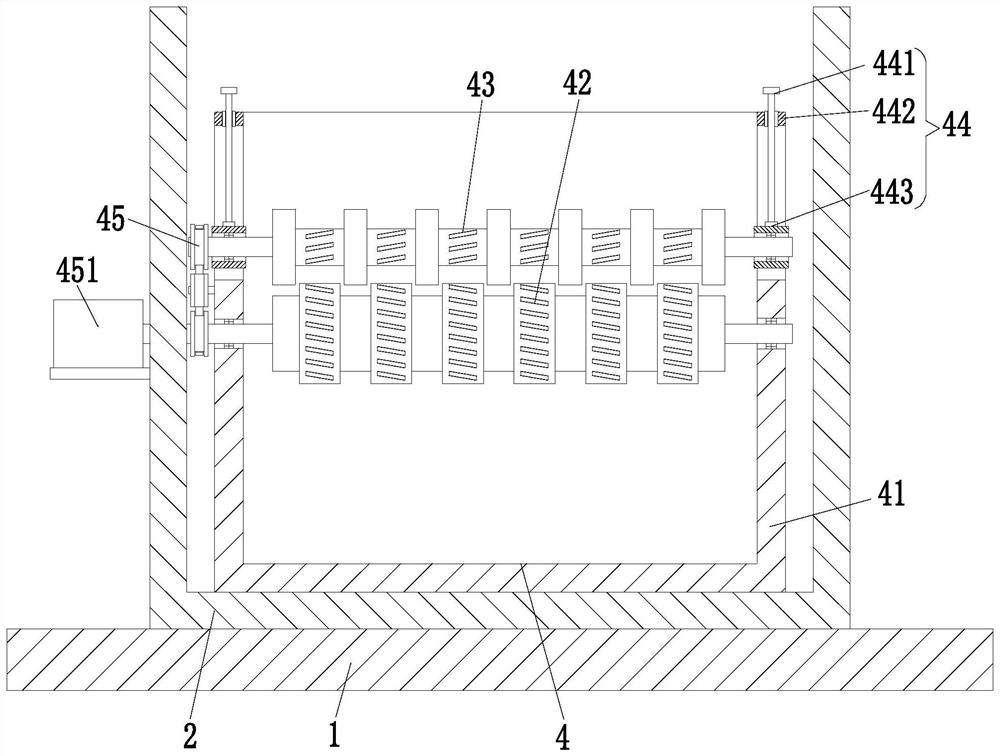

Wire and cable stripping and recycling machine

ActiveCN111917070APrecise positioningGood peeling effectBasic electric elementsApparatus for removing/armouring cablesElectric cablesMachining

The invention relates to an electric wire and cable peeling and recycling machine, and the machine comprises a bottom plate, a supporting frame, a wire peeling device and a peeling device; the supporting frame is installed in the middle of the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, the wire peeling device is installed on the left side in thesupporting frame, and the peeling device is installed on the right side in the supporting frame. The invention can solve the problems that when an existing device is used for stripping a cable, the stripping effect is poor, positioning is inaccurate, the cutting effect of the cable is poor, an inner core wire in the cable is not prone to being exposed, the subsequent machining effect of the cableis affected, and when the existing device is used for recycling and stripping the inner core wire of the cable, the stripping effect is poor, stripping is incomplete, and the broken plastic insulatinglayer is not liable to fall off, so the insulating layer is adhered to the inner core wire, and the recovery effect of the wire is influenced.

Owner:FUYANG SANHUAN POWER EQUIP CO LTD

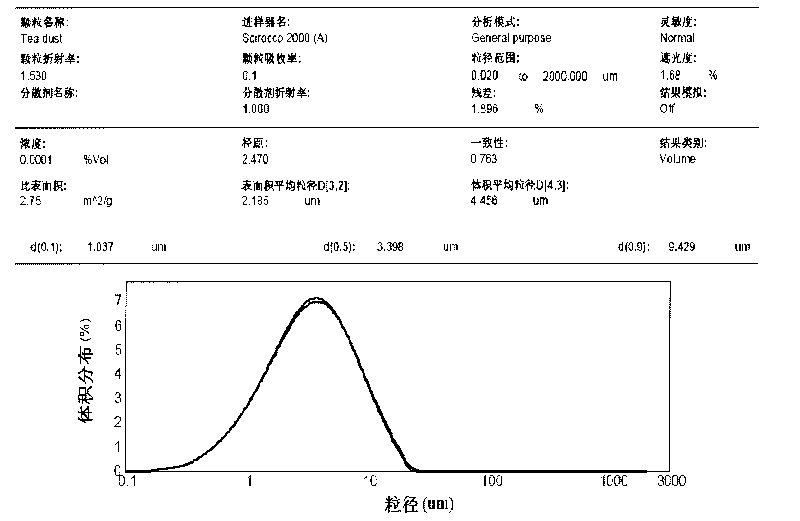

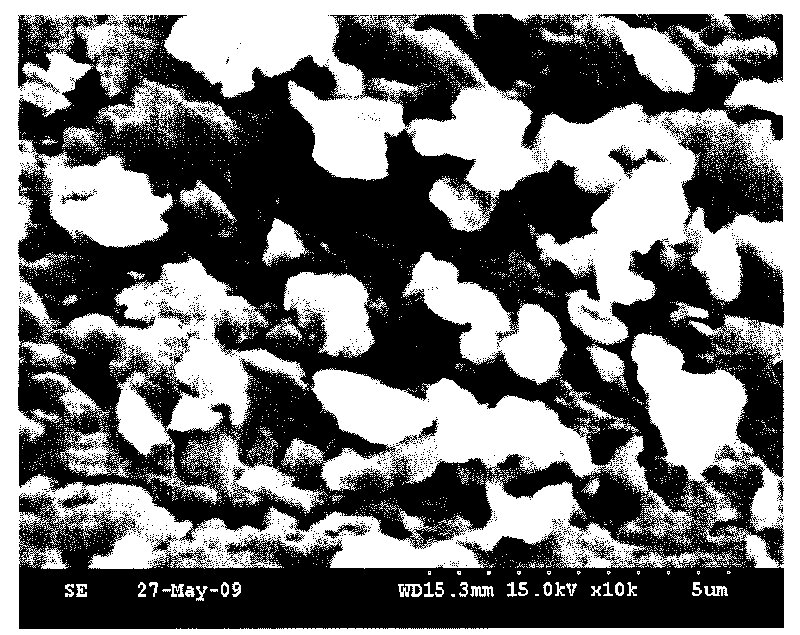

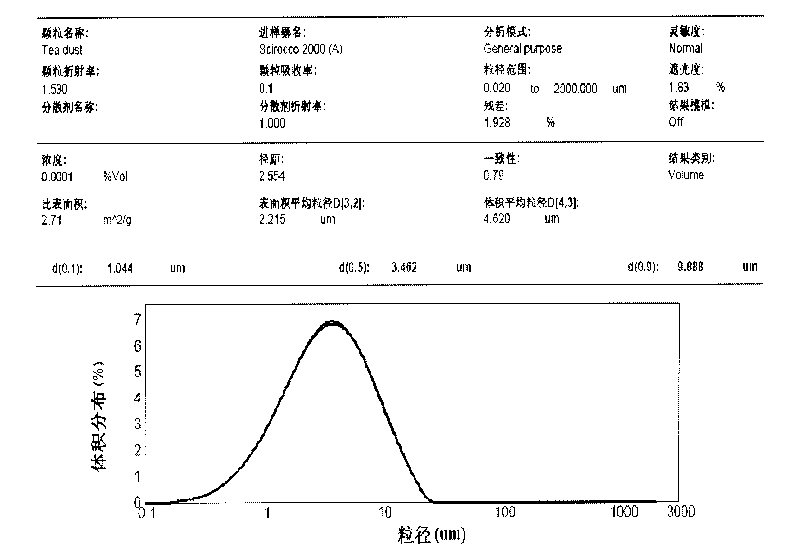

Method for preparing ultrafine tea powder

InactiveCN101715844AChange shape featuresFine granularityCosmetic preparationsToilet preparationsGreen teasGreen tea (dietary)

The invention discloses a method for preparing ultrafine green tea powder and belongs to the technical field of deep machining of tea leaves. The method comprises the following steps: screening middle-grade and low-grade summer and autumn fresh green tea leaves in accordance with national pollution-free production standard; spreading the tea leaves, performing fixation on the tea leaves by combining steam heat and frying technology, drying the tea leaves by novel microwave grading technology, and performing low-temperature ultrafine pulverization to prepare the ultrafine green tea powder with D50 more than or equal to 2,500. The method for preparing the ultrafine green tea powder is characterized by simple process, reasonable steps, low cost, and suitability for industrialized production. The ultrafine tea powder produced by the method has complete breaking of cell wall, and high uniformity and dispersibility. During processing, nutrient components and pharmacologic components of green tea are retained to the maximum; a chemical additive can be widely replaced; the shelf life of food is prolonged; food is endowed with natural emerald green color and specific tea flavor; dietary fiber, active polysaccharide and other substances of the green tea are fully utilized; tea drinking is changed into tea eating; and products can be widely used in the fields of food, cosmetics, commodity and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

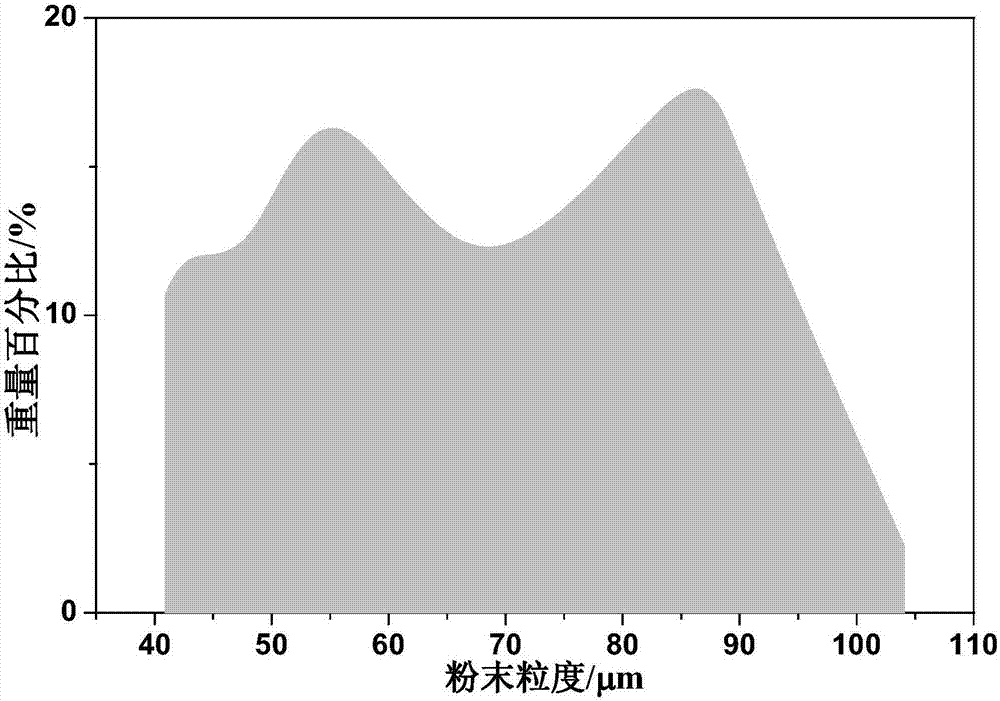

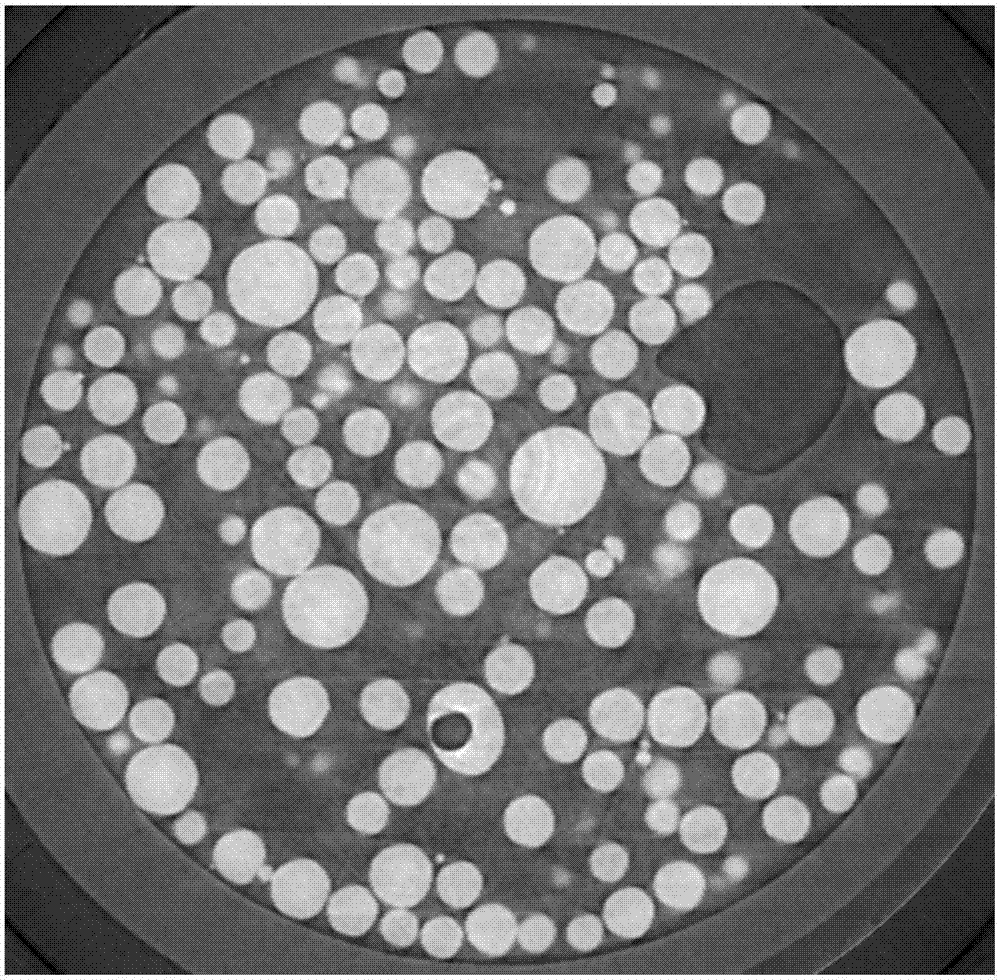

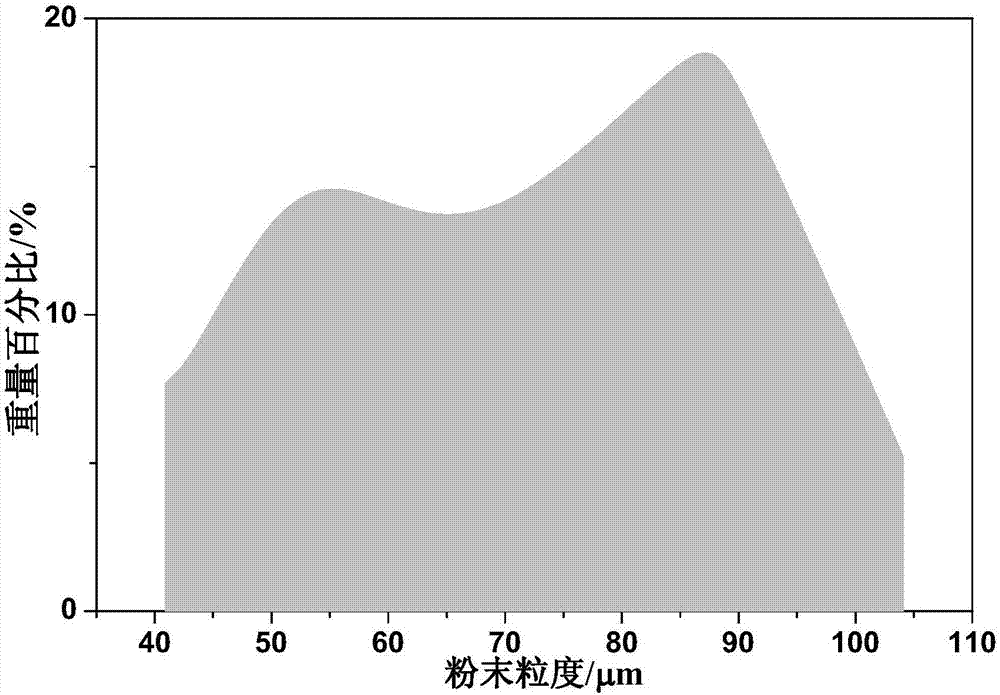

Method for preparing titanium based spherical powder with reduced particle size through gas atomization

ActiveCN107498059AGood physical propertiesLarge particle sizeTransportation and packagingMetal-working apparatusCrucibleGlobular shaped

The invention discloses a method for preparing titanium based spherical powder with reduced particle size through gas atomization. The method comprises steps as follows: step one, a titanium based raw material and a tin material are placed in a smelting crucible, and the smelting crucible is put in a smelting chamber of a vacuum induction melting gas atomization equipment for vacuum induction melting; step two, after the titanium based raw material and the tin material are melted through vacuum induction melting, argon is introduced for protection, a graphite diversion pipe located at the bottom of the smelting crucible is heated, a melted liquid produced after melting of the titanium based raw material and the tin material freely falls into an atomization chamber through the graphite diversion pipe and subjected to vacuum induction melting gas atomization treatment, atomized powder is obtained, and titanium based spherical powder is obtained from a collecting tank. According to the method, tin is introduced into the titanium raw material or a titanium alloy raw material for reducing viscosity of the melted liquid obtained after smelting, so that the raw materials are easy to break during gas atomization, the particle size of the prepared powder becomes small, wherein the yield of the powder with the particle size smaller than 45 mu m in the titanium based spherical powder is not lower than 28%, pores in the powder are reduced, and the amount of hollow powder is reduced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Ultrasonic-assisted extraction method for polysaccharide extract and pectin extract of okra

The invention discloses an ultrasonic-assisted extraction method for a polysaccharide extract and a pectin extract of okra. The method comprises the following steps: freeze-drying and pulverizing the okra to obtain a dried okra powder; conducting hot water extraction on the dried okra powder under ultrasonic assistance, collecting a liquid supernatant, namely an okra polysaccharide-pectin aqueous solution, after centrifuging; deproteinizing after concentrating the okra polysaccharide-pectin solution; leaving to stand after adding ethyl alcohol into the deproteinized okra polysaccharide-pectin aqueous solution, drying an upper layer to obtain the okra pectin extract, and freeze-drying after dialyzing a lower layer to obtain the okra polysaccharide extract. Through the method, the pectin extract and the okra polysaccharide extract are obtained at the same time, the used time is short, the energy consumption is low, the operation is simple, and the polysaccharide with the antioxidant activity and the high quality pectin are obtained.

Owner:CHINA AGRI UNIV

Corn particle impact crushing device for processing agricultural and sideline products

InactiveCN110314723AAchieving a grinding effectAchieve fragmentationGrain treatmentsDrive motorEngineering

The invention discloses a corn particle impact crushing device for processing agricultural and sideline products, and relates to the technical field of processing of the agricultural and sideline products. The device comprises a supporting frame, a crushing tank is arranged below a discharge hopper, the supporting frame is in driving connection with a sliding frame through a vertical reciprocatingmechanism, and the bottom of the sliding frame is provided with a crushing mechanism which is eccentrically arranged relative to the center of the crushing tank. A steering mechanism comprises a rotating shaft fixed at the center of the bottom of the crushing tank. An impact head moves up and down in a reciprocating mode under the drive of the vertical reciprocating mechanism, corn particles on ametal mesh plate are subjected to impact crushing, and meanwhile, the impact head is driven to rotate under the drive of a driving motor, so that the grinding effect of the corn particles is realized, and the corn particles are more thoroughly crushed. The arranged steering mechanism can drive the crushing tank to rotate, the crushing effect of the impact head on the corn particles at different positions in the crushing tank is realized, and the crushing process of the corn particles is more comprehensive and sufficient.

Owner:卢月簪

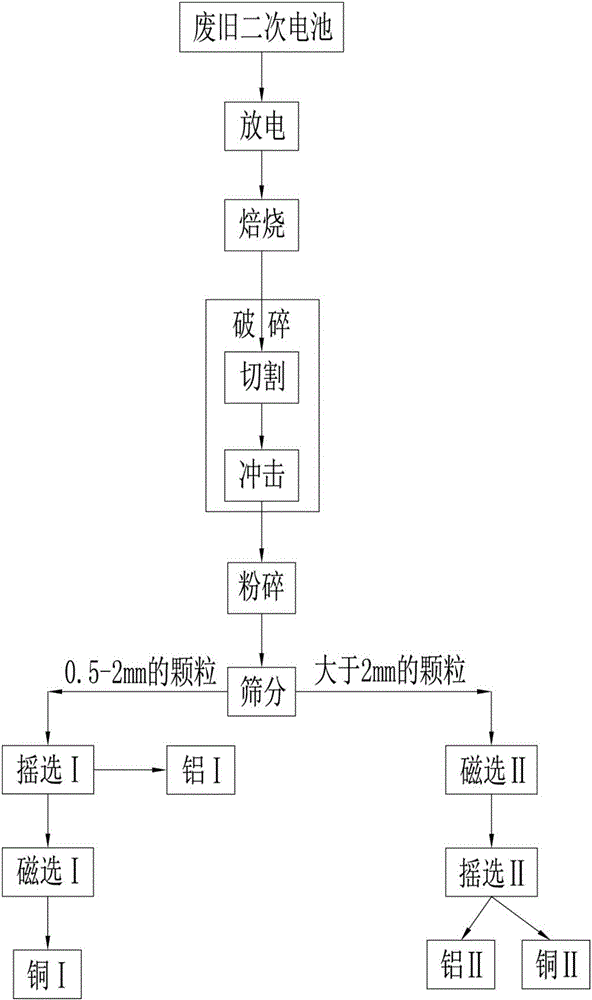

Method for recovering copper and aluminum from waste secondary batteries

InactiveCN106099239AEliminate hazardsTo achieve the effect of safety and environmental protectionWaste accumulators reclaimingBattery recyclingRecovery methodOrganic solvent

The invention relates to a battery recovery method, in particular to a method for recovering copper and aluminum from waste secondary batteries, and aims to eliminate potential safety hazards and avoid leakage pollution in a battery treatment process by providing the method for recovering copper and aluminum from the waste secondary batteries. The method comprises is used for obtaining end products, namely copper and aluminum, in such manners as electric discharging, calcination, crushing, smashing, sieving, shaking separation and magnetic separation, so that the recovery and the utilization of copper and aluminum are realized. Compared with the prior art, the method provided by the invention has the advantages that due to the treatment process of crushing after calcination, that is, easy-to-decompose organic solvents and electrolyte solutions in the waste secondary batteries are decomposed and released through heating and calcination, and then crushing is carried out, so that leakage of organic matters and the electrolyte solutions can be avoided in the follow-up crushing process, treatment safety of follow-up procedures is guaranteed; according to the treatment process provided by the invention, not only is treatment safety realized, but also leakage of harmful substances is prevented, so that the effect of environmental protection is realized.

Owner:GANZHOU HIGHPOWER TECH CO LTD

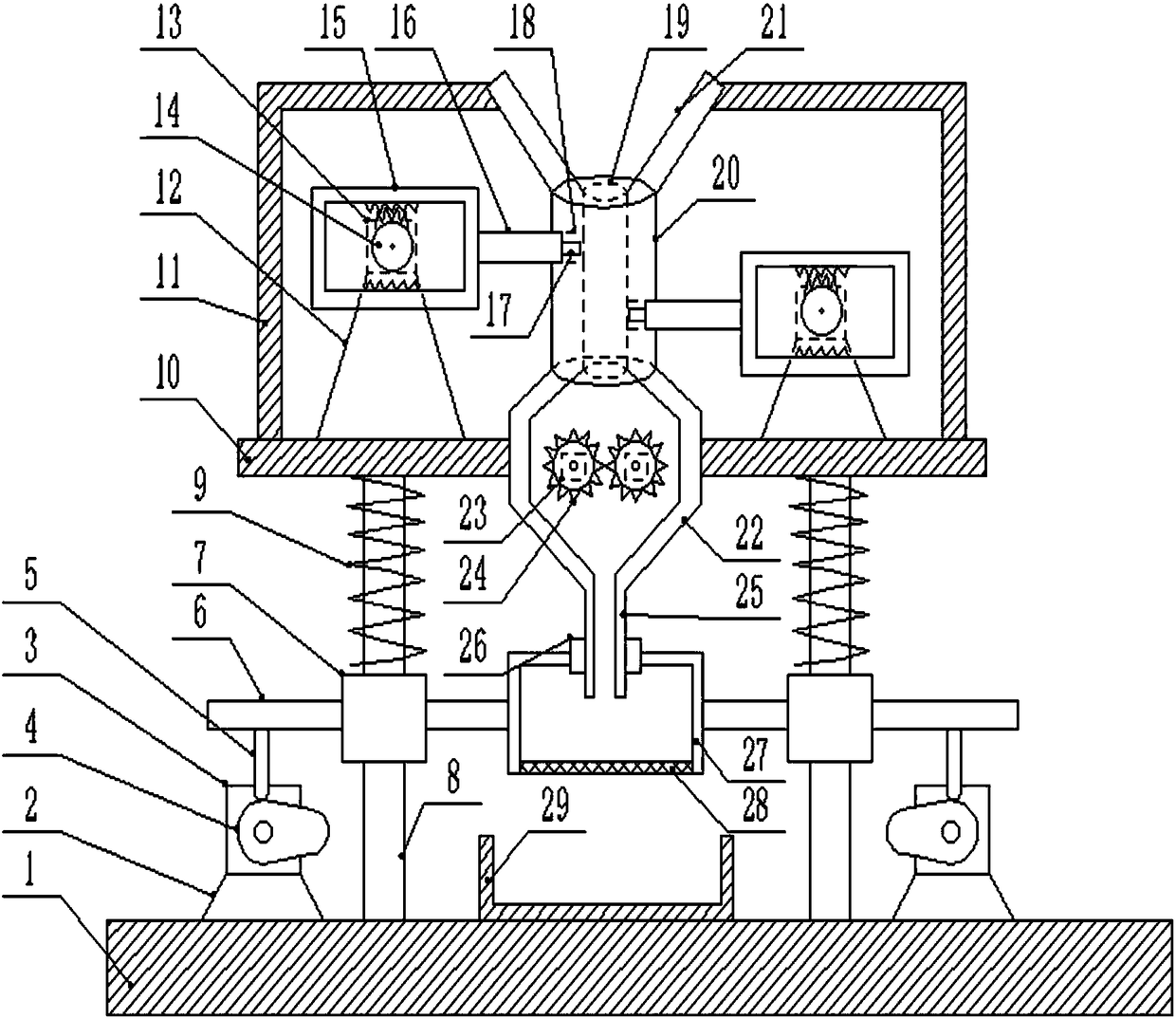

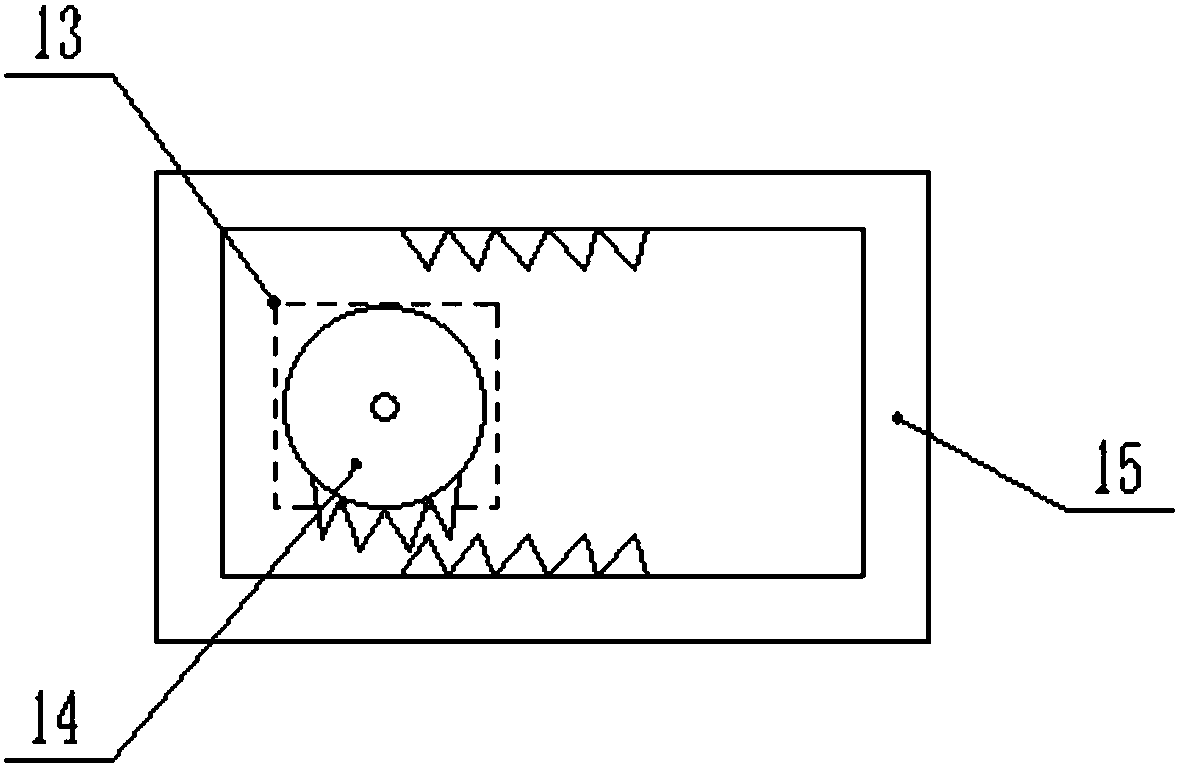

Recovery treatment device for waste batteries

InactiveCN108405550ACompletely brokenPromote fragmentationSolid waste disposalWaste accumulators reclaimingEngineeringCam

The invention discloses a recovery treatment device for waste batteries. The recovery treatment device comprises a base, wherein first motor supports are fixedly connected above the left side and theright side of the base; a first motor is fixedly installed above each first motor support; a cam is connected dead ahead the middle of each first motor; a first push rod is connected above the outer surface of each cam in a contact manner; a connection rod is fixedly connected to the upper end of each first push rod; a slide block is fixedly connected to the middle part in the horizontal directionof each connection rod; a slide rod is connected to the interior in the vertical direction of each slide block in a contact manner; a fixing frame is connected to the upper ends of the two slide rods; springs are fixedly connected to the middle part below the fixing frame; the upper part of each slide rod penetrates through the interior of the corresponding spring; second motor supports are fixedly connected to the middle part above the fixing frame; and a second motor is fixedly installed above each second motor support. The recovery treatment device disclosed by the invention is great in crushing effect for the waste batteries, and more thorough in crushing, so that screening for harmful substances in the crushed waste batteries is benefited, and the working efficiency of recovery treatment for the waste batteries is increased.

Owner:HEFEI TOTEM LONG MACHINERY DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com